Sony HVR-1500 Service manual

DIGITAL HD VIDEOCASSETTE RECORDER

HVR-1500

ANALOG INPUT BOARD

HVBK-1505

FORMAT CONVERTER BOARD

HVBK-1520

SERVICE MANUAL

Volume 1 1st Edition (Revised 1)

! WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

HVR-1500

Für Kunden in Deutschland

Entsorgungshinweis: Bitte werfen Sie nur entladene

Batterien in die Sammelboxen beim Handel oder den

Kommunen. Entladen sind Batterien in der Regel dann,

wenn das Gerät abschaltet und signalisiert “Batterie

leer” oder nach längerer Gebrauchsdauer der Batterien

“nicht mehr einwandfrei funktioniert”. Um

sicherzugehen, kleben Sie die Batteriepole z.B. mit

einem Klebestreifen ab oder geben Sie die Batterien

einzeln in einen Plastikbeutel.

Voor de klanten in Nederland

Gooi de batterij niet weg maar lever deze in als klein

chemisch afval (KCA).

For the customers in Taiwan only

HVR-1500

1 (P)

CAUTION

ADVARSEL!

Lithiumbatteri-Eksplosionsfare ved fejlagtig

håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the manufacturer.

Dispose of used batteries according to the

manufacturer’s instructions.

Vorsicht!

Explosionsgefahr bei unsachgemäßem Austausch

der Batterie.

Ersatz nur durch denselben oder einen vom

Hersteller empfohlenen ähnlichen Typ. Entsorgung

gebrauchter Batterien nach Angaben des

Herstellers.

ATTENTION

Il y a danger d’explosion s’il y a remplacement

incorrect de la batterie.

Remplacer uniquement avec une batterie du même

type ou d’un type équivalent recommandé par le

constructeur.

Mettre au rebut les batteries usagées conformément

aux instructions du fabricant.

ADVARSEL

Lithiumbatteri - Eksplosjonsfare.

Ved utskifting benyttes kun batteri som

anbefalt av apparatfabrikanten.

Brukt batteri returneres

apparatleverandøren.

VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en likvärdig typ

som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt gällande

föreskrifter.

VAROITUS

Paristo voi räjähtää jos se on virheellisesti

asennettu.

Vaihda paristo ainoastaan laitevalmistajan

suosittelemaan tyyppiin.

Hävitä käytetty paristo valmistajan ohjeiden

mukaisesti.

2 (P)

HVR-1500

Table of Contents

Manual Structure

Purpose of this manual ................................................................. 4

Related manuals ........................................................................... 4

Trademark ..................................................................................... 4

1. Installation

1-1. Operating Conditions ......................................................1-1

1-2. Power Supply ..................................................................1-2

1-2-1. Voltage and Power Requirements .........................1-2

1-2-2. Recommeded Power Cord ..................................... 1-2

1-3. Supplied Accessories ......................................................1-3

1-4. Optional Accessories ...................................................... 1-3

1-5. Matching Connectors/Cables ..........................................1-3

1-6. Input/Output Signals of the Connectors .........................1-4

1-7. Installation Setup and Adjustment ..................................1-6

1-7-1. Front Panel Setting ................................................1-6

1-7-2. System Adjustment After Installation ...................1-6

2. Service Overview

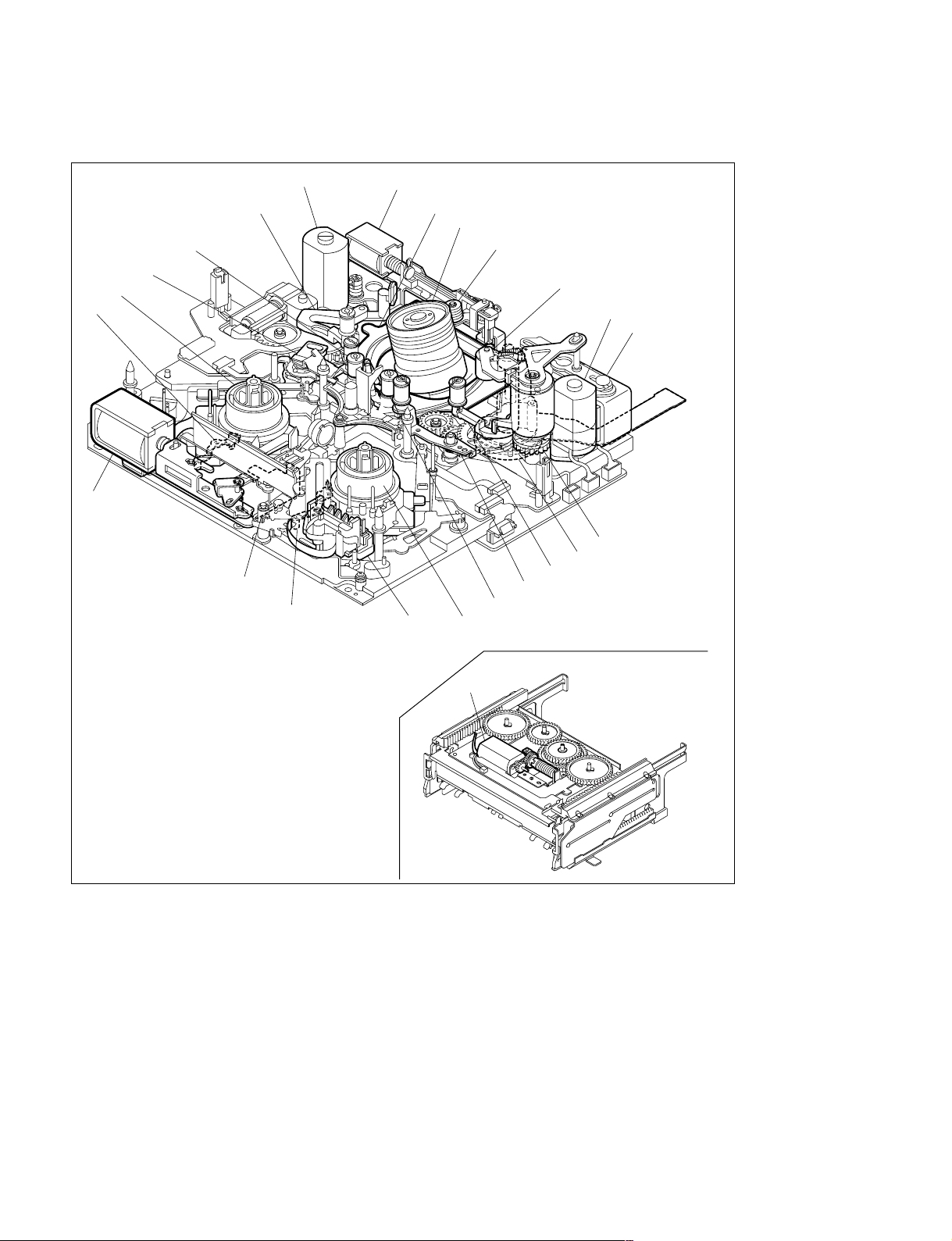

2-1. Location of Main Parts ...................................................2-1

2-1-1. Location of Printed Circuit Boards .......................2-1

2-1-2. Location of Main Mechanical Parts ...................... 2-4

2-2. Function and Location of Sensors ..................................2-5

2-3. Functions of Cassette ......................................................2-7

2-4. How to Take Out the Cassette Whose Tape is Slacked

(MANUAL EJECT) ........................................................ 2-8

2-5. Head Cleaning when Head Clogging Occurs ................. 2-8

2-6. Operating the VTR without a Cassette Tape .................. 2-9

2-7. Removing/Installing the Cabinets ................................. 2-10

2-7-1. Removal/Installation of the Top Panel ................2-10

2-7-2. Removal/Installation of the Bottom Plate ........... 2-10

2-7-3. Removal/Installation of the Front Panel .............. 2-11

2-7-4. Removal/Installation of the Rear Panel ............... 2-11

2-8. Removing/Installing the Cassette Compartment .......... 2-12

2-9. Function of Indicators on Circuit Boards .....................2-13

2-10. Switch Setting on Circuit Boards .................................2-14

2-11. Circuit Protection Parts (Fuse/IC Link) ........................2-15

2-12. Replacing NV-RAM and Memory Backup Battery .....2-16

2-13. Equipment and Fixtures List for Check/Adjustment ....2-18

2-13-1. Equipment for Check/Adjustment ....................... 2-18

2-13-2. Fixtures and Tools ...............................................2-19

2-14. Alignment Tapes ........................................................... 2-21

2-15. Tools for Board Extension ............................................2-23

2-16. Writing and Rewriting the PLD Internal Data .............. 2-25

2-17. Firmware Update .......................................................... 2-27

2-17-1. Upgrading the Version Using the

Fixture Board ....................................................... 2-27

2-17-2. Version Upgrade from a PC through RS-422 ..... 2-29

2-18. Internal Video Test Signal ............................................2-31

2-19. Service Action after Replacing or

Repairing the Board ......................................................2-31

2-20. Removing/Installing Flexible Card Wire ...................... 2-32

2-21. Unleaded Solder ............................................................ 2-35

2-22. Precautions for use of Condensation Sensor ................2-35

3. Error Messages

3-1. Alarm Display ................................................................. 3-1

3-1-1. Alarm Display when the Main Power is

Turned On .............................................................3-1

3-2. Error Codes .....................................................................3-3

3-2-1. Display of Previously Detected Error Codes ........ 3-5

3-2-2. Main Codes and Sub Codes ..................................3-6

3-2-3. Error Codes ...........................................................3-8

3-2-4. Possible Causes of Errors ....................................3-14

4. Maintenance Menu

4-1. Menu Structure ............................................................... 4-1

4-2. How to Operate Maintenance Menu ............................... 4-3

4-2-1. Location and Function of Switches .......................4-3

4-2-2. How to Enter the Maintenance Menu ...................4-3

4-2-3. How to Exit the Maintenance Menu .....................4-3

4-3. Contents of Maintenance Menu ......................................4-4

4-3-1. MENU DATA CONTROL ................................... 4-4

4-3-2. EDIT CHECK ....................................................... 4-7

4-3-3. SERVO CHECK ................................................... 4-9

4-3-4. SERVO ADJUST ................................................4-24

4-3-5. TAPE PATH ADJUST........................................ 4-31

4-3-6. ELECTRICAL ADJUST..................................... 4-32

HVR-1500

1

4-3-7. SERVICE SUPPORT .......................................... 4-40

4-3-8. OTHERS ............................................................. 4-42

5. Periodic Inspection and Maintenance

5-1. Periodic Inspection List .................................................. 5-1

5-2. Hours Meter ....................................................................5-2

5-2-1. Displaying Hours Meter Information ....................5-3

5-2-2. How to Reset Hours Meter ....................................5-4

5-3. Cleaning ..........................................................................5-5

5-3-1. Video Head Cleaning Procedure ...........................5-5

5-3-2. Tape Running Path Cleaning ................................. 5-5

5-3-3. Cassette Compartment Entrance Cleaning ............5-6

5-3-4. Cassette Compartment Shaft Cleaning ..................5-6

5-3-5. Cassette Guide Assembly Cleaning ......................5-6

6. Replacement of Mechanical Parts

6-1. General Information on Parts Replacement and

Adjustment ......................................................................6-1

6-1-1. Preparation Before Starting Parts Replacement ....6-1

6-1-2. Drum Assembly ..................................................... 6-1

6-1-3. Grease ....................................................................6-1

6-1-4. Tightening Torque and Handling of Washers .......6-2

6-2. Drum Replacement ......................................................... 6-3

6-3. Brake Solenoid Replacement ..........................................6-8

6-4. Pinch Roller Replacement ............................................6-12

6-5. Elevator Cam Replacement .......................................... 6-14

6-6. Pinch Solenoid Assembly Replacement ....................... 6-16

6-7. Reel Motor (T) Assembly Replacement .......................6-18

6-8. Reel Motor (S) Assembly Replacement ....................... 6-23

6-9. M Stop Solenoid Replacement ..................................... 6-27

6-10. S Tension Regulator Assembly Replacement ............... 6-31

6-11. T Drawer Arm Assembly Replacement ........................6-34

6-12. TG1 Arm Assembly Replacement ................................6-36

6-13. TG8 Arm Assembly Replacement ................................6-38

6-14. Rail Assembly Replacement .........................................6-40

6-15. Capstan Motor Replacement ......................................... 6-46

6-16. Loading Motor Replacement ........................................ 6-48

6-17. Reel Shift Motor Assembly Replacement ....................6-49

6-18. MIC Assembly Replacement ........................................6-51

6-19. MIC Holder Assembly Replacement ............................6-55

6-20. HC Roller Assembly Replacement ...............................6-57

6-21. Head Cleaner Solenoid Replacement ........................... 6-60

6-22. Cassette Compartment Motor Replacement ................. 6-62

6-23. Removing/Installing the MD Assembly ....................... 6-64

6-24. LCD Replacement ........................................................6-65

