Sony HDS-X5800 User Manual

ROUTING SWITCHER PROCESSOR

HDS-X5800

33 INPUT BOARD SET

HKS-5810M

HKS-5810SD

34 CASCADE INPUT BOARD SET

HKS-5811M

HKS-5811SD

33 INPUT DISTRIBUTION BOARD

HKS-5820M

264 x 34 MATRIX BOARD

HKS-5830M

HKS-5830SD

34 OUTPUT BOARD SET

HKS-5860M

HKS-5860SD

INSTALLATION MANUAL

1st Edition (Revised 2)

! WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

HDS-X5800 Serial No. 10001 and Higher

HKS-5810M Serial No. 10001 and Higher

HKS-5810SD Serial No. 10001 and Higher

HKS-5811M Serial No. 10001 and Higher

HKS-5811SD Serial No. 10001 and Higher

HKS-5820M Serial No. 10001 and Higher

HKS-5830M Serial No. 10001 and Higher

HKS-5830SD Serial No. 10001 and Higher

HKS-5860M Serial No. 10001 and Higher

HKS-5860SD Serial No. 10001 and Higher

HDS-X5800

Attention-when the product is installed in Rack:

(For HDS-X5800)

For the customers in the Netherlands

Voor de klanten in Nederland

1. Prevention against overloading of branch circuit

When this product is installed in a rack and is

supplied power from an outlet on the rack, please

make sure that the rack does not overload the supply

circuit.

2. Providing protective earth

When this product is installed in a rack and is

supplied power from an outlet on the rack, please

confirm that the outlet is provided with a suitable

protective earth connection.

3. Internal air ambient temperature of the rack

When this product is installed in a rack, please make

sure that the internal air ambient temperature of the

rack is within the specified limit of this product.

4. Prevention against achieving hazardous

condition due to uneven mechanical loading

When this product is installed in a rack, please make

sure that the rack does not achieve hazardous

condition due to uneven mechanical loading.

5. Install the equipment while taking the operating

temperature of the equipment into consideration

For the operating temperature of the equipment, refer

to the specifications of the Operation Manual.

Hoe u de batterijen moet verwijderen, leest u in de

Onderhoudshandleiding.

Gooi de batterij niet weg maar lever deze in als klein

chemisch afval (KCA).

Für Kunden in Deutschland

Entsorgungshinweis: Bitte werfen Sie nur entladene

Batterien in die Sammelboxen beim Handel oder den

Kommunen. Entladen sind Batterien in der Regel dann,

wenn das Gerät abschaltet und signalisiert “Batterie

leer” oder nach längerer Gebrauchsdauer der Batterien

“nicht mehr einwandfrei funktioniert”. Um

sicherzugehen, kleben Sie die Batteriepole z.B. mit

einem Klebestreifen ab oder geben Sie die Batterien

einzeln in einen Plastikbeutel.

6. When performing the installation, keep the rear of

the unit 10 cm (4 inches) or more away from walls

in order to obtain proper exhaust and radiation of

heat.

When using a LAN cable:

For safety,do not connect to the connector for

peripheral device wiring that might have excessive

voltage.

HDS-X5800

1 (P)

Table of Contents

Manual Structure

Purpose of this manual ........................................................................................ 3 (E)

Related manuals................................................................................................... 3 (E)

Contents ............................................................................................................... 4 (E)

Trademarks .......................................................................................................... 4 (E)

1. Installation

1-1. Installation Procedure............................................................................ 1-1 (E)

1-2. Operating Environment .........................................................................1-2 (E)

1-3. Power Supply ........................................................................................ 1-2 (E)

1-3-1. Power Specifications ............................................................1-2 (E)

1-3-2. Power Cord ........................................................................... 1-2 (E)

1-4. Installation Space .................................................................................. 1-3 (E)

1-5. Rack Mounting ...................................................................................... 1-4 (E)

1-5-1. Precautions for Rack Mounting ...........................................1-4 (E)

1-5-2. Rack Mounting Procedure .................................................... 1-5 (E)

1-6. Installation of Optional Boards ............................................................. 1-7 (E)

1-6-1. Table of Optional Boards ..................................................... 1-7 (E)

1-6-2. List of Installation Slots ....................................................... 1-7 (E)

1-6-3. Installation/Removal of Plug-in Boards ............................... 1-8 (E)

1-6-4. Installation/Removal of Connector Boards ........................1-10 (E)

1-7. Matching Connectors and Cables........................................................ 1-12 (E)

1-8. Input and Output Signals of Connectors ............................................. 1-13 (E)

1-9. System Connection.............................................................................. 1-14 (E)

1-9-1. S-BUS Data Link ...............................................................1-14 (E)

1-10. How to Extend Inputs and Outputs ..................................................... 1-16 (E)

1-10-1. Equipment Required for System Extension ....................... 1-16 (E)

1-10-2. How to Configure Optional Boards ...................................1-18 (E)

1-10-3. Cascade Connection Example ............................................1-19 (E)

1-10-4. Output Extension Example ................................................1-20 (E)

1-10-5. Input/Output Extension Example .......................................1-21 (E)

1-10-6. Control System Connection Example and Setup ............... 1-22 (E)

HDS-X5800

1 (E)

1-11. Setting the On-Board Switches and Description of LEDs ..................1-23 (E)

1-11-1. CPU-339 Board (HDS-X5800) .......................................... 1-23 (E)

1-11-2. MX-103 Board (HKS-5830M) ........................................... 1-30 (E)

1-11-3. MX-104 Board (HKS-5830SD) ......................................... 1-32 (E)

1-11-4. IPM-98 Board (HKS-5820M) ............................................ 1-32 (E)

1-11-5. EQ-91 Board (HKS-5811M) ..............................................1-33 (E)

1-11-6. EQ-92 Board (HKS-5811SD) ............................................ 1-33 (E)

1-11-7. FP-129 Board (HDS-X5800) .............................................1-34 (E)

1-11-8. CNI-11 Board (HKS-5810M) ............................................ 1-38 (E)

1-11-9. CNI-12 Board (HKS-5810M) ............................................ 1-38 (E)

1-11-10. CNI-13 Board (HKS-5810SD) ........................................... 1-38 (E)

1-11-11. CNI-14 Board (HKS-5810SD) ........................................... 1-39 (E)

1-11-12. CNO-13 Board (HKS-5860M) ........................................... 1-39 (E)

1-11-13. CNO-14 Board (HKS-5860M) ........................................... 1-39 (E)

1-11-14. CNO-15 Board (HKS-5860SD) ......................................... 1-40 (E)

1-11-15. CNO-16 Board (HKS-5860SD) ......................................... 1-40 (E)

1-11-16. SPG-16 Board (HDS-X5800) ............................................1-40 (E)

1-11-17. RM-192 Board (HDS-X5800) ............................................ 1-41 (E)

1-11-18. TR-127 Board (HDS-X5800) ............................................. 1-41 (E)

1-12. Setting IP Address ............................................................................... 1-42 (E)

2. Service Overview

2-1. Main Parts Location .............................................................................. 2-1 (E)

2-2. Removing/Installing the Front Panel ....................................................2-4 (E)

2-3. Error Indication ..................................................................................... 2-5 (E)

2-3-1. Error Number Display on the CPU-339 Board .................... 2-5 (E)

2-3-2. Front Panel Status Indication (LE-251/FP-129 Board) ........ 2-6 (E)

2-4. Cleaning Filter ..................................................................................... 2-12 (E)

2-5. CPU Battery ........................................................................................ 2-12 (E)

2-6. Data Backup ........................................................................................2-13 (E)

2-6-1. Connection .........................................................................2-13 (E)

2-6-2. Installing BZR-20 ............................................................... 2-14 (E)

2-6-3. Uploading Data ..................................................................2-15 (E)

2-6-4. Downloading Data .............................................................2-16 (E)

2 (E)

HDS-X5800

Purpose of this manual

Related manuals

Manual Structure

This manual is the installation manual of Routing Switcher Processor HDS-X5800

and the optional boards.

This manual is intended for use by trained system and service engineers, and

describes the information on installing the HDS-X5800.

Besides this Installation Manual, the following manuals are prepared for HDSX5800 and the optional boards.

..

. Operation Manual (Supplied with HDS-X5800)

..

This manual describes the application and operation of HDS-X5800.

..

. System Setup Manual (Supplied with HDS-X5800)

..

This manual describes the software initialization or operation confirmation.

..

. e-Manual (Tentative name) (Available on request)

..

This electronic manual intended for use by trained system and service engineers

describes detailed parts list, block diagrams, schematic diagrams, and board layouts

required for parts-level service.

For obtaining, contact your local Sony Sales Office/Service Center.

..

. Protocol Manual (Available on request)

..

This manual describes the protocol for controlling this unit.

The manual below is provided for the protocol that this unit can support.

If this manual is required, please contact your local Sony Sales Office/Service Center.

S-BUS PROTOCOL AND COMMAND SPECIFICATIONS

(S-BUS remote terminal control protocol)

Part No.: 9-977-477-1X

..

. “Semiconductor Pin Assignments” CD-ROM (Available on request)

..

