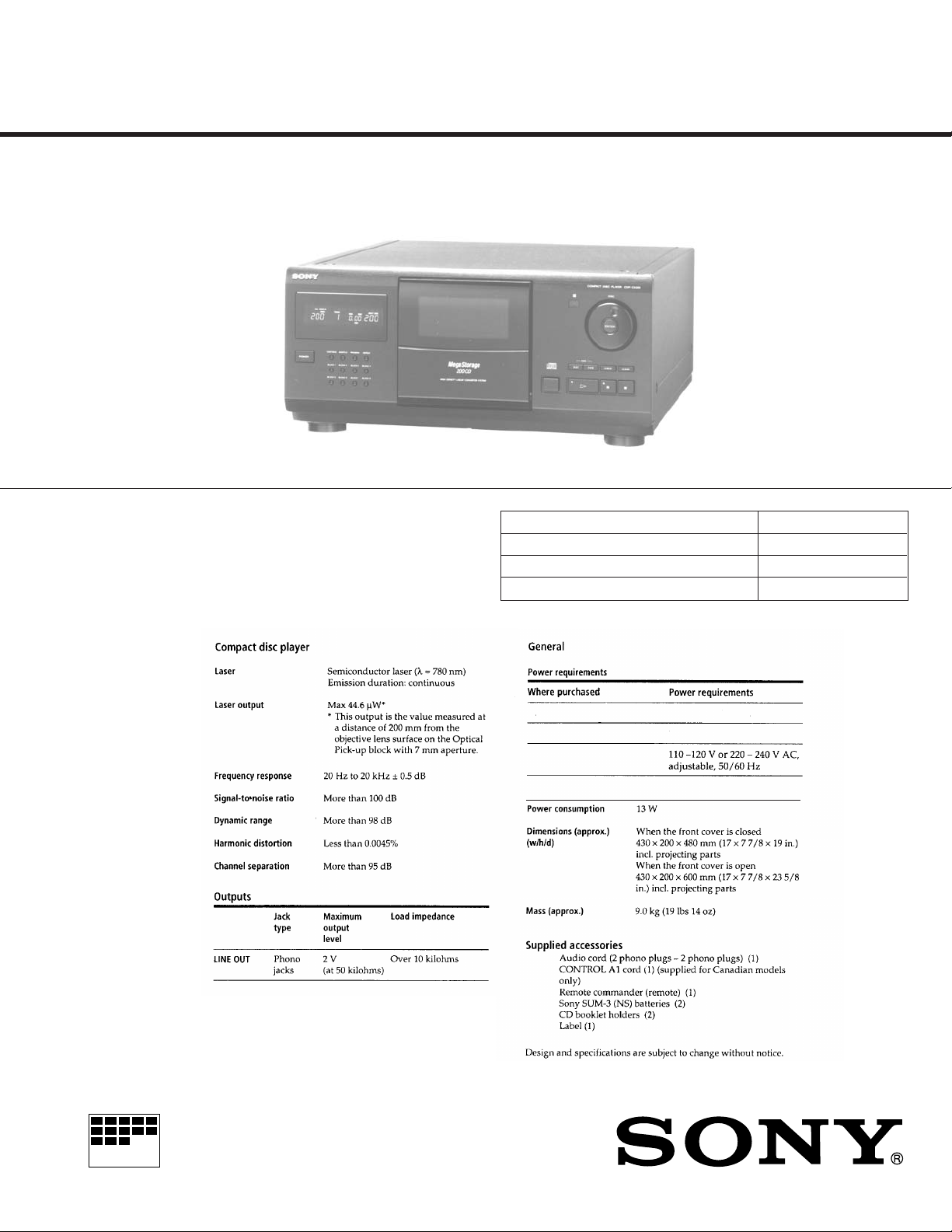

Sony CDP-CX200 Schematic

CDP-CX200

SERVICE MANUAL

Model Name Using Similar Mechanism NEW

CD Mechanism Type CDM-40

Base Unit Type KSM-213BKN/M-N

Optical Pick-up Type KSS-213B/S-N

SPECIFICATIONS

US Model

Canadian Model

AEP Model

UK Model

E Model

Australian Model

PX Model

MICROFILM

USA, Canada

Europe and Singapore

E, PX

Australia

COMPACT DISC PLAYER

120V AC, 60Hz

220V - 230V AC, 50Hz

240V AC, 50Hz

— 1 —

TABLE OF CONTENTS

1. SERVICING NOTE ........................................................... 3

2. GENERAL ....................................................................4

3. DISASSEMBLY

3-1. Front Panel Assembly ......................................................... 9

3-2. Back Panel Assembly ......................................................... 9

3-3. T able Assembly ................................................................10

3-4. Mechanism Deck Assembly ............................................. 10

3-5. Base Unit Assembly ......................................................... 11

4. TEST MODE ............................................................... 12

5. ADJUSTMENTS

5-1. Mechanical Adjsument ..................................................... 13

5-2. Electrical Block Checking................................................ 19

MODEL IDENTIFICATION

— BACK PANEL —

4-982-790-

US Model : 0π

Canadian Model : 1π

AEP,German Model : 2π

UK Model : 3π

E,PX Model : 4π

Singapore Model : 5π

Austrarian Model : 6π

6. DIAGRAMS

6-1. Circuit Boards Location ...................................................21

6-2. IC Pin Function

• IC101 Digital Servo, Digital Signal Processor

(CXD2545Q) ................................................................ 22

• IC303 System Control (CXP84332-Q28Q) .................25

6-3. Block Diagram ................................................................. 27

6-4. Printed Wiring Board — BD, DISP Section — ............... 31

6-5. Schematic Diagram — BD, DISP Section — .................. 35

6-6. Printed Wiring Board — MAIN Section — .....................39

6-7. Schematic Diagram — MAIN Section —........................43

6-8. IC Block Diagrams ........................................................... 47

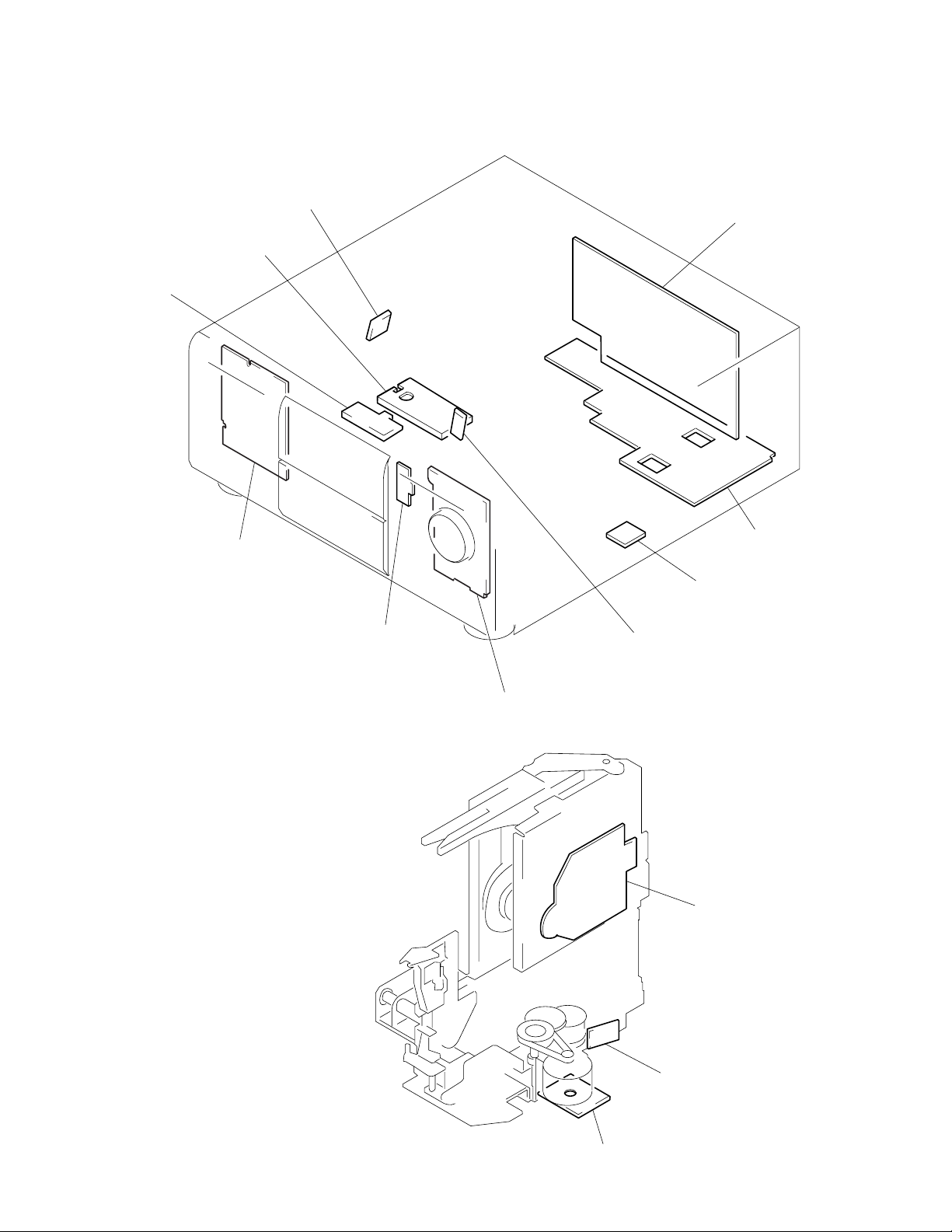

7. EXPLODED VIEWS

7-1. Case and Back Panel Section ...........................................50

7-2. Disc Table Section ............................................................51

7-3. Front Panel Section .......................................................... 52

7-4. Mechanism Section-1 (CDM-40) ..................................... 53

7-5. Mechanism Section-2 (CDM-40) ..................................... 54

7-6. Base Unit Section-1 (KSM-213BKN/M-N).....................55

7-7. Base Unit Section-2 (KSM-213BKN/M-N).....................56

8. ELECTRICAL PARTS LIST ........................................ 57

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

The laser component in this product

is capable of emitting radiation

exceeding the limit for Class 1.

This appliance is classified as

a CLASS 1 LASER product.

The CLASS 1 LASER

PRODUCT MARKING is

located on the rear exterior.

