Page 1

Operators

Manual

Part Number 0120843

September 2010

Serial number 000000 and after

Page 2

Page 3

Table of Contents

Declaration of Conformity ...........................................2

Safety Rules ...............................................................3

Introduction .................................................................4

Component Identication ............................................4

Special Limitations......................................................5

Platform Capacity ....................................................5

Manual Force ..........................................................5

Lift Level Sensor Interlock .......................................5

Lowering Alarm .......................................................5

Lowering Interrupt ...................................................5

Controls and Indicators...............................................6

Lower Controls ...........................................................6

Emergency Stop Button ..........................................6

Control Selector Switch ...........................................6

Ground Operation Button ........................................7

Platform Raise/Lower Buttons .................................7

Battery Charger Mode Selector ...............................7

Upper Controls ...........................................................7

Emergency Stop Button ..........................................7

Interlock Button .......................................................7

Platform Raise/Lower Buttons .................................7

Pre-Operation Safety Inspection ................................8

System Function Inspection .......................................9

Operation ..................................................................10

Preparing for Operation ............................................ 10

Lower Controls .........................................................10

Upper Controls .........................................................10

Table of Contents

Table of Contents

Platform .................................................................... 11

Raising and Lowering ............................................ 11

Lowering Interrupt ................................................. 11

Component Tray ....................................................... 11

Emergency Lowering ................................................ 11

Transporting the Machine .........................................12

Preparing for Transportation .................................12

Transporting ..........................................................12

Lifting With a Forklift ..............................................12

Lifting With a Tail Lift .............................................12

Maintenance .............................................................13

Hydraulic Fluid ......................................................13

Check Hydraulic Fluid ...........................................13

Battery Maintenance .............................................13

Battery Charging ...................................................13

Inspection and Maintenance Schedule.....................14

Daily Preventative Maintenance Checklist ...............15

Preventative Maintenance Report ......................... 15

General Specications – PUSH6..............................16

General Specications – PUSH8..............................17

General Specications – PUSH10............................18

PUSH6/PUSH8/PUSH10 – 0120843 1

Page 4

EC DECLARATION OF CONFORMITY

FOR MACHINERY

MACHINERY:

Powered Aerial Platform known as:

Type: Pop Up PUSH8

Serial Number: PUSH8-04-xxxxxx

The machine specified above conforms to the following provisions:

Machinery directive 2006/42/EC (using document EC Community Legislation on Machinery and taking guidance

from EN280:2001 + Amendment A2:2009)

Council Directive 2004/108/EC on Electromagnetic Compatibility

Council Directive 2006/95/EC on Low Voltage Equipment Safety

Powered Access Certification LTD

Type approval in accordance with

P. O. Box 98, Windermere

Cumbria, LA23 1WF, UK

Notified Body Identification Number: 0545

2006/42/EC performed by:

E. C. Type Examination Certificate No:

Authorized Representative in

The Tanfield Group, PLC

Vigo Centre, Birtley Road

Washington, Tyne & Wear

NE38 9DA, UK

Note: Modification of the specified unit renders this declaration invalid.

2 PUSH6/PUSH8/PUSH10 – 0120843

European Union:

Page 5

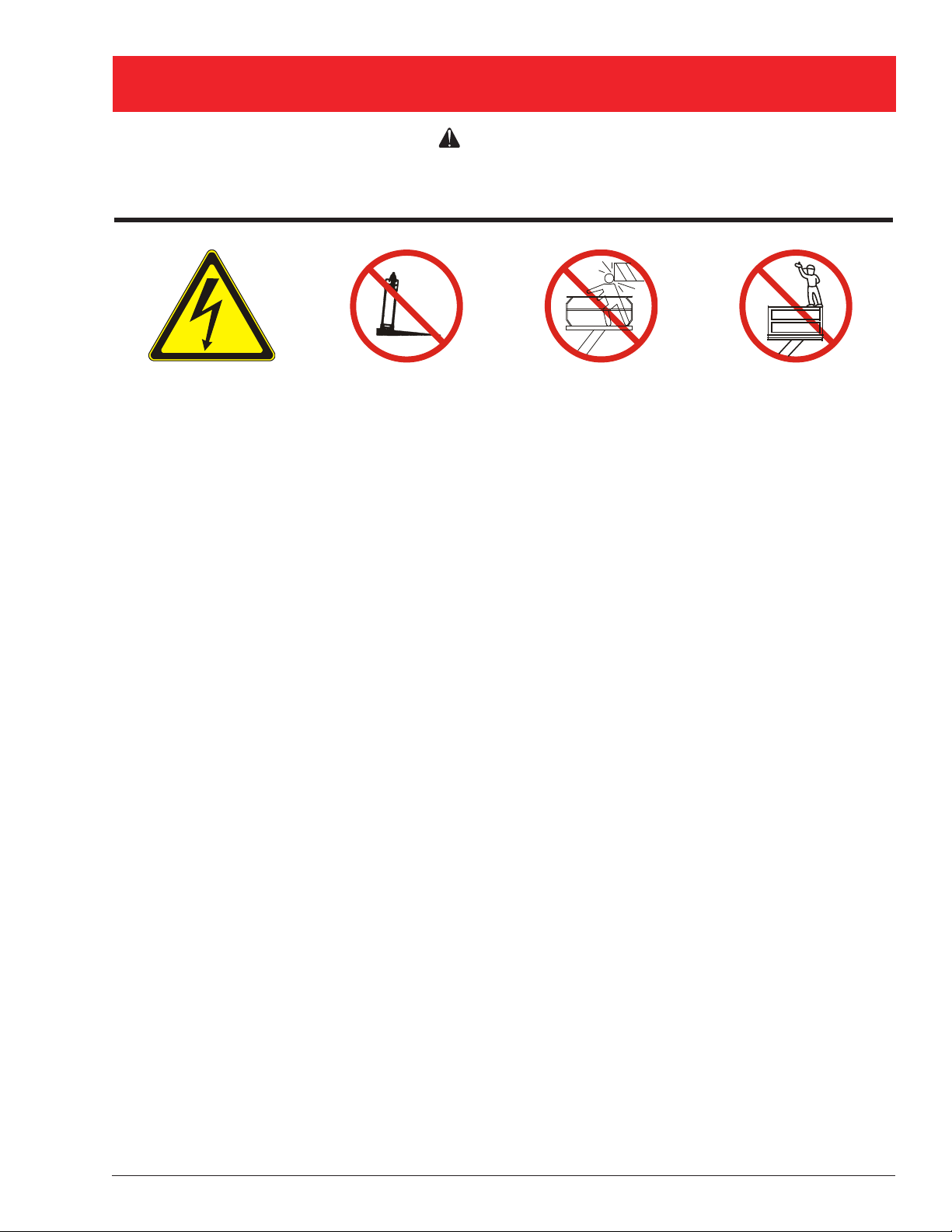

SAFETY RULES

Warning

All personnel shall carefully read, understand and follow all safety rules and operating instructions

before operating or performing maintenance on any Pop Up aerial work platform.

Electrocution Hazard Tip Over Hazard Collision Hazard Fall Hazard

THIS MACHINE IS

NOT INSULATED!

USE OF THE AERIAL WORK PLATFORM: This aerial work platform is intended to lift persons and his tools as well as the

material used for the job. It is designed for repair and assembly jobs and assignments at overhead workplaces (ceilings,

buildings etc.). Uses or alterations to the aerial work platform must be approved by Pop Up.

THIS AERIAL WORK PLATFORM IS NOT INSULATED! For this reason it is imperative to keep a safe distance from live

parts of electrical equipment!

Exceeding the specied permissible maximum load is prohibited! See “Platform Capacity” on page 5 for details.

The use and operation of the aerial work platform as a lifting tool or a crane is prohibited!

NEVER exceed the manual force allowed for this machine. See “Manual Force” on page 5 for details.

DISTRIBUTE all platform loads evenly on the platform.

NEVER operate the machine without rst surveying the work area for surface hazards such as holes, drop-offs, bumps, curbs,

or debris; and avoiding them.

OPERATE machine only on surfaces capable of supporting wheel loads.

NEVER operate the machine outdoors or indoors when wind speeds exceed 0 m/s (0 mph).

Do not operate the aerial platform in windy or gusty conditions. Do not add anything to or take anything into the aerial platform

that will increase the wind loading such as billboards, banners, flags, etc.

IN CASE OF EMERGENCY push EMERGENCY STOP switch to deactivate all powered functions.

IF ALARM SOUNDS while platform is elevated, STOP, carefully lower platform. Move machine to a rm, level surface.

Climbing up the railing of the platform, standing on or stepping from the platform onto buildings, steel or prefab concrete

structures, etc., is prohibited!

Dismantling the entry gate or other railing components is prohibited! Always make certain that the entry gate is closed!

It is prohibited to keep the entry gate in an open position when the platform is raised!

To extend the height or the range by placing of ladders, scaffolds or similar devices on the platform is prohibited!

NEVER perform service on machine while platform is elevated without blocking elevating assembly.

INSPECT the machine thoroughly for cracked welds, loose or missing hardware, hydraulic leaks, loose wire connections, and

damaged cables or hoses before using.

VERIFY that all labels are in place and legible before using.

NEVER use a machine that is damaged, not functioning properly, or has damaged or missing labels.

To bypass any safety equipment is prohibited and presents a danger for the persons on the aerial work platform and in its

working range.

NEVER charge batteries near sparks or open ame. Charging batteries emit explosive hydrogen gas.

Modications to the aerial work platform are prohibited or permissible only at the approval by Pop Up.

AFTER USE, secure the work platform from unauthorized use by turning the keyswitch off and removing key.

The driving of MEWP’s on the public highway is subject to national trafc regulations.

Certain inherent risks remain in the operation of this machine despite utilizing proper design practices and safeguarding.

Care must be taken to ensure that the machines meets the requirements of stability during use, transportation, assembly,

dismantling when out of service, testing, or foreseeable breakdowns.

In the event of an accident or breakdown see “Emergency Lowering” on page 11, do not operate the aerial platform if it is

damaged or not functioning properly. Qualied maintenance personnel must correct the problem before putting the aerial

platform back into service.

NEVER elevate the platform

or drive the machine while

elevated unless the machine

is on a firm, level surface.

NEVER position the platform

without first checking for

overhead obstructions or

other hazards.

NEVER climb, stand, or sit

on platform guardrails or

midrail.

PUSH6/PUSH8/PUSH10 – 0120843 3

Page 6

Introduction

Introduction

This manual covers the PUSH6, PUSH8, and PUSH10

Aerial Work Platforms.

This manual must be stored on the machine at all times.

Read, understand and follow all safety rules and operating

instructions before attempting to operate the machine.

