Page 1

Local Service Organization Service

Manual

BE INSPIRED

C

C

C 5 5 / 2 1 2 8

5

5

5

5 //

2

2

1

1

2

2

8

8

WHICH SIDE ARE YOU ON?

Our Innovation Shapes the Future

Page 2

SIEMENS Pte Ltd

C55/2128 Level 2 Service Manual

TABLE OF CONTENTS

1 GPRS (GENERAL PACKET RADIO SERVICE).............................................. 1

2 K-JAVA APPLICATION ...................................................................................... 2

3 KEY FEATURES.................................................................................................... 3

4 OTHER FEATURES.............................................................................................. 4

5 COMPARISON WITH PREVIOUS PRODUCTS.............................................. 5

6 ACCESSORIES ...................................................................................................... 6

6.1 A

CCESSORIES PART NUMBER....................................................................7

7 UNIT DESCRIPTION L55 TUNA........................................................................ 8

7.1 ASSEMBLY CONCEPT FOR THE CUSTOMER .................................................8

7.2 C55 / 2128 MECHANICAL DIAGRAM...........................................................9

7.3 PCB

7.4 PCB

TOP-SIDE .......................................................................................10

BOTTOM-SIDE.................................................................................10

8 DISASSEMBLY OF C55/2128 ............................................................................ 11

9 REASSEMBLY OF C55/2128 ............................................................................. 13

10 SPARE PARTS & PART NUMBERS ................................................................ 14

11 MOBILE SOFTWARE PROGRAMMING....................................................... 15

11.1 MOBILE SOFTWARE UPDATING.......................................................16

11.2 F

LOW CHART FOR S/W UPGRADING .........................................................17

12 SIEMENS SERVICE EQUIPMENT USER MANUAL ................................... 18

12.1 INTRODUCTION .......................................................................................18

12.2 SIEMENS MOBILE SERVICE EQUIPMENT.................................................... 18

12.2.1 R&S CMD55 Test Station .................................................................19

12.2.2 R&S CTS55 Test Station ..................................................................19

12.2.3 Wavetek 4201S Test Station.............................................................20

12.3 O

12.4 S

THER EQUIPMENT ................................................................................20

OFTWARE INSTALLATION .......................................................................21

12.4.1 Configuring the test software ............................................................22

12.4.2 Running the test sequence ...............................................................23

Copyright © Siemens Pte. Ltd. Siemenes Techincal Support Center

All rights reserved

ICM MP CCQ ASP/ASC

Contents Page 1

