Sony HDW-F900R MAINTENANCE MANUAL

HD CAMCORDER

HDW-F900R

DOWN CONVERTER BOARD

HKDW-702

PICTURE CACHE BOARD

HKDW-703

2-3 PULL-DOWN/DOWN CONVERTER BOARD

HKDW-902R

SLOW SHUTTER/IMAGE INVERTER BOARD

HKDW-905R

MAINTENANCE MANUAL

Volume 1 1st Edition (Revised 1)

Serial No. 10001 and Higher : HDW-F900R (SY)

! WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

HDW-F900R/V1 (E)

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the manufacturer.

Dispose of used batteries according to the

manufacturer’s instructions.

ADVARSEL!

Lithiumbatteri-Eksplosionsfare ved fejlagtig

håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

ADVARSEL

Lithiumbatteri - Eksplosjonsfare.

Ved utskifting benyttes kun batteri som

anbefalt av apparatfabrikanten.

Brukt batteri returneres

apparatleverandøren.

Vorsicht!

Explosionsgefahr bei unsachgemäßem Austausch

der Batterie.

Ersatz nur durch denselben oder einen vom

Hersteller empfohlenen ähnlichen Typ. Entsorgung

gebrauchter Batterien nach Angaben des

Herstellers.

ATTENTION

Il y a danger d’explosion s’il y a remplacement

incorrect de la batterie.

Remplacer uniquement avec une batterie du même

type ou d’un type équivalent recommandé par le

constructeur.

Mettre au rebut les batteries usagées conformément

aux instructions du fabricant.

VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en likvärdig typ

som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt gällande

föreskrifter.

VAROITUS

Paristo voi räjähtää jos se on virheellisesti

asennettu.

Vaihda paristo ainoastaan laitevalmistajan

suosittelemaan tyyppiin.

Hävitä käytetty paristo valmistajan ohjeiden

mukaisesti.

HDW-F900R/V1 (E)

1 (P)

For the customers in the Netherlands

Voor de klanten in Nederland

Hoe u de batterijen moet verwijderen, leest u in de tekst

van deze handleiding.

Gooi de batterij niet weg maar lever deze in als klein

chemisch afval (KCA).

Für Kunden in Deutschland

Entsorgungshinweis: Bitte werfen Sie nur entladene

Batterien in die Sammelboxen beim Handel oder den

Kommunen. Entladen sind Batterien in der Regel dann,

wenn das Gerät abschaltet und signalisiert “Batterie

leer” oder nach längerer Gebrauchsdauer der Batterien

“nicht mehr einwandfrei funktioniert”. Um

sicherzugehen, kleben Sie die Batteriepole z.B. mit

einem Klebestreifen ab oder geben Sie die Batterien

einzeln in einen Plastikbeutel.

For the customers in the U.S.A. and Canada

RECYCLING LITHIUM-ION BATTERIES

Lithium-Ion batteries are recyclable.

You can help preserve our environment

by returning your used rechargeable

batteries to the collection and recycling

location nearest you.

For more information regarding recycling of rechargeable batteries, call toll free

1-800-822-8837, or visit http://www.rbrc.org/

Caution: Do not handle damaged or leaking Lithium-Ion

batteries.

2 (P)

HDW-F900R/V1 (E)

Table of Contents

Manual Structure

Purpose of this manual ................................................................. 6

Related manuals ........................................................................... 6

1. Service Overview

1-1. Locations of Main Parts and Circuit Configuration .......1-1

1-1-1. Circuit Configuration and Locations of

the Printed Wiring Boards .....................................1-1

1-1-2. Locations of Main Mechanical Parts ..................... 1-4

1-1-3. Functions and Locations of Sensors ......................1-6

1-2. Matching Connectors ......................................................1-8

1-3. Signal Inputs and Outputs ............................................... 1-8

1-4. Removing and Reinstalling the Outside Panel

Assembly ...................................................................... 1-11

1-5. Opening and Closing the Inside Panel Assembly .........1-12

1-6. Removing and Reinstalling the Connector Box ........... 1-13

1-7. Removing and Reinstalling the Plug-in Boards ............ 1-14

1-7-1. DCP Board Assembly .........................................1-14

1-7-2. DVP Board Assembly ......................................... 1-16

1-8. Removing and Reinstalling the Flexible

Card Wires ....................................................................1-18

1-9. Removing and Reinstalling the Cassette

Compartment ................................................................1-19

1-10. On-Board Switch/Slit Land Description ....................... 1-22

1-10-1. AT-172 Board ..................................................... 1-22

1-10-2. EQ-88G Board ..................................................... 1-23

1-10-3. FP-152 Board ...................................................... 1-24

1-10-4. MDC-13G Board .................................................1-25

1-10-5. SS-92G Board ..................................................... 1-26

1-10-6. RP-131 Board ......................................................1-27

1-10-7. AXM-33 Board ................................................... 1-27

1-11. How to Eject a Cassette Tape Manually .......................1-28

1-12. How to Insert a Cassette Tape While the Outside

Panel Assembly is Being Removed ..............................1-30

1-13. How to Clean the Heads When the Heads are

Clogged .........................................................................1-30

1-14. List of Tools and Measuring Equipment ...................... 1-31

1-14-1. Tools ....................................................................1-31

1-14-2. Measuring Equipment ......................................... 1-34

1-14-3. Alignment Tapes ................................................. 1-35

1-15. How to Extend the Circuit Board ................................. 1-36

1-15-1. Extending the AT-172 Board .............................. 1-36

1-15-2. Extending the HKDW-702 (DC-110A Board)/

HKDW-902R (DC-139 Board) ........................... 1-37

1-15-3. Extending the DCP Board Assembly ..................1-38

1-15-4. Extending the DCP Board Assembly

(When you want to check the B side or a

part of A side of the DVP board assembly) ........1-39

1-15-5. Extending the DVP Board Assembly ..................1-40

1-15-6. Extending the DVP Board Assembly

(When you want to check the B side or a

part of A side of the SS-92G board) .................... 1-41

1-15-7. Extending the EQ-88G Board ............................. 1-42

1-15-8. Extending the HKDW-703 (MY-99 Board) ........ 1-43

1-15-9. Extending the SS-92G Board .............................. 1-44

1-15-10. Extending the RP-131 Board

(When you want to check the B side or

the A side of the PA-340 board) .......................... 1-45

1-15-11. Extending the CCD Unit ..................................... 1-46

1-15-12. Extending the Mechanical Deck Assembly ........1-47

1-16. Description on Cassette Mechanism ............................. 1-49

1-17. Adjustments/Setting Items When Boards Are

Replaced ....................................................................... 1-51

1-17-1. DR-614 Board ..................................................... 1-51

1-17-2. CN-2871 Board ................................................... 1-51

1-17-3. PA-340 Board ...................................................... 1-51

1-17-4. RP-131 Board ......................................................1-51

1-17-5. TG-256 Board .....................................................1-52

1-17-6. CCD Unit ............................................................. 1-52

1-17-7. DCP-43 Board .....................................................1-52

1-17-8. MDC-13G Board ................................................. 1-52

1-17-9. MDR-14G Board ................................................. 1-52

1-17-10. FP-152 Board ...................................................... 1-53

1-17-11. EQ-88G Board ..................................................... 1-53

1-17-12. CCM-45G Board .................................................1-53

1-17-13. IFA-19G Board ...................................................1-53

1-17-14. DC-110A Board (HKDW-702) ...........................1-53

1-17-15. DC-139 Board (HKDW-902R) ........................... 1-53

1-17-16. PM-23 Board (HKDW-905R) .............................1-53

1-18. Contents of the EEPROM, NV-RAM and

FRAM Data .................................................................. 1-54

1-19. Description on the CCD Block Number .......................1-55

1-20. Filter Knob Position Adjustment ..................................1-56

1-21. Memory Backup Battery ............................................... 1-57

HDW-F900R/V1 (E)

1

1-22. Fuse and IC Link Replacement ..................................... 1-57

1-23. Circuit Protection Element ........................................... 1-58

1-24. Upgrading the ROM Version ........................................ 1-59

1-24-1. Confirming the ROM Version ............................. 1-59

1-24-2. When a Memory Stick is Used for Version

Upgrading (AT-172 Board, FP-152 Board,

SS-92G Board) .................................................... 1-59

1-24-3. When the ROM-28 Board is Used for Version

Upgrading (AT-172 Board) ................................. 1-61

1-24-4. When the FL-272 Board is Used for Version

Upgrading (SS-92G Board) ................................. 1-62

1-25. How to Replace the Photo Sensors on

the MDC-13G Board ....................................................1-63

1-26. Circuit Description ........................................................ 1-64

1-26-1. CCD Block (TG-256 Board, DR-614 Board,

BI-199/200/201 Board, and PA-340 Board) ....... 1-64

1-26-2. Camera System (DCP-43 Board) ........................ 1-65

1-26-3. Video Signal System (DVP-41 Board) ............... 1-66

1-26-4. Audio System (FP-152 Board, IFA-19G

Board, APR-59AG Board, AL-43 Board,

and AXM-33 Board) ...........................................1-67

1-26-5. System Control (FP-152 Board and

SS-92G Board) .................................................... 1-71

1-26-6. Servo Control System (SS-92G Board,

MDC-13G Board, MDR-14G Board,

and SE-613 Board) ..............................................1-74

1-26-7. RF System (EQ-88G Board) ............................... 1-75

1-26-8. Power Supply Systems (CNB-23 Board,

RE-186 Board, and RE-187B Board) .................. 1-76

1-26-9. Option Board (DC-110A Board,

DC-139 Board, MY-99 Board, PM-23 Board) ... 1-77

1-27. Unleaded Solder ............................................................ 1-80

1-28. Notes on Repair Parts ...................................................1-80

1-29. Precautions for use of Condensation Sensor ................ 1-80

2. Periodic Maintenance and Inspection

2-1-6. Cleaning the S/T Plate Assemblies and S/T

Slider Assemblies ..................................................2-7

2-1-7. Cares after Using under Special Environment ...... 2-8

2-2. Periodic Inspection .........................................................2-9

2-2-1. Hours Meter ........................................................... 2-9

2-2-2. Periodic Inspection List ....................................... 2-10

2-2-3. Applying Oil to Reel Drive Gear Assembly ....... 2-11

2-2-4. Applying Grease to S Tension Regulator

Assembly .............................................................2-12

2-2-5. Notes on Repair Parts ..........................................2-14

2-2-6. Recommended Periodic Replacement Parts ........ 2-15

2-2-7. Recommended Replacement Parts ......................2-17

3. Error Diagnostics

3-1. When Does the Error Code Appear? .............................. 3-1

3-1-1. Description of Error Codes ................................... 3-2

3-1-2. Details of Error Codes ...........................................3-4

3-2. Device Check ..................................................................3-8

4. Setup Menu

4-1. Setup Menus ................................................................... 4-1

4-1-1. Basic Operations of Setup Menus ......................... 4-1

4-1-2. How to Display the SERVICE Menu .................... 4-2

4-2. TOP Menu ......................................................................4-3

4-3. USER Menu ....................................................................4-4

4-4. OPERATION Menu ....................................................... 4-5

4-5. PAINT Menu ................................................................ 4-23

4-6. MAINTENANCE Menu ............................................... 4-36

4-7. FILE Menu .................................................................... 4-52

4-8. DIAGNOSIS Menu ......................................................4-62

4-9. SERVICE Menu ........................................................... 4-66

4-10. Setup Menu List ............................................................ 4-78

2-1. Cleaning ..........................................................................2-1

2-1-1. General Information for Cleaning .........................2-1

2-1-2. Cleaning the Upper Drum Tape Running

Surface and Video Heads ...................................... 2-3

2-1-3. Cleaning the Lower Drum Tape Running

Surface and Rabbet Guide .....................................2-4

2-1-4. Cleaning the Stationary Heads .............................. 2-5

2-1-5. Cleaning the Tape Running Path and

Cleaning Blade ...................................................... 2-6

2

5. File System

5-1. Structure of File System ................................................. 5-1

5-2. Data Structure ................................................................. 5-2

5-3. Operating the USER File ................................................5-3

5-4. Operating the ALL File ..................................................5-6

5-5. Operating the SCENE File ............................................ 5-10

5-6. Operating the REFERENCE File .................................5-13

HDW-F900R/V1 (E)

5-7. Operating the LENS File .............................................. 5-16

5-8. Special Saving Items ..................................................... 5-18

5-8-1. White Gain .......................................................... 5-18

5-8-2. Master Gain .........................................................5-19

5-8-3. Shutter .................................................................5-19

6. Parts Replacement

6-1. CCD Unit and its Components Parts Replacement

Procedure ........................................................................ 6-1

6-1-1. CCD Unit Replacement ......................................... 6-1

6-2. Filter Disk Unit Replacement ......................................... 6-5

6-3. Replacement of the Circuit Boards inside

the CCD Unit .................................................................. 6-6

6-4. Shutter, AUTO W/B BAL Switch and AUDIO

Volume Controls Replacement .......................................6-8

6-5. MIC IN Connector Replacement .................................. 6-10

6-6. Rotary Encoder Replacement ....................................... 6-11

6-7. Connector Box Board Replacement .............................6-13

6-7-1. Removing the Connector Box Assembly ............6-13

6-7-2. Removing the CNB-23 Board and

AL-43 Board ....................................................... 6-13

6-7-3. Removing the IO-202 Board ............................... 6-13

6-7-4. Removing the RM-201 Board .............................6-14

6-7-5. Removing the SW-1309 Board and

the AXM-33 Board .............................................. 6-14

6-7-6. Removing the DC IN Connector .........................6-15

6-7-7. Removing the DC OUT/HD SDI OUT

Connectors ........................................................... 6-15

6-8. DC-DC Converter Replacement ................................... 6-16

6-9. Fan Replacement .......................................................... 6-18

6-9-1. Replacing the Fan on the Inside Panel

Assembly .............................................................6-18

6-9-2. Replacing the Fan in the Unit .............................. 6-19

6-10. Camera SW Ornamental Plate (3) Replacement .......... 6-20

6-11. 50P Fitting Bracket Assembly Replacement ................ 6-21

6-12. MS Lid Assembly Replacement ................................... 6-22

6-13. VF Connector Replacement .......................................... 6-25

6-14. POWER Switch Replacement ......................................6-26

6-15. IFA-19G Board Replacement ....................................... 6-27

6-16. Battery Connector Assembly (DC-111 Board)

