SONY KE-P37XS1, KE-P42XS1, KDE-P37XS1, KDE-P42XS1, KE-MX42A1 Service Manual

...

MODIFICATION HISTORY

MODEL NAME : KE-P37XS1/P42XS1

SERVICE MANUAL

PARTS No. : 9-878-248-02

* Blue characters are linking.

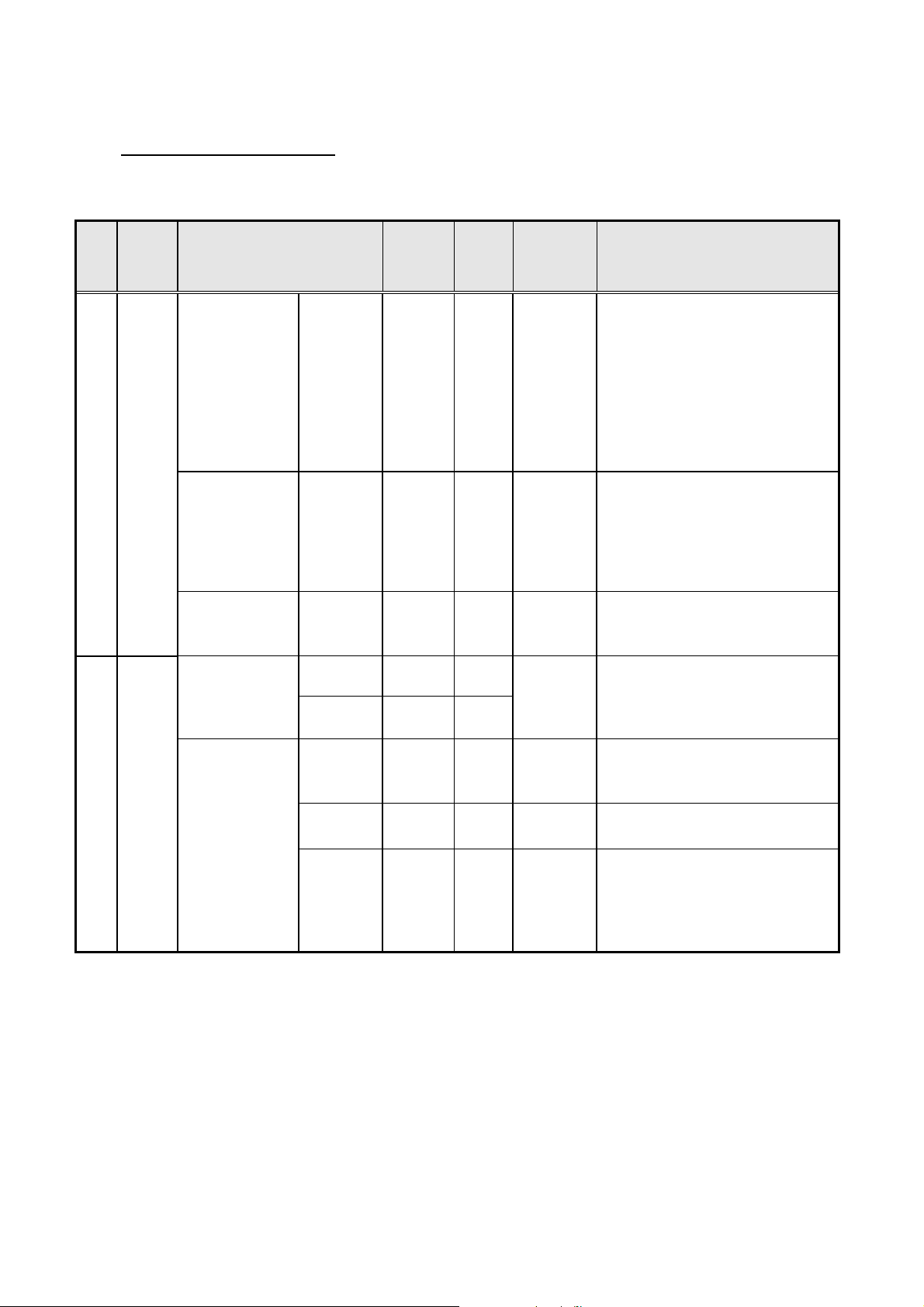

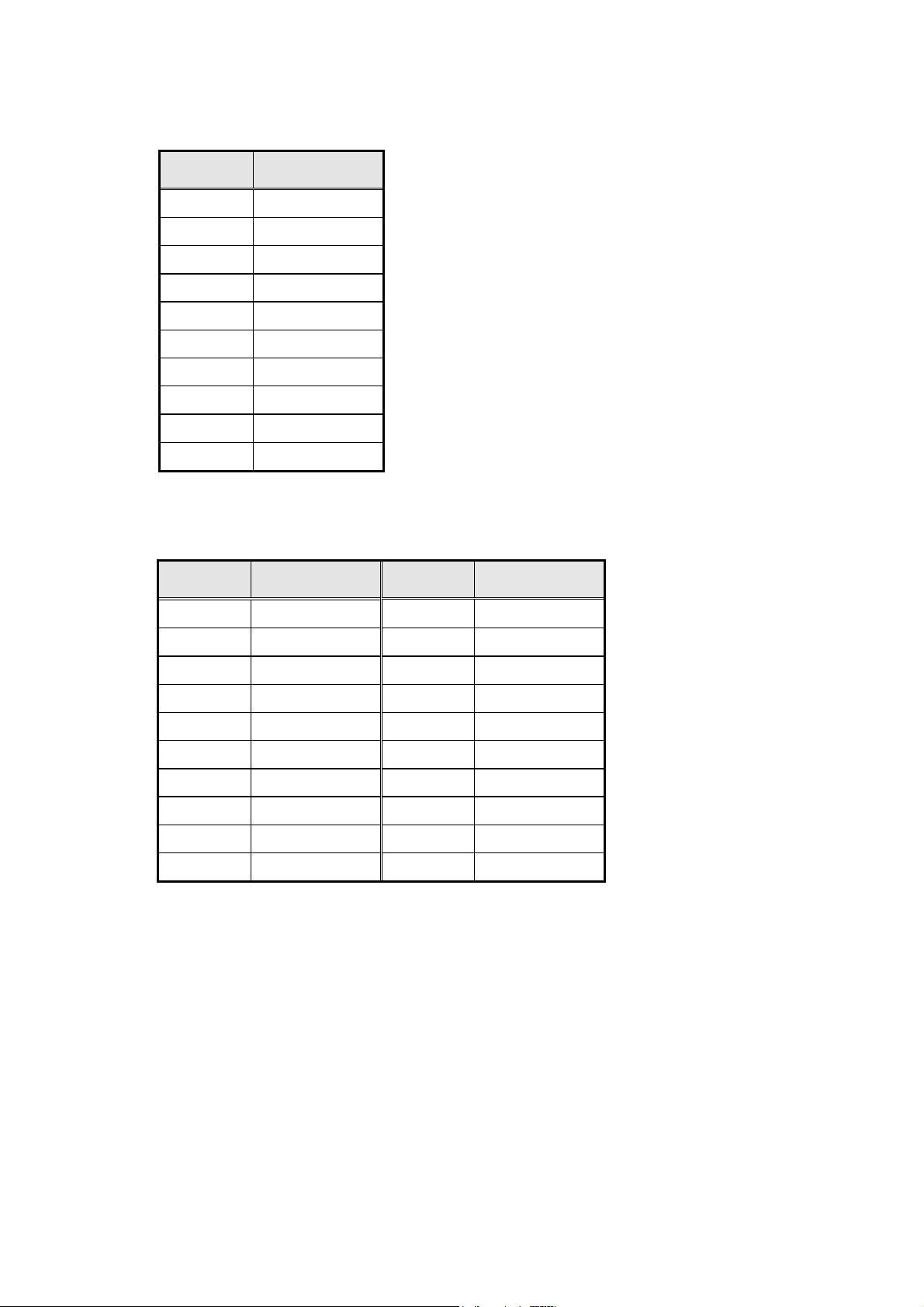

No. DATA CONTENTS

KE-MX42A1/MX42S1/MX42M1

KDE-P37XS1/P42XS1

1

2004. 6 Addition of Hong Kong, ME, China, OCE and UK Models.

