Page 1

XG-P25X

SERVICE MANUAL

SERVICE-ANLEITUNG

S62L5XG-P25X/

LCD PROJECTOR

LCD PROJEKTOR

MODEL

MODELL

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

Im lnteresse der Benutzersicherheit (erforderliche Sicherheitsregeln in einigen Ländern) muß das Gerät in seinen

Originalzustand gebracht werden. Außerdem dürfen für die spezifizierten Bauteile nur identische Teile verwendet

werden.

XG-P25X

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

XG-P25X

• SPECIFICATIONS ............................................. 3

• IMPORTANT SERVICE SAFETY

NOTES (for USA)............................................... 4

• NOTE TO SERVICE PERSONNEL ................... 5

• OPERATION MANUAL ...................................... 8

• REMOVING OF MAJOR PARTS ..................... 12

• RESETTING THE TO TAL LAMP TIMER ......... 19

• THE OPTICAL UNIT OUTLINE ....................... 20

• CONVERGENCE AND FOCUS

ADJUSTMENT................................................. 21

• ELECTRICAL ADJUSTMENT ......................... 28

• TROUBLE SHOOTING TABLE ........................ 36

• CHASSIS LAYOUT ........................................ 110

CONTENTS

Page Page

• BLOCK DIAGRAM......................................... 112

• OVERALL WIRING DIAGRAM ...................... 114

•

DESCRIPTION OF SCHEMATIC DIAGRAM ..

• WAVEFORMS ................................................ 117

• SCHEMATIC DIAGRAM ................................ 118

• PRINTED WIRING BOARD ASSEMBLIES... 166

• PARTS LIST

Ë

ELECTRICAL PARTS............................... 173

Ë

CABINET AND MECHANICAL PARTS.... 193

Ë

ACCESSORIES PARTS........................... 198

Ë

PACKING PARTS ..................................... 198

• PACKING OF THE SET ................................. 199

116

Seite Seite

• TECHNISCHE DATEN..................................... 58

• HINWEISE FÜR DAS

WARTUNGSPERSONAL................................. 59

• BEDIENUNGSANLEITUNG ............................ 60

• ENTFERNEN DER HAUPTTEILE ................... 64

• RücKSTELLEN DES

LAMPENBETRIEBSZEIT-TIMERS ................. 71

• ÜBERSICHT DER OPTIK-EINHEIT ................ 72

• EINSTELLUNG VON KONVERGENZ UND

BRENNPUNKT ................................................ 73

• ELEKTRISCHE EINSTELLUNG...................... 80

• FEHLERSUCHTABELLE ................................. 88

• CHASSIS-ANORDNUNG .............................. 110

• BLOCKSCHALTBILD ..................................... 112

INHALT

• GESAMTSCHALTPLAN ................................ 114

• BESCHREIBUNG DES SCHEMATISCHEN

• WELLENFORMEN ........................................ 117

• SCHEMATISCHER SCHALTPLAN................ 118

• LEITERPLATTENEINHEITEN ....................... 166

• ERSATZTEILLISTE

• VERPACKEN DES GERÄTS......................... 199

SCHALTPLANS ............................................. 116

Ë

ELEKTRISCHE BAUTEILE...................... 173

Ë

CEHÄUSE UND MECHANISCHE

BAUTEILE ................................................ 193

Ë

ZUBEHÖRTEILE...................................... 198

Ë

VERPACKUNGSTEILE ............................ 198

2

Page 3

Specifications

XG-P25X

Product type

Video system

LCD Projector

Model

XG-P25X

PAL/PAL 60/PAL-M/PAL-N/SECAM/NTSC 3.58/NTSC 4.43

DTV 480I/480P/580I/580P/720P/1035I/1080I

Display method

LCD panel

LCD panel × 3, RGB optical shutter method

Panel size: 1.3″ (33mm) (20.0 [H] ×26.6 [W] mm)

Display method: Translucent TN liquid crystal panel

Drive method: TFT (Thin Film Transistor) Active Matrix panel

No. of dots: 786,432 dots (1,024 [H] ×768 [V])

Standard Lens

Projection lamp

Video input signal

1–1.3 × zoom lens, F1.7–2.4, f = 49.2–63.8 mm

AC 270 W lamp

RCA Connector (INPUT 4): VIDEO, composite video, 1.0 Vp-p, sync negative, 75Ω

terminated

RCA Connector: AUDIO, 0.5 Vrms more than 22 kΩ (stereo)

S-video input signal

4-pin Mini DIN connector (INPUT 5)

Y (luminance signal): 1.0 Vp-p, sync negative, 75Ω terminated

C (chrominance signal): Burst 0.286 Vp-p, 75Ω terminated

Component input signal

BNC Connector (INPUT 2)

Y: 1.0 Vp-p, sync negative, 75Ω terminated

B

: 0.7 Vp-p, 75Ω terminated

P

P

R

: 0.7 Vp-p, 75Ω terminated

Horizontal resolution

RGB input signal

520 TV lines (S-video input), 750 TV lines (DTV 720P input, STRETCH mode)

PIN MINI

D-

15-

SUB CONNECTOR

(INPUT 1), 5 BNC

CONNECTOR

(INPUT 2):

RGB separate/composite sync/sync on gr een type analog input: 0–0.7 Vp-p, positive,

75Ω terminated

Pixel clock

Ver tical frequency

Horizontal frequency

Computer contr ol signal

Speaker system

CONNECTOR

DVI

ORIZONTAL SYNC.SIGNAL

H

ERTICAL SYNC.SIGNAL

V

TEREO MINIJACK

S

12–230 MHz

43–200 Hz

15–126 kHz *

9-pin D-sub connector (RS-232C Input Port/Output Port)

49

⁄64 (4.5 cm) round × 2

1

(29-

PIN

) (INPUT 3), RGB (DIGITAL), 250–1,000 mV, 50Ω

: TTL level (positive/negative) or composite sync (Apple only)

: Same as above

: AUDIO, 0.5 Vrms, more than 22 kΩ (stereo)

2 W+2 W (stereo)

Rated voltage

Input current

Rated frequency

Power consumption

Heat dissipation

Operating temperature

Storage temperature

Cabinet

I/R carrier frequency

Dimensions (approx.)

AC 100–240 V

3.9 A

50/60 Hz

380 W

1,430 BTU/hour

41°F to 104°F ( 5°C to 40°C)

++

-4°F to 140°F (- +20°C to 60°C)

Plastic

38 kHz

9

⁄16" (W) × 63⁄32" (H) × 1621⁄32" (D) (319.0 × 155.0 × 423.0 mm) (main body only)

12

11

12

⁄32" (W) × 727⁄64" (H) × 1717⁄32" (D) (322.5 × 188.5 × 445.0 mm) (including standard

lens, adjustment feet and projecting par ts)

Weight (approx.)

Supplied accessories

21.4 lbs. (9.7 kg)

Remote control, Two R-6 batteries, Power cord, RGB cable (9' 10", 3 m), Computer audio

cable (9' 10", 3 m), Three BNC-RCA adaptors, Extra air filter, Lens cap, CD-ROM, LCD

projector operation manual, Quick reference guides, ID number seal

Replacement parts

Lamp unit (Lamp/cage module) (BQC-XGP25X//1), Remote contr ol (RRMCGA048WJSA),

Two R-6 batteries (“AA” size, UM/SUM-3, HP-7 or similar), Power cord for U.S., Canada

etc. (QACCDA010WJPZ), Power cord for Europe, except U.K. (QACCV4002CEZZ), Power

cord for U.K., Hong Kong and Singapor e (QACCBA012WJPZ), Power cord for Australia,

New Zealand and Oceania (QACCL3022CEZZ), RGB cable (QCNWGA012WJPZ),

Computer audio cable (QCNWGA013WJPZ), BNC-RCA adaptors (QPLGJ0107GEZZ), Air

filter (PFILD0080CEZZ), Lens cap (PCAPH1056CESA), CD-ROM (UDSKAA004WJZZ,

UDSKAA005WJZZ), LCD projector operation manual (TINS-A133WJZZ), Quick reference

guides, Sharp Advanced Presentation Software installation guide (TINS-A139WJZZ), ID

number seal (TLABZ0781CEZZ)

* When the RGB input is used for displaying moving images r eceived as interlaced image signal, the images may not be displayed as you

intended depending on the type of the signal. Please use the component input, video input, or s-video input in case this happen s.

This SHARP projector uses LCD (Liquid Crystal Display) panels. These

very sophisticated panels contain 786,432 pixels (

Film Transistors). As with any high technology electr onic equipment

such as large screen TVs, video systems and video cameras, there

are certain acceptable tolerances that the equipment must confor m

to.

×

RGB) TFTs (Thin

This unit has some inactive TFT s within acceptable tolerances which

may result in illuminated or inactive dots on the picture scr een. This

will not affect the picture quality or the life expectancy of the unit.

Specifications are subject to change without notice.

3

Page 4

XG-P25X

2

2

IMPORTANT SERVICE SAFETY NOTES (for USA)

Ë Service work should be performed only by qualified service technicians who are

thoroughly familiar with all safety checks and servicing guidelines as follows:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

BEFORE RETURNING THE PROJECTOR:

(Fire & Shock Hazard)

Before returning the projector to the user, perform

the following safety chec ks:

1. Inspect lead wires are not pinched between the

chassis and other metal parts of the projector.

2. Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacity networks, mechanical

insulators, etc.

3. To be sure that no shock hazard exists, check for

current leakage in the following manner:

» Plug the AC cord directly into a 120-volt AC outlet,

(Do not use an isolation transformer for this test).

» Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in parallel

between all exposed metal cabinet parts and earth

ground.

» Use an AC voltmeter with sensitivity of 5000 ohm per

volt., or higher , sensitivity to measure the AC v oltage

drop across the resistor (See Diagram).

» All checks must be repeated with the AC plug

connection reversed. (If necessary, a non-polarized

adapter plug must be used only for the purpose of

completing these checks.)

Any reading of 0.3 volts RMS (this corresponds to

0.2 milliamp. AC.) or more is excessive and indicates

a potential shock hazard which must be corrected

before returning the unit to the owner.

AC

VOLTMETER

1.5k ohm (10W)

0.15µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO KNOWN

EARTH GROUND

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

SAFETY NOTICE

Many electrical and mechanical parts in LCD Projector

have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

components having such features are identified by “å”

and shaded areas in the Replacement Parts Lists and

Schematic Diagrams. For continued protection,

replacement parts must be identical to those used in the

original circuit. The use of a substitute replacement parts

which do not have the same safety characteristics as

the factory recommended replacement parts shown in

this service manual, may create shock, fire or other

hazards.

AVIS POUR LA SECURITE

De nombreuses pièces, électriques et mécaniques, dans

les projecteur à LCD présentent des caractéristiques

spéciales relatives à la sécurité, qui ne sont souvent

pas évidentes à vue.

Le degré de protection ne peut pas être nécessairement

augmentée en utilisant des pièces de remplacement

étalonnées pour haute tension, puissance, etc.

Les pièces de remplacement qui présentent ces

caractéristiques sont identifiées dans ce manuel;

les pièces électriques qui présentent ces particularités

sont identifiées par la marque “å” et hachurées dans la

liste des pièces de remplacement et les diagrammes

schématiques. Pour assurer la protection, ces pièces

doivent être identiques à celles utilisées dans le circuit

d’origine. L’utilisation de pièces qui n’ont pas les mêmes

caractéristiques que les pièces recommandées par

l’usine, indiquées dans ce manuel, peut provoquer des

électrocutions, incendies ou autres accidents.

WARNING: The bimetallic component has the primary

conductive side exposed. Be very careful in

handling this component when the power is on.

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

AVERTISSEMENT:La composante bimétallique dispose du

conducteur primaire dénudé. Faire

attention lors de la manipulation de cette

composante sous tension.

4

Page 5

XG-P25X

NOTE T O SERVICE

PERSONNEL

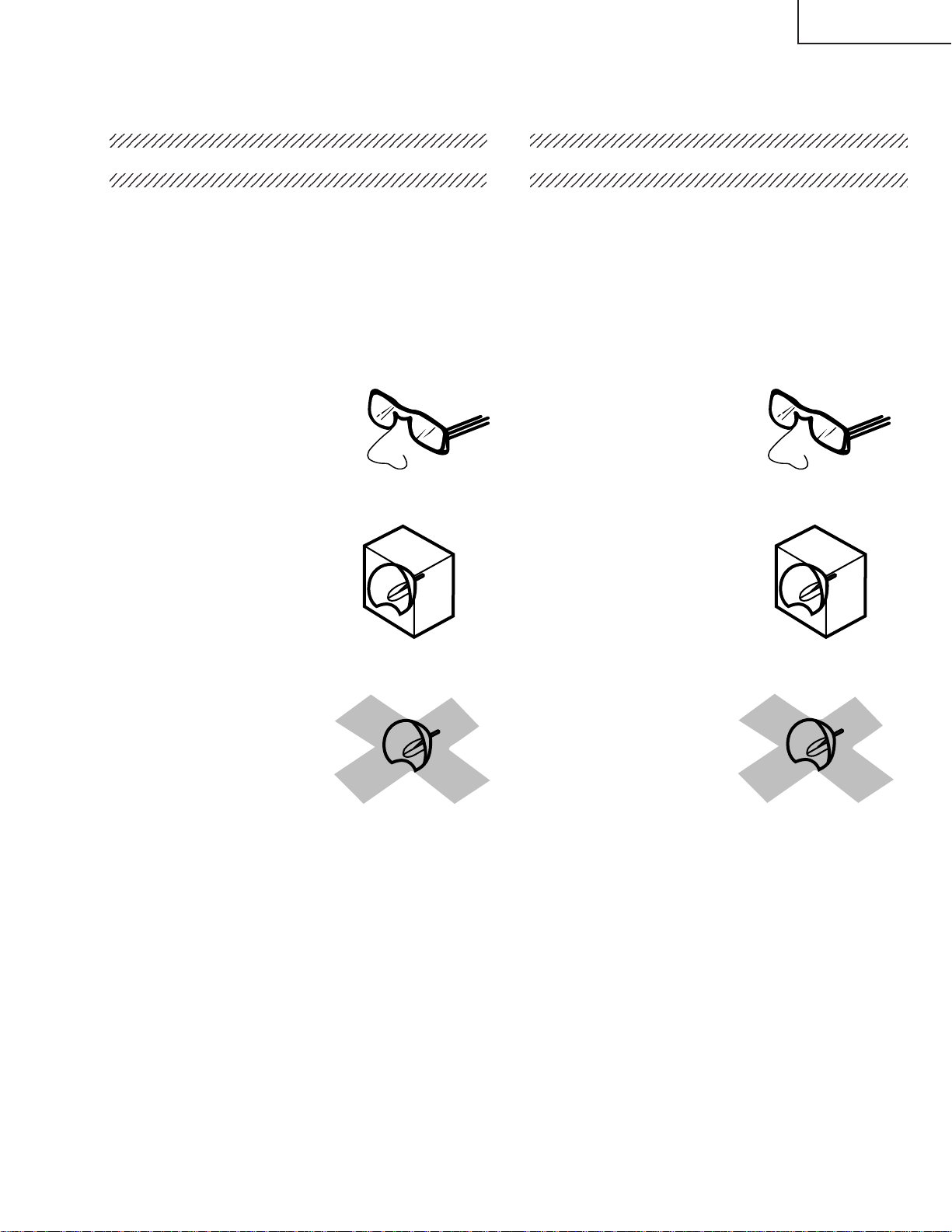

UV-RADIATION PRECAUTION

The light source, metal halide lamp, in the LCD

projector emits small amounts of UV-Radiation.

A VOID DIRECT EYE AND SKIN EXPOSURE.

To ensure safety please adhere to the following:

1. Be sure to wear sun-glasses when ser vicing the

projector with the lamp

turned “on” and the top

enclosure removed.

2. Do not operate the lamp outside of the lamp housing.

NO TE POUR LE PERSONNEL

D’ENTRETIEN

PRECAUTION POUR LES RADIATIONS UV

La source de lumière, la lampe métal halide, dans le

projecteur LCD émet de petites quantités de radiation

UV.

EVITEZ TOUTE EXPOSITION DIRECTE

DES YEUX ET DE LA PEAU.

Pour votre sécurité, nous vous prions de respecter

les points suivants:

1. Toujours por ter des lunettes de soleil lors d’un

entretien du projecteur

avec la lampe allumée

et le haut du coffret retiré.

2. Ne pas faire fonctionner la lampe à l’extérieur du

boîtier de lampe.

3. Do not operate for more than 2 hours with the

enclosure removed.

UV-Radiation and Medium Pressure

Lamp Precautions

1. Be sure to disconnect the AC plug when replacing

the lamp.

2. Allow one hour for the unit to cool down before

servicing.

3. Replace only with same type lamp. Type

CLMPFA002DE02 or BQC-XGP25X//1 rated 80V/

270W.

4. The lamp emits small amounts of UV-Radiation, av oid

direct-eye contact.

5. The medium pressure lamp involves a risk of

explosion. Be sure to follow installation instructions

described below and handle the lamp with care.

3. Ne pas faire fonctionner plus de 2 heures avec le

coffret retiré.

Précautions pour les radiations UV

et la lampe moyenne pression

1. Toujours débrancher la fiche AC lors du

remplacement de la lampe.

2. Laisser l’unité refroidir pendant une heure avant de

procéder à l’entretien.

3. Ne remplacer qu’avec une lampe du même type. Type

CLMPFA002DE02 ou BQC-XGP25X//1

caractéristique 80V/270W.

4. La lampe émet de petites quantités de radiation UV éviter tout contact direct avec les yeux.

5. La lampe moyenne pression implique un risque

d’explosion. Toujours suivre les instructions

d’installation décrites ci-dessous et manipuler la

lampe avec soin.

5

Page 6

XG-P25X

4

5

UV-RADIATION PRECAUTION (Continued)

23456789012345678901234567890121234567890123

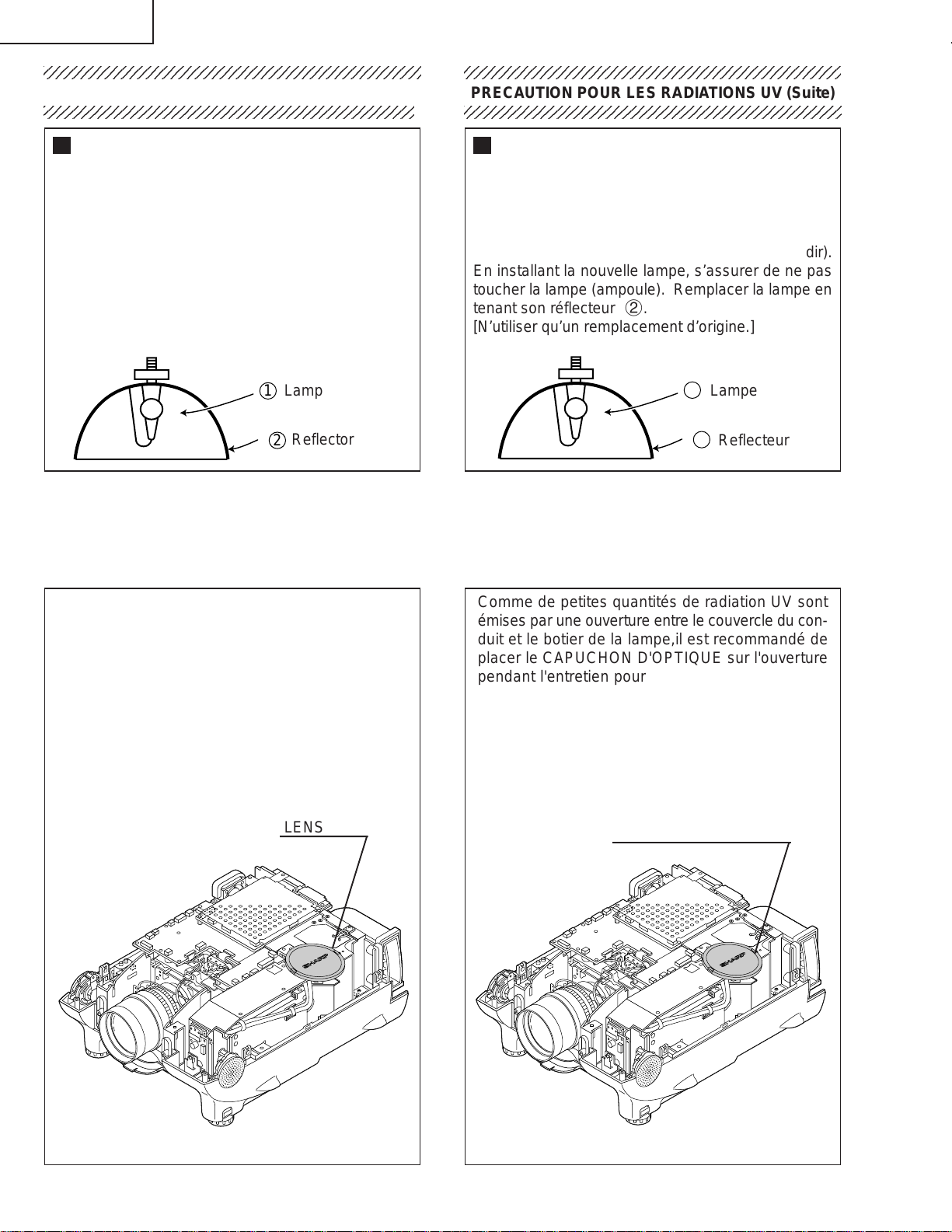

Lamp Replacement

Note:

Since the lamp reaches a very high temperature

during units operation replacement of the lamp

should be done at least one hour after the power

has been turned off. (to allow the lamp to cool off.)