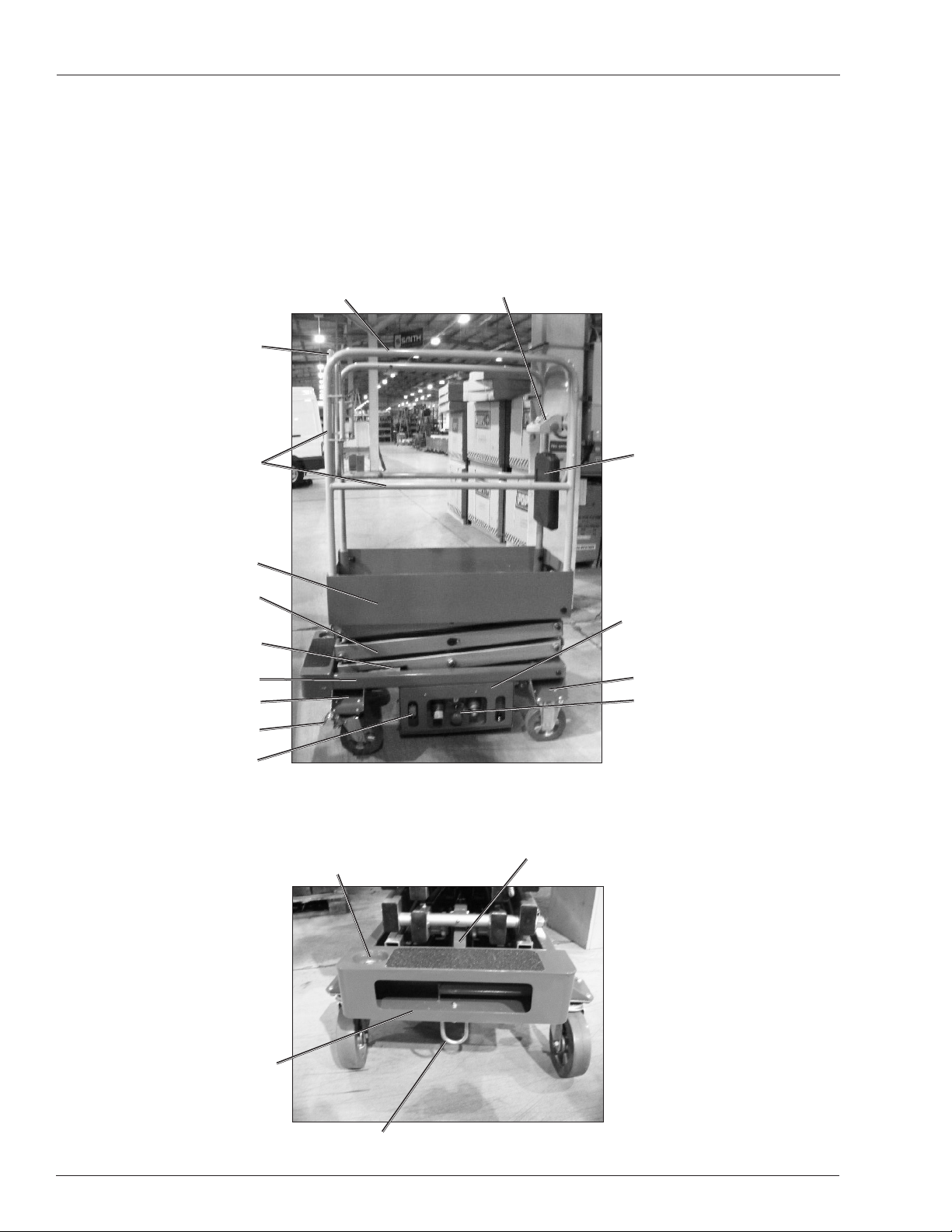

Component Identication

Platform

Entry Gate

Guardrails

When contacting Pop Up for service or parts information,

be sure to include the MODEL and SERIAL NUMBERS

from the equipment nameplate. Should the nameplate

be missing, the SERIAL NUMBER is also stamped on

the front of the chassis.

Upper Controls

Operators

Manual

Toeboards

Scissors

Structure

Safety Prop

One on Each Side

Chassis

Forklift Pocket

Brake Lever

Battery Charge

Indicator

Bubble Level

Right Side

Emergency

Lowering Lever

Component Tray

Hydraulic Reservoir/Pump • Batteries

Forklift Pocket

Lower Controls

Entry Step

Tow Hitch

Rear

4 PUSH6/PUSH8/PUSH10 – 0120843

Page 7

Special Limitations

Special Limitations

Elevating the platform is limited to firm, level surfaces

only.

Danger

The elevating function shall ONLY be used when the

work platform is level and on a firm surface.

The work platform is NOT intended to be pushed over

uneven, rough, or soft terrain.

Platform Capacity

One person and tools may occupy the platform when the

machine is indoors only. The maximum platform capacity

for the aerial platform is stated in the “Specifications” on

pages 16 to 18.

Danger

DO NOT exceed the maximum platform capacity or

the platform occupancy limits for this machine.

Manual Force

Manual force is the force applied by the occupants to

objects such as walls or other structures outside the

work platform.

In zero wind conditions the maximum allowable manual

force is limited to 200 N.

Lift Level Sensor Interlock

The aerial platform lift function is interlocked through a

level sensor system.

If the chassis is tilted more than 2 degrees side-to-side or

front-to-rear, an alarm will sound when the power is turned

on and the lift function will not operate. When the alarm

sounds, only the platform lower function will operate.

Position the machine on a level surface when the lift level

sensor alarm sounds. When the machine is properly positioned on a level surface, the alarm will not sound and

all functions will be operational.

The lift level sensor system is for added protection and

does not justify operating on anything other than firm,

flat, level surfaces.

Lowering Alarm

When a platform control button is pressed to lower the

platform, the alarm emits a loud beeping sound to warn

personnel in the work area to stand clear.

Danger

Pinch points exist on the scissors structure. Death

or serious injury will result if the scissors structure

lowers onto personnel within the scissors arms or

under the raised platform. Stand clear while raising

and lowering the platform.

Danger

DO NOT exceed the maximum amount of manual

force for this machine.

Be careful when lowering the platform. Keep hands and

fingers away from the scissors structures components.

Lowering Interrupt

When the platform is lowered to about 1.5 m (5′) lowering stops. The platform will not lower for five seconds

regardless of the control position to allow personnel to

clear the area of the scissors before the platform completely lowers.

Release the control to reset the lowering function, then

continue to lower the platform.

BEAUFORT

RATING

3 3,4~5,4 12,25~19,4 11.5~17.75 7.5~12.0 Papers and thin branches move, ags wave.

4 5,4~8,0 19,4~28,8 17.75~26.25 12.0~18 Dust is raised, paper whirls up, and small branches sway.

5 8,0~10,8 28,8~38,9 26.25~35.5 18~24.25

6 10,8~13,9 38,9~50,0 35.5~45.5 24.5~31

7 13,9~17,2 50,0~61,9 45.5~56.5 31.~38.5 Whole trees sway. It is difcult to walk against the wind.

m/s km/h ft/s mph

WIND SPEED

GROUND CONDITIONS

Shrubs with leaves start swaying. Wave crests are apparent in ponds

or swamps.

