Page 1

Operating Manual

POWER PLANT CONTROLLER

PPC-BE-P7-en-13 | 98-113900.02 | Version 1.3 ENGLISH

Page 2

Legal Provisions SMA Solar Technology AG

Legal Provisions

The information contained in this document is the property of SMA Solar Technology AG. Publishing its content, either

partially or in full, requires the written permission of SMA Solar Technology AG. Any internal company copying of the

document for the purposes of evaluating the product or its correct implementation is allowed and does not require

permission.

SMA Warranty

You can download the current warranty conditions from the Internet at www.SMA-Solar.com.

Trademarks

All trademarks are recognized, even if not explicitly identified as such. A lack of identification does not mean that a

product or symbol is not trademarked.

The BLUETOOTH

marks by SMA Solar Technology AG is under license.

®

Modbus

is a registered trademark of Schneider Electric and is licensed by the Modbus Organization, Inc.

QR Code is a registered trademark of DENSO WAVE INCORPORATED.

®

Phillips

Torx

and Pozidriv® are registered trademarks of Phillips Screw Company.

®

is a registered trademark of Acument Global Technologies, Inc.

®

word mark and logos are registered trademarks owned by Bluetooth SIG, Inc. and any use of these

SMA Solar Technology AG

Sonnenallee 1

34266 Niestetal

Germany

Tel. +49 561 9522-0

Fax +49 561 9522-100

www.SMA.de

E-mail: info@SMA.de

© 2004 to 2015 SMA Solar Technology AG. All rights reserved.

2 PPC-BE-P7-en-13 Operating Manual

Page 3

SMA Solar Technology AG Table of Contents

Table of Contents

1 Information on this Document. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1 System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 Design of the Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.3 Operating and Display Elements of the Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.4 User Interface of the Power Plant Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.4.1 Design of the User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.4.2 "My System" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.4.3 "PPC" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4 Scope of Delivery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5 Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.1 Requirements for Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2 Mounting the Power Plant Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.1 Overview of the Connection Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.2 Connecting the Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.3 Connecting Digital Inputs and Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.4 Connecting Analog Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.5 Connecting Network Cables and Optical Fibers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.1 Safety during Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.2 Adjusting Network Settings on the Computer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.3 Installing the Droid Sans Font on the Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.4 Changing the Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.5 Changing Language and Time Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.6 Adjusting the Device Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.6.1 Adjusting IP Addresses of the Power Plant Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

7.6.2 Adjusting the Configuration of the Sunny Centrals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

7.6.3 Adjusting the Configuration of the Cluster Controllers and Inverter Managers. . . . . . . . . . . . . . . . . . . . . . . . .30

7.6.4 Adjusting the Configuration of the Network Analyzers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

7.6.5 Adjusting the Configuration of the Power Plant Controller Slaves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

7.7 Adjusting the Settings of the Modbus Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.8 Transmitting Output Values to Devices of the PV System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.9 Selecting the Signal Source and Adjusting the Scaling of Measured Values. . . . . . . . . . . . . . . . . . . . . . . . 34

7.10 Local Specification of Setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.11 Saving and Restoring Settings of the Power Plant Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.12 Calling Up the System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.12.1 Calling Up the Overview of the Entire System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

7.12.2 Retrieving the Status and Current Data of All Devices in the System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Operating Manual PPC-BE-P7-en-13 3

Page 4

Table of Contents SMA Solar Technology AG

8 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

8.1 Calling up Information on Software Version and Service-Relevant Information. . . . . . . . . . . . . . . . . . . . . . 40

8.2 Calling-Up and Acknowledging Error, Warning and Event Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.3 Errors and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.4 Corrective Measures in the Event of Disturbance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

9 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

9.1 Maintenance and Replacement Intervals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

9.2 Checking the Mounting Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

9.3 Switching the Power Plant Controller On and Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

9.4 Checking the Enclosure and Enclosure Interior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9.5 Replacing the SD Memory Card of the Power Plant Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

10 Decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

10.1 Disassembling the Power Plant Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10.2 Disposing of the Power Plant Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

11 Periodic Actions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

11.1 Cable Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

11.1.1 Inserting the Cable into the Cable Feed-Through Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

11.1.2 Inserting the Cable in the Cable Gland. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

11.2 Clamp Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

11.2.1 Connecting Insulated Conductors to Spring-Cage Terminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

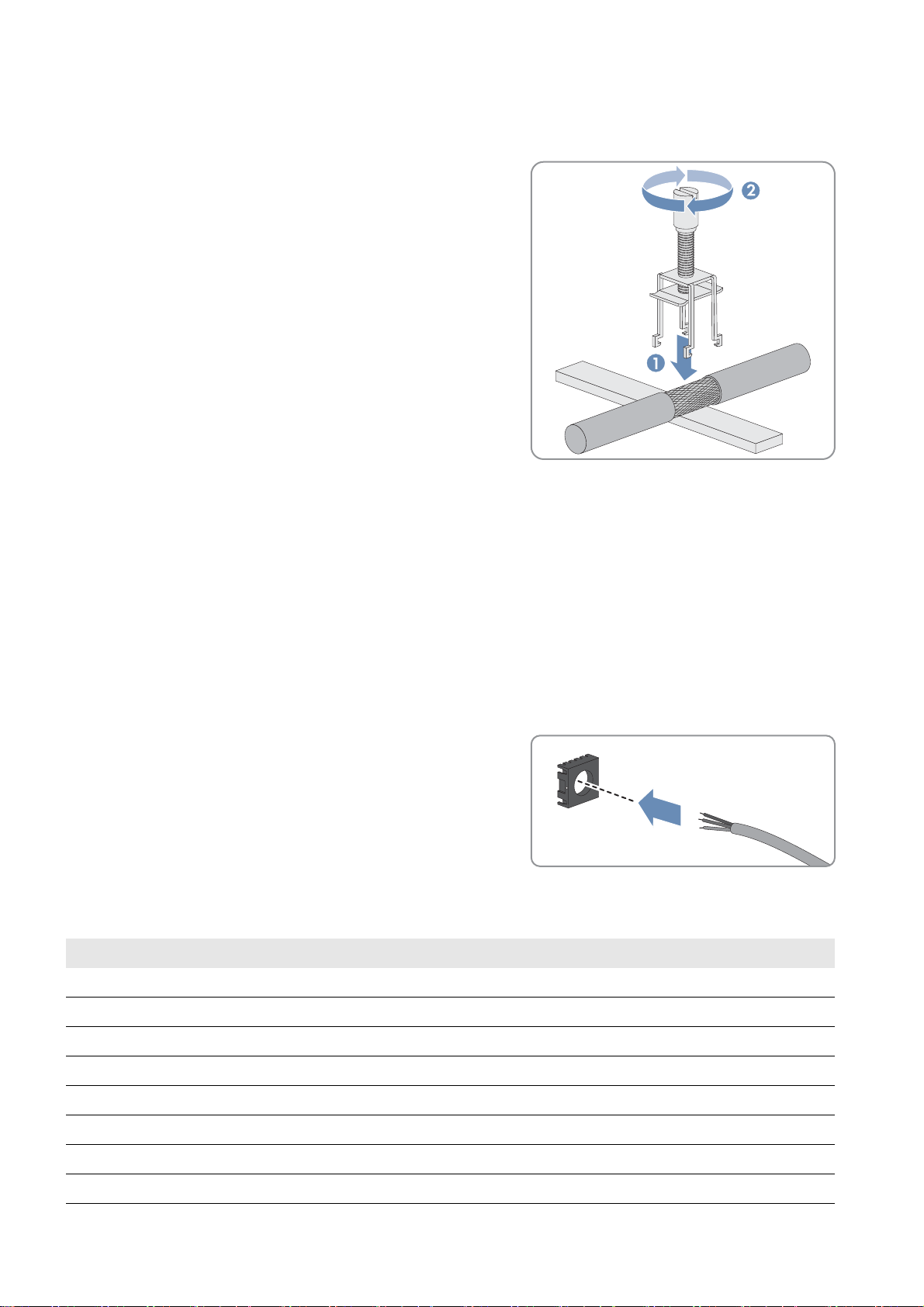

11.2.2 Connecting the Shield Contact of the Cable Using a Shield Clamping Saddle . . . . . . . . . . . . . . . . . . . . . . . .52

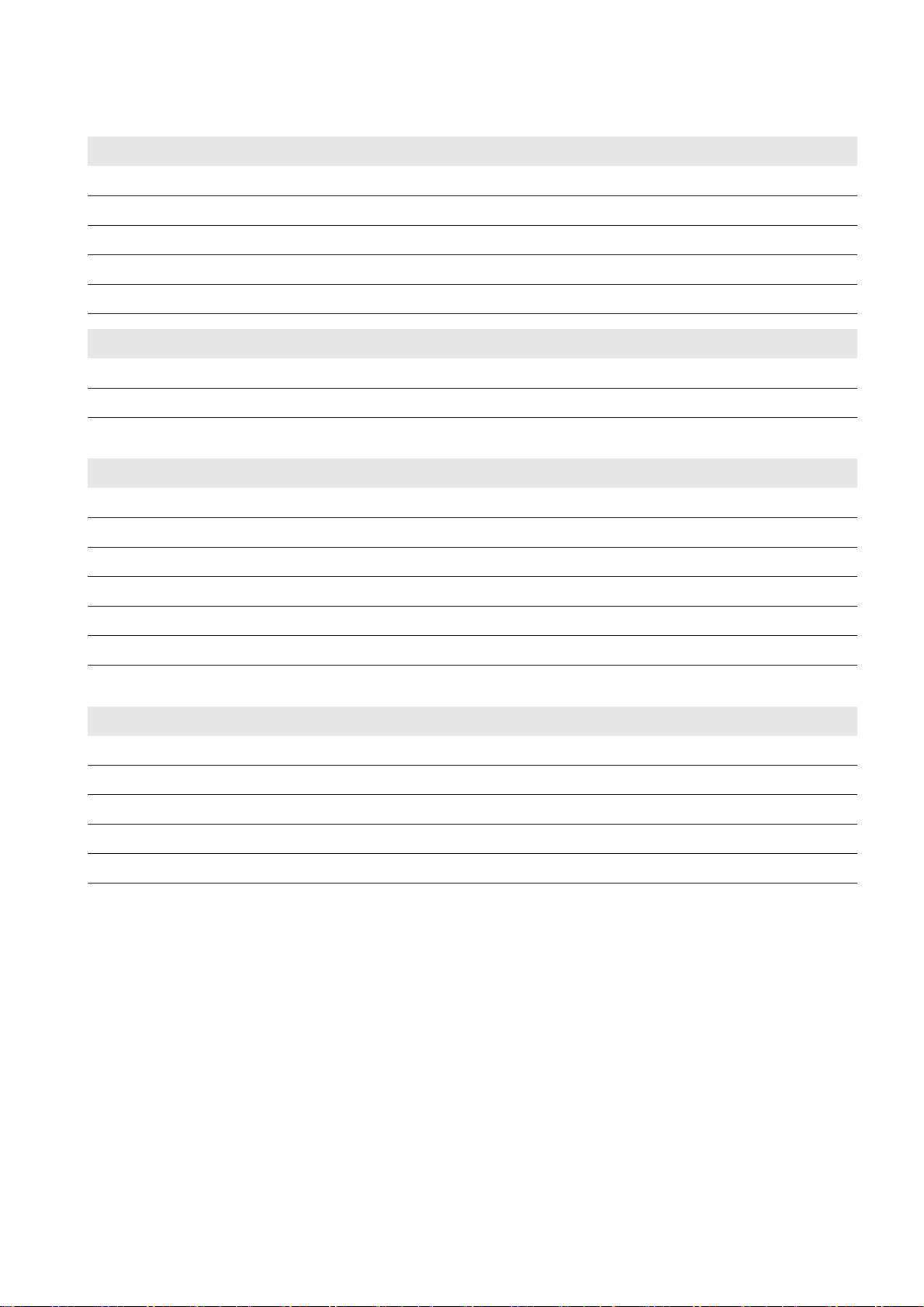

11.2.3 Installing Network Cables to the RJ45 Keystone Pin Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

11.3 Settings on the User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

11.3.1 Logging Into the User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

11.3.1.1 Logging In at the Touch Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

11.3.1.2 Logging In on the Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

11.3.2 Logging Out of the User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

12 Technical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

13 Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

13.1 Structure of the System Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

13.2 Principle of the Communication Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

13.3 Scaling of the Analog Measuring Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

13.4 Output Value Specification Under Fault Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

13.5 Directive for Secure Passwords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

13.6 Type Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

14 Contact. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

4 PPC-BE-P7-en-13 Operating Manual

Page 5

SMA Solar Technology AG 1 Information on this Document

'$1*(5

:$5 1,1*

&$87,21

/05*$&

1 Information on this Document

Validity

This document is valid for the following device types from production version P7 and software version 01.03.20.R.:

• Power Plant Controller (PPC-10)

The production version is indicated on the type label.

You can read off the software version via the user interface.

Target Group

The activities described in this document must only be performed by qualified persons. Qualified persons must have the

following skills:

• Knowledge of how to deal with the dangers and risks associated with installing and using electrical devices

• Training in the installation and configuration of IT systems

• Knowledge of all applicable standards and directives

• Knowledge of operation and control of PV power plants on medium-voltage grids and high-voltage grids

• Knowledge of and compliance with this document and all safety information

Additional Information

Links to additional information can be found at www.SMA-Solar.com:

Document title Document type

Interface for Modbus Communication SUNNY WEBBOX / SC-COM Modbus

Interface

Technical Description

Symbols

Symbol Explanation

Indicates a hazardous situation which, if not avoided, will result in death or serious injury

Indicates a hazardous situation which, if not avoided, can result in death or serious injury

Indicates a hazardous situation which, if not avoided, can result in minor or moderate injury

Indicates a situation which, if not avoided, can result in property damage

Information that is important for a specific topic or goal, but is not safety-relevant

☐ Indicates a requirement for meeting a specific goal

☑ Desired result

✖ A problem that might occur

Operating Manual PPC-BE-P7-en-13 5

Page 6

1 Information on this Document SMA Solar Technology AG

Typographies

Typography Use Example

bold • Display messages

• Elements on a user interface

• Parameters

•Terminals

•Slots

• Elements to be selected or entered

> • Connects several elements to be selected • Select PV system > Detection.

