Page 1

User Manual

Scope MultimeterGuided Component

Tests

Tools

OBD-II/EOBD

Previous Vehicles

and Data

Scanner

TSBs

ZEEMSGB341A Rev. A

Page 2

Legal Information

IMPORTANT:

Trademarks

Snap-on, ShopStream Connect, and MODIS are trademarks registered in the United States and other countries, of

Snap-on Incorporated. All other marks are trademarks or registered trademarks of their respective holders.

Copyright Information

© 2016 Snap-on Incorporated. All rights reserved.

Disclaimer of Warranties and Limit ation of Liabilities

All pictures and illustrations shown are for reference purposes only. All information, specifications and illustrations in

this manual are based on the latest information available at the time of printing and are subject to change without

notice. While the authors have taken due care in the preparation of this manual, nothing contained herein:

• Modifies or alters in any way the standard terms and conditions of the purchase, lease, or rental agreement

under the terms of which the equipment to which this manual relates was acquired.

• Increases in any way the liability to the customer or to third parties.

Snap-on

®

reserves the right to make changes at any time without notice.

Before operating or maintaining this unit, please read this manual carefully paying extra attention to the safety

warnings and precautions.

Contact Information (United Kingdom)

Visit our websites at:

https://www1.snapon.com/diagnostics/UK/Diagnostics.htm

ShopStream Connect

https://www1.snapon.com/ukssc

For Technical Assistance

Phone / E-mail:

+44 (0) 845 601 4736 / diagnosticsUKproductsupport@snapon.com

For technical assistance in all other markets, contact your selling agent.

ZEEMSGB341A Rev. A 31-H-16 GB

i

Page 3

Content s

Safety Information................................................................................................................v

Chapter 1: Using This Manual.............................................................................................1

Conventions............................................................................................................................ 1

Bold Text.......................................................................................................................... 1

Symbols ...........................................................................................................................1

Terminology .....................................................................................................................1

Notes and Important Messages ....................................................................................... 2

Hyperlinks ........................................................................................................................2

Procedures....................................................................................................................... 2

Chapter 2: Introduction........................................................................................................3

Control Buttons.......................................................................................................................3

Data and Power Connections................................................................................................. 4

Battery Pack and Stand..........................................................................................................5

Power Sources ....................................................................................................................... 6

Internal Battery Pack........................................................................................................ 6

AC/DC Power Supply....................................................................................................... 6

Vehicle Power ..................................................................................................................6

Technical Specifications ......................................................................................................... 7

Chapter 3: Basic Operation and Navigation ......................................................................8

Turning On/Off and Emergency Shutdown............................................................................. 8

Turning On .......................................................................................................................8

Turning Off .......................................................................................................................8

Emergency Shutdown...................................................................................................... 9

Basic Navigation.....................................................................................................................9

Home Screen Layout .......................................................................................................9

Title Bar.......................................................................................................................... 10

Home Screen Icons ....................................................................................................... 11

Common Toolbar Control Icons ..................................................................................... 12

Scroll Bar .......................................................................................................................13

Screen Messages.................................................................................................................13

System Messages.......................................................................................................... 13

Communication Messages............................................................................................. 14

Data Cable Connection ........................................................................................................ 14

Chapter 4: Scanner.............................................................................................................16

Screen Layout and Toolbar Icons......................................................................................... 16

Screen Layout................................................................................................................ 16

Scanner Control Icons ................................................................................................... 17

Scanner Demonstration Program .........................................................................................17

Scanner Operation ..............................................................................................................18

Connecting the Data Cable............................................................................................18

Vehicle Identification ......................................................................................................18

ii

Page 4

System Selection ...........................................................................................................20

System Main Menu Options........................................................................................... 25

Exiting Scanner ....................................................................................................................39

SureTrack .............................................................................................................................40

SureTrack Operation...................................................................................................... 40

Chapter 5: OBD-II/EOBD ....................................................................................................47

Basic Operations .................................................................................................................. 47

Screen Layout and Toolbar Controls .............................................................................47

Connecting the Data Cable............................................................................................47

Saving and Reviewing Data Files .................................................................................. 47

OBD-II/EOBD Menu ............................................................................................................. 47

OBD Health Check......................................................................................................... 48

OBD Direct .....................................................................................................................50

Chapter 6: TSBs..................................................................................................................57

Operation..............................................................................................................................57

Chapter 7: Guided Component Tests...............................................................................61

Extras Menu (Top Level Menu Items) .................................................................................. 61

Power User Tests .......................................................................................................... 61

How To Guide ................................................................................................................62

Features and Benefits....................................................................................................62

Index ..............................................................................................................................62

Screen Layout and Icons...................................................................................................... 63

Screen Layout................................................................................................................ 63

Guided Component Tests Control Icons ........................................................................ 63

Operation..............................................................................................................................65

Component Information ................................................................................................. 66

Tests .............................................................................................................................. 68

Saving and Reviewing Data Files .................................................................................. 70

Chapter 8: Previous Vehicles and Data............................................................................71

Previous Vehicles and Data Menu ....................................................................................... 71

Vehicle History ............................................................................................................... 71

View Saved Data ........................................................................................................... 72

Viewing Codes and Code Scan Results ........................................................................ 73

Delete Saved Data......................................................................................................... 75

Chapter 9: Scope Multimeter.............................................................................................76

Overview............................................................................................................................... 76

Digital Multimeter (DMM) ............................................................................................... 76

Graphing Multimeter (GMM) .......................................................................................... 77

Lab Scope...................................................................................................................... 78

Tests and Capabilities (Quick Reference) ............................................................................79

Test Leads and Accessories ................................................................................................81

Channel 1 Lead.............................................................................................................. 81

Channel 2 Lead.............................................................................................................. 81

Alligator Clips and Probes..............................................................................................82

Secondary Ignition Coil Adapter Lead and Clip-on Adapter

(optional) ..............................................................................................................82

iii

Page 5

Low Amp Current Probe (optional).................................................................................83

Pressure Transducers and Adapters (optional) ............................................................. 83

General Information..............................................................................................................84

Scope Multimeter Screen Layout and Features............................................................. 84

Measurement Out of Range (Alert) ................................................................................ 86

Operation and Controls ........................................................................................................87

Test Lead / Probe Connection ....................................................................................... 87

Test Lead / Probe Calibration ........................................................................................ 88

Control Panel and Settings ............................................................................................ 89

Secondary Ignition Testing .......................................................................................... 104

Optional Settings ................................................................................................................106

Display (Grid on/off) .....................................................................................................106

Divisions.......................................................................................................................107

Saving and Reviewing Scope / Multimeter Data Files ........................................................ 110

Data Buffer................................................................................................................... 110

Saving Files .................................................................................................................111

Stopping and Reviewing Data Files ............................................................................. 112

Saving Screens............................................................................................................ 113

Using the Zoom Function .............................................................................................114

General Reference ............................................................................................................ 117

Basic Setup Tips (unknown signal type) ..................................................................... 117

Using Known Good Waveforms ...................................................................................118

Troubleshooting Signals ............................................................................................. 119

Units of Measurement / Conversions ........................................................................... 120

Glossary of Common Terms ....................................................................................... 122

Chapter 10: Tools .............................................................................................................125

Tools Menu.........................................................................................................................125

Connect-to-PC .............................................................................................................126

Configure Shortcut Button............................................................................................ 126

System Information ...................................................................................................... 127

Settings ........................................................................................................................128

Chapter 11: ShopStream Connect..................................................................................143

Chapter 12: Maintenance.................................................................................................147

Cleaning and Inspecting the Diagnostic Tool ..................................................................... 147

Cleaning the Touch Screen ......................................................................................... 147

Battery Pack Service .......................................................................................................... 147

Battery Pack Safety Guidelines ................................................................................... 148

Replacing the Battery Pack.......................................................................................... 149

Disposing of the Battery Pack......................................................................................150

Index..................................................................................................................................151

iv

Page 6

Safety Information

READ ALL INSTRUCTIONS

For your own safety, the safety of others, and to prevent damage to the product and vehicles upon

which it is used, it is important that all instructions and safety messages in this manual and the

accompanying Important Safety Instr uction s manual be read and understood by all persons

operating, or coming into contact with the product, before operating. We suggest you store a copy

of each manual near the product in sight of the operator.

For your safety, read all instructions. Use your diagnostic tools only as described in the tool user’s

manual. Use only manufacturer recommended parts and accessories with your diagnostic tools.

This product is intended for use by properly trained and skilled professional automotive

technicians. The safety messages presented throughout this manual and the accompanying

Important Safety Ins tructions manual are reminders to the operator to exercise extreme care when

using this product.

There are many variations in procedures, techniques, tools, and parts for servicing vehicles, as

well as in the skill of the individual doing the work. Because of the vast number of test applications

and variations in the products that can be tested with this instrument, we cannot possibly

anticipate or provide advice or safety messages to cover every situation. It is the responsibility of

the automotive technician to be knowledgeable of the system being tested. It is essential to use

proper service methods and test procedures. It is important to perform tests in an appropriate and

acceptable manner that does not endanger your safety, the safety of others in the work area, the

equipment being used, or the vehicle being tested.

It is assumed that the operator has a thorough understanding of vehicle systems before using this

product. Understanding of these system principles and operating theories is necessary for

competent, safe and accurate use of this instrument.

Before using the equipment, always refer to and follow the safety messages and applicable test

procedures provided by the manufacturer of the vehicle or equipment being tested. Use the

product only as described in it’s user manual. Use only manufacturer recommended parts and

accessories with your product.

Read, understand and follow all safety messages and instructions in this manual, the

accompanying Important Safety Instr uction s manual, and on the test equipment.

Environmental Conditions:

• This product is intended for indoor use only

• This product is rated for Pollution Degree 2 (normal conditions)

v

Page 7

Safety Information Safety Signal Words

'$1*(5

:$51 ,1*

&$87,21

:$51 ,1*

Safety Signal Words

All safety messages contain a safety signal word that indicates the level of the hazard. An icon,

when present, gives a graphical description of the hazard. Safety Signal words are:

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious

injury to the operator or to bystanders.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious

injury to the operator or to bystanders.

Indicates a potentially hazardous situation which, if not avoided, may result in moderate or minor

injury to the operator or to bystanders.

Safety Message Conventions

Safety messages are provided to help prevent personal injury and equipment damage. Safety

messages communicate the hazard, hazard avoidance and possible consequences using three

different type styles:

• Normal type states the hazard.

• Bold type states how to avoid the hazard.

• Italic type states the possible consequences of not avoidi ng the ha zard.

An icon, when present, gives a graphical description of the potential hazard.

Safety Message Example

Risk of unexpected vehicle movement.

• Block drive wheels before performing a test with engine runn ing.

A moving vehicle can cause injury.

Important Safety Instructions

For a complete list of safety messages, refer to the accompanying Important Safety Instructions

manual.

SAVE THESE INSTRUCTIONS

vi

Page 8

Chapter 1 Using This Manual

This manual contains tool usage instructions. Some of the illustrations shown in this manual may

contain modules and optional equipment that are not included on your system. Contact your sales

representative for availability of other modules and optional equipment.

1.1 Conventions

The following conventions are used.

1.1.1 Bold Text

Bold emphasis is used in procedures to highlight selectable items such as buttons and menu

options.

Example:

• Press the OK button.

1.1.2 Symbols

Different types of arrows are used.

The “greater than” arrow (>) indicates an abbreviated set of selection instructions.

Example:

• Select Tools > Connect-to-PC.

The example statement abbreviates the following procedure:

1. Select Tools from the home screen.

2. Highlight Connect-to-PC on the Tools menu.

3. Select Connect-to-PC.

The solid arrows (e, c, d, b) are navigational instructions referring to the four directions of the

directional arrow keys.

