Page 1

User Manual

June 2010

EAZ0067L10A Rev. A

Page 2

Trademarks

IMPORTANT:

Blue Point, MICROSCAN, Scanner, Snap-on, and ShopStre am Conne ct are trademar ks of Snap- on Inco rpor ated,

registered in the United States and other countries.

All other marks are trademarks or registered tr ademarks of th eir resp ective hold ers.

Copyright Information

©2010 Snap-on Incorporated. All rights rese rved.

Disclaimer of Warranties and Limitation of Liabilities

The information, specifications and illustrations in this manual are based on the latest information available at the

time of printing. While the authors have taken due care in the p rep ara tion of this manua l, nothing con t ained he rein:

• Modifies or alters in any way the standard terms and cond itions of the purchase, lea se, or rent al agre ement

under the terms of which the equipment to which this m anual relate s was acquired.

• Increases in any way the liability to the customer or to third parties.

Snap-on reserves the right to make changes at any time without notice.

Before operating or maintaining this u nit, please read this ma nual carefully paying extra attention to the safety

warnings and precautions.

Visit our websites at:

www.diagnostics.snapon.com/microscan (North America)

snapondiag.com (United Kingdom)

sun-diagnostics.com (United Kingdom)

For Technical Assistance Call

1-800-424-7226 (North America)

CALL +44 (0) 845 601 4736 (United Kingdom)

E-mail DiagnosticsUKproductsupport@snapon.com (United King dom)

For technical assistance in all other markets, cont act your selling agent.

ii

Page 3

Safety Information

!

DANGER

!

WARNING

!

CAUTION

For your own safety and the safety of others, and to prevent damage to the equipment an d

vehicles upon which it is used, it is important that these Safety Messages be read and understood

by all persons operating, or coming into contact with, the equip ment.

This product is intended for use by properly trained and ski lled pro fessional automo tive

technicians. The safety messages presented throughout this manual are reminders to the

operator to exercise extreme care when using this test instrument.

There are many variations in procedures, techniques, tools, and p art s for servicing vehicles, as

well as in the skill of the individual doing the work. Because of the vast number of test applications

and variations in the products that can be tested with this instrument, we cannot possibly

anticipate or provide advice or safety messages to cover every situation. It is the automotive

technician’s responsibility to be knowledgeable of the system being tested. It is essential to use

proper service methods and test procedures. It is import ant to perform tests in an appropriate and

acceptable manner that does not endanger your sa fety, the safety of others in the work area, the

equipment being used, or the vehicle being tested.

It is assumed that the operator has a thorough underst anding of vehicle systems before using this

product. Understanding of these system principl es and oper ating theor ies is nece ssary for

competent, safe and accurate use of this instrument.

Before using the equipment, always refer to and follow the safety messages and app licable te st

procedures provided by the manufacturer of the vehicle or equipment being tested. Use the

equipment only as described in this manual.

Read, understand and follow all safety messag es and instructio ns in this manual, the

accompanying safety manual, and on the test equi pment.

Safety Message Conventions

Safety messages are provided to help prevent personal injury and equipm ent damage. All safety

messages are introduced by a signal word indicating the haza rd level.

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious

injury to the operator or to bystanders.

Indicates a potentially hazardous situation which, if n ot avoided, could result in death o r serious

injury to the operator or to bystanders.

Indicates a potentially hazardous situation which, if not a voided, may r esult in modera te or mino r

injury to the operator or to bystanders.

iii

Page 4

Safety Information Important Safety Instructio ns

!

WARNING

Safety messages contain three different type styles.

• Normal type states the hazard.

• Bold type states how to avoid the hazard.

• Italic type states the possible consequences of not avoid ing th e hazard.

An icon, when present, gives a graphical description of the potential hazard.

Example:

Risk of unexpected vehicle movement.

• Block drive wheels before performing a test with engine running.

A moving vehicle can cause injury.

Important Safety Instructions

For a complete list of safety mess ages, refer to the accomp anying safety manual.

SAVE THESE INSTRUCTIONS

iv

Page 5

Contents

Safety Information..................................................................................................................... iii

Contents...................................................................................................................................... v

Chapter 1: Using This Manual................................................................................................... 1

Conventions.................................................................................................................................. 1

Bold Text................................................................................................................................ 1

Terminology ........................................................................................................................... 1

Notes and Important Messages............................................................................................. 1

Procedures............................................................................................................................. 2

Additional Manuals........... ... .... ... ....................................... ... ... ... ... .... ... ........................................ 2

Chapter 2: Introduction.............................................................................................................. 3

Functional Description...................................... .... ... ... ... .... ... ...................................... .... ... ........... 3

Technical Specifications............................................................................................................... 5

Control Buttons............................................................................................................................. 6

Y (Accept) Button................................................................................................................... 6

N (Back) Button...................................................................................................................... 6

Power Button ......................................................................................................................... 6

Up Button............................................................................................................................... 6

Down Button .......................................................................................................................... 6

Connections.................................................................................................................................. 7

USB Port....................... .... ... ... ... ....................................... ... ... .... ... ... ... .................................. 7

Data Cable Connector ........................................................................................................... 7

Power Supply ............................................................................................................................... 7

Vehicle Power........................................................................................................................ 7

USB Power ... ... .... ... ... ....................................... ... ... .... ... ... ... ....................................... ... ........ 7

Battery Power ........................................................................................................................ 7

Data Cable.................................................................................................................................... 7

Chapter 3: Getting Started......................................................................................................... 8

Supplying Power.................. .... ...................................... .... ... ... ... ... ............................................... 8

Installing the Battery..................................................................................................................... 8

Connecting to Vehicle Power ....................................................................................................... 9

Powering On the Unit ................................................................................................................... 9

Selecting a Language................................................................................................................... 9

Chapter 4: On-Board Diagnostics (OBD) ............................................................................... 10

Global OBD and What it Means ................................................................................................. 10

OBD-II Start-up Phase......................................................................................................... 10

EOBD Start-up Phase.......................................................................................................... 11

OBD-II/EOBD Limitations ..................................... ... ... ... .... ... ... ... ....................................... ... ...... 11

OBD-II/EOBD Advantages ............ ....................................... ... ... ... .... ... ... ................................... 11

Communication Protocols........................................................................................................... 11

What is CAN? ...................................................................................................................... 12

v

Page 6

Contents

Diagnostic Services Introduction...... ... .... ... ... ... .... ...................................... .... ... ... ... ... .... ............12

Readiness Monitor Test Status............................................................................................ 12

MIL Status............................................................................................................................ 14

Diagnostic Service Definitions.............................. ... ....................................... ... ... ... ... .... ... ......... 15

Service $01: Display Current Data....................................................................................... 15

Service $02: Powertrain Freeze Frame Data....................................................................... 15

Service $03: Emission-related DTCs................................................................................... 16

Service $04: Clear/Reset Emission-related Diagnostic Data............................................... 17

Service $05: Oxygen Sensor Monitoring Test Results......................................................... 18

Service $06: Specific Monitored Systems Test Results....................................................... 22

Service $07: Emission-related DTCs detected during Current or

Last Completed Drive Cycle (Pending Codes)..................................................................... 23

Service $08: On-board Activation Tests............................................................................... 24

Service $09: Vehicle Information ...................... ... ... .... ... ... ....................................... ... ... ... ... 24

Service $09: In-use Performance Tracking.......................................................................... 24

Chapter 5: Navigation .............................................................................................................. 26

Screen Layout ............................................................................................................................ 26

Trouble Code Screens................................................................................................................ 26

Menu Screens ......................... ... ... ... ... ....................................... ... .... ... ... ... .... ............................ 27

Main Menu ........................................................................................................................... 28

Global OBD-2/EOBD Menu............................ ... ... ... ....................................... ... ... .... ... ... ... ... 28

Exit Menu............................................................................................................................. 29

Data Screens.............................................................................................................................. 30

Text View ............................................................................................................................. 30

Graph View ..........................................................................................................................31

Screen Messages....................................................................................................................... 33

Loading and Connecting Messages..................................................................................... 33

Confirmation Messages ....................................................................................................... 33

Warning Messages .............................................................................................................. 33

Error Messages.................................................................................................................... 33

Chapter 6: Operations.............................................................................................................. 34

Global OBD-2/EOBD.................................. ... ....................................... ... ... .... ... ... ... ................... 34

Readiness Status................................................................................................................. 34

Current Data . ... .... ... ... ... ....................................... ... .... ... ... ... ... ....................................... ...... 35

Freeze Frame Data........... ... ....................................... ... ... ... ... .... ... ...................................... 35

Confirmed Codes.................................................................................................................36

Clear Codes......................................................................................................................... 36

O2 Monitors ......................................................................................................................... 37

Non-Cont. Monitors..............................................................................................................37

Pending Codes .................................................................................................................... 38

Request Control of On-board System............ ... ... ... .... ... ... ...... .... ... ... ... .... ... ... ... ... .... ... ... ... ... 38

Vehicle Information ..............................................................................................................38

Movie.......................................................................................................................................... 39

Settings....................................................................................................................................... 39

Global OBD-2/EOBD Help................ ... .... ... ....................................... ... ... ... .... ... ... ......................40

Select Protocol ........................................................................................................................... 40

vi

Page 7

Contents

Chapter 7: Data Parameters .................................................................................................... 42

Long Parameter Names .......................... ... ... ... .... ...................................... .... ... ... ... ... .... ............ 42

Short Parameter Names ...................................................................................................... 46

DTC Association .................................................................................................................. 50

Chapter 8: Maintenance........................................................................................................... 54

Cleaning and Damage Inspection .............................................................................................. 54

Replacing the Battery....... ... .... ... ....................................... ... ... ... ... .... ... ...................................... 54

Storage Tips........... .... ... ... ....................................... ... ... .... ... ... ... ................................................ 55

Appendix A: Troubleshooting................................................................................................. 56

Communication Problems ..........................................................................................................56

Erratic or No Communication............................................................................................... 56

Testing the Data Link Connector ......................................................................................... 56

Check the Malfunction Indicator Lamp................................................................................. 58

Appendix B: Downloading and Installing Software Updates ............................................... 59

Check for Service Updates Before Use...................................................................................... 59

Verifying Minimum PC Requirements......................................................................................... 59

Verifying PC System Properties........................................................................................... 60

Downloading and Installing ShopStream Connect..................................................................... 60

Downloading Service Updates ................................................................................................... 62

Before You Begin................................................................................................................. 63

Installing a Service Update .................................................................................................. 63

Appendix C: Software License Agreement............................................................................ 66

Appendix D: Product Warranty............... ... ... .... ... ... ... ....... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ... ... 69

Index.......................................................................................................................................... 70

vii

Page 8

Chapter 1 Using This Manual

This manual contains tool usage instructions.

Some of the illustrations shown in this manual may contain modules and optional equipment that

are not included on your system. Contact your sales representative for availability of other

modules and optional equipment.

1.1 Conventions

The following conventions are used.

1.1.1 Bold Text

Bold is used in procedures to highlight selectable items such as bu ttons and menu o ptions.

Example:

• Press the Y button.

1.1.2 Terminology

The term “select” means highlighting a button or menu item u sing the arrow buttons an d pressing

the Y button to confirm the selection.

Example:

• Select Clear Codes.