[Button/Key] • Button or key to be selected or pressed • Select [Start detection].

• Select the parameter

ExlTrfErrEna and set to Off.

• Select the tab Parameters.

Nomenclature

Complete designation Designation in this document

SMA Power Plant Controller Power Plant Controller

SMA Cluster Controller Cluster Controller

Sunny Central CP XT Sunny Central

The Sunny Centrals and Cluster Controllers connected to the Power Plant Controller are referred to as devices.

Abbreviations

Abbreviation Designation Explanation

AC Alternating Current ‒

DC Direct Current ‒

ESD Electrostatic Discharge ‒

IP Internet Protocol ‒

LAN Local Area Network ‒

LED Light-Emitting Diode ‒

PE Protective Earth Protective conductor

PV Photovoltaics ‒

SC Subscriber Connector Plug for connection via optical fiber

6 PPC-BE-P7-en-13 Operating Manual

Page 7

SMA Solar Technology AG 2 Safety

2 Safety

This section contains safety information that must be observed at all times when working on or with the product. To prevent

personal injury or property damage and to ensure long-term operation of the product, read this section carefully and

observe all safety information at all times.

2.1 Intended Use

The Power Plant Controller is a device for the automatic control of large-scale PV power plants and the implementation

of active power and reactive power setpoints in large-scale PV power plants according to grid operator specifications.

The Power Plant Controller is suitable for indoor use. The Power Plant Controller without touch display is also suitable for

outdoor use.

The Power Plant Controller is designed for industrial use.

The Power Plant Controller must only be used with supported devices:

• Sunny Central Communication Controller (SC-COM) from firmware version 1.01

• Sunny Central 2200 / Sunny Central 2500 from firmware version 1.0

• SMA Cluster Controller from firmware version 1.0

• Sunny Tripower 60 with Inverter Manager from firmware version 1.45

• Transducer and network analyzer* :

Manufacturer Model

Ardetem TRM4

Janitza UMG 604 / UMG 605

Schneider Electric ION 7550 / ION 7650 / ION 8600

Schweitzer Engineering Laboratories SEL-735

When using the network analyzer Janitza UMG 604 / UMG 605, do not operate it in the same grid segment as

the inverters connected to the Power Plant Controller, since mutual interference may occur.

Only perform work on the Power Plant Controller using the appropriate tools and in compliance with the ESD protection

regulations.

For safety reasons, it is not permitted to modify the product or install components that are not explicitly recommended or

distributed by SMA Solar Technology AG for this product. Unauthorized changes or modifications will void any warranty

claims.

Any use of the product other than that described in the Intended Use section does not qualify as appropriate.

The type labels must be permanently attached to the product.

Only use the Power Plant Controller in accordance with the information provided in the enclosed documentation. Any

other use can result in personal injury or property damage.

The enclosed documentation is an integral part of this product.

• Read and observe the documentation.

• Keep the documentation in a convenient place for future reference.

* More transducers and network analyzers are available on request.

Operating Manual PPC-BE-P7-en-13 7

Page 8

2 Safety SMA Solar Technology AG

'$1*(5

:$5 1,1*

/05*$&

2.2 Safety Information

Electric shock due to live voltage

Danger of electric shock if work is executed incorrectly or under fault conditions. This results in death or serious injury.

• Wear personal protective equipment.

• Disconnect the supply voltage before performing any work on the Power Plant Controller.

• Observe the five safety rules when disconnecting the supply voltage:

– Disconnect from voltage sources

– Ensure that the device cannot be reconnected.

– Ensure that no voltage is present

– Ground and short-circuit the device

– Cover and isolate any adjacent live components

• Wait one minute for the capacitors of the redundant electricity supply to discharge.

Electric shock due to damaged Power Plant Controller

Operating a damaged Power Plant Controller can lead to hazardous situations that result in death or serious injuries

due to electric shock.

• Only operate the Power Plant Controller when it is in perfect working order and safe to operate.

• Check the Power Plant Controller regularly for visible damage.

• Make sure that all external safety equipment is freely accessible at all times.

• Make sure that all safety equipment is in good working order.

Danger to life due to blocked escape routes

In hazardous situations, blocked escape routes can lead to death or serious injury.

• An escape route of at least 500 mm width must be available at all times. Make sure the minimum passage width

of the escape route meets local standards.

• Observe the minimum clearances when installing the Power Plant Controller.

• Do not place any objects in the escape route area.

• Remove all tripping hazards from escape routes.

Damage to the Power Plant Controller due to moisture penetration

Dust intrusion or moisture penetration can damage the Power Plant Controller or impair its functionality.

• Do not open the Power Plant Controller when humidity exceeds 95%.

• Only perform maintenance work on the Power Plant Controller when the environment is dry and free of dust.

Damage to the Power Plant Controller due to overvoltage

When overvoltage occurs, the Power Plant Controller can be damaged.

• Provide the Power Plant Controller with an external overvoltage protection.

8 PPC-BE-P7-en-13 Operating Manual

Page 9

SMA Solar Technology AG 2 Safety

/05*$&

Damage to the Power Plant Controller due to unauthorized access

If the Power Plant Controller is left unlocked, it will be freely accessible to unauthorized persons.

• Lock the Power Plant Controller after commissioning.

• Remove the key from the door lock.

• Store the keys in a safe place.

• Secure the user interface using a secure password.

• Secure your Internet connection from cyber attacks by appropriate safety measures.

Operating Manual PPC-BE-P7-en-13 9

Page 10

3 Product Overview SMA Solar Technology AG

3 Product Overview

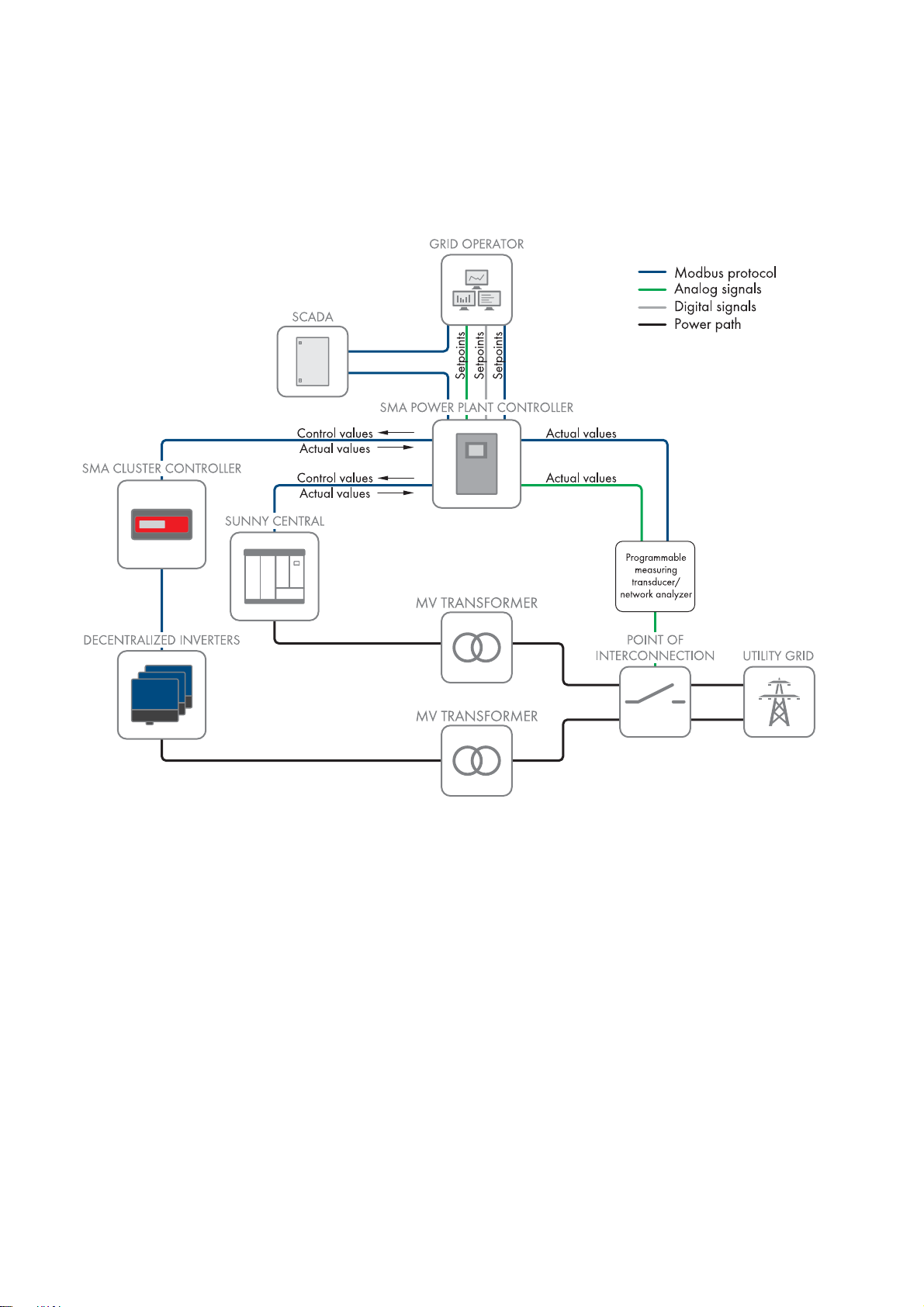

3.1 System Overview

The Power Plant Controller assumes the park management function in large PV systems. The PV system can combine both

central inverters and decentralized string inverters, which are monitored and controlled by Cluster Controllers.

Figure1: Principle of signal transfer in a PV system with Power Plant Controller

In the Power Plant Controller, the setpoints for grid management services are received and compared with the values

measured at the point of interconnection. Based on this comparison, the Power Plant Controller calculates the required

output values and transmits these values to the central inverters and the Cluster Controllers or the Inverter Manager.

The Power Plant Controller can receive setpoints digitally, analog, and via Modbus protocol. The setpoints are

transmitted by the grid operator or by a higher-level SCADA system via Modbus protocol.

The measured values that the Power Plant Controller receives are measured at the point of interconnection, processed by

a network analyzer, and transmitted to the Power Plant Controller as analog values or via Modbus protocol.

Transmission of the output values from the Power Plant Controller to central inverters, Cluster Controllers and the

Inverter Manager takes place via Modbus protocol.

