Page 1

Information and Communication Mobile

Devices

C35(i), M35(i), S35i

Level 2.5

Repair Documentation

V 1.3

V1.3 Page 1 of 41 ICM D CC ST

D. Schnoor

12/01

Page 2

Information and Communication Mobile

Devices

Table of Contents:

1 INTRODUCTION .......................................................................................................................................... 3

2 ANTENNA CONNECTOR ........................................................................................................................... 4

3 RINGER .......................................................................................................................................................... 7

4 BOTTOM CONNECTOR (LUMBERG) ................................................................................................... 10

5 DISPLAY CONNECTOR ........................................................................................................................... 14

6 KEYBOARD LEDS ..................................................................................................................................... 18

7 DISPLAY LEDS ........................................................................................................................................... 21

8 INFRARED DIODES .................................................................................................................................. 25

9 CHARGING DIODE V210.......................................................................................................................... 29

10 DIPLEXER Z503.......................................................................................................................................... 34

11 VOLTAGE PROTECTION DIODE V279 ................................................................................................ 39

V1.3 Page 2 of 41 ICM D CC ST

D. Schnoor

12/01

Page 3

Information and Communication Mobile

Devices

1 Introduction

The C/M/S35 product family consists of 5 different dualband handsets (GSM-900 and GSM-

1800), which can easily be distinguished from the second block of the partnumber printed on

the IMEI label. There also exist Asian variants of C/M/S35 named 3508 / 3518 / 3568

respectively. All information below also applies to the Asian variants unless otherwise noted.

Partnumber on IMEI label:

1) C35 / 3508: S30880-S4000-Xxxx

2) C35i / 3508i: S30880-S4050-Xxxx

Same as C35 / 3508 but with additional WAP and fax/data capabilities

3) M35 / 3518: S30880-S4200-Xxxx

4) M35i / 3518i: S30880-S4250-Xxxx

Same as M35 / 3518 but with additional WAP and fax/data capabilities

5) S35i / 3568i: S30880-S4100-Xxxx

This manual is intended to help you carry out repairs on level 2.5, meaning limited

component repairs. Failure highlights are documented and should be repaired in the local

workshops.

It must be noted that all repairs have to be carried out in an environment set up according to

the ESD (Electrostatic Discharge Sensitive Devices) regulations defined in international

standards.

If you have any questions regarding the repair procedures or spare parts do not hesitate to

contact our technical support team in Kamp-Lintfort, Germany:

