Page 1

XG-NV7XU

SERVICE MANUAL

S09P7XG-NV7XU

DLP PROJECTOR

MODEL

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

XG-NV7XU

CONTENTS

Page Page

• SPECIFICATIONS.............................................. 2

• IMPORTANT SERVICE SAFETY NOTES..........3

• NOTE TO SERVICE PERSONNEL....................4

• OPERATION MANUAL ...................................... 8

• REMOVING OF MAJOR PARTS ...................... 14

• RESETTING THE TOTAL LAMP TIMER .......... 19

• OPTICAL ADJUSTMENT................................. 20

• DMD AND PRINCIPLE OF

OPTICAL SYSTEM .......................................... 21

• ELECTRICAL ADJUSTMENT .......................... 24

• ADJUSTING THE PC INTERFACE .................. 30

• TROUBLE SHOOTING TABLE......................... 31

• CHASSIS LAYOUT........................................... 46

• BLOCK DIAGRAM ........................................... 48

• OVERALL WIRING DIAGRAM .........................50

• DESCRIPTION OF CONNECTOR................... 52

• DESCRIPTION OF SCHEMATIC DIAGRAM....53

• WAVEFORMS .................................................. 53

• SCHEMATIC DIAGRAM ................................... 54

• PRINTED WIRING BOARD ASSEMBLIES ....100

• PARTS LIST

Ë

ELECTRICAL PARTS ............................... 107

Ë

CABINET AND MECHANICAL PARTS.....126

Ë

ACCESSORIES PARTS ...........................132

Ë

PACKING PARTS...................................... 132

• PACKING OF THE SET..................................133

SHARP CORPORATION

DLP is the trademark of Texas Instruments, Inc., U.S.A

*

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

1

Page 2

XG-NV7XU

Specifications

2

Page 3

XG-NV7XU

2

2

IMPORTANT SERVICE SAFETY NOTES

Ë Service work should be performed only by qualified service technicians who are

thoroughly familiar with all safety checks and servicing guidelines as follows:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

BEFORE RETURNING THE PROJECTOR:

(Fire & Shock Hazard)

Before returning the projector to the user, perform

the following safety checks:

1. Inspect lead wires are not pinched between the

chassis and other metal parts of the projector.

2. Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacity networks, mechanical

insulators, etc.

3. To be sure that no shock hazard exists, check for

current leakage in the following manner:

» Plug the AC cord directly into a 120-volt AC outlet,

(Do not use an isolation transformer for this test).

» Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in parallel

between all exposed metal cabinet parts and earth

ground.

» Use an AC voltmeter with sensitivity of 5000 ohm per

volt., or higher , sensitivity to measure the AC voltage

drop across the resistor (See Diagram).

» All checks must be repeated with the AC plug

connection reversed. (If necessary, a non-polarized

adapter plug must be used only for the purpose of

completing these checks.)

Any reading of 0.3 volts RMS (this corresponds to

0.2 milliamp. A C.) or more is e xcessive and indicates

a potential shock hazard which must be corrected

before returning the unit to the owner.

AC

VOLTMETER

1.5k ohm (10W)

0.15µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO KNOWN

EARTH GROUND

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

SAFETY NOTICE

Many electrical and mechanical parts in DLP Projector

have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

components having such features are identified by “å”

and shaded areas in the Replacement Parts Lists and

Schematic Diagrams. For continued protection,

replacement parts must be identical to those used in the

original circuit. The use of a substitute replacement parts

which do not have the same safety characteristics as

the factory recommended replacement parts shown in

this service manual, may create shock, fire or other

hazards.

AVIS POUR LA SECURITE

De nombreuses pièces, électriques et mécaniques, dans

les projecteur à DLP présentent des caractéristiques

spéciales relatives à la sécurité, qui ne sont souvent

pas évidentes à vue.

Le degré de protection ne peut pas être nécessairement

augmentée en utilisant des pièces de remplacement

étalonnées pour haute tension, puissance, etc.

Les pièces de remplacement qui présentent ces

caractéristiques sont identifiées dans ce manuel;

les pièces électriques qui présentent ces particularités

sont identifiées par la marque “å” et hachurées dans la

liste des pièces de remplacement et les diagrammes

schématiques. Pour assurer la protection, ces pièces

doivent être identiques à celles utilisées dans le circuit

d’origine. L’utilisation de pièces qui n’ont pas les mêmes

caractéristiques que les pièces recommandées par

l’usine, indiquées dans ce manuel, peut provoquer des

électrocutions, incendies ou autres accidents.

WARNING: The bimetallic component has the primary

conductive side exposed. Be very careful in

handling this component when the power is on.

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

AVERTISSEMENT:La composante bimétallique dispose du

conducteur primaire dénudé. Faire

attention lors de la manipulation de cette

composante sous tension.

3

Page 4

XG-NV7XU

NOTE TO SERVICE

PERSONNEL

UV-RADIATION PRECAUTION

The light source, metal halide lamp, in the DLP

projector emits small amounts of UV-Radiation.

AVOID DIRECT EYE AND SKIN EXPOSURE.

To ensure safety please adhere to the following:

1. Be sure to wear sun-glasses when servicing the

projector with the lamp

turned “on” and the top

enclosure removed.

2. Do not operate the lamp outside of the lamp housing.

NOTE POUR LE PERSONNEL

D’ENTRETIEN

PRECAUTION POUR LES RADIATIONS UV

La source de lumière, la lampe métal halide, dans le

projecteur DLP émet de petites quantités de radiation

UV.

EVITEZ TOUTE EXPOSITION DIRECTE

DES YEUX ET DE LA PEAU.

Pour votre sécurité, nous vous prions de respecter

les points suivants:

1. Toujours porter des lunettes de soleil lors d’un

entretien du projecteur

avec la lampe allumée

et le haut du coffret retiré.

2. Ne pas faire fonctionner la lampe à l’extérieur du

boîtier de lampe.

3. Do not operate for more than 2 hours with the

enclosure removed.

UV-Radiation and Medium Pressure

Lamp Precautions

1. Be sure to disconnect the AC plug when replacing

the lamp.

2. Allow one hour for the unit to cool down before

servicing.

3. Replace only with same type lamp. Type

CLMPF0078DE01 or BQC-XGNV7XU/1 rated 85V/

120W.

4. The lamp emits small amounts of UV-Radiation, a void

direct-eye contact.

5. The medium pressure lamp involves a risk of

explosion. Be sure to follow installation instructions

described below and handle the lamp with care.

3. Ne pas faire fonctionner plus de 2 heures avec le

coffret retiré.

Précautions pour les radiations UV

et la lampe moyenne pression

1. Toujours débrancher la fiche AC lors du

remplacement de la lampe.

2. Laisser l’unité refroidir pendant une heure avant de

procéder à l’entretien.

3. Ne remplacer qu’avec une lampe du même type.

Type CLMPF0078DE01 or BQC-XGNV7XU/1,

caractéristique 85V/120W.

4. La lampe émet de petites quantités de radiation UVéviter tout contact direct avec les yeux.

5. La lampe moyenne pression implique un risque

d’explosion. Toujours suivre les instructions

d’installation décrites ci-dessous et manipuler la

lampe avec soin.

4

Page 5

XG-NV7XU

5

4

5

5

234567890123456789012345678901212345678901234

UV-RADIATION PRECAUTION (Continued)

23456789012345678901234567890121234567890123

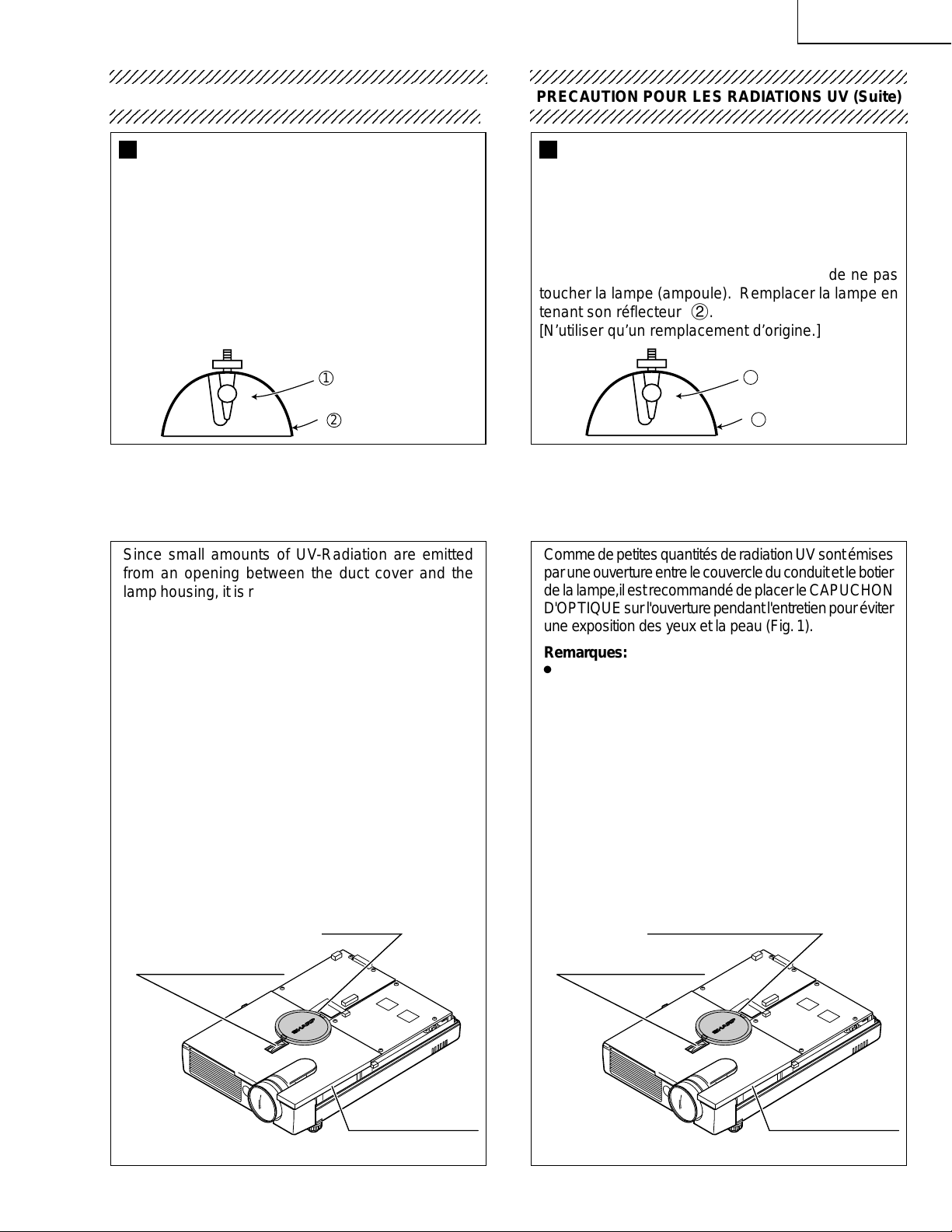

Lamp Replacement

Note:

Since the lamp reaches a very high temperature

during units operation replacement of the lamp

should be done at least one hour after the power

has been turned off. (to allow the lamp to cool off.)

Installing the new lamp, make sure not to touch the

lamp (bulb) replace the lamp by holding its reflector

2.

[Use original replacement only.]

Lamp

1

Reflector

2

DANGER ! –– Never turn the power on without the

lamp to avoid electric-shock or damage of the

devices since the stabilizer generates high voltages

at its start.

234567890123456789012345678901212345678901234

PRECAUTION POUR LES RADIATIONS UV (Suite)

234567890123456789012345678901212345678901234

Remplacement de la lampe

Remarque:

Comme la lampe devient très chaude pendant le

fonctionnement de l’unité, son remplacement ne doit

être effectué au moins une heure après avoir coupé

l’alimentation (pour permettre à la lampe de refroidir).

En installant la nouvelle lampe, s’assurer de ne pas

toucher la lampe (ampoule). Remplacer la lampe en

tenant son réflecteur 2.

[N’utiliser qu’un remplacement d’origine.]

1

Lampe

Reflecteur

2

DANGER ! –– Ne jamais mettre sous tension sans

la lampe pour éviter un choc électrique ou des

dommages des appareils car le stabilisateur génère

de hautes tensions à sa mise en route.

Since small amounts of UV-Radiation are emitted

from an opening between the duct cover and the

lamp housing, it is recommended to place the LENS

CAP on the opening during servicing to avoid eye

and skin exposure (Fig. 1).

Notes:

» The internal par ts of this model are cooled down

with the top panel tightly closed. If the power is

kept on for a long time with the top panel open, the

power may be turned off or the lamp may go out.

To avoid this during servicing, place the service

cover over the lamp and the cooling fan.

» Place the lens cap over the service cover.

» Please obtain a lens cap before servicing a model

XG-NV7XU that is received without one.

» The color wheel is running at high speed. Do not

touch it nor bring anything nearby.

COLOR WHEEL HOLE

Comme de petites quantités de radiation UV sont émises

par une ouverture entre le couvercle du conduit et le botier

de la lampe,il est recommandé de placer le CAPUCHON

D'OPTIQUE sur l'ouverture pendant l'entretien pour éviter

une exposition des yeux et la peau (Fig. 1).

Remarques:

» Les pièces internes de ce modèle sont refroidies av ec

le panneau supérieur hermétiquement fermé. S i

l'énergie électrique est maintenue pendant longtemps

avec le panneau supérieur laissé ouvert, l'énergie risque

de s'arrêter ou la lampe de s'éteindre. Pour éviter cela

lors d'un entretien, placer le couvercle de l'entretien sur

la lampe et le ventilateur de refoidissement.

» Placer le bouchon de l'objectif sur le couvercle de

l'entretien.

» Priére de se procurer un capuchon d'optique acant

d'entretien un modéle XG-NV7XU qui est livré sans.

» Le disque chromatique opère à une vitesse élevée. Ne

pas le toucher ni apporter quoi que ce soit à proximité.

CAPUCHON D'OPTIQUELENS CAP

ORIFCE DU DISQUE

CHROMATIQUE

SERVICE COVER

Figure 1. Figure 1.

(PCOVN0009CEKZ)

5

SERVICE COVER

(PCOVN0009CEKZ)

Page 6

XG-NV7XU

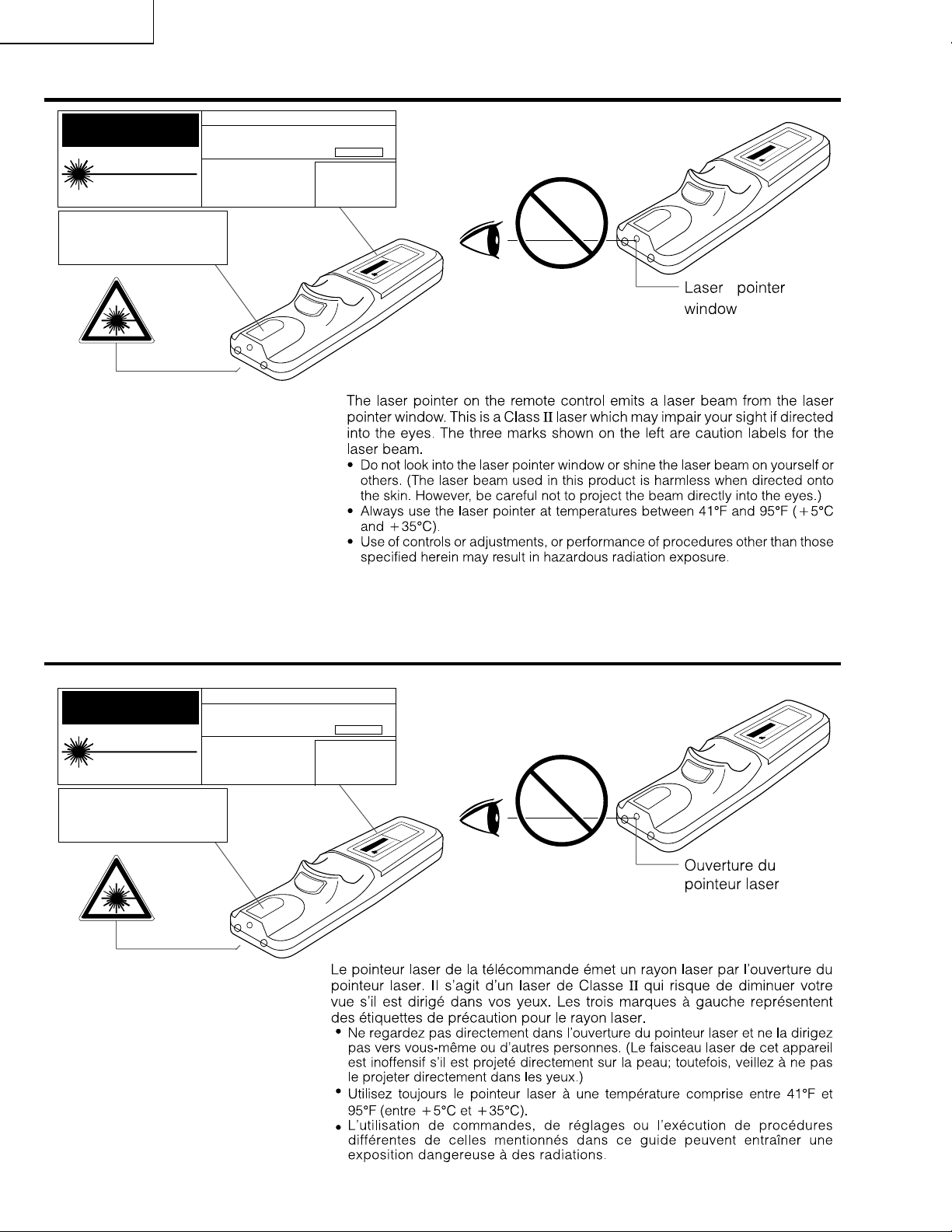

Cautions Concerning the Laser Pointer

"COMPLIES WITH 21 CFR SUBCHAPTER J"

CAUTION

LASER RADIATIONDO NOT STARE INTO BEAM

WAVE LENGTH : 650nm

MAX. OUTPUT : 1mW

CLASS II LASER PRODUCT

SHARP ELECTRONICS CORPORATION

SHARP PLAZA, MAHWAH, NEW JERSEY 07430

TEL : 1-800-BE-SHARP

REMOTE CONTROL

MODEL NO. : RRMCG1530CESA

DC3V (1.5VX2PCS.)

MADE IN CHINA

FABRIQU AU CHINE

U.S.A. ONLY

AVOID EXPOSURE

LASER

-

RADIATION IS EMITTED

FROM THIS APERTURE.

Précautions Liées au pointeur laser

"COMPLIES WITH 21 CFR SUBCHAPTER J"

CAUTION

LASER RADIATIONDO NOT STARE INTO BEAM

WAVE LENGTH : 650nm

MAX. OUTPUT : 1mW

CLASS II LASER PRODUCT

AVOID EXPOSURE

SHARP ELECTRONICS CORPORATION

SHARP PLAZA, MAHWAH, NEW JERSEY 07430

TEL : 1-800-BE-SHARP

REMOTE CONTROL

MODEL NO. : RRMCG1530CESA

DC3V (1.5VX2PCS.)

MADE IN CHINA

FABRIQU AU CHINE

LASER

-

RADIATION IS EMITTED

FROM THIS APERTURE.

