Page 1

HD ELECTRONIC VIEWFINDER

HDVF-20A

MAINTENANCE MANUAL

1st Edition

Serial No. 10001 and Higher

Page 2

! WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

X-RAY RADIATION WARNING

Be sure that parts replacement in the high voltage block

and adjustments made to the high voltage circuits are

carried out precisely in accordance with the procedures

given in this manual.

HDVF-20A

Page 3

Table of Contents

Manual Structure

Purpose of this manual ........................................................................................ 3 (E)

Relative manual ................................................................................................... 3 (E)

Contents ............................................................................................................... 4 (E)

1. Service Overview

1-1. Location of Printed Circuit Boards .......................................................1-1 (E)

1-2. Connector Input/Output Signals............................................................1-1 (E)

1-3. Replacing CRT......................................................................................1-2 (E)

1-4. Disconnecting/Connecting Flexible Card Wire ....................................1-3 (E)

1-5. Notes on Repair Parts............................................................................1-3 (E)

1-6. Circuit Description ................................................................................1-4 (E)

2. Electrical Alignment

2-1. General Information for Electrical Adjustment ....................................2-1 (E)

2-1-1. Notes on Adjustment............................................................2-1 (E)

2-1-2. Equipment/Fixtures Required ..............................................2-1 (E)

2-1-3. Connection ...........................................................................2-1 (E)

2-1-4. Extending Viewfinder ..........................................................2-2 (E)

2-1-5. Setting of the VF SCAN Mode ............................................2-2 (E)

2-1-6. Setting of the Format............................................................2-2 (E)

2-2. Power Supply Voltage Adjustment.......................................................2-3 (E)

2-3. Vertical Hold Adjustment .....................................................................2-3 (E)

2-4. Horizontal Hold Adjustment .................................................................2-3 (E)

2-5. Horizontal Duty Adjustment .................................................................2-4 (E)

2-6. Heater Voltage Adjustment...................................................................2-4 (E)

2-7. Focus Adjustment..................................................................................2-5 (E)

2-8. Picture Frame Adjustment.....................................................................2-6 (E)

2-9. Bright Extent Adjustment .....................................................................2-7 (E)

2-10. Horizontal Picture Positioning Adjustment ..........................................2-8 (E)

2-11. Peaking Level Adjustment ....................................................................2-9 (E)

2-12. Clamping Level Adjustment .................................................................2-9 (E)

2-13. 4:3 Picture Frame Adjustment ............................................................2-10 (E)

HDVF-20A

1 (E)

Page 4

3. Spare Parts

3-1. Exploded Views .......................................................................................... 3-1

3-2. Electrical Parts List ..................................................................................... 3-3

3-3. Supplied Accessories ..................................................................................3-9

3-4. Tools and Fixtures.......................................................................................3-9

4. Semiconductor Pin Assignments

5. Block Diagram

Overall Block ..............................................................................................5-2

6. Schematic Diagrams

VF-70 ..........................................................................................................6-1

DF-58 ..........................................................................................................6-4

VDA-41 .......................................................................................................6-5

VR-266 ........................................................................................................6-5

Frame Wiring ..............................................................................................6-6

7. Board Layouts

VF-70 ..........................................................................................................7-1

DF-58 ..........................................................................................................7-2

LP-105 .........................................................................................................7-2

VDA-41 .......................................................................................................7-2

VR-266 ........................................................................................................7-2

2 (E)

HDVF-20A

Page 5

Purpose of this manual

Relative manual

Manual Structure

This manual is the maintenance manual for HD Electronic Viewfinder HDVF-20A.

This manual describes the information items necessary when the unit is supplied and

installed, items that premise the service based on the components parts such as

alignment, schematic diagrams, board layouts and spare parts lists, assuming use of

system and service engineers.

Besides this maintenance manual the following manual is available for this unit.

..

. Operation Manual (Supplied with this unit)

..

This manual is necessary for application and operation of this unit.

..

. “Semiconductor Pin Assignments” CD-ROM (Available on request)

..

This “Semiconductor Pin Assignments” CD-ROM allows you to search for

semiconductors used in Communication System Solutions Network Company

equipment.

Semiconductors that cannot be searched for on this CD-ROM are listed in the

maintenace manual for the corresponding unit. The maintenance manual contains

a complete list of all semiconductors and their ID Nos., and thus should be used

together with the CD-ROM.

Part number: 9-968-546-XX

HDVF-20A

3 (E)

Page 6

Contents

The following are summaries of the each section for understanding the manual.

Section 1 Service Overview

Describes information about board locations, connector input/output signals,

cleaning and replacement of CRT.

Section 2 Elect`rical Alignment

Explains the general information for adjustment procedures and the electrical

adjustments of this unit.

Section 3 Spare Parts

Describes parts list, exploded views and supplied accessories used in the unit.

Section 4 Semiconductor Pin Assignments

Contains information on semiconductors used for the unit.

It includes a complete list of the semiconductors and their ID Nos. for retrieving

information on “Semiconductor Pin Assignments” CD-ROM, which is available

separately.

Please refer to this section together with the “Semiconductor Pin Assignments”

CD-ROM.

Information on the semiconductors not contained in the CD-ROM at the time of

issue of this manual, if any, is given in this section as well.

Section 5 Block Diagram

Describes overall block diagram of this unit.

Section 6 Schematic Diagrams

Describes schematic diagrams for every circuit board and frame wiring .

Section 7 Board Layouts

Describes board layouts for every circuit board.

4 (E)

HDVF-20A

Page 7

Section 1

Service Overview

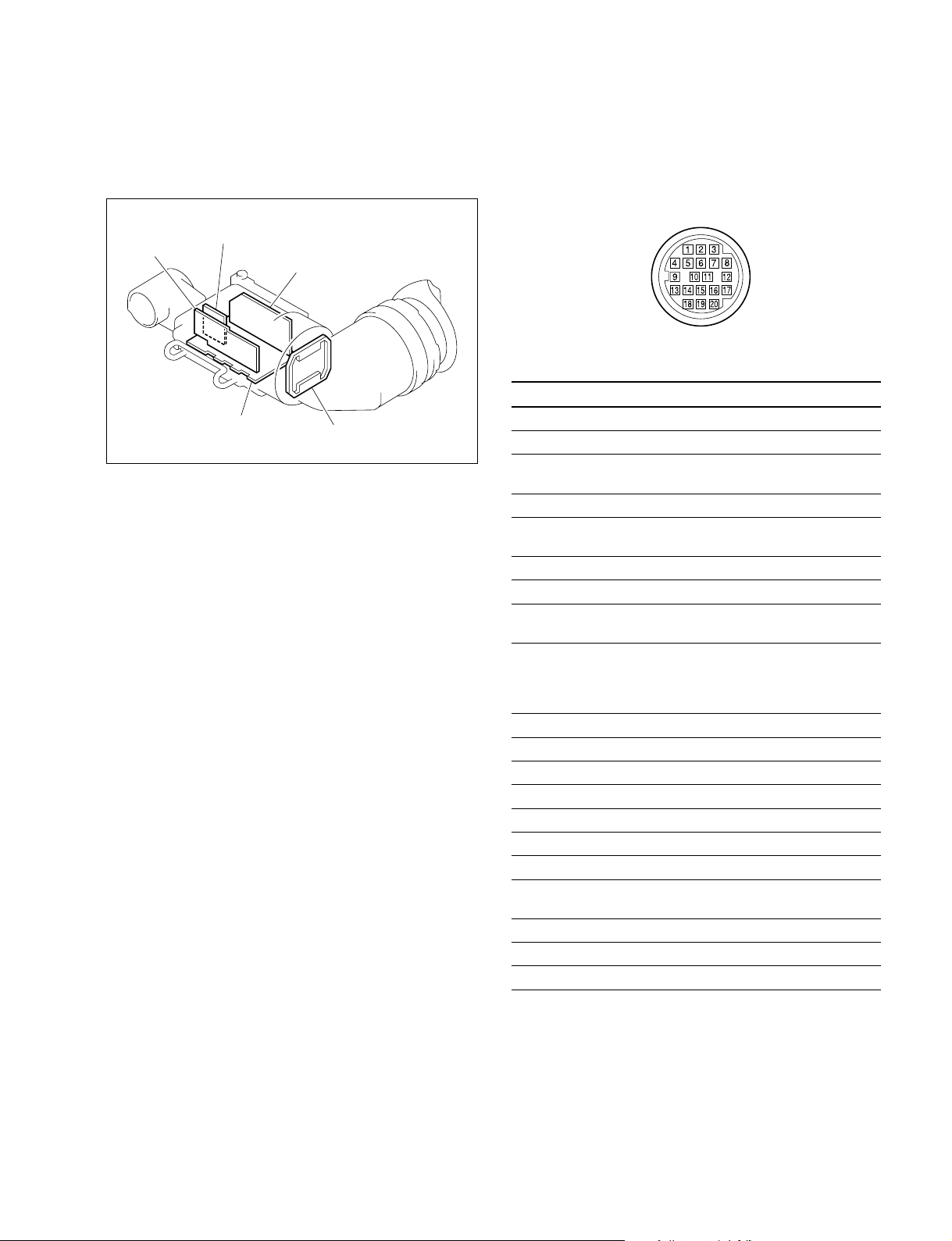

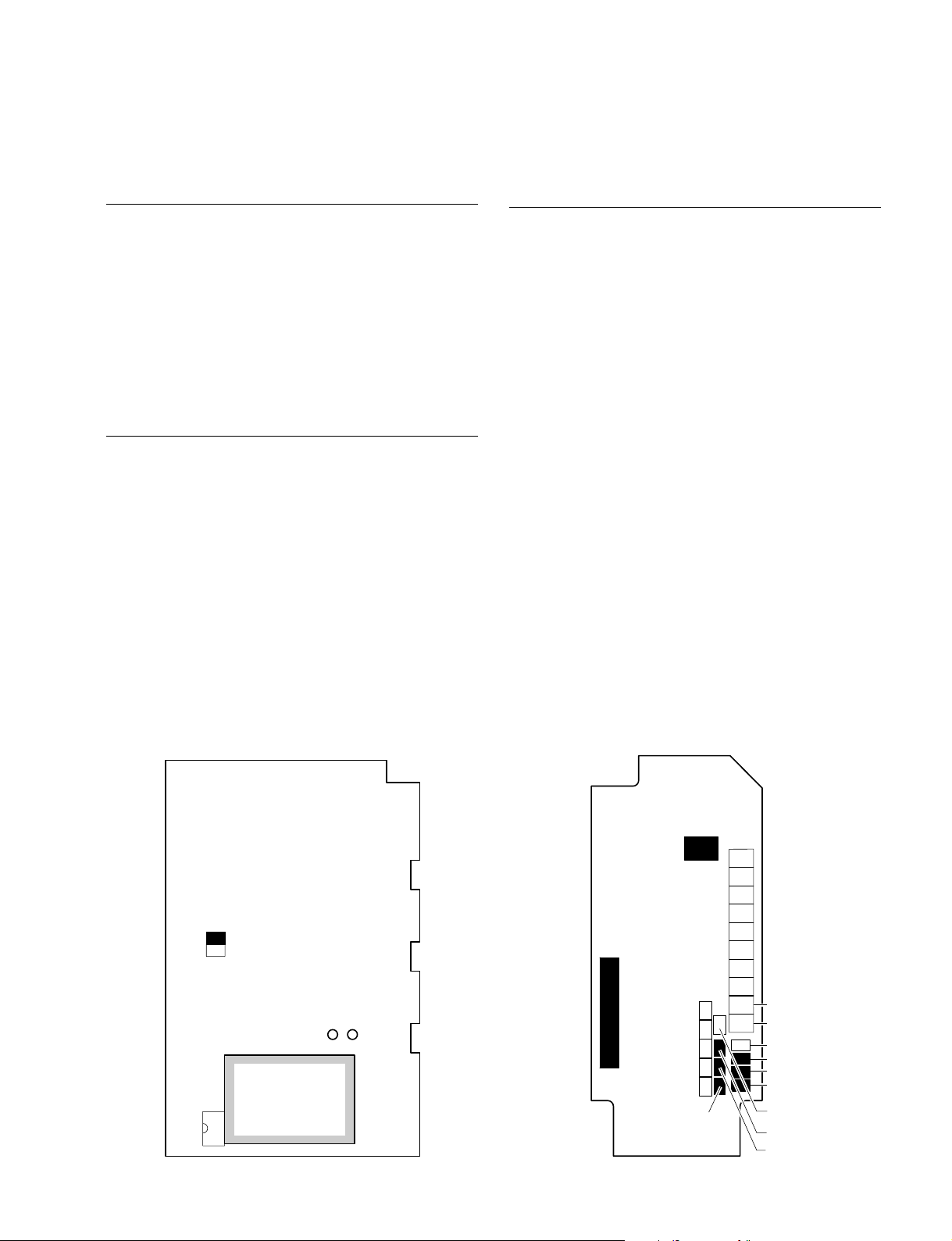

1-1. Location of Printed Circuit Boards 1-2. Connector Input/Output Signals

VF (20P MALE)

VR-266

VDA-41

VF-70

DF-58

LP-105

(EXTERNAL VIEW)

Pin No. Signal I/O Specifications

1 S-DATA IN/OUT TTL level

2NC

3 POWER IN ON : OPEN

OFF CTL OFF : GND

4 SCK IN TTL level

5 COLOR/BW OUT B/W : GND

COLOR : OPEN

6NC

7NC

8 G TALLY IN ON : 5V

OFF : GND

9 PEAKING OUT VF to CAM (Ro = 1 kZ)

CTL 0 V to 5 V

0 V : PEAKING OFF

5 V : PEAKING MAX

10 NC

11 NC

12 Y VIDEO IN 1.0 V p-p (Ro = 75 kZ)

13 VIDEO GND

14 NC

15 NC

16 NC

17 R TALLY IN ON : 5 V

OFF : GND

18 NC

19 UNREG GND

20 UNREG +10.5 V to 17 V

HDVF-20A

1-1 (E)

