Page 1

CDP-CX555G

• Audio cord (1)

• Monaural (2P) mini-plug cord (1)

• Remote commander (remote) (1)

• Size AA (LR6) batteries (2)

Compact disc player

Laser Semiconductor laser (λ = 780 nm)

Emission duration: continuous

Laser output Max 44.6 µW*

* This output is the value measured at

a distance of 200 mm from the

objective lens surface on the Optical

Pick-up block with 7 mm aperture.

Frequency response 20 Hz to 20 kHz ±0.5 dB

Signal-to-noise ratio More than 108 dB

Dynamic range More than 87 dB

Harmonic distortion Less than 0.009%

Output

LINE OUT

DIGITAL OUT

(OPTICAL)

Jack

type

Phono

jacks

Optical

output

connector

Maximum

output

level

2 V

(at 50 kilohms)

–18 dBm

Load

impedance

Over 10 kilohms

Wave length: 660 nm

General

Power requirements

Power consumption 16 W

1 W (at the Power Saving Mode)

Dimensions (approx.) 430 × 189 537 mm

(w/h/d) (17 7 1/2 21 1/4 in.) incl. projecting

parts

Mass (approx.) 8.8 kg (19 lbs 7 oz.)

Supplied accessories

Design and specifications are subject to change without notice.

100 V AC, 60 Hz

×

××

SERVICE MANUAL

Ver 1.0 2002. 10

Model Name Using Similar Mechanism NEW

CD Mechanism Type CDM62-K1BD46A

Base Unit Type BU-K1BD46A

Optical Pick-up Type KSM-213BFN

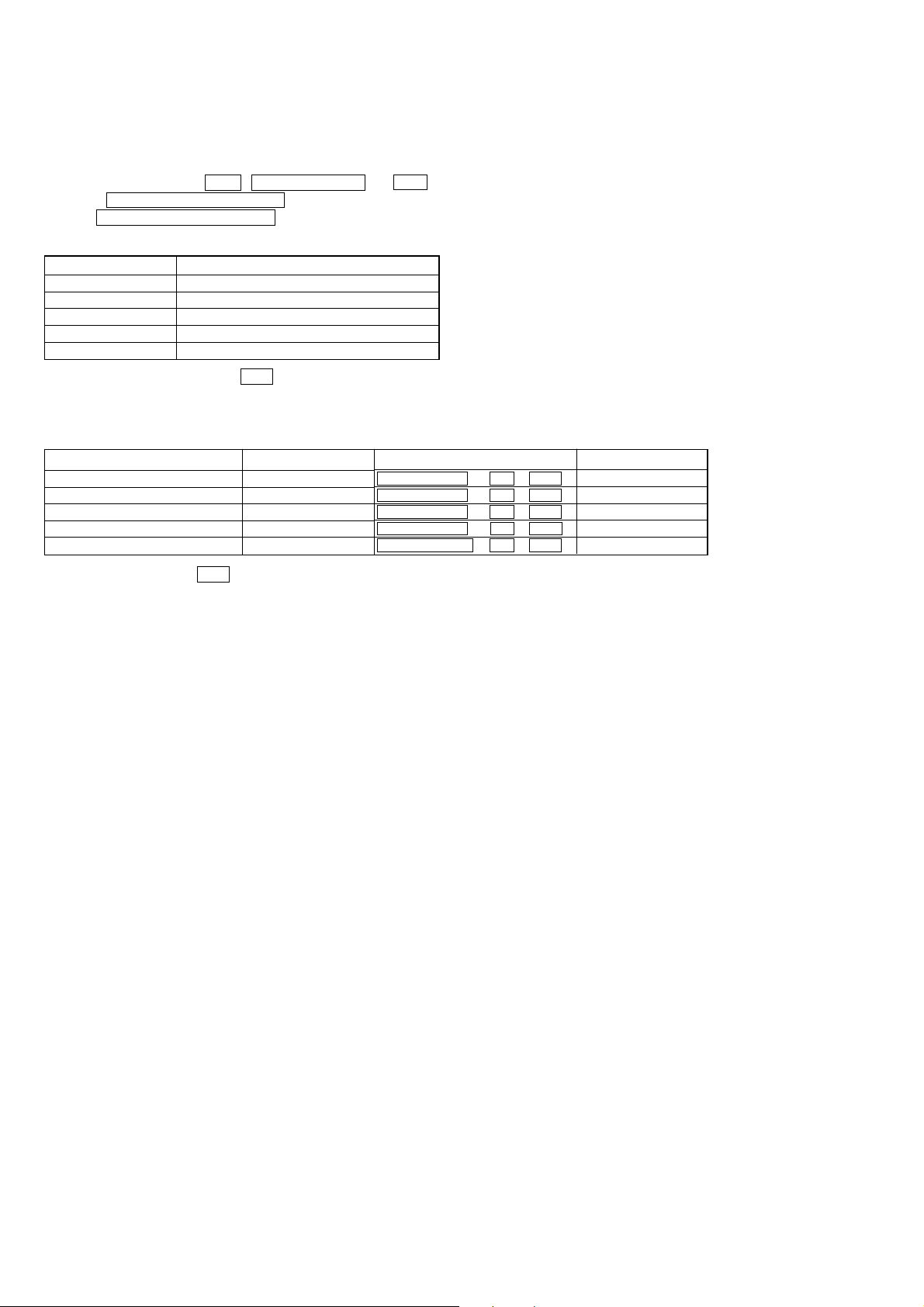

SPECIFICATIONS

Taiwan Model

9-874-178-01

2002J1600-1

© 2002.10

Sony Corporation

Home Audio Company

Published by Sony Engineering Corporation

COMPACT DISC PLAYER

Page 2

CDP-CX555G

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

This appliance is classified as

a CLASS 1 LASER product.

The CLASS 1 LASER

PRODUCT MARKING is

located on the rear exterior.

The following

caution label is

located inside of

the unit.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

Notes on chip component replacement

•Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

•Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE WITH

MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

2

Page 3

CDP-CX555G

SECTION 1

SERVICE NOTE

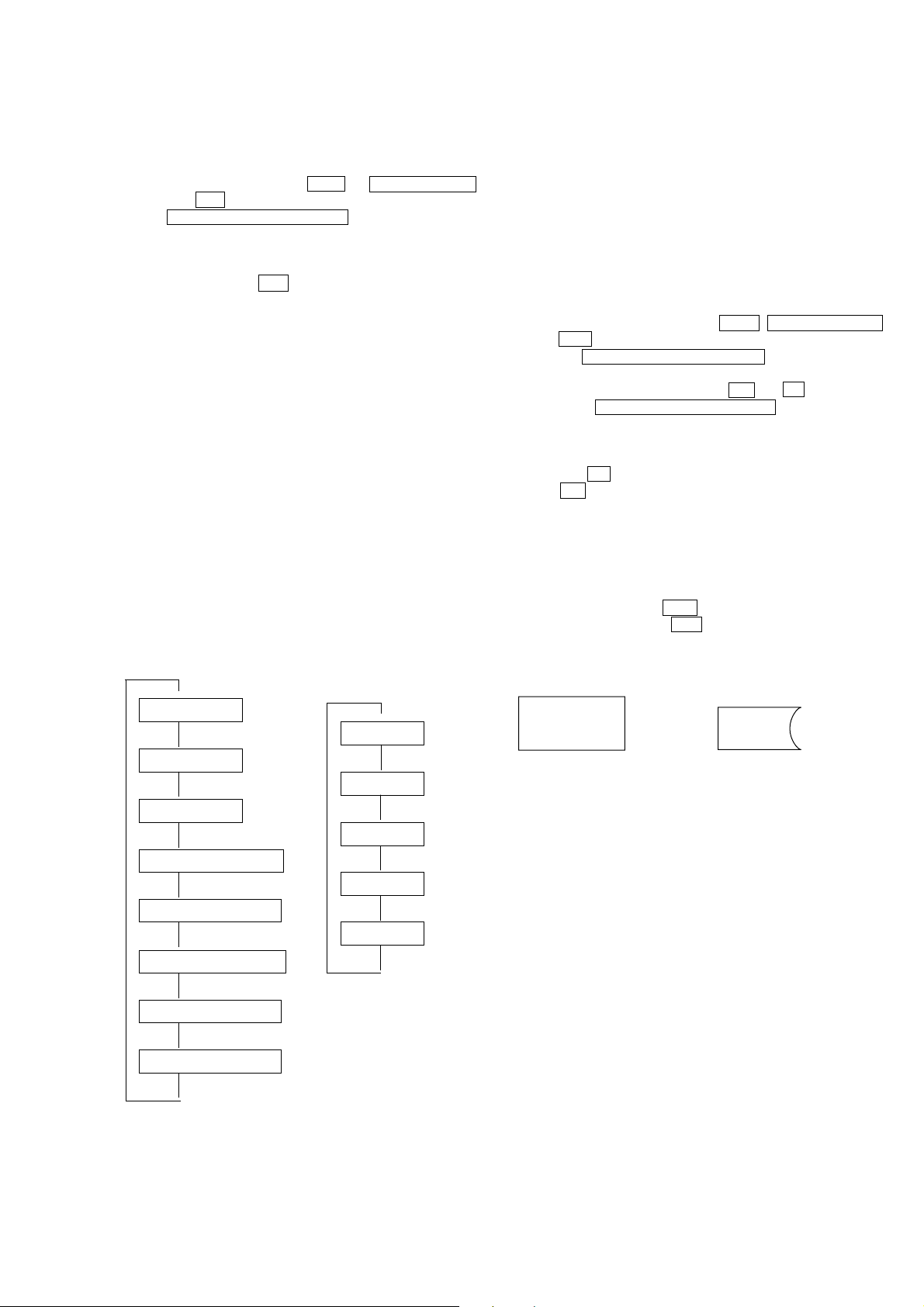

TABLE OF CONTENTS

1. SERVICE NOTE ·······························································3

2. GENERAL ··········································································6

3. DISASSEMBLY ································································7

3-1. Case ···············································································8

3-2. MAIN Board ································································· 8

3-3. TRANS Board ······························································· 9

