Page 1

LCD MONITOR

LMD-2140MD

MONITOR STAND

SU-560

SERVICE MANUAL

1st Edition

Page 2

! WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

LMD-2140MD

Page 3

Table of Contents

1. Service Overview

1-1. Appearance Figure ...................................................................................... 1-1

1-2. Board Locations .......................................................................................... 1-1

1-3. Disassembly ................................................................................................ 1-2

1-3-1. Rear Cabinet ............................................................................... 1-4

1-3-2. Shield Case Assembly ................................................................1-4

1-3-3. Bezel Assembly .......................................................................... 1-5

1-3-4. LCD Module-1 ........................................................................... 1-6

1-3-5. LCD Module-2 ........................................................................... 1-7

1-3-6. H Board and X Board ................................................................. 1-8

1-3-7. G1 Board and B2 Board .............................................................1-8

1-3-8. T Board ....................................................................................... 1-9

1-3-9. B Board ...................................................................................... 1-9

1-3-10. Switching Regulator ................................................................. 1-10

1-3-11. D2 Board .................................................................................. 1-10

1-4. Warning on Power Connection ................................................................. 1-11

2. Electrical Adjustments

2-1. Preparation .................................................................................................. 2-1

2-2. White Balance Adjustment ......................................................................... 2-1

2-3. A/D Adjustment (COMPONENT) .............................................................. 2-2

2-4. A/D Adjustment (RGB) .............................................................................. 2-2

2-5. A/D Adjustment (COMPOSITE) ................................................................2-3

2-6. A/D Adjustment (Y/C) ................................................................................2-3

2-7. A/D Adjustment (COMPUTER) ................................................................. 2-4

3. Semiconductors................................................................................... 3-1

4. Spare Parts

4-1. Notes on Repair Parts .................................................................................. 4-1

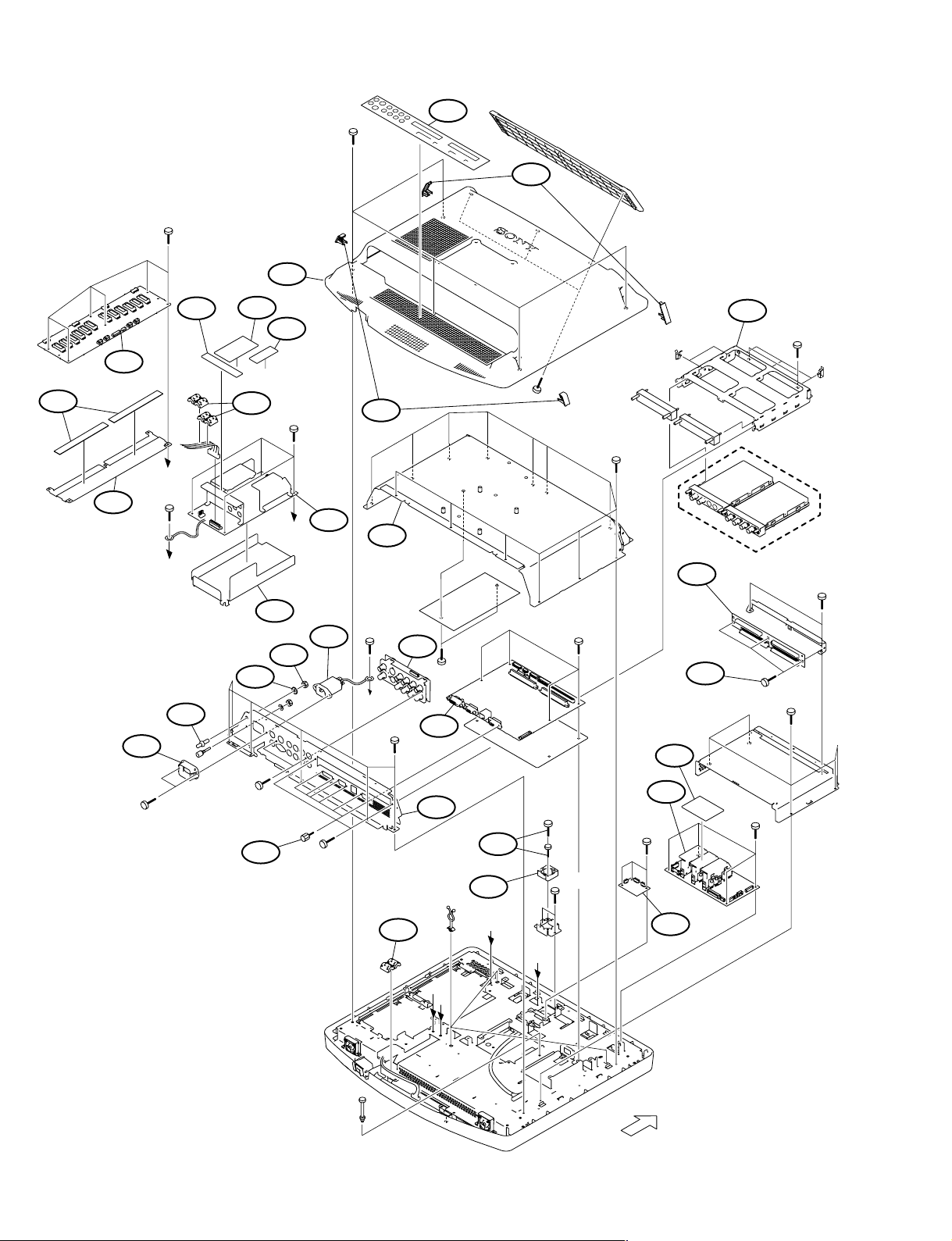

4-2. Exploded Views .......................................................................................... 4-2

4-3. Electrical Parts List ..................................................................................... 4-6

LMD-2140MD

5. Block Diagrams

B, Q, B2, D2, G1, H, T, X ......................................................................................5-1

B (1/4), Q ................................................................................................................ 5-2

1

Page 4

B (2/4) ..................................................................................................................... 5-3

B (3/4) ..................................................................................................................... 5-4

B (4/4), H ................................................................................................................ 5-5

D2, G1, B2, X ......................................................................................................... 5-6

6. Diagrams

6-1. Frame Schematic Diagram ..........................................................................6-2

Frame ........................................................................................................ 6-2

6-2. Schematic Diagrams and Board Layouts .................................................... 6-3