Page 8

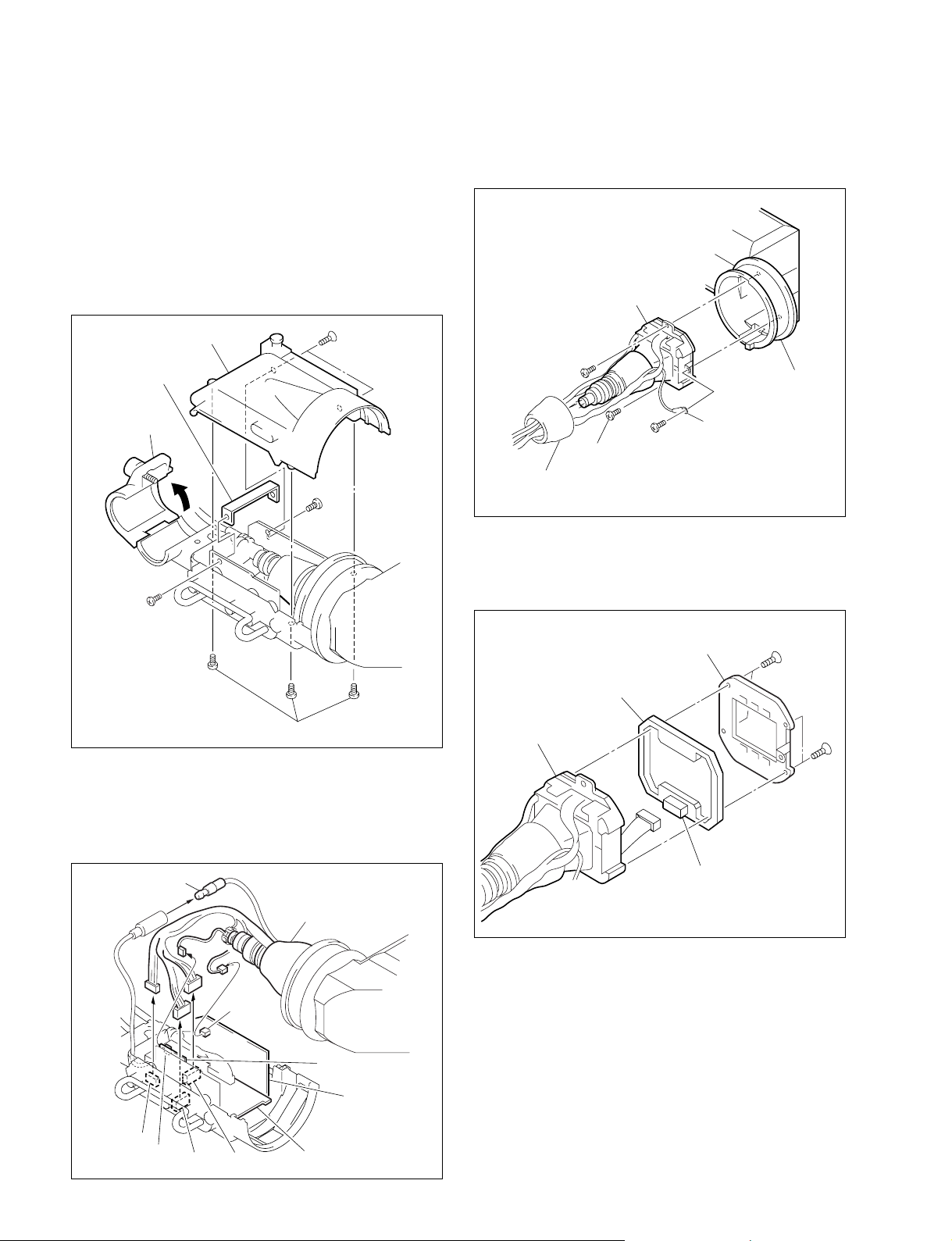

1-3. Replacing CRT

1-3. Replacing CRT

1. Loosen the screw of the MIC clamp and open the MIC

clamp.

2. Remove the two screws (K2.6 x 4).

3. Remove the three hexagonal socket bolts (2.6 x 6) and

remove the upper chassis.

4. Remove the two screws (P2 x 3.5) and the board

bracket.

Upper chassis

Board bracket

MIC clamp

P2 x 3.5

K2.6 x 4

P2 x 3.5

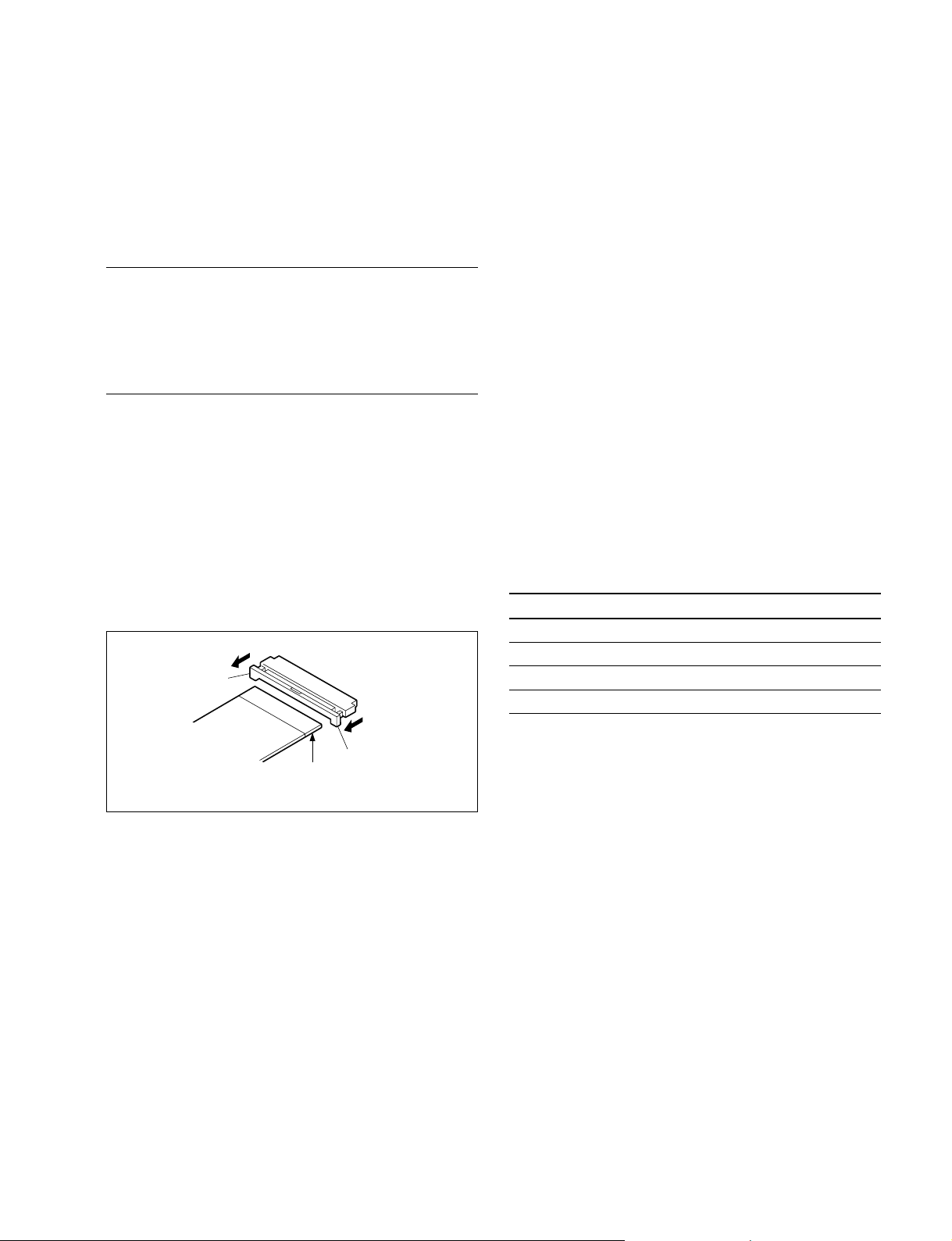

6. Remove the four screws and remove the CRT from the

VF tube assembly.

7. Remove the CRT tube from the CRT.

CRT

PTP2.6 x 8

VF tube

assembly

Lug

PTP2 x 6

PTP2.6 x 8

CRT tube

8. Remove the four screws and remove the microphone

spacer.

9. Disconnect the connector CN21 on the LP-105 board.

Microphone

spacer

K2 x 5

Hexagonal socket bolts 2.6

x 6

5. Disconnect the five connectors CN301, CN501 and

CN502 on the VF-70 board, CN102 on the DF-58

board and CN263 on the VDA-41 board and the anode

cable.

Anode cable

CRT

CN102

VDA-41 board

DF-58 board

CN501

CN263

CN301

CN502

VF-70 board

LP-105 board

CRT

K2 x 5

CN21

10. Install a new CRT in the reverse procedures of

removal.

n

When installing the upper chassis, take care not to

catch the harness between upper and lower chassis.

1-2 (E)

HDVF-20A

Page 9

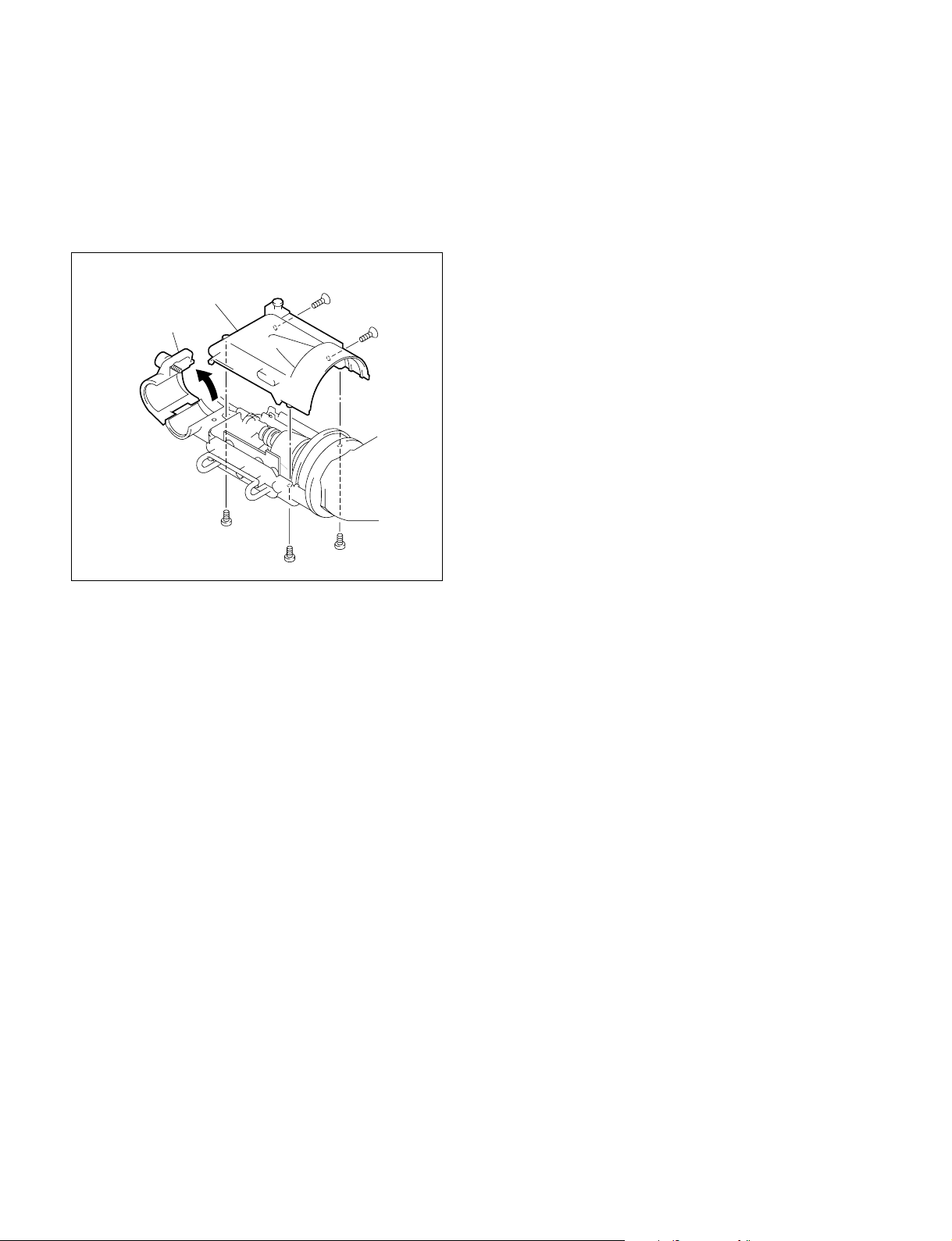

1-4. Disconnecting/Connecting Flexible Card Wire

1-5. Notes on Repair Parts

1-4. Disconnecting/Connecting Flexible

Card Wire

The flexible card wire is used between the VF-70 board

and VR-266 board. Take care not to break this flexible

card wire. This shorten the wire life.

Disconnecting

1. Turn off the power.

2. Slide portions A in the direction of the arrow to unlock

and pull out the flexible card wire.

Connecting

m

. Be careful not to insert the flexible card wire obliquely.

. Check that the conductive surface of the flexible card

wire is not soiled with dust.

1. Slide portions A in the direction of the arrow and

insert the flexible card wire as far as it will go with the

conductive surface down.

2. Slide portions A in the reverse direction to lock.

A

1-5. Notes on Repair Parts

1. Safety Related Components Warning

w

Components marked ! are critical to safe operation.

Therefore, specified parts should be used in the case of

replacement.

2. Standardization of Parts

Some repair parts supplied by Sony differ from those

used for the unit. These are because of parts commonality and improvement.

Parts list has the present standardized repair parts.

3. Stock of Parts

Parts marked with “o” at SP (Supply Code) column of

the spare parts list may not be stocked. Therefore, the

delivery date will be delayed.

4. Units Representation

The following represented units are changed or

omitted in writing.

Units Representation

Capacitance uFuF

Inductance uHuH

Resistance Z Abbreviation

Temperature dC XXX-DEG-C

HDVF-20A

A

Conductive

surface

1-3 (E)

Page 10

1-6. Circuit Description

1-6. Circuit Description

VF-70 board

The VF-70 board consists of a power supply block, H

deflection drive circuit and serial interface circuit for

various controls.

A switching regulator consists of IC401 and Q401 to

Q404, where +9.5 V and about +7.5 V for H driving are

generated from UNREG (10.5 to 17 V) input at pin B10 of

CN001. And H size adjustment is performed by controlling the reference dc voltage for IC401 with RV110 (H

SIZE) on the DF-58 board.