Example:

• Press the down d arrow.

1.1.3 Terminology

The term “select” means tapping an item on the touch screen, or highlighting a button or menu

item and pressing the Accept, OK, Yes, or other similar button to confirm the selection.

Example:

• Select Brightness.

The above statement abbreviates the following procedure:

1

Page 9

Using This Manual Conventions

NOTE:

IMPORTANT:

IMPORTANT:

1. Navigate to and highlight the Brightness selection.

2. Press the OK, or similar, button.

1.1.4 Notes and Important Messages

The following messages are used.

Notes

A NOTE provides helpful information such as additional explanations, tips, and comments.

Example:

i For additional information refer to...

Important

IMPORTANT indicates a situation which, if not avoided, may result in damage to the test

equipment or vehicle.

Example:

Do not disconnect the data cable while the Scanner is communicating with the ECM.

1.1.5 Hyperlinks

Hyperlinks, or hot links, that take you to other related articles, procedures, and illustrations are

available in electronic documents. Blue colored text indicates a selectable hyperlink.

Example:

Read all applicable before using this tool!

1.1.6 Procedures

An arrow icon in the left-margin area indicates a procedure.

Example:

z To change screen views:

1. Select the Graph icon.

The dropdown menu displays.

2. Select an option from the menu.

The screen layout changes to the format selected.

2

Page 10

Chapter 2 Introduction

Scope MultimeterGuided Component

Tests

Tools

OBD-II/EOBD

Previous Vehicles

and Data

Scanner

TSBs

The MODIS™ Edge is a multi-function tool that combines a Diagnostic Scan Tool with a

two-channel lab scope, graphing multimeter, and the exclusive Snap-on

Tests database into a single hand-held unit.

This chapter introduces the basic features of the Diagnostic Tool, including the control buttons,

data ports, battery pack, and power sources. Technical Specifications are provided at the end of

this chapter.

2.1 Control Buttons

There are four “push type” control buttons and one “thumb pad rocker type” multi-directional

button located on the right side of the Diagnostic Tool. All other Diagnostic Tool operations are

controlled through the touch screen.

®

Guided Component

1

2

3

4

Figure 2-1 Front view

Item Button Description

• To exit a menu or program.

1

N/X or Cancel - Push

type button

• To close an open list and return to the previous

menu or screen.

• To answer “No” when a yes/no choice is given.

• To confirm a selection from a menu or program.

2

a or Accept - Push

Y/

type button

• To select an item that was highlighted using the

direction arrows.

• To advance to the next screen in a series.

• To answer “Yes” when a yes or no choice is

given.

5

3

Page 11

Introduction Data and Power Connections

Item Button Description

Buttons move the cursor or highlight in their

respective direction:

3

Directional - Thumb

pad rocker type buttons

• Up (b)

• Down (d)

• Left (e)

• Right (c)

Programmable function button that can provide a

4

S (Shortcut) - Push type

button

shortcut for performing a variety of routine tasks.

Refer to Configure Shortcut Button‚ on page 126 for

additional information.

5

Power (On/Off) - Push

type button

Turns the Diagnostic Tool on and off. Also, press

and hold for 5 seconds for emergency shutdown.

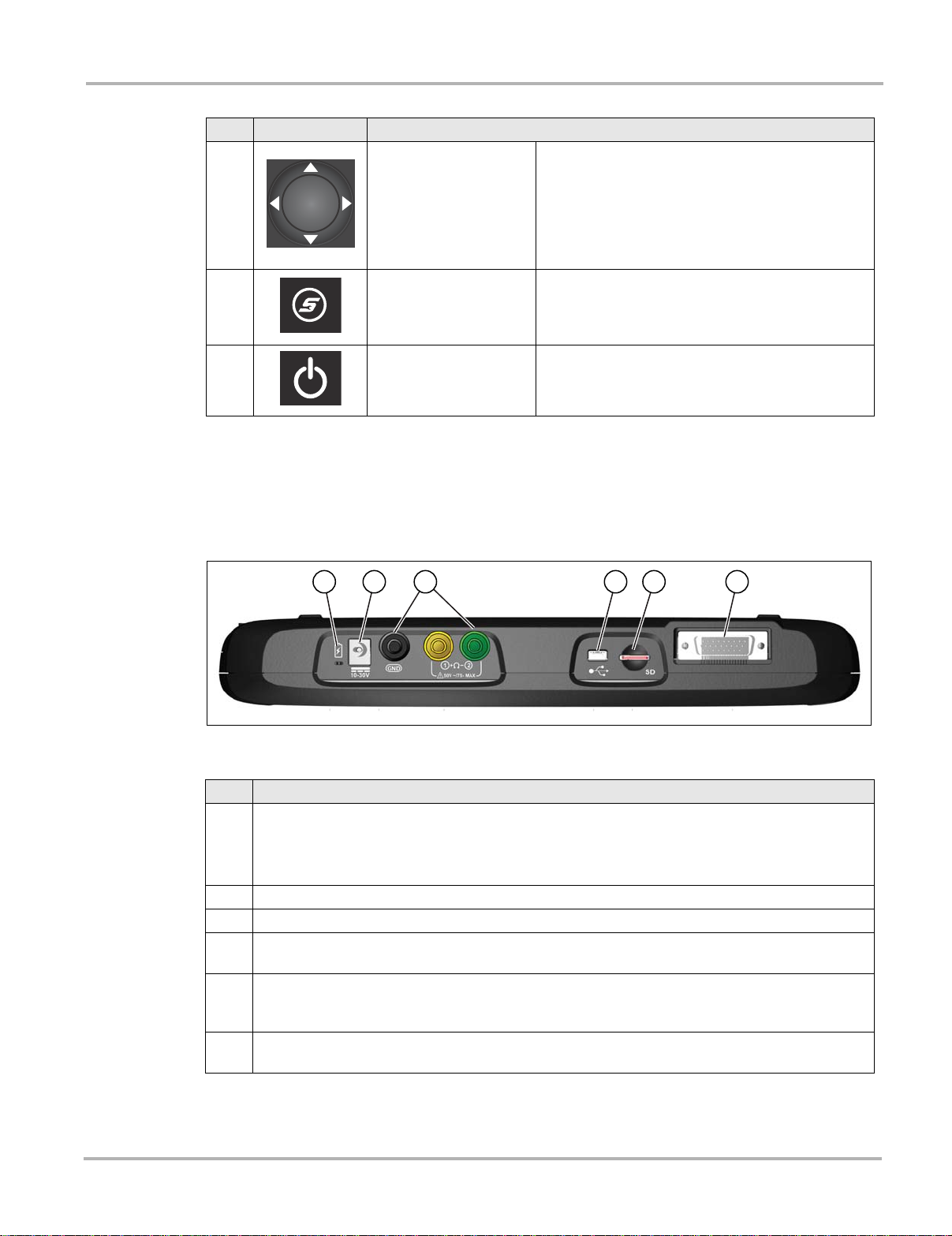

2.2 Data and Power Connections

Connectors and jacks for the scope multimeter, data communication cables and the AC/DC power

supply are located on the top of the Diagnostic Tool.

Item Description

Battery Status Indi ca to r LED

• Green - battery is fully charged

1

• Red - battery is charging

• Amber - indicates there is a battery issue (correct before operating)

2 DC Power Supply Jack - AC/DC power supply connection

3 Scope/Multimeter Jacks - Scope and multimeter lead connections

Mini USB Jack - USB cable connection used to connect the Diagnostic Tool to a personal

4

computer

Micro secure digital (uSD) Card - contains operating system programming. IMPORTANT The

5

uSD card must be installed for the Diagnostic Tool to operate. Do not remove the uSD card

while the Diagnostic Tool is powered on.

Data Cable Connector - Data cable connection used to connect the Diagnostic Tool to a vehicle

6

data link connector

Figure 2-2 Top view

4

Page 12

Introduction Battery Pack and Stand

2.3 Battery Pack and St and

Figure 2-3 Rear view

Item Description

Built in-Stand (shown closed) - The built-in stand extends from the back of the Diagnostic Tool

1

and clips into the Diagnostic Tool for storage.

2 Battery Cover

5

Page 13

Introduction Power Sources

IMPORTANT:

IMPORTANT:

2.4 Power Sources

Your Diagnostic Tool can receive power from any of the following sources:

• Internal Battery Pack

• AC/DC Power Supply

• Vehicle Power

2.4.1 Internal Battery Pack

The Diagnostic Tool can be powered from the internal rechargeable battery pack. A fully charged

battery provides sufficient power for about 3 hours of continuous operation.

Battery charging occurs when the Diagnostic Tool is connected to the AC/DC Power Supply and

to a live AC power source.

The Battery Status Indicator LED (located next to the DC power supply jack) indicates battery

status (Figure 2-3).

• Green - indicates battery is fully charged

• Red - indicates battery is charging

• Amber - indicates a battery issue. This is usually caused by excessive battery temperature

(above 104°F/40°C), which disables charging. Allow the Diagnostic Tool to cool down before

continuing operation.

2.4.2 AC/DC Power Supply

The Diagnostic Tool can be powered from a standard AC outlet using the AC/DC power supply.

The connector on the end of the output cable of the AC/DC power supply attaches to the DC

power supply input jack on top of the Diagnostic Tool. Use only the AC/DC power supply provided.

Never connect the AC/DC power supply to the DC power supply input on the Diagnostic Tool when

the Diagnostic Tool is communicating with a vehicle.

2.4.3 V e hicle Power

All OBD-II/EOBD vehicles have vehicle battery power (B+) available on the DLC. The Diagnostic

Tool is powered through the Data Cable when connected to the vehicle DLC. A green LED

indicator on the DLC end of the data cable, illuminates when power is being supplied to the cable.

If the LED fails to illuminate, check that the data cable is properly connected and then check the

DLC power circuit. See Data Cable Connection‚ on page 14 for additional data cable information.

An optional power cable is required when testing non-OBD-II/EOBD models that do not have

vehicle battery power (B+) available on the DLC. Contact your sales representative for availability.

Never connect the optional power cable to the DC power supply input on the Diagnostic Tool when

the Diagnostic Tool is communicating with a vehicle.

6

Page 14

Introduction T echnical Specifications

2.5 T echnical S pecifications

Item Description / Specification

Touch Screen

Display

Meter

Battery

Power Supply

DC Operating V oltage

Width

Height

Depth

Weight (including

battery):

Operating Temperature

Range (ambient)

Storage Temperature

(ambient)

Operating Altitude

Environmental

Conditions

Resistive Touch Panel

8.0 inch diagonal, Color LCD

800 x 480 resolution SWVGA

Category 1

Rechargeable lithium-ion battery pack

Approximately 3 hour run time

Approximately 5 hour charge time

Supply Rating; 15VDC, 2A

10 to 30VDC

11.06 in. (281.0 mm)

6.29 in. (160.0 mm)

1.58 in. (40.3 mm)

2.65 lb (1.20 kg)

At 0 to 90% relative humidity (non-condensing)

32 to 113°F (0 to 45°C)

At 0 to 70% relative humidity (non-condensing)

–4 to 140°F (–20 to 60°C)

Maximum 2000 m

This product is intended for indoor use only

This product is rated for Pollution Degree 2 (normal conditions)

7

Page 15

Chapter 3 Basic Operation and

IMPORTANT:

Navigation

This chapter describes basic Diagnostic Tool operation, navigation, screen layout, icon functions,

and screen messages. Before you operate the Diagnostic Tool, make sure the battery pack is fully

charged or the Diagnostic Tool is powered by the AC power supply.

3.1 T urning On/Off and Emergency Shut down

The following sections describe how to turn the Diagnostic Tool on and off and how to perform an

emergency shutdown.

