Page 1

User Manual

Quick Lookups

OBD-II/EOBD

Tools

Scanner

Previous Vehicle

and Data

BC

ZEESC332A Rev. C

Page 2

Legal Information

IMPORTANT:

Trademarks

Snap-on is a trademark, registered in the United States and other countries, of Snap-on Incorporated. This

publication contains many Snap-on Incorporated trademarks, including but not limited to Snap-on and

ETHOS. All other marks are trademarks or registered trademarks of their respective holders.

Copyright Information

© 2018 Snap-on Incorporated. All rights reserved.

Disclaimer of Warranties and Limitation of Liabilities

All pictures and illustrations shown are for reference purposes only. All information, specifications and illustrations in

this manual are based on the latest information available at the time of printing and are subject to change without

notice. While the authors have taken due care in the preparation of this manual, nothing contained herein:

• Modifies or alters in any way the standard terms and conditions of the purchase, lease, or rental agreement

under the terms of which the equipment to which this manual relates was acquired.

• Increases in any way the liability to the customer or to third parties.

Snap-on

Before operating or maintaining this unit, please read this manual carefully paying extra attention to the safety

warnings and precautions.

®

reserves the right to make changes at any time without notice.

Manuals / Technical Documentation - The information in this manual is periodically revised to ensure the latest

information is included. Download the latest version of this manual and other related technical documentation from

the Snap-on Diagnostics website.

Software License Information

Use of Software is governed by the terms and conditions of the End User License Agreement. The End User License

Agreement is provided with the diagnostic tool and the device should not be initially operated until the End User

License Agreement is read. Use of the device acknowledges your acceptance of the End User License Agreement.

Patent Information

For a listing of Snap-on products that are protected by patents in the United States and elsewhere,

visit: https://patents.snapon.com

ZEESC332A Rev. C 6-M-17 NA

i

Page 3

Contact Information (North America)

Websites:

Snap-on Diagnostics and Information

• https://diagnostics.snapon.com

Software Subscription - Learn how to always have the latest diagnostic software on your diagnostic tool.

• https://diagnostics.snapon.com/theprogram

ShopStream Connect - Download free PC-based companion software used to transfer, save, manage, review,

annotate, e-mail and print files saved or recorded on your Snap-on diagnostic tool.

• https://diagnostics.snapon.com/ssc

Training and Support - Find product support information, and watch free instructional product videos.

• https://diagnostics.snapon.com/trainingsolutions

Manuals / Technical Documentation - The information in this manual is periodically revised to ensure the latest

information is included. Download the latest version of this ma nual and other related technical documentation at :

• https://diagnostics.snapon.com/usermanuals

Customer Care and Technical Assistance - Phone / E- mail

1-800-424-7226 / diagnostics_support@snapon.com

For technical assistance in all other markets, contact your selling agent

ii

Page 4

Safety Information

READ ALL INSTRUCTIONS

For your own safety, the safety of others , and to pr event dam age to the product and vehicles upon

which it is used, it is important that all instructions and safety messages in this manual and the

accompanying Important Safety Instr uction s manual be read and understood by all persons

operating, or coming into contact with the product, before operating. We suggest you store a copy

of each manual near the product in sight of the operator.

For your safety, read all instructions. Use your diagnostic tools only as described in the tool user’s

manual. Use only manufacturer recommended parts and accessories with your diagnostic tools.

This product is intended for use by properly trained and skilled professional automotive

technicians. The safety messages presented throughout this manual and the accompanying

Important Safety Ins tructions manual are reminders to the operator to exercise extreme care when

using this product.

There are many variations in procedures, techniques, tools, and parts for servicing vehicles, as

well as in the skill of the individual doing the work. Because of the vast number of test applications

and variations in the products that can be tested with this instrument, we cannot possibly

anticipate or provide advice or safety messages to cover every situation. It is the responsibility of

the automotive technician to be knowledgeable of the system being tested. It is essential to use

proper service methods and test procedures. It is important to perform tests in an appropriate and

acceptable manner that does not endanger your safety, the safety of others in the work area, the

equipment being used, or the vehicle being tested.

It is assumed that the operator has a thorough understanding of vehicle systems before using this

product. Understanding of these system principles and operating theories is necessary for

competent, safe and accurate use of this instrument.

Before using the equipment, always refer to and follow the safety messages and applicable test

procedures provided by the manufacturer of the vehicle or equipment being tested. Use the

product only as described in it’s user manual. Use only manufacturer recommended parts and

accessories with your product.

Read, understand and follow all safety messages and instructions in this manual, the

accompanying Important Safety Instr uction s manual, and on the test equipment.

Environmental Conditions:

• This product is intended for indoor use only

• This product is rated for Pollution Degree 2 (normal conditions)

iii

Page 5

Safety Information Safety Signal Words

'$1*(5

:$51 ,1*

&$87,21

:$51 ,1*

Safety Signal Words

All safety messages contain a safety signal word that indicates the level of the hazard. An icon,

when present, gives a graphical description of the hazard. Safety Signal words are.

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious

injury to the operator or to bystanders.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious

injury to the operator or to bystanders.

Indicates a potentially hazardous situation which, if not avoided, may result in moderate or minor

injury to the operator or to bystanders.

Safety Message Conventions

Safety messages are provided to help prevent personal injury and equipment damage. Safety

messages communicate the hazard, hazard avoidance and possible consequences using three

different type styles:

• Normal type states the hazard.

• Bold type states how to avoid the hazard.

• Italic type states the possible consequences of not avoidi ng the ha zard.

An icon, when present, gives a graphical description of the potential hazard.

Safety Message Example

Risk of unexpected vehicle movement.

• Block drive wheels before performing a test with engine running.

A moving vehicle can cause injury.

Important Safety Instructions

For a complete list of safety messages, refer to the accompanying Important Safety Instructions

manual.

SAVE THESE INSTRUCTIONS

iv

Page 6

Contents

Safety Information ............................................................................................................... iii

Chapter 1: Using This Manual ............................................................................................. 4

Content ...................................................................................................................................4

Conventions............................................................................................................................ 4

Terminology .....................................................................................................................4

Symbols ...........................................................................................................................4

Bold Text.......................................................................................................................... 5

Notes and Important Messages ....................................................................................... 5

Hyperlinks ........................................................................................................................5

Procedures....................................................................................................................... 5

Chapter 2: Introduction........................................................................................................6

Control Buttons.......................................................................................................................7

Data and Power Connections................................................................................................. 8

Battery Pack Cover and Stand ............................................................................................... 8

Power Sources ....................................................................................................................... 9

Vehicle Power ..................................................................................................................9

Internal Battery Pack........................................................................................................ 9

AC Power Supply ............................................................................................................. 9

Technical Specifications .......................................................................................................10

Chapter 3: Basic Operation and Navigation .................................................................... 11

Turning On/Off and Emergency Shutdown........................................................................... 11

Turning On .....................................................................................................................11

Turning Off .....................................................................................................................11

Emergency Shutdown ....................................................................................................12

Basic Navigation...................................................................................................................12

Home Screen Layout .....................................................................................................12

Title Bar.......................................................................................................................... 13

Home Screen Icons ....................................................................................................... 14

Common Toolbar Control Icons ..................................................................................... 15

Scroll Bar .......................................................................................................................15

Screen Messages................................................................................................................. 16

System Messages.......................................................................................................... 16

Communication Messages.............................................................................................16

Data Cable Connection ........................................................................................................ 17

Chapter 4: Quick Training Guide ......................................................................................18

Scanner Demonstration........................................................................................................ 1

OB

D-II/EOBD Demonstration ............................................................................................... 22

Chapter 5: Scanner.............................................................................................................25

Scanner Demonstration Program ......................................................................................... 25

Screen Layout and Toolbar Icons......................................................................................... 26

8

1

Page 7

Screen Layout................................................................................................................26

Scanner Control Icons ................................................................................................... 27

Scanner Operation ............................................................................................................... 28

Vehicle Identification ......................................................................................................28

Code Scan .....................................................................................................................30

System Main Menu Options ...........................................................................................32

Codes Menu................................................................................................................... 33

Saving Scanner / OBD-II/EOBD Data Files ................................................................... 41

Functional Tests............................................................................................................. 42

Generic Functions.......................................................................................................... 43

Exiting Scanner ....................................................................................................................43

Chapter 6: OBD-II/EOBD .................................................................................................... 44

Basic Operations .................................................................................................................. 44

Screen Layout and Toolbar Controls .............................................................................44

Connecting the Data Cable ............................................................................................44

Saving and Reviewing Data Files .................................................................................. 44

OBD-II/EOBD Menu ............................................................................................................. 45

OBD Health Check......................................................................................................... 45

OBD Direct .....................................................................................................................48

Chapter 7: Quick Lookups................................................................................................. 55

Oil Specs and Resets ...........................................................................................................55

Operation .......................................................................................................................56

Reset Procedure ............................................................................................................60

Tire and Wheel Service ........................................................................................................63

Operation .......................................................................................................................63

Chapter 8: Previous Vehicles and Data............................................................................70

Previous Vehicles and Data Menu .......................................................................................70

Vehicle History ...............................................................................................................70

View Saved Data ........................................................................................................... 71

Delete Saved Data ......................................................................................................... 72

Chapter 9: Tools ................................................................................................................. 73

Tools Menu...........................................................................................................................73

Connect-to-PC ...............................................................................................................74

Configure Shortcut Button.............................................................................................. 75

System Information ........................................................................................................ 75

Settings ..........................................................................................................................76

Chapter 10: ShopStream Connect ....................................................................................91

Scanner DataViewer.............................................................................................................93

Image Viewer........................................................................................................................94

Scanner Codes Viewer............................................

............................................................. 95

Software Upgrades and Updates .........................................................................................96

Chapter 11: Maintenance ................................................................................................... 97

Cleaning and Inspecting the Diagnostic Tool ....................................................................... 97

Cleaning the Touch Screen ........................................................................................... 97

Battery Pack Service ............................................................................................................ 97

2

Page 8

Battery Pack Safety Guidelines ..................................................................................... 98

Replacing the Battery Pack............................................................................................ 99

Disposing of the Battery Pack ......................................................................................100

3

Page 9

Chapter 1 Using This Manual

1.1 Content

This manual contains basic operating instructions and is structured in a manner to help you

become familiar with your diagnostic tool features and perform basic operations.

