Siemens Fuji-Reader Installation manual

FUJI-Reader

Service Manual

SP

Installation

© Siemens AG 2003

The reproduction, transmission or

use of this document or its contents

is not permitted without express

written authority. Offenders will be

liable for damages. All rights,

including rights created by patent

grant or registration of a utility

model _or_ design,_are_ reserved.

English

Print No.: SPB7-420.840.50.01.02 Doc. Gen. Date: 01.03

Replaces: n.a.

CR-IR347/CR-IR347P

Service Manual

Installation (IN)

Contents Installation

CR-IR347 Service Manual – Contents

Installation (IN)

1. Work Flow ..................................................................................................................... IN-2

2. Preparation for Installation ......................................................................................... IN-4

2.1 Precautions for Installation............................................................................... IN-5

2.2 Unpacking and Unloading................................................................................. IN-6

2.3 Transfer............................................................................................................... IN-7

2.4 Temporary Placement ....................................................................................... IN-7

2.5 Checking the Items Supplied ............................................................................ IN-8

3. Removing the Covers .................................................................................................. IN-12

4. Unclamping................................................................................................................... IN-16

4.1 Front Shelf Cover (Front) .................................................................................. IN-16

0.1

4.2 Pulling Out the Tray ........................................................................................... IN-17

4.3 Cassette Set Unit/IP Removal Unit (Front/Right-Hand Side/Left-Hand Side) IN-19

4.4 Pushing In the Tray............................................................................................ IN-20

4.5 Subscanning Unit (Left-Hand Side).................................................................. IN-20

4.6 Subscanning Unit (Rear) ................................................................................... IN-21

4.7 Subscanning Unit (Right-Hand Side) ............................................................... IN-22

4.8 Pulling Out the Scanner Unit ............................................................................ IN-24

4.9 Subscanning Unit (Front) .................................................................................. IN-28

4.10 Subscanning Unit (Inside)................................................................................. IN-29

4.11 Side-Positioning Conveyor (Rear).................................................................... IN-30

5. Installing the Separate Packaged Items ..................................................................... IN-31

5.1 Light-Collecting Guide Assembly (for the Front)............................................ IN-32

5.2 Light-Collecting Guide Assembly (for the Back) ............................................ IN-35

5.3 Pushing In the Scanner Unit ............................................................................. IN-41

5.4 Erasure Lamp Assembly ................................................................................... IN-42

5.5 Memory Boards (Only for Machine with Shipment Control Number of

5079 or Earlier) ................................................................................................... IN-44

6. Removing the Board Retaining Plate ......................................................................... IN-46

7. Setting the Boards ....................................................................................................... IN-47

8. Installing the Boards.................................................................................................... IN-50

9. Installing the Board Retaining Plate........................................................................... IN-52

10. Connecting the Interface Cables ................................................................................ IN-53

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

0.1

Contents Installation

11. Turning OFF the High-Voltage Switch ........................................................................ IN-54

12. Connecting the Power Cable....................................................................................... IN-55

13. Checking the Resistance Values ................................................................................ IN-56

14. Powering ON ................................................................................................................. IN-58

15. Checking the Fan Operation ....................................................................................... IN-61

16. Measuring and Adjusting the Voltage ........................................................................ IN-62

17. Clearing the Backup Memory...................................................................................... IN-63

18. Setting the Date and Time ........................................................................................... IN-64

19. Turning ON the High-Voltage Switch .......................................................................... IN-65

0.2

20. Installing the Covers .................................................................................................... IN-66

21. Setting the Configuration ............................................................................................ IN-70

22. Checking for Image Problems..................................................................................... IN-76

23. Checking and Deleting the Error Log during Setup ................................................. IN-80

23.1 Checking the Error Log ..................................................................................... IN-80

23.2 Deleting the Error Log ....................................................................................... IN-81

24. Powering OFF ............................................................................................................... IN-82

25. Cleaning the Covers .................................................................................................... IN-82

26. Attaching the Labels .................................................................................................... IN-83

27. Final Placement ............................................................................................................ IN-84

27.1 Securing the Machine with the Adjustable Feet ............................................. IN-85

27.2 Securing the Machine with the Clamps ........................................................... IN-86

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

0.2

Contents Installation

0.3

Appendix 1. Connecting the Peripheral Devices (for Network Connection) ..................... IN_A1-1

Appendix 1.1 Checking the Connectable Peripheral Devices ................................ IN_A1-1

Appendix 1.2 Basic Pattern of System Configuration ............................................ IN_A1-4

Appendix 1.2.1 Pattern Where IDT-IV Is Connected to CPU90E .................. IN_A1-5

Appendix 1.2.2 Pattern Where IDT-IV Is Connected to CPU90F .................. IN_A1-6

Appendix 1.3 IDT Type and CSL Type..................................................................... IN_A1-10

Appendix 1.4 List of Setup Items Related to Network and Setup Examples ...... IN_A1-11

Appendix 2. *** ...................................................................................................................... IN_A2-***

Appendix 2.1 ***........................................................................................................ IN_A2-***

Appendix 2.2 ***........................................................................................................ IN_A2-***

Appendix 3. Menu Editor Setup ............................................................................................ IN_A3-1

Appendix 4. Procedures for Connecting with CR Console (CR-IR348CL) ........................ IN_A4-1

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

0.3

Installation (IN) Control Sheet

Control Sheet

Issue date

10/20/2000 00 New release (FM2732) All pages

05/15/2001 01 Corrections (FM3052) IN - 50–87

08/30/2001 02 Support for “plus”; measures against IN - 9, 24, 51, 51.1-51.4, 52,

08/30/2002 03 Image checks and other information added IN - 2–10, 44, 50, 51, 51.2,

Revision number Reason Pages affected

IN - 1

IN_A1 - 2–4, 9, 10, 12, 16

noise (FM3142) 53, 57-59, 70, 71,

IN_A1 - 2–4, 9, IN_A4-All pages

(FM3476) 53, 63, 76-79, 79.1–79.4,

IN_A1 - 3, 13, 15, 18,

IN_A3 - 3

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

IN - 1

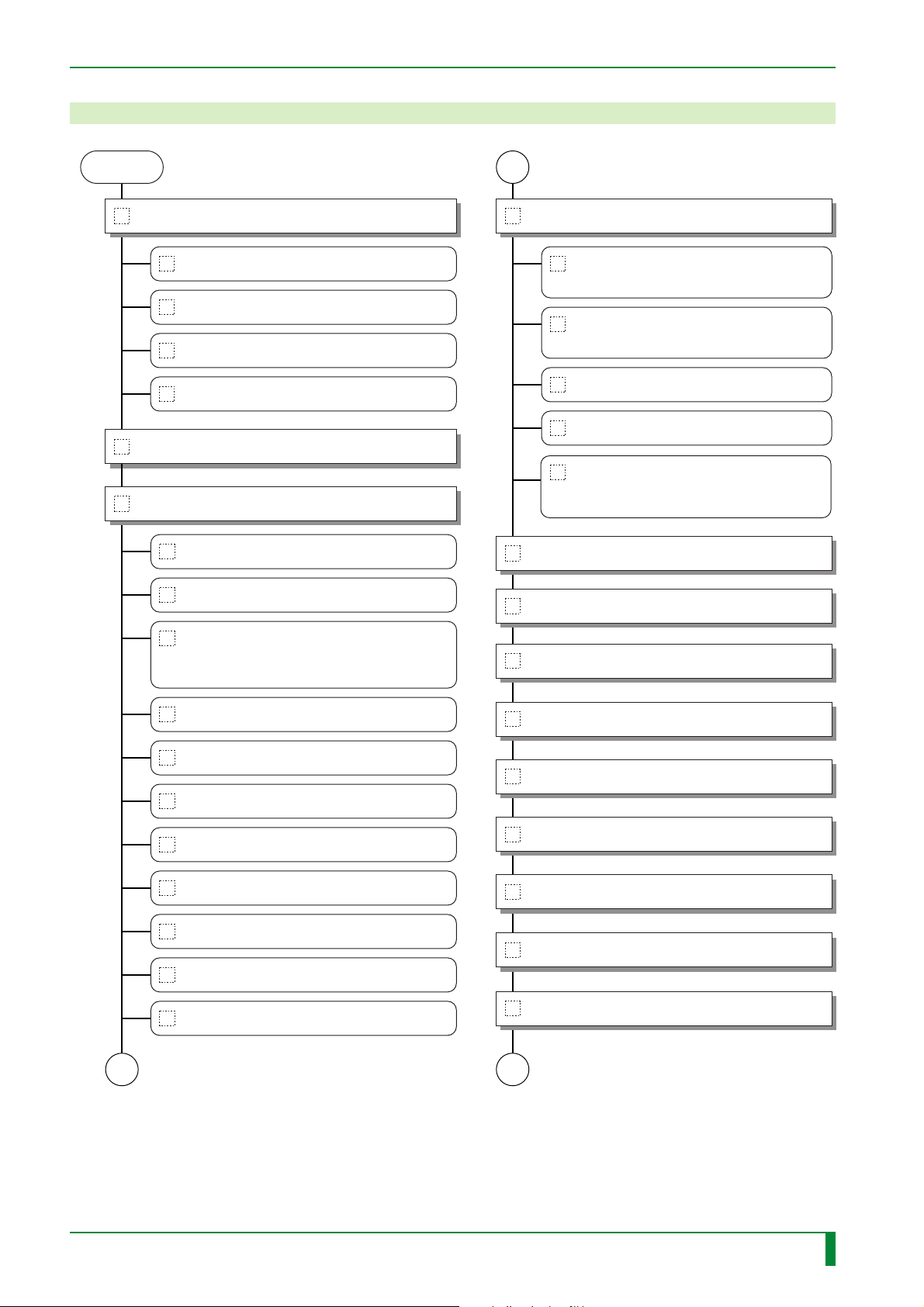

1. Work Flow

IN - 2

START

2. Preparation for Installation

2.2 Unpacking and Unloading

2.3 Transfer

2.4 Temporary Placement

2.5 Checking the Items Supplied

3. Removing the Covers

4. Unclamping

4.1 Front Shelf Cover (Front)

4.2 Pulling Out the Tray

A

5. Installing the Separate Packaged Items

5.1 Light-Collecting Guide Assembly

(for the Front)

5.2 Light-Collecting Guide Assembly

(for the Back)

5.3 Pushing In the Scanner Unit

5.4 Erasure Lamp Assembly

5.5 Memory Boards (Only for Machine

with Shipment Control Number of

5079 or Earlier)

6. Removing the Board Retaining Plate

7. Setting the Boards

4.3 Cassette Set Unit/IP Removal Unit

(Front/Right-Hand Side/Left-Hand

Side)

