Page 1

Information

Base Station System

Technical Description (TED:BSS)

BS-240/241

A30808-X3247-L14-2-7618

Page 2

Technical Description (TED:BSS)

BS-240/241

Information

Base Station System

!

Important Notice on Product Safety

DANGER - RISK OF ELECTRICAL SHOCK OR DEATH - FOLLOW ALL INSTALLATION INSTRUCTIONS.

The system complies with the standard EN 60950 / IEC 60950. All equipment connected to the system must

comply with the applicable safety standards.

HazardousvoltagesarepresentattheACpowersupplylinesinthiselectricalequipment.Somecomponentsmay

also have high operating temperatures.

Failure to observe and follow all installation and safety instructions can result in serious personal injury

or property damage.

Therefore, only trained and qualified personnel may install and maintain the system.

The same text in German:

Wichtiger Hinweis zur Produktsicherheit

LEBENSGEFAHR - BEACHTEN SIE ALLE INSTALLATIONSHINWEISE.

Das System entspricht den Anforderungen der EN 60950 / IEC 60950. Alle an das System angeschlossenen

Geräte müssen die zutreffenden Sicherheitsbestimmungen erfüllen.

In diesen Anlagen stehen die Netzversorgungsleitungen unter gefährlicher Spannung. Einige Komponenten

können auch eine hohe Betriebstemperatur aufweisen.

Nichtbeachtung der Installations- und Sicherheitshinweise kann zu schweren Körperverletzungen oder

Sachschäden führen.

Deshalb darf nur geschultes und qualifiziertes Personal das System installieren und warten.

Caution:

This equipment has been tested and found to comply with EN 301489. Its class of conformity is defined in table

A30808-X3247-X910-*-7618, which is shipped with each product. This class also corresponds to the limits for a

Class A digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment.

This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the relevant standards referenced in the manual “Guide to Documentation”, may cause harmful interference to radio communications.

For system installations it is strictly required to choose all installation sites according to national and local requirements concerning construction rules and static load capacities of buildings and roofs.

Forallsites,inparticular in residential areas it is mandatory to observe all respectively applicable electromagnetic

field / force (EMF) limits. Otherwise harmful personal interference is possible.

Trademarks:

Alldesignationsused in this document can be trademarks, the use of which bythirdpartiesfor their own purposes

could violate the rights of their owners.

Copyright (C) Siemens AG 2003.

Issued by the Information and Communication Mobile Group

Hofmannstraße 51

D-81359 München

Technical modifications possible.

Technical specifications and features are binding only insofar as

they are specifically and expressly agreed upon in a written contract.

2

A30808-X3247-L14-2-7618

Page 3

Information

Base Station System

Technical Description (TED:BSS)

BS-240/241

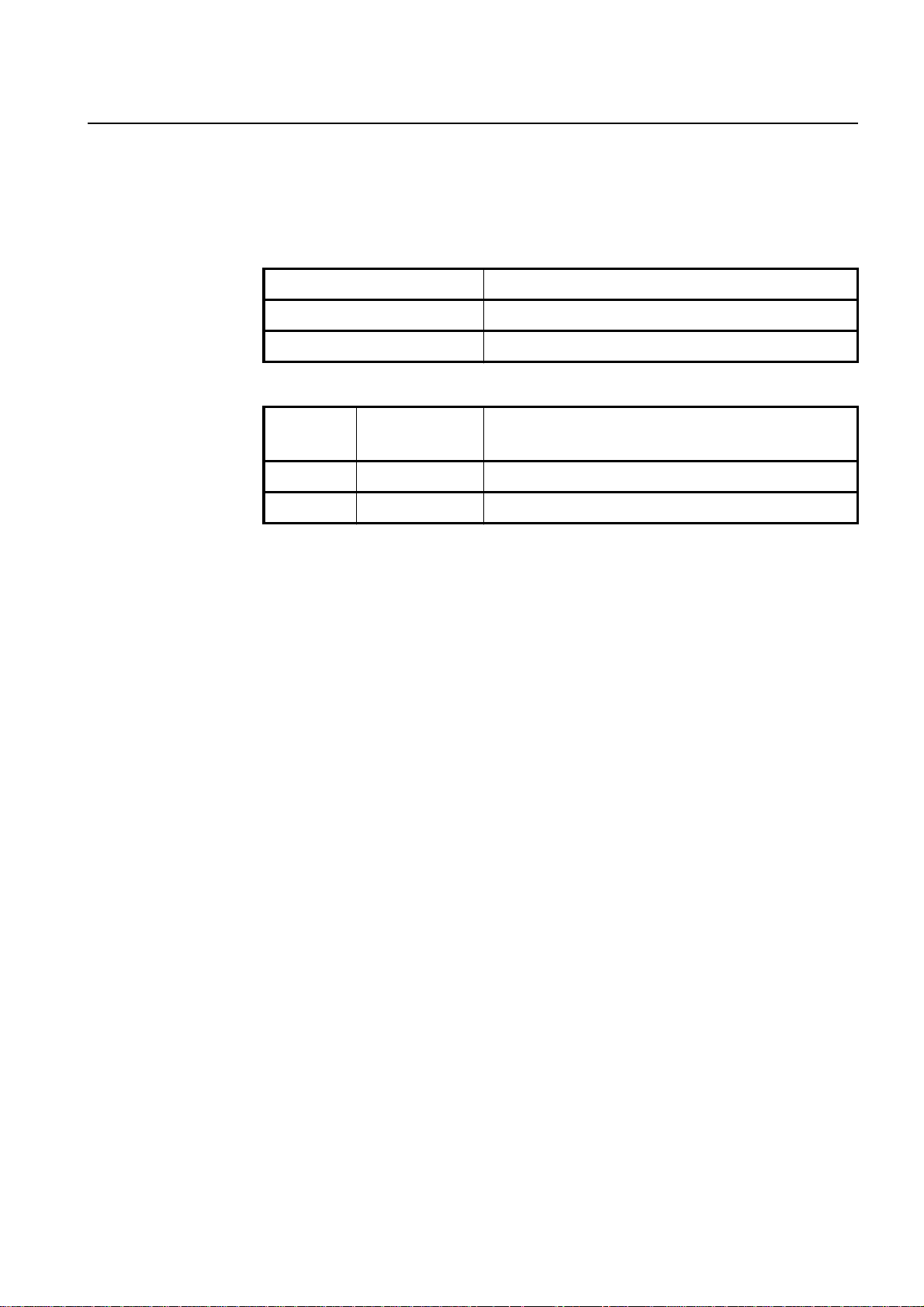

Reason for Update

Summary:

Second Edition for Release BR7.0

Details:

Chapter/Section Reason for Update

All New Release BR7.0

Revised Chapter

Issue History

Issue

Number

1 07/2003 First Edition for new Release BR7.0

2 12/2003 Second Edition for Release BR7.0

Date of issue Reason for Update

A30808-X3247-L14-2-7618

3

Page 4

Technical Description (TED:BSS)

BS-240/241

Information

Base Station System

4

A30808-X3247-L14-2-7618

Page 5

Information

Base Station System

Technical Description (TED:BSS)

BS-240/241

This document consists of a total of 70 pages. All pages are issue 2.

Contents

1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1 Main Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.2 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2 Hardware Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.1 Board Redundancy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.1.1 AC/DC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.1.2 Core . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.2 Power Amplifier Output Level (typical values) . . . . . . . . . . . . . . . . . . . . . . 18

2.3 Rack Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3 Description of Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.1 Core (COBA and COSA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.1.1 Core Basis (COBA2P8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.1.2 Core Satellite (COSA6P16) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.2 Carrier Unit (CU). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.3 EDGE Carrier Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.4 GMSK Carrier Units (GCU). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.5 Duplexer Amplifier Multi Coupler (DUAMCO). . . . . . . . . . . . . . . . . . . . . . . 37

3.6 DI(=2) Amplifier Multi Coupler (DIAMCO). . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.7 Filter Combiner (FICOM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.8 Tower Mounted Amplifier (TMA). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.9 High Power Duplexer Unit (HPDU). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.10 DC Panel (DCP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.11 Alarm Collection Terminal (ACT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.12 AC/DC Converter (AC/DC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.12.1 DC and Battery Controller (DCBCTRL) . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.13 Overvoltage Protection and Tracer (OVPT) . . . . . . . . . . . . . . . . . . . . . . . . 41

3.14 Abis Connection Module (ABISCON) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.15 Abis Link Equipment (LE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.16 Cover Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.17 Backup Battery (BATTERY) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.18 Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.19 Heat Exchanger (HEX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

A30808-X3247-L14-2-7618

4 Antenna Combiners and Receiving Paths . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.1 Methods of Combining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.1.1 Typical Combiner Losses (TX path) and Output Power Level . . . . . . . . . . 52

4.1.2 DUAMCO - DIAMCO GAIN (RX Path) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.1.3 Parameters of Tower Mounted Amplifier (TMA) . . . . . . . . . . . . . . . . . . . . 55

4.1.4 Examples of possible BTSE configurations . . . . . . . . . . . . . . . . . . . . . . . . 57

4.2 Receiving Paths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4.2.1 Antenna diversity techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4.2.1.1 Antenna System Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4.2.2 Receiver Sensitivity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

4.3 Transmission Diversity Time Delay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5

Page 6

TechnicalDescription(TED:BSS)

BS-240/241

4.3.1 Functionality. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4.4 FCC Issues (for US Market only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

5 Power Supply and Battery Backup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

5.1 Support of Emergency Operation for 3rd Party BBU System . . . . . . . . . . . 67

6 Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Information

Base Station System

6

A30808-X3247-L14-2-7618

Page 7

Information

Base Station System

Technical Description (TED:BSS)

BS-240/241

Illustrations

Fig. 2.1 BS-240 Indoor Cabinet and BS-241 Outdoor Cabinet (Base Racks) . . 14

Fig. 2.2 Functional Blocks of the BS-240/241. . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Fig. 2.3 Redundant COREs and their Interfaces . . . . . . . . . . . . . . . . . . . . . . . . 17

Fig. 2.4 BS-240 Base Rack and 2 Extension Racks. . . . . . . . . . . . . . . . . . . . . . 20

Fig. 2.5 BS-241 Base Rack and 2 Extension Racks. . . . . . . . . . . . . . . . . . . . . . 21

Fig. 2.6 Possible Configuration of Service1 Rack and Service2 Rack . . . . . . . . 22

Fig. 2.7 BS-240/241 fully Equipped with 24 Carriers . . . . . . . . . . . . . . . . . . . . . 23

Fig. 3.1 Backplane Slot Configuration of Core . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Fig. 3.2 COBA2P8 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Fig. 3.3 Structure of ACLK Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Fig. 3.4 COSA6P16 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Fig. 3.5 Carrier Unit Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Fig. 3.6 PATRX Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Fig. 3.7 Principal Data Flow on SIPRO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Fig. 3.8 EPATRX and ESIPRO Function Block Diagram . . . . . . . . . . . . . . . . . . 34

Fig. 3.9 Data Flow in ESIPRO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Fig. 3.10 Alarm Collection Terminal (ACTM and ACTP). . . . . . . . . . . . . . . . . . . . 40

Fig. 3.11 Example of Battery Backup Systems Connected to the AC/DC . . . . . . 43

Fig. 4.1 Overview of Combining Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Fig. 4.2 DUAMCO 2:2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Fig. 4.3 DUAMCO 4:2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Fig. 4.4 DUAMCO 8:2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Fig. 4.5 FICOM 8:1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Fig. 4.6 DIAMCO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Fig. 4.7 HPDU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Fig. 4.8 Configuration with HPDU, DUBIAS and TMA . . . . . . . . . . . . . . . . . . . . 52

Fig. 4.9 Multi-cell (3,3,2): with 3 DUAMCO 4:2. . . . . . . . . . . . . . . . . . . . . . . . . . 57

Fig. 4.10 Multi-cell (3,3,2): with 2 DUAMCO 4:2 and 1 DUAMCO 2:2 . . . . . . . . . 58