3.1.1 Turning On

The Diagnostic Tool will automatically turn on and open the Home screen (Figure 3-1) when power

is supplied through the Data Cable or by the AC/DC Power Supply. If the Diagnostic Tool does not

automatically turn on, press and release the Power button on the front of the Diagnostic Tool to

turn the Diagnostic Tool on.

3.1.2 Turning Off

All vehicle communication must be terminated BEFORE turning off the Diagnostic Tool. A warning

message displays if you attempt to turn the Diagnostic Tool off while communicating with the

vehicle. Forcing a shut down while communicating may lead to ECM problems on some vehicles.

Never disconnect the Data Cable when the Diagnostic Tool is communicating with the vehicle

ECM.

z To turn off the Diagnostic Tool:

1. Press the N/X button or select the Back or Home icon to navigate to the Home screen.

The “stopping communication” message appears briefly before the Home screen displays.

2. Disconnect the Diagnostic Tool Data Cable from the vehicle.

3. Press and release the Power button.

A confirmation screen displays.

4. Press the Y/a button or select OK from the menu to turn the Diagnostic Tool off. To continue

operating, press the N/X button or select Cancel from the menu.

8

Page 16

Basic Operation and Navigation Basic Navigation

IMPORTANT:

1

2

Scope MultimeterScanner Guided Component

Tests

Tools

OBD-II/EOBD

Previous Vehicles

and Data

TSBs

3.1.3 Emergency Shutdown

Using the emergency shutdown procedure while communicating with the vehicle ECM may lead

to ECM problems on some vehicles.

During normal operation turn the Diagnostic Tool off using the Turning Off procedure above. The

emergency shutdown procedure should only be used If the Diagnostic Tool does not respond to

navigation or control buttons or exhibits erratic operation. To force an emergency shutdown, press

and hold the Power button for five seconds until the Diagnostic Tool turns off.

3.2 Basic Navigation

3.2.1 Home Screen Layout

The Home screen includes a title bar and main body. The Home screen contains icons, one for

each of the primary Diagnostic Tool functions.

1— Title Bar

2— Main Body

Figure 3-1 Home screen

9

Page 17

Basic Operation and Navigation Basic Navigation

3.2.2 Title Bar

The title bar at the top of the screen provides basic information about current Diagnostic Tool

operating conditions. Title bar options vary depending upon vehicle make and model, what

function is active, what test is being performed, or what menu is selected. The title bar contains

information only, there are no selectable items.

Elements of the Title bar let you know at a glance:

• What Diagnostic Tool function is currently active.

• The current time.

• Wi-Fi signal strength

• The source and status of the power being supplied to the Diagnostic Tool.

An active function icon is always displayed along the left-hand edge of the Title bar. These icons

resemble their Home screen icon counterparts in appearance and color. The name of the function

displays to the right of the icon on some screens.

A real time clock displays to the left of the power supply icon. The clock is powered by a dedicated

internal battery, so the correct time is maintained even when the main battery pack is discharged.

Use the Tools function to set the clock and format how time is displayed. See Clock Settings‚ on

page 132 for additional information.

The Title bar displays other information that varies depending upon what functions are being

performed. Other information may include:

• The identification (ID) of the test vehicle

• The name of the active menu or function

• The name of the test being performed

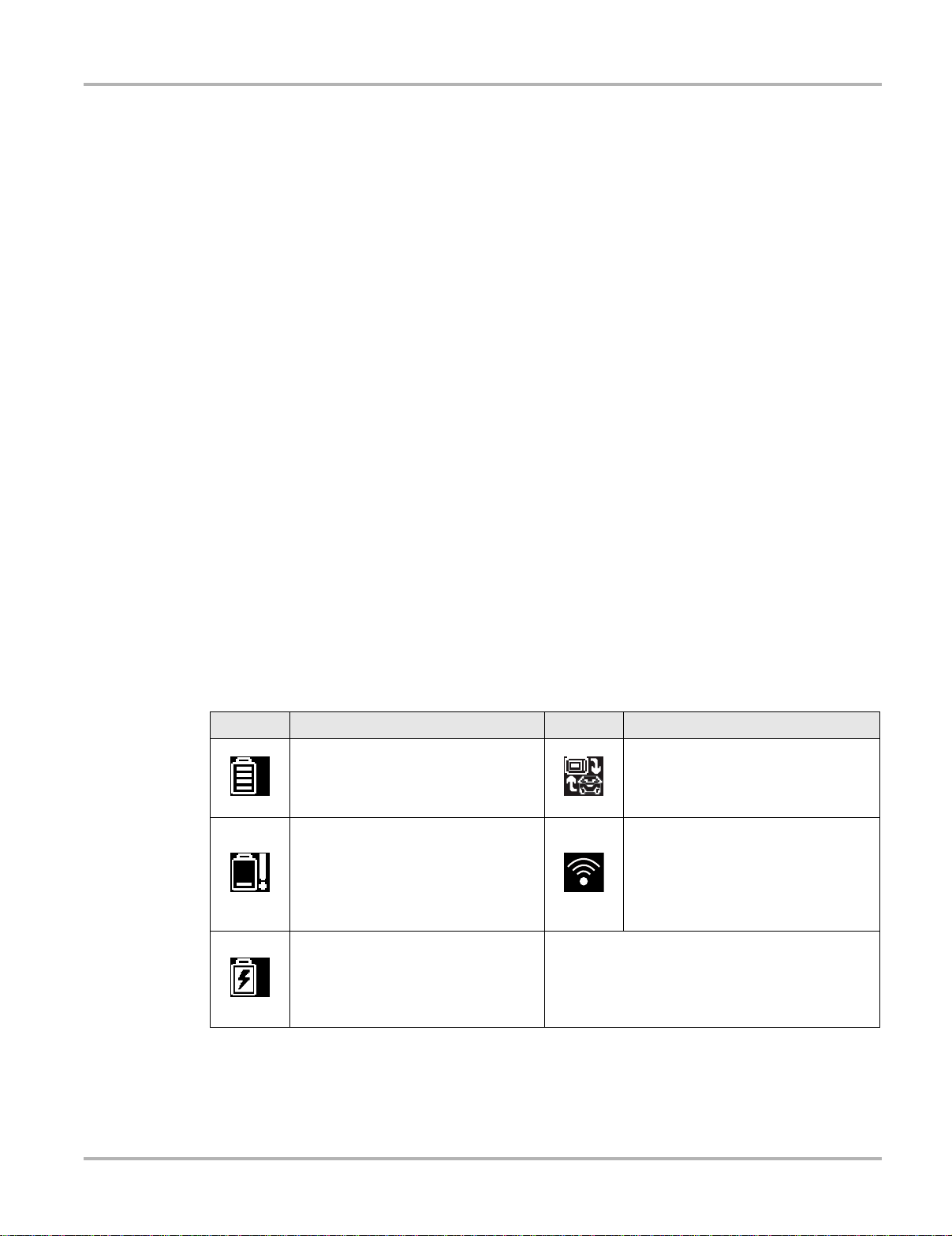

Table 3-1 Title Bar Icons

Icon Function Icon Function

Full Battery Charge Level - Indicates

power is being supplied by the internal

battery pack. Horizontal bars diminish

as the battery discharges.

Low Battery Charge Level - Indicates

the internal battery pack is low and

needs to be recharged immediately. A

warning message will also display on

the screen when the battery gets low.

External Power Connected -

Indicates power is being supplied

through the data cable connection to a

vehicle or by the AC/DC Power Supply

and charging the battery pack.

Active Vehicle Communication -

Indicates the Diagnostic Tool is actively

communicating with a vehicle.

Wi-Fi Signal Strength - Indicates

signal strength of the wireless network

connection.

Three bars - indicate full strength signal

Zero to 1 bar - indicate weak or no

signal

10

Page 18

Basic Operation and Navigation Basic Navigation

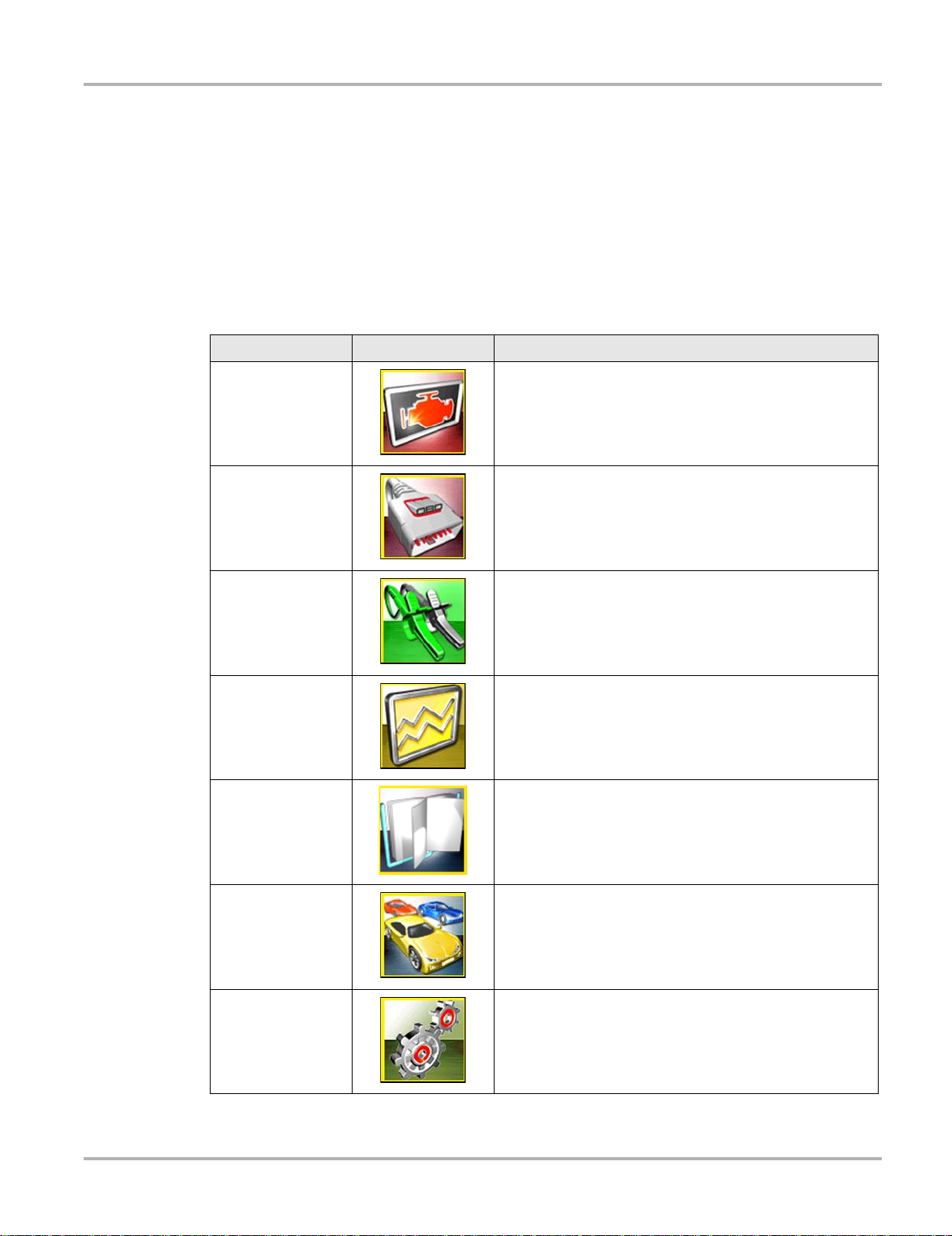

3.2.3 Home Screen Icons

Each available Diagnostic Tool function is represented by a icon on the home screen. The table

below provides descriptions of the icon functions.

Select an icon from the Home screen to start a function. You can also use the control buttons to

activate a function, a yellow border around the icon indicates it is highlighted, or in focus. Use the

Directional buttons (e, c, b, d) to highlight the desired function and then press the Y/a button

to select it. A “please wait” message may display briefly, then automatically clear once the function

is loaded and ready for use.

