Page 1

SIMA

TIC 505

High Speed Counter

and Encoder Module

User

Manual

Order Number: PPX:505–81

Manual Assembly Number: 2586546–0019

Second Edition

13–2

Page 2

Copyright

1992 by Siemens Industrial Automation, Inc.

All Rights Reserved — Printed in USA

Reproduction,

contents is not permitted without express consent of

Siemens Industrial

created by patent grant or registration of a utility model or

design, are reserved.

Since Siemens Industrial Automation, Inc. does not possess

full access to data concerning all of the uses and applications

of customer’s products, we do not assume responsibility either

for customer product design or for any infringements of patents

or rights of others which may result from our assistance.

01/21/92

transmission or use of this document or

Automation, Inc. All rights, including rights

T

echnical data is subject to change.

W

e check the contents of every manual for accuracy at the

time it is approved for printing; however

undetected errors. Any errors found will be corrected in

subsequent editions. Any suggestions for improvement are

welcomed.

, there may be

Page 3

Contents

Chapter

1.1 Features 1-2.

1.2 Inputs 1–4

1.3 Outputs 1–5

1.4 LED Indicators 1–6.

1.5 Counting Modes 1–7.

Chapter

2.1 Before Installing the Module 2–2.

1

Overview

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.1 Pulse-Counter

1.5.2 Quadrature

1.5.3 1X

1.5.4 2X

1.5.5 4X

2

Quadratur

Quadratur

Quadratur

Installation

Mode

Mode

e 1-8.

e 1-9.

e 1-10.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1 Visual

2.1.2 Additional

2.1.3 Handling

2.1.4 General Wiring Considerations

2.1.5 Hierarchy

Inspection

Refer

the Module

of Installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ences 2-2.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–7.

1–8.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2.

2-2.

2-3.

2-4.

2.2 Selecting Counter Operation 2-5.

2.2.1 Selecting

2.2.2 Selecting

Counter Mode

the Reset Filter

2.3 Inserting the Module in the I/O Base 2-7.

2.4 Wiring the Module 2-8.

2.4.1 Wiring

2.4.2 Powering

the Terminal Block

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Up the Module

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Logging the Module into the Controller 2-10.

2.5.1 Updating

2.5.2 Selecting

2.5.3 Viewing

Chapter

3

Programming

3.1 Controller Input Wor

3.1.1 WX1

3.1.2 WX2

3.1.3 WY4

3.1.4 WY5

3.1.5 I/O

the I/O Configuration Definition

the I/O Configuration

I/O Configuration Chart

ds

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(Status W

and WX3 (Channel Count)

(Setup W

– WY8 (Pr

Update Consideration

ord) 3-2.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ord) 3-3.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

eset W

ords) 3-4.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-10.

2-10.

2-11.

3-2.

Contents iii

2-5.

2-6.

2-8.

2-8.

3-3.

3-4.

Page 4

Chapter

4

Troubleshooting

4.1 Checking the Operation of the Module 4-2.

Chapter

5.1 Sprayer Example 5-2.

5.2 Flow Rate Example 5-5.

5.3 Tank Filling Example 5-6.

Appendix A Ter

A.1 Terminal Block Worksheet A-1.

Appendix

B.1 Environmental Specifications B-2.

B.2 Electrical Specifications B-3.

5

Applications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.1 Description 5-2.

5.1.2 Solution 5-3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 Description 5-5.

5.2.2 Solution 5-5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 Description 5-6.

5.3.2 Solution 5-6

minal Block W

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

orksheet

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B

Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.3 Additional Compliances B-6.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv Contents

Page 5

List

of Figur

es

1-1 High Speed Counter Module 1-3.

1-2 Output 1-5

1-3 High Speed Counter LEDs 1-6.

1-4 Pulse Counter Mode 0 1-7.

1-5 1X Quadrature Mode 1-8.

1-6 2X Quadrature Mode 1-9.

1-7 4X Quadrature Mode 1-10.

2-1 Hierarchy of Installation 2-4.

2-2 Jumper Settings 2-5.

2-3 Inserting the Module into the I/O Base 2-7.

2-4 Wiring Guidelines 2-8.

2-5 Sample Terminal Block Wiring Diagram 2-9.

2-6 Sample I/O Definition Chart 2-10.

2-7 I/O Configuration Chart 2-11.

3-1 Status Word Format 3-2.

3-2 Setup Word Format 3-3.

5-1 Sprayer Application 5-2.

5-2 HSC Connections 5-3.

5-3 Waveform Pattern 5-3.

5-4 Ladder Logic for Sprayer Example 5-4.

5-5 Ladder Logic for Flow Rate Example 5-5.

5-6 Tank Filling Application 5-6.

5-7 Ladder Logic for Tank Filling Example 5-7.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents v

Page 6

List

of T

ables

1-1 Determining Count in Pulse Counter Mode 1-7.

B-1 Environmental Specifications B-2.

B-2 Electrical Specifications B-3.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

vi Contents

Page 7

Chapter 1

Overview

1.1 Features 1-2.

1.2 Inputs 1-4

1.3 Outputs 1-5

1.4 LED Indicators 1-6.

1.5 Counting Modes 1-7.

1.5.1 Pulse-Counter Mode 1-7.

1.5.2 Quadrature Mode Overview 1-8.

1.5.3 1X Quadrature 1-8.

1.5.4 2X Quadrature 1-9.

1.5.5 4X Quadrature 1-10.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Series

505 High Speed Counter

and Encoder Module User

’

s Manual

Overview

1-1

Page 8

1.1 Features

The

Series 505 High Speed Counter (HSC) module (PPX:505-7002)

provides two independent high-speed counter channels.

Each channel has the following features.

Four counter modes:

Pulse counter

Quadrature counter modes: 1X, 2X, 4X

A 10 kHz count rate with a minimum pulse width of 25

Four inputs:

two count inputs

s.

reset

inhibit

T

wo field outputs, each controlled by a separate programmable preset.

LED indicators display the status of the A and B count inputs, and of

Y1 and Y2 outputs.

!

The

All inputs may be sinking or sourcing (with external 24 VDC power

supply).

The HSC module operates asynchronously from the controller scan. Y

ou

can program the controller to monitor the HSC and/or to provide high-level

control of the HSC’

s operation. T

o support these functions, the HSC

provides reset, inhibit, output and counter status to the controller and

accepts reset and inhibit commands, and preset values from the controller

HSC module controls its four outputs. If the controller switches from the Run

mode to the Program mode, the HSC continues to function as programmed, and

outputs may be activated by the HSC. This means that if you switch the controller

to Program mode, any devices controlled by the four outputs of the HSC will

continue to operate as programmed.

.

1-2

Series

and Encoder Module User

505 High Speed Counter

’

