Sony MDX-C8500R, MDX-C8500X Service manual

MDX-C8500R/C8500X

SERVICE MANUAL

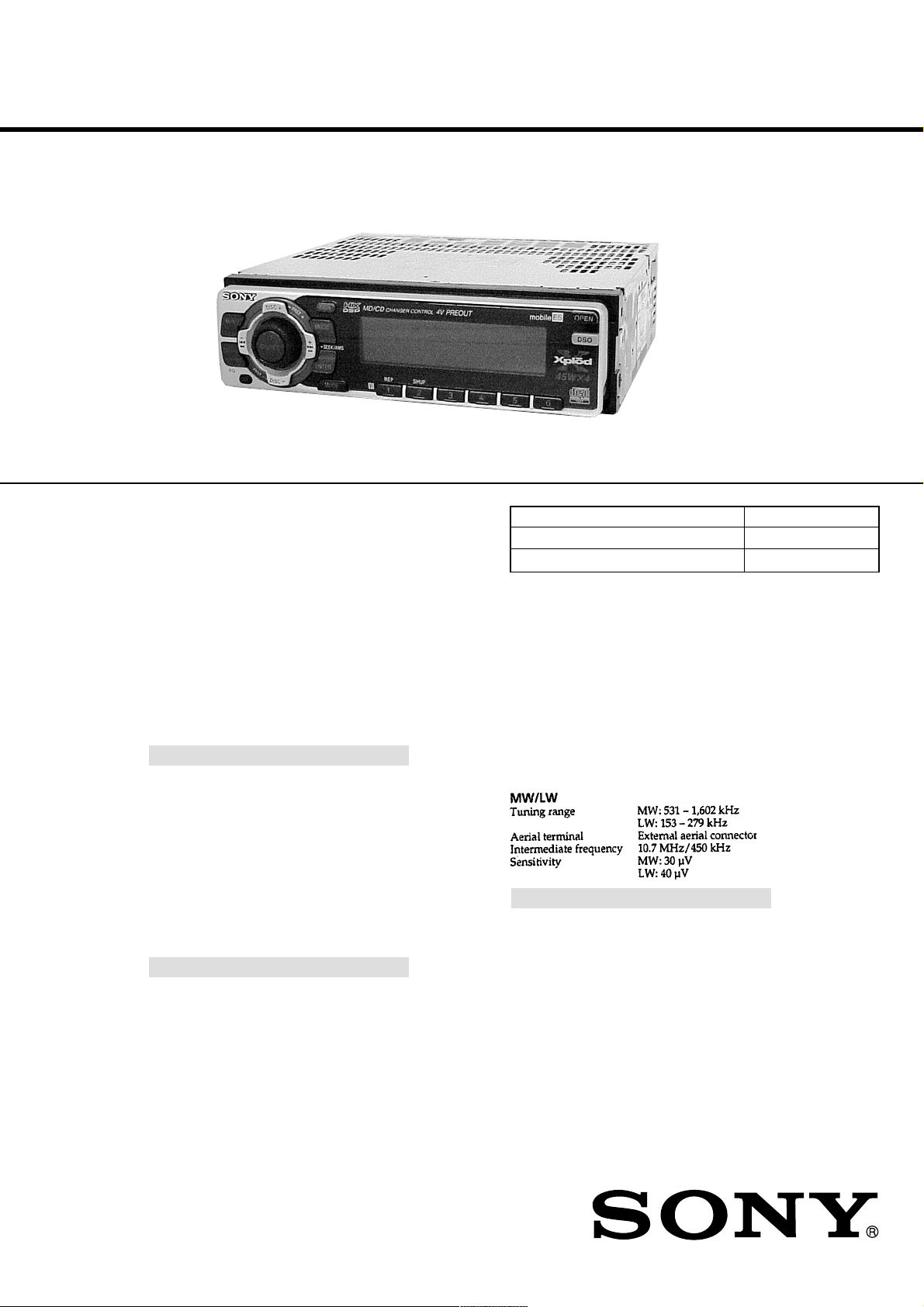

Photo: MDX-C8500X

Model Name Using Similar Mechanism NEW

Base Mechanism Type MG-164NV-138

Optical Pick-up Name KMS-241C/J1NP

SPECIFICATIONS

AUDIO POWER SPECIFICATIONS (MDX-C8500X)

POWER OUTPUT AND TOTAL HARMONIC DISTORTION

19 watts per channel minimum continuous average power into 4ohms, 4

channels driven from 10 Hz to 20 kHz with no more than 1% total harmonic

distortion.

US Model

MDX-C8500X

AEP Model

UK Model

MDX-C8500R

Other specifications

Disc player section

MD player

Signal-to-noise ratio 90 dB

Frequency response 10 – 20,000 Hz

Wow and flutter Below measurable limit

Laser Diode Properties

Material GaAlAs

Wavelength 780 nm

Emission Duration Continuous

Laser output power Less than 44.6 W*

* This output is the value measured at a distance

of 200 mm from the objective lens surface on

the Optical Pick-up Block.

Tuner section

FM

Tuning range 87.5 – 107.9 MHz

87.5 – 108.0 MHz

Antenna terminal External antenna connector

Intermediate frequency 10.7 MHz/450 kHz

Usable sensitivity 8 dBf

Selectivity 75 dB at 400 kHz

Signal-to-noise ratio 66 dB (stereo),

Harmonic distortion at 1 kHz

Separation 35 dB at 1 kHz

Frequency response 30 – 15,000 Hz

72 dB (mono)

0.6 % (stereo),

0.3 % (mono)

(MDX-C8500X)

(MDX-C8500R)

AM (MDX-C8500X)

Tuning range 530 – 1,710 kHz

Antenna terminal External antenna connector

Intermediate frequency 10.7 MHz/450 kHz

Sensitivity 30 µV

Outputs Speaker outputs

Speaker impedance 4 – 8 ohms

Maximum power output 50 W × 4 (at 4 ohms)

(MDX-C8500R)

Power amplifier section

(sure seal connectors)

– Continued on next page –

FM/AM(MW/LW) MINIDISC PLAYER

General

Outputs Audio outputs

Power requirements 12 V DC car battery

Dimensions Approx. 178 × 50 × 183 mm

Mounting dimensions Approx. 182 × 53 × 162 mm

Mass Approx. 1.2 kg (2 lb 10 oz)

Supplied accessories Card remote commander

Power antenna relay

control lead

Power amplifier control

lead

Telephone ATT control

lead

(negative ground)

1

(7

(w/h/d)

1

(7

(w/h/d)

RM-X91 (MDX-C8500X)

Parts for installation and

connections (1 set)

Front panel case (1)

/

× 2 × 7

8

/

× 2

4

1

/8 in.)

1

3

/

× 6

/8 in.)

8

TABLE OF CONTENTS

1. SERVICING NOTES ............................................... 3

2. GENERAL

Location of Controls ....................................................... 4

Setting the Clock ............................................................. 4

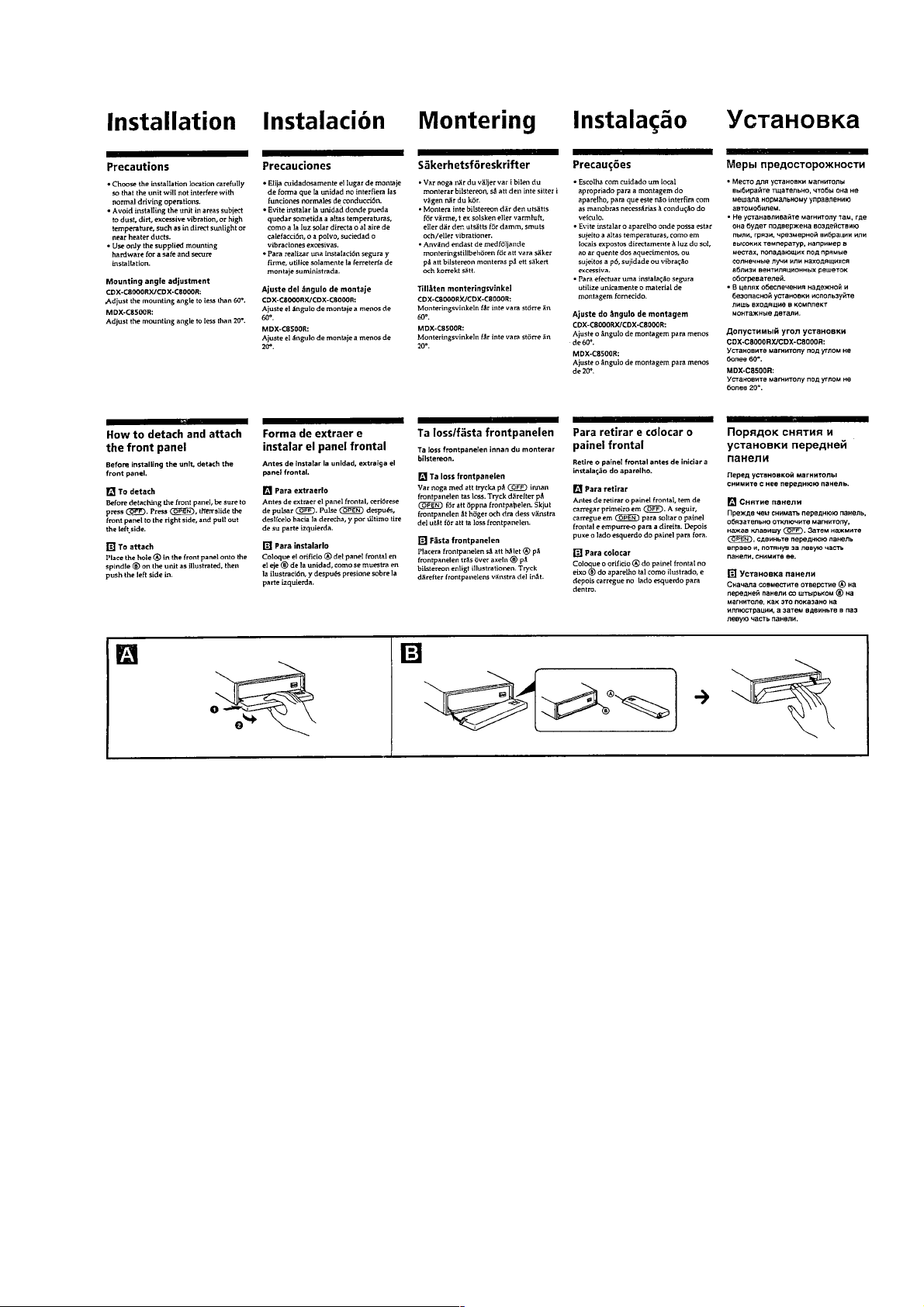

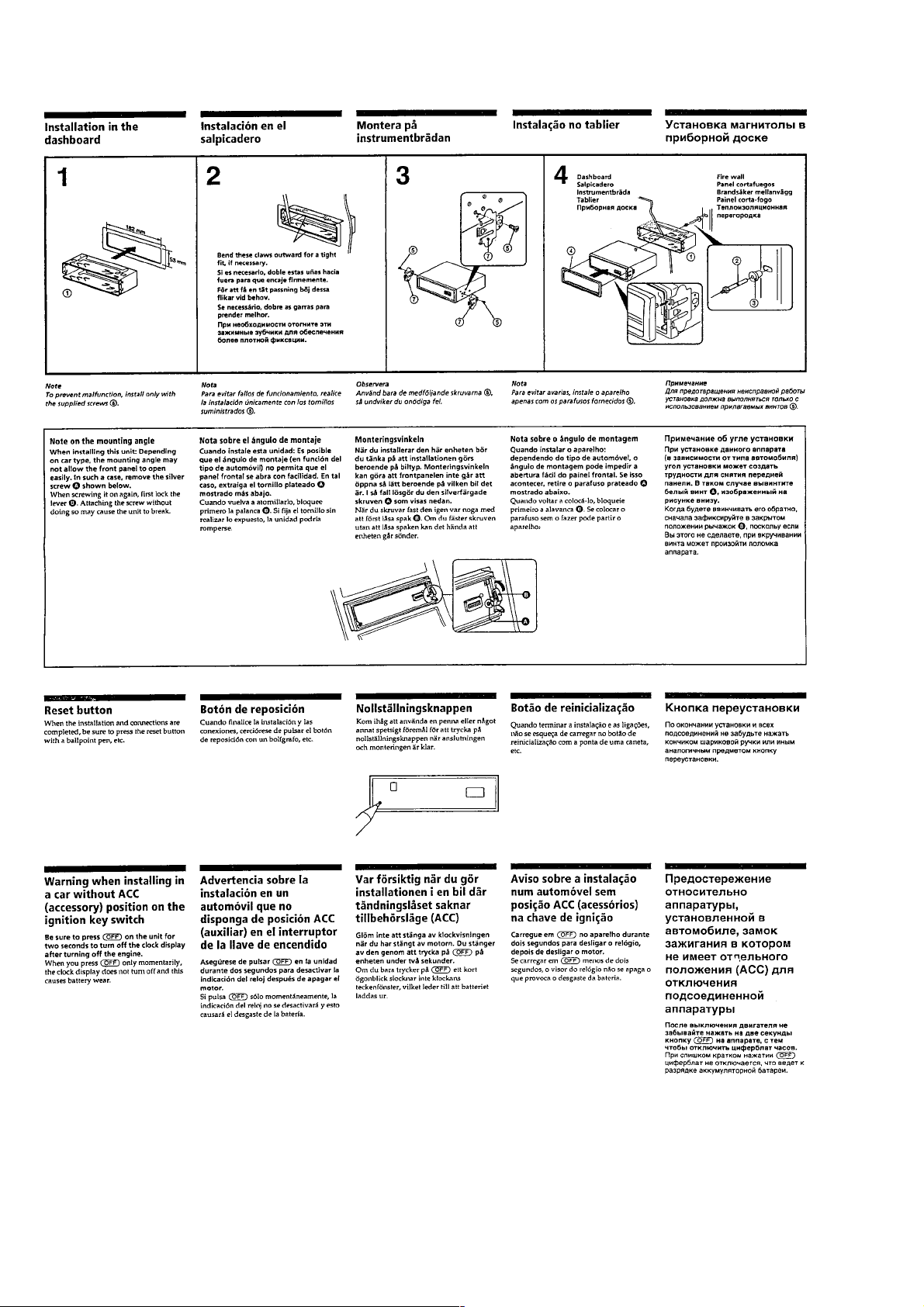

Installation....................................................................... 5