6-25. Removing/Installing the Switching Regulator .............. 6-65

6-26. Removing/Installing the Mounted Board .....................6-66

6-26-1. Plug-in Board ...................................................... 6-66

6-26-2. CN-1968A Board ................................................ 6-66

6-26-3. CN-2905 Board ................................................... 6-66

6-26-4. DDE-22 Board ..................................................... 6-67

6-26-5. DR-428BG Board ................................................ 6-67

6-26-6. DVP-42 Board .....................................................6-68

6-26-7. HP-136 Board ...................................................... 6-69

6-26-8. HPR-20 Board .....................................................6-69

6-26-9. KY-614 Board .....................................................6-70

6-26-10. KY-616 Board .....................................................6-70

6-26-11. MB-1098 Board ................................................... 6-71

6-26-12. RP-133 Board and RT-10 Board .........................6-72

6-26-13. SDI-94 Board ...................................................... 6-73

6-26-14. SE-521G Board ................................................... 6-73

6-26-15. SE-522G Board ................................................... 6-74

6-26-16. SE-525G Board (LED Holder Assembly) ........... 6-74

6-26-17. VNS-2 Board .......................................................6-75

7. Tape Path Alignment

7-1. General Information for Tape Path Adjustment ............. 7-1

7-2. Tape Path Adjustment ..................................................... 7-7

7-3. RF Switching Position Adjustment ..............................7-10

7-4. Tape Path Adjustment Confirmation ............................7-13

7-5. Search Forward (x5) Waveform Check ....................... 7-14

7-6. Search Reverse (x5) Waveform Check ........................7-15

7-7. RF Waveform Raiseup Check ...................................... 7-16

7-8. Tape Curl Check at Tape Guide ................................... 7-17

8. Electrical Alignment

8-1. Electrical Alignment Overview ...................................... 8-1

8-1-1. Precautions ............................................................ 8-1

8-1-2. Outline of Electrical Alignment ............................ 8-1

8-1-3. Equipment and Fixture ..........................................8-1

8-2. Audio Adjustment ........................................................... 8-2

8-2-1. Audio Output Level Adjustment ...........................8-2

8-2-2. Audio EE Level Adjustment ................................. 8-2

2

HVR-1500

8-3. Video Adjustment ...........................................................8-3

8-3-1. Preparation in the 59.94 Hz Mode ........................8-3

8-3-2. HCK Frequency Adjustment .................................8-4

8-3-3. HD HCK Frequency Adjustment .......................... 8-4

8-3-4. SYNC Phase Adjustment ...................................... 8-5

8-3-5. CHARACTER DC Adjustment ............................8-6

8-3-6. CF DET CENTER Adjustment .............................8-6

8-3-7. S VIDEO Y Level Adjustment .............................. 8-7

8-3-8. COMPOSITE Video Level Adjustment ................ 8-7

8-3-9. COMPOSITE Burst Level Adjustment .................8-8

8-3-10. S VIDEO Chroma Level Adjustment .................... 8-8

8-3-11. COMPONENT SD Y Level Adjustment .............. 8-9

8-3-12. COMPONENT HD Y Level Adjustment .............. 8-9

8-3-13. COMPONENT Y REC Level Adjustment .......... 8-10

8-3-14. COMPONENT R-Y REC Level Adjustment ...... 8-10

8-3-15. COMPONENT B-Y REC Level Adjustment ...... 8-11

8-3-16. COMPOSITE Y REC Level Check .................... 8-11

8-3-17. COMPOSITE Chroma REC Level Check .......... 8-12

8-3-18. S VIDEO Y REC Level Check ........................... 8-12

8-3-19. S VIDEO Chroma REC Level Check ................. 8-13

8-3-20. Adjustment in the 50 Hz Mode ........................... 8-14

8-4. SDI Free-running Adjustment ......................................8-15

8-5. LCD Adjustment ........................................................... 8-16

8-5-1. Contrast Adjustment ............................................8-16

8-5-2. V-COM Adjustment ............................................8-16

8-5-3. Sample Hold Timing Adjustment .......................8-17

8-5-4. White Balance Adjustment .................................. 8-18

8-6. Adjustment Related Parts Layout Diagram .................. 8-19

HVR-1500

3

Purpose of this manual

Related manuals

Manual Structure

This manual is the Service Manual Volume 1 for the digital HD videocassette

recorder HVR-1500, the option board Analog Input Board HVBK-1505 and Format

Converter Board HVBK-1520.

This manual contains the maintenance information of this equipment, and servicing

information necessary for parts replacement and adjustments.

In addition to this Service Manual Volume 1, the following manuals are provided.

..

. Operation Instructions

..

HVR-1500 (Supplied with HVR-1500 )

Part number : 3-993-538-1X

..

. Installation Instructions

..

HVBK-1505 (Supplied with HVBK-1505)

HVBK-1520 (Supplied with HVBK-1520)

Trademark

..

. CD-ROM Manual (Supplied with SY model)

..

This manual contains the Japanese, English, French, German, Italian, and Spanish

operating instructions (PDF).

Part number : 3-993-560-0X

..

. Service Manual Volume 2 (Not Supplied with equipment)

..

Contains the semiconductor pin assignments, parts lists, block diagrams, board

layouts and schematic diagrams.

Part number : 9-968-317-0X

..

. “Semiconductor Pin Assignments” CD-ROM (Available on request)

..

This “Semiconductor Pin Assignments” CD-ROM allows you to search for

semiconductors used in Broadcast and Professional equipment.

The service manual volume 2 contains a complete list of semiconductors and their

ID Nos., and thus should be used together with the CD-ROM.

Part number: 9-968-546-06

Trademark or registered trademark used in this manual is follows.

. Windows is a registered trademark of Microsoft Corporation.

4

HVR-1500

Section 1

Installation

Be sure to install the HVR-1500 in location satisfying the required operational environment described

below to assure the HVR-1500 superior performance and to maintain the excellent serviceability and

accessibility.

1-1. Operating Conditions

c

Good air circulation is essential to prevent internal heat build-up. Place the unit in location with sufficient

air circulation.

Do not block the ventilation holes of the cabinet and the front and rear panels.

Operating temperature: 5 dC to 40 dC

Operating humidity: Less than 80 %

Storage temperature: _20 dC to 60 dC

Locations to avoid:

. Areas where the unit will be exposed to direct sunlight of any other strong lights.

. Areas near heat sources.

. Dusty areas or areas subject to vibration.

. Areas with strong magnetic field.

. Areas with much electrical noise.

. Areas with much static electricity.

. Areas windtight.

Tilt allowance: Within 30d (Do not slant the front and rear of the unit more than 30d.)

c

Fix the unit securely to avoid drop when the unit is operated at not-horizontal place.

HVR-1500

1-1

1-2. Power Supply

1-2-1. Voltage and Power Requirements

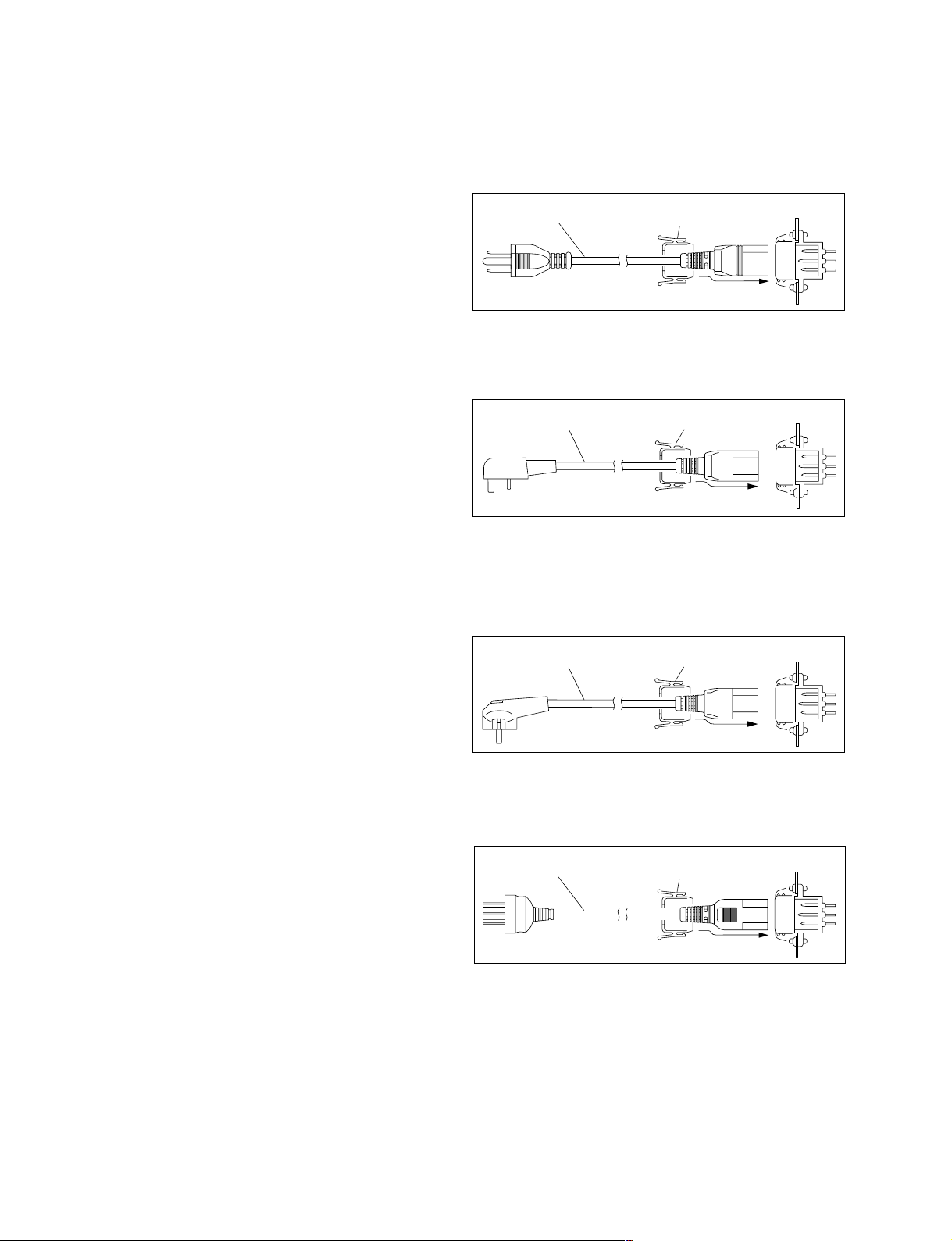

For customers in the U.S.A. and Canada:

1 Power cord 125 V 10 A (2.4 m): ! 1-551-812-11

2 Plug holder (Brown): 3-613-640-01

This unit’s power line has a switching regulator.

c

Be sure to operate the unit within the range of following

power voltage.

Power voltage: AC 100 to 240 V ±10 %

Power frequency: 50 Hz or 60 Hz

Power consumption: 60 W

Rush current: Power voltage 100 V IN: 12 A

Power voltage 240 V IN: 34 A

n

AC power supply is required a capacity which is commensurate with rush current.

If the capacity of the AC power supply is not enough, the

breaker of AC power of a supply side may operate or this

unit may not operate normally.

1-2-2. Recommeded Power Cord

This unit does not come with a power cord.

To get a power cord, please contact your local Sony Sales

Office/Service Center.

1

2

AC inlet

For customers in the United Kingdom:

1 Power cord 250 V 10 A (2.4 m): ! 1-782-165-11

2 Plug holder (Brown): 3-613-640-01

21

AC inlet

For customers in European countries except the United

Kingdom:

1 Power cord 250 V 10 A (2.0 m): ! 1-551-631-15

2 Plug holder (Brown): 3-613-640-01

21

AC inlet

w

. Use the approved Power Cord (3-core mains lead)/

Appliance Connector/Plug with earthing-contacts that

conforms to the safety regulations of each country if

applicable.

. Use the Power Cord (3-core mains lead)/Appliance

Connector/Plug conforming to the proper ratings (Voltage, Ampere).

If you have questions on the use of the above Power Cord/

Appliance Connector/Plug, please contact your local Sony

Sales Office/Service Center.

w

. Never use an injured power cord.

