Page 1

ASIMON V3

Configuration software for

AS-Interface safety monitors

Programming and Operating Manual · 09/2008

AS-Interface

Page 2

Page 3

General Information

1

ASIMON V3

Configuration software for

AS-Interface safety monitor

Programming and Operating Manual

Installation of hardware

and software

First steps

Configuring the

AS-Interface safety

monitor

Commissioning the

AS-Interface safety

monitor

Diagnostics and error

handling

Diagnostics via

AS-Interface

2

3

4

5

6

7

Configuration software for Microsoft®-Windows®

Apendix:

Selection and ordering

data

Edition 09/2008

GWA 4NEB 333 1558 02 DS 02

Page 4

Safety Guidelines

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

Danger

indicates that death or severe personal injury will result if proper precautions are not taken.

Warning

indicates that death or severe personal injury may result if proper precautions are not taken.

Caution

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

Caution

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

Notice

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be

used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The device/system may only be set up and used in conjunction with this documentation. Commissioning and

operation of a device/system may only be performed by qualified personnel. Within the context of the safety notes

in this documentation qualified persons are defined as persons who are authorized to commission, ground and

label devices, systems and circuits in accordance with established safety practices and standards.

Prescribed Usage

Note the following:

Warning

This device may only be used for the applications described in the catalog or the technical description and only in

connection with devices or components from other manufacturers which have been approved or recommended by

Siemens. Correct, reliable operation of the product requires proper transport, storage, positioning and assembly as

well as careful operation and maintenance.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

Automation and Drives

Postfach 48 48

90437 NÜRNBERG

GERMANY

Order No.: GWA 4NEB 333 1558 02 DS 02

Edition 09/2008

Copyright © Siemens AG 2006

Technical data subject to change

Page 5

Table of Contents

Table of Contents

1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 About the ASIMON program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Version information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3 Explanation of symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4 Definition of terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.5 Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2 Installation of hardware and software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.1 Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.1.1 Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.1.2 Connection between the AS-Interface safety monitor and the PC . . . . . . . . . . . . . . . . . . . . . . 13

2.2 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.2.1 System requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.2.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3 First steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1 Launching the program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2 Description of the user interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2.1 The menu bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2.2 The toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.2.3 The status/info bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.2.4 The work area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.3 Program settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.3.1 Setting the program language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.3.2 Selecting the serial interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4 Configuring the AS-Interface safety monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.1 Function of the AS-Interface safety monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.2 General procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.3 Creating and changing a configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.3.1 Monitoring devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.3.2 Logic devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

4.3.3 External device monitoring devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

4.3.4 Start devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

4.3.5 Output devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

4.3.6 System devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

4.3.7 User devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

ASIMON V3 - Configuration software for AS-Interface safety monitor

Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

5

Page 6

Table of Contents

4.3.8 Activating and deactivating devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

4.4 Saving / loading a configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

5 Commissioning the AS-Interface safety monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

5.1 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

5.2 Reading in a configuration from the AS-Interface safety monitor . . . . . . . . . . . . . . . . . . . . . . . 140

5.3 Transferring a configuration to the AS-Interface safety monitor . . . . . . . . . . . . . . . . . . . . . . . . 140

5.4 Teach safe configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

5.5 Validating the configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

5.6 Starting the AS-Interface safety monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

5.7 Stopping the AS-Interface safety monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

5.8 Configuration documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

5.9 Entering and changing the password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

6 Diagnostics and error handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

6.1 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

6.2 Troubleshooting and error rectification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .162

6.3 Known problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

7 Diagnostics via AS-Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

7.1 General procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

7.2 Assignment of the AS-Interface diagnosis indices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

7.3 Telegrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

7.3.1 Diagnosis of AS-Interface safety monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

7.3.2 Diagnosis of devices, sorted by OSSD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

7.3.3 Diagnosis of devices, unsorted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

7.4 Example: Querying with diagnosis sorted according to OSSD . . . . . . . . . . . . . . . . . . . . . . . . . 176

Apendix

Selection and ordering data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

ASIMON V3 - Configuration software for AS-Interface safety monitor

6 Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

Page 7

General Information 1

General Information

1.1 About the ASIMON program

The software described here is intended for the configuration and commissioning of the AS-Interface safety monitor with the use of a PC.

By means of an easy-to-use user interface, the AS-Interface safety monitor can be configured

in combination with safe AS-Interface slaves, such as emergency shutdown switches, safety

gate switches, protective photoelectric sensors etc., within an AS-Interface bus system to provide safeguarding of the danger areas present at power-driven machinery.

The commissioning and documentation of your safe application are also supported by

ASIMON.

Note

A brief introduction to secure AS-Interface transmission can be found in the operating manual

of the AS-Interface safety monitor.

This version of the ASIMON configuration software has been developed for use under the

®

Microsoft

Windows 95/98/ME/NT/2000/XP/Vista® operating systems.

ASIMON V3 - Configuration software for AS-Interface safety monitor

Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

7

Page 8

General Information

1.2 Version information

1.2 Version information

The AS-Interface safety monitor and the corresponding ASIMON configuration software have

been further developed and their functionality expanded since their production start in the year

2001.

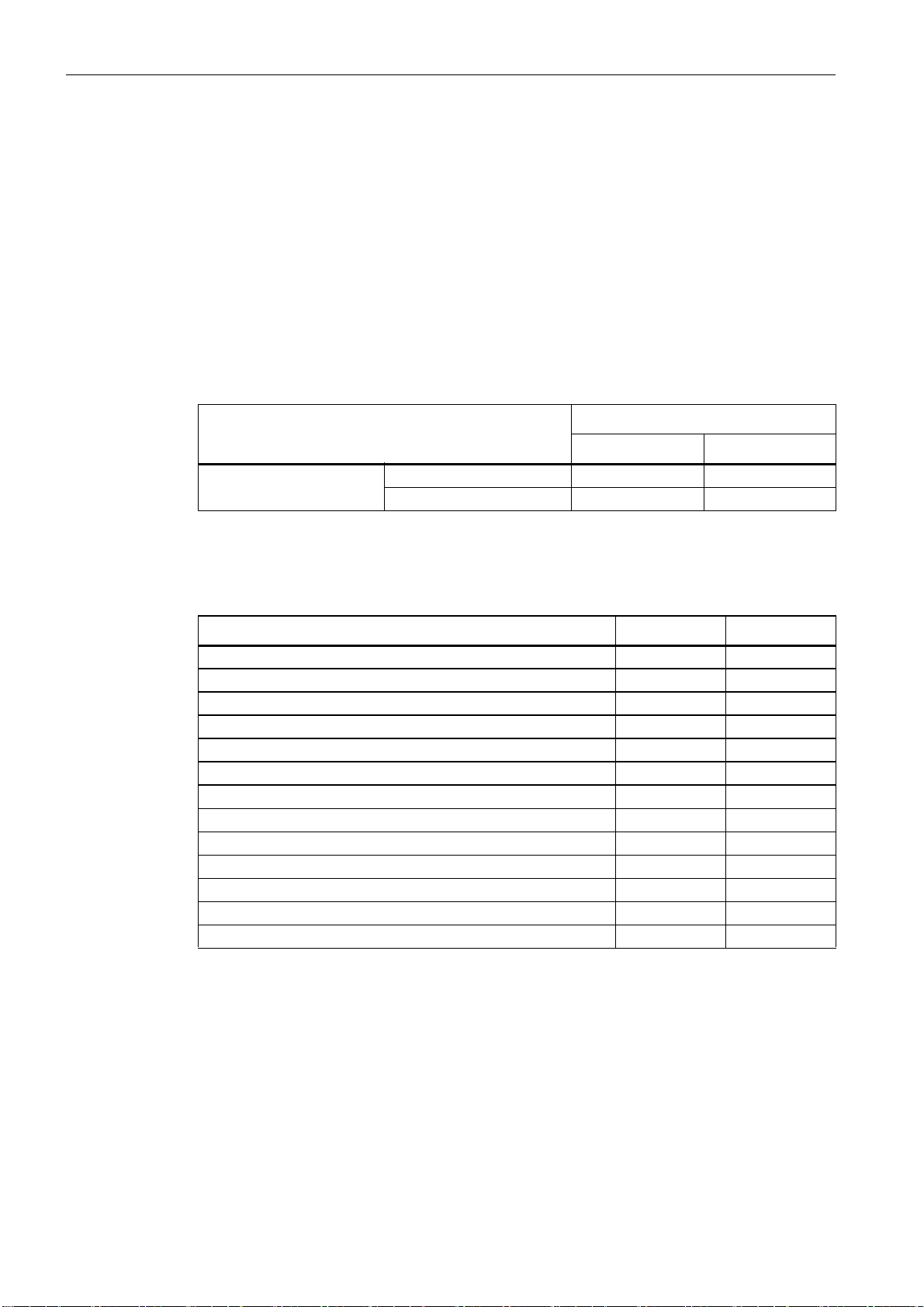

This handbook describes software version 3.0. Listed below is an overview of the new features with respect to software version 1.

New features in software version 2

In addition to the old device types, type 1 and type 2 of version 1, the device types of version 2

support type 1 to type 4 of the AS-Interface safety monitor:

