Siemens 7SR10 Argus, 7SR1003 Argus, 7SR1002 Argus, 7SR1004 Argus Series Manual

7SR10 Argus

Overcurrent Relay

Reyrolle

Protection

Devices

Siemens Protecti on Devices Limit ed 2

Contents

Technical Manual Chapters

1. Description of Operation

2. Settings & Instruments Guide

3. Performance Specification

4. Data Communications

5. Installation

6. Commissioning and Maintenance

7SR10 Argus Contents

7. Applications Guide

The copyright and other intellectual property rights in this document, and in any model or article produced from it

(and including any registered or unregistered design rights) are the property of Siemens Protection Devices

Limited. No part of this document shall be reproduced or modified or stored in another form, in any data retrieval

system, without the permission of Siemens Protection Devices Limited, nor shall any model or article be

reproduced from this document unless Siemens Protection Devices Limited consent.

While the information and guidance given in this document is believed to be correct, no liability shall be accepted

for any loss or damage caused by any error or omission, whether such error or omission is the result of

negligence or any other cause. Any and all such liability is disclaimed.

© 2018 Siemens Protection Devices Limited

7SR10 Description of Operation

7SR10

Description of Operation

Document Release History

This document is issue 2018/07. The list of revisions up to and including this issue is:

2018/07

2018/06 Eleventh Issue

2017/09 Tenth Issue

2017/07

2017/04

2017/03

2016/11 Sixth Issue

2015/09 Fifth Issue

2015/06

2015/03

2015/02

2013/11 First Issue

Software Revision History (7SR1002/7SR1003)

2018/05 2437H80001 R4h-2d Operating system upgrade

2017/09 2437H80001 R4d-2c Data Communications improvements

2017/04 2437H80001 R4c-2b Minor modification in Analog

2016/11 2437H80001 R4b-2b Support for Reydisp manager tool

2015/09 2437H80001 R4b-2a Addition of AR variants

Twelfth Issue

Nineth Issue

Eighth Issue

Seventh Issue

Fourth Issue

Third Issue

Second Issue

2015/06 2437H80001 R4b-1f 81THD function added

2015/03 2437H80001 R4b-1e Addition of non-directional SEF device variants

2015/02 2437H80001 R4b-1d First Maintenance

2013/11 2436H80015 R2d-1a First Release

Software Revision History (7SR1004)

2018/06 2437H80008 R4h-1a First Release

The copyright and other intellectual property rights in this document, and in any model or article produced from it

(and including any registered or unregistered design rights) are the property of Siemens Protection Devices

Limited. No part of this document shall be reproduced or modified or stored in another form, in any data retrieval

system, without the permission of Siemens Protection Devices Limited, nor shall any model or article be

reproduced from this document unless Siemens Protection Devices Limited consent.

While the information and guidance given in this document is believed to be correct, no liability shall be accepted

for any loss or damage caused by any error or omission, whether such error or omission is the result of

negligence or any other cause. Any and all such liability is disclaimed.

©2018 Siemens Protection Devices Limited

7SR10 Description of Operation

Contents

Section 1: Introduction ....................................................................................................................................... 8

1.1 Current Transform er Circuits .............................................................................................................. 8

1.2 External Resistors.............................................................................................................................. 8

1.3 Description ........................................................................................................................................ 8

1.4 Ordering Options ............................................................................................................................... 9

1.5 Functional Diagram .......................................................................................................................... 11

1.6 Terminal Diagram ............................................................................................................................ 12

1.6.1 Terminal Diagram with Control Push Buttons ...................................................................... 12

Section 2: Hardware Description ...................................................................................................................... 14

2.1 General ........................................................................................................................................... 14

2.2 Front Fascia .................................................................................................................................... 15

2.2.1 Front Fascia with Control Push Buttons ............................................................................... 15

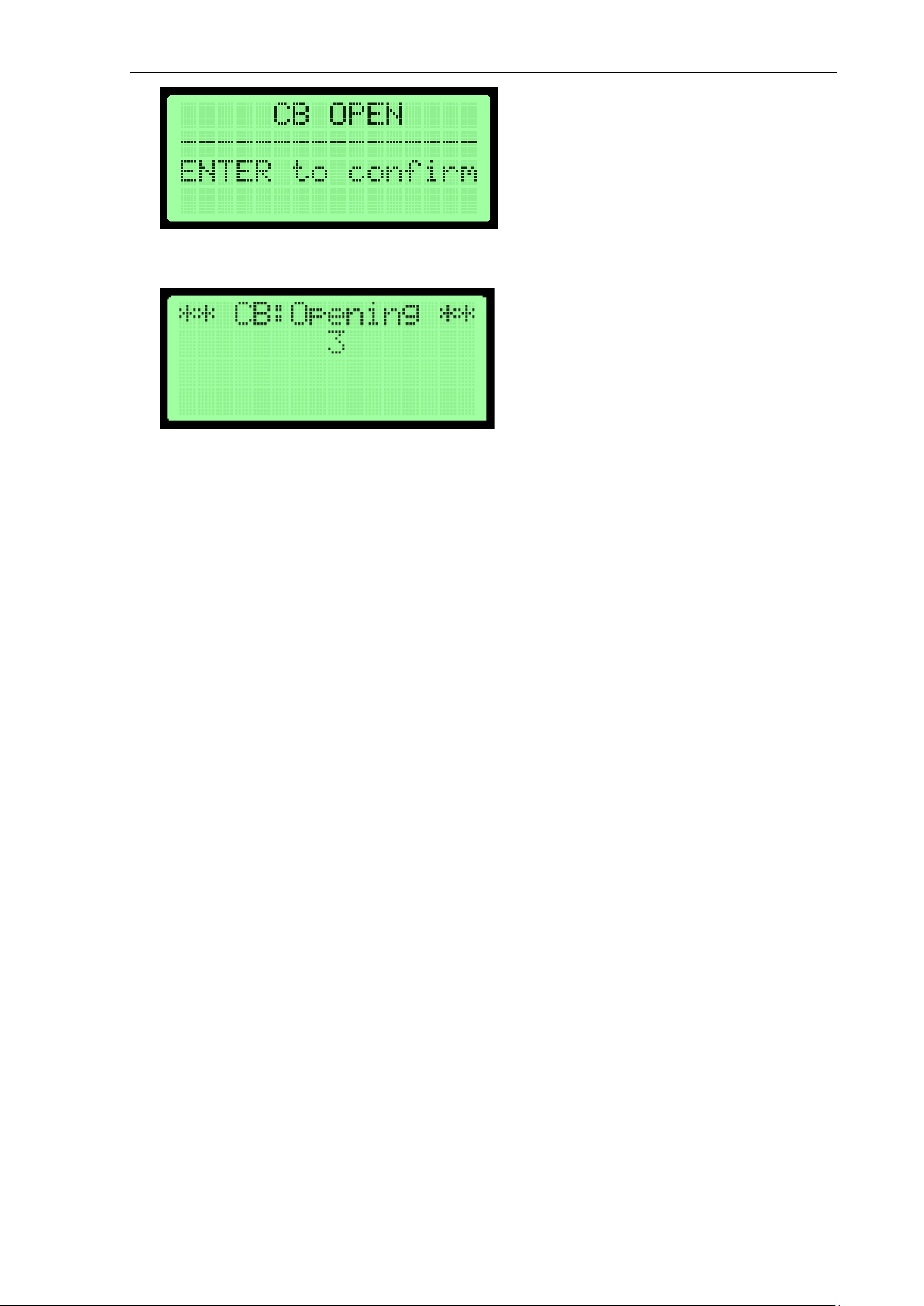

2.3 CB Open/Close ............................................................................................................................... 15

2.4 Power Supply Unit (PSU) ................................................................................................................. 16

2.5 Connectors ...................................................................................................................................... 17

2.5.1 Connectors with Control Push Buttons ................................................................................ 17

2.6 Relay Information ............................................................................................................................ 17

2.7 Operator Interface............................................................................................................................ 19

2.7.1 Liquid Crystal Display (LCD) ............................................................................................... 19

2.7.2 LCD Indication ................................................................................................................... 19

2.7.3 Standard Keys ................................................................................................................... 19

2.7.4 Protection Healthy LED ...................................................................................................... 20

2.7.5 Indication LEDs .................................................................................................................. 20

2.8 Current Inputs.................................................................................................................................. 20

2.9 Voltage Inputs ................................................................................................................................. 21

2.10 Binary Inputs ................................................................................................................................... 21

2.11 Binary Outputs (Output Relays) ........................................................................................................ 21

2.12 Virtual Input/Outputs ........................................................................................................................ 22

2.13 Self Monitoring ................................................................................................................................ 23

2.13.1 Protection Healthy/Defective ............................................................................................... 24

Section 3: Protection Functions ........................................................................................................................ 25

3.1 Current Protection: Phase Overcurrent (67, 51, 50) ........................................................................... 25

3.1.1 Directional Control of Overcurrent Protection (67) ................................................................ 25

3.1.2 Instantaneous Overcurrent Protection (50) .......................................................................... 26

3.1.3 Time Delayed Overcurrent Protection (51) .......................................................................... 27

3.1.4 Current Protection: Voltage Controlled Overcurrent (51V) .................................................... 29

3.2 Current Protection: Derived Earth Fault (67N, 51N, 50N)................................................................... 30

3.2.1 Directional Control of Derived Earth Fault Protection (67N) .................................................. 30

3.2.2 Instantaneous Derived Earth Fault Protection (50N) ............................................................ 31

3.2.3 Time Delayed Derived Earth Fault Protection (51N) ............................................................. 32

3.3 Current Protection: Measured Earth Fault (67G, 51G, 50G)............................................................... 34

3.3.1 Directional Control of Measured Earth Fault Protection (67G) .............................................. 34

3.3.2 Instantaneous Measured Earth Fault Protection (50G) ......................................................... 35

3.3.3 Time Delayed Measured Earth Fault Protection (51G) ......................................................... 36

3.4 Current Protection: Sensitive Earth Fault (67SEF, 51SEF, 50SEF) .................................................... 37

3.4.1 Directional Control of Sensitive Earth Fault Protection (67SEF) ............................................ 37

3.4.2 Instantaneous Sensitive Earth Fault Protection (50SEF) ...................................................... 38

3.4.3 Time Delayed Sensitive Earth Fault Protection (51SEF) ...................................................... 38

3.4.4 Current Protection: High Impedance Restricted Earth Fault - (64H) ...................................... 40

3.4.5 Current Protection: Cold Load (51c) .................................................................................... 40

3.4.6 Current Protection: Negative Phase Sequence Overcurrent - (46NPS) ................................. 41

3.4.7 Current Protection: Under-Current (37) ............................................................................... 42

3.4.8 Current Protection: Thermal Overload (49) .......................................................................... 43

3.4.9 Voltage Protection: Phase Under/Over Voltage (27/59) ....................................................... 44

3.4.10 Voltage Protection: Negative Phase Sequence Overvoltage (47NPS) .................................. 45

3.4.11 Voltage Protection: Neutral Overvoltage (59N) .................................................................... 46

3.4.12 Voltage Protection: Under/Over Frequency (81) .................................................................. 47

3.4.13 Power Protection: Power (32) ............................................................................................. 48

©2018 Siemens Protection Devices Limited Chapter 1 Page 2 of 77

7SR10 Description of Operation

3.4.14 Power Protection: Sensitive Power (32S) ............................................................................ 49

3.4.15 Power Protection: Power Factor (55) ................................................................................... 50

Section 4: Auto-Reclose (79) Optional Function ................................................................................................ 51

4.1.1 Overview............................................................................................................................ 51

4.1.2 Auto Reclose sequences .................................................................................................... 53

4.1.3 Autoreclose Prot’n Menu .................................................................................................... 54

4.1.4 Autoreclose Config Menu ................................................................................................... 54

4.1.5 P/F Shots sub-menu ........................................................................................................... 55

4.1.6 E/F Shots sub-menu ........................................................................................................... 55

4.1.7 SEF Shots sub-menu ......................................................................................................... 55

4.1.8 Extern Shots sub-menu ...................................................................................................... 55

4.2 Quick Logic ..................................................................................................................................... 58

4.3 Manual CB Control .......................................................................................................................... 59

4.4 Circuit Breaker (CB) ......................................................................................................................... 60

Section 5: Supervision Functions ...................................................................................................................... 62

5.1 Circuit Breaker Failure (50BF) .......................................................................................................... 62

5.2 2nd Harmonic Block/Inrush Restraint (81HBL2) Phase Elements Only .............................................. 63

5.3 Total Harmonic Distortion Supervision (81THD) ................................................................................ 63

5.4 VT Supervision (60VTS) .................................................................................................................. 64

5.5 CT Supervision (60CTS) .................................................................................................................. 65

5.5.1 60CTS-I ............................................................................................................................. 65

5.5.2 60CTS ............................................................................................................................... 66

5.6 Broken Conductor (46BC) ................................................................................................................ 66

5.7 Trip/ Close Circuit Supervision (74TCS & 74CCS) ............................................................................ 67

Section 6: Other Features ................................................................................................................................ 68

6.1 Data Communications ...................................................................................................................... 68

6.1.1 Communication Ports ......................................................................................................... 68

6.2 CB Maintenance .............................................................................................................................. 71

6.2.1 Output Matrix Test .............................................................................................................. 71

6.2.2 CB Counters ...................................................................................................................... 71

6.2.3 I2t CB Wear ........................................................................................................................ 72

6.3 Data Storage ................................................................................................................................... 72

6.3.1 General .............................................................................................................................. 72

6.3.2 Demand ............................................................................................................................. 72

6.3.3 Event Records ................................................................................................................... 72

6.3.4 Waveform Records............................................................................................................. 73