10 PPC-BE-P7-en-13 Operating Manual

Page 11

SMA Solar Technology AG 3 Product Overview

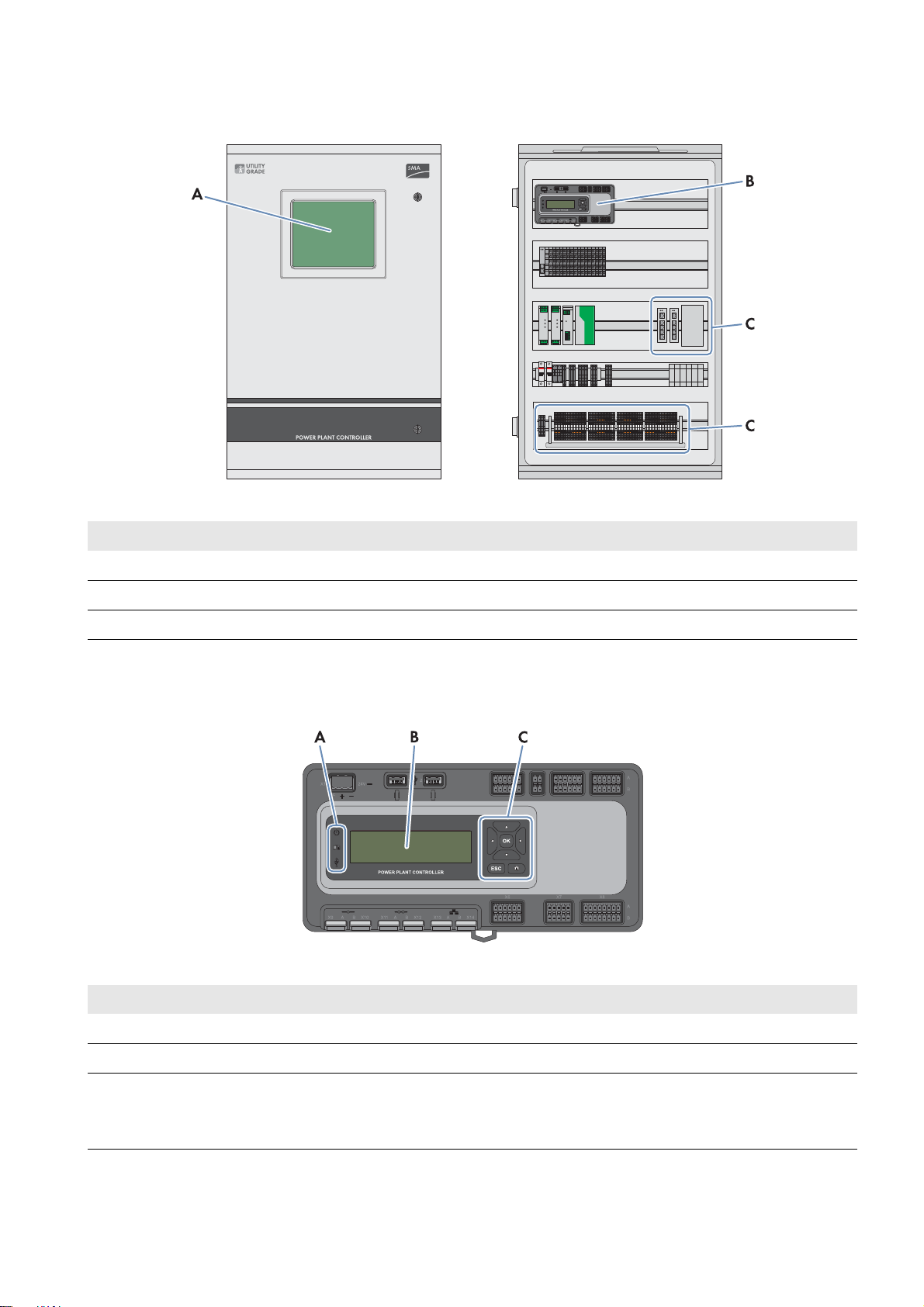

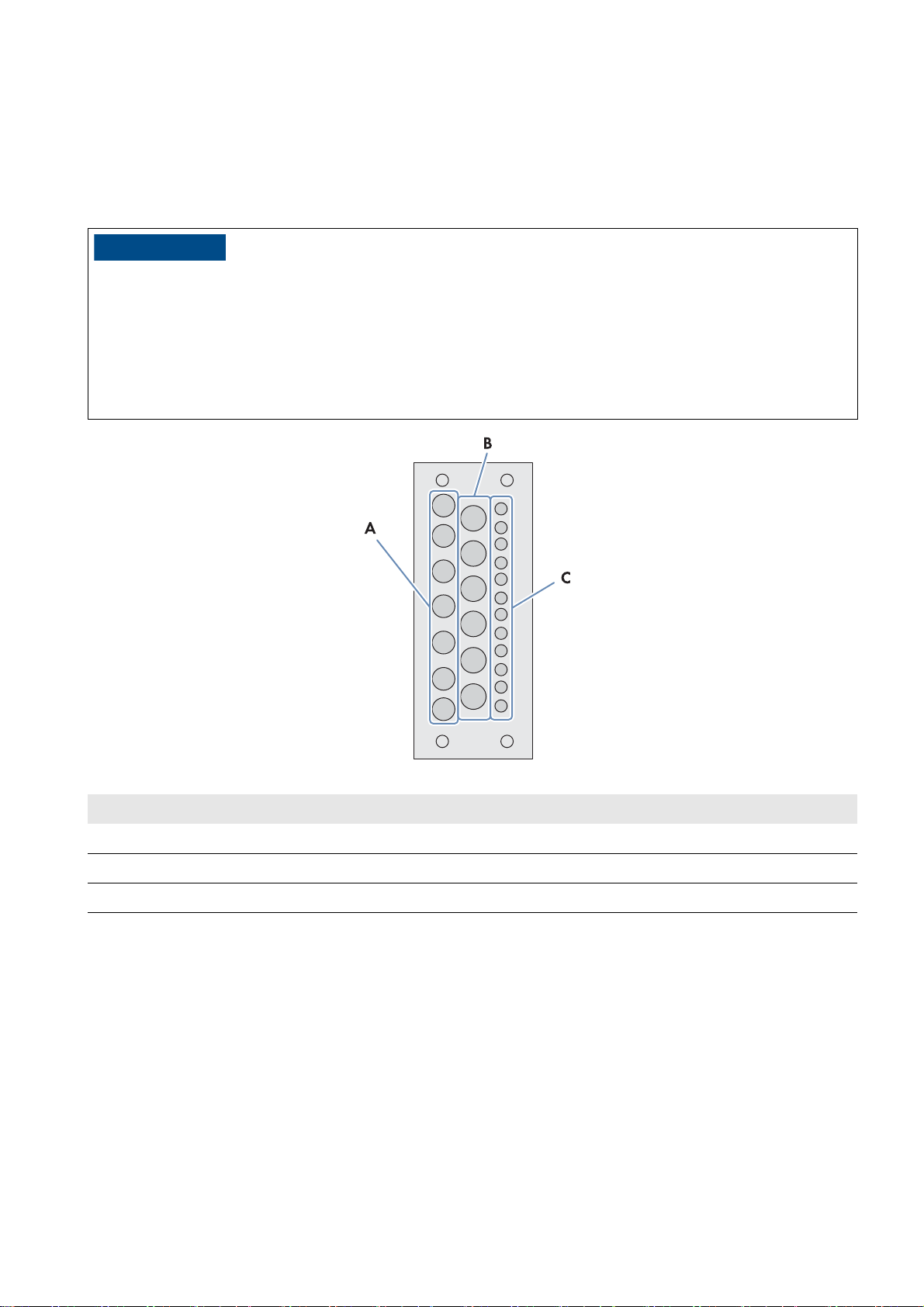

3.2 Design of the Product

Figure2: Exterior and interior views of the Power Plant Controller

Position Designation

ATouch display*

B Control unit

CConnection area

*optional

3.3 Operating and Display Elements of the Control Unit

Figure3: Operating and display elements of the control unit

Position Designation

ALEDs

BDevice display

CKeypad

The network settings of the three LAN interfaces of the Power Plant Controller can be displayed

using the info button.

Operating Manual PPC-BE-P7-en-13 11

Page 12

3 Product Overview SMA Solar Technology AG

LEDs

LED Designation Explanation

Power LED • Glowing red: The Power Plant Controller is starting.

• Glowing green: The start process has been completed.

The Power Plant Controller is working normally.

Status LED The status LED is only relevant if the start process has been

completed and the Power LED is glowing green.

• Glowing red: The Power Plant Controller shows a

disturbance.

• Glowing yellow: The Power Plant Controller shows a

warning.

• Glowing green: The Power Plant Controller is working

normally.

Data carrier status LED This LED is for service purposes.

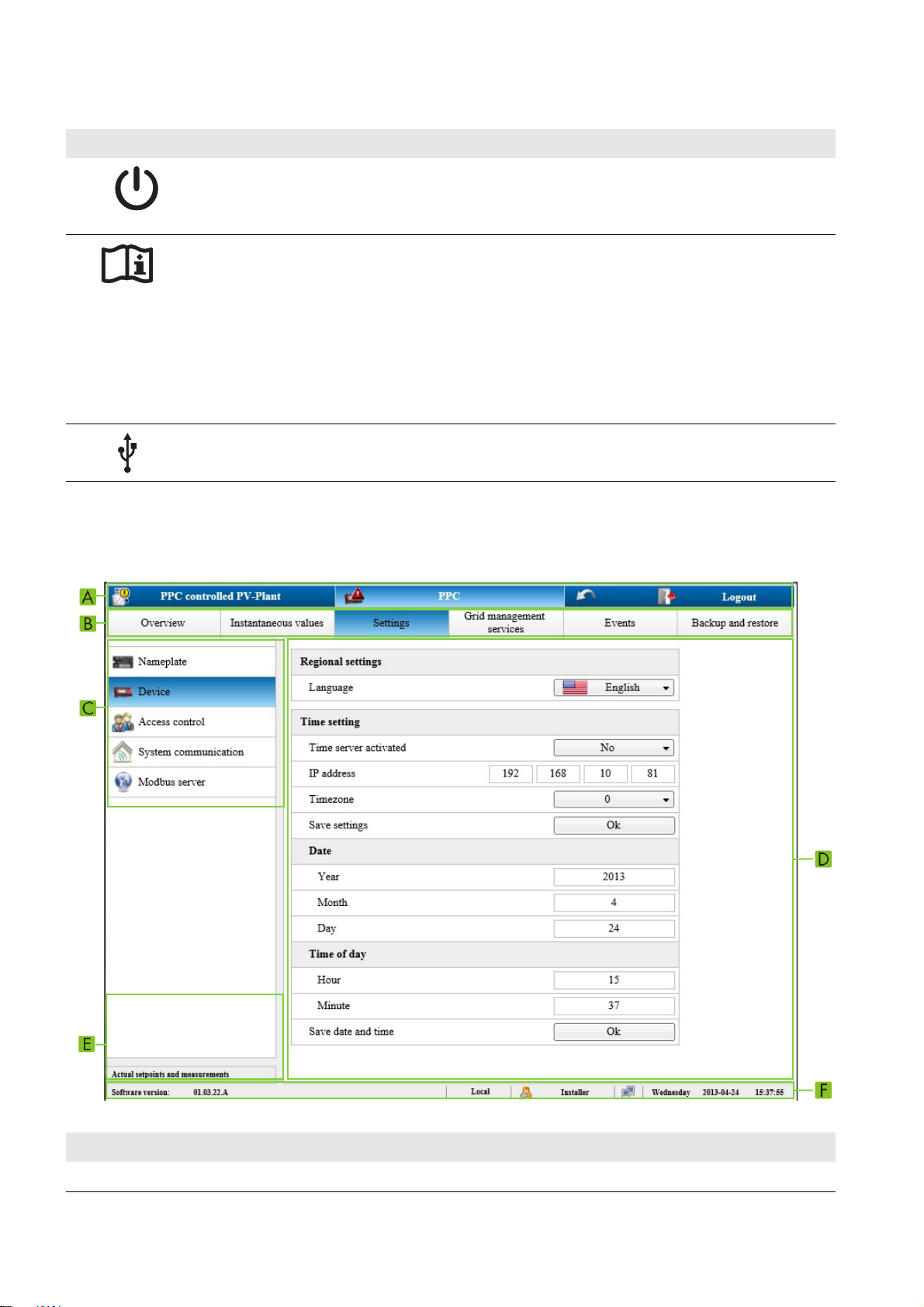

3.4 User Interface of the Power Plant Controller

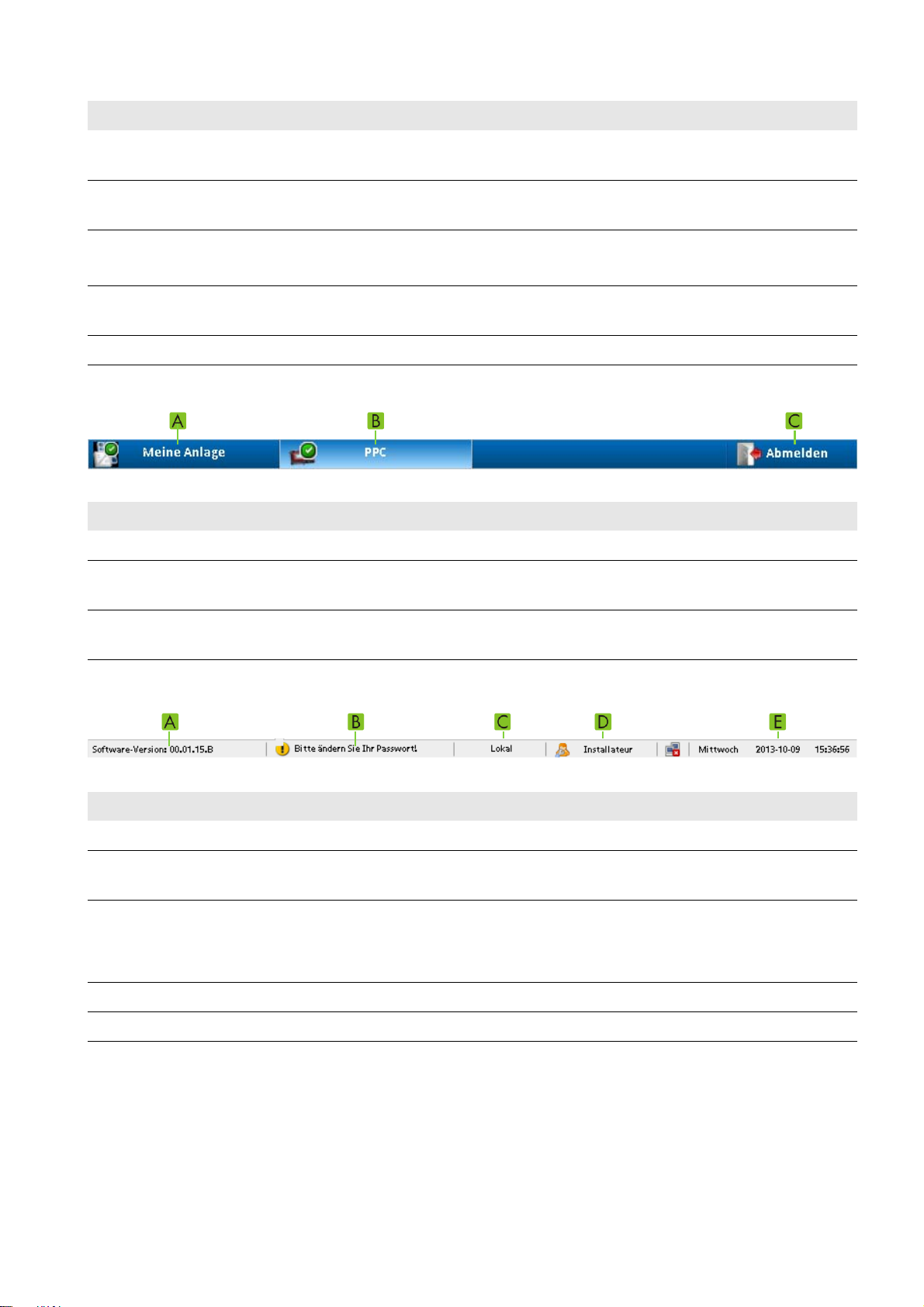

3.4.1 Design of the User Interface

Figure4: Design of the user interface (example)

Position Explanation

A First-level navigation line

12 PPC-BE-P7-en-13 Operating Manual

Page 13

SMA Solar Technology AG 3 Product Overview

Position Explanation

B Second-level navigation line (see Section3.4.3 ""PPC"", page14)

This navigation line only appears if PPC has been selected in the first-level navigation line.