Internal Service Use Only

Page 3

SIEMENS Pte Ltd

C55/2128 Level 2 Service Manual

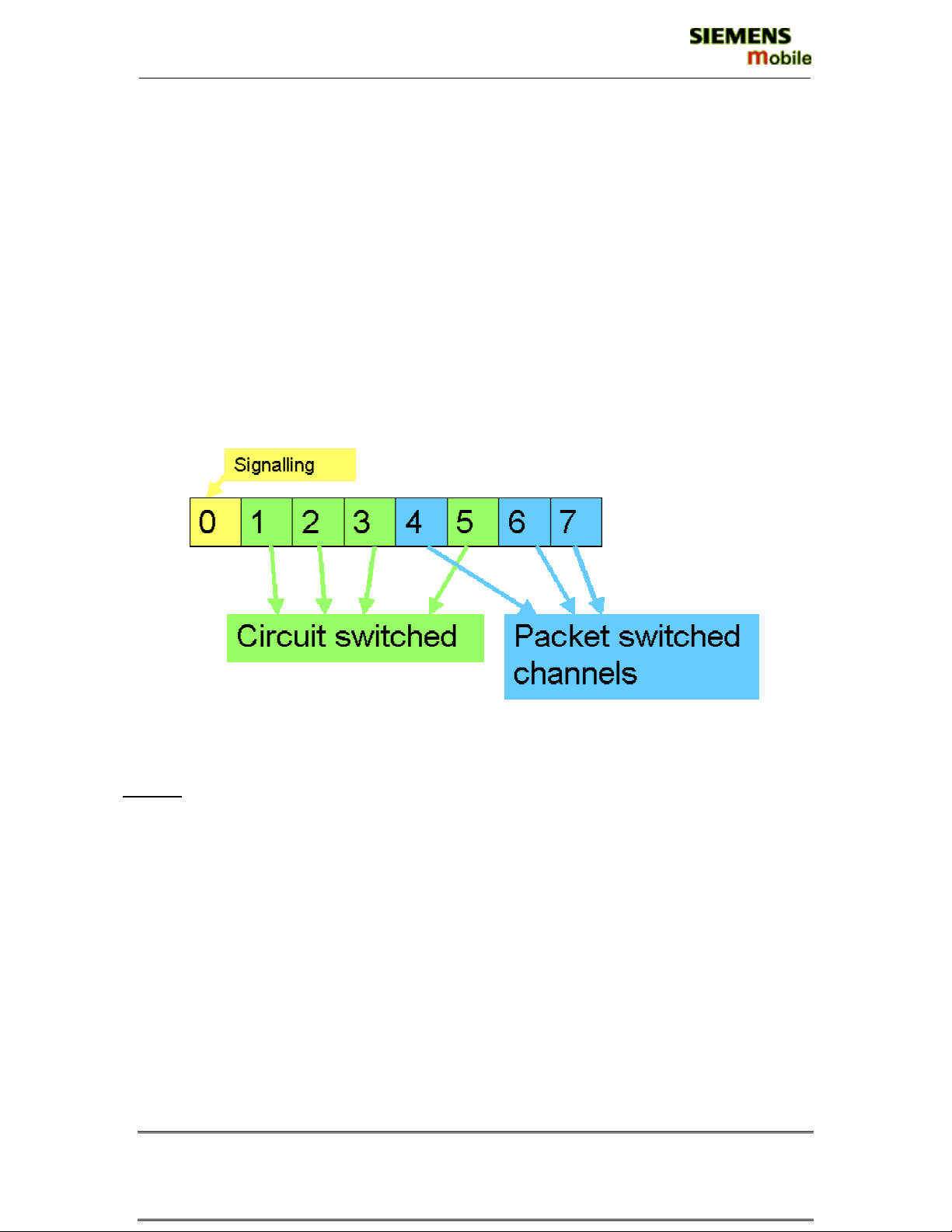

1 GPRS (GENERAL PACKET RADIO SERVICE)

PRS is a new non-voice value added services that allows information to be

sent and received across a GSM mobile telephone network. It supplements

today’s Circuit Switched Data (CSD) and Short Message Services (SMS).

G

circuit switched GSM network. This gives the option to use a packet-based data

service. The information is split into separated but related “packets” before being

transmitted and reassembled at the receiving end. Theoretically, maximum speeds

of up to 171.2 kilobits per second (kbps) are achievable with GPRS using all eight

timeslots at the same time. This is about 3 times as fast as the data transmission

speed possible over today’s fixed telecommunications networks and 10 times as fast

as current Circuit Switched Data services on GSM networks.

GPRS involves overlaying a packet based air interface on the existing

Figure1. Example of GPRS data transmission

Example: Cell with 1 Frequency channel:

1 physical channel for signalling, 4 physical channels for Circuit switched

and 3 physical channels for Packet switched

Copyright © Siemens Pte. Ltd. Siemenes Techincal Support Center

All rights reserved

ICM MP CCQ ASP/ASC

1 of 28

Internal Service Use Only

Page 4

SIEMENS Pte Ltd

C55/2128 Level 2 Service Manual

2 K-JAVA APPLICATION

Java-based

game system

Java Application Manager

(JAM)

RAM for Java applications

MIDP 1.0, CLDC 1.0

'OEM extensions'

HTTP API over GPRS

Application launcher and download manager.

Supports HTTP-based OTA download of applications

over GPRS and CSD.

Available RAM for Java applications (ie. program code

and data) during application runtime:

Minimum: 100 Kbyte

(Has to be taken as working assumption for application

development.)

Goal: 145 Kbyte as SL45i (not committed)

As SL45i, including performance optimizations from

SL45i-Infusio.

Proprietary API extensions as SL45i. Including

'Siemens Game API'

SL45i: only over CSD

yes

yes

yes

yes

yes

Copyright © Siemens Pte. Ltd. Siemenes Techincal Support Center

All rights reserved

ICM MP CCQ ASP/ASC

2 of 28

Internal Service Use Only

Page 5

SIEMENS Pte Ltd

C55/2128 Level 2 Service Manual

3 KEY FEATURES

General:

Battery:

Stand-by

Time:

Talk Time:

SIM Card:

Speech

Coder:

Display:

Keypad:

Acoustics:

• Hands free

• Flash file system

• New sound concept with polyphonic ringing tones / social

noises

• Kjava (identical to K45-Manta)

• LiIon Battery Pack 700 mAh

• Power Input: 1.8 A (0.6 ms) / 0.2 A (4 ms)

• Cut-off Threshold 3.2 V

• approx. 250 h measured at BSPAMFRMS = 9; number of

neighbouring cells = 0

• Best case approx. 5 hours (lowest output level with DTX)

• Worst case approx. 2.5 hours (highest output level without

DTX)

• Conditions for DTX: 40% user talk time

• Small (=”Plug In“) 1.8 V or 3 V-SIM card (Phase II).

• To insert the SIM the battery pack must be removed.

• The SIM reader coding will be realized by lower case.

• Full Rate, Enhanced Full Rate, Adaptive Multi Rate and

Half Rate speech coders are available as standard.

