Sony HDVF-C30W Maintenance Manual

ELECTRONIC VIEWFINDER

HDVF-C30W

MAINTENANCE MANUAL

1st Edition

Serial No. 10001 and Higher

! WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

HDVF-C30W

Table of Contents

Manual Structure

Purpose of this manual ........................................................................................ 3 (E)

Relative manual ................................................................................................... 3 (E)

Contents ............................................................................................................... 4 (E)

1. Service Overview

1-1. Check Item before Starting Maintenance ..............................................1-1 (E)

1-2. Check Item after Completing Maintenance .......................................... 1-1 (E)

1-3. Board Layouts ....................................................................................... 1-1 (E)

1-4. Circuit Description ................................................................................1-2 (E)

1-5. Input and Output Signals of Connectors ............................................... 1-2 (E)

1-6. Functions of On-board Switches and Controls ..................................... 1-3 (E)

1-6-1. PR-267 Board .......................................................................1-3 (E)

1-6-2. VR-208 Board ...................................................................... 1-6 (E)

1-7. Replacing the Main Parts ...................................................................... 1-6 (E)

1-7-1. Replacing the LCD Panel .....................................................1-6 (E)

1-7-2. Replacing the Protection Glass ............................................ 1-8 (E)

1-7-3. Replacing the Anti-Glare Sheet ........................................... 1-9 (E)

1-8. Setup after Replacement of the Main Parts and Board ....................... 1-11 (E)

1-8-1. When the LCD Panel is Replaced ......................................1-11 (E)

1-8-2. When the PR-267 Board is Replaced .................................1-11 (E)

1-9. Fixtures and Measuring Instruments ...................................................1-12 (E)

1-9-1. List of Fixtures and Measuring Instruments ...................... 1-12 (E)

1-9-2. How to Extend the RE-208 Board ..................................... 1-12 (E)

1-10. Diagnostics ..........................................................................................1-13 (E)

1-10-1. Diagnostics of the PR-267 Board and the LCD Panel ....... 1-13 (E)

1-10-2. Voltage Check of the RE-208 Board ................................. 1-19 (E)

1-11. How to Measure Luminance ............................................................... 1-19 (E)

1-12. Precautions When Repairing the High-Voltage Areas of

the DC/AC Inverter Transformer ........................................................1-20 (E)

1-13. Rewriting the PLD Internal Data ........................................................ 1-20 (E)

1-14. Notes on Repair Parts ..........................................................................1-21 (E)

1-15. Unleaded Solder ..................................................................................1-21 (E)

1-16. Recommended Replacement Parts ......................................................1-22 (E)

1-17. Viewfinder Rotating Torque Adjustment ............................................ 1-23 (E)

1-18. When Rotation of Viewfinder Becomes Difficult .............................. 1-24 (E)

HDVF-C30W

1 (E)

2. Spare Parts

2-1. Notes on Repair Parts .................................................................................. 2-1

2-2. Exploded Views .......................................................................................... 2-2

2-3. Electrical Parts List ..................................................................................... 2-5

2-4. Packing Materials and Supplied Accessories List .................................... 2-13

2-5. Optional Fixtures List ............................................................................... 2-13

3. Semiconductor Pin Assignments

4. Block Diagram

Overall Block.......................................................................................................... 4-1

5. Schematic Diagrams

RE-208 .................................................................................................................... 5-1

PR-267 ....................................................................................................................5-2

SW-1092 ................................................................................................................. 5-5

VR-280 ................................................................................................................... 5-5

Frame Wiring.......................................................................................................... 5-6

6. Board Layouts

PR-267 ....................................................................................................................6-1

RE-208 .................................................................................................................... 6-2

SW-1092 ................................................................................................................. 6-2

VR-280 ................................................................................................................... 6-2

2 (E)

HDVF-C30W

Purpose of this manual

Relative manual

Manual Structure

This manual is the maintenance manual for Electronic Viewfinder HDVF-C30W.

This manual describes the information items necessary when the unit is supplied and

installed, items that premise the service based on the components parts such as main

parts replacement, schematic diagrams, board layouts and spare parts lists, assuming

use of system and service engineers.

Besides this maintenance manual the following manual is available for this unit.

..

. Operation Manual (Supplied with this unit)

..

This manual is necessary for application and operation of this unit.

..

. “Semiconductor Pin Assignments” CD-ROM (Available on request)

..

This “Semiconductor Pin Assignments” CD-ROM allows you to search for

semiconductors used in B&P Company equipment.

Semiconductors that cannot be searched for on this CD-ROM are listed in the

maintenance manual for the corresponding unit. The maintenance manual contains

a complete list of all semiconductors and their ID Nos., and thus should be used

together with the CD-ROM.

Part number: 9-968-546-XX

HDVF-C30W

3 (E)

Contents

The following are summaries of the each section for understanding the manual.

Section 1 Service Overview

Describes information about board locations, connector input/output signals, and

replacement of LCD panel.

Section 2 Spare Parts

Describes parts list, exploded views and supplied accessories used in the unit.

Section 3 Semiconductor Pin Assignments

Contains information on semiconductors used for the unit.

It includes a complete list of the semiconductors and their ID Nos. for retrieving

information on “Semiconductor Pin Assignments” CD-ROM, which is available

separately.

Please refer to this section together with the “Semiconductor Pin Assignments”

CD-ROM.

Information on the semiconductors not contained in the CD-ROM at the time of

issue of this manual, if any, is given in this section as well.

Section 4 Block Diagram

Describes overall block diagram of this unit.

Section 5 Schematic Diagrams

Describes schematic diagrams for every circuit board and frame wiring .

Section 6 Board Layouts

Describes board layouts for every circuit board.

4 (E)

HDVF-C30W

Section 1

Service Overview

1-1. Check Item before Starting

Maintenance

Before connecting to the HDW-750/730 series camcorder,

confirm these two points beforehand.

If either one or both of these points is satisfied, the HDVFC30W that is connected to the HD camcorder will have the

B/W video picture on display.

If this error occurs, modification of the HD camcorder is

needed.

Points to be confirmed

1. Version number of the ROM on the AT-143 board of

HD camcorder is “V1.51 or lower”.

n

Version number can be confirmed using the DIAGNOSIS menu of HD camcorder.