Installing the new lamp, make sure not to touch the

lamp (bulb) replace the lamp by holding its reflector

2.

[Use original replacement only.]

Lamp

1

Reflector

2

DANGER ! –– Never turn the power on without the

lamp to avoid electric-shock or damage of the de vices

since the stabilizer generates high voltages at its

start.

PRECAUTION POUR LES RADIATIONS UV (Suite)

234567890123456789012345678901212345678901234

Remplacement de la lampe

Remarque:

Comme la lampe devient très chaude pendant le

fonctionnement de l’unité, son remplacement ne doit

être effectué au moins une heure après avoir coupé

l’alimentation (pour permettre à la lampe de refroidir).

En installant la nouvelle lampe, s’assurer de ne pas

toucher la lampe (ampoule). Remplacer la lampe en

tenant son réflecteur 2.

[N’utiliser qu’un remplacement d’origine.]

1

Lampe

2

Reflecteur

DANGER ! –– Ne jamais mettre sous tension sans

la lampe pour éviter un choc électrique ou des

dommages des appareils car le stabilisateur génère

de hautes tensions à sa mise en route.

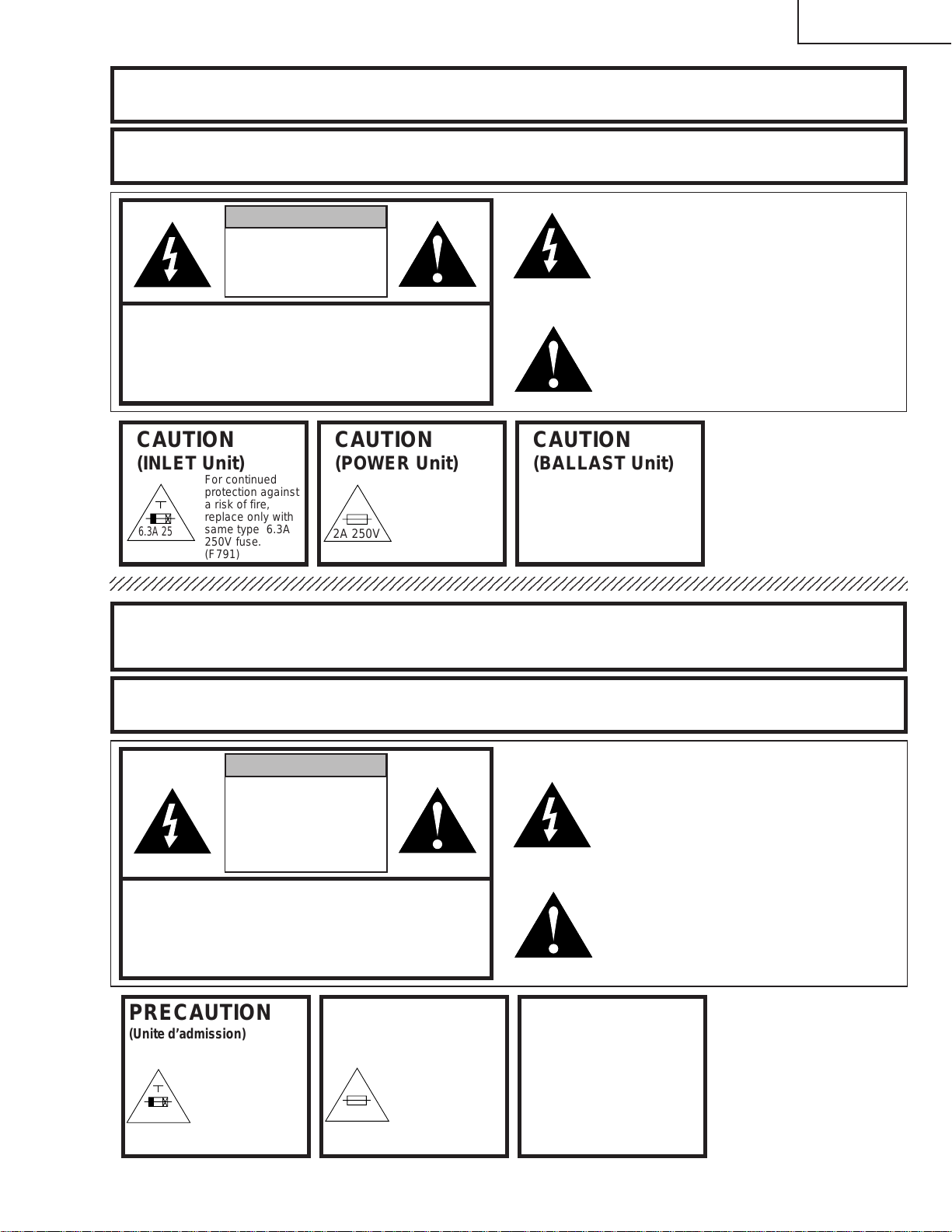

Since small amounts of UV-Radiation are emitted

from an opening between the duct cover and the

lamp housing, it is recommended to place the LENS

CAP on the opening during servicing to avoid eye

and skin exposure (Fig. 1).

Note: Please obtain a lens cap before servicing a

models XG-P25X that is received without one.

LENS CAP

Comme de petites quantités de radiation UV sont

émises par une ouverture entre le couvercle du conduit et le botier de la lampe,il est recommandé de

placer le CAPUCHON D'OPTIQUE sur l'ouverture

pendant l'entretien pour éviter une exposition des

yeux et la peau (Fig. 1).

Remarque: Priére de se procurer un capuchon

d'optique acant d'entretien un modéle

XG-P25X qui est livré sans.

CAPUCHON D'OPTIQUE

Figure 1.

Figure 1.

6

Page 7

XG-P25X

WARNING: High brightness light source, do not stare into the beam of light, or view directl y . Be especially

careful that children do not stare directly in to the beam of light.

WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE THIS UNIT TO

MOISTURE OR WET LOCATIONS.

CAUTION

RISK OF ELECTRIC SHOCK.

DO NOT REMO VE SCREWS

EXCEPT SPECIFIED USER

SERVICE SCREW

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

NO USER-SERVICEABLE PARTS EXCEPT LAMP UNIT.

CAUTION

(INLET Unit)

6.3A 250V

DO NOT REMO VE CABINET.

REFER SERVICING T O QU ALIFIED SERVICE

PERSONNEL.

CAUTION

For continued

protection against

a risk of fire,

replace only with

same type 6.3A

250V fuse.

(F791)

(POWER Unit)

2A 250V

For continued

protection against a

risk of fire, replace

only with same type

P110A, ANZEN

DENGU, 2A, 250V

117°C fuse.(TF701)

CAUTION

(BALLAST Unit)

The lighting flash with arrowhead within a

triangle is intended to tell the user that

parts inside the product are risk of electric

shock to persons.

The exclamation point within a triangle is

intended to tell the user that important

operating and servicing instructions are in

the manual with the projector.

For continued

protection against a

risk of fire, replace

only with same type

P110A, ANZEN

DENGU, 2A, 250V

117°C fuse.(THP1701)

AVERTISSEMENT: Source lumineuse de grande intensité. Ne pas fixer le faisceau lumineux ou le regarder

directement. Veiller particulièrement à éviter que les enfants ne fixent directement le

faisceau lumineux.

A VERTISSEMENT : AFIN D’EVITER TOUT RISQUE D’INCENDIE OU D’ELECTROCUTION, NE PAS PLACER

CET APPAREIL DANS UN ENDROIT HUMIDE OU MOUILLE.

ATTENTION

RISQUE

D’ELECTR OCUTION NE

PASRETIRER LES VIS, A

L’EXCEPTION DES VIS DE

REPARATION UTILISATEUR

SPECIFIEES

ATTENTION: POUR EVITER TOUT RISQ UE

D’ELECTR OCUTION, NE PAS RETIRER LE CAPOT.

AUCUNE DES PIECES INTERIEURES N’EST REPARABLE

PAR L ’UTILISATEUR, A L’EXCEPTION DE L’UNITE DE

LAMPE. POUR T OUTE REPARATION, S’ADRESSER A UN

PRECAUTION

(Unite d’admission)

6,3A 250V

TECHNICIEN D’ENTRETIEN QUALIFIE.

PRECAUTION

Pour une protection

continue contre les

risques d’incendie,

ne remplacer

qu’avec un fusible

6,3A 250V du même

type.

(F791)

(Unité de NETZ)

2A 250V

Pour une protection

continue contre un

risques d’incendie, ne

remplacer qu’avec un

fusible P110A, ANZEN

DENGU 2A 250V,

117°C du même type.

(TF701)

PRECAUTION

(Unité de PUTSSANCE)

L’éclair terminé d’une flèche à l’intérieur

d’un triangle indique à l’utilisateur que les

pi‘eces se trouvant dans l’appareil sont

susceptibles de provoquer une décharge

électrique.

Le point d’exclamation à l’intérieur d’un

triangle indique à l’utilisateur que les

instructions de fonctionnement et

d’entretien sont détaillées dans les

documents fournis avec le projecteur.

Pour une protection

continue contre un

risques d’incendie, ne

remplacer qu’avec un

fusible P110A, ANZEN

DENGU 2A 250V,

117°C du même type.

(THP1701)

7

Page 8

XG-P25X

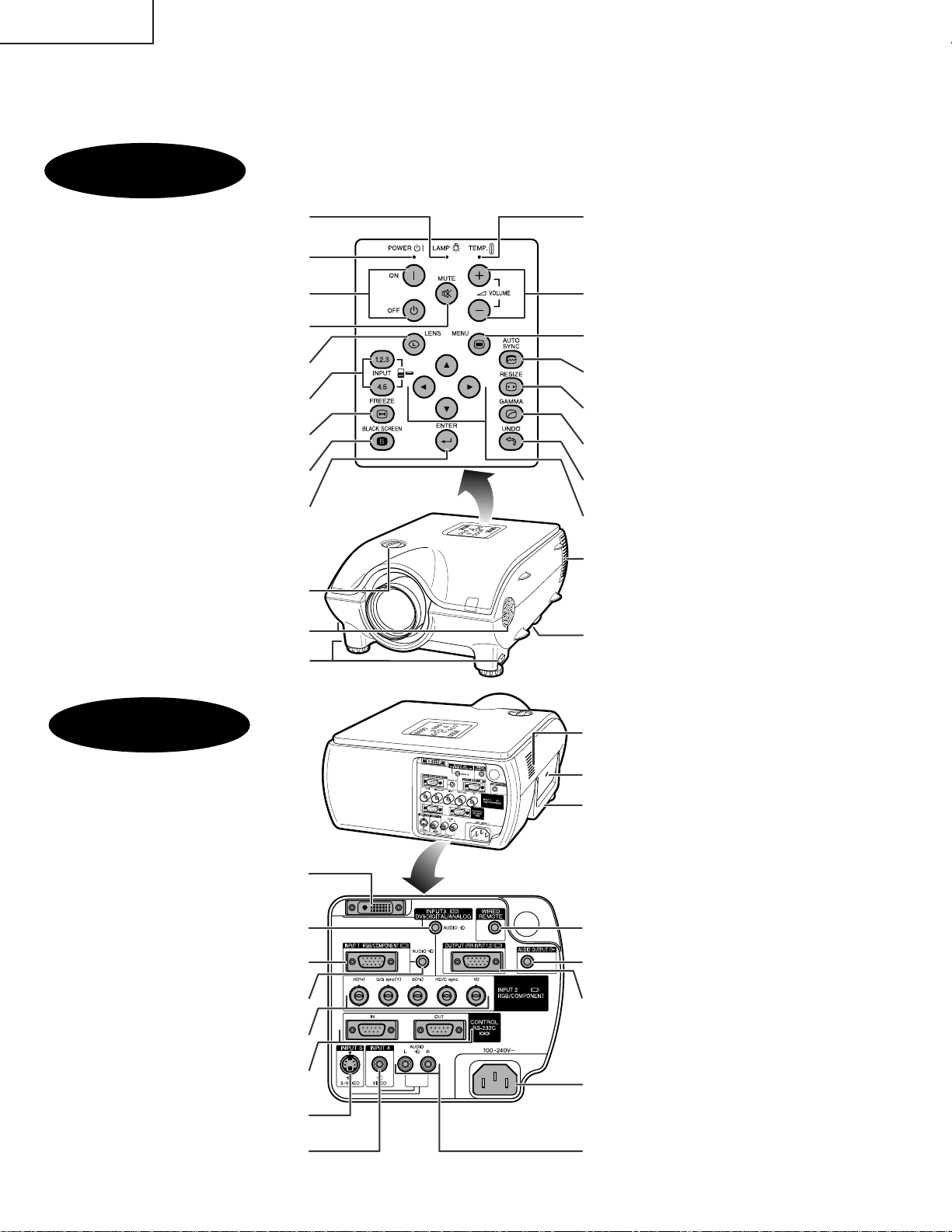

Location of Controls

Projector

Front View

LAMP REPLACEMENT indicator

POWER indicator

POWER buttons (ON/OFF)

MUTE button

LENS button

INPUT 1, 2, 3, 4, 5 buttons

FREEZE button

BLACK SCREEN button

ENTER button

Lens shift dial

Speakers

Foot releases

TEMPERATURE WARNING

indicator

VOLUME buttons ( / )

MENU button

AUTO SYNC button

RESIZE button

GAMMA button

UNDO button

ADJUSTMENT buttons

(///)

Cooling fan (Exhaust vent)

Air filter/Cooling fan

(Intake vent)

|

|

|

|

-+

Rear View

INPUT 3 port (DVI)

Computer AUDIO INPUT 2/3 terminal

(ø3.5 mm stereo minijack)

INPUT 1 port (15-pin Mini D-sub)

Computer AUDIO INPUT 1 terminal

(ø3.5 mm stereo minijack)

INPUT 2 terminals (BNC)

RS-232C INPUT port/

RS-232C OUTPUT port

S-VIDEO INPUT 5 terminal

(4-pin Mini DIN)

VIDEO INPUT 4 terminal (RCA)

Cooling fan (Intake vent)

Kensington Security

Standard connector

Carrying handle

WIRED REMOTE control

input terminal

(ø3.5 mm stereo minijack)

AUDIO OUTPUT terminal

(ø3.5 mm stereo minijack)

OUTPUT port (15-pin Mini

D-sub) for INPUT 1, 2

AC socket

AUDIO INPUT 4/5

terminals (RCA)

8

Page 9

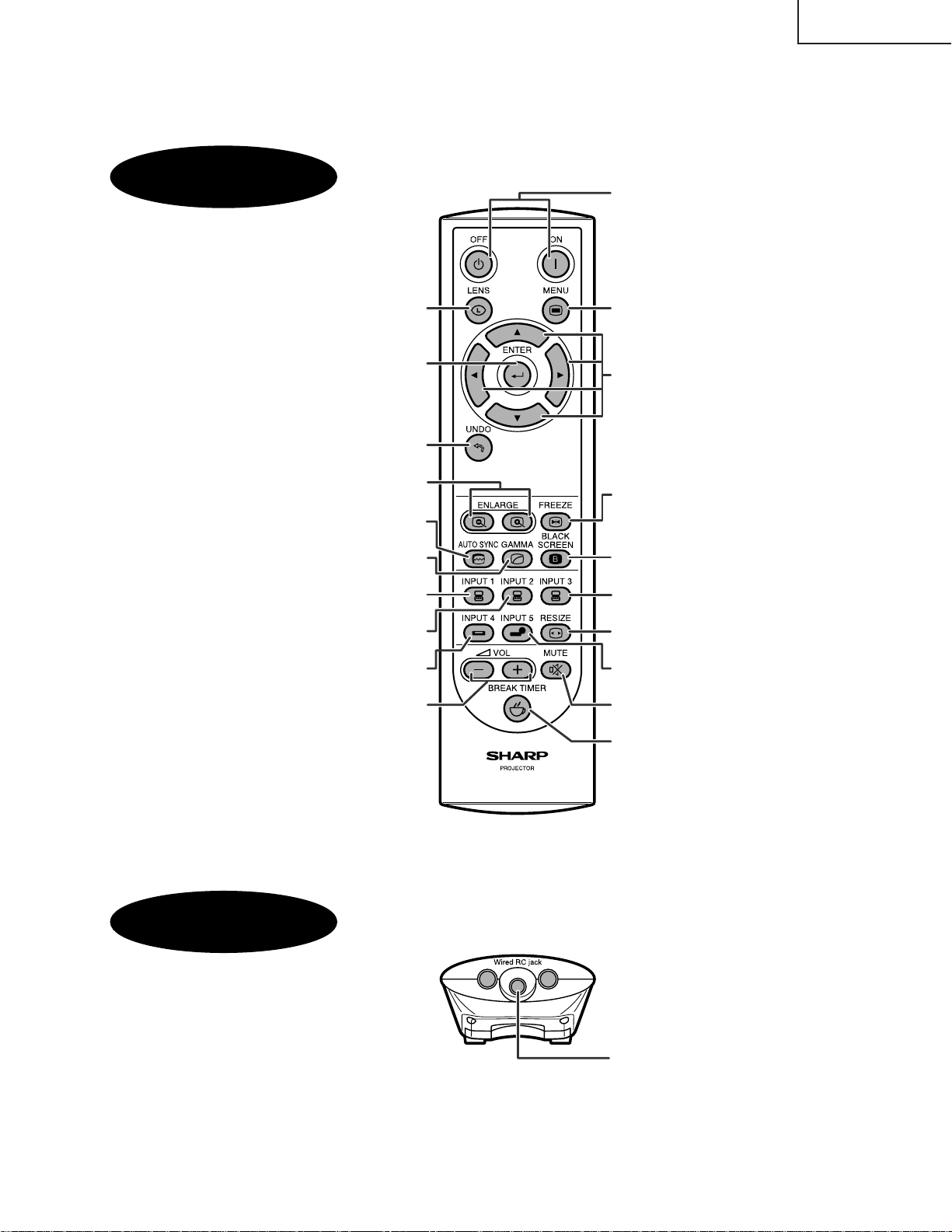

Operating the Wireless Mouse Remote Control

Remote Control

XG-P25X

Front View

LENS button

ENTER button

UNDO button

ENLARGE buttons

AUTO SYNC button

GAMMA button

INPUT 1 button

POWER buttons (ON/OFF)

