Page 1

Local Service Organization Service Manual

BE INSPIRED

M

M

M

7

7

7

5

5

5

Version Date Department Notes to change

R1.0 10.06.2005 ICM MP CCQ SLI RHQ New Document

Our innovation shapes the future

Page 2

M75 Level 2 Service Manual

Table of Contents

1 GPRS (GENERAL PACKET RADIO SERVICE)……………………………..….3

2 K JAVA APPLICATION……………………………………………………………….4

3 KEY FEATURES……………………………………………………………………….5

4 COMPARISON WITH PERVIOUS PRODUCT...……………………………………7

5 ACCESSORIES……………………………………………………………………......8

6 UNIT DESCRIPTION M75....………..……………………………………………….10

7 DISASSEMBLY OF M75........……………………………………………………….12

8 REASSEMBLY OF M75....…..………………………………………………………19

9 ASSEMBLING AND DISASSEMBLING OF CAMERA MODULE………………21

10 MOBILE SOFTWARE PROGRAMMING…………………………………………..23

11 SIEMENS SERVICE EQUIPMENT USER MANUAL……………………………..26

12 JPICS INTERNET.……………………………………………………………………27

13 INTERNATIONAL MOBILE EQUIPMENT IDENTITY, IMEI…….………………..33

14 GENERAL TESTING INFORMATION……………………………….……………..34

Annex 1……………………………………………………………………………….……….39

Annex 2…………………………………………………………………………….………….40

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 2 of 40 Internal Use Only

Page 3

M75 Level 2 Service Manual

1 GPRS (General Packet Radio Service)

GPRS is a new non-voice value added services that allows information to be sent

and received across a GSM mobile telephone network. It supplements today’s Circuit

Switched Data (CSD) and Short Message Services (SMS). GPRS involves overlaying

a packet based air interface on the existing circuit switched GSM network. This gives

the option to use a packet-based data service. The information is split into separated

but related “packets” before being transmitted and reassembled at the receiving end.

Theoretically, maximum speeds of up to 171.2 kilobits per second (kbps) are

achievable with GPRS using all eight timeslots at the same time. This is about 3

times as fast as the data transmission speed possible over today’s fixed

telecommunications networks and 10 times as fast as current Circuit Switched Data

services on GSM networks

.

Example: Cell with 1 Frequency channel:

1 physical channel for signaling, 4 physical channels for Circuit switched and 3 physical

channels for Packet switched.