Tree branches move. Power lines whistle. It is difcult to open an

umbrella.

Figure 1 – Beaufort Scale

PUSH6/PUSH8/PUSH10 – 0120843 5

Page 8

Controls and Indicators

Controls and Indicators

The operator shall know the location of each control and

indicator and have a thorough knowledge of the function

and operation of each before attempting to operate the

machine.

1

2

Figure 2 – Lower Controls and Indicators

1. Tilt/lowering alarm

2. Battery charge indicator

3. 110V battery charger plug

4. Battery charger mode selector

5. 230V/240V battery charger plug

6. Tray latch

7. Ground operation button

8. Platform raise button

9. Emergency stop button

10. Platform lower button

11. Control selector switch

3

7

8

4 5

9

10

6

11

Danger

Pinch points may exist between moving components.

Death or serious injury will result from becoming

trapped between components, buildings, structures,

or other obstacles. Make sure all personnel stand

clear while operating the aerial platform.

Controls to position the platform are located on the

•

lower control panel on the chassis and on the upper

control panel in the platform.

Lower Controls

The lower controls (refer to Figure 2) are located on the

right side of the chassis.

The following are located on the lower control panel:

Emergency stop button

•

Control selector switch

•

Ground operation button

•

Platform raise/lower buttons

•

Battery charger selector/plugs/indicator

•

Warning

The aerial platform is free to move when the brakes

are released. Death or serious injury can result.

Engage the brakes before operating the aerial platform.

Emergency Stop Button

The emergency stop is a two-position red push button.

Push the button inward to disconnect power to all

•

control circuits.

Pull the button outward to restore power.

•

Control Selector Switch

Insert the key into the control selector switch.

Turn the switch to the lower controls position to oper-

•

12

Figure 3 – Upper Controls and Indicators

12. Interlock button

13. Battery condition indicator

14. Platform lower button

15. Platform raise button

16. Emergency stop button

6 PUSH6/PUSH8/PUSH10 – 0120843

13

14

15

16

ate aerial platform functions from the lower controls.

The upper controls will not operate while the control

selector is in the lower position.

Turn the switch to the upper controls position to

•

operate the aerial platform functions from the upper

controls.

In the center position, aerial platform functions will not

•

operate from the lower or upper controls.

Page 9

Controls and Indicators

Ground Operation Button

The ground operation button prevents platform movement

if the platform raise or lower button is accidentally pressed.

This switch is spring returned to the off position.

Press and hold the ground operation switch inward continually to operate the machine from the lower controls.

Platform Raise/Lower Buttons

The platform raise/lower buttons are used to raise or

lower the platform. The buttons are spring returned to

the off position.

Press and hold the platform raise button to raise the

•

platform.

Press and hold the platform lower button to lower the

•

platform.

An alarm will sound as the platform lowers.

•

Battery Charger Mode Selector

The battery charger may be operated on either 110V or

230V/240V electrical circuits.

Move the toggle switch to the left for operation on

•

110V circuits.

Emergency Stop Button

The emergency stop is a two-position, red push button

on the right side of the upper control panel.

Push the button inward to disconnect power from all

•

control circuits at the upper controls.

Twist the button clockwise to restore power.

•

Push the button in when the upper controls are not in use

to help protect against unintentional platform operation.

Interlock Button

The interlock button prevents platform movement if the

platform raise or lower button is accidentally pressed. This

switch is spring returned to the off position.

Press and hold the interlock button inward continually to

operate the machine from the upper controls.

Platform Raise/Lower Buttons

The platform raise/lower buttons are used to raise or

lower the platform. The buttons are spring returned to

the off position.

Press and hold the platform raise button to raise the

•

platform.

Move the toggle switch to the right for operation on

•

230V/240V circuits.

In the middle position, the battery charger is off and

•

will not charge.

Upper Controls

The upper controls (refer to Figure 3) are located on the

control panel at the front of the platform.

The following controls are located on the upper control

panel:

Interlock button

•

Battery condition indicator

•

Platform raise/lower buttons

•

Emergency stop button

•

Warning

The aerial platform is free to move when the brakes

are released. Death or serious injury can result.

Engage the brakes before operating the aerial platform.

Press and hold the platform lower button to lower the

•

platform.

An alarm will sound as the platform lowers.

•

PUSH6/PUSH8/PUSH10 – 0120843 7

Page 10

Pre-Operation Safety Inspection

Pre-Operation Safety Inspection

Note

Carefully read, understand and follow all safety rules,

operating instructions, labels and National Safety Instructions/Requirements. Perform the following steps each

day before use.

1. Open the tray and inspect for damage, fluid leaks or

missing parts.

2. Check the level of the hydraulic fluid with the platform

fully lowered. The fluid level must be within 6 mm (¼″)

of the top of the fill hole. Add recommended hydraulic

fluid if necessary. See “Specifications” on pages 16

to 18.

3. Check that the fluid level in the batteries is correct.

See “Battery Maintenance” on page 15.

4. Verify that the batteries are charged.

5. Check that the AC extension cord has been disconnected from the outlet on the side of the chassis.

6. Inspect the brakes on the rear castor wheels for

proper operation. Step down on the brake levers and

verify that the machine will not move.

7. Check that all guardrails are in place and all fasteners

are properly tightened.

8. Inspect the machine thoroughly for cracked welds

and structural damage, loose or missing hardware,

hydraulic leaks, damaged control cable and loose

wire connections.

8 PUSH6/PUSH8/PUSH10 – 0120843

Page 11

System Function Inspection

System Function Inspection

Refer to “Controls and Indicators” on page 6 for the locations of various controls and indicators.

Warning

STAND CLEAR of the work platform while performing

the following checks.

Before operating the machine, survey the work area

for surface hazards such as holes, drop-offs, bumps

and debris.

Check in ALL directions, including above the work

platform, for obstructions and electrical conductors.

1. Move the machine, if necessary, to an unobstructed

area to allow for full elevation.