This caution label

is located inside

the unit.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

— 2 —

SECTION 1

SERVICING NOTE

SAFETY CHECK-OUT

(US model only)

After correcting the original service problem, perform the following safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

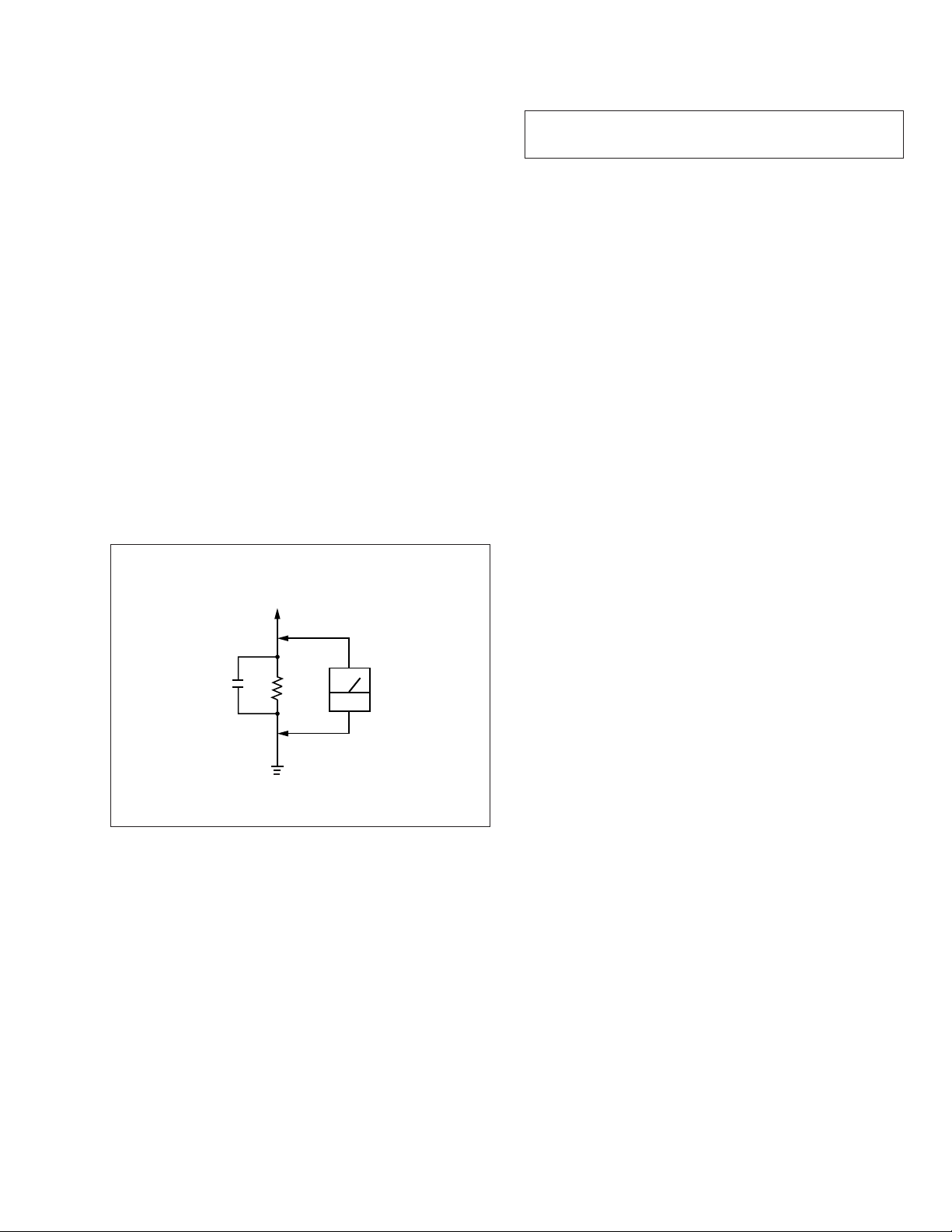

LEAKAGE

The AC leakage from any exposed metal part to earth Ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers). Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated AC voltmeter. The “limit” indication is 0.75

V, so analog meters must have an accurate low-volta ge scale.

The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery operated digital

multimeters that have a 2V AC range are suitable. (See Fig. A)

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic breakdown and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objecti ve lens in the optical pick-up

block. Therefore, when checking the laser diode emission, observe

from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERA TION CHECK

Carry out the “S curve check” in “CD section adjustment” and check

that the S curve waveform is output repeatedly.

To Exposed Metal

Parts on Set

0.15µF

1.5k

Ω

Earth Ground

AC

voltmeter

(0.75V)

Fig. A. Using an AC voltmeter to check AC leakage.

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY MARK ! OR DO TTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE ! SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE

FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS

QUE PAR DES PIÈCES SONY DONT LES NUMÉROS

SONT DONNÉS DANS CE MANUEL OU DANS LES

SUPPLÉMENTS PUBLIÉS PAR SONY.

— 3 —

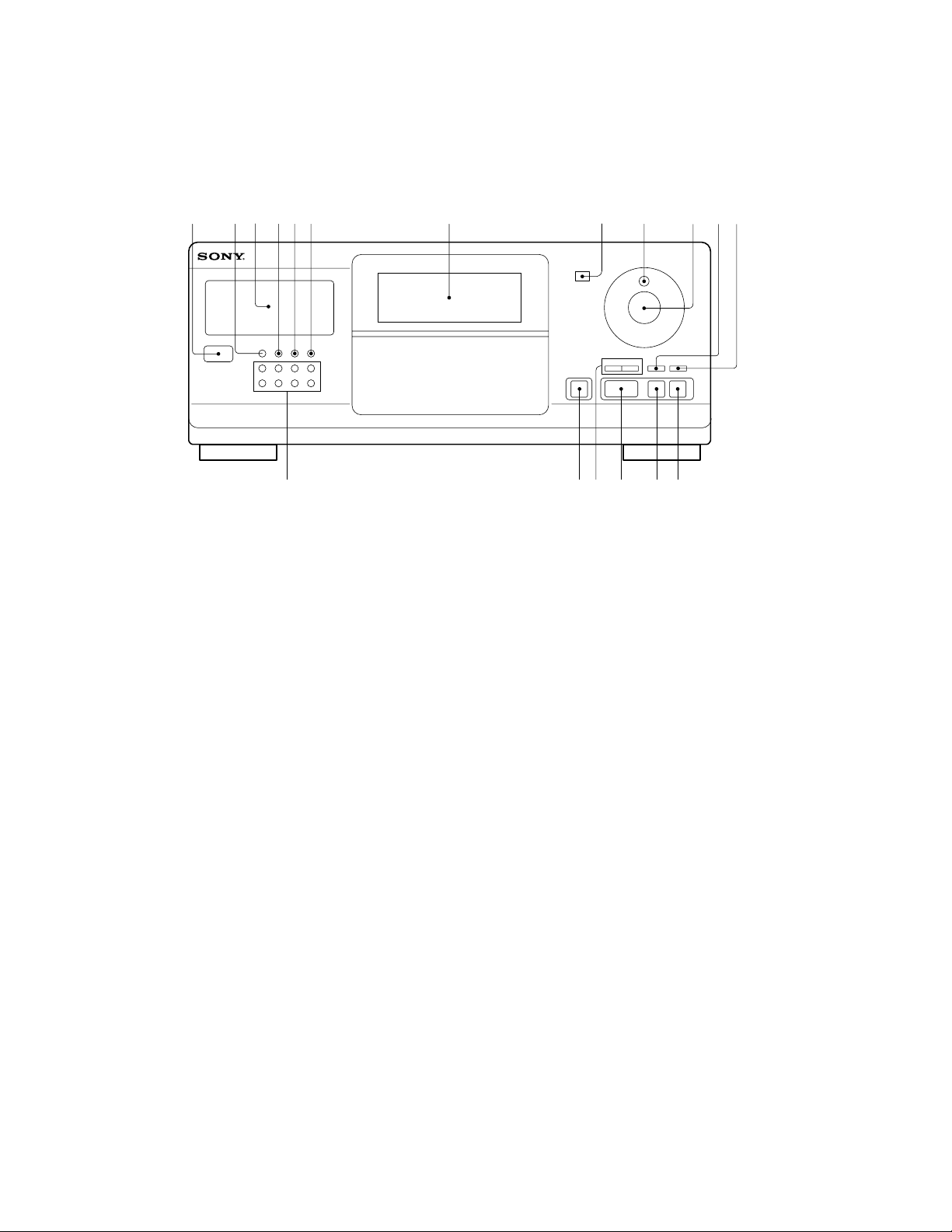

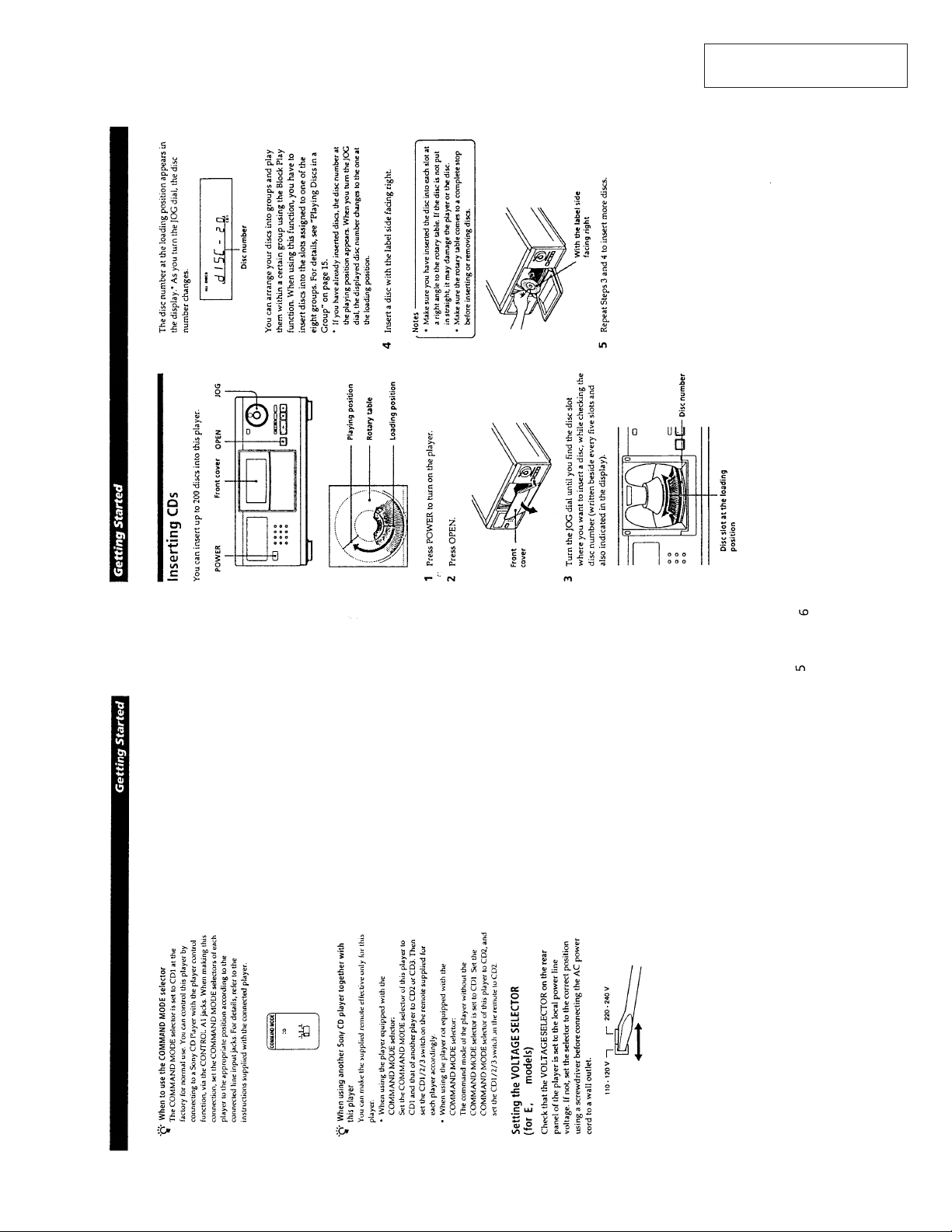

LOCATION OF PARTS AND CONTROLS

Front Panel

SECTION 2

GENERAL

1 POWER button

2 CONTINUE button

3 Display window

4 SHUFFLE button

5 PROGRAM button

6 REPEAT button

7 Front cover

8 Remote sensor

9 JOG dial

!º ENTER button

12

3

5

4

!•

6

7

!§!¶

!¡ CHECK button

!™ CLEAR button

!£ p (stop) button

!¢ P (pause) button

!∞ · (play) button

!§ ≠ AMS* ± button

!¶ OPEN button

!• BLOCK 1-8 buttons

* AMS is the abbreviation for Automatic Music Sensor.