3-4. Front Panel Assembly···················································· 9

3-5. JOG Board, DISP Board, KEYBOARD Board··········· 10

3-6. Cover (PT), Table (400) Assembly······························ 11

3-7. LED Board, Guide (Door)··········································· 11

3-8. DOOR SW Board························································ 12

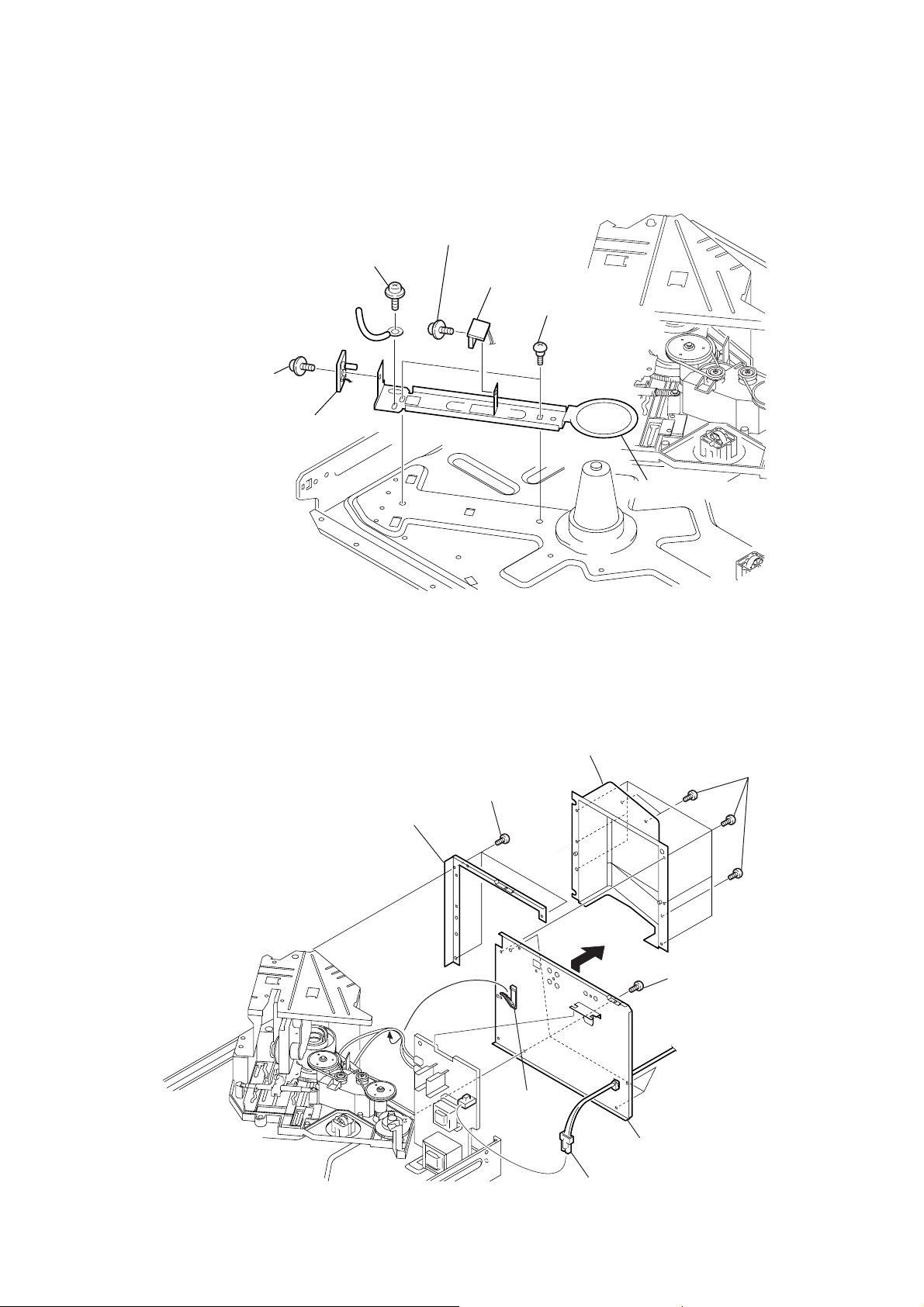

3-9. Base (Door Driving) Assembly ···································13

3-10.Pop-up Assembly·························································13

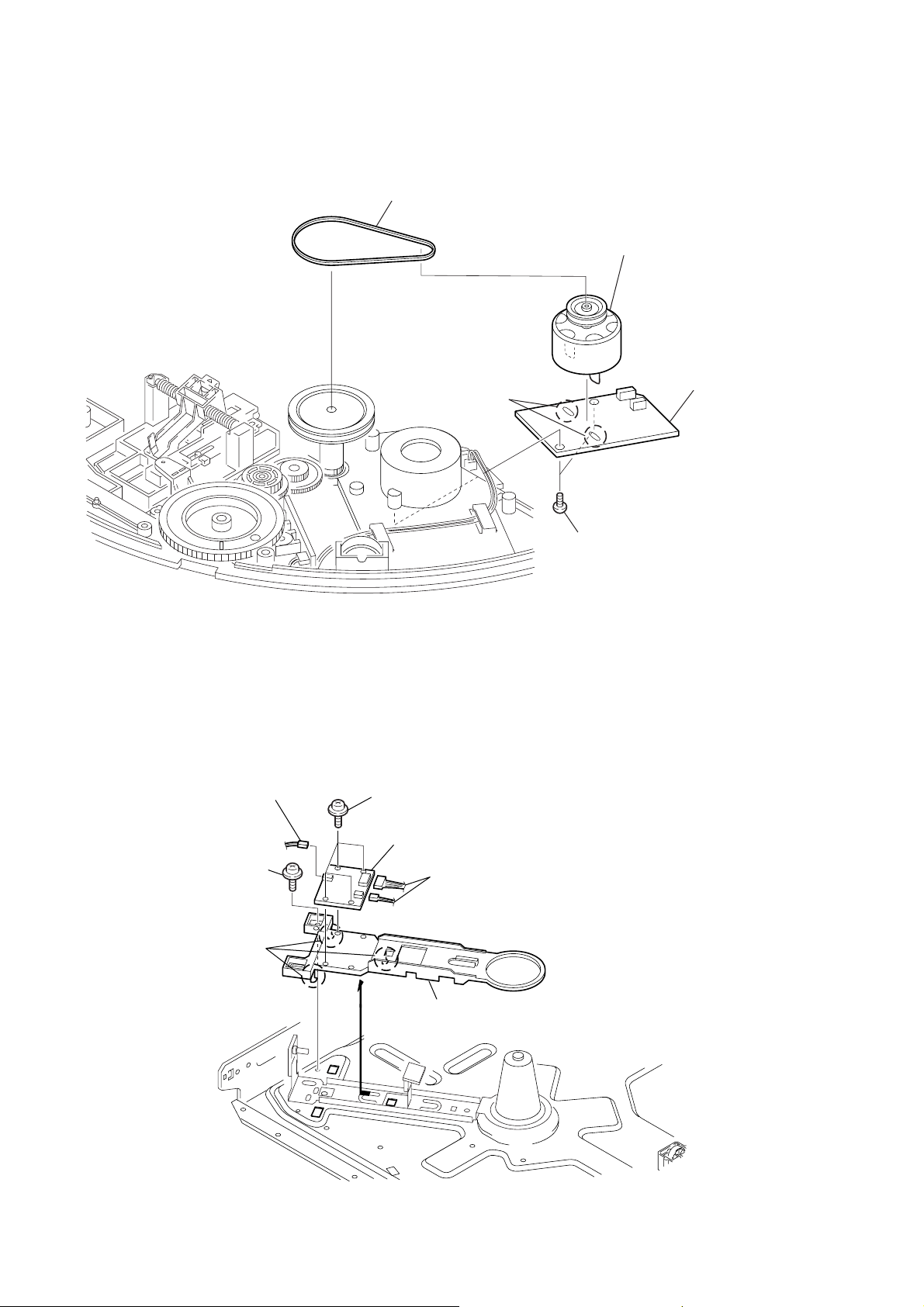

3-11.D.MOTOR Board, Motor Assembly (Door) (M603) ··14

3-12.T.SENS Board, Holder (Table Sensor 400) ················· 14

3-13.D.SENS (OUT) Board, D.SENS (IN) Board ··············15

3-14.Back Panel Section······················································ 15

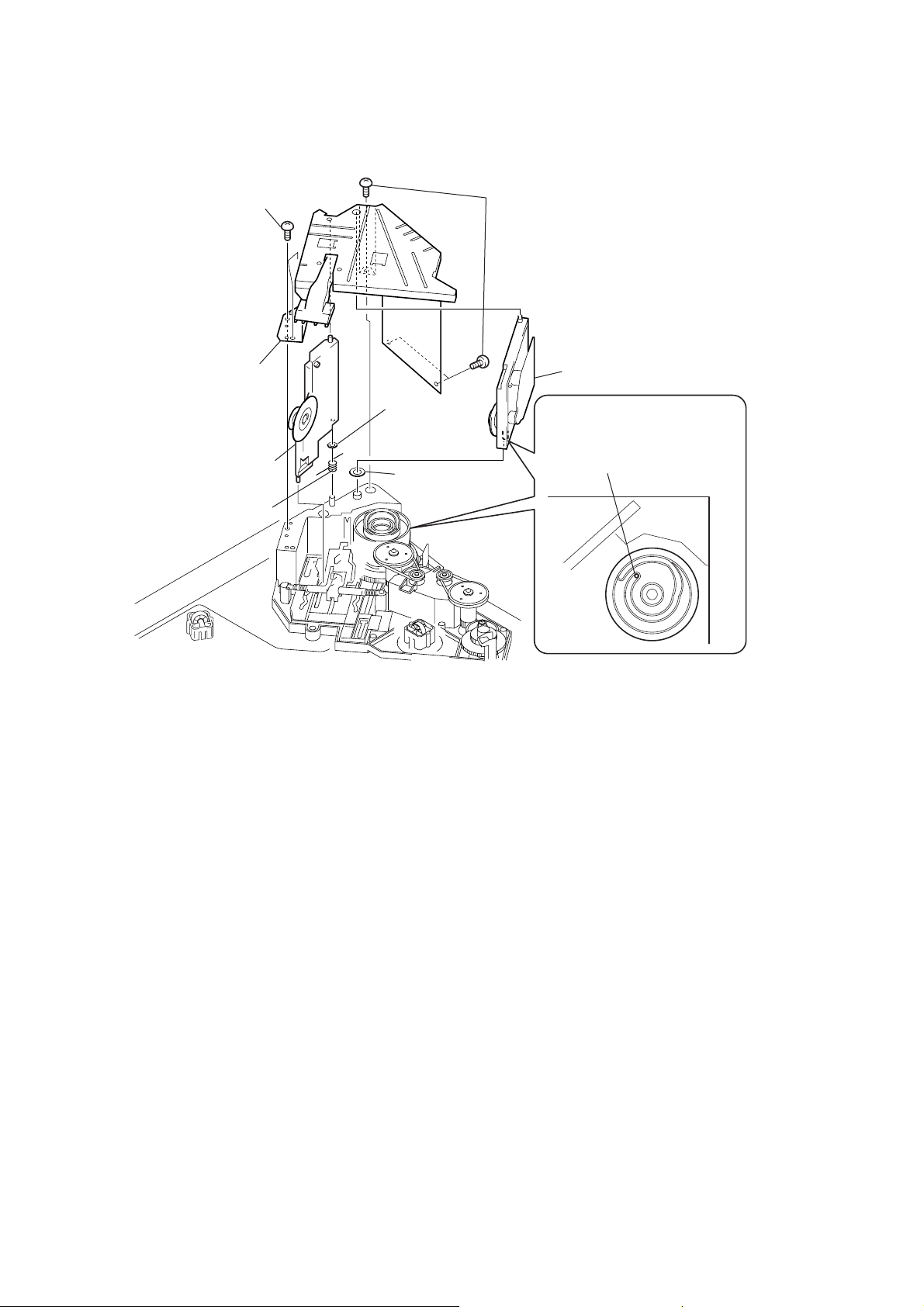

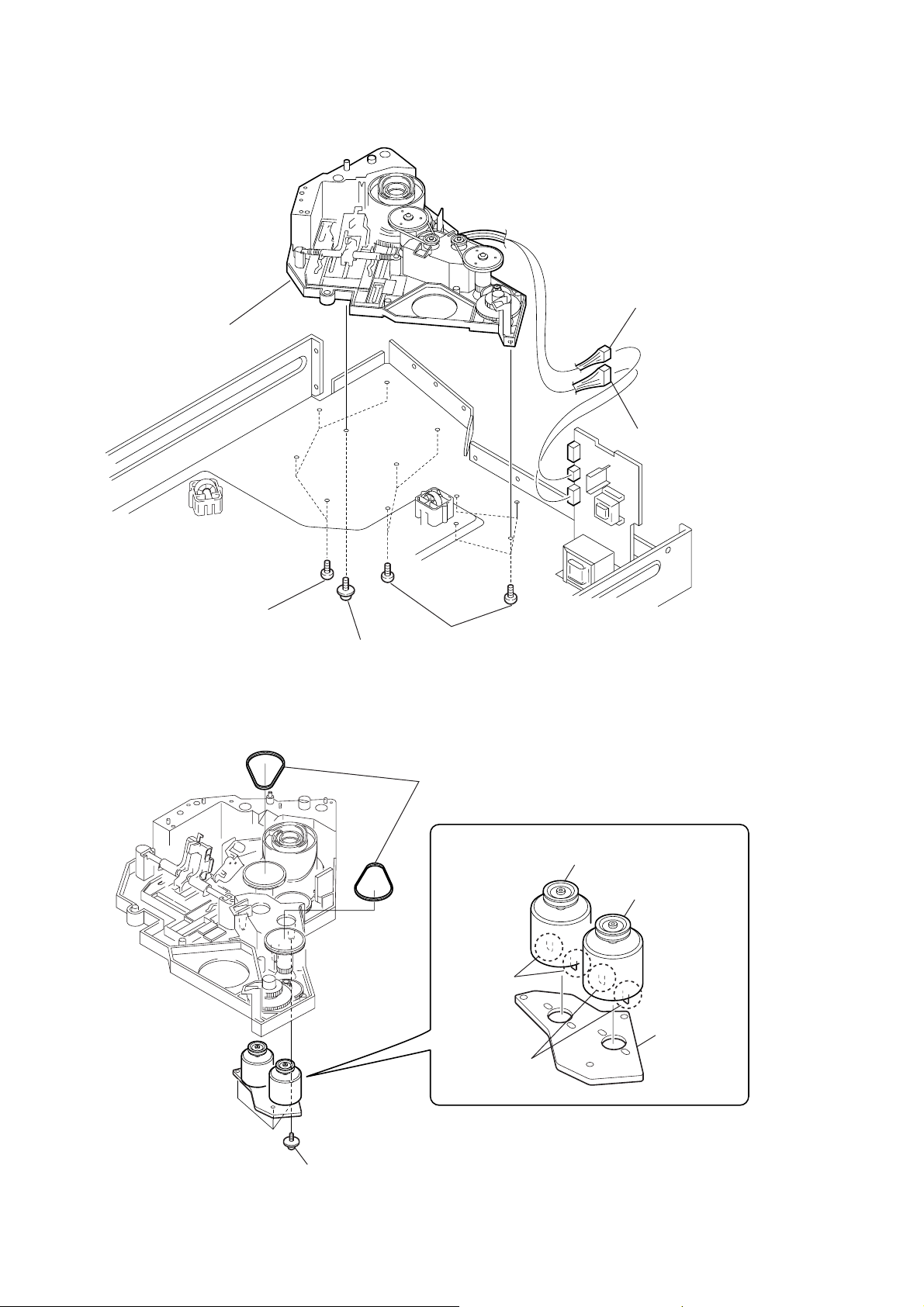

3-15.CD Mechanism, Magnet Assembly····························· 16

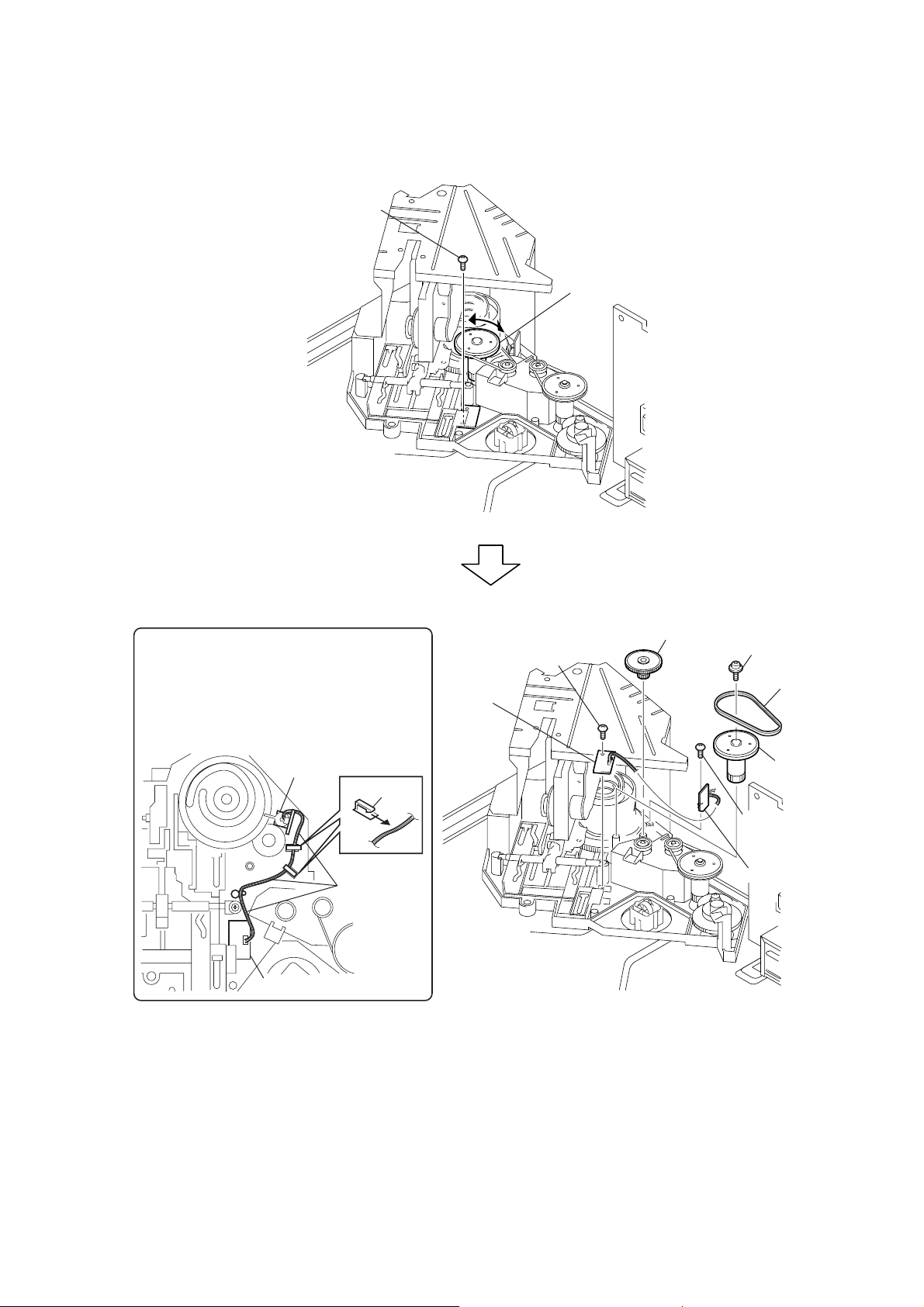

3-16.LOADING SW Board, LOCK SW Board ·················· 17

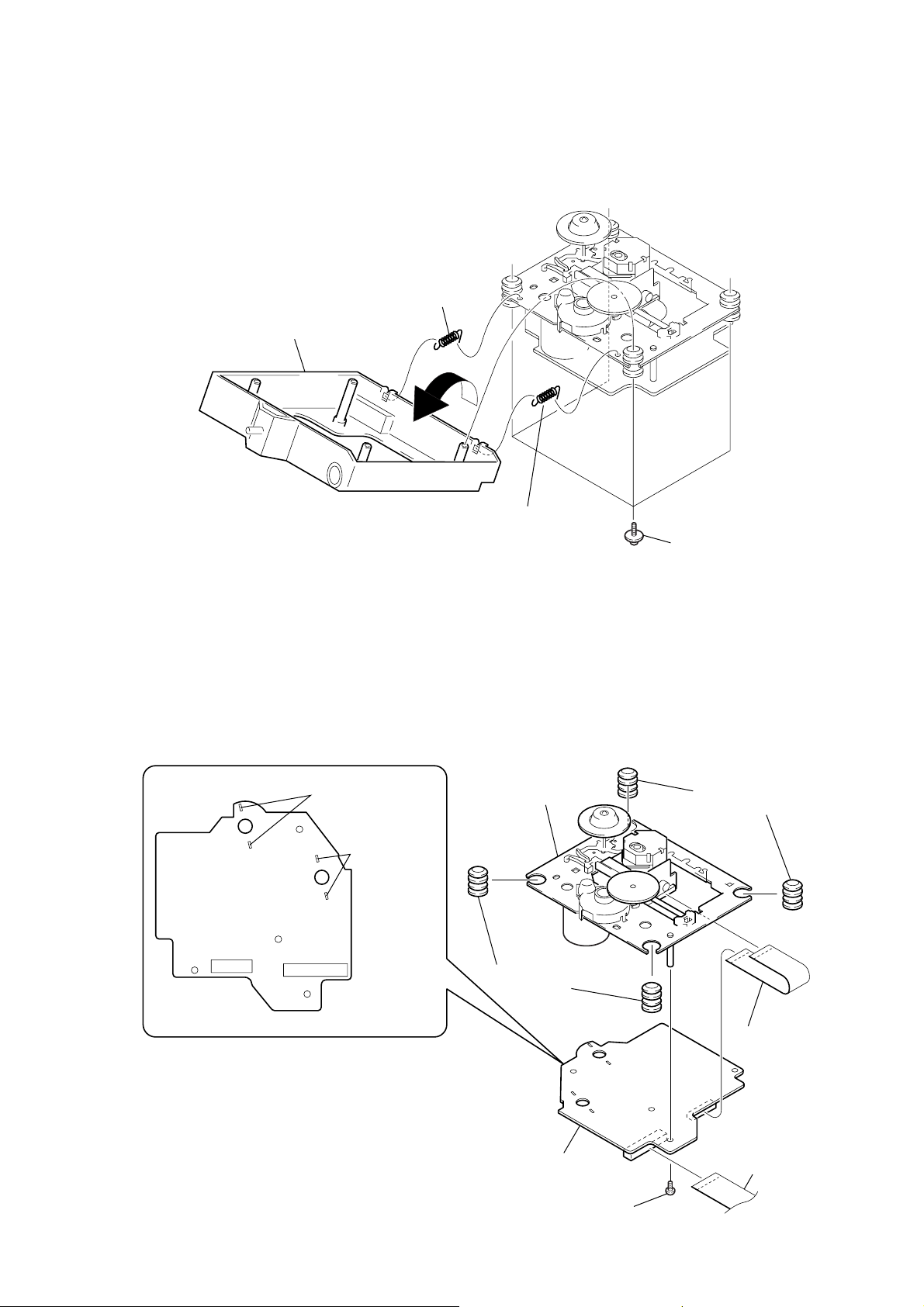

3-17.CDM Assembly ··························································· 18

3-18.Motor Assembly (Table) (M601),

Motor Assembly (Loading) (M602)···························· 18

3-19.BU Holder ···································································19

3-20.BD Board, Optical Pick-up (KSM-213BFN) ·············· 19

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repain parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

The emission check enables continuous checking of the S curve.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and check

that the S curve waveform is output three times.