Schematic Diagrams

Q ................................................................................................................ 6-3

B (1/17) ..................................................................................................... 6-5

B (2/17) ..................................................................................................... 6-6

B (3/17) ..................................................................................................... 6-7

B (4/17) ..................................................................................................... 6-8

B (5/17) ..................................................................................................... 6-9

B (6/17) ................................................................................................... 6-10

B (7/17) ................................................................................................... 6-11

B (8/17) ................................................................................................... 6-12

B (9/17) ................................................................................................... 6-13

B (10/17) ................................................................................................. 6-14

B (11/17) ................................................................................................. 6-15

B (12/17) ................................................................................................. 6-16

B (13/17) ................................................................................................. 6-17

B (14/17) ................................................................................................. 6-18

B (15/17) ................................................................................................. 6-19

B (16/17) ................................................................................................. 6-20

B (17/17) ................................................................................................. 6-21

B2 ............................................................................................................6-25

G1 ............................................................................................................ 6-27

D2 ............................................................................................................ 6-29

H .............................................................................................................. 6-31

X .............................................................................................................. 6-32

T .............................................................................................................. 6-33

Board Layouts

Q ................................................................................................................ 6-4

B ..............................................................................................................6-22

B2 ............................................................................................................6-25

G1 ............................................................................................................ 6-26

D2 ............................................................................................................ 6-28

H .............................................................................................................. 6-30

X .............................................................................................................. 6-32

T .............................................................................................................. 6-32

2

LMD-2140MD

Page 5

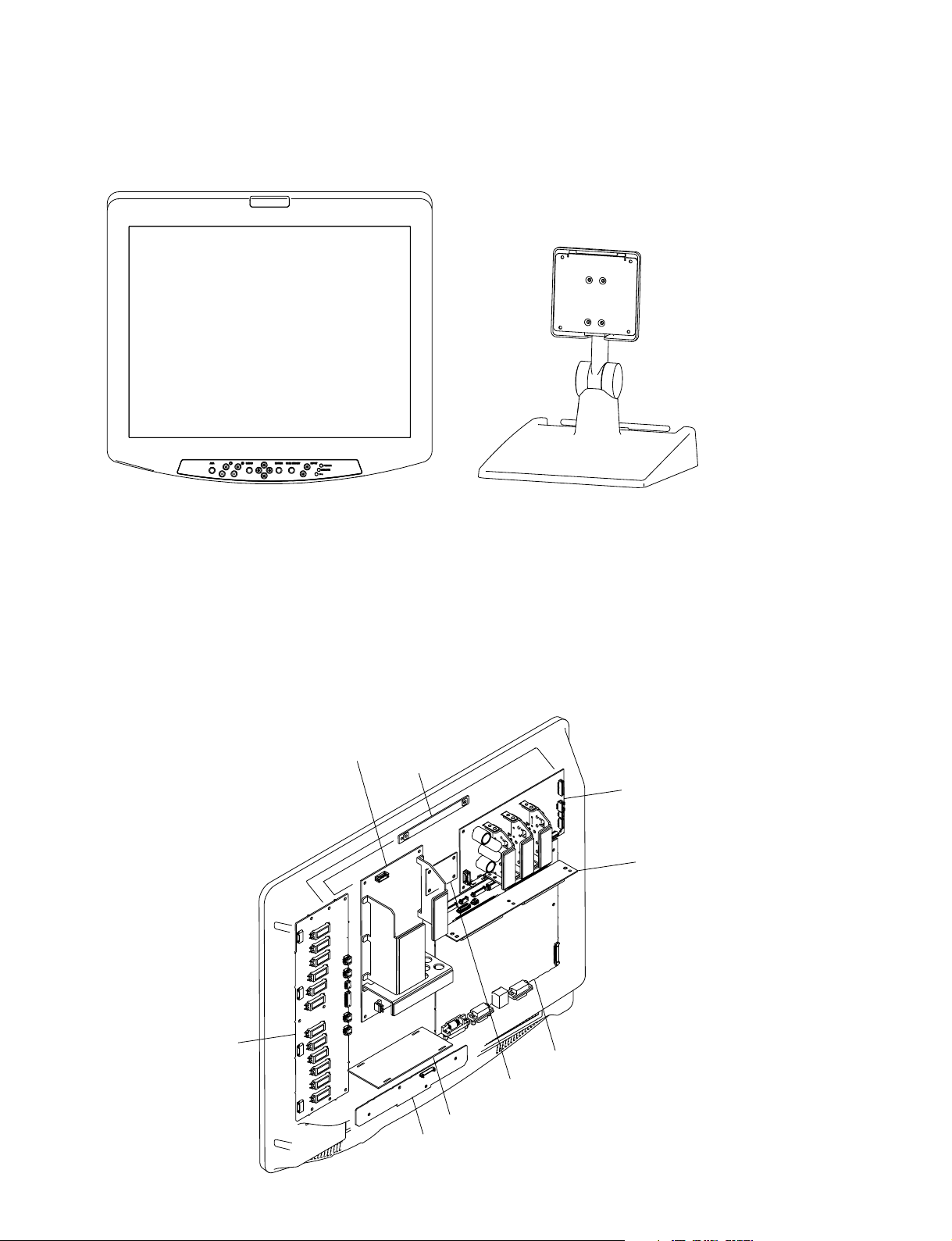

1-1. Appearance Figure

Section 1

Service Overview

LMD-2140MD

1-2. Board Locations

SU-560

Switching regulator

X

G1

T

LMD-2140MD

D2

B

B2

Q

H

1-1

Page 6

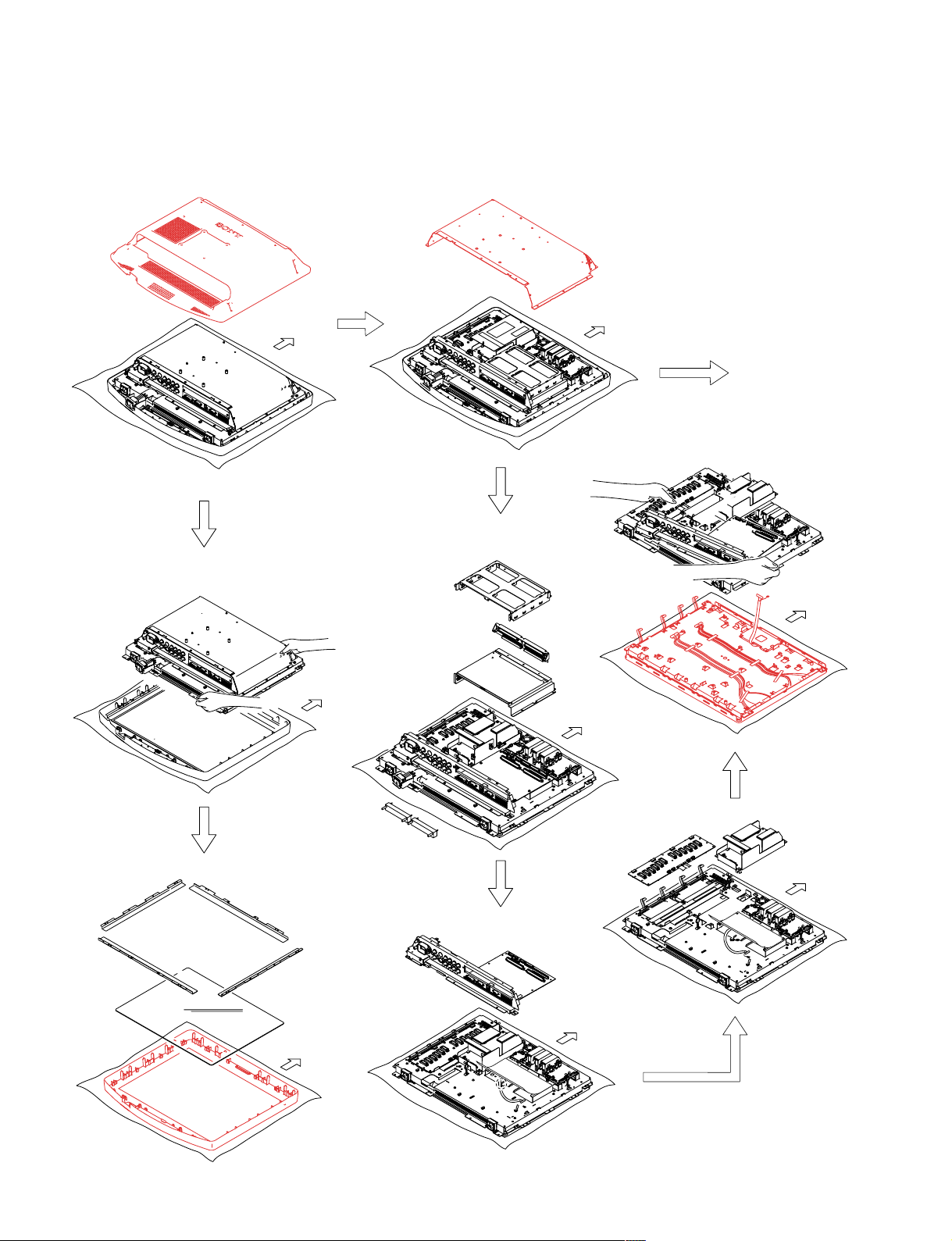

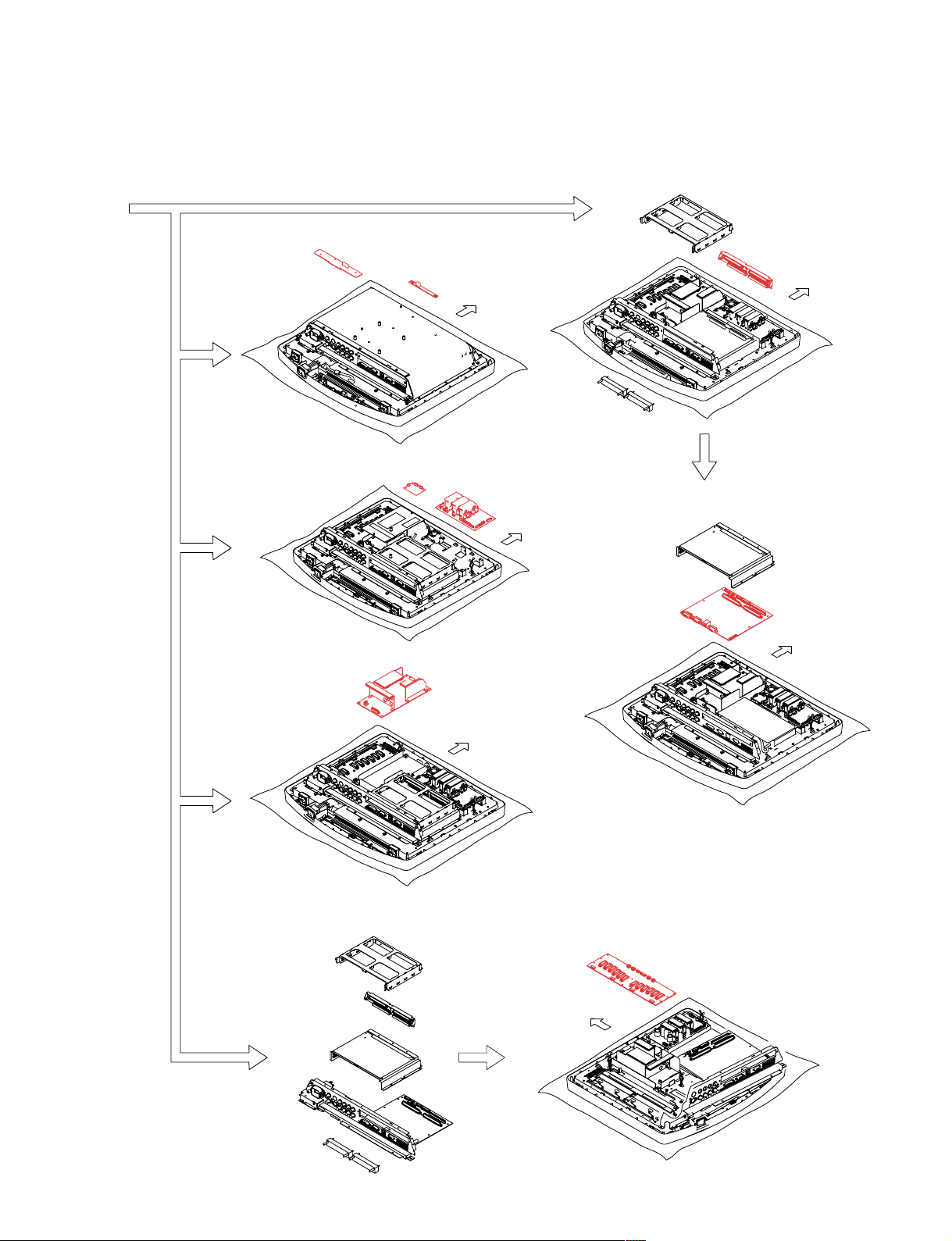

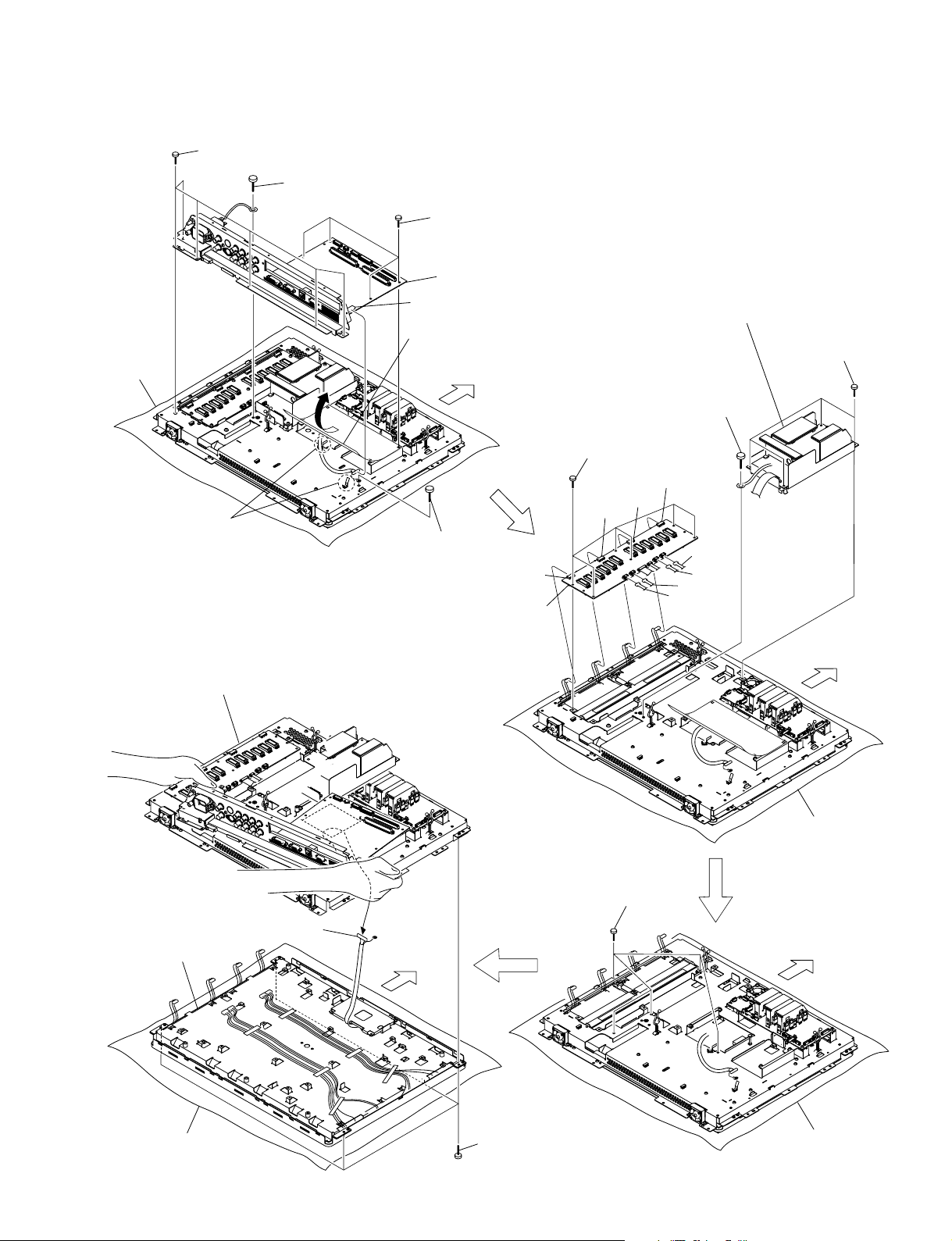

1-3. Disassembly

1-3-1. Rear Cabinet

1-3-3. Bezel Assembly

Upper

Side

1-3-2. Shield Case Assembly

Upper

Side

A

1-3-4. LCD Module-1

Upper

Side

Upper

Side

Upper

Side

!-

1-3-5. LCD Module-2

Upper

Side

Upper

Side

Upper

Side

1-2

LMD-2140MD

Page 7

A

1-3-6. H Board and X Board

Upper

Side

1-3-7. G1 Board and B2 board

1-3-8. T Board

Upper

Side

1-3-10. Switching Regulator

Upper

Side

For removal procedure,

refer to "LCD Module-1.-2".

Upper

Side

1-3-9. B Board

Upper

Side

1-3-11. D2 Board

LMD-2140MD

Upper

Side

1-3

Page 8

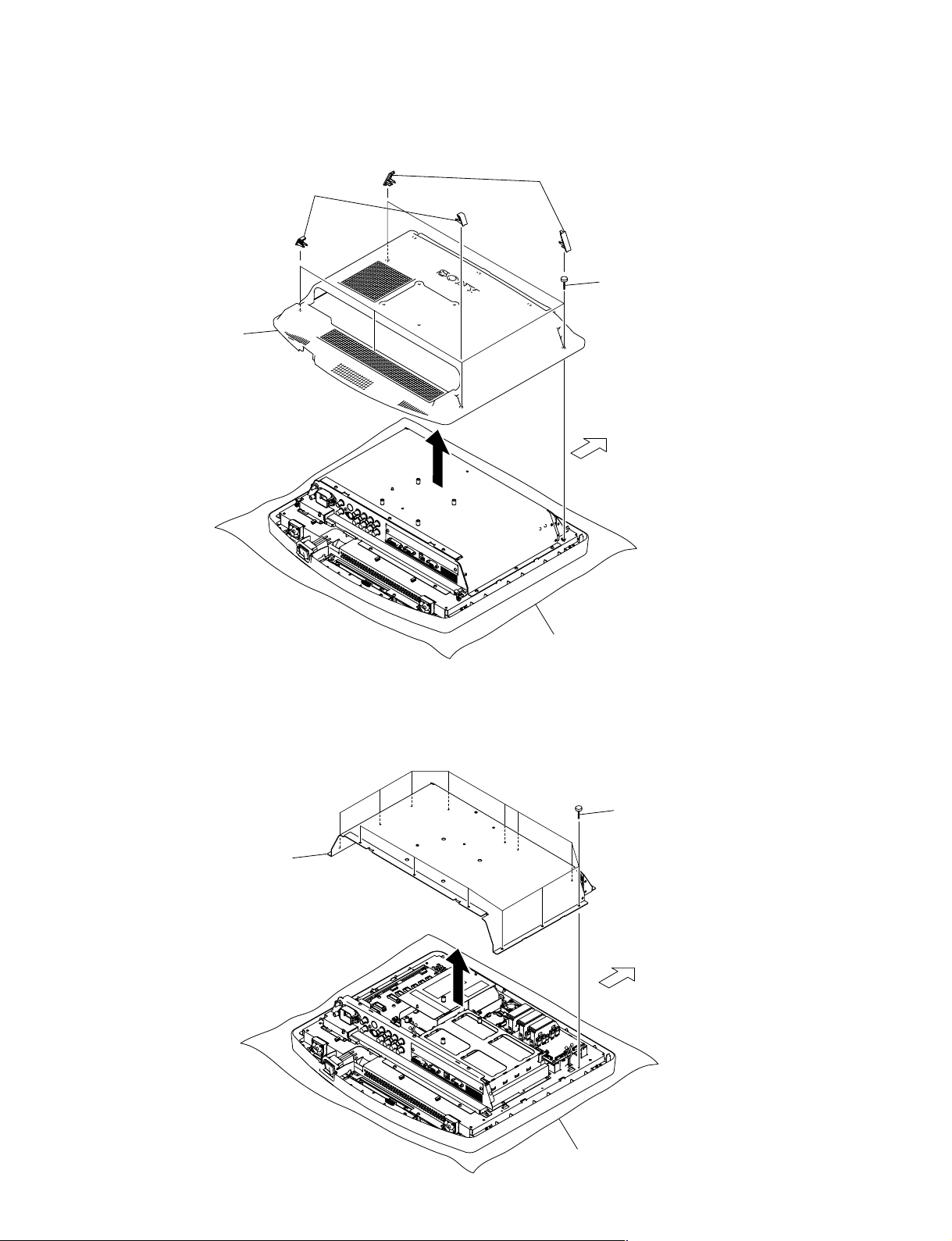

1-3-1. Rear Cabinet

4

Rear cabinet

2 Two s

A assemblies

crew cover

1 Two s

B assemblies

crew cover

3

Five screws

(+B 4 x10)

Upper

Side

1-3-2. Shield Case Assembly

2

Shield case assembly

Cushion

1

Thirteen screws

(+BVTT 3 x 6)