Table 3-2 Home screen icons

Function Name Function Icon Description

Used to communicate with the electronic control systems of

Scanner

OBD-II/EOBD

a vehicle. This function allows you to retrieve diagnostic

trouble codes (DTCs), view PID data and perform diagnostic

tests. See Scanner‚ on page 16 for details.

Allows you to access generic OBD-II/EOBD data and tests

without identifying the vehicle being tested. See OBD-II/

EOBD‚ on page 47 for details.

Guided Component

Tests

Scope Multimeter

TSBs

Previous

Vehicles & Data

Tools

Allows you to perform diagnostic tests for the identified

vehicle. See Guided Component Tests‚ on page 61.

Allows you to perform lab scope, graphing multimeter and

digital multimeter tests and measurements. See Scope

Multimeter‚ on page 76.

Allows you quick access to vehicle OEM technical service

bulletins. See TSBs‚ on page 57.

Allows you to quickly reconfigure the Diagnostic Tool to a

recently tested vehicle and to access saved data files.See

Previous Vehicles and Data‚ on page 71 for details.

Allows you to adjust Diagnostic Tool settings to your

personal preferences and perform other special functions.

See To ol s ‚ on page 125 for details.

11

Page 19

Basic Operation and Navigation Basic Navigation

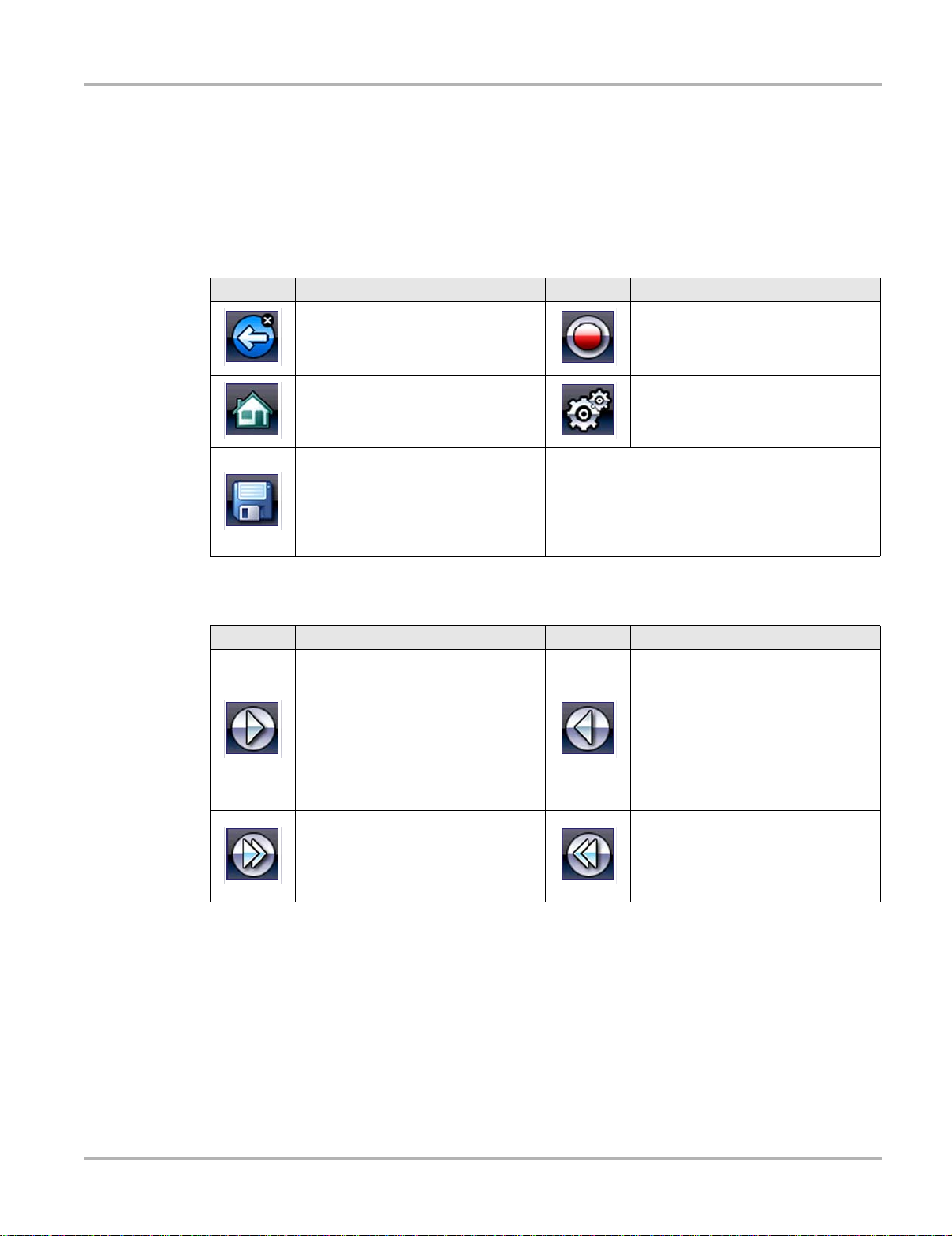

3.2.4 Common Toolbar Control Icons

Common control icon functions are described in the following table. Specific function control icons

are described in their applicable chapters. Displayed control icons vary depending on the active

function or test. Select a control icon on a screen to activate a control function. You can also use

the control buttons to activate a function, a yellow border around the icon indicates it is highlighted,

or in focus. Use the Directional buttons (e, c, b, d) to highlight the desired function and then

press the icon, or the Y/a button to select it.

Icon Function Icon Function

Back - Returns to the previously

viewed screen. Icon is located on the

left-hand edge of the toolbar.

Home - Returns to the Home screen.

Icon is located next to the Back icon

on the left side of the toolbar.

Save - Writes data from buffer

memory to a file. The saved “movie”

file can be accessed for future

reference by selecting Previous

Vehicles and Data > View Saved

Data.

Record - Indicates the data being

displayed is paused and not being

updated. Selecting resumes data

collection.

Tools - Opens the tools menu.

—

The icons below are used to navigate through paused or saved data (“movie”) files during

playback.

Icon Function Icon Function

Step Forward - allows forward

movement in singular steps. To

quickly step forward, select this icon

(yellow frame appears) then press and

hold the Y/

(Note: To quickly step forward during

Scanner data playback, press and

hold the icon down until a red frame

appears around the icon.)

Skip Forward - allows forward

movement in multiple steps. To quickly

skip forward, select this icon (yellow

frame appears around icon) then

press and hold the Y/

a button.

a button

Step Back - allows backward

movement in singular steps. To

quickly step backward, select this icon

(yellow frame appears) then press and

hold the Y/

(Note: To quickly step backward

during Scanner data playback, press

and hold the icon down until a red

frame appears around the icon.)

Skip Back - allows backward

movement in multiple steps. To quickly

skip backward, select this icon (yellow

frame appears around icon) then

press and hold the Y/a button.

a button.

12

Page 20

Basic Operation and Navigation Screen Messages

3.2.5 Scroll Bar

A vertical scroll bar appears along the right-hand edge of the screen when additional data

expands above or below what is currently on the screen (Figure 3-2).

Figure 3-2 Scroll bar

1— Beginning - Moves to beginning of data displayed.

2— Step up - Moves up one increment of the data displayed.

3— Slider (position indicator) - Select and drag the Slider to scroll through data. The slider

indicates the relative position of the current screen to the total available data.

4— Step down - Moves down one increment of the data displayed.

5— End - Moves to end of data displayed.

The Up (b) and Down (d) directional buttons can also be used to move through the data one line

at a time. Press and hold a directional button to rapidly scroll through data.

3.3 Screen Messages

3.3.1 System Messages

There are four types of system messages that may be displayed:

Message Type Description

Loading and connecting messages display when the Diagnostic Tool is performing an

Loading and

Connecting

Confirmation

Warning

Error

internal operation, such as loading a database, establishing communications with the

vehicle, or initiating a test. The message automatically clears once the internal

operation is complete.

Confirmation messages inform you when you are about to perform an action that cannot

be reversed or when an action has been initiated that requires a confirmation to

continue.When a response is not required, the message displays briefly, then

disappears.

Warning messages inform you when completing the selected action may result in an

irreversible change or in the loss of data. A confirmation is required to continue

Error messages inform you when a system or procedural error has occurred, for

example if the data cable becomes disconnected during operation.

13

Page 21

Basic Operation and Navigation Data Cable Connection

IMPORTANT:

3.3.2 Communication Messages

When “no communication” messages are displayed, it indicates the Diagnostic Tool and the

vehicle electronic control module are not communicating.

The following conditions cause “no communication” messages to display:

• The Diagnostic Tool is unable to establish a communication link with the vehicle.

• The vehicle is not equipped with the system that was selected.

• There is a loose connection.

• There is a blown vehicle fuse.

• There is a wiring fault on the vehicle.

• There is a circuit fault in the data cable or adapter.

• Incorrect vehicle identification was entered.

Refer to the Vehicle Communication Software manuals for manufacturer-specific problems.

3.4 Data Cable Connection

Connection of the data cable to the Diagnostic Tool and vehicle data link connector (DLC) is

required for Scanner and OBD-II/EOBD testing.

Use the approved cables and accessories for your diagnostic tool. Cable length must not exceed

114.17 inches (2.9 meters).

Depending on the vehicle, the supplied DA-4 data cable may be used alone or may require

optional adapters.

• All OBD-II/EOBD compliant vehicles - Use the supplied DA-4 data cable. The 26-pin end of

the cable attaches to the data cable connector on the top of the Diagnostic Tool. The16-pin

end connects to the vehicle DLC.

• All OBD-I (non-OBD-II/EOBD) compliant vehicles - Use the supplied DA-4 data cable with

the optional DA-5 adapter and a manufacturer specific adapter. The 26-pin end of the cable

attaches to the data cable connector on the top of the Diagnostic Tool. The16-pin end

connects to the DA-5 adapter, the DA-5 adapter connects to the manufacturer specific adapter

and then connects to the vehicle DLC.

On-screen cable and adapter connection instructions are provided while using the Scanner and

OBD-II/EOBD functions. The instructions may also include the location of the vehicle DLC

(Figure 3-3).

Figure 3-3 Vehicle connection data cable message

14

Page 22

Basic Operation and Navigation Data Cable Connection

NOTE:

For data cable vehicle power connection information, see Vehicle Power‚ on page 6.

i The data cable, includes an LED light on the vehicle DLC connector end, that can be used for

locating the vehicle DLC. The LED light is powered by the diagnostic tool battery.

z To connect the data cable to the vehicle:

1. After identifying a vehicle using the Scanner or OBD-II/EOBD function, review the on-screen

information for data cable usage and DLC location (Figure 3-3).

2. Connect the data cable to the diagnostic tool.

3. If needed, press the LED light button switch on the end of the cable to turn the LED light on,

and locate the DLC.

4. Turn the vehicle ignition on.

5. Select Continue once the data cable is connected.

The Diagnostic Tool establishes communication with the vehicle, then displays a list of

available tests. If the Diagnostic Tool is unable to establish a communications link, a “no

communications” message displays.

15

Page 23

Chapter 4 Scanner

This chapter describes the basic operation of the Scanner function.

The Scanner icon is located on the Home screen.

The Scanner function allows your diagnostic tool to communicate with the electronic control

systems of a vehicle. This allows you to retrieve diagnostic trouble codes (DTCs), view PID data

and perform diagnostic tests.

