Page 1

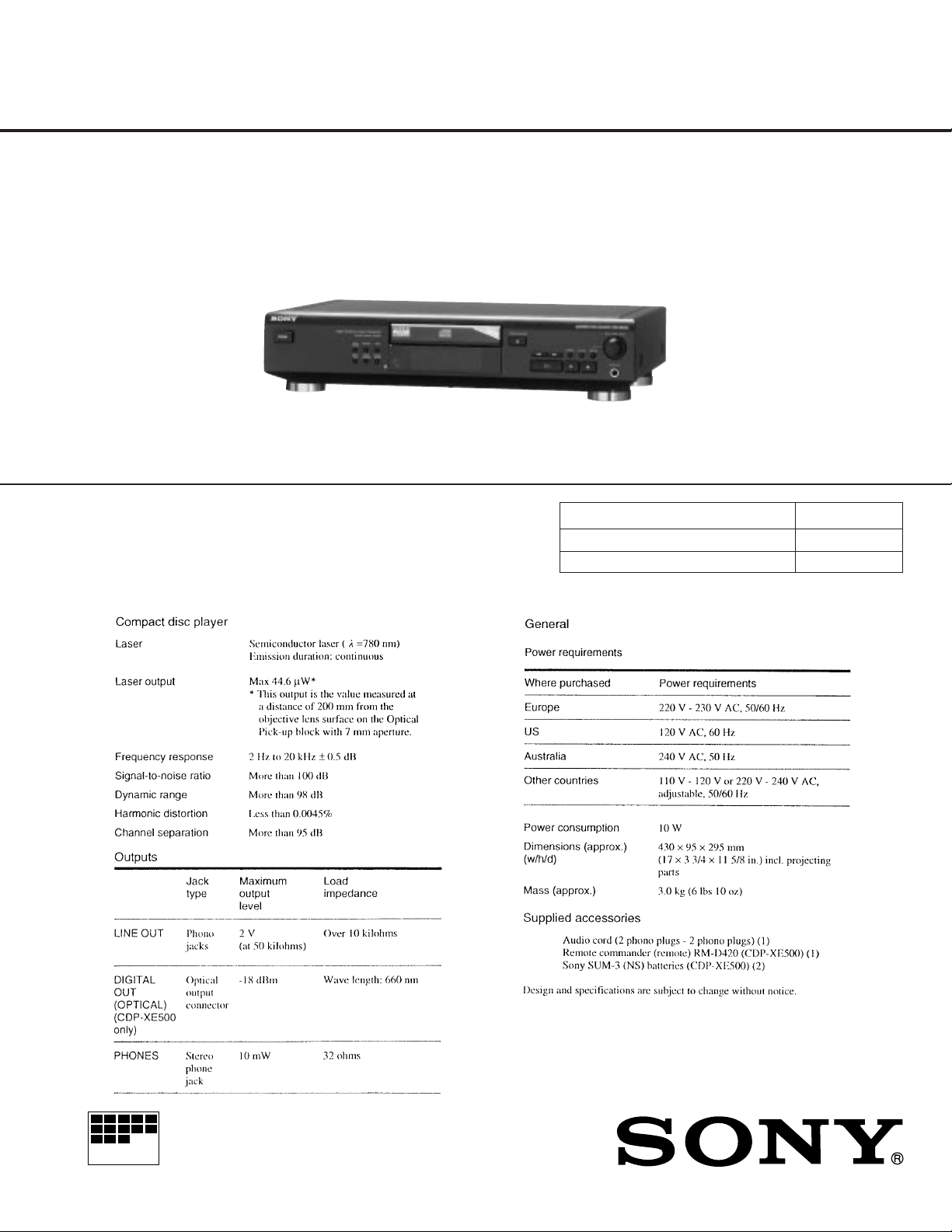

CDP-XE400/XE500

SERVICE MANUAL

Photo: CDP-XE500

SPECIFICATIONS

US Model

CDP-XE400/XE500

AEP Model

UK Model

E Model

Australian Model

Chinese Model

CDP-XE500

Model Name Using Similar Mechanism CDP-261/361

CD Mechanism Type CDM14-5BD20

Base Unit Name BU-5BD20

MICROFILM

COMPACT DISC PLAYER

– 1 –

Page 2

The laser component in this product

is capable of emitting radiation

exceeding the limit for Class 1.

The following caution label is located inside of the unit.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a return to chassis, must not exceed 0.5 mA (500 microampers).

Leakage current can be measured by any one of three methods.

This appliance is classified

as a CLASS 1 LASER

product.

The CLASS 1 LASER

PRODUCT MARKING is

located on the rear exterior.

CAUTION

Use of controls or adjustments or performance of procedures other than those specified herein may result in hazardous radiation exposure.

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

MODEL IDENTIFICATION

– Back Panel –

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated A C milliammeter. The Data Precision 245 digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated AC voltmeter. The “limit” indication is 0.75

V, so analog meters must have an accurate low-voltage scale. The

Simpson 250 and Sanwa SH-63Trd are examples of a passi ve VOM

that is suitable. Nearly all battery operated digital multimeters that

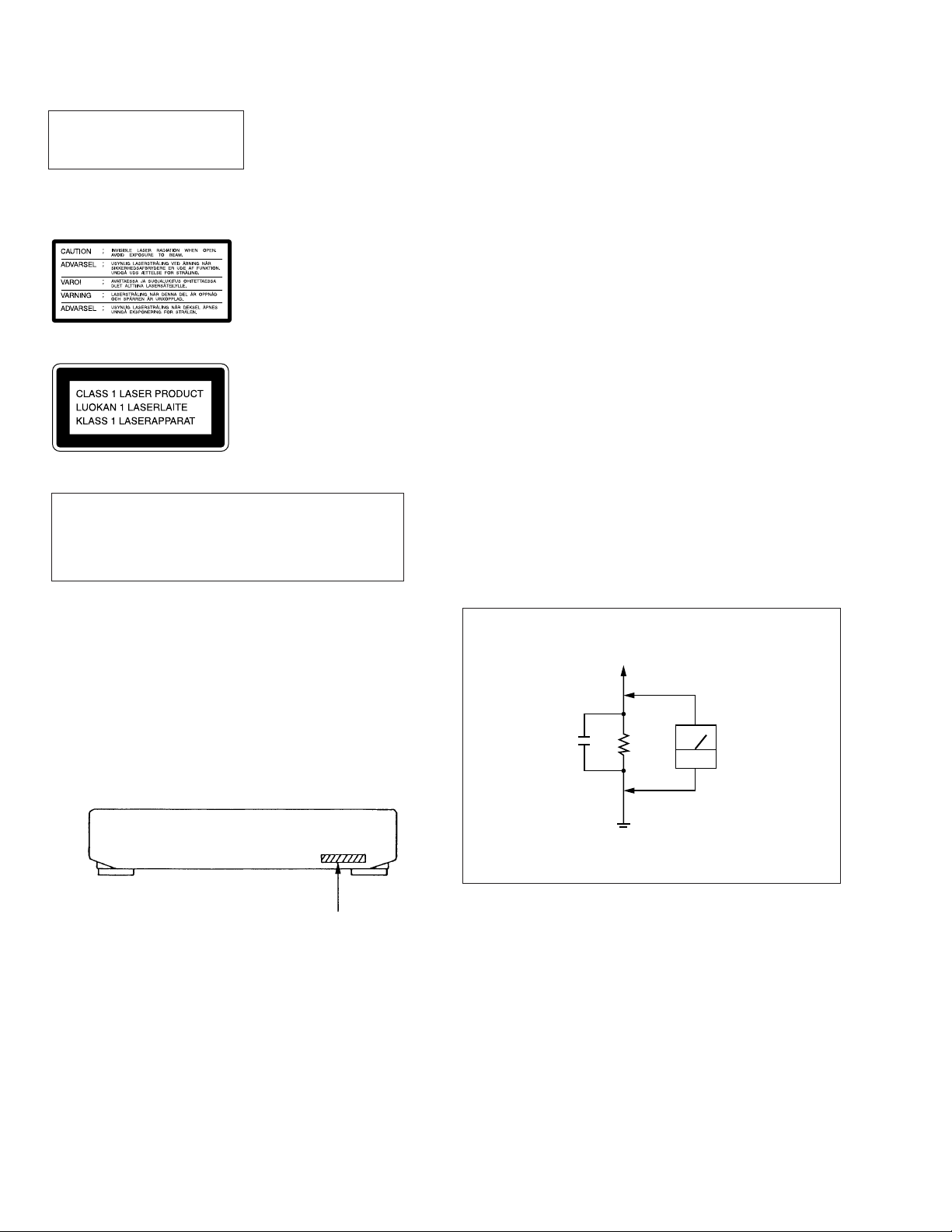

have a 2V AC range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

0.15µF

1.5k

Ω

AC

voltmeter

(0.75V)

CDP-XE400

US Model : 4-977-587-5π

CDP-XE500

US Model : 4-977-587-1π

E Model : 4-977-587-3π

Australian Model : 4-977-587-4π

Chinese Model : 4-977-587-9π

AEP, German, East European Model : 4-978-388-0π

UK Model : 4-978-388-1π

Earth Ground

Fig. A. Using an AC voltmeter to check AC leakage.