MENU button

|

|

Adjustment ( / / / )

buttons

FREEZE button

BLACK SCREEN button

INPUT 3 button

|

|

T op View

INPUT 2 button

INPUT 4 button

VOLUME ( / )

-+

buttons

RESIZE button

INPUT 5 button

MUTE button

BREAK TIMER button

Wired RC jack (ø3.5 mm minijack)

9

Page 10

XG-P25X

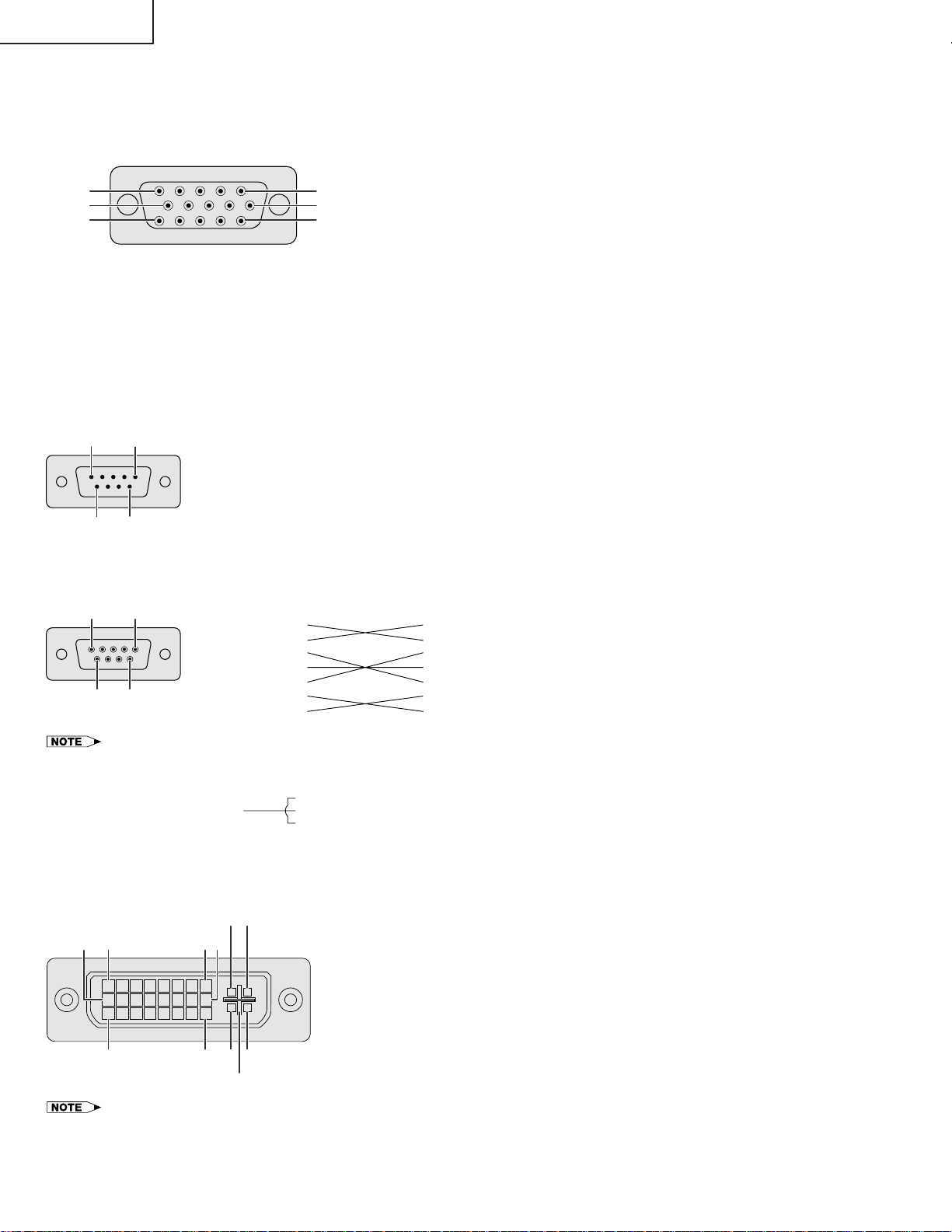

Connection Pin Assignments

INPUT 1 RGB and OUTPUT (INPUT 1, 2) Signal Ports: 15-pin Mini D-sub female connector

RGB Input

Analog

1. Video input (red)

2. Video input

(green/sync on green)

3. Video input (blue)

4. Reserve input 1

5. Composite sync

6. Earth (red)

7. Earth (green/sync on green)

10

15

5

1

6

11

Component Input

Analog

1. P

R

(CR)

2. Y

3. P

B

(CB)

4. Not connected

5. Not connected

6. Earth (P

7. Earth (Y)

8. Earth (P

R

)

B

)

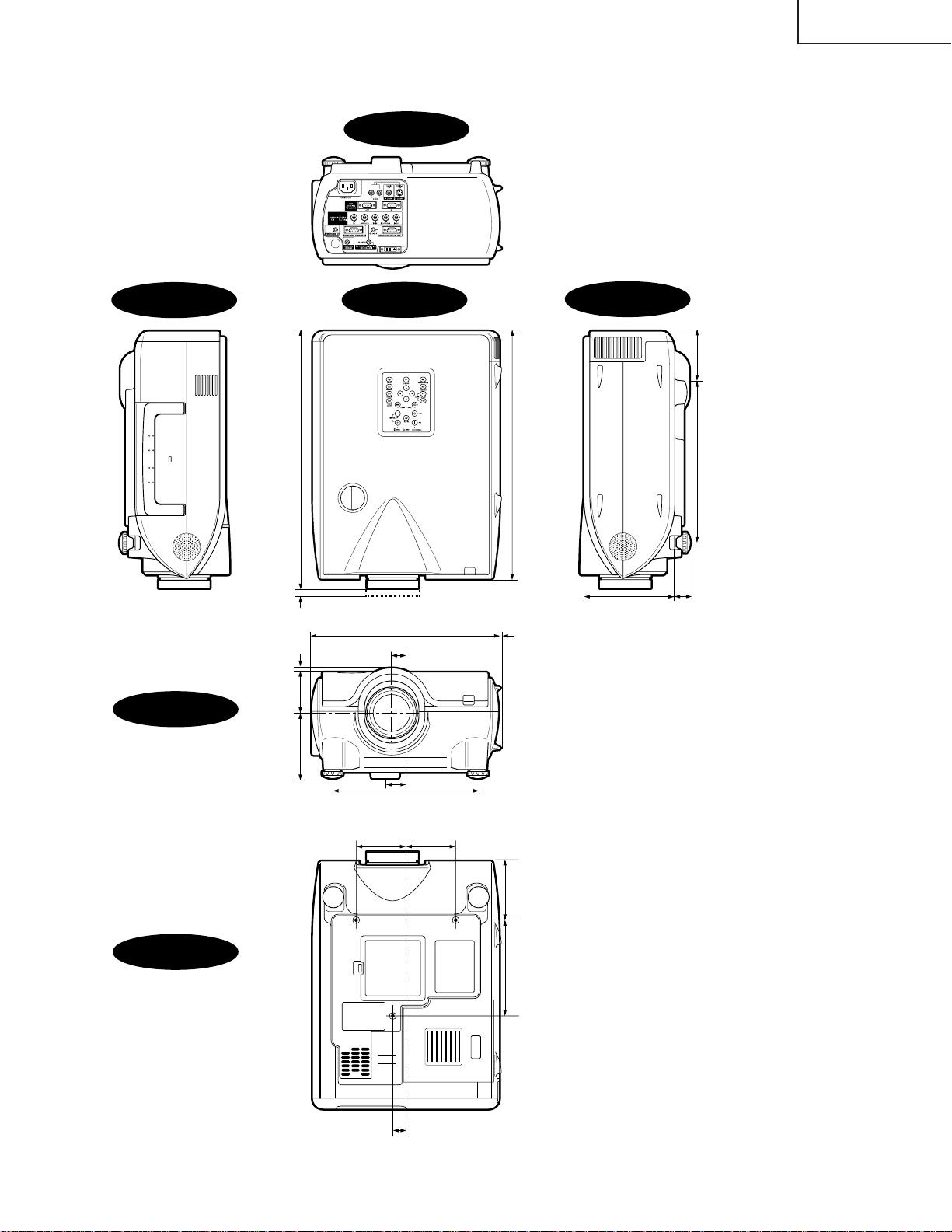

RS-232C Port: 9-pin D-sub male connector

15

69

Pin No. Signal Name I/O Reference

1 CD Not connected

2 RD Receive Data Input Connected to internal circuit

3 SD Send Data Output Connected to internal circuit

4 ER Not connected

5 SG Signal Ground Connected to internal circuit

6 DR Data Set Ready Not connected

7 RS Request to Send Output Connected to internal circuit

8 CS Clear to Send Input Connected to internal circuit

9 CI Not connected

RS-232C Cable recommended connection: 9-pin D-sub female connector

5

1

6

9

Signal SignalPin No. Pin No.

1

2

3

4

5

6

7

8

9

CD

RD

SD

ER

SG

DR

RS

CS

CI

1

2

3

4

5

6

7

8

9

CD

RD

SD

ER

SG

DR

RS

CS

CI

8. Earth (blue)

9. Not connected

10. GND

11. GND

12. Bi-directional data

13. Horizontal sync signal

14. Vertical sync signal

15. Data clock

9. Not connected

10. Not connected

11. Not connected

12. Not connected

13. Not connected

14. Not connected

15. Not connected

• Depending on the system layout, it is necessary to connect Pin 4 and Pin 6 on the controlling device (e.g. PC).

Projector

Pin No.PCPin No.

4

5

6

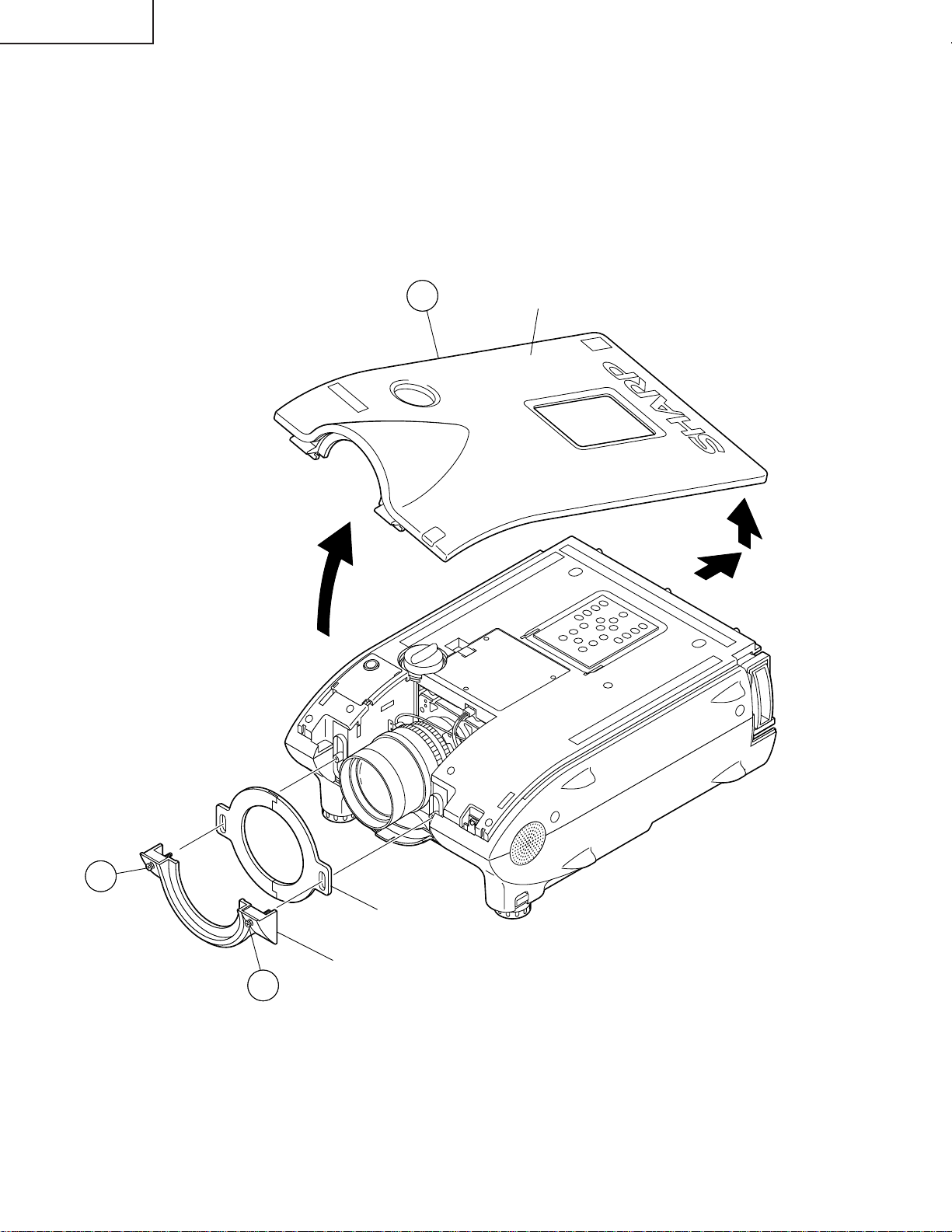

INPUT 3 DVI Port: 29-pin

C1C2

91 816

4

5

6

Pin No. Name

1 T.M.D.S. Data 2

2 T.M.D.S. Data 2

3 T.M.D.S. Data 2/4 Shield

4 T.M.D.S. Data 4 *

5 T.M.D.S. Data 4 *

6 DDC Clock

7 DDC Data

8 Analog Vertical Sync

9 T.M.D.S. Data 1

10 T.M.D.S. Data 1

11 T.M.D.S. Data 1/3 Shield

12 T.M.D.S. Data 3 *

13 T.M.D.S. Data 3 *

14 5 V Power

15 Ground*

1

Pin No. Name

16 Hot Plug Detect

17 T.M.D.S. Data 0

3

3

3

3

18 T.M.D.S. Data 0

19 T.M.D.S. Data 0/5 Shield

20 T.M.D.S. Data 5 *

21 T.M.D.S. Data 5 *

22 T.M.D.S. Clock Shield

23 T.M.D.S. Clock

24 T.M.D.S. Clock

C1 Analog Red

C2 Analog Green

C3 Analog Blue

C4 Analog Horizontal sync

C5 Analog Ground*

C32417 C4

C5

• *1 Return for 5 V, Hsync. and Vsync.

2

• *

Analog R, G and B return

3

• *

These pins are not used on this equipment.

10

3

3

2

Page 11

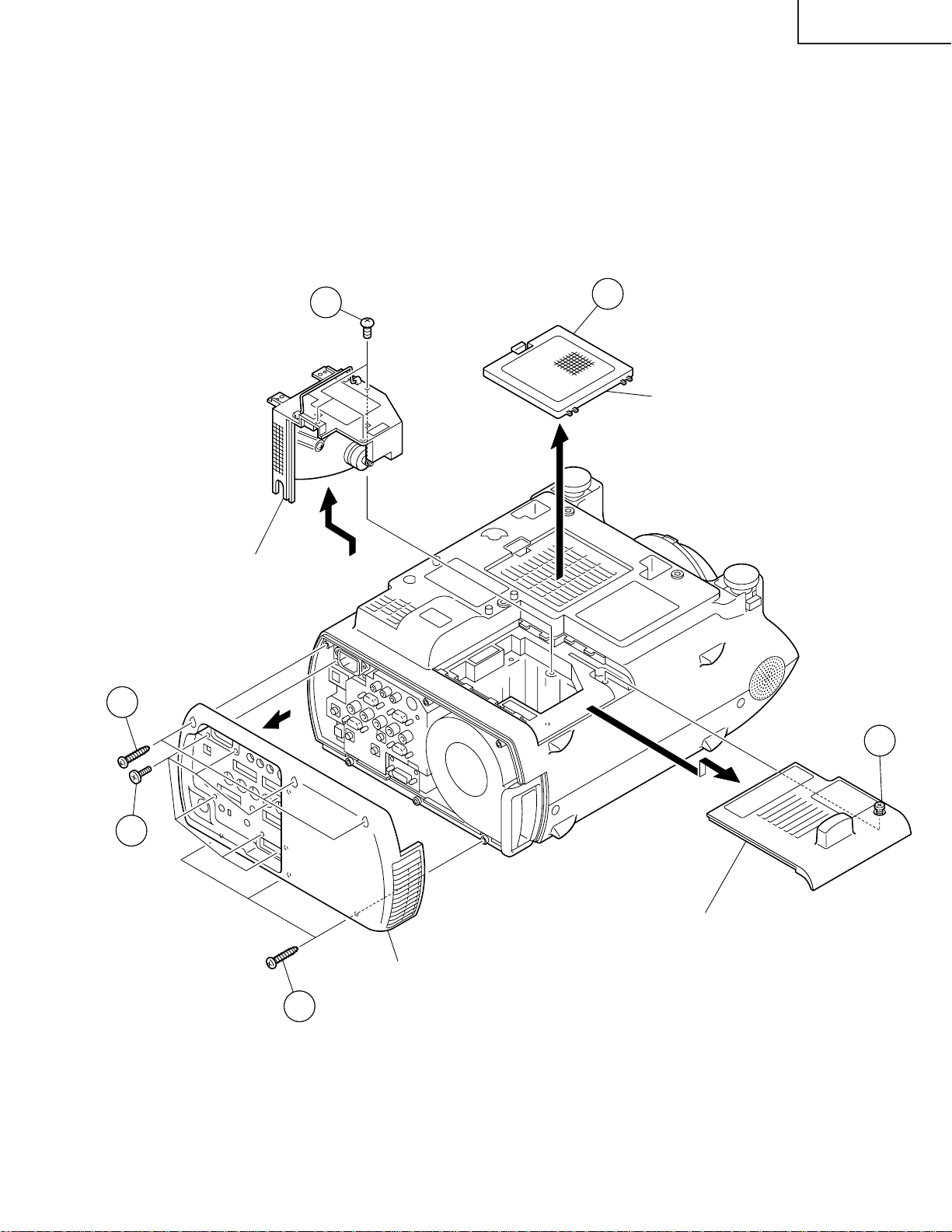

Dimensions

XG-P25X

Rear View

Side View

Front View

(445)

32

/

17

17

(4.5)

16

/

3

(7)4

32

/

9

(65)

16

/

9

2

(116.5)

64

/

37

Top Vie w

129/16 (319)

29

/32 (23)

111/32 (34)

3

9

/4 (248)

21

9

/64 (3.5)

(423)

32

/

16

Side View

63/32 (155)

3

/64 (26.5)

1

(79)

6

/

1

3

(282.5)

25

/

3

11

Bottom View

331/64 (88.5) 2 15/16 (74.5)

M4

M4

13

/16(20.27)

M4

11

(103.2)

64

/

5

4

(158.9)

64

/

17

6

Units: inches (mm)

