Page 1

X2 TECH, X2 Graphic

Printer User Guide

701P36677 February 2001

Page 2

Page 3

Introduction

This Introduction overviews the ColorgrafX X2. Additionally, this

chapter provides information on how to use this guide as well as

the location of information you will need to operate, maintain,

and service the ColorgrafX X2.

Welcome to the ColorgrafX X2

Congratulations on acquiring your new ColorgrafX X2.

Xerox Engineering Systems (XES) looks forward to helping you

increase your organizational productivity through full XES

support with the ColorGrafX hardware, software, supplies, and

service.

Your ColorgrafX X2 is a flexible, high speed six-color (graphics

model) or four-color TECH model) inkjet printer, with piezo head

technology. The printer produces vivid, near photographic quality

prints. Its two media input rolls, automatic cutter, extra large ink

capacity, and heavy-duty design make this production printer

ideal for high volume print production. The compact footprint,

quiet printing, auto-alignment, auto-cleaning and permanent

heads (no more replacing cartridges in the middle of a print

operation) also make this printer ideal for the in-house corporate

graphics environment.

About this guide

This user guide contains information you need to operate and

maintain the ColorgrafX X2 safely and efficiently. Please read

this guide carefully. Always refer to this user guide if a problem

occurs during the use of the ColorgrafX X2.

Introduction i

Page 4

About this guide (con’t)

