Page 1

LCD MONITOR

LMD-2110W

SERVICE MANUAL

2nd Edition

Serial No. 3200001 and Higher: LMD-2110W (SY)

Serial No. 5200001 and Higher: LMD-2110W (CN)

Page 2

!警告

このマニュアルは,サービス専用です。

お客様が,このマニュアルに記載された設置や保守,点検,修理などを行うと感電や火災,

人身事故につながることがあります。

危険をさけるため,サービストレーニングを受けた技術者のみご使用ください。

! WARNING

This manual is intended for qualifi ed service personnel only.

To reduce the risk of electric shock, fi re or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualifi ed to do so. Refer all servicing to

qualifi ed service personnel.

! WARNUNG

Die Anleitung ist nur für qualifi ziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifi ziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afi n

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifi é pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

警告

万一,異常が起きた際に,お客様が電源を切ることが

できるように,設置の際には,機器近くの固定配線内

に専用遮断装置を設けるか,機器使用中に,容易に抜

き差しできるコンセントに電源プラグを接続してくだ

さい。

WARNING

When installing the unit, incorporate a readily accessible

disconnect device in the fi xed wiring, or connect the

power cord to a socket-outlet which must be provided

near the unit and easily accessible, so that the user can

turn off the power in case a fault should occur.

WARNUNG

Beim Einbau des Geräts ist daher im Festkabel

ein leicht zugänglicher Unterbrecher einzufügen,

oder das Netzkabel muß mit einer in der Nähe

des Geräts befi ndlichen, leicht zugänglichen

Wandsteckdose verbunden werden, damit sich bei

einer Funktionsstörung die Stromversorgung zum Gerät

jederzeit unterbrechen läßt.

本機をラックに設置するときは,本機の上下に 4.4cm

以上の空間を確保してください。

When performing the installation, keep the following

space away from walls in order to obtain proper

exhaust and radiation of heat.

Lower, Upper: 4.4 cm (1 3/4 inches) or more

安全のために,周辺機器を接続する際は,過大電圧を持

つ可能性があるコネクターを以下のポートに接続しない

でください。

: PARALLEL REMOTE コネクター

上記のポートについては本書の指示に従ってください。

For safety, do not connect the connector for peripheral device wiring that might have excessive voltage to the following port.

: PARALLEL REMOTE connector

Follow the instructions for the above port.

LMD-2110W

Page 3

Table of Contents

Manual Structure

Purpose of this manual ............................................................ 2 (E)

Related manuals ...................................................................... 2 (E)

1. Service Overview

1-1. Appearance Figure/Board Location ..........................1-1 (E)

1-2. Tighten Torque .......................................................... 1-2 (E)

1-3. Disassembly ..............................................................1-3 (E)

1-3-1. Rear Cover ....................................................... 1-3 (E)

1-3-2. Q Board ............................................................1-4 (E)

1-3-3. G2 Board ..........................................................1-5 (E)

1-3-4. G1 Board ..........................................................1-6 (E)

1-3-5. B Board/S Board ..............................................1-7 (E)

1-3-6. DC Fan .............................................................1-8 (E)

1-3-7. H Board/X Board/Speaker ............................... 1-9 (E)

1-3-8. LCD Panel......................................................1-10 (E)

1-4. System Software Update ......................................... 1-11 (E)

1-5. Circuit Description .................................................. 1-13 (E)

1-5-1. G1 Board ........................................................1-13 (E)

1-5-2. G2 Board ........................................................1-13 (E)

1-5-3. B Board .......................................................... 1-13 (E)

1-5-4. Q Board ..........................................................1-13 (E)

1-5-5. H Board ..........................................................1-13 (E)

1-5-6. S Board ..........................................................1-13 (E)

1-5-7. X Board ..........................................................1-13 (E)

1-6. Lead-free Solder ...................................................... 1-14 (E)

3. Troubleshooting

3-1. Backlight does not light.............................................3-1 (E)

3-2. System does not start .................................................3-2 (E)

3-3. Image is abnormal .....................................................3-3 (E)

3-4. TALLY lamp is not lit ...............................................3-4 (E)

3-5. Fan is abnormal ......................................................... 3-5 (E)

4. Spare Parts

4-1. Notes on Repair Parts ...................................................... 4-1

4-2. Exploded Views ............................................................... 4-2

4-3. Packing Materials & Supplied Accessories ..................... 4-5

5. Block Diagrams

Overall ............................................................................. 5-1

6. Frame Wiring

Frame Wiring...................................................................6-1

2. Electrical Alignment

2-1. Preparation ................................................................2-1 (E)

2-1-1. Required Equipment ........................................2-1 (E)

2-1-2. Warm-up Time .................................................2-1 (E)

2-1-3. How to Enter the Service Mode .......................2-1 (E)

2-1-4. How to Exit the Service Mode .........................2-1 (E)

2-1-5. Preparing the Power Supply and Signals .........2-1 (E)

2-2. White Balance Adjustment ........................................ 2-1 (E)

2-3. A/D Adjustment (COMPONENT) ............................2-3 (E)

2-4. A/D Adjustment (RGB) ............................................. 2-3 (E)

2-5. A/D Adjustment (COMPOSITE) .............................. 2-4 (E)

2-6. A/D Adjustment (Y/C) .............................................. 2-4 (E)

LMD-2110W

1 (E)

Page 4

Purpose of this manual

Related manuals

Manual Structure

This manual is the Service Manual of the LCD Monitor LMD-2110W.

This manual contains the service overview, electrical alignment, troubleshooting,

spare parts, block diagrams, and frame wiring.

The service of this unit is basically performed by the replacement of board.

Therefore, the schematic diagram, board layout and electrical parts list are not

contained.

In addition to this Service Manual the following manuals are provided.

. “Operating Instructions” (supplied with this unit)

This manual is necessary for application and operation of this unit.

. “Service Manual” 1st Edition (available on request)

This manual describes the information for repair and service of the following models.

Serial No. 3,000,001 to 3,200,000 (SY)

Serial No. 5,000,001 to 5,200,000 (CN)

2 (E)

