Sony VFH-990, HDVF-C950W Maintenance Manual

HD ELECTRONIC VIEWFINDER

HDVF-C950W

OUTDOOR HOOD

VFH-990

MAINTENANCE MANUAL

1st Edition

Serial No. 100001 and Higher

! WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

HDVF-C950W

Table of Contents

Manual Structure

Purpose of this manual ........................................................... 3 (E)

Relative manual ...................................................................... 3 (E)

1. Service Overview

1-1. Board Layout ........................................................... 1-1 (E)

1-2. Matching Connectors and Cables ............................ 1-1 (E)

1-2-1. Cable Input/Output Signals ............................ 1-1 (E)

1-2-2. VF Connecting Cable ..................................... 1-2 (E)

1-3. Circuit Overview ..................................................... 1-3 (E)

1-4. List of Tools, Used Equipment, and

Adjustment Equipment ............................................ 1-4 (E)

1-5. Firmware and Software ............................................ 1-5 (E)

1-5-1. Checking the ROM and Software Version ..... 1-5 (E)

1-5-2. Writing and Rewriting PLD Internal Data ..... 1-5 (E)

1-6. Description of On-board Switches ........................... 1-7 (E)

1-7. Removal/Installation of Main Parts ......................... 1-8 (E)

1-7-1. Removing LCD Module ................................. 1-8 (E)

1-7-2. Removing the LE-317 Board ....................... 1-10 (E)

1-7-3. Removing the PR-292 Board ....................... 1-10 (E)

1-7-4. Removing the RE-237 Board ....................... 1-11 (E)

1-7-5. Removing the LE-315 Board ....................... 1-11 (E)

1-7-6. Removing the LE-316 Board ....................... 1-12 (E)

1-7-7. Removing the SW-1298 Board .................... 1-13 (E)

1-7-8. Removing the VR-315 Board ....................... 1-13 (E)

1-7-9. Removing the Harness (VF) ......................... 1-14 (E)

1-8. Extending the Circuit Board .................................. 1-15 (E)

1-8-1. Service Position ............................................ 1-15 (E)

1-8-2. RE-237 Board ............................................... 1-15 (E)

1-9. Fuse and IC Link Replacement .............................. 1-16 (E)

1-10. Unleaded Solder ..................................................... 1-16 (E)

2. Setting Menu

2-1. Setting Menu ............................................................ 2-1 (E)

2-2. TOP Menu ............................................................... 2-2 (E)

2-3. OPERATION Menu ................................................ 2-3 (E)

2-4. SERVICE Menu ...................................................... 2-3 (E)

3. Electrical Alignment

3-1. Preparation ............................................................... 3-1 (E)

3-1-1. Description of Switches, Controls, and

Menu Settings ................................................. 3-1 (E)

3-1-2. Used Equipment ............................................. 3-1 (E)

3-1-3. Connection ..................................................... 3-1 (E)

3-1-4. Format Settings .............................................. 3-1 (E)

3-2. Inverter Power Supply Voltage Adjustment ............ 3-2 (E)

3-3. Brightness Initial Adjustment .................................. 3-2 (E)

3-4. Color Temperature Adjustment ............................... 3-2 (E)

3-5. Brightness Final Adjustment ................................... 3-3 (E)

4. Spare Parts

4-1. Notes on Repair Parts ..................................................... 4-1

4-2. Exploded Views .............................................................. 4-2

4-3. Electrical Parts List .........................................................4-6

4-4. Packing Materials & Supplied Accessories ..................4-19

5. Semiconductor Pin Assignments

6. Block Diagrams

HDVF-C950W

Overall ............................................................................6-2

RE-237 ............................................................................6-3

1 (E)

7. Schematic Diagrams

LE-315 ............................................................................ 7-1

LE-316 ............................................................................ 7-1

LE-317 ............................................................................ 7-2

PR-292 ............................................................................ 7-3

RE-237 ..........................................................................7-10

SW-1298 .......................................................................7-12

SW-1299 .......................................................................7-12

VR-315 .........................................................................7-12

Frame Wiring ................................................................7-13

8. Board Layouts

LE-315 ............................................................................ 8-2

LE-316 ............................................................................ 8-2

LE-317 ............................................................................ 8-2

PR-292 ............................................................................ 8-4

RE-237 ............................................................................8-5

SW-1298 .........................................................................8-5

SW-1299 .........................................................................8-5

VR-315 ...........................................................................8-5

2 (E)

HDVF-C950W

Purpose of this manual

Relative manual

Manual Structure

This manual is the maintenance manual for HD Electronic Viewfinder HDVFC950W. This manual describes the information items necessary when the unit is

supplied and installed, items that premise the service based on the components parts

such as service overview, electrical alignment, spare parts lists, block diagram and

schematic diagrams, assuming use of system and service engineers.

Besides this maintenance manual the following manual is available for this unit.

..

. Operation Manual (supplied with this unit)

..

This manual is necessary for application and operation of this unit.

. “Semiconductor Pin Assignments” CD-ROM (Available on request)

This “Semiconductor Pin Assignments” CD-ROM allows you to search for

semiconductors used in Broadcast and Professional equipment.

The maintenance manual contains a complete list of semiconductors and their ID

Nos., and thus should be used together with the CD-ROM.

Part number: 9-968-546-0X

HDVF-C950W

3 (E)

Section 1

Service Overview

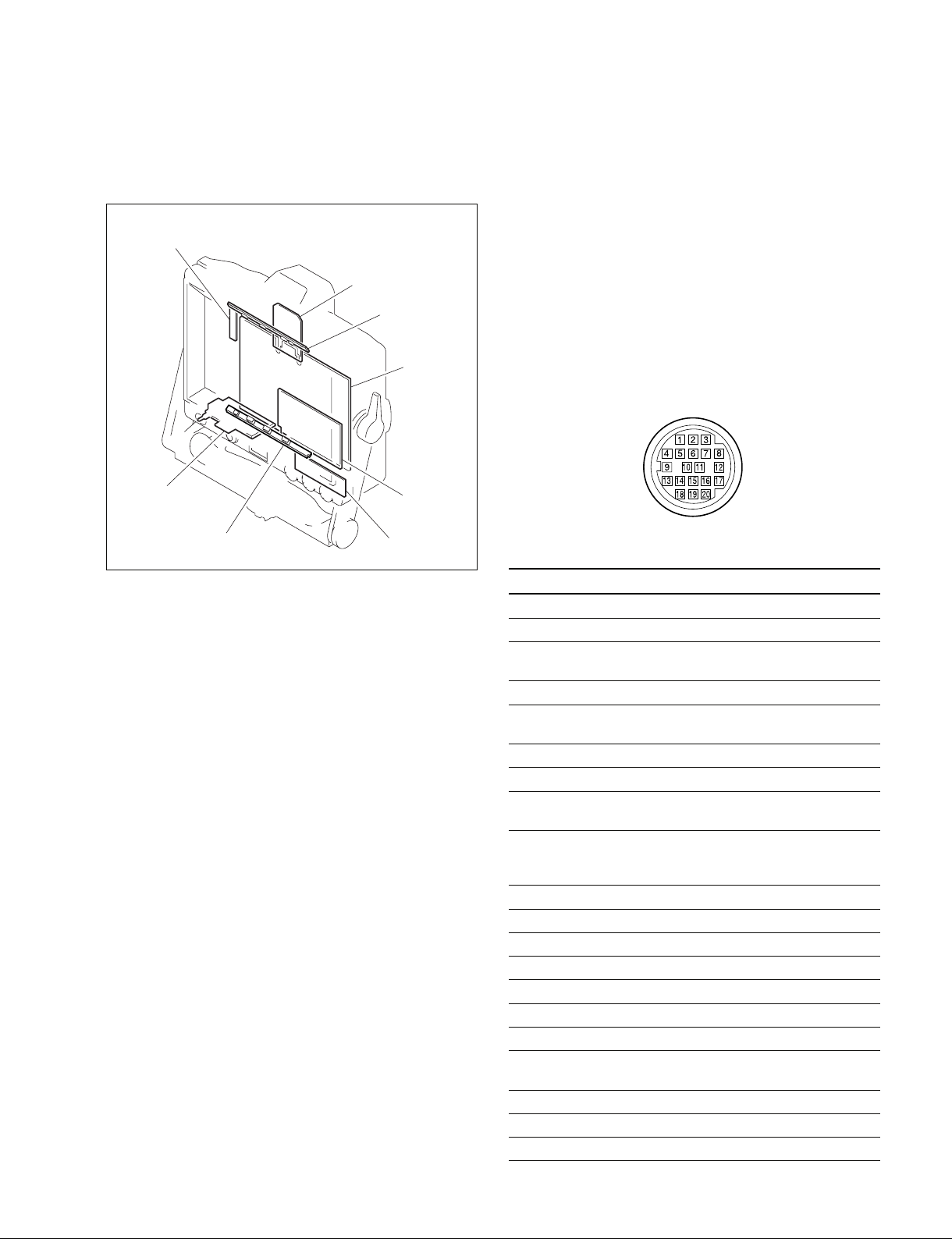

1-1. Board Layout 1-2. Matching Connectors and Cables

Use the included VF connection cable when connecting to

SW-1299

the camera for installation or servicing.

SW-1298

LE-316

LE-317

LE-315

PR-292

RE-237

VR-315

1-2-1. Cable Input/Output Signals

The VF connection cable input/output signals are as

follows.

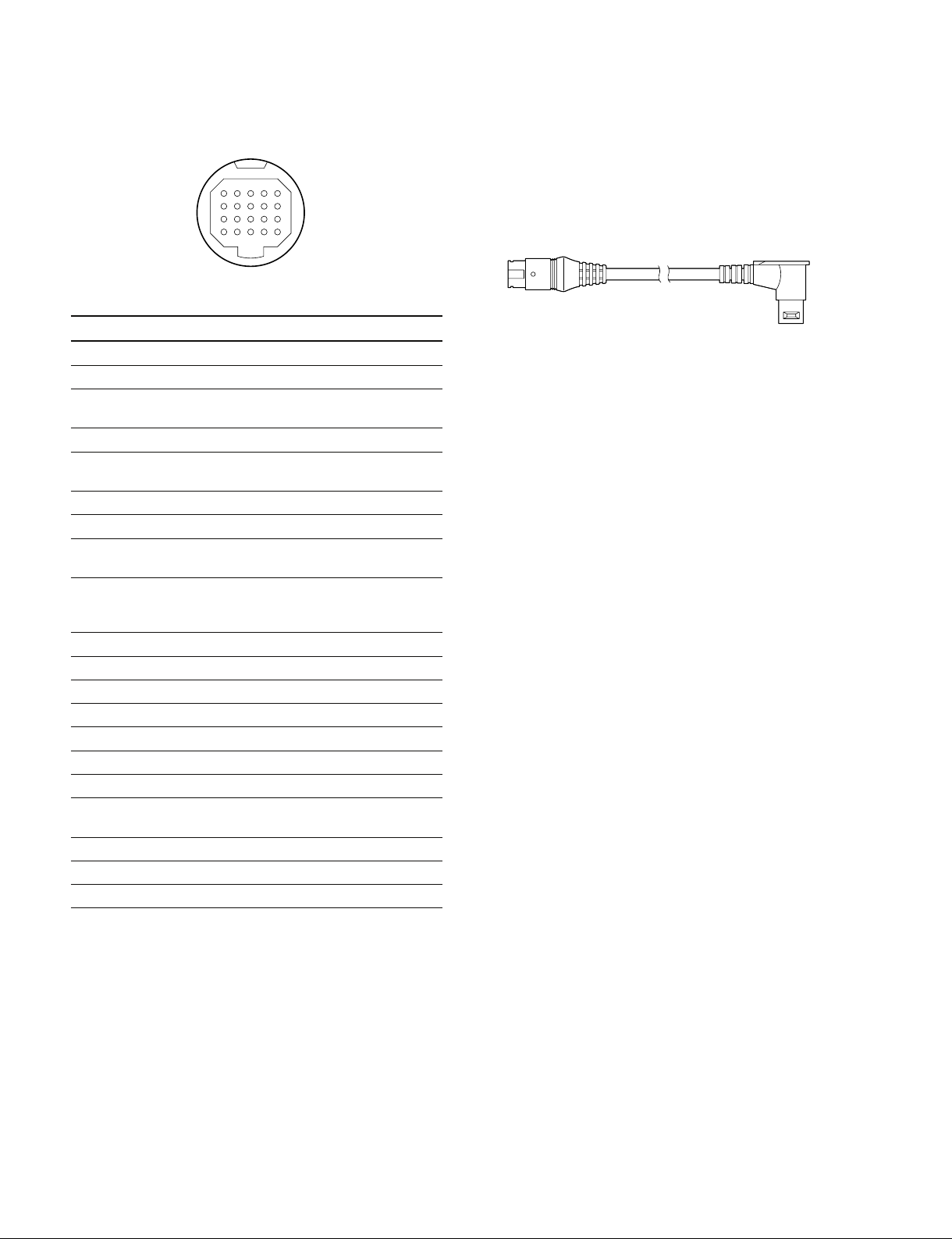

. CAMERA (20-pin Male)

