Sony DCR-PC115E, DCR-PC120E Service Manual

DCR-PC115E/PC120E

Video camera

recorder

System

Video recording system

2 rotary heads

Helical scanning system

Audio recording system

Rotary heads, PCM system

Quantization: 12 bits (Fs 32 kHz,

stereo 1, stereo 2), 16 bits

(Fs 48 kHz, stereo)

Video signal

PAL colour, CCIR standards

Usable cassette

Mini DV cassette with the

mark printed

Tape speed

SP: Approx. 18.81 mm/s

LP: Approx. 12.56 mm/s

Recording/playback time (using

cassette DVM60)

SP: 1 hour

LP: 1.5 hours

Fastforward/rewind time (using

cassette DVM60)

When using the battery pack:

Approx. 2 min. and 30 seconds

When using the AC power adaptor:

Approx. 1 min. and 45 seconds

Viewfinder

Electric viewfinder (colour)

Image device

4.5 mm (1/4 type) CCD (Charge

Coupled Device)

Approx. 1 550 000 pixels

(Effective (moving): 970 000 pixels)

(Effective (still): 1 390 000 pixels)

Lens

Carl Zeiss Vario-Sonnar T*

Combined power zoom lens

Filter diameter: 37 mm (1 1/2 in)

10× (Optical), 120× (Digital)

Focal length

4.2 – 42 mm (3/16 – 1 11/16 in.)

When converted to a 35 mm still

camera

Camera mode:

48 – 480 mm (1 15/16 – 19 in.)

Memory mode:

40 – 400 mm (1 5/8 – 15 3/4 in.)

Colour temperature

Auto, HOLD (Hold),

Indoor

(3 200 K),

Outdoor (5 800 K)

Minimum illumination

7 lx (lux) (F 1.8)

0 lx (lux) (in the NightShot mode)*

* Objects unable to be seen due to

the dark can be shot with infrared

lighting.

Input/Output connectors

S video input/output

4-pin mini DIN

Luminance signal: 1 Vp-p,

75 Ω (ohms), unbalanced

Chrominance signal: 0.3 Vp-p,

75 Ω (ohms), unbalanced

Audio/Video input/output

AV MINI JACK, 1 Vp-p,

75 Ω (ohms), unbalanced, sync

negative

327 mV, (at output impedance

more than 47 kΩ (kilohms))

Output impedance with less than

2.2 kΩ (kilohms)/Stereo minijack

(ø 3.5 mm)

Input impedance more than

47 kΩ (kilohms)

DV input/output

4-pin connector

Headphone jack

Stereo minijack (ø 3.5 mm)

LANC jack

Stereo mini-minijack (ø 2.5 mm)

USB jack

mini-B

MIC jack

Minijack, 0.388 mV low impedance

with 2.5 to 3.0 V DC, output

impedance 6.8 kΩ (kilohms) (ø 3.5

mm)

Stereo type

LCD screen

Picture

6.2 cm (2.5 type)

50 × 37 mm (2 × 1 1/2 in.)

Total dot number

211 200 (960 × 220)

Wireless communications

(DCR-PC120E only)

Communications system

Bluetooth standard Ver.1.1

Max. baud rate

1) 2)

Approx. 723 kbps

Output

Bluetooth standard Power Class 2

Communications distance

2)

Max. wireless distance Approx. 10 m

(393 3/4 in.) (When connecting to

BTA-NW1 (optional))

Compatible Bluetooth profile

3)

Generic Access Profile

Dial-up Networking Profile

Operating frequency band

2.4 GHz band (2.400 GHz-

2.483 5 GHz)

1) Max. baud rate of Bluetooth

standard Ver.1.1

2) Varies according to the distance

between communicating devices,

presence of obstacles, radiowave

conditions, and other factors.

3) This is a specification matched to

specific usage requirements

between Bluetooth compatible

devices. It is laid down in the

Bluetooth standards.

General

Power requirements

7.2 V (battery pack)

8.4 V (AC power adaptor)

Average power consumption

(when using the battery pack)

During camera recording using

LCD

4.1 W

Viewfinder

3.6 W

Operating temperature

0°C to 40°C (32°F to 104°F)

Storage temperature

–20°C to +60°C

(–4°F to +140°F)

Dimensions (Approx.)

57 × 118 × 113 mm

(2 1/4 × 4 3/4 × 4 1/2 in.)

(w/h/d)

RMT-811

SERVICE MANUAL

SERVICE MANUALSERVICE MANUAL

Level 1

Ver 1.0 2001. 09

Photo : DCR-PC120E

RMT-811

SPECIFICATIONS

AEP Model

DCR-PC115E/PC120E

UK Model

DCR-PC120E

J MECHANISM

DIGITAL VIDEO CAMERA RECORDER

— Continued on next page —

DCR-PC115E/PC120E

Mass (approx.)

580 g (1 lb 4 oz)

main unit only

690 g (1 lb 8 oz)

including the battery pack

NP-FM50, cassette DVM60 and lens

cap

Supplied accessories

See page 3.

AC power adaptor

Power requirements

100 – 240 V AC, 50/60 Hz

Power consumption

23 W

Output voltage

DC OUT: 8.4 V, 1.5 A in the

operating mode

Operating temperature

0°C to 40°C (32°F to 104°F)

Storage temperature

–20°C to + 60°C (–4°F to + 140°F)

Dimensions (approx.)

125 × 39 × 62 mm

(5 × 1 9/16 × 2 1/2 in.) (w/h/d)

excluding projecting parts

Mass (approx.)

280 g (9.8 oz)

excluding power cord

Battery pack

Maximum output voltage

DC 8.4 V

Output voltage

DC 7.2 V

Capacity

8.5 Wh (1 180 mAh)

Dimensions (approx.)

38.2 × 20.5 × 55.6 mm

(1 9/16 × 13/16 × 2 1/4 in.)

(w/h/d)

Mass (approx.)

76 g (2.7 oz)

Type

Lithium ion

“Memory Stick”

Memory

Flash memory

8MB: MSA-8A

Operating voltage

2.7 – 3.6 V

Power consumption

Approx. 45 mA in the operating

mode

Approx. 130 µA in the standby

mode

Dimensions (approx.)

50 × 2.8 × 21.5 mm

(2 × 1/8 × 7/8 in.) (w/h/d)

Mass (approx.)

4 g (0.14 oz)

Design and specifications are

subject to change without notice.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair . Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

— 2 —

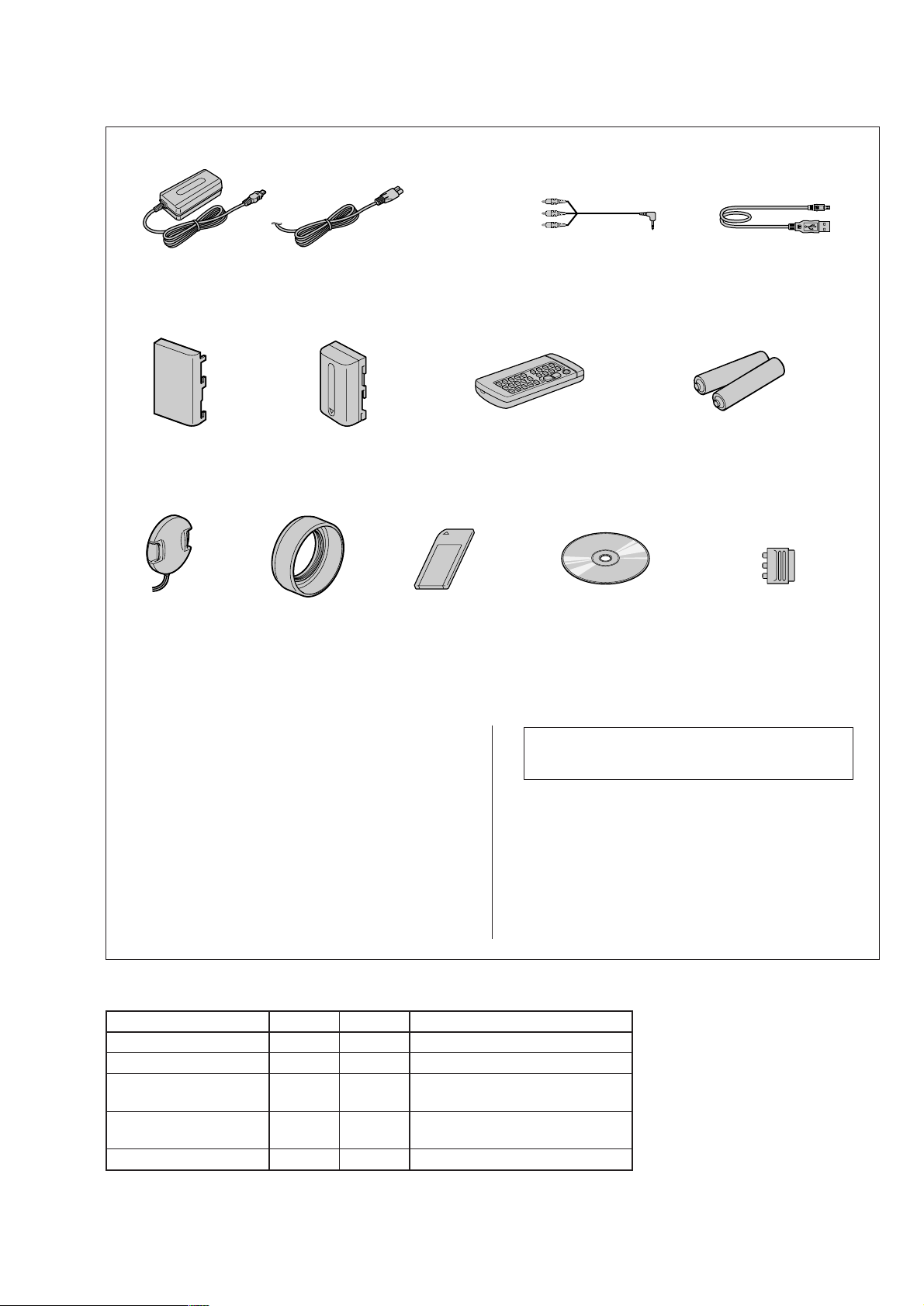

Checking supplied accessories.

Make sure that the following accessories are supplied with your camcorder.

DCR-PC115E/PC120E

AC power adaptor (1)

(AC-L10A)

0

1-475-599-11

Battery terminal cover (1)

3-057-482-01

Lens cap (1)

X-3949-944-1

Power cord (Main lead)(1) (AEP model)

0

1-769-608-11

Power cord (Main lead)(1) (UK model)

0

1-783-374-11

NP-FM50 battery pack (1)

(Not supplied)

Lens hood (1)

3-063-515-01

Memory stick (1)

MSA-8A

A-7024-735-A

Other accessories

3-070-988-11 MANUAL, INSTRUCTION (ENGLISH/RUSSIAN)

3-070-988-21 MANUAL, INSTRUCTION (ITALIAN/GREECE) (PC115E)

3-070-988-31 MANUAL, INSTRUCTION (SPANISH/PORTUGUESE)

3-070-988-41 MANUAL, INSTRUCTION (FRENCH/GERMAN)

3-070-988-51 MANUAL, INSTRUCTION (ENGLISH/DUTCH)

(PC115E/PC120E:UK)

(PC120E:AEP)

(PC120E:AEP)

A/V connecting cable (1.5m) (1)

1-765-080-11

Wireless Remote Commander (1)

RMT-811

1-475-950-21

CD-ROM

(SPVD-004(P) USB Driver)(1)

3-066-676-01

Note : The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

(PC115E)

USB cable (1)

1-757-293-21

Size R6 (AA) battery for

Remote Commander (2)

(not supplied)

21-pin adaptor (1)

1-573-291-11

3-071-132-11 OPERATING INSTRUCTION(NETWORK)

3-071-132-21 OPERATING INSTRUCTION(NETWORK)

(ENGLISH/FRENCH)(PC120E)

(GERMAN/DUTCH) (PC120E:AEP)

Table for difference of functions

DCRDestination

NETWORK (Bluetooth)

Flash memory

PC115E

AEP

✕

4Mbit

PC120E

AEP, UK

32Mbit

(VC-270 board IC1406)

SDRAM

16Mbit

64Mbit

(VC-270 board IC1404)

BT-003 board

✕

Remarks

X301 of VC-270 board is 40.5MHz.

a

With BT-003 board

a

— 3 —

DCR-PC115E/PC120E

TABLE OF CONTENTS

SERVICE NOTE

1. POWER SUPPLY DURING REPAIRS ····························· 5

2. TO TAKE OUT A CASSETTE WHEN NOT EJECT

(FORCE EJECT) ································································5

3. DISCHARGING OF THE FLASHLIGHT POWER

SUPPLY CAPACITOR ······················································ 6

3-1. DISCHARGING THE CAPACITOR USING THE

SHORT JIG ········································································ 6

3-1-1.PREPARING THE SHORT JIG········································· 6

3-1-2.DISCHARGING THE CAPA CIT OR································· 6

3-2. DISCHARGING THE CAPACITOR USING THE

REMOTE COMMANDER ················································ 6

3-2-1.DISCHARGING THE CAPA CIT OR································· 6

3-2-2.PROCESSING AFTER COMPLETING REPAIRS/

ADJUSTMENTS································································ 6

SELF-DIAGNOSIS FUNCTION

1. SELF-DIAGNOSIS FUNCTION······································· 7

2. SELF-DIAGNOSIS DISPLAY ·········································· 7

3. SERVICE MODE DISPLAY ············································· 7

3-1. Display Method ·································································· 7

3-2. Switching of Backup No. ··················································· 7

3-3. End of Display···································································· 7

4. SELF-DIAGNOSIS CODE TABLE··································· 8

1. MAIN PARTS

1. ORNAMENTAL PARTS···················································· 9

2. DISASSEMBLY······························································· 10

2-1. CABINET (L) SECTION················································· 12

2-2. VTR COMPLETE, CABINET (R) SECTION ················ 13

2-3. FJ-035 BOARD································································ 14

2-4. VM-027 BOARD ····························································· 15

2-5. CD-349P BOARD, LENS DEVICE ································ 15

2-6. VC-270 BOARD ······························································ 16

2-7. MECHANISM DECK······················································ 16

2-8. FLASH UNIT (MC) ·························································17

2-9. FLASH UNIT (ST) ·························································· 17

2-10. CABINET (G) BLOCK ASSEMBLY, ETC.···················· 18

2-11. CONTROL SWITCH BLOCK (FK-1850) ······················ 19

2-12. CONTROL SWITCH BLOCK (PS-1850) ······················· 19

2-13. BLIND PLATE ASSEMBLY ···········································20

PD-148B BOARD, INVERTER TRANSFORMER UNIT ·

2-14.

2-15. HINGE ASSEMBLY························································ 21

3. REPAIR PARTS LIST ······················································ 22

3-1. EXPLODED VIEWS ······················································· 22

3-1-1.OVERALL SECTION······················································ 22

3-1-2.CABINET (L) SECTION················································· 23

3-1-3.VTR OVERALL SECTION············································· 24

3-1-4.LENS-EVF SECTION ····················································· 25

3-1-5.CABINET (R) SECTION-1 ············································· 26

3-1-6.CABINET (R) SECTION-2 ············································· 27

2. GENERAL

Main Features ············································································· 28

Quick Start Guide ······································································· 28

Getting started

Using this manual ··································································· 29

Checking supplied accessories ··············································· 29

Step 1 Preparing the power supply ········································· 30

Installing the battery pack···················································· 30

Charging the battery pack ····················································30

Connecting to a wall socket ·················································31

Step 2 Setting the date and time ············································· 31

Step 3 Inserting a cassette······················································· 32

Recording – Basics

Recording a picture·································································32

Shooting backlit subjects – BACK LIGHT ···························· 35

Shooting in the dark – NightShot/Super NightShot ··············· 35

Self-timer recording································································ 35

Checking the recording – END SEARCH / EDITSEARCH /

Rec Review ··········································································36

Playback – Basics

Playing back a tape ································································· 36

20

To display the screen indicators – Display function ··············· 36

Viewing the recording on TV ················································· 37

Advanced Recording Operations

Recording a still image on a tape – Tape Photo recording ····· 38

Adjusting the white balance manually···································· 39

Using the wide mode ······························································ 40

Using the fader function ························································· 40

Using special effects – Picture effect······································ 41

Using special effects – Digital effect······································ 41

Using the PROGRAM AE function ········································ 42

Adjusting the exposure manually ··········································· 43

Focusing manually·································································· 43

Interval recording···································································· 44

Frame by frame recording – Cut recording ····························44

Advanced Playback Operations

Playing back a tape with picture effects ································· 45

Playing back a tape with digital effects ·································· 45

Enlarging images recorded on tapes – Tape PB ZOOM ·········45

Quickly locating a scene using the zero set memory function·····

Searching the boundaries of recorded tape by title – Title search ·

Searching a recording by date – Date search·························· 47

Searching for a photo – Photo search/Photo scan··················· 47

Editing

Dubbing a tape ········································································48

Dubbing only desired scenes – Digital program editing (on tapes) ··

Using with analog video unit and your computer

– Signal convert function····················································· 52

Recording video or TV programmes ······································ 53

Inserting a scene from a VCR – Insert editing························ 54

Audio dubbing ········································································ 55

Superimposing a title ······························································ 56

Making your own titles ···························································57

Labelling a cassette································································· 57

Customising Y our Camcorder

Changing the menu settings···················································· 58

“Memory Stick” Operations

Using a “Memory Stick” – introduction ·································60

Recording still images on “Memory Stick”s

– Memory Photo recording ··················································63

Recording an image from a tape as a still image ···················· 65

Superimposing a still image in the “Memory Stick” on an

image – MEMORY MIX····················································· 66

Recording moving pictures on “Memory Stick”s

– MPEG movie recording ····················································68

Recording a picture from a tape as a moving picture ············· 68

Recording edited pictures as a moving picture

– Digital program editing (on “Memory Stick”s)················ 69

Copying still images from a tape – Photo save······················· 70

Viewing a still image – Memory photo playback ··················· 71

Viewing a moving picture – MPEG movie playback ············· 72

Viewing images using computer ············································· 72

Copying the image recorded on “Memory Stick”s to tapes ····

Enlarging still images recorded on “Memory Stick”s

– Memory PB ZOOM ··························································75

Playing back images in a continuous loop – SLIDE SHOW·····

Preventing accidental erasure – Image protection ·················· 76

Deleting images ······································································ 76

Writing a print mark – PRINT MARK··································· 76

Using the optional printer ······················································· 77