98!º!¡

!¢

!∞

!£

!™

— 4 —

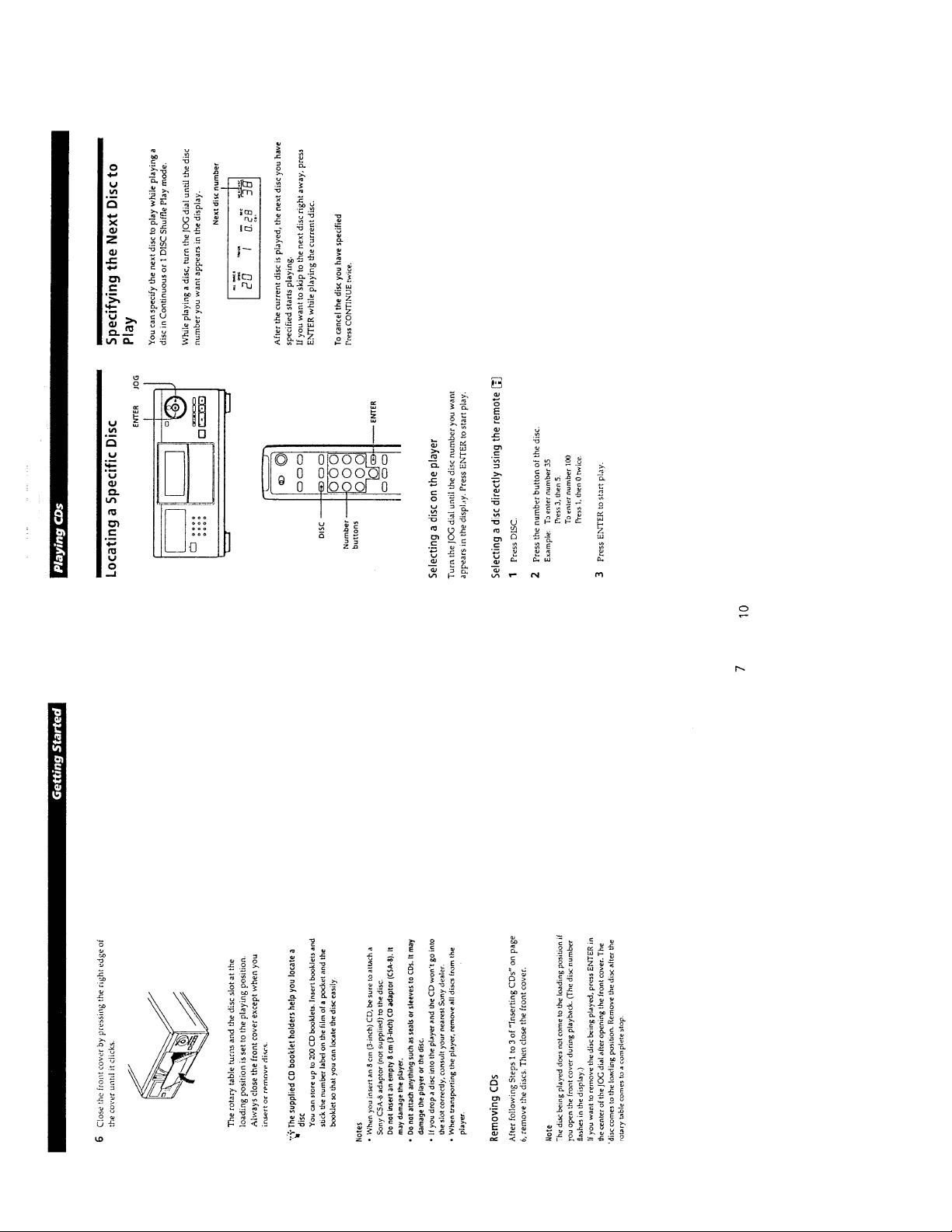

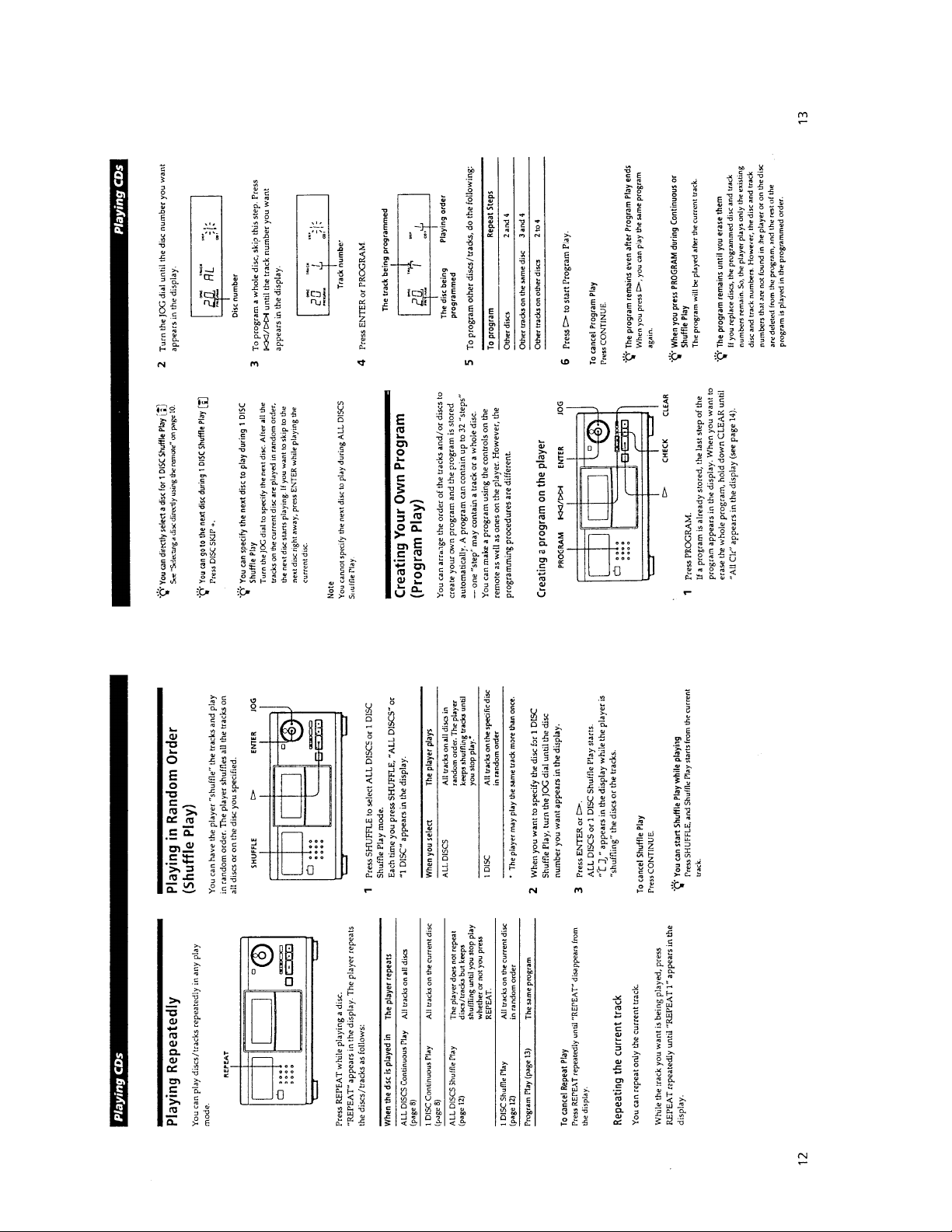

This section is extracted from

instruction manual.

