Snap-On POLARTEK HYBRID EEAC332, POLARTEK PLUS EEAC331, POLARTEK EEAC330, POLARTEK YF EEAC333 User Manual

EEAC332

R134a Refrigerant

Recovery / Recycle / Recharge

Service Hybrid and Non-Hybrid

Vehicle A/C System

INTRODUCTION

Snap-on® Model No. EEAC332 is ETL Laboratories approved, in compliance with SAE J2788. We are dedicated to solving the issues

surrounding the safe containment and proper management of refrigerants. Your new machine incorporates the latest technology

and state of the art features to aid you in servicing R134a air conditioning and refrigeration systems. We hope you get as much

enjoyment using this equipment as we did designing and building it.

MANUEEAC.332 ED.8

• 1 •

• 2 •

INDEX

INDEX ....................................................................3

SAFETY ..................................................................5

SAFETY SIGNAL WORDS ................................................... 5

SAFETY INFORMATION ..................................................... 5

EXPLOSION HAZARDS 5

HEAT/FREEZING HAZARDS 5

GENERAL SAFETY MESSAGES 6

FUME HAZARDS 6

ADDITIONAL SAFETY INFORMATION 6

HOSES CONNECTION ........................................................ 7

SAFETY DEVICES 7

REFRIGERANT AND LUBRICANT - PERSONAL

PROTECTIVE EQUIPMENT AND PRECAUTIONS ............ 7

PRECAUTIONS FOR HANDLING AND USE OF R134a

FLUIDS .................................................................................. 7

SETUP ....................................................................8

COUNTERS ........................................................................... 8

ALARMS .............................................................. 15

ERROR MESSAGES ............................................. 16

PRELIMINARY OPERATIONS ............................. 17

AUTOMATIC PROCEDURE ................................. 18

EDIT VACUUM DATA ....................................................... 18

EDIT CHARGE AMOUNT DATA ...................................... 18

EDIT CHARGE MODE ....................................................... 18

START AUTOMATIC PROCEDURE ................................. 19

MANUAL PROCEDURE ....................................... 21

RECOVERY/RECYCLING ................................................... 21

VACUUM ............................................................................ 22

FLUSHING HOSES ............................................................. 24

CHARGE .............................................................................. 24

EDIT CHARGE DATA 24

EDIT CHARGE MODE 25

START PROCEDURE 25

LANGUAGE .......................................................................... 8

MEASURE UNITS ................................................................. 8

PLATE NUMBER ................................................................... 8

QUICKSETUP ........................................................................ 9

SET DATE / TIME .................................................................. 9

SETUP HEADER PRINT ....................................................... 9

VACUUM SETTINGS ........................................................... 9

INTRODUCTION ................................................. 10

CERTIFICATION ................................................................. 10

ABOUT THIS MANUAL ..................................................... 10

ABOUT YOUR AIR CONDITIONING SERVICE CENTER 10

GENERAL INFORMATION .................................. 11

PRINCIPLES OF OPERATION ............................. 11

THE MACHINE .................................................... 12

SERVICES ............................................................ 26

SEARCH BY PLATE ............................................................ 26

SEARCH BY DATE .............................................................. 27

EXTRACT ARCHIVE ........................................................... 27

MAINTENANCE .................................................. 28

A/C PRESSURES CHECK ................................................... 28

AIR PURGE MANUAL ........................................................ 30

CALIBRATION .................................................................... 30

CHANGE DRYER FILTER ................................................... 31

DATABASE ......................................................................... 33

EMPTY HOSES ................................................................... 33

MAINTENANCE REPORT.................................................. 34

SERVICES ARCHIVE ........................................................... 34

TANK CELL CHECK ............................................................ 34

TANK FILLING .................................................................... 35

PLASTIC COVER ................................................................. 12

CONTROL PANEL .............................................................. 13

LIGHT SIGNALS 13

DISPLAY ICONS .................................................. 13

BASIC COMPONENTS ........................................ 14

VACUUM PUMP OIL CHANGE ........................................ 36

VACUUM PUMP ................................................................ 36

EMPTYING THE USED OIL CONTAINER ........................ 38

REPLACING THE PRINTER PAPER .................................. 39

INFO .................................................................... 39

• 3 •

WARRANTY ........................................................ 40

NOTES ................................................................ 41

• 4 •

SAFETY

The following safety information is provided as guidelines to

help you operate your new system under the safest possible

conditions. Any equipment that uses chemicals can be

potentially dangerous to use when safety or safe handling

instructions are not known or not followed. The following safety

instructions are to provide the user with the information

necessary for safe use and operation. Please read and retain

these instructions for the continued safe use of your service

system.

SAFETY SIGNAL WORDS

All safety messages contain a safety signal word that indicates

the level of the hazard. An icon, when present, gives a graphical

description of the hazard.

Safety Signal words are:

Danger

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury to the operator or to

bystanders.

Warning

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury to the operator or to

bystanders.

Caution

Indicates a potentially hazardous situation which, if not avoided,

may result in moderate or minor injury to the operator or to

bystanders.

SAFETY INFORMATION

Every craftsman respects the tools with which they work. They

know that the tools represent years of constantly improved

designs and developments. The true craftsman also knows that

tools are dangerous if misused or abused. To reduce risk of

discomfort, illness, or even death, read, understand, and follow

the following safety instructions. In addition, make certain that

anyone else that uses this equipment understands and follows

these safety instructions as well.

READ ALL SAFETY INFORMATION CAREFULLY before attempting

to install, operate, or service this equipment. Failure to comply

with these instructions could result in personal injury and/or

property damage.

RETAIN THE FOLLOWING SAFETY INFORMATION FOR FUTURE

REFERENCE.

requirements also provide a basis for equipment installation, use,

and service.