Correction of The Parts Information. (P.83)

KE-P37XS1/P42XS1

KDE-P37XS1/P42XS1

KE-MX42A1/MX42S1/MX42M1

PANEL MODULE SERVICE MANUAL

PDP Module Name

FPF37C128128UB

FPF42C128128UC

KE-P37XS1 AEP Model

KE-P42XS1 AEP Model

KDE-P37XS1 UK Model

KDE-P42XS1 UK Model

KE-MX42A1 Hong Kong Model

KE-MX42A1 ME Model

KE-MX42M1 China Model

KE-MX42S1 OCE Model

FLAT PANEL COLOR TV

CONTENTS

1 OUTLINE

1.1 Panel Dimension ................................................................................................................1

1.2 Feature...............................................................................................................................1

1.3 Specification ....................................................................................................................... 2

1.3.1 Functional specification ...............................................................................................2

1.3.2 Display quality specification......................................................................................... 3

1.3.3 I/O Interface Specification............................................................................................ 4

1.3.4 Connector Specifications ............................................................................................. 7

2 SAFETY HANDLING of THE PLASMA DISPLAY

2.1 Notes to Follow During Servicing ..................................................................................... 10

3 NAME and FUNCTION

3.1 Configuration .................................................................................................................... 11

3.2 Block Diagrams ................................................................................................................12

3.2.1 Signal Diagrams ........................................................................................................12

3.2.2 Power Diagrams ........................................................................................................ 13

3.3 Function............................................................................................................................14

3.3.1 Logic board Function .................................................................................................14

3.3.2 Function of X-SUS Board ..........................................................................................23

3.3.3 Function of Y-SUS Board ..........................................................................................23

3.4 Protection function............................................................................................................24

4 PROBLEM ANALYSIS

4.1 Outline of Repair Flow......................................................................................................25

4.2 Outline of PDP Module Repair Flow................................................................................. 26

4.3 Checking the Product Requested for Repair....................................................................29

4.4 Operation Test Procedure ................................................................................................31

4.5 Fault Symptom .................................................................................................................32

4.6 Problem Analysis Procedure............................................................................................ 35

4.6.1 "The entire screen does not light.(Main power is turned off)” Problem analysis

procedure............................................................................................................................35

4.6.2 "Vertical line/Vertical bar" Problem analysis procedure..............................................42

4.6.3 "Horizontal bar" Problem analysis procedure ............................................................46

4.7 Problem Analysis Using a Personal Computer................................................................. 47

4.7.1 Connecting a computer..............................................................................................47

4.7.2 Preparing a computer ................................................................................................47

4.7.3 Problem Analysis Procedure......................................................................................48

5 Disassembling and Reassembling

5.1 Exploded View..................................................................................................................52

5.2 X-SUS Circuit Board Removal/Installation Procedure......................................................53

5.3 Y-SUS Circuit Board Removal/Installation Procedure......................................................55

5.4 ABUS-L Circuit Board Removal/Installation Procedure....................................................57

5.5 ABUS-R Circuit Board Removal/Installation Procedure ................................................... 59

5.6 LOGIC Board Removal/Installation Procedure................................................................. 61

5.7 Complete Panel Chassis Removal/Installation Procedure ............................................... 63

6 Operation Check and Adjustment Method

6.1 List of Check and Adjustment Items.................................................................................66

6.2 Check and Adjustment Method ........................................................................................ 67

6.2.1 Check and adjustment procedure..............................................................................67

6.2.2 Parameter adjustment ...............................................................................................68

6.2.3 Operation performance check items..........................................................................70

6.2.4 Heat Run Test............................................................................................................72

6.2.5 Logic board parameter forwarding.............................................................................74

6.2.6 Accumulation time reset ............................................................................................76

6.2.7 Setup before shipment...............................................................................................77

7 37A1 Mechanical drawing

FPF37C128128UB-63, 73 ................................................................................................78

8 THE PARTS INFORMATION ..................................................................................................83

Scope; 42A1 series

Caution

(Model name; FPF42C128128UC)

Before doing the service operation please be sure to read this service

analysis manual. This module has a lot of devices to secure the safety

against the fire, electric shock, injury and harmful radiation.

To maintain the safety control, please follow the instructions and remarks

described in this service analysis manual.

1 OUTLINE

The module is a plasma display module which can be designed in there is no fan in addition to a

general feature of the plasma display such as a flat type, lightness, and high-viewing-angle and

terrestrial magnetism.

1.1 PANEL DIMENSION

994

921.6

585

522.24

Pixel pitch(horizontal)

0.90mm

R G B

R G B

R G B

R G B

R G B

R G B

R G B

R G B

R G B

R G B

Sub- pixel pitch(horizontal)

0.30mm

R G B

R G B

R G B

R G B

R G B

1.2 FEATURE

1. For high definition television by ALIS method

2. For FAN Less design(Low consumption electric power)

3. Flat type・Lightness

4. Customizing of module equipped with communication function

Pixelpitch(Vertical)

0.51 mm

– 1 –

R G B

R G B

R G B

1.3 SPECIFICATION

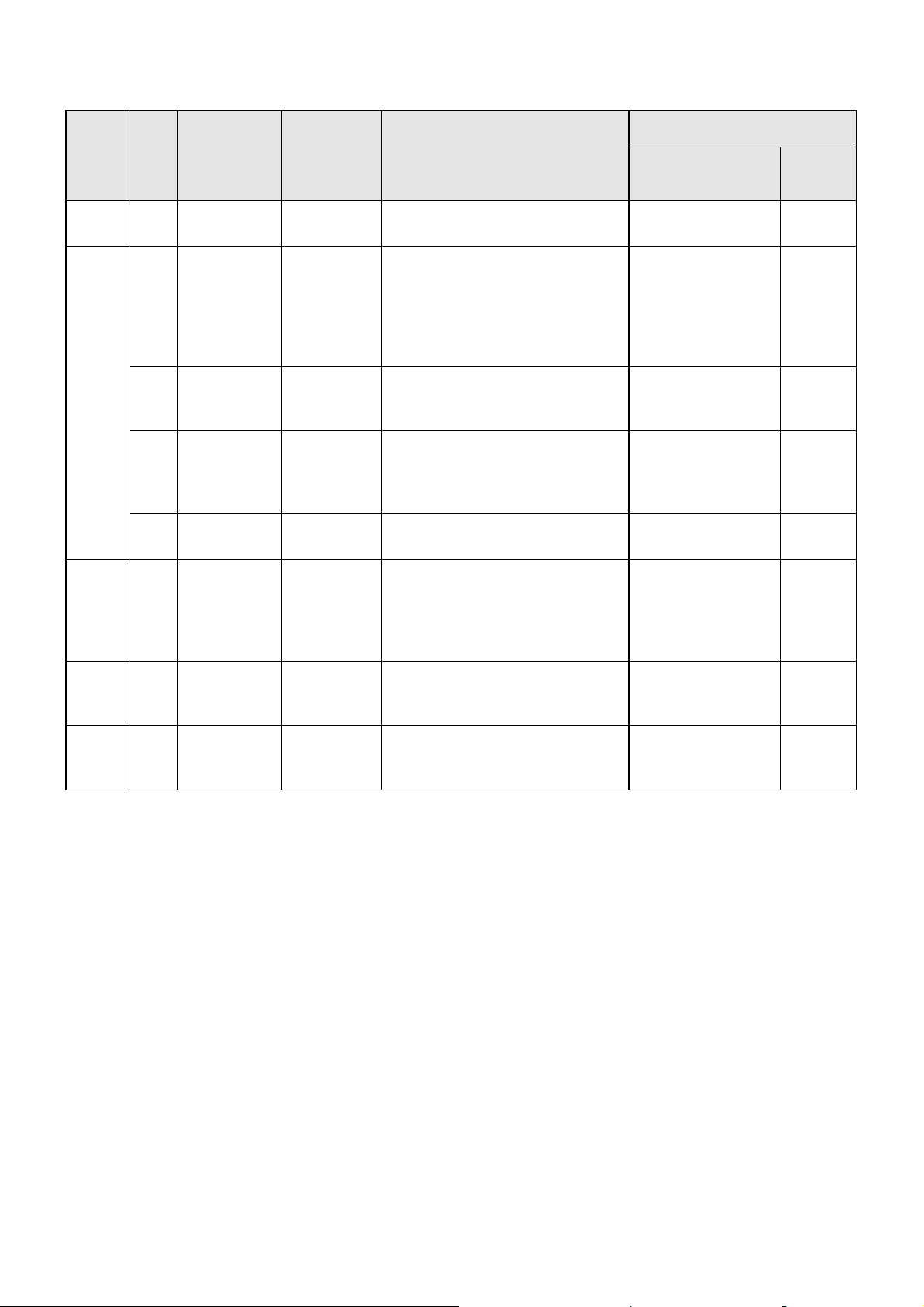

1.3.1

Functional specification

Item NO

Externals

Display panel

Color Grayscale(standard)

BrightNess

Chromaticity

Coordinates

Module size

Weight

Display size

Resolution

Pixel pitch

Sub pixel pitch

White(display load Ratio 100%)