s Manual

Page 9

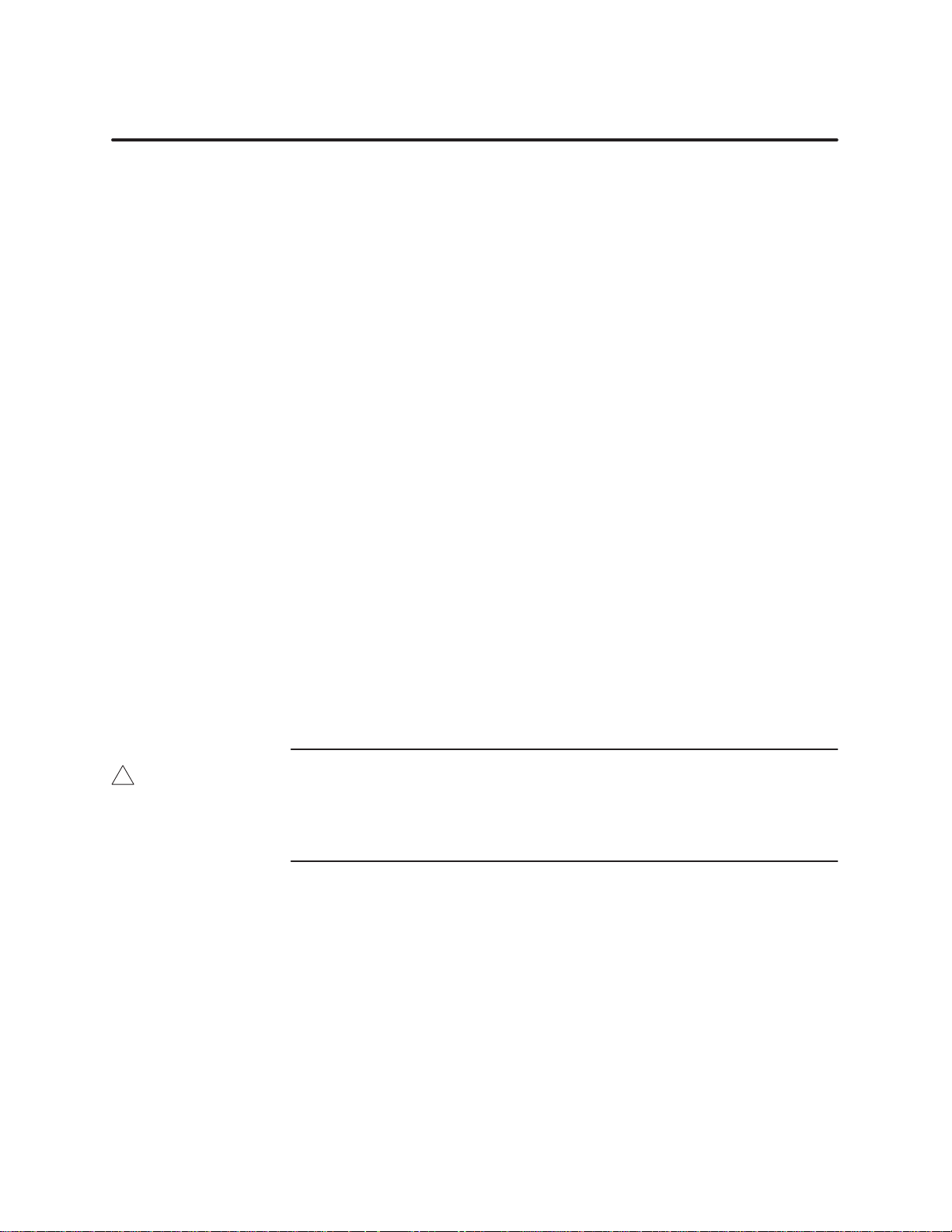

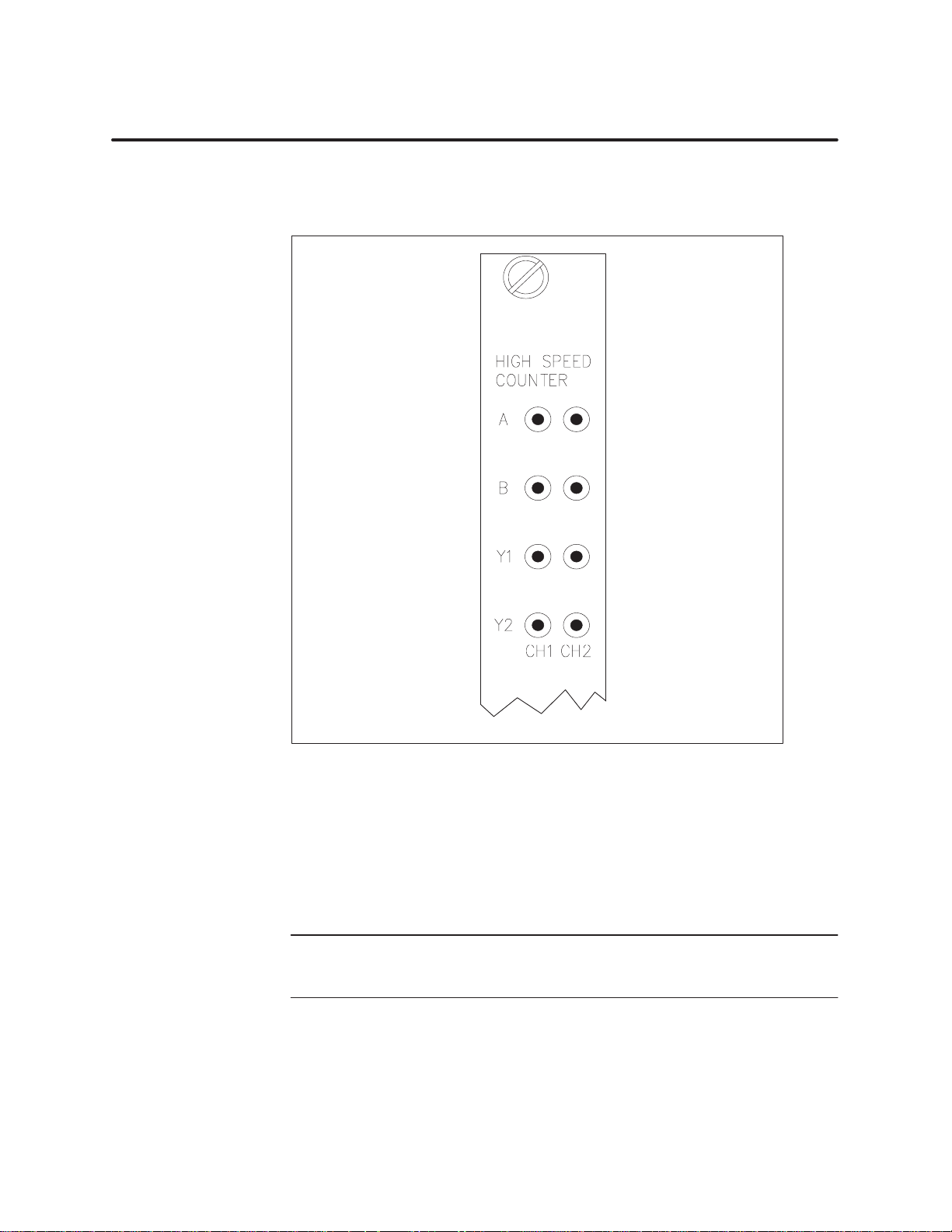

Bezel Screw

LEDs

Base

Plane

Connector

Terminal

Block

Printed

Circuit

Board

Front Bezel

Bezel Screw

Series 505 High Speed Counter

and Encoder Module User

’

s Manual

Figure 1-1

High

Speed Counter Module

Overview

1-3

Page 10

1.2 Inputs

The

HSC module has two independent channels. Each channel has four

inputs.

Reset

Inhibit

T

wo counter inputs

Each input may be used as either sinking or sourcing (with external 5–24

VDC power supply). The input signals are connected to the field wiring

terminal block on the front bezel.

Counter Inputsą

Each channel has two counter inputs — Input A and

Input B.

Reset

Current flow through the reset input sets the channel’

s counter to

zero. The counter will be held at zero until the reset input becomes

inactive.

Inhibitą

Current flow through the inhibit input inhibits the channel from

counting. The counter holds at the last value and does not change until the

inhibit input becomes inactive.

NOTE:

When in the pulse counter mode, if the A or B input is in a

different state at the beginning and end of an inhibit signal, the count will

change according to the normal counting logic. If both A and B inputs are

in different states, the change may be as much as two counts.

NOTE:

There are also software reset and inhibit functions. See Section 3.

1-4

Series

and Encoder Module User

505 High Speed Counter

’

s Manual

Page 11

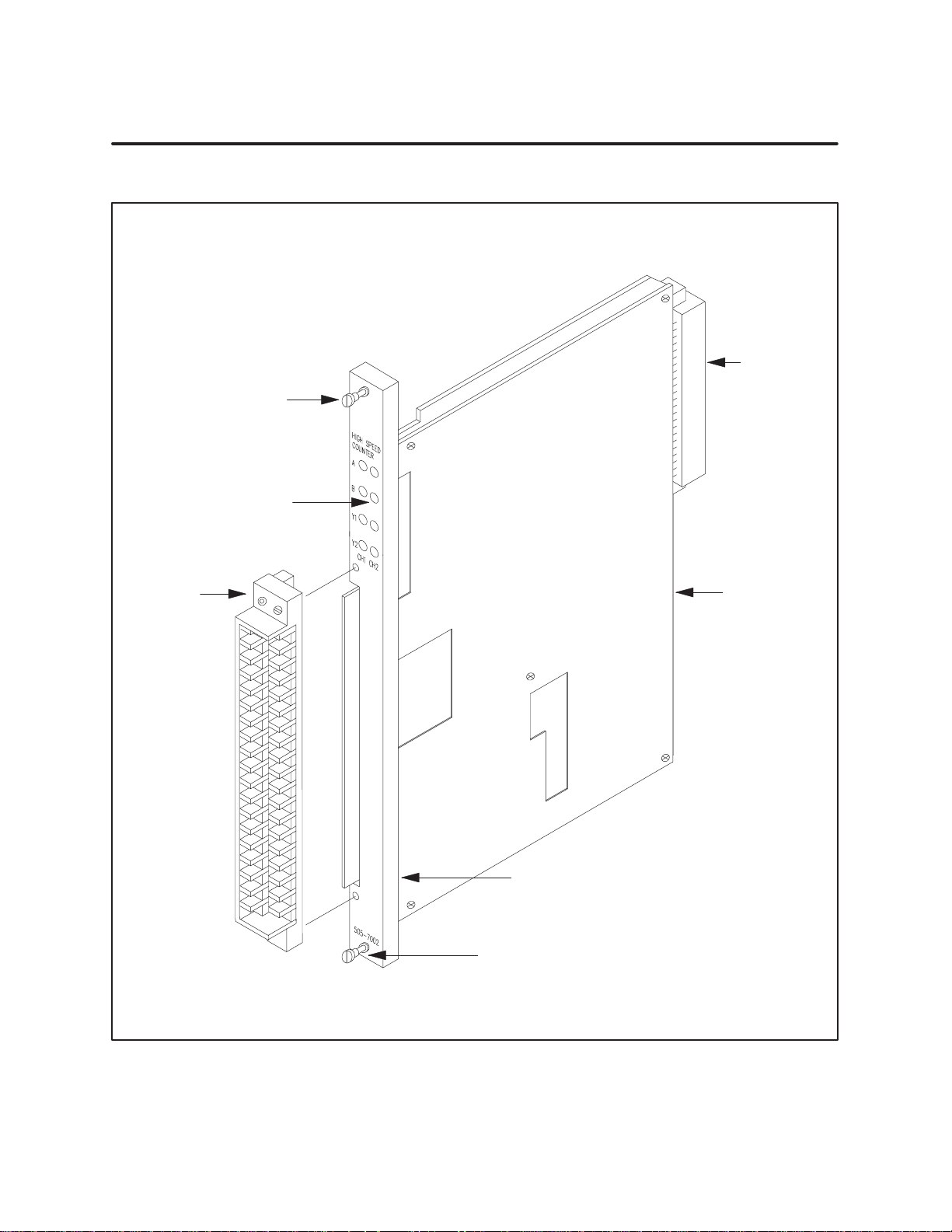

1.3 Outputs

Each

channel has two open collector outputs capable of driving TTL level

signals or sinking up to 0.4 Amps of current (at 40_C) from an external 24

VDC source and load.

Y

Output

Output Return

Output Circuit

Y2

Y1

0 P1 P2 65,535

Counter V

Figure 1-2

The

output transistor (Y1 or Y2) turns on when the count is greater than or

alue

Output

equal to the corresponding preset. Figure 1-2 shows the field output

operation. Y

ou can invert this operation by setting the appropriate bits in

the setup word, WY4. See Section 4.1.

Series

505 High Speed Counter

and Encoder Module User

’

s Manual

Overview

1-5

Page 12

1.4 LED Indicators

Each

indication of the channel’

channel contains four LED indicators which provide a visual

s status as shown in Figure 1-3.

1-6

Figure 1-3

A Turns

B T

Y1 T

Y2 T

NOTE:ă

on when there is current flow through the A input.

urns on when there is current flow through the B input.

urns on when Output 1 is on.

urns on when Output 2 is on.

If Reset or Inhibit is turned on, the HSC does not count, and the A

and B LEDs are frozen.

High

Speed Counter LEDs

and Encoder Module User

Series

505 High Speed Counter

’

s Manual

Page 13

1.5 Counting Modes

1.5.1

Pulse

Mode

Counter

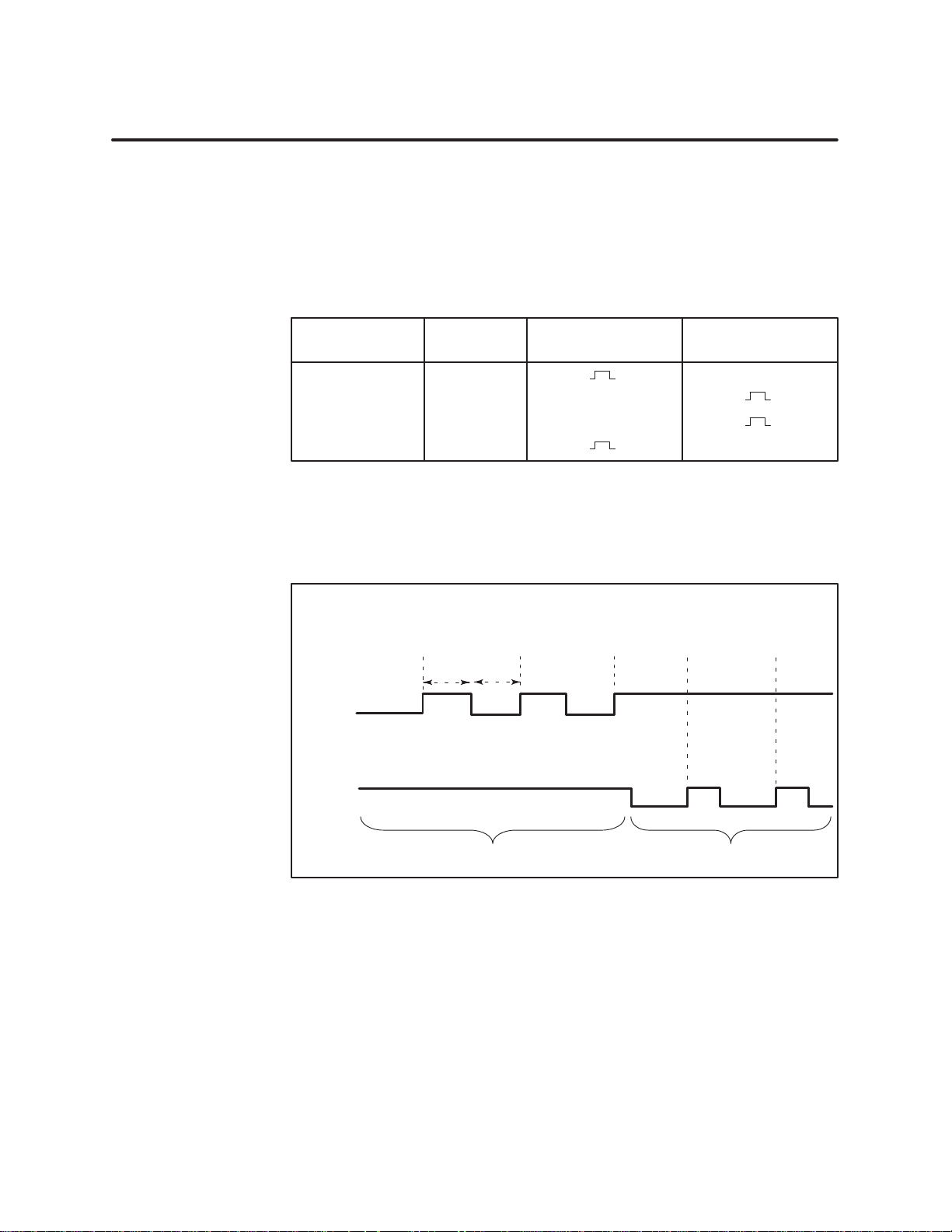

Each channel has two inputs, A and B. In the pulse counter mode, counting

occurs on the rising or falling edge of the incoming pulses. The relationship

of the states of these two inputs determines the direction of the count. See

T

able 1-1. T

incremental encoders.