4.4 Pushing In the Tray

4.5 Subscanning Unit (Left-Hand Side)

4.6 Subscanning Unit (Rear)

4.7 Subscanning Unit (Right-Hand Side)

4.8 Pulling Out the Scanner Unit

4.9 Subscanning Unit (Front)

4.10 Subscanning Unit (Inside)

4.11 Side-Positioning Conveyor (Rear)

A

8. Installing the Boards

9. Installing the Board Retaining Plate

10. Connecting the Interface Cables

11. Turning OFF the High-Voltage Switch

12. Connecting the Power Cable

13. Checking the Resistance Values

14. Powering ON

B

FR7H7001.EPS

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

IN - 2

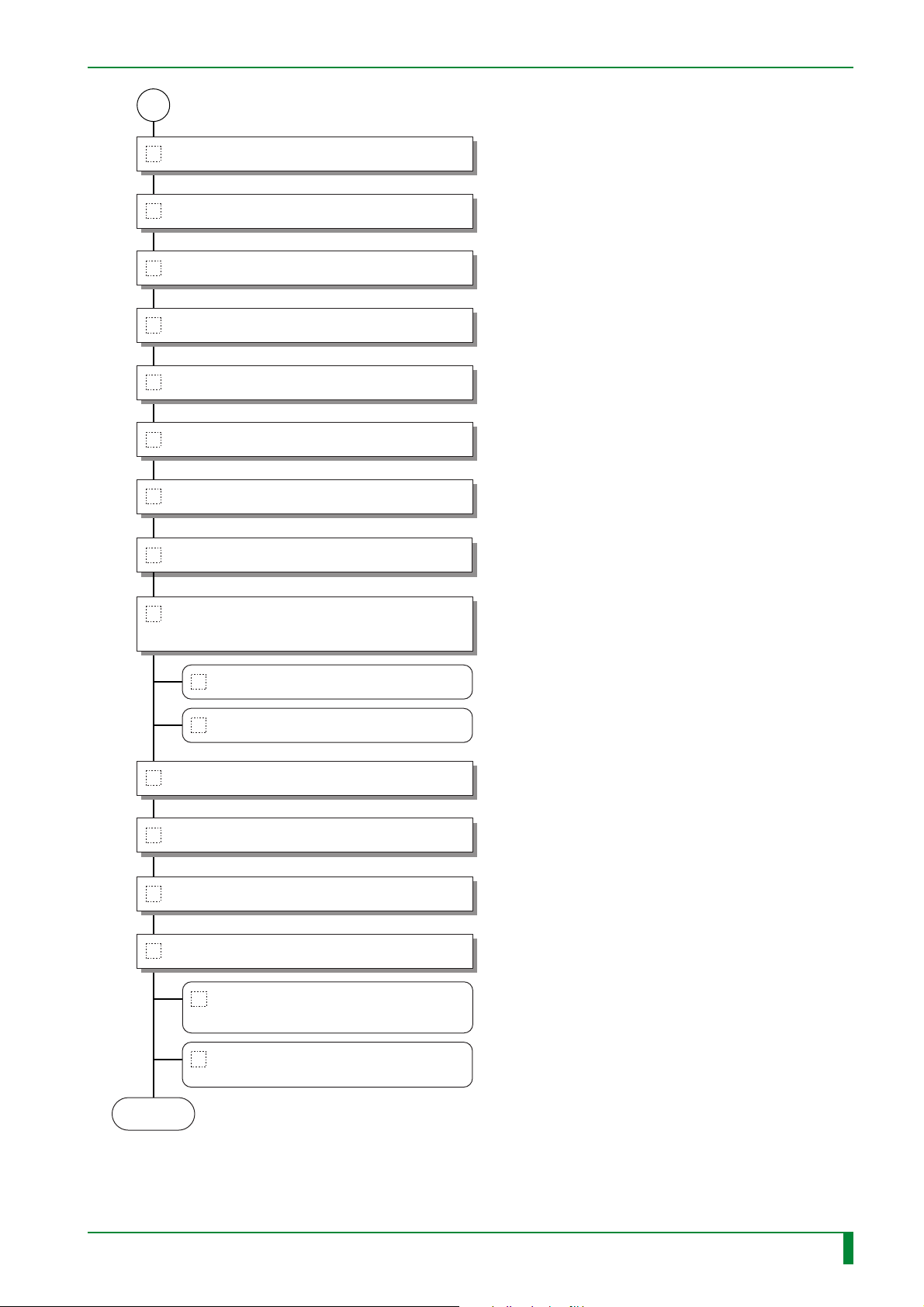

B

15. Checking the Fan Operation

16. Measuring and Adjusting the Voltage

17. Clearing the Backup Memory

18. Setting the Date and Time

19. Turning ON the High-Voltage Switch

20. Installing the Covers

21. Setting the Configuration

IN - 3

22. Checking for Image Problems

23. Checking and Deleting the Error Log

during Setup

23.1 Checking the Error Log

23.2 Deleting the Error Log

24. Powering OFF

25. Cleaning the Covers

26. Attaching the Labels

27. Final Placement

27.1 Securing the Machine with the

Adjustable Feet

END

009-058-03

08.30.2002 FM3476

27.2 Securing the Machine with the

Clamps

FR7H7002.EPS

CR-IR347

Service Manual

IN - 3

2. Preparation for Installation

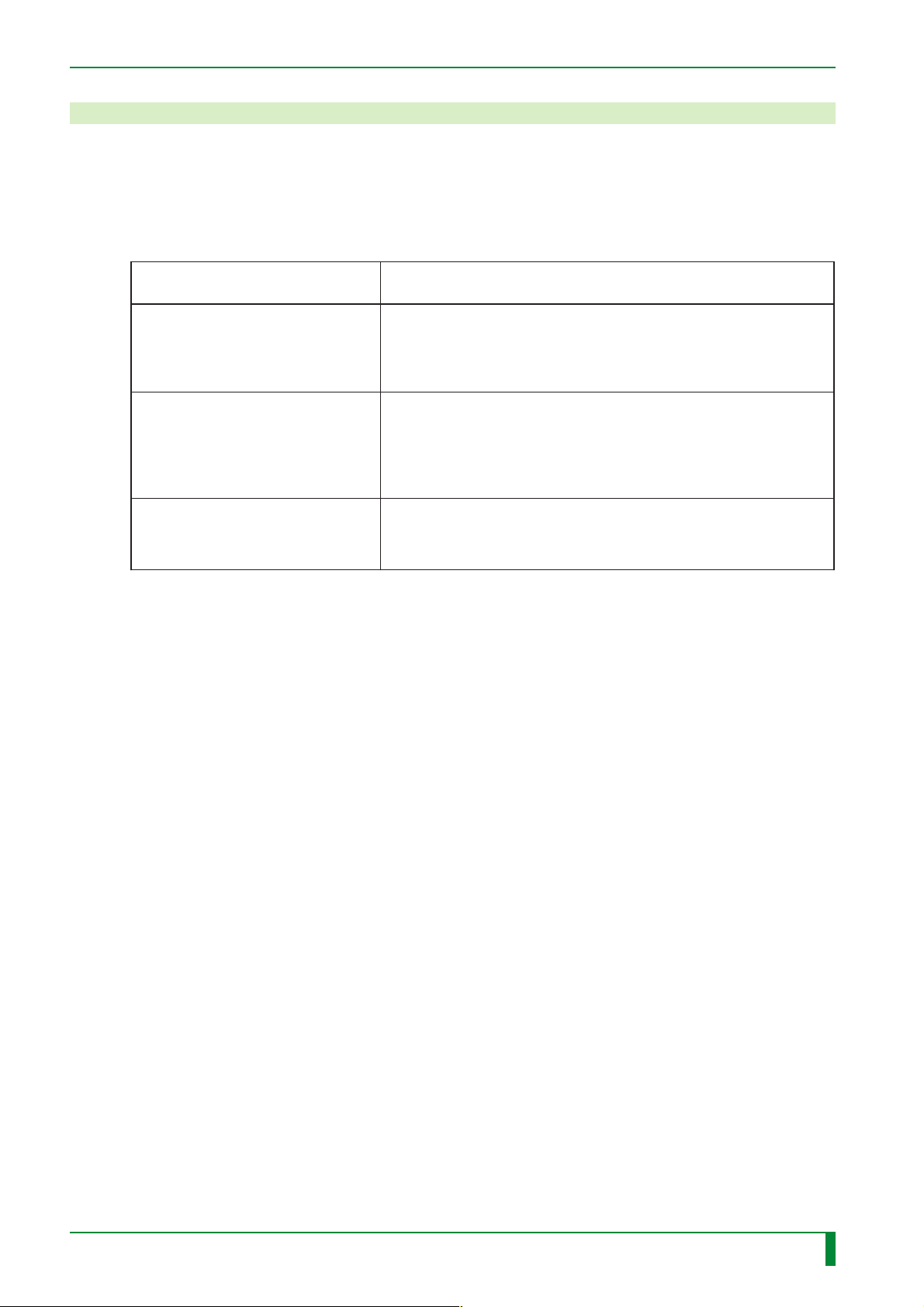

■ Notation of Board Names in Manual

Information about modifications to the boards installed in the machine is summarized here.

Unless spelled out or enumerated in the manual, board names shall be replaced as follows.

IN - 4

Change to boards installed

MTH08C → MTH08D

MMA90A → DIM08A

MMB90A → DIM08A

CPU90F → LAN90B

Summary of change

● Features of the MTH08D board

• DIP switch (S1) was added.

• The fuse was changed to a replaceable glass tube type.

• The subject to be protected by the fuse was changed.

● Features of the DIM08A board

• Memory module for the MTH08D board.

• The procedure for its removal/reinstallation was changed

to horizontal detachment.

• Shipped as installed in the machine.

● Features of the LAN90B board

• To install the LAN90B board, it is necessary that the bracket

located on the rear side of the controller be version D or later.

TR7H7022.EPS

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

IN - 4

2.1 Precautions for Installation

The place where the machine is to be installed needs to meet the criteria set forth in “Getting

Started” and “■ Installation Site Requirements.” Preinstallation procedures should also be

performed beforehand for necessary construction work, electrical utility, and air-conditioning

system installation.

■ Installation Site Requirements

Avoid the following installation sites:

• Places where the temperature changes drastically.

• Places near heat sources such as heaters.

• Places where water leakage or equipment submersion may occur.

• Places where the machine may be exposed to any corrosive gas.

• Dusty places.

• Places where the machine is subject to constant or excessive vibration or shock.

• Places that are exposed to direct sunlight.

IN - 5

■ Power Supply and Grounding Requirements

When the 200-240 VAC power supply is used, a circuit breaker rated over 250V/20A should

be provided for the single power supply of the CR-IR347. For grounding, the machine

should be connected to the protective ground line of the indoor wiring.

■ Handling Precautions for Printed Circuit Boards and Scanning Optics Unit

When servicing a printed circuit board or scanning optics unit, be sure to wear an antistatic

wristband to ground your body. If your body is not grounded, static electricity built on your

body may cause damage to the electronic parts.