The following safety alert symbols identify important safety

messages in this manual.

When you see one of the symbols shown here, be alert to the

possibility of personal injury and carefully read the message that

follows.

EXPLOSION HAZARDS

Warning

Risk of explosion

Do not fill the tank to more than 80% of the

maximum capacity.

Explosion can cause death or personal injury.

HEAT/FREEZING HAZARDS

Warning

Risk of personal injury

Handle refrigerants and pressure vessles

with caution.

Wear safety glasses, gloves, and suitable

clothing.

Avoid contact with the skin.

Avoid breathing A/C refrigerant and

lubricant vapor mist.

Contact with refrigerant can cause health risks,

blindness, and other physical damage (frostbite) and

possibly death.

Risk of personal injury and equipment damage

Always use an identifier before recovering

refrigerent from a vehicle.

Recover only the refrigerent the product

was certified to be used with.

Recovery of refrigerents other than the one the unit

was certified for may cause injury, equipment

damage and possible death. Alternate refrigerants

may contain flammables such as butane or propane

and can explode or cause a fire.

Published standards on safety are available and are listed at the

end of this section under ADDITIONAL SAFETY INFORMATION.

The National Electrical Code, Occupational Safety and Health Act

regulations, local industrial codes and local inspection

• 5 •

y

v

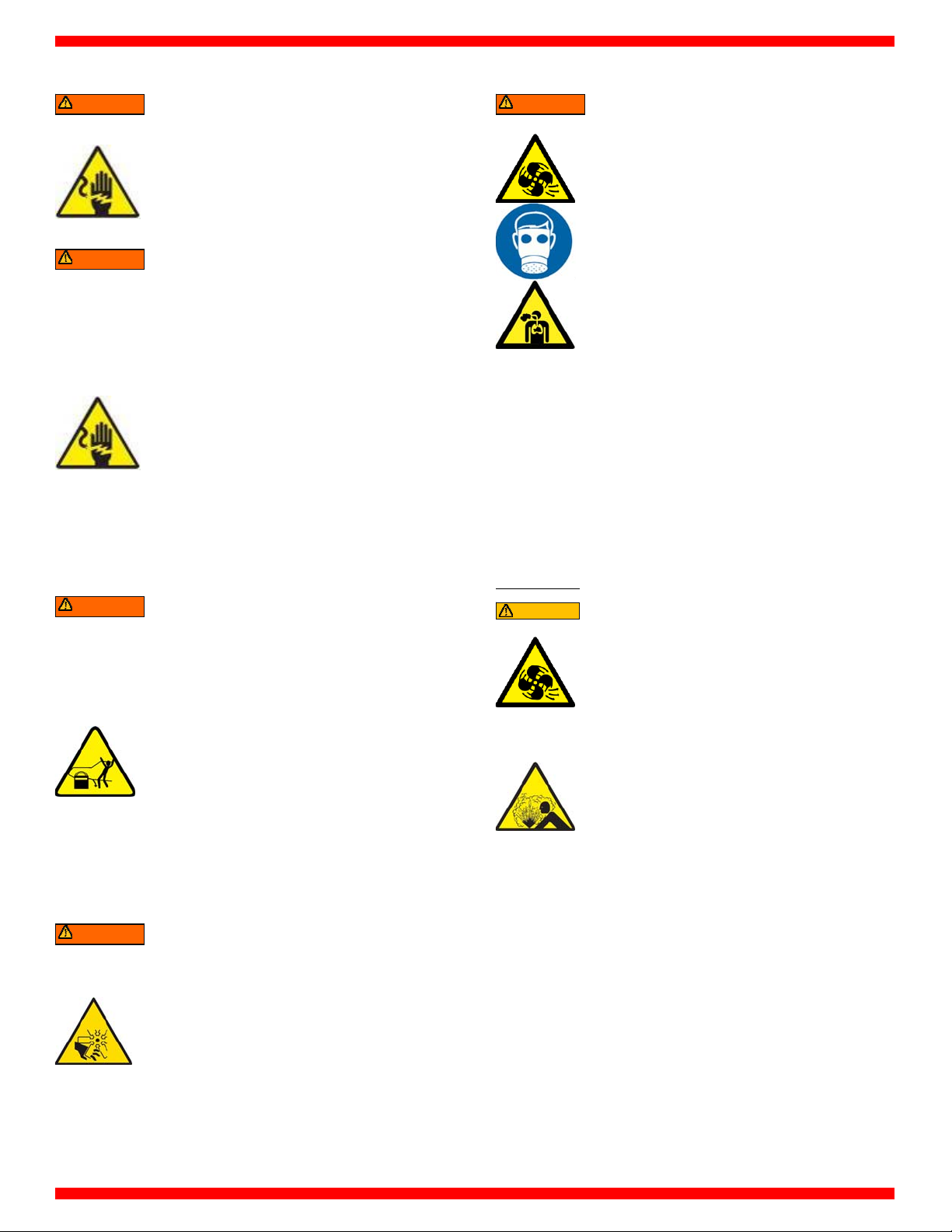

GENERAL SAFETY MESSAGES

Warning

Warning

Warning

Warning

Risk of electric shock

Unplug unit before attempting any

maintenance or cleaning.

Do not operate unit with damaged cord or

plug.

Electric shock can cause injury or death.

Risk of equipment or circuit damage

Always unplug equipment from electrical

outlet when not in use.

Never use the cord to pull plug from an

outlet. Grasp the plug and pull it to

disconnect.

If an extension cord is necessary, a cord with

a current rating equal to or more than the

equipment should be used. Cords rated for

less current may overheat.

DO NOT adapt your unit for a different

refrigerant — system failure will result.

