Page 1

CDP-CX57

SERVICE MANUAL

SPECIFICATIONS

US Model

Canadian Model

AEP Model

UK Model

E Model

Australian Model

Model Name Using Similar Mechanism CDP-CX50/CX571

CD Mechanism Type CDM-46C1

Base Unit Type

Optical Pick-up Type KSS-213B/S-N

KSM-213BFN/M-NP

Compact disc player

Laser Semiconductor laser (λ = 780 nm)

Emission duration: continuous

Laser output Max 44.6 µW*

* This output is the value measured at

a distance of 200 mm from the

objective lens surface on the

Optical Pick-up block with 7 mm

aperture.

Frequency response 20 Hz to 20 kHz ± 1dB

Signal-to-noise ratio More than 107 dB

Dynamic range More than 88 dB

Harmonic distortion Less than 0.013%

Channel separation More than 100 dB

Outputs

Jack Maximum Load impedance

type output

level

LINE OUT Phono 2V Over 10 kilohms

Jacks (at 50 kilohms)

DIGITAL Optical –18 dBm Wave length: 660 nm

OUT output

(OPTICAL) connector

General

Power requirements

Where purchased Power requirements

US/Canada 120 V AC, 60 Hz

Australia 240 V AC, 50/60 Hz

UK 220 V – 230 V AC, 50/60 Hz

Other countries 110 V – 120 V or 220 V – 240 V AC,

adjustable, 50/60 Hz

Power consumption 12 W

Dimensions (approx.) When the front cover is closed

(w/h/d) 430 × 182.5 × 295 mm (17 × 7 1/4 × 11 5/8 in.)

incl. projecting parts

When the front cover is open

430 × 182.5 × 414 mm (17 × 7 1/4 × 16 3/8 in.)

incl. projecting parts

Mass (approx.) 5.5 kg (12 lbs 3 oz)

Supplied accessories

Audio cord (2 phono plugs – 2 phono plugs) (1)

CONTROL A1 cord (supplied for Canadian models only) (1)

Remote commander (remote) (1)

Sony SUM-3 (NS) batteries (2)

CD booklet holder (1) and Label (1)

Design and specifications are subject to change without notice.

COMPACT DISC PLAYER

MICROFILM

Page 2

SECTION 1

SERVICING NOTES

TABLE OF CONTENTS

1. SERVICING NOTES............................................... 2

2. GENERAL ................................................................... 6

3. DISASSEMBLY ......................................................... 7

4. TEST MODE.............................................................. 11

5. MECHANICAL ADJUSTMENTS ....................... 14

6. ELECTRICAL ADJUSTMENTS......................... 17

7. DIAGRAMS................................................................. 20

7-1. Block Diagrams

• BD Section .................................................................... 23

• Main Section ................................................................. 25

7-2. Printed Wiring Board – BD Section – ........................... 27

7-3. Schematic Diagram – BD Section – ............................... 29

7-4. Printed Wiring Board – Audio Section –....................... 31

7-5. Schematic Diagram – Audio Section –.......................... 33

7-6. Printed Wiring Board – Main Section – ........................ 35

7-7. Schematic Diagram – Main Section – ........................... 37

7-8. Printed Wiring Boards – Panel Section – ...................... 39

7-9. Schematic Diagram – Panel Section – .......................... 41

7-10. Printed Wiring Boards – Sensor/Motor Section –......... 43

7-11. Schematic Diagram – Sensor/Motor Section – ............. 45

7-12. IC Pin Function Description ........................................... 49

8. EXPLODED VIEWS................................................ 55

9. ELECTRICAL PARTS LIST ............................... 61

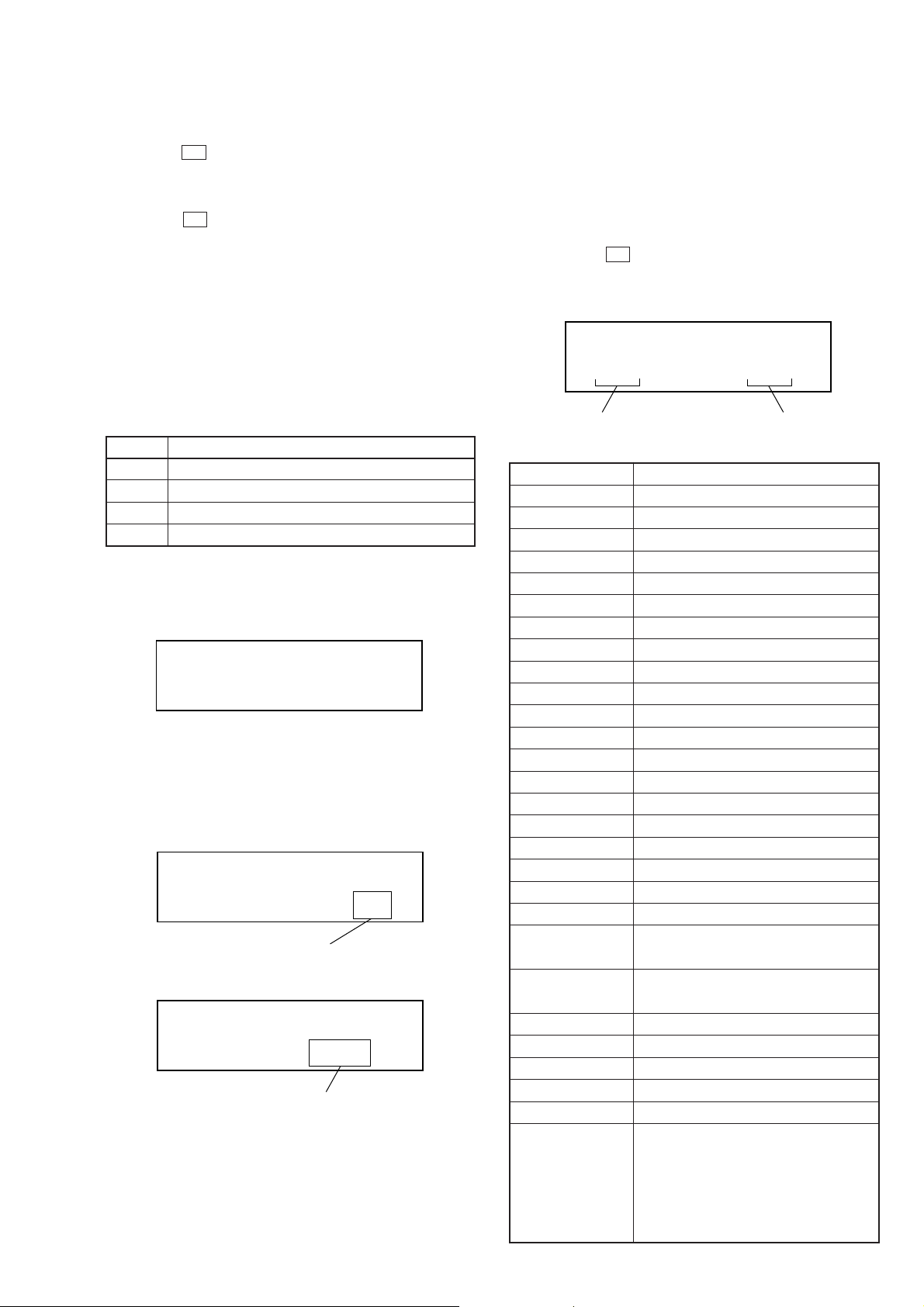

MODEL IDENTIFICATION

— BACK PANEL —

PART No.

PART No. MODEL

4-997-568-0π

4-997-568-1π

4-997-568-2π

4-997-568-3π

4-997-568-4π

4-997-568-5π

4-997-568-6π

US model

Canadian model

AEP, AED model

UK model

Australian model

E model

Singapore model

• Abbreviation

AED: North European

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

The laser component in this product

is capable of emitting radiation

exceeding the limit for Class 1.

This appliance is classified as

a CLASS 1 LASER product.

The CLASS 1 LASER

PRODUCT MARKING is

located on the rear exterior.

(Except for the customers in the United States and

Canada)

The following caution label is located inside the unit.

CAUTION :

INTERLOCKS DEFEATED. AVOID EXPOSURE TO BEAM.

ADVARSEL :

SIKKERHEDSAFBRYDERE ER UDE AF FUNKTION. UNDGÅ UDSAETTELSE

FOR STRÅLING.

VORSICHT :

ABDECKUNG GEÖFFNET UND SICHEREITSVERRIEGELUNG

ÜBERBRÜCKT. NICHT DEM STRAHL AUSSETZEN.

VARO!:

TIINA NÄKYMÄTTÖMÄLLE LASERSÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN.

VARNING :

OCH SPÄRREN ÄR URKOPPLAD. BETRAKTA EJ STRÅLEN.

ADVERSEL :

SIKKERHEDSLÅS BRYTES. UNNGÅ EKSPONERING FOR STRÅLEN.

VIGYAZAT!:

GÁRVESZÉLY

INVISIBLE LASER RADIATION WHEN OPEN AND

USYNLIG LASERSTRÅLING VED ÅBNING NÅR

UNSICHTBARE LASERSTRAHLUNG, WENN

AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALT -

OSYNLING LASERSTRÅLING NÄR DENNA DEL ÄR ÖPPNAD

USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES OG

A BURKOLAT NYITÁSAKOR LÁTHATATLAN LÉZERSU-

!

KERÜLJE A BESUGÁRZÁST!

– 2 –

Page 3

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

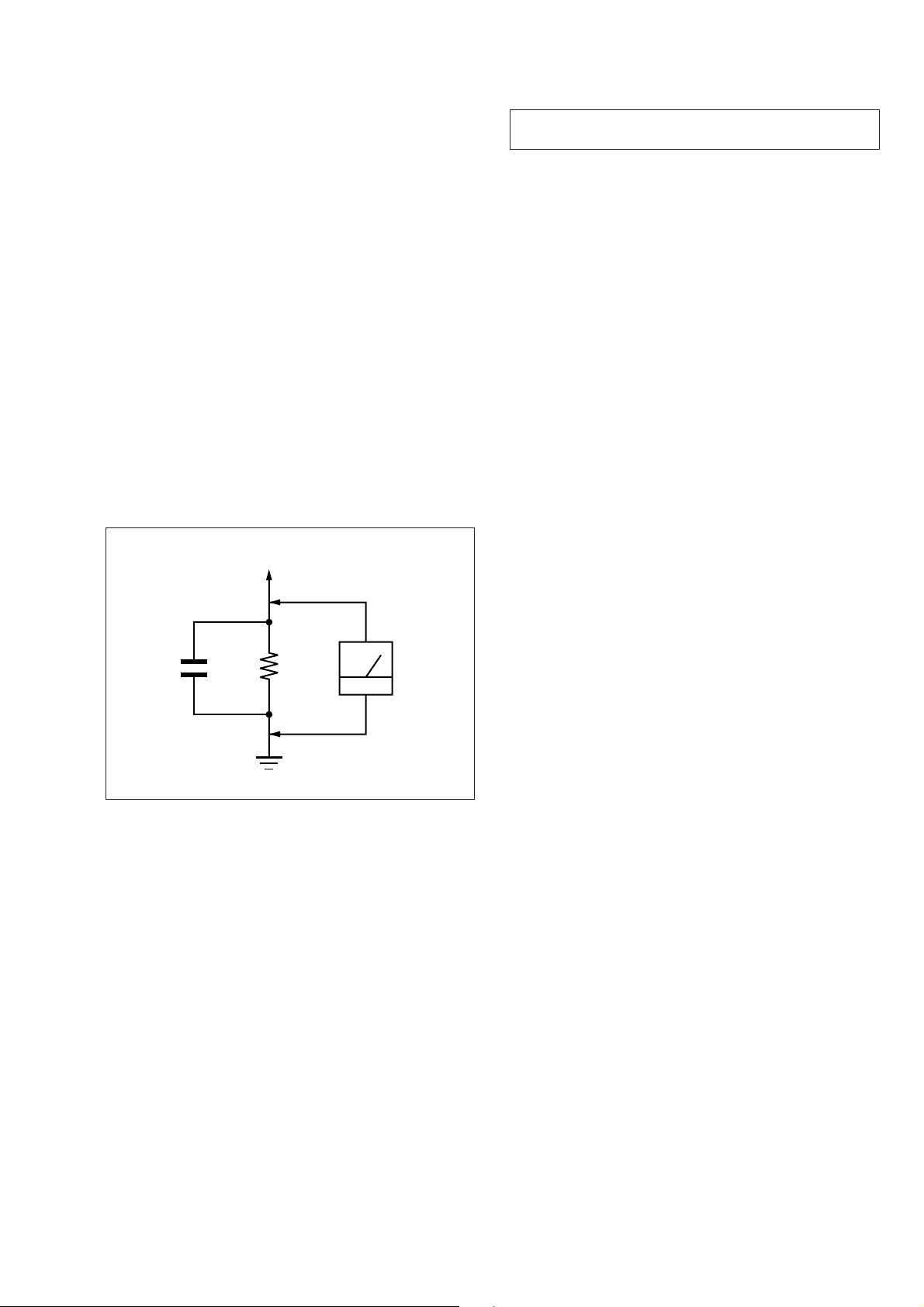

LEAKAGE

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester , such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication is 0.75 V, so analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery

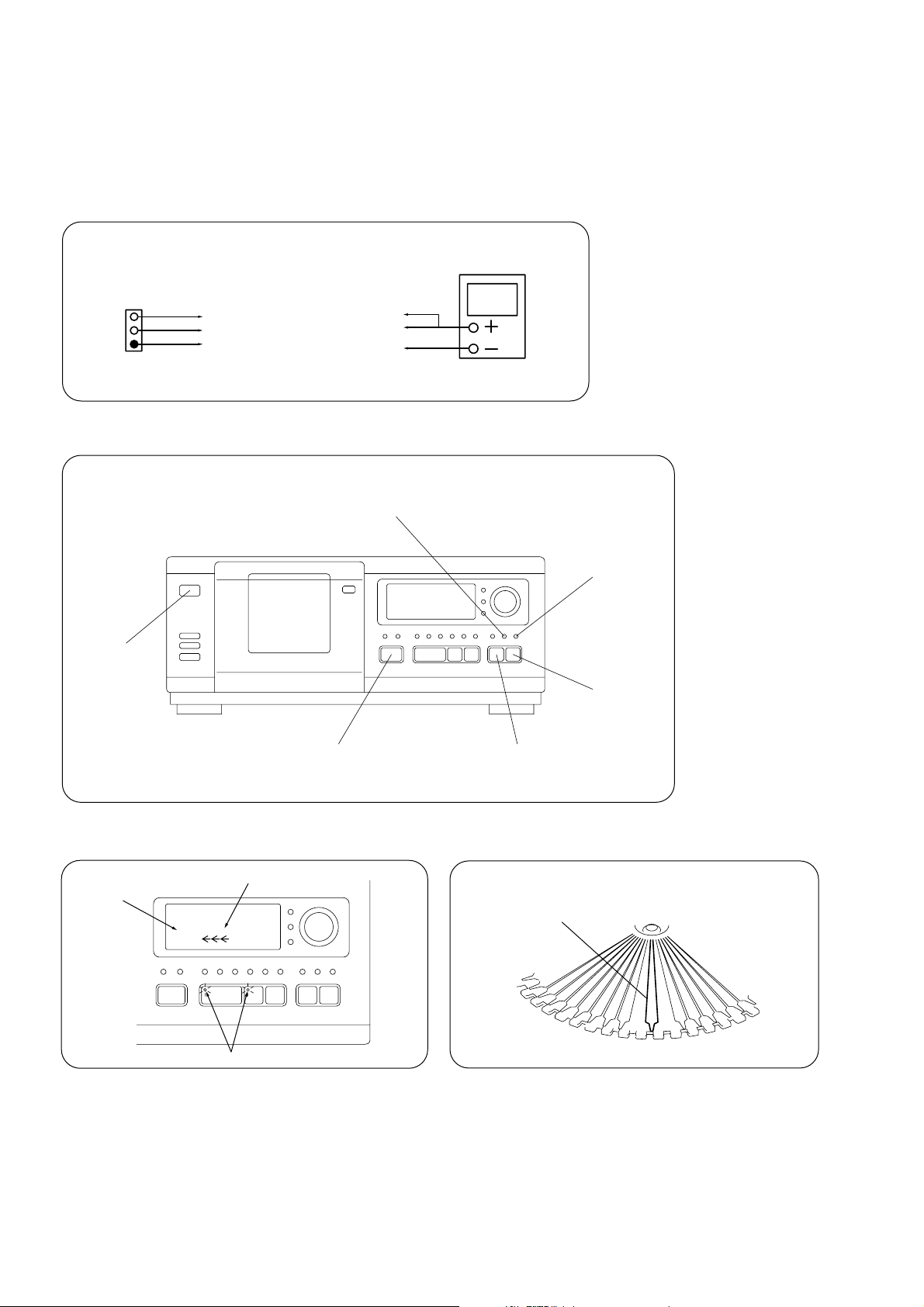

operated digital multimeters that have a 2 V A C range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in ”CD section adjustment” and

check that the S curve waveform is output repeatedly.