Tel.: +49 2842 95 4666

Fax: +49 2842 95 4302

e-mail: dominik.schnoor@klf.siemens.de

V1.3 Page 3 of 41 ICM D CC ST

D. Schnoor

12/01

Page 4

Information and Communication Mobile

From

Power

Amplifier/

To / From

Internal

Antenna

Devices

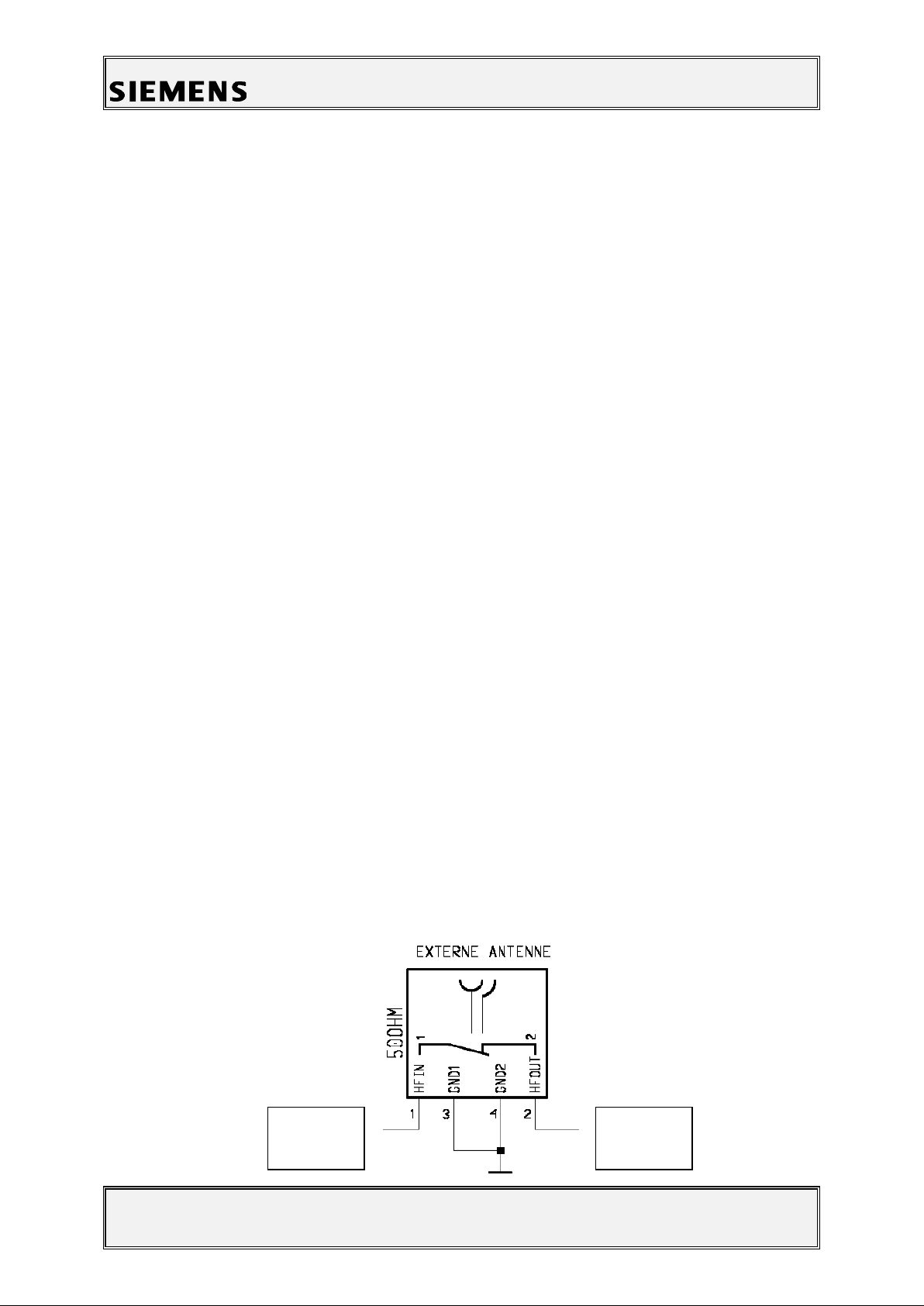

2 Antenna Connector

2.1 Affected Units

2.1.1 Type: C/M/S35

2.1.2 Affected IMEIs / Date Codes: All / All

2.1.3 Affected SW-Versions: All

2.2 Fault Description

2.2.1 Fault Symptoms for customers:

Network Search when using the external antenna

(carkit)

No location update possible on external antenna (carkit)

2.2.2 Fault Symptom on GSM-Tester:

Output power problems on the external antenna

No location update possible

2.2.3 Component Information

The Antenna Connector is a mechanical switch operated by the RF plug of a carkit or, for testing

purposes, of an RF clip.

Normally the RF signal goes to and comes from the internal antenna. Whenever an RF plug is plugged

into the antenna connector the connection to the internal antenna is opened and the connection to the

external antenna socket is made. See drawing below.

V1.3 Page 4 of 41 ICM D CC ST

D. Schnoor

12/01

Page 5

Information and Communication Mobile

Devices

2.3 Priority:

........ Mandatory

........ Repair

........ Optional

........ Not Yet Defined

2.4 Repair Documentation

2.4.1 Description of procedure:

2.4.1.1 Diagnosis

Check the output power of the handset with the LSO testprogram.

Especially watch the external antenna power!

2.4.1.2 Repair by component change

Use hot air blower to remove defective connector

Avoid excessive heat!

Watch surrounding components!

Resolder new connector afterwards.

2.4.1.3 Repair by SW-Booting

Not possible!

2.4.1.4 Test

Retest handset after repair as described above.

2.4.2 List of needed material

2.4.2.1 Components

X35 antenna connector

Attention: This is not the same connector as C25/S25 !!!