R134a systems have special fittings (per SAE

specifications) to avoid cross contamination.

Improper use of equipment can cause equipment or

circuit damage.

Risk of unexpected vehicle movement

Block drive wheels with chocks before

performing a test with engine running.

Unless instructed otherwise, set parking

brake, and put gear selector in neutral or

park.

If the vehicle has an automatic parking

brake release, disconnect the release

mechanism for testing and reconnect when

finished.

Do not allow bystanders to stand in front of

or behind the vehicle while testing.

Do not leave a running engine unattended.

A moving vehicle can cause death or serious injury.

Risk of personal injur

Keep yourself, clothing and other objects

clear of hot or moving parts.

Keep hoses and cords clear of moving parts.

Do not wear watches, rings, or loose

clothing when working in an engine

compartment.

Contact with hot or moving parts can cause injury.

FUME HAZARDS

Warning

Risk of fume, gas, and vapor hazards

Avoid breathing A/C refrigerant and

lubricant vapor mist.

Always perform vehicle service in a properly

ventilated area.

Never run an engine without proper

ventilation for its exhaust.

Fume, gas, and vapors can cause irritation to eyes,

nose, and throat, cause illness or death.

ADDITIONAL SAFETY INFORMATION

For additional information concerning safety, refer to the

following standards.

ANSI Standard Z87.1 — SAFE PRACTICE FOR OCCUPATION AND

EDUCATIONAL EYE AND FACE PROTECTION - obtainable from

the American National Standards Institute, 11 West 42nd St., New

York, NY 10036, Telephone (212) 642-4900, Fax (212) 398-0023 www.ansi.org

Caution

NOTE: Use only new lubricant to replace the amount

removed during the recycling process. Used lubricant

should be discarded per applicable federal, state, and local

requirements.

The manufacturer shall not be responsible for any additional

costs associated with a product failure including, but not

limited to, loss of work time, loss of refrigerant, cross

contamination of refrigerant, and unauthorized shipping

and/or labor charges.

Risk of

Must have at least four air changes per hour

Poor ventilation can cause irritation to eyes, nose,

and throat, illness, or death.

Risk of explosion

Do not pressure test or leak test R134a

Explosion can cause injury or death.

entilation hazards

or equipment should be located at least 18”

(457 mm) above the floor.

equipment and/or vehicle air conditioning

systems with compressed air.

• 6 •

y

y

Danger

Warning

Risk of explosion

Ensure that you are only recovering from the

fitting on the AC system.

Some car manufacturers on the fuel intake

manifold install a connector identical to the

A/C low pressure fitting.

Explosion can cause injury or death.

Risk of personal injur

Do not operate equipment with damaged

cord or hoses.

Do not operate the unit if it has been

damaged until it has been examined by a

qualified service personnel.

Damaged parts can cause injury or death.

HOSES CONNECTION

Hoses may contain refrigerant under pressure. Before

disconnecting the quick coupler verify the corresponding

pressure in the service hoses (gauge).

SAFETY DEVICES

REFRIGERANT AND LUBRICANT PERSONAL PROTECTIVE EQUIPMENT

AND PRECAUTIONS

Warning

Risk of personal injur

Handle refrigerants and pressure vessles

with caution.

Wear safety glasses, gloves, and suitable

clothing.

Avoid contact with the skin.

Contact with refrigerant can cause health risks,

blindness, and other physical damage (frostbite).

Risk of equipment damage and personal injury

Should be operated by certified personnel.

Do not remove the seals of the safety valves

and control systems.

Do not use external tanks or other storage

containers that are not approved.

Do not block air vents and ventilation

equipment.

Improper use of equipment can cause equipment

damage and personal injury.

The machine is equipped with the following safety devices:

SAFETY PRESSURE SWITCH: Stops the compressor in case of

excessive pressure.

SAFETY VALVE: Opens when the pressure inside the system

reaches a level of pressure above the estimated limits.

MAIN SWITCH: Connects and disconnects machine AC electrical

power. Disconnect main power cord from electrical power

sourcebefore servicing.

ANY KIND OF TAMPERING OF THE SAFETY DEVICES

MENTIONED ABOVE IS NOT ALLOWED.

PRECAUTIONS FOR HANDLING AND USE

OF R134a FLUIDS

Warning

Risk of personal injury. Risk for handling pressurized R134a

containers

Avoid inhaling highly concentrated vapors.

Avoid use of R134a near open flames and incandescent

elements.

Wear protective garments such as to ensure that no jets

of liquid or gas can come into contact with the skin.

Wear goggles to avoid contact with the eyes.

Avoid dispersing the R134a refrigerant fluid utilized in the

machine into the atmosphere.

Mishandling of pressurized R134a containers can cause loss of

Consciousness, injury or death.