2. Serial number falls within the followings:

HDW-750 : 70001 to 70557

HDW-750 : 10001 to 10400, 20001 to 20003

HDW-750P : 40001 to 40097

HDW-750CE : 40001 to 40036

HDW-730 : 10001 to 10053

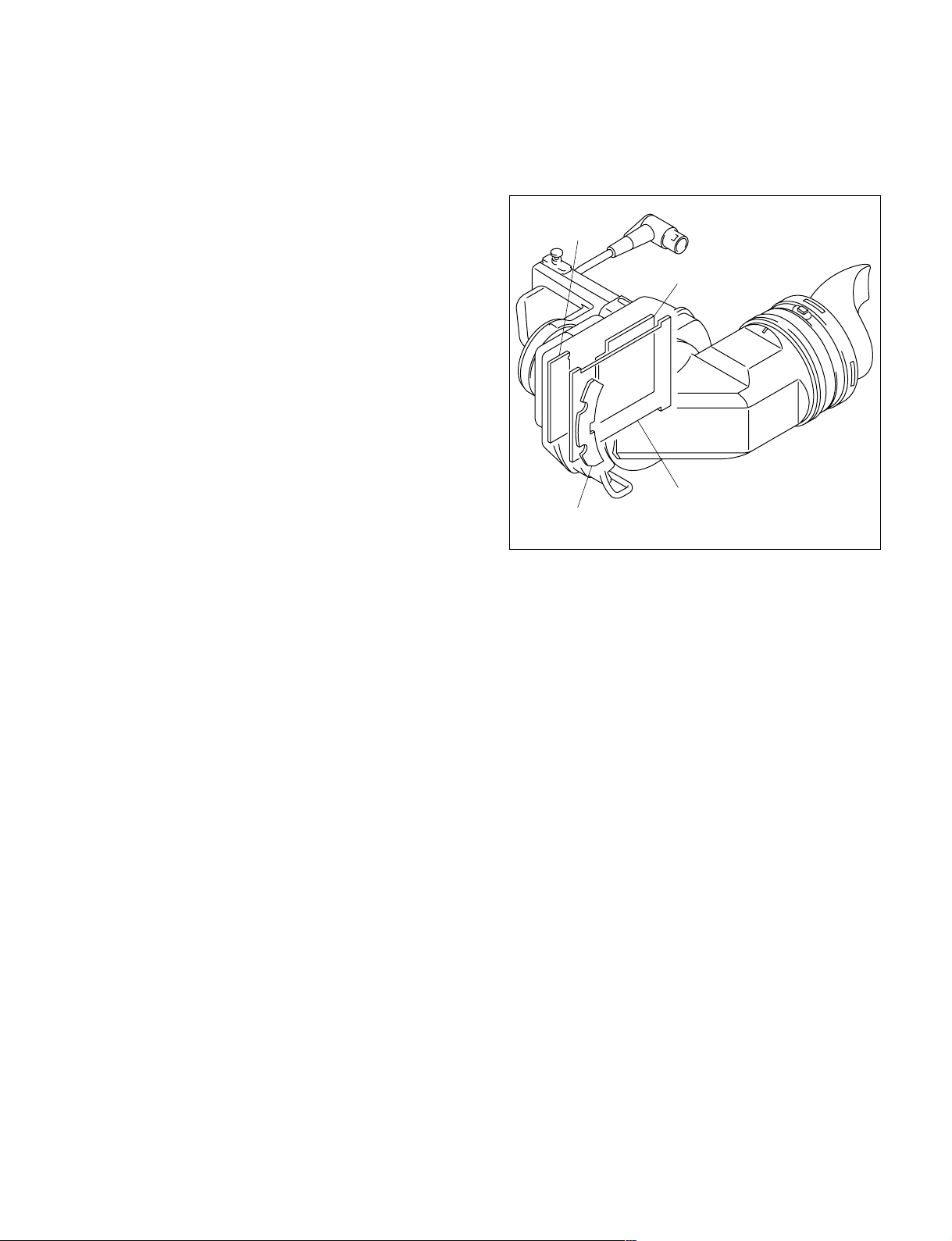

1-3. Board Layouts

SW-1092

RE-208

PR-267

VR-280

If modification of HD camcorder is needed, contact your

local Sony Sales Office/Service Center.

1-2. Check Item after Completing

Maintenance

When maintenance work is completed, check that the

SEL1/SEL2 selector switch is set to the SEL1 position

(lower position).

If it is set to the SEL2 position (upper position), the

BRIGHT/CONTR/PEAKING adjustment controls are

disabled.

HDVF-C30W

1-1 (E)

1-4. Circuit Description

PR-267 board

The input Y, Pb and Pr signals are passed through the

buffer and the pre-filter and are A/D-converted to the 10bit digital signals. Then resultant signals are sent to the

FPGA.

The digital input Y, Pb and Pr signals are clamped inside

the FPGA, receive the BRIGHT, CONTRAST and PEAKING controls, and are finally converted to the RGB signals

that are output to LCD. The above controls are realized by

A/D-converting the analog control voltages from the VR280 board and are supplied to FPGA.

The H1 signal and H2 signal are generated from the sync

signal by the two comparators. The H1 signal extracts the

zero-cross point of the three-level sync signal and the H2

signal extracts the sync signal near the zero-cross point.

The H1 and H2 signals are supplied to FPGA that generates the H and V sync signals. The LCD drive pulse signals

are generated from the H and V sync signals. The LCD

drive pulse signals that are thus generated are supplied to

LCD together with the RGB video signal and the LCD

gamma correction voltage.

The various controls from the camera and VF are sent

through IIC and are processed by FPGA from which the

control commands are distributed to the respective circuits

as the control signals as necessitated.

RE-208 board

The RE-208 board contains the following three types of

voltage regulator. 1. The voltage regulator supplying the

analog and digital signal processing, generating the 3.1 V

regulated voltage. 2. The voltage regulators supplying the

LCD drive voltages, generating the 10.5 V, 20 V and -7.2

V regulated voltages. 3. The voltage regulator supplying

the CCFL drive regulated voltage.

The maximum contrast of LCD is set by the variable

resistor located inside the LCD. The LCD contrast can be

controlled within the range with the use of CONTRAST

under the maximum contrast set by the above variable

resistor.

VR-280 board

The VR-280 board contains the two sets of BRIGHT,

CONTRAST and PEAKING controls. One set of these

controls is for the external control. The other set of these

controls is for the internal control. Either the external or

the internal controls can be selected with the use of the

SEL switch. The VR-280 board contains the tally lamp

drive circuit that turns on or off the TALLY lamp in

accordance with the command supplied from the camera.

The VR-280 board contains also the switch that inverts the

scanning direction from the right or left of display screen.

This switch is interlocked with the viewfinder barrel

presence so that the appropriate scanning direction is

automatically selected as the viewfinder barrel is installed.

SW-1092 board

The SW-1092 board contains the tally, zebra, marker,

B&W and MAG function selector switches. The status

information of these selector switches is sent to the PR-267

board.

1-5. Input and Output Signals of

Connectors

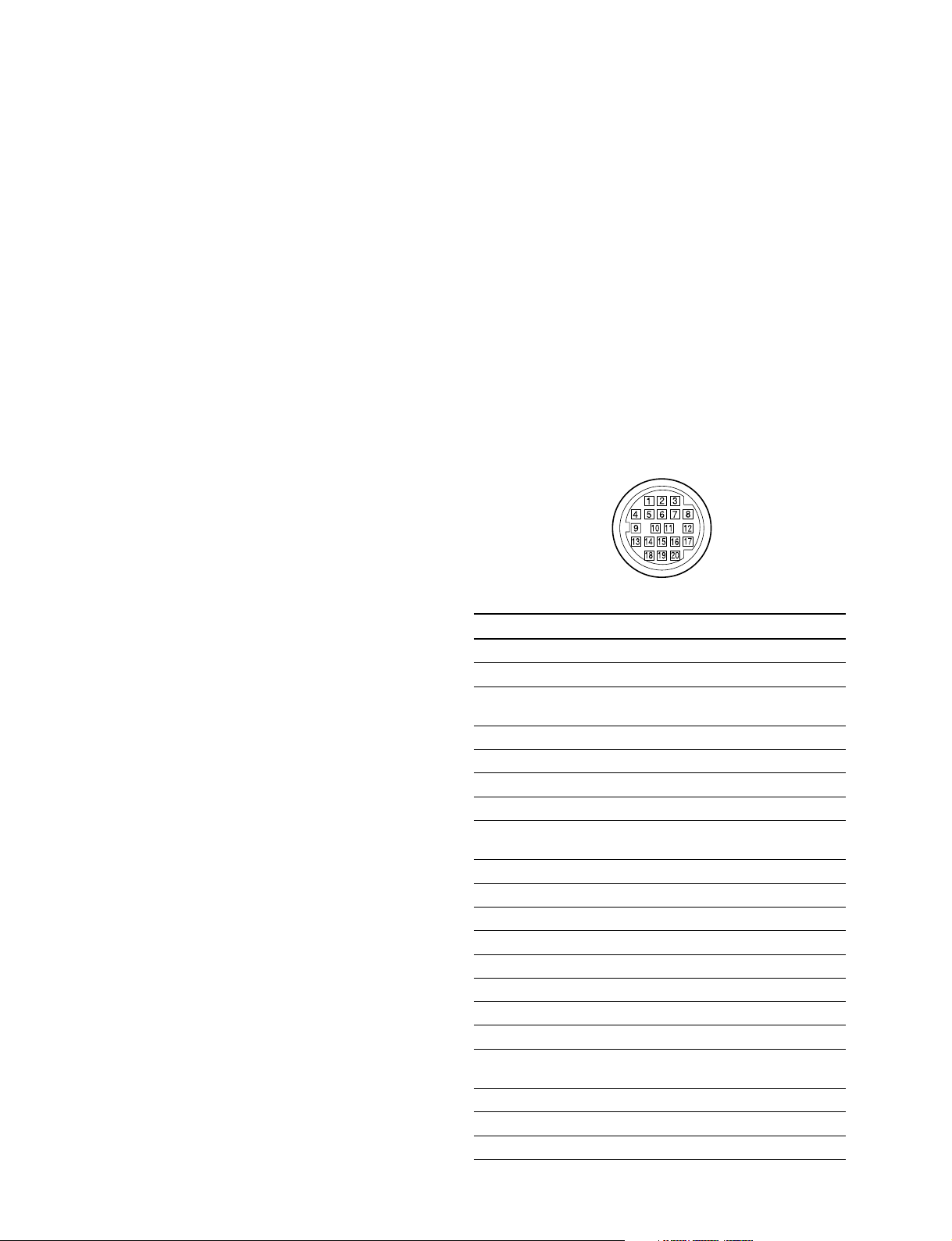

VF (20P MALE)