(External view)

No. Signal I/O Specifications

1 S-DATA IN/OUT TTL level

2 NC No connection

3 POWER OFF IN ON : OPEN

OFF : GND

4 SCK IN TTL level

5 COLOR/MONO OUT MONO : GND

COLOR : OPEN

6 NC No connection

7 NC No connection

8 G TALLY IN ON : +5 V

OFF : GND

9 PEAKING CTL OUT 0 V to +5 V

0 V : PEAKING OFF

+5 V : PEAKING MAX

10 NC No connection

11 NC No connection

12 Y VIDEO IN 1.0 Vp-p, Zi=75 Z

13 VIDEO GND _ GND for VIDEO

14 Pb VIDEO IN 0.7 Vp-p, Zi=75 Z

15 Pr VIDEO IN 0.7 Vp-p, Zi=75 Z

16 NC No connection

17 R TALLY IN ON : +5 V

OFF : GND

18 NC No connection

19 UNREG GND _ GND for UNREG

20 UNREG IN +10.5 V to 17 V

HDVF-C950W

1-1 (E)

. VF (20-pin Male)

5

10

15

20

1

6

11

16

(External view)

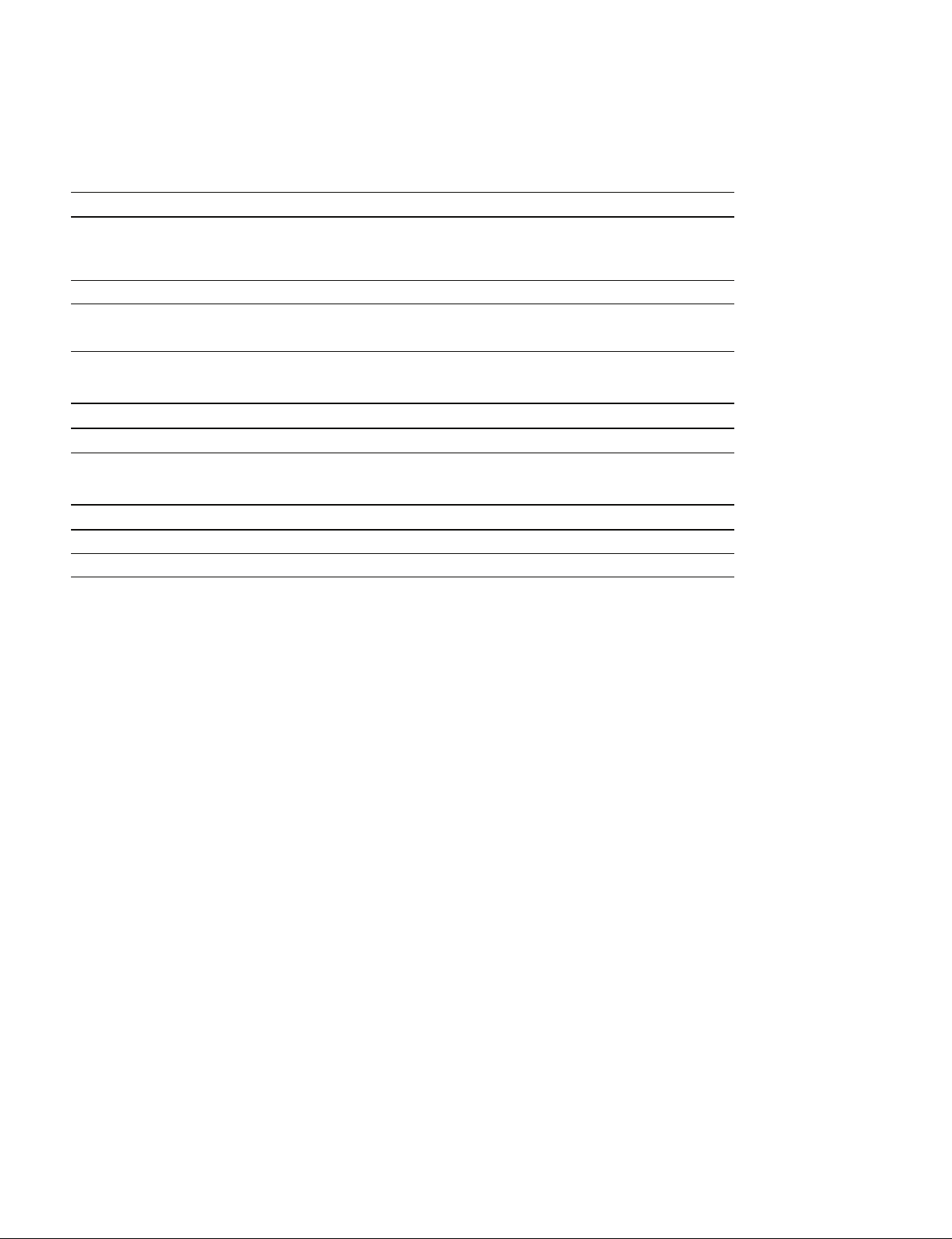

1-2-2. VF Connecting Cable

This cable is used for connecting the main unit to the

camera.

1-830-631-11

No. Signal I/O Specifications

1 S-DATA IN/OUT TTL level

2 NC No connection

3 POWER OFF IN ON : OPEN

OFF : GND

4 SCK IN TTL level

5 COLOR/MONO OUT MONO : GND

COLOR : OPEN

6 NC No connection

7 UNREG IN +10.5 V to 17 V

8 G TALLY IN ON : +5 V

OFF : GND

9 PEAKING CTL OUT 0 V to +5 V

0 V : PEAKING OFF

+5 V : PEAKING MAX

10 NC No connection

11 UNREG GND _ GND for UNREG

12 Y VIDEO IN 1.0 Vp-p, Zi=75 Z

13 VIDEO GND _ GND for VIDEO

14 Pb VIDEO IN 0.7 Vp-p, Zi=75 Z

15 Pr VIDEO IN 0.7 Vp-p, Zi=75 Z

16 NC No connection

17 R TALLY IN ON : +5 V

OFF : GND

18 NC No connection

19 UNREG GND _ GND for UNREG

20 UNREG IN +10.5 V to 17 V

VF side CAMERA side

1-2 (E)

HDVF-C950W

1-3. Circuit Overview

PR-292 board

The PR-292 board consists of the video amplifier circuit,

A/D conversion circuit, video processing circuit, clock

generation circuit, tally control circuit, and micro computer.

The analog HD Y/Pb/Pr signal input from CN1 passes

through the pre-filter (FL200-202) and the video amplifier

before it is converted into a 74 Msps rate, 10 bit digital

signal with the A/D converter (IC214-216). It then passes

through FPGA (IC300) before finally being input to the

video processing IC (IC400).

In FPGA, PLL is added to the sync signal generated in the

sync separation circuit and HD/VD is output.

In addition, the parameter settings for video processing IC

and clock generation IC (IC306) are configured, the

internal test signal is generated, and IIC communication is

performed with the connected camera.

The video processing IC converts the input HD Y/Pb/Pr

digital signal into a WVGA RGB digital signal and outputs

that signal. Brightness and contrast settings are also

performed.

The RGB digital signal is entered into FPGA again where

peaking processing and knee correction processing are

performed before the signal is converted into an 8 bit

digital signal. The video signal is superimposed on the

OSD signal and indicator display, and then the signal is

output to the LVDS transmitter circuit (IC700).

The LVDS transmitter converts 8 bit RGB digital signals

and sync signals into LVDS signals and outputs them to

CN5.

RE-237 board

The voltage comparison circuit (IC2) supplies power to

each control IC (IC3, IC6, IC7) when the input voltage

falls within the appropriate range.

The power supply turns on when the input voltage is

within the range of +9.8 V to +19.0 V. After the power

supply turns on, it continues to operate until the input

voltage falls below the lower limit (+7.5 V).

Each output is connected to a short-circuit detection

circuit. If any of the outputs are short-circuited or if a

signal is not output due to some error, the short-circuit

detection circuit outputs the H SHUT DOWN signal.

This signal causes the supplied UNREG +12 V to be cut

off at the source.

+5 V, +3.3 V, and +1.8 V use a step-down chopper

circuit, and _5 V uses an inverse chopper circuit.

+12 V uses a rising and falling voltage circuit and can

control output voltage in a range of +10.0 V to +13.5 V

with the control voltage (BRIGHT ADJ) from the PR-292

board.

CPU (IC600) performs parallel communication with

FPGA, controls the character generator (IC601) and D/A

converter (IC614), and performs IIC communication with

the panel module.

The A/D input port connects to the signal wires for

brightness, contrast, peaking, and volume level and

controls these parameters.

The D/A converter controls the dimmer for the external

tally lamp and the voltage for the backlight power supply.

IIC communication with the panel module controls PWM

modulated light for the backlight and the black insertion

rate.

Data such as luminance and color temperature adjustment

data are saved on EEPROM (IC606) on the board.

FPGA can be upgraded for E-Production through CN14.

(Refer to Section 1-5-2.)

HDVF-C950W

1-3 (E)

1-4. List of Tools, Used Equipment, and Adjustment Equipment

Tools

No. Part No. Name Usage

1 A-1239-470-A PR/RE extension assembly RE-237 board extension

1-A 1-832-098-11 Flexible card wire Refer to Section 1-8.

(30p, 150 mm)

2 J-7120-140-A Data download cable PLD data download

3 J-6352-400-A Torque screwdriver (3 kgf.cm) Panel module mounting

3-A Torque screwdriver bit (M2.6)

Used equipment

Used equipment Model name

HDVS camera HDC-1500 series or HDW-F900R

Adjustment equipment

Adjustment equipment Model name

Display color analyzer Konica Minolta sensing CA-210 or equivalent

Digital voltmeter Advantest TR6845 or equivalent

1-4 (E)

HDVF-C950W

1-5. Firmware and Software

n

Do not version down the ROM. The equipment may stop

working correctly.

The PR-292 board on the unit is equipped with the ROMs.

Board Ref. No. Address

PR-292 IC305 D2/A side

IC314 D2/A side

IC600 C3/A side

1-5-1. Checking the ROM and Software

Version

1. Display the TOP menu.

Refer to “2-2. TOP Menu”.

2. Display the VERSION screen in the SERVICE menu.

VF MENU

S08 VERSION

SOFTWARE

MAIN: 1.00

BOOT: 1.00

FPGA : 1.00

3. Check the ROM version.

1-5-2. Writing and Rewriting PLD Internal

Data

The device is equipped with a PLD (Programmable Logic

Device) that can be written and rewritten using the eProduction (EPR) method.

When replacing the following parts or upgrading the PLD

version, contact your local Sony Sales Office/Service

Center.

n

The part number of the PLD (or the ROM for the PLD)

noted in “Spare Parts” is for a part with no data written.

When you need to replace any part, write data using the

steps on the next page.

For a PLD that has a program operating on the externally

connected ROM, when a part in the PLD is defective, if

you replace only the defective part, you do not have to

rewrite the data.

About e-Production

. When writing or rewriting the PLD internal data,

1. Standard tools (cables) can be used.

2. Standard software (PLD Download Tool) can be

used.

. The PLD internal data is managed on the Sony database

server as a Project file (E_xxx_xxx_xx_xx).

. The standard connector (EPR connector) for writing

PLD internal data on the board is equipped. “EPR” is

displayed on the board.