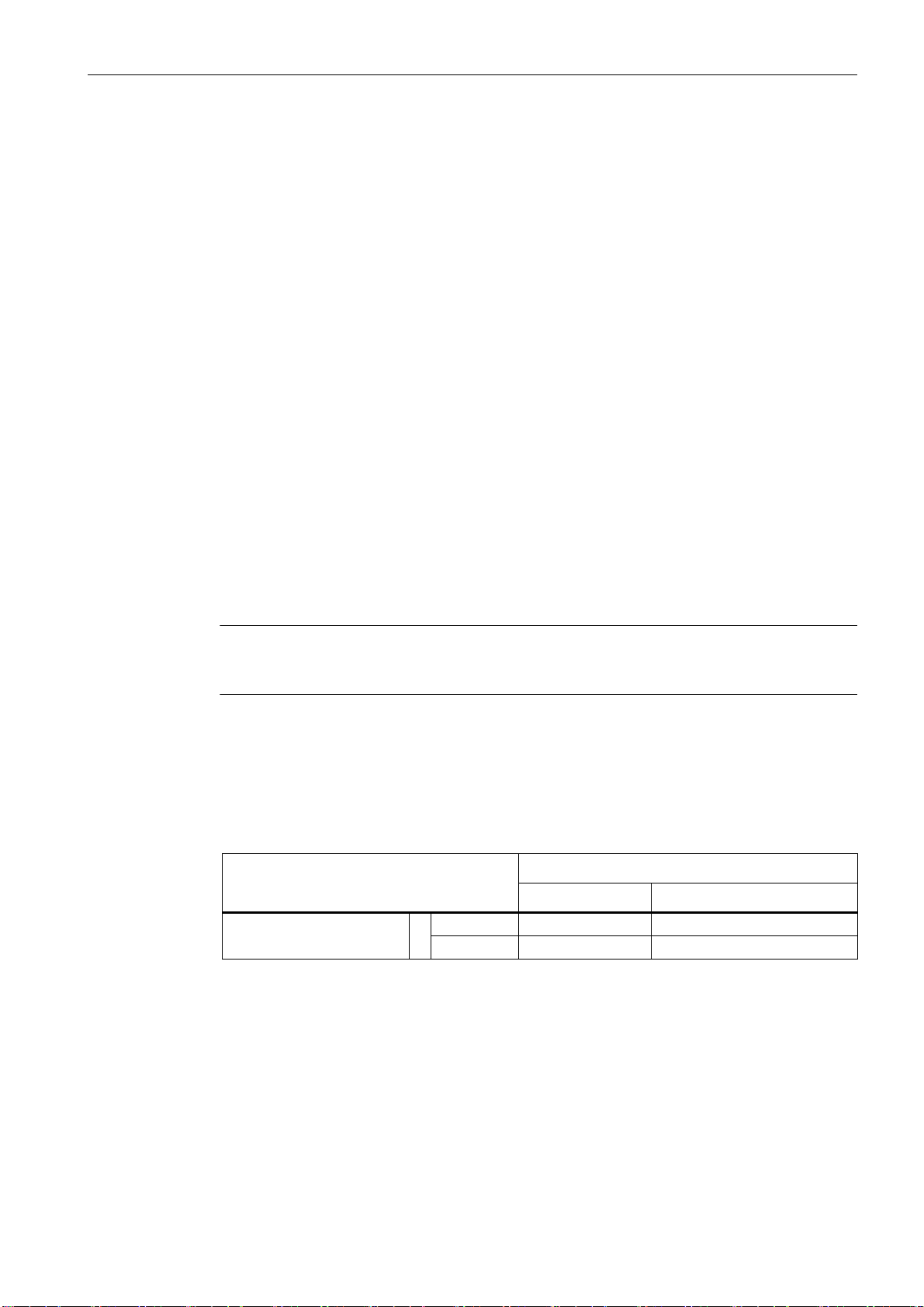

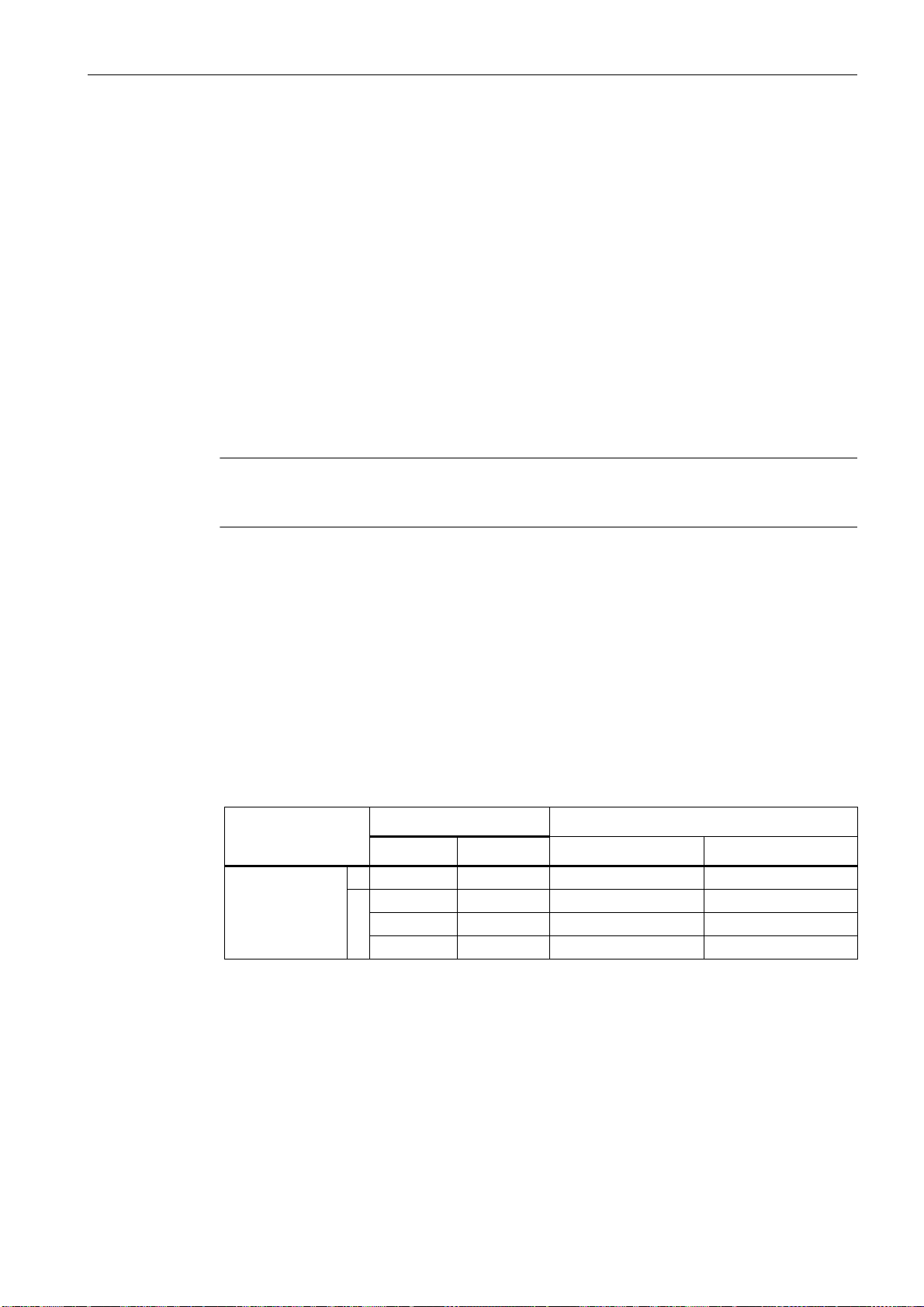

Table 1-1 Features of device versions

Number of output circuits

Function range

"Basic" "Enhanced"

1 Type 1 Type 3

2 Type 2 Type 4

The "Basic" and "Enhanced" function ranges differ as follows:

Table 1-2 "Basic" and "Enhanced" function ranges

"Basic" "Enhanced"

Number of functional devices at logic level 32 48

OR gates (inputs) 2 6

AND gates (inputs) no 6

Safe time function, switch-on and switch-off delay no yes

Function "button" no yes

Safety guard/module with debouncing no yes

Safety guard with lock no yes

Deactivation of functional devices yes yes

Reset of error condition yes yes

Diagnosis stop yes yes

Support of A/B technology for non-safe slaves yes yes

New functional devices (flip-flop, pulse on pos. edge, etc.) no yes

Dummy device (NOP) no yes

ASIMON V3 - Configuration software for AS-Interface safety monitor

8 Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

Page 9

New features in software version 2.1

Version 2.1 of the ASIMON configuration software includes the following new features:

• New monitoring device zero sequence detection

• Expansion of the output device door lock by means of delay time:

now optionally available with stop category 1 for the first OSSD

• Expansion of the output device door lock by means of zero-speed relay and delay time:

now optionally available with stop category 1 for the first OSSD

• New start device activation via standard slave (level-sensitive)

• New start device activation via monitor input (level-sensitive)

• New monitoring device operational switching by means of monitor input

• Expansion of monitoring device double channel dependent with debouncing for local

acknowledgement and startup test

• Expansion of monitoring device double channel independent for local acknowledgement

and startup test

• Incremental teaching of the code sequences

General Information

1.2 Version information

• Device index assignment

• Display of inverted icon when standard slave is inverted

• Number of simulated slaves can be selected

• Signalling of relay outputs and message outputs via the AS-Interface

Notice

The new functions of software version 2.1 can only be used in combination with AS-Interface

safety monitors of version 2.12 and higher.

New features in software version 3.0

In addition to the previous device types type 1 … type 4, also supported are two new device

types of version 3 (type 5 and type 6) of the AS-Interface safety monitor with safe AS-i out-

put:

Table 1-3 Features of device versions

Number of output circuits

Function range "Enhanced"

Output circuit 1 Output circuit 2

Type 5 Relay Safe AS-i output

2

Type 6 Relay Relay + safe AS-i output

ASIMON V3 - Configuration software for AS-Interface safety monitor

Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

9

Page 10

General Information

1.3 Explanation of symbols

Version 3.0 of the ASIMON configuration software includes the following new features:

• Support of safe AS-Interface transmission for controlling safe AS-Interface actuators

• Coupling of multiple safe AS-i networks through the function of the safety monitor as a

safe input slave (only for new device types with safe AS-i output)

• Multi-window technology with graphical printout of the configuration for each window

• Circuit diagram display of the logical links from left to right

• Extension of the device library and restructuring of the monitoring devices

• New monitoring device: 2-channel dependent with filtering

• Definition of user-specific functional devices

• Manual input of code sequences

• Availability of the standard out bits of the safe slaves for operational switching tasks

(acknowledgements, validations, unlocking, etc.)

Notice

The new functions of software version 3.0 can only be used in combination with AS-Interface

safety monitors of version 3.0 and higher.

Compatibility

With version 3.0 of the ASIMON configuration software, old configurations from version 1 and

version 2 can be opened, edited and saved.

Note

ASIMON configuration files have the extension *.ASI (version 1 AS-Interface safety moni-

tors), *.AS2 (version 2 AS-Interface safety monitors) or *.AS3 (version 3 AS-Interface safety

monitors).

1.3 Explanation of symbols

The symbols used in this manual are explained below.

Note

This symbol indicates text which contains important information.

ASIMON V3 - Configuration software for AS-Interface safety monitor

10 Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

Page 11

1.4 Definition of terms

Output switching element (safety output) of the AS-Interface safety monitor

Element activated by the logic of the monitor which is able to safely switch off the downstream

control elements. The output switching element may switch to or remain in the ON state only

when all components are functioning as intended.

Output circuit

Consists of the two logically connected output switching elements.

OSSD

The safe AS-Interface components and functional devices assigned to an output circuit of the

AS-Interface safety monitor. They are responsible for releasing the machine element which generates the hazardous movement.

Integrated slave

Component with which sensor and/or actuator functions are grouped together with the slave

into a unit.

General Information

1.4 Definition of terms

Configuration operation

Operating state of the safety monitor in which the configuration is loaded and checked.

Master

Component for data transmission which controls the logical and temporal behaviour on the

AS-Interface line.

Protective operation

Operating state of the safety monitor in which the sensors are monitored and the output switching elements are switched.

Safety output

See output switching element.

Safe output slave

Slave to which the safe ON or OFF state is transferred by the safety monitor and which controls

a safe actuator for switching off or shutting down while under voltage.

Safe input slave

Slave which reads in the safe ON or OFF state of the connected sensor or command device

and transmits it to the master or safety monitor.

Safe slave

Slave for connecting safe sensors, actuators and other devices.

Safety monitor

Component which monitors the safe slaves and the correct function of the network.

ASIMON V3 - Configuration software for AS-Interface safety monitor

Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

11

Page 12

General Information

1.5 Abbreviations

Slave

Component for data transmission; the master cyclically addresses this component by its

address. Only then does it generate an answer.

Standard slave

Slave for connecting non-safe sensors, actuators and other devices.

Synchronisation time

The maximum permissible temporal offset between the occurrence of two events which are

dependent on one another.

ON state

Switched on, logical "1", TRUE.

This state means that the device has agreed to validate the circuit, i.e. to activate the safe

switching outputs. Depending on the device type, various conditions must first be met.

OFF state

Switched off, logical "0", FALSE.

This state means that the device has not agreed to validate the circuit, i.e. it results in the

switching off of the safe switching outputs.

1.5 Abbreviations

AS-Interface

AOPD

EDM

PLC

Actuator Sensor Interface

Active Optoelectronic Protective Device

External Device Monitoring

Programmable Logic Control

ASIMON V3 - Configuration software for AS-Interface safety monitor

12 Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

Page 13

Installation of hardware and software 2

Installation of hardware and software

2.1 Hardware

2.1.1 Prerequisites

To configure the AS-Interface safety monitor via a PC, you will need:

• an AS-Interface safety monitor type 1 … type 6

• the interface cable for connecting the PC and AS-Interface safety monitor

• a PC or a laptop with the following minimum requirements:

-an Intel

(or compatible models, e.g. AMD

- a CD-ROM drive for installing from CD-ROM

- a mouse (recommended)

- a free RS 232 (serial) interface with 9-pin Sub-D connection

Notice

®

processor at Pentium® level

®

or Cyrix®)

When using a USB-RS 232 interface converter or a serial interface card, communication problems may occur with the safety monitor.

2.1.2 Connection between the AS-Interface safety monitor and the PC

Note

The connection of the AS-Interface safety monitor to the PC is described here only briefly. Detailed information can be found in the operating manual for the AS-Interface safety monitor.

To configure the AS-Interface safety monitor with ASIMON, you must connect your PC and the

AS-Interface safety monitor using the serial interface cable (available as accessory).

Caution

Use only the interface cable which is available as an accessory. The use of a different cable

may lead to data loss or damage to the connected AS-Interface safety monitor!

ASIMON V3 - Configuration software for AS-Interface safety monitor

Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

13

Page 14

Installation of hardware and software

2.2 Software

To connect, plug the interface cable end with the RJ45 connector into the 'CONFIG' socket on

the front of the AS-Interface safety monitor and the other end with the 9-pin Sub-D socket connector to a free COM port (serial RS232 interface) on your PC.

Notice

If the connection between the AS-Interface safety monitor and the PC is already established

when the PC is started, the mouse cursor may move erratically about the screen.

Remedy:

• When starting the PC, unplug the connection cable between the PC and the safety monitor.

• Change the start behaviour of the PC (see user documentation for the PC or that of the

operating system manufacturer).

2.2 Software

2.2.1 System requirements

The following system requirements are necessary for the AS-Interface safety monitor configuration software:

- at least 32 MB free main memory (RAM)

- at least 32 MB free hard disk memory

-Microsoft

®

Windows 95/98/ME/NT/2000/XP/Vista® as operating system

2.2.2 Installation

To install the configuration software, you need the installation CD-ROM.

Upon execution of the setup program setup.exe on the installation CD-ROM, a self-explanatory installation routine is started. After the installation, the program is ready to be started.

With an update installation, the setup program checks whether ASIMON version 2.x is already

installed on the PC. If a previous installation is detected, the setup program offers the option

of replacing the existing installation with version 3.0 or, as an alternative, creating a second

subfolder.

ASIMON V3 - Configuration software for AS-Interface safety monitor

14 Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

Page 15

First steps 3

First steps

Note

Connect the interface cable to the PC and the safety monitor as described in chapter 2.1.2.

Switch on the power supply for the safety monitor before starting the configuration software.

Data transmission is otherwise not possible.