– 2 –

Page 3

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK OR

BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic breakdown and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

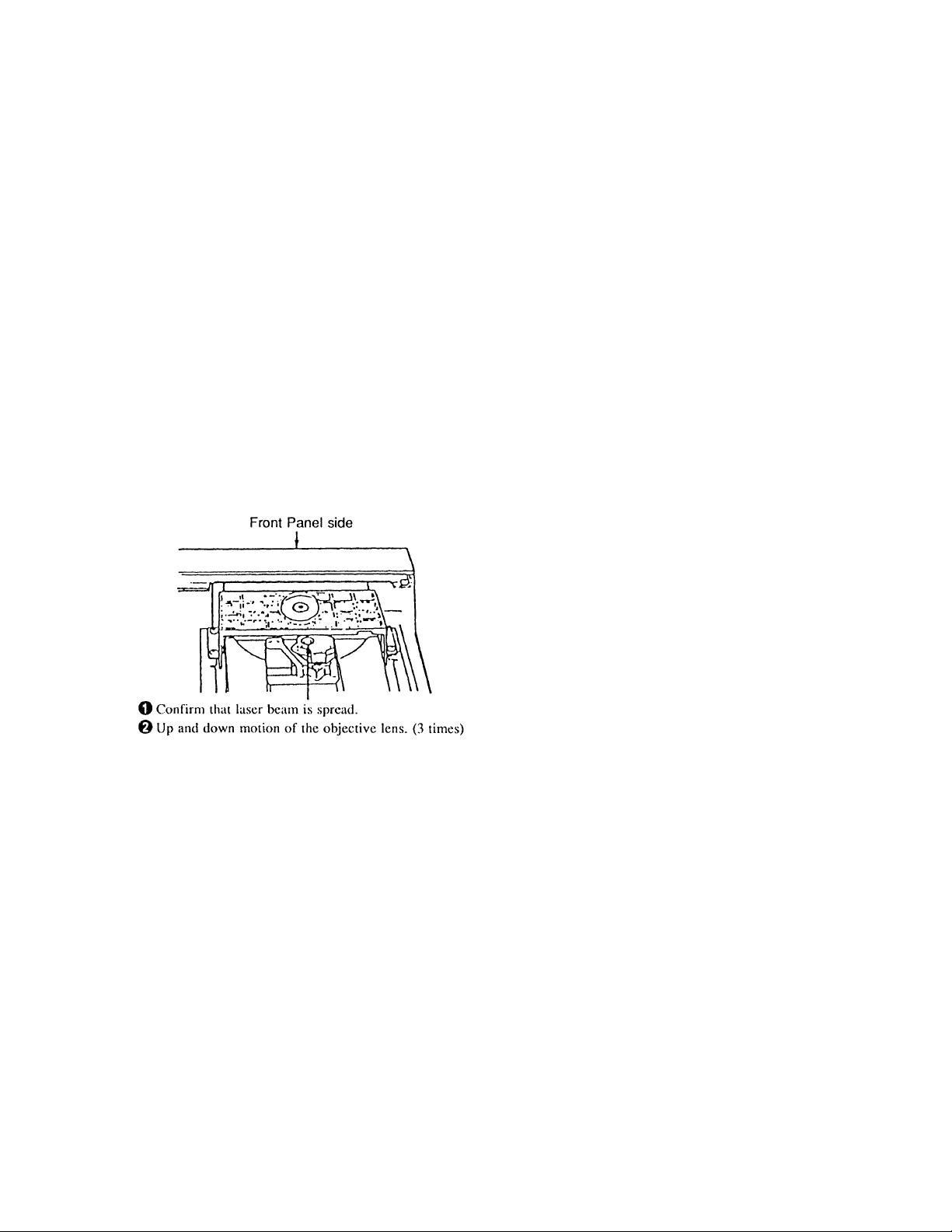

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objectiv e lens in the optical pick-up

block. Therefore, when checking the laser diode emission, observe

from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERA TION CHECK

1. Make POWER switch on with no disc inserted and disc table

closed.

2. Confirm that the following operation is performed while

observing the objective lens.

TABLE OF CONTENTS

1. GENERAL

Identifying the Parts .................................................................. 4

Playing a CD.............................................................................. 5

2. DISASSEMBLY

2-1. Front Panel .............................................................................. 6

2-2. Base Unit Block ...................................................................... 6

3. ELECTRICAL BLOCK CHECKING ............................. 7

4. DIAGRAMS

4-1. IC Pin Functions...................................................................... 9

4-2. Printed Wiring Board – BD Section –................................... 13

4-3. Schematic Diagram – BD Section –...................................... 15

4-4. Printed Wiring Boards – Main Section – .............................. 17

4-5. Schematic Diagram – Main Section –................................... 21

5. EXPLODED VIEWS

5-1. Case Section .......................................................................... 28

5-2. Back Panel Section................................................................ 29

5-3. CD Mechanism Section......................................................... 30

5-4. Base Unit Section .................................................................. 31