White(display load Ratio 1%,standard)

(x,y)、white 10%

Specification

UC-5X

1 994 × 585 × 66mm

2 16kg

3 921.60 × 522.24mm

(42inch: 16:9)

4 1024 × 1024 pixel

5 0.90(H) × 0.51(V)mm

6 0.30(H) × 0.51(V)mm

7 RGB each color 256 Grayscale

8 140cd/ m2

2

9 (1000) cd/ m

10 (0.300,0.300)

Contrast Contrast in Darkroom(60Hz)

Data signal

Sync Signal

Powersupply

Noise Shade noise at 18dB(A) or less

Guarantee

environment

Video signal (RGB each color)

Dot clock(max)

Horizontal Sync Signal(max)

Vertical Sync Signal

Input voltage/current

Standby electric power(max)

Temperature(operation)

Temperature(storage)

Humidity(operation)

Humidity(storage)

11 (1000:1)

12 LVDS(10bit)

13 52MHz

14 50KHz(LVDS)

15 50Hz ± 1.9 / 60 ± 1.7Hz (LVDS)

16 +3.3/+5/+75-90/+50-65VDC, 0.05/6/4/2A

17 1W

18 25dB(A) or less

19

20

21 20 ~ 85 %RH (no condensation)

22 20 ~ 80 %RH (no condensation)

0 ~ 45 °C

0 ~ 45 °C

*It is made to give priority when there is a delivery specification according to the customer.

– 2 –

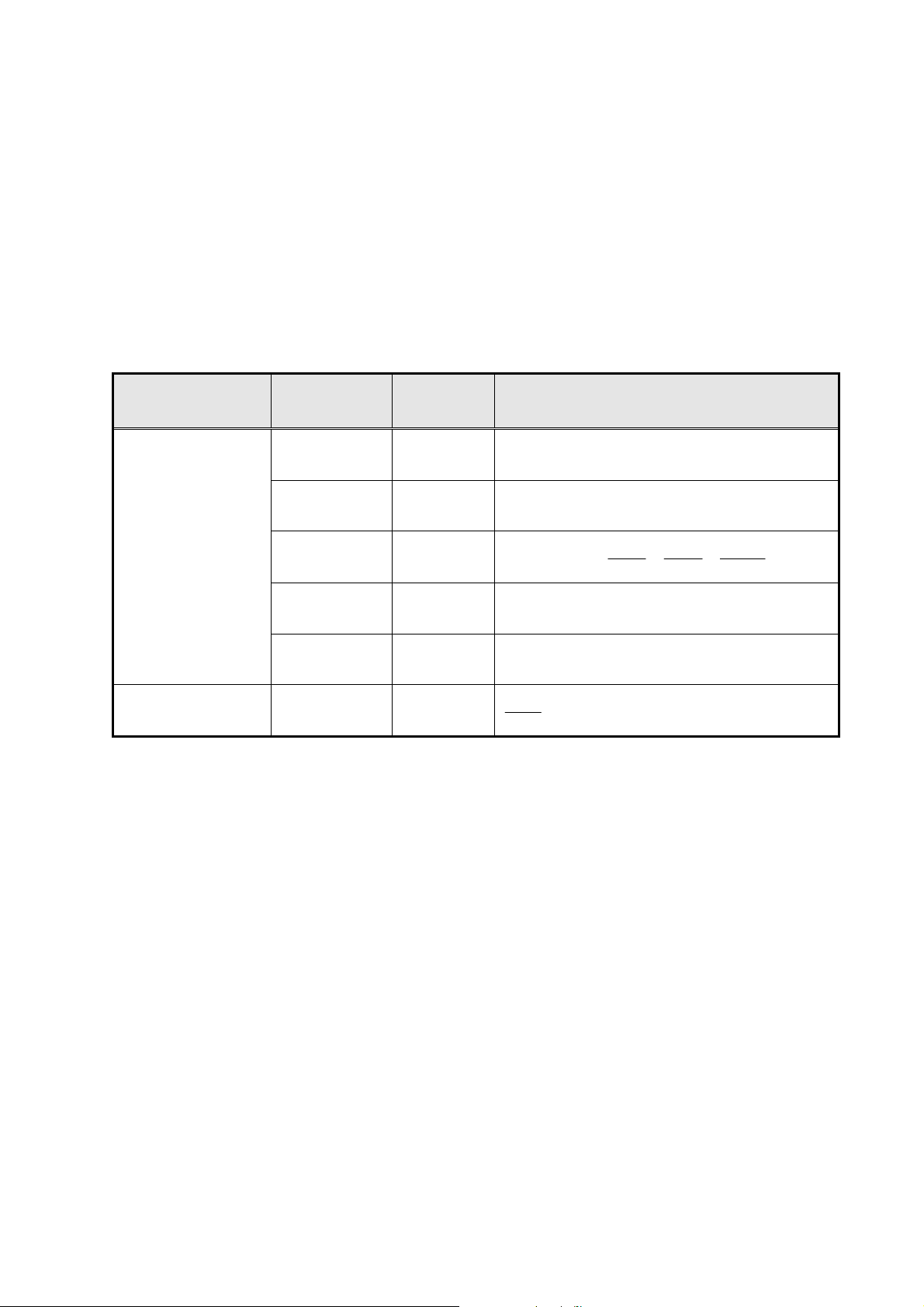

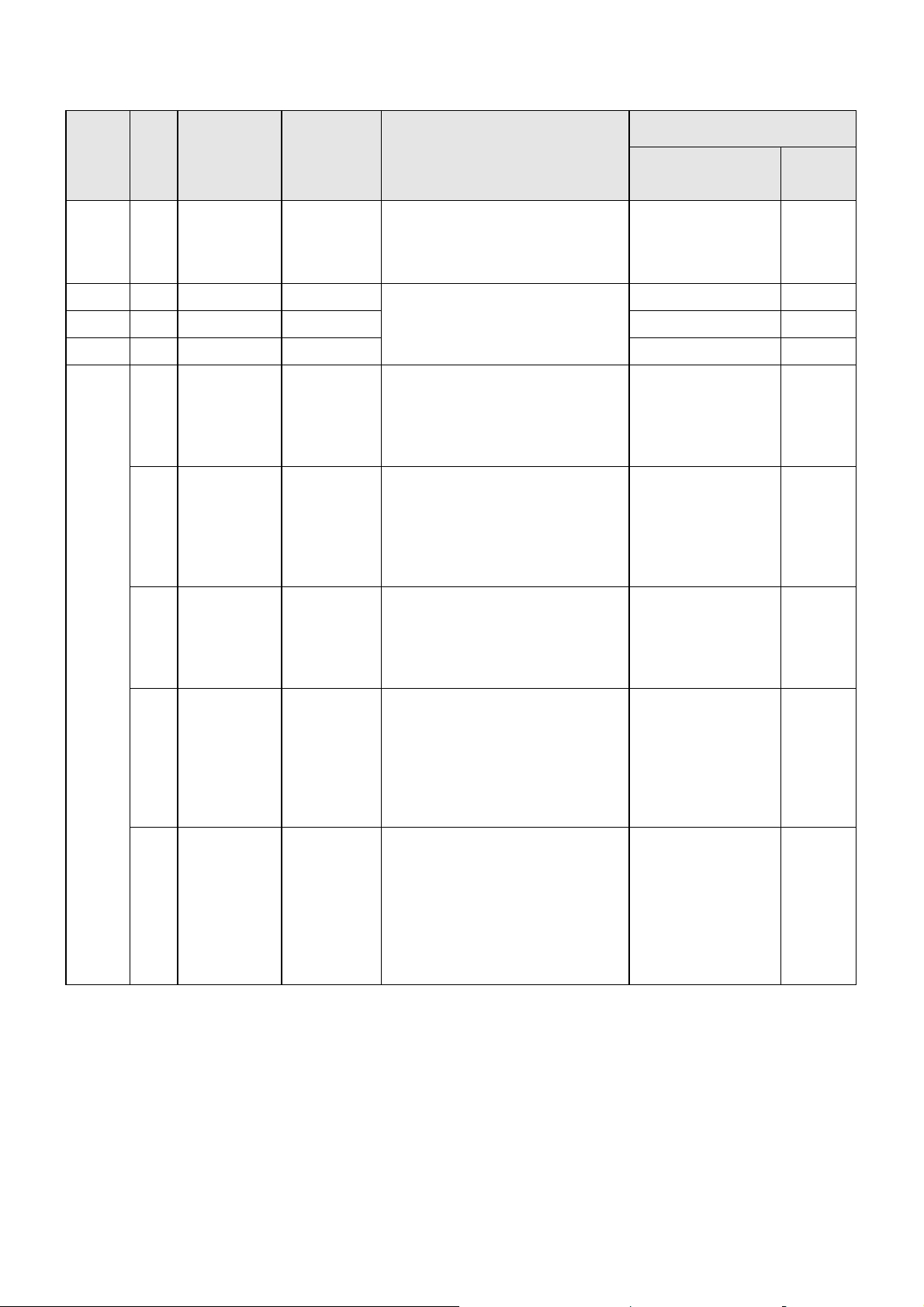

1.3.2

Display quality specification

Non-lighting cell

defect

Non-extinguishing

cell defect

Flickering cell defect

High intensity cell

defect

Item NO

Total number (subpixel)