The above statement abbreviates the following procedu re:

1. Scroll with the arrow buttons to highlight Clear Codes on the menu.

2. Press the Y button.

1.1.3 Notes and Important Messages

The following messages are used.

Notes

A NOTE provides helpful information such as additional explanations, tips, and comment s.

Example:

1

Page 9

Using This Manual Additional Manuals

NOTE:

IMPORTANT:

i For additional information refer to...

Important

IMPORTANT indicates a situation which, if not avoided, may result in damage to the test

equipment or vehicle.

Example:

The Test ID Table below is for CAN Protocol only.

1.1.4 Procedures

An arrow icon indicates a procedure.

Example:

z To change screen views:

1. Scroll to highlight Settings on the main menu and press Y to select.

A sub-menu of language options displays.

2. Highlight the desired language and press Y to select.

1.2 Additional Manuals

This tool works in conjunction with other software products. All of the required manuals are

included on the Diagnostics website. See the appropriate manu al for information regarding these

products.

2

Page 10

Chapter 2 Introduction

Y our new MICROSCAN™ scan tool provides European On-board Diagnostic (EOBD) trouble

codes and datastream information for electronic vehicle control systems. Your MICROSCAN

can also graph live data parameters, recor d data, clear diagnostic trouble codes (DTCs) from

the electronic control module (ECM), and reset the vehicle malfunction indicator lamp (MIL).

Contact your sales representative for availability of accessories and upgrades.

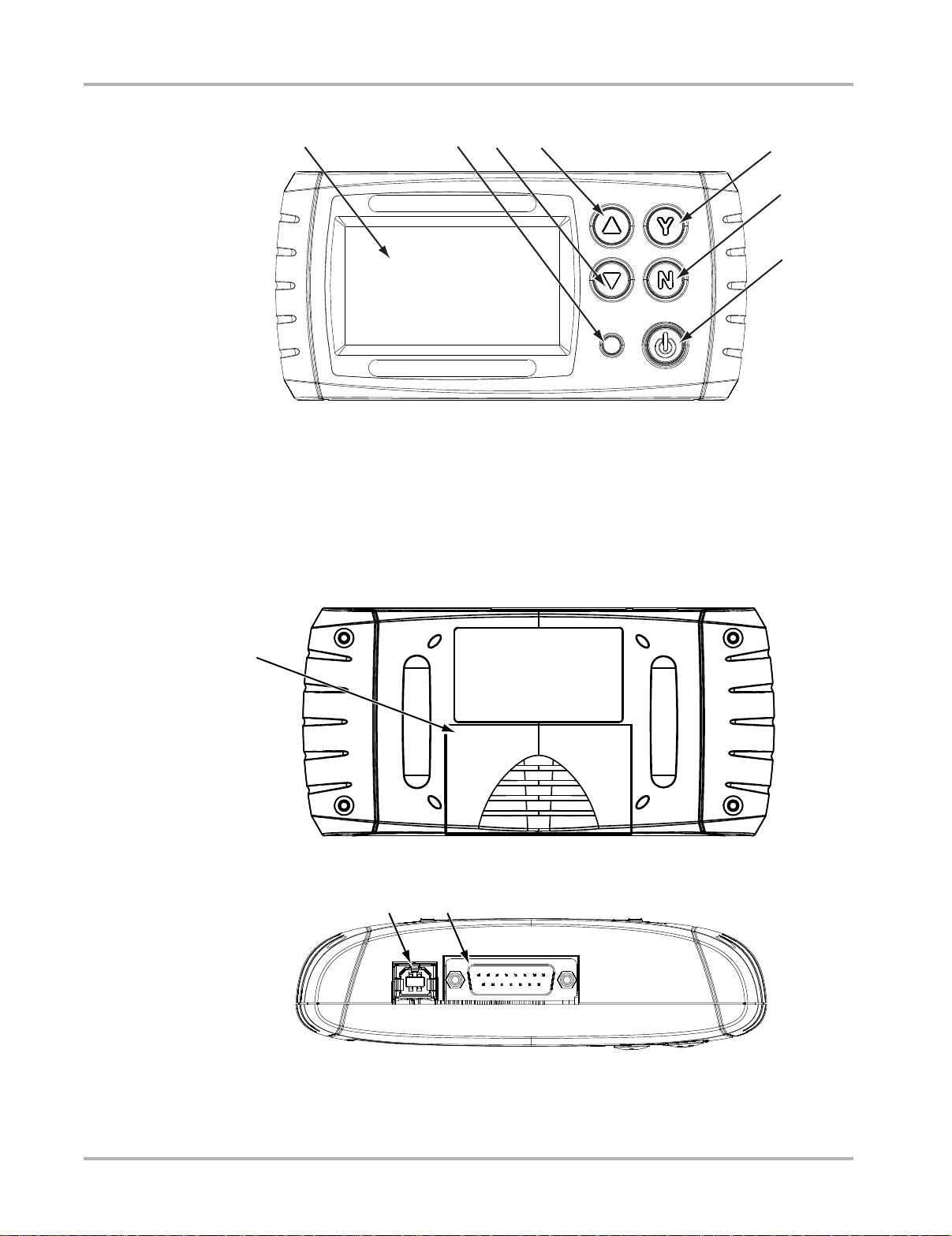

Figure 2-1

2.1 Functional Description

This section illustrates external features, ports and connectors of the OBD unit.

MICROSCAN

3

Page 11

IntroductionFunctional Description

1234

5

6

7

1

2

1— Liquid Crystal Display (LCD) Screen

2— Power Light emitting Diode (LED)

3— Down or Right Button

4— Up or Left Button

5— Y (Yes) Button

6— N (No) Button

7— Power Button

Figure 2-2

Front view

1

1— Battery Cover

1— USB Port

2— Data Cable Connector

Figure 2-3

Figure 2-4

Back view

T op view

4

Page 12

IntroductionTechnical Specifications

2.2 T echnical S pecifications

Display:

Liquid Crystal display (LCD) backlight monochrome screen

2.83 inch (72 mm) diagonal

Battery:

9-volt

Dimensions:

Width:

5.53 inch

140.4 mm

Height:

2.68 inch

68 mm

Depth:

1.57 inch

40 mm

Weight:

Without battery:

6.4 ounce

199 g

Operating Temperature Range:

14 to 140°F

–10 to 40°C

Storage Temperature Range:

–4 to 149°F

–20 to 65°C

Data Buffer:

64 data frames (values per parameter)

Communication Protocols:

Your MICROSCAN supports the following OBD-II/EOBD communications protocols:

• SAE J1850 (VPW and PWM)

• ISO 9141-2

• ISO 14230-2 (KWP 2000)

• ISO 15765-4 (CAN)

5

Page 13

IntroductionControl Buttons

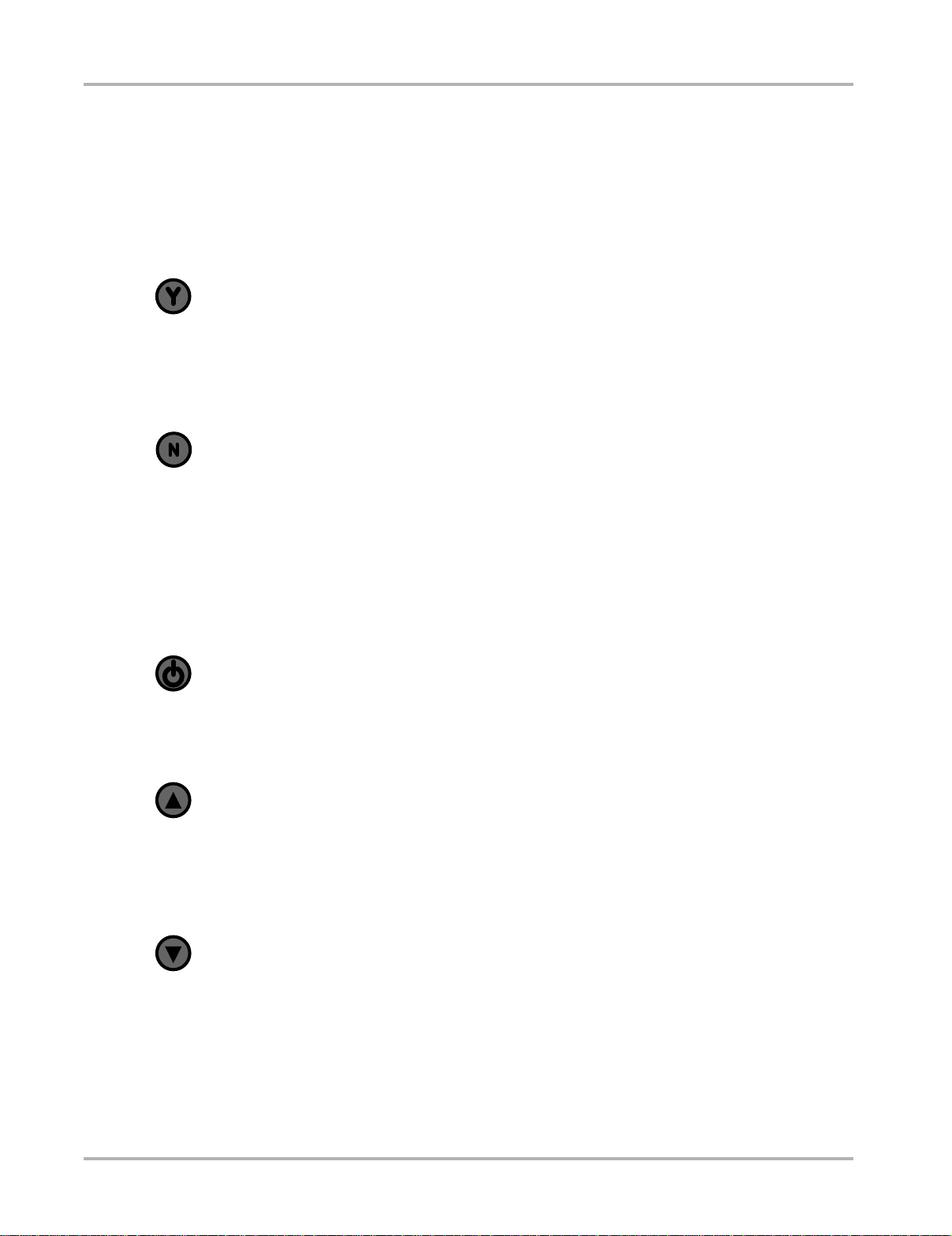

2.3 Control Buttons

The MICROSCAN has the following control buttons; N (back), Y (accept), b (Up), d (Down),

and Power (Figure 2-2).

2.3.1 Y (Accept) Button

The Y button is used to do the following:

• To select the item that you highlighted using the direction buttons.

• To answer “Yes” when a Yes or No choice is given.

2.3.2 N (Back) Button

The N button is used to do the following:

• To open the Exit Menu

• To exit a menu or program.

• To close an open list and return to the previous menu.

• To answer “No” when a Yes or No choice is given.

• To return to the main menu.

2.3.3 Power Button

The Power button powers up the tool, and turns it off.

2.3.4 Up Button

The Up button is used to do the followin g:

• Move the highlight or cursor up when the screen arr ows are vertically aligned.

• Move the highlight or cursor right when the screen arrows ar e horizontally aligned.