6. ELECTRICAL PARTS LIST .......................................... 32

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE

P AR TS LIST ARE CRITICAL TO SAFE OPERATION. REPLACE

THESE COMPONENTS WITH SONY PARTS WHOSE PART

NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

– 3 –

Page 4

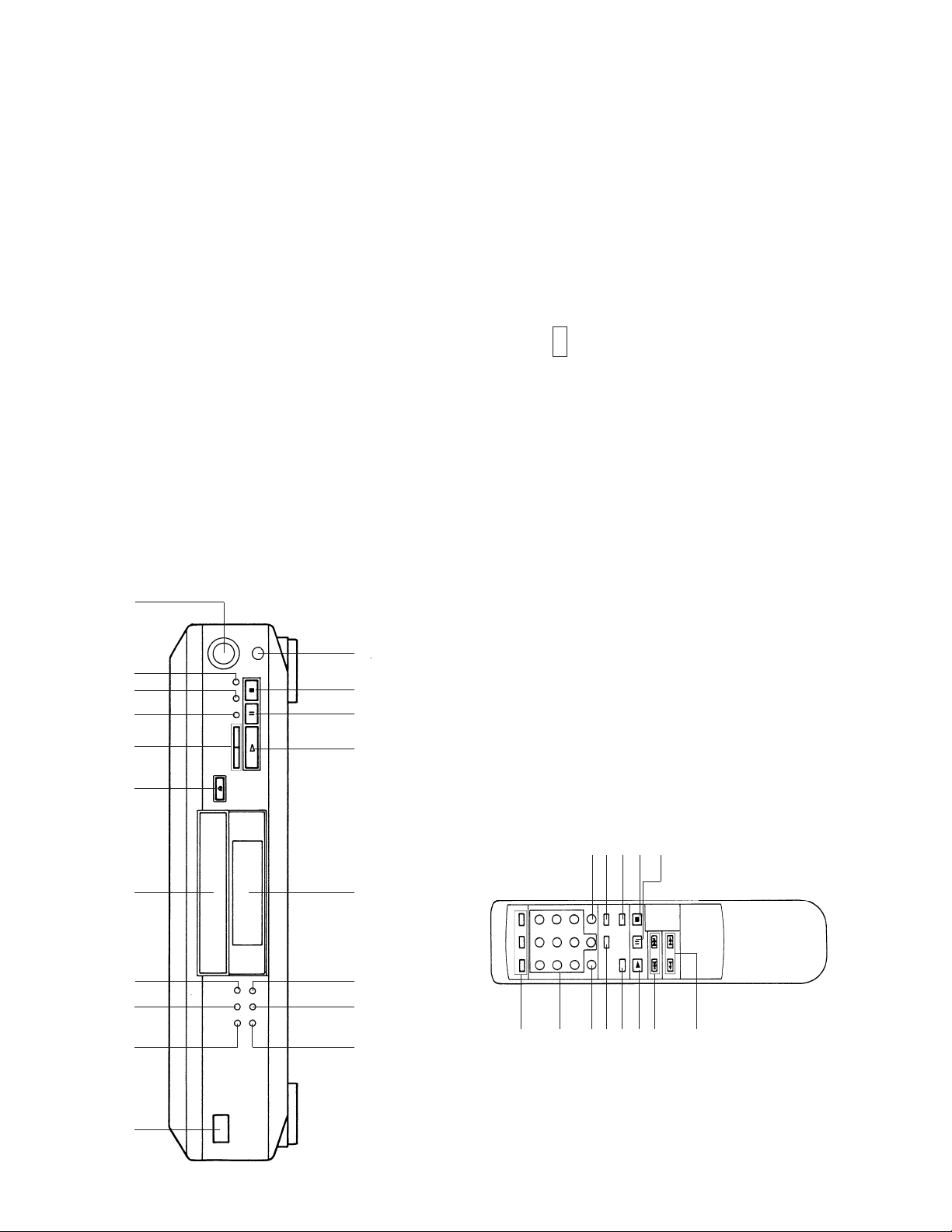

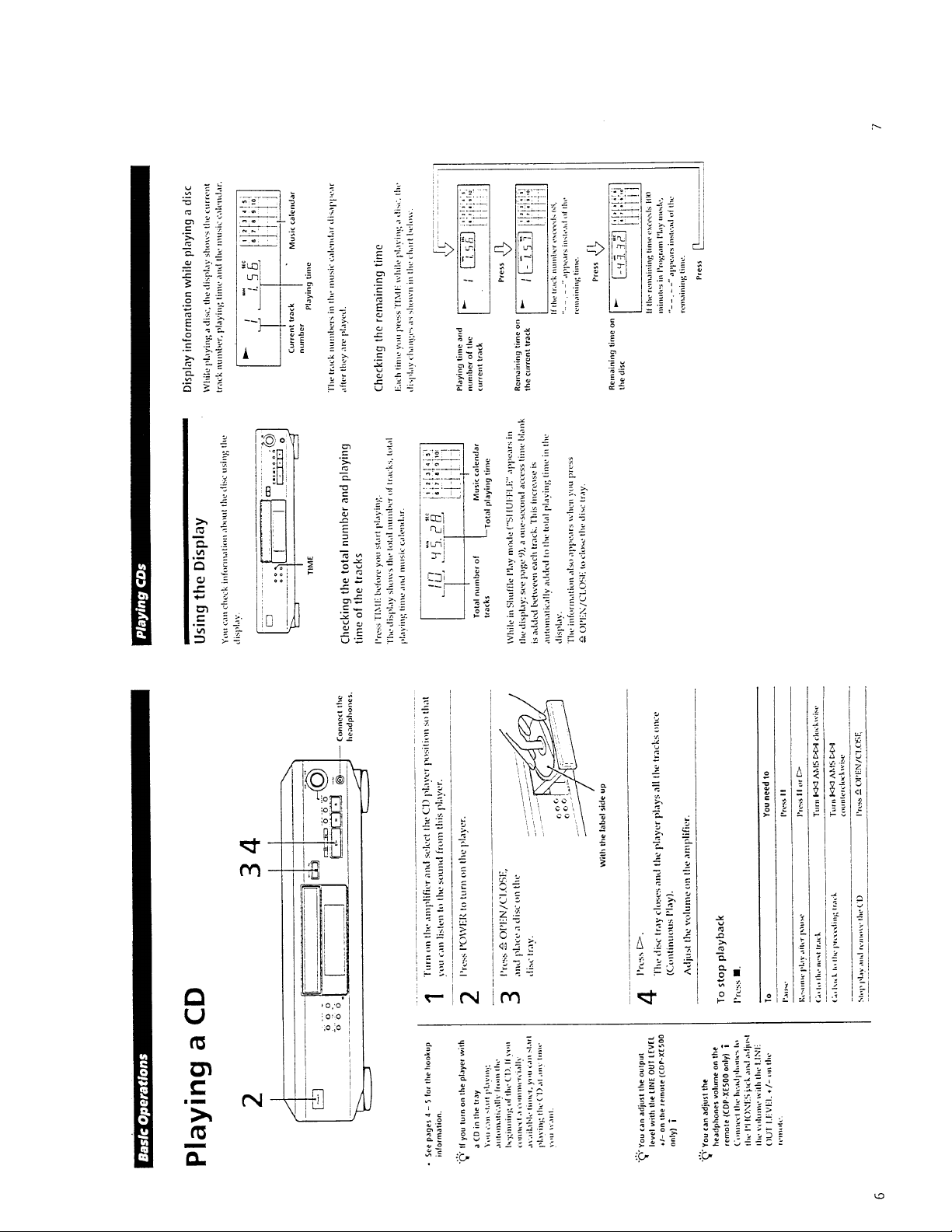

Front Panel/Remote

Commander

1 POWER switch

2 PLAY MODE button

3 REPEAT button

4 TIME button

SECTION 1

GENERAL

CONTINUE button

SHUFFLE button

PROGRAM button

5 Disc tray

6 § OPEN/CLOSE button

7 0/) (manual search) button

8 CHECK (program check) button

9 CLEAR (program clear) button

0 ENTER button

!¡ ≠ AMS ± (AMS*) control

!™ PHONES Jack

!£ p (Stop) button

!¢ P (Pause) button

!∞ · (Play) button

!§ Display

!¶ MUSIC SCAN button

!• PEAK SEARCH button

!ª EDIT/TIME button

@º Play Mode buttons

@¡ Numeric buttons

@™ >10 (over 10) button

@£ TIME button

@¢ =/+ (AMS*) button

@∞ FADER button

*AMS is the abbreviation of Automatic

Music Sensor.

•

•

•

•

•

•

•

•

•

•

•

•

•

•••

•

!ª !• !¶ !§ !∞ !¢ !£ !™

@º

98@∞!£!¢

•

•

@¡

@™@£3!∞@¢

••••

•

•

•

7

1234 5 67890!¡

IDENTIFYING THE P ARTS

•

RM-D420 (CDP-XE500 only)

– 4 –

Page 5

– 5 –

Page 6

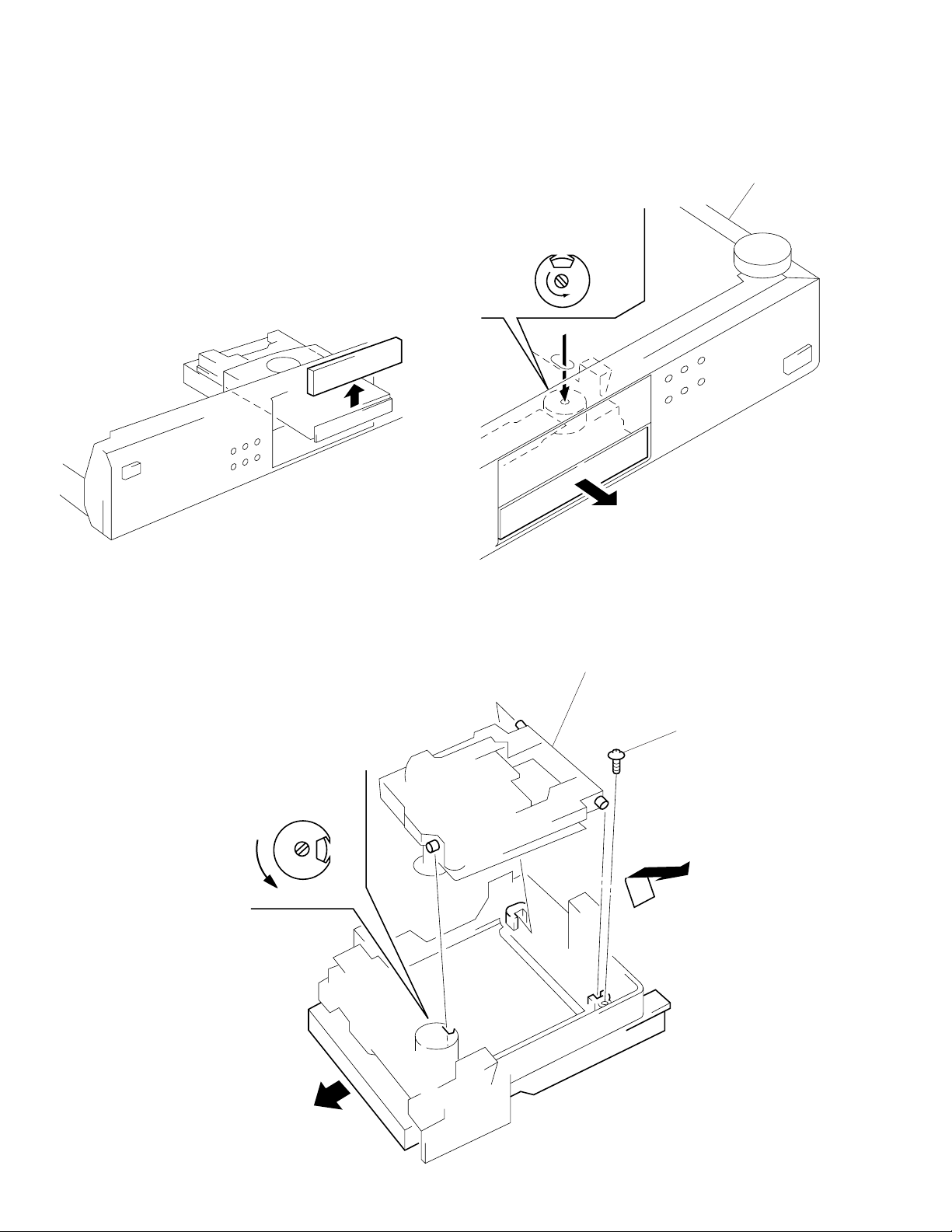

SECTION 2

DISASSEMBLY

Note : Follo w the disassembly procedure in the numerical order giv en.

2-1. FRONT PANEL

• When removing the front panel assembly on electric power failure,

first open the loading block by turning cam with a screwdriver as

shown in the figure, next pull out the loading block with hand, and

remove the loading panel as shown in the figure, then remove the

front panel assembly.

3

Remove loading panel in the arrow direction.

1

Turn in the direction

of the arrow.

bottom of chassis

2-2. BASE UNIT BLOCK

1

Turn the cam to direction of arrow (Counter clockwise) by

minus screw driver.

2

Take off the disc table.

3

Remove the yoke bracket.

4

Remove the MD (BU-5BD20) to the direction of arrow.

1

cam

2

4

BU-5BD20

Pull out disc table.

