Sony DF759 User Manual

DIGITAL FILM IMAGER

UP-DF750

SERVICE MANUAL

Volume 1 1st Edition

!警告

このマニュアルは,サービス専用です。

お客様が,このマニュアルに記載された設置や保守,点検,修理などを行うと感電や火災,

人身事故につながることがあります。

危険をさけるため,サービストレーニングを受けた技術者のみご使用ください。

! WARNING

This manual is intended for qualifi ed service personnel only.

To reduce the risk of electric shock, fi re or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualifi ed to do so. Refer all servicing to

qualifi ed service personnel.

! WARNUNG

Die Anleitung ist nur für qualifi ziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifi ziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afi n

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifi é pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

安全のために,周辺機器を接続する際は,過大電圧を持

つ可能性があるコネクターを以下のポートに接続しない

でください。

: ネットワーク端子

上記のポートについては本書の指示に従ってください。

For safety, do not connect the connector for peripheral device wiring that might have excessive voltage to the following port.

: Network connector (RJ-45)

Follow the instructions for the above port.

UP-DF750

注意

FÖRSIKTIGHET!

指定以外の電池に交換すると,破裂する危険があります。

必ず指定の電池に交換してください。

使用済みの電池は,国または地域の法令に従って

処理してください。

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by the manufacturer.

When you dispose of the battery, you must obey the

law in the relative area or country.

ATTENTION

Il y a danger d’explosion s’il y a remplacement incor-

rect de la batterie. Remplacer uniquement avec

une batterie du même type ou d’un type équivalent

recommandé par le constructeur.

Lorsque vous mettez la batterie au rebut, vous devez

respecter la législation en vigueur dans le pays ou la

région où vous vous trouvez.

Fara för explosion vid felaktigt placerat batteri.

Byt endast mot samma eller likvärdig typ av batteri,

enligt tillverkarens rekommendationer.

När du kasserar batteriet ska du följa rådande lagar

för regionen eller landet.

PAS PÅ

Fare for eksplosion, hvis batteriet ikke udskiftes

korrekt.

Udskift kun med et batteri af samme eller tilsvarende

type, som er anbefalet af fabrikanten.

Når du bortskaffer batteriet, skal du følge

lovgivningen i det pågældende område eller land.

HUOMIO

Räjähdysvaara, jos akku vaihdetaan virheellisesti.

Vaihda vain samanlaiseen tai vastaavantyyppiseen,

valmistajan suosittelemaan akkuun.

Noudata akun hävittämisessä oman maasi tai

alueesi lakeja.

VORSICHT

Explosionsgefahr bei Verwendung falscher Batterien.

Batterien nur durch den vom Hersteller empfohlenen

oder einen gleichwertigen Typ ersetzen.

Wenn Sie die Batterie entsorgen, müssen Sie die

Gesetze der jeweiligen Region und des jeweiligen

Landes befolgen.

FORSIKTIG

Eksplosjonsfare hvis feil type batteri settes i.

Bytt ut kun med samme type eller tilsvarende

anbefalt av produsenten.

Kasser batteriet i henhold til gjeldende avfallsregler.

UP-DF750

1 (P)

Table of Contents

Manual Structure

Purpose of this manual .................................................................. 3

Related manuals ............................................................................ 3

Trademarks .................................................................................... 3

1. Installation

1-1. Operating Environment ................................................... 1-1

1-2. Outside Dimension Diagram ...........................................1-2

1-3. Installation Space ............................................................1-3

1-4. Caster (2T) Assembly Installation Procedure..................1-3

1-5. Film Tray/Output Tray .................................................... 1-5

1-6. Setting Procedure ..........................................................1-14

1-7. Film Loading Procedure ................................................ 1-15

1-8. DICOM Setting Method ................................................1-16

1-8-1. Preparation ........................................................... 1-16

1-8-2. Setup .................................................................... 1-17

1-8-3. Modality ConnectionCustomizing ....................... 1-25

1-9. Check List .....................................................................1-35

2-5. Optional Fixtures ...........................................................2-18

2-5-1. Reference Sheet ................................................... 2-18

2-5-2. Torque Driver Bit for M4 Setscrew ..................... 2-18

2-6. Periodic Inspection ........................................................2-18

2-6-1. Cleaning of Main Unit ......................................... 2-18

2-6-2. Tray Cleaning....................................................... 2-20

2-6-3. Fan Filter .............................................................. 2-20

2-6-4. Dust Cleaning Roller ...........................................2-20

2-6-5. Replacing the Periodic Replacement Parts .......... 2-20

2-7. Maintenance Check ....................................................... 2-21

2-7-1. Preparation ........................................................... 2-21

2-7-2. Appearance Check ............................................... 2-22

2-7-3. Check of Current Status .......................................2-22

2-7-4. Periodic Replacement Parts and Cleaning ........... 2-23

2-7-5. Version Upgrade and Virus Patch ........................ 2-23

2-7-6. Confi rmation ........................................................ 2-23

2-8. Priority of Each Setting ................................................. 2-24

2-9. Servicing the CT-252 Board and MA-171 Board ......... 2-24

2-10. Lead-free Solder ............................................................ 2-24

3. Replacing the Main Parts

2. Service Overview

2-1. Board Location ................................................................2-1

2-2. Main Parts Location ........................................................ 2-4

2-3. Sensor/Actuator Location and Function .......................... 2-7

2-4. Removing/Installing the Cabinet ..................................... 2-9

2-4-1. Front Sash (HR) Assembly .................................... 2-9

2-4-2. MD Cover (BD) ..................................................... 2-9

2-4-3. Front Panel (L) (HR) Assembly ........................... 2-10

2-4-4. Front Panel (R) Assembly .................................... 2-10

2-4-5. MD Front Panel Assembly/MD Upper Cover ..... 2-11

2-4-6. Side Panel (L) ......................................................2-13

2-4-7. Side Panel (R) ...................................................... 2-13

2-4-8. Outer Frame L Cover ...........................................2-14

2-4-9. Top Cover (D) ...................................................... 2-14

2-4-10. Rear Cover (TD)/PH2 Flap .................................. 2-15

2-4-11. Rear Cover (Sub) ................................................. 2-16

2-4-12. Rear Cover (BD) ..................................................2-16

2-4-13. Side Panel (Sub)...................................................2-17

3-1. Replacing the Board ........................................................ 3-1

3-1-1. MA-171 Board ....................................................... 3-1

3-1-2. DR-628 Board ........................................................ 3-4

3-1-3. KEY-61 Board/LE-356 Board/SW-1418 Board ....3-5

3-1-4. CN-3094 Board ...................................................... 3-6

3-2. MD (HR) Assembly ........................................................ 3-7

3-3. PH1 (HR) Assembly ........................................................ 3-9

3-4. PH0 Assembly ............................................................... 3-11

3-5. PH2 Assembly ............................................................... 3-13

3-6. PH3 (HR) Assembly ...................................................... 3-15

3-7. Head Block (HR) Assembly .......................................... 3-17

3-8. Thermal Head Assembly ...............................................3-19

3-9. Transfer Cleaning Roller ............................................... 3-23

3-10. Capstan B/Platen ...........................................................3-24

3-11. Rear Chassis Assembly ................................................. 3-30

3-12. Base Chassis Assembly ................................................. 3-32

3-13. Pinch Press Lever Assembly ......................................... 3-33

3-14. Switching Regulator ...................................................... 3-34

3-15. DICOM BOARD .......................................................... 3-36

UP-DF750

1

3-16. Paper Feed Chassis Assembly (Lower) ......................... 3-37

3-17. Paper Feed Chassis Assembly (Upper) ......................... 3-40

3-18. Switching Regulator (For DICOM) ..............................3-42

3-19. Paper Feed Roller Assembly ......................................... 3-43

3-19-1. Paper Feed Roller Assembly (Upper) .................. 3-43

3-19-2. Paper Feed Roller Assembly (Lower) ..................3-44

3-20. Separation Roller Assembly .......................................... 3-45

3-21. Cleaning Roller ............................................................. 3-46

3-22. Installing the Alternate Unit .......................................... 3-47

4. Procedures after Replacement

4-1. Adjustment after Replacing the Thermal Head ...............4-1

4-1-1. Adjusting the Density ............................................4-1

4-1-2. Adjusting the Head Position .................................. 4-3

4-2. Procedures after Replacing the Board ............................. 4-5

4-2-1. MA-171 Board ....................................................... 4-5

4-2-2. CT-252 Board......................................................... 4-6

4-2-3. SE-880 Board and SE-943 Board .......................... 4-8

4-2-4. DICOM BOARD ................................................... 4-8

4-3. Printing Position Adjustment Procedures ........................4-9

4-4. Operation List during Replacement of

Main Assembly Parts ..................................................... 4-12

5. Circuit Description

5-1. MA-171 Board ................................................................5-1

5-1-1. Outline ................................................................... 5-1

5-1-2. Confi guration ......................................................... 5-1

5-1-3. Digital Media Processors, FPGA, and

Peripheral Circuits .................................................5-2

5-1-4. USB Interface Block .............................................. 5-3

5-1-5. Stepping Motor Controller Block and

Sensor A/D Input Block ......................................... 5-3

5-1-6. Switches and LED Interface Block ........................ 5-3

5-1-7. LCD Interface Block .............................................. 5-4

5-1-8. UART Block .......................................................... 5-4

5-1-9. Control of Sensors and Switches ........................... 5-4

5-2. DR-628 Board ................................................................. 5-5

5-2-1. Outline ................................................................... 5-5

5-2-2. Confi guration ......................................................... 5-5

5-3. CT-252 Board ................................................................5-18

5-3-1. Outline ................................................................. 5-18

5-3-2. Confi guration ....................................................... 5-18

5-3-3. CPU and Its Peripheral Circuit ............................5-18

5-4. DICOM BOARD ..........................................................5-20

5-4-1. Interface ............................................................... 5-20

5-4-2. Functions .............................................................. 5-20

6. Service Mode

6-1. Service Mode Startup Method......................................... 6-1

6-2. Basic Operation and Confi guration of Menu ..................6-2

6-2-1. Information ............................................................ 6-4

6-2-2. Print Quality ........................................................... 6-5

6-2-3. Calibration ............................................................. 6-6

6-2-4. Default Gamma ...................................................... 6-7

6-2-5. Print Operation ....................................................... 6-8

6-2-6. System Settings ...................................................... 6-9

6-2-7. Test Print .............................................................. 6-13

6-2-8. Test Print (Svc) .................................................... 6-14

6-2-9. Manual Mecha ..................................................... 6-15

6-2-10. Error Info .............................................................6-18

6-2-11. Adjust ................................................................... 6-19

6-2-12. Self Check ............................................................ 6-21

6-2-13. Media (Tag) Menu ............................................... 6-22

6-3. Firmware Version Upgrade Procedure ..........................6-23

6-3-1. Required Equipment ............................................ 6-23

6-3-2. Version Upgrade Procedure .................................6-23

6-3-3. Version Check ...................................................... 6-24

6-4. DICOM Version Upgrade Procedure ............................ 6-24

6-4-1. Required Equipment ............................................ 6-24

6-4-2. Version Upgrade Procedure .................................6-24

6-4-3. Version Check ...................................................... 6-24

6-5. FilmStation Support Software .......................................6-25

6-5-1. Installation of FilmStation Support Software ...... 6-25

6-5-2. How to use FilmStation Support Software .......... 6-25

6-6. DICOM Virus Patch Method ......................................... 6-27

7. Troubleshooting

7-1. Error Display ................................................................... 7-1

7-1-1. Error Display.......................................................... 7-1

7-1-2. Error Message List ................................................. 7-2

7-1-3. Error History ........................................................ 7-11

7-2. Mechanical Troubleshooting ......................................... 7-14

7-3. Electrical Troubleshooting ............................................ 7-18

7-3-1. Electrical Troubleshooting ................................... 7-18

7-3-2. Operation Defects of Motors and Sensors ........... 7-19

2

UP-DF750

Purpose of this manual

Related manuals

Manual Structure

This manual is the Service Manual Vol.1 of the Digital Film Imager UP-DF750.