HDVF-C950W

Corresponding PLDs :

Name of board

PLD/ROM EPR connector Project file No.

PR-292

IC305*1, IC314*1,

IC300 CN14 E_000_003_61_01

*1 : IC305 and IC314/PR-292 are the ROMs for IC300/PR-292.

1-5 (E)

Used equipment

. PLD download tool (Sony part No. : J-7120-140-A)

Cable to connect PC and the device

. PC

Computer with a parallel port.

Computer with PLD Download Tool installed.

For the supported OS and operating environment, refer

to “Download Tool Operation Manual (Device Writing

Volume)”.

Operation procedure

The procedure to write data to the PLD (or the ROM for

the PLD) is outlined below.

For details on these steps, refer to “Download Tool

Operation Manual (Device Writing Volume)”.

“Download Tool Operation Manual (Device Writing

Volume)” can be obtained on the same Web site where the

PLD Download Tool software is downloaded.

Step 1. Prepare the Project file.

n

Download the Project file from the Sony database

server.

Step 2. With the power of the device turned off, connect

the parallel port on the PC and the EPR connector

on the target board with the PLD download tool

(cable).

Step 3. Turn on the power of the device.

Launch the PLD Download Tool software, and

import the Project file.

Step 4. Program the PLD (or the ROM for the PLD) by

using the PLD Download Tool software.

Step 5. When the programming completes correctly

(without an error message), restart the device.

1-6 (E)

HDVF-C950W

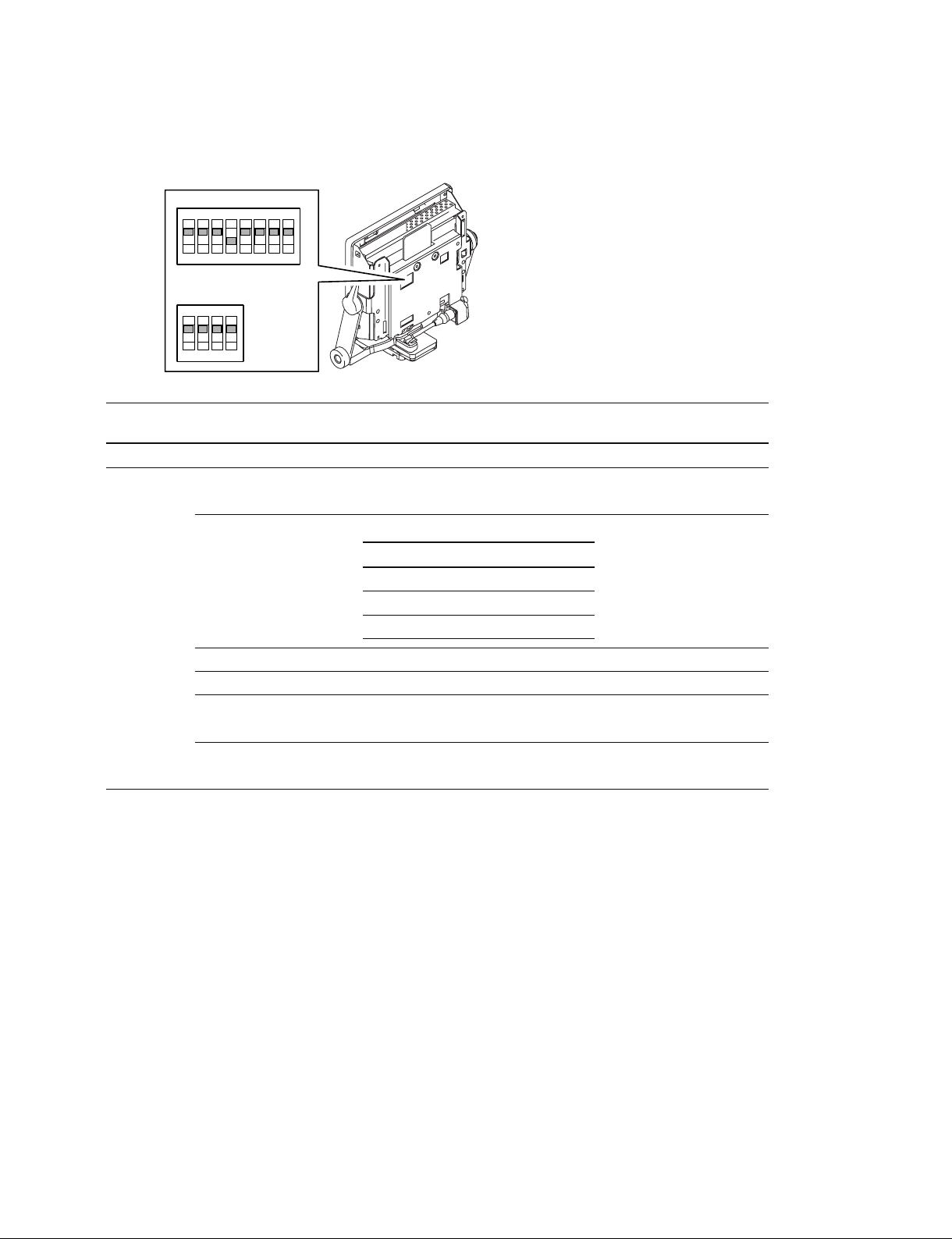

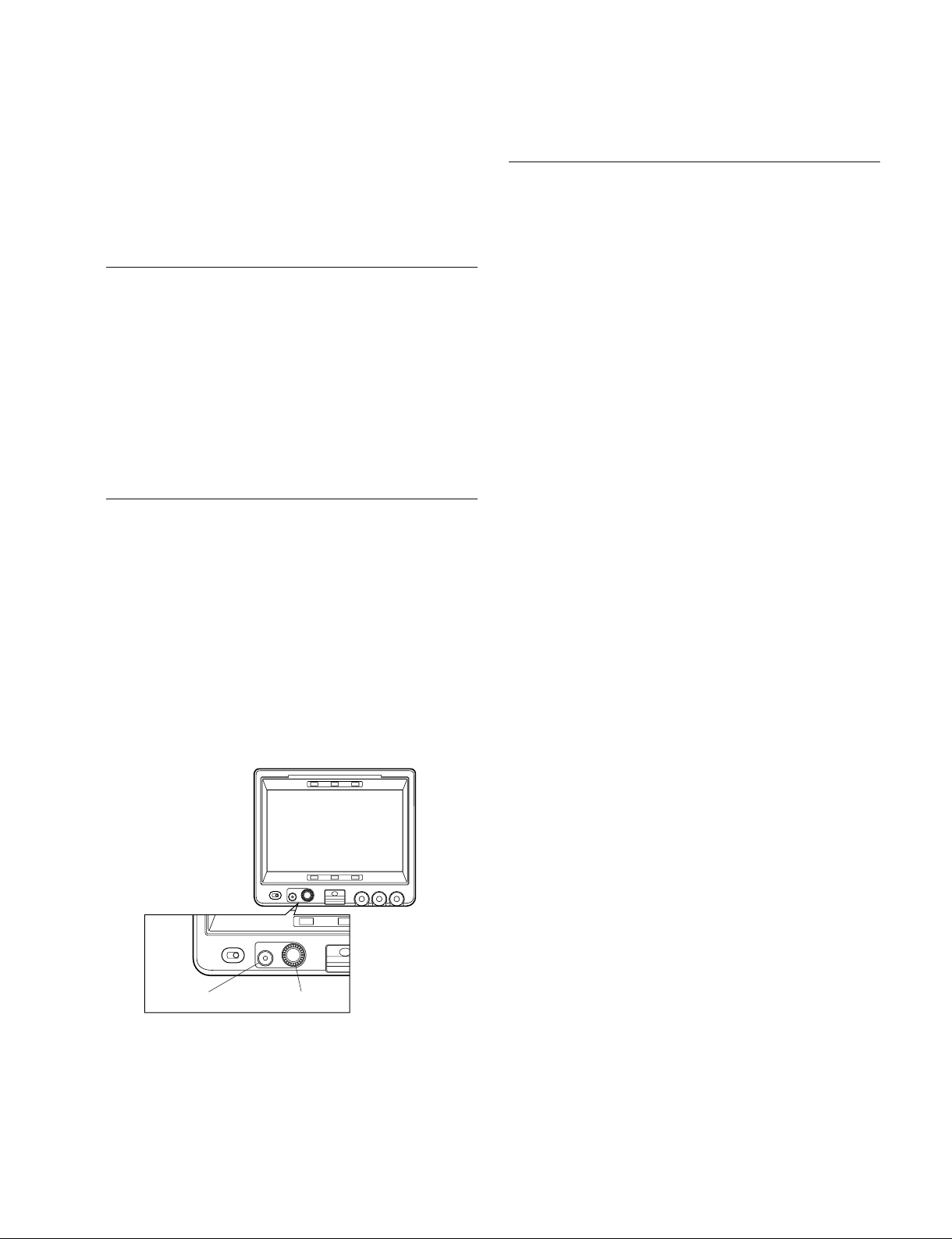

1-6. Description of On-board Switches

PR-292 board

8

4

7

S600

3

S601

6

2

N

2

1

3

4

5

O

N

1

O

Ref. No. Name Bit Contents Factory default

setting

S600 Model ID 1 to 4 All OFF

S601 SECOND VF settings 1 OFF: Normal OFF

ON : When used as the Second VF

Input signal format 2 to 4 All OFF

*2

settings

AUTO 60i 50i 24PsF

*1

2 OFF ON OFF ON

3 OFF OFF ON ON

4 OFF OFF OFF OFF

5ON

6 OFF

BOOT SOFT VERSION UP 7 OFF : Normal OFF

ON : During VERSION UP

MAIN SOFT VERSION UP 8 OFF: Normal OFF

ON : During VERSION UP

*1 : Set this to ON only when using the device as the second VF by connecting it to the EXT I/O (20P) connector of HDC-950 or HDC-

930. (No setting change is required when using the device alone.)

In this case, a dedicated VF connection cable and the corresponding camera settings are needed.

Contact your nearest SONY Office/Service Center for details.

No setting change is required when connecting the device to the EXT I/O (20P) connector of HDC-F950.

*2 : The input signal format must be set according to the connected camera. Change the setting only when you want to fix the format on

the VF side.

HDVF-C950W

1-7 (E)

