Sony KLV-26T400A-G, KLV-32T400A Schematic

REVISION HISTORY

TG1 (GA)

CHASSIS

MODEL

KLV-26T400A

KLV-26T400G

KLV-32T400A

NO. SUFFIX DATE SUPP / CORR DESCRIPTION

1 -01 2008/08 _ _ 1st Issue

PA RT NO.: 9-888-100-01

SERVICE MANUAL

TG1 (GA)

CHASSIS

MODEL COMMANDER DEST.

KLV-26T400A

KLV-26T400G

KLV-32T400A

RM-GA013 E, GE, India, ME,

New Zealand,

South Africa

RM-GA013 E, GE, India, ME,

RM-GA013 E, GE, India, ME,

Thailand, South Africa

MODEL COMMANDER DEST.

KLV-26T400A

RM-GA013

KLV-32T400A

KLV-26T400G

LCD COLOR TV

KLV-26T400A, T400G, 32T400A

RM-GA013

TABLE OF CONTENTS

Section Title Page

1. SAFETY NOTES

1-1. Caution Handling of LCD Panel ..................................... 3

1-2. Safety Check Out ............................................................. 3

1-3. Leakage Test .................................................................... 3

1-4. WARNING ! .................................................................... 3

1-5. Lead Free Information ..................................................... 4

2. SELF DIAGNOSTIC FUNCTION

2-1. Overview of Control Buttons .......................................... 5

2-2. LED Display Specification.............................................. 5

2-3. LED Display Control ....................................................... 5

2-4. LED Pattern ..................................................................... 5

2-5. Viewing the Service Diagnosis Display .......................... 5

2-6. Standby LED Error Display ............................................ 6

3. DISASSEMBLY

3-1. Stand Assy Removal ........................................................ 7

3-2. Rear Cover Removal........................................................ 7

3-3. GPT Board and Bracket Removal ................................... 7

3-4. BT Board and Bracket Removal ..................................... 8

3-5. Vesa Frame Removal ....................................................... 8

3-6. HT Board and Speaker Removal..................................... 8

3-7. LCD Panel and Bezel Assy Removal .............................. 9

Section Title Page

6. DIAGRAMS

6-1. Block Diagram ............................................................... 23

6-2. Connector Diagram ....................................................... 23

6-3. Circuit Board Location .................................................. 25

6-4. Schematic Diagram ....................................................... 25

6-5. Printed Wiring Boards ................................................... 25

6-6. Semiconductor ............................................................... 25

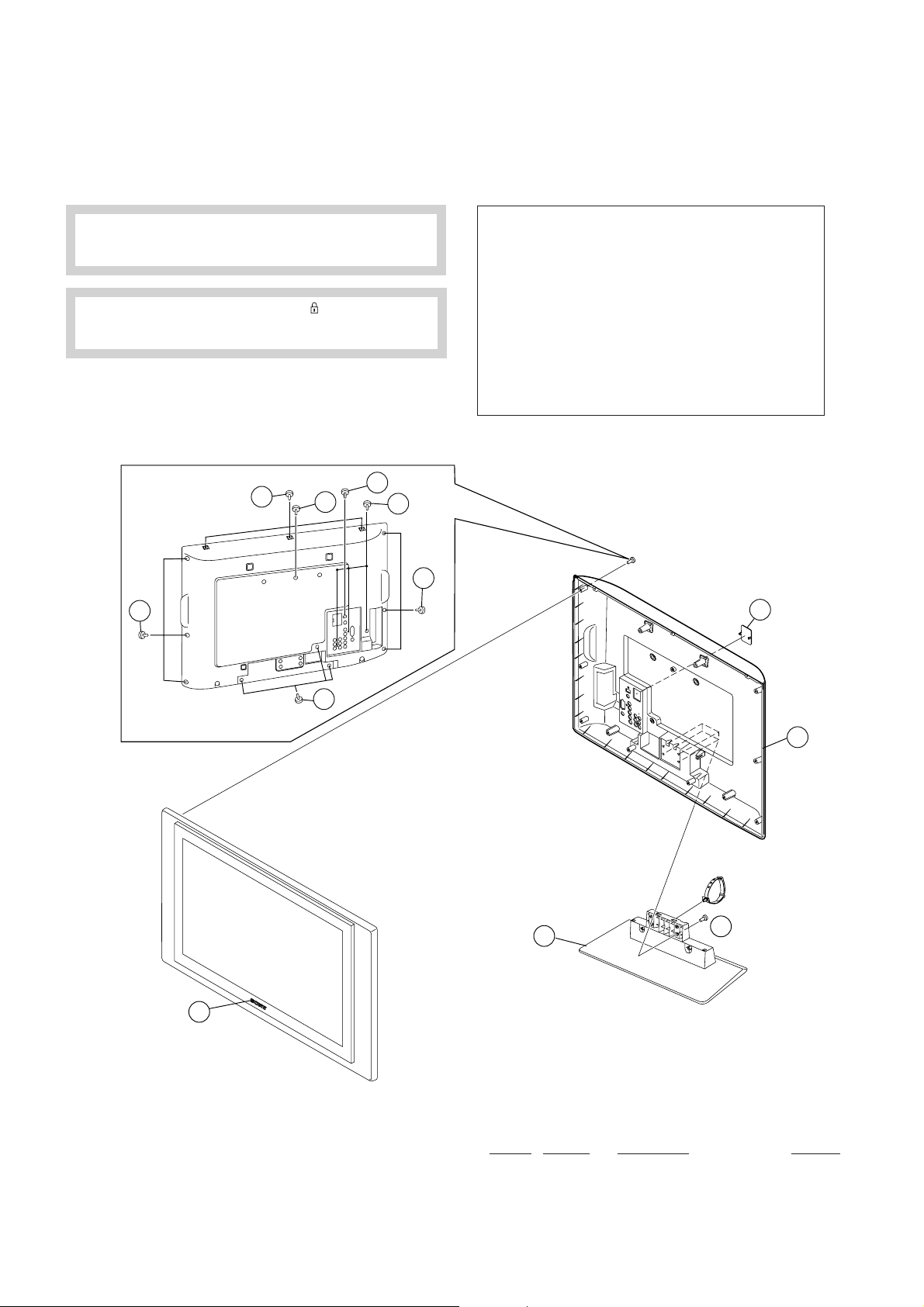

7. EXPLODED VIEWS

7-1. (KLV-26T400)

7-1-1. Rear Cabinet ...................................................... 26

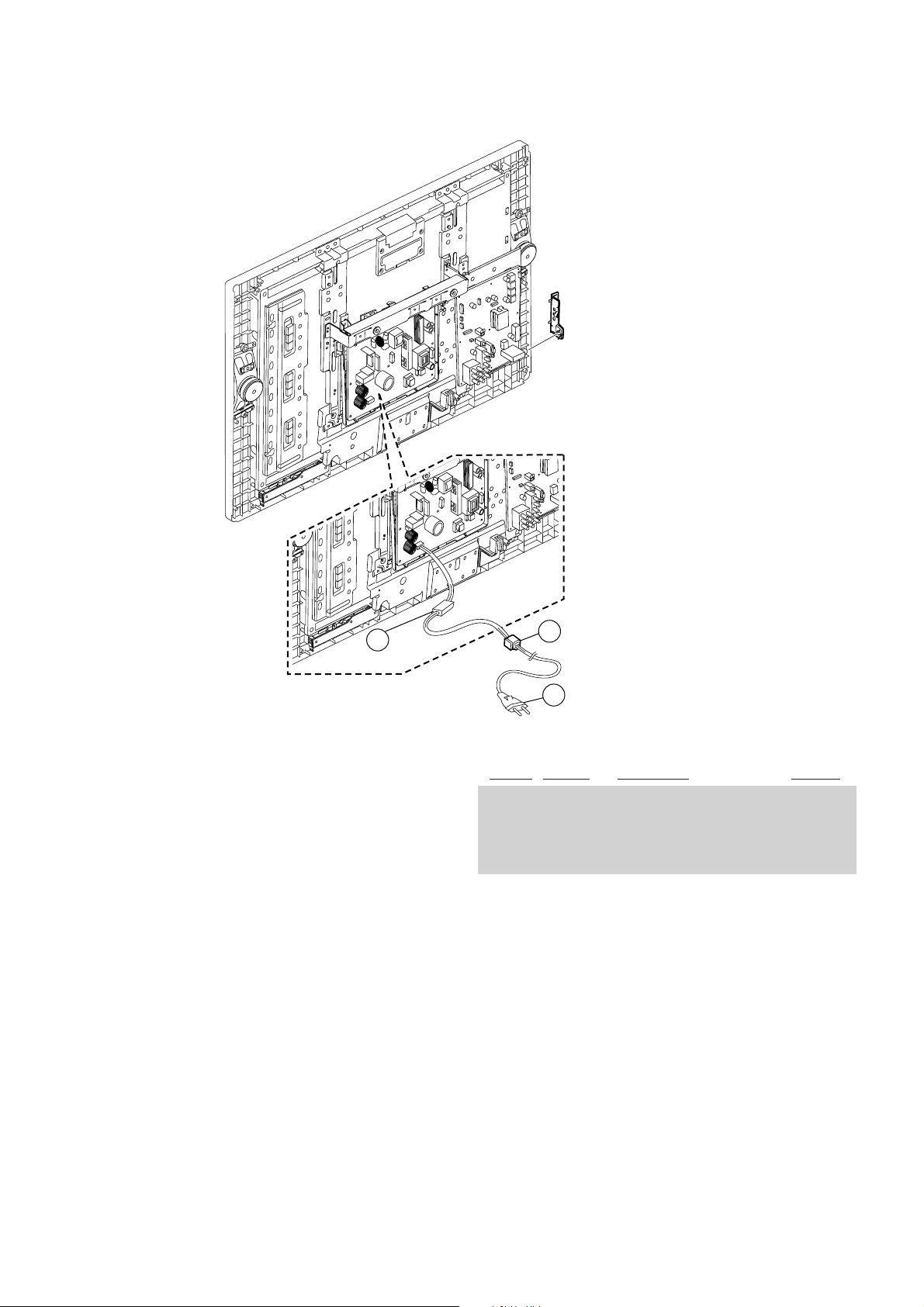

7-1-2. Power Cord, AC Cord Holder ........................... 27

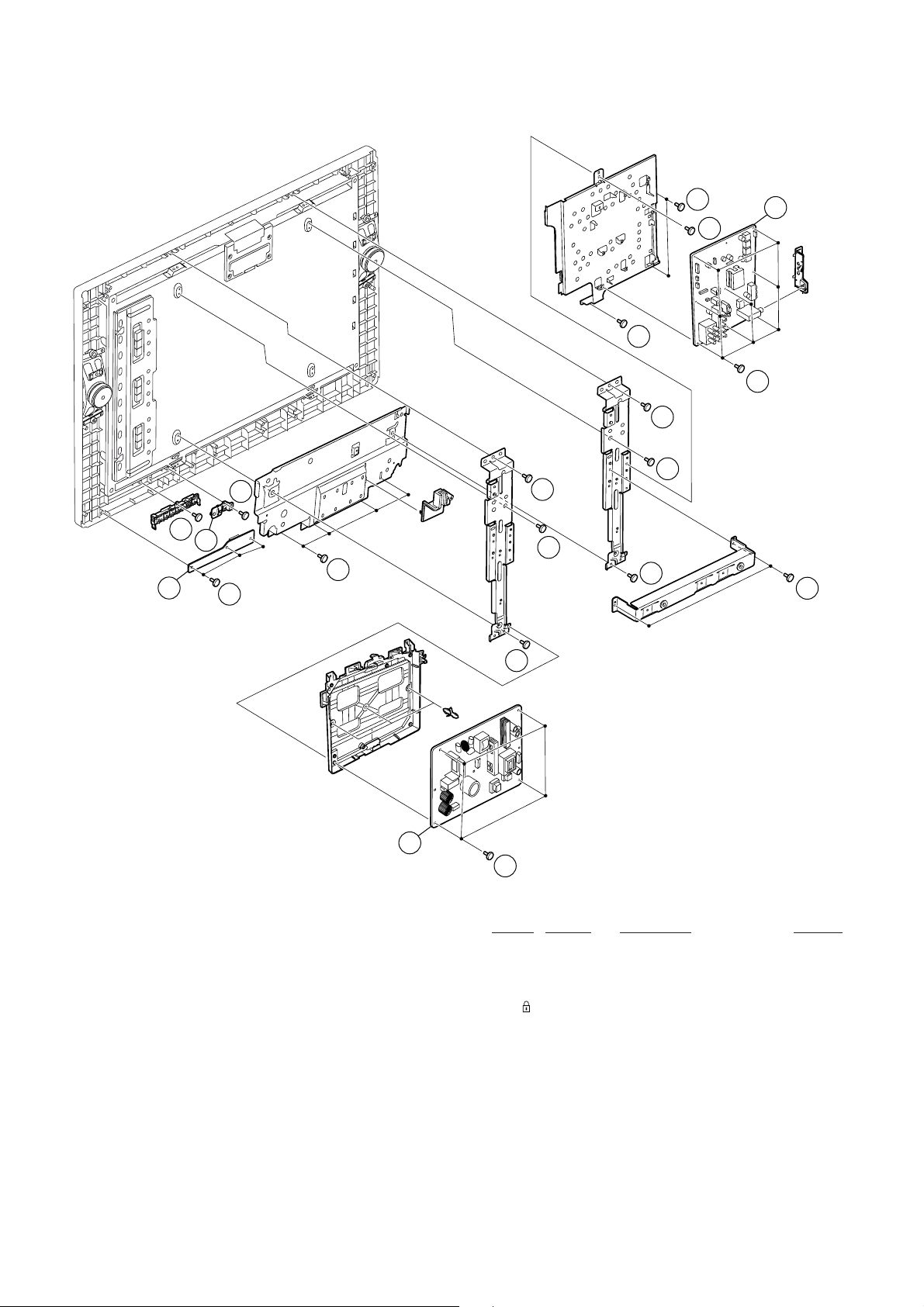

7-1-3. BT, HT, GPT ...................................................... 28

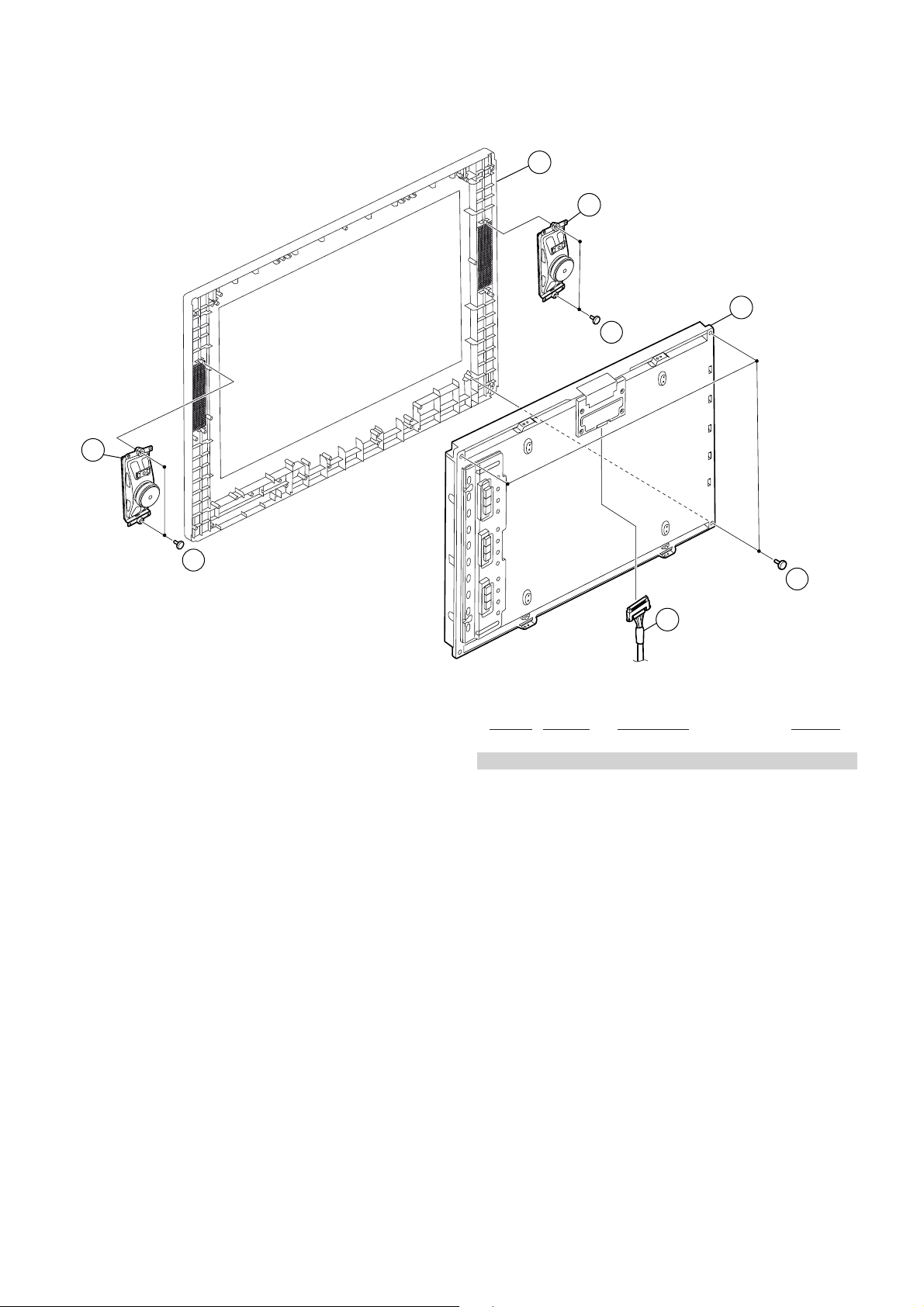

7-1-4. Speaker, Bezel Assy and LCD Panel ................ 29

7-2. (KLV-32T400)

7-2-1. Rear Cabinet ...................................................... 30

7-2-2. Power Cord, AC Cord Holder ........................... 31

7-2-3. BT, HT, GPT ...................................................... 32

7-2-4. Speaker, Bezel Assy and LCD Panel ................ 33

8. ELECTRICAL PARTS LIST .............................................. 34

OPERATING INSTRUCTIONS

4. WIRE DRESSING

4-1. (KLV-26T400) ............................................................... 10

4-2. (KLV-32T400) ............................................................... 15

5. SERVICE ADJUSTMENTS

5-1. Accessing Diagnostic Menu .......................................... 20

5-2. Viewing the Service Mode Display ..............................20

5-3. Control Keys Via Remote Commander......................... 20

5-4. Adjustment Method ....................................................... 20

5-5. Table 1 ............................................................................ 22

5-6. Board & Panel Replacement ......................................... 22

– 2 –

SECTION 1

SAFETY NOTES

KLV-26T400A, T400G, 32T400A

RM-GA013

1-1. Caution Handling of LCD Panel

When installing the LCD Panel, make sure you are grounded

with a wrist band.