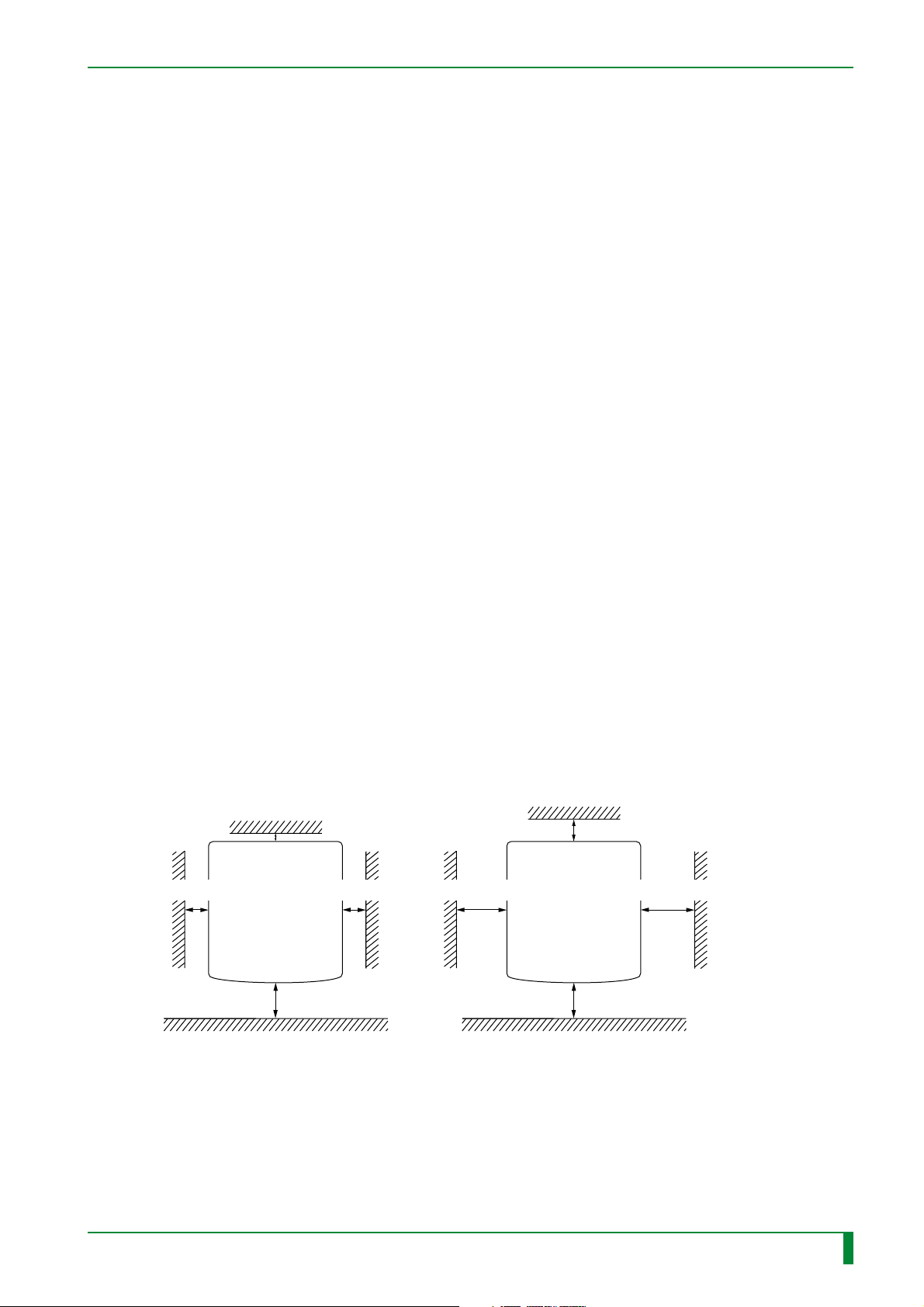

■ Check for Installation Space

When not secured by the clamps When secured by the clamps

Height: 1800 or more

Rear

Machine

50 or more

Height: 1800 or more

Rear

700 or more 700 or more200 or more 200 or more

100 or more

Machine

009-058-03

08.30.2002 FM3476

Front

700 or more

CR-IR347

Front

Service Manual

700 or more

Unit: mm

FR7H7003.EPS

IN - 5

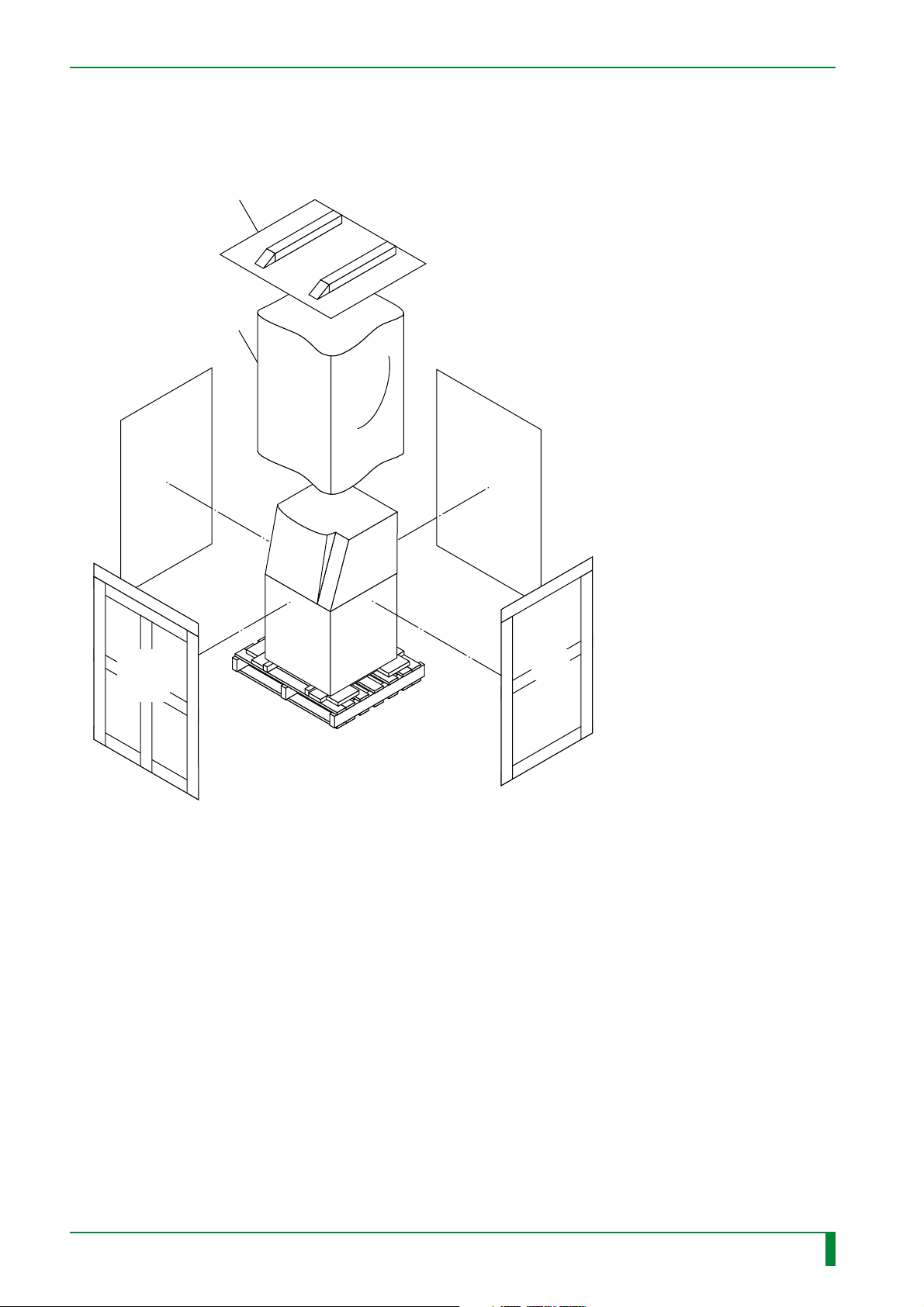

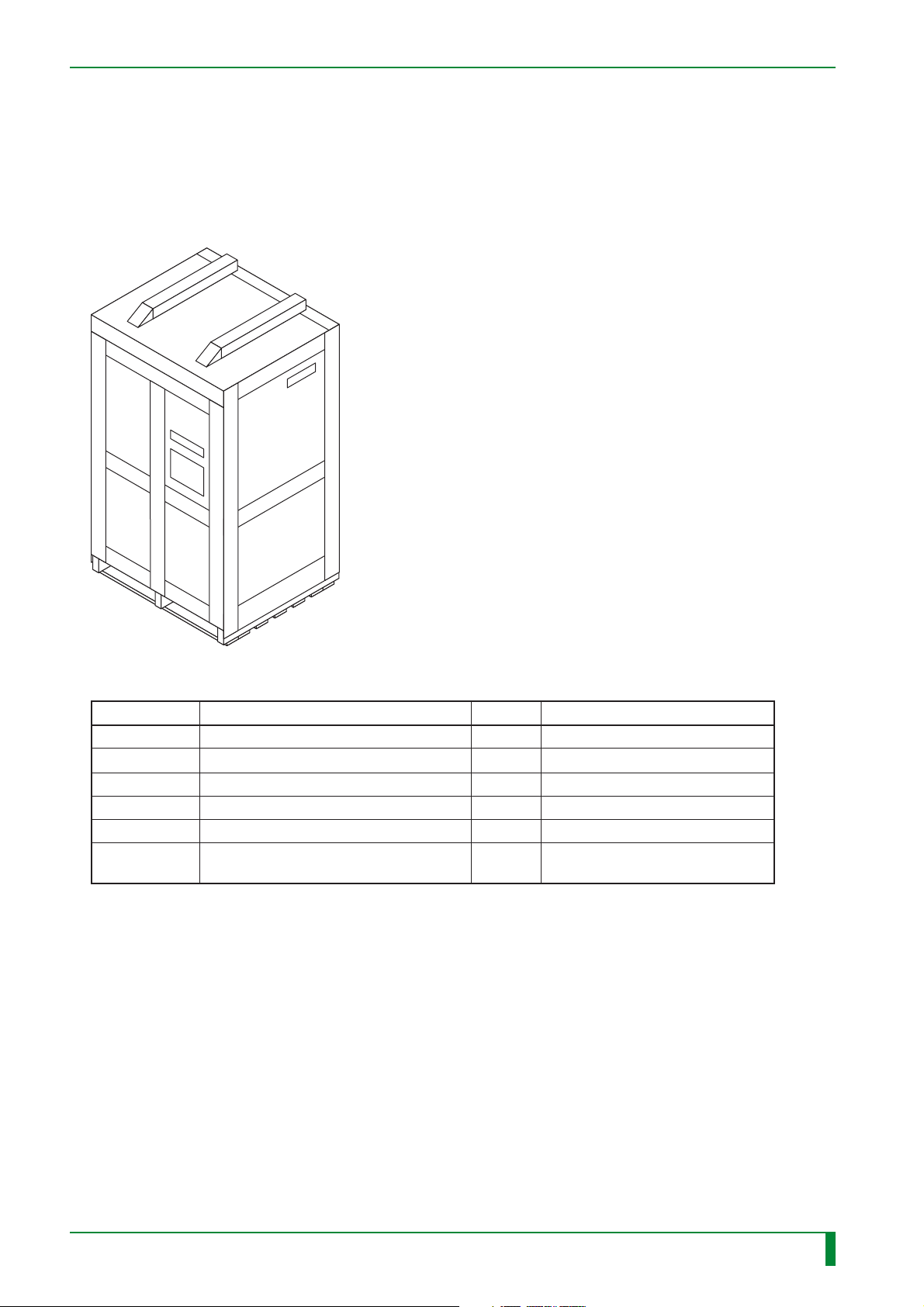

2.2 Unpacking and Unloading

■ Unpacking

Top protective cover

(Placed upside down

for use as slope)

Moisture-proof sheet

IN - 6

Wooden

crate piece

Wooden

crate

piece

Wooden

crate piece

Wooden

crate

piece

Carrier pallet

FR7H7203.EPS

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

IN - 6

2.3 Transfer

CAUTIONS

• When the machine is transferred with its casters, be sure to raise the adjustable feet of the

machine all the way up.

• When bringing the machine into the installation place, support it so that it will not topple down.

Because the machine is top-heavy, it may topple during transit.

• If the machine should be moved over some step or bump, move it as slowly as possible to

avoid shock to it. Note that the step over which the machine may move over is about 10 mm

high at most.

Bring the machine into the installation place.

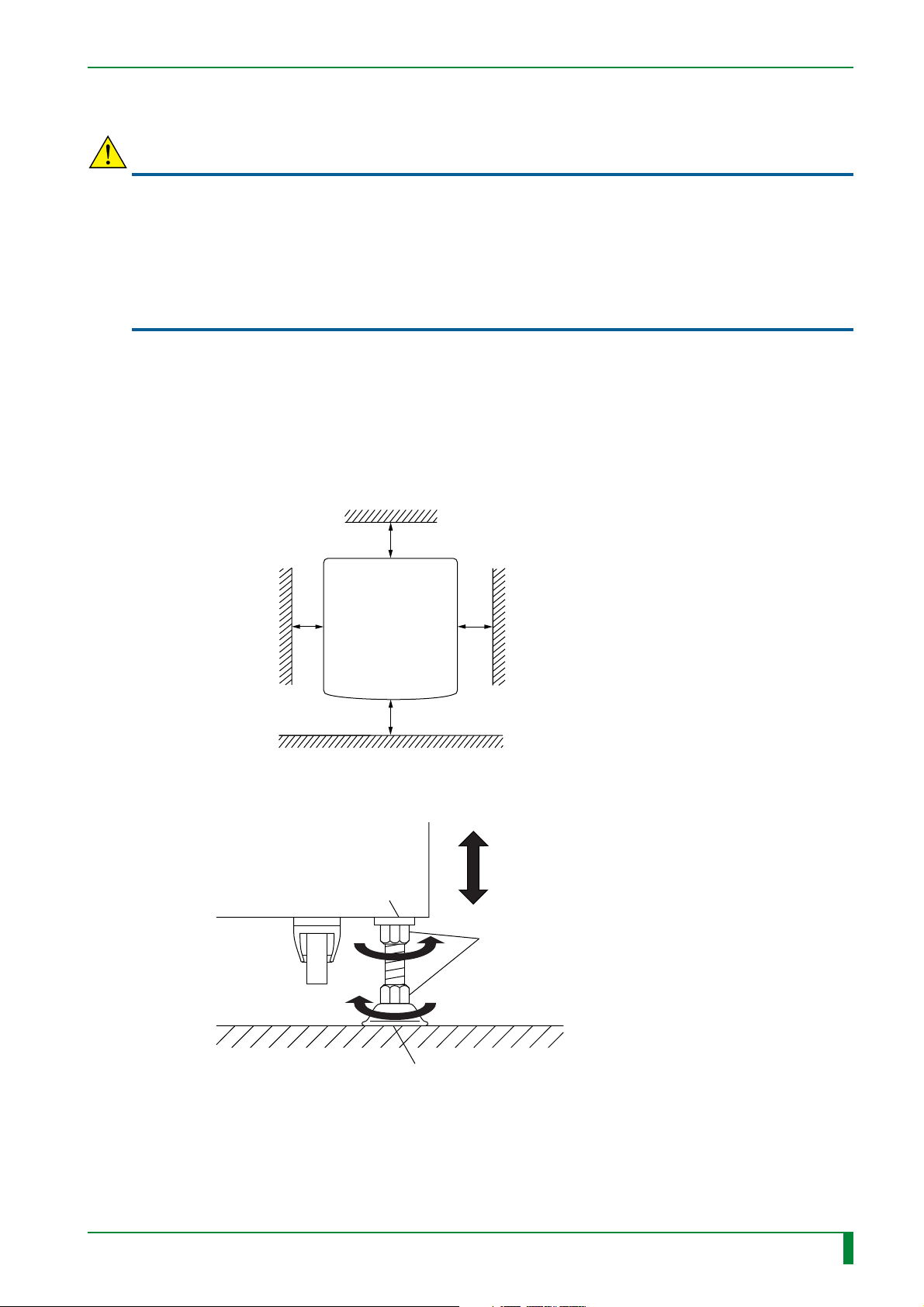

2.4 Temporary Placement

(1) Secure space required for installation procedures and temporarily place the machine.