4. TEST MODE···································································· 20

5. ADJUSTMENTS ···························································· 25

6. DIAGRAMS······································································29

6-1. Circuit Boards Location ··············································29

6-2. Block Diagrams··························································· 30

6-3. Printed Wiring Board – BD Board – ··························· 32

6-4. Schematic Diagram – BD Board – ······························ 33

6-5. Printed Wiring Board – MAIN Board – ······················34

6-6. Schematic Diagram – MAIN Board (1/2) – ················ 35

6-7. Schematic Diagram – MAIN Board (2/2) – ················ 36

6-8. Printed Wiring Board – Sensor Section –···················· 37

6-9. Schematic Diagram – Sensor Section – ······················ 37

6-10.Printed Wiring Board – Display Section – ··················38

6-11.Schematic Diagram – Display Section –····················· 39

6-12.Printed Wiring Board – JOG Board – ························· 40

6-13.Schematic Diagram – JOG Board – ····························41

6-14.Printed Wiring Board – Power Section – ···················· 42

6-15.Schematic Diagram – Power Section – ·······················43

6-16.IC Block Diagrams······················································ 44

6-17.IC Pin Function Descriptions ······································46

7. EXPLODED VIEWS ······················································50

7-1. Case Section ································································50

7-2. Chassis Section 1························································· 51

7-3. Chassis Section 2························································· 52

7-4. Front Panel Section ····················································· 53

7-5. Mechanism Section 1 (CDM62-K1BD46A)··············· 54

7-6. Mechanism Section 2 (CDM62-K1BD46A)··············· 55

7-7. Mechanism Section 3 (CDM62-K1BD46A)··············· 56

7-8. Mechanism Section 4 (CDM62-K1BD46A)··············· 57

7-9. Optical Pick-up Section (BU-K1BD46A)··················· 58

8. ELECTRICAL PARTS LIST······································· 59

3

Page 4

CDP-CX555G

CD-TEXT TEST DISC

This unit is able to display the TEXT data (character information) written in the CD on its fluorescent indicator tube.

The CD-TEXT TEST DISC (TGCS-313:J-2501-126-A) is used for checking the display.

To check, perform the following procedure.

Checking Method:

1. Turn ON the power , set the disc on the disc ta ble with the side labeled as “test disc” as the right side, close the front cover , and chuck the

disc.

2. The following will be displayed on the fluorescent indicator tube. (The display switches each time the DISPLAY button is pressed.)

Display : CD TEXT Test Disc (Album Title)

3. Press the · button and play back the disc.

4. The following will be displayed on the fluorescent indicator tube. (If nothing is displayed, press the DISPLAY button.)

Display : 1kHz/0 dB/ L&R

5. Rotate l AMS L knob to switch the track. The text data of each track will be displayed.

For details of the displayed contents for each track, refer to “Table 1 : CD-TEXT TEST DISC Text Data Contents” and “Table 2 : CDTEXT TEST DISC Recorded Contents and Display”.

Restrictions in CD-TEXT Display

In this unit, some special characters will not be displayed properly . These will be displayed as a space or a character resembling it. For details,

refer to “Table 2 : CD-TEXT DISC Recorded Contents and Display”.

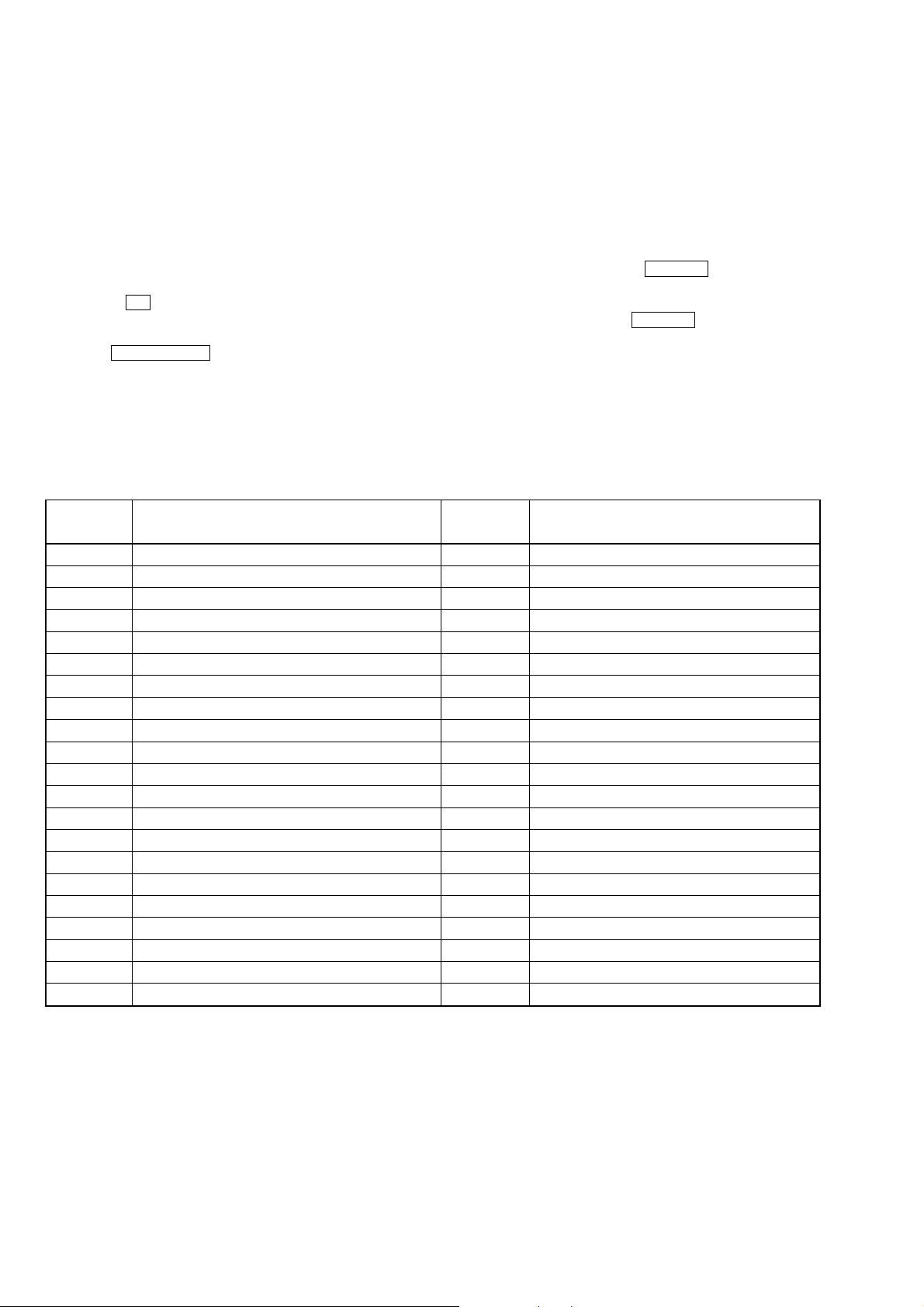

Table 1 : CD-TEXT TEST DISC Text Data Contents (TRACKS No. 1 to 41:Normal Characters)

TRACK

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

Displayed Contents

1kHz/0dB/L&R

20Hz/0dB/L&R

40Hz/0dB/L&R

100Hz/0dB/L&R

200Hz/0dB/L&R

500Hz/0dB/L&R

1kHz/0dB/L&R

5kHz/0dB/L&R

7kHz/0dB/L&R

10kHz/0dB/L&R

16kHz/0dB/L&R

18kHz/0dB/L&R

20kHz/0dB/L&R

1kHz/0dB/L&R

1kHz/-1dB/L&R

1kHz/-3dB/L&R

1kHz/-6dB/L&R

1kHz/-10dB/L&R

1kHz/-20dB/L&R

1kHz/-60dB/L&R

1kHz/-80dB/L&R

TRACK

No.

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

Displayed Contents

1kHz/-90dB/L&R

Infinity Zero w/o emphasis//L&R

Infinity Zero with emphasis//L&R

400Hz+7kHz(4:1)/0dB/L&R

400Hz+7kHz(4:1)/-10dB/L&R

19kHz+20kHz(1:1)/0dB/L&R

19kHz+20kHz(1:1)/-10dB/L&R

100Hz/0dB/L*

1kHz/0dB/L*

10kHz/0dB/L*

20kHz/0dB/L*

100Hz/0dB/R*

1kHz/0dB/R*

10kHz/0dB/R*

20kHz/0dB/R*

100Hz Squere Wave//L&R

1kHz Squere Wave//L&R

1kHz w/emphasis/-0.37dB/L&R

5kHz w/emphasis/-4.53dB/L&R

16kHz w/emphasis/-9.04dB/L&R

NOTE : The contents of Track No. 1 to 41 are the same as those of the current TEST DISC-their titles are displayed.

4

Page 5

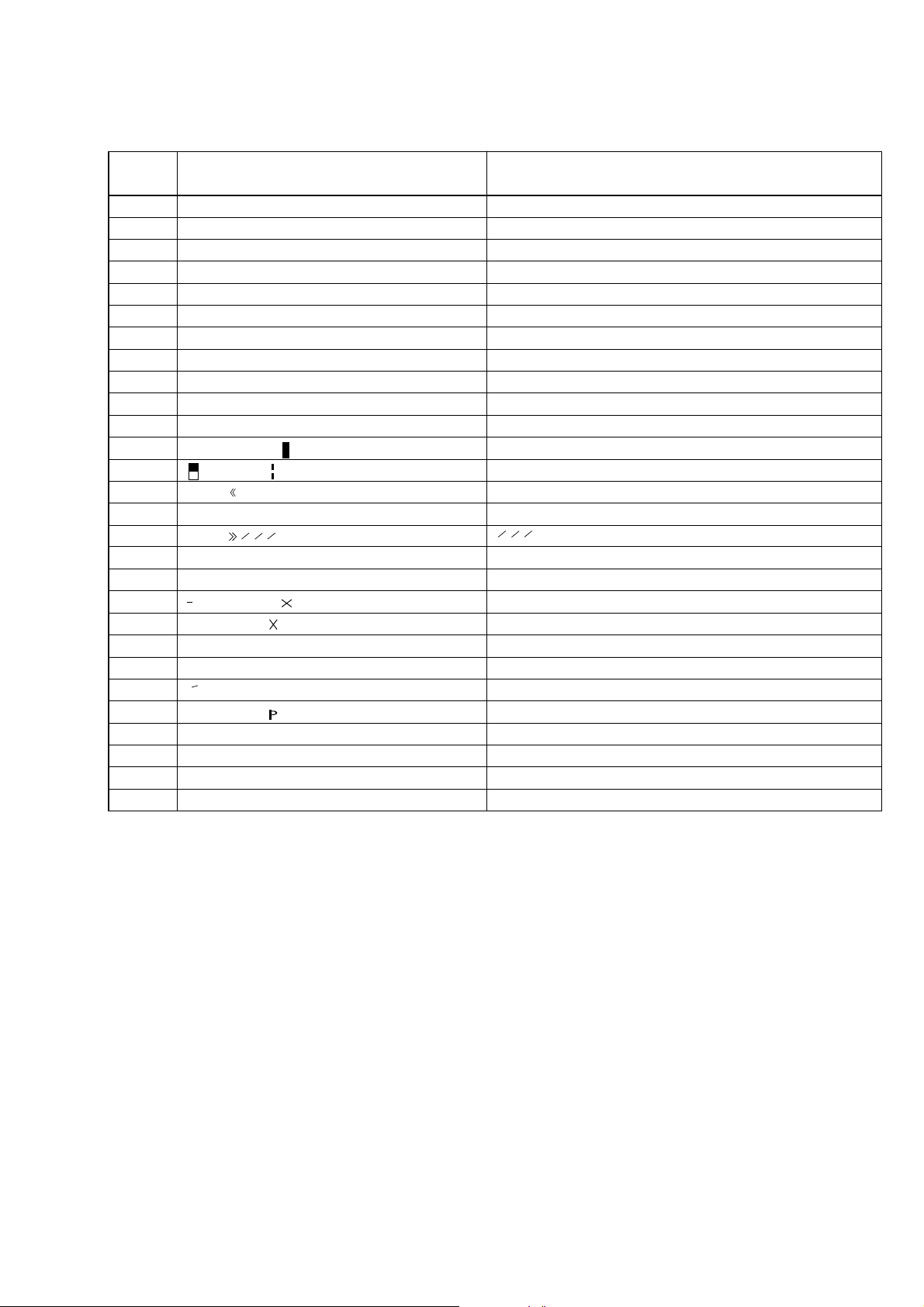

Table 2: CD-TEXT TEST DISC Recorded Contents and Display

(In this unit, some special characters cannot be displayed. This is no a fault.)

CDP-CX555G

TRACK

No.

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

to

99

Recorded contents Display

!”#$%& ´ (21h to 27h)1kHz 0dB L&R

( )+,–./ (28h to 2Fh)

*

01234567 (30h to 37h)

89:;<=>? (38h to 3Fh)

@A BCDEFG (40h to 47h)

HIJKLMNO (48h to 4Fh)

PQRSTUVW (50h to 57h)

XYZ[¥]^_ (58h to 5Fh)

abcdefg (60h to 67h)

′

hijklmno (68h to 6Fh)

pqrstuvw (70h to 77h)

xyz{I }

~

(78h to 7Fh)

i ¢£¤¥ § (A0h to A7h) 8859-1

¬

≥ C ª

•±23

1

º ¿ (B8h to BFh)

†

–

PR

µ ¶• (B0h to B7h)

′

14123

(A8h to AFh)

4

АБВГДЕЖЗ (C0h to C7h)

ИЙКЛМНОП (C8h to CFh)

DСТУФХЦ

Ø ÙÚÛÜY

˙

(D0h to D7h)

ß (D8h to DFh)

абвгдежз (E0h to E7h)

ийклмноп (E8h to EFh)

∂ стуфхц÷ (F0h to F7h)

ø ùúûüy

ÿ (F8h to FFh)

´

No.66

No.67

to

No.99

N All the same

N All the same

N All the same

N All the same

N All the same

N All the same

N All the same

XYZ[\]^_(58····

N All the same

N All the same

N All the same

N All the same

N All the same

N All the same

N All the same

14123

are displayed without “/”

