Sony MDX-C800REC Service Manual

MDX-C800REC

SERVICE MANUAL

SUPPLEMENT-1

File this supplement with the service manual.

Subject : Electrical Adjustments

AEP Model

UK Model

E Model

1

ELECTRICAL ADJUSTMENT

TEST MODE

This set has the test mode functionality. The test mode should be

always set before performing adjustments.

<Setting the Test Mode>

1. Input the specified voltage (14.4 V) to the ACC and BATT

terminals.

2. “1:00” is displayed on the LCD display.

3. Press 4 key.

4. Press 5 key.

5. Press 1 key for more than 2 seconds.

6. All segments are lit on the LCD display entering the test mode.

<Releasing the Test Mode>

1. Press OFF key.

DISPLA Y TEST

1. Once the test mode is set, each pressing of the DSPL key will

cause the LCD display to change as follows:

All segments ON

Press DSPL key.

Half segments ON (1)

Press DSPL key.

Half segments ON (2)

(The other half segments that were OFF in (1) are ON.)

Press DSPL key.

All segments OFF

Press DSPL key.

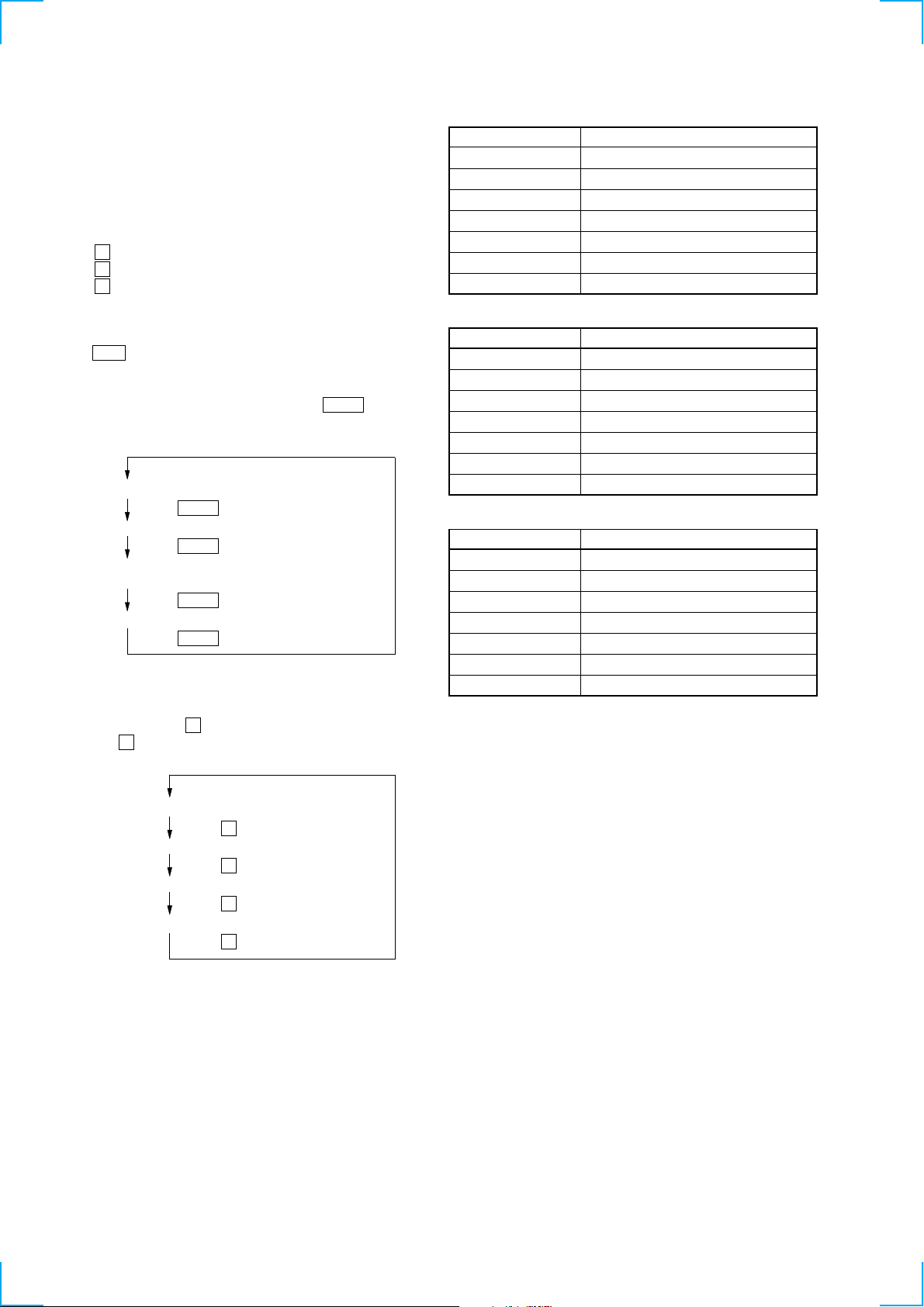

TEST MODE STRUCTURE

1. Set the test mode.

2. Insert a disc and press 5 key.

3. Each time 6 key is pressed, the mode will change as follows:

ADJUSTMENT mode: SHUF indication off

Key Description of test

2 Laser power adjustment mode

3 Traverse adjustment mode

4 Focus bias adjustment mode

5STOP

6 Switch the mode

ENTER CLV jitter measurement

DSPL Select the display

PLAY mode: SHUF1

Key Description of test

2 Laser power check mode

3 Focus + CLV ON

4 Tracking servo ON/OFF

5STOP

6 Switch the mode

ENTER CPLAY mode (middle/outer/inner area)

DSPL Select the display

REC mode: SHUF2

Key Description of test

2 Laser power check mode

3 Focus + CLV ON

4 Tracking servo ON/OFF

5STOP

6 Switch the mode

ENTER CREC mode (middle/outer/inner area)

DSPL Select the display

Unused mode: SHUF ALL

ADJUSTMENT mode “SHUF” indication off

Press 6 key.

PLAY mode “SHUF1” indication is lit.

Press 6 key.

REC mode “SHUF2” indication is lit.

Press 6 key.

Unused mode “SHUF ALL” indication is lit.

Press 6 key.