Replacement .................................................................6-28

6-17. CCM-45G Board Replacement ..................................... 6-29

6-18. PS-595 Board Replacement ..........................................6-30

6-19. IF-794G Board, HN-277G Board and

RX-54G Board Replacement ........................................6-31

6-20. SS-92G Board Replacement .........................................6-34

6-21. LP-114 Board Replacement .......................................... 6-35

6-22. SW-1312 Board Replacement ......................................6-36

6-23. MB-1096 Board Replacement ...................................... 6-37

6-24. Mechanical Deck Assembly Boards Replacement .......6-38

6-24-1. MDR-13G Board Replacement ...........................6-38

6-24-2. MDR-14G Board Replacement ...........................6-38

6-24-3. SE-613 Board Replacement ................................ 6-39

7. Part Replacement of Mechanical Deck

Assembly

7-1. General Information on Mechanical

Part Replacement ............................................................ 7-1

7-1-1. Index ...................................................................... 7-1

7-1-2. Notes ...................................................................... 7-2

7-1-3. Threading-End State and Unthreading-

End State ...............................................................7-3

7-1-4. How To Eject a Cassette Tape Manually ..............7-4

7-1-5. About Oil and Grease ............................................7-6

7-1-6. Screw Tightening Torque and Washer ..................7-7

7-2. Upper Drum Assembly Replacement ............................. 7-8

7-3. Drum Assembly Replacement ...................................... 7-24

7-4. Replacement of Brush Assembly for Slip Ring ............ 7-31

7-5. Slip Ring Assembly Replacement ................................ 7-34

7-6. Replacement of AHC Roller Assembly for

Video Head ................................................................... 7-38

7-7. Pinch Roller Assembly Replacement ........................... 7-41

7-8. S-Tension Regulator Band Assembly Replacement ..... 7-44

7-9. T-Tension Regulator Band Assembly Replacement ..... 7-47

7-10. Timing Belt Replacement .............................................7-50

7-11. S Idler Assembly Replacement and T Idler

Assembly Replacement ................................................ 7-52

7-12. CTL Head Replacement ...............................................7-54

7-13. FE Head Replacement ..................................................7-57

7-14. Holder Assembly Sensor (REC) Replacement .............7-60

7-15. End Sensor Assembly Replacement ............................. 7-62

7-16. Full Top Sensor Assembly Replacement ...................... 7-63

7-17. S1, T1, T3 Tape Guide Replacement ............................ 7-64

7-18. (S) Soft Brake Assembly Replacement ........................ 7-66

7-19. T Soft Brake Replacement ............................................7-68

7-20. Manual Eject Assembly Replacement ..........................7-70

HDW-F900R/V1 (E)

3

7-21. S-Tension Regulator Assembly Replacement .............. 7-72

7-22. T-Tension Regulator Assembly Replacement .............. 7-75

7-23. Cassette Stopper Replacement ...................................... 7-78

7-24. Gear Block Assembly Replacement ............................. 7-80

7-25. S Reel Table Replacement and T Reel Table

Replacement .................................................................7-83

7-26. Reel Drive Gear Assembly Replacement ..................... 7-87

7-27. Holder Assembly Sensor (ID) Replacement ................. 7-90

7-28. Top Sensor Assembly Replacement ............................. 7-92

7-29. Pinch Arm Assembly Replacement .............................. 7-94

7-30. Threading Arm Assembly Replacement ....................... 7-97

7-31. CUE/TC Head Assembly Replacement ......................7-101

7-32. S Slider Assembly Replacement ................................. 7-106

7-33. T Slider Assembly Replacement ................................7-111

7-34. Cam Gear Assembly Replacement ............................. 7-116

7-35. Mechanical Deck Assembly Removal/

Installation ..................................................................7-122

7-36. MDC-13G Board Replacement ..................................7-126

7-37. Capstan Motor Replacement ....................................... 7-131

8. Mechanical Adjustmen

8-1. Mechanical Adjustment .................................................. 8-1

8-1-1. Reel Table Height Adjustment ..............................8-3

8-1-2. S Tension Regulator Operating Position

Adjustment ............................................................ 8-5

8-1-3. FWD Back Tension Adjustment ........................... 8-7

8-1-4. REV Back Tension Adjustment ............................ 8-9

8-1-5. Timing Belt Tension Adjustment ........................8-11

8-1-6. T Tension Regulator Operating Position

Adjustment .......................................................... 8-12

8-1-7. S3 Guide Height Adjustment .............................. 8-14

8-1-8. Gear Chain Phase Adjustment ............................. 8-16

8-2. Tape Run System Adjustment ...................................... 8-19

8-2-1. Tape Run Adjustment .......................................... 8-21

8-2-2. Video Tracking Adjustment ................................ 8-27

8-2-3. CTL Head Height Adjustment ............................8-32

8-2-4. CTL Head Position Adjustment .......................... 8-34

8-2-5. CUE/TC Head Height Adjustment ...................... 8-36

8-2-6. CUE/TC Head Azimuth Adjustment ................... 8-39

8-2-7. CUE/TC Head Tape-to-Head Contact

Adjustment .......................................................... 8-41

8-2-8. CUE/TC Head Position Adjustment ................... 8-43

8-2-9. CUE/TC Output Level Check ............................. 8-46

9. Electrical Alignment of Camera System

9-1. General Information on Electrical Alignment ................ 9-1

9-1-1. Notes on Electrical Alignment .............................. 9-1

9-1-2. Required Equipment, Fixtures and Tools .............. 9-1

9-1-3. Initial Position of Switches during Adjustment ....9-1

9-1-4. Gray-Scale Chart and its Maintenance ..................9-2

9-2. VCO Frequency Adjustment .......................................... 9-4

9-3. TEST OUT Level Adjustment ........................................9-4

9-4. VF DC Level Adjustment ...............................................9-5

9-5. VA Gain Adjustment ...................................................... 9-6

9-6. Black Offset Adjustment ................................................9-7

9-7. VSUB Adjustment ..........................................................9-9

9-8. PA Gain Adjustment .....................................................9-10

9-9. Pre Knee Adjustment ....................................................9-11

9-10. DCC Pre Knee Adjustment ........................................... 9-12

9-11. Black Shading Adjustment ........................................... 9-13

9-12. White Shading Adjustment ........................................... 9-14

9-13. Flare Adjustment ..........................................................9-16

9-14. Gamma Correction Adjustment ....................................9-17

9-15. Knee and White Clip Adjustment .................................9-18

9-16. DCC Knee Adjustment .................................................9-19

9-17. Crispening Adjustment ................................................. 9-20

9-18. Level Depend Adjustment ............................................ 9-20

9-19. Detail Signal Frequency Adjustment ............................9-21

9-20. H/V Ratio Adjustment .................................................. 9-22

9-21. Detail Signal Level Adjustment .................................... 9-22

9-22. Knee Aperture Adjustment ...........................................9-23

9-23. H. Detail Black Clip Adjustment ..................................9-23

9-24. V. Detail Black Clip Adjustment ..................................9-24

9-25. Skin Tone Adjustment .................................................. 9-25

9-26. Zebra Adjustment ......................................................... 9-26

9-27. Auto Iris Adjustment .................................................... 9-27

9-28. Adjustment upon Replacement of Filter Disc Unit ...... 9-27

9-29. SD VCO Adjustment .................................................... 9-28

9-30. SD Y Level Adjustment ................................................ 9-28

9-31. SD ZEBRA Clamp Level Adjustment .......................... 9-29

9-32. SD ZEBRA Y Level Adjustment .................................9-30

9-33. VF 2-3 Pull Down HD Y Level Adjustment ................ 9-30

9-34. RPN Concealment ........................................................9-31

9-34-1. Manual RPN Concealment ..................................9-31

9-34-2. When RPN Concealment Does Not Succeed ......9-32

9-34-3. Effectively Performing Auto RPN

Recognition ......................................................... 9-32

9-34-4. RPN Concealment Flowchart ..............................9-33

4

HDW-F900R/V1 (E)

10. Electrical Alignment of VTR System

11. VTR Maintenance Mode

10-1. Preparation ....................................................................10-1

10-2. Audio System Alignment ............................................. 10-2

10-2-1. Audio A/D Error Adjustment ..............................10-2

10-2-2. Audio D/A Error Adjustment ..............................10-3

10-2-3. AUDIO LEVEL Volume Control

(Inside Panel) Adjustment ...................................10-3

10-3. CUE Audio Alignment ................................................. 10-4

10-3-1. Bias Trap Adjustment .......................................... 10-4

10-3-2. CUE Playback Level Adjustment ....................... 10-4

10-3-3. CUE Recording Bias Preset Adjustment ............. 10-5

10-3-4. CUE Record Level Adjustment-1 ....................... 10-6

10-3-5. CUE Record Level Adjustment-2 ....................... 10-7

10-4. System Control Alignment ........................................... 10-8

10-4-1. Battery Voltage Correction Adjustment .............. 10-8

10-4-2. Antenna Tuning Frequency

Adjustment (Tele-File) ........................................10-8

10-5. Servo System Alignment .............................................. 10-9

10-5-1. Servo System Adjustment Data Initialization ..... 10-9

10-5-2. Capstan FG Duty Ratio Adjustment .................. 10-10

10-5-3. Capstan Add-On Recording Adjustment ........... 10-10

10-5-4. Drum Phase Adjustment .................................... 10-11

10-6. RF System Alignment ................................................. 10-11

10-6-1. RF System Continuous Automatic

Adjustment ........................................................ 10-11

10-6-2. Saving the RF System Adjustment Data ...........10-12

10-6-3. PB Channel Condition Check ...........................10-13

10-6-4. REC Channel Condition Check ......................... 10-13

11-1. Introduction ................................................................... 11-1

11-2. Operation Procedure ..................................................... 11-2

11-2-1. Identifying Switches ............................................ 11-2

11-2-2. How to Enter VTR Maintenance Mode ..............11-2

11-2-3. How to Exit VTR Maintenance Mode ................ 11-3

11-2-4. Tips on Operations .............................................. 11-3

11-3. Contents of Menus ........................................................11-4

11-3-1. Servo System Self-Diagnosis Mode

(C0 : SERVO CHECK) .......................................11-4

11-3-2. RF System Self-Diagnosis Mode

(C1 : RF CHECK) .............................................11-14

11-3-3. Audio System Adjustment Value

Check Mode (C2 : AUDIO CHECK) ...............11-18

11-3-4. SERVO System Adjustment Mode

(A0 : SERVO ADJUST) ................................... 11-19

11-3-5. RF System Adjustment Mode

(A1 : RF ADJUST) ...........................................11-24

11-3-6. Audio System Adjustment Mode

(A2 : AUDIO ADJUST) ...................................11-38

11-3-7. Mechanism Adjustment Mode

(A4 : MECHANISM ADJUST) ........................11-41

11-3-8. Other Adjustments

(A9 : OTHERS ADJUST) .................................11-42

HDW-F900R/V1 (E)

5

Purpose of this manual

Related manuals

Manual Structure

This manual is the maintenance manual volume 1 of HD Camcorder HDW-F900R.

This manual is intended for use by the trained system engineers and service engineers. The volume 1 describes the information (periodic inspection and maintenance, diagnosis, part replacements and adjustment procedures) on the premise of

component level service.

Beside this Maintenance Manual Volume 1, the following manuals are available for

the unit.

. Operation Manual (Supplied with this unit)

This manual is necessary for application and operation of this unit.

Part number: 3-991-852-0X

. Maintenance Manual Vol. 2 (Available on request)

This manual intended for use by trained system and service engineers describes

(the parts list, semiconductor model list, block diagrams, schematic diagrams and

board layouts) required for parts-level service.

For obtaining, contact your local Sony Sales Office/Service Center.

Part number: 9-968-282-0X

. HDVF-20A Maintenance Manual (Available on request)

This manual is the maintenance manual of the supplied viewfinder.

This manual is intended for use by trained system and service engineers, and

describes the information regarding the service overview, electrical alignment,

parts list, semiconductor pin assignments, block diagrams, schematic diagrams

and board layouts.

For obtaining, contact your local Sony Sales Office/Service Center.

Part number: 9-968-559-0X

..

. “Semiconductor Pin Assignments” CD-ROM (Available on request)

..

This “Semiconductor Pin Assignments” CD-ROM allows you to search for

semiconductors used in Broadcast and Professional equipment.

This manual contains a complete list of semiconductors and their ID Nos., and

thus should be used together with the CD-ROM.

Part number: 9-968-546-0X

6

HDW-F900R/V1 (E)

Section 1

Service Overview

1-1. Locations of Main Parts and Circuit Configuration

1-1-1. Circuit Configuration and Locations of the Printed Wiring Boards

System Board Name Circuit No.

Configuration Function

CCD Block BI-199, 200, 201 CCD Imager #[

CN-2871 Connector for $\

DR-614 CCD Driver $]

PA-340 Pre AMP #]

RP-131 Pulse Generator #=

TG-256 Timing #/

Camera AT-172 System ![

System Control

DCP-43 Camera Processor 2

Video Signal DVP-41 VTR Processor 3

System

Audio System AL-43 Audio AMP 0

APR-59AG Audio Volume !,

AXM-33 Connector 9

FP-152 Audio Processor 1

IFA-19G Lens Control #;

System/Servo MDC-13G Mecha Deck @/

Control Control

MDR-14G Drum Motor @-

SE-613 Sensor @.

SS-92G Servo/System !.

RF System EQ-88G Equalizer @'

Power Supply CNB-23 Circuit Breaker 8

DC-111 Battery DC Filter 6

RE-186 Regulator $/

RE-187B Regulator #.

Connector IO-202 In/Out !Box

Mic MA-103 Mic AMP #'

LP-114 Rear Tally 4

RM-201 Connector (RM) @]

DR-614

Generator

Drive

Control

System Board Name Circuit No.

Configuration Function

Others BP-33 Battery !]

CCM-45G TELE-FILE @[

CI-32G 50pin adaptor $[

Interface

ENC-61 Rotary Encoder !'