When installing the LCD Panel on the wall, the panel must be

secured using the 4 mounting holes on the rear cover.

1) Do not press the panel or frame edge to avoid the risk of

electric shock.

2) Do not scratch or press on the panel with any sharp

objects.

3) Do not leave the module in high temperature or in areas of

high humidity for an extended period of time.

4) Do not expose the LCD panel to direct sunlight.

5) Avoid contact with water. It may cause short circuit within

the module.

6) Disconnect the AC adapter when replacing the backlight

(CCFL) or inverter circuit. (High voltage occurs at the inverter

circuit at 650Vrms)

7) Always clean the LCD panel with a soft cloth material.

8) Use care when handling the wires or connectors of the

inverter circuit. Damaging the wires may cause a short circuit.

9) Protect the panel from ESD to avoid damaging the electronic circuit (C-MOS).

1-2. Safety Check-Out

After correcting the original service problem, perform the

following safety checks before releasing the set to the

customer:-

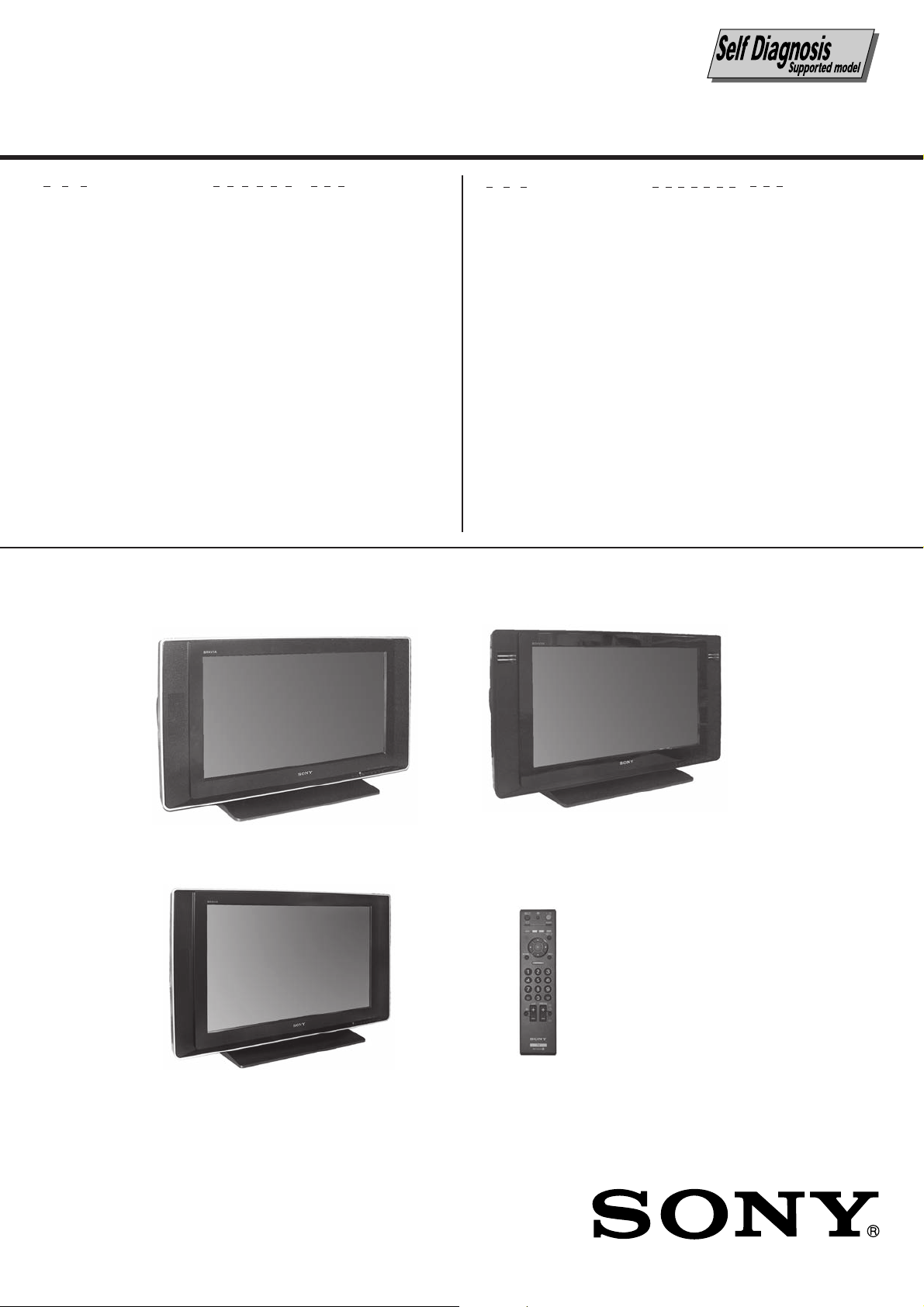

1-3. Leakage Test

The AC leakage from any exposed metal part to earth

ground and from all exposed metal parts to any exposed

metal part having a return to chassis must not exceed 0.5mA

(500 microamperes). Leakage current can be measured by

any one of the three methods:-

1. A commercial leakage tester such as the SIMPSON 229 or

RCA WT-540A. Follow the manufacturers instructions to use

those instructions.

2. A battery-operated AC milliampmeter. The DATA

PRECISION 245 digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of

a VOM or battery operated AC voltmeter. The 'limit' indication

is 0.75V so analog meters must have an accurate low voltage

scale. The SIMPSON'S 250 and SANWA SH-63TRD are

examples of passive VOMs that are suitable. Nearly all battery

operated digital multimeters that have a 2 VAC range are

suitable. (see Figure 1.)

To Exposed Metal

Parts on Set

0.15 µF

1.5 k

Ω

AC

Voltmeter

(0.75 V)

1) Check the area of your repair for unsoldered or poorly

soldered connections. Check the entire board surface for

solder splashes and bridges.

2) Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3)Check all control knobs, shields, covers, ground straps and

mounting hardware have been replaced. Be absolutely certain

you have replaced all the insulators.

4) Look for unauthorized replacement parts, particularly

transistors that were installed during a previous repair. Point

them out to the customer and recommend their replacement.

5) Look for parts which, though functioning show obvious

signs of deterioration. Point them out to the customer and

recommend their replacement.

6) Check the line cords for cracks and abrasion.

Recommend the replacement of any such line cord to the

customer.

7) Check the antenna terminals, metal trim, "metallized"

knobs, screws and all other exposed metal parts for AC

leakage. Check leakage test as described next.

Earth Ground

Figure 1. AC voltmeter to check AC leakage

1-4. WARNING !

SAFETY-RELATED COMPONENT WARNING!

COMPONENTS IDENTIFIED BY SHADING AND MARK !

ON THE EXPLODED VIEWS ARE CRITICAL FOR SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY. CIRCUIT ADJUSTMENTS THAT ARE

CRITICAL FOR SAFE OPERATION ARE IDENTIFIED IN

THIS MANUAL. FOLLOW THESE PROCEDURES

WHENEVER CRITICAL COMPONENTS ARE REPLACED

OR IMPROPER OPERATION IS SUSPECTED.

– 3 –

KLV-26T400A, T400G, 32T400A

RM-GA013

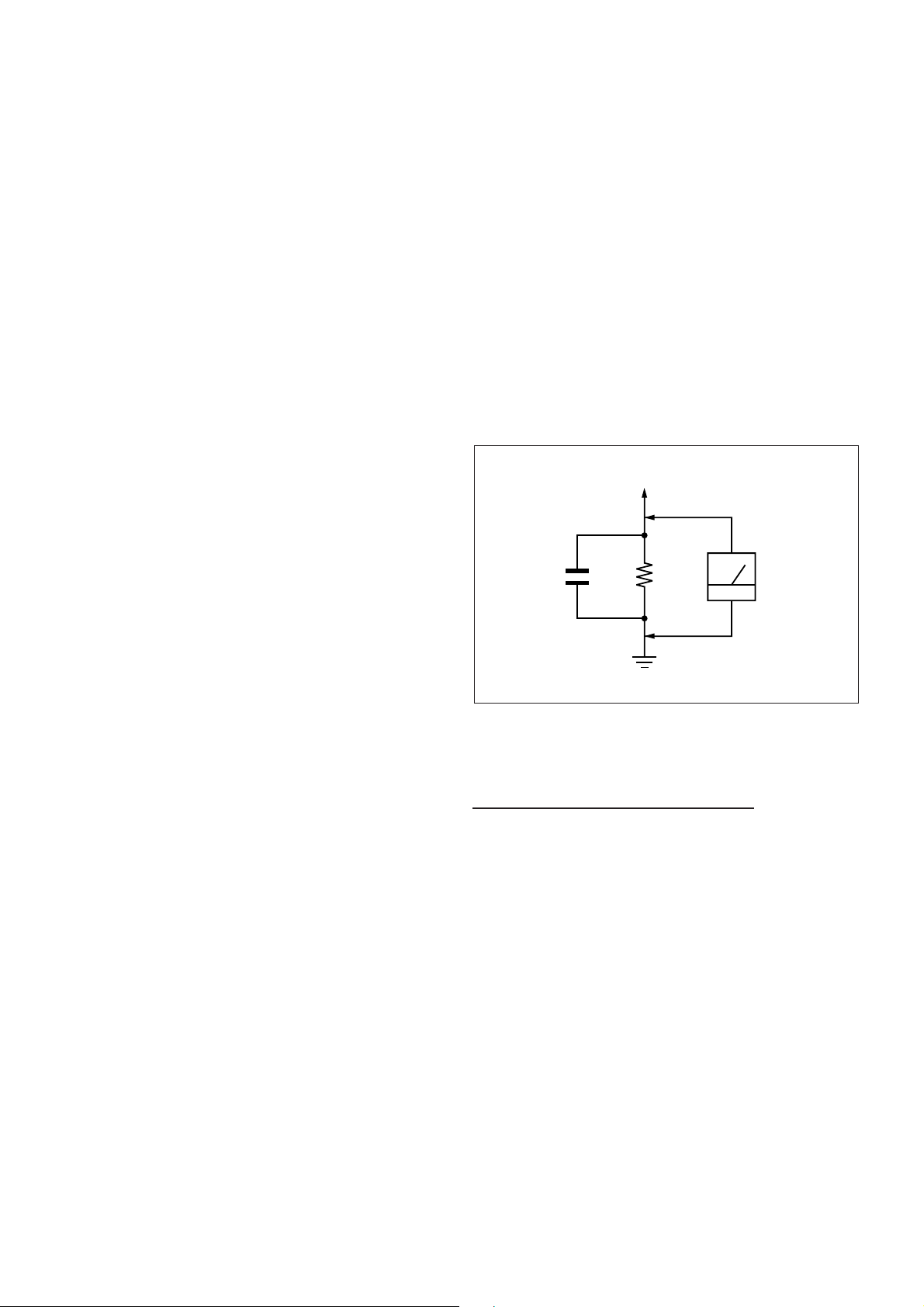

1-5. Lead Free Information

The circuit boards used in these models have been processed

using Lead Free Solder. The boards are identified by the LF

logo located close to the board designation.

Figure 2: LF logo

Figure 3: LF logo on circuit board

The servicing of these boards requires special precautions. It

is strongly recommended to use Lead Free Solder material in

order to guarantee optimal quality of new solder joints. Lead

Free Solder is available under the following part numbers:-

rebmuntraP retemaiD skrameR

7

91-500-046-mm

02-500-046-7m4.0Kg05.0

12-500-046-7m5.0Kg05.0

22-500-046-7m6.0Kg52.0

32-500-046-7m8.0Kg00.1

42-500-046-7m0.1Kg00.1

52-500-046-7m2.1Kg00.1

62-500-046-7m6.1Kg00.1

3.0Kg52.0

m

m

m

m

m

m

m

Due to high melting point of Lead Free Solder, the soldering

iron tip temperature needs to be set to 370 degrees

centigrade. This requires soldering equipment capable of

accurate temperature control coupled with a good heat

recovery characteristics.

For more information on the use of Lead Free Solder,

please refer to

http://www.sony-training.com

– 4 –

SECTION 2

SELF DIAGNOSTIC FUNCTION

KLV-26T400A, T400G, 32T400A

RM-GA013

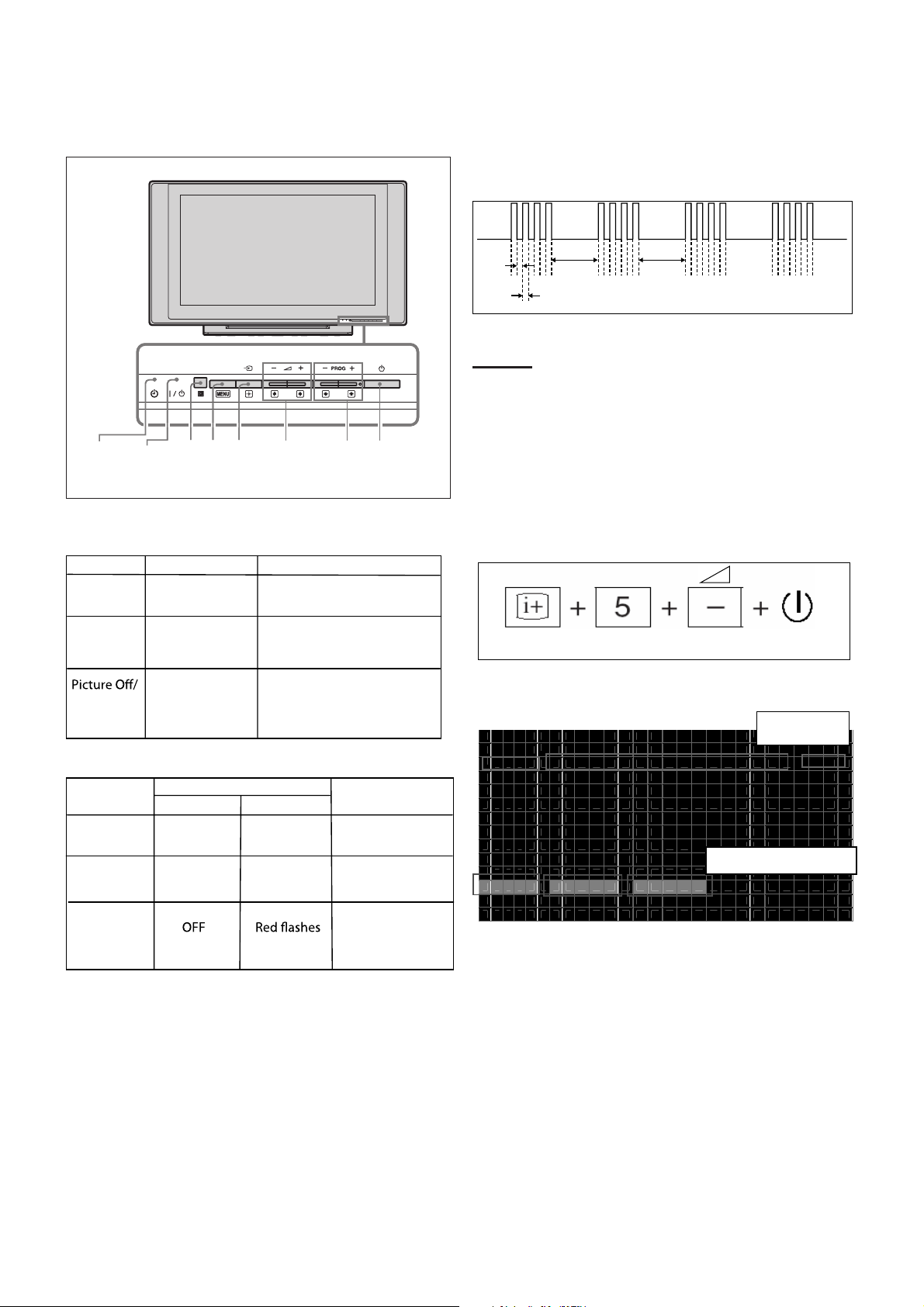

2-1. Overview of Control Buttons

Timer

Indicator

Power

Standby

Indicat

Sensor

MenuRemote

TV/

Video

2-2. LED Display Specification

LED Type Description

Volume

Channel

Remark

Power

2-4. LED Pattern

When safety shutdown occurs, Standby LED display reports the

cause by using the blinking patterns as indicated below.