Upper

Side

1-4

Cushion

LMD-2140MD

Page 9

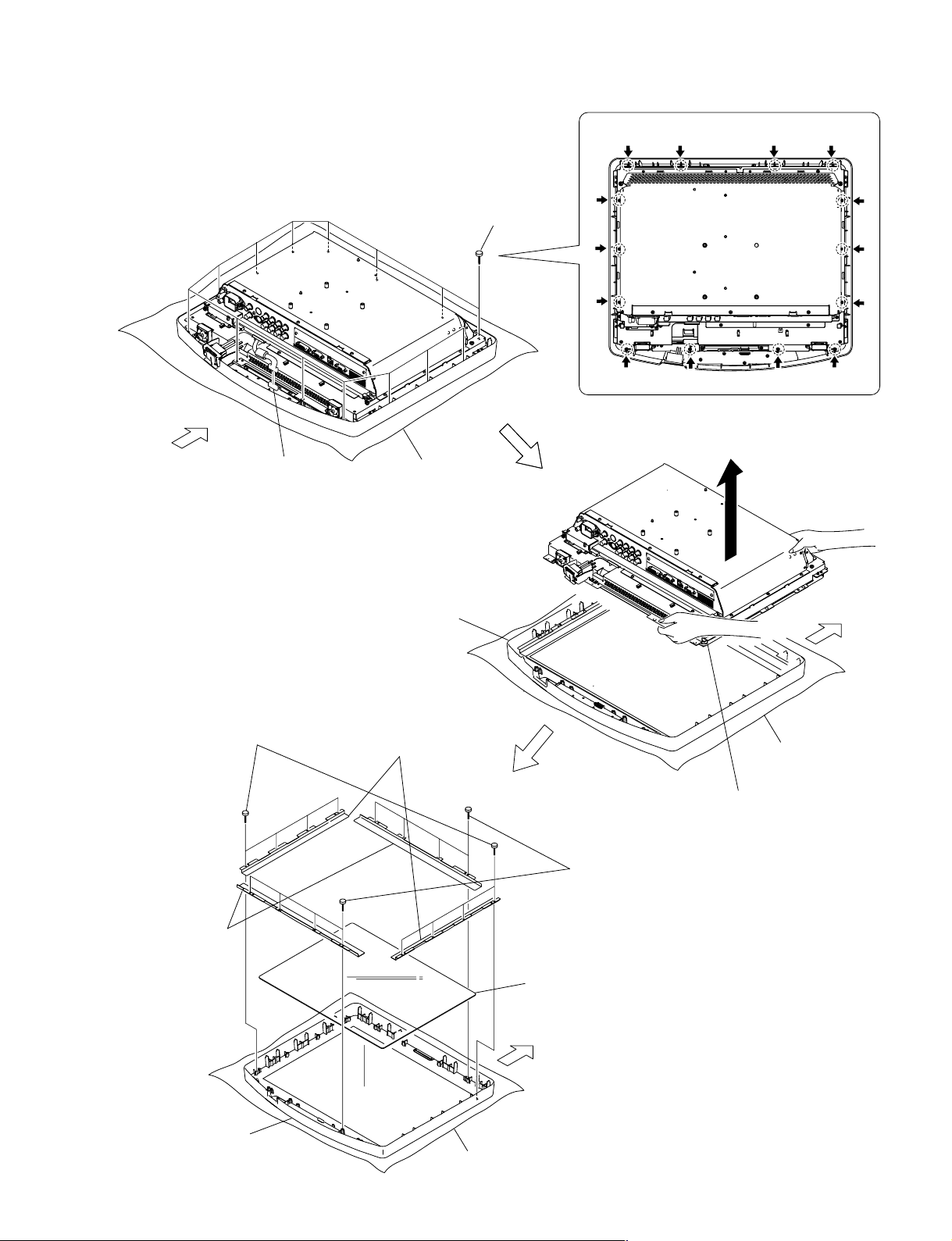

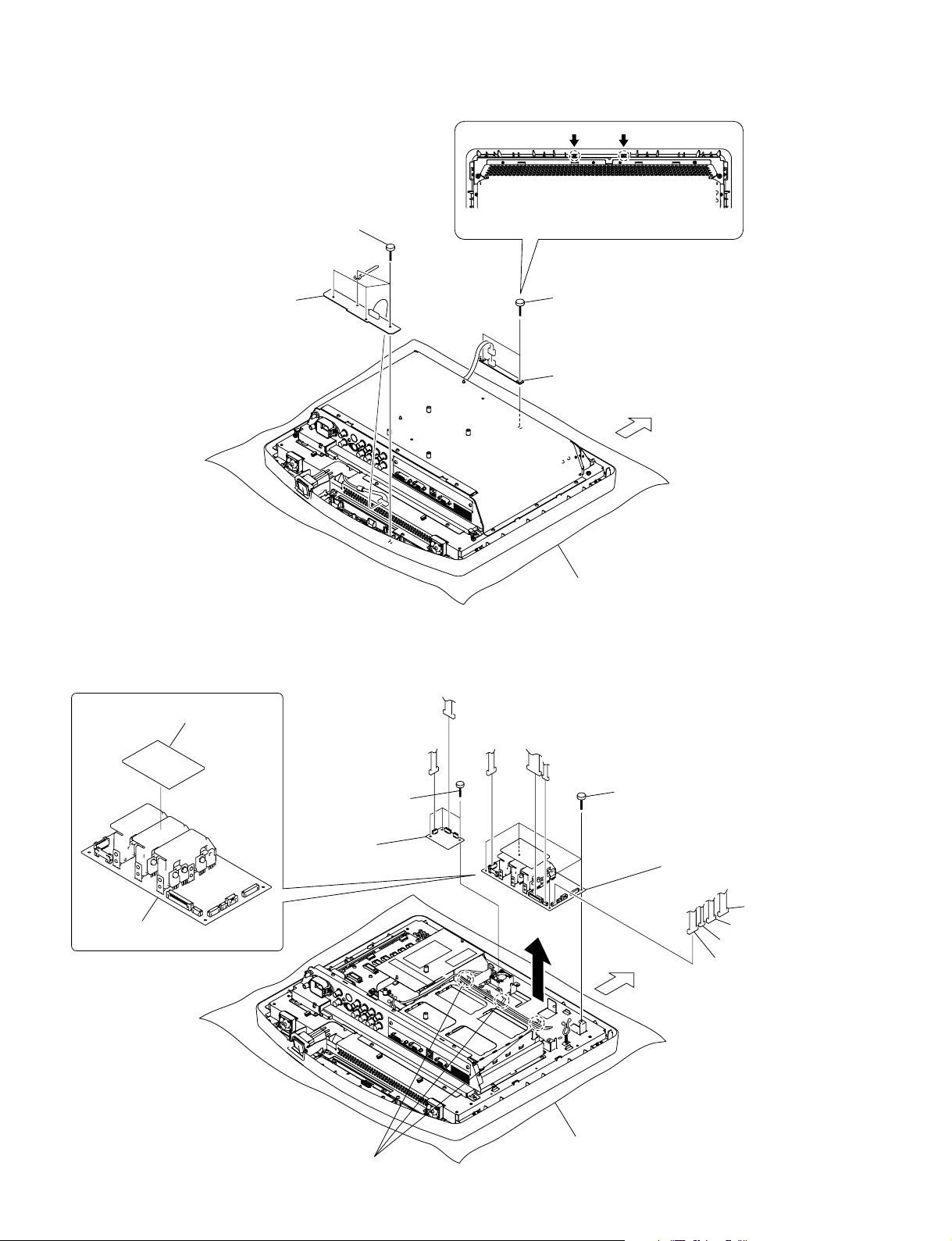

1-3-3. Bezel Assembly

2

Fourteen screws

(+BVTP 3 x10)

1

Connector

CN1001

3 LCD panel section,

Shield case assembly, etc.

4 Bezel section

5 Eight screws

(+BVTP 3 x 10)

6 Two bracket (A)

assemblies

8

Two bracket (B)

assemblies

7

Eight screws

(+BVTP 3 x 10)

0

Bezel assembly

9

Protection plate

Upper

Side

Upper

Side

Upper

Side

Cushion

Cushion

Cushion

LMD-2140MD

1-5

Page 10

1-3-4. LCD Module-1

1

(+PSW 3 x 8)

Four screws

2

Four clamps

Cushion

Upper

Side

6

Two screws

(+BVTT 3 x 6)

9

5

Two screws

(+BVTT 3 x 6)

0 Bracket (T),

T board

Board to board

CN803

CN4100

CN804

CN4101

7

Option case assembly

8

Two screws

(+BVTT 3 x 6)

!- Five screws

(+BVTT 3 x 6)

!= Remove the case in the

direction of the arrow.

Upper

Side

1-6

Cushion

4 Two blank panel

assemblies

3 Loosen four screws

LMD-2140MD

Page 11

1-3-5. LCD Module-2

2

Six screws

(+BVTT 3 x 6)

Cushion

7 Two clamp

s

3

Screw

(+PSW 4 x 8)

1

Four screws

(+BVTT 3 x 6)

4

B board, Connector panel section

CN7501

6

Flip the shield sheet.

Upper

Side

5

Screw

(+BVTT 3 x 6)

!=

CN8202

D2 board

!- Five screws

(+BVTT 3 x 6)

CN8204

CN8203

0

Switching regulator, Sheet G,

Three radiation sheets

8

(+BVTT 3 x 6)

9

Screw

(+PSW 4 x 8)

CN8205

CN8209

CN8208

CN8207

CN8206

Four screws

!;

Connector panel section

,

Frame, G1 board, etc.

!\ Connector

!' LCD module

Upper

Side

![

Five screws

(+BVTT 3 x 6)

Upper

Side

Cushion

Upper

Side

LMD-2140MD

Cushion

!]

Four screws

(+PSW 3 x 8)

Cushion

1-7

Page 12

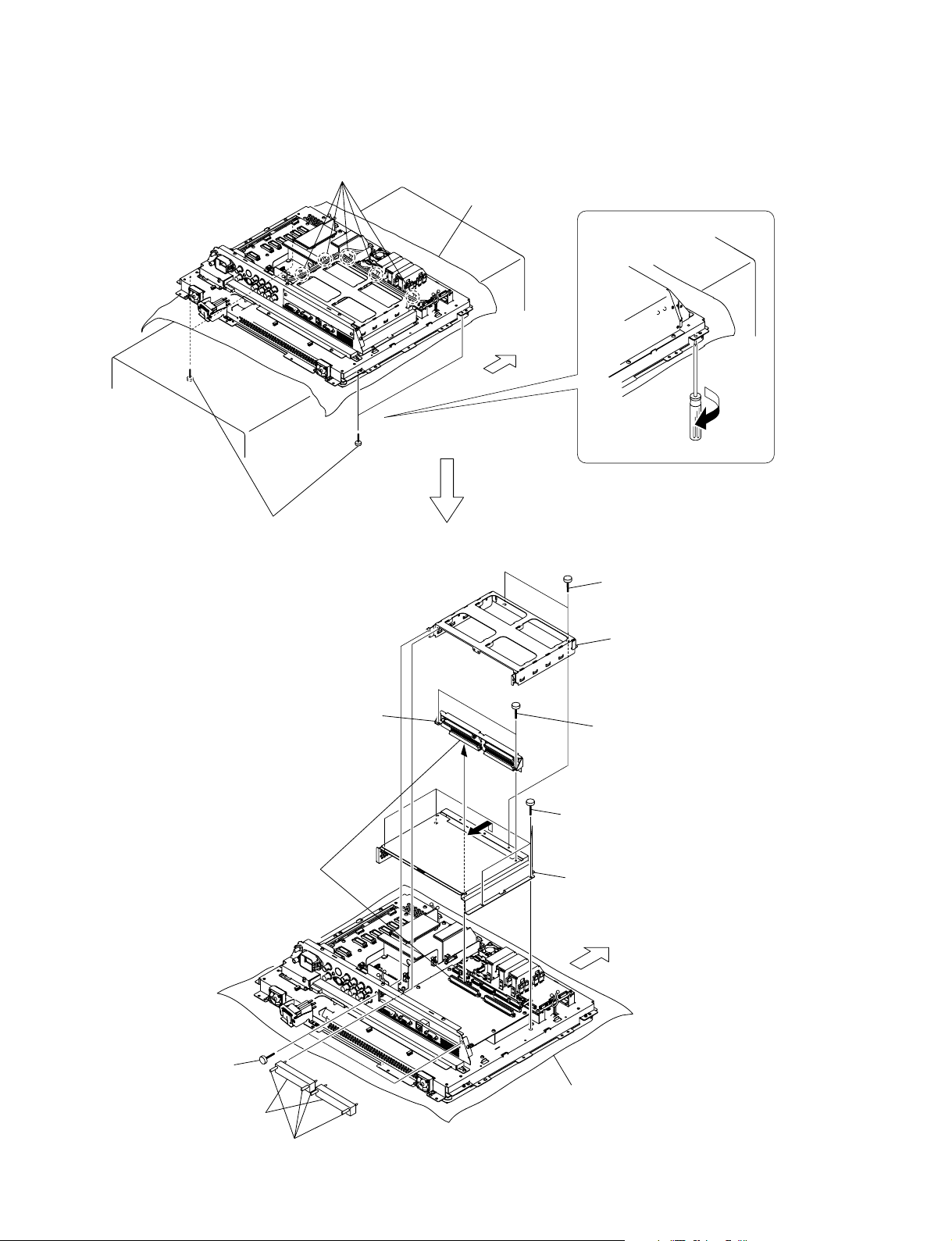

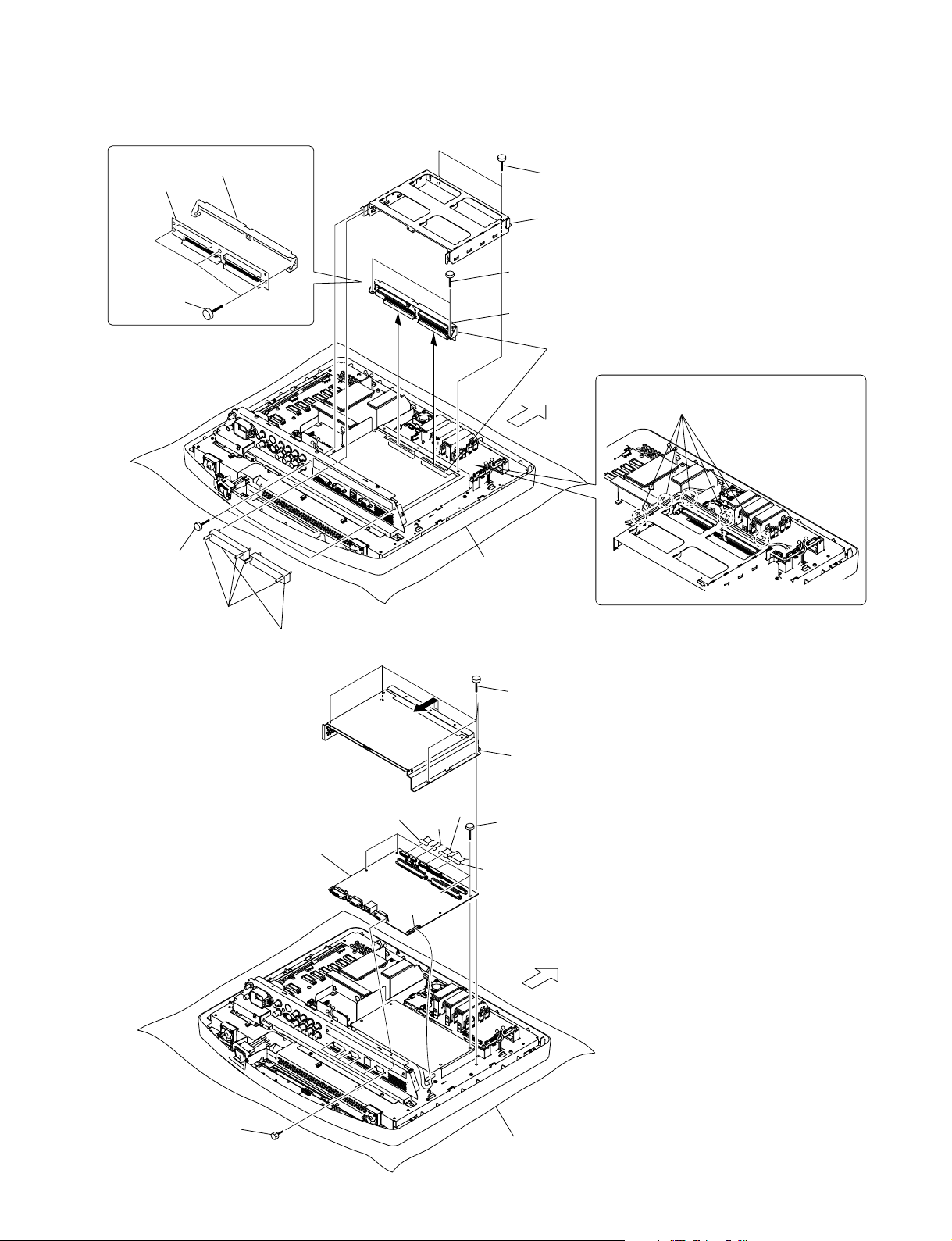

1-3-6. H Board and X Board

1

Four screws

(+BVTP 3 x 10)

2

H board

CN1001

CN1901

3

Two screws

(+BVTT 3 x 6)

4

X board

Upper

Side

1-3-7. G1 Board and B2 Board

4

Radiation sheet (C)

5

G1 board

6

Three screws

(+BVTT 3 x 6)

7 B board

CN1301

CN1302

CN601

CN606

Cushion

CN607

1

Four screws

(+BVTT 3 x 6)

3

G1 board,

Radiation sheet (C)

Upper

Side

CN602

CN603

CN605

CN604

1-8

2 Three

Cushion

clamps

LMD-2140MD

Page 13

1-3-8. T Board

Bracket (T)

!-

!=

T board

0

Three screws

(+PSW 3 x 6)

3

Two screws

(+BVTT 3 x 6)

CN803

CN4100

CN4101

CN804

Cushion

5

Two screws

(+BVTT 3 x 6)

6

Option case assembly

7

Two screws

(+BVTT 3 x 6)

9 T board,

Bracket (T)

8

Board to board

Upper

Side

4

Five clamps

1 Loosen four screws

1-3-9. B Board

2 Two blank panel

assemblies

5 B board

CN2702

CN7501

CN301

CN3

1

Five screws

(+BVTT 3 x 6)

2

Remove the case in the

direction of the arrow.