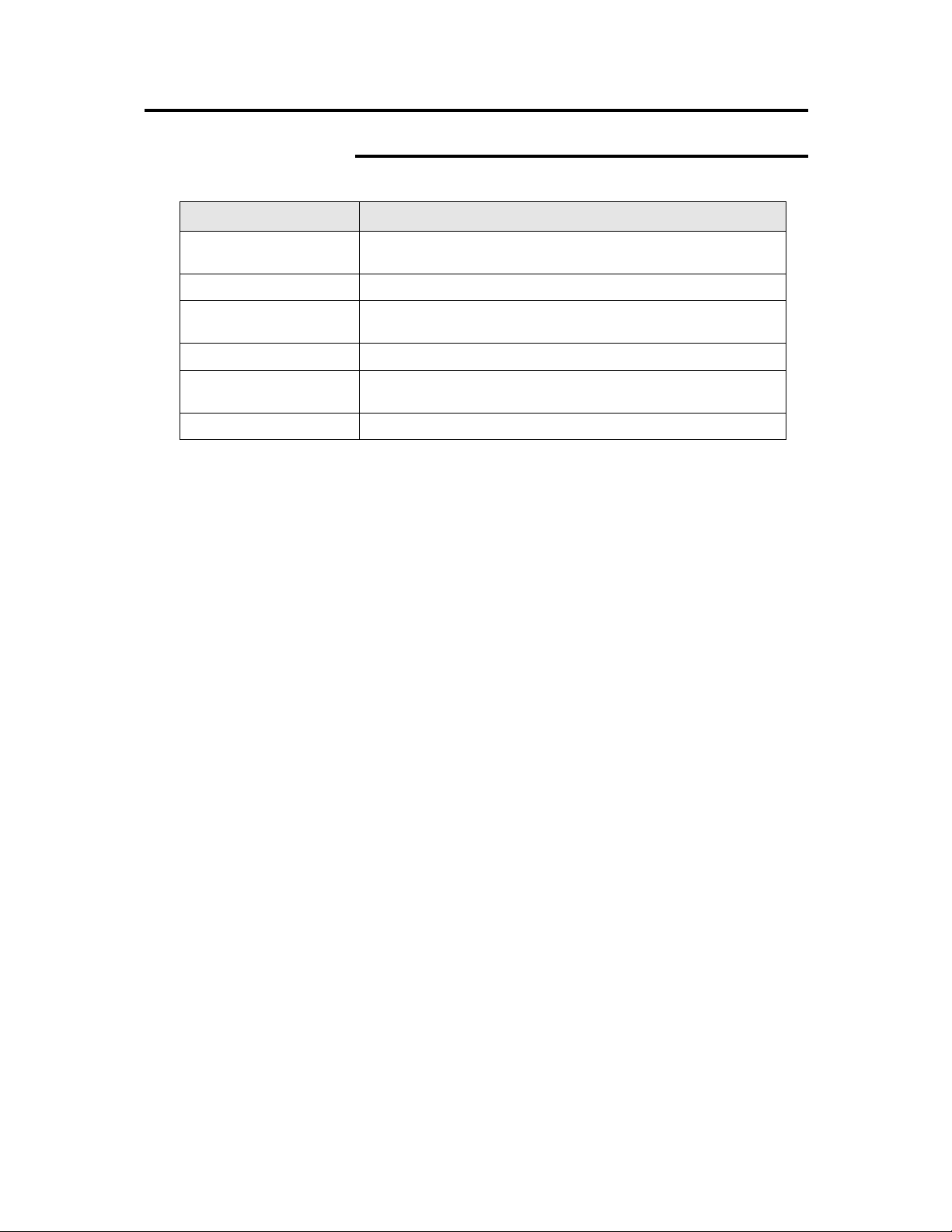

Conventions

Special conventions are used in this user guide to help you get

the most from the guide.

Typefaces and symbols in the guide identify terms and

conditions. The table below provides you with a description of

the typefaces and symbols used in this user guide.

Typeface Symbol Description

Bold

Italic

Italic

Bold and

Normal

Bold

Normal

None Identifies an action to perform, like press a button or select

an area on the touch screen It also identifies terms, a

feature, an option or message.

Example 1: Select print.

Example 2: The ready to copy message is displayed.

Example 3: The normal R/E screen is displayed.

None Identifies a chapter or section title in this guide. For more

information refer to the chapter or the section title.

Note: The symbol on the left and the word note at the

beginning of a sentence indicates additional information,

explanations, and helpful suggestions.

Caution: The symbol on the left and the word Caution at

the beginning of a sentence alerts the user that certain

operations or procedures may cause damage to the

machine.

WARNING: The symbol on the left and the word

warning at the beginning of a sentence alerts the user to

an operation that could cause injury to them.

This symbol identifies a web site address.

Normal

ii Introduction

This symbol identifies a phone number.

Page 5

About this guide (con’t)

Organization

The ColorgrafX X2 user guide contains seven chapters and two

appendices. Each chapter may contain several sections. This

section provides you with a brief overview of each chapter.

For detailed information, refer to the appropriate chapter and

section.

Introduction This chapter provides customer support, compliance, legal

issues, safety information, and the phone numbers for service

and supplies.

Getting to know

the ColorgrafX X2 This chapter introduces you to the ColorgrafX X2’s features and

components.

Operation This chapter describes the procedures to operate the ColorgrafX

X2, including menu options used at the printer’s operation panel.

Supplies This chapter provides the procedures to replace inks and media

as well as the requirements to properly store your supplies to

ensure optimal print quality.

Maintaining

Print quality This chapter provides detailed procedures to adjust the printer

for clear, sharp print output with maximum resolution and sharp

details.

Jam clearance This chapter provides the procedures to clear media jams from

both the media transport and the cutter assembly.

Appendix A

In case of difficulty Appendix A provides problem solving information. When a

machine problem occurs, go to this section first to assist you with

troubleshooting the problem. This chapter also provides the

phone number to call for service.

Appendix B

Menu tree Appendix B provides a complete operations panel menu tree

along with associated descriptions of each option.

Introduction iii

Page 6

Customer support

Service

Should you be unable to resolve a problem, place a call to your

Xerox Engineering Systems service representative.

Your service representative will assist you in keeping your

ColorgrafX X2 operating and if required, arrange for a customer

service engineer to inspect your ColorgrafX X2 and restore its

performance.

When you call service you will need the machine serial number.

You can determine the serial number from the label located on

the rear of the unit.

Fill in each item below. When you call for service, they will

request this information.

Customer account name:

Customer account number:

Machine type:

Machine serial number:

Purchase date:

Please call your Xerox Engineering Systems service representative.