Fig. 4.11 Single-cell (8,0,0): with FICOM and DIAMCO . . . . . . . . . . . . . . . . . . . . 58

Fig. 4.12 Single-cell (8,0,0): with 2 DUAMCO 4:2. . . . . . . . . . . . . . . . . . . . . . . . . 59

Fig. 4.13 Multi-cell (2,2,2): with 3 DUAMCO 2:2. . . . . . . . . . . . . . . . . . . . . . . . . . 59

Fig. 4.14 Single-cell (11...16,0,0): FICOMs, DIAMCOs and HPDUs in 2 Racks. . 60

Fig. 4.15 Capacity Downlink Improvements for TX Diversity . . . . . . . . . . . . . . . . 63

Fig. 4.16 BTS Rack Cabling for Transmitter Diversity Operation . . . . . . . . . . . . . 64

A30808-X3247-L14-2-7618

7

Page 8

Technical Description (TED:BSS)

BS-240/241

Tables

Tab. 1.1 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Tab. 1.2 Frequency Bands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Tab. 2.1 Power Amplifier Output Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Tab. 3.1 Units and Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Tab. 3.2 GMSK/8PSK Linear Modulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Tab. 4.1 Insertion loss of DUAMCOs, FICOMs, HPDU and TMA. . . . . . . . . . . . . 52

Tab. 4.2 Parameters of DUAMCO - DIAMCO. . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Tab. 4.3 Parameters of 900 MHz Tower Mounted Amplifier. . . . . . . . . . . . . . . . . 55

Tab. 4.4 Parameters of 1800 MHz Tower Mounted Amplifier. . . . . . . . . . . . . . . . 56

Tab. 4.5 Parameters of 900/1800 MHz Tower Mounted Amplifier . . . . . . . . . . . . 57

Tab. 4.6 Maximum RF Power Output Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Tab. 4.7 Maximum RF Power Output Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Information

Base Station System

8

A30808-X3247-L14-2-7618

Page 9

Information

Base Station System

Technical Description (TED:BSS)

BS-240/241

1 Introduction

The architecture of BS-240/241 provides maximum flexibility to develop higher capacity

BTSs with reduced volume and an expanded number of 24 TRXs in 3 Racks with a

modularity of 8 TRXs per Rack. Any operation for rack extension or TRX substitution

doesn’t involve service interruption.The provision of a full spectrum of combining equipment allows high power and minimized numberof antennas. High receiversensitivity is

also guaranted.

The modular architecture and the flexible internal structure, enables the BS-240/241 to

provide new GSM features such as EDGE; this platform ensures that network evolution

is as smooth as possible.

The use of the latest technology reduces power consumption and improves reliability;

the reliability is also increased by the redundancy of all core modules. Easy integration

is possible in the already installed sites, for the backward compatibility with existing

SIEMENS SBS systems. High Site efficiency is assured for composite transmit power

with minimal footprint requirements.

Homogenous service throughout the network is assured by common BTS SW running

on all the platforms.

The BS-240/241 primarily consists of:

• Carrier oriented boards called carrier unit (CU),

• Core boards (COSA, COBA) and

• Combining equipment

A30808-X3247-L14-2-7618

9

Page 10

Technical Description (TED:BSS)

BS-240/241

1.1 Main Features

The BS-240/241 is designed for max. 24 carriers in 3 Racks/Shelters plus Service

Racks/Shelters, if needed. The minimum configuration is one Rack or one Shelter with

a Service Rack/Shelter. Service Racks/Shelters can be configured to accommodate

Backup Batteries and Link Equipment. A Service Rack/Shelter can be equipped with

AC/DC Converters. Easy Rack/Shelter Extension is possible with one or two Extension

Racks/Shelters.

The BS-240/241 can be configured for the systems GSM 850, GSM 900, GSM 1800 and

GSM 1900 with the following configurations:

– Single band

– Dualband: GSM 900, GSM 1800; GSM 900, GSM 1900; GSM 850, GSM 1800 and

GSM 850, GSM 1900 :

– GSM 900, GSM 1800 cell mixed frequencies

– Common BCCH channel for GSM 900, GSM 1800 cell (dual band)

– Single cell

– Multi cell

Up to 6 cells per Rack and up to 12 cells can be supported. A special case is the feature

“concentric cell”; one cell with 2 supply areas (inner and complete area). This feature

can be used in omnicells as well as in multicells with sectors.

The following combining options are supported:

– Antenna combining with CU pairs to apply transmission diversity time delay.

– Antennacombining withduplexers(DUAMCO) can be appliedfor 2, 4 and8carriers.

RF amplifier and multicoupler for the RX path are integrated

– Antenna combining with Filter Combiners (FICOM) is possible for up to 8 carriers

onto one TX antenna

– Cascading of multicoupler equipment (DIAMCO) is possible for up to 24 carriers

– High Power Duplexer (HPDU) for reduction of the necessary numbers of antennas

in case of FICOM per cell for up to 8 carriers can be applied

– Every BTSE has core equipment in the Base Rack/Shelter

– Sensitivityis better than GSM requirements at the Rack entry by using DUAMCO or

DIAMCO units

– BTSplus sensitivity is better than GSM requirements at the antenna connector by

using Tower Mounted Amplifiers (TMA)

– EDGE Carrier Units (ECU)

– Mixed Configurations of Cells/Sectors applying both EDGE Carrier Units (ECU) and

“normal” Carrier Units (CU)

Traffic Channels:

– Full-Rate (FR)

– Half-Rate (HR)

– Enhanced Full-Rate (EFR)

– Adaptive Multi Rate Codec (AMR)

Services:

– GPRS

– HSCSD

– EDGE

Frequency Hopping:

– Baseband

– Synthesizer

Information

Base Station System

10

A30808-X3247-L14-2-7618

Page 11

Information

Base Station System

Technical Description (TED:BSS)

BS-240/241

Redundancy:

– SW Support of Core Redundancy

– SW Support of BCCH Redundancy

– AC/DC n+1 redundancy. (n+1) AC/DCConverterswork in load sharing, butn AC/DC

are able to supply the whole BS-240/241 including Service Racks/Shelters

Abis interface:

– Enhanced Full-Rate TCH

– Full-Rate and Half-Rate TCH

– AMR TCH

– Submultiplexing4x16kbit/s onto one 64 kbit/s timeslot for handling Full-Rate TCH

on Um interface

– Handling of 4x(2x8) kbit/s onto one64 kbit/s timeslot for half-rate TCH on Uminter-

face

– Drop and insert feature on 2 Mbit/s (E1) and 1.5 Mbit/s (T1) links is available on a

16 kbit/s and a 64 kbit/s basis

– Star, loop and multidrop chain connections

– Cross connect function

– Change of PCM line configuration from star to multidrop or loop and vice versa is

possible without any interruption of service

– Multiple Abis LAPD links; load sharing and LAPD fault recovery

– External clock synchronisation

– Over-Voltage Protection with OVPT

Abis link media:

– Wire

– Fiber optic

– Micro-Wave

Fault procedures:

– Automatic Recovery procedure of faulty objects in BTS

– Online RF Loopback

A30808-X3247-L14-2-7618

11

Page 12

Technical Description (TED:BSS)

BS-240/241

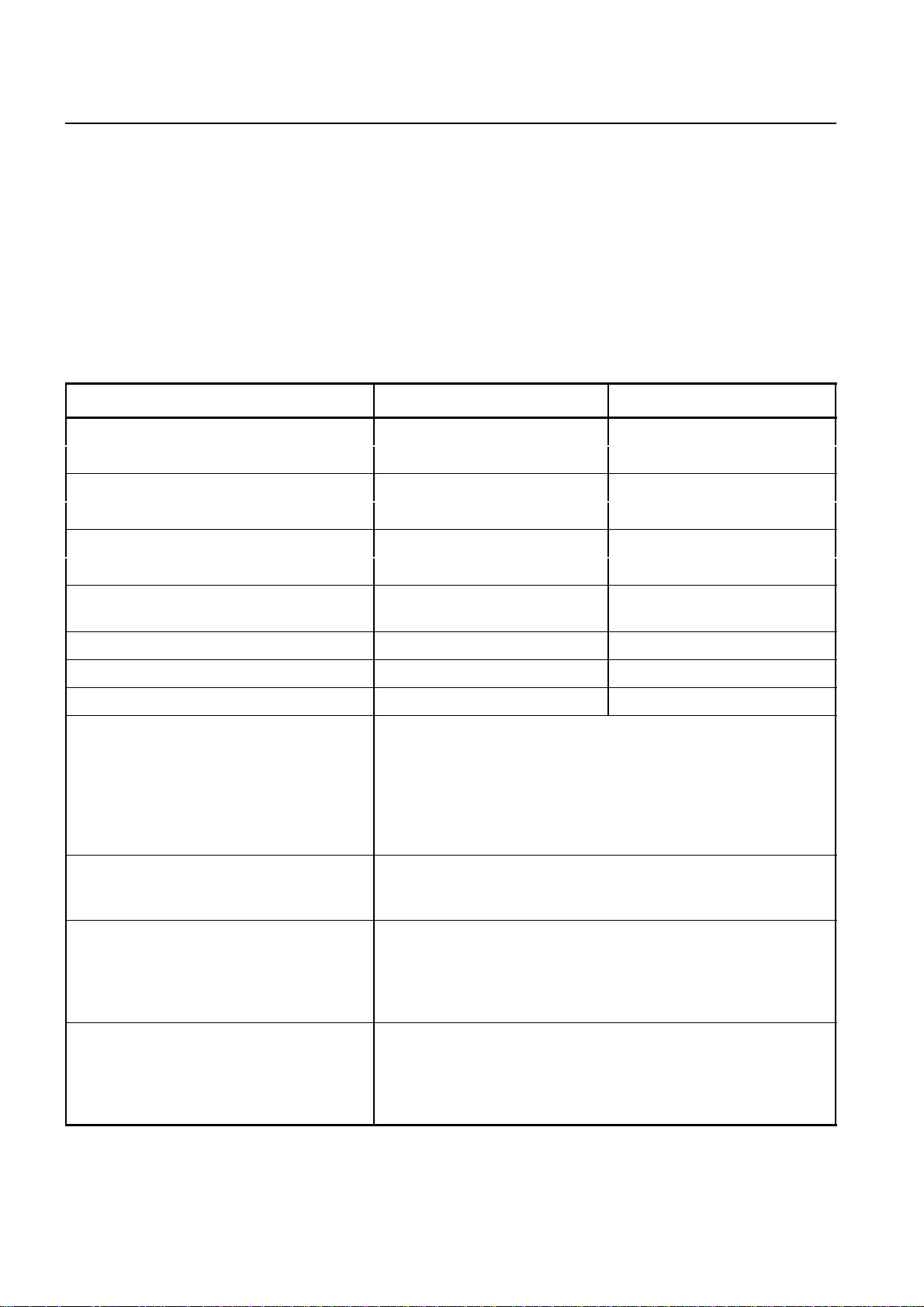

1.2 Technical Data

The BS-240/241 family with 24 transceivers can be supplied in the following versions:

– A BS-240 for indoor installation.

– A BS-241 for outdoor installation (also equipped with: integrated power supply,

battery, microwave equipment, integrated link equipment, heat exchangerand cross

connector).

BS-240/241 consist in a split BTS architecture, with:

- 1 Base Rack

- Up to 2 Extension Racks

- Up to 2 Service Racks (Service1 or Service2).