U.S.A. ONLY

6

Page 7

XG-NV7XU

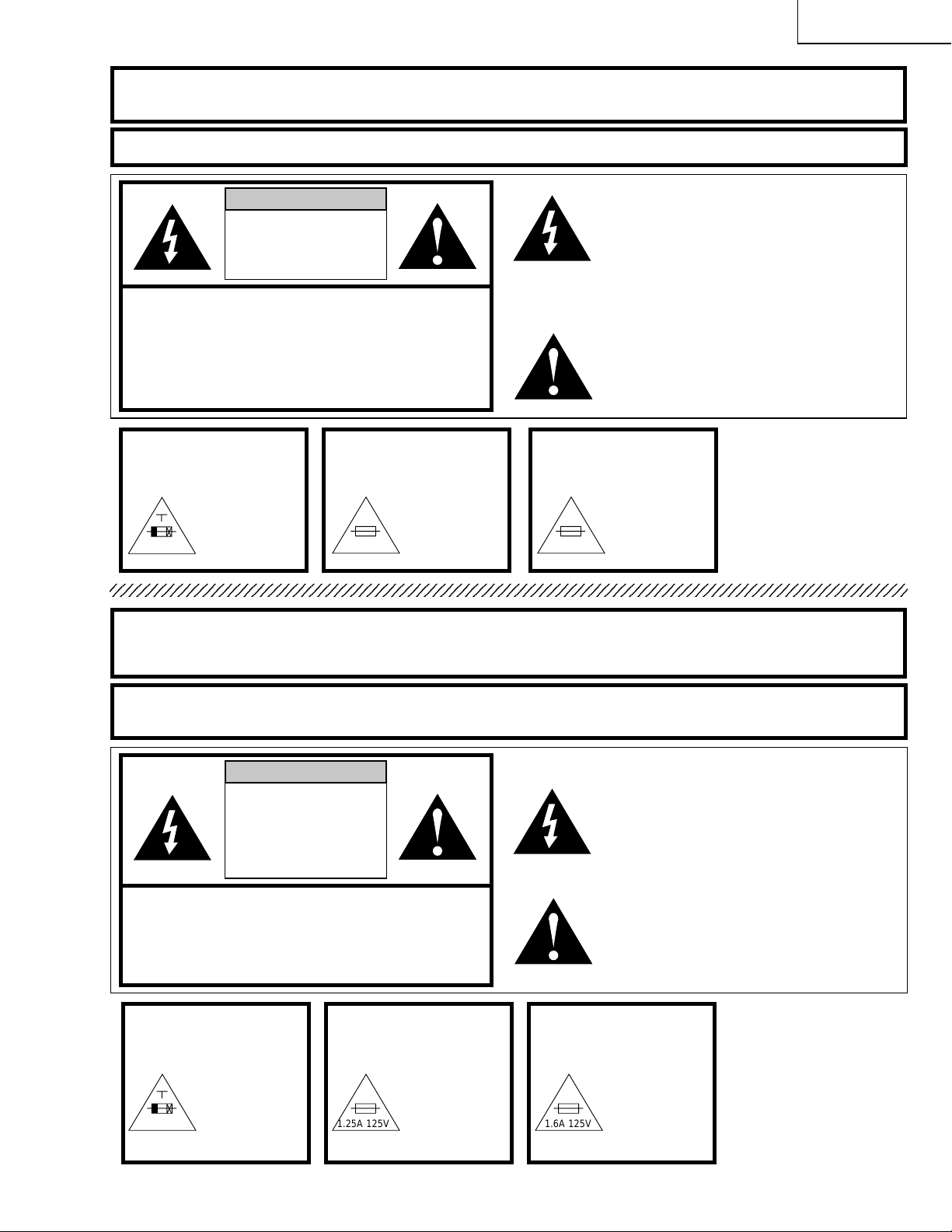

WARNING: High brightness light source. Do not stare into the beam of light, or view directly . Be especially

careful that children do not stare directly into the beam of light.

WARNING: To reduce the risk of fire or electric shock, do not expose this product to rain or moisture.

CAUTION

RISK OF ELECTRIC SHOCK.

DO NOT REMOVE SCREWS

EXCEPT SPECIFIED USER

SERVICE SCREW.

The lightning flash with arrowhead symbol,

within an equilateral triangle, is intended to

alert the user to the presence of uninsulated

“dangerous voltage” within the product’s

enclosure that may be of sufficient magnitude

to constitute a risk or electric shock to

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE COVER.

NO USER-SERVICEABLE PARTS EXCEPT LAMP UNIT.

REFER SERVICING TO QUALIFIED SERVICE

PERSONNEL.

persons.

The exclamation point within a triangle is

intended to alert the user to the presence of

important operating and maintenance

(servicing) instructions in the literature

accompanying the product.

CAUTION

(POWER Unit)

5A 250V

For continued

protection against

a risk of fire,

replace only with

same type and

rating of fuse.

(F1101)

CAUTION

(PC I/F Unit)

1.25A 125V

For continued

protection against

a risk of fire,

replace only with

same type

4511.25, Littelfuse

1.25A 125V.

CAUTION

(PC I/F Unit)

1.6A 125V

For continued

protection against

a risk of fire,

replace only with

same type

45101.6, Littelfuse

1.6A 125V.

A VERTISSEMENT: Source lumineuse de grande intensité. Ne pas fixer le faisceau lumineux ou le regar der

directement. V eiller particulièrement à éviter que les enfants ne fixent directement le

faisceau lumineux.

AVERTISSEMENT: Afin d’éviter tout risque d’incendie ou d’électrocution, ne pas exposer cet appareil à

la pluie ou à l’humidité.

ATTENTION

RISQUE

D’ELECTROCUTION. NE

PAS RETIRER LES VIS, A

L’EXCEPTION DES VIS DE

REPARATION UTILISATEUR

SPECIFIEES.

ATTENTION: POUR EVITER TOUT RISQUE

D’ELECTROCUTION, NE PAS RETIRER LE CAPOT.

AUCUNE DES PIECES INTERIEURES N’EST REPARABLE

PAR L’UTILISATEUR, A L’EXCEPTION DE L’UNITE DE LAMP.

POUR TOUTE REP ARATION, S’ADRESSER A UN

TECHNICIEN D’ENTRETIEN QUALIFIE.

PRECAUTION

(Unité d’alimentation)

5A 250V

Pour une protection

continue contre les

risques d’incendie,

ne remplacer

qu’avec un fusible

du même type.

(F1101)

PRECAUTION

(Unité d’interface PC)

1.25A 125V 1.6A 125V

Pour une protection

continue contre les

risques d’incendie,

ne remplacer

qu’avec un fusible

du même type

4511.25, miniature,

1.25A, 125V.

PRECAUTION

(Unité d’interface PC)

L’éclair terminé d’une flèche à l’intérieur

d’un triangle indique à l’utilisateur la

présence à l’intérieur de l’appareil d’une

«tension dangereuse» non isolée ayant

une amplitude suffisante pour provoquer

une électrocution.

Le point d’exclamation à l’intérieur d’un

triangle indique que des instructions de

fonctionnement et d’entretien importantes

sont détaillées dans les documents

fournis avec l’appareil.

Pour une protection

continue contre les

risques d’incendie,

ne remplacer

qu’avec un fusible

du même type

45101.6, miniature,

1.6A, 125V.

7

Page 8

XG-NV7XU

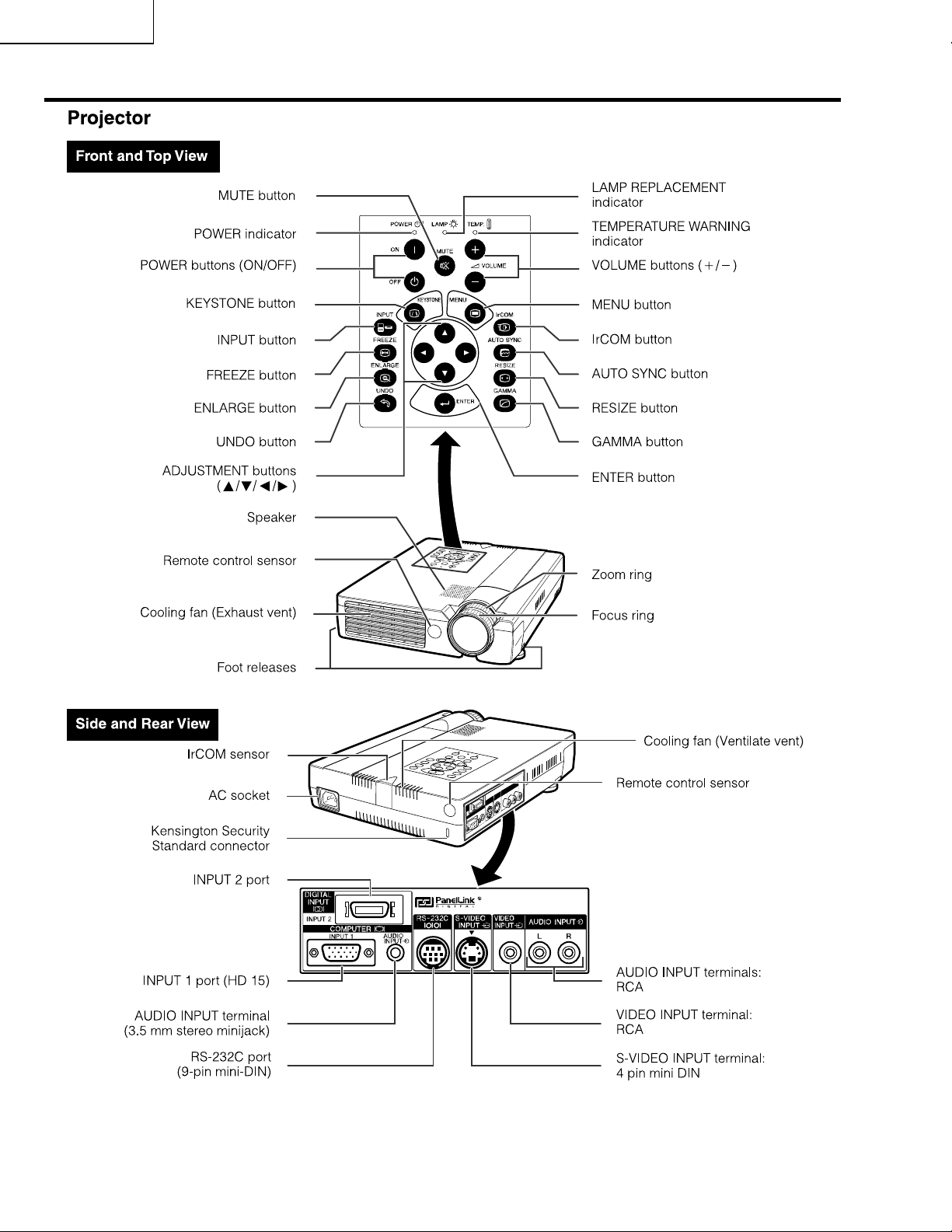

Location of Controls

8

Page 9

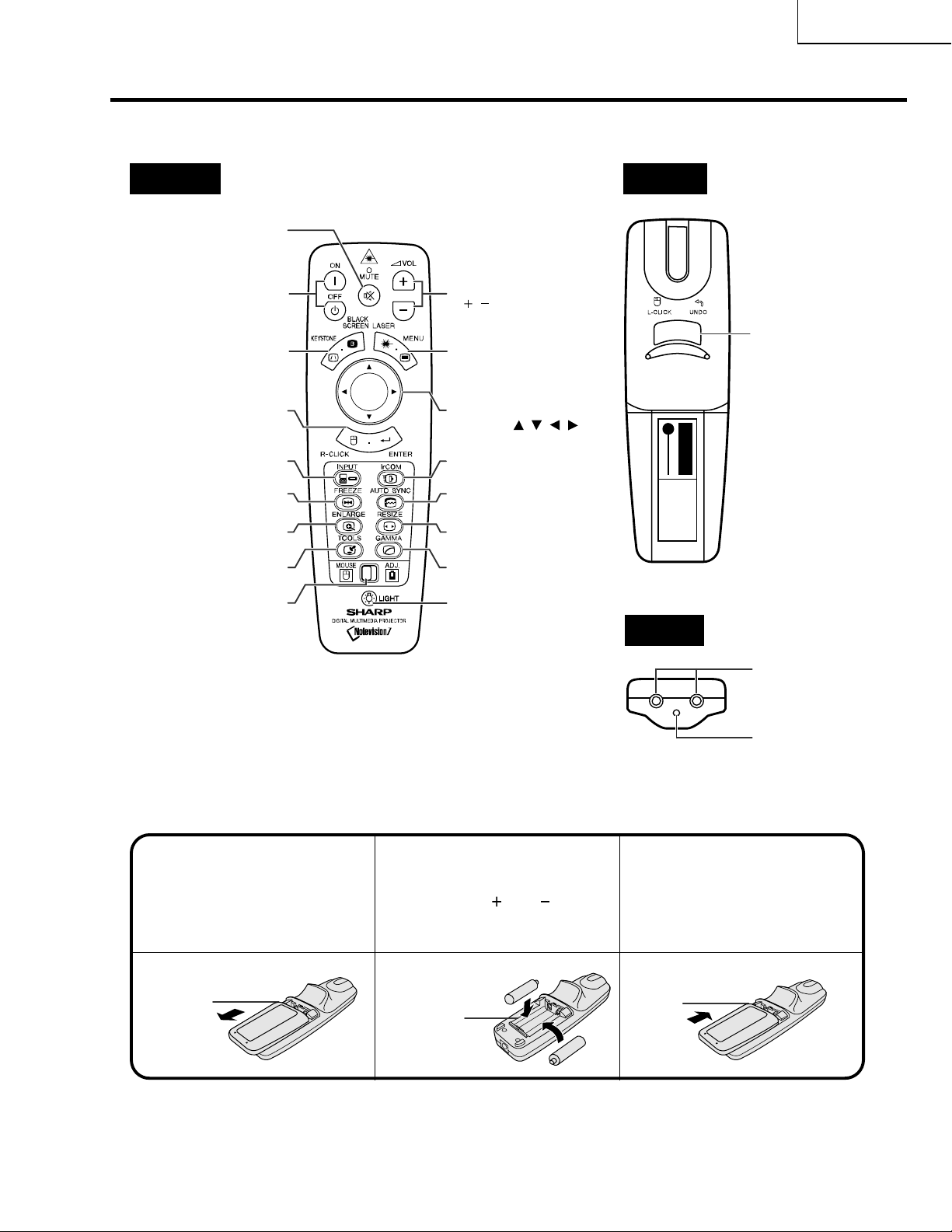

Operating the Wireless Mouse Remote Control

Remote Control

XG-NV7XU

Front View

MUTE button

POWER buttons

(ON/OFF)

KEYSTONE/BLACK

SCREEN button

RIGHT-CLICK/

ENTER button

FREEZE button

ADJUSTMENT

MOUSE/

switch

VOLUME buttons

(

/ )

LASER POINTER/

MENU button

MOUSE/

ADJUSTMENT

buttons

IrCOM buttonINPUT button

AUTO SYNC button

RESIZE buttonENLARGE button

GAMMA buttonTOOLS button

BACKLIGHT button

(///)

Rear View

LEFT-CLICK/

UNDO

button

T op View

Inserting the batteries

Press in and downward

on the arrow to remove

the battery cover.

Battery

cover

Remote control

signal transmitter

Laser

pointer

window

I

nsert two AA size batteries

213

for the remote control,

making sure their polarities

match the

and marks

inside the battery

Insert the side tabs of

the battery cover into

their slots and press the

cover in until it is

properly seated.

compartment.

Battery

Battery

compartment

cover

9

Page 10

XG-NV7XU

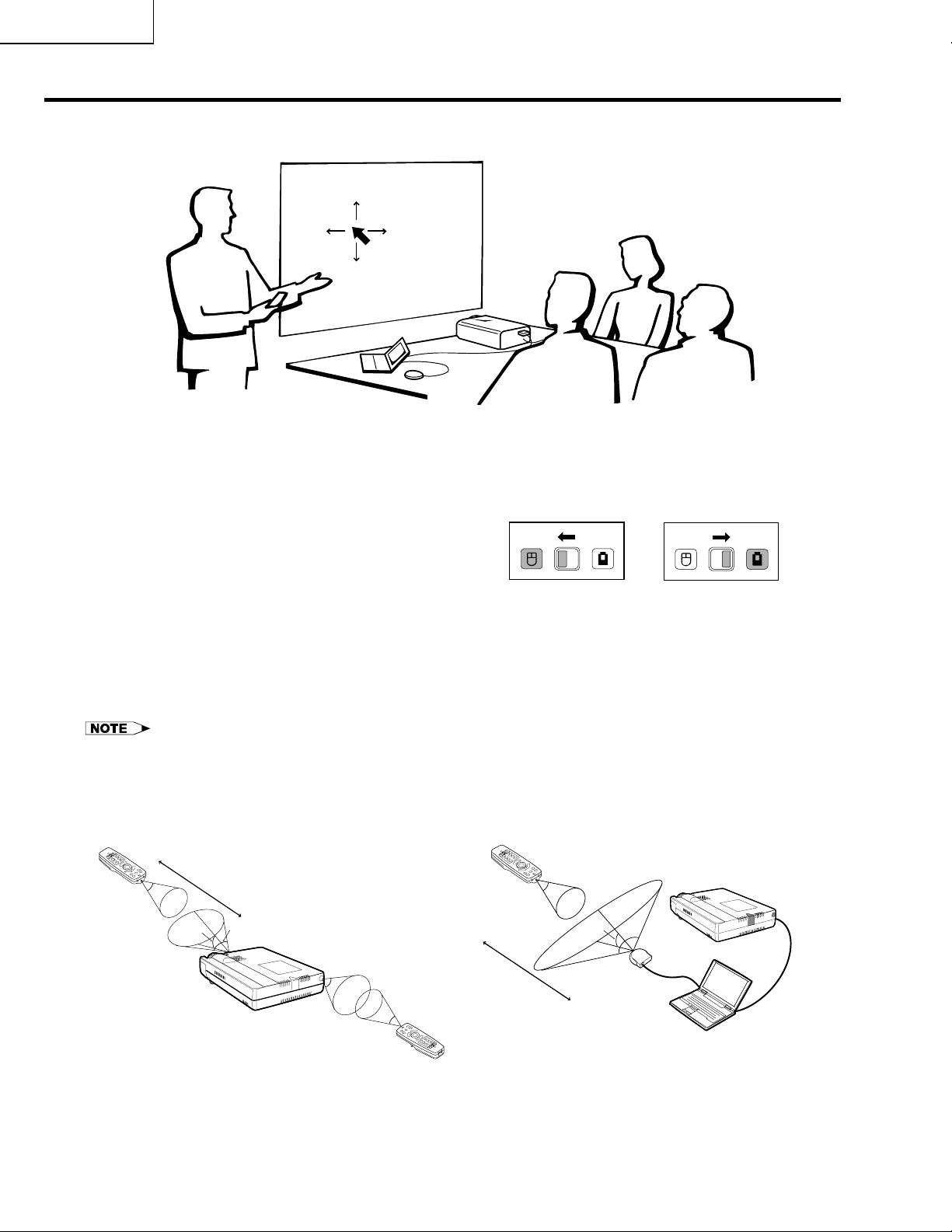

Using the Remote Control as a Wireless Mouse

The remote control has the following three functions:

• Projector control

MOUSE/ADJUSTMENT switch

(Remote control)

• Wireless mouse

• Laser pointer

MOUSE

ADJ.

Wireless mouse

Laser pointer

MOUSE

ADJ.

Projector control

Remote Control/Mouse Receiver Positioning

• The remote control can be used to control the projector within the ranges shown below.

• The remote mouse receiver can be used with the remote control to control the mouse functions of a connected

computer within the ranges shown below.

• The signal from the remote control can be reflected off a screen for easy operation. However, the effective distance of the

signal may differ due to the screen material.