This manual contains the installation, service overview, replacing the main parts,

procedures after replacement, circuit description, service mode, and troubleshooting.

In addition to this Service Manual Vol.1, the following manuals are provided.

. Service Manual Vol.2

Contains the spare parts, block diagrams, schematic diagrams, and board layouts.

. Instruction for Use/Setup Manual

This manual describes the information required for the actual management and operation of this unit.

. “Semiconductor Pin Assignments” CD-ROM (Available on request)

This “Semiconductor Pin Assignments” CD-ROM allows you to search for

semiconductors used in Broadcast and Professional equipment.

Part number: 9-968-546-06

Trademarks

Trademarks and registered trademarks used in this manual are as follows.

. Windows and Internet Explorer are registered trademarks of Microsoft Corporation

in the United States and Other countries.

. Memory Stick and Memory Stick PRO Duo are trademarks of Sony Corporation.

Other system names, product names, and company names appearing in this manual

are trademarks or registered trademarks of their respective holders.

UP-DF750

3

Section 1

Installation

m

. Keep the packing material because it is used for the transportation in servicing.

When transporting this unit, remove the output tray tray and caster from this unit.

Remove the fi lm from the fi lm tray 1 and fi lm tray 2.

. When installing this unit, check the following setting items.

IP Address: Network setting

Subnet Mask: Network setting

Default Gateway: Network setting

UP-DF750 installation location and space:

Location and power supply, network cable

UP-DF750 carry-in route: Check of elevator, door, step, etc.

Size of fi lm used

Attendance of Modality service personnel, or advance setting

1-1. Operating Environment

. Electric voltage: 100 V AC to 120 V AC/200 V AC to 240 V AC, 50/60 Hz

. Electric current consumption: 4.4 A/2.4 A

. Operation temperature: 10 dC to 30 dC

. Storage/transportation temperature: _20 dC to 60 dC

. Storage/transportation humidity: 20% to 80%

. Maximum outside dimension: Approx. 600 x 316 x 686 mm

(Width/height/depth) (Largest protrusion is not included.)

. Mass: Approx. 65 kg

UP-DF750

1-1

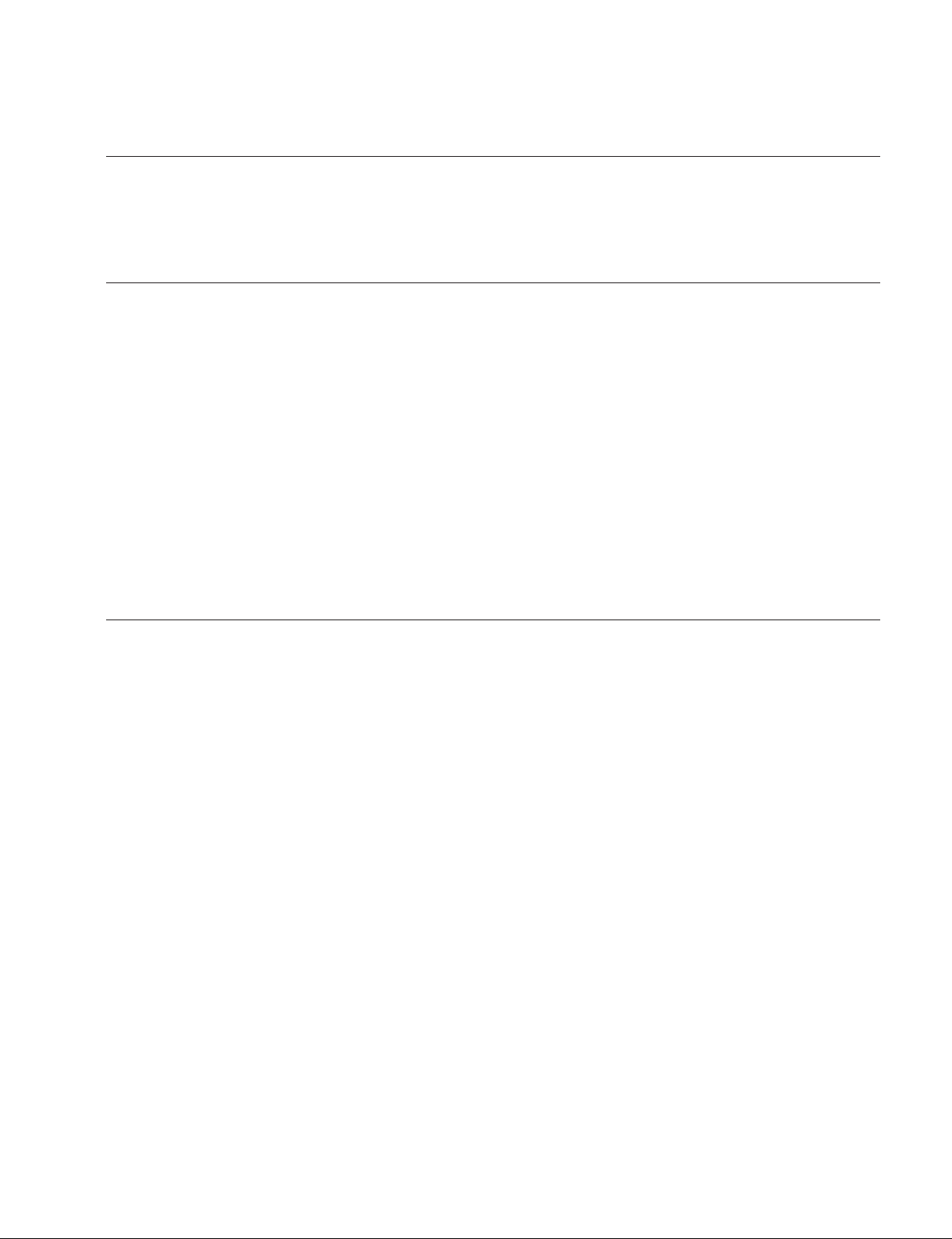

1-2. Outside Dimension Diagram

600

686

316

354

(When a caster is installed.)

Unit: mm

21

622

1-2

UP-DF750

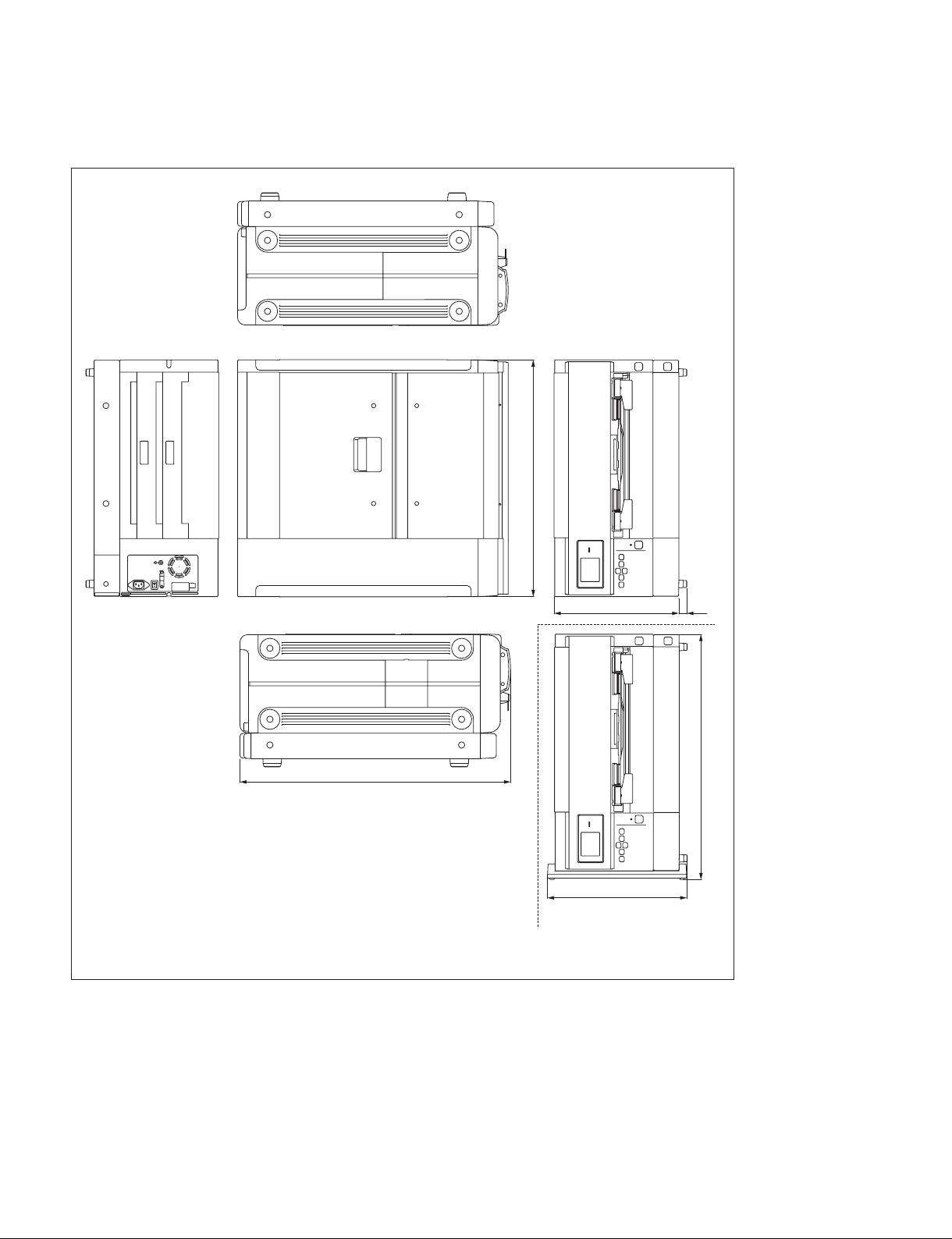

1-3. Installation Space

This unit can be installed in either horizontal or vertical direction. (Refer to Section 1-4.)

When installing, be sure to make space for the unit as

shown in the right illustration.

Unit: mm

Avoid installing this unit in the following places to prevent

it from being damaged by foreign material, condensation,

etc.