(EXTERNAL VIEW)

Pin No. Signal Name I/O Specifications

1 S-DATA IN/OUT TTL level

2 NC No connection

3 POWER IN POWER ON : OPEN

OFF CTL POWER OFF : GND

4 SCK IN TTL level

5 NC No connection

6 NC No connection

7 NC No connection

8 G TALLY IN ON : 5 V

OFF : GND

9 NC No connection

10 NC No connection

11 NC No connection

12 Y VIDEO IN 1.0 V p-p Zo = 75 Z

13 VIDEO GND GND for VIDEO

14 Pb VIDEO IN 0.7 V p-p Zo = 75 Z

15 Pr VIDEO IN 0.7 V p-p Zo = 75 Z

16 NC No connection

17 R TALLY IN ON : 5 V

OFF : GND

18 NC No connection

19 UNREG GND GND for UNREG

20 UNREG IN DC 10.5 V to 17 V

1-2 (E)

HDVF-C30W

1-6. Functions of On-board Switches and Controls

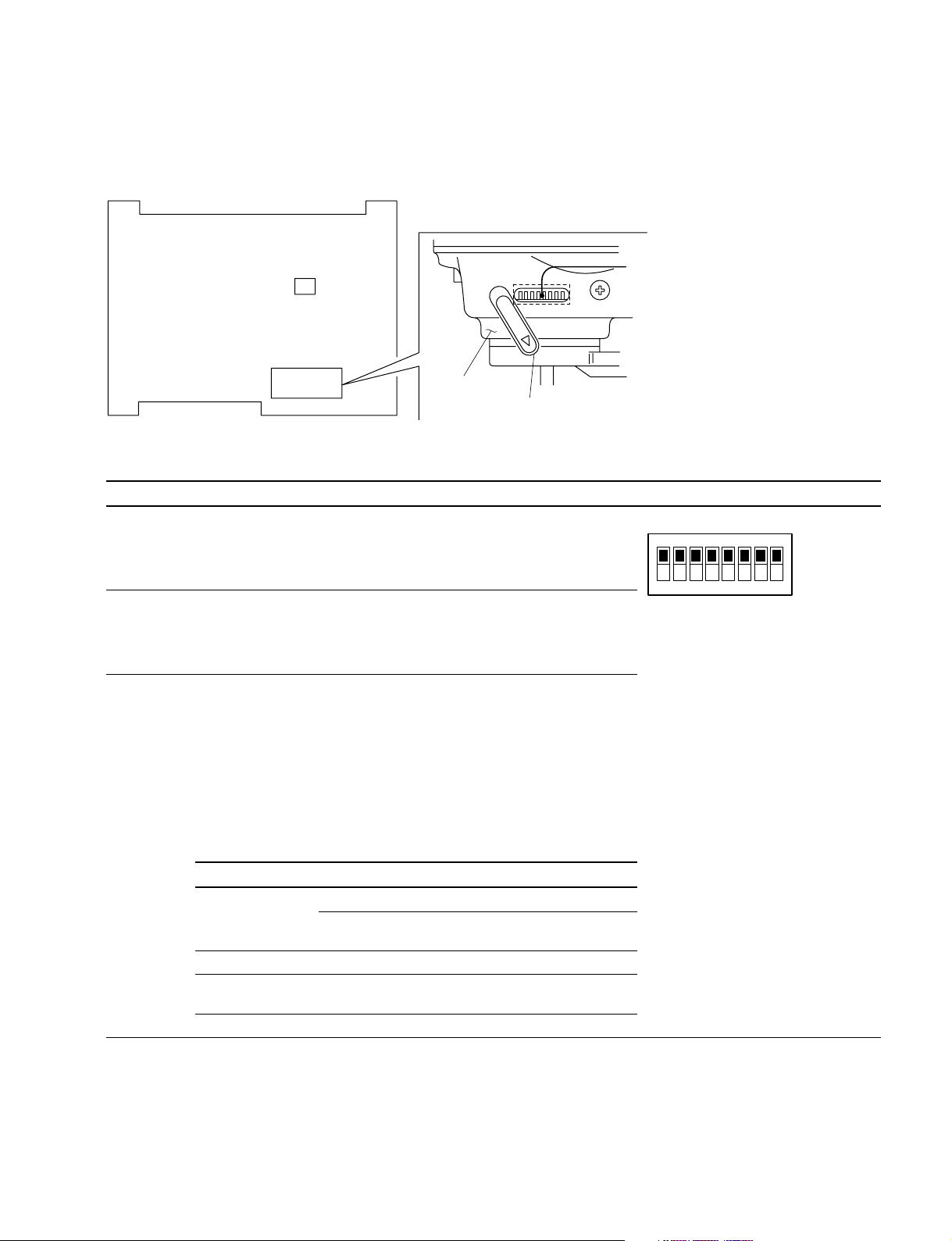

1-6-1. PR-267 Board

S2

S1

Side panel

Switch cover

S1

S1 Switch

Ref. No. Description Factory setting

S1-1 Selects whether to enable all of the indicators in the upper and lower sections

of the LCD screen, or only the BATT indicator.

OFF : Enable all indicators.

ON : Enable the BATT indicator only.

S1-2 Selects the function of the B&W button on the front panel, B&W display priority

S1-3

or grayscale display priority.

OFF : Priority given to B&W display.

ON : Priority given to grayscale display.

Selects whether the PEAKING variable resistor (RV2/VR-208 board) on the front

panel and the PEAKING control on the side panel should work together with

the MAG button on the front panel or the SEL1/SEL2 switch on the side panel.

OFF : Work together with the SEL1/SEL2 switch.

ON : Work together with the MAG button.

This allows you to use different peaking settings for magnified and normal

display.

The following table shows the relationship between switch S1-3 settings and

the times when the PEAKING control and the PEAKING variable resistor are

enabled and disabled.

12345678

OFF (Upper side)All OFF

ON (Lower side)

HDVF-C30W

S1-3: OFF S1-3: ON

SEL1/SEL2 switch

SEL1 SEL2 ON OFF

PEAKING control*Yes No No Yes

PEAKING adjustment

variable resistor

* : Refer to the Section 1-6-2. (Yes : Enabled, No : Disabled)

*

No Yes Yes No

MAG button

(Magnified display) (Normal display)

(Continued to next page)

1-3 (E)

(Continued from previous page)

Ref. No. Description Factory setting

S1-4 Selects whether the magnified section of the picture is fixed as the center

S1-5 Not used.

S1-6 to 8 Adjust color temperature.

section or can be selected from the upper left, upper right, lower left, lower right,

and center sections.

(Refer to “Magnifying the Picture” of the Operation Manual for the selection method.)

OFF : Selectable from among the 5 sections.

ON : Fixed as the center section.

In this case, the display automatically returns to normal about 5 seconds

after the MAG button is pressed.

S1-6 S1-7 S1-8 Color temperature

OFF OFF OFF Factory setting (approx. 6500 K)

ON OFF OFF Decreases approx. 500 K (becomes reddish)

OFF ON OFF Increases approx. 500 K (becomes bluish)

ON ON OFF Increases approx. 1000 K (becomes bluish)

OFF OFF ON Increases approx. 1500 K (becomes bluish)

n

Color temperature does not change except by the above switch combinations.

The screen display luminance decreases as a result of color temperature

adjustment.