Controlling the Projector

Remote control

23 (7 m)

30˚

45˚

30˚

Using the Wireless Mouse

Remote control

30˚

30˚

120˚

45˚

30˚

Remote control

10

13(4 m)

Remote

mouse

receiver

Page 11

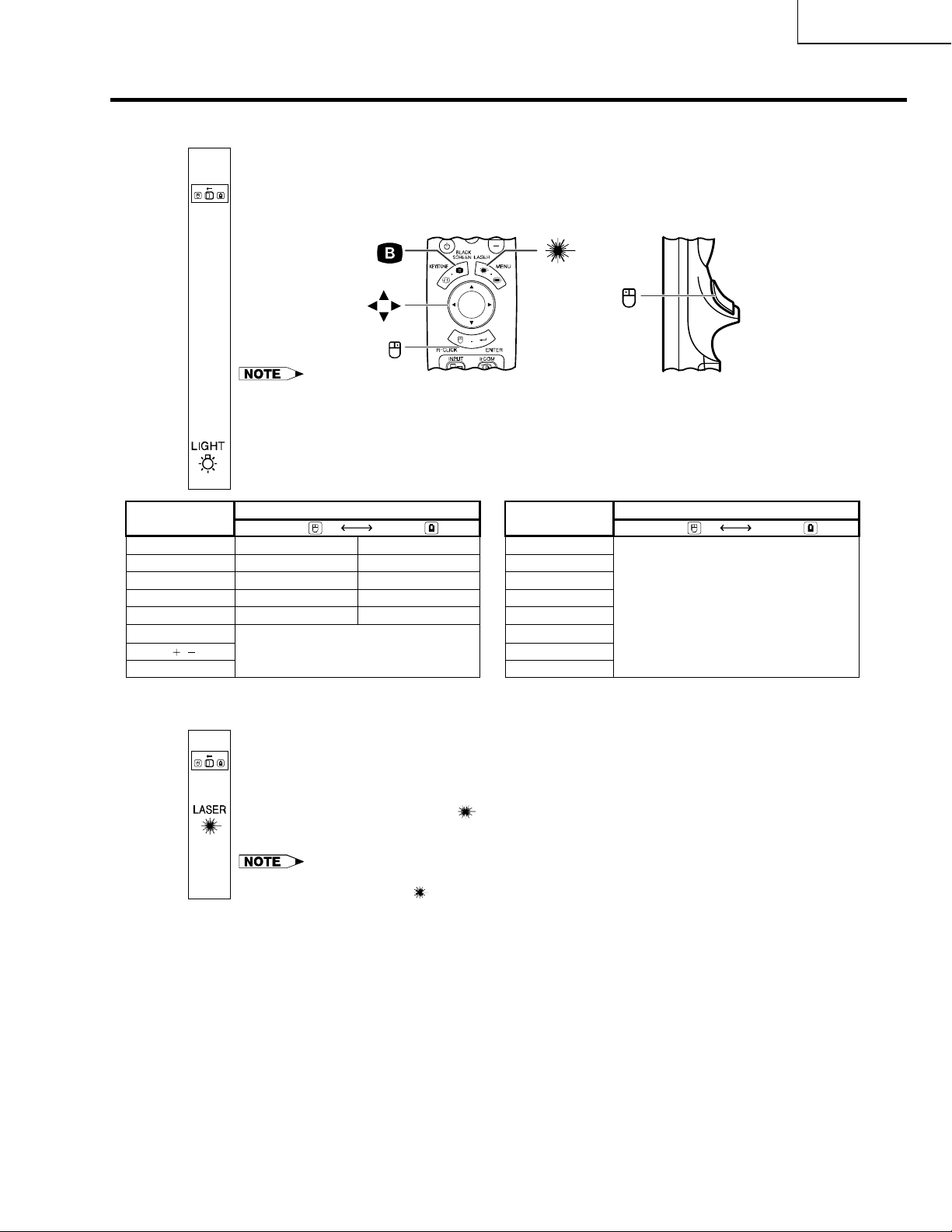

Use as a Wireless Mouse

Be sure the supplied remote mouse receiver is connected to your computer.

MOUSE

ADJ.

Slide the MOUSE/ADJUSTMENT switch to MOUSE.

1

Effective buttons in MOUSE mode

BLACK SCREEN

XG-NV7XU

LASER

POINTER

MOUSE

RIGHT-CLICK

¥ The wireless mouse may not operate correctly if your computer serial port is not correctly set up. Refer

to the computers operation manual for details of setting up/installing the mouse driver.

¥ For one-button mouse systems, use either the LEFT-CLICK or RIGHT-CLICK button.

Using the remote control in a dark room

Press BACKLIGHT, and the buttons will light up. Gr een lights refer to mouse operations, and red

lights to projector adjustments.

Button name

LASER POINTER/MENU

BLACK SCREEN/KEYSTONE

RIGHT-CLICK/ENTER

MOUSE/ADJUSTMENT

LEFT-CLICK/UNDO

POWER ON/OFF

VOLUME

MUTE

/

Position of MOUSE/ADJUSTMENT switch

MOUSE

LASER POINTER (GREEN)

BLACK SCREEN (GREEN)

RIGHT-CLICK (GREEN)

MOUSE (NOT LIT)

LEFT-CLICK (NOT LIT)

Use as a Laser pointer

ADJ.

MENU (RED)

KEYSTONE (RED)

ENTER (RED)

ADJUSTMENT (NOT LIT)

UNDO (NOT LIT)

ON (RED)

LEFT-CLICK

Button name

INPUT

IrCOM

FREEZE

AUTO SYNC

ENLARGE

RESIZE

TOOLS

GAMMA

Position of MOUSE/ADJUSTMENT switch

MOUSE ADJ.

ON (RED)

1

2

MOUSE

ADJ.

Slide the MOUSE/ADJUSTMENT switch to MOUSE.

Press LASER POINTER (

) to activate the laser pointer.

When the button is released, the light automatically goes off.

¥ For safety, the laser pointer automatically goes off after 1 minute of continuous use. To turn it on,

release LASER POINTER (

) and press again.

11

Page 12

XG-NV7XU

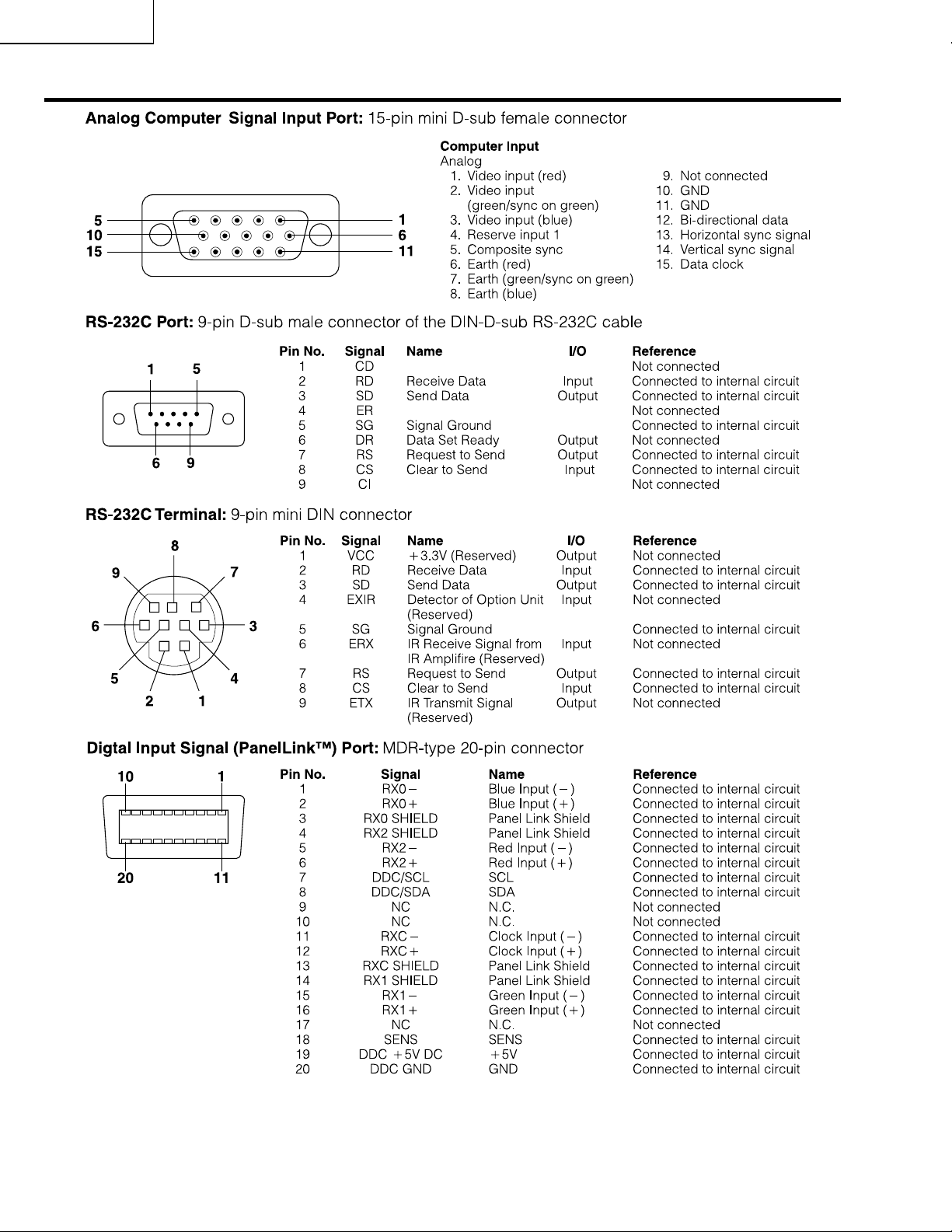

Connection Pin Assignments

12

Page 13

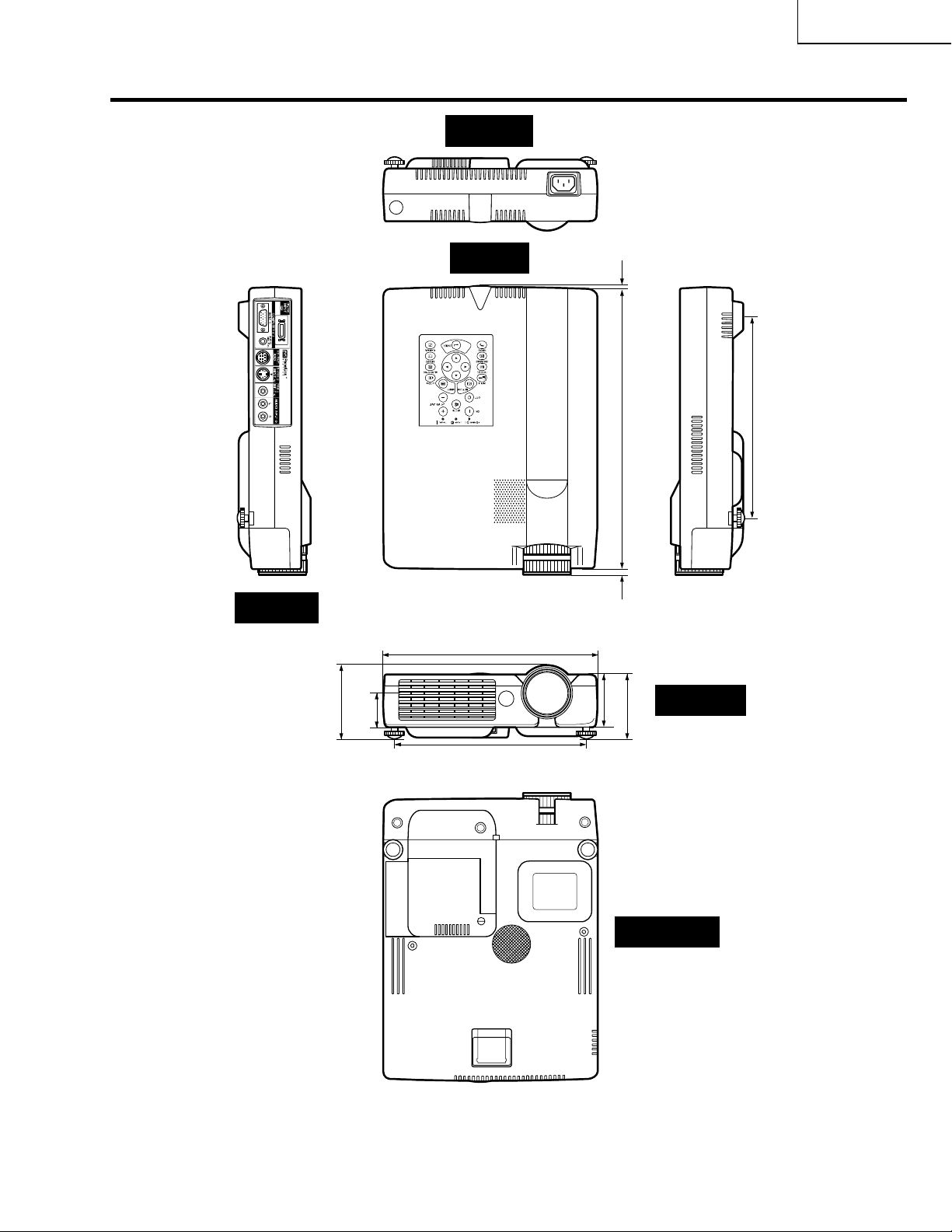

Dimensions

XG-NV7XU

Rear View

Side View

(82 )

64

/

15

3

(37.5)

32

/

15

1

T op View

9 1/4 (235)

11

/32 (212)

8

(58)

32

/

9

2

(1.2)

64

/

3

(312.5)

64

/

19

12

(8.1)

16

/

5

Front View

(71.5 )

16

/

13

2

(219)

8

/

5

8

13

Bottom View

Units: inches (mm)

Page 14

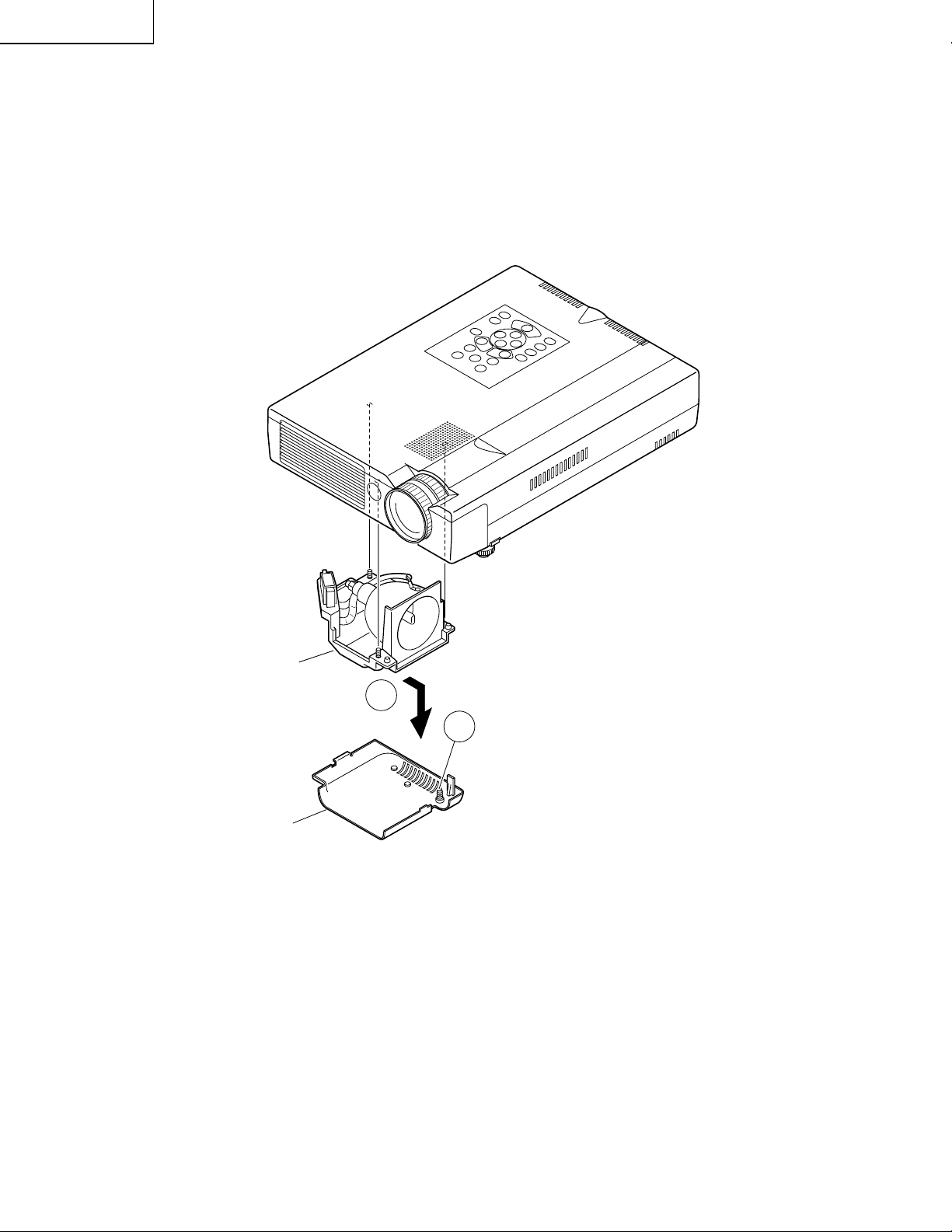

XG-NV7XU

REMOVING OF MAJOR PARTS

1.Removing the Lamp Unit

1-1. Remove the screw from the lamp cover and detach the lamp cover.

1-2. Remove the three screws from the lamp unit and take out the lamp unit.

Lamp Unit

Lamp Cover

1-2

1-1

14

Page 15

XG-NV7XU

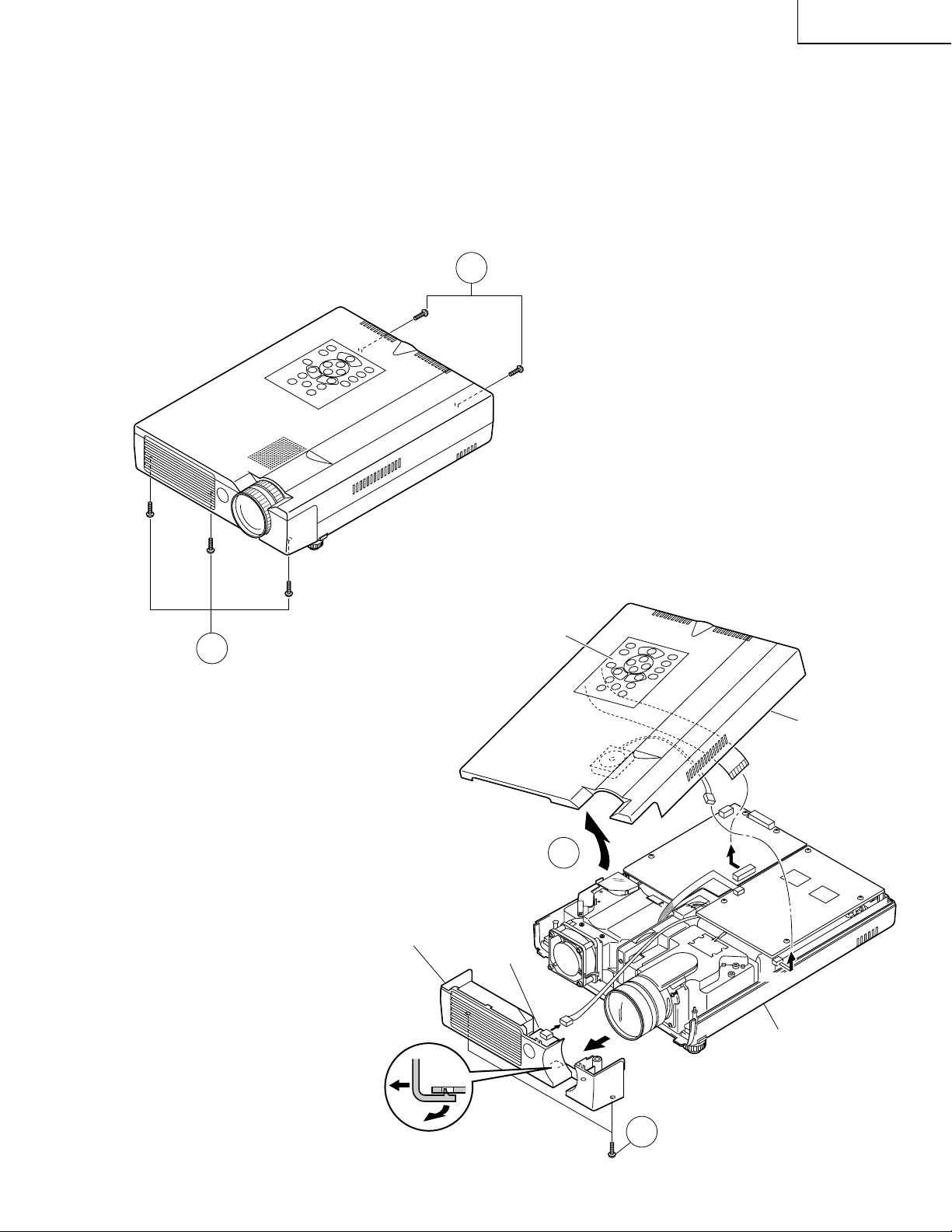

2.Removing the Top and Front Cabinets

2-1. Remove the two screws from the top and bottom cabinets.