6.3.5 Fault Records..................................................................................................................... 73

6.3.6 Energy Storage .................................................................................................................. 73

6.3.7 Disk Activity W arning .......................................................................................................... 74

6.4 Metering .......................................................................................................................................... 75

6.5 Operating Mode ............................................................................................................................... 75

6.6 Control Mode ................................................................................................................................... 75

6.7 Real Time Clock .............................................................................................................................. 76

6.7.1 Time Synchronisation – Data Communication Interface ....................................................... 76

6.7.2 Time Synchronisation – Binary Input ................................................................................... 76

6.8 Settings Groups ............................................................................................................................... 76

6.9 Password Feature............................................................................................................................ 76

©2018 Siemens Protection Devices Limited Chapter 1 Page 3 of 77

7SR10 Description of Operation

List of Figures

Figure 2-1

Figure 2-2 7SR10 Non-Directional and Directional Overcurrent Relay with Connectors ....................................... 17

Figure 2-3 Relay Rating Label ........................................................................................................................... 18

Figure 2-4 Fascia Relay Rating Label ................................................................................................................ 18

Figure 2-5 Safety Symbols ................................................................................................................................ 18

Figure 2-6 Close up of Relay Identifier ............................................................................................................... 19

Figure 2-7 LED Indication Label ........................................................................................................................ 20

Figure 2-8 Binary Input Logic ............................................................................................................................. 21

Figure 2-9 Binary Output Logic .......................................................................................................................... 22

Figure 2-10 Start-up Counter Meter ..................................................................................................................... 23

Figure 2-11 Unexpected Restarts Lockout Text .................................................................................................... 23

Figure 2-12 Start-up Events ................................................................................................................................ 24

Figure 3-1 Logic Diagram: Directional Overcurrent Element (67)......................................................................... 26

Figure 3-2 Logic Diagram: Instantaneous Over-current Element ......................................................................... 27

Figure 3-3 Logic Diagram: Time Delayed Overcurrent Element ........................................................................... 28

Figure 3-4 Logic Diagram: Voltage Controlled Overcurrent Protection ................................................................. 29

Figure 3-5 Logic Diagram: Derived Directional Earth Fault Element .................................................................... 30

Figure 3-6 Logic Diagram: Derived Instantaneous Earth Fault Element ............................................................... 31

Figure 3-7 Logic Diagram: Derived Tim e Delayed Earth Fault Protection ............................................................ 33

Figure 3-8 Logic Diagram: Measured Directional Earth Fault Protection .............................................................. 34

Figure 3-9 Logic Diagram: Measured Instantaneous Earth-fault Element ............................................................ 35

Figure 3-10 Logic Diagram: Measured Time Delayed Earth Fault Element (51G) .................................................. 36

Figure 3-11 Logic Diagram: SEF Directional Element (67SEF) ............................................................................. 37

Figure 3-12 Logic Diagram: 7SR10 SEF Instantaneous Element .......................................................................... 38

Figure 3-13 Logic Diagram: 7SR10 SEF Instantaneous Element .......................................................................... 38

Figure 3-14 Logic Diagram: 7SR10 SEF Time Delayed Element (51SEF) ............................................................. 39

Figure 3-15 Logic Diagram: 7SR10 SEF Time Delayed Element (51SEF) ............................................................. 39

Figure 3-16 Logic Diagram: High Impedance REF (64H) ...................................................................................... 40

Figure 3-17 Logic Diagram: Cold Load Settings (51c)........................................................................................... 41

Figure 3-18 Logic Diagram: Negative Phase Sequence Overcurrent (46NPS) ....................................................... 42

Figure 3-19 Logic Diagram: Phase Current Inputs Undercurrent Detector (37) ...................................................... 42

Figure 3-20 Logic Diagram: Earth Current Inputs Undercurrent Detector (37G) ..................................................... 43

Figure 3-21 Logic Diagram: Sensitive Earth Current Inputs Undercurrent Detector (37SEF) .................................. 43

Figure 3-22 Logic Diagram: Thermal Overload Protection (49) ............................................................................. 44

Figure 3-23 Logic Diagram: Under/Over Voltage Elements (27/59) ....................................................................... 45

Figure 3-24 Logic Diagram: NPS Overvoltage Protection (47) .............................................................................. 45

Figure 3-25 Logic Diagram: Neutral Overvoltage Element (59N) ........................................................................... 46

Figure 3-26 Logic Diagram: Under/Over Frequency Detector (81)......................................................................... 47

Figure 3-27 Logic Diagram: Power Protection (32) ............................................................................................... 48

Figure 3-28 Logic Diagram: Sensitive Power Protection (32S) .............................................................................. 49

Figure 3-29 Logic Diagram: Power Factor Protection (55) .................................................................................... 50

Figure 4-1 Typical AR Sequence with 3 Inst and 1 Delayed trip .......................................................................... 53

Figure 4-2 Basic Auto-Reclose Sequence Diagram ............................................................................................ 57

Figure 4-3 Sequence Diagram: Quick Logic PU/DO Timers (Counter Reset Mode Off) ........................................ 58

Figure 4-4 Logic Diagram: Circuit Breaker Status ............................................................................................... 61

Figure 5-1 Logic Diagram: Circuit Breaker Fail Protection (50BF) ....................................................................... 62

Figure 5-2 Logic Diagram: Harmonic Block Feature (81HBL2) ............................................................................ 63

Figure 5-3 Logic Diagram: Total Harmonic Distortion Supervision Element (81THD) ........................................... 64

Figure 5-4 Logic Diagram: VT Supervision Function (60VTS) ............................................................................. 65

Figure 5-5 Logic Diagram: CT Supervision Function (60CTS) ............................................................................. 66

7SR10 Argus Overcurrent Relay with Control Push Buttons ............................................................... 15

©2018 Siemens Protection Devices Limited Chapter 1 Page 4 of 77

7SR10 Description of Operation

Figure 5-6 Logic Diagram: CT Supervision Function (60CTS) ............................................................................. 66

Figure 5-7 Logic Diagram: Broken Conductor Function (46BC) ........................................................................... 67

Figure 5-8 Logic Diagram: Trip Circuit Supervision Feature (74TCS) .................................................................. 67

Figure 5-9 Logic Diagram: Close Circuit Supervision Feature (74CCS) ............................................................... 67

Figure 6-1 Communication to Front USB Port .................................................................................................... 68

Figure 6-2 Connect Icon .................................................................................................................................... 68

Figure 6-3 Port Selection in Connection Manager .............................................................................................. 69

Figure 6-4 System Information Icon ................................................................................................................... 69

Figure 6-5 System Inform ation Icon ................................................................................................................... 70

Figure 6-6 Communication to Multiple Devices from Control System using RS485 .............................................. 71

Figure 6-7 Energy Direction Convention............................................................................................................. 74

©2018 Siemens Protection Devices Limited Chapter 1 Page 5 of 77

7SR10 Description of Operation

List of Tables

Table 2-1

Table 6-1 Operation Mode ............................................................................................................................... 75

Summary of 7SR10 Argus Overcurrent Relay Configurations ............................................................. 14

©2018 Siemens Protection Devices Limited Chapter 1 Page 6 of 77

7SR10 Description of Operation

Symbols and Nomenclature

The following notational and formatting conventions are used within the remainder of this document:

• Setting Menu Location MAIN MENU>SUB-MENU

• Setting: Elem name -Setting

• Setting value: value

• Alternatives: [1st] [2nd] [3rd]

©2018 Siemens Protection Devices Limited Chapter 1 Page 7 of 77

7SR10 Description of Operation

!

!

Section 1: Introduction

This manual is applicable to the following relay:

• 7SR10 Overcurrent Relay

General Safety Precautions

1.1 Current Transformer Circuits

The secondary circuit of a live CT must not be open circuited. Non-observance of this precaution can

result in injury to personnel or damage to equipment.

1.2 External Resistors

Where external resistors are connected to the relay circuitry, these may present a danger of electric

shock or burns, if touched.

1.3 Description

The 7SR10 Overcurrent relay is developed by using the latest generation of hardware technology and is available

in multiple variants depending on power supply, binary input/output

communication facility. 7SR10 is a member of Siemens Reyrolle

The 7SR10 overcurrent relay consists of non directional functions and with additional voltage inputs providing

directional functions (based on the ordering option).

The 7SR10 Overcurrent relay is housed in a 4U high, size 4 non draw-out case and these relays provide

protection, monitoring, instrumentation, and metering with integrated input and output logic, data logging and fault

reports.

Communication access to the relay functionality is via a front USB port for local PC connection or rear electrical

RS485 (optional) port for remote connection.

configuration, voltage input, and data

®

protection devices Argus product family.

©2018 Siemens Protection Devices Limited Chapter 1 Page 8 of 77

7SR10 Description of Operation

Product Description

Variants

Order No.

1 2 3 4 5 6 7 - 8 9 10

11

12 - 13

14

15

16

7SR10 Argus

7 S R 1 0 0 - 0 - A 0

Non-Directional O/C Relay (Argus)

Case, I/O and Fascia

Size 4 Moulded case, 4 CT, 3 Binary Inputs/3 Binary Outputs, 10

LEDs

2 1 1

Size 4 Moulded case, 4CT, 6 Binary Inputs/6 Binary Outputs, 10 LEDs

3

Measuring input

1/5 A, 50/60Hz 1)

2/3 1

1/5 A, 50/60Hz with SEF input 2)

3 2

Auxiliary voltage

AC/DC 60-240V, Binary input threshold 44 V AC/DC

L

AC/DC 60-240V, Binary input threshold 88 V AC/DC

K

DC 24-60 V, Binary input threshold 19 VDC

J

Protective Cover

Standard version – No Cover

Plastic Cover with 1 Push Button for Test/Reset

A B

Communication

Front Port : USB

2

1

Front Port : USB and Rear Port : RS-485 supporting IEC 60870-5-103

or Modbus RTU or DNP 3.0

3 2

Front Fascia

Standard Version – with Breaker Control Push Buttons

2

Protection Function Packages

C

Standard version - included in all models

46BC

Broken conductor/Load unbalance

46NPS

Negative phase sequence overcurrent

49

Thermal overload

50

Instantaneous phase fault overcurrent

50BF

Circuit breaker fail

50G/N

Instantaneous earth fault

50SEF

2)4)

Instantaneous sensitive earth fault overcurrent

51

Timed delayed phase fault overcurrent

51 G/N

Timed delayed earth fault

51SEF

2)4)

Time delayed sensitive earth fault

74T/CCS

Trip/close circuit supervision

81HBL2 3)

2nd Harmonic block/Inrush restraint

86

Hand reset contacts

51C

Cold load pickup

Programmable logic

81THD

Total harmonic distortion supervision

Standard version – plus

79 Autoreclose

D Additional Functionality

No Additional Functionality

A

Z Y 2 0

1.4 Ordering Options

Special version

1)

4CT is configured as 3PF + EF

2)

4CT is configured as 3PF + SEF

3)

Not available on SEF input

4)

Only with position 7 = 3

5)

Special version for Turkey market with thermal withstand capability of 500A (5A CT), 1 sec and

5)

supporting Turkish scripts.

Available only with position 8 = 1

©2018 Siemens Protection Devices Limited Chapter 1 Page 9 of 77

7SR10 Description of Operation

Product Description

Variants

Order No.

1 2 3 4 5 6 7 - 8 9 10

11

12 - 13

14

15

16

7SR10 Argus

7 S R 1 0 0 - 0 - A 0

Directional Overcurrent Relay (Argus)

Case, I/O and Fascia

Size 4 Moulded case, 4CT, 3 VT, 9 Binary Inputs/6 Binary Outputs,

10 LEDs

4

Measuring input

1A/5A, 50Hz/60Hz, 63.5/110V 1)

3

1A/5A, 50Hz/60Hz with SEF input, 63.5/110V 2)

4

Auxiliary voltage

AC/DC 60-240V, Binary input threshold 44V AC/DC

L

AC/DC 60-240V, Binary input threshold 88V AC/DC

K

DC 24-60V, Binary input threshold 19V DC

J

Protective Cover

Standard version – No Cover

Plastic Cover with 1 Push Button for Test/Reset

A B

Communication

Front Port : USB and Rear Port : RS-485 supporting IEC 60870-5-103

or Modbus RTU or DNP 3.0

2

Front Fascia

Standard Version – with Breaker Control Push Buttons

2

Protection Function Packages

C

Standard version - included in all models

27/59

Under/overvoltage

32

Power

32S

Sensitive Power

37

Undercurrent

37G1)

Undercurrent measured earth fault

37SEF2)

46BC

Broken conductor/Load Unbalance

46NPS

Negative phase sequence overcurrent

47NPS

Negative phase sequence ov ervoltage

49

Thermal overload

50BF

Circuit breaker fail

51V

Voltage dependent overcurrent

55

Power Factor

59N

Neutral voltage displacement

60CTS

CT supervision

60VTS

VT supervision

64H

High impedance REF

67/50

Directional instantaneous phase fault overcurrent

67/50G1) 67/50N

Directional instantaneous earth fault

67/50SEF 2)

67/51

Directional time delayed phase fault overcurrent

67/51G1) 67/51N

67/51SEF 2)

Directional time delayed sensitive earth fault

81HBL2 3)

74T/CC

Trip & close circuit supervision

51C

Cold load pickup/Programmable Logic

81U/O

Under/Over Frequency

86

Hand reset contacts

Standard version – plus

79 Autoreclose

D

Additional Functionality

No Additional Functionality

A

Undercurrent sensitive earth fault

Instantaneous sensitive earth fault

Directional time delayed earth fault

2nd Harmonic block/Inrush restraint

1)

4CT is configured as 3PF + EF

2)

