Sony CDPCX-355 Service manual

CDP-CX355

Compact disc player

Laser Semiconductor laser (λ = 780 nm)

Emission duration: continuous

Laser output Max 44.6 µW*

* This output is the value measured at

a distance of 200 mm from the

objective lens surface on the Optical

Pick-up block with 7 mm aperture.

Frequency response 20 Hz to 20 kHz ±0.5 dB

Signal-to-noise ratio More than 107 dB

Dynamic range More than 86 dB

Harmonic distortion Less than 0.009 %

Channel separation More than 100 dB

Outputs

ANALOG OUT

DIGITAL OUT

(OPTICAL)

General

Where purchased

USA and Canadian

Australia

Load impedance

Over 10 kilohms

Wave length: 660 nm

Maximum

output

level

2 V

(at 50 kilohms)

–18 dBm

Jack

type

Phono

jacks

Optical

output

connector

Power consumptions Power requirements

120 V AC, 60 Hz 13 W

14 W

13 W

13 W

240 V AC, 50/60 Hz

Europe and Asia 230 V AC, 50/60 Hz

Other countries

Dimensions (approx.) 430 189 493 mm

(w/h/d) (17 ×

× ×

× 7

1

/2 19 3/8 in.)

incl. projecting parts

Mass (approx.) 8.5 kg (18 lbs 12 oz)

Supplied accessories

Design and specifications are subject to change without notice.

• Audio cord (1)

• Remote commander (remote) (1)

• Size AA (R6) batteries (2)

120 V AC, 50/60 Hz

SERVICE MANUAL

Ver 1.0 2002. 02

Model Name Using Similar Mechanism NEW

CD Mechanism Type CDM54-K1BD45

Base Unit Type BU-K1BD45

Optical Pick-up Type KSS-213BFN

US Model

Canadian Model

AEP Model

UK Model

E Model

Australian Model

9-873-551-01

2002B1600-1

© 2002.02

Sony Corporation

Home Audio Company

Published by Sony Engineering Corporation

SPECIFICATIONS

COMPACT DISC PLAYER

CDP-CX355

Laser component in this product is capable

of emitting radiation exceeding the limit for

Class 1.

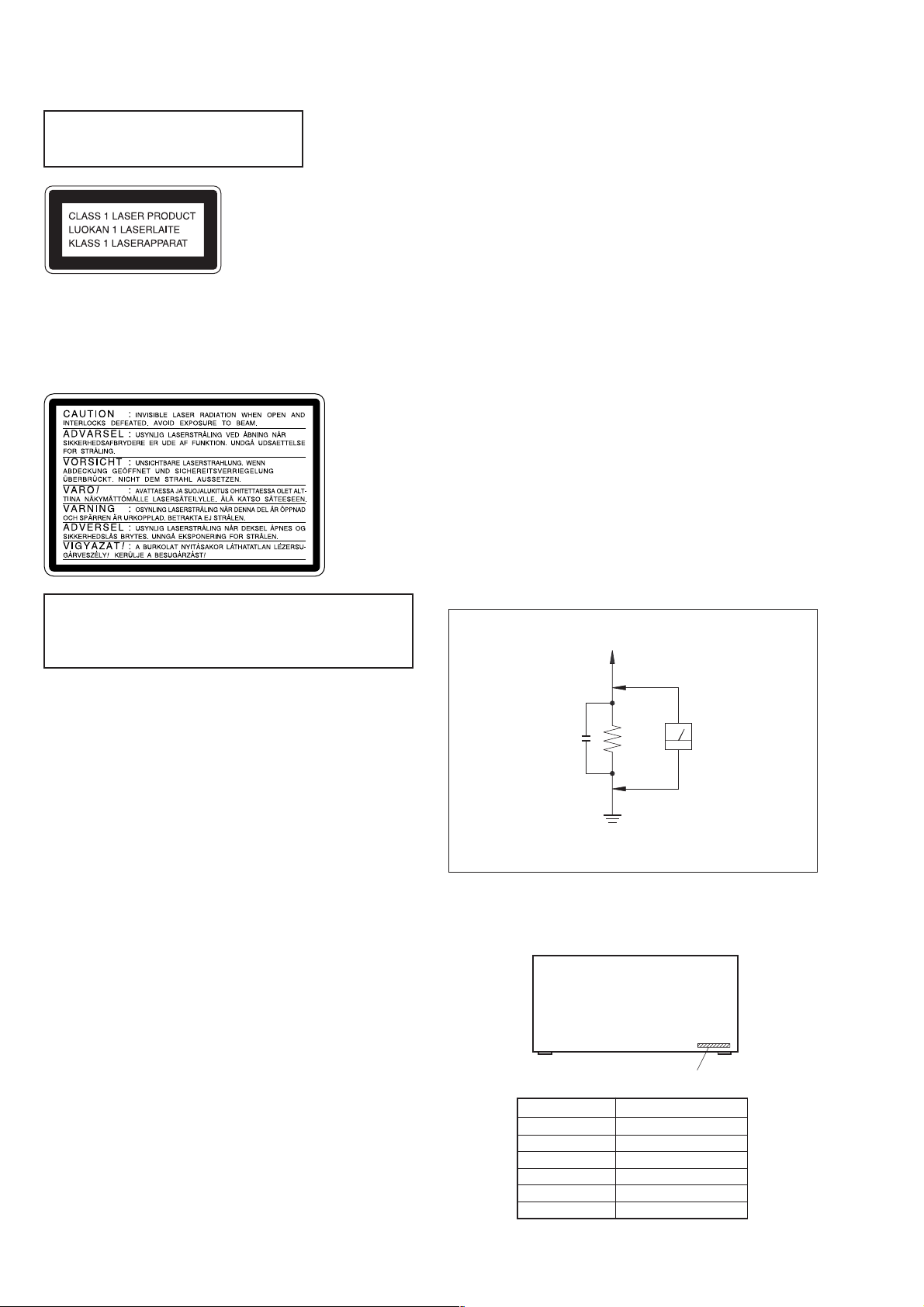

This appliance is classified as a CLASS 1 LASER product. The

CLASS 1 LASER PRODUCT MARKING is located on the rear

exterior.

The following caution label is located inside the unit.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

SAFETY CHECK-OUT

After correcting the original service problem, perform the

following safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for A C leakage. Check leakage as

described below.

LEAKAGE

The A C leakag e from any exposed metal part to earth g round and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated A C voltmeter . The “limit” indication

is 0.75 V, so analog meters must have an accurate low-voltage

scale. The Simpson 250 and Sanwa SH-63Trd are e xamples of

a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2V AC range are suitable. (See

Fig. A)

To Exposed Metal

Parts on Set

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS PAR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

0.15 µF

Fig. A. Using an AC voltmeter to check AC leakage.

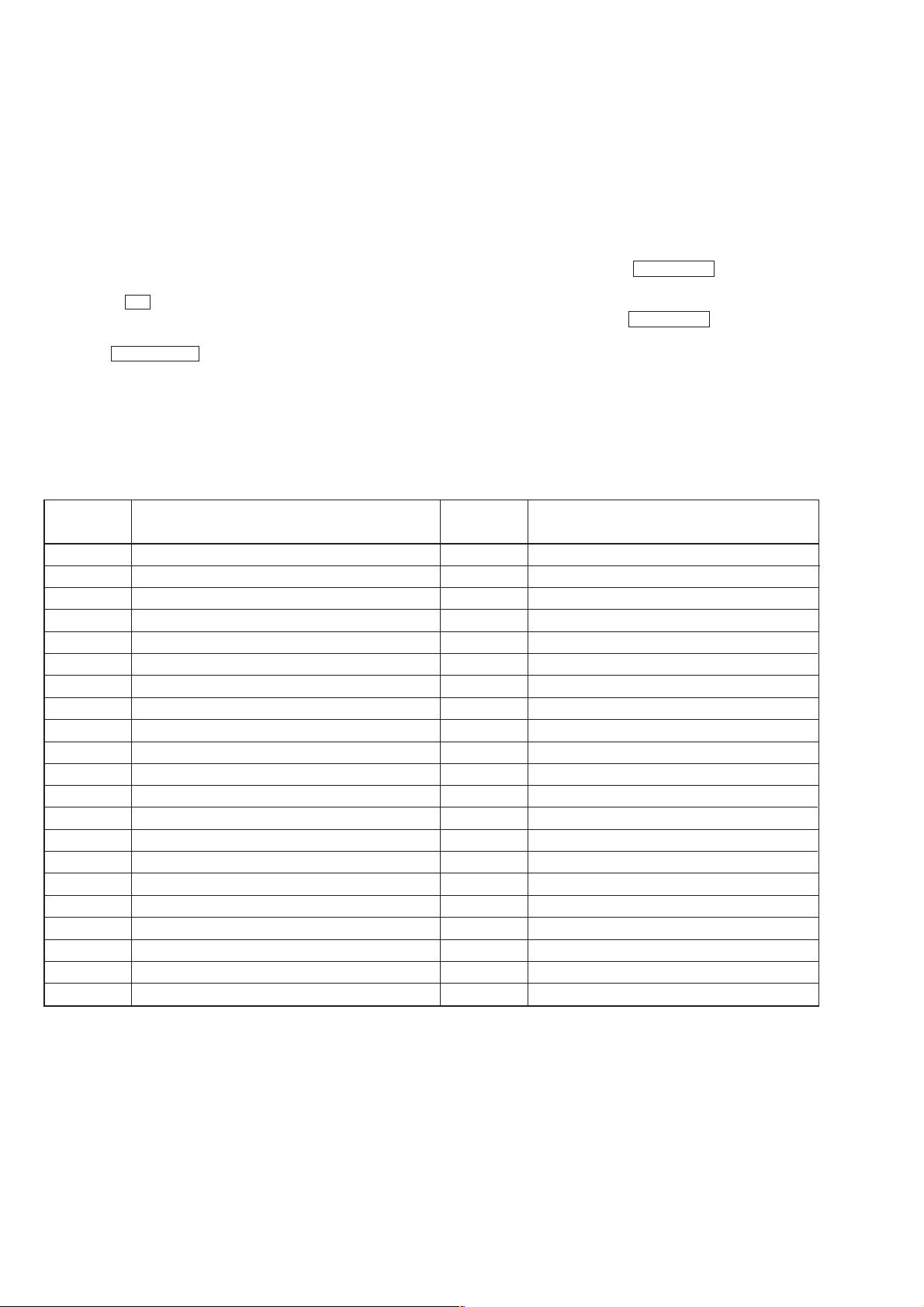

MODEL IDENTIFICATION

— BACK PANEL —

PARTS No. MODEL

4-238-109-0π

4-238-109-1π

4-238-109-2π

4-238-109-3π

4-238-109-4π

4-238-109-5π

1.5 kΩ

Earth Ground

PA RT NO.