Using the Network function

Accessing the network ····························································77

Troubleshooting

Types of trouble and their solutions ········································78

Self-diagnosis display ·····························································79

Warning indicators and messages ··········································· 79

Additional Information

Usable cassettes ······································································ 80

About the “InfoLITHIUM” battery pack································ 81

About i.LINK·········································································· 81

Using your camcorder abroad················································· 82

Maintenance information and precautions······························ 82

Quick Reference

Identifying the parts and controls ··········································· 84

46

46

49

74

75

— 4 —

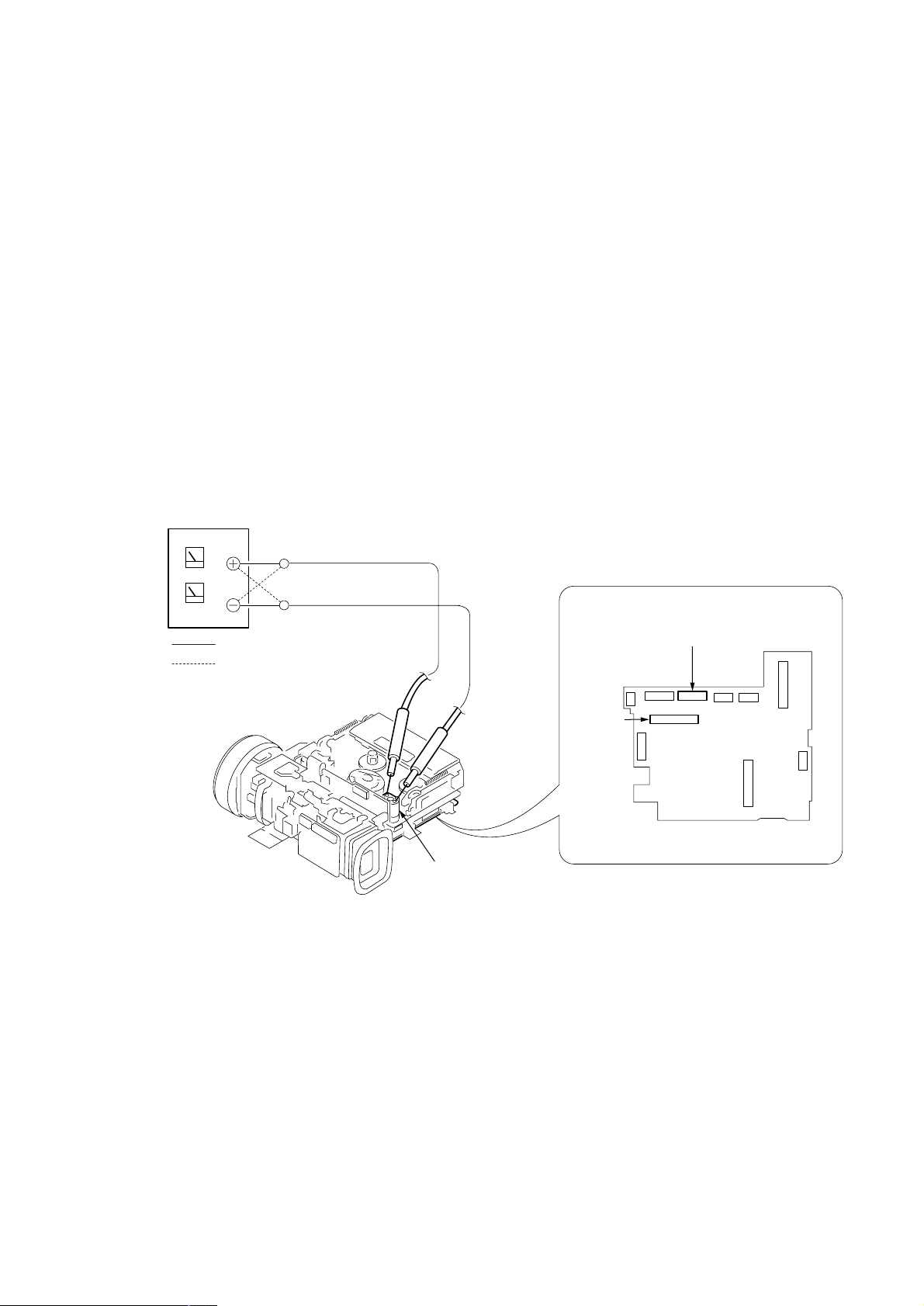

SERVICE NOTE

: Unloading

: Loading

VC-270 board

Loading motor

Regulated power supply

(+4.5Vdc)

CN006

CN302

DCR-PC115E/PC120E

1. POWER SUPPLY DURING REPAIRS

In this unit, about 10 seconds after power is supplied to the battery terminal using the regulated power supply (8.4V), the po wer is shut of f so

that the unit cannot operate.

This following two methods are available to prevent this. Take note of which to use during repairs.

Method 1

Use the AC power adaptor (AC-L10, AC-VQ800, AC-SQ950 etc.).

Method 2

Connect the servicing remote commander RM-95 (J-6082-053-B) to the LANC jack, and set the commander switch to the “ADJ” side.

2. TO TAKE OUT A CASSETTE WHEN NOT EJECT (FORCE EJECT)

1 Refer to 2-2. to remove the HS cover.

2 Refer to 2-2. to remove the jack cover.

3 Refer to 2-2. to remove the cabinet (R) assembly.

4 Refer to “3. DISCHARGING OF THE FLASHLIGHT POWER SUPPL Y CAPACITOR” to dischar ge the flash power supply capacitor .

5 Refer to 2-3. to remove the mechanism deck and the lens block and the EVF block from the cabinet (L) block.

6 Disconnect CN302 (72P, 0.4mm) of VC-270 board.

7 Disconnect CN006 (27P, 0.3mm) of VC-270 board.

8 Supply +4.5V from the DC power supply to the loading motor and unload with a pressing the cassette compartment.

— 5 —

DCR-PC115E/PC120E

3. DISCHARGING OF THE FLASHLIGHT POWER SUPPLY CAPACITOR

The capacitor (C2010) of the flash unit (MC1850) is charged up to the maximum 300V potential. There is a danger of electric shock by this

high voltage when the flash unit (MC1850 or ST1850) is handled by hand. The electric shock is caused by the char ged v oltage which is kept

without discharging when the main power of the unit is simply turned of f. Ther efore, the remaining volta ge must be discharged as described

below.

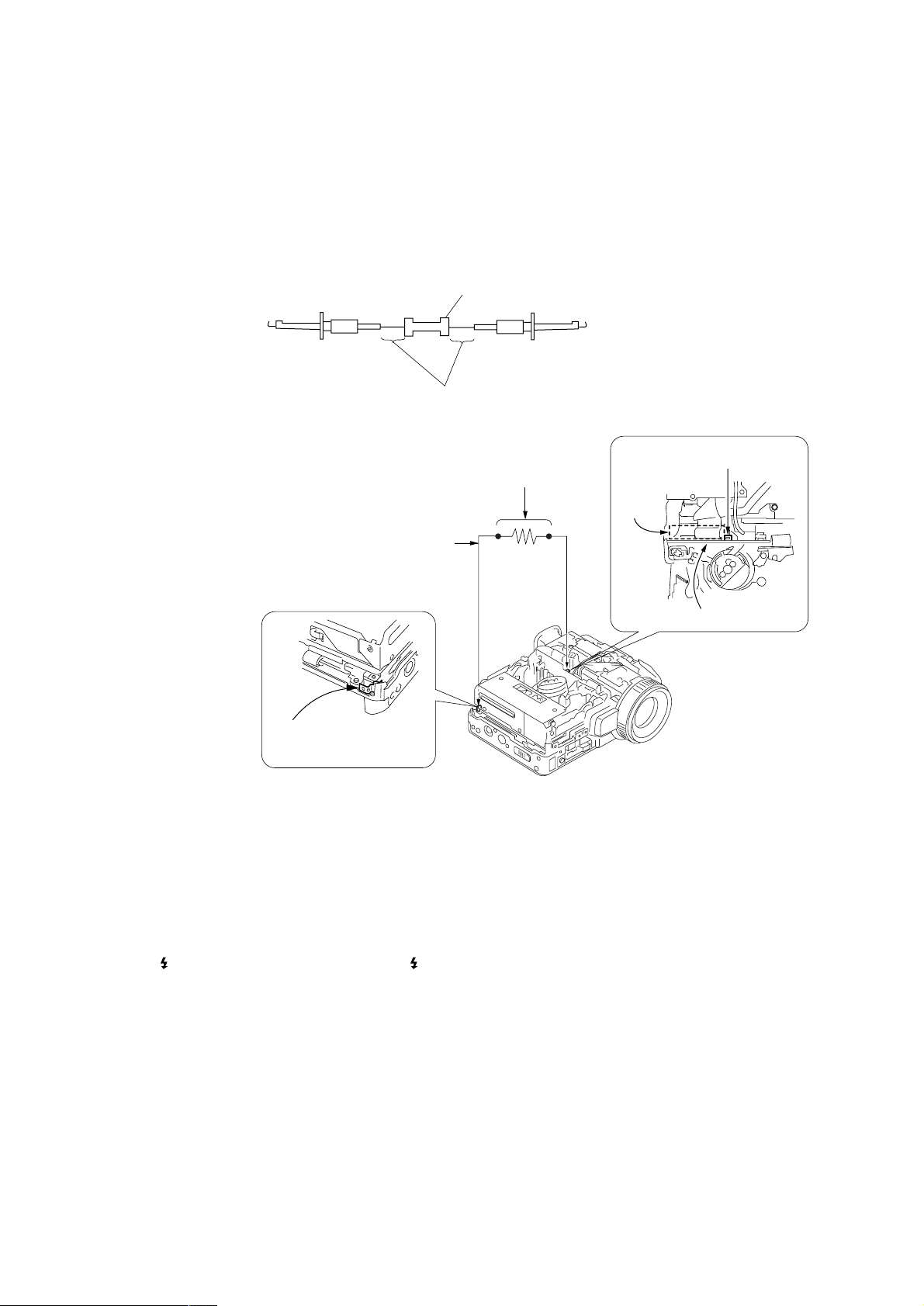

3-1. DISCHARGING THE CAPACITOR USING THE SHORT JIG

3-1-1. PREPARING THE SHORT JIG

T o preparing the short jig. a small clip is attached to each end of a resistor of 1kΩ/1W (1-215-869-11). Wrap insulating tape fully around the

reads of the resistor to prevent electric shock.

1 k

Ω

/1 W

Wrap insulating tape

3-1-2. DISCHARGING THE CAP ACIT OR

Connect the short jig with the capacitor directly.

1 k

Ω

1 Remove the power supply (Battery or AC power adaptor).

2 Short circuit between TP001 of the flash unit (MC1850) and the GND

(Chassis etc.) with the short jig about 10 seconds.

Short jig

GND

Chassis

(Sheet metal bending block)

/1 W resistor

(1-215-869-11)

C2010

Flash unit (MC1850)

3-2. DISCHARGING THE CAPACITOR USING THE REMOTE COMMANDER

3-2-1. DISCHARGING THE CAP ACIT OR

Note: Perfect discharge can’t be done in this method. (Remaining voltage = Approx. 90V)

1 Connect the power supply (Battery or AC power adaptor).

2 Set POWER switch to “CAMERA”.

3 Connect the adjustment remote commander to the LANC jack, and set the HOLD switch to the “ADJ” side.

4 Select page: 0, address: 01. and set data: 01.

5 Select page: D, address: F4. set data: 04, and press PAUSE button of the adjustment remote commander.

6 Press FLASH ( ) button and set to the forced flash mode ( ), and press PHOTO button to pop up the flash.

7 Select page: 6, address: B3. and set data: 03.

8 Select page: 6, address: B1. and set data: 01.

9 Select page: 6, address: B0. and set data: 01.

→The flash flashes, and data are returned to “00”

0 Repeat step 9, until the flash dose not flash.

After completing repairs/adjustments, perform “PROCESSING AFTER COMPLETING REPAIRS/ADJUSTMENTS”

Flash unit

(MC1850) TP001

3-2-2. PROCESSING AFTER COMPLETING REPAIRS/ADJUSTMENTS

1 Connect the power supply (Battery or AC power adaptor).

2 Set POWER switch to “CAMERA”.

3 Connect the adjustment remote commander to the LANC jack, and set the HOLD switch to the “ADJ” side.

4 Select page: 0, address: 01. and set data: 01.

5 Select page: D, address: F4. set data: 00, and press PAUSE button of the adjustment remote commander.

6 Select page: 6, address: B3. and set data: 00.

7 Select page: 6, address: B1. and set data: 00.

8 Select page: 0, address: 01. and set data: 00.

— 6 —

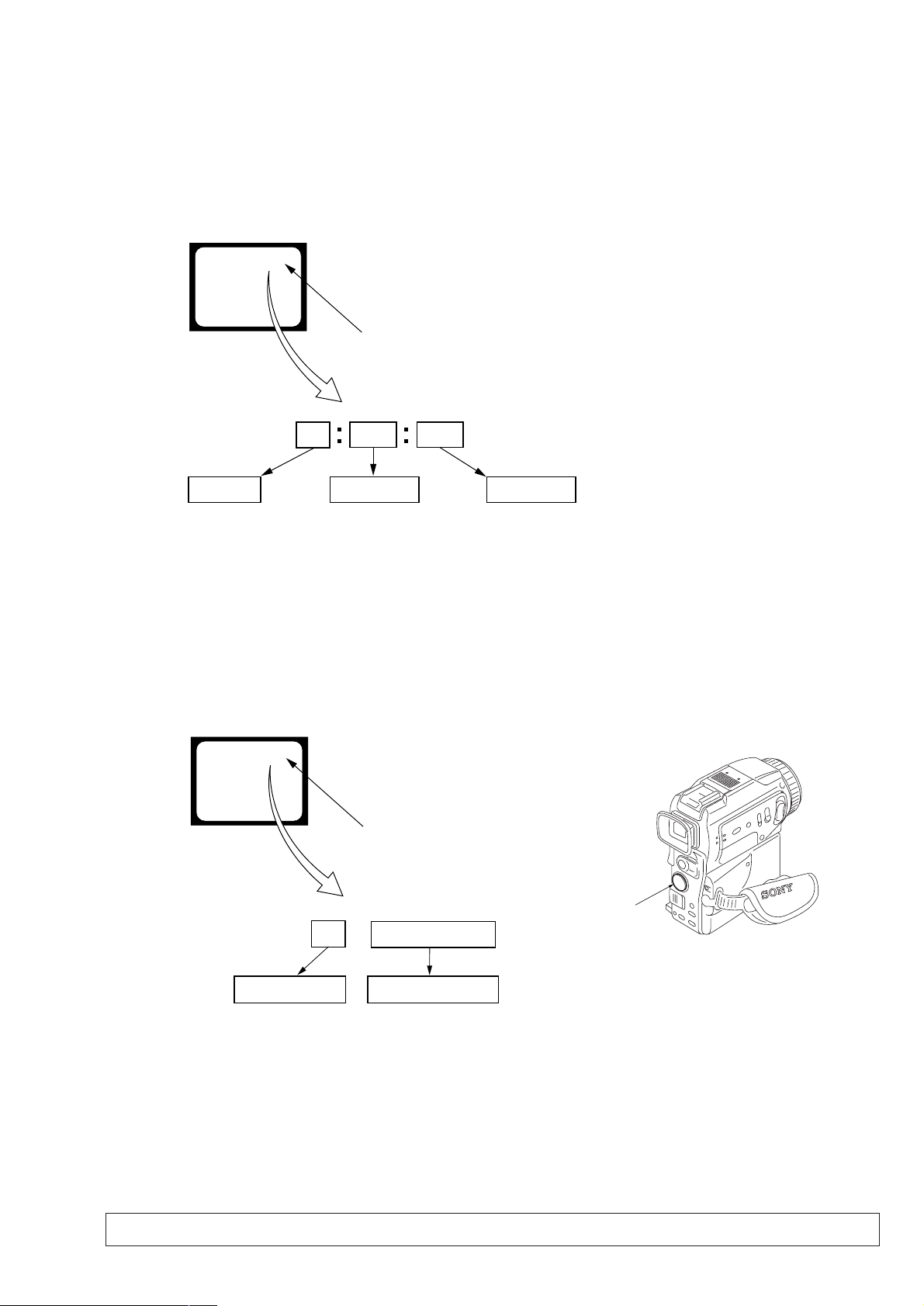

SELF-DIAGNOSIS FUNCTION

DCR-PC115E/PC120E

1. SELF-DIAGNOSIS FUNCTION

When problems occur while the unit is operating, the self-diagnosis

function starts working, and displays on the viewfinder or LCD

screen what to do. This function consists of two display; selfdiagnosis display and service mode display .

Details of the self-diagnosis functions are provided in the Instruction

manual.

Viewfinder or LCD screen

C : 3 1 : 1 1

Repaired by:

C : Corrected by customer

H : Corrected by dealer

E : Corrected by service

engineer

Blinks at 3.2Hz

3 1C

Block

Indicates the appropriate

step to be taken.

E.g.

31 ....Reload the tape.

32 ....Turn on power again.

1 1

2. SELF-DIAGNOSIS DISPLAY

When problems occur while the unit is operating, the counter of the

viewfinder or LCD screen consists of an alphabet and 4-digit

numbers, which blinks at 3.2 Hz. This 5-character display indicates

the “repaired by:”, “block” in which the problem occurred, and

“detailed code” of the problem.

Detailed Code

Refer to page 8.

Self-diagnosis Code Table.

3. SERVICE MODE DISPLAY

The service mode display shows up to six self-diagnosis codes shown in the past.

3-1. Display Method

While pressing the “STOP” key, set the switch from OFF to “VCR”, and continue pressing the “STOP” key for 5 seconds continuously. The

service mode will be displayed, and the counter will show the backup No. and the 5-character self-diagnosis codes.

Viewfinder or LCD screen

[3] C : 3 1 : 1 1

Lights up

Control button

[3]

Backup No.

Order of previous errors

3-2. Switching of Backup No.

By pressing up side or down side of the control button, past self-diagnosis codes will be sho wn in order. The backup No. in the [] indicates the

order in which the problem occurred. (If the number of problems which occurred is less than 6, only the number of problems which occurred

will be shown.)

[1] : Occurred first time [4] : Occurred fourth time

[2] : Occurred second time [5] : Occurred fifth time

[3] : Occurred third time [6] : Occurred the last time

C : 3 1 : 1 1

Self-diagnosis Codes

3-3. End of Display

Turning OFF the power supply will end the service mode display.