This “Semiconductor Pin Assignments” CD-ROM allows you to search for

semiconductors used in B&P Company equipment.

Semiconductors that cannot be searched for on this CD-ROM are listed in the

maintenance manual for the corresponding unit. The maintenance manual contains

a complete list of all semiconductors and their ID Nos., and thus should be used

together with the CD-ROM.

Part number: 9-968-546-XX

HDS-X5800

3 (E)

Contents

Trademarks

The following is a summary of all the sections of this manual.

Section 1 Installation

This section describes the operating environment, power supply, installation space,

rack mounting, installation of optional boards, connectors, input and output signals

of connectors, system connection, extension of inputs/outputs and on-board switch/

LED.

Section 2 Service Overview

This section describes the location of main parts, error indication, data backup.

Trademarks and registered trademarks used in this manual are follows.

. Ethernet is a registered trademark of Xerox Corporation.

. IBM and AT are registered trademarks of International Business Machines

Corporation.

. Pentium is a registered trademark of Intel Corporation.

. Windows is a registered trademark of Microsoft Corporation.

4 (E)

HDS-X5800

Section 1

Installation

1-1. Installation Procedure

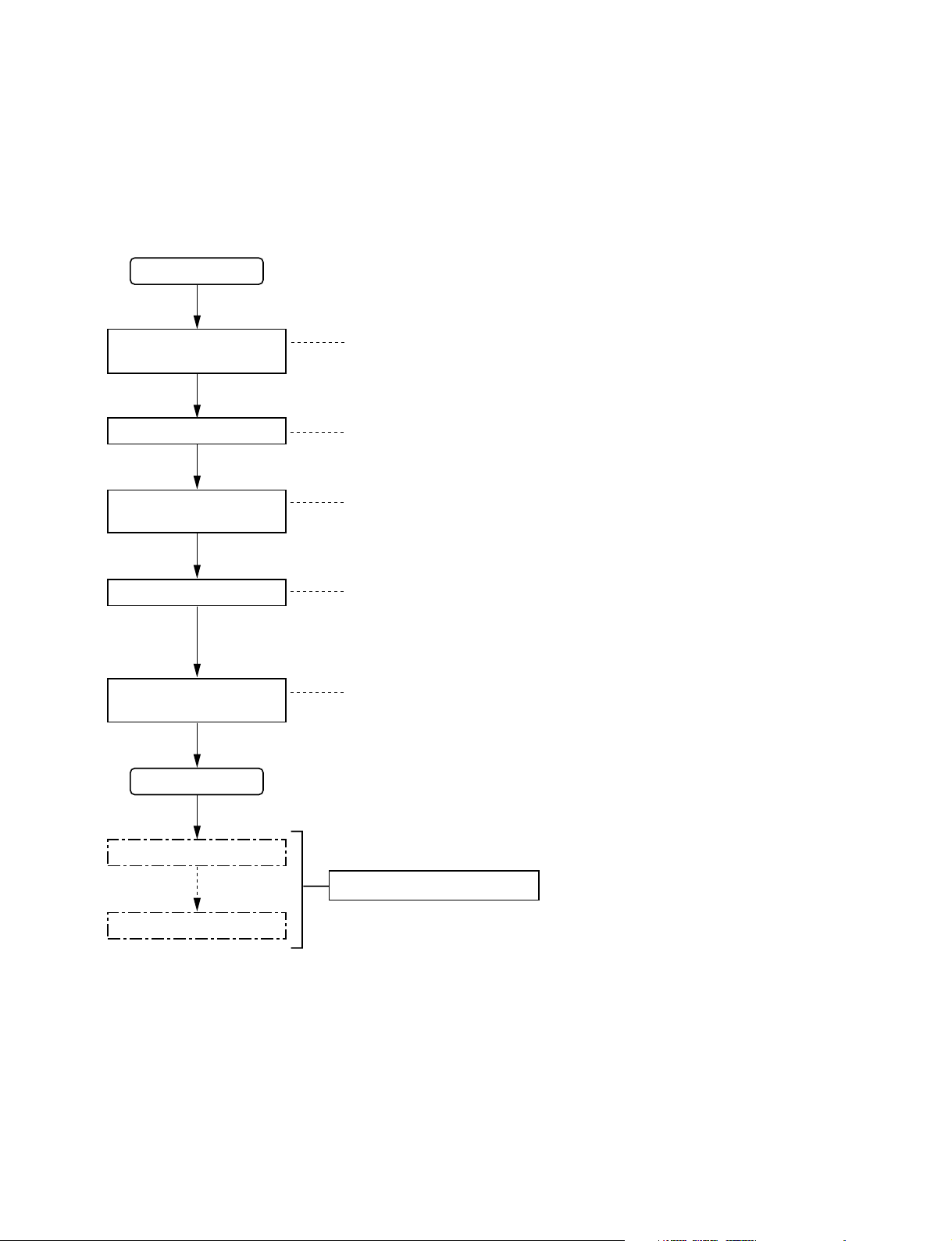

The following chart shows the procedure for installing the unit.

For details of the following chart, refer to the relevant section or related manual.

Start

Operating Environment

Selection of installation

place

1-2.

Power Supply

1-3.

Installation Space

1-4.

Rack mounting

Installation of optional

boards

Connection

Setting the On-Board

Switches

End

Initial setting

Rack Mounting

1-5.

Installation of Optional Boards

1-6.

Matching Connectors and Cables

1-7.

Input and Output Signals of Connectors

1-8.

System Connection

1-9.

How to Extend Inputs and Outputs

1-10.

Setting the On-Board Switches and

1-11.

Description of LEDs

System Setup Manual

Operation check

HDS-X5800

1-1 (E)

1-2. Operating Environment

1-3. Power Supply

1-2. Operating Environment

w

Do not install the unit in a place subject to excessive oil

vapor, steam, moisture, or dust, otherwise a fire or electric

shock may result.

m

. To prevent the temperature rising inside the unit, ensure

there is adequate circulation of air near where the unit is

installed. Never block the ventilation holes.

. Never install the unit near a heat source.

Operating temperature : 5 dC to 40 dC

Storage temperature : _20 dC to +60 dC

Operating humidity : 10% to 90% (no condensation)

1-3. Power Supply

The HDS-X5800 contains the four power supply units as

the standard installation.

The units A1 and B1, and the units A2 and B2 back up the

two power line systems respectively. Therefore, turn on all

of the four power supply units when using the HDSX5800.

(Refer to Section 2-1 for the location of the power supply

units.)

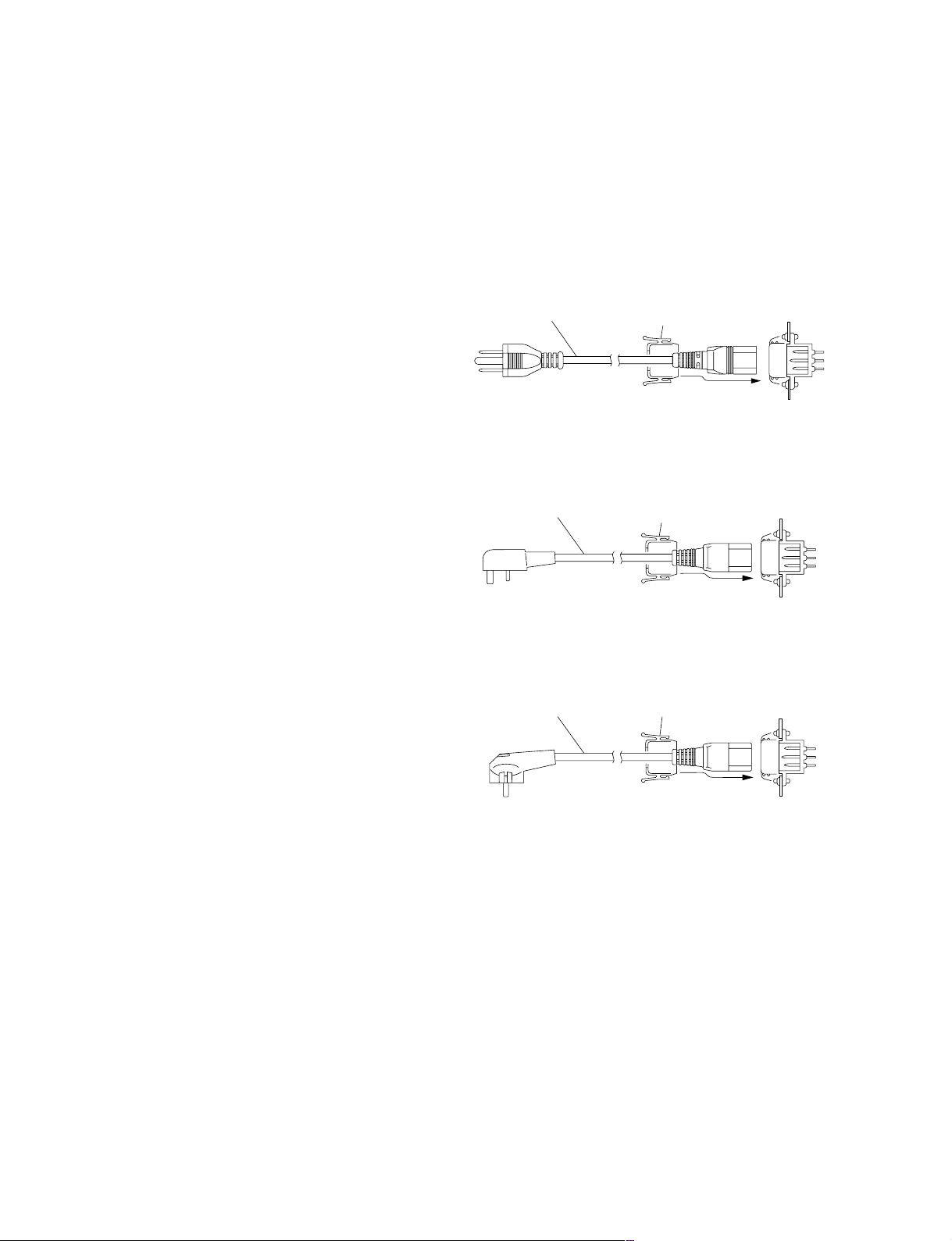

1-3-2. Power Cord

w

The power cords are not supplied with the unit. Be sure to

use power cords that are suitable for the place of operation.