HN-277G Harness #,

HP-103 Headphone !;

HP-104 Headphone 5

IF-794G Interface $-

KY-475G Function Key @,

MB-1096 Motherboard 7

PS-595 Power Supply @=

(Light)

RX-54G Wireless $=

Receiver

Interface

SW-1312 Light Switch #-

SW-1031 Switch #\

SW-1038 Switch !\

SW-1309 MIC SWITCH $;

TX-78 HDSDI Driver @;

Option DC-110A Down Converter !=

(HKDW-702)

MY-99 Picture Cache @\

(HKDW-703)

DC-139 2-3 Pull-Down/ !=

(HKDW-902R) Down Converter

PM-23 Slow Shutter/ $'

(HKDW-905R) Image Inverter

HDW-F900R/V1 (E)

1-1

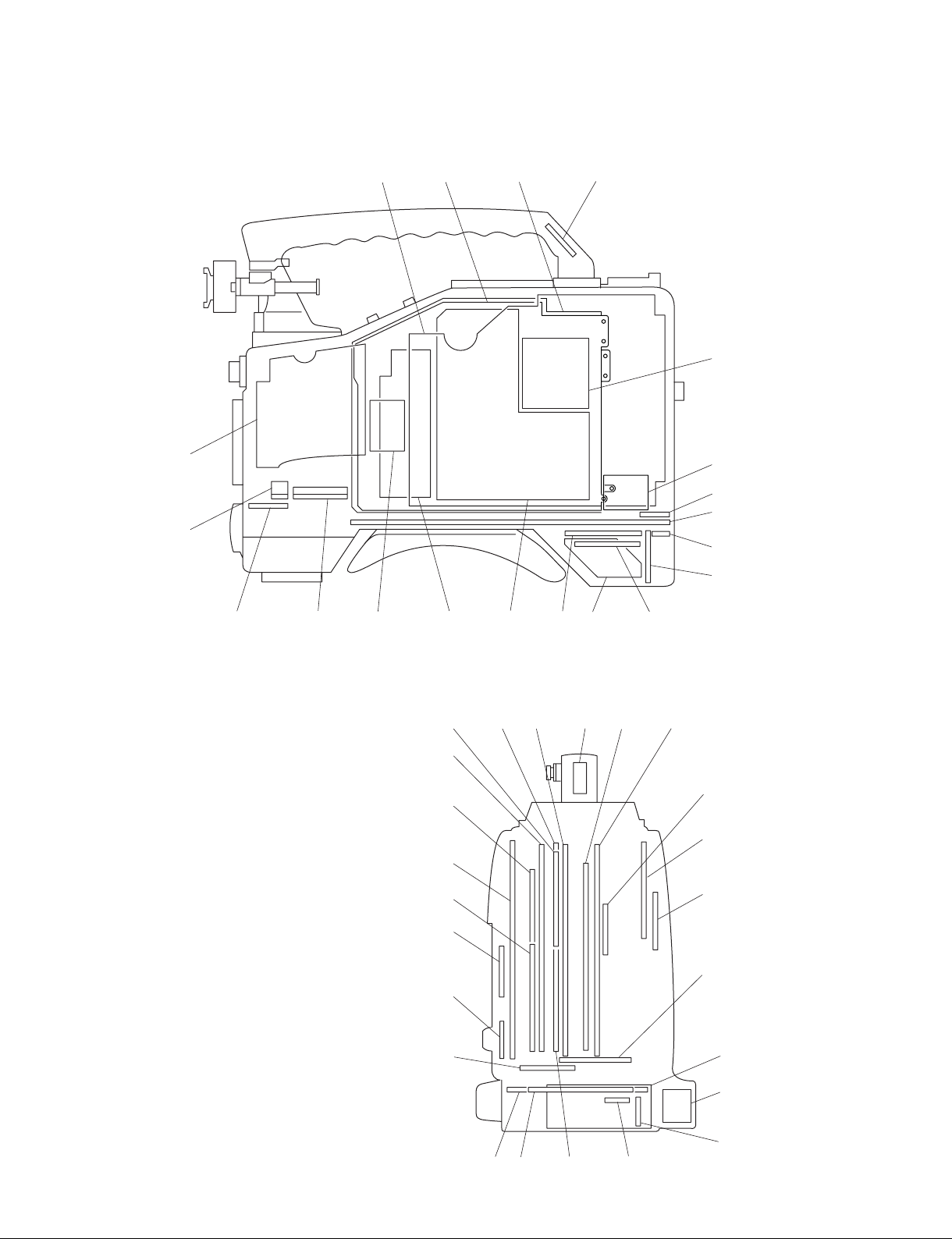

<View of the inside panel assembly>

!,

!'

1

23

![!]!\!;

!=

8

!-

4

$'

5

6

7

$;

9

0

<Rear view>

@;

2

$'

1

!=

!]

5

7

@'

$;

3

4

!.

@\8

@/

@-

@=

@[

6

9

@]

!-

0

1-2

HDW-F900R/V1 (E)

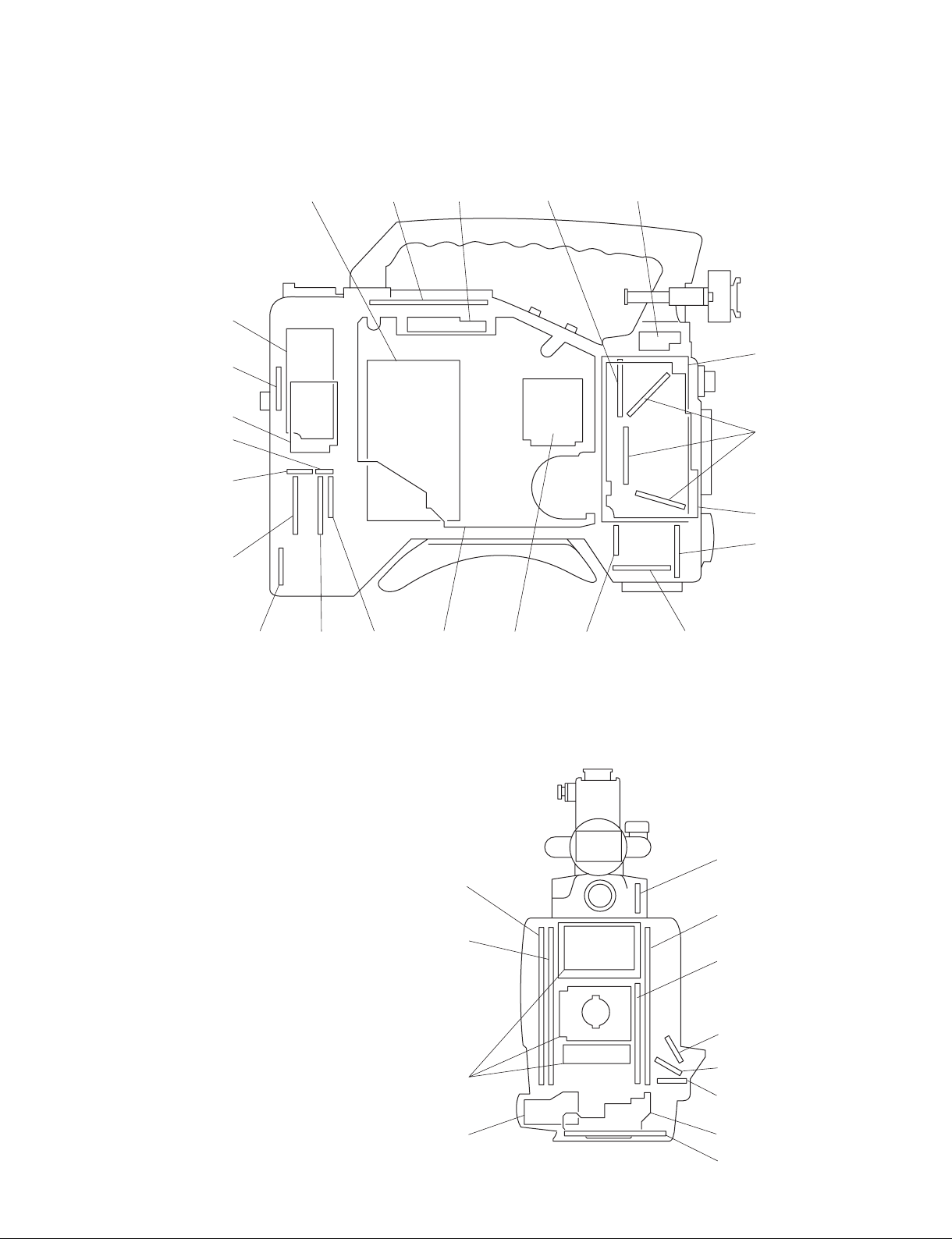

<View of the outside panel assembly>

!. @.

@=

@,

#/ #-

$[

@[

$=

$-

$/

@]

#.

#,

@/

<Front view>

@-

#'

#=

#[

#]

#\

#;

HDW-F900R/V1 (E)

#=

#]

#[

#'

#-

$]

$\

!'

!\

!;

#\

#;

1-3

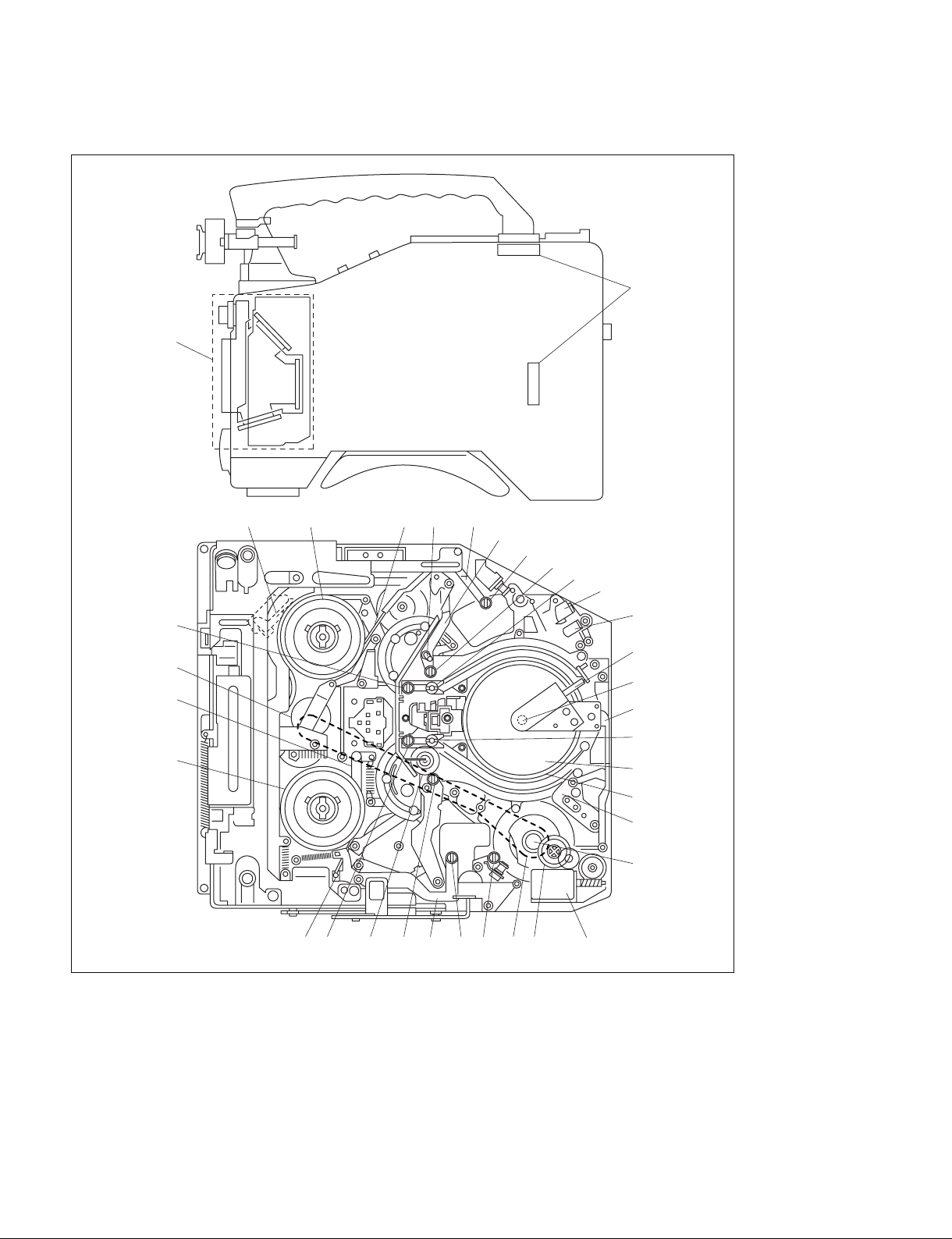

1-1-2. Locations of Main Mechanical Parts

1

#=

#/

@.

6

#\

3

7

8

2

4

9

5

#[

@;

@'

#-

@]

@[

@- @=#]

!;

@,

!,

0

!-

!=

![

@\

!]

!\

!'

@/

!.