• 7 •

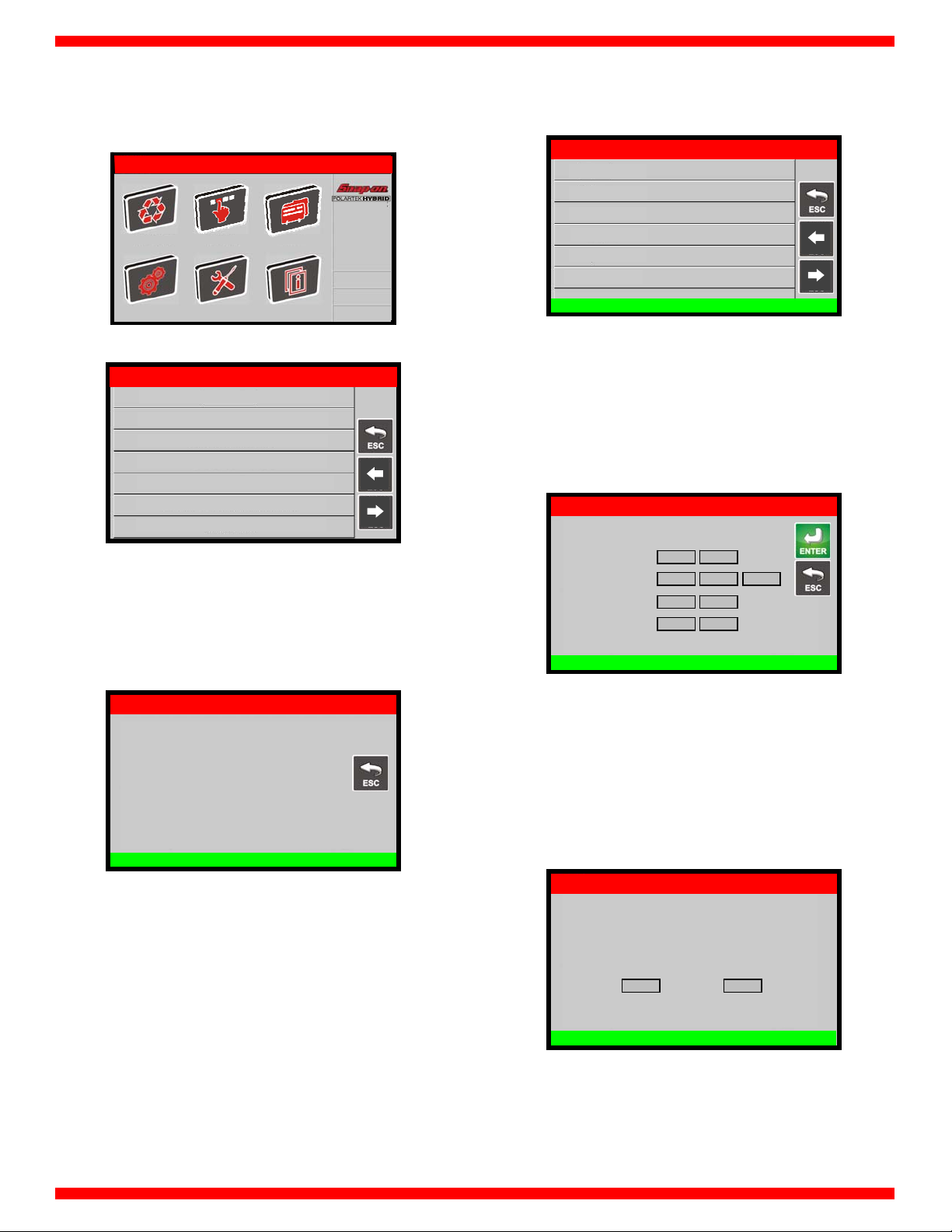

SETUP

From the MAIN MENU:

R134a

AUTOMATIC MANUAL SERVICES

xxxxxxx

hh:mm

SETUP MAINTENANCE INFO

Select the SETUP, the following screen will be displayed:

R134a SETUP

COUNTERS

LANGUAGE

MEASURE UNITS

PLATE NUMBER

QUICKSETUP

SET DATE / TIME

SETUP HEADER PRINT

COUNTERS

mm/dd/yyyy

PREV

PAGE

NEXT

PAGE

LANGUAGE

From the SETUP, select LANGUAGE :

R134a SETUP

English

Français

Espanol

LANGUAGE

PREV

PAGE

NEXT

PAGE

NOTE: Current language is indicated by red dot.

Select a language, the unit will change the language in few

seconds.

MEASURE UNITS

From the SETUP MENU, select MEASURE UNITS, the following

screen is displayed:

R134a SETUP

Pressure

Weight

Temperature

Volume

SETTINGS

bar psi

g lb lb: oz

°C °F

ml oz

From the SETUP MENU, select COUNTERS, the following screen is

displayed:

R134a SETUP

Recovered gas xxx lb

Service xxx lb

Filter xx %

Vacuum xxx min

Charged gas xxx lb

Tank filling xx lb

COUNTERS

This screen displays the total values for: gas recovered, service

alarm counters, filter status, total vacuum time (minutes), gas

injected, and gas recovered in the internal tank using the “Tank

filling” function.

MEASURE UNITS

Select the unit of measurement to change, then select between

international system of units (SI) and imperial system units (IMP).

When finished press ENTER to exit. The machine will reboot to

update measure units.

PLATE NUMBER

From the SETUP MENU, select PLATE NUMBER, the following

screen is displayed:

R134a SETUP

ACTIVATE PLATE NUMBER

ON OFF

Select ON to visualize insert plate screen during automatic or

manual procedures, or OFF to skip this screen.

PLATE NUMBER

• 8 •

V

QUICKSETUP

The first time the machine is used, a quick startup guide appears:

the operator is guided through the steps described at the start of

the PRELIMINARY OPERATIONS section. From the SETUP MENU,

select QUICKSETUP, the following screen is displayed:

R134a SETUP

Welcome to POLARTEK Quick Setup

Press ENTER to proceed

Press ENTER to proceed with QUICKSETUP, the user will be

guided throught the following steps:

Language selection

Measure units selection

License plate recording

Date and time selection

Setup header print

Vacuum settings

Leak check test

Tank filling

Press ESC to exit.

QUICKSETUP

SETUP HEADER PRINT

The printout can be personalized by entering 4 lines containing

the workshop’s details (e.g. name, address, telephone number

and e-mail).

From the SETUP, select SETUP HEADER PRINT:

R134a SETUP

SETUP HEADER PRINT

Use the keypad to modify the 4 lines, then press ENTER to return

to SETUP menu.