Part-Number: L36334-Z93-C272

V1.3 Page 5 of 41 ICM D CC ST

D. Schnoor

12/01

Page 6

Information and Communication Mobile

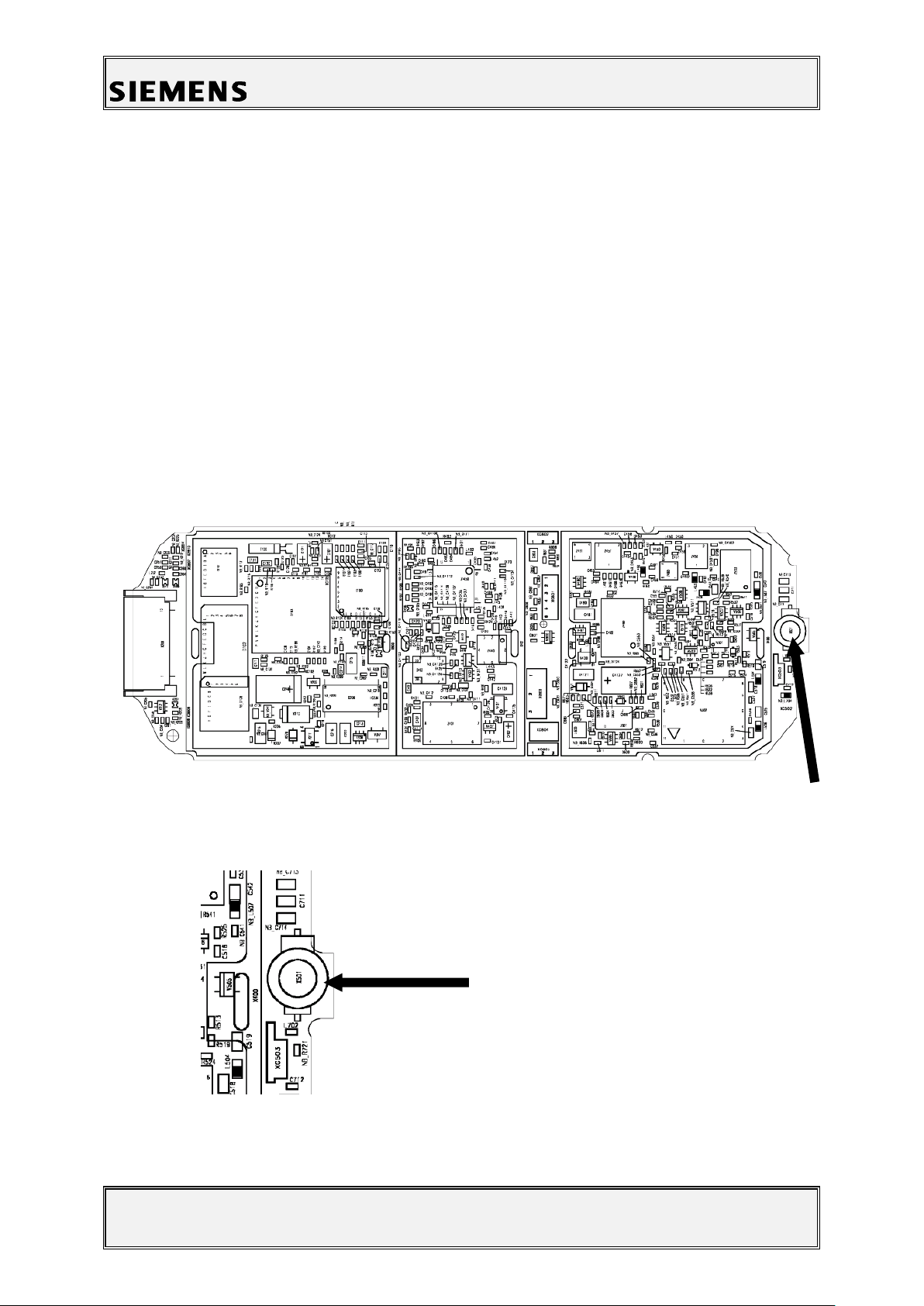

Figure 1: X35 Board Antenna Connector Side (Top View)

Figure 2: X35 Antenna Connector Placement (X501) (Top View)

Devices

2.4.2.2 Jigs and Tools

Hot Air Blower

Soldering Iron

2.4.2.3 Special Tools

None

2.4.2.4 Working materials

Desolder Wick / Braid

Solder

2.4.3 Drawings

V1.3 Page 6 of 41 ICM D CC ST

D. Schnoor

12/01

Page 7

Information and Communication Mobile

Devices

3 Ringer

3.1 Affected Units

3.1.1 Type: C/M/S35

3.1.2 Affected IMEIs / Date Codes: All / All

3.1.3 Affected SW-Versions: All

3.2 Fault Description

3.2.1 Fault Symptoms for customers:

Problems with the handset ringer. No ringer tone

audible.

3.2.2 Fault Symptom on GSM-Tester:

Handset fails ringer test.

3.3 Priority:

........ Mandatory

........ Repair

........ Optional

........ Not Yet Defined

V1.3 Page 7 of 41 ICM D CC ST

D. Schnoor

12/01

Page 8

Information and Communication Mobile

Devices

3.4 Repair Documentation

3.4.1 Description of procedure:

3.4.1.1 Diagnosis

Visually check the ringer. Watch for physical damage or dry joints.

3.4.1.2 Repair by component change

Resolder dry soldering joints.

If the ringer is physically damaged use hot air blower or wick to remove

defective connector.

Avoid excessive heat!

Watch surrounding components!

Resolder new ringer afterwards.

3.4.1.3 Repair by SW-Booting

Not possible!

3.4.1.4 Test

Retest handset after repair.

3.4.2 List of needed material

3.4.2.1 Components

Ringer P35:

Part-Number: L36178-Z2-C26

3.4.2.2 Jigs and Tools

Hot Air Blower

Soldering Iron

V1.3 Page 8 of 41 ICM D CC ST

D. Schnoor

12/01

Page 9

Information and Communication Mobile

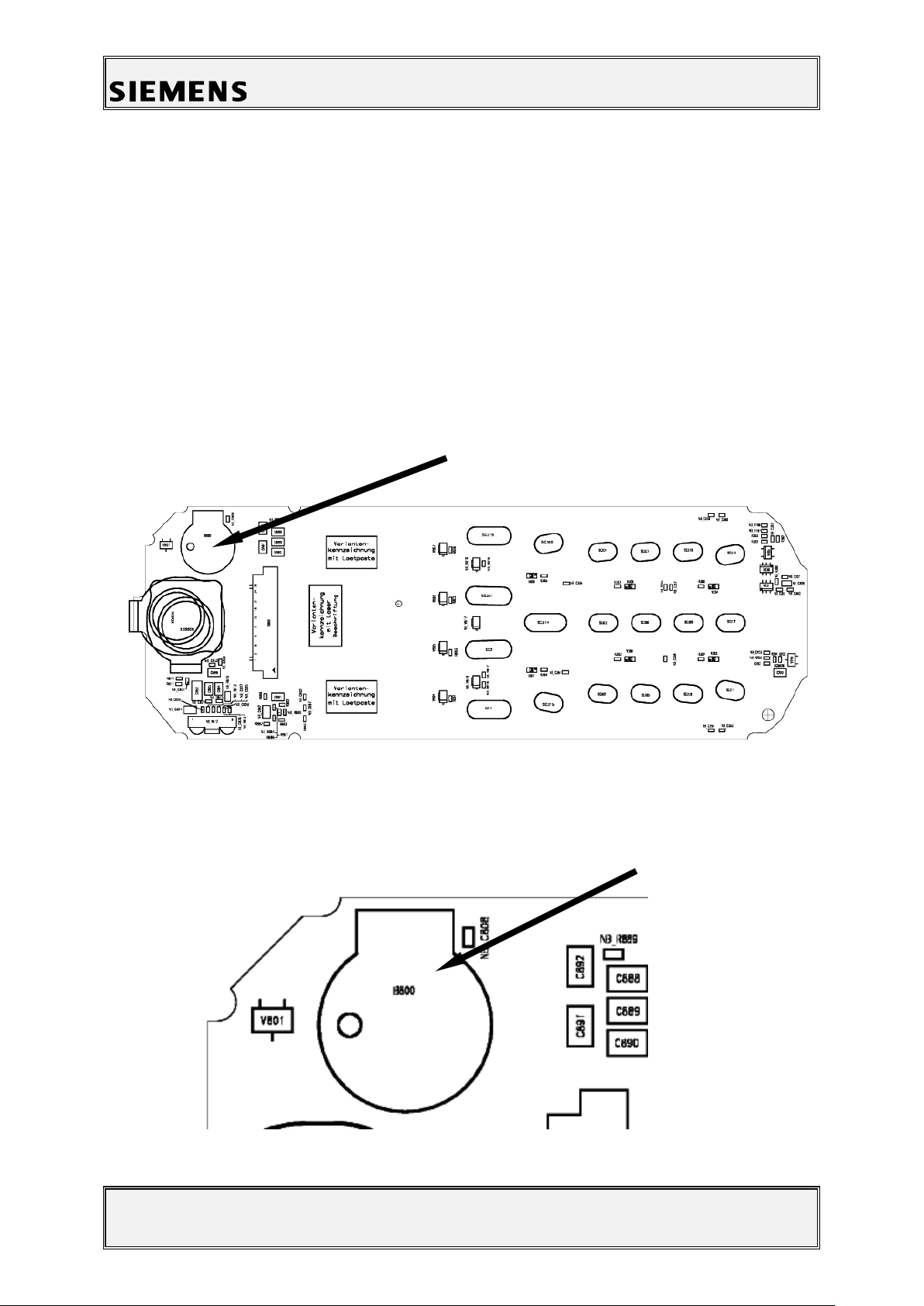

Figure 1: X35 Board Ringer Side

Figure 2: X35 Ringer (B800) Placement (Top View)

Devices

3.4.2.3 Special Tools

None

3.4.2.4 Working materials

Desolder Wick / Braid

Solder

Flux

3.4.3 Drawings

V1.3 Page 9 of 41 ICM D CC ST

D. Schnoor

12/01

Page 10

Information and Communication Mobile

Devices

4 Bottom Connector (Lumberg)

4.1 Affected Units

4.1.1 Type: C/M/S35

4.1.2 Affected IMEIs / Date Codes: All / All

4.1.3 Affected SW-Versions: All

4.2 Fault Description

4.2.1 Fault Symptoms for customers:

Charging problems.

Problems with external loudspeaker or microphone

when using a car kit.

Problems with accessories connected at the bottom

connector.

Problems with SW booting.

4.2.2 Fault Symptom on GSM-Tester:

This problem cannot be detected with a GSM-Tester.

4.3 Priority:

........ Mandatory

........ Repair

........ Optional

........ Not Yet Defined

V1.3 Page 10 of 41 ICM D CC ST

D. Schnoor

12/01

Page 11

Information and Communication Mobile

Devices

4.4 Repair Documentation

4.4.1 Description of procedure:

4.4.1.1 Diagnosis

Visually check the bottom connector. Watch for dry joints!

4.4.1.2 Repair by component change

Use hot air blower remove defective bottom connector.

Avoid excessive heat!

Watch surrounding components!

Resolder new bottom connector afterwards.

4.4.1.3 Repair by SW-Booting

Not possible!

4.4.1.4 Test

Retest handset after repair.