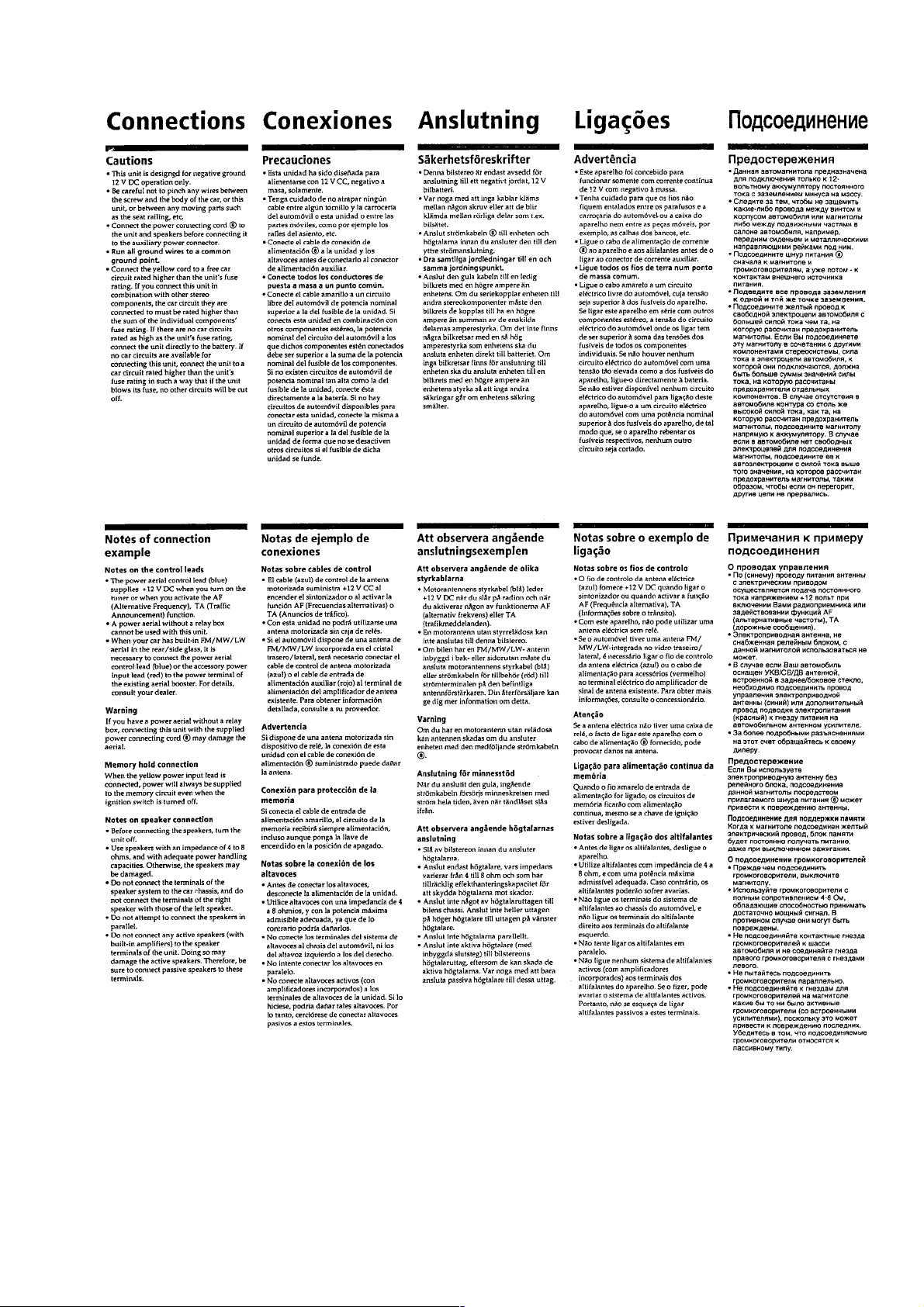

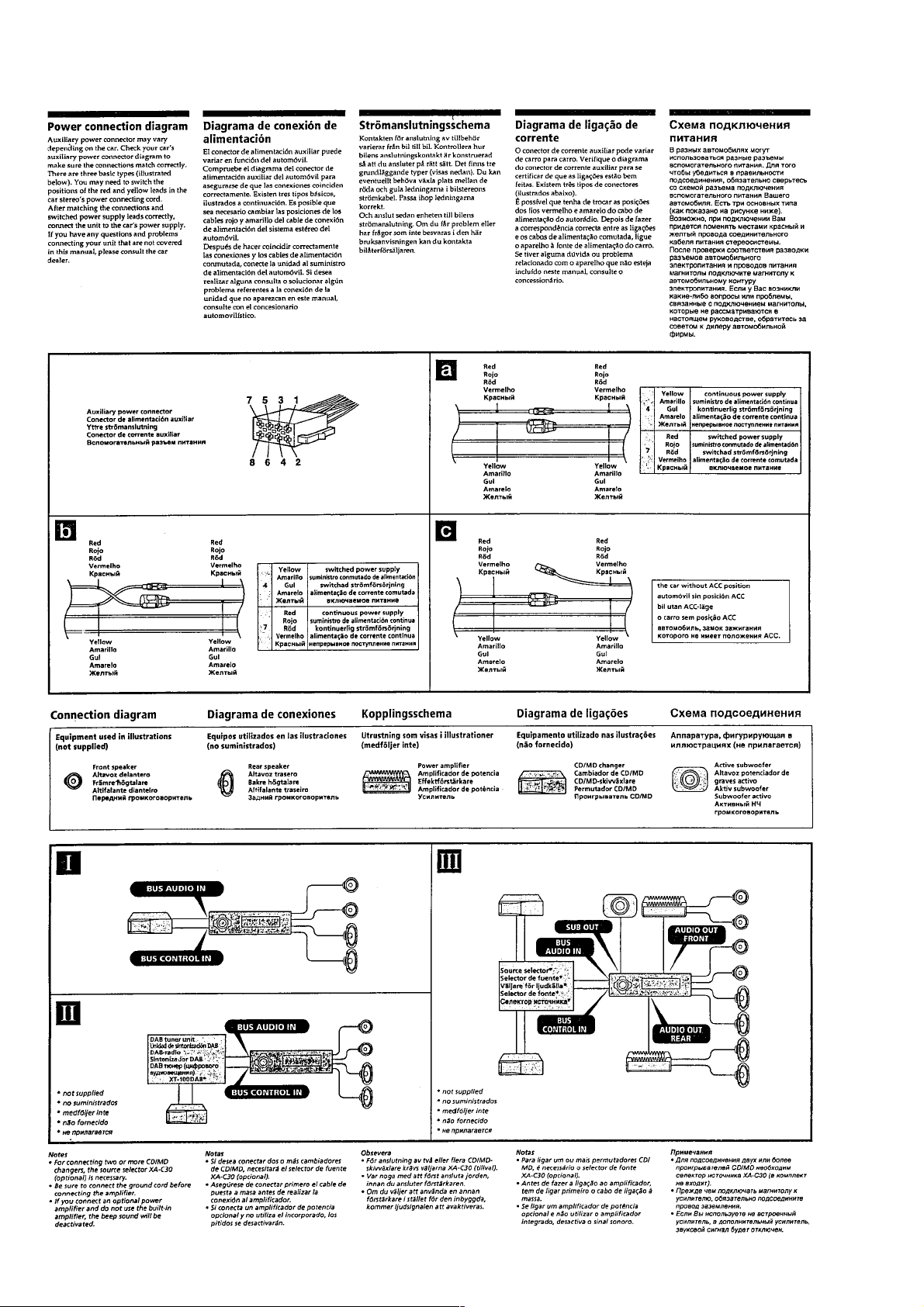

Connections ..................................................................... 7

