Sony CCD-TRV55E Owner’s Manual

BMECHANISM

OPERATION MANUAL

Video8

l_!MECHANISMDECK

CONTENTS

1. Main parts layout diagram ....................................................................... 4

2. Operation of main parts ............................................................................ 5

3. Operation of each part .............................................................................. 6

3-1. Driving of LS chassis ......................................................................................... 6

3-2. Driving of pinch roller ....................................................................................... 8

3-3. Driving of tension regulator and TG1 ............................................................ 10

3-4. Driving of S reel and S ratchet ....................................................................... 12

3-5. Driving of T ratchet and T soft gear .............................................................. 14

4. Operation in each mode ........................................................................... 17

4-1. Cassette IN _ STOP ............................................................................. 17

4-2. STOP _ PB ............................................................................................ 23

4-3. STOP _ REC ......................................................................................... 27

4-4. STOP _ FF ............................................................................................ 31

4-5. STOP =:===:_ REWIND ................................................................................ 35

4-6. PB =====_ CUE ............................... ............................................................... 38

4-7. PB _ REVIEW. ........................................ _............................................ 40

4-8. PB _ PAUSE ......................................................................................... 42

4-9. STOP _ EJECT .................................................................................... 45

-3-

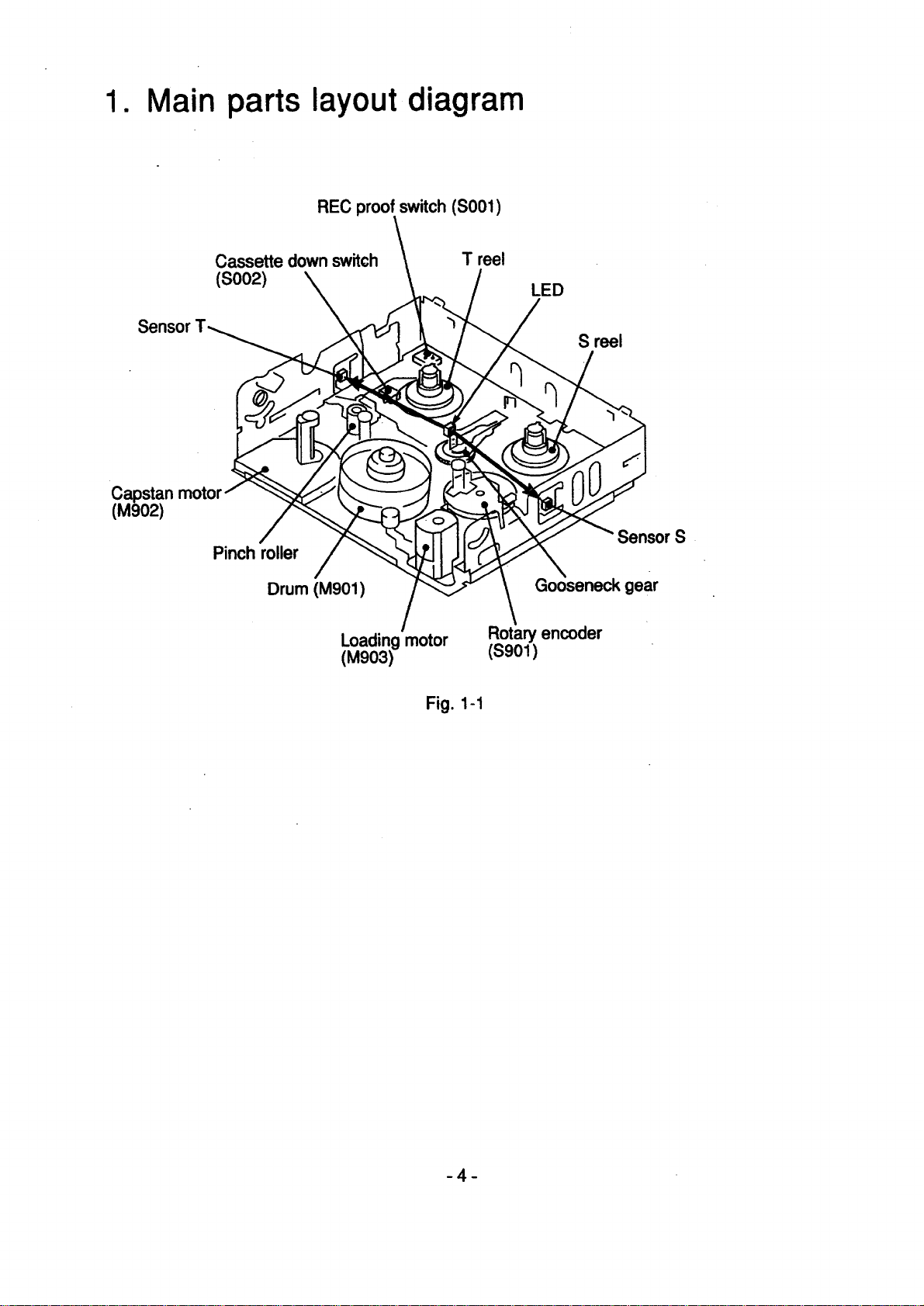

1. Main parts layout diagram

REC proof switch (S001)

Sensor

Capstan moto

(M902)

Cassette down switch

(soo2)

Pinch roller

Drum (M901)

Loading motor

(M903)

T reel

LED

S reel

Sensor S

gear

Rotary encoder

(sg01)