T

able 1-1

Counter

Direction

ypical devices for counting are high-speed static switches or

Deter

mining Count in Pulse Counter Mode

Edge A

Input

B Input

up

up

down

down

In

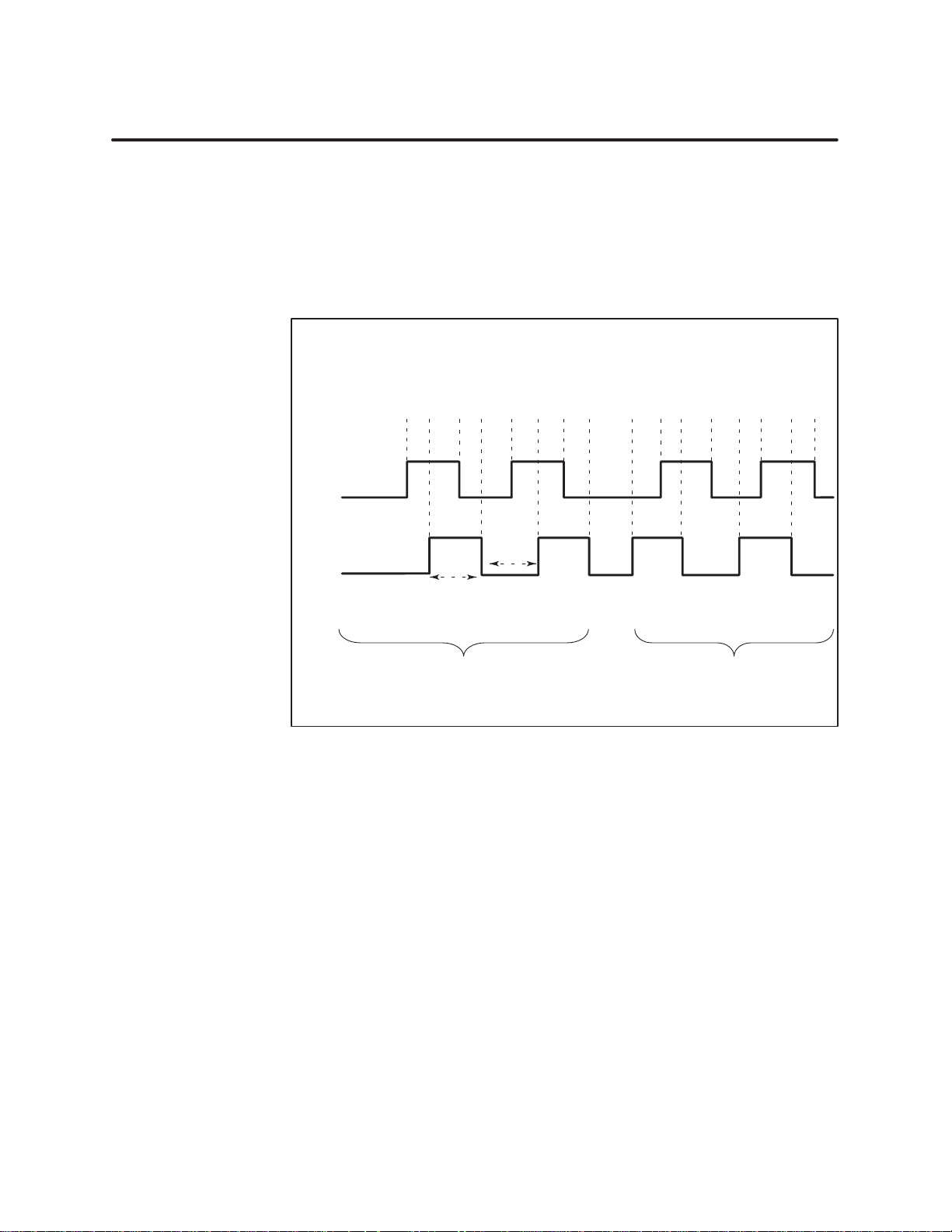

the pulse counter mode, the channel senses the edges

input to count up or down. See Figure 1-4. T

”

#

”

#

low

high

o reliably record this transition

from low to high, the pulse width must be at least 8

Pulse Counter Mode

Count Value

Count Input

Input A

Input B

1

8 s

min

2 3 2 1

11 s

min

high

low

of the A or the B

s.

Series

505 High Speed Counter

and Encoder Module User

’

s Manual

Count Up

Figure 1-4

Pulse

Counter Mode 0

Count Down

Overview

1-7

Page 14

Counting Modes (continued)

1.5.2

Quadrature

Mode

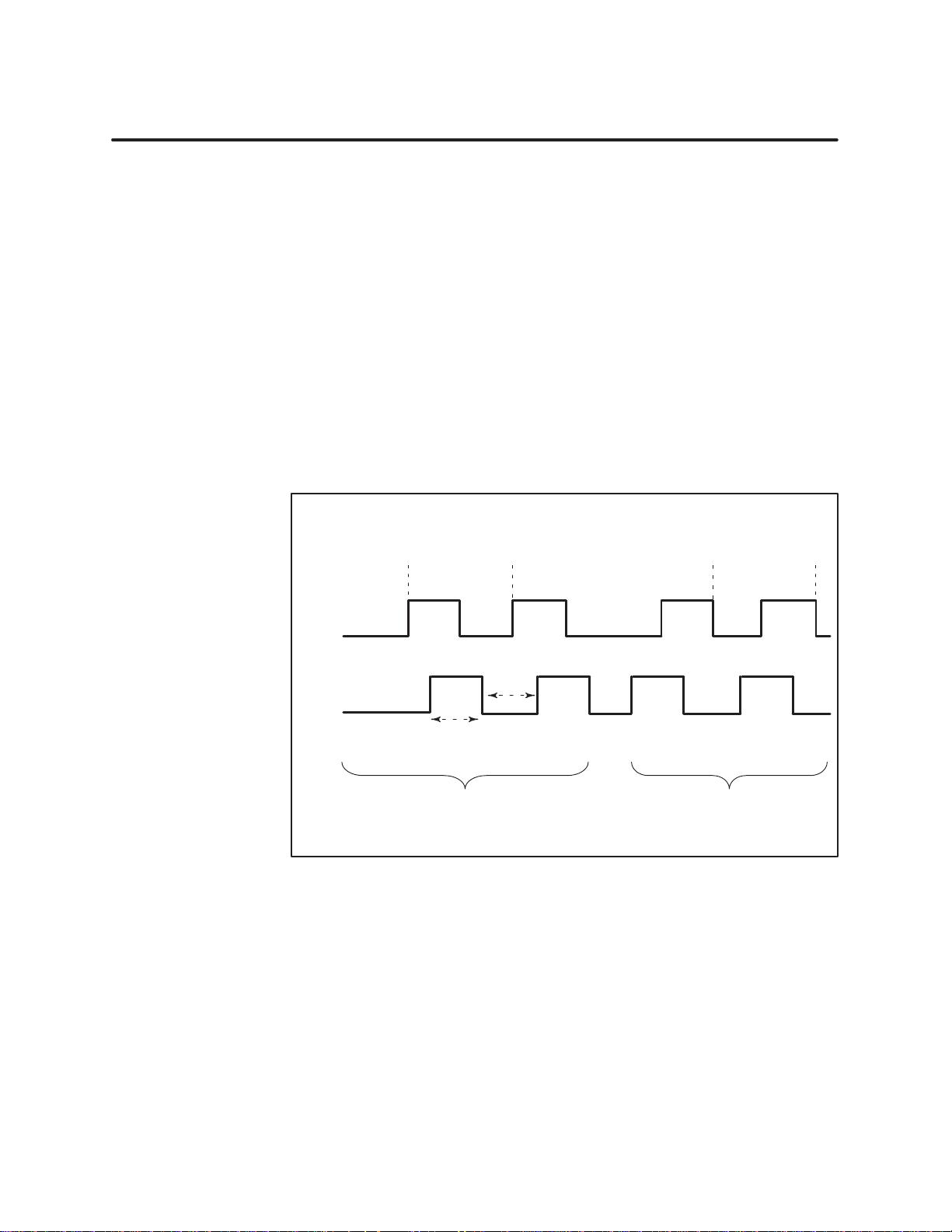

1.5.3

1X Quadratur

e

For quadrature mode, each channel counts according to rising and/or

falling edges. T

Different quadrature modes are selected based on the resolution required

by the application and the encoder used.

The module counts on the edges of the A input pulses.

When input A leads input B, the HSC counts up on each rising edge of

input A.

When input B leads input A, the HSC counts down on the falling edge

of input A.

Figure 1-5 illustrates the relationship between inputs A and B and the

count value in

1X Quadrature

ypical devices for quadrature inputs are optical encoders.

1X Quadrature mode.

Count Value

A

B

12 10

26.7 s

25 s

min

Count Up

(A Leading)

Figure 1-5

min

1X

Quadrature Mode

Count Down

(B Leading)

1-8

Overview

Series

and Encoder Module User

505 High Speed Counter

’

s Manual

Page 15

1.5.4

Quadratur

2X

e

If input A leads input B, the module counts up on both the rising and

falling edges of input A. If input B leads input A, the module counts down

on the rising and falling edges of input A.

Figure 1-6 illustrates the relationship between inputs A and B and the

count value in the 2X quadrature mode.