2-2. Remove the three screws from the top and front cabinets.

2-3. Slowly lift the back of the top cabinet and disconnect the operation key unit connector (KY) and the speaker

connector (SP). Pull up and off the top cabinet.

2-4. Remove the two screws from the front cabinet and disconnect the remote control unit connector (RC). Unhook

the center of the front cabinet and take out the front cabinet.

2-1

2-2

Front Cabinet

Operation Key Unit

2-3

R/C Unit

(RC)

Top Cabinet

(KY)

(SP)

(SC)

(SP(P301))

Bottom Cabinet

15

2-4

Page 16

XG-NV7XU

3-1

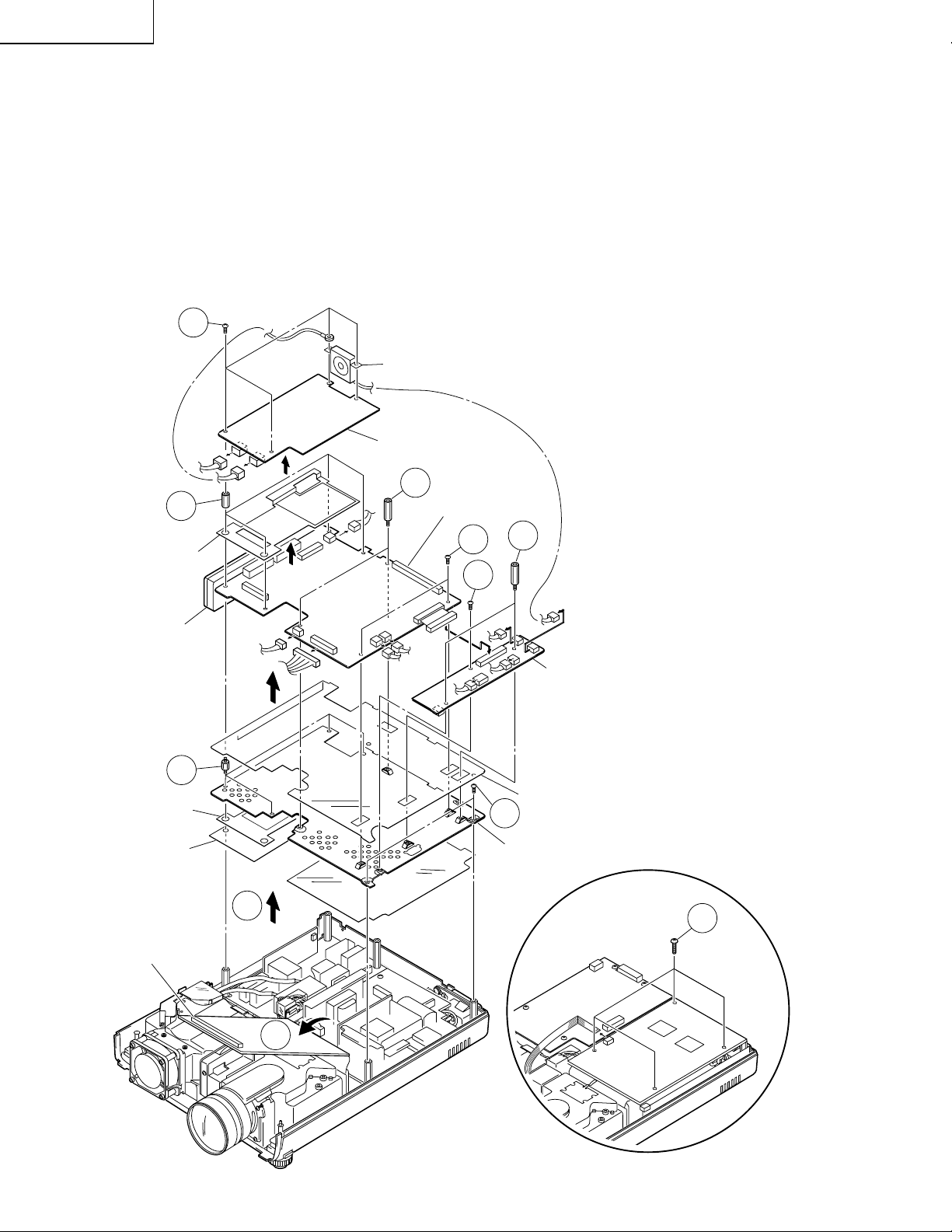

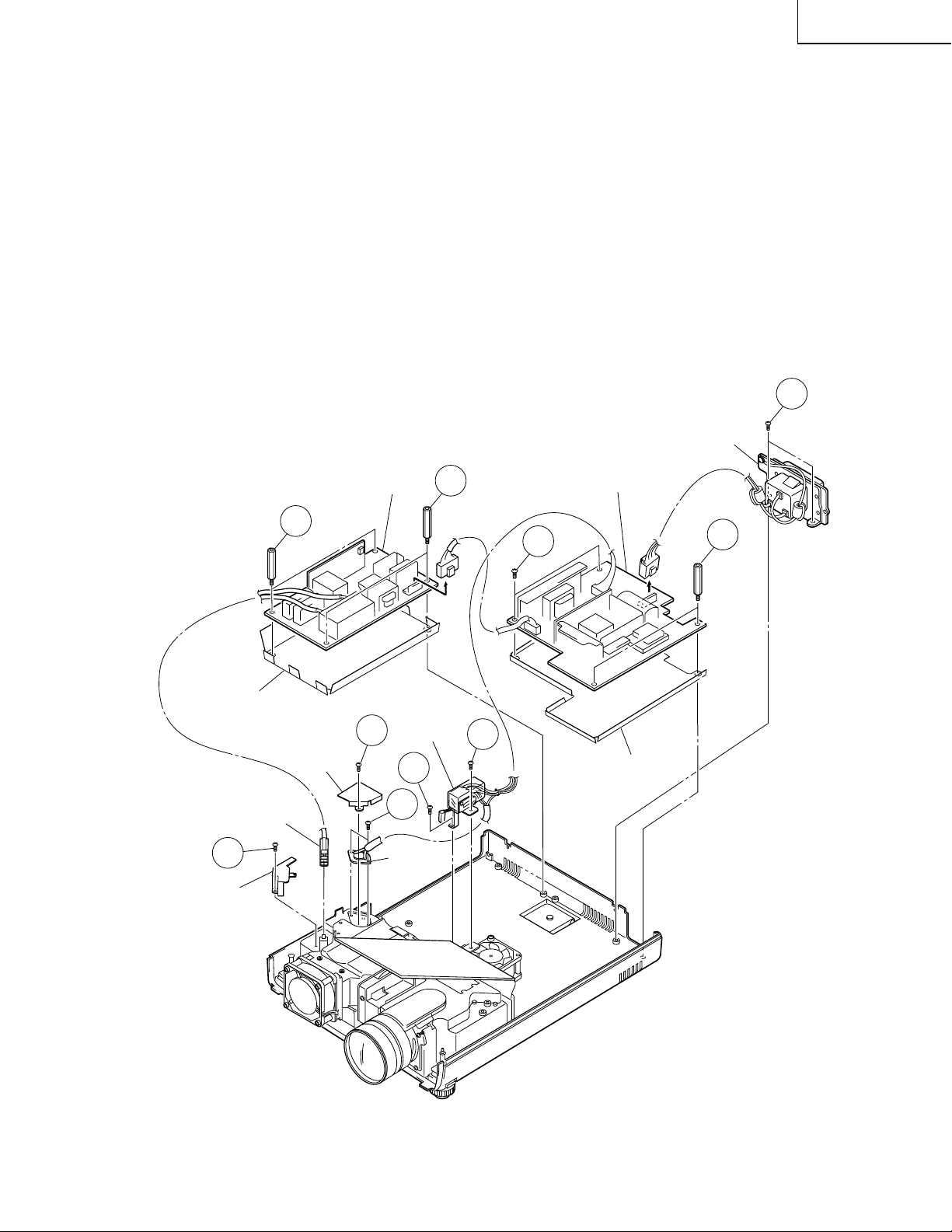

3.Removing the PWB Units

3-1. Remove the four screws from the output unit and disconnect the color wheel unit connector (J501).

3-2. Disconnect the output unit from the PC I/F unit connector. Tilt this unit toward the optical mechanism unit.

3-3. Remove the four screws from the main unit and detach the cooling fan (intake). Disconnect the S-out unit

connector (AU) and the temperature ensor connector (TI). Now take out the main unit.

3-4. Remove the two spacers, the screw and all the connectors from the S-out unit. Detach the S-out unit.

3-5. Remove the six spacers, the two screws and all the connectors from the PC I/F unit. Pull up and off the PC I/

F unit and the terminal unit together.

3-6. Detach the insulation barrier from the PC I/F unit.

3-7. Remove the four spacers and the two screws from the shielded board. Detach the shielded board.

3-8. Detach the insulation barrier from the power/ballast unit.

3-3

Cooling Fan (Intake)

3-5

Shield-1

Terminal Unit

3-7

Shield-2

Insulation Barrier

(AU)

Main Unit

(TI)

3-5

(P8503)

PC I/F Unit

3-5

3-4

(FE)

(AU)

(SP)

3-4

(FB)

(FA)

(FC)

S-Out Unit

(DB)

(PA)

(DC)

(RC)

(PB)

Insulation Barrier

3-7

Shield Board

Output Unit

3-8

3-2

(J501)

16

Page 17

XG-NV7XU

4.Removing the Power/Ballast Unit

4-1. Remove the two lock screws off the Inlet Ass’y.

4-2. Remove the screw from the bimetal cover and detach this cover

4-3. Remove the two screws from the bimetal assembly and detach this assembly.

4-4. Remove the two screws from the AC power switch and detach this switch.

4-5. Remove the two spacers, the two screws and all the connectors from the power unit. Detach the power unit

and the insulation barrier.

4-6. Remove the screw from the lamp socket holder and detach the lamp socket.

4-7. Remove the four spacers from the ballast unit. Detach the ballast unit and the insulation barrier.

<DMD handling precautions>

Be very careful never to bend and twist the flexible cable.

To protect the parts from static electricity, be sure to wear an earth band when handling them.

4-1

Inlet Ass’y

Insulation Barrier

(Ballast Unit)

Lamp Socket

4-6

Socket Holder

4-7

Bimetal

Cover

Ballast Unit

AC Power

4-2

Switch

4-4

4-3

Bimetal

Ass’y

4-7

4-4

(CN105)

Power Unit

4-5

Insulation Barrier

(Power Unit)

(CN102)

4-5

(CN101)

17

Page 18

XG-NV7XU

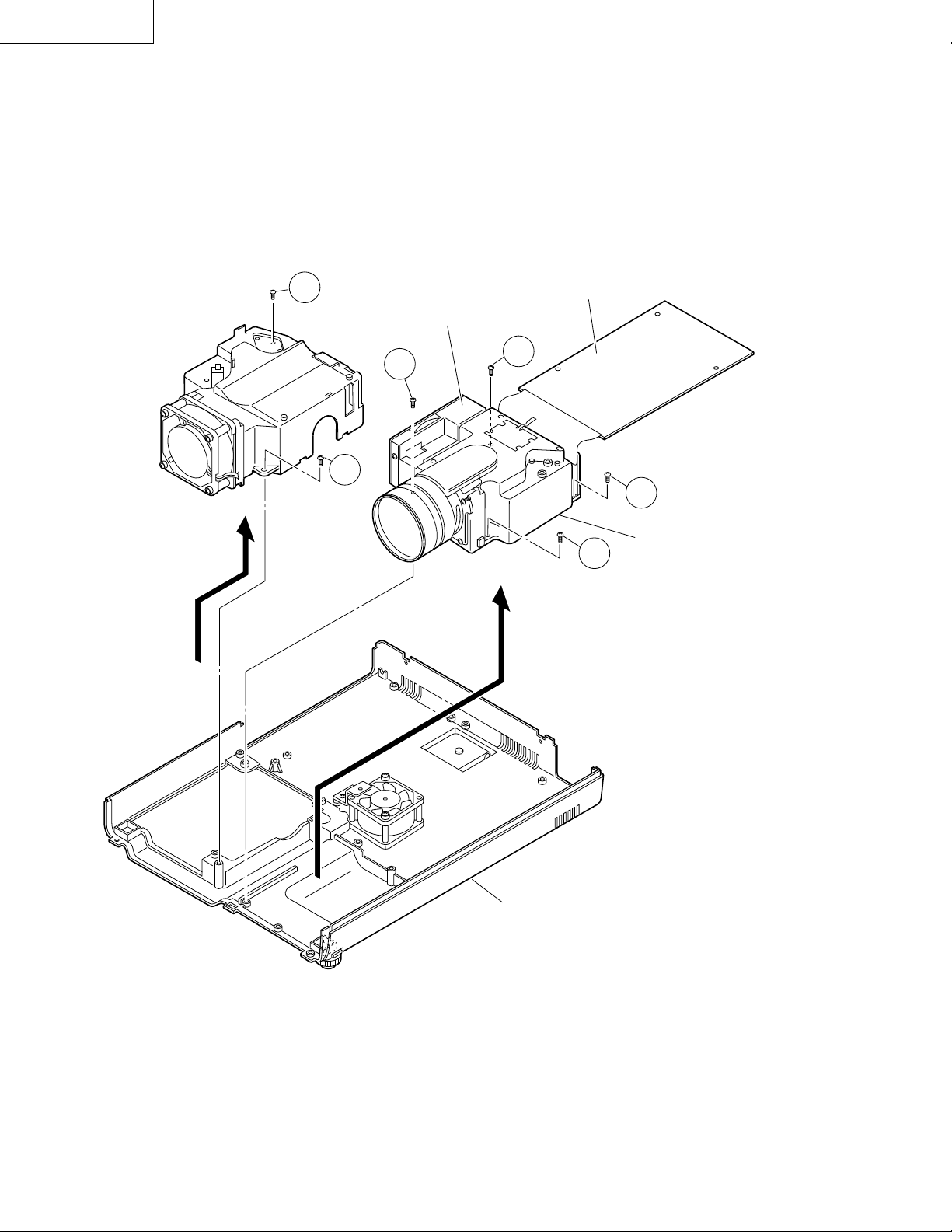

5.Removing the Optical Mechanism and Lamp Housing

5-1. Remove the two screws from the lamp housing and detach the housing.

5-2. Remove the four screws from the optical mechanism unit and detach this unit.

`: When removing these screws, be careful not to damage the capacitors nearby.

5-1

5-1

Color Wheel Unit

5-2

`

5-2

Output Unit

`

5-2

5-2

Optical Mechanism

Unit

18

Bottom Cabinet

Page 19

XG-NV7XU

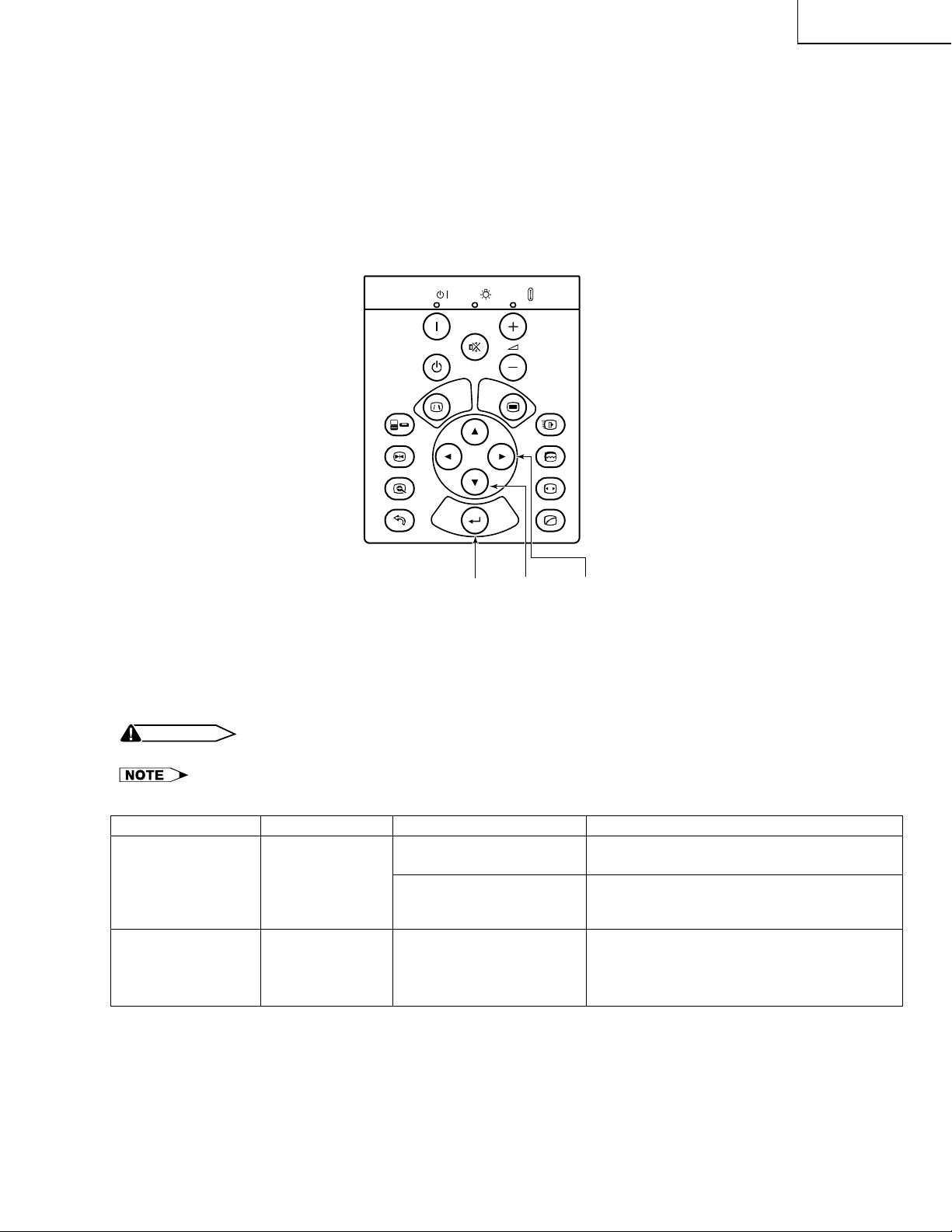

RESETTING THE T OTAL LAMP TIMER

When the lamp has been replaced, reset the total lamp timer in the following steps.

Resetting procedure

1. While holding down the “ENTER”, “ADJ."” and “ADJ.|” keys on the set at the same time, turn on the POWER

ON key.

2. Now the total lamp timer is reset to zero. “0000H” appears on the screen.

INPUT

FREEZE

UNDO

POWER

ON

OFF

LAMP

ENTER ADJ." ADJ.|

MUTE

MENULENS

ENTER

TEMP.

VOLUME

IrCOM

AUTO SYNC

RESIZEENLARGE

GAMMA

Lamp

The lamp in this projector operates for approximately 1,500 cumulative hours, depending on the usage environment. It is recommended that the lamp be replaced after 1,400 cumulative hours of ues or when you notice a

significant deterioration of the picture and color quality. The lamp usage time can be checked with the On-screen

Display.

CAUTION

» Intense light hazard. Do not attempt to look into the aperture and lens while the projector is operating.

» As the usage environment can vary significantly, the projector lamp may not operate for 1,500 hours.

Maintenance Indicator

TEMPERATURE

WARNING indicator

The internal

temperature is

abnormally high.

Condition

Problem

· Blocked air intake.