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 3 of 40 Internal Use Only

Page 4

M75 Level 2 Service Manual

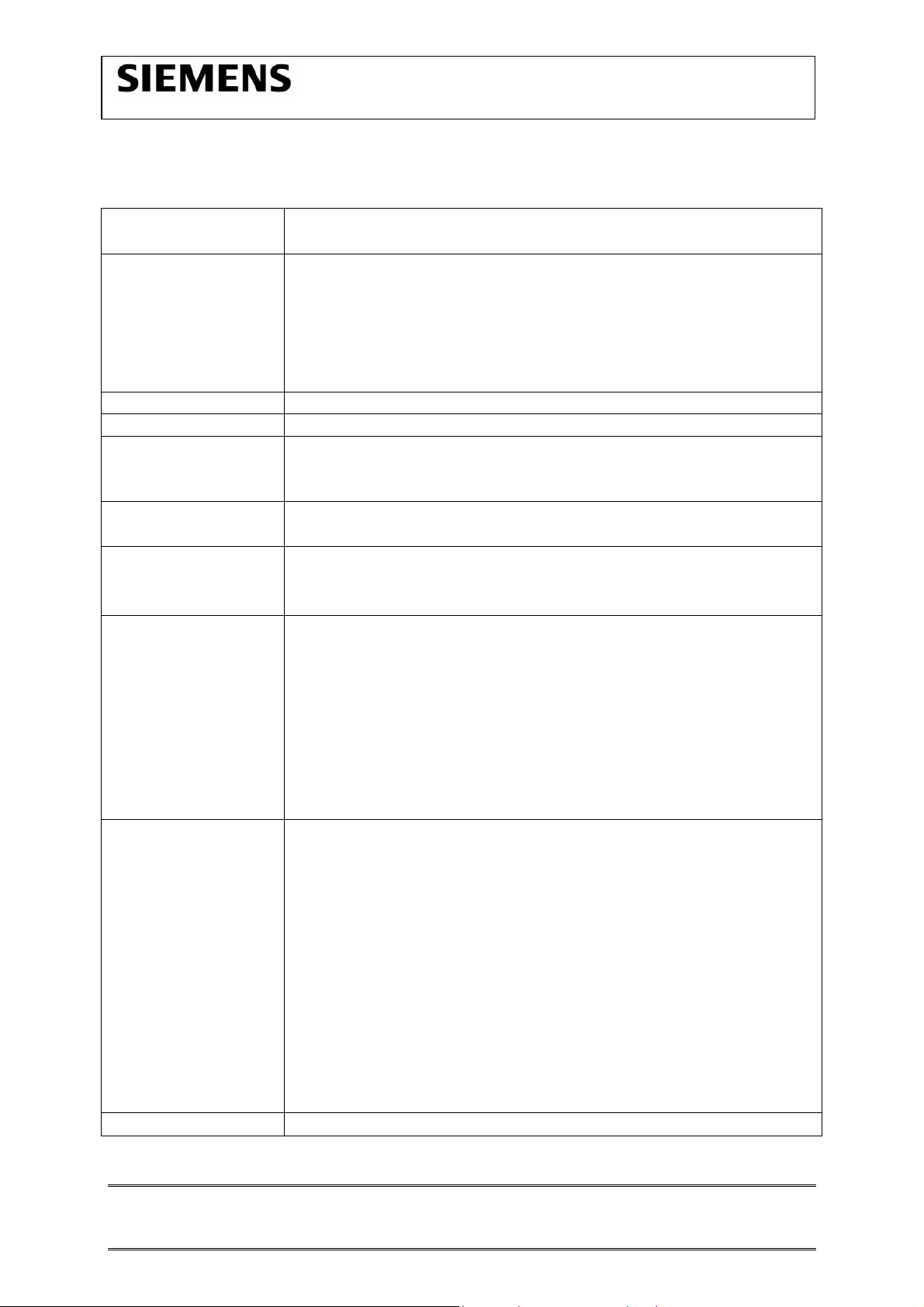

2 K-Java Application

Java-based game system

Java Application Manager

(JAM)

Application launcher and

download manager.

Supports HTTP-based OTA

download of applications over

GPRS and CSD.

RAM for Java applications Available RAM for Java

applications (i.e. Program code

and data) during application

runtime:

Minimum 100 Kbytes (Has to be

taken as working assumption

for application development).

Goal: 145 Kbytes as SL45i (not

committed)

MIDP 1.0, CLDC 1.0 As SL45i, including

performance optimizations from

SL45i-Infusio.

yes

yes

yes

‘OEM extensions’ Proprietary API extension as

yes

SL45i. Including ‘Siemens

Game API’

HTTP API over GPRS Sl45i: only CSD yes

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 4 of 40 Internal Use Only

Page 5

M75 Level 2 Service Manual

3 Key Features

Bands

Battery

Stand-by Time ≥ Approx. 250 h (Best Case)

Talk Time ≥ 5 hrs (Best Case)

SIM Card

Speech Codec

Temperature

Range

Display

Keypad

Side keys

• Triple Band E-GSM 900 / GSM 1800 / GSM 1900

• GPRS Multi Class 10

• Li-Ion Battery Pack

• Nominal Voltage : 3.7V

• Nominal Capacity : 780 mAh

• GSM Capacity : 750 mAh

• Power Input : 2.0A (0.6 ms) / 0.25A (4 ms)

• Cut-off Threshold : 3.2V

• Small (”Plug In”) 1.8 or 3V SIM card (Phase II)

•

To insert the SIM card, the battery pack must be

removed.

• Triple Rate (HR/FR/EFR) and Adaptive Multi Rate are

available as standard

• -10

• -20

• -40

0

C to +550C (Normal operation)

0

C to +650C (External Power Source)

0

C to +850C (Storage capability)

• Type: Full Graphic

• Resolution: 132 x 176 Pixel

• Color depth: 262K

• Technology: TFT

• Active area / mm: 27.7 x 37.0

• Illumination: White LED (6 LEDs integrated)

• Frame rate: maximum 15 frames/seconds

• Pixel size per mm: 0.21mm x 0.21mm ( 1 pixel consist

of 3 sub pixels in red, green and blue)

• Plating function key + IMF number key

• 12-key-block (0-9, #, *)

• two function keys (SEND, END)

• ON/OFF key combined with the END key; the symbol (I

inside O) is used as a symbol for ON/OFF.

• 5 way-joystick with design-cap (soft material), phonebook

symbol required on navikey (Siemens standard)

• 2 soft-keys for different SW-enabled functions

• 1 dedicated hardkey (provider key), target to only have a

specific hardkey only for Vodafone and TMO

• white as illumination colour

• tactile finder on key “5“

• 6 white LEDs for keypad

•

one for Pat (Push and Talk) control, one for camera activation

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 5 of 40 Internal Use Only

Page 6

M75 Level 2 Service Manual

Acoustics

Memory

Connectivity

Ring tones

Multimedia

Camera

• Three-in-one-earpiece for handset, handsfree and ringing

tones

• uni-directional microphone

• Loud signal emitter (soundringer) (>100dB(A) SPL @5cm,

'Hongkong-Spec.') only for rectangular sound signals (NOT

POSSIBLE for all Soundringer melodies)

• Polyphonic ringer tones (parallel to GPRS: 16 voices; all

other Use Cases: 40 voices)

• Hands free mode

• different selectable volume levels for handsfree, handset

and ringer mode (for the amount see SW product

description)

• Approx 14MB, Slot RS-MMC, Bundled with 32MB card

• USB

• Bluetooth®

• Infrared

• Polyphonic 40 voices

• AAC& AAC+ Melodies and MP3

• Video recording / encoding

• AAC, AAC+ and MP3 music support

• Integrated 1.3 Mega pixel (attachable Flash accessory)