2.3.5 Down Button

The Down button is used to do the following:

• Move the highlight or cursor down when the screen arrows are ver tically aligned.

• Move the highlight or cursor left when the screen ar rows are h orizo nt ally aligne d.

6

Page 14

IntroductionConnections

2.4 Connections

The MICROSCAN scan tool uses two connections; a USB port and a data cab le port

(Figure 2-4 on page 4):

2.4.1 USB Port

The USB port is for connecting to a personal computer (PC) and is used for up dating the

internal software, and for transferring saved files. The scan tool also re ceives power through

the USB port when it is connected to a PC.

2.4.2 Data Cable Connector

The data cable connector is used to connect the MICROSCAN scan tool to a vehicle data link

connector (DLC) for testing.

2.5 Power Supply

The MICROSCAN scan tool can receive power from th e test vehicle or through the USB port

when connected to a personal computer.

2.5.1 V ehicle Power

Vehicle power is required for the scan to ol to proper ly communica te with th e vehicle during

testing. The Data Cable provides power to th e unit throu gh the vehicle dat a link conn ector

(DLC). The scan tool turns on automatically and checks for stored codes whenever it is

connected to a DLC that provides power.

2.5.2 USB Power

The MICROSCAN scan tool can be powered by a personal computer (PC) when connected

to the PC with a standard USB cable.

2.5.3 Battery Power

The MICROSCAN scan tool can receive power from the internal 9V battery. Use battery

power to review saved files only.

2.6 Data Cable

A Data Cable is included with your MICROSCAN scan tool. The data cable plugs directly into

the 16-pin data link connector (DLC) on OBD-II vehicles.

7

Page 15

Chapter 3 Getting Started

To get started using your new MICROSCAN™ supply power to the tool.

3.1 Supplying Power

There are three ways to supply power to this scan tool:

• Install the battery

• Connect to vehicle power

• Connect to a personal computer (PC) with a USB cable

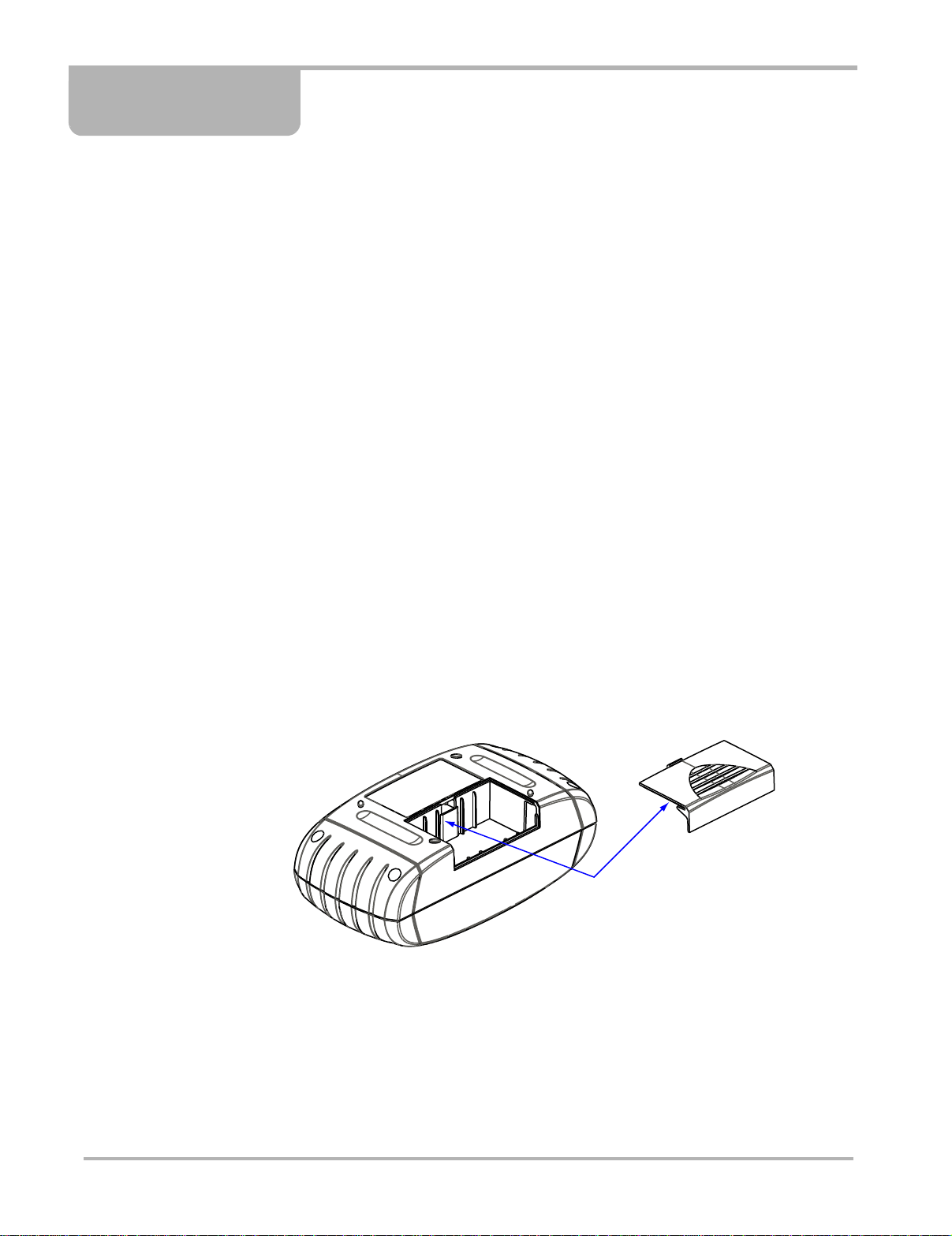

3.2 Installing the Battery

The MICROSCAN scan tool comes with a 9V battery that inst alls into a compartment on the

back side of the unit. When replacing the battery , use a heavy-duty typ e battery from a reliable

manufacturer . Ligh t-duty in expensive batter ies may not pr ovide suf ficient po wer to opera te

the scan tool, and may leak and damage your MICROSCAN.

z To install the battery:

1. Slide the battery cover on the back of the MICROSCAN unit down to release the lock tabs.

2. Pivot the cover up slightly and lift it off of the unit (Figure 3-1).

Figure 3-1

3. Connect a new 9-volt battery to the connector and fit the battery into th e comp artmen t.

4. Fit the center tab on the battery cover into the slot on the tool housing, pivot the cover

down, and slide it into position so that it locks into place on the housing.

Note the following safety warnings when installing batteries.

Battery cover removal

8

Page 16

Getting Started Connecting to Vehicle Power

!

WARNING

Risk of personal injury or harm.

• Always make sure the battery polarities (“+” and “–”) are correct when installing.

• Do not expose batteries to excessive heat.

• Use batteries from a reputable manufacturer only.

• Do not try to recharge batteries that are not specifically designed to be recharged.

• Do not allow children to install batteries unsupervised.

• Follow the battery manufacturer's instructions as to proper handling, storage, and

disposal of batteries.

Improper use of batteries can result in personal harm.

3.3 Connecting to V ehicle Power

The Data Cable, included with your MICROSCAN unit, plugs directly into the data link

connector (DLC) on OBD-II/EOBD vehicles.

z To connect to vehicle power:

1. Attach the 15-pin connector of the Data Cable to the MICROSCAN unit. Tighten the

captive screws to ensure a good connection.

2. Connect the 16-pin connector of the Data Cable to the DLC of the test vehicle.

3. Switch the vehicle ignition on.

4. The MICROSCAN unit automatically powers on and checks for diagnostic trouble codes

(DTCs) stored in the electronic control module (ECM) of the vehicle.

3.4 Powering On the Unit

When vehicle power is not available, you can manually power on your MICROSCAN unit

using the internal 9-volt battery. To manually power the tool, Press the Power button on the

front of the unit. Press the Power button on the front of the unit.

3.5 Selecting a Language

English is the default language selection in the scan tool software. Howe ver , you can ch ange

the language setting if desired.

z To change the language setting:

1. Select Settings from the main menu.

2. Select Languages from the settings menu.

3. Scroll to highlight the desired language and press Y.

4. Press N to exit.

The language remains as selected after powering down.

9

Page 17

Chapter 4 On-Board Diagnostics (OBD)

Y our new MICROSCAN conforms to Global OBD (OBD-II in North America and EOBD in Europe)

standards, and is designed for testing compliant vehicles. This chapter describes Global OBD.

4.1 Global OBD and What it Means

Many countries have enacted strict emission related regulations that will drive increased

technology into the modern automobile in order to reduce the exhaust emissions. Eur opean and

North American countries lead the way by adopting technology that st and ardizes the way these

vehicles can be checked for compliance.

The OBD-I (On-Board Diagnostics I) system was introduced in the ear ly 1980s an d by 1988 all

new cars and light trucks sold in California had to have OBD-I. The fund ament al e lement s of the

OBD-I are the electrical components (which influe nce exhaust emissions) that are mo nitored by

the engine management system. An optical warning signal is given in the event of an OBD-I

relevant failure. This fault can be read out by way of a flashing code.

OBD-II has been compulsory on all vehicles in the US market since January 1 996. EOBD

(European On-Board Diagnostics) is the European e quivalent to OBD-II. It was introduced in 2000

and became effective in January 2001. There a re a few differences between EOBD and OBD-II

but none that will affect scan tool operation. All the communication protocols for both programs are

identical. Vehicle emission strategies an d certification procedures vary betwe en countries, states

and regions. Always use service information specific to the country and emission certification.

EURO-3, also known as EOBD, is a continuation of the emission regulations known as EURO-1

and EURO-2. In addition to introducing stricter emission limits, the directive now also covers the

monitoring of emission related components and fun ctions during opera tion.

The OBD-II and EOBD system must show the failure of an emission related component or system

to the driver using a MIL (Malfunction Indicator).

What does OBD-II and EOBD mean for the Rep air Shop?

A universal connector can now be used on any OBD-II 1996 and newer an d EOBD 2001 and

newer vehicle, giving the shop more diagnostic cove rage th at was not pr eviously possib le.

4.1.1 OBD-II St art-up Phase

About 40% of the vehicles of model year 1995 sold in the USA were OBD-II prepared. Beginning

in 1996, all vehicles sold in the USA were supposed to comply with OBD-II standards.

However, some 1996 and 1 997 ve hicles were not fu lly OBD-II complian t. This mea ns that so me

early OBD-II vehicles may:

• Not have the standardized diagnostic connector location o r

• Have missing or only partially implemented OBD-II monitors.

10

Page 18

On-Board Diagnostics (OBD) OBD-II/EOBD Limitations

4.1.2 EOBD St art-up Phase

The European vehicle manufacturers also needed time to phase in and develop EOBD tests and

software in their electronic control modules (ECMs). Some of th e manufacturer s alre ady had

experience with the USA OBD-II. Others may still have to improve their most recent software

versions. This means that EOBD is experiencing similar phase in problems as OBD-II, with some

2001 and 2002 vehicles having limited EOBD functionality.

4.2 OBD-II/EOBD Limitations

Generic OBD-II/EOBD data is currently limited to:

• Emission diagnostics or

• Problems related to the Malfunction Indicator.

Access to all available data in the ECM (other systems, other parameters, enhanced diagnostics)

will still require a scan tool with manufacturer specific capabilities.