Page 12

XG-P25X

REMOVING OF MAJOR PARTS

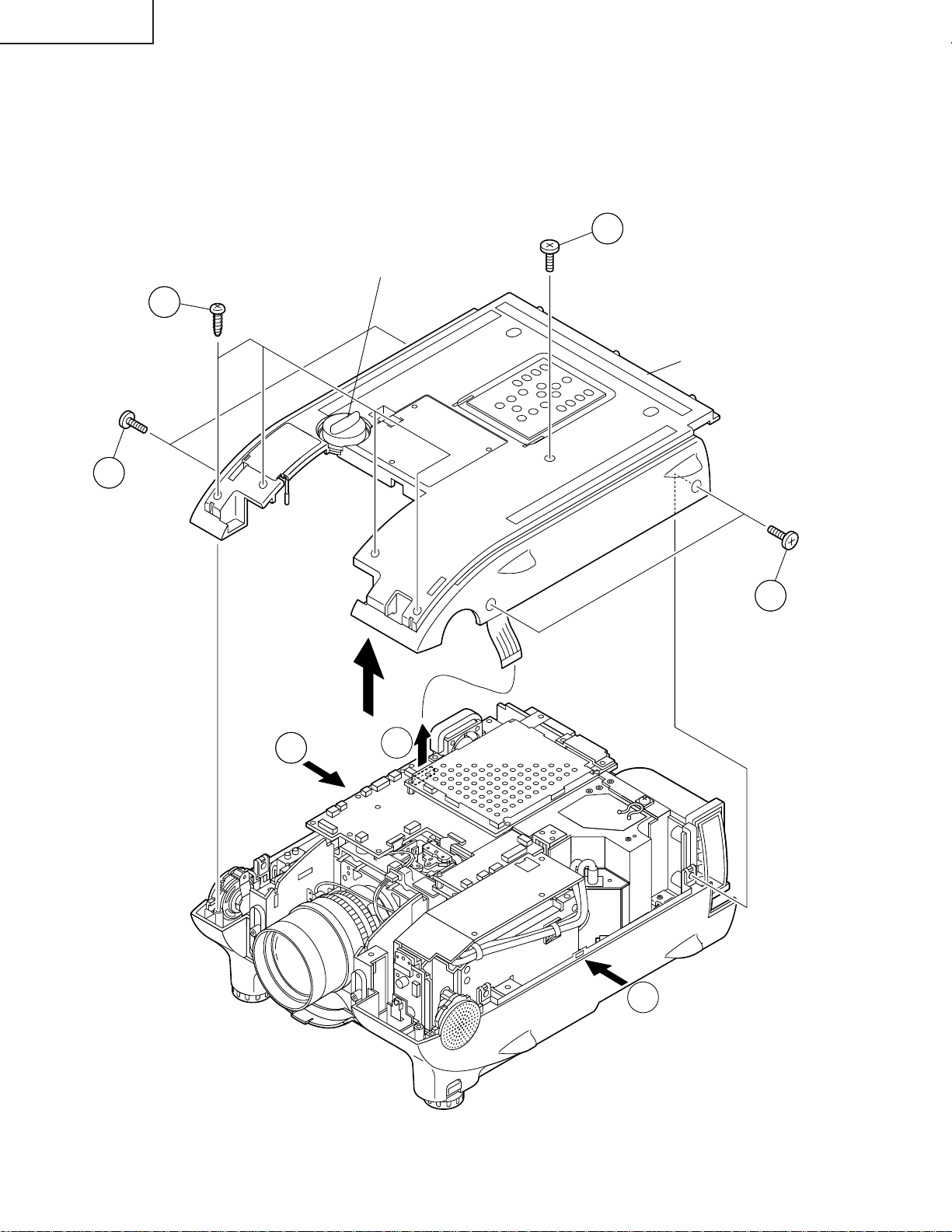

1.Removing the top cover and lens cover.

1-1. Remove the two screws and detach the lens cover.

1-2. Hold the lens top cover and tilt it up until its back end alone stays hooked. Then slide and detach the top cover.

Detach the lens shutter.

(When attaching the lens shutter back in position, match the left (L) and right (R) markings.)

2

Top Cover

1

Lens Shutter

Lens Cover

1

12

Page 13

2.Removing the Intake cover and lamp unit.

2-1. Detach the intake cover.

2-2. Loosen the screw and slide the lamp cover out of position.

2-3. Remove the three screws and lift the lamp unit out of position.

3.Removing the rear body.

3-1. Remove the six screws off the terminal board at the back.

3-2. Remove the six screws and detach the rear body.

XG-P25X

3-2

Lamp Unit

2-3

2-1

Intake Cover

2-2

3-1

Lamp Cover

Rear Body

3-2

13

Page 14

XG-P25X

4.Removing the top panel.

4-1. Remove the five screws.

4-2. Remove the four screws.

4-3. Press on both sides of the set and undo the hooks. Lift the top body with lens shift knob and disconnect the

connector.

4-1

Lens Shift Knob

4-2

Top Body

4-1

4-3

4-1

4-3

4-3

14

Page 15

(RP)

(BP)

(GP)

(FF)(FD)(LF)(F)

(AZ)

(SO) (Q)

(GP)

(D)(FR)

(EA)

(FE)

5-5

5-3

5-6

5-1

5-4

5-2

Output/Input

PWB Ass'y

Output Sub PWB

PC I/F Unit

XG-P25X

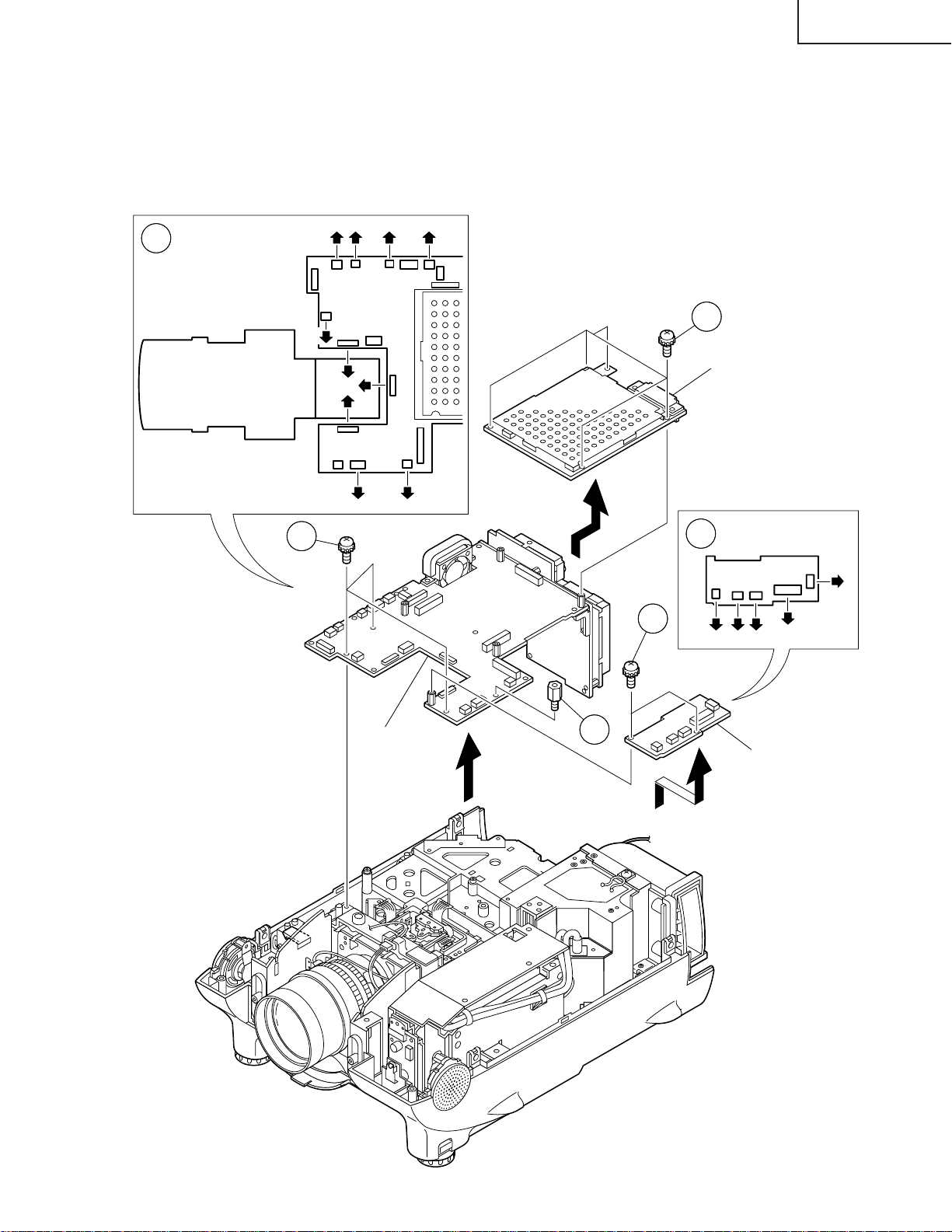

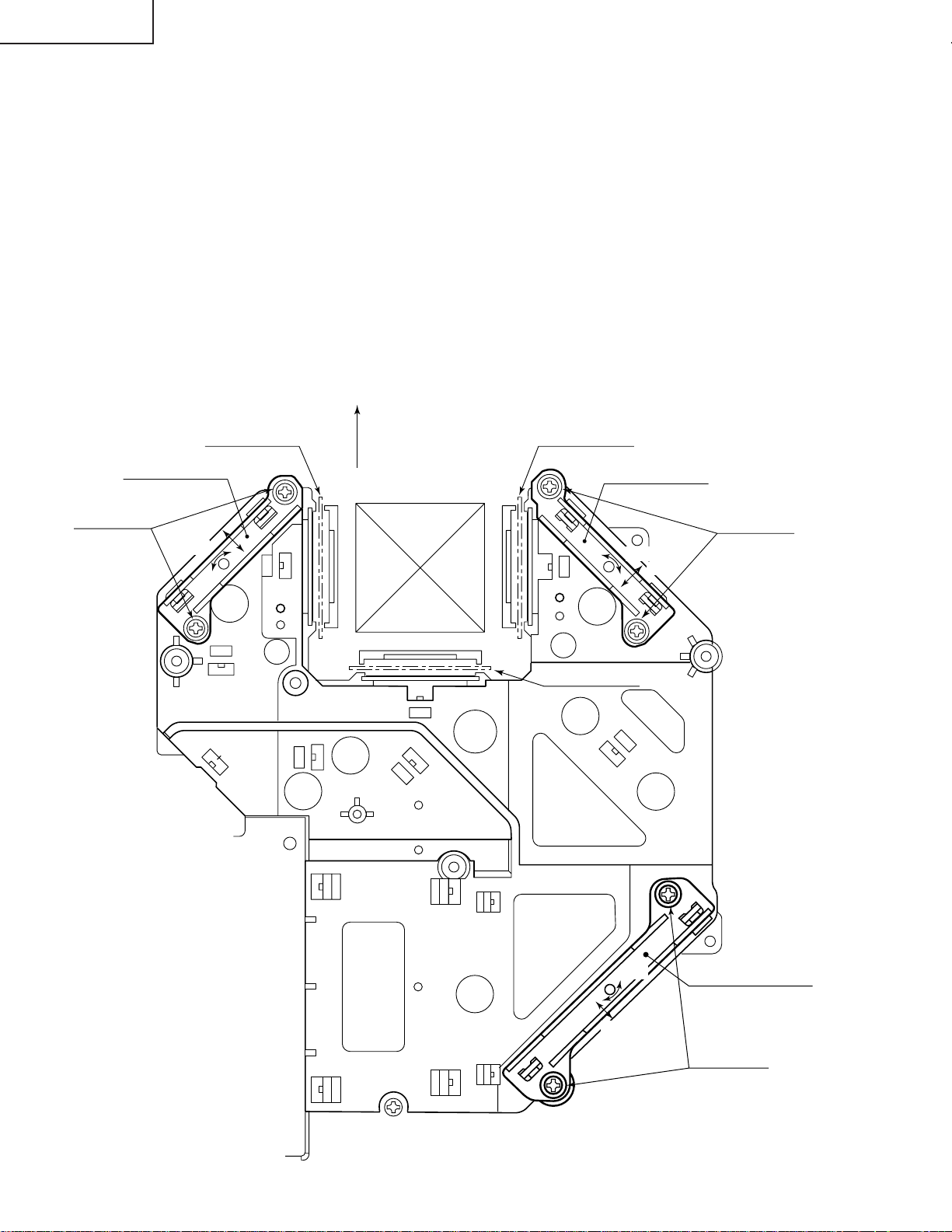

5.Removing the PWB unit.

5-1. Remove the five screws and detach the PC I/F unit.

5-2. Disconnect the five connectors.

5-3. Remove the two screws and detach the output sub-PWB.

5-4. Disconnect the twelve connectors.

5-5. Take out the hexagonal supports.

5-6. Remove the three screws and detach the output/input PWB assembly.

15

Page 16

XG-P25X

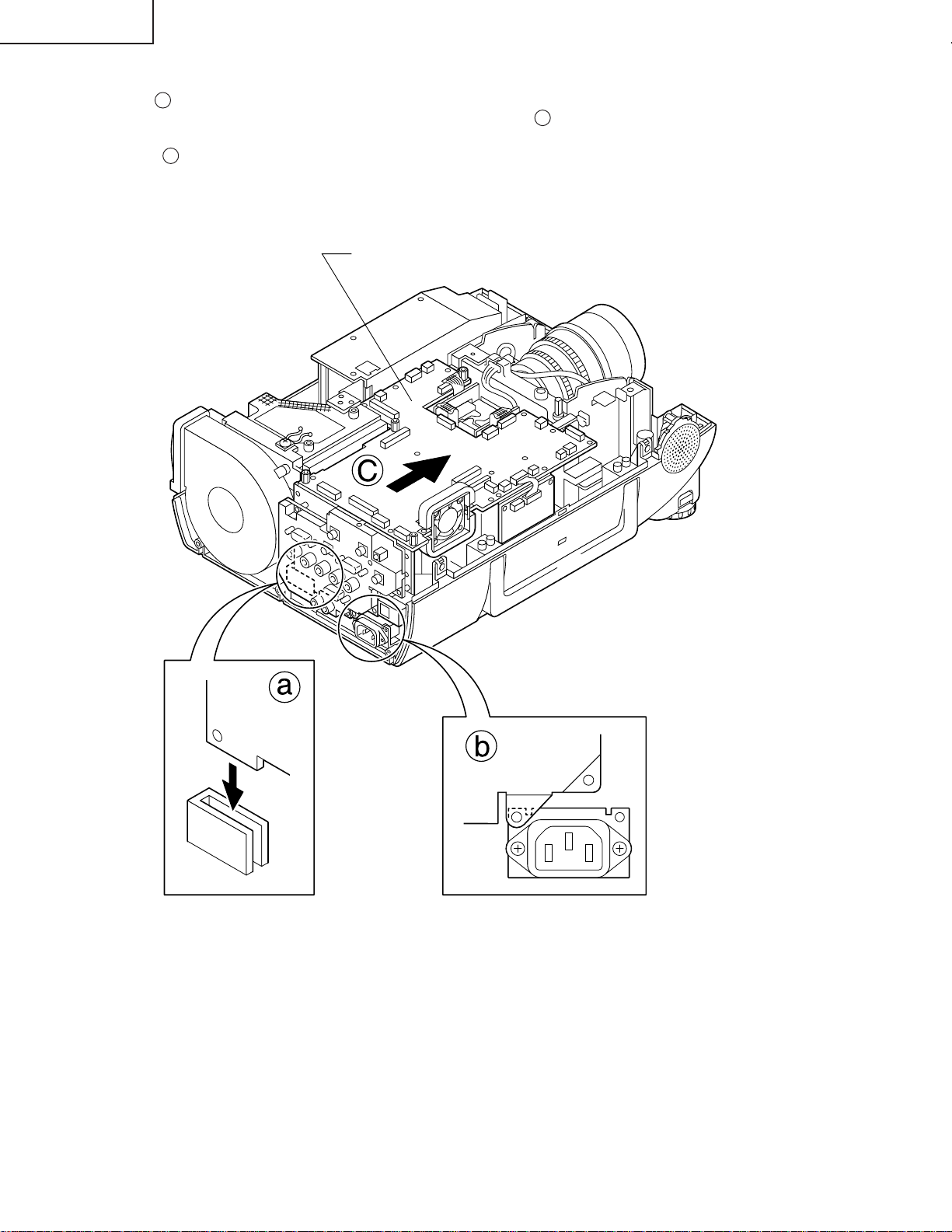

Reassembling precautions

5-7. Fit part a of the input PWB to the slit of the bottom cover.

5-8. Align the input PWB’s shield with the top of the AC inlet shield ( b ).

5-9. Before tightening up the screws (5-7) as well as the screws and hex nuts (5-8), move the PWB unit forward

enough ( c ).

PWB Unit Ass'y

16

Page 17

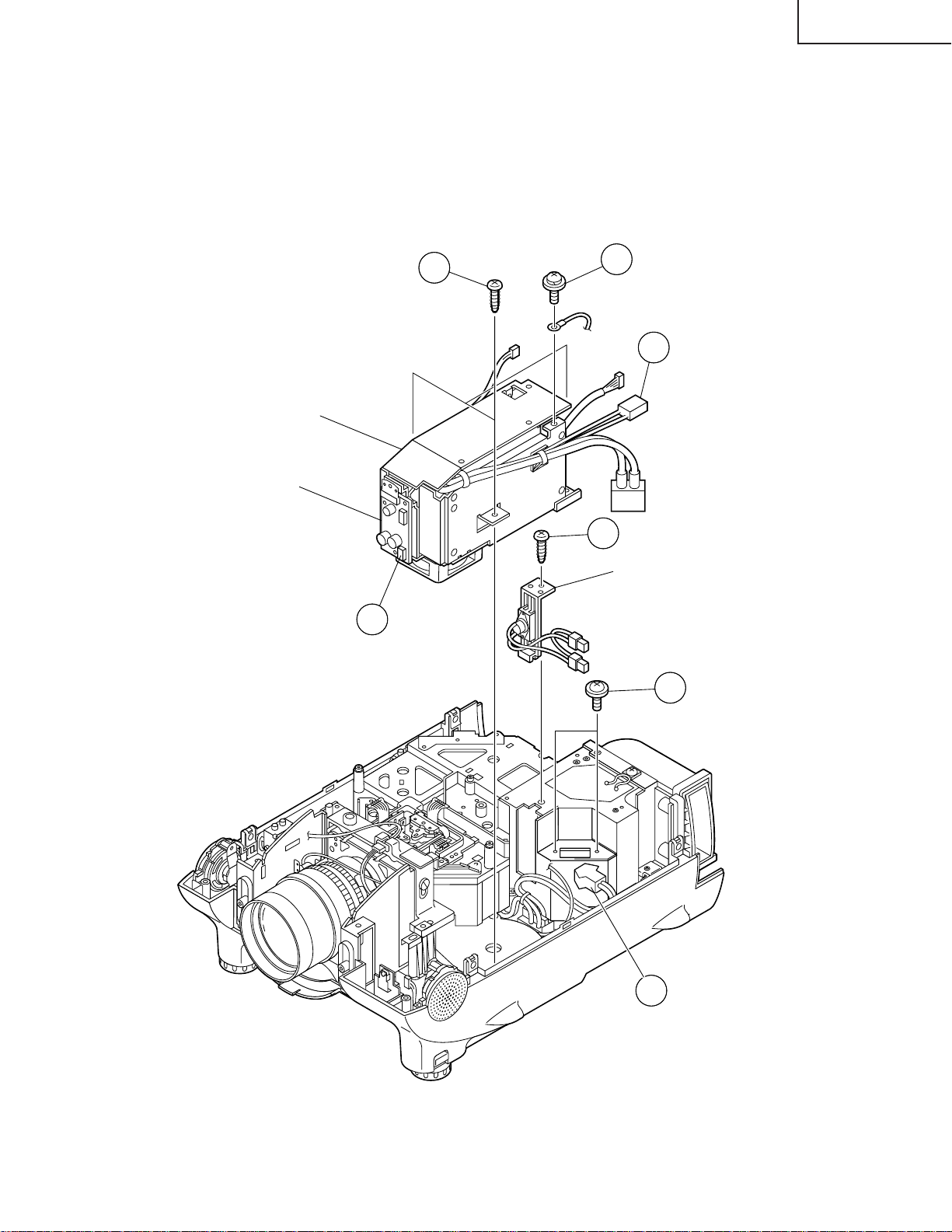

6.Removing the power / ballast / sound-out / bimetal unit assembly.