4.4.2 List of needed material

4.4.2.1 Components

Bottom Connector X35

Part-Number: L36334-Z93-C262

4.4.2.2 Jigs and Tools

Hot Air Blower

Soldering Iron

4.4.2.3 Special Tools

None

V1.3 Page 11 of 41 ICM D CC ST

D. Schnoor

12/01

Page 12

Information and Communication Mobile

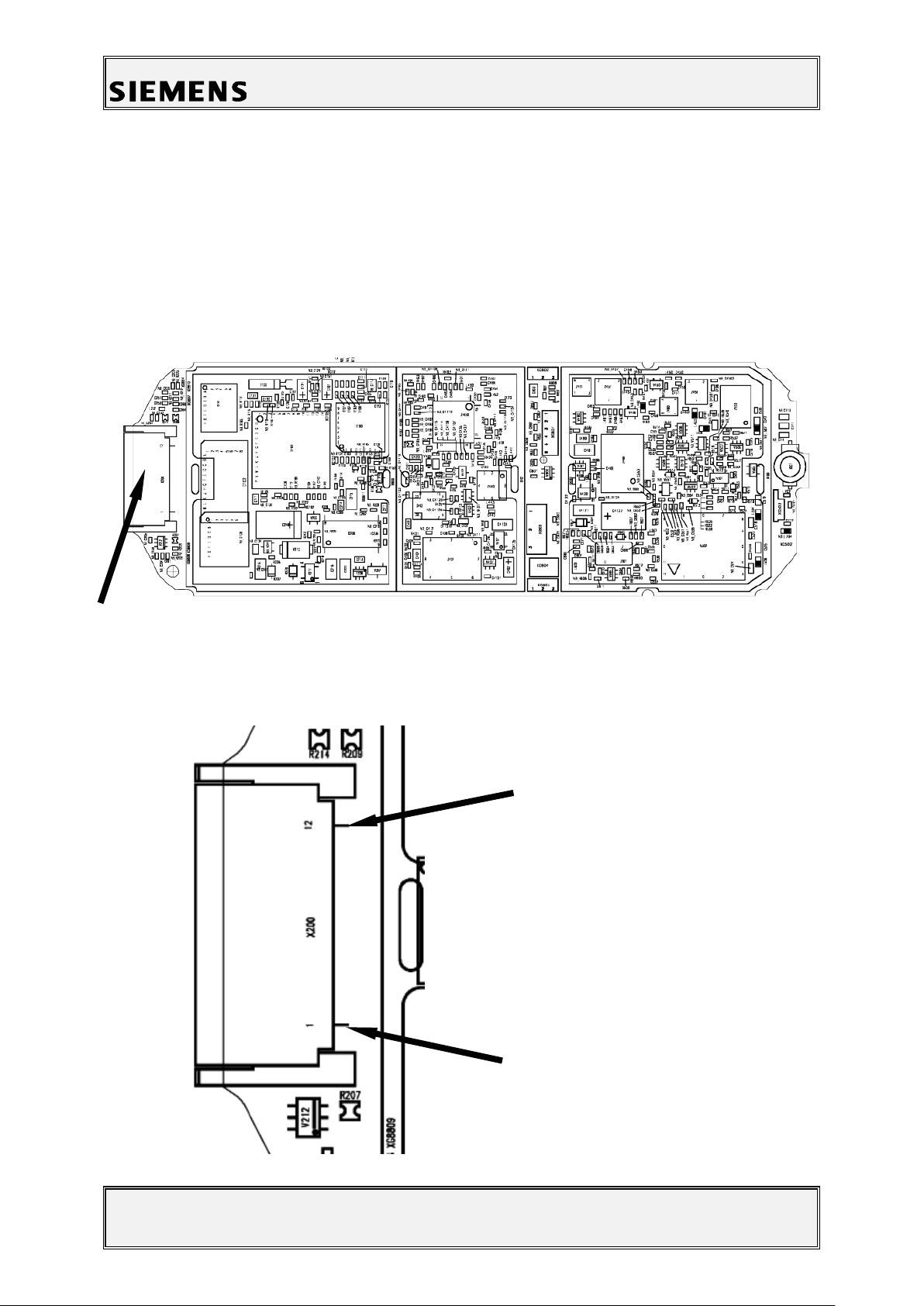

Figure 1: X35 Board Bottom Connector Side

Figure 2: X35 Bottom Connector Placement (Top View)

Pin 12

Pin 1

Devices

4.4.2.4 Working materials

Desolder Wick / Braid

Solder

4.4.3 Drawings

V1.3 Page 12 of 41 ICM D CC ST

D. Schnoor

12/01

Page 13

Information and Communication Mobile

Pin

Name

IN/OUT

Notes

1

GND

2

SB

I/O

Charger coding and

charger control.

3

POWER

I

Charging Current

4

FBatt+

O

Power supply for the

accessories.

5

TX O Serial interface

6

RX I Serial interface

7

ZUB_CLK

I/O

Clock line for

accessory bus

Use as DTC In data

operation

8

ZUB_DATA

I/O

Data line for

accessory bus.

Use as CTS in data

operation

9

GND_MIC

For external

microphone

10

HF_MIC

I

External microphone

11

AUDO

O

Trigger for external

loudspeaker

12

GNDA

For external

loudspeaker

Table 1: X35 Bottom Connector Pin Description

Devices

V1.3 Page 13 of 41 ICM D CC ST

D. Schnoor

12/01

Page 14

Information and Communication Mobile

Devices

5 Display Connector

5.1 Affected Units

5.1.1 Type: C/M/S 35

5.1.2 Affected IMEIs / Date Codes: All / All

5.1.3 Affected SW-Versions: All

5.2 Fault Description

5.2.1 Fault Symptoms for customers:

Display problems, like missing lines or columns on the

LCD or display contrast problems.

5.2.2 Fault Symptom on GSM-Tester:

Display test fails.

5.3 Priority:

........ Mandatory

........ Repair

........ Optional

........ Not Yet Defined

V1.3 Page 14 of 41 ICM D CC ST

D. Schnoor

12/01

Page 15

Information and Communication Mobile

Devices

5.4 Repair Documentation

5.4.1 Description of procedure:

5.4.1.1 Diagnosis

Visually check the status of the display connector. Watch for oxidation

and dry solder joints.

Mechanically check the opening / closing mechanism.

5.4.1.2 Repair by component change

Use hot air to remove defective connector

Avoid excessive heat!

Watch surrounding components!!

Resolder new connector afterwards

5.4.1.3 Repair by SW-Booting

Not possible!

5.4.1.4 Test

Retest handset after repair.