For customers in the U.S.A. and Canada

1 Power cord, 125 V 10 A (2.4 m) : ! 1-557-377-11

2 Plug holder (Black) :

1

For customers in the United Kingdom

1 Power cord, 250 V 10 A (2.4 m) : ! 1-782-165-11

2 Plug holder (Brown) :

1

For customers in European countries except the United Kingdom

1 Power cord, 250 V 10 A (2.0 m) : ! 1-551-631-22

2 Plug holder (Brown) :

1

2

2

2

2-990-242-01

AC inlet

3-613-640-01

AC inlet

3-613-640-01

AC inlet

1-3-1. Power Specifications

Power requirements AC 100 to 240 V ± 10%

Power frequency 50/60 Hz

Current consumption AC100 V : 12 A (max.)

AC240 V : 4 A (max.)

Inrush current

Power consumption 1200 VA (max.)

n

The capacity of the AC power must be commensurate with

the inrush current. If the capacity of the AC power is not

sufficiently large, the breaker of the AC power on the

supply side will trip or the unit will not operate normally.

At power voltage of 100 V : 60 A

(Maximum when all of the four

power supply units are turned on)

At power voltage of 240 V : 85 A

(Maximum when all of the four

power supply units are turned on)

n

For the customer outside of the area as shown above,

please contact your local Sony Sales Office/Service

Center.

1-2 (E)

HDS-X5800

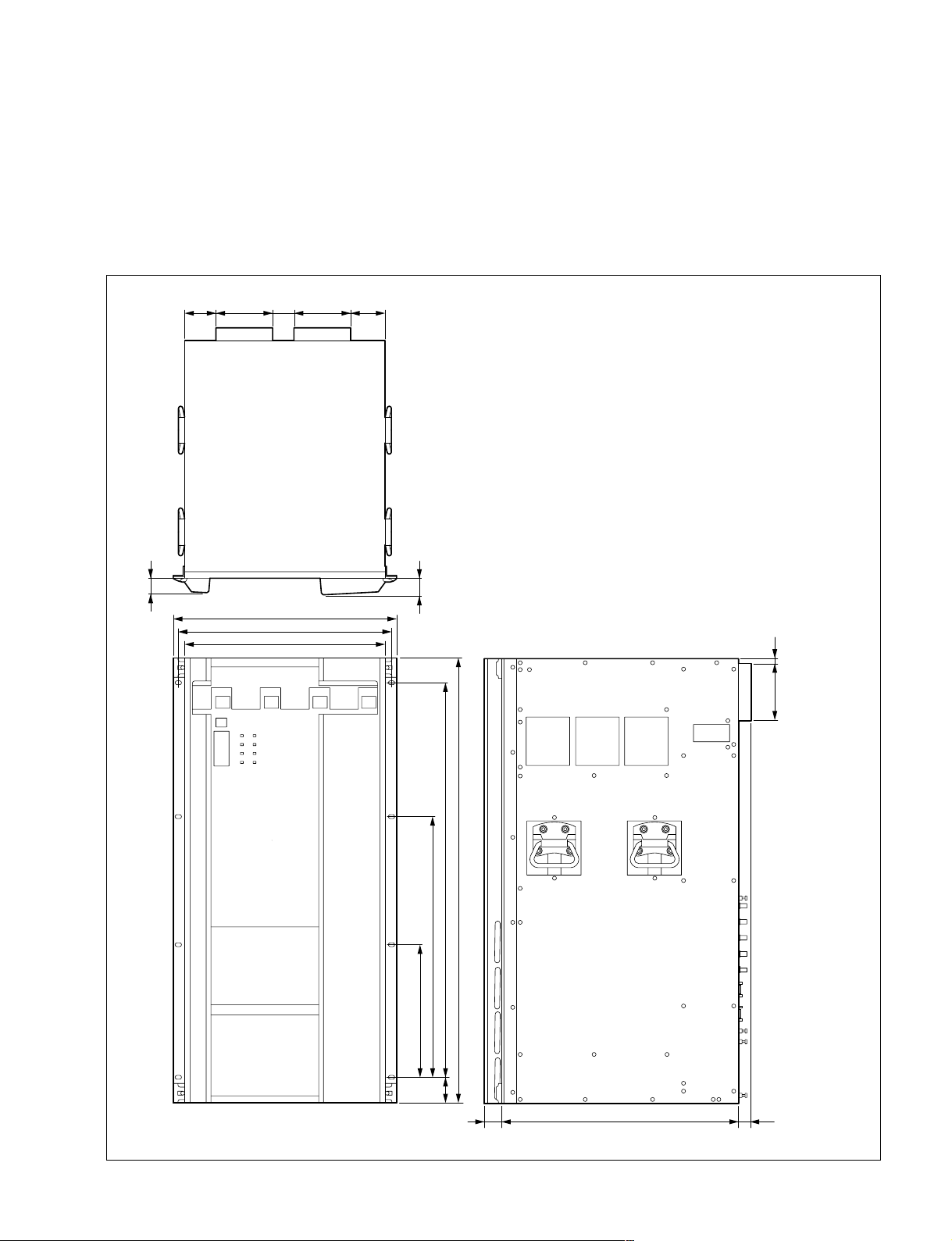

1-4. Installation Space

m

. The rear side of the unit should be at least 40 cm (16 inches) away from walls for ventilation and

maintenance.

. If a fan stops or the exhaust port is blocked, failure or problems may result because the fans at the rear,

top, and bottom of the unit cool the air.

1-4. Installation Space

72 72

31

48124 124

482

465

440

35

13

124

HDS-X5800

562

282.6

844.6

974 (22 U)

64.7

35

520

29

Unit : mm

1-3 (E)