LMD-2110W

Page 5

Section 1

Service Overview

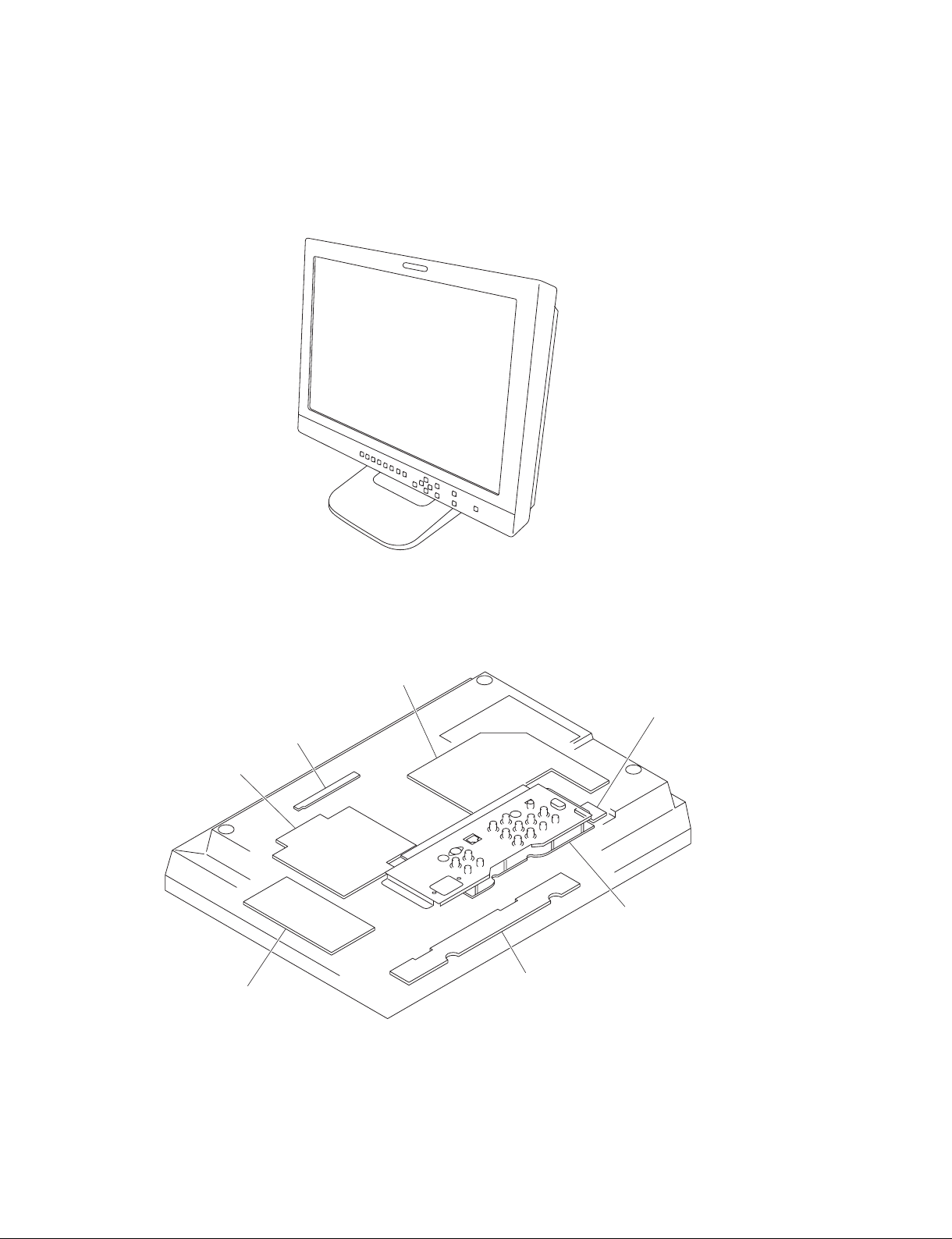

1-1. Appearance Figure/Board Location

Appearance fi gure

Board location

B board

S board

X board

G1 board

Q board

H board

G2 board

LMD-2110W

1-1 (E)

Page 6

1-2. Tighten Torque

Tighten the each screw with the torque below.

n

. The screw (PTPWH3 x 8) of this unit have the two different tightening torques. Be careful not to

confuse.

. When using the torque driver with the notation of cN.m, interpret it as follows.

Example: 0.8 N.m = 80 cN.m

. 3 x 6: 0.2 to 0.4 N.m

. 4 x 8: 0.8 to 1.0 N.m

. B3 x 4: 0.2 to 0.4 N.m

. B3 x 14: 0.4 to 0.6 N.m

. F2.5 x 6: 0.2 to 0.4 N.m

. K4 x 8: 0.8 to 1.0 N.m

. KTP3 x 10: 0.6 to 0.8 N.m

. PS4 x 8: 0.8 to 1.0 N.m

. PTPWH3 x 8 (for excluding speaker and X board): 0.6 to 0.8 N.m

. PTPWH3 x 8 (for speaker and X board): 0.4 to 0.6 N.m

. PWH3 x 6: 0.6 to 0.8 N.m

. PWH3 x 10: 0.4 to 0.6 N.m

. PWH4 x 12: 1.0 to 1.2 N.m

1-2 (E)

LMD-2110W

Page 7

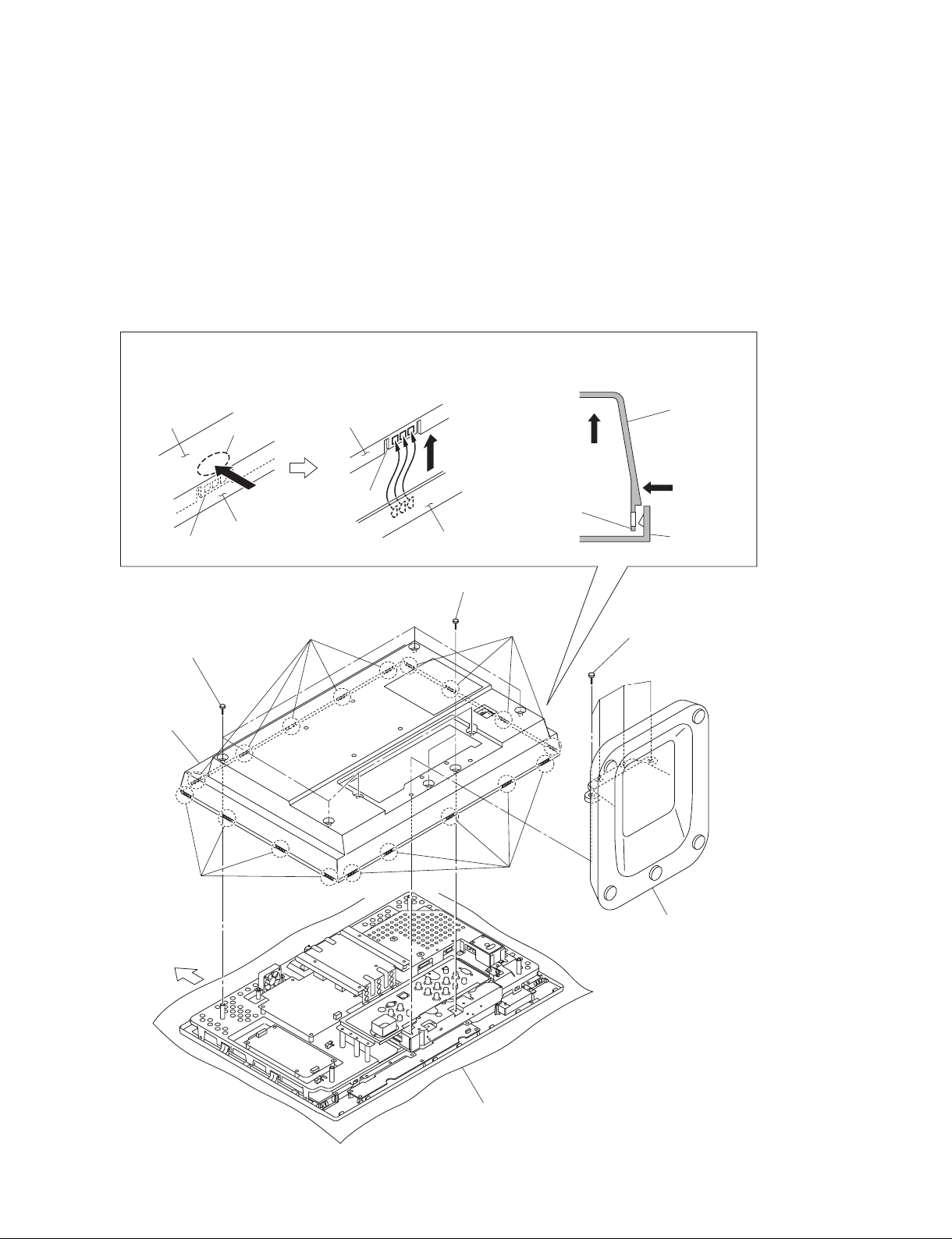

1-3. Disassembly

m

. In this section, remove parts in the order of numbers shown in the fi gure.