Characteristics BS-240 (indoor) BS-241 (outdoor)

Max. TRX per BTSE 24 24

(in more than one Rack)

Max. TRX per cell 24 24

(in more than one Rack)

Information

Base Station System

Dimensions (mm) (HxWxD) 1600x600x450 (5’3”x2’x1’6”) 1750x700x650 (5’9”x2’4”x2’2”)

(Base Racks) (incl. Plinth)

Volume net 432 l 705 l

796 l (incl. Plinth)

Maximum power consumption 1600 W 1750 W

Weight of Basic Rack empty ca.60 kg (132 Lbs) ca.60 kg (132 Lbs)

Weight of Shelter empty ca.110 kg (242 Lbs)

Weight of Service1 Rack equipped with: - 1 Frame AC/DC incl. 6 AC/DC Modules (ca. 27 kg/60 Lbs)

- 1 Frame for Battery incl. 1Battery (48V / 85 Ah) (ca. 140 kg/309

Lbs)

-1 Mounting Kitfor Link Equipmentincl. 1 Frame NTPM, Frame for

Fan Unit and two FAN's (ca. 16 kg/ 35 Lbs)

- 1 Rack (ca. 60 kg/132 Lbs)

Sum: ca. 243 kg (536 Lbs)

Weight of Service1 Rack equipped with: - 2 Frames AC/DC and

- 2 Frames for Battery

Not possible: max. 3 Frames pro Rack / Shelter can be equipped.

Weight of Service1 Rack equipped with: - 1 Frame AC/DC incl. 6 AC/DC Modules (ca. 27 kg/60 Lbs)

-1 Mounting Kitfor Link Equipmentincl. 2 Frame NTPM, Frame for

Fan Unit and two FAN's (ca. 21 kg/46 Lbs)

- 1 Rack (ca. 60kg/132 Lbs)

Sum: ca. 108 kg (238 Lbs)

Weight of Frame: Frame with Battery ca. 140 kg (309 Lbs)

FrameAC/DC with 6 AC/DC Modules ca. 27 kg (60 Lbs)

Frame with 4 CU's and 2 MUCO's ca. 40 kg (88 Lbs)

Frame with 4 ACOM's ca. 40 kg (88 Lbs))

1 HEX ca. 5.6 kg (12 Lbs)

Tab. 1.1 Technical Data

12

A30808-X3247-L14-2-7618

Page 13

Information

Base Station System

Characteristics BS-240 (indoor) BS-241 (outdoor)

Technical Description (TED:BSS)

BS-240/241

Temperature range (˚C) -5 °C to +55 °C

+23 °F to +131 °F

Tab. 1.1 Technical Data

Frequency-Band Uplink (MHz) Downlink (MHz)

GSM 850 824.2 - 848.8 869.2 - 893.8

P-GSM 900 (Primary) 890.2 - 914.8 935.2 - 959.8

E-GSM 900 (Extension) 880.2 - 914.8 925.2 - 959.8

R-GSM 900 (Railway) 876.2 - 914.8 921.2 - 959.8

GSM-RE 900 (Railway Extension) 876.2 - 901.0 921.2 - 946.0

GSM 1800 1710.2 -1784.8 1805.2 -1879.8

GSM 1900 1850.2 -1909.8 1930.2 -1989.8

Tab. 1.2 Frequency Bands

-45 °C to +50 °C

-49 °F to +122 °F

A30808-X3247-L14-2-7618

13

Page 14

Technical Description (TED:BSS)

BS-240/241

2 Hardware Architecture

The BS-240/241 is designed to achieve commonality of boards to serve both GSM 850,

GSM 900 with its different deviates (GSM 1800, GSM 1900) and standards selected for

mobile communication systems. Moreover, the architecture of BS-240/241 provides

maximum flexibility to develop large and small BTSs which havesimilar costs per TRX.

Fig. 2.1 shows the Base Rack Cabinets.

Information

Base Station System

Fig. 2.1 BS-240 Indoor Cabinet and BS-241 Outdoor Cabinet (Base Racks)

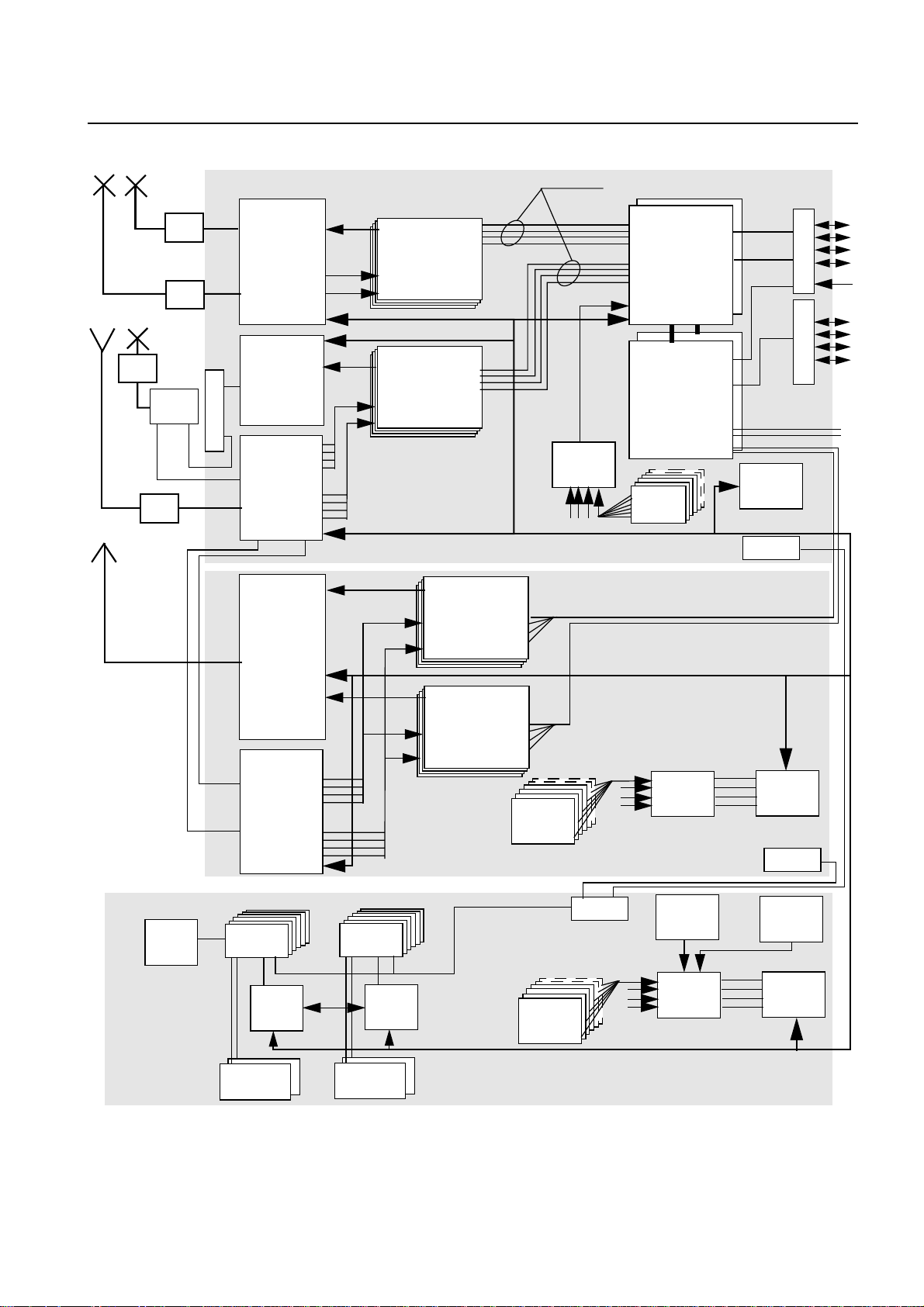

The BTS functional blocks of the BS-240/241 are shown in Fig. 2.2

14

A30808-X3247-L14-2-7618

Page 15

Information

Base Station System

Technical Description (TED:BSS)

BS-240/241

Cell 0

Cell 1

Cell 1

TMA

TMA

TMA

DUBIAS

TMA

Base Rack

DUAMCO

H

P

D

U

RXCA0

FICOM

DIAMCO

FICOM

4xTX

RX

RXDIV

4xTX

RX

RXCA1

RXDIV

4xTX

RXDIV

RX

CU 0

CU 7

CU 0

CC-Links

ACTC

2 PCM

COBA

COSA

FAN

Ext. Sync.

2 PCM

4 PCM

to next ext. rack

*

ACTM

DCP

Extension Rack

O

V

P

O

V

P

T

T

Abis

Sync.

Abis

4xTX

Cascading

DIAMCO

RX

RXDIV

RX

RXDIV

CU 7

Service Rack

ACP

AC/DC

DCBCTRL

BATTERY

AC/DC

DCBCTRL

BATTERY

* not present in case of BTSE with reduced number of fan

FAN

FAN

CAN BUS

*

DCP

*

ACTC

LE 0

ACTC

ACTP

DCP

LE 1

ACTP

Fig. 2.2 Functional Blocks of the BS-240/241

A30808-X3247-L14-2-7618

15

Page 16

Technical Description (TED:BSS)

BS-240/241

AC/DC AC/DC converter DCBCTRL DC and Battery Controller

ACP AC Panel DCP DC Panel

ACTC Alarm Collection Terminal Connection module DIAMCO DI(2) Amplifier Multi Coupler

ACTM Optional Alarm Collection Terminal for Master Rack DUAMCO Duplex Amplifier Multicoupler

ACTP Alarm Collection Terminal for Slave Rack FICOM Filter Combiner

CAN Controller Area Network HPDU High Power Duplexer

COBA Core Basis (COBA2P8) LE Link Equipment

COSA Core Satellite (COSA6P16) TMA Tower Mounted Amplifier

CU Carrier Unit

The architecture of BS-240/241 provides maximum flexibility to develop large and small

BTSs.

The BS-240/241 mainly consists of:

– carrier oriented boards called carrier unit (CU),

– core boards (COSA, COBA) and

– combining equipment

Up to 8PCM linescan beconnected to the core boards. In order to provide cost effective

solutions, the core boards are scalable (COBA, COSA). In addition, also the BTS itself

is scalable. It is possible to connect up to 2 Extension Racks to a Base Rack.

The main communication between the modules is provided by means of bi-directional

serial link communications between the carrier units (CU) and the core boards. The

serial link also provides an effective means to realize baseband frequency hopping.

Despite the fact that synchronization information is also transported via the serial links,

no differential length constraints apply for the lines of the serial link.

All alarms, beside the alarms that are generated in the core and in the CU boards, are

transported via theCAN bus. Alarms of the CU boards are transmitted via CC-Link.Core

boards use their interface bus.

The carrier unit(s) provide all analog and digital signal processing including a RF power

stage necessary to process a single carrier (e.g., GSM 8 TCHs). The carrier unit(s) interface with the combining equipment on the one side and with the core modules on the

other. The core boards provide functions common to all carriers within the BS-240/241

(e.g., clock generation, O&M processing,...) as well as LAPD processing for the different

carriers.

Base Station System

Information

16

A30808-X3247-L14-2-7618

Page 17

Information

Base Station System

2.1 Board Redundancy

2.1.1 AC/DC

2.1.2 Core

Technical Description (TED:BSS)

BS-240/241

Redundancy in the SBS ensures survival of the system even in the event of multiple failures. Modular architecture, in conjunction with the concept of split functions, guarantees

maximum survivability with a minimum of additional hardware.

Up to 6 AC/DC converters can be equipped in the service1 Rack which provide N+1

redundancy. AC/DC converters work in load sharing, but n AC/DC are able to supply the

whole BS-240/241.

The Core can consist of up to 2 (without redundancy) or up to 4 (with redundancy)

boards, which have a common backplane. The block diagram depicts the 2n CORE

redundancy and the embedding of the active and the passive CORE into the BTS, and

the interrelation of both COREs.

CU

SELIC

SELIC

BISON

FALC

ABIS

CAN

LMT

Fig. 2.3 Redundant COREs and their Interfaces

Both COREs (COBA0/COSA0 and COBA1/COSA1) have link interfaces to the ABIS

lines, but only one (the active CORE) can be connected.

On the backplane of the BTS, one connector provides a link of the LMT to the current

active CORE. In the case of a CORE switch over, the switch logic switches that

connector to the new active CORE. The same holds for the CAN bus (alarm bus), i.e.,

both COREs have the same CAN bus address where at any time at most one CORE is

an active CAN bus node.