US

Canadian

AEP, UK

Singapore

Australian

E

AC

Voltmeter

(0.75 V)

2

SECTION 1

SERVICING NOTE

CDP-CX355

TABLE OF CONTENTS

1. SERVICING NOTE ·····················································3

2. GENERAL ···································································6

3. DISASSEMBLY ··························································7

3-1. Case··············································································· 8

3-2. Bracket (F. W. ) ····························································· 8

3-3. Front Panel Assy··························································· 9

3-4. DISP Board, JOG Board, KEYBOARD Board············ 9

3-5. LED Board, Guide (Door. T)······································ 10

3-6. Table (300) Assy, Cover (P.T.) ···································· 10

3-7. D. MOTOR Board, Door Motor Assy (M83) ············· 11

3-8. D. SW Board······························································· 12

3-9. Base (Door, Gear) Assy ·············································· 13

3-10. Pop-up Assy ································································ 13

3-11. D. SENS (OUT) Board ·············································· 14

3-12. T. SENS Board···························································· 14

3-13. D. SENS (IN) Board ·················································· 15

3-14. Back Panel Section ····················································· 15

3-15. MAIN Board, JACK Board ········································ 16

3-16. POWER Board···························································· 16

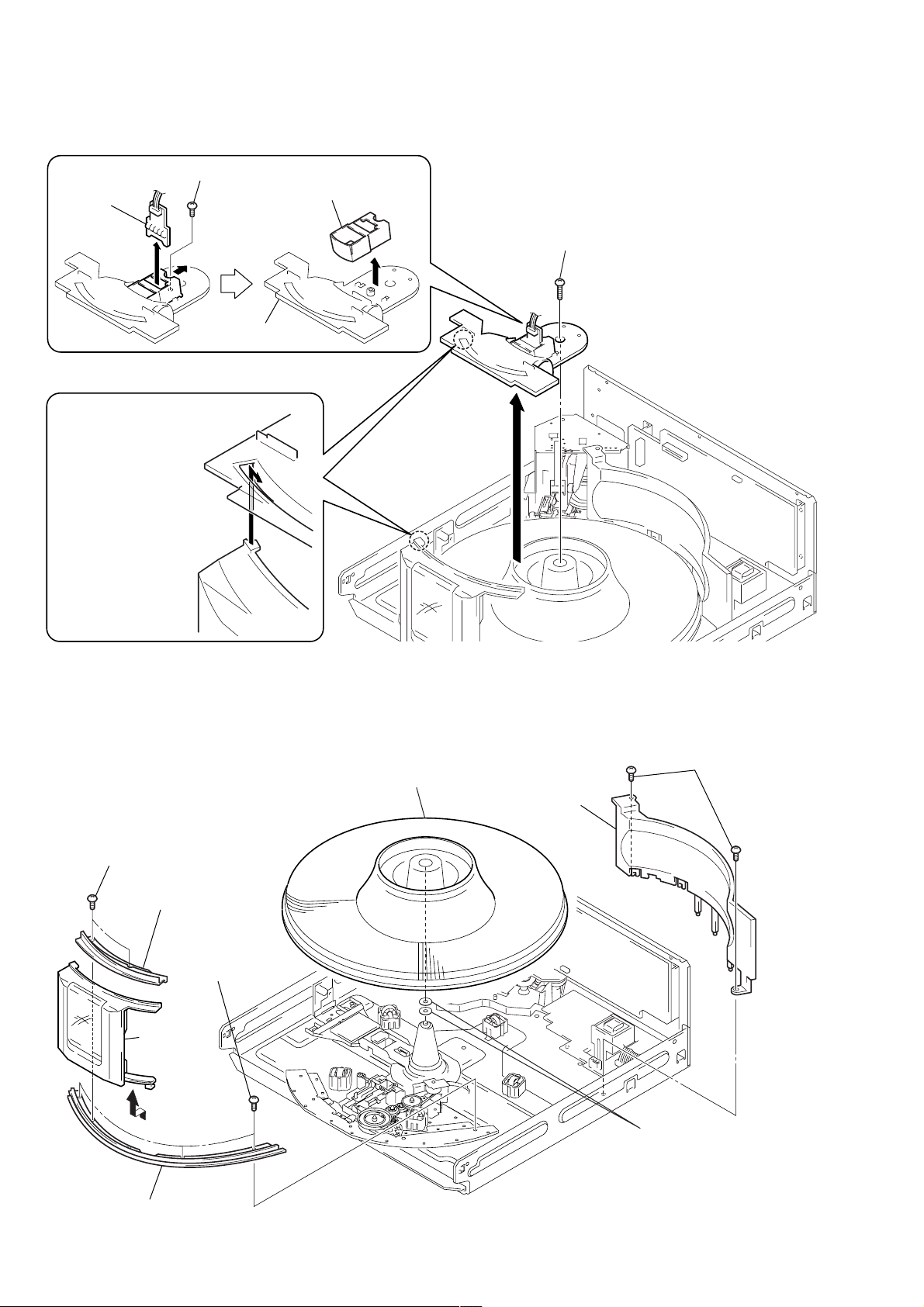

3-17. Bracket (Top) , BU Assy ············································· 17

3-18. BU Holder Assy ·························································· 17

3-19. BD Board, Optical Device (KSM-213 BFN)·············· 18

3-20. L. SW (A) Board, L. SW (B) Board ························· 19

3-21. CDM Assy ·································································· 20

3-22. Motor Assy (Loading) (M82) ,

Motor Assy (Table) (M81) , L. T. MOTOR Board ····· 20

4. SERVICE MODE ···························································· 21

5. TEST MODE ···································································· 25

5-1. ADJ Mode··································································· 25

5-2. Key and Display Check Mode ···································· 25

6. ADJUSTMENTS ···························································· 26

6-1. Mechanical Adjustments············································· 26

6-2. Electrical Adjustment·················································· 28

7. DIAGRAMS······································································ 31

7-1. Block Diagrams – BD Section –································· 32

– MAIN Section –······················································· 33

7-2. Printed Wiring Board – BD Section – ························ 34

7-3. Schematic Diagram – BD Section – ···························35

7-4. Printed Wiring Board – MAIN Section – ··················· 36

7-5. Schematic Diagram – MAIN Section (1/2) – ············· 37

7-6. Schematic Diagram – MAIN Section (2/2) – ············· 38

7-7. Printed Wiring Board – T.SENS Section – ················· 39

7-8. Printed Wiring Board – D.SENS (IN) Section – ········ 39

7-9. Printed Wiring Board – D.SENS (OUT) Section – ···· 39

7-10. Schematic Diagram – SENSOR Section – ················· 39

7-11. Printed Wiring Board – DISPLAY Section – ·············40

7-12. Schematic Diagram – DISPLAY Section – ················ 41

7-13. Printed Wiring Board – JOG Section –······················· 42

7-14. Schematic Diagram – JOG Section – ························· 43

7-15. Printed Wiring Board – POWER Section – ················ 44

7-16. Schematic Diagram – POWER Section –··················· 44

7-17. Printed Wiring Board – JACK Section – ····················45

7-18. Schematic Diagram – JACK Section ·························· 45

7-19. Printed W iring Board – SWITCH/MO T OR Section –··· 46

7-20. Schematic Diagram – SWITCH/MOT OR Section – ····· 46

7-21. IC Pin Functions ························································· 50

8. EXPLODED VIEWS ······················································ 54

8-1. Case Section································································ 54

8-2. Chassis Section 1 ························································ 55

8-3. Chassis Section 2 ························································ 56

8-4. Back Panel Section ····················································· 57

8-5. Front Panel Section····················································· 58

8-6. Mechanism Section 1 (CDM54-K1BD45)

(Pop-up Assy, Base (Door. Gear) Assy)······················59

8-7. Mechanism Section 2 (CDM54-K1BD45) ················· 60

8-8. Mechanism Section 3 (CDM54-K1BD45) ················· 61

8-9. Mechanism Section 4 (CDM54-K1BD45) ················· 62

8-10. Optical Pick-up Section (BU-K1BD45) ····················· 63

9. ELECTRICAL PARTS LIST ·······································64

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repain parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

The emission check enables continuous checking of the S curve.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and check

that the S curve waveform is output three times.

3

CDP-CX355

CD-TEXT TEST DISC

This unit is able to display the TEXT data (character information) written in the CD on its fluorescent indicator tube.

The CD-TEXT TEST DISC (TGCS-313:J-2501-126-A) is used for checking the display.

To check, perform the following procedure.

Checking Method:

1. Turn ON the power , set the disc on the disc ta ble with the side labeled as “test disc” as the right side, close the front cover , and chuck the

disc.

2. The following will be displayed on the fluorescent indicator tube. (The display switches each time the TIME/TEXT b utton is pressed.)

Display : CD TEXT TEST DISC (Album Title)

3. Press the · button and play back the disc.

4. The following will be displayed on the fluorescent indicator tube. (If nothing is displayed, press the TIME/TEXT button.)

Display : 1kHz/0 dB/ L&R

5. Rotate ≠ and ± knob to switch the track. The text data of each track will be displayed.

For details of the displayed contents for each track, refer to “Table 1 : CD-TEXT TEST DISC Text Data Contents” and “Table 2 : CDTEXT TEST DISC Recorded Contents and Display”.

Restrictions in CD-TEXT Display

In this unit, some special characters will not be displayed properly . These will be displayed as a space or a character resembling it. For details,

refer to “Table 2 : CD-TEXT DISC Recorded Contents and Display”.

Table 1 : CD-TEXT TEST DISC Text Data Contents (TRACKS No. 1 to 41:Normal Characters)

TRACK

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

Displayed Contents

1kHz/0dB/L&R

20Hz/0dB/L&R

40Hz/0dB/L&R

100Hz/0dB/L&R

200Hz/0dB/L&R

500Hz/0dB/L&R

1kHz/0dB/L&R

5kHz/0dB/L&R

7kHz/0dB/L&R

10kHz/0dB/L&R

16kHz/0dB/L&R

18kHz/0dB/L&R

20kHz/0dB/L&R

1kHz/0dB/L&R

1kHz/-1dB/L&R

1kHz/-3dB/L&R

1kHz/-6dB/L&R

1kHz/-10dB/L&R

1kHz/-20dB/L&R

1kHz/-60dB/L&R

1kHz/-80dB/L&R

TRACK

No.

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

Displayed Contents

1kHz/-90dB/L&R

Infinity Zero w/o emphasis//L&R

Infinity Zero with emphasis//L&R

400Hz+7kHz(4:1)/0dB/L&R

400Hz+7kHz(4:1)/-10dB/L&R

19kHz+20kHz(1:1)/0dB/L&R

19kHz+20kHz(1:1)/-10dB/L&R

100Hz/0dB/L*

1kHz/0dB/L*

10kHz/0dB/L*

20kHz/0dB/L*

100Hz/0dB/R*

1kHz/0dB/R*

10kHz/0dB/R*

20kHz/0dB/R*

100Hz Squer Wave//L&R

1kHz Squer Wave//L&R

1kHz w/emphasis/-0.37dB/L&R

5kHz w/emphasis/-4.53dB/L&R

16kHz w/emphasis/-9.04dB/L&R

NOTE : The contents of Track No. 1 to 41 are the same as those of the current TEST DISC-their titles are displayed.

4

Table 2: CD-TEXT TEST DISC Recorded Contents and Display

(In this unit, some special characters cannot be displayed. This is no a fault.)

CDP-CX355

TRACK

No.

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

to

99

Recorded contents Display

! ” #$%&´ (21h to 27h)1kHz 0dB L&R

( ) +,– . / (28h to 2Fh)

*

01234567 (30h to 37h)

8 9 : ; < = > ? (38h to 3Fh)

@A B C D E F G (40h to 47h)

H I J K L M N O (48h to 4Fh)

P QR S T U V W (50h to 57h)

XYZ [ ¥ ] ^ _ (58h to 5Fh)

a b c d e f g (60h to 57h)

′

h i j k l m n o (68h to 6Fh)

p q r s t u v w (70h to 77h)

xyz{ I }

~ (78h to 7Fh)

i¢£¤¥ § (A0h to A7h) 8859-1

≥ C ª¬PR–(A8h to AFh)

•±23

1

†

µ ¶• (B0h to B7h)

′

14123

º ¿ (B8h to BFh)

4

АБВГДЕЖЗ (C0h to C7h)

ÈÉÊË ÌÍÎÏ (C8h to CFh)

D СТУФХЦ

ШЩЪЫЬY

˙

(D0h to D7h)

ß (D8h to DFh)

абвгдежз (E0h to E7h)

ийклмноп (E8h to FFh)

∂ стуфхц÷ (F0h to F7h)

шщъыьy

ÿ (F8h to FFh)