4

Four screws

(+BVTT 3 x 6)

CN501

Upper

Side

3Six hexagon

LMD-2140MD

screws

Cushion

1-9

Page 14

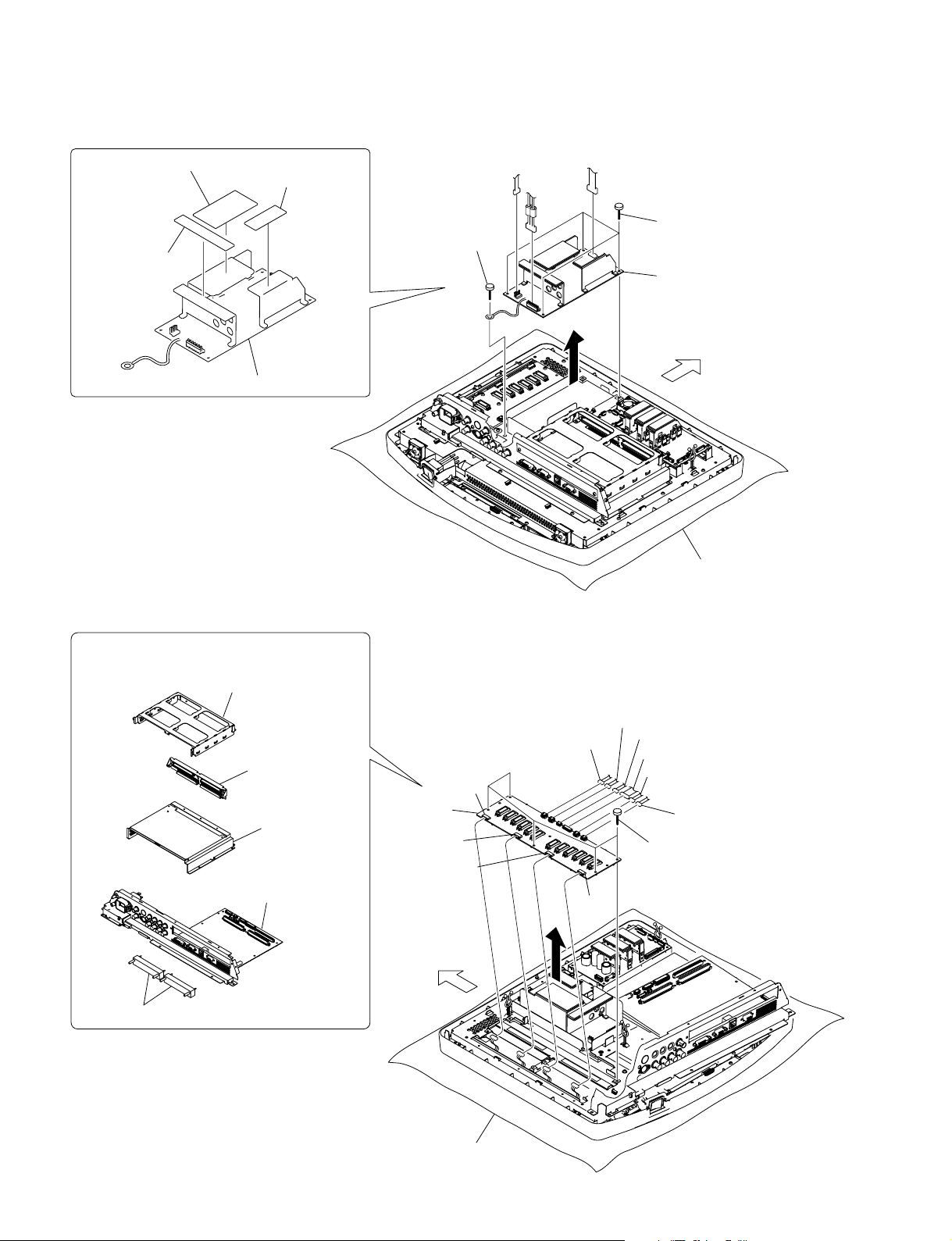

1-3-10. Switching Regulator

5

Radiation sheet (C)

6

Radiation sheet (D)

1-3-11. D2 Board

4

Radiation sheet (B)

7

Switching regulator

2

Screw

(+PSW 4 x 8)

CN1

CN2

CN103

1

Four screws

(+BVTT 3 x 6)

3

Switching regulator,

Three radiation sheets (B,C,D)

Upper

Side

Cushion

For removal procedure, refer to "LCD Panel-1.-2".

2

Option case assembly

3 Bracket (T),

5

B board, Connector panel section

1 Two blank panel assemblies

T board

4 Case B

7 D2

CN8205

board

CN8204

CN8203

Upper

Side

CN8208

CN8209

CN8202

CN8210

CN8201

CN8207

CN8206

6

Five screws

(+BVTT 3 x 6)

1-10

Cushion

LMD-2140MD

Page 15

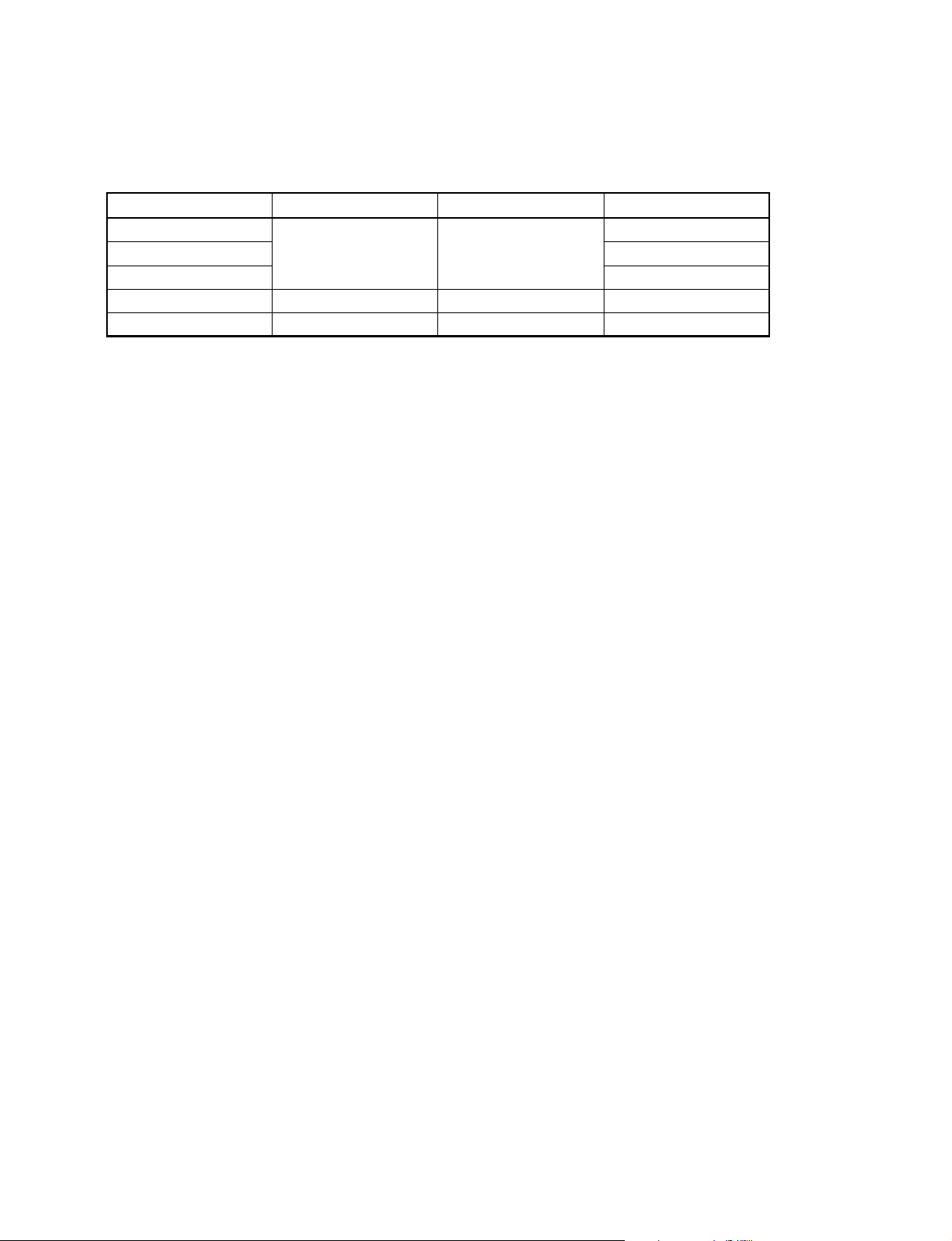

1-4. Warning on Power Connection

Use a proper power cord for your local power supply

Plug type

Female end

Cord type

Rated Voltage & Current

Safety approval

The United States

HOSPITAL GRADE

E41395

E41395-A

10A/125V

UL

Canada

HOSPITAL GRADE

LL33182

LL76662

10A/125V

CSA

Continental Europe

LP-34A

LS-60

H05VV-F

10A/250V

VDE

LMD-2140MD

1-11

Page 16

Page 17

Section 2

Electrical Adjustments

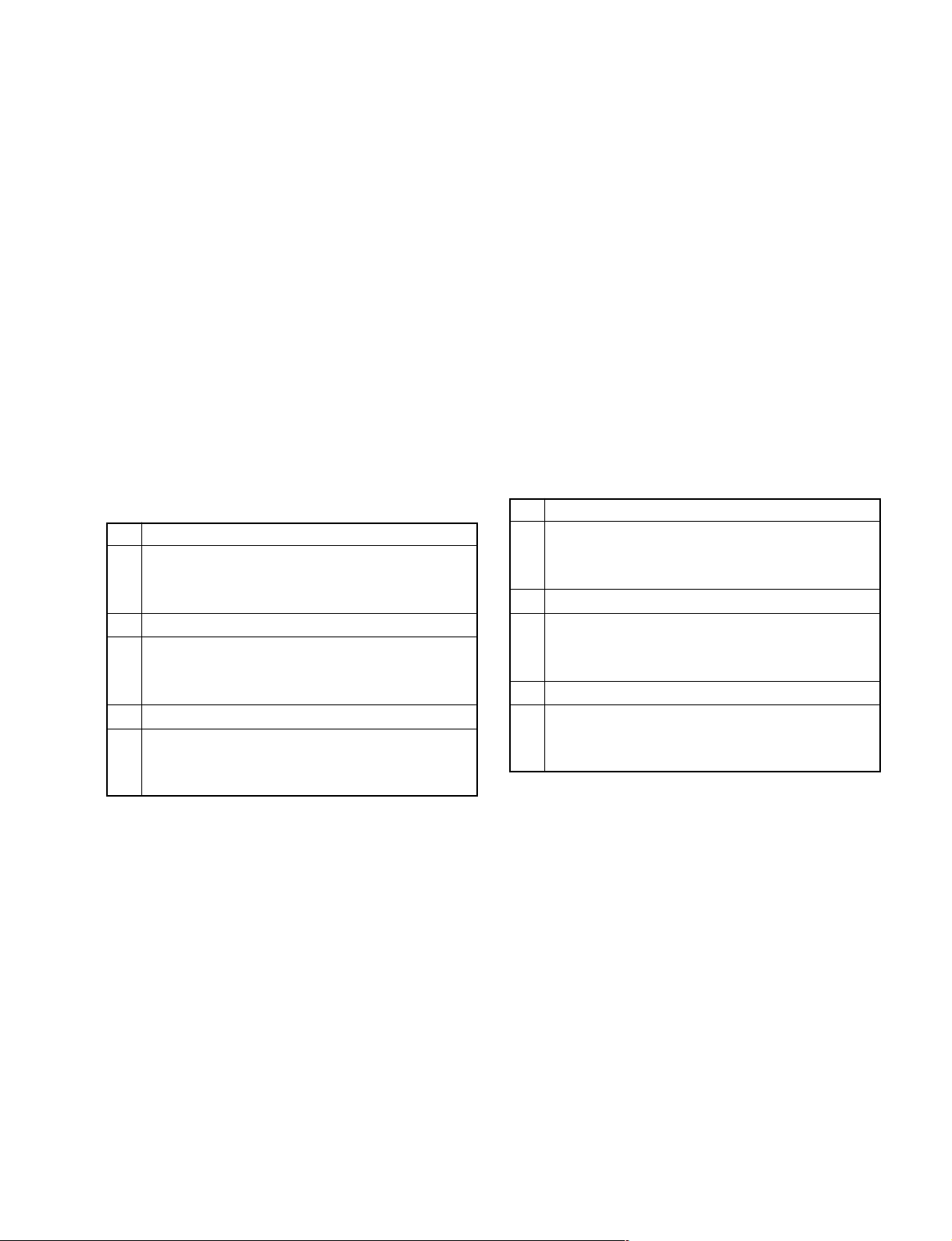

2-1. Preparation

. Required tools and measuring equipment

Luminance meter :Minolta CA-210, CA-110 or equiva-

lent.

If Minolta CA-210, CA-110 or

equivalent, is not available, make

adjustment by comparing the LCD

monitor with the reference monitor

that has already been calibrated

correctly.

Signal generator : VG-854 or equivalent

. Warm-up time

Before starting adjustment, allow a warm-up of minimum

120 minutes to stabilize the back light of the LCD panel.

. How to enter service mode

1. Press MENU to display the MENU screen.

2. Press the APA and ENTER buttons simultaneously

with MENU screen appeared.

. HIGH adjustment

1. Select HIGH from COLOR TEMP and set it by

pressing ENTER.

Target value : x = 0.283, y = 0.298

2. Select ADJUST GAIN, and adjust the GAIN. Adjust

using R and B while G is fixed.

3. Select ADJUST BIAS, and adjust the BIAS. Adjust

using R and B while G is fixed.

4. Repeat steps 2 and 3 until all of the required specifications are met all at the same time.

. LOW adjustment

1. Select LOW from COLOR TEMP and set it by

pressing ENTER.

Target value : x = 0.313, y = 0.329

2. Select ADJUST GAIN, and adjust the GAIN.

Adjust using R and B while G is fixed.

3. Select ADJUST BIAS, and adjust the BIAS.

Adjust using R and B while G is fixed.

4. Repeat steps 2 and 3 until all of the required specifications are met all at the same time.

Preparing the power supply and signals

1. Connect the supplied power cord to AC IN of the set.

Power voltage : 100 to 240 V AC, 50/60Hz

2. Connect the signal coming from the VG-854 to the

VIDEO IN connector of the set. Because this signal is

used for synchronization, any type of signal can be

used as long as the signal has the receivable format.

3. Turn on the power of the LMD-2140MD. For set,

select the signal that is used for signal input.

2-2. White Balance Adjustment

1. Move the cursor to SIG using the Down ↓ key and

press ENTER to enter the SIGNAL layer.

2. Move the cursor to WHITE BALANCE using the

Down ↓ key and press ENTER to enter the SIGNAL/

WHITE BALANCE layer.

To move the cursor to select an item, use the Up ↑ or

Down ↓ key. To set the selected item, press the ENTER

key.

. LOW2 adjustment

1. Select LOW2 from COLOR TEMP and set it by

pressing ENTER.

Target value : x = 0.330, y = 0.345

2. Select ADJUST GAIN, and adjust the GAIN.

Adjust using R and B while G is fixed.

3. Select ADJUST BIAS, and adjust the BIAS.

Adjust using R and B while G is fixed.

4. Repeat steps 2 and 3 until all of the required specifications are met all at the same time.

. LOW3 adjustment

1. Select LOW3 from COLOR TEMP and set it by

pressing ENTER.

Target value : x = 0.316, y = 0.326

2. Select ADJUST GAIN, and adjust the GAIN.

Adjust using R and B while G is fixed.

3. Select ADJUST BIAS, and adjust the BIAS.

Adjust using R and B while G is fixed.

4. Repeat steps 2 and 3 until all of the required specifications are met all at the same time.

LMD-2140MD

2-1

Page 18

2-3. A/D Adjustment (COMPONENT)

2-4. A/D Adjustment (RGB)

1. Input the 575/50I 100% 8 color bar COMPONENT

signal to the LMD-2140MD.

2. Press the COMPONENT switch to accept the COMPONENT input signal.

3. Enter the Service menu, then select SIG → SIGNAL

LEVEL → AUTO ADJ. Perform the following

automatic adjustments.

. Y LEVEL

. PB LEVEL

. PR LEVEL

. Y OFFSET

. PB OFFSET

. PR OFFSET

4. Confirm that the A/D AUTO ADJ has terminated

normally and the monitor screen is normally displayed.

5. Perform the adjustments of items 1-2 to 1-4 in table 1

shown below by repeating the above described

procedures.

However, before performing AUTO ADJ, adjust the

COMPONENT level or NTSC SETUP appropriately

according to the respective conditions described in

table 1.

COMPONENT selection input

1-1 575/50I 100% 8 color bar signal

Y/G LEVEL

PB/B LEVEL Conditions :

PR/R LEVEL

Y/G OFFSET NTSC SETUP No specific conditions

PB/B OFFSET

PR/R OFFSET

1-2 480/60I BETA0 100% 8 color bar signal

Y/G LEVEL

PB/B LEVEL Conditions :

PR/R LEVEL COMPONENT LEVEL BETA 0

Y/G OFFSET NTSC SETUP No specific conditions

PB/B OFFSET

PR/R OFFSET

1-3 480/60I BETA7.5 100% 8 color bar signal

Y/G LEVEL

PB/B LEVEL Conditions :

PR/R LEVEL COMPONENT LEVEL BETA 7.5

Y/G OFFSET NTSC SETUP No specific conditions

PB/B OFFSET

PR/R OFFSET

1-4 1080/60I 100% 8 color bar signal

Y/G LEVEL

PB/B LEVEL Conditions :

PR/R LEVEL

Y/G OFFSET NTSC SETUP No specific conditions

PB/B OFFSET

PR/R OFFSET

COMPONENT LEVEL No specific conditions

COMPONENT LEVEL No specific conditions

Table 1

2-2

1. Input the 480/60I 100% 8 color bar RGB signal to the

LMD-2140MD.

2. Press the RGB switch to accept the RGB input signal.

3. Enter the Service menu, then select SIG → SIGNAL

LEVEL → AUTO ADJ. Perform the following

automatic adjustments.