. Near the air exit of air conditioner

210

. Near the open window or door

. Near the busy passageway

. Places easily getting spattered with liquid

. Places being subjected by direct sunlight

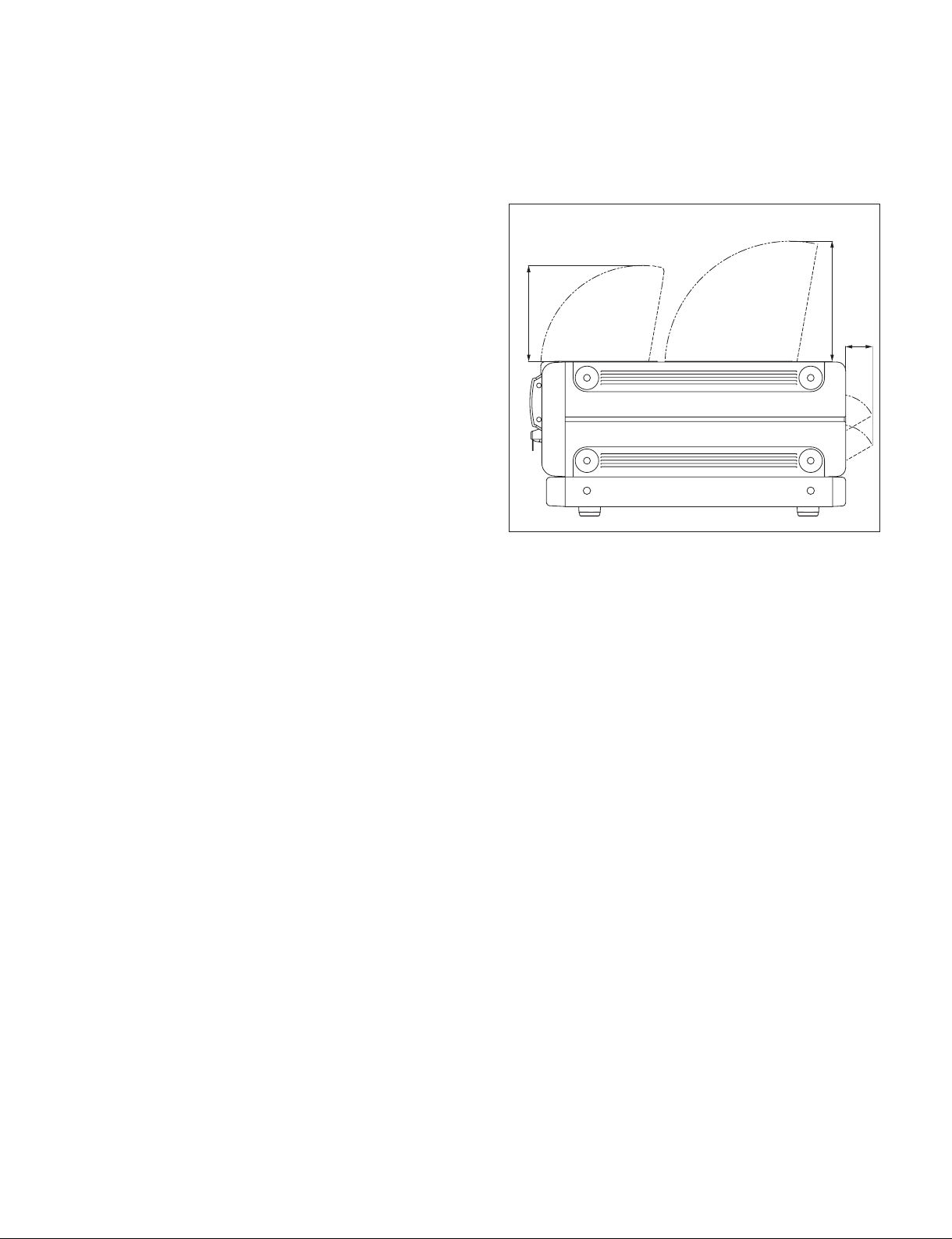

1-4. Caster (2T) Assembly Installation Procedure

This unit can be installed in vertical direction by attaching the supplied caster (2T) assembly.

265

70

m

. When attaching the caster (2T) assembly, be sure to work by two persons.

. Be sure to keep the four screws and four shoulder washers removed from the side panel (L).

. When attaching the caster (2T) assembly, make sure that there is no gap between the side panel (L) and

front panel (L).

. When attaching the caster (2T) assembly, place the unit with the caster 2T sheet affi xed surface facing

downward.

. When installing this unit in vertical direction, it is recommended to place it with the left side facing

downward.

. This unit is differently controlled depending on the direction it is installed; horizontal direction, vertical

direction with right side down or left side down. The sensor can detect the difference between vertical

and horizontal direction. But it cannot detect the difference between right and left when the unit is

installed in vertical direction. Therefore, the setting is performed on the service mode. (Section 6-2-6,

System Setting → Setting Position)

. When attaching the caster (2T) assembly, be sure to use the supplied stopper sheet. (Refer to the instruc-

tion manual for the usage.)

UP-DF750

1-3

1. Remove the four screws (RK4 x 8) and four shoulder

washers from the side panel (L) and side panel (sub).

Side panel (L)

Shoulder washers

RK4 x 8

Side panel (sub)

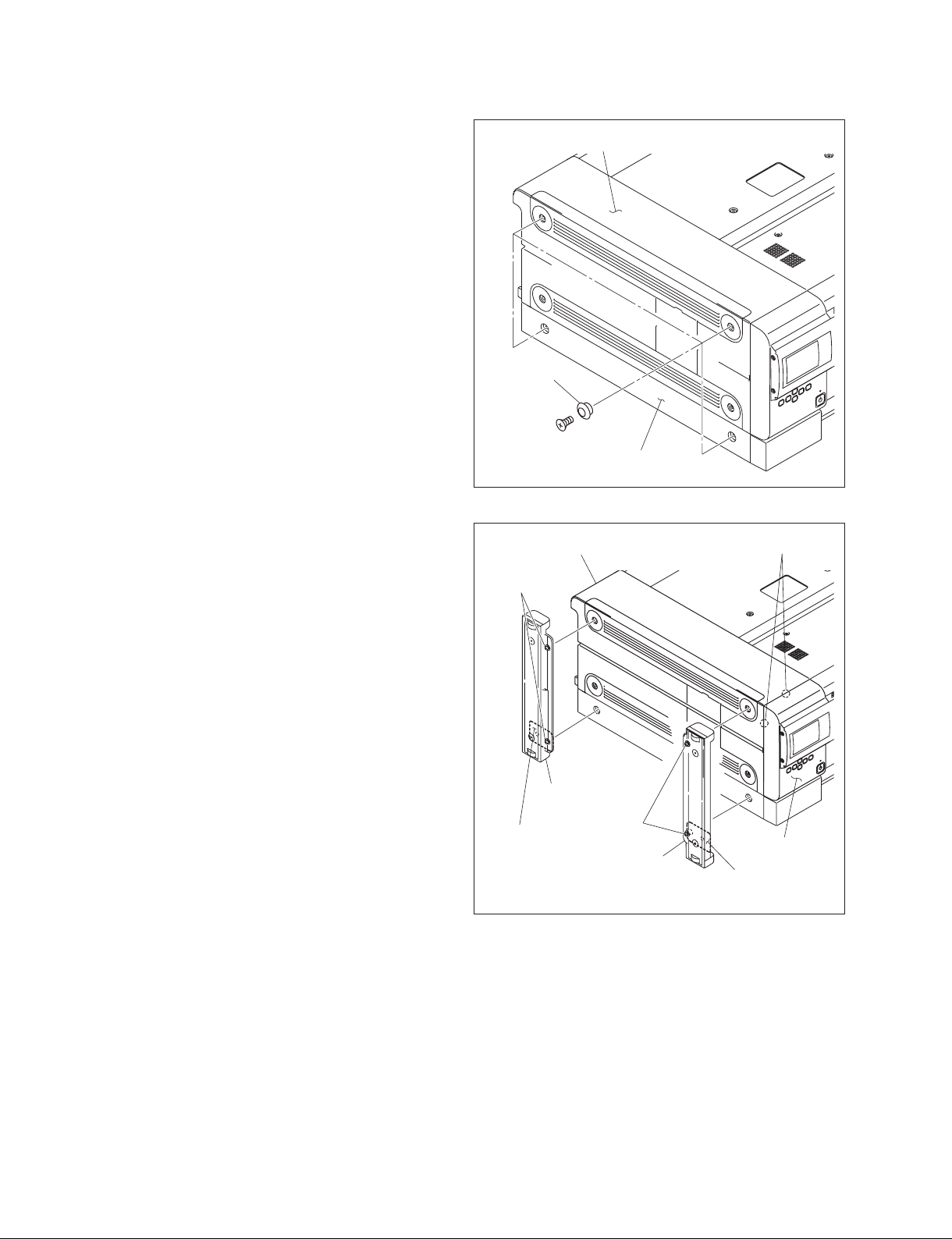

2. Attach the caster (2T) assembly using the four screws

(B4 x 16).

Side panel (L)

B4 x 16

Caster (2T)

assembly

Caster 2T sheet

B4 x 16

Caster (2T)

assembly

Space

Front panel (L)

Caster 2T sheet

1-4

UP-DF750

1-5. Film Tray/Output Tray

m

. The lower tray and upper tray have the stopper for preventing mis-insertion. Therefore, do not push the

tray forcefully.

. Do not load the fi lm of size that is different from the internal fi lm position guide setting.

Otherwise, it may cause a jam or a serious trouble due to malfunction.

. Both upper tray and lower tray support all the following fi lm sizes.

8 x 10 inch (UPT-510BL/UPT-M710BL)

10 x 12 inch (UPT-512BL/UPT-M712BL)

11 x 14 inch (UPT-514BL)

14 x 17 inch (UPT-517 BL)

. The factory-installed fi lm trays are as follows.

Upper tray: 14 x 17 inch

Lower tray: 8 x 10 inch

When using the tray size (10 x 12 inch, 11 x 14 inch) other than the above, use the supplied fi lm size

change kit for the upper tray. As for the lower tray, move the fi lm position guide.

. No operation is required for the fi lm size because it is automatically recognized by the IC tag.

. In the case of using the fi lm size of 10 x 12 inch or 8 x 10 inch, attach the output tray stopper.

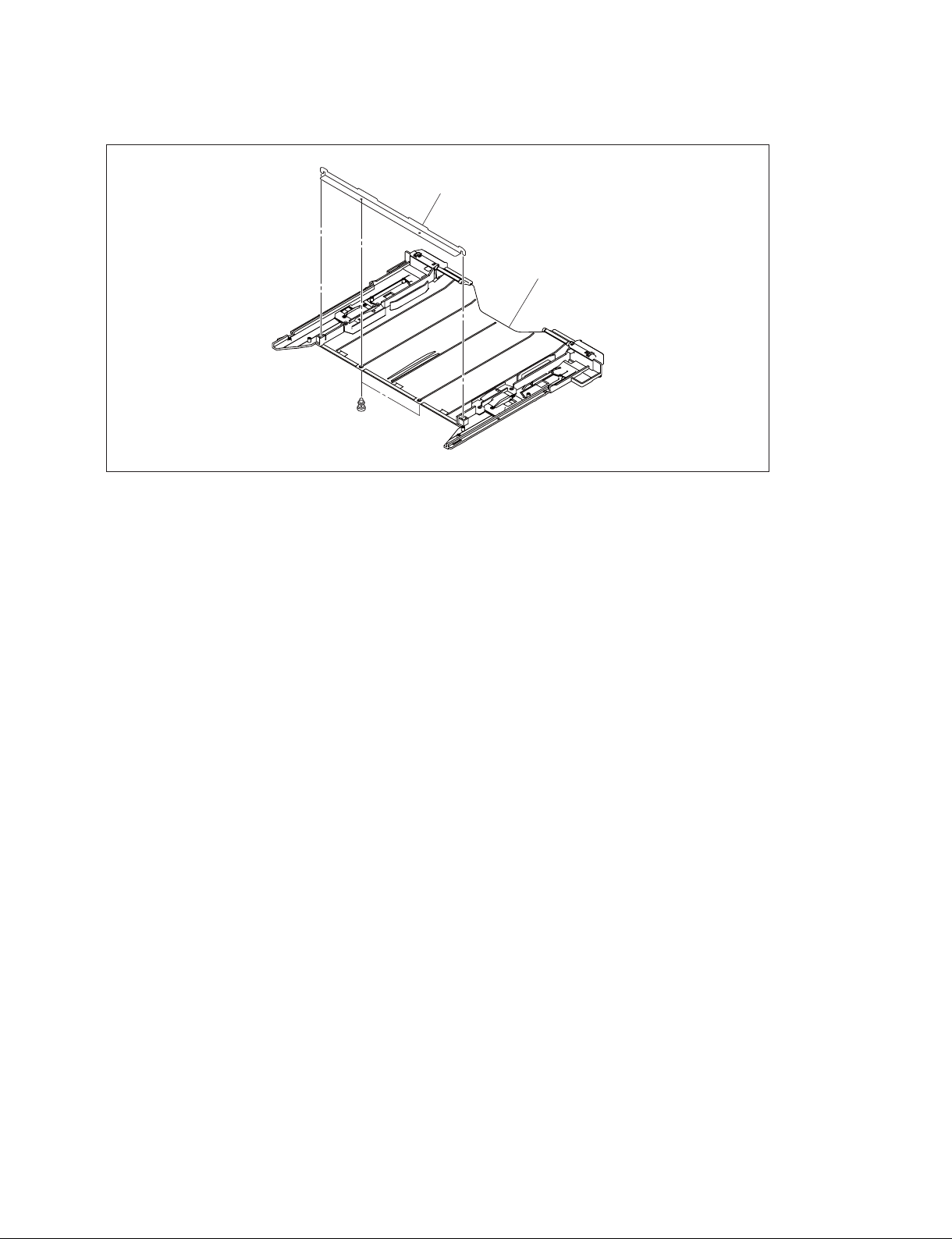

Film tray

Film size changing method

Upper tray:

Use the supplied fi lm size change kit.