However, even if the safety monitor is not connected to the PC, you may still define device configurations and save them on your PC or edit a previously stored configuration

ASIMON V3 - Configuration software for AS-Interface safety monitor

Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

15

Page 16

First steps

4

2

3

1

1 Start Assistant window

2 Menu bar

3 Toolbar

4 Status/Info bar

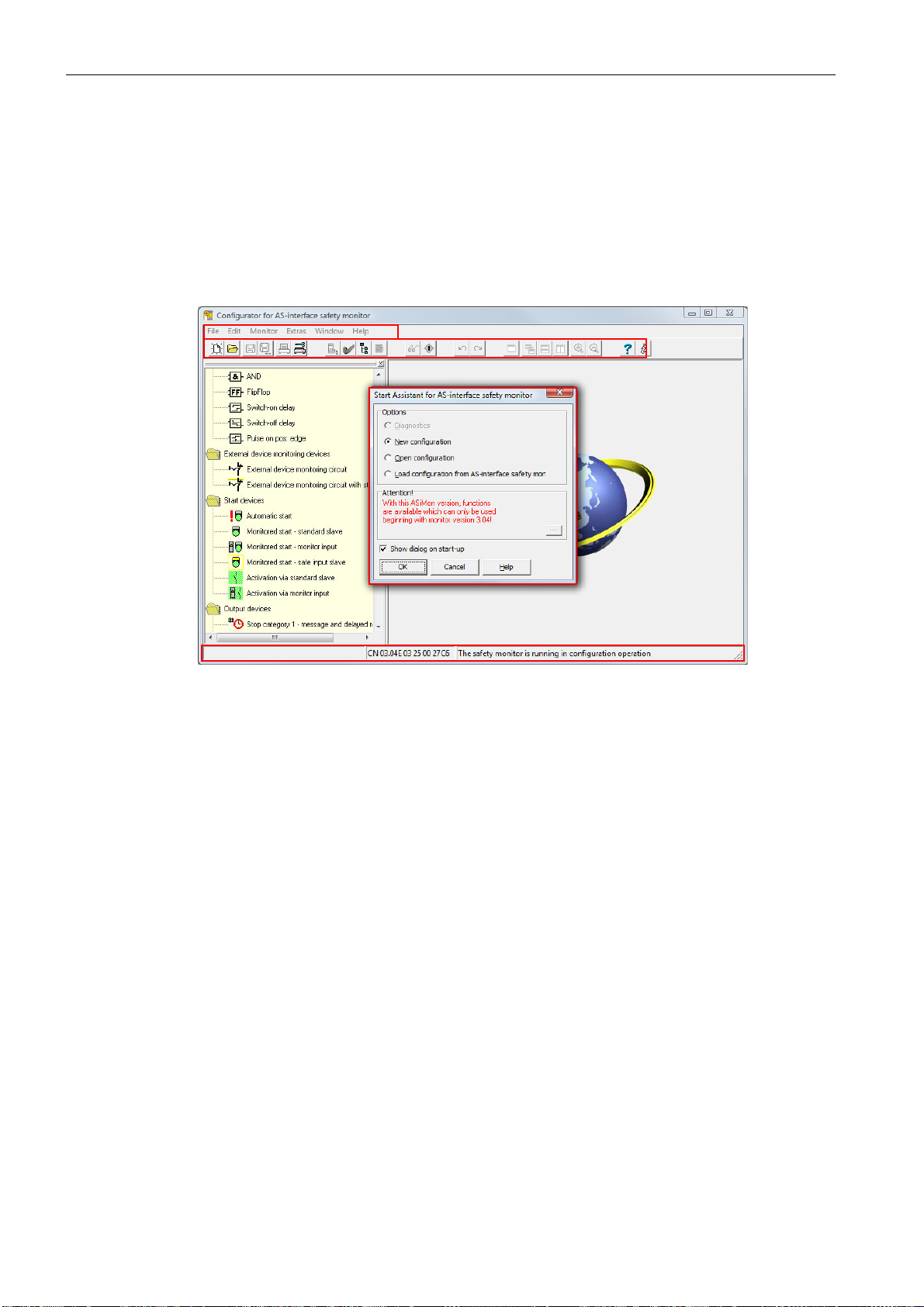

3.1 Launching the program

3.1 Launching the program

To start the configuration software for the AS-Interface safety monitor, select from the Start

menu the ASIMON item, which is located in the program folder you specified during installati-

on.

After the program has started, the window with the ASIMON configuration software user interface appears on the screen. When the program is started, the Start Assistant is called up to

guide you through the first steps following program startup.

Figure 3-1 User interface of the ASIMON configuration software after starting the software

16 Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

ASIMON V3 - Configuration software for AS-Interface safety monitor

Page 17

Start Assistant

First steps

3.1 Launching the program

Note

In order to query the diagnostic information, the connected AS-Interface safety monitor must

be in protective operation.

If a connection to the AS-Interface safety monitor cannot be established on program startup

(no AS-Interface safety monitor connected, connected to wrong interface etc.) or if the connected AS-Interface safety monitor is in configuration operation, the Diagnostics option is deactivated.

In this case, it is only possible to create a new configuration, load and edit a configuration which

has been stored on a data carrier or to search for errors (see chapter 6.2 "Troubleshooting and

error rectification").

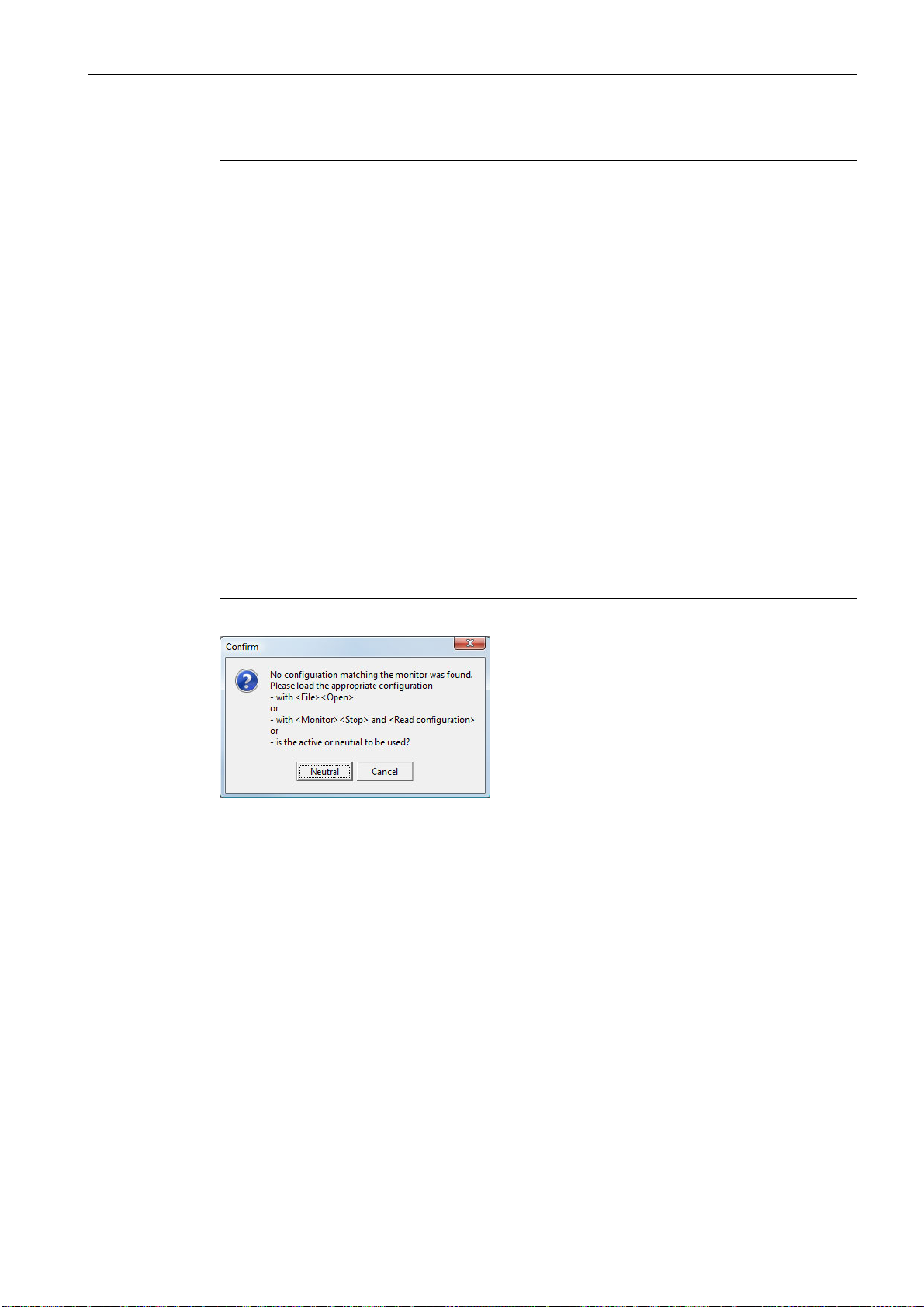

Option Diagnostics

When you select the Diagnostics option, first a window opens with the following query. By

clicking Neutral, the diagnostic information of the connected AS-Interface safety monitor is

queried, even if no configuration is loaded in ASIMON.

Note

Querying the diagnostic information of an unknown configuration can take several minutes, as

the configuration of the connected AS-Interface safety monitor must be reconstructed in ASI-

MON. In this way you can load an unknown configuration without needing to exit protective

operation.

Figure 3-2 Query with the Diagnostics option

Next, the Diagnostics window opens (see chapter 6.1 "Diagnostics").

ASIMON V3 - Configuration software for AS-Interface safety monitor

Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

17

Page 18

First steps

3.1 Launching the program

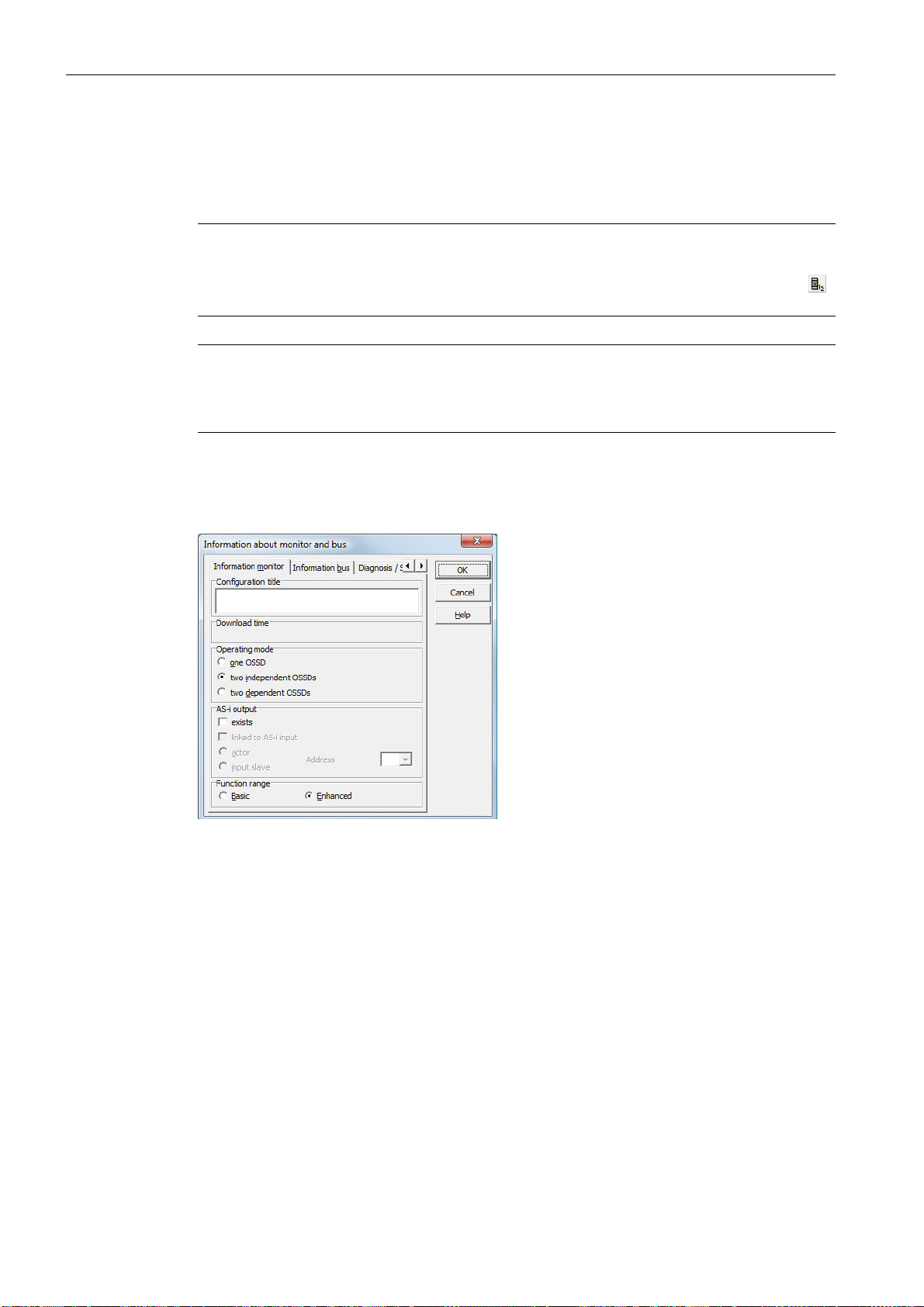

Option New configuration

With the New configuration option, you can create a completely new configuration for the

AS-Interface safety monitor. First, you must enter the base data for the new configuration in

the Information about monitor and bus window. This window is displayed automatically.