1-7. Removal/Installation of Main Parts

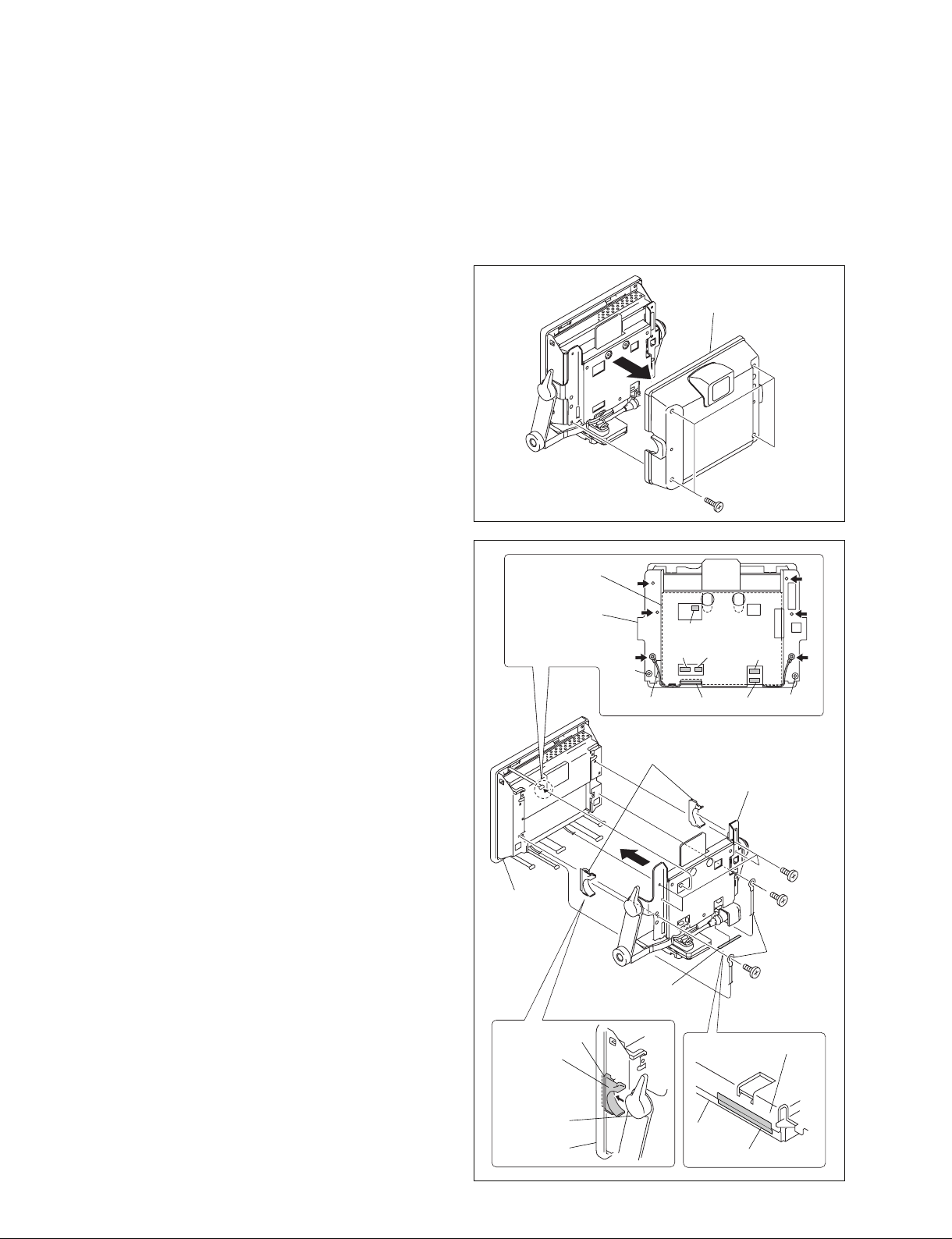

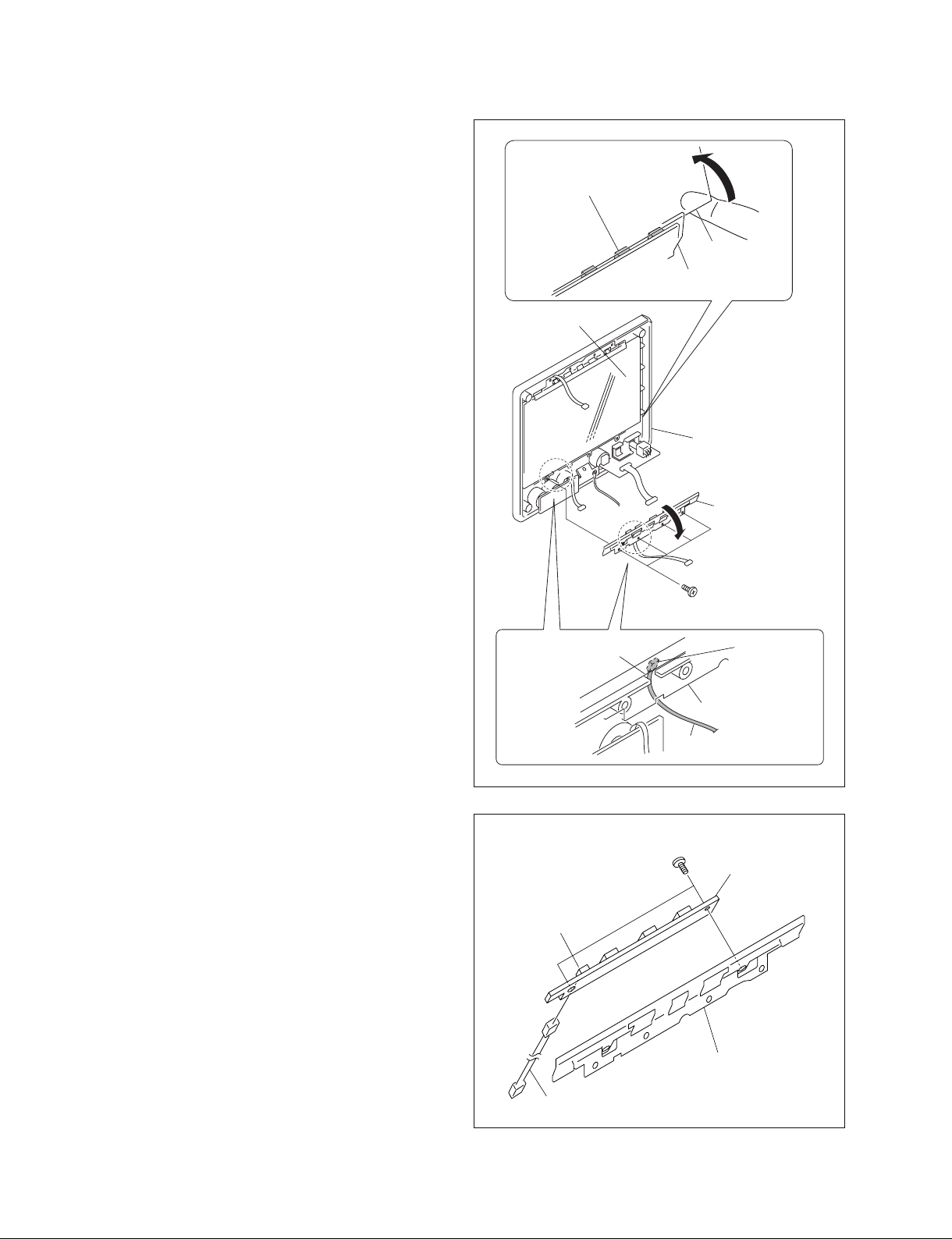

1-7-1. Removing LCD Module

n

When installing the dustproof cushions, install new

dustproof cushions.

Dustproof cushions (H), (V), conductive fabric tape

1. Remove the four screws and remove the rear cover

assembly.

2. Disconnect the six harnesses from the connectors

(CN5, CN6, CN8, CN9, CN11 and CN12) of the PR292 board.

3. Remove the two screws and remove the two GND

terminals from the CN box bracket.

n

When installing the GND terminals, install them in the

remote location from the hole “A” with the terminal

facing inside.

4. Peel the conductive fabric tape at the bottom of the CN

box bracket.

Precautions for installation

. Affix the conductive fabric tape before connecting

the harness.

. Affix the conductive fabric tape to the CN box

bracket and the EMC cover after installing the CN

box bracket to the bezel assembly.

PR-292 board

CN box bracket

Bezel

assembly

CN9

Hole

“A”

GND terminal

Tilt shaft covers

Rear cover assembly

B3 x 8

CN12

CN11

CN8

CN5

Hole “A”

CN6

CN box bracket

B2.6 x 5

B2.6 x 5

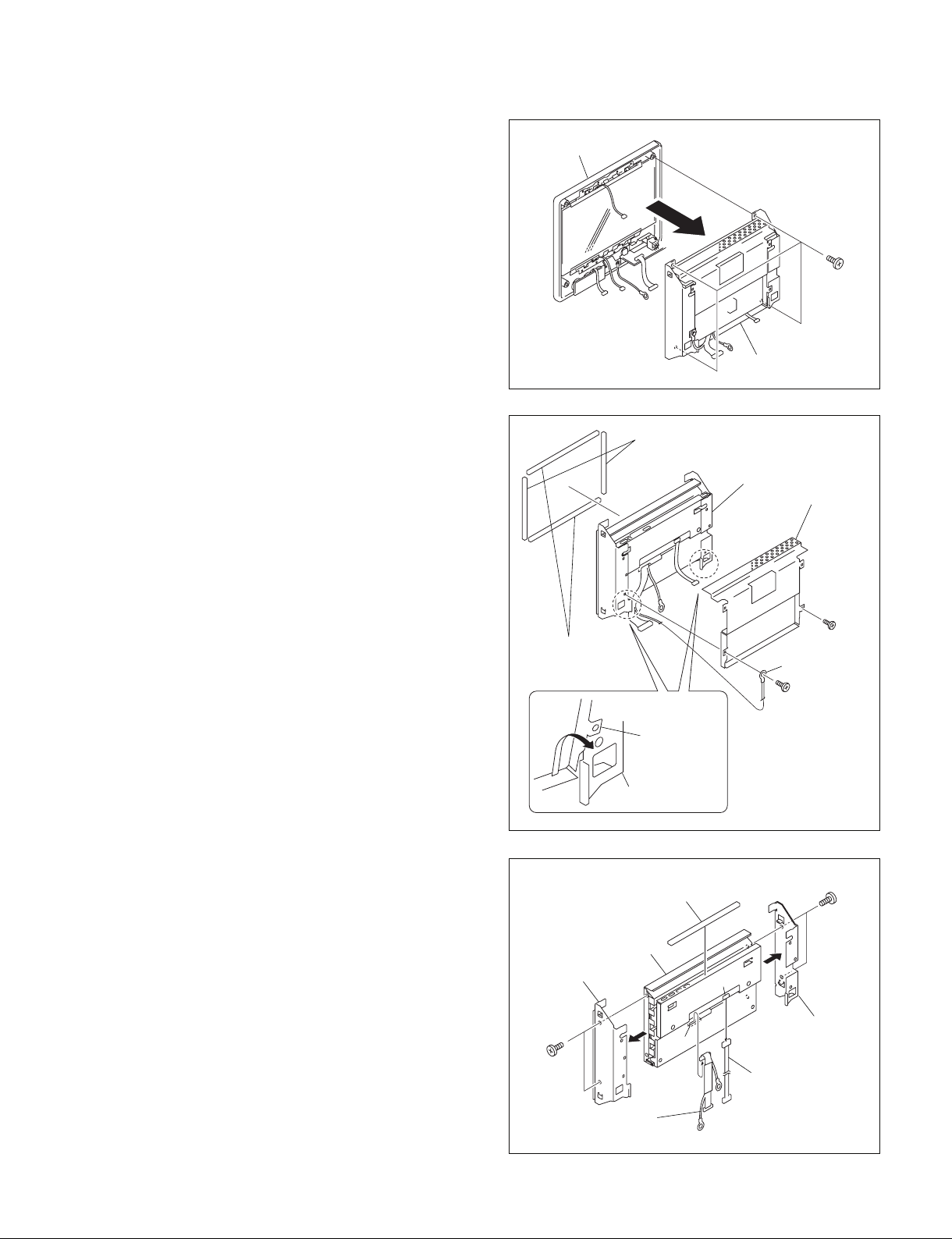

5. Remove the four screws and remove the bezel assembly from the CN box bracket.

m

. When the CN box bracket is removed from the bezel

assembly, the tilt shaft covers are removed. Be

careful not to drop them.

. When installing the bezel assembly to the CN box

bracket, install the bezel assembly to the CN box

bracket first of all. Then, connect the harnesses.

6. Remove the right and left tilt shaft covers from the

groove of the bezel cover assembly.