For more information, visit the Xerox Engineering Systems web site

at http://www.xes.com

.

Supplies

To order supplies for the ColorgrafX X2, call your Xerox Engineering

Systems representative.

For more information, visit the Xerox Engineering Systems web site

at http://www.xes.com

.

iv Introduction

Page 7

Compliance information

FCC Compliance in the USA

WARNING: This equipment has been tested and found to

comply with the limits for a Class A computing device pursuant

to Subpart B of Part 15 FCC Rules.

This equipment generates, uses, and can radiate radio

frequency energy and, if it is not installed and used in

accordance with the instruction guide, may cause interference to

radio communications. These limits are designed to provide

reasonable protection against such interference when operated

in a commercial environment. Operation of this equipment in a

residential area is likely to cause interference, in which case the

user, at his own expense, will be required to take whatever

measures may be required to correct the interference.

EME Compliance in Canada

This digital apparatus does not exceed the Class A limits for

radio noise emissions from digital apparatus set out in the radio

interference regulations of the Canadian Department of

Communications.

Conformité EEM

Cet appareil numérique est conforme aux limites d'émission de

bruits radioélectriques pour les appareils de classe A stipulées

dans le Règlement sur le brouillage radioélectrique du Ministère

des Communications du Canada.

Introduction v

Page 8

It’s illegal

In the USA

It is against U.S. law to reproduce copyrighted material without

the permission of the copyright owner unless the copying falls

within the "Fair Use" library reproduction rights of the copyright

law.

Further information on these U.S. provisions may be obtained from

the Copyright Office, Library of Congress, Washington, D.C. 20550,

or telephone the Copyright Office at (202) 707-9100 and ask for

circular 21. Copying other items may be prohibited. If you have any

questions seek legal advice.

In Canada

Parliament, by statute, has forbidden the copying of the following

subjects under certain circumstances. Penalties of fines or

imprisonment may be imposed on those guilty of making such

copies.

Current bank notes or current money.

Obligations or securities of a government or bank.

Exchequer bill paper or revenue paper.

The public seal of Canada or of a province, or the seal of a

public body or authority in Canada, or of a court of law.

Proclamations, orders, regulations or appointments, or notices

thereof (with intent to falsely cause same to purport to have been

printed by the Queen’s Printer for Canada, or the equivalent

printer for a province).

Marks, brands, seals, wrappers, or designs used by or on behalf

of the Government of Canada or of a province, the government

of a state other than Canada, or a department, board,

commission or agency established by the Government of

Canada, or a province or a government of a state other than

Canada.

Impressed or adhesive stamps used for the purpose of revenue

by the Government of Canada or a province or the government

of a state other than Canada.

Documents, registers, or records kept by public officials charged

with the duty of making or issuing certified copies thereof, where

the copy falsely purports to be a certified copy thereof.

Copyright material or trademarks of any manner or kind without

the consent of the copyright or trademark owner.

The above list is provided for your convenience and assistance,

but is not all-inclusive, and no liability is assumed for its

completeness or accuracy. In case of doubt, consult your

solicitor.

vi Introduction

Page 9

Safety notes

Your system has been designed and tested to meet strict safety

requirements. These include safety agency examination and

approval plus compliance with established environmental

standards.

WARNING: Failure to follow the recommendations in this

section may result in personal injury or rescinding of the

machine operation agreement.

Maintenance safety

Follow all warnings and instructions marked on or supplied with

the product.

Unplug the units from the wall outlet before cleaning the exterior.

Always use materials specifically designated for the ColorgrafX

X2. Use of other materials may result in poor performance and

could create a hazardous situation.

Do not use aerosol cleaners. Follow the instructions in this

operator guide for the correct cleaning methods.

Never use supplies or cleaning materials for purposes other than

what they were intended. Keep all supplies and materials out of

the reach of children.

Do not use the units near water, wet locations, or outdoors.