Height: 1900 or more

IN - 7

Rear

600 or more

Front

700 or more

Machine

700 or more

700 or more

Unit : mm

FR7H7016.EPS

(2) Secure the machine with the adjustable feet in place

Machine

Seating face on the frame side

[Secure] Nut (x4)

009-058-03

08.30.2002 FM3476

Adjustable foot

CR-IR347

FR7H7017.EPS

Service Manual

IN - 7

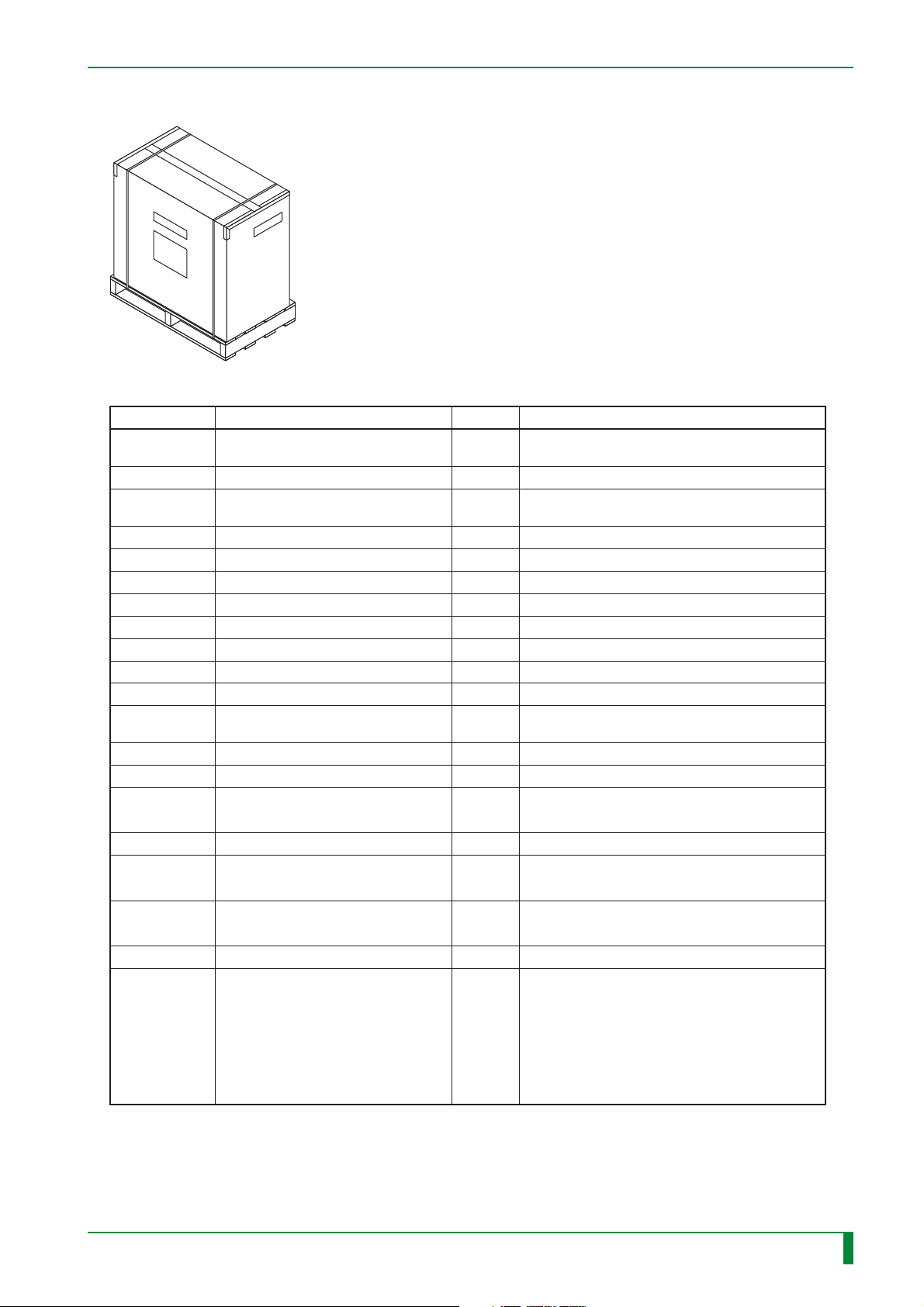

2.5 Checking the Items Supplied

Check whether all the items are supplied in accordance with the packing list that is contained

in each carton. The service technician must keep the test result sheet.

■ Machine Main Body

IN - 8

FR7H7015.EPS

Check Item Qty. Remarks

Machine main body

Clamps 4

CPU90E board (installed in the machine)

IMG07B board (installed in the machine)

BSP08A board (installed in the machine)

DIM08A board (installed in the machine)

1

1

1

1

2

Only for machine with shipment

control number of 5080 or later

TR7H7008.EPS

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

IN - 8

■ Separate Packaged Items

FR7H7111.EPS

Check Item Qty. Remarks

Instruction Manual (for the

machine main body)

Test Result Sheet

Floppy diskette (for machinespecific data)

Floppy diskette (PC MENU EDITOR)

Label

Hex head bolt (SUS 12x25)

Grip anchor (M12x50)

Spring washer (M12)

Plain washer (M12)

NK clamp (NK-18N, 13N, 10N)

T4x8 For installing the optional board

BR4x8

T4x12

T4x20

Memory boards

(MMA90A and MMB90A)

1

1

1

1 set

1 set

8

8

8

8

4 for each

6

3

4

2

1 for each

IN - 9

For installing the erasure lamp assembly.

Two for spare.

For upper front cover and lower front cover

For retaining the interface cable (rear cover)

Only for machine with shipment control number

of 5079 or earlier

009-058-03

08.30.2002 FM3476

Erasure lamp assembly

Light-collecting guide assembly

(for the front)

Light-collecting guide assembly

(for the back)

FUJI FILM Warranty Sheet

Power cable kit

• 100-200 V spec for Japan and

US

• 100 V spec for Japan (JIS

patient environment supported)

• 200-240 V spec for Europe

(excluding UK)

• 200-240V spec for UK

CR-IR347

1

1

1

1

1

(either

model)

Service Manual

TR7H7009.EPS

IN - 9

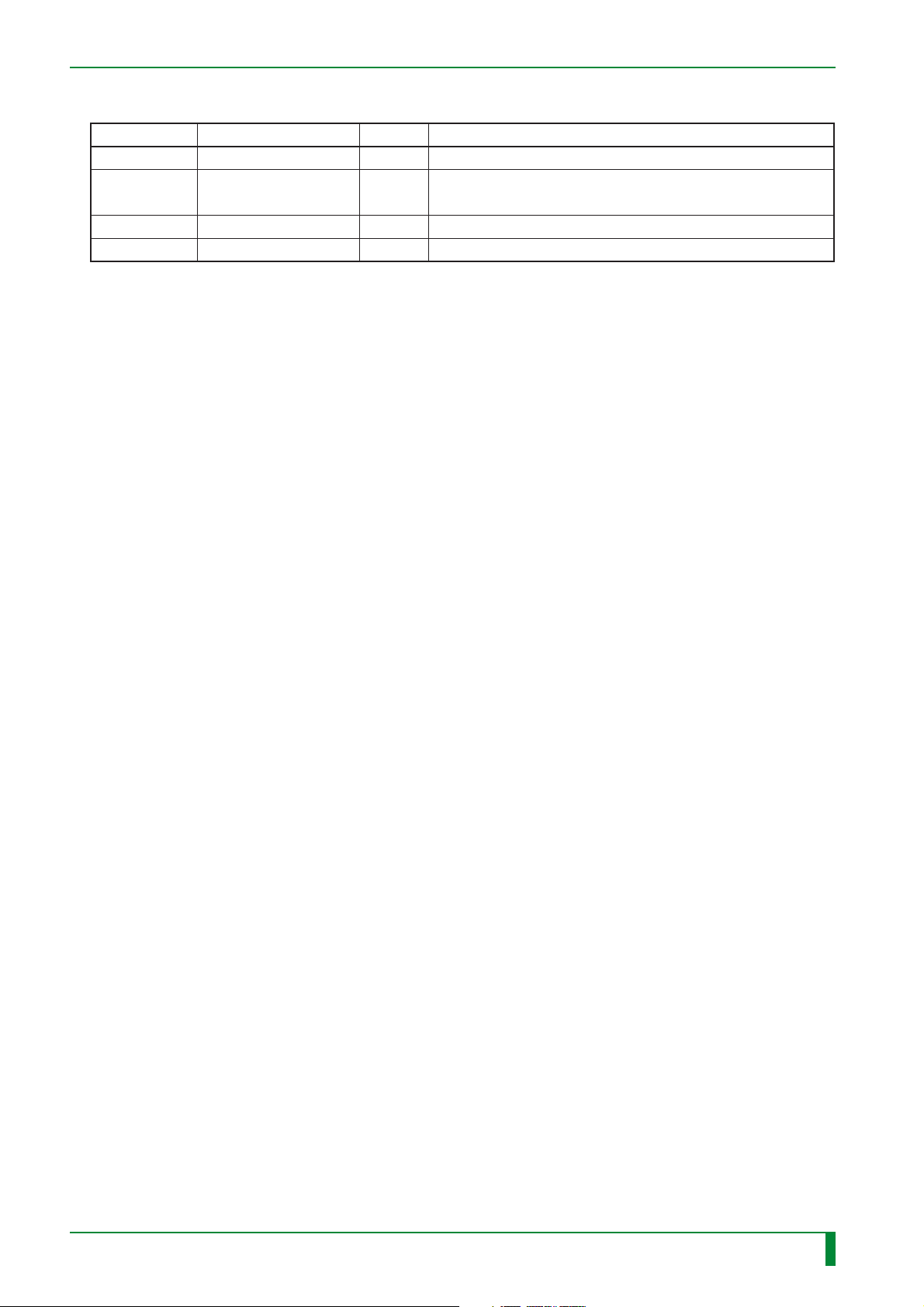

■ Optional Items

IN - 10

Check

Item

IMG08M board

IMG08H board

HCP08A board

CPU90F/LAN90B board

Qty.