For customers in the China:

1 Power cord 250 V 10 A (1.8 m): ! 1-783-481-41

2 Plug holder (Brown): 3-613-640-01

1

2

AC inlet

If the unit is used in the area except above, please contact

your local Sony Sales Office/Service Center.

1-2

HVR-1500

1-3. Supplied Accessories

. Operating instructions : 1

. Operating instructions (CD-ROM) : 1

1-4. Optional Accessories

. AC power cord

. Analog input board : HVBK-1505

. Format converter board : HVBK-1520

. 9-pin remote conrtrol cable : RCC-5G (Length : 5 m (16 ft))

. Remote control unit : DSRM-10

. Digital video cassette : PDV-184*/124*/94*/64* (Standard-size (L) )

PDVM-40*/32*/22*/12* (Mini-size (S) )

PHDV-276DM*/186DM*/124DM*/64DM* (Standard-size (L) )

PHDVM-63DM* (Mini-size (S) )

n

The * in each model name is actually “ME” (indicating that a cassette

memory is contained), “N” (indicating that no cassette memory is

contained) or “MEM” (indicating a master tape).

. Cleaning cassette tape : PDV12CL (Standard size), PDVM12CL (Mini size)

1-5. Matching Connectors/Cables

When external cables are connected to the connector on a connector panel during maintenance, the

following connectors, cables (or their equivalents) must be used.

Connectors on HVR-1500 Side Matching connector/cable

Panel indication Designation Sony Part No. Remark

ANALOG IN BNC, MALE 1-560-069-11

REF. VIDEO IN (SD/HD)

TC IN When HVBK-1505

VIDEO IN is attached

AUDIO IN CH-1/3, 2/4 XLR 3P, MALE 1-508-083-11 When HVBK-1505

is attached

ANALOG OUT BNC, MALE 1-560-069-11

TC OUT

VIDEO OUT

MONITOR AUDIO PIN PLUG Standard Product

AUDIO OUT CH-1/3, 2/4 XLR 3P, FEMALE 1-508-084-11

HDV/DV IEEE1394 6P (1 m) 1-782-408-21

IEEE1394 6P (3.5 m) 1-791-184-11

SDI IN BNC, MALE 1-560-069-11

SDI OUT1, 2 BNC, MALE 1-560-069-11

HD-SDI OUT 1, 2 BNC, MALE 1-560-069-11

AUDIO I/O (AES/EBU) BNC, MALE 1-560-069-11

IN CH-1/2, 3/4

OUT CH-1/2, 3/4 BNC, MALE 1-560-069-11

REMOTE D-SUB 9P, MALE 1-560-651-11

HVR-1500

1-3

1-6. Input/Output Signals of the Connectors

INPUT

REF. VIDEO IN (SD/HD) : BNC x 2 (loop-through with 75 Z automatic terminator)

SD composite sync, black burst: 0.286 V p-p (525/60) or 0.3 V p-p (625/

50), 75 Z, negative sync

HD tri-level sync: 0.3 V, 75 Z, negative sync

VIDEO IN: BNC x 4 (When HVBK-1505 is attached)

Composite

Y/S-Y/CPST and 1 loop-through connector with 75 Z automatic

terminator: 1.0 V p-p, 75 Z, negative sync

Component

Y/S-Y/CPST: 1.0 V p-p, 75 Z, negative sync

R-Y/S-C and B-Y: 0.7 V p-p (75 % color bars for 525/59.94 or 100%

color bars for 625/50) , 75 Z

S-video

Y/S-Y/CPST: 1.0 V p-p, 75 Z, negative sync

R-Y/S-C: 0.286 V p-p (525/59.94) or 0.3 V p-p (625/50), 75 Z (burst

level)

SDI IN: BNC x 1

Serial digital interface format (270 Mbps), SMPTE 259M/ITU-R BT.656

AUDIO IN: XLR 3-pin x 2, FEMALE (When HVBK-1505 is attached)

+4/0/_3*/_6 dBm , high impedance, balanced

*

: For 625/50 only

AUDIO I/O (AES/EBU) : BNC x 2

Complying with AES-3id-1995

TC IN: BNC x 1, SMPTE timecode (525/59.94) or EBU timecode (625/50)

0.5 V p-p to 18 V p-p, 3.3 kZ, unbalanced

HDV/DV: 6-pin IEEE 1394 connector x 1

OUTPUT

VIDEO OUT: BNC x 3

Composite

Y/CPST: 1.0 V p-p, 75 Z, negative sync

Component (SD)

Y/CPST: 1.0 V p-p, 75 Z, negative sync

Pr/R-Y/S-C and Pb/B-Y/S-Y: 0.7 V p-p (75% color bars for 525/59.94

or 100% color bars for 625/50),75 Z

Component (HD)

Y: 1.0 V p-p, 75 Z, negative sync

Pr, Pb: 0.7 V p-p, 75 Z

S-video

Pb/B-Y/S-Y: 1.0 V p-p, 75 Z, negative sync

Pr/R-Y/S-C: 0.286 V p-p (525/59.94) or 0.3 V p-p (625/50), 75 Z (burst

level)

Monitor video output

BNC x 1

(SUPER) CPST: 1.0 V p-p, 75 Z, negative sync

SDI OUT: BNC x 2

Serial digital interface format (270 Mbps), SMPTE 259M/ITU-R BT.656

1-4

HVR-1500

HD-SDI OUT: BNC x 2

Serial digital interface format (1.485, 1.485/1.001 Gbps), SMPTE 292M

AUDIO OUT: XLR 3-pin x 2, MALE

*

+4/0/_3

*

: For 625/50 only

/_6 dBu, 600 Z loading, low impedance, balanced

MONITOR AUDIO: Phono jack x 1

_∞ to _11 dBu ±1 dB (_20 dBFS) /_9 dBu ± 1 dB (_18 dBFS), 47 kZ,

unbalanced

PHONES: Stereo phone jack x 1

_∞ to _13 dBu (_20 dBFS) /_11 dBu (_18 dBFS), 8 Z, unbalanced

AUDIO I/O (AES/EBU) : BNC x 2

Complying with AES-3id-1995

TC OUT: BNC x 1

SMPTE timecode (525/59.94), EBU timecode (625/50)

2.2 V p-p ±3 dB (when 600 Z terminated) , unbalanced

HDV/DV: 6-pin IEEE 1394 connector

Remote control connectors

CONTROL-S: Stereo minijack x 1

HDV/DV: 6-pin IEEE 1394 connector

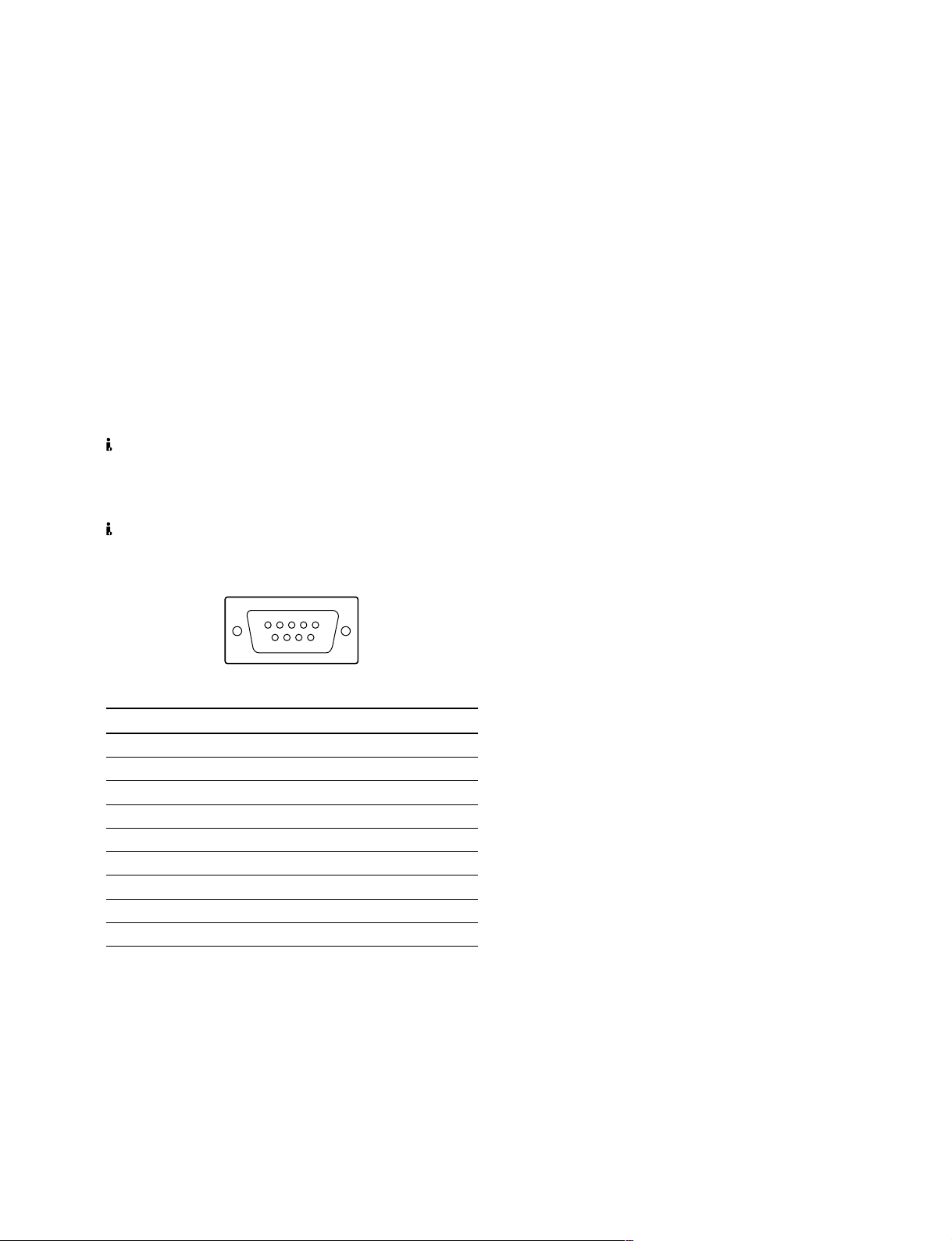

REMOTE (D-sub 9-pin : MALE)

5

9

__

_ EXT VIEW

__

Pin No. Controlling Device Controlled Device

1 FRAME GROUND FRAME GROUND

2 RECEIVE A TRANSMIT A

3 TRANSMIT B RECEIVE B

4 TRANSMIT COMMON RECEIVE COMMON

5 PRIORITY IN PRIORITY OUT

6 RECEIVE COMMON TRANSMIT COMMON

7 RECEIVE B TRANSMIT B

8 TRANSMIT A RECEIVE A

9 FRAME GROUND FRAME GROUND

1

6

__

_

__

HVR-1500

1-5

1-7. Installation Setup and Adjustment

1-7-1. Front Panel Setting

Front panel

1. i.LINK INPUT SELECT button setting

i.LINK : HDV: Video and audio signals in HDV

format

i.LINK : DV

i.LINK : DVCAM

*

: The display follows the recording format setting in

the REC FORMAT menu item. (Refer to the

operating instructions for details)

2. VIDEO INPUT SELECT button setting

COMPOSITE: Composite video signal

S VIDEO: S-video (separated Y and C)

COMPONENT SD: Component video signals

SDI: SDI video signal

SG: Video test signal

3. AUDIO INPUT SELECT button setting

ANALOG: Analog audio signal

AES/EBU: Digital audio signal in AES/

SDI: Digital audio signal in SDI

SG: Audio test signal

*

: Video and audio signals in DV

format

*

: Video and audio signals in

DVCAM format

(When HVBK-1505 is attached)

signals (When HVBK-1505 is

attached)

(When HVBK-1505 is attached)

(When HVBK-1505 is attached)

EBU format

format

Layout of switch and buttons on the front panel

3. CH1 1/2 button

CH2 3/4 button

4. VARIABLE switch

2. VIDEO button

1. i.LINK button

1-7-2. System Adjustment After Installation

Observe the following precautions when this equipment is

used for editing system.

. The REF. VIDEO IN requires video signal which is in

conformity with the RS-170A (525/60).

. Adjust the sync phase of this equipment to the system

sync with [SYNC PHASE] control of the setup menu.

. Adjust the SCH phase of this equipment to the system

SCH with [SUB CARRIER] control of the setup menu.

. When this unit is connected to a switcher that does not

have the sync switching function, the SYNC/BURST

level adjustment is required.

4. AUDIO VARIABLE switch setting

PRESET : Sets both the REC and PB levels

to the normal level.

REC : Sets the REC audio level of the

channels respectively with the

CH-1/2/3/4 knobs.

PB : Sets the PB audio level of the

channels respectively with the

CH-1/2/3/4 knobs.