Lower tray:

Change the size as follows.

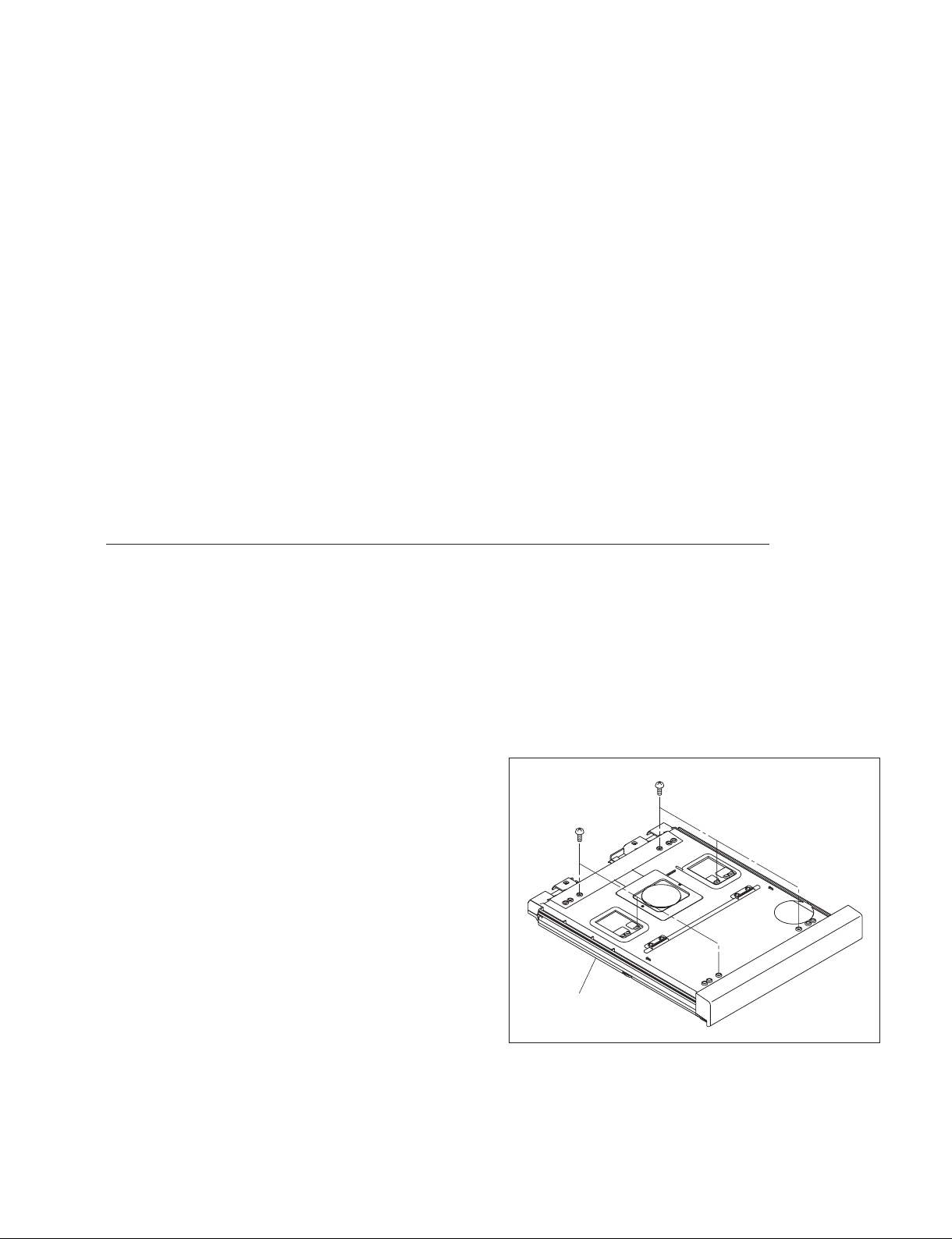

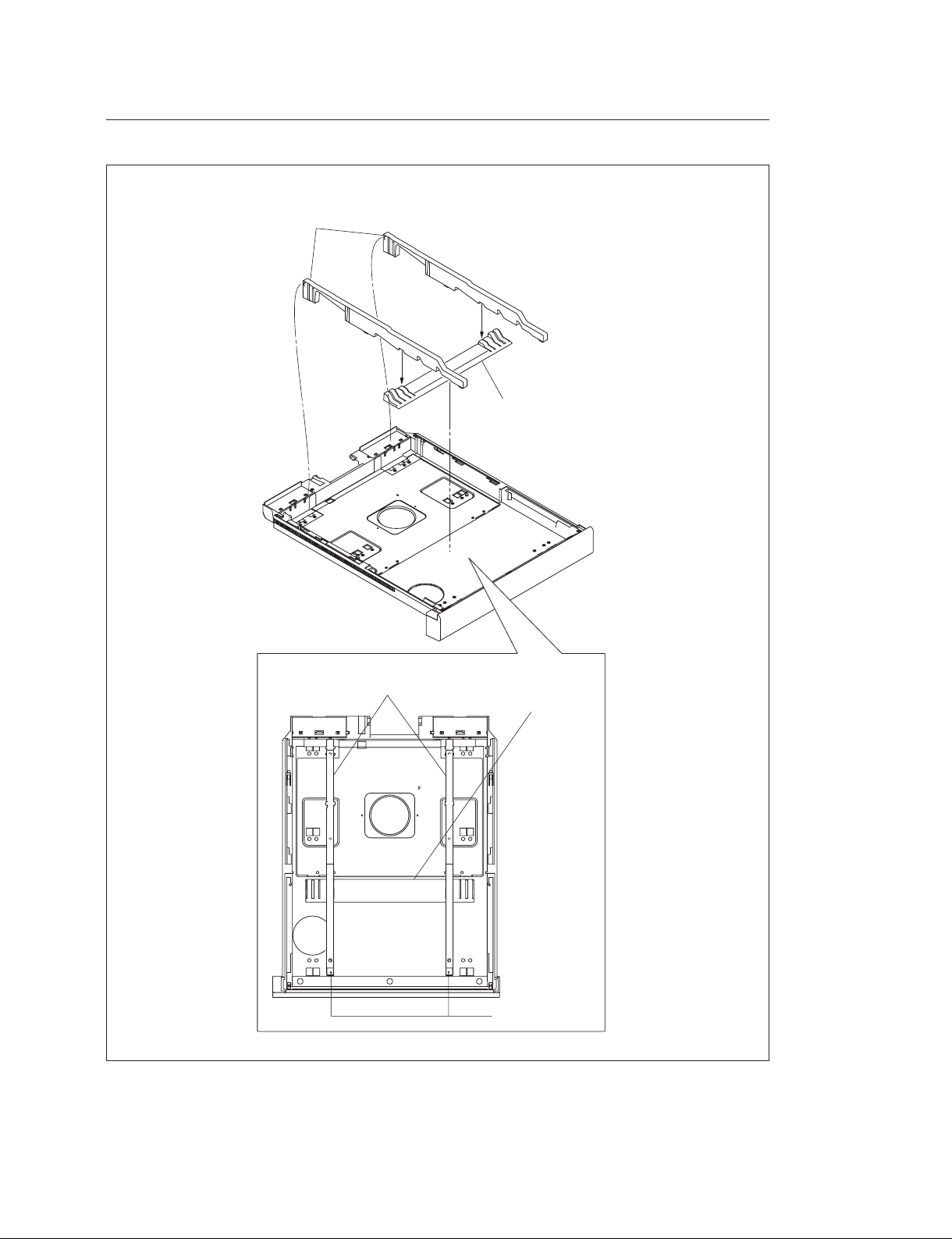

1. Remove the six screws with the tray cover facing

downward.

BTP

3 x 10

Film tray

BTP

3 x 10

UP-DF750

1-5

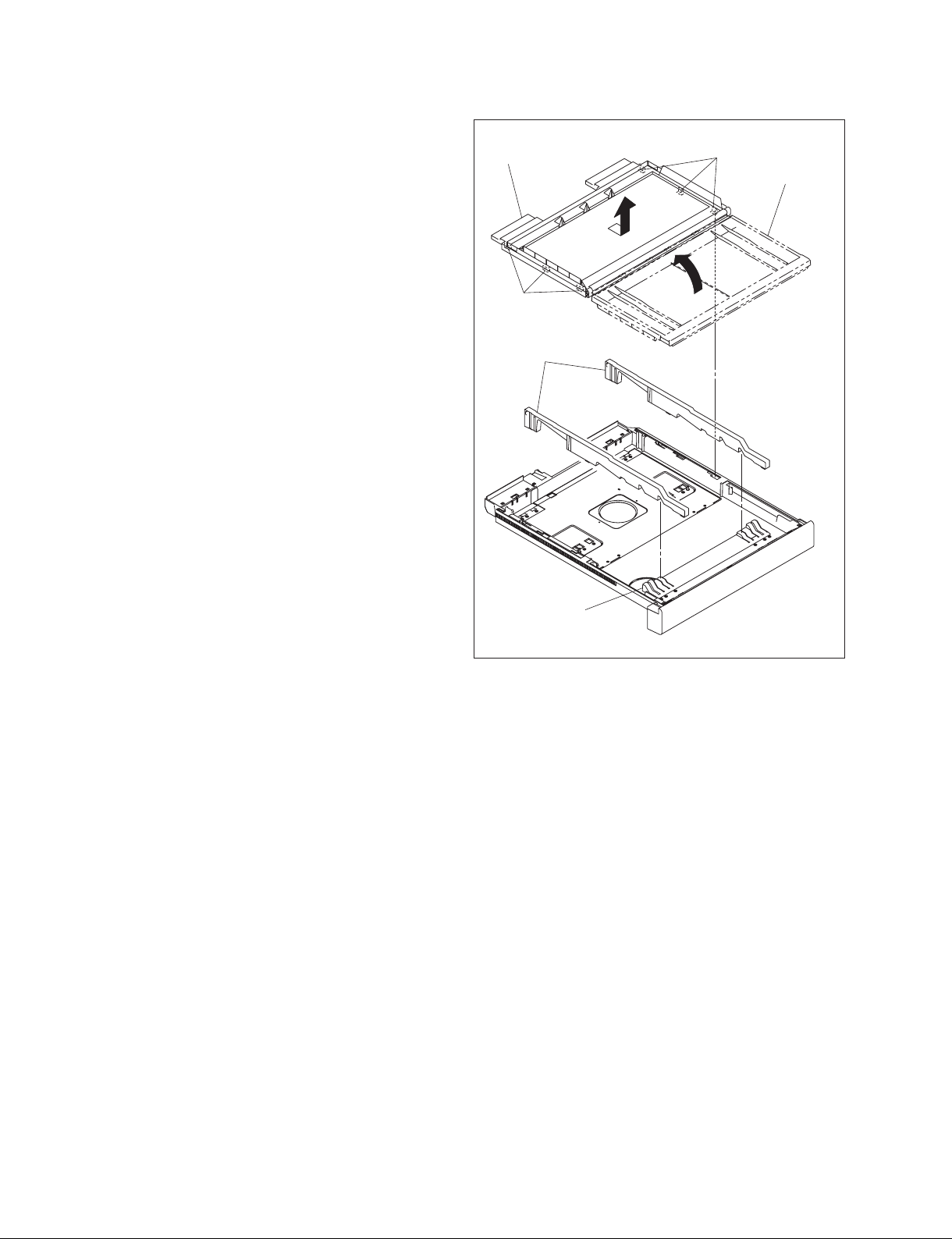

2. Open the tray cover (front) in the direction of the

arrow with the tray cover facing upward.