0.3 sec

0.3 sec

2.0 sec 2.0 sec

Example:

The figure above shows LED display when

SHUTDOWN is caused by audio failure. It repeats

flashing for a specified number of times in 0.3sec/

cycle and has a 2 seconds interval of lighting off.

Please note that a 2 seconds interval of lighting off

is fixed regardless of abnormal state types.

2-5. Viewing the Service Diagnosis Display

1. While TV on standby mode, press the following sequence on

the Remote commander.

POWER Green: One LED

Green lights at power ON.

STANDBY Red: One LED Red lights during standby.

Green lights during Picture

OFF and amber lights

Timer

Green/Amber

: Two LEDs

during Timer activation.

2-3. LED Display Control

Status

Power LED

POWER ON Green lights OFF

STANDBY

Display

Standby LED

OFF Red lights

Remark

Microcomputer is

in a normal state.

Microcomputer is

in a sleep state.

Classify the

Failure

trouble causes by

the no. of red

blinking.

On screen

display

Channel 5

Volume (-)

POWER

(if wrong key is pressed or passed 3 seconds during each

process, cancel entering the self-diagnosis display.)

S E L F C H E C K

0 0 2 M A I N _ P O W E R _ E R R O R 0 0

0 0 3 5 V _ P O W E R _ E R R O R 0 0

0 0 4 A U D I O _ E R R O R 0 0

0 0 5 B A C K _ L I G H T _ E R R O R 0 0

0 0 6 T E M P _ E R R O R 0 0

1 2 3 4 5 - 0 9 8 7 6 - 0 1 2 3 4

12345: Total operation time by hour (0-65535)

09876: Boot count (0-65535)

01234: Panel operation time by hour (0-65535)

002: LED blinking times

MAIN_POWER_ERROR:

Detection name

00: Error Count (00-99)

2. To Exit, press the <I/1> key.

– 5 –

KLV-26T400A, T400G, 32T400A

RM-GA013

2-6. STANDBY LED ERROR DISPLAY

Blinking times Detection items Countermeasure

2 Main power failure Replace either/both z BT board

3 5V power failure Replace BT board.

4Audio failure Replace either/board.

5 Back light failure Replace either/board.

z GT board (19”)

z GPT board (26”/32”)

z BT board

z GT board (19”)

z GPT board (26”/32”)

z Speaker

z Woofer

z BT board

z GT board (19”)

z GPT board (26”/32”)

6 Internal temperature Replace GT board (19”)/ GPT Board (26”/ 32”)

failure

7 SMIC error Replace BT Board

Note: Each of the above blinking repeats every 2 seconds.

– 6 –

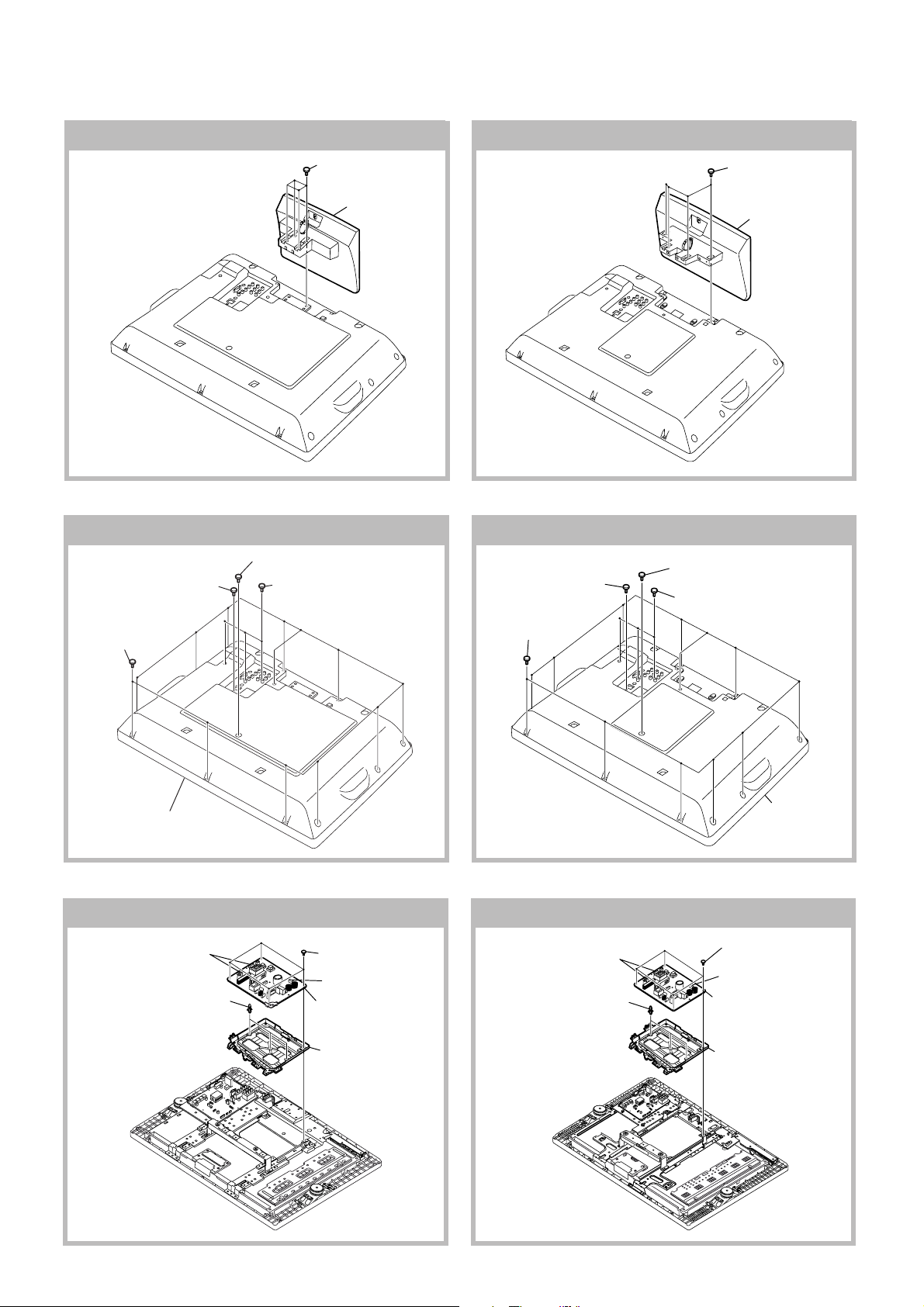

3-1. Stand Assy Removal

KLV-26T400A, T400G, 32T400A

RM-GA013

SECTION 3

DISASSEMBLY

(KLV-32T400)(KLV-26T400)

1 Four screws

(+PSW 5 X 16)

2 Stand assy

3-2. Rear Cover Removal

(KLV-26T400) (KLV-32T400)

3 One screw

2 One screw

(+PSW M3 X 5)

1 Twelves screws

(BVTP2 4 X 16)

(PSW 5 X 8)

4 Three screws

(+BVTP 3 X 12)

2 One screw

(+PSW M3 X 5)

1 Twelves screws

(BVTP2 4 X 16)

1 Four screws

(+PSW 5 X 16)

3 One screw

(PSW 5 X 8)

4 Three screws

(+BVTP 3 X 12)

2 Stand assy

5 Lift to remove Rear Cover

3-3. GPT Board and Bracket Removal

(KLV-26T400) (KLV-32T400)

2 Tw o connectors

CN6201 and CN6202

5 Three holder

PC board

1 Four screws

(+PSW 3SG)

3 One connector

CN6102

4 GPT board

6 GPT bracket

2 Two connectors

CN6201 and CN6202

5 Three holder

PC board

5 Lift to remove

Rear Cover

1 Four screws

(+PSW 3SG)

3 One connector

CN6102

4 GPT board

6 GPT bracket

– 7 –

KLV-26T400A, T400G, 32T400A

RM-GA013

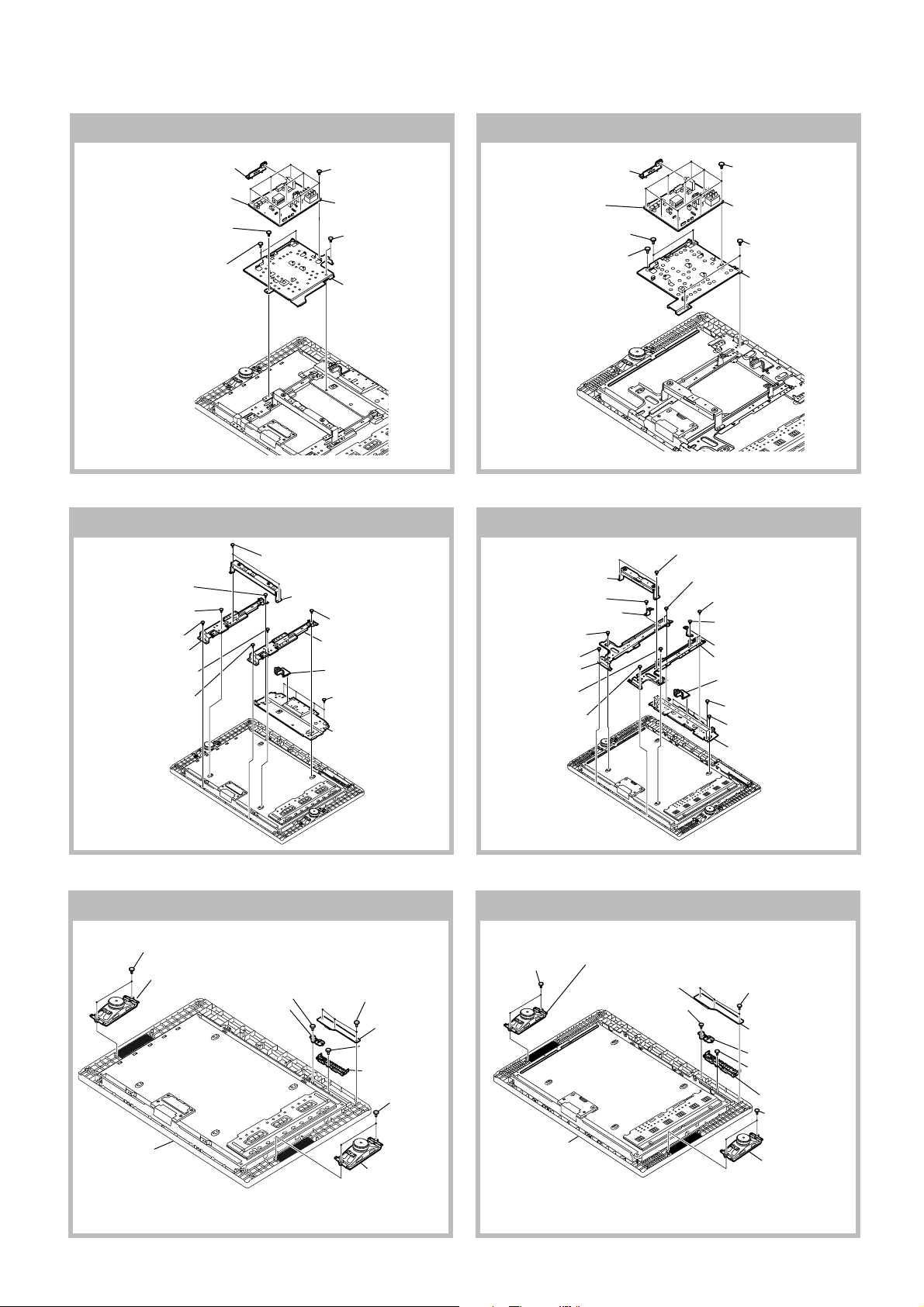

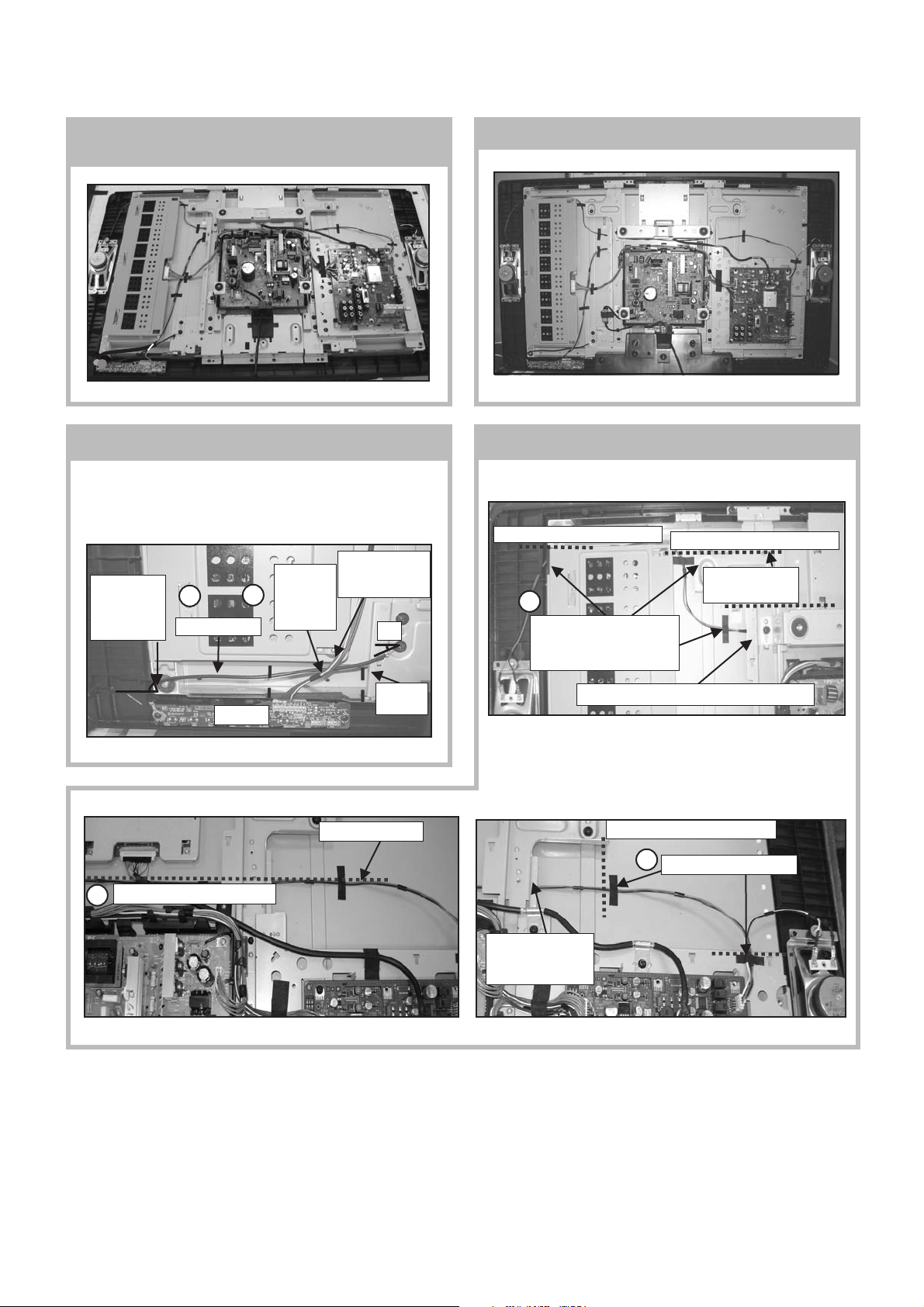

3-4. BT Board and Bracket Removal

(KLV-32T400)(KLV-26T400)

4 Side Jack Bracket Assy

2 Five connectors

CN2000, CN2004, CN3000,

CN3003, CN7000

6 One screw

(+PSW M4 X 8)

7 Tw o screws

(BVTP2 4 X 16)

1 Nine screws

(+BVST 3 X 8)

3 BT board

5 Tw o screws

(+BVST 3 X 8)

8 Main Bracket

4 Side Jack Bracket Assy

2 Six connectors

CN2000, CN2004, CN3000,

CN3003, CN7000

7 Two screws

(BVTP2 4 X 16)

6 One screw

(+PSW M4 X 8)

3-5. Vesa Frame Removal

(KLV-26T400) (KLV-32T400)

1 Tw o screws

3 One screw

(+PSW M4 X 8)

4 One screw

(+PSW M4 X 8)

5 One screw

(BVTP2 4 X 16)

6 Frame, spine (L)

8 One screw

(+PSW M4 X 8)

9 One screw

(BVTP2 4 X 16)

(+PSW M4 X 8)

2 Vesa top

q; Frame Spine (R)

qa Bracket AC

7 One screw

(+PSW M4 X 8)

qs Four screws

(BVTP2 4 X 16)

qd Frame Bottom

3 One screw

(+PSW M4 X 8)

4 Vesa Frame (Bottom) (32L)

6 One screw

(+PSW M4 X 8)

7 One screw

(BVTP2 4 X 16)

8 Frame, spine (L)

qs One screw

(+PSW M4 X 8)

qd One screw

(BVTP2 4 X 16)

2 Vesa top

1 Nine screws

(+BVST 3 X 8)

3 BT board

5 Two screws

(+BVST 3 X 8)

8 Main Bracket

1 Tw o screws

(+PSW M4 X 8)

5 Tw o screws

(+PSW M4 X 8)

qa Tw o screws

(+PSW M4 X 8)

9 One screw

(+PSW M4 X 8)

q; Vesa Frame (Bottom) (32R)

qf Frame Spine (R)

qg Bracket AC

qh Four screws

(BVTP2 4 X 16)

qj Four screws

(+PSW M4 X 8)

qk Frame Bottom

3-6. HT Board and Speaker Removal

(KLV-26T400) (KLV-32T400)