2. Pull the Lower Control Emergency Stop Switch to the

ON position.

3. Turn the Upper Control Emergency Stop Switch

clockwise to the ON position.

4. Visually inspect the scissors structure, lift cylinder,

and hoses for cracked welds and structural damage,

loose hardware, hydraulic leaks, loose wire connections, and erratic operation. Check for missing or

loose parts.

5. Press and hold the ground operation button inward.

Test each machine function from the lower control

station (refer to Figure 2).

6. Test the emergency lowering system for proper operation.

7. Push the Lower Control Emergency Stop Button to

check for proper operation. All machine functions

should be disabled. Pull the Lower Control Emergency Stop Button outward to resume.

8. Enter the platform and close the gate.

9. Check that the route is clear of obstacles (persons,

obstructions, debris), is level, and is capable of supporting the wheel loads.

10. Test each machine function from the upper control

station by engaging the interlock and operating the

function controls (refer to Figure 3).

11. Push the Upper Control Emergency Stop Button to

check for proper operation. All machine functions

should be disabled. Turn the Upper Control Emergency Stop Button clockwise to resume.

PUSH6/PUSH8/PUSH10 – 0120843 9

Page 12

Operation

Operation

The aerial platform may be operated from either the lower

or upper controls.

Danger

The aerial platform is not electrically insulated. Death

or serious injury will result from contact with, or inadequate clearance from, an energized conductor.

Do not go closer than the minimum safe approach

distance as defined by national safety regulations.

Pinch points may exist between moving components.

Death or serious injury will result from becoming

trapped between components, buildings, structures,

or other obstacles. Make sure there is sufficient

clearance around the machine before moving the

chassis or platform. Allow sufficient room and time

to stop movement to avoid contact with structures

or other hazards.

The aerial platform can tip over if it becomes unstable.

Death or serious injury will result from a tip-over accident. Operate the aerial platform on a firm, flat, level

surface. Engage both of the rear brakes befor entering the platform. Do not position the aerial platform

for elevated use near any drop-off, hole, slope, soft

or uneven ground, or other tip-over hazard. Do not

raise the platform in wind speeds above 0 m/s.

The platform rated work load is the total weight of the personnel and equipment that may be lifted in the platform.

The work loads are stated on the platform rating placard

at the entrance to the platform.

Danger

The aerial platform can tip over if it becomes unstable.

Death or serious injury will result from a tip-over accident. Do not exceed the capacity values indicated

on the platform rating placard.

Capacity values indicate the rated lifting capacity and do

not indicate aerial platform stability.

The operator bears ultimate responsibility for ensuring

that the aerial platform is properly set up for the particular

conditions encountered.

Preparing for Operation

Use the following procedure to prepare the aerial platform

for operation:

before the platform can be safely eleveted. Refer to

Figure 4.

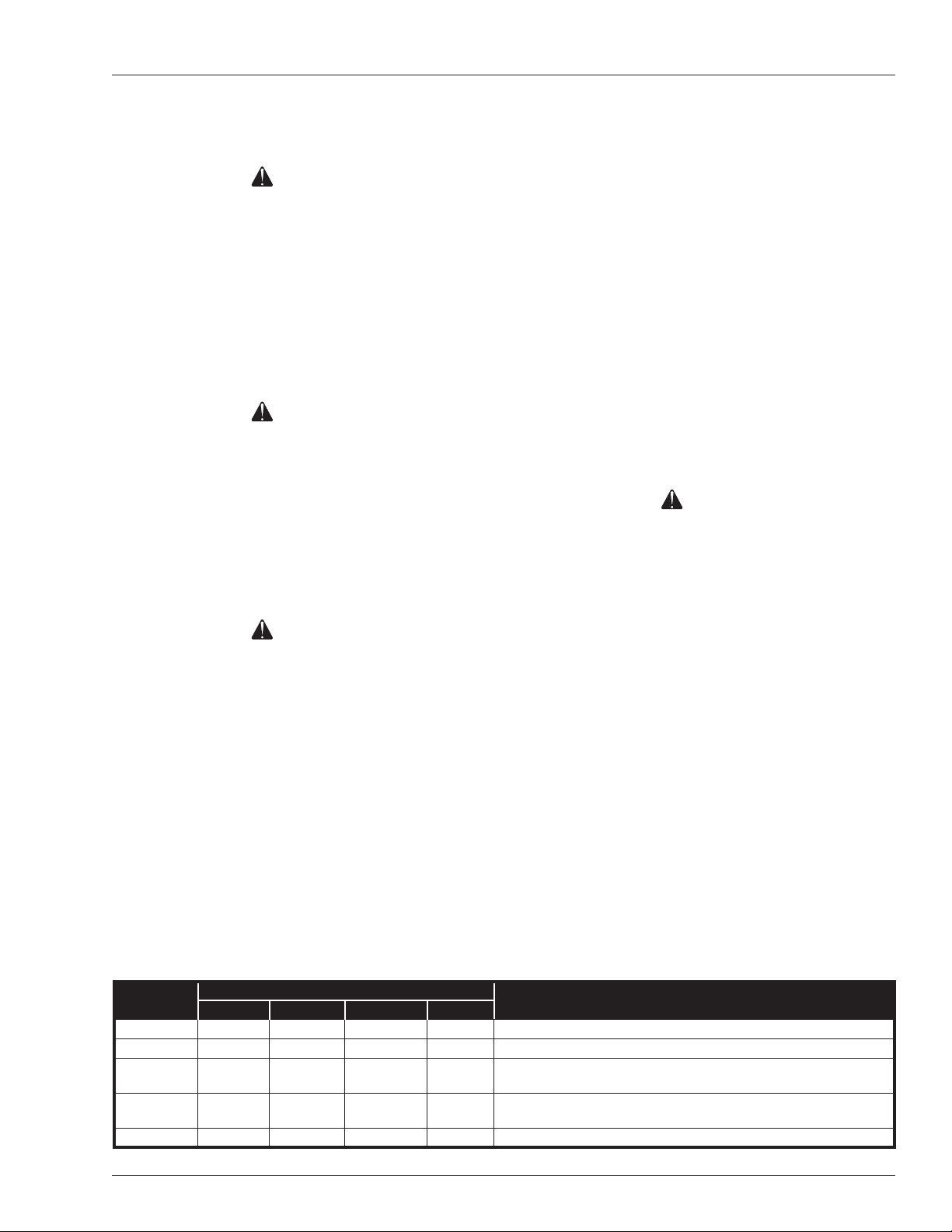

Bubble Level

Figure 4 – Rear of Chassis

4. Step down on each of the brake levers to lock the

rear wheels in position. Verify that the brakes are

engaged before entering the platform.