• Type: Full Graphic

• Resolution: 101 X 64 Pixel

• Illumination: Amber

• 12-digit block (0-9, #, *), small letters

• two function keys (SEND, END)

• ON/OFF key combined with the END key; the symbol ¢ (I

inside O) is used as a symbol for ON/OFF.

• 4 way navigation key as centered rocker type (up&down / 2

softkeys on left & right position)

• amber as illumination colour

• orientation at the housing in the area between keys “5“ and

“8”

• comfortable earpiece with optimal acoustics

• unidirectional microphone (similar to SL45 with modified

rubber gasket)

• loud signal emitter (soundringer) (>100dB(A) SPL @5cm,

'Hongkong-Spec.')

• different call melodies (for the amount see SW product

description). Realized with DSP firmware sound solution. All

melodies with increasing volume because of the danger of

acoustic shock. Additional measures to protect from

acoustic shock, see SW product description.

Copyright © Siemens Pte. Ltd. Siemenes Techincal Support Center

All rights reserved

ICM MP CCQ ASP/ASC

3 of 28

Internal Service Use Only

Page 6

SIEMENS Pte Ltd

C55/2128 Level 2 Service Manual

• handsfree mode

• different selectable volume levels for handsfree, handset

and ringer mode (for the amount see SW product

description)

4 OTHER FEATURES

•

Games (Java Based)

•

Voice command/dialing

•

Integrated handsfree

•

Calling Images: Download a photo of your friend and link it to his phone book

entry

•

Greetings (Reminder of important dates)

•

Get in touch (Conference Call) & SMS to group

•

Text modules (SMS)

•

Diary (appointments, notes)

•

Flexible Memory

•

PIN protected screensaver & notes

•

Various animations (menu, welcome)

•

Silent Alert

•

Various user profiles

•

Intelligent Typing (T9) + Libraries

•

Mobile Internet Access (WAP 1.2.1)

•

Built in data & fax modem @ 9.6 kbps

•

Moon phase screensaver (2128 only)

•

VOIP Predial

• Integrated sound concept (polyphonic melodies with up to 16 voices) for:

- MMI

- Ringer melodies

- Recordable sounds

Copyright © Siemens Pte. Ltd. Siemenes Techincal Support Center

All rights reserved

ICM MP CCQ ASP/ASC

4 of 28

Internal Service Use Only

Page 7

SIEMENS Pte Ltd

C55/2128 Level 2 Service Manual

5 COMPARISON WITH PREVIOUS PRODUCTS

Feature K45 Flipper L55 Tuna Improvement

Supported

Systems

Dual Band

E-GSM 900 / GSM

1800

Dual Band

E-GSM 900 / GSM

1800

Stand-by Time Up to 200 h Up to 250 h +20% stand-by time

Talk Time Up to 5 h Up to 5 h Same

Battery

Technology

Battery Capacity

Ni-MH Battery Pack

Nominal Cap. : 550

mAh

Weight Approx. 106 g

Li-Ion Battery Pack

Nominal Cap.: 750

mAh

Approx. 84 g -20% weight

Volume Approx. 82 cm3

Approx. 69 cm3 -16% volume

Length 108,9 mm (Panther) 100,9 mm

Width 42.0 ... 46.0 mm

41.0 ... 44.0 mm 1.0 mm … 2.0 mm

(Panth)

Thickness 19.0 ... 23.0 mm

17.9 ... 20.8 mm 1.1 mm … 2.2 mm

(Panth)

SIM Plug-In 1.8V/3V Plug-In 1.8V/3V Same

Antenna Integrated Integrated Same

Antenna

Performance in

-0,5 dB @ 900 MHz

-0,3 dB @ 1800 MHz

comparison to

-0,8 dB @ 900 MHz

-0,5 dB @ 1800

MHz

S35:

Half Rate Yes Yes Same

Enhanced Full

Yes Yes Same

Rate

AMR No Tbc New in C-segment

Fax/Data Yes Yes Same

GPRS No Yes New in C-segment

Keypad

Yes (amber) Yes (amber) Same

Illumination

Display /

Display

Illumination

Ringer volume

level

FSTN full dot

matrix, 5 lines

graphic

Min. 100 dB(A) @

5cm

Typ. >103 dB(A) @

5cm

FSTN full dot

matrix, 5 lines

graphic

Min. 100 dB(A) @

5cm

Typ. >103 dB(A) @

5cm

Same

Li-Ion first time as

standard in Csegment

reduction

reduction

8 mm shortening

width reduction

thickness reduction

Same

Same

Copyright © Siemens Pte. Ltd. Siemenes Techincal Support Center

All rights reserved

ICM MP CCQ ASP/ASC

5 of 28

Internal Service Use Only

Page 8

SIEMENS Pte Ltd

C55/2128 Level 2 Service Manual

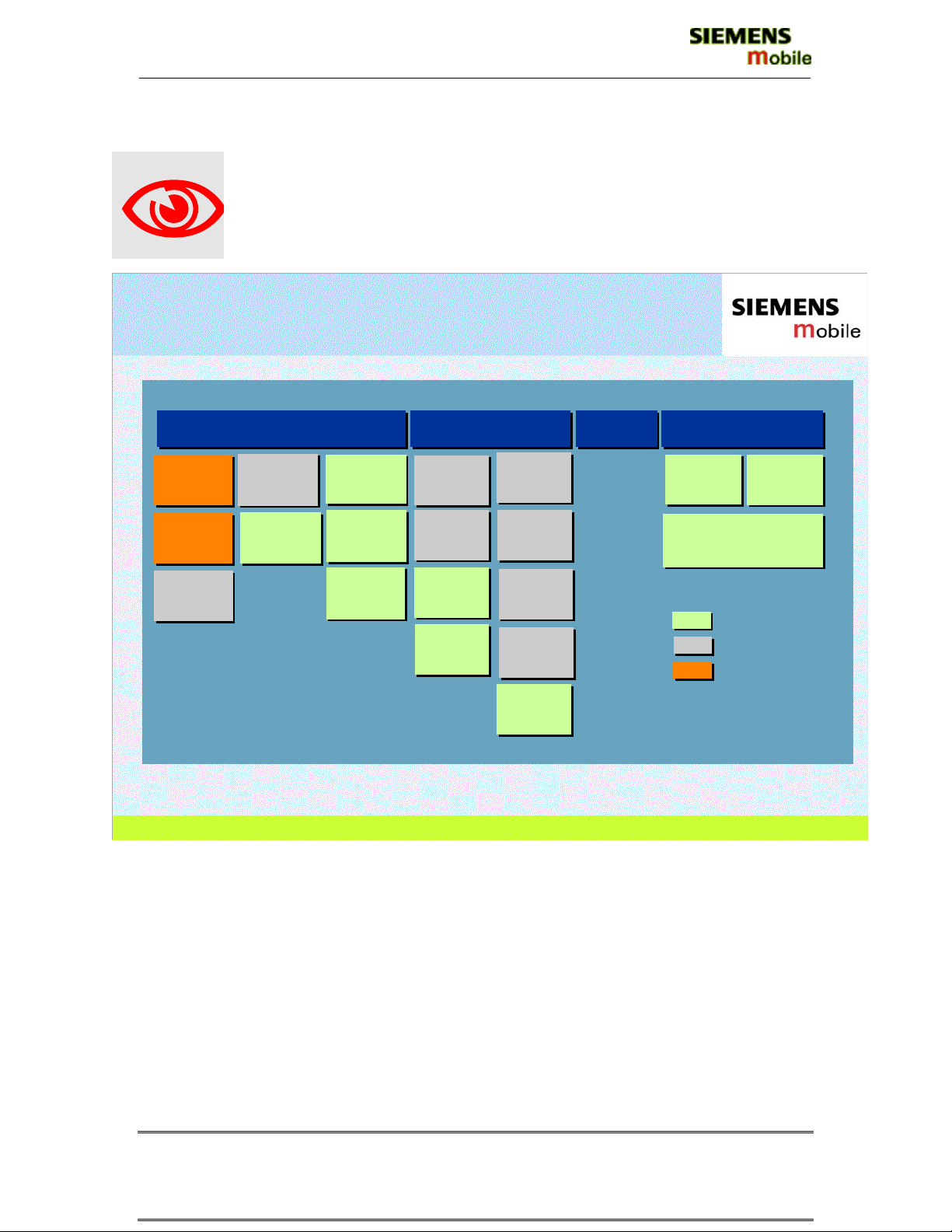

6 ACCESSORIES

Due to changes on the connector from “Lumberg” to “Slim

Lumberg”, accessories using the old “Lumberg” connector will

not be able to be used on the new “Slim Lumberg” platform.

C55 Original Accessories

EMEA Portfolio

Basics

Basics

Li-Ion

Carry Set

Carry Set

FCS-500

FCS-500

CLIPit

CLIPit

Covers

Covers

Carrying

Carrying

Cases

Cases

ICM MP CCQ SF www.my-siemens.com/customercare Page 1

Li-Ion

Battery

Battery

EBA-510

EBA-510

Headset

Headset

PTT

PTT

HHS-510

HHS-510

Desk Top

Desk Top

Charger

Charger

EDC-510

EDC-510

Travel

Travel

Charger

Charger

ETC-500

ETC-500

ETC-510

ETC-510

Car Charger

Car Charger

ECC-500

ECC-500

Car Solutions

Car Solutions

Car Kit

Car Kit

Prof. Voice

Prof. Voice

HKV-500

HKV-500

Car Kit

Car Kit

Comfort

Comfort

HKC-500

HKC-500

Car Kit

Car Kit

Portable

Portable

HKP-500

HKP-500

Basic

Basic

Car Pack

Car Pack

HKB-500

HKB-500

Mobile

Mobile

Holder

Holder

HMH-500

HMH-500

Mobile

Mobile

Holder

Holder

Antenna

Antenna

HMH-510

HMH-510

Car Kit

Car Kit

Upgrade

Upgrade

HKO-500

HKO-500

Car Kit

Car Kit

Upgrade

Upgrade

HKO510

HKO510

Car

Car

Handset

Handset

HKO-550

HKO-550

Innov.