The components of this product are equipped with a three-wire,

grounding-type plug (i.e., a plug having a grounding pin). This

plug will only fit into a grounding-type power outlet. This is a

safety feature. To avoid the risk of electric shock, contact your

electrician to replace the receptacle if you are unable to insert

the plug into the outlet.

Never use a ground adapter plug to connect the system to a

power source that lacks a ground connection terminal.

This system should be operated from the type of power source

indicated on the marking label. If you are not sure of the type of

power available, consult your local power company.

The power supply cord is the disconnect device for this

equipment. Make sure that the installation is near the socket

outlet and is easily accessible.

Do not allow anything to rest on the power cord. Do not locate

the units where someone will step on the cord.

The units should not be placed in a built-in installation unless

correct ventilation is provided.

Introduction vii

Page 10

Safety notes (con’t)

Maintenance safety (con’t)

Never push objects of any kind into the slots of the units as they

may touch dangerous voltage points or short out parts that could

result in a risk of fire or electric shock.

Never spill liquid of any kind on the units.

Never remove any covers or guards that require a tool for

removal. There are no operator serviceable areas within these

covers.

Never attempt any maintenance function that is not specified in

this operator guide.

Never defeat interlock switches. Machines are designed to

prevent operator access to unsafe areas. Covers, guards, and

interlock switches are provided to ensure that the system will not

operate with the covers opened.

If the power plug is used as a disconnect device, instructions

shall comply with UL 1950 Sec. 1.7.2. The power switch does

not break power to the low voltage power supply.

Unplug the reprographic system from the wall outlet and call for

service under the following conditions:

When the power cord is damaged or frayed.

If the gas piston springs in the upper cover of the printer lose

their strength.

If liquid has been spilled into the product.

If the units have been exposed to rain or water.

If the units are producing unusual noises or odors.

If the units or the cabinets have been damaged.

If you need additional safety information concerning the

ColorgrafX X2 or XES supply materials, call:

Please call your Xerox Engineering Systems representative.

viii Introduction

Page 11

Table of contents

Introduction .....................................................................................................................i

Welcome to the ColorgrafX X2....................................................................................i

About this guide ........................................................................................................... i

Conventions ............................................................................................................ ii

Organization........................................................................................................... iii

Customer support ....................................................................................................... iv

Service ................................................................................................................... iv

Supplies.................................................................................................................. iv

Compliance information.............................................................................................. v

FCC Compliance in the USA................................................................................... v

EME Compliance in Canada.................................................................................... v

Conformité EEM..................................................................................................... v

It’s illegal................................................................................................................... vi

In the USA ............................................................................................................. vi

In Canada ............................................................................................................... vi

Safety notes............................................................................................................... vii

Maintenance safety................................................................................................ vii

Getting to know your ColorgrafX X2 .............................................................................. 1

Feature overview.........................................................................................................1

High-speed / high quality printing ...........................................................................1

Quick drying Ink ..................................................................................................... 2

Media widths........................................................................................................... 3

Media types.............................................................................................................3

Minimum down-time...............................................................................................4

Printer components...................................................................................................... 5

Front view ............................................................................................................... 5

Right-side view ....................................................................................................... 5

Rear view ................................................................................................................ 6

Operation panel ....................................................................................................... 9

Operations..................................................................................................................... 12

Operations panel menu.............................................................................................. 12

Entering menu mode.............................................................................................. 12

Menu options......................................................................................................... 13

Set mode ...............................................................................................................14

Starting a print job..................................................................................................... 22

Operating the cutter...................................................................................................23

Replacing cutter blade ........................................................................................... 24

Using the take-up roller ............................................................................................. 26

Setup the take-up assembly.................................................................................... 26

Starting the take-up roller ...................................................................................... 27

Operating the printer from RIP software....................................................................27

Supplies ........................................................................................................................ 28

Replacing ink bottles................................................................................................. 28

Precautions............................................................................................................28

When to replace ink bottle ..................................................................................... 28

Introduction ix

Page 12

Replacement procedures........................................................................................29

Replacement procedures........................................................................................30

Replacing the waste ink bottle ................................................................................... 30

Precautions............................................................................................................30