The illustrations in this manual are intended as reference only and may not depict actual screen

results, information, functions or standard equipment. Contact your sales representative for

availability of other functions and optional equipment.

1.2 Conventions

The following conventions are used.

1.2.1 Terminology

The terms “Scanner” and “Scanner function” are used to describe the Scanner Function(s) of the

diagnostic tool.

Examples:

• Select Scanner from the Home screen.

• From the Scanner main menu select Continue.

• The Scanner function provides many diagnostic tests.

The term “select” describes tapping/touching an icon on the touch screen, or highlighting an icon

or menu choice and then selecting the confirmation menu choice such as Continue, Accept, OK,

Yes, or other similar choice.

Abbreviated example for the following procedure: “Select Brightness”

1. Navigate to and highlight the Brightness selection.

2. Select OK, or similar, button.

1.2.2 Symbols

Different types of arrows are used. The “greater than” arrow (>) indicates an abbreviated set of

selection (navigation) instructions.

Abbreviated example for the following procedure: “Select Tools > Connect-to-PC”

1. Select Tools from the home screen.

2. Highlight Connect-to-PC on the Tools menu.

3. Select Connect-to-PC.

The solid arrows (e, c, d, b) are navigational instructions for the four directions of the directional

buttons.

Example: Press the down d arrow.

4

Page 10

Using This Manual Conventions

NOTE:

IMPORTANT:

IMPORTANT:

1.2.3 Bold Text

Bold emphasis is used in procedures to highlight selectable items such as control buttons, icons

and menu options.

Example: Press the OK button.

1.2.4 Notes and Important Messages

The following messages are used.

Notes

A NOTE provides helpful information such as additional explanations, tips, and comments.

Example:

i For additional information refer to...

Important

IMPORTANT indicates a situation which, if not avoided, may result in damage to the test

equipment or vehicle.

Example:

Do not disconnect the data cable while the diagnostic tool is communicating with the ECM.

1.2.5 Hyperlinks

Hyperlinks, or hot links, that take you to other related articles, procedures, and illustrations are

available in electronic documents. Blue colored text indicates a selectable hyperlink.

Example:

Read all applicable Safety Information before using this diagnostic tool!

1.2.6 Procedures

An arrow icon in the left-margin area indicates a procedure.

Example:

z To change screen views:

1. Select the Graph icon.

The dropdown menu displays.

2. Select an option from the menu.

The screen layout changes to the format selected.

5

Page 11

Chapter 2 Introduction

This diagnostic tool allows you to communicate with various vehicle control systems (e.g. engine,

transmission, antilock brake system (ABS), body, instrument cluster, etc) to:

• Perform OEM specific functional tests and relearn procedures

• Retrieve and clear diagnostic trouble codes (DTCs)

• View parameter (PID) data in text or graph format, and save it for future review

• Set and arm PID triggers to automatically capture and save PID data to buffer memory

• Access global OBD-II/EOBD service modes, freeze frame data, readiness monitors, and

more

In addition you can:

• Quickly retrieve previously tested vehicles, to save setup time during repeat testing

• Save screen shots, to quickly capture specific data for future review

• Interface with ShopStream Connect™ software on your PC to transfer files from the

diagnostic tool to your PC, download software updates and more.

This chapter introduces the basic features of the diagnostic tool, including the control buttons,

data connections, battery pack and power sources. Technical Specifications are provided at the

end of this chapter.

6

Page 12

Introduction Control Buttons

Quick Lookups

OBD-II/EOBD

Tools

Scanner

Previous Vehicle

and Data

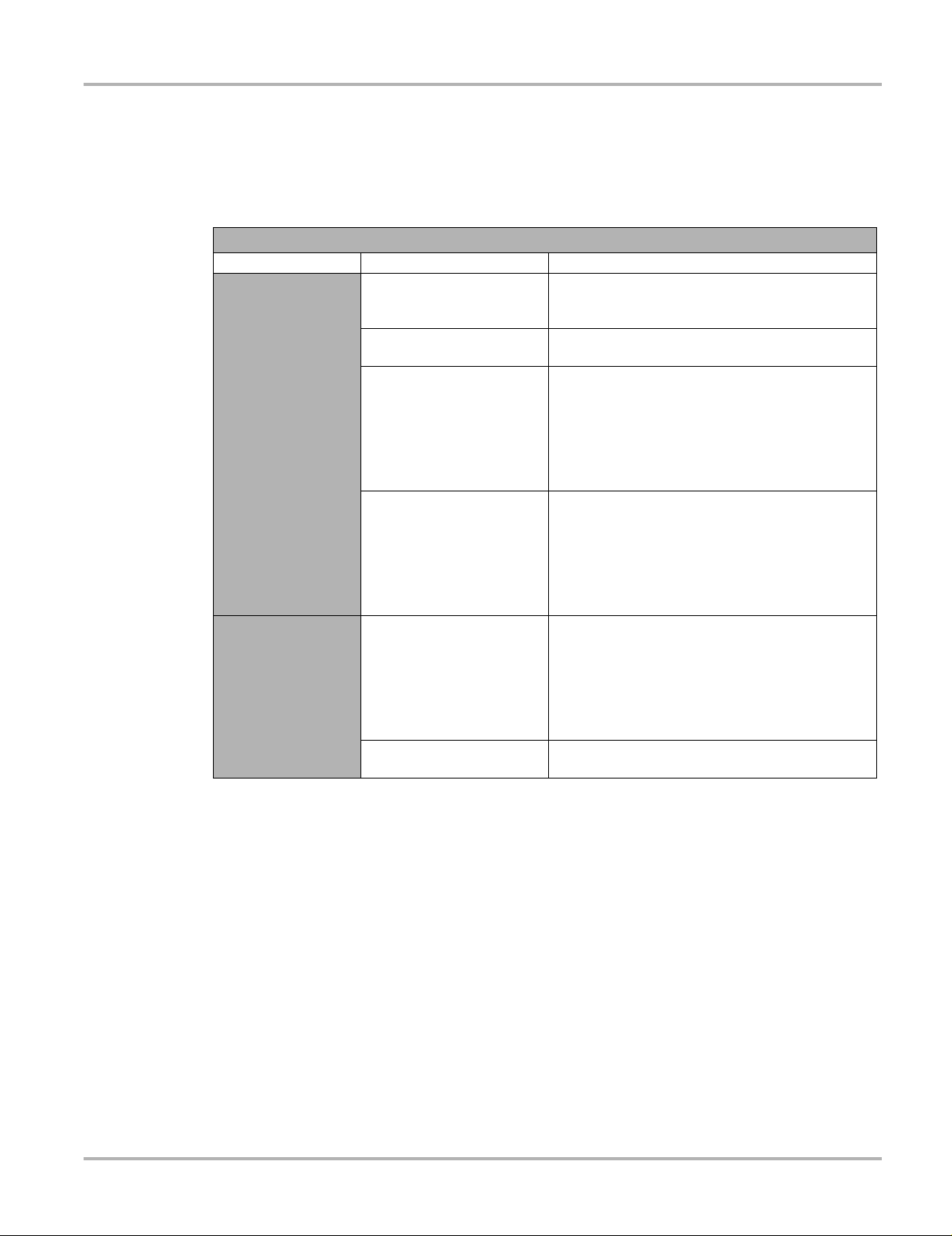

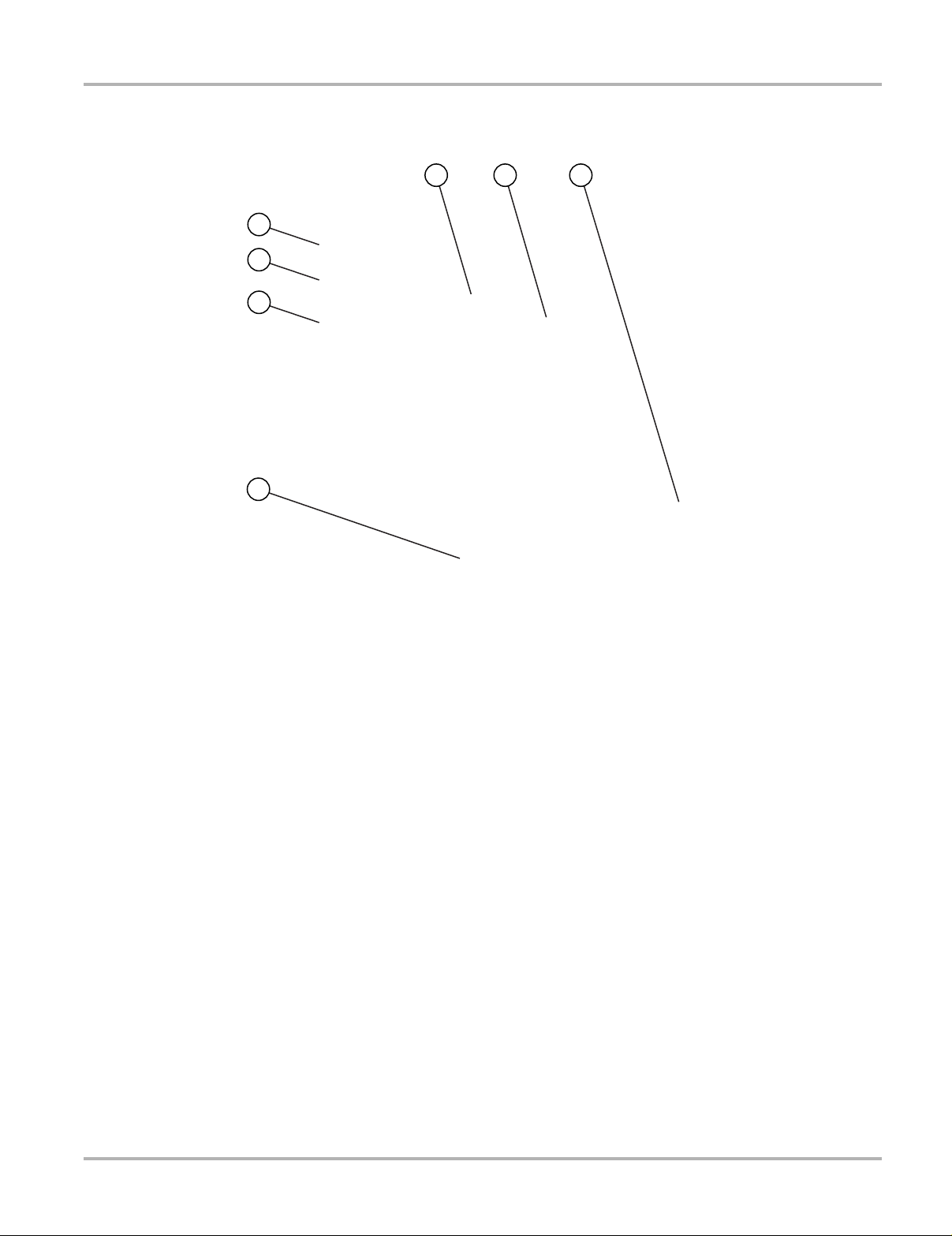

2.1 Control Buttons

There are four “push type” control buttons and one “thumb pad rocker type” multi-directional

button located on the right side of the diagnostic tool. All other diagnostic tool operations are

controlled through the touch screen.