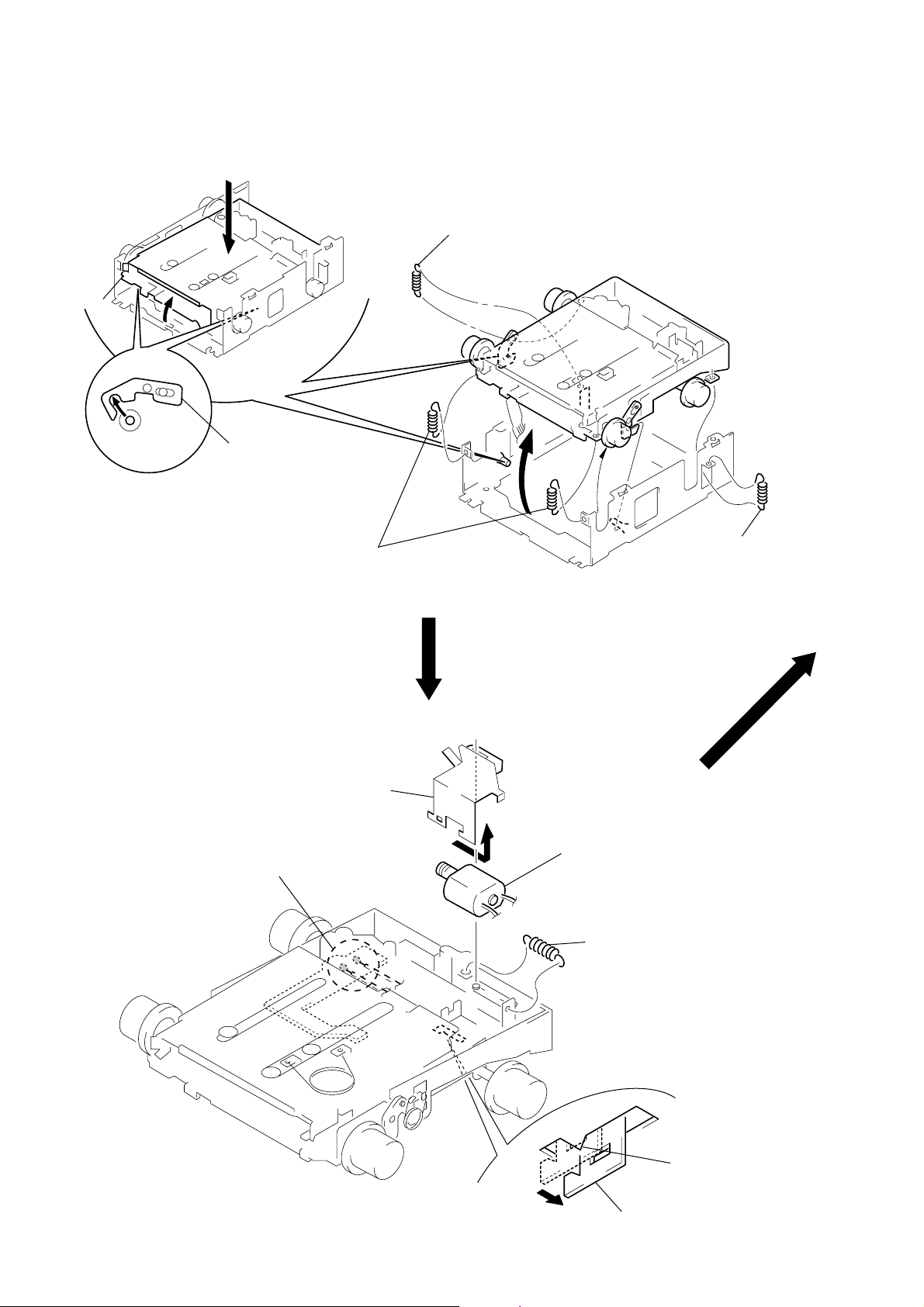

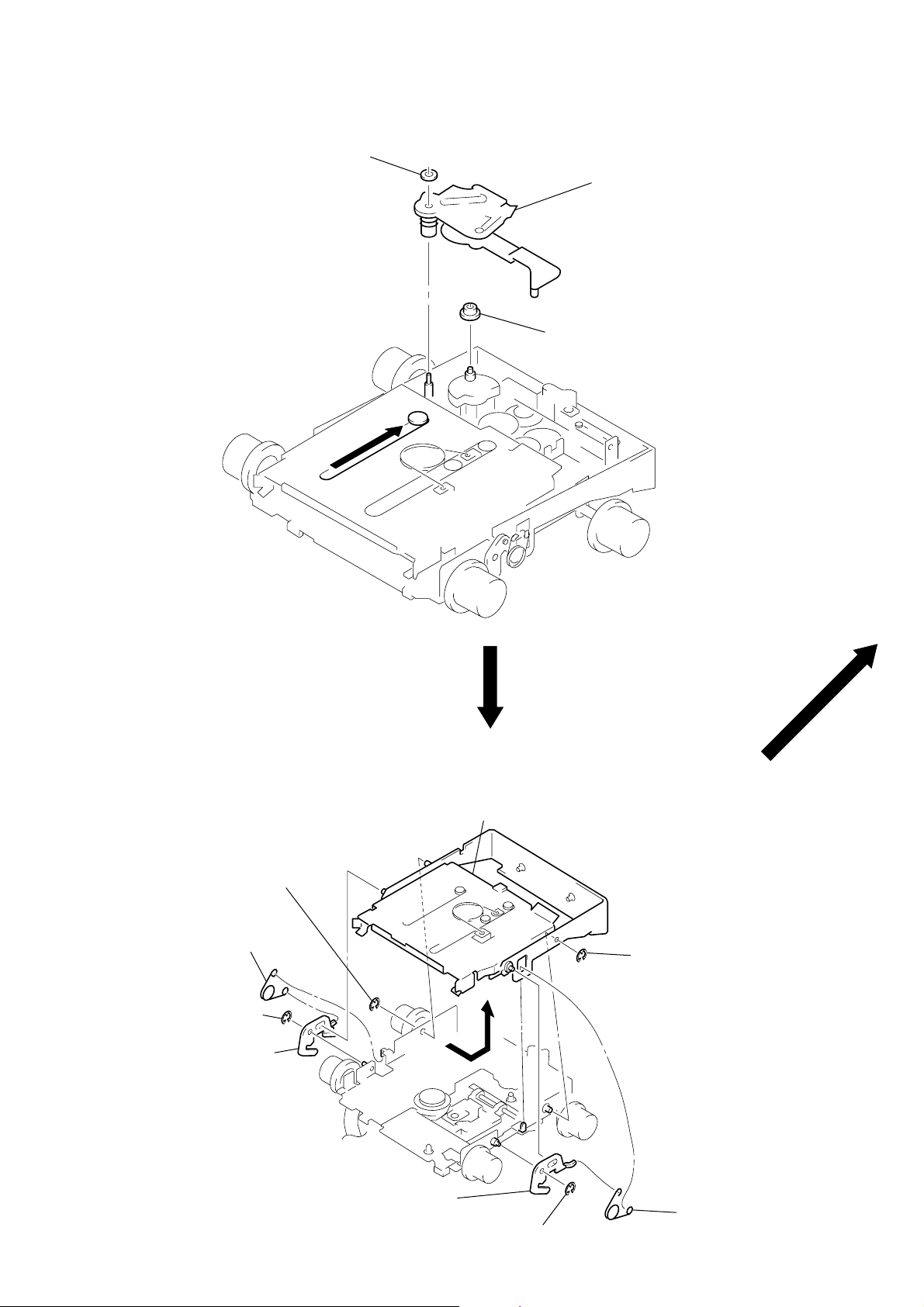

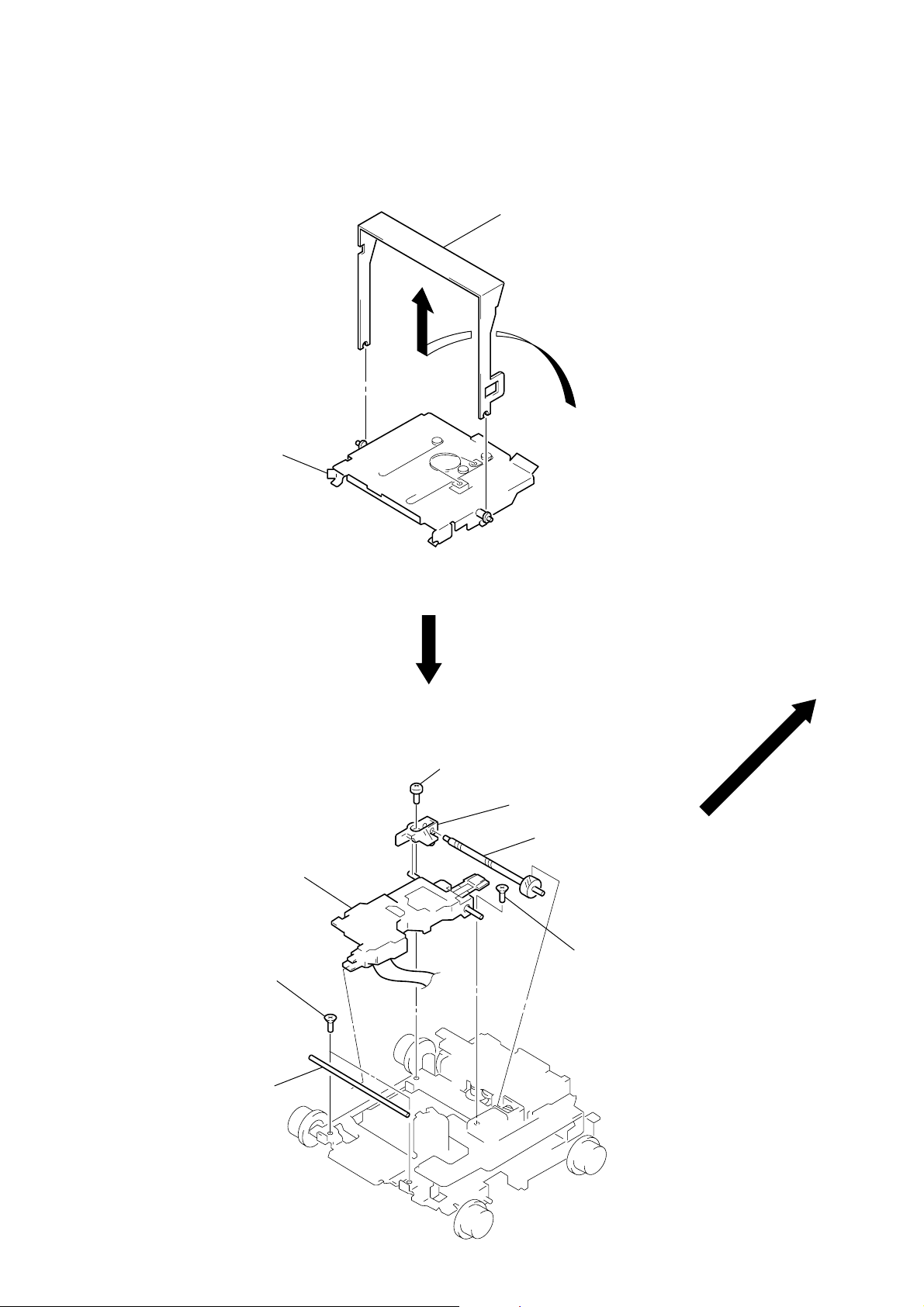

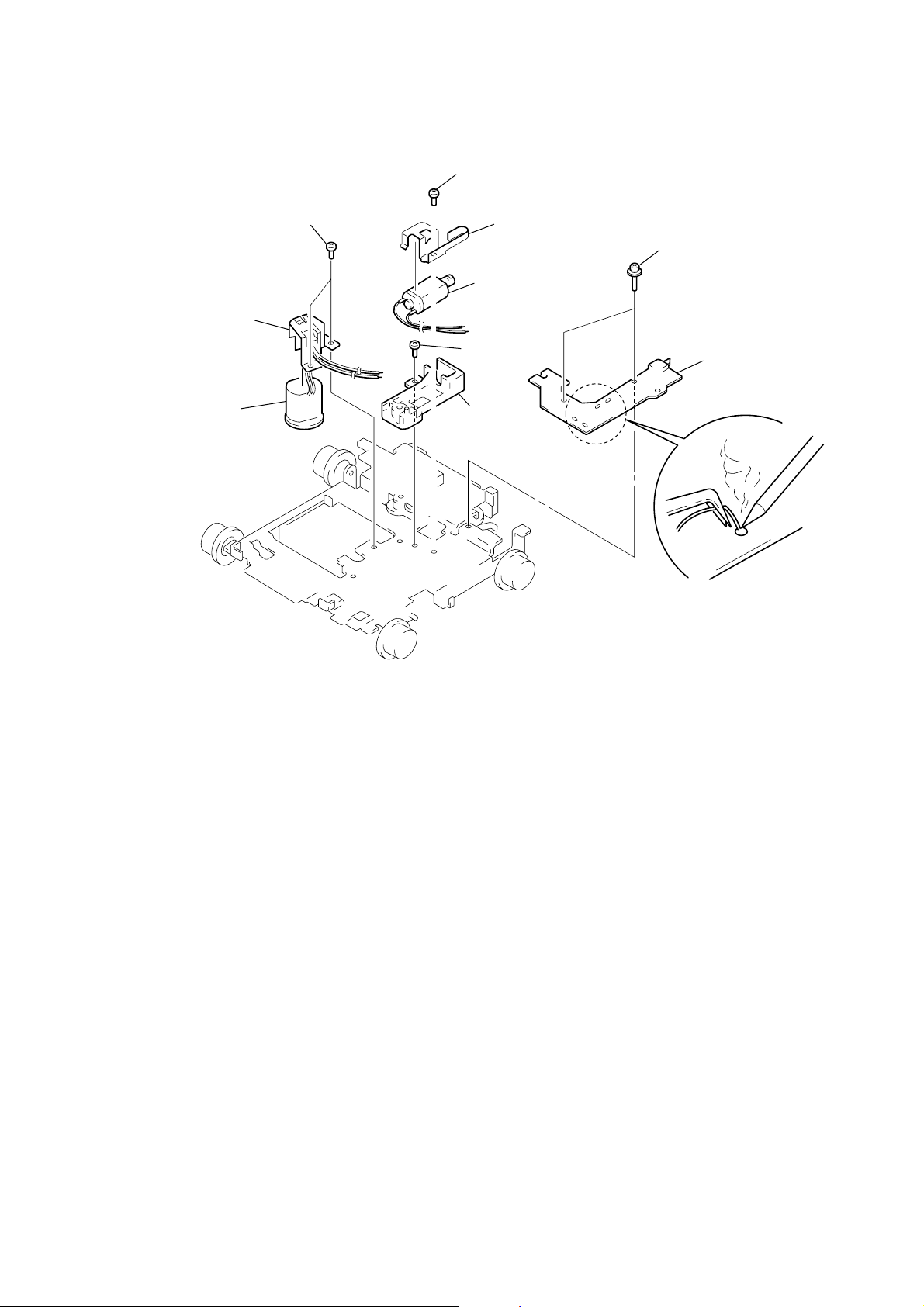

3. DISASSEMBLY ......................................................... 11

4. ELECTRICAL ADJUSTMENTS

Test Mode........................................................................ 18

MD Section ..................................................................... 18

Tuner Section .................................................................. 18

U.S. and foreign patents licensed from Dolby

laboratories Licensing Corporation.

Design and specifications are subject to change

without notice.

5. DIAGRAMS

5-1. Block Diagram – SERVO Section –............................... 19

5-2. Block Diagram – TUNER Section – .............................. 20

5-3. Block Diagram – MAIN Section –................................. 21

5-4. Block Diagram

– DISPLAY/KEY CONTROL Section –........................ 22

5-5. Block Diagram

– BUS CONTROL/POWER SUPPLY Section –........... 23

5-6. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 24

5-7. Printed Wiring Boards

– SERVO Board (Component Side)/

SENSOR Board –............................................................ 26

5-8. Printed Wiring Board

– SERVO Board (Conductor Side) – .............................. 27

5-9. Schematic Diagram

– SERVO Board (1/2)/ SENSOR Board–...................... 28

5-10. Schematic Diagram – SERVO Board (2/2) –................. 29

5-11. Printed Wiring Board

– MAIN Board (Component Side) – .............................. 30

5-12. Printed Wiring Board

– MAIN Board (Conductor Side) – ................................ 31

5-13. Schematic Diagram – MAIN Board (1/4) – ................... 32

5-14. Schematic Diagram – MAIN Board (2/4) – ................... 33

5-15. Schematic Diagram – MAIN Board (3/4) – ................... 34

5-16. Schematic Diagram – MAIN Board (4/4) – ................... 35

5-17. Printed Wiring Board – DSO Board – ............................ 36

5-18. Schematic Diagram – DSO Board – ............................... 37

5-19. Printed Wiring Board – SUB Board – ............................ 38

5-20. Schematic Diagram – SUB Board – ............................... 39

5-21. Printed Wiring Board – KEY Board –............................ 40

5.22. Schematic Diagram – KEY Board – .............................. 41

5-23. IC Pin Function Description ........................................... 47

6. EXPLODED VIEWS ................................................ 59

7. ELECTRICAL PARTS LIST ............................... 63

2

SECTION 1

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

Never look into the laser diode emission from right avove when

checking it for adustment. It is feared that you will lose your sight.

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

(KMS-241C/J1NP)

The laser diode in the optical pick-up block may suffer electrostatic break-down easily. When handling it, perform soldering

bridge to the laser-tap on the flexible board. Also perform m easures

against electrostatic break-down suff iciently before the operation.

The flexible board is easily damaged and should be handled with

care.

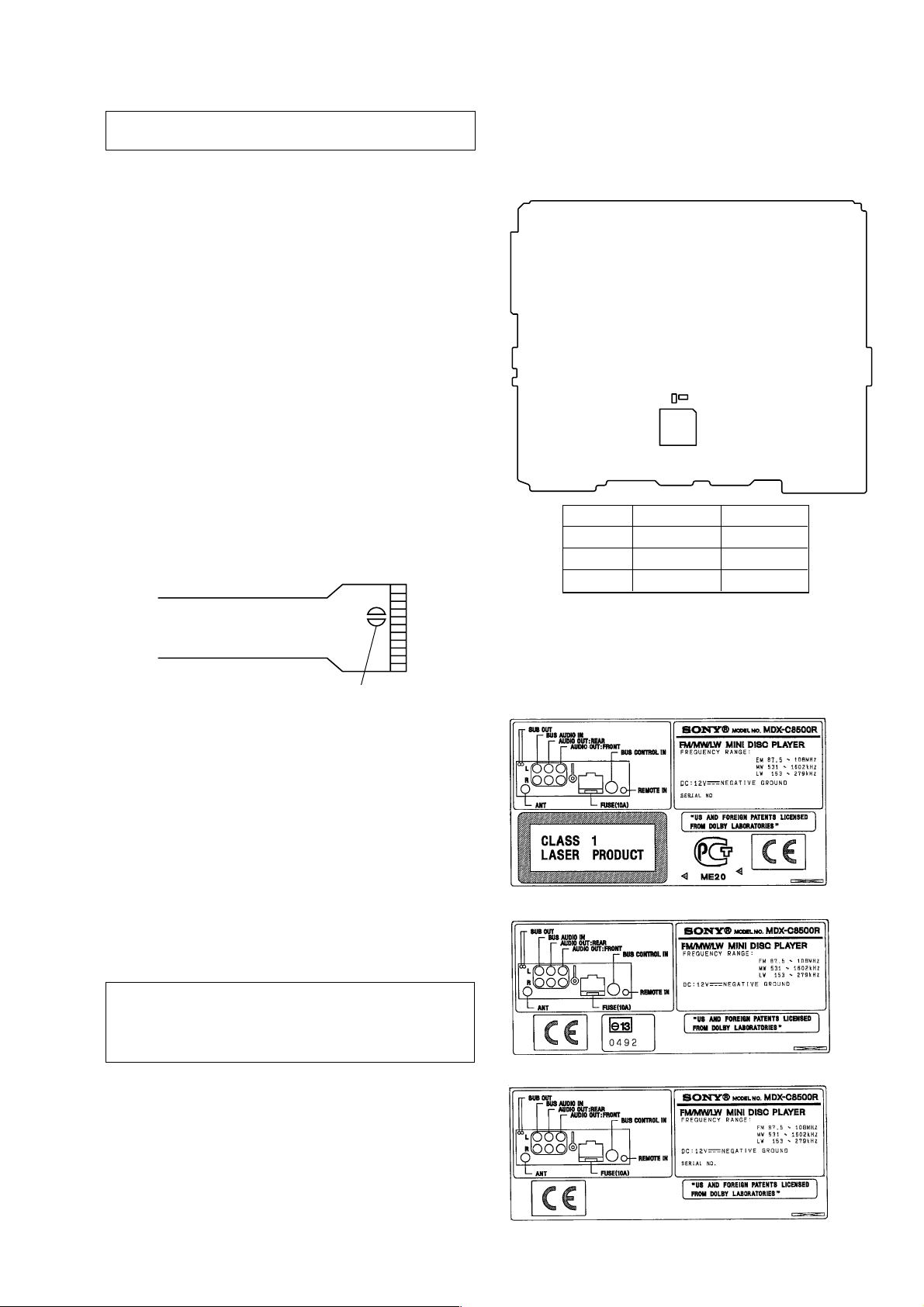

• Model Identification

There are three types of main board in according of destination

for MDX-C8500R.