3

yoke bracket

2

disc table

– 6 –

Page 7

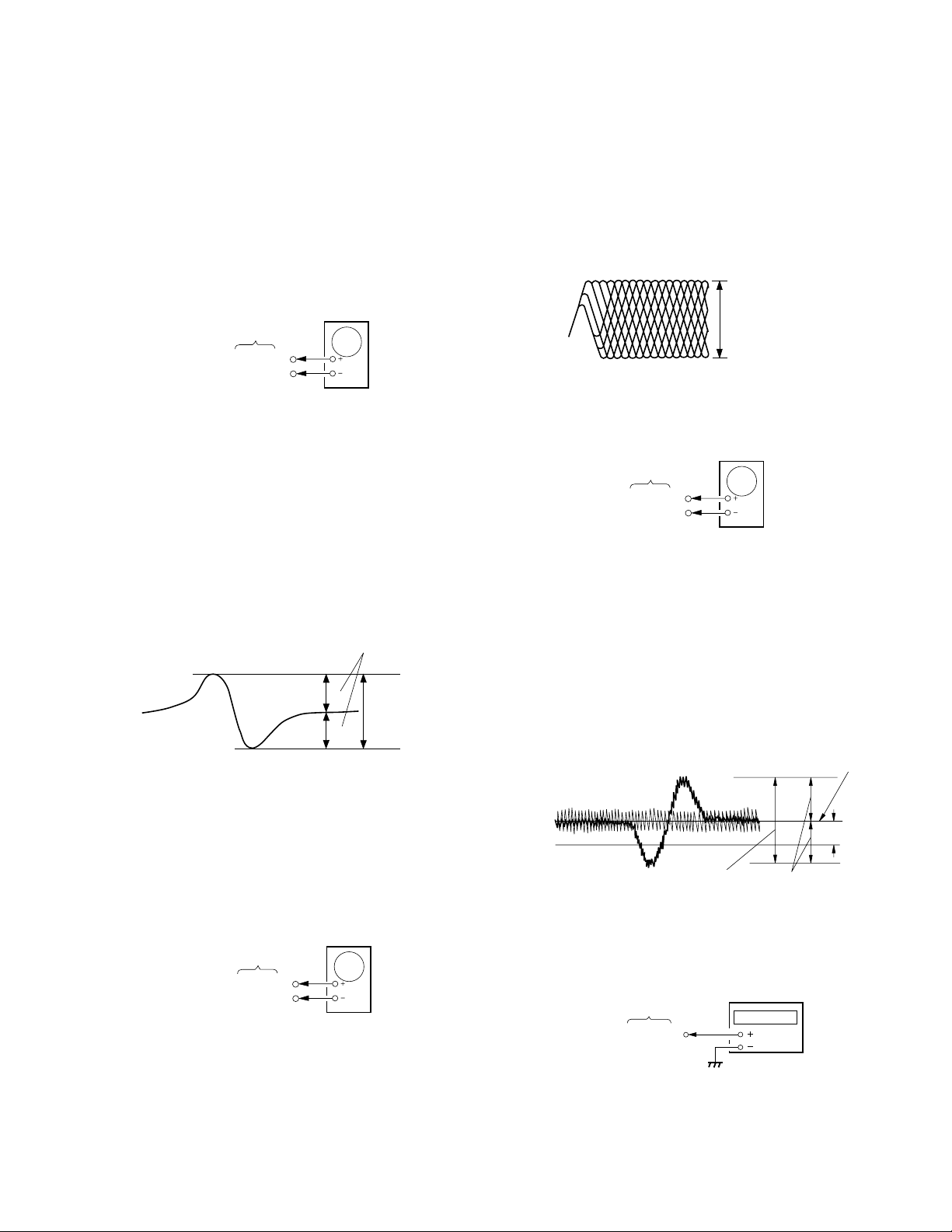

SECTION 3

ELECTRICAL BLOCK CHECKING

Note :

1. CD Block is basically designed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the objective lens using an applicator with neutral detergent

when the signal level is low than specified value with the follo wing

checks.

S Curve Check

oscilloscope

BD board

TP (FE)

TP (VC)

Procedure :

1. Connect oscilloscope to test point TP (FE) on BD board.

2. Connect between test point TP (FEI) and TP (VC) by lead wire.

3. Turn Power switch on.

4. Put disc (YEDS-18) in and turn Power switch on again and actuate

the focus search. (Actuate the focus search when disc table is moving

in and out.)

5. Check if the oscilloscope waveform (S-curve) is symmetrical

between A and B. And confirm peak to peak le v el within 3±1 Vp-p.

S-curve waveform

symmetry

A

within 3±1 Vp-p

B

3. Put disc (YEDS-18) in and playback.

4. Confirm that oscilloscope waveform is clear and check if RF

signal level is correct or not.

Note :

A clear RF signal waveform means that the shape “ ≈ ” can be

clearly distinguished at the center of the waveform.

RF signal waveform

VOLT/DIV : 200mV

TIME/DIV : 500nS

level : 1.2

+0.25

–0.20

Vp-p

E-F Balance (1 Track Jump) Check

oscilloscope

(DC range)

BD board

TP (TE)

TP (VC)

Procedure :

1. Connect oscilloscope to test point TP (TE) on BD board .

2. Turn Power switch on.

3. Put disc (YEDS-18) in to play the number five track.

4. Press the “P (pause)” button. (Becomes the 1 track jump mode.)

5. Check the level B of the oscilloscope’s waveform and the A (DC

voltage) of the following :

A/B×100 = less than ± 20%.

1 track jump waveform

6. After check, remove the lead wire connected in step 2.

Note : • Try to measure several times to make sure than the ratio of

A : B or B : A is more than 10 : 7.

•Set sweep time as long as possible and set the brightness to

obtain best waveform.

RF Level Check

oscilloscope

BD board

TP (RF)

TP (VC)

Procedure :

1. Connect oscilloscope to test point TP (RF) on BD board.

2. Turn Power switch on.

Center of the waveform

B

level : 1.5±0.7Vp-p

symmetry

RF PLL Free-run Frequency Check

Procedure :

1. Connect frequency counter to test point (PLCK) with lead wire.

frequency counter

MAIN board

TP (PLCK)

2. Turn Power switch on.

3. Confirm that reading on frequency counter is 4.3218MHz.

– 7 –

A (DC voltage)

Page 8

Adjustment Location : BD board

–BD board (conductor side) –

(PLCK)

120

IC103

10 11

IC101

(RF)

(VC)

(FE)

(FEI)

(TE)

– 8 –

Page 9

SECTION 4

DIAGRAMS

4-1. IC PIN FUNCTIONS

• IC101 CXD2545Q (DIGITAL SERVO & DIGITAL SIGNAL PROCESSOR)

Pin No. Pin Name I/O Function

1 SRON O Sled drive output (Not used.)

2 SRDR O Sled drive output

3 SFON O Sled drive output (Not used.)

4 TFDR O Tracking drive output

5 TRON O Tracking drive output (Not used.)

6 TRDR O Tracking drive output

7 TFON O Tracking drive output (Not used.)

8 FFDR O Focus drive output

9 FRON O Focus drive output (Not used.)

10 FRDR O Focus drive output

11 FFON O Focus drive output (Not used.)

12 VCOO O VCO output for analog EFM PLL. (Not used.)

13 VCOI I VCO input for analog EFM PLL. (Ground)

14 TEST I TEST pin connected normally to Ground.

15 DVSS — Digital Ground

16 TES2 I TEST pin connected normally to Ground.

17 TES3 I TEST pin connected normally to Ground.

18 PDO O Charge-pump output for analog EFM PLL. (Not used.)

19 VPCO O Charge-pump output for variable pitch PLL. (Not used.)

20 VCKI I Clock input from variable pitch external VCO. (Ground)

21 AVD2 — Analog power supply

22 IGEN I Power supply pin for operational amplifiers.

23 AVS2 — Analog Ground

24 ADIO I (Not used.)

25 RFC O (Not used.)

26 RFDC I RF signal input

27 TE I Tracking error signal input

28 SE I Sled error signal input

29 FE I Focus error signal input

30 VC I Center voltage input pin

31 FILO O Filter output for master PLL.

32 FILI I Filter input for master PLL.

33 PCO O Charge-pump output for master PLL.

34 CLTV I Control voltage input for master VCO.

35 AVS1 — Analog Ground

36 RFAC I EFM signal input

37 BIAS I Asymmetry circuit constant current input

38 ASYI I Asymmetry comparate voltage input

39 ASYO O EFM full swing output

40 AVD1 — Analog power supply

41 DVDD — Digital power supply

42 ASYE I Asymmetry circuit ON/OFF

43 PSSL I Audio data output mode selection input

44 WDCK O 48-bit slot D/A interface. Word clock

45 LRCK O 48-bit slot D/A interface. LR clock

46 DATA O DA 16 output when PSSL=1. 48-bit slot serial data when PSSL=0.

47 BCLK O DA 15 output when PSSL=1. 48-bit slot data when PSSL=0.

– 9 –

Page 10

Pin No. Pin Name I/O Function

48 64DATA O DA 14 output when PSSL=1. 64-bit slot data when PSSL=0. (Not used.)

49 64BCLK O DA 13 output when PSSL=1. 64-bit slot data when PSSL=0. (Not used.)

50 64LRCK O DA 12 output when PSSL=1. 64-bit slot data when PSSL=0. (Not used.)

51 GTOP O DA 11 output when PSSL=1. GTOP output when PSSL=0. (Not used.)

52 XUGF O DA 10 output when PSSL=1. XUGF output when PSSL=0. (Not used.)

53 XPLCK O DA 09 output when PSSL=1. XPLCK output when PSSL=0.

54 GFS O DA 08 output when PSSL=1. GFS output when PSSL=0.

55 PFCK O DA 07 output when PSSL=1. RFCK output when PSSL=0.

56 C2PO O DA 06 output when PSSL=1. C2PO output when PSSL=0. (Not used.)

57 XRAOF O DA 05 output when PSSL=1. XRAOF output when PSSL=0. (Not used.)

58 MNT3 O DA 04 output when PSSL=1. MNT3 output when PSSL=0.

59 MNT2 O DA 03 output when PSSL=1. MNT2 output when PSSL=0.

60 MNT1 O DA 02 output when PSSL=1. MNT1 output when PSSL=0.

61 MNT0 O DA 01 output when PSSL=1. MNT0 output when PSSL=0.

62 XTAI I X’tal oscillator circuit input

63 XTAO O X’tal oscillator circuit output (Not used.)

64 XTSL I X’tal selection input pin (Ground)

65 DVSS – Digital Ground

66 FSTI I 2/3 divider input of pins 62 and 63.

67 FSTO O 2/3 divider output of pins 62 and 63.

68 FSOF O (Not used.)

69 C16M O 16.9344MHz output (Not used.)

70 MD2 I Digital-out ON/OFF control pin (+5V)

71 DOUT O Digital-out output pin

72 EMPH O Playback disc output in emphasis mode. (Not used.)

73 WFCK O WFCK output

74 SCOR O Sub-code sync output

75 SBSO O Sub-P through Sub-W serial output (Not used.)

76 EXCK I Clock input for SBSO read-out. (Ground)

77 SUBQ O Sub-Q 80-bit output

78 SQCK I Clock input for SQSO read-out.

79 MUTE I Muting selection pin

80 SENS O SENS output

81 XRST I System reset

82 DIRC I Used in 1-track jump mode (+5V)

83 SCLK I SENS serial data read-out clock

84 DFSW I DFCT selection pin (Ground)

85 ATSK I Input pin for anti-shock. (Ground)

86 DATA I Serial data input, supplied from CPU.

87 XLAT I Latch input, supplied from CPU.

88 CLOK I Serial data transfer clock input, supplied from CPU.

89 COUT O Numbers of track counted signal output. (Not used.)

90 DVDD – Digital power supply

91 MIRR O Mirror signal output

92 DFCT O Defect signal output

93 FOK O Focus OK output

94 FSW O Output to select spindle motor output filter. (Not used.)

95 MON O Output to control ON/OFF of spindle motor. (Not used.)

96 MDP O Output to control spindle motor servo

– 10 –

Page 11

Pin No. Pin Name I/O Function

97 MDS O Output to control spindle motor servo. (Not used.)

98 LOCK O GFS is sampled by 460Hz. H when GFS is H. (Not used.)

99 SSTP I Input signal to detect disc innermost track.

100 SFDR O Sled drive output

– 11 –

Page 12

• IC501 CXP82612-021Q (MASTER CONTROL)