C Left menu bar

The design of the menu bar depends on the selection in the second-level navigation line.

DInput area

If an entry is not plausible, it will not be accepted or the field will turn red.

E Display of the current measured values

The display can be shown or hidden by clicking on the header.

F Status bar

First-Level Navigation Line

Figure5: Design of the first-level navigation line (example)

Position Explanation

A Provides an overview of instantaneous values for the entire PV system

B Opens the second-level navigation line which is used to make settings for the Power Plant Controller and

the connected devices

C Logs the user or installer out of the user interface

The Power Plant Controller is only protected from unauthorized access after logout.

Status bar

Figure6: Design of the status bar (example)

Position Explanation

A Current software version

B Opens the dialog to change the passwords

This icon only appears if the password is not in line with the security guidelines.

C Indicates which parameters of the Power Plant Controller are used for control:

• Local: The Power Plant Controller is using the parameters set on the user interface.

• Remote: The Power Plant Controller uses the values received through communication.

D Information on the status of the logged-in user

E Information on the current system time of the Power Plant Controller

3.4.2 "My System"

Once you have logged in to the user interface of the Power Plant Controller, the system overview opens. The designation

"My system" is used as a placeholder for the name that you give to your system.

Here you can find information on the name and total power of the PV system as well as the instantaneous values for grid

voltage, power frequency, active power and reactive power measured at the selected network analyzer.

Operating Manual PPC-BE-P7-en-13 13

Page 14

3 Product Overview SMA Solar Technology AG

For each instantaneous value, the field Active values indicates whether the default value or the redundant value is used.

3.4.3 "PPC"

Menu field Explanation

Overview Displays the number of all installed Sunny Centrals and Cluster Controllers in the entire PV system,

as well as the number of connected and inaccessible devices

Instantaneous

values

Settings In this area, the following settings can be displayed and adjusted:

Grid management

services

Provides an overview of instantaneous values of the Sunny Centrals, Cluster Controllers and

network analyzers

• Type label: provides unchanging, service-relevant information which is required if faults have

occurred

• Device: User interface language and Power Plant Controller time settings

• Access control: Passwords of the user groups

• System communication: IP addresses of Power Plant Controllers, Sunny Centrals,

Cluster Controllers and Inverter Managers as well as activating and deactivating the

communication

• Modbus server: Configuration of the Modbus server (installer mode only)

In this area, the following settings can be adjusted:

• Device table inverters: IP addresses of the Sunny Centrals and configuration of the

communication between the Sunny Centrals and the Power Plant Controller (installer mode

only)

• Device table Modbus gateways: IP addresses of the Cluster Controller and

Inverter Manager as well as configuration of the communication between these devices and

the Power Plant Controller (installer mode only)

• Device table PPC Slave: IP addresses of the Power Plant Controller slaves and the type of

slave operation as well as grouping of the slaves

• Device table Power analyzers: Configuration of the network analyzers and entry of the

corresponding IP address (installer mode only)

• Setpoint: Change of setpoint mode from Remote (Modbus protocol or analog values) to

Local (fixed setpoint) and entry of the fixed setpoints for active power and reactive power

with local setpoint transmission (installer mode only)

• Input signals: Selection and scaling of the signals sent from the point of interconnection to

the Power Plant Controller

Events Displays all the errors and warnings that have occurred

The errors and warnings are acknowledged here.

Backup and

restore

14 PPC-BE-P7-en-13 Operating Manual

Enables the current configuration of the Power Plant Controller to be saved or updated via SD

memory card

Page 15

SMA Solar Technology AG 4 Scope of Delivery

4 Scope of Delivery

Check the scope of delivery for completeness and any externally visible damage. Contact your distributor if the scope of

delivery is incomplete or damaged.

Figure7: Components included in the scope of delivery

Position Quantity Designation

A 1 Power Plant Controller

B 1 Wall mounting bracket

C2Screw

D 1 each Operating manual, circuit diagram

E4/8Keystone jack*

F 2 Patch cable*

*optional

Operating Manual PPC-BE-P7-en-13 15

Page 16

5 Mounting SMA Solar Technology AG

:$5 1,1*

5 Mounting

5.1 Requirements for Mounting

Requirements for the Mounting Location

Danger to life due to fire or explosion if mounted at an unsuitable location

Mounting the Power Plant Controller in areas with a high fire hazard can result in fire. This can result in death or serious

injury.

• Do not mount the Power Plant Controller on flammable construction materials.

• Do not mount the Power Plant Controller in areas containing highly flammable materials.

• Do not mount the Power Plant Controller in potentially explosive atmospheres.

☐ The mounting location must not be in a living or office area.

☐ The mounting location must not block any escape routes.

☐ The mounting location must be freely and safely accessible at all times without the necessity for any auxiliary

equipment (such as scaffolding or lifting platforms). Non-fulfillment of these criteria may restrict servicing.

☐ The mounting location and the mounting foundation must be suitable for the weight and dimensions of the

Power Plant Controller (see Section12 "Technical Data", page55).

☐ The ambient conditions at the mounting location must be suitable for the operation of the Power Plant Controller

(see Section12 "Technical Data", page55).

☐ The mounting location should not be exposed to direct solar irradiation.

☐ The Power Plant Controller with touch display must be mounted indoors.

☐ The Power Plant Controller must be mounted on a solid support surface.

16 PPC-BE-P7-en-13 Operating Manual

Page 17

SMA Solar Technology AG 5 Mounting

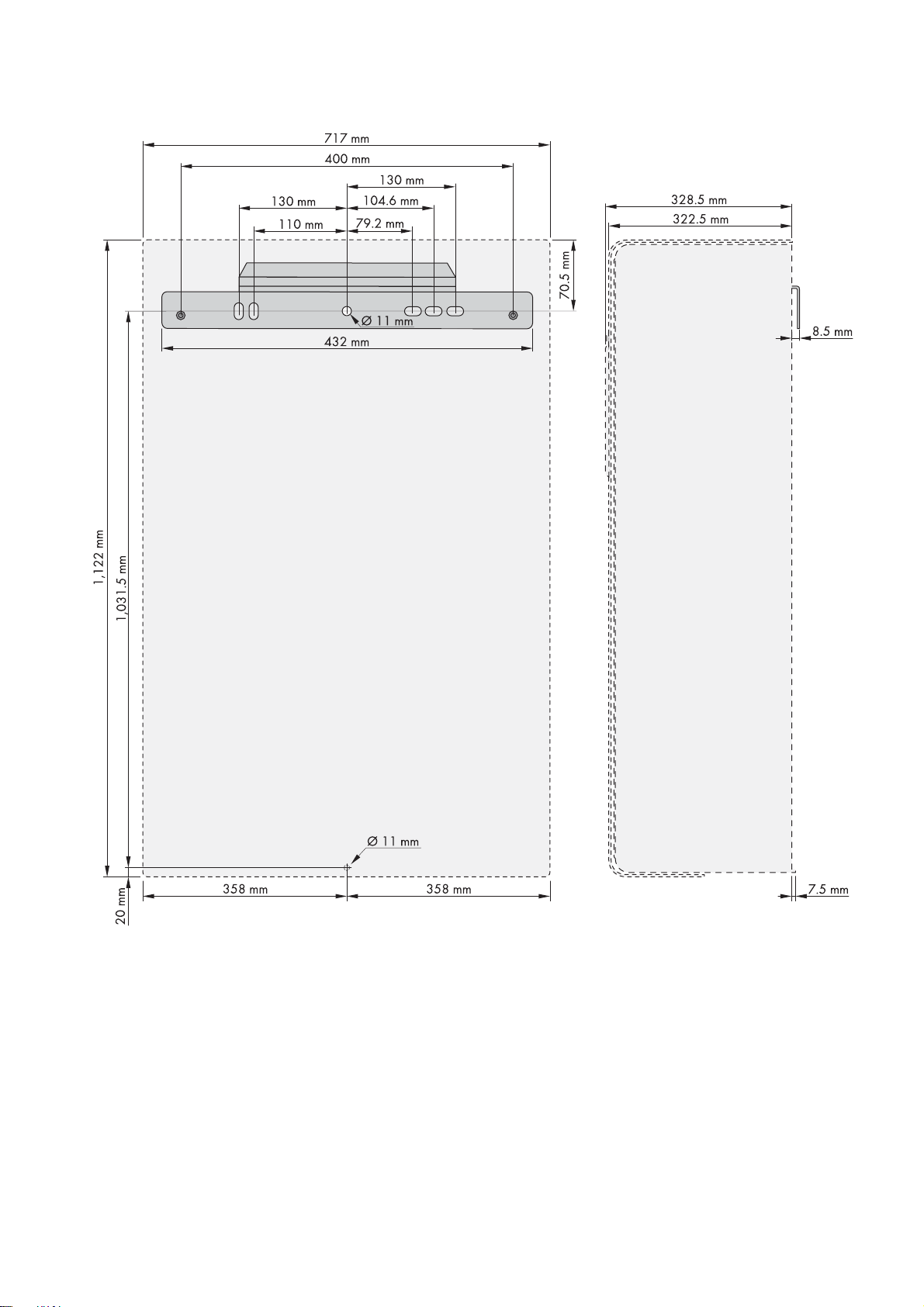

Dimensions for Mounting

Figure8: Dimensions of the Power Plant Controller

Operating Manual PPC-BE-P7-en-13 17

Page 18

5 Mounting SMA Solar Technology AG

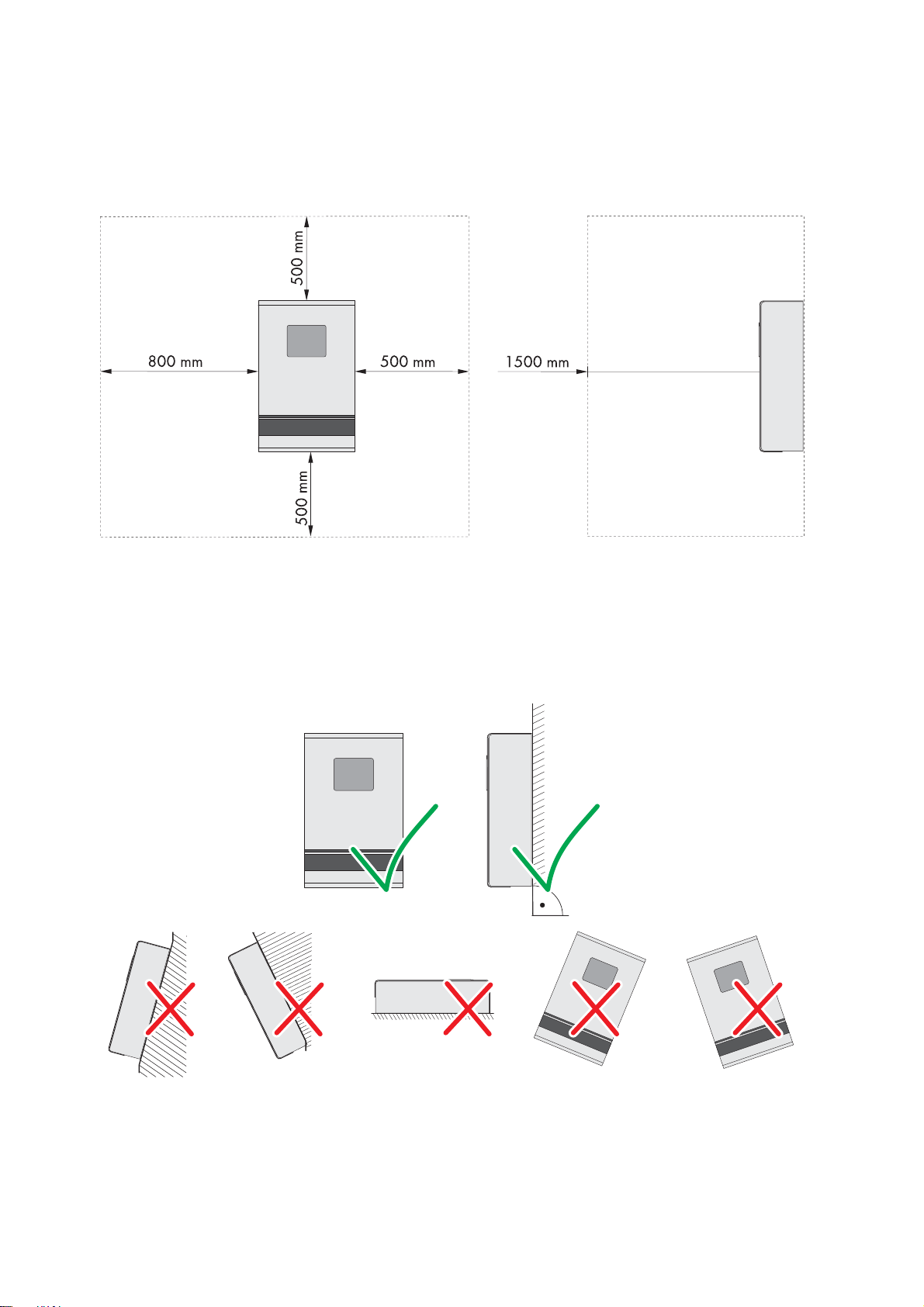

Minimum Clearances

Observing the minimum clearances allows you to easily mount, open and close the Power Plant Controller. The opening

angle of the door is 180°.