2X Quadrature

Count V

A

B

alue

1234 3210

25 s

min

Counts Up

(A Leading)

Figure 1-6

26.7 s

min

2X

Quadrature Mode

Counts Down

(B Leading)

Series

505 High Speed Counter

and Encoder Module User

’

s Manual

Overview

1-9

Page 16

Counting Modes (continued)

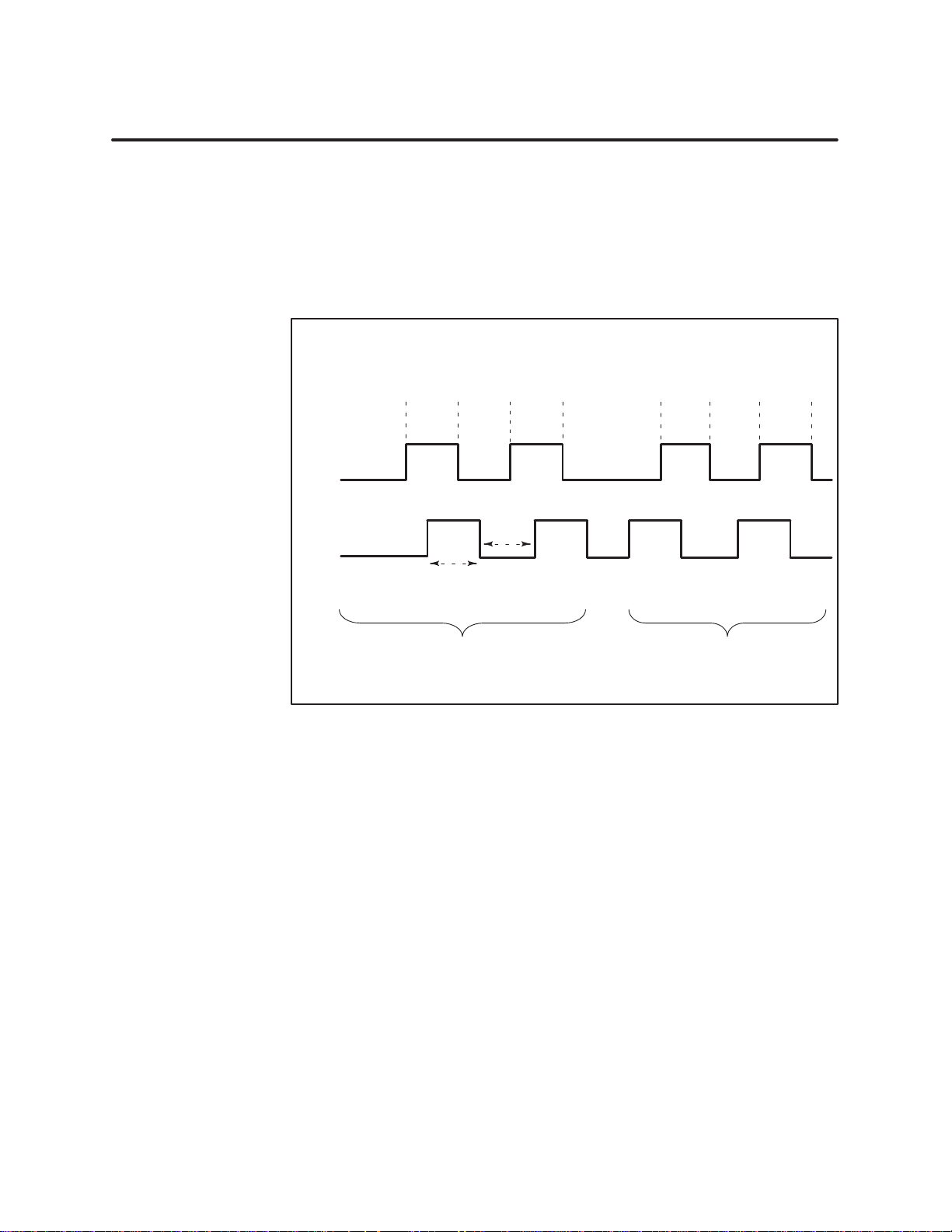

1.5.5

Quadratur

4X

e

If input A leads input B, the module counts up on rising and falling edges

of both input A and input B. If input B leads input A, the module counts

down on the rising and falling edges of input A and input B.

Figure 1-7 shows the relationship between inputs A and B and the count

value in the 4X

4X Quadrature

quadrature mode.

Count V

A

B

alue

12 34 5 6 7 8 7 65 4 32 10

25 s

min

Counts Up

(A Leading)

Figure 1-7

26.7 s

min

4X

Quadrature Mode

Counts Down

(B Leading)

1-10

Overview

Series

and Encoder Module User

505 High Speed Counter

’

s Manual

Page 17

Chapter 2

Installation

2.1 Before Installing the Module 2–2.

2.1.1 Visual Inspection 2-2.

2.1.2 Additional References 2-2.

2.1.3 Handling the Module 2-2.

2.1.4 General Wiring Considerations 2-3.

2.1.5 Hierarchy of Installation 2-4.

2.2 Selecting Counter Operation 2-5.

2.2.1 Selecting Counter Mode 2-5.

2.2.2 Selecting the Reset Filter 2-6.

2.3 Inserting the Module in the I/O Base 2-7.

2.4 Wiring the Module 2-8.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.1 Wiring the Terminal Block 2-8.

2.4.2 Powering Up the Module 2-8.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Logging the Module into the Controller 2-10.

2.5.1 Updating the I/O Configuration Definition 2-10.

2.5.2 Selecting the I/O Configuration 2-10.

2.5.3 Viewing I/O Configuration Chart 2-11.

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Series

505 High Speed Counter

and Encoder Module User

’

s Manual

Installation

2-1

Page 18

2.1 Before Installing the Module

2.1.1

Inspection

Visual

2.1.2

Additional

Refer

ences

If there is any visible damage to the module, contact your Siemens

Industrial Automation, Inc. distributor for replacement.

Refer to the manuals listed below for instructions on installing,

programming, and troubleshooting your Series 505

E

controller

.

2.1.3

Handling the Module

D SIMATICr TI545 System Manual

D SIMATICr TI525

/

TI535

Hardware and Installation Manual

(PPX:545–8101)

(PPX:505–8103)

D SIMATICr TI505

Programming

Reference Manual

(PPX:505–8104)

Many integrated circuit (IC) devices are susceptible to damage by the

discharge of static electricity

. Follow the suggestions listed below to reduce

the probability of damage to these devices when you are handling a

controller

, a base controller

, or any of the I/O modules.

Both the module and the person handling the module should be at the

same ground potential. To accomplish this, ensure the following.

D

The module is transported in an anti-static container or antistatic

material.

D

The work area has a conductive pad with a lead connecting it to a

common ground.

D Y

ou are grounded by making contact with the conductive pad and/or by

wearing a grounded wrist strap.

2-2

Installation

Series

and Encoder Module User

505 High Speed Counter

’

s Manual

Page 19

2.1.4

W

General

iring

Considerations

The count, inhibit, and unfiltered reset inputs are high-speed inputs which

may respond to noise present on the lines. T

o avoid problems, follow these

guidelines when installing the HSC module.

D

Use the shortest possible wires.

D A

void placing signal wires parallel to high-energy wires. If the two

must meet, cross them at right angles.

D A

void bending the wire into sharp angles.

D

Use wireways for wire routing.

D

When using shielded wires, ground them only at the source end for

better noise immunity

D

Place wires so that they don’t interfere with existing wiring.

D

Label the wires.

.

In some installations when both the HSC and TI505-49XX series of relay

modules are used, false counts may be induced when switching high

voltage in the relay module, (voltage > 40 V

rms). This is the result of

internal arcing of the relay contacts.

If you encounter this problem, place a snubber consisting of a 47 ohm 1/4

watt resistor and a 0.022 Fd capacitor across the relay contact terminals

on the terminal block. Snubbers were not included in the relay modules in

order to meet the need for lower current leakage in many applications.

Series

505 High Speed Counter

and Encoder Module User

:

Snubber components must be ULr component r

and/or CSA Certified for use acr

by the r

’

s Manual

elay module.

ecognized

oss the rated voltage being switched

Installation

2-3

Page 20

Before Installing the Module (continued)

2.1.5

Hierarchy

Installation

of

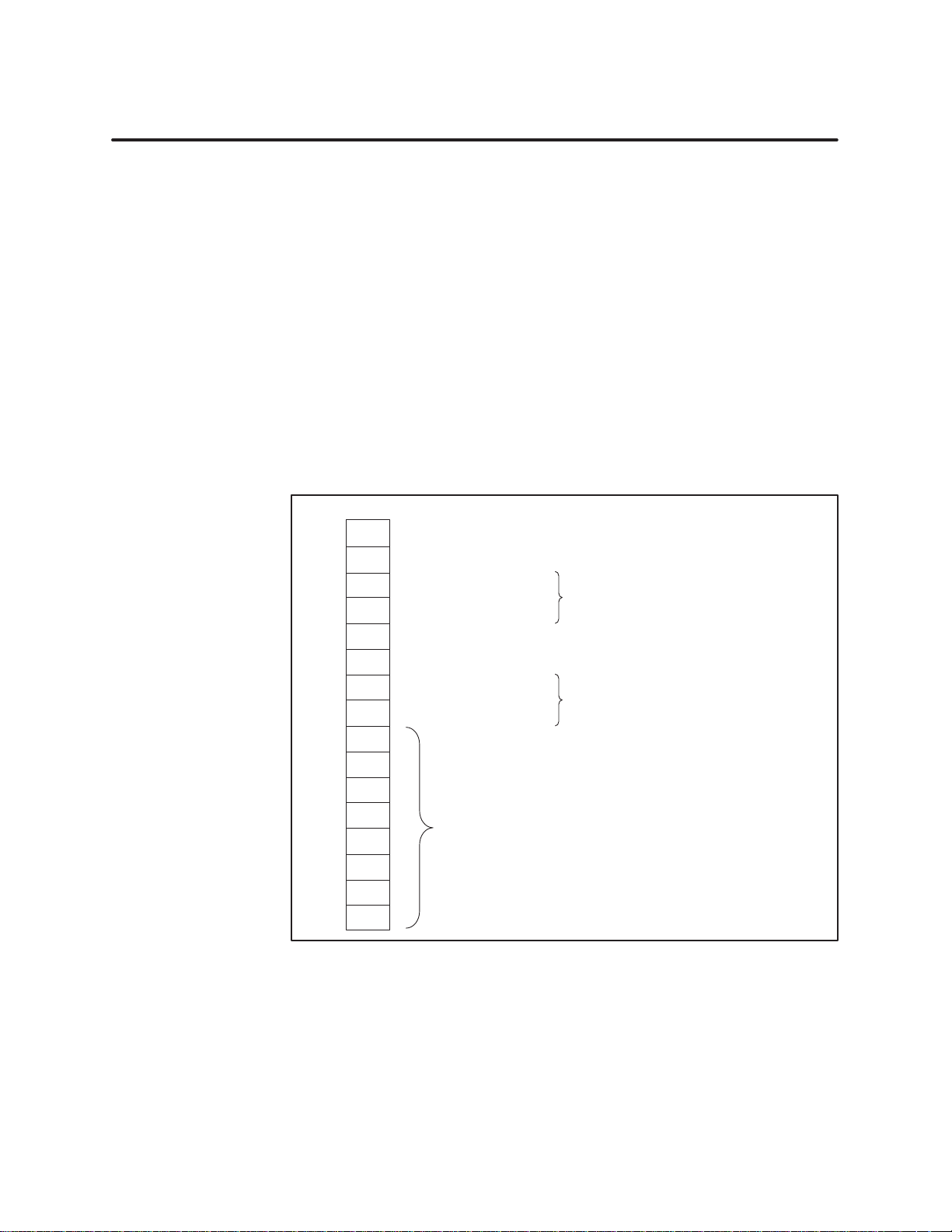

Figure 2-1 provides a simple flowchart of the installation process.

Set Jumper Configuration on Module

Insert the Module

Connect W

Power Up

Log into Controller

Figure 2-1 Hierar

ires

chy of Installation

2-4

Installation

Series

and Encoder Module User

505 High Speed Counter

’

s Manual

Page 21

2.2 Selecting Counter Operation

2.2.1

Selecting The

Counter Mode

HSC module has two channels. Y

to operate in any of four counter modes.