. When removing/installing the cabinet and replacing the board, place the unit on the conductive cushion.

1-3-1. Rear Cover

n

Remove the hooks inside of the bezel assembly while pushing the portion A of the rear cover, then remove

the rear cover in the direction of B.

Rear cover

Hook

4 Six screws

(PWH4 x 12)

9 Rear cover

A

Bezel assembly

5 Five hooks

Rear cover

Hook

B

Bezel assembly

3 Two screws

(PWH3 x 6)

7 Four hooks

Rear cover

B

A

Hook

Bezel

assembly

1 Four screws

(PWH4 x 12)

6 Four hooks

LMD-2110W

8 Five hooks

2 Stand

Upper side

Conductive cushion

1-3 (E)

Page 8

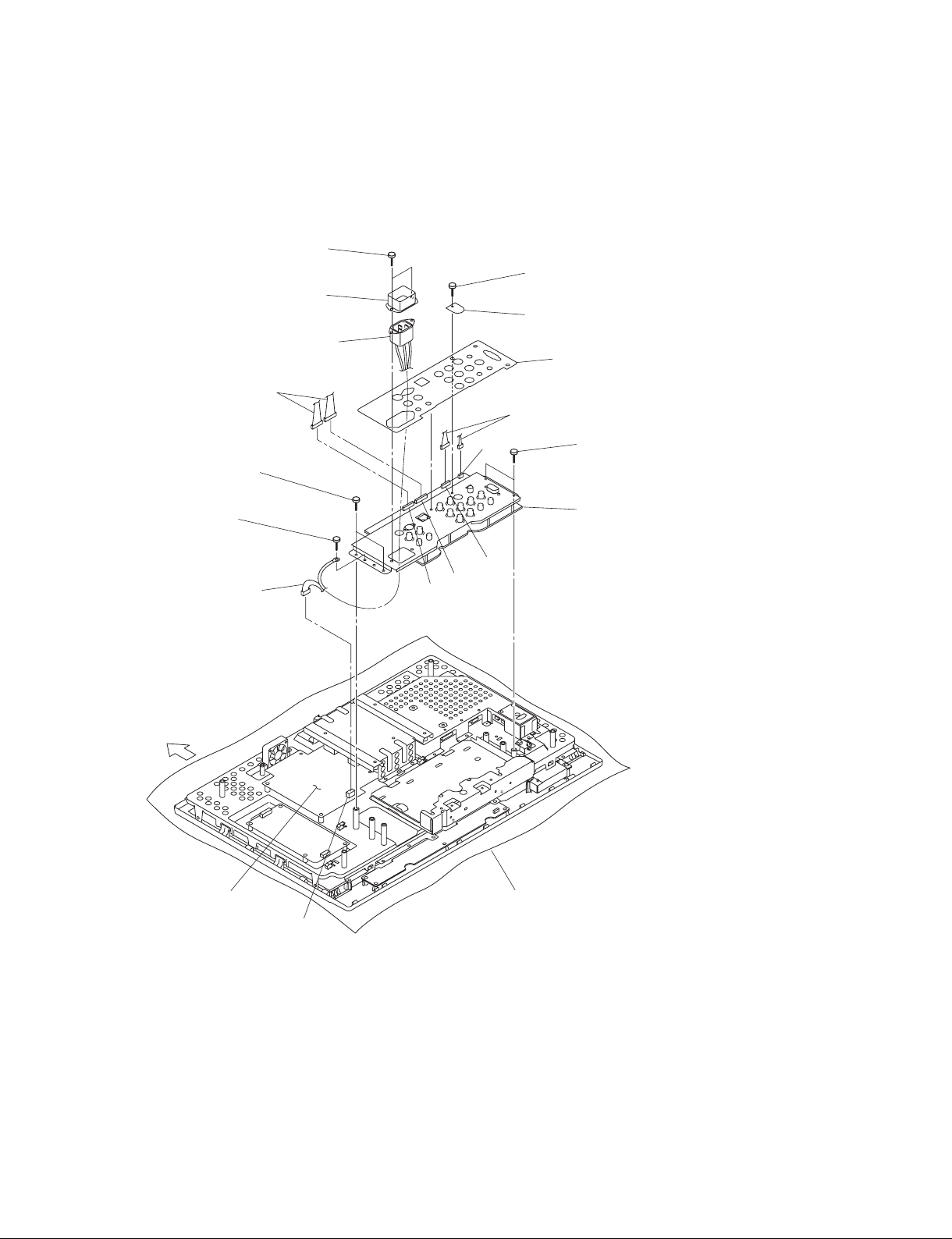

1-3-2. Q Board

. Remove the rear cover. (Refer to Section 1-3-1.)

8 Two screws

(PWH3 x 10)

9 Plug holder

0 AC inlet assembly

2 Two harnesses

!- Screw

(F2.5 x 6)

!= DL cover

!\ Connector label

1 Two harnesses

5 Two screws

3 Screw

Upper side

(PWH3 x 6)

(4 x 8)

4 Harness

J22

J10

J23

J24

6 Two screws

(PWH3 x 6)

7 Q board

1-4 (E)

G1 board

Conductive cushion

CN601

LMD-2110W

Page 9

1-3-3. G2 Board

. Remove the rear cover. (Refer to Section 1-3-1.)

2 Four screws

(PWH3 x 6)

3 G2 board

Upper side

Conductive cushion

1 Two Harnesses

CN801

CN802

LMD-2110W

1-5 (E)