– MAIN BOARD (Component Side)

R502 R503

IC502

R502 R503

TYPE A a ×

TYPE B × a

TYPE C aa

laser-tap

OPTICAL PICK-UP FLEXIBLE BOARD

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

Type A, B and C can be identified by its model number label at

the buttom of the set.

– SPECIFICATION LABEL –

TYPE A

TYPE B

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANU AL OR IN SUPPLEMENTS PUBLISHED BY SONY.

TYPE C

3

SECTION 2

GENERAL

This section is extracted from

instruction manual.

Setting the clock

The clock uses a 12-hour digital indication.

Example: To set the clock to 10:08

1 Press (MENU), then press either side of

(DISC/PRST) repeatedly until “Clock”

appears.

1 Press (ENTER).

The hour indication flashes.

2 Press either side of (DISC/PRST) to set

the hour.

3 Press (+) side of (SEEK/AMS).

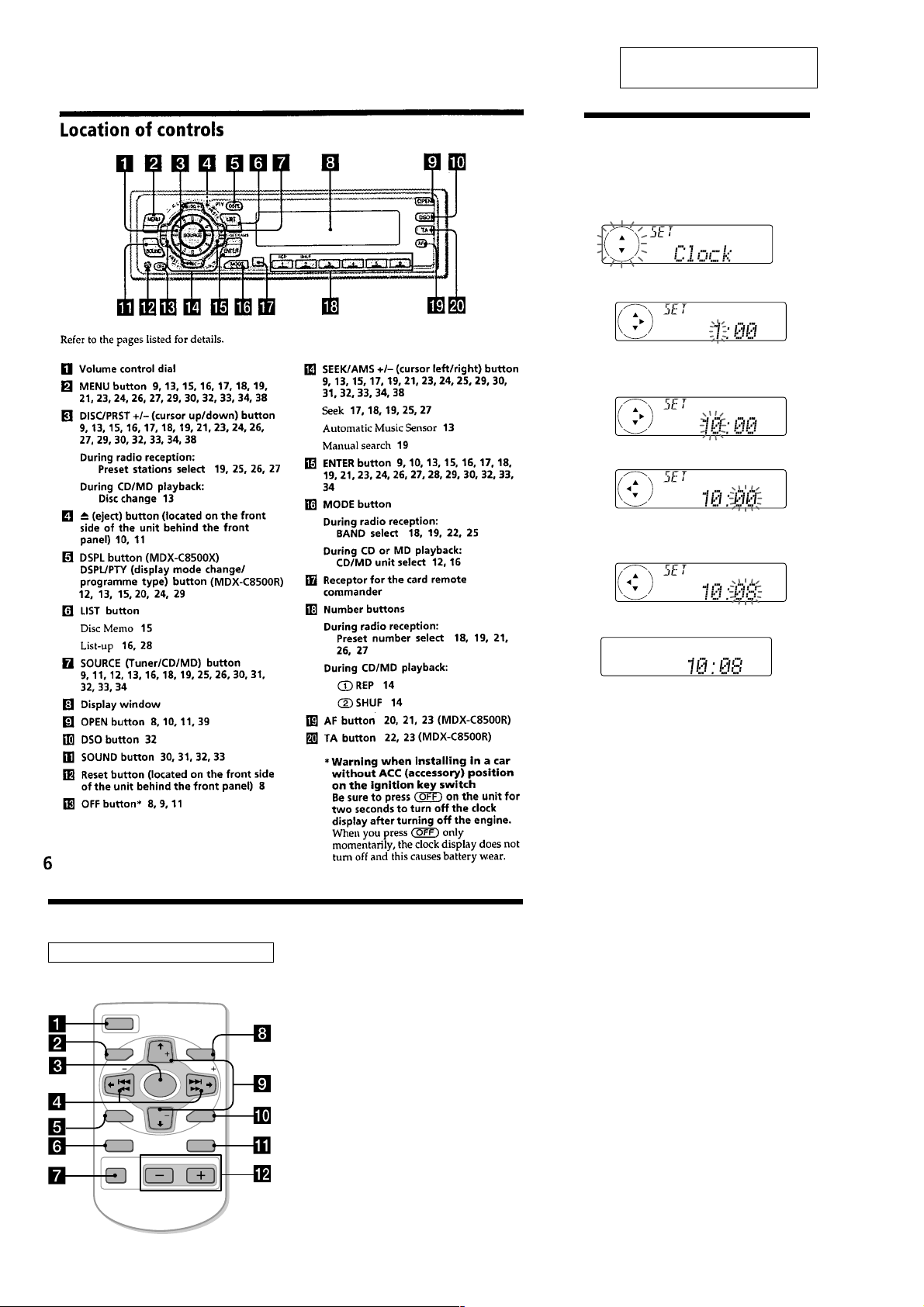

Location of controls (MDX-C8500X)

Card remote commander RM-X91

The minute indication flashes.

4 Press either side of (DISC/PRST) to set

the minute.

2 Press (ENTER).

The clock starts.

After the clock setting is completed, the

display returns to normal playback mode.

Tip

You can set the clock automatically with the RDS

feature (see page 24). (MDX-C8500R)

Note

In the initial setting, the clock indication appears

while the unit is turned off.

When you select the “on” setting of the “D.Info”

item (page 29), you can see the clock indication in

the upper part of the display while you are

enjoying any source.

The corresponding buttons of the card

remote commander control the same

functions as those on this unit.

1 OFF button

2 MENU button

3 SOURCE button

4 SEEK/AMS (cursor </,) buttons

5 SOUND button

6 DSPL button

7 ATT button

8 LIST button

9 DISC/PRST (cursor M/m) buttons

0 ENTER button

qa MODE button

qs VOL buttons

DISC

SOURCE

DISC

OPEN/CLOSE

ENTER

VOLATT

OFF

MENU LIST

SEEK SEEK

SOUND

DSPL MODE

4

56789

(MDX-C8500R)

y

(MDX-C8500X)

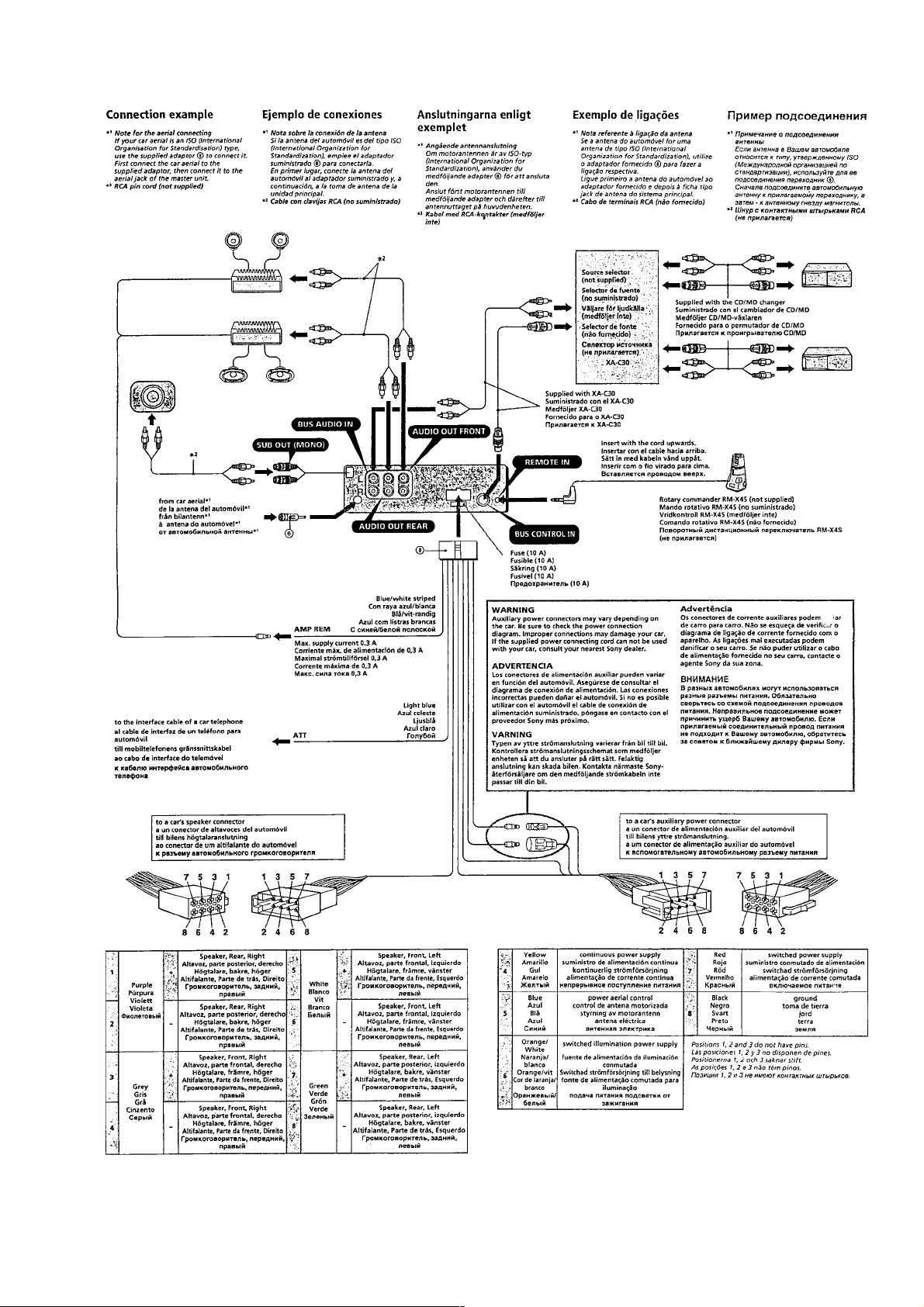

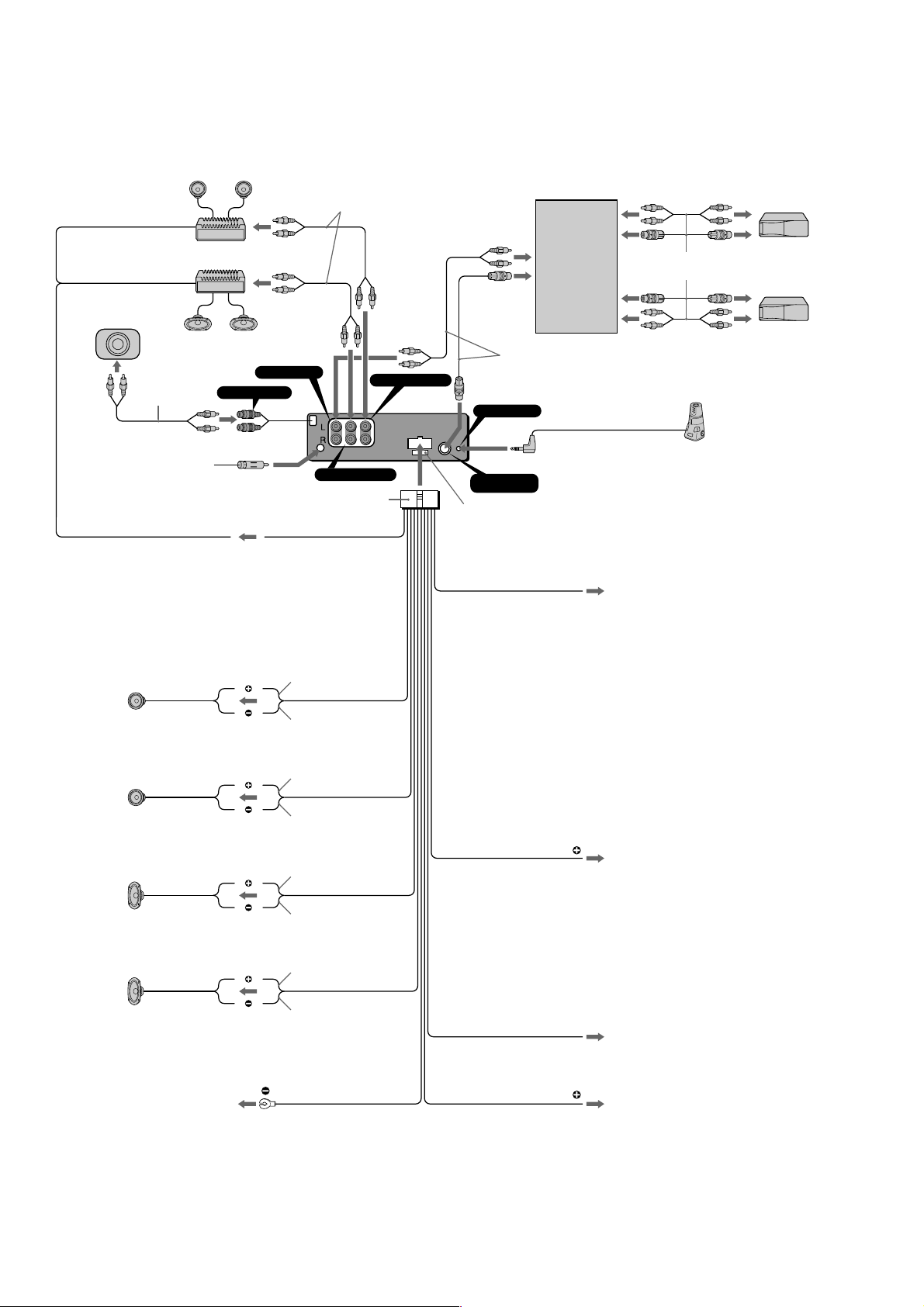

Connection example

Exemple de connection

Ejemplo de conexiones

*

from car antenna

de l’antenne de la voiture

de la antena del automóvil

To AMP REMOTE IN of an optional power amplifier.

This connection is only for amplifiers. Connecting any

other system may damage the unit.

Pour effectuer le raccordement à AMP REMOTE IN de

l’amplificateur de puissance en option.

Cette connexion s’applique uniquement aux

amplificateurs. Le branchement de tout autre système

risque d’endommager l’appareil.

Para conectar a AMP REMOTE IN del amplificador de

potencia opcional.

Esta conexión es sólo para amplificadores.

La conexión de cualquier otro sistema puede dañar la

unidad.

Left

Gauche

Izquierdo

Right

Droit

Derecho

Left

Gauche

Izquierdo

Right

Droit

Derecho

to a metal surface of the car

First connect the black ground lead, then connect the

yellow and red power input reads.

vers un point métallique de la voiture

Branchez d‘abord le fil de masse noir et, ensuite, les fils

d‘entrée d‘alimentation jaune et rouge.

a un punto metálico del automóvil

En primer lugar conecte el conductor de puesta a masa

negro y, a continuación, los cables de entrada de

alimentación amarillo

rojo.