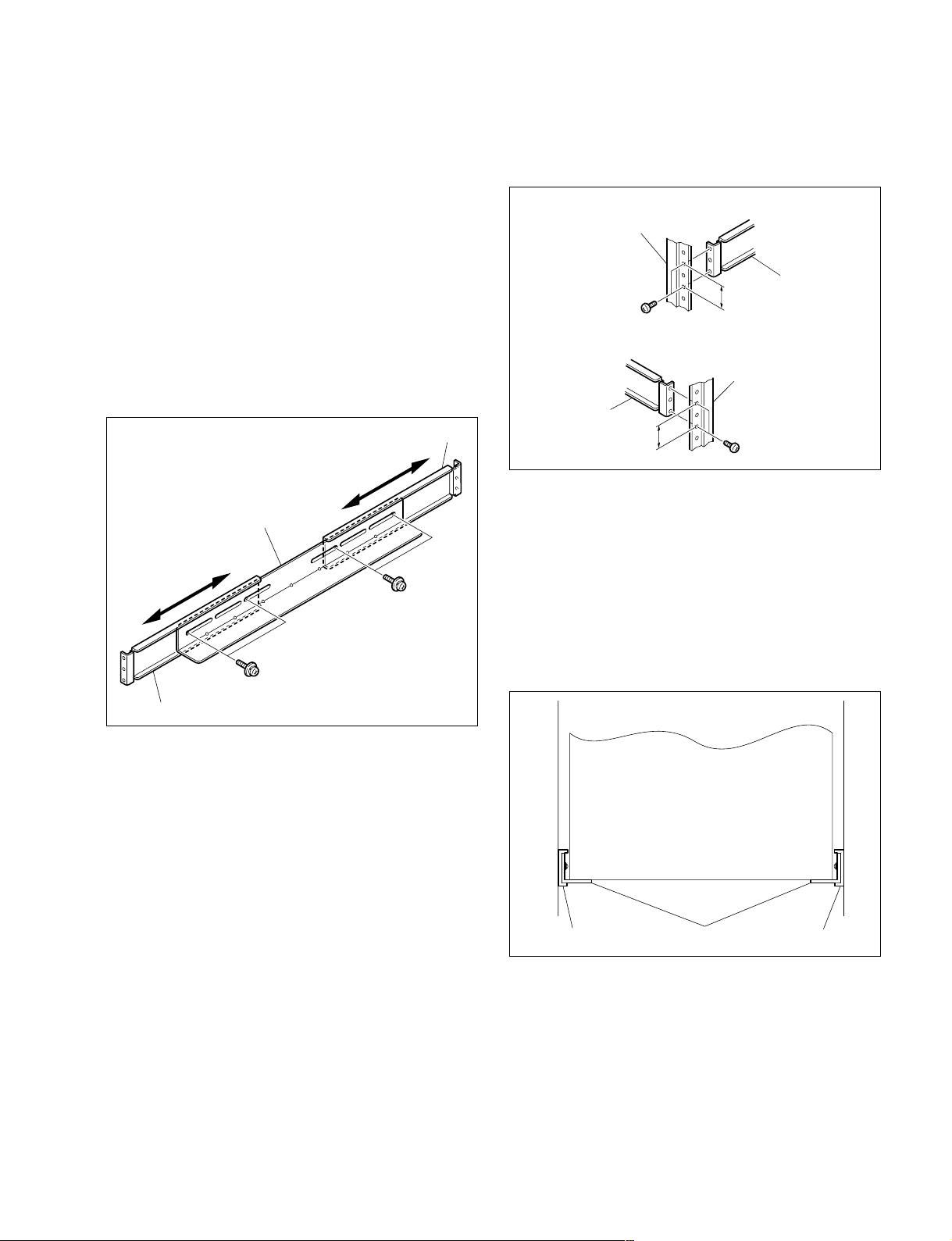

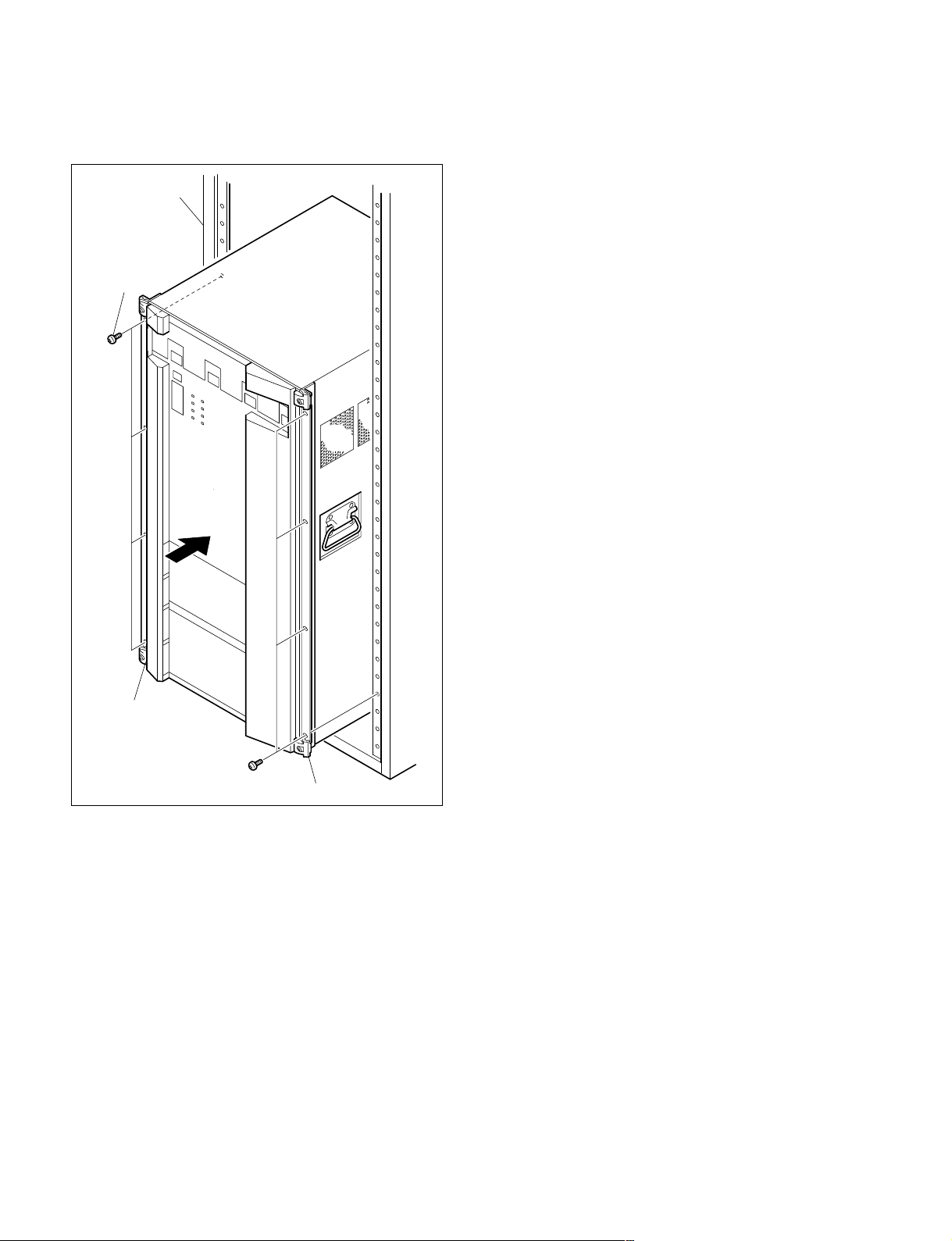

1-5. Rack Mounting

1-5. Rack Mounting

The HDS-X5800 is mounted in the 19-inch standard rack.

To mount the HDS-X5800 in the rack, use the rack mount

kit that is supplied with the HDS-X5800 and follow the

procedure described below.

n

If other than the specified rack mount kit is used, the HDSX5800 may not be mounted in the 19-inch standard rack.

Parts of the supplied rack mount kit

. Support angle 2 pcs

. Bracket 4 pcs

. Support angle fixing screw 8 pcs

(PSW4 x 10 : 7-682-962-01)

. Bracket fixing screw 8 pcs

(B4 x 10 : 7-682-562-04)

Other required parts

To mount in the rack, the supplied rack mount parts and

the following part are required.

. Screw for rack mounting 4 pcs

(B5 x 12 : 7-682-576-04)

1-5-1. Precautions for Rack Mounting

w

. Be sure to mount in the rack with four persons or more.

. Mount in the rack in a stable position.

. To prevent the rack from falling or moving, fix the rack

on a flat and steady floor using bolt or others.

If the rack falls due to the weight of the equipment, it

may cause death or injury.

. After rack mounting, be sure to tighten the screws on the

rack angle and fix the unit in the rack.

If the screws on the rack angle are not tightened, the unit

may slip from the rack and fall, causing injury.

c

When mounting the unit in the rack, note the following:

. Be sure to use the supplied rack mount kit.

If not, injury may result and the equipment may fall due

to insufficient strength.

. Be careful not to catch your fingers or hands in the rack

mount rail or others.

n

If several units are mounted in a rack, it is recommended to

install a ventilation fan to prevent temperature rise inside

the rack.

1-4 (E)

HDS-X5800

1-5. Rack Mounting

1-5-2. Rack Mounting Procedure

This section describes the rack mounting procedure using

the rack mount kit supplied with the HDS-X5800.

n

Tighten the screws to the following torque.

Tightening torque : 120 x 10_2 N.m {12.2 kgf.cm}

1. Attach the bracket to the support angle tentatively

using the specified four screws.

2. Loosen the front and rear screws that are tentatively

fastened in step 1. Adjust the length of the brackets

according to the depth of the rack.

(The illustration below shows the left bracket.)

Bracket

Support angle

PSW4 x 10

PSW4 x 10

3. Attach the right and left brackets to the rack completely using the specified eight screws.

(The illustration below shows the left bracket.)

Front side

Rack

Bracket

31.75

B4 x 10

Rear side

Rack

Bracket

31.75

B4 x 10

Unit : mm

4. Tighten the screws (four screws each on the right and

left) for adjusting the length of the bracket completely

(the screws that were loosened in step 2).

5. Place the right and left ends of the bottom of the HDSX5800 on top of the support angles, and slide the

equipment to the rear.

n

The support angles support the bottom of the HDSX5800 as shown below.

Bracket

n

Maximum depth of bracket : 750 mm

Minimum depth of bracket : 595 mm

Bracket Bracket

Support angles

HDS-X5800

1-5 (E)

1-5. Rack Mounting

6. Fix the rack angle in the rack using the specified eight

screws.

Rack

B5 x 12

Rack angle

B5 x 12

Rack angle

1-6 (E)

HDS-X5800

1-6. Installation of Optional Boards

1-6. Installation of Optional Boards

m

The usable optional boards are different depending on the type of signal to handle.

. The HKS-58xxM is the optional board that supports multi-bit rate signal including the HDTV SDI signal.

For the signal system that handles the HDTV SDI signal, use the HKS-58xxM boards for all the optional boards starting

from input to up to output.

. For the signal system that handles the 270 Mbps serial bit stream signal conforming to the DVB-ASI standard, use the

HKS-5830M board for the matrix board. If the HKS-5830SD board is used, an error may occur in the signal.