6-1. Remove the screw and disconnect the grounding wire from the shield case of the power/ballast unit.

6-2. Disconnect the connectors from the sound out PWB.

6-3. Take out the bimetal socket.

6-4. Remove the two screws and detach the lamp socket.

6-5. Remove the three screws and detach the power unit.

6-6. Remove the screw and slide the bimetal assembly upward out of position.

XG-P25X

Power/Ballast Unit

Sound Out PWB

6-2

6-5

6-1

6-3

6-6

Bimetal Ass'y

6-4

17

6-3

Page 18

XG-P25X

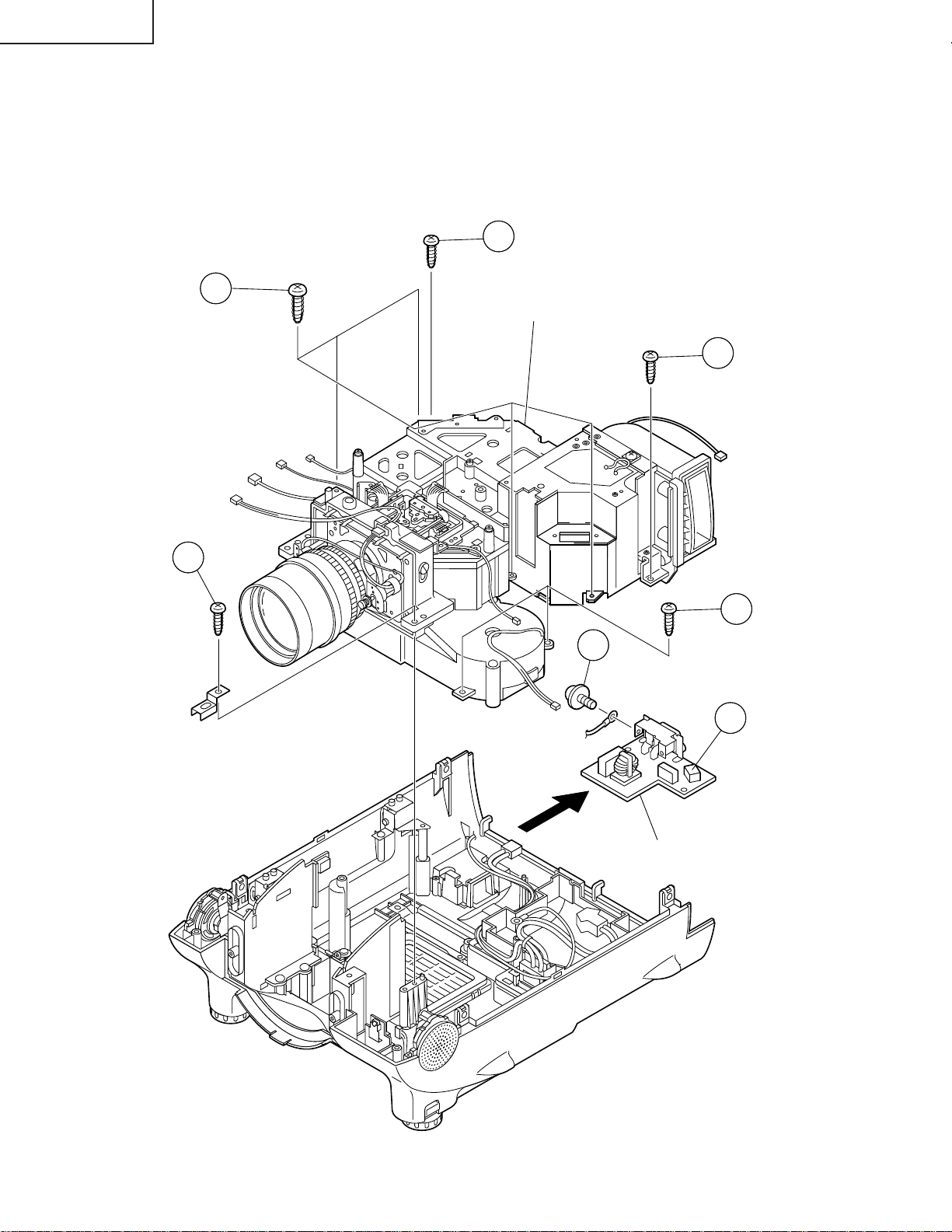

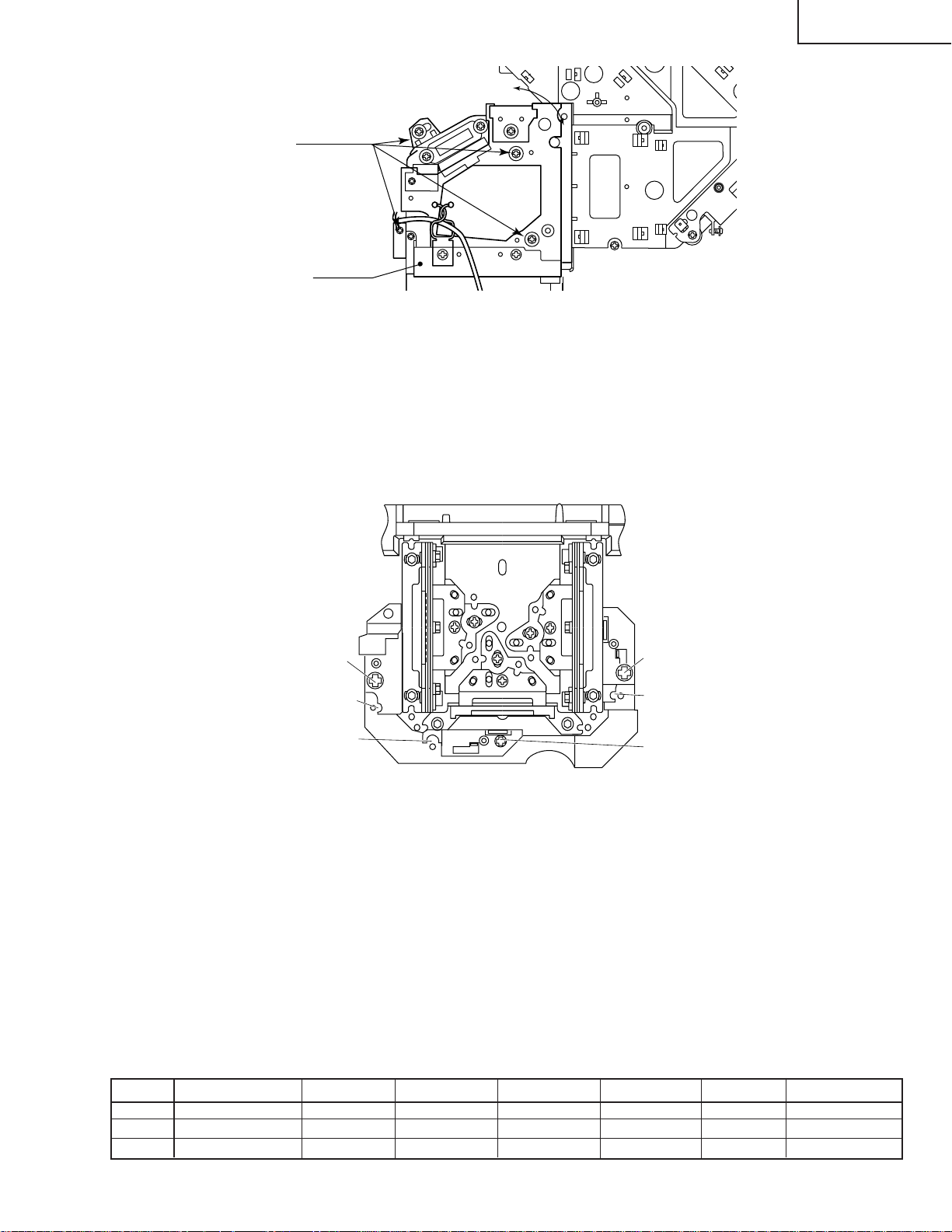

7.Removing the optical mechanism unit

7-1. Remove the two screws off the optical mechanism intake fan.

7-2. Remove the eight screws and take out the optical mechanism unit.

7-3. Remove the screw and disconnect the grounding wire.

7-4. Disconnect the connector and detach the AC inlet unit.

7-2

7-2

Optical Mechanism Unit

7-2

7-2

7-1

7-3

7-4

AC Inlet Unit

18

Page 19

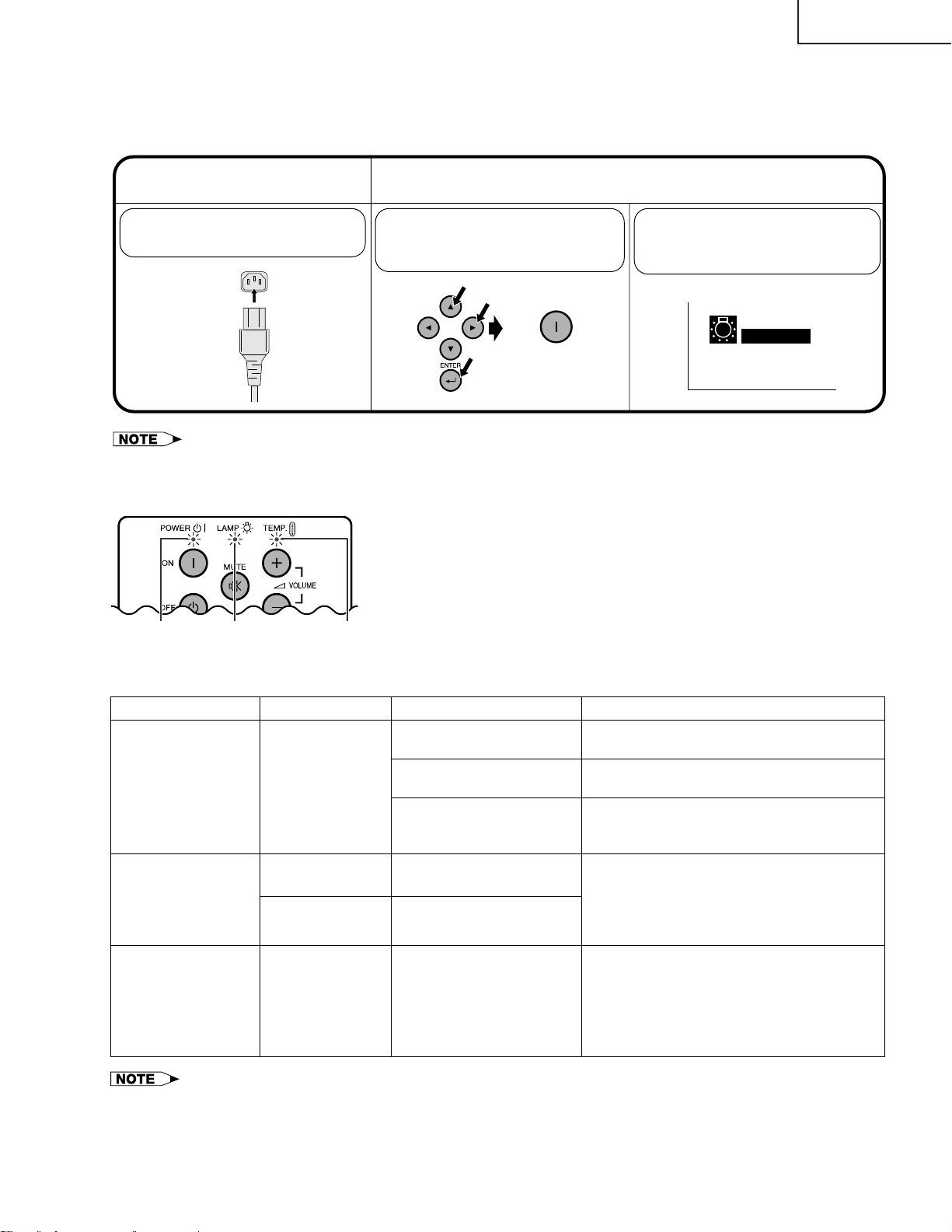

RESETTING THE TOT AL LAMP TIMER

ON

•Reset the lamp timer only after replacing the lamp.

Resetting the lamp timer

2

Connect the power

cord.

1

Reset the lamp timer.

Plug the power cord into the AC

socket of the projector.

While pressing ",| and

ENTER on the projector,press

POWER ON on the projector.

“LAMP 0000H ” is displayed,

indicating that the lamp timer is

reset.

LAMP 0000H

XG-P25X

Maintenance Indicators

POWER

indicator

Maintenance Indicator

TEMPERATURE

WARNING indicator

LAMP REPLACEMENT indicator

POWER indicator

LAMP

REPLACEMENT

indicator

• The warning lights on the projector indicate problems

inside the projector.

• There are two warning lights: a TEMPERATURE

WARNING indicator which warns that the projector is

too hot, and a LAMP REPLACEMENT indicator which

lets you know when to change the lamp.

TEMPERATURE

WARNING

indicator

• If a problem occurs, either the TEMPERATURE

WARNING indicator or the LAMP REPLACEMENT

indicator will light up red. After turning off the power,

follow the procedures given below.

Condition Possible Solution

The internal

temperature is

abnormally high.

The lamp does not

light up.

The lamp requires

replacement.

• Blocked air intake.

• Clogged air filter.

• Cooling fan breakdown.

• Internal circuit failure.

• Burnt-out lamp.

• Lamp circuit failure.

• Lamp has been used for

The POWER

indicator blinks in

red when the

projector is on.

• The filter cover is open.

Problem

over 1,400 hours.

• Relocate the projector to an area with

proper ventilation.

• Clean the filter.

• Take the projector to your nearest Sharp

Authorized LCD Projector Dealer or Service

Center for repair.

• Carefully replace the lamp.

• Take the projector to your nearest Sharp

Authorized LCD Projector Dealer or Service

Center for repair.

• Securely install the filter cover.

• If the POWER indicator blinks even when

the filter cover is securely installed, contact

your nearest Sharp Authorized LCD

Projector Dealer or Service Center for

advice.

• If the TEMPERATURE WARNING indicator lights up, follow the above possible solutions and then wait until the pr ojector has

cooled down completely before turning the power back on. (At least 5 minutes.)

• If the power is tur ned off and then turned on again, as during a brief rest, the LAMP REPLACEMENT indicator may be

triggered, preventing the power from going on. Should this occur, take the power cord out of the wall outlet and put it back

in again.

19

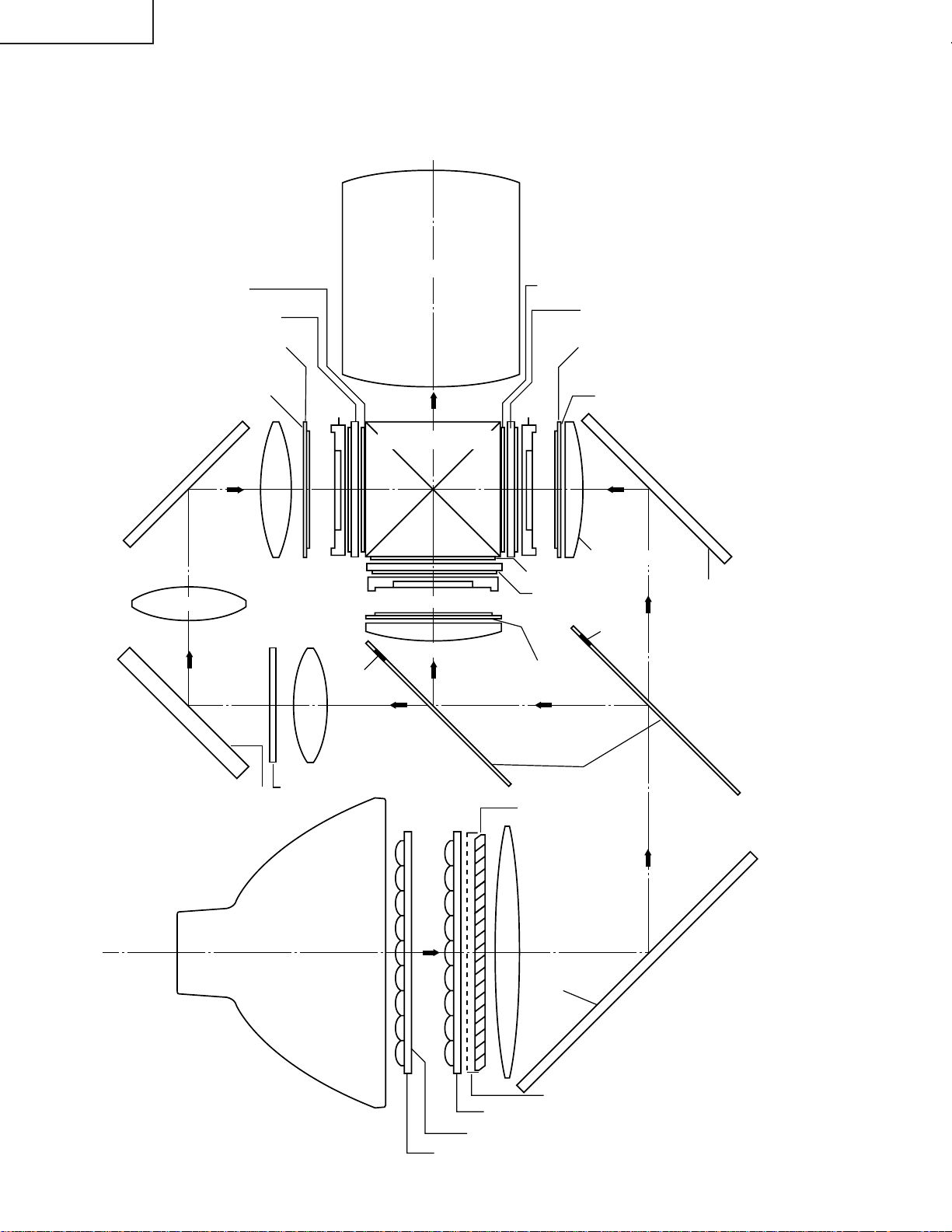

Page 20

XG-P25X

THE OPTICAL UNIT OUTLINE

Layout of the optical system

Note: Layout for positioning the optical system.

1/2λ plate

Sapphire glass

Polarizing plate

Incident polarizing plate B

Projection Lens

1/2λ plate + polarizing plate

Sapphire glass

Polarizing plate

Incident polarizing plate R

Dichroic coating

(B transmission)

M6

BLUE

AL-coated mirror B

G03 L2

Relay lens 1

Relay lens 2

G02 L2

AL-coated mirror B

M4

AL-deposited face

B-LCD

Cross dichroic prism

G-LCD

Incident polarizing plate G

Condenser lens G

Marking

BLUE

G01

Relay lens 1

UV-absorption-filter

* M3

GREEN

G reflector

Dichroic coating

R-LCD

1/2λ plate

Sapphire glass

Polarizing plate

Dichroic coating

(R, G transmission)

Dichroic coating

PBS(polarization

beam splitter)

(R transmission)

Condenser lens R

Marking

AL-coated mirror R

M5

AL-deposited face

RED

(R reflection)

M2

B/G reflector

* The M3 mirrors have a coating

wedge (for different film thickness). Set up these mirrors, with

their markings positioned as

shown above, so that their

coated faces and both sides be

in the correct directions.