4CT is configured as 3PF + SEF

3)

Not available on SEF input

©2018 Siemens Protection Devices Limited Chapter 1 Page 10 of 77

7SR10 Description of Operation

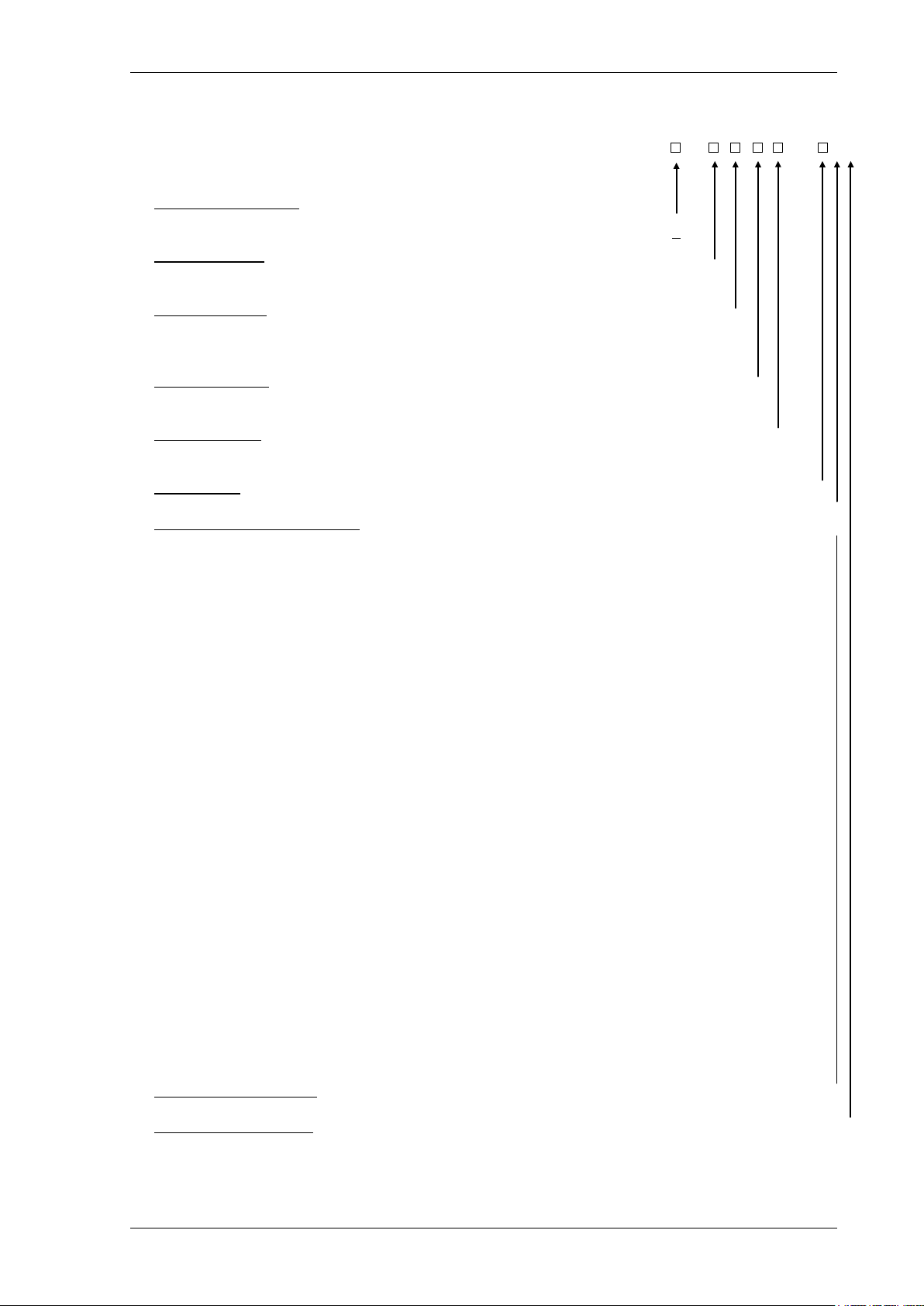

7

SR10

49

50

(x2)51(x2)

50G

(x2)

51G

(x2)

50

BF

50N

(x2)

51N

(x2)

46

BC

46

NPS

(x

2

)

81

HBL2

49

50

(x2)

50

BF

81

HBL

2

49

50

(x2)

50

BF

81

HBL2

74

T/CCS

51

(

x2

)

51

(x2)

81

HBL2

N

81

HBL2

G

I

L1

(I

A

)

I

L

2

(IB)

I

L3

(I

C

)

50

BF

51c

51c

51c

86

I

4

(I

G

)

51SEF

(x2)

50SEF

(x2)