1-4

HDW-F900R/V1 (E)

1 CCD block

2 Fan motor

3 Threading arm assembly

4 S1 tape guide (on top of S-slider assembly)

5 S2 tape guide (on top of S-slider assembly)

6 S4 tape guide (on top of threading arm assembly)

7 S5 tape guide (on top of S-tension regulator assembly)

8 S3 tape guide (on top of threading arm assembly)

9 Full erase head

0 CTL head

!- Brush assembly

!= Slip ring assembly

![ Cleaning assembly

!] Upper drum

!\ Lower drum

!; T4 guide

!' CUE/TC head

!, Manual eject gear (A)

!. Loading motor

@/ Capstan motor

@- T3 tape guide

@= T5 guide (on top of T-tension regulator assembly)

@[ Pinch roller assembly

@] T2 tape guide (on top of T slider assembly)

@\ T1 tape guide (on top of T slider assembly)

@; (T) soft brake

@' T reel table assembly

@, Timing belt

@. S-tension regulator band assembly

#/ S reel table assembly

#- T-tension regulator band assembly

#= (S) soft brake assembly

#[ Reel drive gear assembly

#] T-tension regulator assembly

#\ S-tension regulator assembly

HDW-F900R/V1 (E)

1-5

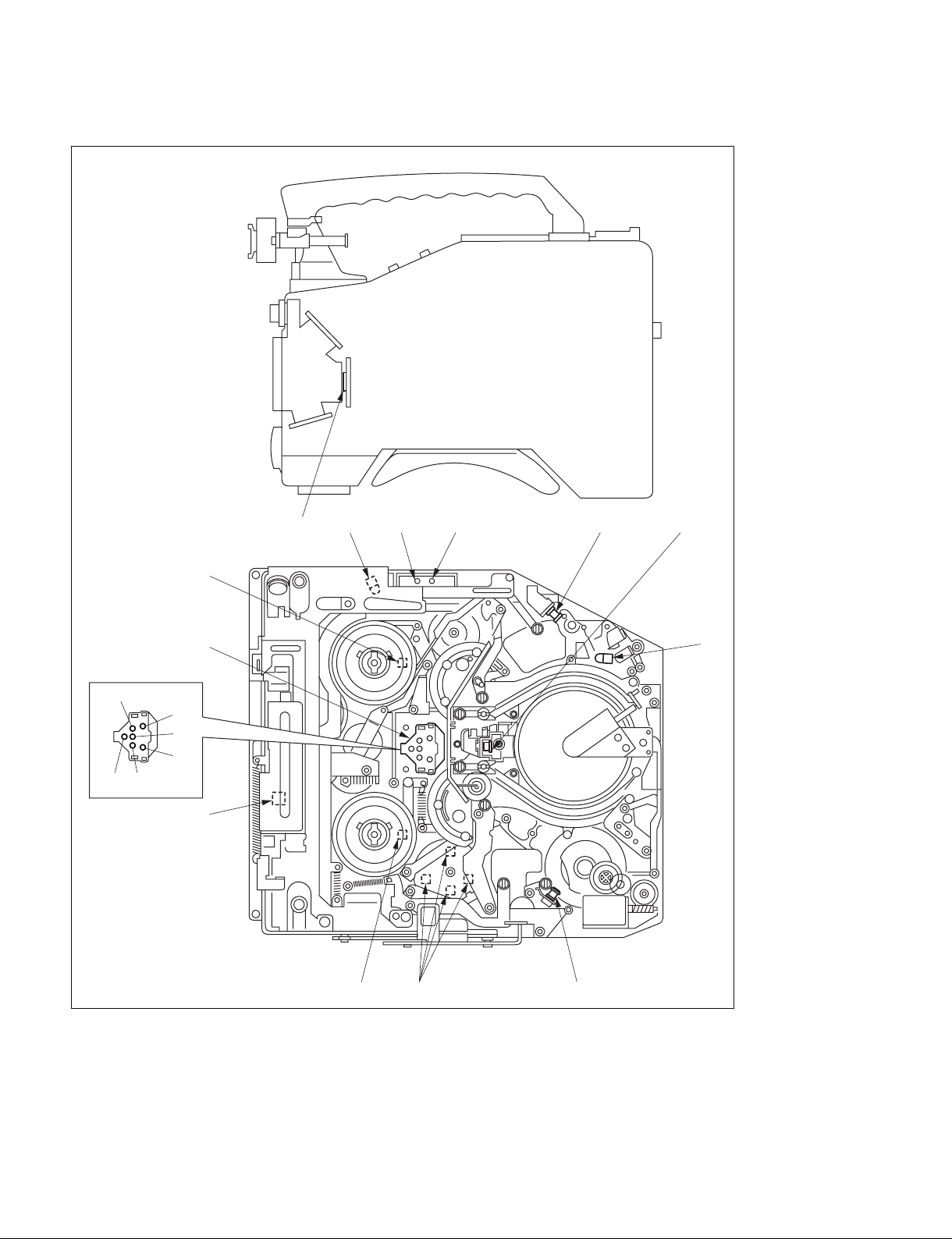

1-1-3. Functions and Locations of Sensors

ID6

ID5

ID4

ID3

ID1

ID2

!=

!-

0

1

6

2

3

4

5

6

1-6

9

8

7

HDW-F900R/V1 (E)

1 Temperature sensor

Detects temperature and drives the fan.

2 Cassette-in sensor

Detects whether a cassette is inserted or not.

3 REC INHIBIT sensor

Detects REC INHIBIT plug of a cassette tape.

4 Tape end sensor

Detects the tape end of a tape that is running in the FWD direction.

5 Full top sensor

Detects whether the inserted cassette tape is in the full top position or not.

6 Humid sensor

Detects the dew condensation inside the unit.

7 Tape top sensor

Detects the tape end of a tape that is running in the REV direction.

8 Function cam sensor

Detects the rotary position of the function cam.

9 T-reel table assembly rotation sensor

Detects rotation of the take-up reel table with the use of the T-reel table assembly rotation sensor. The

FG generator output of this sensor is input to the servo circuit where diameter of the remaining tape is

calculated.

0 Cassette lock sensor (switch)

Detects whether the cassette compartment assembly is locked or not.

!- Cassette ID sensor

ID1 : Tape type

Detects the tape type (Oxide or Metal).

ID2 : Tape thickness

Detects thickness of the tape that is wound in the cassette tape inserted in the set, with the

use of the tab on the rear of a cassette tape.

ID3 : Reel hub diameter

The reel hub diameter of a cassette tape is different depending on the length of a tape that

is wound in the cassette tape. The reel hub diameter sensor detects the reel hub diameter

with the use of a tab on the rear of a cassette tape.

ID4 to 6 : Tape format

Detects whether a cassette conforms to the HDCAM format or not.

!= S-reel table assembly rotation sensor

Detects rotation of the supply reel table with the use of the S-reel table assembly rotation sensor. The

output of this sensor is input to the servo circuit where diameter of the remaining tape is calculated.

HDW-F900R/V1 (E)

1-7

1-2. Matching Connectors

Use the following connectors at the ends of the cables

when connecting the cables during installation and maintenance, or alternately use the following cables.

Panel indication Matching connectors/cables

GENLOCK IN (RETURN)

TC IN 1-569-370-12

TC OUT Plug, BNC

TEST OUT

VBS/SDI OUT

HD SDI OUT 1-750-489-21 Plug, BNC or

AUDIO IN CH1/CH2 1-508-084-00 XLR 3-pin, male

AUDIO OUT Audio cable

MIC IN +48 V 1-508-370-00 XLR 5-pin, male

DC IN 1-508-362-00 XLR 4-pin, female

DC OUT 12 V 1-566-425-11 round type 4-pin,

REMOTE 1-766-848-11 round type 8-pin,

EARPHONE Mini jack (commercially available

LIGHT Power tap (OE)

WIRELESS WRR-855A (by Sony) only

RECEIVER IN connectable

* : Camcorder in which DC-110A board (HKDW-702) and DC-139 board

(HKDW-902R) is installed.

*

BELDEN 8281 or equivalent

(XLR 5 pin-XLR 3-pin, 2 m)

CCXA-53 made by Sony or

equivalent

male

male

on market)

Made by ANTONBAUER Inc.,

33710 or equivalent

n

Do not connect with a connector/

cable other than above.

1-3. Signal Inputs and Outputs

Inputs

GENLOCK IN (RETURN) : 1.0 V p-p, 75 Z

TC IN : 0.5 V to 18 V p-p, 10 kZ

1

4

23

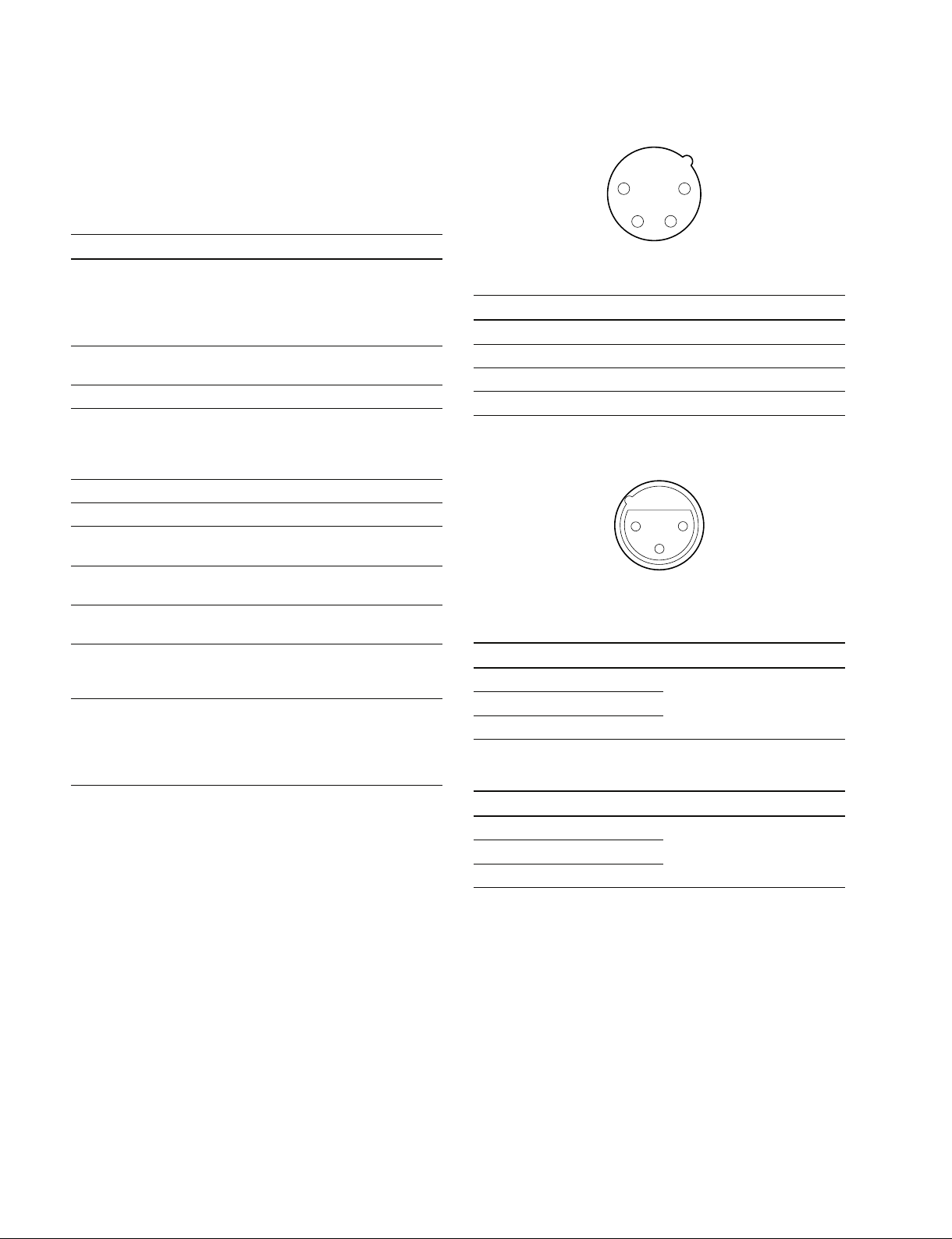

DC IN : XLR, 4-pin (Male)

__

_ EXT VIEW

__

No. Signal I/O Specifications

1 GND _ GND for BATT OUT (+)

2 _ No connection

3 _ No connection

4 BATT OUT (+)IN +11 to 17 V dc

__

_

__

AUDIO IN CH-1, CH-2 : XLR, 3-pin (Female)

2

__

_ EXT VIEW

__

1

3

__

_

__

(0 dBu = 0.775 V rms)

MIC/LINE INPUT

No. Signal I/O Specifications

1 MIC/LINE (G) __60 dBu/+4 dBu, selectable

2 MIC/LINE (X) IN

3 MIC/LINE (Y) IN

High impedance, Balanced

AES/EBU INPUT

No. Signal I/O Specifications

1 AES/EBU (G) _ 1Vp-p, 110Z, Balanced

2 AES/EBU (X) IN

3 AES/EBU (Y) IN

Outputs

TEST OUT : 1.0 V p-p, 75 Z unbalanced

VBS/SDI OUT

*1, 2

: VBS 1.0 V p-p, 75 Z unbalanced,

or SDI 0.8 V p-p, 75 Z, 270 Mbps

TC OUT : 1.0 V p-p, 75 Z

HD SDI OUT : 0.8 V p-p, 75 Z, 1.485 Gbps

EARPHONE : 8 Z or more, _∞ to _18 dBu variable

*1 : Camcorder in which DC-110A board (HKDW-702) and DC-139 board

(HKDW-902R) is installed.

*2 : Selectable by the SD REAR BNC OUT in the OUTPUT SEL page of the

menu.

1-8

HDW-F900R/V1 (E)

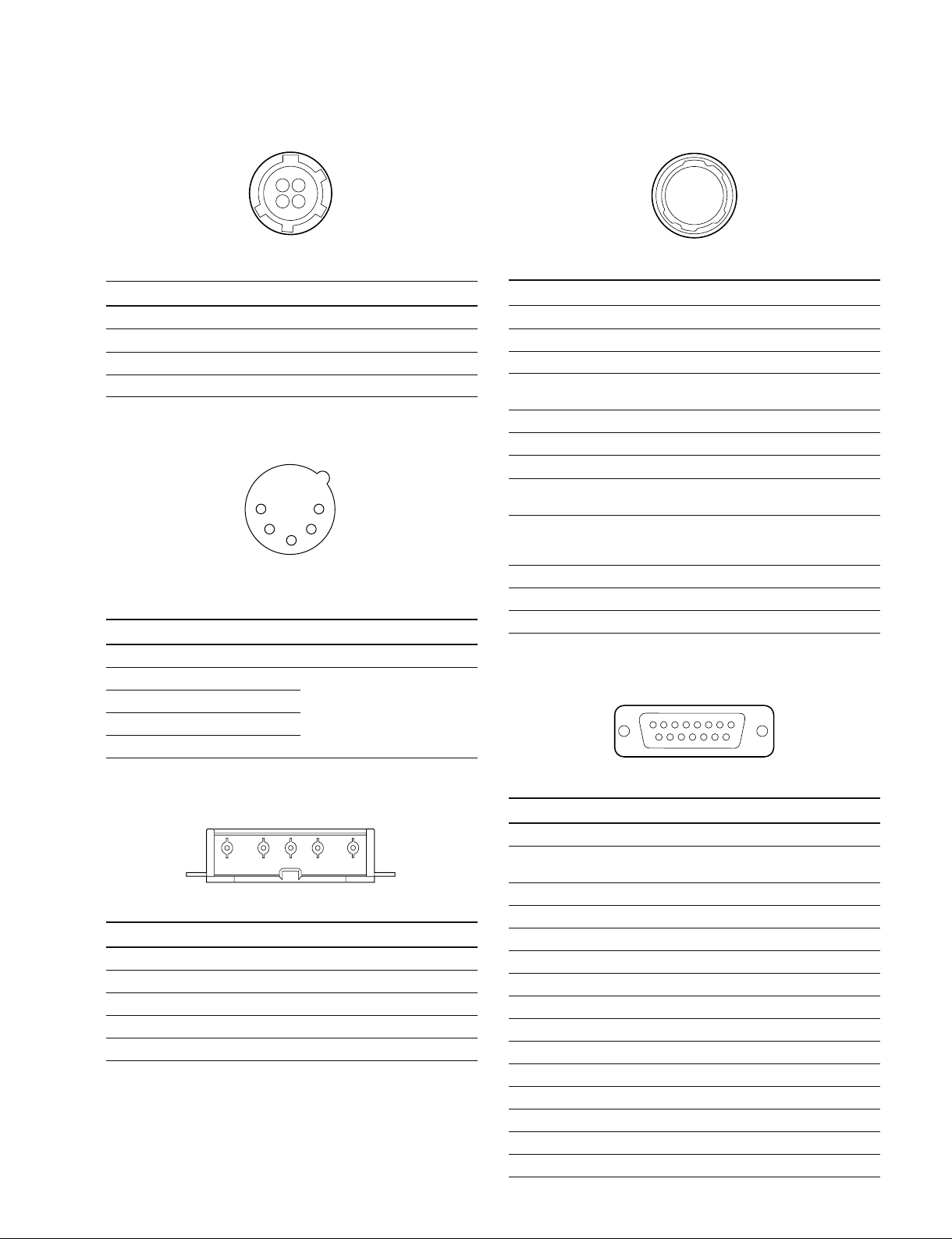

DC OUT 12 V : DIN, 4-pin (Female)