The H deflection circuit IC501 and Q501 are also used to

drive a flyback transformer. The flyback transformer

outputs HV (6 kV), G2 (500 V), 60 V and heater pulse

voltage. The heater pulse voltage is smoothed by C513,

and is adjusted in voltage by RV501 (HEATER). The

resultant is applied to the heater through IC503.

The voltage for feedback circuit is output at pin 1 of the

flyback transformer and is sent to a feedback circuit

consisting of IC501, IC502, Q502 and Q503 to stabilize a

high-voltage portion. When the voltage goes higher than

the reference, the power is turned off as pin 8 of IC502

goes high and a protection circuit operates.

IC301 and IC302 are serial interface ICs, which are used to

control indicators and to grab switch data and so on.

IC304 is a timer IC. It is used to set the time period during

which the zebra pattern is displayed in MOMENTARY

mode, and during which the brightness increases momentarily as the internal tally signal is turned on.

VR-266 board

The VR-266 board consists of a video amplifier circuit and

bright control circuit.

The video signal input at pin 3 of CN201 is adjusted in

level with RV201 (CONTRAST), and is sent through the

peaking circuit to the VDA-41 board.

DC voltage is adjusted with RV205 and RV206 (BRIGHT)

and is sent to the VF-70 board as a bright control voltage.

VDA-41 board

The video signal from the VR-266 board is shifted by a

constant voltage at D261 zener diode. And then the video

signal is amplified by Q261 and Q262, and is output to G1

through a drive circuit of Q263 to Q266. Q267 clamps the

blanking portion to stabilize the black level.

DF-58 board

The DF-58 board provides an external sync circuit, V

deflection drive circuit and blanking pulse generation

circuit.

IC104 is a sync separator, which separates sync signals

from the video signal input to the DF-58 board and outputs

the HD signal from pin 7 and VD signal from pin 3. The

HD signal is compared in phase with a flyback pulse at

IC101 and then enters AFC circuit.

The VD signal is input to pin 21 of IC101, and is then sent

to the V deflection drive circuit consisting of Q104 to

Q107 as a trigger pulse.

IC106 generates a video clamp pulse, and IC108 to IC115

generate a beam blanking pulse. These pulses are output to

the VF-70 board.

1-4 (E)

HDVF-20A

Page 11

Section 2

Electrical Alignment

2-1. General Information for Electrical

Adjustment

2-1-1. Notes on Adjustment

w

There is a danger of an electric shock around the CRT due

to its high voltage. Great care should be taken in servicing.

Never touch a live CRT by bare hands.

Before performing adjustment, read throughly the following comments.

. Calibration for all measuring equipment should be

completed.

. Alignment of peripheral equipment such as camera

should be completed.

2-1-2. Equipment/Fixtures Required

Equipment

. HDVS camera system

HDC-950 or HDW-F900

. AC adaptor

AC-550/550CE or equivalent

. Oscilloscope

(Input capacitance of probe : 12 pF or below)

Tektronix 2465B or equivalent

. HDTV waveform monitor

Tektronix 1735HD/1730HD or equivalent

. HDTV B/W monitor

. Digital voltmeter

. Frequency counter

Fixtures

Fixtures Sony P/N

Pattern box PTB-500 J-6029-140-B

Resolution chart (16:9) J-6395-320-A

VF extension harness J-6395-050-A

2-1-3. Connection

VIEWFINDER

HDVF-20A

ENG/EFP LENS

PATTERN

BOX

COLOR VIDEO

CAMERA

HDC-950

or HDW-F900

(Figure : HDC-950)

TEST

OUT

75 Z

AC ADAPTOR

AC-550

A-ch

WAVEFORM

MONITOR

HDVF-20A

2-1 (E)

Page 12

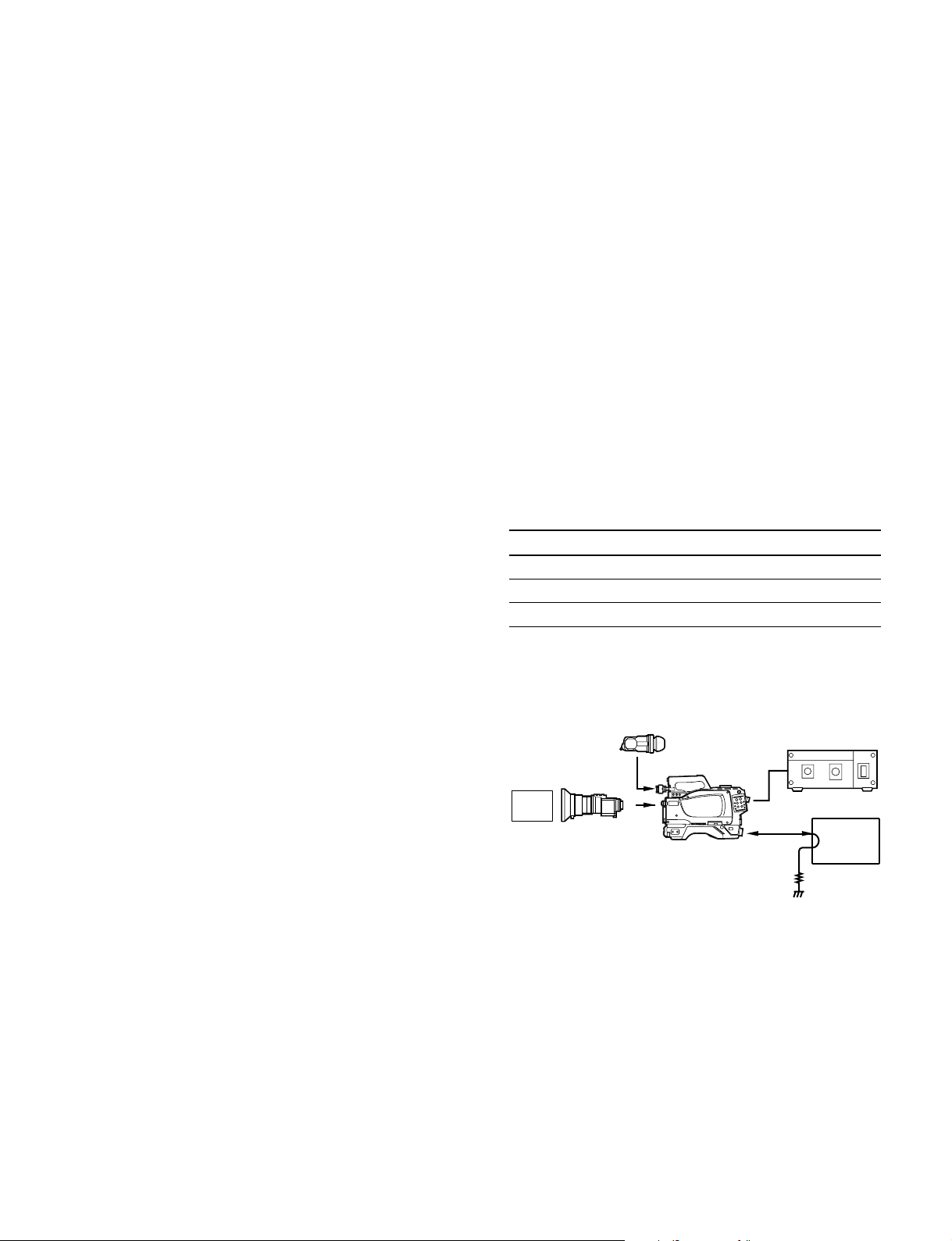

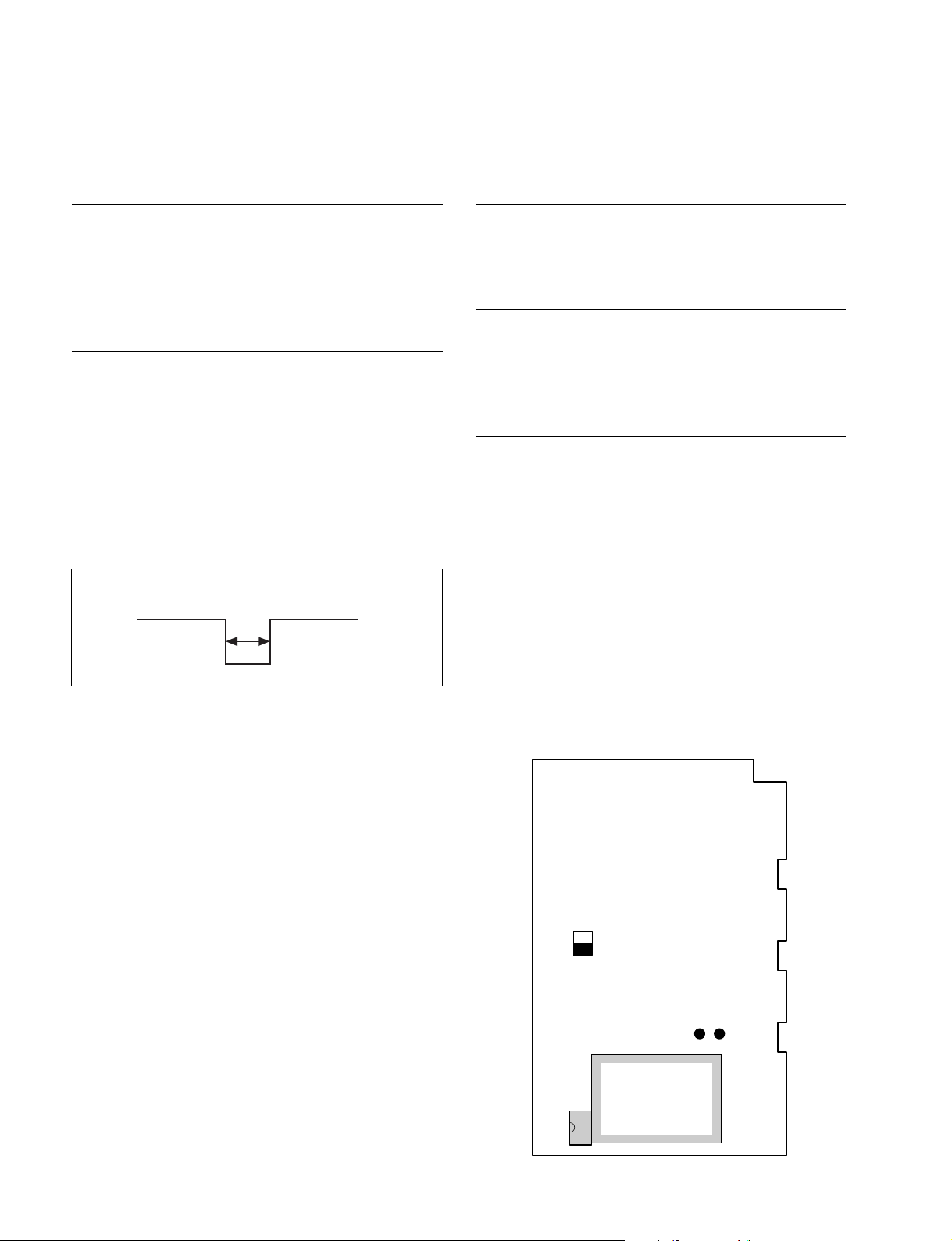

2-1-4. Extending Viewfinder

2-1-5. Setting of the VF SCAN Mode

2-1-6. Setting of the Format

2-1-4. Extending Viewfinder

1. Turn off the power before performing adjustment.

2. Remove the viewfinder from the camera.

3. Open the MIC clamp and remove the upper chassis.

(Refer to Section 1-3 “Replacing CRT” for details.)

Upper chassis

MIC clamp

2-1-5. Setting of the VF SCAN Mode

1. Before adjustment, set the VF SCAN mode to 16:9

following to the camera’s setup menu. (Refer to HDC950 or HDW-F900 Operation Manual for details.)

MENU : Operation

PAGE : VF Setup

ITEM : VF Scan → 16:9

2. Whenever you press DISPLAY/SCAN switch on the

viewfinder to SCAN, the picture frame mode toggles

between 16:9 and 4:3. Perform the adjustment in 16:9

mode unless otherwise specified.

2-1-6. Setting of the Format

There are some items which need adjusting by switching

among the each formats of 60i, 50i and 48i.

As for the switching method of the format, refer to the

HDC-950 or HDW-F900 Operation manual. Adjust in the

60i mode unless any specification exists.

4. Connect the viewfinder to the camera via the VF

extension harness.

5. Turn on the power.

2-2 (E)

HDVF-20A

Page 13

DF-58 - component side -

RV120

RV119

RV107

RV106

RV112

RV108

RV101

RV121

RV114

RV113

RV123

CN101

CN102

RV102

RV111

RV116

RV122

RV110

RV109

RV105

RV118

RV117

RV104

RV103

RV115

2-2. Power Supply Voltage Adjustment

2-3. Vertical Hold Adjustment

2-4. Holizontal Hold Adjustment

2-2. Power Supply Voltage Adjustment

Equipment : Digital voltmeter

Adjustment Procedure

Test point : CN101-1pin/DF-58

Adjustment point : 1RV401/VF-70

Specification : 9.50 ±0.05 V dc

2-3. Vertical Hold Adjustment

Equipment : Frequency counter

Adjustment Procedure

Switch the format to 60i, 50i and 48i by the camera and

adjust the following RVs corresponding to each format.

Test point : CN102-1pin/DF-58

GND : Shielding case of FBT501/VF-70

Adjustment point : 1RV105/DF-58 (60i)

1RV117/DF-58 (50i)

1RV118/DF-58 (48i)

Specification : 55.0 ±0.5 Hz

2-4. Horizontal Hold Adjustment

Equipment : Frequency counter

Adjustment Procedure

Switch the format to 60i, 50i and 48i by the camera and

adjust the following RVs corresponding to each format.

Test point : CN101-7pin/DF-58

GND : Shielding case of FBT501/VF-70

Adjustment point : 1RV103/DF-58 (60i)

1RV115/DF-58 (50i)

1RV116/DF-58 (48i)

Specification : 33.75 ±0.25 kHz

HDVF-20A

IC501

RV401

RV501

*Soldering side

FBT501

*TP22

VF-70 - component side -

*TP23

2-3 (E)

Page 14

2-5. Horizontal Duty Adjustment

2-6. Heater Voltage Adjustment

2-5. Horizontal Duty Adjustment

Equipment : Oscilloscope

Preparations

. Iris of the lens : CLOSE

. BRIGHT control : Fully counterclockwise 3

. CONTRAST control : Fully counterclockwise 3

. PEAKING control : Fully counterclockwise 3

Adjustment Procedure

Test point : IC501-7pin/VF-70

GND : Shielding case of FBT501/VF-70

Adjustment point : 1RV104/DF-58

Specification : T = 2.9 ±0.1 us

Turn 1RV104 fully counterclockwise, and slowly turn it

clockwise until the specification

is satisfied.