· Cooling fan breakdown.

· Internal circuit failure.

· Relocate the projector to an area with

proper ventilation.

· Take the projector to your nearest Authorized Sharp Industrial DLP Products

Possible Solution

Dealer or Service Center for repair.

LAMP REPLACEMENT indicator

The lamp does

not light up.

· Burnt-out lamp.

· Lamp circuit failure.

· Carefully replace the lamp.

· Take the projector to your nearest Au-

thorized Sharp Industrial DLP Products

Dealer or Service Center for repair.

19

Page 20

XG-NV7XU

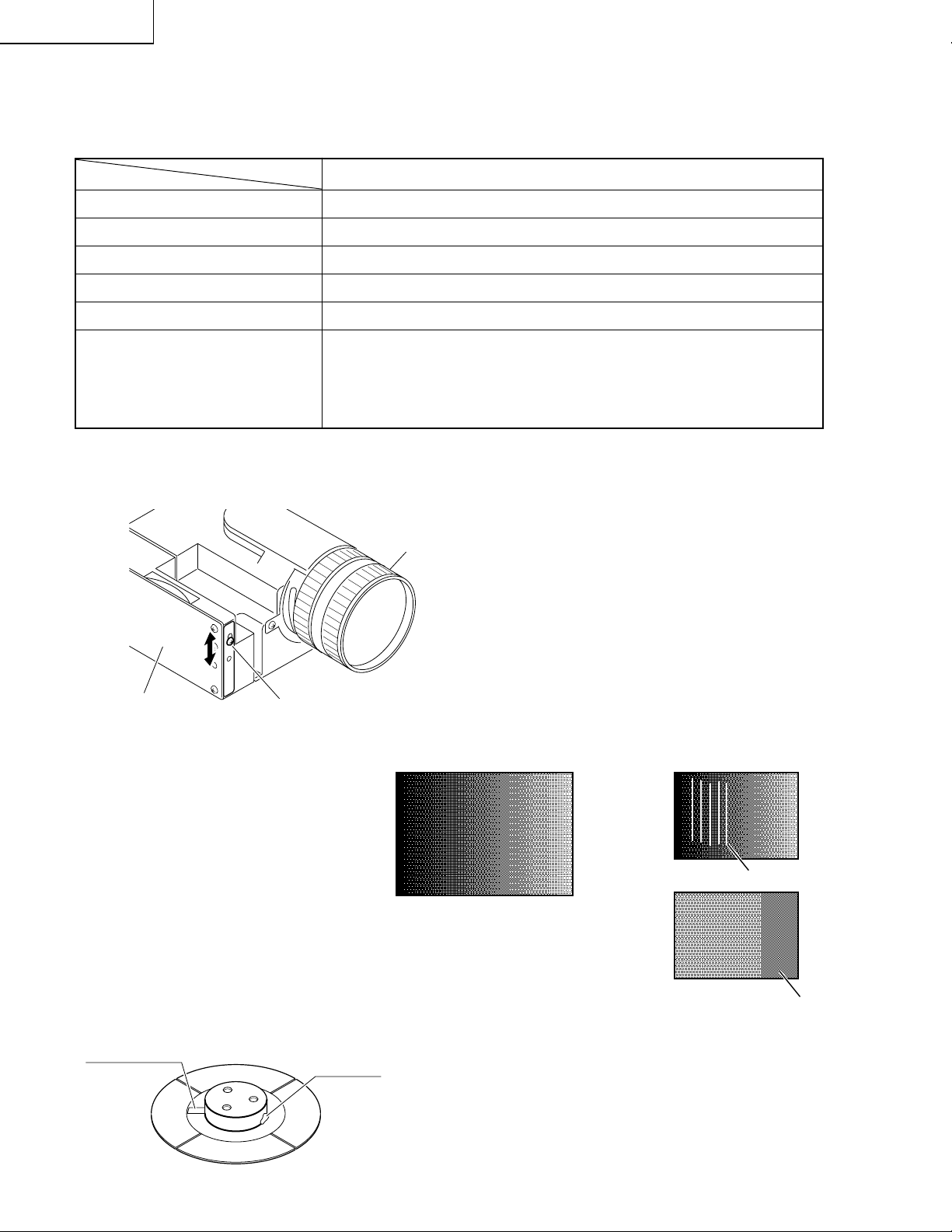

OPTICAL ADJUSTMENT

What to readjust after replacement

Readjustment

Reflection lens

Cylinder mirror

Mirror A

Mirror B

Requirements for adjustments

Color wheel

Not needed.

Not needed.

Not needed.

Not needed.

Phillips screwdriver, red gradation pattern signal.

Enter the red gradation pattern from RGB1. Make sure the pattern

appears normal on screen.

If not, loosen the wheel sensor screw and move the sensor up and

down until the gradation appears crisp on screen. (White lines and

magenta portions are not allowed.)

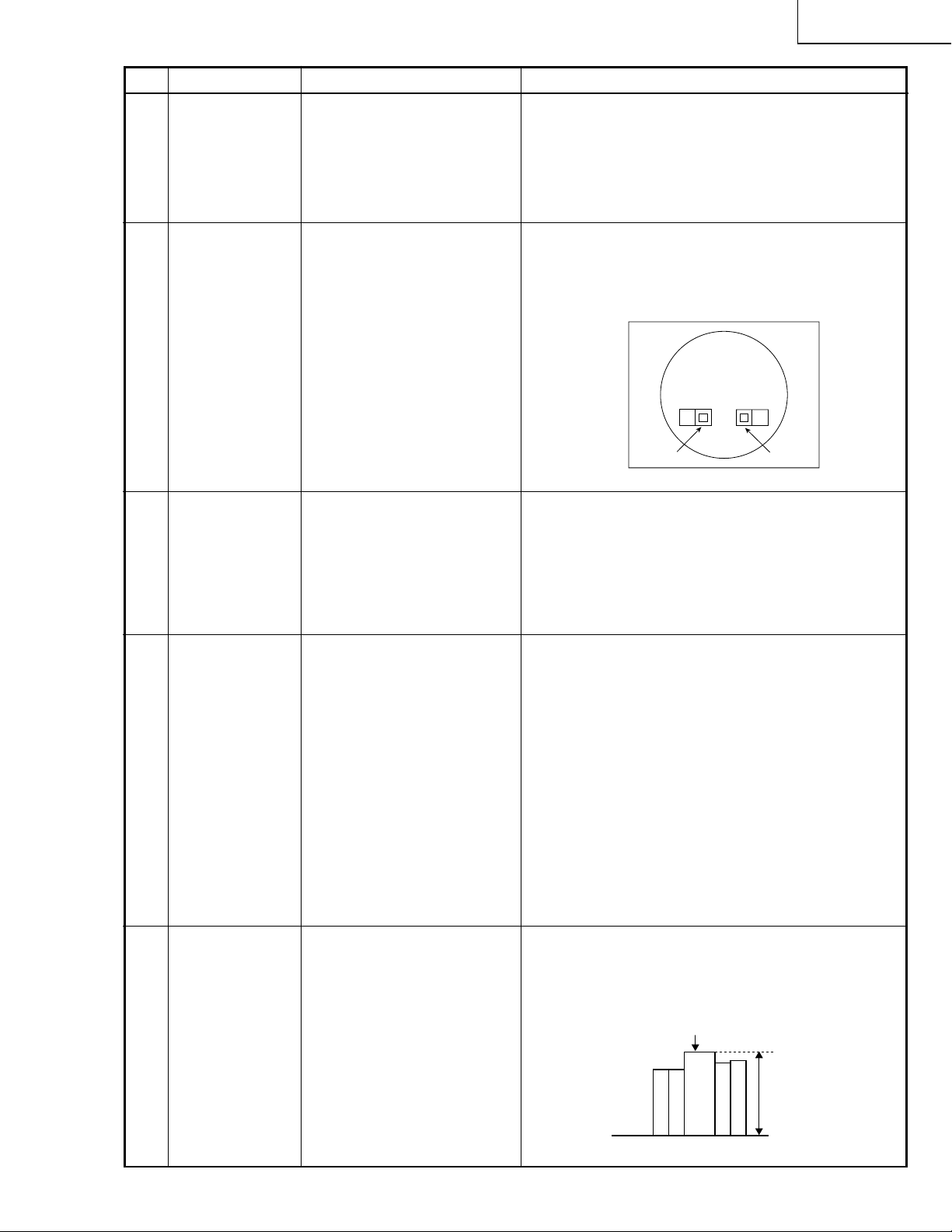

Adjustment after color wheel replacement

Lens

Color Wheel

Note: Never peel off the sensing seal and

balancer from around the motor.

Sensing Seal

Wheel Sensor Screw

Balancer

Normal Unacceptable

Black RedBlack

Gradation pattern

Red

White lines

RedRed

Magenta

20

Page 21

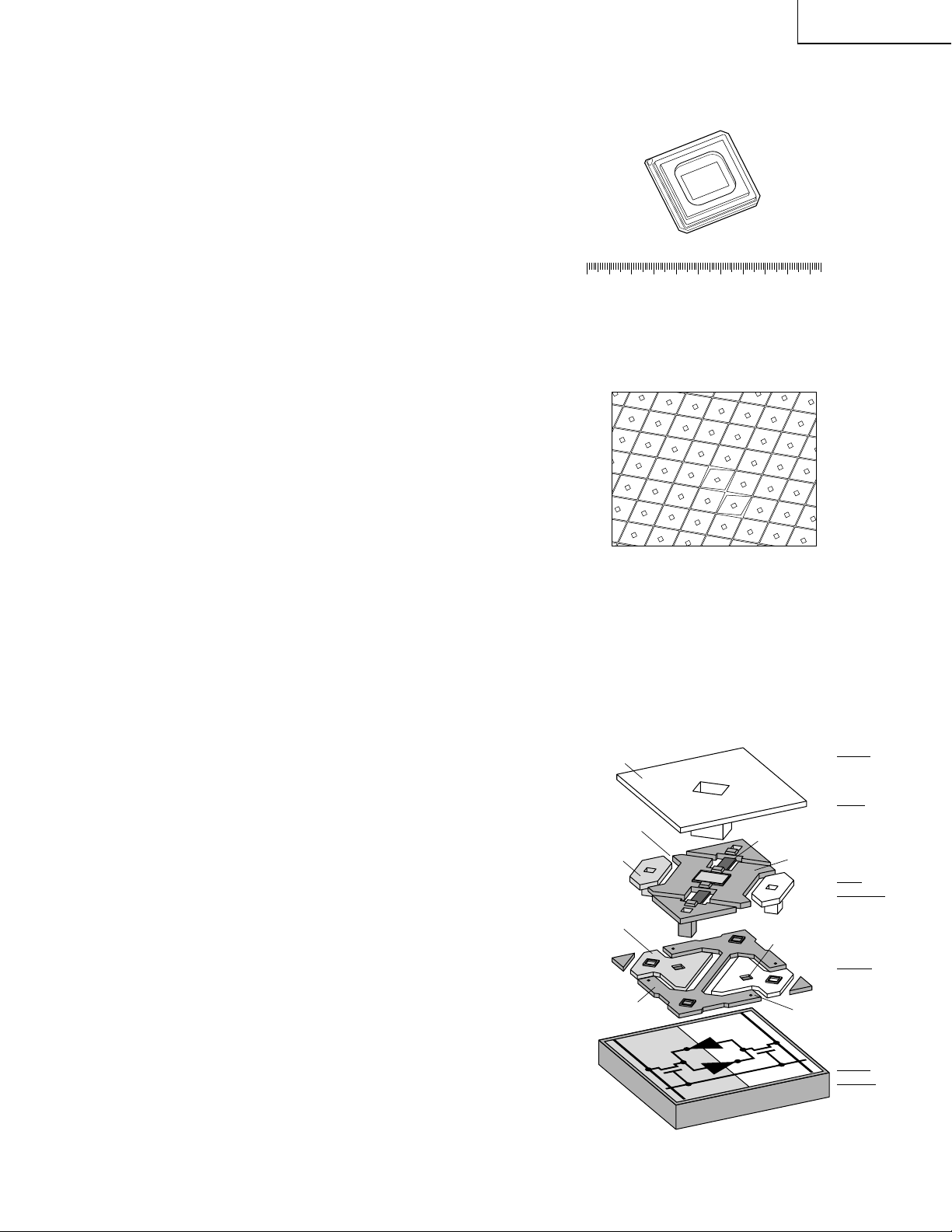

DMD AND PRINCIPLE OF OPTICAL SYSTEM

1.Outline of DMD

(Digital Micro Mirror Device)

The DMD is one of the ultra-micro electromechanical

systems called MEMS (Microeletromechanical System).

The DMD can be fabricated by employing the existing

0.8 micron rule, which is the established semiconduc-

tor manufacturing technology.

The DMD is an optical switch of semiconductor chip

fabricated by connecting several hundred thousand to

one million and several hundred thousand mirrors

(16µm X 16µm in size) onto the CMOS SRAM

semiconductor memory and these mirrors rotate

mechanically when digital electric signal is received.

In the DMD, the mirror rotates at an angle of ±10

degrees by the action of electrostatic field produced by

voltage which is generated on the SRAM memory . The

rotation of this mirror changes the direction of reflected

light, the principle of which is applied for the optical

switch. The gray scale (or color gradation) of reflected

light is achieved by controlling the response time (or

ON-time) of the mirror with digital signal (8-bit pulse

width modulation [PWM] signal) (Processing with 10bit PWM signal is now also available).

The gray scale has 256 tones. Hence, the total nµmber

of tones for RGB full primary colors counts as many as

256 X 256 X 256 = 16,700,000.

XG-NV7XU

2 3 4 5 6 7 8 9 10 11 12

About 500,000 micro mirrors are found at the

central white part.

Figure 1. DMD (SVGA Specification)

Mirrors (each one of squares).

Area of a mirror is 16 µm X 16 µm. The space

between adjacent mirrors is 1 µm.

Figure 2. Microscopic View of DMD

2.Structure of DMD Pixel

Figure 3.

The DMD monolithically consists of the four layers;

mirror, yoke and hinge, metal-3, and CMOS memory.

The mirror is made of 16 µm X 16 µm alµminµm plate.

The mirror is rigidly connected to the yoke below. The

yoke, in turn, is connected by two thin mechanically

compliant torsion hinges to the posts that are attached

to the PWB below . The address electrodes for the mirror

and yoke are connected to the complementary sides

of the PWB below . The yoke and mirror are connected

to the bias-reset bus formed on the metal-3 layer. The

bias-reset bus interconnects the yoke and mirrors of

each pixel to the bond pad around the chip.

When the digital signals [1] and [0] are written on the

CMOS SRAM, the mirror supported by the posts

inclines diagonally toward the PWB side. The angle of

inclination is ±10 degrees.

* DMD and DLP are the trademarks of Texas Instruments, Inc., U.S.A.

shows an exploded view of the DMD pixel.

Mirror

Landing Tip

Mirror

Address

Electrode

Yoke

Address

Electrode

Bias-Reset

Bus

Torsion Hinge

Yoke

Via 2 Contact

to CMOS

Landing

Site

Figure 3. DMD pixel exploded view

(Layers)

Mirror

Yoke

and Hinge

Metal-3

CMOS

Memory

21

Page 22

XG-NV7XU

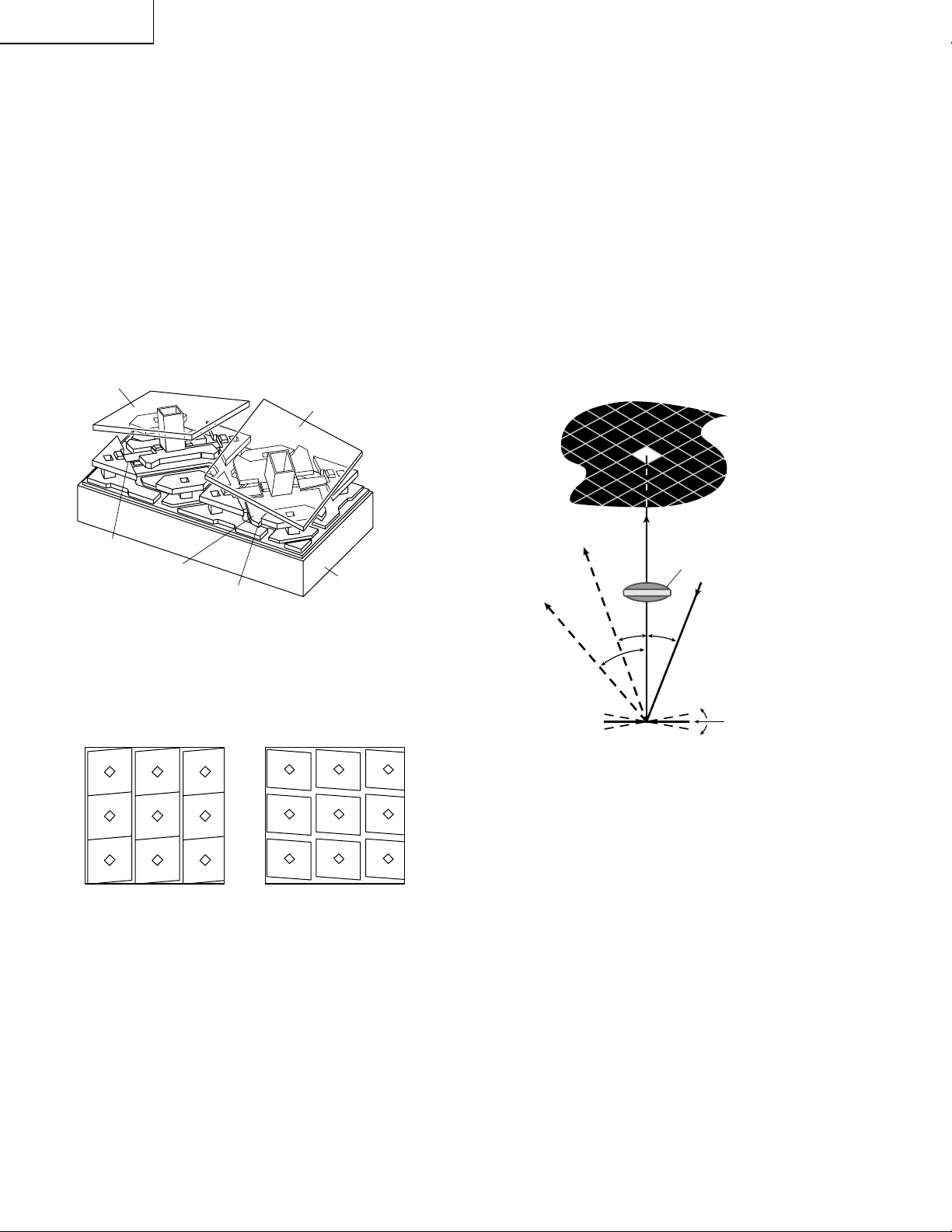

3.Switching of Mirror

The mirror reflects light in one of two directions,

depending of the state of underlying memory cell. The

mirror rotates by a force of electrostatic attraction

produced by voltage diff erence betw een the mirror and

the memory cell. With the memory cell being in the ON

(1) state, the mirror rotates by +10 degrees. With the

memory cell being in the OFF (0) state, the mirror rotates

by -10 degrees.

mirrors operating.

Mirror – 10 deg

Figure 5.

shows a close-up of DMD

Mirror + 10 deg

By combining the DMD with a suitable light source and

projection optics (

Figure 6.

), the mirror reflects incident

light either into or out of the center of the projection lens

by a simple beam steering technique. Thus , the (1) state

of the mirror appears bright and the (0) state of the mirror

appears dark.

Pixel

Image

Hing

Yoke

Landing Tip

Figure 4. Two DMD pixels

(mirrors are shown as transparent)

Figure 5. Images of operating DMD

CMOS

Substrate

+10°

Flat

–10°

40°

20°

Pixel

Mirror

Projection

Lens

Light From

Illuminator

20°

–10°

Flat

+10°

Figure 6. DMD optical switching principle

22

Page 23

GRB

1

23

4

56

7

4.Digital Light Processing Signal and

Gray Scale

When the mirror rotates, it reflects incident light either

into or out of the projection lens to create a burst of

digital light pulses, which the eye interprets as an analog

image.