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 6 of 40 Internal Use Only

Page 7

M75 Level 2 Service Manual

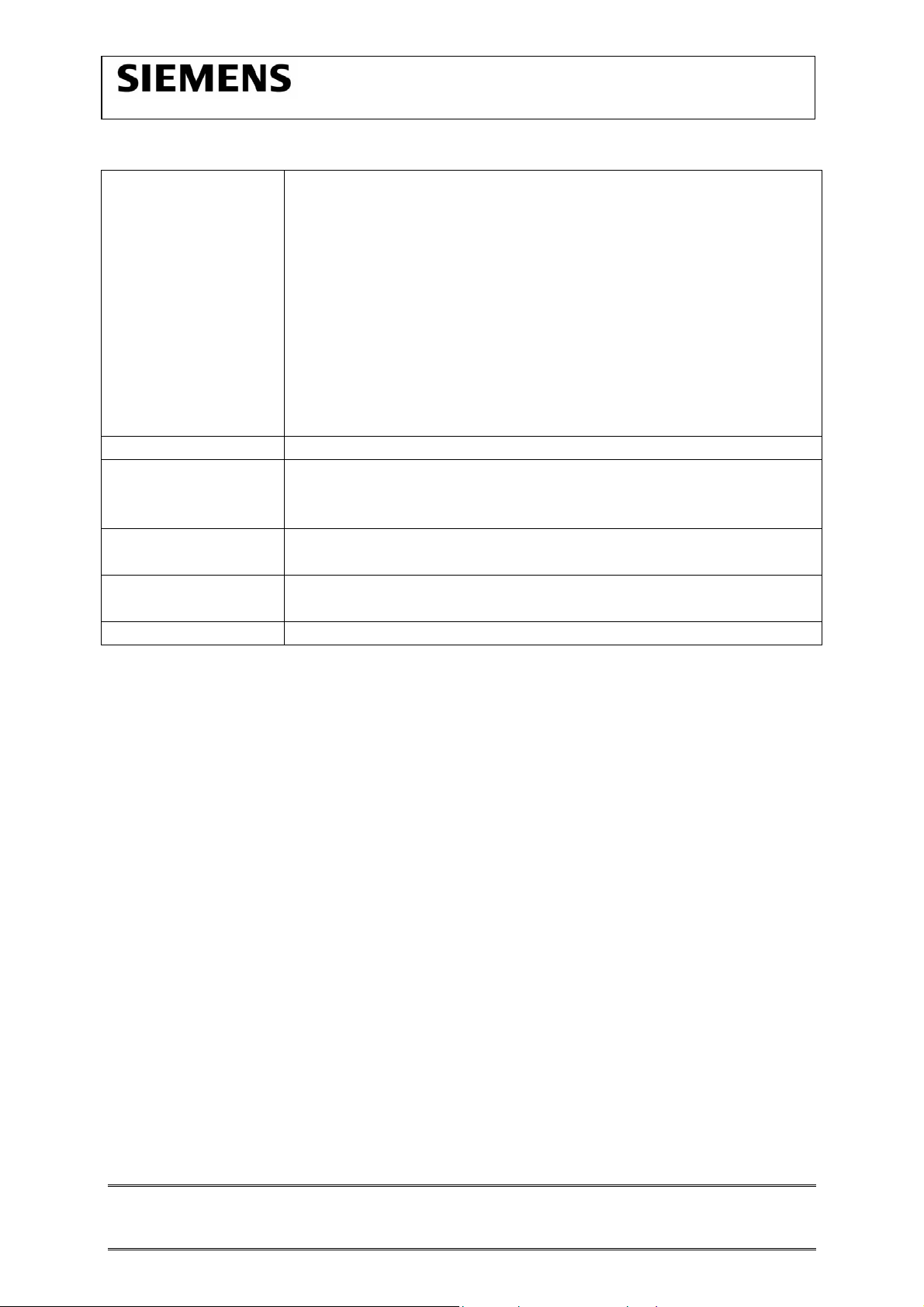

4 Comparison with Previous Product

Feature Penelope Sirius Delta

Supported Systems Triple Band

EGSM 900/GSM1800/

GSM1900 (EMEA,

APAC)

Stand-by Time ≥ 250h

(approx. 3mA quiescent

current)

Talk Time ≥ 5 h

(approx. 150mA

average current for

lowest TX-power level)

Battery Technology

Battery Capacity

Weight Approx. 102 g approx. 108 g

Volume approx. 110 cm3

Length 108.9mm 110.7 mm

Width 48 mm 51.1 mm

Thickness 20.5 mm 20.5 mm

SIM Plug-In 1.8V/3V Plug-In 1.8V/3V

Antenna Integrated Integrated

Antenna Performance

in comparison

Half Rate Yes Yes

Enhanced Full Rate Yes Yes

AMR Yes Yes

Fax/Data Yes Yes

GPRS Class 10 Class 10

Keypad Illumination White LED White LED

DISPLAY /

DISPLAY

ILLUMINATION

EXCHANGEABLE

MEMORY

CAMERA Mega pixel camera

IRDA SIR (slow Infrared) SIR

BLUETOOTH supported SUPPORTED

AAC/AAC+ Not supported Supported

Ringer volume level Min. 95 dB(A) @ 5cm

Li-Ion Battery Pack

NOMINAL CAP.: 780

MAH

~28 dBm @ 900 MHz

~24,5 dBm @ 1800 MHz

~23,5 dBm @ 1900 MHz

(2,7-Band-Antenna)

TFT/TFD

132 x 176 Pixel

65k colour

Yes

(RS-MULTI-MEDIA

CARD)

(integrated)

Typ. ≥98dB(A) @ 5cm

(for dedicated Siemens-

standard melodies)

Min. 100dB(A) @ 5cm

(only for rectangular

sound signals)

Triple Band

EGSM 900/GSM1800/

GSM1900 (EMEA,

APAC)

≥ 250h

(approx. 3mA quiescent

current)

≥ 5 h

(approx. 150mA

average current for

lowest TX-power level)

Li-Ion Battery Pack

NOMINAL CAP.: 780

MAH

~27 dBm @ 900 MHz

~24 dBm @ 1800 MHz

~23,5 dBm @ 1900 MHz

(2,7-Band-Antenna)

TFT

132 x 176 Pixel

262k colour

Yes

(RS-MULTI-MEDIA

CARD)

Mega pixel camera

(integrated)