1

2

3

4

5

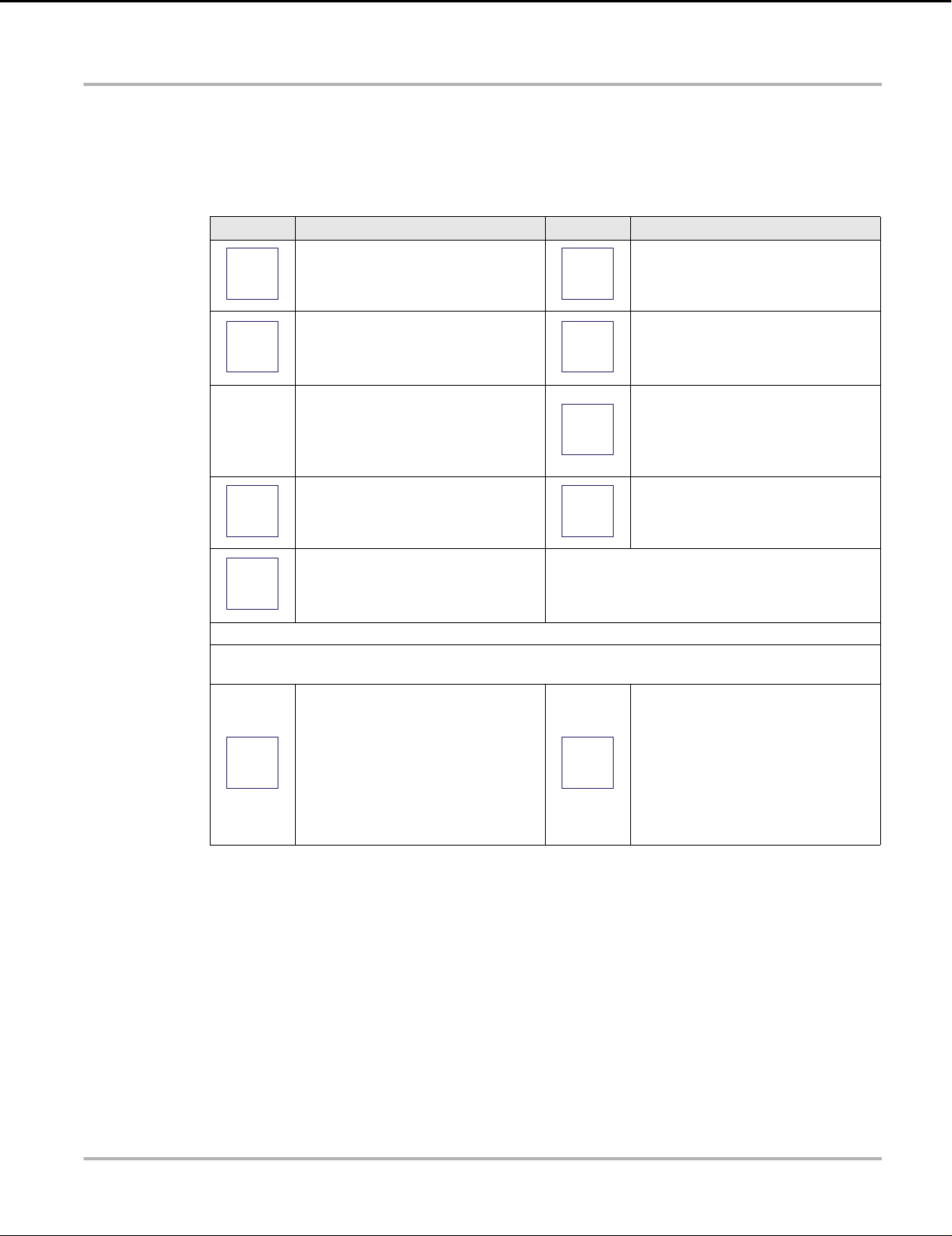

Item Button Description

Y/

1

2

3

4

a or Accept - Push

type button

N/X or Cancel - Push

type button

Directional - Thumb

pad rocker type buttons

(Shortcut) - Push type

button

Figure 2-1 Front view

• To confirm a selection from a menu or program.

• To select an item that was highlighted using the

direction arrows.

• To advance to the next screen in a series.

• To answer “Yes” when a yes or no choice is

given.

• To exit a menu or program.

• To close an open list and return to the previous

menu or screen.

• To answer “No” when a yes/no choice is given.

Buttons move the cursor or highlight in their

respective direction:

• Up (b)

• Down (d)

• Left (e)

• Right (c)

Programmable function button that can provide a

shortcut for performing a variety of routine tasks.

Refer to Configure Shortcut Button‚ on page 75 for

additional information.

5

Power (On/Off) - Push

type button

7

Turns the diagnostic tool on and off. Also, press and

hold for 5 seconds for emergency shutdown.

Page 13

Introduction Data and Power Connections

1

2

3

2.2 Data and Power Connections

All diagnostic tool connections are located on the top of the diagnostic tool.

1 2 3 4 5

Figure 2-2 T op view

Item Description

1 Power Supply Jack - connection for AC power supply

Battery Status Indicator LED

• Green - battery is fully charged

2

• Red - battery is charging

• Amber - indicates there is a battery issue (correct before operating)

3 Mini-b USB Jack - connection for USB cable to a personal computer.

Micro secure digital (µSD) Card - contains operating system programming. IMPORTANT The

4

µSD card must be installed for the diagnostic tool to operate. Do not remove the µSD card

while the diagnostic tool is powered on.

5 Data Cable Connector - connection for vehicle data cable to vehicle data link connector (DLC).

2.3 Battery Pack Cover and Stand

1— Built-in Stand - The built-in stand extends from the back of the diagnostic tool and clips

into the diagnostic tool for storage.

2— Battery Pack Cover

3— Battery Pack Cover Screw

Figure 2-3 Back view

8

Page 14

Introduction Power Sources

IMPORTANT:

2.4 Power Sources

Your diagnostic tool can be powered from any of the following sources:

2.4.1 Vehicle Power

All OBD-II/EOBD vehicles have vehicle battery power (B+) available on the DLC. The diagnostic

tool is powered through the Data Cable when connected to the vehicle DLC. A green LED

indicator on the DLC end of the data cable, illuminates when power is being supplied to the cable.

If the LED fails to illuminate, check that the data cable is properly connected and then check the

DLC power circuit. See Data Cable Connection‚ on page 17 for additional data cable information.

2.4.2 Internal Battery Pack

The diagnostic tool can be powered from the internal rechargeable battery pack. A fully charged

battery provides sufficient power for about 3 hours of continuous operation.

Battery charging occurs when the diagnostic tool is connected to the AC Power Supply and to a

live AC power source, or when the data cable is connected to an OBD-II/EOBD vehicle.

The Battery Status Indicator LED (located next to the power supply jack) indicates battery status

(Figure 2-3).

• Green - indicates battery is fully charged

• Red - indicates battery is charging

• Amber - indicates a battery issue. This may be caused by excessive battery temperature

(above 104°F/40°C), which disables charging. Allow the diagnostic tool to cool down before

continuing operation.

2.4.3 AC Power Supply

The diagnostic tool can be powered from a standard AC outlet using the AC power supply. The

connector on the end of the output cable of the AC power supply attaches to the power supply

input jack on top of the diagnostic tool. Use only the AC power supply provided.

Never connect the AC power supply to the power supply input on the diagnostic tool when the

diagnostic tool is communicating with a vehicle.

9

Page 15

Introduction Technical Specifications

2.5 Technical Specifications

Item Description / Specification

Touch Screen Resistive Touch Panel

5.6 inch diagonal, LCD TFT

Display

Battery Pack

Operating System SMX

Processor Motorola

Input Operating Voltage 10 to 30VDC

AC Power Supply Rating Input 110-240VAC, Output 15VDC - 2A

Width 8.90 in. (226 mm)

Height 5.67 in. (144 mm)

Depth 1.75 in. (44.5 mm)

Weight (including battery

pack)

Operating Temperature

Range (ambient)

Storage Temperature

(ambient)

Environmental

Conditions

640 x 480 resolution

24 bit color

Rechargeable lithium-ion battery pack

Approximately 3 hour run time

Approximately 5 hour charge time

2.1 lb (952 g)

At 0 to 90% relative humidity (non-condensing)

32 to 113°F (0 to 45°C)

At 0 to 70% relative humidity (non-condensing)

–4 to 140°F (–20 to 60°C)

This product is intended for indoor use only

This product is rated for Pollution Degree 2 (normal conditions)

10

Page 16

Chapter 3 Basic Operation and

IMPORTANT:

Navigation

This chapter describes basic operation, navigation, screen layout, and icon functions. Before you

operate the diagnostic tool, make sure the battery pack is fully charged or the diagnostic tool is

powered by the AC power supply.

3.1 Turning On/Off and Emergency Shutdown

The following sections describe how to turn the diagnostic tool on and off and how to perform an

emergency shutdown.