1.5 k

0.15 µF

Fig. A. Using an AC voltmeter to check AC leakage.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMATIC DIA GRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

Ω

Earth Ground

AC

voltmeter

(0.75 V)

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE !

SUR LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

– 3 –

Page 4

CD-TEXT TEST DISC

This unit is able to display the test data (character information) written in the CD on its fluorescent indicator tube.

The CD-TEXT TEST DISC (TGCS-313:4-989-366-01) is used for checking the display.

To check, perform the following procedure.

Checking Method:

1. Turn ON the power, set the disc on the disc table with the side labeled as “test disc” as the right side, close the front co v er, and chuck the

disc.

2. Press the · button and play back the disc.

3. The following will be displayed on the fluorescent indicator tube.

Display : 1kHz/0 dB/ L&R

4. Press the ≠ and ± buttons to switch the track. The text data of each track will be displayed.

For details of the displayed contents for each track, refer to “Table 1 : CD-TEXT TEST DISC TEXT Data Contents” and “Table 2 : CDTEXT TEST DISC Recorded Contents and Display”.

Restrictions in CD-TEXT Display

In this unit, some special characters will not be displayed properly. These will be displayed as a space or a character resembling it. For

details, refer to “Table 2 : CD-TEXT DISC Recorded Contents and Display”.

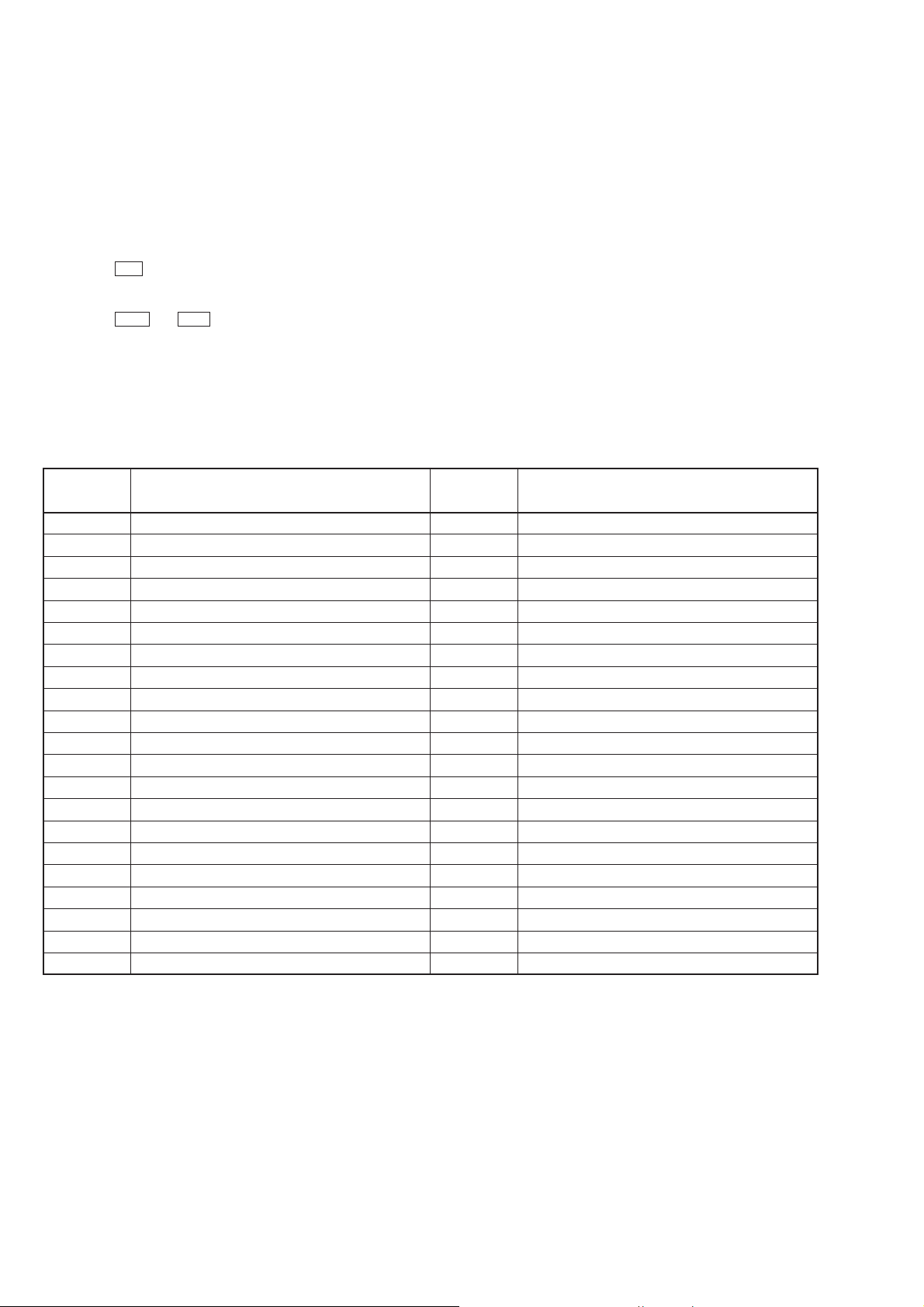

Table 1 : CD-TEXT TEST DISC TEXT Data Contents (TRACKS No. 1 to 41:Normal Characters)

TRACK

No.

1 1kHz/0dB/L&R 22 1kHz/-90dB/L&R

2 20Hz/0dB/L&R 23 Infinity Zero w/o emphasis//L&R

3 40Hz/0dB/L&R 24 Infinity Zero with emphasis//L&R

4 100Hz/0dB/L&R 25 400Hz+7kHz(4:1)/0dB/L&R

5 200Hz/0dB/L&R 26 400Hz+7kHz(4:1)/-10dB/L&R

6 500Hz/0dB/L&R 27 19kHz+20kHz(1:1)/0dB/L&R

7 1kHz/0dB/L&R 28 19kHz+20kHz(1:1)/-10dB/L&R

8 5kHz/0dB/L&R 29 100Hz/0dB/L*

9 7kHz/0dB/L&R 30 1kHz/0dB/L*

10 10kHz/0dB/L&R 31 10kHz/0dB/L*

11 16kHz/0dB/L&R 32 20kHz/0dB/L*

12 18kHz/0dB/L&R 33 100Hz/0dB/R*

13 20kHz/0dB/L&R 34 1kHz/0dB/R*

14 1kHz/0dB/L&R 35 10kHz/0dB/R*

15 1kHz/-1dB/L&R 36 20kHz/0dB/R*

16 1kHz/-3dB/L&R 37 100Hz Squer Wave//L&R

17 1kHz/-6dB/L&R 38 1kHz Squer Wave//L&R

18 1kHz/-10dB/L&R 39 1kHz w/emphasis/-0.37dB/L&R

19 1kHz/-20dB/L&R 40 5kHz w/emphasis/-4.53dB/L&R

20 1kHz/-60dB/L&R 41 16kHz w/emphasis/-9.04dB/L&R

21 1kHz/-80dB/L&R

Displayed Contents

TRACK

No.

Displayed Contents

NOTE : The contents of Track No. 1 to 41 are the same as those of the current TEST DISC-their titles are displayed.

– 4 –

Page 5

Table 2: CD-TEXT TEST DISC Recorded Contents and Display

(In this unit, some special characters cannot be displayed. This is no a fault.)

TRACK

No.

Recorded Contents Display

42 ! ” # $%& ´ (21h to 27h)1kHz 0dB L&R N All the same

43 ( ) + , – . / (28h to 2Fh) N All the same

*

44 01234567 (30h to 37Fh) N All the same

45 8 9 : ; < = > ? (38h to 3Fh) N All the same

46 @A B C D E FG (40h to 47Fh) N All the same

47 H I J K L MN O (48h to 4Fh) N All the same

48 P Q R S T U VW (50h to 57Fh) PQR S T U VW (50h to 57h)

49 X Y Z [ ¥ ] ^ _ (58h to 5Fh) XY Z [ \ ] ^ _ (58····

50 a b c d e f g (60h to 67Fh) a b c d e f g (60h to 67h)

′

′

51 h i j k l m n o (68h to 6Fh) N All the same

52 p q r s t u v w (70h to 77Fh) p q r s t u v w (70h to 77h)

53 x y z { I } (78h to 7Fh) x y z { } ~ (78····

~

54 i¢£¤¥ § (A0h to A7h) 8859-1 i ¢ £ ¤ ¥ § (A0···· is not displayed

55 ≥ C ª¬PR (A8h to AFh) ≥ (A8···· C ª ¬ P R – are not displayed

56

•±23

57 †1º ¿ (B8h to BFh) † ¿ (B8····

–

µ¶ • (B0h to B7h) µ • (B0····

′

14123

4

′

• ± 2 3

¶ are not displayed

14123

1

º are not displayed

4

58 АБВГДЕЖЗ (C0h to C7Fh) ÀÁ Â Ã Ä ÅÆÇ (C0h to C7h)

59 ÈÉÊË ÌÍÎÏ (C8h to CFh) N All the same

60 DСТУФХЦ (D0h to D7Fh) D СТУФХЦ (D0h to D7h)

61 ШЩЪЫЬY Я (D8h to DFh) Ù Ú Û Ü Y ß (D8····

˙

´

62 абвгдежз (E0h to E7h) а бвгдежз (E0h to E7h)

63 ийклмноп (E8h to EFh) N All the same

64 ∂ стуфхц÷ (F0h to F7Fh) стуфхц÷ (F0h to F7h)

65 шщъыьy я (F8h to FFFh) шщъыьy я (F8h to FFh)