81

THD

81

THD

81

THD

79

Optional Version D software

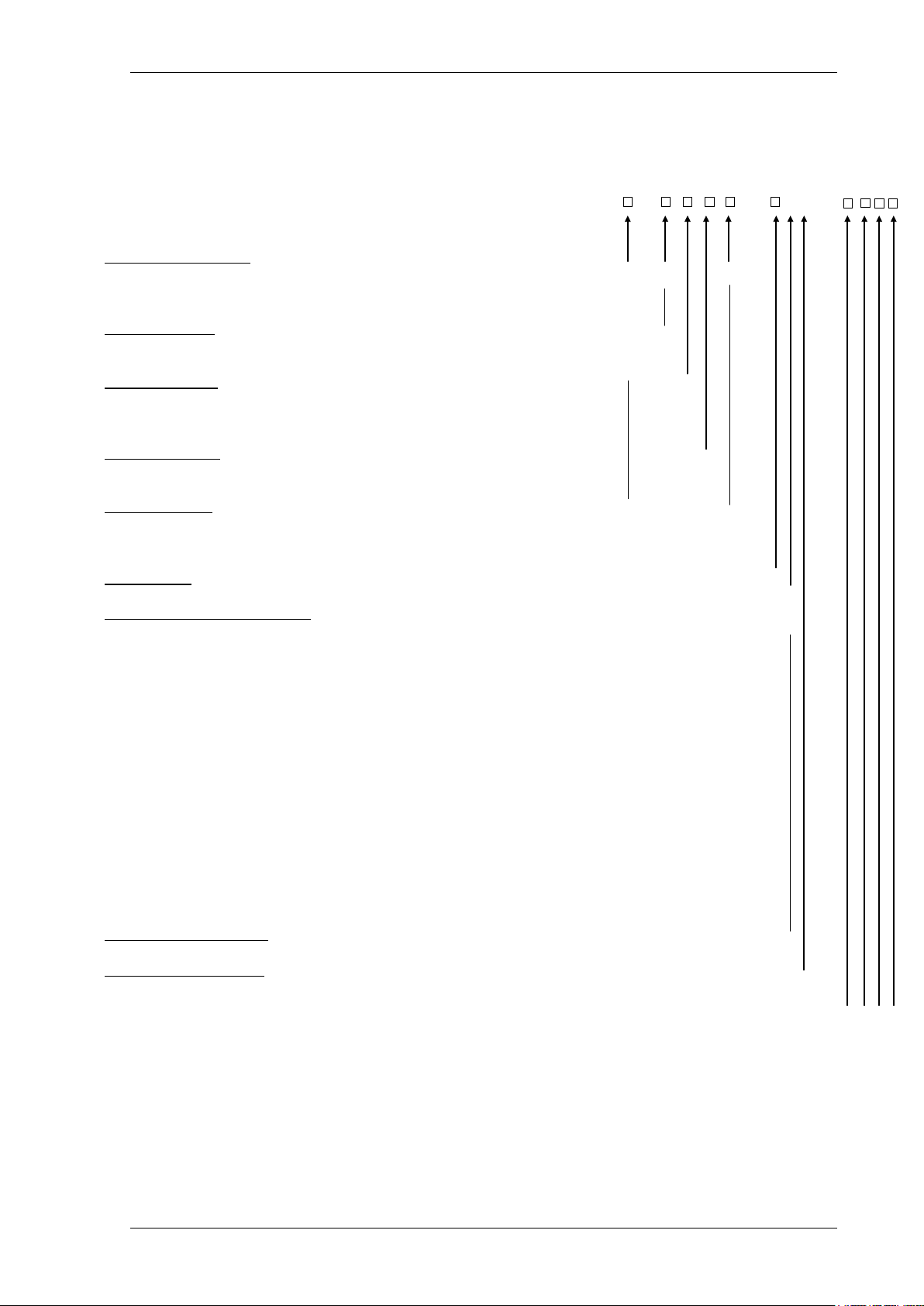

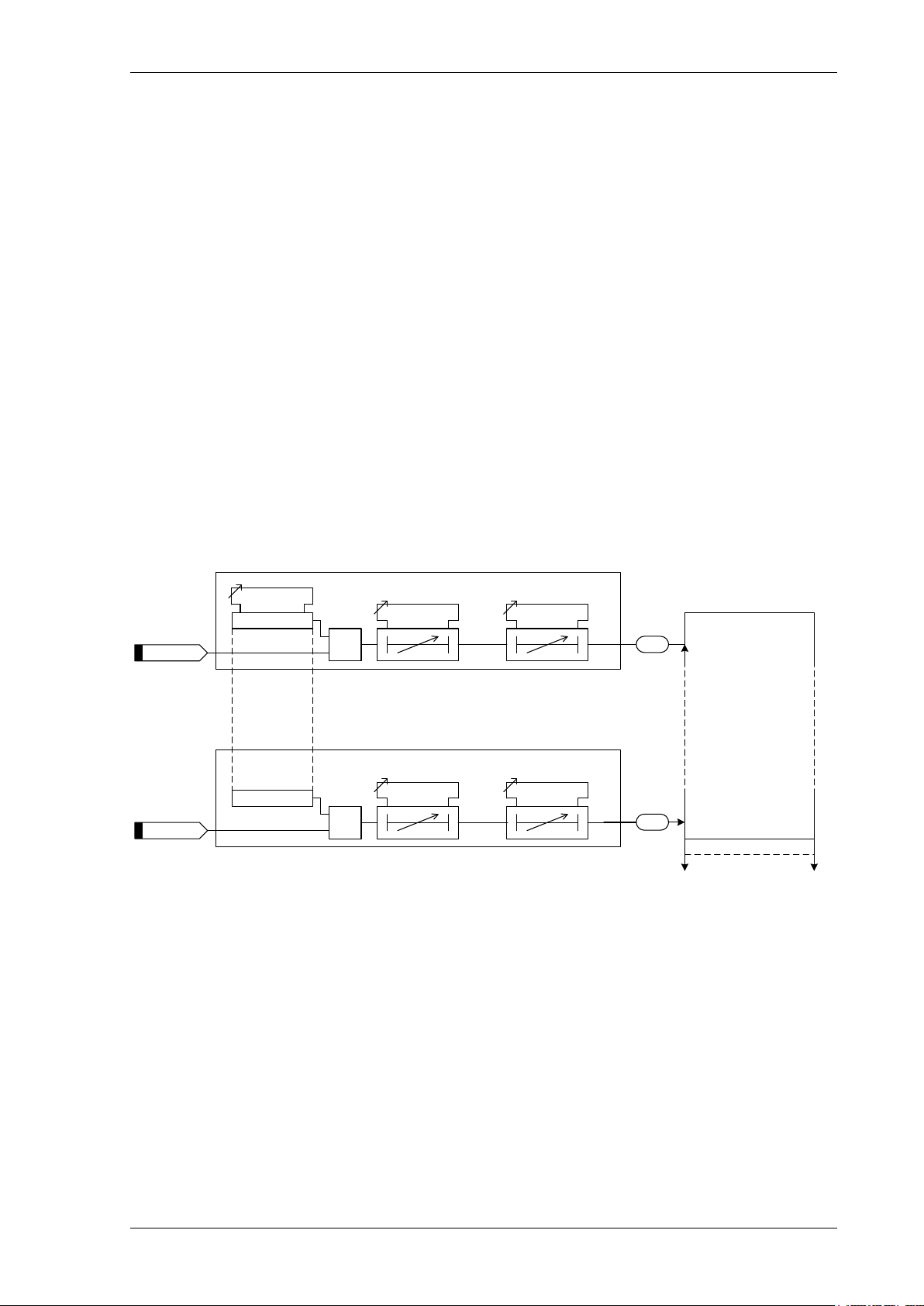

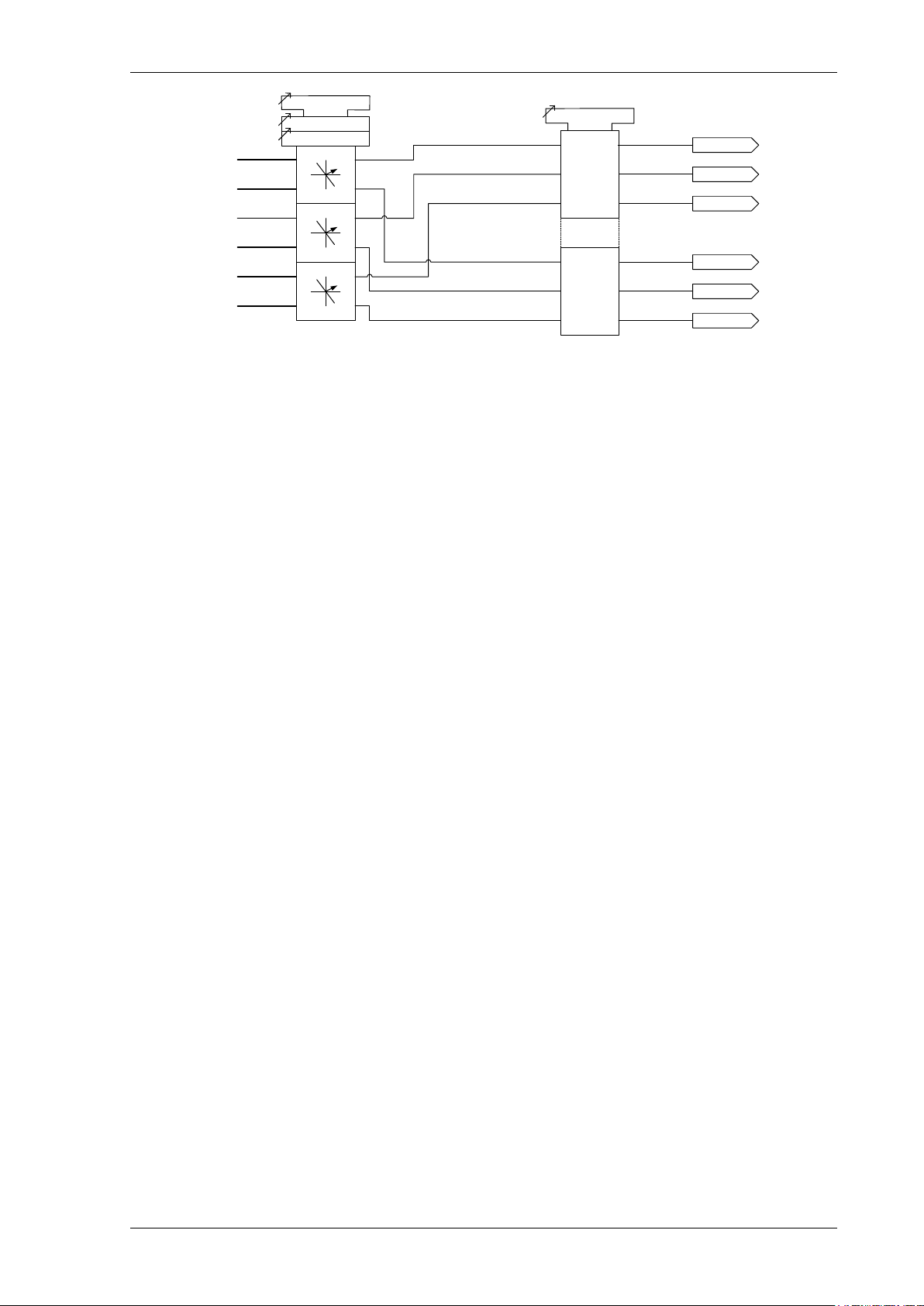

Fig 1. 7SR10 Overcurrent Relay (Non-Directional)

7SR10

64H

46

BC

46

NPS

(x2)

37

(x2)

49

50

BF

V1

V2

V3

37

(x2)

49

50

BF

37

(x2)

49

50

BF

60

CTS

74

T/CCS

67/

50

(x4)

67/

51

(x4)

67/

50N

(x4)

67/

50

(x4)

67/

50

(x4)

67/

51

(x4)

67/

51

(x4)

67/

51N

(x4)

67/

50G

(x4)

67/

51G

(x4)

27

59

(x4)

27

59

(x4)

27

59

(x4)

59N

(x2)

47

(x2)

50

BF

50

BF

37 SEF

(x2)

81

HBL 2

81

HBL 2

81

HBL 2

51V

51V

51V

67/

50SEF

(x4)

67/

51SEF

(x4)

81

(x4)

86

I

L1

(IA)

I

L2

(IB)

I

L3

(IC)

I

4

(I

G/

SEF

)

32S

(x2)

60

VTS

51c

51c

51c

32

(x2)

32

(x2)

32

(x2)

55

(x2)

55

(x2)

55

(x2)

81

HBL 2

G

37G

(x2)

79

Optional Version D software

Fig 2. 7SR10 Overcurrrent Relay (Directional)

1.5 Functional Diagram

©2018 Siemens Protection Devices Limited Chapter 1 Page 11 of 77

7SR10 Description of Operation

BI 1

Term.

RS485

A

GND

B

+ve

-ve

1

2

3

1

2

BI 2

+ve

-ve

3

4

BI 3

+ve

-ve

5

6

1

2

3

4

BI 4

+ve

-ve

7

8

BI 5

+ve

-ve

9

10

BI 6

+ve

-ve

11

12

X2

X3

X4

X5

BO3

7

8

BO5

11

12

BO6

13

14

IL4

5A

10

11

12

1A

IL3

5A

7

8

9

1A

IL2

5A

4

5

6

1A

IL1

5A

1

2

3

1A

5

6

4

BO 2

BO 1

2

3

1

BO4

9

10

X1

GND

L

N

E

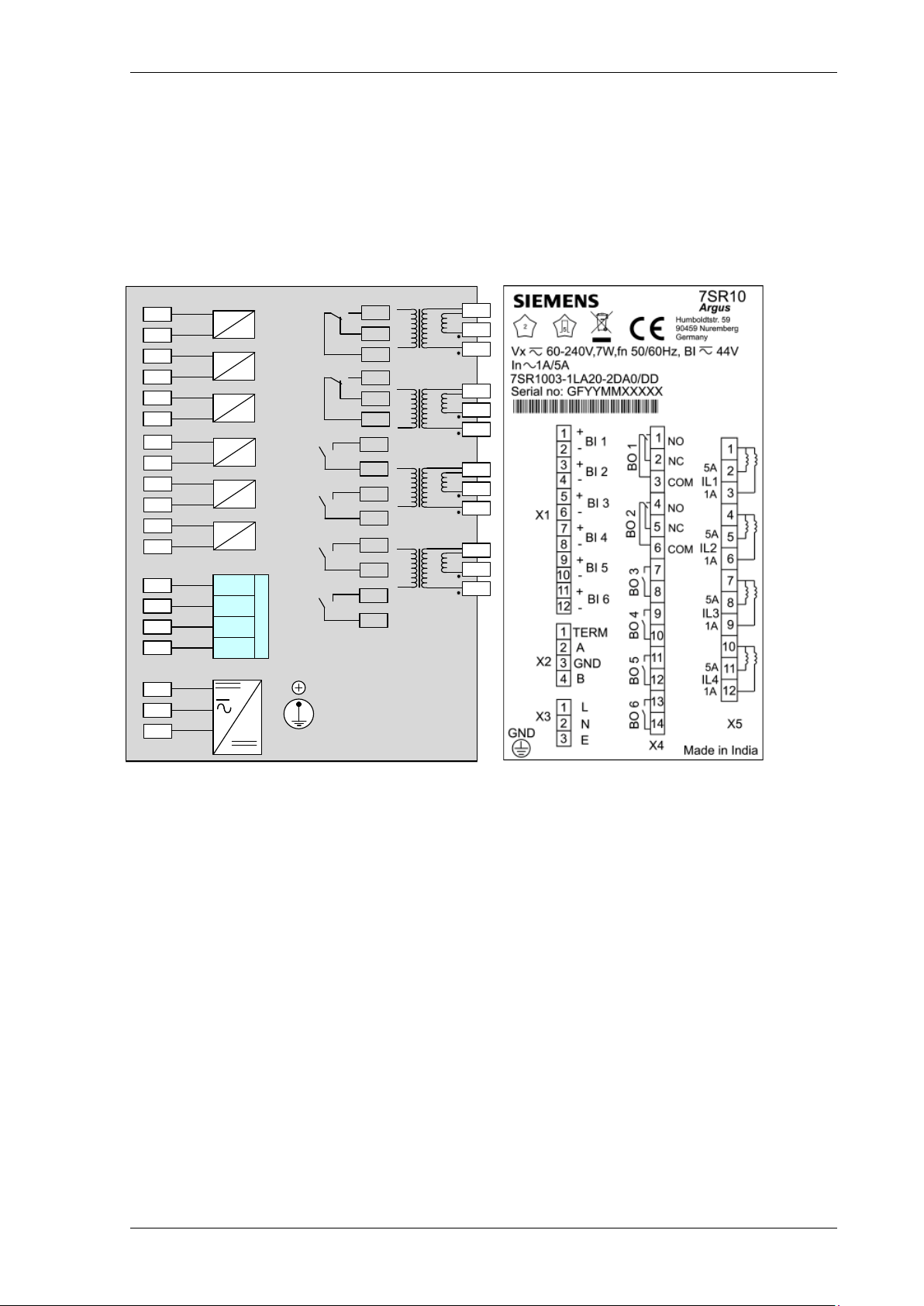

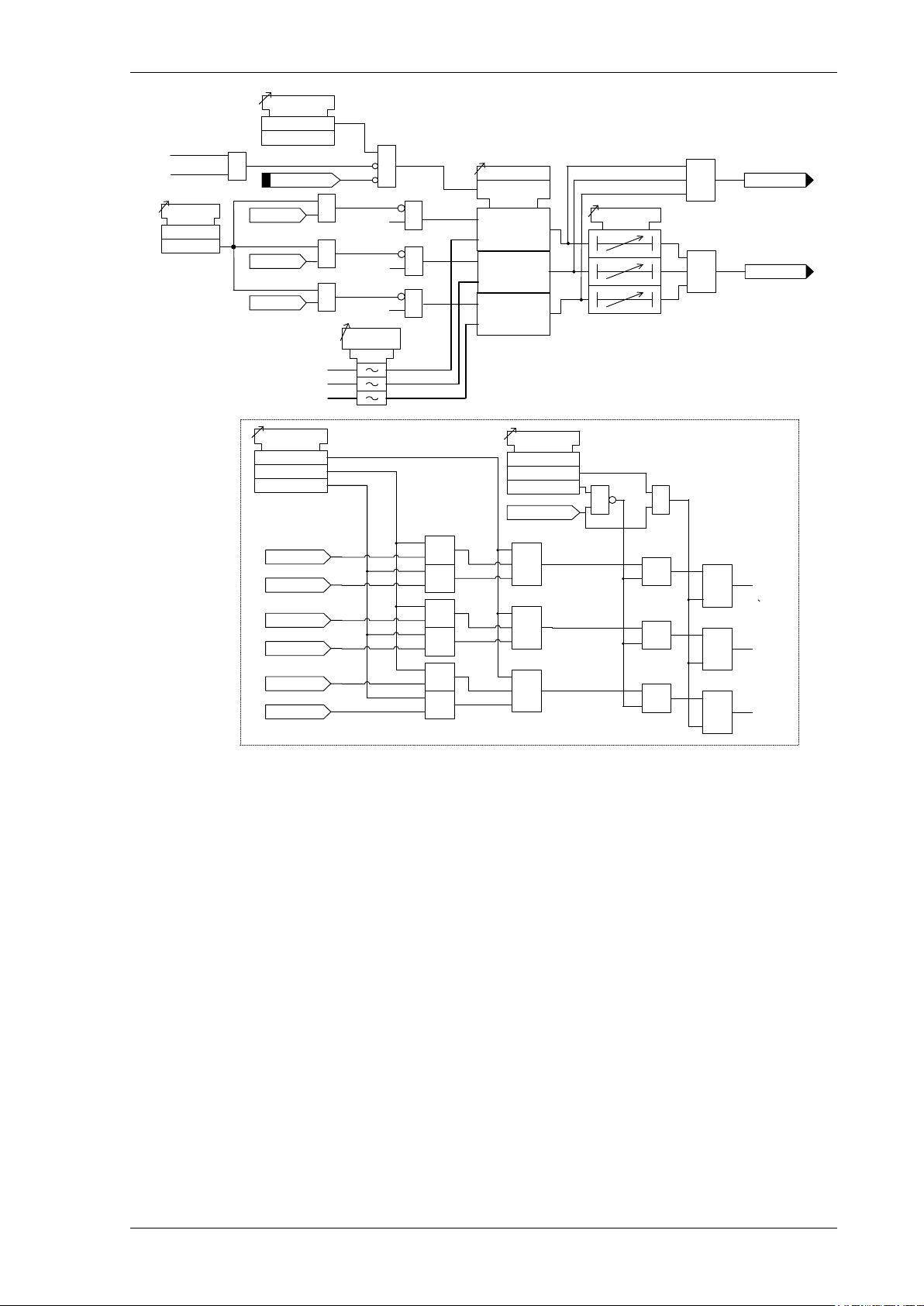

Fig 3. Terminal/Wiring Diagram of 7SR10 Non-Directional Overcurrent Relay

1.6 Terminal Diagram

The relay is housed in a non draw-out case 4U high Size 4 case. The rear connection comprises of user friendly

pluggable type terminals for the Voltage Inputs, Binary Inputs, Binary Outputs, Communication, and Power

Supply.

The CT terminals are fixed type and suitable for ring type lug connection to provide a secure and reliable

termination.

1.6.1 Terminal Diagram with Control Push Buttons

NOTE:

For DC variants, connect the positive and negative terminals to X3: L and X3: N terminals respectively.