. To use the HKS-58xxM board, the software in the CPU-339 board in the HDS-X5800 should be upgraded to version 1.20

or higher.

Type of signal Input board Distribution Matrix board Output board Input expansion

HDTV SDI signal HKS-5810M HKS-5820M HKS-5830M HKS-5860M HKS-5811M

SDTV SDI signal HKS-5810SD/5810M HKS-5820M HKS-5830SD/5830M HKS-5860SD/5860M HKS-5811SD/5811M

DVB-ASI signal HKS-5810SD/5810M HKS-5820M HKS-5830M HKS-5860SD/5860M HKS-5811SD/5811M

1-6-1. Table of Optional Boards

There are the following optional boards for the HDS-X5800.

board board

1-6-2. List of Installation Slots

The HDS-X5800 can be configured to the various configurations in order to support the various systems and to expand

Option name Board configuration

33 INPUT BOARD SET

HKS-5810M

HKS-5810SD

34 CASCADE INPUT

BOARD SET

HKS-5811M Plug-in board : EQ-91 1 pc

HKS-5811SD Plug-in board : EQ-92 1 pc

33 INPUT DISTRIBUTION

BOARD

HKS-5820M Plug-in board : IPM-98 1 pc

264 x 34 MATRIX BOARD

HKS-5830M Plug-in board : MX-103 1 pc

HKS-5830SD Plug-in board : MX-104 1 pc

34 OUTPUT BOARD SET

HKS-5860M

HKS-5860SD

HDS-X5800

Connector board : CNI-11 1 pc

Connector board : CNI-12 1 pc

Connector board : CNI-13 1 pc

Connector board : CNI-14 1 pc

Connector board : CI-29 2 pcs

Connector board : CI-29 2 pcs

Connector board : CNO-13 1 pc

Connector board : CNO-14 1 pc

Connector board : CNO-15 1 pc

Connector board : CNO-16 1 pc

the functions. Select a proper combination of the plug-in

boards and connector boards for these purposes. The

respective boards have the specified slots to which they must

be inserted. Therefore, confirm that the respective boards are

inserted into the specified slots correctly as follows.

For the installation method of the respective boards, refer

to “1-6-3. Installation/Removal of Plug-in Boards” and

“1-6-4. Installation/Removal of Connector Boards”.

n

If any plug-in board or connector board is inserted into

wrong slot, the system error occurs and the HDS-X5800

will not work properly.

Board name

CI-29 _ CASCADE IN slot

CNI-11 _ IN 1 slot

CNI-12 _ IN 2 slot

CNI-13 _ IN 1 slot

CNI-14 _ IN 2 slot

CNO-13 _ OUT 1 slot

CNO-14 _ OUT 2 slot

CNO-15 _ OUT 1 slot

CNO-16 _ OUT 2 slot

EQ-91 Connect it to the _

EQ-92 Connect it to the _

IPM-98 1 IN to 8 IN slot _

MX-103 1 OUT to 8 OUT slot _

MX-104 1 OUT to 8 OUT slot _

Slots of the front side

MX-103 board.

MX-104 board.

Slots of the rear side

1-7 (E)

1-6. Installation of Optional Boards

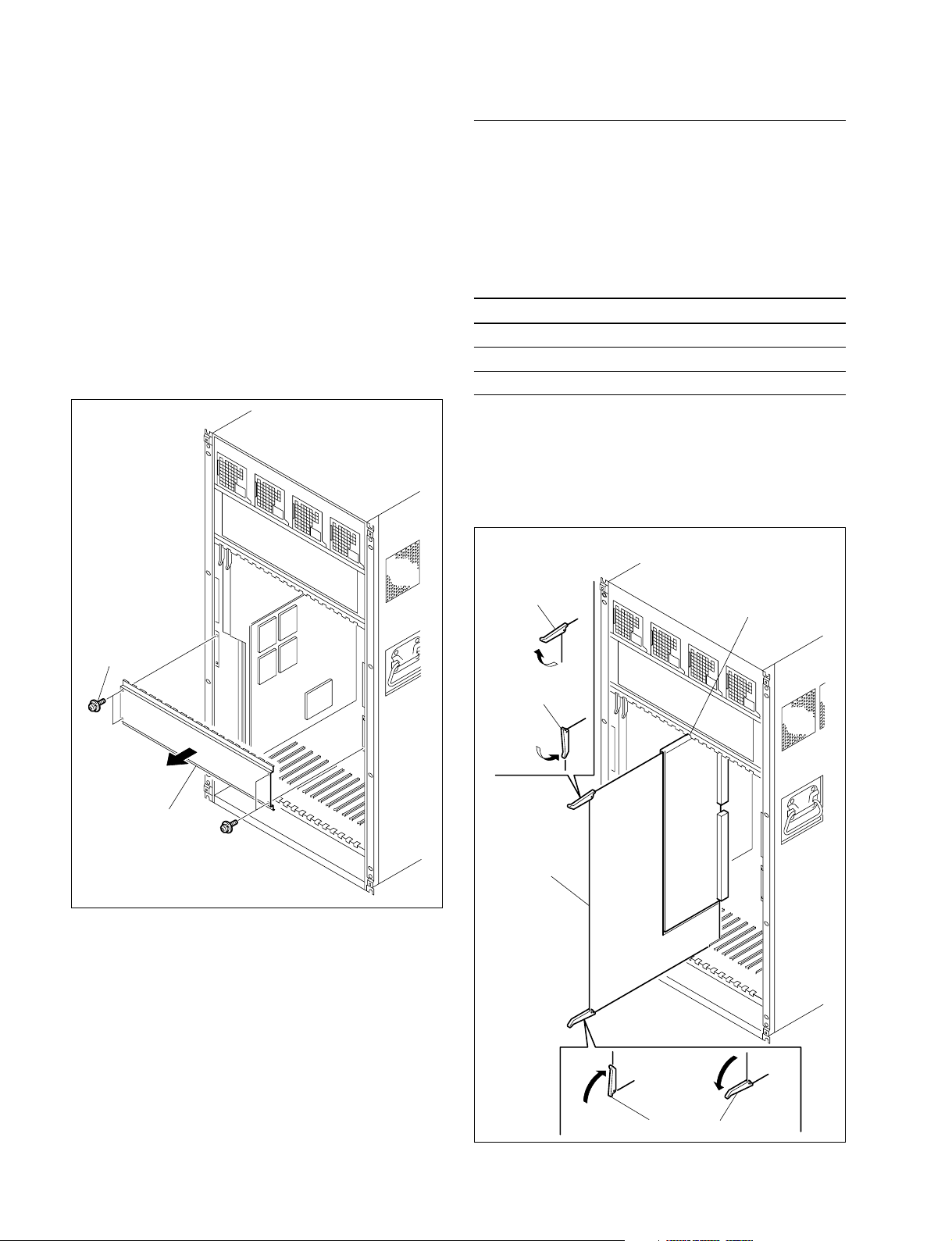

1-6-3.

Installation/Removal of Plug-in Boards

c

Before installing or removing the boards, be sure to turn

off the power switches and disconnect all of the power

cords (4 cords) from the wall outlet. If the board is attached or removed with the power on, an electric shock

may result or the board may be damaged.