. Y LEVEL

. PB LEVEL

. PR LEVEL

. Y OFFSET

. PB OFFSET

. PR OFFSET

4. Confirm that the A/D AUTO ADJ has terminated

normally and the monitor screen is normally displayed.

5. Perform the adjustment of item 1-6 in table 2 shown

below by repeating the above described procedures.

RGB selection input

1-5 480/60I RGB 100% 8 color bar signal

Y /G LEVEL

PB/B LEVEL

PR/R LEVEL Conditions :

Y/G OFFSET No specific conditions

PB/B OFFSET

PR/R OFFSET

1-6 1080/60I RGB 100% 8 color bar signal

Y /G LEVEL

PB/B LEVEL

PR/R LEVEL Conditions :

Y/G OFFSET No specific conditions

PB/B OFFSET

PR/R OFFSET

Table 2

LMD-2140MD

Page 19

2-5. A/D Adjustment (COMPOSITE)

2-6. A/D Adjustment (Y/C)

1. Input the NTSC 100% 8 color bar COMPOSITE signal

to the LMD-2140MD.

2. Press the COMPOSITE switch to accept the COMPOSITE input signal.

3. Enter the Service menu, then select SIG → SIGNAL

LEVEL → AUTO ADJ. Perform the following

automatic adjustments.

. Y LEVEL

. PB LEVEL

. PR LEVEL

4. Confirm that the A/D AUTO ADJ has terminated

normally and the monitor screen is normally displayed.

5. Perform the adjustments of items 1-8 and 1-9 in table 3

shown below by repeating the above described

procedures.

COMPOSITE selection input

1-7 NTSC SETUP 0 100% 8 color bar signal

Y /G LEVEL

PB/B LEVEL Conditions :

PR/R LEVEL NTSC SETUP NTSC SETUP 0

1-8 PAL 100% 8 color bar signal

Y /G LEVEL

PB/B LEVEL Conditions :

PR/R LEVEL No specific conditions

1-9 NTSC SETUP 7.5 100% 8 color bar signal

Y /G LEVEL

PB/B LEVEL Conditions :

PR/R LEVEL NTSC SETUP NTSC SETUP 7.5

Table 3

1. Input the NTSC 100% 8 color bar Y/C signal to the

LMD-2140MD.

2. Press the Y/C switch to accept the Y/C input signal.

3. Enter the Service menu, then select SIG → SIGNAL

LEVEL → AUTO ADJ. Perform the following

automatic adjustments.

. Y LEVEL

. PB LEVEL

. PR LEVEL

4. Confirm that the A/D AUTO ADJ has terminated

normally and the monitor screen is normally displayed.

5. Perform the adjustments of items 1-11 and 1-12 in

table 4 shown below by repeating the above described

procedures.

Y/C selection input

1-10 NTSC SETUP 0 100% 8 color bar signal

Y /G LEVEL

PB/B LEVEL Conditions :

PR/R LEVEL NTSC SETUP NTSC SETUP 0

1-11 PAL 100% 8 color bar signal

Y /G LEVEL

PB/B LEVEL Conditions :

PR/R LEVEL No specific conditions

1-12 NTSC SETUP 7.5 100% 8 color bar signal

Y /G LEVEL

PB/B LEVEL Conditions :

PR/R LEVEL NTSC SETUP NTSC SETUP 7.5

Table 4

LMD-2140MD

2-3

Page 20

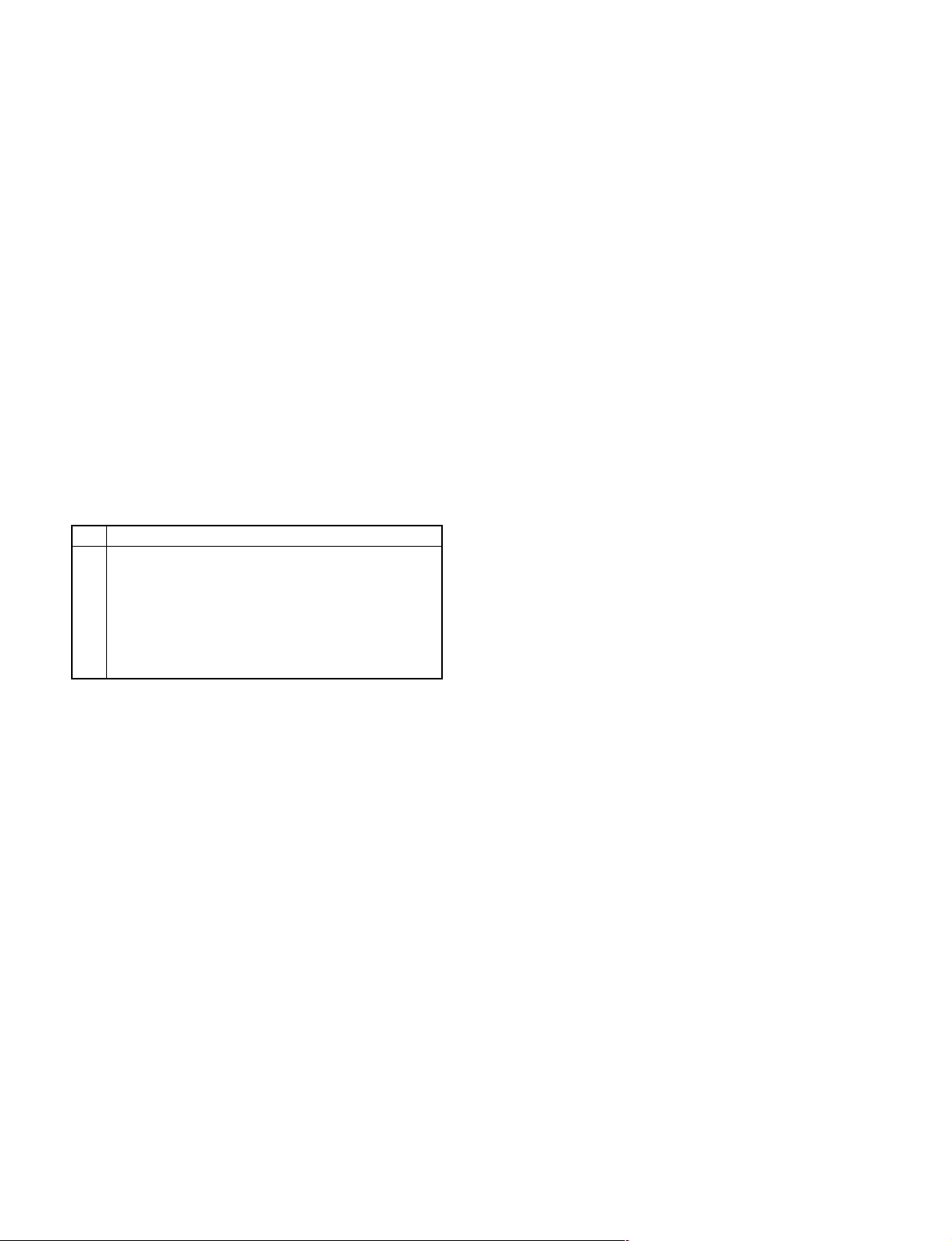

2-7. A/D Adjustment (COMPUTER)

1. Input the 640 x 480 60 Hz 100% 8 color bar signal to

the LMD-2140MD.

2. Press the COMPUTER switch to accept the COMPUTER input signal.

3. Enter the Service menu, then select SIG → SIGNAL

LEVEL → AUTO ADJ. Perform the following

automatic adjustments.

. Y LEVEL

. PB LEVEL

. PR LEVEL

. Y OFFSET

. PB OFFSET

. PR OFFSET

4. Confirm that the A/D AUTO ADJ has terminated

normally and the monitor screen is normally displayed.

COMPUTER selection input

1-13 VGA60 100% 8 color bar signal

Y /G LEVEL

PB/B LEVEL

PR/R LEVEL Conditions :

Y/G OFFSET No specific conditions

PB/B OFFSET

PR/R OFFSET

Table 5

2-4

LMD-2140MD

Page 21

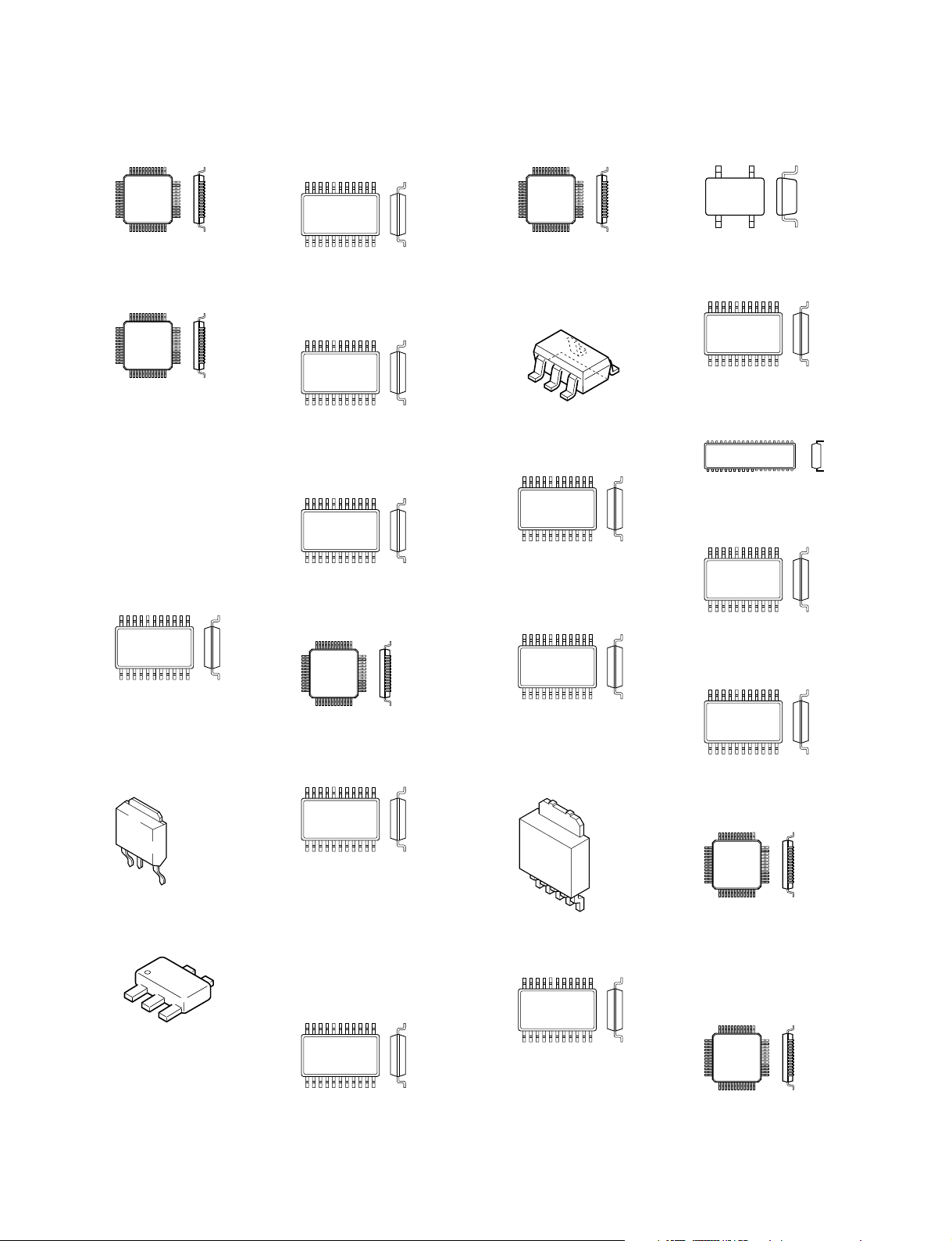

Section 3

1

TOP VIEW

1

2

3

4

5

Semiconductors

IC

AD9882KSTZ-140

1

TOP VIEW

100pin QFP

AD9883AKST-110

1

TOP VIEW

80pin QFP

BA033FP

BA033FP-E2

BA10358FV-E2

FDS6690A

L5972D

L5972D013TR

NJM2903M

NJM2903M-TE2

TC7W53FU(TE12R)

TC7W53FU-TE12R

UPA1716G-E2

BD9766FV-E2

MB90098APF-G-168-ERE1

1

TOP VIEW

28pin SOP

BU9882F-WE2

TC74VHCT14AFT(EL)

1

TOP VIEW

14pin SOP

EMC6D102-CZC-TR

ICS1523MLFT-ER

1

TOP VIEW

24pin SOP

HD6417709SF133BV

IP00C713

256pin QFP

LP2985IM5X-3.3

PST9229NL

5

4

1

2

3

MBM29DL324BE-90PFTNLMD1100

1

TOP VIEW

48pin SOP

MSM56V16160F-8T3FM1

MSM56V16160F-8T4FM1

TC7W125FU-TE12R

1

8pin CHIP

THC63LVDM83R-T

1

TOP VIEW

56pin SOP

TL431CPK-E2

1

TOP VIEW

8pin DIP

TPS5103IDBR

1

TOP VIEW

20pin SOP

1

TOP VIEW

8pin SOP

BA18BC0FP-E2

BA25BC0FP-E2

BA25BC0FP-TE2

2

1

3

BD4831FVE-TR

BD4845FVE-TR

5

1

2

3

TPS5120DBTR

1

1

TOP VIEW

208pin QFP

HY57V641620HGTP-H

TOP VIEW

50pin SOP

PQ070XZ01ZPH

PQ1CZ41H2ZPH

1

TOP VIEW

30pin SOP

UPD64011AGM-8ED-A

1

TOP VIEW

54pin SOP

1

ICS1523M-ER

MAX202CSE

TOP VIEW

160pin QFP

MAX202CSE-T

TC74HC4053AFT(EL)

4

TC74LCX138FT(EL)

TC74VHC165FT (EL)

TC74VHC165FT(EL)

1

TOP VIEW

16pin SOP

TC7SZ125FU(TE85R)

1

TOP VIEW

5pin SOP

XC18V02-MEU1VP1-V100

XC18V02-MEU1VP1-V101

XC18V02-MEU1VS1-V101

XC9536XL-5-MEU1-V023

1

TOP VIEW

44pin QFP

LMD-2140MD

3-1

Page 22

IC, Transistor, Diode

XC2S200E-6FTG256C

A

1

BOTTOM VIEW

256pin PGA

2SA1576A-T106-QR

2SA1610-T1Y34

2SA1610-Y33

2SC4081-R

2SC4081T106R

2SC4176-B34

2SC4176T1B33B34B35

DTC144EKA (T146)

DTC144EKA-T146

DTC144EUA-T106

MMBT3904

MMBT3904LT1

C

B

E

2SK3018-T106

D

G

S

DTA144EUA-T106

OUT

IN

GND

IMT2AT108

4

5

6

3

2

1

4

5

3

2

6

1

IMX2

IMX2-T109

4

3

2

1

4

3

2

1

RTQ035P02

RTQ035P02TR

6

1

2

3

1

2

3

SI4425DY-T1

D

S

S

S

G

UMH2NL02TN

1

2

3

6

1

2

3

UMW1NTR

1SS184

MA152WK-TX

5

6

2

5

6

2

3

1

3

1

1SS226

1SS226-TE85L

3

5

4

6

5

4

2

1

3

2

1

1SS302

1SS302-TE85L

HN1D03FU-TE85L

HN1D03FU-TE85R

4

5

6

3

2

1

4

5

3

2

6

1

MA3J14700LSO

CATHODE

ANODE

PTZ-TE25-27A

RB060L-40TE25

RB063L-30TE25

3

D

D

D

1

2

3

1

2

CATHODE

ANODE

RB160M-30TR

1SS352

1SS352-TPH3

1SS355TE-17

6

5

4

1SS357(T3SONY1)

MA111-TX

RD13SB-T1

UDZSTE-1713B

UDZSTE-173.9B

UDZS-TE17-5.1B

UDZSTE-175.1B

ANODE

RD3.3SB

RD3.3SB-T1

5

4

ANODE

CATHODE

RD12SB-T1

CATHODE

2

3-2

5

4

1

2

3

5

1

2

3

4

C10T03QL-11A

3

2

1

3

2

1

1

1

CATHODE

ANODE

2

LMD-2140MD

Page 23

SML-020MLTT87

SML-020MLTT87

4

3

1

3

4

1

UDZS-TE17-5.6B

ANODE

CATHODE

Diode

2

2

UDZSTE-175.6B

CATHODE

SML-011EBTT86

ã^ñ‚

ANODE

LMD-2140MD

3-3

Page 24

Page 25

4-1. Notes on Repair Parts

1. Safety Related Components Warning

w

Components marked ! are critical to safe operation.