Prior to installing the module into the I/O backplane, configure the module

by setting the jumper for each channel. Figure 2-2 shows the location of the

jumpers on the printed circuit board. The top set of four pins set the

counter mode for Channel 1. The bottom set of four pins set the counter

mode for Channel 2. The default setting for the jumpers is 1X Quadrature

mode for both channels.

ou can configure each channel

CH

1

Jumper in SLW

(filtered)

position

Each channel

CH

2

Jumper in FST

(unfiltered) position

Figure 2-2 Jumper

must

have one (and only one) jumper installed.

Settings

Series

505 High Speed Counter

and Encoder Module User

’

s Manual

Installation

2-5

Page 22

Selecting Counter Operation (continued)

2.2.2 Selecting the Reset Filter

Some applications require faster response on the reset input line than

the standard 3.75-ms filter allows. For faster response, select the optional

0.95-ms filter

. (The 0.9-ms filter is more sensitive to noisy signals, as noted

in the Environmental Specifications in Appendix B.)

The reset filter may be selected independently for each input channel by

placing the jumper in the

Figure 2-2.

(fast) or

(slow) position as shown in

2-6

Installation

Series

and Encoder Module User

505 High Speed Counter

’

s Manual

Page 23

2.3 Inserting the Module in the I/O Base

The

HSC is a single-wide module. Insert it into any available slot on any

Series 505 I/O base. Do not touch the printed circuit board while inserting

the module. This could cause electrostatic damage to the components on

the board. Insert the module as shown in Figure 2-3.

!

T

o minimize potential shock, tur

modules installed in the base befor

Failur

e to do so may r

esult in potential injury to personnel or damage to

equipment.

n of

f power to the I/O base and any

e inserting or r

emoving a module.

3ĂĂĂ(2.6ĂĂ)Ă maxĂ

Base Plane

Connectors

Series

505 High Speed Counter

and Encoder Module User

’

s Manual

Figure 2-3

Inserting the Module into the I/O Base

Installation

2-7

Page 24

2.4 Wiring the Module

2.4.1

Wiring the W

Ter

minal Block

iring the module consists of wiring the the input and output signals.

See Figure 2-4 and Figure 2-5 for general guidelines. All connections are

made at the module terminal block. See Figure 2-5. Output returns for

Channel 1 and 2 are internally connected.

!

Tur

2.4.2 Powering Up the Module

Use the T

n of

befor

erminal Block W

orksheet in Appendix B for planning your wiring.

f power to the I/O base and any modules installed in the base

e inserting or removing a module. Failur

e to do so may cause

potential injury to personnel or can damage equipment.

After wiring the terminal block for the HSC, restore power to the

base.

Wire

Gauge: 22–16

1cm

(0.4 in.)

2-8

Installation

Stud

Size: #4 (2.5mm)

Amp Part#: 321462

Stud

Size: #4 (2.5mm)

Amp Part#: 327891

(Specify 2pt. connector)

Figure 2-4 W

Max. Width: 5.54 mm (.218 in.)

Max. Width: 4.62 mm (.182 in.)

iring Guidelines

Series

and Encoder Module User

505 High Speed Counter

’

s Manual

Page 25

5–24 VDC

Sinking

Driver

Encoder

5–24 VDC

Ch1 A–

Ch1 B–

Ch1 RST–

Ch1 INH–

+ –

Ch1 Y1

Ch1 Y2

Ch2 A–

Ch2 B–

Ch2 RST–

Ch2 INH–

Ch1 A+

Ch1 B+

Ch1 RST+

Ch1 INH+

Ch2 A+

Ch2 B+

Ch2 RST+

Ch2 INH+

5–24 VDC

Sourcing

Driver

5–24 VDC

Series

505 High Speed Counter

and Encoder Module User

+ –

Ch2 Y1

Ch2 Y2

Figure 2-5 Sample Ter

’

s Manual

minal Block W

iring Diagram

Installation

2-9

Page 26

2.5 Logging the Module into the Controller

2.5.1

Updating

the I/O

Configuration

Definition

2.5.2 Selecting the I/O Configuration

After inserting the module into the base, update the I/O configuration

in the controller

. The module does

A VPU or other programming device must be connected to the controller to

register and verify controller module communication.

W

ith your VPU or other programming device, select the I/O Configuration

option. For example, if you have the module inserted into the first slot of

the first I/O base, configure it as displayed in Figure 2-6. Refer to the

manual that came with the programming device for instructions.

not

automatically onfigure itself.

I/O Address

The

HSC module is logged in as

three input words (WX) and five

output words (WY).

I/O MODULE DEFINITION FOR :

I/O

Number of Bit and W

Base Number

Displays number

of the current

base.

CHANNEL 1

ord I/O

BASE 00

Special

Slot Address X Y WX WY Function

0001

.....

1

0000

.....

2

0000

.....

3

0000

.....

4

0000

.....

5

0000

.....

6

0000

.....

7

0000

.....

8

.....

.....

.....

.....

.....

.....

.....

.....

Slot Number

Install

the HSC into any avail

able I/O slot on the Series 505

base.

00

00

00

00

00

00

00

00

03 05

..

00

..

..

00

..

..

00

..

..

00

..

..

00

..

..

00

..

..

00

..

..

00

..

-

..

00

..

00

00

..

00

00

..

00

00

..

00

00

..

00

00

..

00

00

..

00

SF Module

The HSC is not an SF

.......

.......

.......

.......

.......

.......

.......

.......

Module. The default for this

definition is

NO.

No

No

No

No

No

No

No

No

2-10

Installation

Figure 2-6

Sample I/O Definition Chart

Series

and Encoder Module User

505 High Speed Counter

’

s Manual

Page 27

2.5.3

Viewing

the I/O Use SHOW to view the I/O Configuration Chart. If the HSC is

Configuration

Chart

installed in slot 1, for channel 1, base 00, the I/O chart will appear

as displayed in Figure 2-7.

I/O CONFIGURA

Slot 1

Slot 2

Slot 3

Slot 4

Slot 5

Slot 6

WX001 WX002 WX003 WY004WY005 WY006 WY007 WY008

00000 00000 00000 00000 00000 00000 00000 00000

00000

00000

00000

00000

TION CHART FOR :

I/O POINTS

00000

00000

00000

00000

Figure 2-7

00000

00000

00000

00000

I/O Configuration Chart

00000

00000

00000

00000

CHANNEL 1, BASE 00

00000

00000

00000

00000

00000

00000

00000

00000

00000

00000

00000

00000

00000

00000

00000

00000

Series

505 High Speed Counter

and Encoder Module User

’

s Manual

Installation

2-11

Page 28

Chapter 3

Programming

3.1 Controller Input Words 3-2.

3.1.1 WX1

3.1.2 WX2

3.1.3 WY4

3.1.4 WY5

3.1.5 I/O

(Status W

and WX3 (Channel Count)

(Setup W

– WY8 (Pr

Update Consideration

ord) 3-2.

ord) 3-3.

eset W

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ords) 3-4.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3.

3-4.

Series

505 High Speed Counter

and Encoder Module User

’

s Manual

Programming

3-1

Page 29

3.1 Controller Input Words

The

HSC module is configured as three word inputs (WX) and five word

outputs (WY). It occupies eight words of the controller’s word image

register.

3.1.1

WX1 (Status W

ord) W

each of the two channels. Figure 3-1 shows the format of the status word.

ord 1 (WX) is the module’

BIT

s status word. Eight bits provide the status of

MSB

LSB

10

11

12

13

14

15

16

1

2

3

4

5

6

7

8

CH 1 — RESET ST

CH 1 — INHIBIT ST

ATUS

ATUS

CH 1 — OUTPUT 1 ST

CH 1 — OUTPUT 2 ST

CH 2 — RESET ST

CH 2 — INHIBIT ST

ATUS

ATUS

CH 2 — OUTPUT 1 ST

CH 2 — OUTPUT 2 ST

(1 = Counter reset)

(1 = Count inhibited)

ATUS

ATUS

(1 = On)

(1 = On)

(1 = Counter reset)

(1 = Counts inhibited)

ATUS (1 = On)

ATUS (1 = On)

9

Reserved and will be returned as zeros

3-2

Programming

the channel’

s RESET field input is active, this bit will be 1; otherwise this

bit will be 0.

af

The Reset Command bit (see Setup Word, Section 3.1.3) does not

fect the r

eset status bit.

Figure 3-1

Status Word For

mat

Each channel has a Reset Status bit in the status word. If

Series

and Encoder Module User

505 High Speed Counter

’

s Manual

Page 30

Inhibit Status. Each

the channel’

(see Setup W

s

ord, Section 3.1.3), this bit will be 1 and the counter will not

channel has an Inhibit Status bit in the status word. If

Inhibit

field input is active or if its Inhibit Command bit is 1

count. Otherwise, this bit will be 0.

3.1.2 WX2 and WX3 (Channel Count)

3.1.3

WY4 (Setup W

ord) W

Output Status.

Each channel has an Output 1 Status and an Output 2

Status bit in the status word. If the corresponding field output is on, the bit

will be 1. Otherwise, the bit will be 0.

W

ord 2 (WX2)

register

count register

, and W

contains

ord 3 (WX3)

the current value of the Channel 1 count

contains

the current value of the Channel 2

. These values are unsigned integers between 0 and 65,535

(inclusive).

ord 4 (WY4) is the module setup word. The controller uses eight bits to

control the HSC module’

s operation. See Figure 3-2.

BIT

MSB

CH 1 — RESET

1

2

CH 1 — INHIBIT

3

CH 1 — OUTPUT 1

4

CH 1 — OUTPUT 2

CH 2 — RESET

5

6

CH 2 — INHIBIT

CH 2 — OUTPUT 1

7

CH 2 — OUTPUT 2

8

(1 = Reset counter; default: 0)

(1 = Inhibits counts; default: 0)

0: Count P = On (default)

1: Count < P = On

(1 = Reset counter; default: 0)

(1 = Inhibits counts; default: 0)

0: Count P = On (default)

1: Count < P = On

9

10

11

12

Reserved and should be set to 0 (off)

13

14

15

LSB

16

Series

505 High Speed Counter

and Encoder Module User

’

s Manual

Figure 3-2

Setup Word For

mat

Programming

3-3

Page 31

Controller Input Words (continued)

Reset Command. Both

channels have a Reset Command bit. A transition

from 0 (off) to 1 (on) of the Reset Command acts as a one-shot (providing a

momentary reset of the channel), setting the count to 0. Even though the

bit remains 1, counting resumes.

Inhibit Command.

Both channels have an Inhibit Command bit. When this

bit is set to 1, the channel stops counting.

NOTE:

differ

will change accor

inputs ar

When in the pulse counter mode, if the A or B input is in a

ent state at the beginning and end of an inhibit signal, the count

e in dif

ding to the nor

fer

ent states, the change may be as much as two

mal counting logic. If both A and B

counts.

Output Level.

The output level bit specifies when the outputs for each

channel turn on.

Setting the output level bit to 0 turns the output on when the current

count is greater than or equal to the preset. If the current count is less

than the preset, the output is off.

Setting the output level bit to 1 turns the output on when the current

count is less than the preset. If the current count is greater than or

equal to the preset, the output is off.

3.1.4

WY5 – WY8

(Pr

eset W

ords) Y

W

ords WY5 through WY8 specifies preset values for each channel.

ou can specify any value between 0 and 65,535.

WY5

WY6

WY7

WY8

specifies the value for Preset 1, Channel 1.

specifies the value for Preset 2, Channel 1.

specifies the value for Preset 1, Channel 2.

specifies the value for Preset 2, Channel 2.