Fig. 1-1

-4-

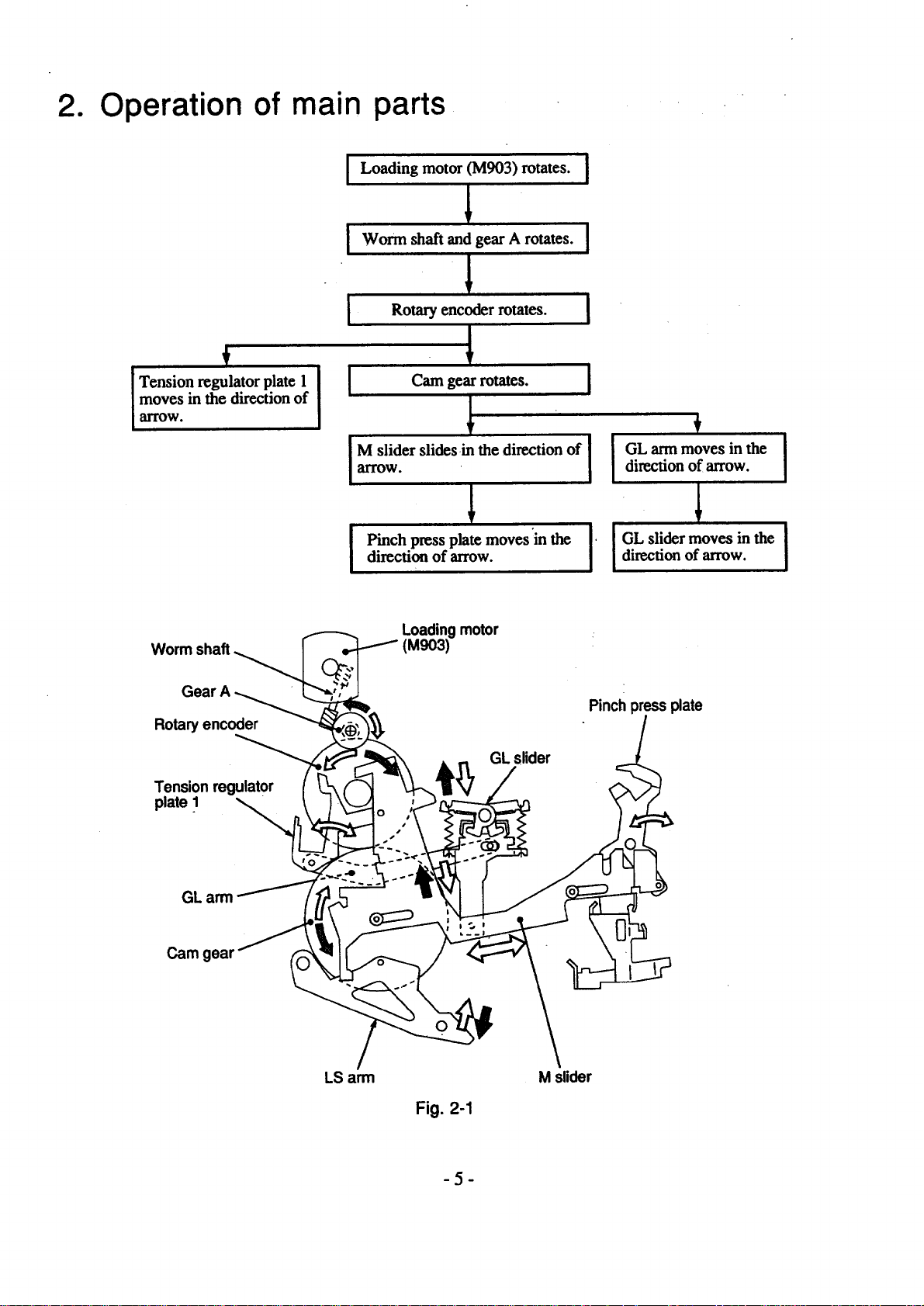

2. Operation of main parts

I Loading motor (M903) rotates. I

IWorm_ha_and,o__ro_os.I

] Rotary encoder rotates. I

f

Tension regulator plate 1

moves in the direction of

arrow.

M slider slides in the direction of I

arrow °

f

direction of arrow.

I GL arm moves in the

I

I

Rotary encoder

Tension regulator

plate .1 _

GL arm

Cam gear

direction of arrow.

I Pinch press plate moves:in the I'

Loading motor

(M903)

GL slider

direction of arrow.

I GL slider moves in the

Pinch press plate

!

LS arm

M slider

Fig. 2-1

-5-

3. Operation of each part

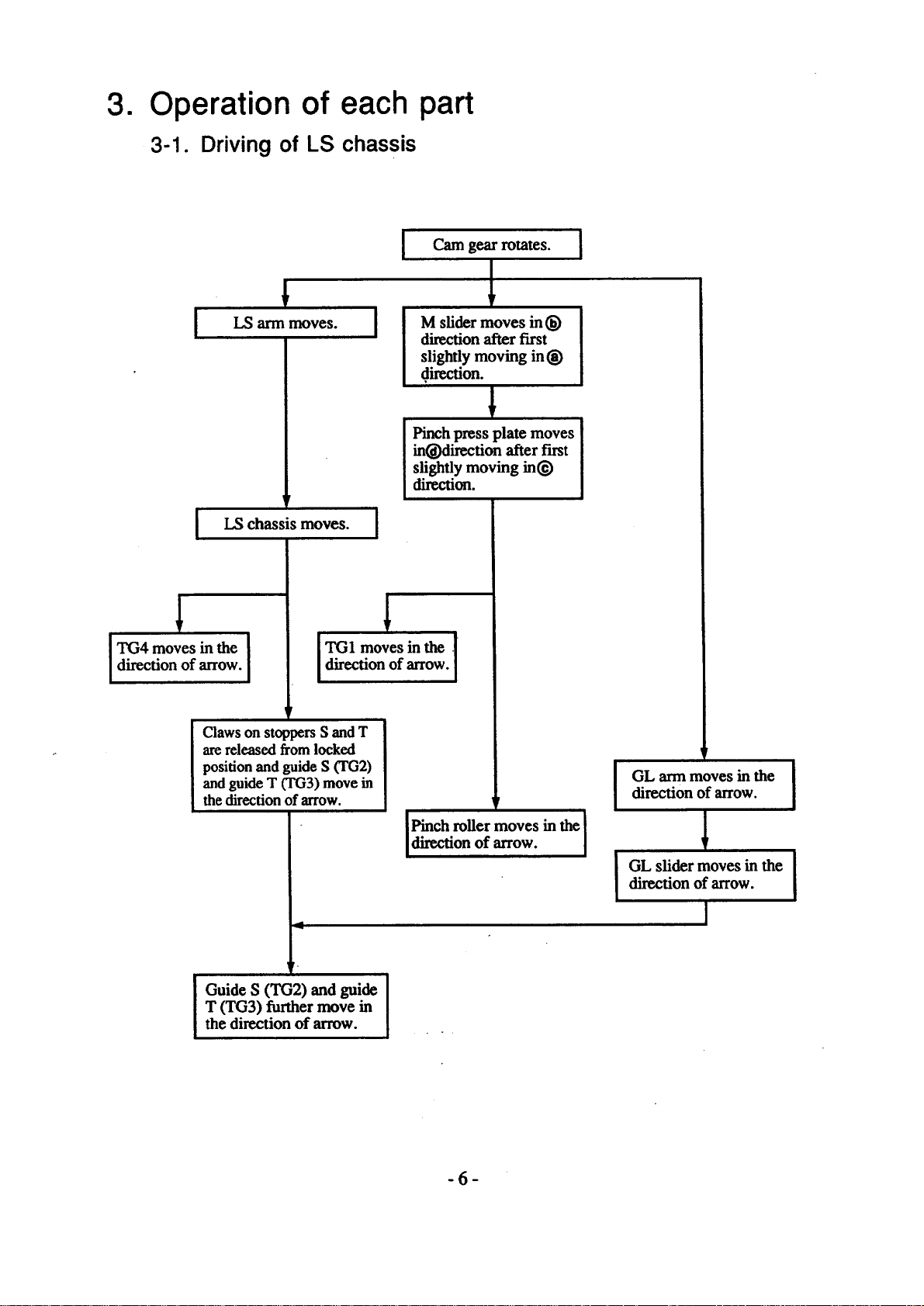

3-1. Driving of LS chassis

Cam gear rotates.