1-8 (E)

Groove

Tilt shaft

cover

Tilt stand

assembly

Bezel

assembly

Conductive fabric tape

EMC cover

GND

terminals

B2.6 x 5

CN box bracket

Conductive fabric tape

HDVF-C950W

Harness (BL)

Harness (LVDS)

CN1

P1

LCD bracket (L)

Shield cushion

LCD module

LCD bracket (R)

B2.6 x 5

B2.6 x 5

LCD bracket (L)

LCD unit

B2.6 x 5

B2.6 x 5

EMC cover

EMC cover

GND terminal

Dustproof cushions (V)

Dustproof

cushions (H)

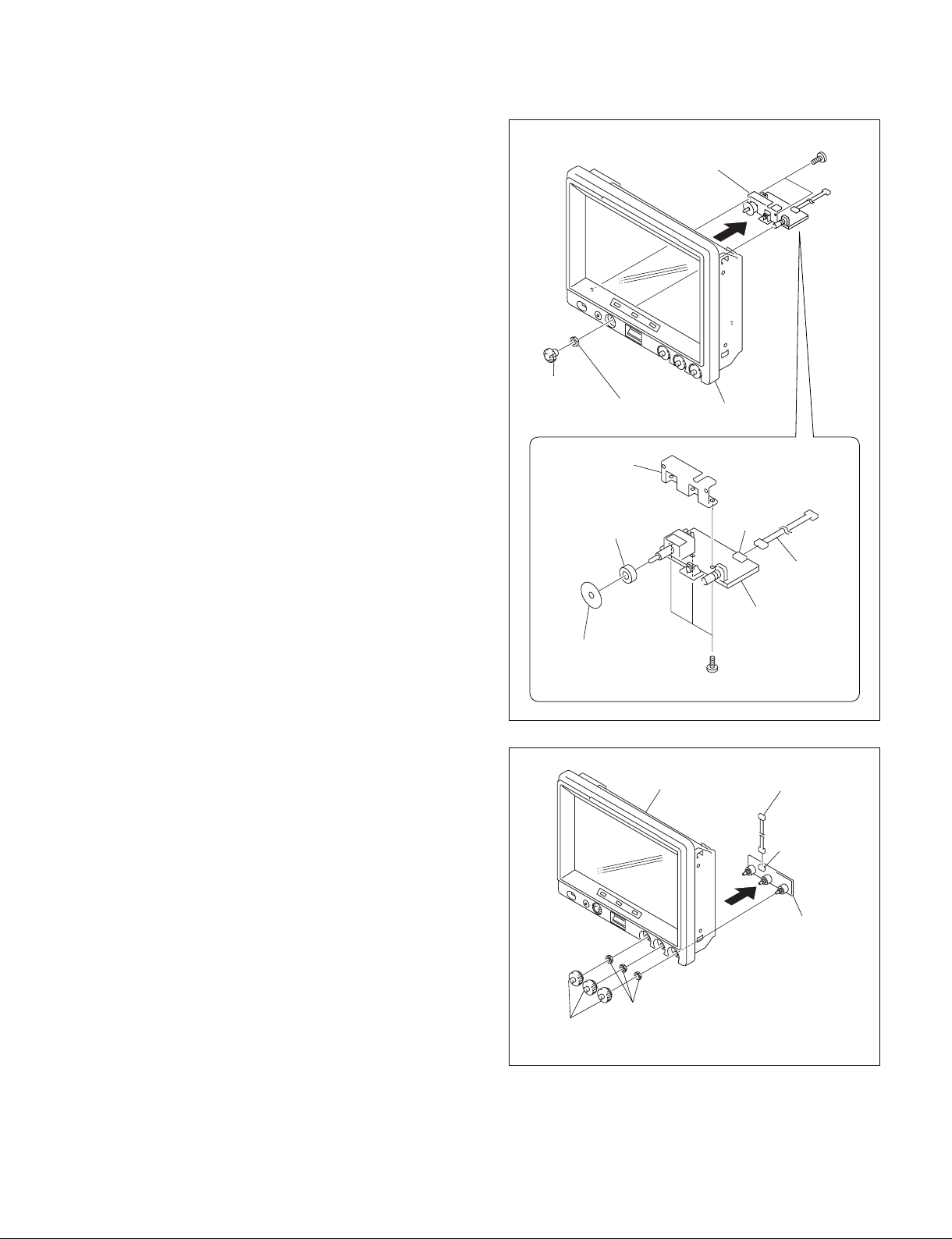

7. Remove the four screws and remove the LCD unit.

n

Standard tightening torque :

_2

25 x 10

N.m (2.5 kg.cm)

8. Remove the two screws and remove the GND terminal

and the EMC cover in the direction of arrow.

9. Remove the two dustproof cushions (V) and the two

dustproof cushions (H) from the front of the LCD

panel.

Bezel assembly

B2.6 x 5

LCD unit

10. Remove the four screws and remove the LCD brackets

(L) / (R).

11. Disconnect the harnesses from the two connectors

(CN1, P1) of the LCD module, and remove the shield

cushion.

12. Reinstall it by reversing the steps 1 to 11 of disassembling.

n

When the LCD module is replaced, the adjustment is

required. Refer to “Section 3. Electrical Adjustment”.

HDVF-C950W

1-9 (E)

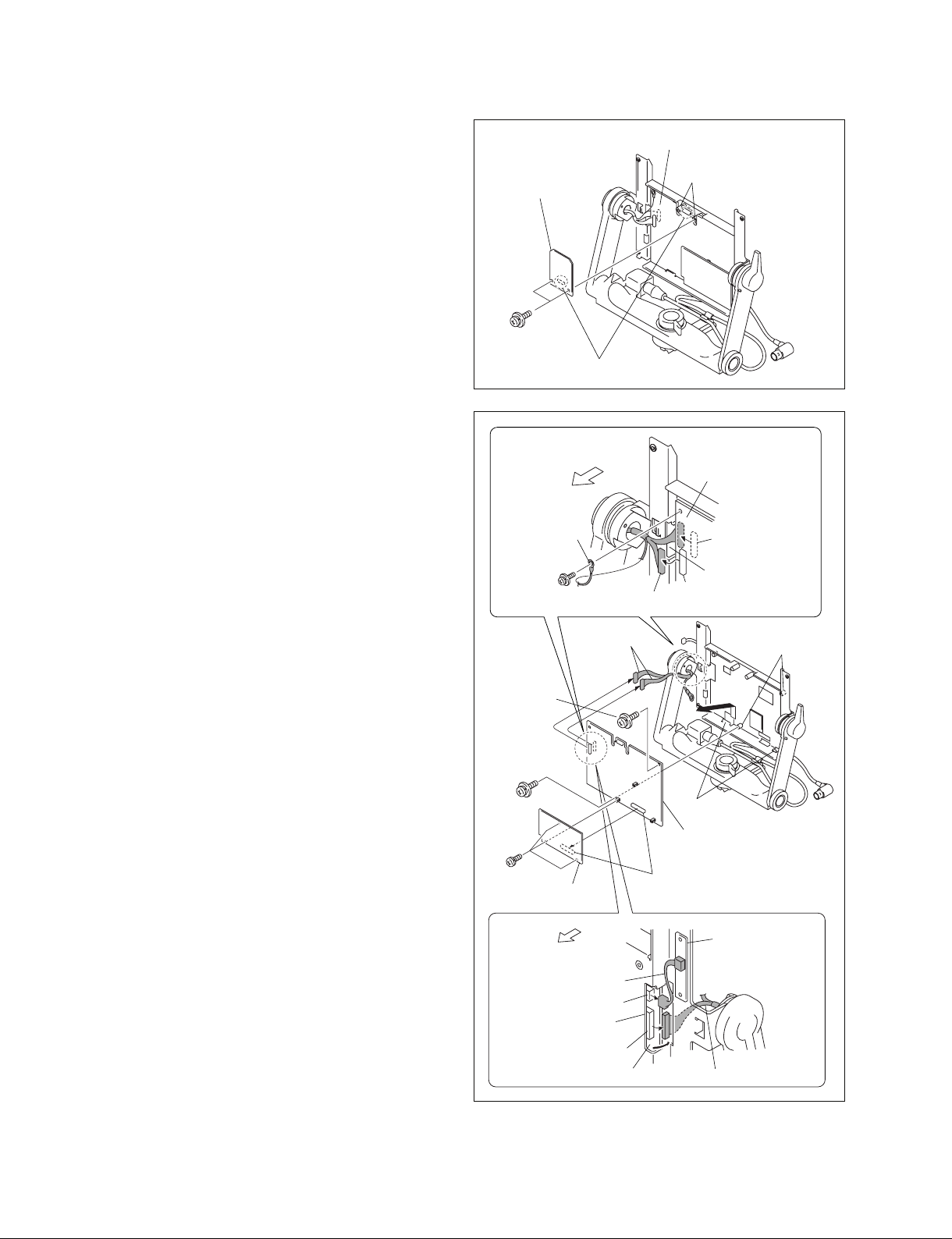

1-7-2. Removing the LE-317 Board

PR-292 board

1. Remove the rear cover assembly.

(Refer to Section 1-7-1 step 1.)

2. Remove the bezel assembly.

(Refer to Section 1-7-1 steps 2 to 5.)

3. Remove the two screws and remove the LE-317 board

from the board-to-board connector of the PR-292

board.

4. Reinstall it by reversing the steps 1 to 3 of disassembling.

1-7-3. Removing the PR-292 Board

1. Remove the rear cover assembly.

(Refer to Section 1-7-1 step 1.)

2. Remove the bezel assembly.

(Refer to Section 1-7-1 steps 2 to 5.)

3. Remove the LE-317 board.

(Refer to Section 1-7-2 step 3.)

4. Remove the screw and remove the GND terminal.

5. Disconnect the harness from the connector (CN1) of

the PR-292 board.

6. Disconnect the two harnesses from the connectors

(CN2, CN10) of the PR-292 board.

n

Disconnect the harness (VF) on the connector (CN2)

side of the PR-292 board toward the front side of the

main unit through the CN box bracket A hole.

LE-317 board

PSW3 x 6

To the front of

the main unit

GND terminal

PSW3 x 6

PSW3 x 6

PSW3 x 6

Board-to-board

Harness (VF)

Harness (VF)

Dowel for LE-317 board

PR-292 board

CN2

CN box bracket

A hole

CN1

Dowel for

PR-292 board

7. Remove the two screws and remove the PR-292 board.

8. Remove the three screws (PS2.5 x 5), and remove the

RE-237 board.

n

When installing the RE-237 board, apply the screw

locking compound.

9. Reinstall it by reversing the steps 1 to 8 of disassembling.

1-10 (E)

PS2.5 x 5

RE-237 board

To the rear of

the main unit

Harness (SW1)

CN box bracket

A hole

Board-to-board

CN10

CN2

PR-292 board

Claws

PR-292 board

SW-1299 board

Harness (VF)

HDVF-C950W

Board-to-board

PR-292 board

RE-237 board

PS2.5 x 5

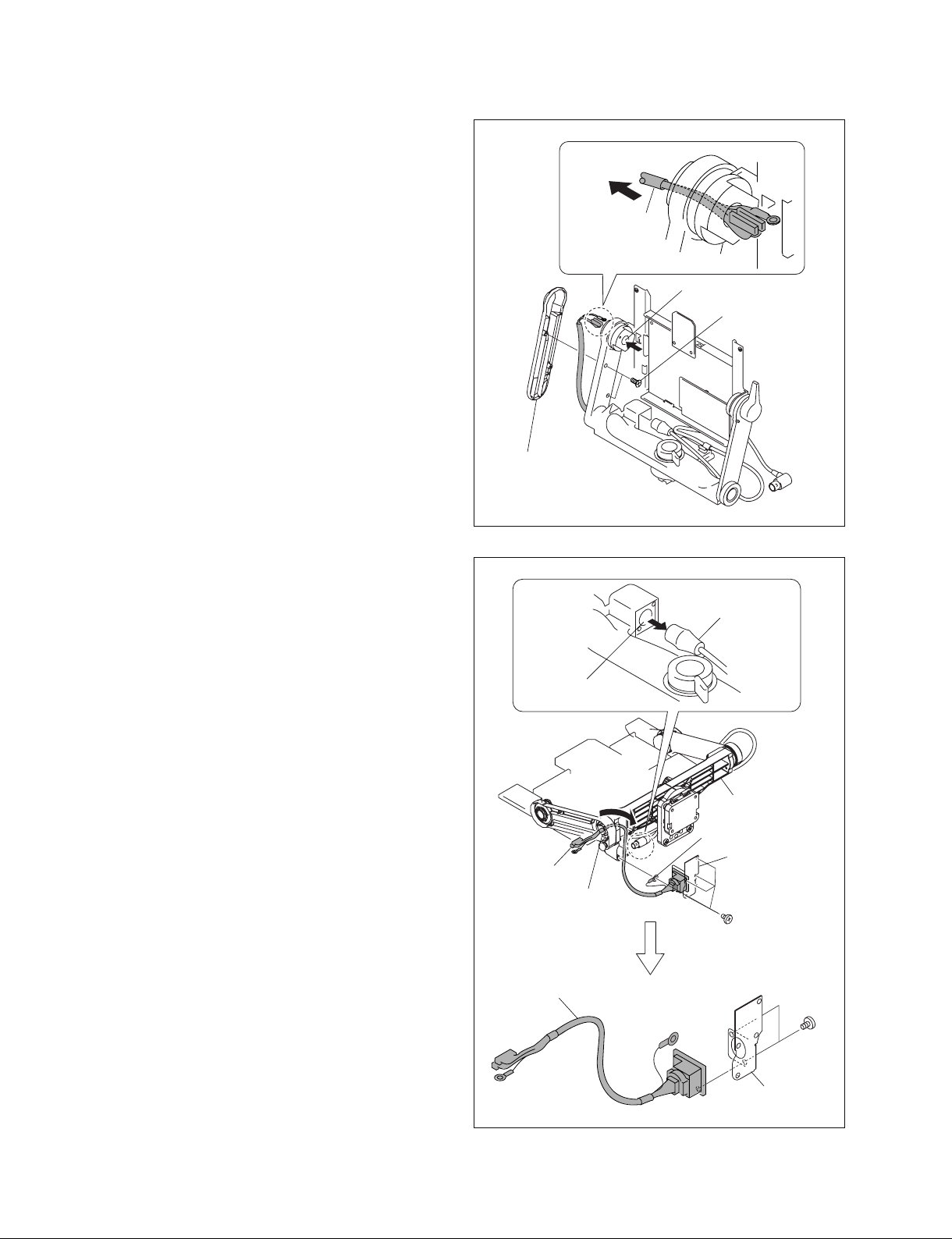

1-7-4. Removing the RE-237 Board

1. Remove the rear cover assembly.

(Refer to Section 1-7-1 step 1.)

