Sony HXC-100 Service Manual

HD COLOR CAMERA

HXC-100

SERVICE MANUAL

Volume 1 1st Edition

!警告

このマニュアルは,サービス専用です。

お客様が,このマニュアルに記載された設置や保守,点検,修理などを行うと感電や火災,

人身事故につながることがあります。

危険をさけるため,サービストレーニングを受けた技術者のみご使用ください。

! WARNING

This manual is intended for qualifi ed service personnel only.

To reduce the risk of electric shock, fi re or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualifi ed to do so. Refer all servicing to

qualifi ed service personnel.

! WARNUNG

Die Anleitung ist nur für qualifi ziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifi ziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afi n

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifi é pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

HXC-100/V1 (E)

注意

ADVARSEL!

指定以外の電池に交換すると,破裂する危険があり

ます。

使用済の電池は,説明書に従って処理してください。

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the manufacturer.

Dispose of used batteries according to the

manufacturer’s instructions.

Vorsicht!

Explosionsgefahr bei unsachgemäßem Austausch

der Batterie.

Ersatz nur durch denselben oder einen vom

Hersteller empfohlenen ähnlichen Typ. Entsorgung

gebrauchter Batterien nach Angaben des

Herstellers.

Lithiumbatteri-Eksplosionsfare ved fejlagtig

håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

ADVARSEL

Lithiumbatteri - Eksplosjonsfare.

Ved utskifting benyttes kun batteri som

anbefalt av apparatfabrikanten.

Brukt batteri returneres

apparatleverandøren.

VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en likvärdig typ

som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt gällande

föreskrifter.

ATTENTION

Il y a danger d’explosion s’il y a remplacement

incorrect de la batterie.

Remplacer uniquement avec une batterie du même

type ou d’un type équivalent recommandé par le

constructeur.

Mettre au rebut les batteries usagées conformément

aux instructions du fabricant.

VAROITUS

Paristo voi räjähtää jos se on virheellisesti

asennettu.

Vaihda paristo ainoastaan laitevalmistajan

suosittelemaan tyyppiin.

Hävitä käytetty paristo valmistajan ohjeiden

mukaisesti.

HXC-100/V1 (E)

1 (P)

Table of Contents

Manual Structure

Purpose of this manual .................................................................. 3

Related manuals ............................................................................ 3

Trademarks .................................................................................... 3

1. Service Overview

1-1. Connectors and Cables .................................................... 1-1

1-1-1. Connector Input/Output Signals ............................1-1

1-1-2. Wiring Diagrams for Cables .................................. 1-7

1-1-3. Connection Connectors/Cables .............................. 1-7

1-2. Location of Printed Circuit Boards .................................1-8

1-3. Circuit Description ........................................................ 1-10

1-4. Opening/Closing the Side Panel .................................... 1-16

1-5. Description of Onboard LED Indicators .......................1-17

1-6. Switch Settings ..............................................................1-20

1-7. Notes on Flexible Card Wire ......................................... 1-22

1-7-1. Disconnecting/Connecting Flexible Card Wire ... 1-22

1-7-2. Forming Flexible Card Wire ................................ 1-24

1-8. Notes on Replacement of Circuit Board .......................1-25

1-8-1. EEPROM Data .....................................................1-25

1-8-2. Actions to Be Taken during Board Replacement

and after Board Replacement/Repair ................... 1-25

1-8-3. Adjustment and Settings when Replacing SY-363

Board .................................................................... 1-26

1-9. Setting Intercoms........................................................... 1-27

1-10. Upgrading the Software Programs ................................ 1-28

1-10-1. Upgrading the Main Program .............................. 1-28

1-10-2. Upgrading the Boot Program ............................... 1-29

1-11. Note on Replacement of Lithium Battery ..................... 1-30

1-12. Periodic Check and Maintenance .................................. 1-31

1-12-1. Recommended Replacement Parts....................... 1-31

1-12-2. Periodic Replacement Parts ................................. 1-32

1-12-3. Cleaning the Air Vents .........................................1-32

1-13. Description of CCD Block Number .............................. 1-32

1-14. Optional Fixtures ........................................................... 1-33

1-15. Notes on Repair Parts .................................................... 1-33

1-16. Unleaded Solder ............................................................ 1-33

1-17. Installing the Accessory Shoe ....................................... 1-34

2. Replacement of Main Parts

2-1. Replacing the CCD Unit .................................................2-1

2-2. Replacing CCD Unit Boards ........................................... 2-3

2-2-1. DR-632 Board ........................................................ 2-3

2-2-2. NR-80 Board .......................................................... 2-3

2-2-3. PA-353 Board......................................................... 2-4

2-2-4. TG-265 Board ........................................................ 2-5

2-2-5. SE-949 Board .........................................................2-5

2-3. Replacing the DC Fan ..................................................... 2-6

2-4. Replacing Operation Parts ............................................... 2-7

2-5. Replacing Connectors .....................................................2-8

2-5-1. CCU (TRIAX) Connector ...................................... 2-8

2-5-2. SDI Connector .....................................................2-10

2-6. Replacing the Power Supply Assembly ........................ 2-11

2-7. Removing/Installing the Connector Panel..................... 2-12

2-8. Replacing Boards .......................................................... 2-13

2-8-1. CD-61 Board ........................................................ 2-13

2-8-2. CN-3069 Board .................................................... 2-14

2-8-3. CN-3070 Board .................................................... 2-15

2-8-4. CN-3071 Board .................................................... 2-15

2-8-5. CN-3072 Board .................................................... 2-16

2-8-6. DPR-298 Board ...................................................2-17

2-8-7. ENC-112 Board ...................................................2-17

2-8-8. FL-348 Board .......................................................2-18

2-8-9. LE-355 Board ......................................................2-19

2-8-10. MB-1125 Board ................................................... 2-19

2-8-11. MS-91 Board ....................................................... 2-20

2-8-12. PS-755 Board ....................................................... 2-20

2-8-13. RE-263 Board ...................................................... 2-20

2-8-14. SW-1404 Board.................................................... 2-21

2-8-15. SW-1405 Board.................................................... 2-21

2-8-16. SW-1406/A Board ................................................ 2-22

2-8-17. SW-1407 Board.................................................... 2-22

2-8-18. SY-363 Board ....................................................... 2-23

2-8-19. TX-126 Board ...................................................... 2-23

HXC-100/V1 (E)

1

3. Electrical Alignment

4. File System

3-1. Preparations ..................................................................... 3-1

3-1-1. Equipment Required .............................................. 3-1

3-1-2. Precautions on Adjustments ................................... 3-1

3-1-3. File Data at Adjustment ......................................... 3-2

3-1-4. Maintaining the Grayscale Chart ........................... 3-2

3-1-5. Setup Menu ............................................................ 3-4

3-1-6. Connection of Equipment ...................................... 3-5

3-1-7. Initial Settings ........................................................ 3-6

3-1-8. Adjustment Items and Setup Menu Items .............. 3-7

3-2. Automatic Adjustment..................................................... 3-8

3-3. Electrical Alignment ........................................................3-8

3-3-1. BLACK SET Adjustment ...................................... 3-8

3-3-2. Sensitivity Adjustment ........................................... 3-9

3-3-3. V-SUB Adjustment .............................................. 3-10

3-3-4. Black Shading Adjustment................................... 3-11

3-3-5. White Shading Adjustment .................................. 3-12

3-3-6. RPN Adjustment .................................................. 3-14

3-4. Video System Level Adjustment ................................... 3-15

3-4-1. H/V Ratio Adjustment ......................................... 3-15

3-4-2. Detail Level Adjustment ...................................... 3-16

3-4-3. Crispening Adjustment ........................................ 3-17

3-4-4. Level Dependent Adjustment............................... 3-18

3-4-5. Detail Clip Adjustment ........................................ 3-19

3-4-6. Auto-iris Adjustment ........................................... 3-20

3-4-7. Pedestal Level Adjustment................................... 3-21

3-4-8. Flare Adjustment .................................................. 3-22

3-4-9. Gamma Correction Adjustment ........................... 3-23

3-4-10. Knee Point/Knee Slope Adjustment .................... 3-24

3-4-11. White Clip Level Adjustment .............................. 3-25

3-4-12. File Store ..............................................................3-25

3-5. ND Offset Adjustment ...................................................3-26

3-6. RPN Compensation .......................................................3-27

3-6-1. Automatic Compensation (APR) ......................... 3-27

3-6-2. Manual RPN Compensation Adjustment ............. 3-27

3-6-3. Procedures to Be Taken When the RPN

Compensation Fails .............................................3-29

3-6-4. Performing Automatic RPN Detection

Effectively ............................................................ 3-30

3-6-5. RPN Compensation Flowchart ............................ 3-31

3-7. Vertical Line Compensation .......................................... 3-32

3-8. TRIAX Transmission System Adjustment .................... 3-34

3-8-1. 1.4-MHz Modulation Circuit Adjustment ............3-34

3-8-2. Demodulation Circuit Adjustment .......................3-35

3-9. TEST OUT Output Level Adjustment........................... 3-36

4-1. File Structure ...................................................................4-1

4-2. Operator File ...................................................................4-2

4-3. Preset Operator File ......................................................... 4-3

4-4. Scene File ........................................................................ 4-4

4-5. Reference File .................................................................4-6

4-6. Lens File .......................................................................... 4-8

4-7. OHB File ....................................................................... 4-10

4-8. File Items ....................................................................... 4-12

5. Setup Menu

5-1. Entering the SERVICE Menu ......................................... 5-1

5-2. Settable Special Functions ..............................................5-1

5-3. Description on SERVICE Menu ..................................... 5-2

2

HXC-100/V1 (E)

Purpose of this manual

Related manuals

Manual Structure

This manual is the service manual Volume 1 for HD Color Camera HXC-100.

This manual describes the information items that premise the service based on the

components parts such as service overview, replacement of main parts, electrical

alignment, fi le system, SERVICE menu, assuming use of system and service engi-

neers.

Besides this service manual Volume 1 the following manual is available for this unit.

. HXC-100 Operating Instructions (Supplied with HXC-100)

This manual is necessary for application and operation of HXC-100.

Part number: 4-137-704-0X (Japanese)

Part number: 4-137-704-1X (English)

. HXC-100 Operating Instructions CD-ROM (Supplied with UC and CE

model)

This manual is necessary for application and operation of HXC-100.

The CD-ROM contains the English, French, German, Italian, and Spanish operating

instructions (PDF).

Part number: 4-137-707-0X

Trademarks

. Service Manual Volume 2 (Available on request)

Describes the parts list, block diagrams, schematic diagrams and board layouts of

HXC-100.

. “Semiconductor Pin Assignments” CD-ROM (Available on request)

This “Semiconductor Pin Assignments” CD-ROM allows you to search for semiconductors used in Broadcast and Professional equipment.

The service manual Volume 2 contains a complete list of semiconductors and their

ID Nos., and thus should be used together with the CD-ROM.

Part number: 9-968-546-06

Trademarks and registered trademarks used in this manual are follows.

. FRAM is a registered trademark of Ramtron International Corporation.