UHP lamp

(Light source)

L1

AL-deposited

face

PBS aperture

Fly-eye lens (outgoing light)

UV-IR coating

Fly-eye lens (incoming light)

20

M1

AL-coated mirror W

Page 21

XG-P25X

CONVERGENCE AND FOCUS ADJUSTMENT

» Start the convergence and focus adjustments with the top cabinet and the LCD cover

removed but the power on. Use the remote control to adjust the image. Take the following procedures.

1. Focusing the projection lens

(A) Replacing all the 3 LCD panels

1. Before replacing all the 3 LCD panels, project an image on the screen and bring it into focus.

2. Replace the panels with new ones. But until the focus has been completely readjusted, be careful not to

change the distance between the set and the screen, nor to move the projection lens f ocus and zoom rings.

If the focus is readjusted with a different positional relation, the relation between the projection distance

and the screen size is affected. In other words, a short-distance image (40 WIDE, for example) may get

out of the focus range, or a long-distance image (300 WIDE, for example) may come out of focus.

(B) Replacing 1 or 2 of the 3 LCD panels

1. In adjusting the focus after replacement of one or two LCD panels, project an image on the screen and turn

the projection lens focus ring to get the non-replaced LCD panel into focus.

2. But until the focus has been completely adjusted for the new LCD panels, be careful not to change the

distance between the set and the screen, nor to move the projection lens focus and zoom rings.

(If the distance has been changed or the projection lens readjusted, repeat the above steps 1 and 2.)

2. Adjusting the G-LCD panel

(A) Focus adjustment. (Make this adjustment on the white-only screen.)

1. Right-and-left focus adjustment (θY direction) .

Loosen the lock screws "b" and "c" and insert the eccentric screwdriver into the notch and hole "b". Turn

the screwdriver until the right and left halves on the screen get into focus.

First get the right and left halves in balance. Then improve the accuracy while making the adjustment 2

below.

2. Top-center-bottom focus adjustment (θX and Z directions).

Loosen the lock screws "a" and "c" and insert the eccentric screwdriver into the notch and hole "a" or "c".

Turn the screwdriver until the top, center and bottom on the screen get into focus. In adjusting this top-tobottom focus, temporarily tighten the lock screw "b" to fix the θY direction adjustment.

3. Repeat the above steps 1 and 2 to finely adjust the focus. Finally tighten up all the lock screws.

Notes :

1 Carefully proceed with the focus adjustment because the adjusting directions are correlated.

2 In adjusting the conv ergence and f ocus , do not mo ve the projection lens z oom and f ocus rings until the end

of all the adjustments.

(B) Convergence adjustment

» The G-LCD panel has no convergence adjustment mechanism. Use this panel as convergence adjustment

reference.

3. B-LCD panel adjustment (the same for the R-LCD panel)

(A) Focus adjustment

» Take the same procedure as for the G-LCD panel focus adjustment. Note that the adjustment range is small

in the Z direction. If the con v ergence is quite diff erent between the B-LCD and G-LCD panels , roughly adjust

the convergence first and then the focus.

(B) Convergence adjustment

» Use a crosshatch pattern signal for this adjustment.

Make the adjustment just for the G-color and the relevant color.

(1) Loosen the convergence lock screw "d".

(2) With the G-LCD panel’s screen center as ref erence, adjust the B-LCD panel in the X, Y and θZ directions.

(3) Finally tighten up the convergence lock screw "d".

21

Page 22

XG-P25X

Notes :

1 The eccentric cam is used for convergence adjustment. This means that the cam’s turning and the linear

movement are not always uniform.

2 This model is not equipped with the LCD image adjustment mechanism. This is because the dichroic prism

is used for image formation. When the LCD panels all get into the best focus, the images are almost

completely converged.

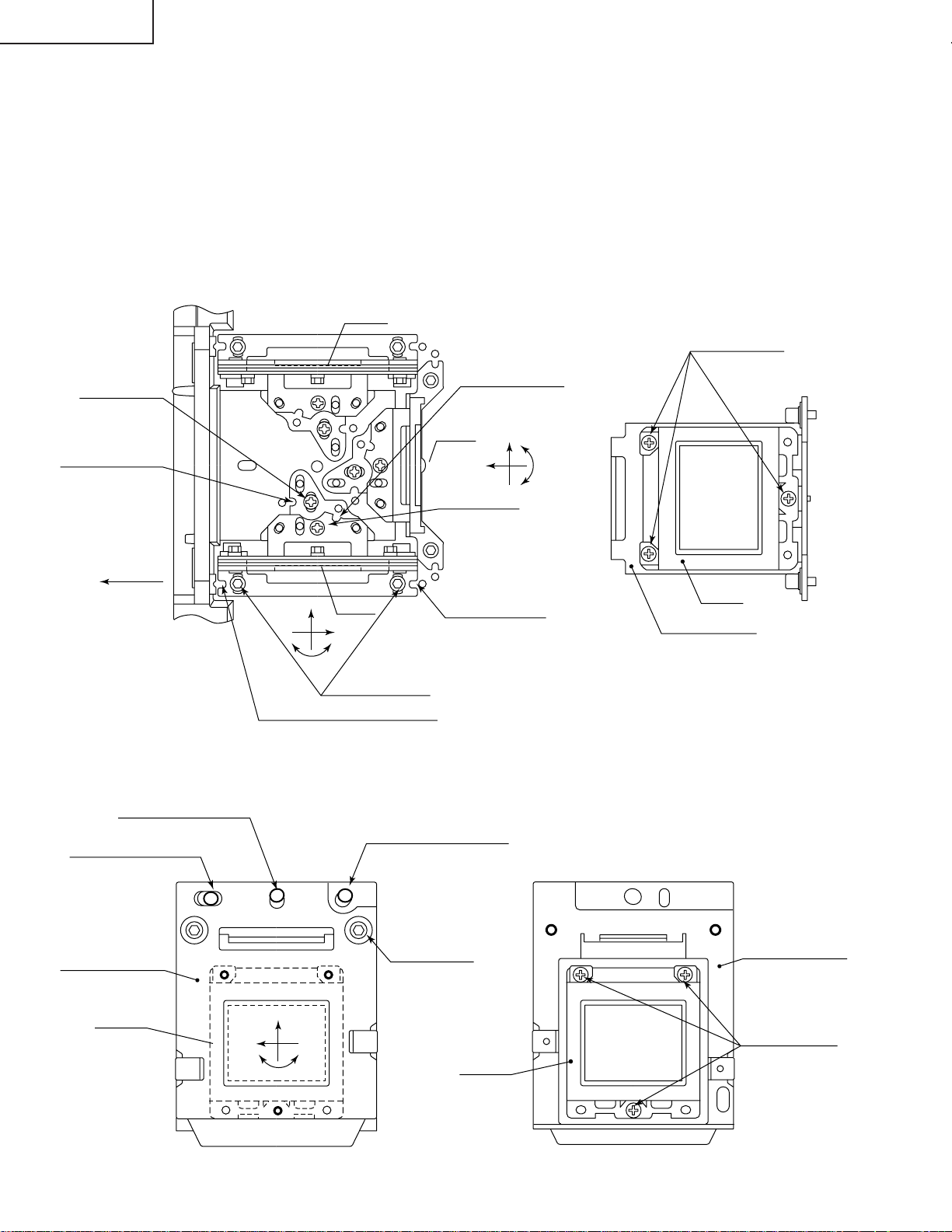

Convergence and Focus Adjustments Mechanism

TOP VIEW

Lock screw "a"

Notch and hole "a"

(Use an eccentric

screwdriver.)

FRONT

R-LCD

B-LCD

Z

X

θY

Lock screws "c"

Notch and hole "c"

(Use an eccentric screwdriver.)

Notch and hole "b"

(Use an eccentric

screwdriver.)

G-LCD

Lock screw "b"

(θY direction)

Notch and

hole "c"

(Use on eccentric

screwdriver.)

X

Z

SIDE VIEW

G-LCD panel

mounting screws

θY

G-LCD

G adjusting plate

SIDE VIEW (from inside)

Eccentric cam

(X direction adjustment)

Eccentric cam

(Y direction adjustment)

R•B adjusting plate

R•B-LCD

SIDE VIEW (from outside)

Eccentric cam

(θZ direction adjustment)

Lock screw "d"

(convergence

adjustment)

Y

X

θZ

R•B-LCD

R•B adjusting plate

R•B-LCD panel

mounting screws

22

Page 23

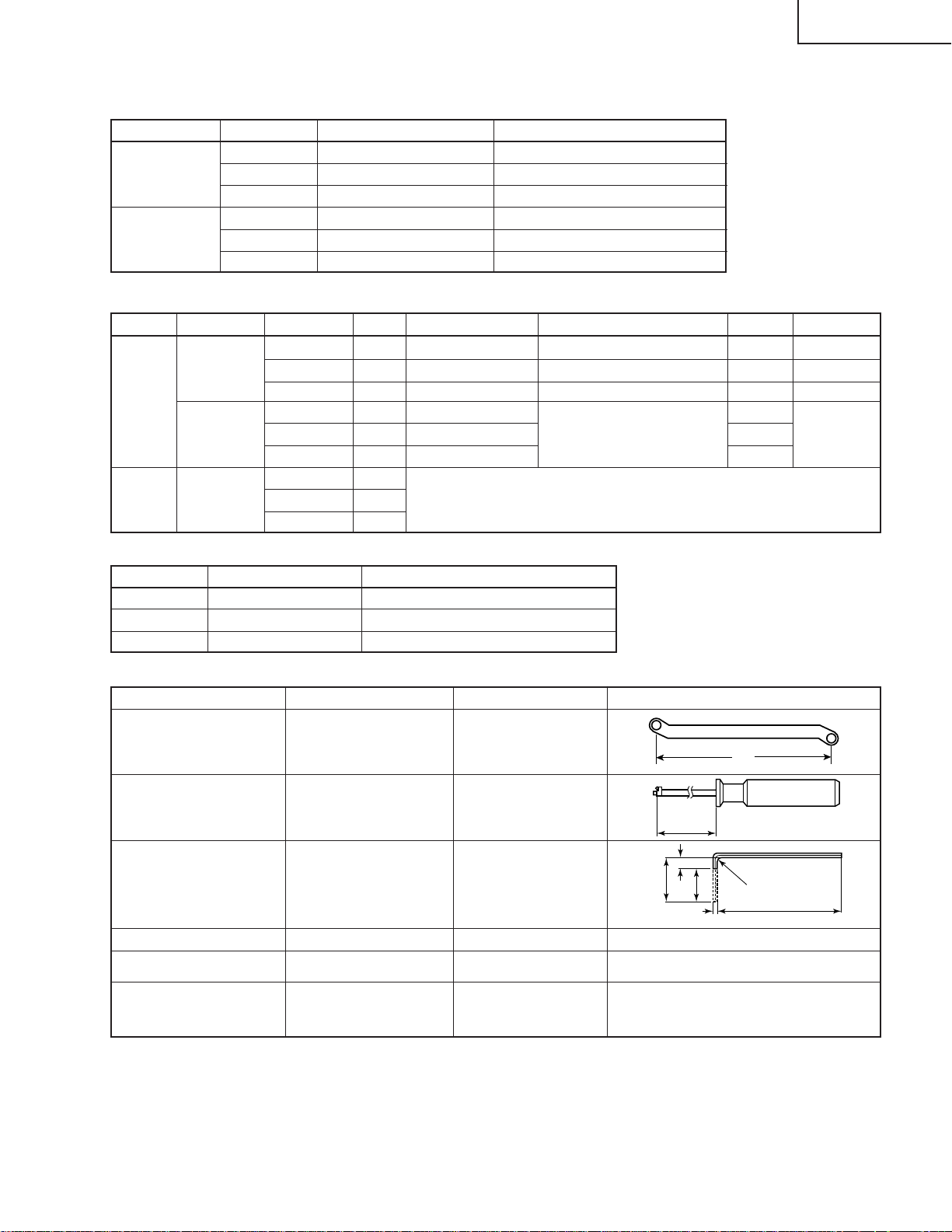

Convergence and Focus Adjustments at a Glance

2

5

16

R2

50

CUT

Adjustment directions

Adjustment Direction Definition Direction of LCD panel

X direction LCD right and left

Convergence Y direction LCD top and bottom

θZ direction Rotation around Z axis LCD turning axis

Z direction LCD optical axis

Focus θX direction Rotation around X axis LCD top-to-bottom flapping

θY direction Rotation around Y axis LCD right-to-left flapping

Convergence and Focus Adjustment for the Optical Mechanism

XG-P25X

Color Adjustment Direction

X direction ±0.8mm Eccentric cam Eccentric cam adjusting wrench d Hex wrench

Convergence Y direction ±0.8mm Eccentric cam Eccentric cam adjusting wrench d Hex wrench

R/B θZ direction ±1° Eccentric cam Eccentric cam adjusting wrench d Hex wrench

colors Z direction ±0.8mm

Focus θX direction ±1°

θY direction ±1°

Z direction ±0.2mm

G color Focus θX direction ±1° Same as for R and B colors

θY direction ±1°

Movement

Position Adjusting tool

Notch and hole "a" & "c"

Notch and hole "a" & "c"

Notch and hole "b" & "c"

Eccentric screwdriver, a, c

Lock screw

a, c

b, c

Tightening tool

Phillips

screwdriver,

*Hex wrench

Focus Adjustments the Other Way

Lock screw Position Related direction

a Notch and hole "a" Z and θX directions

b Notch and hole "b" θY direction

c Notch and hole "c" Z, θX and θY directions

Convergence and Focus Adjusting and Tightening Tools

Tool Specific or General Tool code Configuration

Eccentric cam Specific 9DASPN-XGNV1U

adjusting wrench

80

Eccentric screwdriver Specific 9EQDRiVER-NV1A

100

Hex wrench General (redesigned) 9EQLNC-XGNV1U

Phillips screwdriver General — For M2.6 pan-head machine screw

*Hex wrench General —

23

Preferably use a 70 mm or longer

screwdriver (with a handle).

Page 24

XG-P25X

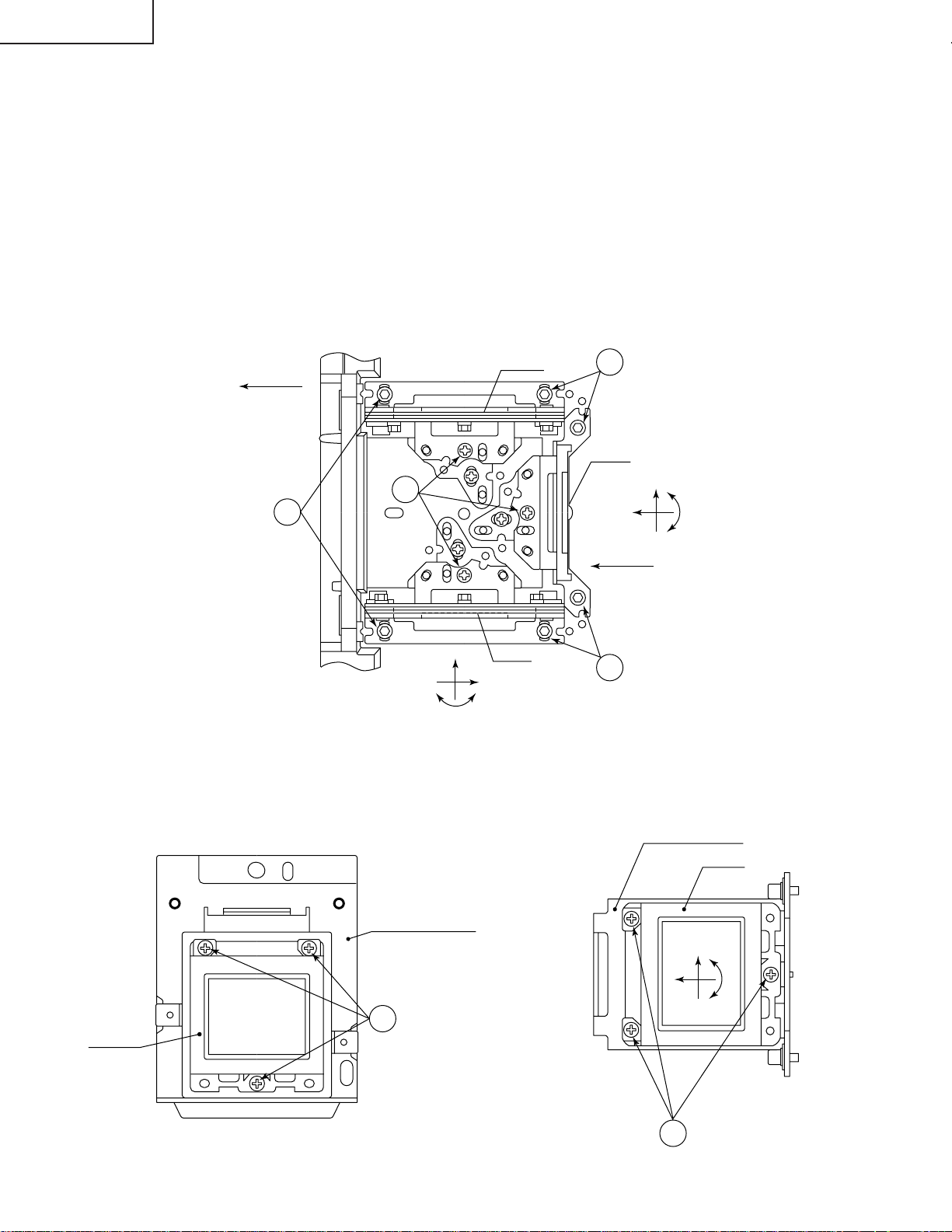

Replacing the G-LCD and B-LCD panels

With the top cabinet removed

(1)Disconnect the LCD flat cable from the output PWB connector.

(2)Remove the lock screws "b" and "c". Detach the R/B adjusting plate or the G adjusting plate together with the LCD

panel.

(3)Separate the LCD panel from the adjusting plate.

(4)Mount a new LCD panel in the reverse order of the above steps (1), (2) and (3).

~ Readjust the convergence and focus. Note that the G LCD panel needs no convergence adjustment and has

a small adjustment range in the Z direction.