1-6

HVR-1500

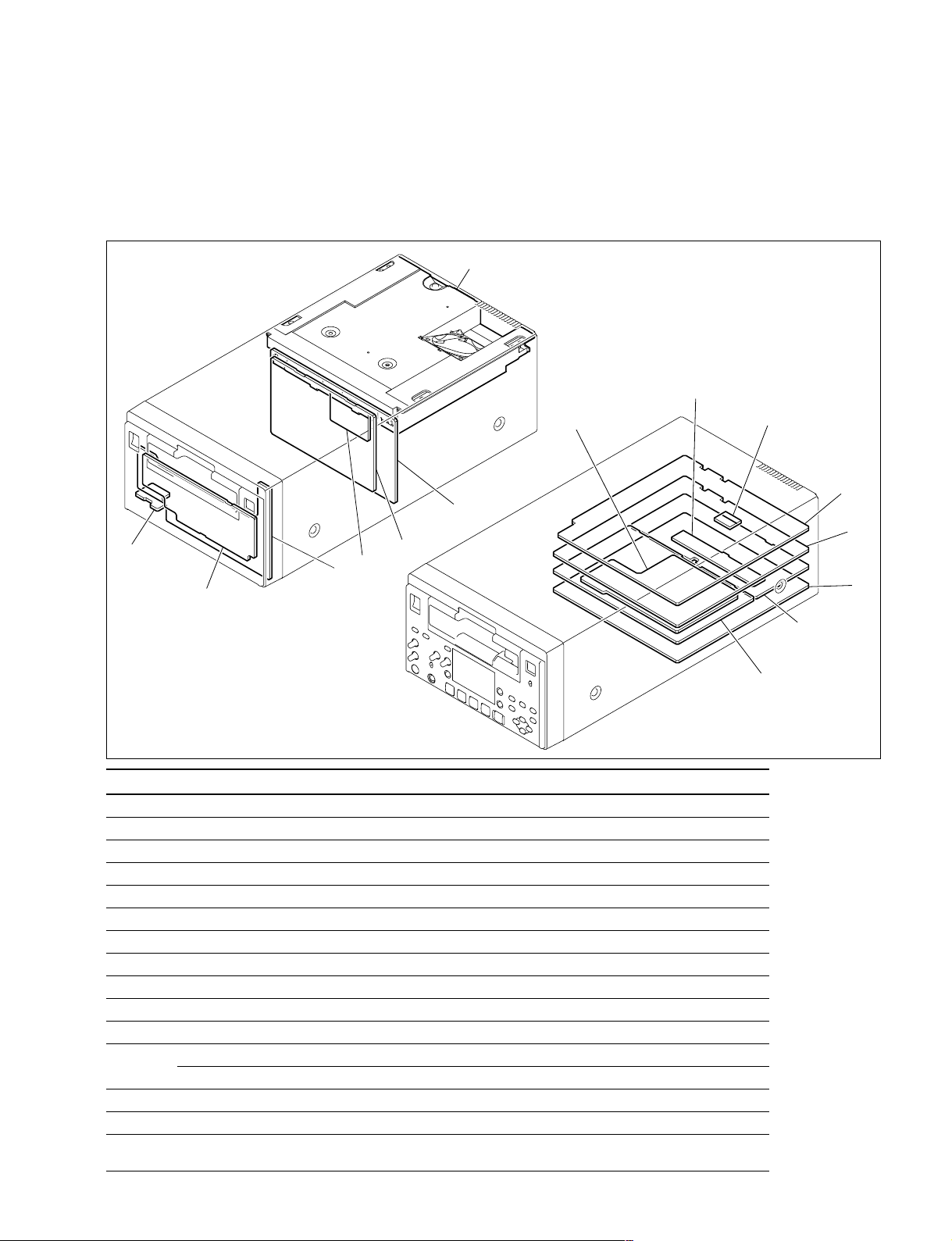

Service Overview

2-1. Location of Main Parts

2-1-1. Location of Printed Circuit Boards

Section 2

Switching regulator

!=

!]

1

3

4

5

Board name Circuit function Remarks

1 MB-1098 Motherboard

2 RP-133 RF REC/PB, ATF Detection

3 HP-136 Headphone, Remote Control

4 KY-614 Key Board

5 KY-616 Graphics Renderer

6 RT-10 HDV Equalizer

7 CN-1968A HDV/DV Connector Board

8 DDE-22 Analog Video/Audio Input Board HVBK-1505 (Option)

9 AVP-7 Analog Video/Audio Output Board

0 SDI-94 Digital Input/Output Board S/N 100001-101559 (SY), S/N 300001-300745 (J)

!- SSS-12 System/Servo Control

!= CN-2905 Intermediate Board

VNS-2 Format Converter Board HVBK-1520 (Option)

![ DVP-42 DV Video/Audio Digital Process S/N 100001-101559 (SY), S/N 300001-300745 (J)

!] HPR-20 HDV Video/Audio Digital Process

0 +

Locations of mechanism deck

1

2

6

5

3

Board name Circuit function

1 SE-521G Threading Mode Sensor, Tape End Sensor, Loading Motor FG Sensor

2 SE-538G Tension Sensor

3 CN-1863 REC INHIBIT Sensor, MIC Terminal

4 SE-525G Tape Top/End LED

5 SE-522G Tape Top Sensor, Reel Position Sensor

6 DR-428BG Drum/Reel/Capstan Control Board

4

2-2

HVR-1500

Locations of cassette compartment

1

2

5

4

3

Board name Circuit function

1 CN-2021G Intermediate Board

2 CC-83G Cassette Compartment Mode Detection, Intermediate Board

3 CC-85G Cassette In Detection

4 CC-84G Cassette Type Detection

5 CN-2022G Intermediate Board

HVR-1500

2-3

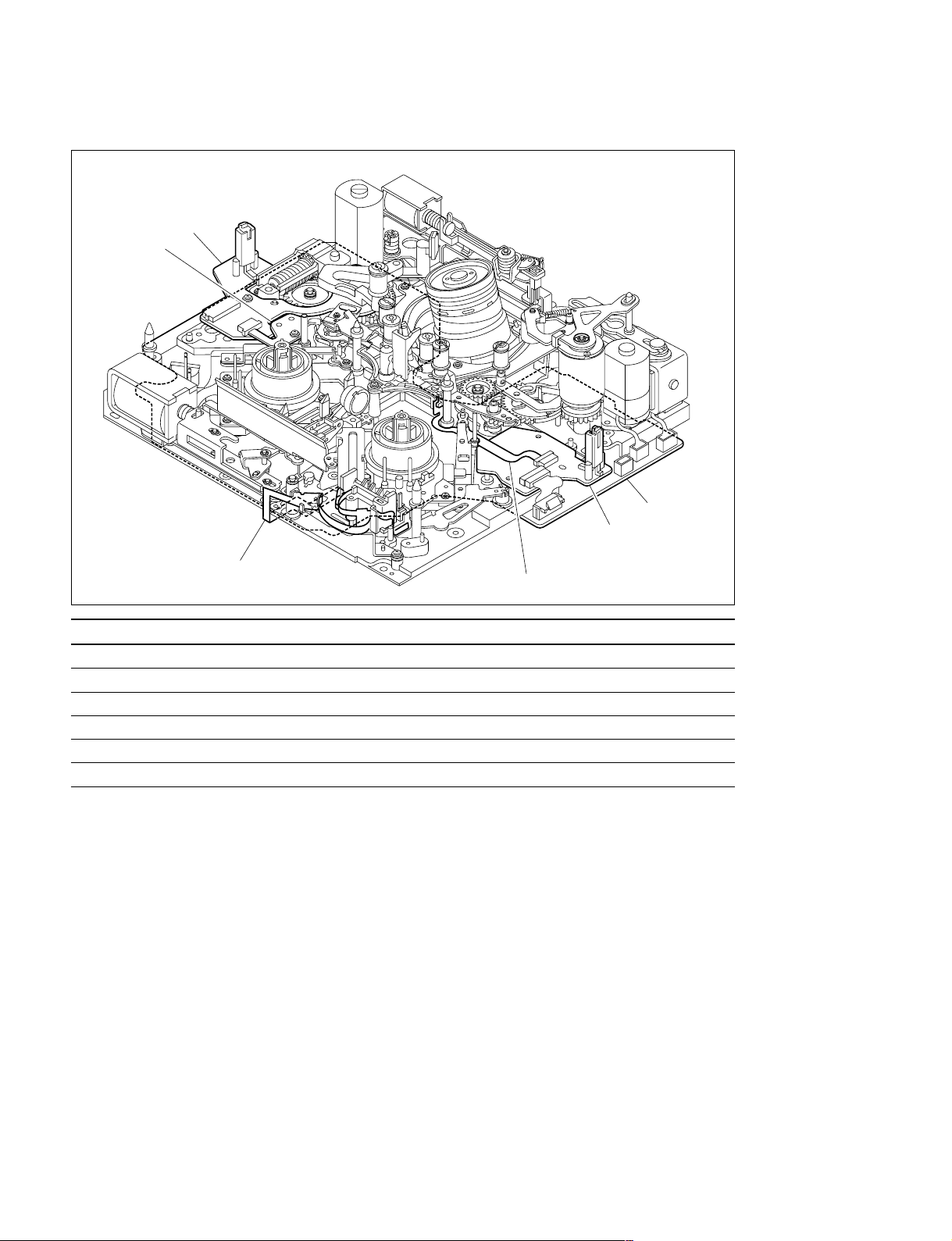

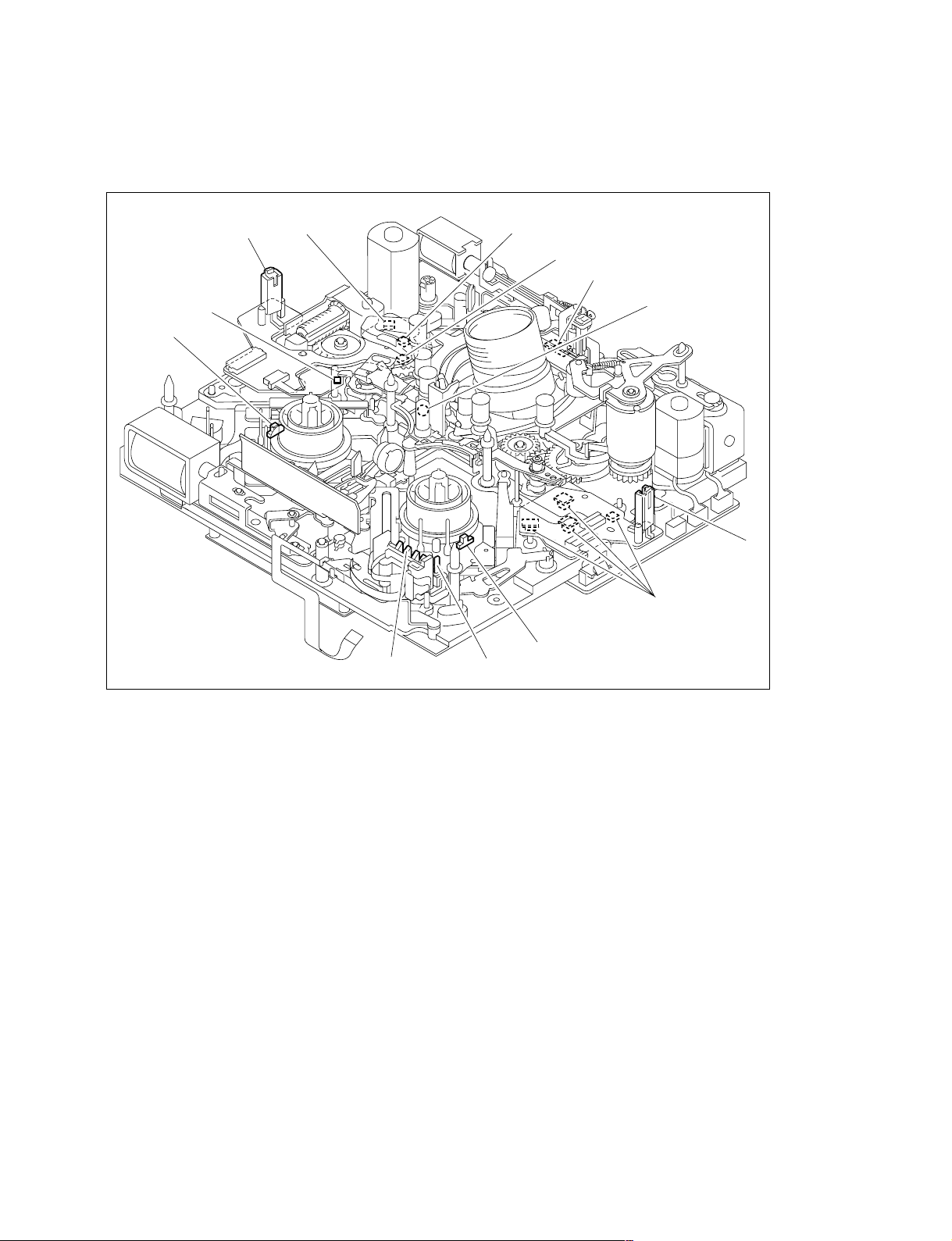

2-1-2. Location of Main Mechanical Parts

8

7

6

5

4

9

3

0

2

1

!-

!=

@]

@[

@=

@-

@/

!.