1 Tw o screws

(BVTP2 4 X 16)

qa Bezel assy

2 Loudspeaker

(5.5 X 12cm)

7 One screw

(BVTP2 3 X 12)

8 Guide Light

5 Three screws

(BVTP2 3 X 12)

6 HT board

9 One screw

(BVTP2 3 X 12)

0 Control Button

3 Tw o screws

(BVTP2 4 X 16)

4 Loudspeaker

(5.5 X 12cm)

1 Tw o screws

(BVTP2 4 X 16)

qs Bezel assy

– 8 –

2 Loudspeaker

(5.5 X 12cm)

6 One connector

8 One screw

(BVTP2 3 X 12)

5 Three screws

(BVTP2 3 X 12)

7 HT board

9 Guide Light

q; One screw

(BVTP2 3 X 12)

qa Control Button

3 Tw o screws

(BVTP2 4 X 16)

4 Loudspeaker

(5.5 X 12cm)

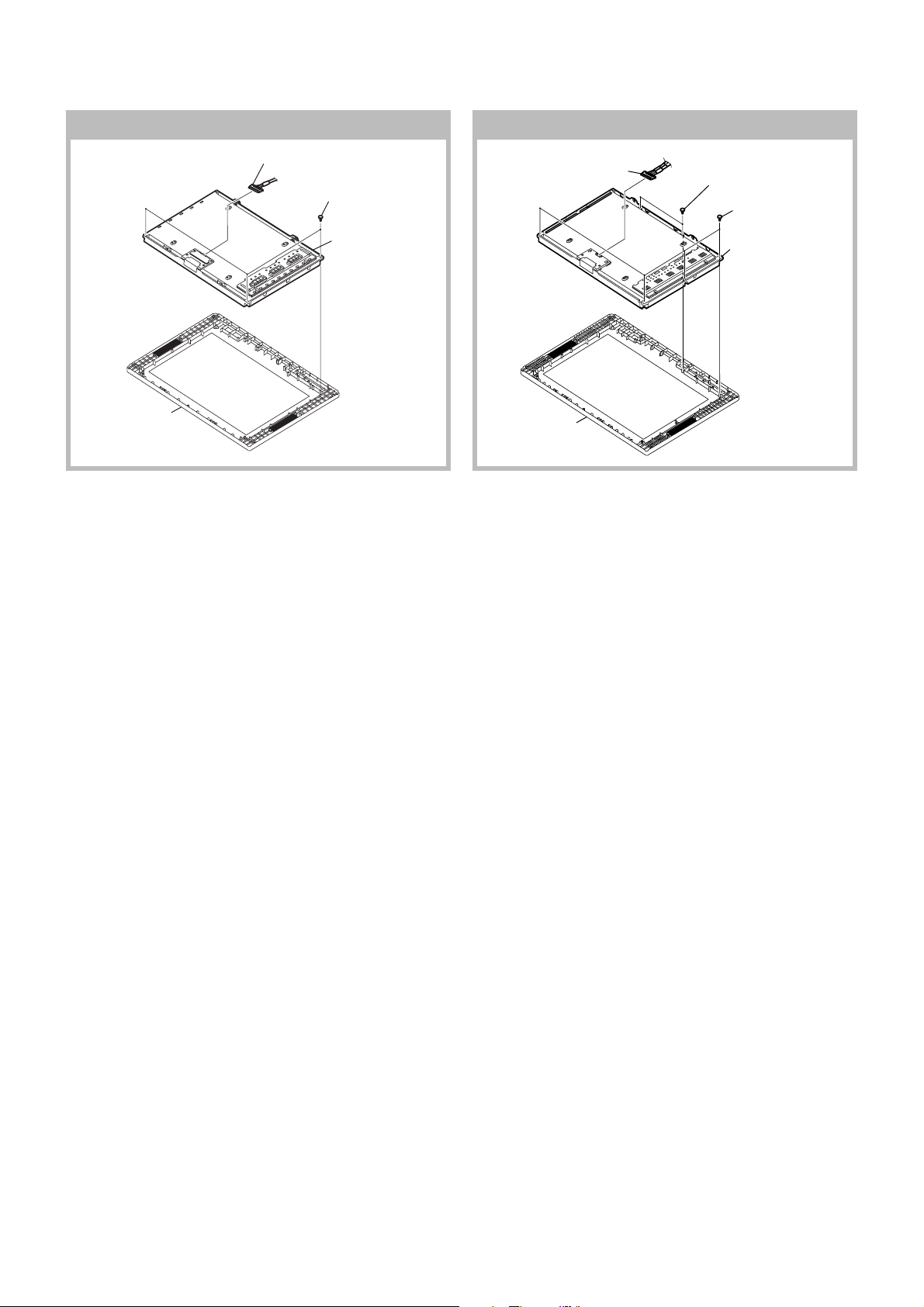

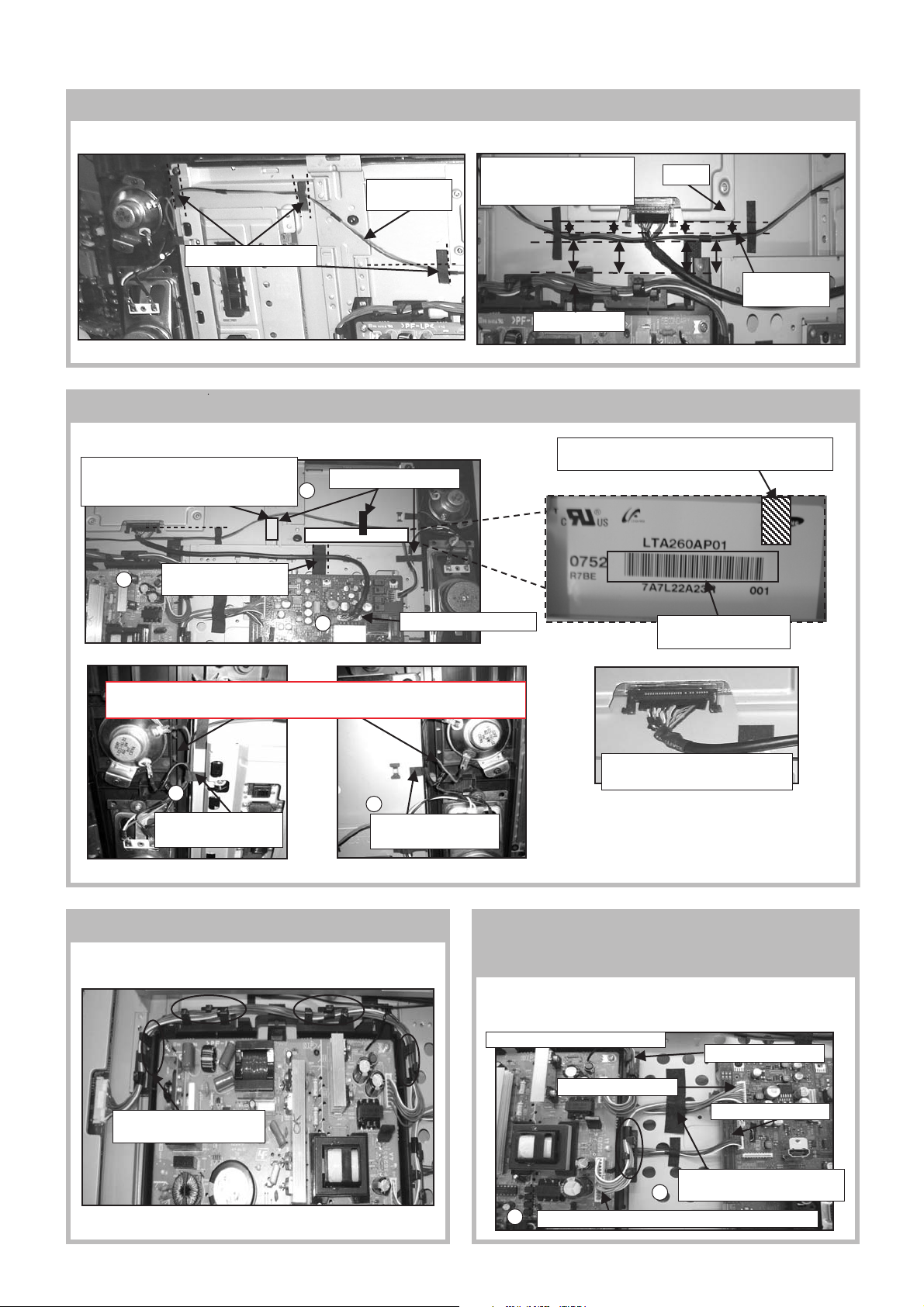

3-7. LCD Panel and Bezel Assy Removal

KLV-26T400A, T400G, 32T400A

RM-GA013

(KLV-32T400)(KLV-26T400)

4 Bezel assy

2 Harness

with connector

1 Three screws

(BVTP2 4 X 16)

3 LCD panel

3 Harness

with connector

5 Bezel assy

1 Two screws

(BVTP2 4 X 16)

2 Four screws

(BVTP2 4 X 16)

4 LCD panel

– 9 –

KLV-26T400A, T400G, 32T400A

RM-GA013

SECTION 4

WIRE DRESSING

4.1 (KLV-26T400)

4-1-1. Wire Dressing overview for

Non-CISPR model.

4-1-3. Wire Dressing overview for 26T400G

model.

CAUTION :

1. Do not overpull the wires during dressing

Legend:

--> avoid disconnection of wires.

2. Make sure wires are kept away from

sharp edges, heatsinks & other

high-temperature parts.

Hook

4-1-2. Wire Dressing overview for CISPR model.

4-1-4. Dressing of Connector Assy 1P

1) Insert Connector Assy 1P to HT PWB's screw hole and panel's

screw hole as shown.

2) Attach Sheet Core, C (X1) to panel at location of Connector

Assy 10P.

4-1-5. Dressing of Connector Assy 10P

Attach Tape, LCD (X1) to Connector Assy 10P as shown.

Use datum lines shown as an indication for attaching Tape,

LCD to Connector Assy 10P

Tape,

LCD

Conn Assy 1P

1

HT PWB

Attach Sheet Core,

2

C to panel

– 10 –

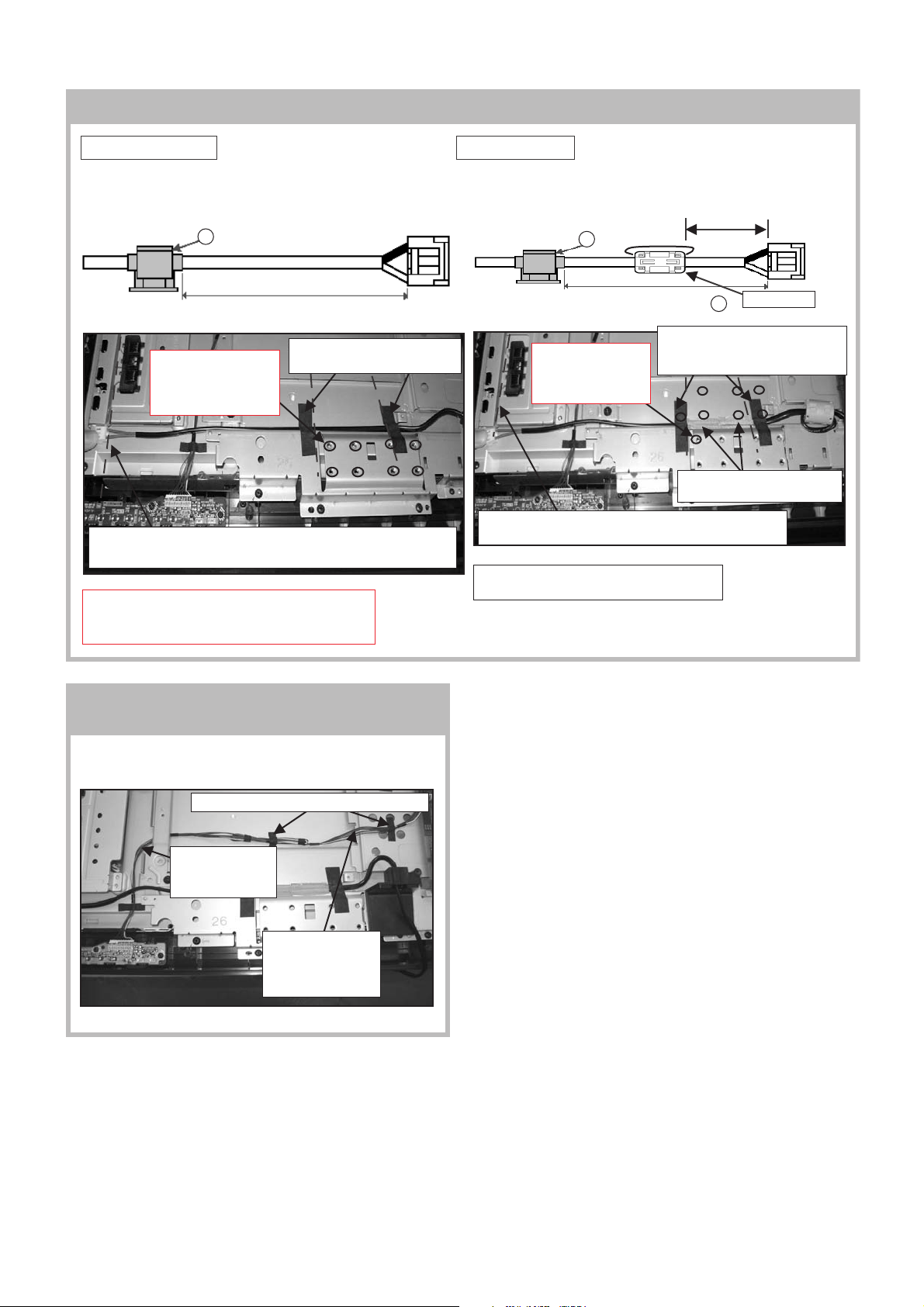

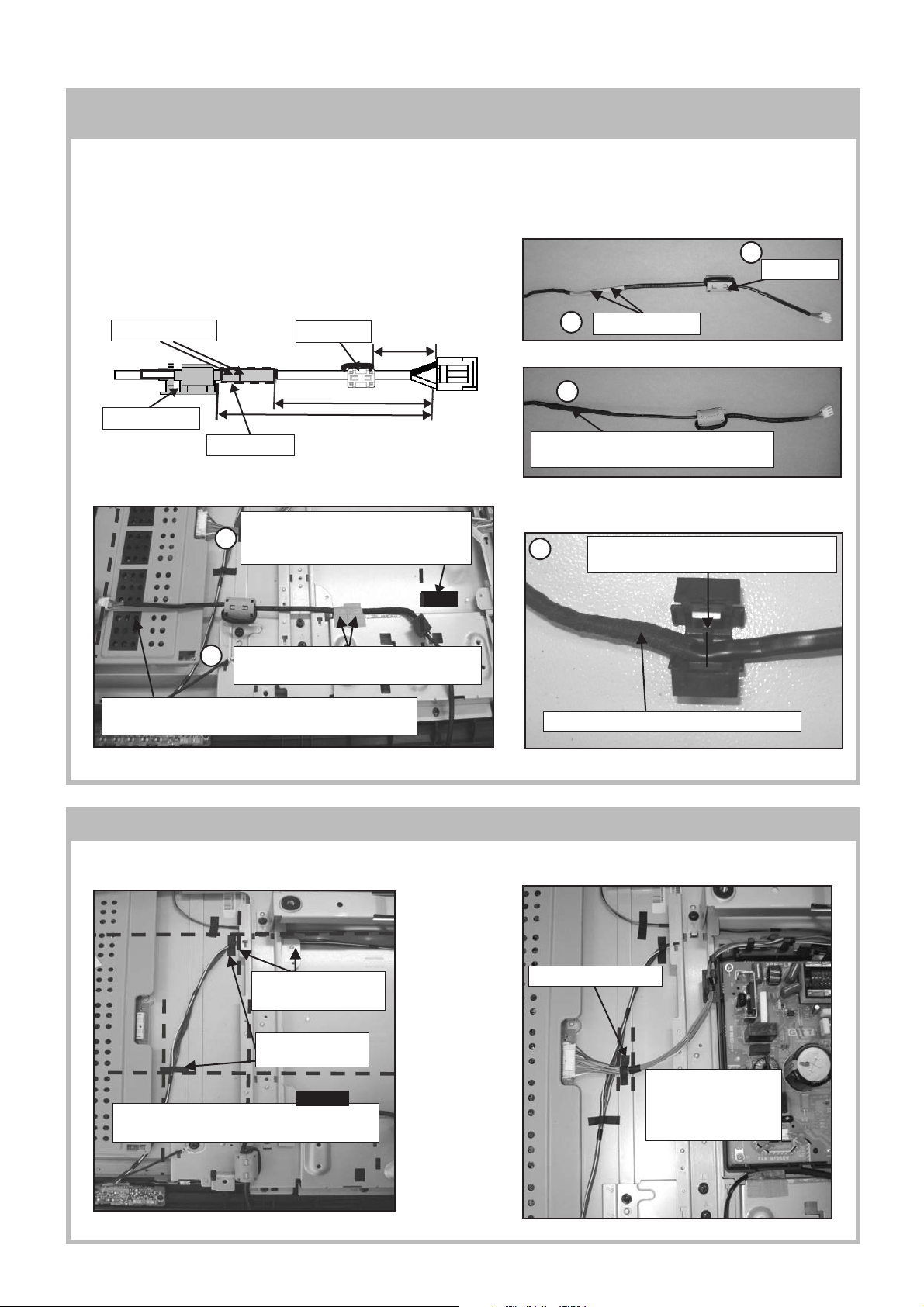

4-1-6. AC Power Cord Wire Dressing (Before installing G1 Bracket with GPT PWB)

Non-CISPR model CISPR model

1) Install AC cord holder to AC power cord at specified position

as shown.