Both the active and the passive CORE have links to the carrier units (CU); in reverse,

each CU is linked with both COREs. The traffic data are transmitted transparently

through the active CORE. Signal processing takes place only within the CUs.

The endpoints of each link are built up by SELIC ASICs (note: one SELIC contains

double functionality), where on the CU, one SELICserves two COREs. In thecase of a

SELIC SELIC SELIC

RD

Interf.

µP

Switch

Logic

Route Clock

CLK

CORE 0

CU

SELIC

Redundancy Link

Switch Logic Link

Route Clock

(Frame Sync)

RD

Interf.

Switch

Logic

CLK

SELICSELIC

µP

Route Clock

CORE 1

CU

SELIC

BISON

FALC

A30808-X3247-L14-2-7618

17

Page 18

Technical Description (TED:BSS)

BS-240/241

switch over, the SELICs on the active CORE are disabled by the switch logic and the

SELICs on the passive one are enabled. The SELICs on the CORE have to know

whether they are on the active or on the passive CORE. For this reason the SELICs

need a active/passive pin, which is served by the redundancy switch logic. When a

switch over occurs, the switch logic sets the active/passive pin of the former active

SELICs to "passive" and that of the former passive SELICs to "active".

The SELICs on the CUs have to recognize automatically which link comes from the

active CORE and which link from the passive one, i.e. it has to recognise a CORE switch

over by itself.

The RD interface (redundancy interface) is realized as a 2 Mbit/s HDLC link which

provides a communication interface between the two main processors (mP).

The switch logic is a flip-flop distributed over the two COREs. It manages the HW part

of a switch over and enables the COREs to know about their states as active/passive.

The CLK of the active CORE is connected with the one on the passive CORE. It allows

the passive CLK to be synchronized to the active one.

NOTE: the redundancy is implemented in a cold-standby mode, i.e., all calls will get lost

if a CORE switch over occurs.

Information

Base Station System

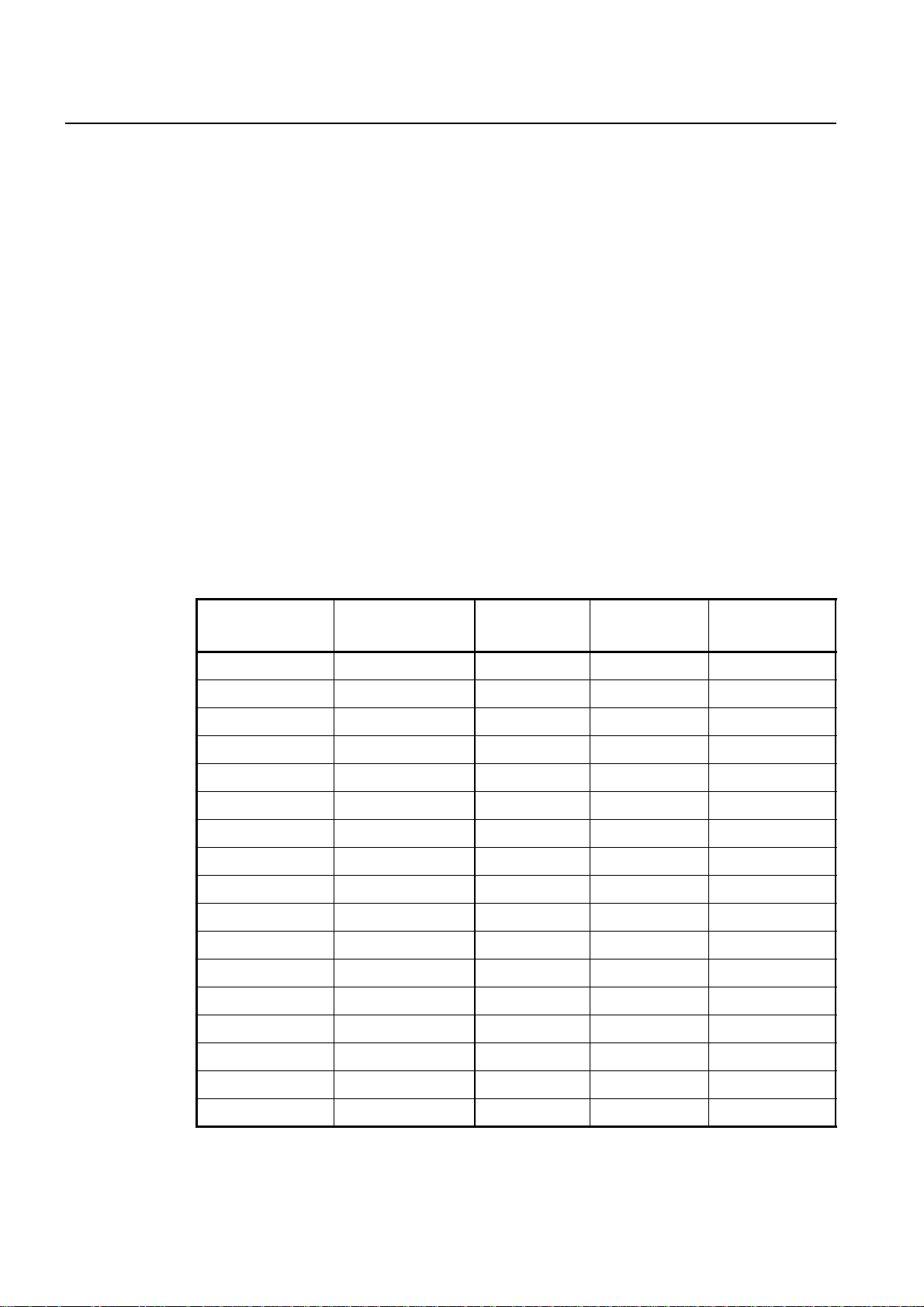

2.2 Power Amplifier Output Level (typical values)

Modulation Output Power

(dBm)

GSM 900 CUGV3 GMSK 47.3 53.7

GSM 900 CUGV4 GMSK 47.3 53.7

GSM 1800 CUDV3 / CUDV4 GMSK 45.7 37.1

GSM 1900 CUPV4 GMSK 45.7 37.1

GSM 900 GCUGV2 GMSK 47.3 53.7

GSM 1800 GCUDV2 GMSK 47.3 53.7

GSM 850 ECU 850 HPV2 GMSK 48.3 67.6

“ “ “ “ 8PSK 46.3 42.7

GSM 850 ECU 850 V3 GMSK 48.3 67.6

“ “ “ “ 8PSK 46.3 42.7

GSM 900 ECU GV3 GMSK 48.3 67.6

Output Power

(Watt)

“ “ “ “ 8PSK 46.3 42.7

GSM 1800 ECU DV2 GMSK 47.3 53.7

“ “ “ “ 8PSK 45.3 33.9

GSM 1800 ECU DHPV3 GMSK 48.3 67.6

Tab. 2.1 Power Amplifier Output Level

18

A30808-X3247-L14-2-7618

Page 19

Information

Base Station System

Technical Description (TED:BSS)

BS-240/241

“ “ “ “ 8PSK 45.3 33.9

GSM 1900 ECU PV2 GMSK 47.3 53.7

“ “ “ “ 8PSK 45.3 33.9

GSM 1900 ECU PHPV2 GMSK 48.3 67.6

“ “ “ “ 8PSK 45.3 33.9

GSM 1900 ECU PHPV3 GMSK 48.3 67.6

“ “ “ “ 8PSK 45.3 33.9

Tab. 2.1 Power Amplifier Output Level

Carrier Unit (CU )

GSM 900: minimum guaranteed output power CU = 50 Watt tolerance value: 47.0 dBm

i

- 47.6 dBm (50 W - 57.5 W); GSM1800, GSM1900: minimumguaranteed outputpower

CU = 34 Watt tolerance value: 45.3 dBm - 46.0 dBm (34 W - 39.5 W).

The mentioned data are guaranteed from Module Factory Test only. The typical output

power at CU output is for:

GSM 900: 47,3 dBm GSM 1800: 45.7 dBm

To verify the typical output power values in fieldmeasurements, the tolerance value of

the used measurement equipment, environmental conditions and GSM 05.05 specifications have to be considered.

Modulation Output Power

(dBm)

Output Power

(Watt)

Carrier Unit (GCU )

GSM 900: minimum guaranteed output power GCU = 50 Watt (GSMK); GSM 1800:

i

minimum guaranteed output power GCU = 50 Watt (GSMK).

The GSM 1800 variant of the GCU V2 offers higher output power than the corresponding CU (about 15 Watt): the increased output power of the GSM 1800 GCU V2,

has to be taken into consideration in the radio network planning.

EDGE Carrier Unit (ECU )

GSM 850, GSM 900: minimum guaranteed output power ECU = 63 Watt (GMSK) / 40

i

Watt (8PSK); GSM 1800, GSM 1900: minimum guaranteed output power ECU = 50

Watt (GMSK) / 32 Watt (8PSK).

The mentioned data are guaranteed from Module Factory Test only.

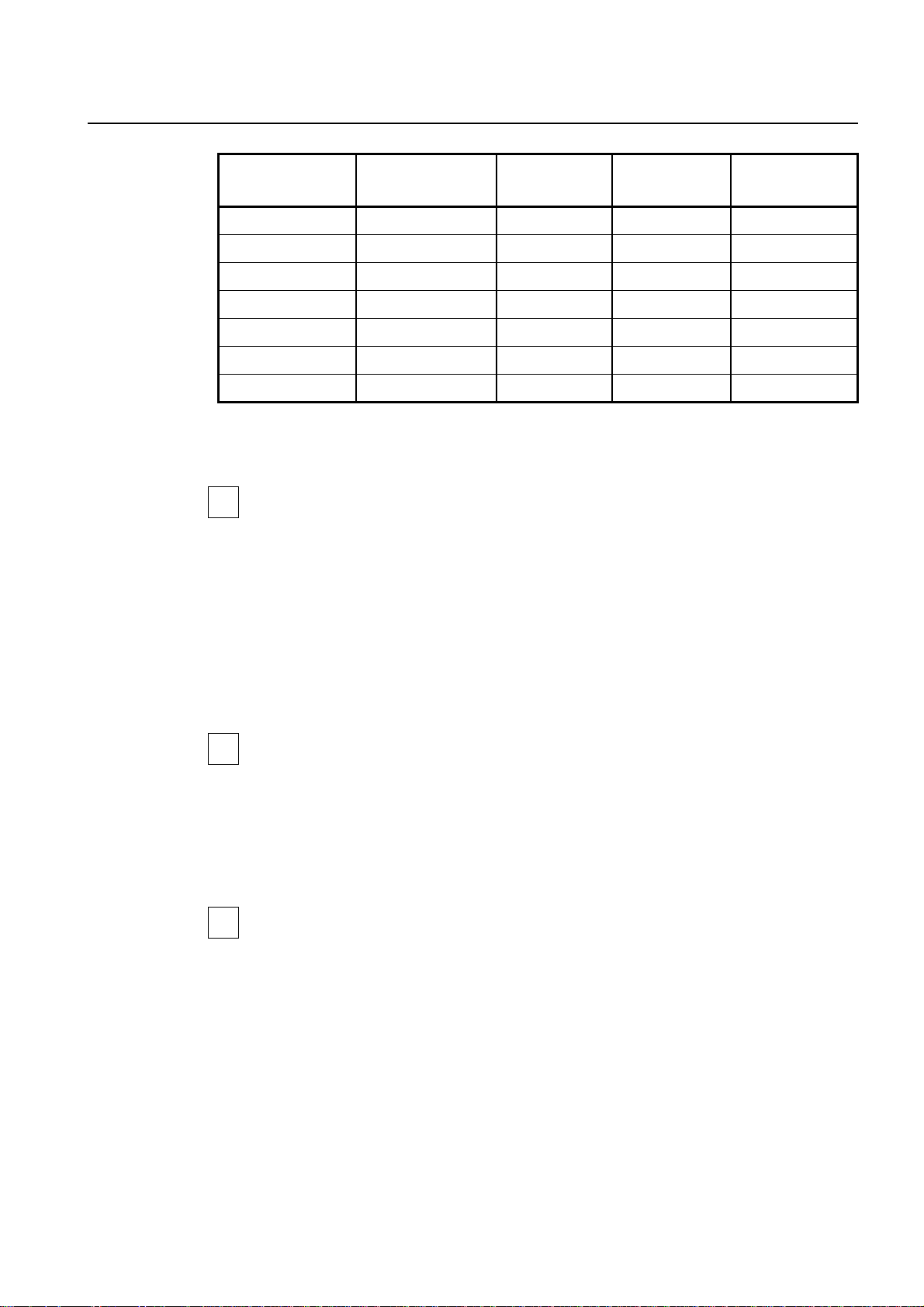

2.3 Rack Configuration

The BS-240/241 family, with 8 transceivers per Rack, which is expandable up to 24

transceivers in 3 Racks and can be supplied in two versions:

– a BS-240 for indoor installation, and

– a BS-241 for outdoor installation (also equipped with integrated link equipment,

Battery Backup and a cooling system).