4

N All the same

N All the same

N All the same

N All the same

N All the same

N All the same

N All the same

N All the same

N All the same

N All the same

to

N All the same

5

Page 6

CDP-CX555G

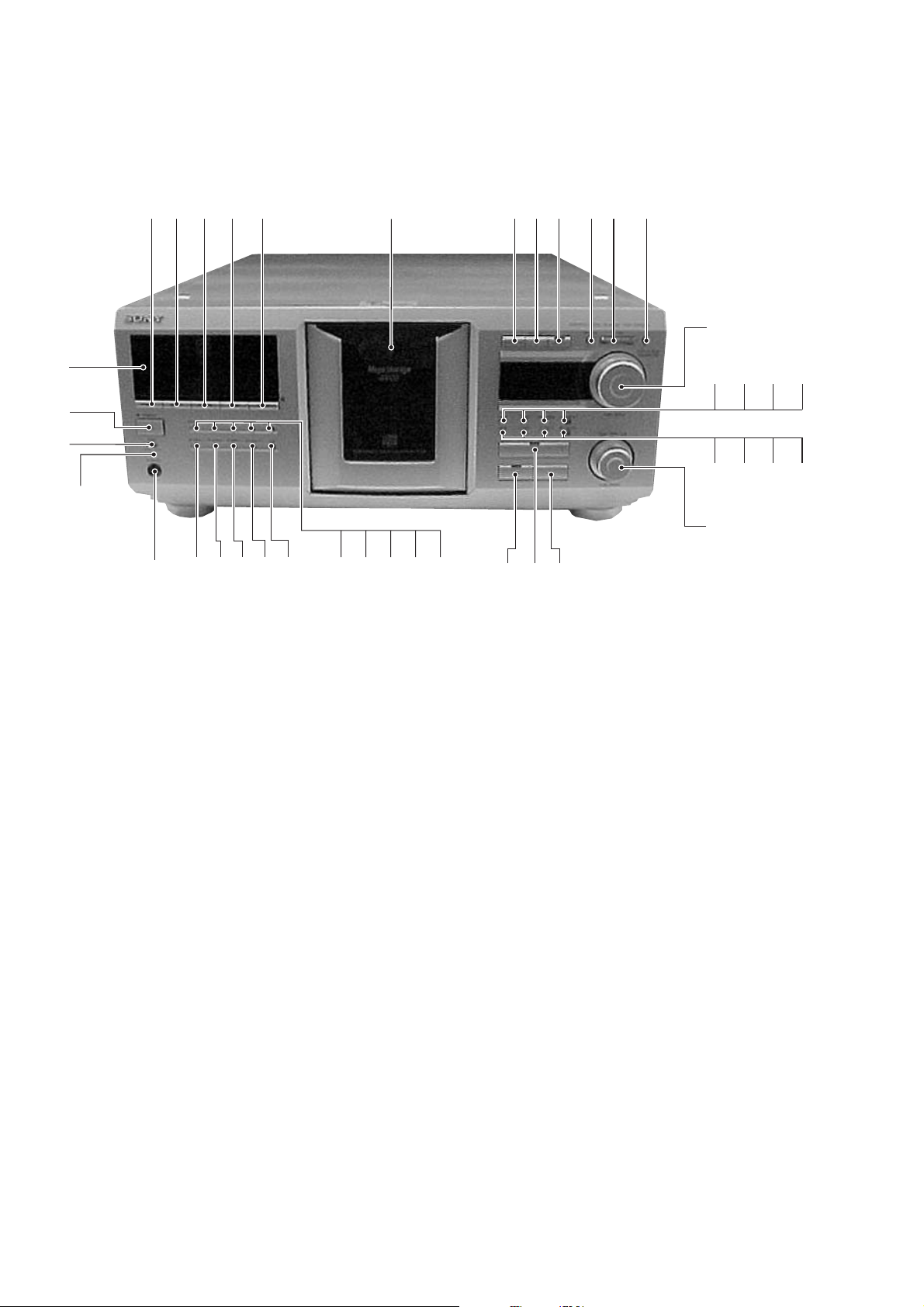

Front Panel

SECTION 2

GENERAL

3

2

1

r;

4

el

765

9q;qaqsqdqfqg8

qh

qj w;qk ql

wa

wfws wd

wg

efejeheg

ed wles

ea e;ek

wk wj wh

LOCATION OF PARTS AND CONTROLS

1 1/u (power) button

2 STANDBY indicator

3 Display window

4 CONTINUE button

5 SHUFFLE button

6 PROGRAM button

7 REPEAT button

8 DISPLAY button

9 Front cover

q; OPEN/CLOSE button

qa DISC EJECT button

qs HISTORY button and indicator

qd MENU/NO button

qf +100 button

qg YES button

qh DISC/ALBUM/CHARACTER/PUSH ENTER knob and button

qj CHECK button

qk CLEAR button

ql NAME SEARCH button

w; ALBUM SELECT button and indicator

wa FADER button

ws X-FADE button

wd NO DELAY button

wf MEGA CONTROL button and indicator

wg l AMS L /PUSH ENTER knob and button

wh p (stop) button

wj · (play) button and indicator

wk P (pause) button and indicator

wl ARTIST MODE button and indicator

e; TOP ARTIST 4 button and indicator

ea TOP ARTIST 3 button and indicator

es TOP ARTIST 2 button and indicator

ed TOP ARTIST 1 button and indicator

ef TIME button

eg TOP ARTIST 8 button and indicator

eh TOP ARTIST 7 button and indicator

ej TOP ARTIST 6 button and indicator

ek TOP ARTIST 5 button and indicator

el KEYBOARD jack

r; TIMER OFF/PLAY switch

6

Page 7

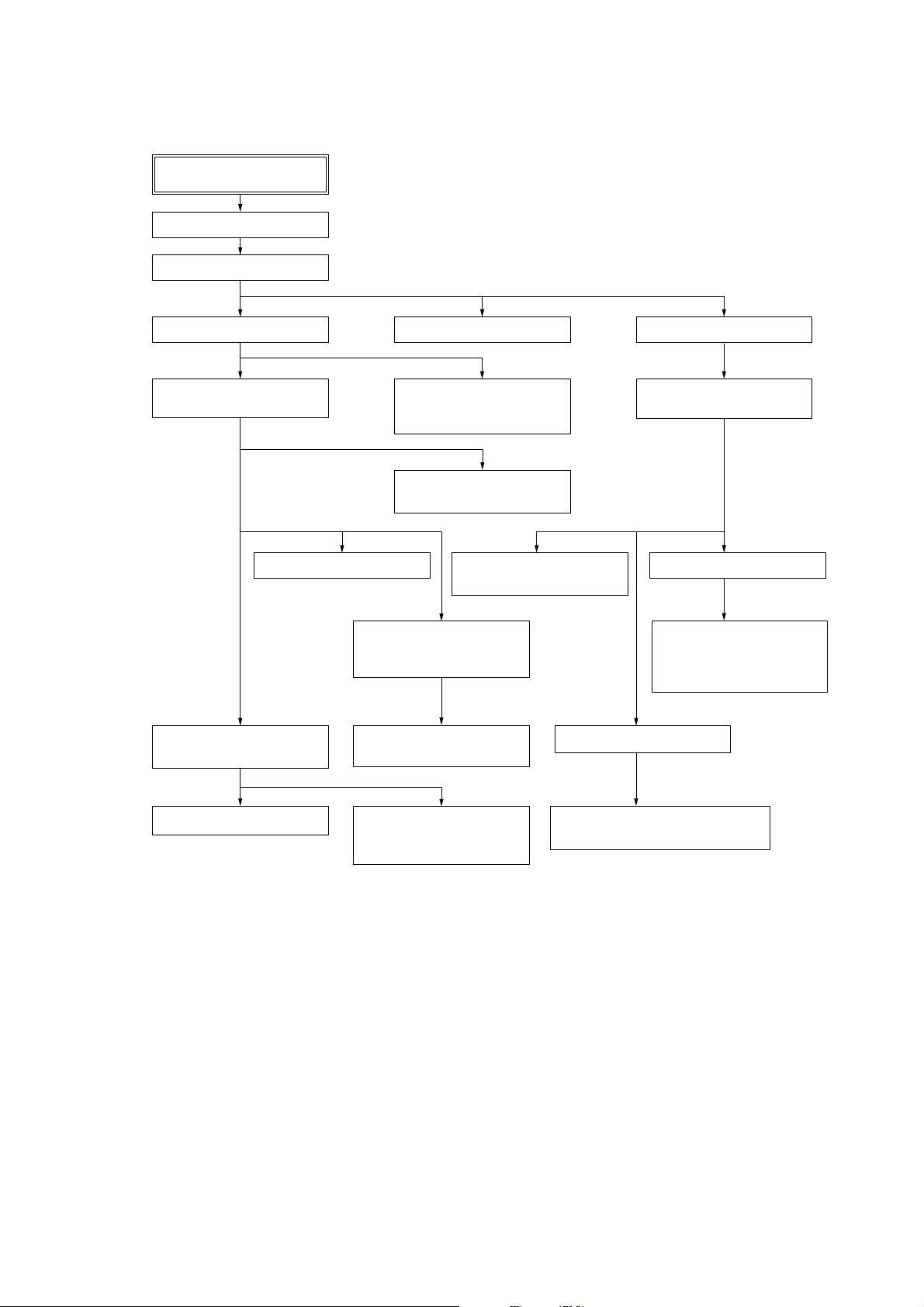

SET

CASE

MAIN BOARD

CDP-CX555G

SECTION 3

DISASSEMBLY

FRONT PANEL ASSEMBLY

COVER (PT),

TABLE (400) ASSEMBLY

DOOR SW BOARD

BASE (DOOR DRIVING)

ASSEMBLY

TRANS BOARD

JOG BOARD,

DISP BOARD,

KEYBOARD BOARD

LED BOARD,

GUIDE (DOOR)

LOADING SW BOARD,

LOCK SW BOARD

T. SENS BOARD,

HOLDER

(TABLE SENSOR 400)

D. SENS (OUT) BOARD,

D. SENS (IN) BOARD

BACK PANEL SECTION

CD MECHANISM,

MAGNET ASSEMBLY

CDM ASSEMBLY

MOTOR ASSEMBLY

(TABLE) (M601),

MOTOR ASSEMBLY

(LOADING) (M602)

BU HOLDER

POP-UP ASSEMBLY

D. MOTOR BOARD,

MOTOR ASSEMBLY (DOOR)

(M603)

OPTICAL PICK-UP (KSM-213BFN)

BD BOARD,

7

Page 8

CDP-CX555G

e

)

Note : Follow the disassembly procedure in the numerical order given.

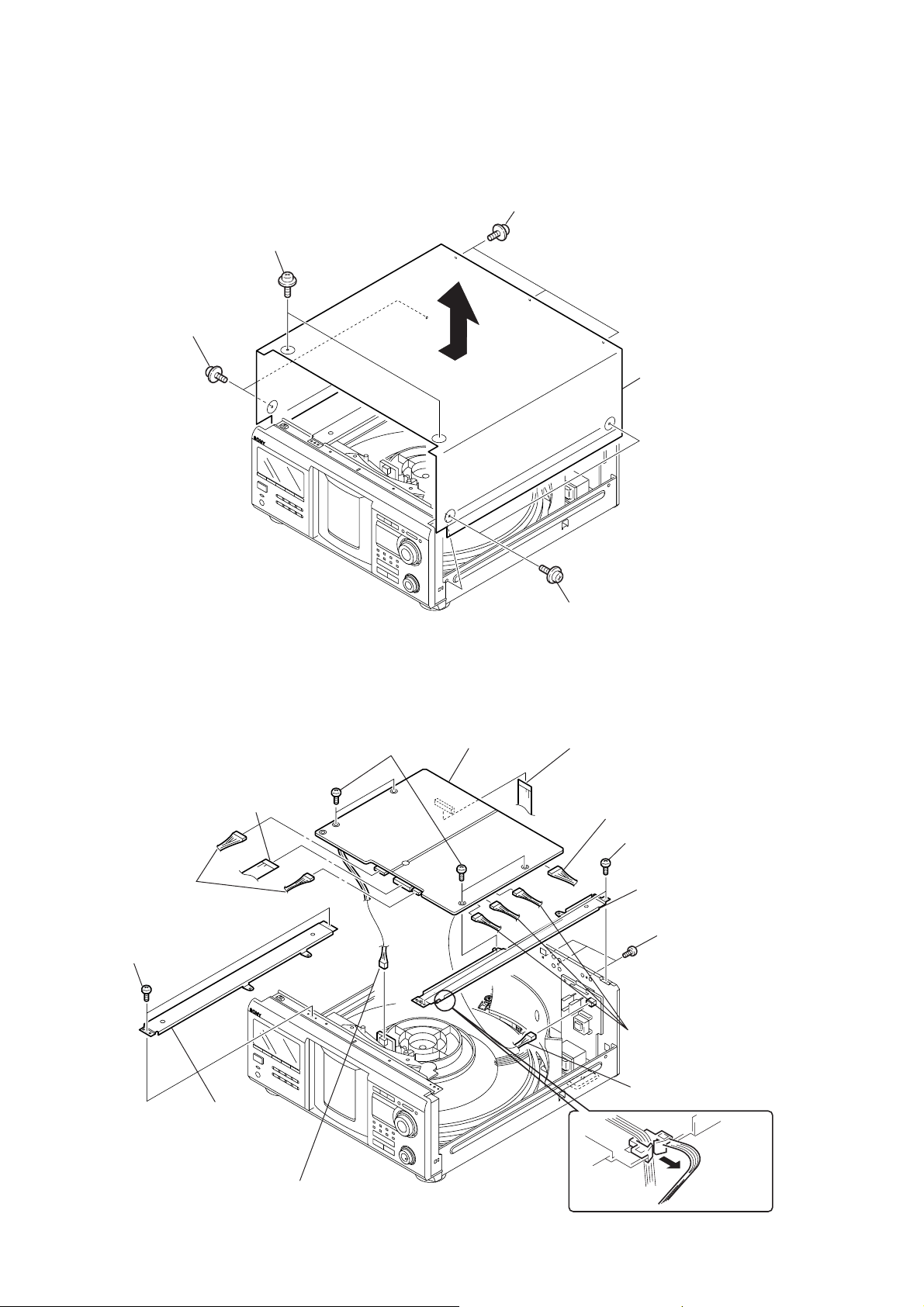

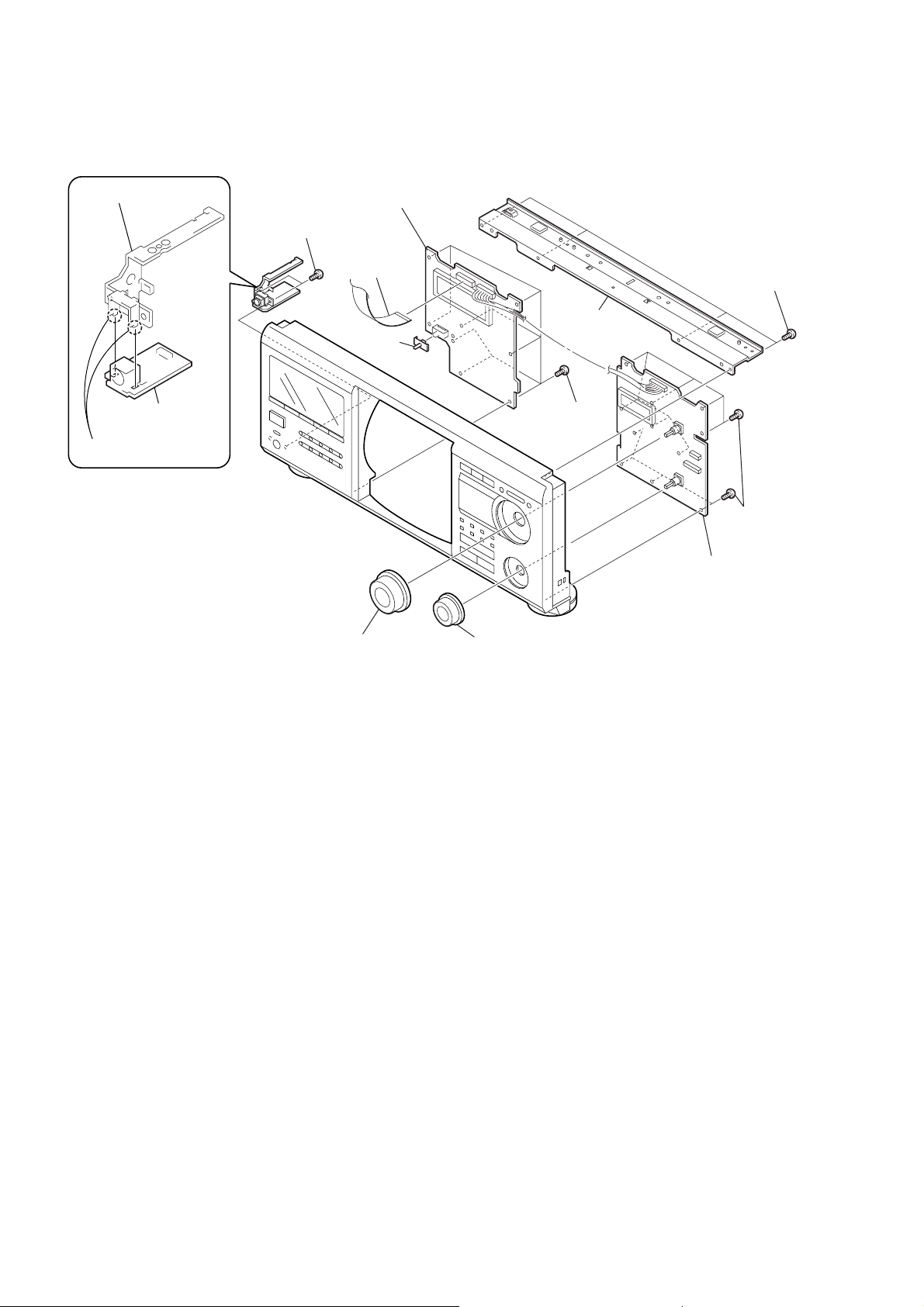

3-1. Case

2

two screws

(case 3 screw)

3

two screws

(case 3 screw)

1

three screws

(case 3 screw)

5

cas

3-2. MAIN Board

4

two connectors

(CN505, CN506)

qa

two screws

(BVTP 3 × 8)

5

flat type wire

(CN502)(17 core)

8

four screws

(BVTP 3 × 8)

0

MAIN board

4

two screws

(case 3 screw)

9

flat type wire

(CN501)(31 core)

2

connector (CN901)

qs

two screws (BVTP 3 × 8)

qg

bracket (R)

7

three screws

(BVTP 3 × 8)

1

three connectors

(CN503, CN801, CN903

3

connector (CNP902)

qf

bracket (L)

6

connector (CNP504)

qd

8

Page 9

3-3. TRANS Board

7

two screws

(PTTWH 3

A

2

connector

(CN602)

CDP-CX555G

5

screw (BVTP 3 × 8)

×

6)

A

6

bracket (PT)

3

connector (CN603)

8

TRANS board

3-4. Front Panel Assembly

3

4

screw

(BVTP 3 × 8)

connector (CNP503)

4

connector

(CN601)

7

2

Remove the claw.