— 5 —

PX

— 6 —

— 7 —

— 8 —

SECTION 3

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

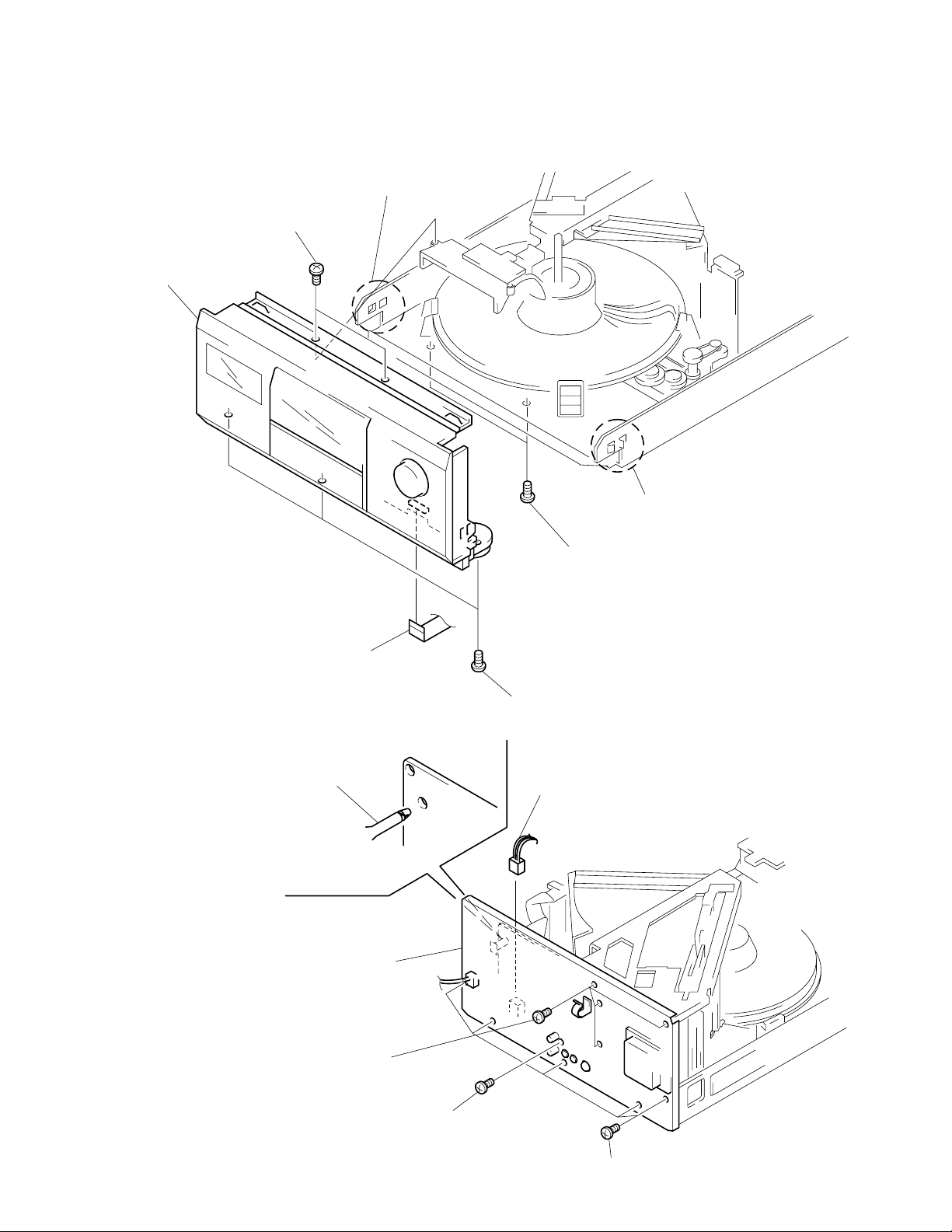

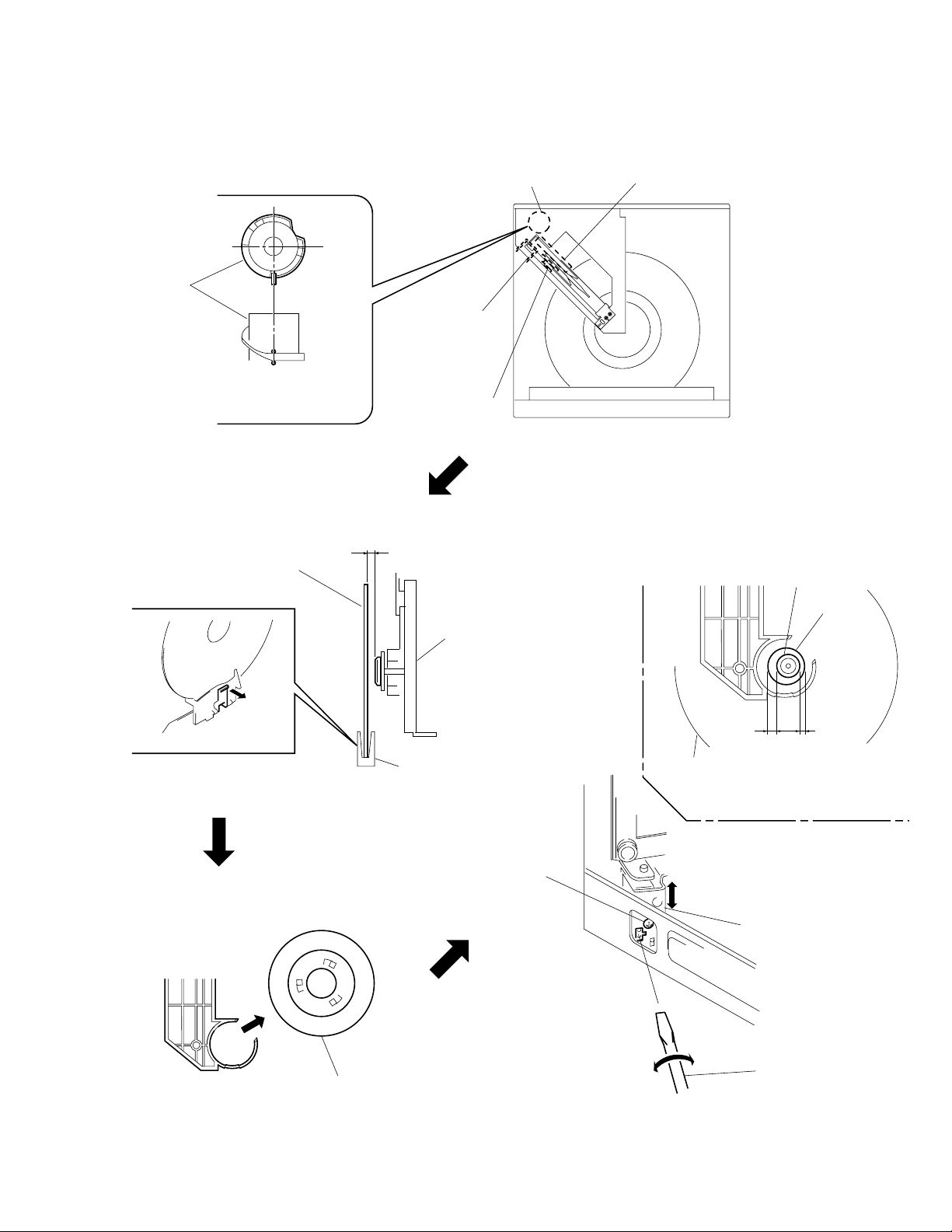

3-1. FRONT PANEL ASSEMBLY

6

Remove the claw

1

Two screws

(BVTP 3x8)

7

Front panel assembly

5

Remove the claw

4

Flat type wire (CN601)

3-2. BACK PANEL ASSEMBLY

5

Remove the PC board holder

6

Back panel

3

Two screws (BVTT 3x6)

2

Three screws (BVTT 3x6)

1

Connector

(CN501)

2

Four screws (BVTT 3x6)

4

Screw

(BVTP3x10)

— 9 —

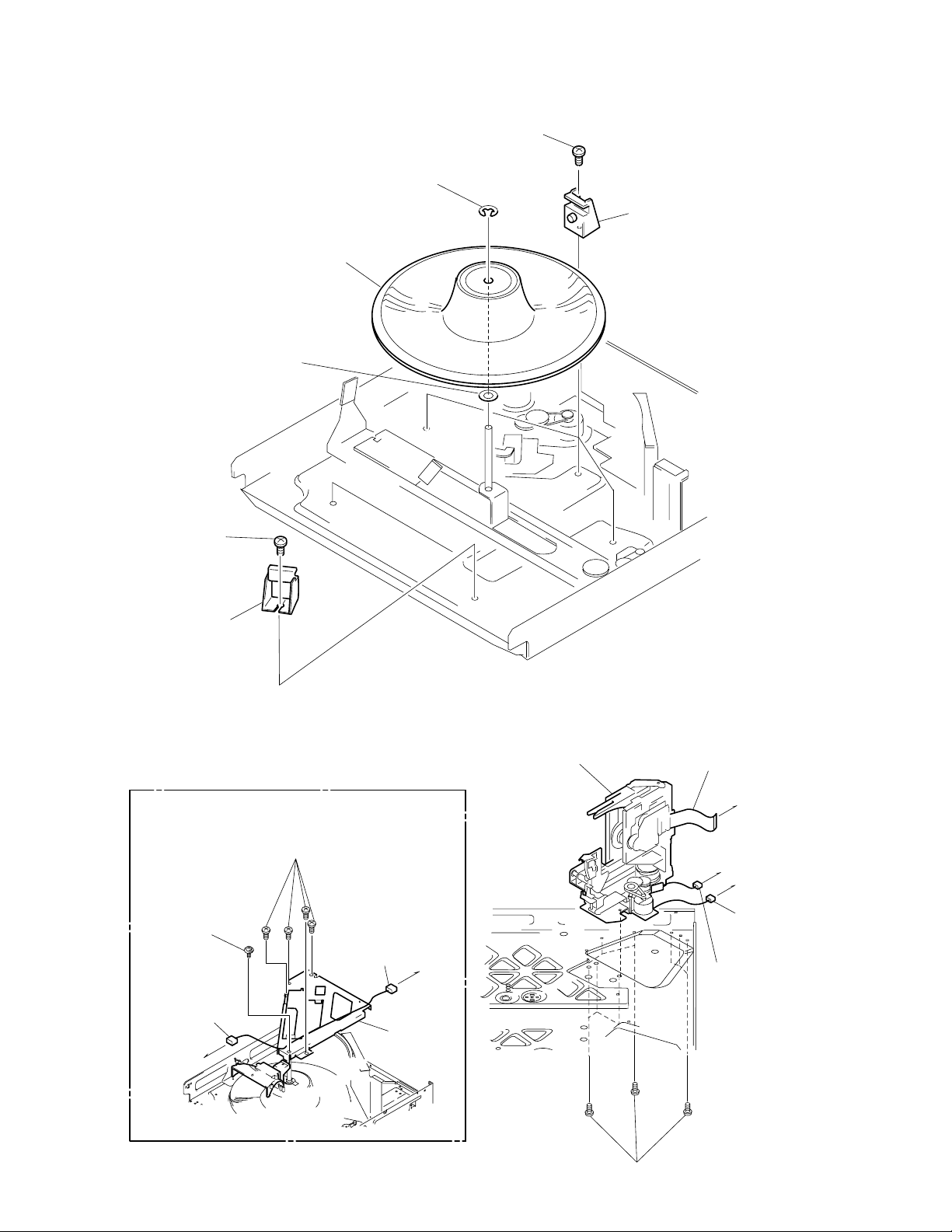

3

Five screws

(BVTT3x6)

3-3. T ABLE ASSEMBLY

2

Two screws

(BVTT3x6)

7

Washer

1

Stop ring (E type)

6

Table assembly

4

Three screws (BVTT3x6)

5

Three holder assemblies

3

Two holder assemblies

3-4. MECHANISM DECK ASSEMBLY

1

Four screws (BVTT3x6)

2

Screw

(BVTT3x6)

3

Connector

(CN303)

Illumination

board

4

Connector

(CN308)

5

Guide

assembly

Jack

board

!º

Mechanism deck

6

Flat type wire

(23core) (CN303)

Jack board

8

Connector (CN504)

Main board

Main board

7

Connector

(CN304)

— 10 —

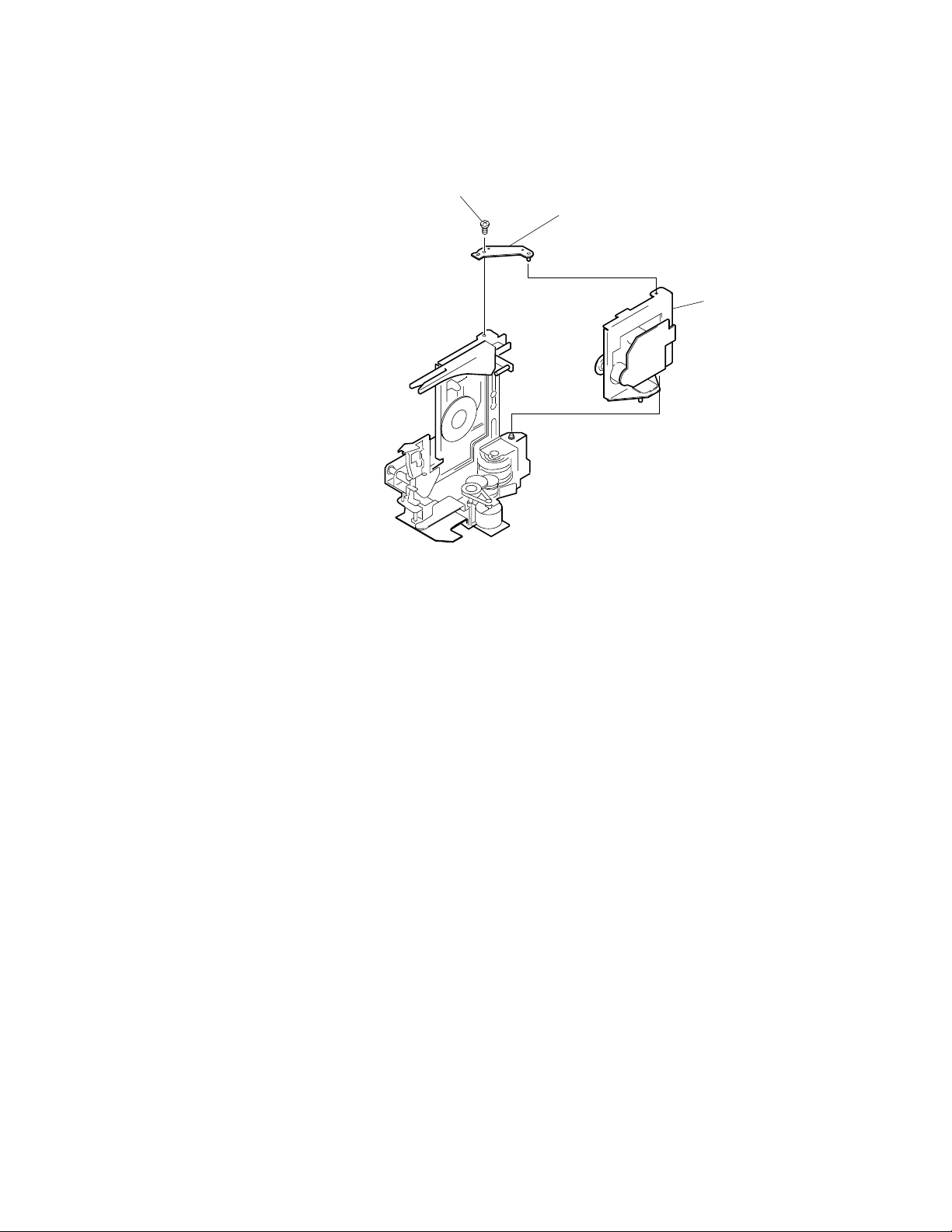

9

Nine screws (BVTT3x8)