´

´

66 No.66 N All the same

67 No.67 N All the same

to to to

99 No.99 N All the same

– 5 –

Page 6

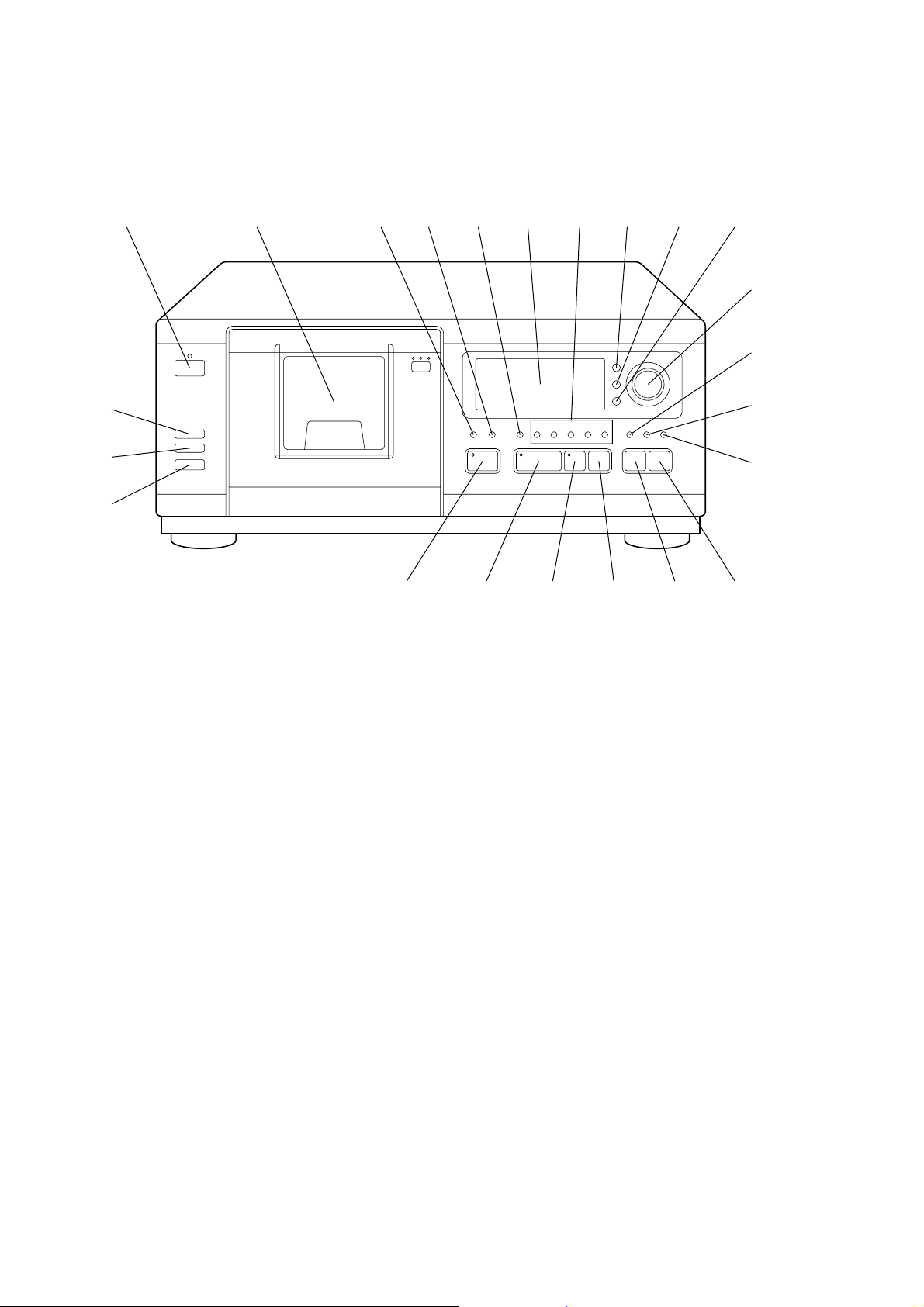

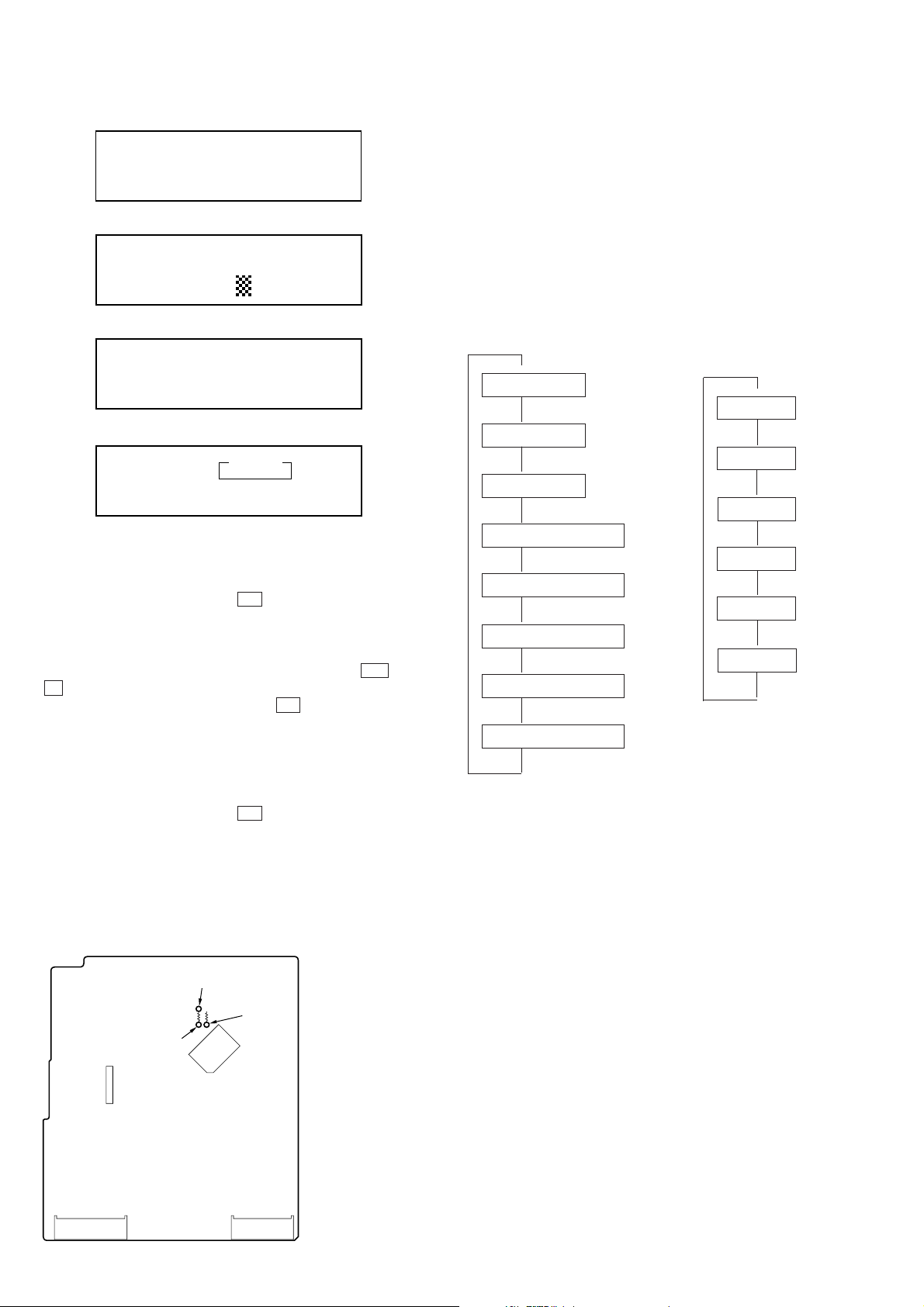

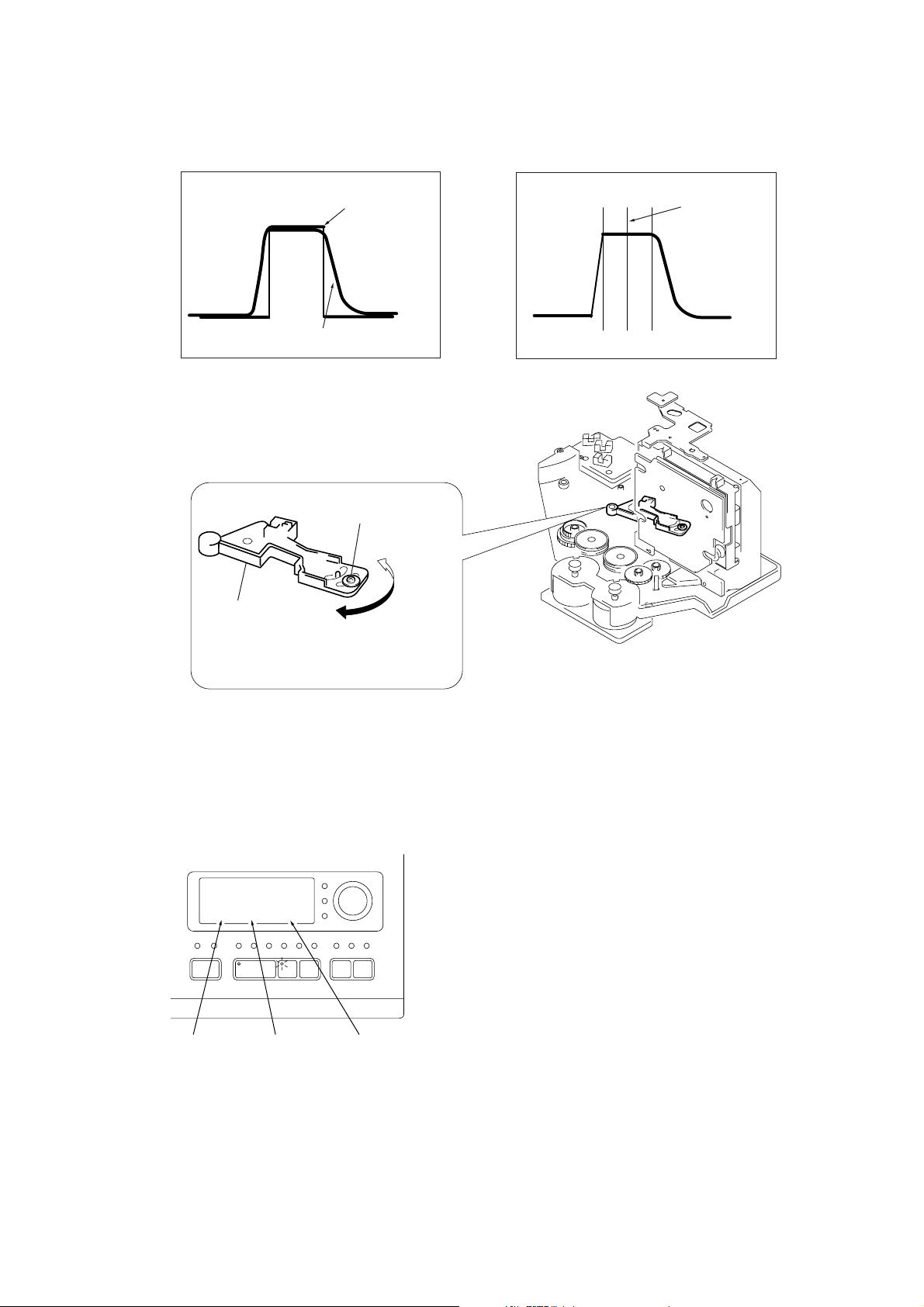

LOCATION OF PARTS AND CONTROLS

@

!

!

!

!

!

Front Panel

SECTION 2

GENERAL

1 2 3456 78 9

STANDBY

1/u

@¡

X-FADE

@™

NO DELAY

MEGA

CONTROL

@£

1 I/u (power switch) button

2 Front cover

3 PLAY MODE button

4 REPEAT button

5 GROUP FILE button

6 Display window

7 GROUP 1-5 buttons

8 TIME/TEXT button

9 INPUT button

!º MEMO SEARCH button

!¡ JOG dial (DISC/CHARACTER/PUSH ENTER knob)

!™ FADER button

PUSH

OPEN

PLAY MODE REPEAT GROUP FILE 1 2 3

PULS ONE

º

ª

!£ CHECK button

!¢ CLEAR button

!∞ ± button

!§ ≠ button

!¶ p button

!• P button

!ª · button

@º PLUS ONE button

@¡ X-FADE button

@™ NO DELAY button

@£ MEGA CONTROL button

GROUP

ª

•

Pp

DISC/CHARACTER

TIME/TEXT

INPUT

MEMO SEARCH

PUSH ENTER

4 5 CHECKFADER CLEAR

±

±

¶

0

!¡

!™

g

!£

!¢

§

∞

– 6 –

Page 7

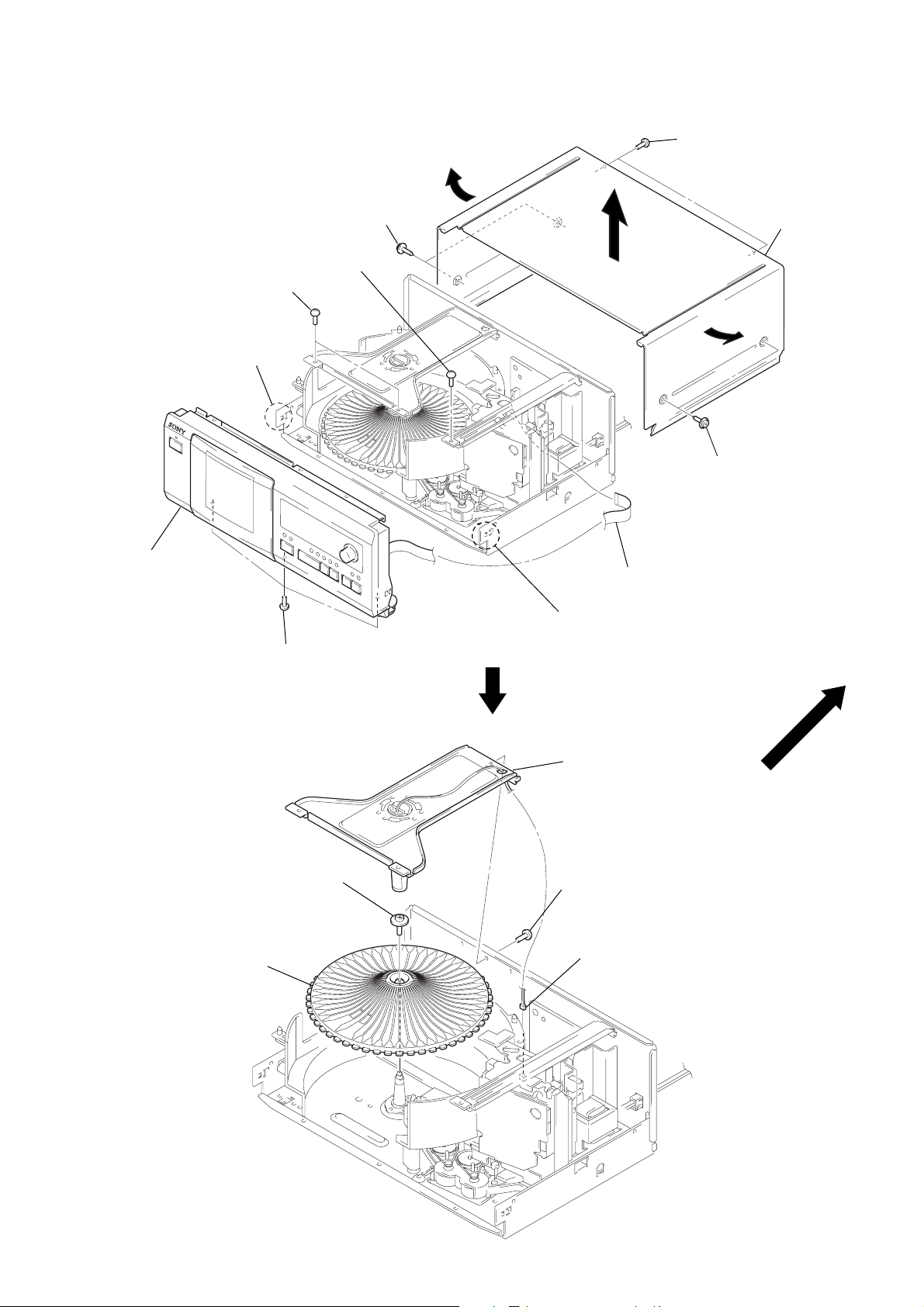

SECTION 3

e

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

CASE, FRONT PANEL

1

two screws

×

8)

(M3

4

3

two screws

(BVTT3

7

claw

×

screw

(BVTT3

6)

×

6)

1

two screws

(M3

×

8)

1

two screws

(M3

2

cas

×

8)

8

front panel

TABLE (50)

5

table (50)

4

screw

(PTPWH2.6

6

three screws

(BVTT3

5

wire (flat type) (19 core)

(CN503)

7

claw

×

6)

3

bracket

(ILLUMINATION)

1

×

8)

screw

(BVTT3

2

connector

(NO 806)

×

6)

– 7 –

Page 8

CD MECHANISM DECK SECTION

)

r

3

two screws

0

0

connector

(CN52)

connector

(CN51)

!¡

connector

(CN61)

9

4

screw

(P3

9

ring (B)

screw

(BVTT3

×

14)

(BVTP3

×

8)

2

reinforcement

×

8)

5

two screws

(BVTT3

×

10)

6

connector

(CN53)

8

base (LOADING)

7

wire (flat type) (16 core)

(CN102)

7

5

screw

(BVTT3

1

wire (flat type) (9 core

(CN103)

×

6)

6

connector

screw

(BVTT3

!™

(CN54)

×

6)

base (CDM)

AUDIO BOARD, MAIN BOARD

1

1

two screws

2

ring (A)

screw

(BVTP3

×

8)

5

two screws

(BVTT3

×

6)

3

connector

(CN 801)

8

two screws

(BVTT3

!¡

AUDIO board

9

4

MAIN board

6

transformer cove

×

6)

!º

connector

(CN201)

7

screw

(BVTT3

three screws

(BVTP3

×

10)

×

6)