A30808-X3247-L14-2-7618

19

Page 20

Technical Description (TED:BSS)

BS-240/241

There are 4 different types of Rack:

– Base Rack/Shelter (with Core modules)

– Extension Rack/Shelter (for more then 8 CU’s)

– Service1 Rack/Shelter (with AC/DC modules)

– Service2 Rack/Shelter (for LE and batteries)

It is possible to connect up to 3 Racks/Shelters together (1 Base Rack, 2 Extension

Racks; the more possible Racks/Shelters called Service Rack/Shelter are not part of a

Rack Extension in the proprietary sense) that realizes then the performance of a 24 TRX

BTSE as shown in Fig. 2.4 and Fig. 2.5:

Information

Base Station System

SIEMENS

ACOM

0

CU

2

CU

0

FAN 0

ACOM

FAN 2

CU

3

FAN 4 *

CU

1

1

ACOM

MUCO 1

MUCO 0

1

0

0

DC-PANEL

ACT-C

FAN 1

ACOM

2

FAN 3

CU

6

FAN 5*

CU

4

1

3

CU

7

CU

BS-240

5

SIEMENS

ACOM

0

CU

2

CU

0

FAN 0

FAN 2

CU

3

FAN 4*

CU

1

ACOM

1

ACOM

0

MUCO

DC-PANEL

ACT-C

FAN 1

ACOM

2

FAN 3

CU

1

6

MUCO

FAN 5*

CU

4

3

BS-240

CU

7

CU

5

SIEMENS

ACOM

0

CU

2

CU

0

FAN 0

FAN 2

CU

3

FAN 4*

CU

1

ACOM

1

ACOM

0

MUCO

DC-PANEL

ACT-C

FAN 1

ACOM

2

FAN 3

CU

1

6

MUCO

FAN 5*

CU

4

BS-240

3

CU

7

CU

5

COSA

COBA

COSA

COBA

* not present in case of BTSE with reduced number of fans

Fig. 2.4 BS-240 Base Rack and 2 Extension Racks

20

A30808-X3247-L14-2-7618

Page 21

Information

Base Station System

Technical Description (TED:BSS)

BS-240/241

SIEMENS

CU

0

CU

2

ACOM

0

FAN 0

CU

1

FAN 2

CU

3

FAN 4*

ACOM

1

1

0

0

COBA

COSA

COBA

MUCO 0

ACOM

DC-PANEL

ACT-C

FAN 1

CU

4

1

COSA

FAN 3

CU

6

MUCO 1

FAN 5*

ACOM

2

CU

5

CU

7

3

BS-241

SIEMENS

CU

0

CU

2

ACOM

0

FAN 0

CU

1

FAN 2

CU

3

FAN 4*

ACOM

1

DC-PANEL

MUCO 1

MUCO 0

ACOM

2

ACT-C

FAN 1

CU

4

FAN 3

CU

6

FAN 5*

ACOM

CU

5

CU

7

3

BS-241

SIEMENS

CU

0

CU

2

ACOM

0

FAN 0

CU

1

FAN 2

CU

3

FAN 4*

ACOM

1

DC-PANEL

MUCO 1

MUCO 0

ACOM

2

ACT-C

FAN 1

CU

4

FAN 3

CU

6

FAN 5*

ACOM

BS-241

CU

5

CU

7

3

* not present in case of BTSE with reduced number of fans

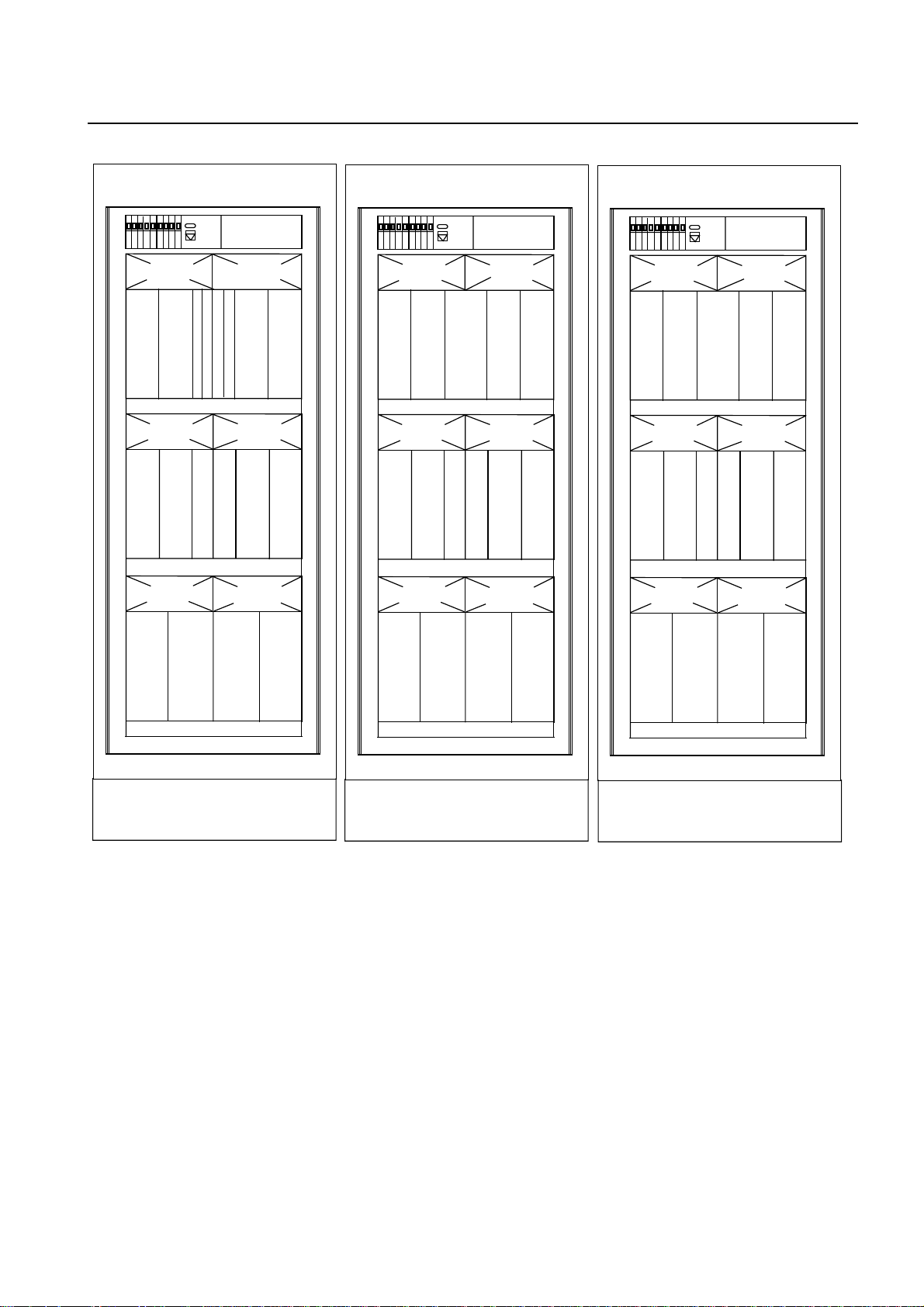

Fig. 2.5 BS-241 Base Rack and 2 Extension Racks

Fig. 2.7 shows the max possible configurations. The Base Rack and the Extension

Racks can be located physically in any position.

The Service Rack (see Fig. 2.6 for possible configuration) satisfies various applications

depending on number of CU units configured and/or number and kind of Network termination equipment provided and the Battery Backup time required.

All AC/DC frames are housed in the same Service Rack thus there are two basic kinds

of the Service Rack, one being connected to the AC mains (Service1 Rack) and one

being connected to DC only (Service2 Rack).

A30808-X3247-L14-2-7618

21

Page 22

Technical Description (TED:BSS)

BS-240/241

Information

Base Station System

SIEMENS

D

C

B

C

T

R

L

D

C

B

C

T

R

L

DC-PANEL

FAN 0

AC/

AC/

AC/

AC/

DC

DC

01

00

AC + DC Distribution

FAN 2

AC/

AC/

DC

DC

11

10

AC + DC Distribution

DC

02

AC/

DC

12

DC

03

AC/

DC

13

ACT-C

FAN 1

AC/

DC

04

FAN 3

AC/

DC

14

AC/

DC

05

AC/

DC

15

SIEMENS

1/4

Battery

Set

FAN 0

LE 0

LE 1

LE 2

LE 3

LE 4

LE 5

DC-PANEL

ACT-C

FAN 1

1/4

Battery

Set

1/4

Battery

Set

1/4

Battery

Set

1/4

Battery

Set Set

1/4

Battery

Fig. 2.6 Possible Configuration of Service1 Rack and Service2 Rack

On the digital side there is an extension of the CC links (connection between Core Backplane and the CU’s not housed in the Base Rack) and the CAN Bus. The CAN Bus

connection cannot be shown in the right way because it strongly depends on the number

of Extension and Service Racks present.

On the RF side there is an extension in the RX path only for omni and specific sector

cell (e.g., 5/5/5) configurations and diversity reception with more than 8 TRX. Thus a

maximum of 2 RF cables (cascading) are connected between two Racks. There is no

TX combining over Rack borders thus the TRXs of different Racks is combined on air

only. Some configurations are not possible with 2 Racks only e.g., 5/5/5 with FICOM

because of the number of available ACOM slots.

22

A30808-X3247-L14-2-7618

Page 23

Information

Base Station System

Service2 Rack

Technical Description (TED:BSS)

BS-240/241

Service1 Rack

Base Rack

Extension Rack

Extension Rack

Fig. 2.7 BS-240/241 fully Equipped with 24 Carriers

For the BS-241 outdoor cabinet only one type of the Shelter exists to be used for all

outdoor Base Shelter, Extension Shelters, Service1 and Service2 Shelters.