3. Pull the rear (SH) cover once in the direction of the

arrow and remove the six hooks, and then lift up

and remove the rear (SH) cover.

4. Remove the fi lm position guide.

5. Align the fi lm position guide with the size position of

the fi lm used.

Rear (SH) cover

Hooks

Film position

guides (side)

Hooks

Tray cover (front)

Film position

guide (front)

1-6

UP-DF750

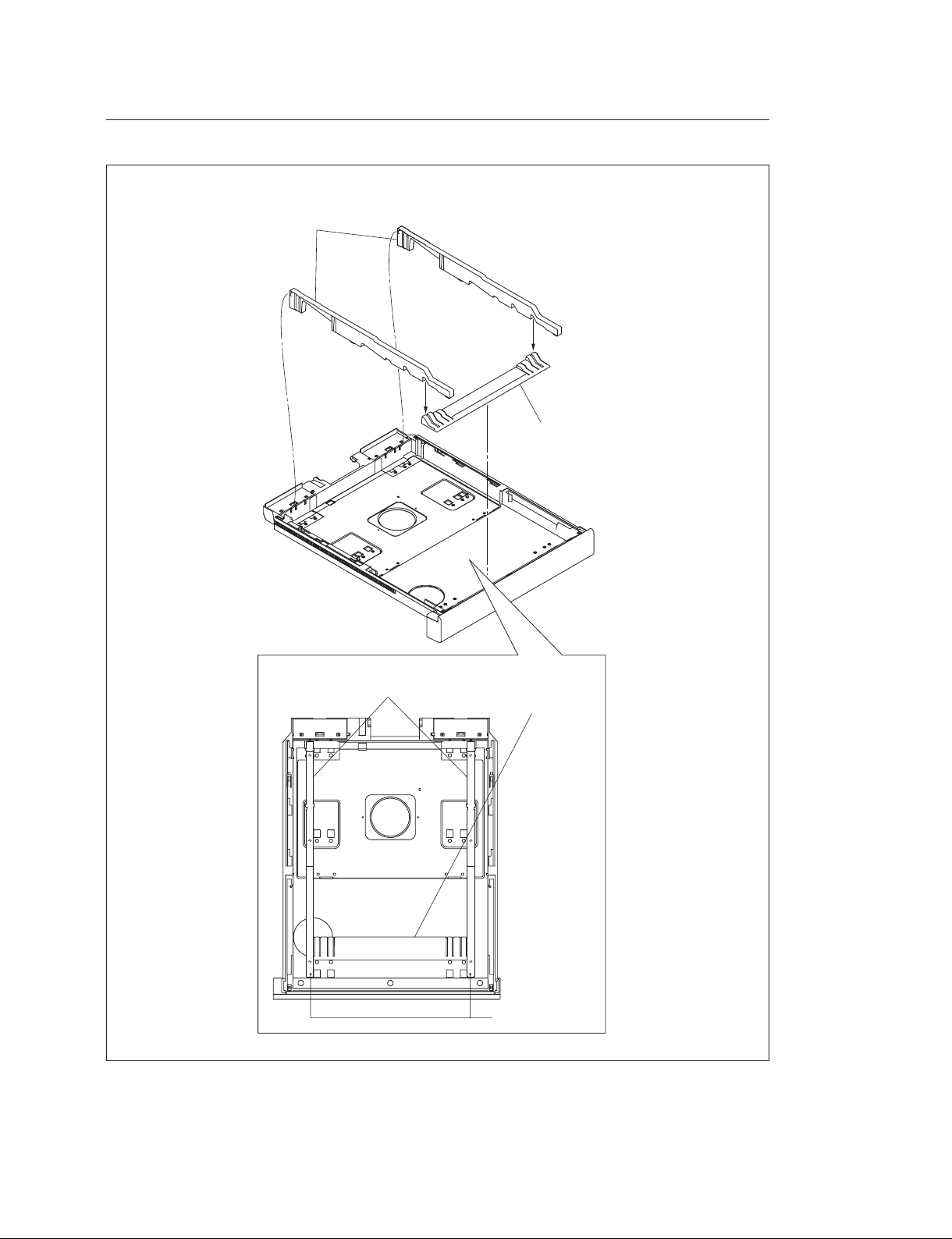

11 x 14 inch

Film position

guides (side)

Film position

guide (front)

Film position

guides (side)

6. To install, reverse the removal procedure.

Film position

guide (front)

11 x 14 inch

UP-DF750

1-7

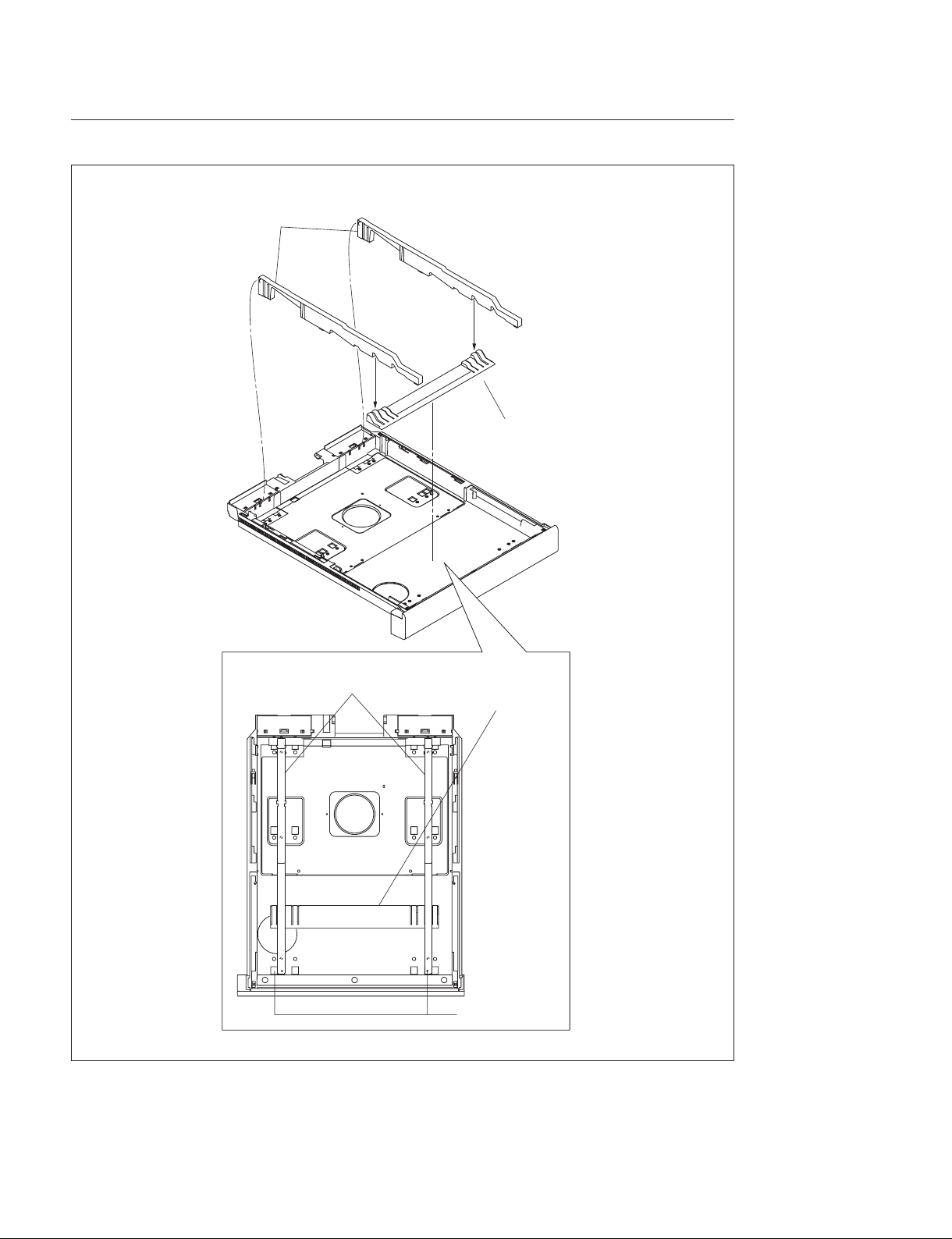

10 x 12 inch

Film position

guides (side)

Film position

guide (front)

Film position

guides (side)

6. To install, reverse the removal procedure.

Film position

guide (front)

10 x 12 inch

1-8

UP-DF750

8 x 10 inch

Film position

guides (side)

Film position

guide (front)

Film position

guides (side)

6. To install, reverse the removal procedure.

Film position

guide (front)

8 x 10 inch

UP-DF750

1-9

Output tray

m

. Depending on the combination of the fi lm size, it is required to change the confi guration of output tray.

. Factory setting is the large size.

. When installing the output tray, securely push it as far as it will go.

For more details, refer to the Instruction for Use.

Large size

In the combination of the following fi lm size, it is not required to change the tray installed at the factory.

Use the supplied stopper for output tray. The stopper for output tray is used to prevent the fi lm ejected in

the upper output tray from going into backward and being diffi cult to be taken out.

Combination of fi lm size Output tray stopper

8 x 10 8 x 10 Required

8 x 10 10 x 12

8 x 10 14 x 17

10 x 12 10 x 12

10 x 12 14 x 17

11 x 14 11 x 14 Not required

11 x 14 14 x 17

14 x 17 14 x 17

n

When using the 11 x 14 inch size fi lm, the stopper for output tray may cause the fi lm jamming.

Stack assist

(14 inch paper

eject detection)

Stack assist 2

(11 inch paper

eject detection)

Guide 10 x 12

Stack assist

(14 inch paper

eject detection)

Stack assist 2

(11 inch paper

eject detection)

1-10

UP-DF750

Small size

In the combination of the following fi lm size, it is required to change the tray installed at the factory.

Use the supplied stopper for output tray. The stopper for output tray is used to prevent the fi lm ejected in

the upper output tray from going into backward and being diffi cult to be taken out.