Note

The Information about monitor and bus window can be called up at any time. To do this, on

the Edit menu, select the Information about monitor and bus… menu item or click the

button.

Note

If a valid configuration has been loaded to or from an AS-Interface safety monitor, the time at

which the current configuration in the program was transmitted to the AS-Interface safety monitor is shown in the Download time window area.

In the Information monitor tab, you must enter a title for the configuration, select the operating mode, specify whether a safe AS-i output exists and specify the "Basic" or "Enhanced"

function range of the AS-Interface safety monitor.

Figure 3-3 Information about monitor and bus window, Information monitor tab

Configuration title

In this field, enter a title for the new configuration. The title may contain up to 63 characters.

ASIMON V3 - Configuration software for AS-Interface safety monitor

18 Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

Page 19

Operating mode

First steps

3.1 Launching the program

You can select from three operating modes:

•one OSSD

for AS-Interface safety monitors of type 1 or type 3 with 1 OSSD (1 redundant safe relay

output)

• two independent OSSDs

for AS-Interface safety monitors of type 2 or type 4 with 2 independently functioning

OSSDs (2 redundant safe relay outputs)

Select this operating mode when you would like to configure two completely independent

shutdown modes.

• two dependent OSSDs

for AS-Interface safety monitors of type 2 or type 4 with 2 OSSDs (2 redundant safe relay

outputs) in which the second OSSD is dependent on the first (see chapter 4.3.5 "Output

devices").

Special switch-off functions are available in this operating mode.

Note

Prior to a subsequent change of operating mode, determine whether this operating mode is

compatible with the AS-Interface safety monitor type which you are using (see table 3-1).

AS-i output

Here, you specify whether the AS-Interface safety monitor which is to be configured has a safe

AS-i output and whether it is linked to a safe AS-i input. Furthermore, you also specify here

whether a safe actuator is connected or whether the AS-Interface safety monitor functions as

a safe input slave in a coupled AS-Interface network. In this case, you must specify the

AS-Interface address of the actuator or assign the safe input slave an AS-Interface address.

Function range

Here, enter the function range of the AS-Interface safety monitor which is to be configured. The

following table shows how the six device types of the AS-Interface safety monitor differ from

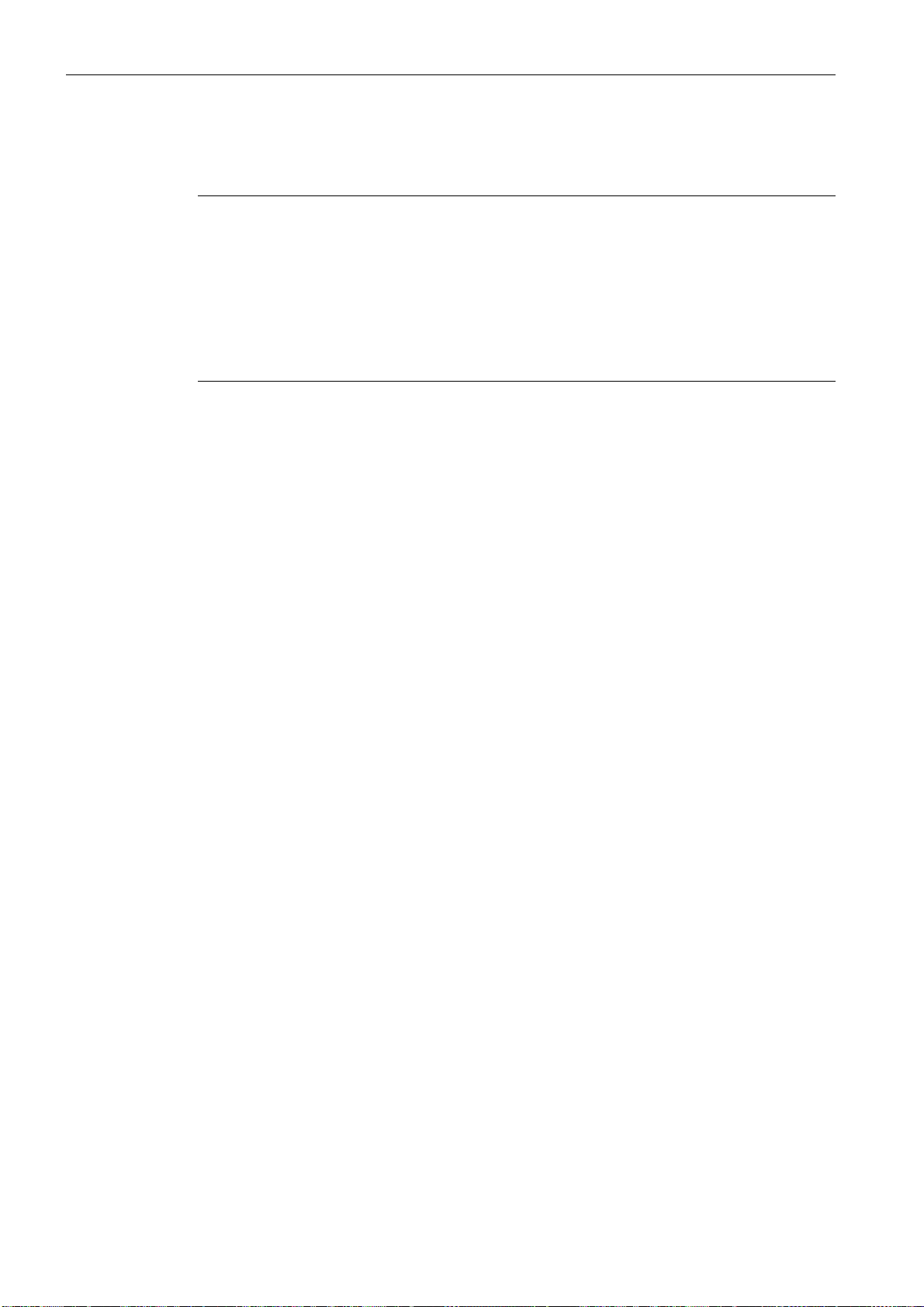

one another:

Table 3-1 Features of device versions

Function range Type

"Basic" "Enhanced" Output circuit 1 Output circuit 2

1 Type 1 Type 3 Relay –

Number of out-

put circuits

Type 2 Type 4 Relay Relay

2

– Type 5 Relay AS-i output

– Type 6 Relay Relay + AS-i output

ASIMON V3 - Configuration software for AS-Interface safety monitor

Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

19

Page 20

First steps

3.1 Launching the program

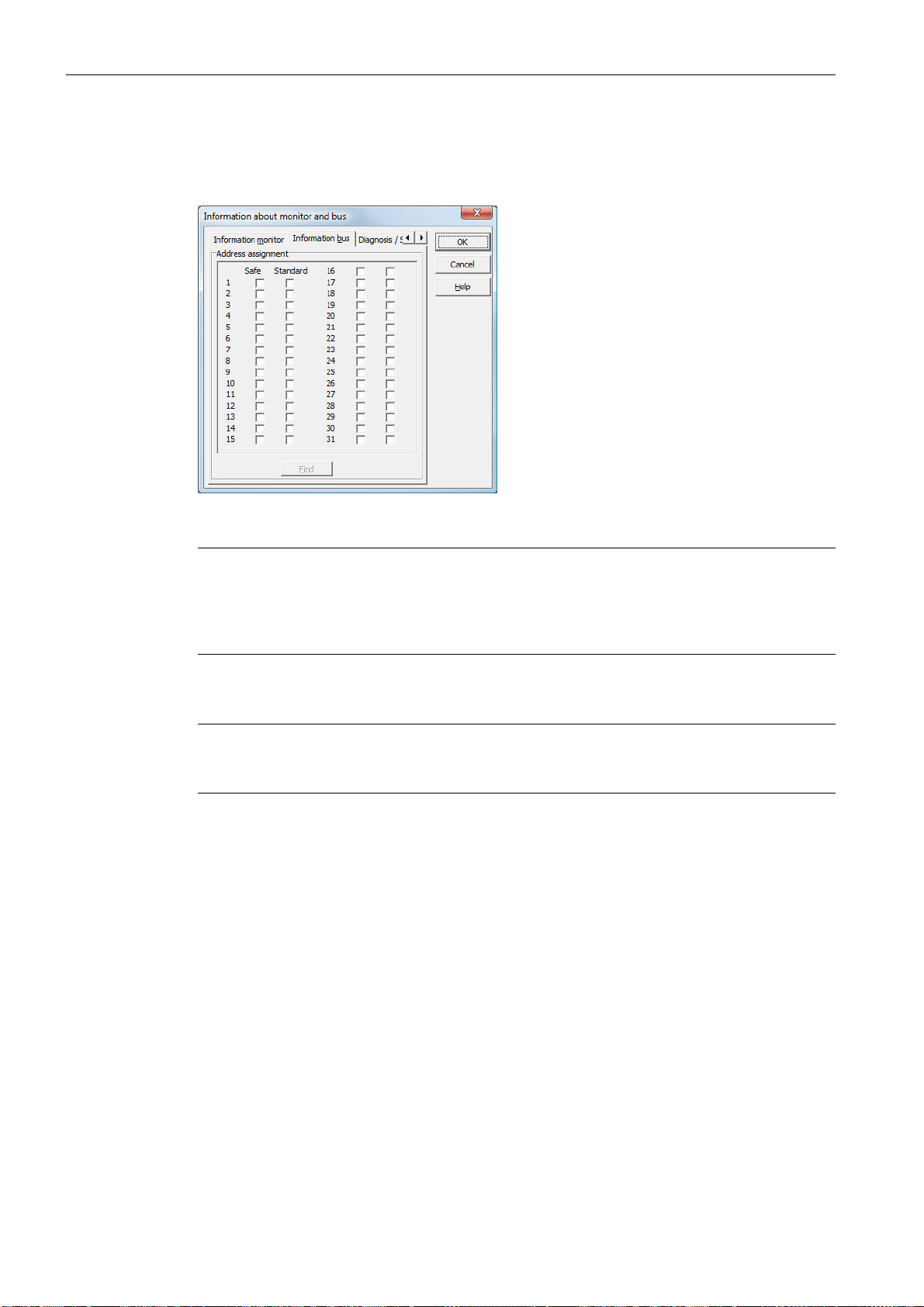

On the Information bus tab, you must enter the AS-Interface bus addresses of the used standard slave and the safety-oriented AS-Interface slaves which are present in this AS-Interface

network.

Figure 3-4 Information about monitor and bus window, Information bus tab

Notice

If you would like to operate two or more AS-Interface safety monitors on the same AS-Interface

bus, you must enter for all AS-Interface safety monitors all safe slaves on this AS-Interface bus

in the Information bus tab even when they are not monitored by the given AS-Interface safety

monitor.

With the Find button, you can also search the AS-Interface bus for slaves when the AS-Inter-

face safety monitor is in configuration operation.

Note

The AS-Interface slaves found when searching the AS-Interface bus are first all listed in the

Information bus tab as standard. You must then manually assign each as safe/standard!

If you clicked the Simulate slaves checkbox on the Diagnosis / Service tab, two or four bus

addresses are automatically assigned for the simulated slaves and the corresponding checkbox deactivated. In order to be able to activate Simulate slaves, the one or three addresses

which follow the monitor address must be free.