Min. 95 dB(A) @ 5cm

Typ. ≥98dB(A) @ 5cm

(for dedicated Siemensstandard melodies)

Min. 100dB(A) @ 5cm

(only for rectangular

sound signals)

No GSM 850

-1db @ 900 MHz

-0,5db @ 1800 MHz

+/-0db @ 1900 MHz

Increased number of

colors

Improved optical

performance, socket

concept

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 7 of 40 Internal Use Only

Page 8

M75 Level 2 Service Manual

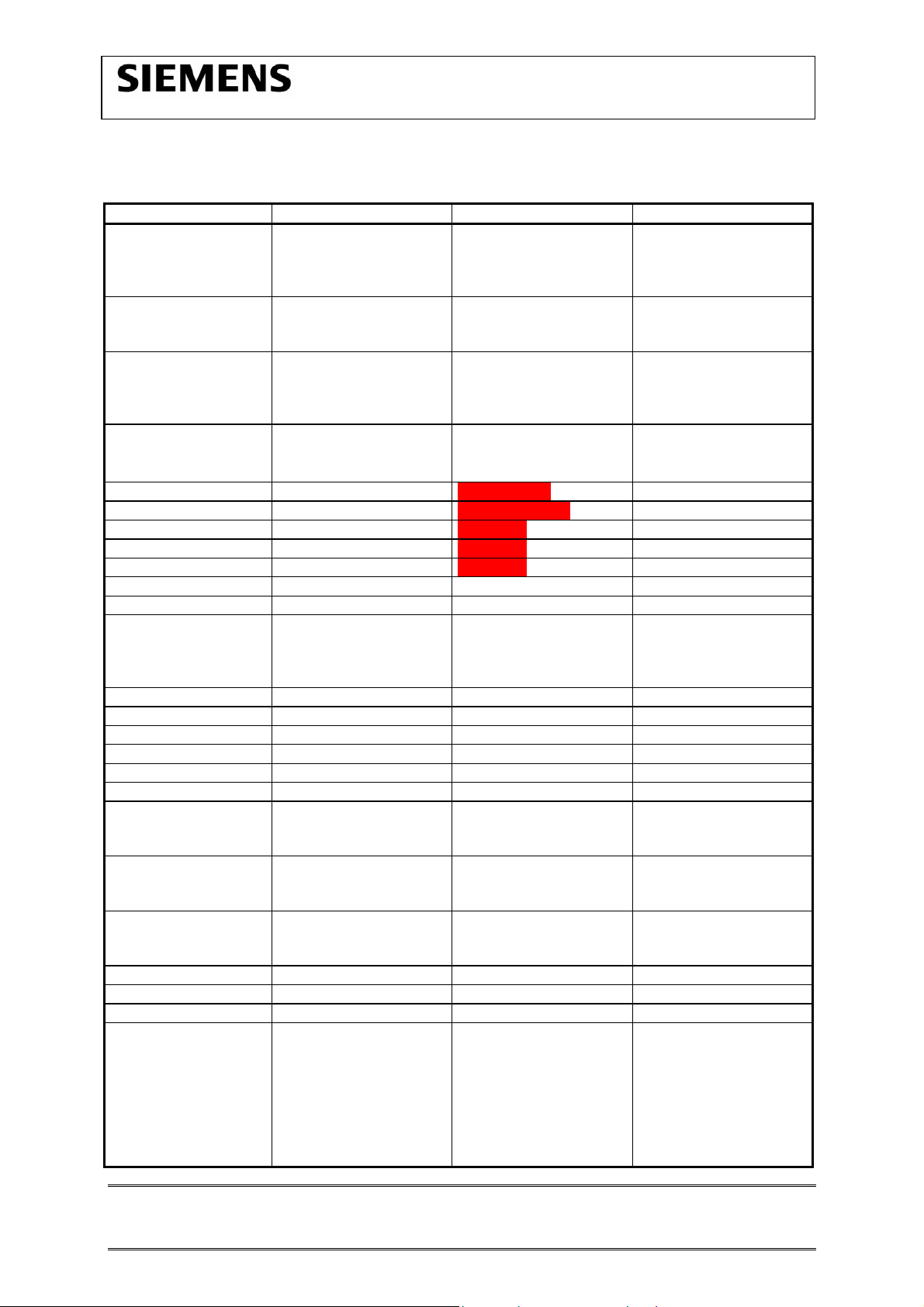

5 Accessories

For M75, the following accessories will be available.

Description Part number

Tour Case FCT-700 TBC

Belt Case FCL-710 TBC

Li-Ion Battery 750mAh EBA-660 L36880-N7101-A111

Travel Charger ETC-500 L36880-N5601-A104

Travel Charger ETC-510 L36880-N5601-A105

Car Charger Plus ECC-600 L36880-N7101-A109

Car Charger ECC-500 TBC

Headset Bluetooth® HHB-600 L36880-N7401-A100

Headset Bluetooth® HHB-610 L36880-N7401-A101

Headset Purestyle HHS-610 L36880-N7101-A500

Headset HHS-510 L36880-N5601-A108

Headset Stereo HHS-700 TBC

Charger Adapter ECA-500 (for Headset Bluetooth®) L36880-N7401-A104

Car Kit Bluetooth® Portable HKW-700 TBC

Car Kit Bluetooth® HKW-600 L36880-N6551-A100

Car Kit Comfort Basic HKC-700 TBC

Car Kit Easy HKP-700 TBC

Car Kit Portable HKP-500 L36880-N5601-A109

Mobile Holder Antenna HMH-710 TBC

Car Kit Upgrade HKO-700 (for Car Kit Easy) TBC

Car Data Adapter HKO-690 (for Car Kit Comfort) L36880-N7101-A800

Car Kit Upgrade HKO-650 (for Car Kit Bluetooth®) L36880-N7401-A120

Mobile Music Set IMS-700 TBC

Flash IFL-600 L36880-N7101-A400

Data Cable DCA-500 L36880-N5601-A110

Data Cable USB – serial DCA-510 L36880-N5601-A111

Data Cable USB – USB DCA-540 L36880-N6501-A102

Note: Visit the Communication Market for updated accessories:

https://communication-market.siemens.de/

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 8 of 40 Internal Use Only

Page 9

M75 Level 2 Service Manual

5.1 M75 Interface to accessories

The phone has got a full compatible interface to accessories. The I/O-Connector

(Lumberg-(slim)-connector) and RF-Connector is in the same position as in the

65series Because of the M75 design it’s not possible to use the same car holder as

R65 Ulysses.

All shown interfaces are for car-cradle. Interfaces for Belt-Clip will not be necessary.

Accessory-

Accessory-

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 9 of 40 Internal Use Only

Page 10

M75 Level 2 Service Manual

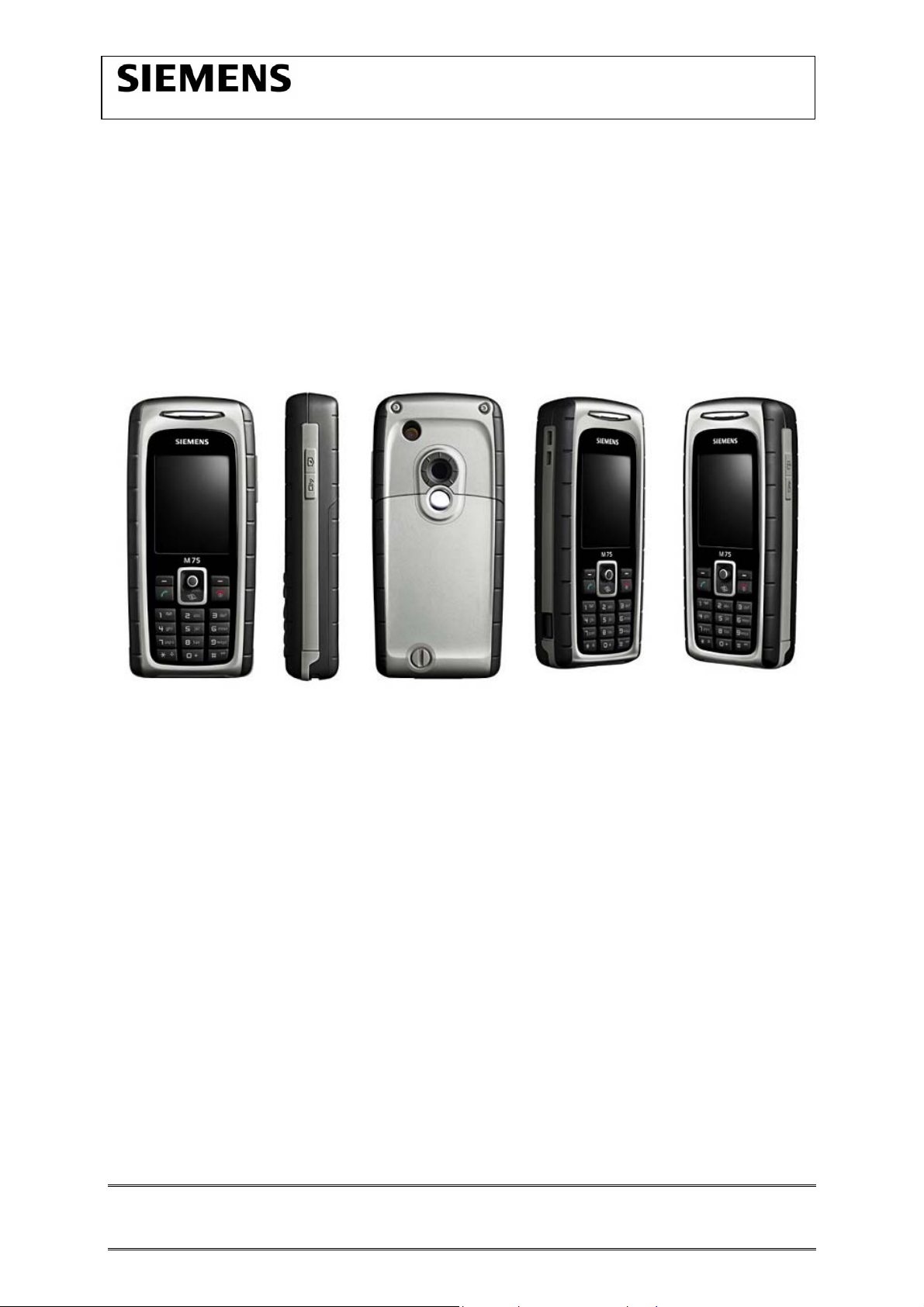

6 Unit Description of M75

The M75 is designed as a two-PCB phone with exchangeable battery cover. The

upper case is a two-shot-molded part (chassis with rubber like component) with a real

metal part is attached.

The lower case and battery cover are two-shot-molded parts with a painted deco part

attached.