3-5. BASE UNIT ASSEMBLY

1

Screw (BVTT3x6)

2

Fulcrum plate

(BU UPPER) assy

3

Base unit

— 11 —

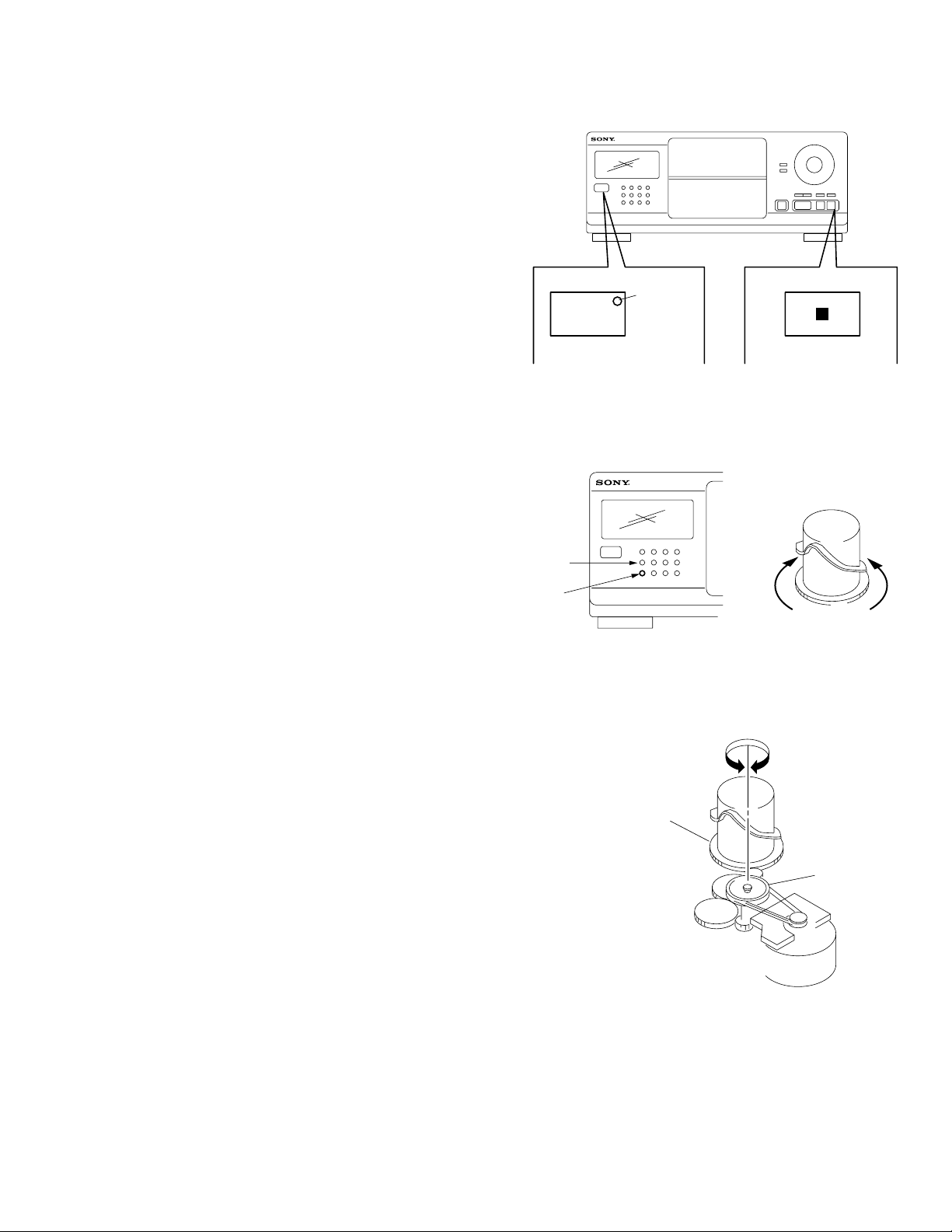

SECTION 4

TEST MODE

4-1. Display Check Mode

With the pow er turned off (standby state), press the POWER button

while pressing the P (pause) button.

All FL segments and grids light up together with the · (play), P

(pause), and standby LEDs.

At the same time, the GROUP LEDs are scanned one by one.

Note: To exit this mode, press the POWER button.

4-2. ADJ Mode

1. Turn ON the power of the unit, set disc to disc table, and perform

chucking.

2. Disconnect the power supply plug from the outlet.

3. T o set ADJ mode, connect the test point (TP301:ADJ) of the MAIN

board to Ground, and turn on the power supply plug to the outlet.

The power will turn on automatically , and the first track will be played.

In this mode, table rotation and loading operations are not performed

because it is taken that the disc has already been chucked.

Note: The same operations are also performed in the following when

the test point (TP301:ADJ) is connected to Ground after turning on the power.

• Direct search (movement of sledding motor) is not performed dur-

ing accessing

• Ignored even when GFS becomes L

• Ignored even when the Q data cannot be read

• Focus gain does not decrease

• Spindle gain does not decrease

• Servo related settings can be set manually and checked (Refer to

ADJ Mode Special Functions Table)

ADJ Mode Special Functions Table

(The buttons shown with ( ) function by using the supplied remote commander only)

Button

CONTINUE

SHUFFLE

PROGRAM

BLOCK 1 (1)

BLOCK 2 (2)

BLOCK 3 (3)

BLOCK 4 (4)

BLOCK 5 (5)

BLOCK 6 (6)

BLOCK 7 (7)

BLOCK 8 (8)

(9)

(10/0)

CHECK

CLEAR

Servo average display

Displays VC, FE, RF, TE and traverse in hexadecimal

numbers

Focus bias display

Each time this is pressed, the focus bias is switched

between 1 and 2

(1)

Bias actually set Optimum bias Minimum jitter

(2)

U:Upper aliasing bias L:Lower aliasing bias

Auto gain display

Displays focus, tracking, sledding in hexadecimal

numbers

Increases the focus bias in 8 steps.

Sets the focus bias in the middle of aliasing.

Turns off the tracking and sledding servo

Returns the auto gain to the initial value (30)

Turns off the focus servo

Decreases the focus bias in 8 steps.

Re-adjusts the focus bias

Turns on the tracking and sledding servo

Switches the focus servo gain between normal and down

08: normal, 0C: down

Sets the focus bias to 0 (no bias)

Next, displays the jitter measured at the focus bias set

S-curve observation mode

Automatic eccentric measurement

The results of measurement is displayed in µm directly.

Function

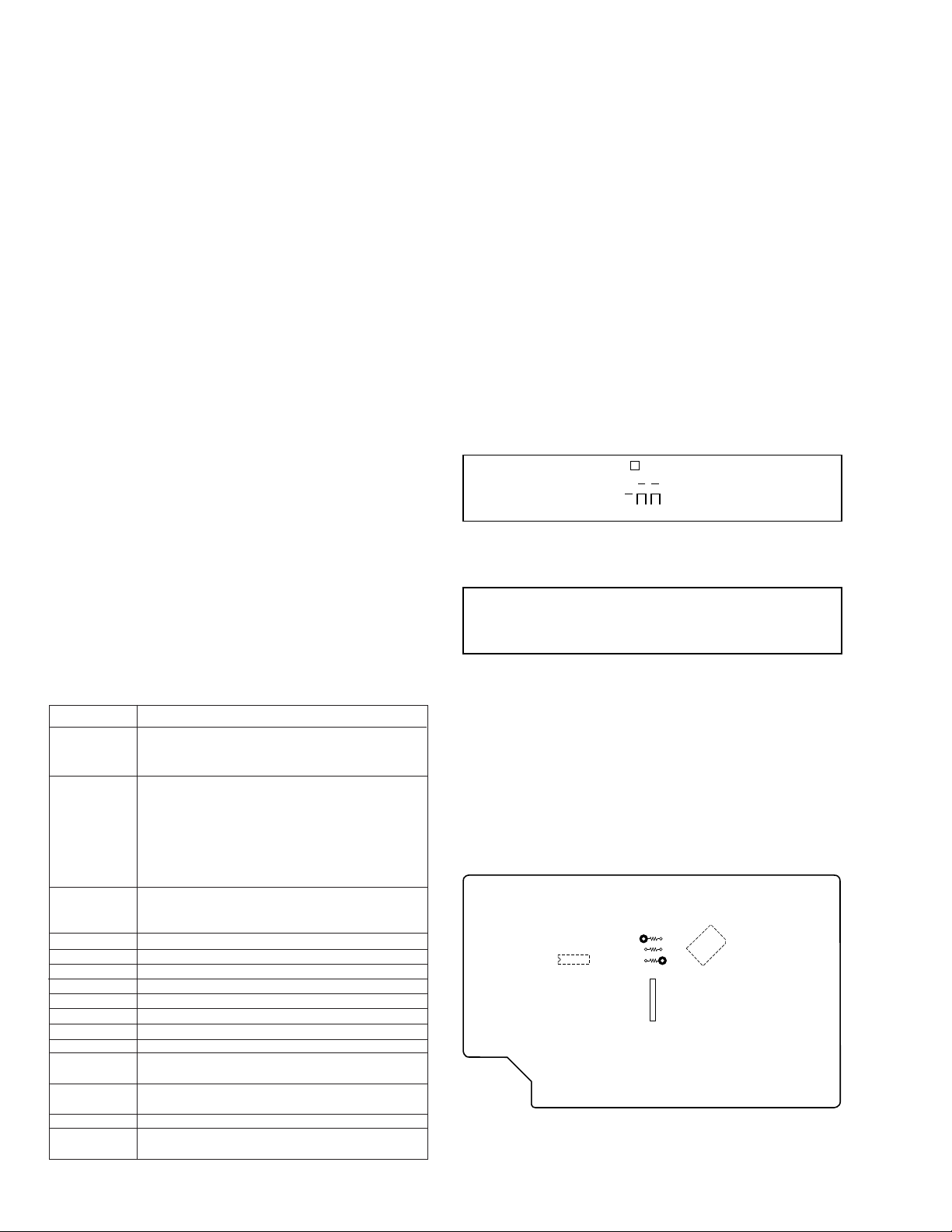

4-3. Key and Display Check Mode

To set this mode, connect the test point (TP302:AF ADJ) on the MAIN

board to Ground, and turn on the power supply plug to the outlet.

• All FL segments and grids will light up. (All lit check)

When a button is pressed, the types of buttons pressed until then

will be displayed on the left side and the number of the buttons will

be displayed on the right side. However , these will not be displayed

for the following special buttons.

p(stop) button: FL segment check

(Refer to FL Tube Check Patterns)

P(pause) button: FL grid check (Refer to FL Tube Check P atterns)

The pause LED also lights up simultaneously.