When to replace the waste ink bottle...................................................................... 31

Replacement procedures........................................................................................31

Loading and removing media .................................................................................... 32

Supported media.................................................................................................... 32

Loading media in the printer..................................................................................32

When to replace media .......................................................................................... 35

Removing media ................................................................................................... 35

Supply storage........................................................................................................... 36

Ink bottle storage...................................................................................................36

Media storage........................................................................................................37

Maintaining print quality...............................................................................................38

Overview .................................................................................................................. 38

Head Maintenance..................................................................................................... 38

Normal maintenance.............................................................................................. 38

Manual maintenance process ................................................................................. 38

Test Print............................................................................................................... 39

Jam clearance................................................................................................................40

Clearing a media jam................................................................................................. 40

Overview............................................................................................................... 40

More tips for clearing media jams.......................................................................... 43

Clearing a cutter jam ................................................................................................. 44

Overview .................................................................................................................. 46

Trouble isolation procedures .....................................................................................46

Quick checks......................................................................................................... 46

Common operating problems..................................................................................... 51

LCD error messages .................................................................................................. 55

User resolvable......................................................................................................55

Menu Tree .................................................................................................................... 57

SET menu – first level only....................................................................................... 58

SET menu – detailed ................................................................................................. 59

HEAD MAINTENANCE menu ................................................................................ 62

REPLACING BLADE menu.....................................................................................63

x Introduction

Page 13

Getting to know your ColorgrafX X2

The printer’s ability to select and print from pre-installed media

widths, coupled with its large ink capacity, makes the printer a flexible

“workgroup” printing resource that is easy-to-use and maintain.

Feature overview

Your ColorgrafX X2 is an easy to use, large format color inkjet

printer. The printer’s features include:

Bi-directional printing for maximum print speed

•

High image quality with resolution up to 720 dpi

•

Six color (graphics model) or four color TECH model) inks.

•

six ink colors for the graphics model are black, cyan, light cyan,

magenta,

TECH model are black, cyan, magenta, and yellow.

UV resistant, water resistant, and dry quickly so prints are ready

to be handled as soon they are printed.

High capacity ink bottles (0.5 or 0.25 liter) for sustained, high-volume

•

printing

The 54” model holds two user-selectable media roll width sizes:

•

54”, 50”, 42”, 36”, 23.4”.

The 36” model holds two user-selectable media roll width sizes:

•

36”, 23.4, and 11”.

light magenta and yellow. The four ink colors for the

The

The inks are

Wide variety of available media

•

Self-cleaning design requires minimum maintenance down-time

•

High-speed / high quality printing

The printer has a wide inkjet printing head for each of the six ink

colors: black, cyan, light cyan, magenta,

Combined with the printer’s accurate, bi-directional print capability,

the ColorgrafX X2 can produce high-quality prints in full color

at speeds up to 622 sq.ft. / 57.8 sq.m. per hour. The speed is

based on print mode used. Available modes are:

One pass, bi and uni-directional 360 dpi mode Fastest

•

One pass, bi and uni-directional 3 black 360 dpi

•

mode---

Two pass, bi and uni-directional 360 dpi mode

•

Four pass, bi and uni-directional 360 dpi mode

•

Eight pass, bi and uni-directional 360 dpi mode

•

Sixteen pass, bi and uni-directional 360 dpi mode

•

Two pass, bi and uni-directional 720 dpi mode

•

Four pass, bi and uni-directional 720 dpi mode

•

Eight pass, bi and uni-directional 720 dpi mode

•

TECH model

light magenta and yellow.

Sixteen pass, bi and uni-directional 720 dpi mode Highest

•

Quality

Getting to Know Your ColorgrafX X2 1

Page 14

Feature overview (con’t)

r

Quick drying Ink

X2 Inks are pigmented, oil-based, and designed

specifically for use with X2 printers and supplies.

These inks are formulated to be smudge resistant

and instant drying. The color gamut is based on the

SWOP (Standard Web Offset Printing) standards fo

press-quality, color graphics, versatility and easy

color calibration. The inks do not require any special

drying time after printing.