NOTE: the numerical keys include an alphabet that is used

similar to text messaging; for example: press “2” once to display

“2”, twice to display “A”, three times for “B”, four times for “C”, five

times for “a”, six times for “b”, seven times for “c”, eight times for

“2” again.

Follow the instructions displayed. At the end of the procedure,

press ENTER to print a summary report of the guided procedure.

Press ESC to exit.

NOTE: If the guided procedure is not completed, it will be

displayed again the next time the machine is switched on.

NOTE: To display the QUICKSETUP at any time, select from the

menu of the same name under SETUP.

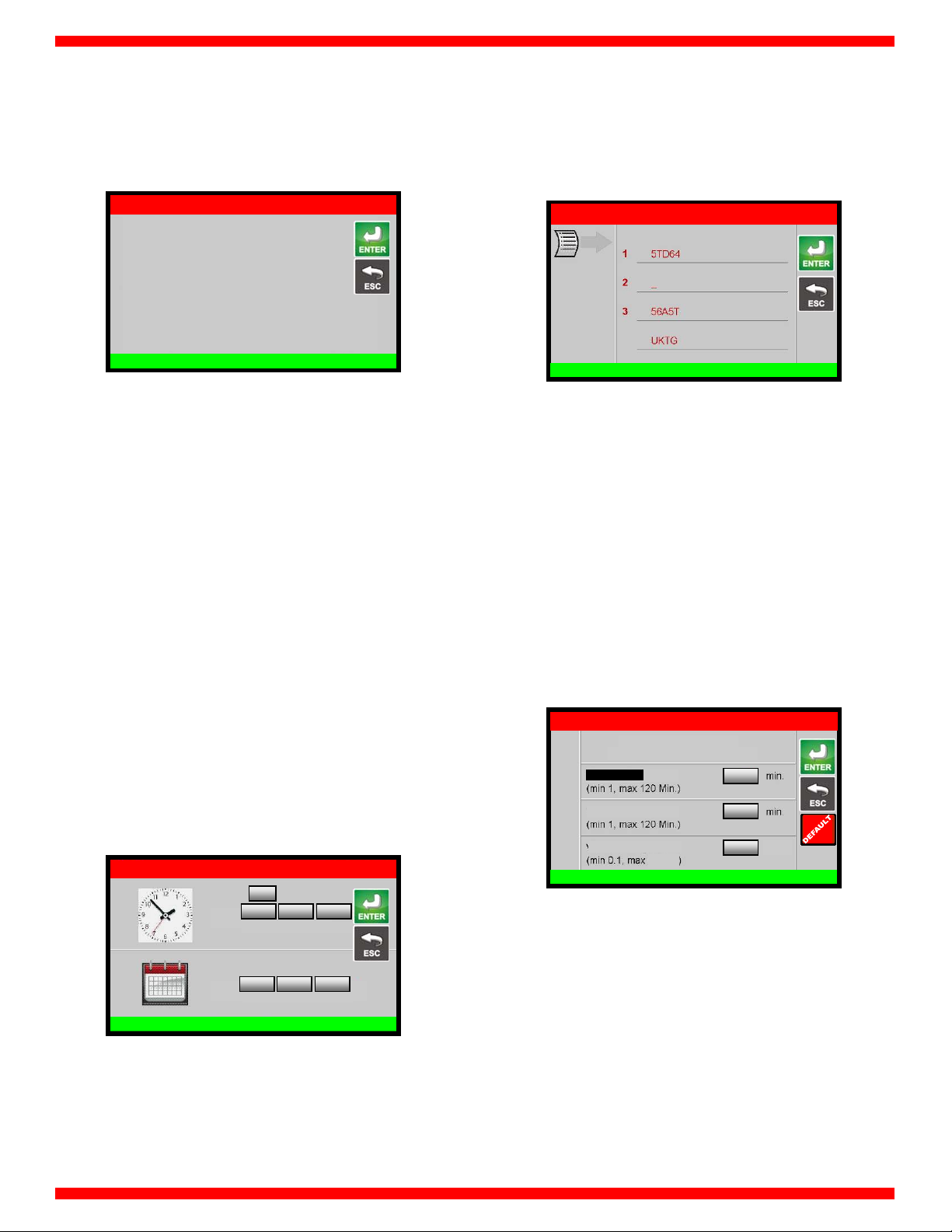

SET DATE / TIME

The machine keeps date and time settings even if it is not used

for around one year. From the SETUP MENU, select SET DATE /

TIME:

R134a SETUP

PM

Time

Date

Use keypad to change date and time. Press ENTER to confirm, or

press ESC to return to SETUP menu without saving the changes.

For example, to insert the date January 21

month then type “1” using the keypad, select the day then type

“21” using the keypad, select the year then type “2015” using the

keypad; press ENTER to confirm and exit.

xx xx xx

Hours Minutes Seconds

xx xx xxxx

Month Day Year

SET DATE / TIME

st

2015, select the

VACUUM SETTINGS

Allows to modify the default vacuum time and the default time

of check.

From the SETUP, select VACUUM SETTINGS, default setting is

displayed:

R134a SETUP

ACUUM SETTINGS

Pressing INFO set default values

Vacuum Time

Time of check

Vacuum rising

9 psi

VACUUM SETTINGS

xx

xx

xx

psi

Each value can be modified, within the values shown in

parentheses.

NOTE: Press DEFAULT to restore default values:

Vacuum time 25 min

Time of check 2 min

Vacuum rising 1 psi

• 9 •

INTRODUCTION

ABOUT YOUR AIR CONDITIONING

SERVICE CENTER

Snap-on® Model No. EEAC332 is ETL Laboratories approved, in

compliance with SAE J2788. We are dedicated to solving the

issues surrounding the safe containment and proper

management of refrigerants. Your new machine incorporates the

latest technology and state of the art features to aid you in

servicing R134a air conditioning and refrigeration systems. We

hope you get as much enjoyment using this equipment as we

did designing and building it.