Note: The “self-diagnosis display” data will be backed up by the coin-type lithium battery (BT001) of the control switch block (FK-1850). When the

cabinet (L) assembly is removed, the “self-diagnosis display” data will be lost by initialization.

— 7 —

DCR-PC115E/PC120E

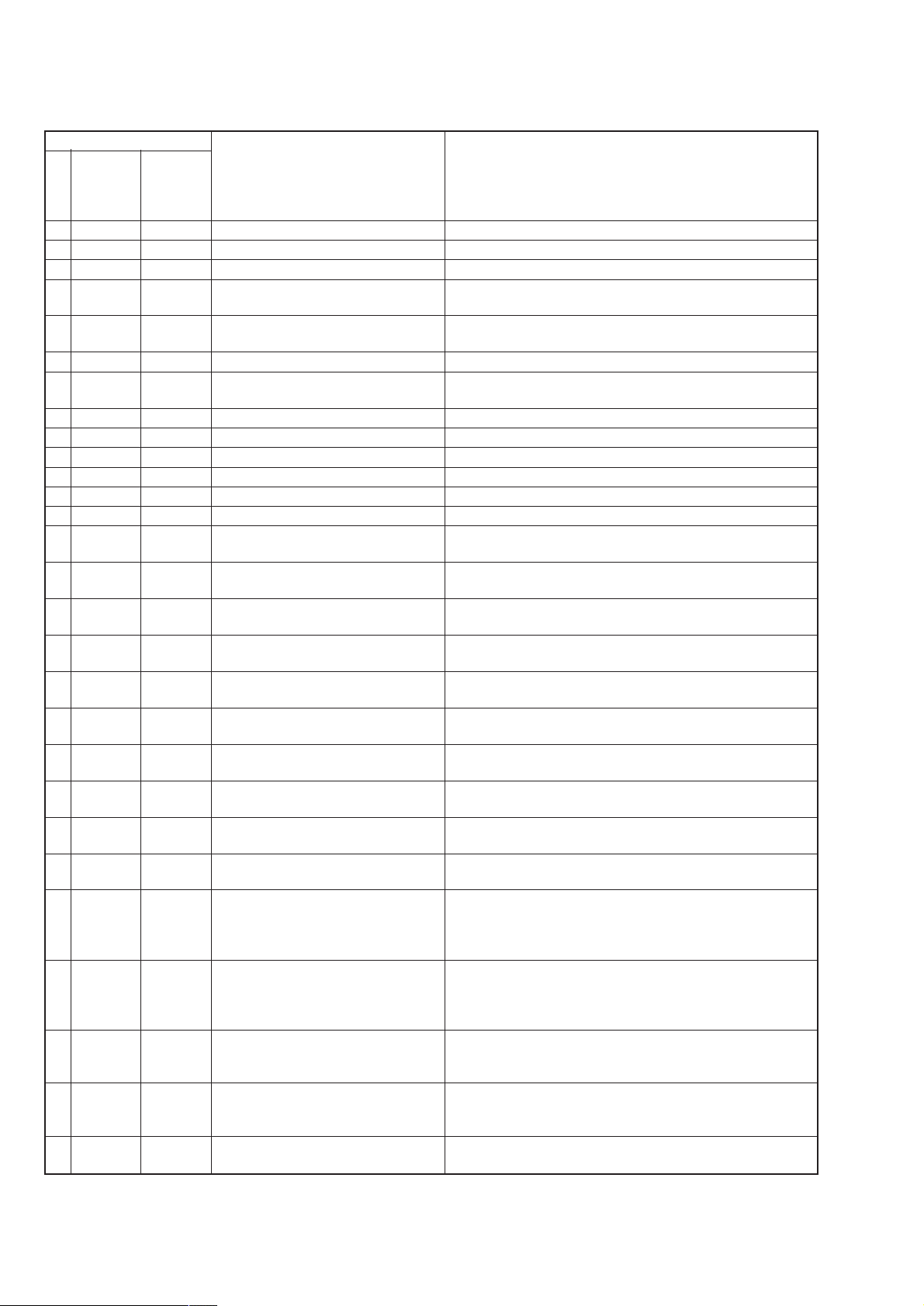

4. SELF-DIAGNOSIS CODE TABLE

Self-diagnosis Code

Function

Repaired by:

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

E

E

E

E

E

Block

04

21

22

31

31

31

31

31

31

31

31

31

31

31

31

32

32

32

32

32

32

32

32

61

61

62

62

91

Detailed

Code

00

00

00

10

11

20

21

22

23

24

30

40

42

10

11

20

21

22

23

24

30

40

42

00

10

00

01

01

Symptom/State

Non-standard battery is used.

Condensation.

Video head is dirty.

LOAD direction. Loading does not

complete within specified time

UNLOAD direction. Loading does not

complete within specified time

T reel side tape slacking when unloading

Winding S reel fault when counting the

rest of tape.

T reel fault.

S reel fault.

T reel fault.

FG fault when starting capstan.

FG fault when starting drum.

FG fault during normal drum operations.

LOAD direction loading motor time-

out.

UNLOAD direction loading motor

time-out.

T reel side tape slacking when

unloading.

Winding S reel fault when counting the

rest of tape.

T reel fault.

S reel fault.

T reel fault.

FG fault when starting capstan.

FG fault when starting drum

FG fault during normal drum

operations

Difficult to adjust focus

(Cannot initialize focus.)

Zoom operations fault

(Cannot initialize zoom lens.)

Steadyshot function does not work well.

(With pitch angular velocity sensor output

stopped.)

Steadyshot function does not work well.

(With yaw angular v elocity sensor output

stopped.)

Charging the flash does not complete

witin the specified time.

Correction

Use the info LITHIUM battery.

Remove the cassette, and insert it again after one hour.

Clean with the optional cleaning cassette.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Inspect the lens block focus MR sensor (Pin 8,9 of CN151 of

CD-349 board) when focusing is performed when the focus ring is

rotated in the focus manual mode, and the focus motor drive circuit

(IC201 of VC-270 board) when the focusing is not performed.

Inspect the lens block zoom MR sensor (Pin ql,wa of CN151 of

CD-349 board) when zooming is performed when the zoom lens is

operated and the zoom motor drive circuit (IC201 of VC-270 board)

when zooming is not performed.

Inspect pitch angular velocity sensor (SE3450 of VM-027 board)

peripheral circuits.

Inspect yaw angular velocity sensor (SE3451 of VM-027 board)

peripheral circuits.

Inspect the flash unit (ST1850 and MC1850).

— 8 —

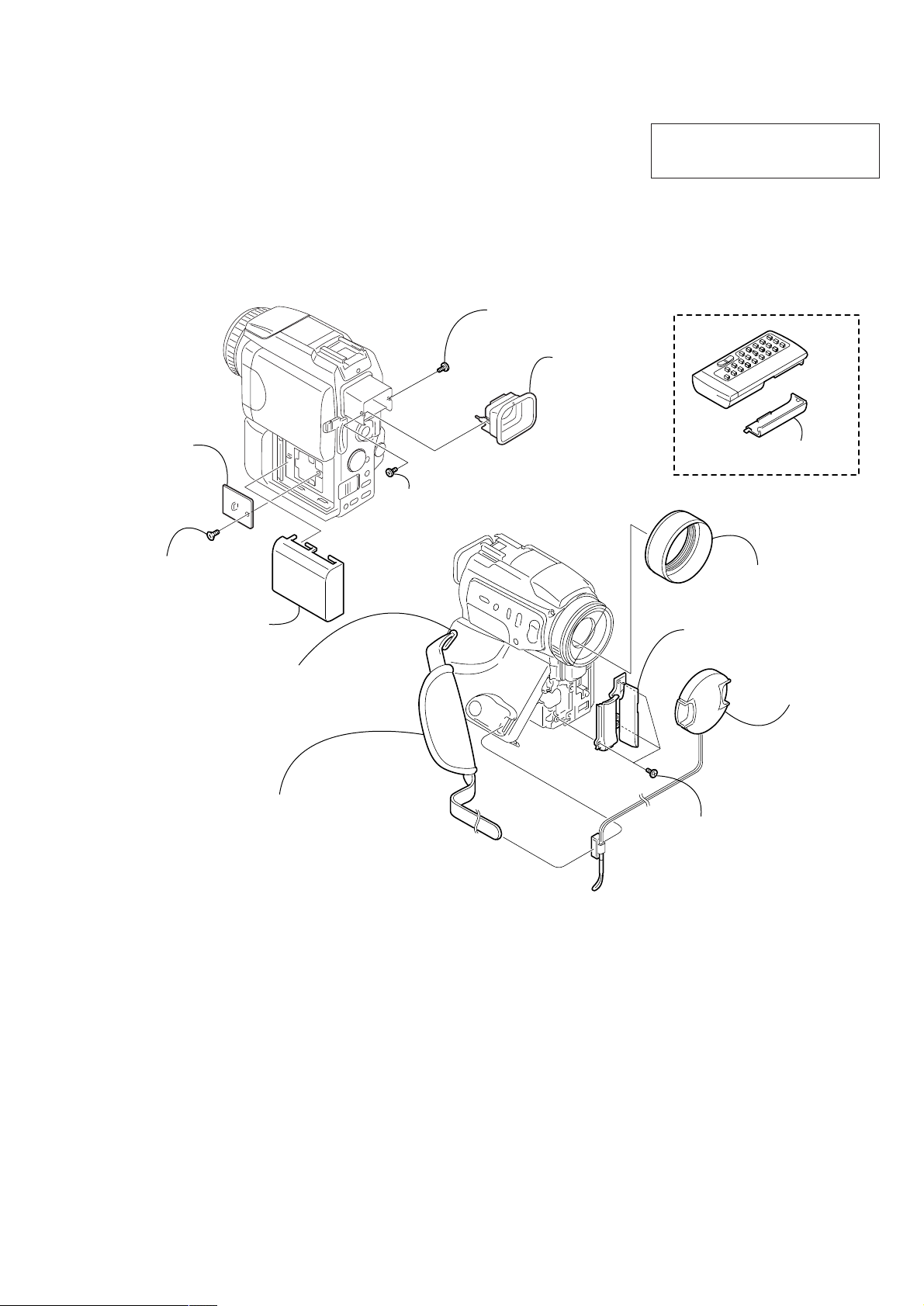

1. MAIN PARTS

Jack ornamental cover assembly

X-3951-962-1

VF lens assembly

X-3951-894-1

Lens cap assembly

X-3949-944-1

Lens hood

3-063-515-01

Grip belt

Remote commander (RMT-811)

1-475-950-21

Battery case lid (for RMT-811)

3-053-056-01

Jack cover (G)

Note: Disassembling the main unit

is necessary to replace it.

Note: Disassembling the main unit

is necessary to replace it.

Lockace (M1.7)

3-057-437-01

Three screws

(M1.7), lockace, P2

3-989-735-01

Screw

(M1.7), lockace, P2

3-989-735-01

Screw

(M1.7), lockace, P2

3-989-735-01

CPC lid

3-070-369-01

Battery cover

3-057-482-01

Note:

• Follow the disassembly procedure in the numerical order given.

• Items marked “*” are not stocked since they are seldom required for routine service.

Some delay should be anticipated when ordering these items.

• The parts numbers of such as a cabinet are also appeared in this section.

Refer to the parts number mentioned below the name of parts to order.

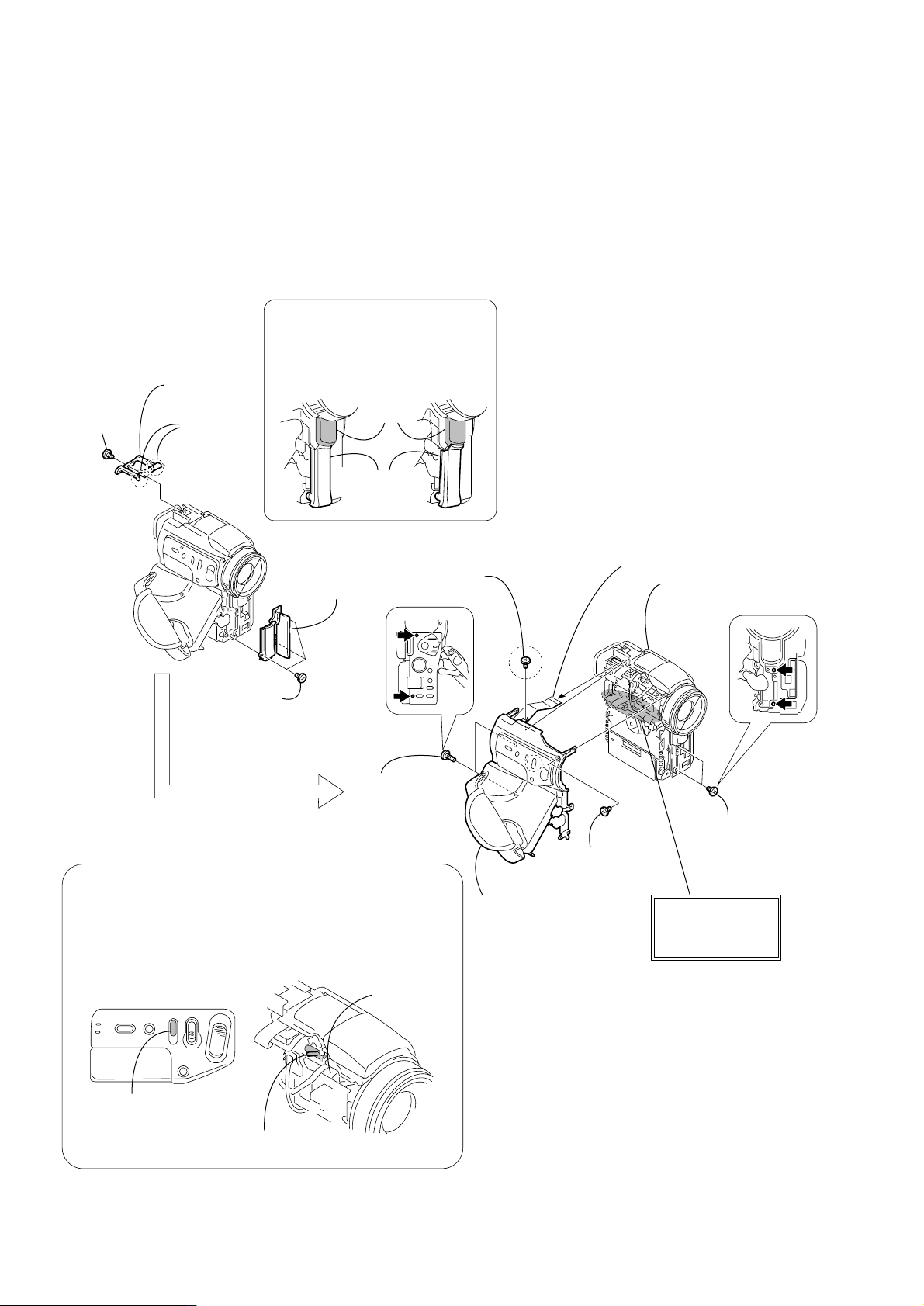

1. ORNAMENTAL PARTS

DCR-PC115E/PC120E

The components identified by mark 0 or

dotted line with mark 0 are critical for safety.

Replace only with part number specified.

— 9 —

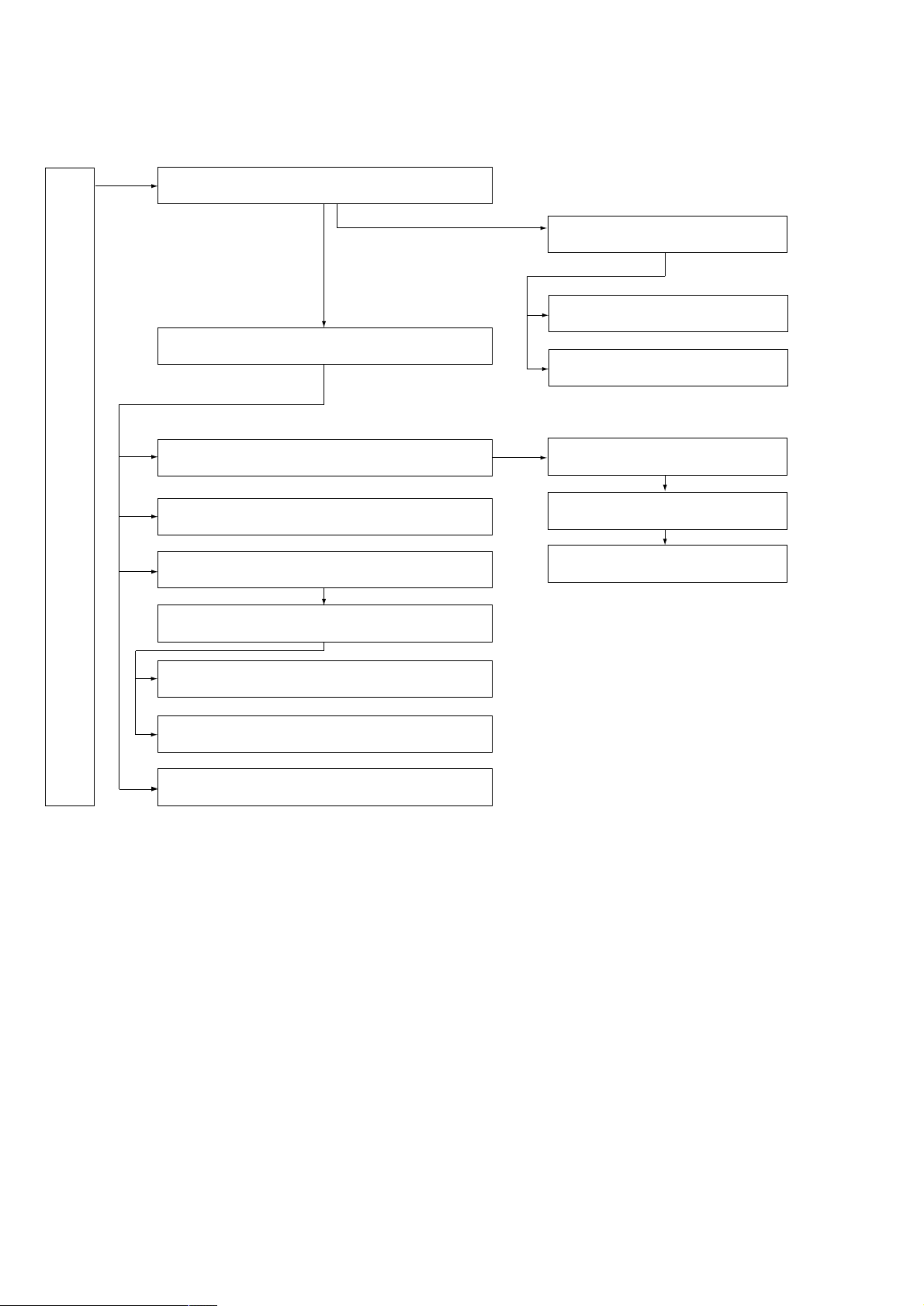

DCR-PC115E/PC120E

2. DISASSEMBLY

The following flow chart shows the disassembly procedure.