4.3 OBD-II/EOBD Advantages

The advantage of OBD-II and EOBD is the simple “Plug and Play” function:

• Unlike using a manufacturer specific scan tool or vehicle communication sof tware , one does

not have to select the vehicle make, year or model.

• The communication protocol can be automatically dete cted by the scan tool software.

• Depending on the ECM and amount of parameters selected, dat a update rates may vary. By

using functions as Custom Data List and Manual Select PID in Service $01, sometimes data

update rates may be higher than with manu factu rer specific so f tware. This can be help ful in

finding intermittent signal gulches.

Data and monitors that are not described in the OBD/EOBD st anda rds are filtered out, altho ugh

they are selectable.

4.4 Communication Protocols

A communication protocol is a standardized way of dat a commun ication b etween an ECM a nd a

scan tool.

For vehicles that comply with OBD-II and EOBD, the following communi catio n protocol s are

permitted:

• ISO 9141-2 (K-LINE)

• SAE J1850 PWM (Pulse Width Modulation) and VPW (Variable Pulse Width)

• ISO 14230-2 (Keyword Protocol 2000)

• ISO 15765-4 (CAN)

The scan tool can be setup so it will automatically determine the communication protocol used in

the vehicle under test.

11

Page 19

On-Board Diagnostics (OBD) Diagnostic Services Introduction

4.4.1 What is CAN?

CAN stands for Controller Area Network and means tha t control units are part of a network and

can interchange data. Although some car manufacturer s have used CAN for some year s for

communication between electronic control modules (E CMs), it was not d irectly conn ected to the

diagnostic connector . In approximately 2001/2002 for Europe and 2003 for No rth America, the first

car manufacturers started to connect the CAN communication lines to the dia gnostic connecto r.

CAN will be the only required protocol in near future for OBD.

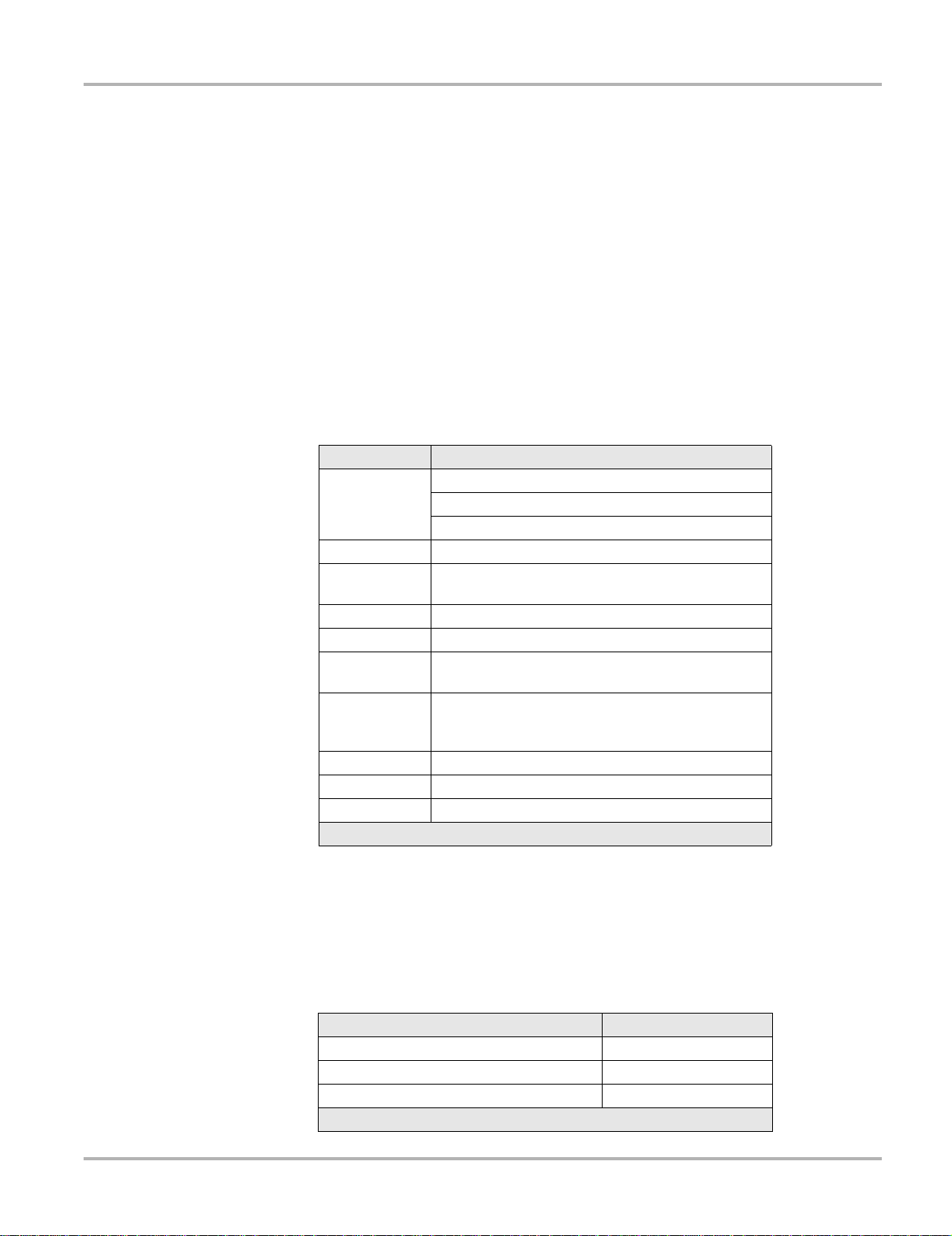

4.5 Diagnostic Services Introduction

The OBD program is divided into several sub programs, called ‘Service $xx’. This complies to the

EOBD/OBD-II standards:

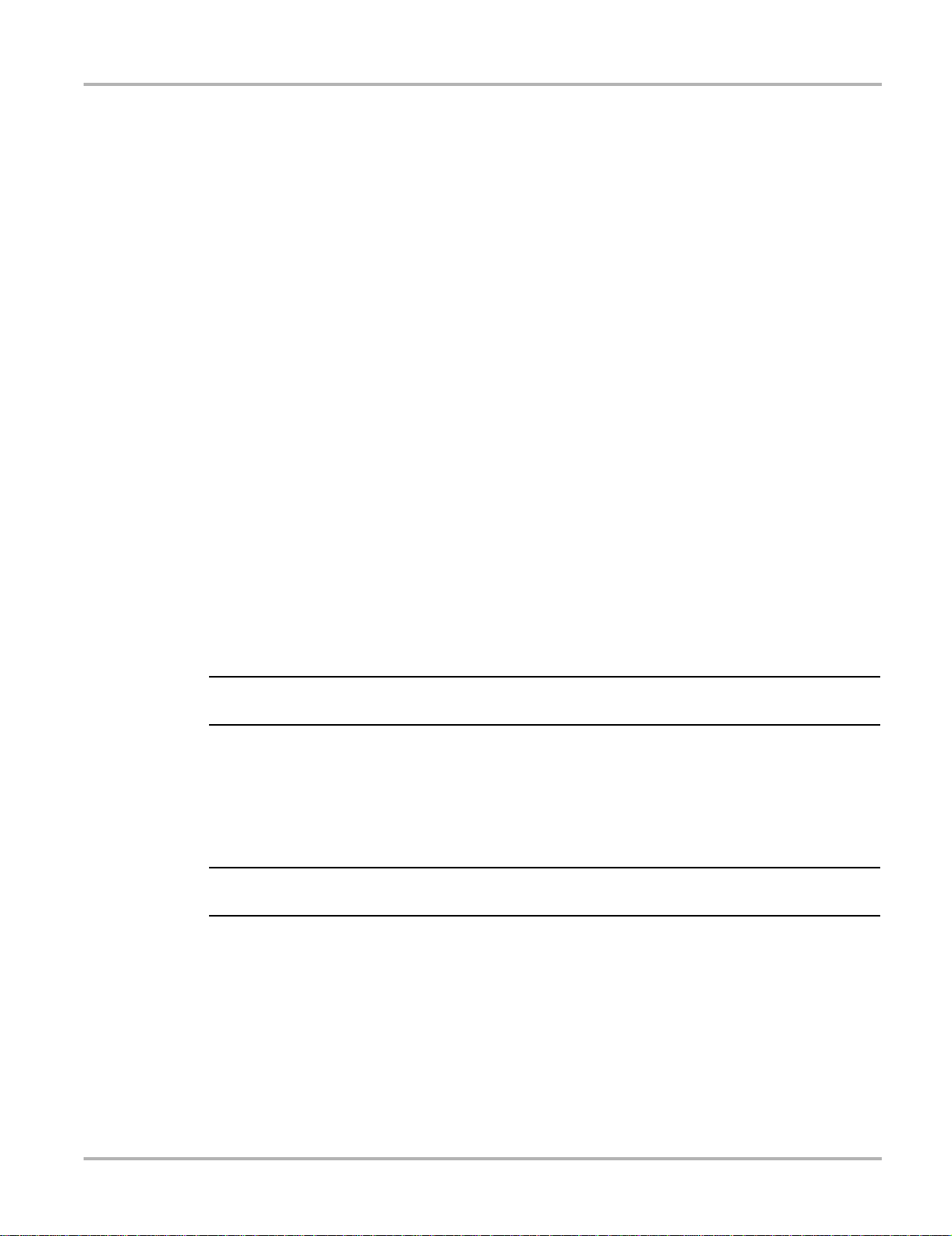

Table 4-1

1. Manual selection of Test IDs is not supported.

Diagnostic services

Service Description

System readiness test status display

$01

$02 Request powertrain freeze frame data

$03

$04 Clear/reset emission-related diagnostic data

$05 Oxygen sensor monitoring test results

$06

$07

$08 Onboard system activation tests

$09 Request vehicle information

$09 In-use Performance Tracking

MIL (malfunction indicator) Status & Control

Request current powertrain diagnostic data

Request emission-related DTCs (Diagnostic Trouble

Codes)

Request on-board monitoring test results for specific

monitored systems

Request Pending Codes (emission related

diagnostic trouble codes) detected during current or

last completed driving cycle

1

4.5.1 Readiness Monitor Test Status

OBD-II/EOBD stipulates the monitoring (continuous or non-continuous) of the functions of the

following emission control related subsystems):

Table 4-2 Continuous or Non-continuous monitors

Readiness Monitor Remark

Misfire monitoring Continuous

Fuel system monitoring Continuous

Comprehensive component monitoring Continuous

† Will only be monitored if the correct conditions are met.

12

Page 20

On-Board Diagnostics (OBD) Diagnostic Services Introduction

NOTE:

Table 4-2 Continuous or Non-continuous monitors

Readiness Monitor Remark

Catalyst monitoring †

Heated catalyst monitoring †

Evaporative system monitoring †

Secondary air system monitoring †

A/C system refrigerant monitoring †

Oxygen sensor monitoring †

Oxygen sensor heater monitoring †

EGR system monitoring †

† Will only be monitored if the correct conditions are met.

i Not all data is applicable or supported by all vehicles.

Each vehicle manufacturer has unique m onitor te st criteria. The Readine ss Test Status indicates

whether a particular diagnostic monitor or function pa ssed it s sp ecific test criteria an d was found

to be within specification.