ASIMON V3 - Configuration software for AS-Interface safety monitor

20 Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

Page 21

First steps

3.1 Launching the program

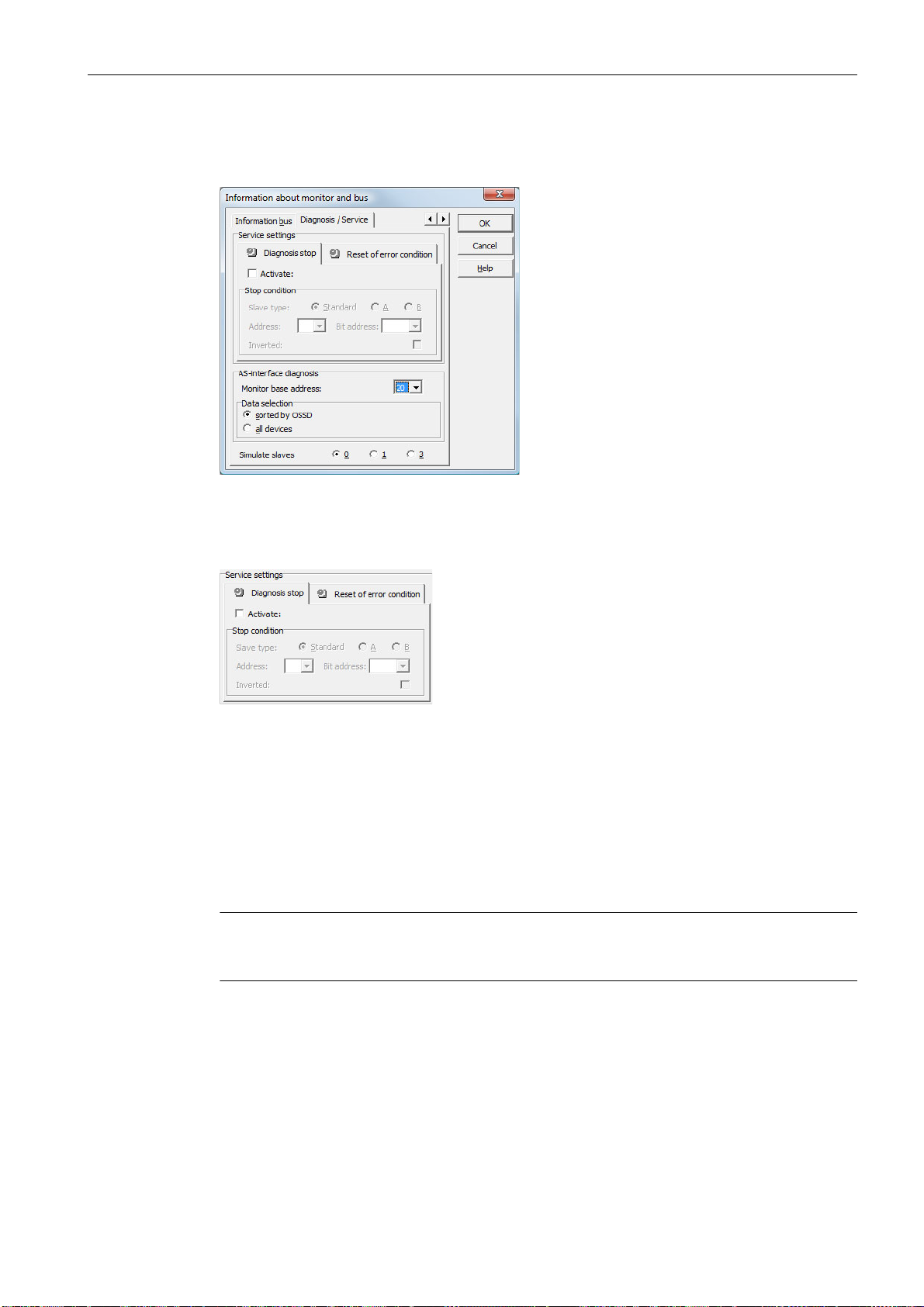

On the Diagnosis / Service tab, you can make service settings for Diagnosis stop and for Reset of error condition as well as configure the diagnostics via the AS-Interface bus.

Figure 3-5 Information about monitor and bus window, Diagnosis / Service tab

Service settings, Diagnosis stop sub-tab

Figure 3-6 Diagnosis stop sub-tab of the Diagnosis / Service tab

The Diagnosis stop function is activated by clicking the Activate: checkbox. This function is

used when a stop condition is fulfilled (specified AS-Interface standard/A/B slave is in the ON

state) to keep the devices in a ready state (diagnostics LED yellow, waiting for confirmation).

This does not occur with activated local acknowledgement. The diagnosis stop is level-sensitive and is deactivated if the specified standard/A/B slave has no bus communication.

This function is very useful, for example, for detecting during very brief switch-off actions which

device, and, thus, which safe input slave caused the switch-off.

Note

For additional information on calling up diagnostic information see chapter "Diagnostics and

error handling" and chapter "Diagnostics via AS-Interface".

ASIMON V3 - Configuration software for AS-Interface safety monitor

Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

21

Page 22

First steps

3.1 Launching the program

Service settings, Reset of error condition sub-tab

Figure 3-7 Reset of error condition sub-tab of the Diagnosis / Service tab

By selecting the Activate: checkbox, the global reset of error conditions via one of the standard/A/B slaves connected to the AS-Interface bus is activated.

If a device detects an error, the AS-Interface safety monitor enters the error state. The error

state is locked (error lock). With versions of the AS-Interface safety monitor before 2.0, the error state can be rectified only by resetting the AS-Interface communication or by resetting the

AS-Interface safety monitor by switching off and then switching back on the AS-Interface safety

monitor or by pressing the Service button on the AS-Interface safety monitor.

As of version 2.0 of the AS-Interface safety monitor, it is possible to differentiate the reset of

error conditions (Reset). Reset of error condition can be activated by an AS-Interface standard/

A/B slave, e.g. a button, and acts only on a device level. Thus, the complete safety monitor is

not reset, but rather only the device locked in the error. For a safety monitor with two independent OSSDs, therefore, only that OSSD is reset in which the device locked in the error is configured.

AS-Interface diagnosis

Monitor base address

You can assign an AS-Interface bus address for the AS-Interface safety monitor. In this case,

it is possible to query diagnostic information about the AS-Interface bus from your AS-Interface

master (e.g. the PLC). If you do not assign an AS-Interface bus address, the AS-Interface safety monitor functions strictly as a "listener", i.e. only as a monitor on the bus. It is not possible

to communicate with the safety monitor via AS-Interface in this case.

For assigned monitor base addresses, you can set under Data selection whether the diagnostic data are to be output via AS-Interface sorted by OSSD or are to be left unsorted (all

devices) (see chapter 7).

Note

When performing diagnostics via the AS-i, the PLC is informed of the indices of the devices

which are switched off. Previously, if a device was added to or deleted from the configuration,

all subsequent indices were shifted. As a result, it was necessary for the user to modify the

diagnostics program in the PLC.

In the Edit menu of ASIMON version 2.1, you can now use the Device index assignment

menu item to freely assign the diagnosis indices to the devices for AS-Interface diagnostics

(see chapter 7.2 "Assignment of the AS-Interface diagnosis indices").

ASIMON V3 - Configuration software for AS-Interface safety monitor

22 Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

Page 23

First steps

3.1 Launching the program

Simulate slaves

If less than four safe or unsafe AS-Interface slaves are connected to the AS-Interface bus, you

must set Simulate slaves to zero in order for the AS-Interface safety monitor to function

correctly.

The number of simulated slaves can be 1 (for large AS-Interface networks) or 3 (for small

AS-Interface networks).

Note

If Simulate slaves is set unequal to zero, either 1 or 3 additional AS-Interface slaves are

simulated internally. These slaves are automatically assigned the first or first three bus

address(es), respectively, which follow on the AS-Interface safety monitor.

If the Simulate slaves function is activated (number of simulated slaves: 1 or 3), the state of

the relay- and message outputs can be queried by the AS-Interface master (PLC) via the

AS-Interface at monitor base address+1, data bits D3 … D0. Bit state 0 identifies an inactive

output, bit state 1 an active output, corresponding to the substitute value in the process image

of the AS-Interface master.

Data bit Content

D0 State of relay output 1

D1 State of message output 1

D2 State of relay output 2

D3 State of message output 2

According to this, the AS-Interface safety monitor occupies a different number of bus

addresses in the AS-Interface network:

Number of

occupied bus

addresses

0 No bus address was assigned to the AS-Interface safety monitor. No communi-

cation and, thus, no diagnostics possible via AS-Interface with the safety monitor.

1 One bus address was assigned to the AS-Interface safety monitor. Diagnostics

possible via AS-Interface with the safety monitor. Number of simulated slaves

equal to 0.

2 One bus address was assigned to the AS-Interface safety monitor. Diagnostics

possible via AS-Interface with the safety monitor. Number of simulated slaves

equal to 1. State of relay- and message outputs can be accessed via AS-Interface at monitor base address+1 (monitor version 2.12 and higher).

4 One bus address was assigned to the AS-Interface safety monitor. Diagnostics

possible via AS-Interface with the safety monitor. Number of simulated slaves

equal to 3. State of relay- and message outputs can be accessed via AS-Interface at monitor base address+1 (monitor version 2.12 and higher).

Meaning

ASIMON V3 - Configuration software for AS-Interface safety monitor

Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

23

Page 24

First steps

3.1 Launching the program

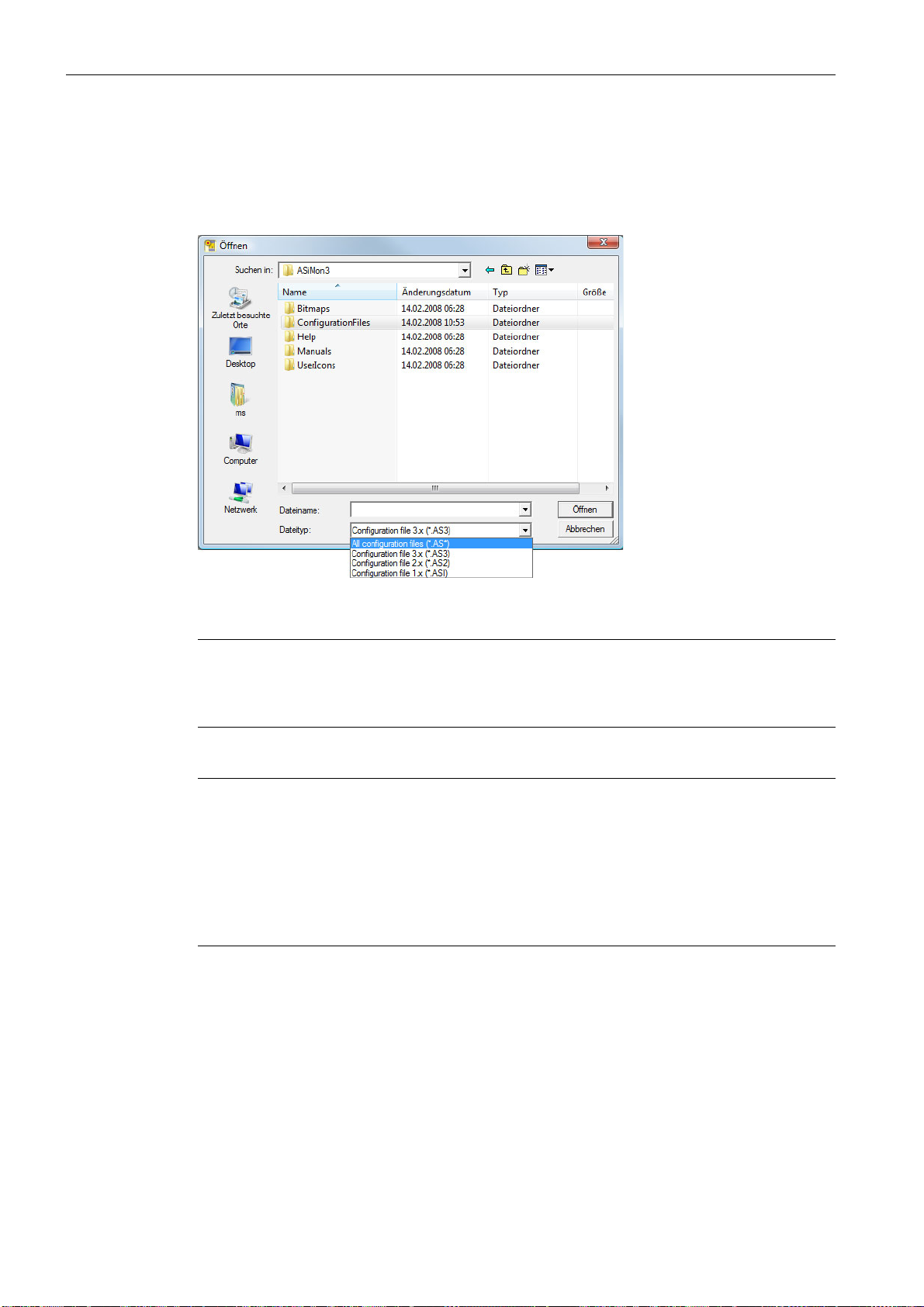

Option Open configuration

With the Open configuration option, you can open an existing configuration file (*.asi) which

was previously stored on a data carrier for purposes of editing or transmitting to an AS-Interface safety monitor.

Figure 3-8 Opening a stored configuration file

Note

ASIMON configuration files have the extension *.ASI (version 1 AS-Interface safety moni-

tors), *.AS2 (version 2 AS-Interface safety monitors) or *.AS3 (version 3.x AS-Interface

safety monitors).

Option Load configuration from AS-Interface safety monitor

Note

If a connection to the AS-Interface safety monitor cannot be established on program startup

(no AS-Interface safety monitor connected, connected to wrong interface etc.) or if the connected AS-Interface safety monitor is in protective operation, the Load configuration from AS-In-

terface safety monitor option is deactivated.

In this case, it is only possible to create a new configuration, load and edit a configuration which

has been stored on a data carrier or to search for errors (see chapter 6.2 "Troubleshooting and

error rectification").

When you select the Load configuration from AS-Interface safety monitor option, the configuration of the connected AS-Interface safety monitor is queried and displayed in the main

program window.

Checkbox Show dialog on startup

When this checkbox is activated, the Start Assistant is called up each time the ASIMON pro-

gram is started. If you do not wish to use this program feature, simply deactivate this checkbox

and the Start Assistant will no longer automatically be opened on program startup.

On the Extras menu under Use Start Assistant, you can reactivate or deactivate the automatic call of the Start Assistant on program startup at any time.