Density (subpixel/cm2)

Size (H x V) (subpixel)

Total number (subpixel)

Density (subpixel/ cm

Flickering lighting cell defect

(sub pixel/cm

Flickering non-extinguishing cell defect

Twice or more bright point

2

)

2

)

Specification

UC-51 (Standard)

1 15 or less

2 2 or less

(However,1 continuousness or less)

3 1x2 or less, Or 2x1 or less

4

5 Each color 2 cells max

6 5 or less

7 Number on inside of

8 0

6 or less(each color 2 or less)

(

However,1 continuousness or less)

Non-extinguishing cell defect

Brightness variation

Color variation White block of 10% load [9 point]

White block of 10% load [9 point] (%)

In area adjacent 20mm [White] (%)

9 20 or less

10 10 or less

11

X: Average ± 0.015

y: Average ± 0.015

*It is made to give priority when there is a delivery specification according to the customer.

– 3 –

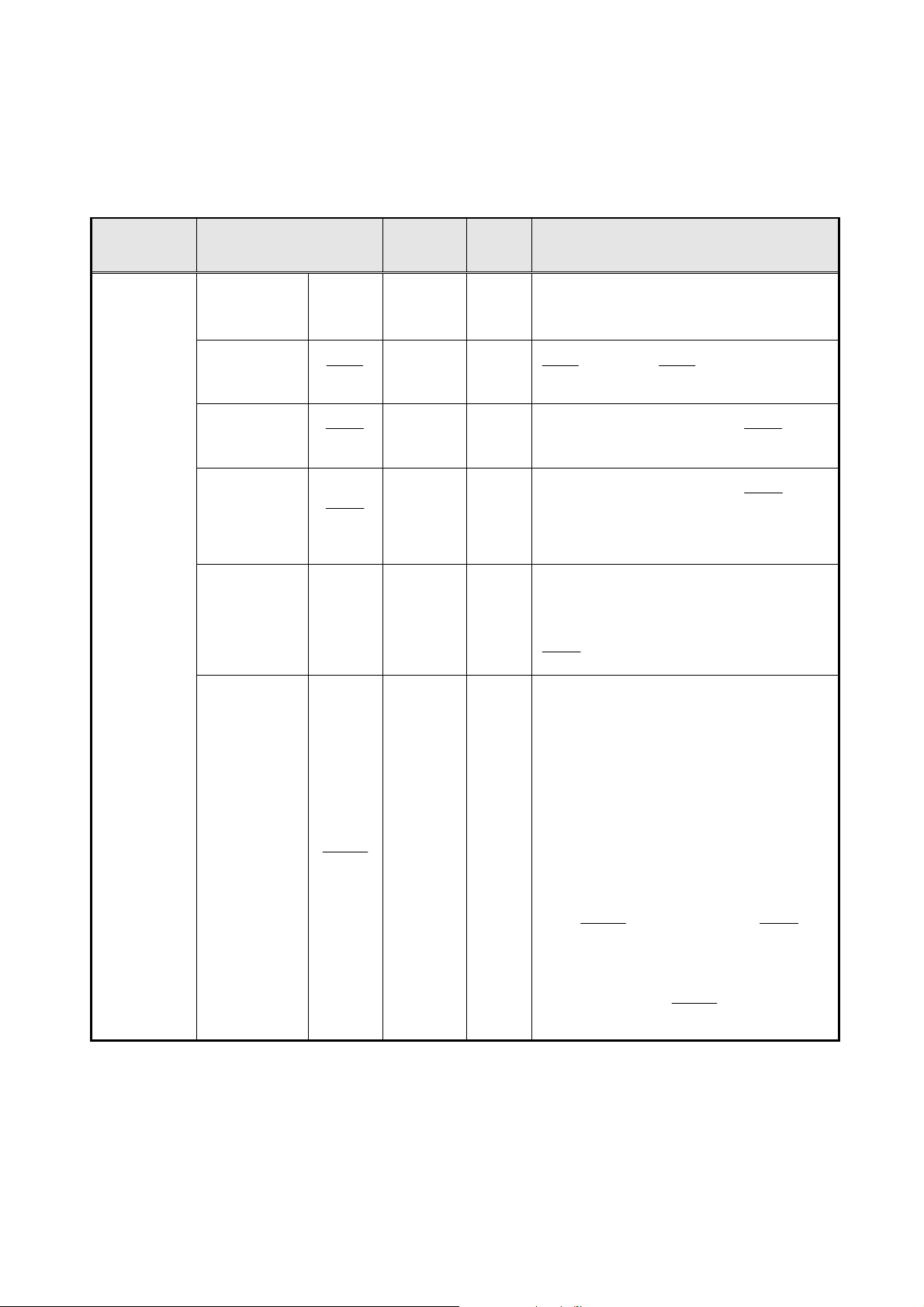

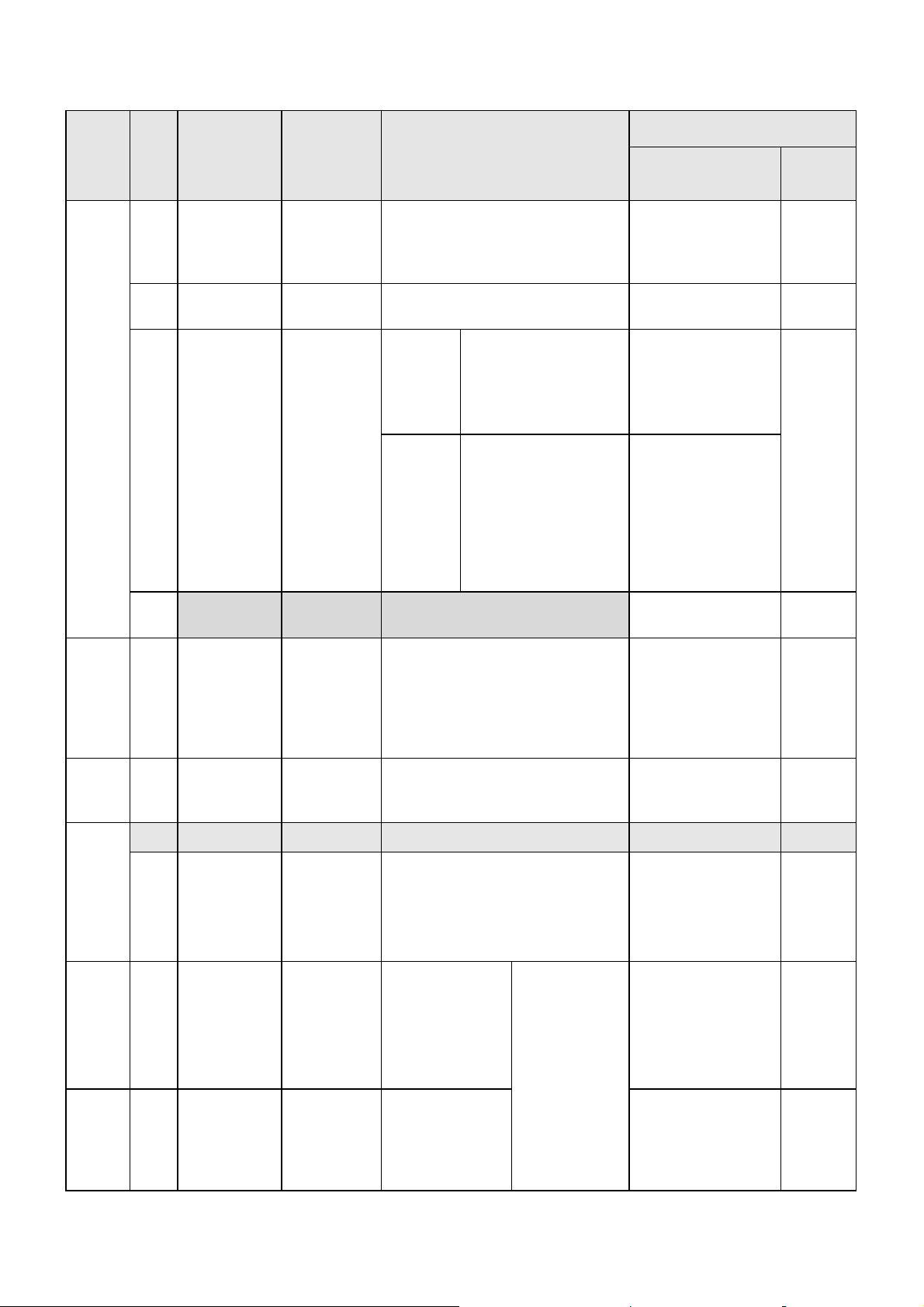

1.3.3

I/O Interface Specification

(1) I/O Signal

No. Item Signal Name

Video Signal

Timing Signal

1

Display data

Clock

RA-

RA+

RB-

RB+

RC-

RC+

RD-

RD+

RE-

RE+

RXCLKIN-

RXCLKIN+

Number

of

signals

1

1

1

1

1

1

1

1

1

1

1

1

I/O Form Content of definition

Differential serial data signal.