AC Cord Holder

1

1) Install Ferrite core to AC power cord at specified position as shown

2) Next, install AC cord holder to AC power cord at specified position.

AC Cord Holder

2

KLV-26T400A, T400G, 32T400A

RM-GA013

360± 5mm

400 ± 5mm

Caution:

Do not cover the

screw holes

with the Sheet Core, C

Use edge of Inverter board's cover and AC power cord connector

as a guideline for placement of power cord

CAUTION:

1. Ensure that AC power cord is not stressed whilst

inserting it into AC cord bracket.

Attach Sheet Core, C (X2) to

AC Power Cord

4-1-7. Conn Assy 10P Dressing (Before installing

G1 Bracket with GPT PWB)

510 ± 5mm

2. Attach Sheet Core, C (X2) to

Caution:

Do not cover the

screw holes with the

Sheet Core, C

Use edge of Inverter board's cover and AC power cord

connector as a guideline for placement of power cord

CISPR models only

Attach Tape, Shield to AC Power Cord (X2)

AC Power Cord. Make sure both

Sheet Core, C overlaps the two

1. Attach Tape, Shield to AC

Ferrite Core

1

Power Cord (X2)

Dress Conn Assy 10P below Spine, Frame.

Next, attach Tape, LCD (X2) to Conn Assy 10P as shown.

Attach Tape, LCD (X2) to Conn Assy 10P

Dress Conn Assy

10P underneath

Spine, Frame

Ensure Conn Assy

10P passes through

the slot on main

bracket

– 11 –

KLV-26T400A, T400G, 32T400A

RM-GA013

4-1-7. SP Connector Assy 4P Dressing for 26T400A

SP Connector Assy 4P wire dressing for 26T400A model as below.

Attach Tape,

LCD (3X)

SP Conn

Assy 4P

Keep distance between SP Conn

T-CON, Conn Assy 14P

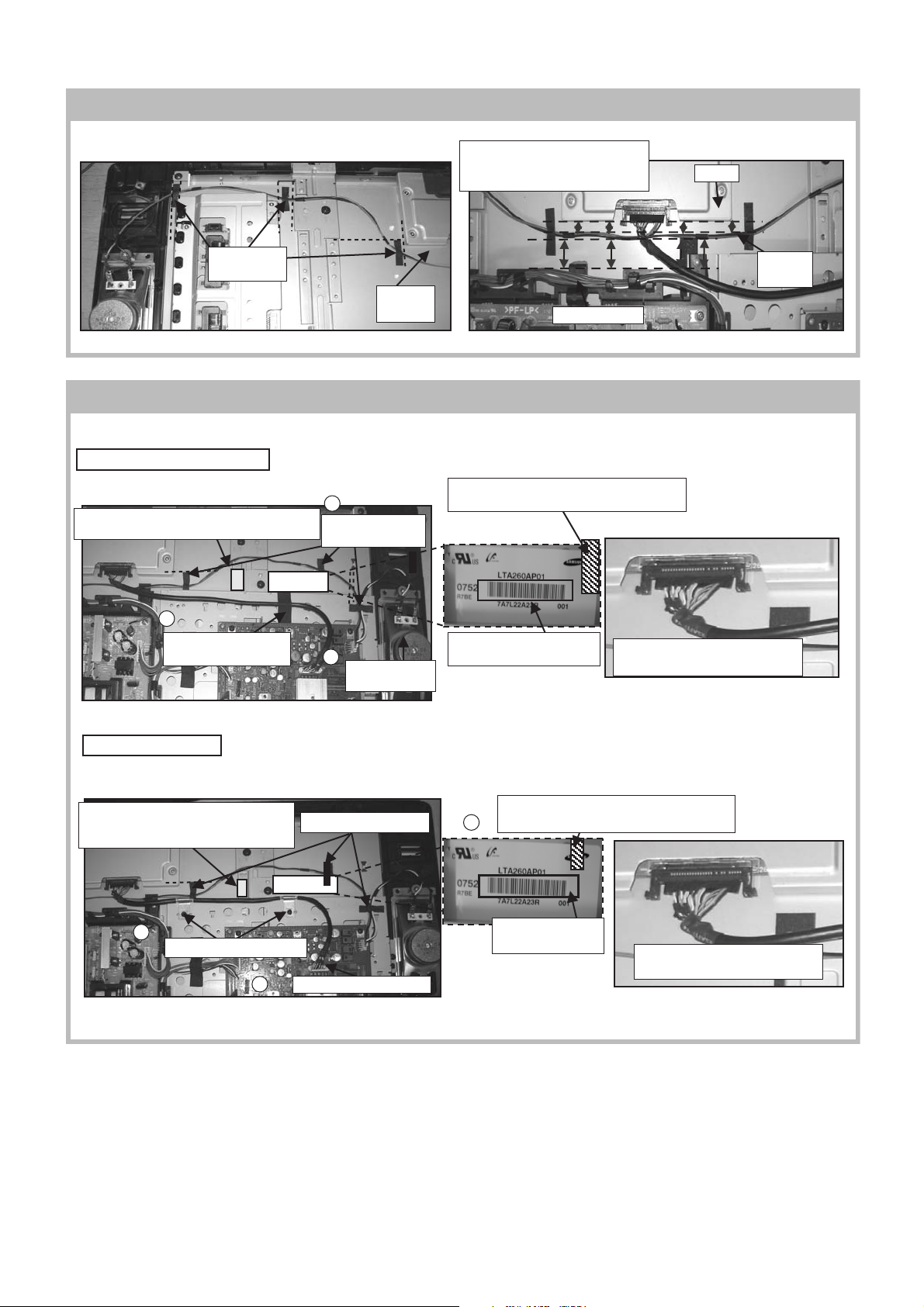

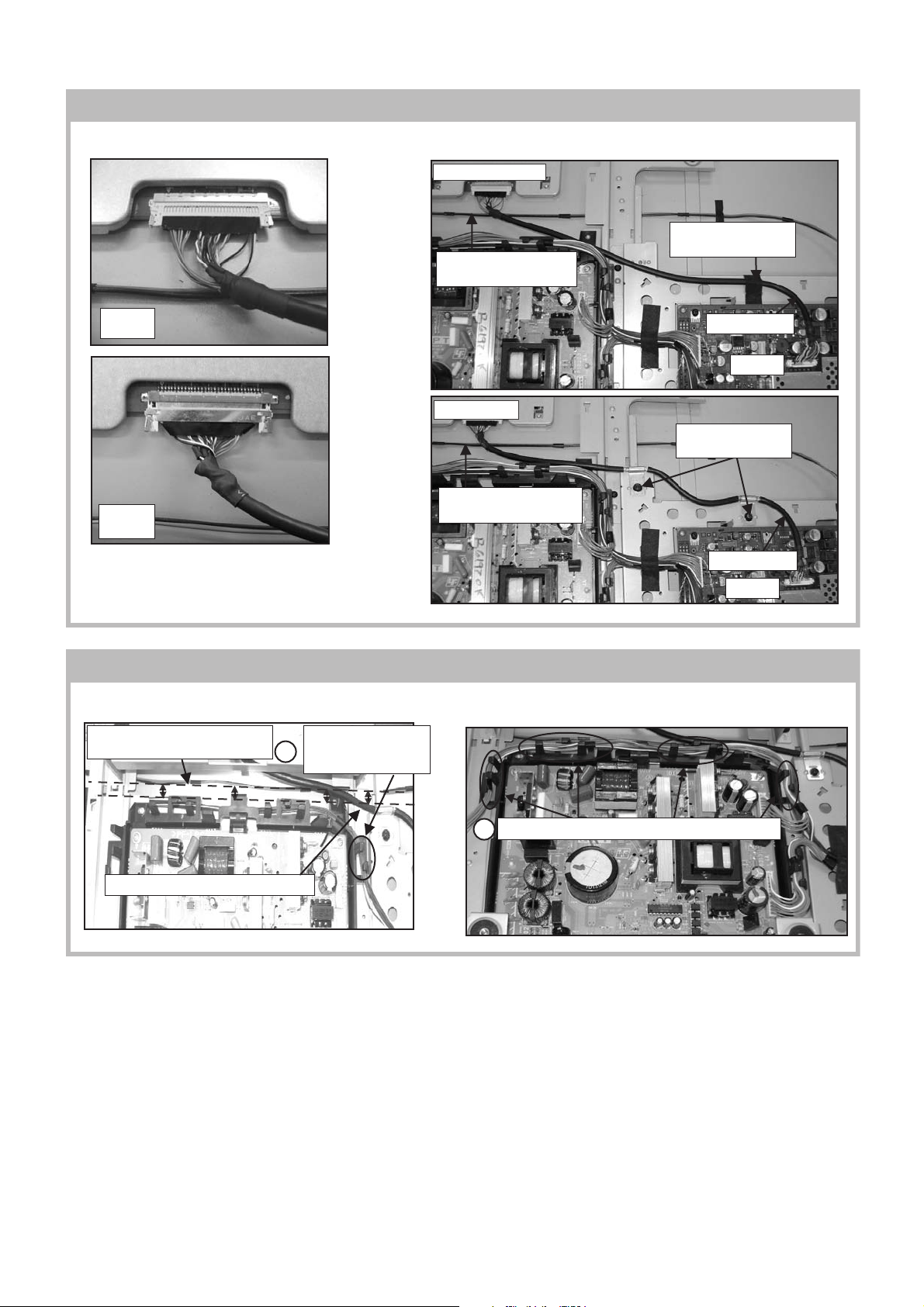

4-1-8. LVDS Harness and SP Connector Assy 4P Dressing

See steps below for LVDS harness and SP Connector Assy 4P wire dressing.

KLV-26T400A Non-CISPR model

When attaching Tape, LCD, ensure that it

Make sure SP Conn Assy 4P is above this

area as Vesa Frame will be assembled later

1

Attach Tape, LCD

(X3)

covers and hides the SAMSUNG logo

Assy 4P and:

Conn Assy 14P

T-CON

SP Conn

Assy 4P

3

Attach Sheet Core, C

to LVDS harness

26T400A CISPR model

See steps below for LVDS harness and SP Connector Assy 4P wire dressing.

Make sure SP Conn Assy 4P is above

this area as Vesa Frame will be

assembled later

3

Screw earth clamps (X2)

2

2

Connect LVDS

harness

Attach Tape LCD (X3)

Connect LVDS harness

Be careful not to cover the

1

cover the bar code

Note: When inserting LVDS harness to panel, make sure it is fully

inserted and in the correct direction as shown.

bar code

Note: When inserting LVDS harness to panel,

make sure it is fully inserted and in the correct

direction as shown.

When attaching Tape, LCD, ensure that it

covers and hides the SAMSUNG logo

Be careful not to

Make sure LVDS harness is fully

inserted in direction as shown

Make sure LVDS harness is fully

inserted with direction as shown

– 12 –

4-1-9. SP Connector Assy 4P Dressing for KLV-26T400G

SP Connector Assy 4P wire dressing for 26T400G model as below.

KLV-26T400A, T400G, 32T400A

RM-GA013

Keep distance between SP

SP Conn Assy

4P

Attach Tape, LCD (3X)

Conn Assy 4P and:

T-CON, Conn Assy 14P

Conn Assy 14P

4-1-10 LVDS Harness and SP Connector Assy 4P Dressing for KLV-26T400G

See steps below for LVDS harness and SP Connector Assy 4P wire dressing.

Make sure SP Conn Assy 4P is above

this area as Vesa Frame will be

assembled later

Attach Sheet Core, C

3

to LVDS harness

Attach Tape LCD (X3)

1

When attaching Tape, LCD, ensure that it covers

and hides the SAMSUNG logo

T-CON

SP Conn Assy

4P

2

Caution: Dress wires downward towards the panel and bezel.

Ensure capacitor does not touch tweeter or any conductive parts.

4

Attach Tape LCD (X1)

to wire and panel

Connect LVDS harness

5

Attach Tape LCD (X1)

to wire and panel

Be careful not to cover

the bar code

Make sure LVDS harness is fully

inserted with direction as shown

Note: When inserting LVDS harness to panel,

make sure it is fully inserted and in the

correct direction as shown.

4-1-11. Dressing of Connector Assy 14P 4-1-12. Dressing of Connector Assy 14P,

Dress Connector Assy 14P into G1 bracket's hook (4X) as shown.

Connector

Assy 10P

1) Dress Connector Assy 13P into G1 bracket's hook as shown.

2) Align Connector Assy 14P and Connector Assy 13P together

and dress them using Sheet Core, C.

Common for all 26T400 models

Assy 13P and Connector

Connector Assy 14P

Dress Conn Assy 14P into

G1 bracket's hook (4X)

– 13 –

Connector Assy 13P

Connector Assy 10P

Dress Conn Assy 14P and

Conn Assy 13P using Sheet,

2

1

Dress Conn Assy 13P into G1 bracket's hook (1X)

KLV-26T400A, T400G, 32T400A

RM-GA013

4-1-13. AC Power Cord Wire Dressing

1) Install the AC power cord with holder into AC cord bracket.

2) Dress the AC power cord wire pin, wire A6101.

Non-CISPR model

Dress AC power cord

with pin, wire A6101

2

AC cord bracket

CAUTION:

1. Ensure that AC power cord is not stressed

whilst inserting it into AC cord bracket.

Install AC power cord with

1

holder into AC cord bracket

4-1-14. AC Power Cord Wire Dressing at Rear Cover

CISPR model

1) Install the AC power cord with holder into AC cord bracket.

2) Dress the AC power cord using Sheet Core, C on to main bracket.

3) Dress the AC power cord wire pin, wire A6101.

Dress AC Power Cord using Sheet

2

Core, C on to Main Bracket

No need to attach Sheet

Core, C here

Install AC power

1

Dress AC power cord

3

with pin, wire A6101

cord with holder

into AC cord

bracket

AC cord bracket

Tie the root of the AC

plug.

Hook the AC-band to

the rear cover.

– 14 –

4.2 (KLV-32T400)

KLV-26T400A, T400G, 32T400A

RM-GA013

4-2-1. Wire Dressing overview for

Non-CISPR model.

4-2-3. Dressing of Connector Assy 1P

1) Insert Connector Assy 1P to HT PWB's screw hole and bracket

bottom's screw hole as shown.

2) Attach Sheet Core, C (X1) to panel at location of Connector

Assy 10P.

Conn Assy 10P

Use dowel

as guide to

attach Conn

Assy 1P

1

Conn Assy 1P

2

Attach

Sheet

Core, C to

pane

is above Conn

Assy 1P

45º

4-2-2. Wire Dressing overview for CISPR model.

4-2-4. SP Connector Assy 4P Dressing

1) See steps 1 ~ 3 below for SP Connector Assy 4P wire dressing.

Use datum lines as reference

1

Attach Tape, LCD (3X).

Ensure wires go around

inverter board.

Use datum lines as reference

Use datum lines

as reference

Use datum line as reference

2

HT PWB

Bracket,

Bottom

SP Conn Assy 4P

SP Conn Assy 4P

is below Frame,

Spine

SP Conn Assy 4P is below Frame, Spine

Use datum lines as reference

3

Attach Tape, LCD (2X)

– 15 –

KLV-26T400A, T400G, 32T400A

RM-GA013

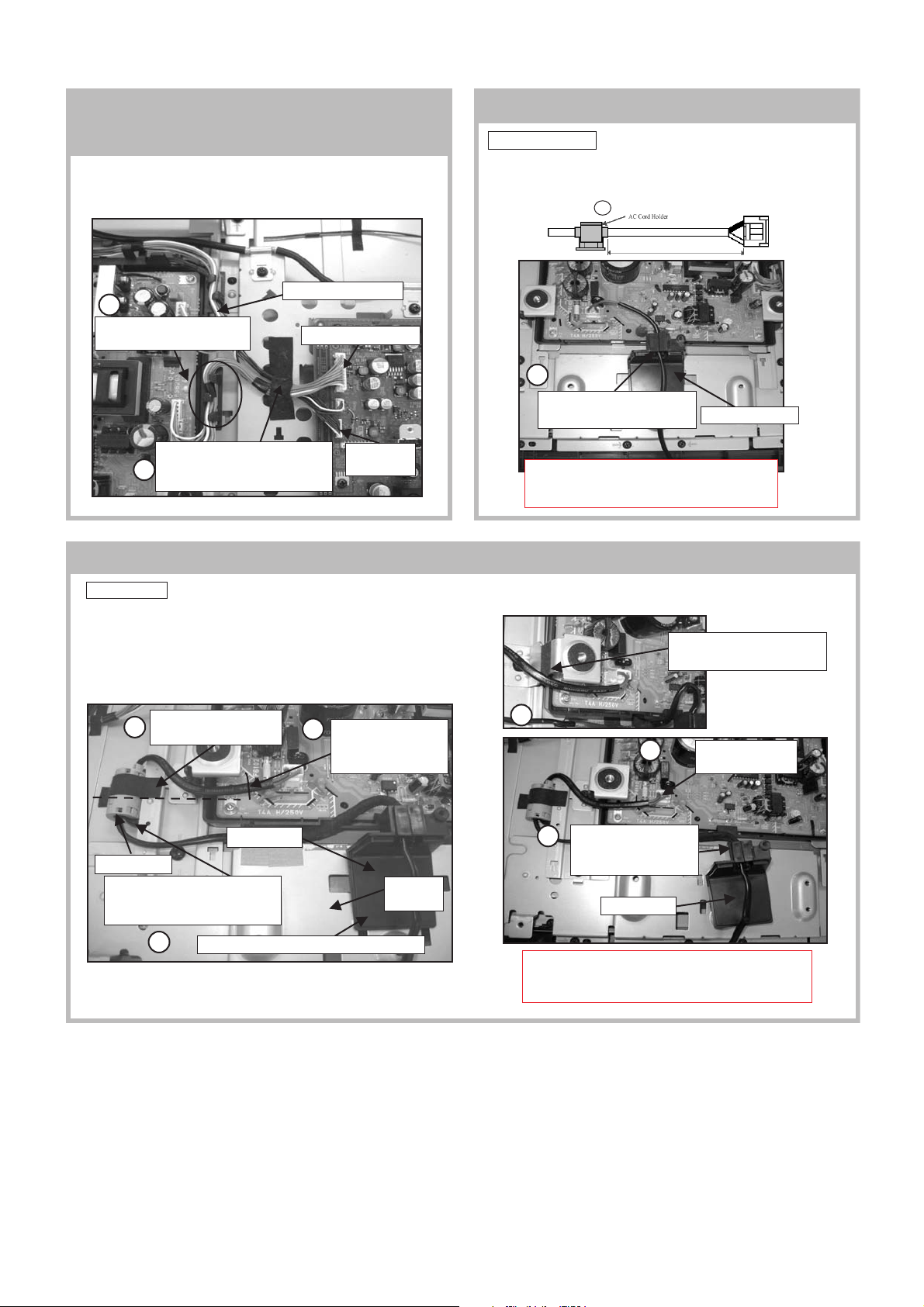

4-2-5. AC Power Cord Wire Dressing (Before

installing G1 Bracket with GPT PWB) for CISPR Models.