BUS AUDIO IN

SUB OUT (MONO)

AMP REM

Max. supply current 0.3 A

Courant max. fourni 0,3 A

Corriente máx. de

alimentación de 0,3 A

*

AUDIO OUT REAR

Blue/white striped

Rayé bleu/blanc

Con raya azul/blanca

White

Blanc

Blanco

White/black striped

Rayé blanc/noir

Con raya blanco/negro

Grey

Gris

Gris

Gray/black striped

Rayé gris/noir

Con raya gris/negro

Green

Vert

Verde

Green/black striped

Rayé vert/noir

Con raya verde/negro

Purple

Mauve

Púrpura

Purple/black striped

Rayé mauve/noir

Con raya púrpura/negro

AUDIO OUT FRONT

8

Black

Noir

Negro

Source selector

(not supplied)

Sélecteur de source

(non fourni)

Selector de fuente

(no suministrado)

Supplied to XA-C30

Fourni avec le XA-C30

Suministrado con el XA-C30

REMOTE IN

BUS

CONTROL IN

Fuse (10 A)

Fusible (10 A)

Fusible (10 A)

Blue

Bleu

Azul

Max. supply current 0.1 A

Courant max. fourni 0,1 A

Corriente máx. de alimentación de 0,1 A

Red

Rouge

Rojo

Light blue

Bleu ciel

Azul celeste

Yellow

Jaune

Amarillo

Insert with the cord upwards.

Insérez avec le câble vers le haut.

Insertar con el cable hacia arriba.

ANT REM

*

RCA pin cord (not supplied)

Cordon à broche RCA (non fourni)

Cable con pines RCA (no suministrado)

Supplied to the CD/MD changer

Fourni avec le changeur de CD/MD

Suministrado con el cambiador de CD/MD

XA-C30

Rotary commander RM-X4S (not supplied)

Satellite de commande RM-X4S (non fourni)

Mando rotativo RM-X4S (no suministrado)

to the power antenna control lead or power supply lead of

antenna booster amplifier

Notes

• It is not necessary to connect this lead if there is no power

antenna or antenna booster, or with a manually-operated

telescopic antenna.

• When your car has a built-in FM/AM antenna in the rear/side

glass, see “Notes on the control and power supply leads.”

vers le fil de commande de l‘antenne électrique ou le fil

d‘alimentation de l‘amplificateur d‘antenne

Remarques

• Il n’est pas nécessaire de raccorder ce fil s’il n’y a pas

d’antenne électrique ni d’amplificateur d’antenne, ou avec

une antenne télescopique manuelle.

• Si votre voiture est équipée d’une antenne FM/AM intégrée

dans la vitre arrière/latérale, voir les “Remarques sur les

câbles de commande et d’alimentation”.

al cable de control de la antena motorizada o al cable de

fuente de alimentación del amplificador de antena

Notas

• Si no se dispone de antena motorizada ni de amplificador de

antena, o se utiliza una antena telescópica accionada

manualmente, no será necesario conectar este cable.

• Si el automóvil incorpora una antena de FM/AM en el cristal

trasero/lateral, consulte “Notas sobre los cables de control y

de fuente de alimentación”.

to the +12 V power terminal which is energized in the

accessory position of the ignition key switch

Notes

• If there is no accessory position, connect to the +12 V power

(battery) terminal which is energized at all times.

Be sure to connect the black ground to it first.

• When your car has a built-in FM/AM antenna in the rear/side

glass, see “Notes on the control and power supply leads.”

à la borne +12 V qui est alimentée quand la clé de contact

est sur la position accessoires

Remarques

• S’il n’y a pas de position accessoires, raccordez la borne

d’alimentation (batterie) +12 V qui est en permanence sous

tension.

Veillez à raccorder le fil noir en premier lieu.

• Si votre voiture est équipée d’une antenne FM/AM intégrée

dans la vitre arrière/latérale, voir les “Remarques sur les

câbles de commande et d’alimentation”.

al terminal de alimentación de +12 V que se active en la

posición auxiliar de la llave de encendido

Notas

• Si no existe posición auxiliar, realice la conexión al terminal

de alimentación (batería) de +12 V que reciba energía

permanentemente.

Asegúrese de conectar primero a este terminal el conductor

de puesta a masa negro.

• Si el automóvil incorpora una antena de recepción de FM/

AM en el cristal trasero/lateral, consulte “Notas sobre los

cables de control y de fuente de alimentación”.

to the interface cable of a car telephone

ATT

vers le cordon de liaison d’un téléphone de voiture

al cable de interfaz de un teléfono para automóvil

to the +12 V power terminal which is energized at all times

Be sure to connect the black ground to it first.

à la borne +12 V qui est alimentée en permanence

Raccordez d‘abord le fil de masse noir.

al terminal de alimentación de +12 V que esté

permanentemente energizado

Asegúrese de conectar primero a este terminal el conductor de

puesta a masa negro.

10

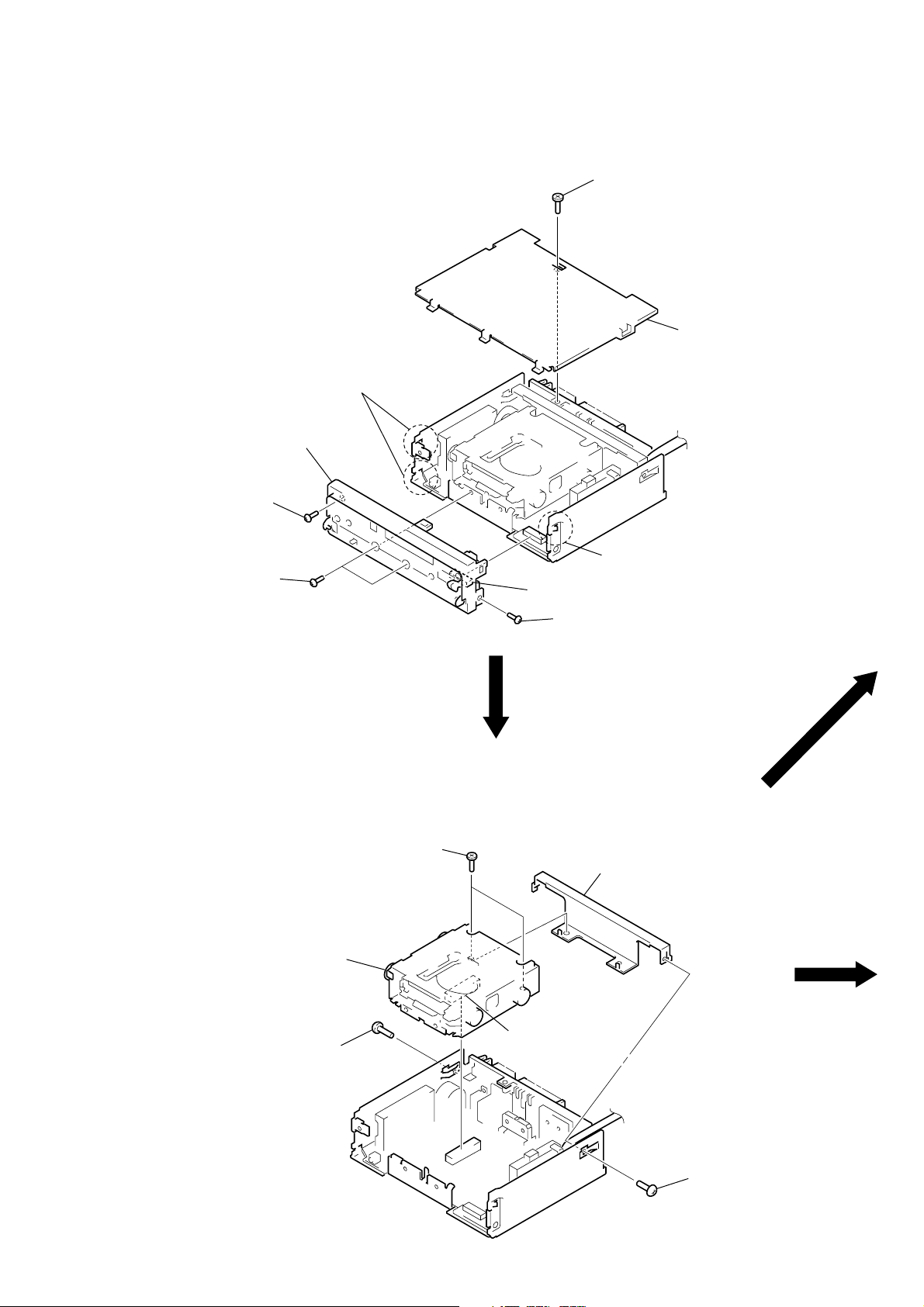

SECTION 3

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

SUB PANEL ASS’Y

4 two claws

6 sub panel ass’y

3 screw

(PTT2.6 × 8)

1 screw

(PTT2.6 × 6)

2 cover

3 two screws

(PTT2.6 × 8)

MECHANISM DECK (MG-164NV-138)

3 two screws

(PTT2.6 × 10)

5 mechanism deck

(MG-164NV-138)

4 claw

5 connector (CN752)

3 screw

(PTT2.6 × 8)

4 bracket (MD)

1 screw

(PTT2.6 × 6)

2 connector

(CN101)

1 screw

(PTT2.6 × 6)

11

SERVO BOARD

d

)

1 sensor flexible board

2 two screws

(BVTT2 × 4)

2 two screws

(BVTT2 × 4)

3 servo board

(CN102)

1 flexible boar

(CN103)

MAIN BOARD

2 three ground point

4 cord (with connector) (sub out)

5 two screws

(PTT2.6 × 10)

3 screw (PTT2.6 × 10

screws

1 connector (CN301)

6 main board

12

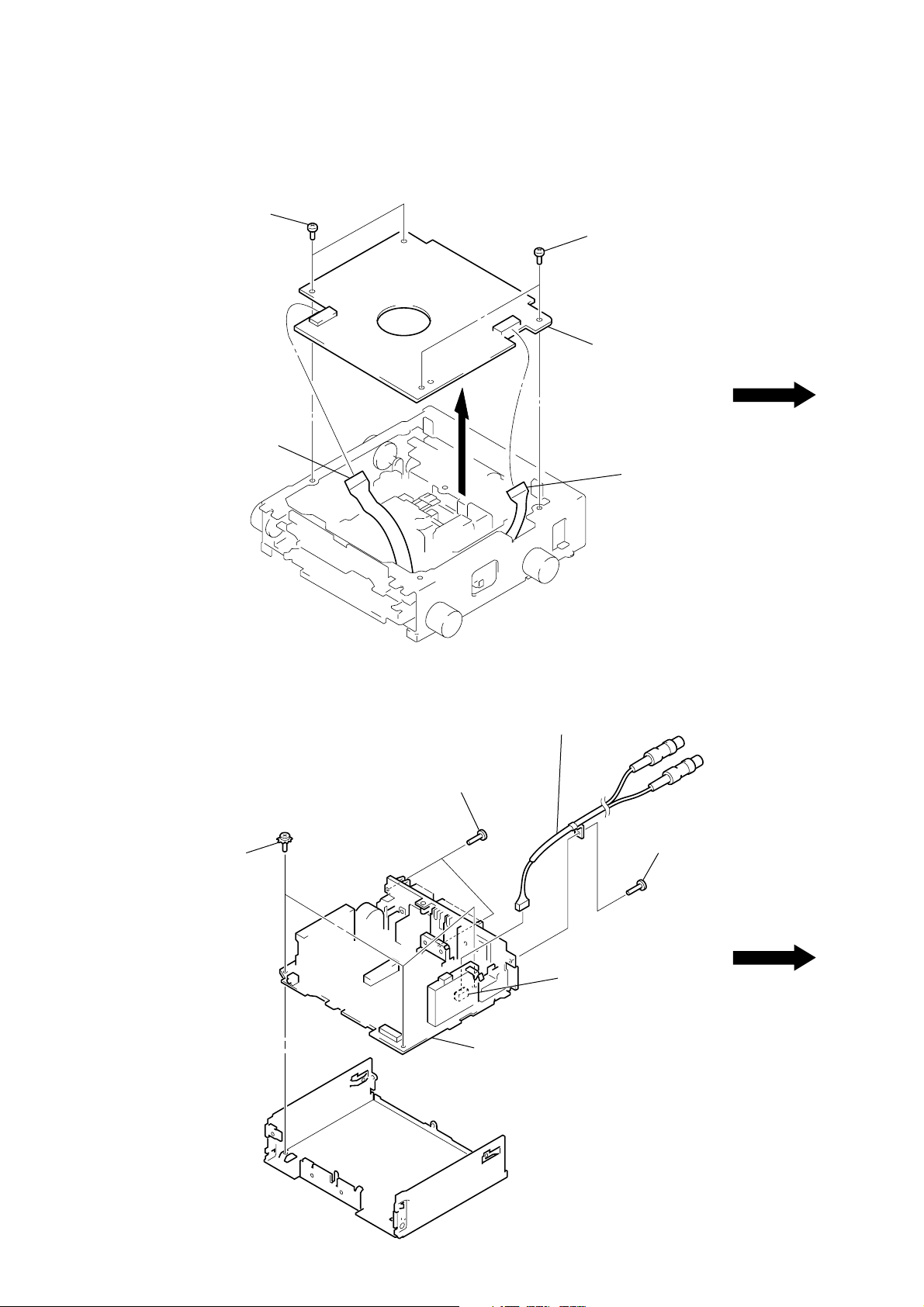

MD COVER ASS’Y

s

3 MD cover ass’y

cassette holder

1 four screws

(B2 × 3)

shaft (MD cover guide)

HEAT SINK

A

2 Pushing the Cassette Holder in the direction of arrow A with a

screwdriver, etc., disengage the Shaft (MD Cover Guide) from

the slot in the MD Cover Assy.

Note: Take care not to scratch the optiocal Pick-up when pushing

the Cassette Holder with a screwdriver. etc.

1 four screws

(PTT2.6 × 8)

2 two screws

(PTT2.6 × 12)

3 heat sink

1 three screw

(PTT2.6 × 8)

13

FLOAT BLOCK

)

3 Pushing arrow A part, raise the float block

up ward at the front to release a lock.

float block

A

lever (lock R)

lever (lock L)

1 tension spring (float B)

1 tension spring (float B

2 two tension springs (float F)

LO MOTOR ASS’Y (LOADING) (M903)

4 Remove the bracket (LO)

in the direction of arrow A.