CERTIFICATION

All technicians opening the refrigeration circuit in automotive air

conditioning systems must now be certified in refrigerant

recovery and recycling procedures to be in compliance with

Section 609 of the Clean Air Act Amendments of 1990. For

information on certification call MACS Worldwide at (215) 631-

7020.

ABOUT THIS MANUAL

CAUTION

This manual includes a safety summary,

machine preparation for use, operation

procedures, and maintenance instructions, for

your Air Conditioning Service Center.

Your machine incorporates a highly accurate electronic scale for

determining charging weights, etc. Other functions can also be

performed with the electronic scale as you will discover during

the operating procedures. Either standard or metric units of

measure can be selected. This machine is a piece of equipment

designed to recover R134a from air conditioning systems (A/C)

for vehicles, to operate within the objectives of the Montreal

Protocol.

Anyone intending to use the machine should

become familiar with ALL the information

included in this manual (especially the safety

summary) before attempting to use it.

Before operating this machine for the first time, perform all

preparation for use instructions.

If your new machine is not properly prepared to perform a

service, your service data could be erroneous. In order to

properly perform a complete air conditioning service, follow all

procedures in the order presented. Please take the time to study

this manual before operating the machine. Then keep this

manual close at hand for future reference. Please pay close

attention to the safety summary and all warnings and cautions

provided throughout this manual. To activate the published

warranty, mail the attached warranty card.

CAUTION

The machine is intended for indoor use only.

• 10 •

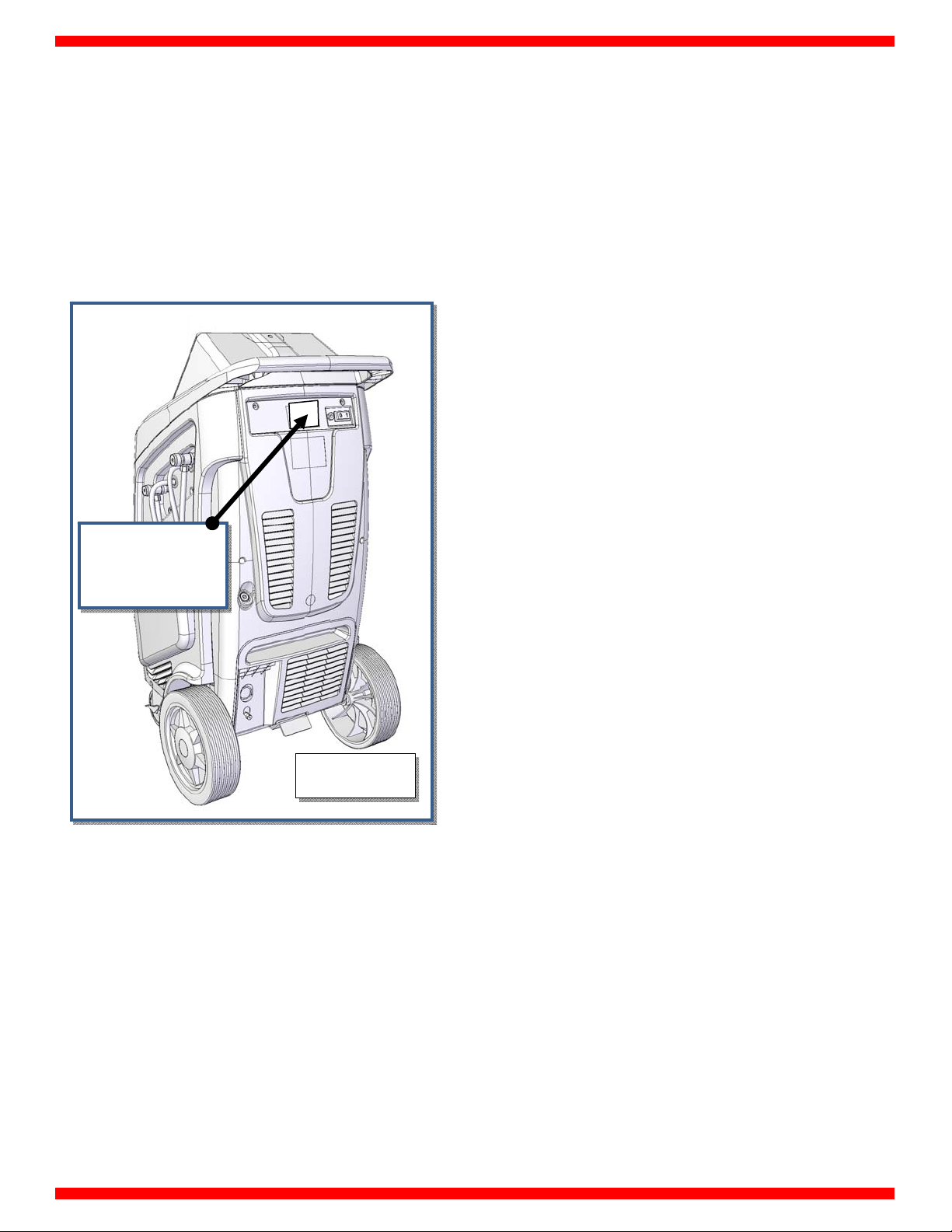

GENERAL INFORMATION

Machine model information are printed on the data plate (see

Fig. 1). Overall machine dimensions:

Height: 47" (120 cm)

Width: 25" (64 cm)

Depth: 25" (64 cm)

Weight: 200 lbs (90 kg)

Operating temperature 50/122°F (10/50°C)

Storage temperature -13/122°F (-25/50°C)

PRINCIPLES OF OPERATION

In a single series of operations, the machine permits recovering

and recycling R134a refrigerant fluids with no risk of releasing the

fluids into the environment, and also permits purging the A/C

system of humidity and deposits contained in the oil.