Therefore, specified parts should be used in the case of

replacement.

2. Standardization of Parts

Some repair parts supplied by Sony differ from those

used for the unit. These are because of parts commonality and improvement.

Parts List has the present standardized repair parts.

3. Stock of Parts

Parts marked with “o” at SP (Supply Code) column of

the Spare Parts list may not be stocked. Therefore, the

delivery date will be delayed.

Items with no part number and no description are not

stocked because they are seldom required for routine

service.

Section 4

Spare Parts

4. Units for Capacitors, Inductors and Resistors

The following units are assumed in Schematic Diagrams, Electrical Parts List and Exploded Views

unless otherwise specified.

Capacitors : µF

Inductors : µH

Resistors : Ω

LMD-2140MD

4-1

Page 26

Cover

4-2. Exploded Views

27

28

5

+BVTT 3x6

C

+PSW 4x8

18

17

32

20

16

+BVTT 3x6

B

+B 4x10

11

22

14

8

+BVTT 3x6

+PWHTP 3x10

7

Option

+BVTT 3x6

BKM-227W,

BKM-229X

9

23

+PSW 3x12

D

24

26

+BVTT 3x6

31

19

25

13

+BVTT 3x6

+PSW 4x8

A

+BVTT 3x6

32

1

+BVTT 3x6

10

A

D

6

+BVTT 3x6

+BVTT 3x6

30

+BVTT 3x6

3

17

4

+BVTT 3x6

+BVTT 3x6

29

12

C

+BVTT 3x6

2

B

4-2

Upper

Side

LMD-2140MD

Page 27

No. Part No. SP Description

1 A-1088-792-A s MOUNTED CIRCUIT BOARD, Q

2 A-1088-794-A s MOUNTED CIRCUIT BOARD, B2

3 A-1088-800-A s MOUNTED CIRCUIT BOARD, B

4 A-1088-801-A s MOUNTED CIRCUIT BOARD, G1

5 A-1071-809-A s MOUNTED CIRCUIT BOARD, D2

6 A-1410-194-A s MOUNTED CIRCUIT BOARD, T

7 X-2025-299-1 s COVER ASSY(A), SCREW

8 X-2025-300-1 s ASSY, OPTION CASE

9 X-2025-301-2 s ASSY, SHIELD CASE

10 X-2025-356-3 s ASSY,CN PANEL

11 ! 1-468-893-11 s REGULATOR,SWITCHING

12 ! 1-787-034-11 s D.C. FAN

13 ! 1-819-054-11 s AC INLET

14 2-546-511-01 s COVER,SCREW(B)

16 ! 2-546-517-01 s SHEET,RADIATION(B)

17 ! 2-546-518-01 s SHEET,RADIATION(C)

18 ! 2-546-519-01 s SHEET,RADIATION(D)

19 ! 2-546-520-01 s SHEET G

20 ! 2-546-534-01 s CABINET, REAR

22 2-547-102-01 s LABEL, CONNECTOR

23 2-990-241-02 s HOLDER (A), PLUG

24 3-175-740-01 o TERMINAL

25 3-175-741-01 o NUT

26 3-175-742-01 o WASHER

27 4-095-186-01 o SHEET (D), RADIATION

Cover

28 4-095-194-01 o HEAT SINK (D)

29 4-382-854-21 s SCREW +PSW M3X14(EP-FE/ZN/CM2)

30 4-382-854-51 s SCREW +PSW M3X6(EP-FE/ZN/CM2)

31 4-635-966-01 s SCREW (HEX)

32 1-469-969-11 s CLAMP, FERRITE

7-682-562-04 s SCREW +B 4X10

7-682-950-09 s SCREW +PSW 3X12(EP-FE/ZNBK/CM2)

7-682-961-01 s SCREW +PSW 4X8

7-685-871-01 s SCREW,+BVTT 3X6

7-685-903-31 s SCREW,+PWHTP 3X10(EP-FE/ZNBK/C)

LMD-2140MD

4-3

Page 28

Panel

101

103

109

111

102

106

104

110

110

105

Upper

Side

+BVTP 3x10

+BVTT 3x6

+BVTP 3x10

+BVTP 3x10

+BVTP 3x10

+BVTP 3x10

+BVTP 3x10

+BVTT 3x6

+PSW 3x8

+BVTT 3x6

105

+BVTT 3x6

+BVTT 3x6

108

107

+BVTT 3x6

+BVTT 3x6

+BVTT 3x6

A

A

No. Part No. SP Description

101 A-1088-791-A s MOUNTED CIRCUIT BOARD, H

102 A-1088-796-A s MOUNTED CIRCUIT BOARD, X

103 ! X-2025-292-1 s ASSY,BEZEL

104 ! 1-762-179-21 s SWITCH, AC POWER

105 ! 1-787-034-11 s D.C. FAN

106 ! 1-805-323-51 s LCD MODULE

107 2-176-190-01 s CUSHION, PANEL

108 2-176-190-11 s CUSHION, PANEL

109 2-546-523-01 s PLATE,PROTECTION

110 4-382-854-21 s SCREW +PSW M3X14(EP-FE/ZN/CM2)

111 4-662-796-01 o CLIP,COATING

7-682-948-01 s SCREW +PSW 3X8

7-685-647-79 s SCREW +BVTP3X10(EP-FE/ZNBK/CM2)

7-685-871-01 s SCREW,+BVTT 3X6

4-4

LMD-2140MD

Page 29

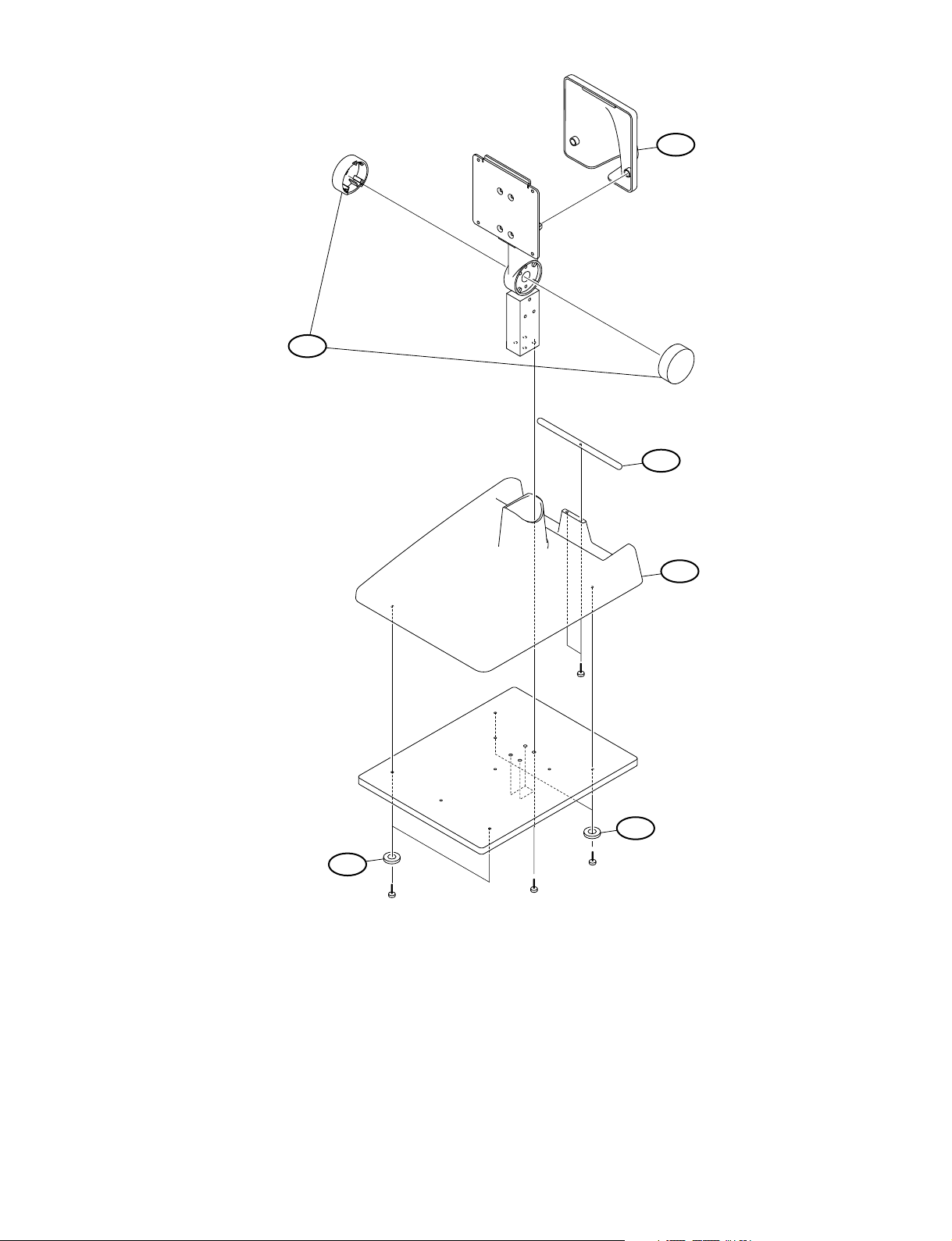

202

Display Stand (SU-560)

203

204

205

+B 3x10

No. Part No. SP Description

201 2-188-810-01 s COVER, BOTTOM

202 2-188-811-01 s COVER, HINGE

203 2-188-812-01 s COVER, VESA

204 2-541-782-01 s SHAFT. CABLE

205 4-310-333-01 s CUSHION, FOOT

201

+B 3x8

205

+BVTP 4x12

+B 4x10

7-685-647-71 s +B 3x10

7-685-661-14 s +BVTP 4x12(EP-FE/CU.NI.CR)

7-682-548-09 s SCREW +B 3x8

7-682-562-09 s +B 4x10 (EP-FE/ZNBK/CM2)

LMD-2140MD

4-5

Page 30

4-3. Electrical Parts List

CAUTION: DOUBLE POLE/NEUTRAL FUSING

------B BOARD

------ Ref. No.

or Q’ty Part No. SP Description

1pc A-1088-800-A s MOUNTED CIRCUIT BOARD, B

C1 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C2 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C4 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C6 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C7 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C8 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C9 1-126-412-11 s CAPACITOR,ELECT 220MF/4V(CHIP)

C13 1-126-392-11 s CAPACITOR,CHIP ELECT100MF/6.3V

C14 1-125-837-91 s CAPACITOR,CHIP CERAMIC1MF/6.3V

C15 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C16 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C17 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C18 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C19 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C20 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C21 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C22 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C23 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C24 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C25 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C26 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C27 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C28 1-164-315-11 s CAPACITOR,CERAMIC 470PF/50V CH

C29 1-164-315-11 s CAPACITOR,CERAMIC 470PF/50V CH

C30 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C31 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C32 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C33 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C34 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C35 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C36 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C37 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C38 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C39 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C40 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C41 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C42 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C43 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C44 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C45 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C46 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C47 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C48 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C49 1-127-692-11 s CAP, CHIP CERAMIC 10MF B 3216

C50 1-127-692-11 s CAP, CHIP CERAMIC 10MF B 3216

C51 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C52 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C53 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C54 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C55 1-131-998-11 s CAP, SOLID ELECT 82MF 6.3 V

C56 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C57 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C501 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

(B BOARD)

Ref. No.

or Q’ty Part No. SP Description

C502 1-100-159-91 s CAP, CERAMIC 22MF B (SMD) 3216

C503 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C504 1-100-159-91 s CAP, CERAMIC 22MF B (SMD) 3216

C505 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C506 1-128-396-11 s CAPACITOR,ELECT 470MF/10V CHIP

C507 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C508 1-128-396-11 s CAPACITOR,ELECT 470MF/10V CHIP

C509 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C510 1-128-396-11 s CAPACITOR,ELECT 470MF/10V CHIP

C511 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C512 1-128-396-11 s CAPACITOR,ELECT 470MF/10V CHIP

C513 1-100-159-91 s CAP, CERAMIC 22MF B (SMD) 3216

C514 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C701 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C702 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C703 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C704 1-127-692-11 s CAP, CHIP CERAMIC 10MF B 3216

C705 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C706 1-162-967-11 s CAPACITOR,CERAMIC 3300PF/50V B

C707 1-164-217-11 s CAPACITOR,CERAMIC 150PF/50V CH

C708 1-127-692-11 s CAP, CHIP CERAMIC 10MF B 3216

C709 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C710 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C711 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C712 1-127-692-11 s CAP, CHIP CERAMIC 10MF B 3216

C713 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C714 1-127-692-11 s CAP, CHIP CERAMIC 10MF B 3216

C715 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C2504 1-162-927-11 s CAPACITOR,CERAMIC 100PF/50V CH

C2505 1-162-927-11 s CAPACITOR,CERAMIC 100PF/50V CH

C2506 1-164-218-11 s CAPACITOR,CERAMIC 180PF/50V CH

C2507 1-164-218-11 s CAPACITOR,CERAMIC 180PF/50V CH

C2508 1-162-927-11 s CAPACITOR,CERAMIC 100PF/50V CH

C2509 1-162-927-11 s CAPACITOR,CERAMIC 100PF/50V CH

C2510 1-125-837-91 s CAPACITOR,CHIP CERAMIC1MF/6.3V

C2511 1-126-392-11 s CAPACITOR,CHIP ELECT100MF/6.3V

C2512 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C2513 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C2514 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C2515 1-162-927-11 s CAPACITOR,CERAMIC 100PF/50V CH

C2516 1-162-927-11 s CAPACITOR,CERAMIC 100PF/50V CH

C2518 1-125-891-11 s CAPACITOR CERAMIC 0.47MF/10V

C2519 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C2520 1-162-959-11 s CAPACITOR,CERAMIC 330PF/50V SL

C2521 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C2524 1-135-344-11 s CAPACITOR,SOLID ELECT 270MF

C2525 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C2526 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C2527 1-165-875-11 s CAPACITOR, CHIP CERAMIC 10MF B

C2550 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C2551 1-137-894-21 s CAPACITOR,ELECT(CIHP TYPE) 470

C2552 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C2553 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C2554 1-162-966-11 s CAPACITOR,CERAMIC 2200PF/50V B

C2556 1-162-968-11 s CAPACITOR,CERAMIC 4700PF/50V B

C2557 1-162-966-11 s CAPACITOR,CERAMIC 2200PF/50V B

C2559 1-125-837-91 s CAPACITOR,CHIP CERAMIC1MF/6.3V

C2701 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C2702 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

4-6

LMD-2140MD

Page 31

(B BOARD)

(B BOARD)

Ref. No.

or Q’ty Part No. SP Description

C2703 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C2704 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C2741 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C2742 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C2743 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C2761 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C2762 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C2763 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C2781 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C2782 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C2783 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3101 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3102 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3103 1-127-760-11 s CAPACITOR,CERAMIC 4.7MF/6.3V

C3104 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3105 1-127-692-11 s CAP, CHIP CERAMIC 10MF B 3216

C3106 1-127-760-11 s CAPACITOR,CERAMIC 4.7MF/6.3V

C3107 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3108 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3109 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3110 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3111 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3112 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3113 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3114 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

Ref. No.

or Q’ty Part No. SP Description

C3152 1-100-202-21 s CAP, CHIP ELECT 330MF

C3153 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3154 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3156 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3157 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C3158 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3159 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3160 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3161 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3162 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3163 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3164 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3165 1-165-176-11 s CAPACITOR,CERAMIC 47000PF/16V

C3166 1-162-927-11 s CAPACITOR,CERAMIC 100PF/50V CH

C3167 1-164-217-11 s CAPACITOR,CERAMIC 150PF/50V CH

C3168 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3169 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3170 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3171 1-162-915-11 s CAPACITOR,CERAMIC 10PF/50V CH