1 Remove solders of motor (M903)

A

5 LO motor ass’y (loading)

(M903)

2 tension spring (rack)

3 claw

14

bracket (LO)

– bottom view –

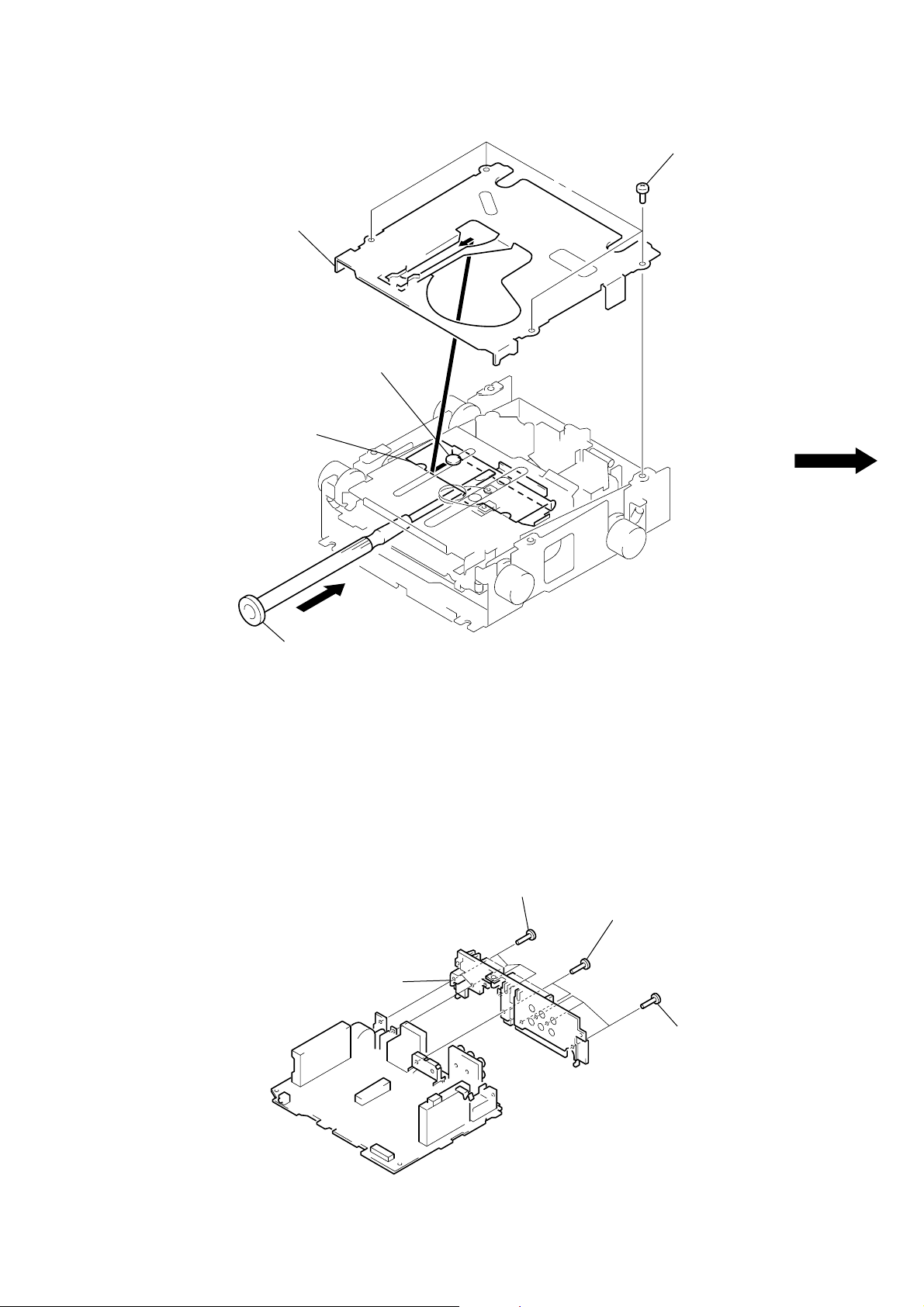

LEVER (LE) ASS’Y

2

stopper washer

1

2

3

roller (gear E)

lever (LE) ass’y

HOLDER ASS’Y

2 type-E stopring 1.5

1 spring (chucking)

2 type-E stopring 1.5

3 lever (lock R)

4 Remove the holder ass’y in the

direction of the arrow.

2 type-E stopring 1.5

3 lever (lock L)

2 type-E stopring 1.5

1 spring (chucking)

15

CHUCKING ARM ASS’Y

y

holder ass’y

1 Remove the chucking arm ass’y

in the direction of the arrow.

OPTICAL PICK-UP (KMS-241C/J1NP)

7 optical pick-up

(KMS-241C/J1NP)

1 two screws

(K2 × 3)

2 guide shaft (OPT L)

4 screw

(B2 × 3)

6 bearing (SL)

5 feed screw ass’

3 screw

(K2 × 3)

16

SL MOTOR ASS’Y (SLED) (M902), SP MOTOR ASS’Y (SPINDLE) (M901)

4 screw

(P1.7 × 1.8)

5 bracket (SL)

9 two screws

(P1.7 × 1.8)

0 bracket (SP)

qa SP motor ass’y

(spindle) (M901)

7 screw

(B2 × 3)

2 two screws

(2 × 8)

3 sensor board

1 Remove solders of motors

(M901, M902)

8 base (SL)

6 SL motor ass’y

(sled) (M902)

17

SECTION 4

ELECTRICAL ADJUSTMENTS

TEST MODE

This set have the test mode function.

<Set the Test Mode>

1. Turn ON the regulated power supply. (The clock is displayed)

Note: Press the [OFF] button, if the clock is not displayed.

2. Push the preset [4] button.

3. Push the preset [5] button.

4. Press the preset [1] button for more than two seconds.

5. Then the display indicates all lights, the test mode is set.

<Release the Test mode>

1. Push the [OFF] button.

MD SECTION

MD section adjustments are done automatically in this set.

TUNER SECTION

Tuner section adjustments are done automatically in this set.

18

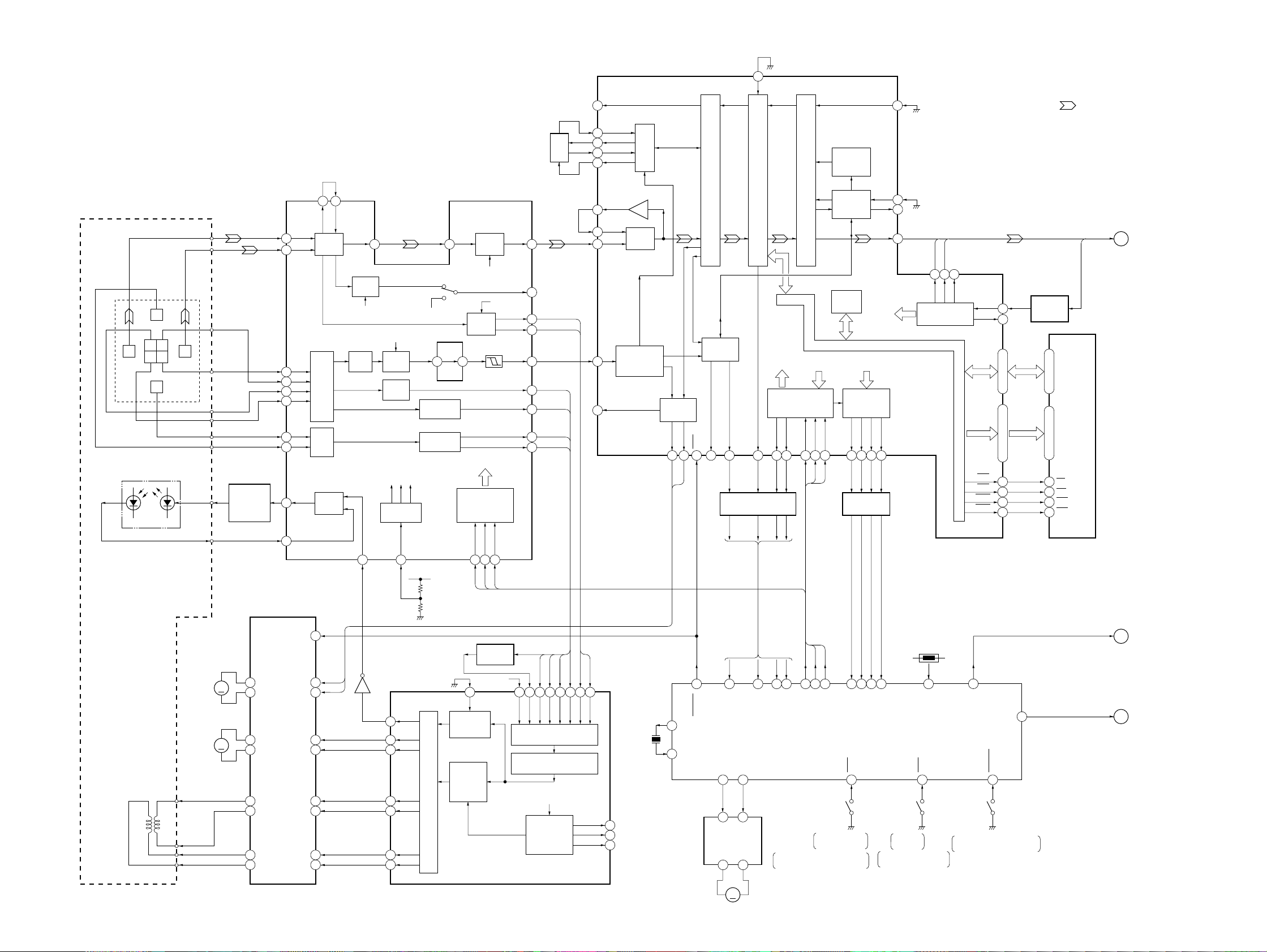

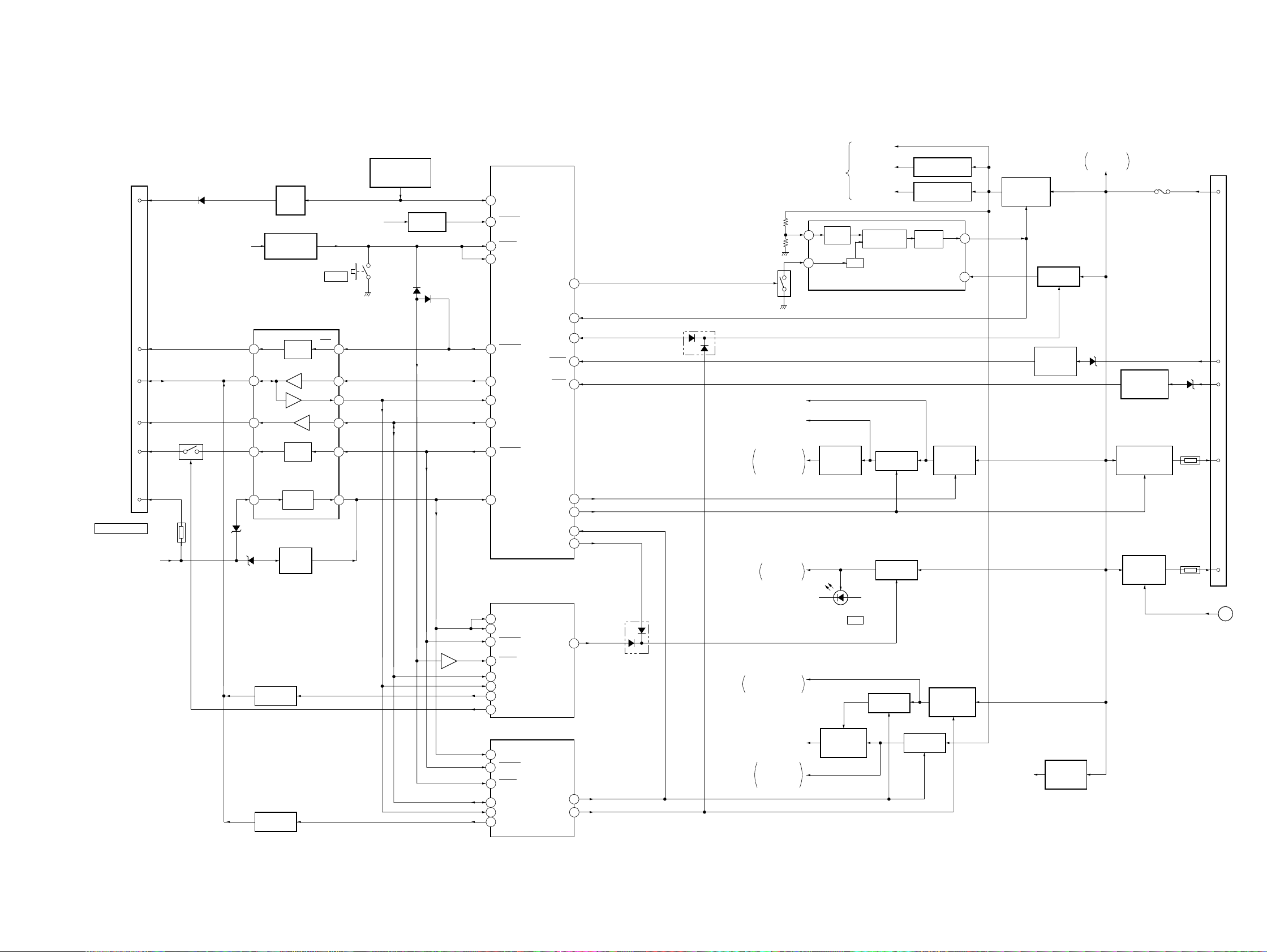

5-1. BLOCK DIAGRAM – SERVO Section –

SECTION 5

DIAGRAMS

100

EFMO

MDX-C8500R/C8500X

15

TX

IC301 (1/2)

ADDT

• SIGNAL PATH

23

: MD PLAY

OPTICAL PICK-UP BLOCK

05

F

C B

I J

D A

E

DETECTOR

LASER DIODE

LDPD

(KMS-241C)

2-AXIS

DEVICE

(FOCUS)

(TRACKING)

ILCC

PD

M901

(SPINDLE)

M902

(SLED)

FCS+

FCS–

TRK+

TRK–

FILI

59

PCO

58

61

FILTER

60

RF AMP,

FOCUS/TRACKING ERROR AMP

48 47

MORFI

MORFO

IC303

I

1

RF AMP

J

2

A

4

B

5

I-V

C

AMP

6

D

7

E

8

I-V

F

AMP

9

APC

PD

IN4R

IN4F

IN2F

IN2R

IN1F

IN1R

IN3F

IN3R

LD/PD

16PSB

3

4

29

30

19

18

14

15

11

10

AMP

SPFD

SPRD

RFO

B.P.F.