The machine is in fact equipped with a built-in

evaporator/separator that removes oil and other impurities from

the refrigerant fluid recovered from the A/C system and collects

them in a container for that purpose.

The fluid is then filtered and returned perfectly recycled to the

tank installed on the machine.

The machine also permits running certain operational and seal

tests on the A/C system.

NAMEPLATE

FIG. 1

Like any equipment with moving parts, the machine inevitably

produces noise. The construction system, panelling, and special

provisions adopted by the Manufacturer are such that during

work, the average noise level of the machine is not in excess of

64 dB (A).

• 11 •

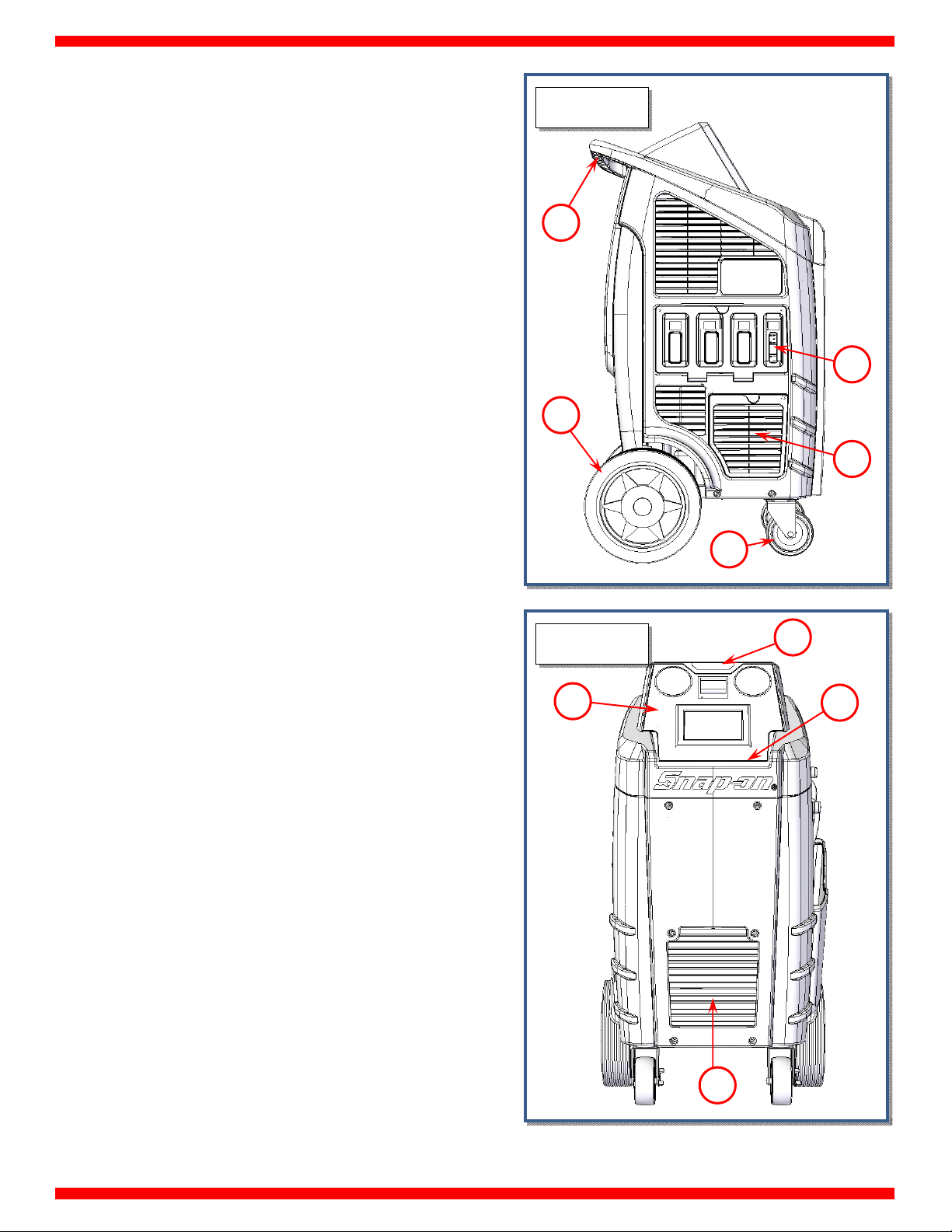

THE MACHINE

PLASTIC COVER

Refer to Fig. 4a .

1) Upper plastic body

2) Frontal body shell

Disassembly: Screw off 6 screws marked (+)

3) Right side body shell

Disassembly: Remove frontal and rear body shell, both

right doors and then screw off 8 screws marked (+)

4) Right upper door

5) Right bottom door

3

+

Refer to Fig. 4b.