·(play) button: All FL segment and grid will light up

The play LED also lights up simultaneously.

FL Tube Check Patterns

Segment check

2

1

Grid check

PROGRAM

REPEAT 1

• When the jog dial is rotated to the right, the Block indicators of FL

light up in the order of 1n2..8n1.

• When the jog dial is rotated to the left, the Block indicators of FL

light up in the order of 8n7..1n8.

• The standby LED lights up when the door switch is shut.

• Abbreviation

FL: Fluorescent Indicator Tube

[ MAIN BOARD ] — Component Side —

IC303

R311

TP302

AFADJ

IC307

R337

TP301

ADJ

R310

IC301

REMOTE

— 12 —

SECTION 5

ADJUSTMENTS

5-1. MECHANICAL ADJUSTMENT

Perform the following steps before carrying out adjustments.

1. Turn ON the power of the unit, set disc to disc table No. 92, and

perform chucking.

2. Turn OFF the power.

3. Remove the case.

4. While pressing the STOP button, turn ON the POWER button.

The test mode is set.

5. The POWER button LED starts blinking.

(Test mode)

LED

POWER

NOTE 1: The cam will start rotating when the BLOCK 1 or BLOCK

5 button is pressed continuously in the test mode.

POWER button

BLOCK 1

button

BLOCK 5

button

STOP button

BLOCK 1 button

BLOCK 5 button

NOTE 2: If the power cannot be supplied, the cam can be rotated by

rotating the pulley with your finger.

Cam

Pulley

— 13 —

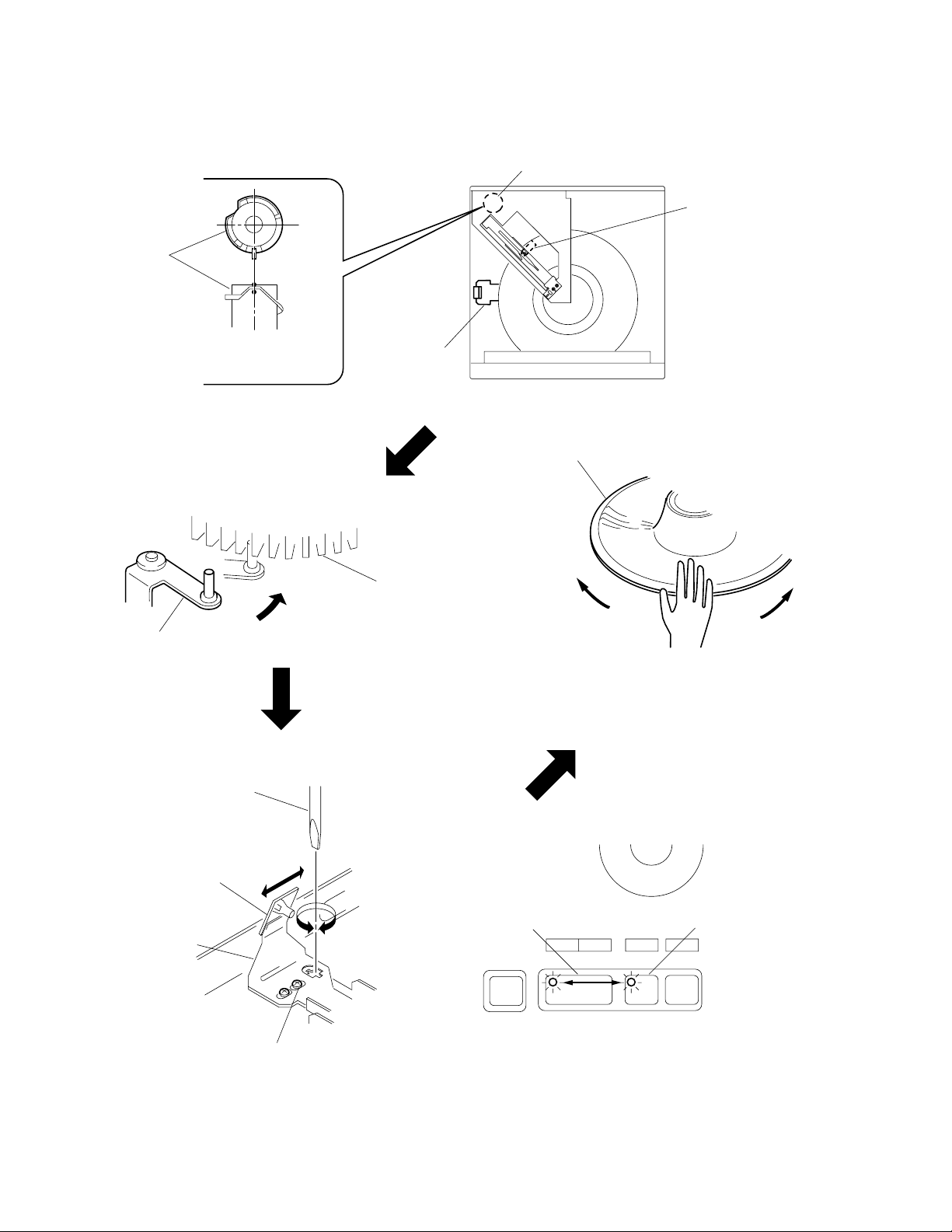

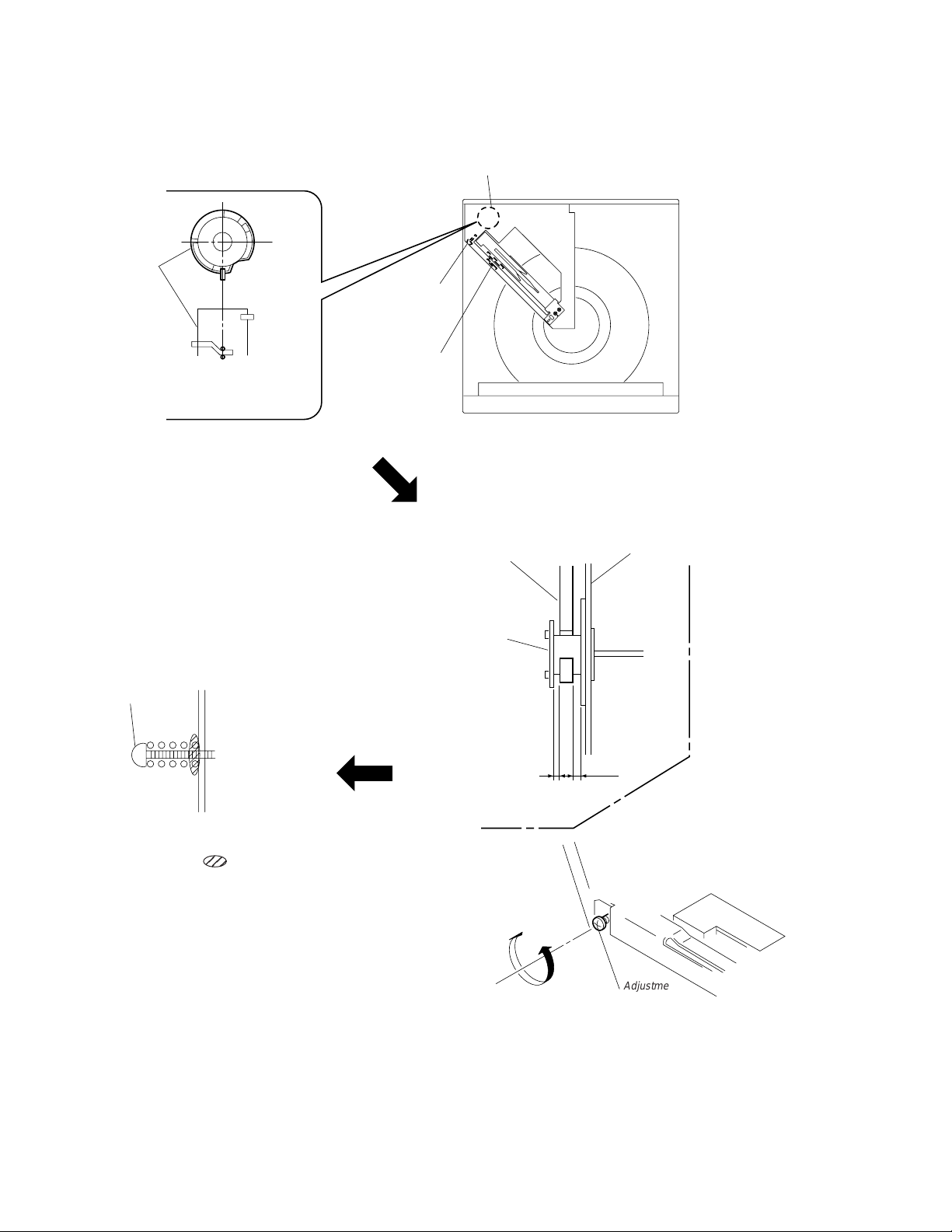

SENSOR ALIGNMENT

If the disc table swings to the left and right just before the disc is

chucked, perform the following adjustment.

Cam

Cam

LEVER (stopper)

assembly

(1) Rotate the cam and adjust to the position

shown in the figure.

(2)Check that the lever (stopper) assem-

bly secures the disc table as shown in

the figure.

Lever (stopper) assembly

Tepering screwdriver

Bracket (sensor)

Table assembly

Disc table

Swing

(4)Moving the disc table right and left with a hand after the screw is

fixed, the table will move by the play of a disc table. If the LEDs

light up alternately, the adjustment will be performed correctly)

Luminus board

PLAY button

Bracket (sensor)

Fixed screw

PAUSE button

(3)Loosen the fixed screw by 60° to 90°, and use a tapering screwdriver to adjust the screw as shown in the figure.

Move the bracket (sensor) with the tapering screwdriver little by little, and fix the fixed at where the paly botton's LED (green) is switched to

the pause button's LED (orange) (or its reverse).