HXC-100/V1 (E)

3

Service Overview

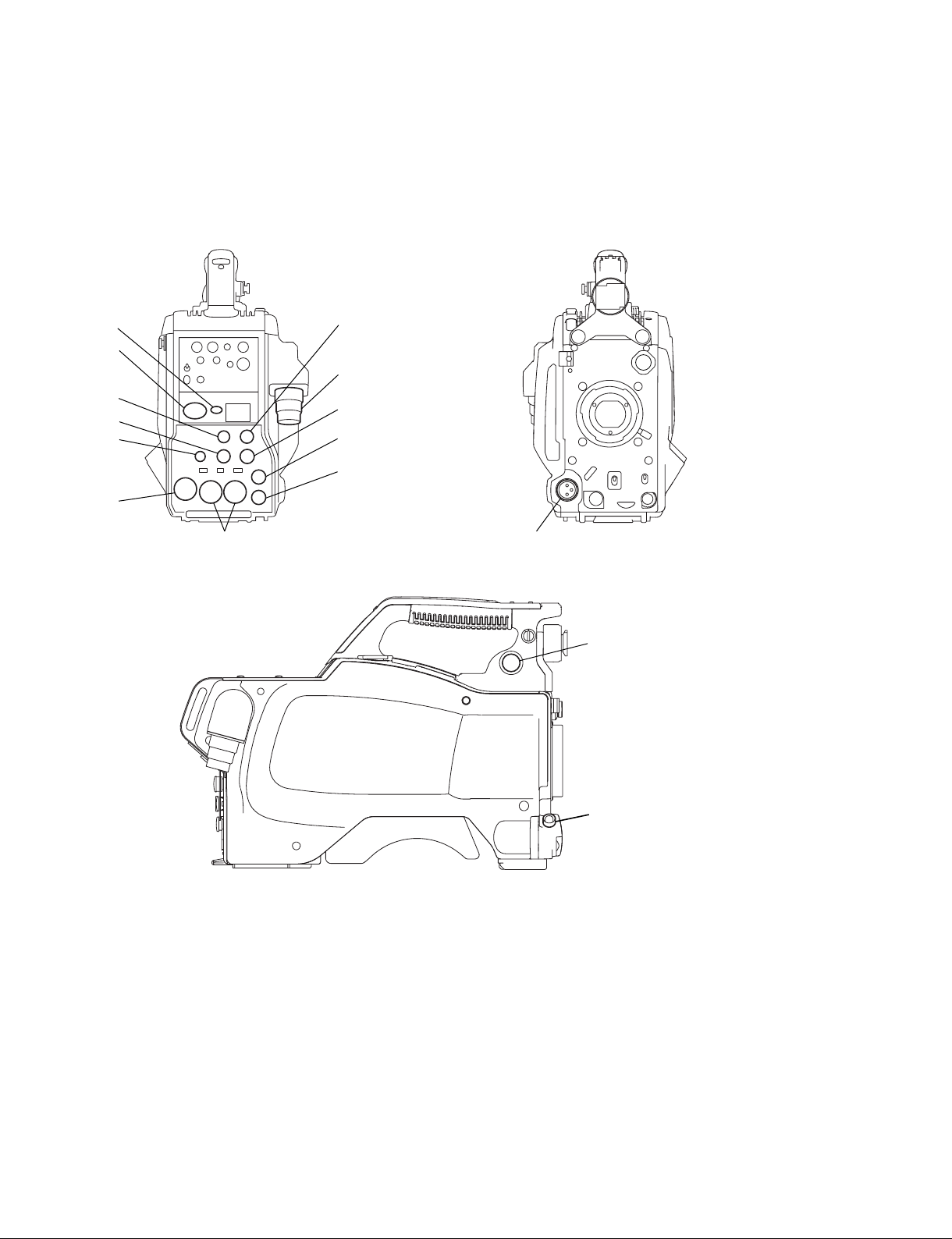

1-1. Connectors and Cables

1-1-1. Connector Input/Output Signals

Section 1

5

6

8

9

0

!-

!=

7

1

2

3

4

![

!]

Input/Output Signals

1 CCU (TRIAX) connector

J: TAGIMI Triax connector

UC: LEMO Triax connector

CE: Fischer Triax connector

2 PROMPTER/GENLOCK/RET

BNC type 75 Z, 1.0 V p-p

3 TEST OUT

BNC type 75 Z, 1.0 V p-p

HXC-100/V1 (E)

!\

Output Signals

4 SDI

HD SDI signal

BTA-S004A compliant

BNC type 75 Z, 0.8 V p-p 1.485 Gbps

5 EARPHONE

EARPHONE φ3.5 mm stereo mini jack

1-1

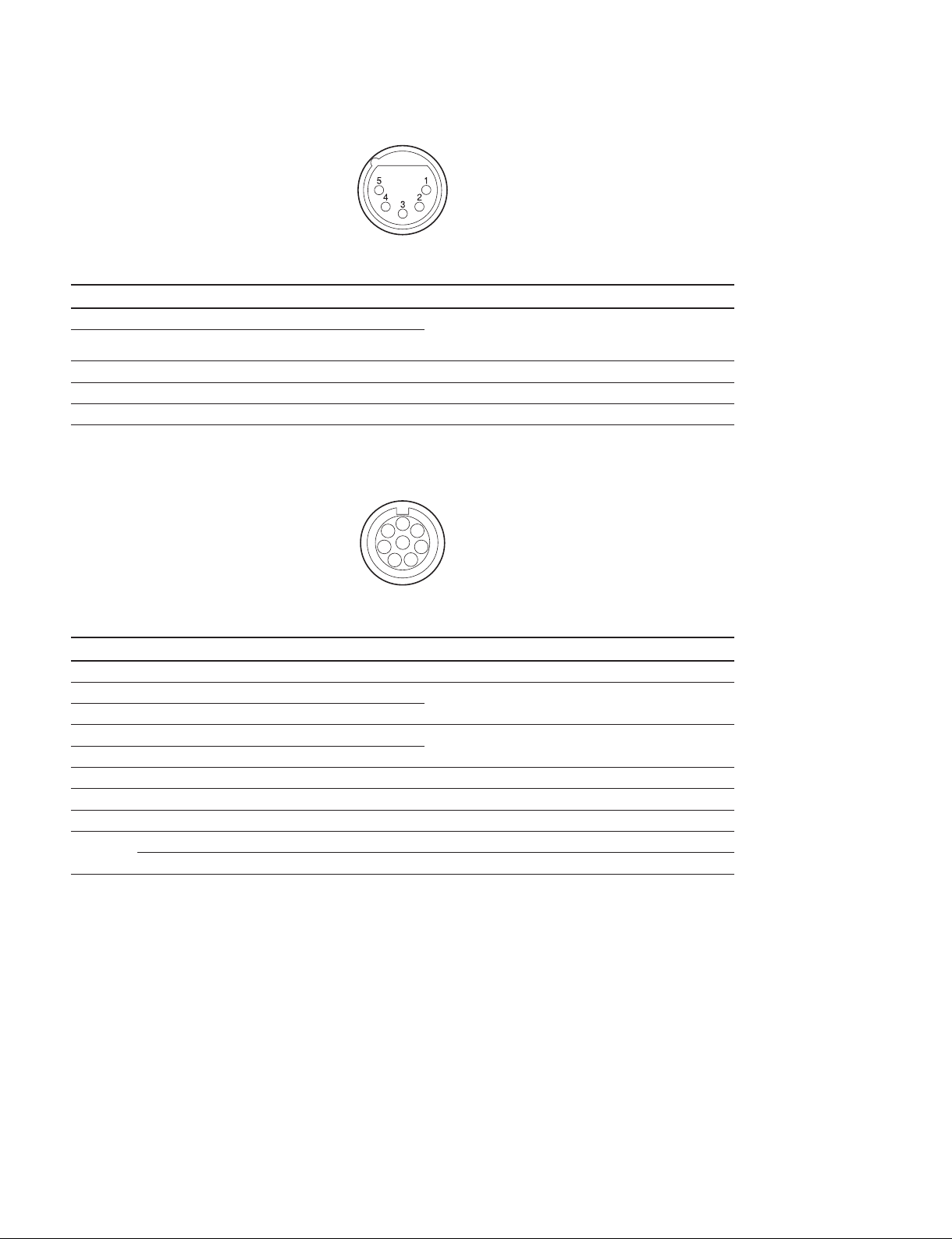

6 INTERCOM (5P FEMALE)

(External view)

No. Signal I/O Specifi cations

1 Intercom MIC (Y) IN CARBON (_20 dBu, Unbalance)

2 Intercom MIC (X) IN

3 GND

_

DYNAMIC (_60 dBu, Balance/Unbalance)

MANUAL (_20/_40/_60 dBu, Balance/Unbalance)

GND

4 Intercom Left OUT 11 dBu (VR Max, 250 Z Load)

5 Intercom Right OUT 11 dBu (VR Max, 250 Z Load)

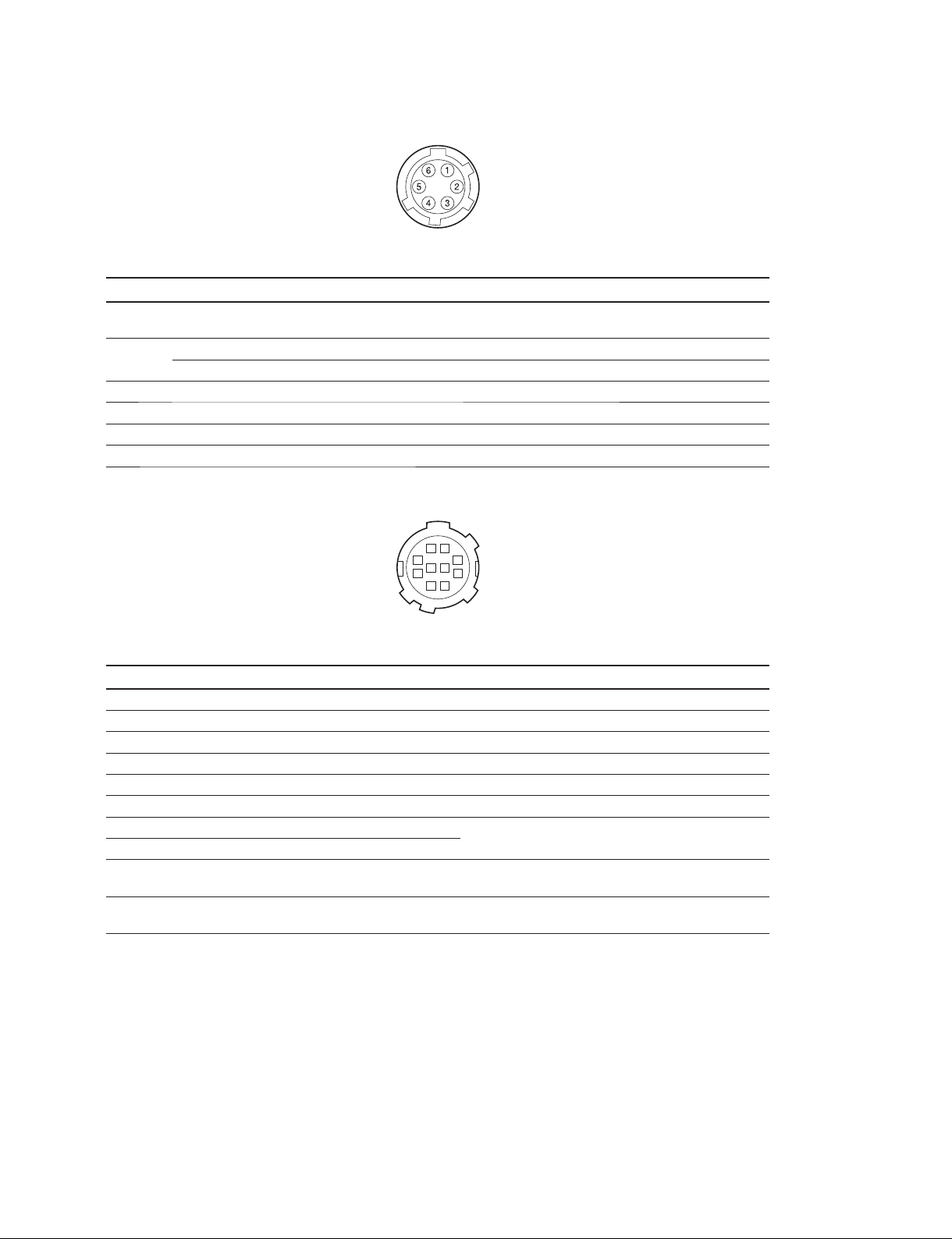

7 REMOTE (8P FEMALE)

1

7

2

8

3

6

5

4

(0 dBu = 0.775 Vrms)

(External view)

No. Signal I/O Specifi cations

for RCP for TRUNK (RS-422A)

1 TX (X) TX1 (+) OUT SERIAL DATA OUT/TRUNK DATA OUT

2 TX (Y) TX1 (_) OUT

3 RX (X) RX1 (+) IN SERIAL DATA IN/TRUNK DATA IN

4 RX (Y) RX1 (_)IN

5 TX-GND

_

6 UNREG-OUT OUT

7 UNREG-GND

_

GND for TX

+10.5 to +17 V dc, 200 mA (max)

GND for UNREG-OUT

8 RCP-PIX OUT 75 Z, 1.0 V p-p (SD Video)

CHASSIS GND

_

CHASSIS GND

1-2

HXC-100/V1 (E)