!,

!'

!;

!\

!]

![

1 Head cleaning solenoid

2 Loading motor

3 TG1 arm assembly

4 Shuttle (left) assembly

5 S tension regulator assembly

6 S reel motor

7 S brake assembly

8 Brake solenoid

9 M stop solenoid assembly

!/ T brake assembly

!- MIC assembly

!= MIC holder assembly

![ T reel motor

@\

!] Shuttle (right) assembly

!\ T drawer arm assembly

!; TG8 arm assembly

!' Capstan motor

!, Elevator cam

!. Pinch solenoid assembly

@/ Reel shift motor

@- Pinch roller

@= HC roller assembly

@[ Drum assembly

@] Rail assembly

@\ Cassette compartment motor assembly

2-4

HVR-1500

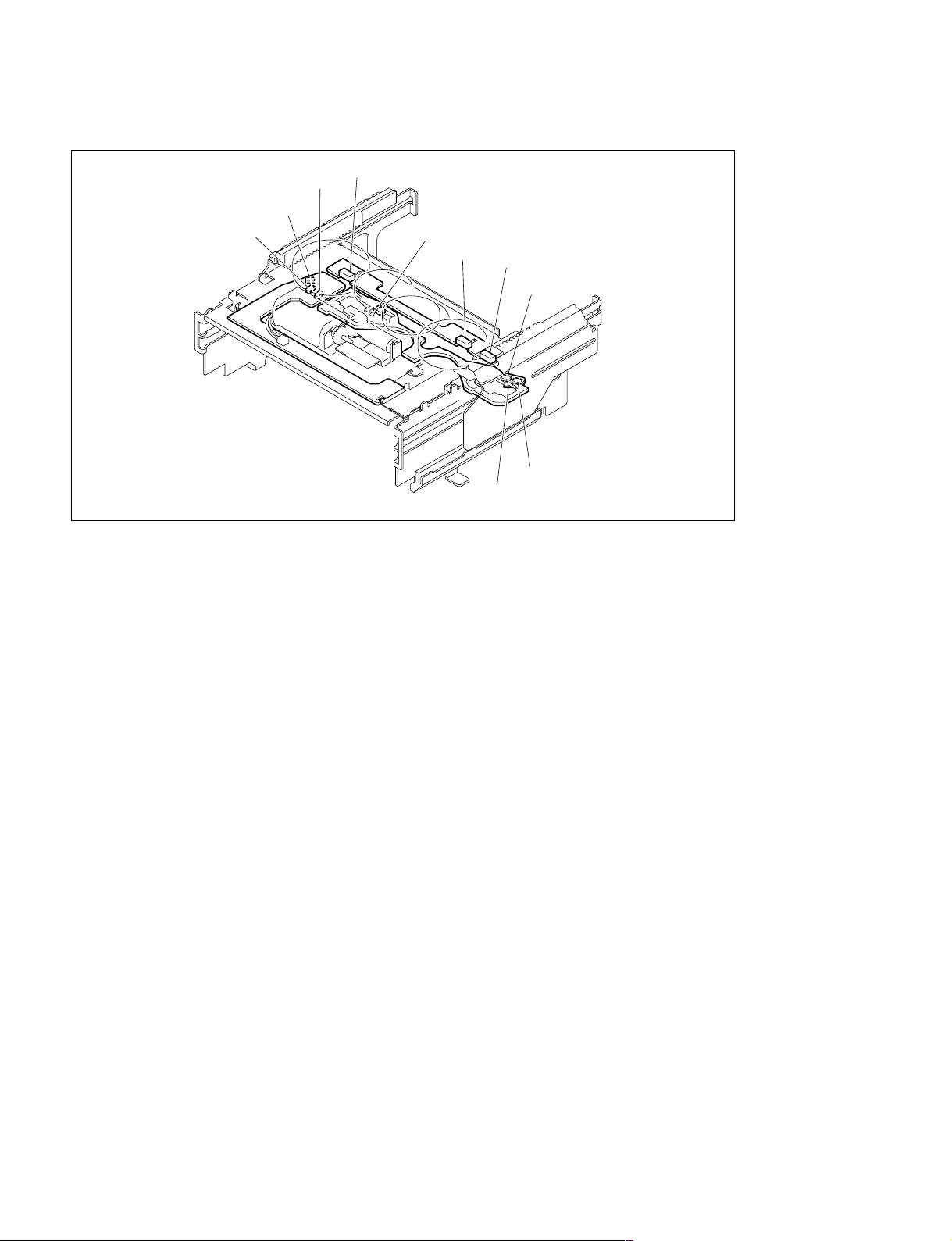

2-2. Function and Location of Sensors

(1) Mechanism deck

!-

!/

!=

(2) Cassette compartment

1 S3

2 PH1

2 PH2

2 PH3

3 PH4

1 S1

1 S2

3 PH5

3 PH7

3 PH6

1 The sensors S1, S2 and S3 discriminate the inserted cassette type among the mini, M, standard

cassettes and the cassette adaptor for DVCPRO by on/off of the sensors.

2 The sensors PH1, PH2 and PH3 detect the movement of a cassette compartment by their combina-

tion.

3 The sensors PH4 and PH5 detect that a mini cassette got inserted.

The sensors PH4 and PH6 detect that a M cassette got inserted.

The sensors PH4 and PH7 detect that a standard cassette got inserted.

2-6

HVR-1500

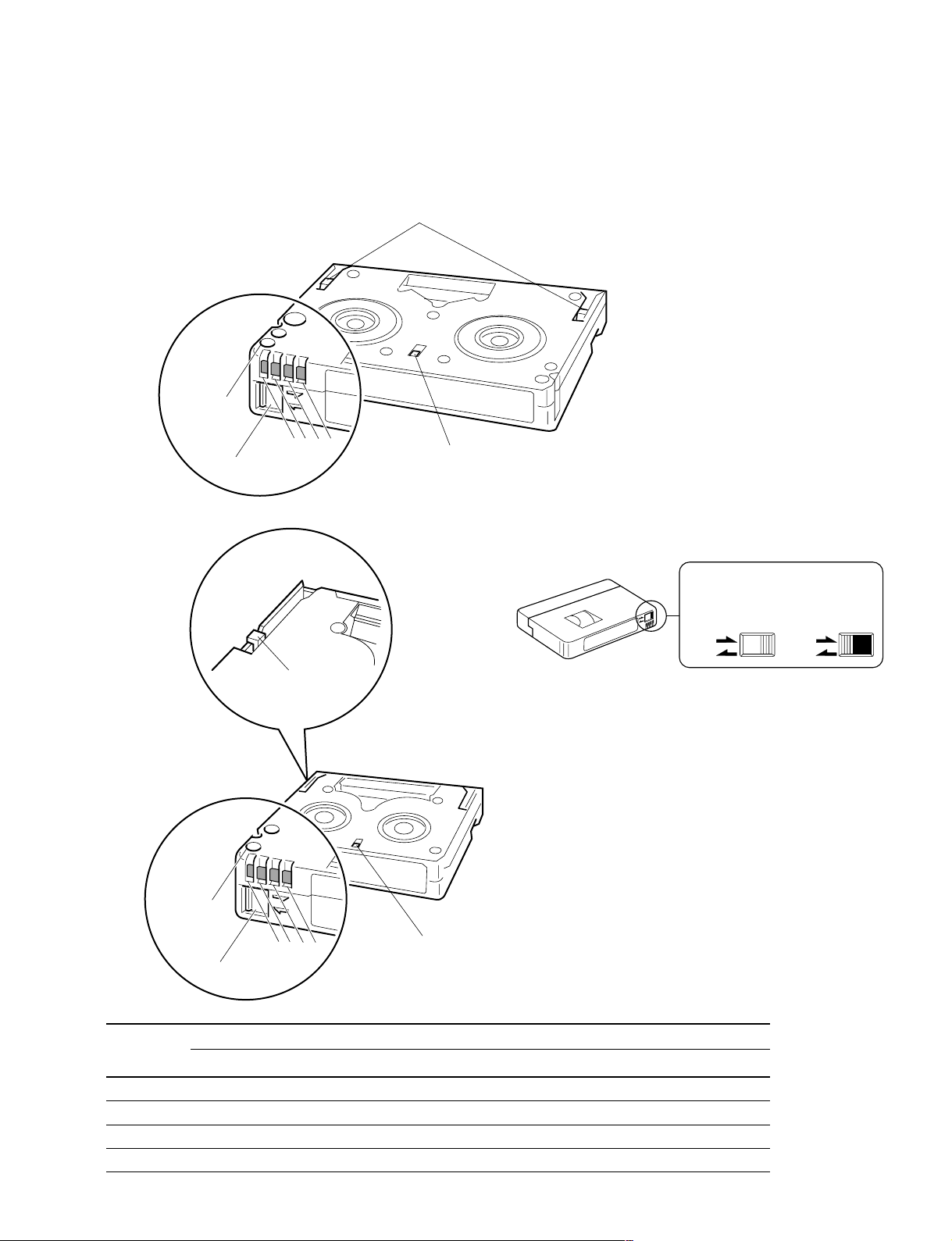

2-3. Functions of Cassette

Standard cassette, M cassette

Cassette cover release claw

Record proof

hole

4

1

32

Record proof plug

Mini cassette Hole and plug for record proof

Reel rotation stopper

Record enable Record protect

REC

SAVE

Cassette cover release claw

. This plug controls the record proof

switch according to open or close

position.

Record proof

hole

4

32

1

Reel rotation stopper

Record proof plug

Pin No. Function

Equipped with built-in memory Not equipped with built-in memory

1 +DC Detecting tape thickness

2 DATA Detecting tape type (Example: ME/MP)

3 CLOCK Detecting tape application (Example: consumer/professional)

4 GND _

REC

SAVE

HVR-1500

2-7

2-4. How to Take Out the Cassette

Whose Tape is Slacked (MANUAL

EJECT)

(1) Turn the power off.

(2) Remove the top panel. (Refer to Section 2-7-1.)

(3) Remove the front panel. (Refer to Section 2-7-3.)