Innov.

©

Data

Data

Data Cable

Data Cable

DCA-500

DCA-500

SyncStation

SyncStation

DSC-500

DSC-500

(Desk Top Stand, Y-Adapter,

(Desk Top Stand, Y-Adapter,

Data Cable)

Data Cable)

compatible to L55

and future products

C55 and S55 only

C55 only

e

m

Si

e

n

s

,

2

002

Data Cable

Data Cable

USB

USB

DCA-510

DCA-510

Copyright © Siemens Pte. Ltd. Siemenes Techincal Support Center

All rights reserved

ICM MP CCQ ASP/ASC

6 of 28

Internal Service Use Only

Page 9

SIEMENS Pte Ltd

C55/2128 Level 2 Service Manual

6.1 Accessories Part Number

Accessories

L36104-F3090-X903 Handsfree Loudspeaker S45/ME45/C45/M45/C55/S55

L36146-A2053-D Con.Cable Battery Install. Comfort GPS/rat C35/C35

L36254-Z6-C95 Handsfree Microphone aktiv S45/ME45/C45/M45/C55/S5

L36880-N4501-A135 HKO-520 Push-To-Talk-Key

L36880-S4501-A300 E-Box Carkit Voice S45/ME45/C45/M45/C55/S55 german

L36880-S4501-A301 E-Box Carkit Voice S45/ME45/C45/M45/C55/S55 englis

L36880-S4501-A302 E-Box Carkit Voice S45/ME45/C45/M45/C55/S55 french

Copyright © Siemens Pte. Ltd. Siemenes Techincal Support Center

All rights reserved

ICM MP CCQ ASP/ASC

7 of 28

Internal Service Use Only

Page 10

SIEMENS Pte Ltd

C55/2128 Level 2 Service Manual

7 UNIT DESCRIPTION L55 TUNA

The L55 Tuna is designed as a single-pcb phone with exchangeable covers and

exchangeable keypad. The upper- and lower-cover are designed as two-coloured

parts, which is realized in 2-shot-moulding technology.

7.1 Assembly Concept for the Customer

Chassis

exchangeable

Rear-Cover

exchangeable

Front-Cover

battery

SIM-Card

exchangeable

keypad

The C55 is the first Siemens Mobile phone that enables the customer to freely

customize the outlook of their phone via the means of exchangeable Front/Rear

covers as well as keypad.

Copyright © Siemens Pte. Ltd. Siemenes Techincal Support Center

All rights reserved

ICM MP CCQ ASP/ASC

8 of 28

Internal Service Use Only

Page 11

SIEMENS Pte Ltd

A

C55/2128 Level 2 Service Manual

7.2 C55 / 2128 Mechanical Diagram

Display-Window

Upper-Case

SAR-Frame

ESD-Frame

Keypad

SAR-Absorber

(optional)

LCD Speaker-Gasket

Lightguide

Speaker

PCB

ntenna

Mounting-Frame

Ba ttery

Lower-Case

Metaldome-Foil

Vibra-motor

Microphone

Copyright © Siemens Pte. Ltd. Siemenes Techincal Support Center

All rights reserved

ICM MP CCQ ASP/ASC

9 of 28

Internal Service Use Only

Page 12

SIEMENS Pte Ltd

C55/2128 Level 2 Service Manual

7.3 PCB top-side

7.4 PCB bottom-side

The C55/2128 assembly concept differs from the previous models (P35 & K45

series) slightly. The C55/2128 is no longer employing the concept of “No

Screws”. Instead of the previous upper & lower mounting frame to hold the PCB

and the housing together, the C55/2128 uses six screws to hold the light guide,

PCB and the mounting frame together.

As seen from the mechanical diagram, the C55/2128 also uses two other

different techniques from the previous models (P35 & K45 series). (1) The use of

a light guide on the front panel to disperse the light evenly throughout the keypad

& display area. (2) The use of a metal dome foil as keypad contact as opposed to

the carbon/metallic contact keypads used in the P35 & K45 series.

Copyright © Siemens Pte. Ltd. Siemenes Techincal Support Center

All rights reserved

ICM MP CCQ ASP/ASC

10 of 28

Internal Service Use Only

Page 13

SIEMENS Pte Ltd

C55/2128 Level 2 Service Manual

8 DISASSEMBLY OF C55/2128

Step 1

Front view of the C55/2128

Step 3

Remove the battery cover by pushing it

upwards as indicated by the arrow.