14

32

LENS : 12-pin (Female)

7

8

6

9

0

5

1

!-!=

2

3

4

__

_ EXT VIEW

__

__

_

__

No. Signal I/O Specifications

1 UNREG GND _ GND for POWER

2 _ No connection

3 _ No connection

4 UNREG +12 V OUT +11 to 17 V dc

AUDIO OUT : XLR, 5-pin (Male)

1

__

_ EXT VIEW

__

5

2

4

3

__

_

__

(0 dBu = 0.775 V rms)

No. Signal I/O Specifications

1 ANALOG GND _

2 AUDIO CH-1 (X) OUT 0 dBm (600 Z terminated)

3 AUDIO CH-1 (Y) OUT

4 AUDIO CH-2 (X) OUT

5 AUDIO CH-2 (Y) OUT

__

_ EXT VIEW

__

__

_

__

No. Signal I/O Specifications

1 RET (SW) IN ON : 0 V, OFF : OPEN

2 VTR TRIG IN ON : 0 V, OFF : OPEN

3 LENS GND _

4 AUTO +5 V IN AUTO : +5 V,

MANU : 0 V or OPEN

5 IRIS CONT OUT +3.4 V (F16) to +6.2 V (F2.8)

6 UNREG +12 V OUT +11 V to 17 V

7 IRIS PSTN IN +3.4 V (F16) to +6.2 V (F2.8)

8 REMOTE/LOCAL OUT AUTO IRIS : 0 V

MANUAL IRIS : +5 V

9 EXTENDER IN EX 2 ON : 0 V

EX 0.8 ON : +1.8 V

OFF : +4.8 V

10 ZOOM PSTN IN WIDE : 2 V, TELE : 7 V

11 LENS RX

12 LENS TX

WIRELESS RECEIVER IN : D-sub, 15-pin (Female)

8

15

1

9

BATT IN : 5-pin (Male)

12345

__

_ EXT VIEW

__

No. Signal I/O Specifications

1 BATT (_)IN

2 BATT ID IN

3 BATT REM IN

4 LIGHT CONT OUT

5 BATT (+) IN+11 to 17 V dc

HDW-F900R/V1 (E)

__

_

__

__

_ EXT VIEW

__

__

_

__

No. Signal I/O Specifications

1 GND _ GND for AUDIO IN

2 AUDIO IN IN WIRELESS RECEIVER

AUDIO IN

3 _

4 DC +7V OUT OUT

5 GND _

6 _

7 _

8 GND _

9 WRR CLK IN WRR SERIAL CLOCK

10 CS OUT WRR SELECT

11 WRR DI OUT WRR SERIAL IN

12 WRR DO IN WRR SERIAL OUT

13 _

14 EXT OSC OUT _

15 OSC GND _

1-9

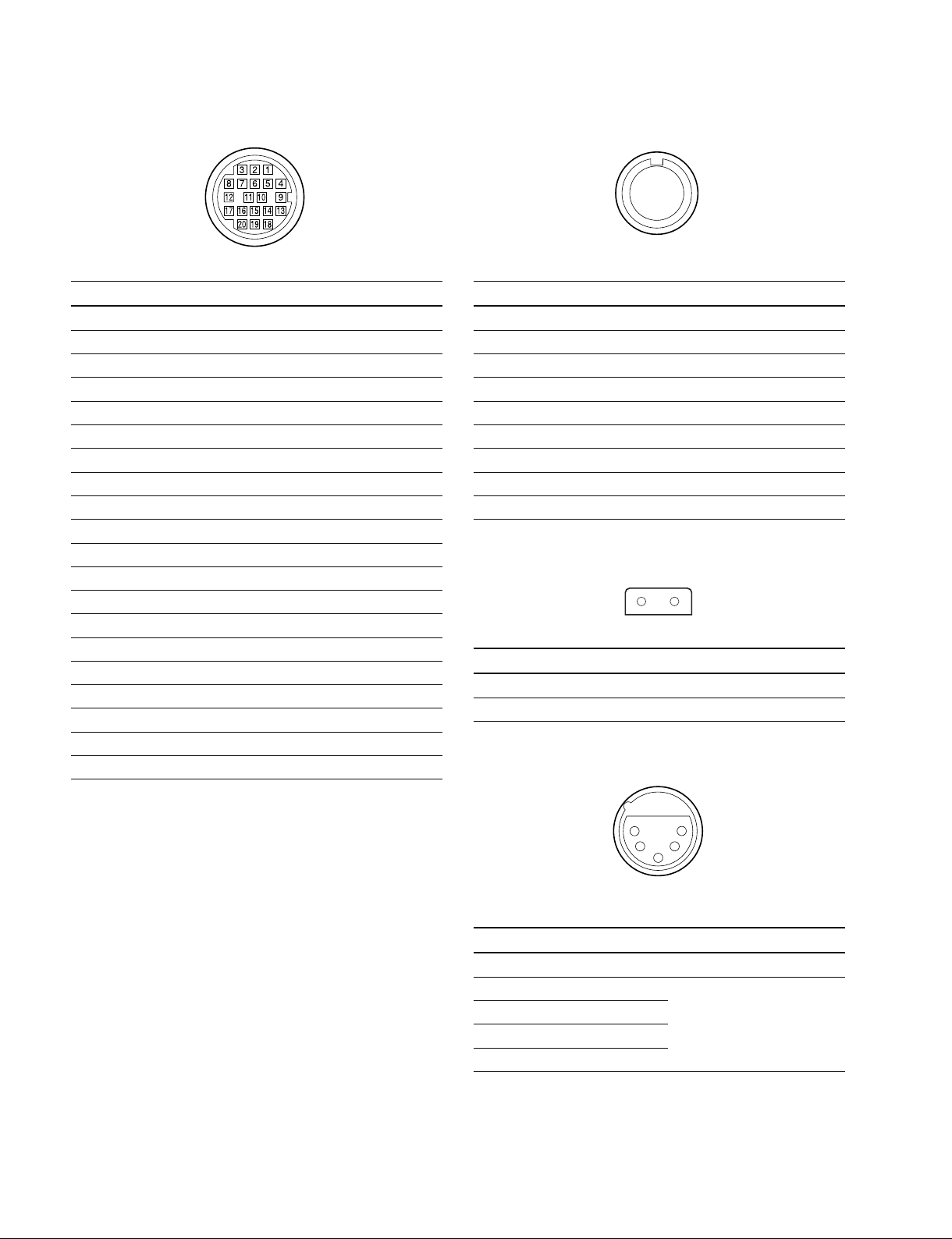

VF : 20-pin (Female)

REMOTE : 8-pin (Female)

36

1

27

8

45

__

_ EXT VIEW

__

No. Signal I/O Specifications

1 SDA VF I/O TTL level

2 _ No connection

3 _ No connection

4 SCL VF OUT TTL level

5 COLOR/BW IN ON : Color, OFF : B/W

6 _ No connection

7 _ No connection

8 G TALLY OUT ON : 5 V, OFF : GND

9 VF PEAKING CTL OUT 1.0 V p-p, Zo = 75 Z

10 _ No connection

11 _ No connection

12 VF VIDEO (Y) OUT 1.0 V p-p, Zo = 75 Z

13 VF VIDEO GND _ GND for VIDEO

14 VF VIDEO (Pb) OUT ± 0.35 V p-p, Zo = 75 Z

15 VF VIDEO (Pr) OUT ± 0.35 V p-p, Zo = 75 Z

16 _ No connection

17 R TALLY (UP) OUT ON : 5 V, OFF : GND

18 _ No connection

19 VF GND _ GND for VF

20 UNREG +12 V OUT +11 V to 17 V

__

_

__

__

_ EXT VIEW

__

No. Signal I/O Specifications

1 TX RCP DATA (X) OUT SERIAL DATA OUT

2 TX RCP DATA (Y) OUT SERIAL DATA OUT

3 RX RCP DATA (X) IN SERIAL DATA IN

4 RX RCP DATA (Y) IN SERIAL DATA IN

5 TX GND _ GND for TX

6 UNREG +12 V OUT +11 V to 17 V

7 UNREG (GND) _ GND for UNREG

8 Y OUT 1.0 V p-p, Zo = 75 Z

CHASSIS GND _ CHASSIS GND

__

_

__

LIGHT : 2-pin (Female)

12

__

_ EXT VIEW

__

No. Signal Specifications

1 LIGHT +12 V OUT 50 W MAX

2 GND

MIC IN

++

+48 V : XLR, 5-pin (Female)

++

__

_

__

1-10

5

__

_ EXT VIEW

__

1

2

4

3

__

_

__

(0 dBu = 0.775 V rms)

No. Signal I/O Specifications

1 CAM MIC (G) __50 dBu

2 CAM MIC1 (X) IN High impedance, Balanced

3 CAM MIC1 (Y) IN

4 CAM MIC2 (X) IN

5 CAM MIC2 (Y) IN

HDW-F900R/V1 (E)