Input video and timing signals after

differential serial conversion using a

dedicated transceiver.

The serial data signal is transmitted

seven times faster than the base

signal.

Differential clock signal.

Input the clock signal after

differential conversion using a

dedicated transceiver.

The clock signal is transmitted at

the same speed as the base signal.

Input

Input

LVDS

Differential

LVDS

Differential

Power down

Signal

Communication

2

Control

MPU Communication / Control

PDWN 1 Input LVTTL

SDA 1 I/O

SCL 1 I/O

CPUGO 1 Input LVTTL

PDPGO 1 Input LVTTL

IRQ 1 Output LVTTL

LVTTL

2

(I

C)

Low :LVDS receiver outputs are all

“L”.

High: Input signals are active.

2

I

C bus serial data communication

signal.

Communication with the control

MPU of this product is enabled.

Low power consumption mode of

the control MPU of this product is

released.

“High”: This product is started.

(CPUGO=“High” Effective)

It changes into "Low" → "High"

when this product enters the

undermentioned state.

1. Vcc/Va/Vs output decrease

2. Circuit abnormality detection

– 4 –

(2) LVDS Signal Definition and Function

A video signal (display data signal and control signal) is converted from parallel data to serial

data with the LVDS transmitter and further converted into four sets of differential signals before

input to this product.

These signals are transmitted seven times faster than dot clock signals.

The dot clock signal is converted into one set of differential signals by the transmitter before

input to this product.

The LVDS signal definition and function are summarized below:

Signal name Symbol Number of

Video signal

Timing signal

Transmission line

Clock transmission

line

RA-

RA+

RB-

RB+

RC-

RC+

RD-

RD+

RE-

RE+

RXCLKIN-

RXCLKIN+

signals

1

1

1

1

1

1

1

1

1

1

1

1

Signal definition and function

Display data signal

R2, R3, R4, R5, R6, R7, G2

Display data signal

G3, G4, G5, G6, G7, B2 B4

Display data signal,Sync Signal,Control signal

B4, B5, B6, B7,

Display data signal, Control signal

R8, R9, G8, G9, B8, B9, PARITY

Display data signal, Control signal

R0, R1, G0, G1, B0, B1, N.S

Clock signal

DCLK

Hsync , Vsync ,

BLANK

– 5 –

(3) Video Signal Definition and Function

The table below summarizes the definitions and functions of input video signals before LVDS

conversion.

Item Signal name

Original

Display signal

(before LVDS

transmittance)

Video signal

(digital RGB)

Data Clock

Horizontal

sync signal

Vertical sync

signal

Parity signal

Number

of signals

DATA-R

DATA-G

DATA-B

DCLK

Hsync

Vsync

PARITY 1 Input

10

10

10

1 Input

1 Input

1 Input

Input/

output

Input

Signal definition and function

Display data signal

R9/G9/B9 is the highest intensity bit.

R0/G0/B0 is the lowest intensity bit.

Display data timing signal: Data are read when

DCLK is lowerd. DCLK is continuously

input.

Regulates one horizontal line of data: Begins

control of the next screen when

lowered.

Screen starts up control timing signal: Begins

control of the next screen when

lowered.

Input the same frequency in both

odd-numbered and even-numbered fields.

This signal specifies the display field.

H: Odd-numbered field

L: Even-numbered field

Parity signal should be alternated in every

Vsync cycle.

Hsync is

Vsync is

Display period timing signal.

H indicates the display period and L indicates

the non display period.

Note:

Set this timing properly like followings, as is

used internally for signal processing.

・Set the blanking period so that the number of

effective display data items in one horizontal

Blanking

signal

BLANK

1 Input

period is 1024.

・Set the number of blanking signals in one

vertical period to 512, which is one half the

number of effective scan lines.

If the

BLANK changes when the Vsync

frequency is switched, the screen display may

be disturbed or brightness may change.

The screen display is restored to the normal

state later when the

constant again.

BLANK

length is

*This product does not correspond to the progressive display mode by the parity signal fixation.

When the parity signal is fixed, this product is reversed arbitrarily internally and used.

– 6 –

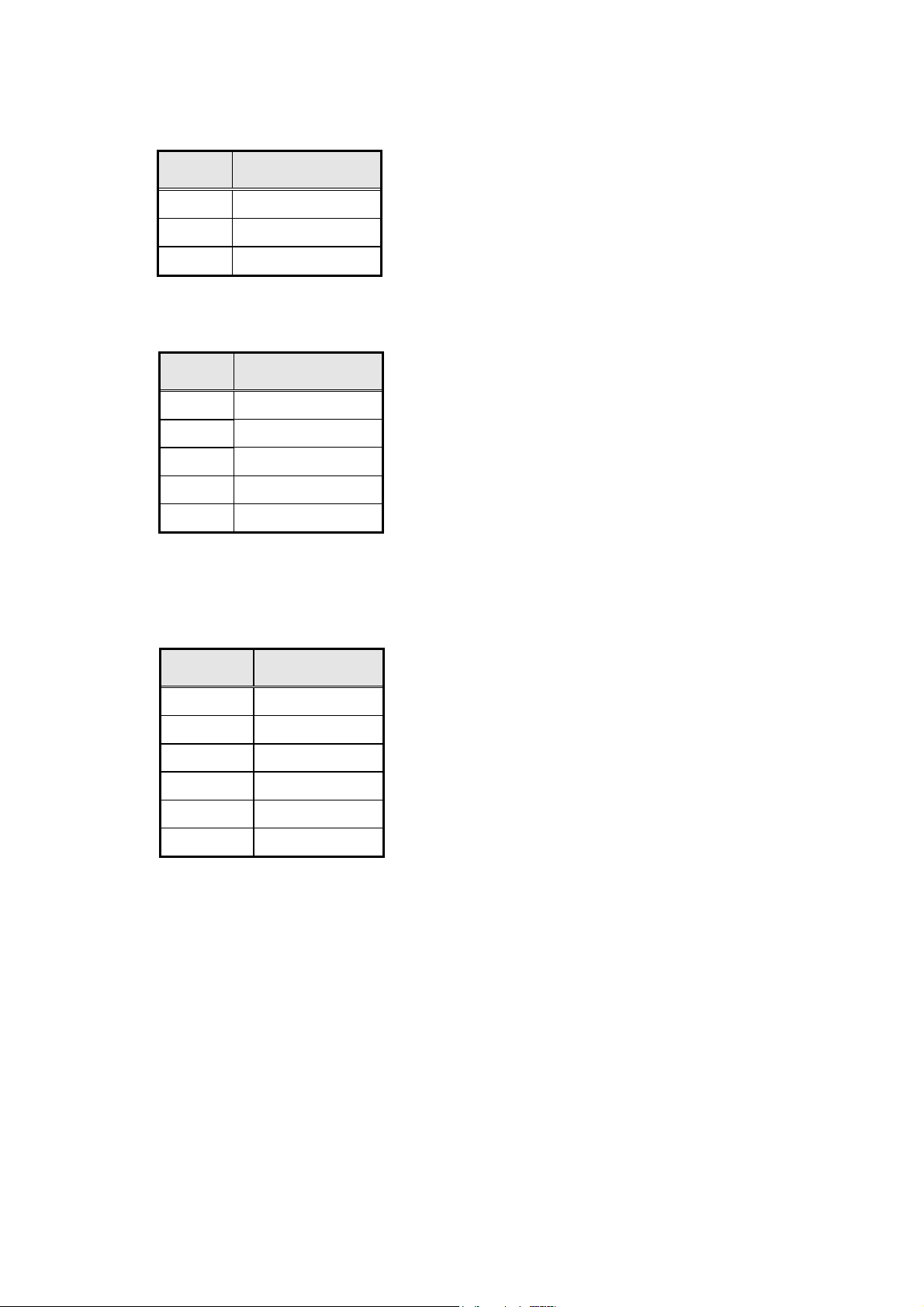

1.3.4

Connector Specifications

The connector specification is shown below. Please do not connect anything with the terminal

NC.