Usually the monitors should run and set the Readiness Test Status during normal vehicle

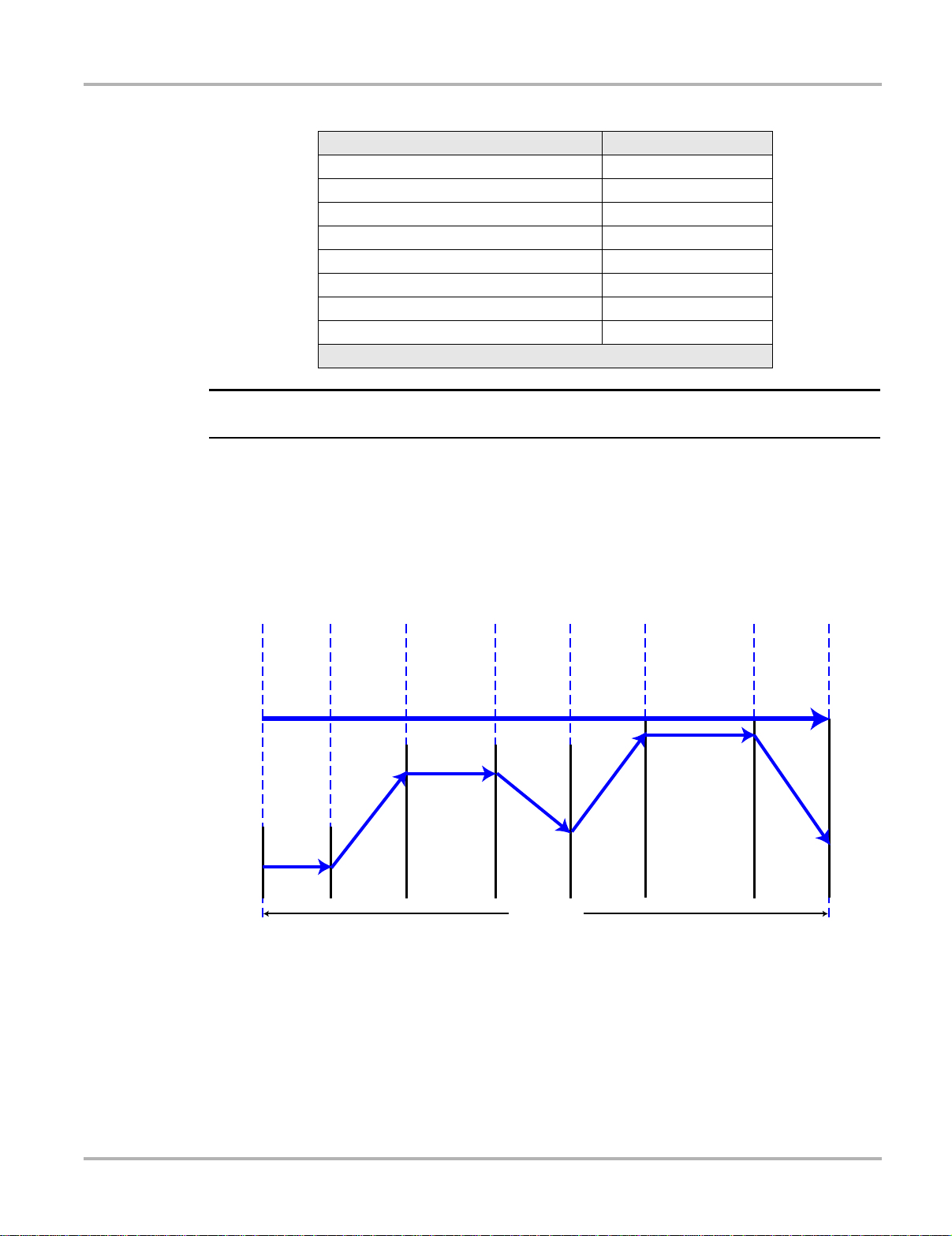

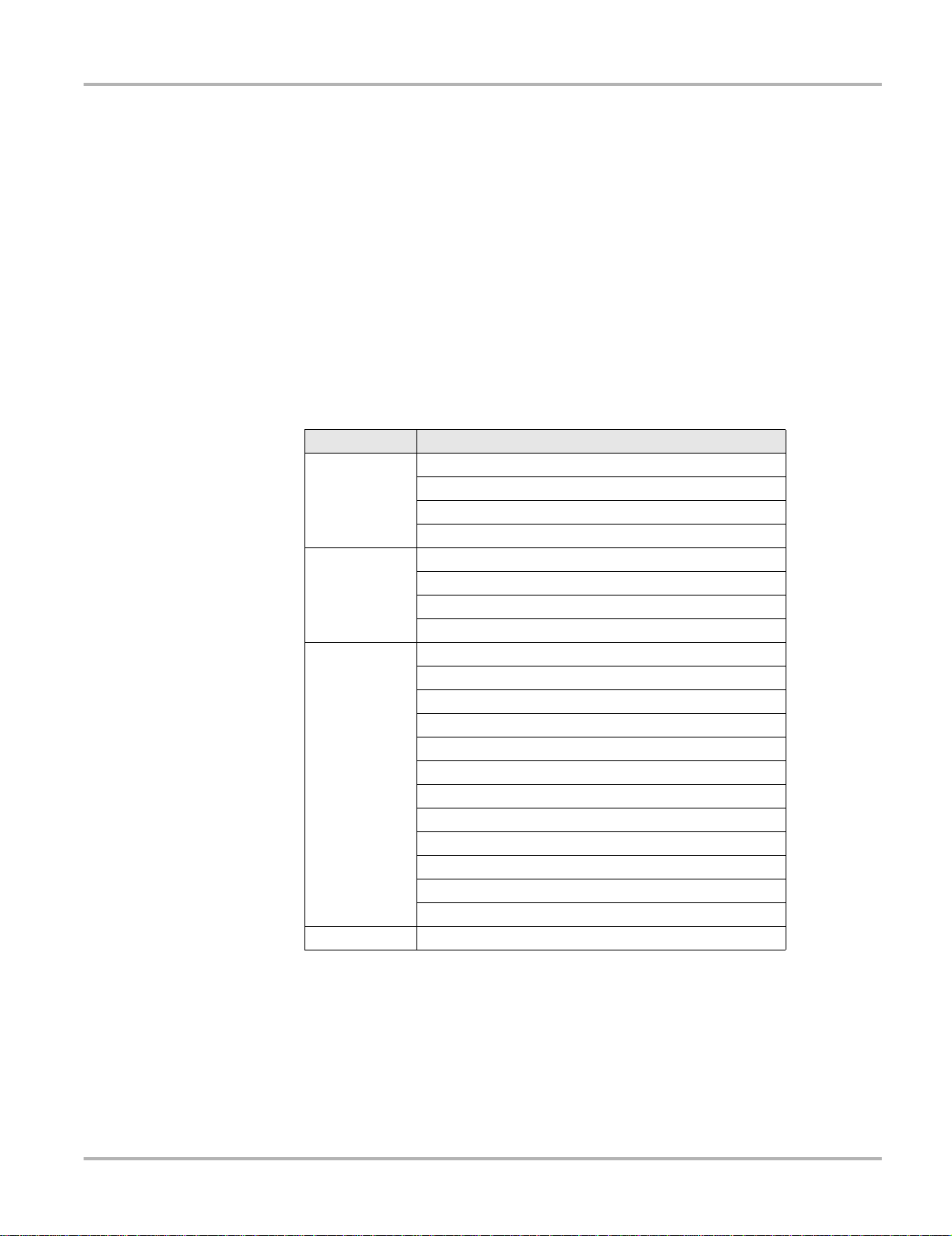

operation. The OBD-II Drive Cycle (see Figure 4-1: ‘Typical OBD-II Drive Cycle’) can be used to

drive the vehicle in a prescribed manner.

HO2 Heater, Misfire,

AIR, Fuel Trim, and

Purge Monitors

Idle 2.5 Minutes

in Drive, A/C &

Rear Defrost ON

Cold Start

ECT < 50C

Misfire, Fuel Trim, and

Purge Monitors

Accelerate at 50%

Throttle to 55 mph/

89 kph A/C OFF

Misfire, EGR, AIR, Fuel Trim,

HO2, and Purge Monitors

3 Minutes

Steady State Cruise

55 mph/89 kph

Figure 4-1

EGR, Fuel Trim, and

Purge Monitors

Decelerate to

20 mph/32 kph

with the Clutch

Engaged and

No Brakes

Total Time 12 Minutes

Misfire, Fuel Trim, and

Purge Monitors

Accelerate at

75% Throttle to

55 to 60 mph/

89 to 97 kph

Typi cal OB D- II Dr ive Cycl e

Catalyst, Misfire, EGR, Fuel

Trim, HO2, and Purge Monitors

5 Minutes

Steady State Cruise

55 to 60 mph/

89 to 97 kph

EGR, and Purge Monitors

Decelerate to

End of Cycle

Without Brakes

As this is a generic drive cycle, it may have limited results o n some vehicles. If available, use the

drive cycle information as supplied by the vehicle manufacturer.

System malfunctions that occur later and record a DTC (Diagnostic Trouble Code) will not change

the Readiness T est S t atus. When the failure is repaired and the DTC is era sed, all Readiness T est

Status will be reset to a ‘Not Completed’ st atus.

13

Page 21

On-Board Diagnostics (OBD) Diagnostic Services Introduction

NOTE:

NOTE:

Repair validation

Use the following procedure to validate a repair.

z To validate the repair:

1. Perform a drive cycle (generic or vehicle specific).

2. Check Service $07 (refer to 4.6.7: ‘Service $07: Emission-related DTCs detected during

Current or Last Completed Drive Cycle (Pending Codes)’ on page 23) and Service $03 (refer

to 4.6.3: ‘Service $03: Emission-related DTCs’ on page 16).

If no DTCs are reported (that relate to the initial failure), it can be assumed that the fault has been

repaired correctly.

4.5.2 MIL St atus

Emission related malfunctions set failure specific DTC(s). The MIL (Malfunction Indicator Lamp)

may light up as soon as the first emission related DTC has been stor ed and confirme d (stored a

second time). Depending on the type of malfunction, it may take multiple drive cycles before the

MIL turns on.

The MIL is located in the instrument p anel. The MIL may display a symbol of an engine and sho uld

light up as soon as the ignition is switched on . Three different st ates are possible when the engine

is running:

1. OFF: no emission limits exceeded.

2. ON: at least one OBD-II/EOBD emission limit exceeded.

3. Blinking: possibility of damage to the catalytic converter.

Figure 4-2

Example of Malfunction Indicator Lamp

i The MIL may also be called the “Check Engine” lamp.

The ECM transmits the status of the Malfunction Indicator in cluding the id entification of th e ECM

that commanded the MIL to turn on.

i The MIL status indicates “off” during the ignition key on, engine off instrum ent p anel bu lb check

unless the MIL has been commanded “on” for a detected malfunction.

14

Page 22

On-Board Diagnostics (OBD) Diagnostic Service Definitions

NOTE:

NOTE:

4.6 Diagnostic Service Definitions

4.6.1 Service $01: Display Current Data

The ECMs transmit the data value stored by the system. The data is commonly called PID

(Parameter IDentification). All of the sensors parameters show the actual readings. Not default or

substitute values used by the system, because of a fault with that sensor.