3.1.5

I/O Update In each scan, the controller reads the module WX words before updating

Consideration

the WY words. For example, during a scan when the controller resets the

module, the WX word(s) contain counter values existing prior to the reset.

3-4

Programming

Series

and Encoder Module User

505 High Speed Counter

’

s Manual

Page 32

Chapter 4

Troubleshooting

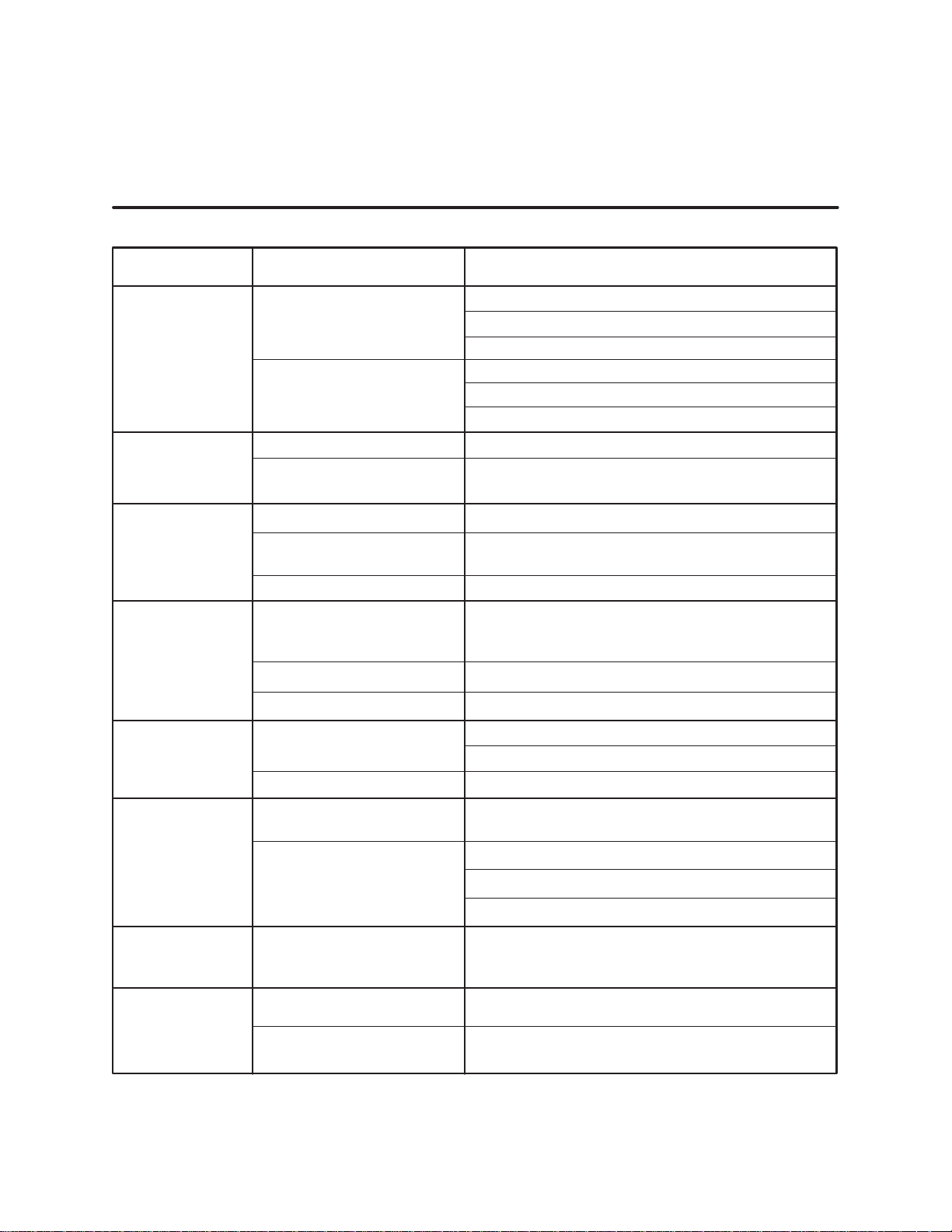

Symptom

Input LED is

not on

and

Output LED is

not on

Counts in wrong

direction

Incorrect count

Counts erratically

Does not count

Probable Cause Corrective Action

No power to board

Problems with input

signals, or output being

reset or inhibited

Connections wrong

Input wires substantially

dif

ferent lengths

Connections wrong

Input wires substantially

dif

ferent lengths

Broken wire

Wrong quadrature mode

or 2 jumpers on same chan

nel

Signal wire noise

Broken wire

Count being reset or in

hibited

-

Re-seat board

Check for bent pins on board connector

Check your base power supply

Check wiring

Check encoder or field inputs

Check Reset and Inhibit bits in Setup word (WY4)

Reverse wiring for inputs A and B

Check that wires are as short as possible, and make

wires the same length (if possible)

T

race wiring connections

Check that wires are as short as possible, and make

wires the same length (if possible)

Check continuity

Check jumper position

-

and condition of jumper (metal insert intact)

See wiring considerations ( Section 2.1.4)

Check continuity

Check Reset and Inhibit signals from field

Check Reset and Inhibit bits in Setup word (WY4)

Broken wire

Counts too fast

or too slow

Controller does

not communicate

with module

Nonfatal error

as a result of the

module

Series

505 High Speed Counter

and Encoder Module User

Pulse too narrow

frequency too high

Module not configured

in controller I/O

configuration table

Module configured

incorrectly in controller

Module has failed

self-diagnostics

’

s Manual

, or

Check continuity

Use slower gear ratio and

higher resolution count

Check quadrature mode

Check signal wire noise

Marginal input signal

Configure module

Reconfigure the module

Return module for repair

Troubleshooting

4-1

Page 33

4.1 Checking the Operation of the Module

To

check the operation of the module, follow these steps.

1.

2.

Module outputs will turn on during this procedure.

Using a programming device, force all presets to 0.

Reset both counters through the reset signals from your application.

Using the default configuration, the outputs should turn on.

3.

Using your programming device, force the presets to any number

greater than 0.

The outputs should turn off.

Before resuming normal operation, clear any words that you have

forced. Otherwise, these words remain forced during operation and could

yield unexpected results.

If you used the setup word to configure the module, then the output follows

your configuration.

4-2

Troubleshooting

T

o check the output operation look at the counter status word (WX1), the

outputs correspond to the following bits.

Channel 1, Output 1 bit 3

Channel 1, Output 2 bit 4

Channel 2, Output 1 bit 7

0 = Output of

1 = Output on

f

Channel 2, Output 2 bit 8

Series

and Encoder Module User

505 High Speed Counter

’

s Manual

Page 34

Chapter 5

Applications

5.1 Sprayer Example 5-2.

5.1.1 Description 5-2.

5.1.2 Solution 5-3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Flow Rate Example 5-5.

5.2.1 Description 5-5.

5.2.2 Solution 5-5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Tank Filling Example 5-6.

5.3.1 Description 5-6.

5.3.2 Solution 5-6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Series

505 High Speed Counter

and Encoder Module User

’

s Manual

Applications

5-1

Page 35

5.1 Sprayer Example

5.1.1 Description A

reversible DC motor drives a paint sprayer up and down a vertical

assembly

relative position of the sprayer

enable the sprayer during a pre-defined section of travel. (See Figure 5-1.)

The encoder resolution is 500 cycles per revolution. One shaft revolution

equals 1 inch of sprayer travel. When encoder signal A leads, the direction

of travel is up.

. A quadrature encoder on the drive shaft senses the direction and

. Channel 1 of the HSC will be used to

LS2 – Reverse Motor

“Stop Spray”

“Start Spray”

LS1 – (Home) Reverses Motor

Figure 5-1

Sprayer Application

5-2

Applications

Series

and Encoder Module User

505 High Speed Counter

’

s Manual

Page 36

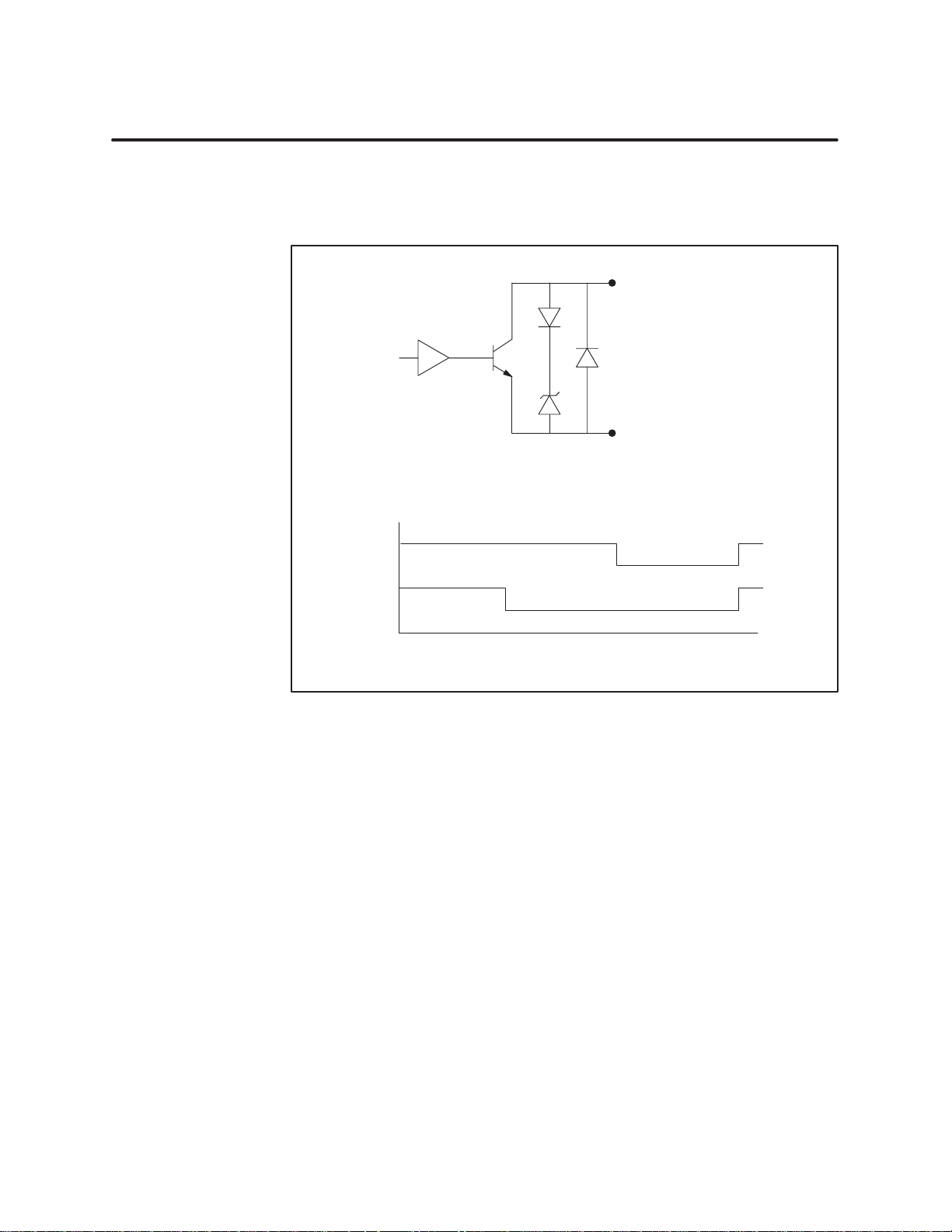

5.1.2 Solution Connect

5–2. Limit switch 1 (sprayer home) drives channel 1 Reset. Channel 1

outputs 1 and 2 are wire ORed and drive the sprayer enable. Select 1X

Quadrature mode for channel 1, setup channel 1 output 1 to turn off when

count

preset,

are loaded with the Start Sprayer and Stop Sprayer counts, respectively

The Start Sprayer count = 500 X Distance (inches) from LS1 to Start

Sprayer position. The Stop Sprayer count = 500 X Distance (inches) from

LS1 to Stop Sprayer position.

encoder signals A and B to inputs A and B of the HSC. See Figure

output 2 to turn on when count preset. Presets 1 and 2

.