TOP VIEW

Lock screws "c"

R-LCD

FRONT

2

SIDE VIEW

2

Lock

screws "c"

Lock

screws "b"

2

G-LCD

X

θY

Z

~

θY

X

B-LCD

2

Lock screws "c"

Z

SIDE VIEW

G adjusting plate

G-LCD

B-LCD

B adjusting plate

3

B-LCD panel

mounting screws

24

X

Y

G-LCD panel

3

mounting screws

θZ

Page 25

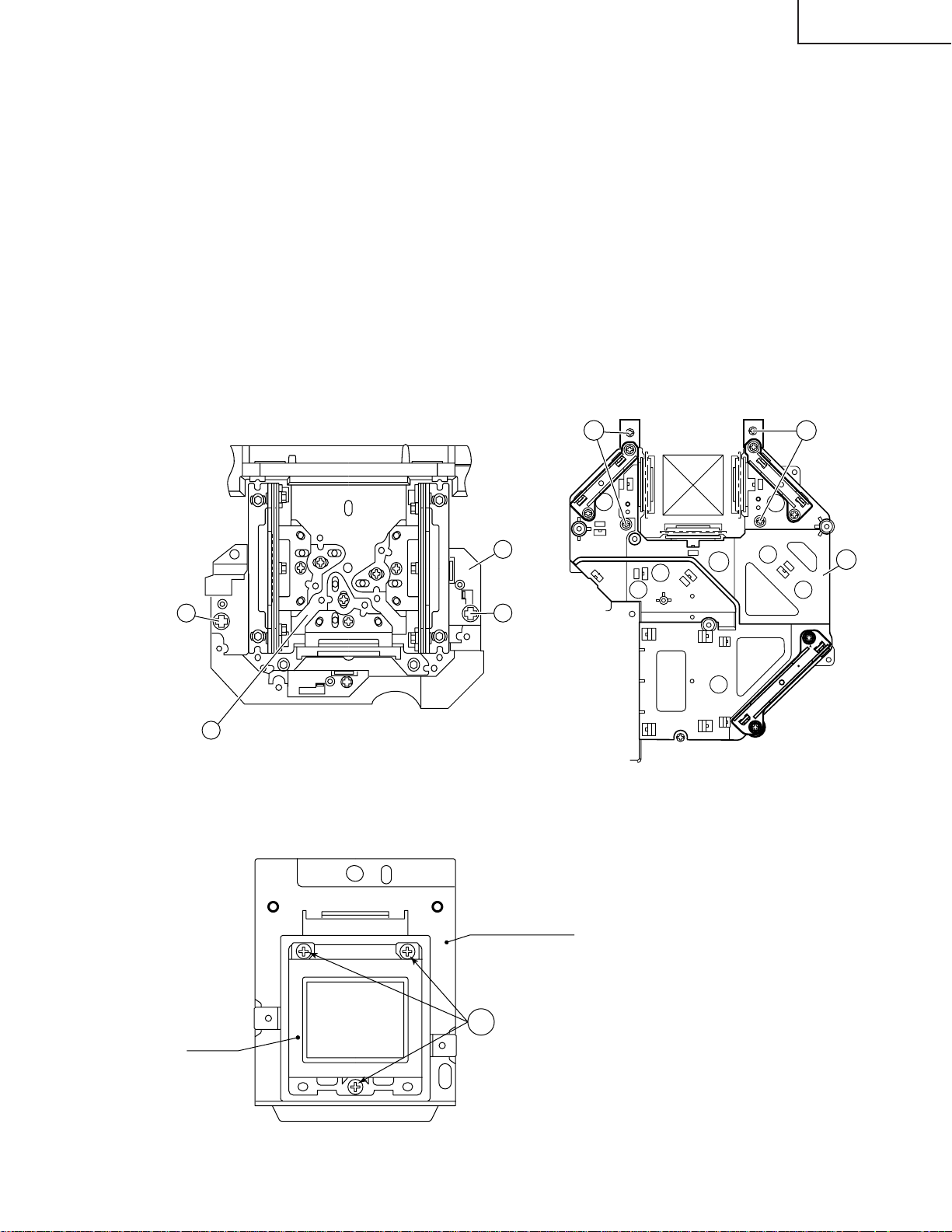

XG-P25X

Replacing the R-LCD panel

(1)Disconnect the LCD flat cable from the output PWB connector.

<Figure 1>

(2)Remove the two screws "A".

(3)Lift and detach the plate "B" together with the incident light deflection plate.

<Figure 2>

(4)Remove the four screws "C" and separate the units D and E from each other.

(5)Take the R-LCD panel out of the adjusting plate.

(6)Place and fix a new R-LCD panel in the reverse steps.

(7)Adjust the deflection plate. (See page 26).

(8)Adjust the focus and convergence. (See page 21.)

~ Readjust the convergence and focus. Note that the G LCD panel needs no convergence adjustment and has

a small adjustment range in the Z direction.

C

B

A

D

A

C

E

Fig.1

Fig.2

SIDE VIEW

R-LCD

R adjusting plate

4

R-LCD panel

mounting screws

25

Page 26

XG-P25X

Adjusting the optical axis of the mirrors (M1, M5 and M6)

The optical axis must be readjusted if an eclipse happens with the R. G or B mirrors. Generally speaking,

this adjustment is needed when any of the internal optical components has been replaced.

Adjustment procedure required when any of the panels has been replaced or the convergence has been

adjusted

(1)Disconnect the flat cables of all the LCD panels.

(2)Let the lamp light up.

(3)To adjust the G mirror, shield the R and B mirrors with shielding plates (You can use a business card or the like to

block the light).

(4)Loosen the lock screw of the M1 adjust lever.

(5)Looking at the G image on the screen, turn or slide the M1 adjust lever until the eclipse on the screen disappears.

Tighten up the screw.

(6)To adjust the R mirror, shield the G and B mirrors and adjust the M5 adjust lever. For the B mirror, shield the R and

G mirrors and adjust the M6 adjust lever.

(Take the same steps 4 and 5 above.)

(7)Remove all the shielding plates to have a white image.

Make sure there is no eclipse.

M6

Lock screws

Shielding plate B

adjust lever

slide

turn

FRONT

Shielding plate R

M5

Shielding plate G

adjust lever

Lock screws

turn

slide

26

slide

turn

M1

adjust lever

Lock screws

Page 27

XG-P25X

Adjusting the lamp duct.

Lock screws

Lamp duct

turn

Adjustment procedure reguired when the lamp has been replaced and you can see ununifomity. (Case of

Right and Left have ununifomity on the screen)

(1) Let the lamp light up.

(2) Receive the white pattern signal at 100%.

(3) Loosen the four lock screws from the lamp duct.

(4) Looking at the white image on the screen, turn the lamp duct until the uniformity comes to best point on the screen.

(5) Tighten the lock screws of the lamp duct. (Tighten torque is 10±2kg·cm)

Adjustment of incident polarizing plate.

Carry it out when removing polarizingplate.

Screw C

Notch & Hole C

Notch & Hole B

Screw A

Notch & Hole A

Screw B

(From the condition that the top cabinet opens.)

1.Remove screws, earth plate from the output PWB.

2.Extend each FFC cable of R, G, B (Using QCNW-4852CEZZ) and try so that it can move a PWB so that it can

see the part which adjusts polarizing plate from the top.

3.Turn on the power, and indicate a black screen on the screen.

<Adjusting the G-LCD incident polarizing plate.>

4.Move an output PWB so that you can see screw B and notch & hole B.

5.Put an eccentric screwdriver (9EQDRIVER-NV1A) in notch & hole B, and loosen screw B.

(Loosen it too much, and be careful that the screw doesn't come off.)

6.Adjust with the eccentric screwdriver in the place where a brightness is the lowest, and tighten screw B, and fix it

with seeing a black screen.

Adjust it with screw A and notch & hole A when adjusting incident polarizing plate of R-LCD.

Adjust it with screw C and notch & hole C when adjusting incident polarizing plate of B-LCD.

❈Adjust it in the turn of Green, Red, Blue with 3 place of RGB as well when adjusting it.

❈Be careful not to make it short-circuit when moving an output PWB.

Color adjustment

Red

Green

Blue

polarizing plate adjustment

polarizing plate adjustment

polarizing plate adjustment

Adjustment directionAmount of adjustment. Adjustment place form

θ direction ±1° Notch & Hole A

θ direction ±1° Notch & Hole B

θ direction ±1° Notch & Hole C

Ajdustment jig Fixing screw Fixed screw tool.

eccentric screwdriver

eccentric screwdriver

eccentric screwdriver

A Phillips screwdriver

B Phillips screwdriver

C Phillips screwdriver

27

Page 28

XG-P25X

ELECTRICAL ADJUSTMENT

Hook up a signal generator, or a DOSV or Mac personal computer to the projector in order to feed the

signals specified in the Adjusting conditions.

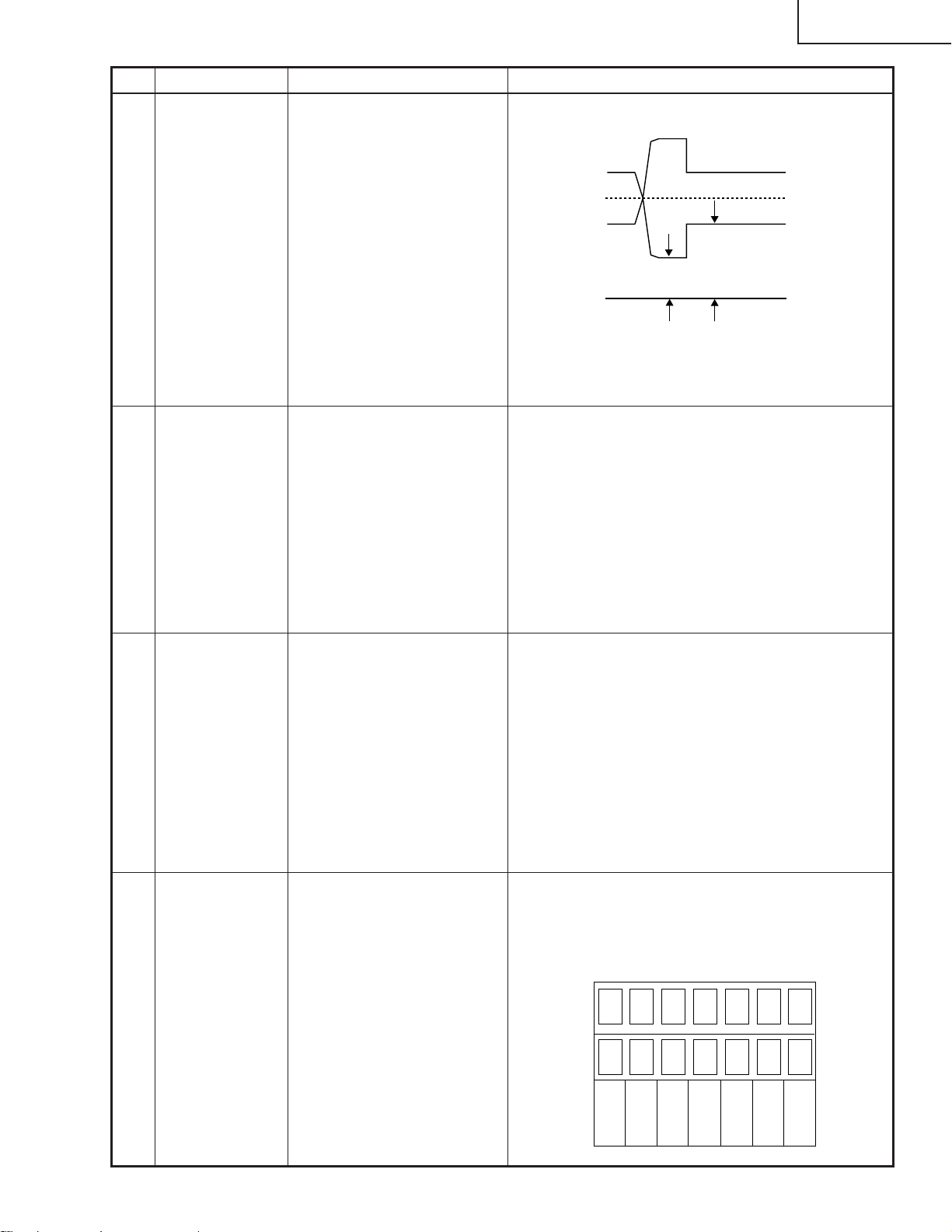

No. Adjusting point Adjusting conditions Adjusting procedure

1 EEPROM

initialization

1. Turn on the power (make

sure the lamp lights up) and

warm up the unit for 15 minutes.

» Make the following settings:

Press S2601 to call up the process mode and

execute S2 and S4 in the SSS menu. Now the

system, with the PC I/F unit not included, is

initialized. Do not execute S1 because otherwise

the PC board will be initialized.

To adjust the PC I/F unit, follow the instruction in

"Adjusting the PC Interface". (See page 34)

2 R drive 1. Make the following choice.

Group : A/D

2. F eed the 100% red-only signal. Make the following

choice.

Group : A/D

Subject : R-D

3 B drive 1. Feed the 100% blue-only

signal. Make the following

choice.

Group : A/D

Subject : B-D

4 G drive 1. Feed the 100% green-only

signal. Make the following

choice.

Group : A/D

Subject : G-D

» Using the control switches or the remote controller

buttons, adjust the data so that the signal becomes bit-less (noise).

» Using the control switches or the remote controller

buttons, adjust the data so that the signal becomes bit-less (noise).

» Using the control switches or the remote controller

buttons, adjust the data so that the signal becomes bit-less (noise).

5 RGB 1 system

black level

signal amplitude

(odd-numbered)

1. Make the following choice:

Group : OUTPUT 1

Subject : G1-BLK

G1-GAIN

For green, choose the subjects R1-BLK and R1GAIN.

For blue, choose the subjects B1-BLK and B1-GAIN.

2. Connect the oscilloscope to

TP1101 for red

TP1201 for green

TP1301 for blue

» Choose the subject G1-GAIN and adjust the sig-

nal amplitude to 3.8 ±0.05 Vp-p using the control

switches or the remote controller buttons.

» Next, choose the subject G-BLK and adjust the

white peak level to 2.1Vp-p ±0.1V.

2.1Vp-p

» Make the same adjustments for green and blue.

3.8Vp-p

28

Page 29

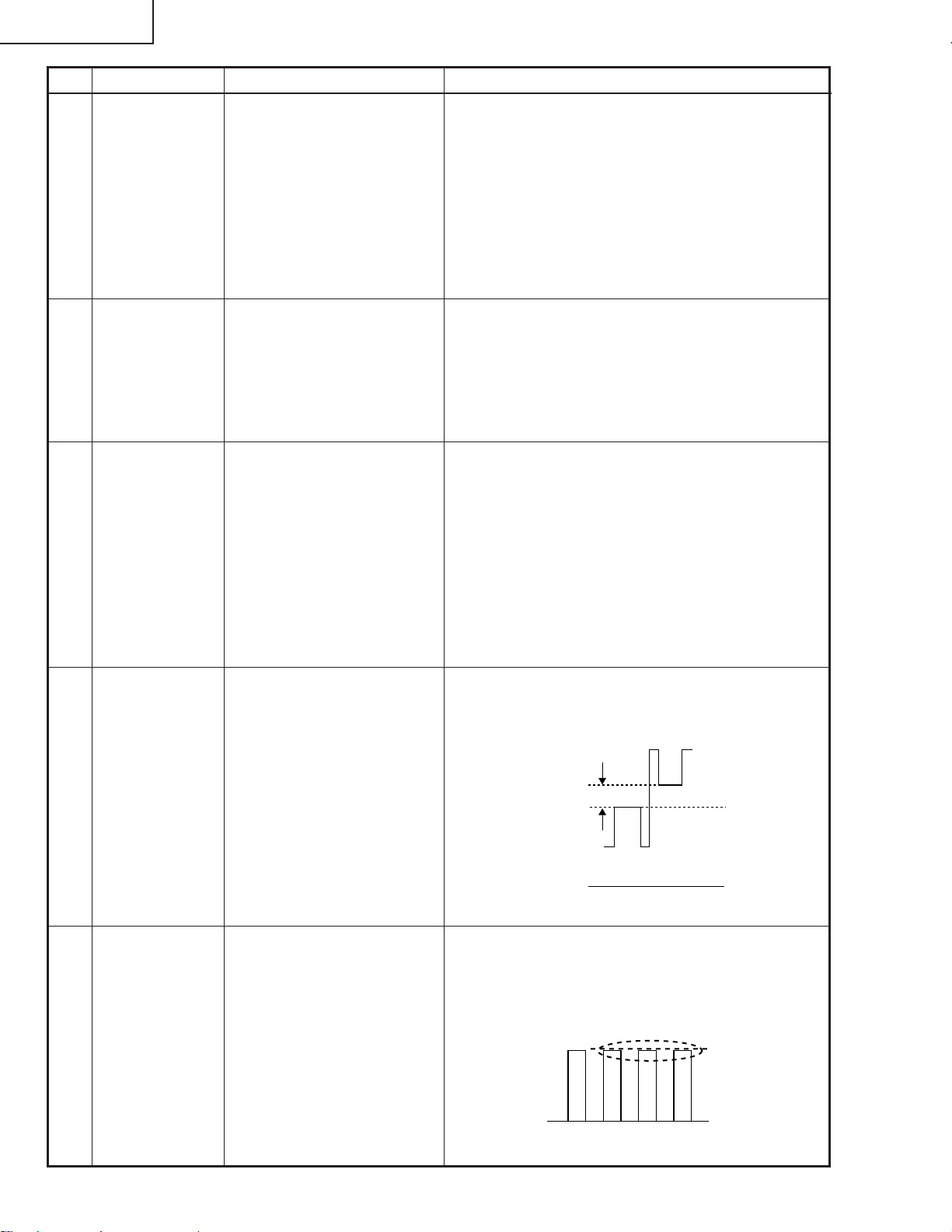

No. Adjusting point Adjusting conditions Adjusting procedure

XG-P25X

6 P SIGNAL 1. Connect the oscilloscope to

TP1102 for red.

2. Make the following choice:

Group : OUTPUT 2

Subject : PSIG-H

: PSIG-L

7 Sample-and-

hold pulse

phase

RCK-PHASE

GCK-PHASE

BCK-PHASE

1. Feed the XGA mode 75-Hz

black signal.

2. Make the following choice:

Group : OUTPUT 3

Subject : SH-PHASE

(Have the standard le vel at

8.)

Fix the GCK-PHASE settings all to 6.

» Adjust the PSIG waveform to the one shown below.

PSIG

2.5V DC 5.0V DC

(Adjust with PSIG-L.)(Adjust with PSIG-H.)

GND

» For the green and blue colors, mak e sure their wa ve-

forms are similar to that of the red color.

» Using the control switches or the remote controller

buttons, make sure that the “OUTPUT 3” characters are not blurry and there is no ghost image. If

such blur or ghost occurs, finely adjust the setting

in the range of 7~9.

8 RGB counter-

voltage

adjustment

9 RGB gradation

regeneration

adjustment

1. Feed the black-and-red

(25%) stripe signal (XGA).

2. Make the following choice:

Group : OUTPUT 3

Subject : RC (R)

: BC (B)

: GC (G)

1. Feed the INFO COM. gray

scale and color bar pattern.

2. Make the following choice:

Group : OUTPUT 1

Subject : G1-BLK

» Using the control switches or the remote controller

buttons, adjust the data in order to minimize the

flicker.

» Make the same adjustment for BC (B) and GC (G).

» See if the image is equally adjusted at the center

and both sides of the screen. If not, readjust the

setting to have the image equal at center.

» After adjusting, adjust the value of GC down 2

points (only "GC").

» Make sure that scale (white side) to No.251 and

scale (black side) to No.8 can be seen.

» If white scale can't be seen properly, readjust with

G1-BLK.

4812

249 251

29

Page 30

XG-P25X

2.2Vp-p

No. Adjusting point Adjusting conditions Adjusting procedure

10 RGB white

balance

1. Feed the 32-step g ray scale

signal (XGA 60Hz).

Group : OUTPUT 1

Subject : R1-BLK (R)

R1-GAIN(R)

B1-BLK (B)

B1-GAIN(B)

» Adjust the R1-BLK and B1-BLK data for the black

balance on the gray scale. Then adjust the R1GAIN and B1-GAIN data for the center-to-white

balance on the gray scale.

(Adjust to the best point.)

11 Horizontal

center

12 Video

brightness

adjustment

13 Video picture

adjustment

1. Feed the NTSC monoscope pattern signal.

2. Group : VIDEO 1

Subject : NTSC-H

1. Feed the baseband (0 step

gray scale :0% Black to

100% White) signal.

Group : VIDEO 1

Subject : BRIGHT

2. Press the control switch or

the remote control’s mute

button (to set the gamma

correction to the process

setting).

1. F eed the split color bar signal.

Group : VIDEO 1

Subject : PICTURE

» Using the control switches or the remote controller

buttons, adjust the data to have the same

overscan.

» Using the control switches or the remote controller

buttons, adjust the setting until the blac k signal (0%)

becomes bit-less.

» Using the control switches or the remote controller

buttons, adjust the white to white (100%) level

difference to 2.2 ± 0.05 Vp-p.