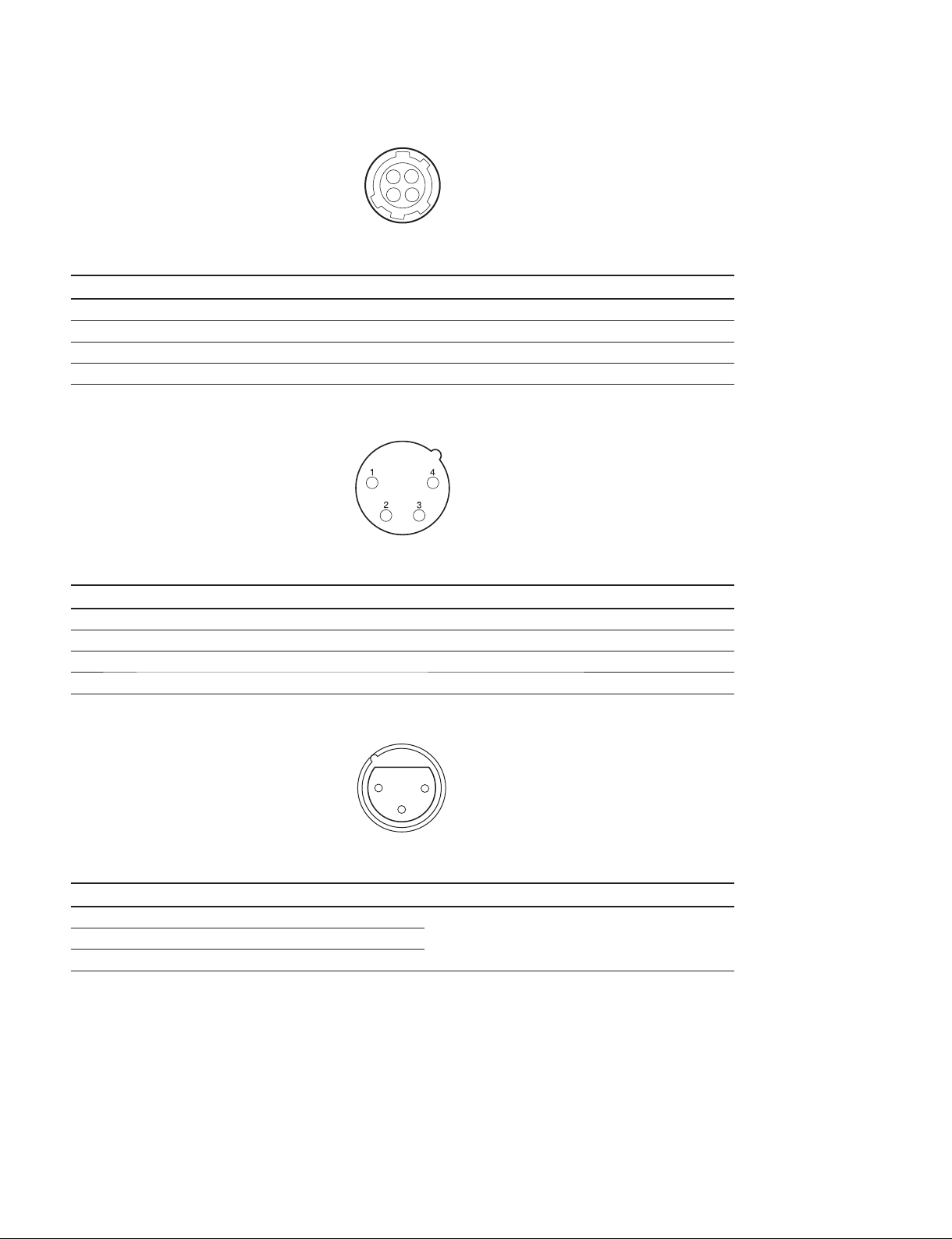

8 RET CTRL (6P FEMALE)

(External view)

No. Signal I/O Specifi cations

1 INCOM MIC-ON/OFF (J, UC)

IN Zi > 10 kZ, ON : GND, OFF : OPEN

ENG (CE)

2 NC (J, UC) No connection

PROD (CE) IN Zi > 10 kZ, ON : GND, OFF : OPEN

3 GND

_

4 RET 3-ON/OFF IN Zi > 10 kZ, ON : GND, OFF : OPEN

5 RET 1-ON/OFF IN Zi > 10 kZ, ON : GND, OFF : OPEN

6 RET 2-ON/OFF IN Zi > 10 kZ, ON : GND, OFF : OPEN

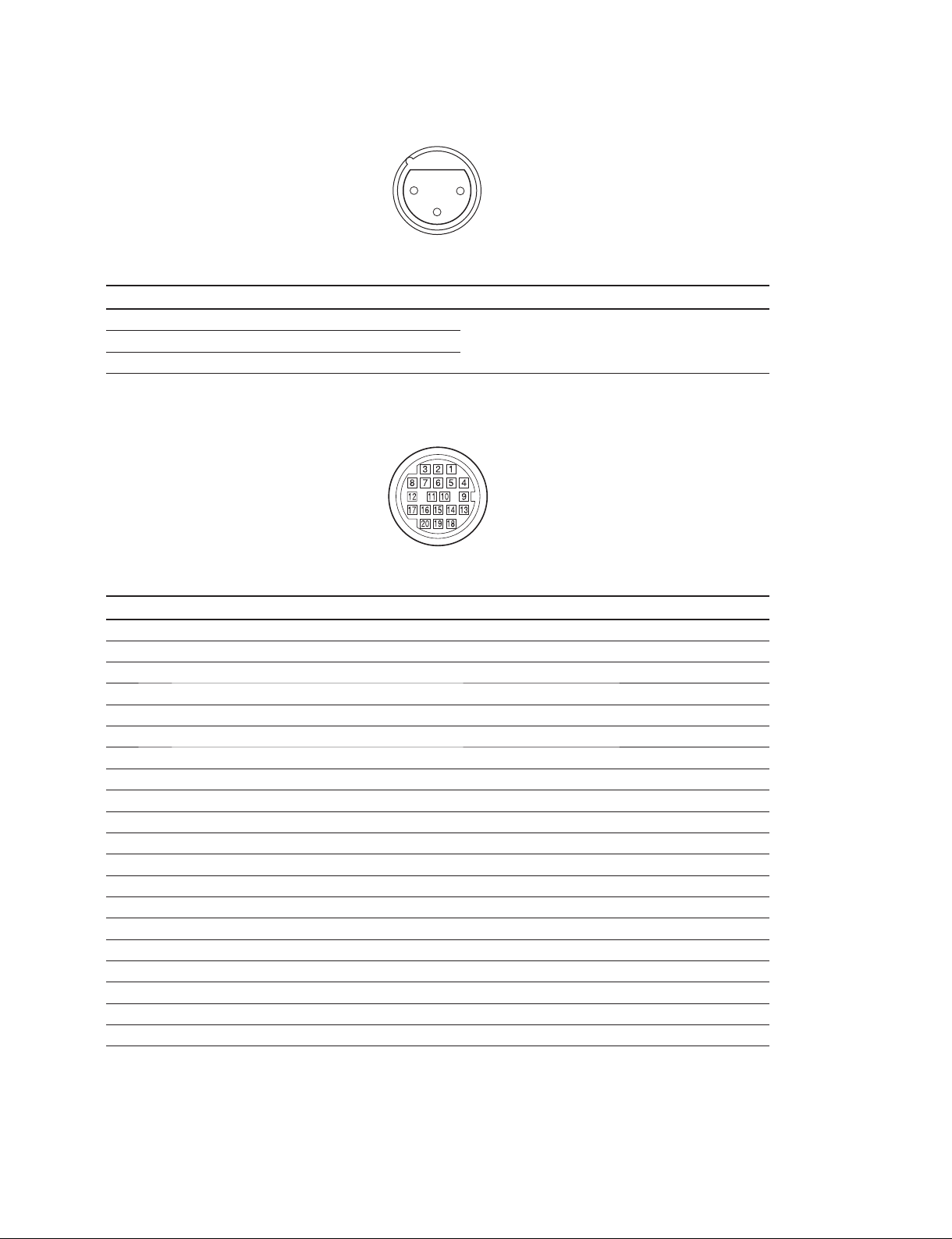

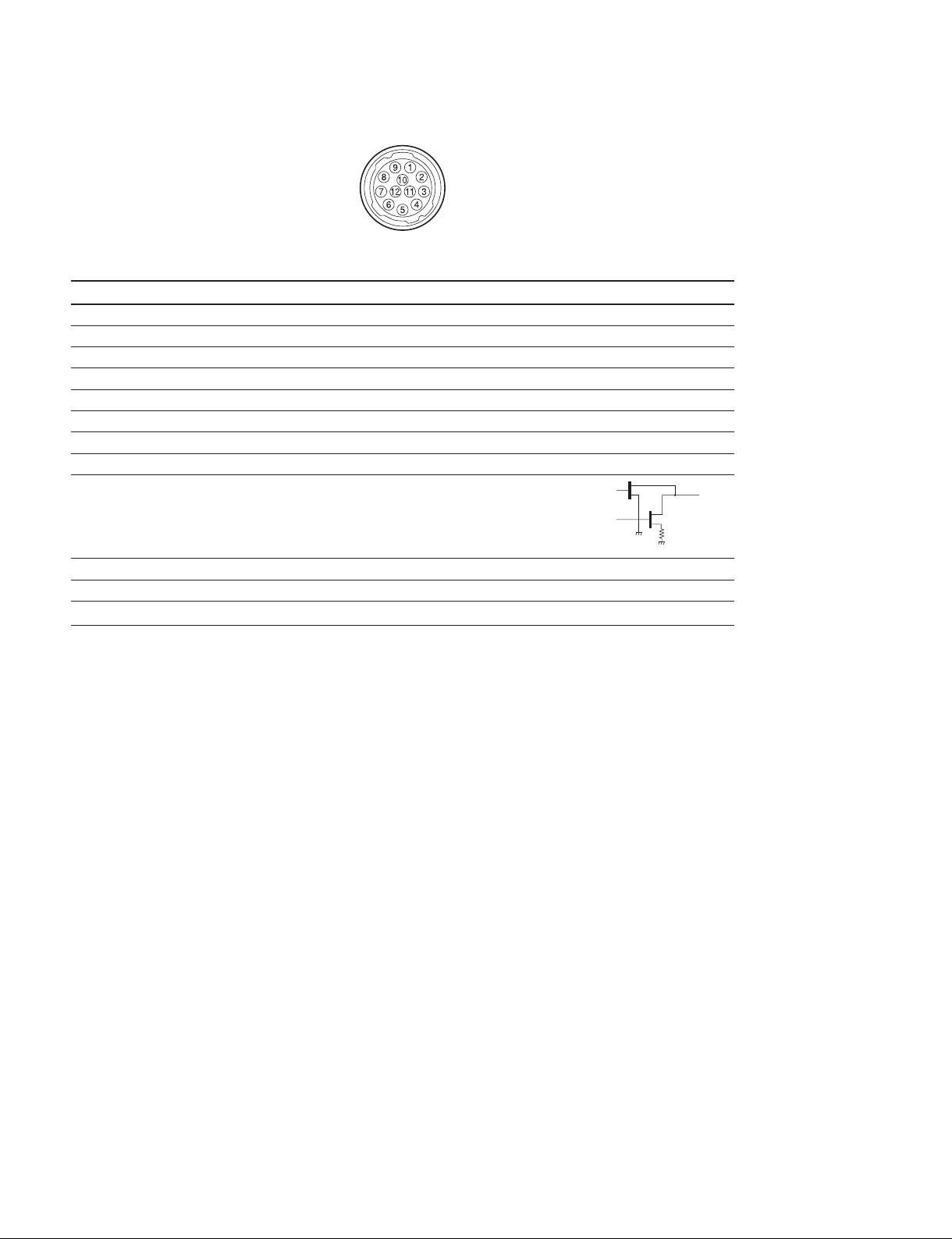

9 TRACKER (10P FEMALE)

81

27

10 9

63

54

(External view)

No. Signal I/O Specifi cations

1 TRACKER LEFT OUT TRACKER Output, _20 dBu unbalance

2 GND (TALK)

3 GND (RECEIVE/PGM/TALLY)

_

_

GND for TRACKER TALK

GND for RECEIVE/PGM/TALLY

4 TRACKER RIGHT OUT TRACKER Output, _20 dBu unbalance

5 UNREG OUT

6 GND (UNREG)

_

+10.5 to 17 V dc

GND for UNREG

7 TRACKER TALK (X) IN TRACKER TALK

8 TRACKER TALK (Y) IN

0 dBu /_20 dBu, High impedance balanced

9 G TALLY OUT ON : GND

OFF : High impedance (Open collector)