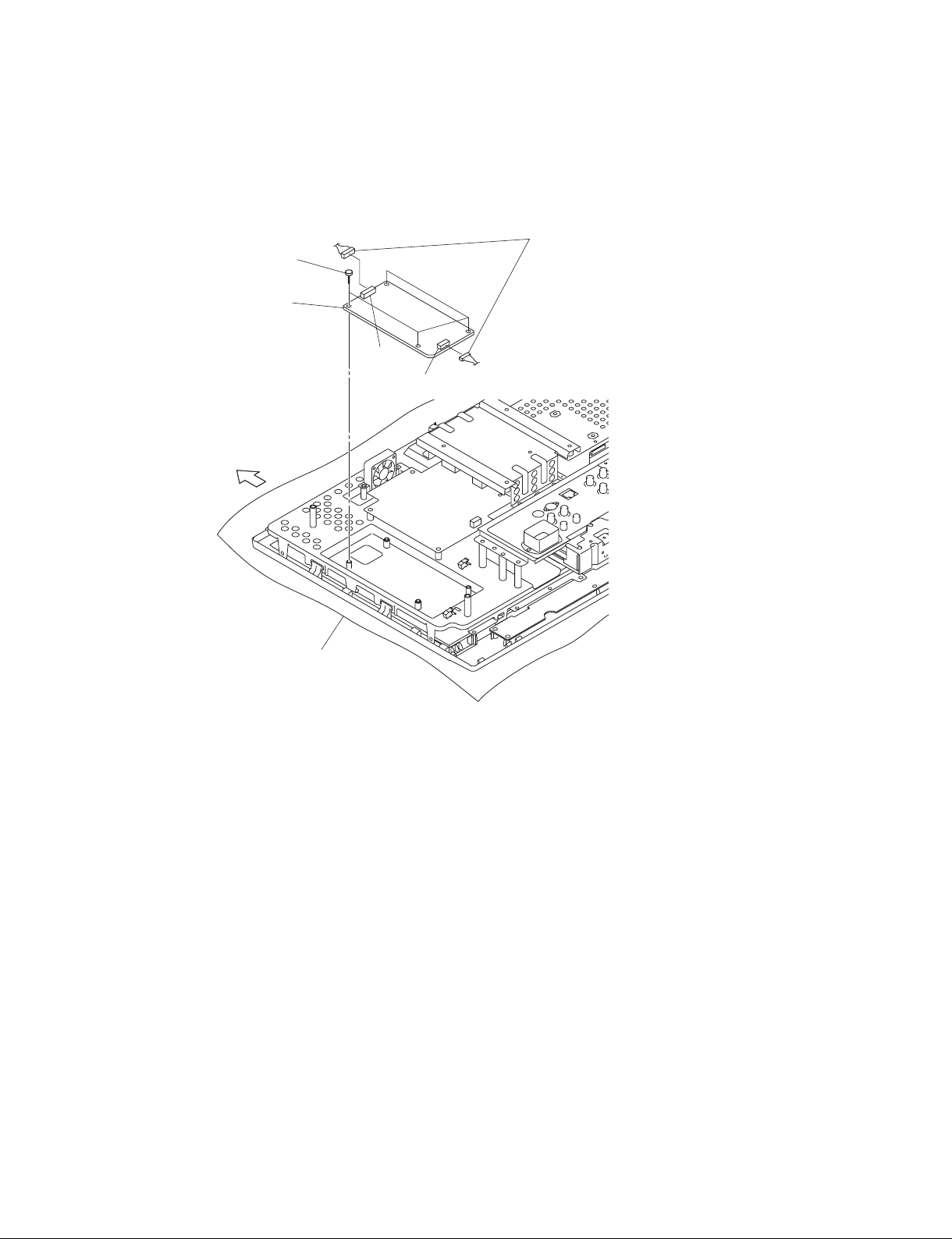

Page 10

1-3-4. G1 Board

. Remove the rear cover. (Refer to Section 1-3-1.)

5 Four screws

(PWH3 x 6)

6 G1 board

CN701

Upper side

1 Four screws

(PWH3 x 6)

3 Two harnesses

CN702

CN601

4 Harness

2 Wall mount bracket

1-6 (E)

Conductive cushion

LMD-2110W

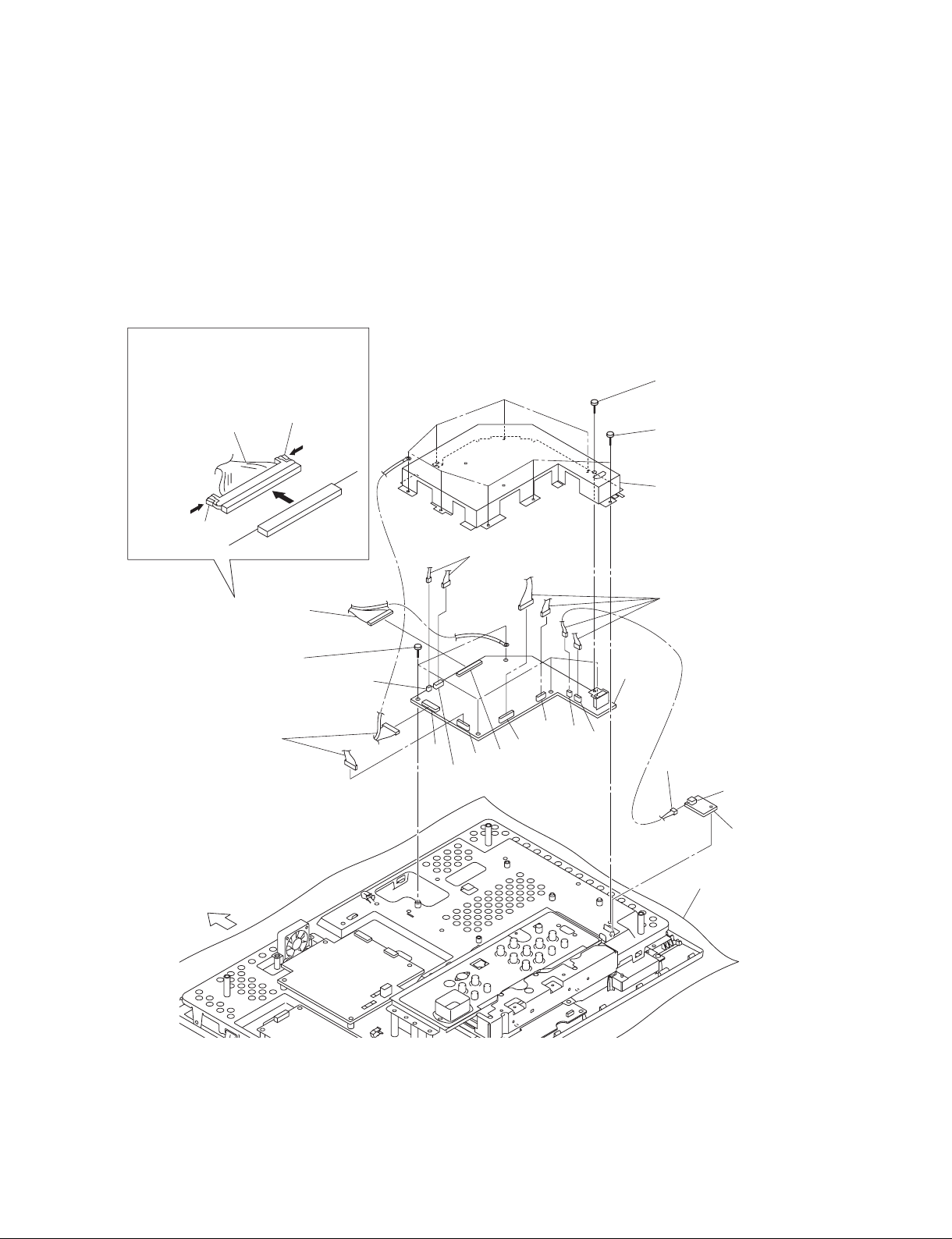

Page 11

1-3-5. B Board/S Board

n

When replacing the B board, be sure to perform the white balance adjustment and A/D adjustment.

(Refer to Sections 2-2 to 2-6.)

. Remove the rear cover. (Refer to Section 1-3-1.)

. Remove the wall mount bracket. (Refer to steps 1 and 2 in Section 1-3-4.)

When removing the LVDS cable, remove

it in the direction of the arrow C while

holding the two hooks in the direction of

the arrows A and B.