☐ Minimum clearances must be observed.

Figure9: Minimum clearances

Permitted and prohibited mounting positions:

☐ Only mount the Power Plant Controller in a permitted position.

☐ The Power Plant Controller should be mounted at eye level. This will make it easier to adjust settings on the display.

☐ The Power Plant Controller should be closed for mounting. This will prevent dust from penetrating the enclosure.

Figure10: Permitted and prohibited mounting positions

18 PPC-BE-P7-en-13 Operating Manual

Page 19

SMA Solar Technology AG 5 Mounting

&$87,21

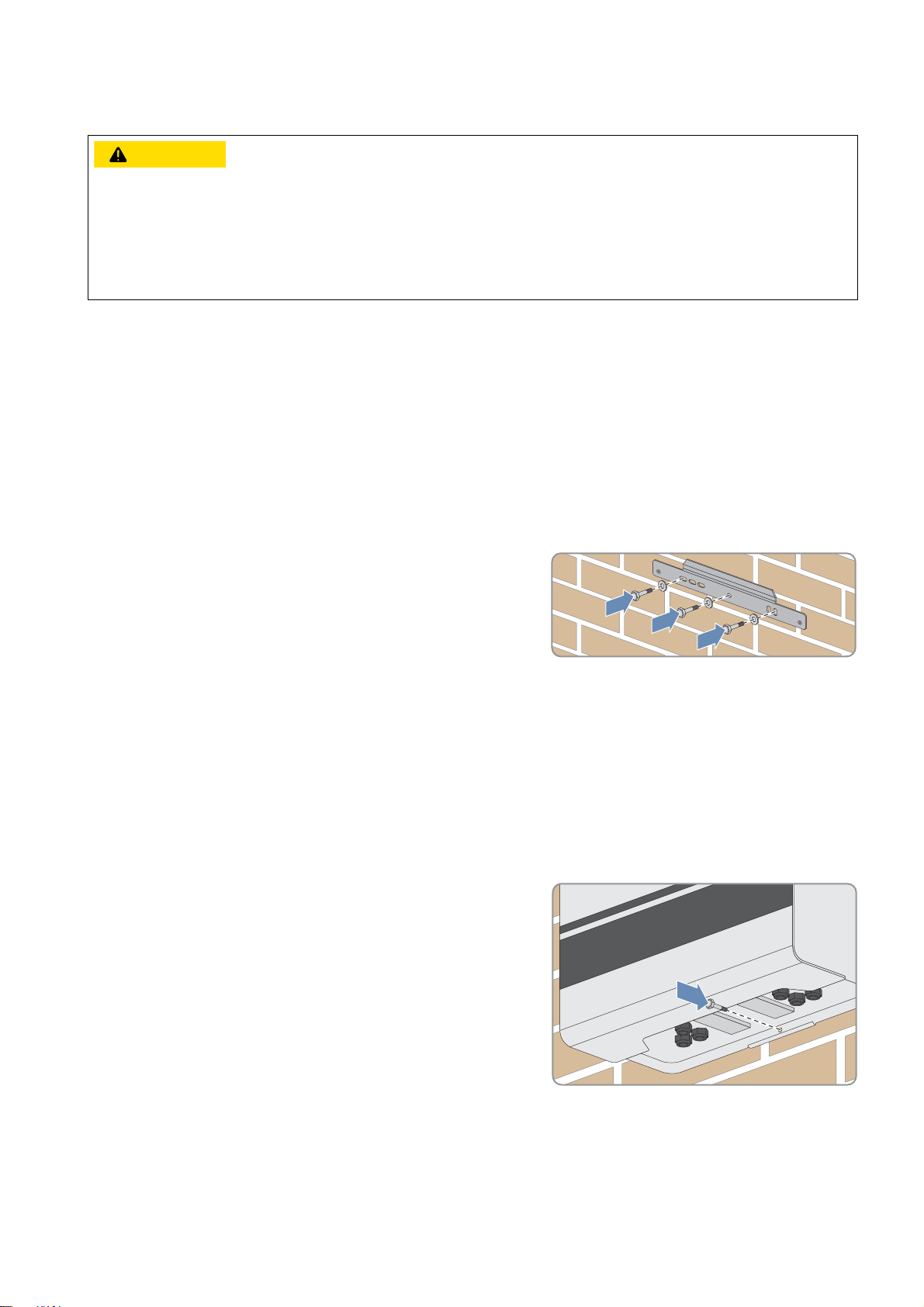

5.2 Mounting the Power Plant Controller

Danger of crushing from falling Power Plant Controller if mounted incorrectly

The Power Plant Controller is very heavy. If inappropriately transported or mounted, the Power Plant Controller can fall

down. This can result in crushing.

• Two people are needed to transport and mount the Power Plant Controller.

• Use mounting material suitable for the support surface when mounting the Power Plant Controller.

Additionally required mounting material (not included in the scope of delivery):

☐ At least four screws suitable for the support surface and the weight of the Power Plant Controller

☐ At least four washers

☐ If required, at least four screw anchors suitable for the support surface

Procedure:

1. Align the wall mounting bracket horizontally on the wall and use it to mark the position of the drill holes. Use at least

three holes in the wall mounting bracket.

2. Drill holes at the marked positions.

3. Insert screw anchors, if necessary.

4. Attach the wall mounting bracket using appropriate screws and

washers.

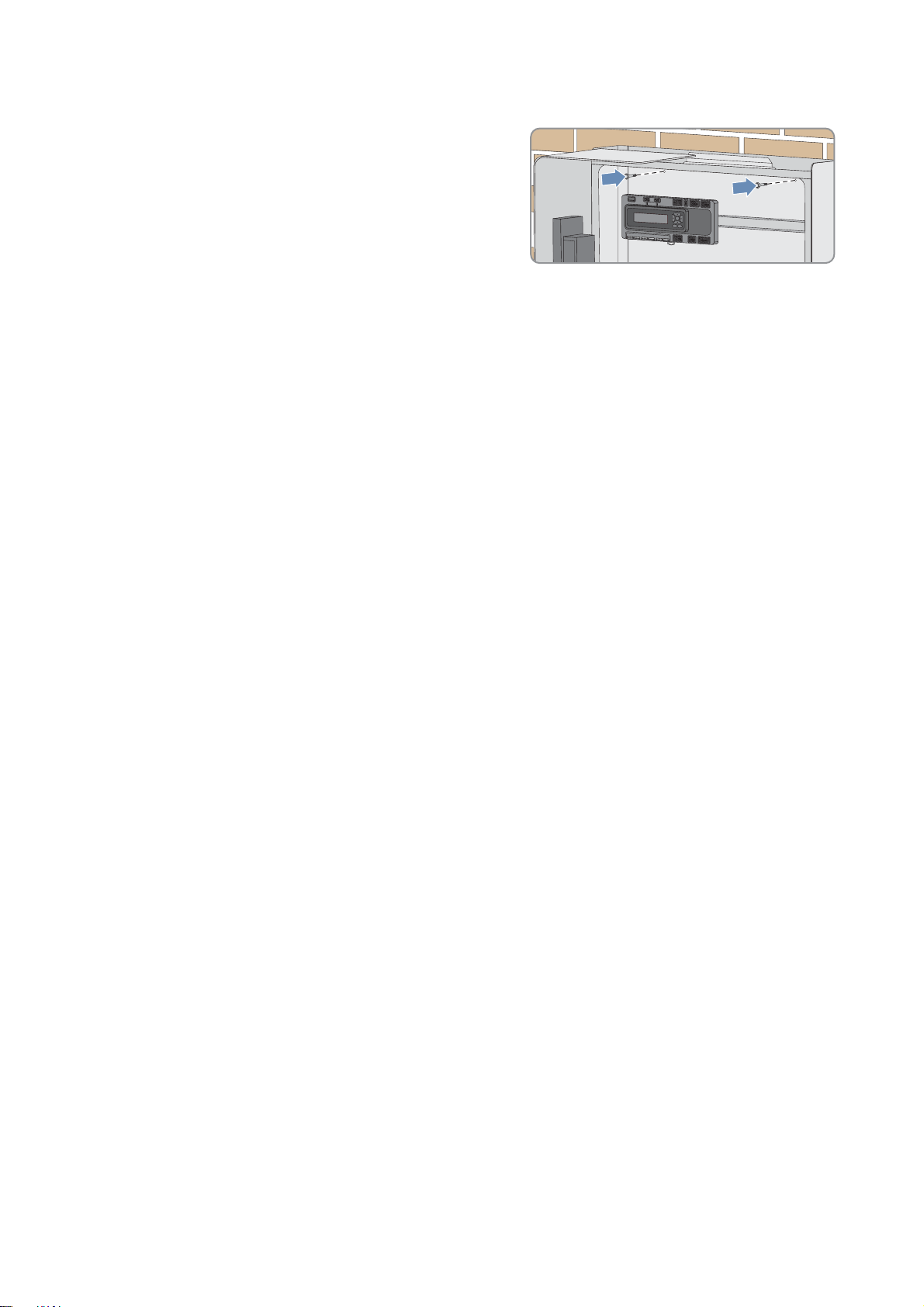

5. Hook the Power Plant Controller into the wall mounting bracket.

6. Make sure that the Power Plant Controller is correctly positioned on the wall mounting bracket and can be secured

with two screws in the inside.

7. Mark the drill hole on the bottom side of the Power Plant Controller.

8. Lift the Power Plant Controller vertically out of the wall mounting bracket and place it on a suitable support surface.

9. Drill the hole at the marked position.

10. If necessary, insert the screw anchor.

11. Hook the Power Plant Controller into the wall mounting bracket.

12. Attach the Power Plant Controller to the wall using suitable screws

and washers.

Operating Manual PPC-BE-P7-en-13 19

Page 20

5 Mounting SMA Solar Technology AG

13. Open the door of the Power Plant Controller.

14. Secure the Power Plant Controller to the inside of the wall

mounting bracket using the two screws provided. Only fasten the

screws hand-tight (torque: 6 Nm).

15. Make sure that the Power Plant Controller is securely attached.

20 PPC-BE-P7-en-13 Operating Manual

Page 21

SMA Solar Technology AG 6 Installation

6 Installation

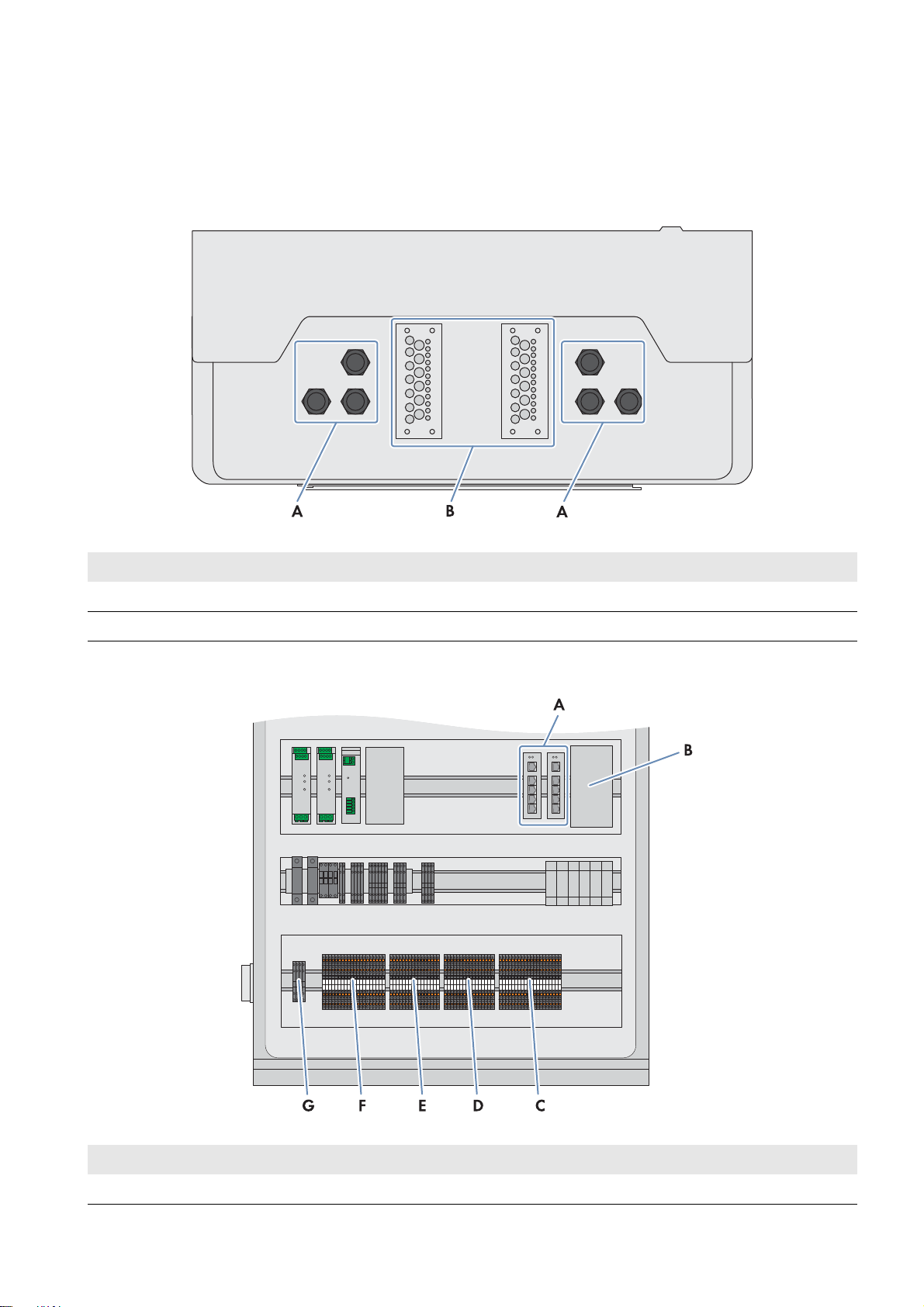

6.1 Overview of the Connection Area

Bottom View of the Power Plant Controller

Figure11: Bottom view of the Power Plant Controller

Position Designation

A Cable glands for the connection of the pre-assembled cables

B Cable entry plates for the connection of the cables that are not pre-assembled

Terminals in the Power Plant Controller

Figure12: Terminals in the Power Plant Controller

Position Designation Explanation

A -A3 / -A4 / -A5 Network (copper)

Operating Manual PPC-BE-P7-en-13 21

Page 22

6 Installation SMA Solar Technology AG

'$1*(5

Position Designation Explanation

B -A5 Network (optical fiber)

C -X703 Analog outputs

D-X702 Analog inputs

E -X701 Digital outputs

F -X700 Digital inputs

G -X300 Voltage supply

6.2 Connecting the Supply Voltage

The Power Plant Controller is equipped with a redundant voltage supply to ensure maximum system availability, e.g. in

case of a failure of a line conductor or a DC voltage source.