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 10 of 40 Internal Use Only

Page 11

M75 Level 2 Service Manual

6.1 Exploded View of M75

Upper Case Shell

Keypa

Display

Earphone

Camera module

Rear cover

Joystick cap

Swapboar

Vibramotor

Microphon

Screws 1.6 x 6.8

Battery Li-Ion 750mAh

Battery cover

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 11 of 40 Internal Use Only

Page 12

M75 Level 2 Service Manual

7 Disassembly of M75

Note: ESD concept; the internal circuits will be more susceptible to ESD because of

the use of exchangeable housing. The construction of the internal block must be/is

designed, in the best possible way, to protect the circuit against sparks.

The keypad must be completely closed to prevent any occurrence of an ESD

disruptive discharge.

The SIM contacts may be open, thus reachable for ESD contact discharge. This

could lead to damage or destruction of the S-Goldlite pins.

It is a requirement for the service personnel to observe ESD protection rules while

performing servicing the M75.

Step 1

Step 3

Front view of the SP65

Step 2

Back View of the SP65

Remove Camera lens cover

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 12 of 40 Internal Use Only

Page 13

M75 Level 2 Service Manual

Step 4

Step 5

Remove Plug

Step 6

Remove Battery cover

Remove Battery

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 13 of 40 Internal Use Only

Page 14

M75 Level 2 Service Manual

Step 7

Remove SIM card

Step 8

Unscrew the 6 T5 plus screws using a Torque screw driver

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 14 of 40 Internal Use Only

Page 15

M75 Level 2 Service Manual

Step 9

Step 10

Remove Lower mounting frame

Step 11

Remove Vibramotor

Remove Microphone

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 15 of 40 Internal Use Only

Page 16

M75 Level 2 Service Manual

Step 10

Remove Main Board

Step 11

Step 12

Remove Display module – place protective foil over on the display module.

Remove Joystick cap

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 16 of 40 Internal Use Only

Page 17

M75 Level 2 Service Manual

Step 13

Remove Camera module – Refer to Chapter N for Camera module assembling and disassembling instructions

Step 14

Remove earphone

Step 15

Remove MMI and Keypad

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 17 of 40 Internal Use Only

Page 18

M75 Level 2 Service Manual

Fully disassembled M75 - upper parts (top) and lower parts (bottom).

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 18 of 40 Internal Use Only

Page 19

M75 Level 2 Service Manual

8 Reassembly of M75

For the reassembly of the M75, reverse the disassembly procedures from Step 15 to Step

1. However there are some areas to be taken note of during reassembling of the phone.

During the installation of the SIM card, make sure that the SIM card is inserted properly and that

the golden contact area is facing downwards. Insert the SIM card downwards to lock the SIM card

into position.

Installation of the SIM card

During the installation of the battery, make sure that the hinges are properly in place (See picture

below). Otherwise the battery will not be able to fit into the phone properly.

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 19 of 40 Internal Use Only

Page 20

M75 Level 2 Service Manual

When placing the screws, set Torque to 18cNm.

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 20 of 40 Internal Use Only

Page 21

M75 Level 2 Service Manual

9 Assembling and Disassembling of Camera Module

Assembling of camera module

Place the Camera with the rounded corner into the corresponding corner of the Camera

Connector.

Disassembling of camera module

Tools required:

or

Description: Camera Ejector Jig Description: Camera Ejector Tool Professional

Part number: F30032-P514-A1 Part number: F30032-P507-A1

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 21 of 40 Internal Use Only

Page 22

M75 Level 2 Service Manual

To disassemble the Camera, put the Camera Ejector jig or the camera ejector tool

professional through the four edges between the Camera and the Camera connector.

Now push the Ejector jig and pull out the Camera.

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 22 of 40 Internal Use Only

Page 23

M75 Level 2 Service Manual

10 Mobile Software Programming

The common mobile software available is divided into language groups. However, this

software does not contain the specific settings, such as ringing tones, greeting text, and

short dial list etc., required by the operator or service provider. Therefore, it is common to

have some menu item(s) differ in different variants or are not visible at all. These settings

are stored in different memory area of the mobile and will be activated depending on the

customer specific model or variant of the phone by a separate test step during the

production process.

Due to this separation of common mobile software and customer specific initialization, it

is possible to fulfil the demands of the market requiring customization and flexibility. As a

consequence the software programming process in the LSO is divided into two different

steps as followed:

- Software update to actual version and appropriate language group

- Programming of CUSTOMER SPECIFIC INITIALIZATION

Usage of GRT is mandatory!! For more detail check GRT User manual

Figure 1. M75 Software Programming Setup

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 23 of 40 Internal Use Only

Page 24

M75 Level 2 Service Manual

10.1 Mobile Software Updating

The software of the 75 series mobiles, is loaded from a PC directly. Hardware

interconnection between the mobile and the PC is shown in Figure 1. Because of the new

type of external connector used since 55 series (Slim-Lumberg type) an additional

adaptor cable between mobile and boot adaptor is required. Table 1 listed all the

hardware requirements

If you use the battery dummy, make sure that the power supply voltage is correctly

adjusted.

Description Part No.

Bootadapter 2000 incl. AC-Adapter, serial

cable and mobile connection cable

IBM Compatible PC – Pentium -

Adapter cable – Slim Lumberg to Old F30032-P226-A1

TABLE 1. EQUIPMENT LIST FOR SOFTWARE PROGRAMMING

L36880-N9241-A200

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 24 of 40 Internal Use Only

Page 25

M75 Level 2 Service Manual

10.2 Flow Chart for Software Upgrading

Plug in the Boot

Adaptor to the PC

and Mobile

Connect the AC

adaptor to the

Boot Adaptor

Power up Boot

Adaptor & check

LED.

OK?