6-color printing adds two tonal inks, Light Cyan and

Light Magenta, to the typical suite of 4-color process

printing (Cyan, Magenta, Yellow, and Black). It helps

reduce the gradient perception between dithered

process color shifts, or “smooths out” blended areas

of an image by introducing lighter tones of the colors

that construct the blend. For example, skin tones

appear more true because the color of the dots that

create the image on paper are not as dark from one

percentage to the next.

Because the X2 inks are almost instantly dry when

printed, images can be laminated immediately.

However, X2 prints are NOT waterproof. That is,

they CANNOT be submerged in water or subjected

to running water. Finishing guidelines for outdoor

durability (i.e. prints must be encapsulated) must be

followed when constructing a print for outdoor use.

Refer to your

Applications Guide

requirements.

Caution: ColorgrafX authorized inks, media or

other supplies are designed and quality tested to

assure optimum performance from your X2 printer.

Other materials may not produce the same quality

product and may, in some cases, cause service

problems or damage to your unit.

IMPORTANT NOTE: Such damage will void the

warranty and may require additional service cost.

ColorgrafX X2 Inkjet Graphics

for specific application

2 Getting to Know Your ColorgrafX X2

Page 15

Feature overview (con’t)

Media widths

The printer holds one of each of the following width

media rolls for each roll location:

54 inches (1390 mm) –

•

50 inches (1270 mm) –

•

42 inches (1066 mm) –

•

36 inches (914 mm)

•

23.4 inches (594 mm)

•

11 inches (297 mm) – 36

•

When two media sizes are installed in the printer,

two size graphics can be printed without having to

physically replace and re-install the media rolls.

Media types

The printer can use a variety of media optimized for

different purposes. These include:

Paper, Presentation, 360 dpi

•

Paper, Presentation, 720 dpi

•

Paper, Reinforced, 360 dpi

•

Paper, Line Art, 360 dpi

•

Paper, Photo-base, 360 dpi

•

Film, White Matte, 360 dpi

•

54” only

54” only

54” only

” only

Backlit Film, 360 and 720 dpi

•

Pressure Sensitive Vinyl (PSV), 360

•

Cloth, Polyester, 360 dpi

•

Canvas, Polyester, 360 dpi

•

Refer to your

Applications Guide

type and available widths.

ColorgrafX X2 Inkjet Graphics

for a description of each media

Getting to Know Your ColorgrafX X2 3

Page 16

Feature overview (con’t)

f

X2 supplied products are all direct-write, specially

coated materials that vary in coating structure,

physical properties (such as basis weight and

overall product thickness), and base material type

(such as paper, fabric, film or vinyl). These

variances not only cause the printer setup for each

material to be unique in order to successfully run

each material through the printer, but also cause the

achievable image quality per product to be different.

The coating layer on each media is different

because it must adhere to the individual base

material (i.e., thick or porous, smooth or woven) as

well as image in either 360 or 720 dpi print mode.

Therefore, the image quality will vary per media

type.

For example, Poly Canvas image quality is not equal

to that of Presentation Paper, even though both are

360 dpi. Your RIP should provide curves that are

calibrated specifically for the unique requirements o

each media.

The recommended print media has controlled

curling properties optimized for the printer’s media

transport mechanism. Using the recommended

media will reduce media jams.

Minimum down-time

The ColorgrafX X2 inkjet printer is a self-maintaining

printer and requires no routine maintenance. The

printer performs automatic head cleaning during

routine use

.

4 Getting to Know Your ColorgrafX X2

Page 17

Printer components

The following identifies the locations of the ColorgrafX X2’s

components.

Front view

1

2 3 4

5

6

7

9

8

The picture to the left identifies the location of the

ColorgrafX X2’s main components as viewed with

the front covers open.