2. Remove the bezel assembly.

(Refer to Section 1-7-1 steps 2 to 5.)

3. Remove the three screws and remove the RE-237

board.

n

When installing the RE-237 board, apply the screw

locking compound to the screws.

4. Reinstall it by reversing the steps 1 to 3 of disassembling.

1-7-5. Removing the LE-315 Board

1. Remove the rear cover assembly.

(Refer to Section 1-7-1 step 1.)

2. Remove the LCD unit.

(Refer to Section 1-7-1 steps 2 to 7.)

3. Remove the four screws and remove the LED bracket

and the LE-315 board from the bezel assembly in the

direction of arrow.

m

. To install the LED bracket and the LE-315 board to

the bezel assembly, pass the harness (LE) through

the cut-out for the harness (LE).

Be careful not to pinch the harness (LE) with the

LED bracket.

. Do not scar the protection panel.

Cut-out for the harness (LE)

LED bracket

Harness (LE)

LE-315 board

(CN1)

BTP2.6 x 6

n

Standard tightening torque :

25 x 10_2 N.m (2.5 kg.cm)

4. Disconnect the harness from the connector (CN1) of

the LE-315 board.

5. Remove the two screws and remove the LED bracket

from the LE-315 board.

6. Reinstall it by reversing the steps 1 to 5 of disassembling.

HDVF-C950W

LED bracket,

LE-315 board

Bezel assembly

LED bracket

Harness (LE)

LE-315 board

B2.6 x 5

1-11 (E)

1-7-6. Removing the LE-316 Board

1. Remove the rear cover assembly.

(Refer to Section 1-7-1 step 1.)

2. Remove the bezel assembly.

(Refer to Section 1-7-1 steps 2 to 5.)

3. Remove the four screws. Raise the protection panel in

the direction of arrow A, and remove the LED bracket

and the LE-316 board in the direction of arrow B.

m

. To install the LED bracket and the LE-316 board in

the bezel assembly, pass the harness (LE) through

the cut-out for the harness (LE).

Be careful not to pinch the harness (LE) with the

LED bracket.

. Do not scar the protection panel.

n

Standard tightening torque :

25 x 10_2 N.m (2.5 kg.cm)

LE-316 board

Protection panel

A

Protection panel

LED bracket

Bezel assembly

B

BTP2.6 x 6

LED bracket,

LE-316 board

4. Disconnect the harness from the connector (CN1) of

the LE-316 board.

5. Remove the two screws and remove the LED bracket

from the LE-316 board.

6. Reinstall it by reversing the steps 1 to 5 of disassembling.

Cut-out for the

harness (LE)

CN1

Harness (LE)

LE-316 board

(CN1)

LED bracket

Harness (LE)

B2.6 x 5

LE-316 board

LED bracket

1-12 (E)

HDVF-C950W

BTP2.6 x 6

B2.6 x 5

SW-1298 board

CN1

Bezel assembly

SW bracket

RE knob

Hexagon nut

Splash-proof cushion

Splash-proof rubber

Harness

SW-1298 board,

SW bracket

1-7-7. Removing the SW-1298 Board

1. Remove the rear cover assembly.

(Refer to Section 1-7-1 step 1.)

2. Remove the bezel assembly.

(Refer to Section 1-7-1 steps 2 to 5.)

3. Remove the RE knob and the hexagon nut from the

bezel assembly.

n

Do not scar the front panel.

4. Remove the two screws (BTP2.6 x 6), and remove the

SW bracket and the SW-1298 board.

5. Remove the three screws (B2.6 x 5), and remove the

splash-proof rubber, the splash-proof cushion and the

SW bracket from the SW-1298 board.

6. Disconnect the harness from the connector (CN1) of

the SW-1298 board

7. Reinstall it by reversing the steps 1 to 6 of disassembling.

1-7-8. Removing the VR-315 Board

1. Remove the rear cover assembly.

(Refer to Section 1-7-1 step 1.)

2. Remove the bezel assembly.

(Refer to Section 1-7-1 steps 2 to 5.)

3. Remove the three VR control knobs from the bezel

assembly.

4. Remove the three VR nuts M6 and remove the VR-

5. Disconnect the harness from the connector (CN1) of

6. Reinstall it by reversing the steps 1 to 5 of disassem-

315 board.

n

Do not scar the front panel.

the VR-315 board.

bling.

VR control knob

Bezel assembly

VR nut M6

Harness (VR)

CN1

VR-315 board

HDVF-C950W

1-13 (E)

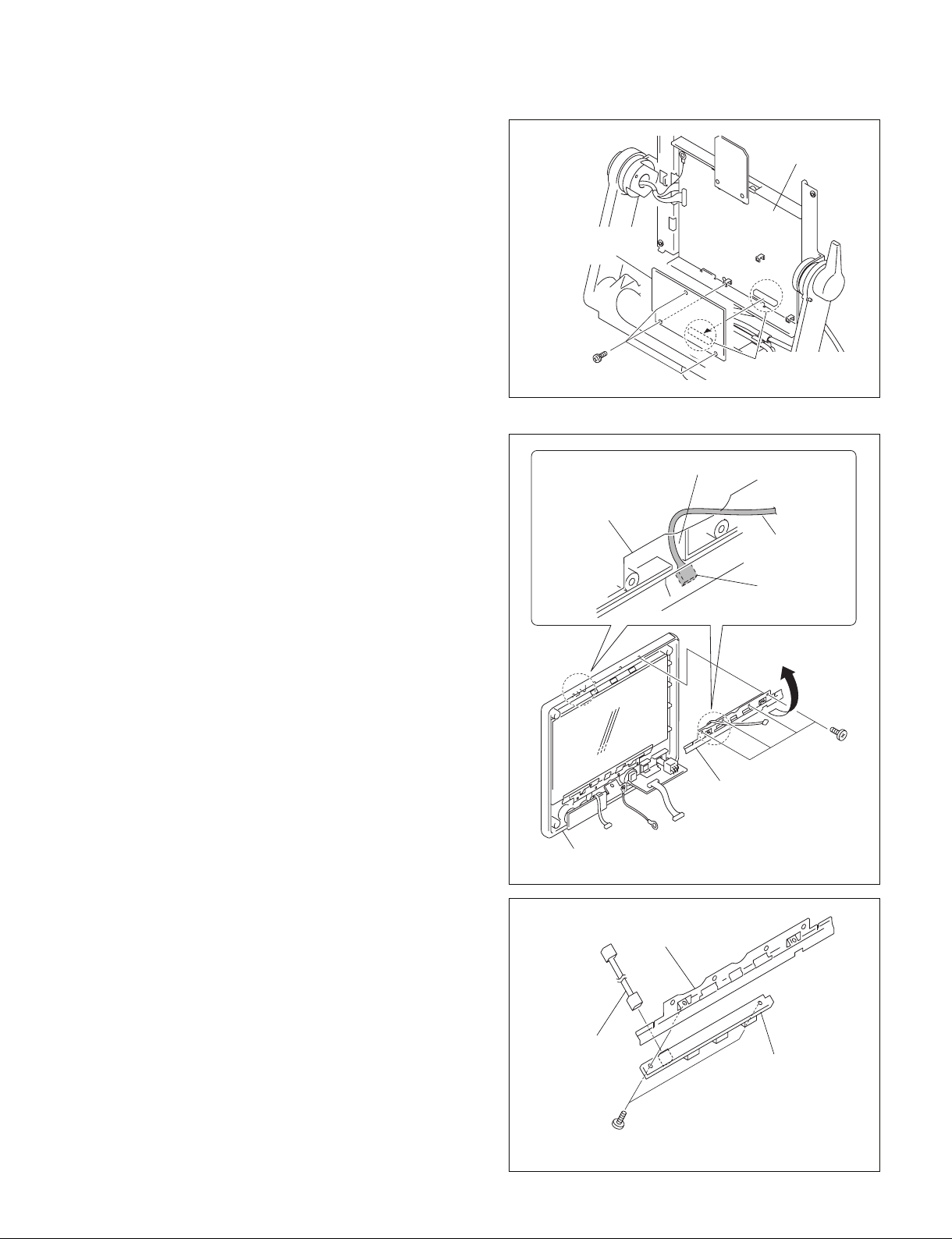

1-7-9. Removing the Harness (VF)

1. Remove the rear cover assembly.

(Refer to Section 1-7-1 step 1.)

2. Remove the bezel assembly.

(Refer to Section 1-7-1 steps 2 to 5.)

3. Remove the screw and remove the GND terminal.

(Refer to Section 1-7-3 step 4.)

4. Disconnect the harness from the connector (CN1) of

the PR-292 board. (Refer to Section 1-7-3 step 5.)

5. Disconnect the harness from the connector (CN2) of

the PR-292 board and remove it toward the front of the

machine through the CN box bracket A hole.

(Refer to Section 1-7-3 step 6.)

6. Remove the two screws and remove the arm cover (L).

7. Disconnect the harness through the tilt shaft (L) hole

in the direction of arrow.

n

Be careful not damage the harness (VF).

8. Disconnect the VF connection cable from the harness.

9. Remove the four screws (P2.6 x 5), and remove the

GND terminal, the bottom plate and harness from the

pan arm.

10. Remove the harness from the arm lift shaft in the

direction of arrow.

n

Be careful not damage the harness (VF).

Harness (VF)

Tilt shaft (L) hole

BTTP2.6 x 8

Arm cover (L)

VF connection cable

Harness (VF)

11. Remove the two screws (M2 x 5) and remove the

harness (VF) from the bottom plate.