10 R TALLY OUT ON : GND

OFF : High impedance (Open collector)

(0 dBu = 0.775 Vrms)

HXC-100/V1 (E)

1-3

0 DC OUT (4P FEMALE)

1

4

23

(External view)

No. Signal I/O Specifi cations

1 UNREG GND

2 NC No connection

3 NC No connection

4 UNREG-OUT OUT

_

GND for UNREG-OUT

+10.5 to 17 V dc, 500 mA (max)

!- DC IN (4P MALE)

(External view)

No. Signal I/O Specifi cations

1 EXT_DC (C)

2 NC No connection

3 NC No connection

4 EXT_DC (H) IN

AUDIO IN CH1/CH2 (3P FEMALE)

!=

No. Signal I/O Specifi cations

1 AUDIO CH1/CH2 (G)

2 AUDIO CH1/CH2 (X) IN

3 AUDIO CH1/CH2 (Y) IN

_

21

(External view)

__60 dBu, _50 dBu, _40 dBu, _30 dBu, _20 dBu,

GND for DC (+)

+10.5 to 17 V dc

3

LINE (0 dBu) selectable, Balanced

(0 dBu = 0.775 Vrms)

1-4

HXC-100/V1 (E)

![ FRONT MIC (3P FEMALE)

21

3

(External view)

No. Signal I/O Specifi cations

1 MIC 1 (G)

2 MIC 1 (X) IN

3 MIC 1 (Y) IN

__60 dBu, _50 dBu, _40 dBu, _30 dBu, _20 dBu,

selectable, Balanced

!] VF (20P FEMALE)

(External view)

(0 dBu = 0.755 Vrms)

No. Signal I/O Specifi cations

1 S-DATA IN/OUT TTL level

2 NC No connection

3 NC No connection

4 SCK OUT TTL level

5 NC No connection

6 NC No connection

7 NC No connection

8 G TALLY OUT ON : 5 V, OFF : GND

9 NC No connection

10 NC No connection

11 NC No connection

12 Y VIDEO OUT 1.0 V p-p, Zo = 75 Z

13 VIDEO GND

14 Pb VIDEO OUT

15 Pr VIDEO OUT

16 NC No connection

17 R TALLY OUT ON : 5 V, OFF : GND

18 NC No connection

19 UNREG GND

20 UNREG OUT

_

_

GND for VIDEO

?0.35 V p-p, Zo = 75 Z

?0.35 V p-p, Zo = 75 Z

GND for UNREG

+10.5 to +17 V

HXC-100/V1 (E)

1-5

!\ LENS (12P FEMALE)

(External view)

No. Signal I/O Specifi cations

1 RET VIDEO ENABLE IN ENABLE : 0 V, DISABLE : +5 V or OPEN

2 VTR START/STOP IN ENABLE : 0 V, DISABLE : +5 V or OPEN

3 GND

4 SERVO MA/AT OUT AUTO : +5 V, MANU : 0 V or OPEN

5 IRIS POSITION OUT

6 UNREG OUT

7 IRIS POSITION IN

8 IRIS AT/MA OUT AUTO IRIS : 0 V, MANUAL IRIS : +5 V

9 EXTENDER ON/OFF IN EX 2 ON : GND

10 ZOOM POSITION IN WIDE : 2 V, TELE : 7 V

11 FOCUS POSI (/LENS RX) IN

12 (LENS TX) OUT

_

GND for UNREG

+3.4 V (F16) to +6.2 V (F2.8)

+10.5 to +17 V

+3.4 V (F16) to +6.2 V (F2.8)

EX 0.8 ON : 30 kZ to GND

OFF : OPEN

% : 7 V, min. : 2 V

EX 2 ON

EX 0.8 ON

30 k7

1-6

HXC-100/V1 (E)

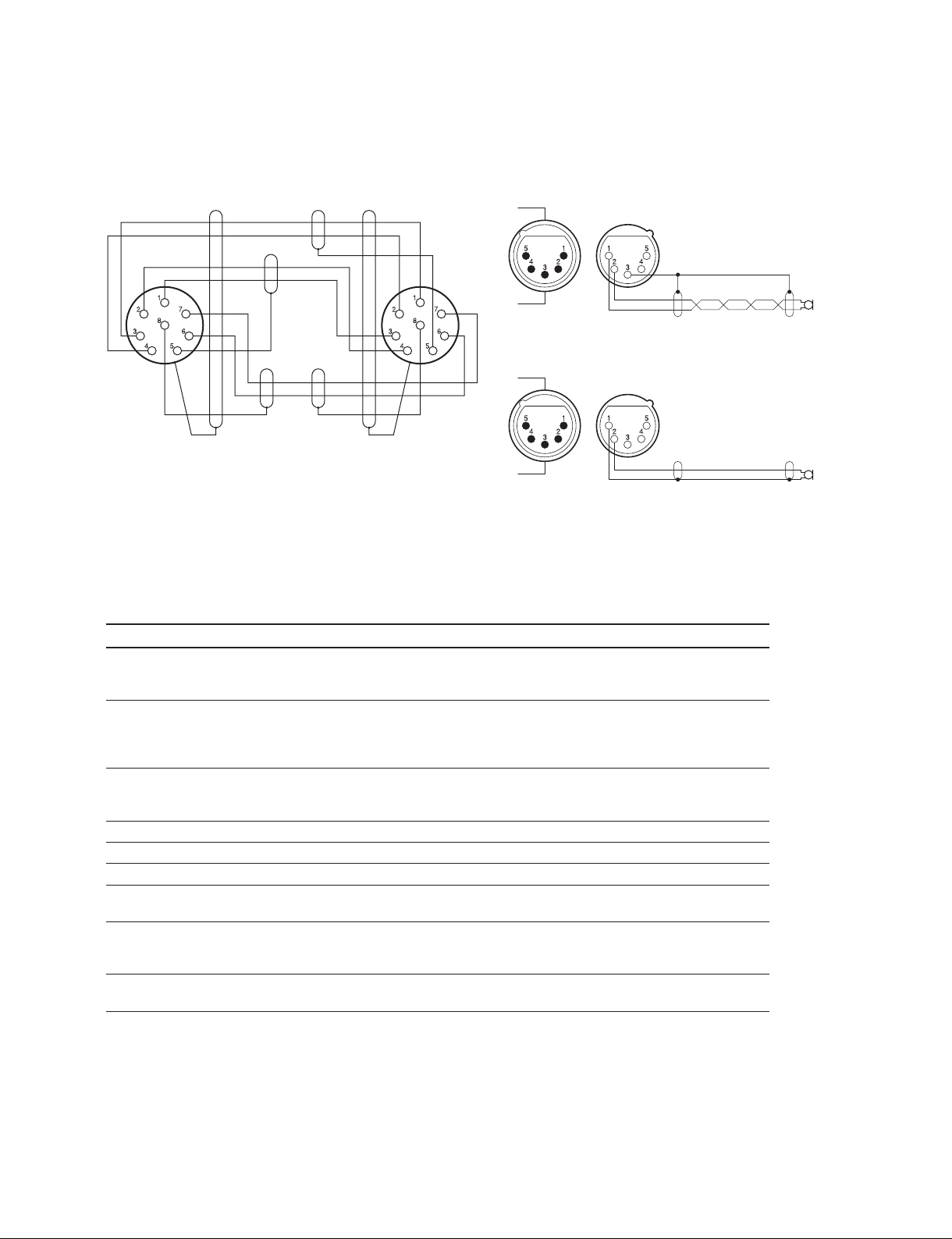

1-1-2. Wiring Diagrams for Cables

CCA-5 Cable

INTERCOM MIC Cable

(1) Balance (HEAD SET menu UNBAL: OFF)

Black

White

Orange

White

Brown

Red

G

X

Y

(2) Unbalance (HEAD SET menu UNBAL: ON)

White

Red

BrownBrown

— 8P CONNECTOR (MALE) —

(WIRING SIDE)

X

Y

1-1-3. Connection Connectors/Cables

Connection made with the connector panels during installation or service, should be made with the connectors/complete cable assemblies specifi ed in the following list, or equivalent parts.

INTERCOM

MIC

INTERCOM

MIC

Connector Name Connector/Cable

CCU (TRIAX) Fujikura φ8.5 mm

Fujikura φ14.5 mm

Belden 9232 φ13.2 mm

TEST OUT

1-569-370-12 Plug, BNC

PROMPTER/GENLOCK/RET

SDI

(BNC)

AUDIO IN CH1/CH2

1-508-084-00 XLR, 3P Male or ITT Cannon XLR-3-12C equivalent

MIC

(3P FEMALE)

RET CONTROL (6P FEMALE) 1-560-078-00 Plug, 6P Male or HIROSE HR10-7PA-6P equivalent

DC OUT (4P FEMALE) 1-566-425-11 Plug, 4P Male or HIROSE HR10A-7P-4P equivalent

INTERCOM (5P FEMALE) 1-508-370-11 XLR, 5P Male or ITT Cannon XLR-5-12C equivalent

DC IN (4P MALE) 1-508-362-00 XLR, 4P Female or ITT Cannon XLR-4-11C equivalent

DC cable CCDD-X2 (2 m)

REMOTE (8P FEMALE)

. 1-766-848-11 Plug, 8P Male or CCA-5 cable assembly

(CCA-5-10 (10 m)/CCA-5-3 (3 m)) (optional)

*2 *3

. REMOTE cable 1-783-372-11 (supplied with RM-B150, 10 m)

*1 *2 *3

TRACKER (10P FEMALE) 1-506-522-12 Connector, Round Type 10P

or HIROSE HR10A-10P-10P equivalent

*1: Use of REMOTE cable enables to monitor video signals. (The pin 8 is available for the video signal line.)

The down-converted SD signal is output.

*2: If you want to use a cable of length different from a standard product, contact your local Sony Sales Offi ce/Service Center.

n

*3: The pin 8 of CCA-5 cable is GND (ground).

The pin 8 of REMOTE cable is not GND (ground).

HXC-100/V1 (E)

1-7

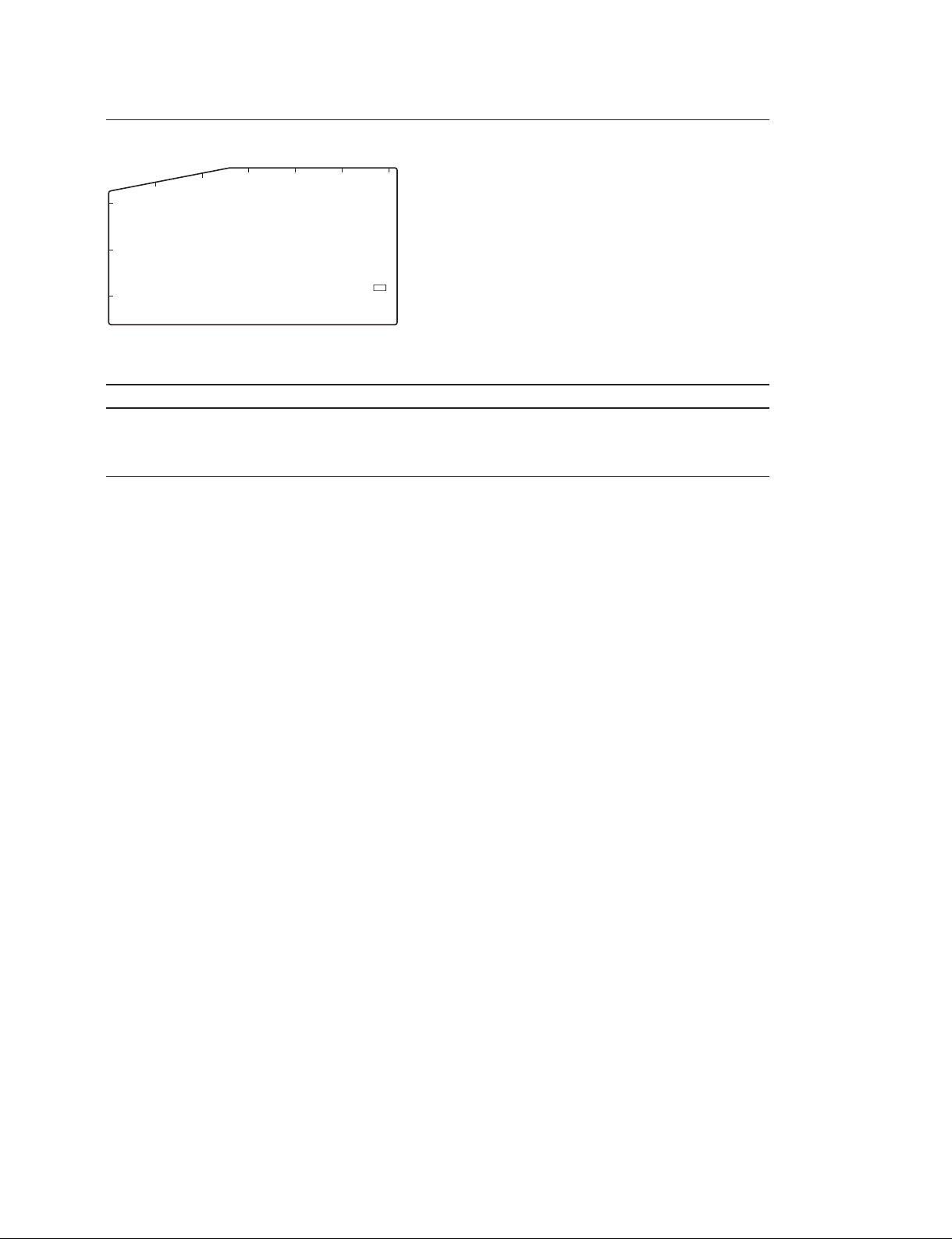

1-2. Location of Printed Circuit Boards

TX-126

ENC-112

CD-61

FL-348

DPR-298

PS-755

SY-363

RE-263

CN-3069

CN-3701

CN-3070

SW-1403

MB-1125

LE-355

CN-3074

CN-3075

SW-1406 (J, UC)