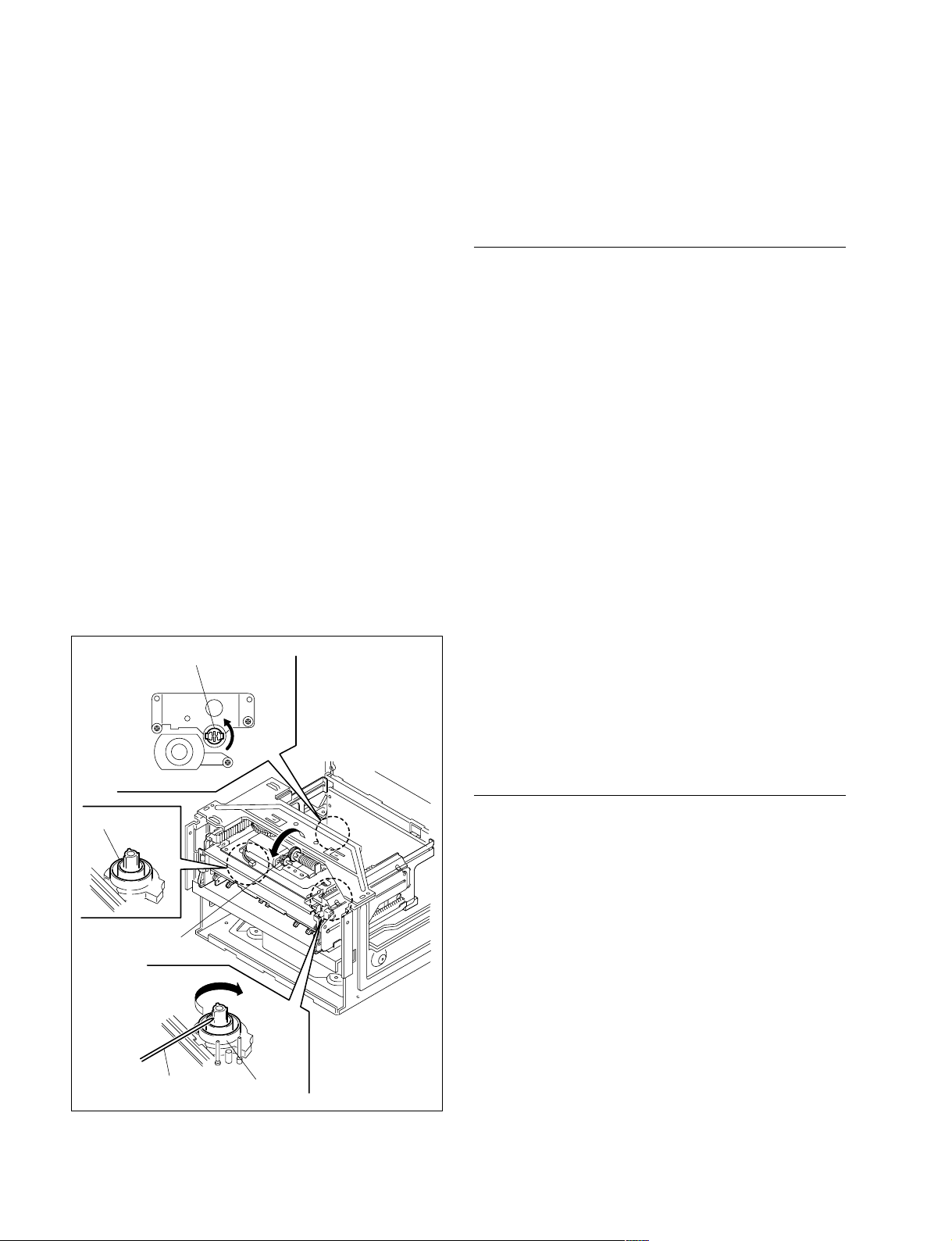

(4) Turn the manual eject gear A (red) in the arrow

direction with a phillips screwdriver while pressing the

gear. When the tape comes to slack, turn the reel table

from the front side utilizing a skewer and wind the

tape.

n

In a case of standard cassette and M cassette :

Turn the reel table (T)

In a case of mini cassette :

Turn the reel table (S)

(5) Repeat step (4) until each guide comes to the unthread-

ing end position and furthermore the tape completely

returns into the cassette.

(6) Turn the manual eject gear B (red) in the arrow

direction until the cassette compartment completely

comes into cassette out state.

Manual eject gear A (red)

2-5. Head Cleaning when Head Clogging

Occurs

Clean the video head as follows when the video head gets

dirty.

Procedure to Use the Cleaning Cassette

n

Use only the cleaning cassette tape as follows.

If another cleaning cassette tape is used, abnormal abrasion

or breakage of the video head could occur.

Cleaning cassette tapes :

PDV12CL (Standard)

PDVM12CL (Mini)

1. Insert the specific cleaning cassette tape in this unit.

The unit is automatically set in the PLAY mode and

the cleaning tape starts running.

Confirm that the [PLAY] key lights and the display

appears.

2. The cleaning cassette tape is automatically ejected

after running for 10 seconds.

n

Do not rewind the cleaning cassette tape to use it

again.

Reel table (S)

Manual

eject gear B (red)

Skewer

3. Make sure that the head is no longer dirty.

If the video head is still dirty after step 2 above, clean

the video head as follows.

Procedure to Use the Cleaning Cloth

1. Soak the cleaning cloth with cleaning liquid and bring

it into contact lightly with the video head.

2. Turn the upper drum slowly by hand in the rotating

direction of the head (counterclockwise when viewed

from the top) to clean the video head.

m

. Never move the cleaning cloth in the vertical direction

against the video head because it may break the head.

. Turn the power switch off when cleaning the video head.

Reel table (T)

2-8

HVR-1500

2-6. Operating the VTR without a

Mini M STD

Cassette Tape

The VTR can be operated without a cassette tape by the

following switch setting.

Switch Setting

1. Remove the cassette compartment from this unit.

2. Turn on switches S401-4 of the SSS-12 board.

3. Then turn on the main power.

Operating Method

REC

While pressing the record proof sensor on the right side of

the T side reel table, press both the [PLAY] key and the

[REC] key.

The pinch roller is pressed against the capstan shaft to

enter REC status.

When the record proof sensor is released, the REC status is

released and the recorder returns to PLAY status.

Unthreading

Press the [EJECT] key.

Each guide moves to the specified position to complete the

unthreading.

Threading

While pressing the S/T reel motors, press the [STOP] key.

The upper drum rotates, threading ring rotates. The unit

enters the threading mode.

The tension arm and the threading ring move to the

specified position, then the threading is completed.

This condition in which the threading is completed is

referred to as the STOP status.

PLAY

Press the [PLAY] key.

The pinch roller is pressed against the capstan shaft to

enter the PLAY status.

When the [PLAY] key is pressed during threading, the

pinch roller is pressed against the capstan shaft to enter the

PLAY status after the threading has completed.

FF

Press the [F|FWD] key.

The pinch roller is pressed against the capstan shaft to set

the FWD.SEARCH to five-times speed.

Reel position selection

Press the SET (YES) key on the control panel.

Reel position will be changed as shown below in accordance with the number of pressing the SET (YES) key.

n

Make sure to turn off switches S401-4 on the SSS-12

board after the adjustment.

REW

Press the [REW] key.

The pinch roller is pressed against the capstan shaft to set

REV.SEARCH to five-times speed.

HVR-1500

2-9

2-7. Removing/Installing the Cabinets

n

Before removing the cabinets, be sure to turn off the main

power.

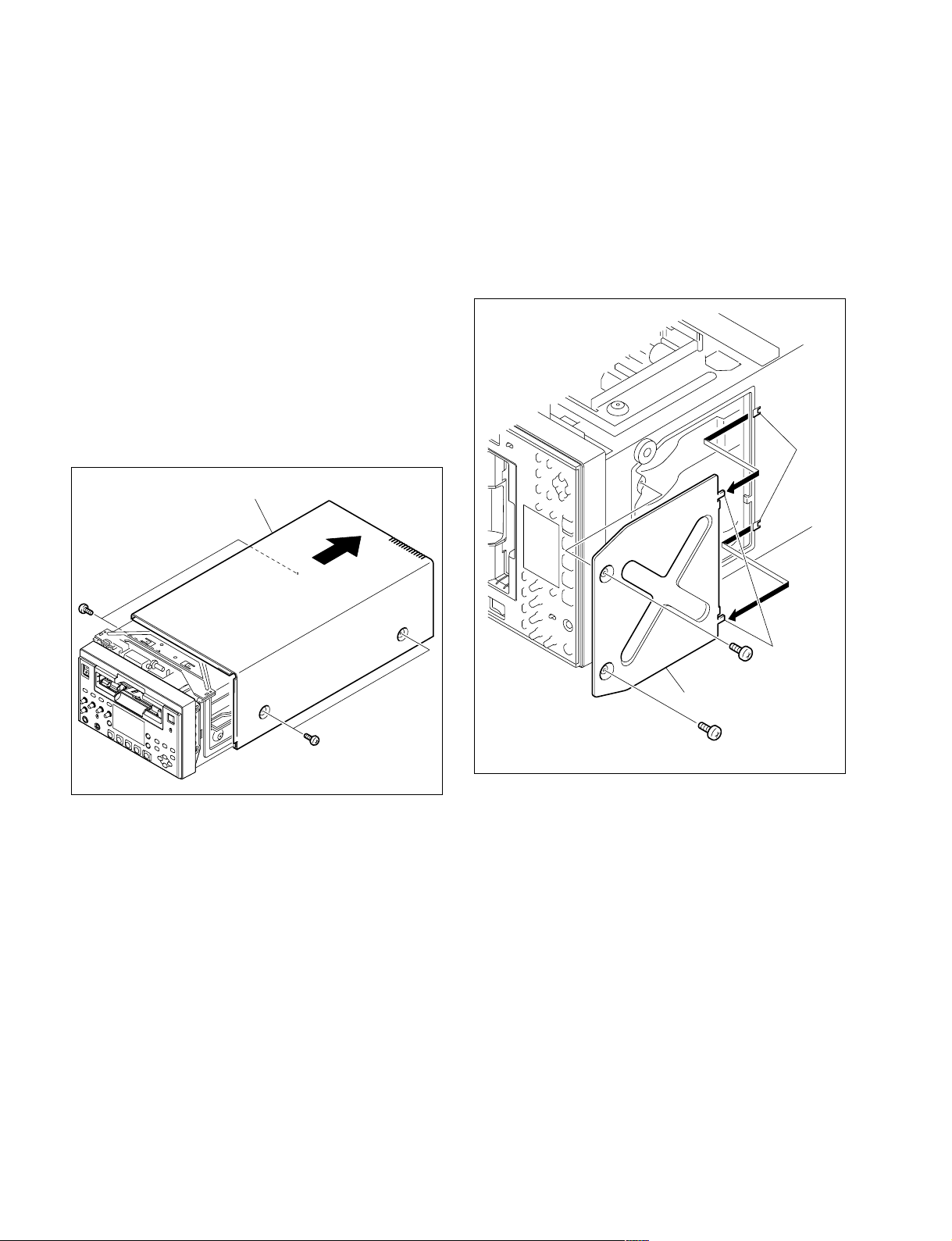

2-7-1. Removal/Installation of the Top Panel

1. Remove the four screws and remove the top panel in

the direction of the arrow.

n

Be careful not to break or peel off the internal packing.

2. Re-attach the parts in reverse order of the disassembling procedure.

Top panel

2-7-2. Removal/Installation of the Bottom

Plate

1. Stand the main unit on the left side.

2. Remove the two screws and remove the bottom plate

in the direction of the arrow.

3. Re-attach the parts in reverse order of the disassembling procedure.

Holes

B4 x 6

B4 x 6

Claws

BVTT3 x 6

Bottom plate

BVTT3 x 6

2-10

HVR-1500

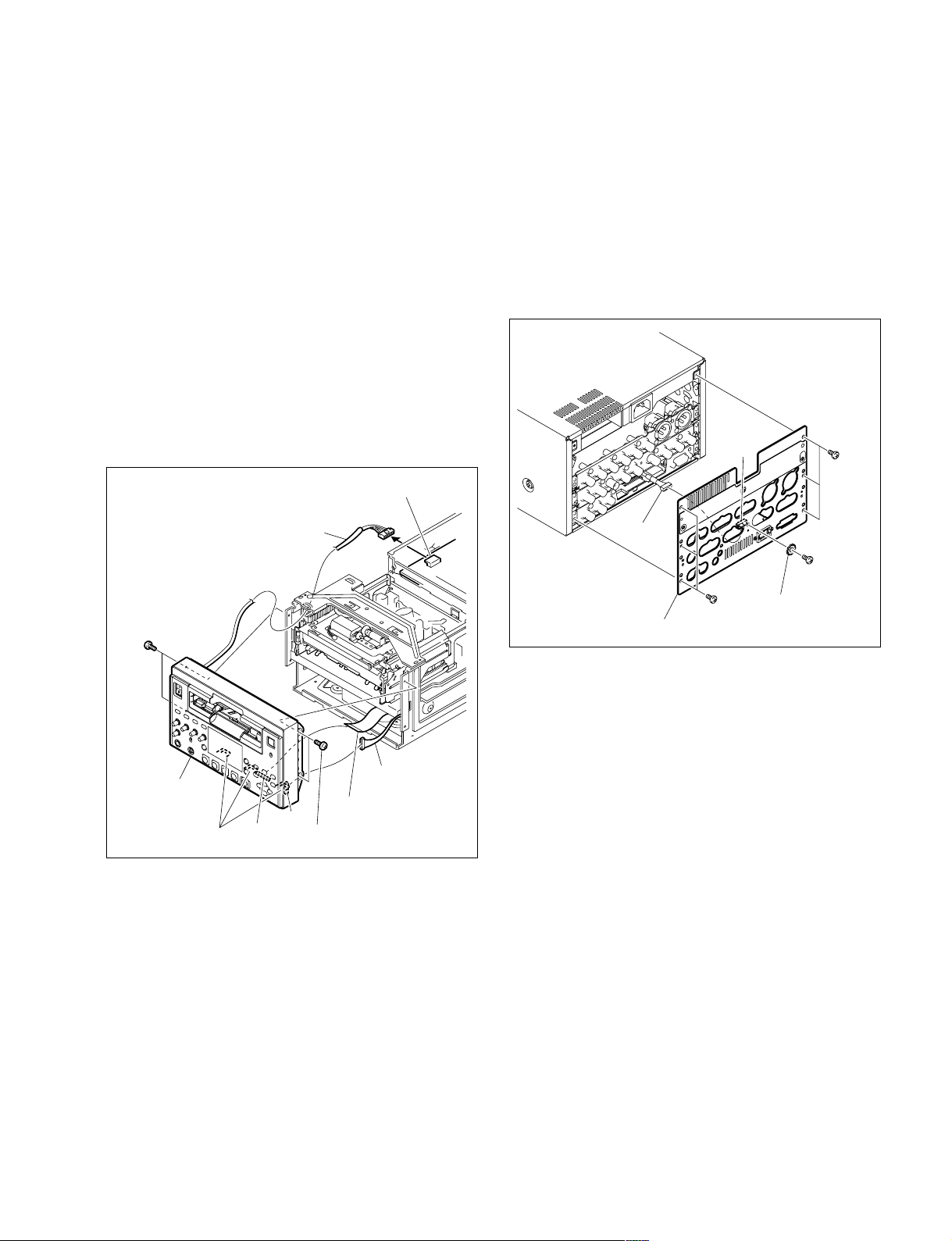

2-7-3. Removal/Installation of the Front

Panel

1. Remove the top panel. (Refer to Section 2-7-1.)

2. Remove the bottom plate.

(Refer to Section 2-7-2.)