1

connector

(CN991)

5

two screws

(BVTP 3 × 8)

1

6

three screws

(BVTP 3 × 8)

8

Remove the claw.

9

front panel assembly

9

Page 10

CDP-CX555G

s

3-5. JOG Board, DISP Board, KEYBOARD Board

qd

bracket (keyboard)

qf

KEYBOARD

board

qs

Remove two solderings.

qa

two screws

(BVTP 2.6 x 8)

8

DISP board

9

flat type wire

(17 core)

0

knob

(timer)

4

bracket (case)

assembly

7

eight screws

(BVTP 2.6 x 8)

3

four screws

(BVTP 2.6 x 8)

2

knob (disc)

1

knob (AMS)

6

JOG board

5

eleven screw

(BVTP 2.6 x 8)

10

Page 11

3

screw (BVTP 3 × 16)

4

guide (door)

5

table (400) assembly

6

washer

Note during re-assembling

When re-assembling, align

the positions as shown.

1

two screws

(BVTP 3

×

8)

2

cover (PT)

3-6. Cover (PT), Table (400) Assembly

CDP-CX555G

3-7. LED Board, Guide (Door)

2

LED board

1

screw (BVTP 3 x 8)

4

3

7

guide (door)

6

window (internal illumination)

5

11

Page 12

CDP-CX555G

3-8. DOOR SW Board

1

screw (PTPWH 2.6 × 8)

2

gear (cam)

3

screw (PTPWH 2.6 × 8)

4

gear (B)

5

two screws

(BVTP 2.6

6

DOOR SW board

×

8)

Precaution during the gear (cam) installation

1

Move the slider (pop-up) and the lever (pu joint) fully

in the direction of the arrow

slider (pop-up)

The levers of the two rotary switches on the D. SW board

are shown in the illustration below.

A

A

.

lever (pu joint)

two rotary switches

DOOR SW board

2

Install the gear (cam) in the direction shown

in the illustration and rotate it fully

in the direction of the arrow

3

When the gear (cam) happens to go too deep,

return it to the original position

in the direction of the arrow

B

C

.

.

gear (cam)

B

12

C

Page 13

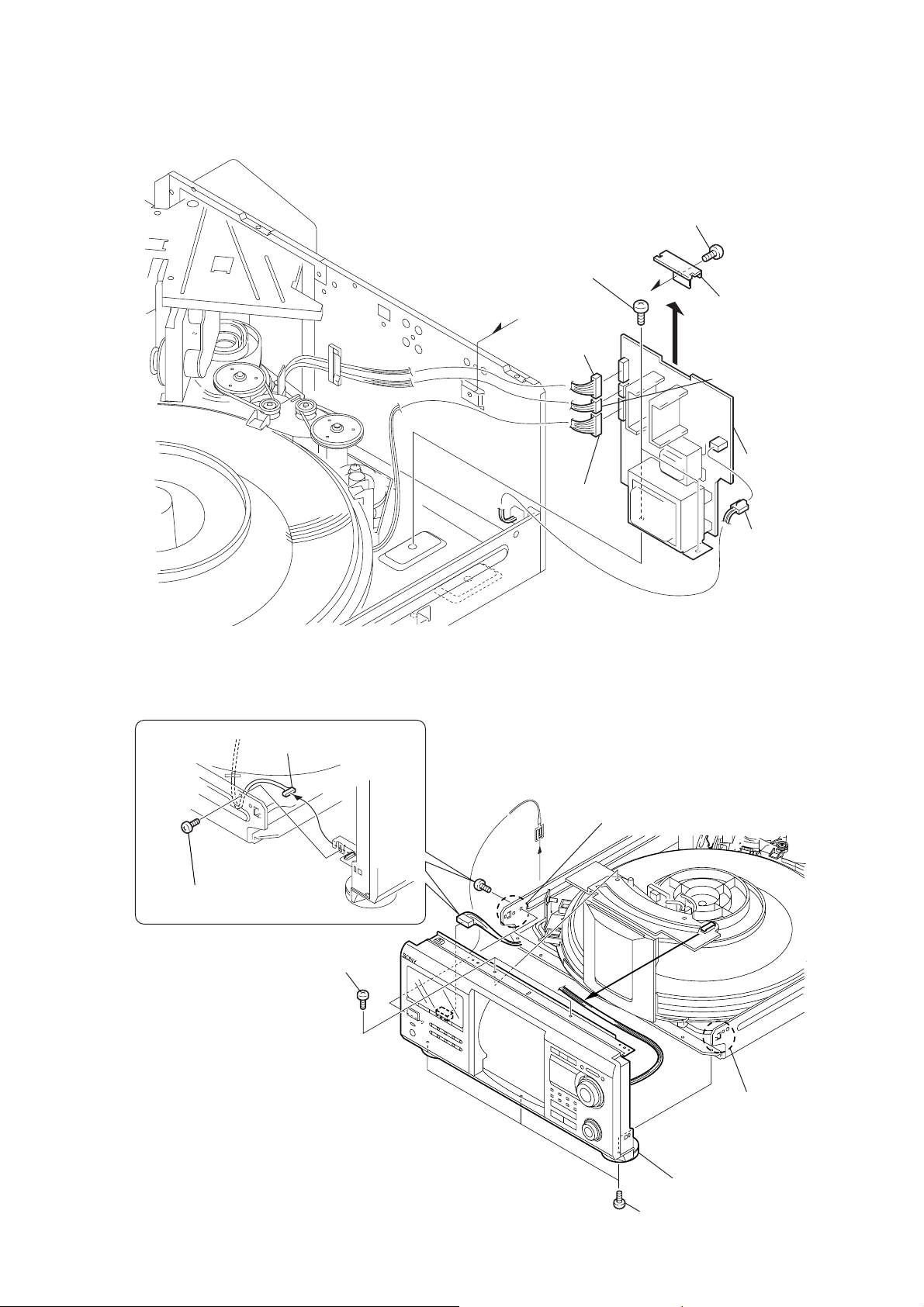

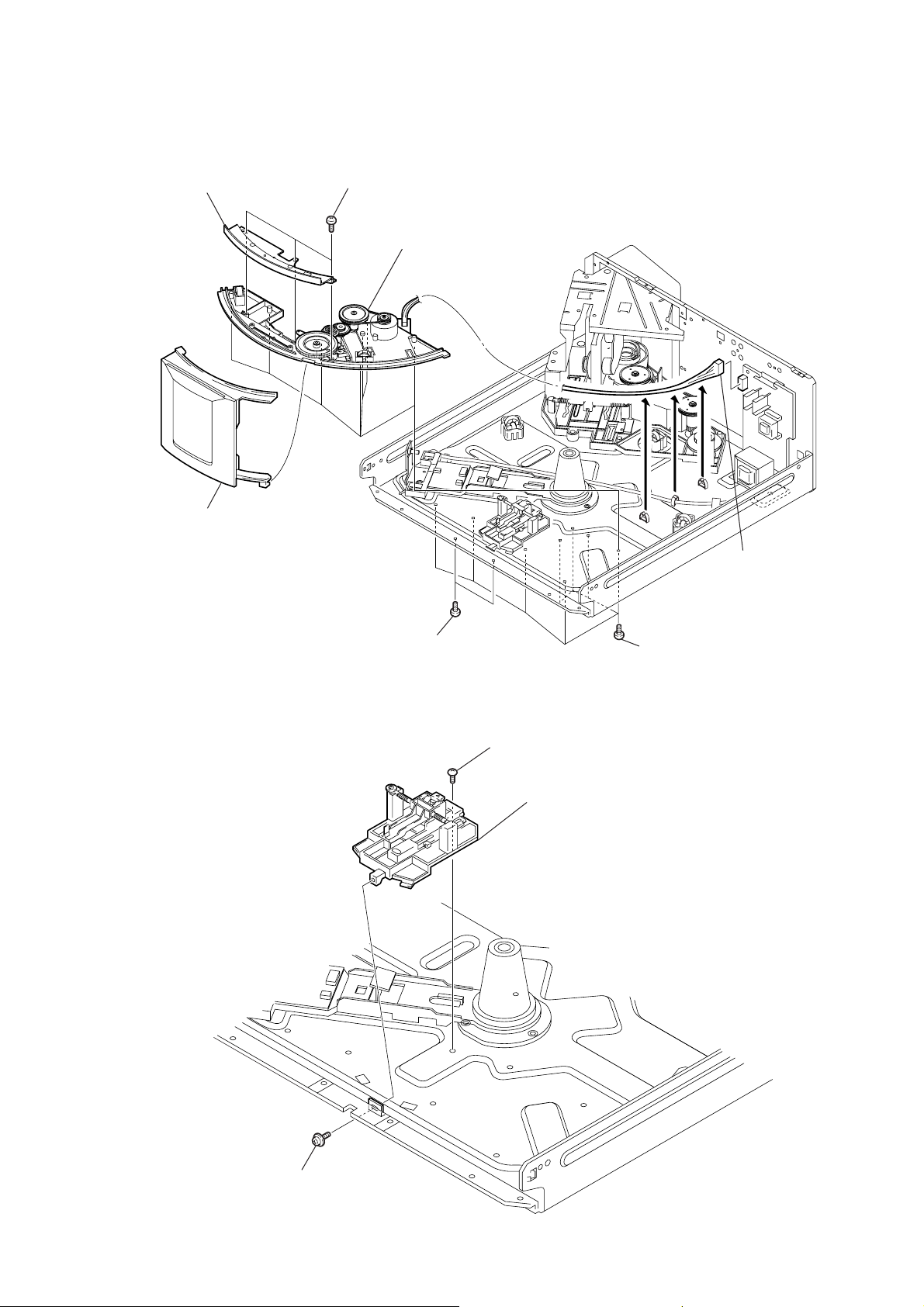

3-9. Base (Door Driving) Assembly

3

cover (table)

2

three screws (BVTP 3 × 8)

7

base (door driving)

assembly

CDP-CX555G

4

door assembly

3-10. Pop-up Assembly

5

two screws (BVTP 3 × 8)

2

step screw

3

pop-up assembly

1

connector

(CN602)

6

eight screws (BVTP 3 × 8)

1

screw (PTPWH 3 × 6)

13

Page 14

CDP-CX555G

d

3-11. D.MOTOR Board, Motor Assembly (Door) (M603)

1

belt

3-12. T.SENS Board, Holder (Table Sensor 400)

4

Remove two

solderings.

5

door motor assembly

3

2

two screws (BVTP 3 × 8)

(M603)

D.MOTOR boar

2

(CN83)

5

screw

(PTTWH 3

6

three claws

connector

×

6)

1

four screws

(PTPWH 3

4

T.SENS board

3

(CN81,CN82)

7

(table sensor 400)

×

6)

two connectors

holder

14

Page 15

3-13. D.SENS (OUT) Board, D.SENS (IN) Board

6

screw

1

screw

(PTTWH 3

4

screw

(PSW 3

×

8)

5

D.SENS (OUT) board

×

(PTTWH 3

6)

×

6)

7

D.SENS (IN) board

2

two step screws (T1)

3

bracket (sensor 400)

CDP-CX555G

3-14. Back Panel Section

4

bracket (CDM)

5

3

three screws

(BVTP 3

flat cable clamp

2

cover (CDM)

1

nine screws (BVTP 3 × 8)

×

8)

7

four screws

(BVTP 3

×

8)

8

back panel section

6

connector (CN991)

15

Page 16

CDP-CX555G

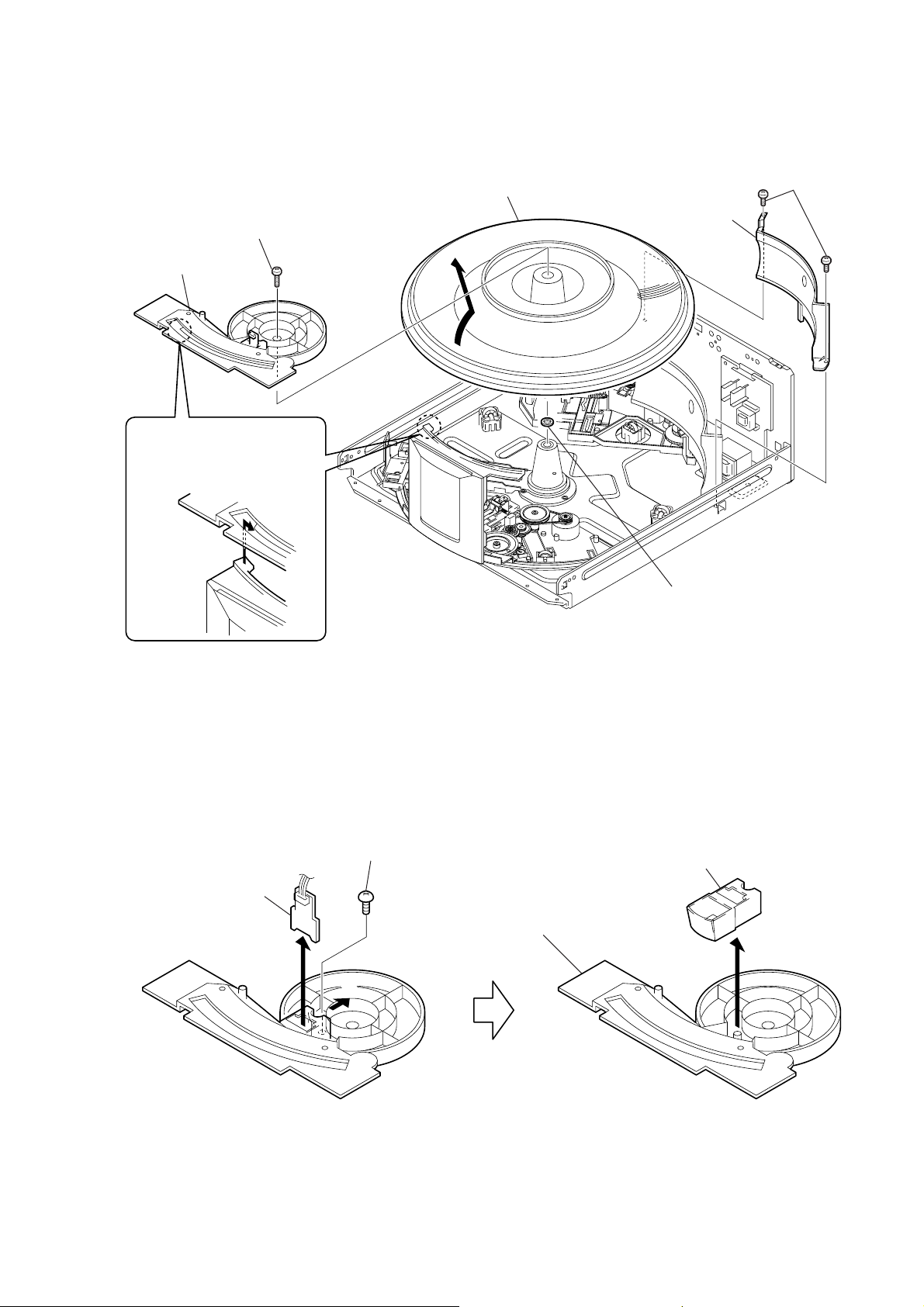

3-15. CD Mechanism, Magnet Assembly

1

three screws (BVTP 3 × 8)

3

bracket (top 400)

4

magnet assembly

5

washer

8

washer

2

three screws (BVTP 3 × 8)

7

CD mechanism

Note during re-assembling

When re-assembling,

align the positions as shown.