Pin No. Pin Name I/O Function

1 TIMER – Connected to +5V.

2 RM I Audio bus input

3 +5V – Connected to +5V.

4-6 – – Not used. (Open)

7 PGML O Latch signal output to digital filter (IC201).

8 CLK O Serial clock output

9 SENSE I SENSE signal input

10 DATA O Serial data output

11 SQCK O Read out clock output for subcode Q data.

12 SUBQ I Subcode Q data input

13 – – Not used. (Open)

14 AMUTE O Analog muting control signal output

15 LDON O Optical pick-up laser diode control output

16 XLT O Serial data latch signal output

17 – – Not used. (Open)

18 RV+ – Not used. (Open)

19 RV- – Not used. (Open)

20 LDOUT O Loading motor control signal output

21 LDIN I Loading motor control signal input

22 KEY0 I Key input (S530)

23 KEY1 I Key input (S520-S527)

24 KEY2 I Key input (S501-S506)

25 KEY3 – Connected to +5V.

26,27 KEY4,KEY5 I Key input (S531)

28 ADJ/AFADJ – ADJ/AFJ test pin

29 IN/OUTSW I Loading IN/OUT switch input

30 RST I Reset signal input

31 EXTAL I Clock input (4MHz)

32 XTAL O Clock output (4MHz)

33 VSS – Ground

34-41 – – Not used. (Open)

42-62 S1-S21 O FL segment output

63-70 1G-7G O FL grid output

71 VFDP(-30V) – -30V pin for FL display tube.

72 VDD(+5V) – +5V pin

73 +5V – +5V pin

74 SEL1 – Connected to Ground.

75-77 – – Connected to Ground.

78 SCOR I Read out timing signal input for subcode Q data.

79,80 SEL2,SEL3 – Connected to +5V.

– 12 –

Page 13

Page 14

Page 15

Page 16

Page 17

NOTE:

• The mechanical parts with no reference

number in the exploded views are not supplied.

• Items marked “*” are not stocked since

they are seldom required for routine service.

Some delay should be anticipated

when ordering these items.

• Abbreviation

AUS : Australian model

CH : Chinese model

G : German model

EE : East European model

5-1. CASE SECTION

CDM14-5BD20

8

SECTION 5

EXPLODED VIEWS

• -XX and -X mean standardized parts, so

they may have some difference from the

original one.

• Color Indication of Appearance Parts

Example :

KNOB, BALANCE (WHITE) ... (RED)

#1

N

Parts Color Cabinet’s Color

2

4

N

• Hardware (# mark) list and accessories

and packing materials are given in the

last of this parts list.

The components identified by

mark ! or dotted line with mark.

! are critical for safety.

Replace only with part number

specified.

1

#1

3

9

7

5

2

5

11

10

24

12

not supplied

5

6

5

13

16

5

20

19

17

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

* 1 4-978-901-21 CASE (408226) (BLACK)

* 1 4-978-901-91 CASE (408226) (SILVER)

2 3-363-099-01 SCREW (CASE 3 TP2) (AEP,UK,G,EE)

2 3-704-366-31 SCREW (CASE) (M3X6) (US,E,AUS,CH)

3 4-956-370-02 BAND, PLUG FIXED (UK,AUS)

18

#1

supplied with J601

11 X-4946-531-1 PANEL ASSY, FRONT (AEP:BLACK,UK,G,EE)

11 X-4946-957-1 PANEL ASSY, FRONT (SILVER)

12 X-4947-021-1 PANEL ASSY, FRONT (XE500:E, AUS, CH)

12 X-4947-022-1 PANEL ASSY, FRONT (XE500:US)

12 X-4947-083-1 PANEL ASSY, FRONT (XE400)

not supplied

4 1-776-100-11 WIRE (FLAT TYPE) (23 CORE)

5 4-951-620-01 SCREW (2.6X8), +BVTP

6 1-776-099-11 WIRE (FLAT TYPE) (21 CORE)

* 7 A-4673-727-A PANEL BOARD, COMPLETE

* 8 1-658-840-11 POWER SW BOARD

9 4-977-589-01 BUTTON (POWER) (BLACK)

9 4-977-589-11 BUTTON (POWER) (SILVER)

10 4-977-588-01 PANEL, LOADING (XE500:BLACK)

10 4-977-588-11 PANEL, LOADING (XE400)

10 4-977-588-41 PANEL, LOADING (XE500:SILVER)

13 4-963-404-21 EMBLEM (5-A), SONY (US,E,AUS,CH)

16 4-977-583-01 BUTTON (PLAY) (BLACK)

17 4-977-590-01 KNOB (AMS) (US,E,AUS,CH)

17 4-977-590-11 KNOB (AMS) (SILVER)

18 3-354-981-01 SPRING (SUS), RING

* 19 1-658-839-11 H.P BOARD

20 X-4947-207-1 FOOT ASSY (F50150S) (BLACK)

20 X-4947-124-1 FOOT ASSY (F50150S) (SILVER)

24 4-977-584-11 BUTTON (MODE)

– 28 –

Page 18

5-2. BACK PANEL SECTION

UK Model US Model AEP, G, EE Model E Model

CNP901

CNP901

CNP901

CNP901

55

52

54

53

#1

#1

T901

51

#2

not supplied

#1

#1

CH Model

CNP901

56

AUS Model

CNP901

The components identified by

mark ! or dotted line with mark.

! are critical for safety.

Replace only with part number

specified.

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

51 3-703-244-00 BUSHING, CORD (EXCEPT US,E)

* 51 3-703-571-11 BUSHING (S) (4516), CORD (US,E)

* 52 4-977-587-11 PANEL, BACK (XE500:US)

* 52 4-977-587-31 PANEL, BACK (E)

* 52 4-977-587-41 PANEL, BACK (AUS)

* 52 4-977-587-51 PANEL, BACK (XE400)

* 52 4-977-587-91 PANEL, BACK (CH)

* 52 4-978-388-01 PANEL, BACK (AEP,G,EE)

* 52 4-978-388-11 PANEL, BACK (UK)

* 53 A-4673-738-A MAIN BOARD, COMPLETE (XE400)

* 53 A-4673-739-A MAIN BOARD, COMPLETE (E)

53 A-4673-740-A MAIN BOARD, COMPLETE (EXCEPT US,E)

53 A-4673-753-A MAIN BOARD, COMPLETE (XE500:US)

* 54 4-954-051-51 HOLDER, PC BOARD

! 55 1-569-007-11 ADAPTOR, CONVERSION 2P (E)

! 56 1-569-008-11 ADAPTOR, CONVERSION 2P (CH)

! CNP901 1-558-943-81 CORD, POWER (E)

! CNP901 1-558-945-21 CORD, POWER (POLAR.SPT-1) (US)

! CNP901 1-575-651-21 CORD, POWER (AEP,G,EE)

! CNP901 1-696-845-11 CORD, POWER (AUS)

! CNP901 1-696-907-11 CORD, POWER (UK)

! CNP901 1-696-966-11 CORD, POWER (CH)

! T901 1-423-979-11 TRANSFORMER, POWER (EXCEPT US,E)

! T901 1-426-621-11 TRANSFORMER, POWER (US)

! T901 1-426-622-11 TRANSFORMER, POWER (E)

– 29 –

Page 19

5-3. CD MECHANISM SECTION

(CDM14-5BD20)

108

109

110

107

106

104

111

115

113

112

BU-5BD20

114

105

#3

103

102

M151

101

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

* 101 1-645-721-11 LOADING BOARD

102 4-933-111-11 CHASSIS (MD) (AEP,UK,G,EE)

102 4-933-111-41 CHASSIS (MD) (US,E,AUS,CH)

* 103 4-917-583-21 BRACKET, YOKE

104 4-927-649-01 BELT

105 4-933-109-01 CAM

106 4-927-651-01 PULLEY (S)

107 4-967-268-01 GEAR (C)

108 4-933-107-01 GEAR (PL)

109 4-933-112-11 TABLE, DISC

110 4-933-110-41 HOLDER (MG)

* 111 1-452-538-11 MAGNET

112 4-933-134-01 SCREW (+PTPWH M2.6X6)

113 4-959-996-01 SPRING (932), COMPRESSION

114 4-933-129-01 HOLDER (BU)

115 4-925-315-31 DAMPER

M151 A-4604-363-A MOTOR (L) ASSY (LOADING)

– 30 –

Page 20

5-4. BASE UNIT SECTION

(BU-5BD20)

155

r

A

156

#4

153

152

151

M101

(Including rA)

M102

152

158

157

#5

The components identified by

mark ! or dotted line with mark.