T

2-6. Heater Voltage Adjustment

Equipment : Digital voltmeter

Note

During adjustment, do not set heater voltage to 700 mV or

over.

Preparations

. BRIGHT control : Mechanical center

. CONTRAST control : Mechanical center

. PEAKING control : Mechanical center

Adjustment Procedure

Test point : TP22/VF-70

GND : TP23/VF-70

Adjustment point : 1RV501/VF-70

Specification : 650 ±30 mV dc

Turn 1RV501 fully clockwise, and

slowly turn it counterclockwise

until the specification is satisfied.

(Do not set heater voltage to

700 mV or over.)

n

If T is set to 2.5 us or below, high-voltage protection

circuit may become activated. In this case, power off once

and turn 1RV104/DF-58 fully counterclockwise. After

that power on again to perform the adjustment.

IC501

RV401

RV501

*Soldering side

FBT501

*TP22

VF-70 - component side -

*TP23

2-4 (E)

HDVF-20A

Page 15

DF-58 - component side -

RV120

RV119

RV107

RV106

RV112

RV108

RV101

RV121

RV114

RV113

RV123

CN101

CN102

RV102

RV111

RV116

RV122

RV110

RV109

RV105

RV118

RV117

RV104

RV103

RV115

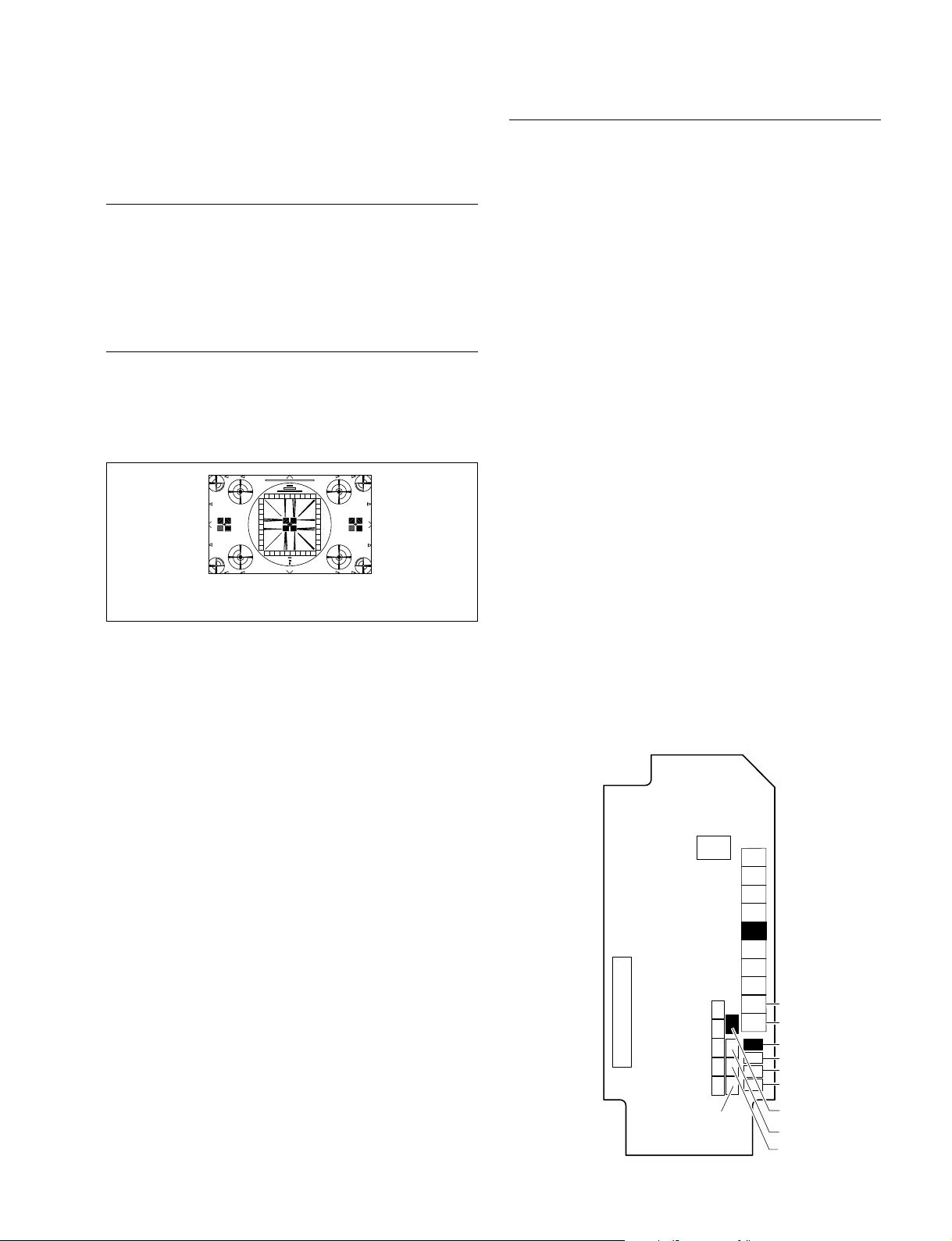

2-7. Focus Adjustment

2-7. Focus Adjustment

Subject : Resolution chart

Note

This focus adjustment, “2-8. Picture Frame Adjustment”

and “2-9. Bright Extent Adjustment” affect each other.

Therefore, repeat these adjustments until all specifications

are satisfied.

Preparations

. Shoot the resolution chart so that the chart frame is

aligned with the underscanned monitor frame with the

zoom control.

Adjustment Procedures

1. Adjustment point : 1RV109/DF-58

Specification : Turn1RV109 fully counter-

clockwise, and slowly turn it

clockwise until the optimum focus

is achieved.

2. After the adjustment, confirm that the focus can be

achieved at all settings of BRIGHT, CONTRAST and

PEAKING controls.

m

. If the picture frame adjustment is out of specifications,

especially in horizontal size, the focus may not be achieved.

In this case, turn 1RV112/DF-58 clockwise a little

(referring to Section 2-8), and perform the focus adjustment.

. The application of too-high voltage may make the high-

voltage protection circuit activated. In this case, power

off once and turn 1RV109/DF-58 fully counterclockwise.

After that power on again to perform the adjustment.

. Adjust the iris of the lens so that the output level (Y

level) at TEST OUT connector on the camera is 500 ±50

mV.

. BRIGHT control : Mechanical center

. CONTRAST control : Mechanical center

. PEAKING control : Fully counterclockwise 3

HDVF-20A

(Viewfinder screen)

2-5 (E)

Page 16

2-8. Picture Frame Adjustment

2-8. Picture Frame Adjustment

Subject : Resolution chart

Note

This picture frame adjustment, “2-7. Focus Adjustment”

and “2-9. Bright Extent Adjustment” affect each other.

Therefore, repeat these adjustments until all specifications

are satisfied.

Preparations

. Shoot the resolution chart so that the chart frame is

aligned with the underscanned monitor frame with the

zoom control.

2. Adjustment points : 1RV112/DF-58

1RV106/DF-58

1Centering magnet

Specification : Adjust 1RV112 and 1RV106

so that the chart frame position

within the CRT frame is as shown

below.Turn the centering magnet

only when centering the chart

About 3 mm

About 1 mm

CRT frame

Chart frame

*1

: Measure on the CRT surface

.

*1

*1

(Viewfinder screen)

.

Adjust the iris of the lens so that the output level (Y level)

at TEST OUT connector on the camera is 500 ±50 mV.

. BRIGHT control : Mechanical center

. CONTRAST control :Mechanical center

. PEAKING control : Fully counterclockwise 3

Adjustment Procedures

1. Vertical Linearity Adjustment

Adjustment point : 1RV108/DF-58

Specification :

Minimize the distortion of the four

circles at the corners of the

resolution chart.

3. Press the portion A to the lower chassis as shown

below to recreate the same situation as when the upper

chassis is installed to the viewfinder, and confirm that

the picture is positioned in the center of the viewfinder.

Centerring magnet

A

2-6 (E)

HDVF-20A

Page 17

DF-58 - component side -

RV120

RV119

RV107

RV106

RV112

RV108

RV101

RV121

RV114

RV113

RV123

CN101

CN102

RV102

RV111

RV116

RV122

RV110

RV109

RV105

RV118

RV117

RV104

RV103

RV115

2-9. Bright Extent Adjustment

Subject : Resolution chart

Note

This bright extent adjustment, “2-7. Focus Adjustment”

and “2-8. Picture Frame Adjustment” affect each other.

Therefore, repeat these adjustments until all specifications

are satisfied.

Preparations

. Shoot the resolution chart so that the chart frame is

aligned with the underscanned monitor frame with the

zoom control.

2-9. Bright Extent Adjustment

.

Adjust the iris of the lens so that the output level (Y level)

at TEST OUT connector on the camera is 500 ±50 mV.

. BRIGHT control : Fully counterclockwise 3

. CONTRAST control : Fully counterclockwise 3

. PEAKING control : Fully counterclockwise 3

Adjustment Procedure

Switch the format to 60i, 50i and 48i by the camera and

adjust the following RVs corresponding to each format.

Adjustment point : 1RV205/VR-266 (60i)

Specification : The central circle of the resolution

HDVF-20A

(Viewfinder screen)

1RV207/VR-266 (50i)

1RV208/VR-266 (48i)

chart shall be barely discriminated.

RV-204

RV-201

RV-206

RV-203

RV-202

RV-207

RV-205

RV-208

VR-266 - component side -

2-7 (E)

Page 18

DF-58 - component side -

RV120

RV119

RV107

RV106

RV112

RV108

RV101

RV121

RV114

RV113

RV123

CN101

CN102

RV102

RV111

RV116

RV122

RV110

RV109

RV105

RV118

RV117

RV104

RV103

RV115

2-10. Horizontal Picture Positioning Adjustment

2-10. Horizontal Picture Positioning

Adjustment

Subject : Resolution chart

Preparations

. Shoot the resolution chart so that the chart frame is

aligned with the underscanned monitor frame with the

zoom control.

(Viewfinder screen)

.

Adjust the iris of the lens so that the output level (Y level)

at TEST OUT connector on the camera is 500 ±50 mV.

. BRIGHT control : Fully clockwise 2

. CONTRAST control :Fully counterclockwise 3

. PEAKING control : Fully counterclockwise 3

Adjustment Procedure

Switch the format to 60i, 50i and 48i by the camera and

adjust the following RVs corresponding to each format.

Adjustment point : 1RV101/DF-58 (60i)

Specification : Adjust the position of the resolu-

A B

2-8 (E)

1RV121/DF-58 (50i)

1RV122/DF-58 (48i)

tion chart for A = B

Underscanned monitor frame (raster)

Chart frame

RV-204

RV-201

RV-206

RV-203

RV-202

RV-207

RV-205

RV-208

VR-266 - component side -

HDVF-20A

Page 19

2-11. Peaking Level Adjustment

2-12. Clamping Level Adjustment

2-11. Peaking Level Adjustment

Equipment : Oscilloscope

Subject : Resolution chart

Preparations

. Shoot the resolution chart so that the chart frame is

aligned with the underscanned monitor frame with the

zoom control.

(Viewfinder screen)

.

Adjust the iris of the lens so that the output level (Y level)

at TEST OUT connector on the camera is 500 ±50 mV.

. BRIGHT control : Mechanical center

. CONTRAST control : Mechanical center

. PEAKING control : Fully counterclockwise 3

2-12. Clamping Level Adjustment

Equipment : Oscilloscope (DC mode)

(Input capacitance of probe : 12 pF or below)

Subject : Resolution chart

Preparations

. Shoot the resolution chart so that the chart frame is

aligned with the underscanned monitor frame with the

zoom control.

(Viewfinder screen)

.

Adjust the iris of the lens so that the output level (Y level)

at TEST OUT connector on the camera is 500 ±50 mV.

. BRIGHT control : Mechanical center

. CONTRAST control :Mechanical center

. PEAKING contro : Fully counterclockwise 3

Adjustment Procedure

Test point : TP261/VDA-41

GND : Viewfinder cabinet

Adjustment point : 1RV203/VR-266

Specification : The waveform level A shall not

change at all settings of PEAKING control.

A

Adjustment Procedure

Test point : TP261/VDA-41

GND : Grounding plate/VR-266

Adjustment point : 1RV202/VR-266

Specifications : Adjust the overshoot A for 9 ±1 V.

Check to see that blanking B is

from 5 V to 20 V.

A

Pedestal Level

B

TP261

HDVF-20A

VDA-41 - soldering side -

2-9 (E)

Page 20

DF-58 - component side -

RV120

RV119

RV107

RV106

RV112

RV108

RV101

RV121

RV114

RV113

RV123

CN101

CN102

RV102

RV111

RV116

RV122

RV110

RV109

RV105

RV118

RV117

RV104

RV103

RV115

2-13. 4:3 Picture Frame Adjustment

2-13. 4:3 Picture Frame Adjustment

Subject : Full white pattern

Preparations

. Shoot the fully occupied white area in the underscanned

monitor frame with the zoom control.

.

Adjust the iris of the lens so that the output level (Y level)

at TEST OUT connector on the camera is 350 ±35 mV.

. BRIGHT control : Fully clockwise 2

. CONTRAST control :Mechanical center

. PEAKING control : Mechanical center

. Press the DISPLAY/ASPECT switch to ASPECT to

enter the 4:3 mode.

Adjustment Procedure

Adjustment points : 1RV102 (4:3 PHASE)/DF-58

1RV111 (4:3 SIZE)/DF-58

Specifications : Adjust the 4:3 picture frame for

A = 2 ±1 mm with 1RV102 and

1 RV111. (Adjust the gray area)

Setting after Adjustment

Press the DISPLAY/ASPECT switch to ASPECT to return

the 16:9 mode.