HSC

Channel 1

Encoder A

Encoder B

LS1

Input A

Input B

Reset

Spray

Enable

Output 1

Output 2

Figure 5-2

HSC Connections

As the sprayer moves up and down, the channel 1 outputs and the sprayer

enable signal levels produce the waveform shown in Figure 5-3.

T

Sprayer

OUTPUT

OUTPUT

Travel

1

2

ravels Up

LS1 P1 P2 LS2 P2 P1 LS1

T

ravels Down

Series

505 High Speed Counter

and Encoder Module User

Sprayer Enable

’

s Manual

OFF

ON

Figure 5-3 Wavefor

OFF

m Patter

ON

n

Applications

OFF

5-3

Page 37

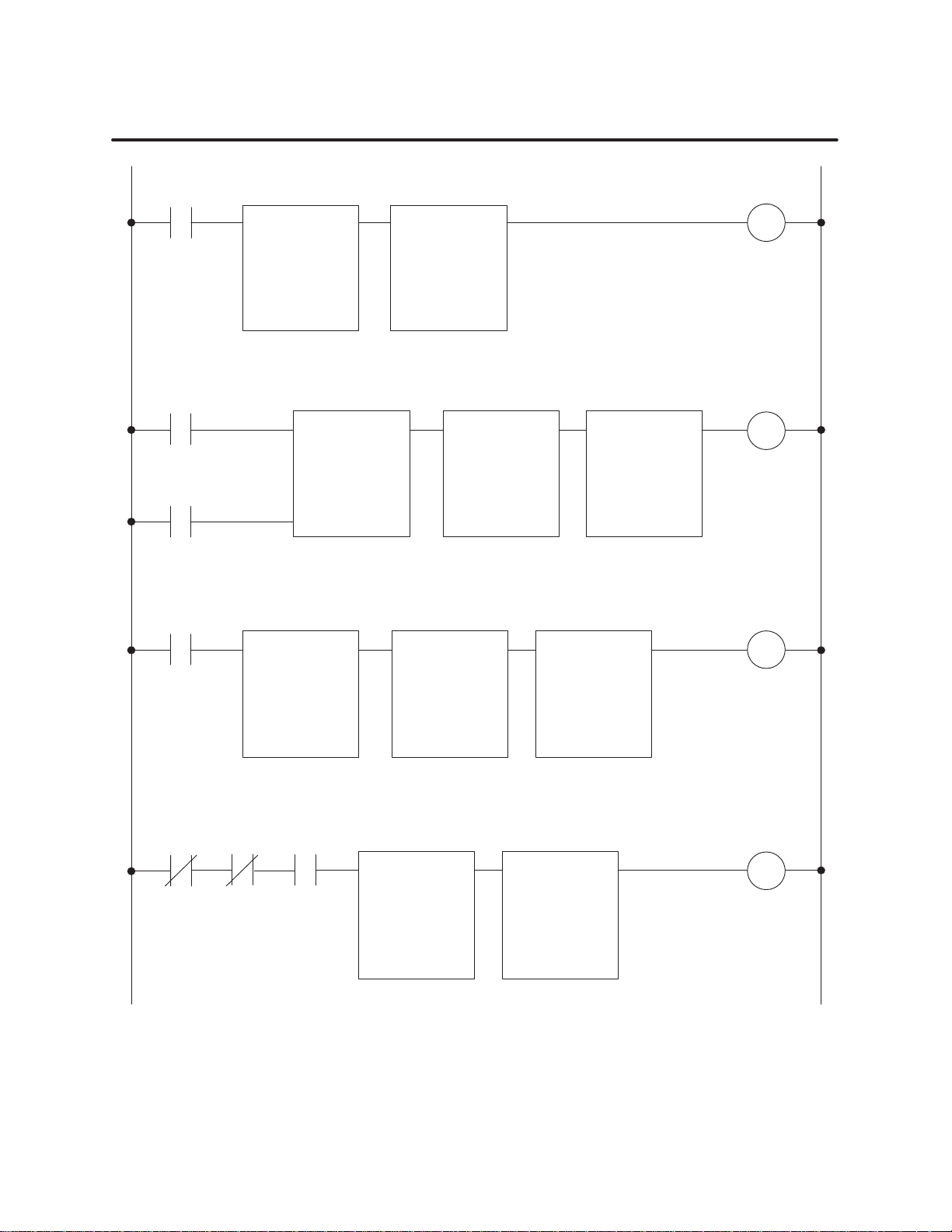

Sprayer Example (continued)

CLEAR CHANNEL

SETUP

WORD

SETUP

1

CHANNEL

OUTPUT

LOW AT PRESET

2 TO GO

1

SELECT

COUNT

INHIBIT

ON CHANNEL

1

C12C1

LDC1

A:N=WY4

0

LOADS CHANNEL

PRESETS 1 & 2

FROM V200 & V201

1

MOVW1

A:N=V200

B: WY5

2

Figure 5-4 Ladder

BITS1

A:N=WY4

A:N=WY4

4

INHIBIT

CHANNEL

BIT

IS CLEARED

COUNTING IS ENABLED

1

BITC23

A:N=WY4

2

Logic for Sprayer Example

BITS2

2

C15C14

5-4

Applications

Series

505 High Speed Counter

and Encoder Module User

’

s Manual

Page 38

5.2 Flow Rate Example

5.2.1 Description A

5.2.2 Solution

flow meter outputs 200 pulses per gallon. The program requires

calculation of flow rate in gallons per minute (GPM).

Configure the HSC as WX9–WX1

flow meter

1-second fast timer

GPM by the following calculation (using the controller memory locations).

Equation: GPM = Pulses per Sec 60 ? 200

Program Locations: (V23,V24) = (WX10) (V20) ? (V19)

1, WY12–WY16. Attach channel 1 to the

. The HSC accumulates flow meter pulses for the duration of a

. In the controller

, accumulated pulses are scaled to

Following each calculation, reset the HSC, restart the T

a new calculation 1 second later

: ONE

C23

C23

C24

C25

SECOND TIMER HAS EXPIRED, COMPUTE FLOW

RESTAR

:

SCALE COUNTER V

IN LOCA

:

TURN OFF CHANNEL 1 RESET T

T TIMER ON NEXT SCAN

TMRF2

P= 01.000

TIONS V23–V24, RESET HSC CHANNEL 1

MULT1

A: WX10

B:C:V20

V21

BITC1

A:N=WY12

.

ALUE IN GALS/MINUTE PUT RESUL

DIV1

A: V21

B:C:V19

V23

O HSC

A:N=WY12

imer

, and perform

TS

BITS1

1

C23C20

C24C23

C25C23

Series

505 High Speed Counter

and Encoder Module User

’

s Manual

1

Figure 5-5 Ladder

Logic for Flow Rate Example

Applications

5-5

Page 39

5.3 Tank Filling Example

5.3.1 Description The

HSC module measures the volume of liquid and control the filling

valve. (See Figure 5-6.) A flow meter

connected to the HSC channel 2, input A. Output 2 controls the filling

valve. In this example, the HSC operates in the pulse counter mode.

Solution

A count of 100,000 pulses is required to fill the tank to 500 gallons. As this

would overflow the HSC, the following RLL is used to count 10 sets of

10,000 pulses before closing the filling valve. In this program, output 1 is

used to indicate 10,000 pulses. Since the HSC runs asynchronous to the

PLC, the program accumulates overcounts for each loop and adjusts the

final loop to reach the exact count. The program utilizes the fact that the

HSC WX’

Several V memory locations are used in the program, their initial values

are:

s are read before the WY’

, generating 200 pulses per gallon, is

s are written in an I/O cycle.

V200 = 10,000 =

V201 = 30,000 =

V100 = 0

Input A

Output 2

HSC Channel 2

Y20

channel 2, preset 1

channel 2, preset 2 initial value

(overcounts will be accumulated here)

5-6

Applications

Figure 5-6 T

ank Filling Application

Series

and Encoder Module User

505 High Speed Counter

’

s Manual

Page 40

C140

C140 IS USED T

O INITIA

TE/TERMINA

TE FILLING

X128

C140 C256

C1

C140

C141

C1

: RESET HSC, LOAD INIT

Y20

LDC4

A: WY4

N = 0

: CLEAR RESET BIT

BITC1

A: WY4

AL PRESETS

BITS1

A: WY4

N = 5

C140

C1

MOVW1

A: V200

B: WY7

N = 2

C141

N

Y20

C1

Y20 C140

: ENABLE LIQUID FLOW

Series

505 High Speed Counter

and Encoder Module User

= 5

Figure 5-7 Ladder

’

s Manual

Logic for T

ank Filling Example

Y20

Applications

5-7

Page 41

Tank Filling Example (continued)

C61

C8

C256

C51

C51

C140

C8

: ACCUMULA

: AFTER

AND LOAD THE REMAINING COUNT INT

:

TEST FOR COMPLETION OF 100,000 COUNTS, INHIBIT FUR

COUNTS, AND CLEAR OVERCOUNT ACCUMULATOR. C256 WILL THEN

TURN OFF C140 AND DISABLE THE V

TE THE OVERCOUNTS

SUB1

A: WX3

B: V200

C: V101

90,000 PULSES, SUBTRACT THE OVERCOUNTS FROM 10,000

CTR2

P =

9

BITP2

A: WX1

ADD1

A: V101

B: V100

C: V100

BITS2

A: WY4

O PRESET 2.

SUB2

A: V200

B: V100

C:

WY8

ALVE.

THER

LDC3

A: V100

MOVW2

A: V201

B: WY7

N = 1

C61

C8

C256

C51 :

5-8

C51

C8 Y20

Applications

N = 6N = 8

WHEN HSC CH2 OUTPUT 1 TURNS ON, PULSE COUNT IS 10,000

OR GREA

Figure 5-7 Ladder

TER, RESET COUNTER AND START NEW COUNT

BITP5

A: WX1

N = 7

Logic for T

ank Filling Example (continued)

N = 0

.

BITS5

A: WY4

N = 5

and Encoder Module User

Series

505 High Speed Counter

C51

’

s Manual

Page 42

Appendix A

Terminal

Block W

orksheet

Series

505 High Speed Counter

and Encoder Module User

’

s Manual

T

erminal Block W

orksheet

A-1

Page 43

Appendix B

Specifications

B.1 Environmental Specifications B-2.

B.2 Electrical Specifications B-3.