12345678

OFF (Upper side)All OFF

ON (Lower side)

y

+1500 K

B

Chromaticity diagram

G

+1000 K

+500 K

_500 K

R

[6500 K]

x

1-4 (E)

HDVF-C30W

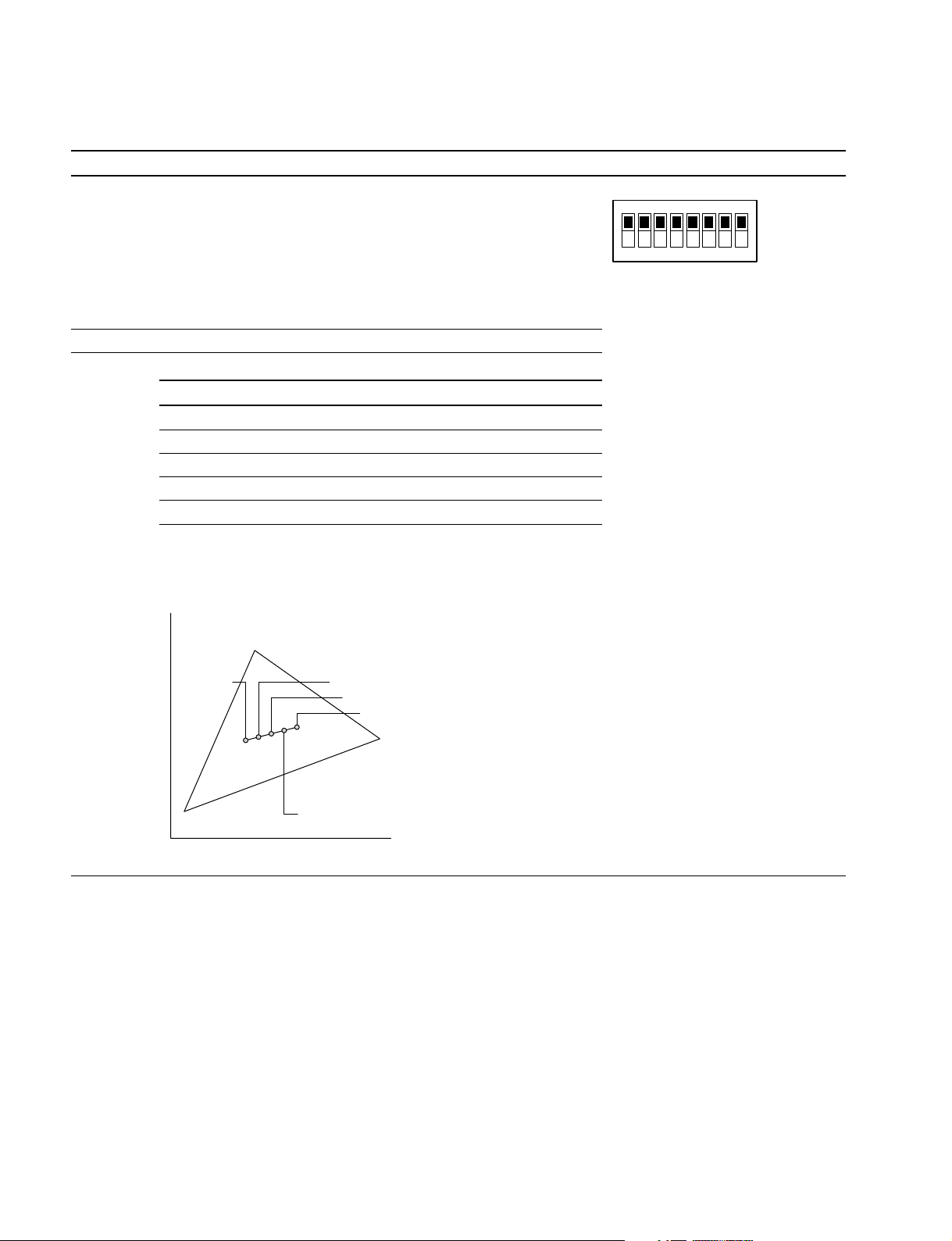

S2 Switch

1234

All OFF

ON

Ref. No. Description Factory setting

S2-1, 2 Selects whether to enlarge the range of color temperature

adjustment range or not on the y-axis of the chromaticity diagram

with the use of the switch S1-6 to S1-8.

S2-1 S2-2 Chromaticity (y-axis direction)

__

(WB

_Y) (WB

__

OFF OFF Factory default setting (As shown in 1 on the

ON OFF Chromaticity is adjusted toward the minus

OFF ON Chromaticity is adjusted toward the plus (Green)

ON ON _

n

The switches S2-1 and S2-2 should be adjusted in combination

with the switches S1-6 through S1-8.

y

++

+Y)

++

following diagram)

(Magenta) direction. (As shown in 2 on the

following diagram)

direction. (As shown in 3 on the following diagram)

G

3

1

2

B

S2-3 Selects direction of the display scanning forcibly from the right or the left.

OFF : Normal direction (The switch S2 on the VR-208 board is enabled.)

ON : Direction of scanning can be selected forcibly (The switch S2 on the

VR-208 board is disbled.)

S2-4 TEST SAW waveform output switch

ON : Generates the TEST SAW waveform within viewfinder.

Use the TEST SAW signal to check the video signal system using the

EX-909 board.

R

x

HDVF-C30W

1-5 (E)

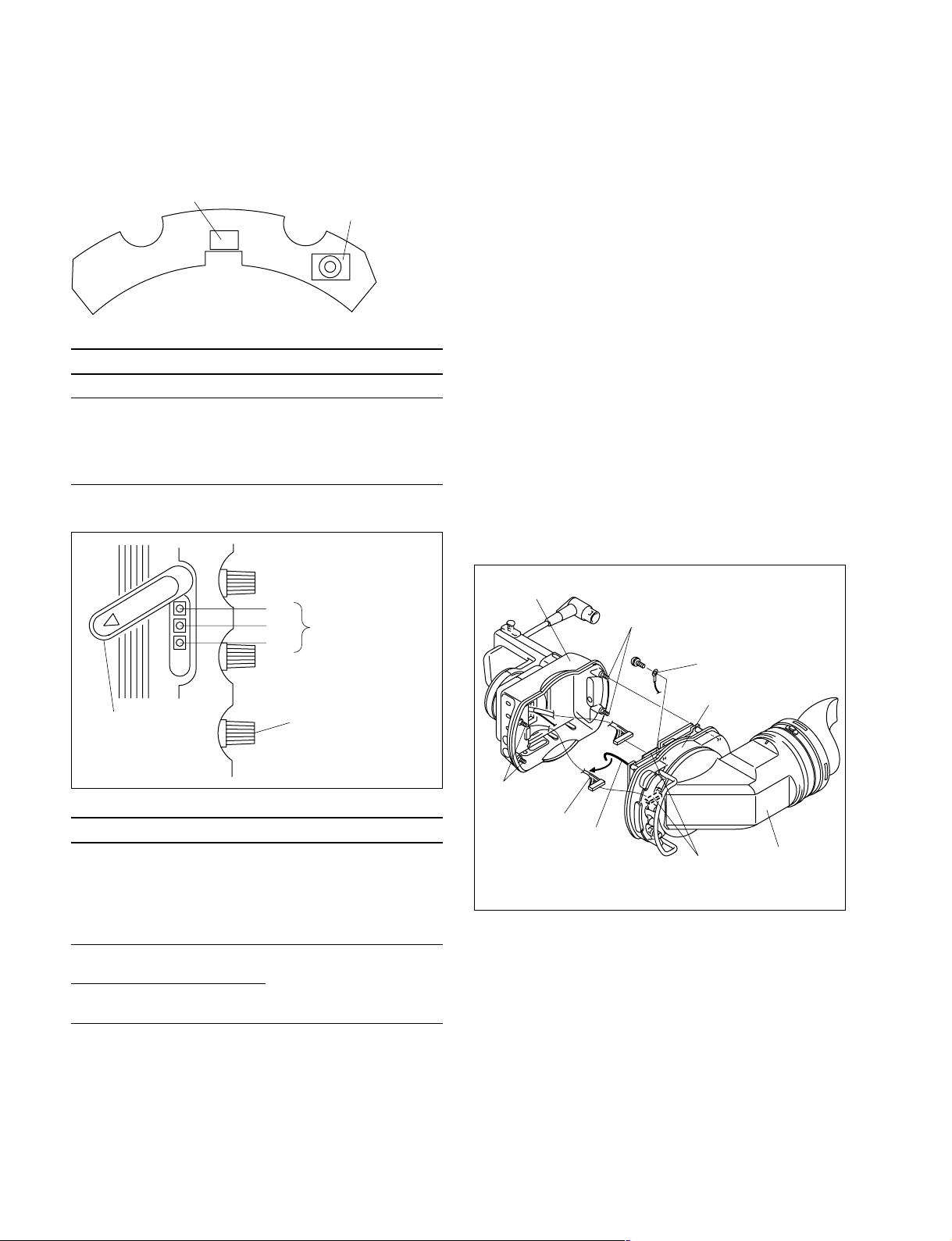

1-6-2. VR-208 Board

1-7. Replacing the Main Parts

Switch

S2

S1

A side

Ref. No. Description

S1 SEL1/SEL2 selector switch (on side panel)

S2 Selects direction of the display scanning from the

right or the left.

When the viewfinder barrel is installed, this switch is

set to ON so that the scanning in the reverse

direction is obtained.

Variable Resistor

RV4

Adjustment variable

RV6

resistor

RV2

1-7-1. Replacing the LCD Panel

n

Replacement of the LCD panel backlight:

The backlight of the LCD panel has the life of about

40,000 hours as far as the set color temperature remains

constant.