2-10 (E)

A AGray area

*1 Measure on the CRT surface

*1

HDVF-20A

Page 21

3-1. Exploded Views

Section 3

Spare Parts

13

19

30

17

21

26

6

20

10

B2 x 4

27

29

Precision

18

P2 x 3.5

1

B2 x 4

11

K2.6 x 5

24

24

16

4

BOLT, HEXAGON

SOCKET 2.6 x 6

8

9

Precision

2 12

P2 x 3.5

7

5

25

Precision

P2 x 3.5

14

3

15

BOLT, HEXAGON

23

BOLT, HEXAGON

SOCKET 2.6 x 6

No. Part No. SP Description

1 1-761-333-11 o MOUNTED CIRCUIT BOARD, VF-70

2 1-761-334-11 o MOUNTED CIRCUIT BOARD, DF-58

3 1-761-335-11 o MOUNTED CIRCUIT BOARD, VR-266

4 X-3678-575-3 o CHASSIS B ASSY,BOTTOM(LOWER)

5 1-761-339-11 o MOUNTED CIRCUIT BOARD, VDA-41

6 1-777-131-22 s CORD, CONNECTION (VF)

7 9-885-005-93 o CABLE, FLAT (12 CORE)

8 2-277-457-01 s KNOB, STOPPER

9 2-277-466-01 s SPRING, COMPRESSION

10 3-165-904-01 s WASHER, SCREW STOPPER

11 3-609-582-01 o PLATE, BOARD FIX

12 3-609-583-01 o SHEET, INSULATING

SOCKET 2.6 x 6

28

Precision

P2 x 3.5

No. Part No. SP Description

18 3-692-132-03 o COVER,TALLY

19 3-692-134-01 o MIC CLAMP

20 3-692-138-01 s MIC CUSHION,RUBBER

21 X-3604-579-1 s VOLUME KNOB ASSY

23 3-609-735-01 o BAR, GUARD

24 3-697-152-01 o SPRING,LEAF(2)

25 3-697-153-01 o PLATE,GROUND(2)

26 A-8277-112-A o CASE ASSY, TOP

27 3-697-156-01 o CUSHION,DRROP PROTECCTION(2)

28 3-697-161-01 o LID,COVER

29 3-710-008-02 s HOUSING, STOPPER

30 3-697-160-01 o LABEL, VF (C)

13 3-657-657-02 s SCREW (M5)

14 3-679-693-01 o BASE,SLIDE

15 3-679-694-01 o COVER,SLIDE

7-621-772-18 s SCREW, +B 2X4

7-627-454-38 s SCREW, PRECISION +K 2.6X5

7-627-554-18 s SCREW,PRECISION +P 2X3.5 TYPE1

16 3-679-695-01 o COVER,TALLY

7-683-412-05 s BOLT,HEXAGON SOCKET 2.6X6

17 3-693-327-01 s NUT (M6), CONTROL

HDVF-20A

3-1

Page 22

120

PTP2.6 x 8

P2 x 6

128

102

PTP2.6 x 8

110

101

108

113

118

110

103

K2 x 5

122

107

P2 x 6

111

K2 x 5

125

116

115

112

105

114

Ball 2.5 dia

106

115

105

121

124

109

106

104

Ball

2.5 dia

Precision

P2 x 10

123

117

127

119

104

Precision

P2 x 10

122126

No. Part No. SP Description

101 A-7612-389-B s TUBE SUB ASSY, VF

102 ! 1-251-636-11 s CRT ASSY, 2" HD

103 A-8315-579-A o MOUNTED CIRCUIT BOARD, LP-105

104 3-176-414-01 o RETAINER, RING

105 3-335-207-01 s SHAFT, MOTOR

106 3-573-150-00 o SPRING, COMPRESSION

107 3-603-499-02 s SPACER, MASK

108 3-608-806-01 o MIRROR(3)

109 3-692-136-03 o FIXED RING

110 3-692-144-01 o SPACER, LP

111 3-697-159-02 o PLATE A,DISPLAY

No. Part No. SP Description

118 3-723-073-01 o CUSHION, MIRROR

119 A-8319-943-A s EYE CUP (RP)

120 3-725-220-02 o TUBE (A), CRT

121 3-726-904-01 o RING (MT), O

122 3-742-038-01 o NUT (2), PLATE

123 3-742-052-03 o HOLDER, EYECUP

124 3-742-053-02 o RING

125 3-742-054-01 o TUBE

126 3-742-060-01 o HOLDER, RING

127 3-623-709-01 o MC HOLDER

128 9-885-005-86 o SOKET, CRT

112 3-697-151-01 o RING,VF

113 3-697-154-01 o HOLDER,MIRROR(3)

114 3-697-167-03 o VF TUBE(4)

115 3-722-485-01 o ROLLER, SLIDE

7-627-452-38 s SCREW,PRECISION +K 2X5

7-627-553-78 s SCREW,PRECISION +P 2X10

7-671-158-01 s BALL, STAINLESS (2.5 DIA)

7-685-104-19 s SCREW +P 2X6 TYPE2 NON-SLIT

116 3-722-492-01 o HOLDER (B), LENS

7-685-134-19 s SCREW +PTP 2.6X8 TYPE2 NON-SLIT

117 3-623-710-01 o MC, GLASS

7-685-104-14 s SCREW +P 2X6 TYPE2 NON-SLIT

3-2

HDVF-20A

Page 23

3-2. Electrical Parts List

----------DF-58 Board

---------- Ref. No.

or Q'ty Part No. SP Description

(DF-58 Board)

Ref. No.

or Q'ty Part No. SP Description

1pc 1-761-334-11 o MOUNTED CIRCUIT BOARD, DF-58

D101 8-719-951-22 s DIODE IMN10

D103 8-719-941-23 s DIODE DA204U

C101 1-115-581-11 s TANTALUM,CHIP 100uF 20% 16

D104 8-719-056-22 s DIODE MA2S728-(K8).SO

C102 1-104-913-11 s TANTALUM, CHIP 10uF 20% 16V

C103 1-115-581-11 s TANTALUM,CHIP 100uF 20% 16

C104 1-163-251-11 s CERAMIC, CHIP 100PF 5% 50V

C105 1-164-691-11 s CERAMIC 0.0024uF 5% 50V

IC101 ! 8-759-394-25 s IC LA7858

IC102 8-759-075-70 s IC TA75S393F

IC103 8-759-234-08 s IC TA78L05F

IC104 8-759-394-30 s IC GS4981IKA

C106 1-163-135-00 s CERAMIC 560PF 5% 50V

IC105 8-759-242-78 s IC TC7W02F

C107 1-164-182-11 s CERAMIC 0.0033uF 10% 50V

C108 1-135-091-00 s TANTALUM, CHIP 1uF 20% 16V

C109 1-135-091-00 s TANTALUM, CHIP 1uF 20% 16V

C110 1-104-551-11 s FILM 0.01uF 5% 16V

IC106 8-759-180-08 s IC TC74HC4538AFS

IC107 8-759-058-62 s IC TC7S08FU(TE85R)

IC108 8-759-082-61 s IC TC4W53FU

IC109 8-759-180-08 s IC TC74HC4538AFS

C111 1-104-542-11 s CHIP FILM 0.0018uF 5% 50V

IC110 8-759-394-32 s IC TC4427EOA

C112 1-163-145-00 s CERAMIC 0.0015uF 10% 50V

C113 1-164-004-11 s CERAMIC, CHIP 0.1uF 10% 25V

C114 1-104-913-11 s TANTALUM, CHIP 10uF 20% 16V

C115 1-115-581-11 s TANTALUM,CHIP 100uF 20% 16

IC111 8-759-082-59 s IC TC7W32FU

IC112 8-759-180-08 s IC TC74HC4538AFS

IC113 8-759-058-64 s IC TC7S32FU(TE85R)

IC114 8-759-082-55 s IC TC7W00FU

C116 1-135-070-00 s TANTALUM, CHIP 0.1uF 10% 35V

IC115 8-759-180-08 s IC TC74HC4538AFS

C117 1-135-179-21 s TANTAL 2.2uF 10% 16V

C118 1-135-145-11 s TANTALUM, CHIP 0.47uF 10% 35V

IC116 8-759-180-08 s IC TC74HC4538AFS

C119 1-164-004-11 s CERAMIC, CHIP 0.1uF 10% 25V

C120 1-163-251-11 s CERAMIC, CHIP 100PF 5% 50V

Q101 8-729-802-80 s TRANSISTOR 2SC3661

Q102 8-729-042-52 s TRANSISTOR IMT1AT108

C121 1-115-581-11 s TANTALUM,CHIP 100uF 20% 16

C122 1-104-913-11 s TANTALUM, CHIP 10uF 20% 16V

C123 1-163-018-00 s CERAMIC, CHIP 0.0056uF 5% 50V

Q103 8-729-042-52 s TRANSISTOR IMT1AT108

Q104 8-729-905-36 s TRANSISTOR 2SC4081-S

Q105 8-729-402-84 s TRANSISTOR XN4601

C124 9-885-005-12 s ELECT, CHIP 470uF 16V

C125 1-163-021-91 s CERAMIC 0.01uF 10% 50V

Q106 8-729-905-36 s TRANSISTOR 2SC4081-S

Q107 8-729-905-36 s TRANSISTOR 2SC4081-S

C126 1-115-185-11 s CERAMIC 0.033uF 10% 25V

C127 1-163-275-11 s CERAMIC, CHIP 1000PF 5% 50V

C128 1-163-275-11 s CERAMIC, CHIP 1000PF 5% 50V

Q108 8-729-905-36 s TRANSISTOR 2SC4081-S

Q109 8-729-036-19 s TRANSISTOR IMB2A

Q110 8-729-425-41 s TRANSISTOR 2SK1374

C129 1-164-004-11 s CERAMIC, CHIP 0.1uF 10% 25V

C130 1-164-004-11 s CERAMIC, CHIP 0.1uF 10% 25V

Q111 8-729-425-41 s TRANSISTOR 2SK1374

Q112 8-729-026-53 s TRANSISTOR 2SA1576A-T106-QR

C131 1-164-004-11 s CERAMIC, CHIP 0.1uF 10% 25V

C151 1-104-913-11 s TANTALUM, CHIP 10uF 20% 16V

C152 1-107-686-11 s CHIP, TANTALUM 4.7uF 20% 16V

Q113 8-729-042-52 s TRANSISTOR IMT1AT108

Q114 8-729-028-91 s TRANSISTOR DTA144EUA-T106

Q115 8-729-036-19 s TRANSISTOR IMB2A

C153 1-163-235-11 s CERAMIC, CHIP 22PF 5% 50V

C154 1-107-686-11 s CHIP, TANTALUM 4.7uF 20% 16V

R101 1-216-833-11 s METAL, CHIP 10K 5% 1/16W

R102 1-216-825-11 s METAL, CHIP 2.2K 5% 1/16W

C155 1-164-004-11 s CERAMIC, CHIP 0.1uF 10% 25V

C156 1-164-004-11 s CERAMIC, CHIP 0.1uF 10% 25V

C157 1-163-235-11 s CERAMIC, CHIP 22PF 5% 50V

R103 1-216-837-11 s METAL, CHIP 22K 5% 1/16W

R104 1-216-834-11 s METAL, CHIP 12K 5% 1/16W

R105 1-216-832-11 s METAL, CHIP 8.2K 5% 1/16W

C158 1-163-251-11 s CERAMIC, CHIP 100PF 5% 50V

C159 1-164-004-11 s CERAMIC, CHIP 0.1uF 10% 25V

R106 1-216-845-11 s METAL, CHIP 100K 5% 1/16W

R107 1-216-832-11 s METAL, CHIP 8.2K 5% 1/16W

C160 1-163-251-11 s CERAMIC, CHIP 100PF 5% 50V

C161 9-885-005-13 s CAPACITOR, PP 0.0015uF 100V

C162 9-885-005-13 s CAPACITOR, PP 0.0015uF 100V

R108 1-216-839-11 s METAL, CHIP 33K 5% 1/16W

R109 1-218-345-11 s METAL, CHIP 9.1K 5% 1/16W

R110 1-216-821-11 s METAL, CHIP 1K 5% 1/16W

C163 1-163-235-11 s CERAMIC, CHIP 22PF 5% 50V

C164 1-164-004-11 s CERAMIC, CHIP 0.1uF 10% 25V

R111 1-218-294-11 s METAL, CHIP 30K 5% 1/16W

R112 1-216-836-11 s METAL, CHIP 18K 5% 1/16W

C171 1-115-419-11 s CERAMIC 0.0033uF 10% 25V

C172 1-164-004-11 s CERAMIC, CHIP 0.1uF 10% 25V

C175 1-163-235-11 s CERAMIC, CHIP 22PF 5% 50V

R114 1-218-830-11 s METAL, CHIP 5.6K 5% 1/16W

R115 1-216-798-11 s METAL, CHIP 12 5% 1/16W

R116 1-216-848-11 s METAL, CHIP 180K 5% 1/16W

C176 1-164-004-11 s CERAMIC, CHIP 0.1uF 10% 25V

C182 1-163-135-00 s CERAMIC 560PF 5% 50V

R117 1-216-846-11 s METAL, CHIP 120K 5% 1/16W

R118 1-216-822-11 s METAL, CHIP 1.2K 5% 1/16W

C183 1-163-251-11 s CERAMIC, CHIP 100PF 5% 50V

C184 1-163-275-11 s CERAMIC, CHIP 1000PF 5% 50V

C185 1-164-004-11 s CERAMIC, CHIP 0.1uF 10% 25V

R119 1-216-845-11 s METAL, CHIP 100K 5% 1/16W

R120 1-218-272-11 s METAL, CHIP 5.1K 5% 1/16W

R121 1-218-272-11 s METAL, CHIP 5.1K 5% 1/16W

C186 1-163-235-11 s CERAMIC, CHIP 22PF 5% 50V

C187 1-163-275-11 s CERAMIC, CHIP 1000PF 5% 50V

R122 1-216-813-11 s METAL, CHIP 220 5% 1/16W

R123 1-216-308-00 s METAL, CHIP 4.7 5% 1/10W

CN102 1-564-704-11 s CONNECOR, 2P, MALE

R124 1-216-829-11 s METAL, CHIP 4.7K 5% 1/16W

HDVF-20A

3-3

Page 24

(DF-58 Board)

(DF-58 Board)

Ref. No.