! are critical for safety.

Replace only with part number

specified.

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

151 A-4673-509-A BD BOARD, COMPLETE (US,E,AUS,CH)

* 151 A-4673-511-A BD BOARD, COMPLETE (AEP,UK,G,EE)

152 4-951-940-01 INSULATOR (BU)

153 4-917-565-01 SHAFT, SLED

! 155 8-848-367-11 PICK-UP BLOCK, OPTICAL KSS-213B/K-N

156 4-917-567-21 GEAR (M)

157 4-917-564-01 GEAR (P), FLATNESS

158 1-769-069-11 WIRE (FLAT TYPE) (16 CORE)

M101 X-4917-523-3 BASE (OUTSERT) ASSY (SPINDLE)

M102 X-4917-504-1 MOTOR ASSY (SLED)

– 31 –

Page 21

SECTION 6

BD

NOTE:

• Due to standardization, replacements in

the parts list may be different from the

parts specified in the diagrams or the

components used on the set.

• -XX and -X mean standardized parts, so

they may have some difference from the

original one.

• RESISTORS

All resistors are in ohms.

METAL:Metal-film resistor.

METAL OXIDE: Metal oxide-film resistor.

F:nonflammable

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

A-4673-509-A BD BOARD, COMPLETE (US,E,AUS,CH)

* A-4673-511-A BD BOARD, COMPLETE (AEP,UK,G,EE)

*******************

< CAPACITOR >

C101 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C102 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C103 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C105 1-135-155-21 TANT ALUM CHIP 4.7uF 10% 16V

C106 1-164-346-11 CERAMIC CHIP 1uF 16V

C107 1-164-346-11 CERAMIC CHIP 1uF 16V

C108 1-163-035-00 CERAMIC CHIP 0.047uF 50V

C109 1-163-145-00 CERAMIC CHIP 0.0015uF 5% 50V

C110 1-163-017-00 CERAMIC CHIP 0.0047uF 5% 50V

C111 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C112 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C113 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C115 1-126-607-11 ELECT CHIP 47uF 20% 4V

C116 1-126-607-11 ELECT CHIP 47uF 20% 4V

C117 1-126-209-11 ELECT 100uF 20% 4V

C118 1-163-275-11 CERAMIC CHIP 0.001uF 5% 50V

C119 1-163-231-11 CERAMIC CHIP 15PF 5% 50V

C123 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C124 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C140 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C141 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C151 1-163-237-11 CERAMIC CHIP 27PF 5% 50V

C153 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C154 1-164-336-11 CERAMIC CHIP 0.33uF 25V

C156 1-163-237-11 CERAMIC CHIP 27PF 5% 50V

C157 1-163-145-00 CERAMIC CHIP 0.0015uF 5% 50V

C159 1-163-019-00 CERAMIC CHIP 0.0068uF 10% 50V

C161 1-163-038-00 CERAMIC CHIP 0.1uF 25V

< CONNECTOR >

CN101 1-770-072-11 CONNECTOR, FFC 23P

CN102 1-770-014-11 CONNECTOR, FFC/FPC 16P

< IC >

IC101 8-752-369-78 IC CXD2545Q

IC102 8-759-176-09 IC BA6392FP

IC103 8-752-072-45 IC CXA1821M-T6

ELECTRICAL PARTS LIST

• Items marked “*” are not stocked since

they are seldom required for routine service.

Some delay should be anticipated

when ordering these items.

• SEMICONDUCTORS

In each case, u : µ, for example:

uA.. : µA.. uPA.. : µPA..

uPB.. : µPB.. uPC.. : µPC.. uPD.. : µPD..

• CAPACITORS

uF : µF

• COILS

uH : µH

Q101 8-729-010-08 TRANSISTOR MSB710-R

R101 1-216-077-00 METAL CHIP 15K 5% 1/10W

R102 1-216-097-00 METAL GLAZE 100K 5% 1/10W

R103 1-216-077-00 METAL CHIP 15K 5% 1/10W

R104 1-216-085-00 METAL CHIP 33K 5% 1/10W

R105 1-216-097-00 METAL GLAZE 100K 5% 1/10W

R106 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R107 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R108 1-216-073-00 METAL CHIP 10K 5% 1/10W

R109 1-216-121-00 METAL GLAZE 1M 5% 1/10W

R110 1-216-025-00 METAL GLAZE 100 5% 1/10W

R112 1-216-049-11 METAL GLAZE 1K 5% 1/10W

R123 1-216-073-00 METAL CHIP 10K 5% 1/10W

R124 1-216-097-00 METAL GLAZE 100K 5% 1/10W

R125-127

1-216-049-11 METAL GLAZE 1K 5% 1/10W

R131 1-216-037-00 METAL CHIP 330 5% 1/10W

R135-138

1-216-295-00 CONDUCTOR, CHIP (2012)

R141 1-216-089-00 METAL GLAZE 47K 5% 1/10W

R142 1-216-081-00 METAL CHIP 22K 5% 1/10W

R143 1-216-103-00 METAL GLAZE 180K 5% 1/10W

R144 1-216-103-00 METAL GLAZE 180K 5% 1/10W

R146 1-216-073-00 METAL CHIP 10K 5% 1/10W

R147 1-216-081-00 METAL CHIP 22K 5% 1/10W

R148 1-216-001-00 METAL CHIP 10 5% 1/10W

R149 1-216-003-11 METAL GLAZE 12 5% 1/10W

R158 1-216-111-00 METAL GLAZE 390K 5% 1/10W

R159 1-216-101-00 METAL CHIP 150K 5% 1/10W

R160 1-216-295-00 CONDUCTOR, CHIP (2012)

R161 1-216-308-00 METAL CHIP 4.7 5% 1/10W

R162 1-216-101-00 METAL CHIP 150K 5% 1/10W

S101 1-572-085-11 SWITCH, LEAF (LIMIT SW)

**************************************************************

The components identified by mark

! or dotted line with mark. ! are

critical for safety.

Replace only with part number

specified.

When indicating parts by reference

number, please include the board.

• Abbreviation

AUS : Australian model

CH : Chinese model

G : German model

EE : East European model

< TRANSISTOR >

< RESISTOR >

< SWITCH >

– 32 –

Page 22

H.P

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

* 1-658-839-11 H.P BOARD

*********

< CAPACITOR >

C604 1-162-291-31 CERAMIC 560PF 10% 50V

C605 1-162-291-31 CERAMIC 560PF 10% 50V

C608 1-164-159-21 CERAMIC 0.1uF 50V

< CONNECTOR >

* CN601 1-568-941-11 PIN, CONNECTOR 3P

< JACK >

J601 1-568-519-41 JACK, LARGE TYPE (PHONES)

< COIL >

L601-603

1-410-397-21 FERRITE BEAD INDUCTOR 1.1uH

**************************************************************

* 1-645-721-11 LOADING BOARD

**************

< CONNECTOR >

* CN151 1-568-943-11 PIN, CONNECTOR 5P

< SWITCH >

S151 1-572-086-11 SWITCH, LEAF (LOAD OUT)

S152 1-572-086-11 SWITCH, LEAF (LOAD IN)

**************************************************************

* A-4673-738-A MAIN BOARD, COMPLETE (XE400)

* A-4673-739-A MAIN BOARD, COMPLETE (E)

* A-4673-740-A MAIN BOARD, COMPLETE (EXCEPT US,E)

* A-4673-753-A MAIN BOARD, COMPLETE (XE500:US)

*********************

< CAPACITOR >

C201 1-101-006-00 CERAMIC 0.047uF 50V

(US,E,AUS,CH)

C201 1-161-494-00 CERAMIC 0.022uF 25V

(AEP,UK,G,EE)

C202 1-162-290-31 CERAMIC 470PF 10% 50V

C205 1-104-666-11 ELECT 220uF 20% 25V

C211 1-101-006-00 CERAMIC 0.047uF 50V

(US,E,AUS,CH)

C211 1-161-494-00 CERAMIC 0.022uF 25V

(AEP,UK,G,EE)

C251 1-162-282-31 CERAMIC 100PF 10% 50V

C252 1-101-006-00 CERAMIC 0.047uF 50V

(US,E,AUS,CH)

C252 1-161-494-00 CERAMIC 0.022uF 25V

(AEP,UK,G,EE)