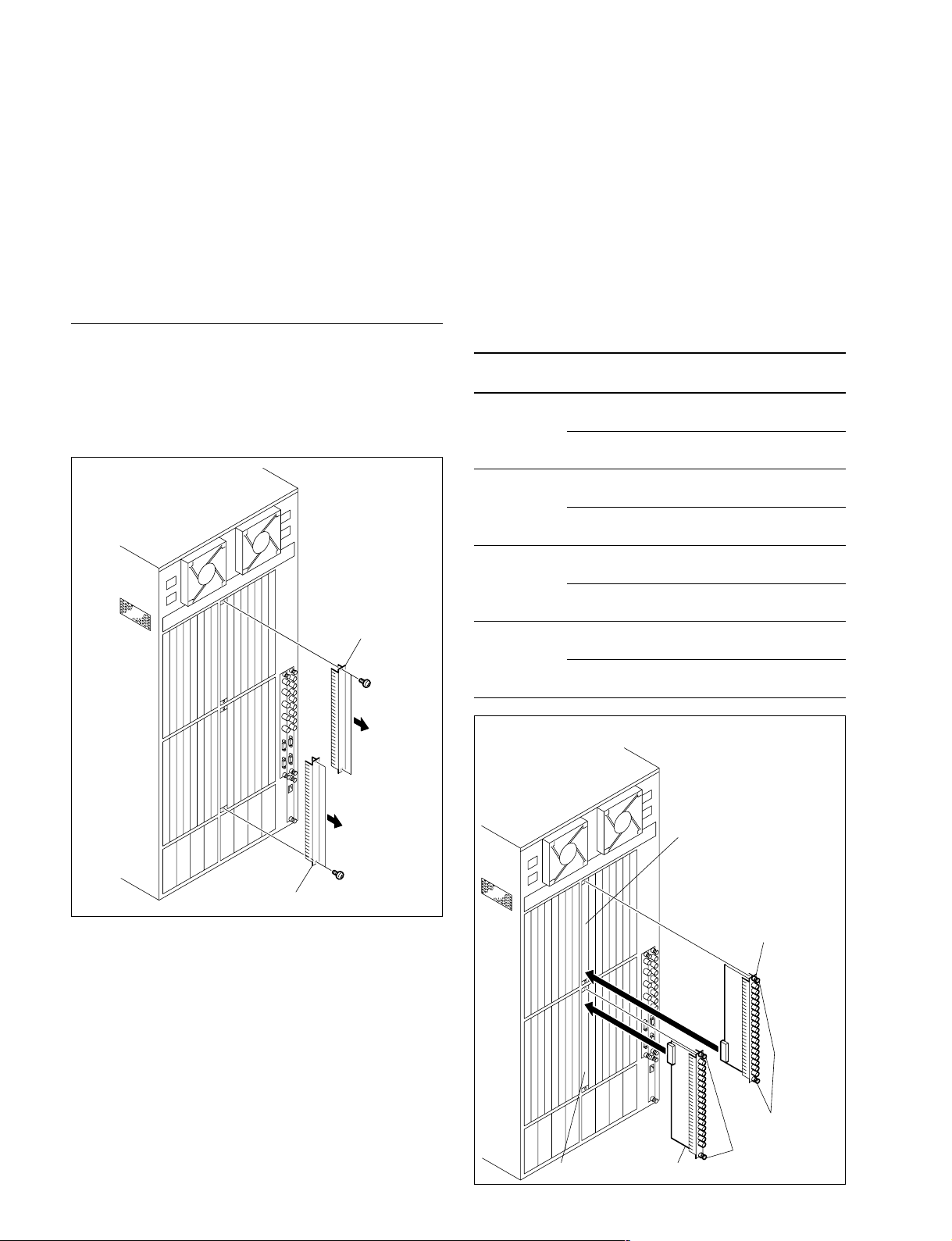

On the front panel side

1. Remove the front panel. (Refer to Section 2-2.)

2. Remove the four screws, and then remove the board

retainer plate.

HKS-5820M/5830M/5830SD

Installation

1. With the eject lever opened, insert the desired board

into the corresponding slot.

n

Insert the board while applying equal force to the eject

levers at both ends of the board.

Model name Board name Installation slot

HKS-5820M IPM-98 IN slot

HKS-5830M MX-103 OUT slot

HKS-5830SD MX-104 OUT slot

2. While closing the eject levers in the direction of the

arrow A, push in the board.

n

Check that the board is securely connected to the MB939 board.

(In the case of the HKS-5820M)

PSW3 x 6

Board retainer plate

Eject lever

IN slot

B

Eject lever

A

PSW3 x 6

IPM-98 board

1-8 (E)

A

B

Eject levers

3. Attach the board retainer plate and the front panel.

HDS-X5800

1-6. Installation of Optional Boards

Removal

1. Open the eject levers of the board in the direction of

arrow B.

2. Remove the board from the HDS-X5800.

n

Remove the board while applying equal force to the eject

levers at both ends of the board.

HKS-5811M/5811SD (EQ Board)

The HKS-5811M/5811SD consists of the two types of the

boards : EQ board (EQ-91 board/EQ-92 board) and CI-29

boards.

Installation and removal of the EQ board are described below.

For the CI-29 board, refer to Section 1-6-4.

n

When

the EQ board

is going to be installed in the existing

MX board (MX-103/MX-104 board), remove the MX board

from the slot beforehand. (Refer to this section “HKS5820M/5830M/5830SD”.)

2. Install the desired board into the corresponding shield

plate.

m

. When inserting the EQ board, be careful that the

side-B (soldering side) of the EQ board must not

touch the shield plate.

. Check that the EQ board is securely connected.

Model name Board name Installation slot

HKS-5811M EQ-91 Shield plate of the MX-103 board

HKS-5811SD EQ-92 Shield plate of the MX-104 board

(In the case of the HKS-5811SD)

MX-104 board

EQ-92 board

Installation

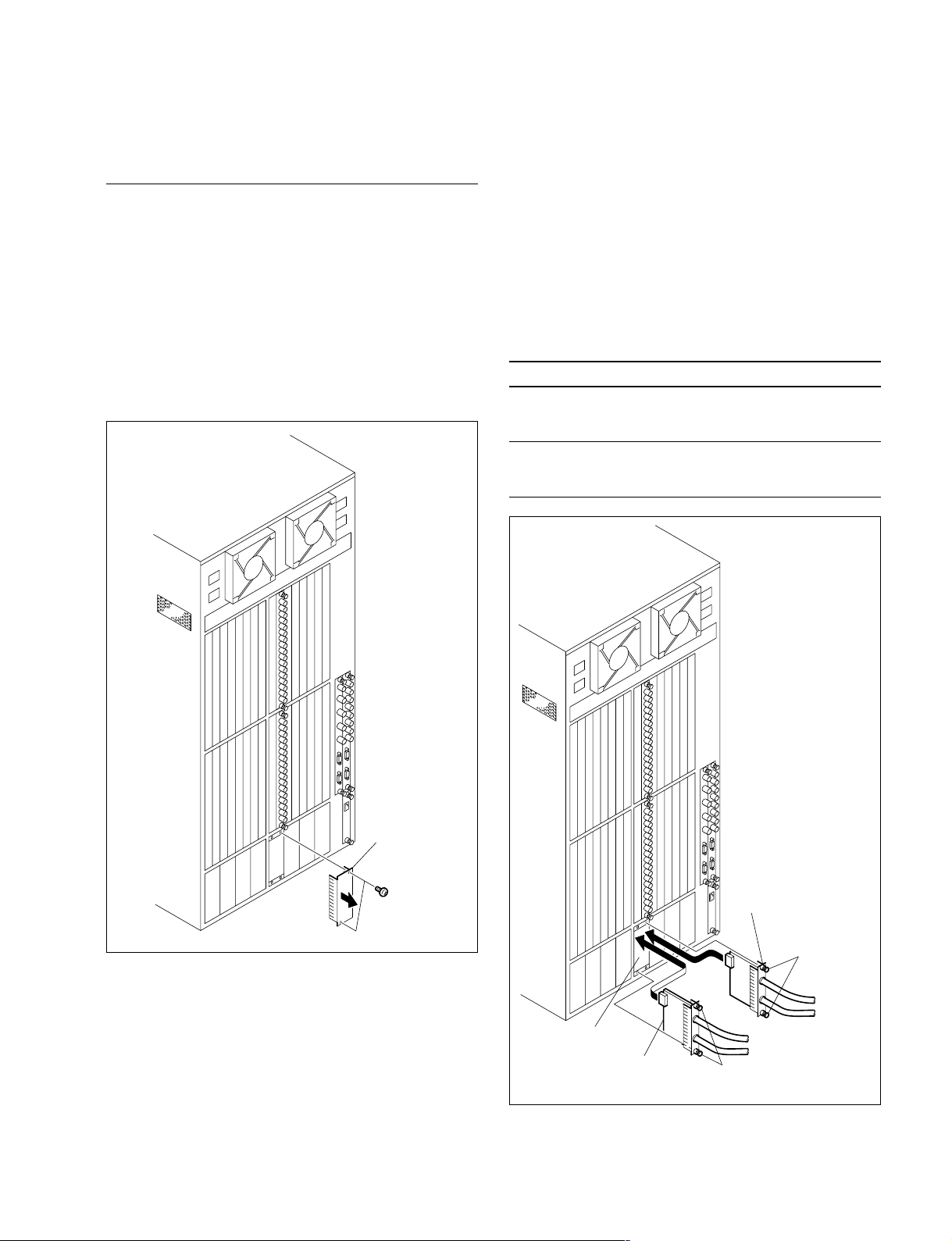

1. Remove the eight screws and remove the board

bracket (MX).

n

Keep the removed board bracket (MX).

(In the case of the HKS-5811SD)

MX-104 board

Board bracket (MX)

PSW3 x 6

PSW3 x 6

Connectors

3. Secure the EQ board with the eight screws removed in

step 1.

PSW3 x 6

PSW3 x 6

PSW3 x 6

4. Install the MX board.

(Refer to this section “

HKS-5820M/5830M/5830SD

”.)

Shield plate (MX)

HDS-X5800

Removal

Remove it by reversing the installation procedure.