or Q'ty Part No. SP Description

R125 1-216-827-11 s METAL, CHIP 3.3K 5% 1/16W

R126 1-216-308-00 s METAL, CHIP 4.7 5% 1/10W

R127 1-216-308-00 s METAL, CHIP 4.7 5% 1/10W

R128 1-216-037-00 s METAL, CHIP 330 5% 1/10W

R129 1-216-801-11 s METAL, CHIP 22 5% 1/16W

Ref. No.

or Q'ty Part No. SP Description

R186 1-216-841-11 s METAL, CHIP 47K 5% 1/16W

R187 1-216-821-11 s METAL, CHIP 1K 5% 1/16W

R188 1-216-821-11 s METAL, CHIP 1K 5% 1/16W

R189 1-216-821-11 s METAL, CHIP 1K 5% 1/16W

R190 1-216-850-11 s METAL, CHIP 270K 5% 1/16W

1-216-849-11 s METAL, CHIP 220K 5% 1/16W

R130 1-216-308-00 s METAL, CHIP 4.7 5% 1/10W

R131 1-216-821-11 s METAL, CHIP 1K 5% 1/16W

R132 1-216-816-11 s METAL, CHIP 330 5% 1/16W

R191 1-216-850-11 s METAL, CHIP 270K 5% 1/16W

1-216-849-11 s METAL, CHIP 220K 5% 1/16W

R133 1-216-818-11 s METAL, CHIP 560 5% 1/16W

R134 1-218-272-11 s METAL, CHIP 5.1K 5% 1/16W

RV101 9-885-005-14 s RES, ADJ METAL 5K

RV102 9-885-005-09 s RES, ADJ METAL 4.7K

R135 1-216-836-11 s METAL, CHIP 18K 5% 1/16W

R136 1-216-829-11 s METAL, CHIP 4.7K 5% 1/16W

R137 1-216-832-11 s METAL, CHIP 8.2K 5% 1/16W

RV103 9-885-005-09 s RES, ADJ METAL 4.7K

RV104 9-885-005-09 s RES, ADJ METAL 4.7K

RV105 9-885-005-15 s RES, ADJ METAL 220K

R138 1-216-825-11 s METAL, CHIP 2.2K 5% 1/16W

R139 1-218-331-11 s METAL, CHIP 51K 50% 1/16W

RV106 9-885-005-16 s RES, ADJ METAL 200

RV107 9-885-005-14 s RES, ADJ METAL 5K

R140 1-216-835-11 s METAL, CHIP 15K 5% 1/16W

R141 1-216-833-11 s METAL, CHIP 10K 5% 1/16W

R142 1-216-836-11 s METAL, CHIP 18K 5% 1/16W

RV108 9-885-005-14 s RES, ADJ METAL 5K

RV109 9-885-005-09 s RES, ADJ METAL 4.7K

RV110 9-885-005-14 s RES, ADJ METAL 5K

R143 1-218-272-11 s METAL, CHIP 5.1K 5% 1/16W

R144 1-216-816-11 s METAL, CHIP 330 5% 1/16W

RV111 9-885-005-09 s RES, ADJ METAL 4.7K

RV112 9-885-005-17 s RES, ADJ METAL 50K

R145 1-216-816-11 s METAL, CHIP 330 5% 1/16W

R146 1-216-816-11 s METAL, CHIP 330 5% 1/16W

R147 1-216-816-11 s METAL, CHIP 330 5% 1/16W

RV113 9-885-005-09 s RES, ADJ METAL 4.7K

RV114 9-885-005-10 s RES, ADJ METAL 47K

RV115 9-885-005-18 s RES, ADJ METAL 470

R148 1-216-841-11 s METAL, CHIP 47K 5% 1/16W

R149 1-216-841-11 s METAL, CHIP 47K 5% 1/16W

RV116 9-885-005-19 s RES, ADJ METAL 1K

RV117 9-885-005-19 s RES, ADJ METAL 1K

R151 1-216-841-11 s METAL, CHIP 47K 5% 1/16W

R152 1-216-825-11 s METAL, CHIP 2.2K 5% 1/16W

R153 1-216-825-11 s METAL, CHIP 2.2K 5% 1/16W

RV118 9-885-005-09 s RES, ADJ METAL 4.7K

RV119 9-885-005-20 s RES, ADJ METAL 500

RV120 9-885-005-20 s RES, ADJ METAL 500

R154 1-216-833-11 s METAL, CHIP 10K 5% 1/16W

R155 1-216-851-11 s METAL, CHIP 330K 5% 1/16W

RV121 9-885-005-14 s RES, ADJ METAL 5K

RV122 9-885-005-14 s RES, ADJ METAL 5K

R156 1-216-813-11 s METAL, CHIP 220 5% 1/16W

R157 1-216-833-11 s METAL, CHIP 10K 5% 1/16W

R158 1-216-993-11 s METAL, CHIP 2.4K 5% 1/16W

R159 1-216-827-11 s METAL, CHIP 3.3K 5% 1/16W

R160 1-216-827-11 s METAL, CHIP 3.3K 5% 1/16W

R161 1-216-821-11 s METAL, CHIP 1K 5% 1/16W

R162 1-216-826-11 s METAL, CHIP 2.7K 5% 1/16W

R163 1-216-994-11 s METAL, CHIP 13K 5% 1/16W

R164 1-216-813-11 s METAL, CHIP 220 5% 1/16W

R165 1-216-801-11 s METAL, CHIP 22 5% 1/16W

R166 1-216-816-11 s METAL, CHIP 330 5% 1/16W

R167 1-216-816-11 s METAL, CHIP 330 5% 1/16W

R168 1-216-816-11 s METAL, CHIP 330 5% 1/16W

R169 1-216-816-11 s METAL, CHIP 330 5% 1/16W

R171 1-216-834-11 s METAL, CHIP 12K 5% 1/16W

R172 1-218-292-11 s METAL, CHIP 20K 5% 1/16W

R173 1-216-839-11 s METAL, CHIP 33K 5% 1/16W

R174 1-216-994-11 s METAL, CHIP 13K 5% 1/16W

R175 1-220-372-11 s METAL, CHIP 200K 5% 1/16W

1-216-848-11 s METAL, CHIP 180K 5% 1/16W

1-216-861-11 s METAL, CHIP 220K 5% 1/16W

R176 1-216-827-11 s METAL, CHIP 3.3K 5% 1/16W

R178 1-216-801-11 s METAL, CHIP 22 5% 1/16W

R179 1-216-818-11 s METAL, CHIP 560 5% 1/16W

R180 1-216-801-11 s METAL, CHIP 22 5% 1/16W

R181 1-218-830-11 s METAL, CHIP 5.6K 5% 1/16W

R182 1-218-830-11 s METAL, CHIP 5.6K 5% 1/16W

R183 1-218-271-11 s METAL, CHIP 2K 5% 1/16W

R184 1-216-809-11 s METAL, CHIP 100 5% 1/16W

R185 1-216-809-11 s METAL, CHIP 100 5% 1/16W

3-4

HDVF-20A

Page 25

-----------LP-105 Board

----------- Ref. No.

or Q'ty Part No. SP Description

-----------VDA-41 Board

----------- Ref. No.

or Q'ty Part No. SP Description

1pc A-8315-579-A o MOUNTED CIRCUIT BOARD, LP-105

CN21 1-565-651-11 o PIN, CONNECTOR 8P

1pc 1-761-339-11 o MOUNTED CIRCUIT BOARD, VDA-41

C261 1-110-497-11 s CERAMIC, CHIP 0.1uF 20% 100V

C262 1-163-259-91 s CERAMIC 220PF 5% 50V

D1 8-729-026-39 s TRANSISTOR 2SA933AS-QT

D2 8-719-026-40 s DIODE CL-150UR-CD-T

D3 8-719-987-43 s DIODE CL-150PG-CD

C263 1-164-004-11 s CERAMIC, CHIP 0.1uF 10% 25V

C264 1-110-497-11 s CERAMIC, CHIP 0.1uF 20% 100V

C265 1-164-004-11 s CERAMIC, CHIP 0.1uF 10% 25V

D4 8-719-026-16 s DIODE CL-150D-CD-T

D5 8-719-026-40 s DIODE CL-150UR-CD-T

D261 8-719-984-56 s DIODE HZK2ALL

D262 8-719-052-18 s DIODE RLS245TE-11

D6 8-719-026-16 s DIODE CL-150D-CD-T

Q261 8-729-036-39 s TRANSISTOR 2SC4104

Q262 8-729-036-38 s TRANSISTOR 2SC4080

Q263 8-729-036-39 s TRANSISTOR 2SC4104

Q264 8-729-036-40 s TRANSISTOR 2SA1580

Q265 8-729-036-39 s TRANSISTOR 2SC4104

Q266 8-729-036-40 s TRANSISTOR 2SA1580

Q267 8-729-036-39 s TRANSISTOR 2SC4104

R261 1-218-289-11 s METAL, CHIP 510 5% 1/16W

R262 1-202-923-91 s METAL, CHIP 130 5% 1/16W

R263 9-885-005-00 s METAL, CHIP 3.9K

R264 1-216-809-11 s METAL, CHIP 100 5% 1/16W

R265 1-216-833-11 s METAL, CHIP 10K 5% 1/16W

R266 1-216-809-11 s METAL, CHIP 100 5% 1/16W

R267 1-216-834-11 s METAL, CHIP 12K 5% 1/16W

R268 1-216-809-11 s METAL, CHIP 100 5% 1/16W

R269 1-216-834-11 s METAL, CHIP 12K 5% 1/16W

R270 1-216-809-11 s METAL, CHIP 100 5% 1/16W

R271 1-216-809-11 s METAL, CHIP 100 5% 1/16W

R272 1-216-803-11 s METAL, CHIP 33 5% 1/16W

R273 1-216-803-11 s METAL, CHIP 33 5% 1/16W

R274 1-218-179-11 s RES, CHIP 10M 5% 1/10W

R275 1-218-289-11 s METAL, CHIP 510 5% 1/16W

R276 1-218-273-11 s METAL, CHIP 510K 5% 1/16W

R277 1-216-033-00 s METAL, CHIP 220 5% 1/10W

HDVF-20A

3-5

Page 26

----------VF-70 Board

---------- Ref. No.

or Q'ty Part No. SP Description

(VF-70 Board)

Ref. No.

or Q'ty Part No. SP Description

1pc 1-761-333-11 o MOUNTED CIRCUIT BOARD, VF-70

D306 8-719-056-80 s DIODE UDZ5.1B

D307 8-719-056-80 s DIODE UDZ5.1B

C301 1-164-004-11 s CERAMIC, CHIP 0.1uF 10% 25V

C302 1-164-004-11 s CERAMIC, CHIP 0.1uF 10% 25V

C303 1-164-004-11 s CERAMIC, CHIP 0.1uF 10% 25V

D401 8-719-989-76 s DIODE SC802-04

D402 8-719-989-76 s DIODE SC802-04

D501 8-719-941-23 s DIODE DA204U

C304 1-164-004-11 s CERAMIC, CHIP 0.1uF 10% 25V

C305 1-164-004-11 s CERAMIC, CHIP 0.1uF 10% 25V

D502 8-719-941-23 s DIODE DA204U

D503 8-719-941-23 s DIODE DA204U

C306 1-135-160-21 s CHIP, TANTALUM 15uF 10% 16V

C307 1-107-686-11 s CHIP, TANTALUM 4.7uF 20% 16V

C308 1-164-001-11 s CERAMIC 150PF 5% 50V

D504 8-719-941-86 s DIODE DAN202U

D505 8-719-941-23 s DIODE DA204U

D506 8-719-941-86 s DIODE DAN202U

C309 1-104-913-11 s TANTALUM, CHIP 10uF 20% 16V

C310 1-164-001-11 s CERAMIC 150PF 5% 50V

C311 1-164-004-11 s CERAMIC, CHIP 0.1uF 10% 25V

D507 8-759-394-26 s IC LM4041EIM3-1.2

FBT1 ! 1-453-243-11 s TRANSFORMER, FLYBACK

C312 1-164-004-11 s CERAMIC, CHIP 0.1uF 10% 25V

C401 9-885-005-02 s ELECT 220uF 25V

HLC1 ! 1-416-387-11 s COIL, LINEARITY

C402 1-135-091-00 s TANTALUM, CHIP 1uF 20% 16V

C403 1-164-686-91 s CERAMIC 0.0015 5% 50V

IC301 8-759-990-61 s IC PCF8574T

IC302 8-759-990-61 s IC PCF8574T

C404 1-104-919-11 s TANTALUM, CHIP 10uF 20% 25V

C405 1-163-275-91 s CERAMIC 0.001 5% 50V

C406 1-164-001-11 s CERAMIC 150PF 5% 50V

IC303 8-759-394-34 s IC BR24C02F

IC304 8-759-939-51 s IC BA225F

IC305 8-759-082-59 s IC TC7W32FU

C407 9-885-005-03 s CAPACITOR, OS 150uF 16V

C408 1-104-913-11 s TANTALUM, CHIP 10uF 20% 16V

IC306 8-759-209-57 s IC TC4S69F

IC401 8-759-485-77 s IC BA9743AFV-E2

C409 1-107-686-11 s CHIP, TANTALUM 4.7uF 20% 16V

C410 1-163-251-91 s CERAMIC 0.0001 5% 50V

C411 1-164-686-91 s CERAMIC 0.0015 5% 50V

IC501 8-759-394-31 s IC TC4426EOA

IC502 8-759-060-00 s IC BA10324AF

IC503 8-759-075-66 s IC TA75S01F

C412 1-164-686-91 s CERAMIC 0.0015 5% 50V

C413 1-163-275-91 s CERAMIC 0.001 5% 50V

C414 1-164-001-11 s CERAMIC 150PF 5% 50V

C415 9-885-005-03 s CAPACITOR, OS 150uF 16V

C501 1-163-251-91 s CERAMIC 0.0001 5% 50V

IC504 8-759-050-14 s IC SN74HC175APW-E05

L401 1-411-877-11 s COIL, CHOKE 56uH

L402 1-411-877-11 s COIL, CHOKE 56uH

L403 1-411-227-11 s COIL, CHOKE 100uH

C502 1-164-001-11 s CERAMIC 150PF 5% 50V

C503 1-164-001-11 s CERAMIC 150PF 5% 50V

LED301 8-719-989-53 s DIODE CL-200HR-C-TSL

C504 1-135-179-21 s TANTAL 2.2uF 10% 16V

C505 1-107-686-11 s CHIP, TANTALUM 4.7uF 20% 16V

C506 1-164-001-11 s CERAMIC 150PF 5% 50V

C507 1-164-001-11 s CERAMIC 150PF 5% 50V

C508 1-164-686-91 s CERAMIC 0.0015 5% 50V

C509 1-164-691-11 s CERAMIC 0.0024uF 5% 50V

C510 ! 9-885-005-04 s CAPACITOR, PP 6800P 250V

C511 ! 9-885-005-06 s CAPACITOR, PP 2200P 250V

C512 1-164-686-91 s CERAMIC 0.0015 5% 50V

C513 1-104-913-11 s TANTALUM, CHIP 10uF 20% 16V

C514 1-164-001-11 s CERAMIC 150PF 5% 50V

C515 1-164-346-11 s CERAMIC 1uF 16V

C516 9-885-005-08 s CAPACITOR, ELECT 470uF

Q301 8-729-036-19 s TRANSISTOR IMB2A

Q302 8-729-036-19 s TRANSISTOR IMB2A

Q303 8-729-036-48 s TRANSISTOR IMH2A

Q304 8-729-036-48 s TRANSISTOR IMH2A

Q305 8-729-036-19 s TRANSISTOR IMB2A

Q306 8-729-036-20 s TRANSISTOR IMH3A

Q401 8-729-905-36 s TRANSISTOR 2SC4081-S

Q402 8-729-040-75 s TRANSISTOR SI4953DY-T1

Q403 8-729-402-84 s TRANSISTOR XN4601

Q404 8-729-402-84 s TRANSISTOR XN4601

Q501 9-885-005-01 s TRANSISTOR 2SK2534

Q502 8-729-037-55 s TRANSISTOR 2SK1826(TE85L)