Danger to life due to electric shock

Omitted disconnection device or incorrect working practices can cause electric shock. This results in death or serious

injury.

• Prior to installation work, install a disconnection device close to the Power Plant Controller. The disconnection

device must meet the requirements of local standards and directives. All-pole disconnection is recommended.

• Prior to cable connection, disconnect the supply voltage via the disconnection device.

• Observe the five safety rules when disconnecting the supply voltage:

– Disconnect from voltage sources

– Ensure that the device cannot be reconnected.

– Ensure that no voltage is present

– Ground and short-circuit the device

– Cover and isolate any adjacent live components

• Connect the cables in the Power Plant Controller in accordance with the supplied circuit diagram and observe the

terminal assignment.

Cable requirements:

☐ Conductor cross-section if a bootlace ferrule is used: 0.25 mm

2

to 2.5 mm

☐ Conductor cross-section if no bootlace ferrule is used: 0.25 mm2 to 4 mm

2

2

Requirements:

☐ The fuse protection of the supply voltage must comply with the country-specific requirements.

☐ No supply voltage must be present.

☐ Provide for external strain relief.

Procedure:

1. Insert the supply voltage cable into the Power Plant Controller (see Section11.1, page49).

2. Dismantle the supply voltage cable.

3. Strip 10 mm to 12 mm off the conductor insulation.

4. If you are using bootlace ferrules, crimp them.

22 PPC-BE-P7-en-13 Operating Manual

Page 23

SMA Solar Technology AG 6 Installation

5. When connecting the AC supply voltage, perform the following steps:

• Connect the insulated conductors to the connecting terminal plate -X300 in accordance with the circuit diagram

(see Section11.2.1, page51). Observe the correct terminal assignment and ensure that the insulation is not

trapped.

Signal Terminal

L1 Terminal 1

L2 Terminal 2

NTerminal 3

Grounding

Terminal 4

conductor

• If you choose a single-phase voltage supply, you need to bridge the terminals 1 and 2.

6. When connecting the DC supply voltage, perform the following steps:

• Connect the insulated conductors to the connecting terminal plate -X300 in accordance with the circuit diagram

(see Section11.2.1, page51). Observe the correct terminal assignment and ensure that the insulation is not

trapped.

Signal Terminal

L+ Terminal 1

L+ Terminal 2

L‒ Terminal 3

Grounding

Terminal 4

conductor

• If you choose a single-phase voltage supply, you need to bridge the terminals 1 and 2.

7. Ensure that the cable is securely in place.

6.3 Connecting Digital Inputs and Outputs

Cable requirements:

☐ Conductor cross-section if a bootlace ferrule is used: 0.14 mm

2

to 1.0 mm

☐ Conductor cross-section if no bootlace ferrule is used: 0.14 mm2 to 1.5 mm

2

2

Requirement:

☐ Provide for external strain relief.

Procedure:

1. Strip 8 mm off the cable insulation.

2. If you are using bootlace ferrules, crimp them.

3. Connect the cables to the connecting terminal plates -X700 and -X701 in accordance with the circuit diagram (see

Section11.2.1, page51). Observe the correct terminal assignment and ensure that the insulation is not trapped.

4. Ensure that the cables are securely in place.

Operating Manual PPC-BE-P7-en-13 23

Page 24

6 Installation SMA Solar Technology AG

6.4 Connecting Analog Inputs and Outputs

Cable requirements:

☐ Conductor cross-section if a bootlace ferrule is used: 0.14 mm

☐ Conductor cross-section if no bootlace ferrule is used: 0.14 mm2 to 1.5 mm

Requirement:

☐ Provide for external strain relief.

Procedure:

1. Dismantle the cables.

2. Connect the shield contact of the cable (see Section11.2.2, page52).

3. Strip 8 mm off the cable insulation.

4. If you are using bootlace ferrules, crimp them.

5. Connect the cables to the connecting terminal plates -X702 and -X703 in accordance with the circuit diagram (see

Section11.2.1, page51). Observe the correct terminal assignment and ensure that the insulation is not trapped.

6. Ensure that the cables are securely in place.

2

to 1.0 mm

2

2

6.5 Connecting Network Cables and Optical Fibers

Cable requirements:

☐ Network cable: at least CAT5E

☐ Optical fiber with multi-mode switch: class OM2 50/125 μm

☐ Optical fiber with single-mode network switch: class OM2 9/125 μm

To connect the network cables and the optical fibers to the patch panel, carry out the following steps in the given

sequence. The exact procedure is described in the following sections.

Procedure:

1. Disassemble the modules of the patch panel.

2. Install the optical fibers.

3. Install the network cables.

4. Mount the modules of the patch panel.

Disassembling the Modules of the Patch Panel

1. Remove the patch cables.

2. Loosen two screws at the front of each module.

3. Pull out the modules from the front of the patch panel enclosure

24 PPC-BE-P7-en-13 Operating Manual

Page 25

SMA Solar Technology AG 6 Installation

&$87,21

/05*$&

Installing the Optical Fibers

Damage to eyes due to visible and invisible laser radiation

The Power Plant Controller contains laser components. The laser beam is emitted at the end of the optical fiber.

Looking directly into the laser beam can cause eye damage.

• Do not look into the laser beam.

• Do not look at the laser beam using optical instruments.

• Do not point the laser beam at persons.

Damage to optical fibers due to too tight bend radii

Excessive bending or kinking of optical fibers will damage the fibers.

• Observe the minimum permissible bend radii of the optical fibers.

Additionally required mounting material (not included in the scope of delivery):

☐ Optical fiber pigtails with subscriber connectors or

☐ Subscriber connectors

Requirement:

☐ The optical fibers must be inserted in the Power Plant Controller (see Section11.1, page49).

Procedure:

1. Loosen the cable gland of the module.

2. Insert the optical fibers through the cable gland into the module.

3. Strip sufficient insulation off the optical fibers.

4. Install the optical fibers:

• If optical fiber pigtails are used, splice the optical fibers with the optical fiber pigtails and fasten the splice points

in the splice holders.

• If subscriber connectors are used, install the subscriber connectors on the optical fibers.

• Push the plug down until it locks in the adapters.

5. Position the fiber in the fiber holder. Observe the bend radii of the optical fibers.

6. Tighten the cable gland.

Installing the Network Cables

Requirement:

☐ The network cables must be inserted in the Power Plant Controller (see Section11.1, page49).

Procedure:

1. Take the RJ45 Keystone pin connectors out of the accessory kit.

2. Connect the network cables to the RJ45 Keystone pin connectors (see Section11.2.3, page52).

3. Push the RJ45 Keystone pin connectors down until they lock in the cutouts of the module.

4. Secure the network cables to the metal bracket with the Velcro strip provided.

Operating Manual PPC-BE-P7-en-13 25

Page 26

6 Installation SMA Solar Technology AG

Mounting the Modules of the Patch Panel

1. Insert the module with the installed cables in the enclosure of the patch panel.

2. Attach the modules to the front side using two screws each.

3. Connect the patch cables. Observe the send and receive direction of the optical fibers.

26 PPC-BE-P7-en-13 Operating Manual

Page 27

SMA Solar Technology AG 7 Operation

/05*$&

7 Operation

7.1 Safety during Operation

Operation failure of the PV system due to incorrectly set parameters

If the parameter settings for grid management services are incorrect, the PV system may not be able to meet the

requirements of grid management services. This may lead to yield losses and disconnection of the inverters by the grid

operator.

• When setting the modes of grid management services, ensure that the control procedures agreed with the grid

operator are parameterized.

• If the PV system is operated with a Power Plant Controller, ensure that the procedure WCtlCom for active power

limitation and the procedure VArCtlCom for reactive power control are selected in the Sunny Central.

7.2 Adjusting Network Settings on the Computer

In order to access the Power Plant Controller user interface, the network settings of the computer must tally with those of

the Power Plant Controller. If the network address of the computer is not located in the same address range as the network

address of the Power Plant Controller, you will first need to adjust the network settings of the computer.

Procedure:

1. Write down the current IP address of the computer.

2. Adjust the IP address of the computer to the address range of the Power Plant Controller.

7.3 Installing the Droid Sans Font on the Computer

You can access the user interface via the display of the Power Plant Controller or with a computer via the system network.

If you wish to access the user interface via the system network, you will need to have the license-free font Droid Sans

installed on the computer to ensure error-free display.

Procedure:

• In Windows XP, check under Windows Start > Control Panel > Fonts whether the font Droid Sans is already

installed. If this font is installed, no further steps are necessary. If the font Droid Sans is not yet installed, download it

from the Internet and install.

or

•In Windows 7 check under Control Panel > Appearance and Personalization > Fonts whether the font Droid

Sans is already installed. If this font is installed, no further steps are necessary. If the font Droid Sans is not yet

installed, download it from the Internet and install.

7.4 Changing the Password

After initial login on the user interface of the Power Plant Controller, you should change the password of the

Power Plant Controller to protect your system. As long as the password is still rated insecure by the system, the request

Please change your password! will continue to be displayed in the bottom line of the user interface.

If you are logged in as user, you can change the user password. If you are logged in as installer, you can change the

user password and the installer password. Be sure to create a password that conforms to the guidelines for secure

passwords (see Section13.5, page59).

Operating Manual PPC-BE-P7-en-13 27

Page 28

7 Operation SMA Solar Technology AG

Procedure:

1. Log into the user interface (see Section11.3.1, page54).

2. Go to PPC > Settings > Access control.

3. To change the user password:

• Enter the new password in the field Set user password.

• Repeat the new password in the field Confirm password.

4. To change the installer password:

• Enter the new password in the field Set installer password.

• Repeat the new password in the field Confirm password.

5. Select [Save].

☑The [Next] button and the message You have changed the password appear.

6. Select [Next]. This completes the password changing procedure.

7.5 Changing Language and Time Settings

You can change the language of the user interface and the time settings. For the time setting, you can choose between

entering the date and time manually or having the time settings entered from an external source.

Procedure:

1. Log into the user interface (see Section11.3.1, page54).

2. Go to PPC > Settings > Device.

3. To change the language of the user interface, select the desired language in the field Language.

4. To set up time input from a time server, proceed as follows:

• In the drop-down list Time server activated, select Yes.

• Enter the IP address in the field IP address.

• To save the settings, click the [Ok] button in the field Save settings.

• To adjust the time zone, select the correct time difference to UTC in the drop-down list Time zone.

5. To set the time manually, make the appropriate settings in the fields Date and Time of day.

6. To complete the time setting, click the [Ok] button in the field Save date and time.

7.6 Adjusting the Device Settings

7.6.1 Adjusting IP Addresses of the Power Plant Controller

If the system network is changed after commissioning the Power Plant Controller, it may be necessary to adjust the IP

addresses of the Power Plant Controller.

For the assignment of system devices within the networks, be sure to comply with the recommended setup of the system

network (see Section13.1, page57).

Procedure:

1. Log into the user interface (see Section11.3.1, page54).

2. Go to PPC > Settings > System communication > PPC.

3. To adjust the IP address of the Power Plant Controller, configure the settings at the relevant inputs.

4. To save the Power Plant Controller network settings, click the button [Ok].

☑ After saving the network settings, you will be automatically logged off from the Power Plant Controller.

28 PPC-BE-P7-en-13 Operating Manual

Page 29

SMA Solar Technology AG 7 Operation

7.6.2 Adjusting the Configuration of the Sunny Centrals

After commissioning the Power Plant Controller, you can still change the IP address of individual Sunny Centrals, assign

a unique name to Sunny Centrals or disable the setpoint specified by the Power Plant Controller for individual

Sunny Centrals.

Figure13: User interface: Device table inverters (example)

Procedure:

1. Log into the user interface as an installer (see Section11.3.1, page54).

2. Go to PPC > Grid system services > Device table inverters.

3. Adjust the desired settings for the Sunny Centrals as follows:

– enter a unique name for the inverter in the field Device name

– deactivate the setpoint specified by the Power Plant Controller in the Active column (adjust setting to FALSE) or

activate (adjust setting to TRUE)

– change the IP address, port and UID of the inverter

– in the field Read profile, change the profile of the Modbus protocol with which the measured values are

transmitted by the Sunny Central.