´

No.66

No.67

to

No.99

N All the same

N All the same

N All the same

N All the same

N All the same

N All the same

N All the same

X Y Z [ \ ] ^ _ (58····

N All the same

N All the same

N All the same

xyz{I}

i¢£¤¥

~ (78····

§ (A0···· is not displayed

≥ (A8···· C ª¬PR–are not displayed

′

µ • (B0····

†¿(B8····

•±23

1

¶ are not displayed

1

3

1

º are not displayed

4

4

2

N All the same

N All the same

N All the same

Φ ÙÚÛÜY ß (D8····

˙

N All the same

N All the same

o стуфхц÷ (F0····

N All the same

N All the same

N All the same

to

N All the same

5

CDP-CX355

SECTION 2

GENERAL

39

3

45678

2

9

10 11 12

13

14

1

15 16 17 18

19 20 21 22

38

36 35 34 33 32

31 30 29 28 27

26

2425

23

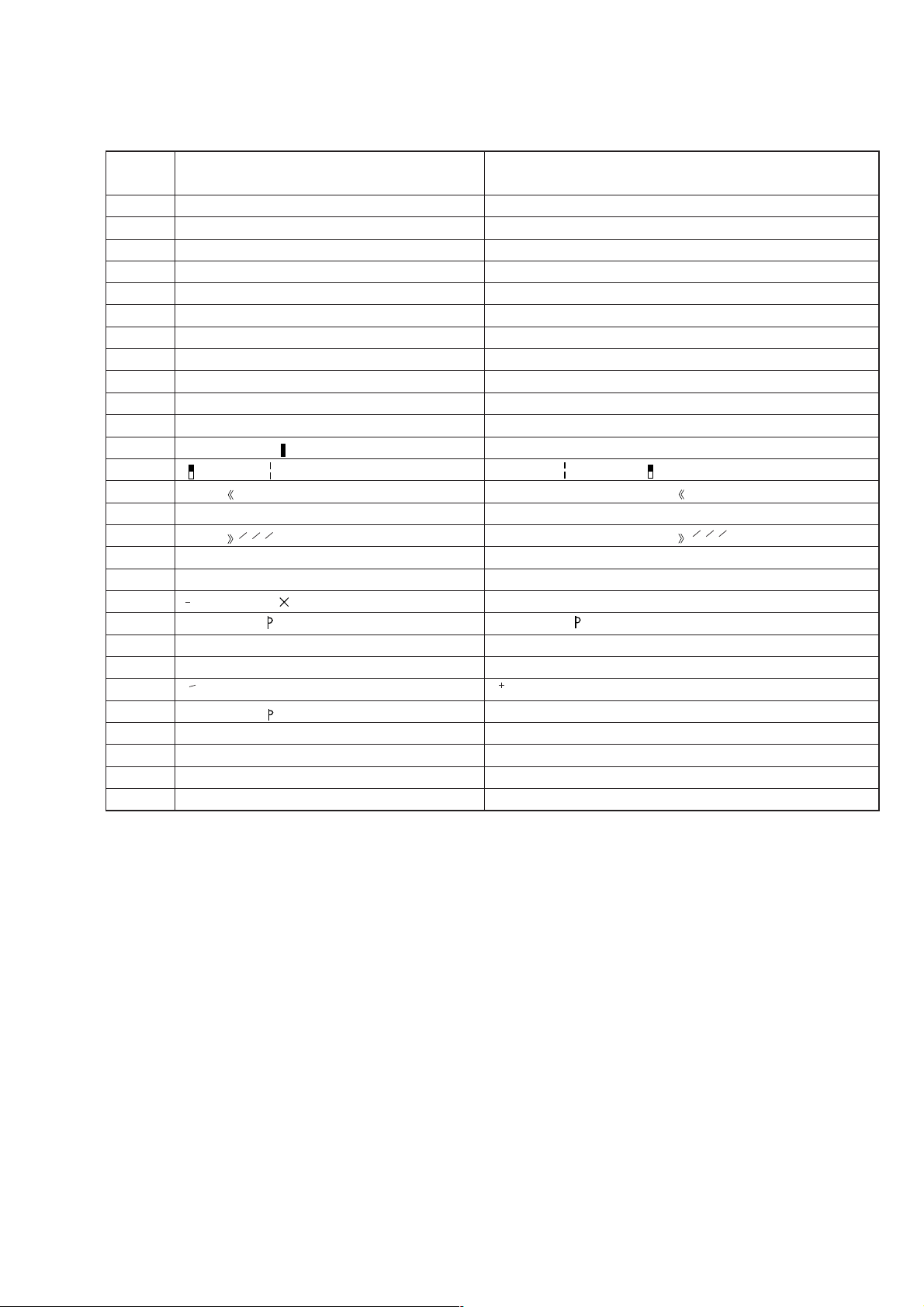

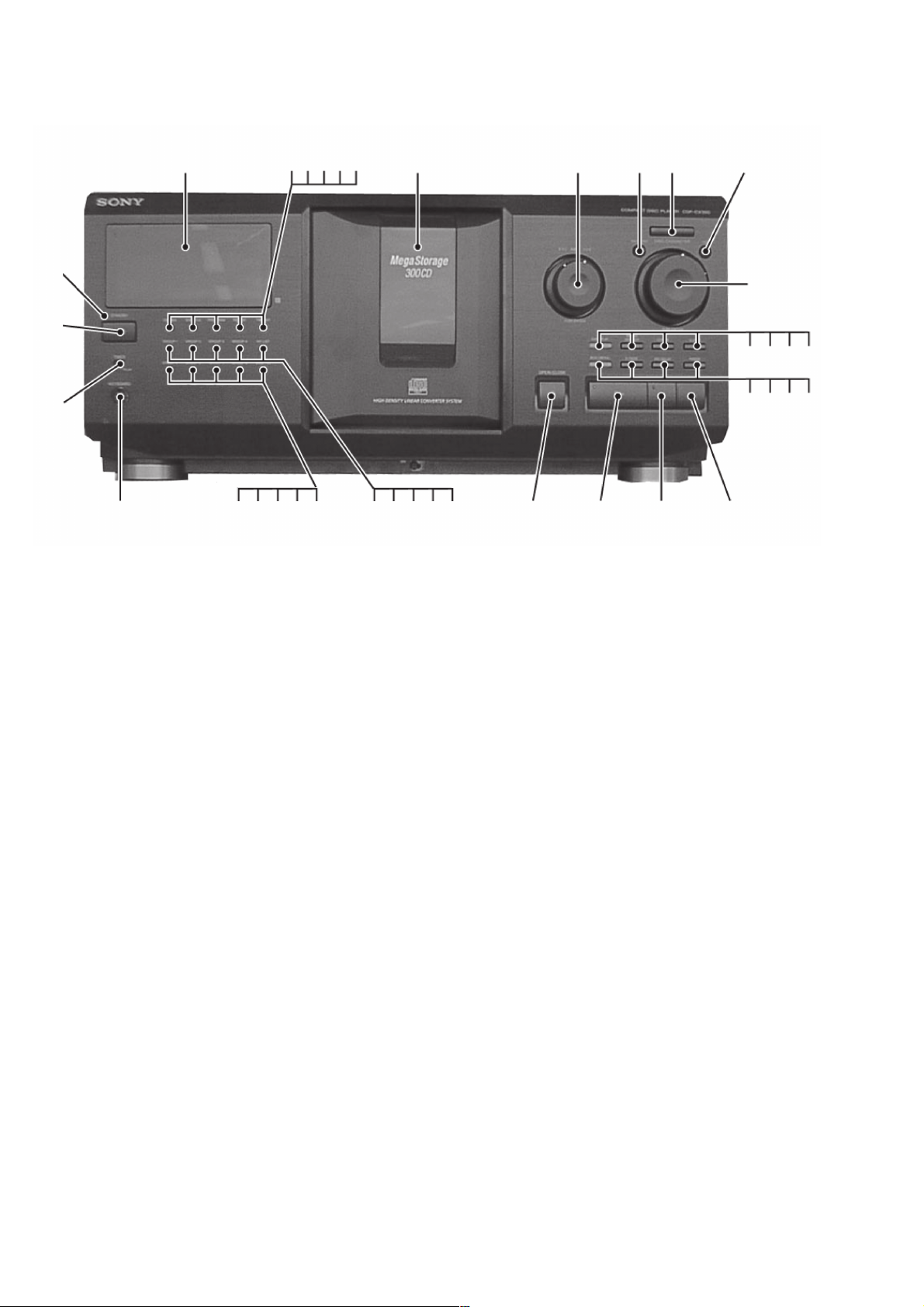

Location of Parts and Controls

1 1/u (power) button

2 STANDBY indicator

3 Display window

4 CONTINUE button

5 SHUFFLE button

6 PROGRAM button

7 REPEAT button

8 TIME/TEXT button

9 Front cover

10 ≠ AMS ±/PUSH ENTER knob and button

11 MENU/NO button

12 +100 button

13 YES button

14 DISC/CHARACTER/PUSH ENTER knob and button

15 EASY PLAY button and indicator

16 MEMO/SEARCH button

17 CHECK button

18 CLEAR button

19 MEGA CONTROL button and indicator

20 X-FADE button

21 NO DELAY button

22 FADER button

23 p (stop)/DISC EJECT button

24 P (pause) button and indicator

25 · (play) button and indicator

26 § OPEN/CLOSE button

27 HIT LIST button and indicator

28 GROUP 4 button and indicator

29 GROUP 3 button and indicator

30 GROUP 2 button and indicator

31 GROUP 1 button and indicator

32 GROUP FILE button

33 GROUP 8 button and indicator

34 GROUP 7 button and indicator

35 GROUP 6 button and indicator

36 GROUP 5 button and indicator

38 KEYBOARD jack

39 TIMER OFF/PLAY switch

* AMS is abbreviation for Automatic Music Sensor.

6

SECTION 3

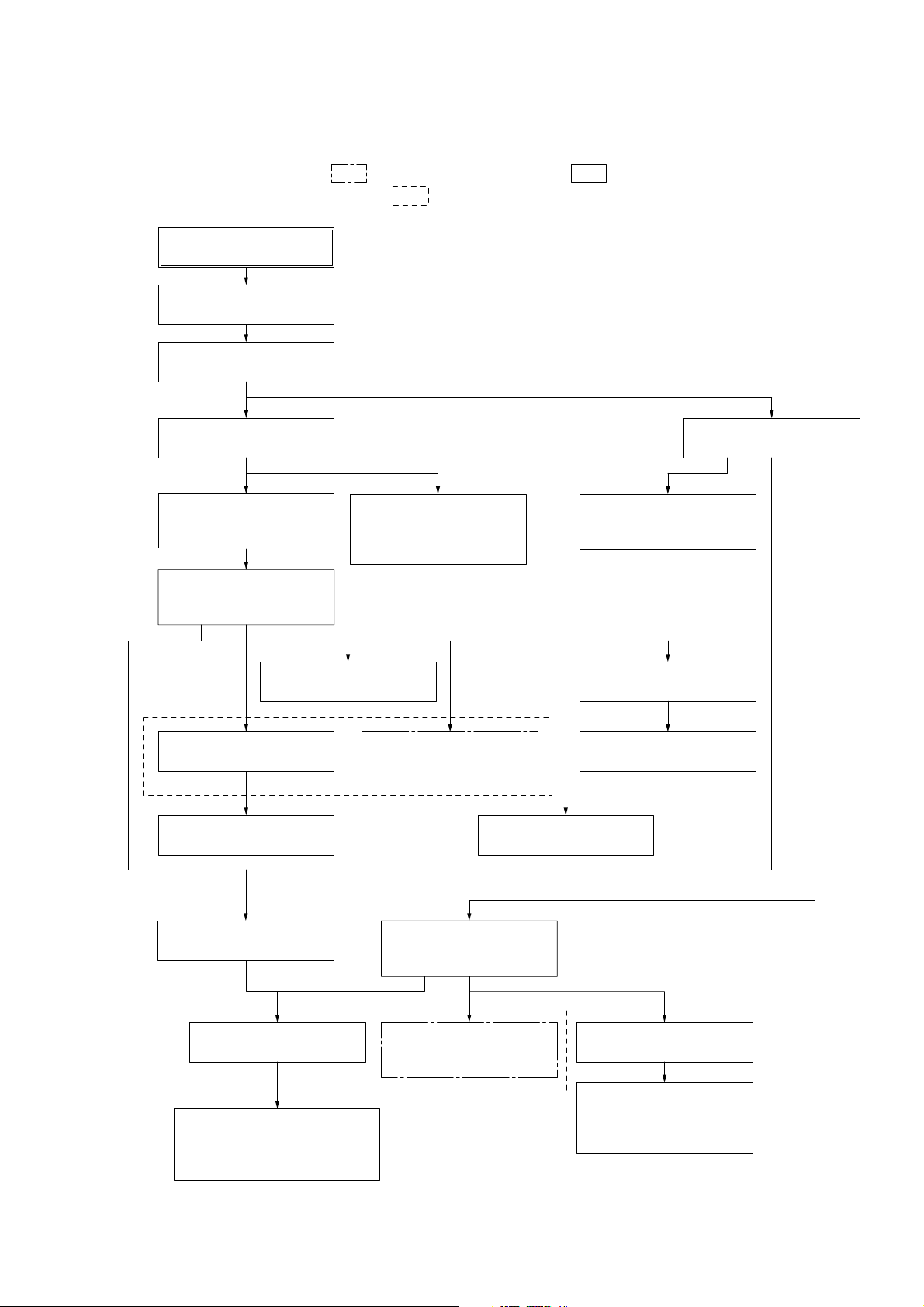

BRACKET (F.W.)

(Page 8)

SET

DISP BOARD,

JOG BOARD,

KEYBOARD BOARD,

(Page 9)

FRONT PANEL ASSY

(Page 9)

CASE

(Page 8)

LED BOARD,

GUIDE (DOOR.T)

(Page 10)

TABLE (300) ASSY,

COVER (P.T.)