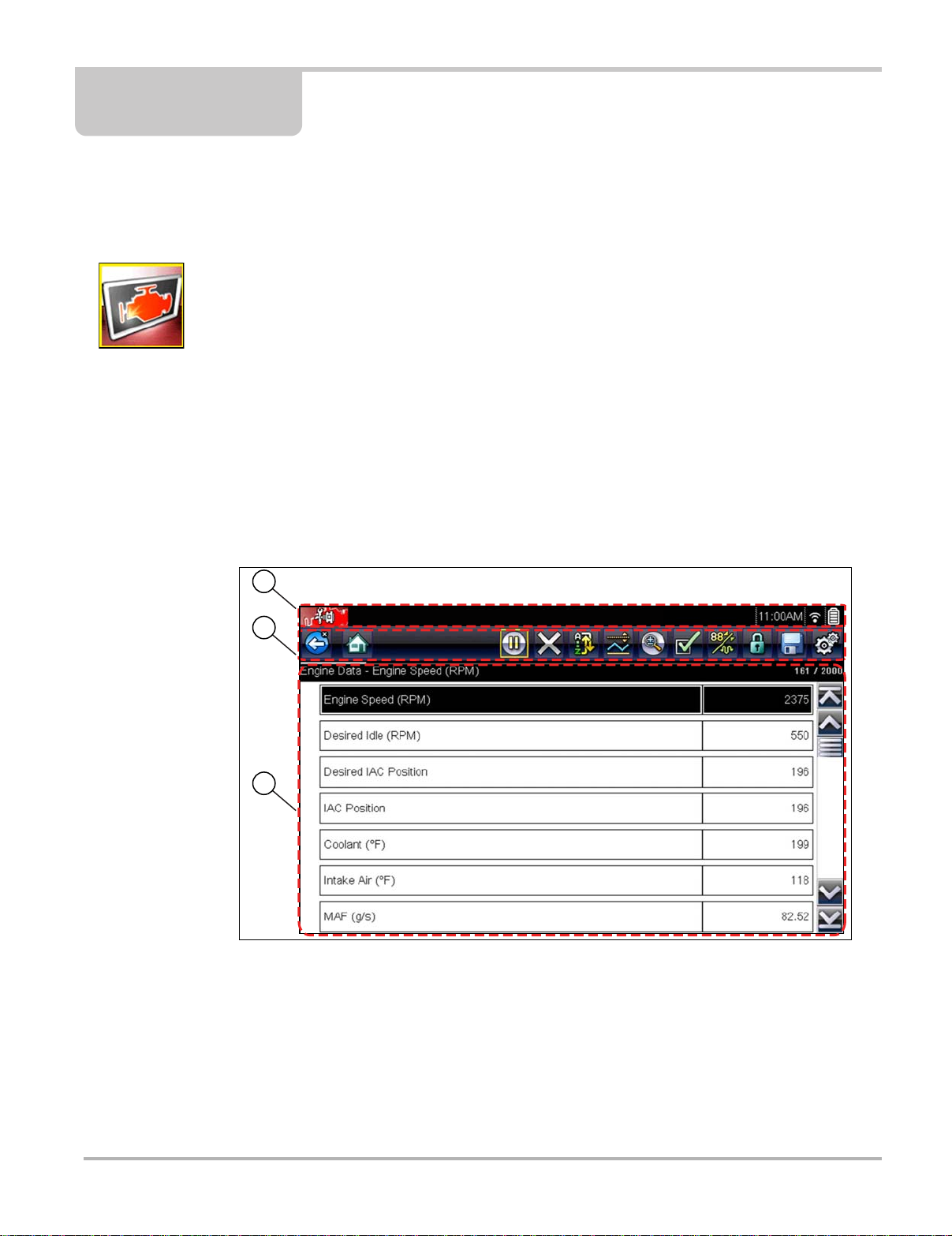

4.1 Screen Layout and Toolbar Icons

The following screen layout and toolbar controls apply to both the Scanner and the OBD-II/EOBD

functions.

4.1.1 Screen Layout

1

2

3

1— Title bar—shows active test, vehicle and diagnostic tool status

2— Toolbar—contains control icons

3— Main body—displays menus, PID and test data

2009 Peugeot 407 1.6L 16V T-Diesel (9HZ)

Figure 4-1 Screen layout

The Title bar appears for all functions and displays information only, there are no selectable items.

Refer to Title Bar‚ on page 10 for details.

16

Page 24

Scanner Scanner Demonstration Program

IMPORTANT:

4.1.2 Scanner Control Icons

The scanner toolbar contains control icons. Control icons may vary depending on the active

function or test. A yellow frame surrounding an icon (highlighted), indicates it is selected. Other

control icons (not shown) are described in Common Toolbar Control Icons‚ on page 12.

Icon Function Icon Function

Pause - Indicates PID data from the

vehicle is being displayed. Selecting

pauses data collection.

Custom Data List - Opens a menu for

selecting which PIDs display in the list.

Clear - Erases all the PID data in the

buffer and begins a new recording.

Selecting opens a confirmation

message.

Trigger - Opens a menu that allows

you to set, arm, and clear threshold

values that automatically trigger PID

data to be saved from buffer memory

to a file.

Zoom - Incrementally increases and

decreases the scale of the data being

displayed.

Change View - Changes display

options between PID list or graph

displays.

Lock/Unlock - Locks or unlocks the

highlighted parameter. Locked PIDs

move to the top of the list and do not

scroll as you move through the data.

Sort - Determines the order in which

PIDs are listed on the screen.

4.2 Scanner Demonstration Program

The Scanner demonstration program contains actual ECM PID data that allows you to navigate

and become familiar with the many capabilities of the Scanner function without actually

connecting to a vehicle. The following sections in this chapter provide detailed information on

navigating through the Scanner function and various menus. As you navigate through the

Demonstration program, refer to the applicable section for additional information.

z To start the demonstration program:

1. From the Home screen, select the Scanner icon.

The manufacturer menu displays.

2. Select the Demonstration icon.

Do not connect a vehicle to the diagnostic tool while using the Demonstration program.

3. Follow the on-screen instructions and make the selection as needed until the confirmation

screen displays.

4. Select OK on the confirmation screen to load the demonstration database.

A message displays “Demo mode: Do not connect to vehicle.”

5. Select Continue.

A systems menu, which shows all of the systems available for testing, displays.

6. Select a system from the menu, then select submenus as applicable to display the desired

demonstration information.

17

Page 25

Scanner Scanner Operation

NOTE:

NOTE:

4.3 Scanner Operation

Scanner Operation (Quick Reference)

z

1. Connect the data cable to the vehicle, and diagnostic tool.

Note: If the diagnostic tool is turned off, when the OBD-II data cable is connected to the

vehicle DLC, the diagnostic tool will automatically turn on.

2. Turn the diagnostic tool on (if required).

3. Turn the vehicle ignition switch on.

4. Select Scanner from the Home screen.

5. Select the vehicle year and make

6. Select Auto or Manual ID and enter the vehicle information at the screen prompts to continue.

7. Select a System to test.

8. Select a Test to be performed.

i The above information applies to most OBD-II vehicles.

4.3.1 Connecting the Data Cable

Connection of the data cable to the diagnostic tool and vehicle DLC is required for Scanner

testing, see Data Cable Connection‚ on page 14.

4.3.2 Vehicle Identification

The vehicle must be correctly identified for the diagnostic tool to communicate and display data

correctly. Menus and navigation will vary by vehicle.

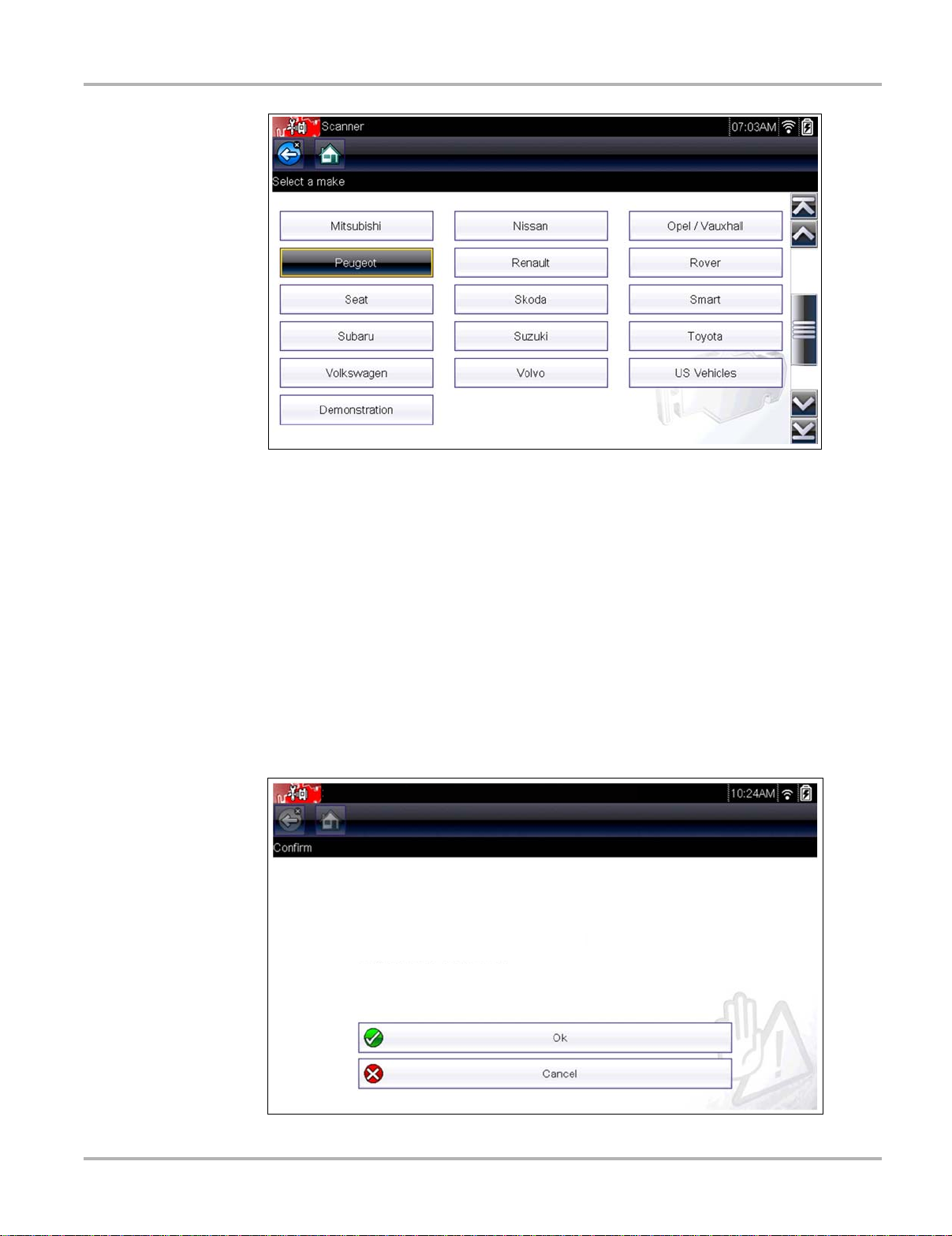

z Identifying a vehicle:

i Menus and navigation will vary by vehicle.

1. Select Scanner from the Home screen.

A list of vehicle manufacturers (make) displays (Figure 4-2).

The list includes Demonstration, which opens the Demonstration program (see Scanner

Demonstration Program‚ on page 17).

2. Select a vehicle manufacturer (Figure 4-2).

18

Page 26

Scanner Scanner Operation

Figure 4-2 Manufacturer list

A model year menu displays.

3. Select the vehicle year.

4. If the vehicle supports automatic identification, a menu choice will display providing the option

to either “Auto ID the vehicle” or “Manual ID the vehicle”.

Selecting Auto ID will automatically enter the vehicle’s information, and then display the

vehicle confirmation screen, see step 7.