Combination of fi lm size Output tray stopper

8 x 10 11 x 14 Required

10 x 12 11 x 14

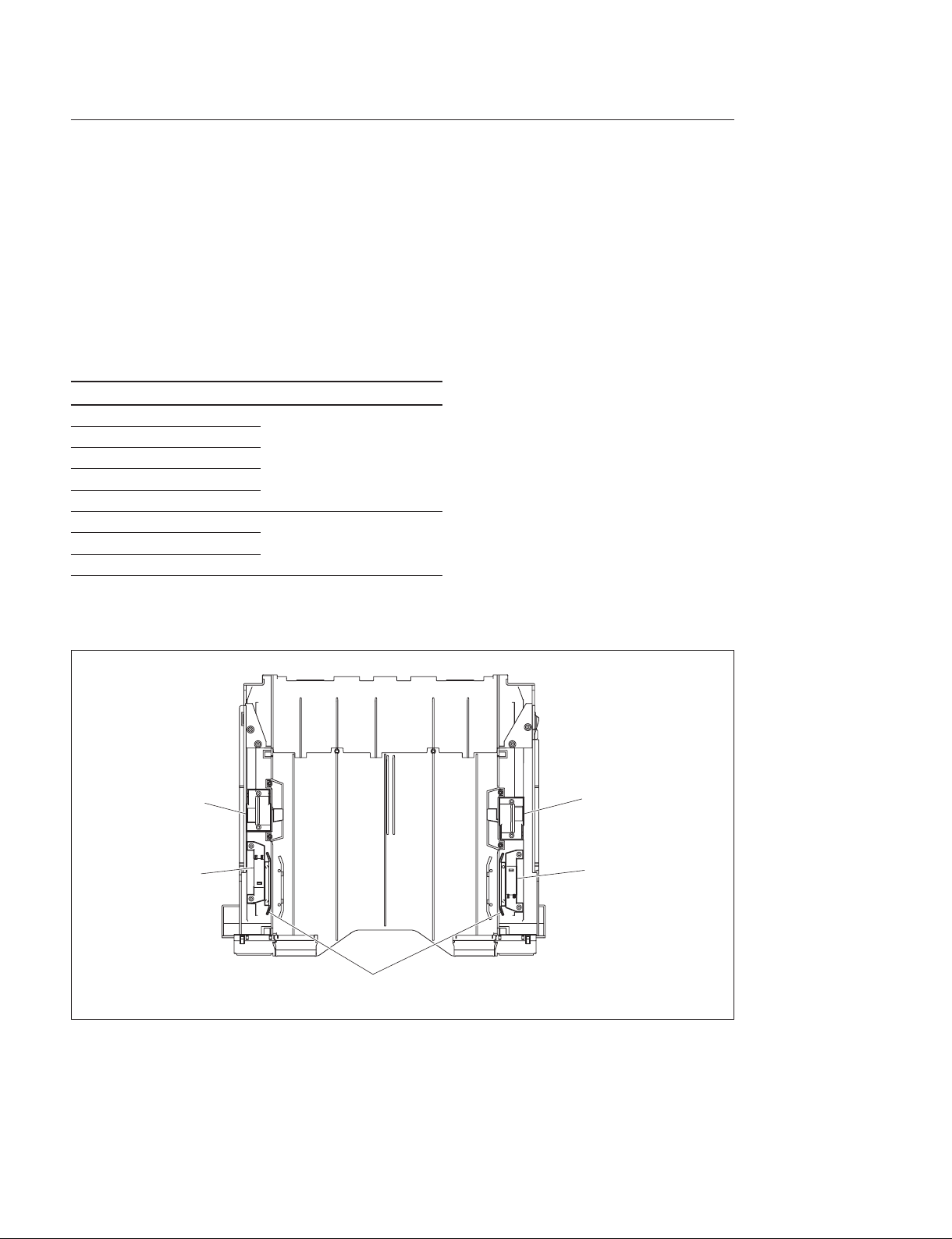

Changing from large size to small size

1. Remove the four screws, then remove the output tray rear.

n

Keep the removed output tray rear.

2. Remove the four screws, then remove the two stack assists.

3. Remove the four screws, then remove the two stack assists 2.

4. Remove the four screws, then remove the two guides 10 x 12.

B2.6 x 6

Output tray rear

Stack

assist

B2.6 x 6

Guide 10 x 12

Stack

assist 2

B2.6 x 6

B2.6 x 6

Stack

assist

Stack assist 2

B2.6 x 6

Guide 10 x 12

B2.6 x 6

UP-DF750

B2.6 x 6

Film tray

B2.6 x 6

1-11

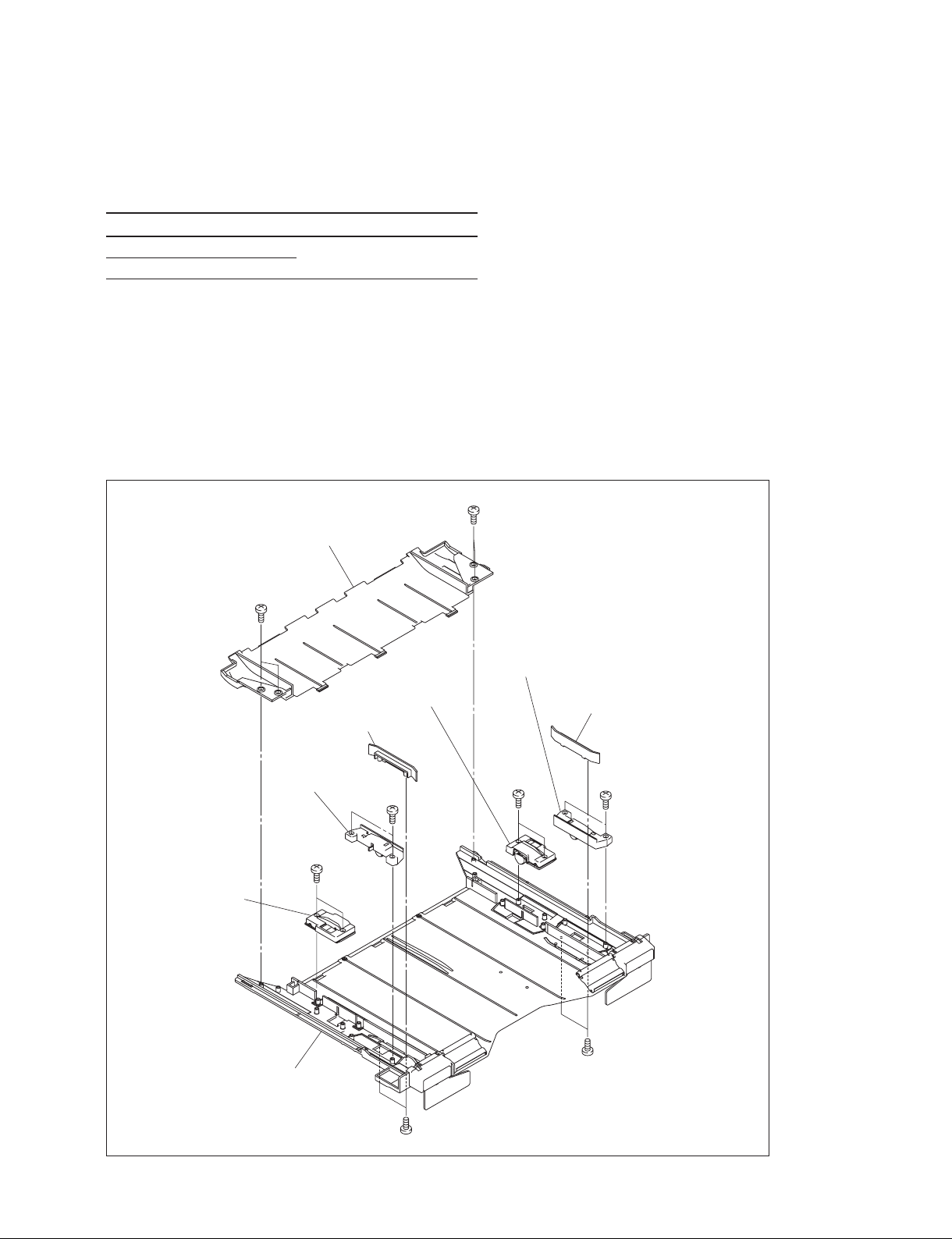

5. Attach the two stack assists 2 to the position with the four screws.

6. Attach the two stack assists to the position with the four screws.

7. Attach the two guides 10 x 12 to the position with the four screws.

Output tray stopper

Stack assist 2

Stack assist 2

B2.6 x 6

Guide 10 x 12

B2.6 x 6

B2.6 x 6

Guide

10 x 12

B2.6 x 6

Stack assist

Stack assist 2

Guide 10 x 12

Stack assist Stack assist

Stack assist

Stack assist 2

1-12

B2.6 x 6

Output tray

B2.6 x 6

UP-DF750

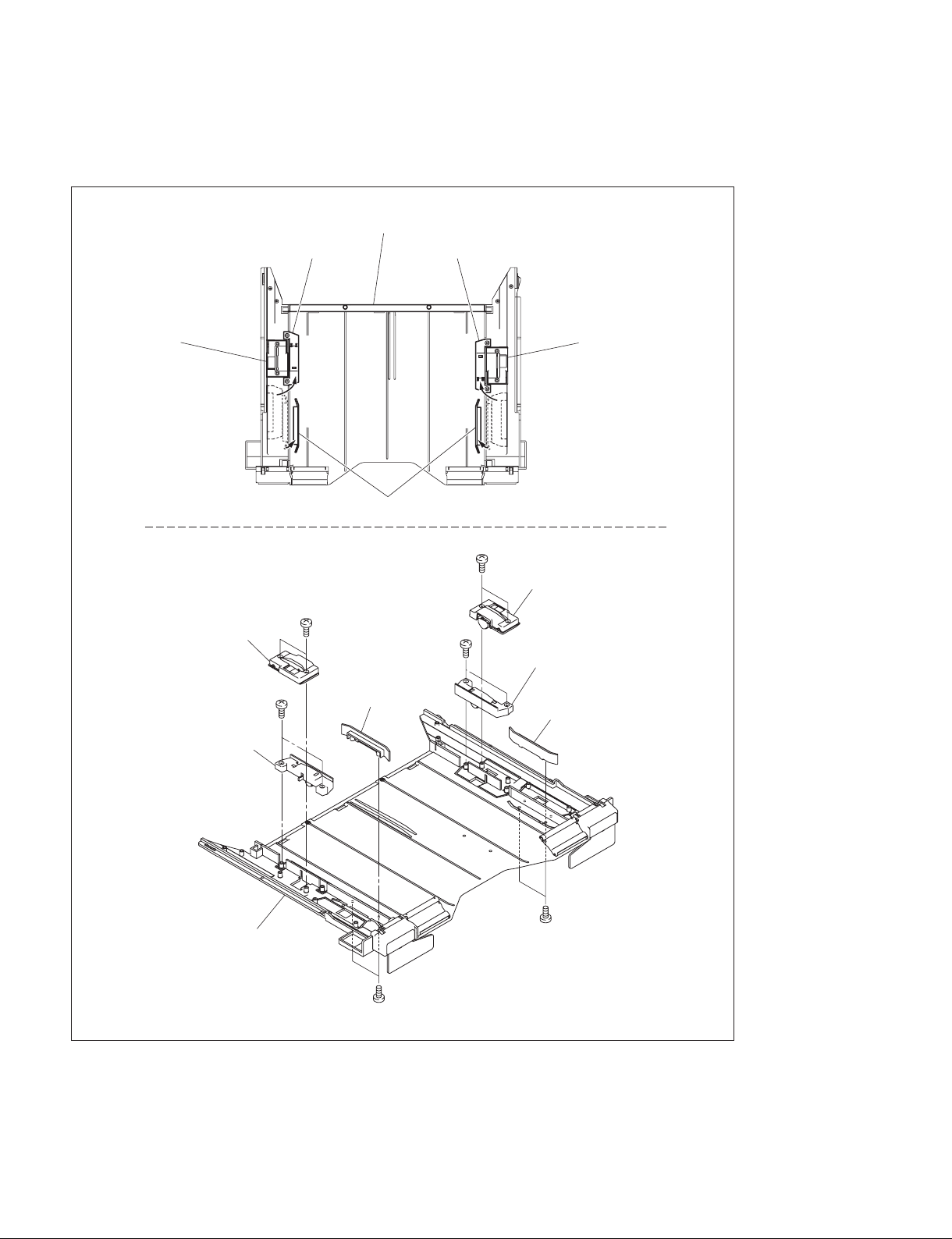

8. Attach the output tray stopper with the two nylon rivets.

Output tray stopper

Nylon rivets

Output tray

UP-DF750

1-13

1-6. Setting Procedure

Each setting is as follows.