2-1. Cabinet (L) section

2-2. VTR complete, Cabinet (R) section

2-10. Cabinet (G) block assembly, etc

2-11. Control switch block (FK-1850)

2-12. Control switch block (PS-1850)

2-3. FJ-035 board

2-4. VM-027 board

DCR-PC115E/PC120E

2-5. CD-349P board, Lens device

2-6. VC-270 board

2-7. Mechanism deck

2-8. Flash unit (MC)

2-9. Flash unit (ST)

2-13. Blind plate assembly

2-14. PD-148B board,

Inverter transformer unit

2-15. Hinge assembly

— 10 —

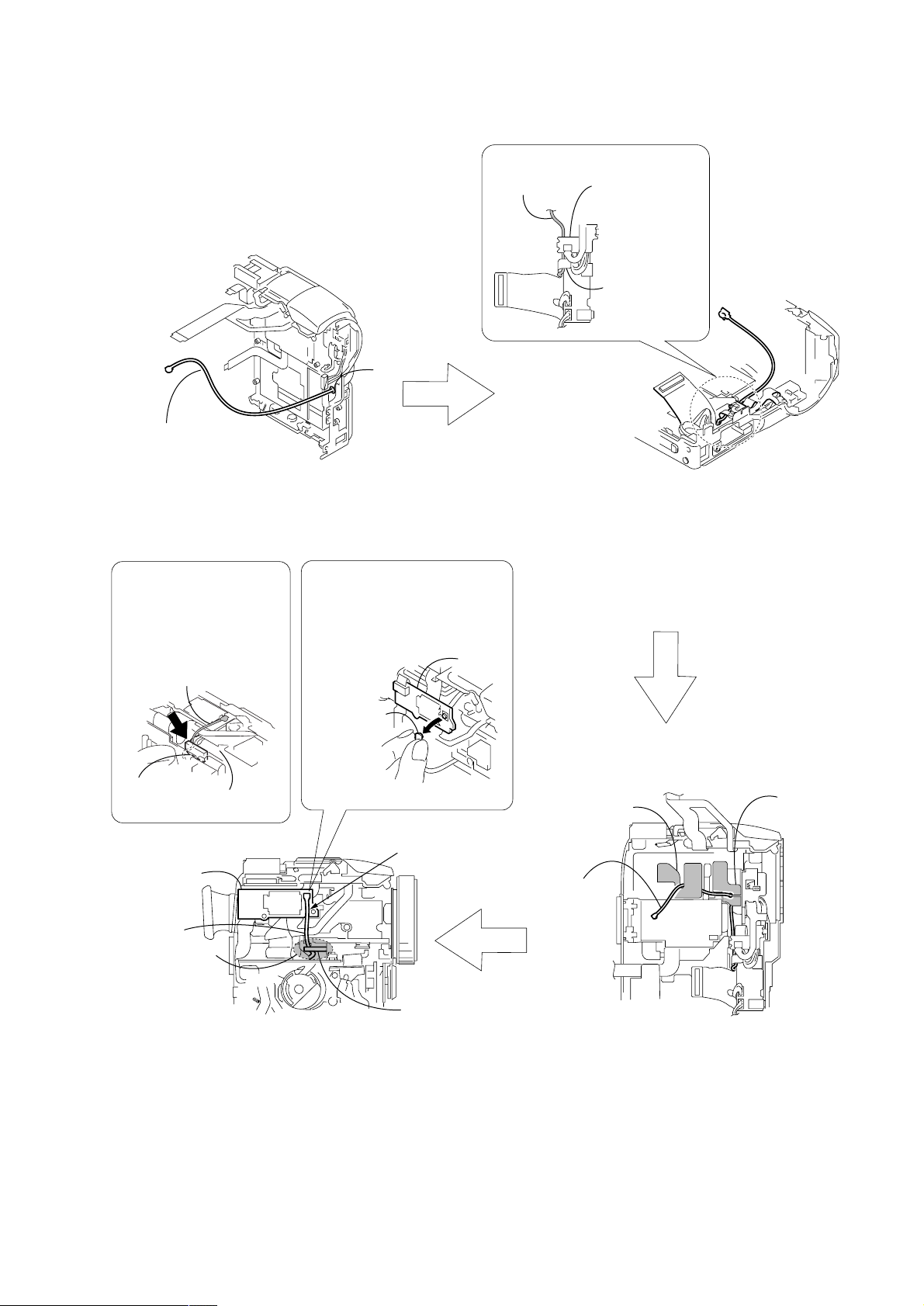

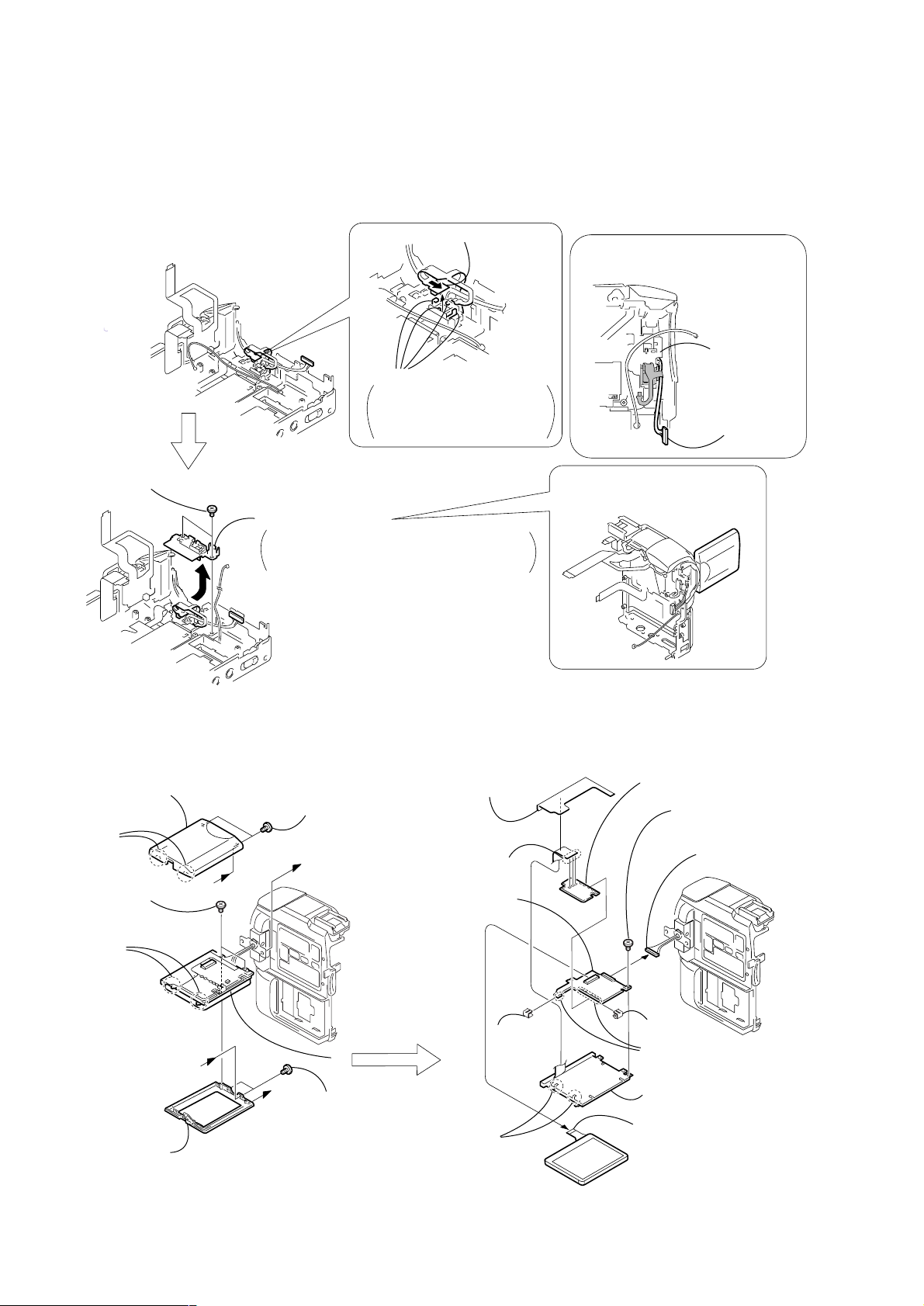

[Routing the Bluetooth BT cable] (PC120E)

DCR-PC115E/PC120E

BT cable

Pass the cable through the hole A of the

1

Cabinet (R) section.

Route the cable through the

clearance

it on the clearance between

the BT cable guide and

lens device.

B

, and then hook

BT cable

When removing the BT cable

from the BT-003 board, be sure

to hold the connector of the

BT-003 cable and remove it.

A

BT-003

board

BT cable

2

board of the FJ-035 board and route it under the

flexible board of the FJ-035 board.

3

FJ-035 board.

Rigid portion of the

FJ-035 board

Flexible board of

the FJ-035 board

Draw the cable through clearance of the flexible

Route the cable under the rigid portion of the

Connector of

BT cable

BT cable

guide

BT-003 board

BT cable

6

Route the cable through the clearance B.

7

Insert it to the connector on the BT-003 board.

Lens device

B

Attach the BT cable so

that it stretches straight

downward.

BT cable

guide

BT cable

sheet

BT cable

4

Insert it into the notch of the lens rubber (R).

5

Insert it into the notch of the BT cable sheet.

Lens

rubber (R)

— 11 —

DCR-PC115E/PC120E

NOTE: F ollo w the disassembly procedure in the numerical order given.

2-1. CABINET (L) SECTION

Note: The power capacitor (C2010) of the flash unit is charged to the high tension voltage as high as 300 V at a maximum.

You will get electrical shock when you touch the Flash unit (MC) mounted with the terminal of the charged capacitor.

The charged potential remains even after the main power of the machine is turned off.

Discharge the remaining power in the capacitor referring to Service Note (page 6).

PRECAUTION DURING

JACK ORNAMENTAL COVER

ASSEMBLY INSTALLATION

Be careful that top of the Jack

ornamental cover assembly does not

hang over the IR window assembly.

1

Screw

(M1.7 × 2.5),

lock ace, p2

3

HS Cabinet

2

T wo claws

4

Three screws

(M1.7 × 2.5),

lock ace, p2

OK NG

IR window

assembly

Jack ornamental

cover assembly

5

Jack ornamental

cover assembly

3

(M1.7 × 4),

lock ace, p2

PRECAUTION DURING CABINET (L) SECTION

INSTALLATION

When installing the Cabinet (L) section to the Cabinet (R) section

and to the VTR complete, install it while the "Night-Shot switch

outside the Cabinet (L) section" and "Night-Shot switch on top of

the Lens Device" are facing upward.

1

Screw

(M1.7

lock ace, p2

T wo screws

×

2.5),

7

Cabinet (L) section

5

Control switch block

(FK-1850) (51P)

6

Cabinet (R) section,

VTR complete

4

Screw

(M1.7 × 2.5),

lock ace, p2

(Caution:

High voltage)

Flash unit (MC)

2

T wo screws

(M1.7 × 2.5),

lock ace, p2

OFF

ON

Night-Shot switch outside the

Cabinet (L) section

Night-Shot switch on top of

the Lens Device

Lens Device

— 12 —

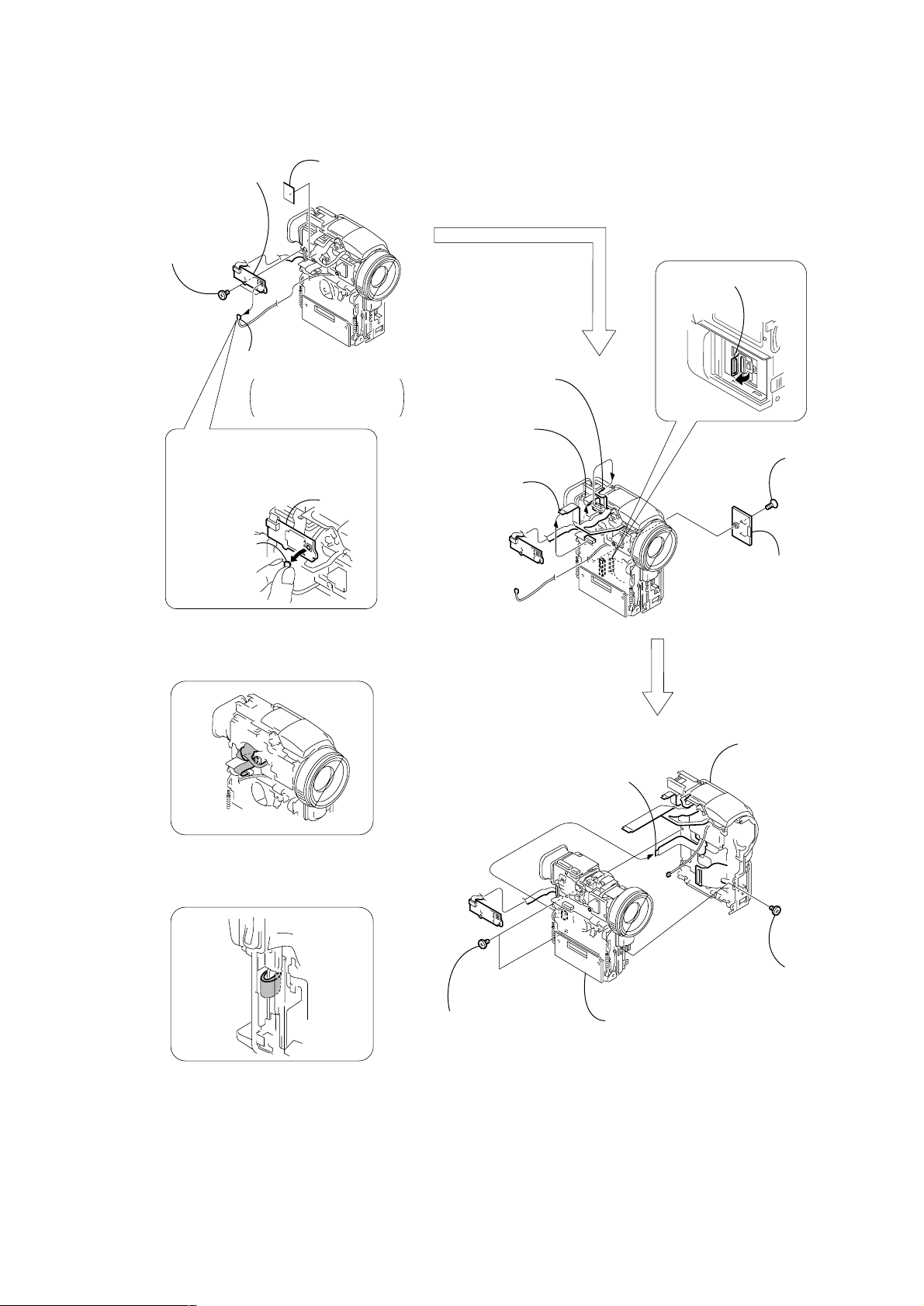

2-2. VTR COMPLETE, CABINET (R) SECTION

4

FK flexible guard

6

BT-003

board

Flash unit (ST) (33P)

5

Microphone unit (5P)

4

board (27P)

2

T wo screws

(M1.4 × 2),

lock ace

(PC120E)

3

BT-003 board

(PC120E)

1

Antenna (2.4GHz)

(PC120E)

See to "Routing the

Bluetooth BT cable" when

re-assembling parts

When removing the BT cable

from the BT-003 board, be sure

to hold the connector of the

BT-003 cable and remove it.

FP-385 flexible

DCR-PC115E/PC120E

3

FJ-035 board (88P)

1

Screw

(M1.7

lock ace, k3

×

2.5),

Connector of

BT cable

Routing of the flexible board of the

Operation Flash unit (ST) when

attaching the Cabinet (L) section.

Routing of the flexible board of the

Operation FP-383 flexible board when

attaching the Cabinet (L) section.

3

FP-383 flexible board

(15P)

2

T wo screws

(M1.7 × 2.5),

lock ace, p2

5

VTR complete

2

CPC lid

4

Cabinet (R) section

1

Screw

(M1.7 × 2.5),

lock ace, p2

— 13 —

DCR-PC115E/PC120E

r

2-3. FJ-035 BOARD

2

T wo claws

4

Harness

(PT-128) (16P)

PRECAUTION DURING

HARNESS (PT-128) INSTALLATION

The harness (PT-128) is pulled when the LCD

panel is opened and is loosened when closed.

When the harness (PT-128) is going to be

inserted into the connector on the FJ-035 board

and when hooking the two claws of the rigid

portion of the FJ-035 board, perform these

works while the LCD panel is opened.

3

FJ-035 board

1

FP-387 flexible board

(6P)

1

BT cable sheet

PRECAUTION DURING RIGID PORTION

OF FJ-035 BOARD INSTALLATION

Attach the FJ-035 board so that the

harness (PT-128) is routed under the

rigid portion of the FJ-035 board.

Harness

(PT-128)

Rigid portion

of FJ-035 board

FJ-035 board

2

Battery terminal board

(Note)

3

FJ-035 board,

DC-IN connector

(Note)

Harness (PT-128)

1

(Note)

3

MS flexible

sheet

5

BT terminal

retainer

4

(M1.7 × 2.5),

lock ace, p2

Battery terminal board (3P)

qs

FJ-035 board

7

Battery terminal

board

T wo screws

6

T wo screws

(M1.7 × 2.5),

lock ace, p2

qa

connector

8

Screw

(M1.7 × 2.5),

lock ace, p2

2

Lens

rubber (R)

9

Screw

(M1.7 × 2.5),

lock ace, p2

q;

DC retaine

plate

DC-IN

Battery terminal

board

DC-IN connector

FJ-035 board

CN1334

(Blue)

CN1335 (White)

Note:

CN1335 (for the DC-IN connector) and CN1334 (for the battery terminal board)of

FJ-035 board are the same size, and the number of the pins is the same.

So these connectors may be mistaken for each other. When these connectors

are mistaken, the charge system of the unit may break.