ASIMON V3 - Configuration software for AS-Interface safety monitor

24 Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

Page 25

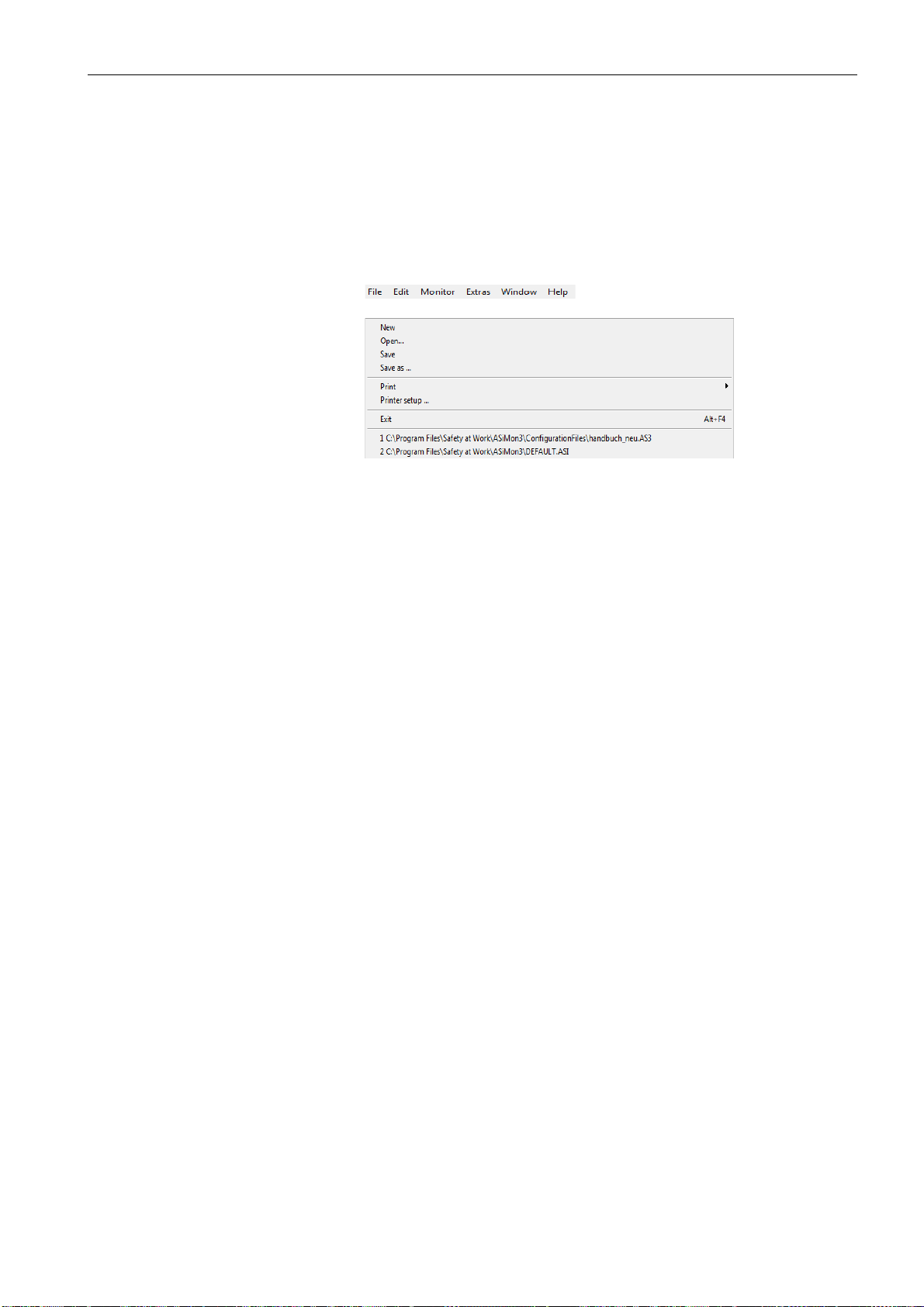

3.2 Description of the user interface

Main menu bar

File menu

3.2.1 The menu bar

Menu overview

Figure 3-9 Menu overview 1

First steps

3.2 Description of the user interface

ASIMON V3 - Configuration software for AS-Interface safety monitor

Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

25

Page 26

First steps

Edit menu

Monitor menu

Extras menu

Help menu

Window menu

3.2 Description of the user interface

Figure 3-10 Menu overview 2

Note

Depending on the program state, particularly when no connection to an AS-Interface safety

monitor exists, not all menu commands are available.

ASIMON V3 - Configuration software for AS-Interface safety monitor

26 Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

Page 27

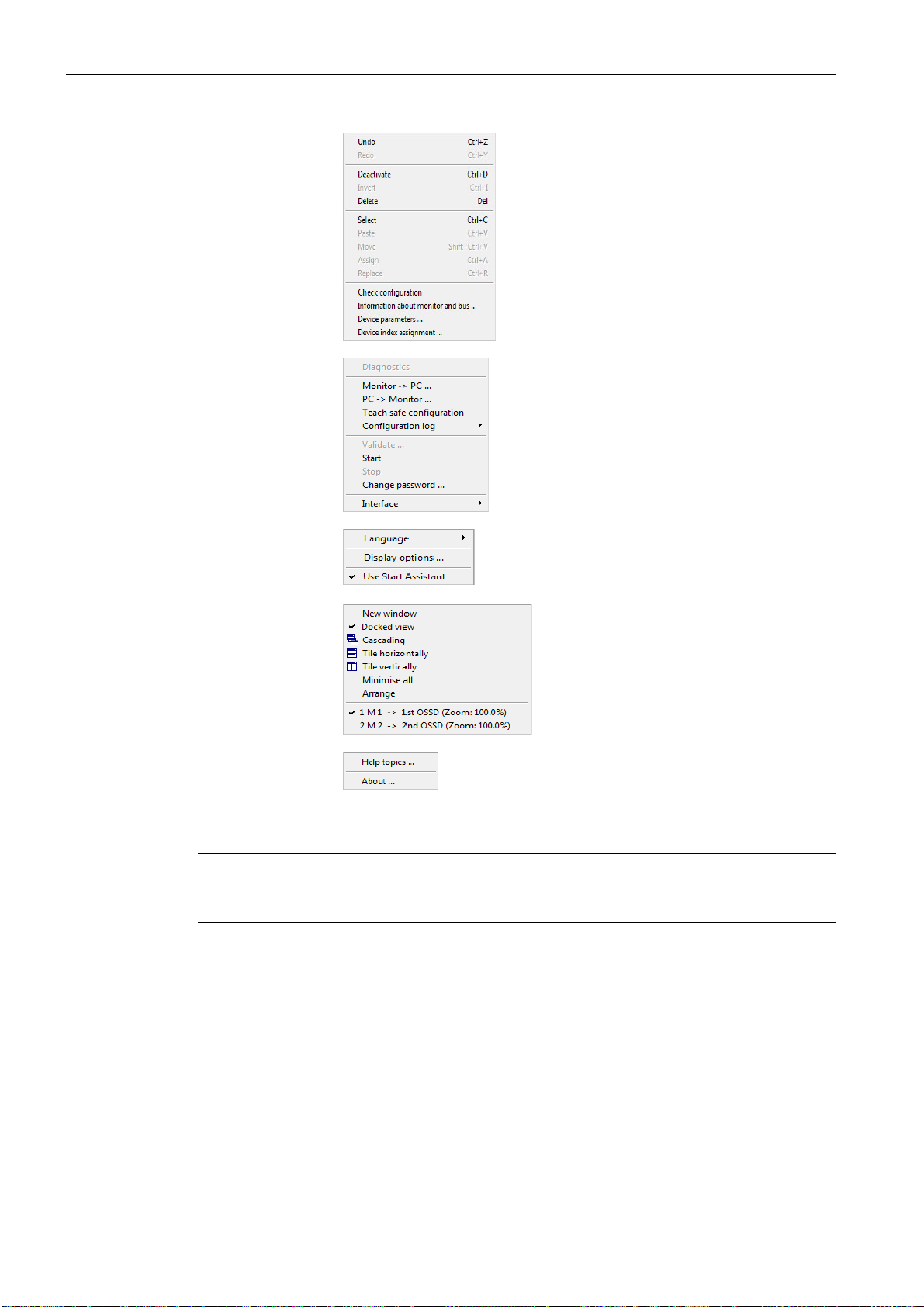

3.2.2 The toolbar

Menu command

Monitor –> Start/Stop

Monitor –> Diagnostics

Device index assignment

Display options…

Check configuration

Information about monitor and bus…

File –> Printer setup…

File –> Print

File –> Save as…

File –> Save

File –> Open…

File –> New

Menu command

Help –> About…

Help –> Help topics…

Reduce (zoom out)

Enlarge (zoom in)

Windows tiled vertically

Windows tiled horizontally

Cascading windows

New window

Redo

Undo

As in other Windows® programs, you can use the buttons located in the toolbar to directly execute important functions without accessing the menu.

First steps

3.2 Description of the user interface

Figure 3-11 Toolbar

ASIMON V3 - Configuration software for AS-Interface safety monitor

Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

27

Page 28

First steps

Left side:

Help information

Right side:

Status and error information

Centre:

Monitor version

(in configuration operation)

3.2 Description of the user interface

3.2.3 The status/info bar

The status/info bar provides valuable information regarding program operation and alerts you

of problems and errors during program execution.

Figure 3-12 Status/info bar

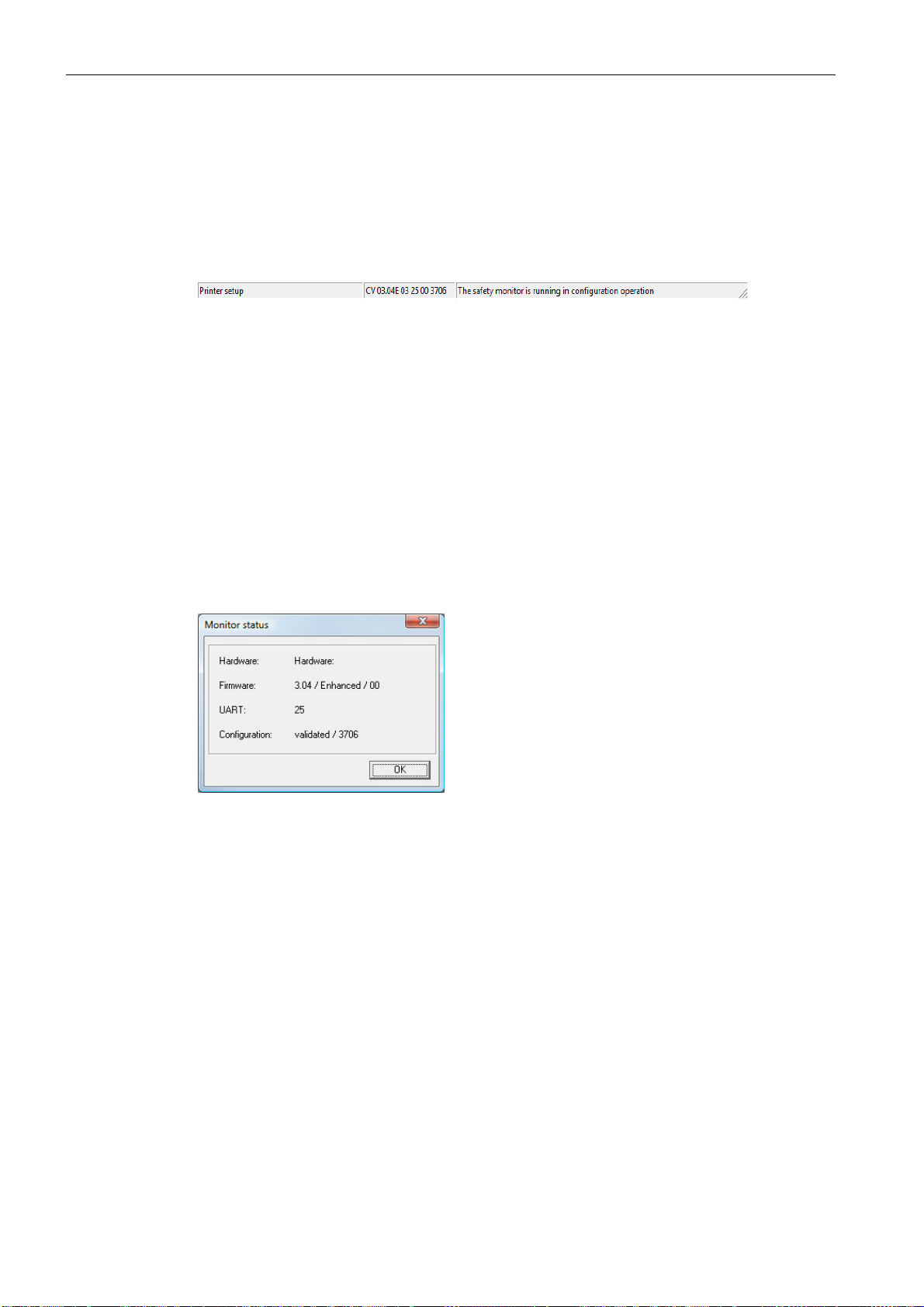

The information on the monitor version in the centre has the following meaning:

CV - Configuration Validated

03.00E - safety monitor version

03 - number of safety outputs (00 = type1/type3, 01 = type2/type4, 02 = type5, 03 = type6)

25 - UART version

00 - free

90C4 - 4-digit code

Click the status/info bar in configuration operation to open a window with status information on

the connected AS-Interface safety monitor.