14 Tint

2. Connect the oscilloscope

between pin TP1201and

GND.

1. Feed the split color bar signal.

Group : VIDEO 1

Subject : TINT

2. Connect the oscilloscope to

TP1301.

» Using the control switches or the remote controller

buttons. Adjust the setting so that the points indicated in the waveform figure are at the same level.

SAME LEVEL

30

Page 31

No. Adjusting point Adjusting conditions Adjusting procedure

100% White Red

100% White Red

XG-P25X

15 NTSC color

saturation level

16 PAL color

saturation level

1. Feed the split color bar signal.

Group : VIDEO 1

Subject : N-COLOR

2. Connect the oscilloscope to

TP1101.

1. Feed the PAL color bar signal.

Group : VIDEO 1

Subject : P-COLOR

2. Connect the oscilloscope to

TP1101.

» Using the control switches or the remote controller

buttons, adjust the difference betw een the 100%

white portion and the red portion to 0.30 ±0.02 Vp-p.

(same as 100% white)

» Using the control switches or the remote controller

buttons, adjust the difference betw een the 100%

white portion and the red portion to 0.35 ±0.02 Vp-p.

100% White Red

17 SECAM color

saturation level

18 Video white

balance

19 DVD Brightness 1. Feed the color bar signal of

1. Feed the SECAM color bar

signal.

Group : VIDEO 1

Subject : S-COLOR

2. Connect the oscilloscope to

TP1101.

1. Feed the NTSC monoscope pattern signal

Group : VIDEO 2

Subject : R1-BLK

B1-BLK

the 480I component signal

to the BNC G(Y) input terminal.

» Using the control switches or the remote controller

buttons, adjust the data to have a level difference

of 0.35 ±0.02 Vp-p between the 100% white

portion and the red portion.

» Using the control switches or the remote controller

buttons, adjust so that the entire screen looks

evenly colorless.

» Using the control switches or the remote controller

buttons, adjust the setting until the black signal

(0%) becomes bit-less.

2. Select the follo wing subject.

Group : DVD

Subject : BRIGHT

31

Page 32

XG-P25X

100% White Red

No. Adjusting point Adjusting conditions Adjusting procedure

20 DVD Contrast 1. Feed the color bar signal of

the 480I component signal

to the BNC G(Y) input terminal.

2. Select the follo wing subject.

Group : DVD

Subject : CONTRAST

21 DVD Tint 1. Feed the color bar signal of

the 480I component signal

to the BNC Y , Pb and Pr input terminals. Feed the

sync signal only for the Y

signal.

2. Select the follo wing subject.

Group : DVD

Subject : TINT

3. Connect the oscilloscope to

TP1301.

» Using the control switches or the remote controller

buttons, adjust the setting until the white signal

(100%) becomes bit-less.

» After adjusting, adjust the value of "CONTRAST"

down 2 points.

» Using the control switches or the remote controller

buttons. Adjust the setting so that the points indicated in the waveform figure are at the same level.

SAME LEVEL

22 DVD Color 1. Feed the color bar signal of

the 480I component signal

to the BNC G(Y) input terminal.

2. Select the f ollo wing subject.

Group : DVD

Subject : COLOR

3. Connect the oscilloscope to

TP1101.

23 DVD White

balance

24 Checking and

readjustment of

white balance

1. Feed the NTSC monoscope signal to G(Y) input

terminal of the BNC terminal.

2. Select the follo wing subject.

Group : DVD

Subject : R1-BLK

B1-BLK

1.The adjustment condition of

each item is as mentioned

in the following.

RGB input:Refer to No.11

VIDEO input:Refer to No .19

DVD input:Refer to No.23

» Adjust the level difference between the 100% white

and red portions to 0.25 ±0.02 Vp-p.

» Adjust so that a white balance may become the best

condition by using the control switch or buttons of

the R/C.

» Make sure that a white balance is the best condi-

tion.

32

Page 33

No. Adjusting point Adjusting conditions Adjusting procedure

XG-P25X

25 Color system

performance

check

26 Video system

performance

check

27 Audio system

performance

check

28 RGB

performance

check

29 Off-timer

performance

check

30 Thermistor

performance

check

1. Receive the color bar signal.

1. Receive the monoscope

pattern signal.

» In the process mode and select L1. Check the color

and tint.

» In the process mode and select L2. Check the pic-

ture, brightness and sharpness.

» In the process mode nad select L3. Check the bass,

treble and balance.

1. Receive the RGB signal. » In the process mode and select L4. Check the pic-

ture, brightness, red, blue, clock, phase, hor izontal

position, and vertical position.

» In the process mode and select OFF. Make sure that

the off-timer starts with “5” (minutes), counts down

each minute in 1 second, and turns off the set at “0”.

1. Heat the thermistor using a

» Make sure the “TEMP” is displayed.

dryer.

31 Automatic

synchronization

32 Keystone

correction

performance

check

1. Receive the PHASE check

pattern signal.

Group; SSS

» Call the VGA/S-VGA/XGA mode and make sure

that the clock, phase, horizontal and vertical

positions can be automatically adjusted.

» Make sure the keystone correction functions well.

» Make the following settings.33 Factory settings 1. Select the follo wing subject.

Process

adjustment

S4 "Factory setting 4" for USA and Canada

S3

Remote controller setting

"Factory setting 3" for Europe, Austraia

and Hong Kong

33

Page 34

XG-P25X

ADJUSTING THE PC INTERFACE (CPCi-0054CE11. PC I/F Unit)

1.The initialization of the set.

1) Press the S2601 switch to go to the process mode.

2) Perform S1 of the SSS menu. (S1 initializes only a PC I/F unit. Don’t perform S2 because adjustment data except

for the PC board are initialized.

3) Make sure that version of the SPECIAL program (VER.XXX) of the menu is the latest.

2.Adjusting the level.

2-1. Setting the oscilloscope

Set the range to DC 1 V/div and 5µ/div.

2-2. Connecting the PC Interface

1) Connect the cable between the ANALOG OUTPUT (PC computer) and the DSUB connector (INPUT1 of the

proejctor).

2) Set the PC computer in the XGA mode (1024 x 768, 60 Hz, 32-step scale). Adjust the output amplitude to 700

mVp-p (terminated with 75 ohms) for the black-to-white portions.

3) Turn on the power.

2-3. Adjusting and checking the level

1) Press the S2601 switch to go to the process mode.

2) Set the SH-PHASE on the OUTPUT3 menu to 8. (Make the characters on screen clear and crisp.)

3) Adjust black level of red signal with R-BRIGHT of the A/D in a place to become bit less condition, and 4 points

adds.

4) Adjust black level of blue signal with B-BRIGHT of the A/D in a place to become bit less condition, and 3 points

adds.

5) Adjust black level of g reen signal with G-BRIGHT of the A/D in a place to become bit less condition, and 4 points

adds.

2-4. Adjusting the DTV

1) Set the switch to the BNC input terminal of INPUT1

2) Set up a signal generator in 1080i 60Hz mode white signal.Output amplitude makes space between black - white

700mVp-p (75ohm terminated) .

3) Connect the analog output terminal of the signal generator and BNC connector (the INPUT1 terminal of projector)

with the cable.

4) Make G-BRIGHT of DTV the numerical value which is (G-BRIGHT of A/D) 2 points adds.

5) After adjusting the CB-OFFSET and CR-OFFSET, set to 16.

6) Press the S2601, to comes out of the process mode.

Servicing precautions

(1) If the convergence gets out of spec in servicing the set, call the process mode and select the following group

and subjects.

Group: NOKO

Subject: R-CNV-H, R-CNV-V

G-CNV-H, G-CNV-V

B-CNV-H, B-CNV-V

(H and V are for horizontal and vertical adjustments, respectively.)

Adjust the above settings to the range of 0 to 4.

(2) When entering the process mode, select the following group and subjects too.

Group: VIDEO1

Subject: SET-UP B

SET-UP C

Make sure the SET-UP B and SET-UP C settings are 10 and 2, respectively. To exit from the process mode,

be sure to take either of the following ways: Go to the subject SET-UP 1 and quit the mode, or select Group:

SSS and Subject: S4 and quit the mode.

34

Page 35

ADJUSTMENT PROCESS MENU LIST

P25X( )

A/D

OUTPUT1

OUTPUT2

DTV

OUTPUT3

VIDEO1

VIDEO2

DVD

NOKO

LINE

SSS

PATTERN

CVIC

LENS

SPECIAL

XG-P25X

A/D

R-BRIGHT 45

G-BRIGHT 45

B-BRIGHT 45

R-D 83

B-D 83

G-D 83

DTV

G-BRIGHT 45

CB-OFFSET 16

CR-OFFSET 16

VIDEO2

R1-BLK 90

B1-BLK 90

PEAK FIL 2

PEAK GAIN 3

N358 DLY 4

PAL DLY 5

SECAM DLY 0

]

OUTPUT1

R1-BLK 92

R1-GAIN 143

G1-BLK 90

G1-GAIN 145

B1-BLK 90

B1-GAIN 145

OUTPUT3

RC 127

GC 125

BC 131

SH-PHASE 8

GCK-PHASE 8

DVD

CONTRAST 22

BRIGHT 196

TINT 32

COLOR 21

R1-BLK 90

B1-BLK 90

Each menu list

OUTPUT2

PSIG-H 80

PSIG-L 170

R2-BLK 128

G2-BLK 128

B2-BLK 128

VIDEO

NTSC-H 2

PICTURE 45

BRIGHT 128

TINT 130

N-COLOR 108

P-COLOR 107

S-COLOR 110

SET UP 0

SET UP 10

SET UP 1

NOKO

NOKO-LH OFF

NOKO-RL OFF

CC 00

R-CNV-H 2

G-CNV-H 2

B-CNV-H 2

R-CNV-V 2

G-CNV-V 2

B-CNV-V 2

LINE

L1

L2

L3

L4

OFF

TEMP OFF

SENSER CHECK

ID CHECK

CIVIC

PROGRESSIVE

ENHANCE-VIDE

ENHANCE-HDTV

ENHANCE-RGB

SCREEN

IDC

SSS

TIME

S1

S2

S3

S4

S5

LAMP

LENS

LENS AUTO

LENS TOP

LENS BOTTOM

PATTERN

RGB 1

RGB(50) 2

CROSS 1

STEP

COLOR

CHR 1

SPECIAL

IPL

E2PROM

ADR RD/WR

PRG VER.0223

OSD VER.0215

SUB VER.S0201b

CIVIC VER.0216

35

Page 36

XG-P25X

TROUBLE SHOOTING TABLE

Checking the PWB performance

Video input in trouble

Go to "Checking the video unit

circuit".

RGB input in trouble

Feed test pattern signal from

PC.

Is specified cable connected

between PC and projector?

Yes

Is supply voltage as specified?

Yes

Does image appear?

Yes

Through-output in trouble

Through-output circuit in

trouble.

No

Use specified cable.

No

Power circuit in trouble.

No

Check the connectors, starting

from the PC input circuit.

Remote control in trouble

Go to "Checking the remote

control".

Check the PC I/F unit.

36

Page 37

TROUBLE SHOOTING TABLE (Continued)

Checking the video system

XG-P25X

Is the lamp on?

Is specified voltage fed to EA

connectors?

Are there signal inputs at pins (9),

(19) and (21) of SC401?

Are there signal outputs at pins

(1),(12) and (14) of SC4303?

Yes

Check SC4303,P4303 and

their peripheral circuits.

(Go to "Checking the output

PWB unit".)

No

Yes

No

Yes

No

Yes

No

Check IC4311, IC4502,

IC4501and their peripheral

circuits.

Go to "Lamp fails to light-up".

Check the power circuit and its parts.

Are there signals at pin (7) of IC5555?

No

Check the IC5555 and its

peripheral circuits.

Checking the video unit circuit

Is there video signal output at P401

pin (9).

Yes

Is there video signal input at pins

(76) and (88) of IC4502?

Yes

Are there signal outputs at pins (83)

and (84) of IC4502?

Yes

Check the buffer circuits of Q4503

thru Q4504. Is the signal as

specified?

Yes

Check IC4501,IC4311and their

peripheral circuits.

(Go to "Checking the output

PWB unit".)

No

Check the IC5555 selector switch,

terminal voltage and input circuit.

No

Check the low-pass and buffer

circuits of Q4501,Q4502,and

Q4508,Q4509.

No

Check IC4502,IC4503 and their

peripheral circuits (bias).

No

Check Q4503 thru Q4504 and their

peripheral circuits.

37

Page 38

XG-P25X

TROUBLE SHOOTING TABLE (Continued)

Checking RGB signal output circuit

Are there RGB input waveforms at

pins (1), (3) and (5) of IC4301?

Yes

Are there output waveforms at pins

(16), (18), (20) of IC4301?

Yes

Check SC4301,P4301 and their

peripheral circuits.

Go to"Checking the output PWB unit".

No

Check the IC3302 of input unit

and its peripheral circuits.

No

Check the IC4301 selector switch,

terminal voltage and peripheral

circuits.

Checking the 480P, 720P signals.

Are there signal inputs at pins (8),

(10) and (12) of SC4301?

Yes

Are there output waveforms at pins

(16) (18) (20) of IC4301 (RGB signal)?

Yes

Check SC4301,P4301 and their

peripheral circuits.

Go to "Checking the output PWB

No

Go to "Checking the signal unit

circuit". (signal unit-3/3)

No

Check the IC4301 selector switch

terminal voltage and peripheral circuits?

38

Page 39

TROUBLE SHOOTING TABLE (Continued)

No or unusual Y signal

XG-P25X

Is there Y signal input at pin (84) of

IC4502?

Yes

Is there Y signal output at pin (7) of

IC4501?

Yes

Is there Y signal output at pin (5) of

IC4311?

Yes

Check SC4303 and its peripheral

circuits.

No

Check IC4502 and its peripheral

circuits.

No

Check IC4501 and its peripheral

circuits.

No

Check IC4311 and its peripheral

circuits.

39

Page 40

XG-P25X

TROUBLE SHOOTING TABLE (Continued)

Checking the output PWB unit

If there is no signal at P4302,

P4303 and P4301, go to

"Checking the video system".

Are there signal inputs at

SC8405, SC8502, SC8404?

Are voltages applied to EA

connectors?

Yes

Are there signal outputs at

pins (18) (16) (14) of IC1401?

Yes

Are there signal inputs at

pin(44) and (47) of IC1101,

IC1102, IC1201, IC1202,

IC1301 and IC1302?

Yes

Are there signal outputs at pins

(17), (19), (21), (28), (30) and

(32) of IC1101, IC1102,

IC1201, IC1202, IC1301 and

IC1302?

Yes

NoNo

If there is no signal at EA

connector or SC8404, SC8405

and SC8502, go to Checking

the power unitblock.

No

Check IC1401,Q1401,Q1402,

Q1403 and their peripheral

circuits.

No

Check IC2102, IC2202,

IC2302 and their peripheral

circuits.

No

Check IC1101,IC1201,IC1301

and their peripheral circuits.

If there is no signal input at

pins (1) and (31) of SC1101,

SC1102 and SC1103, check

the switching circuit and

amplifier circuit of IC1101,

IC1201, IC1301, IC1102,

IC1202, IC1302 and their

peripheral circuits.

No

Are there signal inputs at

SC1101, SC1201 and

SC1301?

Check the R, G and B panels.

Yes

Yes

No

If there is no signal input at

pins (15) and (30) of

SC1101, SC1102 and

SC1103, check IC1001,

IC1004 and their

peripheral circuits.

Check IC1558, IC1559,

IC1551~IC1556 and their

peripheral circuits.

40

Page 41

TROUBLE SHOOTING TABLE (Continued)

No audio output

XG-P25X

Are there audio signal inputs at pins

(2) and (23) of IC331?

Are there audio signal outputs at pins

(1) and (2) of P301?

Are there audio signal outputs at pin

(4)(6) of IC302?

If the voltage at pin (7) of IC302 is not

as specified, check Q7055, Q7054

and their peripheral circuits.

No

Yes

No

Yes

No

Yes

Check IC302 and its peripheral

circuits, and the SP connectors and

speakers.

Checkig the Power Unit

Check the input, the switching circuit

of IC461 ~ IC464, and their peripheral

circuit.

Check the IC331 control voltage,and

its peripheral circuits.

Check IC302 and its peripheral

circuits.

Replace.

There is no voltage output at

EA connector.

Is EA connector disconnected

or loose?

Is AC voltage (85-264V)

applied across the PA

connector?

Yes

Is TF701 broken?

Is R711 broken?

Replace R711,R713 or

Q701.

No

No

Yes

No

Yes

Yes

Reconnect the EA connector.

No

Replace F791.

No

There is a short-circuit along

the EA output line. Using a

tester, check the resistance

between each voltage line and

the ground.

41

Page 42

XG-P25X

TROUBLE SHOOTING TABLE (Continued)

Power on

Is the right input selected?

Yes

Are the PC, video and LCP cables as

specified and properly connected?

Yes

With the contrast control at maximum,

does the image appear?

No

Is the voltage at SC8502

connector as specified?

Yes

Hook up a personal computer.

Does the image appear?

No

Select the right input with remote

control.

No

Use the right cables or reconnect the

cables.

Yes

Readjust the video system.

No

Power circuit faulty.

No

Yes

Is the image as specified?

Yes

Is the image's colour as specified?

Yes

Does the on-screen display function?

Yes

Does the remote control function?

Yes

End

Go to "Checking the clock circuit and

its peripheral circuits".

No

Check the sync signal circuit and its

peripheral circuits.

No

Check the video circuit and its

peripheral circuits.

No

Go to "Checking the OSD circuit and

its peripheral circuits".

No

Go to "Checking the remote control".

42

Page 43

TROUBLE SHOOTING TABLE (Continued)

Is the lamp out of socket?

Yes

Reconnect the

lamp into socket.

No

Replace the

lamp.

Lamp fails to light-up

Turn on the power switch. Is

Yes

discharging sound heard from

the lamp?

No

Is the ballast cooling fan

running?

Yes

XG-P25X

No

Check the power circuit.

Replace the ballast.

Is DC 360V voltage applied

between PL connector pins?

Yes

Is 3.5V or higher voltage

applied between pins (1) and

(2) of ballast's D connector?

Is power EA connector

disconnected?

Yes

Reconnect the

connector into socket.

No

Yes

No

No

Check the

microcomputer circuit.

43

Page 44

XG-P25X

TROUBLE SHOOTING TABLE FOR PC I/F UNIT

Checking the PC PWB

0

Is the user menu

displayed onscreen?

NO

Check the onscreen

display.

Check the RGB input.

Check the component

input signals.

YES

Check the basic signal flow. The

component signals and video signals flow

in the same way from CVIC IC to DAC

OUT. So there is no need to check the

lines after the CVIC IC.

The component input signals flow through

the same circuitry as for the RGB input

signals. Check the SOG (Sync On Green)

circuit and the color correction circuit.

Check the video input

signals.

Check the DVI input

signals.

End.

The video input signals flow into the CVIC

IC through a different route from the RGB

input signals. Therefore check the videosignal DAC and PLL IC.

Check the DVI digital as well as analog

input signals.

44

Page 45

XG-P25X

TROUBLE SHOOTING TABLE FOR PC I/F UNIT (Continued)

Checking the RGB input

Feed the sync-pulseseparated RGB signals to the

INPUT1 or INPUT2 terminal.

1

Using the control panel key or

the remote controller, select

INPUT1 or INPUT2.

2

Does the image appear?

YES

Is the image distorted?

3

Are the R, G and B colors as

specified?

Activate the AUTOSYNC

function.

Is the image contour as

specified?

NO

YES

NO

Check the video input

signals.

YES

Check the sync signals.

NO

Check the RGB signals.

NO

YES

Is there any distortion in the

vertical stripe pattern?

NO

End.

45

YES