PSW3 x 6

1-9 (E)

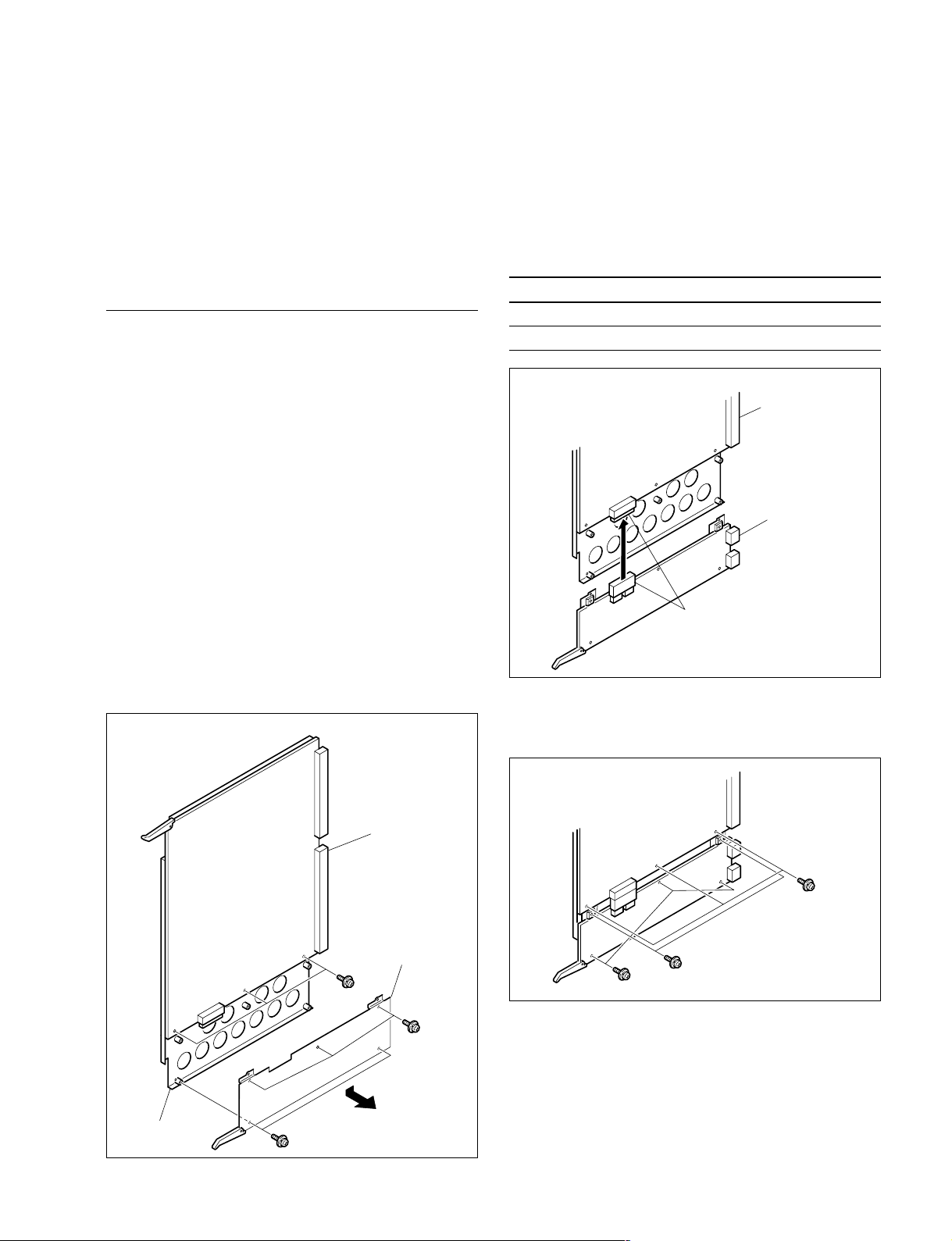

1-6. Installation of Optional Boards

1-6-4. Installation/Removal of Connector

Boards

c

Before installing or removing the boards, be sure to turn

off the power switches and disconnect all of the power

cords (4 cords) from the wall outlet. If the board is attached or removed with the power on, an electric shock

may result or the board may be damaged.

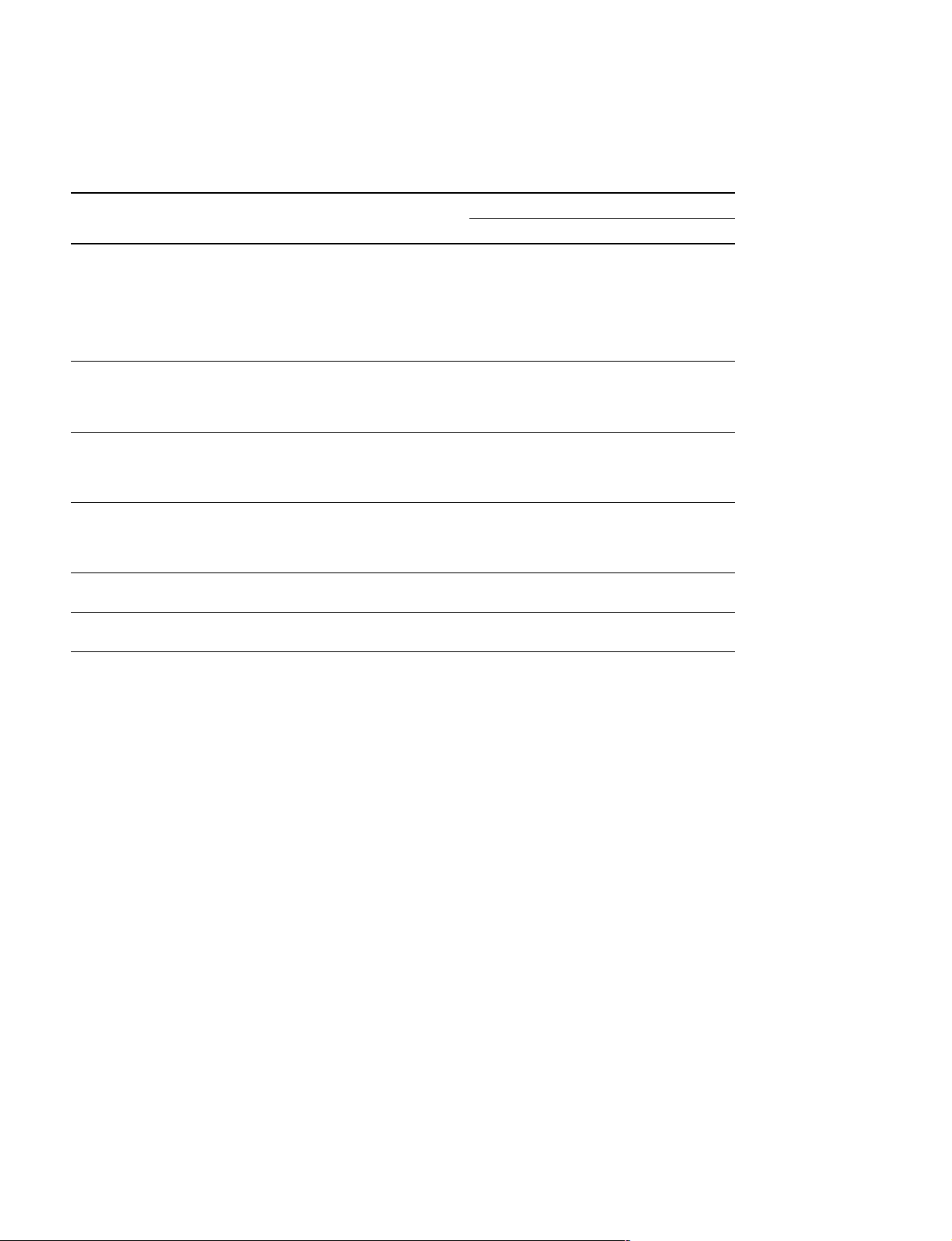

HKS-5810M/5810SD/5860M/5860SD

Installation

1.

Remove the four screws and remove the two blank panels.

n

Keep the removed blank panels.

Blank panel

B3 x 4

2. Insert the desired board into the corresponding slot and

tighten the two screws (with drop-safe) of the each

board.

m

. Insert the board while applying equal force to the

screws at both ends of the board.

. Check that the boards are securely connected to the

MB-939 board.

. Be careful not to turn them upside down by

observing the top and bottom of these boards when

installing the each board.

Option name Board Installation slot

HKS-5810M CNI-11 The IN1 slot of the same position as

HKS-5810SD CNI-13 The IN1 slot of the same position as

HKS-5860M CNO-13 The OUT1 slot of the same position

HKS-5860SD CNO-15

name

in the HKS-5820M (IPM-98 board)

CNI-12 The IN2 slot of the same position as

CNI-14 The IN2 slot of the same position as

CNO-14 The OUT2 slot of the same position

CNO-16

in the HKS-5820M (IPM-98 board)

in the HKS-5820M (IPM-98 board)

in the HKS-5820M (IPM-98 board)

as in the HKS-5830M (MX-103 board)

as in the HKS-5830M (MX-103 board)

The OUT1 slot of the same position as

in the HKS-5830SD (MX-104 board)

The OUT2 slot of the same position as

in the HKS-5830SD (MX-104 board)

1-10 (E)

Blank panel

B3 x 4

(In the case of the HKS-5810SD)

IN 2 slot

CNI-14 board

IN 1 slot

CNI-13 board

Screws

(with drop-safe)

Screws

(with drop-safe)

HDS-X5800

CI-29 board

CI-29 board

Screws

(with drop-safe)

Screws

(with drop-safe)

CASCADE IN slot

1-6. Installation of Optional Boards

Removal

Remove them by reversing the installation procedure.