C3172 1-162-915-11 s CAPACITOR,CERAMIC 10PF/50V CH

C3173 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3174 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C3175 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3176 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C3177 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3115 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3116 1-127-760-11 s CAPACITOR,CERAMIC 4.7MF/6.3V

C3117 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3118 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3119 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3120 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3121 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3122 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3123 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3124 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3125 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3126 1-127-760-11 s CAPACITOR,CERAMIC 4.7MF/6.3V

C3127 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3128 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3129 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3130 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3131 1-165-176-11 s CAPACITOR,CERAMIC 47000PF/16V

C3132 1-165-176-11 s CAPACITOR,CERAMIC 47000PF/16V

C3133 1-165-176-11 s CAPACITOR,CERAMIC 47000PF/16V

C3134 1-165-176-11 s CAPACITOR,CERAMIC 47000PF/16V

C3135 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3136 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C3140 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3141 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3142 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3143 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3144 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3145 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3146 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3147 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3178 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C3179 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3180 1-100-566-91 s CAP, CHIP CERAMIC 0.1MF B 1608

C3181 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3182 1-126-392-11 s CAPACITOR,CHIP ELECT100MF/6.3V

C3183 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3184 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3185 1-126-392-11 s CAPACITOR,CHIP ELECT100MF/6.3V

C3186 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3189 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3190 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3191 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C3401 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3402 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3403 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3404 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3405 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3406 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3407 1-126-392-11 s CAPACITOR,CHIP ELECT100MF/6.3V

C3412 1-126-392-11 s CAPACITOR,CHIP ELECT100MF/6.3V

C3413 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3414 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3415 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3416 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3417 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3418 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3501 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3502 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3503 1-164-388-91 s CAPACITOR,CERAMIC 270PF/50V CH

C3504 1-162-921-11 s CAPACITOR,CERAMIC 33PF/50V CH

C3148 1-164-230-11 s CAPACITOR,CERAMIC 220PF/50V

C3149 1-162-959-11 s CAPACITOR,CERAMIC 330PF/50V SL

C3150 1-165-176-11 s CAPACITOR,CERAMIC 47000PF/16V

C3151 1-100-566-91 s CAP, CHIP CERAMIC 0.1MF B 1608

LMD-2140MD

C3505 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3506 1-164-388-91 s CAPACITOR,CERAMIC 270PF/50V CH

C3507 1-162-921-11 s CAPACITOR,CERAMIC 33PF/50V CH

C3508 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

4-7

Page 32

(B BOARD)

(B BOARD)

Ref. No.

or Q’ty Part No. SP Description

C3509 1-164-388-91 s CAPACITOR,CERAMIC 270PF/50V CH

C3510 1-162-921-11 s CAPACITOR,CERAMIC 33PF/50V CH

C3511 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3512 1-115-340-11 s CAPACITOR CERAMIC 0.22MF/25V B

C3513 1-115-340-11 s CAPACITOR CERAMIC 0.22MF/25V B

C3514 1-115-340-11 s CAPACITOR CERAMIC 0.22MF/25V B

C3515 1-115-340-11 s CAPACITOR CERAMIC 0.22MF/25V B

C3516 1-115-340-11 s CAPACITOR CERAMIC 0.22MF/25V B

C3517 1-115-340-11 s CAPACITOR CERAMIC 0.22MF/25V B

C3518 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3519 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3520 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3522 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3523 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3524 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3526 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3527 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3528 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3529 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3530 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3531 1-131-998-11 s CAP, SOLID ELECT 82MF 6.3 V

C3532 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3533 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3534 1-131-998-11 s CAP, SOLID ELECT 82MF 6.3 V

C3535 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

Ref. No.

or Q’ty Part No. SP Description

C3571 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3573 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3575 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3576 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3577 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3578 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3579 1-131-998-11 s CAP, SOLID ELECT 82MF 6.3 V

C3580 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3581 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3582 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3583 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3584 1-165-176-11 s CAPACITOR,CERAMIC 47000PF/16V

C3585 1-162-968-11 s CAPACITOR,CERAMIC 4700PF/50V B

C3586 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3587 1-162-928-11 s CAPACITOR,CERAMIC 120PF/50V CH

C3588 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3589 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3590 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3591 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3592 1-131-998-11 s CAP, SOLID ELECT 82MF 6.3 V

C3593 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3594 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3595 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3596 1-115-416-11 s CAPACITOR,CERAMIC 1000PF/25V

C3597 1-115-416-11 s CAPACITOR,CERAMIC 1000PF/25V

C3536 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3537 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3538 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3539 1-165-176-11 s CAPACITOR,CERAMIC 47000PF/16V

C3540 1-162-968-11 s CAPACITOR,CERAMIC 4700PF/50V B

C3541 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3542 1-162-928-11 s CAPACITOR,CERAMIC 120PF/50V CH

C3543 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3544 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3545 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3546 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3547 1-131-998-11 s CAP, SOLID ELECT 82MF 6.3 V

C3548 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3549 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3550 1-125-891-11 s CAPACITOR CERAMIC 0.47MF/10V

C3551 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3552 1-125-891-11 s CAPACITOR CERAMIC 0.47MF/10V

C3553 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3554 1-125-891-11 s CAPACITOR CERAMIC 0.47MF/10V

C3556 1-162-928-11 s CAPACITOR,CERAMIC 120PF/50V CH

C3557 1-164-677-11 s CAPACITOR,CERAMIC 0.033MF/16V

C3558 1-162-967-11 s CAPACITOR,CERAMIC 3300PF/50V B

C3559 1-165-176-11 s CAPACITOR,CERAMIC 47000PF/16V

C3560 1-164-677-11 s CAPACITOR,CERAMIC 0.033MF/16V

C3561 1-125-891-11 s CAPACITOR CERAMIC 0.47MF/10V

C3562 1-162-967-11 s CAPACITOR,CERAMIC 3300PF/50V B

C3563 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3564 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3565 1-131-998-11 s CAP, SOLID ELECT 82MF 6.3 V

C3566 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3598 1-115-416-11 s CAPACITOR,CERAMIC 1000PF/25V

C3599 1-115-416-11 s CAPACITOR,CERAMIC 1000PF/25V

C3600 1-115-416-11 s CAPACITOR,CERAMIC 1000PF/25V

C3601 1-115-416-11 s CAPACITOR,CERAMIC 1000PF/25V

C3602 1-115-416-11 s CAPACITOR,CERAMIC 1000PF/25V

C3603 1-100-159-91 s CAP, CERAMIC 22MF B (SMD) 3216

C3604 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C3605 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3606 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C3607 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3608 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3610 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3611 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3612 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3613 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3614 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3615 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3616 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3617 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3695 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C4002 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C4003 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C4004 1-126-392-11 s CAPACITOR,CHIP ELECT100MF/6.3V

C4006 1-126-392-11 s CAPACITOR,CHIP ELECT100MF/6.3V

C4007 1-126-392-11 s CAPACITOR,CHIP ELECT100MF/6.3V

C4008 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C4009 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C4010 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C4012 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C4013 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3567 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3568 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C3569 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C3570 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C4014 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C4015 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C4016 1-126-392-11 s CAPACITOR,CHIP ELECT100MF/6.3V

C4017 1-126-392-11 s CAPACITOR,CHIP ELECT100MF/6.3V

4-8

LMD-2140MD

Page 33

(B BOARD)

(B BOARD)

Ref. No.

or Q’ty Part No. SP Description

C4018 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C4019 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C4020 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C4021 1-125-837-91 s CAPACITOR,CHIP CERAMIC1MF/6.3V

C4022 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C4023 1-125-837-91 s CAPACITOR,CHIP CERAMIC1MF/6.3V

C4024 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C4025 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C4026 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C4027 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C4028 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C4029 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C4030 1-126-412-11 s CAPACITOR,ELECT 220MF/4V(CHIP)

C4031 1-126-412-11 s CAPACITOR,ELECT 220MF/4V(CHIP)

C4032 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C4033 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C4034 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C4035 1-125-837-91 s CAPACITOR,CHIP CERAMIC1MF/6.3V

C4036 1-125-837-91 s CAPACITOR,CHIP CERAMIC1MF/6.3V

C4037 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C4038 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C4039 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C4040 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C4041 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C4042 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

Ref. No.

or Q’ty Part No. SP Description

C5031 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5032 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5033 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5034 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5035 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5036 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5501 1-126-392-11 s CAPACITOR,CHIP ELECT100MF/6.3V

C5502 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5503 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5504 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5505 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5506 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5507 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5508 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5509 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5510 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5511 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C5512 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5513 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5514 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5515 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5516 1-100-566-91 s CAP, CHIP CERAMIC 0.1MF B 1608

C5517 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5518 1-100-566-91 s CAP, CHIP CERAMIC 0.1MF B 1608

C5519 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C4043 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C4100 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C4101 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C4102 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C4103 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C5002 1-126-392-11 s CAPACITOR,CHIP ELECT100MF/6.3V

C5003 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5004 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5005 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5006 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C5007 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5008 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5009 1-104-610-11 s CAPACITOR, ELECT 47MF/4V(CHIP)

C5010 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5011 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5012 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5013 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C5014 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5015 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5016 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C5017 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5018 1-126-412-11 s CAPACITOR,ELECT 220MF/4V(CHIP)

C5019 1-104-610-11 s CAPACITOR, ELECT 47MF/4V(CHIP)

C5020 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C5021 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5022 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5023 1-104-610-11 s CAPACITOR, ELECT 47MF/4V(CHIP)

C5024 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5025 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C5026 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5520 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5521 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5522 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5523 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5524 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5525 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5526 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C5527 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5528 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5529 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5530 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5531 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5532 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5533 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C5534 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5535 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5536 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5537 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5538 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5540 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5541 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5542 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C5543 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5544 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5545 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5546 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C5547 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5548 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5549 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C5550 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5027 1-126-392-11 s CAPACITOR,CHIP ELECT100MF/6.3V

C5028 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C5029 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5030 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

LMD-2140MD

C5551 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5552 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C5553 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C7022 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

4-9

Page 34

(B BOARD)

(B BOARD)

Ref. No.

or Q’ty Part No. SP Description

C7027 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C7030 1-126-392-11 s CAPACITOR,CHIP ELECT100MF/6.3V

C7031 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C7203 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C7204 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C7205 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C7206 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C7207 1-127-692-11 s CAP, CHIP CERAMIC 10MF B 3216

C7208 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C7209 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C7210 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C7211 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C7212 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C7213 1-125-837-91 s CAPACITOR,CHIP CERAMIC1MF/6.3V

C7214 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C7215 1-125-837-91 s CAPACITOR,CHIP CERAMIC1MF/6.3V

C7218 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C7219 1-100-566-91 s CAP, CHIP CERAMIC 0.1MF B 1608

C7220 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C7222 1-100-566-91 s CAP, CHIP CERAMIC 0.1MF B 1608

C7223 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C7224 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C7226 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C7227 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C7228 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

Ref. No.

or Q’ty Part No. SP Description

CN3 1-764-099-11 s PIN, CONNECTOR (PC BOARD) 14P

CN5 1-695-890-11 o PIN, CONNECTOR (PC BOARD) 12P

CN6 1-778-533-11 s CONNECTOR, BOARD TO BOARD 140P

CN501 1-815-889-21 s PIN, CONNECTOR (PC BOARD) 14P

CN2701 1-695-210-21 o PIN, CONNECTOR (PC BOARD) 15P

CN3501 1-817-074-11 s DVI CONNECTOR

CN3502 1-764-644-11 s JACK, MODULAR (TM11R-5L-88) 8P

CN3503 1-794-930-21 s CONNECTOR, D SUB

CN4001 1-764-080-21 o PIN, CONNECTOR (PC BOARD) 8P

CN7501 1-816-544-22 o PIN, CONNECTOR (PC BOARD) 20P

D1 8-719-069-55 s DIODE UDZS-TE17-5.6B

D2 8-719-069-55 s DIODE UDZS-TE17-5.6B

D3 8-719-037-25 s DIODE RD13SB-T1

D4 8-719-037-25 s DIODE RD13SB-T1

D5 8-719-037-25 s DIODE RD13SB-T1

D6 8-719-037-25 s DIODE RD13SB-T1

D7 8-719-037-25 s DIODE RD13SB-T1

D8 8-719-037-25 s DIODE RD13SB-T1

D9 8-719-083-58 s DIODE UDZSTE-173.9B

D10 8-719-083-58 s DIODE UDZSTE-173.9B

D11 8-719-083-58 s DIODE UDZSTE-173.9B

D12 8-719-083-58 s DIODE UDZSTE-173.9B

D13 8-719-083-58 s DIODE UDZSTE-173.9B

D18 8-719-404-50 s DIODE MA111-TX

D301 8-719-083-63 s DIODE UDZSTE-1713B

C7229 1-125-837-91 s CAPACITOR,CHIP CERAMIC1MF/6.3V

C7230 1-100-566-91 s CAP, CHIP CERAMIC 0.1MF B 1608

C7231 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C7234 1-100-566-91 s CAP, CHIP CERAMIC 0.1MF B 1608

C7236 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C7237 1-125-837-91 s CAPACITOR,CHIP CERAMIC1MF/6.3V

C7238 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C7239 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C7240 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C7241 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C7244 1-126-412-11 s CAPACITOR,ELECT 220MF/4V(CHIP)

C7245 1-126-392-11 s CAPACITOR,CHIP ELECT100MF/6.3V

C7246 1-126-392-11 s CAPACITOR,CHIP ELECT100MF/6.3V

C7247 1-126-412-11 s CAPACITOR,ELECT 220MF/4V(CHIP)

C7248 1-126-392-11 s CAPACITOR,CHIP ELECT100MF/6.3V

C7501 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C7502 1-162-908-11 s CAPACITOR,CERAMIC 3PF/50V 1608

C7503 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C7504 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C7505 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C7506 1-162-970-11 s CAPACITOR CERAMIC 0.01MF/25V B

C7507 1-126-396-11 s CAPACITOR,ELECT 47MF/16V(CHIP)

C7508 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C7509 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C7510 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C7511 1-100-566-91 s CAP, CHIP CERAMIC 0.1MF B 1608

C7512 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C7514 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C7515 1-107-826-11 s CAPACITOR,CHIP CERAMIC 0.1MF

C7516 1-100-566-91 s CAP, CHIP CERAMIC 0.1MF B 1608

D303 8-719-069-55 s DIODE UDZS-TE17-5.6B

D304 8-719-069-55 s DIODE UDZS-TE17-5.6B

D305 8-719-069-55 s DIODE UDZS-TE17-5.6B

D306 8-719-069-55 s DIODE UDZS-TE17-5.6B

D2501 8-719-016-74 s DIODE 1SS352

D2502 8-719-016-74 s DIODE 1SS352

D2503 8-719-016-74 s DIODE 1SS352

D2504 8-719-016-74 s DIODE 1SS352

D2553 8-719-016-74 s DIODE 1SS352

D2701 8-719-404-50 s DIODE MA111-TX

D2702 8-719-404-50 s DIODE MA111-TX

D2703 8-719-404-50 s DIODE MA111-TX

D2704 8-719-404-50 s DIODE MA111-TX

D2705 8-719-404-50 s DIODE MA111-TX

D2706 8-719-404-50 s DIODE MA111-TX

D2707 8-719-083-58 s DIODE UDZSTE-173.9B

D2721 8-719-404-50 s DIODE MA111-TX

D2722 8-719-404-50 s DIODE MA111-TX

D2741 8-719-404-50 s DIODE MA111-TX

D2742 8-719-404-50 s DIODE MA111-TX

D2761 8-719-404-50 s DIODE MA111-TX

D2762 8-719-404-50 s DIODE MA111-TX

D2781 8-719-404-50 s DIODE MA111-TX

D2782 8-719-404-50 s DIODE MA111-TX

D3101 8-719-404-50 s DIODE MA111-TX

D3501 8-719-069-55 s DIODE UDZS-TE17-5.6B

D3502 8-719-069-55 s DIODE UDZS-TE17-5.6B

D3503 8-719-069-55 s DIODE UDZS-TE17-5.6B

D3504 8-719-059-53 s DIODE MA3J14700LSO

D3505 8-719-059-53 s DIODE MA3J14700LSO

C7519 1-127-692-11 s CAP, CHIP CERAMIC 10MF B 3216

D3506 8-719-059-53 s DIODE MA3J14700LSO

D3507 8-719-069-55 s DIODE UDZS-TE17-5.6B

CN1 1-764-079-21 s PIN, CONNECTOR (PC BOARD) 4P

CN2 1-565-269-11 s SOCKET,CONNECTOR 9P

D3508 8-719-069-55 s DIODE UDZS-TE17-5.6B

D3509 8-719-069-55 s DIODE UDZS-TE17-5.6B

4-10

LMD-2140MD

Page 35

(B BOARD)