(1) Signal connector [CN1]

Pin No.

1 RA- 2 GND(LVDS)

3 RA+ 4 SCL

5 RB- 6 GND

7 RB+ 8 SDA

9 RC- 10 GND(LVDS)

11 RC+ 12 CPUGO

13 RXCLKIN- 14 PDPGO

15 RXCLKIN+ 16 IRQ

17 RD- 18 PDWN

19 RD+ 20 GND(LVDS)

Signal name

Pin No.

Signal name

21 RE- 22 GND

23 RE+ 24 GND

25 GND 26 GND

27 GND 28 GND

29 GND 30 GND

DF13-30DP-1.25 V (tin-plated) (Maker: HIROSE DENKI)

[Conforming connector] Housing: DF13-30DS-1.25C

Contact: DF13-2630SCF

(2) Power Source Connectors (PSU only is used on repair working)

(a) Power input connector [CN61]

Pin No.

1 AC(L)

2 N.C

Symbol

3 AC(N)

4 N.C

5 N.C

6 F.G

B06P-VH (Maker: JST)

[Conforming connector]

Housing: VHR-06N(or M)

Contact: SVH-21T-P1.1

– 7 –

(b) Power supply output connector for system [CN62]

Pin No.

Symbol

B03P-VH (Maker: JST)

1 V

2 N.C

3 GND

AUX

[Conforming connector]

Housing: VHR-06N(or M)

Contact: SVH-21T-P1.1

(c) Power supply output connector for system [CN63]

Pin No.

1 Vpr1

2 N.C.

3 Vpr2

4 N.C.

5 GND

Symbol

B5B-XH-A (Maker: JST)

[

Conforming connector]

Housing: XHP-5

Contact:

SXH

(iii) Power Source Connectors

(a) Power supply output connector for system [CN6]

-001T-P0.6

Pin No.

1 Vpr2

2 N.C.

3 GND

4 GND

5 N.C.

6 Vcc

Symbol

B6B-PH-SM3(JST)

[Conforming connector]

Housing: PHR-6

Contact: SPH-002T-P0.5L

– 8 –

(b) [CN23]

Pin No.

1 Va

2 N.C.

3 Vcc

4 GND

5 GND

6 GND

7 N.C.

8 Vs

9 Vs

10 Vs

Symbol

B10P-VH(JST)

[Conforming connector]

Housing: VHR-10N

Contact: SVH-21T-P1.1

(c) Power supply output connector for system [CN7]

Pin No. Symbol Pin No. Symbol

1 N.C. 11 GND

2 N.C. 12 Vra

3 N.C. 13 GND

4 N.C. 14 Vrs

5 GND 15 GND

6 VSAGO 16 Iak

7 GND 17 GND

8 VCEGO 18 Vak

9 GND 19 GND

10 PFCGO 20 Vsk

00 6200 520 330 000 [ZIF Right Angle Connector] (Kyocera elco)

– 9 –

2 SAFETY HANDLING of THE PLASMA DISPLAY

2.1 NOTES TO FOLLOW DURING SERVICING

The work procedures shown with the Note indication are important for ensuring the

safety of the product and the servicing work. Be sure to follow these instructions.

Before starting the work, secure a sufficient working space.

At all times other than when adjusting and checking the product, be sure to turn OFF the

main POWER switch and disconnect the power cable from the power source of the display

(jig or the display itself) during servicing.

To prevent electric shock and breakage of PC board, start the servicing work at least 30

seconds after the main power has been turned off. Especially when installing and removing

the power supply PC board and the SUS PC board in which high voltages are applied, start

servicing at least 2 minutes after the main power has been turned off.

While the main power is on, do not touch any parts or circuits other than the ones specified.

The high voltage power supply block within the PDP module has a floating ground. If any

connection other than the one specified is made between the measuring equipment and

the high voltage power supply block, it can result in electric shock or activation of the

leakage-detection circuit breaker.

When installing the PDP module in, and removing it from the packing carton, be sure to

have at least two persons perform the work while being careful to ensure that the flexible

printed-circuit cable of the PDP module does not get caught by the packing carton.

When the surface of the panel comes into contact with the cushioning materials, be sure to

confirm that there is no foreign matter on top of the cushioning materials before the surface

of the panel comes into contact with the cushioning materials. Failure to observe this

precaution may result in the surface of the panel being scratched by foreign matter.

When handling the circuit PC board, be sure to remove static electricity from your body

before handling the circuit PC board.

Be sure to handle the circuit PC board by holding the such large parts as the heat sink or

transformer. Failure to observe this precaution may result in the occurrence of an

abnormality in the soldered areas.

Do not stack the circuit PC boards.

Failure to observe this precaution may result in problems resulting from scratches on the

parts, the deformation of parts, and short-circuits due to residual electric charge.

Routing of the wires and fixing them in position must be done in accordance with the

original routing and fixing configuration when servicing is completed.

All the wires are routed far away from the areas that become hot (such as the heat sink).

These wires are fixed in position with the wire clamps so that the wires do not move,

thereby ensuring that they are not damaged and their materials do not deteriorate over

long periods of time. Therefore, route the cables and fix the cables to the original position

and states using the wire clamps.

Perform a safety check when servicing is completed.

Verify that the peripherals of the serviced points have not undergone any deterioration

during servicing. Also verify that the screws, parts and cables removed for servicing

purposes have all been returned to their proper locations in accordance with the original

setup.

– 10 –

3 NAME and FUNCTION

3.1 CONFIGURATION

(1) FPF42C128128UC-53 (LOGIC set out left side)

– 11 –

Y

O

O

S

3.2 BLOCK DIAGRAMS

3.2.1

Signal Diagrams

-SUS B.

Y-SUS

POS /NEG

RE

CN31

EVEN SW

Y-SCAN

EVEN SW

Y-SUS

ODD SW

Y-SCAN

ODD SW

ET SW

S

D

M

S

D

M

X-SUS B.

ADM1 ADM2 ADM3 ADM5 ADM6 ADM7 ADM8

ABUSL B

CN51

....

ADM4

ABUSR B.

CN41

X

B

B

X

B

B

X-SUS

X-SCAN

EVEN SW

X-SUS

DD SW

X-SCAN

DD SW

POS

RESET

CN21

SIGNAL

INPUT

CN3

24MHz

CN1

10MHz

OSC

LVDS

I2C

Analog Sw

OSC

DATA PROCESSOR

γ comp.

V-SYNC cont

Failure DET.

FLASH MEMORY

RGB

GAIN

.

SCI.

SCAN CONTROLLER

DITHER

MPU

.

APC cont

I/O

CN7

TIMMING ROM

DATA CONVERTER

SUB FIELD

PRC.

PFCgo

Vsago

Vcego

OSC

80MH

Vrs

Vra

Vrw

Vrx

OSC

40MH

EEPROM

D/A

CN69

LOGIC B.

MEMORY

CONTROLLER

FRAME

MEMORY

PSU B.

CN2

*

CN5

CN4

– 12 –

Y

g

g

V

p

V

p

V

a

s

w

3.2.2

Power Diagrams

-SUS B.

Y-SUS

EVEN SW

Y-SCAN

EVEN SW

Y-SUS

ODD SW

Y-SCAN

ODD SW

POS/NEG

RESET SW

YFVE Vy VE

18V 18V 17V

CONVERTER

CN36

Vcc 5V

Vs 85V

Va 63V

Vw 190V

Vu 55V

DC/DC

S

D

M

S

D

M

CN32

CPUgo

PDPgo

CN52

ADM1

Va 63V

Vcc 5V

Vpr2 3.3V

ABUSR B....

....

Vr

Vr

Vr

Va 63V

Vcc 5V

ADM4 ADM2 ADM5

ADM3 ADM6 ADM7 ADM8

ABUSL B

D/A

MPU

Vcc 5V

Vrst

RST

CN42

CN22

Vxwgo

X

B

B

X

B

B

CN26

X

18V 20V 17V

X-SUS B.

X-SUS

EVEN SW

X-SCAN

EVEN SW

X-SUS

ODD SW

X-SCAN

ODD SW

POS/NEG

RESET SW

DC/DC

CONVERTER

FVE

Vxx VE

DC/DC

CONVERTER

Vcc 5V

Vs 85V

Va 63V

Vx

55V

Vs 85V

AC100

~240V

PFCgo

Vsago

10A

CN61

control

PSU B.