Replace the backlight when luminance of the backlight

decreases to 150 cd/m2 or less as a guideline.

Replacement of the backlight only is not possible. Replace

the entire LCD panel.

1. Loosen the four screws (with drop-safe) securing the

rear chassis and remove the rear chassis.

2. Disconnect the harness from the harness clamp and

disconnect the harness from the connectors (CN1,

CN3) on the PR-267 board.

3. Remove the screw (PS2 x 4) and remove the GND

terminal.

Rear chassis

Screws

(with drop-safe)

PS2 x 4

GND terminal

Adjustment variable

resistor cover

Ref. No. Description

RV2 PEAKING adjustment This adjustment is enabled

RV4 BRIGHTNESS They can be adjusted when

adjustment the SEL1/SEL2 selector

RV6 CONTRAST

adjustment

PEAKING control

by setting of the SEL1/SEL2

selector switch or that of the

MAG button.

For details, refer to Section

1-6-1, Switch S1-3.

switch (on the side panel) is

set to the SEL2 position.

Screws

(with drop-safe)

Harness

Harness

clamp

Viewfinder main unit

PR-267 board

(CN1 and CN3)

Viewfinder

barrel

1-6 (E)

HDVF-C30W

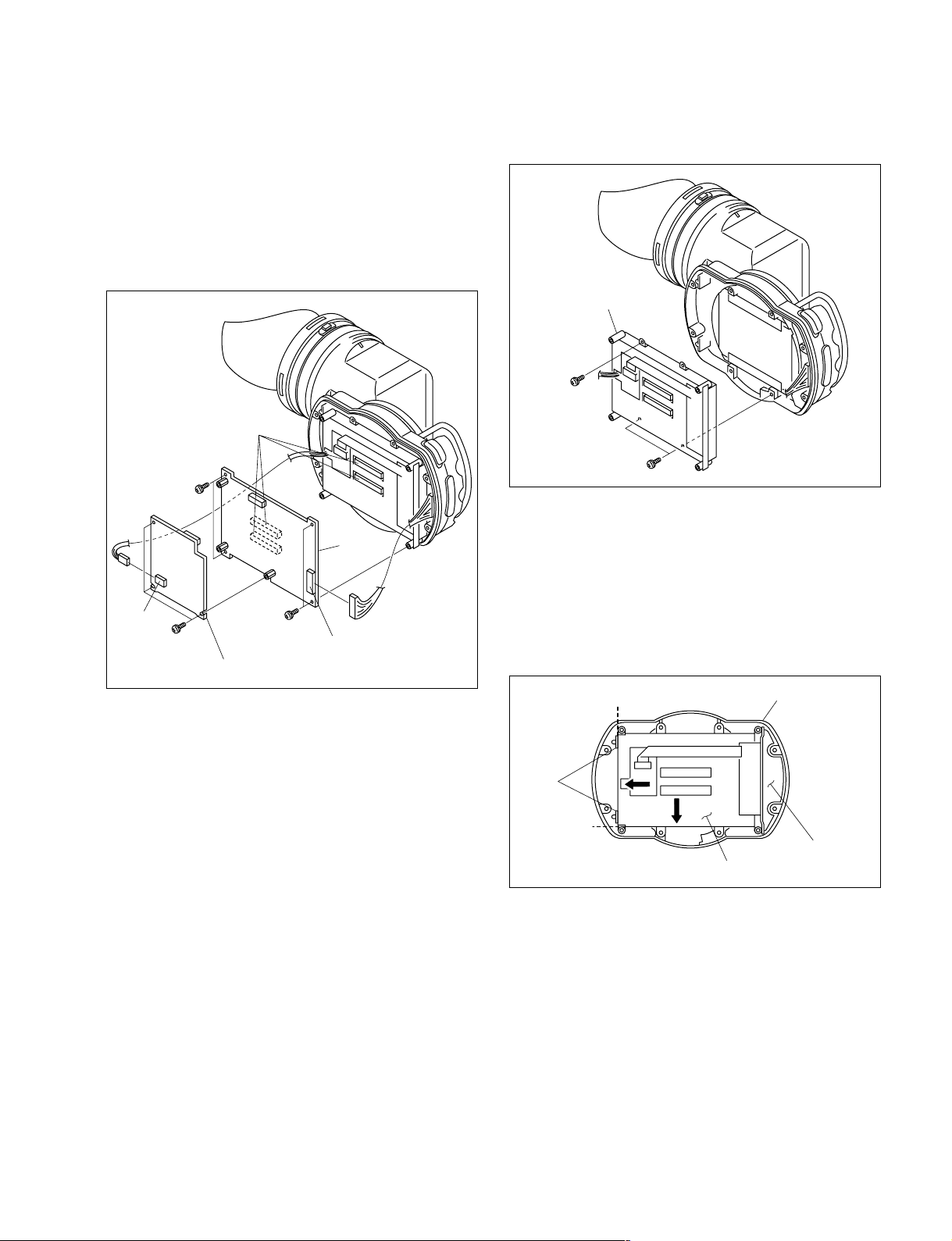

4. Disconnect the harness from the connector (CN2) on

a

VR-280 board

b

Front chassis

LCD panel

Ribs

the RE-208 board.

5. Disconnect the harness from the connector (CN7) on

the PR-267 board.

6. Remove the three screws (M2 x 5) and remove the

RE-208 board from the PR-267 board.

7. Remove the four screws (PS2 x 4) and remove the

board-to-board connector from the PR-267 board.

Board-to-board

connectors

PS2 x 4

PR-267

board

CN2

M2 x 5

PS2 x 4

CN7

RE-208 board

8. Remove the three screws (PS2 x 4) and remove the

LCD panel.

LCD panel

PS2 x 4

PS2 x 4

9. Install the new LCD panel.

Precaution for installation

When installing the new LCD panel, be careful not to

attach dust or fingerprint on the display area of the

LCD panel.

Installation position

Install the LCD panel by pushing it against the sides

“a” and “b” as far as it can go, of the front chassis.

10. Perform the setting of the switches S1 and S2 of the

PR-267 board. (Refer to Section 1-8-1.)

11. Install the removed parts by reversing the steps 1 to 7

of removal.

Precaution for installation

Be sure to insert the connectors to the circuit board

HDVF-C30W

securely for sure connection of the connectors.

1-7 (E)