3.1.1 Turning On

The diagnostic tool will automatically turn on and open the Home screen (Figure 3-1) when power

is supplied through the Data Cable or by the AC Power Supply. If the diagnostic tool does not

automatically turn on, press and release the Power button on the front of the diagnostic tool to turn

the diagnostic tool on.

3.1.2 Turning Off

All vehicle communication must be terminated BEFORE turning off the diagnostic tool. A warning

message displays if you attempt to turn the diagnostic tool off while communicating with the

vehicle. Forcing a shut down while communicating may lead to ECM problems on some vehicles.

Never disconnect the Data Cable when the diagnostic tool is communicating with the vehicle

ECM.

z To turn off the diagnostic tool:

1. Press the N/X button or select the Back or Home icon to navigate to the Home screen.

If vehicle communication is active, the “stopping communication” message appears briefly

before the Home screen displays.

2. Disconnect the diagnostic tool Data Cable from the vehicle.

3. Press and release the Power button.

A confirmation screen displays.

4. Press the Y/a button or select OK from the menu to turn the diagnostic tool off. To continue

operating, press the N/X button or select Cancel from the menu.

11

Page 17

Basic Operation and Navigation Basic Navigation

IMPORTANT:

1

2

Quick Lookups

OBD-II/EOBD

Tools

Scanner

Previous Vehicle

and Data

3.1.3 Emergency Shutdown

Using the emergency shutdown procedure while communicating with a vehicle may lead to control

module problems on some vehicles.

During normal operation turn the diagnostic tool off using the Turning Off procedure described

previously. The emergency shutdown procedure should only be used If the diagnostic tool does

not respond, or exhibits erratic or abnormal operation. To force an emergency shutdown, press

and hold the Power button for five seconds until the diagnostic tool turns off.

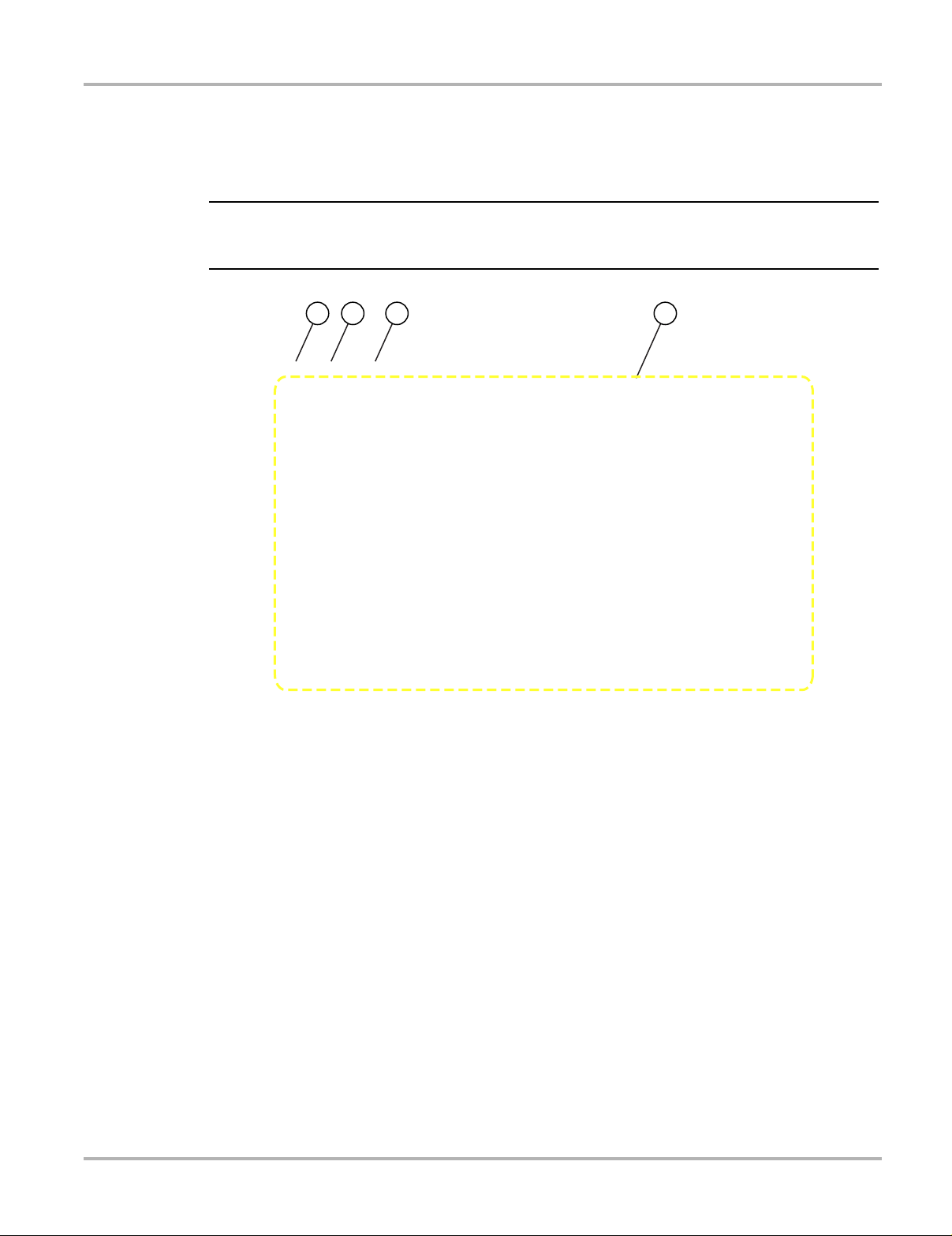

3.2 Basic Navigation

3.2.1 Home Screen Layout

The Home screen includes the title bar and function icons.