SW-1406A (CE)

CN-3073

CN-3072

CN-3076

CN-3078

SW-1407

CN-3077

SW-1402

1-8

SW-1405

SW-1404

MS-91

HXC-100/V1 (E)

TG-265

DR-632

NR-80

SE-949

PA-353

HXC-100/V1 (E)

1-9

1-3. Circuit Description

Optical System Block (CCD Unit)

PA-353 Board

This board, consisting of a CCD drive H driver and a sample-hold IC, performs correlated double sampling for signals from the CCD and outputs them differentially. The sample-hold IC adjusts sensitivity.

DR-632 Board

This board consists of a CCD V driver circuit and a buffer for CCD and sample-hold IC drive pulses.

TG-265 Board

This board consists of the following circuits.

. A PLD that generates CCD and sample-hold IC drive pulses and a video amplifi er

. A circuit to lock (using PLL) and synchronize the INT PLL H signal generated by the PLD with the

PLL H X and PLL H Y signals sent from the DPR-298 board

The master gain is switched with the step gain in the video amplifi er.

NR-80 Board

This board performs CCD defect correction and black shading, etc.

SE-949 Board

This board detects the ND fi lter disk position.

Signal Processing Block

DPR-298 Board

This board performs main camera signal processing for video signals.

Video signals are digitized by the video amplifi er and the A/D converter, and are transferred to the main

process IC (IC401) through the pre-process PLDs (IC301 to 303) for video signal processing.

The sub-process IC (IC501) and the PLD (IC701) perform video processing for the external interface.

This board also contains a serial digital signal converter IC, an analog video D/A converter, and a reference clock signal generator.

CD-61 Board

This board encodes the main-line signal and decodes the return signal and the prompter signal.

Main-Line Signal

The main-line signal processed on the DPR-298 board is encoded by the encoder and is transferred to the

OFDM modulation IC. This IC multiplexes the main-line signal and the audio signal and a command sent

from the SY-363 board to a 2-channel signal, D/A-converts the 2-channel signal, and then sends it to the

TX-126 board.

Return Signal

This board receives the OFDM-demodulated stream signal from the TX-126 board, and divides it into a

return video signal, prompter signal, audio signal for intercom, and a command signal.

The return video signal is decoded to a baseband signal by the decoder, and is then sent to the DPR-298

board.

The audio signal and the command are sent to the SY-363 board.

1-10

HXC-100/V1 (E)

Prompter Signal

This signal is sent to the MPEG2 decoder on the ENC-112 board for decoding.

In the case of the VBS prompter, the decoded signal is output from the VBS encoder (IC1201) on the

CD-61 board to the SY-363 board.

In the case of the HD prompter, the decoded signal is sent to the DPR-298 board.

ENC-112 Board

This small board is mounted on the CD-61 board, and compresses/decompresses the video signal for

prompter.

IC100 functions for MPEG2 encoding and decoding, but is used only for decoding in this unit.

Signal Transmission Block

TX-126 Board

This board consists of a OFDM signal transmitter/receiver circuit for transmission of the video signal,

audio signal, intercom signal, and commands, and an FM modulation/demodulation circuit for transmission of the standby intercom signal, synchronizing signal, and TONE signal.

OFDM Signal Transmitter/Receiver Circuit

The OFDM signal output consists of six waves F1 to F6 to transmit video, sub video, microphone, intercom, and command signals.

The OFDM signal transmitter, consisting of two systems: LOW band (F1 to F3) and MID band (F4 to F6),

amplifi es the OFDM signal generated by the D/A converter on the CD-61 board independently for each

band. The LOW band signal is mixed with the 1.4 MHz FM-modulated signal and is combined with the

MID band signal in the MPX fi lter (FL601), and then the composite signal is output to the CCU.

The OFDM signal input consists of three waves F7 to F9 to transmit return video, prompter video, intercom, PGM, and command signals.

The OFDM signal receiver that is composed independently for F7 to F9 amplifi es the waves F7 to F9

output from the HPF of the MPX fi lter (FL601), selects them by band with the BPF (FL301, FL401, and

FL501), and then processes them.

The level of each signal selected by band is regulated by the step gain amplifi er that automatically switch-

es amplifi er gain to four steps according to the input level and by the AGC amplifi er (IC302, IC402, and

IC502), and then the center frequency of F7 to F9 is converted to 36 MHz by the MIXER IC (IC303,

IC403, and IC503). The converted OFDM signal is converted to TS data by the demodulator ICs (IC603,

IC604, and IC605), and then the serial data is output to the CD-61 board.

FM Modulation and Demodulation Circuits

The FM modulation circuit mixes the standby INCOM signal (STB INCOM TO CCU: CHU → CCU)

and the TONE signal (16.38 kHz), modulates (FM) the mixed signal with a carrier frequency of 1.4 MHz,

and then sends the signal to the CCU.

In the FM demodulation circuit, the FM signal (that is modulated with 1.0 MHz carrier frequency) is

extracted from the RF signal sent from the CCU by the MPX fi lter (FL601) and the BPF (FL2), and the

FM signal is demodulated to a standby INCOM signal (STB INCOM FR CCU: CCU → CHU) and a

synchronizing signal by the demodulator (IC13 LA2135M).

The demodulated standby INCOM signal is output by the output amplifi er at a signal level of 220 mVp-p

(0 dBu input). The synchronizing signal waveform is shaped, and the signal is output with an amplitude of

3.3 Vp-p.

The 1.0 MHz FM-modulated wave is detected by IC16 to check the presence of an FM signal wave.

HXC-100/V1 (E)

1-11

System Control Block

SY-363 Board

This board comprises a CPU, peripheral devices, interfaces, a sync separator circuit, a video amplifi er,

and a audio circuit.

CPU and Peripheral Devices

The CPU runs on the program stored in the fl ash memory (IC118, IC119).

The program can be upgraded with a Memory Stick through the Memory Stick controller (IC128).

The SY-363 board also comprises SRAM chips (IC122, IC123) and a FRAM chip (IC127) to record

system setup data and other data.

The CPU’s serial communication port is used to control the CCD block, and serial lens.

The analog input ports (AN0 to AN7) are used to read analog lens signals (Iris, Focus, Zoom, and Extender), temperatures of the CCD and boards, and audio volume.

The CPU’s external bus (IC109, IC114, and IC125) is used to control the video signal processing LSI and

PLD on the DPR-298 board and the communication LSI and PLD on the CD-61 board through the

MB-1125 board.

In addition to these, this board is provided with a calendar function RTC (IC108). BT101 and C118

function as the RTC backup power supply.

700 Protocol Communication

IC145 performs 700 protocol communication between the camera and the REMOTE connector of the

CCU. Data to be sent for communication with the CCU is multiplexed on the CD-61 board, and is then

sent to the CCU. The REMOTE connector is shared with TRUNK, which are switched by the AT-PLD.

AT-PLD (IC151)

The AT-PLD is a PLD to control external inputs/outputs and the internal devices of the unit. The AT-PLD

has the following functions.

. I2C communication and 3-wire serial communication with the CCD block

. I2C communication with the viewfi nder and tally output

. I2C communication with the front boards

. Inputs of rear panel switches, handle switch, and two rotary encoders

. Tally output to the handle and TRACKER connector

. D/A converter output for lens iris control

. CPU’s V interrupt control

. Communication with the character generator on the DPR-298 board

. Fan speed detection

. Monitoring PLD and power status on each board

1-12

HXC-100/V1 (E)

VDAP-PLD (IC655)

The VDAP-PLD adjusts the phases of the genlock timing generator, SD sync signal, and HD sync signal,

and controls the video selector, audio matrix processing, and the analog circuit (including the microphone

amplifi er).

. Video block

The video block has two functions: a sync separator circuit for genlock and a video amplifi er circuit for

the VF, TEST OUT, and PROMPTER connectors. The VF analog signal from the DPR-298 board

passes through the LPF and is output from the VF connector and the BUILD UP connector. The VBS

signal passes through the LPF and is output from the REMOTE connector (PIX output) and the TEST

OUT connector.

The SD sync and HD sync signals are phase-adjusted by the VDAP-PLD, and are then output from the

TEST OUT connector.

The same connector is used for prompter output and genlock input. When the CCU is connected, the

connector outputs the prompter signal from the CD-61 board. When the unit is standalone, the connector is used for genlock input, and the Reference-H, F signals are generated by the sync separator circuit

and are then sent to the DPR-298 board.

. Audio Processing Block

This block is provided with input/output amplifi ers and A/D and D/A converters for the microphone,

intercom, earphone, and TRACKER, and a digital matrix to add signals. This block also has a standby

intercom circuit for communication with the CCU in the standby state.

The FRONT MIC connector or AUDIO IN connector is selectable for the microphone input, and only

the AUDIO IN connector is compatible with the LINE-level input. The microphone input is provided

with variable gain that can be switched within a range of -60 dBu to -20 dBu in 10 dBu step and +48V

Phantom power supply. The microphone input is not compatible with AB POWER.

The intercom input is provided with gain switching (-20, -40, or -60 dBu) and power supply (approx. 10

V) for carbon microphone. The TRACKER input is provided with gain switching (0 or -20 dBu).

Each input passes through the pre-fi lter, is A/D-converted, and is then input to the VDAP-PLD.

The microphone and intercom outputs are switched and added by the VDAP-PLD, are multiplexed on

the CD-61 board, and are then output to the CCU. Signals from the CCU are transferred to the CD-61

board and then input to the VDAP-PLD that performs signal addition according to each output and

volume processing. Then the signals are output to the D/A converters for the intercom, earphone, and

TRACKER. The D/A converter output signals pass through the analog LPFs and the output drivers, and

are then output from each connector.

In the standby state, the standby audio input (STBY Incom in signal) from the TX-126 board is adjusted

for volume by the electronic potentiometer (IC603), and then becomes an intercom output. The mute

circuit (IC588 to IC591) prevents the Triax-H signal from becoming an intercom output.

MS-91 Board

This board contains a Memory Stick slot, an access indicator LED, and two I2C controllers for board

input/output at the front and inside.

LE-355 Board

This board contains handle tally LEDs (red, green ) and an ON/OFF switch.

CN-3069 Board

This board contains a VF connector.

CN-3070 Board

This board contains a LENS connector.

HXC-100/V1 (E)

1-13

CN-3071 Board

This board contains a FRONT MIC connector (XLR 3-pin, female).

CN-3072 Board

This board contains an INTERCOM connector (XLR 5-pin, female).

CN-3073 board

This board contains an EARPHONE connector (φ3.5 mm stereo mini jack).

CN-3074 Board

This board contains a REMOTE connector (round, 8-pin).

CN-3075 Board

This board contains a TEST OUT connector, PROMPTER/GENLOCK/RET connector, and two BNC

connectors.

CN-3076 Board

This board contains the following switches and connectors.