Q503 8-729-035-20 s TRANSISTOR 2SK1920

C517 1-115-581-11 s TANTALUM,CHIP 100uF 20% 16V

C518 1-110-497-11 s CHIP CERAMIC 1uF 20% 100V

R301 1-216-827-11 s METAL, CHIP 3.3K 5% 1/16W

R302 1-216-827-11 s METAL, CHIP 3.3K 5% 1/16W

C519 1-110-497-11 s CHIP CERAMIC 1uF 20% 100V

C520 1-110-497-11 s CHIP CERAMIC 1uF 20% 100V

C521 1-163-018-00 s CERAMIC, CHIP 0.0056uF 5% 50V

CN1 1-580-539-11 o PIN, CONNECTOR (PC BOARD) 20P

CN501 1-564-705-11 s CONNECTOR, 3P, MALE

CN502 1-564-706-11 o PIN HEADER, STRAIGHT 4P

CN101A 1-750-710-11 o CONNECTOR, BOARD TO BOARD

CN201A 1-569-528-11 s HOUSING 12P

D301 8-719-941-23 s DIODE DA204U

D302 8-719-941-23 s DIODE DA204U

D303 8-719-056-80 s DIODE UDZ5.1B

D304 8-719-056-80 s DIODE UDZ5.1B

D305 8-719-056-80 s DIODE UDZ5.1B

R303 1-218-288-11 s METAL 300 5% 1/16W

R304 1-218-288-11 s METAL 300 5% 1/16W

R305 1-216-821-11 s METAL, CHIP 1K 5% 1/16W

R306 1-216-803-11 s METAL, CHIP 33 5% 1/16W

R307 1-216-841-11 s METAL 47K 5% 1/16W

R308 1-216-837-11 s CHIP, METAL 22K 5% 1/16W

R309 1-216-855-11 s METAL, CHIP 680K 5% 1/16W

R310 1-216-842-11 s METAL, CHIP 56K 5% 1/16W

R312 1-216-818-11 s METAL, CHIP 560 5% 1/16W

R313 1-216-832-11 s METAL, CHIP 8.2K 5% 1/16W

R314 1-216-821-11 s METAL, CHIP 1K 5% 1/16W

R315 1-216-821-11 s METAL, CHIP 1K 5% 1/16W

R316 1-216-821-11 s METAL, CHIP 1K 5% 1/16W

3-6

HDVF-20A

Page 27

(VF-70 Board)

(VF-70 Board)

Ref. No.

or Q'ty Part No. SP Description

R317 1-216-821-11 s METAL, CHIP 1K 5% 1/16W

Ref. No.

or Q'ty Part No. SP Description

RV501 9-885-005-10 s RES, ADJ METAL 47K

R318 1-216-821-11 s METAL, CHIP 1K 5% 1/16W

R319 1-216-827-11 s METAL, CHIP 3.3K 5% 1/16W

R320 1-216-821-11 s METAL, CHIP 1K 5% 1/16W

R321 1-216-825-11 s METAL, CHIP 2.2K 5% 1/16W

S301 1-762-019-11 s SWITCH, TOGGLE

S302 1-762-020-11 s SWITCH, TOGGLE

S303 1-762-489-11 s SWITCH, TOGGLE

R322 1-216-825-11 s METAL, CHIP 2.2K 5% 1/16W

R323 1-216-825-11 s METAL, CHIP 2.2K 5% 1/16W

R401 1-216-833-11 s METAL, CHIP 10K 5% 1/16W

R402 1-216-821-11 s METAL, CHIP 1K 5% 1/16W

R403 1-216-049-91 s METAL 1K 5% 1/10W

R404 1-216-821-11 s METAL, CHIP 1K 5% 1/16W

R405 1-216-793-11 s METAL 4.7 5% 1/16W

R406 1-216-816-11 s CHIP, METAL 390 5% 1/16W

R407 1-218-745-11 s METAL, CHIP 160K 5% 1/16W

R408 1-216-837-11 s CHIP, METAL 22K 5% 1/16W

R409 1-216-839-11 s METAL, CHIP 33K 5% 1/16W

R410 1-216-839-11 s METAL, CHIP 33K 5% 1/16W

R411 1-216-839-11 s METAL, CHIP 33K 5% 1/16W

R412 1-216-827-11 s METAL, CHIP 3.3K 5% 1/16W

R413 1-216-833-11 s METAL, CHIP 10K 5% 1/16W

R414 1-216-834-11 s METAL, CHIP 12K 5% 1/16W

R415 1-216-832-11 s METAL, CHIP 8.2K 5% 1/16W

R416 1-216-837-11 s CHIP, METAL 22K 5% 1/16W

R417 1-216-049-91 s METAL 1K 5% 1/10W

R418 1-216-821-11 s METAL, CHIP 1K 5% 1/16W

R419 1-216-793-11 s METAL 4.7 5% 1/16W

R420 1-216-816-11 s CHIP, METAL 390 5% 1/16W

R421 1-218-295-11 s METAL 43K 5% 1/16W

R422 1-216-833-11 s METAL, CHIP 10K 5% 1/16W

R501 1-216-827-11 s METAL, CHIP 3.3K 5% 1/16W

R502 1-216-833-11 s METAL, CHIP 10K 5% 1/16W

R503 1-216-793-11 s METAL 4.7 5% 1/16W

R504 1-218-331-11 s CHIP, METAL 51K 5% 1/16W

R505 1-218-272-11 s METAL, CHIP 5.1K 5% 1/16W

R506 1-218-890-11 s CHIP, METAL 62K 5% 1/16W

R507 1-216-839-11 s METAL, CHIP 33K 5% 1/16W

R508 1-216-839-11 s METAL, CHIP 33K 5% 1/16W

R509 ! 1-218-725-11 s CHIP, METAL 24K 5% 1/16W

R510 ! 1-218-890-11 s CHIP, METAL 62K 5% 1/16W

R511 1-216-833-11 s METAL, CHIP 10K 5% 1/16W

R512 1-216-827-11 s METAL, CHIP 3.3K 5% 1/16W

R513 1-216-827-11 s METAL, CHIP 3.3K 5% 1/16W

R514 1-216-827-11 s METAL, CHIP 3.3K 5% 1/16W

R515 1-216-793-11 s METAL 4.7 5% 1/16W

R516 1-216-809-11 s METAL, CHIP 100 5% 1/16W

R517 1-216-833-11 s METAL, CHIP 10K 5% 1/16W

R518 1-216-838-11 s METAL, CHIP 27K 5% 1/16W

R519 1-216-803-11 s RES, CHIP 3.3M 5% 1/4W

R520 1-216-803-11 s RES, CHIP 3.3M 5% 1/4W

R521 1-216-803-11 s RES, CHIP 3.3M 5% 1/4W

R522 1-216-033-00 s CHIP, METAL 220 5% 1/10W

R527 1-216-845-11 s METAL, CHIP 100K 5% 1/16W

R528 1-216-845-11 s METAL, CHIP 100K 5% 1/16W

R529 1-216-837-11 s CHIP, METAL 22K 5% 1/16W

R530 1-216-837-11 s CHIP, METAL 22K 5% 1/16W

R531 1-216-809-11 s METAL, CHIP 100 5% 1/16W

R532 1-216-809-11 s METAL, CHIP 100 5% 1/16W

R533 1-216-809-11 s METAL, CHIP 100 5% 1/16W

RV401 9-885-005-09 s RES, ADJ METAL 4.7K

HDVF-20A

3-7

Page 28

-----------VR-266 Board

----------- Ref. No.

or Q'ty Part No. SP Description

(VR-266 Board)

Ref. No.

or Q'ty Part No. SP Description

1pc 1-761-335-11 o MOUNTED CIRCUIT BOARD, VR-266

2pcs 3-697-153-01 o PLATE,GROUND(2)