So ascertain the color of the connector when assembling these connectors.

CN1334 (for the battery terminal board) ········ Blue

CN1335 (for the DC-IN connector) ················· White

— 14 —

2-4. VM-027 BOARD

Mechanism deck

Cassette compartment cover

CD-349 board (72P)

Drum or Pinch arm of

Mechanism deck

VM-027 board (88P)

VC-270 board

9

qs

5

"B" of the

chassis

"B" of the

chassis

"A" of the

chassis

"A" of the

chassis

Note: If the drum or pinch arm of mechanism deck is pressed down,

the mechanism deck may not work correction.

Also if you touch the "B" portion of the chassis of the mechanism

deck as shown in the illustration, grease will adhere your hands.

When inserting the connector (88P) of the VM-027 board and the

connector (72P) of the CD-349 board into the VC-270 board

connectors, hold the "A" block of the chassis or the cassette

compartment cover of mechanism deck and insert them.

(Note)

Drum or Pinch arm

of Mechanism deck

8

VF Frame (B)

7

Two precision screws

(dia,1.7 × 4)

3

Two tapping screws

(M1.7 × 3)

2

Screw

(M1.7 × 2.5),

lock ace, p2

4

Screw

(M1.7 × 2.5),

lock ace, p2

6

Screw

(M1.7 × 2.5),

lock ace, p2

qa

VF lens assembly,

Sleeve assembly,

VF regulation ring

1

VM-027

board (88P)

q;

T wo claws

qd

T wo claws

qf

Light guide plate block,

LCX033AN-1, etc

qg

VM-027 board,

VM guard sheet

y

DCR-PC115E/PC120E

2-5. CD-349P BOARD, LENS DEVICE

9

Lens device,

CD-349P board, etc

1

CD-349P board (72P)

3

FK flexible guard

7

(M1.7 × 2.5),

lock ace, p2

Screw

2

Screw

(M1.7 × 2.5),

lock ace, p2

4

Control switch block

(MF-30550) (8P)

6

MF base assembly,

Control switch block

(MF-30550),

IR window assembl

(Note)

Drum or Pinch arm

of Mechanism deck

8

Claw

— 15 —

5

Two dowels

DCR-PC115E/PC120E

)

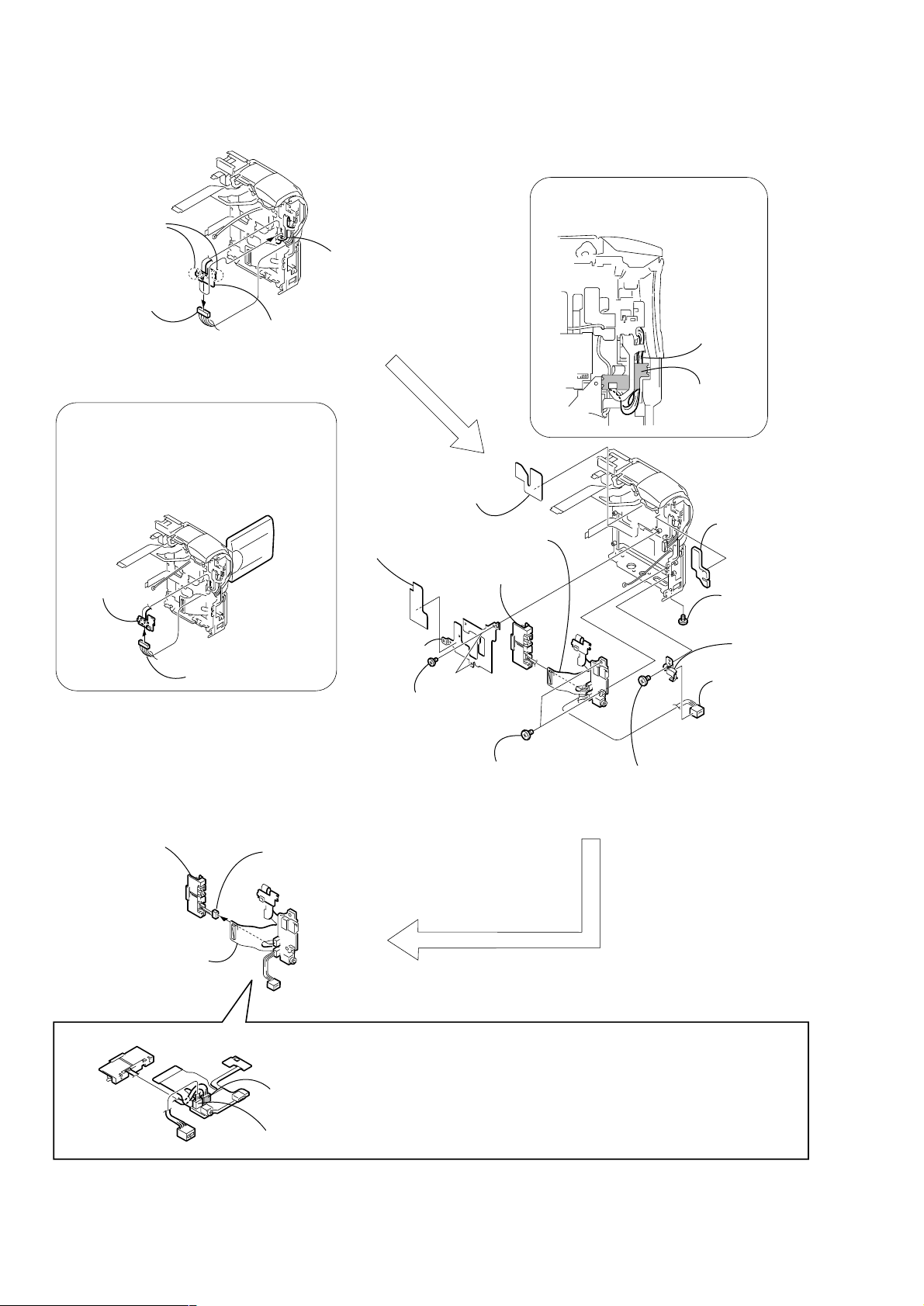

2-6. VC-270 BOARD

5

VF tape

3

FP-386 board

1

Screw

(M1.7 × 2.5),

lock ace, p2

2

FP-386 board (6P)

4

VM-027 board (88P)

2

FP-102 Flexible board

(27P)

1

Flexible board (27P)

(from capstan motor)

6

Flexible board (27P)

(from Flash unit (MC))

3

Flexible board (10P)

(from video head)

4

Flexible board (10P)

(from drum motor)

7

Mechanism deck,

Flash unit (MC),

EVF block assembly, etc

q;

VC-270 board

9

BT-003 board

(PC120E),

FP-384 flexible board

(PC120E)

8

FP-384 flexible board

(PC120E)

(15P)

5

Three screws

(M1.7 × 2.5),

lock ace, p2

2-7. MECHANISM DECK

5

Cassette compartment

cover

4

T wo screws

(M1.7 × 2.5),

lock ace, p2

3

EVF block assembly,

Flash unit (MC),

MD frame assembly, etc

2

T wo screws

(M1.4 × 1.5)

6

Mechanism deck

1

T wo screws

(M1.4

×

1.5

— 16 —

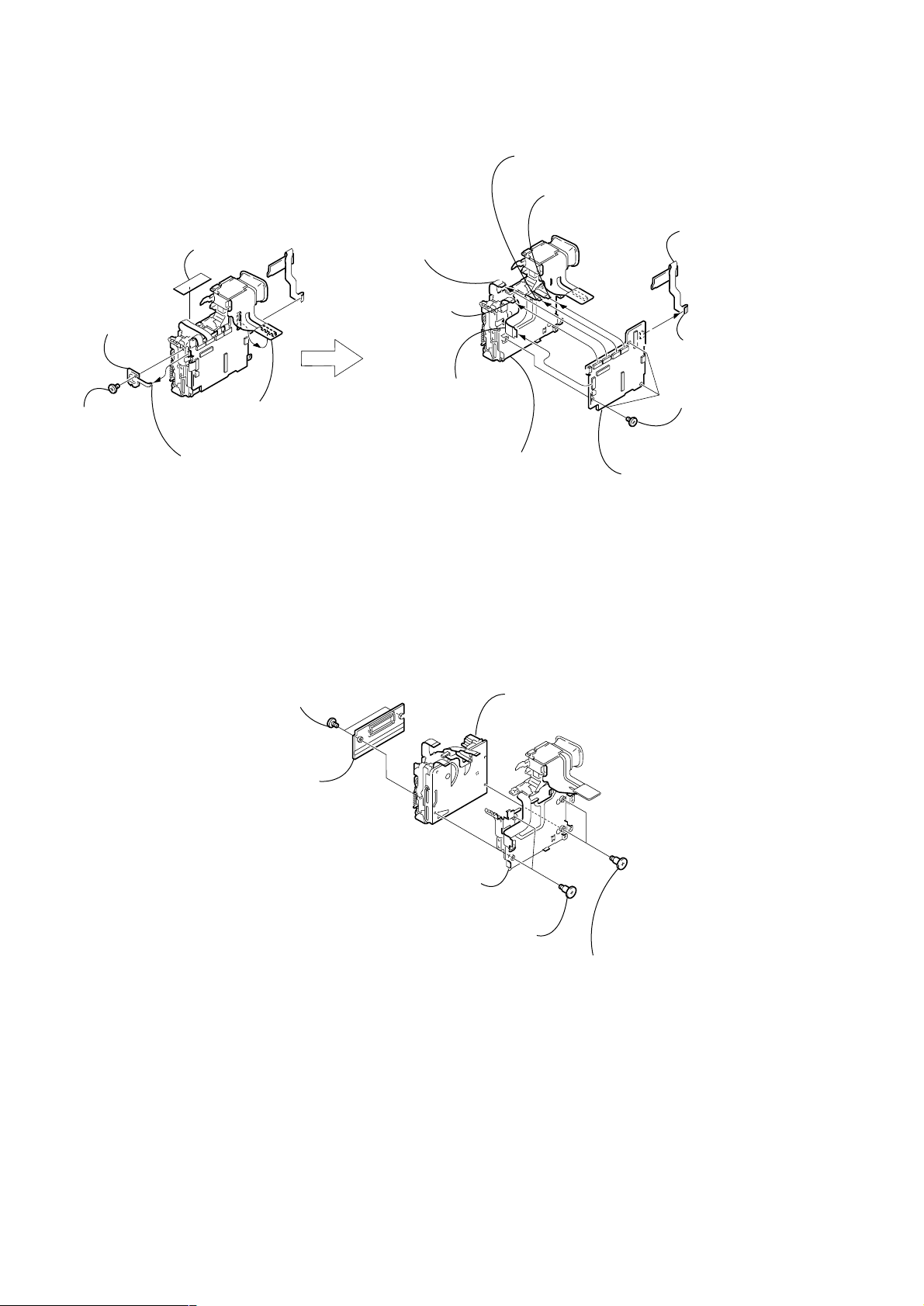

2-8. FLASH UNIT (MC)

2

Mechanism deck,

MD frame assembly

3

EVF block assembly,

VF frame assembly

Flash unit (MC),

MC guard sheet

1

Screw

(M1.7

lock ace, p2

×

2.5),

3

MC guard sheet

2

EVF block assembly,

VF frame assembly

DCR-PC115E/PC120E

4

Flash unit (MC)

1

T wo screws

(M1.7 × 2.5),

lock ace, p2

2-9. FLASH UNIT (ST)

1

T wo screws

(M1.7

lock ace, p2

×

2.5),

4

(M1.7

lock ace, p2

2

Screw

×

2.5),

1

Insulating sheet (ST)

8

Flash unit (ST)

6

Peel off the

adhesive side.

5

4

3

Bolt

(M1.4 × 3)

7

Stroboscope assembly,

ST cabinet lower

ST cabinet upper

Three claws

6

Stroboscope

cushion (A)

7

3

Precision screw

(dia, 1.7

×

4)

5

Screw

(M1.7 × 2.5),

lock ace, p2

2

precision screw

Hexagon hole

— 17 —

DCR-PC115E/PC120E

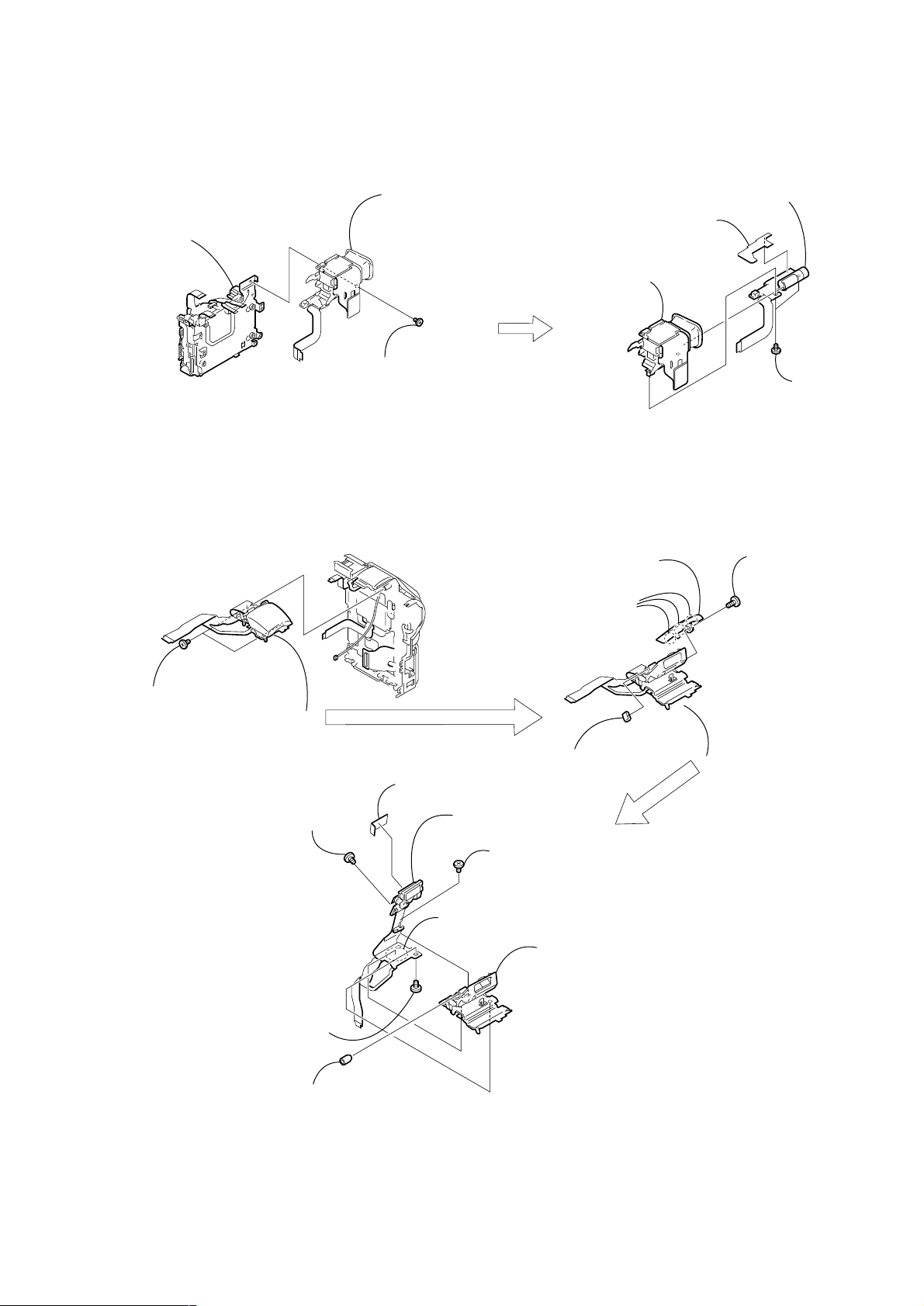

2-10. CABINET (G) BLOCK ASSEMBLY, ETC.

Note:

The +P2 (0-No.) screws (M1.7 × 2.5) are MEC-processed. If the screws that are once removed,

are re-used, the screws may be loosened.

When re-assembling the mechanism, use the new +P2 (0-No.) screws (M1.7

2

Sheet (L)

7

Cabinet (G) assembly,

Control switch block

(FK-1850)

6

Claw

3

(M1.7

0-No, +p2

4

T wo screws

(M1.7 × 2.5),

lock ace, p2

(Note)

5

T wo screws

(M1.7

lock ace, p2

1

Compression spring

T wo screws

×

2.5),

Battery lock,

×

2.5),

×

2.5).

3

assembly

1

Jack

cover (G)

Cabinet (G)

4

Control switch block

(FK-1850)

2

(dia, 1.7

Four precision

screws

×

4)

Routing of the flexible board of the

Operation Control switch block (FK-1850)

when attaching the G frame assembly,

Cabinet (rear) assembly.