NO

YES

Start the SWUP

program

Select & Execute

the "Mobile S/W"

ERROR?

YES

Check

H/W setup = S/W

NO

S/W upgrading in

progress

ERROR?

NO

TEST Mobile

Take note of error

and repeat

process

YES

Check AC Adaptor

YES

Faulty AC Adaptor

Faulty Boot

FLOW CHART FOR S/W PROGRAMMING PROCESS

OK?

NO

Adaptor

OK?

Correct Settings

Feedback Error to

Tech. Supp. Dep

END

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 25 of 40 Internal Use Only

Page 26

M75 Level 2 Service Manual

11 Siemens Service Equipment User Manual

Introduction

Every LSO repairing Siemens handset must ensure that the quality standards are

observed. Siemens has developed an automatic testing system that will perform all

necessary measurements. This testing system is known as:

Siemens Mobile Service Equipment

All mobile Phones have to be tested with the GRT-Software.

The Service Partner is responsible to ensure that all required hardware is

available.

For additional Software and Hardware options as well as the supported GRT

equipment, please check the GRT User manual

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 26 of 40 Internal Use Only

Page 27

M75 Level 2 Service Manual

12 JPICS (Java based Product Information Controlling System)

Overview

The following functions are available for the LSO:

• General mobile information

• Generate PINCODE

• Generate SIMLOCK-UNLOCK-Code

• Print IMEI labels

• Lock, Unlock and Test the BF-Bus

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 27 of 40 Internal Use Only

Page 28

M75 Level 2 Service Manual

The access to the JPICS server which is located in Kamp-Lintfort is

and in addition using secure socket layer (SSL) connection.

card

protected by chip

The JPICS server is only available for authorized users with a specially coded chip card.

These chip cards and the administration of the JPICS web server and the PICS

database-server can only be provided by the JPICS-TRUST-Center of the

responsible

department in Kamp-Lintfort.

In case of any questions or requests concerning chip cards or administration of

the databases please ask your responsible Siemens Customer Care Manager.

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 28 of 40 Internal Use Only

Page 29

M75 Level 2 Service Manual

Installation overview

The following installation description assumes that a web browser is already installed.

JPICS is tested with the following

Internet Explorer Version 5.5 and higher

1.

2.

Netscape Version 6 and higher

For further information regarding supported browsers, browser version and supported

browsers

operating systems, see the

Sun FAQ's.

Here is a step by step instruction to install all the required components:

It is necessary to follow this order!

1. Card reader (Omnikey)

2.

CardOS interface (Siemens)

3.

JPICS Certificates

4.

Java Plugin JVM/JRE (Sun)

5.

Java additional components

Every user is responsible for a proper installation matching the license

agreements.

For installation and further access you need the following:

1. The JPICS Installation-CD

2. A chip card. Chip cards can be ordered via your responsible Customer Care

Manager within Siemens.

3. A supported chip card reader (Smarty or Siemens B1) in order to access your chip

card.

Remark:

We recommend using Siemens B1 reader. Similar device to B1 is Cardman 9010.

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 29 of 40 Internal Use Only

Page 30

M75 Level 2 Service Manual

Generate Codes

In the module “Generate Codes“you can choose to generate:

- Master – Phonecodes

- Simlock Unlock – Codes

Master - Phonecodes

The Master – Phonecode is used to unlock blocked mobiles.

Master – Phonecodes can only be supplied for mobiles which have been delivered

in a regular manner.

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 30 of 40 Internal Use Only

Page 31

M75 Level 2 Service Manual

Simlock Unlock - Code

The Simlock-Unlock-Codes can only be generated if the following conditions are

given:

- Mobile must have an active Simlock inside.

- The user must be given the authorization to obtain Simlock Unlock- Codes for the

variant of the operator to which the mobile was delivered last time.

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 31 of 40 Internal Use Only

Page 32

M75 Level 2 Service Manual

Printing IMEI label

The module “Print IMEI label” offers the possibility to re-print IMEI labels for mobiles

again.

You are able to print 1 label in just one step.

To prevent that misaligned labels are being printed, the setting "Print test labels = " is

activated as default. After having printed a well-aligned test label you can uncheck the

setting and print the correct label.

Hint:

For correct printing of IMEI labels you must have a Zebra – label printer with special

material that fits for label printing. This printer has to be connected to local LPT1

printer port (also see Installation of IMPRINT) and MUST feature a printing resolution

of 300dpi.

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 32 of 40 Internal Use Only

Page 33

M75 Level 2 Service Manual

13 International Mobile Equipment Identity , IMEI

The mobile equipment is uniquely identified by the International Mobile Equipment

Identity, IMEI, which consists of 15 digits. Type approval granted to a type of mobile is

allocated 6 digits. The final assembly code is used to identify the final assembly plant and

is assigned with 2 digits. 6 digits have been allocated for the equipment serial number for

manufacturer and the last digit is spare.

The part number for the M75 is S30880-S7430-Axx-x where the last 4 letters specify the

housing and software variant.

M75 series IMEI label is accessible by removing the battery.

Re-use of IMEI label is possible by using a hair-dryer to remove the IMEI label.

On this IMEI label, Siemens has also includes the date code for production or service,

which conforms to the industrial standard DIN EN 60062. The date code comprises of 2

characters: first character denotes the Year and the second character denotes the

Month.

For example: M3

CODE YEAR MONTH CODE

M

2000 MARCH

3

N 2001 APRIL 4

P 2002 MAY 5

R 2003 JUNE 6

S 2004 JULY 7

TABLE 2 DIN EN 60062 DATE CODE

To display the IMEI number, exit code and SW/HW version, key: *#06#.