– 8 –

Page 9

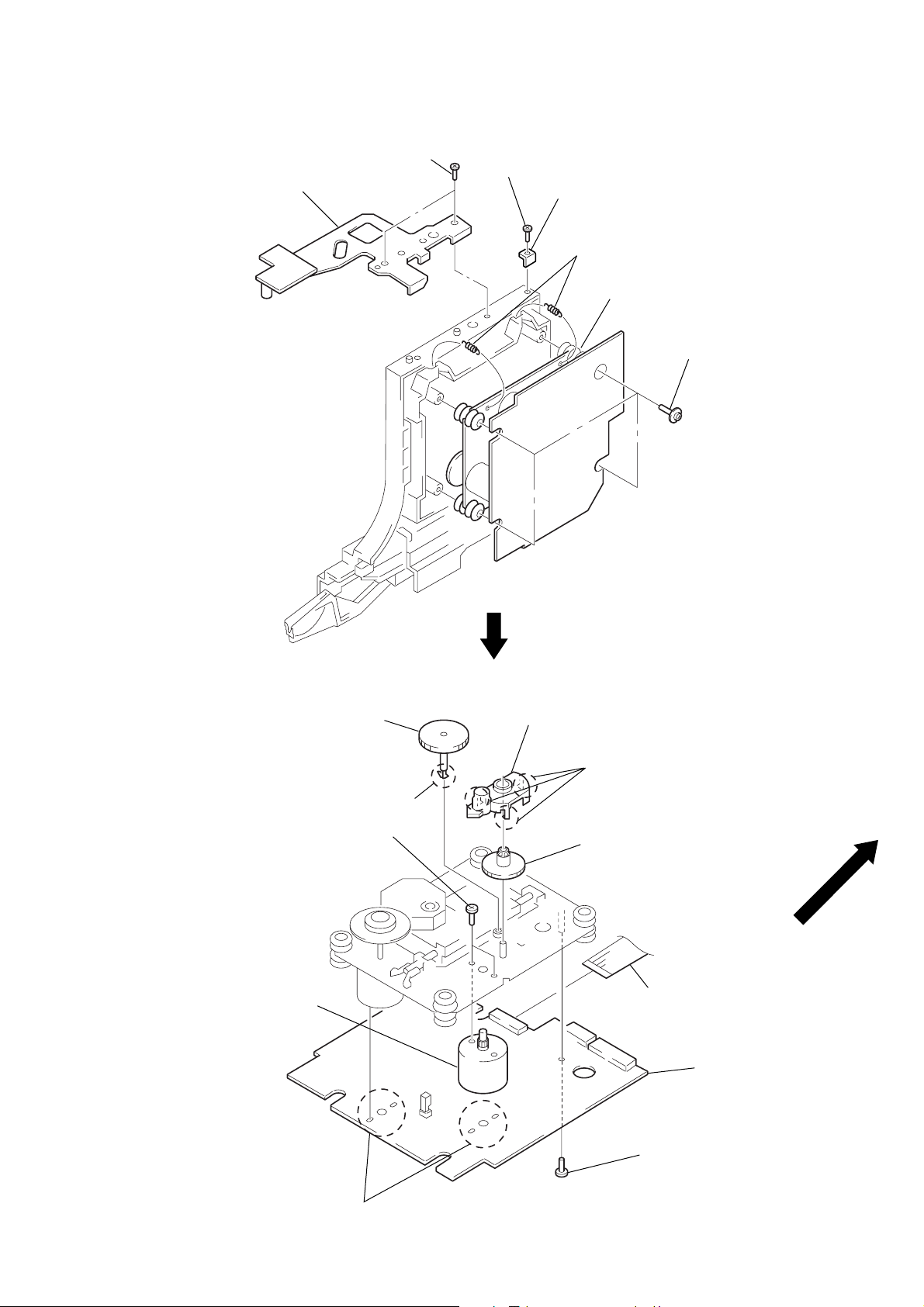

BASE UNIT

)

2

bracket

1

two screws

(BTP2.6

3

×

8)

screw

(BTP2.6

×

10)

4

reinforcement (small)

5

two tention springs

7

base unit

6

four screws

(PTPWH2.6

×

8

BD BOARD, SLED MOTOR (M102)

6

gear (A) (S)

0

two screws

×

3)

(2

!¡

sled motor

(M102)

5

claw

8

gear cover

7

three claws

9

gear (B) (RP)

1

wire (flat type) (16 core)

(CN101)

4

BD board

3

Removal

four solders.

– 9 –

2

screw

(B2

×

5)

Page 10

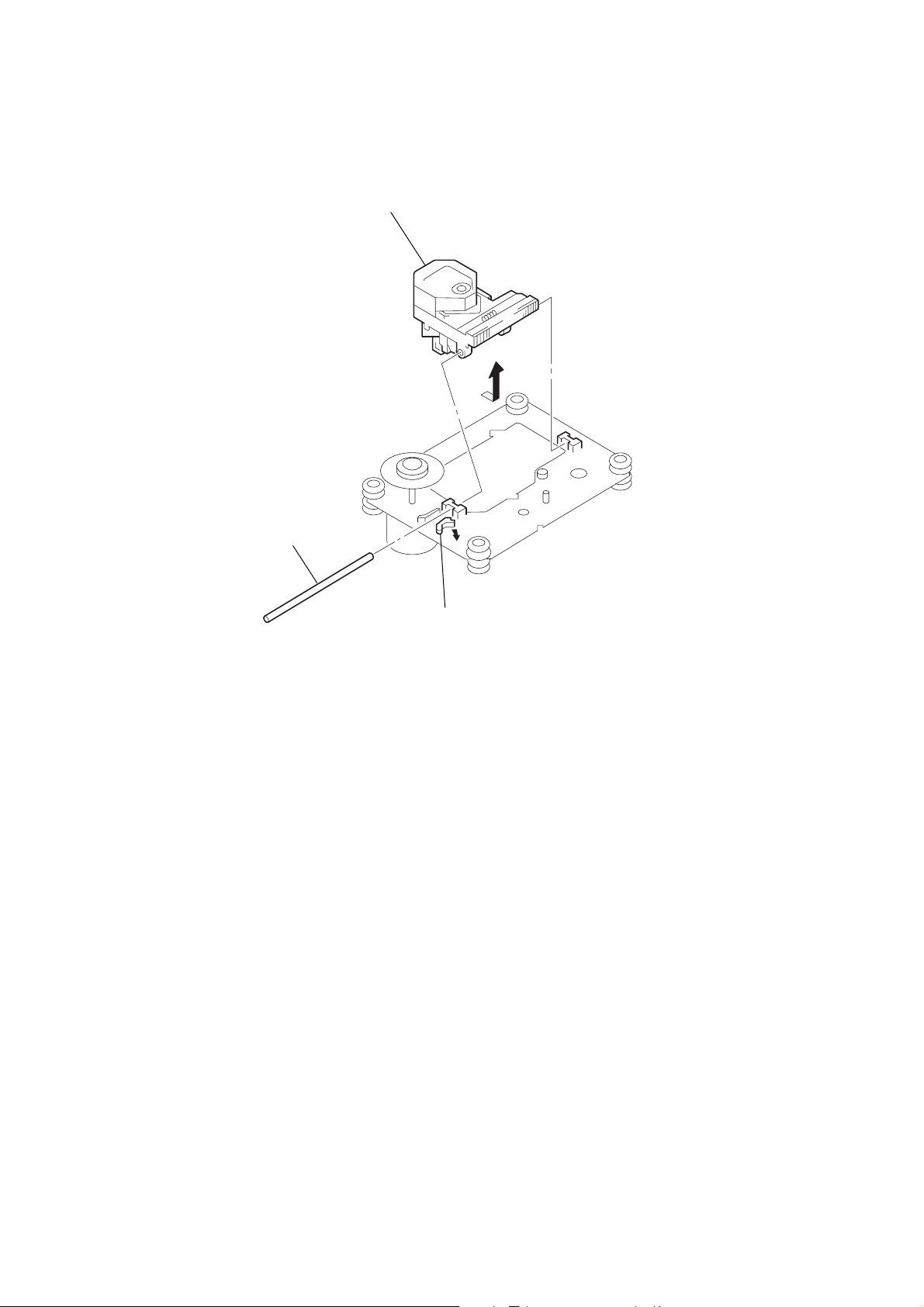

OPTICAL PICK-UP (KSS-213B/S-N)

3

Remove the optical

pick-up to direction

of the arrow

2

sled shaft

A

.

A

1

claw

– 10 –

Page 11

SECTION 4

r

TEST MODE

ADJ MODE

1. Press the I/u button to turn ON the power, and open the front

cover .

2. Place the CD on the slit, close the front cover, and chuck the

the CD.

3. Press the I/u button to turn OFF the power.

4 Disconnect the power supply from the outlet.

5. Short-circuit the test point (TP ADJ) and test point (TP GND)

of the MAIN board with a lead wire.

6. Insert the power plug into the outlet.

The CD is played back automatically and the ADJ mode is set.

• Prohibits high speed search during accessing

• Ignores even if GFS becomes L

ADJ Mode Special Function Table

(The buttons shown in the ( ) function only when the remote

commander provided is used.)

Button Function

(3)

Tracking servo, sled servo OFF

(8)

Tracking servo, sled servo ON

CHECK

CLEAR

Observation mode during S

Automatic eccentricity measurement (Not used for servicing)

Display of special functions in ADJ mode

• Observation mode during S

When this mode is set, the below will be displayed. *1

*1

ALL DISCS

CD1

S-JI mode

• Automatic eccentricity measurement (Not used for servicing)

When this mode is set, the below will be displayed.The

Sokuteichu count down display will be counted down from 4 to

to 1 *2.After counting down, the eccentricity value will be

displayed *3.

*2

ALL DISCS

DISC

CD1

TRACK

MIN

NEXT

DISC

SEC

Sokuteichu -4

Sokuteichu count down display

FLUORESCENT INDICATOR TUBE, LED ALL LIT,

AND KEY CHECK MODE

1. Short-circuit the test point (TP ADJ) and test point (TP AF ADJ)

of the MAIN board with a lead wire.

2. Insert the power plug into the outlet. The whole fluorescent

indicator tube lights up.

When the SRAM is faulty, “SRAMNG” will be displayed.

3. Pressing the I/u button sets the key check mode.

All buttons have individual button numbers.

When a button is pressed, the button number is counted up

and displayed.

1 DISCS

CD1

DISC

** **

Count up display Displays button numbe

Buttons and Corresponding Button Numbers

Button Button Number or Display

CLEAR

CHECK

FADER

MEMO SEARCH

INPUT

TIME/TEXT

PUSH ENTER

±

≠

REPEAT

PLAY MODE

I/u

X-FADE

NO DELAY

GROUP 5

GROUP 4

GROUP 3

GROUP 2

GROUP 1

GROUP FILE

PUSH OPEN

(DOOR SW ON)

0

1

2

3

4

5

6

8

9

14

15

16

17

18

24

25

26

27

28

29

STANDBY LED OFF

*3

ALL DISCS

CD1

Henshin 021

Eccentricity value

– 11 –

PUSH OPEN

(DOOR SW OFF)

·

P

p

PLUS ONE

MEGA CONTROL

DISC/CHARACTER

STANDBY LED ON

All lit (LED lights up)

Partially lit 1 (LED lights up)

Partially lit 2

LED lights up

Partially lit 3 (LED lights up)

Partially lit 4

Each time JOG is rotated, GROUP FILE 1 2 3 4

5 is displayed on the fluorescent indicator tube,

and 1, 2, 3, 4, 5 light up one by one, and GROUP

LED 1, 2, 3, 4, 5 lights up one by one.

Clockwise : GROUP FILE 1n2n3n4n5

Counterclockwise : GROUP FILE

5n4n3n2n1

Page 12

Partially lit 1

1 DISCS

CD1

G

A B C D E F

Partially lit 2

1 DISCS

CD1

Partially lit 3

1 DISCS

2nd

**

Partially lit 4

1 DISCS

**

FLUORESCENT INDICATOR TUBE AND LED

CHECK MODE

This mode is set by pressing the I/u button while pressing the

[CHECK] and [PLUSONE] buttons in order in the power-off

(standby) state.

The whole fluorescent indicator tube lights up, and the

[MEGACONTROL], [GROUP1-5], [PLUSONE], · and

P LEDs light up.

This mode can be exited by pressing the I/u button.

SHIPMENT MODE

(Set to this mode when returning the unit to the

user.)

This mode is set by pressing the I/u button while pressing the

[PUSHENTER] and [PLUSONE] buttons in order in the power -

off (standby) state.

The power goes off automatically after the SRAM is all-erased

and the BD is opened (loading out state).

CD1

CD1

GROUP FILE

1

[STANDBY],

AGING MODE

• Mode which repeatedly changes and plays back discs automatically in the unit.

• It will repeat aging as long as no errors occur.

• If an error occurs during aging, it will stop all servos, motors,

etc. instantaneously, display the error number, and stop oper ations. However, the stopping conditions differ according to

whether the unit is equipped with the “self-protection function

during errors” described later.

The function serves to maintain the state of the unit when errors

occur.

Sequence of Aging Mode

$

1. Disc change

$

2. Load in

$

3. TOC read

$

4. Access of last track

$

5. 3 second playback

$

6. Access of first track

$

7. 3 second playback

$

8. Load out

$

* DISC No. 40 chucks twice during one cycle.

To differentiate, the “

fluo rescent indicator tube will light up during the second

chucking.

Special Functions in Aging Mode

Order of Disc Change

(1 cycle takes 3 minutes)

$

1. No. 51

$

2. No. 20

$

3. No. 40

$

4. No. 30

$

5. No. 10

$

6. No. 40*

$

[2nd]” on the block indicator of the

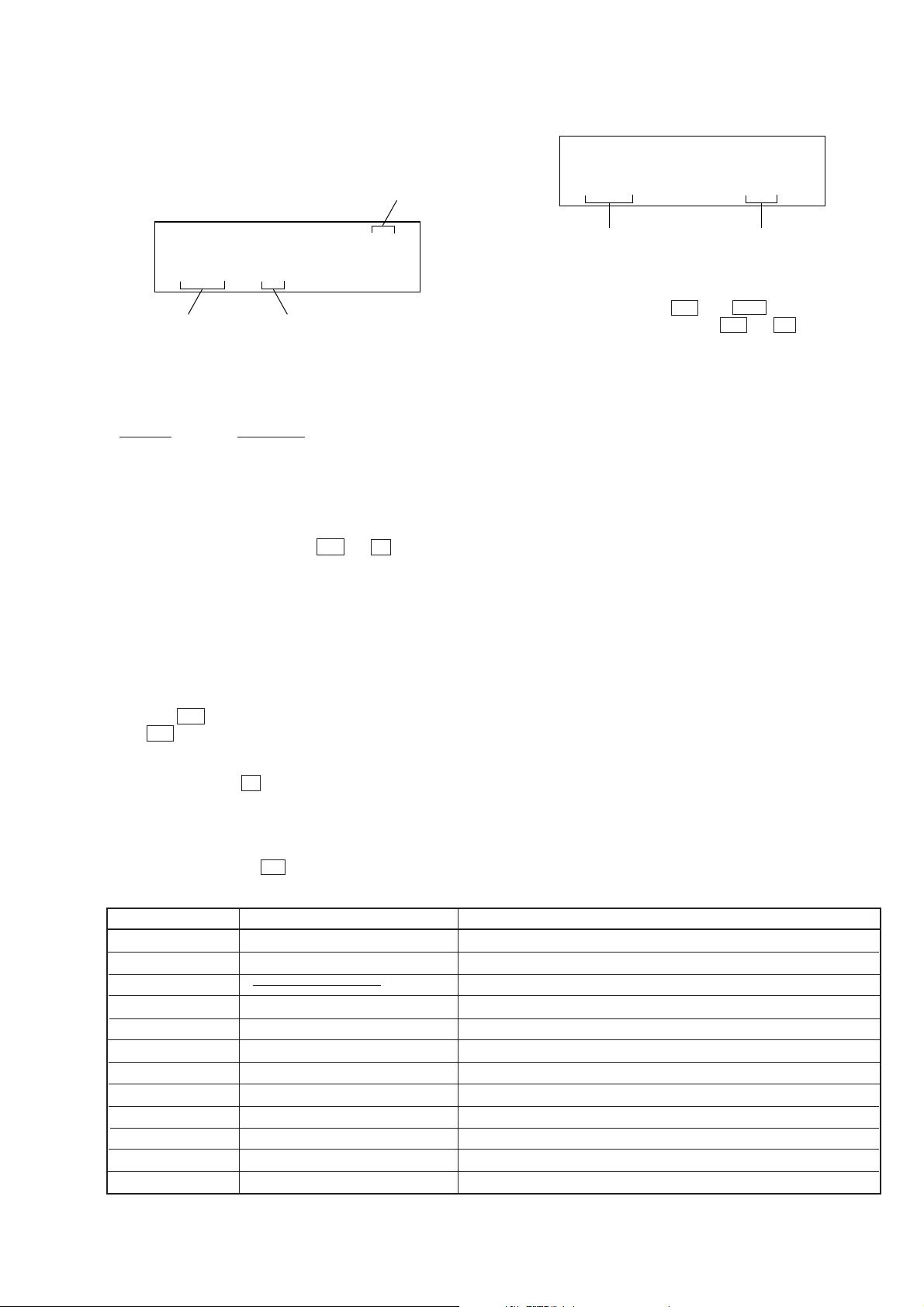

Test points and connecting points:

[MAIN BOARD] – CONDUCTOR SIDE –

TP

(GND)

R505

TP

(AFADJ)

IC201

CN704 CN702

R504

TP (ADJ)

IC501

There are some useful function in the aging mode.