V1.3 Page 15 of 41 ICM D CC ST

D. Schnoor

12/01

Page 16

Information and Communication Mobile

Devices

5.4.2 List of needed material

5.4.2.1 Components Display connector

Part-Number: L36195-Z26-C629

5.4.2.2 Jigs and Tools

Soldering Iron

Hot Air Blower

5.4.2.3 Special Tools

None

5.4.2.4 Working materials

Desolder Wick / Braid

Solder

V1.3 Page 16 of 41 ICM D CC ST

D. Schnoor

12/01

Page 17

Information and Communication Mobile

Figure 1: X35 board display connector side

Figure 2: X35 display connector placement (Top View)

Devices

5.4.3 Drawings

V1.3 Page 17 of 41 ICM D CC ST

D. Schnoor

12/01

Page 18

Information and Communication Mobile

Devices

6 Keyboard LEDs

6.1 Affected Units

6.1.1 Type: C/M/S 35

6.1.2 Affected IMEIs / Date Codes: All / All

6.1.3 Affected SW-Versions: All

6.2 Fault Description

6.2.1 Fault Symptoms for customers:

Keyboard Illumination not working.

6.2.2 Fault Symptom on GSM-Tester:

This fault cannot be detected with a GSM-Tester

6.3 Priority:

........ Mandatory

........ Repair

........ Optional

........ Not Yet Defined

V1.3 Page 18 of 41 ICM D CC ST

D. Schnoor

12/01

Page 19

Information and Communication Mobile

Devices

6.4 Repair Documentation

6.4.1 Description of procedure:

6.4.1.1 Diagnosis

Use the diode test function of a multimeter to check the status of the

diode.

The typical voltage drop on the diode is 1.7V when testing the diode

function with the multimeter.

6.4.1.2 Repair by component change

Use soldering iron to remove defective diode

Avoid excessive heat!

Watch surrounding components!

Resolder new diode afterwards.

6.4.1.3 Repair by SW-Booting

Not possible!

6.4.1.4 Test

Retest handset after repair.

6.4.2 List of needed material

6.4.2.1 Components

LED keyboard X35

Part-Number: L36840-L2031-D670

6.4.2.2 Jigs and Tools

Hot Air Blower

Soldering Iron

V1.3 Page 19 of 41 ICM D CC ST

D. Schnoor

12/01

Page 20

Information and Communication Mobile

Figure 1: X35 board keyboard LED Side

Figure 2: X35 keyboard LED placement and polarity (top view)

Devices

6.4.2.3 Special Tools

None

6.4.2.4 Working materials

Desolder Wick / Braid

Solder

6.4.3 Drawings

V1.3 Page 20 of 41 ICM D CC ST

D. Schnoor

12/01

Page 21

Information and Communication Mobile

Devices

7 Display LEDs

7.1 Affected Units

7.1.1 Type: C/M/S 35

7.1.2 Affected IMEIs / Date Codes: All / All

7.1.3 Affected SW-Versions: All

7.2 Fault Description

7.2.1 Fault Symptoms for customers:

Display Illumination not working.

7.2.2 Fault Symptom on GSM-Tester:

This fault cannot be detected with a GSM-Tester

7.3 Priority:

........ Mandatory

........ Repair

........ Optional

........ Not Yet Defined

V1.3 Page 21 of 41 ICM D CC ST

D. Schnoor

12/01

Page 22

Information and Communication Mobile

Devices

7.4 Repair Documentation

7.4.1 Description of procedure:

7.4.1.1 Diagnosis

Use the diode test function of a multimeter to check the status of the

diode.

The typical voltage drop on the diode is 1.7V when testing the diode

function with the multimeter.

Attention: There are two different types of display LEDs, one for

C/M35 and one for S35! Also they use different placement

location, see drawings 1 and 3.

7.4.1.2 Repair by component change

Use soldering iron to remove defective diode

Avoid excessive heat!

Watch surrounding components!

Resolder new diode afterwards.

7.4.1.3 Repair by SW-Booting

Not possible!

7.4.1.4 Test

Retest handset after repair.

7.4.2 List of needed material

7.4.2.1 Components

Display LED S35

Part-Number: L36840-L2048-D670

Display LED C/M35

Part-Number: L36840-L2047-D670

7.4.2.2 Jigs and Tools

Hot Air Blower

Soldering Iron

V1.3 Page 22 of 41 ICM D CC ST

D. Schnoor

12/01

Page 23

Information and Communication Mobile

Figure 1: C/M35 board display LED Side

Figure 2: C/M35 board display LED placement and polarity

Devices

7.4.2.3 Special Tools

None

7.4.2.4 Working materials

Desolder Wick / Braid

Solder

7.4.3 Drawings

V1.3 Page 23 of 41 ICM D CC ST

D. Schnoor

12/01

Page 24

Information and Communication Mobile

Figure 3: S35 board display LED side

Figure 4: S35 board display LED placement and polarity

Devices

V1.3 Page 24 of 41 ICM D CC ST

D. Schnoor

12/01

Page 25

Information and Communication Mobile

Devices

8 Infrared Diodes

8.1 Affected Units

8.1.1 Type: S 35

8.1.2 Affected IMEIs / Date Codes: All / All

8.1.3 Affected SW-Versions: All

8.2 Fault Description

8.2.1 Fault Symptoms for customers:

No infrared connection possible.