©2018 Siemens Protection Devices Limited Chapter 1 Page 12 of 77

7SR10 Description of Operation

BI 1

Term

RS485

A

GND

B

+ve

-ve

1

2

3

1

2

BI 2

+ve

-ve

3

4

BI 3

+ve

-ve

5

6

1

2

3

4

BI 4

+ve

-ve

7

8

BI 5

+ve

-ve

9

10

BI 6

+ve

-ve

11

12

X2

X3

X4

X5

BO3

7

8

BO5

11

12

BO6

13

14

IL4

5A

10

11

12

1A

IL3

5A

7

8

9

1A

IL2

5A

4

5

6

1A

IL1

5A

1

2

3

1A

5

6

4

BO 2

BO 1

2

3

1

BO4

9

10

X1

BI 7

+ve

-ve

1

2

BI 8

+ve

-ve

3

4

BI 9

+ve

-ve

5

6

X6

V1

1

2

V2

3

4

V3

5

6

X7

GND

L

N

E

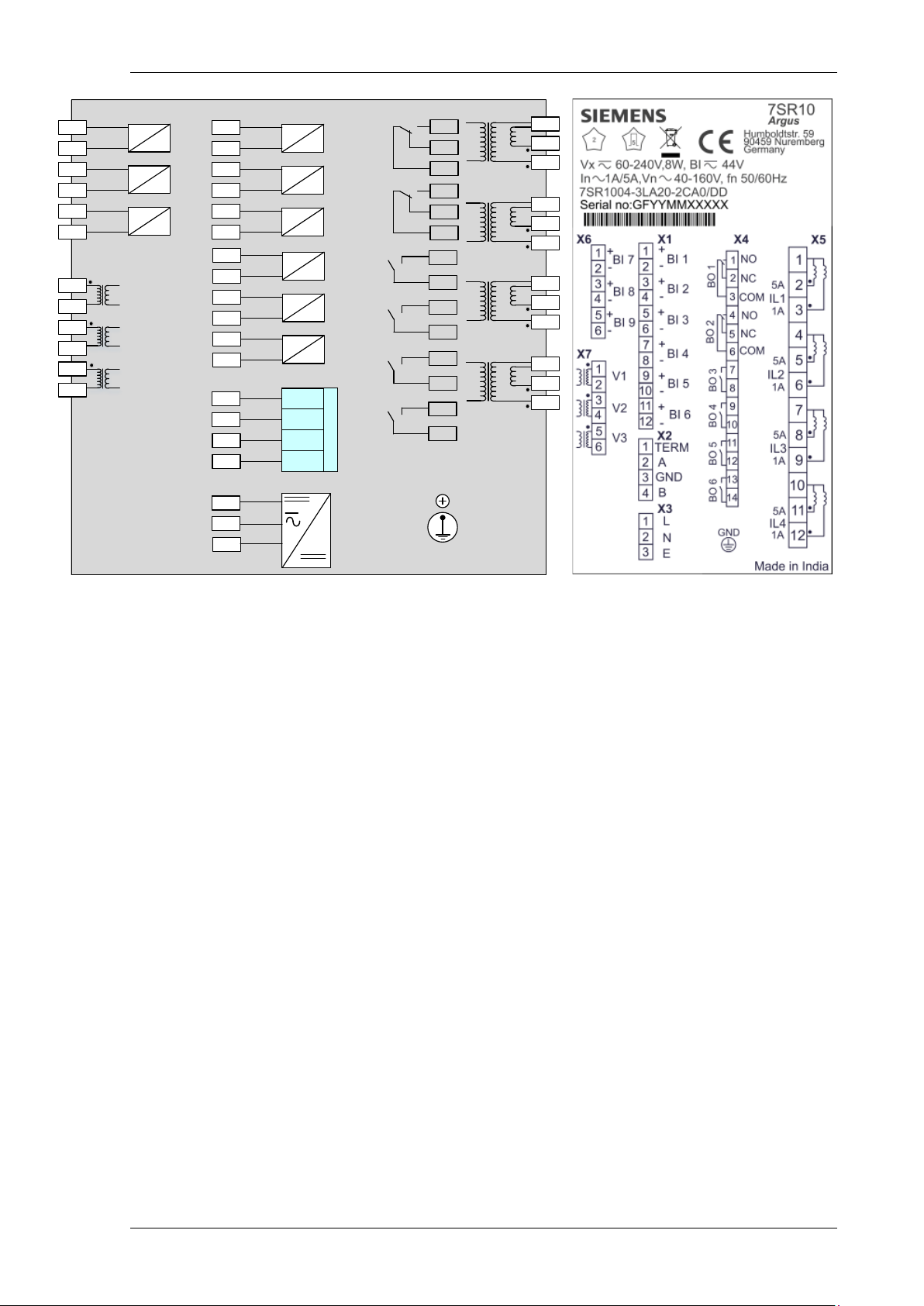

Fig 4. Terminal/Wiring Diagram of 7SR10 Directional Overcurrent Relay

NOTE:

For DC variants, connect the positive and negative terminals to X3: L and X3: N terminals respectively.

©2018 Siemens Protection Devices Limited Chapter 1 Page 13 of 77

7SR10 Description of Operation

Section 2: Hardware Description

2.1 General

The structure of the relay is based upon the compact hardware platform. The relays are supplied in a Size 4 case.

The hardware design provides a commonality between the products and components across the range of relays.

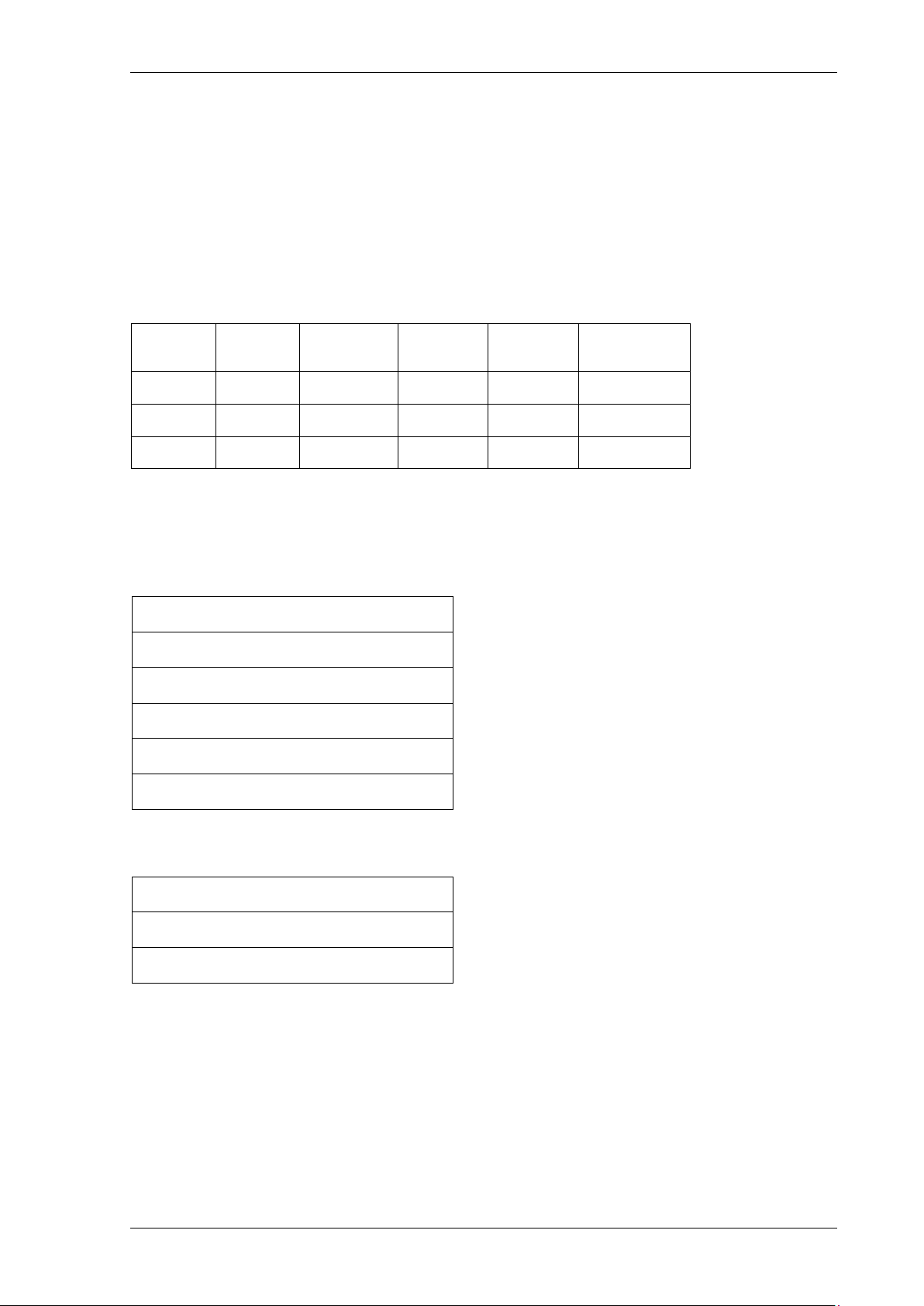

Table 2-1 Summary of 7SR10 Argus Overcurrent Relay Configurations

Relay Current

Inputs

7SR1002 4 0 3 3 10

7SR1003 4 0 6 6 10

7SR1004 4 3 9 6 10

The 7SR10 Argus Overcurrent Relay is assembled from the following modules:

1. Front Fascia with 9 configurable LEDs and 1 Relay Healthy LED

2. Processor module

3. Current Analogue, Voltage Analogue, Input module and Output module

With control push buttons

4 x Current (Terminal X5)

6 x Binary Input (Terminal X1)

6 x Binary Outputs (Terminal X4)

3 x Voltage Inputs (Terminal X7)

Voltage

Inputs

Binary

Inputs

Binary

Outputs

LEDs

3 x Binary Input (Terminal X6)

4. Communication and Power Supply module

With control push buttons

RS485 (Terminal X2)

Power supply (Terminal X3)

©2018 Siemens Protection Devices Limited Chapter 1 Page 14 of 77

7SR10 Description of Operation

Button

Function

Description

2.2 Front Fascia

The front fascia is an integral part of the relay and allows the user to access all the push buttons and performs the

setting changes and control actions. The fascia provides an option to reset the fault data display, latched binary

outputs, and LEDs by using the TEST/RESET► button. The front fascia contains the label strip which provides

the information about LED indicators.

Front Fascia consists of CB control push buttons to open and close.

2.2.1 Front Fascia with Control Push Buttons

Figure 2-1 7SR10 Argus Overcurrent Relay with Control Push Buttons

2.3 CB Open/Close

The circuit breaker (CB) control function is used to manually open and close the CB when it is connected to the

network. Two dedicated push buttons are provided on the HMI to execute the CB manual close and open

operations.

Close Press Close button and confirm ENTER to execute the close

operation of circuit breaker.

Open Press Open button and confirm ENTER to execute the open

operation of circuit breaker.

The user can configure the binary input, binary output, and LED configuration for the CB open and close control

functions.

To perform the CB open and close control operations, follow the procedure given below:

1. Apply CB Close Binary Input (BI) to get the breaker status.

2. Press CB OPEN control key. The confirmation pop-up appears.

©2018 Siemens Protection Devices Limited Chapter 1 Page 15 of 77

7SR10 Description of Operation

3. Press ENTER key to confirm.

4. The CB Open delay count-down starts and reaches to zero.

5. The configured BO and LED’s for the CB OPEN control functions will operate.

6. Press RESET button to reset LED and BO states.

Repeat the same procedure for CB CLOSE control logic operation.

NOTE:

If the "Control Password" is already configured in the settings, use the control password to execute the CB

open/close via control keys. For more information about the Control Password function, see

NOTE:

If the operating mode of 7SR10 Relay is remote, the user can perform the CB open and close operations when

the “FUNCTION KEY CONFIG” setting is enabled.

Section 6.9

2.4 Power Supply Unit (PSU)

The relay is supplied with the following nominal power supply ranges:

• 60 V - 240 V AC/DC power supply (BI threshold - 88 V AC/DC or 44 V AC/DC)

• 24 V - 60 V DC power supply (BI threshold - 19 V DC)

The power supply module is equipped with 3 or 6 Binary Inputs. It also consists of one RS485 communication

interface (half duplex) for communicating with RTUs and parameterization of relays via remote locations.

For AC connections, the auxiliary supply is made with the live connection to positive terminal and neutral

connection to negative for consistency and safety.

For DC connections, the auxiliary supply is made with the positive connection to Line terminal (L) and negative

connection to Neutral (N) for consistency and safety.

In the event of the supply voltage levels are falling below the relay minimum operate level, the PSU will

automatically switch off itself and latch out and this prevents any PSU overload conditions occurring. The PSU is

reset by switching the auxiliary supply off and on.