6

spring

16

Page 17

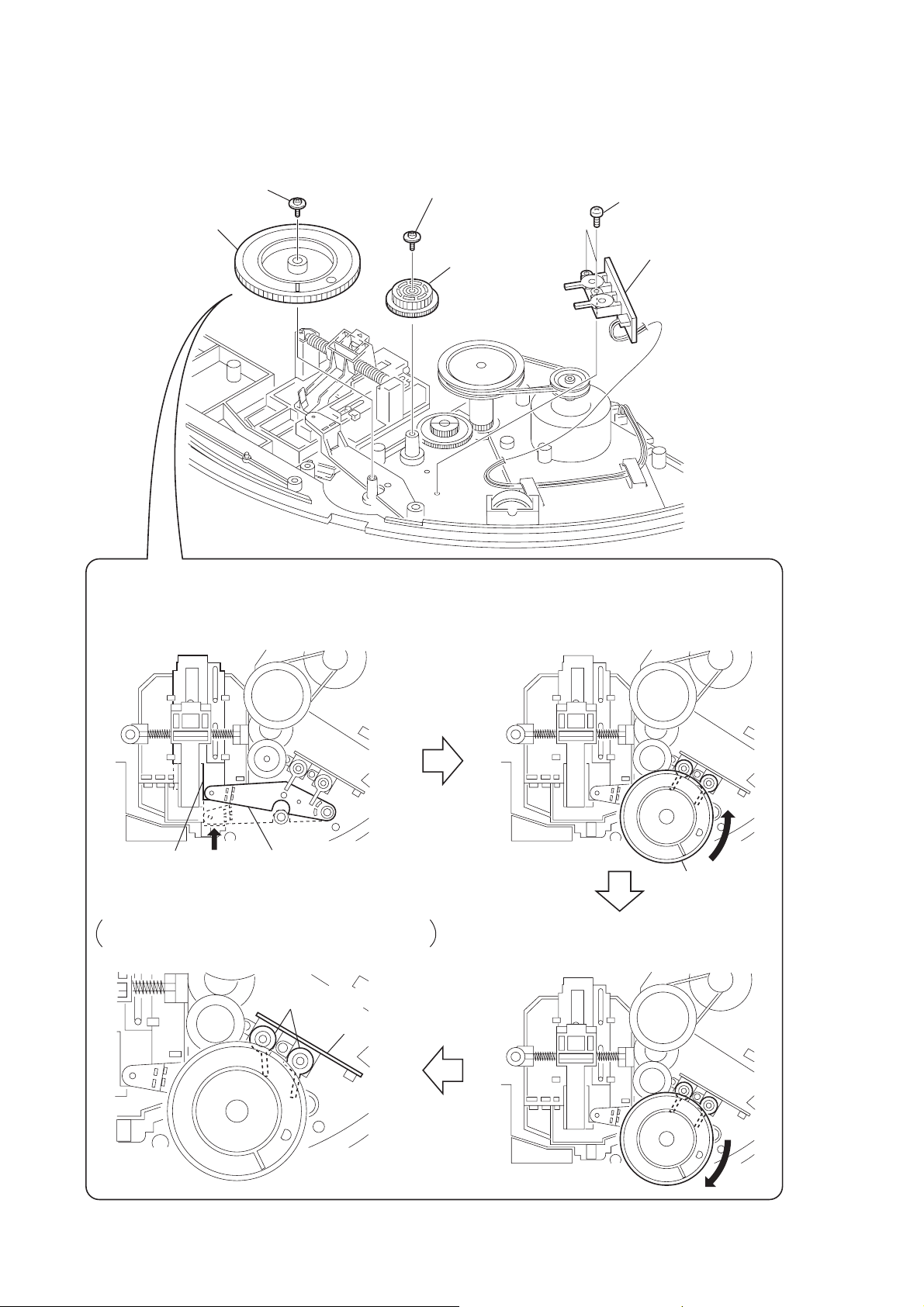

3-16. LOADING SW Board, LOCK SW Board

2

screw

(BVTP3 × 8)

A

B

1

Rotate the pulley (400) in the

direction of the arrow fully.

3

Rotate the pulley (400) in the

direction of the arrow fully.

A

B

CDP-CX555G

Note during re-assembling

When re-assembling the

LOADING SW board and

LOCK SW board,

align the leads position as shown.

LOADING SW board

LOCK SW board

Leads

position

claws

9

LOCK SW

board

8

screw

(BVTP 3 × 8)

7

gear (center)

5

tapping screw

4

belt

6

pulley (400)

0

screw

(BVTP 2.6 × 8)

qa

LOADING SW

board

17

Page 18

CDP-CX555G

)

3-17. CDM Assembly

6

CDM assembly

1

connector (CN603)

2

connector (CN601

4

four screws

×

(BVTP 3

8)

3

screw (PSW 3 × 8)

5

seven screws

(BVTP 3

×

8)

3-18. Motor Assembly (Table) (M601),Motor Assembly (Loading) (M602)

1

two belts

3

Remove two

solderings.

5

Remove two

solderings.

4

motor assembly (loading)

(M602)

6

motor assembly (table)

(M601)

7

board

L.T. MOTOR

18

2

three screws

(PTPWH 2.6

×

8)

Page 19

)

)

3-19. BU Holder

5

BU holder assy

3

tension spring (F-1)

CDP-CX555G

2

3-20. BD Board, Optical Pick-up (KSM-213BFN)

3

Remove two

solderings.

(spindle)

4

Remove two

solderings.

(sled)

4

tension spring (F-2)

9

optical pick-up

(KSM-213BFN)

1

four screws

(PTP WH 2.6 x 8

7

two vibration

proof rubbers

8

two vibration

proof rubbers

6

BD board

2

screw (+B 2 x 5)

5

wire (flat type)

(16 core) (CN102

1

wire (flat type)

(31 core)

(CN101)

19

Page 20

CDP-CX555G

SECTION 4

TEST MODE

• This unit is provided with several test modes.

Details are shown in the following tables.

<Menu Method>

Turn on the power and press TIME , MEGA CONTROL and 1/u buttons.

Rotate the DISC/ALBUM/CHARACTER dial to select any of the following modes.

Push the DISC/ALBUM/CHARACTER dial to enter the test mode.

Display

Version

BU Test

CDM Test

Aging Mode

Ship Mode

To exit the mode, usually press the 1/u button to enter the standby state.

(When selecting the Ship mode, the standby mode is automatically entered.)

<3 Buttons Method>

Mode name

DOOR POP UP AGING MODE

ALL LIT MODE

MODEL NAME DISPLAY

SPRAY MODE

SHIPMENT MODE

To exit the mode, press the 1/u button to enter the standby state.

(When selecting the Ship mode, the standby mode is automatically entered.)

Software version display

BU test mode

CDM test mode

Normal aging mode

Default mode

Contents

Power supply state

ON

ON

ON

ON

ON

Mode name

TOP AR TIST 3 + H + +100

TOP AR TIST 4 + H + +100

TOP AR TIST 6 + H + +100

TOP AR TIST 8 + H + +100

ARTIST MODE + H + +100

Power supply state

Same as Ship Mode

20

Page 21

CDP-CX555G

SOFT WARE VERSION DISPLA Y

• Software version can be displayed on the fluorescent indicator tube.

Procedure:

With the power ON, while pressing the TIME and MEGA CONTROL

buttons, press the 1/u b utton.

Rotate the DISC/ALBUM/CHARACTER dial, select “Version”

and press the dial.

Software version is displayed on the fluorescent indicator tube.

To end this mode, press the 1/u button.

BU TEST MODE

• This mode is used for electrical adjustments.

Refer to the section on Electrical Adjustment.

CDM TEST MODE

•This mode is used for mechanical adjustments and electrical

adjustments.

Refer to the section on Mechanical adjustment and Electrical

Adjustment.

AGING MODE

• Mode which repeatedly changes and plays back discs automati-

cally in the unit.

• It will repeat aging as long as no errors occur.

• If an error occurs during aging, it will stop all servos, motors, etc.

instantaneously, display the error number, and stop operations.

The function serves to maintain the state of the unit when errors

occur.

Sequence of Aging Mode

$

1. Disc change

$

2. Load in

$

3. TOC read

$

4. Access of last track

$

5. 3 second playback

$

6. Access of first track

Order of Disc Change

(1 cycle takes 3 minutes)

$

1. No. 80

$

2. No. 320

$

3. No. 240

$

4. No. 400

$

5. No. 160

$

Special Aging Mode Functions

The aging mode is provided with the following convenient functions

1.Disc setting mode:

5 discs are set before setting the aging mode. This mode makes

the setting of these discs more easy.

2.Aging disc count function:

Functions which displays the number of aging discs carried out

on the Fluorescent indicator tube in numbers.

Aging Procedure

1. Turn on the power and press the TIME , MEGA CONTROL

and 1/u buttons.

2. Rotate DISC/ALBUM/CHARACTER dial, select “Aging

Mode” and press the dial to start the aging mode.

3. When the disc set mode is set, the · and P LEDs blink.

4. Rotate the DISC/ALBUM/CHARACTER dial. The slits (No.

80, 160, 240, 320, 400) for setting the discs will come forward.

Insert the discs into these slits. Do not set the discs in other

slits.

5. Press the · button.

6. The · LED blinks, the aging mode is set, and aging is started.

7. The aging cycle lasts 3 minutes. If errors occur during aging,

the error number will be displayed on the Fluorescent indicator

tube. (Refer to the following table for the details of the errors.)

8. Aging will be repeated as long as no errors occur.

9. After disc load out, the number displayed on the Fluorescent

indicator tube will increase.

10. To end aging, press the 1/u button .

If an error occurs and the 1/u button is useless, disconnect the

power cord from the outlet.

Display in aging cycle

AGED 10

DISC 180

$

7. 3 second playback

$

8. Load out

$

21

Page 22

CDP-CX555G

Error Display

1. Disc sensor error

120

1

PROGRAM 1 2 3 X-FADE DELETE

MULTI

Disc number

with error

Error code

Code number

2. Mechanism error

12 34 56 78

1

PROGRAM 1 2 3 X-FADE DELETE

CDTEXT

MULTI

Error code1

Error code2

Error code 1

Code number

0X

1X

2X

3X

4X

FX

X : negligible number

SECSTEPMINART.

CDTEXT

DISC

NO DELAY

HITART.NEXT2nd

REPEATSHUFFLE 1

CD2

GROUP

CD3

alternating

Y

GROUPTRACK

1234

Aging counter

Contents

No disc in the speified slit, or Disc in the

other slits

DISC

NO DELAY

HITART.NEXT2nd

REPEATSHUFFLE 1

CD2

CD3

GROUPTRACK

GROUP

Error code3

Y

alternating

SECSTEPMINART.

Error code4

1234

Aging counter

Contents

With no problem

With no problem

Error during door initialization

Error during loading initialization

Error during door initialization

With no problem

Error code 2

Code number

1X

2X

3X

4X

X : negligible number

Error code 3

Code number

1X

2X

X : negligible number

Error code 4

Code number

0X

1X

X : negligible number

3. BD error

DISC

12 34 56

1

PROGRAM 1 2 3 X-FADE DELETE

MULTI

CDTEXT

The state

during aging

Error code

Code number

01

02

03

04

05

06

Contents

Error during loading in

Error during loading out

With no problem

With no problem

Contents

Error during table operation

With no problem

Contents

With no problem

Error during table operation

SECSTEPMINART.

NO DELAY

HITART.NEXT2nd

REPEATSHUFFLE 1

CD2

GROUPTRACK

GROUP

CD3

alternating

Y

1234

Aging counter

Contents

From chucking to TOC read

From chucking to TOC read

From TOC read to end of last track playback

From TOC read to end of last track playback

From end of last track playback to end of first

track playback

From end of last track playback to end of first

track playback

22

Page 23

CDP-CX555G

SHIPMENT MODE

• This mode is used for setting the unit to the shipment state.

Do not execute it without a proper reason as it erases the

memory of the title memo recorded by the customer.

Procedure1:

With the power ON, while pressing the TIME button and MEGA

CONTROL button, press the 1/u button.

Rotate the DISC/ALBUM/CHARACTER dial, select “Ship Mode”

and press the dial. “-OFF-” is displayed and the standby mode is

automaticaly entered.

Procedure2:

With the power ON, while pressing the ARTIST MODE button

and H button, press the +100 button. “-OFF-” is displayed and

the standby mode is automatically entered.

DOOR POP UP AGING MODE

• This mode is used for performing aging of the CD pop up part

and door open/close.

It is used for checking if operations are performed normally.

Procedure1:

1. With the power ON, while pressing the TIME button and

MEGA CONTROL button, press the 1/u button.

2. Rotate the DISC/ALBUM/CHARACTER dial, select “CDM

Test”and press the dial.

3. Rotate the DISC/ALBUM/CHARACTER dial, select

“DoorPopup Aging” and press the dial.

4. Aging starts, and door open/close and up/down operations of

the pop up part are performed continuously.

5. To end this mode, press the 1/u button.

ALL LIT MODE

• This mode is used for lighting the whole fluorescent indicator

tubes and LEDs.

Procedure:

With the power ON, while pressing the TOP ARTIST4 and ·

buttons, press the +100 button.

Both the fluorescent indicator tubes and LEDs will light up

completely.

To end this mode, press the 1/u button.

MODEL NAME DISPLAY

• Model names can be displayed on the fluorescent indicator tube

for checking the microprocessor model setting, etc.

Procedure:

With the power ON, while pressing the TOP ARTIST6 and ·

buttons, press the +100 button.

The model name is displayed on the fluorescent indicator tube.

To end this mode, press the 1/u button.

SPRAY MODE

• This mode is used for the electrical adjustments.

Refer to the sedtion on Electrical Adjustment.

Procedure2:

1. With the power ON, while pressing the TOP ARTIST 3 b utton

and · button, press the +100 button.

2. Aging starts, and door open/close and up/down operations of

the pop up part are performed continuously.

3. To end the mode, press the 1/u button.

23

Page 24

CDP-CX555G

ADJ Mode

1. Turn ON the power of the unit, set disc to disc table, and perform

chucking.

2. Disconnect the power supply plug from the outlet.

3. To set ADJ mode, connect the test point (ADJ) of the MAIN

board to Ground, and connect the power supply plug to the

outlet.

In this mode, table rotation and loading operations are not performed

because it is taken that the disc has already been chucked.

Note: The same operations are also performed in the following when

the test point (ADJ) is connected to Ground after turning on

the power.

• Direct search (movement of sledding motor) is not performed dur-

ing accessing

• Ignored even when GFS becomes L

• Ignored even when the Q data cannot be read

•Focus gain does not decrease

To end the ADJ mode

1. Press the 1/u button and disconnect the plug.

2. Remove the wire between ADJ and GND.

Key and Display Check Mode

To set this mode, connect the test point (AFADJ) on the MAIN

board to Ground, and connect the power supply plug to the outlet.

Note:When this mode is executed, all title memos recorded will be

erased.

•When this button is pressed, “line # No. #” will be displayed.

However, these will not be displayed for the following special

buttons. However, these will not be displayed for the following

special buttons.

p (stop) button: FL segment check

(Refer to FL Tube Check Patterns)

P (pause) button: FL grid check

(Refer to FL Tube Check Patterns)

The P LED also lights up simultaneously.

· (play) button: All FL segment and grid will light up.

· LED also lights up simultaneously.

TIMER switch: When the switch position is PLAY , the

STANDBY LED lights up. It goes OFF

when set to OFF .

Each time this button is pressed, the value of the “Got ## keys”

increases. Buttons pressed once will not be counted when pressed

again.

FL Tube Check Patterns

Segment check

Grid check

Magnified

A B C D E F G

•When the jog dial and AMS is rotated to the right, the TOP AR T-

IST LEDs light up in the order of 1n 2..8n ARTIST

MODEnHISTORY ALBUM SELECTnMEGA CONTROL

n1.

•When the jog dial and AMS is rotated to the left, the TOP ART-

IST LEDs light up in the order of 8n7..1 nMEGA CONTR OL

ALBUM SELECTnHISTORYnARTIST MODEn8.

• Abbreviation

FL: Fluorescent Indicator Tube

To end the ADJ mode

1. Disconnect the plug.

2. Remove the wire between AFADJ and GND.

24

Adjustment Location: MAIN board (See page 28)

Page 25

SECTION 5

L

T

Holder (table sensor 400)

S tight, screw

(PTTWH 3

×

6)

Swing

Table (400) assembly

At this position,this

part will be locked.

ADJUSTMENTS

CDP-CX555G

Mechanical Adjustments

Pop Up Mechanism Adjustment

1. Turn on the power and set the disc to number 24.

2. With the power ON, while pres sing the TIME and MEGA

CONTROL buttons, press the

3. Rotate the JOG dial and select “CDM Test”.

Press the JOG dial.

4. Rotate the JOG dial and select the mechanism adjustment mode.

(“Mech Adjust” is displayed.)

Press the JOG dial.

5. Keep pressing the TOP AR TIST 1 button to operate the loading

mechanism, and continue pressing until the disc table locks.

(Fig. 1)

6. Keep pressing the TOP ARTIST 2 button to raise the pop up

part.