1

1 or 2

1

1

Remarks

LP interface board

• High-speed multi-frequency processing (MFP) board

• High-speed mammography pattern enhancement (PEM) board

Compression/decompression processing board

Ethernet board, 100Base-TX Intelligent LAN board

TR7H7010+.EPS

009-058-03

08.30.2002 FM3476

CR-IR347

Service Manual

IN - 10

BLANK PAGE

IN - 11

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

IN - 11

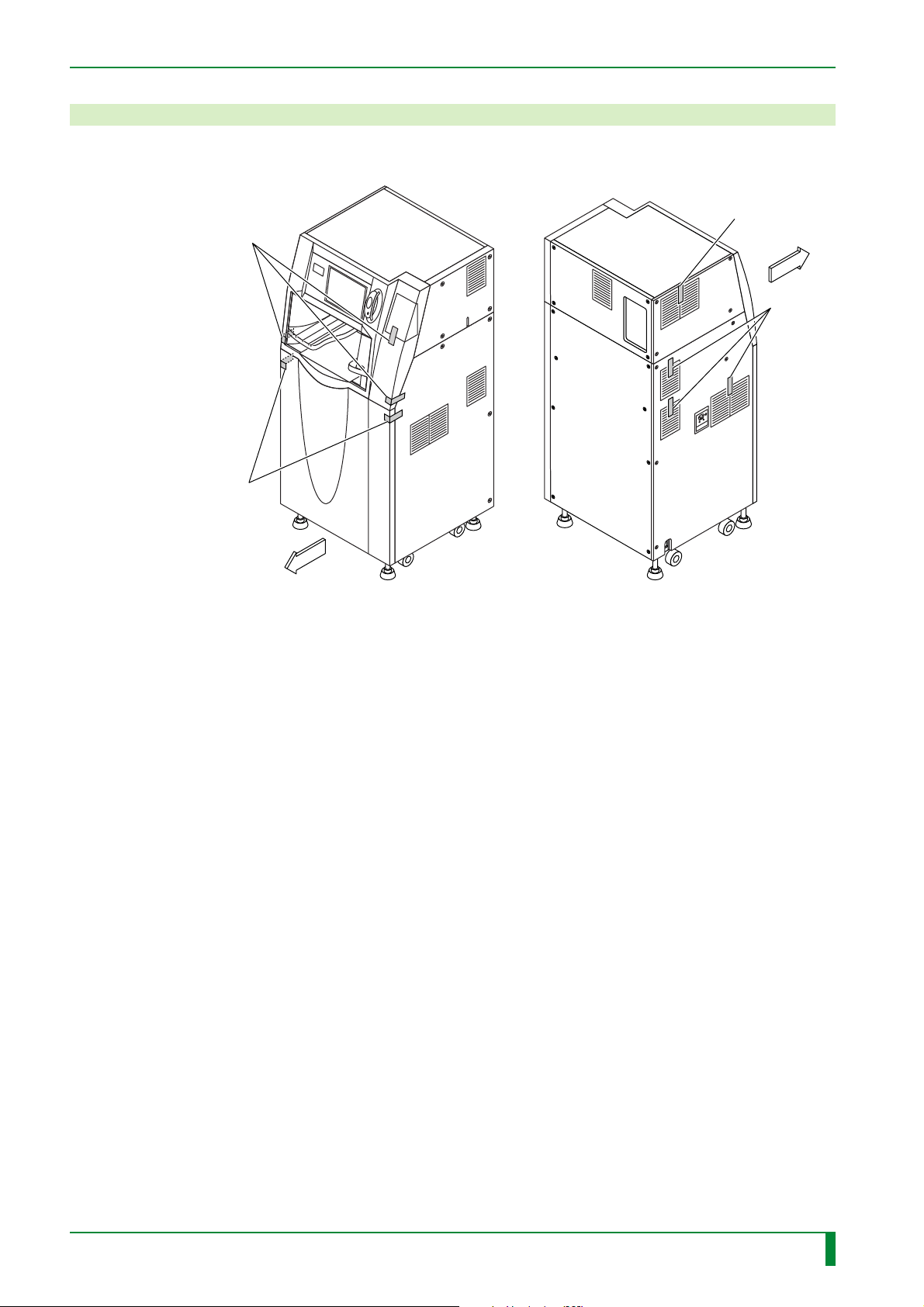

3. Removing the Covers

(1) Remove the tapes.

[Remove]

Tape (x3)

[Remove]

Tape (x2)

IN - 12

[Remove]

Tape

FRONT

[Remove]

Tape (x3)

FRONT

FR7H7104.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

IN - 12

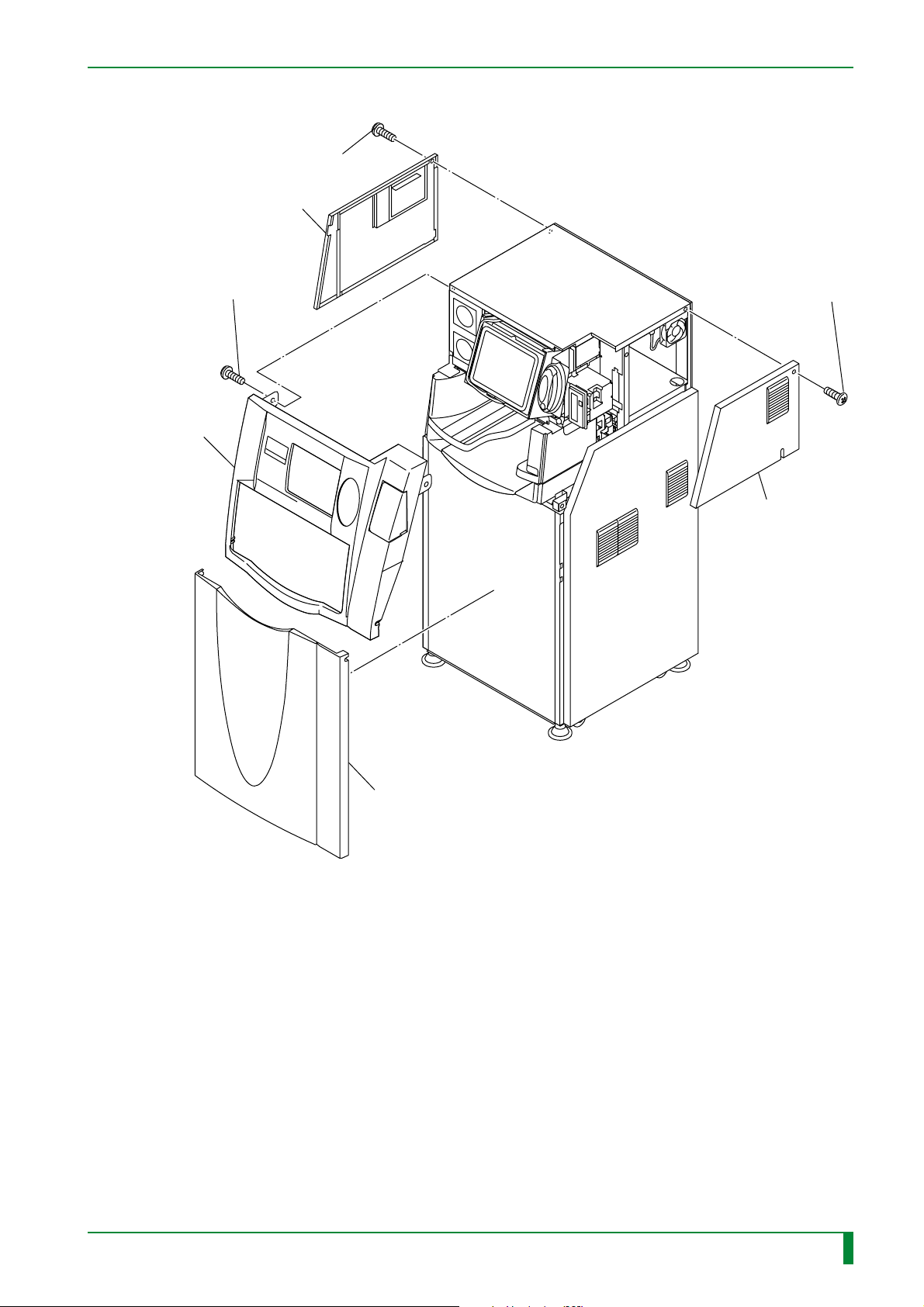

(2) Remove the covers.

[Remove] T4x12 (x4)

Upper left-hand side cover

IN - 13

#1

[Remove] BR4x8 (x2)

Upper front cover

#3

#2

[Remove]

T4x6 (x4)

Upper right-hand

side cover

Lower front cover

FR7H7112.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

IN - 13

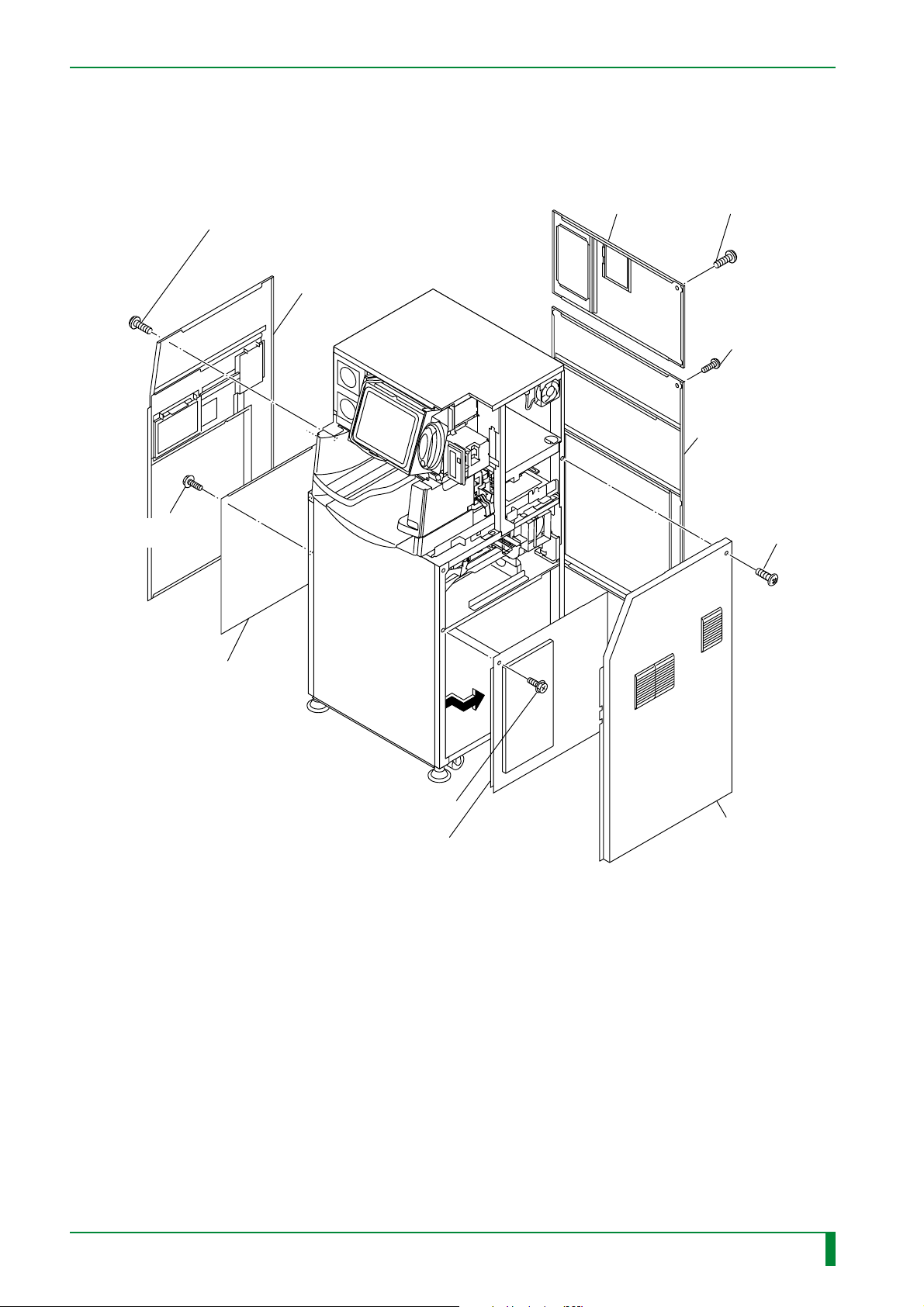

IN - 14

#9

[Remove]

BR4x8 (x6)

Left-hand side inner cover

#8

[Remove] T4x12 (x6)

T4x6 (x3)

Lower left-hand

side cover

Upper rear cover

Lower rear cover

#6 [Remove]

T4x12 (x4)

#7 [Remove]

T4x12 (x8)

#4 [Remove]

T4x6 (x7)

009-058-00

10.20.2000 FM2732 (2)

#5

[Remove] BR4x8 (x5)

Right-hand side inner cover

CR-IR347

Service Manual

Lower right-hand

side cover

FR7H7113.EPS

IN - 14

BLANK PAGE

IN - 15

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

IN - 15

4. Unclamping

REFERENCE

For unclamping, the procedures may be performed along the string attached to the clamps.