12. Reinstall it by reversing the steps 1 to 11 of disassembling.

1-14 (E)

Harness (VF)

Arm lift shaft

Harness (VF)

Pan arm

GND terminal

Bottom plate,

harness (VF)

P2.6 x 5

M2 x 5

Bottom plate

HDVF-C950W

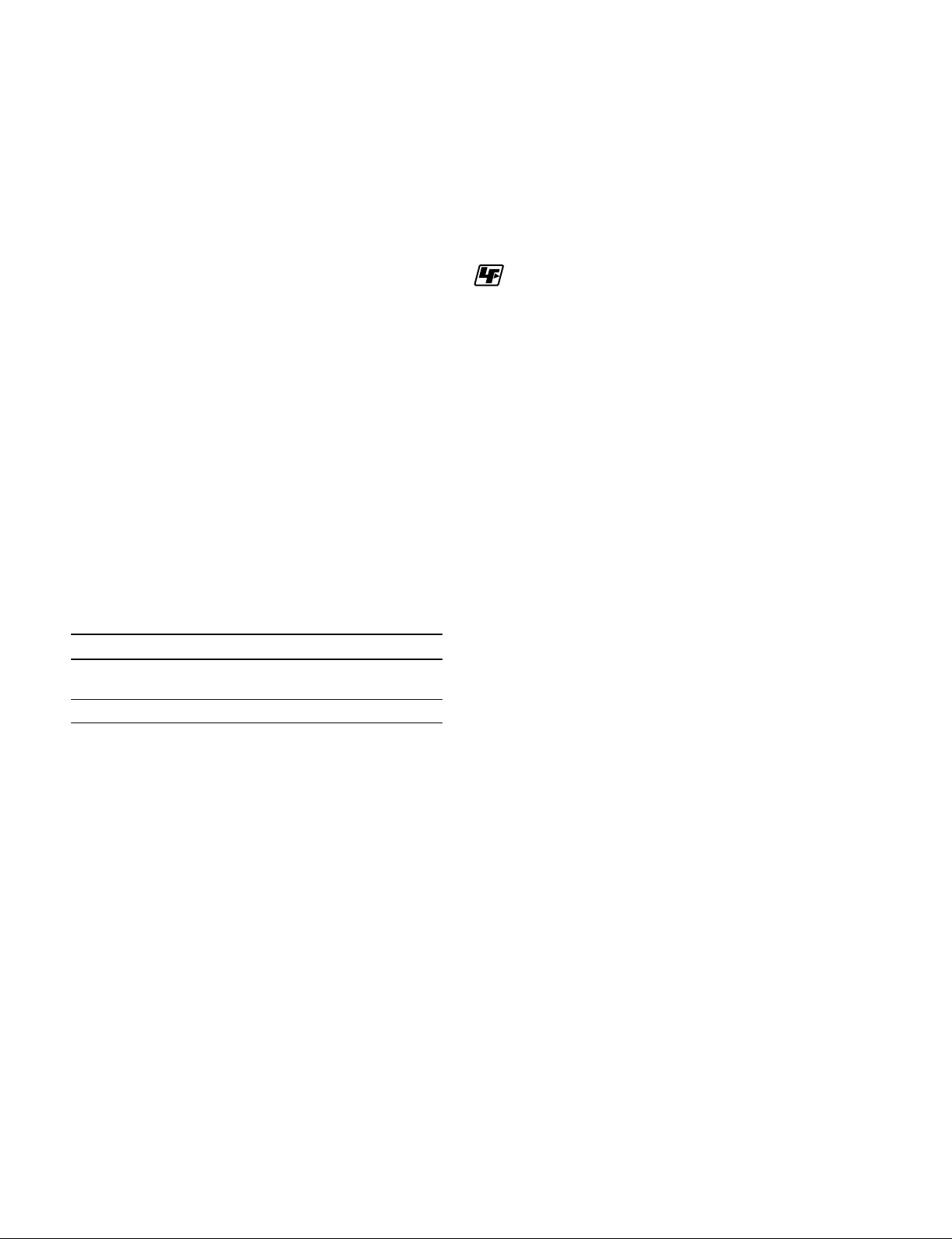

1-8. Extending the Circuit Board

B3 x 8

PR-292

board

PR/RE extension

assembly

RE-237 board

EX-1018 board

EX-1017 board

CN1

CN4

Fixture required: PR/RE extension assembly

n

Life of flexible card wire will be significantly shortened if

it is folded. Be very careful not to fold the flexible card

wire.

1-8-1. Service Position

1. Remove the rear cover assembly.

(Refer to Section 1-7-1 step 1.)

2. Disconnect the two harnesses from the connectors

(CN11, CN12) of the PR-292 board. (Refer to Section

1-7-1 step 2.)

3. Remove the bezel assembly.

(Refer to Section 1-7-1 steps 3 to 5.)

4. Insert the claws of the CN box bracket (L)/(R) into the

grooves (L)/(R) of the LCD bracket as shown in the

figure.

1-8-2. RE-237 Board

Groove of the LCD bracket (L)

Claws of the CN box

bracket (L)/(R)

Groove of the LCD

bracket (R)

Groove of the LCD

bracket (L)/(R)

1. Set the unit to the service position.

(Refer to Section 1-8-1.)

2. Remove the RE-237 board.

(Refer to Section 1-7-4 step 3.)

3. Connect the PR/RE extension assembly (EX-1017

board side) to the connector (CN4) of the PR-292

board.

4. Install the PR/RE extension assembly (EX-1018 board

side) with the screw to the CN box bracket.

n

Fix the EX-1018 board to the position shown in the

figure with the screw (B3 x 8) removed from the rear

cover.

5. Connect the RE-237 board to the connector of the PR/

RE extension assembly (EX-1018 board side).

HDVF-C950W

1-15 (E)

1-9. Fuse and IC Link Replacement

1-10. Unleaded Solder

w

The fuse and IC link are critical parts to safe operation.

Replace the components with Sony parts whose part

number appear in the manual published by Sony. If the

components are replaced by any parts other than the

specified ones, this may cause a fire or electric shock.

c

If a fuse or IC link is replaced while the main power is kept

on, this may cause electric shock.

Before replacing fuse or IC link, not only turn off the

POWER switch but also remove the power cable that is

connected to the DC IN connector.

The RE-237 board is equipped with fuse. The PR-292

board is equipped with IC link.

Any an excessive current flow due to abnormality inside

the equipment, the fuse and IC link blow. If a fuse or IC

link blows, turn off the main power of the equipment once

and inspect inside of the equipment and remove the cause

of excessive current. After that, replace the fuse and/or IC

link.

Boards requiring use of unleaded solder are printed with a

lead free mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come

printed with the lead free mark due to their particular size.)

: LEAD FREE MARK

m

. Be sure to use the unleaded solder for the printed circuit

board printed with the lead free mark.

. The unleaded solder melts at a temperature about 40 dC

higher than the ordinary solder, therefore, it is recommended to use the soldering iron having a temperature

regulator.

. The ordinary soldering iron can be used but the iron tip

has to be applied to the solder joint for a slightly longer

time. The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful.

Board Ref. No. Description Part No.

RE-237 F1 Fuse !1-576-269-21

(3.15 A/125 V)

PR-292 PS1, 2, 3, 4 IC link 0.6 A !1-576-259-21

1-16 (E)

HDVF-C950W

Section 2

MENU

POWER

ONOFF

Setting Menu

2-1. Setting Menu

The setting menu is used for selecting and adjusting all of

the parameters.

Setting menu configuration

The Setting menu consists of the following menus.

. OPERATION menu

. SERVICE menu

n

The TOP menu screen is also available for displaying the

entire configuration of the menu items.

For information about how to display the TOP menu, refer

to “2-2. TOP Menu”.

Description of switches

MENU knob

Selects items in the menu or changes the parameters.

Turn : Move to the next item or page and change parame-

ters.

Press : Select the next item or page and set parameters.

MENU switch

Displays the setting menu.

Deletes changed parameters during setting and returns to

page selection mode or the TOP menu.

PEAKING BRIGHT

CONTRAST

MENU switch

POWER

MENU

ONOFF

MENU knob

Basic operations

1. Display the menu

Press the MENU switch to display the OPERATION menu.

2. Select the menu page

With the “?” mark displayed in front of the page

number (page selection mode), turn the MENU knob.

When the desired page is displayed, press the MENU

knob.

3. Select the item

With the cursor mark “→” display in front of the setting

items in the selected page (item selection mode), turn the

MENU knob. When the cursor mark “→” lines up with

the item you want to change, press the MENU knob.

4. Change the parameter

With the “?” mark displayed in front of the parameter (parameter changing mode), turn the MENU

knob to change the parameter.

If the parameter is a number, turning the MENU

knob clockwise increases the value and turning it

counter-clockwise decreases the value.

Turning the knob far increases the value quickly,

while slowly turning the knob fine-tunes the value.

5. Set the parameter

Press the MENU knob.

This sets the parameter and returns to item selection

mode.

n

If the MENU switch it pressed before pressing the

MENU knob, the parameter returns to the value

before making changes and the screen returns to

item selection mode.

6. Exit the menu display

Every time the MENU switch is pressed, a different

operation is performed. First, the screen switches to

item selection mode, then page selection mode, then

returns to the TOP menu*1.

Pressing the MENU switch a final time exits menu

display.

HDVF-C950W

7. Return the parameters to the defaults

Move the cursor mark “→” in front of the parameter that you want to return to default. Press and hold

the MENU knob for two or more seconds.

*1 : Only has to be performed when operating from the TOP menu.

Refer to “2-2. TOP Menu”.

2-1 (E)

2-2. TOP Menu

The TOP menu displays all of the menu items.

Displaying the TOP Menu

1. Set the control knob on the front to the following

settings.

1 CONTRAST knob : 99 (Turned fully clockwise)

2 BRIGHT knob : _99 (Turned fully counter-

clockwise)

3 PEAKING knob : 100 (Turned fully clockwise)

2. Press the MENU switch while holding down the

MENU knob.

The TOP menu is displayed.

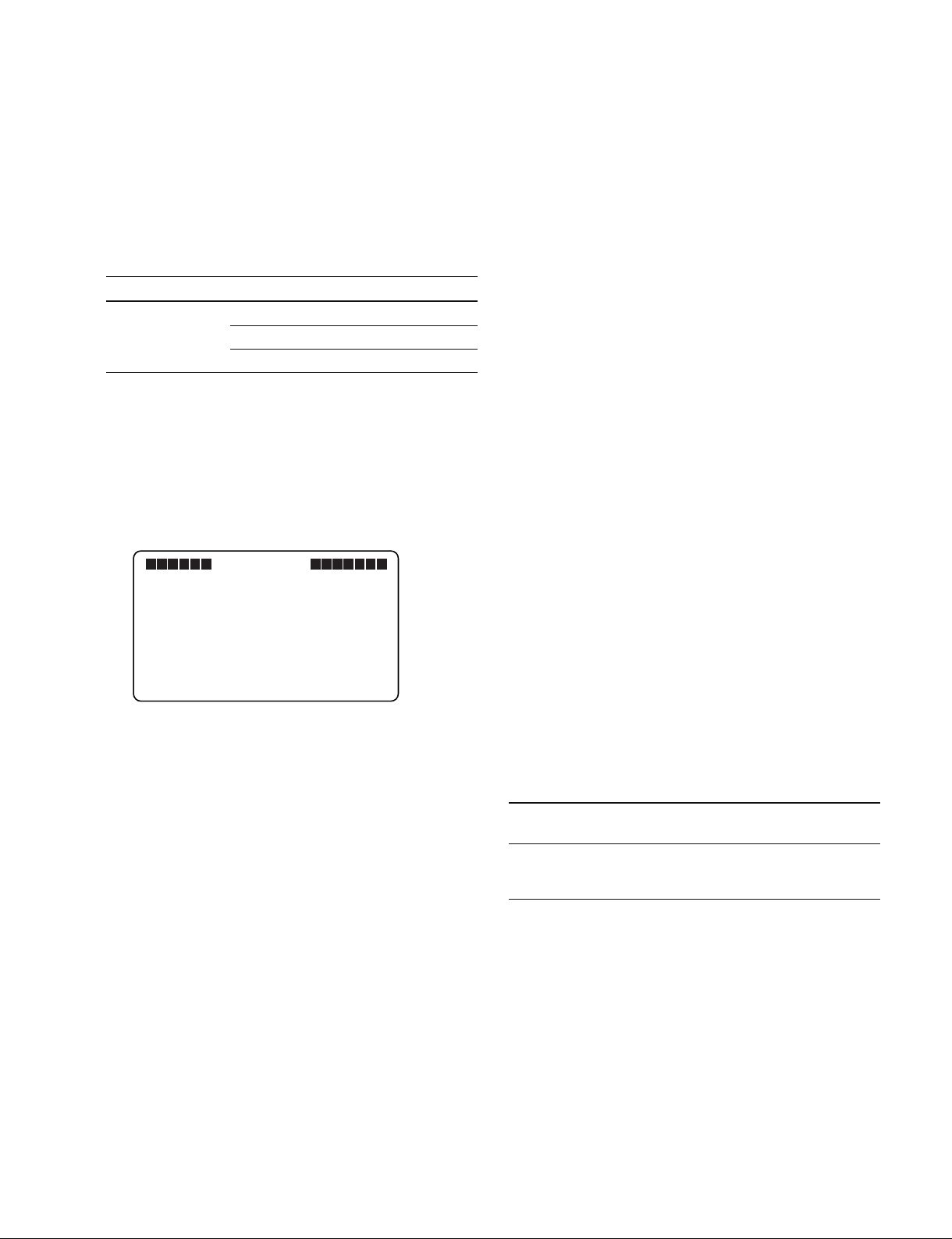

TOP MENU screen

VF MENU

<TOP MENU>

OPERATION

SERVICE

Menu items Contents

OPERATION Contains the setting items required when the

SERVICE Contains items required for maintaining the

camera operator is using the device.