8.2.2 Fault Symptom on GSM-Tester:

This fault cannot be detected with a GSM-Tester.

8.3 Priority:

........ Mandatory

........ Repair

........ Optional

........ Not Yet Defined

V1.3 Page 25 of 41 ICM D CC ST

D. Schnoor

12/01

Page 26

Information and Communication Mobile

Devices

8.4 Repair Documentation

8.4.1 Description of procedure:

8.4.1.1 Diagnosis

Visually check the status of the IrDa module. Watch for dry solder

joints.

Use a reference infrared port (eg. from a notebook) to check the IrDa

function. If the notebook recognizes the S35, the infrared function is

ok.

8.4.1.2 Repair by component change

Use hot air to remove defective infrared module.

Avoid excessive heat!

Watch surrounding components!!

Resolder new module afterwards

8.4.1.3 Repair by SW-Booting

Not possible!

8.4.1.4 Test

Retest handset after repair.

V1.3 Page 26 of 41 ICM D CC ST

D. Schnoor

12/01

Page 27

Information and Communication Mobile

Devices

8.4.2 List of needed material

8.4.2.1 Components Infrared module S35

Part-Number: L36810-U6030-D670

8.4.2.2 Jigs and Tools

Soldering Iron

Hot Air Blower

8.4.2.3 Special Tools

None

8.4.2.4 Working materials

Desolder Wick / Braid

Solder

V1.3 Page 27 of 41 ICM D CC ST

D. Schnoor

12/01

Page 28

Information and Communication Mobile

Figure 1: S35 board infrared module side

Figure 2: S35 infrared module placement (Top View)

Devices

8.4.3 Drawings

V1.3 Page 28 of 41 ICM D CC ST

D. Schnoor

12/01

Page 29

Information and Communication Mobile

Devices

9 Charging Diode V210

9.1 Affected Units

9.1.1 Type: C/M/S35

9.1.2 Affected IMEIs / Date Codes: All / All

9.1.3 Affected SW-Versions: All

9.2 Fault Description

9.2.1 Fault Symptoms for customers:

Charging symbol in the display even if no charger is

connected.

Very low standby time and deeply discharged batteries.

9.2.2 Fault Symptom on GSM-Tester:

This fault cannot be detected with a GSM-Tester.

9.3 Priority:

........ Mandatory

........ Repair

........ Optional

........ Not Yet Defined

V1.3 Page 29 of 41 ICM D CC ST

D. Schnoor

12/01

Page 30

Information and Communication Mobile

Charging

Voltage

input

V210

a)

b)

Devices

9.4 Repair Documentation

9.4.1 Description of procedure:

9.4.1.1 General Information

The purpose of the diode V210 is to prevent the feedback of the

battery voltage to the charging circuitry. That would make the

microprocessor detect a charging voltage which is not present in reality

causing

a) The charging symbol to appear on the display and/or

b) The battery to be drained constantly, even when the phone is

switched off.

The above circuit diagram extract shows the power supply IC including the charging circuitry.

The charging voltage coming from the bottom connector is called POWER and it is

connected to the charging circuitry a) and to the microporocessor as a signal called

EXT_POWER_UC. This signal is the charging voltage divided down by the two resistors

R227 and R229 and it is led to one of the microprocessor port pins. It indicates the presence

of the charger to the microprocessor triggering the display of the charging symbol.

V1.3 Page 30 of 41 ICM D CC ST

D. Schnoor

12/01

Page 31

Information and Communication Mobile

Devices

If the diode V210 is defective it opens from pin one to pin 2, meaning it does not block the

battery voltage from going to the charging transistor V211 anymore. This FET has a

(unwanted) diode from pin 2,5,6 to pin 4 which opens and connects the battery voltage with

the POWER signal and therefore also with the EXT_POWER_UC signal. In this case the

charging symbol appears on the display. Sometimes, if the battery voltage is very low, the

charging symbol may not appear, but the constant current flow will discharge the battery

anyway, even when the phone is switched off.

This will of course significantly reduce the standby time and may even lead to a

deeply discharged battery!

9.4.1.2 Diagnosis

Check the status (reverse blocking) of the diode V210 with a

multimeter.

9.4.1.3 Repair by component change

Use soldering iron to remove defective diode.

Avoid excessive heat!

Watch surrounding components!!

Resolder new diode afterwards

9.4.1.4 Repair by SW-Booting

Not possible!

V1.3 Page 31 of 41 ICM D CC ST

D. Schnoor

12/01

Page 32

Information and Communication Mobile

Devices

9.4.1.5 Test

Retest handset after repair

9.4.2 List of needed material

9.4.2.1 Components Diode V210

Part-Number: L36840-D5055-D670

9.4.2.2 Jigs and Tools

Soldering Iron

Hot Air Blower

9.4.2.3 Special Tools

None

9.4.2.4 Working materials

Desolder Wick / Braid

Solder

V1.3 Page 32 of 41 ICM D CC ST

D. Schnoor

12/01

Page 33

Information and Communication Mobile

Figure 1: X35 V210 side

Figure 2: X35 V210 placement (Top View)

Devices

9.4.3 Drawings

V1.3 Page 33 of 41 ICM D CC ST

D. Schnoor

12/01

Page 34

Information and Communication Mobile

Devices

10 Diplexer Z503

10.1 Affected Units

10.1.1 Type: C/M/S35

10.1.2 Affected IMEIs / Date Codes: All / All

10.1.3 Affected SW-Versions: All

10.2 Fault Description

10.2.1 Fault Symptoms for customers:

Handset cannot register with the GSM-900 network.