(Page 10)

D. MOTOR BOARD,

DOOR MOTOR ASSY (M83)

(Page 11)

BACK PANEL SECTION

(Page 15)

BRACKET (TOP),

BU ASSY

(Page 17)

BD BOARD

OPTICAL DEVICE

(KSM-213BFM)

(Page 18)

MOTOR ASSY (LOADING) (M82),

MOTOR ASSY (TABLE) (M81),

L.T. MOTOR BOARD

(Page 20)

BU HOLDER ASSY

(Page 17)

MAIN BOARD,

JACK BOARD

(Page 16)

L. SW (A) BOARD,

L. SW (B) BOARD

(Page 19)

D. SW BOARD

(Page 12)

POP-UP ASSY

(Page 13)

POWER BOARD

(Page 16)

BASE (DOOR.GEAR) ASSY

(Page 13)

CDM ASSY

(Page 20)

D. SENS (IN) BOARD

(Page 15)

D. SENS (OUT) BOARD

(Page 14)

T. SENS BOARD

(Page 14)

• The parts surrounded by square are included in the solid line square

in the area shown by the dotted line square .

DISASSEMBLY

Note : Disassemble the unit in the order as shown below.

CDP-CX355

7

CDP-CX355

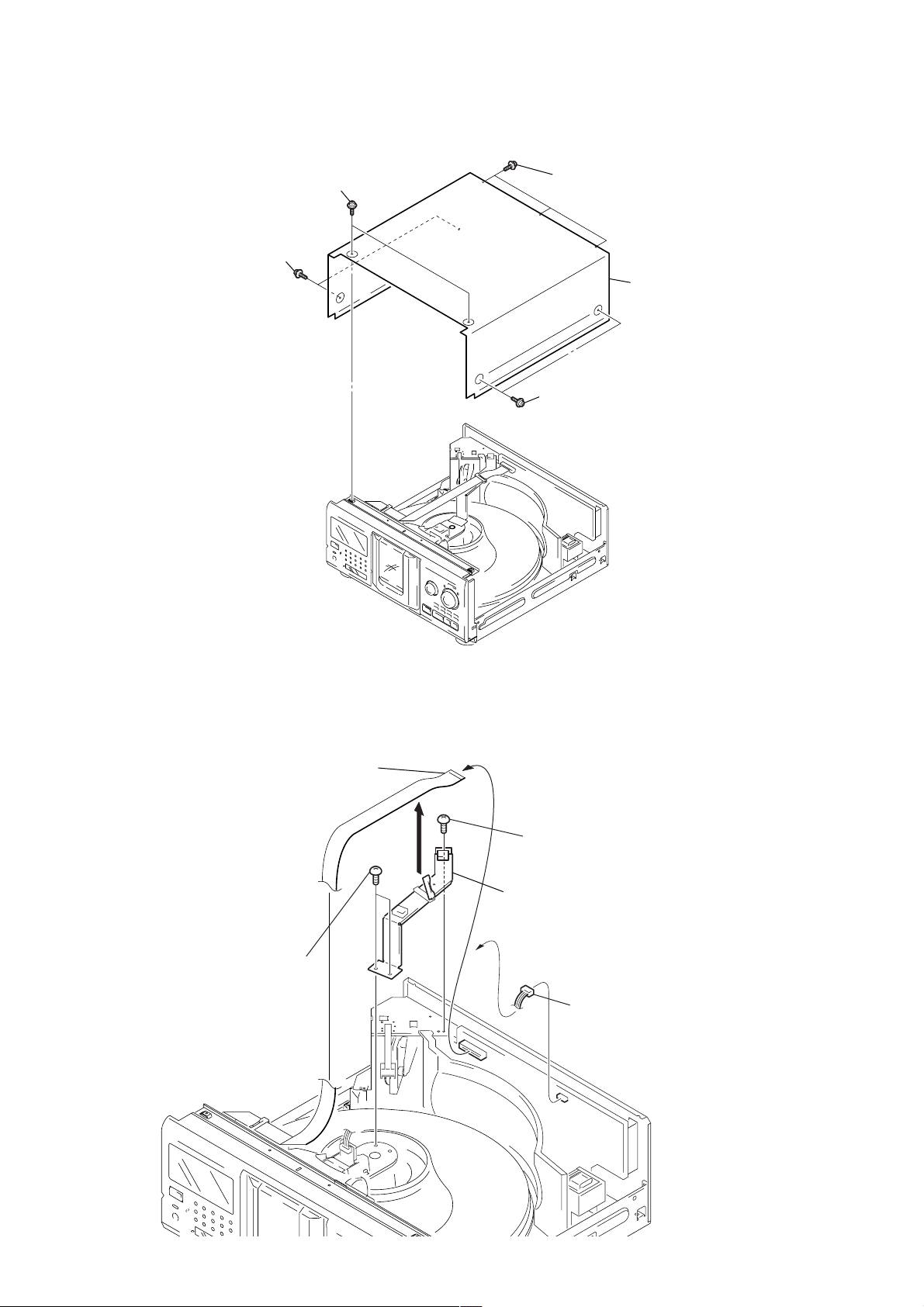

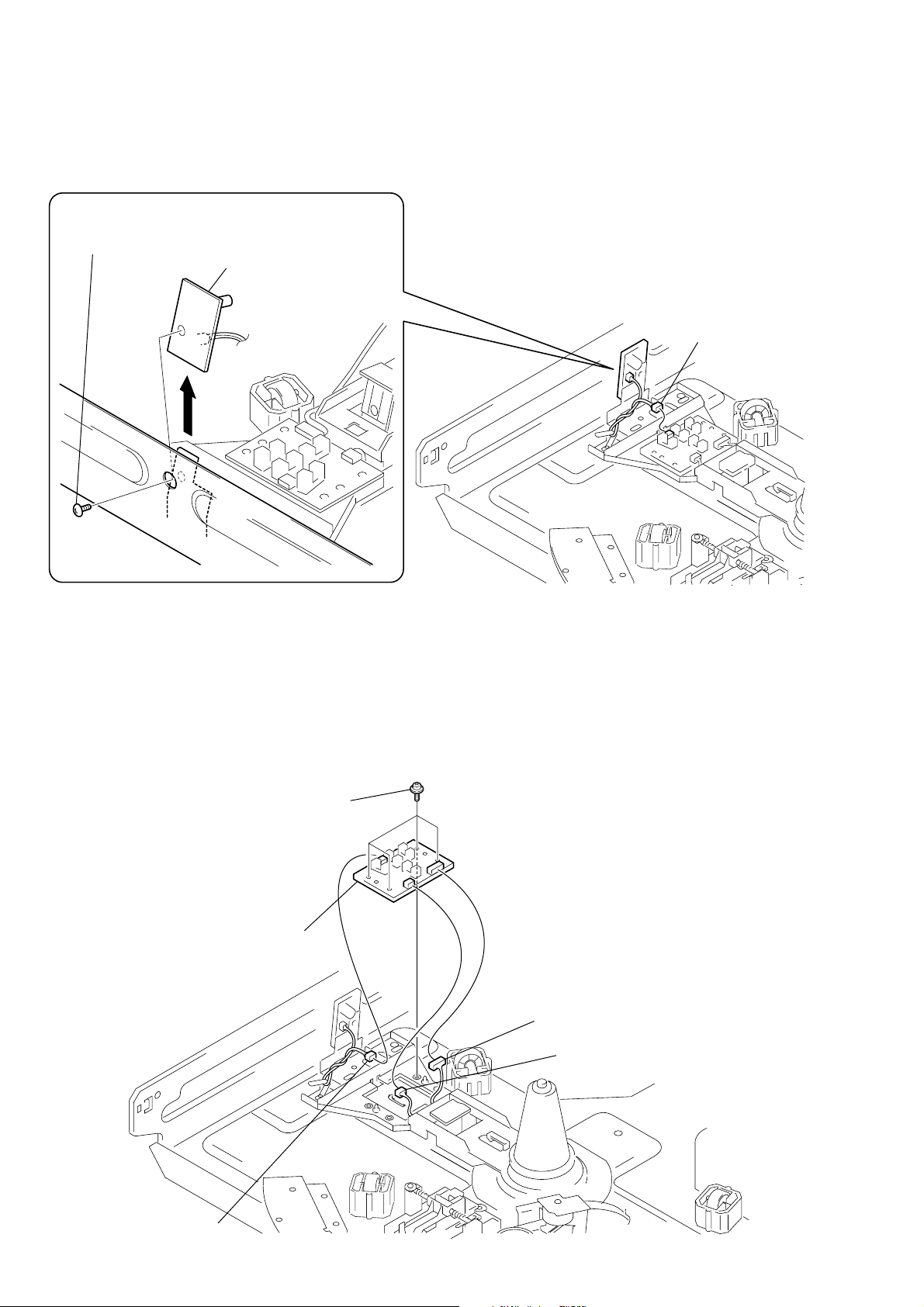

3-1. Case

1 two screws (CASE 3 TP2)

3 two screws (CASE 3 TP2)

2 three screws (CASE 3 TP2)

5 case

4 two screws (CASE 3 TP2)

3-2. Bracket (F. W. )

2

wire (flat type) (21 core)

(CN501)

5

two screws

(+BVTP 3 x 8)

3

4

screw (+BVTP 3 x 8)

6

bracket (F.W.)

LED board

1

connector (CN504)

8

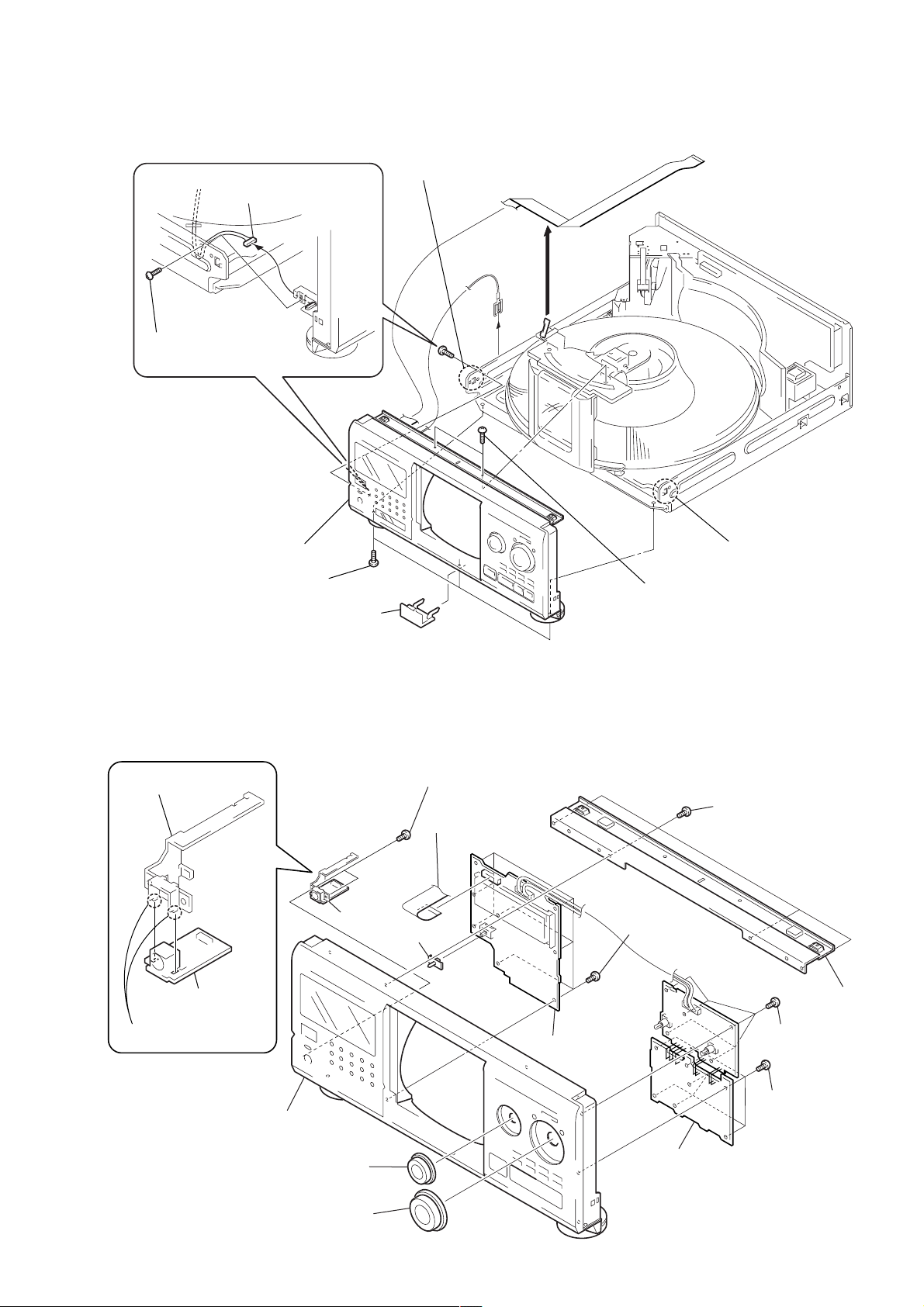

3-3. Front Panel Assy

7

remove two soldrings.