In binary pulse width modulation, the DMD accepts

electrical words representing the gray level of brightness at its input, and puts out optical words, which are

interpreted by the observer’s eye as analog brightness

level.

Taking 4-bit word as an example for simplicity, each bit

in the word represents a time duration for light to be ON

or OFF, and the time durations have relative value of

2°0, 211, 222 and 233 or 1, 2, 4 and 8 (

The video field time is divided into four time durations

of 1/15, 2/15, 4/15 and 8/15, and 24 or 16 equally spaced

gray le vels (0, 1/15, 2/15, 4/15, …, 15/15) are produced

by all the combinations of bits in the 4-bit word.

Currently available DLP systems are of either 24-bit color

(8 bits or 256 gray levels per RGB) or 39-bit color (10

bits or 1024 gray levels per RGB).

In the DLP displays of pulse width modulation, “bitsplitting technology” is combined to produce a “trueanalog” sensation with greater accuracy and stability

than can be achieved by analog projection systems.

Projection Lens

Video Field TIme

(1111)

(1001)

(0100)

(0010)

(0001)

(0000)

(Note: For simplicity, only central colµmn is addressed

(4-Bit Example)

and no light source is shown.)

Figure 7. DMD binary pulsewidth modulation

(4bit example)

Figure 7.

(Sensation of Gray Scale

by Viewer’s Eye)

).

XG-NV7XU

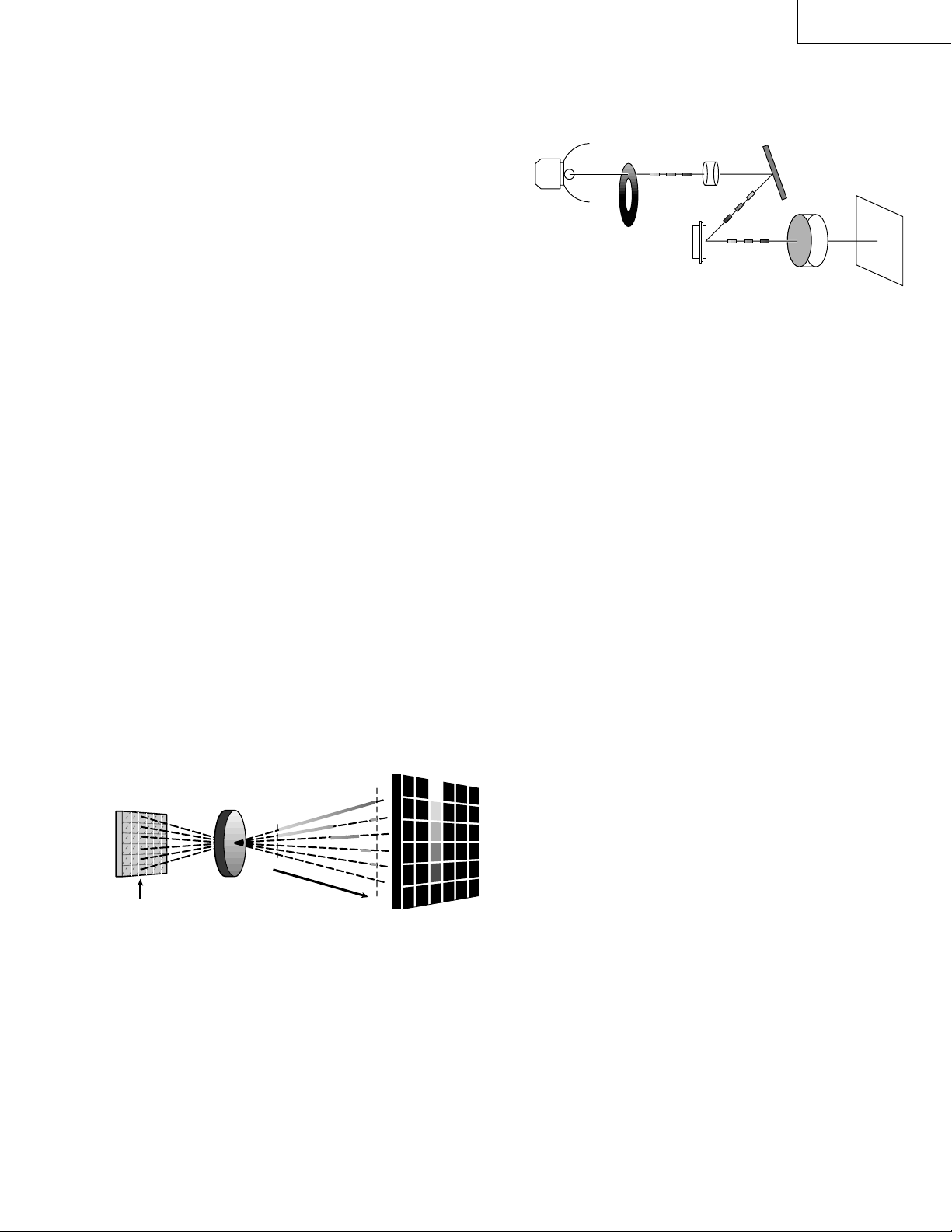

Figure 7. Bloc k Diagram of Optical System Principle

Names of Parts and Operating

Specifications

1 Metal Halide Lamp

The DC light source lamp flickers 180 times or 210

times per second

2 RGB Color Filter (Color Wheel Unit)

This color filter splits light into RGB primary colors.

The rotation-detecting sensor should be synchronized with the timing to turn off the lamp at the seam

of color filter. The maximµm rotating speed is 7200

rpm.

3 Condenser Lens

This lens condenses the light split by the color filter

and projects it to the effective area of the reflection

mirror.

4 Reflection Mirror

This mirror reflects the light projected to the effective

area of the DMD.

5 DMD Chip

This chip turns on and off in proportion to each

color element per dot depending on the input source.

6 Projection Lens

This lens magnifies and projects the incident light

coming from the DMD.

7 Screen

Projected light (RGB components) is interpreted by

viewer’s eye as a synthesized color image due to

after-image phenomenon.

* On the main PWB, the color components are split

per dot depending on the input source, and the

information is sent to the DMD.

23

Page 24

XG-NV7XU

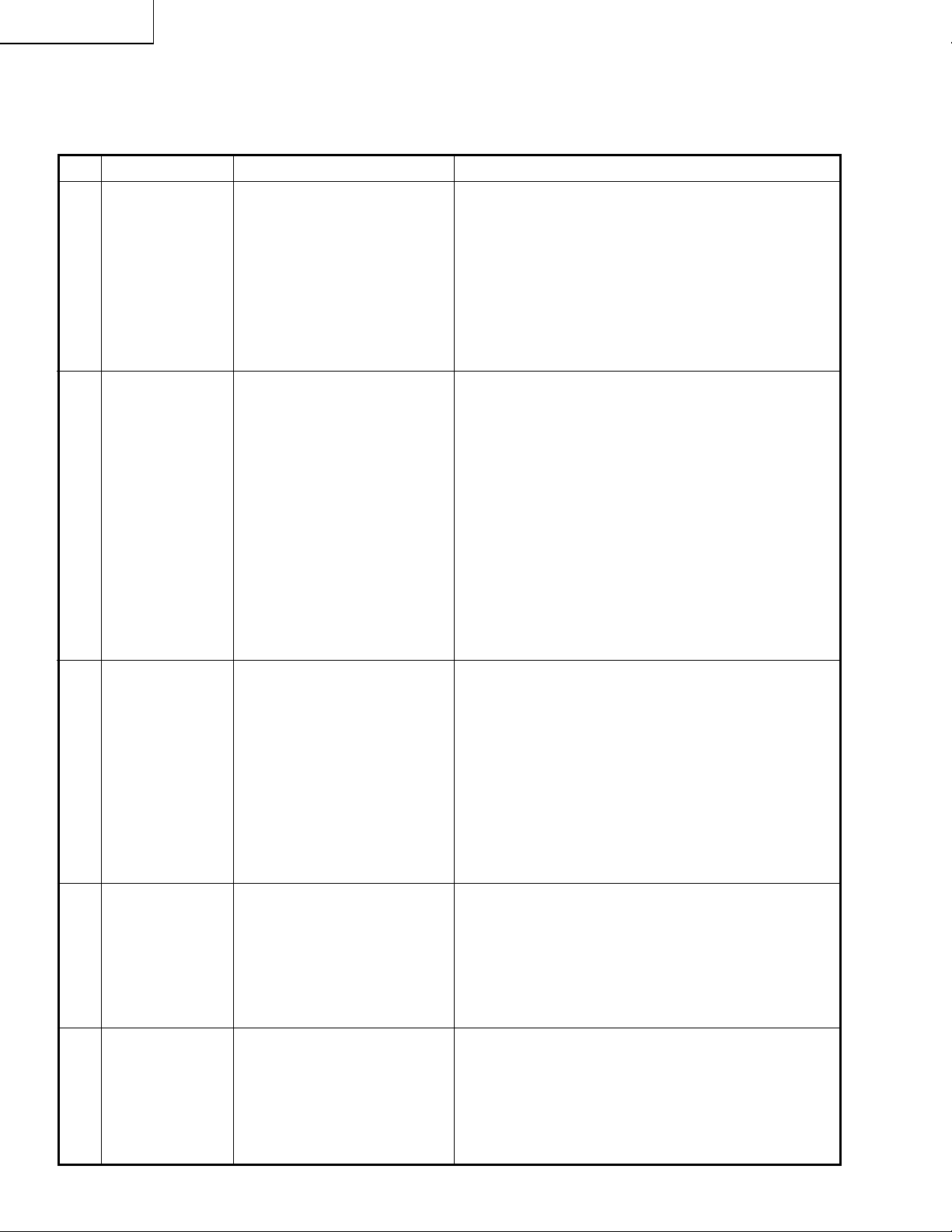

ELECTRICAL ADJUSTMENT

Hook up a signal generator, or a DOSV or Mac personal computer to the projector in order to feed the

signals specified in the Adjusting conditions.

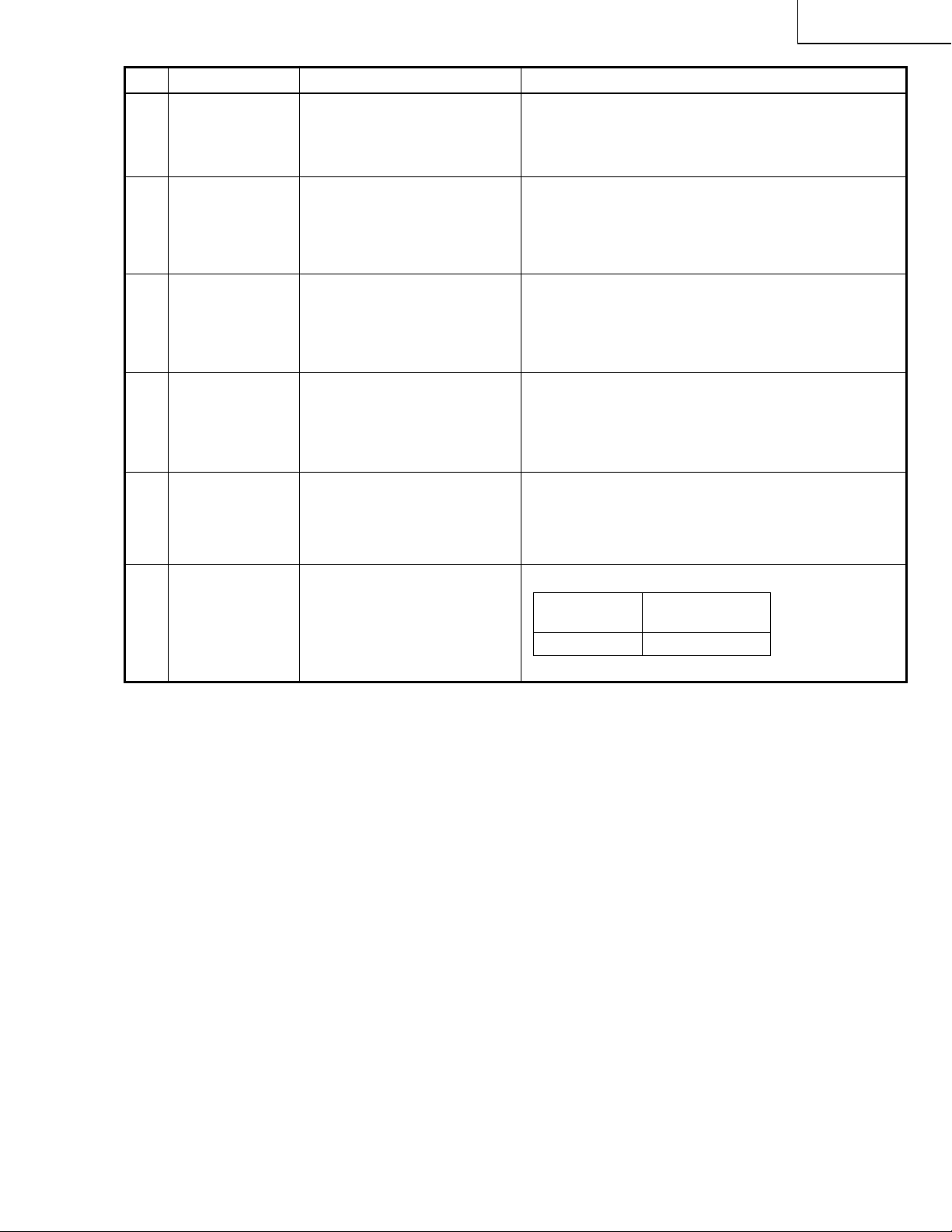

No. Adjusting point Adjusting conditions Adjusting procedure

1 EEPROM

initialization

1. Turn on the power (make

sure the lamp lights up) and

warm up the unit for 15 minutes.

» Make the following settings:

Press S5001 to call up the process mode and

execute S2 in the SSS menu. Now the system,

with the PC board not included, is initialized. Do

not execute S1 because otherwise the PC board

will be initialized.

To adjust the PC board, follow the instruction in

"Adjusting the PC Interface". (See page 30)

2 RGB1 BRIGHT 1. Make the following choice.

Group : A/D

Subject : BRIGHT

Make sure the data value is

125.

2. Make the following choice.

Group : A/D

Subject : R-BRIGHT,

G-BRIGHT,

B-BRIGHT

Adjust until the data value

becomes 135 or so.

3 R drive 1. Make the following choice.

Group : A/D

Subject : GAIN

2. F eed the 100% red-only signal. Make the following

choice.

Group : A/D

Subject : R-D

» With the set's control switch or the remote-control

button, adjust the data until the black-side noise

becomes bitless.

» Using the control switches or the remote controller

buttons, adjust the data so that the signal becomes bit-less (noise).

4 B drive 1. Feed the 100% blue-only

signal. Make the following

choice.

Group : A/D

Subject : B-D

5 G drive 1. Feed the 100% green-only

signal. Make the following

choice.

Group : A/D

Subject : G-D

» Using the control switches or the remote controller

buttons, adjust the data so that the signal becomes bit-less (noise).

» Using the control switches or the remote controller

buttons, adjust the data so that the signal becomes bit-less (noise).

24

Page 25

No. Adjusting point Adjusting conditions Adjusting procedure

XG-NV7XU

6 Gain adjustment 1. Make the following choice.

Group : A/D

Subject : GAIN

Initial value : 137

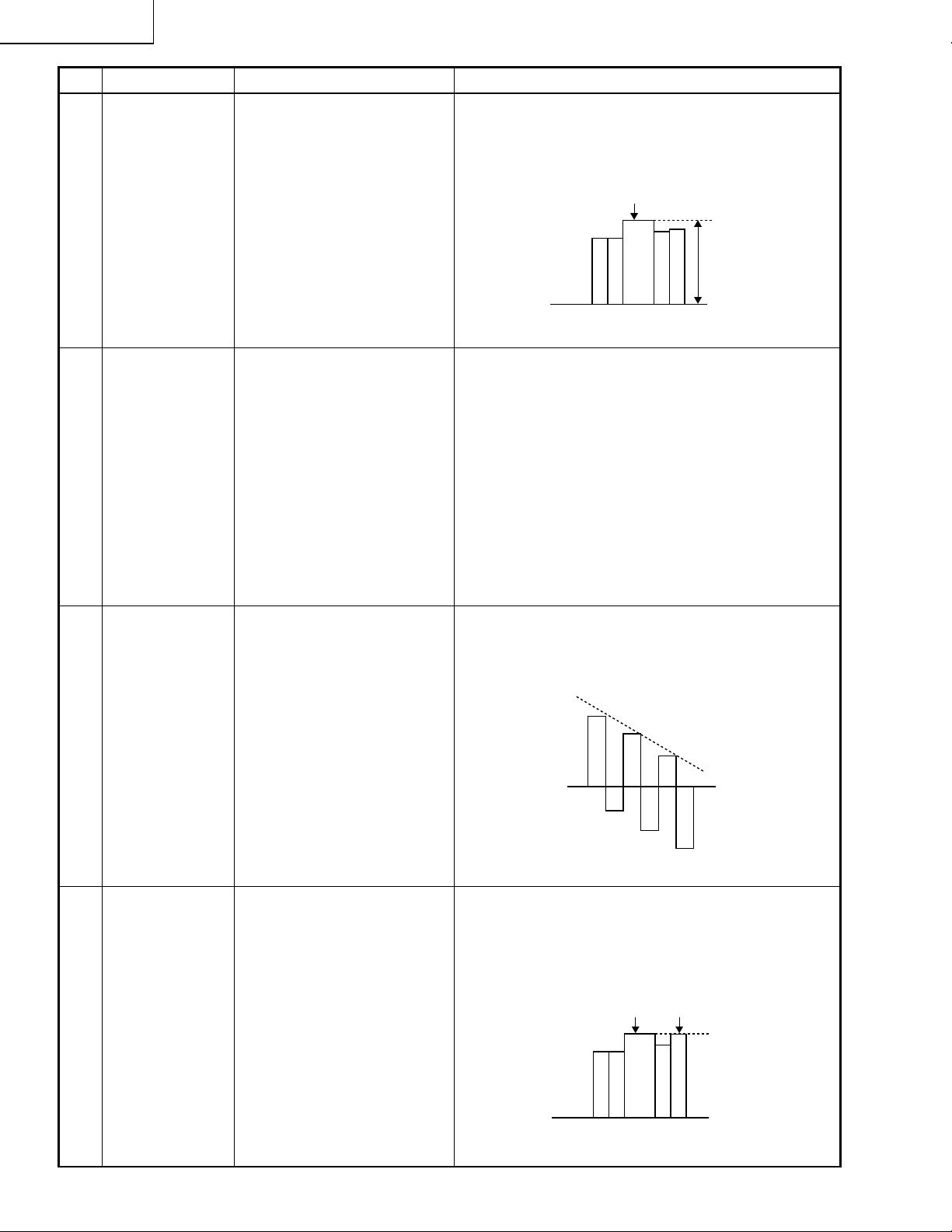

7 RGB gradation

regeneration

adjustment

1. Feed the green-only SMPTE

pattern signal.(XGA)

Group : A/D

Subject : GAIN

8 RGB white

balance

1. Feed the 32-step gray scale

signal (XGA 60Hz).

Group : A/D

Subject : R-BRIGHT

B-BRIGHT

» With the set's control switch or the remote-control

button, adjust the data until the white-side noise

becomes bitless.

» Adjust the G-GAIN data until the gradation of the

portion 1 (95% and 100% white) shown below

can be slightly recognized. Make sure also that

the gradation of the portion 2 (0% and 5% black)

is visible.

2

1

» Adjust the R-BRIGHT and B-BRIGHT data for the

balance on the gray scale.

(Adjust to the best point.)

9 Horizontal

center

10 Video picture

adjustment

1. Feed the NTSC monoscope pattern signal.

2. Group : VIDEO 2

Subject : N358-DLY (10)

N443-DLY (0)

PAL-DLY (10)

SECAM-DLY (10)

Make sure the settings are

as above.