Depending on the ECM and amount of parameter s selected, dat a update r ates may vary. Use

Custom Data List to select the parameters to be displayed in Service $01. The fewer data

parameters were selected, the faster the update r ate.

Only OBD/EOBD defined parameters appear in th e Current Dat a Li st. To view not supported

parameters, select Manual Select PID (the last item of the Current Data List).

4.6.2 Service $02: Powertrain Freeze Frame Data

Engine conditions are stored by the ECM at the time a Monitor detects an emission-related fault.

A “Freeze Frame” is such a group of captured information.

Using Freeze Frame for Diagnostic Purposes

Freeze Frame is useful for determining the exact conditions the vehicle was oper ating under when

the DTC was set.

i Freeze Frame is captured and stored when the DTC is set, not when the problem began.

For example, misfire is evaluated every 1000 rpm. A misfire DTC may be stored 60 to 90 seconds

after the misfire initially occurred, at substantially different speed and load co nditio ns.

The Technician can duplicate these conditions to verify the complaint or the repair . In some cases

the on-board tests for a specific DTC may report no problem found. But when the conditions match

the Freeze Frame conditions, that same DTC would set with the MIL on.

i Freeze Frame data is erased whenever codes are cleared.

Does a stored DTC change?

It can be overwritten by higher priority Emission DTCs. Misfire and Fuel System DTCs have the

highest priority. A lower rated DTC may be overwritten by a higher priority DTC.

Only data parameters supporte d by the ECM are included in th e Free ze Frame dat a list.

15

Page 23

On-Board Diagnostics (OBD) Diagnostic Service Definitions

4.6.3 Service $03: Emission-related DTCs

The purpose of this service is to enable the scan tool to obtain stored DTCs from the power train

ECMs that are emission-related.

The OBD-I ECM primarily identifies a faulty signal or a faulty sensor using three steps:

• Signal or component shorted to ground

• Signal or component shorted to battery positive

• No signal or component (open circuit)

For each of these tests, a specific trouble code is set.

With OBD-II/EOBD, expanded diagnostics now includes “rationality” testing. One input signal is

compared against other input signals to de termin e if the read ing is reasona ble, give n the curre nt

operating conditions.

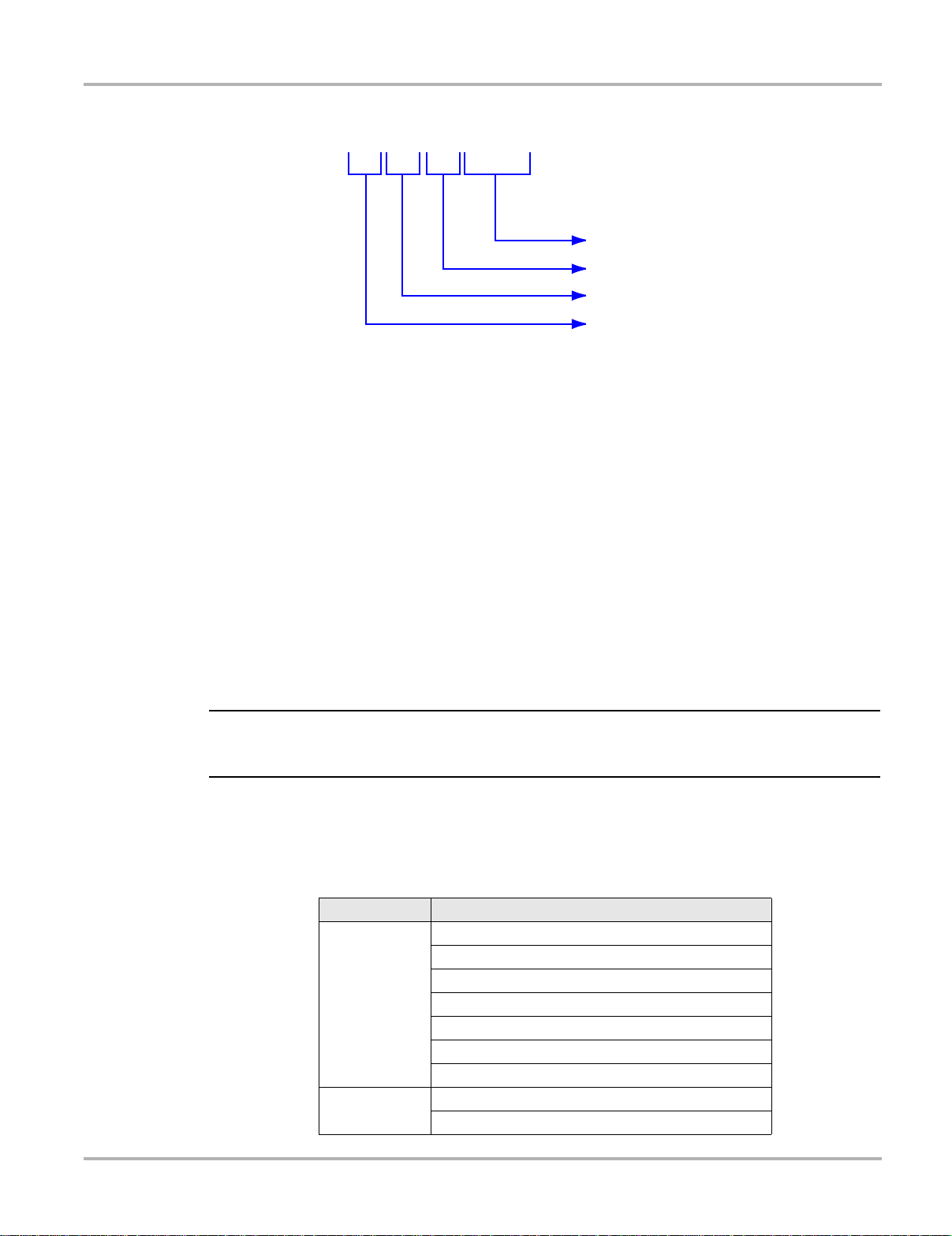

Table 4-3

Diagnostic Trouble Code description

Position Description

P = Power train

1

2

3

4 & 5 Serial numbering of individual components or systems

C = Chassis

B = Body

U = Network

0 = Standardized emission-related trouble code

1 = Manufacturer-specific trouble code

2 = Standardized or Manufacturer-specific trouble code

3 = Standardized or Manufacturer-specific trouble code

0 = Overall system

1 = Secondary air system/Mixture preparation

2 = Fuel system

3 = Ignition system/Misfires

4 = Additional exhaust gas monitoring

5 = Cruise control/Idle speed control

6 = Input/Output signals, Control units

7 = Gearbox/Transmission

8 = Transmission

9 = Transmission

A = Hybrid Propulsion

B = Reserved

16

Page 24

On-Board Diagnostics (OBD) Diagnostic Service Definitions

NOTE:

P0237

Position 4 & 5

Position 3

Position 2

Position 1

Figure 4-3 Example: DTC “P0237”

In this example, definitions listed for Position 3 are only valid for DTCs starting with “P”. For other

codes (C, B, U) there are other definitions. Please refer to ruling OBD standards for more

information.

Code Ranking

OBD-II/EOBD Codes have a priority according to their emission severity , with higher priority codes

overwriting lower priority codes. The priority of the code determines the illumination of the MIL and

the code erase procedure.

Vehicle manufa cturers have implem ented the r anking differently.

4.6.4 Service $04: Clear/Reset Emission-related Diagnostic Data

i It is recommended to perform the Clear Code/Reset function with the engine off and th e ignition

switched on.

The purpose of this service is to clear codes and turn off the MIL. It is recommended to pr int the

DTCs before erasing them, for comparison af ter rep a irs are made.

Clearing the code memory erases all diagnostic information st ated in “Reset Information” below:

Table 4-4 Reset Information (sheet 1 of 2)

Service Items to reset

Status of system monitoring tests

Number of diagnostic trouble codes

Distance travelled while MIL is activated

$01

$02

Number of warm-ups since DTCs cleared

Distance travelled since DTCs cleared

Time run by the engine while MIL is activated

Time since diagnostic trouble codes cleared

Diagnostic trouble code for freeze frame data

Freeze frame data

17

Page 25

On-Board Diagnostics (OBD) Diagnostic Service Definitions

IMPORTANT:

NOTE:

NOTE:

NOTE:

Table 4-4 Reset Information (sheet 2 of 2)

Service Items to reset

$03 Confirmed diagnostic trouble codes

$05 Oxygen sensor test data

$06 Specific on-board monitoring test results

$07 Pending diagnostic trouble codes

The following may occur as well:

• It may also erase engine management adaptive memory (some vehicle manu factur ers only)

when codes are cleared. Depending on the vehicle, adaptive memory ma y not correct it self

without extensive driving.

• Other manufacturer specific actions for clearing and setting may also occur in response to this

request message.

• Normally the MIL automatically turns off after a successful repair , if emissions are normal.

Refer to “Repair validation” on page 14.

For safety and/or technical design reasons, so me ECMs may not respond to this service under all

conditions.

i In most cases, once a MIL is deactivated, the original code remains in memory until forty to eighty

warm-up cycles are completed without the fault reappearing.

4.6.5 Service $05: Oxygen Sensor Monitoring Test Results

The purpose of this service is to allow access to the on-board ox ygen sens or monitoring test

results (if implemented).

i For CAN vehicles, Service $05 is not supported. Oxygen sensor test results are implemented in

Service $06. For non-CAN vehicles, manufacturers can use Service $06 as an alter native to

Service $05.

Different manufacturers may use many methods to calculate test results for this service. The scan

tool converts test values and displays them in the st andard units of measurement.

The ECM transmits the latest test results available from the system. Test results are retained by

the ECM, even over multiple ignition OFF cycles, until replaced by the results of a more recent

test. Test results are requested by Test ID. (See Test ID T able).

Test results can be reported either as a co nst ant or as a calculated value, dep ending on the Test

ID. Calculated values are reported with minimum and maximum limits.

i Depending on the manufacturer, calculated values ma y be roun ded off, which means that a test

may fail despite the values reading within min. and max limits.

18

Page 26

On-Board Diagnostics (OBD) Diagnostic Service Definitions

NOTE:

NOTE:

The scan tool checks if the readiness status of oxygen sensors is completed. If the test is not

completed, the scan tool displays a warning.

$08

Rich

$04

Oxygen

Sensor

$02

$01

Output

$03

Lean

$07

Numbers Refer to Test ID

$06 $05

Figure 4-4

T est ID Values Example

$0A $09

i Refer to Table 4-5 for an explanation of the individual Test ID numbers.

Table 4-5 Test ID Table

Test ID No. Description

$01 Rich to Lean sensor threshold voltage (constant)

$02 Lean to Rich sensor threshold voltage (constant)

$03

$04

$05 Rich to Lean sensor switch time (calculated)

$06 Lean to Rich sensor switch time (calculated)

$07 Minimum sensor voltage for test cycle (calculated)

$08 Maximum sensor voltage for test cycle (calculated)

$09 Time between sensor transitions (calculated)

$0A Sensor Period (calculated)

$0B

$0C

Low sensor voltage for switch time calculation

(constant)

High sensor voltage for switch time calculation

(constant)

EWMA (Exponential Weighted Moving Average)

misfire counts for last 10 driving cycles (calculated)

Calculation: 0.1 * (current counts) + 0.9 * (previous

average)

Initial value for (previous average) = 0

Misfire counts for last/current driving cycles

(calculated)

i Not all test values are applied on or supported by all vehicles. Only supported Test IDs appear in

the selection list.