©2018 Siemens Protection Devices Limited Chapter 1 Page 16 of 77

7SR10 Description of Operation

Current

Inputs

Binary

Output

Binary

Input

Rear

Communic ation

Port

Auxili ary

Supply

Current

Inputs

Binary

Output

Auxili ary

Supply

Rear

Communic ation

Port

Voltage

Inputs

Binary

Input

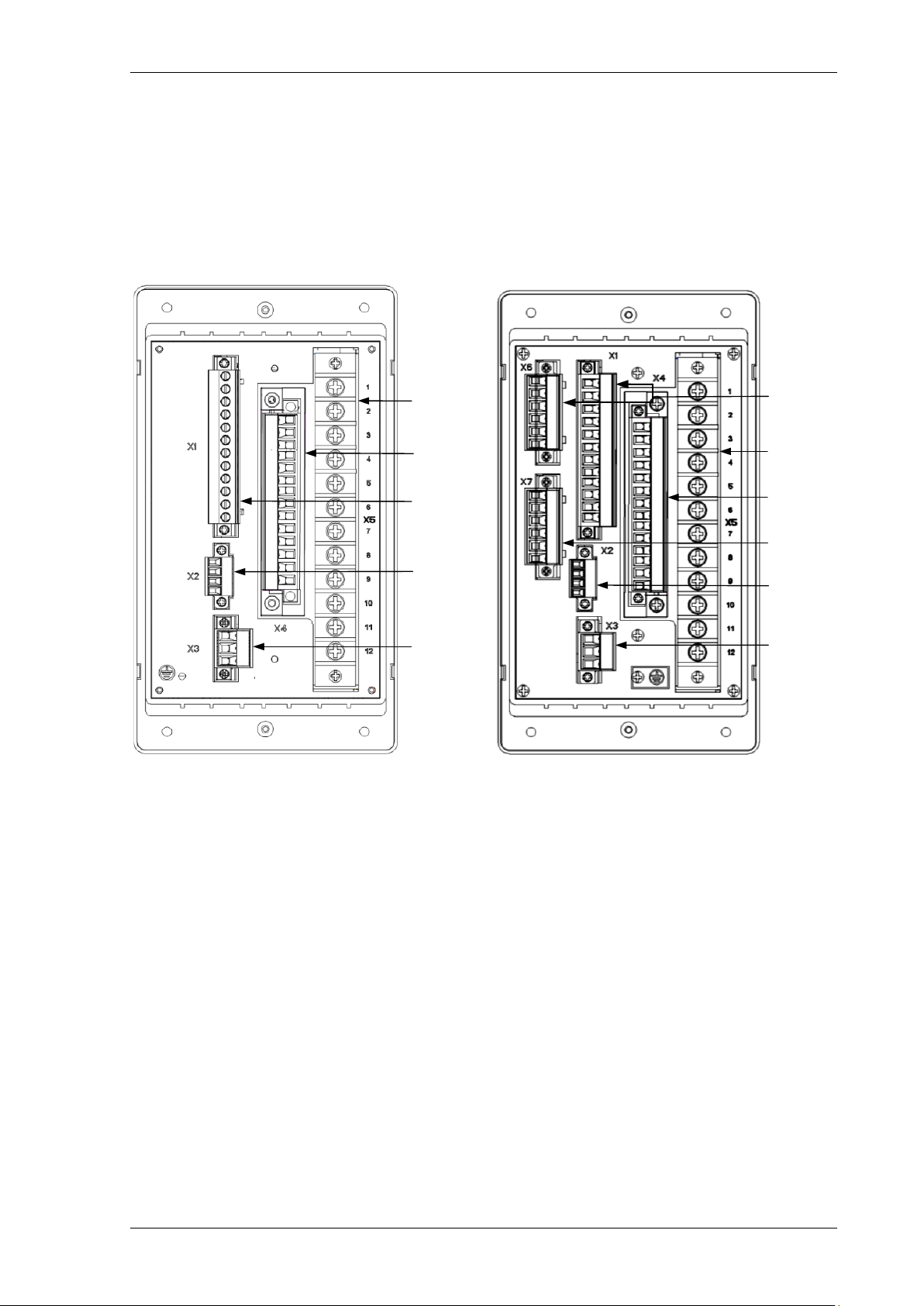

Figure 2-2 7SR10 Non-Directional and Directional Overcurrent Relay with Connectors

2.5 Connectors

In 7SR10 Argus Overcurrent relay, all the connectors are pluggable type except the CT connectors and it consists

of Binary Inputs and Binary Outputs connectors. The connector terminals are designated suitably.

In 7SR10 Argus Overcurrent relay, the CT connectors are fixed type. The other connectors for Voltage Inputs,

Binary Inputs, Binary Outputs, Communication, and Power Supply are pluggable type and designated suitably.

2.5.1 Connectors with Control Push Buttons

2.6 Relay Information

The rating label is located on the housing and provides more technical information about 7SR10 Argus

Overcurrent relay.

Relay Information

The rating label contains the following product Information:

• Product name

• MLFB ordering code, with hardware version suffix

• Nominal current rating

• Nominal voltage rating

• Rated frequency

• Auxiliary supply rating

• Binary input supply rating

• Seri al number

©2018 Siemens Protection Devices Limited Chapter 1 Page 17 of 77

7SR10 Description of Operation

For safety reasons, the following symbols are displayed on the 7SR10 Argus Overcurrent relay.

product should not be disposed with other wastes at the end of its working

responsibly to promote the sustainable reuse of material resources. This will

Caution: Risk of Electric Shock

Caution: Refer to Equipment Documentation

Safety Symbols

Figure 2-3 Relay Rating Label

Figure 2-4 Fascia Relay Rating Label

Dielectric test voltage 2kV

Impulse voltage withstand 5kV

“WEEE" Symbol instructions.

The

life. Please separate the product from other types of wastes and recycle it

help prevent harm to the environment or human health from uncontrolled waste

disposal.

For safety reasons the following symbols are displayed on the fascia.

©2018 Siemens Protection Devices Limited Chapter 1 Page 18 of 77

Figure 2-5 Safety Symbols

7SR10 Description of Operation

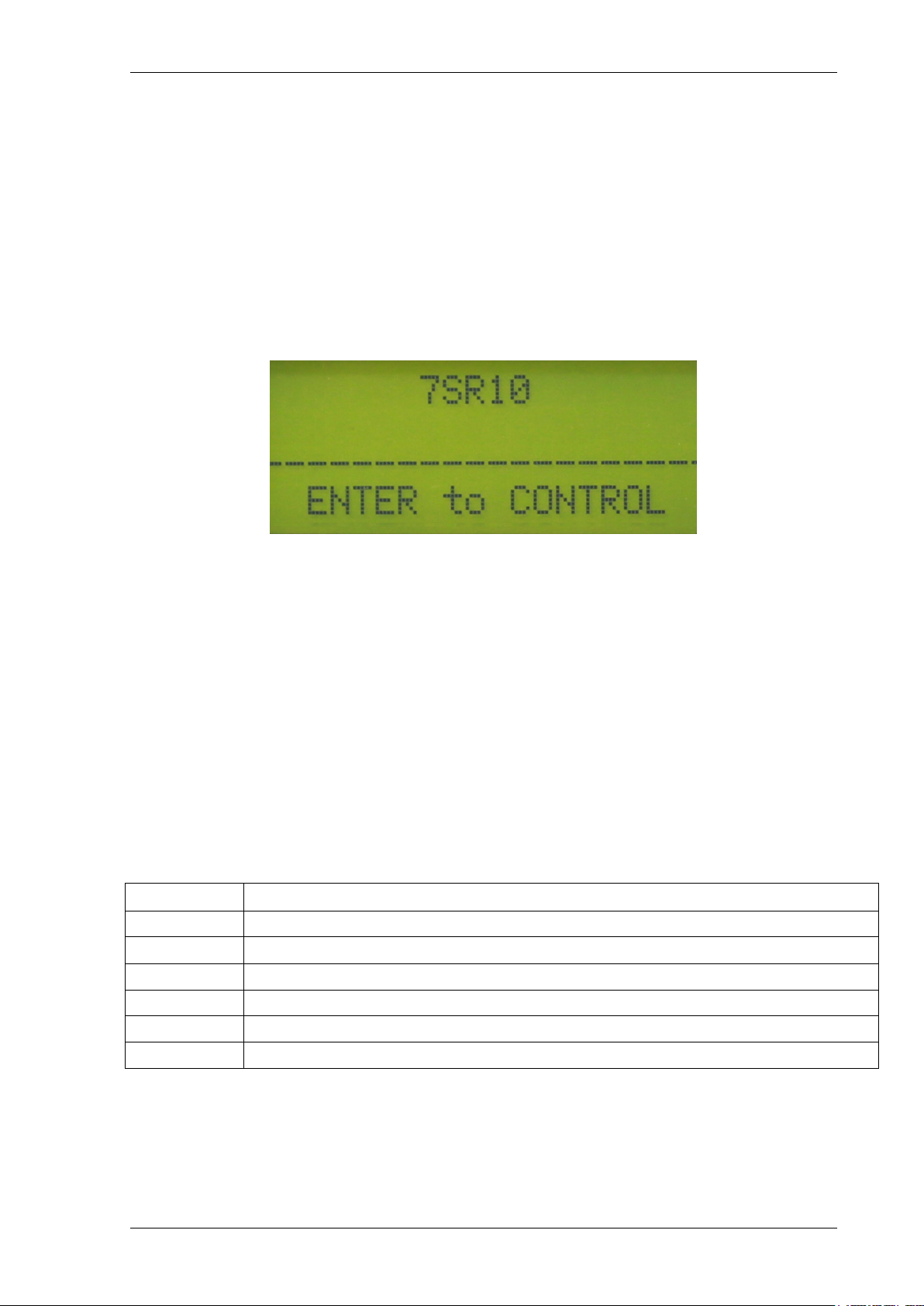

2.7 Operator Interface

2.7.1 Liquid Crystal Display (LCD)

A 4 line by 20-character alpha-numeric liquid crystal display indicates settings, instrumentation, fault data, and

control commands.

To conserve power, the display backlighting is extinguished when no buttons are pressed for a user-defined

period. The ‘backlight timer’ setting within the “SYSTEM CONFIG” menu allows the timeout to be adjusted from 1

to 60 minutes and “Off” (backlight permanently on). Pressing any key will reactivate the display.

User-defined identifying text can be programmed into the relay by using the System config/Relay Identifier and

System config/Circuit Identifier setting. The ‘Identifier’ texts are displayed on the LCD display in two lines at the

top level of the menu structure. The ‘Relay Identifier’ is used in communication with Reydisp to identify the relay.

By pressing the Cancel button several times will return the user to this screen.

Figure 2-6 Close up of Relay Identifier

2.7.2 LCD Indication

General Alarms are user defined text messages displayed on the LCD when mapped to binary inputs or virtual

inputs. Up to six general alarms of 16 characters can be programm ed, each triggered from one or more input.

Each general alarm will also generate an event.

If multiple alarms are activated simultaneously, the messages are displayed on a separate page in a

rolling display on the LCD. The System Config > General Alarm Alert setting Enabled/Disabled allows the user

to select if the alarms are to be displayed on the LCD when active.

All general alarms are raised when a fault trigger is generated and will be logged into the Fault Data record.

2.7.3 Standard Keys

The relay is supplied as standard with seven push buttons. The buttons are used to navigate the menu structure

and control the relay functions. They are labelled:

▲

▼ Decreases a setting or moves down menu.

TEST/RESET► Moves right, can be used to reset selected functionality and for LED test (at relay identifier screen).

ENTER Used to initiate and accept settings changes.

CANCEL Used to cancel settings changes and/or move up the menu structure by one level per press.

OPEN Used to execute the open of circuit breaker

Increases a setting or moves up menu.

CLOSE Used to execute the close of circuit breaker

NOTE:

All settings and configuration of LEDs, BI and BO can be accessed and set by the user using these keys.

Alternatively, the configuration/settings files can be loaded into the relay using ‘Reydisp’ software. When the

System Config > Setting Dependencies is ENABLED, only the functions that are enabled will appear in the

menu structure.

©2018 Siemens Protection Devices Limited Chapter 1 Page 19 of 77

7SR10 Description of Operation

2.7.4 Protection Healthy LED

This green LED is steadily illuminated to indicate that auxiliary voltage has been applied to the relay power supply

and that the relay is operating correctly. If the internal relay watchdog detects an internal fault then the LED will

continuously flash.

2.7.5 Indication LEDs

Relays have 9 user programmable LED indicators. Each LED can be programmed to be illuminated as either

green, yellow, or red. Where an LED is programmed to be lit both red and green, it will illuminate yellow. The

same LED can be assigned two different colours dependent upon whether a Start/Pickup or Operate condition

exists. LED’s can be assigned to the pickup condition and colour selected in the OUTPUT CONFIG > LED

CONFIG menu.

Functions are assigned to the LEDs in the OUTPUT CONFIG > OUTPUT MATRIX menu.

Each LED can be labelled by inserting a label strip into the pocket behind the front fascia. A ‘template’ is available

in the Reydisp software tool to allow users to create and print customised legends.

Each LED can be programmed as hand reset or self reset. Hand reset LEDs can be reset either by pressing the

TEST/RESET ► button, energising a suitably programmed binary input or by sending an appropriate command

over the data communications channel(s).

The status of hand reset LEDs is maintained by a back up storage capacitor in the event of an interruption to the

supply voltage.

Figure 2-7 LED Indication Label

2.8 Current Inputs

Four current inputs are provided on the Analogue Input module. Terminals are available for both 1 A and 5 A

inputs.

The current input is incorporated within the relay and is used for phase fault and earth fault protection.

Current is sampled at 1600 Hz for both 50 Hz and 60 Hz system frequencies. Protection and monitoring functions

of the relay use either the Fundamental Frequency RMS or the True RMS value of current appropriate to the

individual function.

The waveform recorder samples and displays current input waveforms at 1600 Hz.

The primary CT ratio used for the relay instruments can be set in the CT/VT configuration menu.

©2018 Siemens Protection Devices Limited Chapter 1 Page 20 of 77

7SR10 Description of Operation

Event

BI 1

Binary Input 1

=1

Inverted Inputs

BI 1 inverted

BI 1 P/U Delay

Event

BI n

Binary Input n

=1

BI n inverted

BI n P/U Delay

INPUT CONFIG>

INPUT MATRIX

(Or gates)

Logic signals,

e.g. '51-1 Inhibit'

BI 1 D/O Delay

BI n D/O Delay

INPUT

CONFIG>

BINARY

INPUT

CONFIG

2.9 Voltage Inputs

Three voltage inputs are provided on the Analogue Input module on the 7SR10 relay.

Voltage is sampled at 1600Hz for both 50Hz and 60Hz system frequencies. Protection and monitoring functions of

the relay use fundam ental frequency voltage measurement.

The waveform recorder samples and displays voltage input waveforms at 1600Hz.

The primary VT ratio used for the relay instruments can be set in the CT/VT configuration menu.

2.10 Binary Inputs

The binary inputs are opto-couplers operated from a suitably rated power supply.

Relays are fitted with 3 or 6 or 9 binary inputs (BI) depending on the variant. The user can assign any binary input

to any of the available functions (INPUT CONFIG > INPUT MATRIX).

Pick-up (PU) and Drop-off (DO) time delays are associated with each binary input. Where no pick-up tim e delay

has been applied the input may pick up due to induced AC voltage on the wiring connections (e.g. cross site

wiring). The default pick-up time of 20 ms provides AC immunity. Each input can be programmed independently.