3

four screws

(+BVTP 2.6 x 8)

5

two screws

(+BVTP 2.6 x 8)

6

qd

DISP board

9

KEYBOARD

board

8

bracket (keyboard)

4

bracket main

qh

JOG board

qj

front panel assy

q;

eight screws

(+BVTP 2.6 x 8)

qf

five screws

(B+VTP 2.6 x 8)

qg

seven screws

(+BVTP 2.6 x 8)

2

knob (AMS)

qs

knob (timer)

1

knob (disc)

qa

wire (flat type)

(21 core) (CN701)

3 connector (CN792)

CDP-CX355

9 remove the claw

1

4 screw (+BVTP 3 x 8)

q; front panel assy

6 three screws (+BVTP 3 x 8)

5 cover (chassis)

3-4. DISP Board, JOG Board, KEYBOARD Board

2

8 remove the claw

7 two screws (+BVTP 3 x 8)

9

CDP-CX355

)

3-5. LED Board, Guide (Door. T)

3

screw (+BVTP 3 x 8)

6

LED board

5

4

Note during re-assembling

When re-assembling,

align the positions

as shown.

8

(internal illumination)

9

guide (door.T)

window

7

2

1

screw

(+BVTP 3 x 16)

3-6. Table (300) Assy, Cover (P.T.)

3 two screws (+BVTP 3x8)

4 cover (front)

7 three screws

(+BVTP 3x8)

6 door (CD)

assy

5

1 table (300) assy

9 two screws

(+BVTP 3 x 8

q; cover (P.T.)

2 two 10 washers

10

8 guide (door.B)

3-7. D. MOTOR Board, Door Motor Assy (M83)

CDP-CX355

1 remove two soldrings.

2 D. motor board

4 belt

5 door motor assy (M83)

3 two screws (+B 2.6 x 3)

11

CDP-CX355

3-8. D. SW Board

2

gear (door.cam)

4

washer

1

3

washer

gear (door.drive)

7

holder (L-SW)

6

two claws

5

two screws

(+BTP 2.6 x 6)

8

D. SW board

Precaution during the gear (door.cam) installation

1

Move the slider (pop-up) and the lever (cam.pu) fully

in the direction of the arrow

A

slider (pop-up) lever (cam.pu)

The levers of the two rotary switches on the D. SW board

are shown in the illustration below.

A

.

two rotary switches

D. SW board

2

Install the gear (door.cam) in the direction shown

in the illustration and rotate it fully

in the direction of the arrow

3

When the gear (door.cam) happens to go too deep,

return it to the original position

in the direction of the arrow

B

.

B

gear (door.cam)

C

.

12

C

3-9. Base (Door. Gear) Assy

Note during re-assembling

When re-assembling,

align the positions as shown.

CDP-CX355

4 base (door.gear) assy

1 connector (CN508)

3-10. Pop-up Assy

3 two screws (+BVTP 3 x 8)

2 three screws (+BVTP 3 x 8)

1

step screw

3

pop-up assy

2

screw (+PTPWH 3 x 6)

13

CDP-CX355

)

3-11. D. SENS (OUT) Board

2

screw (+BVTP 3 x 6)

4

3

D. SENS (OUT) board

1

connector (CN83

3-12. T. SENS Board

2

four screws (+PTPWH 3 x 6)

5

T. SENS board

3

connector (CN81)

4

connector (CN82)

14

1

connector (CN83)

3-13. D. SENS (IN) Board

)

4

1

two screws (+PTPWH 3 x 6)

2

two claws

screw (+PTPWH 3 x 6)

5

D. SENS (IN) board

3

holder (table sensor)

CDP-CX355

3-14. Back Panel Section

3 connector

(CN507)

2 connector

(CN902)

1 connector

(CN505)

qa four screws (+BVTP 3 x 8)

7 connector (CN903)

6 connector (CN503)

5 connector (CN509)

4 connector

(CN508)

qs back panel section

q; three screws

(+BVTP 3 x 8

9 connector (CN991)

8 connector (CN901)

15

CDP-CX355

)

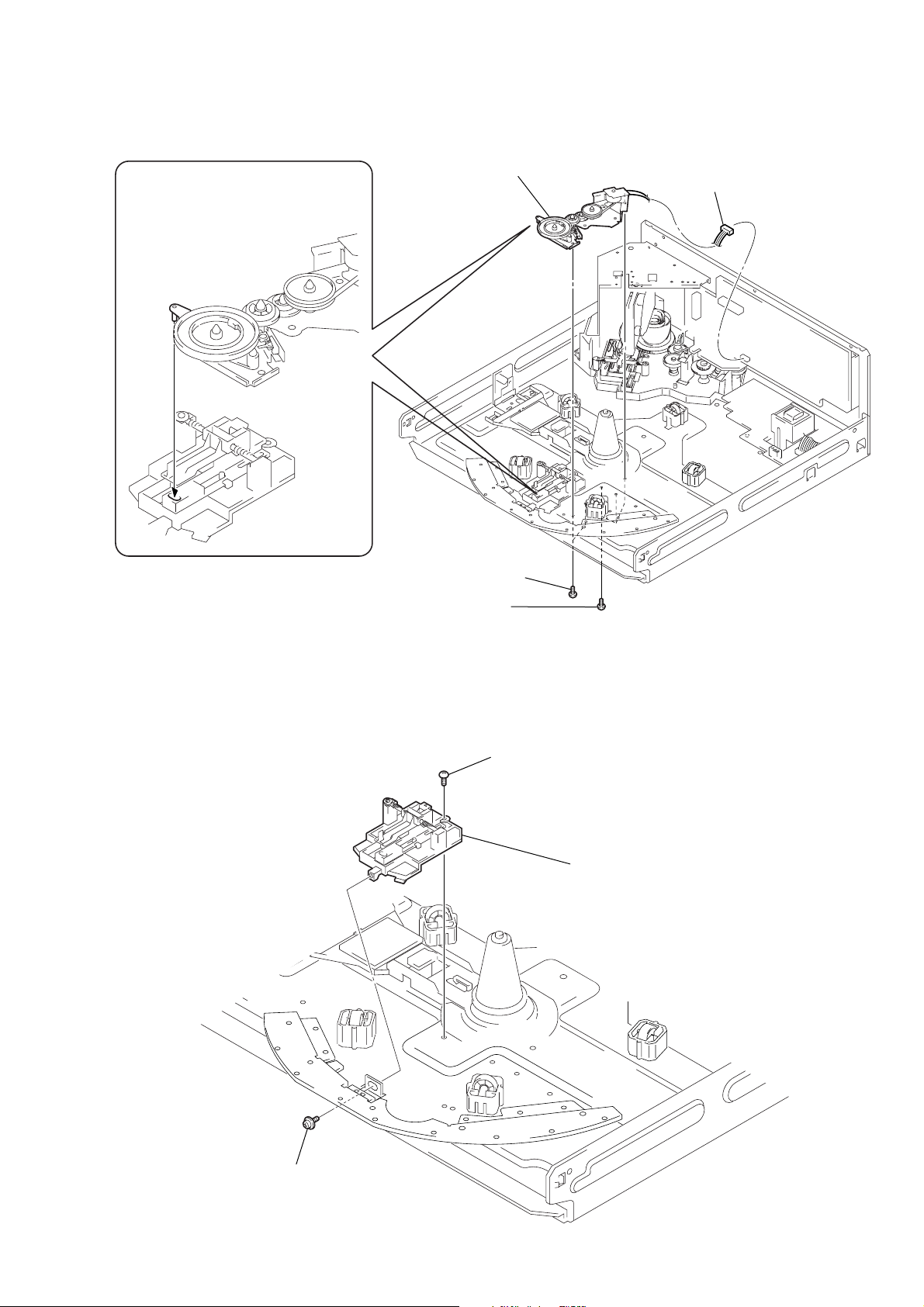

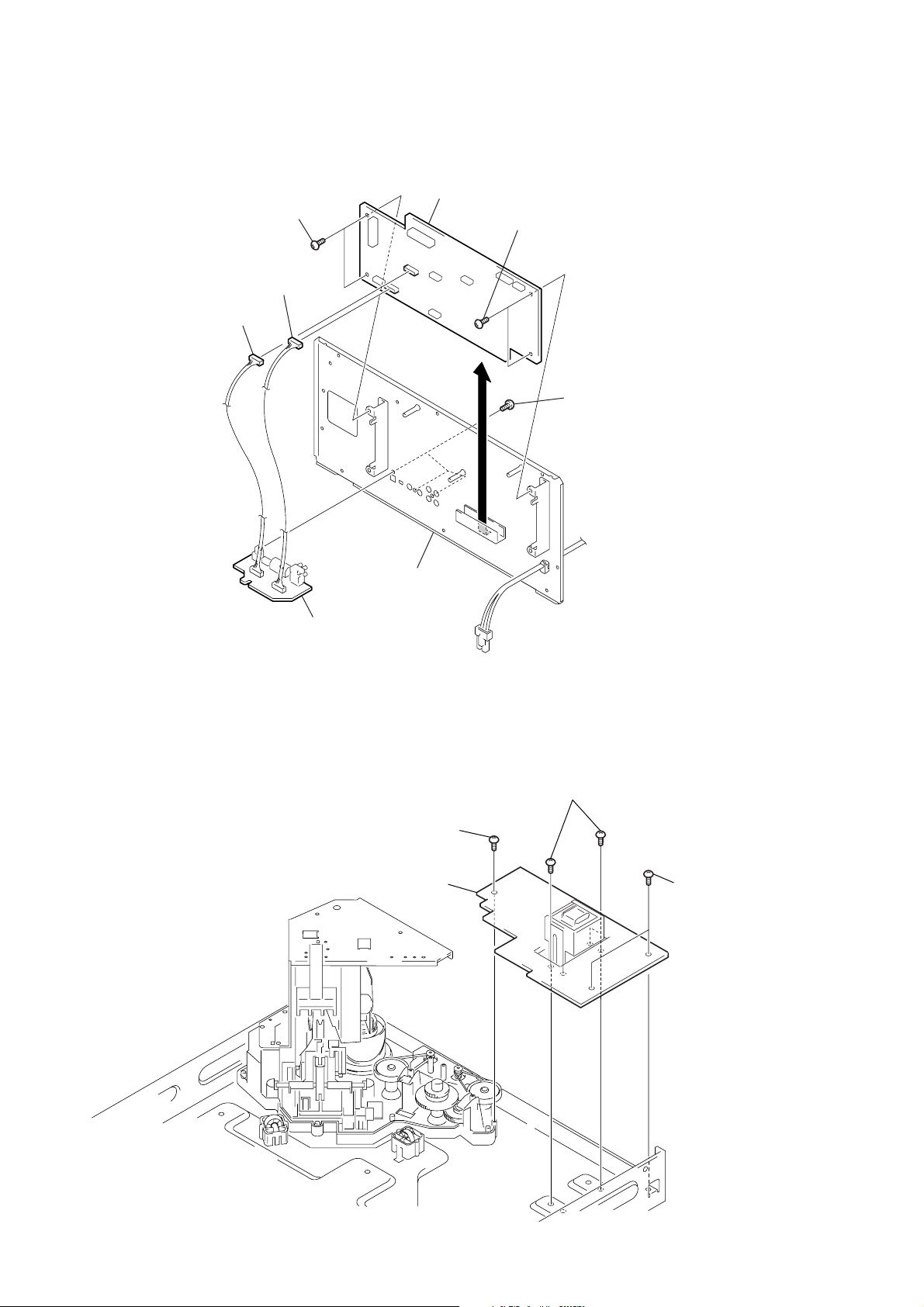

3-15. MAIN Board, JACK Board

3 two screws (+BVTP 3 x 8)

1 connector (CN510)

2 connector (CN511)

6 MAIN board

4 two screws (+BVTP 3 x 8)

3-16. POWER Board

9 JACK board

1

screw

(+BVTP 3 x 8)

5

8 back panel

7 three screws (+BVTP 3 x 8

3

four screws (+BVTP 3 x 8)

16

4

POWER board

2

two screws

(+BVTP 3 x 8)