A30808-X3247-L14-2-7618

23

Page 24

Technical Description (TED:BSS)

BS-240/241

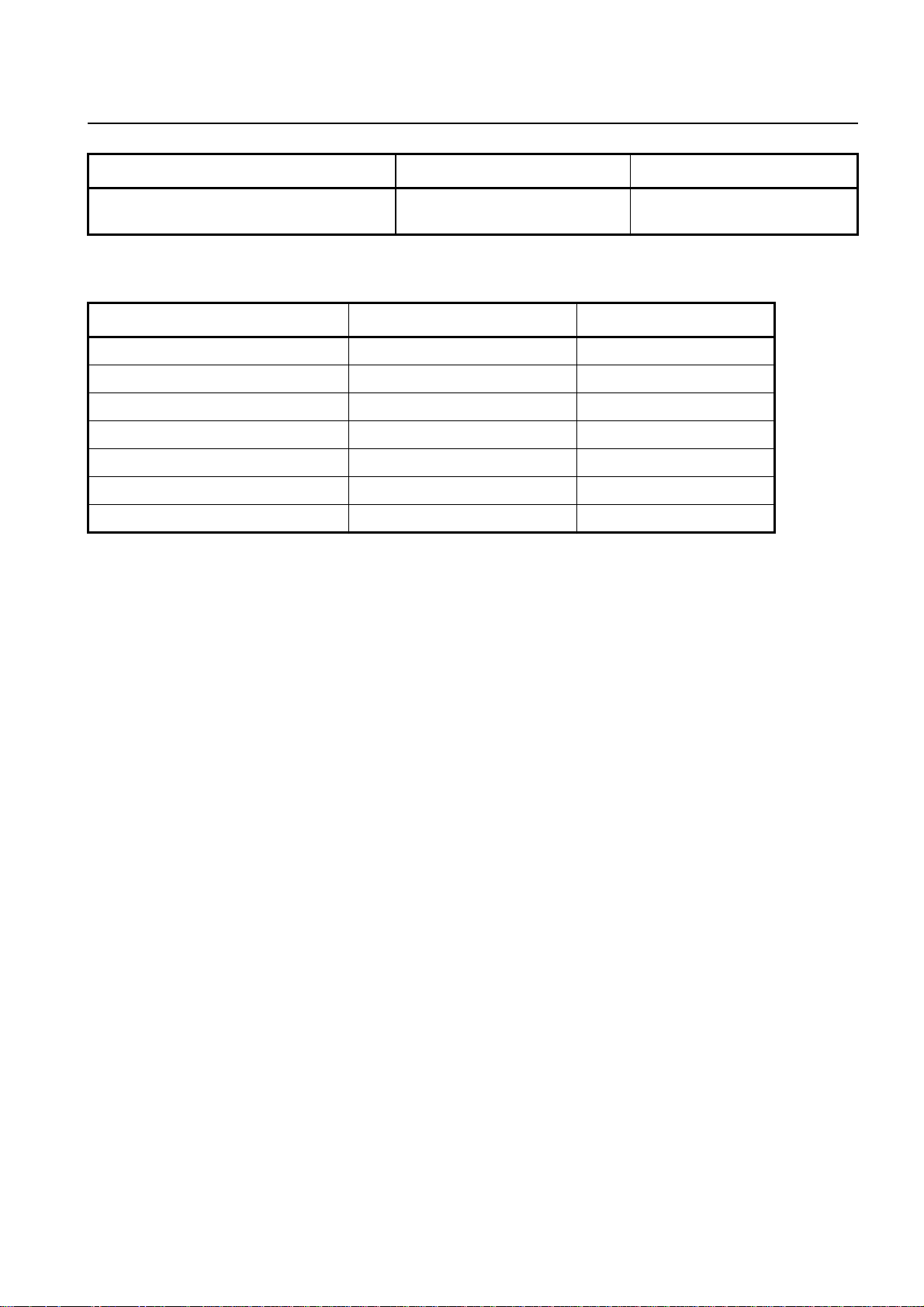

3 Description of Modules

Information

Base Station System

Core modules:

COBA

COSA

Carrier related modules:

CUx

ECUx

Antenna system modules:

DUAMCO2x

DUAMCO4x

DUAMCO8x

DIAMCOx

FICOMBx

FICOMXx

TMAx

HPDUx

Alarm collection modules:

ACTC (part of DC-Panel)

ACTM

ACTP

Name Freq.

Var.

no Up to 8PCM lineswith COBAand COSA

Core basis

Core satellite

Carrier unit yes Carrierunit and EDGE carrier unitcan be

yes Antenna system modules can be

Duplexer 2:2

Duplexer 4:2

Duplexer 8:2

Diversity multi coupler

Filter combiner (base)

Filter combiner (extension)

Tower mounted amplifier

High power duplexer

Alarm collection terminals no ACTCis equipped inevery Rack/Shelter.

equipped (COBA and COSA can be

equipped only in the Base Rack/Shelter).

equipped only in the Base and Extension

Racks/Shelters (see also section 2.2)

equipped only in the Base and Extension

Racks/Shelters.

DIAMCO, FICOM and HPDU are not

available for the GSM 1900 band.

DUAMCO 2:2, DUAMCO 4:2 and HPDU

working in shifted primary GSM band are

available.

A Diplexer can be used in all cases

where GSM 900 and GSM 1800, GSM

1900 or GSM 850 and GSM 1800, GSM

1900 Feeder Cables have to be installed

in parallel.

ACTM can be equipped only in the Base

Rack/Shelter. ACTP can be equipped in

the Extension or Service Racks/Shelters.

Remarks

Power supply modules:

AC/DC

DCBCTRL

OVPT

OVPTCOAX

ABISCON

Abis Link Equipment:

LE

Tab. 3.1 Units and Modules

AC/DC converter

DC battery controller

Over voltage protection

and tracer.

Abis Connection Module

Link Equipment no Link Equipment can be equipped only in

no AC/DC controller used for AC power can

be equipped only in the Service1

Rack/Shelter).

Supervision of the AC/DC converter and

ofthe connected Battery systems(only in

Service1 and Service2 Racks/Shelters).

no 100 Ω / 120 Ω symmetric line

75 Ω coaxial line. The OVPT is an

optional feature.

ABISCON can be installed only as alternative to the OVPT

Service1 and Service2 Racks/Shelters

24

A30808-X3247-L14-2-7618

Page 25

Information

Base Station System

Technical Description (TED:BSS)

BS-240/241

Name Freq.

Var.

Cover Parts:

CP:ACOM

CP:CU

CP:AC/DC

CP:DIAMCO

CP:COBA, COSA

CP:ACT

CP:HEX

Battery Backup Battery systems no upto 4 Battery systems can be equipped

Fan Central Fan unit no for forced convection cooling

Heater:

HEX Single Heater

Frame Compact Rack no Base, Extension, Service1 and Service2

Shelter Shelter of the Cabinet no Base, Extension, Service1 and Service2

Tab. 3.1 Units and Modules

Cover Parts have to be

inserted if the respective

active module is not

needed in a configuration

no the air flow inside the Frame or Shelter is

not affected

(only in the Service1 or Service2 RackShelters)

no Heater can be equipped in all typer of

Shelters

with HEX

Remarks

3.1 Core (COBA and COSA)

The Core has the following tasks inside the BTSE:

– local controlling of the entire BTSE

– generating of system clocks

– providing of up to 8 Abis-interfaces to BSC or other BTSEs

– routing of Abis-data to up to 24 CUs

– providing an interface to the LMT/OMT

– handling and processing of O&M-messages

Therefore, the Core can consist of up to 2 (without redundancy) or up to 4 (with redundancy) boards, which have a common backplane. The following picture gives an idea of

the slot-configurations:

A30808-X3247-L14-2-7618

25

Page 26

Technical Description (TED:BSS)

BS-240/241

Information

Base Station System

Base Rack

CU

OVPT

Backplane

COBA

2 Abis

8

SELIC

COSA COBA red.

6 Abis

16

SELIC

2 Abis

8

SELIC

COSA red

6 Abis

16

SELIC

Fig. 3.1 Backplane Slot Configuration of Core

.

Extension Racks

CU

CABLES

Plugs

Abis

CUs

8

8

8

other

interfaces

For a configuration with less or equal 2 PCM30/24-interfaces and no Extension Rack

one COBA-board is required. The second slot can be used (by adding 1 COSA Board)

for an expansion of the BTSE up to 8 Abis and 24 CU-interfaces or it can be used for

future expansions, e.g.a GPS-Receiver for synchronization, better frequency-standards

or other Abis interfaces than PCM30/24 (e.g., SDH, ATM).

The connection of Abis and CU-interfaces of the Core to the OVPT/Abis-interface and

the CUs is done via cables, which are plugged into the backplane.

The CU-interfaces of the Core and its redundancy are routed with separated wires via

the backplane and cables to the CUs (2 interfaces on one CU required).

The Abis interface ports of the Core and its redundancy ports can only be switched to

the same wires. Only one transceiver at the same time is allowed to be switched to the

same wires (no simultaneous transmitting/receiving of Core and its redundancy on the

same Abis-port possible).

To find the physical place of a Abis-interface/CU out of the logical/memory-map

address, appropriate configuration-rules are created and considered.

Two Core-boards, COBA2P8 (see section 3.1.1) and COSA6P16 (see section 3.1.2),

are developed. The first digit gives the number of Abis-Interfaces, the following letter the

kind of Abis-interface (e.g. P for PCM30/24), and the following number the number of

CU-interfaces, e.g., COSA6P16 (6 PCM30/24 Abis-interfaces, 16 CU interfaces).

Hot Plug-in: A Hot Plug-in of the Core-boards (COBA and COSA) is possible. This

means, that these boards can be plugged in/out with voltage switched on and no other

26

A30808-X3247-L14-2-7618

Page 27

Information

Base Station System

3.1.1 Core Basis (COBA2P8)

Technical Description (TED:BSS)

BS-240/241

HW inside the Rack is disturbed (no loss of data on other boards) or a board is

destroyed.

A COBA-board can only be pulled out, if before the COSA-board is pulled out

i

After plug-in of a Core-board, this board is in the reset-state and all bus-drivers of

external busses are in tristate. These drivers shall be enabled not before initialization of

the devices, which serve the external busses.

The COBA is the central board of the core. The functionality of the advanced clock

generation (ACLK) and the base core controller (BCC) of the entire BTSE are integrated. Additionally two PCM30/24 Abis-interfaces are available on the COBA2P8.

The controller maintains the SW of all BTSE units in FLASH-EPROMs, supervises the

SW download and terminates all internal systemalarms. Beside the O&Mfunctions the

controller handles the signalling messages between BSC (Abis) and CUs (CC-Link). For

interface and feature extensions the COBA can be expanded with one satellite (COSA).

To fulfill the CORE redundancyaspects, the COBAboard with its satellite COSA board

can be duplicated. In this case, one CORE (COBA+COSA) is "providing service" and

works as the master and the other CORE is "cold standby" or is "disabled" if HW problems have occurred. The redundancy switch is controlled by the COBA board. Special

links are provided for information exchange between the two board sets.

SESA

OASI

RDL

TPC

LMT/OTP

LAPD

SMC2

SMC1

SMC4

SMC3

SMC2

TSA-SCC1

SRAM

16MB

SAT-Interface

DC/DC Converter

LOGIC

BCC

SIU

FLASH

3 X 8MB

RDL

ACLK

CAN

WATCH

DOG

CAN-BUS, ALARMs

EEPROMs

I/O

A/D-Conv.

LEDs, Redundancy Control,

MUX

CU_DC_OFF ect.

BISON

SELIC

SELIC

SELIC

SELIC

CU

CU

CU

CU

CU

CU

CU

CU

SELIC-BUS

Abis1

Abis2

BISON-BUS

Route clock

ext CLK sync

A30808-X3247-L14-2-7618

Fig. 3.2 COBA2P8 Block Diagram

The ACLK generates the system specific timing signals which are distributed by SELICs

to the CUs. Fig. 3.3 shows the structure of the ACLK function.

27

Page 28

Technical Description (TED:BSS)

BS-240/241

Information

Base Station System

reference clock to redundant ACLK

reference

clock input

TOP

tracking

oscillator

processor

controlled

master sync input

from redundant ACLK

LTG

loadable

timing

generator

Fig. 3.3 Structure of ACLK Function

reference

clock

divider

master

clock

divider

2

4

8

S

16

Y

4096

N

C

1966080

master counter

BCC Interface

The tracking oscillator TOP synchronizes the oven controlled VCXO to the selected

frequency reference source. The TOP is realized as a phase/frequency lockedloop. The

regulation parameters (P and I constant) are variable by SW. Also, the regulating algorithmis implementedby SW. The output clockof theoscillator is called the master clock.

The cut-off frequency of the TOP depends directly on the pulling gradient of the used

OCVCXO. Since the ACLK has to synchronize to jittered lines the scattering of the

cut-off frequency is very critical. The cut-off frequency has to choose very low to eliminate lowest frequency wander and is therefore near the range of the temperature’s

cut-off frequency. To guarantee less deviation of the required cut-off frequency also with

components from different manufactures (2nd and 3rd source), the OCVCXO is calibrated on the COBA in the factory. The pulling gradient is measured against an atomic

clock and the calibration values is stored on COBA in a serial EEPROM. With Uncalibrated ACLKs must not be installed in the field. This can be achieved by the software

which should check whether the ACLK is calibrated or not.