. AUDIO IN switching switch × 3

. RET CTRL connector (round, 6-pin)

. TRACKER connector (round, 10-pin)

. DC OUT connector (round, 4-pin)

CN-3077 Board

This board contains two AUDIO IN connectors (XLR 3-pin, female) on the connector panel.

CN-3078 Board

This board contains a DC IN connector (XLR 4-pin, male).

SW-1402 Board

This board contains two ASSINABLE switches on the inside panel.

SW-1403 Board

This board contains two handle switches (RET, INCOM).

SW-1404 Board

This board contains fi ve switches (GAIN, DCC, WHITE, MENU, and DISPLAY) on the inside panel.

SW-1405 Board

This board contains three switches on the front panel, a potentiometer, and a rotary encoder.

SW-1406/A Board

This board contains seven switches on the intercom panel, potentiometers (CE: 5 and UC: 3), and a rotary

encoder.

SW-1407 Board

This board contains a CAM POWER switch.

1-14

HXC-100/V1 (E)

Power Supply

PS-755 Board

Input power voltages include 38 Vdc to 180 Vdc supplied by the CCU and 10 Vdc to 17 Vdc supplied by

the external DC power supply unit.

Output power voltages are as follows:

. Standby voltages +13.5 V and _5.5 V

. Voltage 14 V for viewfi nder

. Voltage 14 V for lens

. Voltage 14 V for utility

. Voltage 48 V for audio circuit

. Voltage 26 V for intercom

. Voltages 6.5 V and 1.8 V for CCD

. Other voltages 5.5 V, 3.8 V, and _5.5V

When 38 V is supplied from the CCU, only standby voltages +13.5 V and _5.5 V are output. When 180 V

is supplied from the CCU, all voltages are output. When voltages are supplied by the external DC power

supply unit, all voltages are output.

RE-263 Board

This small board on the PS-755 board outputs voltages 25 V, 15.5 V, and _8.5 V for the CCD.

MB-1125 Board

This is the motherboard of the unit, which contains interface with each board, inductors for power fi lters

of each board, capacitors, a positive-characteristic thermistor to prevent overcurrent, and a fuse.

FL-348 Board

This board isolates RF signals from the DC power for this unit.

HXC-100/V1 (E)

1-15

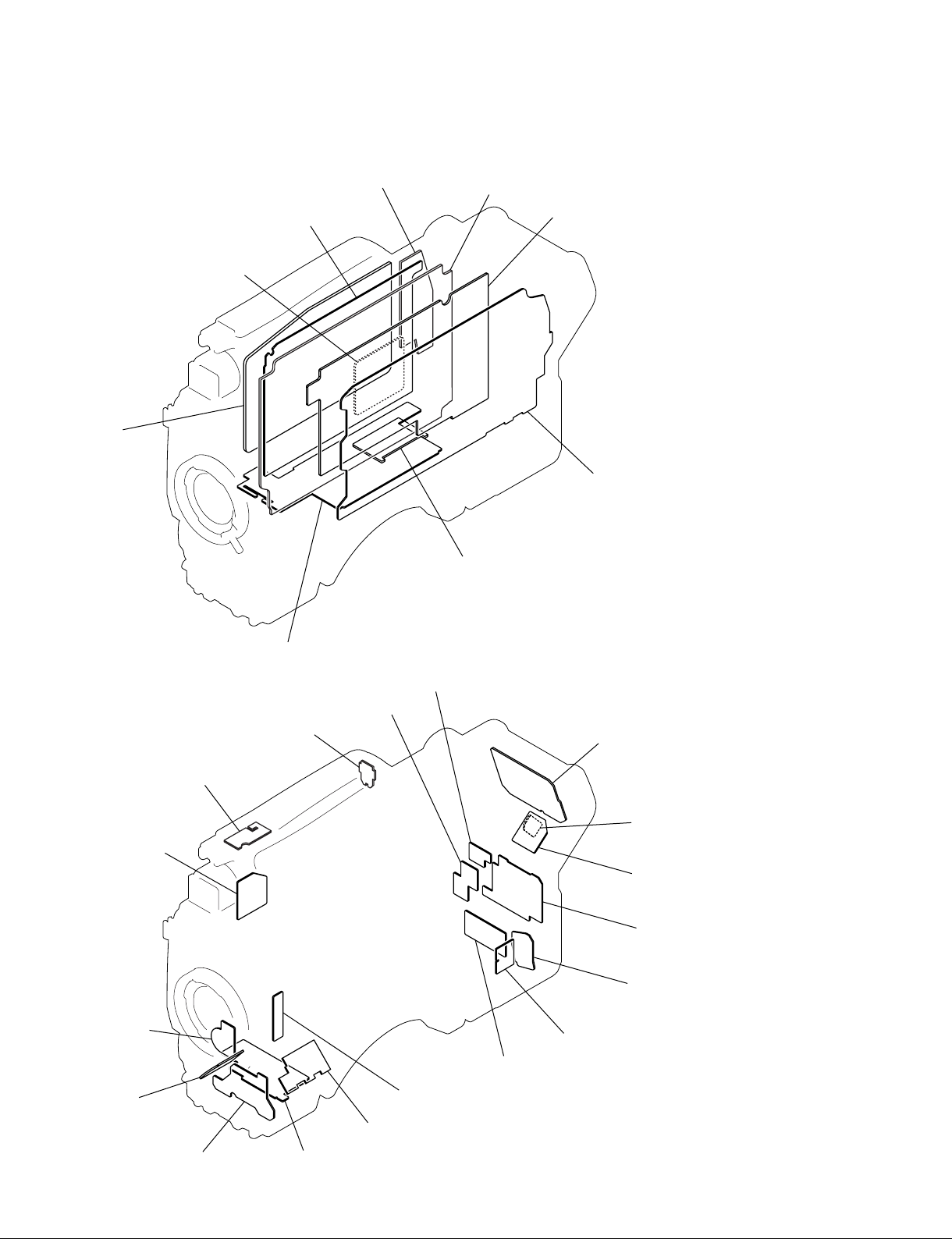

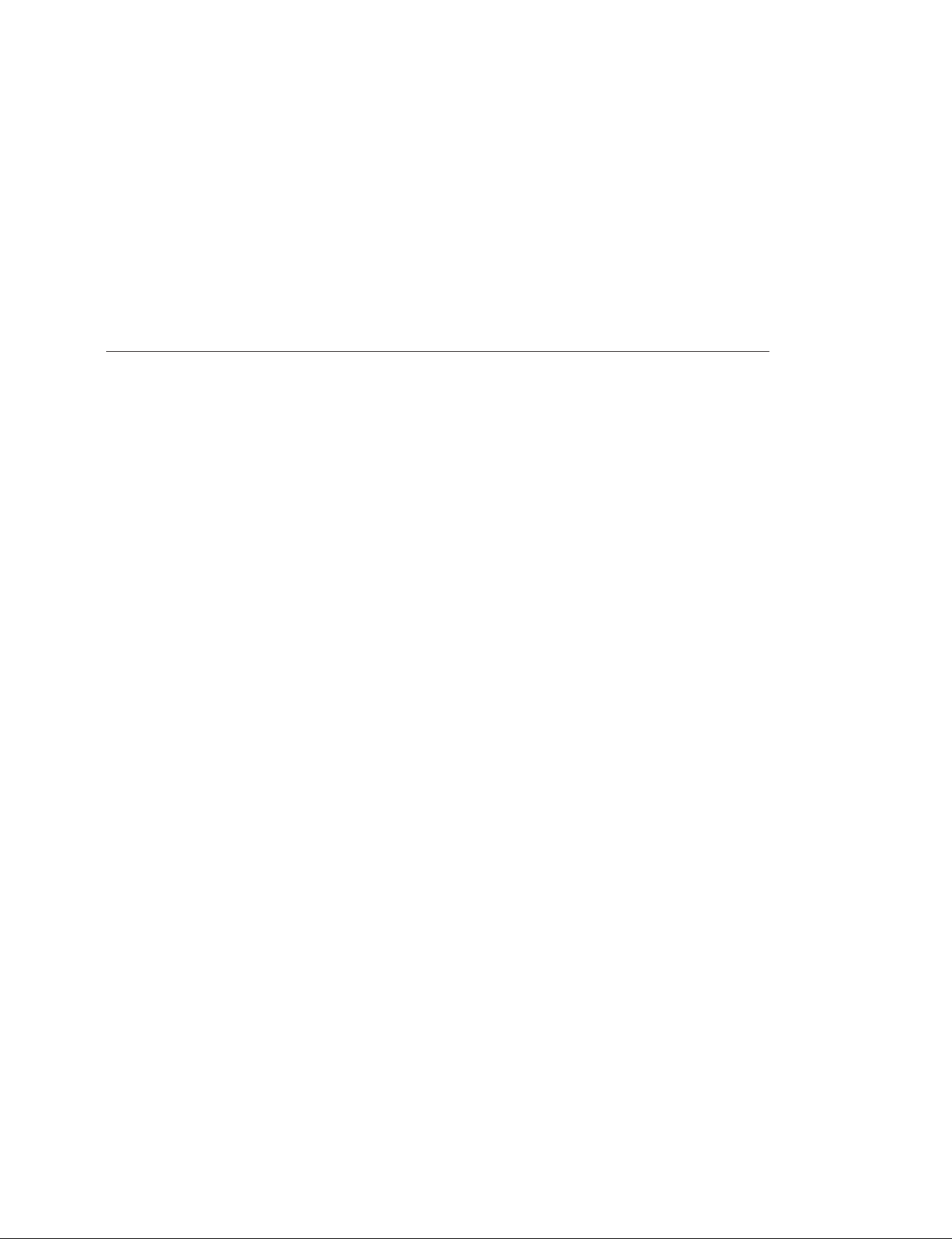

1-4. Opening/Closing the Side Panel

Inside Panel

1. Loosen the four screws with stopper to detach the

inside panel.

2. Reinstall the inside panel by reversing the step above.

n

Turn all the toggle switches to the front side, and then

attach the inside panel.

Toggle switches

Inside panel

Screws with stopper

Outside Panel

1. Loosen the fi ve screws with stopper and open the

outside panel in the arrow direction.

2. Hook the outside panel to potion A (two locations) to

fi x it.

n

Be careful so that the fl exible card wires between the

TX-126 and CD-61 boards do not shift or come off.

3. Close the outside panel by reversing the steps above.

A

Screws with stopper

Outside panel

Flexible card wires

A

Screws with stopper

1-16

HXC-100/V1 (E)