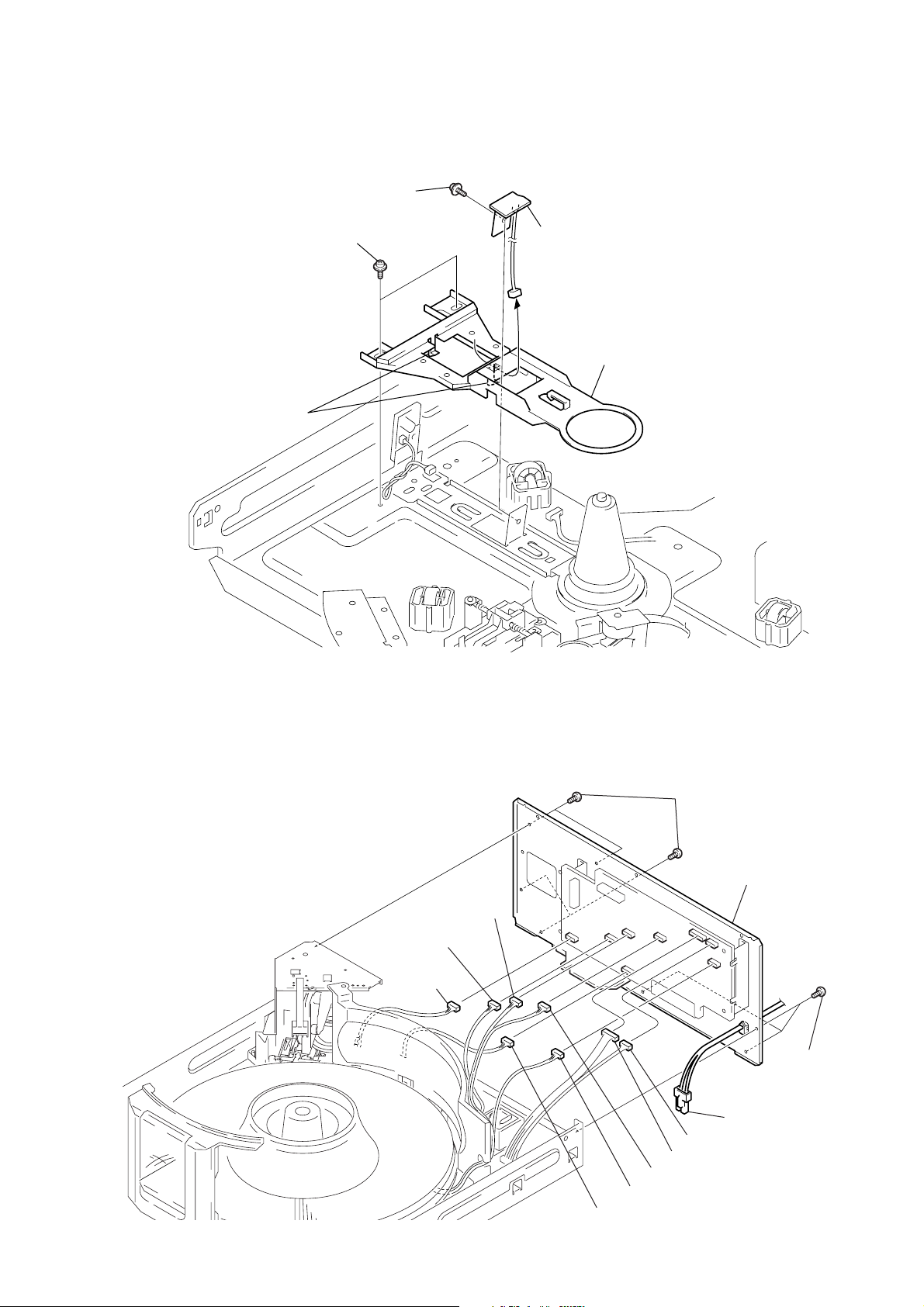

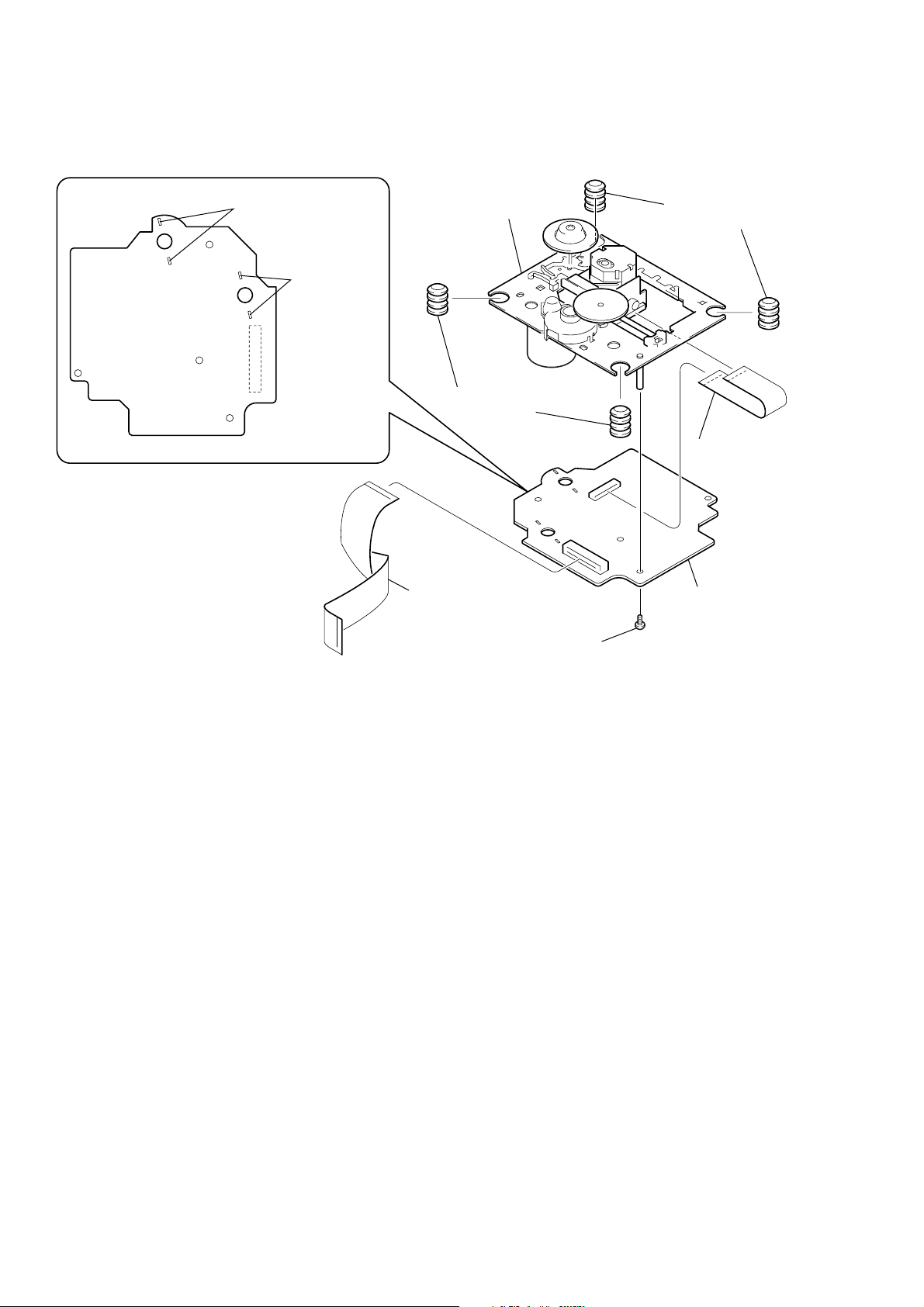

3-17. Bracket (Top) , BU Assy

)

1

four screws

(+BVTP 3 x 8)

2

bracket (top)

CDP-CX355

4

8 washer

3-18. BU Holder Assy

3

BU assy

Note during re-assembling

When re-assembling,

align the positions

as shown.

5

BU holder assy

3

tension spring (F-1)

2

4

tension spring (F-2)

1

four screws

(PTP WH 2.6 x 8

17

CDP-CX355

)

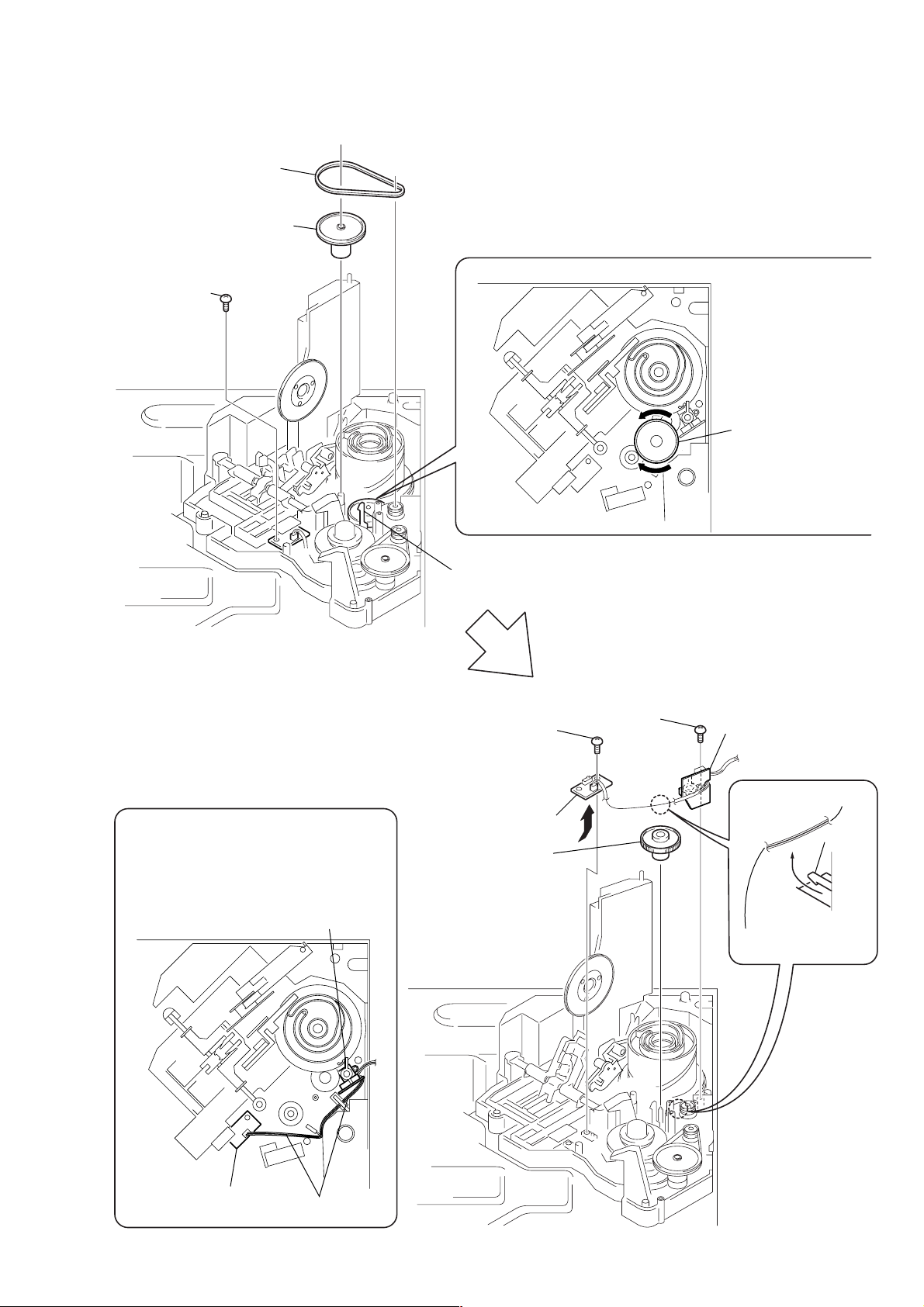

3-19. BD Board, Optical Device (KSM-213 BFN)

3

remove two

solderings.

(sled)

4

remove two

solderings.