In case of redundancy switch-overs no warm up and only a short synchronization phase

(because of effects at the switch-over) of the redundant ACLK is necessary.

The loadable timing generation hardware LTG is implemented in a FPGA device, which

can be loaded by the BCC with the current hardware function. In this stage, all necessary system clocks and the master sync pulse are generated. Also, the master counter

is realized. The count value of the master counter is fed via a serial interface to the

SELIC. In active redundancy mode, the master sync pulse is forwarded to the standby

ACLK. In standby redundancy mode, the generator is synchronized with the master

sync pulse coming from the active ACLK function. So both redundant ACLKs generate

their clocks in aligned. If necessary, a very fast redundancy switch-over is possible.

The FPGA isconfigured after a power-on reset from the BCC. Until the configurationhas

finished, no output clocks are available, i.e., a communication via Abis or CUs is not

phase/

frequency

detector

BCC interface

16,384 MHz

8,192 MHz

4,096 MHz

2,048 MHz

60 ms

D

8 kHz

OCVCXO

32, 768 MHz

A

SYNC

Driver

Stage

master sync to redundant ACLK

master clock

system

clocks

master sync

master counts

28

A30808-X3247-L14-2-7618

Page 29

Information

Base Station System

3.1.2 Core Satellite (COSA6P16)

PCMport1

PCMport2

PCMport3

PCMport4

PCMport5

PCMport6

Technical Description (TED:BSS)

BS-240/241

possible. The communication path from the LMT to the BCC is not affected, i.e., a

SW-download via the LMT is possible.

The COSA6P16 board (COSA6P16) has the following characteristic:

– 6 PCM30/24-interfaces for Abis

– 16 CU-interfaces

The board is controlled from the COBA via the SAT-interface (satellite-interface; 32bit

data). Fig. 3.4 shows a block diagram of the COSA6P16:

OVPT

&

FALC54 for PCM30/24

OVPT

&

FALC54 for PCM30/24

OVPT

&

FALC54 for PCM30/24

BISON

RCLK1-6

CLKX1-6

SELIC

SELIC

SELIC

SELIC

SELIC

SELIC

to

CUs

Working

Clocks

DC/DC

Converter

Route

SAT-Interface

(32bit data)

BISON

BUS

Fig. 3.4 COSA6P16 Block Diagram

The key-element of the PCM-interfaces is the FALC (Framing and Line Interface

Component for PCM30 and PCM24). It has the following tasks:

– analogue receive and transmit circuitry for PCM30 and PCM24

– data- and clock-recovery

– frame alignment/synthesis

– line-supervision

– timing-adaptation to BISON

Data arriving from the Abis-Interface via a PCM-port can be switched non-blocking and

bitwise (8 kbit/s andnx8kbit/s data-rate possible) with the BISON to another PCM-Port

or via a SELIC to a CU.

The Route-Clocks of one FALC can be switched with the Route-Clock multiplexer to the

COBA for synchronization purposes. The COSA6P16 gets its working-clocks from the

COBA.

Clock

Preselector

Route

Clocks

SELIC

SELIC

Interfaces

to COBA

Real-Time BUS (Hopping)

Non-Real-Time BUS (O&M)

A30808-X3247-L14-2-7618

29

Page 30

Technical Description (TED:BSS)

BS-240/241

The COSA6P16 is switched with relays to the PCM-lines. In case of failures, the

PCM-port 1(3)(5) and 2(4)(6) can be connected with each other via appropriate relays.

There is a power-on device on the COSA6P16, which generates a reset at power-on

(board-reset). Via a line, the COSA6P16 can be reset from the COBA (board-reset).

Additionally, single devices on the COSA6P16 can be reset from the COBA via the

SAT-interface.

3.2 Carrier Unit (CU)

The Carrier Unit (CU) takes care for all carrier oriented tasks. In the uplink (UL) direction

two RF signals (diversity) are received and finally converted into TRAU frames and

signalling data. In the downlink (DL) direction, TRAU frames and signalling data are

received and converted into a GMSK modulated RF signal, which is amplified to the

desired power level.

The CU consists of following sub-units:

• Power Amplifier and Transceiver Unit (PATRX)

• Signal Processing Unit (SIPRO)

• Power Supply Unit (PSU)

There are four variants of CU for the frequency bands GSM 850, R-GSM 900, GSM

1800 and GSM 1900. The differences of the variants arise mainly on the sub-unit

PATRX.

Information

Base Station System

Rx inputs

Tx output

Display

Test PC/OMT, SCC,

Layer 1 Trace, JTAG,

PID, Vcce Loop

PATRX

PSU

Fig. 3.5 Carrier Unit Block Diagram

Power Amplifier and Transceiver Unit (PATRX)

PATRX provides the main analogue functions of the CU:

– receives the two (diversity) RF signals from the antenna combining equipment and

converts them down to IF. The downconverted RF signals are then transmitted to

SIPRO where they are sampled and digitally downconverted to baseband.

– receives the GMSK modulated signal from the SIPRO. The signal is then I/Q modu-

lated, upconverted, levelled, power amplified and transmitted to the antenna

combining equipment.

– supports the synthesizer frequency hopping

– provides an RF loop between downlink and uplink path for the unit test of the CU

The power control loop implements 6 static power steps (each 2 dB) and additional 15

dynamic power levels (each 2 dB). For low output power versions of the CU, a further

reduction of 2 dB is provided.

SIPRO

CC-Link

-48V DC

30

A30808-X3247-L14-2-7618

Page 31

Information

Base Station System

Technical Description (TED:BSS)

BS-240/241

Rx input

(diversity)

Tx output

RXFEM

RXFED

RXLO

to SIPRO for

downconversion

to baseband

LCLK from SIPRO

LTL

TXLO

PWSTG

MODUP

PWRDET

Fig. 3.6 PATRX Block Diagram

The functional sub-unit PATRX consists of three PCBs:

– RXA: Analogue receiver board with modules RXFEM, RXFED, RXLO and LTL

– TXA: Analogue transmitter board with modules MODUP, TXLO, PWRDET

– PWRSTG: Power stage including heat sink

RF Control

from SIPRO

GMSK modulated

signal from SIPRO

TXBB

from SIPRO

Signal Processing Unit (SIPRO)

The SIPRO-Board is a part of the Carrier Unit. It contains all digital functions of the

carrier unit namely

• Signal Processing in uplink and downlink

• Control of RF on PATRX

• Baseband and synthesizer hopping

• Channel Control

• Radio Link Control

• O&M parts relevant for carrier unit

• Link to Core via CC link

Additionally, following analogue functions are located on SIPRO:

• Analogue to digital conversion (IF)

• Digital to analogue conversion (baseband)

• Local clock of CU

Due to the analogue functions, SIPRO is specific for the different frequency variants.

There are two types of SIPROs (one for GSM 850, GSM 900, onefor GSM 1800, GSM

1900).

Fig. 3.7 illustrates the principal data flow on SIPRO:

– receives two (diversity!) IF signals from the receiver, then analogue to digital conver-

sion takes place. The next step is digital downconversionto base band and filtering.

The output of the filter is equalized. The soft decisions from the equalizer then are

deciphered. The deciphered data stream is processed by the decoder. After

decoding (including bad frame indication), the data stream is packed into TRAU

A30808-X3247-L14-2-7618

31

Page 32

Technical Description (TED:BSS)

BS-240/241

frames and sent to TRAU.Signalling data (e.g., FACCH)are processed by layer 3 of

BTS software

– receives the TRAUframes orsignalling data. The TRAUframes areunformatted and

sent to the coder. After encoding, data are ciphered. Now, baseband hopping takes

place.Training sequence isinsertedto the data received via the hopping bus.These

bursts are sent to the GMSK modulator. This stream is converted into an analogue

baseband signal leaving the SIPRO

– parallel to the data stream the PLLs for synthesizer hopping are programmed.

Therefore, both for uplink and downlink, a data stream to the PLLs is generated.

Information

Base Station System

diversity

A

Hopping PLL

Central

A

Hopping PLL

Control

2

Digital Down-

D

D

Conversion

GMSK

Modulation

Fig. 3.7 Principal Data Flow on SIPRO

Power Supply Unit (PSU)

The PSU is the DC/DC converter for the CU for all applications. The PSU generates the

voltages +26/28V, +6V (only GSM 1800, GSM 1900), +12V, +5.3V and -5.3V for the

analogue circuitry and +3.35V for the digital circuitry from a -48V primary input voltage.

The PSU is mechanically incorporated in the CU.

2

Equalization

Uplink

Downlink

Deciphering Decoding

Ciphering

Coding

TRAU Frame

Formatting

Signalling

TRAU Frame

Deformatting

Signalling

32

3.3 EDGE Carrier Unit

The ECU unit is a modified CU using the same interfaces as CU but supporting EDGE

functionality in uplink and downlink. In downlink direction, the signalling and traffic data

are received from the Core and converted into GMSK or EDGE modulated signal, which

is amplified to the desired power level.

With thef EDGE it is possible to mix EDGE and non EDGE timeslots on the same carrier.

The ECU carries two independent receivers (normal and diversity channel) to provide

the antenna diversity function. In uplink direction, the received signal is converted to

IF-band. The IF-band is converted to a digital GMSK/8PSK-signal.

The 8PSK is a linear modulation, where three consecutive bits are mapped to symbol

as shown in Tab. 3.2

A30808-X3247-L14-2-7618

Page 33

Information

Base Station System

Technical Description (TED:BSS)

BS-240/241

Modulating bits Symbol

(1,1,1) 0

(0,1,1) 1

(0,1,0) 2

(0,0,0) 3

(0,0,1) 4

(1,0,1) 5

(1,0,0) 6

(1,1,0) 7

Tab. 3.2 GMSK/8PSK Linear Modulation

With the 8PSK modulation, the payload/burst is three times more.

The mechanical design of ECU is identical to that of CU versions.

ECU and CU modules may be installed in any kind of mixed configurations concerning

BS-240/241 hardware (Base/Extension Racks). Further, any cell/sector configuration

with a mixture of EDGE CU and “normal CUs” can be implemented.

The EDGE Carrier Unit (ECU) takes care for all carrier oriented tasks of the BTS. In

uplink (UL) direction, two RF signals (diversity) are received and finally converted into

TRAU frames and signalling data. In downlink (DL) direction, TRAU frames and signalling data are received and converted into a GMSK or EDGE modulated RF signal, which

is amplified to the desired power level.

A BTS Rack can be equipped by any combination of ECU and CU.

Smart Adaptive Filtering

The ECU receiver has a smart adaptive filter function. Depending on the level of a

co-channel interference source, the receive signal passes through an adaptive filter with

variable bandwidth.

The filter bandwidth narrows with increasing interferencelevel, allowingfor bestreceiver

performance under a variety of traffic conditions. The quality of service (QoS) in the

uplink greatly benefits from this feature, which can efficiently match with adaptive

filtering in the mobile station receiver.

Functional Structure of the EDGE Carrier Unit

The ECU unit is a new developed and enhanced CU unit which supports the GMSK and

8PSK Modulation in uplink and downlink. It is a HW compatible to the CU unit and fits

into the BTSplus Rack. A functional description of the whole receive and transmit path

including the EDGE Carrier Unit and the antenna combining equipment can be found

below.

The ECU (Fig. 3.8) consists of following functional subunits:

Power Amplifier and Transceiver Unit (EPATRX)

Signal Processing Unit (ESIPRO)

EDGE Power Supply Unit (EPSU)

A30808-X3247-L14-2-7618

33

Page 34

Technical Description (TED:BSS)

BS-240/241

Information

Base Station System

Fig. 3.8 EPATRX and ESIPRO Function Block Diagram

EDGE Power Amplifier and Tranceiver Unit ( EPATRX)

EPATRX provides the main analog functions of the CU. In uplink direction, two (diversity) preamplified and filtered RF signals are received from the antenna combining

equipment. These signals are down converted to IF and channel filtered in the RXFE

stage. The IF signals are then transmitted to ESIPRO, where they are sampled and digitally down converted to baseband. In downlink direction, the GMSK or 8PSK modulated

signal is received from the ESIPRO, I/Q modulated and up converted by the MODUP

stage, which also provides the levelling of the output power.