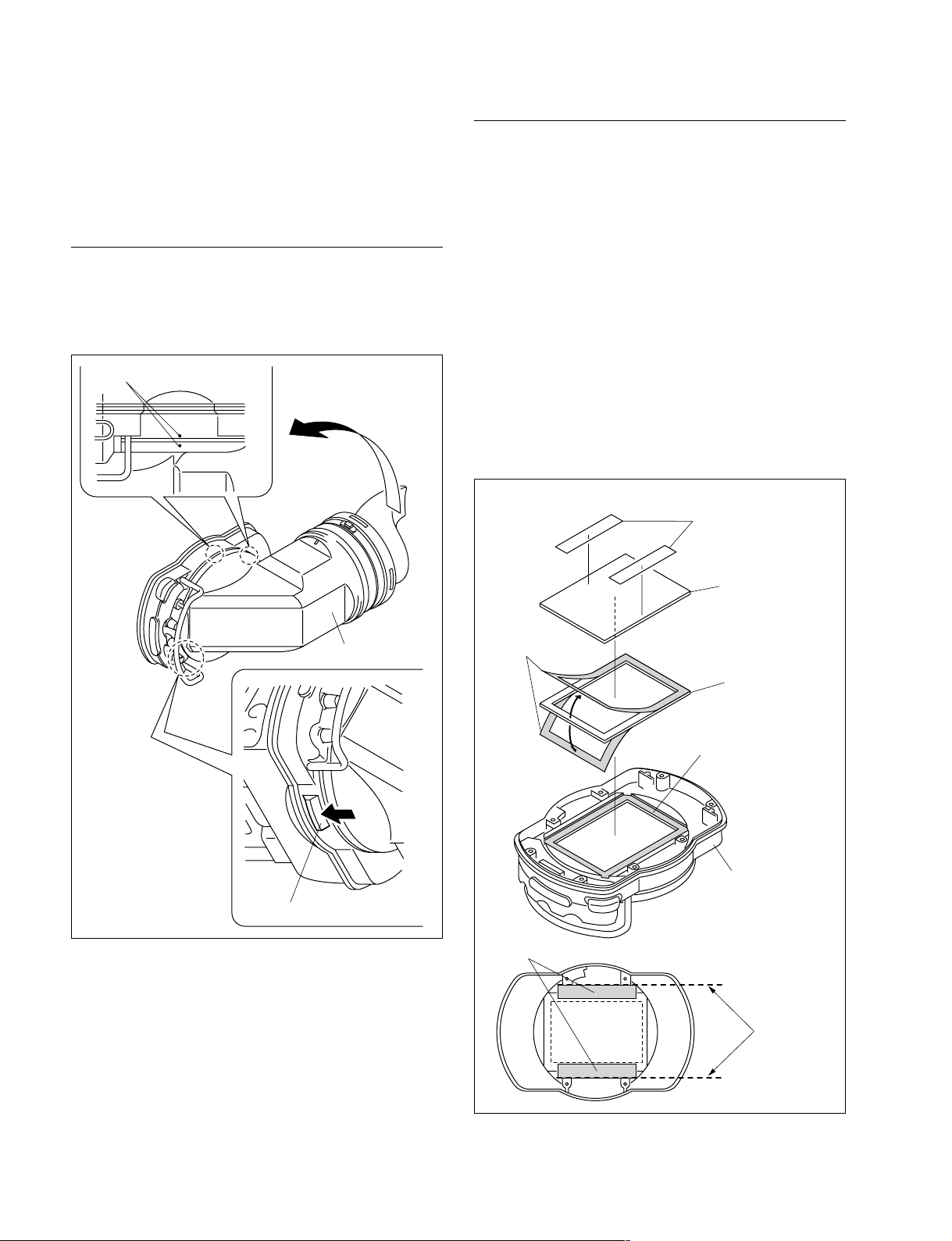

1-7-2. Replacing the Protection Glass

Installation

Parts to be prepared in addition to the protection glass:

. Glass cushion, 1 piece : 3-776-618-xx

. Radiation sheet, 2 pieces : 3-776-623-xx

Removal

1. Push the RELEASE knob in the direction of the arrow

A to release the lock and remove the viewfinder barrel

by rotating it in the direction of the arrow B.

Red marks

Fig. 2

B

6. Peel off the protection sheet from the new glass

cushion and attach the new glass cushion to the

attaching surface.

Precaution for attaching the glass cushion

. Attach the glass cushion so that any portion of the

glass cushion should not protrude from the attaching

surface.

. Attach the glass cushion with care so that any

wrinkle should not be generated.

7.

Peel off the protection sheet form the surface of the glass

cushion attached, and install the new protection glass.

8. Attach the two radiation sheets to the positions as

shown in the illustration.

9.

Install the removed parts by reversing the steps of removal.

Radiation sheets

Protection glass

Viewfinder barrel

A

RELEASE knob

Fig. 1

2. Remove the viewfinder main unit and then remove the

LCD panel.

(Perform steps 1 to 3, 5 and 8 of “1-7-1. Replacing the

LCD Panel.”)

3. Peel off the two radiation sheets.

4. Peel off the protection glass from glass cushion to

remove it.

5. Peel off the glass cushion from the front chassis and

wipe the attaching surface of the glass cushion with

alcohol.

1-8 (E)

Protection

sheets

Glass cushion

Attaching surface

Front chassis

Radiation sheets

Align the

radiation

sheets with

the walls.

Precaution for installation

Align the red marks when installing the viewfinder

barrel. (Fig. 2)

HDVF-C30W

1-7-3. Replacing the Anti-Glare Sheet

The three different types of anti-glare sheet are used as

shown below in this model.

Replace the desired type of anti-glare sheet as necessitated.

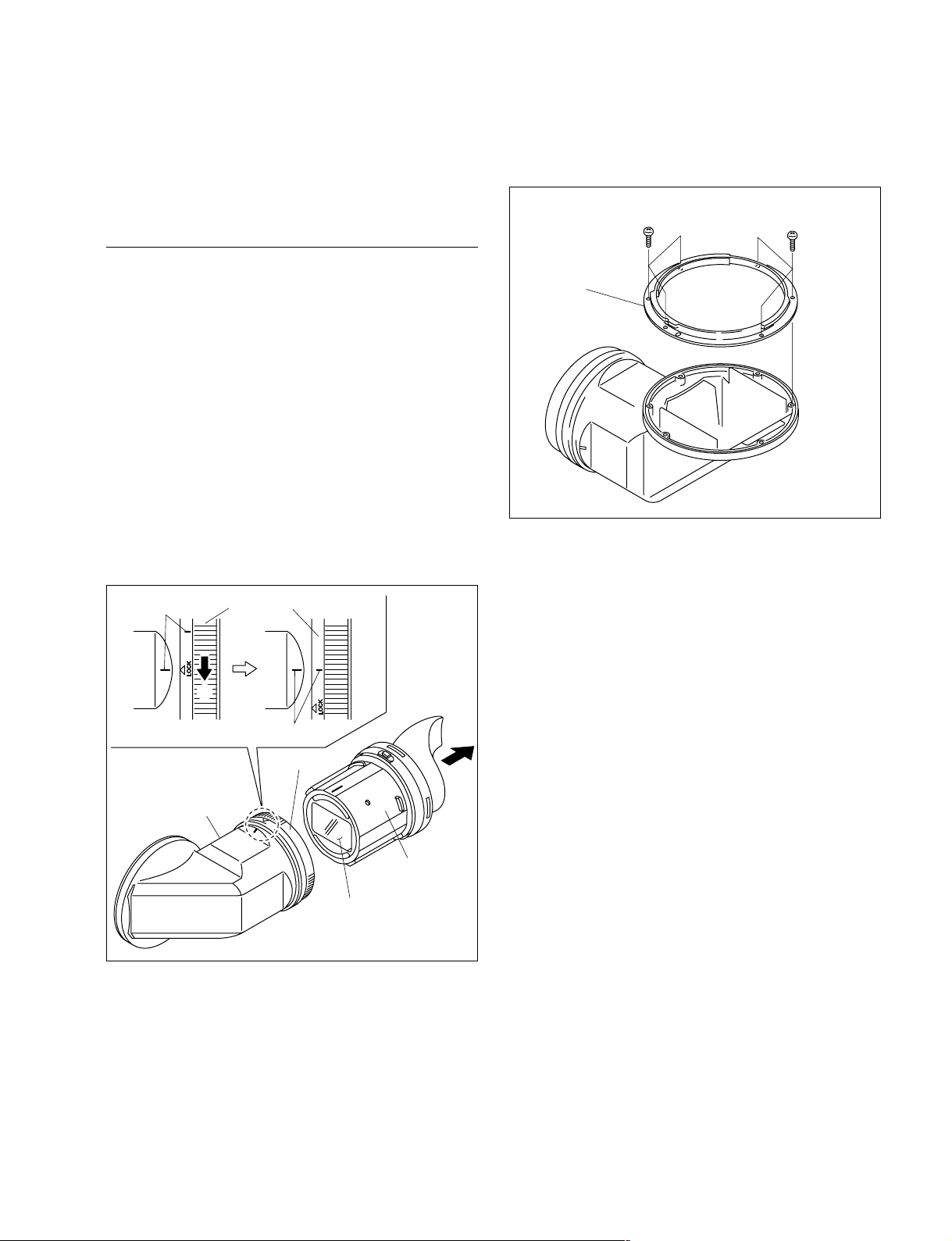

3. Remove the six screws (tapping screw M2 x 5) and

remove the bayonet ring (TUBE) from the viewfinder

barrel.