• Disc setting mode*1

• Switching of use/disuse of protection function in errors *2

• Aging cycle count function *3

*1 Disc setting mode:

5 discs are set before setting the aging mode. This mode makes

the setting of these discs more easy.

*2 Switching of use/disuse of protection function in errors:

Function which voluntarily corrects errors which occur during normal operations by retries.

If this function is not provided, all operations will be stopped

without retiring. It is suitable for checking errors with low reproducibility.

If this function is provided, and errors can be corrected by

retries, aging will be continued without stopping.

(The normal aging should be performed with “be”.)

– 12 –

Page 13

*3 Aging cycle count function:

)

Functions which displays the number of agings carried out on

the Fluorescent indicator tube in numbers. One aging cycle

consists of six discs.

Aging carried

(Hexadecimal

Error Display

1 DISCS

DISC

40

CD1

1Err*01

1

1 DISCS

DISC

51 1

Disc number

CD1

TRACK

Track number

1

MIN

SEC

0.02

Aging procedure:

Some operating method will be changed depending on if the following jig for the aging mode exists or not.

• Jig

Parts. No Description

J-2501-123-A Remote commander (For aging mode)

With remote commander for aging mode:

1. Turn ON the power of the unit. Open the front cover.

2. Press the [AGINGSTART] button of the remote commander for

aging mode.

3. When the disc set mode is set, the · and P LEDs blink.

4. Rotate the JOG dial. The slits (No. 10, 20, 30, 40, 51) for setting

the discs will come forward. Insert the discs into these slits. Do

not set the discs in other slits.

5. Set the use/disuse of the self protection function in errors. Press

the

[REPEAT] button. When REPEAT is displayed on the fluo-

rescent indicator tube, the self protection function during the

error will become “Use”.

If the REPEAT display is OFF, it means that the function is not

used. (Normally set to “Use” when performing aging.)

6. Press the · button.

7. The · LED blinks, the aging mode is set, and aging is started.

8. The aging cycle lasts 3 minutes. When problems occur during

aging, the error number will be displayed on the fluorescent indicator tube, and the P LED will light up.

(Refer to the following table for the details of the errors.)

9. Aging will be repeated as long as no errors occur.

10. After each aging cycle, the number displayed on the Fluores-

cent indicator tube will increase.

11. To end aging, press the I/

u button

Disc number Error code

Without remote commander for aging mode:

1. Turn ON the power of the unit. Open the front cover.

2. Press the

[PLAYMODE], · , and ≠ buttons in order.

3. When the disc set mode is set, the · and P LEDs blink.

The following procedure is the same as in the case “With remote

commander for aging mode”.

Error code

Code number

Err 01

Err 02

Err 03

Err 04

Err 05

Err 06

Err *1

Err *2

Err *3

Err *4

Err *5

Err *6

The * numbers mean the following according to the state of the unit during aging

2 : From checking to end of TOC read

3 : From end of TOC read to end of last track playback

4 : From end of last track playback to end of first track playback

DISC sensor check 1

DISC sensor check 2

Table operation check 2

Loading operation check 1

Loading operation check 2

BU related check 1

BU related check 2

BU related check 3

BU related check 4

BU related check 5

BU related check 6

Name

No disc in the specified slit

Disc in other slits

No function

No table sensor input

Load in timeover

Load out timeover

Access timeover

High speed search NG

Q data read error

BU operation (From focus search to until signal can be read) timeover

GFS monitor error

Focus cannot be imposed by focus search

– 13 –

Contents

Page 14

SECTION 5

MECHANICAL ADJUSTMENTS

To adjust the mechanism section, enter the mechanism section adjustment mode.

For how to enter the mechanism section adjustment mode, refer to each adjustment section.

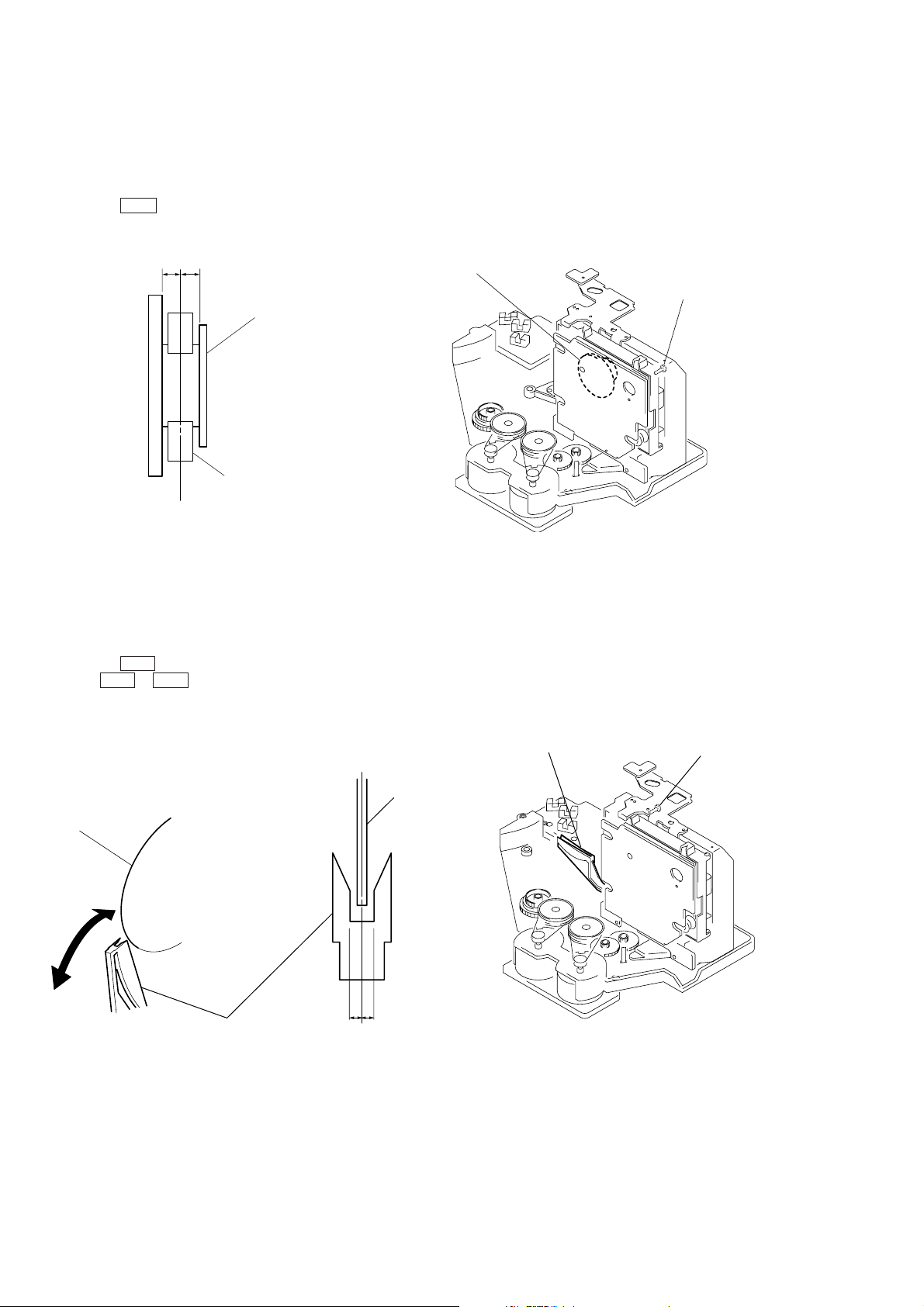

DISC SENSOR ALIGMENT

1. Make sure that there is no disc in the unit.

2. Connect an oscilloscope to TP501 of the MAIN board.

oscilloscope

MAIN board

TP501

3. While pressing the

I/

u

button

GND

HHOUT

D.SENS

D.SENS (CH1)

HHOUT (CH2)

GND

[CLEAR] and [PLUSONE] buttons at the same time and turn ON the power.

CHECK button

CLEAR button

±

PLUS ONE button

≠

button

button

4. The fluorescent indicator tube shows as follows, and the mechanism section adjustment mode is set.

Lit according to rotational direction

DISC No.

ALL DISCS

CD1

DISC

51

SEC

73** .

P

ª

PLUS ONE

Blinks

5. The disc table rotates in the clockwise direction. The disc table rotation time is displayed with ‘’PLUS ONE” slit as a measu ring point.

6. Press the

[CLEAR] button, to be rotated the disc table counterclockwise.

7. Measure the waveform of the oscilloscope when the disc table is rotating.

– 14 –

Page 15

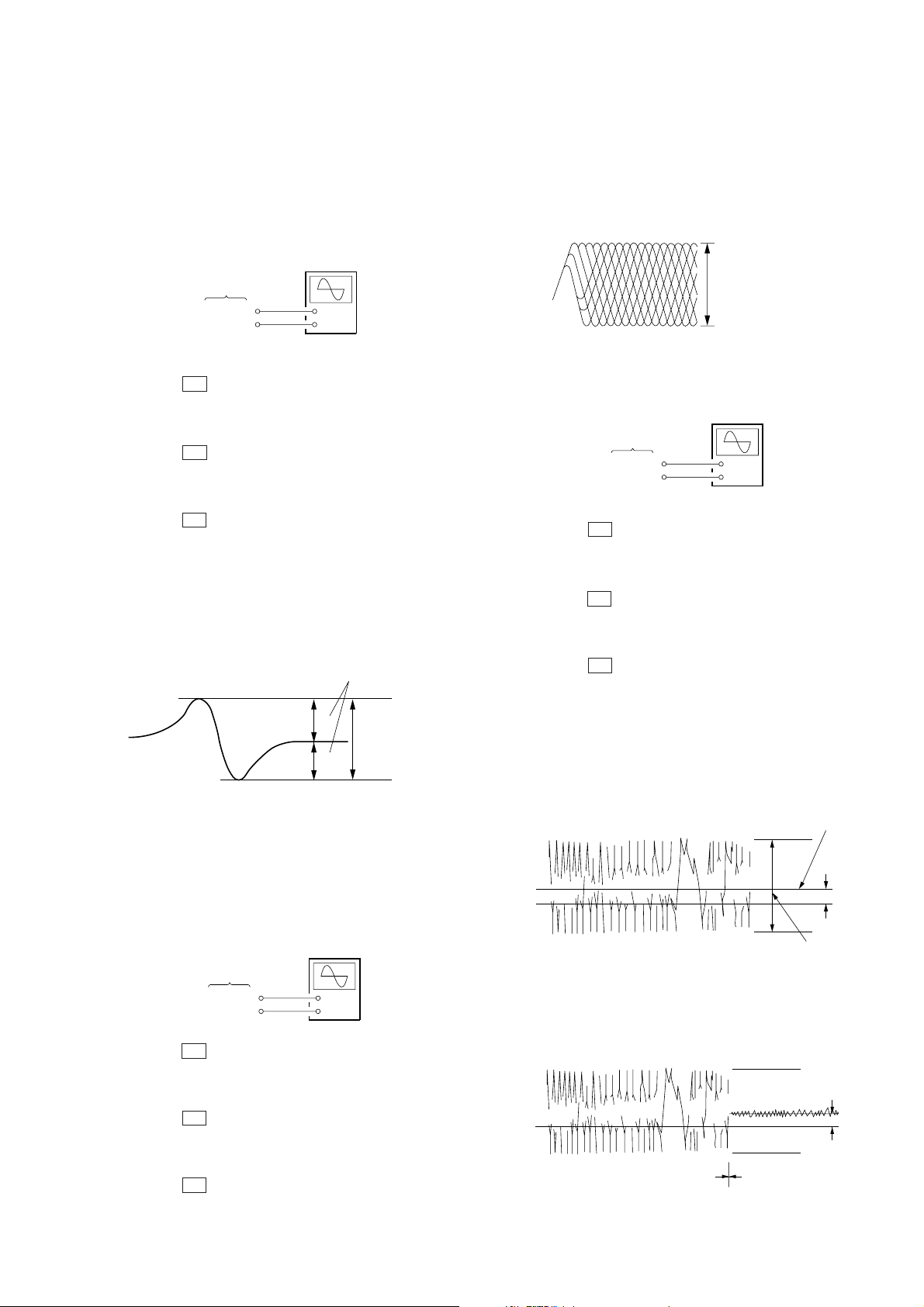

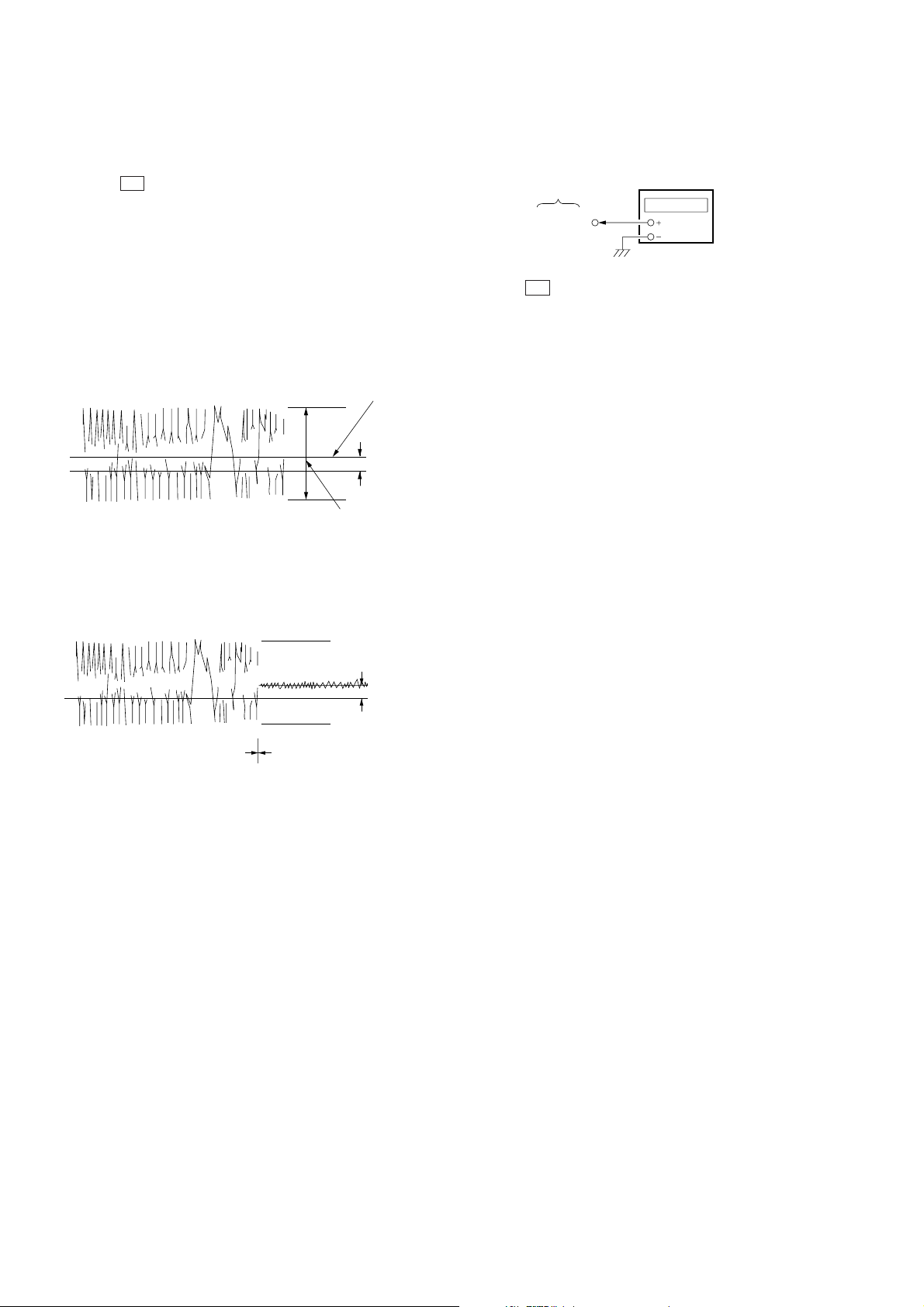

8. Mo ve the holder (sensor) center so that the flat portion center at the top of the D.SENS (CH1) input waveform and the ‘’H” center of

HHOUT (CH2) coincide.