6 LVDS cable

A

Hook

Hook

B

C

5 Two harnesses

1 Screw

(3 x 6)

2 Eight screws

(PWH3 x 6)

3 Main shield assembly

6 LVDS cable

4 Five screws

(PWH3 x 6)

7 Two harnesses

Upper side

J1

J2

J10

J5

J9

J4

J6

J11

8 Four harnesses

9 B board

J3

0 Harness

J1

!- S board

Conductive cushion

LMD-2110W

1-7 (E)

Page 12

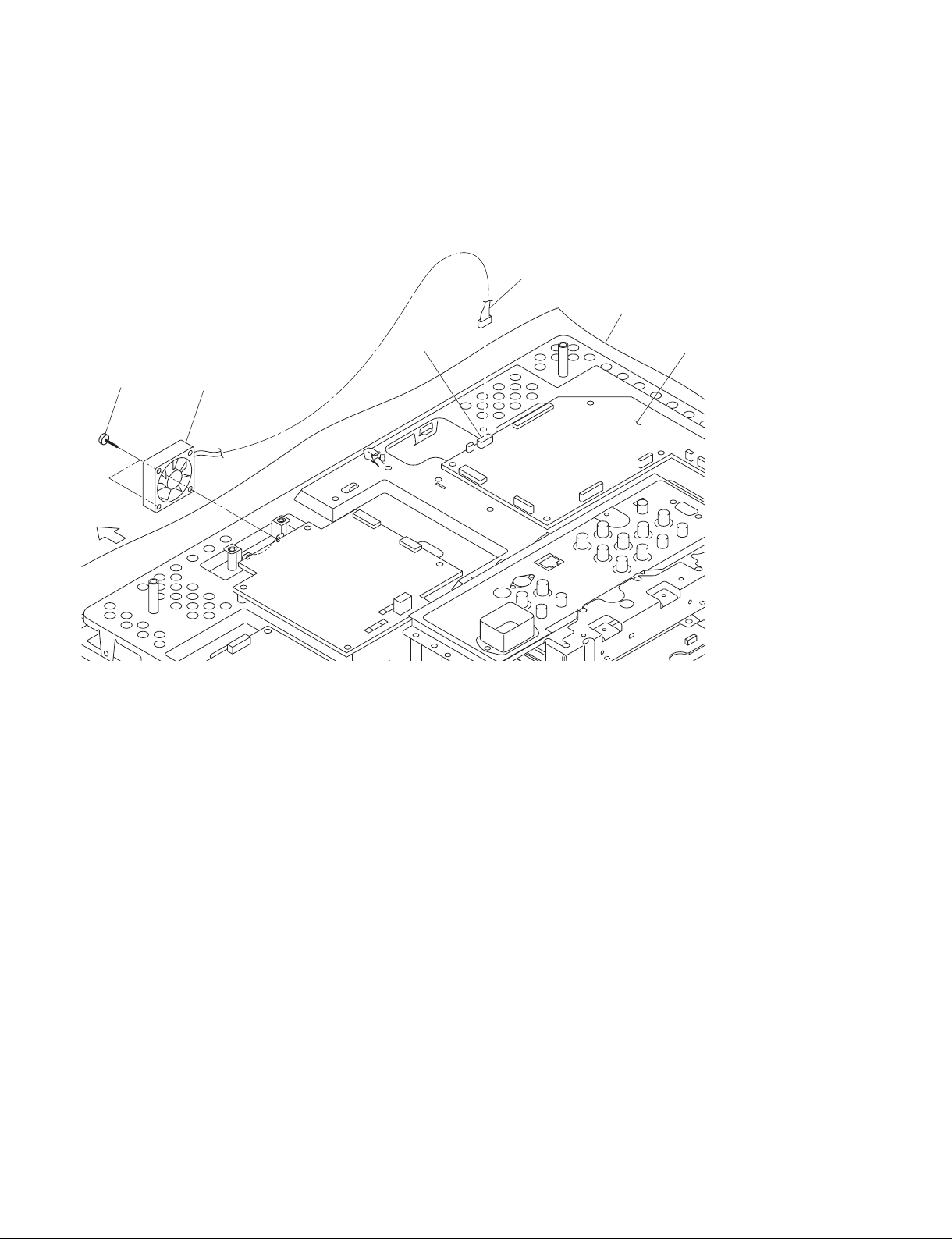

1-3-6. DC Fan

. Remove the rear cover. (Refer to Section 1-3-1.)

. Remove the wall mount bracket. (Refer to steps 1 and 2 in Section 1-3-4.)

. Remove the main shield assembly. (Refer to steps 1 to 3 in Section 1-3-5.)

1 Harness

Conductive cushion

2 Two screws

(B3 x 14)

Upper side

3 DC fan

J10

B board

1-8 (E)

LMD-2110W

Page 13

1-3-7. H Board/X Board/Speaker

. Remove the rear cover. (Refer to Section 1-3-1.)

. Remove the Q board. (Refer to Section 1-3-2.)

2 Two screws

(PTPWH3 x 8)

1 Eleven screws

(PTPWH3 x 8)

3 Harness

8 X board

Upper side

9 Four screws

(PTPWH3 x 8)

J1

!- Standby

button

5 Main frame assembly

4 Harness

0 H board

J1

6 Two hooks

!= Two screws

(PTPWH3 x 8)

1-3-8. LCD Panel

n

When replacing the LCD panel, be sure to perform the white balance adjustment.

(Refer to Section 2-2.)

. Remove the rear cover. (Refer to Section 1-3-1.)

. Remove the Q board. (Refer to Section 1-3-2.)

. Remove the main frame assembly. (Refer to steps 1 to 7 in Section 1-3-7.)

2 Two screws

(B3 x 4)

Upper side

4 Main frame assembly

3 Two screws

(B3 x 4)

5 LVDS cable

6 LCD panel

Conductive cushion

1-10 (E)

1 Harness

When removing the LVDS cable, remove

it in the direction of the arrow C while

holding the two hooks in the direction of

the arrows A and B.

C

A

Hook

Hook

B

5 LVDS cable

LMD-2110W

Page 15

1-4. System Software Update

Required equipment/tool

. Personal computer (hereafter referred to as PC)

. Connecting cable (for upgrade): D-sub 9-pin - Din 8-pin (1-831-247-11)

. Writing application: Pixelworks FlashUpgrader

n

To obtain the writing application and the update fi le, please contact your local Sony Sales Offi ce/Service

Center.

Procedure

1. Create a folder at an arbitrary place on PC, and then store the writing application and the update fi le

in it.

2. Remove the screw, then remove the DL cover.

Screw

DL cover

3. Connect the upgrade connector (I/O terminal plate) of this unit and PC using the connecting cable.

4. Turn on the power of PC to start the writing application.

5. Select the connected serial port number of PC in the COM Port box.

n

To check the serial port number, select My Computer → Properties → Hardware tab → Device

Manager → Port (COM and LPT) on PC.

6. Check that fl asher.hex and appcode.hex are displayed in the Files To Download box.

LMD-2110W

1-11 (E)

Page 16

7. Click the [Flash] button.

“Waiting for target reset...” is displayed.

8. Turn on the power of this unit.

The update is started and the progress bar is displayed.

After the update is completed, “Flash Completed!” is displayed and the area setting menu is displayed

on this unit.

9. Check SYS SW VERSION in VERSION INFO of the service menu.

1-12 (E)

LMD-2110W

Page 17

1-5. Circuit Description

1-5-1. G1 Board

The G1 board mounts the AC/DC converter and the DC/DC converter.

1-5-2. G2 Board

The G2 board mounts the LED backlight driver circuit of the LCD panel

1-5-3. B Board

The B board performs signal processing and system control.

1-5-4. Q Board

The Q board performs input/output terminal and audio processing.

1-5-5. H Board

The H board mounts the control switches on the front panel.

1-5-6. S Board

The S board mounts temperature sensor.

1-5-7. X Board

The X board mounts a tally LED.

LMD-2110W

1-13 (E)

Page 18

1-6. Lead-free Solder

All boards mounted in this unit use lead-free solder. Be sure to use lead-free solder when repairing the

boards of this unit. A lead free mark (LF) indicating that the solder contains no lead is printed on each

board.