3. Group : VIDEO 1

Subject : NTSC-H

1. Feed the split color bar signal.

Group : VIDEO 1

Subject : PICTURE

2. Connect the oscilloscope to

TP805.

» Using the control switches or the remote controller

buttons, adjust the data to have the same

overscan.

» Using the control switches or the remote controller

buttons, adjust the black-to-white (100%) level

difference to 2.1 ±0.02 Vp-p.

100% White

2.1Vp-p

25

Page 26

XG-NV7XU

100% White Red

No. Adjusting point Adjusting conditions Adjusting procedure

11 Video AGC 1. Feed the split color bar sig-

nal.

Group : VIDEO 1

Subject : AGC

2. Connect the oscilloscope to

TP805.

12 Video

brightness

adjustment

1. Feed the baseband (split

color bar) signal.

Group : VIDEO 1

Subject : BRIGHT

2. Press the control switch or

the remote control’s mute

button (to set the gamma

correction to the process

setting).

» Using the control switches or the remote controller

buttons, adjust the black-to-white (100%) level

difference to 1.65 ±0.02 Vp-p.

100% White

1.65Vp-p

» Using the control switches or the remote controller

buttons, adjust the setting until the black signal

becomes bit-less and set to -3 point of value.

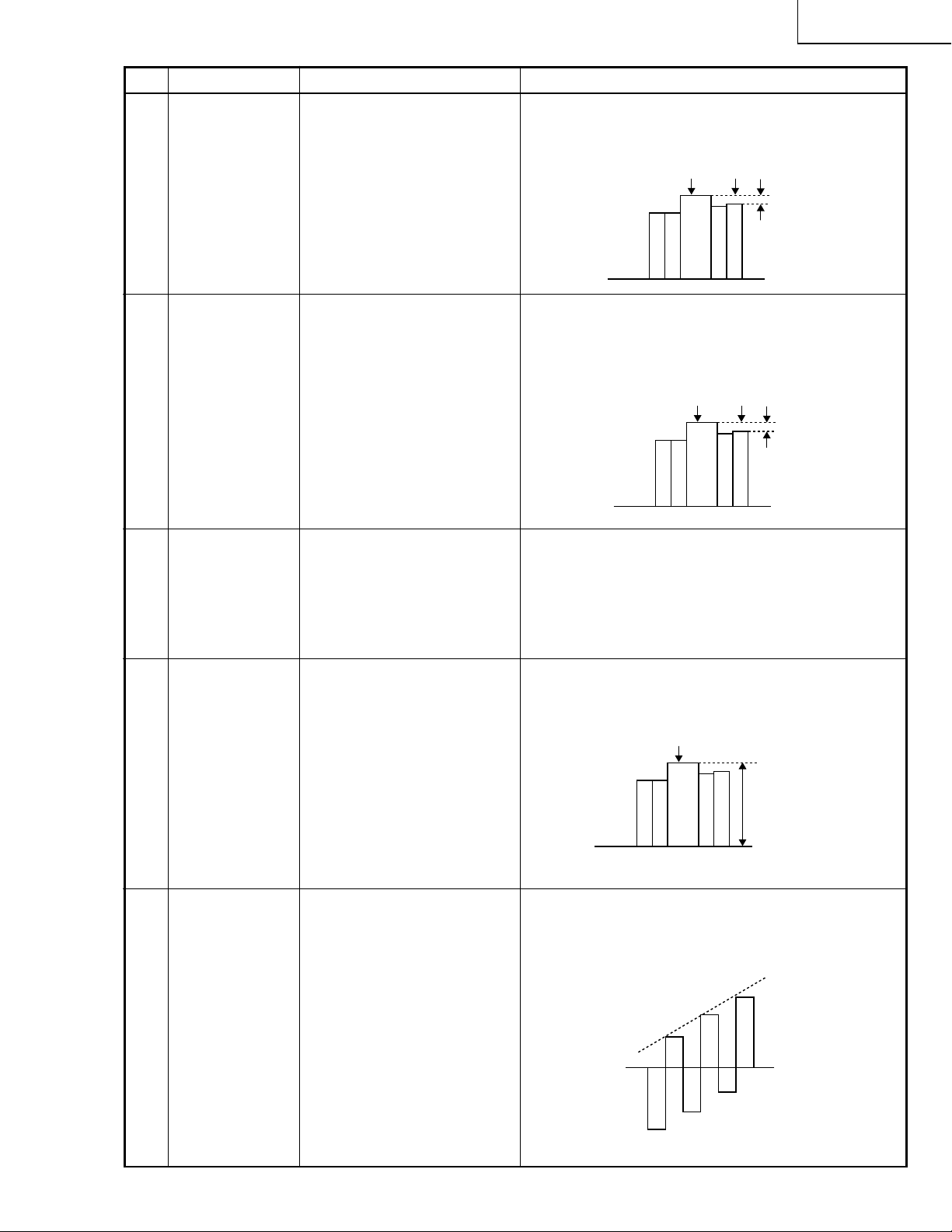

13 Tint 1. Feed the split color bar sig-

nal.

Group : VIDEO 1

Subject : TINT

2. Connect the oscilloscope to

TP807.

14 NTSC color

saturation level

1. Feed the split color bar signal.

Group : VIDEO 1

Subject : N-COLOR

2. Connect the oscilloscope to

TP804.

» Using the control switches or the remote controller

buttons, adjust the data to have the -(B-Y) waveform downhill straight.

» Using the control switches or the remote controller

buttons, adjust the difference betw een the 100%

white portion and the red portion to 0.0 ±0.02 Vp-p.

(same as 100% white)

26

Page 27

No. Adjusting point Adjusting conditions Adjusting procedure

XG-NV7XU

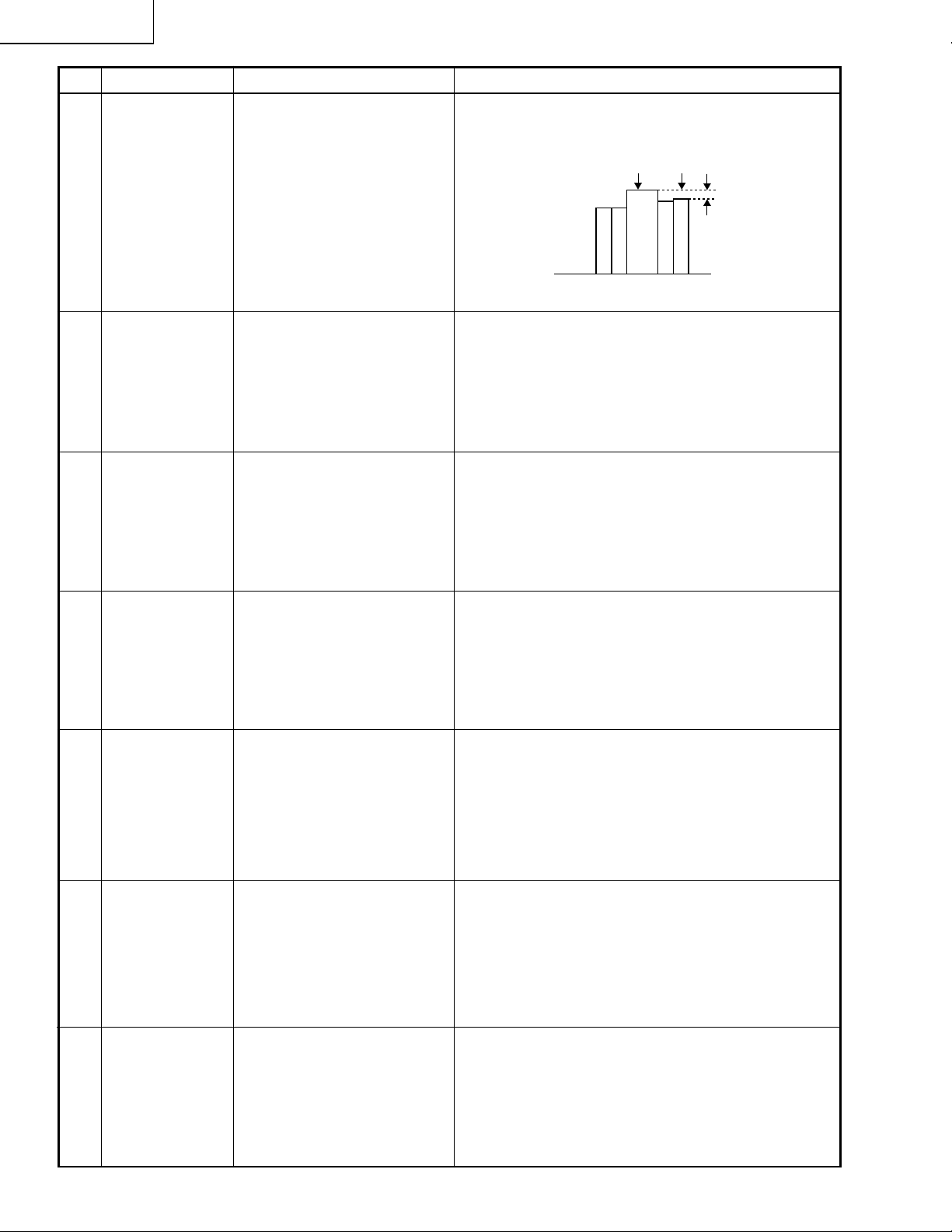

15 PAL color

saturation level

16 SECAM color

saturation level

17 Video white

balance

1. Feed the PAL color bar signal.

Group : VIDEO 1

Subject : P-COLOR

2. Connect the oscilloscope to

TP804.

1. Feed the SECAM color bar

signal.

Group : VIDEO 1

Subject : S-COLOR

2. Connect the oscilloscope to

TP804.

1. Feed the NTSC monoscope pattern signal

Group : VIDEO 2

Subject : R OFF-SET

B OFF-SET

» Using the control switches or the remote controller

buttons, adjust the difference between the 100%

white portion and the red portion to 0.28 ±0.02 Vp-p.

100% White Red

» Using the control switches or the remote controller

buttons, adjust the data to have a level difference

of 0.28 ±0.02 Vp-p between the 100% white

portion and the red portion.

100% White Red

» Using the control switches or the remote controller

buttons, adjust so that the entire screen looks

evenly colorless.

18 DVD Contrast 1. Feed the color bar signal of

the 480I component signal to

the D-SUB input terminal.

2. Select the following subject.

Group : DVD

Subject : CONTRAST

3. Connect the oscilloscope to

TP805.

19 D VD Tint 1. Feed the color bar signal of

the 480I component signal

to the D-SUB input terminals. Feed the sync signal

only for the Y signal.

2. Select the following subject.

Group : DVD

Subject : TINT

3. Connect the oscilloscope to

TP807.

» Using the control switch or the button on the

remote controller, adjust the amplitude between

the black and 100% white to 2.1 ±0.02 Vp-p.

100% White

2.1±0.02Vp-p

» Using the control switch or the button on the

remote controller, adjust the B-Y waveform to form

a straight slope.

27

Page 28

XG-NV7XU

No. Adjusting point Adjusting conditions Adjusting procedure

20 DVD Color 1. Feed the color bar signal of

the 480I component signal to

the D-SUB input terminal.

2. Select the following subject.

Group : DVD

Subject : COLOR

3. Connect the oscilloscope to

TP804.

21 Color system

performance

check

22 Video system

performance

check

1. Receive the color bar signal.

1. Receive the monoscope

pattern signal.

» Adjust the level difference between the 100% white

and red portions to 0.1 ±0.02 Vp-p.

100% White Red

» In the process mode and select L1. Chec k the color

and tint.

» In the process mode and select L2. Check the pic-

ture, brightness and sharpness.

23 Audio system

performance

check

24 RGB1

performance

check

25 RGB2

panel link video

check

26 Off-timer

performance

check

» In the process mode nad select L3. Check the bass,

treble and balance.

1. Receive the RGB1 signal. » In the process mode and select L4. Check the pic-

ture, brightness, red, blue, clock, phase, horizontal

position, and vertical position.

1. Make the following settings:

RGB2 mode and XGA specific for panel link. Enter the

32-step gradation pattern.

» Make sure that the gradation pattern is not corrupted

and that the black portion is not too sinking.

» In the process mode and select OFF. Make sure that

the off-timer starts with “5” (minutes), counts down

each minute in 1 second, and turns off the set at “0”.

28

Page 29

No. Adjusting point Adjusting conditions Adjusting procedure

XG-NV7XU

27 Thermistor

performance

check

28 Automatic

synchronization

RGB1

(ANALOG)

29 Auto sync RGB

2 (panel link)

30 IrDA

performance

check

31 Keystone

correction

performance

check

1. Heat the thermistor using a

dryer.

1. Receive the PHASE check

pattern signal.

1. Receive the PHASE check

pattern signal.

» Make sure the “TEMP” is displayed.

» Call the VGA/S-VGA/XGA/SXGA/UXGA mode and

make sure that the clock, phase, horizontal and

vertical positions can be automatically adjusted.

» In the VGA/S-VGA/XGA/SXGA modes, make sure

that the H-POS and V-POS can be automatically

adjusted.

» Make sure the IrDA signal can be received.

» Make sure the keystone correction functions well.

» Make the following settings.32 Factory settings

Process

adjustment

Remote controller

setting

S4 “Factory setting 4”

29

Page 30

XG-NV7XU

ADJUSTING THE PC INTERFACE (CPCi-0036CE01. PC I/F Unit)

1. Initializing the EEPROM

1) Press the S5001 switch to call the process mode.

2) Pick up the item S1 on the SSS menu. (The S1 is used to initialize the PC interface alone. Do not select the

item S2 because otherwise the other data than the PC interface will be initialized.)

2. Adjusting the levels

1 Oscilloscope setting

Set the range to DC 1 V/div. and 5 µ s/div.

2 Input signal

Feed the XGA 1024x768, 60Hz gradation waveform signal and the DTV (720P for example) signal.

3 Level adjustment and checking

1) Press the S5001 switch to call the process mode.

2) Adjust R750 so that the voltage at test point TL119 be 2.6 ±0.05V.

3) Set the BRIGHT data on the A/D menu to 125.

4) Adjust the R-BRIGHT data on the A/D menu so that the voltage at TP3 be 1.7V.

5) Adjust the G-BRIGHT data on the A/D menu so that the voltage at TP2 be 1.7V.

6) Adjust the B-BRIGHT data on the A/D menu so that the voltage at TP1 be 1.7V.

7) Make sure that the GAIN data on the A/D menu is 155.

8) Connect the synchroscope to TP3. Adjust the R-D data on the A/D menu so that the signal’s white peak be

3.6V. (Be also sure that the white and black portions of the gradation are not corrupted.)

9) Connect the synchroscope to TP1. Adjust the B-D data on the A/D menu so that the signal’s white peak be

3.6V. (Be also sure that the white and black portions of the gradation are not corrupted.)

10)

Connect the synchroscope to TP2. Adjust the G-D data on the A/D menu so that the signal’s white peak

be 3.6V. (Be also sure that the white and black portions of the gradation are not corrupted.)

11)

Feed the DTV signal instead. Enter only the Y component, not the Pb and Pr components.

12)

Adjust the R-BRIGHT data on the DTV menu so that the voltage at TP3 be 2.65V.

13)

Adjust the B-BRIGHT data on the DTV menu so that the voltage at TP1 be 2.65V.

14)

Press the S5001 switch to exit the process mode.

30

Page 31

TROUBLE SHOOTING TABLE

Checking the PWB performance

XG-NV7XU

Video input in trouble

Go to "Checking the video unit

circuit".

RGB input in trouble

Feed test pattern signal from

PC.

Is specified cable connected

between PC and projector?

Yes

Is supply voltage as specified?

Yes

Does image appear?

Yes

Go to "Trouble shooting table

for PC I/F unit ".

Remote control in trouble

Go to "Checking the remote

control".

No

Use specified cable.

No

Power circuit in trouble.

No

Check the connectors, starting

from the PC input circuit.

31

Page 32

XG-NV7XU

TROUBLE SHOOTING TABLE (Continued)

Checking the video system

Is the lamp on?

Are specified voltage fed to PA and

PB connectors?

Are there signal inputs at pins (12),

(13) and (17) of SC302?

Are there signal outputs at pins (7) of

IC6006 and (5) of IC6009?

Yes

Go to "Checking IC801

(RGB signal output circuit)".

No

Yes

No

Yes

No

Yes

No

Check IC6008, IC6006,

IC6009 and their peripheral

circuits as well as switching

circuit.

Go to "Lamp fails to light-up".

Check the power circuit and its parts.

Is there signal at pin (4) of IC6001?

Yes

Check the video unit circuit

(IC4501 and IC4001 and its

peripheral circuits).

No

Check the oscillation circuit

of IC6001, and their

peripheral circuits.

32

Page 33

TROUBLE SHOOTING TABLE (Continued)

Checking the Video unit circuit

XG-NV7XU

Is there video signal output at pin (7)

of IC3401?

Yes

Is there video signal input at IC4001?

Yes

Are there signal outputs at pins (6)

and (8) of IC4001?

Yes

Check the low-pass and buffer circuits

of Q4004 thru Q4008. Is the signal as

specified?

Yes

Go to "Checking IC801 (RGB signal

output circuit)".

No

Check the IC3401 selector switch,

terminal voltage and input circuit.

No

Check the low-pass and buffer

circuits of Q4002 thru Q4005.

No

Check IC4001 and its peripheral

circuits (bias).

No

Check Q4004 thru Q4008 and their

peripheral circuits.

33

Page 34

XG-NV7XU

TROUBLE SHOOTING TABLE (Continued)

Checking IC801 (RGB signal output circuit)

No

Are there RGB output waveforms at

pins (31), (32) and (33) of IC801?

Go to "No color or unusual tone",

"No Y signal" or "Out of sync".

Are there output waveforms at pin

(1) of IC6803, IC6804, IC6805?

Are A/D outputs of IC6805, IC6806

and IC6807 as specified?

Go to "Trouble shooting table for PC

I/F unit".

Yes

Yes

Yes

Checking the chroma and Y signals of IC801

No

Check the data transfer and other

performance at pins (17) and (18) of

video IC801.

No

Check IC6802, IC6803, IC6804,

IC6805 and their peripheral circuits.

No

Check the CLK IC6805, IC6806,

IC6807 and their peripheral circuits.

(RGB signal output)

Are there signal inputs at pins (7), (9)

and (25) of SC401?

Yes

Are there output waveforms at pins

(7) of IC6010 (chroma signal) and

(5), (Y signal)of IC6009?

Yes

Are there signal inputs at pins (20)

(chroma signal) and (21) (Y signal)

of IC801?

Yes

Go to "Checking IC801 (RGB signal

output circuit)".

No

Go to "Checking the video unit

circuit".

No

Check the IC6009 and IC6010

switching and their peripheral circuits. If

there is no signal at pins (1) of IC6010

and pin (16) of IC6009 check 3-D noise

reduction circuit (IC8001).

No

Check IC801 and its peripheral

circuits.

Check IC806 (3-D noise reduction

circuit) and its peripheral circuits.

34

Page 35

TROUBLE SHOOTING TABLE (Continued)

Checking IC6008 (3-D noise reduction circuit)

and its peripheral circuits

XG-NV7XU

Are there signal inputs at pins (40)

(Y signal) and (45)(chroma signal) of

IC6008?

Yes

Are there signal outputs at pins (55)

(Y signal) and (51)(chroma signal) of

IC6008?

Yes

Are there signal outputs at the

emitters of Q6013 (Y signal) and

Q6011 (chroma signal)?

Yes

Check IC6009, IC6010 and IC801

(RGB signal output circuit).

No

Check the buffer circuit of Q6001,

Q6003, Q6004, Q6006 and Q6007

as well as Q6009 and Q6010.

No

Check IC6007, IC6010 (memory) and

their peripheral circuits.

No

Check the low-pass circuit around

Q6011, Q6012 and Q6013.

No color or unusual tone (NTSC, PAL)

Is there chroma signal input at pin

(20) of IC801?

Yes

Are there signal outputs at pins

(46)(R-Y) and (45)(B-Y) of IC801?