I

I

1

LS arm moves.

[

LS chassis moves. J

direction of arrow.

I TG4 moves in the ]

Claws on stoppers S and T

arereleased from locked

position and guide S 0°02)

and guide T 00G3) move in

the direction of arrow. r

1

TG 1 moves in the -I

direction of arrow. ]

i

V

M slider moves in _)

direction after first

slightly moving in (_

direction.

Pinch press plate moves

in_)direction after first

slightly moving in(_)

direction.

!

r

direction of arrow.

GL ann moves in the [

I

4

Guide S (TG2) and guide

T (TG3) further move in

the direction of arrow.

Pinch roller moves in the [

direction of arrow.

-6-

GL slider moves in the

direction of arrow.

I

I

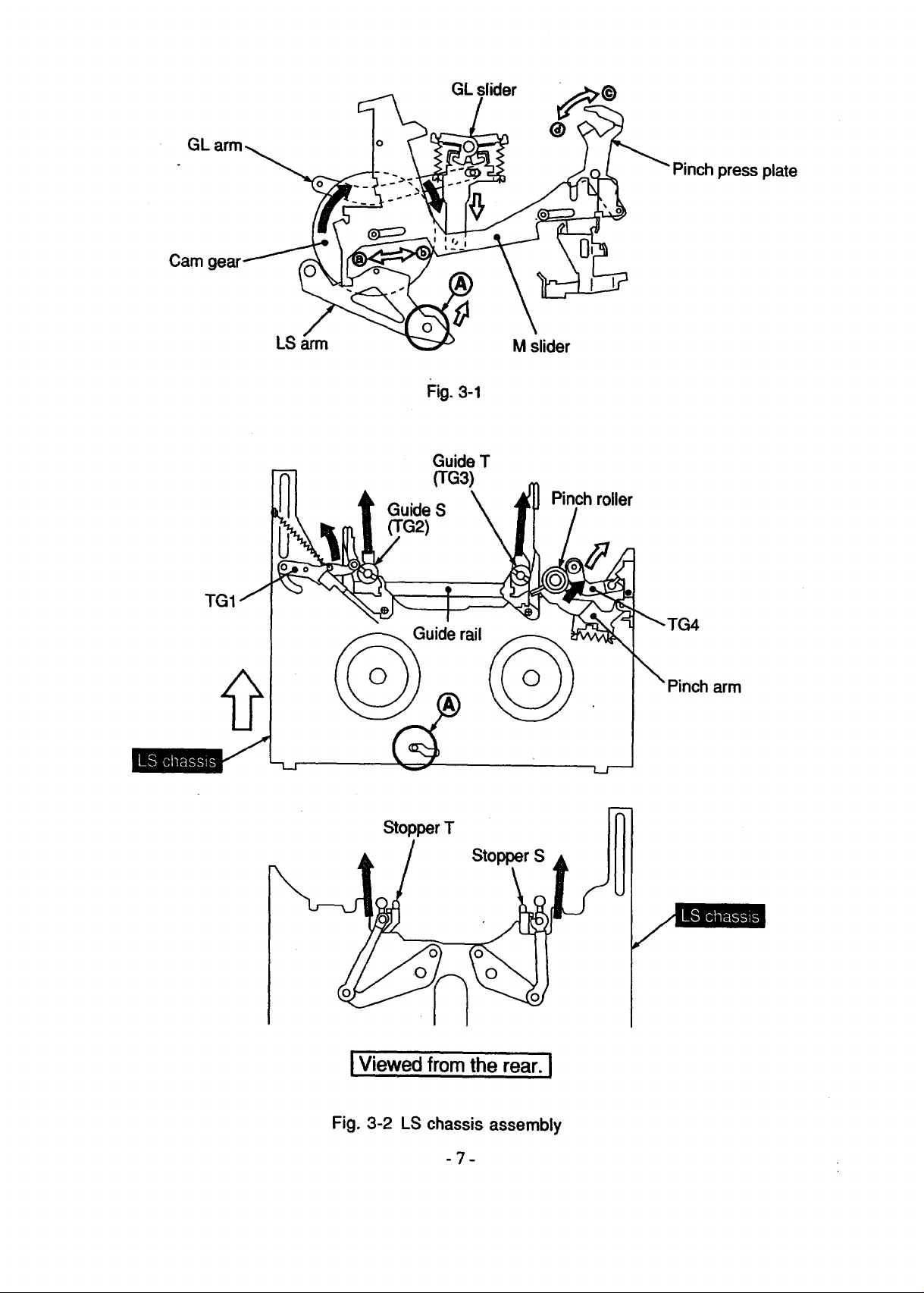

GL slider _)

GL arm__ _oo_._ _ @r_,_

" ___ "" Pinch press plate

Cam gear_-iS _ __

Fig. 3-1

Guide T

(TG3)

Pinchroller

Guide S

(TG2)