1. Power On

Check that the system starts after turning on the power, then enter the service mode.

(Refer to Section 6-1.)

When performing the setting copy using Memory Stick, execute the System Settings → Memory Card →

Load Settings. (Refer to Section 3-22.)

2. Network setting

Perform the network setting such as an IP address via PC or by System Settings. For more details of

System Settings, refer to Section 6-2-6.

3. Film loading

1. Load the fi lm in the upper tray and lower tray.

2. Check that the fi lm size and the number of remaining sheets are displayed on the LCD panel.

n

If Tag Mismatch is displayed, the specifi cations of UP-DF750 do not check to those of the fi lm. Contact

your local Sony Sales Offi ce/Service Center.

4. Calibration

Perform calibration for each fi lm and check that LCD becomes READY state.

n

If the CAL automatic correction cannot be performed, NG is displayed.

The fi lm can be used without calibration because it is adjusted to specifi ed density.

Perform calibration in the following cases. In addition to the manual calibration, it is possible to set the

unit so that the fi rst sheet can be automatically calibrated when new fi lm is loaded. For more details, refer

to Section 6-2-3.

. Accurate density control is required.

. The unit is used under the environment where temperature or humidity changes greatly.

Perform calibration as required when the print density does not seem to meet the gamma setting.

5. Printing from Modality

After checking the setting of UP-DF750 of Modality, perform the printing from Modality.

Check the items below.

. Film size setting

. Max Density and Min Density setting

. AE title name

. Confi guration Information setting

. 604DPI/resize (Magnifi cation Type) setting

n

When changing the connection with the modality, refer to Section 1-8-3.

6. Gamma setting

When the gamma data is available in advance, setting is performed by FSSS. (Refer to Section 6-5.)

If the gamma is specifi ed by Default, change the setting of the main unit. (Refer to Section 6-2-4.)

1-14

UP-DF750

7. Gamma check and approval

Print out the image specifi ed by the user and get the approval of density setting from the responsible

person.

n

If requested by the user, adjust the gamma curve using FSSS. The selection of gamma can be performed

by the default setting, Modality ConnectionCustomizing (Refer to Section 1-8-3.) or Confi guration Infor-

mation setting of modality. In the service mode (Refer to Section 6-1.), the selected gamma is indicated as

G=x in the lower area of the printed output. So it can be checked. Be sure to perform calibration before

printing the image for obtaining the approval of gamma. (Refer to Section 6-2-3.)

8. Check other setting

As for Frame Type, the image frame can be enlarged. The density in the edge of fi lm is not uniform, there-

fore the image quality of the area outside of the specifi ed size (Caption 2) of each fi lm is not assured. In

the case of changing the setting, explain users about this. The factory setting is as follows.

System Settings menu

. Dither: ON

. Mirror: OFF

. L/R Mark: OFF

. Frame Type: Caption2

. Caption Upper: ON (No data)

Lower: OFF (No data)

. Film Empty Buzzer: OFF

. Setting Position: Horizontal

Calibration menu

. Auto Calibration setting: OFF

1-7. Film Loading Procedure

n

. Handle the fi lm wrapped by the moisture-proof bag with both hands. The contamination on the fi lm

surface such as fi ngerprint and sweat may cause degradation of the printed image quality. Be careful not

to touch the print surface.

. When handling the output tray, fi rmly hold the side of the tray and tray cover.

UP-DF750

1-15

1-8. DICOM Setting Method

1-8-1. Preparation

This section gives the system administrator information needed to setup the unit on a network, to reset the

IP address, to custmize the connection with modality and so on.

And describes the preparation required for the setup, gives an overview of the setup window, explains

how to perform the setup related to the IP address, and so on. It also explains how to setup an E-mail

warning to notify you automatically and to check the condisition of this unit via a network when any

trouble occurs.

Required equipment

. Personal Computer (PC): LAN interface equipped

. Operating system: Microsoft Windows 2000, or Windows XP/Vista

. LAN cable (cross)

. Web browser software: Internet Explorer 6.0 or later

Settings of the Web browser software

Set the Web browser software as follows:

. No proxy

. A blank page is opened when the Web browser software is started.

IP Address

When you use the unit for the fi rst time immediately, it is necessary to set up the DICOM part placed

inside the unit, adding an IP address and so on.

Before starting the setup, check the following with the network administrator.

. The IP address this unit will use on the network

. Sub-net mask of the network

. Gateway address, if a gateway is included in the network

To check the IP address

The IP address assigned to this unit can be checked.

1. Turn on the power of this unit.

2. Strat the service mode. (Refer to Section 6-1.)

3. Open the Information menu to check IP address. (Refer to Section 6-2-1.)

1-16

UP-DF750

1-8-2. Setup

Preparation

1. Start the PC to be used for setup.

2. Open the TCP/IP setting page.

3. Enter the following IP address of the computer and the sub-net mask.

IP address of the computer: NNN.NNN.NNN.nnn

NNN.NNN.NNN: Use the same numbers as those of the IP address assigned to this unit on the

network from the fi rst NNN to the third NNN.

nnn: Use any numbers from 1 to 254. However, you should not use the same num-

bers as the numbers of the fourth NNN of the IP address of this unit.

n

NNN.NNN.NNN.NNN: IP address assigned to this unit on the network

Sub-net Mask: 255.255.255.0

4. Restart the PC.

5. Connect this unit and the PC to be used for setup using the network cross cable.

About the setup/status window

This unit can be set up on the setup/status window displayed on the Web browser.

The setup/status window has the following pages:

Status window

http://NNN.NNN.NNN.NNN

. Summary/Print Job page

Displays the summary and print job status of this unit.

. Printer Status page

Displays the status of this unit.

Setup window

http://NNN.NNN.NNN.NNN/PrinterSetup

. Local Settings page

Sets up the IP address, DICOM Local AE title, and so on.

. E-Mail Settings page

Sets up the items related to E-Mail.

ConnectivityCustomizing page

http://NNN.NNN.NNN.NNN/PrinterSetup/PrinterSetup.exe/ConnectivityCustomizing

Set up the connection with the modality.

n

. When the username and password is required, contact your local Sony Sales Offi ce/Service Center.:

. NNN.NNN.NNN.NNN: IP address assigned to this unit.

UP-DF750

1-17

Opening the window

1. Start the PC to be used for setup, and then start the Web browser software.

2. Enter the URL for the window to display.

NNN.NNN.NNN.NNN: IP address assigned to this unit.

Page selection area

3. Click the desired page in the page selection area.

1-18

UP-DF750

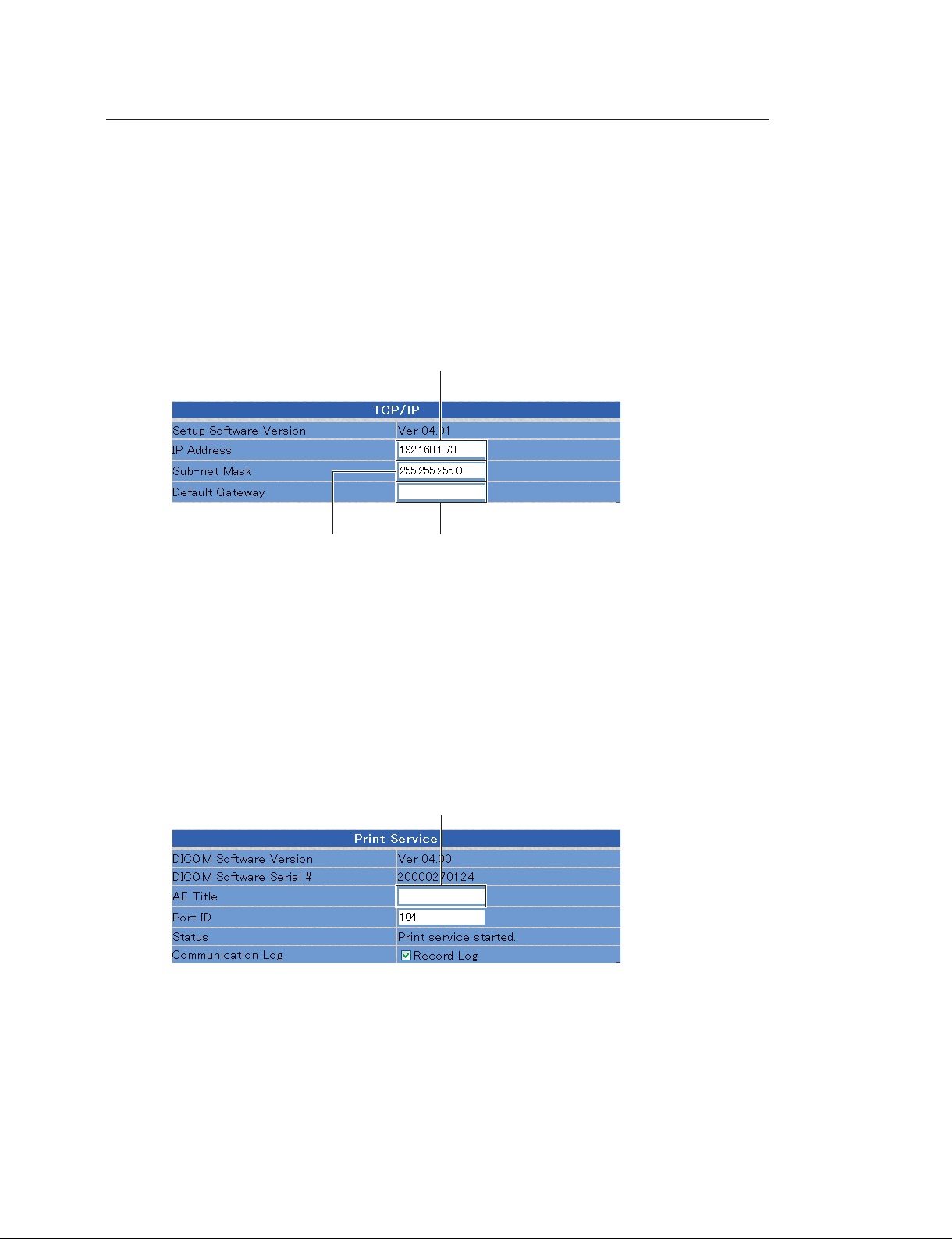

Network setup

Perform the following settings when the unit is used for the fi rst time, or when the IP address assigned to

this unit is changed.