Servce

PFC

Vsago

SW

o

PFC

380V

r2 3.3V

r1 5V

LOGIC B.

CN6

Vsago

Vce

ra

Vcc 5V

63V

5V

CN68

CN64

o

85V

CN23

Vs

85V

*1:Power supply(jig)

– 13 –

3.3 FUNCTION

3.3.1

Logic board Function

(1) Data Processor

- γ adjustment(1 / 2.2 / 2.4 / 2.6 / 2.8)

- NTSC/EBU format(Color matrix) Switch

- RGB gain Control(White balance adjustment, Amplitude limitation)

- Error Diffusion Technology(Grayscale adjustment)

- Dither(Grayscale adjustment)

- Burn-in Pattern generation

(2) Data Converter

- Quasi out-line adjustment (luminous pattern control)

(3) Scan Controller

- Address driver control signal generator(ADM)

- scan driver control signal generator(SDM)

- X/Y sustain control signal generator

(4) Waveform ROM

- Waveform Pattern for drive / Timing memory

(5) MPU

- Synchronous detection

- System control

- Driving voltage(Va, Vs, Vr, Vw) Minute adjustment

- Abnormal watch (breakdown detection)/abnormal processing

- Is(sustain) current control (sustain pulse control)

- Ia(address) current control (sub-field control)

- External communication control

- Flash memory (firmware)

(6) EEPROM

- Control parameter memory

- The accumulation energizing time (Every hour).

- Abnormal status memory (16 careers)

– 14 –

Sub

Address

Data

bit

Symbol Item Function

Setting [hex]

RANGE

INITIAL

value

00 7-0 MAPVER

7 ERRF

01

02 7-0 ERRC ERRor Code

6 OHRF

5 PSDF

4-0 CNDC

address MAP

VERsion

update of

ERRor Flag

update of

Operation

HouRs Flag

Power Shut

Down Flag

CoNDition

Code

Indicates the version number of the

address map.

Indicates that an error has occurred.

It can be cleared with the ErrRST

setting.

If this flag is set, Error code is

written. Cannot enter the PDP-ON

mode.

Indicates that the drive hours are

counted.

Indicates that shutdown of the AC

power is detected and the PDP has

executed the OFF-sequence. It can

be cleared with the PSDRST setting.

Indicates status of the module.

Indicates error code.

The error codes of as many as 16

errors in the past can be retrieved

with the ERRS setting.

code is not stored continuously.

. Same error

00 ~ FF 01

0: Not updated

1: Updated

0: Not updated

1: Updated

0: Not detected

1: Detected

Refer to 4.11.2.6

condition codes.

00~FF 00

0

0

0

Irregular

03 7-0 OHRH

04 7-0 OHRL

Operation

HouRs

Higher bits

Operation

HouRs Lower

bits

Indicates the higher 8 bits of the

module driving hours.

Indicates the lower 8 bits of the

module driving hours.

00~FF 00

00~FF 00

– 15 –

Sub

Address

Data

bit

7 PATSEL

Symbol Item Function

Selecting

patterns

It selects the built-in test pattern

signals of this display. This setting is

valid when the PATON setting is 1.

Setting [hex]

RANGE

0: The single color

display is switched

every 2 seconds. A

total of 8 colors are

displayed.

1:All white (Different

from actual white.)

INITIAL

value

0

20

6 PATON

5 ADEN

4 - -

3 DSPPOL

2 PFCON

1 PDPON

Built-in

pattern

display is set

to ON.

Address

data enable

DiSPlay

POLarity

forcing PFC

ON

High voltage

power supply

ON

Display of the built-in pattern signal

in this product is turned ON/OFF.

The black screen is displayed.

0 is set when the input video signal

has disturbance.

Be sure to use the display with the

setting fixed to 0.

Input reflection polarity setting

When PFCON = 0, If a high voltage

power is switched on, PFCGO is set

high before a high voltage power is

output.

When PDPON = 1, PFCGO is set

high irrespective of the state of a

high voltage power.

Use it for a power control when a

high voltage power is off.

Switches ON/OFF the high voltage

power supply of PDP.

0: Displaying the

input signal

1: Displaying the

built-in pattern

0: Blank

1: Displaying the

input signal

0~1 0

0:Emits light by LOW

1:Emits light by High

0: Power OFF

1: Power ON

0: Power OFF

1: Power ON

0

1

1

0

0

0 DSPBIT Input Data bit Switches 8 bit input / 10 bit input

– 16 –

0: 10 bit input

1: 8bit input

1

Sub

Address

Data

bit

Symbol Item Function

Setting [hex]

RANGE

INITIAL

value

21

7-5 - -

4 CCFMD

3 DCBON

2 PPAON

1 APSON

Color

correction

mode

Dynamic

Color

Balance

Panel Protect

Apc function

Auto Peak

Save

function

Be sure to use the display with the

setting fixed to 0.

Selecting the color correction modes.

Valid when the CCFON setting is 1

Tracking correction of white balance

between the high luminance and the

low luminance.

When a picture with high

luminance/small area is displayed for

about 3 minutes or longer, the

number of pulses is reduced to about

20% at a maximum. This item can be

used to reduce panel

temperature/extend useful life when

the display is used to show a still

image.

If a low display load picture (less

than 2%) is inputted continuously 3

minutes or more, the brightness is

reduced about 50 %.

0~7 0

0:Luminance has

priority.

0

1:Gradation has

priority

0: OFF

0

1: ON

0: OFF

1

1: ON

0: OFF

1

1: ON

22

0 DSETEN

7 CCFON

6 CCFORM

5-3 - -

2-0 GAMSEL

Data

Set

Enable

Color

correction

Color

correction

format

Selecting the

reverse γ

correction

Whether the register value is

reflected to the operating status of

this product, selected by this item.

The following switch is executed.

0:The received register value is

reflected from the next field.

1:The received register value is

stored so that the DSET setting is

reflected from the next field.

(DSET setting: Setting bit 0 of

address FF)

Color collection process is turned

ON/OFF.

Color collection process is switched.

This item is valid when CCFON

setting is 1.

Be sure to use the display with the

setting fixed to 0.

Reverse γ correction level is set.

The setup 7 is the test mode. Do not

select the setup 7.

When the setup 6 is selected, setting

of the addressed in the range of

31~51 become valid.

0: Invalid

1: Valid

0: OFF

1: ON

0: NTSC

1: EBU

0~7 0

0: OFF

1: 1.0 th power

2: 2.2 nd power

3: 2.4 th power

4: 2.6 th power

5: 2.8 th power

6: USER

7: TEST

1

0

0

2

– 17 –

Sub

Address

23 7-0 CONTrast

Data

bit

Symbol Item Function

Peak

luminance

Peak luminance is adjusted.

When the display picture load is

heavy, the peak luminance is

automatically limited.

Setting [hex]

RANGE

00~FF FF

INITIAL

value

24 7-0 R-RATIO R ratio 00~FF FF

25 7-0 G-RATIO G ratio 00~FF FF

26 7-0 B-RATIO B ratio

Clearing the

7 IRQRST

6 ERRRST

5 OHRRST Clearing the

27

4 PSDRST Clearing the

IRQ output

signal

Clearing the

ERRF flag

OHRF flag

PSDF flag

White balance is adjusted.

Use the display with at least one item

being set to FF (hex).

This item implements control to

return the IRQ signal from "HIGH" to

"Low" level when an error occurs.

When this item is set to 1, the IRQ

signal is returned to "Low" level.

This item implements control to

return the ERRF flag to 0 when an

error occurs.

When this item is set to 1, this

setting automatically returns to 0

after returning the ERRF flag to 0.

The control by which the OHRF flag

is returned to 0 is done. This setting

automatically returns to the state of 0

after returning 0 the ERRF flag when

this setting is set to one.

This item exercise control to return

the PSDF flag to 0 when this

machine performs the OFF

sequence at AC power shutdown.

When this item is set to 1, this

setting automatically returns to 0

after returning the PSDF flag to 0.

00~FF FF

0: Normal

1: IRQ signal clear

0: Normal

1: ERRFflag clear

0: Normal

1: OHRF

flag clear

0: Normal

1: PSDF flag clear

0

0

0

0

3-0 ERRS Error code

selection

When this setting is changed and the

ERRC setting is read out, the error

contents (as many as 16 errors) of

the module that have occurred in the

past can be checked.

If more than 16 errors have occurred,

the error code is updated starting

from the oldest error.