The obtained RFsignal is then power amplified by the module EPWRSTand transmitted

to the antenna combining equipment. A part of the transmitted power is fed to the

module PWRDET, which performs the power detection. This signal is used to close the

digital power loop.

The Predistortion Receiver (PDRX) down converts the transmit signal to the TX-IF for

the I/Q-Demodulation and adjusting the predistortion values. The transmitter is linearized by means of an adaptive digital predistortion which is applied to the baseband

signals. For the introduction of the ECU,a static predistortion was choosen for linearization of the transmit path. The HW is able to do adaptive predistortion, which can be

installed by SW update. EPATRX is able to support synthesizer frequency hopping by

the implementation of the synthesizer modules RXLO and TXLO. The unit test of the

34

A30808-X3247-L14-2-7618

Page 35

Information

Base Station System

Technical Description (TED:BSS)

BS-240/241

ECU is supported by the module LTL, which provides an RF loop between downlink and

uplink path.

Signal Processing Unit (ESIPRO)

The ESIPRO-Board of the BTSPLUS is a part of the EDGE Carrier Unit. It contains the

following functions of the EDGE Carrier Unit:

– Signal Processing in uplink and downlink

– Control of RF on EPATRX

– Baseband and synthesizer frequency hopping

– Channel Control

– Radio Link Control

– O&M parts relevant for carrier unit

– Link to Core via ASIC SELIC

– Digital Modulation

– Predistortion signal processing

– Digital part of Power control

– Analog to digital conversion (RXIF)

– Digital to analog conversion (TX-baseband, TX-ramping)

– Analog to digital conversion (PDRX)

– Analog to digital conversion of Diode voltage

– Analog to digital conversion of temperature

– Local clock of CU

To understand the functional structure of ESIPRO,knowledge of the principal data flow

(see Fig. 3.9).

In uplink direction, an IF-signal with a frequency of more than 100 MHz arrives from

ERXA at the ADC (Analog Digital Converter). The ADC output is processed by a DDC

(Digital Down Converter). The DDC transforms the signal into baseband and filters the

useful part of the signal. The quasi analog signal at the output of the DDC is converted

into bits with reliability information (soft decisions) in the equalizer block. The soft decisions are deciphered and decoded. Traffic channels (e.g., TCH/FS) are sent via

TRAU/PCU frames to TRAU/PCU. Signalling channels (e.g., SDCCH) are sent to the

CORE of the BTS.In downlink direction traffic channels arrive as TRAU/PCU frames

from TRAU/PCU and signaling data come from CORE. The data symbols are coded and

ciphered. Afterwards base band hopping takes place via the CC link. ESIPRO sends the

ciphered data to another ECU and receives data to be transmitted. The received data

are modulated as GMSK or 8 PSK signals and given as a base band signal to ETXA.

Both in uplink and downlink direction PLLs have to be programmed once each burst to

implement synthesizer hopping.

A30808-X3247-L14-2-7618

35

Page 36

Technical Description (TED:BSS)

BS-240/241

Information

Base Station System

Fig. 3.9 Data Flow in ESIPRO

EPSU (Power Supply Unit)

The EPSU is the DC/DC converter for the ECU for all applications. The EPSU generates

the voltages +26V/+28V, +12V, +5,3V and -5,3V for the analog circuitry and +3.3V for

the digital circuitry from a -48V primary input voltage. The only interface relevant change

was the change of the analog bias voltage for the EPWRSTD to +12V. The EPSU is

mechanically incorporated in the ECU.

The EPSU is a slightly modified version of the PSU of the GSM CU. In this document,

not all Interface names are changed to EPSU. Therefore, PSU can be seen as a

synchronym for EPSU in this document.

Main differences between ECU and CU

The following major changes to the CU HW were made to support the EDGE functionality:

1. NewPowerAmplifierwith better linearity and approximately 3 dB higher peak power

capability

2. New power levelling concept including a digital power control loop

3. New TX-VGA and PWRDET due to new power control

4. Adaptive predistortion to linearize the transmitter

5. New module Predistortion receiver (PDRX)

6. New IQDEM (IF-sampling ADC) with higher dynamic

7. RXA adaption to new IQDEM

8. New Power Supply Unit (EPSU) with higher power capability

36

A30808-X3247-L14-2-7618

Page 37

Information

Base Station System

3.4 GMSK Carrier Units (GCU)

3.5 Duplexer Amplifier Multi Coupler (DUAMCO)

Technical Description (TED:BSS)

BS-240/241

The GCU is a resembled ECU (the main sub-units are similar) which supports GMSK

modulation only, like the CU.

GCUs and CUs differ in the RF output power value for the GSM 1800 frequency band:

GCU: 53,7 W; CU: 37,1 W.

There are different variants of GCUs for the frequency bands GSM 900 and GSM 1800.

The types of GCU are the following:

• GCUGV2 GMSK Carrier Unit for GSM 900 MHz

• GCUDV2 GMSK Carrier Unit for GSM 1800 MHz

The DUAMCO consists of two identical modules. Each module contains a duplex filter,

which combines the RX and the TX path together, to be fedto a common antenna. The

DUAMCO combines 1 (see Fig. 4.2), up to 2 (see Fig. 4.3) or up to 4 (see Fig. 4.4)

carriers to one antenna and consists of two branches with the following elements:

• a LNA (Low Noise Amplifier) which takes care of a low system noise figure

• an attenuator (in case of installed TMAs, additional gains greater than the cable

losses must be adjusted by means of the attenuator)

• a second low noise amplifier

• a power splitter which distributes the received band to the CUs (Carrier Units)

• a transmit path which consists of:

– an isolator which protects the PAs (Power Amplifiers) inside the CUs from each

other in order to assure the required intermodulation suppression

– a hybridcoupler which provides the referencesignal for dynamicand staticpower

control.The corresponding nottransmitted power is terminatedin a loadincluding

a heat sink (for DUAMCO 4:2 and DUAMCO 8:2)

– an ASU (Antenna Supervision Unit) which is responsible for detecting certain

reflection factors at the antenna connector. The ASU detects the VSWR failure

and generates a failure information towards the O&M (CAN bus interface). This

information is subdivided in several levels with the following characteristics:

- VSWR < 2 neither generation of warning nor of an alarm

- 2 ≤ VSWR ≤ 3 generation of warning 'Antenna not Adjusted'

- VSWR > 3 generation of VSWR alarm 'Antenna Faulty'.

and a common part consisting of:

• a PDU (Power Distribution Unit) fortwo TMAs (Tower mounted Amplifier) connected

to the TMAs by means of an antenna feeder cable

• an O&M interface which transmits error messages to the BTS core via a slow O&M

bus (CAN bus)

The DUAMCO amplifier has two different operation modes:

– the AMCO mode where no TMA is used

– in case a TMA is used the DUAMCO is configured in the MUCO mode

The PDU provides the DC power supply and the alarm supervision of the TMAs. Alarm

monitoring is done with a signalling interface between DUAMCO and TMA, modulated

onto a IF carrier at 7.86 MHz.

A30808-X3247-L14-2-7618

37

Page 38

Technical Description (TED:BSS)

BS-240/241

3.6 DI(=2) Amplifier Multi Coupler (DIAMCO)

For the uplink direction, the DIAMCO is usedto filter and distribute the receivedsignals

to the Carrier Units in one Rack. TheDIAMCO consists of two branches constitutedby:

– a receive filter

– a low noise amplifier (LNA) which takes care of a low system noise figure

– an attenuator

– a second low noise amplifier

– a power splitter which distributes the received band to the CUs (Carrier Units)

and a common part constituted by:

– aPDU (PowerDistribution Unit) for two TMAs (Towermounted Amplifier) connected

to the TMAs by means of an antenna feeder cable

– anO&M interface which transmits error messages to the BTS core via a slow O&M

bus (CAN bus)

The DIAMCO RX amplifier has two different operation modes:

– the AMCO mode where no TMA is used

– in case a TMA is used the DIAMCO is configured in the MUCO mode

Information

Base Station System

3.7 Filter Combiner (FICOM)

With the FICOM, it is possible to combine up to 8 frequencies in downlink direction (TX)

in one Rack. For the uplink direction (RX), the DIAMCO has to be used to filter and

distribute the received signals to the Carrier Units. The FICOM consists of remote

tunable narrowband filters (TNF). The advantage of this filter combining technique is the

very low insertion loss, if e.g., 8 transmitters are combined to one antenna.

In principle, the FICOM offers the following functions:

• RF Functions:

– RF Power Combining

– Transmitter Spurious Signal Suppression

– Isolation between inputs

– Isolation output to input

• Control / Monitoring Functions:

– Antenna VSWR alarm thresholds setting and status reporting

– Internal Performance Monitoring

– Interfacing with BTSE

• LED Display:

– Antenna VSWR alarms

– Tuning alarms

– Presence of DC

• Lightning Protection at the RF output connector (7/16)

38

3.8 Tower Mounted Amplifier (TMA)

The TMA connects the antenna with the BTSE in order to amplify the receive signal and

pass through the transmit signal. The TMA contains two duplex filters, each on one RF

connector, to separate and combinethe receive and transmit path inside the TMA. The

TMA consists of:

– the RX parts of the duplex filter and

– the LNA (Low Noise Amplifier) which takes care of a low system noise figure of the

RX part

A30808-X3247-L14-2-7618

Page 39

Information

Base Station System

3.9 High Power Duplexer Unit (HPDU)

Technical Description (TED:BSS)

BS-240/241

– the TX parts of the duplex filter

The DC power for the TMA is feed into the triplexer by the PDU (Power Distribution Unit)

functionality of the DUAMCO/DIAMCO.

The Encoder/Decoder units of the TMA signalling interface generate an alarm for each

TMA separately by supervising the DC current consumption of each unit.

Note: When the TMA is used the DUAMCO/DIAMCO works in the so called MUCO

(multi coupler) mode. In the MUCO mode, the DUAMCO/DIAMCO mainly works as multi

coupler to split the receive signal for the following CUs.

The High Power Duplexer has the task of combining the TX- and the RX-path into one

antenna, in order to minimize the number of antennas when FICOM is used. The HPDU

contains a duplex filter for the transmit frequency band and for the receive frequency

band, but no Low Noise Amplifier in the RX path.

If the TMA shall be used together with a HPDU a so called BIAS-T (DUBIAS) for

powering and signalling of the TMA is required. Up to two HPDU can be integrated on

top of the Rack below the cover and also up to two HPDU could befit in the gap between

the inner side wall and the Frame in the Shelter.

Note: HPDU is available for working in the P-GSM 900, GSM 1800 and GSM-PS 900.

3.10 DC Panel (DCP)

The DC Panel contains the circuit breakers to protect the DC power lines for the

modules, the ACTP, FAN units, HEX, LE units and the ACTC where the Rack/Shelter

alarms will be connected. The temperature sensor is integrated in the ACTC. The front

panel of the DC Panel for the Base Rack or shelter carries the connector for the Local

Maintenance Terminal (LMT).

3.11 Alarm Collection Terminal (ACT)

The Alarm Collection Terminal contains the interface to the external alarms (Operator

alarms, Rack alarms, shelter alarms,...) and commands and a CAN-BUS interface to the

CORE.

ACTC is part of the DC-Paneland therefore it is installed once inevery Rack/Shelter to

collect all internal alarms. It has inputs for 16 internal alarms (1 Door, 6 Fans and 9

Rack/Shelter, internal alarms, which can be defined by the operator). In the Base

Rack/Shelter the ACTC is direct connected to the COBA. In all other Racks/Shelters, the

ACTC is connected to the ACTP.