Tapping screws

M2 x 5

Tapping screws

M2 x 5

Replacing the Anti-Glare Sheet (Ring)

Required part

Anti-glare sheet (Ring) 1 piece : 3-789-426-xx

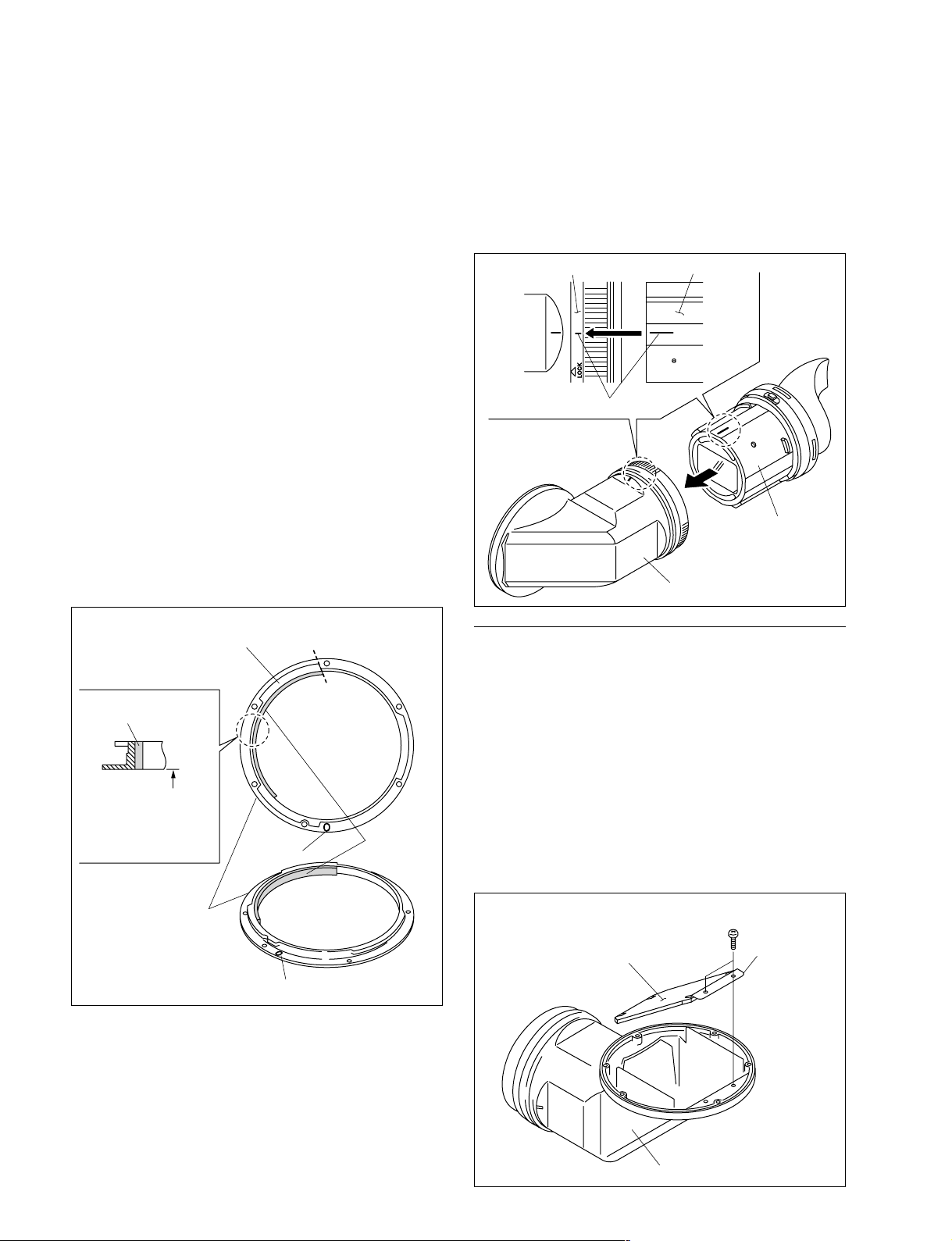

1. Push the RELEASE knob to release the lock and

remove the viewfinder barrel. (Refer to Section 1-7-2,

step 1.)

2. Rotate the fixed ring fully in the direction of the arrow

A and align the key marks (red lines) of the fixed ring

with that of the viewfinder barrel. Then remove the

viewfinder lens unit.

n

Be extremely careful not to give any scar on the

polarizing filter surface of the viewfinder lens unit

during the removal and installation procedures.

Red lines

Fixed rings

A

Bayonet ring

(TUBE)

Viewfinder barrel

Red lines

Fixed ring

Viewfinder

lens unit

Polarizing filter surface

HDVF-C30W

1-9 (E)

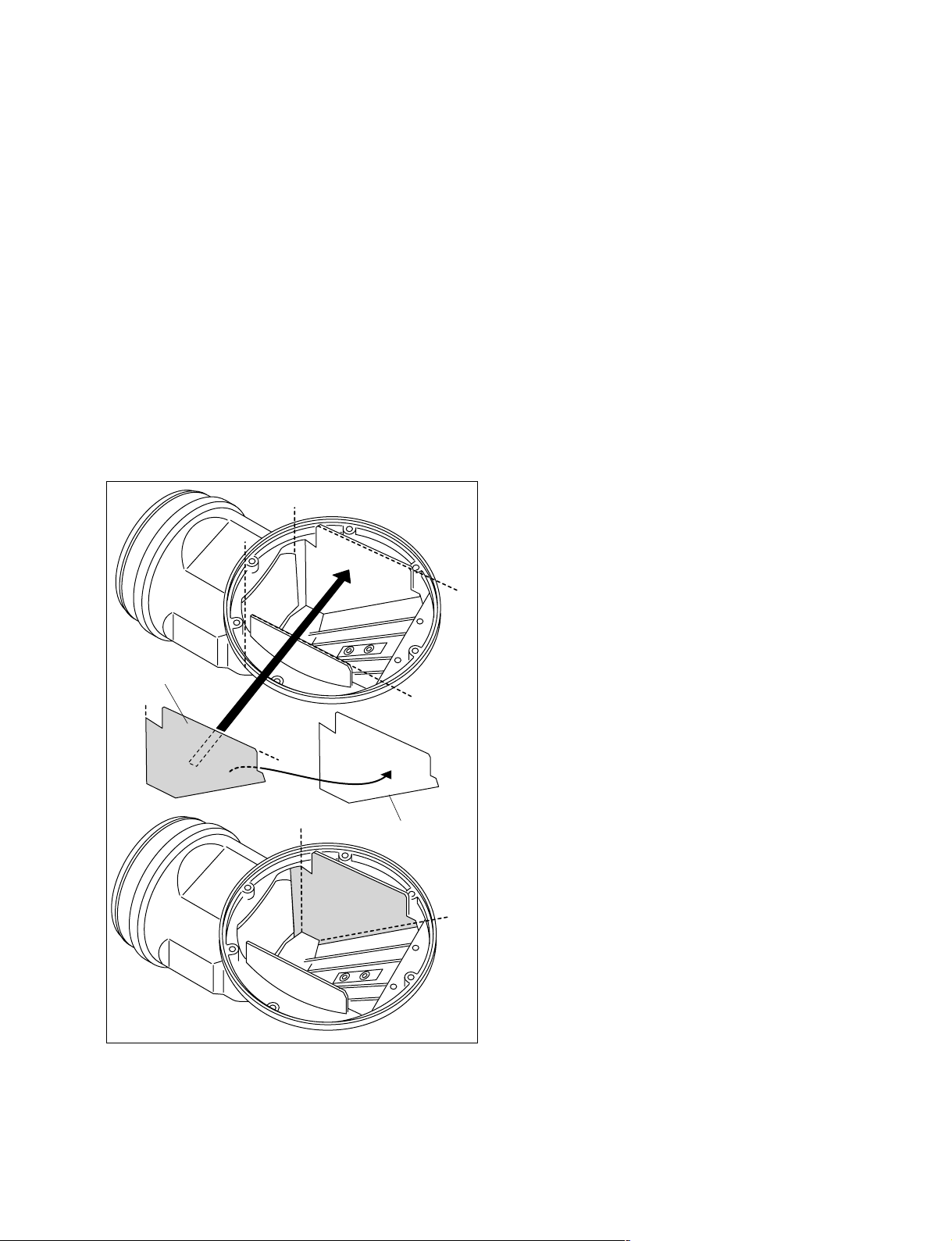

4. Peel off the anti-glare sheet (ring) from the bayonet

ring (TUBE) and wipe the attaching surface with

alcohol.

5. Place the bayonet ring (TUBE) on a flat work bench

with its viewfinder barrel attaching surface facing

downward.

6. Peel off the protection sheet of the new anti-glare sheet

(ring). Align the shorter end-surface of the new antiglare sheet with the flange end surface (side “a”) of the

bayonet ring (TUBE). Attach the new anti-glare sheet

(ring) to the bayonet ring (TUBE) by pressing downward.

Precaution for attaching the anti-glare sheet

(ring)

. Attach the anti-glare sheet (ring) with care so that

the anti-glare sheet (ring) should not float or any

wrinkle should not be generated.

. Attach the anti-glare sheet (ring) so that it should not

protrude exceeding the circumference to which the

viewfinder barrel of the bayonet ring (TUBE) is

going to be installed. (If it protrudes exceeding the

circumference, the anti-glare sheet (ring) becomes

visible on the mirror inside the viewfinder barrel.)

7. Install the removed parts by reversing the steps 1 to 3

of removal.

Precaution for installation

Align the alignment mark (red) of the viewfinder lens

unit with that of the alignment mark (red) of the fixed

ring when installing the viewfinder lens unit, and

insert the viewfinder lens unit.