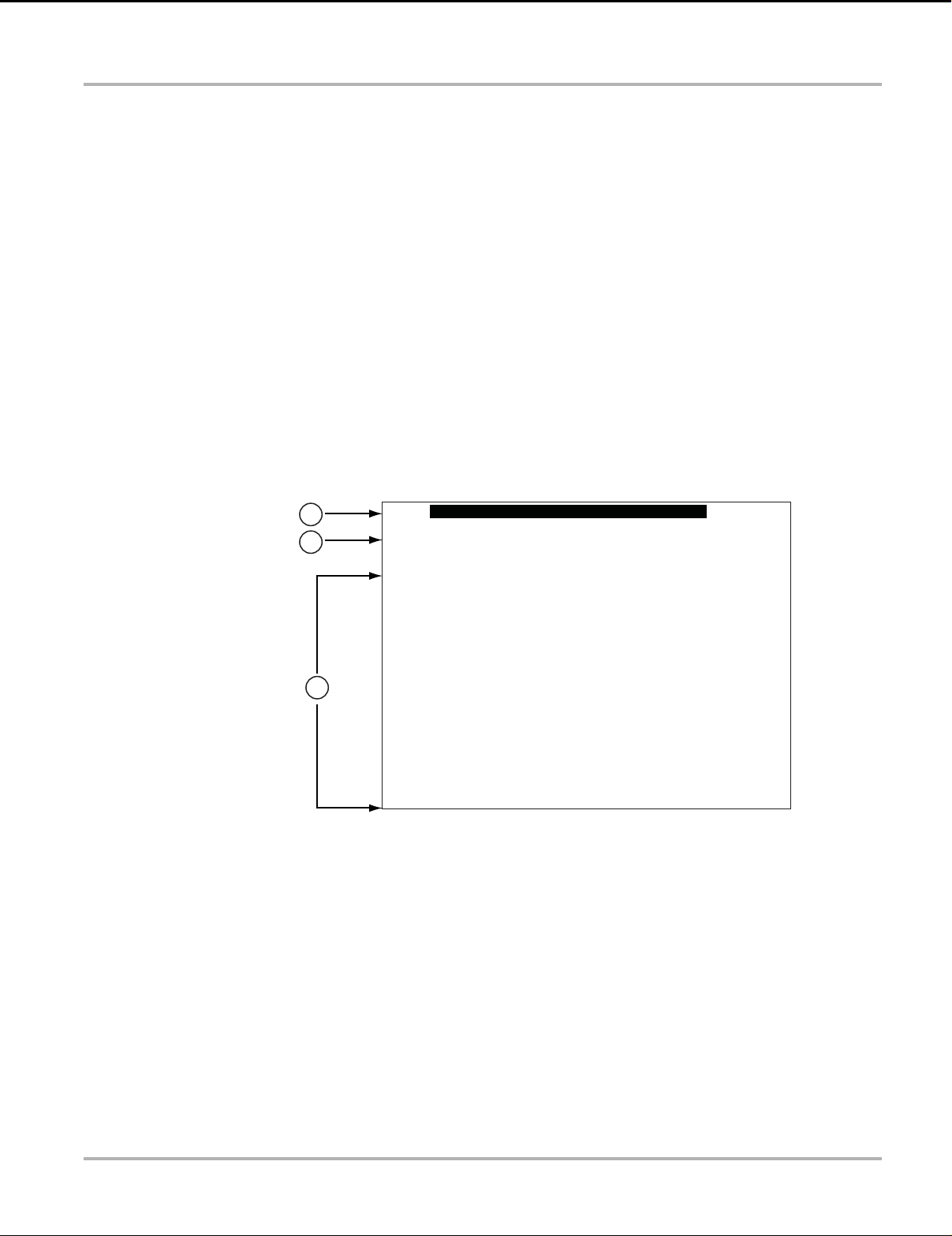

1— Title Bar

2— Function Icons

Figure 3-1 Home screen

12

Page 18

Basic Operation and Navigation Basic Navigation

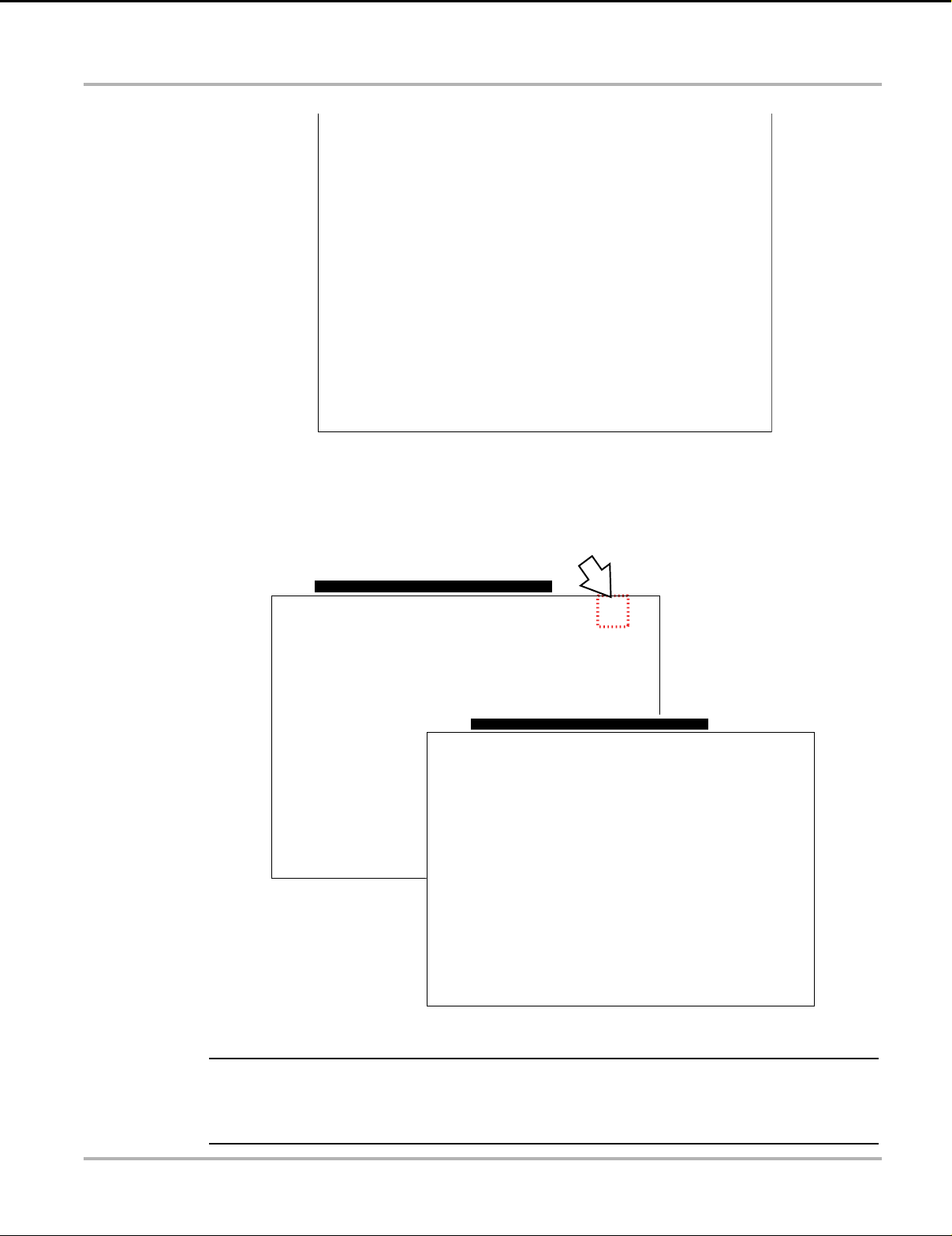

3.2.2 Title Bar

The title bar at the top of the screen (Figure 3-1) provides basic information about current

diagnostic tool operating conditions. Title bar options vary depending upon vehicle make and

model, what function is active, what test is being performed, or what menu is selected. The title bar

contains information only, there are no selectable items.

Figure 3-2 Typical Title Bar (showing vehicle information)

Information the title bar may display (varies upon active function):

• Active diagnostic function.

• Active communication indicator icon.

• Current time.

• Wi-Fi signal strength

• Source and status of the power being supplied to the diagnostic tool.

• The identification (ID) of the test vehicle

• The name of the test being performed

An active function icon is always displayed in the title bar. These icons resemble their Home

screen icon counterparts in appearance and color. The name of the function displays to the right

of the icon on some screens.

A clock is displayed in the title bar, and is powered by a dedicated internal battery, so the correct

time is maintained even when the battery pack is discharged. See Clock Settings‚ on page 81, for

clock setting instructions.

Tab le 3- 1 Title Bar Icons

Icon Function Icon Function

Full Battery Charge Level - Indicates

power is being supplied by the internal

battery pack. Horizontal bars diminish

as the battery discharges.

Low Battery Charge Level - Indicates

the internal battery pack is low and

needs to be recharged immediately. A

warning message will also display on

the screen when the battery gets low.

External Power Connected -

Indicates power is being supplied

through the data cable connection to a

vehicle or by the AC Power Supply.

Active Vehicle Communication -

Indicates the diagnostic tool is actively

communicating with a vehicle.

Wi-Fi Signal Strength - Indicates

signal strength of the wireless network

connection.

Three bars - indicate full strength signal

Zero to 1 bar - indicate weak or no

signal

13

Page 19

Basic Operation and Navigation Basic Navigation

3.2.3 Home Screen Icons

Each available diagnostic tool function is represented by a function icon on the home screen.

Select an icon from the Home (touch) screen to start a function. You can also use the control

buttons to start a function. Use the directional buttons (e, c, b, d) to highlight (a yellow border

around the icon indicates it is highlighted) the desired function and then press the Y/a button to

select it. A “please wait” message may display briefly, then automatically clear once the function

is loaded and ready for use.

Tab le 3- 2 Home screen icons

Function Name Function Icon Description

Used to communicate with the electronic control systems of

Scanner

OBD-II/EOBD

a vehicle. This function allows you to retrieve diagnostic

trouble codes (DTCs), view PID data and perform diagnostic

tests. See Scanner‚ on page 25, for details.

Allows you to access generic OBD-II/EOBD data and tests

without identifying the vehicle being tested.

See OBD-II/EOBD‚ on page 44, for details.

Quick Lookups

Previous

Vehicle & Data

Tools

Allows you quickly access OEM Oil and Tire/Wheel

specifications and instructions on your diagnostic tool. See

Quick Lookups‚ on page 55,.

Allows you to quickly reconfigure the diagnostic tool to a

recently tested vehicle and to access saved data files.See

Previous Vehicles and Data‚ on page 70, for details.

Allows you to adjust diagnostic tool settings to your personal

preferences and perform other special functions. See To ol s‚

on page 73, for details.

14

Page 20

Basic Operation and Navigation Basic Navigation

3.2.4 Common Toolbar Control Icons

Common control icon functions are described in the following table. Specific function control icons

are described in their applicable chapters. Displayed control icons vary depending on the active

function or test. Select a control icon on a screen to activate a control function. You can also use

the control buttons to activate a function, a yellow border around the icon indicates it is highlighted,

or in focus. Use the Directional buttons (e, c, b, d) to highlight the desired function and then

press the Y/a button to select it.

Icon Function Icon Function

Save - Writes data from buffer

Back - Returns to the previously

viewed screen. Icon is located on the

left-hand edge of the toolbar.

Home - Returns to the Home screen.

Icon is located next to the Back icon

on the left side of the toolbar.

memory to a file. The saved “movie”

file can be accessed for future

reference by selecting Previous

Vehicles and Data > View Saved

Data.

Tools - Opens the tools menu.

3.2.5 Scroll Bar

A vertical scroll bar appears along the right-hand edge of the screen when there is more data than

can be displayed (Figure 3-3).

1— Beginning - Moves to beginning of the data.

2— Step up - Moves up one increment of the data.

3— Slider (position indicator) - Select and drag the Slider to scroll through data. The slider

indicates the relative position of the current screen to the total available data.

4— Step down - Moves down one increment of the data.

5— End - Moves to end of the data.

Figure 3-3 Scroll bar

The Up (b) and Down (d) directional buttons can also be used to move through the data one line

at a time. Press and hold a directional button to rapidly scroll through data.

15

Page 21

Basic Operation and Navigation Screen Messages

3.3 Screen Messages

3.3.1 System Messages

There are four types of system messages that may be displayed:

Message Type Description

Loading and connecting messages display when the diagnostic tool is performing an

Loading and

Connecting

Confirmation

Warning

Error

internal operation, such as loading a database, establishing communications with the

vehicle, or initiating a test. The message automatically clears once the internal

operation is complete.

Confirmation messages inform you when you are about to perform an action that cannot

be reversed or when an action has been initiated that requires a confirmation to

continue.When a response is not required, the message displays briefly, then

disappears.

Warning messages inform you when completing the selected action may result in an

irreversible change or in the loss of data. A confirmation is required to continue.

Error messages inform you when a system or procedural error has occurred, for

example if the data cable becomes disconnected during operation.

3.3.2 Communication Messages

When “no communication” messages are displayed, it indicates the diagnostic tool and the vehicle

electronic control module are not communicating.

The following conditions may cause “no communication” messages to display:

• The diagnostic tool is unable to establish a communication link with the vehicle.

• The vehicle is not equipped with the system that was selected.

• There is a loose connection.

• There is a blown vehicle fuse.

• There is a wiring fault on the vehicle.

• There is a circuit fault in the data cable or adapter.

• Incorrect vehicle identification was entered.

16

Page 22

Basic Operation and Navigation Data Cable Connection

3.4 Data Cable Connection

Connection of the data cable to the diagnostic tool and vehicle data link connector (DLC) is

required for Scanner and OBD-II/EOBD testing.

Depending on the vehicle, the supplied DA-4 data cable may be used alone or may require

optional adapters.

• All OBD-II/EOBD compliant vehicles - Use the supplied DA-4 data cable. The 26-pin end of

the cable attaches to the data cable connector on the top of the diagnostic tool (secure with

captive screws). The16-pin end connects to the vehicle DLC.

• All non-OBD-II/EOBD (OBD-I) compliant vehicles - Use the supplied DA-4 data cable with

the optional DA-5 adapter and a manufacturer specific adapter. The 26-pin end of the cable

attaches to the data cable connector on the top of the diagnostic tool. The16-pin end connects

to the DA-5 adapter, the DA-5 adapter connects to the manufacturer specific adapter and then

connects to the vehicle DLC.