AT

AMP

12

46

3T

APCREF

IC306

WBL

B.P.F.

ABCD

AMP

WBL3TEQ

V-I

CONVERTER

F0CNT

20

APCREF

83

SFDR

92

SRDR

91

FFDR

88

FRDR

89

TFDR

86

TRDR

85

TEMP

ADFM

29 30

FOCUS

ERROR AMP

TRACKING

ERROR AMP

+3.3V

PWM GENERATOR

40

I

J

B

A

C

D

E

F

AUTOMATIC

POWER

CONTROL

Q302

FOCUS/TRACKING COIL DRIVE,

SPINDLE/SLED MOTOR DRIVE

6

27

25

21

23

12

10

8

OUT4F

OUT4R

OUT2F

OUT2R

OUT1F

OUT1R

OUT3F

OUT3R

M

M

IC302

AGCI

RF AGC

& EQ

EQ

WBL

PEAK &

BOTTOM

ADIN

COMMAND

SERIAL/

PARALLEL

CONVERTER,

DECODER

XLAT

SCLK

SWDT

1716 18

PEAK HOLD

Q301

+3.3V

13

RECP

AUTOMATIC

POWER

CONTROL

DIGITAL

SERVO

SIGNAL

PROCESS

DIGITAL SERVO

SIGNAL PROCESSOR

IC301 (2/2)

RF

AUX

PEAK

BOTM

ADFG

ABCD

FE

TE

SE

ABCD

AUX1

38

33

37

36

32

35

34

26

28

7465647566 63

FE

TE

AUX2

ABCD

ANALOG MUX

A/D CONVERTER

FROM CPU

INTERFACE

AUTO

SEQUENCER

73 62

SE

PEAK

XLRF

CKRF

DTRF

51

52

55

78

79

BOTM

CLTV

FILO

ASYO

ASYI

COMPA-

RFI

RATOR

ADIP

ADFG

DEMODULATOR/

DECODER

F0CNT

X501

10MHz

80

81

82

PLL

EFM/ACIRC

ENCODER/DECODER

SUBCODE

PROCESSOR

SPINDLE

SERVO

SPFD

SPRD

DQSY11SQSY14XINT

XRST

94 93

10

12

59 62 55 54 52 45 51 64 26 27 28 29

MD-RST

31

EXTAL

XTAL

32

7 6

LOADING

MOTOR DRIVE

IC305

M903

(LOADING)

5 4

RIN FIN

OUT1 OUT2

1 7

SHOCK PROOF

MEMORY CONTROLLER

51331

LEVEL SHIFT

IC502

61242

SQSY

CC-XINT

EJECT

LOAD

M

ATRAC

CPU

INTERFACE

SENS

SRDT

SWDT

9 8 5 6 7

SWDT

SENS

MD-SI

MD-SO

MD MECHANISM CONTROLLER

ON: When the disc loading start

and the disc eject completion.

SAMPLING

RATE

CONVERTER

DIGITAL

AUDIO

ENCODER/DECODER

INTERFACE

D-RAM

INTERNAL BUS

MONITOR

CONTROL

SCLK

XLAT

MNT0

1 2 3 4

13

LEVEL SHIFT

IC503

12

FOK

SCLK

XLAT

MNT0

MD-LAT

MD-CKO

IC501 (1/2)

C-SW

63

LOADING START/

EJECT END

DIN

DOUT

DADT

MNT1

MNT2

MNT3

135

246

SHOCK

XBUSY

SLOCK

MNT1

MNT2

MNT3

ON: When completion of

DIGITAL SIGNAL PROCESSOR,

EFM/ACIRC ENCODER/DECODER,

SHOCK PROOF MEMORY CONTROLLER,

ATRAC ENCODER/DECODER, 2M BIT D-RAM

21

22

24

LOADING

END

the disc loading.

IC301 (1/2)

BCK

LRCK

2526 27

LRCK

XBCK

FS256

CLOCK

GENERATOR

TH501

39

TEMP

E-SW

11 56

OSCI

OSCO

XOE

XWE

XRAS

XCAS

EMPHASIS

66

DEEMP

(LIMIT)

ON: When the optical pick-up is

inner position.

A-MUTE

16

17

D0 – D3A00 – A09

47, 46, 48, 49

32 – 29, 34 – 38, 43

41 22

45 3

44 4

42 23

67

LIMIT-IN

DADT, BCK, LRCK, 512FS

512FS

512FS OSC

IC304

D0 – D3

1, 2, 24, 25

A0 – A9

9 – 12, 14 – 18, 5

OE

WE

RAS

CAS

D-RAM

IC307

EMPHASIS

MD-ATT

(Page 21)

A

(Page 21)

B

C

(Page 21)

1919

MDX-C8500R/C8500X

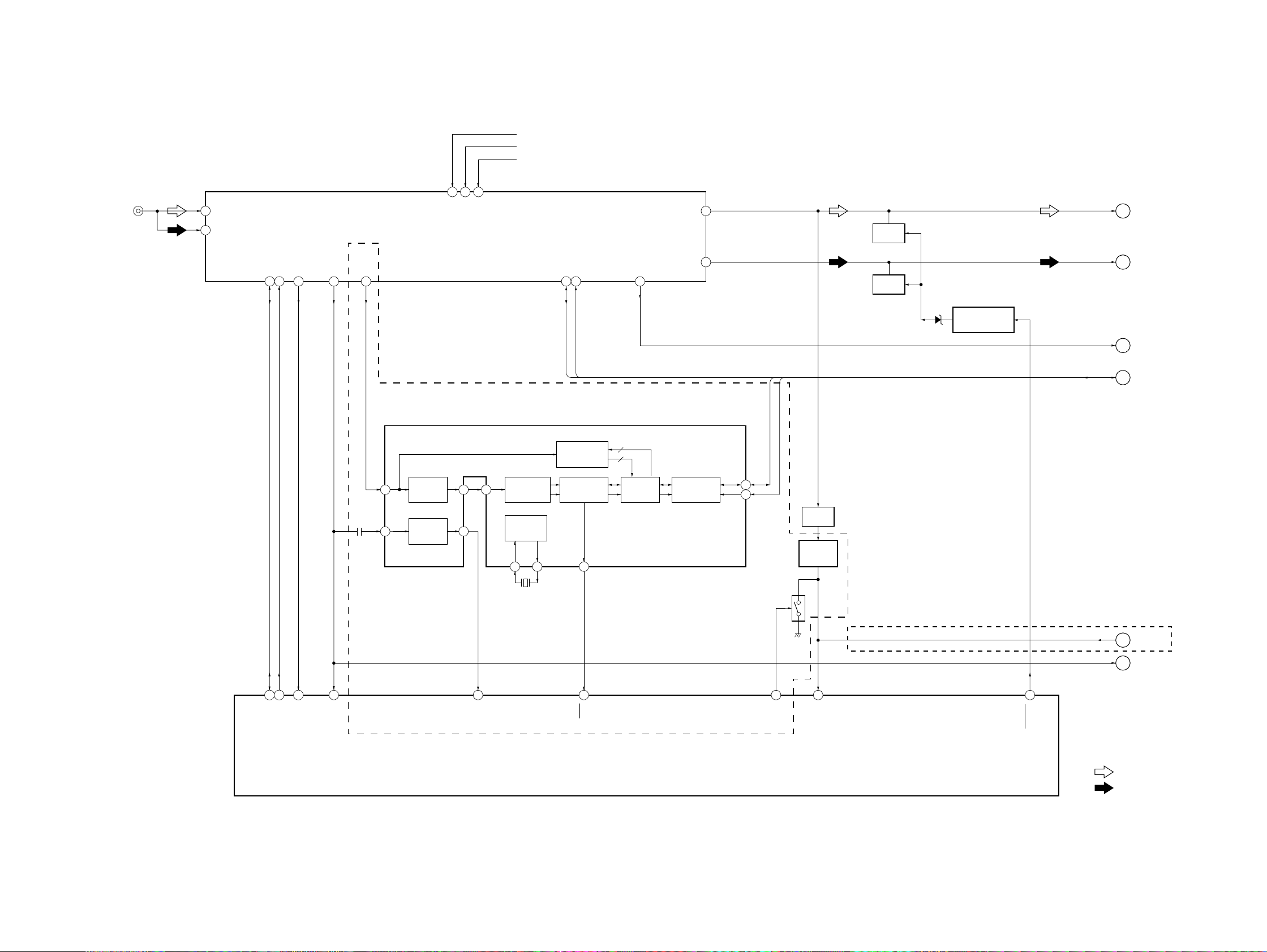

5-2. BLOCK DIAGRAM – TUNER Section –

CN102

(FM/AM ANTENNA)

FM/AM TUNER UNIT

TUX201

FM-ANT

2

AM-ANT

1

EEPROM SDA

EEPROM SCL

17

18

FMAGC

4

SMETER

14

RDSDET

9

11

5

B/U 5V

VCC

16

TUNER 5V

B/U +5V

TUNER VCC

TUNER +5V

SDA

12 13

SCL

19

AM IF

MPX

AMDET

10

MUTING

Q202

8

MUTING

Q205

MUTING

CONTROL SWITCH

D202

Q206, 207

MPX

AM

AM IF

D

E

F

(Page 21)

(Page 21)

(Page 21)

DATA

(MDX-C8500R)

RDS DECODER

IC201

PATH

OUT

SC

MPTH

CIN

19

CLOCKED

COMPARATOR

OSCILLATOR

& CLOCK

OSCI

OSCO

4

5

X101

4.332MHz

18

2

52

MPX

LVIN

57 kHz

BAND-PASS

FILTER

MULTI

DETECTOR

16

20

10

11

51

53

CLOCK

SIGNAL

QUALITY

DECODER

RDS/RDBS

DEMODULATOR

& DECODER

DAVN

8

75

5

4

INTERFACE

REGISTER

IIC BUS

SLAVE

TRANSCEIVER

SDA

SCL

9

10

NOISE DET

DISCHARGE

DATA

Q208

SWITCH

56

CLOCK

BUFFER

Q209

BAND-PASS

FILTER

IC202

50

32

DATA, CLOCK

QUALITY

SMETER

(Page 21)

H

(MDX-C8500X)

(Page 21)

I

(Page 21)

G

T.ROM-SCL

T.ROM-SDA

FMAGC

VSM

MTP

DAVN

MASTER CONTROLLER

IC502 (1/4)

NS-MASK

QUALITY

TUMUTE

• SIGNAL PATH

: FM

05

: AM (MW/LW)

2020

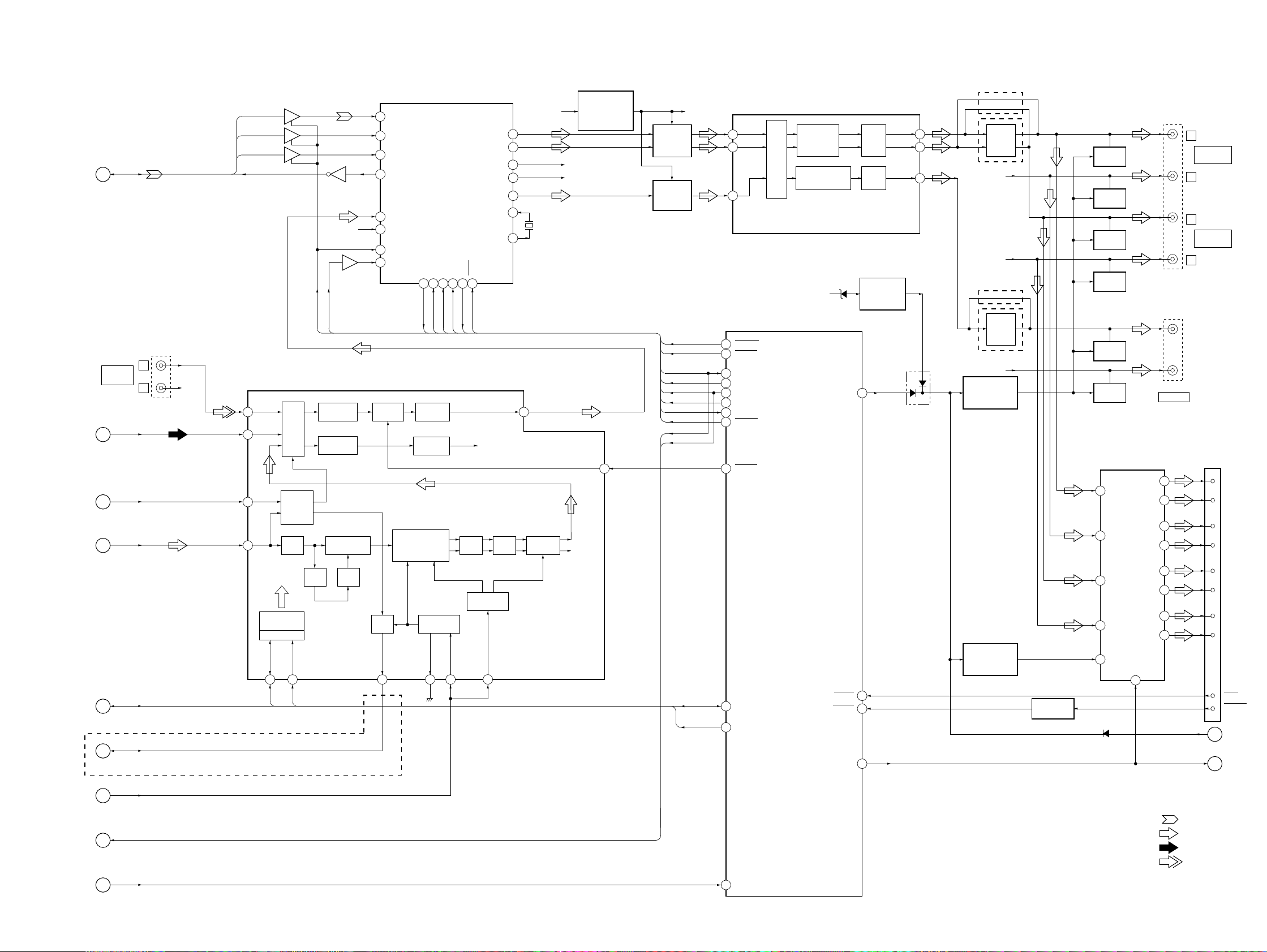

5-3. BLOCK DIAGRAM – MAIN Section –

MDX-C8500R/C8500X

(Page 19)

(Page 20)

(Page 20)

(Page 20)

(Page 20)

(Page 20)

(Page 20)

(Page 22)

(Page 19)

05

DADT,

BCK,

LRCK,

512FS

A

CN302 (1/2)

BUS

AUDIO IN

AM

E

AM IF

F

MPX

D

DATA, CLOCK

H

QUALITY

I

SMETER

G

DSPDATA, DSPCKO

J

EMPHASIS

B

LEVEL SHIFT

IC803 (1/2)

DADT

9

8

LRCK

BCK

512FS

L

R

R-CH

INPUT SELECT, FM MPX

SEL

1

AM

11

AMIF

12

MPX

13

CONTROL

SDA

20

DATA

10

2

3

1

5

6

4

IC806

12

LEVEL SHIFT

IC803 (2/2)

XMST

DSPPLL

IC301 (1/2)

LOUDNESS/

VOLUME

INPUT

MULTIPLEXER

AM/FM

NOISE

BLANKER

L.P.F.