Yes

No

Go back to the signal processing

block.

No

Check the oscillation of X801 and

X802, and their peripheral circuits.

Check IC805, IC814 and their

peripheral circuits.

35

Page 36

XG-NV7XU

TROUBLE SHOOTING TABLE (Continued)

No or unusual Y signal

Is there Y signal input at pin (21) of

IC801?

Yes

Is there Y signal output at pin (40) of

IC801?

Yes

Is there Y signal output at pin (17) of

IC805?

Yes

Check IC805 and its peripheral

circuits.

No

Go back to the signal processing

block.

No

Check IC801 and its peripheral

circuits.

No

Check IC805 and its peripheral

circuits as well as IC807 (AGC).

No or unusual horizontal sync

Is there horizontal sync pulse output

at pin (56) of IC801?

Yes

Is there horizontal sync pulse output

at pin (9) of IC803?

Yes

No

Check IC801 and its peripheral

circuits.

No

Check the pulse shaping circuit of

IC802 and IC803.

Go to "Trouble shooting table for PC

I/F unit".

No or unusual vertical sync

Is there vertical sync pulse output at

pin (4) of IC801?

Yes

Go to "Trouble shooting table for

PC I/F unit".

No

36

Check IC801 and its peripheral

circuits.

Page 37

TROUBLE SHOOTING TABLE (Continued)

No audio output

XG-NV7XU

Is there audio signal inputs at pin (2)

of IC302?

Is there audio signal outputs at pin (7)

of IC302?

Is there audio signal outputs at pin (6)

of IC301?

If the voltage at pin (7) of IC301 is

not as specified, check Q302, Q303

and their peripheral circuits.

Checkig the Power Unit

No

Yes

No

Yes

No

Yes

Check IC301 and its peripheral

circuits, and the SP connectors and

speakers.

Check the input, the switching circuit

of IC3301 and IC3302, and their

peripheral circuit.

Check the IC5201 control voltage,

and its peripheral circuits.

Check IC301 and its peripheral

circuits.

There are no voltage output at

PA and PB connector.

No

Are PA and PB connector

disconnected or loose?

No

Are AC power switch

(QCNW-5413CEZZ) and

bimetal nomal?

Yes

Replace Power Unit.

Yes

Reconnect the PA and PB

connector.

No

Replace AC Power Switch

(QCNW-5413 CEZZ).

37

Page 38

XG-NV7XU

TROUBLE SHOOTING TABLE (Continued)

Power on

Is the right input selected?

Yes

Are the PC, video and LCP cables as

specified and properly connected?

Yes

With the contrast control at maximum,

does the image appear?

No

Is the voltage at PA and PB

connectors as specified?

Yes

Does the image appear?

Yes

Is the image as specified?

No

Select the right input with remote

control.

No

Use the right cables or reconnect the

cables.

Yes

Readjust the video system.

No

Power circuit faulty.

No

Go to "Checking the clock circuit and

its peripheral circuits".

No

Yes

Is the image's colour as specified?

Yes

A

Does the on-screen display function?

Yes

Does the remote control function?

Yes

End

Check the sync signal circuit and its

peripheral circuits.

No

Check the video circuit and its

peripheral circuits.

No

Go to "Checking the OSD circuit and

its peripheral circuits".

No

Go to "Checking the remote control".

38

Page 39

TROUBLE SHOOTING TABLE (Continued)

Lamp fails to light-up

Turn on the power switch. Is

Yes

discharging sound heard from

the lamp?

XG-NV7XU

Is the lamp out of socket?

Yes

Reconnect the

lamp into socket.

No

Replace the

lamp.

Is power supplied on DMD

formatter?

P8503: pins (1), (3) and (5); 5V

pins (7), (9) and (11); 12V

pins (13), (15), (17)

and (21); 3.3V

Is 2.5V voltage applied between

pins (1) and (3) of DC connector?

Are the cooling fans running?

Is DC 380V voltage applied

between pins (1) and (3) of PL

connector and DC 12V voltage

applied between pins (4) and

(5) of PL connector?

Yes

No

No

No

Yes

Check the power circuit.

NoYes

No No

Yes

Is specified voltage applied at

PA and PB connectors?

Yes

Reconnect the connectors to

their sockets.

Ballast unit in trouble.

DMD output formatter in

trouble.

Is color wheel turning?

Yes

Is there vertical sync signal

input at pin (47) of P8503?

Yes

PC board in trouble.

No

No

Is DB connector or flexible

cable out of position or in poor

contact?

Yes

Reconnect the connector

tightly.

DMD output formatter in

trouble.

39

No

DMD output formatter in

trouble.

Page 40

XG-NV7XU

TROUBLE SHOOTING TABLE FOR PC I/F UNIT-1

Checking the clock circuit and its peripheral circuits

Is X8001 (6MHz) oscillating?

Yes

Is X8002 (32.768kHz) oscillating?

Yes

Is X8003 (1.84MHz) oscillating?

Yes

Is X8004 (22.165MHz) oscillating?

Yes

Is X8005 (14.3185MHz) oscillating?

Yes

Does pin (162) of IC8001 function?

Yes

Checking the panel link input.

Is the signal a panel link input?

Yes

No

No

No

No

No

No

No

X8001 or its peripheral part faulty.

X8002 or its peripheral part faulty.

X8003 or its peripheral part faulty.

X8004 or its peripheral part faulty.

X8005 or its peripheral part faulty.

IC8001 or its peripheral circuit faulty.

B

Are there signals at pins (1) thru (8)

of connector P8003?

Yes

Are there sync signals at pins (47)

and (48) of IC8298?

Yes

B

No

No

Terminal unit defective.

IC8298 defective.

40

Page 41

TROUBLE SHOOTING TABLE FOR PC I/F UNIT-2

Checking the sync signal circuit and its peripheral parts

B

No

Is the sync signal of separate type?

Yes

Are there signals at TP4 and TP5?

Yes

No

Is the sync signal SYNC ON GREEN?

Yes

Is there signal at pin (7) of IC8036?

Yes

Are there signals at pins (149)(TL8034)

and (150)(TL8035) of IC8020?

Yes

No

Is the input a lower-than-XGA-resolution

signal or a video signal?

Yes

Are there signals at pins (26)(TL8043),

(28)(TL8041) and (29)(TL8042) of IC8020?

Yes

Are there signals at even-numbered pins

from (52) thru (100) of IC8503?

Yes

No

No

No

No

No

IC302 or terminal unit defective.

IC23, IC34, IC36 or peripheral part

defective.

IC8025 or peripheral part defective.

IC8020 or peripheral part defective.

IC8029 or peripheral part defective.

XG-NV7XU

C

Checking the PLL circuit and its peripheral parts

C

Are there signals at pins (6) and (22) of

IC8015?

Yes

Are there signals at pins (18) and (19) of

IC8015?

Yes

Checking the video circuit and its

peripheral parts.

Is the higher-than-XGA-resolution display

as specified?

Yes

Is the lower-than-XGA-resolution display

as specified?

Yes

No

No

No

No

IC8025 or peripheral part defective.

IC8015 or peripheral part defective.

Is there a panel link input?

Go to "Checking the SXGA video circuit

and its peripheral parts".

Is there a panel link input?

Go to "Checking the aVGA video circuit

and its peripheral parts".

Yes

D

No

Yes

E

No

Is the display as specified with VCR

connected?

Yes

A

No

Go to "Checking the video circuit and its

peripheral parts".

41

Page 42

XG-NV7XU

TROUBLE SHOOTING TABLE FOR PC I/F UNIT-3

Checking the SXGA

red video circuit

and its peripheral

parts

Is there signal at pin (6) of IC8067?

Yes

Is there signal at the base of Q8009?

Yes

Is there signal at pin (6) of IC8011?

D

Are there signals at pins (21) thru (27)

as well as (33) thru (40) of IC8011?

Are there signals at TL8044 and

TL8046?

Yes

Yes

Yes

No No

Terminal unit, IC301, IC313 or IC312

defective.

No No

IC8067 or peripheral part defective.

No No

Q8009 or peripheral part defective.

No No

IC8011 or peripheral part defective.

No

IC8025 or peripheral part defective.

IC8020 or peripheral part defective.

No

No

Checking the VGA

red video circuit

and its peripheral

parts

Is there signal at pin (6) of IC8067?

Yes

Is there signal at the base of Q8009?

Yes

Is there signal at pin (6) of IC8011?

Yes

Are there signals at pins (21) thru (27)

as well as (33) thru (40) of IC8011?

Yes

Are there signals at pins (112) thru

(119) of IC8020?

Yes

Are there signals at pins (69) thru (73)

as well as (189) thru (192) of IC8020?

Yes

E

F

Are there signals at pins (2) thru (9) of

IC8294?

Yes

Are there signals at pins (86), (88), (90),

(92), (94), (96), (98) and (100) of IC8503?

Yes

Connector P8503 or formatter unit

defective.

No

IC8029 or peripheral part defective.

No

IC8294 or peripheral part defective.

Formatter unit defective.

42

Checking the red

video circuit and

its peripheral parts

No

Are there signals at pins (35) thru (42)

of connector SC8001?

Yes

F

Page 43

TROUBLE SHOOTING TABLE FOR PC I/F UNIT-4

XG-NV7XU

Checking the SXGA

green video circuit

and its peripheral

parts

Is there signal at pin (6) of IC8066?

Yes

Is there signal at the base of Q8007?

Yes

Is there signal at pin (6) of IC8010?

D

Are there signals at pins (21) thru (27)

as well as (33) thru (40) of IC8010?

Are there signals at TL8045 and

TL8047?

Yes

Yes

Yes

No No

Terminal unit, IC301, IC313 or IC312

defective.

No No

IC8066 or peripheral part defective.

No No

Q8007 or peripheral part defective.

No No

IC8010 or peripheral part defective.

No

IC8025 or peripheral part defective.

IC8020 or peripheral part defective.

No

No

Checking the VGA

green video circuit

and its peripheral

parts

Is there signal at pin (6) of IC8066?

Yes

Is there signal at the base of Q8007?

Yes

Is there signal at pin (6) of IC8010?

Yes

Are there signals at pins (21) thru (27)

as well as (33) thru (40) of IC8010?

Yes

Are there signals at pins (165) thru

(177) of IC8020?

Yes

Are there signals at pins (178) thru

(187) of IC8020?

Yes

E

G

Are there signals at pins (2) thru (9) of

IC8295?

Yes

Are there signals at pins (70), (72), (74),

(76), (78), (80), (82) and (84) of IC8503?

Yes

Connector P8503 or formatter unit

defective.

No

IC8029 or peripheral part defective.

No

IC8295 or peripheral part defective.

Formatter unit defective.

43

Checking the green

video circuit and its

peripheral parts

No

Are there signals at pins (25) thru (32)

of connector SC8001?

Yes

G

Page 44

XG-NV7XU

TROUBLE SHOOTING TABLE FOR PC I/F UNIT-5

Checking the SXGA

blue video circuit

and its peripheral

parts

Is there signal at pin (6) of IC8065?

Yes

Is there signal at the base of Q8005?

Yes

Is there signal at pin (6) of IC8009?

D

Are there signals at pins (21) thru (27)

as well as (33) thru (40) of IC8009?

Are there signals at TL8048 and

TL8049?

Yes

Yes

Yes

No No

Terminal unit, IC301, IC313 or IC312

defective.

No No

IC8065 or peripheral part defective.

No No

Q8005 or peripheral part defective.

No No

IC8009 or peripheral part defective.

No

IC8025 or peripheral part defective.

IC8020 or peripheral part defective.

No

No

Checking the VGA

blue video circuit

and its peripheral

parts

Is there signal at pin (6) of IC8065?

Yes

Is there signal at the base of Q8005?

Yes

Is there signal at pin (6) of IC8009?

Yes

Are there signals at pins (21) thru (27)

as well as (33) thru (40) of IC8009?

Yes

Are there signals at pins (85) thru (93)

of IC8020?

Yes

Are there signals at pins (74) thru (83)

of IC8020?

Yes

E

F

Are there signals at pins (2) thru (9) of

IC8296?

Yes

Are there signals at pins (54), (56), (58),

(60), (62), (64), (66) and (68) of IC8503?

Yes

Connector P8503 or formatter unit

defective.

No

IC8029 or peripheral part defective.

No

IC8296 or peripheral part defective.

Formatter unit defective.

44

Checking the blue

video circuit and its

peripheral parts

No

Are there signals at pins (15) thru (22)

of connector SC8001?

Yes

H

Page 45

TROUBLE SHOOTING TABLE FOR PC I/F UNIT-6

Checking the OSD circuit and its peripheral circuits

Display OSD on the screen.

XG-NV7XU

Are there signals at pins (56), (58),

(71) and (72) of IC8048 (TL8054,

TL8053, TL8052 and TL8051)?

Yes

Are there signals at pins (12), (14)

thru (17) and (20) of IC8046?

Yes

Are there signals at pins (23) thru

(42) of IC8046?

Yes

IC8048 or its peripheral circuit faulty.

No

IC8029 or its peripheral circuit faulty.

No

IC8048 or its peripheral circuit faulty.

No

IC8046 or its peripheral circuit faulty.

Checking the remote control

Run the remote control. Are there

signals at pin (47) of P8405 connector

(or R294)?

Yes

No

Output unit faulty.

Using remote controller, is there

signal at pin (8) of IC8001?

Yes

IC8001 faulty.

No

IC8006 circuit faulty.

45

Page 46

CHASSIS LAYOUT

MAIN UNIT

H

G

F

DUNTK9965DE01

XG-NV7XU

BALLAST UNIT

9FU768815400

TERMINAL UNIT

DUNTK9966DE01

PC I/F UNIT

CPCI-0036CE01

E

R/C UNIT

DUNTK9967DE01

D

C

POWER UNIT

9FU768813500

OUTPUT UNIT

9FU768550000

B

S-OUT UNIT

DUNTK9968DE01

A

121110987654321

46

47

Page 47

BLOCK DIAGRAM

H

TERMINAL UNIT

G

F

XG-NV7XU

E

D

C

B

A

121110987654321

48

49

Page 48

O VERALL WIRING DIAGRAM

H

G

F

XG-NV7XU

E

TERMINAL

D

C

B

A

121110987654321

50

51

Page 49

XG-NV7XU

P8503

H

Pin No.

1, 3, 5

7, 9, 11

13, 15, 17, 19

21

G

F

E

D

C

23

25

29

31

33

35

37

39

40

41

42

43

45

47

49

52

54, 56, 58, 60,

62, 64, 66, 68

70, 72, 74, 76,

78, 80, 82, 84

86, 88, 90, 92,

94, 96, 98, 100

DESCRIPTION OF CONNECTOR

I/O

O

O

O

I/O

O

O

O

O

O

O

I

I

O

O

O

O

O

O

O

O

O

O

O

Pin Name

VDD

P12V

P3P3V

SCL

SDA

OLACT

TESTEN

CWINDEX

TFIELD

GYO

LAMPSYNC

LAMPEN

LAMPLIT

PWRGOOD

RESETZ

SYNCVAL

HSYNCZ

VSYNCZ

ACTDATA

CLKIN

BU0-7

GY1-8

RV0-7

Signal Name

Serial BUs CLock

Serial BUs Date

Overlay Active

Test Enable

Color Wheel Index

Lamp Sync

Lamp Enable

Lamp Lit Indication

System Power Good

System Reset Sign

Sync V alid

H-sync

V-sync

Active Data

Clock in

+5V

+12V

+3.3V

I2C bus clock

I2C bus data

Not used (pull-down)

Not used (pull-down)

Color wheel turn detection signal

Not used (pull-down)

Not used (pull-down)

Lamp AC drive control pulse signal

Not used (open)

Not used (pull-up)

DMD output power control signal, High = ON

Lamp on control signal

Not used (pull-up)

Horizontal sync

Vertical sync

Screen active signal

Dot clock (57.27MHz)

Blue data signal

Green data signal

Red data signal

Description

P8011 “DC”

Pin No.

1

3

B

I/O

O

I

Pin Name

SCI

LAMPFLUG

Signal Name

Start Control Input

Lamp Flug

Lamp AC drive control pulse signal

Low = Lamp on, High = Lamp off

P8021 “DB”

Pin No.

4

Note: The I/O (input or output) is a signal flow that is seen from the PC interface unit.

A

I/O

I

Pin Name

CWINDEX

Signal Name

Color Wheel Index

Color wheel turn detection signal

52

Description

Description

87109654321

Page 50

DESCRIPTION OF SCHEMATIC DIAGRAM

XG-NV7XU

VOLTAGE MEASUREMENT CONDITION:

1. Voltages at test points are measured at the

supply voltage of AC 120V. Signals are fed by a

color bar signal generator for servicing purpose and

the above voltages are measured with a 20k ohm/V

tester.

WAVEFORM MEASUREMENT CONDITION:

1. Wav eforms at test points are observed at the supply

voltage of AC 120V. Signals are fed by a color bar

signal generator for servicing purpose.

INDICATION OF RESISTOR & CAPACITOR:

RESISTOR

1. The unit of resistance “Ω” is omitted.

(K=kΩ=1000 Ω, M=MΩ).

2. All resistors are ± 5%, unless otherwise noted.

(J= ± 5%, F= ± 1%, D= ± 0.5%)

3. All resistors are 1/10W, unless otherwise noted.

4. All resistors are Carbon type, unless otherwise

noted.

C : Solid

S : Oxide Film T : Special

N : Metal Coating

W

: Cement

CAPACITOR

1. All capacitors are µF, unless otherwise noted.

(P=pF=µµF).

2. All capacitors are 50V, unless otherwise noted.

3. All capacitors are Ceramic type, unless otherwise

noted.

(ML): Mylar (TA): Tantalum

(PF): Polypro Film (ST): Styrol

CAUTION:

This circuit diagram is original one, therefore there may be a

slight difference from yours.

SAFETY NOTES:

1. DISCONNECT THE AC PLUG FROM THE AC

OUTLET BEFORE REPLACEING PARTS.

2. SEMICONDUCTOR HEAT SINKS SHOULD BE

REGARDED AS POTENTIAL SHOCK HAZARDS

WHEN THE CHASSIS IS OPERATING.

IMPORTANT SAFETY NOTICE:

PARTS MARKED WITH “å” ( ) ARE

IMPORTANT FOR MAINTAINING THE SAFETY OF

THE SET. BE SURE TO REPLACE THESE PARTS

WITH SPECIFIED ONES FOR MAINTAINING THE

SAFETY AND PERFORMANCE OF THE SET.

1 TP804

(R)

H : 10µsec/div

V : 0.5V/div

5 Q6008 Emitter

(4FSC)

H : 50µsec/div

V : 0.5V/div

WAVEFORMS

2 TP805

(G)

H : 20µsec/div

V : 0.5V/div

6 Q4008 Emitter

(Y-signal)

H : 10µsec/div

V : 0.2V/div

3 TP807

(B-Y)

H : 20µsec/div

V : 1V/div

7 Q4006 Emitter

(CHROMA signal)

H : 10µsec/div

V : 0.2V/div

4 IC801 56-pin

(H-OUT)

H : 20µsec/div

V : 1V/div

1716 1918151413121110

53

Page 51

XG-NV7XU

Ë

MAIN UNIT-1/7

H

G

F

E

D

C

B

A

121110987654321

54

55

Page 52

XG-NV7XU

Ë

MAIN UNIT-2/7

H

G

F

E

D

C

B

A

121110987654321

56

57

Page 53

XG-NV7XU

Ë

MAIN UNIT-3/7

H

G

F

E

D

C

B

A

121110987654321

58

59

Page 54

XG-NV7XU

Ë

MAIN UNIT-4/7

H

G

F

E

D

C

B

A

121110987654321

60

61

Page 55

XG-NV7XU

Ë

MAIN UNIT-5/7

H

G

F

E

D

C

B

A

121110987654321

62

63

Page 56

XG-NV7XU

Ë

MAIN UNIT-6/7

H

G

F

E

D

C

B

A

121110987654321

64

65

Page 57

XG-NV7XU

Ë

MAIN UNIT-7/7

H