Figure 3-13 Monitor status window

28 Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

ASIMON V3 - Configuration software for AS-Interface safety monitor

Page 29

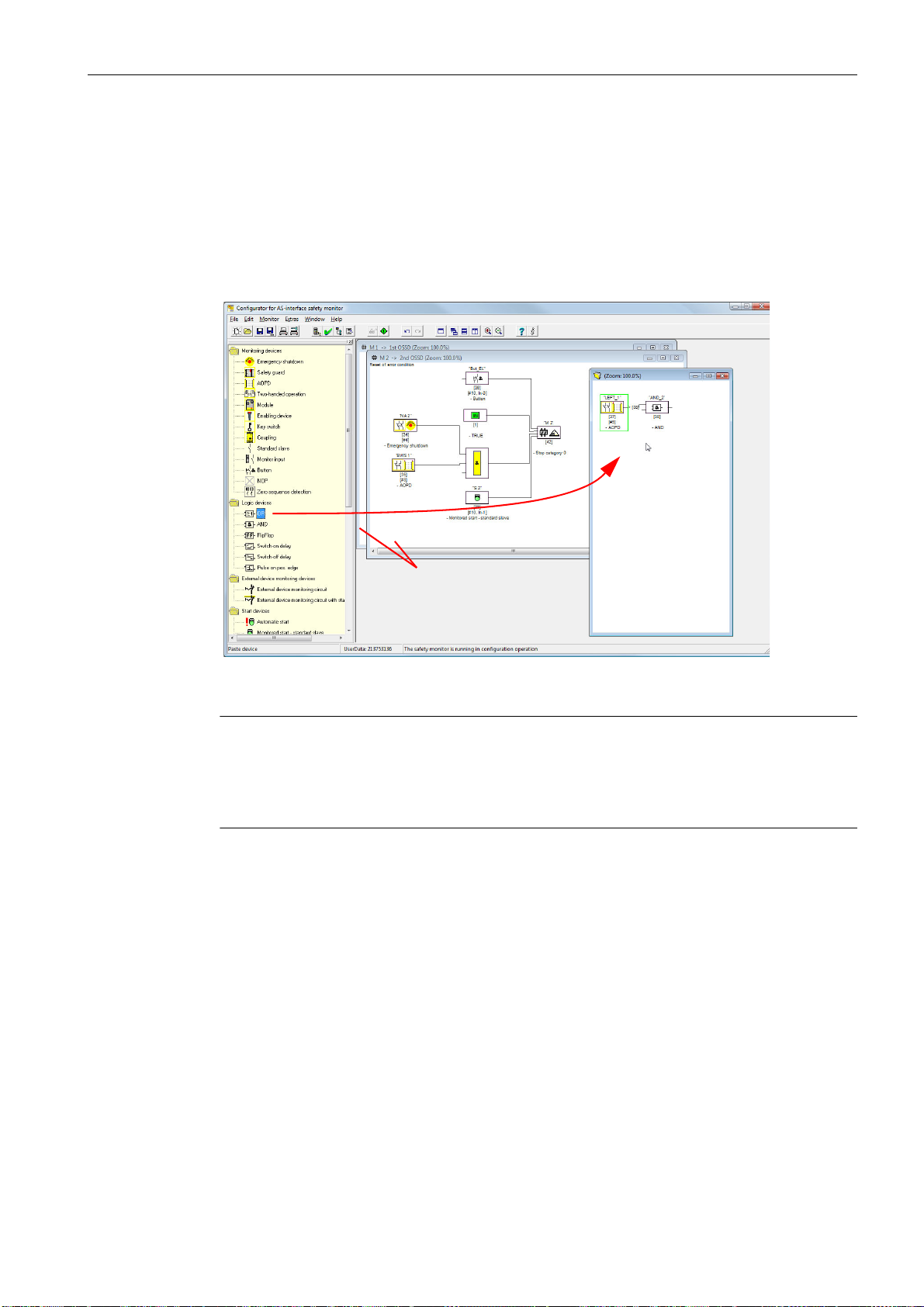

3.2.4 The work area

Icon library

window

(docked)

1st and 2nd OSSD

windows

Active window for

preprocessing or user

device

Work area

Insert a device by

means of

drag&drop

The configuration of an AS-Interface safety monitor with the ASIMON software is performed

graphically and interactively. Using a library of icons representing devices (left window, docked), you can select the safe AS-Interface slaves which are to be monitored as well as other

functional devices and assemble a configuration with them.

The configuration (or parts thereof) are represented in a circuit diagram display as logically

linked devices from left to right in the windows.

First steps

3.2 Description of the user interface

Figure 3-14 Work area with windows

Note

You can switch between the new circuit diagram display (beginning with software version 3)

and the old tree structure display.

To do this, select the Extras –> Display options menu item or press <Ctrl> + <S> or

<Ctrl> + <T>.

The sizes of the individual windows can be adjusted to meet your needs as in other Windows®

programs.

ASIMON V3 - Configuration software for AS-Interface safety monitor

Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

29

Page 30

First steps

3.2 Description of the user interface

Window

The work area may contain any number of windows. The functions in the Window menu are

available for arranging the windows.

As in the past, a device is inserted from the icon library using drag&drop. All windows are initially equal. A window becomes an OSSD window by inserting an output device. If all OSSDs

are defined by a separate configuration window, no further output devices can be inserted in

other windows.

In addition to the OSSD windows, which contain the actual configuration for an AS-Interface

safety monitor, you can use other windows to form substructures (sub-devices) and create

user devices.

Note

The Preprocessing window area familiar from previous software versions no longer exists.

For AS-Interface safety monitors of types 1 and 2 with "Basic" function range, the only possible

logic device available for the linking of two monitoring or system devices is the logic OR function.

In the 1st OSSD and 2nd OSSD windows, the monitoring devices (safe AS-Interface slaves),

start devices, external device monitoring devices, system devices, logic devices and output devices are grouped into the desired configuration and linked to one another using the logical

AND function. Very complex functions can be created in this way.

Operation

Note

The view in the window is updated by pressing the <F5> key; i.e. the window contents are redrawn on the screen.

To paste devices from the icon library into the other windows, as well as to edit, delete, move

and copy devices between the windows, various options are available depending on your personal preference:

• With the mouse:

-by drag&drop from the icon library:

click device with the left mouse button, keep mouse button pressed, and move the device. Simultaneously press the <Ctrl> key for further options:

- If devices are pulled from the selection list to a window with the mouse, the device is

automatically inserted. If the <Ctrl> key is pressed before the mouse button is released, the selected device replaces the device previously present at this position.

•using the right mouse button:

click device with right mouse button and select action from the pop-up menu. If necessary,

change to another window area, click the right mouse button again and select action.

• using menu commands:

click device with the left mouse button, on the Edit menu select one of the commands

Deactivate, Invert, Delete, Select, Paste, Move, Assign or Replace. If necessary, chan-

ge to another window area, click OSSD, Preprocessing, device or position and again click

a command on the Edit menu.

ASIMON V3 - Configuration software for AS-Interface safety monitor

30 Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

Page 31

First steps

1 2 3

Click the output of a

device with the left

mouse button and

hold down.

Pull the connection line ("rubber band")

to the input on the desired device and

release the left mouse button.

Device is

assigned to

the link

3.2 Description of the user interface

• With the keyboard:

- with the <Tab> key: change window areas.

- with the arrow keys: select circuit, device or position.

- execute actions using the following keyboard commands:

<Ctrl> + <D> = Activate/Deactivate

<Ctrl> + <I> = Invert

<Delete> = Delete

<Ctrl> + <C> = Select

<Ctrl> + <V> = Paste

<Shift> + <Ctrl> + <V> = Move

<Ctrl> + <A> = Assign

<Ctrl> + <R> = Replace

In addition to the devices themselves, you can also change the connection lines of the devices

(and thus the device assignment).

Figure 3-15 Device assignment by creating/moving connection lines

Note

If a monitoring device from an OSSD is to be assigned to a link in a new (non-OSSD window),

the link must first be created. After creating the link, select the monitoring device in the OSSD

(<Ctrl> + <C>) and assign it to the logic device in the new window (click the logic device and

press <Ctrl> + <A>).

ASIMON V3 - Configuration software for AS-Interface safety monitor

Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

31

Page 32

First steps

3.2 Description of the user interface

Display options…

You can set with which informational content the devices are to be displayed in the windows

and the size in which the windows are printed out as graphics. To do this, on the Extras menu,

select the Display options… menu item or click the button.

Figure 3-16 Display options - Display

In addition, you can globally set the type of configuration display for all windows here:

• new circuit diagram display (beginning with software version 3) –> tick in Circuit diagram

display.

• old tree structure display –> no tick in Circuit diagram display.

Figure 3-17 Example: Old tree structure display

The Horizontal raster and Vertical raster values determine the distances between the individual devices in the circuit diagram display. By setting the tick for Standard setting, the default values (h:100, v:50) for the device raster are restored.

ASIMON V3 - Configuration software for AS-Interface safety monitor

32 Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

Page 33

First steps

3.2 Description of the user interface

You can specify the scaling for printing the active window as a graphic on the Printer tab.

Figure 3-18 Display options - Printer

ASIMON V3 - Configuration software for AS-Interface safety monitor

Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

33

Page 34

First steps

3.3 Program settings

3.3 Program settings

3.3.1 Setting the program language

The user interface of the ASIMON configuration software supports the following languages:

• German • Spanish • Swedish

• English • Italian

• French • Japanese

To change the language of the user interface, select on the Extras menu under the Language

menu item the desired language. The program does not need to be restarted after changing

the language.

Figure 3-19 Setting the program language

Note

The Japanese characters can be displayed only if the operating system supports such

characters.

ASIMON V3 - Configuration software for AS-Interface safety monitor

34 Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

Page 35

3.3.2 Selecting the serial interface

When starting the program, ASIMON asks if and at which PC serial interface (COM-port) an

AS-Interface safety monitor is connected. If the connection between the PC and safety monitor

is established only after the ASIMON software has been started, you must manually select the

correct COM port in the program. Otherwise, no connection can be established to the AS-Interface safety monitor.

The transmission parameters for serial communication with the AS-Interface safety monitor

are automatically set by ASIMON.

First steps

3.3 Program settings

Figure 3-20 Selecting the serial interface

Notice

When using a USB-RS 232 interface converter or a serial interface card, the intermediate

buffering of data may cause communication problems with the safety monitor.

ASIMON V3 - Configuration software for AS-Interface safety monitor

Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

35

Page 36

ASIMON V3 - Configuration software for AS-Interface safety monitor

36 Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

Page 37

Configuring the AS-Interface safety monitor 4

Configuring the AS-Interface safety monitor

The AS-Interface safety monitor is a universally usable protective device and can, therefore,

be configured for a very wide range of applications.

4.1 Function of the AS-Interface safety monitor

The functional task of the AS-Interface safety monitor is to continuously specify the state(s) of

the OSSD(s) in accordance with the configuration specified by the user based on the states of

the configured devices and to activate or deactivate the assigned safe switching outputs or

safe actuators.

The ASIMON software automatically arranges the devices in the respective windows during

configuration.

Each device can take on two states:

ON state (switched on, logical "1")

This state means that the device has agreed to validate the circuit, i.e. to activate the safe

switching outputs. Depending on the device type, various conditions must first be met.

OFF state (switched off, logical "0")

This state means that the device has not agreed to validate the circuit, i.e. it results in the

switching off of the safe switching outputs.

In the first step of the evaluation, the states of all monitoring, logic and EDM devices are linked

to one another by means of a global logic AND function, i.e. only when all configured monitoring, logic and EDM devices have the ON state is the result of the AND function equal to ON.

In principle, the device states are evaluated in the same way as in an electrical safety circuit in

which all safety switch elements are connected in series and validation is possible only when

all contacts are closed.

In the second step, the start devices which determine the startup behaviour of the OSSD are

evaluated. A start device enters the ON state when the result of the global AND function from

the first step of the evaluation is equal to ON and when the respective start condition is fulfilled.

With regard to the start condition, the start devices have a lock. The start condition must therefore only be fulfilled once. A start device is reset (OFF state) when the result of the global

AND function from the first step of the evaluation returns the OFF state. The states of the start

devices used are linked to one another with an OR function, i.e. only one of the start devices

needs to be in the ON state in order for the internal validation of the circuit to occur.

ASIMON V3 - Configuration software for AS-Interface safety monitor

Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

37

Page 38

Configuring the AS-Interface safety monitor

Index 34

Index 33

Index 35

Index 36

Index 37

Index 38

Index 39

Index 32

Index 40

Index 41

Index 42

>

=

1

OR

OR

AND

AND

GLOBAL

Monitoring devices

Logic devices

External device monitoring

devices

Start devices

Output device

Safety

switching output

and/or

safe actuator

OR function

Global

AND function

Safe input

Safe input

Safe input

Safe input

External device

monitoring circuit

Safe input

4.1 Function of the AS-Interface safety monitor

In the third step, the output device is then analysed. If the circuit has been internally validated

(result of the OR function from the second step of the evaluation is equal to ON), the output

device switches the message and safe switching outputs of the OSSD in accordance with its

function characteristics and time behaviour, i.e. the relays trip and the switching contacts close

or the safe AS-Interface output is set.