Selecting Manual ID will display a list of vehicle models, see step 5.

5. Select the vehicle model.

6. Several selections may be required to get to the vehicle confirmation screen. If applicable,

make any other additional menu sections that may be required to select the vehicle.

7. The vehicle confirmation screen displays (Figure 4-3).

8. Select OK to confirm the vehicle (Figure 4-3).

2009 Peugeot 407 1.6L 16V T-Diesel (9HZ)

Current Vehicle Identication Is:

VIN: ------A----D--1----------Vehicle: 2009 Peugeot 407

Engine: 1.6L T-Diesel (9HZ)

Figure 4-3 Vehicle confirmation screen

19

Page 27

Scanner Scanner Operation

NOTE:

4.3.3 System Selection

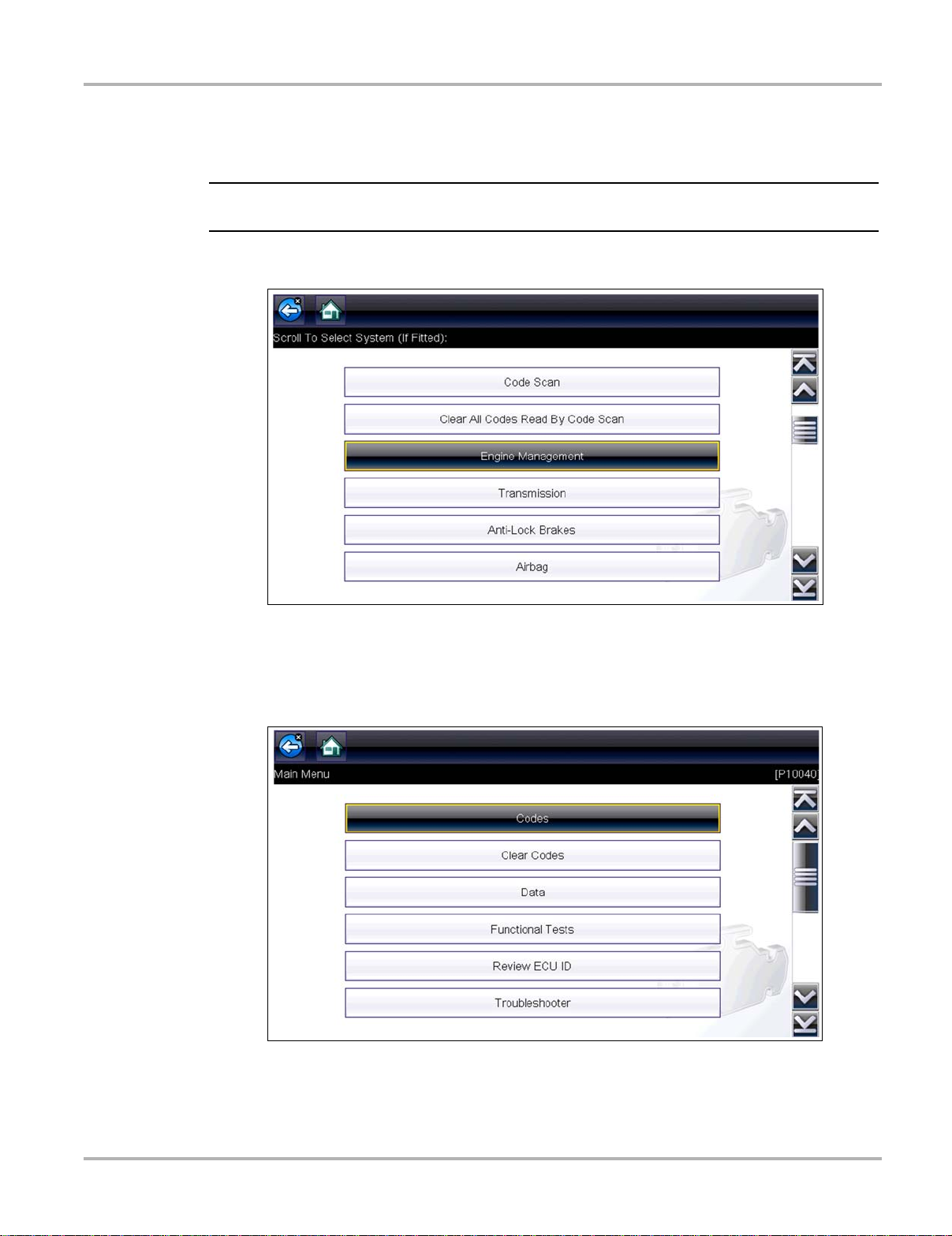

After a vehicle is identified, a menu of available systems, and options are displayed (Figure 4-4).

i Only the systems and options available for the vehicle are included in the menu list.

Select a system or option (Figure 4-4).

Figure 4-4 Typical systems menu

If a system (e.g. Engine, Transmission, Antilock Brakes, etc) is selected, the diagnostic tool may

establish communication with the vehicle, then display the system main menu (available tests)

(Figure 4-5). For sub-menu option information, see System Main Menu Options‚ on page 25.

Figure 4-5 System main menu

20

Page 28

Scanner Scanner Operation

Code Scan

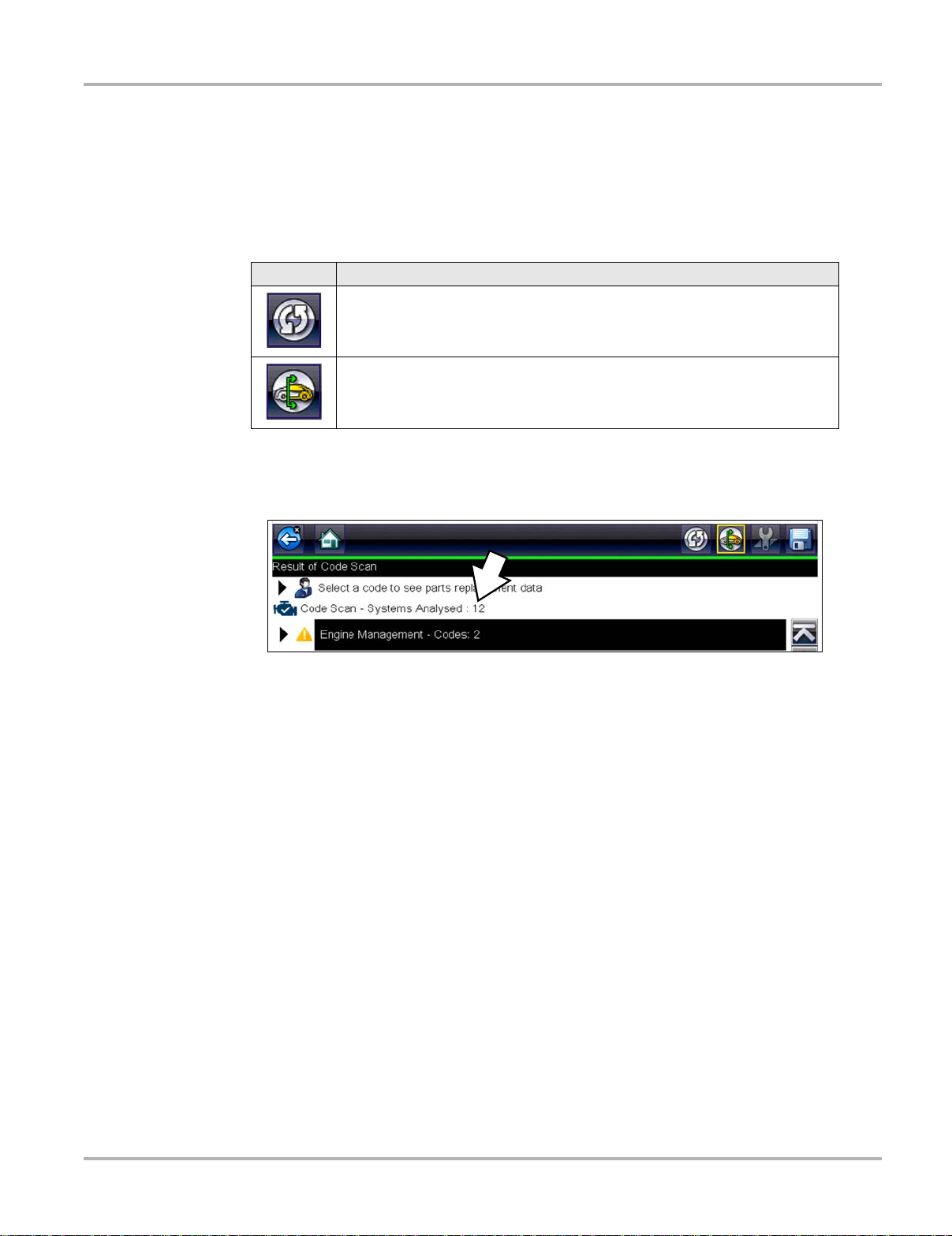

Depending on the vehicle, the Code Scan option (if supported) may be available from the menu.

Selecting Code Scan starts an active scan of vehicle control modules, and opens the Code Scan

results screen (Figure 4-6). A green progress bar is shown at the top indicating the active

scanning progress. Once completed, the results are displayed by system category.

The following Code Scan related control icons are used:

Icon Function

Refresh - Refreshes the code scan data (restarts the code scan)

System - Opens the main menu of the system selected

The following results are displayed progressively as the modules are scanned:

• The total number of systems (modules ) dete cted (Figure 4-6).

Figure 4-6 Code Scan systems analyzed result total

Quick reference indicators are used to show system code status (Figure 4-6):

- Green icon “a” mark - No Codes

- Yellow Triangle icon “!” mark - Codes are present

21

Page 29

Scanner Scanner Operation

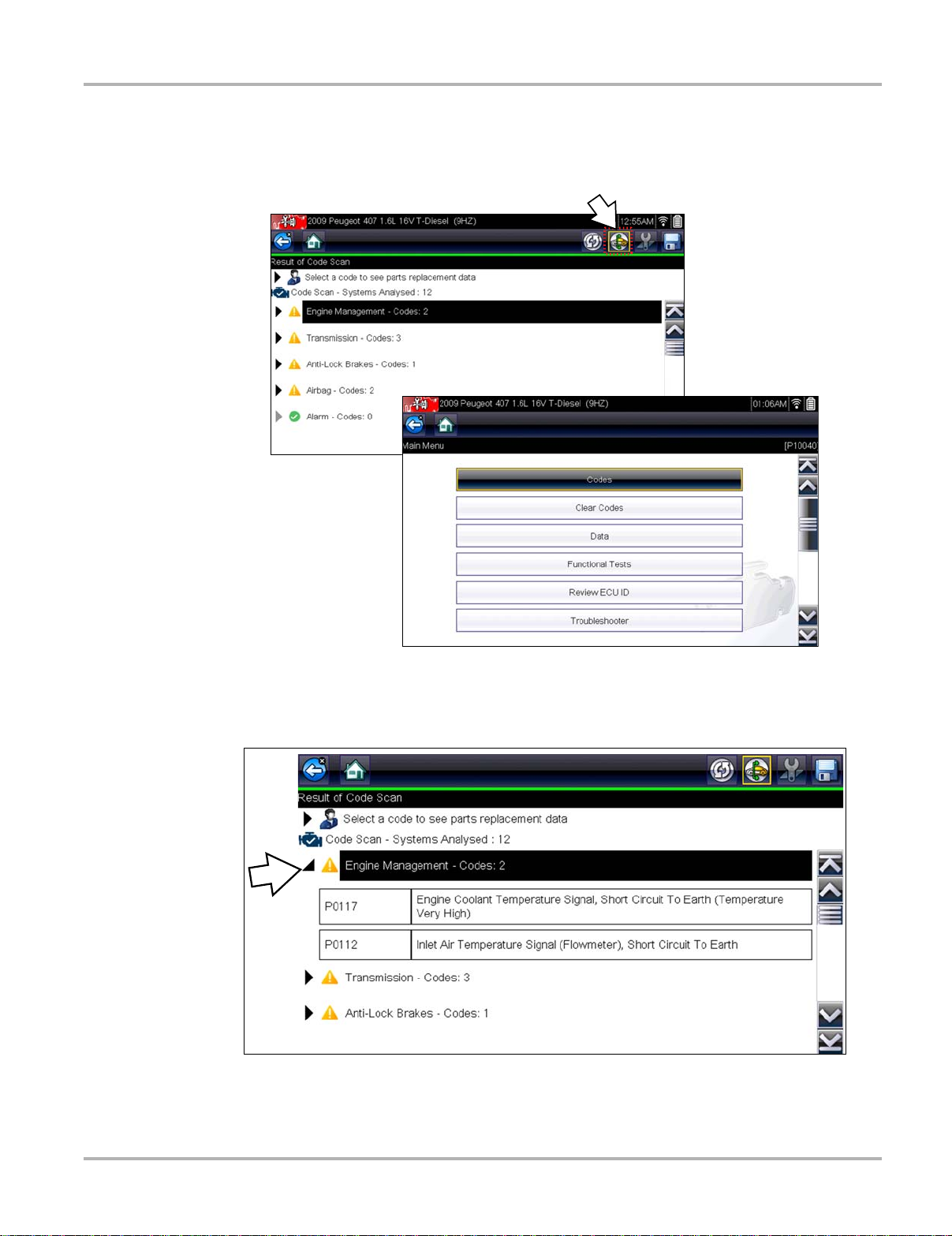

• A list of all the systems analyzed with DTCs tota ls. A categorized system list with DTC