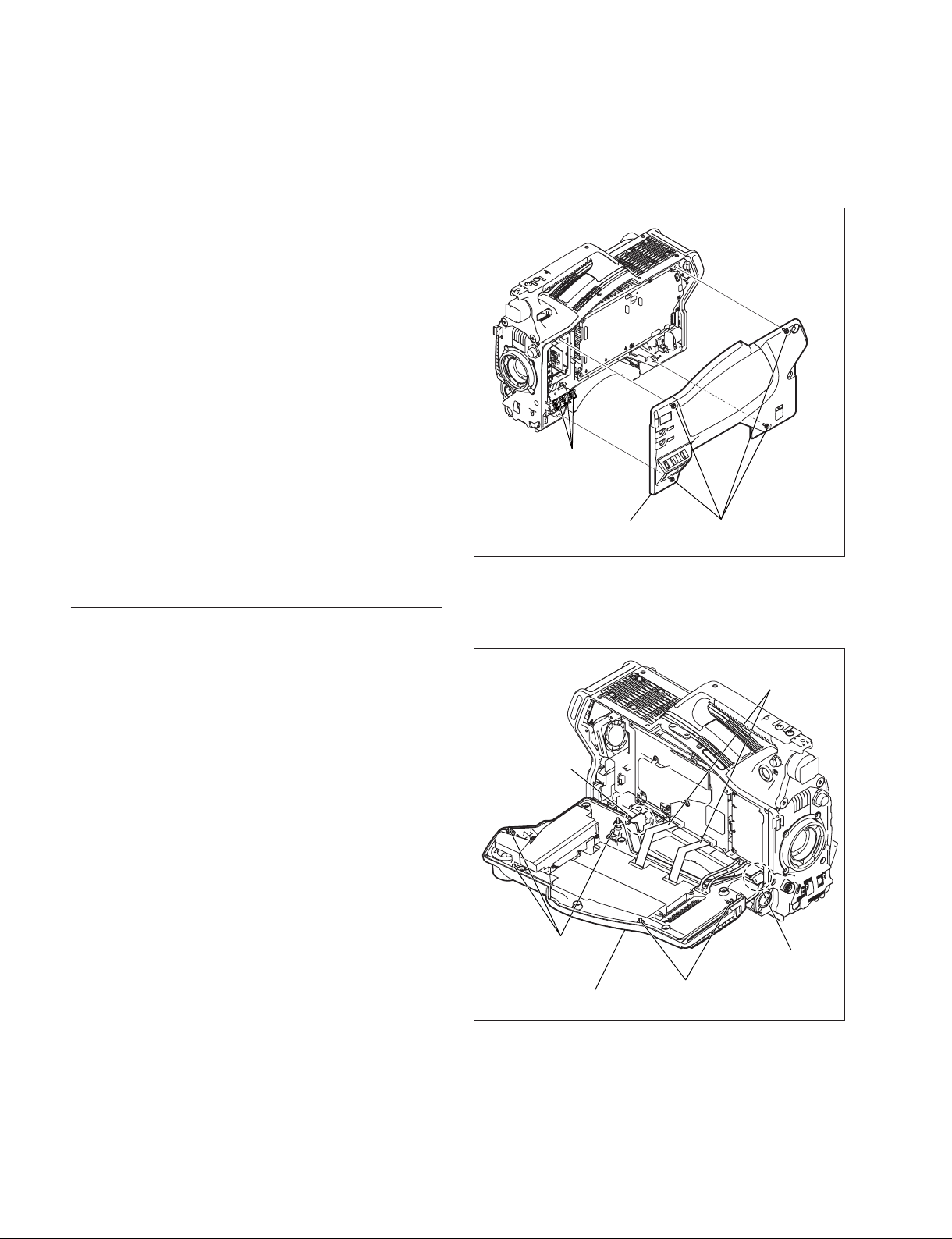

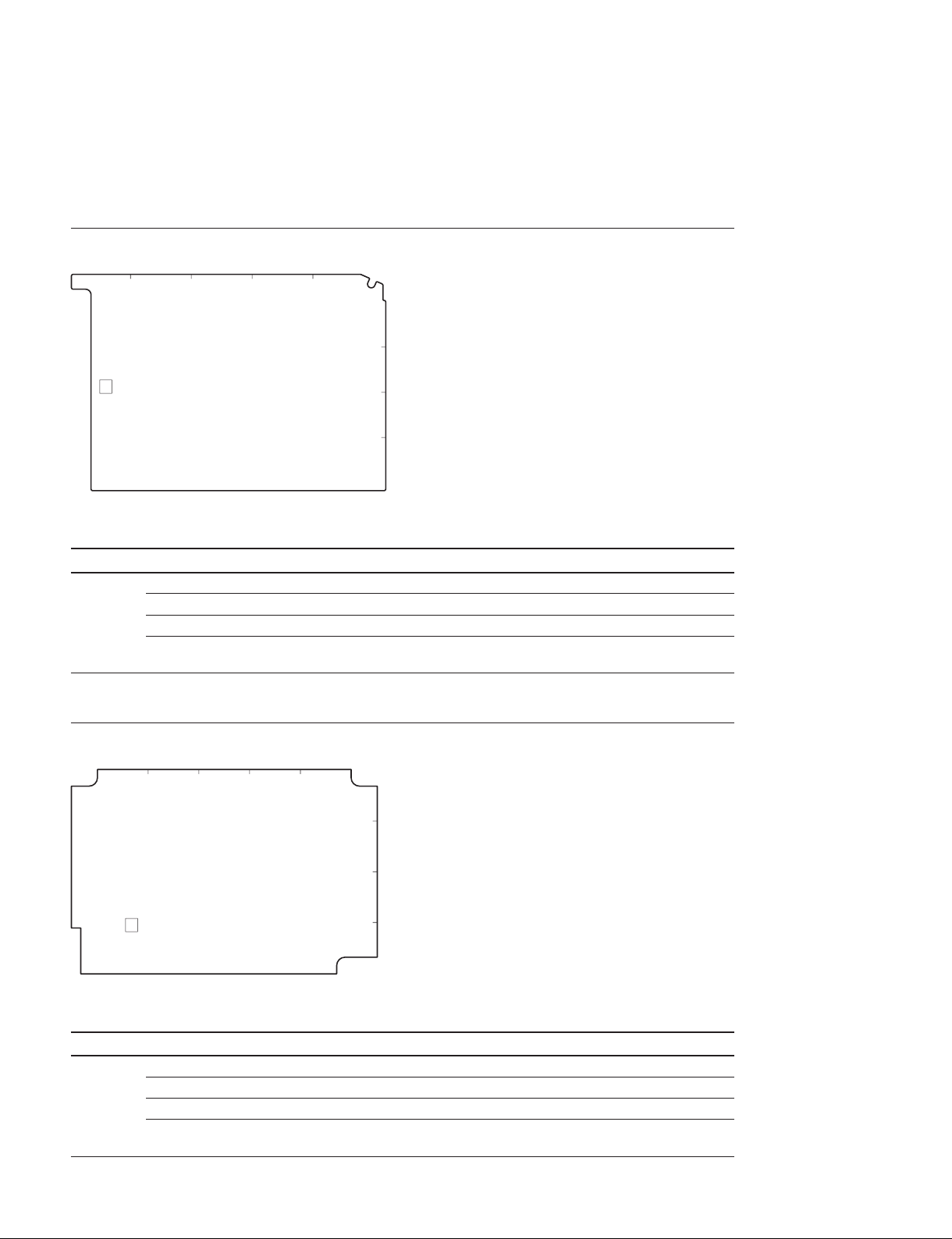

1-5. Description of Onboard LED Indicators

CD-61 Board

AB C DE

D1

1

2

3

4

CD-61 BOARD (SIDE A)

Ref No. Name Color Description Normal state

D1 PWR Green Lights when all power voltages are nor-

mal when the CCU is connected.

Lit

DPR-298 Board

DCBAE

1

2

3

4

D401

DPR-298 BOARD (SIDE B)

Ref No. Name Color Description Normal state

D101 POWER Green Lights when all power voltages on the

D401 CTL Green Lights instantly at power-on and is

D101

Lit

board are normal.

_

turned off immediately by the CPU

control.

HXC-100/V1 (E)

1-17

ENC-112 Board

BA

D100

D101

D102

1

2

ENC-112 BOARD (SIDE B)

Ref No. Name Color Description Normal state

D100 STATUS 0 Green Blinks while IC100 on the ENC-112

D101 STATUS 1 Green

board is functioning.

Blinking

D102 STATUS 2 Green

SY-363 Board

BCDE A

1

D535

D10 D11

2

D201

3

SY-363 BOARD (SIDE B)

Ref No. Name Color Description Normal state

D10 CAM-PW Green Lights while the main power is sup-

plied.

CCU connected

ON: Lit

Standby: Off

D11 STBY-PW Green Lights while the standby power is

Lit

supplied.

D201 Status Green Not used

D535 RTS PW Red While the INTERCOM connector is

_

Off

supplied with RTS PW (+26 V).

1-18

HXC-100/V1 (E)

TX-126 Board

B

A

1

2

3

4

GFEDC

D205

TX-126 BOARD (SIDE A)

Ref No. Name Color Description Normal state

D205 POWER Green Lights while both main power and

standby power are supplied.

CCU connected

ON: Lit

Standby: Off

CCU disconnected: Off

HXC-100/V1 (E)