B.3 Additional Compliances B-6.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Series

505 High Speed Counter

and Encoder Module User

’

s Manual

Specifications

B-1

Page 44

B.1 Environmental Specifications

T

able B-1

Environmental

Specifications

Operating T

Storage T

emperature 0_

to 60_C (32_ to 140

emperature –40_

_F)

to 70_C (–40_ to 158

Relative Humidity 5% to 95% noncondensing

Pollution Degree

2, IEC 664, 664A

Vibration

Sinusoidal

IEC 68–2–6, T

est Fc;

0.15 mm, peak-to-peak, 10-57 Hz;

1.0 g 57-150 Hz

Random NAVMA

T

T P–9492 or IEC 68–2–34,

est Fdc with

0.04 g@/Hz, 80–350 Hz,

and 3 dB/octave rolloff, 80–20 Hz

and 350–2000 Hz at 10 min/axis

Impact Shock

Electrostatic Discharge

Electrical Noise Immunity IEC 801, Part 4, Level 3

Conducted

2

2

IEC 68–2–27, T

Half Sine, 15 g, 1

est Ea;

1 ms

IEC 801, Part 2, Level 4 (15 kV)

MIL STD 461B, Part 4;

CS01, CS02, CS06

IEC 255–4, Appendix E

1

1

EEC 4517/79 Com(78) 766 Final, Part 4

IEEE 472, 2.5 kV

_F)

1

B-2

Specifications

Radiated

IEC 801, Part 3, Level 3

MIL STD 461B, Part 4; RS01, RS02

Corrosion Protection

All parts are of corrosion resistant material

or are plated or painted as corrosion

protection.

Agency Approvals

1

The

unfilltered reset input may be susceptible to these types of EMI.

2

The module responds to noise signals at its count or inhibit inputs that are within its passband.

ULr

Listed, CSA Certified

Series

and Encoder Module User

505 High Speed Counter

’

s Manual

Page 45

B.2 Electrical Specifications

Count Inputs

Frequency (maximum)

Duty Count Mode

Cycle Freq. Freq. (w/ 15 max. phase error)

T

able B-2

Electrical

Specifications

Quadrature Mode

10%

20%

25%

30%

40%

50%

60%

On voltage:

Current on:

Of

f voltage:

10 Khz

25 Khz

30 Khz 10 Khz

35 Khz 12 Khz

50 Khz 15 Khz

45 Khz 15 Khz

35 Khz 15 Khz

4 to 28 VDC, Class 2 supply

8 to 16 mA

–1.5 to 1.5 VDC

Current off:0 to 1 mA

V

olt–Ampere Curve for Count Inputs

30

25

20

Vin

(Volts)

15

4 Khz

8 Khz

Min Max

Series

505 High Speed Counter

and Encoder Module User

’

s Manual

10

Off

5

Region

2

4 6810 12 14 16

Iin (mA)

T

ransition Region

On Region

Specifications

B-3

Page 46

Electrical Specifications (continued)

Count inputs are constant current type inputs.

Reset

and Inhibit Inputs:

Vin

(Volts)

30

25

20

15

On voltage:

Current on:

Of

f voltage:

to 28 VDC, Class 2 supply

2 to 40 mA

–1.5 to 1.5 VDC

Current off:0 to 0.75 mA

Reset delay time:

unfiltered

filtered

Inhibit delay time:

200 s on

200 s of

Volt–Ampere

Curve for Reset and Inhibit Inputs

Min Max

950 s on

950 s of

3.75 ms on

5.00 ms of

f

f

f

B-4

Specifications

10

5

10 20 30 40

Iin

(mA)

Off

Region

T

ransition Region

On Region

Series

and Encoder Module User

505 High Speed Counter

’

s Manual

Page 47

Outputs

User

voltage:

Voltage drop:

Leakage current:

Peak current:

.

. . . . . . . . . . . . . . .

Output current:

.

. . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . .

.

. . . . . . . . . . . .

1.8 VDC max. @ 400 mA

1.0

VDC max. @ 25 mA

500 A max.

500 mA for 1 ms

28 VDC max.

I(mA)

400

300

200

100

Isolation:

User-side

Channel

Channel

Inputs

1

Point per channel

275

mA

2 Points per channel

175 mA

20 40 60 80 100

T (C)

to P/C-side

1 to 2 (inputs)

1 to 2 (outputs)

to outputs 1500 V rms

.

. . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . .

1500 V rms

1500 V rms

0 V rms

Series

505 High Speed Counter

and Encoder Module User

Power

Required from Base:

Response Time

(Input

pulse to output action)

’

s Manual

.

. . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 W

1.1 ms

Specifications

B-5

Page 48

B.3 Additional Compliances

In

addition, the system complies with applicable requirements of V

Deutscher Elektrotechniker (VDE) 0160: Electrical Equipment

Series 505 products have been developed with consideration of the draft

standard for programmable controllers as described in the proposed

standard of the International Electrotechnical Commission Committee

(IEC–65A/WG6, Part 2).

Information concerning product reliability and compliance to the IEC or

other standards can be provided upon request. Contact your Siemens

Industrial Automation, Inc. distributor for additional information.

erband

B-6

Specifications

Series

and Encoder Module User

505 High Speed Counter

’

s Manual

Page 49

Customer

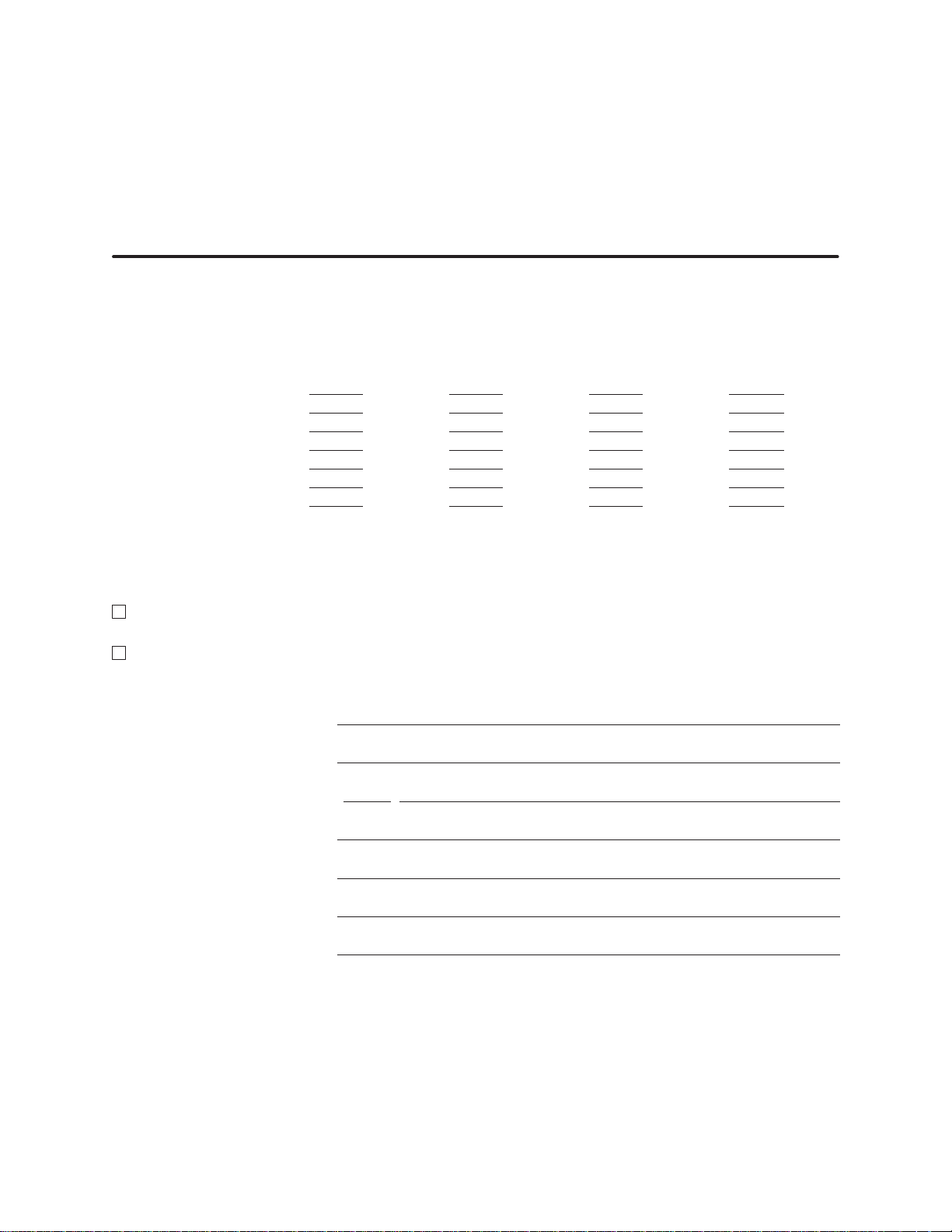

We would like to know what you think about our user manuals so that we can serve you better.

How would you rate the quality of our manuals?

Accuracy

Organization

Clarity

Completeness

Overall

Size

Index

design

Registration

Excellent Good Fair Poor

Would you be interested in giving us more detailed comments about our manuals?

Yes! Please send me a questionnaire.

No. Thanks anyway.

Your Name:

Title:

Telephone Number: ( )

Company Name:

Company Address:

Manual

Manual Assembly Number:

Order Number:

Name:

High Speed Counter and Encoder Module User Manual

PPX:505–8113–2

Edition: Second

2586546-0019 Date: 12/92

Page 50

FOLD

BUSINESS REPL

FIRST CLASS

POST

AGE WILL BE P

Y MAIL

PERMIT NO.3

AID BY ADDRESSEE

JOHNSON CITY

, TN

SIEMENS INDUSTRIAL AUTOMATION, INC.

3000 BILL GARLAND RD.

P.O. BOX 1255

JOHNSON CITY TN 37605–1255

ATTN: Technical Communications M/S 3519

FOLD

NO POST

NECESSARY

IF MAILED

IN THE

UNITED ST

AGE

ATES

Page 51

Index

A

Assistance, 2-2

C

Configuration

selecting, 2-10

updating, 2-10

Configuring

jumpers, 2-5

User Options, 2-10

Count input, 1-4

Count rate, 1-2

Counter mode, 1-7

D

I

I/O

address, 2-10

configuration chart, 2-1

definition chart, 2-10

I/O base, 2-7

Inhibit, 1-2, 1-4

Input, 1-4

count, 1-4

inhibit, 1-4

reset, 1-4

Specifications, B-3

J

Jumper, 2-5

Jumper pins, 2-5

L

1

Double-count quadrature, 1-9

E

Electrical specifications, B-3

Environmental specifications, B-2

F

Features, 1-2

H

Handling the HSC, 2-2

LED, 1-2

A input, 1-6

B input, 1-6

LED indicator

Logging module into controller

, 1-6

O

Output, 1-5

open collector

specifications, B-5

, 1-5

P

Powering up the module, 2-8

Pulse counter mode, 1-7

Pulse width, 1-2, B-4

, 2-10

Index-1

Page 52

Q

T

Quadrature Mode, quadruple count, 1-10

Quadrature mode

double-count, 1-9

single-count, 1-8

Quadruple count, quadrature mode, 1-10

R

References, 2-2

Reset, 1-2, 1-4

S

Single-count quadrature, 1-8

Static electricity

, 2-2

T

erminal block, 2-8

wiring diagram, 2-9

worksheet, 2-8

U

Using status words, 3-2

W

W

iring, 2-3, 2-8

considerations, 2-3

Index-2

Page 53

SIMATIC

Series 505 and TISOFT are trademarks of Siemens Industrial Automation, Inc.

T

TI505, TI525, TI535, and TI545 are trademarks of T

UL is a registered trademark of Underwriters Laboratories.

is a registered trademark of Siemens AG.

exas Instruments and TI are registered trademarks of T

exas Instruments Incorporated.

exas Instruments Incorporated.

Loading...

Loading...