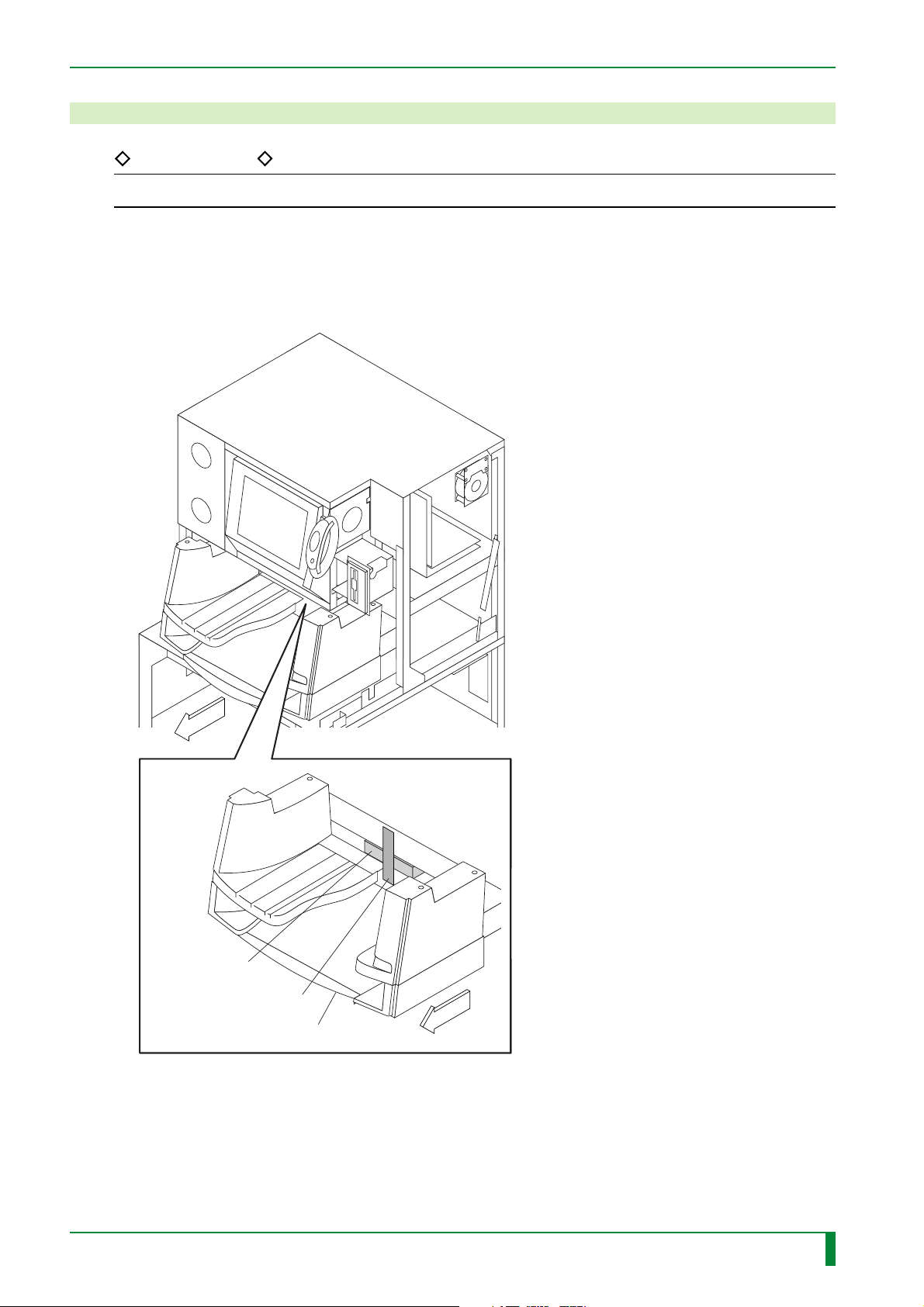

4.1 Front Shelf Cover (Front)

Unclamp the clamps.

IN - 16

FRONT

[Remove]

Foam block

[Remove] Tape

Front shelf cover

FRONT

FR7H7020.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

IN - 16

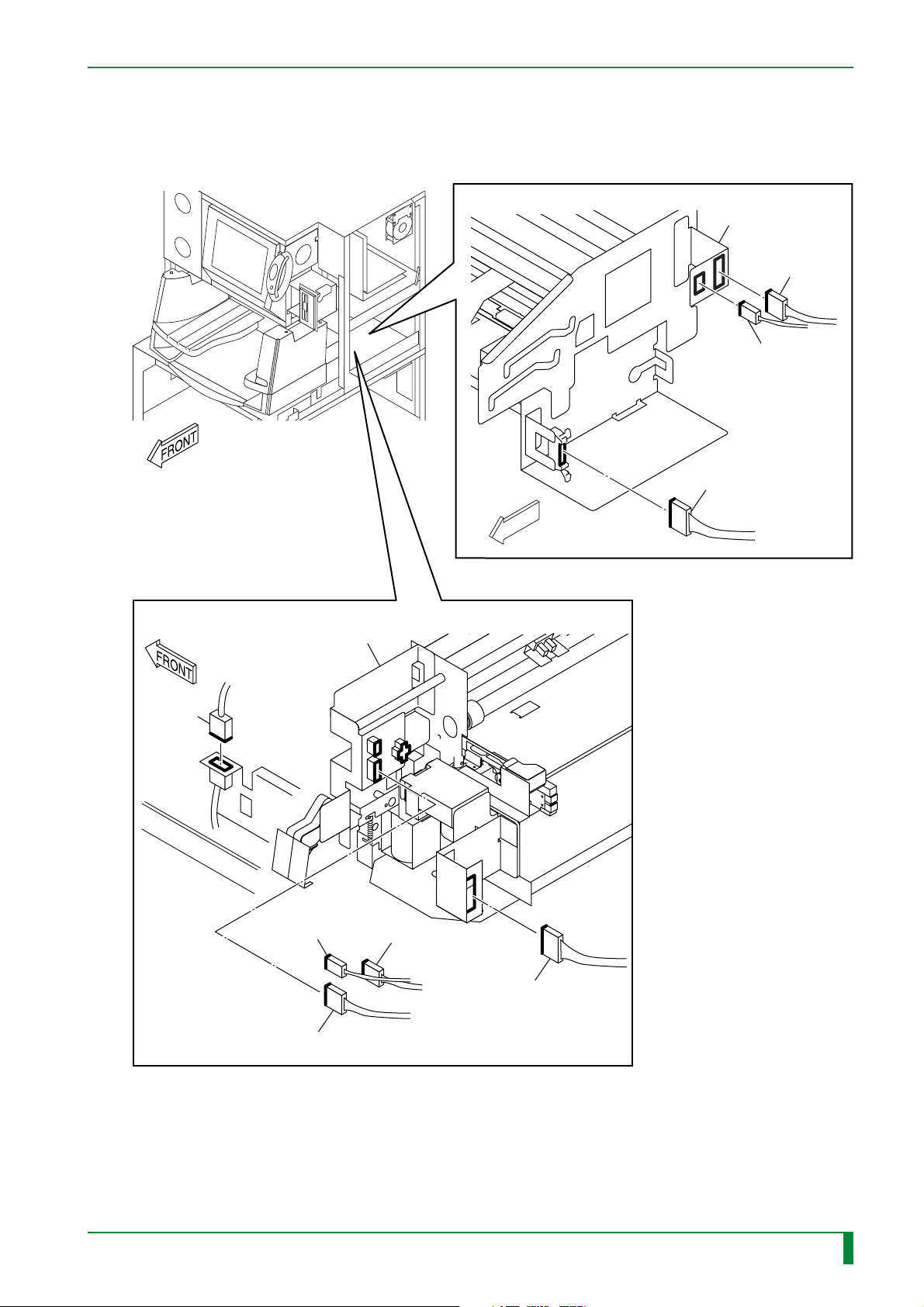

4.2 Pulling Out the Tray

(1) Disconnect the connectors.

IN - 17

[Disconnect] Connectors

IP removal unit

CNL2

CNL3

CNL1

[Disconnect] Connectors

Cassette set unit

CNU1

CNK1

FRONT

CNSOLK1

009-058-00

10.20.2000 FM2732 (2)

CNK2

CR-IR347

BCR08A CN1

Service Manual

FR7H7117.EPS

IN - 17

(2) Pull out the tray.

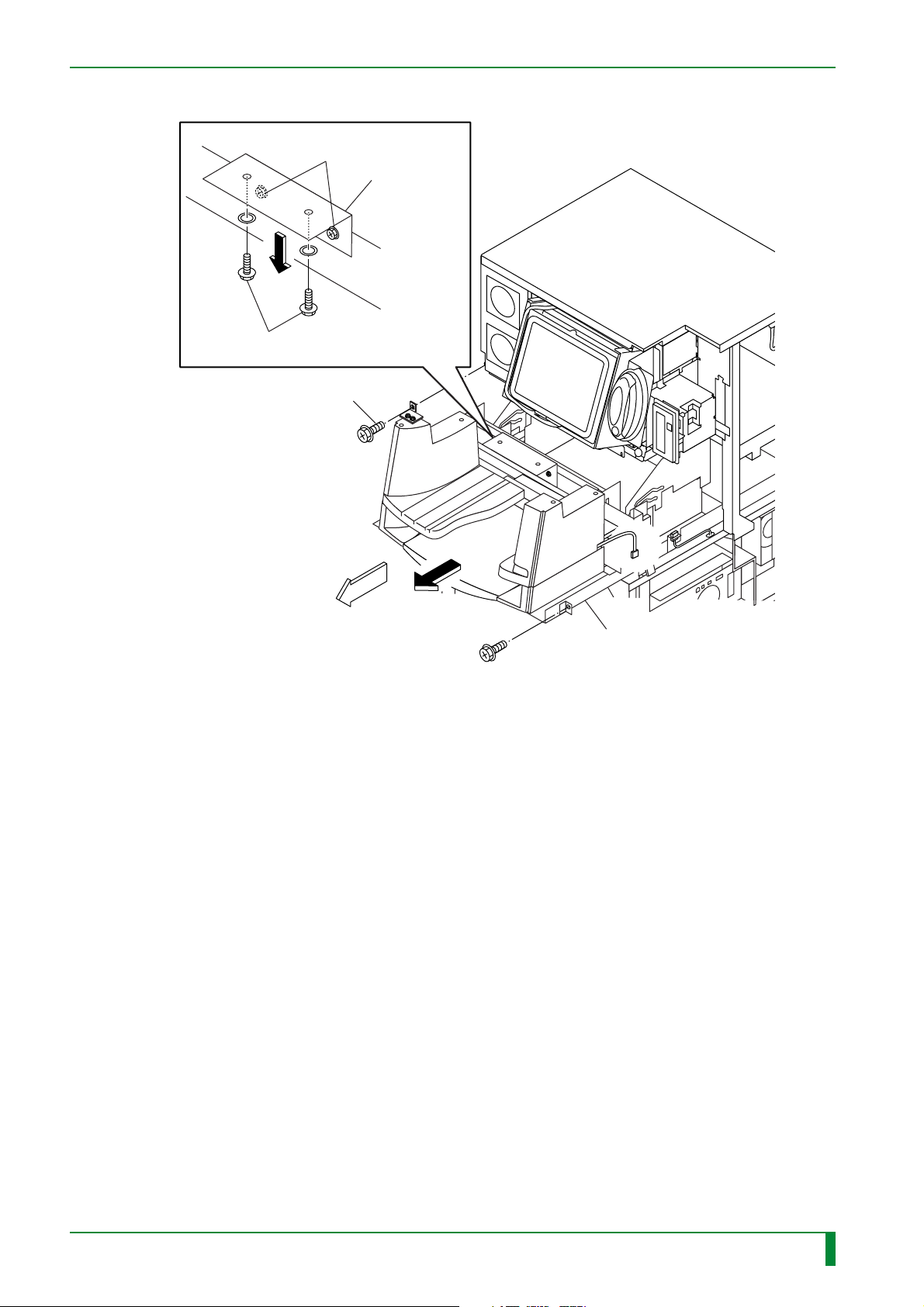

#1 [Loosen] BR4x8 (x2)

#2 [Remove] BR4x8 (x2), W6

[Remove] BR4x8 (x2)