Flat portion center of

HHOUT (CH2) waveform

D.SENS (CH1) waveform

Fixed screw

D. SENS (CH1) waveform

Holder (sensor)

9. Tighten the fixed screw to fix the disc table, then press the

[CLEAR] button.

10. The disc table rotates in the clockwise direction. Measure the waveform and make sure that the flat portion center at the top of the

D.SENS (CH1) input waveform and the ‘’H” center of HHOUT (CH2) conform.

Note: During the adjustment mode, the rotational direction is switched each time the [CLEAR] button is pressed.

Pressing the [CHECK] button enters the loading mode which will be described later. Pressing the [CLEAR] button rotates the disc table again.

Contets of the fluorescent indicator tube's display in the loading mode

ALL DISCS

ON IN OFF

Loading OUT

SW condition

CD1

DISC

51

Loading

direction

Loading IN

SW condition

– 15 –

Page 16

MAGNET ASSY ALIGMENT

)

)

1. Check that there is no disc in the unit and then turn ON the power. Open the door, and set a disc in the PLUS ONE slit.

2. Turn OFF the power, close the door, and while pressing the [CLEAR] and [PLUSONE] buttons simultaneously, turn ON the power

again.

3. Press the

4. Press the ± button and chuck the disc.

5. Adjust the magnet assembly and magnet holder so that A=B as shown in the figure.

[CHECK] button, and set the loading mode.

A B

Magnet ASSY

Magnet holder

Magnet ASSY

Screw (For adjustment

DISC HOLDER A ALIGMENT

1. Check that there is no disc in the unit and then turn ON the power. Open the door, and set a disc in the PLUS ONE slit.

2. Turn OFF the power, close the door, and while pressing the [CLEAR] and [PLUSONE] buttons simultaneously, turn ON the power

again.

3. Press the

4. Press the ± button and chuck the disc.

5. Press ≠ or ± button to stop the disc holder A slightly away from the disc.

6. Rotate and adjust the adjusting screw so that the center of the disc and that of the disc holder coincide.

[CHECK] button, and set the loading mode.

Disc

Disc holder A

a b

a = b

Disc

Disc holder A

Screw (For adjustment

– 16 –

Page 17

SECTION 6

Center of the

waveform

Traverse waveform

B

A (DC voltage)

0 V

level: 0.9

±

0.45 Vp-p

)

ELECTRICAL ADJUSTMENTS

Note :

1. CD Block is basically designed to operate without adjustment. Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent when the

signal level is low than specified value with the following checks.

S Curve Check

oscilloscope

BD board

TP (FE)

TP (VC)

+

–

Procedure :

1. Press the I/u button and turn ON the power supply.

2. Open the front cover, and press the

[PLUSONE] button.

3. Set the disc (YEDS-18) into the “PLUS ONE” slit.

4. Close the front cover, and chuck the disc.

5. Press the I/u button and turn OFF the power.

6. Connect the oscilloscope to TP (FE) of the BD board.

7. Connect TP (ADJ) of the MAIN board and connect TP (GND)

with a lead wire.

8. Press the I/u button and turn ON the power.

9. The first track will be played back automatically. When the

[CHECK] button is pressed, “S-JI mode” will be displayed on

the fluorescent indicator tube, and focus search will be repeated.

10. Check the oscilloscope waveform (S-curv e) is symmetrical be-

tween A and B. And confirm peak to peak level within 1.8 ±

0.6 Vp-p.

S-curve waveform

symmetry

A

B

within 1.8

±

0.6 Vp-p

11. Turn OFF the power, and remove the lead wire connected at

step 7.

Note : A clear RF signal waveform means that the shape “◊” can be

clearly distinguished at the center of the waveform.

RF signal waveform

VOLT/DIV : 200 mV

TIME/DIV : 500 ns

level: 1.8 Vp-p

+0.3

–0.2

E-F Balance (Traverse) Check

The procedure for this checking method differs for when a general remote control unit is used and not used.

oscilloscope

BD board

TP (TE)

TP (VC)

+

–

When a general remote commander is used:

1. Press the I/u button and turn ON the power supply.

2. Open the front cover, and press the

[PLUSONE] button.

3. Set the disc (YEDS-18) into the “PLUS ONE” slit.

4. Close the front cover, and chuck the disc.

5. Press the I/u button and turn OFF the power.

6. Connect the oscilloscope to TP (TE) of the BD board.

7. Connect TP (ADJ) of the MAIN board and connect TP (GND)

with a lead wire.

8. Press the I/u button and turn ON the power.

9. Playback the fifth track of the disc.

10. Press the

[3] button on the remote commander. (The tracking

servo and the sledding servo are turned OFF.)

11. Check the level B of the oscilliscope's waveform and the A

(DC voltage) of the center of the Traverse waveform.

Confirm the following :

A/B x 100 = less than ± 10%

11. Turn OFF the power, and remove the lead wire connected at

step 7.

Note : • Try to measure several times to make sure than the ratio of A

: B or B : A is more than 10 : 7.

• T ake sweep time as long as possible and light up the br ightness

to obtain best waveform.

RF Level Check

oscilloscope

(AC range)

BD board

TP (RF)

TP (VC)

+

–

Procedure :

1. Press the I/

u button and turn ON the power supply.

2. Open the front cover, and press the [PLUSONE] button.

3. Set the disc (YEDS-18) into the “PLUS ONE” slit.

4. Close the front cover, and chuck the disc.

5. Press the I/u button and turn OFF the power.

6. Connect the oscilloscope to TP (RF) of the BD board.

7. Connect TP (ADJ) of the MAIN board and connect TP (GND)

with a lead wire.

8. Press the I/u button and turn ON the power.

9. Playback the fifth track of the disc.

10. Confirm that oscilloscope waveform is clear and check RF

signal level is correct or not.

12. Press the [8] button on the remote control unit. (The tracking

servo and sledding servo are turned ON.) Confirm the C (DC

voltage) is almost equal to the A (DC voltage) is step 11.

Traverse waveform

0 V

Tracking servo

Sled servo

OFF

Tracking servo

Sled servo

ON

13. Turn OFF the power, and remove the lead wire connected at

step 7.

– 17 –

C (DC

voltage

Page 18

When a general remote commander is not used:

)

r

1. Solder lead wires to TP (DVDD) and TP (TOFF) on the BD

board severally.

2. Connect the oscilloscope to TP (TE) of the BD board.

3. Press the I/u button and turn ON the power supply.

4. Open the front cover, and press the

[PLUSONE] button.

5. Set the disc (YEDS-18) into the “PLUS ONE” slit.

6. Close the front cover, and chuck the disc.

7. Playback the fifth track of the disc.

8. Short-circuit the lead wire connected at step 1. (The tracking

servo is turned OFF)

9. Check the level B of the oscilliscope's waveform and the A

(DC voltage) of the center of the Traverse waveform.

Confirm the following :

A/B x 100 = less than ± 10%

Traverse waveform

Center of the

waveform

RF PLL Free-run Frequency Check

Procedure :

1. Connect the frequency counter to TP (PCK) of the BD board.

frequency counte

2. Press the I/

BD board

TP (PCK)

u button and turn ON the power supply.

3. Open the front cover, and press the [PLUSONE] button.

4. Set the disc (YEDS-18) into the “PLUS ONE” slit.

5. Close the front cover, and chuck the disc.

6. Playback th e fifth track of the disc.

7. Confirm that reading on frequency counter is 4.3218 MHz ±

30 kHz.

B

0 V

A (DC voltage

level: 1.3 ± 0.5 Vp-p

10. Disconnect the lead wire short-circuited at step 8. (The tracking servo is turned ON.) Confirm the C (DC voltage) is almost

equal to the A (DC voltage) is step 8.

Traverse waveform

C (DC

0 V

Tracking servo

OFF

Tracking servo

ON

voltage)

11. Turn OFF the power, and remove the lead wire connected at

step 1.

About RV601 on the MAIN board

RV601 of the MAIN board requires no adjustments. Please note

that it should be dixed to mechanical center position when you

moved and do not know origin position.

– 18 –

Page 19

Adjustment Location :

[ BD BOARD ] — CONDUCTOR SIDE —

CN102

TP

(VC)

IC102

TP

(TOFF)

TP

(RF)

IC101

TP

(TE)

TP

(PCK)

TP

(DVDD)

TP

(FE)

[ MAIN BOARD ] — CONDUCTOR SIDE —

TP

(GND)

R504

R505

IC201

TP (ADJ)

IC501

CN103

CN101

[ MAIN BOARD ] — COMPONENT SIDE —

IC201

CN704 CN702

– 19 –

RV601

CN603

IC601

CN702 CN704

NO802

Page 20

• Circuit Boards Location

SECTION 7

DIAGRAMS

TABLE SENSOR board

LED board

DISC SENSOR (R) board

DISC SENSOR (S) board

MAIN board

POWER SW board

DISPLAY board

MOTOR board

AUDIO board

BD board

SW board

– 20 –

Page 21

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed in each block.)

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and

specified.

¢

•

: internal component.

1

4

/

W or less unless otherwise

• C : panel designation.

Note:

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part

number specified.

Note:

Les composants identifiés par

une marque ! sont critiques

pour la sécurité.

Ne les remplacer que par une

piéce portant le numéro

spécifié.

• U : B+ Line.

• V : B– Line.

• H : adjustment for repair.

• Voltages and waveforms are dc with respect to ground

under no-signal conditions.

no mark: PLAY

• Voltages are taken with a VOM (Input impedance 10 M Ω).

Voltage variations may be noted due to normal production tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

• Signal path.

J : CD

c : digital out

• Abbreviation

AED : North European

AUS : Australian model.

CND : Canadian model.

E2 : 120 V AC Area in E model.

E3 : 240 V AC Area in E model.

SP : Singapore model.

Note on Printed Wiring Boards:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

¢

•

: internal component.

• b : Pattern from the side which enables seeing.

• : Solder bridge.

• Indication of transistor.

Q

B

CE

These are omitted.

Q

B

CE

These are omitted.

– 21 –

Page 22

• Wavef orms

– BD Section –

1 IC101 $¡ (RFSM) (PLAY MODE)

2 IC101 @º (FE) (PLAY MODE)

+0.3

1.8 Vp-p

–0.2

560 mVp-p

6 IC102 ^º (16M)

6.2 Vp-p

16 MHz

7 IC102 ^¡ (4.2M)

5.4 Vp-p

4.2 MHz

3 IC101 7 (TE) (PLAY MODE)

4 IC102 @¡ (PCK)

230 ns

5 IC102 $¢ (XOUT)

– MAIN Section –

1 IC501 #™ (XTAL)

460 mVp-p

4.4 Vp-p

10 MHz

– DIAPLAY Section –

1 IC901 %• (OSC0)

6.2 Vp-p

2.3 Vp-p

480 ns

16.9344 MHz

3.6 Vp-p

– 22 –

Page 23

CDP-CX57

7-1. BLOCK DIAGRAMS

– BD SECTION –

DRF

PD

LASER

DIODE

OPTICAL PICK-UP BLOCK

(KSS-213B/S-N)

DETECTOR

E

A

B

SL–

SL+

B+

K

10

TRACKING

COIL

2-AXIS

DEVICE

MOTOR DRIVE

IC103 (2/2)

1

4

2

5

6

AUTOMATIC

POWER CONTROL

Q103

T+

–

T

–

F

F+

19

20

17

18

FIN1

2

FIN2

1

E

3

F

4

TE–

6

TE

7

FE

20

FE–

21

6263LDD

LDS

TRACKING

COIL DRIVE

FOCUS/TRACKING

COIL DRIVE

IC103 (1/2)

FOCUS

COIL DRIVE

SLED SERVO

IC101 (2/2)

FOCUS/TRACKING SERVO,

RF AMP

IC101 (1/2)

22

15

15

TO

16

FD

SPD

27

A

D

D

C

C

B

F

LD

FOCUS

COIL

SLED/SPINDLE

54

DRF

53

55

40

RCHO R-CH

LCHO

37

51

SBCK

SFSY

50

PW

49

SBSY

47

60

16M

42

MUTER R-CH

MUTEL

35

31

DOUT

45

XIN

44

XOUT

27

CONT4

1

EXCK

WFCK

4

2

SBSO

SCOR

3

MCK

5

X101

16.9344MHz

CD-TEXT DECODER

IC104

S101

(LIMIT IN)

DQSY

SRDT

SCLK

XMODM

13

12

11

6

RFSM

DAT

CLK

DEF

SLI

SLC

CV+

CV–

SLOF

HFL

TES

TOFF

TGL

JP+

JP–

EFMIN

41

53

CE

CL

51

52

50

49

44

43

40

39

38

37

36

35

34

33

32

10

54

RWC

CQCK

57

COIN

56

4.2M

61

DEFI

1

9

EFMO

12

CLV+

CLV–

13

V/P

14

HFL

15

TES

16

17

TOFF

TGL

18

JP+

19

JP–

20

CONT2

25

CLV SERVO PROSESSOR,

D/A CONVERTER

WRQ

DIGITAL SIGNAL

PROCESSOR,

DIGITAL FILTER,

IC102

CONT326RES

SQOUT

58

TGL

COIN

CQCK

RWC

WRQ

SQOUT

LOUT

DQSY

SRDT

SCLK

XMODE

MUTEL

DOUT

B

(Page 25)

A

(Page 25)

M102

SLED MOTOR

M101

SPINDLE

MOTOR

05

7

M

•

8

SLED MOTOR

DRIVE

SL–

10

SLD

29

SL+

30

31

SLED MOTOR

DRIVE

Q101, Q102

• Rch is same as Lch.