— 14 —

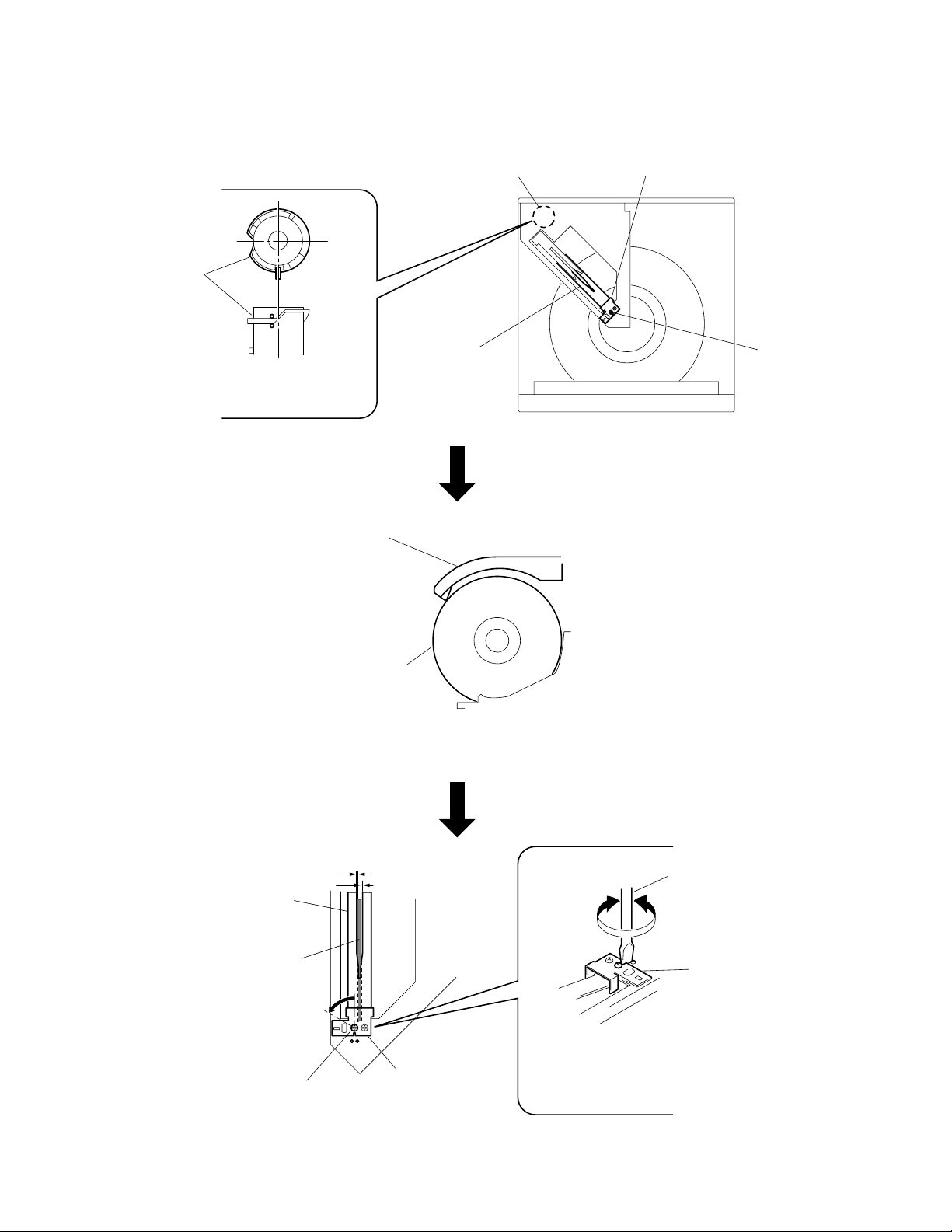

GUIDE (DISC T) ALIGNMENT

Cam

(1)Rotate the cam and adjust to the position

shown in the figure.

Guide (disc T)

(2)Check that the state is as shown in the

figure.

Guide (disc T)

Cam

Holder (guide T)

Fixed screw

Guide (disc T)

Disc

(3)Loosen the fixed screw by about 60 °.

Disc

A

B

Holder

(guide T)

(4)Move the holder (guide T) with a tapering screwdr iver, and

set the position of the guide (disc T) to A:B=1:1.

Tapering screwdriver

Holder (guide T)

— 15 —

HOLDER (DISC A) ALIGNMENT

Cam

(1) Rotate the cam and adjust to the position

shown in the figure.

Holder (disc A)

0–1 mm

Thrust

screw

Cam

Holder (disc A)

Disc

(2)Check that the state is as shown in the

figure.

Thrust screw

Disc

Holder (disc A)

(3)After applying screw-lock to the part, rotate the thrust screw until the holder (Disc A) comes to the center of the disc.

— 16 —

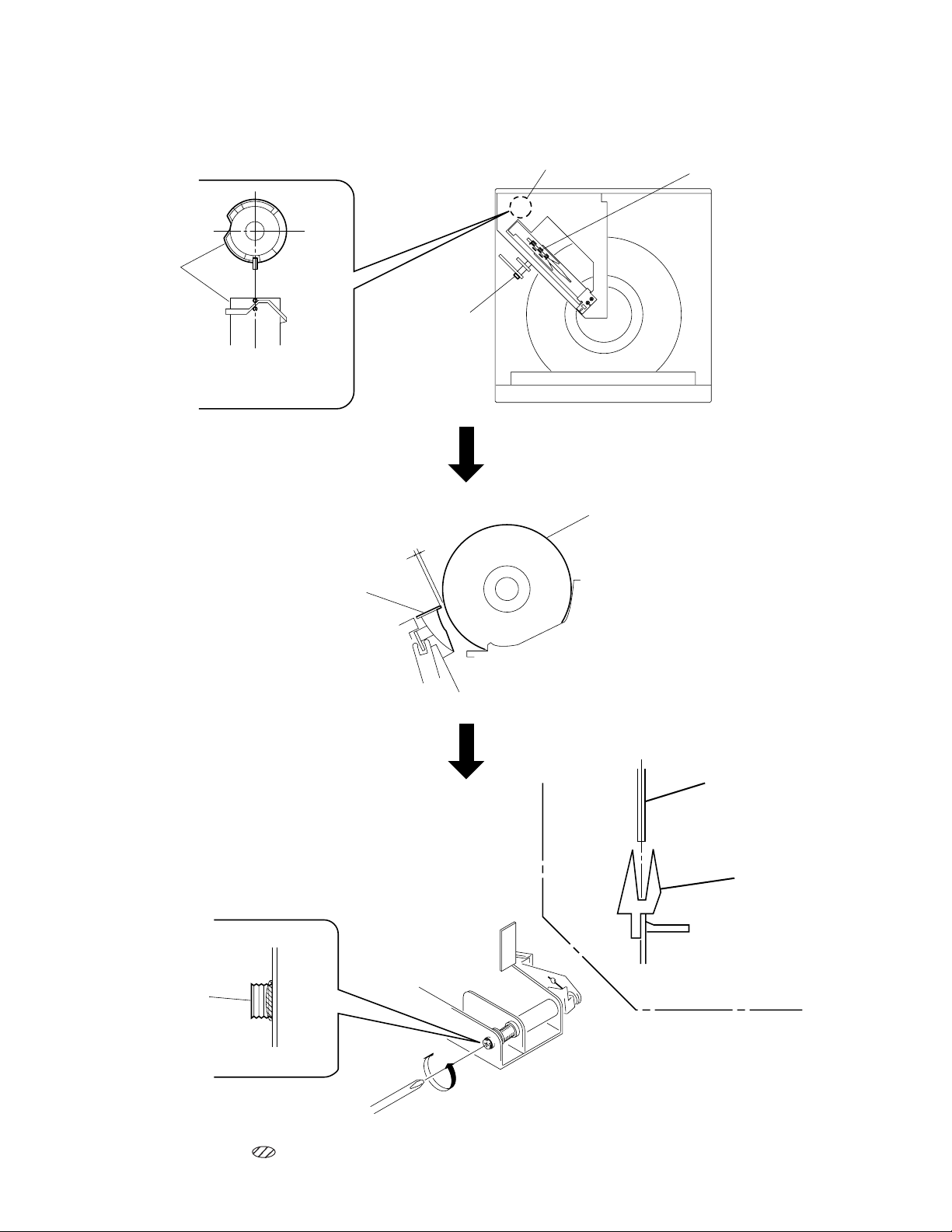

PULLY AND DISC CENTER HOLE ALIGNMENT

Cam

(1)Rotate the cam and adjust to the position

shown in the figure.

(2) Check that the state is as shown

in the figure.

0.5–2mm

Disc

Bracket

(BU adjustment)

Magnet assembly

Cam

Base unit

Disc pulley

Disc hole

Note:The disc should not be fixed.

(3)Remove the Magnet assembly.

Magnet assembly

Base unit

Holer (disc A)

A

B

Fixed screw

Bracket

(BU adjustment)

Tapering screwdriver

Loosen the fixed screw by 60° to 90°, and move and adjust the bracket (BU

adjustment) up and down using a tapering screwdri ver so that the positions of

the disc hole and disc pulley become A=B or between A:B=2:1 and 1:2.

— 17 —

MAGNET ASSY ALIGNMENT

Cam

Cam

Adjustment

screw

(1) Rotate the cam and adjust to the posi-

tion shown in the figure.

Adjustment

screw

Magnet assy

Magnet holder

Magnet assy

Disc

A

B

(3)Apply screw-lock to the part after adjusting.

Adjustment

screw

(2) Rotate the adjustment screw until A=B or between A:B=2:1

and 1:2

— 18 —

5-2. ELECTRICAL BLOCK CHECKING

Note:

1. CD Block is basically designed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent when

the signal level is low than specified value with the following

checks.

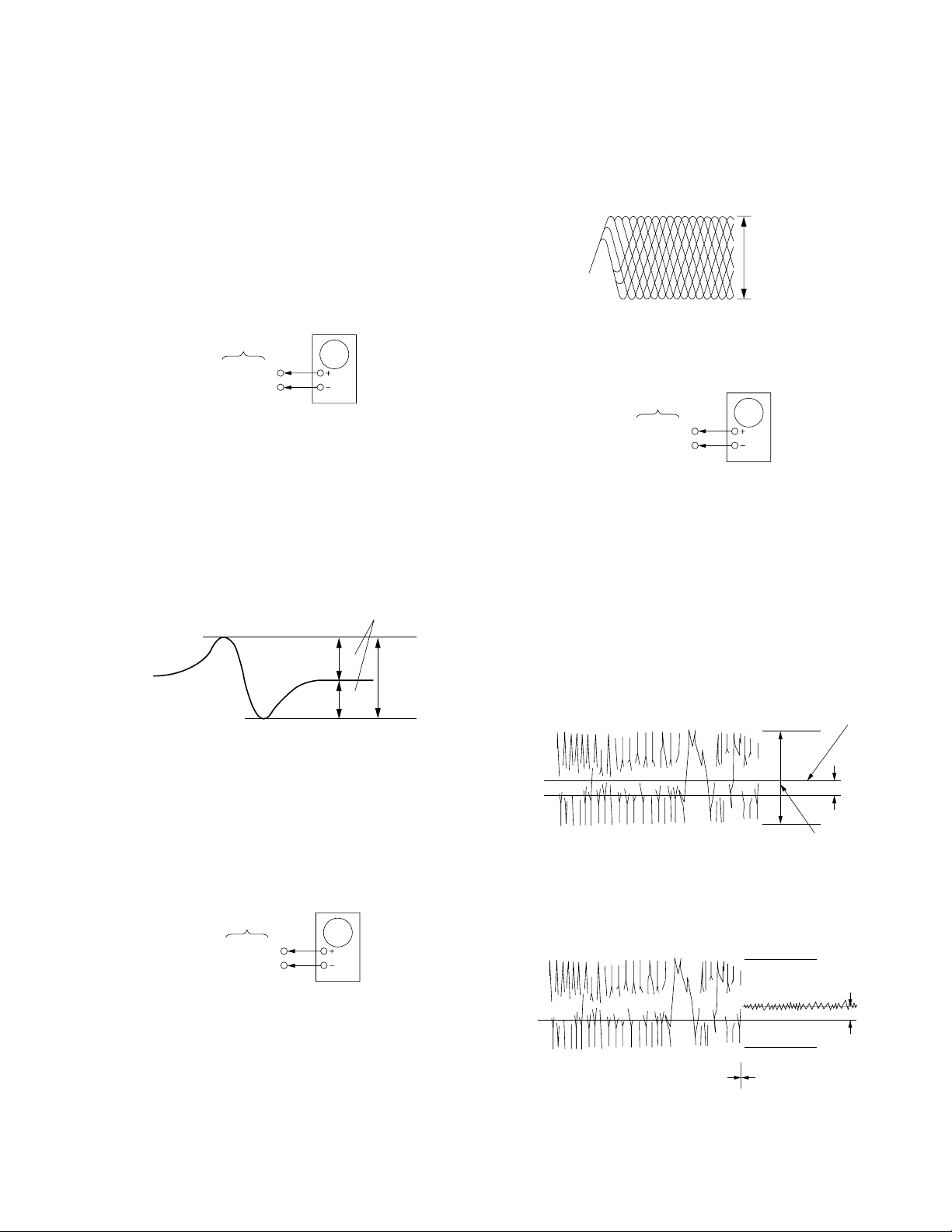

S-Curve Check

Note: A clear RF signal waveform means that the shape “◊” can be

clearly distinguished at the center of the waveform.