1-19

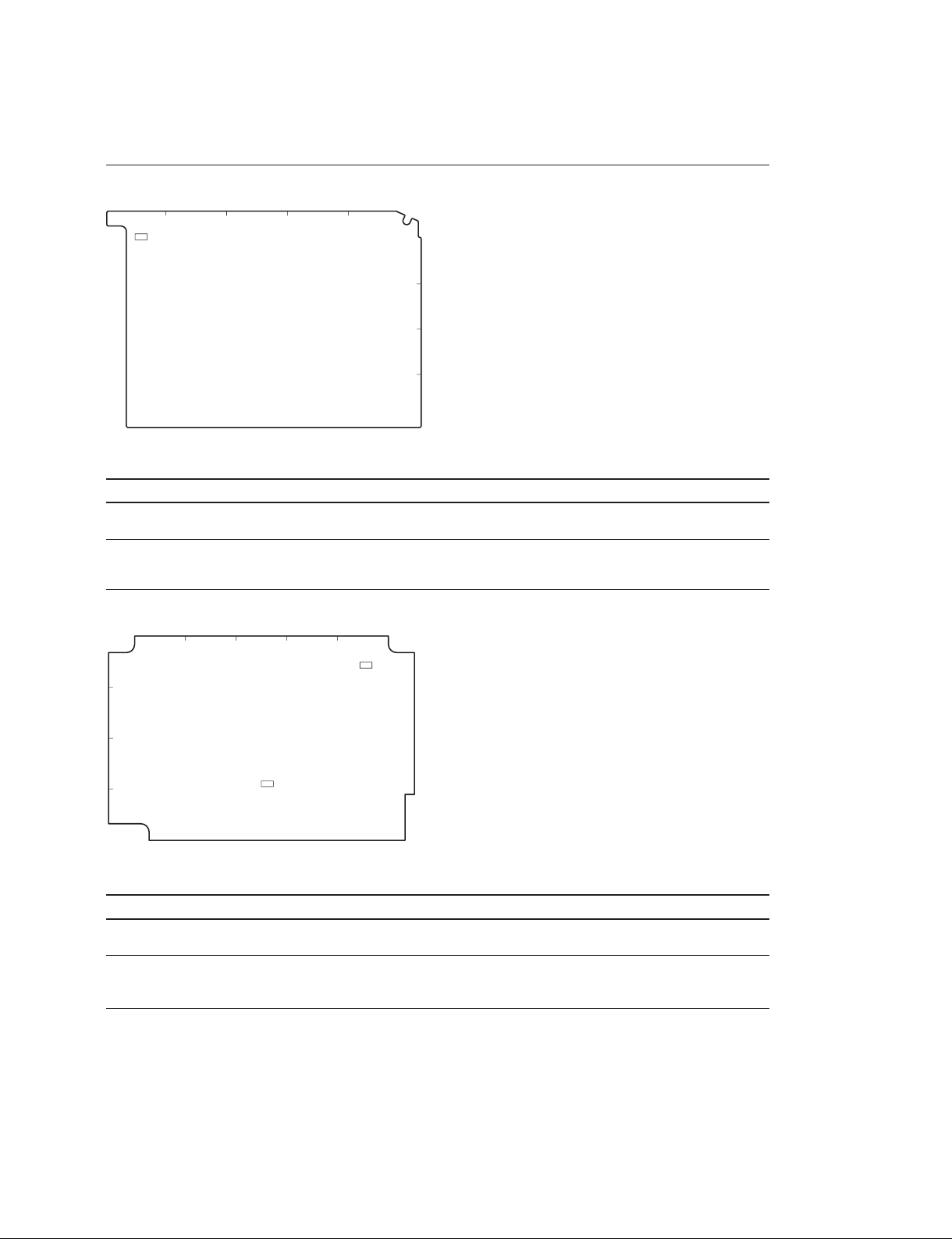

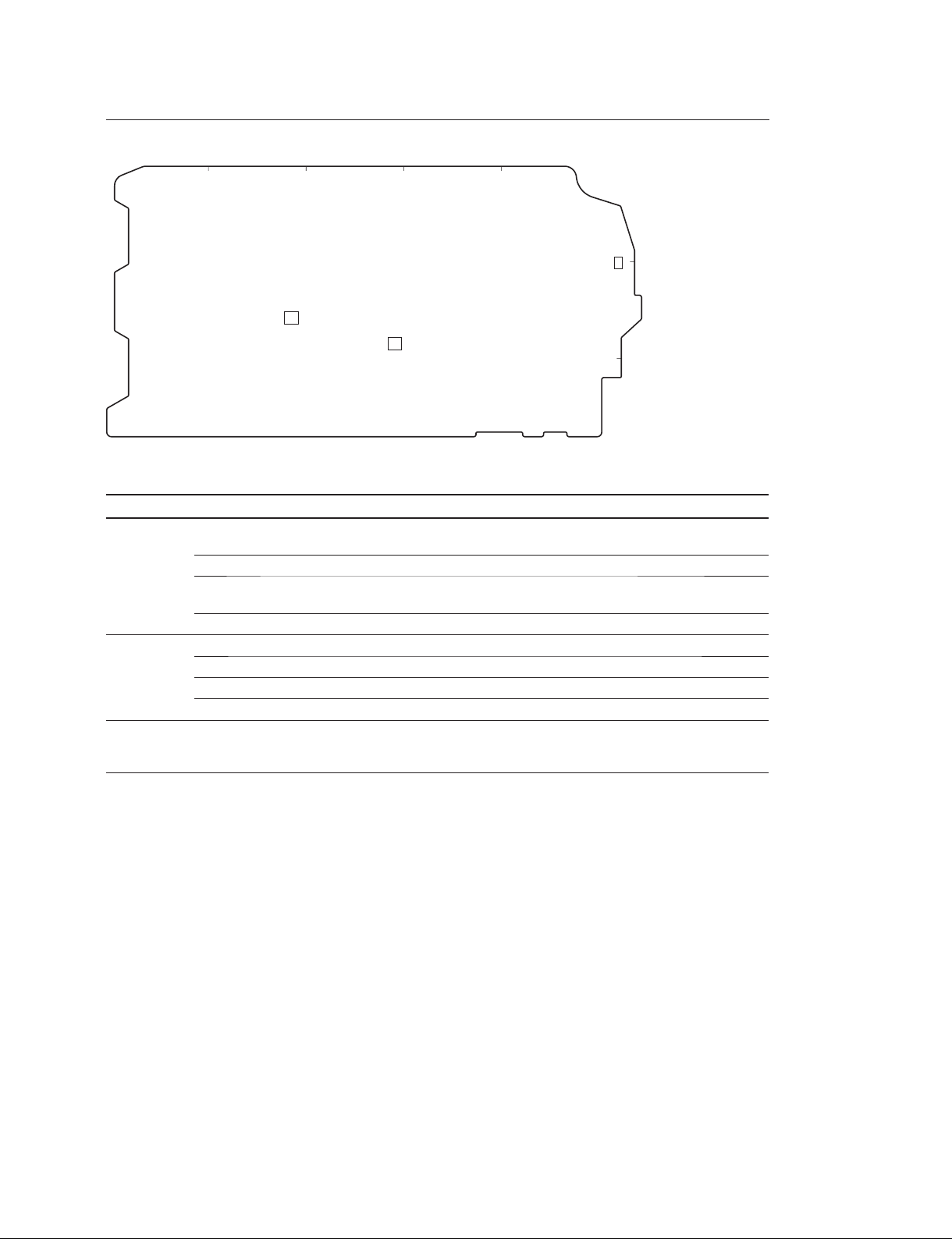

1-6. Switch Settings

n

Do not change the settings of unused switches.

CD-61 Board

AB C DE

1

2

S701

3

4

CD-61 BOARD (SIDE A)

Ref No. Bit Description Factory setting

S701 1 Not used OFF

2 Not used OFF

3 Not used OFF

4 OFF: Normal operation (for upgrading the PLD from the SY-363 board)

OFF

ON: For upgrading the PLD from CN701 on the CD-61 board

DPR-298 Board

BCDEA

1

2

3

S901

4

DPR-298 BOARD (SIDE A)

Ref No. Bit Description Factory setting

S901 1 Not used OFF

2 Not used OFF

3 Not used OFF

4 OFF: Normal operation (for upgrading the PLD from the SY-363 board)

OFF

ON: For upgrading the PLD from CN901 on the DPR-298 board

1-20

HXC-100/V1 (E)

SY-363 Board

BCDE A

1

S502

2

S101

S201

3

SY-363 BOARD (SIDE B)

Ref No. Bit Description Factory setting

S101 1 OFF: Normal operation

ON: Forcible fi rmware upgrade

2 Not used OFF

3 OFF: Normal operation

ON: FRAM clear

4 Not used OFF

S201

(MODE)

1 Not used OFF

2 Not used OFF

3 Not used OFF

4 Not used OFF

S502

_

Intercom output interface switching

Normal: 4-wire

RTS: RTS/Clear-Com

OFF

OFF

OFF

HXC-100/V1 (E)

1-21

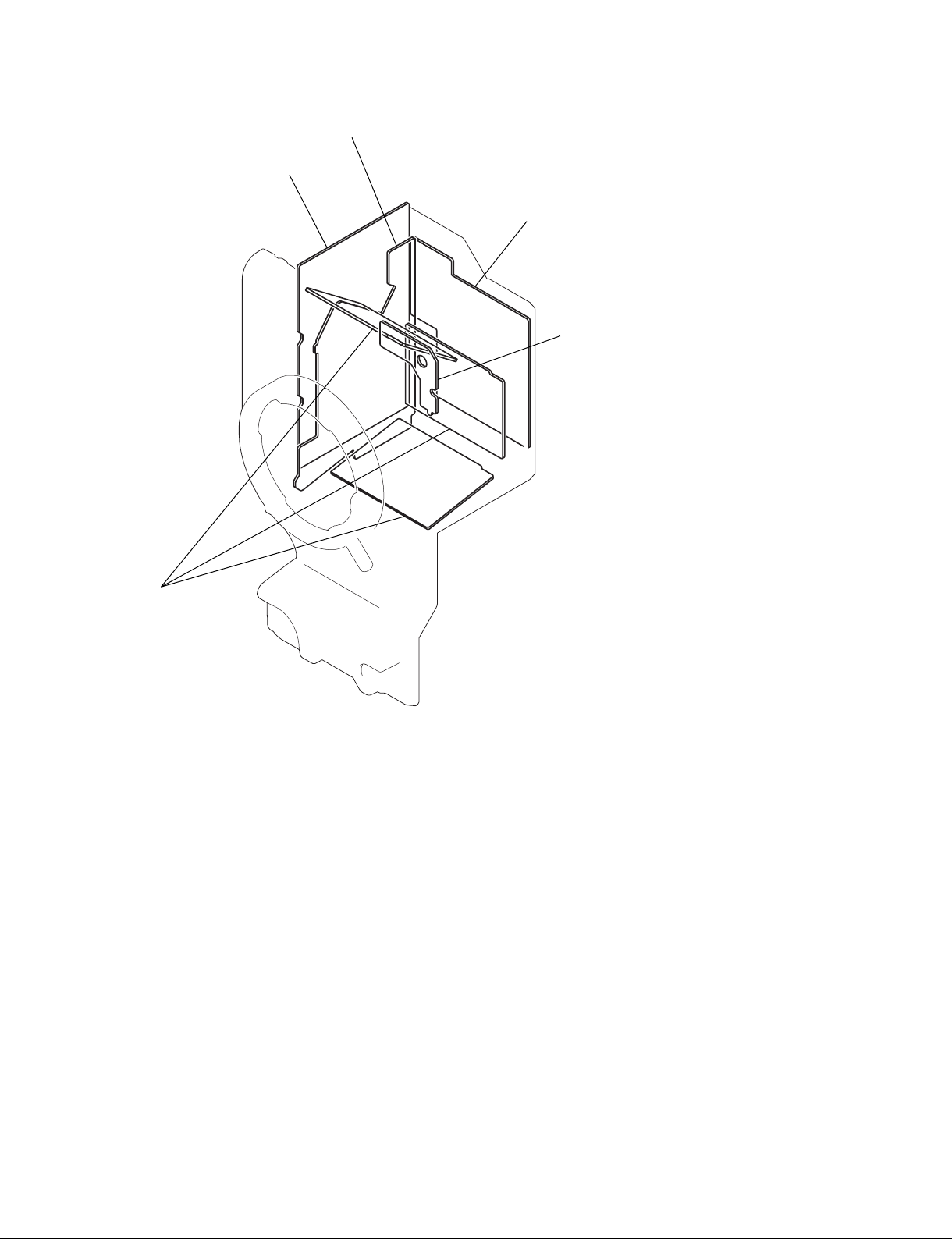

1-7. Notes on Flexible Card Wire

1-7-1. Disconnecting/Connecting Flexible Card Wire

Flexible card wires are used between the boards of this unit. Take care not to bend forcedly these fl exible

card wires. This shortens the wire life.

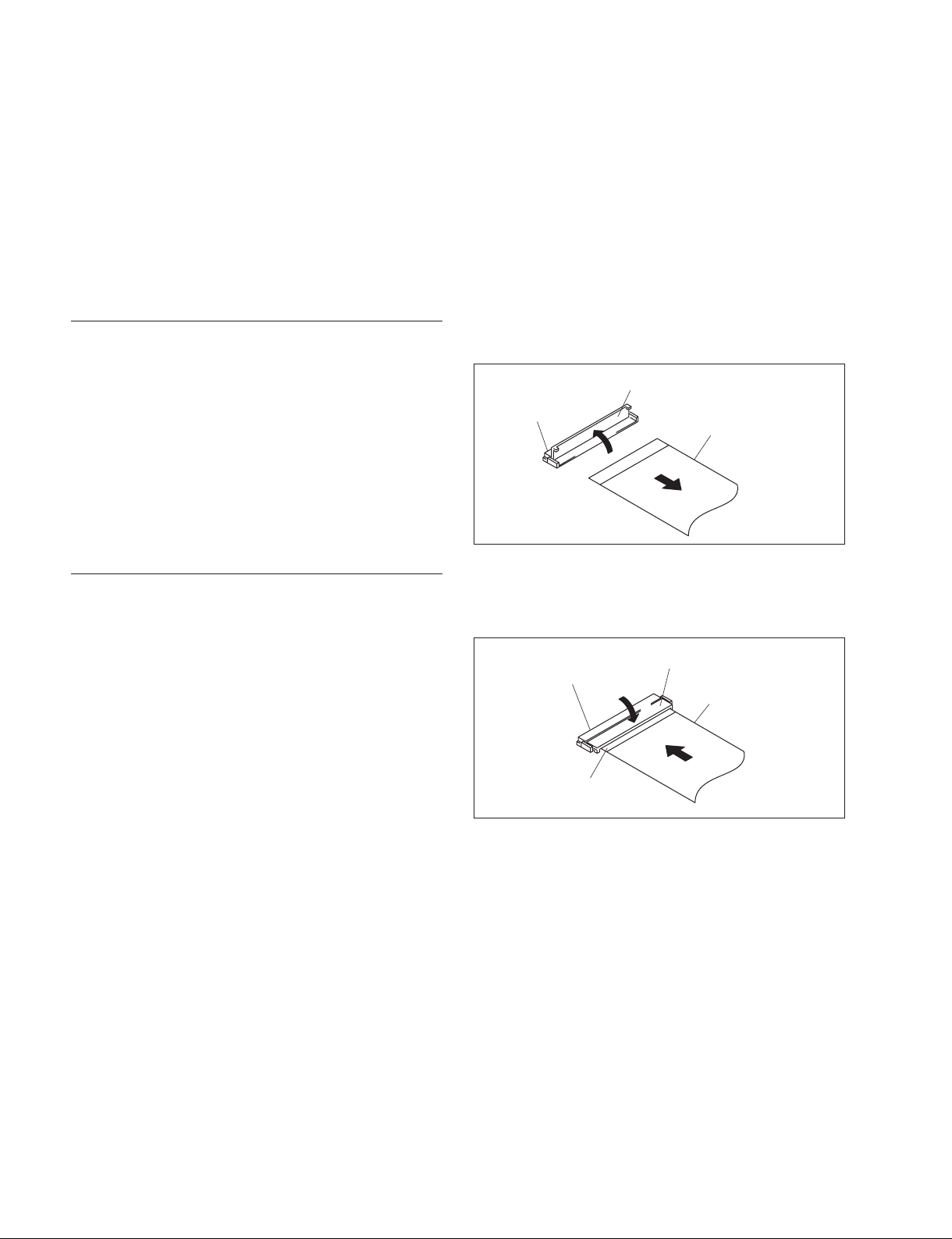

Type-A

Disconnecting

1. Raise the connector open/close lever in the arrow A

direction to unlock the coupling.

2. Pull out the fl exible card wire in the arrow B direction.

Connecting

m

. Be careful not to insert the fl exible card wire obliquely.

. Check that the conducive surface of the fl exible card

wire is not contaminated.

1. Insert the fl exible card wire in the arrow A direction as

far as it will go with the insulating surface facing

upward.

2. Close the connector open/close lever in the arrow B

direction to lock the fl exible card wire.

Connector

Connector

Insulating surface

Connector open/close lever

Flexible card wire

A

B

Connector open/close lever

Flexible card wire

B

A

1-22

HXC-100/V1 (E)

Loading...

Loading...