7. Loosen the adjusting screw , move the screwdri ver left and right

until the lever (POP UP) does not touch the slit wall, and secure

the screw. (Fig. 2)

The following buttons have special functions in this mode.

TOP ARTIST 1 button: Loading mechanism IN operation

TOP ARTIST 5 button: Loading mechanism OUT operation

TOP ARTIST 2 button: Pop up part UP operation

TOP ARTIST 6 button: Pop up part DOWN operation

button to enter the test mode.

1/u

Table Sensor Adjustment

1. Enter the CDM Test mode and select “Mech Adjust” with the

JOG dial, and press the dial.

2. Press the TOP ARTIST 1 b utton to operate the loading mechanism,

and continue pressing until the disc table locks. (Fig. 3)

3. Loosen the fixing screw and move the holder so that both PLAY

button LED (green) and the ALBUM SELECT button LED

(green) light.

If the holder is not in the correct position, the MEGA

CONTROL button LED (orange) or the PA USE b utton LED

(orange) lights.

4. Moving the disc table right and left with a hand after the screw

is fixed, the table will move by the play of a disc table. If the

LEDs light up alternately, the adjustment will be performed

correctly. (Fig. 4)

ALBUM SELEC

MEGA CONTRO

Cover (chassis 400)

Lever (POP-UP 400)

At this position,this

part will be locked.

Fig. 1

Fig. 3

Fix to the center so that the

lever (POP-UP 400) does

not touch the slit.

Fig. 2

Fig. 4

25

Page 26

CDP-CX555G

s

oscilloscope

BD board

TP (RFAC)

TP (DVC)

V

Electrical Adjustment

Note:

1. CD Block is basically designed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent

when the signal level is low than specified value with the

following checks.

S-Curve Check

oscilloscope

BD board

TP (FE1)

TP (DVC)

Procedure :

1. Chuck the disc (YEDS-18) beforehand.

2. Connect oscilloscope to test point TP (FE1) on BD board.

3. With the power ON, while pressing the TIME and MEGA

CONTROL buttons, press the 1/u button.

Rotate the DISC/ALBUM/CHARACTER dial, select “BU

Test” and press the dial.

4. Rotate the DISC/ALBUM/CHARACTER dial, and select “bdt

S CURVE”. Press the dial “LD AL” is displayed.

5. Check the oscilloscope waveform (S-curve) is symmetrical

between A and B. And confirm peak to peak level within 3±1

Vp-p.

RF Level Check

Procedure :

1. Connect oscilloscope to test point TP (RFAC) on BD board.

2. Turn Power switch on.

3. Put disc (YEDS-18) in to play the number five track.

4. Confirm that oscilloscope waveform is clear and check RF

signal level is correct or not.

Note: A clear RF signal waveform means that the shape “◊” can be

clearly distinguished at the center of the waveform.

RF signal waveform

VOLT/DIV : 500m

TIME/DIV : 1 µs

level : 1.2 Vp-p

+0.25

–0.20

Adjustment Location: BD board (See page 28)

S-curve waveform

symmetry

A

B

Within 3

VOLT/DIV : 1V

TIME/DIV : 400

±

1 Vp-p

µ

6. Pressing the MENE/NO button stops the output of the

waveform (S CURVE). “bdt S CURVE”is displayed.

7. To end this mode, press the ?/1 button.

Note : •Try to measure sev eral times to make sure than the ratio of

A : B or B : A is more than 10 : 7.

•Take sweep time as long as possible and light up the

brightness to obtain best waveform.

Adjustment Location: BD board (See page 28)

26

Page 27

CDP-CX555G

S

S

S

Disc Sensor Adjustment

Be sure to perform this adjustment after sensor adjustment in

MECHANICAL ADJUSTMENT .

Connection:

MAIN board

TP1

D.SENS OUT

GND

H-H OUT

D.SENS OUT: Pin

GND: Pin

H-H OUT: Pin

1

2

3

oscilloscope

CH1 CH2

Waveform:

CH1

CH2

D.SEN

H-H

1. Connect the oscilloscope to Pins 1, 2, and 3 of TP1 of the

MAIN board.

2. Check that no discs are loaded in the unit.

3.

With the power ON, while pressing the TIME and MEGA

CONTROL buttons, press the 1/u button. Rotate the DISC/

ALBUM/

CHARACTER dial, select “CDM Test” and press the

dial.

Rotate the DISC/

ALBUM/

CHARACTER dial and select

“TableRotation” and press the dial.

The disc table starts to rotate in the clockwise direction.

4. Loosen the fixing screw , move the mounting board (SENSOR),

and secure the mounting board (SENSOR) at the point the H

portion of the H-H waveform comes the center of the H portion

of the D.SENS waveform.

D. SENS (OUT) board

5. Rotate the DISC/ALBUM/CHARACTER knob in the

counterclockwise direction and the disc table starts to rotate in

the same direction. Check that the waveform at this time is the

same as that in step 4. If larger by a considerable extent, rotate

the DISC/ALBUM/CHARACTER knob in the clockwise

direction and the disc table starts to rotate in the same direction.

Repeat from step 4.

6. Rotate RV501 of the MAIN boar d and adjust so that the H and

L portions of the D.S waveform become the same.

CH1

Adjust so that these widths

become the same.

D.SEN

Adjustment Location: MAIN board (See page 28)

Spray Mode

• This mode is used for the measurement of the table sensor signal

outputs characteristics.

Procedure :

1. Check that no discs are loaded in the unit.

With the power ON, while pressing the TOP ARTIAT 8 and

H buttons, press the +100 button.

“Spray Mode” is displayed.

2. Press the H button to start the measurement. “Now ···ing” is

displayed during the measurement of one rotarion.

3. The result of the measurement is displayed as below.

display

DISC

P=3.6V b=1.4V

1

PROGRAM 1 2 3 X-FADE DELETE

NO DELAY

MULTI

CDTEXT

Minimum value

of the peak at the

High/High part of

TSENS1/TSENS2

HITART.NEXT2nd

REPEATSHUFFLE 1

CD2

GROUPTRACK

GROUP

CD3

Maximum value

of the bottom at the

LOW/LOW part of

TSENS1/TSENS2

SECSTEPMINART.

CH1

CH2

s tight, screw

(PTTWH 3

×

6)

Should be at the center

4. To end this mode, press the

D.SEN

1/u button.

H-H

27

Page 28

CDP-CX555G

Adjustment Location :

[ BD BOARD ] – Conductor Side –

IC 101

TP(RF AC)

TP(DVC)

TP(FE1)

[ MAIN BOARD ] – Component Side –

RV501

DISC SENSOR

ADJUSTMENT

IC 103

– Conductor Side –

GND

TP(AFADJ)

28

TP(ADJ)

IC504

IC501

TP1

13

Page 29

d

d

SECTION 6

LED board

MAIN board

TRANS board

D. MOTOR board

JOG board

BD board

DOOR SW board

T. SENS board

KEYBOARD board

D. SENS

(OUT) board

DISP board

D. SENS (IN) board

LOADING SW board

L. T. MOTOR board

LOCK SW board

DIAGRAMS

CDP-CX555G

THIS NOTE IS COMMON FOR PRINTED WIRING

BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed

in each block.)

For schematic diagrams.

Note:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

¢

•

• C : panel designation.

Note: The components identified by mark 0 or dotted line

• A : B+ Line.

• B : B– Line.

• H : adjustment for repair.

•Voltages and waveforms are dc with respect to ground

•Voltages are taken with a V OM (Input impedance 10 MΩ).

•Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

: internal component.Note:

with mark 0 are critical for safety.

Replace only with part number specified.

under no-signal (detuned) conditions.

no mark : STOP

Voltage variations may be noted due to normal production tolerances.

Voltage variations may be noted due to normal production tolerances.

J : CD

c : digital out

4

W or less unless otherwise

For printed wiring boards.

Note:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

®

•

• : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from the

(Side B) pattern face are indicated.

Parts face side: Parts on the parts face side seen from the

(Side A) parts face are indicated.

: Through hole.

• Indication of transistor

C

Q

EB

These are omitte

Waveforms

1

IC104 yd XO

59ns

1V/DIV, 20ns/DIV

2

IC103 qg (RFAC)

(PLAY)

500mV/DIV, 1µs/DIV

3

IC101 ra TE

APPROX 500mVp-p (PLAY)

200mV/DIV, 20ms/DIV

4

IC101 el FE

APPROX 500m Vp-p (PLAY)

200mV/DIV, 4ms/DIV

5

IC101 wg MDP

7.5 µs

1V/DIV, 4µs/DIV

6

IC501 ek X2

62.5 ns

1V/DIV, 20ns/DIV

6-1. Circuit Boards Location

3.8Vp-p

1.3Vp-p

1.65V

1.65V

2.1 Vp-p

3.5 Vp-p

C

EB

These are omitte

2929

Page 30

CDP-CX555G

6-2. Block Diagrams – BD Section –

OPTICAL PICK-UP

BLOCK

(KSM-213BFN)

VC

A

B

C

D

E

F

LD

GND

PD

VR

F+

FOCUS

COIL

TRACKING

COIL

• R-CH is omitted due to same as L-CH

• Signal Path

F-

T+

T-

+5V

: CD

: DIGITAL OUT

Q101

LD

DRIVE

(SLED)

(SPINDLE)

IC101

IC103

RF AMP

RF AC

VC

27

A

6

B

7

C

8

D

9

E

10

F

11

LD

1

PD

2

IC150

MOTOR/COIL DRIVE

CH1RO

18

CH1FO

17

CH2FO

12

CH2RO

11

CH3FO

14

RFDCO

RFDCI

FEI

SW

CH1RI

CH1FI

CH2FI

CH2RI

CH3FI

15

28

29

FE

16

17

TE

18

12

22

23

6

7

4

M

13

16

CH3RO

CH4RO

CH3RI

CH4INS

5

2

M

CH4FO

15

MUTE

20

DIGITAL SERVO

DIGITAL SIGNAL PROC.

RFAC

50

RFDC

43

FE

39

TE

41

SE

40

FFDR

33

FRDR

34

TFDR

31

TRDR

32

SFDR

29

SRDR

30

MDP

25

D OUT

PCMD

BCLK

LRCK

XTAI

XTAO

DATA

CLOK

XLAT

SQCK

SCLK

SCOR

SQSO

SENS

SSTP

XRST

+3.3V

IC901

+3.3V

OPTICAL

OUT

12

13

14

60

62

63

S101

(LIMIT IN)

+5V

64

66

67

65

71

72

X201

16.9MHz

4

6

5

77

8

15

76

7

26

2

IC121

+3.3V

4

REG

1

+2.5V

5+2.5V

REG

DIGITAL

OPTICAL

OUT

IC104

D/A CONV,

MP3 DECODER

SDIO

BCKIA

LRCKIA

CKO

XI

XO

MP3REQ

LO

RO

PO5

SDA

SCL

RESET

23

36PO4

26

37

5

6

43A MUTE

1

39

LOUT

LMUTE

R-CH

R-CH

IC105

89

10 11

43

Q501,502

MUTE CONT

65

12 13

21

Q327

IC401

LPF

31

IC501 (1/2)

SYSTEM CONTROL

SDA

97

SCL

99

A MUTE

18

MP3RST

7

MP3REQ

96

DATA

4

CLK

5

XLT

20

SQCK

17

SCOR

95

SUBQ

15

SENS

6

46

19

12

11

98

DOOROUT

XRST

PWM3

PWM2

PWM1

RF SW

IC302

AMP

21

SMUTE

29

DOORSW

DOORIN

TBLL

TBLR

TSENS1

TSENS2

TSENS3

TSENS4

DSENS

78

79LDSW

25LDIN

24LDOUT

27

26

23

22

87

91

88

92

86

IC302

AMP

67

Q321,325,326,

328,329

MUTE CONT

+5V

+5V

RV501

DISC

SENSOR

Q552

Q562

IC81-84

TABLE

SENSOR

Q81,D81

SENSOR

Q322

MUTE

Q941,942

MOTOR

SWITCH

Q951,952

MOTOR

SWITCH

DISC

Q324

MUTE

Q323

MUTE

6

7

4

3

4

6

DOWN

OPEN

CLOSE

(LOADING)

S622

(LOCK)

IC961

MOTOR

DRIVE

IC941

MOTOR

DRIVE

UP

S621

J903

S612

(POP UP)

S611

(DOOR)

8

2

2

8

M

M

M

2ND

CD IN

ANALOG

OUT

M602

(LOADING)

M603

(DOOR)

M601

(TABLE)

3030

Page 31

– Main Section –

IC504

SRAM

11

D801

(INSIDE)

D710

STANDBY

13

.

15

19

D0

D7

J821

BOARD

CONTROL

3

RECEIVER

+5V

A0

A14

WE

KEY

IC703+5V

REMOTE

CDP-CX555G

IC501 (2/2)

SYSTEM CONTROL

50

D0

57

D7

FLDATA

1

FLCLK

10

3

.

25

23

.

21

.

2

.

26

.

1

Q551

CE

20

27

X501

16MHz

Q571

Q570

1

Q572

LED

DRIVE

Q576

LED

DRIVE

66

73

.

63

60

.

65

.

49

.

64

47

48

39

38

89

85

45

93

13

31

30

A0

A14

CE

WE

X1

X2

KBDO

KBDI

KBCO

KBCI

RMIN

LED

SB_LED

FLT1

LEDLAT

FLRST

FLDATAI

TJOG1

TJOG2

KEY0

POWER

44

100

43FLT2

84DJOG1

81DJOG2

83

82

80

90

34RESET

94ACIN

2

3

8

RE701

AMS

RE702

DISC/

CHARACTER

S761-768

FUNCTION

KEY

63

DA

62

SCK

61

CS

60

RESET

4

DATA

8

CLK

7

RST

6

LT

IC701

FL DRIVER

DIG1

DIG15

DIG16

SEG01

SEG35

IC702

LED DRIVER

S701-706

FUNCTION

S711-714

FUNCTION

S721-726

FUNCTION

S741-745

FUNCTION

S751-755

FUNCTION

QC

QP

KEY

KEY

KEY

KEY

KEY

40

54

55

39

4AD1(36)

24

13,

11,

12

F1 F2

Q701

5

D701-709,711,

S714,S721

13

15

5

14

12

11

10

9

7

6

FLUORESCENT

INDICATOR TUBE

712,715

IC704

FL DRIVER

SEG0

SIN

SEG8

CLK

RESET

SEG9

SOUT

SEG14

CS

AD0

AD1

AD2

AD4

AD5

FL701

FL702

FLUORESCENT

INDICATOR TUBE

F1 F2

F1

F2

FL701

VFL

F1

F2

FL702

VFL

-20V REG

43

35

34

29

Q941, 942

Q951, 952

AU VCC

Q931

REG

AU VEE

(IC703, 501, 503) +5V

DVDD (+5V)

MUTE

+5V

+7V

+5V

M +B

M -B

D913

Q941

3

3

3

IC930

+5V

3

REG

IC931

+5V REG, RESET

5

VOUT

2

RST

IC910

IC920

IC921

VIN

+5V

REG

+7V

REG

+5V

REG

2

4

Q911

-30V REG

1

1

1

D911

RECT

D921-924

RECT

D931-934

RECT

D901-904

RECT

D905,906

RECT

T911

T901

L991

LINE

FILTER

AC

IN

ICSW

BUSIN

BUSOUT

Q901

28

16

14

Q950

J901

CONTROL A1 II

J902

RELAY

DRIVE

RY991

3131

Page 32

CDP-CX555G

6-3. Printed Wiring Board – BD Board –

12

A

B

• See page 29 for Circuit Boards Location.

34567891011

IC150

C

D

E

F

IC101

IC104

IC103

IC105

IC121

• Semiconductor

Location

Ref. No. Location

IC101 D-8

IC103 E-8

IC104 D-10

IC105 E-1

IC121 F-2

IC150 C-7

Q101 F-4

3232

Page 33

CDP-CX555G

6-4. Schematic Diagram – BD Board –

T

F

CN101

4

0

5

X

0

V

1

L

4

IC

7

C

T

R220

31P

F

.1

0

6

7

2

C

1k

• See page 29 for Waveforms. • See page 44, 45 for IC Block Diagrams.

• See page 46 for IC Pin Function Description.