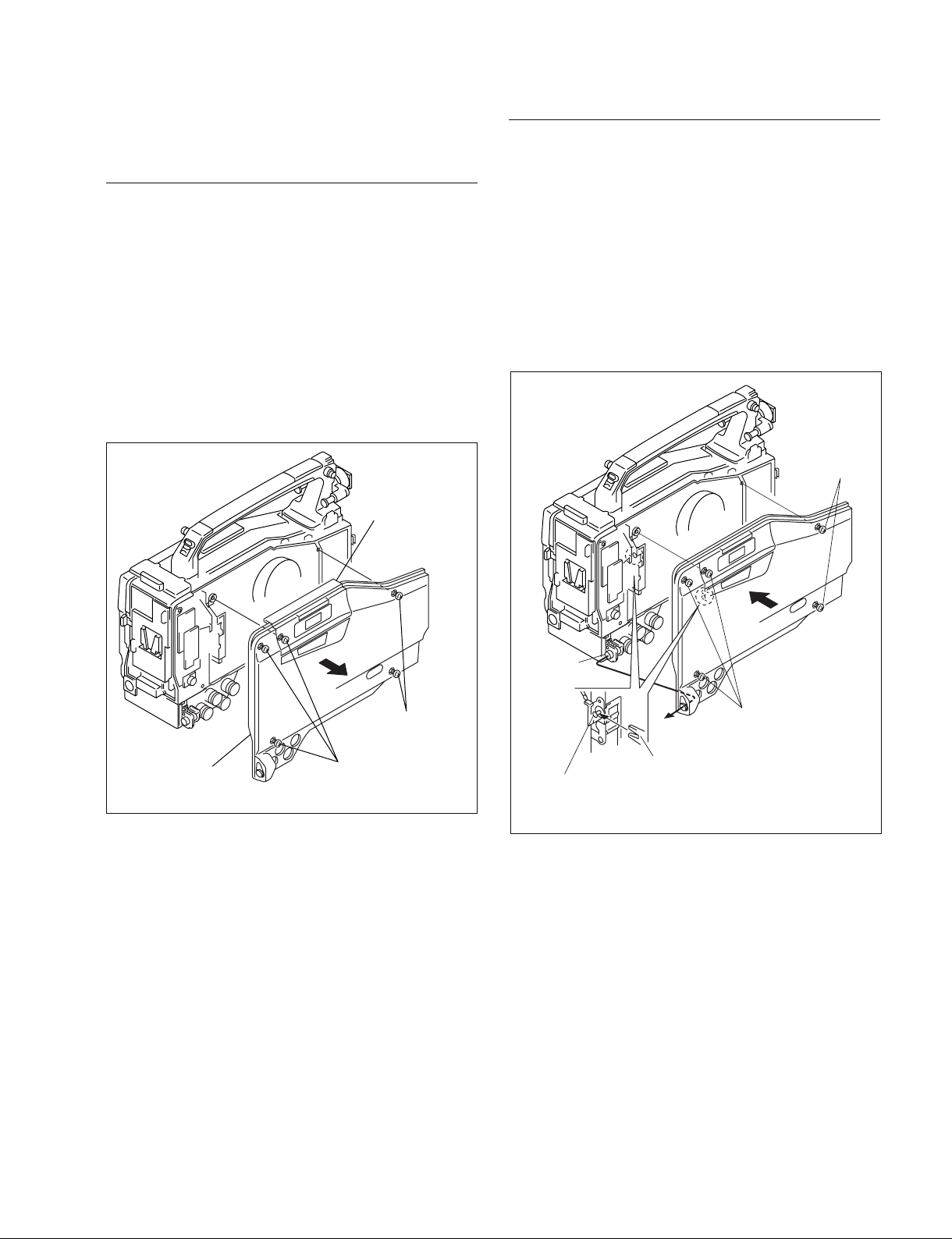

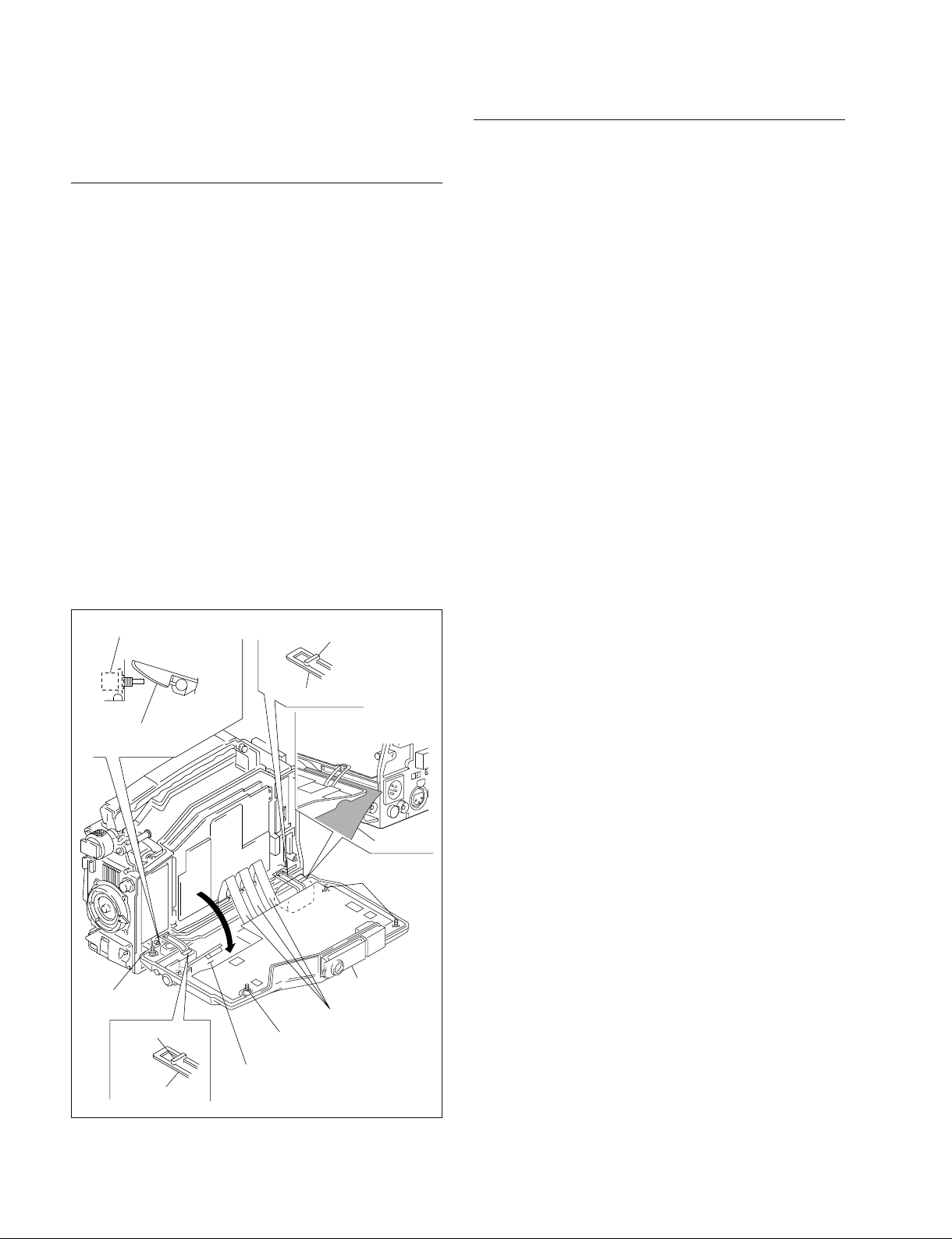

1-4. Removing and Reinstalling the

Outside Panel Assembly

Removal

n

Be sure to set the POWER switch to OFF, unplug the

power cord or remove the battery before starting any of the

following procedure to protect inside of the unit from

damage.

1. Loosen a screw (with drop-safe) in the left of the front

lid assembly.

2. Loosen the four screws (with drop-safe) and remove

the outside panel assembly.

Front lid assembly

Reinstallation

1. Pass the connector of the RM board of the main unit

through the hole of the outside panel assembly.

While inserting the hook of the outside panel assembly

into the guide shaft of the cassette compartment

assembly, install the outside panel assembly.

2. Reinstall it by reversing the steps of disassembling.

n

Standard tightening torque :

Screw (with drop-safe, B3 x 12)

80 x 10-2 N.m (8 kgf.cm)

Screws

(with drop-safe)

Outside panel

assembly

Screws

(with drop-safe)

Screws

(with drop-safe)

RM board

connector

Screws

(with drop-safe)

Hook of outside panel assembly

Guide shaft of

cassette compartment

assembly

HDW-F900R/V1 (E)

1-11

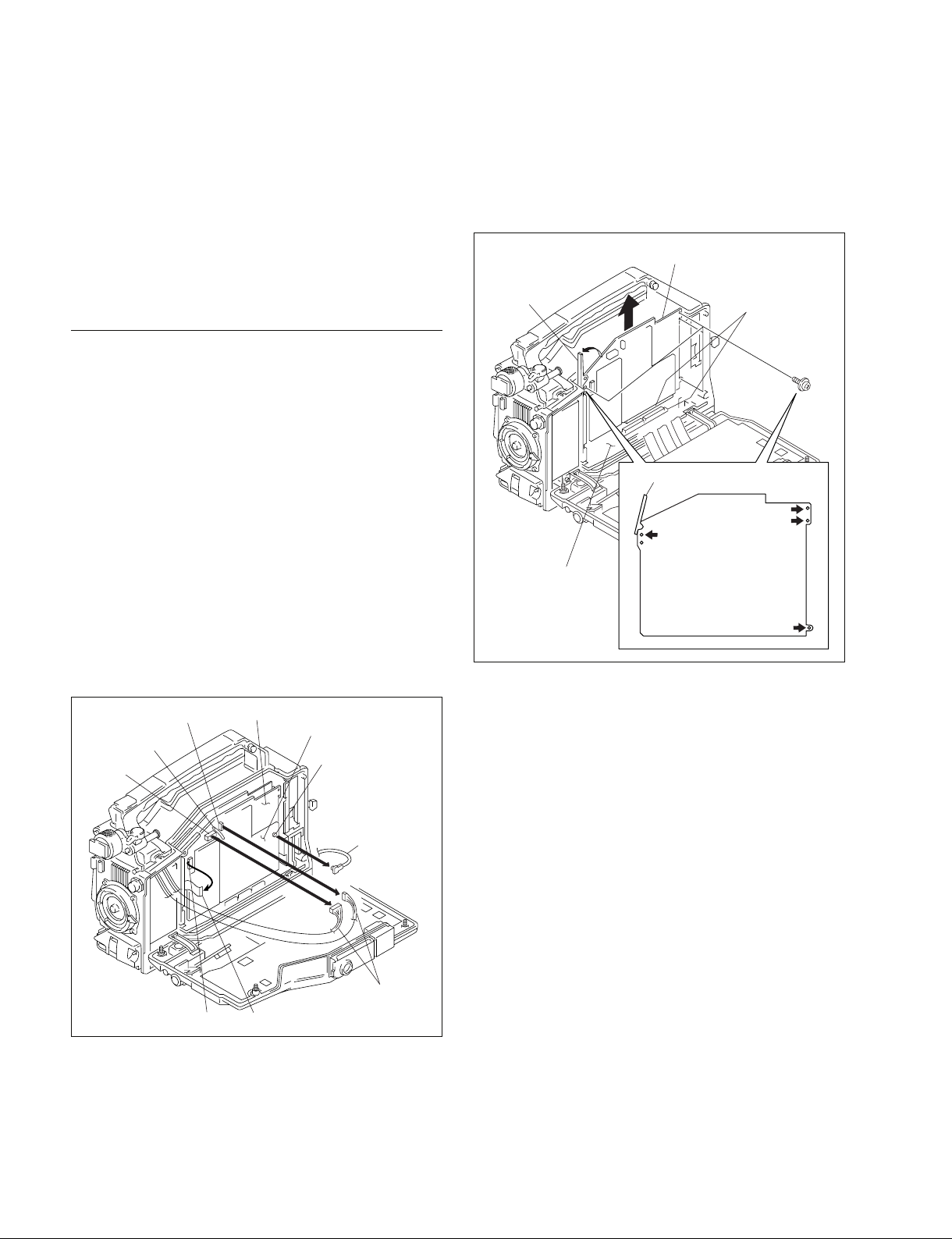

1-5. Opening and Closing the Inside

Panel Assembly

Opening

m

. Be sure to set the POWER switch to OFF, unplug the

power cord or remove the battery before starting any of

the following procedure to protect inside of the unit from

damage.

. Insert a piece of paper between the hinge and the

connector box.

1. Loosen the four screws (with drop-safe) and open the

inside panel assembly in the direction of the arrow.

m

. The flexible card wires that is connected to the FP-

152 board, will be significantly shortened its life if it

is folded. Be very careful not to fold the flexible

card wires.

. Stand the unit in the posture that the POWER switch

side faces upward when the inside panel assembly is

opened.

Closing

1. Check that the hinges in the right and left are engaged

securely with the hooks of the chassis.

2. Insert the inside panel assembly and tighten the four

screws (with drop-safe).

n

Standard tightening torque :

Screw (with drop-safe, B3 x 12)

80 x 10_2 N.m (8 kgf.cm)

n

Be careful not to pinch the harness between the inside

panel assembly and the chassis.

POWER switch

Inside panel

assembly

Screw

(with drop-safe)

Hook

Hinge

Hook

Hinge

Place a sheet of paper

here to protect

the frame.

Paper

Screws

(with drop-safe)

Inside panel

assembly

Flexible card wires

Screw

(with drop-safe)

FP-152 board

1-12

HDW-F900R/V1 (E)