19

Page 27

On-Board Diagnostics (OBD) Diagnostic Service Definitions

1234

Cylinder Bank & O2S Locations, Examples

Figure 4-5 L4 Cylinder Engine with 1 exhaust bank and 1 Catalyst

1— Engine, exhaust bank

2— Sensor 1

3— Catalyst

4— Sensor 2, (heated)

1— Engine, exhaust bank

2— Sensor 1

3— Catalyst

4— Sensor 2, (heated), Bank 1

5— Catalyst

6— Sensor 3 (heated), Bank 1

1234 56

Figure 4-6

L4 Cylinder Engine with 1 exhaust bank and 2 Catalysts

20

Page 28

On-Board Diagnostics (OBD) Diagnostic Service Definitions

V

561A 2A 3A 4A

1B 2B 3B 4B

Figure 4-7 V8 Cylinder Engine with 2 exhaust banks and 3 Catalysts

1— Exhaust Bank X

2— Sensor 1, Bank X

3— Catalyst

4— Sensor 2, (heated), Bank X

5— Catalyst

6— Sensor 3 (heated), Bank X

1A 2A 3A 4A 5A 6A

V

1B 2B 3B 4B 5B 6B

Figure 4-8

1— Exhaust Bank X

2— Sensor 1, Bank X

3— Catalyst

4— Sensor 2, (heated), Bank X

5— Catalyst

6— Sensor 3 (heated), Bank X

V8 Cylinder Engine with 2 exhaust banks and 4 Catalysts

21

Page 29

On-Board Diagnostics (OBD) Diagnostic Service Definitions

IMPORTANT:

4.6.6 Service $06: Specific Monitored Systems Test Results

The purpose of this service is to allow access to the test result s for on-board diagnostic monitoring

tests of specific components or systems that are continuou sly monitored ( CAN only) and

non-continously monitored.

The misfire monitor is an example of a continuously monitored system, a nd th e cat alyst system

would be an example of a non-continously monitored system.

CAN Protocol

For CAN the T est ID Table from Service $05 is us ed. The request message for test values includes

an OBDMID (On-Board Diagnostic Monitor IDentification) that ind ica tes th e infor matio n

requested. Unit information is given with the values. Test values (results) ar e always reported with

the minimum and maximum test limits.

The Test ID Table below is for CAN Protocol only:

Table 4-6

Test ID No. Description

$01 Rich to Lean sensor threshold voltage, (Constant)

$02 Lean to Rich sensor threshold voltage, (Constant)

$03

$04

$05 Rich to Lean sensor switch time, (Calculated)

$06 Lean to Rich sensor switch time, (Calculated)

$07 Minimum sensor voltage for test cycle, (Calculated)

$08 Maximum sensor voltage for test cycle, (Calculated)

$09 Time between sensor transitions, (Calculated)

$0A Sensor Period, (Calculated)

$0B

$0C

Test ID Table for CAN Protocol

Low sensor voltage for switch time calculation,

(Constant)

High sensor voltage for switch time calculation,

(Constant)

EWMA (Exponential Weighted Moving Average)

misfire counts for last 10 driving cycles (calculated)

Calculation: 0.1 * (current counts) + 0.9 * (previous

average)

Initial value for (previous average) = 0

Misfire counts for last/current driving cycles

(calculated)

If an OBDMID has not been completed at least once since Service $04 or battery disconnect, then

the following properties of the parameter are set to zero by the ECM:

• Test Value (Results)

• Minimum Test Limit

• Maximum Test Limit

22

Page 30

On-Board Diagnostics (OBD) Diagnostic Service Definitions

Non CAN Protocol

The vehicle manufacturer is responsible for assigning Test IDs and Component IDs for tests o f

different systems and componen t s. The la test test re sult s a re to be r et aine d, even over multiple

ignition OFF cycles, until replaced by more recent test results. Test results are r equested by Test

ID. Test results are reported only for supported combinations of test limit type and co mponen t ID

and are reported as positive (unassigned) values. Service $06 test valu es and limit s ar e raw

values that not scaled.

To date, only some manufacturers have provided conversion factors for technicians to use this

data. See the example below for a US Ford version of Service $06 Cat alytic Converter test results.

Table 4-7

Test ID Comp ID Test Value Min. Max

$10 $11

$10 $21

Service $06 Catalytic Converter test results

Cat monitor Switch ratio

Bank1

Cat monitor Switch ratio

Bank2

45 0 48

42 0 48

Ford conversion factor: multiply the value by 0.0156 to get a value from 0 to 1.0.

Table 4-8 Calculated values

Item Factor Result

Bank 1 45 * 0.0156 0.702

Bank 2 42 * 0.0156 0.655

Threshold 48 * 0.0156 0.749

This catalyst is about to fail. Normal readings for a good catalyst should be approximately

0to0.1(switch ratio).

Service $06 Notes

Consider the following when performing this service:

• If in Service $01 (Readiness Test St atus) one of th e test s is not completed, a wa rning

message displays indicating that the values may be invalid or not available.

• Not all test values are applicable or supported by all vehicles. Only supported Test IDs appear

on the selection list. T o be able to select none supported T est IDs, the last item of the selection

list is Manual Selection of Test ID.

• This service can be used as an alternative to Service $05 to report oxygen sensor test results

The values are not converted and are displayed in st andar d unit s.

4.6.7 Service $07: Emission-related DTCs detected during Current or

Last Completed Drive Cycle (Pending Codes)

The purpose of this service is to enable the scan tool to obt ain “pen ding” o r maturing d iagnostic

trouble codes. These are codes for emission-related comp onent s or systems that are tested or

continuously monitored during normal driving conditions th at were detected durin g the current o r

last completed driving cycle.

23

Page 31

On-Board Diagnostics (OBD) Diagnostic Service Definitions

Test results for these components or systems are reported in the same format as the DTCs in

Service $03; refer to “Service $03: Emission-related DTCs” on p age 16.

The intended use of this service is to assist the service techn ician af te r a vehicle r ep air and af ter

clearing diagnostic information, by reporting test results after a sing le driving cycle.

• If a test failed during the driving cycle, the DTC associated with that test will be reported. If the

pending fault does not occur again within 40 to 80 warm-up cycles, the fault is automatically

cleared from memory.

• T est results repo rted by this service do not necessarily indicate a faulty component or system.

If test results indicate a failure again after additional driving, then a DTC will set with Service

$03, indicating a faulty component or system. The MIL will be illuminated.

This service can always be used to request the results of the latest test, independent of the setting

of a DTC.

4.6.8 Service $08: On-board Activation Tests

This service controls the operation of vehicle components, tests or systems. These tests are also

known as “On-Board Activation Tests”.

4.6.9 Service $09: Vehicle Information

The purpose of this service is to enable the scan tool to request vehicle specific vehicle

information such as:

• Vehicle Identification Number (VIN)

• Calibration IDs

• Calibration V erifica tion Numbers (CVN, d isplayed as hexadecimal value)

Some of this information may be required by regulations and so me may be desira ble to be

reported in a standard format, if su pported b y the vehicle manu facturer.

4.6.10 Service $09: In-use Performance T racking

This data is used to support possible regulatory requirements for “In-use Performance Tracking”.

Manufacturers are required to implement sof twa re progr ams that track in-use per formance for

each of the following components or systems:

• Catalyst Bank 1

• Catalyst Bank 2

• Primary Oxygen Sensor Bank 1

• Primary Oxygen Sensor Bank 2

• Evaporative Leak Detection System

• EGR System

• Secondary Air System

24

Page 32

On-Board Diagnostics (OBD) Diagnostic Service Definitions

The completion value tracks the number of times that all conditions necessar y fo r a sp eci fic

monitor to detect a malfunction have been encountered. The condition value ind icates the number

of times that the vehicle has been operated in the specified conditions.

OBD Monitoring Conditions—displays the number of times that the veh icle has be en operated

in the specified OBD monitoring conditions.

Engine Starts—displays the count of the number of times that the engine has been started.

Catalyst Monitor Completion Bank X—displays the number of times that all cond itions

necessary to detect a Catalyst System Bank 1 or 2 malfunction have been encountered.

Catalyst Monitor Conditions Ban k X—disp lays the nu mber of time s that the veh icle has b een

operated in the specified Catalyst monitoring conditions.

O2 Sensor Monitor Completion Bank X—displays th e number o f time that all co nditions

necessary to detect an Oxygen Sensor Bank 1 or 2 malfunction have been encoun tered.

O2 Sensor Monitor Conditions Bank X—displays the number of times that the ve hicle has been

operated in the specified Oxygen Sensor monitoring conditions.

EGR Monitor Completion—displays the number of time that all conditions necessary to dete ct

an EGR system malfunction have been encountered.

EGR Monitor Conditions—displays the number of times that the vehicle has been operated in

the specified EGR system monitoring conditions.

Secondary Air Monitor Completion—displays the number of time th at all conditions necessary

to detect a Secondary Air system malfunction have been encounte red.

Secondary Air Monitor Conditions—displays the number of times that the vehicle has been

operated in the specified Secondary Air system monitoring conditions.

EV AP Monitor Completion—displays the number of tim e that all conditions necessary to detect

an EV AP system le ak malfunction ha ve be en encounter ed.

EV AP Monitor Conditions—displays the n umber of times that the vehicle has been o perated in

the specified EVAP system leak malfunction monitoring conditions.

25

Page 33

Chapter 5 Navigation

ID:$ 11

RPM(1/min.) 1800

TPS(%) 50.2

IAT(°C) 88

ECT(°C) 104

A/F Rate(g/s) 11.52

LIVE DATA

1

2

The following sections describe screen layout, how to navigate the interface, and h ow to make

selections using screen menus and buttons. The various types of screen messa ges are al so

explained in this section.

5.1 Screen Layout

MICROSCAN™ display screens typically consist of two sections:

Figure 5-1

1— Title bar—shows the type of test being performed and the power source

2— Main body—shows test data

One of three basic types of screen displays for most scan tool procedures:

Sample screen

• Trouble code screens

• Menu screens

• Data screens

Each type is explained below.

5.2 T rouble Code Screens

A trouble code screen displays a list of the diagnostic trouble codes (DTCs) stor ed in the

electronic control module (ECM) of the test vehicle. The MICROSCAN automatically tests for

codes on connection to a vehicle data link connector (DLC) on power up . An “establishing

communication” message momentarily displays on the screen while the MICROSCAN gathers

code information. A “No Codes” message displays if there are no stored DTCs in the vehicle ECM.

If there are stored codes, a code report similar to the example shown b elow displays. An arr ow

head in the lower right corner of the screen indicates there are a dditional codes, scroll with the

down (d) button to view the entire list.

26

Page 34

Navigation Menu Screens

IMPORTANT:

Confirmed Codes

TROUBLE CODES

P0115

Intake (A) Camshaft Posit...

Engine Coolant Temperatu...

P0105

Confirmed Codes

TROUBLE CODES

P0115

Coolant Thermostat...

Coolant Thermostat (Coola...