Lower Controls

The platform raise and lower functions may be operated

from the lower controls. The lower controls may be used

for initial set up of the aerial platform, and for testing and

inspection.

Use the following procedure to raise or lower the platform

using the lower controls.

1. Pull the emergency stop button outward (refer to

Figure 2).

2. Insert the key into the control selector switch and turn

the switch to the lower controls position.

3. Press and hold the ground operation button inward.

To raise the platform, press and hold the platform

raise button.

To lower the platform,

lower button

4. Release the button to stop movement.

.

press and hold the platform

1. Perform a pre-operation safety and system function

inspection.

2. Close and latch the component tray.

3. Position the machine in the work place and make

certain the area is flat and horizontal. The bubble

level must be inside of the inner circle on the level

10 PUSH6/PUSH8/PUSH10 – 0120843

Upper Controls

Before operating the upper controls, properly set up the

aerial platform as described under Preparing for Operation.

Use the following procedure to operate the aerial platform

from the upper controls:

Page 13

Operation

1. From the lower controls, pull the emergency stop

button outward (refer to Figure 2).

2. Insert the key into the control selector switch and turn

the switch to the upper controls position.

Note

The upper controls will not operate while the control

selector is in the lower position.

3. Enter the platform and secure the gate.

4.

From the upper controls, turn the emergency stop button clockwise to the on position (refer to Figure 3).

5.

The platform may be raised and lowered from the

upper controls.

Platform

Use care when entering and exiting the platform to avoid

slipping and/or falling. Securely close the safety gate

when the platform is occupied.

Raising and Lowering

Press and hold the interlock button on the left side of the

upper control box.

To raise the platform, press and hold the platform raise

•

button until the desired height is reached.

Component Tray

Batteries and hydraulic components are enclosed in the

component tray on the left side of the chassis.

Danger

The aerial platform can tip over if it becomes unstable.

Death or serious injury can result from a tip-over

accident. Do not open the tray when the platform is

elevated.

To open the tray, lift up on the tray latch and pull the tray

open.

Emergency Lowering

Use the following procedure to operate the emergency

lowering system.

Warning

The potential for an accident increases when safety

devices do not function properly. Death or serious

injury can result from such accidents. Immediately

push the emergency stop button inward to disable the

control system before using the emergency lowering

system in the event of an emergency.

1. Immediately push the emergency stop button inward

to disable the control system in the event of an emergency.

To lower the platform,

•

button until the desired height is reached.

Lowering Interrupt

When the platform is lowered to about 1.5 m (5′) lowering

stops. The platform will not lower for five seconds regardless of the joystick position.

Release the platform lower button to reset the lowering

function, then continue to lower the platform.

press and hold the platform lower

2. Make sure there is nothing in the way to obstruct the

platform when it lowers.

Push downward on the lever to lower the plat-

•

form.

3. Make certain the lever/handle is fully released and

the emergency lowering valve is fully closed before

operating the aerial platform.

PUSH6/PUSH8/PUSH10 – 0120843 11

Page 14

Transporting the Machine

Transporting the Machine

Preparing for Transportation

Use the following procedure to prepare the aerial platform

for transportation.

1. Remove any unnecessary tools, materials, or other

loose objects from the platform.

2. Close and latch the component tray.

Transporting

The equipment used to load, unload, and transport the

aerial platform must have adequate capacity. The empty

vehicle weight is listed in “Specifications” on pages 16 to

18 and is stamped on the serial number placard.

The user assumes all responsibility for:

Choosing the proper method of transportation.

•

Choosing the proper selection and use of transporta-

•

tion and tie-down devices.

Making sure the equipment used is capable of sup-

•

porting the weight of the aerial platform.

Making sure all manufacturer’s instructions and warn-

•

ings, regulations and safety rules of their employer,

the DOT, and/or any other state or federal law are

followed.

Lifting With a Tail Lift

Use the following procedure to lift the aerial platform with

a forklift.

1. Properly stow the aerial platform.

2. Remove all personnel, tools, materials, or other loose

objects from the platform.

3. Position the aerial platform on the tail lift.

4. Engage the brakes on both of the rear wheels.

5. Carefully raise the lift and position the aerial platform

in the transport vehicle.

6. Secure the machine to the transport vehicle using

straps through the fork lift pockets.

Lifting With a Forklift

Use the following procedure to lift the aerial platform with

a forklift.

1. Properly stow the aerial platform.

2. Engage the brakes on both of the rear wheels.

3. Remove all personnel, tools, materials, or other loose

objects from the platform.

4. Insert the forklift forks into the pockets on either side

of the machine.

Caution

Lifting the aerial platform with the forklift forks positioned improperly can produce enough force to damage machine components. When lifting the machine

with a forklift, only use the designated lift points.

5. Do not raise the aerial platform higher than necessary

to transport it. Drive the forklift slowly and carefully

when transporting the aerial platform.

12 PUSH6/PUSH8/PUSH10 – 0120843

Page 15

Maintenance

Maintenance

Warning

Always block the elevating assembly whenever it is

necessary to perform maintenance while the platform

is elevated.

Use the following procedure to properly position the

safety props:

1. Remove all tools and material from the platform.

2. Using the lower controls, raise the platform until the

open distance on the chassis is wide enough to position the safety props. Refer to Figure 5.

Safety Prop

Note

Never add fluid if the platform is elevated.