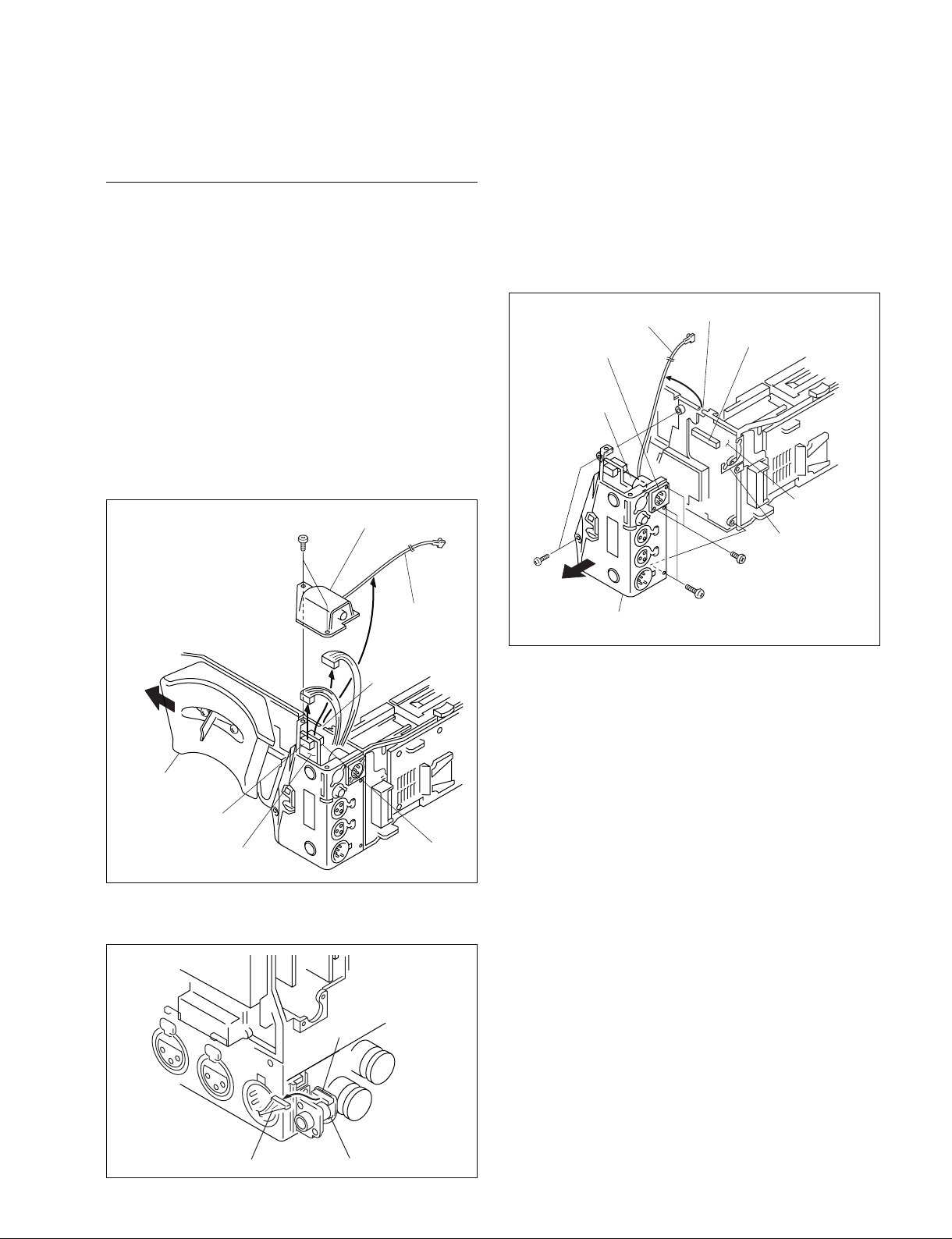

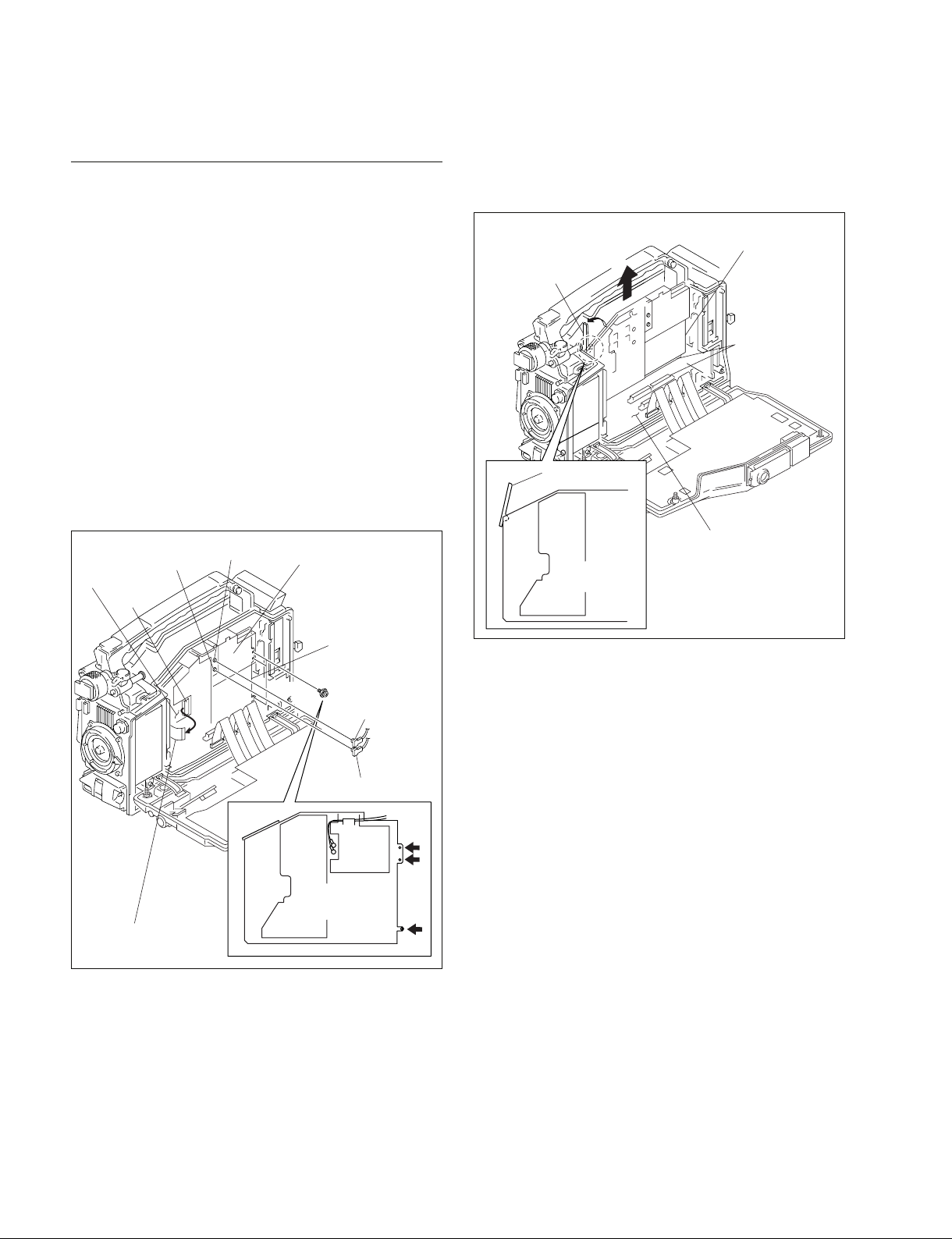

1-6. Removing and Reinstalling the

Connector Box

Removal

1. Remove the outside panel assembly.

(Refer to Section 1-4.)

2. Remove the inside panel assembly.

(Refer to Section 1-5.)

3. Remove the DCP board assembly and the DVP board

assembly. (Refer to Sections 1-7-1 and 1-7-2.)

4. Slide the shoulder pad assembly in the direction of the

arrow.

5. Remove the two screws (P2 x 4). While removing the

VIDEO OUT assembly, remove the coaxial cable from

the groove.

6. Disconnect the harness from connectors (CN101 and

CN103) on CNB-23 board.

P2 x 4

VIDEO OUT assembly

Coaxial cable

(Orange)

8. Remove the two precision screws (P2.6 x 5) fixing

the DC IN connector and separate it from the shield

finger (BATT).

9. Remove the four screws (B3 x 8). Loosen the board-

to-board connector that is connected to the MB-1096

board. While removing the connector box assembly in

the direction of the arrow, remove the coaxial cable

and harness from the groove.

Coaxial cable (Brown)

DC IN connector

Board-to-board

connector

B3 x 8

Connector box assembly

Groove

Precision screws

P2.6 x 5

B3 x 8

Board-to-board

connector

MB-1096

board

Shield finger

(BATT)

Groove

Shoulder pad

assembly

CN103

CNB-23 board

CN101

7. Disconnect the harness from the connector (CN114)

on the RM-201 board.

CN114

10. Reinstall it by reversing the steps of disassembling.

m

. When attaching the VIDEO OUT assembly, route

the coaxial cable such that the coaxial cable passes

through the groove.

. If the coaxial cable is pinched between the frame

and the VIDEO OUT assembly or the CNBOX sub

panel, the coaxial cable can have open-circuit.

n

Standard tightening torque :

P2 x 4 : 19 x 10_2 N.m (1.9 kgf.cm)

B3 x 8 : 80 x 10_2 N.m (8 kgf.cm)

HDW-F900R/V1 (E)

Harness

RM-201 board

1-13

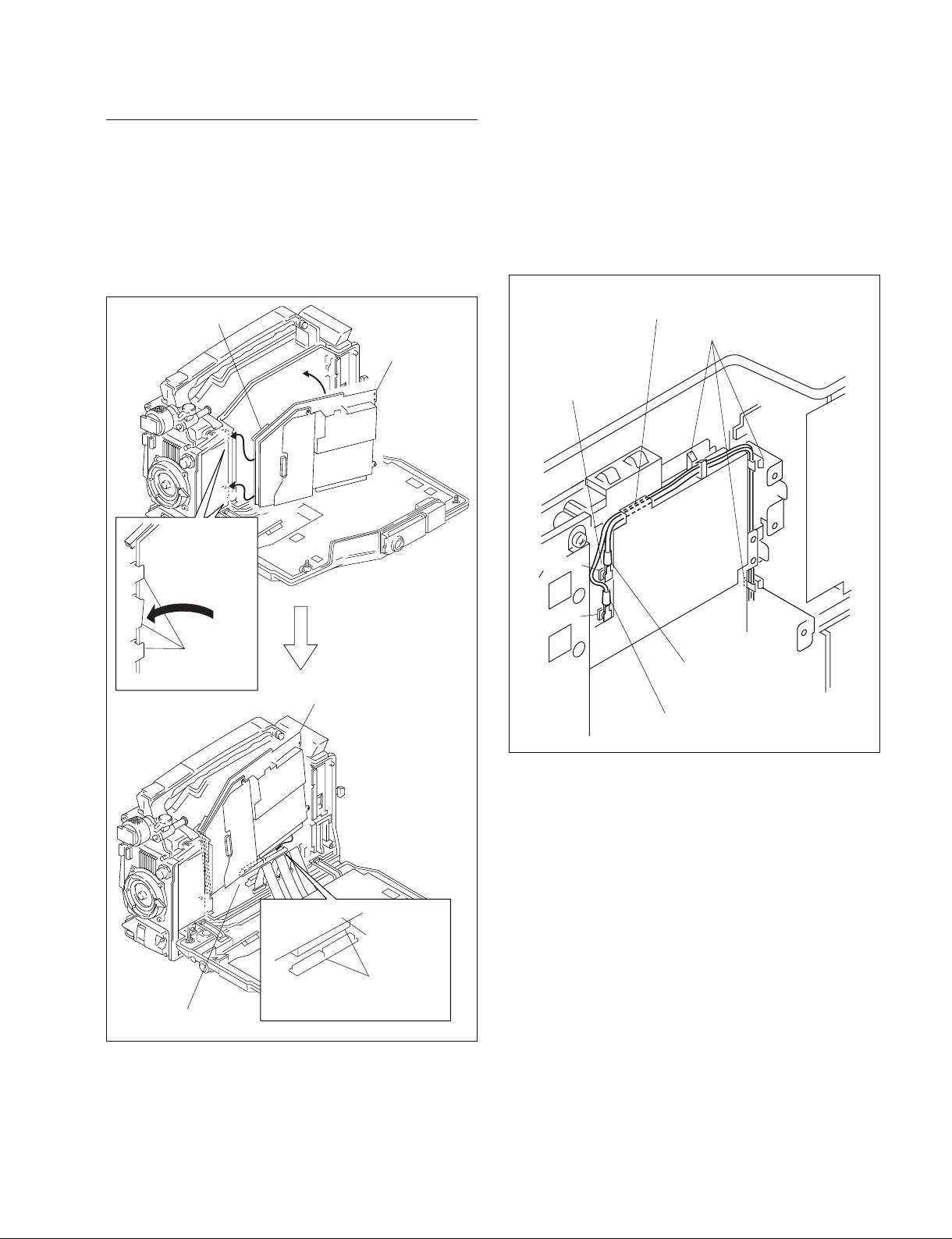

1-7. Removing and Reinstalling the

Plug-in Boards

When removing and reinstalling the plug-in boards, be

very careful not to damage the parts on the printed board

and also not to install them in the wrong direction or in the

wrong slot.

5. Remove the four screws. Open the board levers in the

direction of arrow A to release the board-to-board

connector that is connected to the MB-1096 board.

Pull the DCP board assembly in the direction of arrow

B to disconnect, and remove the DCP board assembly.

DCP board assembly

1-7-1. DCP Board Assembly

Removal

1. Open the inside panel assembly.

(Refer to Section 1-5.)

2. Remove the harness from the coating lead pin, then

disconnect the harnesses from the connectors (CN3

and CN4) of the DCP-43 board.

3. Disconnect the flexible card wire from the connector

(CN105) of the DCP-43 board.

n

. Life of flexible card wire will be significantly

shortened if it is folded. Be very careful not to fold

the flexible card wire.

4. Remove the coaxial cable from the connector (CN1/

DC-110A, CN601/DC-139) when the DC-110A/139

board is installed.

Coating lead pin

CN4

CN3

DCP-43 board

DC-110A/

DC-139 board

CN1/DC-110A

board,

CN601/DC-139

board

Coaxial cable

(Orange)

Board lever

MB-1096 board

Board-to-board

connectors

B

A

PSW2 x 5

Board lever

DCP-43 board

1-14

CN105

Harnesses

Flexible card wire

HDW-F900R/V1 (E)

Reinstallation

1. Close the board levers.

2. Insert the DCP board assembly into the groove on the

board holder in the direction of arrow A, and raise the

DCP board assembly in the direction of arrow B.

3. Connect the DCP board assembly and the MB-1096

board with the board-to-board connector.

Board lever

4. Reinstall it by reversing the steps of disassembling.

m

. When re-installing the harness that is disconnected

in step 2, the CN3 harness must be hooked on the

top edge of the AT-172 board.

. When re-installing the CN4 harness, twist it by 3

turns and install it by pushing in the direction of

arrow A. The CN4 harness must be installed 20 mm

more far from the CN3 harness.

. Fix the harness with the coating lead pin.

Board lever

A

Board holder

(F)

DCP board

assembly

DCP board

B

A

assembly

Board-to-board

connectors

Illustration when viewed

from the top

DCP-43 board

A

Harness

CN4

Harness

Distance of

20 mm

or more

CN3

Illustration when viewed

from the front

Coating

lead pin

DCP-43 board

CN3

CN4

AT-172 board

MB-1096 board

HDW-F900R/V1 (E)

DCP-43 board

AT-172 board

1-15

1-7-2. DVP Board Assembly

Removal

1. Open the inside panel assembly.

(Refer to Section 1-5.)

2. Remove the DCP board assembly.

(Refer to Section 1-7-1.)

3. Remove the flexible card wire from the EQ-88G board

connector (CN101).

n

Life of flexible card wire will be significantly

shortened if it is folded. Be very careful not to fold

the flexible card wire.

4. Remove the two coaxial cables from the connector

(CN201, CN202) on the TX-78 board.

5. Remove the three screws (PSW 2 x 5) that fix the

DVP board assembly.

6. Open the board levers in the direction of arrow A and

remove the board-to-board connector that is connected

to the MB-1096 board, and remove the DVP board

assembly in the direction of arrow B.

DVP board

assembly

Board lever

Board lever

B

A

Board-to-board

connectors

EQ-88G board

CN101

Flexible card wire

CN201

CN202

TX-78 board

DVP board

assembly

PSW2 x 5

Coaxial cable

(Brown)

Coaxial cable (Green)

DVP board

assembly

MB-1096 board

DVP board

assembly

1-16

HDW-F900R/V1 (E)

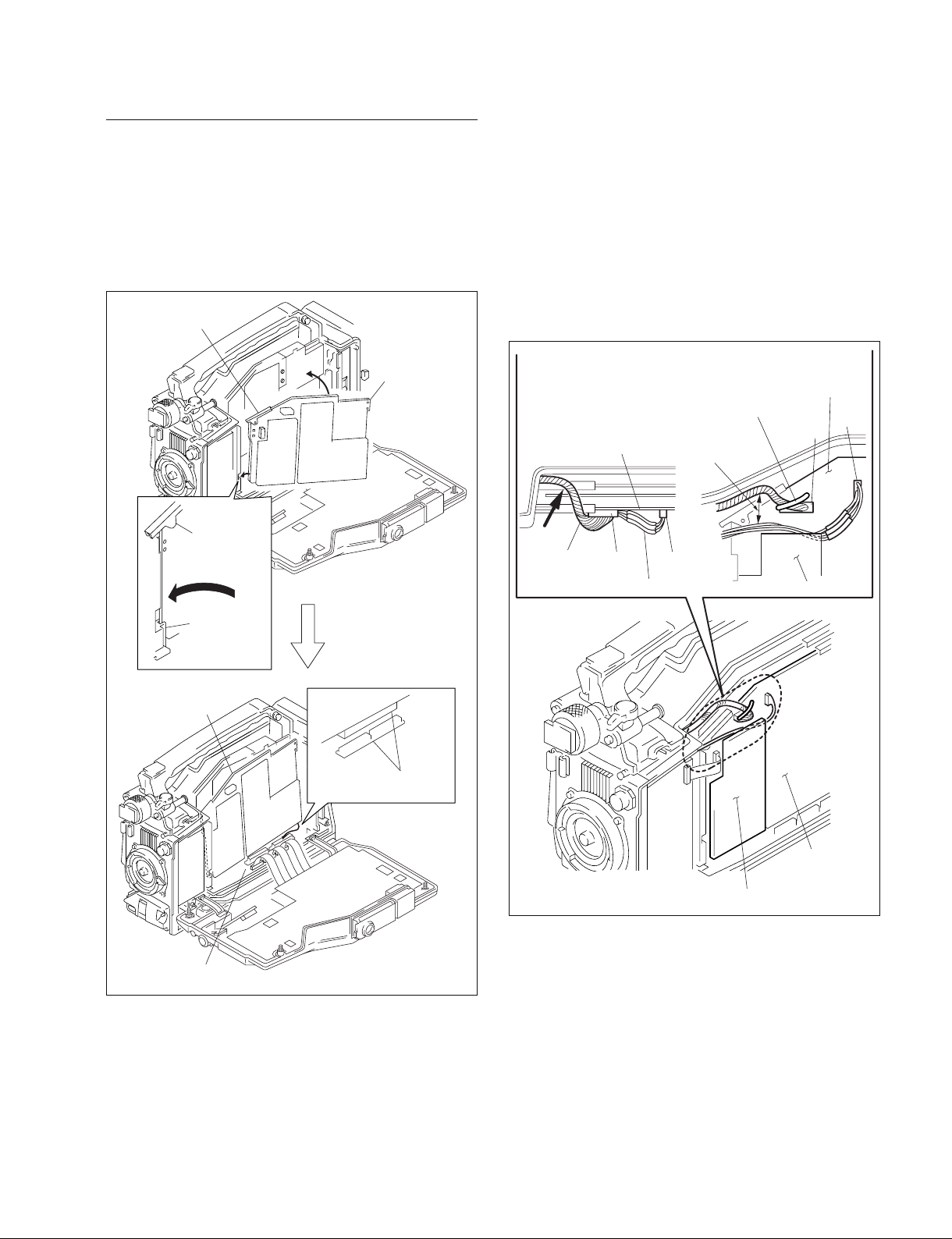

Reinstallation

1. Close the board levers.

2. Insert the DVP board assembly into the groove on the

board holder in the direction of arrow A, and raise the

DVP board assembly in the direction of arrow B.