(Caution: Some printed circuit boards may not come printed with the lead free mark due to their particular

size.)

: LEAD FREE MARK

n

. The lead-free solder melts at a temperature about 40 dC higher than the ordinary solder, therefore, it is

recommended to use the soldering iron having a temperature regulator.

. The ordinary soldering iron can be used but the iron tip has to be applied to the solder joint for a slightly

longer time. The printed pattern (copper foil) may peel away if the heated tip is applied for too long, so

be careful.

1-14 (E)

LMD-2110W

Page 19

Section 2

Electrical Alignment

2-1. Preparation

2-1-1. Required Equipment

. Luminance meter: KONICA MINOLTA CA-310, CA-210, CA-110 or equivalent.

If there is not available, make adjustment by visually comparing the LCD monitor

with the reference monitor that has already been calibrated correctly.

. Signal generator: Tektronix TG700 or equivalent, ASTRODESIGN VG-873 or equivalent

2-1-2. Warm-up Time

Before starting adjustment, allow a warm-up of minimum 120 minutes to stabilize the backlight of the

LCD panel.

2-1-3. How to Enter the Service Mode

1. Press the [MENU] button to display the MENU screen.

2. Press the [LINE] and [ENTER] buttons simultaneously to enter the service mode.

2-1-4. How to Exit the Service Mode

1. Press the [MENU] button not to display the MENU screen.

2-1-5. Preparing the Power Supply and Signals

1. Connect the supplied power cord to AC INLET of this unit.

Power voltage: 100 to 240 V AC, 50/60 Hz

2. Input the composite signal from the signal generator to this unit.

3. Turn on the power of this unit. Select the composite signal to display entirely white screen.

2-2. White Balance Adjustment

When replacing the B board and the LCD panel, be sure to perform the white balance adjustment.

When entering the service mode, the CONTROL menu is displayed.

To move the cursor to select an item, use the [(] or [)] button. To set the selected item, press the [ENTER]

button.

1. Move the cursor to “SIGNAL” using the [)] button and press the [ENTER] button.

2. Select “WHITE BALANCE” using the [)] button and press the [ENTER] button.

LMD-2110W

2-1 (E)

Page 20

HIGH adjustment

Target value: x = 0.283

y = 0.298

1. Select “COLOR TEMP” using the [)] and [(] buttons and press the [ENTER] button.

2. Select “D93” using the [)] and [(] buttons and press the [ENTER] button.

3. Set the signal level of the TG2000 to 80IRE.

4. Adjust the GAIN.

Adjust using “R GAIN” and “B GAIN” while “G GAIN” is fi xed.

5. Set the signal level of the TG2000 to 30IRE.

6. Adjust the BIAS.

Adjust using “R BIAS” and “B BIAS” while “G BIAS” is fi xed.

LOW adjustment

Target value: x = 0.313

y = 0.329

1. Select “COLOR TEMP” using the [)] and [(] buttons and press the [ENTER] button.

2. Select “D65” using the [)] and [(] buttons and press the [ENTER] button.

3. Set the signal level of the TG2000 to 80IRE.

4. Adjust the GAIN.

Adjust using “R GAIN” and “B GAIN” while “G GAIN” is fi xed.

5. Set the signal level of the TG2000 to 30IRE.

6. Adjust the BIAS.

Adjust using “R BIAS” and “B BIAS” while “G BIAS” is fi xed.

2-2 (E)

LMD-2110W

Page 21

2-3. A/D Adjustment (COMPONENT)

When replacing the B board, be sure to perform the adjustments in Sections 2-3 to 2-6.

1. Input the 575/50I 100% 8 color-bar COMPONENT

signal to this unit.

2. Press the INPUT SW to accept the COMPONENT

signal.

3. Enter the Service menu, then select SIGNAL → SIGNAL LEVEL → AUTO ADJ. Perform the following

automatic adjustments.

. Y/G LEVEL

. PB LEVEL

. PR LEVEL

. Y OFFSET

. PB OFFSET

. PR OFFSET

4. Perform the adjustments of items 1-2 to 1-4 in table 1

by repeating the above described procedures.

However, before performing AUTO ADJ, adjust the

COMPONENT LEVEL or NTSC SETUP appropriately according to the respective conditions described

in table 1.

COMPONENT selection input

1-1 575/50I 100% 8 color-bar signal

Y/G LEVEL

PB/B LEVEL

PR/R LEVEL

Y/G OFFSET

PB/B OFFSET

PR/R OFFSET

1-2 480/60I BETA0 100% 8 color-bar signal

Y/G LEVEL

PB/B LEVEL

PR/R LEVEL

Y/G OFFSET

PB/B OFFSET

PR/R OFFSET

1-3 480/60I BETA7.5 100% 8 color-bar signal

Y/G LEVEL

PB/B LEVEL

PR/R LEVEL

Y/G OFFSET

PB/B OFFSET

PR/R OFFSET

1-4 1080/60I 100% 8 color bar-signal

Y/G LEVEL

PB/B LEVEL

PR/R LEVEL

Y/G OFFSET

PB/B OFFSET

PR/R OFFSET

Conditions:

COMPONENT LEVEL No specifi c

NTSC SETUP No specifi c

conditions

Conditions:

COMPONENT LEVEL BETA 0

NTSC SETUP No specifi c

conditions

Conditions:

COMPONENT LEVEL BETA 7.5

NTSC SETUP No specifi c

conditions

Conditions:

COMPONENT LEVEL No specifi c

NTSC SETUP No specifi c

conditions

conditions

conditions

2-4. A/D Adjustment (RGB)

1. Input the 480/60I 16 step RGB signal to this unit.

2. Press the INPUT SW to accept the RGB signal.

3. Enter the Service menu, then select SIGNAL → SIGNAL LEVEL → AUTO ADJ. Perform the following

automatic adjustments.

. Y/G LEVEL

. PB LEVEL

. PR LEVEL

. Y OFFSET

. PB OFFSET

. PR OFFSET

4. Perform the adjustment of item 1-6 in table 2 by

repeating the above described procedures.

Table 1

RGB selection input

1-5 480/60I RGB 16 step signal

Y/G LEVEL

PB/B LEVEL

PR/R LEVEL

Y/G OFFSET

PB/B OFFSET

PR/R OFFSET

1-6 1080/60I RGB 16 step signal

Y/G LEVEL

PB/B LEVEL

PR/R LEVEL

Y/G OFFSET

PB/B OFFSET

PR/R OFFSET

Conditions:

No specifi c conditions

Conditions:

No specifi c conditions

Table 2

LMD-2110W

2-3 (E)

Page 22

2-5. A/D Adjustment (COMPOSITE)

1. Input the NTSC 100% 8 color-bar COMPOSITE signal

to this unit.

2. Press the INPUT SW to accept the COMPOSITE

signal.

3. Enter the Service menu, then select SIGNAL → SIGNAL LEVEL → AUTO ADJ. Perform the following

automatic adjustments.

. Y/G LEVEL

. PB LEVEL

. PR LEVEL

4. Perform the adjustments of items 1-8 and 1-9 in table 3

by repeating the above described procedures.

2-6. A/D Adjustment (Y/C)

1. Input the NTSC 100% 8 color-bar Y/C signal to this

unit.

2. Press the INPUT SW to accept the Y/C signal.

3. Enter the Service menu, then select SIGNAL → SIGNAL LEVEL → AUTO ADJ. Perform the following

automatic adjustments.