totals is displayed in the order they are scanned. To view the main menu for a system in the

list, select the system, then select the System icon (Figure 4-7).

Figure 4-7 System icon (opens Main Menu)

Select the expand/collapse icon (Figure 4-8) on the left side of a system category title to

expand or collapse a systems’ DTC list.

Figure 4-8 Expand/Collapse Icon (expanded result)

22

Page 30

Scanner Scanner Operation

NOTE:

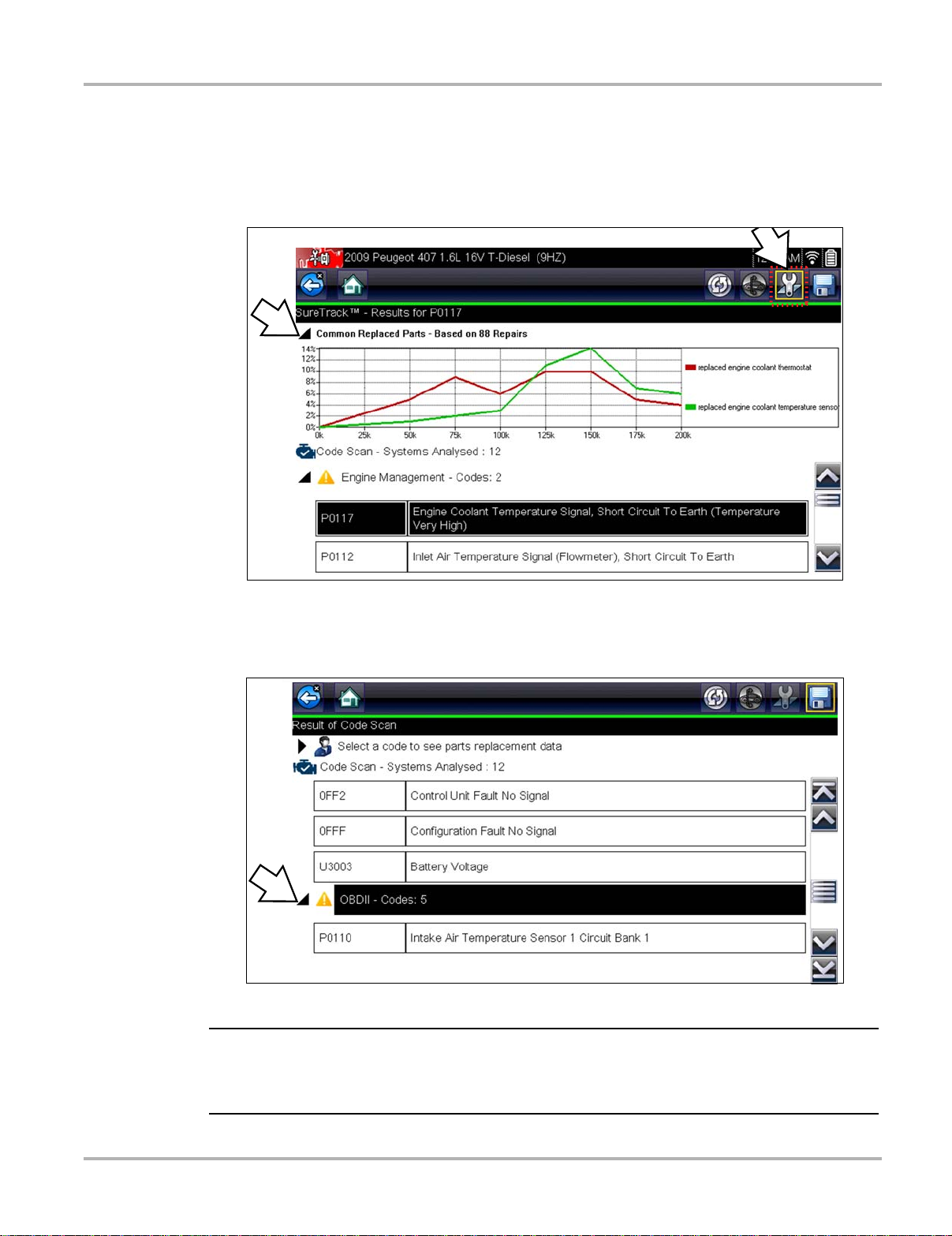

• SureTrack

from a list allows you to view available SureTrack information for the DTC. Select the

Common Replaced Parts graph or the Fix It ! icon from the toolbar to view the information.

For additional information on SureTrack, and common replaced parts graph see SureTrack®‚

on page 40.

®

Common Replaced Parts and rep air information for DTCs. Selecting a DTC

Figure 4-9 Common Replaced Parts graph icon and Fix It! icon (in toolbar)

• Global OBDII DTCs. Towards the end of the Code Scan list Global OBDII DTCs are

displayed.

Figure 4-10

i Some vehicles may not display global OBD-II information in the Code Scan list. A message will be

displayed to inform you the OBD-II - codes and monitors for this vehicle may be accessed using

the global OBD-II function. See OBD-II/EOBD‚ on page 47.

23

Page 31

Scanner Scanner Operation

NOTE:

NOTE:

• Readiness Monitor Test Status. At the end of the Code Scan list, readiness monitor test

results are displayed as “Tests Complete” or “Not Complete”.

Quick reference indicators are used to show monitor status.

- Green icon “a” mark - Monitor test is complete

- Grey icon “—” mark - Monitor test is not complete

Figure 4-11

i Monitors that are not supported by the vehicle are not displayed in Code Scan.

Saving Codes, and Code Scan Results (Vehicle System Report)

When using the code scan feature, or when viewing individual system codes (e.g. engine,

transmission) selecting the Save icon from the toolbar saves the results as report formatted file.

The saved file(s) can be viewed using two methods:

• On the diagnostic tool - See Viewing Code Results on the Diagnostic Tool‚ on page 73.

• In Vehicle System Report format using ShopStream Connect - See Vehicle System Report -

Viewing Code Results Using ShopStream Connect‚ on page 74.

Clear All Codes Read by Code Scan

Selecting Clear All Codes Read by Code Scan erases DTCs from all vehicle system modules

that were read by Code Scan.

i The Clear All Codes Read by Code Scan function may not clear OBD-II generic codes on some

vehicles.

24

Page 32

Scanner Scanner Operation

NOTE:

4.3.4 System Main Menu Options

Once a System is selected (e.g. Engine, Transmission, Antilock Brakes, etc) is selected, the

diagnostic tool may establish communication with the vehicle, then display the System Main Menu

(available tests).

i Menus and navigation will vary by vehicle.

The System Main Menu may include:

• Codes Menu—displays diagnostic trouble code (DTC) records from the vehicle electronic

control module. Selecting may open a submenu of viewing options.

• Clear Codes—erases DTC records and other data from the ECM. This selection is found on

a Codes submenu for some models.

• Data Display— displays PID data from the vehicle electronic control module. Selecting may

open a submenu of viewing options.

• Functional Tests—provides specific subsystem tests. The tests vary depending on the

manufacturer and model.

• Actuator T ests—similar to functional tests, checks the operation of certain actuators, such as

solenoid valves and relays.

• Memory Resets—allows you to reprogram adaptive values for certain components after

making repairs. Selecting opens a submenu. These options are found on the Functional Tests

Menu for some models.

• System Tests—provides specific subsystem testing. Performing these tests is similar to

functional tests.

• Generic Functions—lets you access certain available Generic OBD II functions from a

proprietary menu (1996 and newer vehicles only).

• Troubleshooter—provides step-by-step procedures, integrating PIDs and retrieving trouble

codes when appropriate, for specific symptoms of the identified vehicle.

The following sections, describe some of the System Main Menu items listed above.

Codes Menu

This selection may appear as Codes, Codes Menu, Codes Only, Codes (No Data), Service Codes

or something similar on the menu. Selecting opens a list of viewing options that includes:

• Display Codes‚ on page 26

• Clear Codes‚ on page 27

• Freeze Frame/Failure Records‚ on page 27

• DTC Status‚ on page 28

25

Page 33

Scanner Scanner Operation

Display Codes

This function opens either a list of diagnostic trouble codes (DTCs) stored in the selected vehicle

electronic control module (ECM), or a submenu of DTC viewing options. The code list includes the

DTC and a brief description (Figure 4-12).

If SureTrack

troubleshooting information from SureTrack (e.g. Common Replaced Parts data (Figure 4-12),

Real Fix and Related Fixes) will also be available. For additional information about using

SureTrack, see SureTrack‚ on page 40.

®

(optional) is active and data is available for a selected DTC, additional

2009 Peugeot 407 1.6L 16V T-Diesel (9HZ)

3

4

1

2

5

Figure 4-12 DTC results

1— Fix It! Icon — opens SureTrack Dashboard

2— Save Icon — saves the displayed DTCs to an (.XML) file

3— SureTrack Status Bar — displays active SureTrack status or result

4— Common Replaced Parts Graph Icon — toggles graph display on/off

5— DTC Results List — displays current DTCs

Submenu options may include:

• Trouble Code Info rmation—opens a list of codes in ECM memory

• History Codes—opens a list of codes whose symptoms are not currently present. History

codes indicate an intermittently occurring problem.

• Failed This Ignition—opens a list of codes that set during the current ignition cycle.

• MIL SVS or Message Requested—displays ECM requests to turn on the malfunction

indicator lamp (MIL) or service vehicle soon (SVS) lamp, or display a driver information alert.

• Last Test Failed—displays a complete list of failed tests.

• T est Failed Since Code Cleared—displays a list of tests that failed since the last time codes

were cleared from ECM memory.

26

Page 34

Scanner Scanner Operation

NOTE:

IMPORTANT:

Clear Codes

The diagnostic tool clears codes from the vehicle electronic control module memory on most

vehicles. If this function is not available on the test vehicle, Clear Codes does not appear as a

menu option.

i Clear Codes is also available from OBD-II Health Check (see OBD Health Check‚ on page 48).

z To clear codes:

1. Select Clear Codes from the Codes Menu.

A confirmation message displays.