(spindle)

9

optical device

(KSM-213BFN)

8

two vibration

proof rubbers

7

two vibration

proof rubbers

5

wire (flat type)

(16 core) (CN102

1

wire (flat type) (23 core)

(CN101)

2

screw (+B 2 x 5)

6

BD board

18

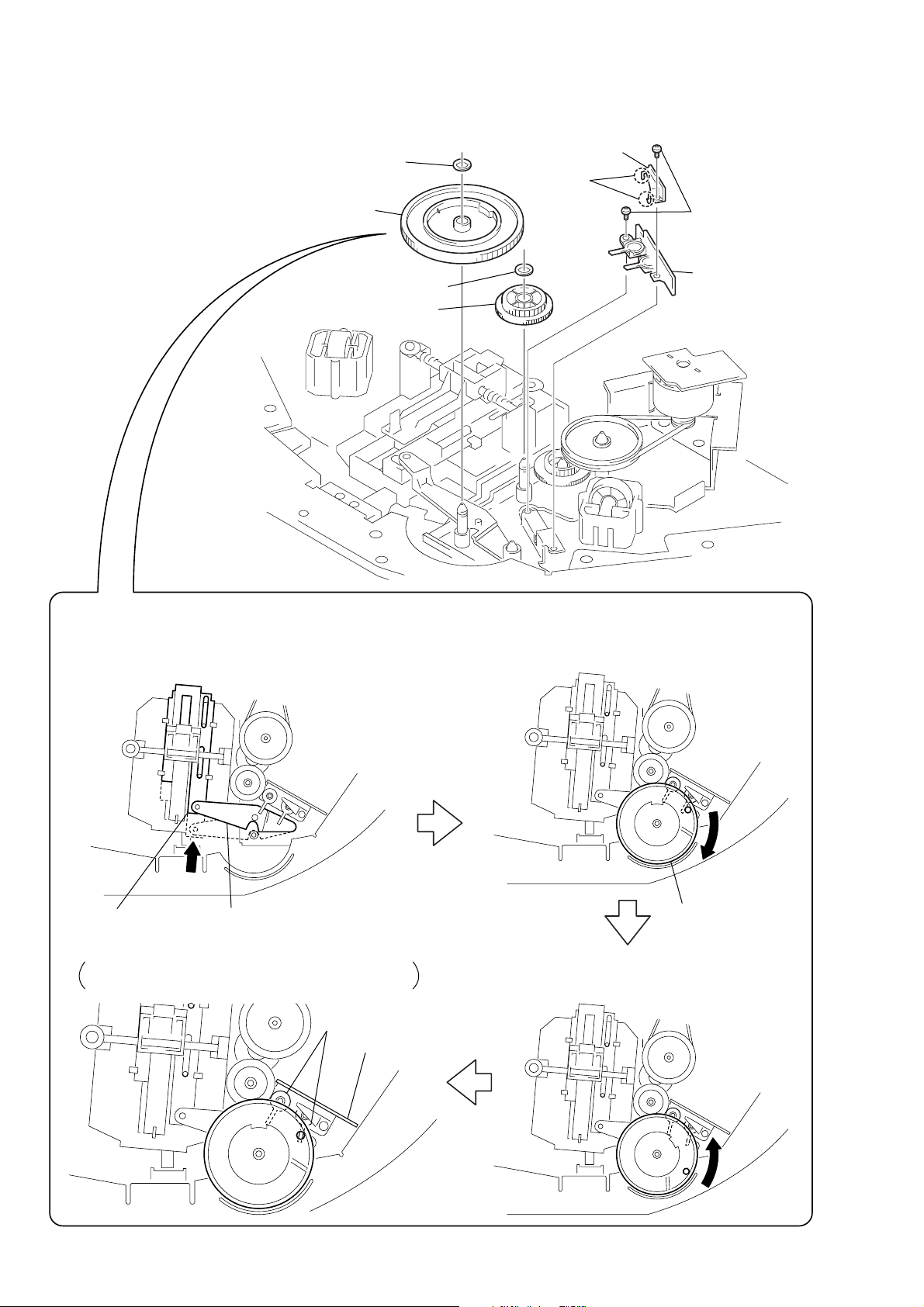

3-20. L. SW (A) Board, L. SW (B) Board

1

belt

3

pulley (1)

5

screw

(+BVTP 3 x 8)

CDP-CX355

4

rotate the gear (center)

in the direction of the

arrow

6

in the direction of the

arrow

A

fully.

rotate the Gear (center)

B

fully.

Note during re-assembling

When re-assembling the L. SW (A) and

L. SW (B) boards,

align the leads position as shown.

2

claw

q;

screw

(+BVTP 3 x 8)

qs

L. SW (B) board

7

gear (center)

B

8

screw

(BVTP 3x8)

qa

A

gear (center)

qd

L. SW (A) board

to L. SW (A) board

9

claw

L. SW (B) board

L. SW (A) board

to L. SW (B) board

Leads position

19

CDP-CX355

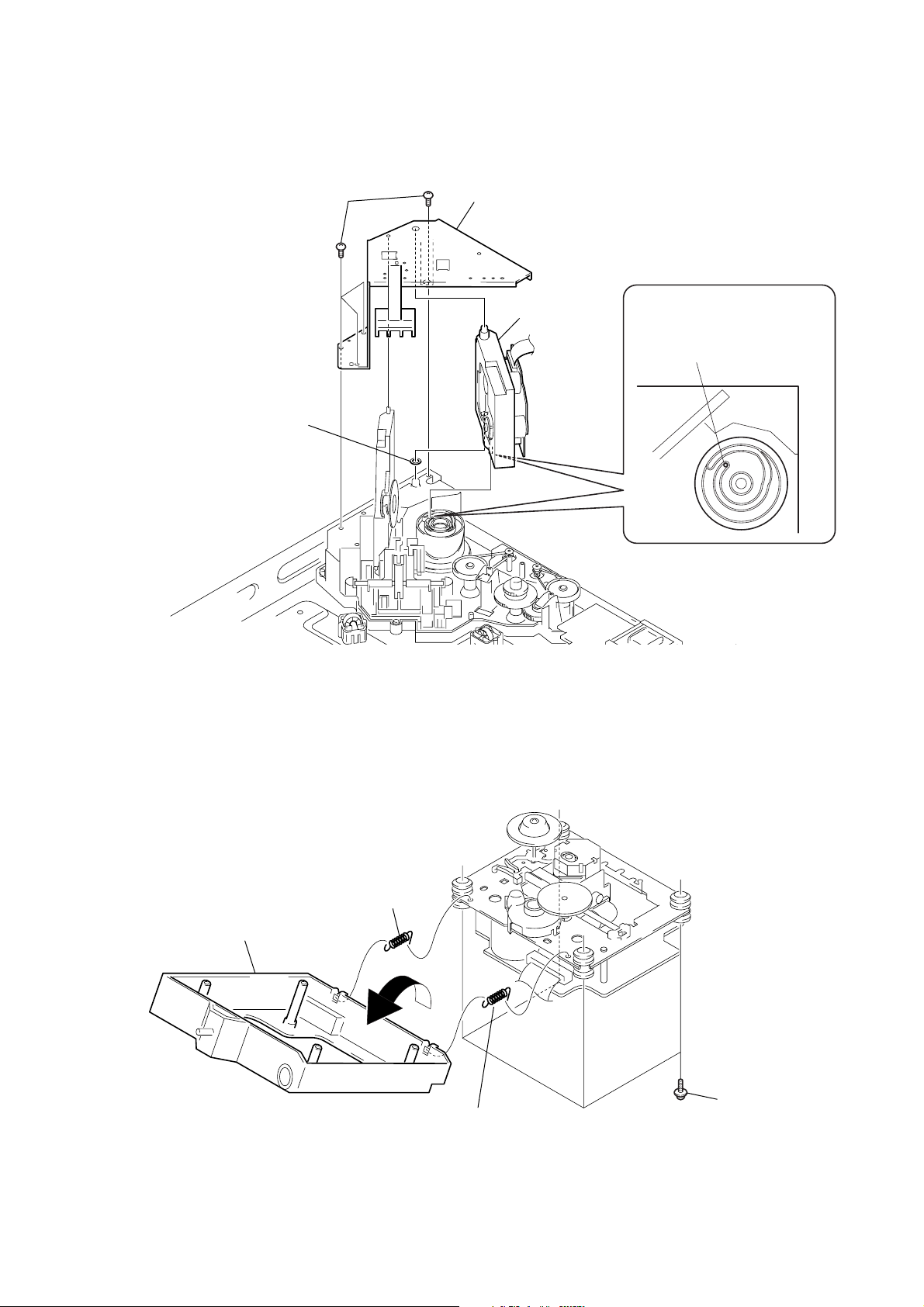

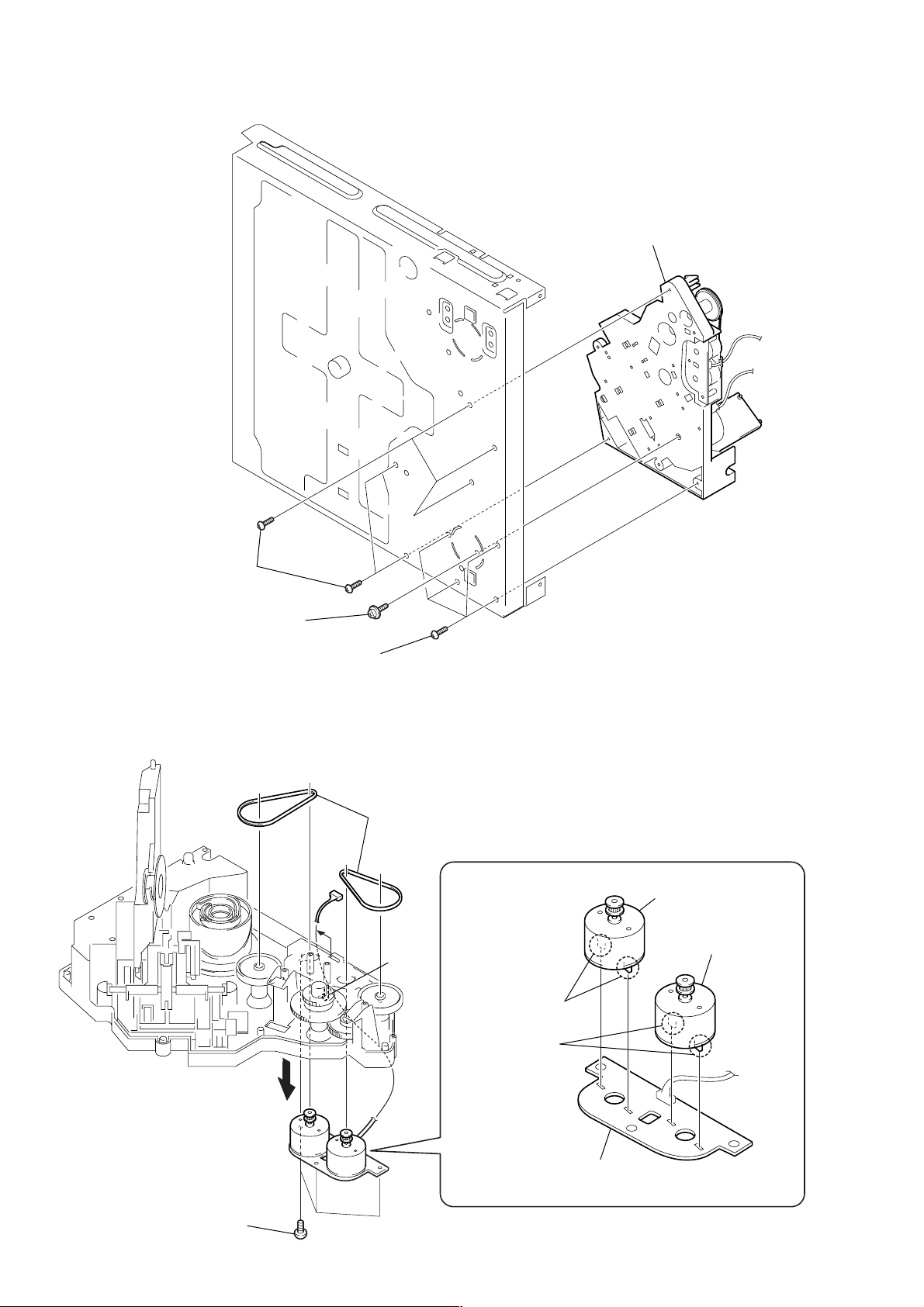

3-21. CDM Assy

4

CDM assy

1

five screws (+BVTP 3 x 8)

3

screw (+PSW 3 x 8)

2

four screws (+BVTP 3 x 8)