Check Hydraulic Fluid

1. Make sure that the platform is fully lowered.

2. Visually check to make sure the fluid is within 6 mm

(¼″) of the top of the fill hole.

3. If necessary, remove the filler cap and add fluid of the

proper type. Replace the cap making sure it is tightly

in place. Refer to “Specifications” pages 16 to18.

Battery Maintenance

Warning

Hazard of explosive gas mixture. Keep sparks, flame,

and smoking material away from the battery.

Always wear safety glasses when working near the

battery.

Battery fluid is highly corrosive. Thoroughly rinse

away any spilled fluid with clean water.

Always replace the battery with a manufacturer approved replacement.

Figure 5 – Safety Props

3. Rotate the safety props downward from the storage

position to the support position.

4. Remove hands and arms from the scissors area.

5. Lower the platform until the scissors are supported

by the safety props.

Hydraulic Fluid

The hydraulic fluid reservoir is located in the component

tray. Refer to Figure 6.

Reservoir Fill Cap

Check the battery uid level daily, especially if the

•

machine is being used in a warm, dry climate.

If electrolyte level is lower than 6 mm (¼″) above

•

the plates add distilled water only. DO NOT use tap

water with high mineral content, as it will shorten

battery life.

Keep the terminals and top of the battery clean.

•

Refer to the Service Manual to extend battery life and

•

for complete service instructions.

Warning

Always use manufacturer approved replacement

parts.

Battery Charging

Charge the battery at the end of each work shift or

sooner if the battery has been discharged.

Warning

Charge the battery in a well ventilated area.

Do not charge the battery when the machine is near

a source of sparks or flames.

Permanent damage to the battery will result if the

battery is not immediately recharged after discharging.

Figure 6 – Component Tray

PUSH6/PUSH8/PUSH10 – 0120843 13

Never disconnect the cables from the battery when

the charger is operating.

Page 16

Inspection and Maintenance Schedule

Keep the charger dry.

1. At the lower controls, turn the control selector switch

to the off position.

2. Open the component tray to access the battery.

Remove the caps from the battery.

3. Visually check the battery fluid level making sure the

level is within 6 mm (¼″) of the bottom of the filler neck

inside each hole. If needed, add distilled water.

4. Tightly replace the caps on each battery and replace

and latch the battery tray covers.

5. Place the battery charger mode selector, on the lower

control panel, in the appropriate position for power

source being used.

Move the toggle switch to the left for operation

on 110V circuits.

Move the toggle switch to the right for operation

on 230V240V circuits.

6. Plug the battery charger into a properly grounded

outlet (100-240 volt AC, 50/60 Hz) using a 3 conductor, 1.5 mm (12 gauge) or larger extension cord. The

extension cord must be as short as possible and in

good electrical condition.

Note

The aerial platform will not operate while the battery

charger is plugged in.

7. Visually inspect the battery charge indicator for proper

charging rate. The LED’s are visible on the left side of

the lower controls. Refer to Figure 7 for the function

of each LED. The battery should be fully charged

when the 95% LED is on.

Steady Red When Charger

Is Plugged In

25% Charge

95% Charge

Note

If the charging cycle exceeds 16 hours without the battery

being fully recharged, unplug the charger and have the

battery checked.

9. After the battery charger turns itself off, it is not necessary to immediately unplug the extension cord

from the battery charger. The charger will monitor

the charge state of the battery and recharge them if

the voltage drops off.

10. Slide the component tray open to access the battery.

Remove the caps from the battery.

11. Visually check the battery fluid level making sure the

level is within 6 mm (¼″) of the bottom of the filler neck

inside each hole. If needed, add distilled water.

12. Tightly replace the caps on the battery and close and

latch the component tray.

Inspection and Maintenance Schedule

Caution

Frequency and extent of periodic examinations may

depend on national regulations.

The Complete Inspection consists of periodic visual and

operational checks, along with periodic minor adjustments

that assure proper performance. Daily inspection will prevent abnormal wear and prolong the life of all systems.

The inspection and maintenance schedule should be

performed at the specified intervals and after prolonged

periods of storage before returning the machine to service. Inspection and maintenance shall be performed by

personnel who are trained and familiar with mechanical

and electrical procedures.

Warning

Before performing preventative maintenance, familiarize yourself with the operation of the machine.

Always block the scissors structure whenever it is

necessary to perform maintenance while the platform

is elevated.

The daily preventative maintenance checklist has been

designed for machine service and maintenance. Please

photocopy the Daily Preventative Maintenance Checklist

and use the checklist when inspecting the machine.

Flashes During Charging

Figure 7 – Battery Charge Indicator

8. Leave the battery charger plugged in until it shuts

itself off.

14 PUSH6/PUSH8/PUSH10 – 0120843

Page 17

Daily Preventative Maintenance Checklist

Preventative Maintenance Report

Daily Preventative Maintenance Checklist

Date:

Owner:

Serial No:

Serviced By:

Model No:

Item Inspect For Y N R

Operator’s Manual In manual holder, all pages readable and intact

Electrical System

Battery fluid level Proper level

Battery terminals Clean, connectors tight

Battery charge indicator Proper operation

Battery charger Proper operation

Cables and wiring harness No wear or physical damage

Hydraulic System

Fluid level Between full and add marks with platform

stowed

Hoses, tubes and fittings No leaks, all fittings tight

Castors Good condition, no damage/smooth movement

Manual Brakes Proper operation, no damage or deformation

Lower Control Station

Operating controls Proper operation

Emergency stop Shuts off lower controls/proper operation

Lowering alarm and interrupt Sounds when platform lowers/proper operation

Emergency Lowering Proper operation

Safety Prop No damage or deformation

Structures

Weldments – Scissors, chassis, steps, platform, etc. Welds intact, no damage or deformation