1) Install Ferrite core to AC power cord at specified position as shown.

2) Attach Tape, Shield (X2) on to specified position.

3) Next, wrap Sheet Core, E around area of Tape, Shield on AC power cord, to cover it.

4) Finally, install AC cord holder to AC power cord at specified position.

5) Attach Tape, Shield to AC power cord (X2) at specified position.

6) Attach Sheet Core, C to overlap the two Tape, Shields.

This is to prevent the Tape, Shields from peeling off.

Tape, Shield (X2)

Ferrite Core

140± 5mm

2

Tape, Shield (X2)

1

Ferrite Core

285± 5mm

AC Cord Holder

Sheet Core, E

6

Make sure it overlaps the Tape, Shields.

5

Attach Tape, Shield to AC Power Cord (X2)

Use edge of Inverter board's cover and AC power cord

connector as a guideline for placement of power cord

360 ± 5mm

CISPR models only

Attach Sheet Core, C to Tape, Shields.

CISPR models only

4-2-6. Dressing of Connector Assy 10P and 14P

3

Wrap Sheet Core, E around area of Tape,

Shield on AC Power Cord, to Cover it

4

When installing AC cord holder, make sure

the Sheet Core, E area is clamped as well

Portion of AC Power Cord with Sheet Core, E

Attach Tape, LCD to Connector Assy 10P and Connector Assy 14P as shown.

Dress Conn Assy 10P

below Frame, Spine

Attach Tape, LCD

(2X)

Use datum lines as an indication for attaching

Tape, LCD to Connector Assy 10P

– 16 –

Attach Tape, LCD (1X)

Use datum lines as an

indication for attaching

Tape, LCD to

Connector Assy 14P

4-2-7. LVDS Harness Dressing

See steps below for LVDS harness and SP Connector Assy 4P wire dressing.

Non-CISPR model

SP Conn Assy 4P below

LVDS harness

KLV-26T400A, T400G, 32T400A

RM-GA013

Attach Sheet Core, C

to LVDS harness.

OK

CISPR model

SP Conn Assy 4P below

LVDS harness

LVDS harness

CN3000

Screw earth clamps

(2X)

NG

Note: When inserting LVDS harness to panel, make sure it is

fully inserted and in the correct direction as shown.

4-2-8. Dressing of Connector Assy 10P and Connector Assy 14P on G1 Bracket

1) Dress Connector Assy 10P into G1 bracket's hook (1X) as shown. 2) Next, dress Connector Assy 14P into G1 bracket's hook (4X).

Keep distance between Conn

Assy 10P and SP Conn Assy 4P

Dress Conn Assy

10P into G1 bracket's

1

hook (1X)

LVDS harness

CN3000

Conn Assy 10P is below G1 bracket

– 17 –

Dress Conn Assy 14P into G1 bracket's hook (4X)

2

KLV-26T400A, T400G, 32T400A

RM-GA013

4-2-9. Dressing of Connector Assy 14P,

Connector Assy 13P and Connector

Assy 10P

1) Dress Connector Assy 13P into G1 bracket's hook as shown.

2) Align Connector Assy 14P, Connector Assy 10P and Connector

Assy 13P together and dress them using Sheet Core, C.

1

Dress Conn Assy 13P into

G1 bracket's hook (1X)

Dress Conn Assy 14P, Conn

Assy, 10P and Conn Assy 13P

2

using Sheet, Core, C

Connector Assy 14P

Connector Assy 13P

Connecto

Assy 10P

4-2-10. AC Power Cord Wire Dressing

Non-CISPR model

1) Install AC cord holder to AC power cord at specified position as

shown.

2) Then install the AC power cord with holder into AC cord bracket.

80 ± 5mm

2

Install AC power cord with

holder into AC cord bracket

CAUTION:

1. Ensure that AC power cord is not stressed

whilst inserting it into AC cord bracket.

AC cord bracket

4-2-11. AC Power Cord Wire Dressing

CISPR model

1) Attach Sheet Core, C to Vesa Frame Bottom (32).

2) Insert AC power cord into CN6102.

3) Install the AC power cord with holder into Bracket, AC.

4) Then, install Bracket, AC into Bracket, Bottom.

5) Attach Sheet Core, C to Ferrite Core.

6) Lastly, dress AC power cord using pin, wire A6101 as shown.

Attach Sheet Core, C

5

to Ferrite Core

Bracket, AC

Ferrite, Core

AC Cord that is looped around

Ferrite Core is inserted under

Frame, Spine

4

Install Bracket, AC into Bracket, Bottom

6

Dress AC power

cord using pin, wire

A6101

Bracket,

Bottom

Attach Sheet Core, C

to Vesa Frame Bottom (32)

1

2

Install AC power cord

3

CAUTION:

1. Ensure that AC power cord is not stressed whilst

inserting it into AC Cord bracket.

with holder into

Bracket, AC

Bracket, AC

Insert AC power

cord to CN6102.

– 18 –

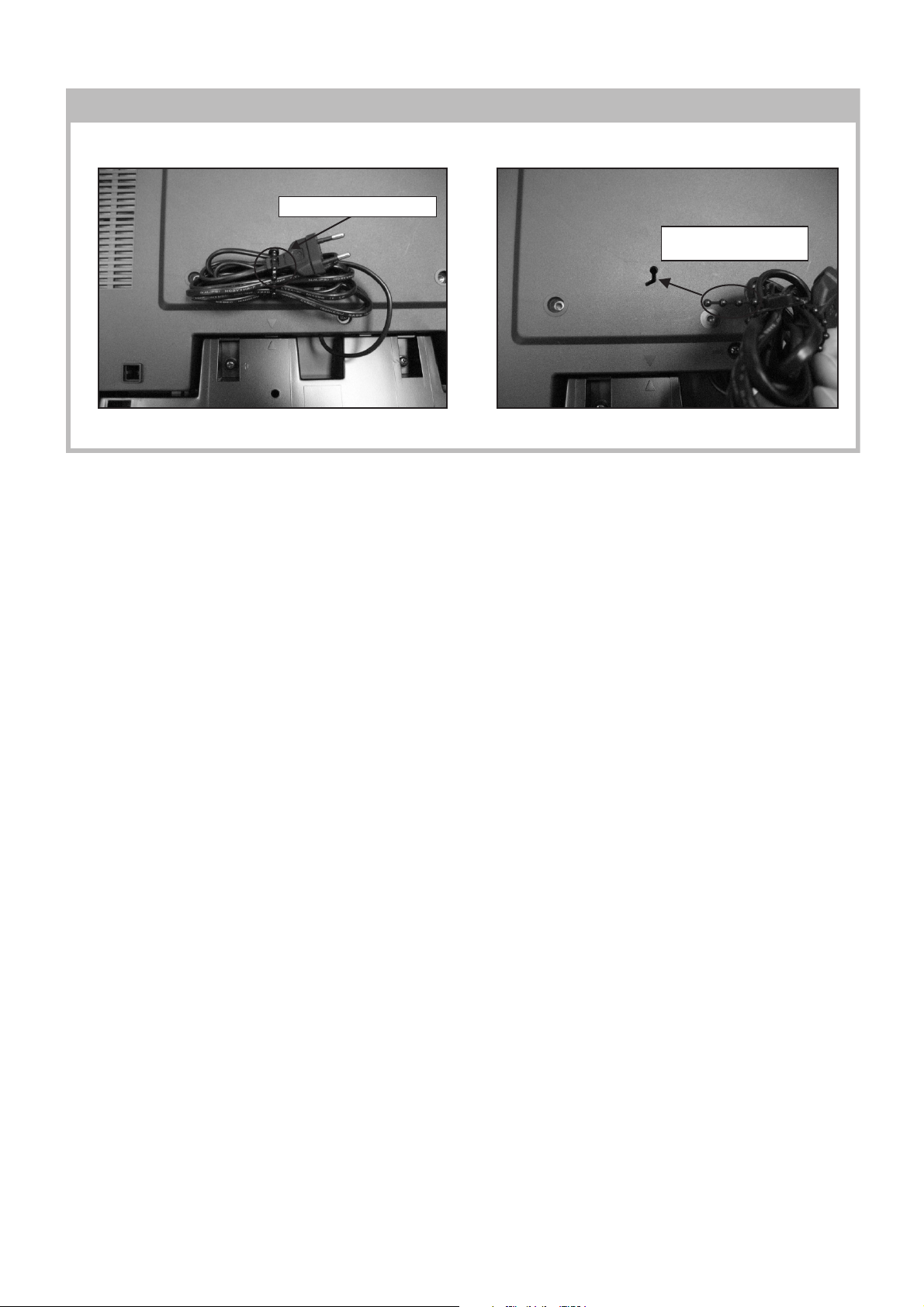

4-2-12. AC Power Cord Wire Dressing at Rear Cover

Tie the root of the AC plug.

KLV-26T400A, T400G, 32T400A

RM-GA013

Hook the AC-band to the

rear cover.

– 19 –

KLV-26T400A, T400G, 32T400A

n

RM-GA013

SECTION 5

SERVICE ADJUSTMENTS

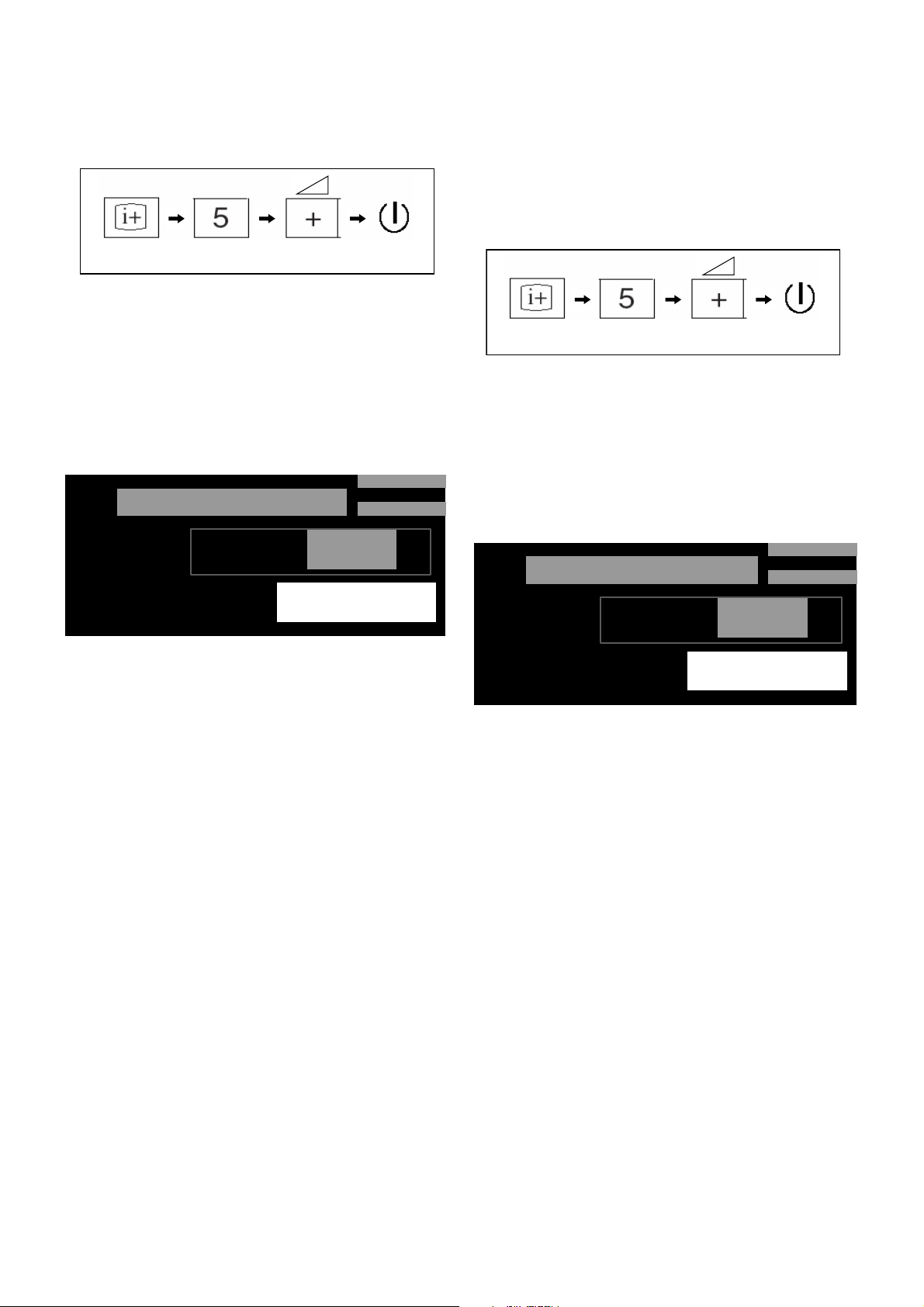

5-1. Accessing Diagnostic Menu

1. While TV set on standby, press the following sequence on

the Remote commander (RMGA013).

On screen

display

Channel 5

Volume (-)

POWER

The following menu will appear on the screen

MAIN_POWER_ERROR

5V_POWER_ERROR

AUDIO_ERROR

BALK_LIGHT_ERROR

TEMP_ERROR

0

0

0

0

0

Figure 1

2. To quit the diagnostic menu, turn off and on the set.

5-2. Viewing the Service Mode Display

1. While TV on standby mode, press the following sequence

on the Remote commander.

5-3. Control keys via Remote Commander.

Buttons on the Remote Commander to access the service

menu items and adjust the data values.

5-4. Adjustment Method

5-4-1. Aging

On screen

display

Channel 5 Volume (+)

POWER

(if wrong key is pressed or passed 3 seconds during each

process, cancel entering the self-diagnosis display.)

Example on screen display:

T V S E R V I C E

0 0 0 B M E

0 0 0 W P R _ 2 5 5

L O C T O P P R O G R A M :

G T V : M R 1 . 0 . 2

N V M : T D 0 . 1 0 0

Categry Item

[Category/Item name] Withi n 17

characters

W

W

[Data] Within 7 characters

C

TM0 . 0 7 0

PROGRAM: Show the Application version

GTV: Show the GTV Library version

NVM: Show the NVM version in the NVM data

(4bytes ASCII data)

2. To reset, press 8 – 0 – .

3. To Exit, press the <I/1> key .

1. While TV on standby mode, press the following sequence

on the Remote commander.

On screen

display

Channel 5 Volume (+)

POWER

2. Select AGING with 2 or 5 On the Remote Commander.

3. Select AGING MODE with 1 or 4 On the Remote

Commander.

4. Select data value with 3 or 6 On the Remote

Commander to 1 to enable. Refer to Service Items

(Table 1) page 17

5. Press <I/1> to exit.

6. When exit it will have the new data value and start aging.

7. Aging condition:

a) Supply voltage : Rating

b) Time: More than 20 minutes

c) Ambient Temp: 22-28 degrees

d) Input : Set no signal except digital and analog

RF(Video/Component/PC)

Example on screen display:

T V

0 0 0

0 0 0

L O C T O P

A G I N G

A G I N G

M O D E

P R O G R A M :

G T V :

N V M :

T M 0 . 0 7 0

M R 1 . 0 . 2

T D 0 . 1 0 0

S E R V I C E

1

PROGRAM: Show the Application versio

GTV: Show the GTV Library version

NVM: Show the NVM version in the NVM data

(4bytes ASCII data)

– 20 –

KLV-26T400A, T400G, 32T400A

n

n

RM-GA013

5-4-2. Resetting the User Menu- Factory Reset

1. While TV on standby mode, press the following sequence

on the Remote commander.

On screen

display

Channel 5 Volume (+)

POWER

2. Select SERVICE with 2 or 5 On the Remote

Commander.

3. Select AUTO SET FACTORY with 1 or 4 On the Remote

Commander.