– 18 –

0: Latest error

1: Previous error

2:

|

E:

F: Oldest error

0

Sub

Address

Data

bit

Symbol Item Function

Setting [hex]

RANGE

INITIAL

value

7 PWMP

6 - -

28

5-4 PWMAX

3-0

29 7-0

- -

PWM

PASS

Power

Maximam

peek control

Maximum

power

consumption

Password of

peak electric

power setting

The PWMAX setting is switched to

constant brightness (peak electric

power) control. The password setting

is necessary to turn on this setting.

Be sure to use the display with the

setting fixed to 0.

PWMP=0 Setting of the maximum

electric power.

PWMP=1 Setting of peak electric

power. Electric power by

which electric power is

permitted in addition to

improve practical

brightness to the

maximum electric power

set 3:+20W

Be sure to use the display with the

setting fixed to 0.

Password of peak electric power

setting.The password is described to

the delivery specifications. When the

password setting is normally done,

the reading value of the real thing

ground becomes 51.

When password is

set

0:OFF 1:ON

0-1 0

0: -40W

1: -20W

2: ±0W

3: +20W

0: ±0W

1: +20W

2: +30W

3: +40W

0~F 0

51: Permission of

PWMP ON

Another: Prohibition

0

2

FF

Password of

2A 7-0 VRPASS

7-4 - -

2B

3-0 RISTIM RISe TIMe

2C 7-0 PsTPW

2D 7-0 PsTTM

VRPOL

setting

Ps-Tank

PoWer

Ps-Tank

TiMe

If ‘AA” is written, VRPOL setting can

be changed. 00~FF 00

-

Setting of wait time for Vs/Va

stabilization at the time of start up

sequence.

Wait time [ms] = 200×Set value

(Ma x:3000[ms])

The maximum

electric power

setting:

The maximum

over electric

power from +20W

Time which can

operate by the

maximum over

electric power

(*10sec)

When the

amount of an

over electric

power becomes

PsTPW×PsTTM

or less at

PWMP=1, the

control by which

brightness is

lowered is

done.

0~F 0

0~F 5

00-FF 28

00-FF 3C

– 19 –

Sub

Address

Data

bit

Symbol Item Function

Setting [hex]

RANGE

INITIAL

value

7-4 - -

Voltage

30

31 7-0 GAM00

32

33 7-0 GAM01[7: 0]

34

35 7-0 GAM02[7: 0]

36

3 VRPOL

2-0 - -

7-2 - <no use> -

1-0 GAM01[9: 8]

7-3 - <no use> -

2-0 GAM02[10: 8]

7-4 - <no use> -

3-0 GAM03[11:8]

Reference

POLarity

Reverse γ

correction

DC

Reverse γ

coefficient 01

Reverse γ

correction 02

Reverse γ

correction 03

Be sure to use the display with the

setting fixed to C.

Setting of Vrs/Vra output polarity.

Set in the following procedures.

1) Write “AA” in the address 2A.

2) Write “0” or “1” in this address.

3) Write other than “AA” in the

address 2A.

Be sure to use the display with the

setting fixed to 0.

Sets the input level that implements

the forced 0 [LSB] output.

Reverse γ coefficient value is set.

Input Output value of 8 [LSB]

Reverse γ coefficient value is set.

Input Output value of 16 [LSB]

Reverse γ coefficient value is set.

Input Output value of 24 [LSB]

0: POSI

0

1:NEGA

00~FF 1F

00~FF 00

00~FF 04

00~FF 00

00~FF 24

00~FF 00

37 7-0

7-4 - <no use> -

38

3-0

39 7-0

7-5 - <no use> -

3A

4-0

7-1

3B

0

7-5 - <no use> -

3C

4-0

7-1

3D

0 - <no use> -

7-5 - <no use> -

3E

4-0

7-2

3F

1-0

GAM03

GAM04

GAM04

GAM05

GAM05

- <no use> -

GAM06

GAM06

GAM07

GAM07

- <no use> -

[7: 0]

[11: 8]

[7: 0]

[12: 8]

[7: 1]

[12: 8]

[7: 1]

[12: 8]

[7: 2]

00~FF 58

Reverse γ

correction 04

00~FF A7

Reverse γ

correction 05

Reverse γ

correction 06

Reverse γ

correction 07

Reverse γ coefficient value is set.

Input Output value of 32 [LSB]

Reverse γ coefficient value is set.

Input Output value of 40 [LSB]

Reverse γ coefficient value is set.

Input Output value of 48 [LSB]

Reverse γ coefficient value is set.

Input Output value of 56 [LSB]

00~FF 00

00~FF 01

00~FF 12

00~FF 01

00~FF 9A

00~FF 02

00~FF 40

– 20 –

Sub

Address

Data

bit

Symbol Item Function

Setting [hex]

RANGE

INITIAL

value

40

41

42

43

44

45

46

47

48

49

7-5 - <no use> -

[12: 8]

[7: 2]

[13: 8]

[7: 4]

[13: 8]

[7: 4]

[13: 8]

[7: 4]

[13: 8]

[7: 4]

Reverse γ

correction 08

Reverse γ

correction 09

Reverse γ

correction 10

Reverse γ

correction 11

Reverse γ

correction 12

4-0

7-2

1-0 - <no use> -

7-6 - <no use> -

5-0

7-4

3-0

7-6 - <no use> -

5-0

7-4

3-0

7-6 - <no use> -

5-0

7-4

3-0

7-6 - <no use> -

5-0

7-4

3-0

GAM08

GAM08

GAM09

GAM09

- <no use> -

GAM11

GAM11

- <no use> -

GAM11

GAM11

- <no use> -

GAM12

GAM12

- <no use> -

00~FF 03

Reverse γ coefficient value is set.

Input Output value of 64 [LSB]

00~FF 04

00~FF 04

Reverse γ coefficient value is set.

Input Output value of 80 [LSB]

00~FF F0

00~FF 07

Reverse γ coefficient value is set.

Input Output value of 96 [LSB]

00~FF 60

00~FF 0A

Reverse γ coefficient value is set.

Input Output value of 112 [LSB]

00~FF 50

00~FF 0D

Reverse γ coefficient value is set.

Input Output value of 128 [LSB]

00~FF D0

4A

4B

4C

4D

4E

4F

50

51

7-6 - <no use> -

5-0

7-4

3-0 - <no use> -

7-6 - <no use> -

5-0

7-4

3-0

7-6 - <no use> -

5-0

7-4

3-0

7 - <no use> -

6-0

7-5

4-0

GAM13

GAM13

GAM14

GAM14

- <no use> -

GAM15

GAM15

- <no use> -

GAM16

GAM16

- <no use> -

[13: 8]

[7: 4]

[13: 8]

[7: 4]

[13: 8]

[7: 4]

[14: 8]

[7: 5]

Reverse γ

correction 13

Reverse γ

correction 14

Reverse γ

correction 15

Reverse γ

correction 16

Reverse γ coefficient value is set.

Input Output value of 160 [LSB]

Reverse γ coefficient value is set.

Input Output value of 192 [LSB]

Reverse γ coefficient value is set.

Input Output value of 224 [LSB]

Reverse γ coefficient

Input Output value of 256 [LSB]

00~FF 16

00~FF A0

00~FF 21

00~FF E0

00~FF 2F

00~FF 90

00~FF 40

00~FF 00

– 21 –

Sub

Address

Data

bit

Symbol Item Function

Setting [hex]

RANGE

INITIAL

value

E5 7-0 UVrs USER Vrs

E6 7-0 UVra USER Vra

7-3

2 RCLVr

FE

1 EWRVr

0

7-1

FF

0 DSET Data setup

- -

UVrs/UVra

RECALL

UVrs/UVra

Write

- -

- -

Setting Vrs voltage Standard

equation: Vrs=2.99*UVrs/255

Setting Vra voltage Standard

equation: Vra=2.99*UVra/255

Be sure to use the display with the

setting fixed to 0.

Resetting the UVrs, UVra in both of

register and EEPROM to the initial

value by setting RCLVr to 1.

This setting automatically returns to

0 after resetting the UVrs,Uvra.

Storing the UVrs,UVra in register

to EEPROM by setting EWRVr to 1.

This setting automatically returns to

0 after resetting the UVrs,UVra.

Be sure to use the display with the

setting fixed to 0.

Be sure to use the display with the

setting fixed to 0.

When the DSETEN setting is 1,

setting this bit causes all the register

setups that have been set up to now,

to be reflected to the operation status

of this product. They are reflected

from the next field after this bit is

accepted.

00~AA

00~AA

0 0

0:Normal

1: UVrs,UVra

initialized

0:Normal

1: UVrs,UVra

stored in EEPROM

0 0

0 0

0: Normal

1: Execute

Adjusted

in factory

Adjusted

in factory

0

0

0

– 22 –

Loading...

Loading...