2

NOTES FOR ADJUSTMENT

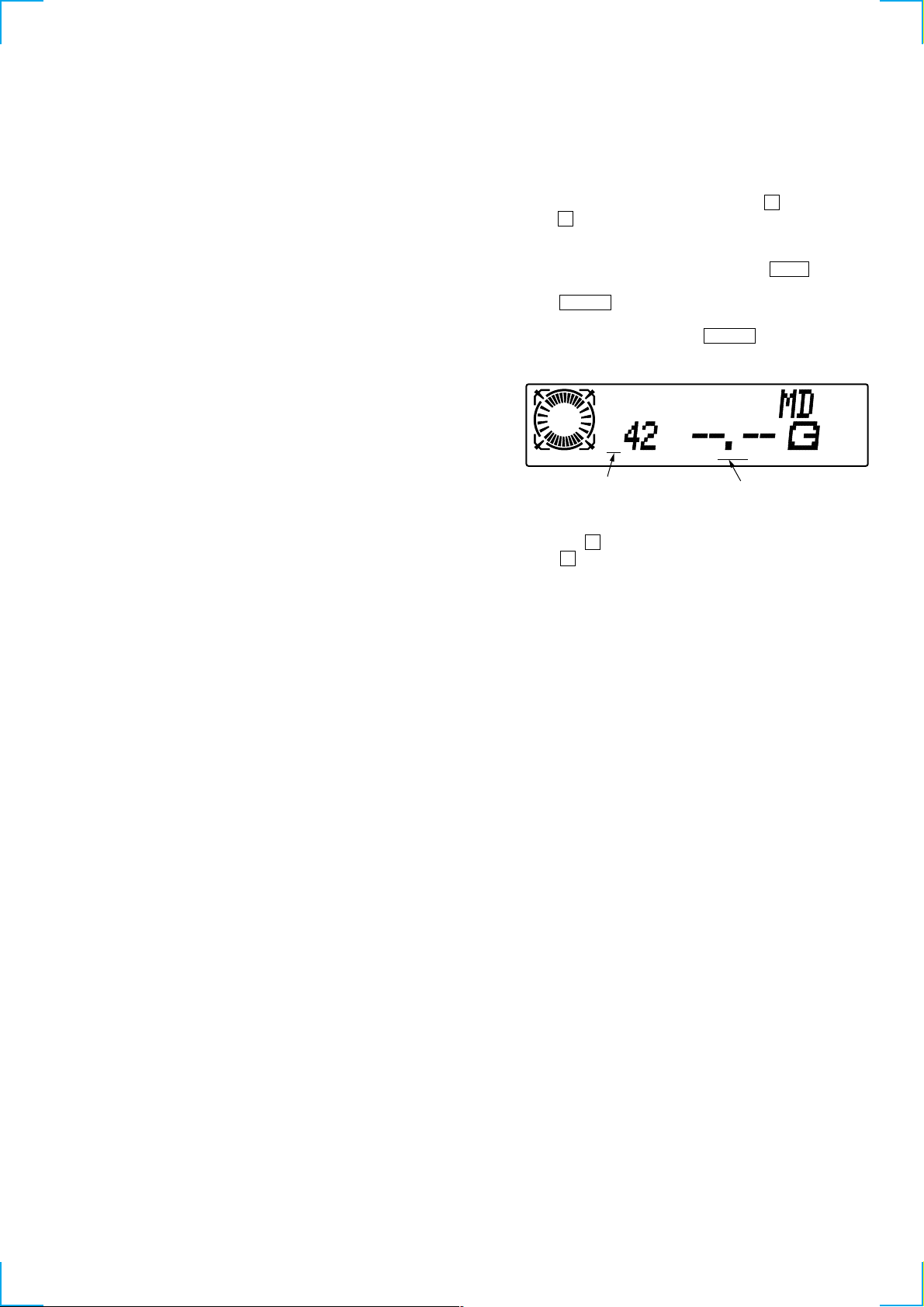

SHUF 2

Disc No. indicator

REC mode

1. Perform the following adjustments as listed when the optical pickup and IC400, IC402 and/or IC440 in the MD SERVO board

have been replaced:

(1) Laser power adjustment

(2) Traverse adjustment

(3) Focus bias adjustment

(4) CD error rate check

(5) MO error rate check

2. Set the test mode to perform these adjustments. Release the test

mode after the adjustments are completed.

3. Perform the adjustments in the order that they are listed.

4. Use the following jigs and measuring equipment:

• Test disc (special disc for playback) TDYS-1

(Part No.: 4-963-646-01)

• Laser power meter LPM-8001

(Part No.: J-2501-046-A)

• Oscilloscope (Measure after the probe is calibrated.)

• Digital voltmeter

5. When observing multiple signals with an oscilloscope or other

equipment, take care to prevent connection between VC and

ground in the oscilloscope. (Otherwise, VC and ground are

shorted.)

PREPARING A CONTINUOUSLY RECORDED DISC

• This disc is used for focus bias adjustment and error rate check.

This disc is prepared as follows:

1. Set the test mode. (See page 2.)

2. Insert a commercial disc (blank) and press 5 key.

3. Press 6 key twice to set the REC mode.

(Verify that the “SHUF2” indication is lit on the LCD display.)

4. Verify that no number is displayed at the disc No. indicator.

If any number is displayed, repeatedly press DSPL key until the

number disappears (only two digits are displayed).

5. Press ENTER key three times and verify that there is no disc

number displayed (the disc is recorded from the inner area).

If “3” or “7” is displayed, press ENTER key again to clear the

indicator.

LCD display

6. Record the data until the disc number indicator shows “9” and

then press 5 key to stop recording.

7. Press Z key and take out the disc.

The continuously recorded disc for focus bias adjustment and error

rate check is now prepared.

Note:

Take care to prevent vibrations during continuous recording.

3

Loading...

Loading...