. Y/G LEVEL

. PB LEVEL

. PR LEVEL

4. Perform the adjustments of items 1-11 and 1-12 in

table 4 by repeating the above described procedures.

COMPOSITE selection input

1-7 NTSC SETUP 0 100% 8 color-bar signal

Y/G LEVEL

PB/B LEVEL

PR/R LEVEL

1-8 PAL 100% 8 color-bar signal

Y/G LEVEL

PB/B LEVEL

PR/R LEVEL

1-9 NTSC SETUP 7.5 100% 8 color-bar signal

Y/G LEVEL

PB/B LEVEL

PR/R LEVEL

Conditions:

NTSC SETUP 0

Conditions:

No specifi c conditions

Conditions:

NTSC SETUP 7.5

Table 3

Y/C selection input

1-10 NTSC SETUP 0 100% 8 color-bar signal

Y/G LEVEL

PB/B LEVEL

PR/R LEVEL

1-11 PAL 100% 8 color-bar signal

Y/G LEVEL

PB/B LEVEL

PR/R LEVEL

1-12 NTSC SETUP 7.5 100% 8 color-bar signal

Y/G LEVEL

PB/B LEVEL

PR/R LEVEL

Conditions:

NTSC SETUP 0

Conditions:

No specifi c conditions

Conditions:

NTSC SETUP 7.5

2-4 (E)

Table 4

LMD-2110W

Page 23

3-1. Backlight does not light

Backlight does not light.

Section 3

Troubleshooting

Are harness

and flexible flat cable

connected correctly?

Yes

Is the POWER LED lit.

No

Is the backlight

lit when another G1 board

is installed?

No

Yes

Yes

No

Connect the harness and

flexible flat cable correctly.

Replace the B board.

(Refer to Section 1-3-5.)

Replace the G1 board.

(Refer to Section 1-3-4.)

Is the

backlight lit when

another G2 board

is installed?

Replace the LCD panel.

(Refer to Section 1-3-8.)

LMD-2110W

No

Yes

Replace the G2 board.

(Refer to Section 1-3-3.)

3-1 (E)

Page 24

3-2. System does not start

System does not start.

Are harness

and flexible flat cable

connected correctly?

Yes

Is the POWER LED lit.

No

Is the symptom

improved when another

G1 board is installed?

No

Is the symptom

improved when another

H board is installed?

Yes

Yes

Yes

No

Connect the harness and

flexible flat cable correctly.

Replace the B board.

(Refer to Section 1-3-5.)

Replace the G1 board.

(Refer to Section 1-3-4.)

Replace the H board.

(Refer to Section 1-3-7.)

Is the

backlight lit when

another G2 board

is installed?

Replace the LCD panel.

(Refer to Section 1-3-8.)

3-2 (E)

No

No

Yes

Replace the G2 board.

(Refer to Section 1-3-3.)

LMD-2110W

Page 25

3-3. Image is abnormal

Image is abnormal.

Are harness

and flexible flat cable

connected correctly?

Yes

Is the symptom

improved when another

Q board is installed?

No

Is the symptom

improved when another

B board is installed?

No

Replace the LCD panel.

(Refer to Section 1-3-8.)

Yes

Yes

No

Connect the harness and

flexible flat cable correctly.

Replace the Q board.

(Refer to Section 1-3-2.)

Replace the B board.

(Refer to Section 1-3-5.)

LMD-2110W

3-3 (E)

Page 26

3-4. TALLY lamp is not lit

TALLY lamp is not lit.

Are harness and

flexible flat cable connected

correctly?

Yes

Is the symptom

improved when another

X board is installed?

No

Replace the B board.

(Refer to Section 1-3-5.)

Yes

No

Connect the harness and

flexible flat cable correctly.

Replace the X board.

(Refer to Section 1-3-7.)

3-4 (E)

LMD-2110W

Page 27

3-5. Fan is abnormal

Fan is abnormal.

Are harness

and flexible flat cable

connected correctly?

Yes

Replace the abnormal fan.

Is the symptom improved?

No

Replace the B board.

(Refer to Section 1-3-5.)

No

Yes

Connect the harness and

flexible flat cable correctly.

No problem.

LMD-2110W

3-5 (E)

Page 28

Page 29

Section 4

Spare Parts

4-1. Notes on Repair Parts

1. Safety Related Components Warning

w

Components marked ! are critical to safe operation.

Therefore, specified parts should be used in the case of

replacement.

2. Standardization of Parts

Some repair parts supplied by Sony differ from those

used for the unit. These are because of parts commonality and improvement.

3. Stock of Parts

Parts marked with “o” at SP (Supply Code) column of

the spare parts list may not be stocked. Therefore, the

delivery date will be delayed.

4. Harness

Harnesses with no part number are not registered as

spare parts.

4-1. 補修部品注意事項

1. 安全重要部品

! 警告

! 印のついた部品は安全性を維持するために重要

な部品です。したがって,交換する時は必ず指定

の部品を使ってください。

2. 部品の共通化

ソニーから供給する補修用部品は,セットに使われて

いるものと異なることがあります。

これは部品の共通化,改良等によるものです。

3. 部品の在庫

部品表の SP(Supplycode)欄に“o”で示される部品は

在庫していないことがあり,納期が長くなることがあ

ります。

4. ハーネス

部品番号の記載されていないハーネスは,サービス部

品として登録されていません。

The components identified by mark contain confidential

information.

Strictly follow the instructions whenever the components

are repaired and/or replaced.

印の部分には,秘密情報が含まれています。

修理の際は,指示に従った対応を行ってください。

LMD-2110W

4-1

Page 30

Cover Block

4-2. Exploded Views

21

20

PTPWH

3 x 8

PTPWH

3 x 8

PWH

3 x 6

PTPWH

3 x 8

20

To B board

To B board

PS4 x 8

10

PTPWH

3 x 8

16

6

14

23

9

15

PWH

M3 x 10

13

24

KTP

3 x 10

K4 x 8

KTP3 x 10

18

22

To B board

11

PWH

3 x 6

To

B board

1

PWH

3 x 6

To G1 board

8

2

12

4

To

B board

17

7

PTPWH

3 x 8

5

PTPWH

3 x 8

3

19

4-2

LMD-2110W

Page 31

No. Part No. SP Description

1 X-2549-516-2 s BEZEL ASSY

2 1-789-802-11 s MOUNTED CIRCUIT BOARD, X

3 1-857-452-31 s MOUNTED CIRCUIT BOARD, H

4 1-857-454-51 s MOUNTED CIRCUIT BOARD, Q

5 1-858-248-11 s SPEAKER

6

! 1-969-791-11 s ASSY, AC INLET

7 1-910-400-37 o SHR CONNECTOR ASSY 7P

8 1-969-795-11 s SHR CONNECTOR ASSY 3P

9 1-969-793-11 s DF13 CONNECTOR ASSY 15P

10 1-910-400-40 o DF13 CONNECTOR ASSY 12P

11 1-969-794-11 s DF13 CONNECTOR ASSY 8P

12 2-434-609-11 s SCREW (M4X8 CR)