6) Rear body shell

Disassembly: Remove rear bottom door, then screw off

6 screws marked (+)

7) Left side body shell

Disassembly: Remove frontal and rear body shell, then

screw off 10 screws marked (+)

+

6

+

5

FIG. 4a

+

+

+

1

+

+

FIG.4b

+

+

+

+

2

• 12 •

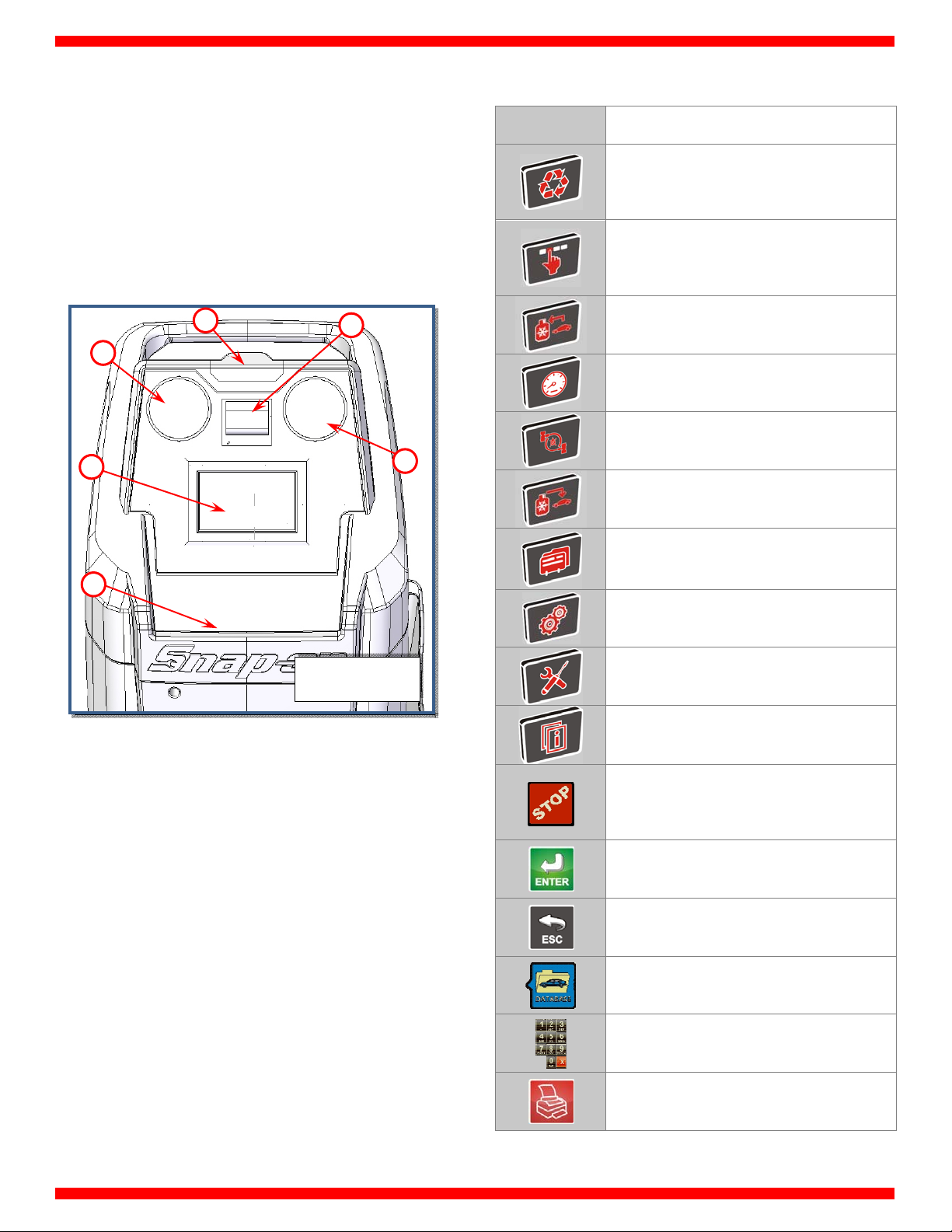

CONTROL PANEL

Refer to Fig. 5:

1) Low pressure gauge

2) High pressure gauge

3) Printer

4) 7” touch color display

5) Tool tray

6) Status light

6

1

4

3

DISPLAY ICONS

ICON DESCRIPTION

AUTOMATIC PROCEDURE: Activates a menu

that helps the user set up an automatic

recover/vacuum/leak test/charge sequence

MANUAL PROCEDURE: Activates a menu

that helps the user to perform a manual

operation

RECOVERY: Activates a menu that helps the

user to perform a recovery/recycling phase

VACUUM: Activates a menu that helps the

user to perform a vacuum phase

FLUSHING HOSES: Activates a menu that

2

helps the user to perform a flushing hoses

CHARGE: Activates a menu that helps the

user to perform a gas charge phase

5

FIG. 5

LIGHT SIGNALS

The machine is provided with a STATUS Light (ref 6, Fig. 5).

Light signals are the following:

GREEN (STEADY): Unit ready

GREEN (FLASHING): Action completed

YELLOW: Unit working

RED: Needs attention or there is a problem

SERVICES: Activates services menu

SETUP: Activates the setup menu of the

service station

MAINTENANCE: Activates the maintenance

menu of the service station

INFO: Activates a menu that contains all the

information of the service station

STOP: Terminates a procedure or operation,

silences the audible alarm or returns to the

previous screen

ENTER: Confirm a procedure or operation

shown on the display

ESC: Return back to previous menu

DATABASE: Activate database menu

KEYPAD: Numerical keypad (includes an

alphabet that is used to text messaging)

PRINTER: To print the receipt of the

procedure

• 13 •

BASIC COMPONENTS

Refer to Fig. 7, Fig. 8, Fig. 9, Fig. 10:

a) Handle

b) Rear wheel

c) Front swirling wheel

d) Filter dryer panel access

e) Used oil container

f) Capsizable control panel

g) Status light

h) Tool tray

i) Ventilation grid

j) Service hoses pocket

k) Oil pump filling cap

l) Drive up pedal

m) Magnet for reference weight

n) Circuit breaker

o) Power cord exit

p) HP service hose outlet

q) HP quick connection

r) USB port

s) LP service hose outlet

t) LP quick connection

FIG.7

a

b

FIG.8

f

e

d

c

g

h

i

• 14 •

Loading...

Loading...