C253 1-126-933-11 ELECT 100uF 20% 16V

C254 1-162-199-31 CERAMIC 10PF 5% 50V

C255 1-162-199-31 CERAMIC 10PF 5% 50V

C256 1-101-006-00 CERAMIC 0.047uF 50V

C256 1-161-494-00 CERAMIC 0.022uF 25V

C257 1-126-933-11 ELECT 100uF 20% 16V

C258 1-101-006-00 CERAMIC 0.047uF 50V

C258 1-161-494-00 CERAMIC 0.022uF 25V

C259 1-126-933-11 ELECT 100uF 20% 16V

C264 1-162-282-31 CERAMIC 100PF 10% 50V

C280 1-164-159-21 CERAMIC 0.1uF 50V

C301 1-162-215-31 CERAMIC 47PF 5% 50V

C302 1-130-479-00 MYLAR 0.0047uF 5% 50V

C303 1-126-933-11 ELECT 100uF 20% 16V

C304 1-162-215-31 CERAMIC 47PF 5% 50V

C305 1-130-472-00 MYLAR 0.0012uF 5% 50V

C306 1-101-006-00 CERAMIC 0.047uF 50V

C306 1-161-494-00 CERAMIC 0.022uF 25V

C307 1-162-291-31 CERAMIC 560PF 10% 50V

C351 1-162-215-31 CERAMIC 47PF 5% 50V

C352 1-130-479-00 MYLAR 0.0047uF 5% 50V

C353 1-126-933-11 ELECT 100uF 20% 16V

C354 1-162-215-31 CERAMIC 47PF 5% 50V

C355 1-130-472-00 MYLAR 0.0012uF 5% 50V

C356 1-101-006-00 CERAMIC 0.047uF 50V

C356 1-161-494-00 CERAMIC 0.022uF 25V

C357 1-162-291-31 CERAMIC 560PF 10% 50V

C400 1-126-964-11 ELECT 10uF 20% 50V

C401 1-101-006-00 CERAMIC 0.047uF 50V

C401 1-161-494-00 CERAMIC 0.022uF 25V

C402 1-162-306-11 CERAMIC 0.01uF 30% 16V

C403 1-104-666-11 ELECT 220uF 20% 25V

C404 1-101-006-00 CERAMIC 0.047uF 50V

C404 1-161-494-00 CERAMIC 0.022uF 25V

C481 1-101-006-00 CERAMIC 0.047uF 50V

C481 1-161-494-00 CERAMIC 0.022uF 25V

C601 1-101-006-00 CERAMIC 0.047uF 50V

C601 1-161-494-00 CERAMIC 0.022uF 25V

LOADING

(XE500:US,E,AUS,CH)

MAIN

(US,E,AUS,CH)

(AEP,UK,G,EE)

(US,E,AUS,CH)

(AEP,UK,G,EE)

(US,E,AUS,CH)

(AEP,UK,G,EE)

(US,E,AUS,CH)

(AEP,UK,G,EE)

(US,E,AUS,CH)

(AEP,UK,G,EE)

(XE500)

(AEP,UK,G,EE)

(US,E,AUS,CH)

(AEP,UK,G,EE)

(US,E,AUS,CH)

(AEP,UK,G,EE)

– 33 –

Page 23

MAIN

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

C602 1-101-006-00 CERAMIC 0.047uF 50V

(US,E,AUS,CH)

C602 1-161-494-00 CERAMIC 0.022uF 25V

(AEP,UK,G,EE)

C607 1-101-006-00 CERAMIC 0.047uF 50V

(US,E,AUS,CH)

C607 1-161-494-00 CERAMIC 0.022uF 25V

(AEP,UK,G,EE)

C680 1-101-006-00 CERAMIC 0.047uF 50V

(US,E,AUS,CH)

C680 1-161-494-00 CERAMIC 0.022uF 25V

(AEP,UK,G,EE)

C702 1-126-964-11 ELECT 10uF 20% 50V

C703 1-162-294-31 CERAMIC 0.001uF 10% 50V

C704 1-104-666-11 ELECT 220uF 20% 25V

C705 1-126-964-11 ELECT 10uF 20% 50V

C706 1-126-933-11 ELECT 100uF 20% 16V

C707 1-124-903-11 ELECT 1uF 20% 50V

C708-710

1-126-964-11 ELECT 10uF 20% 50V

C711 1-124-903-11 ELECT 1uF 20% 50V

C712 1-124-903-11 ELECT 1uF 20% 50V

D403 8-719-010-34 DIODE UZ-4.7BSC

D701 8-719-815-85 DIODE 1S1585

D702 8-719-815-85 DIODE 1S1585

D703 8-719-815-85 DIODE 1S1585

D704 8-719-815-85 DIODE 1S1585

D705 8-719-815-85 DIODE 1S1585

D706 8-719-815-85 DIODE 1S1585 (AEP,UK,G,EE)

D707 8-719-815-85 DIODE 1S1585

D708 8-719-815-85 DIODE 1S1585 (AEP,UK,G,EE)

D901 8-719-200-82 DIODE 11ES2

D902 8-719-200-82 DIODE 11ES2

D903 8-719-200-82 DIODE 11ES2

D904 8-719-200-82 DIODE 11ES2

D905 8-719-200-82 DIODE 11ES2

< IC >

IC201 8-759-362-47 IC CXD8567AM

IC301 8-759-634-51 IC M5218AP

IC302 8-759-634-51 IC M5218AP

IC401 8-759-822-09 IC LB1641

IC601 8-759-634-51 IC M5218AP

C901 1-126-939-11 ELECT 10000uF 20% 16V

C902 1-126-768-11 ELECT 2200uF 20% 16V

C903 1-128-576-11 ELECT 100uF 20% 63V

C904 1-101-006-00 CERAMIC 0.047uF 50V

(US,E,AUS,CH)

C904 1-161-494-00 CERAMIC 0.022uF 25V

(AEP,UK,G,EE)

C905 1-101-006-00 CERAMIC 0.047uF 50V

(US,E,AUS,CH)

C905 1-161-494-00 CERAMIC 0.022uF 25V

(AEP,UK,G,EE)

C906 1-101-006-00 CERAMIC 0.047uF 50V

(US,E,AUS,CH)

C906 1-164-159-21 CERAMIC 0.1uF 50V

(AEP,UK,G,EE)

C907 1-101-006-00 CERAMIC 0.047uF 50V

(US,E,AUS,CH)

C907 1-164-159-21 CERAMIC 0.1uF 50V

(AEP,UK,G,EE)

C908 1-101-006-00 CERAMIC 0.047uF 50V

(US,E,AUS,CH)

C908 1-164-159-21 CERAMIC 0.1uF 50V

(AEP,UK,G,EE)

< CONNECTOR >

* CN201 1-568-839-11 SOCKET, CONNECTOR 23P

CN202 1-568-838-11 SOCKET, CONNECTOR 21P

CN901 1-580-230-11 PIN, CONNECTOR (PC BOARD) 2P (AEP,UK,G,EE)

< DIODE >

D400 8-719-982-22 DIODE MTZJ-30D

D401 8-719-815-85 DIODE 1S1585

D402 8-719-109-97 DIODE RD6.8ES-B2

IC701 8-759-821-93 IC LA5601

IC801 8-749-921-12 IC GP1F32T (DIGITAL OUT OPTICAL) (XE500)

< JACK >

J301 1-770-719-11 JACK, PIN 2P (LINE OUT VARIABLE)

< COIL >

L201 1-410-322-11 INDUCTOR 3.3uH (EXCEPT US)

L205 1-410-322-11 INDUCTOR 3.3uH (XE500)

L206 1-410-507-11 INDUCTOR 6.8uH (XE500)

L211 1-410-507-11 INDUCTOR 6.8uH (XE500)

L220 1-410-322-11 INDUCTOR 3.3uH

L251 1-410-322-11 INDUCTOR 3.3uH

L253 1-410-322-11 INDUCTOR 3.3uH

L254 1-410-397-21 FERRITE BEAD INDUCTOR 1.1uH (US)

L254 1-410-507-11 INDUCTOR 6.8uH (EXCEPT US)

L701 1-414-223-11 INDUCTOR 470uH

L702 1-412-473-21 INDUCTOR 0uH (US)

< TRANSISTOR >

Q301 8-729-922-37 TRANSISTOR 2SD2144S

Q351 8-729-922-37 TRANSISTOR 2SD2144S

Q400 8-729-230-46 TRANSISTOR 2SA1048TP-YG

Q401 8-729-019-64 TRANSISTOR 2SB1041

Q601 8-729-922-37 TRANSISTOR 2SD2144S

Q602 8-729-922-37 TRANSISTOR 2SD2144S

Q701 8-729-029-56 TRANSISTOR DTA144ESA-TP

Q702 8-729-029-56 TRANSISTOR DTA144ESA-TP

– 34 –

Page 24

PANELMAIN

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

< RESISTOR >

R201 1-249-417-11 CARBON 1K 5% 1/4W

R202 1-247-807-11 CARBON 100 5% 1/4W (US)

R202 1-247-815-00 CARBON 220 5% 1/4W

(EXCEPT US)

R203-208

1-249-417-11 CARBON 1K 5% 1/4W

R220 1-247-815-00 CARBON 220 5% 1/4W (US)

R702 1-249-441-11 CARBON 100K 5% 1/4W

R703 1-249-441-11 CARBON 100K 5% 1/4W

R704 1-247-807-11 CARBON 100 5% 1/4W

R705 1-249-417-11 CARBON 1K 5% 1/4W

< SWITCH >

! S901 1-572-675-11 SWITCH, POWER VOLTAGE CHANGE

(VOLTAGE SELECTOR) (E)

R221 1-247-804-11 CARBON 75 5% 1/4W (US)

R221 1-249-400-11 CARBON 39 5% 1/4W

(EXCEPT US)

R251 1-249-436-11 CARBON 39K 5% 1/4W

R252 1-249-436-11 CARBON 39K 5% 1/4W

R253

1-249-424-11 CARBON 3.9K 5% 1/4W

R255 1-249-436-11 CARBON 39K 5% 1/4W

R256 1-249-436-11 CARBON 39K 5% 1/4W

R257 1-247-807-11 CARBON 100 5% 1/4W

R301 1-249-431-11 CARBON 15K 5% 1/4W

R302 1-249-431-11 CARBON 15K 5% 1/4W

R303 1-249-437-11 CARBON 47K 5% 1/4W

R304 1-249-419-11 CARBON 1.5K 5% 1/4W

R305 1-249-419-11 CARBON 1.5K 5% 1/4W

R306 1-249-417-11 CARBON 1K 5% 1/4W

R307 1-249-437-11 CARBON 47K 5% 1/4W

R308 1-249-441-11 CARBON 100K 5% 1/4W

R309 1-249-419-11 CARBON 1.5K 5% 1/4W

R310 1-247-807-11 CARBON 100 5% 1/4W

R351 1-249-431-11 CARBON 15K 5% 1/4W

R352 1-249-431-11 CARBON 15K 5% 1/4W

R353 1-249-437-11 CARBON 47K 5% 1/4W

R354 1-249-419-11 CARBON 1.5K 5% 1/4W

R355 1-249-419-11 CARBON 1.5K 5% 1/4W

R356 1-249-417-11 CARBON 1K 5% 1/4W

R357 1-249-437-11 CARBON 47K 5% 1/4W

R358 1-249-441-11 CARBON 100K 5% 1/4W

R359 1-249-419-11 CARBON 1.5K 5% 1/4W

R360 1-247-807-11 CARBON 100 5% 1/4W

R400 1-249-432-11 CARBON 18K 5% 1/4W

R401 1-249-432-11 CARBON 18K 5% 1/4W

< TRANSFORMER >

! T901 1-423-979-11 TRANSFORMER, POWER (EXCEPT US,E)