6

Cabinet (L),

Control switch block

(FK-1850)

2

Screw

(M1.7 × 2.5),

lock ace, p2

1

Screw

(M1.7

lock ace, p2

×

2.5),

4

Control switch block

(PS-1850) (15P)

5

G frame assembly,

Cabinet (rear) assembly,

Control switch block (PS-1850),

KY-060 board

3

T wo screws

(M1.7

lock ace, p2

×

2.5),

— 18 —

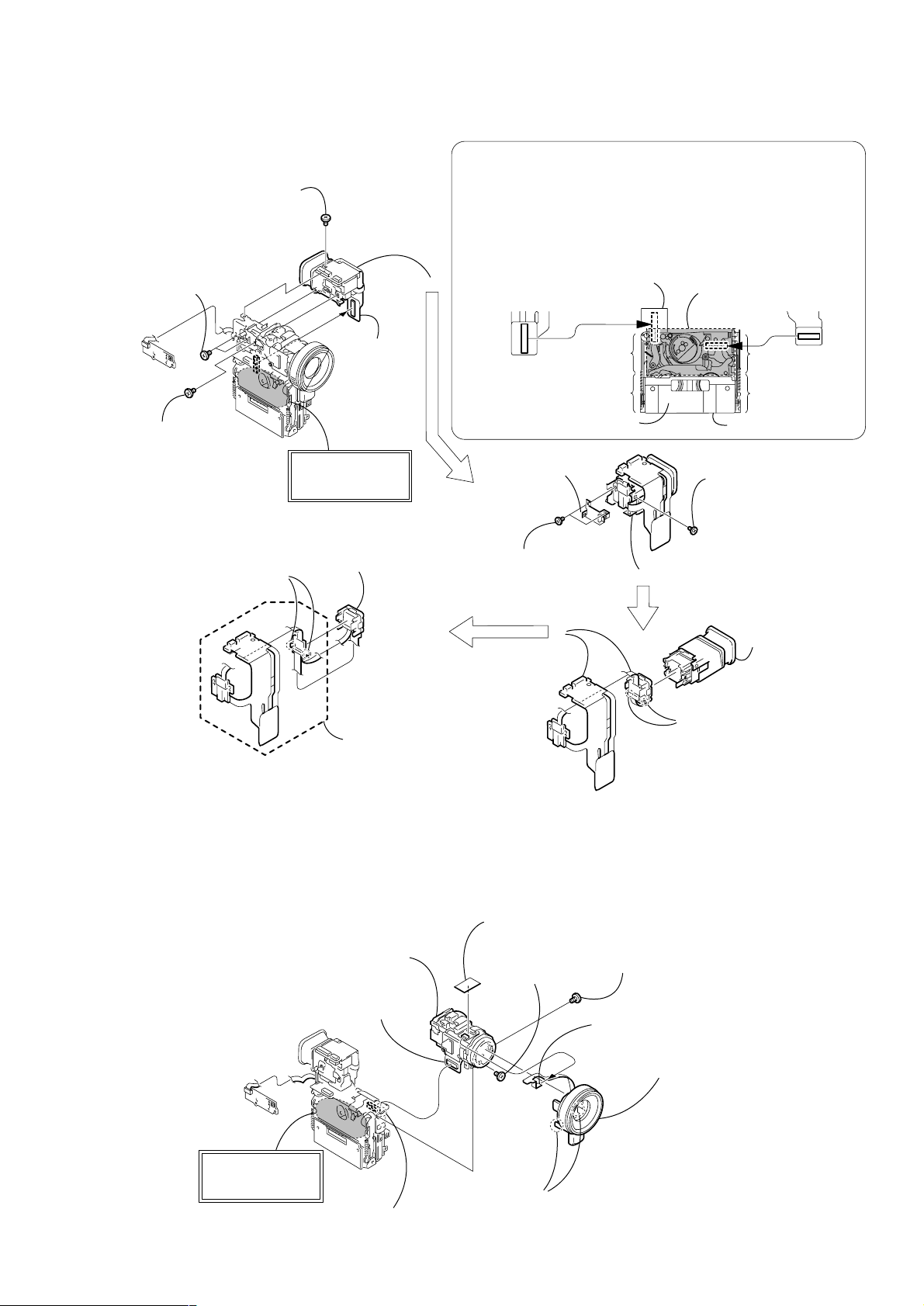

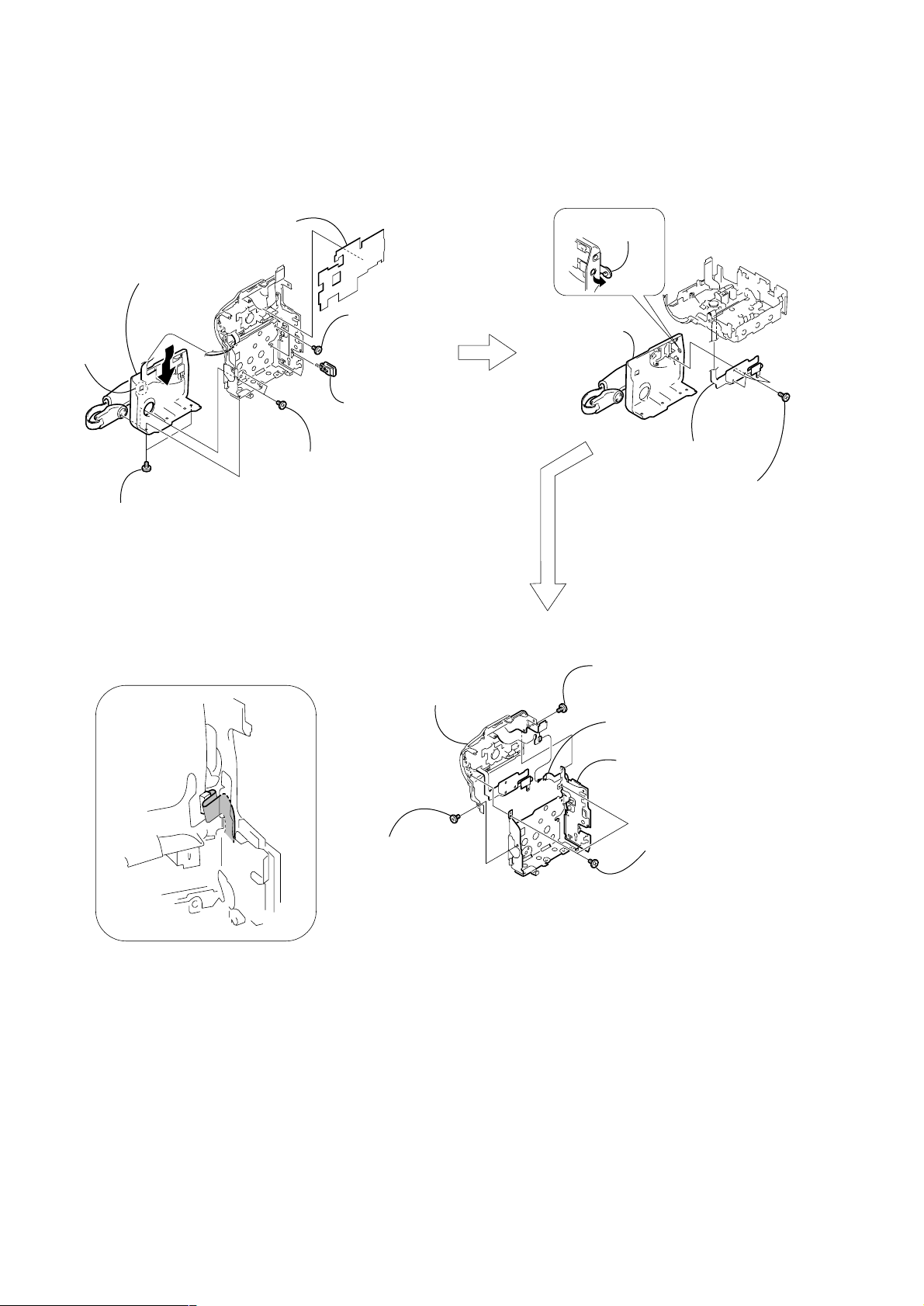

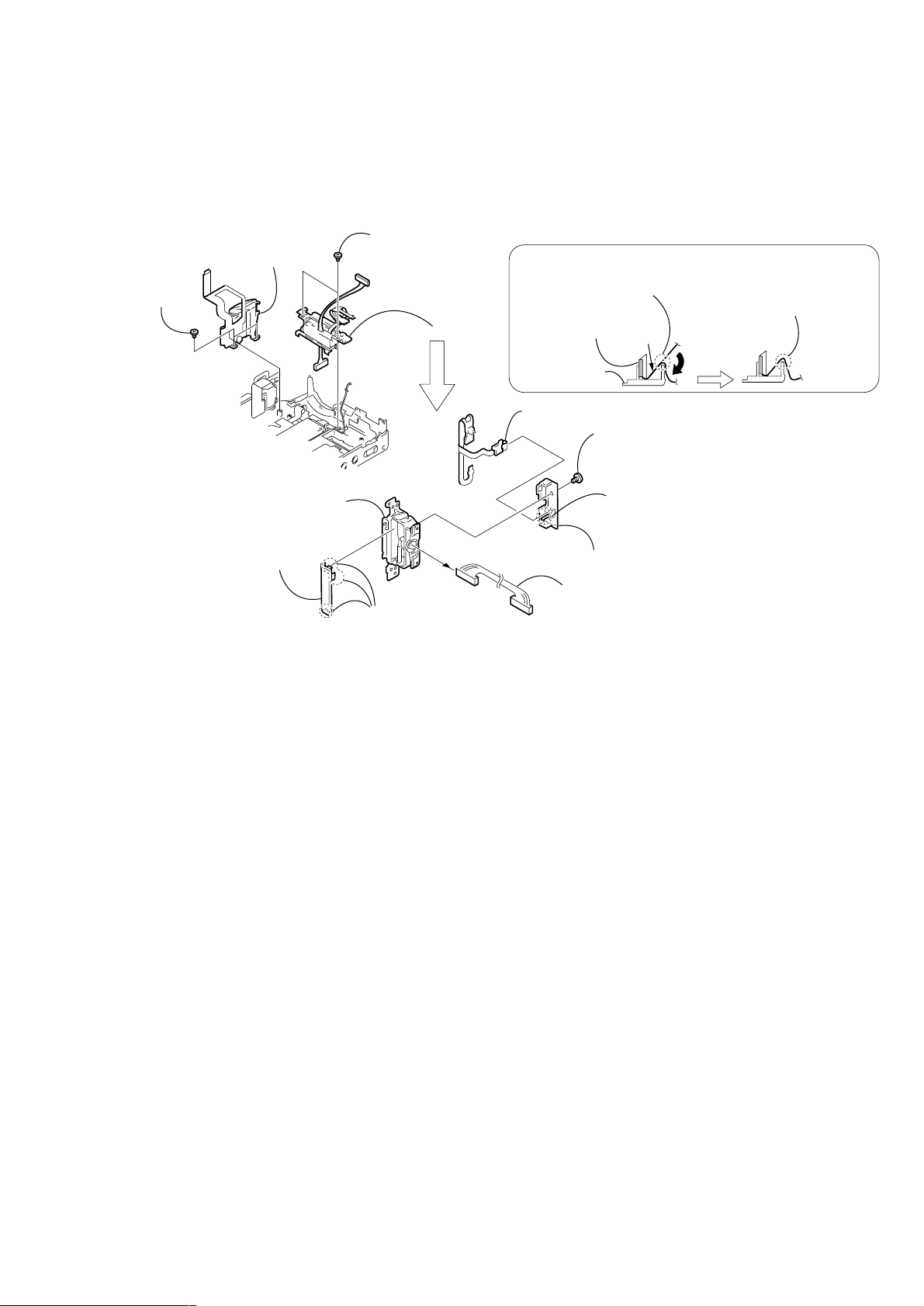

2-11. CONTROL SWITCH BLOCK (FK-1850)

)

q;

Speaker

5

Cabinet (L)

7

T wo claws

3

T wo screws

(M1.7 × 2.5),

lock ace, p2

9

Remove the

two solderings

2

Precision screw

(dia, 1.7

DCR-PC115E/PC120E

4

Precision screw

(dia, 1.7

qa

Control switch block (FK-1850

8

Jack frame assembly

6

T wo screws

(M1.7 × 2.5),

lock ace, p2

1

(M1.7 × 2.5),

lock ace, p2

×

4)

×

4)

Four screws

2-12. CONTROL SWITCH BLOCK (PS-1850)

2

G frame assembly

1

Three precision

screws

(dia, 1.7

×

4)

3

8

Control switch block

6

Control switch block

(PS-1850) (7P)

4

Two precision screws

(dia, 1.7 × 4)

(PS-1850)

5

assembly

7

KY-060 board

Cabinet (rear)

— 19 —

DCR-PC115E/PC120E

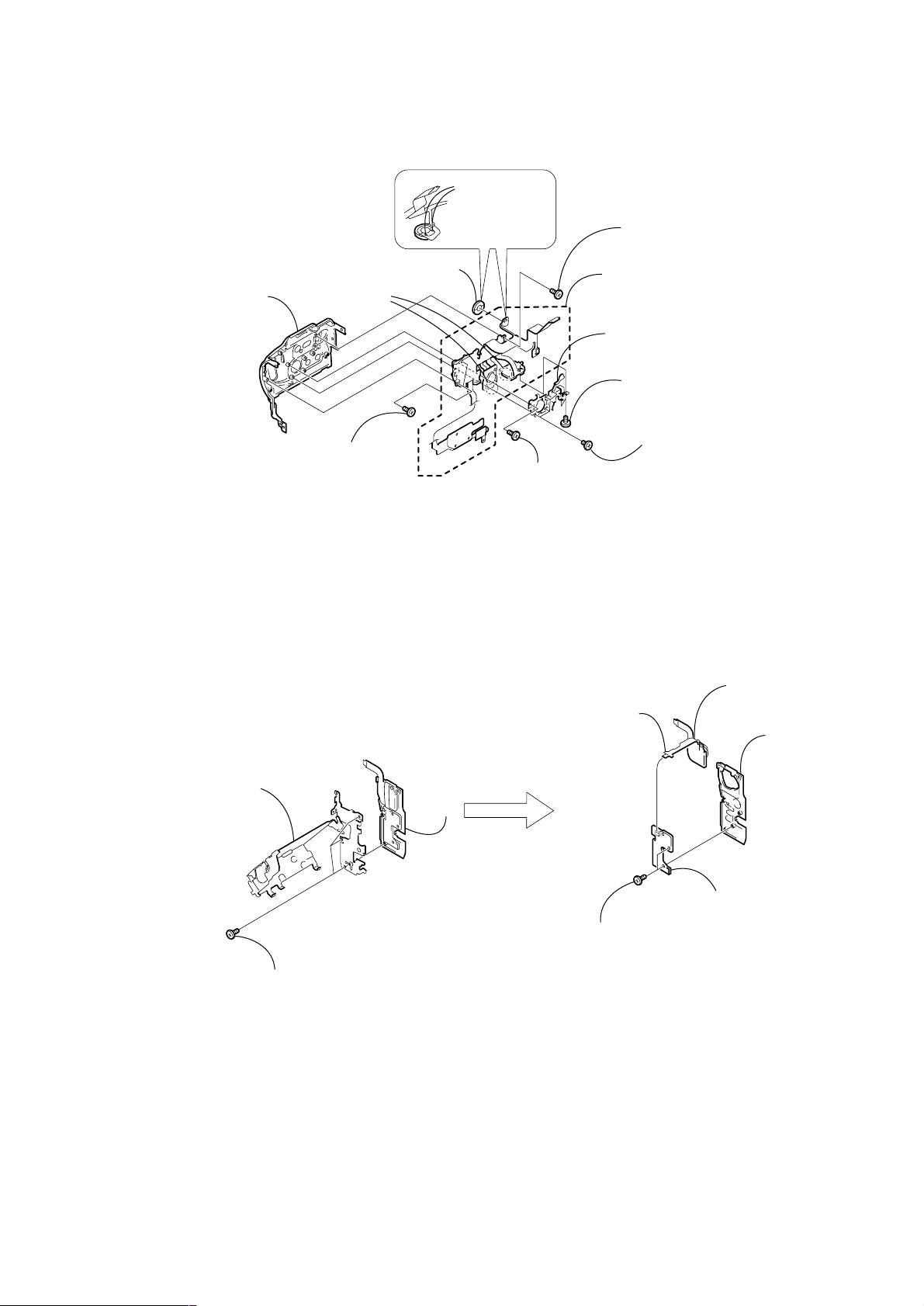

2-13. BLIND PLATE ASSEMBLY

(Remove the FJ-035 board referring to section 2-3 before starting disassembling.)

Note:

The +P2 (0-No.) screws (M1.7 × 2.5) are MEC-processed. If the screws that are once removed,

are re-used, the screws may be loosened.

When re-assembling the mechanism, use the new +P2 (0-No.) screws (M1.7

1

T wo screws

(M1.7

0-No, +p2

(Note)

×

2.5),

2

FP-387 flexible board

A

A

1

Four claws

If the FP-387 flexible board is

pulled in the direction of the

arrow

locations will be released.

2

Blind plate assembly

Remove it while taking care so that it must not

be caught by the flexible board and harnesses,

by pulling it in the direction of the arrow.

A

, the claws at the four

×

2.5).

PRECAUTION DURING

FP-387 FLEXIBLE BOARD

INSTALLATION (1)

Install the flexible wire to the blind plate

so that it covers the harness (PT-128).

Remove the blind plate assembly

after opening the LCD panel.

Blind plate

assembly

Harness (PT-128)

2-14. PD-148B BOARD, INVERTER TRANSFORMER UNIT

2

3

LCD cabinet (R)

assembly

2

T wo claws

5

T wo screws

(M1.7 × 2.5),

lock ace, p2

6

T wo claws

7

LCD cabinet (L)

assembly

B

A

PD-148B

1

(M1.7 × 2.5),

lock ace, p2

B

A

T wo screws

8

4

T wo screws

(M1.7 × 2.5),

MI

Panel insulating

sheet

4

Remove the

three solderings

qs

PD-148B board

6

T wo claws

8

PCB clip

qa

Inverter transformer unit

5

Screw

(M1.7

lock ace, p2

1

(PT-128) (16P)

PD-148B

9

PCB clip

q;

Remove the

six solderings

7

Back light

(Cold cathode fluorescent tube)

3

Liquid crystal

indicator module (24P)

×

2.5),

Harness

— 20 —

2-15. HINGE ASSEMBLY

4

A

Give the folding line along with

the hinge cover (lower) while

taking care so that the portion

A

is not loosened.

Be careful that the margin

between the flexible board

and the hinge cover (lower)

is around 1 mm.

3

T wo screws

(M1.7

×

2.5),

lock ace, p2

1

T wo screws

(M1.7

×

2.5),

lock ace, p2

qs

Hinge assembly

q;

Hinge cover (upper)

8

Hinge cover (lower)

Hinge cover

(lower)

2

Strobe unit

9

Three claws

6

Claw

5

Screw

(M1.7

×

2.5),

0-No, +p2

(Note)

PRECAUTION DURING FP-387 FLEXIBLE

BOARD INSTALLATION (2)

7

FP-387 flexible board

FP-387 flexible

board

qa

Harness (PT-128)

The +P2 (0-No.) screws (M1.7 × 2.5) are MEC-processed. If the screws that are once removed,

are re-used, the screws may be loosened.

When re-assembling the mechanism, use the new +P2 (0-No.) screws (M1.7

×

2.5).

Note:

(Remove the LCD unit referring to section 2-14 before starting disassembling.)

DCR-PC115E/PC120E

— 21 —

DCR-PC115E/PC120E

3. REPAIR PARTS LIST

3-1. EXPLODED VIEWS

NOTE:

• -XX, -X mean standardized parts, so they may

have some differences from the original one.

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering these

items.