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 33 of 40 Internal Use Only

Page 34

M75 Level 2 Service Manual

14 General Testing Information

General Information

The technical instruction for testing GSM mobile phones is to ensure the best repair

quality.

Validity

This procedure is to apply for all from Siemens AG authorized level 2 up to 2.5e

workshops.

Procedure

All following checks and measurements have to be carried out in an ESD protected

environment and with ESD protected equipment/tools. For all activities the

international ESD regulations have to be considered.

Get delivery:

Ensure that every required information like fault description, customer data

a.s.o. is available.

Ensure that the packing of the defective items is according to packing

requirements.

Ensure that there is a description available, how to unpack the defective items

and what to do with them.

Enter data into your database:

(Depends on your application system)

Ensure that every data, which is required for the IRIS-Reporting is available in

your database.

Ensure that there is a description available for the employees how to enter the

data.

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 34 of 40 Internal Use Only

Page 35

M75 Level 2 Service Manual

Incoming check and check after assembling:

!! Verify the customers fault description!!

After a successful verification pass the defective item to the responsible

troubleshooting group.

If the fault description can not be verified, perform additional tests to save time

and to improve repair quality.

- Switch on the device and enter PIN code if necessary unblock phone.

- Check the

- Check the display for error in

function of all keys including side keys.

line and row, and for illumination.

- Check the ringer/loudspeaker acoustics by individual validation.

- Perform a GSM Test as described on page 36.

Check the storage capability:

Check internal resistance and capacity of the battery.

Check battery charging capability of the mobile phone.

Check charging capability of the power supply.

Check current consumption of the mobile phone in different mode.

Visual inspection:

Check the entire board for liquid damages.

Check the entire board for electrical damages.

Check the housing of the mobile phone for damages.

SW update:

Carry out a software update and data reset according to the master tables and

operator/customer requirements.

Repairs:

The disassembling as well as the assembling of a mobile phone has to be

carried out by considering the rules mentioned in the dedicated manuals. If

special equipment is required the service partner has to use it and to ensure

the correct function of the tools.

If components and especially soldered components have to be replaced all

rules mentioned in dedicated manuals or additional information e.g. service

information have to be considered

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 35 of 40 Internal Use Only

Page 36

M75 Level 2 Service Manual

GSM Test:

Connect the mobile/board via internal antenna (antenna coupler) and external

antenna (car cradle) to a GSM tester.

Use a Test SIM.

Skip GSM 900/GSM1800 or GSM1900 test cases if not performed by the

mobile

phone.

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 36 of 40 Internal Use Only

Page 37

M75 Level 2 Service Manual

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 37 of 40 Internal Use Only

Page 38

M75 Level 2 Service Manual

Final Inspection:

The final inspection contains:

1) A 100% network test (location update, and set up call).

2) Refer to point 3.3.

3) A random sample checks of:

- Data reset (if required)

- Optical appearance

- complete function

4) Check if PIN-Code is activated (delete the PIN-Code if necessary).

Basis is the international standard of DIN ISO 2859.

Use Normal Sample Plan Level II and the Quality Border 0,4 for LSO.

Remark: All sample checks must be documented.

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 38 of 40 Internal Use Only

Page 39

M75 Level 2 Service Manual

Annex 1

Test SIM Card

There are two different “Test SIM Cards” in use:

1) Test SIM Card from the company “ORGA”

Pin 1 number: 0000

PUK 1 : 12345678

Pin 2 number: 0000

PUK 2 : 23456789

2) Test SIM Card from the company “T-D1”

Pin 1 number: 1234

PUK : 76543210

Pin 2 number: 5678

PUK 2 : 98765432

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 39 of 40 Internal Use Only

Page 40

M75 Level 2 Service Manual

Annex 2

Battery Date Code overview

Varta

Date code example N 9 A VA

Year (N:2001, O:2002...) Supplier Code

Month (1:Jan, 2:Feb,…9:Sep, O:Oct, N:Nov, D:Dec) (Maker’s marking)

Revision Letter (A, B,…)

Hitachi / Maxwell

Date code example N 9 A MX

Year (N:2001, O:2002...) Supplier Code

Month (1:Jan, 2:Feb,…9:Sep, O:Oct, N:Nov, D:Dec) (Maker’s marking)

Revision Letter (A, B,…)

Sanyo

Date code example N 9 A SY

Year (N:2001, O:2002...) Supplier Code

Month (1:Jan, 2:Feb,…9:Sep, O:Oct, N:Nov, D:Dec) (Maker’s marking)

Revision Letter (A, B,…)

NEC

Date code example N 8 A NT

Year (N:2001, O:2002...) Supplier Code

Month (1:Jan, 2:Feb,…9:Sep, O:Oct, N:Nov, D:Dec) (Maker’s marking)

Revision Letter (A, B,…)

Panasonic

Date code example O N A PAN

Year (N:2001, O:2002...) Supplier Code

Month (1:Jan, 2:Feb,…9:Sep, O:Oct, N:Nov, D:Dec) (Maker’s marking)

Revision Letter (A, B,…)

Sony

Date code example P N A SO

Year (O:2002, P:2003...) Supplier Code

Month (1:Jan, 2:Feb,…9:Sep, O:Oct, N:Nov, D:Dec) (Maker’s marking)

Revision Letter (A, B,…)

Copyright © Siemens Pte Ltd. Siemens Technical Support Centre

COM D CCQ APAC SLI

TI_Repair_L2_M75_R1.0 Page 40 of 40 Internal Use Only

Loading...

Loading...