• Signal Path

5

•

6

SPINDLE MOTOR

DRIVE

MUTE

2

3

RST

– 23 –

– 24 –

M

: CD

: CD (digital)

Page 24

– MAIN SECTION –

CDP-CX57

A

(Page 24)

B

(Page 24)

LOUT

RST

MUTEL

DOUT

XMODE

SCLK

SRDT

DQSY

RWC

WRQ

DRF

COIN

SQOUT

CQCK

SL+

SL–

TGL TGL

LOW-PASS FILTER

DIGITAL OUT

OPTICAL

IC701

LINE AMP,

IC301,401

MUTING

MEGA CONTROL

MUTING SWITCH

532

T501

MIX AMP

IC302

Q331

Q381

RESET

SIGNAL GENERATOR

IC201(1/2)

VF1

VF2

MUTING CONTROL

61

XMODE

51

SCLK

52

SRDT

60

DQSY

58

RWC

55

WRQ

54

DRF

50

COIN

49

SQOUT

48

CQCK

SL+

47

SL–

59

57

60

RESET

1

•

VF1

3

63

•

VF2

65

L

R-CH

POWER ON

MUTING

Q301

POWER ON

SWITCH

Q380

RESET

SWITCH

Q501

FLLT

22 26 27 21 20 42 25

61

CS(FLLT)

6-30,41-31

FL901 FLUORESCENT INDICATOR TUBE

MUTING

Q302

R-CH R-CH

MUTING

CONTROL

SWITCH

Q304

D304

29

FLCK

FLDT

CP(FLCK)

DA(FLDT)

P36

P36

MUTING CONTROL

SWITCH

Q383

ICSW

FL DRIVE

IC901

1G

40

BUFFER

Q901

60

1G

MUTING

DRIVE

Q305

62 63

|

P1

39-4 41-55

|

P1

MUTING

MUTING

CONTROL

SWITCH

2G

59-45

2G

Q303

Q382

28

|

|

ZMUTE

16G

16G

R-CH

LDOUT

LDIN

TBLL

TBLR

17-13

D904-908

R

L

R

15

14

16

17

478 6

FLDT

FLCK

LED DRIVER

IC903

|

QJ

QN

LINE OUT

2ND CD IN

LEDL

LEDT

|

QI

18-20,23,24

LED DRIVE

Q902-907

J301

LOADING/TABLE

3

2

16

17

RST

QC

QG,

QD,

MOTOR DRIVE

IC601

LOADING

MOTOR

DRIVE

TABLE

MOTOR

DRIVE

HHOUT

8

9

10

11

FLAG SENSOR

D.SENS

TP501

DISC

SENSOR

DISC SENSOR

Q51

M61

M

LOADING

MOTOR

M62

M

TABLE

MOTOR

DISC TABLE

IC51

62 63 64

T.SENS1

1

2

3

FLAG SENSOR

DOORSW

S925

PUSH OPEN

DISC TABLE

IC52

T.SENS2

JOG1

23 24 38 39 40 56

1 3

OPEN

CLOSE

JOG

RE901

DISC/CHARACTER

PUSH ENTER

DISC SENSOR

D841-D843

DISC TABLE

HOME POSITION

SENSOR

IC53

JOG2

5

D51

S51

(DOWN)

S52

(UP)

T.SENS3

65

66

KEY0

KEY1

KEY MATRIX

S901-S924

(FOR BD)

|

A0

A14

10-13, 25-23,

21,2,26,1

78-80, 1-5,

11-8,6,12,7

|

A0

A14

DOWNSW

UPSW

KEY241KEY3WERMIN

1

REMOTE

CONTROL

RECEIVER

IC902

+5V

+7V

+5V

71

31

31

S-RAM

IC502

WE

27

13 30

SYSTEM CONTROLLER

+5V REGULATOR

IC201(2/2)

+7V REGULATOR

+5V REGULATOR

IC203(2/2)

D0|D7

11-13,15-19

75-77,68-71

D0|D7

IC501

–30V

IC202

CE

20

–30V REGULATOR

Q201

–12.4V

RESET SWITCH

Q502

RESET

CD1/2/3

BUSOUT

FL901

D201, D202

D203, D204

SIGNAL GENERATOR

IC203 (1/2)

43

BUSIN

46

45

31

EXTAL

32

XTAL

VF1

VF2

RECT

D205

RECT

RECT

RESET

8

CD3

CD2

CD1

AU BUS

BUFFER

Q701

X501

10MHz

T501

POWER

TRANSFORMER

SELECTOR

E MODEL

• Rch is same as Lch.

• Signal path

: CD

: CD (digital)

COMMAND MODE

VOLTAGE

S201

S701

J701

S-LINK

CONTROL A1

AC IN

D901-903,

909-911

05

– 25 –

– 26 –

Page 25

CDP-CX57

• Semiconductor

Location

Ref. No. Location

D151 D-1

IC101 D-3

IC102 B-3

IC103 B-1

IC104 B-2

Q101 B-4

Q102 B-4

Q103 E-1

7-2. PRINTED WIRING BOARD – BD Section –

• See page 20 for Circuit Boards Location. • See page 21 for Note.

(Page 35)

(Page 36)

– 27 –

– 28 –

Page 26

7-3. SCHEMATIC DIAGRAM – BD Section –

• See page 22 for Waveforms. • See page 46 for IC Block Diagrams. • See page 49 for IC Pin Function Description. • See page 21 for Note.

CDP-CX57

• no mark: PLAY

• Signal path.

J : CD

c : digital out

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part number specified.

– 29 –

Les composants identifiés par une marque ! sont

critiques pour la sécurité. Ne les remplacer que

par une piéce portant le numéro spécifié.

(Page 38)

(Page 38)

– 30 –

Page 27

CDP-CX57

7-4. PRINTED WIRING BOARD – AUDIO Section –

• See page 20 for Circuit Boards Location. • See page 21 for Note.

(Page 35)

• Semiconductor Location

Ref. No. Location

D201 C-5

D202 C-5

D203 C-5

D204 D-5

D205 B-5

D701 A-7

IC301 B-8

IC302 B-7

IC401 C-7

IC402 C-6

Ref. No. Location

IC701 A-8

Q301 B-7

Q302 B-7

Q303 A-6

Q331 C-7

Q401 B-6

Q402 B-7

Q403 B-6

Q431 C-7

Q701 A-7

(Page 44)

(Page 36)

(Page 36)

– 31 –

– 32 –

Page 28

7-5. SCHEMATIC DIAGRAM – AUDIO Section –

• See page 21 for Note.

(Page 45)

(Page 38)

CDP-CX57

(Page 38)

(Page 38)

• no mark: PLAY

• Signal path.

J : CD

c : digital out

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part number specified.

– 33 –

Les composants identifiés par une marque ! sont

critiques pour la sécurité. Ne les remplacer que

par une piéce portant le numéro spécifié.

– 34 –

Page 29

CDP-CX57

• Semiconductor

Location

Ref. No. Location

D206 E-2

D207 D-2

D210 C-1

D211 C-1

D212 C-1

D304 E-1

D382 D-1

D404 E-1

D501 C-4

IC201 C-2

IC202 B-1

IC203 A-4

IC501 B-4

IC502 D-4

IC601 E-4

Q201 E-2

Q304 E-1

Q305 A-1

Q380 C-1

Q381 D-1

Q382 D-1

Q383 E-1

Q404 E-1

Q405 B-1

Q481 C-1

Q501 D-3

Q502 D-3

7-6. PRINTED WIRING BOARD – MAIN Section –

• See page 20 for Circuit Boards Location. • See page 21 for Note.

(Page 32) (Page 28)

(Page 43)

(Page 28)

(Page 32)

(Page 44)

(Page 39)

(Page 43)

(Page 43)

(Page 32)

– 35 –

– 36 –

Page 30

7-7. SCHEMATIC DIAGRAM – MAIN Section –

• See page 22 for Waveform. • See page 47 for IC Block Diagrams. • See page 53 for IC Pin Function Description. • See page 21 for Note.

CDP-CX57

(Page 45)

(Page 45) (Page 41)

(Page 30)

(Page 45)(Page 30)

(Page 33)

(Page 33)

(Page 45)

(Page 33)

• no mark: PLAY

• Signal path.

J : CD

c : digital out

– 37 –

– 38 –

Page 31

CDP-CX57

7-8. PRINTED WIRING BOARDS – PANEL Section –

• See page 20 for Circuit Boards Location. • See page 21 for Note.

(Page 36)

(Page 40)

– 39 –

• Semiconductor Location

(DISPLAY Board)

Ref. No. Location

D901 D-7

D902 D-6

D903 D-4

D904 D-5

D905 D-5

D906 D-4

D907 D-4

D908 D-3

Ref. No. Location

IC901 B-5

IC902 A-1

IC903 C-7

Q901 C-4

Q902 E-6

Q903 D-6

Q904 D-5

Q905 D-6

(Page 39)

– 40 –

Page 32

7-9. SCHEMATIC DIAGRAM – PANEL Section –

• See page 22 for Waveform. • See page 48 for IC Block Diagram. • See page 21 for Note.

CDP-CX57

– 41 –

(Page 38)

– 42 –

Page 33

7-10. PRINTED WIRING BOARDS – SENSOR/MOTOR Section –

•

See page 20 for Circuit Boards Location. • See page 21 for Note.

(Page 36)

(Page 36)

(Page 35)

– 43 –

Page 34

(Page 31)

(Page 36)

– 44 –

Page 35

7-11. SCHEMATIC DIAGRAM – SENSOR/MOTOR Section –

• See page 21 for Note.

CDP-CX57

(Page 37)

– 45 –

(Page 38)

(Page 37)

(Page 37)

(Page 33)

Page 36

• IC Block Diagrams – BD Board –

IC101 LA9241M

VCC1

LDS

FIN2

FINI

TE-

TESI

SCI

TD-

LDD

64

1

2

3

E

4

F

TB

5

6

TE

7

8

9

10

TH

11

TA

12

13

TD

14

JR

TO

15

FD

16

62 61 60 59 55 54 53 52 51 50 49

63

APC

I / V

BAL

+

TE

-

T. SERVO & T. LOGIC

- +

BHI

PHI

RF DET

VCA

VCA

F. SERVO & F. LOGIC SPINDLE SERVO SLED SERVO

+ -

+

-

FD-

+ -

191817

20

FE

FA

FA-

IC102 LC78622E

LF2

2221

FE-

AGND

VR

REFI

58 57 56

REF

µ-COM

INTERFACE

23

SP

SPI

VCC2

+ -

SPG

SP-

FSS

DRFCEDATCLCLK

27262524

SPD

SLEQ

2928

LSC

RF AMP

+

-

30

SLD

DEF

48

NC

TBC

47

46

FSC

DGND

45

SLI

44

+ -

SLC

43

42

SL+

RFS-

41

RFSM

40

CV+

39

CV-

38

SLOF

37

HFL

36

TES

TOFF

35

34

TGL

33

JP+

32

JP-

+ -

31

SL-

DEFI

TAI

PDO

VVSS

ISET

VVDD

VSS

EFMO

EFMIN

TEST2

CLV+

CLV-

V / P

HFL

TES

TEST1CSTEST5

64

63 62 61 60 59 58 57 56 55 54 53 52 51 50 49

1

2

3

4

5

6

7

FR

8

9

10

11

12

13

14

15

16

SLICE LEVEL

CONTROL

VCO CLOCK OSCILLATION

CLOCK CONTROL

CLV

DIGITAL SERVO

SYNCRONOUS DETECTION

EFM DEMODULATION

SERVO

COMMANDER

4.2M

RES

TEST1

16M

ERROR DETECTION

FLAG PROTCESS

COCK

C1, C2

&

CORRECTION

GENERAL PORT

INTERFACE

OVERSAMPLING

DIGITAL FILTER

COIN

SQOUT

RWC

µCOM

MUTE

DIGITAL

ATTENUATOR

WRQ

FSX

SUBCODE CLASSIFICATION

SBCK

SFSY

PW

QCRC

XTAL

TIMING GENERATOR

2K x 8BIT

RAM

RAM ADDRESS

GENERATOR

1BIT DAC

DIGITAL OUT

L.P.F

48

EFLG

47

SBSY

46

XVSS

45

XIN

44

XOUT

43

XVDD

42

MUTER

41

RVDD

40

RCHO

39

RVSS

38

LVSS

LCHO

37

36

LVDD

35

MUTEL

34

N.C

33

TEST4

TGL

JP+

22

JP-

PCK

VDD

FSEQ

CONT1

CONT2

CONT3

CONT4

CONT5

EMPH

CF2

DOUT

17 2818 19 20 21 23 24 25 26 27 29 30 31 32

TOFF

– 46 –

TEST3

Page 37

IC103 LA6541

IC104 LC89170M

VCC

MUTE

VINL

VGL

VO1

VO2

VO3

VO4

VG2

VIN2

REG OUT

REG IN

1

2

11kΩ 11kΩ

11kΩ

LEVEL

SHIFT

BTL

DRIVER

BTL

DRIVER

LEVEL

SHIFT

REGULATOR

3

4

5

6

7

8

9

10

11

1

12

LEVEL

SHIFT

BTL

DRIVER

BTL

DRIVER

LEVEL

SHIFT

RESET

+

-

+

11kΩ

Vcc

VCC

24

23

VREF

VIN4

22

VG4

21

VO8

20

VO7

19

VO6

18

17

VO5

VG3

16

15

VIN3

14

CD

13

RES

EXCK

SBSO

SCOR

WFCK

MCK

XMODE

GND

1

2

3

4

5

6

7

32 WORD X 8 BIT

DUAL PORT RAM

CPU INTERFACE

TIMING

&

SYNCHRONIZATION

SIGNAL

PROTECTION

CRC

CHECKER

VDD

14

VDD

13

DQSY

SRDT

12

11

SCLK

10

SW2

SW1

9

8

TEST

– MAIN Board –

IC201 LA5602

1

V IN

CDEL

GND

RES

V OUT

2

EN

3

4

5

CN

6

7

ON/OFF

RESET

GEN

REFERENCE

VOLTAGE

OVER CURRENT

LIMITTER

OVER HEAT

PROTECTION

ERROR

AMP

IC203 LA5601

7

VOMUTE

AMP

2 5

EN

V REF

ON/OFF

6

VID VOD

CD VIN

9

AMP

RESET

1

3

VO

8

RES

4

CN

10

GND

– 47 –

Page 38

IC601 BA6780

VIN1

FIN1

RIN1

IOUT

VREF

VREG

VCC

OUT1+

OUT1-

1

2

3

REVERSIBLE DRIVER

4

5

VOLTAGE

REFERENCE

6

LOW VOLTAGE

7

8

+-

9

OUTPUT

FWD/REV CONTROLLER

VEE

OUTPUT

VEE VCC

COVERNER

18

VIN2

17

FIN2

16

RIN2

COVERNER DRIVER

FWD/REV CONTROLLER

15

CT2

14

VEE

FBIN-

13

AMPLIFIER

DETECTION

12

OUTPUT

FBIN+

11

OUT2+

10

OUT2-

LOAD CURRENT

COVERNER

– DISPLAY Board –

IC903 M66310FP

QC

24

0

CK

DR

1

CK

DR

D

CK

1

D

CK

00

R

R

QD

23

0

CK

DR

1

CK

DR

D

CK

1

D

CK

QE

22

0

CK

DR

1

CK

DR

R

R

QF

21

0

CK

DR

1

CK

DR

QG

20

0

CK

DR

1

CK

DR

QH

19

0

CK

DR

1

CK

DR

QI

18

0

CK

DR

1

CK

DR

QJ

17

0

CK

DR

1

CK

DR

QK

16

0

CK

DR

1

CK

DR

QL

15

0

CK

DR

1

CK

DR

R

R

QN

13

0

CK

DR

1

CK

DR

R

D

CK

1

R

D

CK

QM

14

0

CK

DR

1

CK

DR

D

CK

1

D

CK

00

1 2 3

QA

QB

VCC

4 5 6 7 8 9 10 11 12

ATA

OE

LT

RST

CLK

GND

SQP

QO

– 48 –

QP

Page 39

7-12. IC PIN FUNCTION DESCRIPTION

• BD BOARD IC101 LA9241M (RF AMPLIFIER, FOCUS/TRACKING/SLED SERVO)