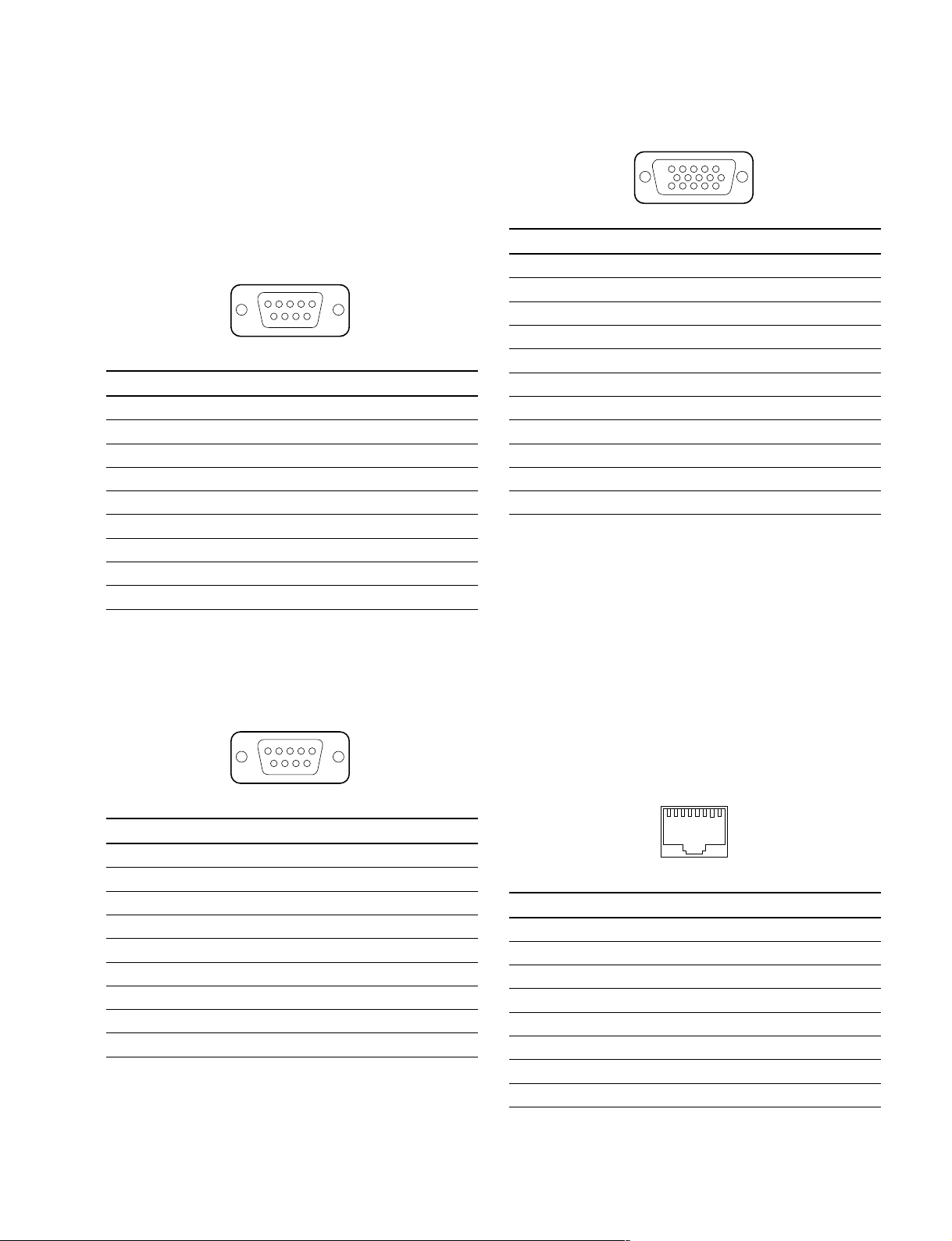

HKS-5811M/5811SD (CI-29 Board)

The HKS-5811M/5811SD consist of the two types of the

boards: EQ board and CI-29 boards. Installation and

removal of the CI-29 board are described below.

For the EQ board, refer to Section 1-6-3.

Installation

1. Remove the two screws and remove the blank panel.

n

Keep the removed blank panel.

2. Insert a pair of CI-29 boards to the CASCADE IN slot

and tighten the two screws (with drop-safe) of the each

board.

m

. Insert the board while applying equal force to the

screws at both ends of the board.

. Check that the boards are securely connected to the

MB-939 board.

. Be careful not to turn them upside down by

observing the top and bottom of these boards when

installing the each board.

Option name Board name Installation slot

HKS-5811M CI-29 board

(2 boards IN slot of the same position as

as a pair) in the MX-103 board.

HKS-5811SD CI-29 board

(2 boards IN slot of the same position as

as a pair) in the MX-104 board.

Connector side, The CASCADE

Connector side, The CASCADE

HDS-X5800

Blank panel

B3 x 4

Removal

Remove it by reversing the installation procedure.

1-11 (E)

1-7. Matching Connectors and Cables

1-7. Matching Connectors and Cables

To connect the cable to the unit, use the following connectors and cables or their equivalents.

Model name/panel indication Connector name Application connector/cable

Name Sony part No.

HDS-X5800

REMOTE1 A /B1/B2/C/D BNC, 75 Z BNC, 75 Z_

REF IN A/B/C/D BELDEN 8281 cable

HKS-5810SD

SDTV Serial VIDEO INPUT 1 to 33

HKS-5860SD

SDTV Serial VIDEO OUTPUT 1 to 34

HKS-5810M

Serial VIDEO INPUT 1 to 33 BNC, 75 Z BNC, 75 Z_

HKS-5860M BELDEN 1694 cable

Serial VIDEO OUTPUT 1 to 34

HDS-X5800

REMOTE2 A/B D-sub 9-pin, Female D-sub 9-pin, Male

Connector 9-pin Male 1-560-651-00

Junction Shell 9-pin 1-561-749-00

HDS-X5800

REMOTE3 D-sub 9-pin, Male D-sub 9-pin, Female

Connector 9-pin Female 1-563-815-21

Junction Shell 9-pin 1-561-749-00

HDS-X5800

ALARM D-sub Mini 15-pin, Female D-sub Mini 15-pin, Male _

HDS-X5800

DATA RJ-45 modular jack 100BASE-TX standard _

*1 : The following crimp contact is required for the plug.

AWG#18 to #22 : 1-566-493-21

AWG#22 to #24 : 1-564-774-11

AWG#24 to #30 : 1-564-775-11

*1

1-12 (E)

HDS-X5800

_ EXT VIEW _

1

5

11

15

6

10

1-8. Input and Output Signals of Connectors

1-8. Input and Output Signals of

Connectors

The input and output signals of the connectors at the rear

panel are as follows.

REMOTE2 A/B : RS-422A (D-sub 9-pin, Female)

5

_ EXT VIEW _

Pin No. Signal name Input/Output Function

1FG _ Frame ground

2 TX (_) O Transmitted data (_)

3 RX (+) I Received data (+)

4 GND _ Common ground

5 __No connection

6 GND _ Common ground

7 TX (+) O Transmitted data (+)

8 RX (_) I Received data (_)

9 __No connection

The frame ground and the common ground are connected

internally inside the system.

REMOTE3 : RS-232C (D-sub 9-pin, Male)

1

69

ALARM : D-sub Mini 15-pin, Female

Pin No. Signal name Input/Output Function

1 ALARM-3 O Alarm drive-3

2 ALARM-1 O Alarm drive-1

3 ALARM-4 O Alarm drive-4

4GND _ Ground

5 ALARM-5 O Alarm drive-5

6 to 8 GND _ Ground

9 ALARM-6 O Alarm drive-6

10 GND _ Ground

11 GND _ Ground

12 ALARM-2 O Alarm drive-2

13 to 15 GND _ Ground

n

Specifications of the alarm output

Open collector output

Voltage that can be applied to the terminal : 0 to 20 V

Pull-in current :

Maximum 50 mA when the output transistor is

saturated (output terminal voltage is 1 V or less).

Output terminal voltage x pull-in current < 50 mV

when the output transistor is non-saturated.

1

5

DATA :

96

_ EXT VIEW _

Pin No. Signal name Input/Output Function

1 DCD I Date carrier detect

2 RX I Received data

3 TX O Transmitted data

4 DTR O Data terminal ready

5 GND _ Signal ground

6 DSR I Date set ready

7 RTS O Request to send

8 CTS I Clear to send

9 __No connection

Pin-6 (DSR) is connected to pin-1 (DCD) internally inside

the system.

HDS-X5800

10BASE-T/100BASE-TX (RJ-45 8-pin Modular jack)

1

_ EXT VIEW _

Pin No. Signal name Input/Output Function

1 TDB O Transmitted data B

2 TDA O Transmitted data A

3 RDB I Received data B

4 BI_D3+_ (*1)

5 BI_D3__ (*1)

6 RDA I Received data A

7 BI_D4+_ (*1)

8 BI_D4__ (*1)

*1 : This signal line is not used in this system. It is connected to the

termination circuit inside the system.

8

1-13 (E)

Loading...

Loading...