TG1

_(_uide rail

arm

Stopper T

iViewed from the rear. I

Fig. 3-2 LS chassis assembly

-'7-

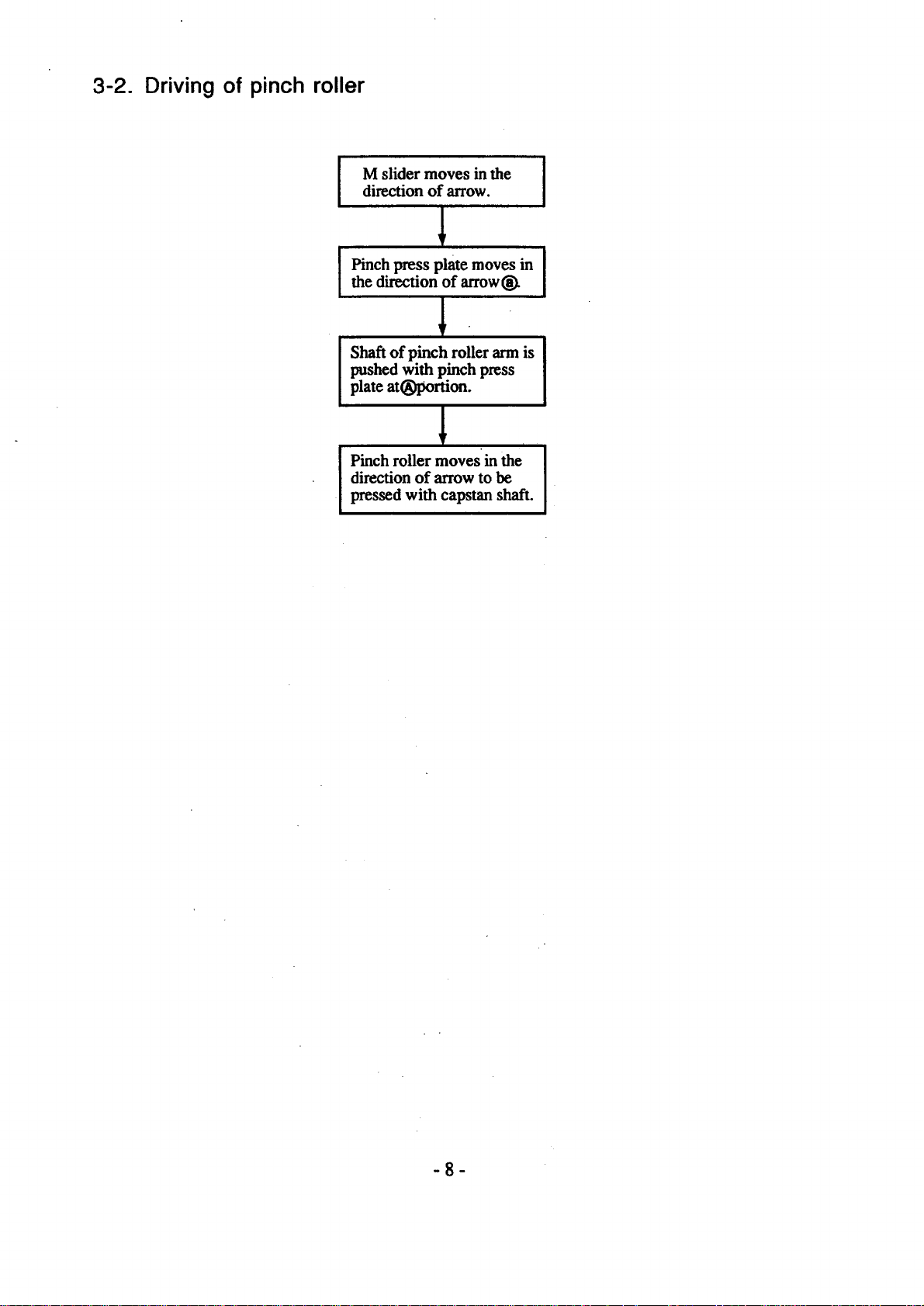

3-2. Driving of pinch roller

I

I

M slider moves in the

direction of arrow.

Pinch press plate moves in

the direction of arrow

Shaft of pinch roller arm is

pushed with pinch press

plate at(_portion.

Pinch roller moves in the

direction of arrow to be

pressed with capstan shaft.

I

-8-

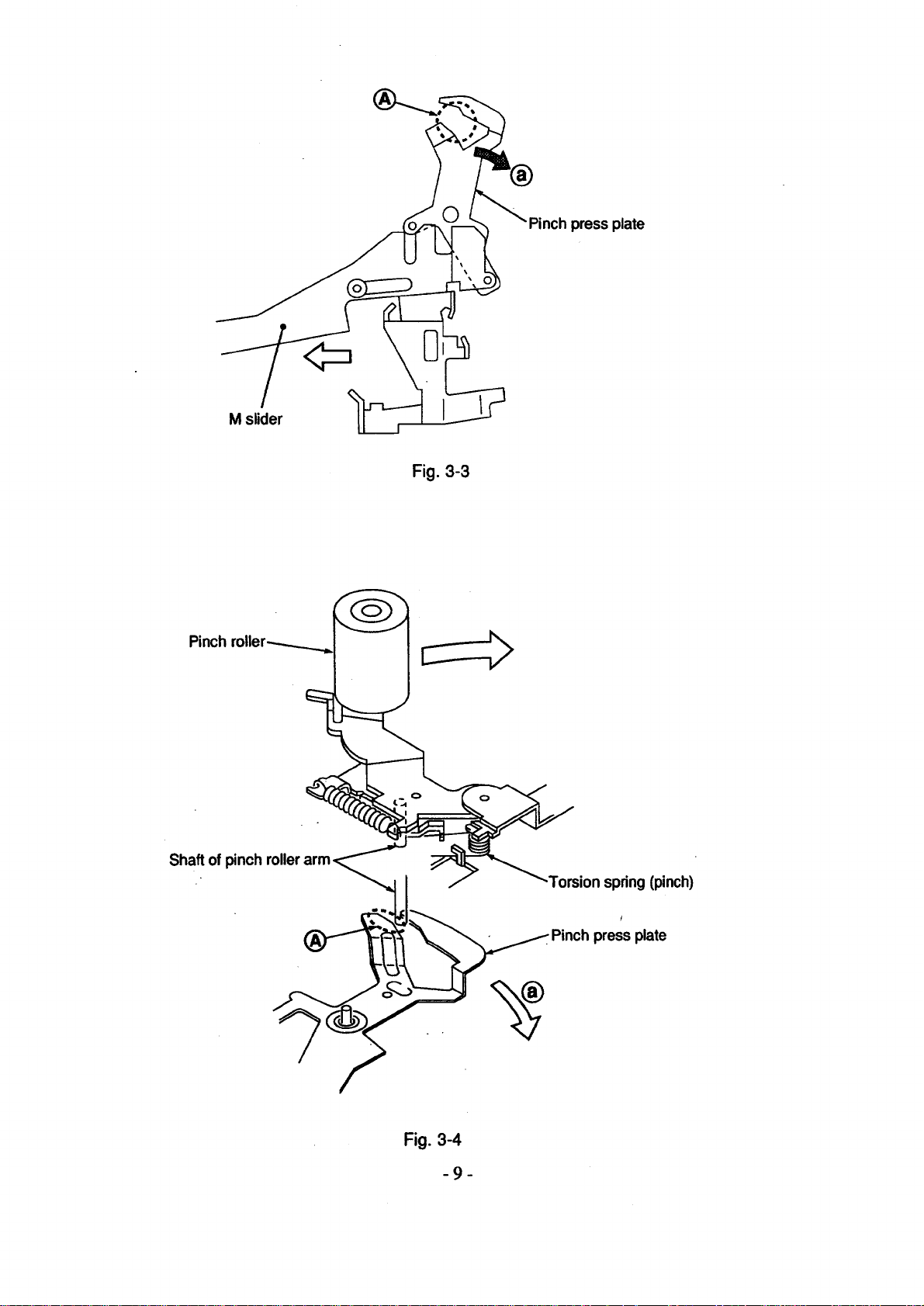

M slider

Pinch roller_...._

press plate

Fig. 3-3

Shaft of pinch

-Torsion spring(pinch)