Platform slide rollers In place, no damage or deformation

Fasteners In place, tight, and no damage

Upper Control Station

Guardrail system Welds intact, no damage or deformation

All fasteners in place, no loose or missing parts

Platform floor No damage or deformation

Clean to prevent slip and fall hazards

Entry gate Proper operation, no damage or deformation

Operating controls Proper operation/raise and lower

Lowering delay Proper operation, limit switch delays lowering

Emergency stop Shuts off upper controls

Operation and Safety Decals In place and readable

Maintenance Table Key: Y = Yes/Acceptable, N = No/Not Acceptable, R = Repaired/Acceptable

PUSH6/PUSH8/PUSH10 – 0120843 15

Page 18

Specications

General Specications – PUSH6

Aerial Platform

Working height 3.83 m

Maximum platform height 1.83 m

Wheelbase 1 m

Ground clearance 1.9 cm

Maximum wheel load 267 kg

Maximum ground pressure 10.4 kg/cm²

Floor loading 782 kg/m²

Weight, EVW

Approximate 295 kg

Stowed width 76.2 cm

Stowed length 1.23 m

Stowed height 1.59 m

Platform

Dimensions 51.3 cm x 109 cm

Guardrail height 110.4 cm

Toeboard height 15.3 cm

Rated work load 240 kg

Maximum number of occupants 1 indoors

Function Speed

Platform raise 6 to 10 seconds

Platform lower 6 to 10 seconds

Lift Level Sensor Interlock

Side-to-side 2 degrees

Front-to-rear 2 degrees

Electrical System

Voltage 12 V DC negative chassis ground

Source One - 12 V 105 amp hour battery

Fluid recommended distilled water

Charger 15 amp

Hydraulic System

Maximum pressure 19,305 kPa

Reservoir capacity 3.78 l

System capacity 3.78 l

Maximum operating temperature 71°C (160°F)

Hydraulic fluid recommended

Above -13°C (10°F) ISO VG32 (Mobil DTE-13M)

Below -13°C (10°F) ISO VG15 (Mobil DTE-11M)

Ambient Air Temperature Operating Range

Celsius -18°C to 43°C

Fahrenheit 0°F to 110°F

Maximum Wind Speed

Gust or steady 0 m/s

Vibration less than 2.5 m/sec²

Sound Pressure Level

At work station below 70 dB(A)

Tires Nonmarking solid rubber

16 PUSH6/PUSH8/PUSH10 – 0120843

Page 19

General Specications – PUSH8

Specications

Aerial Platform

Working height 4.43 m

Maximum platform height 2.43 m

Wheelbase 1 m

Ground clearance 1.9 cm

Maximum wheel load 287 kg

Maximum ground pressure 11.1 kg/cm²

Floor loading 835 kg/m²

Weight, EVW

Approximate 331 kg

Stowed width 76.2 cm

Stowed length 1.23 m

Stowed height 1.67 m

Platform

Dimensions 51.3 cm x 109 cm

Guardrail height 110.4 cm

Toeboard height 15.3 cm

Rated work load 240 kg

Maximum number of occupants 1 indoors

Function Speed

Platform raise 6 to 12 seconds

Platform lower 8 to12 seconds

Lift Level Sensor Interlock

Side-to-side 2 degrees

Front-to-rear 2 degrees

Electrical System

Voltage 12 V DC negative chassis ground

Source One - 12 V 105 amp hour battery

Fluid recommended distilled water

Charger 15 amp

Hydraulic System

Maximum pressure 19 305 kPa

Reservoir capacity 3.78 l

System capacity 3.78 l

Maximum operating temperature 71°C (160°F)

Hydraulic fluid recommended

Above -13°C (10°F) ISO VG32 (Mobil DTE-13M)

Below -13°C (10°F) ISO VG15 (Mobil DTE-11M)

Ambient Air Temperature Operating Range

Celsius -18°C to 43°C

Fahrenheit 0°F to 110°F

Maximum Wind Speed

Gust or steady 0 m/s

Vibration less than 2.5 m/sec²

Sound Pressure Level

At work station below 70 dB(A)

Tires Nonmarking solid rubber

PUSH6/PUSH8/PUSH10 – 0120843 17

Page 20

Specications

General Specications – PUSH10

Aerial Platform

Working height 5 m

Maximum platform height 3.0 m

Wheelbase 1 m

Ground clearance 1.9 cm

Maximum wheel load 293 kg

Maximum ground pressure 11.4 kg/cm²

Floor loading 855 kg/m²

Weight, EVW

Approximate 345 kg

Stowed width 76.2 cm

Stowed length 1.23 m

Stowed height 1.67 m

Platform

Dimensions 51.3 cm x 109 cm

Guardrail height 110.4 cm

Toeboard height 15.3 cm

Rated work load 240 kg

Maximum number of occupants 1 indoors

Function Speed

Platform raise 10 to14 seconds

Platform lower 10 to14 seconds

Lift Level Sensor Interlock

Side-to-side 2 degrees

Front-to-rear 2 degrees

Electrical System

Voltage 12 V DC negative chassis ground

Source One - 12 V 105 amp hour battery

Fluid recommended distilled water

Charger 15 amp

Hydraulic System

Maximum pressure 19,305 kPa

Reservoir capacity 3.78 l

System capacity 3.78 l

Maximum operating temperature 71°C (160°F)

Hydraulic fluid recommended

Above -13°C (10°F) ISO VG32 (Mobil DTE-13M)

Below -13°C (10°F) ISO VG15 (Mobil DTE-11M)

Ambient Air Temperature Operating Range

Celsius -18°C to 43°C

Fahrenheit 0°F to 110°F

Maximum Wind Speed

Gust or steady 0 m/s

Vibration less than 2.5 m/sec²

Sound Pressure Level

At work station below 70 dB(A)

Tires Nonmarking solid rubber

18 PUSH6/PUSH8/PUSH10 – 0120843

Page 21

Page 22

Local Distributor:

Lokaler Vertiebshändler:

Distributeur local:

El Distribuidor local:

ll Distributore locale:

USA

Phone: 1 (785) 989 3000

Toll Free: 1 (800) 255 0317

Fax: 1 (785) 989 3070

Europe

Phone: +44 (0) 845 1550 057

Fax: +44 (0) 845 1557 756

Loading...

Loading...