IN - 18

Bracket

#3

FRONT

#4

[Pull-out] Tray

FR7H7019.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

IN - 18

IN - 19

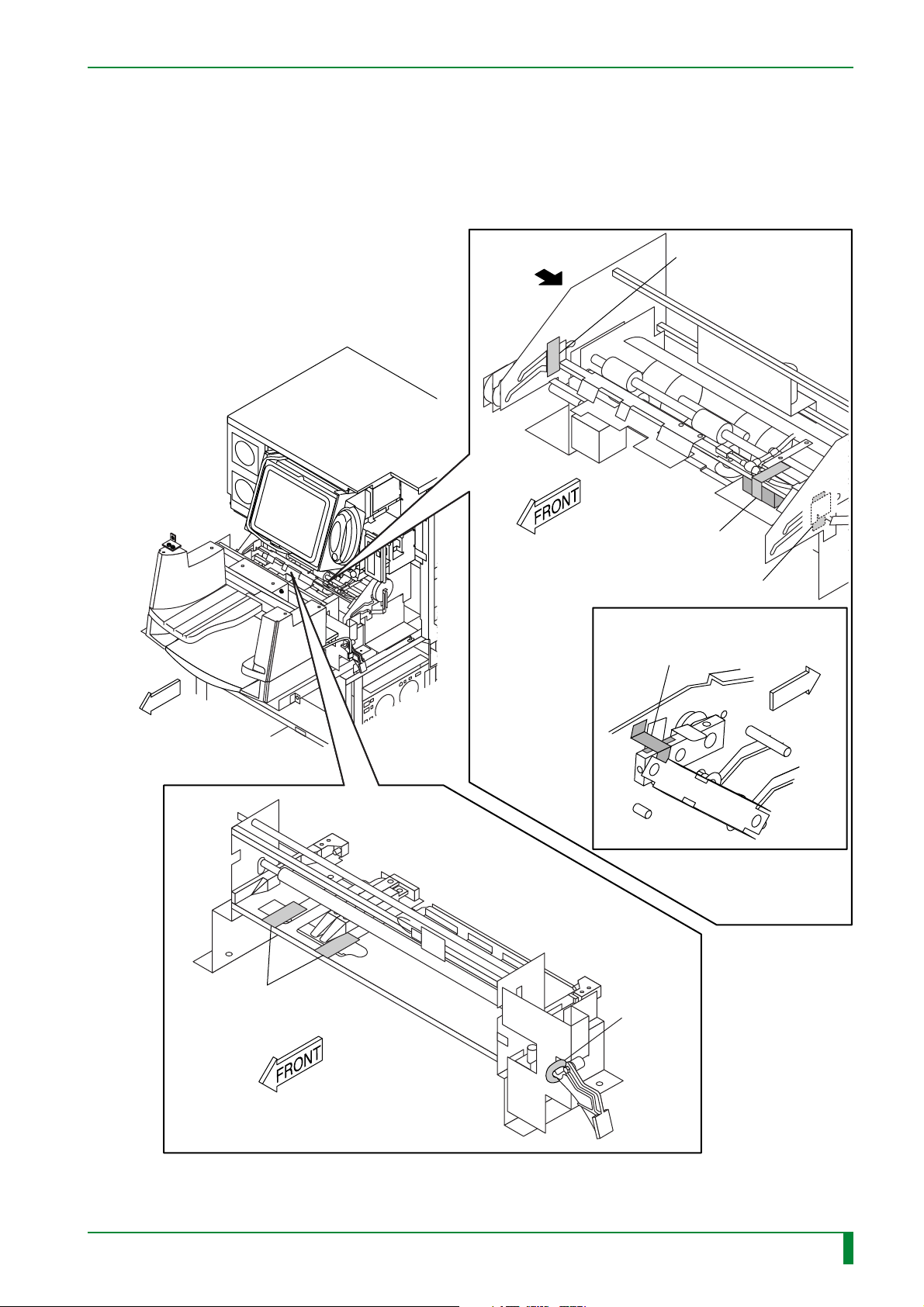

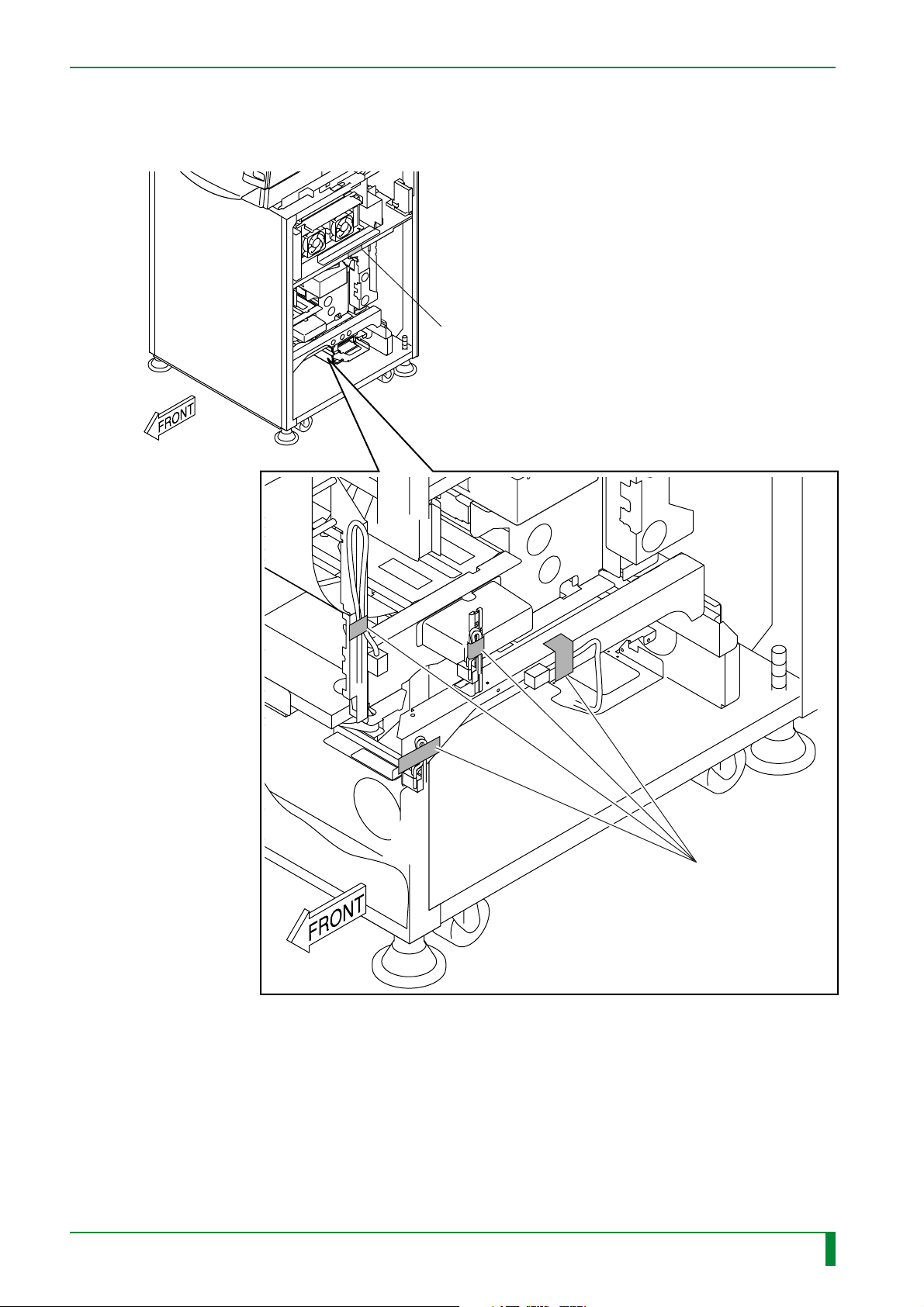

4.3 Cassette Set Unit/IP Removal Unit (Front/Right-Hand Side/ Left-Hand Side)

Unclamp the clamps.

IP removal unit

FRONT

A

[Remove] Tape

[Remove]

Tape and foam block

[Remove]

Tape

DETAIL A

[Remove] Tape and corrugated board

FRONT

Cassette set unit

[Remove]

Tape (x2)

[Cut]

Cable tie

FR7H7105.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

IN - 19

4.4 Pushing In the Tray

By reversing the procedures for pulling out the tray, push in the tray.

4.5 Subscanning Unit (Left-Hand Side)

Unclamp the clamps.

HHS label #2

IN - 20

#2

[Remove] Tape and foam block

009-058-00

10.20.2000 FM2732 (2)

Transparent cover

CR-IR347

Service Manual

#1

[Remove] BR4x8 (x2)

#3

[Attach] BR4x8 (x2)

FR7H7022.EPS

IN - 20

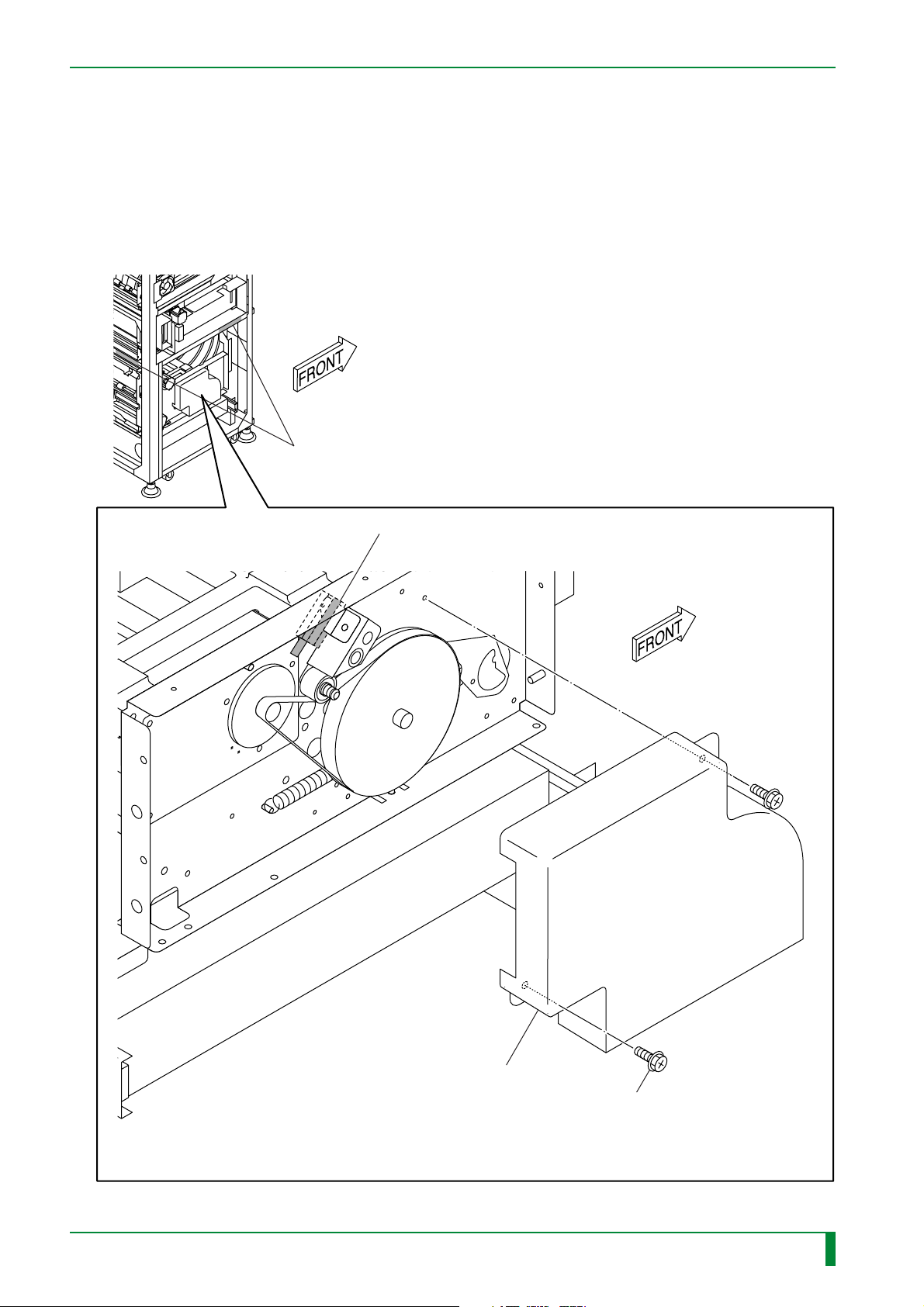

4.6 Subscanning Unit (Rear)

Slide the subscanning unit retaining bracket.

#1

[Remove] BR5x8 (x3)

IN - 21

HHS label #2

#2

[Loosen]

BR5x8 (x3)

#5 [Attach]

BR5x8 (x3) removed at #1

#3

[Slide] Bracket

#4

[Tighten] BR5x8 (x3)

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

FR7H7202.EPS

IN - 21

4.7 Subscanning Unit (Right-Hand Side)

Remove the tapes.