Step 5

With the battery cover removed, proceed to

remove the battery by releasing the catch on

the side.

Step 7

Once the catch has been removed, the SIM

card would pop up from the holder

automatically.

Step 2

Step 4

The C55/2128 comes with a hinge on the top

part of the phone for customers to hang their

accessories.

Step 6

With the battery removed, you would then be

able to see the SIM card, which is held down

by a metallic catch.

Step 8

Proceed to remove the front cover by pushing it

up lightly

.

Back view of the C55/2128

Copyright © Siemens Pte. Ltd. Siemenes Techincal Support Center

All rights reserved

ICM MP CCQ ASP/ASC

11 of 28

Internal Service Use Only

Page 14

SIEMENS Pte Ltd

C55/2128 Level 2 Service Manual

Step 9

nce the front cover has been removed,

O

proceed to remove the 6 screws on the fro

with a “T6” screw driver; as indicated by the re

circles.

nt

Step 11

Once the screws has been removed, the PCB s it can be seen from the photo, the keypad

can also be seperated from the back casingof

the phone. The antenna is built-in on the back

case.

Step 13

Fully disassembled C55

Step 10

Once the screws has been removed, you

would be able to see the internal single PCB.

d

Step 12

A

can also be separated from the front casing.

Copyright © Siemens Pte. Ltd. Siemenes Techincal Support Center

All rights reserved

ICM MP CCQ ASP/ASC

12 of 28

Internal Service Use Only

Page 15

SIEMENS Pte Ltd

C55/2128 Level 2 Service Manual

9 REASSEMBLY OF C55/2128

For the reassembly of the C55/2128, simply reverse the disassembly

procedures from Step 13 to Step 1. However there are some things to note

on the reassembly of the phone.

During the installation of the SIM card, ensure that the SIM card is properly

locked in. If not, it would result in card error, as the SIM card will not be properly

held in place.

Ensure that the SIM card is fully inserted and that the metallic lock is pulled

down.

During the installation of the battery, ensure that the hinges are properly in place.

Otherwise the battery will not be able to fit into the phone properly.

Ensure that the hinges are properly fitted before fixing in the battery.

Copyright © Siemens Pte. Ltd. Siemenes Techincal Support Center

All rights reserved

ICM MP CCQ ASP/ASC

13 of 28

Internal Service Use Only

Page 16

SIEMENS Pte Ltd

C55/2128 Level 2 Service Manual

10 SPARE PARTS & PART NUMBERS

Level 1

L36158-A102-B600 Keypad C55/C56

Level 2.5

L36197-F5005-F782 Display LED blue MT50/M50/M46/C55

L36334-Z93-C272 Antenna Connector C35/C35i/S35i/M35i/SL45/ S45/ME4

L36334-Z97-C160 Battery Connector S45/ME45/C55/S55

L36840-L2055-D670 Display LED Amber S35i/S45/ME45/C45/M50/C55/C56

L36840-L2056-D670 Keyboard LED Amber S35i/S45/ME45/C45/S46/M50/MT50/

Level 2.5E

L36120-F4223-H Resistor Temp_Resistor

L36145-F102-Y8 Quartz EGold/Logic (B1 lay.)

L36145-G100-Y96 Z850 Filter 1LO_VCO

L36145-K260-Y41 Z851 Filter Filter_BALUN

L36820-C6047-D670 Diode / Transistor Tran._Switch

L36820-L6105-D670 D800 Digital Integrated Circuit (IC) Transceiver I

L36830-C1097-D670 Diode / Transistor

L36840-C4049-D670 Diode / Transistor Tran._VCXO_Ampl.

L36840-D5049-D670 Diode / Transistor Feedback_Diode

L36840-D61-D670 Diode / Transistor Capa_Diode

L36851-Z2002-A59 Z900 Filter Power_Amplifier

L36851-Z9105-Z981 Diode / Transistor

Copyright © Siemens Pte. Ltd. Siemenes Techincal Support Center

All rights reserved

ICM MP CCQ ASP/ASC

14 of 28

Internal Service Use Only

Page 17

SIEMENS Pte Ltd

C55/2128 Level 2 Service Manual

11 MOBILE SOFTWARE PROGRAMMING

The common mobile software available is divided into language groups. However, this

software does not contain the specific settings, such as ringing tones, greeting text, short

dial list etc., required by the operator(s) or service provider(s). Therefore, it is not

uncommon to have some menu item(s) differ in different variants or are not visible at all.

These settings are stored in different memory area of the mobile and will be activated

depending on the customer specific model or variant of the phone by a separate test

step during the production process.