P0128

P0128: Coolant

Thermostat (Coolant Temp

Below Thermostat

Regulating Temperature).

MAIN MENU

Global OBD-2/EOBD

Enhanced Codes

Captured Movies

Settings

Global OBD-2/EOBD Help

Select Protocol

Figure 5-2 Sample code report

A sub-title, which can read Confirmed Codes, Pending Codes, or Permanent Codes, appears at

the top of the report. The sub-title changes as you scro ll through the list if there are mor e than one

type of code in memory. Codes are listed in ascending order with a truncated description on the

line immediately below the DTC. Press Y and a window showing the complete description of the

highlighted DTC opens.

Certain “Enhanced Codes”, which are specific to a p a rticular man ufacturer, do not display in the

standard code list that automatically opens when co nnected to a vehicle. Select Enhance d Codes

from the main menu to view these manufacturer specific DTCs.

5.3 Menu Screens

Menu screens present a list of options from which you can select. Selecting a m enu optio n can

open a test, perform a function, or open a sub-menu of additional choices. A typical “main menu ”

is shown below.

Figure 5-3

Sample DTC description window

Figure 5-4

27

Sample main menu

Page 35

Navigation Menu Screens

GLOBAL OBD-2/EOBD

Current Data

Freeze Frame Data

Confirmed Codes

Clear Codes

O2 Monitors

Non-Cont. Monitors

z To select from a menu:

1. Use the up (b) and down (d) buttons to move the highlight to the desired choice.

2. Press Y to make the selection.

5.3.1 Main Menu

The main menu is the default screen that displays under the following conditio ns:

• The MICROSCAN unit is turned on and powered by the internal battery.

• The MICROSCAN unit is powered by the vehicle but cannot estab lish communication with the

vehicle ECM.

• When exiting from a Trouble Cod es screen.

• When Y is selected from a “No Codes” screen.

The main menu may include the following options:

• Global OBD-2/EOBD—opens a sub-menu of test options.

• Movie—opens a previously recorded data file.

• Settings—opens a menu for configuring the MICROSCAN display characteristics.

• Global OBD-2/EOBD Help—opens a “help” file that explains certain global OBD test s.

• Select Protocol—allows you to choose which communication protocol the scan tool uses.

5.3.2 Global OBD-2/EOBD Menu

The Global OBD2/EOBD menu presents a list of st andard test s fro m which you can cho ose.

Figure 5-5

A brief description of each test is presented here, more de t ailed descr iptions can be fou nd in the

Operations Chapter of this manual.

Sample Global OBD-2/EOBD menu

• Current Data—displays “live” data parameter va lues transmitted by the vehicle ECM.

• Extended Data (Optional)—displays additiona l data values not inclu ded on the standard list.

• Freeze Frame Data—displays certain data values that were captured when a DTC set.

• Confirmed Codes—displays any emissions related DTCs stored in ECM memory.

• Clear Codes—erases DTC and freeze frame records from ECM memo ry.

• O2 Monitors—displays the status of the oxygen (O2) sensor monitors.

• Non-Cont. Monitors—displays the status of the non-con tinuous mon itors.

28

Page 36

Navigation Menu Screens

5.3.3 Exit Menu

The exit menu opens as a “pop-up” when th e N button is pressed from most screens an d offers a

series of functions to choose from. The pop-up presents graphic represent a tions for three

functions and the center option is the one that is activated if th e Y bu tton is presse d.

Table 5-1

Protocol Information

Exit menu graphic definitions

Name Graphic Description

Shows the current communication

protocol, the number of emissions

related DTCs, and the serial number of

MICROSCAN unit.

your

Exit

Settings

Screen Capture

Save Movie

Lock/Unlock

Text/Graph

Min/Max

Returns to the previous screen, this is

the default selection for the exit menu.

Opens a menu for configuring the

MICROSCAN display, this is the

same as the Settings selection from the

main menu.

Saves a copy of the last screen viewed

before the N button was pressed.

Saves a copy of the data recorded in

the data buffer.

Locks or unlocks the parameter

highlighted on the previous screen to

either prevent or allow it to scroll.

Switches the data list between a text

view and a graph view.

Recalibrates the minimum and

maximum data values displayed on a

data graph.

Pause/Play

Clear ECM Memory

Custom Data List

Suspends data collection when viewing

live data to allow closer examination,

and restarts data collection when

viewing paused data.

Erases all data, stored codes, pending

codes, and freeze frame information,

from the vehicle ECM.

Allows you to select which data

parameters display on the data list.

29

Page 37

Navigation Data Screens

NOTE:

GLOBAL OBD-2/EOBD

Current Data

Freeze Frame Data

Confirmed Codes

Clear Codes

O2 Monitors

Non-Cont. Monitors

The up (b) and down (d) buttons scroll the graphics right and left respectively when more than

three options are available. The graphics scroll in a continuous l oop so there is no need to reverse

direction while scrolling.

z To use the Exit menu:

1. Press the N button to open the menu.

2. Press the up (b) button to scroll left or the down (d) button to scroll right until the desired

option is in the center position.

3. Press the Y button to activate the selected function.

5.4 Data Screens

Data screens display serial datastream parameter values, which represent in put and outpu t

information that the ECM is receiving and transmitting to the various actuators, sensors, and

switches in the electronic control system.

Vehicle dat astream information can be displayed in two formats; text view and graph view. Use the

Text/Graph function on the Exit menu to switch between viewing modes.

5.4.1 Text View

Text view screens include a parameter description and a p arameter value. Th e units of the valu e,

such as V for volts, mS for milliseconds, and % for percent, are shown in p arenthe sis af te r the

parameter description. A lock icon appears to the right of th e value if the parameter has been

locked to prevent it from scrolling. Up and down scroll arrows appear to the right of the values

whenever additional parameters are above and belo w those sho wn on the curren t screen.

Figure 5-6

Sample Exit menu

i Parameters display in the order in which they are transmitted by the ECM. Therefore, the display

order can vary considerably depending upon make, model, and yea r.

30

Page 38

Navigation Data Screens

RPM(1/min.) 1800

TPS(%) 50.2

TPS(V) 2.7

IAT(°C) 88

ECT(°C) 104

A/F Rate(g/s) 11.52

LIVE DATA

ECT: Engine Coolant

Temperature (°C)

12 34

LIVE DATA

RPM(1/min.) 1800

TPS(%) 50.2

TPS(V) 2.7

IAT(°C) 88

ECT(°C) 104

A/F Rate(g/s) 11.52

1— Parameter description

2— Parameter value unit

3— Parameter value

4— Lock icon

5— Scroll arrows

Figure 5-7

Up to three parameters can be locked in place to allow side-by-side comparison while in the text

view. Use the L ock/Unlock function on the Exit me nu to lock and release parameters. When a

parameter is locked, it is moved to th e top of the data list, when it is released it returns to its original

position in the data list.

An abbreviated, or short version, of the para meter description i s used so that it fit s on one line.

Highlight a parameter and press Y to open a pop-up with th e complete long p arameter name.

Sample text view screen

5

5

5.4.2 Graph View

Graph view screens include a parameter description a nd a data graph parameter value activity.

The units of the data value, the lock icon, a nd the scr oll arrows are similar as for text view. The

short parameter name is shown, but pressing Y opens a pop-up to reve al the complete name. Due

to the height of the data graphs, only two par ameters are displa yed at a time and only o ne

parameter can be locked. A parameter move s to the top o f the da t a list when it is locked. If mor e

than on parameter was locked when graph view i s selected, the top p arameter in the list remains

locked and the others return to their original positions in the data list.

Figure 5-8

Sample long parameter name pop-up

31

Page 39

Navigation Data Screens

IMPORTANT:

LIVE DATA

TPS(%)

50.2

RPM(1/min.)

1850

13 4 5

6

6

2

1— Parameter description

2— Current data value

3— Parameter value unit

4— Parameter data graph

5— Lock icon

6— Scroll arrows

Figure 5-9

Sample graph view screen

The MICROSCAN constructs the graphs from left to right across the screen and generates a point

on the graph for each data stream tr ansmission from the ECM. How quickly the g raph area of the

screen is filled depends upon the transmission speed of the ECM, so expect g raphing spe ed

differences between makes and models. The screen is wide e nough to disp lay 64 dat a point s on

a graph. Once the graph fills the screen older point at the left edge are hidden as new points on

the right edge are added. The value of the current sample point displays below the pa rameter

name alongside the graph.

A special cursor function that allows you to scroll across the data gr aphs is ava ilable on the exit

menu in graph view. When selected a cursor appears as a vertical line on the graphs, arrows on

either side of the graph show the scrolling directio n has cha nged, an d a fr ame counte r the sh ow

the relative position of the cursor displays in the title bar. The sampled value at the point of the

cursor displays below the parameter description.

1— Cursor

2— Frame counter

Y ou cannot scroll up and down through the data list in cursor mode. Make sure the two p arameters

you want to examine are on the screen before selecting the curso r mode.

LIVE DATA

RPM(1/min.)

1225

TPS(%)

23.7

Figure 5-10

12

28 64

Sample graph with cursor

32

Page 40

Navigation Screen Messages

5.5 Screen Messages

There are four types of on-screen messages:

• Loading and connecting

• Confirmations

• Warnings

• Errors

5.5.1 Loading and Connecting Messages

Loading and connecting messages display when the MICROSCAN unit is performing an internal

operation, such as loading a database, initiating a test, or esta blishing communications with the

vehicle. The message automatically clears once the internal operation is complete.

5.5.2 Confirmation Messages

Confirmation messages inform you when you are about to perform an actio n that cannot be

reversed or when an action that requires your confirm ation to co ntinue has b een initiated.

When a response is not required, the message displays briefly before disappearing.

5.5.3 Warning Messages

Warning messages inform you wh en co mpleting the selected action may result in an irreversible

change or loss of data.

5.5.4 Error Messages

Error messages inform you when a system or procedural error has occurred. Examples of

possible errors include a disconnected cable, a poor connection, or some o ther mechanical failure

that prevents the tool from communicating with the vehicle.

33

Page 41

Chapter 6 Operations

This chapter details the tests and procedur es that are ava ilable from th e main me nu, it includes

the following sections:

• “Global OBD-2/EOBD” on page 34

• “Movie” on page 39

• “Settings” on page 39

• “Global OBD-2/EOBD Help” on page 40

• “Select Protocol” on page 40

6.1 Global OBD-2/EOBD

When Global OBD-2/EOBD is selected a service menu that lists all of the tests available on the

identified vehicle. Menu choices typically in clu de:

• Readiness Status

• Current Data

• Freeze Frame Data

• Confirmed Codes

• Clear Codes

• O2 Monitors

• Non-continuous Monitors

• Pending Codes

• Request Control of On-Board System

• Vehicle Information

6.1.1 Readiness St atus

Designated OBD Mode $00, this selection opens a menu of available test s on monitored systems.

Selecting Readiness St atus from the m ain menu opens a su bmenu with the fo llowing options:

• Complete since DTC Cleared

• Enable Status this Cycle

• Complete this Cycle

Each selection opens a listing of test results.

34

Page 42

Operations Global OBD-2/EOBD

READINESS STATUS

ID: $ 11

Misfire Complete

Fuel System Complete

Catalyst Complete

O2 Sensor Not Complete

O2 Heater Not Complete

RPM(1/min.) 1800