Pin No. Pin Name I/O Function

1 FIN2 I

2

3EI

4FI

5TBI

6 TE– I

7TEO

8 TESI I

9 SCI I

10 TH I

11 TA O

12 TD– I

13 TD O

14 JP I

15 TO O

16 FD O

17 FD– I

18 FA O

19 FA– I

20 FE O

21 FE– I

22 AGND —

23 SP O

24 SPI I

25 SPG I

26

27

28

29

30

31

32

33

34

35

36

37

FIN1 I

SP– I

SPD O

SLEQ I

SLD O

SL– I

SL+ I

JP– I

JP+ I

TGL I

TOFF I

TES O

HFL O

Signal input (B+D) from the optical pick-up detector

Added with FIN1 to create RF signal, subtracted with FIN1 to create focus error signal

Signal input (A+C) from the optical pick-up detector

Signal input (E) from the optical pick-up detector

Subtracted with F to create tracking error signal

Signal input (F) from the optical pick-up detector

Tracking error signal input for the tracking balance adjustment

Tracking error signal (invert signal) input terminal

Tracking error signal output terminal

TES (Track Error Sense) comparator input terminal

Tracking error signal is band-passed and input

Shock detection input terminal

Time constant setting terminal for the tracking gain adjustment

TA amplifier output terminal

Creates a tracking phase compensation constant between TD (pin !£) and VR (pin %•) pins

Setting terminal for the tracking phase compensation

Setting terminal for the tracking jump signal (kick pulse) amplitude

Tracking coil (2-axis device) drive signal output to the LA6541 (IC103), and sled motor drive

signal output terminal

Focus coil (2-axis device) drive signal output to the LA6541 (IC103)

Creates a focusing phase compensation constant between FD (pin !§) and FA (pin !•) pins

Creates a focusing phase compensation constant between FD– (pin !¶) and FA– (pin !ª) pins

Creates a focusing phase compensation constant between FA (pin !•) and FE (pin @º) pins

Focus error signal output terminal

Focus error signal (invert signal) input terminal

Ground terminal (analog system)

Single end output of the CV+ (pin $º) and CV– (pin #ª) pins signal

Spindle amplifier input terminal (invert input)

Gain setting resistor is connected when the spindle 12 cm mode

Works together with the SPD (pin @¶) to connect to the spindle phase compensation constant

Spindle motor (M101) drive signal output to the LA6541 (IC103)

Sled phase compensation constant is connected

Sled motor (M102) drive signal output to the LA6541 (IC103)

Sled feeding signal input from the system controller (IC501)

Sled feeding signal input from the system controller (IC501)

Tracking jump control signal input from the DSP (IC102)

Tracking jump control signal input from the DSP (IC102)

Tracking gain control signal input from the DSP (IC102) Gain becomes low when TGL is “H”

Tracking off control signal input from the DSP (IC102)

Tracking becomes off when TOFF is “H”

Tracking error signal output to the DSP (IC102)

Tracking detection signal output to the DSP (IC102) HFL (High Frequency Level) is used to

determine whether the main beam is positioned on a pit or a mirror

38

39

SLOF I

CV– I

Sled servo off control signal input from the DSP (IC102) Rough servo/phase control automatic

switching monitor input “H”: rough servo, “L”: phase servo

CLV error signal input from the DSP (IC102)

– 49 –

Page 40

Pin No. Pin Name I/O Function

40

41

42

CV+ I

RFSM O

RFS– I

CLV error signal input from the DSP (IC102)

Playback EFM RF signal output to the DSP (IC102)

Works together with the RFSM (pin $¡) to set the RF gain and the 3T compensation constant for

the EFM RF signal

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

SLC O

SLI I

DGND —

FSC O

TBC I

NC —

DEF O

CLK I

CL I

DAT I

CE I

DRF O

FSS I

VCC2 —

REFI I

VR O

LF2 I

PH1 I

BH1 I

LDD O

LDS I

VCC1 —

SLI (Slice Level Control) is output to control a data slice level of the RF waveform by the DSP

(IC102)

Input terminal for controlling a data slice level by the DSP (IC102)

Ground terminal (digital system)

Focus search smoothing capacitor output terminal

TBC (Tracking Balance Control) sets a EF balance variable range

Not used (open)

Defect detection signal output to the DSP (IC102)

Reference clock (4.2336 MHz) input from the DSP (IC102)

Command serial clock signal input from the system controller (IC501)

Command serial data input from the system controller (IC501)

Command chip enable signal input from the system controller (IC501)

Focus OK signal output to the system controller (IC501) “L”: NG, “H”: OK

FSS (Focus Search Select) is a switching terminal for the focus search mode (±search/+search for

a reference voltage) Not used (open)

Power supply terminal (+5V) (servo system and digital system)

Connected to the coupling capacitor for the reference voltage (+2.5V)

Reference voltage (+2.5V) output terminal

Constant setting for a disc defect detection

Connected to the capacitor for the RF signal peak hold

Connected to the capacitor for the RF signal bottom hold

Laser drive signal output to the automatic power control circuit

Light amount monitor input of the laser diode (PD)

Power supply terminal (+5V) (RF system)

– 50 –

Page 41

• BD BOARD IC102 LC78622E (DIGITAL SIGNAL PROCESSOR, DIGITAL FILTER, D/A CONVERTER)

Pin No. Pin Name I/O Function

1 DEFI I

2

3 PDO O

4 VVSS —

5 ISET I

6 VVDD —

7FRI

8 VSS —

9 EFMO O

10 EFMIN I

11 TEST2 I

12 CLV+ O

13 CLV– O

14 V/P O

TAI I

Defect detection signal input from the RF amplifier (IC101)

PLL test input terminal Not used (fixed at “L”)

PLL phase comparison output for external VCO control

Ground terminal (internal VCO system)

Connected to a current adjusting resistor for the PDO output

Power supply terminal (+5V) (internal VCO system)

Adjusts the VCO frequency range

Ground terminal (digital system)

Slice level control to EFM signal output

Playback EFM RF signal input from the RF amplifier (IC101)

Test input terminal (fixed at “L” in this set)

Disc motor control signal output to the RF amplifier (IC101)

(3-value output available depending on the command)

Sled servo on/off control signal output to the RF amplifier (IC101) Rough servo/phase control

automatic switching monitor output “H”: rough servo, “L”: phase servo

15 HFL I

16 TES I

17 TOFF O

18 TGL O

19 JP+ O

20 JP– O

21 PCK O

22 FSEQ O

23 VDD —

24 CONT1 I

25 CONT2 I

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

CONT3 O

CONT4 I

CONT5 O

EMPH O

C2F O

DOUT O

TEST3 I

TEST4 I

NC —

MUTEL O

LVDD —

LCHO O

LVSS —

RVSS —

RCHO O

RVDD —

Tracking detection signal input from the RF amplifier (IC101) (Schmitt input) HFL (High

Frequency Level) is used to determine whether the main beam is positioned on a pit or mirror

Tracking error signal input from the RF amplifier (IC101) (schmitt input)

Tracking off control signal output to the RF amplifier (IC101)

Tracking becomes off when TOFF is “H”

Tracking gain control signal output to the RF amplifier (IC101) (Raises gain when “L”)

Track jump control signal output to the RF amplifier (IC101)

(3-value output available depending on the command)

EFM data playback clock monitor output terminal (4.3218 MHz when phase is locked)

Sync signal detection output terminal (“H” when a sync signal detected from the EFM signal and

that generated internally coincide)

Power supply terminal (+5V) (digital system)

Guard frame sync input terminal

Sled servo on/off control signal input terminal

Sled servo drive control signal output terminal

Sled limit-in detect switch (S101) input terminal The optical pick-up is inner position when “L”

Not used (open)

De-emphasis control signal output terminal

The de-emphasis disc is being played back when “H” Not used (open)

C2PO (error condition monitor) signal output terminal

Digital signal output terminal (EIAJ format)

Test input terminal (fixed at “L” in this set)

Test input terminal (fixed at “L” in this set)

Not used (open)

Line muting on/off control signal output terminal (for L-ch side) “H”: muting on

Power supply terminal (+5V) (L-ch D/A converter system)

Analog audio signal output from the internal D/A converter block (for L-ch side)

Ground terminal (L-ch D/A converter system)

Ground terminal (R-ch D/A converter system)

Analog audio signal output from the internal D/A converter block (for R-ch side)

Power supply terminal (+5V) (R-ch D/A converter system)

– 51 –

Page 42

Pin No. Pin Name I/O Function

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

MUTER O

XVDD —

XOUT O

XIN I

XVSS —

SBSY O

EFLG O

PW O

SFSY O

SBCK I

FSX O

WRQ O

RWC I

SQOUT O

COIN I

CQCK I

Line muting on/off control signal output terminal (for R-ch side) “H”: muting on

Power supply terminal (+5V) (crystal oscillator system)

System clock output terminal (16.9344 MHz)

System clock input terminal (16.9344 MHz)

Ground terminal (crystal oscillator system)

C1, C2, single correction, and double correction monitor output to the CD text decoder (IC104)

Subcode P to W output terminal

Subcode frame sync signal output to the CD text decoder (IC104)

Write frame clock signal output to the CD text decoder (IC104)

Subcode reading clock signal input from the CD text decoder (IC104) (schmitt input)

7.35 kHz sync signal output divided from the crystal oscillation

Subcode Q synchronizing signal output to the system controller (IC501)

Command chip enable signal input from the system controller (IC501) (schmitt input)

Subcode Q data output to the system controller (IC501)

Command serial data input from the system controller (IC501)

Command serial clock signal input from the system controller (IC501) (schmitt input)

Fetching clock input or subcode extracting clock input from SQOUT (pin %∞)

58

59

60

61

62

63

64

RES I

TEST11 O

16M O

4.2M O

TEST5 I

CS I

TEST1 I

System reset signal input from the reset signal generator (IC201) “L”: reset

For several hundreds msec. after the power supply rises, “L” is input, then it changes to “H”

Test output terminal Not used (open)

Master clock signal (16.9344 MHz) output to the CD text decoder (IC104)

Reference clock signal (4.2336 MHz) output to the RF amplifier (IC102)

Test input terminal (fixed at “L” in this set)

Chip select signal input terminal Not used (fixed at “L”)

Test input terminal (fixed at “L” in this set)

– 52 –

Page 43

• MAIN BOARD IC501 CXP84340-071Q (SYSTEM CONTROLLER)

Pin No. Pin Name I/O Function

1 to 5 A3 to A7 O

6 A12 O

7 A14 O

8 to 11 A11 to A8 O

12 A13 O

13 WE O

14 LDIN O

15 LDOUT O

16 TBLL O

17 TBLR O

18, 19 NC O

20 HHOUT O

21 LEDL O

22 FLLT O

23 JOG1 I

24 JOG2 I

25 DOORSW I

26 FLCK O

27 FLDT O

28 ZMUTE O

29 ICSW O

30 RESET I

31 EXTAL I

32 XTAL O

33 VSS —

34 TX O

35 TEX I

36 AVSS —

37 AVREF I

38 KEY0 I

Address signal output to the static RAM (IC502)

Data write enable signal output to the static RAM (IC502) “L” active

Loading motor drive signal (load-in direction) output to the BA6780 (IC601) “H” active

Loading motor drive signal (load-out direction) output to the BA6780 (IC601) “H” active

Table motor drive signal (counterclockwise) output to the BA6780 (IC601) “H” active

Table motor drive signal (clockwise) output to the BA6780 (IC601) “H” active

Not used (open)

AND output of T.SENS1 (pin ^™) and T.SENS2 (pin ^£) when the test mode

Serial data latch pulse output to the LED driver (IC903) “H” active

Serial data latch pulse output to the FL driver (IC901) “L” active

Jog dial pulse input from the rotary encoder (RE901)

Jog dial pulse input from the rotary encoder (RE901)

Door open/close detect switch (S925) input “L”: close, “H”: open

Serial data transfer clock signal output to the FL driver (IC901) “L” active

Serial data output to the FL driver (IC901)

Muting on/off control signal output for the 2nd CD IN “H” active

Enable signal output to the LA5602 (IC201) Used for the BD section reset “H” active

System reset signal input from the reset signal generator (IC203) “L”: reset

For several hundreds msec. after the power supply rises, “L” is input, then it changes to “H”

Main system clock input terminal (10 MHz)

Main system clock output terminal (10 MHz)

Ground terminal

Sub system clock output terminal Not used (open)

Sub system clock input terminal Not used (fixed at “L”)

Ground terminal (for A/D converter)

Reference voltage (+5V) input terminal (for A/D converter)

Key input terminal (A/D input) CLEAR, CHECK, FADER, MEMO SEARCH, INPUT,

TIME/TEXT keys input (S901 to 906)

39 KEY1 I

40 KEY2 I

41 KEY3 I

42 D.SENS I

43 CD1/2/3 I

44 TEST I

45 BUSOUT O

46 BUSIN I

47 SL+ O

48 CQCK O

Key input terminal (A/D input)

±, ≠, p, P, ·, PLUS ONE, REPEAT, PLAY MODE keys input (S907 to 914)

Key input terminal (A/D input)

I/u, X-FADE, NO DELAY, MEGA CONTROL keys input (S921 to 924)

Key input terminal (A/D input) GROUP 5 to 1, GROUP FILE keys input (S915 to 920)

Inputs the disc sensor (Q51) detection signal “H” active

COMMAND MODE switch (S701) input terminal

“L”: CD1, “H”: CD3 (CD2: center voltage input)

Setting terminal for the test mode “L”: ADJ mode, center voltage: AFADJ mode

Sircs remote control signal output for the S-LINK CONTROL A1 “H” active

Sircs remote control signal input for the S-LINK CONTROL A1 “L” active

Sled feeding signal (external direction) output to the RF amplifier (IC101) “H” active

Command serial clock signal output to the RF amplifier (IC101) and DSP (IC102)

“L” active

– 53 –

Page 44

Pin No. Pin Name I/O Function

49 SQOUT I

50 COIN O