13 2-582-180-31 s COVER, STAND BASE

14 2-585-969-31 s COVER, STAND FRAME

15 2-635-990-21 s HINGE, STAND

16 2-990-241-02 s HOLDER (A), PLUG

17 3-212-900-01 s SHEET, TALLY

18 4-148-038-01 s SCREW F2.5X6

19 4-149-959-01 s BUTTON, STANDBY

20 4-149-972-01 s SCREW +PWH 4X12

21 4-207-904-02 s COVER, REAR

22 4-256-828-01 s LABEL, CONNECTOR

23 2-635-987-01 s FRAME, STAND

24 2-635-988-01 s BASE, STAND

Cover Block

7-681-000-61 s TAPPING +PWH 3X8 TYPE2 N-S

7-682-261-04 s SCREW +K 4X8

7-682-661-01 s SCREW +PS 4X8

7-682-903-19 s SCREW +PWH 3X6

7-682-903-39 s SCREW +PWH M3X10

7-685-247-14 s SCREW +KTP 3X10 TYPE2 NON-SLIT

LMD-2110W

4-3

Page 32

Chassis Block

B3 x 14

101

105

106

PWH

3 x 6

PWH

3 x 6

PWH

3 x 6

PWH

3 x 6

109

To AC inlet

A

PWH

3 x 6

108

To Q board

To X board

To Q board

107

PWH

3 x 6

To Q board

110

102

111

A

To H board

PWH

3 x 6

104

B3 x 4

No. Part No. SP Description

106 1-895-454-11 s MOUNTED CIRCUIT BOARD, G2

103

107 1-910-058-32 o DF13 CONNECTOR ASSY 2P

112

108 1-969-789-11 s PHDR CONNECTOR ASSY 14P

109 1-969-796-11 s PHDR CONNECTOR ASSY 20P

110 1-969-792-11 s CONNECTOR ASSY, LVDS 30P

No. Part No. SP Description

111 4-670-040-02 s SCREW

101 ! 1-787-891-21 s DC FAN

112 1-969-790-11 s PHR CONNECTOR ASSY 6P

102 1-789-265-11 s MOUNTED CIRCUIT BOARD, S

103 ! 1-811-872-11 s LCD PANEL

104 1-895-466-11 s MOUNTED CIRCUIT BOARD, B

105 ! 1-857-453-31 s MOUNTED CIRCUIT BOARD, G1

7-682-545-09 s SCREW +B 3X4

7-682-551-09 s SCREW +B 3X14

7-682-903-19 s SCREW +PWH 3X6

4-4

B3 x 4

PWH

3 x 6

LMD-2110W

Page 33

4-3. Packing Materials & Supplied

Accessories

---------------------------------------PACKING MATERIALS & SUPPLIED ACCESSORIES

----------------------------------------

*1:[LMD-2110W(SY)]

*2:[LMD-2110W(CN)]

Ref. No.

or Q'ty Part No. SP Description

1pc *2 ! 1-783-481-43 s CORD, POWER (for CN)

1pc *1 ! 1-783-795-25 s CORD, POWER (for J)

1pc 2-990-242-01 s HOLDER (B), PLUG

1pc *1 4-194-400-04 s OPERATING INSTRUCTIONS

(JAPANESE, ENGLISH)

1pc *1 4-194-401-04 s CD-ROM

OPERATING INSTRUCTIONS (PDF)

(JAPANESE, ENGLISH, FRENCH, GERMAN,

ITALIAN, SPANISH, SIMPLEFIED CHINESE,

TRADITIONAL CHINESE, KOREAN, DUTCH)

LMD-2110W

4-5

Page 34

Page 35

Section 5

Block Diagrams

OverallOverall

I2C I/F

x2

H BOARD

BBOARD

PWR_ON/OFF

HDMI

EE

PROM

G/Y

AC IN

DCLK+,DCLK_,D+[0..2], D_[0..2]

G_Y/B_B-Y/R_R-Y

HD LPF

R/R-Y

B/B-Y

G_Y

SWITCH

EXT SYNC

G1 BOARD

CSYNC_ANALOG

+12V, +5V, +5V_AUD, +3.3V

I2C_KEY

COMP & HDMI

VIDEO

DECODER

LCD_BR

R, G, B[0..9]

HS

VS

SO

CLK

FIELD

HDMI AUD

YUV[0..9]

ACT

FIELD

VBLK

VSOUT

HSOUT

CLK

16M

SDRAM

+3.3V, 5V_AUD

+12V, LCD_BR, LCD_ON

INPUT

PORT 0

LIP

SYNC

INPUT

PORT 1

DAC

C_5V

2

I

LCD_ON

SCALER

PW318 RX/TX

TCON_ON

TEMP SENSOR

FAN CONTROLLER

PAR_[0..6]

G2 BOARD

256M

DDR x 2

16M

FLASH

RESET

EE

PROM

MOS

CLK+, CLK_, D+[0..3], D_[0..3]

PAR_[0..3]

+5V_TCON

FAN DRV.

LCD

PANEL

LMD-2110W

WIDEBAND

INPUT

OUTPUT

COMP/RGB EXT

QBOARD

VIDEO

AUDIO

SDI_COMPONENT

SYNC

I/O 1

Y/C

CVBS

COMP AUDIO INPUT

LINE VIDEO AUDIO

SDI_Y/C

WIDEBAND

VIDEO

I/O 0

OPTION IN

SDI

LINE A AUDIO INPUT

I/O

EXPANDER

DUAL

COMPARATORS

SDI_DET

OPTION

SDI AUDIO

5-1

HDMI AUDIO INPUT

I2C_5V

AUDIO

PROCESSOR

AMPLIFIER

5-1

TRANSCEIVER

SHUTDOWN_AMP

RS232C

RX/TX

SERIAL REMOTE

RESET

12V/+5V_AUD

EE

PROM

CMOS

PARALLEL

REMOTE

TALLY_R/G

SENSOR

S BOARD

X BOARD

SPEAKER

FAN

Overall

Page 36

Page 37

Section 6

Frame Wiring

LCD PANEL G2 G1

!

Frame WiringFrame Wiring

1

B

!

BACK

LIGHT

CN802 CN801 CN702 CN701

CN601

J2

Note: The components identified

by mark contain confidential

information.

Strictly follow the instructions

whenever the components are

repaired and/or replaced.

J10

J1

!

FAN

J1

2

X

3

LVDS CABLE

AC INLET

!

SPEAKER

J23

Q

J22

J10

J24

J9

J5

J4

J6

J3

J11

H

J1

4

S

J1

5

Frame Wiring

LMD-2110W

A B C D E F G H

6-1

6-1

Page 38

Page 39

SAFETY CHECK-OUT

After correcting the original service problem,

perform the following safety checks before

releasing the set to the customer :

Check the metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC

leakage. Check leakage as described below.

LEAKAGE TEST

The AC leakage from any exposed metal part

to earth ground and from all exposed metal

parts to any exposed metal part having a return

to chassis, must not exceed 3.5 mA. Leakage

current can be measured by any one of three

methods.

1. A commercial leakage tester, such as the

Simpson 229 or RCA WT-540A. Follow the

manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The

Data Precision 245 digital multimeter is

suitable for this job.

3. Measuring the voltage drop across a resistor

by means of a VOM or battery-operated AC

voltmeter. The “limit” indication is 5.25 V, so

analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa

SH-63Trd are examples of a passive VOM

that is suitable. Nearly all battery operated

digital multimeters that have a 20 V AC

range are suitable. (See Fig. A)

LMD-2110W

To Exposed Metal

Parts on Set

0.15 μF 1.5 k

Fig A. Using an AC voltmeter to check AC leakage.

Z

Earth Ground

AC

voltmeter

(5.25V)

Page 40

LMD-2110W (CN)

LMD-2110W (SY) J, E

9-968-760-11

Sony Corporation

Printed in Japan

2013. 6 32

©2013

Loading...

Loading...