R212 1-216-809-11 s METAL, CHIP 100 5% 1/16W

R213 1-216-821-11 s METAL, CHIP 1K 5% 1/16W

R214 1-216-821-11 s METAL, CHIP 1K 5% 1/16W

C201 1-115-581-11 s TANTALUM,CHIP 100uF 20% 16

C202 1-115-581-11 s TANTALUM,CHIP 100uF 20% 16

R215 1-216-827-11 s METAL, CHIP 3.3K 5% 1/16W

R216 1-220-151-11 s METAL, CHIP 51 5% 1/16W

C203 1-115-581-11 s TANTALUM,CHIP 100uF 20% 16

C204 1-164-004-11 s CERAMIC, CHIP 0.1uF 10% 25V

C205 1-164-346-11 s CERAMIC 1uF 16V

R217 1-216-821-11 s METAL, CHIP 1K 5% 1/16W

R218 1-216-811-11 s METAL, CHIP 150 5% 1/16W

R219 1-216-811-11 s METAL, CHIP 150 5% 1/16W

C206 1-104-913-11 s TANTALUM, CHIP 10uF 20% 16V

C207 1-107-686-11 s CHIP, TANTALUM 4.7uF 20% 16V

R220 1-216-821-11 s METAL, CHIP 1K 5% 1/16W

R221 1-216-821-11 s METAL, CHIP 1K 5% 1/16W

C208 1-163-021-91 s CERAMIC, CHIP 0.01uF 10% 50V

C209 1-164-004-11 s CERAMIC, CHIP 0.1uF 10% 25V

C211 1-164-004-11 s CERAMIC, CHIP 0.1uF 10% 25V

R222 1-218-269-11 s METAL, CHIP 360 5% 1/16W

R223 1-218-269-11 s METAL, CHIP 360 5% 1/16W

R224 1-216-821-11 s METAL, CHIP 1K 5% 1/16W

C212 1-164-004-11 s CERAMIC, CHIP 0.1uF 10% 25V

C213 1-163-235-11 s CERAMIC, CHIP 22PF 5% 50V

R225 1-216-820-91 s RES, CHIP 820 5% 1/16W

R226 1-216-834-11 s METAL, CHIP 12K 5% 1/16W

C214 1-164-004-11 s CERAMIC, CHIP 0.1uF 10% 25V

C215 1-164-004-11 s CERAMIC, CHIP 0.1uF 10% 25V

C216 1-163-275-11 s CERAMIC, CHIP 0.001uF 10% 50V

R227 1-216-833-11 s METAL, CHIP 10K 5% 1/16W

R228 1-220-151-11 s METAL, CHIP 51 5% 1/16W

R229 1-216-813-11 s METAL, CHIP 220 5% 1/16W

C217 1-107-686-11 s CHIP, TANTALUM 4.7uF 20% 16V

C218 1-164-004-11 s CERAMIC, CHIP 0.1uF 10% 25V

R230 1-216-809-11 s METAL, CHIP 100 5% 1/16W

R231 1-216-809-11 s METAL, CHIP 100 5% 1/16W

C219 1-107-688-11 s CHIP,TANTALUM 1.5uF 20% 25V

C220 1-164-691-11 s CERAMIC 0.0024uF 5% 50V

C221 1-164-004-11 s CERAMIC, CHIP 0.1uF 10% 25V

R232 1-216-837-11 s CHIP, METAL 22K 5% 1/16W

R234 1-216-813-11 s METAL, CHIP 220 5% 1/16W

R235 1-218-292-11 s METAL, CHIP 20K 5% 1/10W

C222 1-164-004-11 s CERAMIC, CHIP 0.1uF 10% 25V

C224 1-110-497-11 s CHIP CERAMIC 1uF 20% 100V

R236 1-218-292-11 s METAL, CHIP 20K 5% 1/10W

R237 1-216-844-11 s CHIP, METAL 82K 5% 1/16W

C225 9-885-005-22 s ELECT 4.7uF 100V

R238 1-216-821-11 s METAL, CHIP 1K 5% 1/16W

CN201B 1-569-528-11 s HOUSING 12P

CN202 9-885-005-21 s PIN HEADER

CN203 9-885-005-21 s PIN HEADER

R239 1-216-813-11 s METAL, CHIP 220 5% 1/16W

R240 1-216-833-11 s METAL, CHIP 10K 5% 1/16W

R241 1-216-821-11 s METAL, CHIP 1K 5% 1/16W

R242 1-220-151-11 s METAL, CHIP 51 5% 1/16W

D201 8-719-941-86 s DIODE DAN202U

D202 9-885-005-23 s DIODE UDZ15B

D203 9-885-005-24 s DIODE UDZ5.1B

R243 1-216-841-11 s METAL 47K 5% 1/16W

R244 1-218-272-11 s METAL, CHIP 5.1K 5% 1/16W

R246 1-216-833-11 s METAL, CHIP 10K 5% 1/16W

DL201 1-411-876-11 s DELAY LINE

R247 1-216-833-11 s METAL, CHIP 10K 5% 1/16W

R248 1-216-845-11 s METAL, CHIP 100K 5% 1/16W

IC201 8-759-058-50 s IC XRA10324AF

IC202 8-759-391-22 s IC CA3094M

IC203 8-759-394-29 s IC AD8011AR

IC204 8-759-395-40 s IC HFA1135IB

IC205 8-759-391-21 s IC DG613-DY

R249 1-218-331-11 s CHIP, METAL 51K 5% 1/16W

R250 1-218-331-11 s CHIP, METAL 51K 5% 1/16W

R251 1-218-272-11 s METAL, CHIP 5.1K 5% 1/16W

R252 1-216-817-11 s CHIP, METAL 470 5% 1/16W

R253 1-216-809-11 s METAL, CHIP 100 5% 1/16W

L201 1-412-066-21 s INDUCTOR CHIP 220UH

R254 1-202-926-11 s CHIP, METAL 36K 5% 1/16W

LED201 8-719-989-53 s DIODE CL-200HR-C-TSL

LED202 8-719-989-53 s DIODE CL-200HR-C-TSL

R255 1-216-841-11 s METAL 47K 5% 1/16W

R256 1-216-815-11 s METAL, CHIP 330 5% 1/16W

R257 1-216-815-11 s METAL, CHIP 330 5% 1/16W

Q201 8-729-036-40 s TRANSISTOR 2SA1580

R258 1-216-815-11 s METAL, CHIP 330 5% 1/16W

Q202 8-729-036-39 s TRANSISTOR 2SC4104

Q203 8-729-036-39 s TRANSISTOR 2SC4104

R259 1-216-815-11 s METAL, CHIP 330 5% 1/16W

Q204 8-729-927-87 s TRANSISTOR 2SA1579RR

Q205 8-729-038-81 s TRANSISTOR 2SC4102-T106

RV201 1-238-290-11 s CARBON, VAR 1K

RV202 9-885-005-09 s RES, ADJ METAL 4.7K

Q206 8-729-802-80 s TRANSISTOR 2SC3661

Q207 9-885-005-25 s TRANSISTOR IMT1A

RV203 9-885-005-18 s RES, ADJ METAL 470

RV204 1-238-290-11 s CARBON, VAR 1K

RV205 9-885-005-15 s RES, ADJ METAL 220K

R201 1-216-839-11 s METAL, CHIP 33K 5% 1/16W

R203 1-216-023-00 s CHIP, METAL 82 5% 1/10W

R204 1-216-812-11 s METAL, CHIP 180 5% 1/16W

R205 1-218-331-11 s CHIP, METAL 51K 5% 1/16W

RV206 1-238-293-11 s CARBON, VAR 10K

RV207 9-885-005-09 s RES, ADJ METAL 4.7K

RV208 9-885-005-09 s RES, ADJ METAL 4.7K

R206 1-216-827-11 s METAL, CHIP 3.3K 5% 1/16W

R207 1-216-833-11 s METAL, CHIP 10K 5% 1/16W

R209 1-218-272-11 s METAL, CHIP 5.1K 5% 1/16W

R210 1-218-272-11 s METAL, CHIP 5.1K 5% 1/16W

R211 1-216-833-11 s METAL, CHIP 10K 5% 1/16W

3-8

HDVF-20A

Page 29

----Frame

---- Ref. No.

or Q'ty Part No. SP Description

1pc ! 1-251-636-11 s CRT ASSY, 2inch HD

1pc 1-777-131-11 s CORD, CONNECTION(VF)

3-3. Supplied Accessories

Ref. No.

or Q'ty Part No. SP Description

1pc 3-179-882-01 o SPACER, MICROPHONE(21 mm dia.)

1pc 3-680-582-01 o HOLDER (B), MICROPHONE(19 mm dia.)

3-4. Tools and Fixtures

Part No. SP Description

J-6029-140-B o PATTERN BOX PTB-500

J-6395-050-A o VF EXTENSION HARNESS

J-6395-320-A o RESOLUTION CHART(16:9)

HDVF-20A

3-9

Page 30

Page 31

Section 4

Semiconductor Pin Assignments

The following describes the semiconductor types used in

this unit.

For semiconductors marked with page numbers in the

index, refer to the corresponding pages in this section.

However, in some cases incompatible types are also listed,

therefore, when a part is to be replaced, also refer to the

Spare Parts section.

In addition, for semiconductors with ID Nos., refer to the

separate CD-ROM titled “Semiconductor Pin Assignments”

(Sony Part No. 9-968-546-xx) that allows searching for

parts by semiconductor type or ID No.

The semiconductors in the manual or on the CD-ROM are

listed by equivalent types. Thus the external view or the

index mark indication may differ from the actual type.

Pin assignments and block diagrams are based on the IC

manufacturer’s data book.

Index

DIODE Page or ID No.

DA204U ...........................................................................DC001-01

DA204UT106 ................................................................... DC001-01

DAN202U .........................................................................DC001-03

DAN202UT106.................................................................DC001-03

DTZ5.1B...........................................................................DC008-04

HZK2ALL .........................................................................DC008-04

HZK2ALLTL ..................................................................... DC008-04

IMN10 ..............................................................................DC005-01

MA2S728-(K8).SO ...........................................................DC008-02

RD15UJN-T1 ...................................................................DC008-04

RLS245TE-11 ..................................................................DC006-01

SC802-04 .........................................................................DC008-02

SC802-04-TE12RA ..........................................................DC008-02

UDZ-TE-17-15B ...............................................................DC008-04

UDZ-TE-17-5.1B ..............................................................DC008-04

LED Page or ID No.

CL-150D-CD .................................................................... LC001-01

CL-150D-CD-T ................................................................. LC001-01

CL-150PG-CD.................................................................. LC001-01

CL-150PG-CD-T .............................................................. LC001-01

CL-150UR-CD-T .............................................................. LC001-01

TRANSISTOR Page or ID No.

2SA1576A-T106-QR........................................................ TC001-01

2SA1576A-T106-R........................................................... TC001-01

2SA1579RR ..................................................................... TC001-01

2SA1580 .......................................................................... TC001-01

2SA933AS-QT ................................................................. TR008-02

2SA933AS-RT ................................................................. TR008-02

2SC3661 .......................................................................... TC001-02

2SC4080 .......................................................................... TC002-02

2SC4081-S ...................................................................... TC001-02

2SC4102-T106................................................................. TC001-02

2SC4102T106 .................................................................. TC001-02

2SC4104 .......................................................................... TC001-02

2SK1374 .......................................................................... TC001-07

2SK1826(TE85L) ............................................................. TC001-07

2SK1920-TL..................................................................... TC010-01

2SK2534 ..................................................................................... 4-2

DTA144EUA-T106 ........................................................... TC001-04

IMB2A .............................................................................. TC005-07

IMH2A .............................................................................. TC005-14

IMH3A .............................................................................. TC005-12

IMT1AT108 ...................................................................... TC006-10

SI4953DY-T1 ................................................................... TC012-02

XN4601 ............................................................................ TC006-06

XN4601-TX ...................................................................... TC006-06

HDVF-20A

4-1

Page 32

Index, Transistor

IC Page or ID No.

AD8011AR ..................................................................... AD8011AR

BA10324AF................................................................ XRA10324AF

BA225F-T1.......................................................................... BA225F

BA9743AFV-E2........................................................................... 4-3

BR24C02F ..................................................................... BR24C02F

CA3094M .................................................................................... 4-3

DG613-DY .................................................................................. 4-3

GS4981IKA ..................................................................GS4981CTA

HFA1135IB ................................................................................. 4-3

LA7858.................................................................................LA7858

LM4041EIM3-1.2 ........................................................................ 4-3

PCF8574T.......................................................................PCF8574T

[|TRANSISTOR|]

—TOP VIEW—

2SK2534

S

SN74HC175APW-E05 ...............................................TC74HC175P

TA75S01F ....................................................................... TA75S01F

TA75S393F ................................................................... TA75S393F

TA75S393F-TE85R ...................................................... TA75S393F

TA78L05F .................................................................. NJM78L12UA

TA78L05F-TE12L ......................................................NJM78L12UA

TC4426EOA.................................................................TC4426EOA

TC4427EOA.................................................................TC4427EOA

TC4S69F...........................................................................TC7S04F

TC4S69F(TE85R) .............................................................TC7S04F

TC4W53FU ................................................................... TC4W53FU

TC4W53FU(TE12R) ..................................................... TC4W53FU

TC74HC4538AFS ...................................................MC74HC4538N

TC74HC4538AFS-EL .............................................MC74HC4538N

TC74HC4538AFT(EL) ............................................MC74HC4538N

TC7S08FU(TE85R) ..........................................................TC7S08F

TC7S32FU(TE85R) ..........................................................TC7S32F

TC7W00FU ......................................................................TC7W00F

TC7W00FU(TE12R) ........................................................TC7W00F

TC7W02F.........................................................................TC7W02F

TC7W02FU(TE12R) ........................................................TC7W02F

TC7W08FU ......................................................................TC7W08F

TC7W08FU(TE12R) ........................................................TC7W08F

TC7W32FU ................................................................... TC7W32FU

4-2

HDVF-20A

Page 33

[|IC|]

IC

BA9743AFV-E2 (ROHM)

2-CH SWITCHING REGURATOR CONTROLLER

—TOP VIEW—

1

CT

RT

2

NON1

3

INV1

4

FB1

5

DT1

6

OUT1

7

GND

8

INPUTS

CT

DT1

DT2

INV1

INV2

NON1

NON2

RT

SCP

OUTPUTS

FB1

FB2

OUT1, OUT2

REF

V

: EXTERNAL TIMING CAPACITANCE

: OUTPUT 1 DEAD TIME/SOFT START SETTING

: OUTPUT 2 DEAD TIME/SOFT START SETTING

: NEGATIVE INPUT FOR ERROR AMPLIFIER 1

: NEGATIVE INPUT FOR ERROR AMPLIFIER 2

: POSITIVE INPUT FOR ERROR AMPLIFIER 1

: POSITIVE INPUT FOR ERROR AMPLIFIER 2

: EXTERNAL TIMING RESISTANCE

: TIMER LATCH SETTING

: OUTPUT FOR ERROR AMPLIFIER 1

: OUTPUT FOR ERROR AMPLIFIER 2

: OUTPUT 1, OUTPUT 2

: REFERENCE VOLTAGE (2.505 V) OUTPUT

V

16

REF

SCP

15

NON2

14

INV2

13

FB2

12

DT2

11

OUT2

10

CC

V

9

DG613-DY (SILICONIX)

D/CMOS QUAD ANALOG SWITCHES

—TOP VIEW—

IN2 D2 S2 S3 D3 IN3

16 15 14 13 12 11 10 9

V (+) VL

V (_) GND

1 2 3 4 5 6

IN1 D1 S1 S4 D4 IN4

7 8

TRUTH TABLE

LOGIC S1,S4 S2,S3

01OFF ON

OFFON

LOGIC “0” ≤ 1 V

LOGIC “1” ≥ 4 V

HFA1135IB (HARRIS)

OPERATIONAL AMPLIFIER

—TOP VIEW—

1

NC

2

IN(_)

IN(+)

CT

RT

1

2

_

+

3

V(_)

4

V(+)

8

7

6

5

VH

OUTPUT

VL

NON1

NON2

V

INV1

INV2

SCP

16

REF

3

+

4

_

5

FB1

14

+

13

_

12

FB2

15

REFERENCE

VOLTAGE

REF

V

ERR

AMP 1

ERR

AMP 2

+

+

_

V

REF

SR

TIMER

LATCH

UVLO

R

SCP COMP

CA3094M (HARRIS)

PROGRAMMABLE POWER SWITCH/AMPLIFIER

—TOP VIEW—

EXT. FREQUENCY

COMPENSATION

OR IN-HIBIT INPUT

DIFFERENTIAL

VOLTAGE INPUT

1

2

+

_

3

V (

_

)

4

8

SHINK OUTPUT(COLLECTOR)

7

+

)

V (

DRIVE OUTPUT(EMITTER)

6

CURRENT(PROGRAMMABLE INPUT)

5

V

V

REF

REF

DT16DT2

11

TRIANGLE

OSCILLATOR

_

+

+

PWM COMP1

_

+

+

PWM COMP2

7

OUT1

LM4041EIM3-1.2 (FSC)

SHUNT VOLTAGE REFERENCE

10

—TOP VIEW—

OUT2

2

+

3

_

Reverse breakdown voltage = 1.225V

1

HDVF-20A

4-3

Page 34

Page 35

Section 5

Block Diagram

HDVF-20A

5-1

5-1

Page 36

OverallOverall

TO

CAMERA HEAD

D4

NON STANDARD

D5

TALLY/REC

D6

VTR SAVE

D1

BATT

D2

TALLY/REC

D3

(G TALLY)

LP-105

20-PIN

CONNECTOR

21-5

21-6

21-7

21-8

21-1

21-2

21-3

21-4

1-A7

1-B5

1-B10

1-A2

301-6

301-5

301-8

301-1

301-4

1-B2

1-A1

301-7

301-2

301-3

1-B4

1-A9

TP1

HD

RV401

F-SYNC

NON STANDARD

VTR SAVE

BATT

SCK

SDA

R.TALLY

G.TALLY

G.TALLY

R.TALLY

VIDEO

UNREG

POWER OFF

13

1

2

4

DRIVER

DRIVER

Q306

DRIVER

IC401

OSC

15 SHUTDOWN2

Q305

Q304

Q305 Q304

Q401,405

9

SHUTDOWN1

7

5

8

COMPA-

IC304

5SEC.

TIMER

0.1SEC.

TIMER

Q306

DRIVER

14

10

7

3

16

IC502

RATOR

10

Q302

DRIVER

Q301

DRIVER

Q301

DRIVER

Q303

1

214

3

Q303

Q403

DRIVE

Q404

DRIVE

VREF9

5

OFF

Q402(2/2)

4

P0

5

P1

6

P2

11

P6

ON

S302

ZEBRA

OFF

MOMENTARY

LED301

BACK TALLY

HIGH

S303

LOW

Q402(1/2)

IC301

EXPANDER

SCLSDA

15 14

RV402

+9.5V-ADJ

7

P3

9

P4

5

P5

12

P7

2KBIT

MEMORY

IC303

+9.5V OUT

IC501

IC502

2

COMPA-

3

RATOR

IC502

75

BUFFER

MOMENTARY

OFF

ON

141565

SCLSDASCLSDA