4. Select data value with 3 or 6 On the Remote

Commander to 0 to current condition. Refer to

Service Items (Table 1) page 17

5. Press <I/1> to exit.

Example on screen display:

T V

0 0 0

0 0 0

L O C T O P

S E R V I C E

A U T O G S E T F A C T O R Y

P R O G R A M :

G T V :

N V M :

T M 0 . 0 7 0

M R 1 . 0 . 2

T D 0 . 1 0 0

PROGRAM: Show the Application versio

GTV: Show the GTV Library version

NVM: Show the NVM version in the NVM data

(4bytes ASCII data)

S E R V I C E

0

5-4-3. White Balance Adjustment

Test Pattern:

a) Connect video signal of white to video input

b) Restort to original value : Color temp=0,

Picture=Max,Brightness=50,Backlight=max

1. While TV on standby mode, press the following sequence

on the Remote commander.

On screen

display

Channel 5 Volume (+)

POWER

2. Select WB with 2 or 5 On the Remote Commander.

3. Select WPR_C with 1 or 4 On the Remote Commander.

4. Select data value with 3 or 6 On the Remote

Commander.

5. Press <I/1> to exit.

Note: Refer to Service Items (Table 1) page 17 for other item

and data value.

Example on screen display:

T V

0 0 0

0 0 0

L O C T O P

W B

W P R _ C

P R O G R A M :

G T V :

N V M :

T M 0 . 0 7 0

M R 1 . 0 . 2

T D 0 . 1 0 0

S E R V I C E

2 5 5

PROGRAM: Show the Application versio

GTV: Show the GTV Library version

NVM: Show the NVM version in the NVM data

(4bytes ASCII data)

– 21 –

KLV-26T400A, T400G, 32T400A

RM-GA013

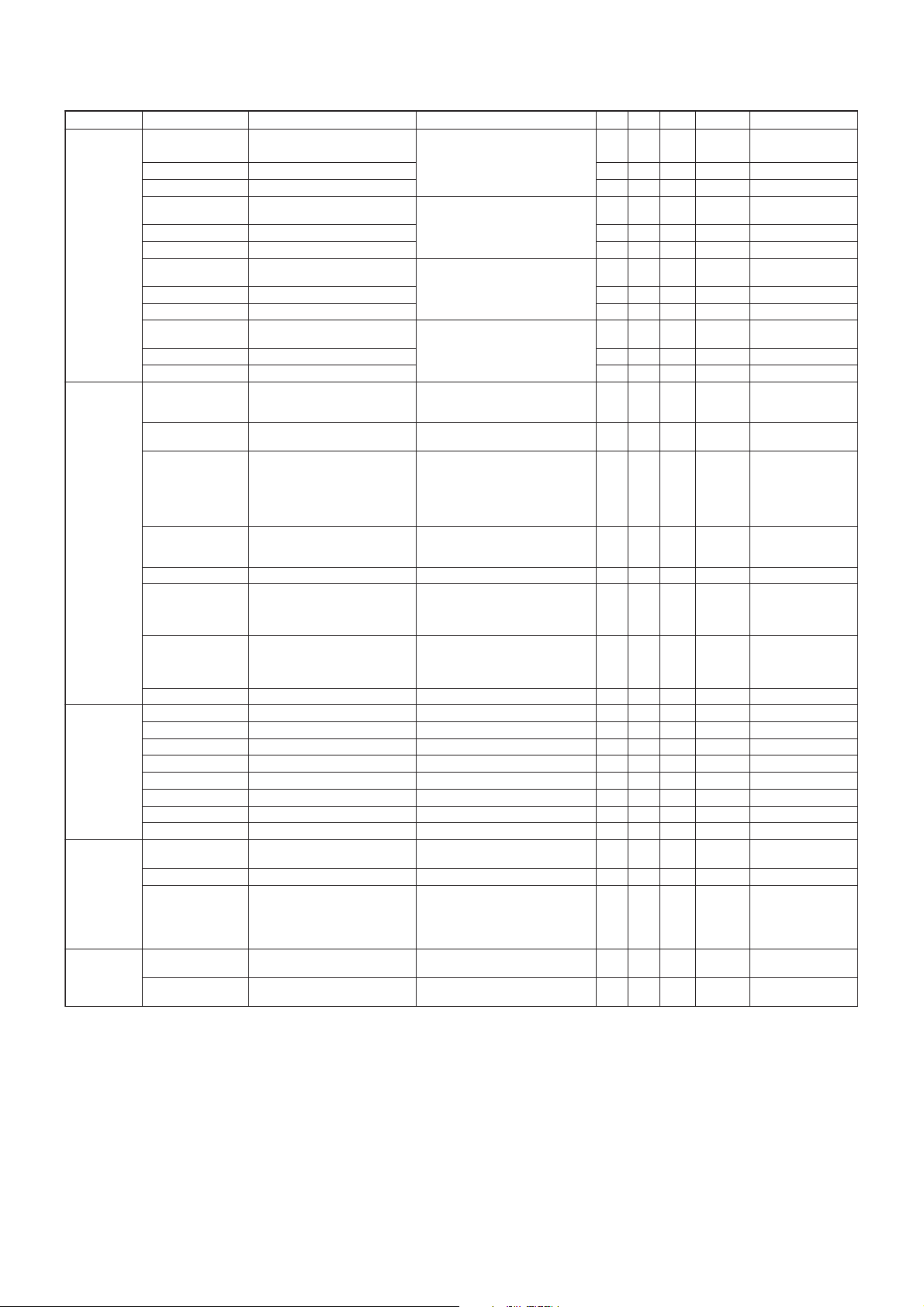

5-5. Table 1

yrogetaCmetInoitpircseDskrameRtibniMxaMlaitinI

CRPWlooCroftnemtsujdaRB/W

CGPWlooCroftnemtsujdaGB/W 80 552eulavJDA

CBPWlooCroftnemtsujdaBB/W 80 552eulavJDA

NRPWlooCroftnemtsujdaRB/W

NGPWlooCroftnemtsujdaGB/W 80 552eulavJDA

BW

ECIVRES

GNIGA

SUTATS

NBPWlooCroftnemtsujdaBB/W 80 552eulavJDA

1WRPW1mraWroftnemtsujdaRB/W

1WGPW1mraWroftnemtsujdaGB/W 80 552eulavJDA

1WBPW1mraWroftnemtsujdaBB/W 80 552eulavJDA

2WRPW2mraWroftnemtsujdaRB/W

2WGPW2mraWroftnemtsujdaGB/W 80 552eulavJDA

2WBPW2mraWroftnemtsujdaBB/W 80 552eulavJDA

METSYSGNINUT

ETUMLANGISON

YROTCAFTESOTUA

CGACIMSfo)nip66(TUOCGAfolortnoC

D2decroF"tnerruC"dna"D2"tceleS 10 10x00 D2:1,tnerruC:0

TPADAMVOnoitatpadanoitarudom-revoMF

WBTLIF.htiwdnabretlifreirracdnuoS

CDAnoitarbilacotuaDA.laCDA1010x00 CDAotuatratS:1

1RES1rebmuNlaireS XEDNI1RAHCONNOISREVYNOS80FFx0eulavJDA

2RES2rebmuNlaireS XEDNI2RAHCONNOISREVYNOS80FFx0eulavJDA

3RES3rebmuNlaireS XEDNI3RAHCONNOISREVYNOS80FFx0eulavJDA

4RES4rebmuNlaireS XEDNI4RAHCONNOISREVYNOS80FFx0eulavJDA

NOITCUDORP

5RES5rebmuNlaireS XEDNI5RAHCONNOISREVYNOS80FFx0eulavJDA

6RES6rebmuNlaireS XEDNI6RAHCONNOISREVYNOS80FFx0eulavJDA

7RES7rebmuNlaireS XEDNI7RAHCONNOISREVYNOS80FFx0eulavJDA

8RES8rebmuNlaireS XEDNI8RAHCONNOISREVYNOS80FFx0eulavJDA

EDOMGNIGAedomgnigAXEDNI_ELBANE_GNIGA_VRPA1010

EMITGNIGAemiteripxegnigAXEDNIEMITGNIGAVRPA80FFx00

ROLOCGNIGArolocgnigAXEDNI_RUOLOC_GNIGA_VRPA80FFx00

PMET"ERUTAREPMET"retsiserdaeRedomecivresPXNsaemaS80FFx0

VEL_RETSOOB_GISlevellangisFRroftropD/AdaeR1NIRAS:tropD/A80FFx0

80 552eulavJDA

looCoterutarepmetrolocegnahC

80 552eulavJDA

lartuaeNoterutarepmetrolocegnahC

80 552eulavJDA

1mraWoterutarepmetrolocegnahC

80 552eulavJDA

2mraWoterutarepmetrolocegnahC

.XIFmetsys"VT"

.etumoiduafoFFO/NO

.langis

"M"ro"I"ro"KD"ro"GB"ro"otuA"

tceles,langisonsiFRnehW

yrotcafteserpdna,yrotcafatceleS

revOekaTCGA

siatadlaitinI

1:I/KD/GB

0:M

1:oidaR

siatadlaitinI

1:I/KD/GB

0:M

1:oidaR

teehsdnasgniwollofehtotrefeR

"YROTCAFTESOTUA"

.eulavtnemtsujdasieulavlaitinI

30 80x00

10 1 0 NO:1,FFO:0

30 80x00

.noitcudorpybtsujdasieulavsihT

80 FFx0eulavJDA

10 10x0

20 30x0

,M:4,I:3

TTS:3

VSS:4

esuoN:-5

tnerruc

noitidnoc

tnerruc

noitidnoc

tnerruc

noitidnoc

tnerruc

noitidnoc

elbasiD:0

elbanE:1

worraN:0

muideM:2

ediW:3

elbasiD:0

elbanE:1

kcalB:0

etihW:1

deR:2

neerG:3

eulB:4

,KD:2,GB:1,otuA:0"

"esuoN:_5

noitidnoctnerruc:0

)HTRON(MEOS:1

)HTUOS(MEOS:2

ediwartxE:1

5-6. Board & Panel Replacement

When replacing the BT board and Panel readjust

the W/B.

– 22 –

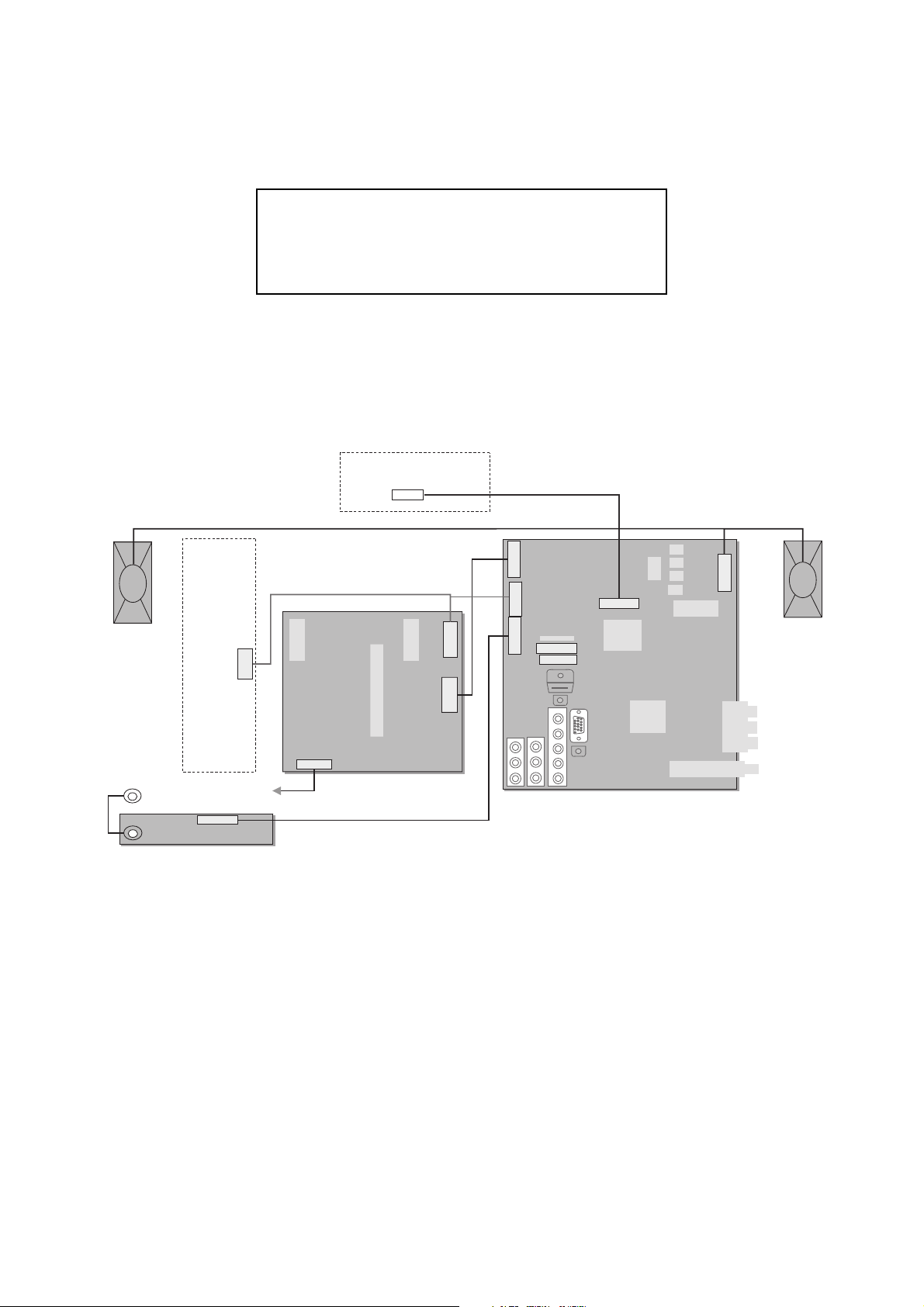

6-1. BLOCK DIAGRAM

CN6202(13

)

R

Due to complexity of the board, performing

component level field repairs are not recommended.

Complete board replacement is required if service is

necessary.

6-2. CONNECTOR DIAGRAM

6-2-1 (KLV-26T400)

T-CON

CNF1(40)

KLV-26T400A, T400G, 32T400A

RM-GA013

SECTION 6

DIAGRAMS

LVDS

Speaker R

Ground

INVERTE

AC Power

CN1000(10)

CN1(14)

HT

GPT

CN6102(3)

Key, SIRCS, LED

Power, Standby, Audio VCC, Main VCC

24V, Inv Err, BL, Dimmer

Speaker L, R

CN7000(11)

CN7001(4)

CN6201(8)

CN3001(10)

ECS

CN3002(18)

CN3003(4)

BT

CN2000(4)

CN3000(40)

Speaker L

– 23 –

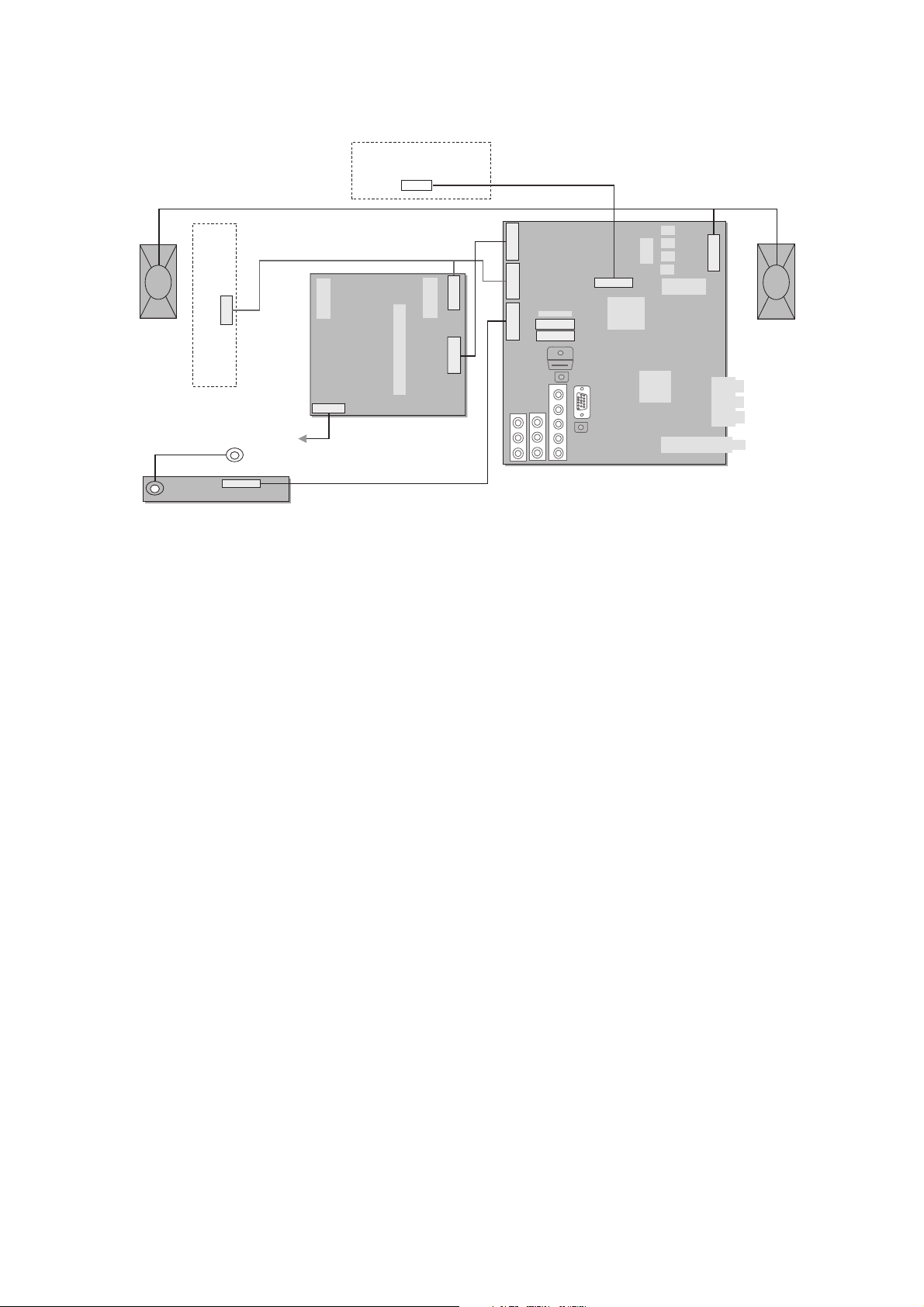

KLV-26T400A, T400G, 32T400A

R

RM-GA013

6-2-2 (KLV-32T400)