Figure 4-1 Order of events during the evaluation of the configured devices

38 Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

ASIMON V3 - Configuration software for AS-Interface safety monitor

Page 39

4.2 General procedure

The process is identical for all device variants of the AS-Interface safety monitor (1 or 2

OSSDs, "Basic" or "Enhanced" function range, with or without safe AS-Interface output).

Step 1 - Information about monitor and bus

In order to create a new configuration, you must first make the required entries in the Information about monitor and bus window for the AS-Interface safety monitor and the slaves which

are to be monitored (see “Start Assistant” on page 17):

• Assign the configuration title

• Specify operating mode of the AS-Interface safety monitor

- One OSSD

- Two independent OSSDs

- Two dependent OSSDs

• Specify safe AS-i output if necessary

- Linked to AS-i input

Configuring the AS-Interface safety monitor

4.2 General procedure

- Control of a safe actuator or safe input slave in the coupled AS-i network

• Specify function range of the AS-Interface safety monitor

- "Basic" or "Enhanced" function range

• Enter the AS-Interface bus addresses of the safe and unsafe AS-Interface slaves which

are to be monitored

• If necessary, activate diagnosis stop via Standard slave

• If necessary, activate reset of error condition via Standard slave

• Activate diagnostics via AS-Interface

- Enter the AS-Interface bus address of the AS-Interface safety monitor

- Selection of the diagnostic data: sorted by OSSD or by all devices

- If necessary, activate the option 1 or 3 Simulate slaves

Step 2 - Create configuration

You can now assemble a new configuration with the required devices from the icon library. see

“Creating and changing a configuration” on page 40. In addition, in ASIMON version 2.1, you

can freely assign the devices diagnosis indices for the AS-Interface diagnostics. see “Assignment of the AS-Interface diagnosis indices” on page 165.

Step 3 - Commissioning

After you have created a valid configuration, you can commission the AS-Interface safety monitor. The commissioning procedure is described in chapter 5.

ASIMON V3 - Configuration software for AS-Interface safety monitor

Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

39

Page 40

Configuring the AS-Interface safety monitor

4.3 Creating and changing a configuration

4.3 Creating and changing a configuration

A valid configuration for the AS-Interface safety monitor must consist of the following devices

for each independent OSSD:

• at least 1 monitoring device

• at least 1 start device (with two dependent output groups, only for OSSD 1)

• exactly 1 output device (with two dependent output groups, only for OSSD 1)

The maximum number of devices is dependent on the function range of the AS-Interface safety

monitor type:

• function range "Basic":maximum 32 devices (device index 32 … 63).

• function range "Enhanced":maximum 48 devices (device index 32 … 79).

Procedure

Select a device from the icon library and insert it into the window of the desired OSSD (see

“Operation” on page 30).

Note

Detailed information about which devices can be used with which configurations can be found

in the description of the individual devices.

When you insert the device into a window, the input mask for the device first opens. Here, you

can make all required entries for this device.

This includes information such as:

• designation (name) of the device within your application, e.g. "Lock gate1"

• type, e.g. "double channel forced"

• AS-Interface bus address

• additional device options which can be activated

• monitoring and delay times

After confirming your entries with the OK button, the device appears in the window of the respective OSSD.

Note

The view in the window is updated by pressing the <F5> key; i.e. the window contents are redrawn on the screen.

ASIMON V3 - Configuration software for AS-Interface safety monitor

40 Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

Page 41

Configuring the AS-Interface safety monitor

Name of the device

AS-Interface address

of the assigned slave

Device index for the device

Device symbol

Device designation

in quotation marks

4.3 Creating and changing a configuration

Example:

Figure 4-2 Graphic depiction of the devices

In addition to icon, designation and name, the respective device index for each device is specified. The index, which is automatically assigned by ASIMON for each configured device,

uniquely identifies each device, regardless of whether it has been configured for the first or second OSSD.

The index begins with 32 and increases incrementally by 1. Within the configuration log, each

configured device can be uniquely identified using the index.

Note

The display of the devices can be modified.

To do this, on the Extras menu select the Display options… menu item or click the button

(see chapter 3.2.4 "The work area").

Note

When performing diagnostics via the AS-i, the PLC is informed of the indices of the devices

which are switched off. Previously, if a device was added to or deleted from the configuration,

all subsequent indices were shifted. As a result, it was necessary for the user to modify the

diagnostics program in the PLC.

In the Edit menu of ASIMON version 2.1, you can now use the Device index assignment

menu item to freely assign diagnosis indices to the devices for AS-Interface diagnostics (see

chapter 7). When making the assignments, you can specify whether the diagnosis index range

is 0 … 47 or analogous to the device indices 32 … 79.

ASIMON V3 - Configuration software for AS-Interface safety monitor

Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

41

Page 42

Configuring the AS-Interface safety monitor

4.3 Creating and changing a configuration

ASIMON automatically organises all devices of a configuration with respect to the device indices in the following order:

1. Monitoring and logic devices in any order

2. External device monitoring (EDM) devices (contactor monitoring)

3. Start devices

4. Output device

Upon insertion of a new device, the indices are correspondingly rearranged.

Note

A monitoring or logic device configured in the 1st OSSD can also be used in the 2nd OSSD

and vice versa.

You can define a device or a logical group of devices as a user device; this user device can

then very easily be used multiple times in the OSSDs.

Example:

Figure 4-3 Example: Structure of a configuration

To delete a device from the configuration, mark it with the mouse and then select the Delete

command from the Edit menu or the pop-up menu (right mouse button) or simply press the

<Delete> key.

To edit a device, double-click its icon to reopen its input mask. Here, you can edit all device

parameters. Alternatively, you can use the Device parameters… command in the Edit menu

or the Edit … command in the pop-up menu.

ASIMON V3 - Configuration software for AS-Interface safety monitor

42 Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

Page 43

4.3.1 Monitoring devices

The monitoring devices constitute the actual safe switching components of the OSSD(s) in the

configuration.

For the safe monitoring devices, a distinction is made depending on type between:

Double channel, forced components

Upon actuation of an emergency-off switch with its two redundant contacts, the two contacts

open simultaneously. As a result of this construction, both contacts are always either open or

closed. If one of the two contacts closes or opens either too early or too late, an error results

after a tolerated transition time has passed.

The functional device for double channel, forced components can, thus, be used for applications such as

• emergency shutdown switches

• safety guards

• active optoelectronic protective device

• zero-speed relays

Configuring the AS-Interface safety monitor

4.3 Creating and changing a configuration

Here, both the direct connection of an integrated AS-Interface slave as well as the connection

of a conventional device via a safe coupling module are possible. Local acknowledgement and/

or the startup test are available as options.

Double channel, dependent components

The monitoring to determine whether a safety guard is open or closed is performed by two protective switches. If this safety guard is opened or closed, the protective switches are not actuated simultaneously. In the double channel dependent functional device, a synchronisation

time can, therefore, be specified. Both switches must close within this synchronisation time. If

the synchronisation time is exceeded, the start-test state results.

The safety monitor also monitors the switches to ensure that one of the two end positions "both

switches open" or "both switches closed" is always achieved.

The functional device for double channel, dependent components can, thus, be used for applications such as

• safety guards with two protective switches

• two-handed operations

Here, both the direct connection of an integrated AS-Interface slave as well as the connection

of a conventional device via a safe coupling module are possible. Local acknowledgement and/

or the startup test are available as options.

ASIMON V3 - Configuration software for AS-Interface safety monitor

Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

43

Page 44

Configuring the AS-Interface safety monitor

4.3 Creating and changing a configuration

Double channel, dependent components with debouncing

Note

These components are only available for the types of the AS-Interface safety monitor with enhanced function range (type 3 … type 6).

The monitoring to determine whether a safety guard is open or closed is performed by two protective switches. If this safety guard is opened or closed, the protective switches are not actuated simultaneously. Moreover, the switches bounce, for example when the guard is closed

too fast. In the double channel dependent functional device with debouncing, it is, therefore,

also possible to specify a bounce time in addition to the synchronisation time. The bounce time

begins when both contacts close the first time. Within the specified bounce time, the switches

can change their state freely. After the bounce time has passed, both contacts are again queried. If they are then closed and if the synchronisation time has not yet passed, the validation

is performed. The selected synchronisation time must be greater than the bounce time. If the

synchronisation time is exceeded, the start-test state results. The safety monitor also monitors

the switches to ensure that one of the two end positions "both switches open" or "both switches

closed" is always achieved.

The functional device for double channel, dependent components with debouncing can, thus,

be used for applications such as

• slow-action switch

• switches with high bounce times

Here, both the direct connection of an integrated AS-Interface slave as well as the connection

of a conventional device via a safe coupling module are possible. Local acknowledgement and/

or the startup test are available as options.

Double channel, dependent components with filtering

Note

These components are only available for the types of the AS-Interface safety monitor with enhanced function range (type 3 … type 6).

The monitoring to determine whether a safety guard is open or closed is performed by two protective switches. If this safety guard is opened or closed, the protective switches are not actuated simultaneously. In addition, guard vibrations may result in short-term, single-channel

interruptions. This monitoring device can be used to "filter out" such interference without causing the system to be switched off. The user defines a synchronisation time, a stabilising time

and, if necessary, a tolerance time for short-term, single-channel interruptions. When switched

on, the protective switch may switch between all possible states (none, one, or both contacts

closed) during the synchronisation time.

If both contacts remain open for the duration of the stabilising time, the synchronisation time is

restarted when the contacts are again closed. If the protective switch is in an undefined state

for the duration of the stabilising time, the functional device switches to the locked error state.

Only if both contacts close within the synchronisation time and remain closed for the duration

of the stabilising time is the validation performed.

The functional device offers various possibilities for handling short-term, single-channel interruptions. Local acknowledgement and/or the startup test are available as options.

ASIMON V3 - Configuration software for AS-Interface safety monitor

44 Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

Page 45

Configuring the AS-Interface safety monitor

4.3 Creating and changing a configuration

Double channel, conditionally dependent components

Note

These components are only available for the types of the AS-Interface safety monitor with enhanced function range (type 3 and type 4).

The monitoring to determine whether a safety guard is open or closed is performed by a protective switch with lock. One contact is switched by the protective switch, the second by the

lock monitor. If the lock is opened, the guard can also be opened. This sequence of events is

monitored. It is an error if the protective switch opens first.

Which contact is dependent on which can be freely selected in the double channel conditionally

dependent functional device. The dependent contact can be freely opened and closed as long

as the independent contact is not opened.

The functional device for double channel, conditionally dependent components can, thus, be

used for applications such as

• door switch with lock

Here, both the direct connection of an integrated AS-Interface slave as well as the connection

of a conventional device via a safe coupling module are possible.

Notice

As a result of the permissible, independent actuation, a loss of redundancy is not detected!

Double channel, independent components

The monitoring to determine whether a safety guard is open or closed is performed by a protective switch with lock. One contact is switched by the protective switch, the second by the

lock monitor. With this functional device, it is possible to open and close the lock without forcing

the guard to open or close.

The functional device for double channel independent components can, thus, be used for applications such as

• protective switch for door monitoring

Here, both the direct connection of an integrated AS-Interface slave as well as the connection

of a conventional device via a safe coupling module are possible. Local acknowledgement

and/or the startup test are available as options.

Notice

As a result of the permissible, independent actuation, a loss of redundancy is not detected!

ASIMON V3 - Configuration software for AS-Interface safety monitor

Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

45

Page 46

Configuring the AS-Interface safety monitor

4.3 Creating and changing a configuration

Standard slave

Within an OSSD, it is also possible to use standard AS-Interface slaves in order to realise, by

means of their switching signals (inputs or outputs), an exclusively operational switching of the

safe switching outputs of the AS-Interface safety monitor in an OSSD.

Notice

The use of a standard slave device for safe switching tasks is not permitted!

Monitor input

Within the OSSDs or preprocessing, the input signals of the 2 or 4 inputs 1.Y1, 1.Y2 and

2.Y1, 2.Y2, respectively, of the AS-Interface safety monitor can also be used to implement

strictly operational switching of the safe switching output(s) of the AS-Interface safety monitor

in an OSSD.

Notice

The use of a monitor input device for safe switching tasks is not permitted!

Button

The Button device can be integrated within the OSSD or Preprocessing. The Button device

makes acknowledgement possible on the device level. As soon as the validation for the device

which is linked to the button is present, this device can be validated by actuating the button,

i.e. acknowledged.

With the aid of the Device button, it is possible, for example, to assign a common local

acknowledgement to multiple light barriers which have been linked together by an AND gate.

NOP

Dummies (NOP - N

o OPeration) can be used within an (OSSD) window to make the configuration or the graphical display in ASIMON easier to organise or to create a sample configuration to be used as a pattern for different configuration variants. An NOP dummy occupies an

index within the configuration. Each functional device can be replaced by an NOP dummy and

vice versa.

ASIMON V3 - Configuration software for AS-Interface safety monitor

46 Programming and Operating Manual, Edition 09/2008, GWA 4NEB 333 1558 02 DS 02

Page 47

Configuring the AS-Interface safety monitor

4.3 Creating and changing a configuration