View Finder, such as electrical alignment,

HOURS METER, and self-diagnosis function.

2-2 (E)

HDVF-C950W

2-3. OPERATION Menu

The OPERATION menu contains the setting items required when the camera operator is using the device.

For more information, refer to the operation manual that comes with this device.

2-4. SERVICE Menu

The SERVICE menu contains items required for maintaining the View Finder, such as electrical alignment, HOURS METER, and self-diagnosis function.

m

. The next menu item may not be selectable depending on the current menu item setting.

. “___” is displayed as the parameter for unselectable items.

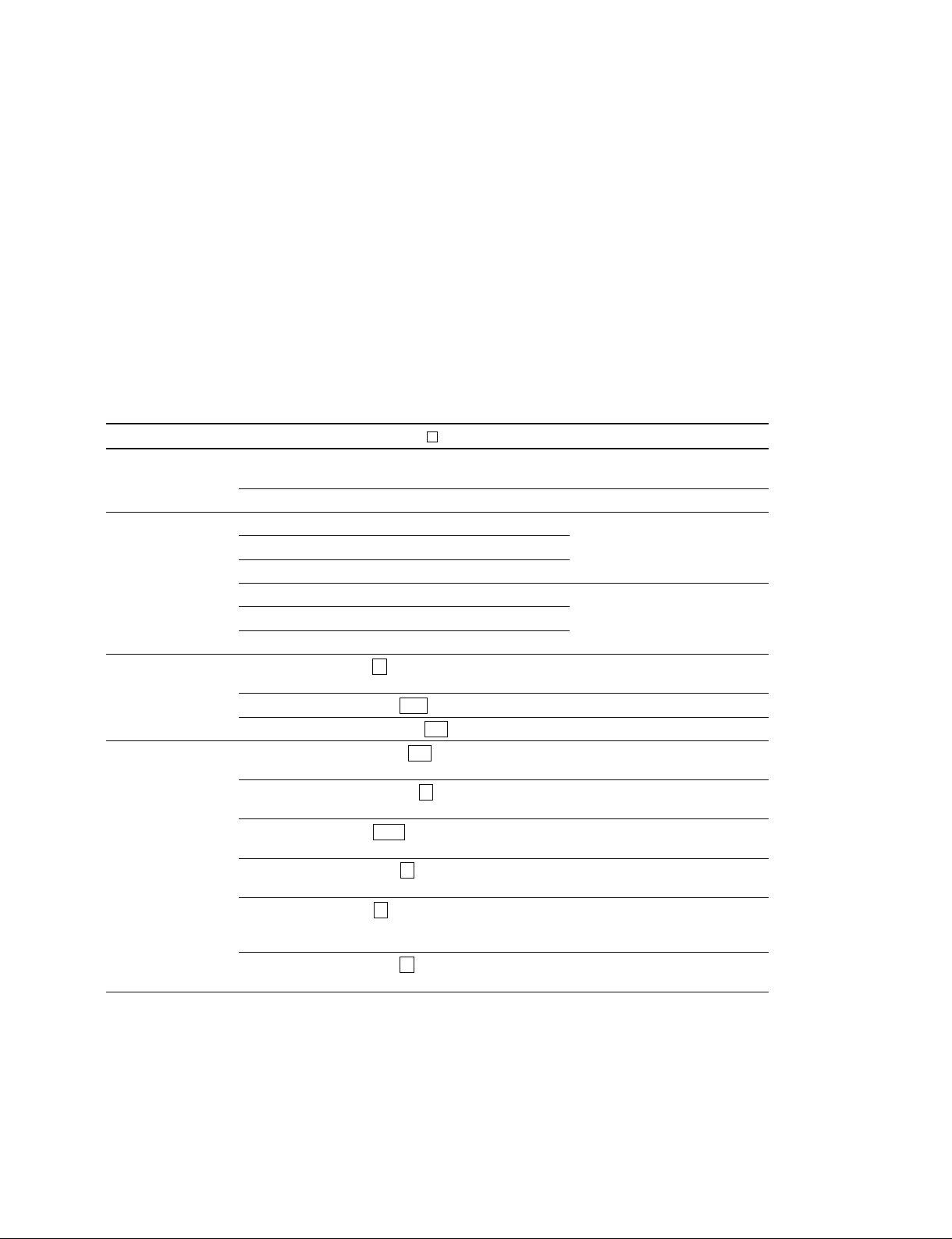

Page Menu Items Setting ( indicates the default) Function

S01*1ADJUST INVERTER POWER 0 to 215 Adjusts the inverter power

supply voltage

BL DIMMER 0 to 255 Adjusts the backlight

S02*1COLOR ADJUST BIAS R _512 to 511 Adjusts the black level color

TEMP

S03 GAMMA/ GAMMA SELECT 1 to 7 Switches the gamma table

KNEE Currently, only 1 is valid

S04 PEAKING FREQUENCY L, M, MH , H Sets the center frequency of the

*1 : The items of S01 and S02 are adjusted when shipped from the factory.

For information about adjustment, refer to Section 3 “Electrical Alignment”.

ADJUST BIAS G _512 to 511

ADJUST BIAS B _512 to 511

ADJUST GAIN R 0 to 255 Adjusts the white level color

ADJUST GAIN G 0 to 255

ADJUST GAIN B 0 to 255

KNEE POINT 0 to 213 to 255 Sets the knee point level

KNEE SLOPE 1/2, 1/3, 1/4 , CLIP Sets the knee slope level

SOURCE NAMY, Y , R, G, B Sets the video signal that makes

B MIX GAIN 0 dB , _6 dB, _12 dB, _18 dB Sets the mix gain that mixes the

CRUMPLE 0 to 1 to 3 Sets the bit shift for crumpling

RGB MIX R , G, B, CY, MG, YL, Sets the mix gain for R ch, G ch,

SKIN, SKY, FOIL, ORAN and B ch when mixing the

CRISPENING 0 to 5 to 63 Sets the level for crispening the

temperature

temperature.

peaking signal

the peaking signal

peaking signal to the B ch

the peaking signal

peaking signal to the main signal

peaking signal

HDVF-C950W

2-3 (E)

Page Menu Items Setting ( indicates the default) Function

S05 FUNCTION2 SECOND VF OFF , ON Switches the IIC address used as

the second VF

OFF : Normal

ON : When used as the second

VF

*1

PANEL REV <H> OFF , ON Inverses the screen display

horizontally

OFF : Normal

ON : Inverses horizontally

PANEL REV <V> OFF , ON Inverses the screen display

vertically

OFF : Normal

ON : Inverses vertically

MAG REL TIME 1 to 5 to 10 Sets the time it takes to return

from the enlarged view to the

normal view when MAG AUTO

RELEASE is set to AUTO

TEST SIGNAL OFF , BARS, SAW, RAST Sets the internal test signal

*2

*3

OFF : Does not output the test

signal

BARS: Outputs a color bar signal

SAW : Outputs a saw-tooth wave

test signal

RAST : Outputs a rectangular test

signal

COLOR SELECT W , R, G, B, Y, C, M Selects a display color when a

rectangular test signal is selected

TEST LEVEL 0 to 255 Sets the signal level when a

rectangular test signal is selected

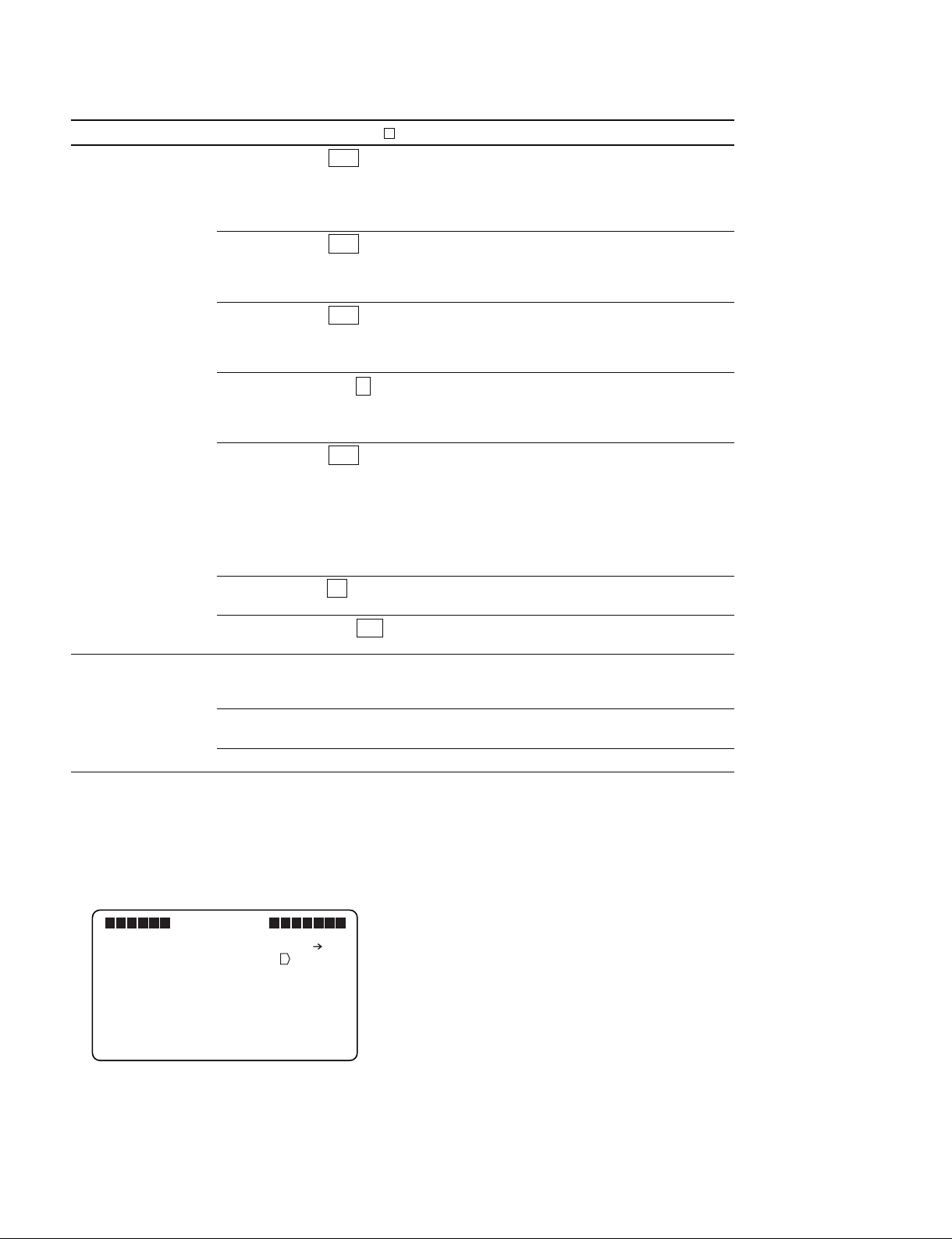

S06 HOURS METER RESET METER EXEC Resets the OPERATION time

Press the MENU knob to move to

the operation screen

*4

OPERATION Display only Displays the total power-on time

(resettable)

TOTAL Display only Displays the total power-on time

*1 : Set this to ON only when using the device as the second VF by connecting it to the EXT I/O (20P) connector of HDC-950 or HDC-

930. (No setting change is required when using the device alone.)

In this case, a dedicated VF connection cable and the corresponding camera settings are needed.

Contact your nearest SONY Office/Service Center for details.

No setting change is required when connecting the device to the EXT I/O (20P) connector of HDC-F950.

*2 : Refer to AUTO RELEASE of OPERATION MENU 03 MEGNIFICATION.

*3 : This parameter will always start in OFF when the power is turned on.

*4 : Place the cursor mark “→” on “EXEC” and press the MENU knob to move to the following operation screen.

Place the cursor mark “→” on “YES” and press the MENU knob to perform reset.

VF MENU

S06 HOURS METER

RESET OK? YES NO

RESET METER : EXEC

OPERATION : XXXXXXH

TOTAL : XXXXXXH

2-4 (E)

HDVF-C950W

Loading...

Loading...