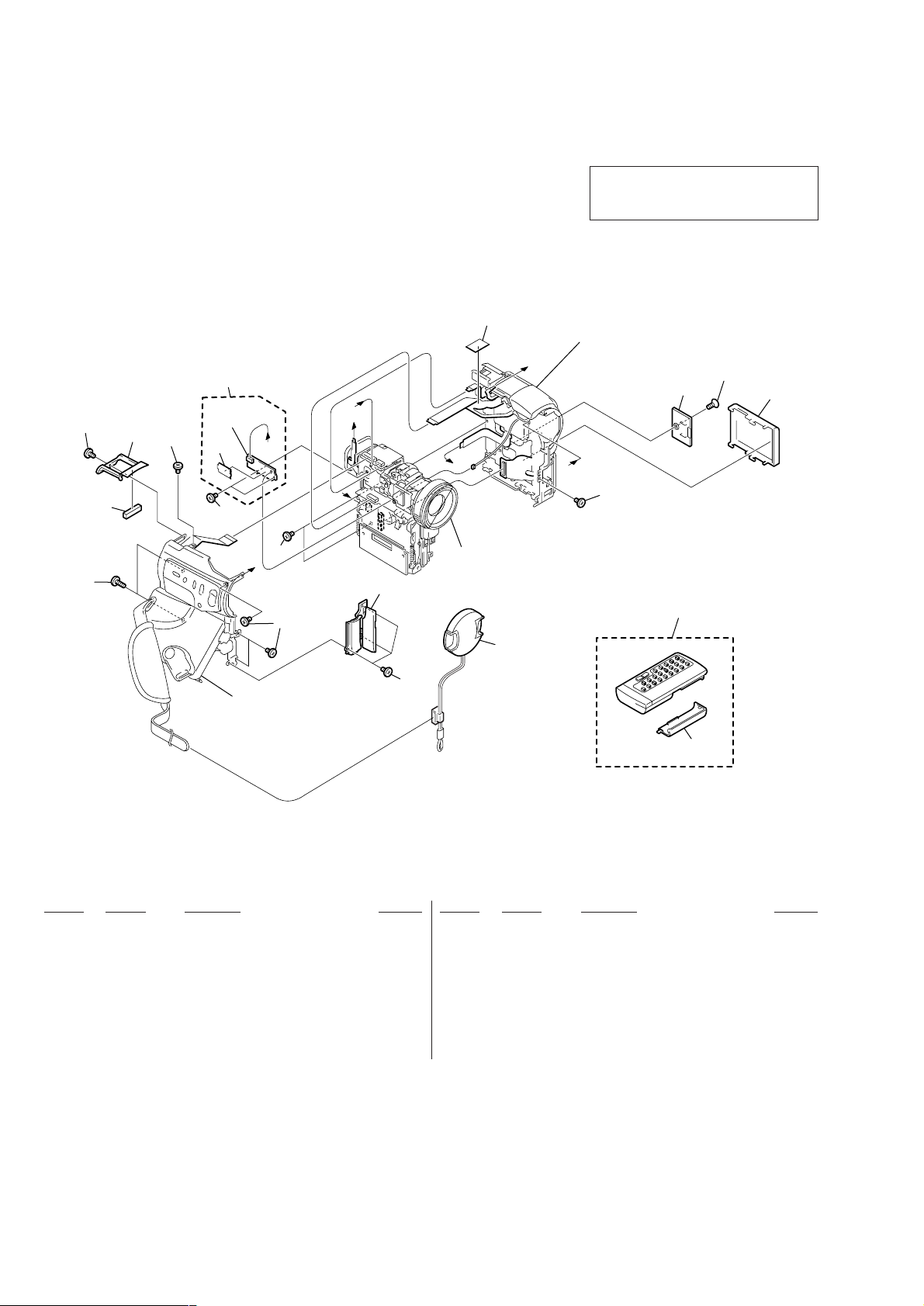

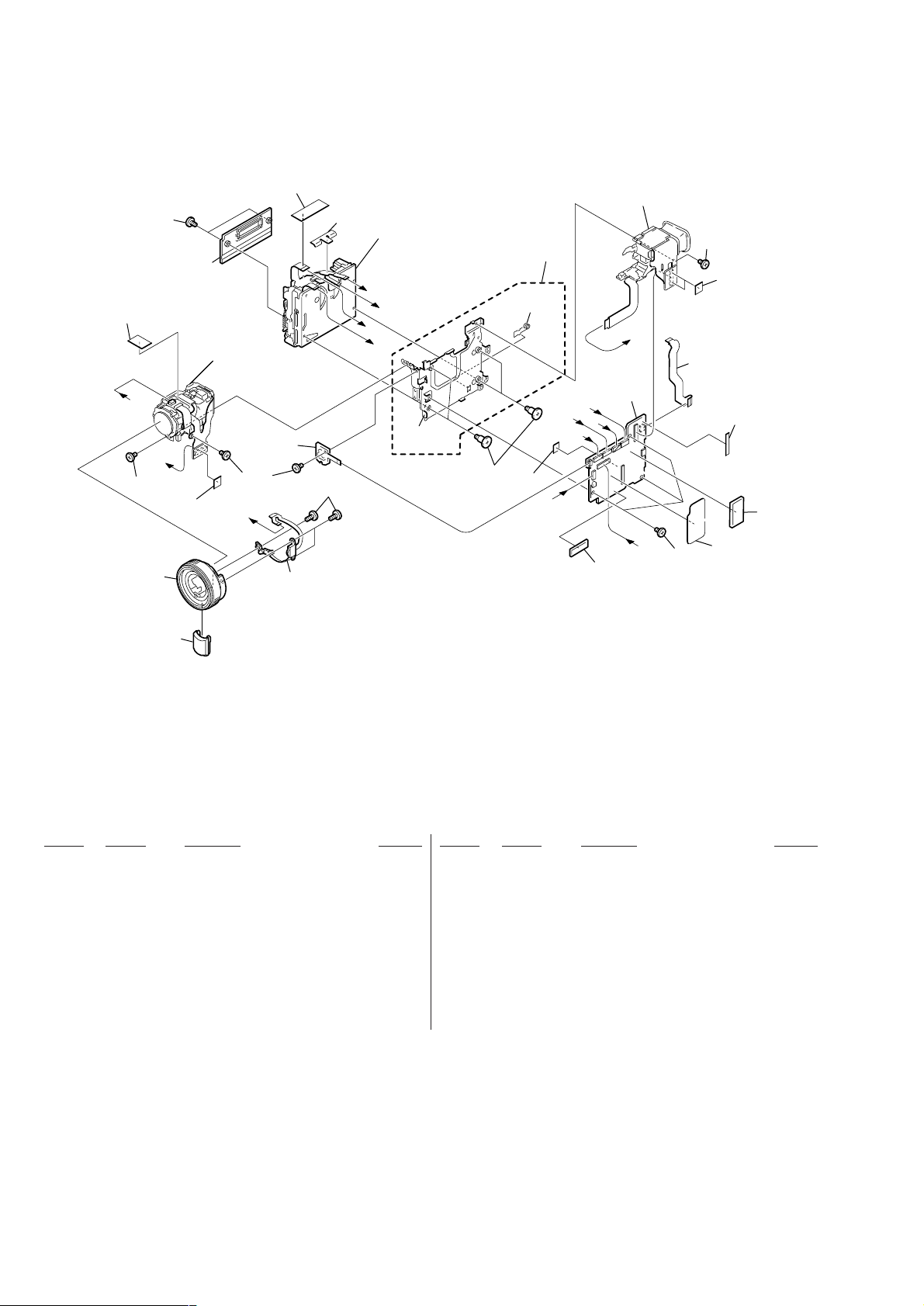

3-1-1. OVERALL SECTION

• The mechanical parts with no reference number

in the exploded views are not supplied.

The components identified by mark 0 or

dotted line with mark 0 are critical for safety.

Replace only with part number specified.

17

B

9

not

2

7

6

supplied

4

10

D

16

4

A

5

B

D

C

C

VTR overall section

(See page 24)

3

4

Cabinet (R) section-1, 2

(See page 26, 27)

A

4

11

14

12

13

1

2

Cabinet (L) section

(See page 23)

15

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

1 X-3949-944-1 CAP ASSY, LENS

2 3-989-735-01 SCREW (M1.7), LOCK ACE, P2

3 X-3951-962-1 COVER ASSY, JACK ORNAMENTAL

4 4-974-725-01 SCREW (M1.7), LOCK ACE, P2

5 3-989-735-21 SCREW (M1.7), LOCK ACE, P2

6 3-070-446-01 CUSHION, ACOUSTIC ISOLATION

7 3-070-441-01 HS CABINET

9 not supplied BT-003 BOARD, COMPLETE (PC120E)

10 not supplied CASE ASSY, BT SHIELD (PC120E)

11 3-070-369-01 LID, CPC

* 12 3-057-437-01 LOCKACE (M1.7)

13 3-057-482-01 COVER, BATTERY

14 1-475-950-21 REMOTE COMMANDER (RMT-811)

15 3-053-056-01 LID, BATTERY CASE (FOR RMT-811)

16 3-389-523-16 SCREW (LOCK ACE) (PC120E)

* 17 3-064-657-01 GUARD, FK FLEXIBLE

— 22 —

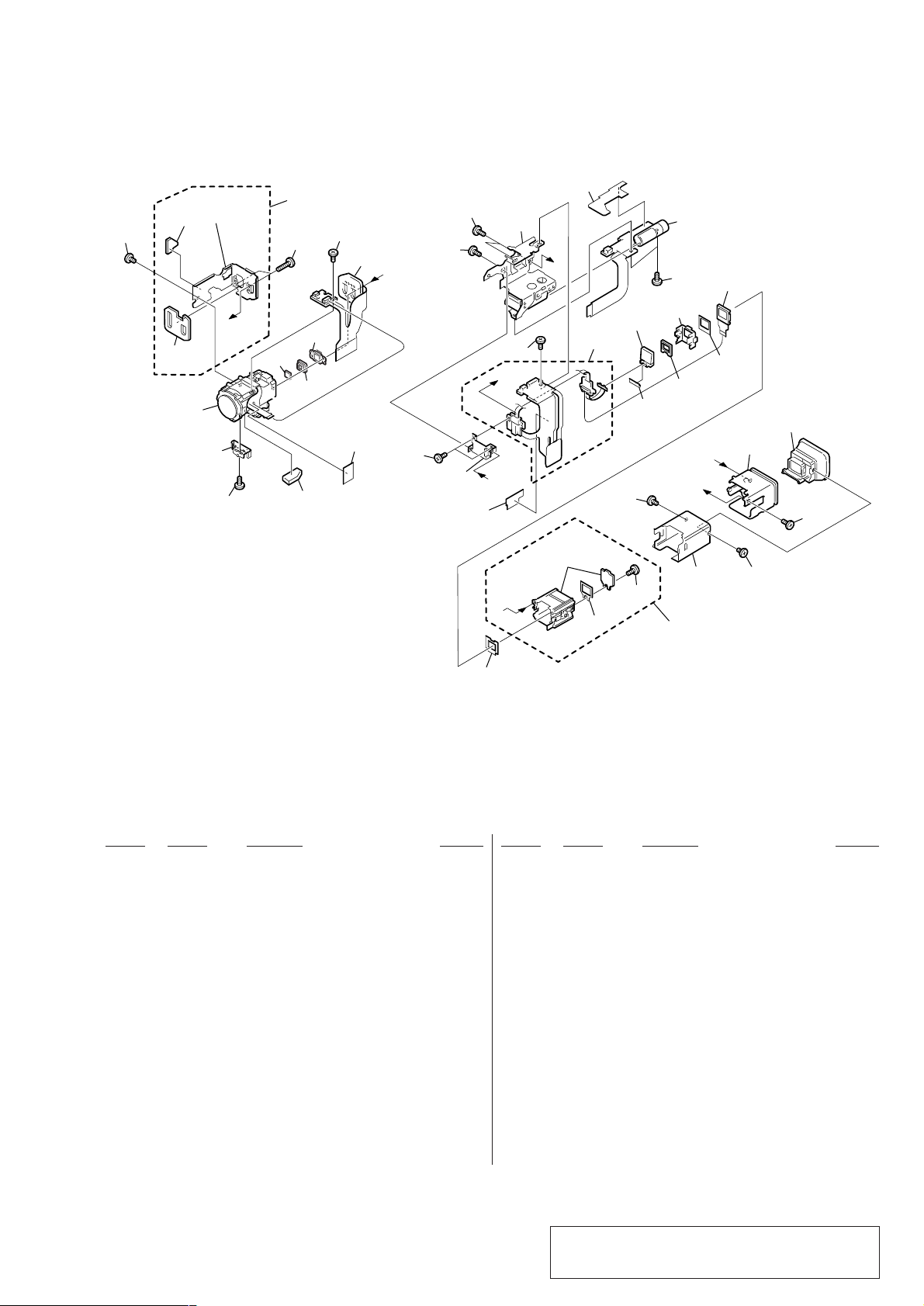

3-1-2. CABINET (L) SECTION

B

B

A

A

60

59

51

62

SP901

not

supplied

62

51

64

62

51

74

(Note)

62

62

62

72

65

66

69

70

71

75

51

73

62

55

54

53

52

51

57

58

51

63

51

61

: BT001 (Lithium battery) Control switch block (FK-1850) on the mount position.

The +P2 (0-No.) screws (M1.7 × 2.5) are MEC-processed. If the screws that are once removed,

are re-used, the screws may be loosened.

When re-assembling the mechanism, use the new +P2 (0-No.) screws (M1.7

×

2.5).

Note:

DCR-PC115E/PC120E

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

51 4-974-725-01 SCREW (M1.7), LOCK ACE, P2

52 X-3951-891-1 GRIP ASSY, HOLD

53 3-969-387-01 FOOT, RUBBER

54 3-070-419-01 COVER (G), JACK

55 3-062-141-01 BELT, GRIP

57 3-070-416-01 BRACKET, BELT

58 X-3951-954-1 CABINET (G) ASSY

59 X-3951-901-2 COVER (L) ASSY, JACK

60 X-3951-956-1 PLATE (L) ASSY, ORNAMENTAL

61 3-070-404-21 CABINET (L)

62 3-914-366-01 SCREW (DIA. 1.7X4), PRECISION

63 1-476-871-11 SWITCH BLOCK, CONTROL (FK-1850)

64 X-3951-896-1 FRAME ASSY, JACK

65 3-070-467-01 SHEET (N), MUFFLE

66 X-3951-955-1 CABINET (REAR) ASSY (PC120E)

66 X-3951-958-1 CABINET (REAR) ASSY (PC115E)

69 3-062-128-01 SPRING, COMPRESSION

70 3-070-431-01 LOCK, BATTERY

71 1-476-870-11 SWITCH BLOCK, CONTROL (PS-1850)

72 not supplied KY-060 (N) BOARD, COMPLETE (PC120E)

72 not supplied KY-060 BOARD, COMPLETE (PC115E)

73 X-3951-889-1 FRAME ASSY, G

74 3-973-497-91 SCREW (M1.7), 0-NO. +P 2

75 3-071-508-01 SHEET (L)

SP901 1-529-857-11 SPEAKER (1.6 CM)

— 23 —

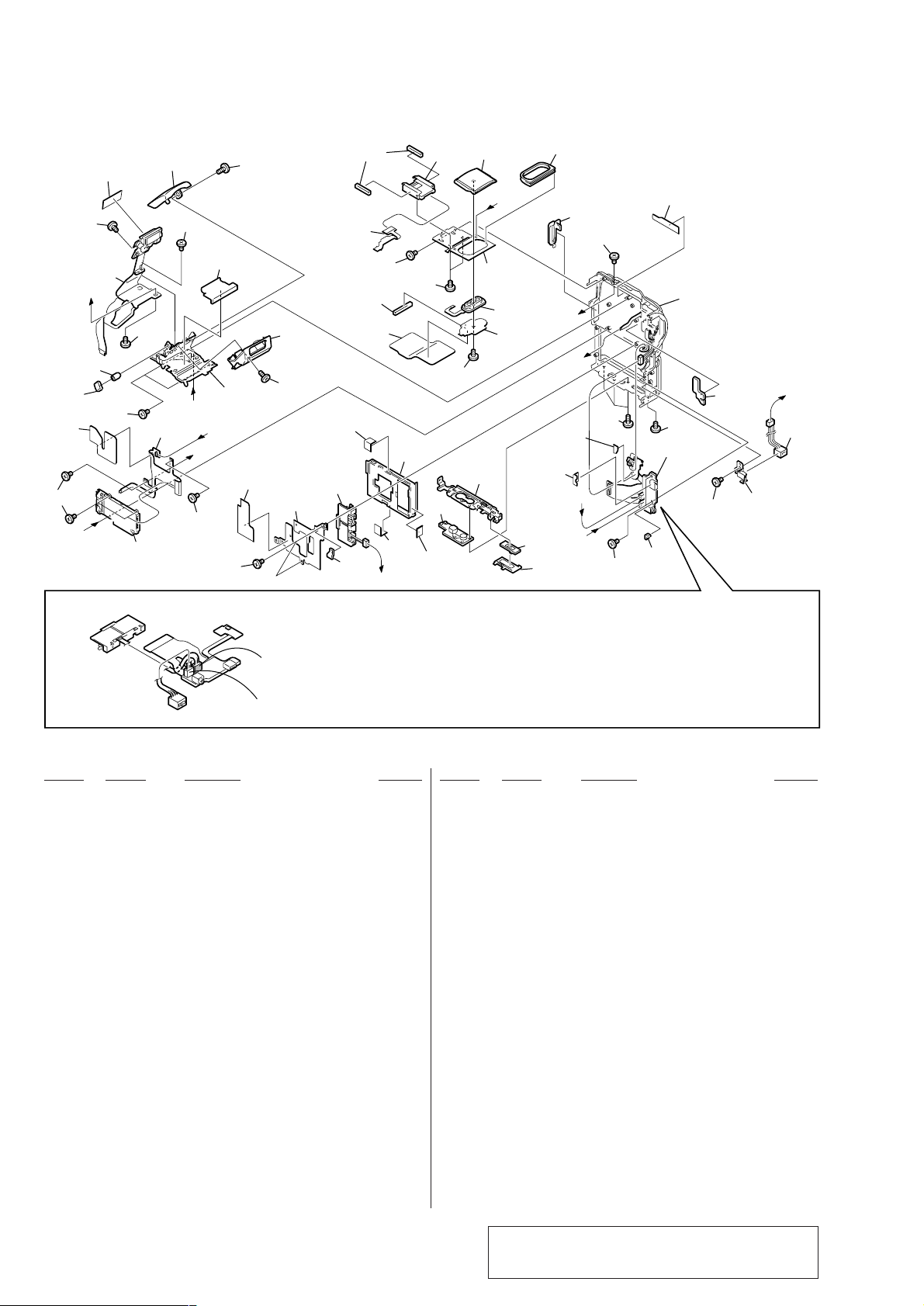

DCR-PC115E/PC120E

3-1-3. VTR OVERALL SECTION

117

105

A

105

102

B

108

LENS section

(See page 25)

not

supplied

105

A

not

supplied

106

103

104

109

Mechanism deck

C

E

F

D

not

supplied

111

110

not

supplied

116

G

E

C

F

EVF section

(See page 25)