(B BOARD)

Ref. No.

or Q’ty Part No. SP Description

D3510 8-719-069-55 s DIODE UDZS-TE17-5.6B

D3511 8-719-069-55 s DIODE UDZS-TE17-5.6B

D3512 8-719-069-55 s DIODE UDZS-TE17-5.6B

D3513 8-719-069-55 s DIODE UDZS-TE17-5.6B

D3514 8-719-069-55 s DIODE UDZS-TE17-5.6B

D3515 8-719-069-55 s DIODE UDZS-TE17-5.6B

D3516 8-719-069-55 s DIODE UDZS-TE17-5.6B

D3519 8-719-059-53 s DIODE MA3J14700LSO

D3520 8-719-801-78 s DIODE 1SS184

D3521 8-719-024-77 s DIODE HN1D03FU-TE85L

D3522 8-719-024-77 s DIODE HN1D03FU-TE85L

D3523 8-719-024-77 s DIODE HN1D03FU-TE85L

D3524 8-719-024-77 s DIODE HN1D03FU-TE85L

D3525 8-719-069-55 s DIODE UDZS-TE17-5.6B

D3526 8-719-069-55 s DIODE UDZS-TE17-5.6B

D3527 8-719-069-55 s DIODE UDZS-TE17-5.6B

D3528 8-719-069-55 s DIODE UDZS-TE17-5.6B

D3529 8-719-801-78 s DIODE 1SS184

D3530 8-719-083-58 s DIODE UDZSTE-173.9B

D4001 8-719-404-50 s DIODE MA111-TX

D5001 8-719-404-50 s DIODE MA111-TX

D7506 8-719-073-39 s DIODE HZU5.6GTRF

D7510 8-719-404-50 s DIODE MA111-TX

Ref. No.

or Q’ty Part No. SP Description

FB3507 1-414-921-11 s INDUCTOR, FERRITE BEAD

FB3508 1-414-921-11 s INDUCTOR, FERRITE BEAD

FB3509 1-469-379-11 s FERRITE, EMI (SMD)

FB3511 1-469-379-11 s FERRITE, EMI (SMD)

FB3513 1-414-921-11 s INDUCTOR, FERRITE BEAD

FB3514 1-216-864-11 s CONDUCTOR, CHIP (1608)

FB3515 1-216-864-11 s CONDUCTOR, CHIP (1608)

FB3516 1-216-864-11 s CONDUCTOR, CHIP (1608)

FB3517 1-414-864-11 s INDUCTOR, MICRO (CHIP TYPE)

FB3518 1-414-921-11 s INDUCTOR, FERRITE BEAD

FB3519 1-414-921-11 s INDUCTOR, FERRITE BEAD

FB3520 1-414-921-11 s INDUCTOR, FERRITE BEAD

FB4002 1-414-864-11 s INDUCTOR, MICRO (CHIP TYPE)

FB4003 1-414-864-11 s INDUCTOR, MICRO (CHIP TYPE)

FB4004 1-414-864-11 s INDUCTOR, MICRO (CHIP TYPE)

FB4005 1-414-864-11 s INDUCTOR, MICRO (CHIP TYPE)

FB4006 1-469-379-11 s FERRITE, EMI (SMD)

FB5001 1-469-379-11 s FERRITE, EMI (SMD)

FB5002 1-469-379-11 s FERRITE, EMI (SMD)

FB5003 1-469-379-11 s FERRITE, EMI (SMD)

FB5004 1-469-379-11 s FERRITE, EMI (SMD)

FB5005 1-469-379-11 s FERRITE, EMI (SMD)

FB5501 1-469-379-11 s FERRITE, EMI (SMD)

FB5502 1-414-921-11 s INDUCTOR, FERRITE BEAD

FB1 1-469-379-11 s FERRITE, EMI (SMD)

FB7011 1-414-864-11 s INDUCTOR, MICRO (CHIP TYPE)

FB2 1-469-379-11 s FERRITE, EMI (SMD)

FB3 1-414-864-11 s INDUCTOR, MICRO (CHIP TYPE)

FB4 1-414-864-11 s INDUCTOR, MICRO (CHIP TYPE)

FB5 1-414-864-11 s INDUCTOR, MICRO (CHIP TYPE)

FB7016 1-414-864-11 s INDUCTOR, MICRO (CHIP TYPE)

FB7105 1-414-864-11 s INDUCTOR, MICRO (CHIP TYPE)

FB7111 1-469-379-11 s FERRITE, EMI (SMD)

FB7501 1-414-445-11 s FERRITE, EMI (SMD)

FB6 1-414-921-11 s INDUCTOR, FERRITE BEAD

FB7502 1-414-445-11 s FERRITE, EMI (SMD)

FB101 1-414-921-11 s INDUCTOR, FERRITE BEAD

FB102 1-414-921-11 s INDUCTOR, FERRITE BEAD

FB103 1-414-921-11 s INDUCTOR, FERRITE BEAD

FB104 1-414-921-11 s INDUCTOR, FERRITE BEAD

FB7503 1-414-445-11 s FERRITE, EMI (SMD)

FB7505 1-469-379-11 s FERRITE, EMI (SMD)

FB7506 1-414-864-11 s INDUCTOR, MICRO (CHIP TYPE)

FB7507 1-469-379-11 s FERRITE, EMI (SMD)

FB105 1-414-921-11 s INDUCTOR, FERRITE BEAD

FB106 1-414-921-11 s INDUCTOR, FERRITE BEAD

FB107 1-414-921-11 s INDUCTOR, FERRITE BEAD

FB108 1-414-921-11 s INDUCTOR, FERRITE BEAD

FB109 1-414-921-11 s INDUCTOR, FERRITE BEAD

FL1 1-239-825-11 s FILTER, CHIP EMI

FL2 1-239-825-11 s FILTER, CHIP EMI

FL3 1-239-825-11 s FILTER, CHIP EMI

FL3501 1-239-289-11 s FILTER, LOW PASS

FL3502 1-239-289-11 s FILTER, LOW PASS

FB701 1-414-864-11 s INDUCTOR, MICRO (CHIP TYPE)

FB702 1-414-864-11 s INDUCTOR, MICRO (CHIP TYPE)

FL3503 1-239-289-11 s FILTER, LOW PASS

FB703 1-414-921-11 s INDUCTOR, FERRITE BEAD

FB704 1-414-864-11 s INDUCTOR, MICRO (CHIP TYPE)

FB705 1-414-921-11 s INDUCTOR, FERRITE BEAD

IC1 8-759-252-59 s IC MAX202CSE

IC2 8-759-832-05 s IC BA18BC0FP-E2

IC3 6-704-560-01 s IC HD6417709SF133BV

FB3101 1-469-379-11 s FERRITE, EMI (SMD)

FB3102 1-469-379-11 s FERRITE, EMI (SMD)

IC4 8-759-592-49 s IC TC7SZ125FU(TE85R)

IC5 8-759-475-44 s IC TC74LCX138FT(EL)

FB3103 1-469-379-11 s FERRITE, EMI (SMD)

FB3104 1-469-379-11 s FERRITE, EMI (SMD)

FB3105 1-414-864-11 s INDUCTOR, MICRO (CHIP TYPE)

IC6 6-706-390-01 s IC HY57V641620HGTP-H

IC7 6-804-839-01 s IC MBM29DL324BE-90PFTN-LMD1100

IC8 6-804-111-01 s IC XC9536XL-5-MEU1-V023

FB3106 1-469-379-11 s FERRITE, EMI (SMD)

FB3107 1-216-864-11 s CONDUCTOR, CHIP (1608)

IC9 8-759-327-60 s IC TC7W125FU-TE12R

IC10 6-705-041-01 s IC BD4845FVE-TR

FB3108 1-216-864-11 s CONDUCTOR, CHIP (1608)

FB3109 1-469-379-11 s FERRITE, EMI (SMD)

FB3501 1-414-921-11 s INDUCTOR, FERRITE BEAD

IC11 6-705-042-01 s IC BD4831FVE-TR

IC12 8-759-327-60 s IC TC7W125FU-TE12R

IC701 6-707-183-01 s IC MB90098APF-G-168-ERE1

FB3502 1-414-921-11 s INDUCTOR, FERRITE BEAD

FB3503 1-414-921-11 s INDUCTOR, FERRITE BEAD

IC702 6-700-733-11 s IC ICS1523M-ER

IC2501 8-759-523-02 s IC TC74HC4053AFT(EL)

FB3504 1-414-921-11 s INDUCTOR, FERRITE BEAD

FB3505 1-414-864-11 s INDUCTOR, MICRO (CHIP TYPE)

FB3506 1-414-921-11 s INDUCTOR, FERRITE BEAD

IC2741 8-759-523-02 s IC TC74HC4053AFT(EL)

IC2761 8-759-523-02 s IC TC74HC4053AFT(EL)

IC2781 8-759-523-02 s IC TC74HC4053AFT(EL)

LMD-2140MD

4-11

Page 36

(B BOARD)

(B BOARD)

Ref. No.

or Q’ty Part No. SP Description

IC3101 6-705-238-01 s IC UPD64011AGM-8ED-A

IC3102 6-703-404-01 s IC MSM56V16160F-8T4FM1

IC3103 6-705-403-01 s IC PQ070XZ01ZPH

IC3104 8-759-460-72 s IC BA033FP

IC3401 8-759-564-49 s IC TC7W53FU-TE12R

IC3402 8-759-564-49 s IC TC7W53FU-TE12R

IC3403 8-759-564-49 s IC TC7W53FU-TE12R

IC3501 6-702-832-11 s IC BU9882F-WE2

IC3502 8-759-564-49 s IC TC7W53FU-TE12R

IC3503 8-759-659-65 s IC LP2985IM5X-3.3

IC3504 6-702-573-01 s IC AD9883AKST-110

IC3507 8-759-659-65 s IC LP2985IM5X-3.3

IC3508 6-707-179-01 s IC AD9882KSTZ-140

IC3509 8-759-524-20 s IC TC74VHC165FT (EL)

IC3510 8-759-564-49 s IC TC7W53FU-TE12R

IC3513 8-759-599-01 s IC TC74VHCT14AFT(EL)

IC4002 6-700-394-01 s IC BA25BC0FP-TE2

IC4004 8-759-666-13 s IC PST9229NL

IC4005 6-804-110-01 s IC XC18V02-MEU1VS1-V101

IC5002 6-703-404-01 s IC MSM56V16160F-8T4FM1

IC5003 6-700-394-01 s IC BA25BC0FP-TE2

IC5501 6-700-681-01 s IC IP00C713

IC5502 6-706-390-01 s IC HY57V641620HGTP-H

IC5503 6-706-390-01 s IC HY57V641620HGTP-H

IC5504 6-706-390-01 s IC HY57V641620HGTP-H

Ref. No.

or Q’ty Part No. SP Description

Q2511 8-729-026-53 s TRANSISTOR 2SA1576A-T106-QR

Q2512 8-729-905-35 s TRANSISTOR 2SC4081-R

Q2513 8-729-905-35 s TRANSISTOR 2SC4081-R

Q2514 6-550-154-01 s TRANSISTOR IMT2AT108

Q2515 8-729-026-53 s TRANSISTOR 2SA1576A-T106-QR

Q2516 8-729-905-35 s TRANSISTOR 2SC4081-R

Q2517 8-729-920-59 s TRANSISTOR IMX2

Q2518 8-729-143-07 s TRANSISTOR 2SA1610-Y33

Q2519 8-729-905-35 s TRANSISTOR 2SC4081-R

Q2557 8-729-026-53 s TRANSISTOR 2SA1576A-T106-QR

Q2559 8-729-905-35 s TRANSISTOR 2SC4081-R

Q2560 8-729-029-14 s TRANSISTOR DTC144EUA-T106

Q2561 8-729-026-53 s TRANSISTOR 2SA1576A-T106-QR

Q2562 8-729-905-35 s TRANSISTOR 2SC4081-R

Q2701 8-729-026-53 s TRANSISTOR 2SA1576A-T106-QR

Q2702 8-729-026-53 s TRANSISTOR 2SA1576A-T106-QR

Q2703 8-729-026-53 s TRANSISTOR 2SA1576A-T106-QR

Q2704 8-729-026-53 s TRANSISTOR 2SA1576A-T106-QR

Q2705 8-729-026-53 s TRANSISTOR 2SA1576A-T106-QR

Q2706 8-729-026-53 s TRANSISTOR 2SA1576A-T106-QR

Q2721 8-729-026-53 s TRANSISTOR 2SA1576A-T106-QR

Q2722 8-729-905-35 s TRANSISTOR 2SC4081-R

Q2723 8-729-028-91 s TRANSISTOR DTA144EUA-T106

Q2724 8-729-029-14 s TRANSISTOR DTC144EUA-T106

Q2741 8-729-905-35 s TRANSISTOR 2SC4081-R

IC7003 8-759-832-05 s IC BA18BC0FP-E2

IC7026 8-759-666-13 s IC PST9229NL

IC7101 6-804-112-01 s IC XC18V02-MEU1VP1-V100

IC7102 6-704-720-01 s IC XC2S200E-6FTG256C

IC7501 6-701-098-11 s IC THC63LVDM83R-T

IC7503 6-704-006-01 s IC BR24L64F-WE2

Q2761 8-729-905-35 s TRANSISTOR 2SC4081-R

Q2781 8-729-905-35 s TRANSISTOR 2SC4081-R

Q3101 8-729-026-53 s TRANSISTOR 2SA1576A-T106-QR

Q3102 8-729-026-53 s TRANSISTOR 2SA1576A-T106-QR

Q3401 8-729-026-53 s TRANSISTOR 2SA1576A-T106-QR

Q3402 8-729-026-53 s TRANSISTOR 2SA1576A-T106-QR

Q3403 8-729-026-53 s TRANSISTOR 2SA1576A-T106-QR

L501 1-416-345-11 s COIL, CHOKE 22UH

L502 1-416-948-21 s COIL, CHOKE (SMD)

L503 1-416-345-11 s COIL, CHOKE 22UH

Q3410 8-729-029-14 s TRANSISTOR DTC144EUA-T106

Q3501 8-729-026-53 s TRANSISTOR 2SA1576A-T106-QR

Q3502 8-729-905-35 s TRANSISTOR 2SC4081-R

L3101 1-414-195-31 s INDUCTOR, CHIP 39UH

L3102 1-412-008-31 s CHIP INDUCTOR 15.0UH (2012)

Q3503 8-729-026-53 s TRANSISTOR 2SA1576A-T106-QR

Q3504 8-729-905-35 s TRANSISTOR 2SC4081-R

L3501 1-469-523-91 s INDUCTOR 2.2UH (NLFV25)

L3502 1-469-523-91 s INDUCTOR 2.2UH (NLFV25)

Q3505 8-729-026-53 s TRANSISTOR 2SA1576A-T106-QR

Q3506 8-729-905-35 s TRANSISTOR 2SC4081-R

Q3507 8-729-026-53 s TRANSISTOR 2SA1576A-T106-QR

Q301 8-729-028-91 s TRANSISTOR DTA144EUA-T106

Q302 8-729-029-14 s TRANSISTOR DTC144EUA-T106

Q305 8-729-028-91 s TRANSISTOR DTA144EUA-T106

Q306 8-729-029-14 s TRANSISTOR DTC144EUA-T106

Q307 8-729-028-91 s TRANSISTOR DTA144EUA-T106