On-screen cable and adapter connection instructions may be provided while using the Scanner

and OBD-II/EOBD functions. The instructions may also include the location of the vehicle DLC

(Figure 3-4).

Figure 3-4 Vehicle connection data cable message

For data cable vehicle power connection information, see Vehicle Power‚ on page 9,.

17

Page 23

IMPORTANT:

IMPORTANT:

Chapter 4 Quick Training Guide

This chapter provides step-by-step instructions that allow you to get started using the diagnostic

tool and become familiar with some of the common Scanner and OBDII functions.

Two built-in demonstration modes allow you to walk-through these functions without connecting to

a vehicle:

• Scanner Demonstration

• OBD-II/EOBD Demonstration

Do not connect the diagnostic tool to a vehicle when using the demonstration modes.

4.1 Scanner Demonstration

The Scanner demonstration program allows you to navigate through many functions of the

Scanner, and displays vehicle data (PIDs) and trouble codes (captured from actual vehicle) to

simulate what you might see on an actual vehicle.

Links are provided (as applicable) within the demonstrations to additional topic information in this

manual.

The following Scanner demonstrations are intended to be completed in sequence:

1 - Vehicle Identification

2 - Scan for Engine Codes and Save the Codes

3 - View, Configure and Save Engine Data (PIDs)

4 - Perform a Functional Test

5 - Perform a Code Scan

6 - View Saved Files (Codes, Code Scan and Data Files)

7 - Activate a Previously Identified Vehicle and View Engine Data (PIDs)

z Scanner Demo 1 - Vehicle Identification

The first process in communicating with any vehicle is identifying the vehicle. The following walkthrough will guide you though this process using the Scanner demonstration mode.

1. From the Home screen, select Scanner .

2. The manufacturer (vehicle make) menu displays, select Demonstration.

Do not connect a vehicle to the diagnostic tool while using the Demonstration program.

The simulated Vehicle ID process starts. The demonstration vehicle to be identified is a 2014

Chevrolet Tahoe, 5.3L, 4WD.

3. The year menu displays, select 2014-E

18

Page 24

Quick Training Guide Scanner Demonstration

4. The make menu displays, select Chevrolet

5. The model menu displays, select Tahoe (4WD) Demo - K

6. The engine menu displays, select 5.3 V8 SFI (LMG) - 0

7. The vehicle confirmation screen displays, select OK. (Selecting OK loads the specific vehicle

database, in this instance it’s our demonstration database).

8. A message displays “Demo mode: Do not connect to vehicle.” Select Continue.

For more on vehicle identification, see Vehicle Identification‚ on page 28.

After the vehicle has been identified, a systems menu displays This menu shows all of the

vehicle systems available (supported by the vehicle) for testing. Typical systems cho ices may

include:

• Code Scan • Body Control Module • Radio

• Clear All Codes Read

by Code Scan

• Door Module - Driver • Seat Module - Driver

• Engine • Door Module - Passenger • Suspension (ESC). If Equipped.

• Transmission • Heating and Air Conditioning • Theft Deterrent

• Antilock Brakes • Instrument Panel Cluster • Tire Pressure Monitor

• Airbag • Passenger Presence System • Transfer Case

Most of the system menu choices are directly related to a specific vehicle system (e.g. Engine,

Airbag, Tire Pressure Monitor), with the exception of Code Scan and Clear All Codes Read by

Code Scan. Code Scan is a time-saving feature that allows you to scan all the vehicle systems

at once for diagnostic trouble codes (DTCs). For more on Code Scan, see Code Scan‚ on

page 30.

Choosing a vehicle system opens the main menu for that system which provides options for

you to analyze and interact with that system. You can choose to scan for DTCs, clear DTCs,

view parameter data (PIDs), perform functional tests and more. For more on System Menu

options, see System Main Menu Options‚ on page 32.

9. Proceed to Scanner Demo 2.

z Scanner Demo 2 - Scan for Engine Codes and Save the Codes

This demonstration simulates performing a typical check for engine trouble codes, and saving the

codes for review at a later time.

1. Select Engine.

2. Select Codes Menu > Display Codes > DTC Display.

A list of current DTCs is displayed.

For more on the Code Menu, see Codes Menu‚ on page 33.

3. Select Save . A confirmation message will briefly display to inform you that the data file

has been saved.

4. Press Back three (3) times to return to the Main Menu (Engine).

5. Proceed to Scanner Demo 3

19

Page 25

Quick Training Guide Scanner Demonstration

NOTE:

z Scanner Demo 3 - View, Configure and Save Engine Data (PIDs)

This demonstration simulates viewing engine data (PIDs) in list and graph views, creating a

custom data list, and saving the data for review at a later time.

Viewing PIDs:

1. From the Main Menu (Engine), select Data Display > Engine Data.

The Engine Data list is displayed showing all supported PIDs. Use the scroll bar to view all the

data.

Changing the displayed view:

2. Select View and then select PID list (to display PIDs in a list format) or 4 graphs (to

display 4 PID graphs onscreen). Use the scroll bar to view all the data.

For more on changing data display views, see Changing Screen Views‚ on page 37.

Saving a PID data file:

3. Select Save . A confirmation message will briefly display to inform you that the data file

has been saved.

Creating a custom PID list:

4. Select Custom Data , then select the Deselect All .

5. Select Engine Speed (RPM), MAF (g/s), and HO2S B1 S1 (mv) from the list. A check mark

appears in the box to indicate a selected item.

For more on customized PID lists, see Customizing the Data List‚ on page 36.

6. Select Back .

You have just created a custom PID list. To change your list, select the Custom Data icon

again and modify your selection.

7. Press Back two (2) times to return to the Main Menu (Engine).

8. Proceed to Scanner Demo 4

z Scanner Demo 4 - Perform a Functional Test

This demonstration simulates performing a functional component test.

i This functional test demonstration is intended to show a typical testing scenario. The data

displayed will not change when performing a test, as it may when testing an actual vehicle.

1. From the Main Menu (Engine) select Functional Tests.

2. Select Output Controls > EVAP VENT SOLENOID VALVE

3. A message displays “Test will not function correctly if on-board EVAP diagnostic is running.”,

select Continue.

The test screen displays showing PIDs related to the system being tested and a functional test

icon at the top labeled EVAP VENT SOLENIOD VALVE.

4. Select the EVAP VENT SOLENIOD VALVE icon and choose an option Venting or Not

Venting. Notice the current state is indicated “Venting or Not Venting” in the title bar just

above the data list on the right side. Toggle the functional icon Venting or Not Venting to see

the status change.

5. Press Back four (4) times to return to the Systems Menu.

6. Proceed to Scanner Demo 5

20

Page 26

Quick Training Guide Scanner Demonstration

z Scanner Demo 5 - Perform a Code Scan

This demonstration simulates performing a typical code scan of all supported vehicle systems,

and saving the code scan data.

1. From the Systems Menu select Code Scan.

The Code Scan results screen displays and starts the automated process of scanning vehicle

systems for codes. A status indicator is displayed at the top of the list as the scan is performed.

2. Use the scroll bar to view the complete list.

3. Select Save . A confirmation message will briefly display to inform you that a file has been

saved.

For more on Code Scan, see Code Scan‚ on page 30.

4. Press Home to return to the Home screen.

5. Proceed to Scanner Demo 6

z Scanner Demo 6 - View Saved Files (Codes, Code Scan and Data Files)

This demonstration walks you through opening the data files saved in the previous demos.

1. From the Home screen select Previous Vehicles and Data .

2. Select View Saved Data.

A list of all saved files is displayed (most current at top).

• Code data and Code Scan files are saved with an .XML file extension and show the date

saved and vehicle information.

• Engine data files are saved with with a .SCM file extension and also show the date saved and

vehicle information.

3. Select the saved data file to view it. If needed, use the scroll bar to view all the data.

For more on viewing data files, see View Saved Data‚ on page 71.

4. Select Back to return to the Previous Vehicles and Data main menu.

5. Proceed to Scanner Demo 7

z Scanner Demo 7 - Activate a Previously Identified Vehicle and View Engine Data (PIDs)

This demonstration simulates activating a previously identified vehicle, and viewing engine data.

1. From the Previous Vehicles and Data main menu select Vehicle History.

A list of all previously identified vehicles is displayed.

For more on Vehicle History, see Vehicle History‚ on page 70.

2. For the purpose of this exercise we will select our same demo vehicle, select 2014 Chevrolet

Tahoe, 5.3L, 4WD. Note: If other vehicles have been previously identified, they will display in

the list.

3. A vehicle confirmation screen displays, select Continue.

4. A message displays “Demo mode: Do not connect to vehicle.”, select Continue.

5. From the Main Menu (Engine), select Data Display > Engine Data.

The Engine Data list is displayed showing all supported PIDs. Use the scroll bar to view all the

data.

6. Select Back two times (2) to return to Main Menu (Engine), or select Home once to

return to the Home screen.

End of Scanner demonstration.

21

Page 27

Quick Training Guide OBD-II/EOBD Demonstration

NOTE:

IMPORTANT:

To become familiar with other capabilities of the Scanner function, navigate through the other

services and menu options within the Scanner Demonstration Mode. Also, watch our product

training videos on our website at: https://diagnostics.snapon.com/trainingsolutions

4.2 OBD-II/EOBD Demonstration

The OBD-II/EOBD training program allows you to navigate through many functions of

OBD-II/EOBD, and displays vehicle data (PIDs) and trouble codes (captured from actual vehicle)

to simulate what you might see on an actual vehicle.

Links are provided (as applicable) within the demonstrations to additional topic information in this

manual.

i The OBD-II/EOBD function allows you to access “generic” OBD-II/EOBD data (data limited to

emission related diagnostics only). The Scanner function allows you to access vehicle specific

systems, parameters and enhanced diagnostics.

The following OBD-II/EOBD demonstrations are intended to be completed in sequence:

1 - Start Communication / Vehicle Identification

2 - Check Monitors Complete This Cycle

3 - Display Current Data

4 - Display Trouble Codes

5 - Display and Save Freeze Frame Data

z OBD-II/EOBD Demo 1 - Start Communication / Vehicle Identification

This demonstration starts the OBD-II/EOBD training demonstration, simulating typical vehicle

connection and identification.