Due to this separation of common mobile software and customer specific initialization, it

is possible to fulfill the demands of the market requiring customization and flexibility. As

a consequence the software programming process in the LSO is divided into two

different steps as followed:

- Software update to actual version and appropriate language group

- Programming of CUSTOMER SPECIFIC INITIALIZATION

FIGURE 2.24 C55 SERIES SOFTWARE PROGRAMMING SETUP

Copyright © Siemens Pte. Ltd. Siemenes Techincal Support Center

All rights reserved

ICM MP CCQ ASP/ASC

15 of 28

Internal Service Use Only

Page 18

SIEMENS Pte Ltd

C55/2128 Level 2 Service Manual

11.1 MOBILE SOFTWARE UPDATING

The software of the mobile, L55 series, is loaded from a PC directly. Hardware

interconnection between the mobile and the PC is shown in Figure 2.24 Because of the

new type of external connector used in X55 series (Slim-Lumberg type) an additional

adaptor cable between mobile and boot adaptor is required. Table 2.1 listed all the

hardware requirements

If you use the battery dummy, make sure that the power supply voltage is correctly

adjusted.

Description Part No.

Bootadapter 2000 incl. AC-Adapter,

serial cable and mobile connection

cable

IBM Compatible PC – Pentium -

TABLE 2.1 EQUIPMENT LIST FOR SOFTWARE PROGRAMMING.

L36880-N9241-A200

Copyright © Siemens Pte. Ltd. Siemenes Techincal Support Center

All rights reserved

ICM MP CCQ ASP/ASC

16 of 28

Internal Service Use Only

Page 19

SIEMENS Pte Ltd

C55/2128 Level 2 Service Manual

11.2 Flow chart for S/W upgrading

Plug in the Boot

Adaptor to the PC

and Mobile

Connect the AC

adaptor to the

Boot Adaptor

Power up Boot

Adaptor & check

LED.

Check AC Adaptor

YES

Faulty AC Adaptor

NO

NO

OK?

OK?

YES

program

Start the SWUP

Select & Execute

the "Mobile S/W"

ERROR?

YES

Check

H/W setup = S/W

OK?

Correct Settings

NO

S/W upgrading in

progress

ERROR?

NO

TEST Mobile

Take note of error

and repeat

process

Feedback Error to

Tech. Supp. Dep

END

YES

Faulty Boot

Adaptor

FLOW CHART FOR S/W PROGRAMMING PROCESS

Copyright © Siemens Pte. Ltd. Siemenes Techincal Support Center

All rights reserved

ICM MP CCQ ASP/ASC

17 of 28

Internal Service Use Only

Page 20

SIEMENS Pte Ltd

C55/2128 Level 2 Service Manual

12 SIEMENS SERVICE EQUIPMENT USER

MANUAL

12.1 Introduction

Every LSO repairing Siemens handset must ensure that the quality standards are

observed. Siemens has developed an automatic testing system that will perform

all necessary measurements. This testing system is known as:

12.2 Siemens Mobile Service Equipment

Using this system vastly simplifies the repair of the phones and will make sure

that:

1. All possible faults are detected

2. Sets, which pass the test, will be good enough to return to customer.

Starting from the P35 Series, Siemens will introduce a simpler and faster testing

platform for testing a repaired Siemens mobile phone. The testing platforms are

either base on R&S CMD 53/55 or CTS55 GSM test set.

There is also test software under development for testing with the Wavetek

4201S and the 4107 GSM test set.

A Level 2.5 service software is also under development for more elaborate

testing for the repair for the P35 series mobile phone.

THE LSO WILL HAVE TO PURCHASE THE SYSTEM, CHOOSING

BETWEEN THE COMPLETE PACKAGE OR SUB-SET OF IT.

A FULLY AUTOMATIC TEST PROCEDURE IS ONLY

POSSIBLE IF THE COMPLETE SYSTEM IS

INSTALLED.

Make sure that your CTS firmware is Version 3.01 or higher. For

CMD 55 it must be Version 4.03 and higher. Please check with the

Service Info SB_0500 for the CTS/CMD Hardware Options.

Copyright © Siemens Pte. Ltd. Siemenes Techincal Support Center

All rights reserved

ICM MP CCQ ASP/ASC

18 of 28

Internal Service Use Only

Page 21

SIEMENS Pte Ltd

C55/2128 Level 2 Service Manual

12.2.1 R&S CMD55 Test Station

12.2.2 R&S CTS55 Test Station

Copyright © Siemens Pte. Ltd. Siemenes Techincal Support Center

All rights reserved

ICM MP CCQ ASP/ASC

19 of 28

Internal Service Use Only

Page 22

SIEMENS Pte Ltd

C55/2128 Level 2 Service Manual

12.2.3 Wavetek 4201S Test Station

12.3 Other Equipment

One Pentium MMX Window 95/98 PC with a serial port to connect to the GSM

test set through the PC serial cable provided for the GSM test set.

One Test SIM card and a fully charged battery for used with the mobile phone

model.