Speaker R

CN1(14)

INVERTE

24V, Inv Err, BL, Dimmer

GPT

CN6102(3)

T-CON

CNF1(40)

Power, Standby, Audio VCC, Main VCC

CN6201(8)

13)

CN6202(

Speaker L, R

CN7000(11)

CN7001(4)

CN3001(10)

LVDS

ECS

CN3002(18)

CN3003(4)

BT

CN2000(4)

CN3000(40)

Speaker L

Ground

CN1000(10)

AC Power

Key, SIRCS, LED

HT

– 24 –

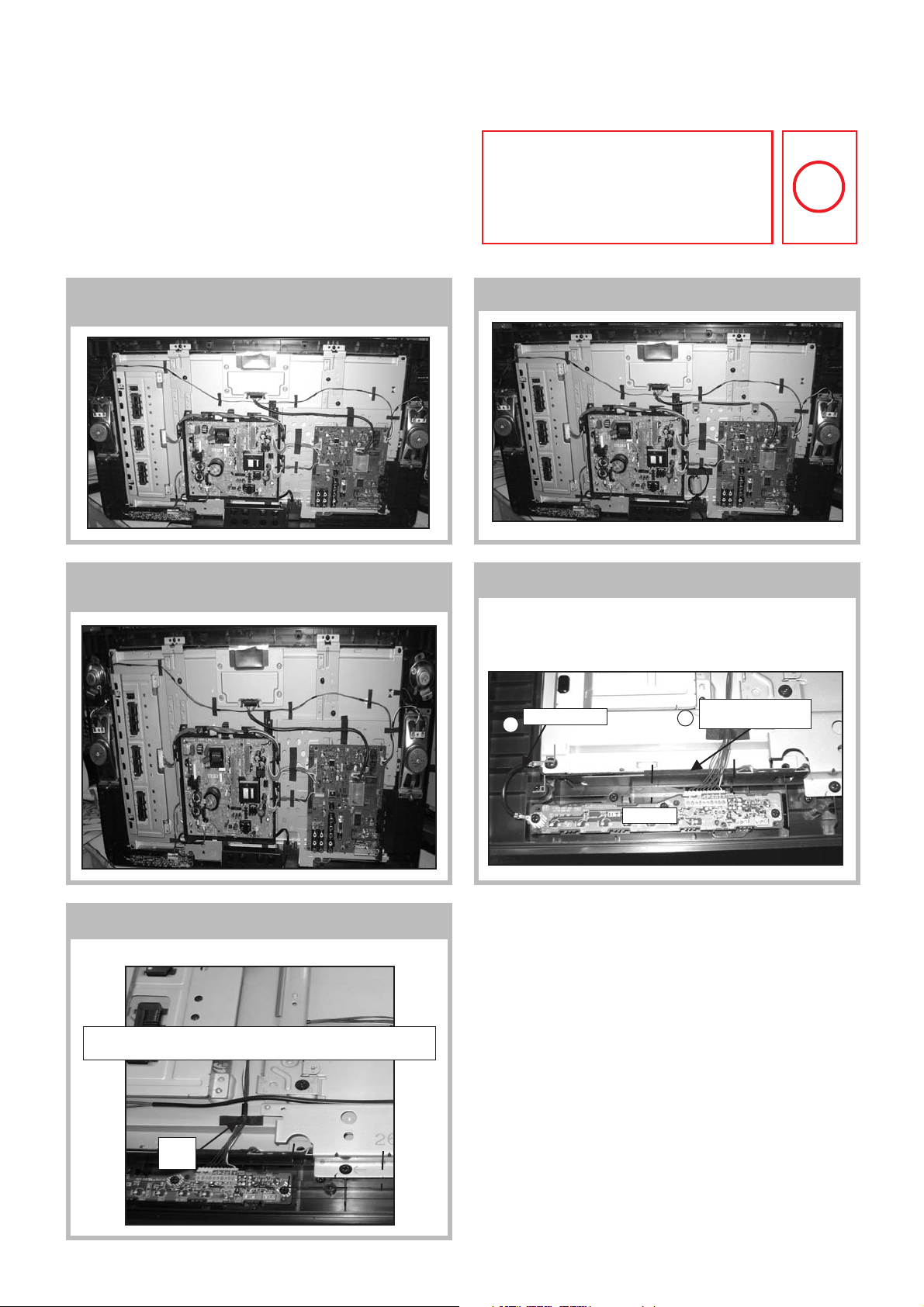

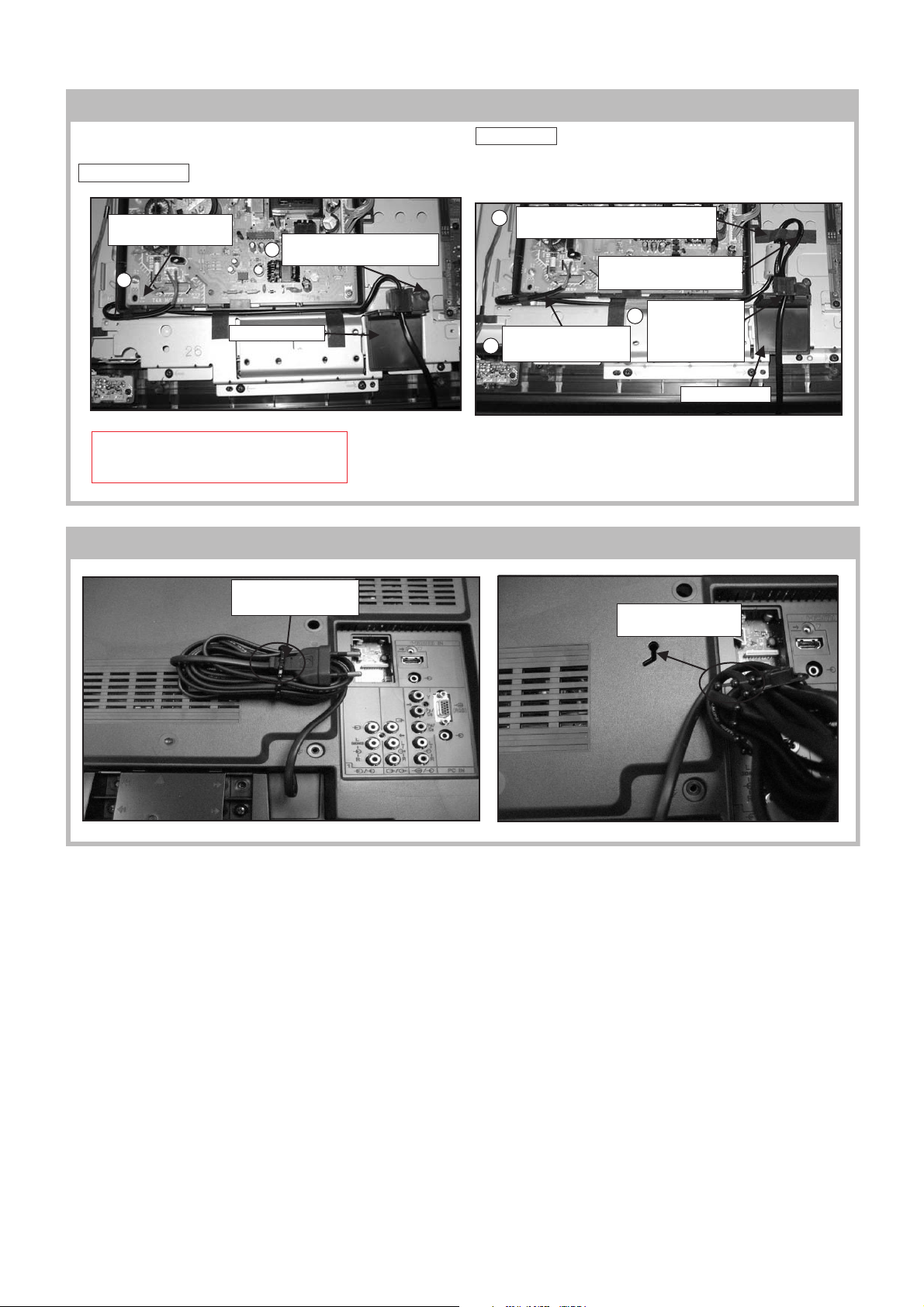

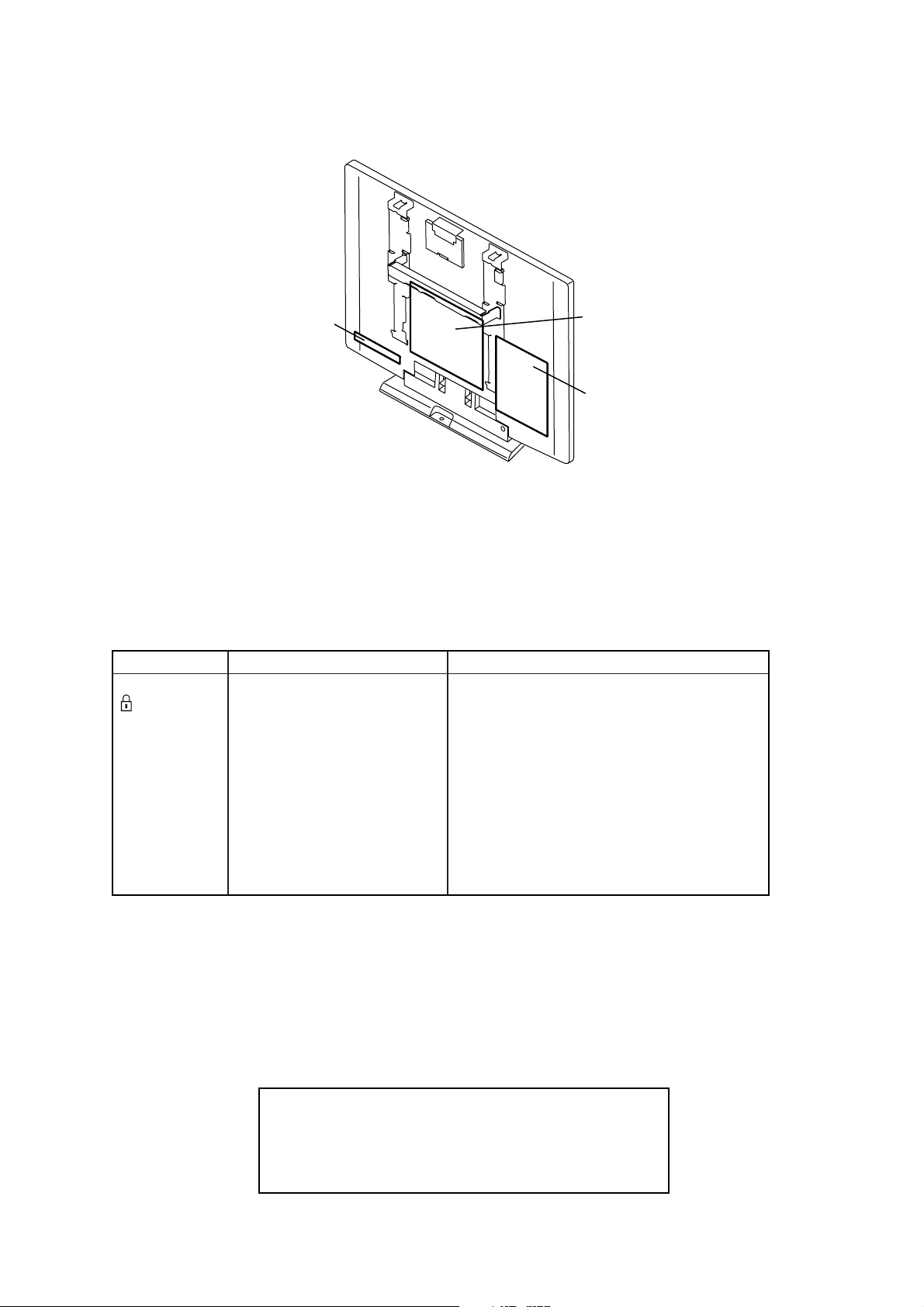

6-3. CIRCUIT BOARD LOCATION

(KLV-26T400, 32T400)

KLV-26T400A, T400G, 32T400A

RM-GA013

HT Board

GPT Board

BT Board

6-4. SCHEMATIC DIAGRAM 6-5. PRINTED WIRING BOARDS

Board Function Note

BT

GPT

I/O, AV INPUT/OUTPUT, HDMI,

PC,I, HP/AUDIO/LOC TOP/DDR/

POWER DC/ TUNER.FM.IF/

AV SWITCH.SMIC

Power Supply

Due to complexity of the board, performing

component level field repairs are not

recommended. Complete board

replacement is required if service is

necessary.

Therefore schematic diagrams and

HT

Key / LED / SIRCS

printed wiring boards are not included.

For part number information, refer to

Exploded View or Electrical Parts List

section in this manual.

6-6. SEMICONDUCTOR

Due to complexity of the board, performing

component level field repairs are not recommended.

Complete board replacement is required if service is

necessary.

– 25 –

KLV-26T400A, T400G, 32T400A

RM-GA013

SECTION 7

EXPLODED VIEWS

• Components not identified by a part

number or description are not stocked

because they are not required for routine

service.

NOTE: The components identified by shading and ! mark are

critical for safety. Replace only with part number specified.

Note: The components identified by mark contain

confidential information. Strictly follow the instructions

whenever the components are repaired and /or replaced.

• The component parts of an assembly

are indicated by the reference numbers

in the far right column of the part list and

within the dotted lines of the diagram.

(KLV-26T400)

7-1-1. REAR CABINET

a

f

b

• Item marked with an asterisk (*) are not

stocked since they are seldom required

for routine service. Some delay should

be anticipated when ordering these

components.

a 2-580-591-01 SCREW, +PSW M3X5

b 2-580-600-01 SCREW, +PSW M4X8

c 2-580-608-01 SCREW, +PSW M5X16

d 2-580-626-01 SCREW, SP 4-4O UNC

e 2-580-629-01 SCREW, +BVST 3X8

f 2-580-640-01 SCREW, +BVTP2 4X16

g 2-580-644-01 SCREW, +KTP2 3X8

h 2-580-649-01 SCREW, +PWTP2 3X12

i 2-580-650-01 SCREW, +PWHTP2 3X16

j 2-580-654-01 SCREW, +PWTP2 4X16

k 2-674-965-31 SCREW, +PSW 3SG

l 4-046-797-01 SCREW (3X12), (+)BVTAP

m 7-685-648-79 SCREW +BVTP 3X12 TYPE2 IT-3

m

f

f

2

f

1

3

i

4

– 26 –

REF. NO. PART NO. DESCRIPTION REMARK

1 X-2190-757-1 REAR COVER (TG26) ASSY (26A)

X-2320-128-1 REAR COVER ASSY (26G)

2*3-106-086-01 COVER, ECS

3 X-2190-754-1 STAND (M) ASSY

4 4-103-599-21 EMBLEM, SONY NO.7

7-1-2. POWER CORD, AC CORD HOLDER

!

!

KLV-26T400A, T400G, 32T400A

RM-GA013

52

51

50

REF. NO. PART NO. DESCRIPTION REMARK

50 ! 1-835-128-11 POWER SUPPLY CORD

(WITH CONNEC (26A (NZ))

1-835-136-11 POWERSUPPLYCORD(WITHCONNECTER)

(26A (E,GE,ME,SAF), 26G (E, GE, ME))

1-835-280-11 POWERSUPPLYCORD(WITHCONNECTOR)

(26A (ID), 26G (ID))

51 4-022-115-00 HOLDER, AC CORD

52 1-500-386-11 FILTER, CLAMP (26A (NZ))

– 27 –

KLV-26T400A, T400G, 32T400A

RM-GA013

7-1-3. BT, HT, GPT BOARD

m

102

103

m

m

f

104

b

e

e

f

b

f

b

f

b

b

101

b

k

REF. NO. PART NO. DESCRIPTION REMARK

101 A-1553-047-A GPT COMPLETE

102 A-1550-333-A HT MOUNT

103 3-452-787-01 GUIDE,LIGHT

104 A-1558-681-A BT MOUNT (SERVICE)

– 28 –

7-1-4. SPEAKER, BEZEL ASSY AND LCD PANEL

150

KLV-26T400A, T400G, 32T400A

RM-GA013

153

150

151

f

f

f

152

REF. NO. PART NO. DESCRIPTION REMARK

150 1-858-037-11 LOUDSPEAKER (13X5.5CM)

151 ! 1-802-706-11 LCD PANEL (26 INCH WXGA TFT)

152 * 1-835-793-11 HARNESS WITH CONNECTOR (LVDS) (26A (NZ))

* 1-835-722-11 HARNESS WITH CONNECTOR (LVDS)

153 X-2190-755-1 BEZEL (TG26) ASSY (26A)

X-2319-390-1 FRONT PANEL (TG26) ASSY (26G)

(except 26A(NZ))

– 29 –

Loading...

Loading...