1. From the Home screen, select OBD-II/EOBD .

2. The main menu displays, select OBD Direct.

Do not connect a vehicle to the diagnostic tool while using the Demonstration program.

3. Select OBD Training Mode.

4. Select Start Communication.

5. The demonstration vehicle data is loaded and a confirmation screen displays, select

Continue.

For more on OBD communication, see Start Communication‚ on page 48.

6. The OBD-II/EOBD Service menu displays.

7. Proceed to OBD-II/EOBD Demo 2.

22

Page 28

Quick Training Guide OBD-II/EOBD Demonstration

z OBD-II/EOBD Demo 2 - Check Monitors Complete This Cycle

This demonstration simulates a typical check of OBD monitors that have run during the current

drive cycle.

1. From the OBD-II/EOBD Service menu, select Readiness Monitors.

2. Select Monitors Complete This Cycle.

3. With the monitor data displayed, select View and then select PID list (to display as a list).

4. A list of monitors is displayed showing status indication (e.g. Test Complete ,

Not Supported or Not Complete ).

Note: Use the scroll bar to view all the data.

For more on readiness monitors, see Readiness Monitors‚ on page 47.

– Select Back two (2) times to return the OBD-II/EOBD Service menu.

5. Proceed to OBD-II/EOBD Demo 3.

z OBD-II/EOBD Demo 3 - Display Current Data

This demonstration simulates a typical check of current OBD data, v iewing OB D data (P IDs) in list

and graph views, and creating a custom data list.

1. From the OBD-II/EOBD Service menu select ($01) Display Current Data.

The Engine Data list is displayed. This list shows all supported PIDs, use the scroll bar to view

all the data.

2. Select Custom Data , then select the Deselect All .

3. Select Short Term Fuel Trim Bank 1(%) and Short Term Fuel Trim Bank 2(%).

4. Select Back .

You have just created a custom PID list. To change your list, select the Custom Data icon

again and modify your selection.

5. With the data displayed, select View and then select PID list (to display PIDs in a list) or

2 graphs (to display each PID as a graph).

Notes:

• Use the scroll bar to view all the data in the file, if needed.

• Use the navigation controls to navigate through the data.

• Select the View icon to view the data as a list or graphs.

• Select the Zoom icon to view data detail in the graph.

For more on displaying current OBD data, see ($01) Display Current Data‚ on page 51.

6. Select Back to return to the OBD-II/EOBD Service menu.

7. Proceed to OBD-II/EOBD Demo 4.

z OBD-II/EOBD Demo 4 - Display Trouble Codes

This demonstration simulates a typical check of current OBD trouble codes.

1. From the OBD-II/EOBD Service menu select ($03) Display Trouble Codes.

A list of OBD trouble codes (DTCs) is displayed.

For more on displaying OBD trouble codes, see ($03) Display Trouble Codes‚ on page 51.

2. Select Back to return to the OBD-II/EOBD Service menu.

3. Proceed to OBD-II/EOBD Demo 5.

23

Page 29

Quick Training Guide OBD-II/EOBD Demonstration

z OBD-II/EOBD Demo 5 - Display and Save Freeze Frame Data:

This demonstration walks you through a typical check of OBD Freeze Frame data, and shows how

to save and review the data.

1. From the OBD-II/EOBD Service menu select ($02) Display Freeze Frame Data.

A freeze frame list of data is displayed. Note: Use the scroll bar to view all the data.

For more on displaying OBD freeze frame data, see ($02) Display Freeze Frame Data‚ on

page 51.

2. Select Save . A confirmation message will briefly display to inform you that a file has been

saved.

3. Select Back once, then press Home once to return to the Home screen.

4. From the Home screen select Previous Vehicles and Data .

5. Select View Saved Data.

A list of all saved files is displayed (most current at top). OBD-II/EOBD Freeze Frame files are

saved with an .SCM file extension, show the date saved and are labeled OBD.

6. Select the saved Freeze Frame file to view it.

Notes:

• Use the scroll bar to view all the data in the file, if needed.

• Use the navigation controls to navigate through the data.

7. Select Back once, then press Home once to return to the Home screen.

For more on viewing saved data, see View Saved Data‚ on page 71.

End of OBD-II/EOBD demonstration.

To become familiar with other capabilities of the OBD-II/EOBD function, navigate through the

other services and menu options within the OBD Training Mode. Also, watch our product

training videos on our website at: https://diagnostics.snapon.com/trainingsolutions

24

Page 30

Chapter 5 Scanner

IMPORTANT:

This chapter describes the basic operation of the Scanner function.

The Scanner icon is located on the Home screen.

The Scanner function allows your diagnostic tool to communicate with the electronic control

systems of a vehicle. This allows you to retrieve diagnostic trouble codes (DTCs), view PID data

and perform diagnostic tests.

5.1 Scanner Demonstration Program

The Scanner demonstration program displays actual vehicle data that allows you to navigate and

become familiar with the many capabilities of the Scanner function without actually connecting to

a vehicle. The following sections in this chapter provide detailed information on navigating through

the Scanner function and various menus. As you navigate through the Demonstration program,

refer to the applicable section for additional information.

z To start the demonstration program:

1. From the Home screen, select the Scanner icon.

The manufacturer menu displays.

2. Select the Demonstration icon.

Figure 5-1

Do not connect a vehicle to the diagnostic tool while using the Demonstration program.

25

Page 31

Scanner Screen Layout and Toolbar Icons

1

2

3

Vehicle Information

3. Follow the on-screen instructions and make the selection as needed until the confirmation

screen displays.

4. Select OK on the confirmation screen to load the demonstration database.

A message displays “Demo mode: Do not connect to vehicle.”

5. Select Continue.

A systems menu, which shows all of the systems available for testing, displays.

6. Select a system from the menu, then select submenus as applicable to display the desired

demonstration information.

5.2 Screen Layout and Toolbar Icons

The following screen layout and toolbar controls apply to both the Scanner and the OBD-II/EOBD

functions.

5.2.1 Screen Layout

1— Title bar—shows active test, vehicle and diagnostic tool status

2— Toolbar—contains control icons

3— Main body—displays menus, PID and test data

The Title bar appears for all functions and displays information only, there are no selectable items.

Refer to Title Bar‚ on page 13 for details.

Figure 5-2 Screen layout

26

Page 32

Scanner Screen Layout and Toolbar Icons

5.2.2 Scanner Control Icons

The scanner toolbar contains control icons. Control icons may vary depending on the active

function or test. A yellow frame surrounding an icon (highlighted), indicates it is selected. Other

control icons (not shown) are described in Common Toolbar Control Icons‚ on page 15.

Icon Function Icon Function

Pause - Indicates PID data from the

vehicle is being displayed. Selecting

pauses data collection.

Custom Data List - Opens a menu for

selecting which PIDs display in the list.

Clear - Erases all the PID data in the

buffer and begins a new recording.

Selecting opens a confirmation

message.

Trigge r - Opens a menu that allows

you to set, arm, and clear threshold

values that automatically trigger PID

data to be saved from buffer memory

to a file.

Zoom - Incrementally increases and

decreases the scale of the data being

displayed.

Record - Indicates the data being

displayed is paused and not being

updated. Selecting resumes data

collection.

The control icons below are used to navigate through

paused or saved “movie” files during playback.

Step Forward - allows forward

movement in singular steps. To

quickly step forward, select this icon

(yellow frame appears) then press and

hold the Y/

Note: To quickly step forward during

Scanner data playback, press and

hold the icon down. During this mode

a red frame appears around the icon.

a button.

Change View - Changes display

options between PID list or graph

displays.

Lock/Unlock - Locks or unlocks the

highlighted parameter. Locked PIDs

move to the top of the list and do not

scroll as you move through the data.

Sort - Determines the order in which

PIDs are listed on the screen.

Step Back - allows backward

movement in singular steps. To

quickly step backward, select this icon

(yellow frame appears) then press and

hold the Y/

Note: To quickly step backward during

Scanner data playback, press and

hold the icon down. During this mode

a red frame appears around the icon.

a button.

27

Page 33

Scanner Scanner Operation

NOTE:

NOTE:

5.3 Scanner Operation

5.3.1 Vehicle Identification

The vehicle must be correctly identified for the diagnostic tool to communicate, and display data

correctly. Menus and navigation will vary by vehicle.

Depending on the vehicle, the vehicle identification process may require manual entry of the

vehicle information, or it may be automated. The following Scanner functions are available to

identify the vehicle:

Auto ID - Automatically completes the identification process after the vehicle make and year are

manually entered.

Manual ID - Allows for manual entry of all required vehicle identification criteria.

z Use the following procedure to identify a vehicle.

i The following procedure applies to most OBD-II vehicles, and may vary depending on the vehicle.

Not all vehicles support the Auto ID function.

1. Connect the data cable to the diagnostic tool. See Data Cable Connection‚ on page 17.

2. Turn the vehicle ignition switch on.

3. Connect the data cable to the vehicle data link connector (DLC). See Data Cable Connection‚

on page 17.

i If the diagnostic tool is off, when the OBD-II data cable is connected to the vehicle DLC, the

diagnostic tool should automatically turn on. If the tool did not turn on when the data cable was

connected to the vehicle, check the vehicle DLC for power. Most OBD-II vehicles supply power to

the DLC, which in-turn supplies power and turns on the diagnostic tool when the cable is

connected.

4. If required, turn the diagnostic tool on.

5. Select Scanner.

6. Enter the vehicle make then year.

7. Select Automatic ID or Manual ID, then follow the screen prompts to enter any additional

information if needed.

28

Page 34

Scanner Scanner Operation

NOTE:

After the vehicle is identified, a menu of available systems, and options are displayed. Select

a system or option (Figure 5-4).

Figure 5-3 Vehicle confirmation screen

i Only the systems and options supported for the vehicle are included in the menu list.

Figure 5-4 Typical systems menu

If a system (e.g. Engine, Transmission, Antilock Brakes, etc) is selected, the diagnostic tool

may establish communication with the vehicle, then display the system main menu (available

tests) (Figure 5-5). For sub-menu option information, see System Main Menu Options‚ on

page 32.