Additional RF connector will be needed for setup using Wavetek 4107 test set

and Wavetek Antenna Coupler.

For LSO Test Station setup base on the Wavetek 4107 test set, you need a TNC

(male) to SMA(female) connector. For the Wavetek Antenna Coupler, you need a

TNC (female) to SMA(female) connector. The part number for the connectors will

be announced soon.

For Wavetek GSM test set For Wavetek Antenna Coupler

Copyright © Siemens Pte. Ltd. Siemenes Techincal Support Center

All rights reserved

ICM MP CCQ ASP/ASC

20 of 28

Internal Service Use Only

Page 23

SIEMENS Pte Ltd

C55/2128 Level 2 Service Manual

12.4 Software Installation

Before executing the test software, it is important to ensure that the software

configuration matches that of the hardware set up. Each GSM Tester will have

specific test software. The test software is named CMD_GO, CTS_GO and for

Wavetek test set, CAT4200 respectively.

First, copy the installation software for the specific GSM tester to a temporary

directory on the harddisk of the Window PC and then Run the Setup from the first

sub directory – Disk1 for CMD_GO test software.

After the installation for the test software, RUN the Test software and check the

configuration setting for the Serial port.

Copyright © Siemens Pte. Ltd. Siemenes Techincal Support Center

All rights reserved

ICM MP CCQ ASP/ASC

21 of 28

Internal Service Use Only

Page 24

SIEMENS Pte Ltd

C55/2128 Level 2 Service Manual

12.4.1 Configuring the test software

For each model of the L55 series mobile phone, Siemens will distribute the

testing configuration file for the specific test station. For testing the phone, just go

to the File menu and select Load Configuration.

Copyright © Siemens Pte. Ltd. Siemenes Techincal Support Center

All rights reserved

ICM MP CCQ ASP/ASC

22 of 28

Internal Service Use Only

Page 25

SIEMENS Pte Ltd

C55/2128 Level 2 Service Manual

Make sure that your CTS firmware is Version 3.01 or higher. For CMD 55 it must be

Version 4.03 and higher. Please check with the Service Info SB_0500 for the

CTS/CMD Hardware Options.

12.4.2 Running the test sequence

Insert a Test SIM card and a fully charged battery into the Siemens mobile phone

and place it onto the phone holder on the Antenna Coupler. Switch the RF switch

to INT ANT position and select the Start button to run the test sequence in the

configuration file.

Copyright © Siemens Pte. Ltd. Siemenes Techincal Support Center

All rights reserved

ICM MP CCQ ASP/ASC

23 of 28

Internal Service Use Only

Page 26

SIEMENS Pte Ltd

C55/2128 Level 2 Service Manual

Follow the instruction on the screen and switch on the phone. The mobile phone

will start Network Search and doing Location Update to the GSM test set through

the off-air signal from Antenna Coupler.

Next, the GSM test set will initial a call to the mobile phone through the Antenna

Coupler. Press the Call key when the mobile phone ring, and the GSM test set

will start Tx Power measurements on the GSM and GSM1800 channel specified

by the configuration setting.

Copyright © Siemens Pte. Ltd. Siemenes Techincal Support Center

All rights reserved

ICM MP CCQ ASP/ASC

24 of 28

Internal Service Use Only

Page 27

SIEMENS Pte Ltd

C55/2128 Level 2 Service Manual

Next, the GSM test set will end the call to the mobile phone and the screen will

prompt for Dialing from the mobile phone. At this test step, please move the

mobile phone to the Antenna Cradle and switch the RF switch to EXT ANT

position. Once the mobile phone logs onto the GSM test set, dial 1234 and the

Send key.

The GSM test set will make Tx Power measurements, Rx BER measurement,

Echo Loop test on the GSM and GSM1800 channel specified by the

configuration setting. There will be an Echo Loop Back test for checking the

speech quality. Speak into the mobile phone when prompted and listen the voice

after approx 1 second and check the speech quality. If not O.K, it may be

microphone or the earphone defective.

Copyright © Siemens Pte. Ltd. Siemenes Techincal Support Center

All rights reserved

ICM MP CCQ ASP/ASC

25 of 28

Internal Service Use Only

Page 28

SIEMENS Pte Ltd

C55/2128 Level 2 Service Manual

The last test is Disconnect Call from the mobile phone. Press the End Call key

and the test sequence will end.

A measurement report screen will show up and a hardcopy can be printed if a

printer is connected to the PC. To close the measurement report screen, click

the third button from the left.

Once the mobile phone pass all the test steps, please make a check for all keys and the

display. After this we can confirm on the proper functioning of the mobile phone after

repair and return the phone back to the customer.

Copyright © Siemens Pte. Ltd. Siemenes Techincal Support Center

All rights reserved

ICM MP CCQ ASP/ASC

26 of 28

Internal Service Use Only

Loading...

Loading...