G

113

D

118

B

105

105

112

not

supplied

115

not

supplied

114

101

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

101 X-3951-884-1 WINDOW ASSY, IR

102 X-3951-885-1 BASE ASSY, MF

103 1-476-285-11 SWITCH BLOCK, CONTROL

104 3-914-366-01 SCREW (DIA. 1.7X4), PRECISION

105 4-974-725-01 SCREW (M1.7), LOCK ACE, P2

106 not supplied FP-386 BOARD, COMPLETE

108 3-059-722-01 COVER, CASSETTE COMPARTMENT

109 3-070-940-01 DF TAPE (2)

110 X-3951-883-1 FRAME ASSY, MD

111 3-059-718-01 SCREW (M1.4X1.5)

112 1-682-648-11 FP-384 FLEXIBLE BOARD (PC120E)

113 not supplied VC-270 (D) BOARD, COMPLETE (SERVICE)

(PC115E)

113 not supplied VC-270 (B) BOARD, COMPLETE (SERVICE)

(PC120E)

114 3-070-444-01 SHEET, IC RADIATION

115 3-070-456-01 SHEET, VC ELECTROSTATIC

116 3-070-967-01 MD CUSHION

* 117 3-064-657-01 GUARD, FK FLEXIBLE

118 3-072-242-01 CUSHION (B), VC

— 24 —

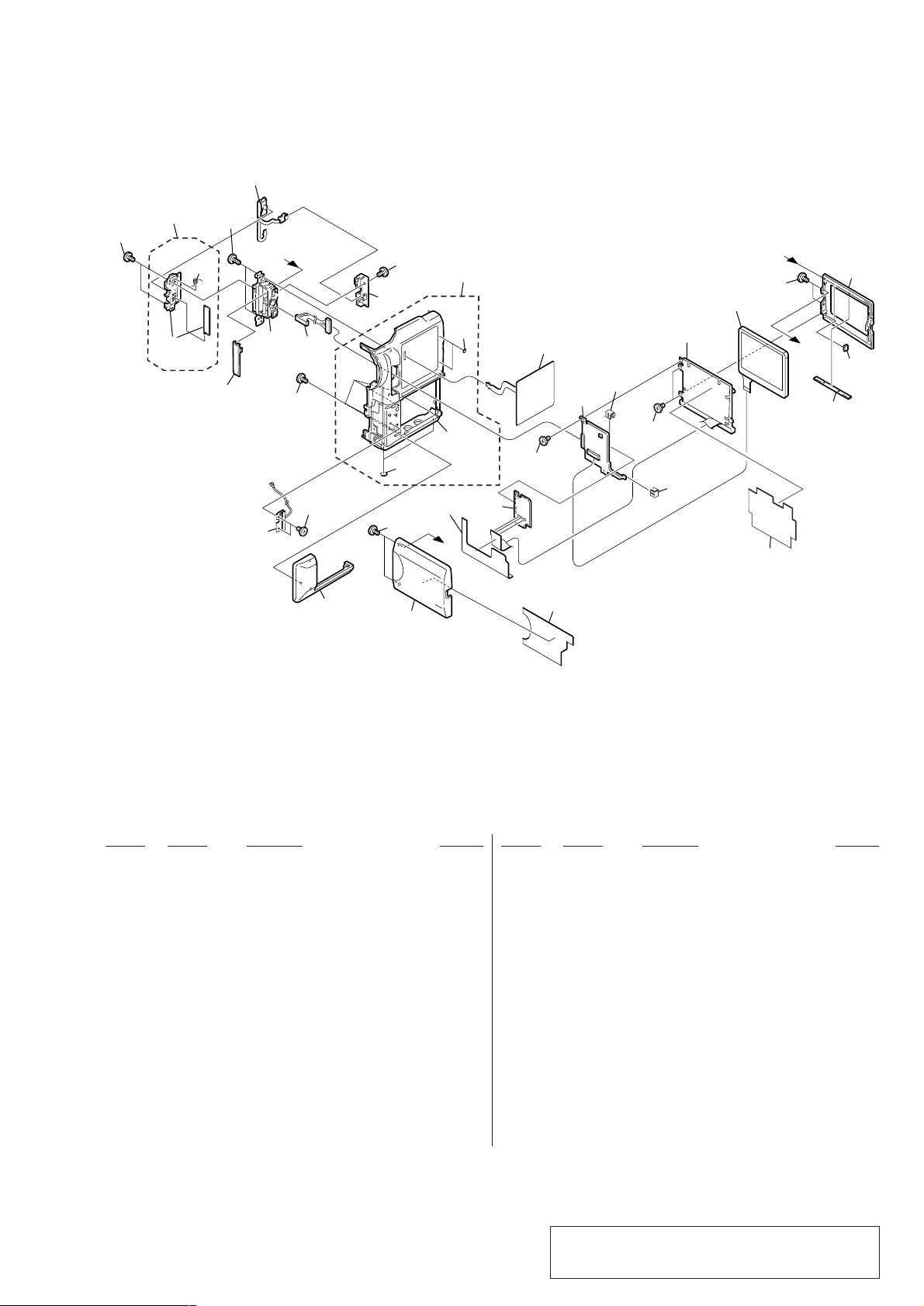

3-1-4. LENS-EVF SECTION

DCR-PC115E/PC120E

151

not

supplied

not

supplied

153

152

151

A

154

159

158

155

180

IC101

151

157

160

A

164

179

165

151

181

C

D

D

161

179

162

B

not

supplied

166

176

LED901

167

178

175

179

169

168

174

163

173

C

LCD902

170

B

171

172

179

178

177

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

151 3-071-505-01 TAPPING (M1.7)

152 3-063-504-01 FRAME, LENS

153 not supplied DEVICE, LENS LSV-690B

154 not supplied FILTER BLOCK, OPTICAL

155 not supplied RUBBER (W), SEAL

157 not supplied CD-349P BOARD, COMPLETE

158 not supplied SCREW (B1.7), TAPPING

159 not supplied CASE ASSY, CD SHIELD

* 160 3-064-657-01 GUARD, FK FLEXIBLE

161 X-3951-895-1 FRAME ASSY, VF

162 3-070-462-01 SHEET, MC GUARD

0 163 not supplied FLASH UNIT (MC)

164 3-914-366-01 SCREW (DIA. 1.7X4), PRECISION

165 3-070-435-01 FRAME (B), VF

166 not supplied VM-027 BOARD, COMPLETE

169 3-070-437-01 BL UNIT

170 3-071-562-01 CUSHION (L) (2), BL

171 X-3951-894-1 LENS ASSY, VF

172 3-070-438-01 RING, VF REGULATION

173 X-3951-935-1 SLEEVE ASSY

174 X-3951-893-1 GUIDE ASSY, VF SLEEVE

175 3-713-791-51 SCREW (M1.7X3.5), TAPPING, P2

176 3-068-805-01 CUSHION, VF

* 177 3-062-767-01 CUSHION, LCD

178 3-989-735-01 SCREW (M1.7), LOCK ACE, P2

179 4-974-725-01 SCREW (M1.7), LOCK ACE, P2

180 3-070-966-01 GUIDE, BT CABLE

181 3-071-631-01 SHEET, VM GUARD

IC101 not supplied CCD BLOCK ASSY (CCD IMAGER)

LCD902 not supplied LCX033AN-1

167 3-069-940-01 SHEET METAL, BL RETAINER

168 3-062-205-11 CUSHION (B), BL

0 LED901 not supplied BLOCK (0.44), LIGHT GUIDE PLATE

Note : The components identified by mark 0 or dotted

— 25 —

line with mark 0 are critical for safety.

Replace only with part number specified.

DCR-PC115E/PC120E

3-1-5. CABINET (R) SECTION-1

not

supplied

237

213

A

242

243

207

211

207

F

Battery terminal

board

DC-IN connector

237

CN003

214

233

210

207

239

236

212

A

E

F

208

207

FJ-035 board

CN1334

(Blue)

CN1335 (White)

221

222

223

B

224

241

226

220

207

219

207

237

216

215

225

237

244

205

BT901

(Note)

206

209

D

Note:

CN1335 (for the DC-IN connector) and CN1334 (for the battery terminal board)of

FJ-035 board are the same size, and the number of the pins is the same.

So these connectors may be mistaken for each other. When these connectors

are mistaken, the charge system of the unit may break.

So ascertain the color of the connector when assembling these connectors.

244

204

not

supplied

MIC901

B

217

E

239

238

235

not

supplied

203

D

C

202

201

CN1334 (for the battery terminal board) ········ Blue

CN1335 (for the DC-IN connector) ················· White

207

207

231

(Note)

234

Cabinet (R) section-2

(See page 27)

228

207

C

J901

(Note)

230

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

201 3-062-193-01 SLIDER, EJECT KNOB

202 3-062-192-01 KNOB, EJECT

203 X-3951-886-1 FRAME ASSY, BOTTOM

204 3-062-191-01 SCREW, TRIPOD

205 X-3951-933-1 HOLDER ASSY, BATTERY

206 3-070-368-01 RETAINER, BT TERMINAL

207 4-974-725-01 SCREW (M1.7), LOCK ACE, P2

208 3-071-466-01 SHEET, MS FLEXIBLE

209 3-072-241-01 CUSHION (A), VC

210 1-682-647-21 FP-383 FLEXIBLE BOARD

211 3-071-465-01 SHEET, BT CABLE

212 X-3951-882-1 STROBOSCOPE ASSY

0 213 not supplied STROBOSCOPE AF BLOCK ASSY (SERVICE)

214 3-070-391-01 ST CABINET UPPER

215 3-070-392-01 ST CABINET LOWER

216 3-070-446-01 CUSHION, ACOUSTIC ISOLATION

217 X-3951-900-1 PLATE ASSY, MICROPHONE RETAINER

219 3-070-394-01 FRAME, SHOE

220 1-682-649-11 FP-385 FLEXIBLE BOARD

221 3-070-818-01 CUSHION (S)

222 1-815-124-11 CONNECTOR, EXTERNAL (HOT SHOE)

223 X-3951-960-1 GRILLE ASSY, MICROPHONE (PC120E)

223 X-3951-961-1 GRILLE ASSY, MICROPHONE (PC115E)

224 3-070-381-01 INSULATOR, OUTER

225 3-071-068-01 SHEET, HS ACOUSTIC ISOLATION

226 3-070-348-01 BASE, PANEL LOCK

228 3-070-440-01 RUBBER (R), LENS

230 3-070-375-01 PLATE, DC RETAINER

231 not supplied FJ-035 (PN) BOARD, COMPLETE (PC120E)

231 not supplied FJ-035 (P) BOARD, COMPLETE (PC115E)

233 3-052-245-01 BOLT (M1.4)

234 3-071-241-01 CUSHION (L),LIGHT INTERCEPTION

235 3-071-467-01 CUSHION, FJ FLEXIBLE

236 3-070-393-01 PLATE, ORNAMENTAL

237 3-989-735-01 SCREW (M1.7), LOCK ACE, P2

238 3-989-735-31 SCREW (M1.7), LOCK ACE, P2

239 3-914-366-01 SCREW (DIA. 1.7X4), PRECISION

241 3-070-464-01 SHEET, (R) HEAT INSULATING

242 3-070-851-01 SCREW, HEXAGON HOLE PRECISION

243 3-072-320-01 CUSHION (A), STROBOSCOPE

244 4-920-257-01 COVER, FLEXIBLE INSULATING

BT901 1-694-796-11 TERMINAL BOARD, BATTERY

CN003 1-815-846-11 CONNECTOR, MEMORY STICK

J901 1-815-005-11 CONNECTOR, DC-IN

MIC901 1-476-282-21 MICROPHONE UNIT

— 26 —

Note : The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

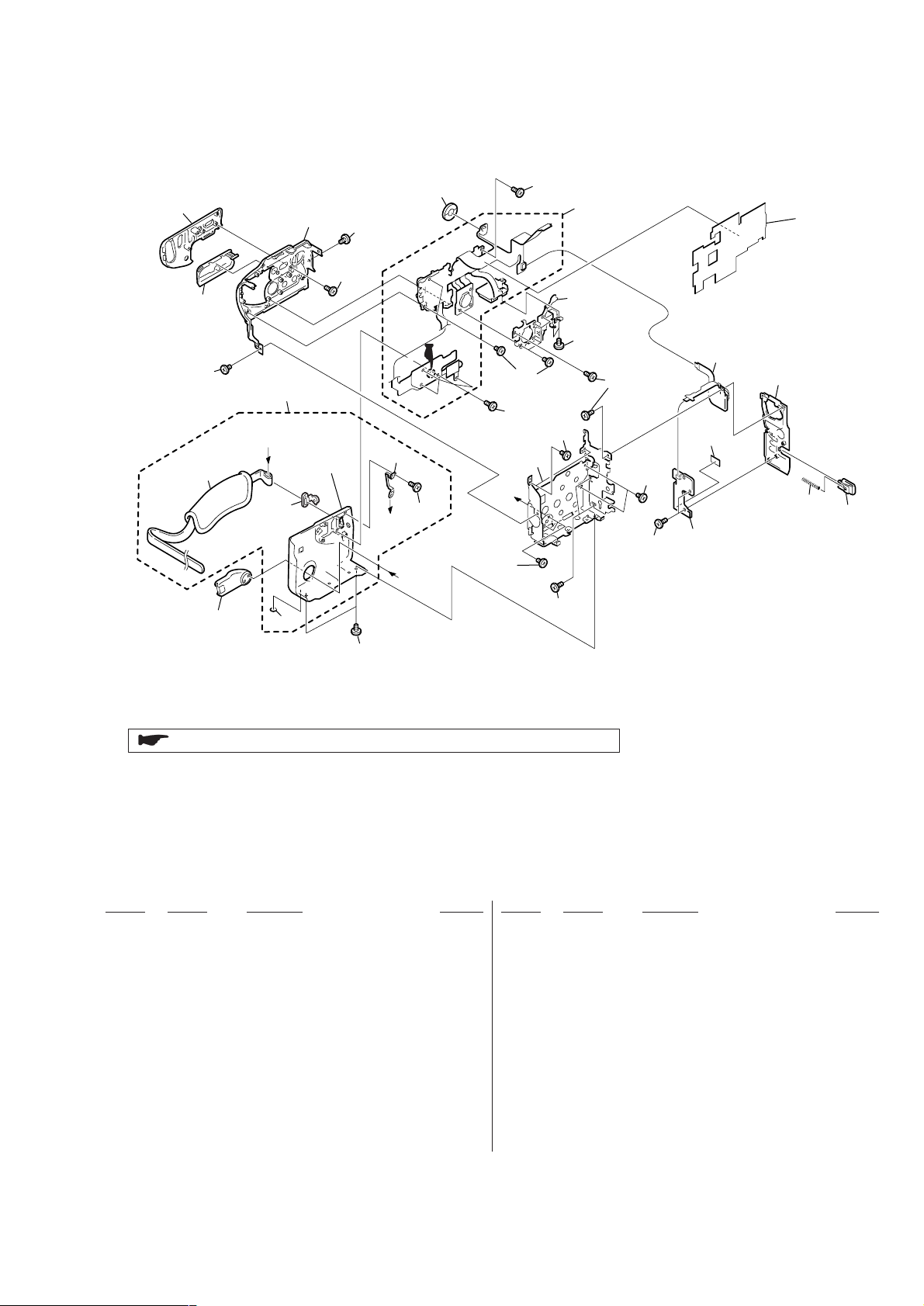

3-1-6. CABINET (R) SECTION-2

271

265

(Note)

273

274

272

B

DCR-PC115E/PC120E

Note:

The +P2 (0-No.) screws (M1.7 × 2.5) are MEC-processed. If the screws that are once removed,

are re-used, the screws may be loosened.

When re-assembling the mechanism, use the new +P2 (0-No.) screws (M1.7

265

(Note)

266

262

LCD901

A

276

×

2.5).

251

not

supplied

269

ANT901

270

268

267

252

260

264

252

259

263

not

supplied

258

A

257

252

261

275

256

PD-148B

255

252

ND901

255

254

B

not

supplied

253

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

251 X-3951-879-1 CABINET (L) ASSY, LCD

252 4-974-725-01 SCREW (M1.7), LOCK ACE, P2

253 3-071-522-01 SHEET, PANEL DROP PROTECTION

254 3-060-704-01 SHEET (N), BL SHIELD

* 255 3-051-232-01 CLIP, PCB

256 not supplied PD-148B BOARD, COMPLETE

0 257 not supplied INVERTER TRANSFORMER UNIT

258 3-072-068-01 SHEET, PANEL INSULATING

259 X-3951-957-1 CABINET (R) ASSY, LCD (PC115E)

259 X-3952-018-1 CABINET (R) ASSY, LCD (PC120E)

260 3-070-367-11 COVER, BT ORNAMENTAL (PC115E)

260 X-3951-898-1 COVER ASSY, BT (PC120E)

261 1-476-867-21 SWITCH BLOCK, CONTROL (ME-1850)

262 X-3951-874-1 CABINET (R) ASSY

263 3-052-521-01 CUSHION (2), PANEL

264 3-969-387-01 FOOT, RUBBER

— 27 —

265 3-973-497-91 SCREW (M1.7), 0-NO. +P 2

266 3-070-377-01 COVER (LOWER), HINGE

267 1-961-286-11 HARNESS (PT-128)

268 3-914-366-01 SCREW (DIA. 1.7X4), PRECISION

269 3-070-376-01 COVER (UPPER), HINGE

270 X-3951-876-1 HINGE ASSY

271 1-682-651-21 FP-387 FLEXIBLE BOARD

272 3-989-735-31 SCREW (M1.7), LOCK ACE, P2

273 X-3951-878-1 PLATE ASSY, BLIND

* 274 3-055-323-01 SPRING (MK), TORSION

275 3-070-465-01 SHEET, PANEL HEAT INSULATING

276 4-223-676-09 SCREW (M1.7), MI

ANT901 1-754-210-21 ANTENNA (2.4GHz) (PC120E)

LCD901 not supplied ACX311AKB-1

0 ND901 not supplied TUBE, FLUORESCENT, COLD CATHODE

Note : The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

Loading...

Loading...