3. Remove the harness (AC PSW) from the

connector (CN2) on the switching regulator.

4. Remove the flexible card wire from the connector (CN500) on the KY-616 board.

5. Remove the harness (KY-MB) from the connector (CN101) on the KY-614 board.

6. Remove the four screws.

7. Pull the front panel to the front to remove it.

8. Re-attach the parts in reverse order of the

disassembling procedure.

CN2

2-7-4. Removal/Installation of the Rear Panel

1. Remove the screw (B3 x 8) and toothed washer.

2. Remove the six screws (BV3 x 6) , and remove the

rear panel.

3. Remove the harness from the connector (CN2) on the

CN-1968A board.

4. Re-attach the parts in reverse order of the disassembling procedure.

CN2

BV3 x 6

BVTT3 x 6

Front panel

Harness (AC PSW)

CN500

Claws

CN101

BVTT3 x 6

Harness (KY-MB)

Flexible card wire

Harness

Rear panel

BV3 x 6

B3 x 8

Toothed washer

HVR-1500

2-11

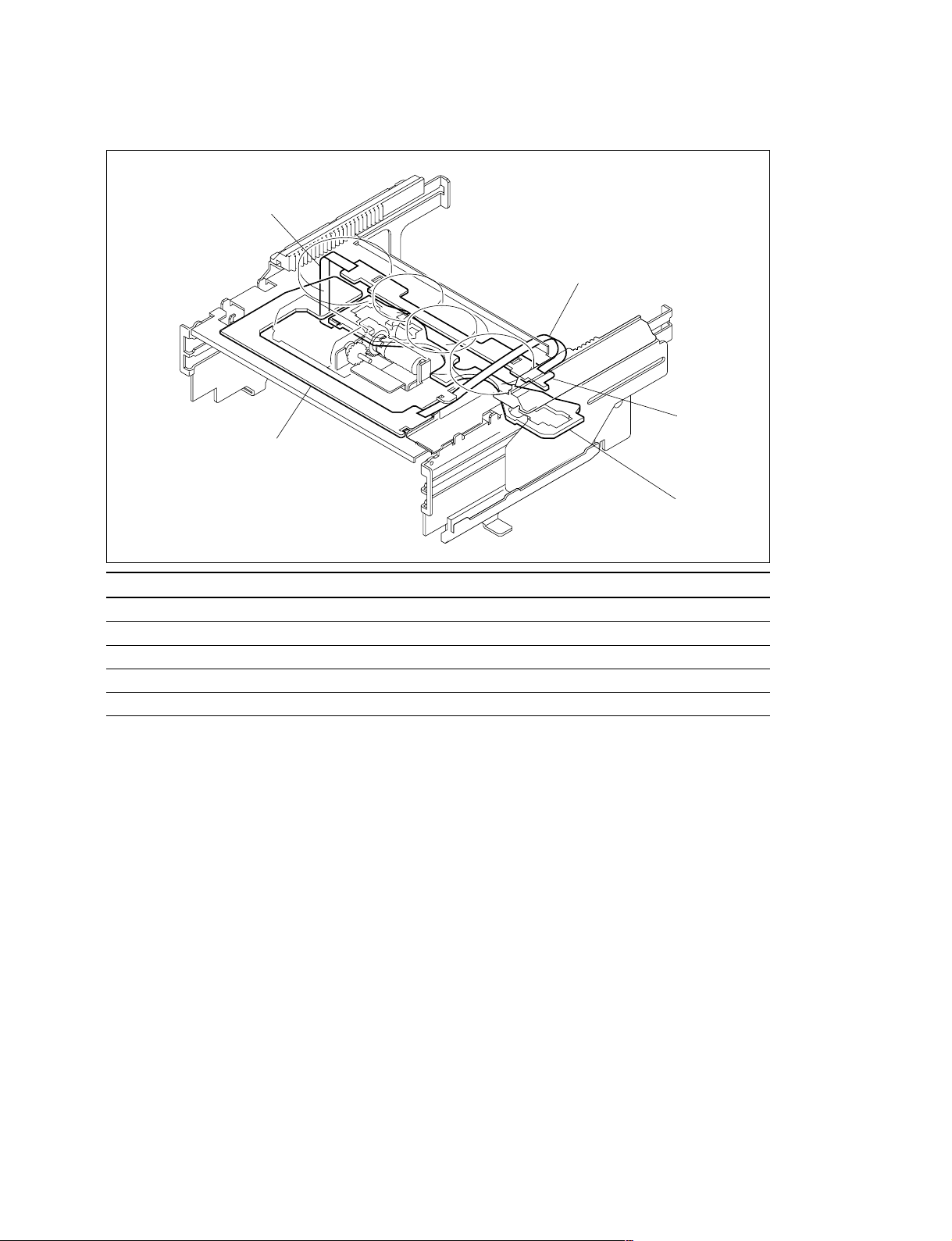

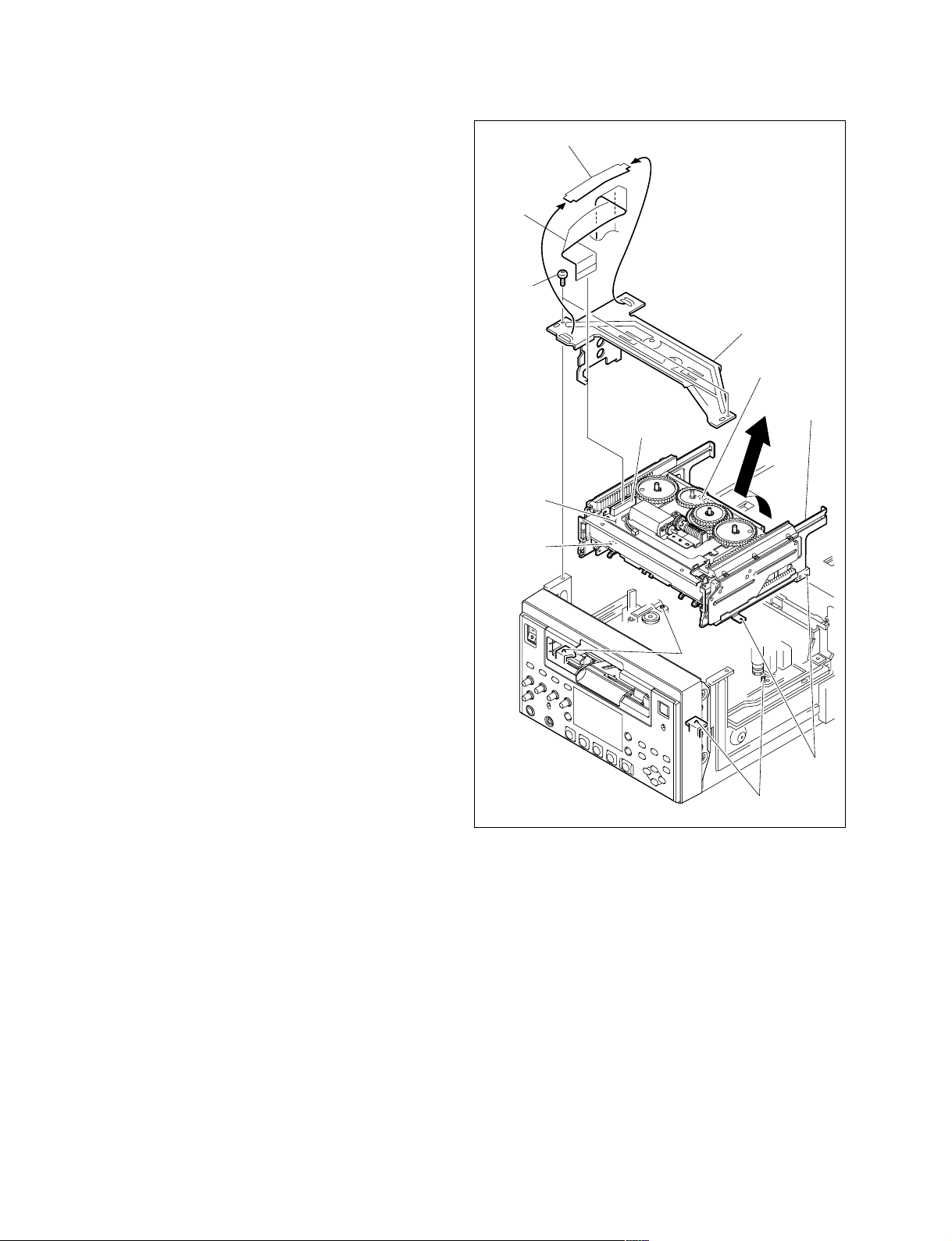

2-8. Removing/Installing the Cassette

Compartment

C cable retainer

Removal

1. Remove the top panel. (Refer to Section 2-7-1.)

2. Remove the C cable retainer.

3. Remove the flexible card wire from the connector

(CN1) on the CC-83G board.

4. Remove the two screws and remove the cassette

compartment retainer.

5. Remove the cassette compartment n the direction of

the arrow.

Installation

1. Put in the cassette compartment in the opposite

direction of the arrow and align the four positioning

holes with the four positioning pins.

2. Attach the cassette compartment with the two screws.

3. Connect the flexible card wire to the connector (CN1)

on the CC-83G board.