Profile Explanation

0 The standard SMA Modbus protocol is used.

1 The Power Plant Controller Modbus profile is used. This option is applicable for future use.

Operating Manual PPC-BE-P7-en-13 29

Page 30

7 Operation SMA Solar Technology AG

– adjust the accuracy with which the output values are sent to the devices of the PV system in the field Write

profile:

Profile Explanation

0 The output values are transmitted with an accuracy of 1%.

1 The output values are transmitted with an accuracy of 0.01%.

– enter the control group in which the Sunny Central is connected to the respective MV transformer. Depending on

the MV transformer, one or two Sunny Centrals can be connected in each control group. Generally, the

Sunny Central devices or the control groups, respectively, can be numbered consecutively.

– Adjust the nominal power of the Sunny Central in [kW] in the field Pac Nom.

– Make the desired settings in the remaining columns:

Column Setting

MB Time Server Activation (TRUE) / deactivation (FALSE) of the specification of time through an external

Modbus time server

Q at Night Activation (TRUE) / deactivation (FALSE) of the "Q at Night" function in the inverters if this

function is available

Qac Nom Input of the nominal reactive power for the particular inverter

first Q limit The first threshold of the reactive power for the particular inverter. If this lower reactive power

limit is reached during operation, the inverter no longer receives higher output values initially.

The effectiveness of this threshold is, however, canceled if the inverter would be able

mathematically to supply reactive powers above the second threshold.

second Q limit The second threshold of the reactive power for the particular inverter.

If the first Q limit and the second Q limit were selected identically (default setting),

this function is deactivated.

7.6.3 Adjusting the Configuration of the Cluster Controllers and

Inverter

After commissioning the Power Plant Controller, you can still change the IP address of individual Cluster Controllers and

Inverter Managers, assign theses devices unique names or disable the setpoint specified by the Power Plant Controller

for individual devices.

Procedure:

1. Log into the user interface as an installer (see Section11.3.1, page54).

2. Go to PPC > Grid system services > Device table Modbus gateways.

3. Adjust the desired settings for each device:

– enter a unique name for the Cluster Controller or the Inverter Manager in the field Device name

Managers

– deactivate the setpoint specified by the Power Plant Controller in the Active column (adjust setting to FALSE) or

activate (adjust setting to TRUE)

– change the IP address, port and UID of the Cluster Controller

– enter a device type matching the respective device in the Model field:

Model Designation

1 Cluster Controller

2 Inverter Manager

– adjust the nominal power of the inverters assigned to the Cluster Controller in [kW] in the field Pac Nom

30 PPC-BE-P7-en-13 Operating Manual

Page 31

SMA Solar Technology AG 7 Operation

– Make the desired settings in the remaining columns:

Column Setting

MB Time Server Activation (TRUE) / deactivation (FALSE) of the specification of time through an external

Modbus time server

Q at Night Activation (TRUE) / deactivation (FALSE) of the "Q at Night: function in the inverters if this

function is available

Qac Nom Input of the nominal reactive power as a total of all inverters connected to the Cluster

Controller

first Q limit The first threshold of the reactive power for all inverters connected to the Cluster Controller.

If this lower reactive power limit is reached during operation, the inverters no longer receive

higher output values initially. The effectiveness of this threshold is however canceled if the

inverters would be able mathematically to supply reactive powers above the second

threshold.

second Q limit The second threshold of the reactive power for all inverters connected to the

Cluster Controller.

If the first Q limit and the second Q limit were selected identically (default setting),

this function is deactivated.

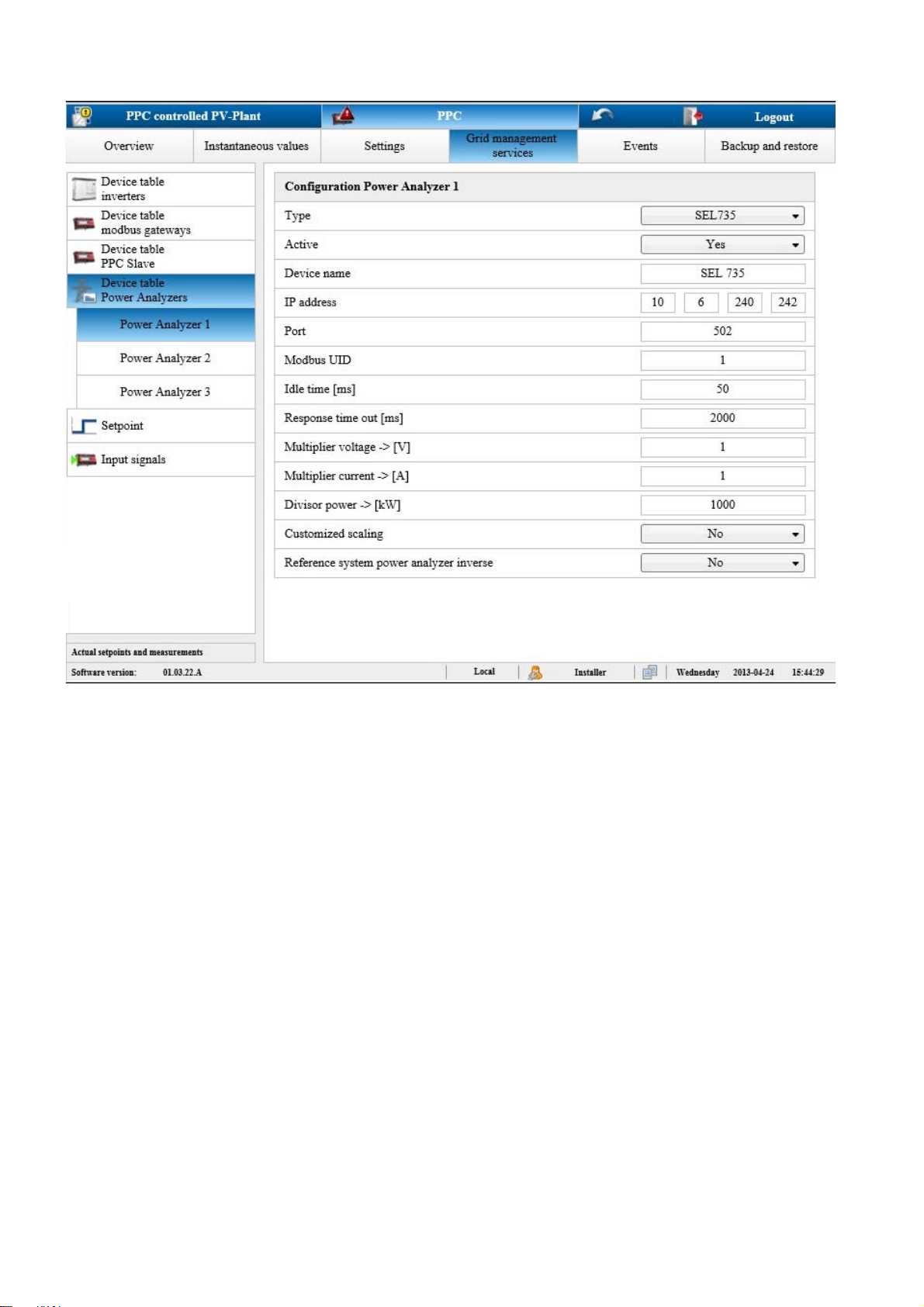

7.6.4 Adjusting the Configuration of the Network Analyzers

At the point of interconnection, the current values for active power, reactive power, voltage and frequency are measured.

The measured values are captured in up to three network analyzers. For each variable, a network analyzer can be

selected as the source for the default value. A second network analyzer independent of the first network analyzer can be

selected as the source for the redundant second measured value. If one of the default values fails, the redundant second

measured value will be used in its place.

The measured values are either queried by the Power Plant Controller via Modbus using a network analyzer or submitted

to the Power Plant Controller as analog input signals.

In order to ensure the correct processing of the measured values, the network analyzer used must be configured.

After commissioning the Power Plant Controller, you can still change the IP address of the network analyzer, adjust its

device type and assign it a unique name.

If a network analyzer is to be serviced or replaced, measurements by this network analyzer should be deactivated in

advance.

Operating Manual PPC-BE-P7-en-13 31

Page 32

7 Operation SMA Solar Technology AG

Figure14: User interface: Device table - network analyzers (example)

Procedure:

1. Log into the user interface as an installer (see Section11.3.1, page54).

2. Go to PPC > Grid system services > Device table Power Analyzers > Power Analyzer 1.

3. If you need to disable network analyzer 1, adjust the setting in the Active column to FALSE.

4. If you need to enable network analyzer 1, adjust the setting in the Active column to TRUE.

5. To change the device type of the network analyzer, click the corresponding button next to the field Type and select

the appropriate device from the device list.

6. To assign a name to a device, enter the desired device name in the field Device name.

7. To change the IP address of a network analyzer, change the IP address of the respective network analyzer in the

corresponding fields.

8. To scale the instantaneous values of voltage, electric current or power, adjust the settings in the associated fields.

9. To scale the input signals on the page PPC > Settings > Modbus server > Standard, in the drop-down list

Customized scaling, select the entry Yes. If No is selected, individual scaling of the measured values P, Q, U and

f is not possible.

10. To adjust the settings for the other network analyzers, go to PPC > Grid system services > Device table Power

Analyzers > Power Analyzer 2 or PPC > Grid system services > Device table Power Analyzers > Power

Analyzer 3.

32 PPC-BE-P7-en-13 Operating Manual

Page 33

SMA Solar Technology AG 7 Operation

7.6.5 Adjusting the Configuration of the Power Plant Controller Slaves

Using Power Plant Controllers, you can monitor a PV power plant with up to 1,000 central inverters. The master/slave

concept of the Power Plant Controllers enables all 1,000 inverters to be controlled uniformly and simultaneously.

The Power Plant Controller master transmits the output values for the active and reactive power control to the

Power Plant Controller slaves and to all inverters connected to the master. A Power Plant Controller master can control

up to ten Power Plant Controller slaves.

In the Power Plant Controller master, the IP addresses of the Power Plant Controller slaves and the mode of the slave

operation must be set. If necessary, the Power Plant Controller slaves can be divided into different control groups. It can

also be set whether the Power Plant Controller master must pass the disconnect command to the slave or not. The settings

for the fast stop command can only be made using the user level "service technician".

Procedure:

1. Log into the user interface of the master as an installer (see Section11.3.1, page54).

2. Go to PPC > Grid system services > Device table PPC slave.

3. Enter the number of slaves for this Power Plant Controller master in the Number PPC slave field.

4. Enter the name of the slave in the Device name field.

5. Enter the IP address of the slave in the fields IP1 to IP4.

6. Adjust the setting for the mode of the slave operation in the Slave mode field:

Mode of slave

operation

1 The active power setpoints are processed by the controller of the master and transmitted as

2 The reactive power setpoints are processed by the controller of the master and transmitted as

3 The active and reactive power setpoints are processed by the controller of the master and

Description

output values to the slave. The slave does not control but transmits the output values to the

inverters.

or

Cascade control: The active power output values of the master are processed by the slave

controller as setpoints and sent to the inverters. For this mode of slave operation, the slave

must receive the actual values from an additional network analyzer. This network analyzer

must record the values of the part of the PV power plant that is to be controlled. For cascade

control, therefore, an additional network analyzer is required for each slave.

The reactive power setpoints are processed by the slave's own controller.

output values to the slave. The slave does not control but transmits the output values to the

inverters.

The active power setpoints are processed by the slave's own controller.

transmitted as output values to the slave. The slave does not control but transmits the output

values to the inverters.

7. If necessary, enter the number of the group that the slave belongs to in the Control group field.

7.7 Adjusting the Settings of the Modbus Server

The communication between the Power Plant Controller and the grid operator or a higher-level SCADA system takes

place via Modbus protocol. You can disable communication with the grid operator via Modbus protocol and change

the IP address of the Modbus server. You can configure whether setpoint changes are only to be accepted if the change

counter register is set simultaneously in the Modbus protocol.

If the Modbus Client is inactive, the connection will automatically be cut off after 60 seconds, even if the setting Setpoint

monitoring is activated. The time can be adjusted from 1 s to 60 s in the field Setpoint monitoring time.

Operating Manual PPC-BE-P7-en-13 33

Page 34

7 Operation SMA Solar Technology AG

Procedure:

1. Log into the user interface as an installer (see Section11.3.1, page54).

2. Go to PPC > Settings > Modbus server.

3. To adjust the profile of the Modbus server, select the desired entry in the drop-down list Modbus server profile.

4. To enable or to disable the Modbus server, select the option Yes or No in the drop-down list Active.

5. In the drop-down list Release IP address range, select the desired option.

6. To enable automatic monitoring of the connection to the Modbus Client, perform the following steps:

• In the drop-down list Setpoint supervision, select the entry Yes.

•In the field Monitoring time setpoint supervision, enter the desired time.

☑ Once the waiting time has expired, the connection is interrupted by the Modbus server.

7. In the drop-down list Enable change counter, select Yes if required. If it is set to No, each change in the Modbus

protocol will be accepted as a setpoint change.

8. To enable scaling of the input signals on the page PPC > Grid system services > Input signals > Measurement

values, select Yes in the drop-down list Customized scaling.

7.8 Transmitting Output Values to Devices of the PV System

If anything in the system is changed after commissioning of the Power Plant Controller, it may be necessary to adjust the

transmission of the output values for the setpoint. It is possible to disable the transmission of output values or adjust the

mode of transmission of output values.

Procedure:

1. Log into the user interface (see Section11.3.1, page54).

2. To adjust the transmission of control values to the Sunny Central devices, select PPC > Settings > System

communication > Inverter.

3. Make the necessary changes in the appropriate fields as follows:

– enable or disable the transmission of output values in the drop-down list Active

– Enter the waiting time between two output value transmissions in the field Idle time [ms]. The recommended time

is 5 ms.

4. To adjust the transmission of control values to the Cluster Controllers, select PPC > Settings > System

communication > Cluster Controller.