_ Pinch press plate

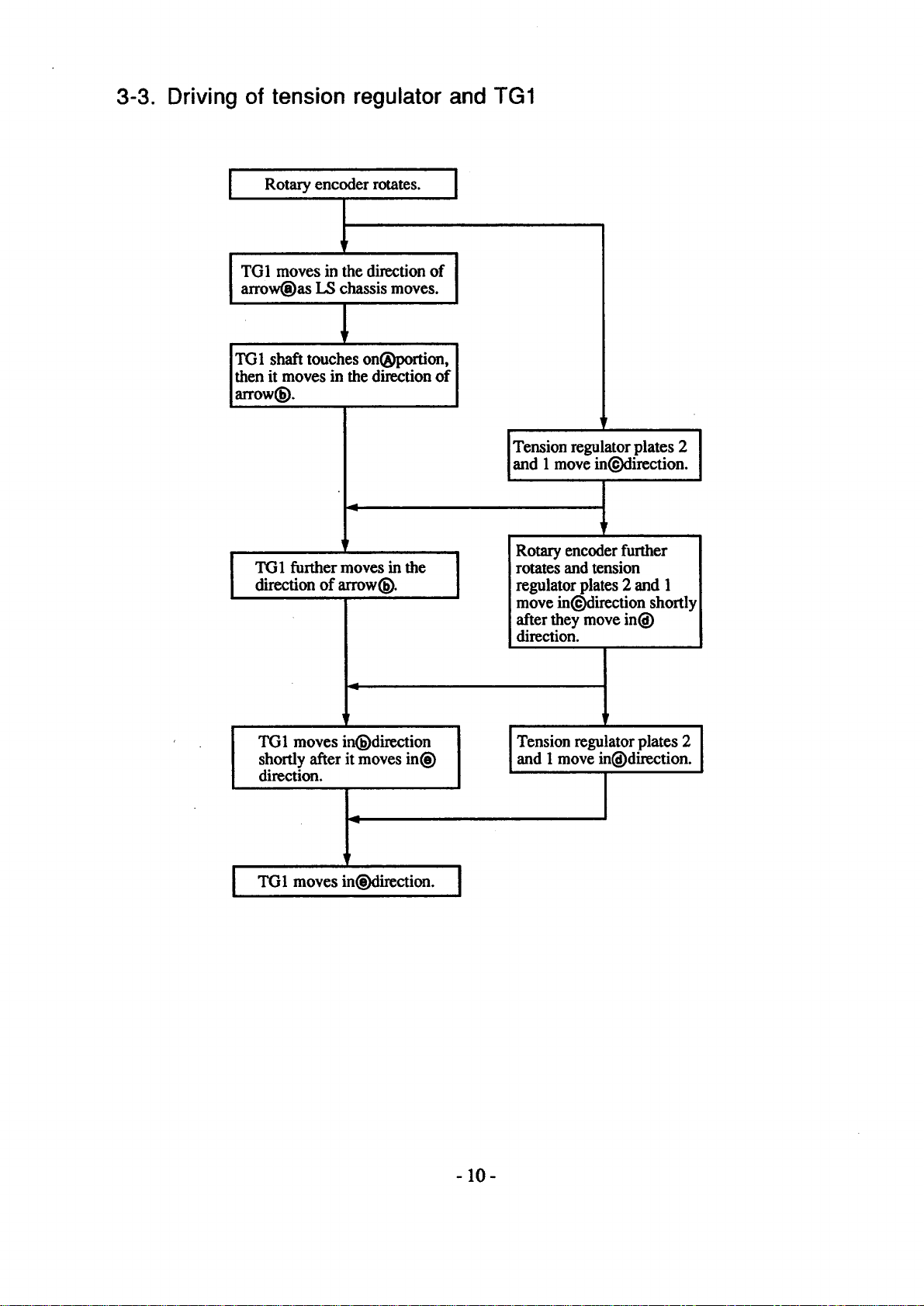

3-3. Driving of tension regulator and TG1

Rotary encoder rotates. [

1

|

I TG1 moves in the direction of J

arrow(_as LS chassis moves.

1

TG1 shaft touches on(_laortion. [

then it moves in the direction of I

arrow_. ]

I

!

9

!

TG1 further moves in the

dire_on of arrow_.

4

p

TG1 moves in(_)direction

shortly after it moves in_)

direction.

I"

TG1 moves in(_iirection.

i

1

Tension regulator plates 2

and 1 move in_:lirection, n

!

Rotary enc_ler further

rotates and tension

regulator plates 2 and 1

move inOdirection shortly

after they move ini_)

dim_ion.

p

Tension regulator plates 2

and 1 move in, direction.