10.2.2 Fault Symptom on GSM-Tester:

Handset Rx-Sensitivity is too low.

10.3 Priority:

........ Mandatory

........ Repair

........ Optional

........ Not Yet Defined

V1.3 Page 34 of 41 ICM D CC ST

D. Schnoor

12/01

Page 35

Information and Communication Mobile

a)

Z503

Devices

10.4 Repair Documentation

10.4.1 Description of procedure:

10.4.1.1 General Information

The purpose of the diplexer is the following:

A) Switching the Rx RF signal coming from the antenna to either the

GSM-900 or GSM-1800 receiver chain.

B) Switching of the Tx RF signal from either the GSM-900 or GSM-

1800 Tx output to the antenna.

V1.3 Page 35 of 41 ICM D CC ST

D. Schnoor

12/01

Page 36

Information and Communication Mobile

Devices

The above circuit diagram extract shows the diplexer IC including the external circuitry. The

diplexer switching direction is controlled by the four control inputs VC1 (pin 2), VC2 (4), VC3

(8), VC4 (10).

The input VC2 is used to switch the Rx_GSM-900 direction. If the diplexer is defective then

the diplexer cannot switch to this direction anymore. As a result of this the phone loses about

25-30 dB when receiving GSM-900 signals.

Important: There are two different types of diplexer used for C/M/S35. Only the silver

type produced by Murata, labeled with a small M is affected by the problem

described above.

There is also another type produced by TDK. This type has a golden housing

and a small hole in the upper right corner. This type is not affected. The

different types have a different external circuitry and are not interchangeable!

10.4.1.2 Diagnosis

Check the status of the diplexer Z503 with a multimeter. Measure the

resistance of pin 4 against ground. It must be around 20k Ohms. If the

diplexer is defective the measured value will be significantly lower, e.g.

2k Ohms. This value however may differ.

Note:

To make the measurement easier, as seen in the circuit diagram

above, you can also use pin 6 of V506. This pin can be reached easier

than pin 4 of Z503.

10.4.1.3 Repair by component change

Use hot air to remove defective diplexer.

Avoid excessive heat!

Watch surrounding components!!

Resolder new diplexer afterwards.

10.4.1.4 Repair by SW-Booting

Not possible!

10.4.1.5 Test

Retest handset after repair

V1.3 Page 36 of 41 ICM D CC ST

D. Schnoor

12/01

Page 37

Information and Communication Mobile

Devices

10.4.2 List of needed material

10.4.2.1 Components

Diplexer Z503

Part-Number: L36145-K280-Y137

10.4.2.2 Jigs and Tools

Soldering Iron

Hot Air Blower

10.4.2.3 Special Tools

None

10.4.2.4 Working materials

Desolder Wick / Braid

Solder

V1.3 Page 37 of 41 ICM D CC ST

D. Schnoor

12/01

Page 38

Information and Communication Mobile

Figure 1: X35 Z503 side

Figure 2: X35 Z503 placement (Top View)

Pin 6 of V506

Devices

10.4.3 Drawings

V1.3 Page 38 of 41 ICM D CC ST

D. Schnoor

12/01

Page 39

Information and Communication Mobile

Devices

11 Voltage Protection Diode V279

11.1 Affected Units

11.1.1 Type: C/M/S35

11.1.2 Affected IMEIs / Date Codes: All / All

11.1.3 Affected SW-Versions: All

11.2 Fault Description

11.2.1 Fault Symptoms for customers:

External equipment which needs power via the I/O

connector does not work.

11.2.2 Fault Symptom on GSM-Tester:

BATT+ rises too fast

11.3 Priority:

........ Mandatory

........ Repair

........ Optional

........ Not Yet Defined

V1.3 Page 39 of 41 ICM D CC ST

D. Schnoor

12/01

Page 40

Information and Communication Mobile

Devices

11.4 Repair Documentation

11.4.1 Description of procedure:

11.4.1.1 General Information

The purpose of the diode V279 is to prevent the feedback of external

connected equipment. An external voltage, connected to the I/O

connector, may damage the accumulator.

11.4.1.2 Diagnosis

Check the status (reverse blocking) of the diode V279 with a

multimeter.

11.4.1.3 Repair by component change

Use soldering iron to remove defective diode.

Avoid excessive heat!

Watch surrounding components!!

Resolder new diode afterwards

11.4.1.4 Repair by SW-Booting

Not possible!

11.4.1.5 Test

Retest handset after repair

11.4.2 List of needed material

11.4.2.1 Components

Diode V279

Part-Number: L36840-D5059-D670

11.4.2.2 Jigs and Tools

Soldering Iron

Hot Air Blower

V1.3 Page 40 of 41 ICM D CC ST

D. Schnoor

12/01

Page 41

Information and Communication Mobile

V279

Devices

11.4.2.3 Special Tools

None

11.4.2.4 Working materials

Desolder Wick / Braid

Solder

11.4.2.5 Drawings

Figure 1: X35 V279 side

Figure 2: X35 V279 placement (Top View)

V1.3 Page 41 of 41 ICM D CC ST

D. Schnoor

12/01

Loading...

Loading...