5. Make the necessary changes in the appropriate fields as follows:

– Enable or disable the transmission of output values in the drop-down list Active

– Enter the waiting time between two output value transmissions in the field Idle time [ms]. The recommended time

is 1,000 ms.

7.9 Selecting the Signal Source and Adjusting the Scaling of Measured Values

The measured values of the PV system that are used to calculate the output values can be transmitted via various channels

to the Power Plant Controller. If the signal transmission changes after commissioning the Power Plant Controller, it can be

adjusted. The settings for the individual measured values of active power, reactive power, voltage, and frequency can

be made separately.

If an error occurs during transmission of the measured values via Modbus protocol, the last calculated output values can

be used (see Section13.4 "Output Value Specification Under Fault Conditions", page59), or you can use substitution

values (see Section7.10 "Local Specification of Setpoints", page37).

34 PPC-BE-P7-en-13 Operating Manual

Page 35

SMA Solar Technology AG 7 Operation

Measured values submitted to the Power Plant Controller as analog signals will be converted to digital values in the

Power Plant Controller. The measured values in technical units must be calculated from the digital signals. The signals

submitted by the transducer to the Power Plant Controller must be scaled (see Section13.3, page57). Scaling of the

measured data is only possible if under PPC > Settings > Modbus server or under PPC > Grid system services >

Device table Power Analyzers > Power Analyzer 1 the entry Yes has been selected in the drop-down list

Customized scaling, or if analog signals are used.

Operating Manual PPC-BE-P7-en-13 35

Page 36

7 Operation SMA Solar Technology AG

Procedure:

1. Log into the user interface (see Section11.3.1, page54).

2. Go to PPC > Grid system services > Input signals > Measurement values.

3. To assign the record from which the active power setpoint is to be calculated, select the button [Active power]

under Measured values 1 (default) or Measured values 2 (redundant) in the right-hand menu bar.

4. If an error has occurred and the Power Plant Controller needs to supply substitution values, select the entry Yes in

the drop-down list Substitution value and enter the required substitution value.

5. To switch the device or the input supplying the measured data, select the appropriate entry in the drop-down list

Signal source.

– Modbus server: The measured values are transmitted via Modbus protocol from the grid operator to the

Power Plant Controller.

– Modbus device: The measured values are transmitted via Modbus protocol from the network analyzer to the

Power Plant Controller.

– Onboard: The cables supplying the analog measured values are connected directly to the analog inputs of the

Power Plant Controller.

– Bus coupler: The cables supplying the analog measured values are connected to a bus terminal of the

Power Plant Controller.

6. If you have selected the setting Modbus device in the drop-down list Signal source, you will now need to define

the network analyzer at which the signal is present.

7. If you have selected the setting Onboard or Bus coupler in the drop-down list Signal source, you will now need

to define the input at which the signal is present. To do this, select the corresponding entry in the drop-down list

Hardware channel.

8. If the measured data are not supplied by a network analyzer or the network analyzer does not have an averaging

function, averaging of the data can be configured here. To do this, enter the desired number of values in the field

Averaging x values. Entries are possible between 1 (no averaging) and 10 (averaging from 10 measured

values).

9. If the measured data are supplied as analog signals, adjust the scaling of the measured values:

– in the field yMin., enter the lowest value in the range of valid measured values

– in the field yMax., enter the highest value in the range of valid measured values

– in the field x0, enter the lowest signal value supplied by the transducer

– in the field x1

– in the field y0, enter the lowest value in the measurement range

– in the field y1, enter the highest value in the measurement range

☑ When measured values are received without errors, No is displayed in the field Error.

✖ Yes is displayed in the Error field?

No measured values are being received by the Power Plant Controller or the values received are outside the

permitted range. An error is displayed and the substitution value is used.

10. To configure the settings for further measured values, repeat the settings from Step 3 for each setpoint.

11. To make settings for the measured values of the sensors, go to PPC > Grid system services > Input signals >

Measurements common.

12. Repeat settings from Step 3 for each sensor.

, enter the highest signal value supplied by the transducer

36 PPC-BE-P7-en-13 Operating Manual

Page 37

SMA Solar Technology AG 7 Operation

7.10 Local Specification of Setpoints

Control of the system by the Power Plant Controller is normally executed remotely via Modbus commands.

In addition, it is possible for the grid operator to specify fixed setpoints so that remote control of the system is not

necessary. In this case, the system control must be adjusted to Local.

If errors occur during transmission of grid management specifications via Modbus protocol, for diagnostic purposes the

system can be controlled directly from the user interface. To enable settings to be made via the user interface, the system

control needs to be adjusted to Local. After completion of the diagnostic work, reset system control to Remote.

Procedure:

1. Log into the user interface as an installer (see Section11.3.1, page54).

2. Go to PPC > Grid system services > Setpoint specification.

3. In the drop-down list System control, select the entry Local.

4. Enter the required values in the fields Active power, Reactive power, Voltage, Power factor and TanPhi.

7.11 Saving and Restoring Settings of the Power Plant Controller

Backing Up Settings

All settings of the Power Plant Controller can be backed up automatically and manually.

Settings backup Description

Automatic All Power Plant Controller settings are saved daily at midnight to the SD memory card in the

Power Plant Controller. This data is always saved alternately in the files AutoSave 1 and

AutoSave 2. This means that, in the event of an error, the records from two different days can be

retrieved. You can recognize which of the two files is the more recent by the date on the user

interface.

Manual It is possible to save all settings to a USB memory stick in one folder

PPC_Backup_xxxxxxxx(serial number). The folder name includes the serial number of the

Power Plant Controller. The Power Plant Controller automatically creates this folder. During

backup, the automatically saved files AutoSave 1 and AutoSave 2 are also transferred to the

USB memory stick.

In addition, all settings, or the settings of all inverters, Cluster Controllers, controllers and IP

addresses, can be saved separately in an internal file of the Power Plant Controller.

Procedure:

1. Log into the user interface (see Section11.3.1, page54).

2. Go to PPC > Backup and restore.

3. To export the settings to a USB memory stick, proceed as follows:

• Select the required USB port in the field Port.

• Select the button [Backup] in the field Ini files.

4. To save separate settings in an internal file on the Power Plant Controller, click the button [Export] of the respective

group.

5. To save all settings in an internal file on the Power Plant Controller, click the button [Export] of the group All.

Operating Manual PPC-BE-P7-en-13 37

Page 38

7 Operation SMA Solar Technology AG

Restoring Settings

All settings can be imported from three different sources on the Power Plant Controller.

Source of saved

settings

USB memory stick If the settings have been saved beforehand to a USB memory stick in a folder

Files AutoSave 1

and AutoSave 2

Internal file of the

Power Plant

Controller

Procedure:

1. Log into the user interface (see Section11.3.1, page54).

2. Go to PPC > Backup and restore.

3. To import the settings from a USB memory stick, proceed as follows:

• Select the required USB port in the field Port.

• Select the button [Restore] in the field Ini files.

• In the open window, select the desired entry from the drop-down list Data source for import:

Description

PPC_Backup_Serial number, these settings can be restored. To do this, all files must be

copied to a folder PPC_Restore_Config. When restoring the file, you can choose whether

the settings are to be imported from the files AutoSave 1 and AutoSave 2 or from the

manually saved export files.

All settings, or the settings of all inverters, Cluster Controllers, controllers, and IP addresses can

be restored separately from the automatically saved files.

If the settings of the Power Plant Controller have been changed but no back up has taken place,

it is possible to restore the settings status stored in the Power Plant Controller. In this case, any

changes made previously are overruled.

Entry Explanation

Export files Settings are imported from the manually saved files.

AutoSave 1 Settings are imported from the file AutoSave 1.

AutoSave 2 Settings are imported from the file AutoSave 2.

• Select the button [Yes].

4. To import settings from the automatically saved files AutoSave 1 and AutoSave 2, proceed as follows:

• Select the desired entry in the drop-down list Data source for import.

• Click the [Import] button next to the desired settings.

5. To import settings from the internal file of the Power Plant Controller, proceed as follows:

• In the drop-down list Data source for import, select the entry Export files.

• Click the [Import] button next to the desired settings.

38 PPC-BE-P7-en-13 Operating Manual

Page 39

SMA Solar Technology AG 7 Operation

7.12 Calling Up the System Overview

7.12.1 Calling Up the Overview of the Entire System

In the overview "My system" you will find an overview of the current data of the entire PV system and the status of the

measured values.

To facilitate identification of your system, you can enter the name of your system on this page. This name will then appear

instead of "My system" in the first-level navigation line.

Procedure:

1. Log into the user interface (see Section11.3.1, page54).

☑The overview "My system" now opens.

2. If required, enter the name of the system in the field System name.

3. If required, adjust the power of the PV system in the field System power (in installer mode).

7.12.2 Retrieving the Status and Current Data of All Devices in the System

1. Log into the user interface (see Section11.3.1, page54).

2. To call up an overview of the number of devices in the PV system and the status of these devices, select PPC >

Overview.

3. To call up the data of the connected sensors, go to PPC > Measurement values > Measurements common.

4. To call up the status and the current data of the connected inverters, go to PPC > Spot values > System

communication > Inverter.

5. To call up the status and the current data of the connected Cluster Controllers, go to PPC > Spot values > System

communication > Cluster Controller.

6. To call up the current data of the network analyzers, go to PPC > Spot values > System communication > Power

Analyzer.

Operating Manual PPC-BE-P7-en-13 39

Page 40

8 Troubleshooting SMA Solar Technology AG

8 Troubleshooting

8.1 Calling up Information on Software Version and Service-Relevant Information

You can find service-relevant information (required if a fault has occurred) in the dialog Type label.

Procedure:

1. Log into the user interface as an installer (see Section11.3.1, page54).

2. Select PPC > Settings > Nameplate.

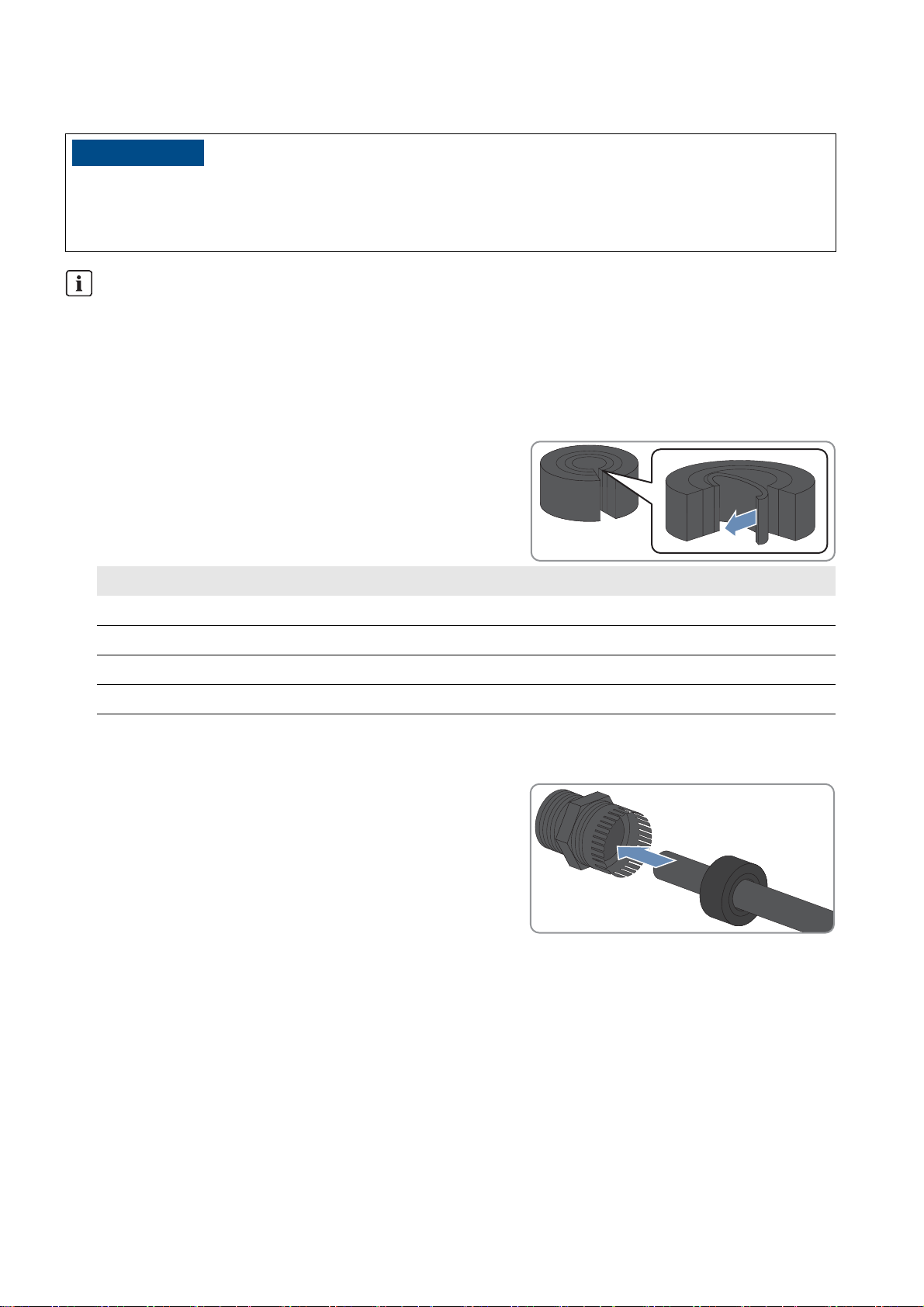

8.2 Calling-Up and Acknowledging Error, Warning and Event Messages