Each input may be logically inverted to facilitate integration of the relay within the user scheme. When inverted the

relay indicates that the BI is energised when no voltage is applied. Inversion occurs before the PU and DO time

delay.

Each input may be mapped to any front Fascia indication LED and/or to any Binary output contact and can also

be used with the internal user programmable logic. This allows the relay to provide panel indications and alarms.

Each binary input is set by default to be read when the relay is in both the local or remote condition. A setting is

provided to allow the user to select if each individual input shall be read when the relay is in the local or remote

condition in the INPUT CONFIG > BINARY INPUT CONFIG menu.

Figure 2-8 Binary Input Logic

2.11 Binary Outputs (Output Relays)

Relays are fitted with 3 or 6 binary outputs (BO). All outputs are fully user configurable and can be programmed to

operate from any or all of the available functions.

In the default mode of operation, binary outputs are self reset and remain energised for a user configurable

minimum time of up to 60 s. If required, the outputs can be programmed to operate as ‘hand reset’ or ‘pulsed’. If

the output is programmed to be ‘hand reset’ and ‘pulsed’ then the output will be ‘hand reset’ only.

The binary outputs can be used to operate the trip coils of the circuit breaker directly where the trip coil current

does not exceed the 'make and carry' contact rating. The circuit breaker auxiliary contacts or other in-series

auxiliary device must be used to break the trip coil current.

Any BO can be assigned as a ‘Trip Contact’ in the OUTPUT CONFIG > TRIP CONFIG menu. Operation of a ‘Trip

Contact’ will operate any LED or virtual assigned from the 'Trip Triggered feature in the same menu and will

initiate the fault record storage, actuate the ‘Trip Alert’ screen where enabled and CB Fail protection when

enabled.

©2018 Siemens Protection Devices Limited Chapter 1 Page 21 of 77

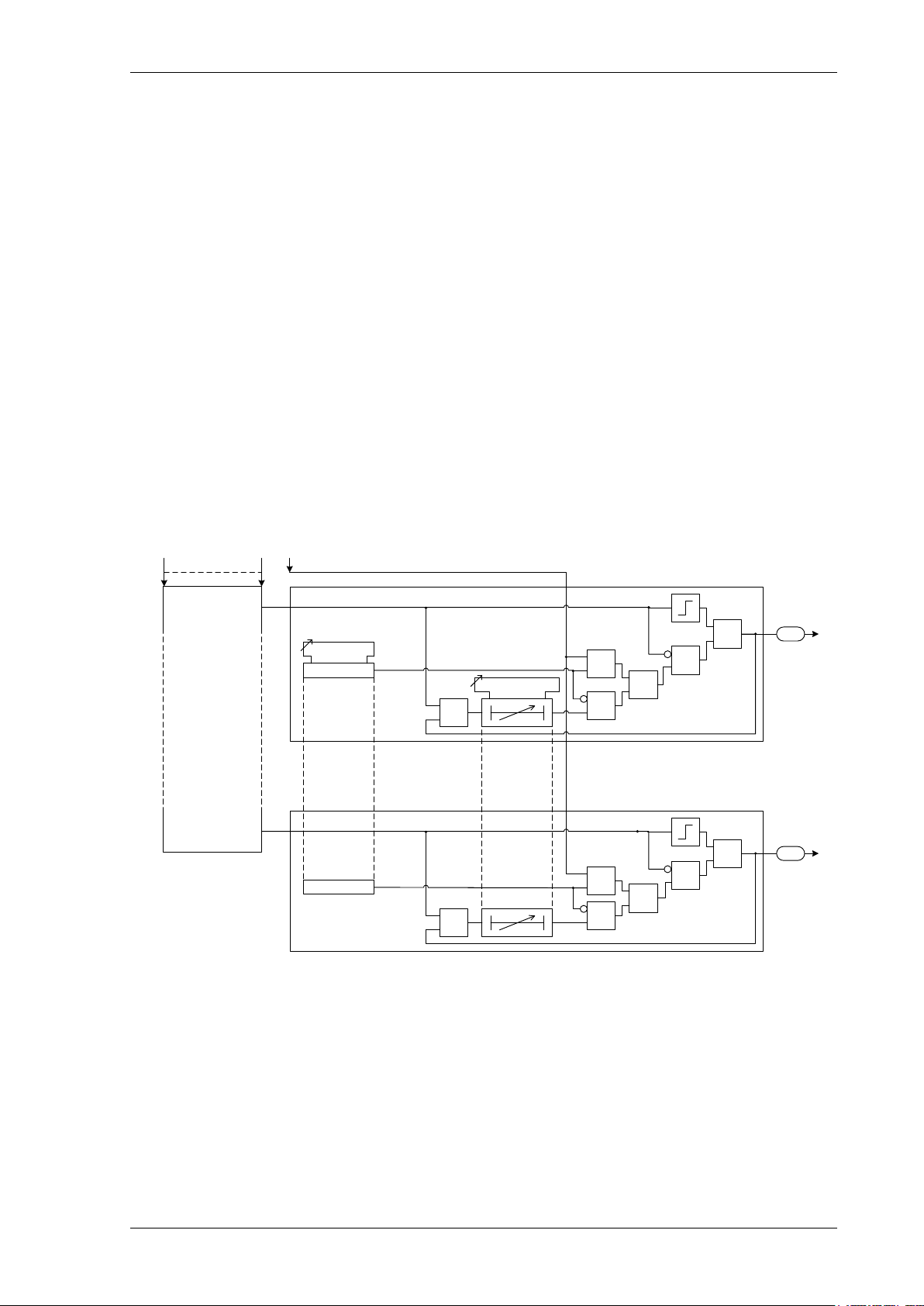

7SR10 Description of Operation

Event

Output 1

Min Operate Time

Hand Reset

BO 1 hand reset

S

R

Q

OUTPUT CONFIG>

OUTPUT MATRIX

(Or gates)

Logic signals,

e.g. '51-1'

Reset LEDs & Outputs (TEST/RESET key, Binary Input, Data Comms)

&

&

&

≥1

≥1

Event

Output n

BO n hand reset

S

R

Q

&

&

&

≥1

≥1

BO 1

BO n

OUTPUT

CONFIG>

BINARY

OUTPUT

CONFIG

OUTPUT

CONFIG>

BINARY

OUTPUT

CONFIG

Where a protection function is mapped to an output contact, the output contact can be configured to trigger when

the protection function picks-up rather than when it operates. Such output contacts are configured via the

OUTPUT CONFIG > BINARY OUTPUT CONFIG > Pickup Outputs setting.

Notes on Pulsed Outputs

When operated, the output will reset after a user configurable time of up to 60 s regardless of the initiating

condition.

Notes on Self Reset Outputs

Self reset operation has a minimum reset time of 100 ms.

With a failed breaker condition, the relay may remain operated until current flow is interrupted by an upstream

device. When the current is removed, the relay will then reset and attempt to interrupt trip coil current flowing vi a

its output contact. When this current level is above the break rating of the output contact, an auxiliary relay with

heavy-duty contacts should be utilised in the primary system to avoid damage to the relay.

Notes on Hand Reset Outputs – 86 Lockout

Any binary output can be programmed to provide an 86 lockout function by selecting it to be hand reset. Hand

reset outputs can be reset by either pressing the TEST/RESET► button, by energising a suitably programmed

binary input, or, by sending an appropriate command over the data communications channel(s).

On loss of the auxiliary supply hand-reset outputs wil l reset. When the auxiliary supply is

re-established the binary output will remain in the reset state unless the initiating condition is still present.

Notes on General Pickup

An output, General Pickup, is available to indicate that the pickup level has been exceeded for one or more

protection functions. Any protection function can be mapped to trigger this output in the OUTPUT CONFIG >

PICKUP CONFIG menu.

2.12 Virtual Input/Outputs

The relays have 8 virtual input/outputs these are internal binary stores. By assigning the status of data items like

starters, alarms, and equations to a virtual input/output, the status of these items can be used to fulfil higher levels

Figure 2-9 Binary Output Logic

of functionality.

The status of various data items can be assigned to virtual inputs/outputs using the INPUT CONFIG > OUTPUT

MATRIX menu.

Virtual input/outputs can be used as inputs to various functions including blocks, inhibits, triggers, and alarms

using the INPUT CONFIG > INPUT MATRIX menu.

Virtual input/outputs can also be used as data items in equations.

The status of the virtual inputs and outputs is volatile i.e. not stored during power loss.

©2018 Siemens Protection Devices Limited Chapter 1 Page 22 of 77

7SR10 Description of Operation

2.13 Self Monitoring

The relay incorporates a number of self-monitoring features. Each of these features can initiate a controlled reset

recovery sequence.

Supervision includes a power supply watchdog, code execution watchdog, memory checks by checksum, and

processor/ADC health checks. When all checks indicate the relay is operating correctly the ‘Protection Healthy’

LED is illuminated.

If an internal failure is detected, a message will be displayed. The relay will reset in an attempt to rectify the

failure. This will result in de-energisation of any binary output mapped to ‘protection healthy’ and flashing of the

protection healthy LED. If a successful reset is achieved by the relay, the LED and output contact will revert back

to normal operational mode and the relay will restart, therefore ensuring the circuit is protected for the maximum

time.

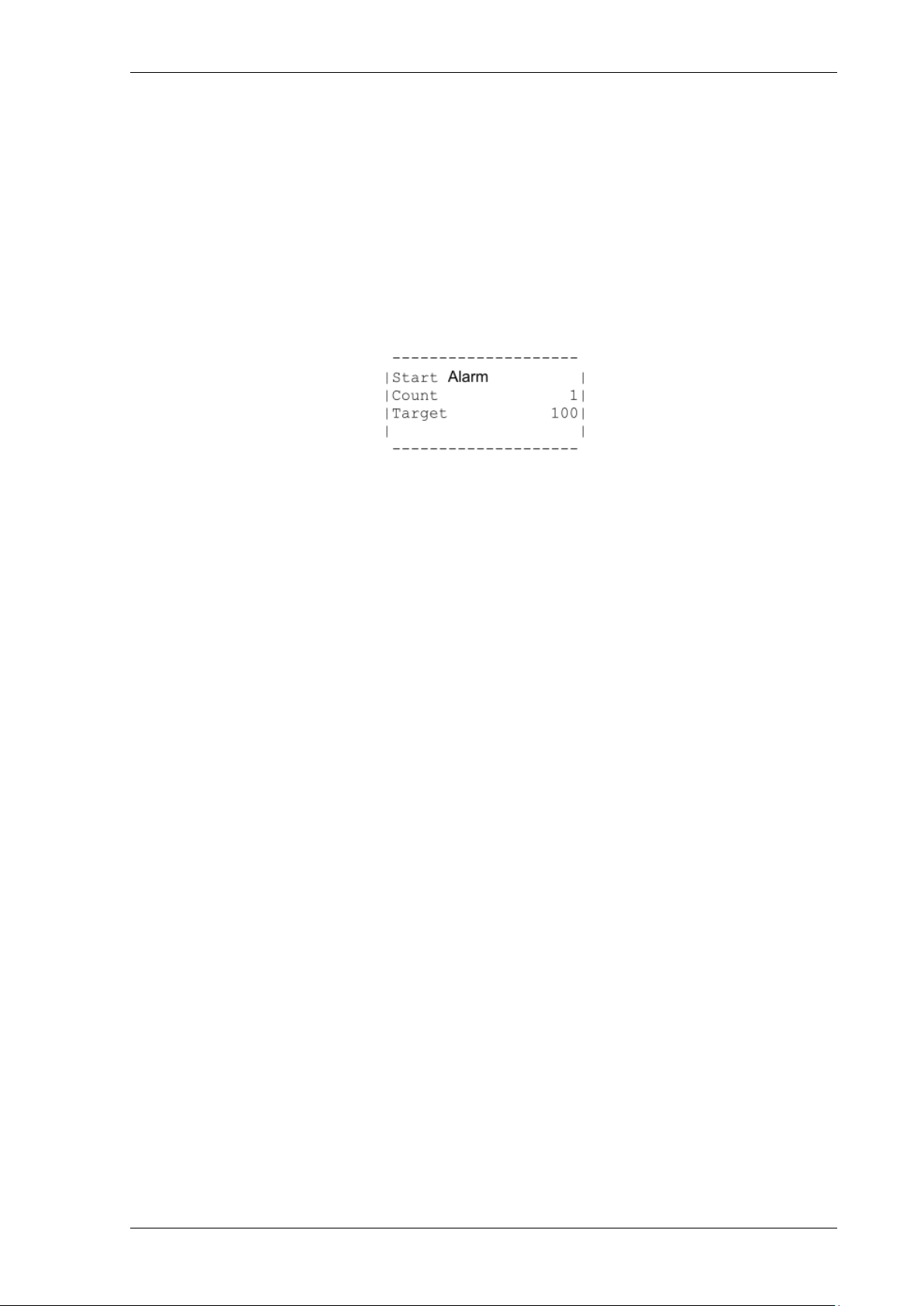

A start-up counter meter is provided to display the num ber of start-ups the relay has performed. Once the number

of start-ups has exceeded a set number, an alarm output can be given.

Figure 2-10 Start-up Counter Meter

Reset of the counter can be done from the meter or via a binary input or a command.

Various types of start-up are monitored by the relay:

1. power-on starts

2. expected starts (user initiated via communications)

3. unexpected starts (caused by the relay watchdog)

Any combination of these can be selected for the start-up count. This is done in the MAINTENANCE MENU >

START COUNT menu using the Start Types setting. All the start-up types selected (ticked) will be added to the

overall start-up count.