Fixed ring

Red lines

Viewfinder lens unit

Viewfinder

lens unit

Viewfinder barrel

Anti-glare sheet

(ring)

It should not protrude

exceeding the bottom

end.

Side view

Bayonet rings

(TUBE)

Flange

Side “a”

Slot

Slot

Top view

Anti-glare

sheet (ring)

Replacing the Anti-Glare Sheet (Upper) and (Lower)

Required parts

. Anti-glare sheet (Upper) 1 piece : 3-789-424-xx

. Anti-glare sheet (Lower) 1 piece : 3-789-425-xx

1. Execute steps 1 through 3 of the anti-glare sheet (ring)

replacement procedure.

2. Remove the two screws (tapping screw M2 x 5) and

remove the mirror assembly from the viewfinder barrel.

n

Be extremely careful not to give any scar or stain on

the mirror surface during the removal and installation

procedures.

Tapping screws

M2 x 5

Mirror surface

Mirror

assembly

1-10 (E)

Viewfinder barrel

HDVF-C30W

3. Peel off the anti-glare sheet (Upper) and (Lower) from

the viewfinder barrel.

4. Peel off the protection sheet of the new anti-glare sheet

(Upper). Align the new anti-glare sheet with the sides

“a” and “b” of the viewfinder barrel. Attach the new

anti-glare sheet (Upper) to the viewfinder barrel.

Precaution for attaching the anti-glare sheet

(Upper)

. Fold the sides “e” and “f” of the sheet so that they fit

to the shape of the barrel and then attach them.

. Attach the anti-glare sheet (Upper) including the

sides “e” and “f” with care so that the anti-glare

sheet (Upper) should not float or should not create

any wrinkle.

5. Similarly, align the anti-glare sheet (Lower) with the

sides “c” and “f” and attach it to the viewfinder barrel.

a

c

1-8. Setup after Replacement of the

Main Parts and Board

1-8-1. When the LCD Panel is Replaced

Return the settings of the switches S1 (C-2) and S2 (B-2)

on the PR-267 board to the default setting when shipped

from the factory.

S1-6 to S1-8 : OFF (Preset the chromaticity setting.)

S2-1 to S2-4 : All OFF

1-8-2. When the PR-267 Board is Replaced

Set the switches S1 (C2) and S2 (B-2) settings to the

original setting of the board.

Anti-glare sheet

(Upper)

a

b

d

b

e

Protection sheet

f

6. Install the removed parts by reversing the steps 1 and 2

of removal.

HDVF-C30W

1-11 (E)

1-9. Fixtures and Measuring Instruments

1-9-1. List of Fixtures and Measuring

Instruments

Name of the fixture/ Sony part Application

measuring instrument

EX-909 board A-8346-442-A Used to check the

RE-208 EX unit A-8346-433-A Used to check the

Connecting cable 1-827-086-21 . Used to check the

Pattern box PTB-500 J-6029-140-B Used to adjust

PLD download tool J-7120-140-A Used to rewrite the

Luminance meter

* : Use of the Minolta Model LS-100 Luminance Meter is recommended.

number

PR-267 board

RE-208 board

. Used to rewrite the

brightness

PLD data

*

_ Used to adjust the

brightness

PR-267/RE-208

board

PLD data

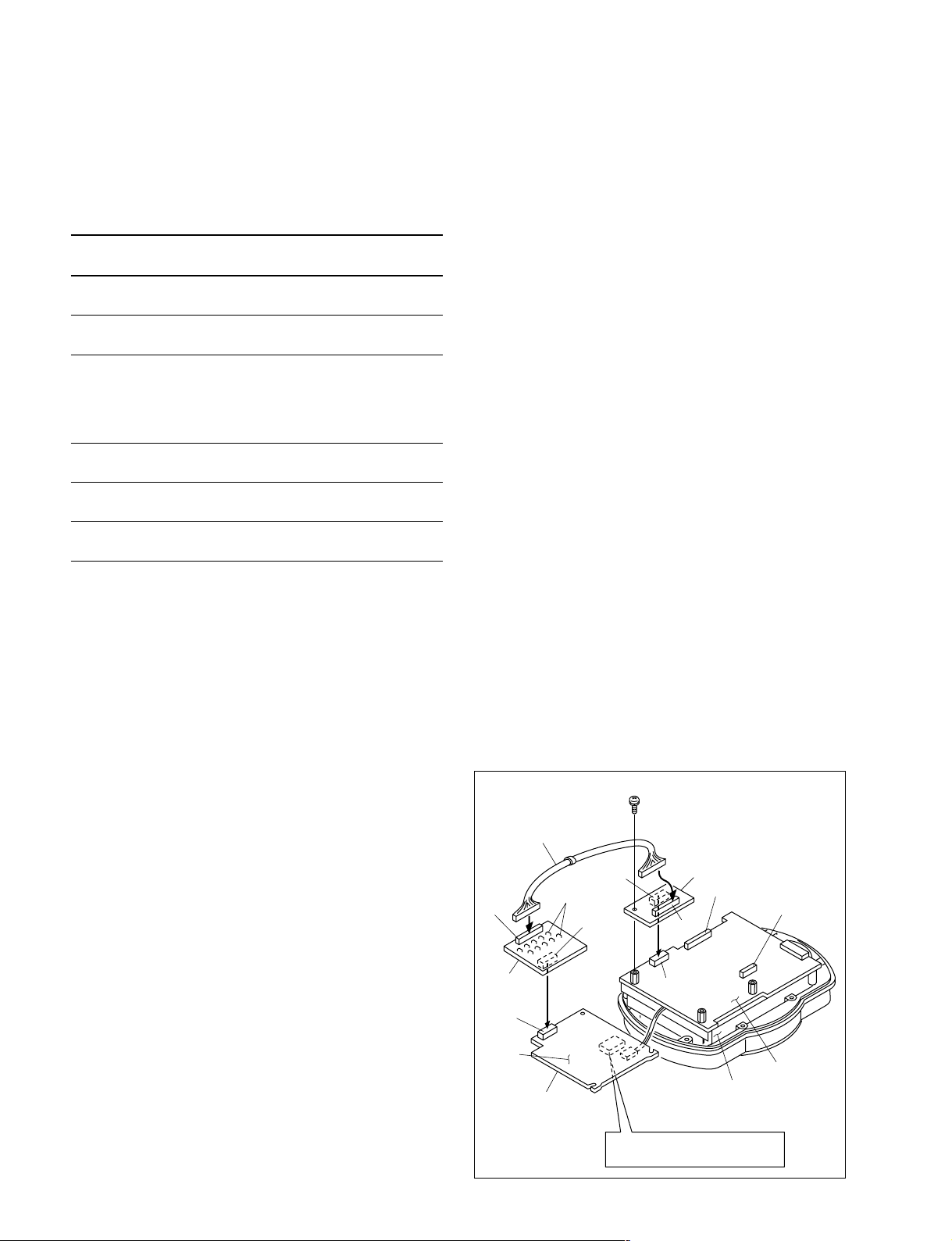

1-9-2. How to Extend the RE-208 Board

1.

Remove the viewfinder barrel.

(Refer to Section 1-7-2, setp 1.)

2. Perform steps 1 to 3 of “1-7-1. Replacing the LCD

Panel.”

3. Remove the RE-208 board.

(Refer to Section 1-7-2, step 6.)

n

Do not disconnect the harness from the connector CN2

on the RE-208 board.

4. Connect the EX-907 board to the CN2 connector on

the PR-267 board. Because this connector is easy to

be dropped off, secure the EX-907 board with the

screw that was removed in the step 3.

5. Connect the EX-908 board to the CN1 connector on

the RE-208 board.

6. Connect the connecting harness to the CN2 on the EX907 and the EX-908 board, respectively.

c

Side A of the RE-208 board has high-voltage area of

DC/AC inverter transformer.

While turning on the electricity, perform the checks

with extreme care so that you might not get the electric

shock. (Refer to Section 1-12.)

7. Connect the connecting cable to the CN1 connector on

the PR-267 board and the camera.

n

Attach the insulating tape to the GND terminal of the

connecting cable.

PS2 x 4

Connecting harness

EX-907

board

CN1

CN3

CN2

CN2

PR-267 board

LCD panel

CN2

EX-908

board

CN1

B side

CN1

TP terminals

CN1

RE-208

board

1-12 (E)

DC/AC inverter transformer:

Caution! High Voltage (A side)

HDVF-C30W

Loading...

Loading...