2. Make sure any conditions shown on the confirmation message are met, then select Yes.

A “codes cleared” message displays once the operation is complete.

3. Select Continue to return to the Codes Menu.

Clearing codes erases all temporary ECM information, including Freeze Frame/Failure Records.

Make sure no vital diagnostic information will be lost before clearing codes.

Freeze Frame/Failure Records

This selection displays the DTC that was set, along with corresponding data, when the ECM

commanded the malfunction indicator lamp (MIL) to turn on.

27

Page 35

Scanner Scanner Operation

DTC Status

This selection allows you to view the records of a particular DTC.

z To check DTC status

1. Select DTC Status from the Codes Menu.

The DTC Status entry field displays (Figure 4-13).

2. Use the touch keypad on the screen to enter the characters of the DTC.

3. Select the Check Mark icon on the toolbar once all the code characters are entered.

The DTC status report displays (Figure 4-13).

4. Select Back to return to the DTC status entry screen.

5. Select Back again to return to the Codes menu.

Figure 4-13 DTC Status entry field

28

Page 36

Scanner Scanner Operation

NOTE:

Data Display

Select Data to view PID data from the vehicle ECM. In data display mode the screen has a toolbar

and a main body (Figure 4-14).

Figure 4-14 Data display screen

The toolbar control icons are described in Scanner Control Icons‚ on page 17 and Common

Toolbar Control Icons‚ on page 12.

During data display the main body of the screen is divided into two columns; the left-hand column

has a description of the parameter and the right-hand column shows the parameter value or state.

Parameters are listed in the order in which they are transmitted by the ECM, so expect variations

between years, makes, and models.

Up to three parameters can be locked, or fixed, at the top of the list. Locked parameters do not

change as you scroll through the parameter list. The Lock/Unlock icon on the toolbar selects

which parameters are fixed (see Locking Parameters‚ on page 31).

Displayed data may also be paused or saved for detailed review and future reference, see Saving

Files‚ on page 34 and Pausing and Reviewing Data Files‚ on page 35.

Customizing the Data List

The Custom Data List icon on the toolbar is used to determine which specific parameters display.

Minimizing the number of parameters on the data list allows you to focus on any suspicious or

symptom-specific data parameters. You can add or remove most parameters from the list. Certain

vital parameters may not be removed. These appear in gray at the top of the list along with a lock

icon, and they cannot be selected.

i Limiting the number of parameters that display to those that apply to a particular situation results

in a faster data refresh rate, and reduces the amount of memory used for saved files.

29

Page 37

Scanner Scanner Operation

z To create a custom data list:

1. Select the Custom Data List icon on the toolbar.

The data selection screen displays and selection icons appear. Check marks to the left of the

parameter description indicate which parameters are selected for display. A second smaller

check box indicates a parameter that is locked.

The toolbar icons provide options for selecting and deselecting parameters to include or

remove from the custom data list:

Icon Description

Select/Deselect, use to mark individual

parameters to hide or display. Locked

parameters cannot be deselected.

Select All/Deselect All, use to hide or

display all of the parameters in the list.

Locked parameters cannot be hidden. Items

at the top of the list that cannot be

highlighted are locked and cannot be turned

off.

2. Create a custom data list by selecting (check mark box by parameter name) the parameters

to include.

3. Select Back to display the updated data list.

Changing Screen Views

Selecting the View icon opens a drop-down menu of options:

• PID List

• 1 Graph

• 2 Graph

• 4 Graph

The PID (parameter identification) List view is a 2-column display with the name of the parameters

in the left column and their current values in the right column (Figure 4-15).

The 1, 2, and 4 Graph views divide the screen horizontally to simultaneously display data graphs

for the indicated number of parameters (Figure 4-15). Use the scroll bar or the up (b) and down

(d) icons to view other parameters in the list.

30

Page 38

Scanner Scanner Operation

NOTE:

Figure 4-15 Four graph view

i Any previously set conditions, such as held data or locked lines of data, remain in effect when the

screen view is changed.

Locking Parameters

Use the Lock/Unlock icon to hold selected lines of the data in place and prevent them from

scrolling, or to release previously locked lines of data. Up to three lines of data may be held at a

time. This feature allows you to position related parameters together, making it easier to monitor

their values and spot inconsistencies.

Locked parameters display as the top frames on the main body of the display screen, as well as

at their usual position within the data list (Figure 4-16). A lock icon appears to the left of the

parameter name to indicate it is locked.

z To lock parameters:

1. Highlight the parameter to be locked.

2. Select the Lock/Unlock icon on the toolbar to lock it.

A copy of the locked parameter is now shown at the top of the data list, and a lock icon

appears alongside the parameter name.

3. Highlight and select additional parameters to lock.

31

Page 39

Scanner Scanner Operation

NOTE:

Up to three parameters can be locked at a time. Once locked, a parameter remains locked

until it is manually unlocked, or communication with the vehicle is stopped.

2009 Peugeot 407 1.6L 16V T-Diesel (9HZ)

Figure 4-16 Locked parameters

i If three parameters are locked, one of them must first be unlocked before another parameter can

be locked.

z To unlock parameters:

1. Scroll through the data list and highlight the parameter to be unlocked, or released.

2. Select the Lock/Unlock icon on the toolbar.

The released parameter and the lock icon disappear from the list at the top of the data list.

3. Repeat Step 1 and Step 2 to release other parameters if needed.

Setting Trigger Levels

The trigger icon allows you to configure the diagnostic tool to automatically save PID data from

buffer memory to a file when a parameter value crosses a threshold. When triggering is armed, a

"Trigger event" pauses data collection and saves data to a file.

Selecting the Trigger icon opens a menu that includes:

• Set Trigger—establishes upper and lower signal values to initiate an event capture for the

highlighted parameter.

• Arm Trigger—activates the diagnostic tool to capture an event when the signal crosses a

threshold value.

Trigger lines change colors to indicate the trigger is armed.

• Clear All Triggers—deletes all previously set trigger levels.

If triggers are set the menu options are:

• Clear Trigger—deletes set trigger levels for the highlighted parameter.

• Disarm T rigger—de-activates event capture capability.

• Clear All Triggers—deletes all previously set trigger levels.

32

Page 40

Scanner Scanner Operation

NOTE:

z To set trigger levels :

1. Highlight the parameter to be used for triggering the recording.

2. Select the Trigger icon.

3. Select Set Trigger from the drop-down menu.

A graph of the highlighted parameter with a trigger toolbar above it fills the main body of the

screen (Figure 4-17).

2009 Peugeot 407 1.6L 16V T-Diesel (9HZ)

Figure 4-17 Trigger set screen

The trigger level line displays as a solid line running horizontally across the data graph. An

upper and lower trigger level must be set, the upper level is set first.

4. Select the plus (+) and minus (–) icons on the toolbar, or use the up b and down d arrow

buttons to position the upper trigger level to where you want it on the graph.

5. Select a on the toolbar, or press the Y/a button, to set the upper threshold.

A lower trigger level line now appears at the mid-point of the graph.

6. Select the plus (+) and minus (–) icons on the toolbar, or use the up b and down d arrow

buttons to position the lower trigger level line to where you want it on the graph.

7. Select a on the toolbar, or press the Y/a button, to set the lower threshold.

The display returns to the PID data view and the trigger points appear as horizontal lines across

the designated parameter graph. Repeat this procedure to establish trigger points for other

parameters if desired. Once armed, any data points that register outside of your set conditions

pause data collection and save data to a file.

i Only three parameters can have trigger levels set at one time, but only one of the conditions needs

to be satisfied for triggering to occur.

33

Page 41

Scanner Scanner Operation

NOTE:

z To arm triggers:

1. Select the Trigger icon on the toolbar.

2. Select Arm Triggers from the drop-down menu.

The trigger lines on the data graphs change color to indicate an armed condition.

Triggers for all of the graphs are armed simultaneously. Once triggering is armed, it remains in that

state until you switch it off. If trigger settings are modified or are added for other parameters, they

are armed as soon as you exit the setting screen.

Saving and Reviewing Scanner / OBD-II/EOBD Data Files

The following procedures are used when saving and reviewing data files for Scanner and

OBD-II/EOBD.

Saving Files

During normal operation, data from the vehicle’s ECM is continuously being stored in buffer

memory as it is displayed onscreen. Buffer memory is limited to a predetermined “total” size and

is displayed on the counter (located below the toolbar on the right side of the screen)

(Figure 4-19).

Selecting Save writes the stored buffer memory to a file. Saving data is useful when trying to

isolate an intermittent problem or to verify a repair during a road test. The saved file can be played

back (similar to a movie clip) by selecting Previous Vehicles and Data > V iew Saved Dat a. See

View Saved Data‚ on page 72 for additional information.

i The Save icon performs the same function as “Save Movie” function choice for the programmable

Shortcut button, see Configure Shortcut Button‚ on page 126 for details.

The saved data file can also be downloaded to a personal computer (PC) using the Mini USB jack.

Once connected to the PC, the data files can be printed, transferred, and copied using

ShopStream Connect. ShopStream Connect is an application that creates an interface between

the diagnostic tool and a PC. The ShopStream Connect application is available free online, see

the ShopStream Connect website information at the front of this manual for additional information.

The toolbar control icons are described in Scanner Control Icons‚ on page 17 and Common

Toolbar Control Icons‚ on page 12.

34

Page 42

Scanner Scanner Operation

4BWJOH4$.

/PUF4BWJOHMBSHFGJMFTNBZUBLFTFWFSBMNJOVUFT

z To save data:

• Select Save.

A save dialog box displays while data is being saved. The data is saved when the message

box disappears.

Figure 4-18 Save dialog box

Saving Screens

The Shortcut button can be programmed to save a snapshot of a visible screen as a bitmap file,

see Configure Shortcut Button‚ on page 126 for details The saved file can be viewed by selecting

Previous Vehicles and Data > View Saved Dat a, see View Saved Data‚ on page 72 for

additional information.

Pausing and Reviewing Data Files

During normal operation, data from the vehicle’s ECM is continuously being stored in buffer

memory as it is displayed onscreen. The Pause feature, allows you to temporarily pause data

collection to review it in detail.

z To pause and review data

Toolbar control icons are described in Scanner Control Icons‚ on page 17 and Common Toolbar

Control Icons‚ on page 12.

1. While viewing data, select the Pause icon.

On the toolbar, the playback control icons are displayed. A counter displays along the right-

hand edge of the screen between the toolbar and the main body. A bar graph to the left of the

counter shows how much data is in the memory buffer. A slider on the bar graph indicates the

position of the current screen in relation to the entire contents of the data buffer.

Use the slider to quickly scroll through the data. Use the control icons to accurately position

the cursor. The cursor (vertical line), indicates your position when in the graph mode, appears

once you begin navigating (Figure 4-19).

35

Page 43

Scanner Scanner Operation

NOTE:

9

87

6

54321

2009 Peugeot 407 1.6L 16V T-Diesel (9HZ)

1— Skip Back

2— Skip Forward

3— Step Back

4— Step Forward

5— Record

Figure 4-19

2. Scroll up or down to review the list of data.

3. Select the desired control icon to move forward or back incrementally in the selected direction.

6— Bar Graph

7— Slider

8— Counter (current position / total)

9— Cursor

z To resume:

• Select the Record icon.

The display changes back to display data and the Pause icon is shown on the toolbar. A

vertical rule runs through the data graph to indicate data was paused at that point.

i The Shortcut icon can be set to perform the Pause/Play function. See Configure Shortcut Button‚

on page 126 for additional information.

Functional T ests

The Functional Tests selection is used to access vehicle-specific subsystem tests. Available

tests vary by manufacturer, year, and model. Only the tests available for the identified vehicle

display in the menu.

There are several types of functional tests:

• Information Test s—these are read-only tests, like selecting “VIN” from a Functional Tests