29

Page 35

Scanner Scanner Operation

Figure 5-5 System main menu

5.3.2 Code Scan

Depending on the vehicle, Code Scan (if supported) may be available from the Systems menu.

Selecting Code Scan starts an active scan of vehicle control modules, and opens the Code Scan

results screen (Figure 5-6). A progress indicator is shown at the top indicating the active scanning

progress. Once completed, the results are displayed by system category.

The following Code Scan related control icons are used:

Icon Function

Refresh - Restarts the code scan

System - Opens the main menu of the system selected

The following results are displayed progressively as the modules are scanned:

• The total number of systems (modules) detected (Figure 5-6).

30

Page 36

Scanner Scanner Operation

NOTE:

Vehicle Information

Vehicle Information

Figure 5-6 Code Scan systems analyzed result total

• A list of all the systems analyzed with DTCs totals. A categorized system list with DTC

totals is displayed in the order they are scanned. To view the main menu for a system in the

list, select the system, then select the System icon (Figure 5-7).

Figure 5-7 System icon (opens Main Menu)

i Some 2005 to 2008 vehicles may not display global OBD-II information in the Code Scan list. A

message will be displayed to inform you the OBD-II - codes and monitors for this vehicle may be

accessed using the global OBD-II function. See OBD-II/EOBD‚ on page 44.

31

Page 37

Scanner Scanner Operation

NOTE:

NOTE:

Saving Codes, and Code Scan Results)

When using the code scan feature, or when viewing individual system codes (e.g. engine,

transmission) selecting the Save icon from the toolbar saves the results as a data file.

The saved file(s) can be viewed using two methods:

• On the diagnostic tool - See View Saved Data‚ on page 71.

• Using ShopStream Connect - See Scanner Codes Viewer‚ on page 62.

Clear All Codes Read by Code Scan

Selecting Clear All Codes Read by Code Scan erases all DTCs from all vehicle system modules

that were read by Code Scan.

i Clear All Codes Read by Code Scan may not clear global OBD-II codes on some vehicles.

5.3.3 System Main Menu Options

Once a System is selected (e.g. Engine, Transmission, Antilock Brakes, etc), the diagnostic tool

may establish communication with the vehicle, then display the System Main Menu (available

tests).

i Menus and navigation will vary by vehicle.

The System Main Menu may include:

• Codes Menu—displays diagnostic trouble code (DTC) records from the vehicle electronic

control module. Selecting may open a submenu of viewing options.

• Clear Codes—erases DTC records and other data from the electronic control module (ECM).

This selection is found on a Codes submenu for some models.

• Data Display— displays PID data from the vehicle ECM. Selecting may open a submenu of

viewing options.

• Functional Tests—provides specific subsystem tests. The tests vary depending on the

manufacturer and model.

• Actuator Tests—similar to functional tests, checks the operation of certain actuators, such as

solenoid valves and relays.

• Memory Resets—allows you to reprogram adaptive values for certain components after

making repairs. Selecting opens a submenu. These options are found on the Functional Tests

Menu for some models.

• System Tests—provides specific subsystem testing. Performing these tests is similar to

functional tests.

• Generic Functions—lets you access certain available Generic OBD II functions from a

proprietary menu (1996 and newer vehicles only).

The following sections, describe some of the System Main Menu items listed above.

32

Page 38

Scanner Scanner Operation

5.3.4 Codes Menu

This selection may appear as Codes, Codes Menu, Codes Only, Codes (No Data), Service Codes

or something similar on the menu. Selecting opens a list of viewing options that includes:

• Display Codes

• Clear Codes‚ on page 33

• Freeze Frame/Failure Records‚ on page 34

Display Codes

This function opens either a list of diagnostic trouble codes (DTCs) stored in the selected vehicle

electronic control module (ECM), or a submenu of DTC viewing options. The code list includes the

DTC and a brief description (Figure 5-8).

Figure 5-8 DTC results

Submenu options may include:

• Trouble Code Information—opens a list of codes in ECM memory

• History Codes—opens a list of codes whose symptoms are not currently present. History

codes indicate an intermittently occurring problem.

• Failed This Ignition—opens a list of codes that set during the current ignition cycle.

• MIL SVS or Message Requested—displays ECM requests to turn on the malfunction

indicator lamp (MIL) or service vehicle soon (SVS) lamp, or display a driver information alert.

• Last Test Failed—displays a complete list of failed tests.

• Test Failed Since Code Cleared—displays a list of tests that failed since the last time codes

were cleared from ECM memory.

Clear Codes

The diagnostic tool clears codes from the vehicle electronic control module memory on most

vehicles. If this function is not available on the test vehicle, Clear Codes does not appear as a

menu option.

33

Page 39

Scanner Scanner Operation

NOTE:

IMPORTANT:

i Clear Codes is also available from OBD-II Health Check (see OBD Health Check‚ on page 45).

z To clear codes:

1. Select Clear Codes from the Codes Menu.

A confirmation message displays.

2. Make sure any conditions shown on the confirmation message are met, then select Yes.

A “codes cleared” message displays once the operation is complete.

3. Select Continue to return to the Codes Menu.

Clearing codes erases all temporary ECM information, including Freeze Frame/Failure Records.

Make sure no vital diagnostic information will be lost before clearing codes.

Freeze Frame/Failure Records

This selection displays the DTC that was set, along with corresponding data, when the ECM

commanded the malfunction indicator lamp (MIL) to turn on.

Data Display

Select Data to view PID data from the vehicle ECM. In data display mode the screen has a toolbar

and a main body (Figure 5-9).

Figure 5-9 Data display screen

The toolbar control icons are described in Scanner Control Icons‚ on page 27 and Common

Toolbar Control Icons‚ on page 15.

During data display the main body of the screen is divided into two columns; the left-hand column

has a description of the parameter and the right-hand column shows the parameter value or state.

34

Page 40

Scanner Scanner Operation

Parameters are listed in the order in which they are transmitted by the ECM, so expect variations

between years, makes, and models.

Up to three parameters can be locked, or fixed, at the top of the list. Locked parameters do not

change as you scroll through the parameter list. The Lock/Unlock icon on the toolbar selects

which parameters are fixed (see Locking Parameters‚ on page 38).

Displayed data may also be paused or saved for detailed review and future reference, see Saving

Files‚ on page 41 and Pausing and Reviewing Data Files‚ on page 35.

Pausing and Reviewing Data Files

During normal operation, data from the vehicle’s ECM is continuously being stored in buffer

memory as it is displayed onscreen. The Pause feature, allows you to temporarily pause data

collection to review it in detail.

z To pause and review data

Toolbar control icons are described in Scanner Control Icons‚ on page 27 and Common Toolbar

Control Icons‚ on page 15.

1. While viewing data, select the Pause icon.

On the toolbar, the playback control icons are displayed. A counter displays along the right-

hand edge of the screen between the toolbar and the main body. A bar graph to the left of the

counter shows how much data is in the memory buffer. A slider on the bar graph indicates the

position of the current screen in relation to the entire contents of the data buffer.

Use the slider to quickly scroll through the data. Use the control icons to accurately position

the cursor. The cursor (vertical line), indicates your position when in the graph mode, appears

once you begin navigating (Figure 5-10).

35

Page 41

Scanner Scanner Operation

NOTE:

NOTE:

1— Step Back

2— Step Forward

3— Record

2. Scroll up or down to review the list of data.

3. Select the desired control icon to move forward or back in the selected direction.

z To resume:

• Select the Record icon.

The display changes back to display data and the Pause icon is shown on the toolbar. A

vertical rule is displayed on the data graph to indicate data was paused at that point.

i The Shortcut icon can be set to perform the Pause/Play function. See Configure Shortcut Button‚

on page 75 for additional information.

Customizing the Data List

The Custom Data List icon on the toolbar is used to determine which specific parameters display.

Minimizing the number of parameters on the data list allows you to focus on any suspicious or

symptom-specific data parameters. You can add or remove most parameters from the list. Certain

vital parameters may not be removed. These appear in gray at the top of the list along with a lock

icon, and they cannot be selected.

4— Cursor

5— Counter (current position / total)

Figure 5-10

i Limiting the number of parameters that display to those that apply to a particular situation results

in a faster data refresh rate, and reduces the amount of memory used for saved files.

36

Page 42

Scanner Scanner Operation

z To create a custom data list:

1. Select the Custom Data List icon on the toolbar.

The data selection screen displays and selection icons appear. Check marks to the left of the

parameter description indicate which parameters are selected for display.

The toolbar icons provide options for selecting and deselecting parameters to include or

remove from the custom data list:

Icon Description

Select/Deselect, hide or display individual

parameters in the list.

Select All/Deselect All, hide or display all

parameters in the list.

2. Create a custom data list by selecting (check mark box by parameter name) the parameters

to include.

3. Select Back to display the updated data list.

Changing Screen Views

Selecting the View icon opens a drop-down menu of options:

• PID List

• 1 Graph

• 2 Graph

• 4 Graph

The PID (parameter identification) List view is a 2-column display with the name of the parameters

in the left column and their current values in the right column (Figure 5-9).

The 1, 2, and 4 Graph views divide the screen horizontally to simultaneously display data graphs

for the indicated number of parameters (Figure 5-11). Use the scroll bar or the up (b) and down

(d) icons to view other parameters in the list.

37

Page 43

Scanner Scanner Operation

NOTE:

Figure 5-11 Four graph view

i Any previously set conditions, such as sort order or locked data, remain in effect when the screen

view is changed.

Locking Parameters

Use the Lock/Unlock icon to hold selected lines of the data in place and prevent them from

scrolling, or to release previously locked lines of data. Up to three lines of data may be held at a

time. This feature allows you to position related parameters together, making it easier to monitor

their values and spot inconsistencies.

Locked parameters display as the top frames on the main body of the display screen, as well as

at their usual position within the data list (Figure 5-12). A lock icon appears to the left of the

parameter name to indicate it is locked.

z To lock parameters:

1. Highlight the parameter to be locked.

2. Select the Lock/Unlock icon on the toolbar to lock it.

A copy of the locked parameter is now shown at the top of the data list, and a lock icon

appears alongside the parameter name.