RF signal waveform

VOLT/DIV : 200mV

TIME/DIV : 500ns

level : 1.2 Vp-p

+0.25

–0.20

BD board

oscilloscope

TP (FE 1)

TP (VC)

Procedure :

1. Connect oscilloscope to test point TP (FE 1) on BD board.

2. Connect test point TP301 (ADJ) on MAIN board to ground with

lead wire.

3. Turn Power switch on to set the ADJ mode.

4. Put disc (YEDS-18) in and playback.

Press the CHECK button.

5. Check the oscilloscope waveform (S-curve) is symmetrical between A and B. And confirm peak to peak level within 3±1 Vp-p.

S-curve waveform

symmetry

A

within 3 ± 1 Vp-p

B

6. After check, remove the lead wire connected in step 2.

Note : • Try to measure several times to make sure than the ratio of

A : B or B : A is more than 10 : 7.

• T ake sweep time as long as possible and light up the brightness to obtain best waveform.

E-F Balance Check

oscilloscope

BD board

TP (TE)

TP (VC)

Procedure :

1. Connect oscilloscpe to test point TP (TE) on BD board.

2. Connect the test point TP301 (ADJ) on MAIN board to the ground

with a lead wire.

3. Turn the Power switch on to set the ADJ mode.

4. Put disc (YEDS-18) in to play the number five track.

5. Press the “BLOCK3” button. (The tracking servo and the sledding servo are turned OFF.)

6. Check the level B of the oscilliscope's waveform and the A (DC

voltage) of the center of the Traverse waveform.

Confirm the following :

A/B x 100 = less than ± 22%

Traverse waveform

Center of the waveform

B

0V

A (DC voltage)

level : 1.3 ± 0.6 Vp-p

RF Level Check

oscilloscope

BD board

TP (RF)

TP (VC)

Procedure :

1. Connect oscilloscope to test point TP (RF) on BD board.

2. Turn Power switc h on.

3. Put disc (YEDS-18) in to play the number five track.

4. Confirm that oscilloscope wav eform is clear and check RF signal

level is correct or not.

7. Press the “BLOCK 8” button. (The tracking servo and sledding

servo are turned ON.) Confirm the C (DC voltage) is almost equal

to the A (DC voltage) is step 6.

Traverse waveform

0V

Tracking servo

Sledding servo

OFF

Tracking servo

Sledding servo

ON

8. Disconnect the lead wire of TP301 (ADJ) connected in step 1.

— 19 —

C (DC

voltage)

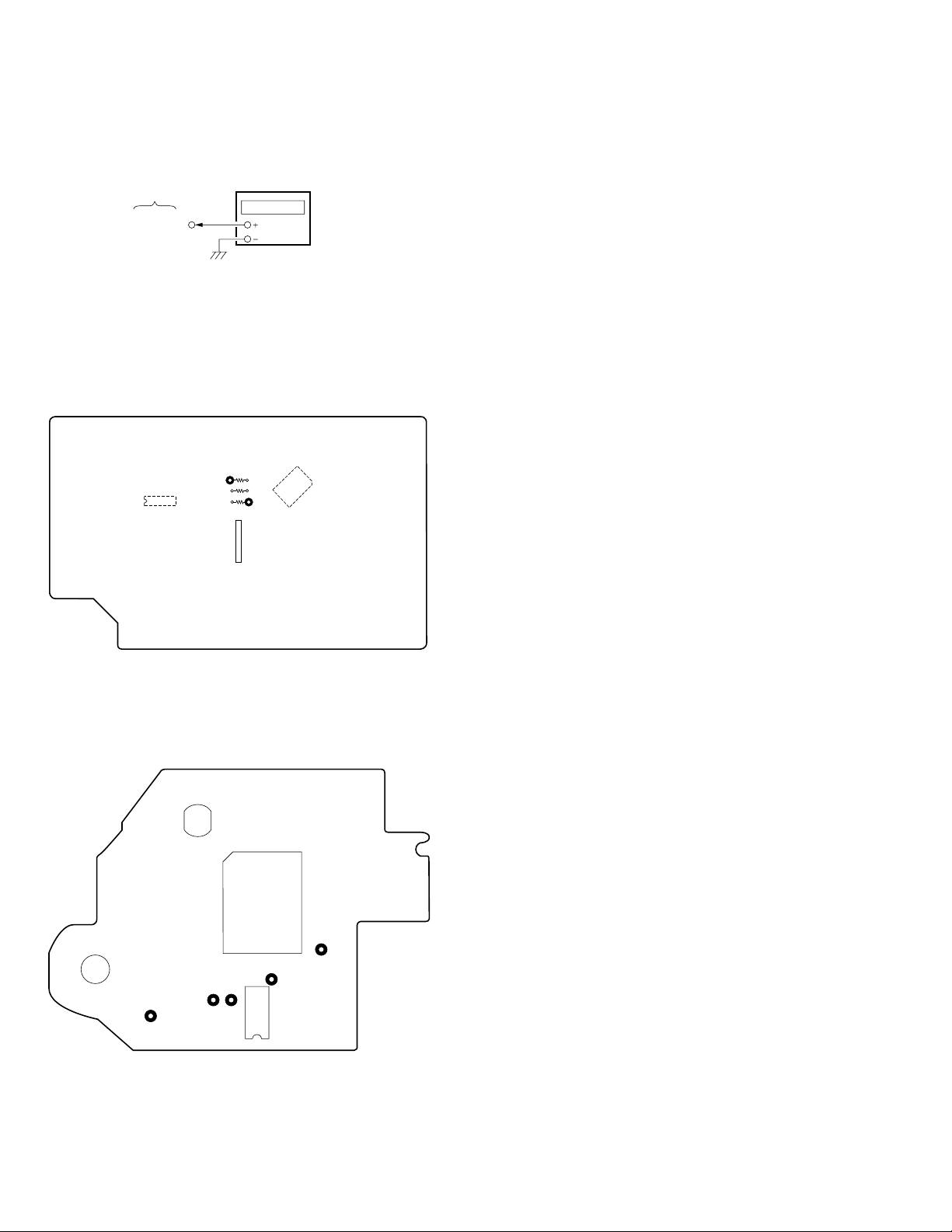

RF PLL Free-run Frequency Check

Procedure :

1. Connect frequency counter to test point TP (PLCK) with lead wire.

BD board

TP (PLCK)

frequency counter

2. Turn Power switch on.

3. Put the disc (YEDS-18) in to play the number five track.

Confirm that reading on frequency counter is 4.3218MHz.

Adjustment Location :

[ MAIN BOARD ] — Component Side —

IC303

R311

TP302

AFADJ

IC307

R337

TP301

ADJ

R310

IC301

[ BD BOARD ] — Side B —

TP (FE1)

TP (RF)

TP

(TE)

IC101

TP

(PLCK)

TP (VC)

IC103

— 20 —

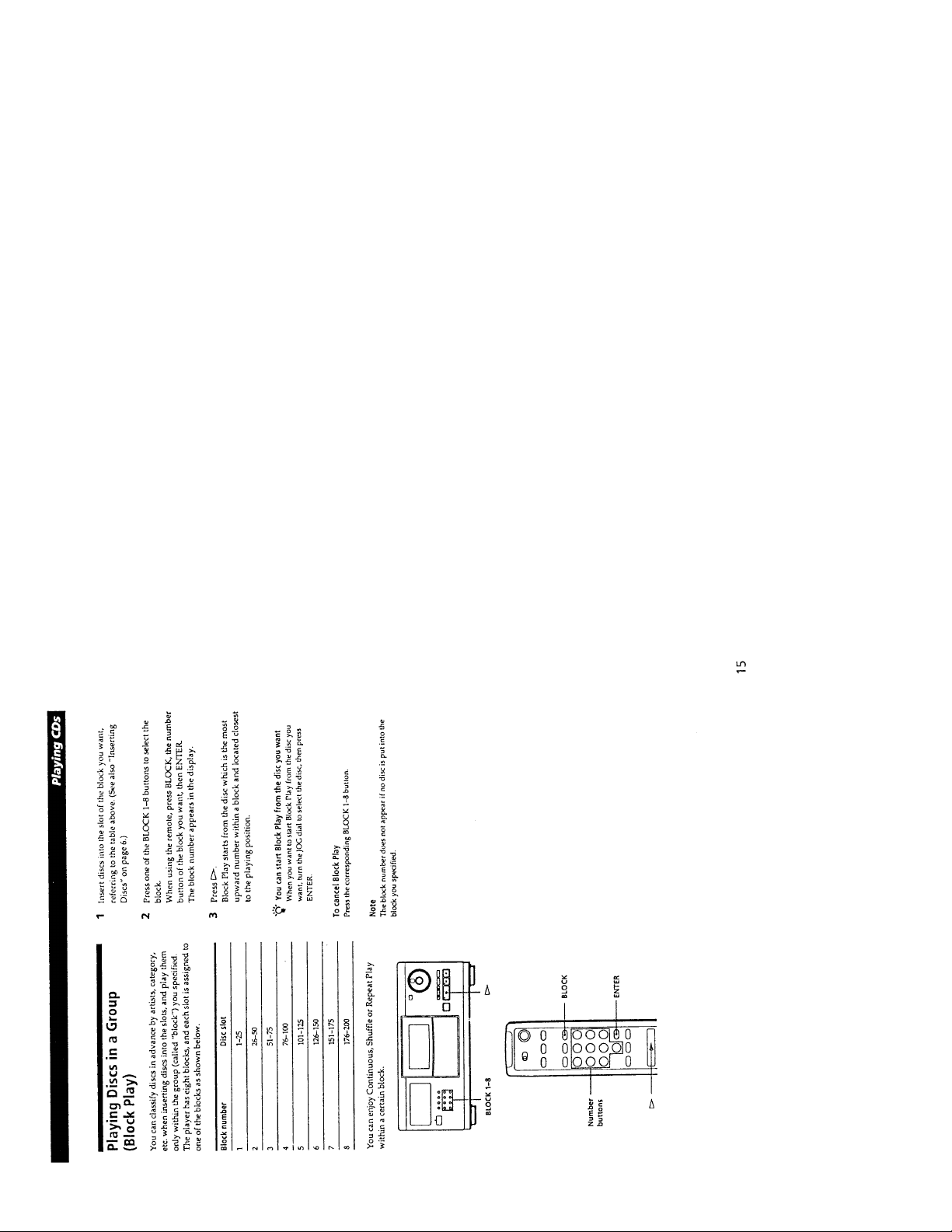

6-1. CIRCUIT BOARDS LOCATION

SECTION 6

DIAGRAMS

T. SENS board

ILLUMINATION board

DISP board

LUMINOUS board

DOOR SW board

MAIN board

JACK board

T. MOTOR board

RAY-CATCHER board

JOG board

BD board

L.SW board

L. MOTOR board

— 21 —

Loading...

Loading...