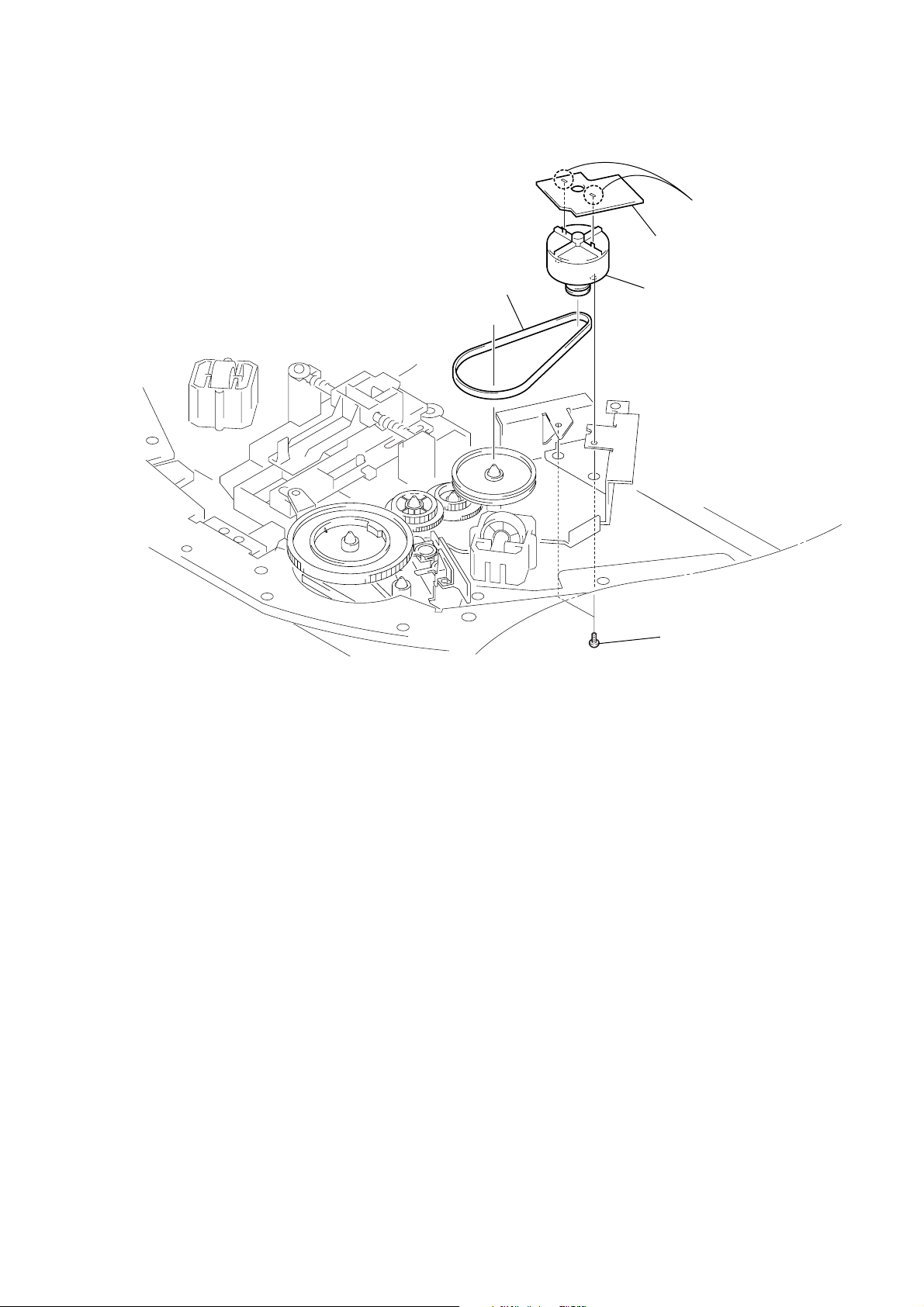

3-22. Motor Assy (Loading) (M82) , Motor Assy (Table) (M81) , L. T. MOTOR Board

1

two belts

2

4

claw

6

remove

two solderings.

7

motor assy (loading)

(M82)

9

motor assy (table)

(M81)

3

three screws (+BVTP 3 x 8)

20

5

8

remove

two solderings.

q;

L.T. MOTOR board

CDP-CX355

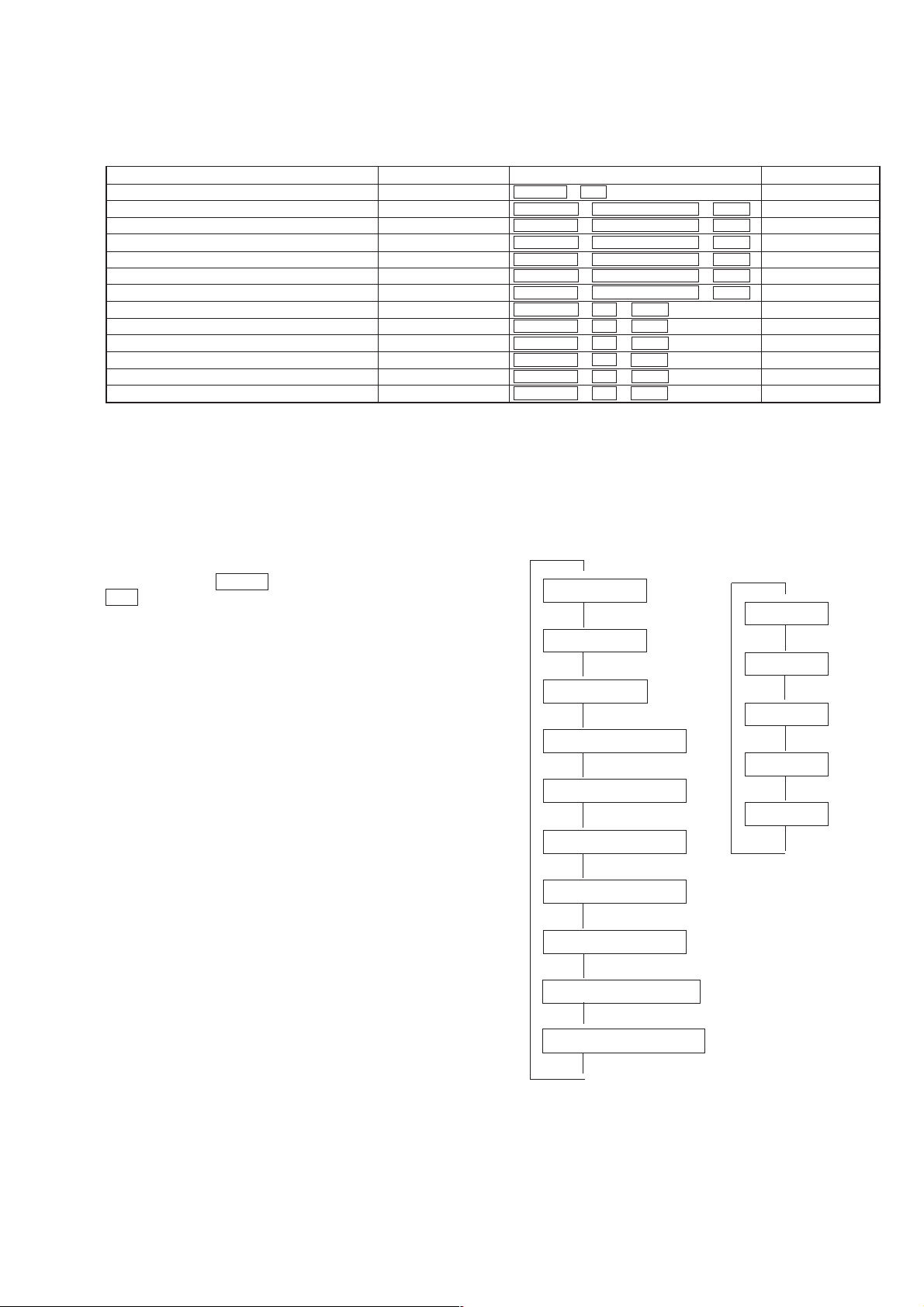

SECTION 4

SERVICE MODE

SPECIAL FUNCTION

This unit is provided with several service modes.

Details are shown in the following table.

Mode name

ALL ERASE

AGING MODE

LOARDING AGING MODE

T ABLE A GING MODE

DOOR POP UP AGING MODE

TABLE LOTATION MODE

TITLE MEMO SHIFT MODE

MODEL NAME DISPLAY

MICROPR OCESSOR VERSION DISPLA Y

ALL LIT MODE

MECHANISM ADJUSTMENT MODE

SHIPMENT MODE

TITLE MEMO RECORDING CHECK MODE

Note 1

Do not execute unless with a proper reason, otherwise the memory of the title memo recorded by the customer will be erased.

The title memo recording check mode is not required for servicing. Do not execute.

ALL ERASE

This mode is used for clearing information such as the title memo.

Do not execute if information such as the title memo is not to be

erased.

Procedure:

While pressing the CLEAR button with the power OFF, press the

1/u button and turn on the power.

The fluorescent display tube displays “ALL ERASE” and all

memories will be cleared.

AGING MODE

• Mode which repeatedly changes and plays back discs automatically in the unit.

• It will repeat aging as long as no errors occur.

• If an error occurs during aging, it will stop all servos, motors, etc.

instantaneously, display the error number, and stop operations.

However , the stopping conditions dif fer according to whether the

unit is equipped with the “self-protection function during errors”

described later.

The function serves to maintain the state of the unit when errors

occur.

Power supply state

OFF

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

Button operation

CLEAR + ?/1

GROUP 1 + § OPEN/CLOSE + +100

GROUP 2 + § OPEN/CLOSE + +100

GROUP 3 + § OPEN/CLOSE + +100

GROUP 4 + § OPEN/CLOSE + +100

GROUP 5 + § OPEN/CLOSE + +100

GROUP 7 + § OPEN/CLOSE + +100

GROUP 1 + · + +100

GROUP 2 + · + +100

GROUP 3 + · + +100

GROUP 4 + · + +100

GROUP 5 + · + +100

GROUP 6 + · + +100

Sequence of Aging Mode

$

1. Disc change

$

2. Load in

$

3. TOC read

$

4. Access of last track

$

5. 3 second playback

$

6. Access of first track

Order of Disc Change

Note 1

Used in adjustment

Note 1

Note 1

(1 cycle takes 3 minutes)

$

1. No. 60

$

2. No. 240

$

3. No. 180

$

4. No. 300

$

5. No. 120

$

Remarks

$

7. 3 second playback

$

8. Load out

$

9. FRONT COVER open

$

10. FRONT COVER close

$

21

CDP-CX355

Special Aging Mode Functions

The aging mode is provided with the following con venient functions

• Disc setting mode (*1)

• Selection of presence of protection function during error (*2)

• Count function of aging cycle (*3)

*1 Disc setting mode:

5 discs are set before setting the aging mode. This mode makes

the setting of these discs more easy.

*2 Self protection function during errors:

Function which voluntarily corrects errors which occur during

normal operations by retries.

If this function is not provided, all operations will be stopped

without retiring. It is suitable for checking errors with low

reproducibility.

If this function is provided, and errors can be corrected by

retries, aging will be continued without stopping.

*3 Aging cycle count function:

Functions which displays the number of agings carried out on

the Fluorescent indicator tube in numbers. One aging cycle

consists of five discs.

number of disc table

1DISC

DISC

CD1

120

AGED 10

number of agings

Aging Procedure

1. Turn ON the power of the unit. Press the § OPEN/CLOSE

and open the front cover.

2. Change the COMMAND MODE switch (S902) on set to CD1 .

3. Press the AGING START button of the remote commander

for aging mode (J-2501-123-A).

4. When the disc set mode is set, the · and P LEDs blink.

5. Rotate the DISC/CHARACTER dial. The slits (No. 60, 120,

180, 240, 300) for setting the discs will come forward. Insert

the discs into these slits. Do not set the discs in other slits.

6. Set whether the self-protection function during errors is

equipped with the unit. Press the REPEAT button. If

“REPEAT” is displayed on the Fluorescent indicator tube, it

means the function is provided. If “REPEAT” is not displayed,

it means the function is not provided.

Error Display

Disc number

when aging

180

120 E01 #

Disc number

with error

7. Press the · button.

8. The · LED blinks, the aging mode is set, and aging is started.

9. The aging cycle lasts 3 minutes. If errors occur during aging,

the error number will be displayed on the Fluorescent indicator

tube. (Refer to the following table for the details of the errors.)

10. Aging will be repeated as long as no errors occur.

11. After each aging cycle, the number displayed on the Fluorescent

indicator tube will increase.

12. To end aging, disconnect the power cord from the outlet.

Error code

Aging cycle

number

Error code

Err 01

Err 02

Err 03

Err 04

Err 05

Err 06

Err *1

Err *2

Err *3

Err *4

Err *5

Err *6

Err *7

DISC sensor check 1

DISC sensor check 2

Table operation check 1

Table operation check 2

Loading operation check 1

Loading operation check 2

BU related check 1

BU related check 2

BU related check 3

BU related check 4

BU related check 5

BU related check 6

BU related check 7

NOTE: As an alternative to steps 2 and 3, press the GROUP 1

button, §OPEN/CLOSE button, and +100 button at the

same time.

ContentsCode number Name

No disc in the specified slit

Disc in other slits

Table motor current over

No table sensor input

Load in timeover

Load out timeover

Access timeover

High speed search NG

Q data read error

BU operation (from focus search to until signal can be read) timeover

GFS monitor error

Focus cannot be imposed by focus search

Auto focus bias adjustment cannot be performed

The following * numbers mean according to the state of the unit during aging

*2 : From chucking to end of TOC read

*3 : From end of TOC read to end of last track playback

*4 : From end of last track playback to end of first track playback

22

Loading...

Loading...