! T901 1-426-621-11 TRANSFORMER, POWER (US)

! T901 1-426-622-11 TRANSFORMER, POWER (E)

< TERMINAL >

* TPT901 1-535-771-11 TERMINAL (US,E,AUS,CH)

* TPT902 1-535-771-11 TERMINAL (US,E,AUS,CH)

< VIBRATOR >

X201 1-579-833-21 VIBRATOR, CRYSTAL (33.8688MHz) (XE400)

X201 1-579-834-11 VIBRATOR, CRYSTAL (33.8688MHz) (XE500)

**************************************************************

* A-4673-727-A PANEL BOARD, COMPLETE

**********************

< CAPACITOR >

C501-503

1-161-494-00 CERAMIC 0.022uF 25V

C505 1-161-494-00 CERAMIC 0.022uF 25V

< CONNECTOR >

* CN501 1-568-864-11 SOCKET, CONNECTOR 21P

< FLUORESCENT INDICATOR TUBE >

FL501 1-517-297-21 INDICATOR TUBE, FLUORESCENT

< IC >

IC501 8-752-869-51 IC CXP82612-021Q

IC502 8-741-810-59 IC SBX1810-59

R402 1-249-441-11 CARBON 100K 5% 1/4W

R403 1-249-425-11 CARBON 4.7K 5% 1/4W

R404 1-249-441-11 CARBON 100K 5% 1/4W

R405 1-249-432-11 CARBON 18K 5% 1/4W

R406 1-249-427-11 CARBON 6.8K 5% 1/4W

R451 1-249-427-11 CARBON 6.8K 5% 1/4W

R601 1-249-403-11 CARBON 68 5% 1/4W

R602 1-249-403-11 CARBON 68 5% 1/4W

R603 1-249-419-11 CARBON 1.5K 5% 1/4W

R604 1-249-419-11 CARBON 1.5K 5% 1/4W

R701 1-249-422-11 CARBON 2.7K 5% 1/4W

< TRANSISTOR >

Q501 8-729-029-67 TRANSISTOR DTC114ESA-TP

< RESISTOR >

R501 1-249-427-11 CARBON 6.8K 5% 1/4W

R502 1-249-427-11 CARBON 6.8K 5% 1/4W

R503 1-249-431-11 CARBON 15K 5% 1/4W

R504 1-249-427-11 CARBON 6.8K 5% 1/4W

R505 1-249-415-11 CARBON 680 5% 1/4W

R506 1-249-417-11 CARBON 1K 5% 1/4W

The components identified by mark

! or dotted line with mark. ! are

critical for safety.

Replace only with part number

specified.

– 35 –

Page 25

PANEL POWER SW

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

R507 1-249-419-11 CARBON 1.5K 5% 1/4W

R508 1-249-421-11 CARBON 2.2K 5% 1/4W

R509 1-249-423-11 CARBON 3.3K 5% 1/4W

R510 1-249-427-11 CARBON 6.8K 5% 1/4W

R511 1-249-415-11 CARBON 680 5% 1/4W

R512 1-249-417-11 CARBON 1K 5% 1/4W

R513 1-249-419-11 CARBON 1.5K 5% 1/4W

R514 1-249-421-11 CARBON 2.2K 5% 1/4W

R515 1-249-423-11 CARBON 3.3K 5% 1/4W

R516 1-249-427-11 CARBON 6.8K 5% 1/4W

R517 1-249-431-11 CARBON 15K 5% 1/4W

R519 1-249-441-11 CARBON 100K 5% 1/4W

R520 1-249-427-11 CARBON 6.8K 5% 1/4W

R530 1-249-429-11 CARBON 10K 5% 1/4W

R531 1-249-429-11 CARBON 10K 5% 1/4W

< SWITCH >

S501 1-554-303-21 SWITCH, TACTILE (MUSIC SCAN)

S502 1-554-303-21 SWITCH, TACTILE (PEAK SEARCH)

S503 1-554-303-21 SWITCH, TACTILE (EDIT/TIME)

S504 1-554-303-21 SWITCH, TACTILE (PLAY MODE)

S505 1-554-303-21 SWITCH, TACTILE (REPEAT)

S506 1-554-303-21 SWITCH, TACTILE (TIME)

S520 1-554-303-21 SWITCH, TACTILE (·)

S521 1-554-303-21 SWITCH, TACTILE (P)

S522 1-554-303-21 SWITCH, TACTILE (p)

S523 1-554-303-21 SWITCH, TACTILE (ENTER)

S524 1-554-303-21 SWITCH, TACTILE (CLEAR)

S525 1-554-303-21 SWITCH, TACTILE (CHECK)

S526 1-554-303-21 SWITCH, TACTILE ())

S527 1-554-303-21 SWITCH, TACTILE (0)

S530 1-554-303-21 SWITCH, TACTILE (§ OPEN/CLOSE)

S531 1-473-452-11 ENCODER, ROTARY (≠ AMS ±)

< VIBRATOR >

X501 1-577-082-11 VIBRATOR, CERAMIC (4MHz)

**************************************************************

4 1-776-100-11 WIRE (FLAT TYPE) (23 CORE)

6 1-776-099-11 WIRE (FLAT TYPE) (21 CORE)

! 55 1-569-007-11 ADAPTOR, CONVERSION 2P (E)

! 56 1-569-008-11 ADAPTOR, CONVERSION 2P (CH)

* 111 1-452-538-11 MAGNET

! 155 8-848-367-11 PICK-UP BLOCK, OPTICAL KSS-213B/K-N

158 1-769-069-11 WIRE (FLAT TYPE) (16 CORE)

! CNP901 1-558-943-81 CORD, POWER (E)

! CNP901 1-558-945-21 CORD, POWER (POLAR.SPT-1) (US)

! CNP901 1-575-651-21 CORD, POWER (AEP,G,EE)

! CNP901 1-696-845-11 CORD, POWER (AUS)

! CNP901 1-696-907-11 CORD, POWER (UK)

! CNP901 1-696-966-11 CORD, POWER (CH)

M101 X-4917-523-3 BASE (OUTSERT) ASSY (SPINDLE)

M102 X-4917-504-1 MOTOR ASSY (SLED)

M151 A-4604-363-A MOTOR (L) ASSY (LOADING)

**************************************************************

ACCESSORIES & PACKING MATERIALS

********************************

1-467-880-11 REMOTE COMMANDER (RM-D420) (XE500)

1-558-271-11 CORD, CONNECTION

3-810-322-11 MANUAL, INSTRUCTION

3-810-322-21 MANUAL, INSTRUCTION (ENGLISH) (US)

3-810-322-31 MANUAL, INSTRUCTION

3-810-322-51 MANUAL, INSTRUCTION (GERMAN) (G)

3-810-322-61 MANUAL, INSTRUCTION

3-810-322-71 MANUAL, INSTRUCTION

* 3-948-574-01 SHEET (ROLL), PROTECTION (AEP,UK,G,EE)

4-962-615-01 COVER, BATTERY (FOR REMOTE COMMANDER)

MISCELLANEOUS

***************

(ENGLISH,FRENCH,SPANISH,CHINESE) (E,AUS,CH)

(ENGLISH,FRENCH,SPANISH) (UK)

(SWEDISH,FINNISH) (AEP)

(ENGLISH,RUSSIAN,POLISH) (EE)

(XE500)

* 1-658-840-11 POWER SW BOARD

****************

< SWITCH >

! S801 1-554-118-00 SWITCH, PUSH (1 KEY) (POWER)

**************************************************************

– 36 –

* 4-979-603-01 INDIVIDUAL CARTON (XE400)

* 4-979-603-21 INDIVIDUAL CARTON (XE500:US,AUS)

* 4-979-603-31 INDIVIDUAL CARTON (E,CH)

* 4-979-604-01 CUSHION (US,E,AUS,CH)

* 4-979-605-11 INDIVIDUAL CARTON (AEP,UK,G,EE)

* 4-979-606-01 CUSHION (AEP,UK,G,EE)

**************************************************************

The components identified by mark

! or dotted line with mark. ! are

critical for safety.

Replace only with part number

specified.

Page 26

Ref. No. Part No. Description Remark

**************

HARDWARE LIST

**************

#1 7-685-646-79 SCREW +BVTP 3X8 TYPE2 N-S

#2 7-682-548-04 SCREW +BVTT 3X8 (S)

#3 7-621-775-10 SCREW +B 2.6X4

#4 7-621-255-15 SCREW +P 2X3

#5 7-685-134-19 SCREW +BTP 2.6X8 TYPE2 N-S

– 37 –

Page 27

CDP-XE400/XE500

9-960-515-11

Sony Corporation

Consumer A&V Products Company

Home A&V Products Div.

– 38 –

English

96B0491-1

Printed in Japan

C1996.2

Published by Home A&V Products Div.

Quality Engineering Dept.

Loading...

Loading...