C258

24p

CH

X201

16.9MHz

R253

1k

C259

0.1

F

FB102

C263

10

FB103

6.3V

FB104

0

F

p

0

0

k

0

0

2

1

2

1

1

7

7

2

2

R

C

C232

0.1

F

FB105

C266

0.1

F

IC121

BA33C25FP

FB101

C231

100

10V

C297

0.1

F

C208

C229

0.1

0.1

F

F

C207

0.1

F

C257

B

0.33

C254

22p

CH

R251

220

R252

1M

C269

6.3V

C253

0.1

F

C251

0.1 F

R265

220

2200p B

C260

220

4V

C201

220

4V

F

10

TC94A20F-CX4

47

4V

C267

k

p

0

0

0

2

1

2

4

0

5

7

2

2

R249

R

C

470

0

2

2

0

5

C256

2

0.1

R

F

IC104

C261C264

C252

0.1

47

F

4V

R266

220

C268

2200p

B

FB251

F

.1

0

5

5

2

C

FB292

0

C292

1

F

C250

0.1 F

FB291

0

C265

47

4V

0.1 F

C227

R230

220

470

R231

470

R232

470

R233

C203

1000p

R216

B

1M

R213

0

C206

47 4V

C202

0.1

F

C205

0.1

F

C230

0.1 F

C121

10

6.3V

C119

1

F

TP5

RFAC

C213

3300p

B

FB111

0

R102

R105

10k

1k

C104

C101

3300p

470p

B

CH

C102

R103

100k

0.1 B

C226

47

4V

7

0

M

2

1

R

k

.2

2

C209

6

100p

0

2

CH

R

k

1

8

0

1

4

2

1

R

2

R

0

5

0

B

1

0

C212

B

2

0

2200p

B

B

.1

0

1

1

2

k

C

1

5

0

2

R

1

C

7

4

.0

0

6

1

k

2

0

C

0

1

k

3

0

k

0

1

.2

2

2

2

R

0

4

2

0

R

2

R

IC101

CXD3068Q

R215

0

C224

k

0.1

3

3

F

1

0

2

R

S101

TP7

DVC

C223

C222

47

0.1

4V

F

k

1

9

1

2

R

TP6

RFDC

0

1

0

1

R

R104

10k

C103

E

E

470p

E

S

F

T

2

P

T

CH

4

3

P

P

T

T

R120

120k

C107

22p CH

C115

C117

0.1 F

100

10V

R117

100k

C116

0.1

B

R114

160k

R111

120k

R113

3.9k

8

k

1

0

1

1

R

C108

C111

0.1

F

R133

2.2k

R132

470k

R131

B

7

.4

0

3

3

1

C

100k

B

B

p

p

0

0

0

0

7

7

4

4

1

2

3

3

1

1

C

C

C158

R151

2200p

100k

B

220k

R152

R156

0

C152

0.1 F

C151

0.1

F

C150

100

10V

IC103

CXA2581N

47

4V

IC150

BA5947FP

C120

47

4V

C109

R126

12k

0.1

F

R125

12k

C110

0.1

B

R122

100k

R153

0

R155

TP8

MGND

TP10

VC

TP11

TP12

TP20

0

VCC

E

TP13

D

TP14

A

TP15

PD

C114

1000p B

Q101

2SB710

R124

10

C113

100

10V

R123

10

TP1

C118

CN102

1

16P

F

B

TP16

C

TP18

TP17

AGND

F

TP19

LD

TP9

IOP

TP21

TP22

TP23

TP24

TP25

TP26

TP27

TP28

3333

Page 34

CDP-CX555G

6-5. Printed Wiring Board – MAIN Board –

12

A

B

C

D

E

F

• See page 29 for Circuit Boards Location.

3456789

(Page 42)

IC921

IC920

IC402

IC901

IC302

IC910

IC401

(Page 42) (Page 42)

IC930

IC931

KEYBOARD

(Page 37) (Page 38)

(Page 40)

DISP

(Page 38)

(Page 40)

• Semiconductor

Location

Ref. No. Location

D327 D-4

D329 D-3

D501 G-4

D502 H-7

D551 G-8

D941 C-8

D942 C-8

IC302 F-3

IC401 E-4

IC402 E-3

IC501 G-6

IC504 G-7

IC901 F-2

IC910 B-4

IC920 C-3

IC921 B-3

IC930 B-4

IC931 B-5

Q321 D-5

Q322 E-3

Q323 E-2

Q324 D-2

Q325 D-3

Q326 E-5

Q327 D-4

Q328 D-3

Q329 D-3

Q421 D-5

Q422 E-2

Q423 E-2

Q424 D-2

Q425 D-3

Q426 D-5

Q501 F-5

Q502 F-5

Q551 G-7

Q552 B-6

Q562 B-6

Q570 B-7

Q571 B-7

Q572 H-6

Q576 H-7

Q941 C-8

Q950 B-2

G

H

(Page 32)

IC501

I

IC504

(Page 37)

3434

Page 35

CDP-CX555G

6-6. Schematic Diagram – MAIN Board (1/2) –

CN801

7P

DTC144-VSA-TP

• See page 29 for Waveforms. • See page 48 for IC Pin Function Description.

F

C550

1F

0.1

IC504

LC35256DM-70-TLM

Q551

5.5V

551

C

100

100

100

R552

R553

R554

8

9

0

7

k

k

k

0

11

1

0k

0k

2

k

k

10

T-7

10

51

0

5

133

D

55

S

551

R

R

1S

R522

100

0k

512

1

R

0

50

5

5

50

00

1

10

1

1

R

R

R5

R

R

1

CN505

9P

R504

2.2k

F

F

22

22

.0

.0

0

0

R503

08

1k

5

509

C

C

C510

C511

0.022

R502

0.022

10k

F

0k

1

R506

5

10k

F

50

R

F

.1

0

3

50

C

CN502

17P

C592

100

93

00

5

1

C

F

.1

0

04

5

C

10V

CN503

CN903

RV501

22k

R591

4.7k

6P

9P

C591

100

10V

Q502

BN1L3M-TP

SDA

TP501

R520

100

R546

100

R521

TP502

100

SCL

TP503

RFSW

R529

100k

Q501

BN1L4M-TP

C594

100

10V

R570

4.7k

BA1A4M-TP

1

57

R

4.7k

L502

Q570

Q571

BA1A4M-TP

JW

100

R535

100

R537

R519

100

100

R536

100

R538

F

k

00

00k

1

1

0.022

2

3

17

53

51

5

R

R

C

F

k

22

00

.7k

k

.0

1

1

4

1k

0

4

1

4

5

3

30

54

5

53

5

51

R

R

R

R

C

R515

4.7k

R514

10k

0

10

100

26

525

5

R

R545

100k

R

0

0

10

10

524

523

R

R

C505

0.1

F

C541

0.01

C542

4700p

00

1

C543

0.47

539

R

IC501

-CX4-3BA

0k

20k

10

2

2

41

5

54

R

R

0

100

10

540

527

R

R

100

28

5

R

D501

1SS133T-72

k

0

1

.2k

2

6

3

51

54

R

R

k

0

1

33

5

R

BN1A4M-TP

Q576

R501

100k

Q572

BA1A4M-TP

X501

16MHz

C519

1

50V

0k

1

C512

0.022

F

518

R

R517

D502

JW

1SS133T-72

TP1

(TEST)

CN504

2P

Q562

BN1L4M-TP

Q552

BN1L4M-TP

L501

C942

R942

2.2

R943

2.2k

C945

100

10V

470 16V

D941

RD6.2ES-T2B2

Q941

2SB734-T-3

C944

100

D942

35V

RD20ES-T2B2

C941

470 16V

4.7

R941

CN506

5P

C943

100

35V

R944

2.2k

3535

Page 36

CDP-CX555G

6-7. Schematic Diagram – MAIN Board (2/2) –

• See page 45 for IC Block Diagrams.

C518

0.1

F

D327

1SS133T-72

C514

0.1

C307

F

1

50V

C407

1

50V

C516

0.1 F

C321

4.7

50V

Q327

BN1L4M-TP

CN501

31P

C403

Q326

BN1L3M-TP

R321

100k

3300p

IC401(1/2)

BA4558

C303

3300p

BA1L4M-TP

R405

JW

R305

JW

IC401(2/2)

BA4558

Q421

C404

22

50V

R406

470k

R306

470k

C304

22

50V

Q426

BN1L3M-TP

R410

IC402(1/2)

BA4558

IC302(1/2)

BA4558

10k

C310

R310

Q425

BN1L4M-TP

0.1 F

10k

R407

2.7k

R409

4.7k

R309

4.7k

R307

2.7k

Q325

BN1L4M-TP

R421

100k

R412

10k

R411

10k

C411C410

0.1 F0.1 F

R311

10k

R425R325

100k100k

IC402(2/2)

BA4558

C311

0.1

F

R312

10k

Q328

BN1L4M-TP

R328

100k

IC302(2/2)

BA4558

D329

1SS133T-72

C405

470k

R313

470k

C305

22

50V

C329

4.7

50V

Q329

BN1L4M-TP

22

R414

50V

220

R422

2.2k

R413

Q422

2SC3622ATP-LK

R322

2.2k

R314

220

R329

100k

R424

2.2k

R415

220

Q423

2SC3622ATP-LK

R423

2.2k

Q323Q322

2SC3622ATP-LK2SC3622ATP-LK

R323

2.2k

R315

220

R324

2.2k

C401

22

50V

C301

22

50V

R327

100k

R403R402

3.3k3.3k

C402

1000p

R401

470k

C302

1000p

R301

470k

R303R302

3.3k3.3k

R426

100

R326

100

Q321

BA1L4M-TP

R417

4.7k

2SC3622ATP-LK

R440

220

R340

220

Q324

2SC3622ATP-LK

R317

4.7k

Q424

C427

22 25V

C428

470p

C328

470p

C327

22 25V

R439

470k

J903

R339

470k

L902

JW

L903

JW

R950

4.7k

C950

0.1

R951

L950

10k

GP1F32T

C954C953

0.1 F100 10V

Q950

2SC2603TP-EF

R952

10

C951

0.1

F

IC901

C952

0.1

J901

J902

F

C513

EB501

C502

C501

0.1

100

F

10V

0.1

F

470 10V

C927

IC910

C917

IC920

TA7807

470

10V

C928

470

10V

C935

100

10V

IC921

220k

R931

C913

1000

16V

L921

C923

1000

16V

IC931

BA3993

C936

3.3

50V

C938

470

10V

C914

1000 16V

C939

0.1

F

R932

2.2

C933

100

16V

C934

100

16V

IC930

NJU7201L50

-T3

CN901

CN902

9P

5P

3636

Page 37

CDP-CX555G

6-8. Printed Wiring Board – Sensor Section – 6-9. Schematic Diagram – Sensor Section –

• See page 29 for Circuit Boards Location.

IC84

H

TO

1-683-723-

MAIN BOARD

CN801

(Page 34)

12

12

IC83

IC82

IC81

D801

SELU5E23C

-TP15

(INSIDE)

R801

R81

820

CN81

7P

CT-L

R82

820

CNP504

47

C801

0.1 F

R83

820

RPI-1391

IC81

RPI-1391

IC82

RPI-1391

IC83

CN82

CT-L

R85

680

2P

CN83

CT-L

CNP82

2P WIRE

CNP83

2P

2P WIRE

(DISC SENSOR)

D81

GL528V

(DISC SENSOR)

Q81

PT483F1

CN504

(Page 34)

1-683-730-

12

12

R84

820

RPI-1391

IC84

12

1-683-724-

12

3737

Page 38

CDP-CX555G

6-10. Printed Wiring Board – Display Section –

12

A

IC703

B

C

• See page 29 for Circuit Boards Location.

34567891011

(Page 40) (Page 34)

63

KEYBOARD BOARD

B

TO

IC701

MAIN BOARD

CN503

(Page 34)

D

E

F

G

H

MODE

IC702

S768

TIMER

12

12

1

3

KEYBOARD

2

4

5

6

1-683-722-

12

12

• Semiconductor

Location

Ref. No. Location

D701 E-5

D702 E-4

D703 E-3

D704 E-2

D705 E-2

D706 F-5

D707 F-4

D708 F-3

D709 F-2

D710 E-7

IC701 C-3

IC702 D-2

IC703 A-1

Q701 D-3

3838

Page 39

CDP-CX555G

6-11. Schematic Diagram – Display Section –

• See page 44 for IC Block Diagrams.

FL701

C782

100

10V

R788 R789

100 100

IC703

NJL64H400A-1

IC702

IC701

PT6302-R-001

Q701

BA1A4M

3.3k

47p

R786

C788

C789

R787

100k

C792

0.001

S768

TIMER

R745

4.7k

J821

S766

S745

R765R766R767

4.7k10k22k

S765

S744

S764

R743R744

2.2k2.2k

S743

0.1

R784

100

C787

0.01

R763R764

2.2k2.2k

S763

R742

1k

S742

C784

100p

C785C786

100p100p

R762

1k

S762

S741

S761

M66310P-FP

100

R785

D701

TP15

SEL5821

R790

220

220p

C791

D702

TP15

SEL5821

D703

TP15

SEL5821

R782

100

R783

100

D704

TP15

SEL5821

D706

TP15

SEL5821

D707

D708

TP15

SEL5821

SEL5821

R791

220

5

709

D

TP1

TP15

C702

0.1

SEL5821

D705

R792

220

TP15

SEL5821

TP15

D710

EL5221

S

470

R793

CN701

9P

D823

RD5.1ES-T2B2

C821

0.1 F

CNP503

R755

4.7k

D822

C822

0.1

F

L821

L823

6P

RD5.1ES-T2B2

D821

RD5.1ES-T2B2

L824

L822

C823

10V

S755

S754

R753R754

2.2k2.2k

S753

R752

1k

S752

S751

CNP502

17P

C781

100

10V

100

781

R

3939

Page 40

CDP-CX555G

6-12. Printed Wiring Board – JOG Board –

A

B

C

• See page 29 for Circuit Boards Location.

12

345678

(Page 38)

DISC EJECT

IC704

D

E

F

G

E

(Page 34)

(Page 34)

H

12

12

4040

Page 41

CDP-CX555G

6-13. Schematic Diagram – JOG Board –

• See page 44 for IC Block Diagrams.

FL702

IC704

M35500BGP

C775

C773

0.1

C774

100

10V

5L

C776

0.1

22p

10k

R701

10k

R711

10k

R721

10k

R731

10k

R741

10k

R751

RE701

CNP701

9P

R775

100

D715 D711

SEL5521C

-TP15

R771 R772

100 150

SEL5521C

-TP15

D712

SEL5821A

-TP15

C778

R702

1k

0.022

C751

C777

100p

R794

100

0.1

0.022

C741

0.022

C731

0.022

C721

0.022

C711

0.022

C701

R774

100

R773

150

R722

S701

R712

1k

S711

1k

S721

S767

R703 R704

2.2k 2.2k

S702

R713 R714

2.2k 2.2k

S712

R723 R724

2.2k 2.2k

S722

S723

S713

S703

R725

4.7k

S724

S704

R726

10k

S725

S714

R705

4.7k

R706

S705

S726

S706

R707

22k

RE702

10k

R727

22k

CNP506 CNP505

5P 9P

4141

Page 42

CDP-CX555G

6-14. Printed Wiring Board – Power Section –

12

A

B

• See page 29 for Circuit Boards Location.

3456789

(Page 34)

CN902

IC941

IC961

CN903

(Page 34)

1-683-729-

12

12

1-683-728-

12

12

C

D

E

1-676-829-

CN901

(Page 34)

BOARD

1-683-726-

12

12

1-683-727-

12

1-683-725-

12

• Semiconductor

Location

Ref. No. Location

D901 B-2

D902 B-2

D903 B-2

D904 B-2

D905 B-2

D906 B-2

D907 B-1

D911 E-3

D912 E-4

D913 D-4

D921 D-3

D922 D-3

12

12

D923 E-3

D924 E-3

D931 D-3

D932 D-3

D933 D-3

D934 D-4

D935 C-3

D991 C-3

IC941 B-2

IC961 B-3

Q901 C-3

Q911 E-4

Q931 C-3

Q941 A-4

Q942 A-4

Q951 B-4

Q952 A-4

4242

Page 43

CDP-CX555G

6-15. Schematic Diagram – Power Section –

R623 R622

RF-500TB

(LOADING)

2.2k 1k

S622

CNP621

2P WIRE

CN621

2P WIRE

M601 M602

RF-500TB

(TABLE)

CNP601

4P WIRE

• See page 45 for IC Block Diagrams.

S621

S611 S612

CNP603

2P WIRE

CNP611

2P WIRE

2P WIRE

CN611

R612 R614

1k 2.2k

R613

CNP902

5P

Q901

2SC2603TP-

EF

T901

C991

0.01

250V

CN991

2P

C992

4700p

C993

L991

4700p

D991

F

RY991

1SS133T-72

D901

11EQS04-TA 2B

D902

D903

D907

1SS133T-72

C902

1

50V

11EQS04-TA 2B

11EQS04-TA 2B

D904

11EQS04-TA 2B

R902

10k