3. Connect the DVP board assembly and the MB-1096

board with the board-to-board connector.

Board lever

DVP board

assembly

B

A

A

4. Reinstall it by reversing the steps of disassembling.

n

When routing the two coaxial cables, pass them

through the three clamps and the groove on the SDI

shield plate, and connect the coaxial cable (green) to

CN201 on the TX-78 board, and the coaxial cable

(brown) to CN202.

Groove on the SDI shield plate Insert

a sheet of paper in the protected part.

TX-78 board

CN202

Clamps

A

Board

holder (F)

MB-1096 board

CN201

Coaxial cable (Brown)

DVP board assembly

Coaxial cable (Green)

DVP board

assembly

Board-to-board

connectors

HDW-F900R/V1 (E)

1-17

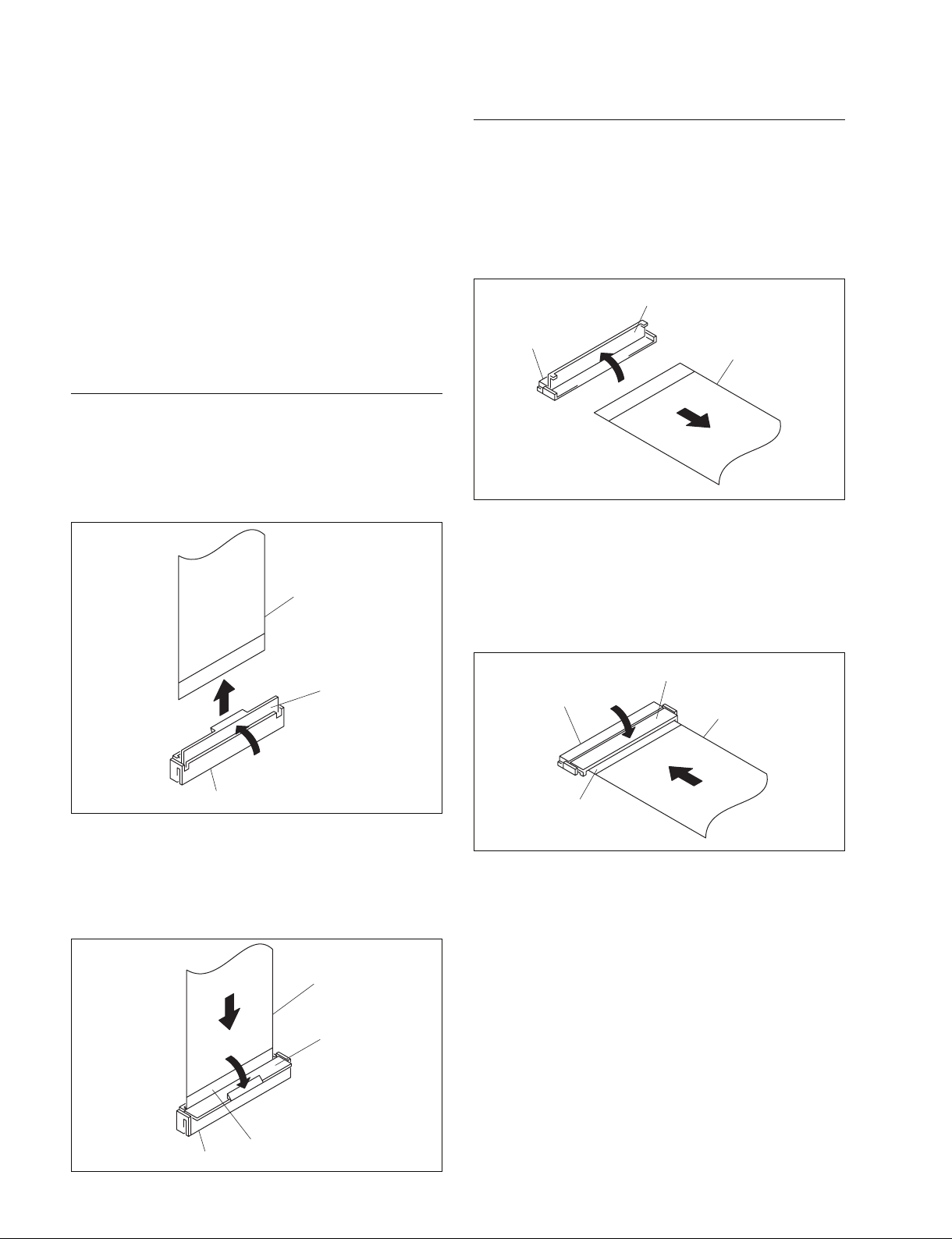

1-8. Removing and Reinstalling the

Flexible Card Wires

Type-B

This unit uses two types of flexible card wire.

m

. Life of flexible card wire will be significantly shortened if it

is folded. Be very careful not to fold the flexible card wire.

.

When a flexible card wire is disconnected, check if it has

peeling-off or scratch on the tin plated contact of the

connector. If the copper plating of the base material

exposes due to wear of the tin plated contact of the

connector, replace it with the new flexible card wire.

Type-A

Removal

1. Open the connector latch in the direction of arrow A to

release the lock.

2.

Remove the flexible card wire in the direction of arrow B.

Flexible card wire

Removal

1. Open the connector latch in the direction of arrow A to

release the lock.

2

Remove the flexible card wire in the direction of arrow B.

Connector latch

Connector

A

Flexible card wire

B

Reinstallation

1. Hold the flexible card wire with its blue surface to the

front, and insert it in the direction of arrow A.

2. Close the connector latch in the direction of arrow B to

lock it.

B

A

Connector

Connector latch

Reinstallation

1. Hold the flexible card wire with its blue surface to the

front, and insert it in the direction of arrow A.

2. Close the connector latch in the direction of arrow B to

lock it.

Flexible card wire

A

B

Connector latch

Connector latch

Connector

Flexible card wire

B

A

Blue surface

1-18

Connector

Blue surface

HDW-F900R/V1 (E)

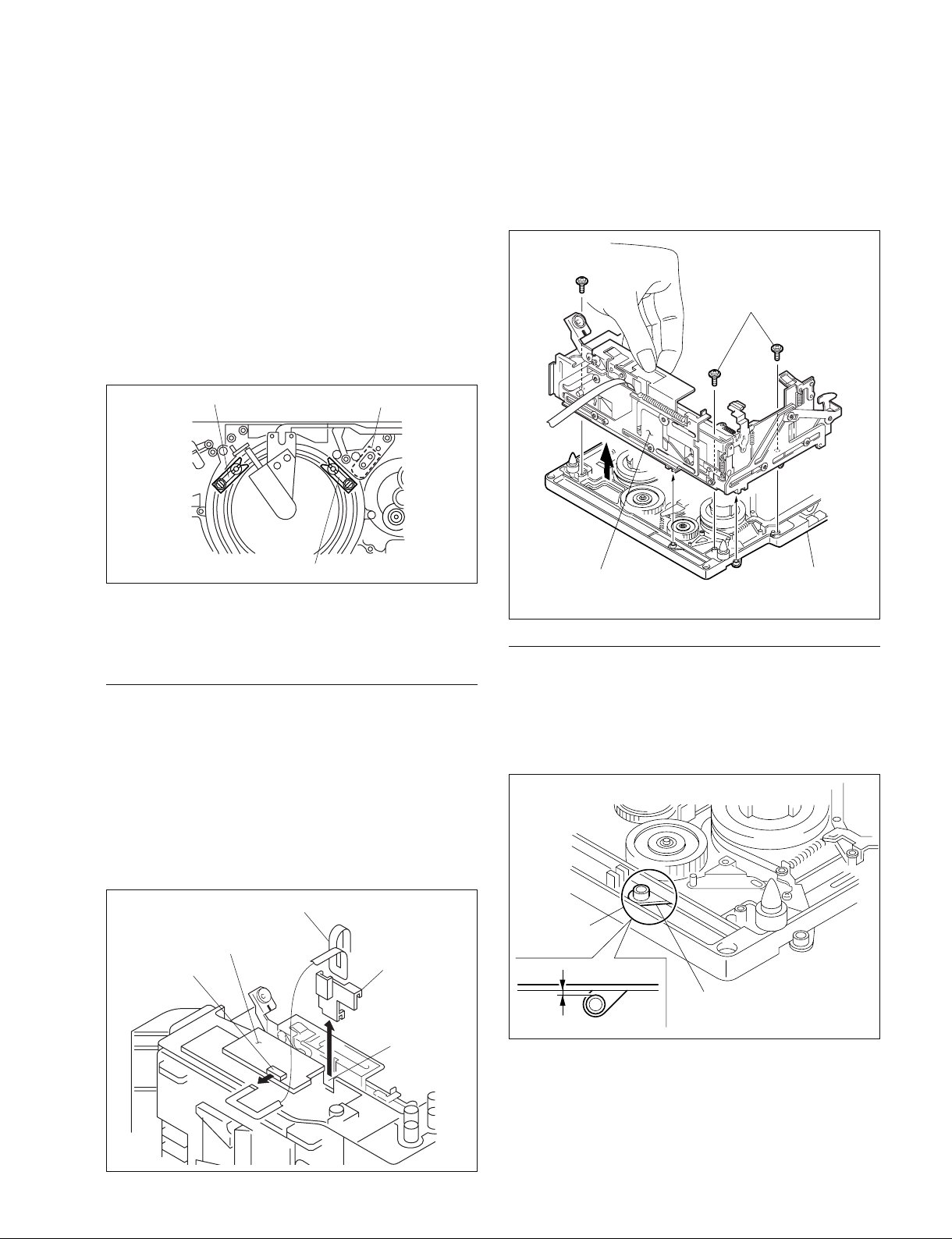

1-9. Removing and Reinstalling the

0.5 mm

Roller (WHT)

Joint arm

Cassette Compartment

m

. Be sure to set the POWER switch to OFF, unplug the

power cord or remove the battery before starting any of

the following procedure to protect inside of the unit from

damage.

. Only when the release plate is attached to the T-tension

regulator assembly, remove and reinstall the Cassette

compartment assembly at the thread position shown in

the illustration below. When the TC head is at the other

position, T-tension regulator assembly interferes with the

cassette compartment.

S slider

TC head

4. Remove the three precision screws (P1.4 x 3.5) and

move the cassette compartment assembly by holding

the specified position as shown in the illustration and

remove the cassette compartment assembly in the

direction of the arrow.

Precision screw

P1.4 x 3.5

Precision screws

P1.4 x 3.5

T slider (at the front of the TC head)

n

. Cassette compartment can be removed when it is raised

up or when it pushed down.

Removal

1. Remove the outside panel assembly.

(Refer to Section 1-4.)

2. Remove the FL-283 printed wiring board from the

connector (CN1) on the CCM-45G board.

3. Remove the FL-283 printed wiring board while

removing the cable retainer 2 from the notch.

n

Life of the FL-283 printed wiring board will be

significantly shortened if it is folded. Be very careful

not to fold the FL-283 printed wiring board.

FL-283 printed wiring board

CCM-45G board

CN1

Cable retainer 2

Cassette compartment

assembly

Mechanical deck

assembly

Reinstallation

1. Adjust position of the joint arm so that the gap between the outside circumference of the white roller of

the joint arm and the end surface of the mechanical

deck assembly is 0.5 mm.

HDW-F900R/V1 (E)

Notch

1-19

2. Raise the white locking roller of the cassette compartment assembly to set the cassette compartment

assembly to its up position.

Locking roller (WHT)

3. Slide the cam plate (A) of the right side of the cassette

compartment assembly in the direction of the arrow as

far as it can go.

4. Hold the cassette compartment assembly at the position

shown in the illustration and insert the chassis so that

the two cassette guide pins enter into the round hole of

the stage.

At this moment, confirm that the white roller at the

other end of the joint arm that is adjusted of its position

at step 1, enters into the notch of the cam plate (A) on

the right side.

5. Press the lid arm (L) of the cassette compartment

assembly and check to see that the stage can move up

and down smoothly. If the stage does not move up and

down smoothly, check above procedure starting from

step 1.

6. Attach the cassette compartment assembly with three

screws.

n

Standard tightening torque :

10 x 10_2 N.m (1.0 kgf.cm)

Precision screw

P1.4 x 3.5

Lever

Precision screws

P1.4 x 3.5

Stage

Cam plate (A)

Round hole

of stage

Cassette

guide pin

Notch

Roller (WHT) of

step 1

Joint arms

Round hole

of stage

Notch of

cam plate (A)

Cassette guide pin

Roller (WHT)

at the other end

1-20

HDW-F900R/V1 (E)

Loading...

Loading...