I

I

|

- 10-

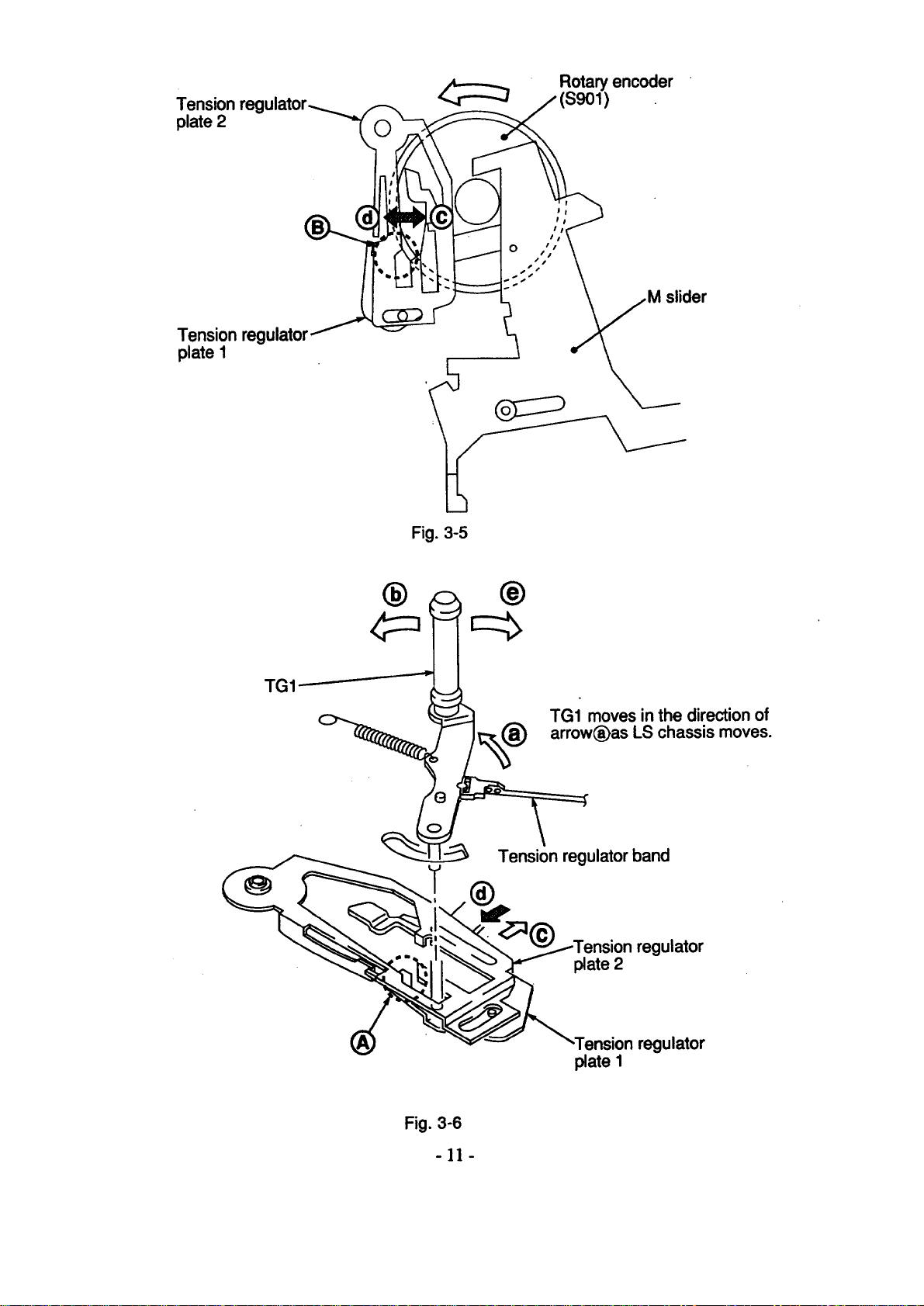

Tension regulator

plate 2

Tension regulator/

plate 1

_'- _ _Rotaryencoder

(S901)

der

TG1

Fig. 3-5

® ®

TG1 moves inthe direction of

arrow(_as LS chassis moves.

Tension regulator band

regulator

plate 2

"Tensionregulator

plate I

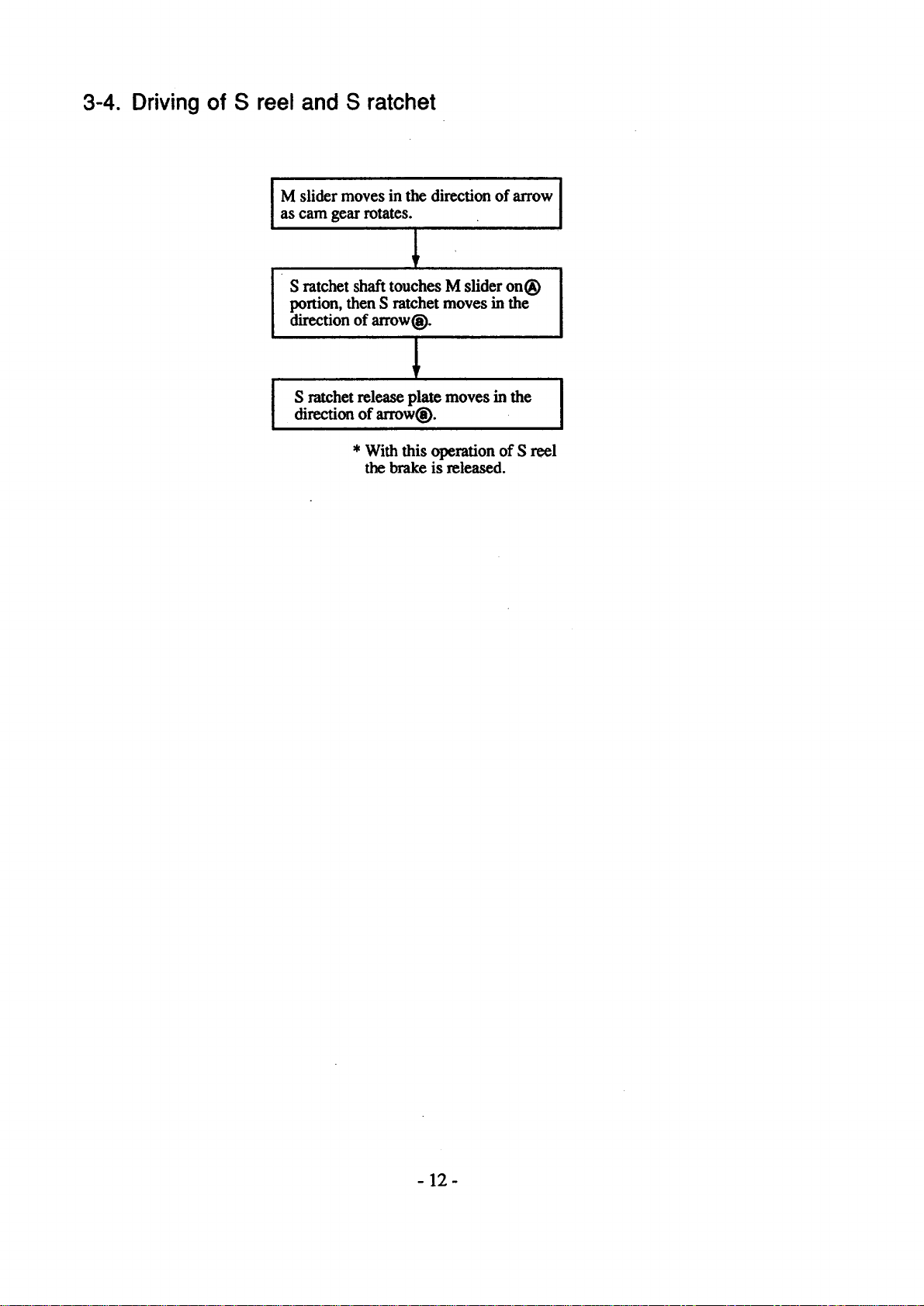

3-4. Driving of S reel and S ratchet

M slider moves in the direction of arrow I

as cam gear rotates.