DIGITAL

IIC BUS

SCL

21 18

CLOCK

CANCELATION

PLL

R-CH

PILOT

PILOT

DET

11

(MDX-C8500X)

DIGITAL SIGNAL PROCESSOR,

SI1

71

76

LRCK

75

BCK

81

PLCLK

35

LIN

46

RIN

77

XMST

82

XECKSTP

SOFT

MUTE

LOUDNESSMUTE

DEMODULATOR

+STEREO ADJUST

+STEREO BLEND

QUAL

QUALITY

DIGITAL FILTER,

D/A CONVERTER

IC805

TRDT

RVDT59SCK

63

62 57

TRDT

SCK

RVDT

TONE

CONTROL

MULTIPATH

DETECTOR

MPOUT16MPIN

15

27

AOUTL1

AOUTR1

29

54

AOUTR3

AOUTL3

52

AOUTR2

43

XTLI38

41

40

XTLO38

XLAT

REDY

XRST

6061

XLAT

REDY

DSPRST

ACOUTL

38

TO

OUTPUT

SELECTOR

L.P.F. S & H HIGH-CUT

D/A

CONVERTER

LEVEL

14

ANALOG +8V

FL-OUT

RL-OUT

FR-OUT

RR-OUT

SUB-OUT

X801

16.9344MHz

CENTER VOLTAGE

GENERATOR

(FOR BIAS)

IC809 (2/2)

R-CH

R-CH

SM

R-CH

ELECTRICAL VOLUME

R-CH

LOW-PASS

FILTER

IC807

LOW-PASS

FILTER

IC809 (1/2)

XMST

DSPPLL

TRDT

RVDT

SCK

XLAT

REDY

DSPRST

DSPDATA

DSPCKO

18

DATA

CLOCK

34

33

35

29

28

25

26

27

35

78

36

31

70

71

ACINLF

ACINLR

SWINR

DSPMST

DSPPLL

DSPSI

DSPSO

DSPCKO

DSPLAT

DSPREADY

DSPRST

VOLATT

I2C SDA

I2C SCL

IC301 (2/2)

MONO FADER MIXER

OUTPUT

SELECTOR

SUBWOOFER

+PHASE CONTROL

BATT B+

MASTER CONTROLLER

IC502 (2/4)

D352

ATT

TESTIN

TELATT

AMPON

MONO

FADER

BATTERY OFF

MUTE DRIVER

Q352

5

84

96

55

OUTLF

OUTLR

OUTSWR

30

29

25

D354

(MDX-C8500R)

LINE

DRIVER

IC303

(MDX-C8500X)

R-CH

R-CH

(MDX-C8500R)

LINE

DRIVER

IC304

(MDX-C8500X)

R-CH

MUTING

CONTROL SWTICH

Q354, 355

MUTING

CONTROL SWITCH

Q353

LEVEL SHIFT

Q111

MUTING

Q356

MUTING

Q357

MUTING

Q358

MUTING

Q359

MUTING

Q360

MUTING

Q361

IN2

12

14

IN4

11

IN1

IN3

15

MUTE

22

D353

POWER AMP

IC351

OUT2+

OUT2–

OUT4+

OUT4–

OUT1+

OUT1–

OUT3+

OUT3–

STBY

4

CN302 (2/2)

CN301

SUB OUT

5

3

21

23

9

7

17

19

MD-ATT

AMPON

L

AUDIO

OUT FRONT

R

L

AUDIO

OUT REAR

R

(L)

(R)

CN101 (1/2)

(POWER CONNECTOR)

1

FL+

9

FL–

4

FR+

12

FR–

2

RL+

10

RL–

3

RR+

11

RR–

15

TEST

13

TEL-ATT

C

(Page 19)

K

(Page 23)

• SIGNAL PATH

: MD PLAY

: FM

: AM (MW/LW)

: BUS AUDIO IN

97

EMPH

2121

MDX-C8500R/C8500X

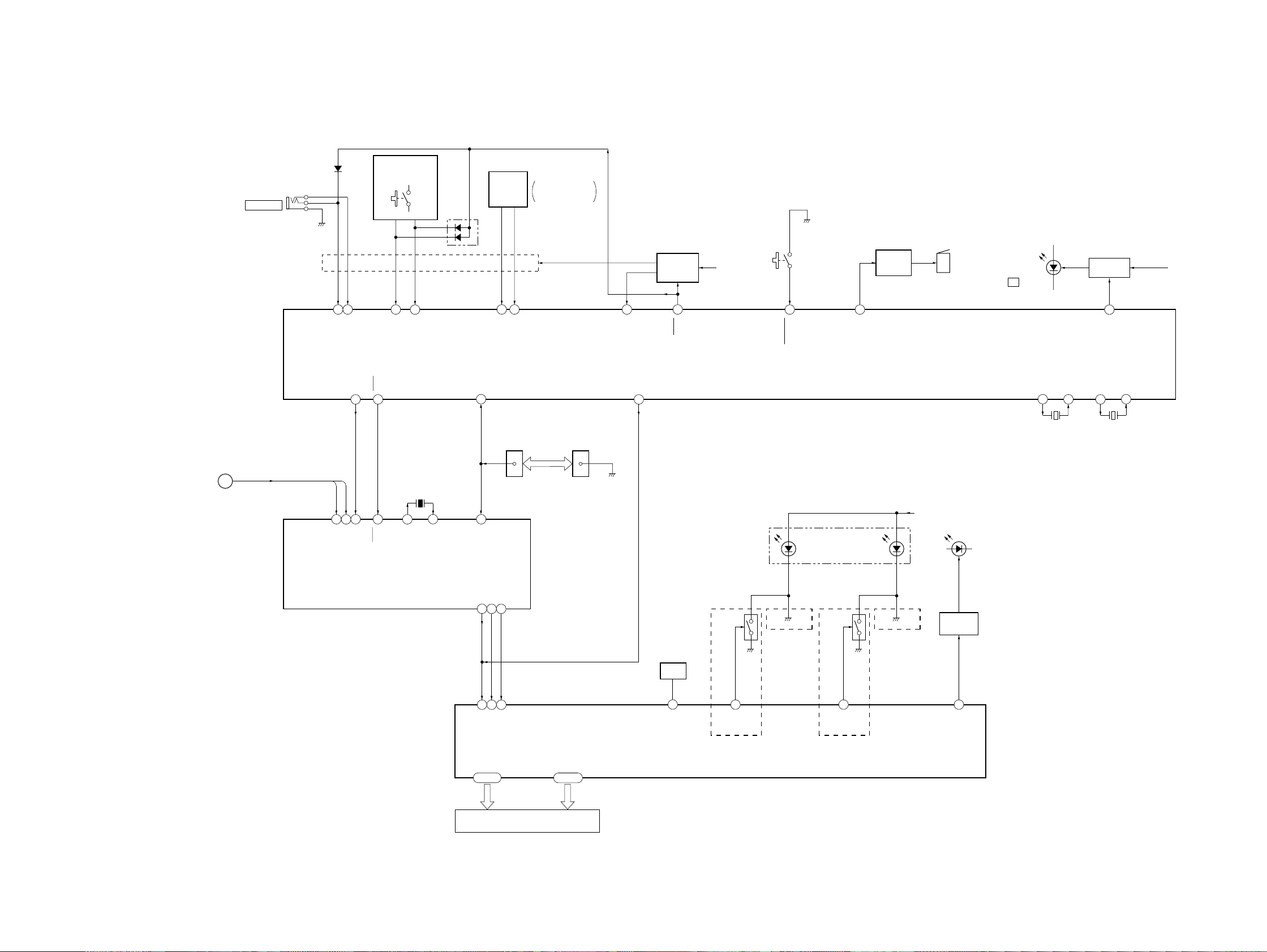

5-4. BLOCK DIAGRAM – DISPLAY/KEY CONTROL Section –

(Page 21)

REMOTE IN

DSPDATA,DSPCKO

J

J651

D611

48 72

TRDT

61

RCIN0

SCK

63

SP-SI

RCIN1

SA LAT

4

33 57

SP-LAT

SP-SCK

LSW751,901–917,

S901 – 904

46

47

KEYIN1

KEYIN0

BOOT

106

X105

18.432MHz

85

86

BOOT

EXTAL

LIQUID CRYSTAL DISPLAY

DRIVE CONTROLLER

IC701 (1/2)

XTAL

D701

ROTARY

ENCODER

RE901

116 115

RX

12

MAIN BODY SIDE

62

RX

REIN0

CN701

RE901

VOLUME/BASS/

TREBLE/BALANCE/

FADER CONTROL

REIN1

CN901

FRONT PANEL SIDE

14 1

79

KEYACK

TX

13

KEY ACTIVE

SWITCH

Q701, 702

80

AD-ON

MASTER CONTROLLER

IC502 (3/4)

MDX-C8500R : LSW901 – 908,

MDX-C8500X : LSW901 – 908,

B/U +5V

LSW910 – 917

LSW912 – 917

(NOSE DETECT)

117

NOSE-SW

S102

BUZZER

DRIVE

Q351

15

BEEP

LCD B+

BZ101

(BUZZER)

(LCD BACK LIGHT)

LED751

(MD DISC SLOT),

LSW751

LED910 – 915

B+ SWITCH

Z

X1

93

X104

3.68MHz

Q751, 752

118

DOORIND

X1A

73

X103

32.768kHz

X0A

74

X0

92

LCD B+

TX/LCD-DATA

LCD-SCK

LCD-CE1

60

64 66

C953, R957

OSC

100

99

98

LCD-CE

LCD-CLK

LCD-DATA

SEG1 – SEG74

1 – 74

LIQUID CRYSTAL DISPLAY

05

LCD901

COM1 – COM8

83 – 76

96

OSC

LED

DRIVE

Q902

85

(MDX-C8500R) (MDX-C8500R)

(MDX-C8500X)

GREEN

LIQUID CRYSTAL DISPLAY DRIVER

IC901

LED

DRIVE

Q901

84

AMBER

(MDX-C8500X)

LED DRIVE

Q903

86

DIMMER

2222

5-5. BLOCK DIAGRAM – BUS CONTROL/POWER SUPPLY Section –

MDX-C8500R/C8500X

SIRCS

RESET

DATA

CLK

BUS ON

3

2

5

4

6

D605

BUS ON SWITCH

Q603

B/U +5V

SIRCS

BUFFER

Q605

RESET SIGNAL

GENERATOR

IC503

SONY BUS INTERFACE

IC601

RST

DATA

CLK

BUS ON

OUT

RESET

SWITCH

BUS ON

SWITCH

2

6

4

1

RST

DATA IN

DATA OUT

CLK IN

BUS

ON IN

S101

RESET

13

11

12

MASTER CONTROLLER

24

85

90

86

18

17

6

9

4

SIRCS

RAMBU

RESET

HSTX

SYSRST

UNISO

UNISI

UNICKO

BUS-ON

IC502 (4/4)

F CH

FSW IN

DSPON

ACCIN

ILLIN

DSP CIRCUIT B+

IN

ERROR

4

AMP

RT

OSC SWITCH

98

65

110

D104

81

95

Q101

ANALOG +8V

TUNER VCC

(TUNER CIRCUIT B+)

TUNER +5V

TUNER CIRCUIT/

RDS DECODER

(IC201) B+

7

+5V

REGULATOR

Q201

REMOTE CONTROL

RECEIVER

IC951

D502

RAM RESET

IC504

D614

B/U +5V

9

8

DSP +5V

DIGITAL +3.3V

ANALOG +3.3V

PWN

COMPARATOR

OSC

+3.3V REGULATOR

+3.3V REGULATOR

OUTPUT

CIRCUIT

POWER CONTROL

IC302

B+ SWITCH

Q203, 204

IC802

IC801, Q801

OUT

VCC

+8V

REGULATOR

Q107 – 109

SWITCHING

REGULATOR

Q103, 105 106

1

2

B+ SWITCH

Q102, 104

ACCESSORY

CHECK

Q112

BATT B+

POWER AMP

(IC351) B+

D109

F1

ILLUMINATION

LINE DETECT

Q113

ANTENNA REMOTE

SWITCH

Q364, 366

CN101 (2/2)

(POWER CONNECTOR)

16

7

D108

14

TH103

6

+B

ACC

ILL

ANT-R

BATT

CN601

BUS CONTROL IN

(FOR SONY BUS)

BATT B+

7

TH101

3

D607

D603

LEVEL SHIFT

LEVEL SHIFT

BATT

Q602

Q601

BATTERY

SWITCH

BATTERY

DETECT

Q604

BU IN

PWON

TUNON

CDMD ON

FLASH ON

MDMON

83

113

116

82

52ILL-ON

65MD-ON

10

D703

LCD B+

LCD DRIVER

(IC901) B+

LO +12V

LOADING MOTOR

DRIVER (IC306) B+

+3.3V

DRIVER +5V

MOTOR/COIL

DRIVER

(IC303) B+

LED901 – 904 (ILLUMINATION)

LSW909 DSO

B+ SWITCH

Q402, 403

VCC

+3.3V

REGULATOR

IC401, Q401

REGULATOR

Q703 – 705

B+ SWITCH

Q406, 407

+12V

REGULATOR

Q401, 404, 405

B/U +5V

+5V

REGULATOR

Q110

AMP REMOTE

SWITCH

Q363, 365

TH102

AMPON

5

K

(Page 21)

AMP-R

BU-IN

10

LEVEL SHIFT

77

LIQUID CRYSTAL DISPLAY

82

NMI (H)

49

BU-IN

BUS-ON

38

IC702

81

RESET

101

UNICKI

UNISI

98

UNISO

97

LINK OFF

50

MD MECHANISM CONTROLLER

60

BU-IN

BUS-ON

61

30

RESET

48

UNICKIO

49

UNISI

UNISO

50

DRIVE CONTROLLER

IC701 (2/2)

IC501 (2/2)

05

2323