HHS label #2

IN - 22

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

[Remove] Tape (x4)

FR7H7118.EPS

IN - 22

BLANK PAGE

IN - 23

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

IN - 23

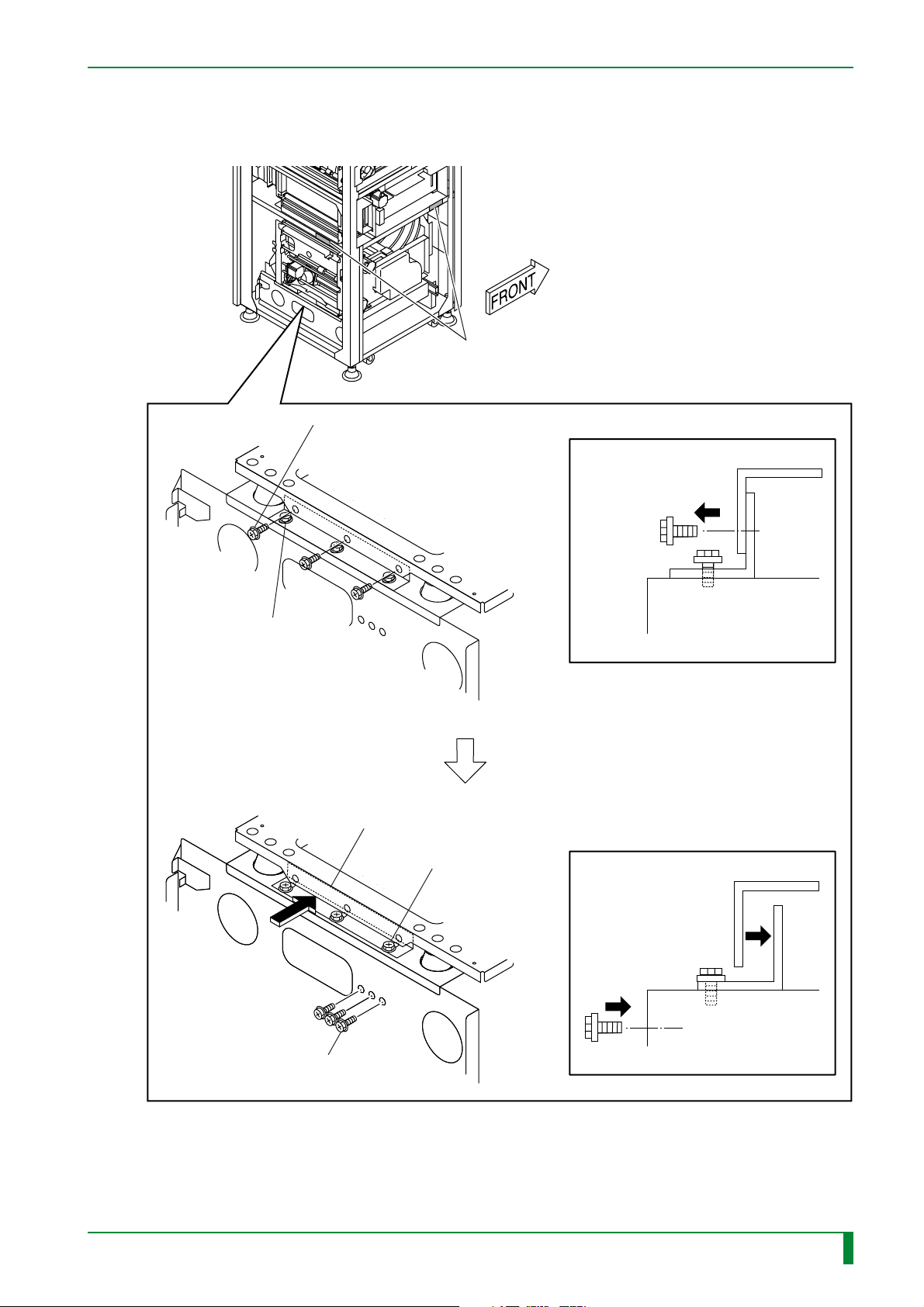

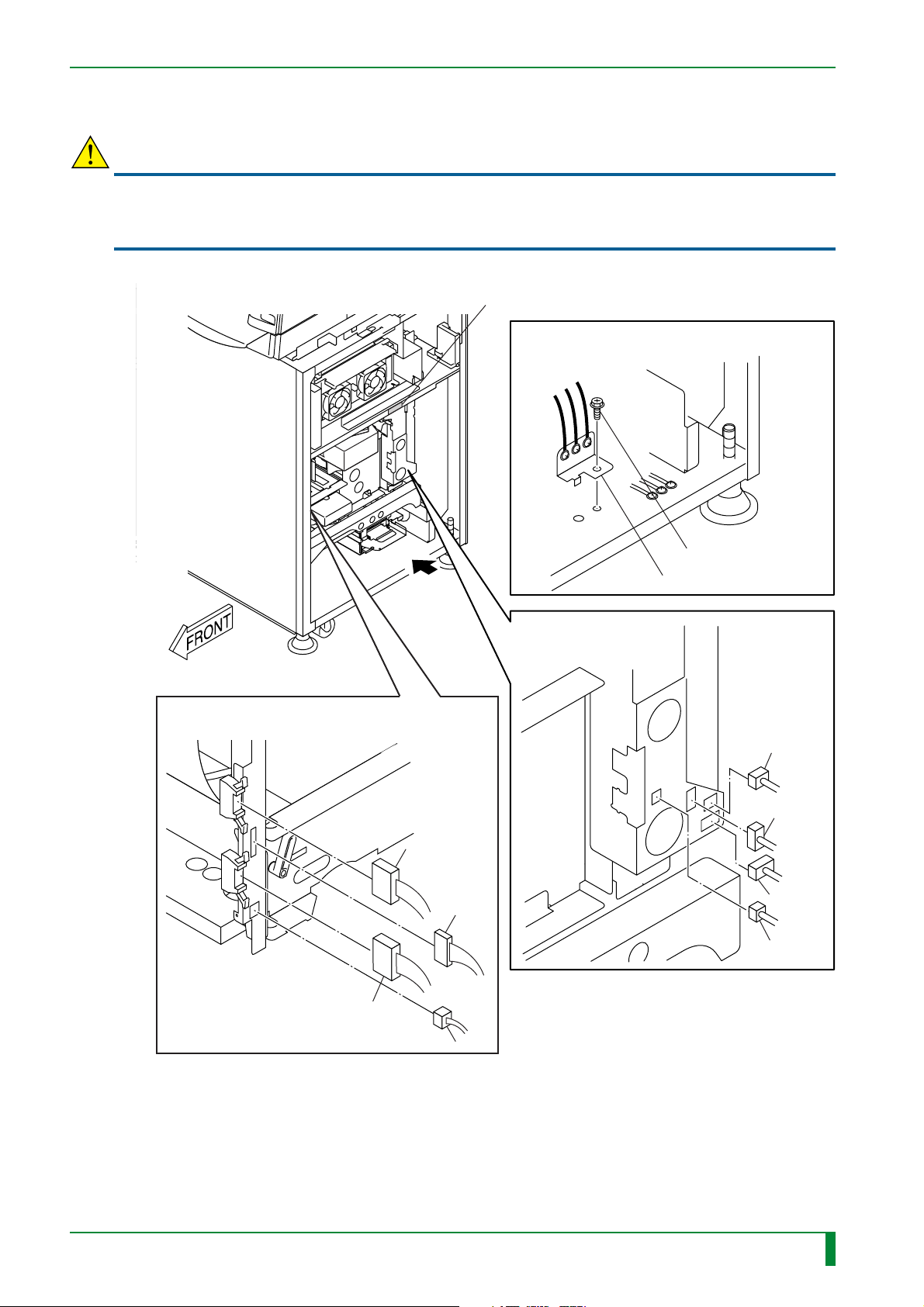

4.8 Pulling Out the Scanner Unit

CAUTION

When servicing any printed circuit board, be sure to wear an antistatic wristband to ground your

body. If your body is not grounded, static electricity built on your body may cause damage to

electronic parts on the board.

(1) Disconnect the connectors.

HHS label #2

DETAIL A

#5005 or later

IN - 24

#1

[Disconnect] Connectors

[Remove] BR4x8

Bracket

A

#2

[Disconnect] Connectors

CN-Z6

CN-Z7

CN-Z2

CN-Z5

CN-Z1

CN-Z8

009-058-00

009-058-02

10.20.2000 FM2732 (2)

08.30.2001 FM3142

CN-Z3

CR-IR347

CN-Z4

Service Manual

FR7H7227.EPS

IN - 24

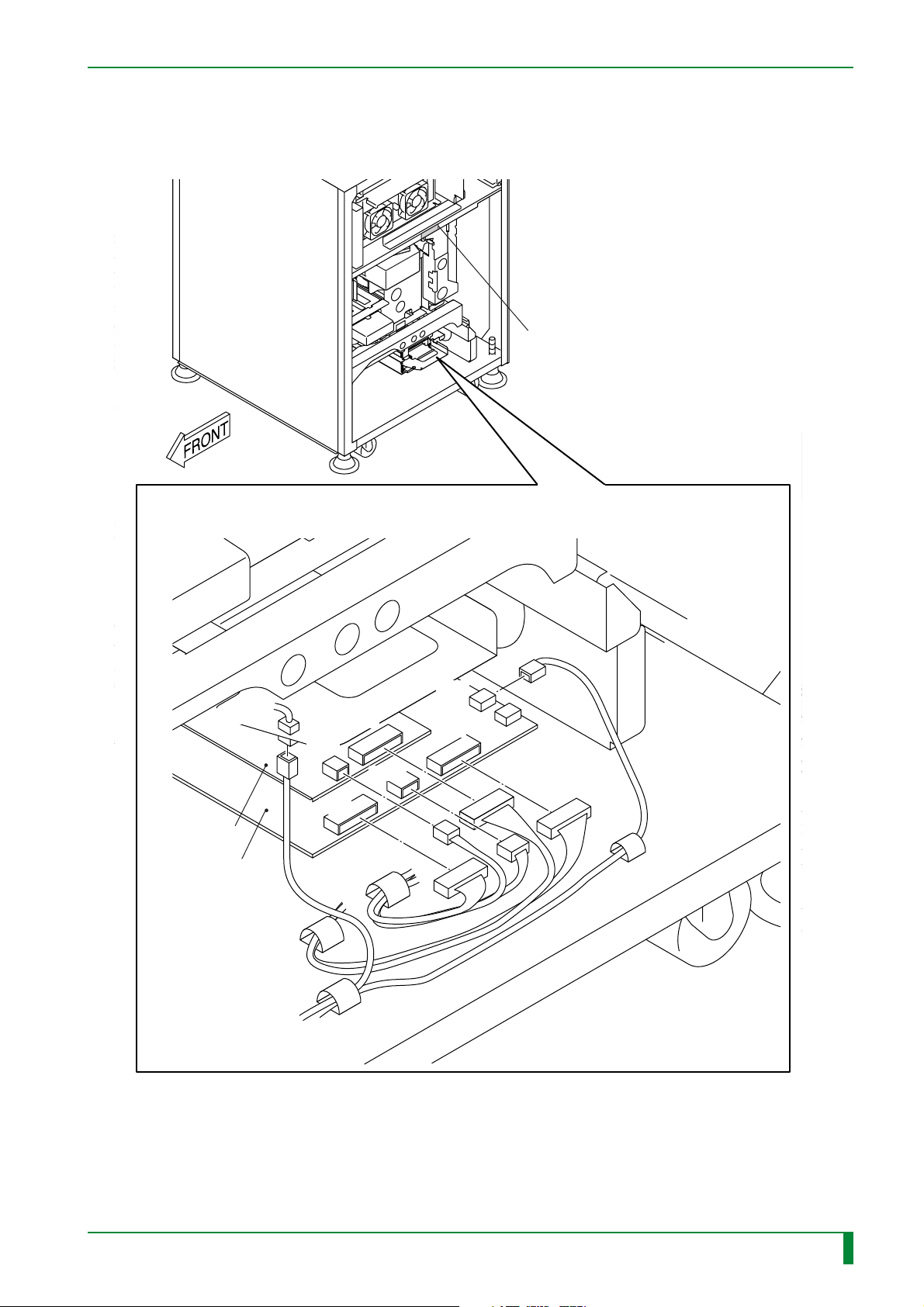

#3

[Disconnect] Connectors

IN - 25

HHS label #2

CN-Z12

SCR08D board

SCN08D board

CN3

CN8

CN6

CN9

CN7

CN12

FR7H7228.EPS

009-058-00

10.20.2000 FM2732 (2)

CR-IR347

Service Manual

IN - 25

Loading...

Loading...