The number of restarts before the alarm output is raised is set in the MAINTENANCE MENU > START COUNT

menu using the Start Count Target setting.

When the number of relay start-ups reaches the target value an output is raised, OUTPUT MATRIX > Start

Count Alarm, which can be programmed to any combination of binary outputs, LED’s or virtual outputs.

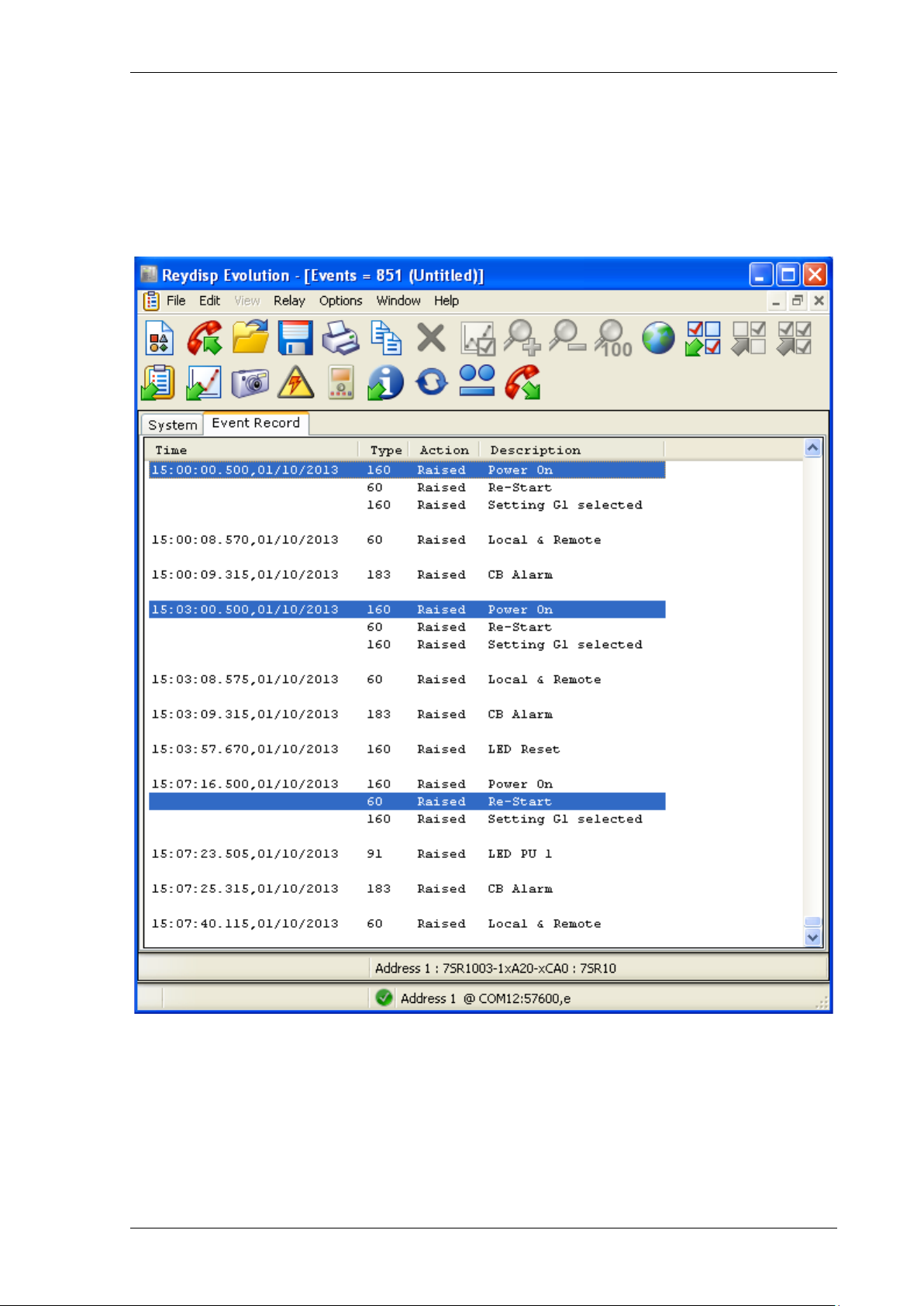

The following screen-shot show the events which are generated when the relay restarts. The highlighted events

show the cause of the re-start. The event which comes next shows the type of restart followed by the relay:

Warm, Cold or Re-Start.

As a further safeguard, if the Rel ay performs a number of unexpected starts SYSTEM CONFIG>Unexpected

Restart Count in a given time SYSTEM CONFIG>Unexpected Restart Period, it can be configured using the

SYSTEM CONFIG>Unexpected Restart Blocking setting to remove itself from service. In this case the Rel ay

will display an error message:

|UNEXPECTED RESTART |

|COUNTS EXCEEDED! |

|DEVICE LOCKED OUT |

| |

--------------------

Figure 2-11 Unexpected Restarts Lockout Text

And enter a locked-up mode. In this mode the Relay will disable operation of all LED’s and Binary Outputs,

including Protection Healthy, all pushbuttons and any data communications.

Once the Relay has failed in this manner, it is non-recoverable at site and must be returned to the manufacturer

for repair.

A meter, Miscellaneous Meters>Unexpected Restarts, is provided to show how many Unexpected Restarts have

occurred during the previous Unexpected Restart Period. This is resettable from the front fascia.

©2018 Siemens Protection Devices Limited Chapter 1 Page 23 of 77

7SR10 Description of Operation

2.13.1 Protection Healthy/Defective

When the relay has an auxiliary supply and it has successfully passed its self-checking procedure, then the front

fascia Protection Healthy LED is turned on.

A changeover or open contact can be mapped via the binary output matrix to provide an external protection

healthy signal.

A changeover or closed contact can be mapped via the binary output matrix to provide an external protection

defective signal. With the ‘Protection Healthy’ this contact is open. When the auxiliary supply is not applied to the

relay or a problem is detected within the relay then this output contact closes to provide external indication.

Figure 2-12 Start-up Events

©2018 Siemens Protection Devices Limited Chapter 1 Page 24 of 77

7SR10 Description of Operation

Section 3: Protection Functions

3.1 Current Protection: Phase Overcurrent (67, 51, 50)

All phase overcurrent elements have a common setting for the 50 elements and 51 elements to measure either

fundamental frequency RMS or True RMS current:

True RMS current: 50 Measurement = RMS, 51 Measurement = RMS

Fundamental Frequency RMS current: 50 Measurement = Fundamental, 51 Measurement =

Fundamental

3.1.1 Directional Control of Overcurrent Protection (67)

The directional element produces forward and reverse outputs for use with overcurrent elements. These outputs

can then be mapped as controls to each shaped and instantaneous over-current element.

If a protection element is set as non-directional then it will operate independently of the output of the directional

detector. However, if a protection element is programmed for forward directional mode then operation will occur

only for a fault lying within the forward operate zone. Conversely, if a protection element is programmed for

reverse directional mode then operation will occur only for a fault lying within the reverse operate zone. Typically

the forward direction is defined as being ‘away’ from the busbar or towards the protected zone.

The Characteristic angle is the phase angle by which the polarising voltage must be adjusted such that the

directional detector gives maximum sensitivity in the forward operate zone when the current is in phase with it.

The reverse operate zone is the mirror image of the forward zone.

Voltage polarisation is achieved for the phase-fault elements using the quadrature voltage i.e. at unity power

factor I leads V by 90°. Each phase current is compared to the voltage between the other two phases i.e for

normal phase sequence 1-2-3:

~ V23 IL2 ~ V31 I

I

L1

When the device is applied to reverse sequence networks, i.e. 1-3-2, the polarizing is corrected internally by the

Gn Phase Rotation setting in the CT/VT Config menu.

The characteristic angle can be user programmed to any angle between -95° and +95° using the 67 Char Angle

setting. The voltage is the reference phasor (Vref) and the 67 Char Angle setting is added to this to adjust the

forward and reverse zones.

The centre of the forward zone is set by (Vref Angle + 67 Char Angle) and should be set to correspond with Ifault

Angle for maximum sensitivity i.e.

For fault current of -60° (I lagging V by 60°) a 67 Char Angle of +30° is required for maximum sensitivity

(i.e. due to quadrature connection 90° - 60° = 30°).

OR

For fault current of -45° (I lagging V by 45°) a 67 Char Angle of +45° is required for maximum sensitivity

(i.e. due to quadrature connection 90° - 45° = 45°).

~ V

L3

12

Two-out-of-three Gate

When the 67 2-Out-Of-3 Logic setting is set to Enabled, the directional elements will only operate for the

majority direction, e.g. if I

flow, phases L

and L3 will operate forwards, while phase L2 will be inhibited.

1

and IL3 are detected as forward flowing currents and IL2 is detected as reverse current

L1

Minimum Polarising Voltage

The 67 Minimum Voltage setting defines the minimum polarising voltage level. Where the measured polarising

voltage is below this level no directional control signal is given and operation of protection elements set as

directional will be inhibited. This prevents mal-operation under fuse failure/MCB tripped conditions where noise

voltages can be present.

©2018 Siemens Protection Devices Limited Chapter 1 Page 25 of 77

7SR10 Description of Operation

V

23

I

L1

V

31

2

-out-of-3

logic

(fwd)

V

12

I

L3

I

L2

fwd

rev

fwd

rev

fwd

rev

2

-out-of-3

logic

(rev)

67

2-

Out-Of-3 Logic

67 Min

. Voltage

67

Charact

. Angle

L1 Fwd

L1 Rev

L3 Fwd

L2 Fwd

L3 Rev

L2 Rev

Directional

Control Signal

Figure 3-1 Logic Diagram: Directional Overcurrent Element (67)

3.1.2 Instantaneous Overcurrent Protection (50)

Two Instantaneous overcurrent elements are provided in the 7SR1002/7SR1003 relay and four elements are

provided in the 7SR1004 relay.

50-1, 50-2, (50-3 & 50-4 – 7SR1004)

Each instantaneous element (50-n) has independent settings. 50-n Setting for pick-up current and 50-n Delay

follower time delay. The instantaneous elem ents have transient free operation.

Where directional elements are present the direction of operation can be set using 50-n Dir. Control setting.

Directional logic is provided independently for each 50-n element, e.g. giving the option of using two elements set

to forward and two to reverse.

Operation of the instantaneous overcurrent elements can be inhibited from:

Inhibit 50-n A binary or virtual input.

79 P/F Inst Trips: 50-n When ‘delayed’ trips only are allowed in the auto-reclose sequence

(79 P/F Prot’n Trip n = Delayed).

50-n Inrush Action: Block Operation of the inrush current detector function.

50-n VTS Action: Inhibit Operation of the VT Supervision function.

©2018 Siemens Protection Devices Limited Chapter 1 Page 26 of 77

7SR10 Description of Operation

≥1

Inhibit 50-n

50-n

50-n Set ting

c

50-n

Enabl ed

Disa bled

>

c

50-n D elay

If d irection al eleme nts are not

presen t this block is om itted and all

'Lx D ir En' signa ls are set TRU E.

Forw ard

Rever se

50-n D ir Cont rol

Non-D ir

≥1

&

&

≥1

&

&

≥1

&

&

L1 Di r En

L2 Di r En

L3 Di r En

IL1 Fwd

IL1 Rev

IL2 Fwd

IL2 Rev

IL3 Fwd

IL3 Rev

&

&

&

≥1

≥1

≥1

50-n VTS Action

Off

Non Di r

Inhibit

VT Fail

& &

>

c

>

c

L1 Di r En

L2 Di r En

L3 Di r En

IL1

IL2

IL3

50/51

Measurement

L1 81HBL2

50-n Inr ush

Ac tion

Off

Inhibit

&

L2 81HBL2

L3 81HBL2

&

&

&

&

&

≥1

General Pickup

&

&

79 P/F Inst Trips

= 50-n

79 P/F P rot’n Trip n

= Delayed

AUTORECLO SE

3.1.3 Time Delayed Overcurrent Protection (51)

Two time delayed overcurrent elements are provided in the 7SR1002/7SR1003 relay and four elements are

provided in the 7SR1004 relay.

51-n Setting sets the pick-up current level. Where the voltage controlled overcurrent function (51VCO) is used a

multiplier is applied to this setting where the voltage drops below the setting VCO Setting, see Section 3.1.4.

A number of shaped characteristics are provided. An inverse definite minimum time (IDMT) characteristic is

selected from IEC, ANSI or user specific curves using 51-n Char. A time multiplier is applied to the characteristic

curves using the 51-n Time Mult setting. Alternatively, a definite time lag delay (DTL) can be chosen using 51-n

Char. When Definite Tim e Lag (DTL) is selected the time multiplier is not applied and the 51-n Delay (DTL)

setting is used instead. Operating curve characteristics are illustrated in Chapter 3 – ‘Performance Specification’.

The 51-n Reset setting can apply a definite time delayed reset, or when the operation is configured as an IEC or

ANSI or user characteristic if the reset is selected as (IEC/ANSI) DECAYING reset the associated reset curve will

Figure 3-2 Logic Diagram: Instantaneous Over-current Element

be used. The reset mode is significant where the characteristic has reset before issuing a trip output – see

‘Applications Guide’.

A minimum operate tim e for the characteristic can be set using 51-n Min. Operate Time setting.

A fixed additional operate time can be added to the characteristic using 51-n Follower DTL setting.

Where directional elements are present the direction of operation can be set using 51-n Dir. Control setting.

Directional logic is provided independently for each 51-n element e.g. giving the option of using two elements set

to forward and two to reverse.

©2018 Siemens Protection Devices Limited Chapter 1 Page 27 of 77

51-1, 51-2, (51-3 & 51-4 – 7SR1004)

Loading...

Loading...