S ratchet shaft touches M slider on®

portion, then S ratchet moves in the

direction of arrow(_).

S ratchetreleaseplatemoves inthe

directionof arrow_.

* With this operation of S reel

the brake is released.

i

I

I

- 12-

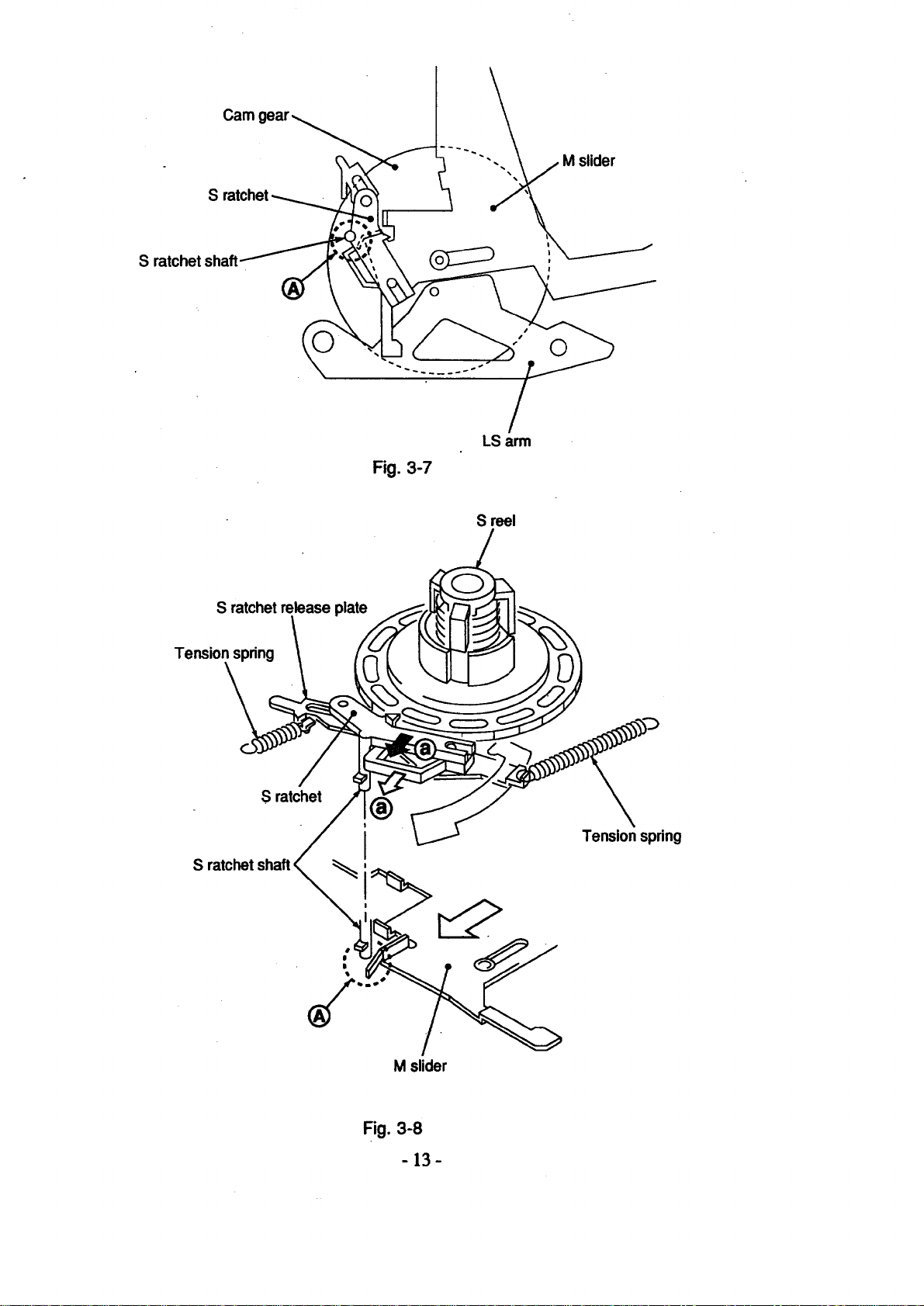

S!