4. Attach the C cable retainer.

5. Attach the top panel. (Refer to Section 2-7-1.)

Flexible

card wire

BVTT3 x 6

Cassette compartment

retainer

Positioning hole

Cassette

compartment

CN1

CC-83G

board

Positioning

hole

Positioning

pins

Positioning pins

Positioning

holes

2-12

HVR-1500

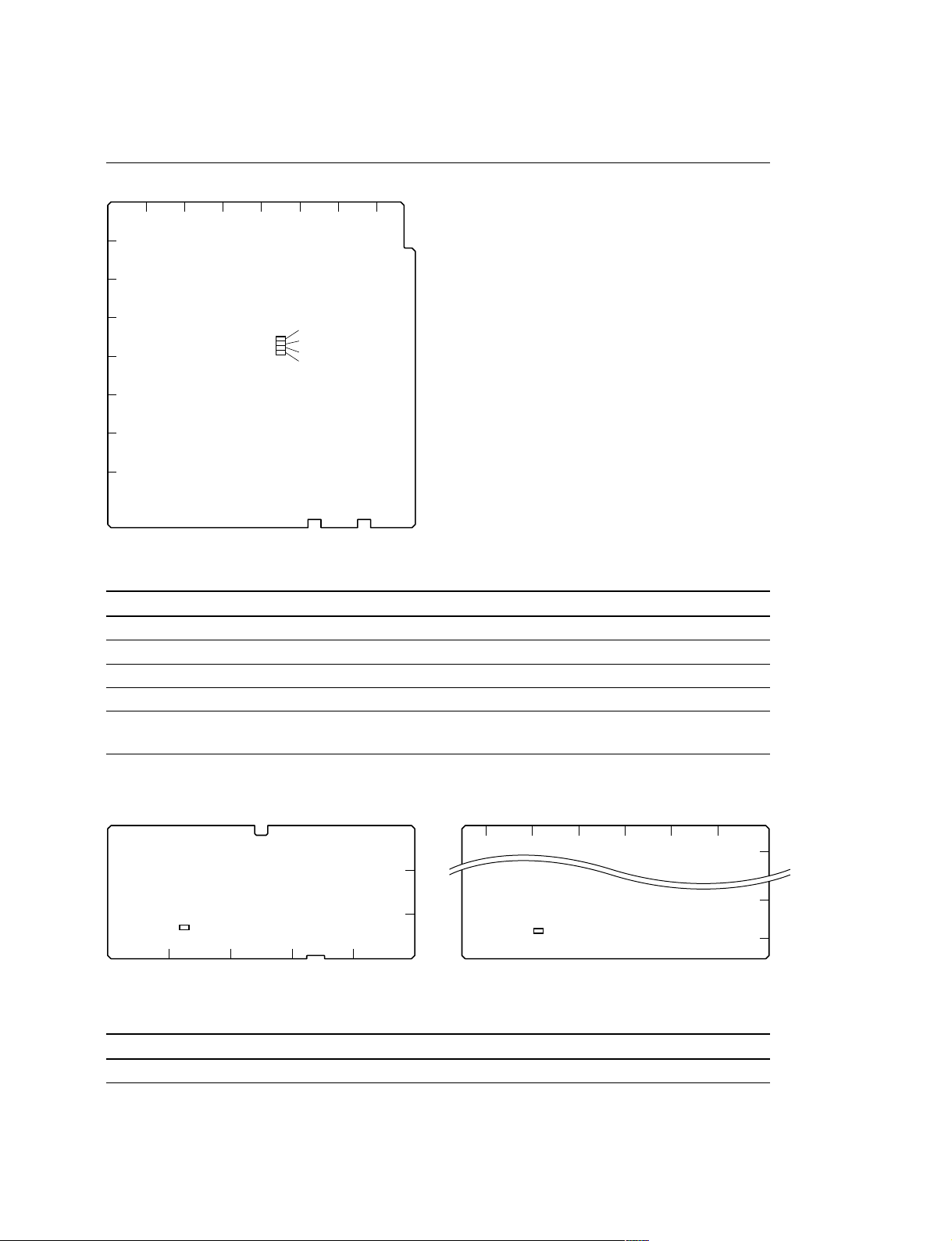

2-9. Function of Indicators on Circuit Boards

DDE-22 Board

1234567

A

B

C

D

E

F

G

H

D203

D202

D201

D200

8

A side (component side)

Ref. No. Name Color Description Normal state

D200 NON INTER Green Blinks in case of non-interlace signal. OFF

D201 NON STD Green Blinks, except for a standard signal. OFF

D202 VCXO SC LOCK Red Lights in case of standard signal OFF

D203 VCXO H LOCK Red Off in case of standard signal Lights

SDI-94 Board or DPR-293 Board

SDI-94 Board DPR-293 Board

3

2

D201

B

1

AEDC

A side (component side) A side (component side)

Ref. No. Name Color Description Normal state

D201, D1001 UNLOCK Red Lights when SDI output signal is unlock. OFF

HVR-1500

76 5 4 3 2 1

D1001

F

G

2-13

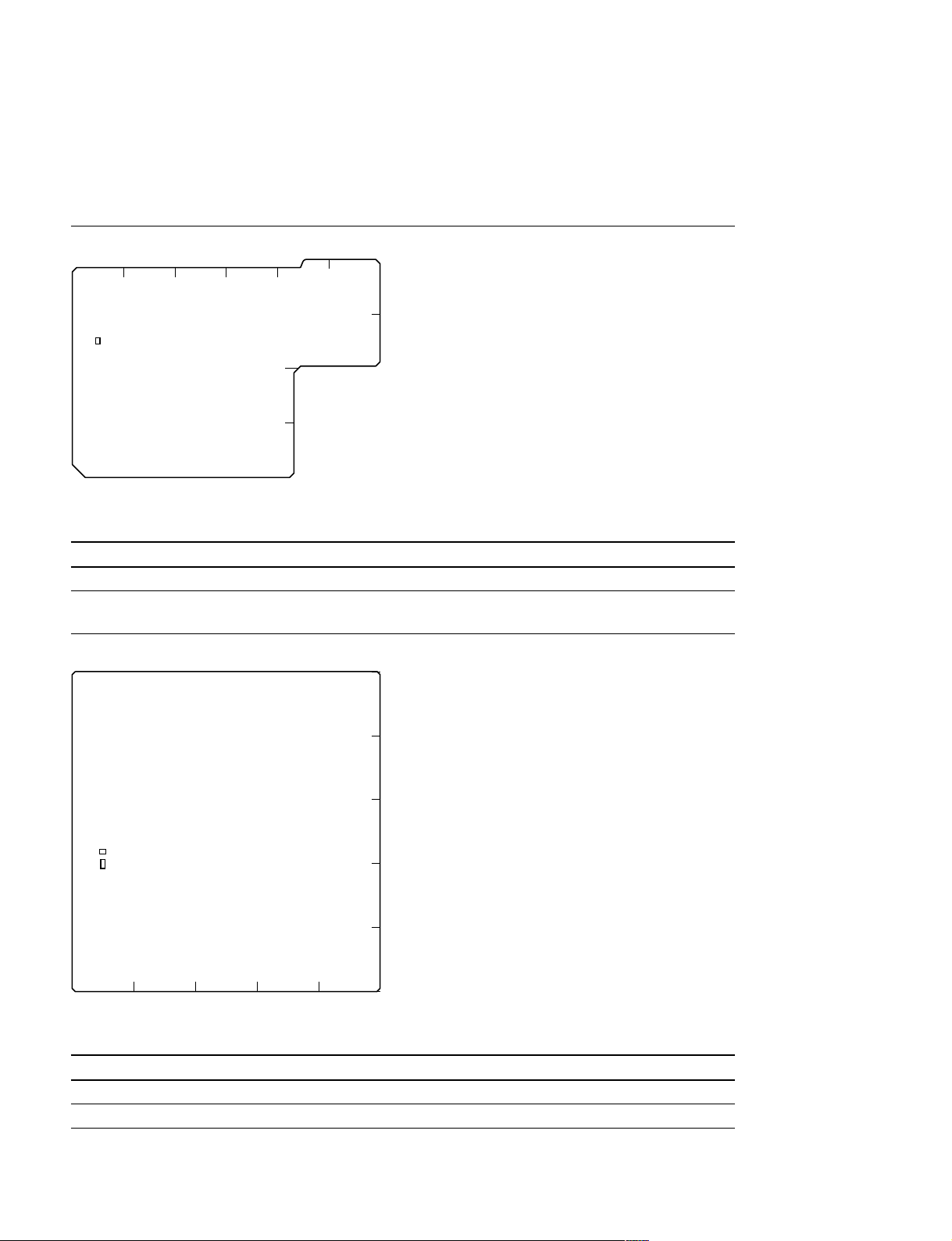

2-10. Switch Setting on Circuit Boards

n

Do not change the setting of switches when the “Factory use” is shown in the description.

HPR-20 Board

6543

21

A

S401

C

D

B

A side (component side)

Ref. No. Name Description Factory setting

S401 — Factory use ALL OFF

SSS-12 Board

5

4

3

S500

S401

2

1

ABCDE

A side (component side)

Ref. No. Name Description Factory setting

S401 — Factory use ALL OFF

S500 RESET Push this switch when resetting the system control. —

2-14

HVR-1500

2-11. Circuit Protection Parts (Fuse/IC

Link)

Circuit Protection Element

This unit is equipped with the positive characteristics

thermister(s) (power thermister) as the circuit protection

element. The positive characteristics thermister limits the

electric current flowing through the circuit as the internal

resistance increases when an exces-sive current flows or

when the ambient temperature increases.

If the positive characteristics thermister works, turn off the

main power of the unit and inspect the internal circuit of

this unit. After the cause of the fault is removed, turn on

the main power again. The unit works normally.

It takes about one minute to cool down the positive

characteristics thermister after the main power is turned off.

Board Ref. No. (Address) Part No.

CN-1968A THP1 (A-1/Side A) ! 1-805-726-11

THP2 (A-1/ Side A) ! 1-805-726-11

THP3 (A-1/ Side A) ! 1-805-726-11

THP4 (A-1/ Side A) ! 1-805-726-11

Fuse/IC Link

w

The fuse and IC link are essential parts for safe operation.

Replace the components with Sony parts whose part

numbers appear in the manual published by Sony. If the

components are replaced with any parts other than the

specified ones, this may cause a fire or electric shock.

This unit is equipped with Fuse(s) and IC link(s).

An excessive current flows due to abnormality inside the

equipment, the fuse and/or IC link blow. If they blow, turn

off the main power of the equipment, inspect inside of the

equipment, and remove the cause of excessive current.

After that, replace the fuse and/or IC link.

Board Ref. No. (Address) Part No./Name

AVP-7 F51 (D-8/Side A) ! 1-576-797-11

Fuse 2.0 A, 125 V

PS51 (C-8/Side A) ! 1-533-282-21

IC link 2 A, 72 V

PS52 (C-8/Side A) ! 1-533-282-21

IC link 2 A, 72 V

PS53 (C-8/Side A) ! 1-533-282-21

IC link 2 A, 72 V

PS54 (C-8/Side A) ! 1-533-282-21

IC link 2 A, 72 V

PS55 (E-9/Side A) ! 1-533-282-21

IC link 2 A, 72 V

Board Ref. No. (Address) Part No./Name

DDE-22 PS300 (A-4/Side A) ! 1-576-282-21

IC link 1.2 A, 72 V

PS301 (A-4/Side A) ! 1-576-282-21

IC link 1.2 A, 72 V

PS302 (A-5/Side A) ! 1-576-282-21

IC link 1.2 A, 72 V

PS303 (A-2/Side A) ! 1-576-282-21

IC link 1.2 A, 72 V

DR-428BG PS1 (E-2/Side A) ! 1-576-123-21

IC link 0.8 A, 72 V

PS2 (E-2/Side A) ! 1-576-123-21

IC link 0.8 A, 72 V

PS3 (F-2/Side A) ! 1-576-123-21

IC link 0.8 A, 72 V

PS4 (E-2/Side A) ! 1-576-123-21

IC link 0.8 A, 72 V

DVP-42 PS1301 (A-3/Side B) ! 1-576-677-21

DPR-293 IC link 4 A, 72 V

PS1302 (A-3/Side B) ! 1-533-282-21

IC link 2 A, 72 V

PS1303 (A-3/Side B) ! 1-533-282-21

IC link 2 A, 72 V

PS1304 (A-4/Side B) ! 1-533-282-21

IC link 2 A, 72 V

KY-614 PS100 (E-3/Side B) ! 1-576-282-21

IC link 1.2 A, 72 V

PS101 (E-3/Side B) ! 1-576-282-21

IC link 1.2 A, 72 V

PS102 (E-3/Side B) ! 1-576-282-21

IC link 1.2 A, 72 V

PS103 (E-3/Side A) ! 1-576-282-21

IC link 1.2 A, 72 V

PS104 (E-3/Side A) ! 1-576-282-21

IC link 1.2 A, 72 V

RP-133 PS101 (B-3/Side A) ! 1-576-282-21

IC link 1.2 A, 72 V

PS102 (B-3/Side A) ! 1-576-282-21

IC link 1.2 A, 72 V

PS103 (B-3/Side A) ! 1-576-282-21

IC link 1.2 A, 72 V

SSS-12 PS102 (C-5/Side A) ! 1-576-282-21

IC link 1.2 A, 72 V

PS103 (C-5/Side A) ! 1-576-282-21

IC link 1.2 A, 72 V

PS104 (C-5/Side A) ! 1-576-282-21

IC link 1.2 A, 72 V

PS105 (C-5/Side A) ! 1-576-282-21

IC link 1.2 A, 72 V

HVR-1500

2-15

2-12. Replacing NV-RAM and Memory Backup Battery

(1) Overview

This unit is provided with a batter backed RAM and EEPROMs on the boards.

These memory devices store system setup data, adjustment data, and other data.

When any of these devices or the backup battery is replaced, the memory data must be rewritten.

Board Ref. No. Type Stored data

AVP-7 IC156 EEPROM AVP BOARD ADJ adjustment value of maintenance menu

DR-428BG IC8 EEPROM Hours meter data

KY-616 IC300 EEPROM LCD ADJ adjustment value of maintenance menu

RP-133 IC501 EEPROM RP adjustment value of maintenance menu

SSS-12 IC538 RAM SYSTEM SEL setting data of setup menu

(with backup battery) Input/output setting data

IC539 EEPROM Setup menu data

Serial number data

Error log data

Mechanical deck adjustment value

Menu bank 1-3 data

2-16

HVR-1500

Loading...

Loading...