Procedure

1. Enter “http://NNN.NNN.NNN.NNN/PrinterSetup” to open the Local Settings page.

n

When the username and password is required, contact your local Sony Sales Offi ce/Service Center.:

2. Perform the required settings related to TCP/IP.

IP Address text box

Default Gateway text boxSub-net Mask text box

(1) Enter the IP address of this unit on the network in the IP Address text box.

(2) Enter the sub-net mask in the Sub-net Mask text box.

(3) Enter the IP address of the default gateway in the Default Gateway text box if a gateway is used

on the network.

3. Enter the DICOM Local AE title in the AE Title text box.

Up to 16 characters can be entered.

n

When Local AE Title is not blank and its setting is different from Called AE title, Association is

rejected. Blank is recommended.

AE Title text box

4. Click the [Save|settings] button.

The settings are saved.

UP-DF750

1-19

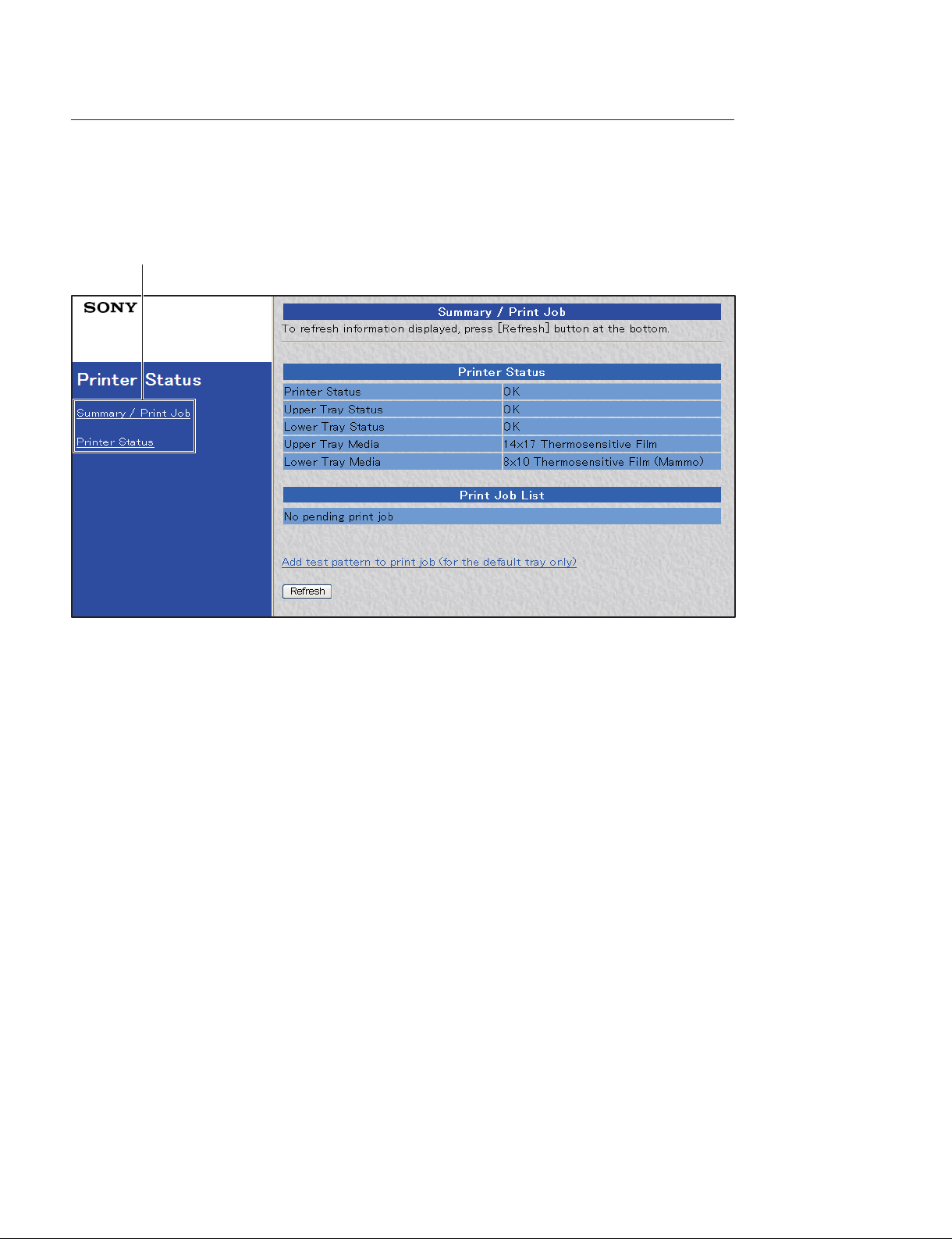

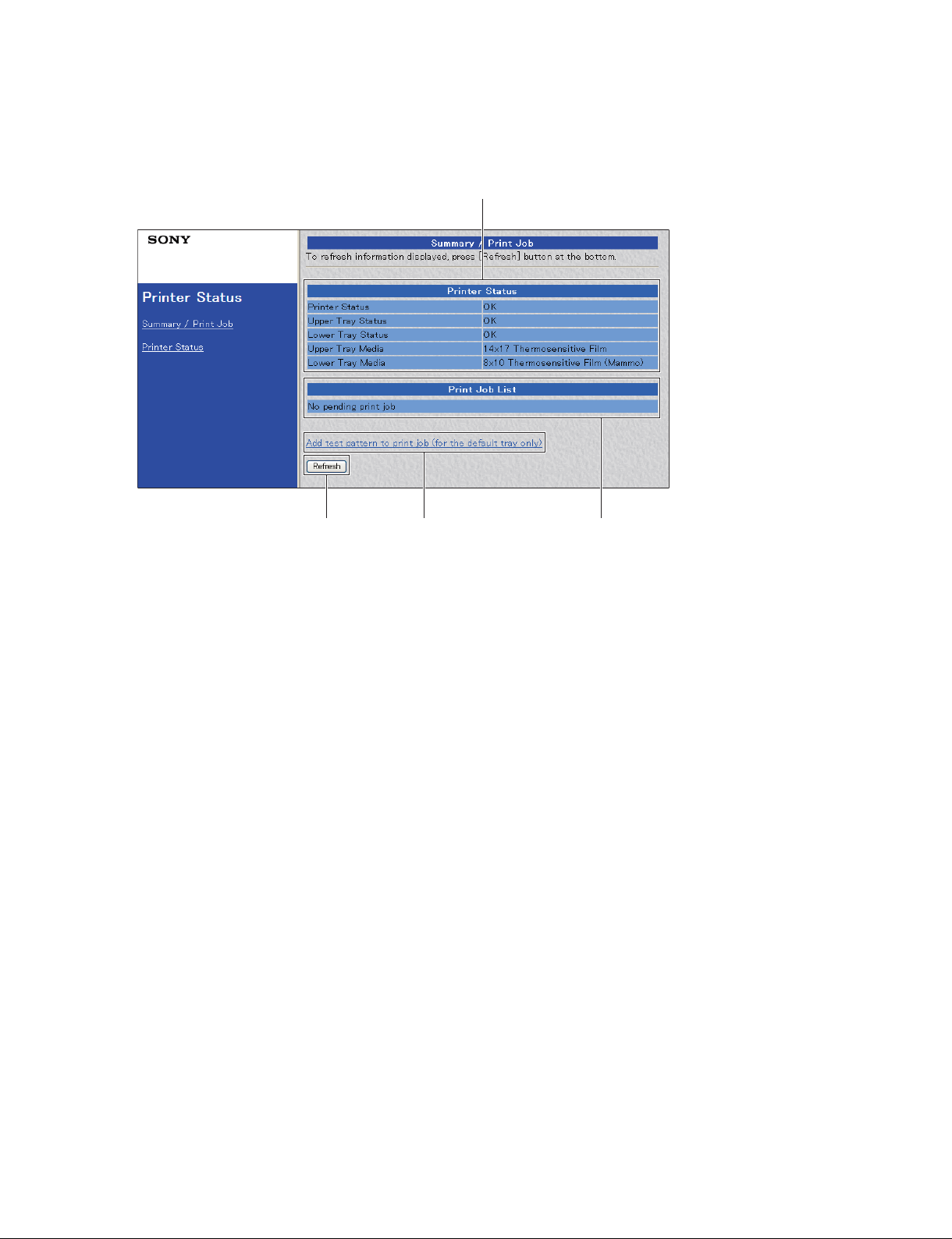

1. Summary/Print Job page

This page displays information on this unit.

Printer (printer status) display section

Printer Status: Displays the printer status.

Upper Tray Status: Indicates the status of fi lm sheets loaded in fi lm tray 1.

OK: Correct

Set Films/Papers...: Film sheets are not loaded.

Set Film/Paper Tray...: Film tray 1 is not inserted.

Lower Tray Status: Indicates the status of fi lm sheets loaded in fi lm tray 2.

OK: Correct

Set Films/Papers...: Film sheets are not loaded.

Set Film/Paper Tray...: Film tray 2 is not inserted.

Upper Tray Media: Displays the type of blue thermal fi lm loaded in fi lm tray 1.

Lower Tray Media: Displays the type of the blue thermal fi lm loaded in fi lm tray 2.

Print Job List display section

Displays when a job is waiting to be printed.

Add test pattern to print job (for the default tray only)

Click this link to print the test pattern. The fi lm sheets loaded in fi lm tray 1 is used for this printing.

Refresh button

Click this button to refresh the window.

1-20

UP-DF750

2. Printer Status Page

This page displays the status of this unit.

Upper Tray display area

Film/Paper Tray: Displays whether or not fi lm tray 1 is inserted.

Films/Papers: Displays whether or not fi lm sheets are loaded in fi lm tray 1.

Film/Paper Output: Displays the status of the fi lm output slot.

Tag: Displays the confi rmability status of the IC tag of the fi lm sheets loaded in

the fi lm tray 1.

Media Type: Displays the type of the fi lm sheets loaded in fi lm tray 1.

Media Size: Displays the size of the fi lm sheets loaded in fi lm tray 1.

Film/Papers Remaining: Displays the remaining amount of fi lm sheets in fi lm tray 1.

UP-DF750

1-21

Lower Tray display area

Film/Paper Tray: Displays whether or not fi lm tray 2 is inserted.

Films/Papers: Displays whether or not fi lm sheets are loaded in fi lm tray 2.

Film/Paper Output: Displays the status of the fi lm output slot.

Tag: Displays the confi rmability status of the IC tag of the fi lm sheets loaded in

fi lm tray 2.

Media Type: Displays the type of the fi lm sheets loaded in the fi lm tray 2.

Media Size: Displays the size of the fi lm sheets loaded in fi lm tray 2.

Film/Papers Remaining: Displays the remaining amount of fi lm sheets in the fi lm tray 2.

Printer Status display area

Motor/Sensor: Displays the error status of the motor/sensor system.

Film /Paper Path: Displays the status of the printing path.

Cover: Displays the status of covers (opened or closed).

Printer Engine Status: Displays the printer operating status (idling, printing and so on)

Printer Statistics display area

Displays the total printings performed by the unit.

Print count with the current thermal head: Displays the total prints after the thermal head has been

replaced.

Lifetime print count: Displays the total prints since the unit has been shipped.

Printer Information display area

Vendor ID, Model Name, Version Number, Resolution: Displays various information on the unit

status.

[Refresh|button]

Click this button to refresh the window.

1-22

UP-DF750

Loading...

Loading...