S ratchet shaft

©

LSarm

S me|

S ratchetretease plate

S ratchet

S

-i'enslonspring

M slider

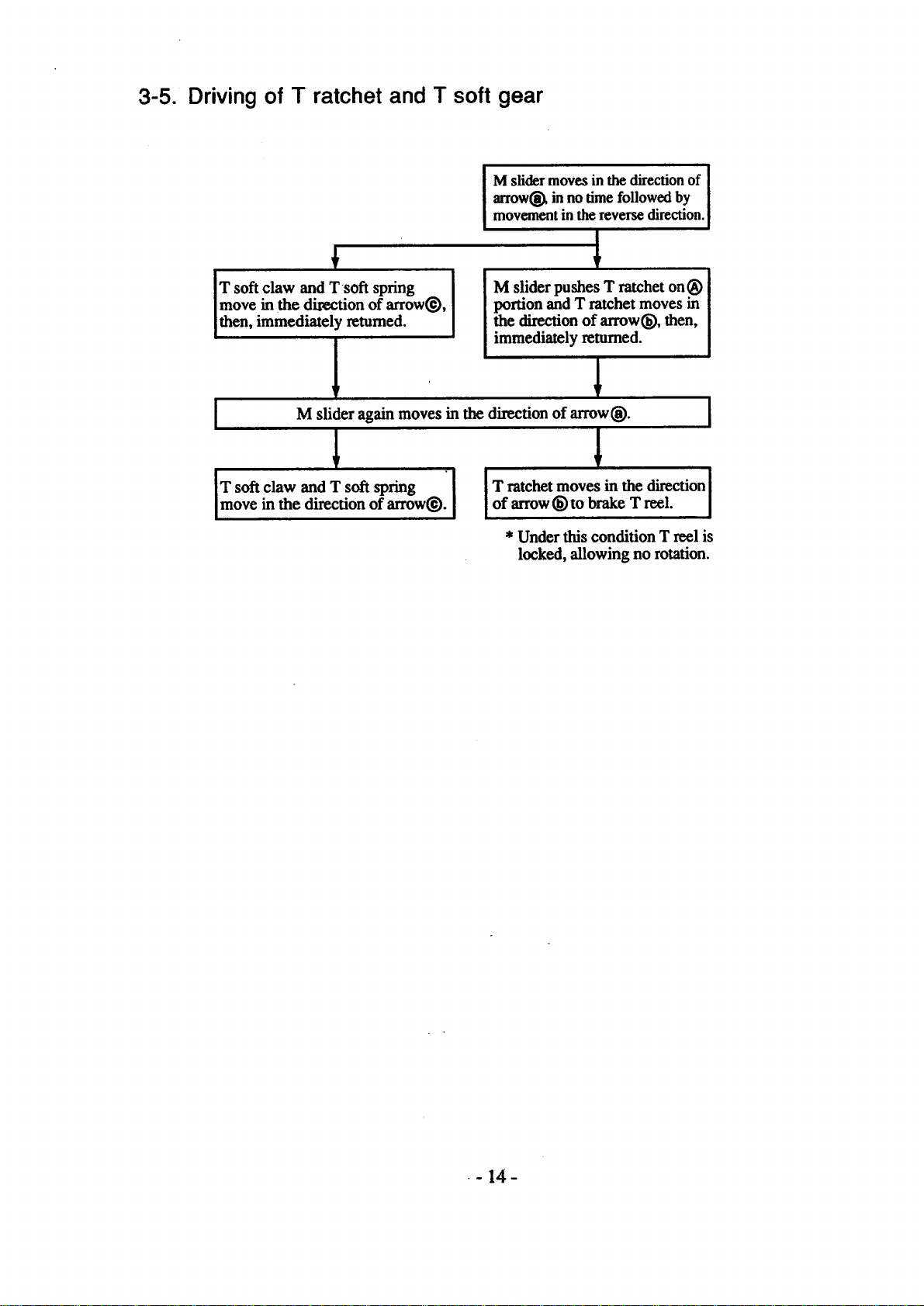

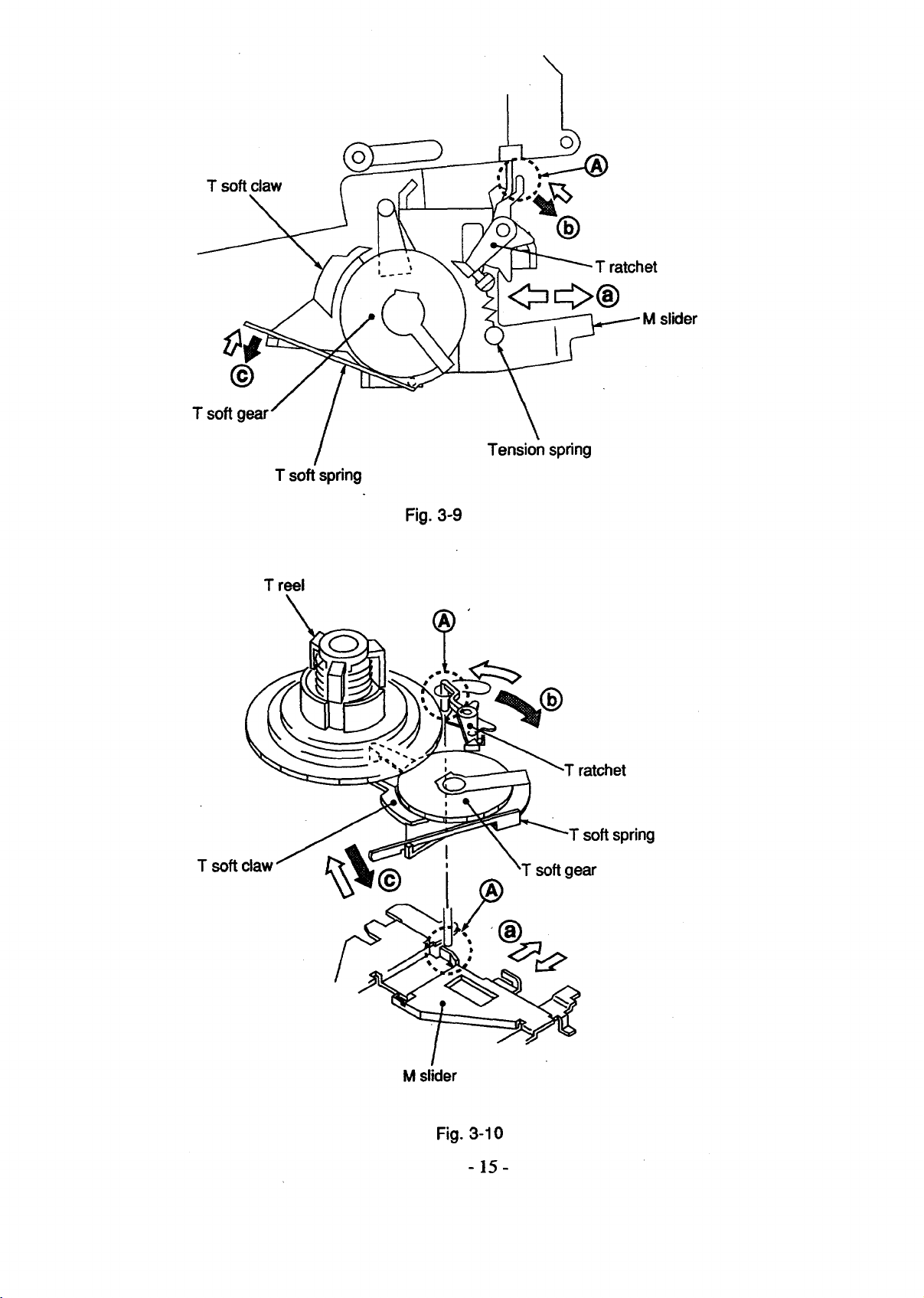

3-5. Driving of T ratchet and T soft gear

M slider moves in the direction of

arrowl_ in no time followed by

movement in thereverse direction.

+

T soft claw and T soft spring

move in the direction of arrowO,

then, immediately returned.

M slider pushes T ratchet on®

portion and T ratchet moves in

the direction of arrow_, then,

immediately returned.

!

I M slider again moves in the direction of arrow@, i

IT soft claw and T soft spring " T ratchet moves in the direction i

move in the direction of arrow_). [ [ of arrow (_) to brake T reel. I

* Under this condition T reel is

locked, allowing no rotation.

1

1

- 14-

T soft claw

©

T soft gear

T ratchet

slider

Tension spring

T soft spring

Fig. 3-9

T reel

Tsoft

soft spring

softgear

M slider

Loading...

Loading...