1. Top cover

2. Media feeding area

3. Media set guide

4. Feed roller knob

5. Release lever

6. Operation panel

7. Front cover

8. Media exit (take-up roller) –

model, optional on 36” model

standard on 54:

9. Stand

11

22

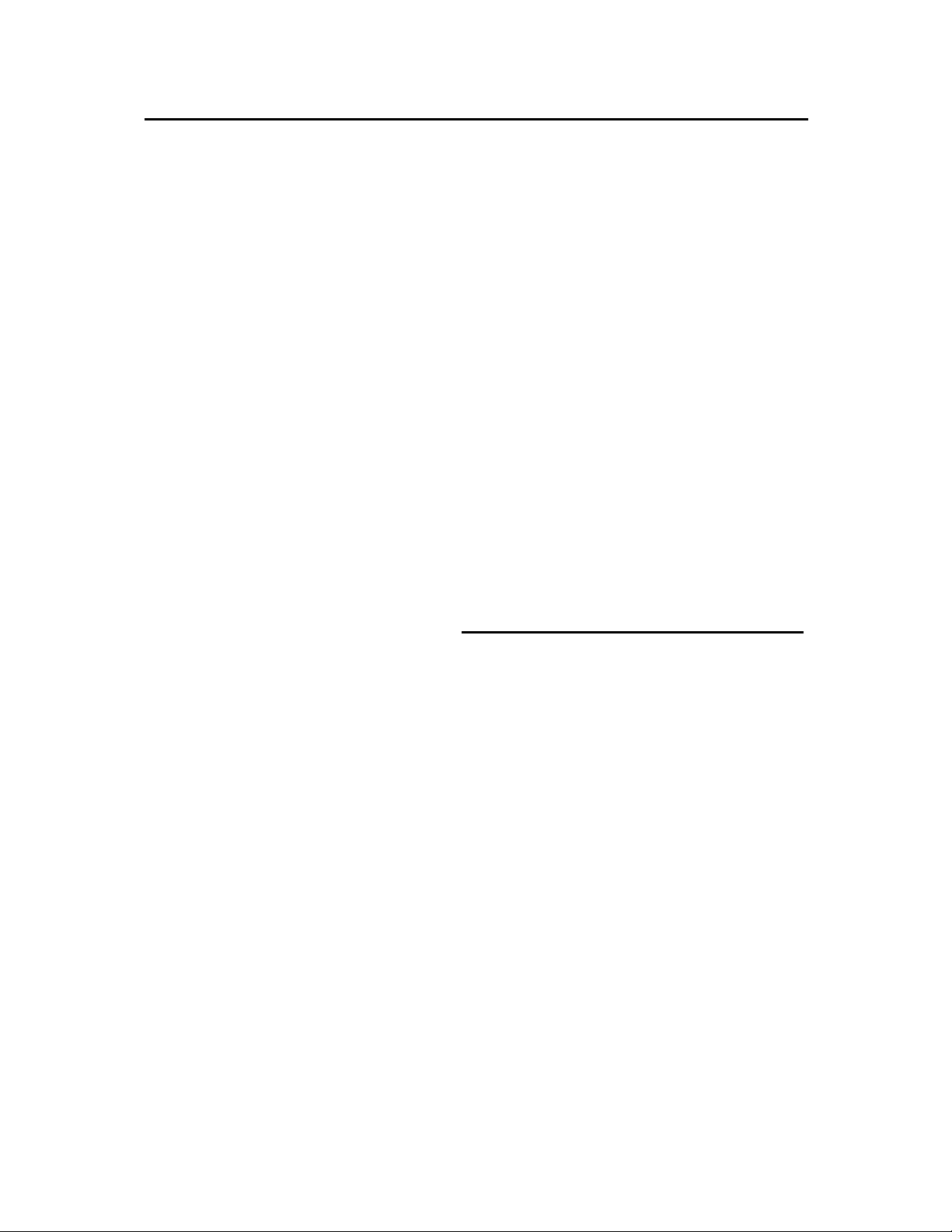

Right-side view

The components located to the right of the printer

are the:

1. Ink bottle holder

2. Waste ink bottle tray

Getting to Know Your ColorgrafX X2 5

Page 18

Printer Components (con’t)

1

2

3

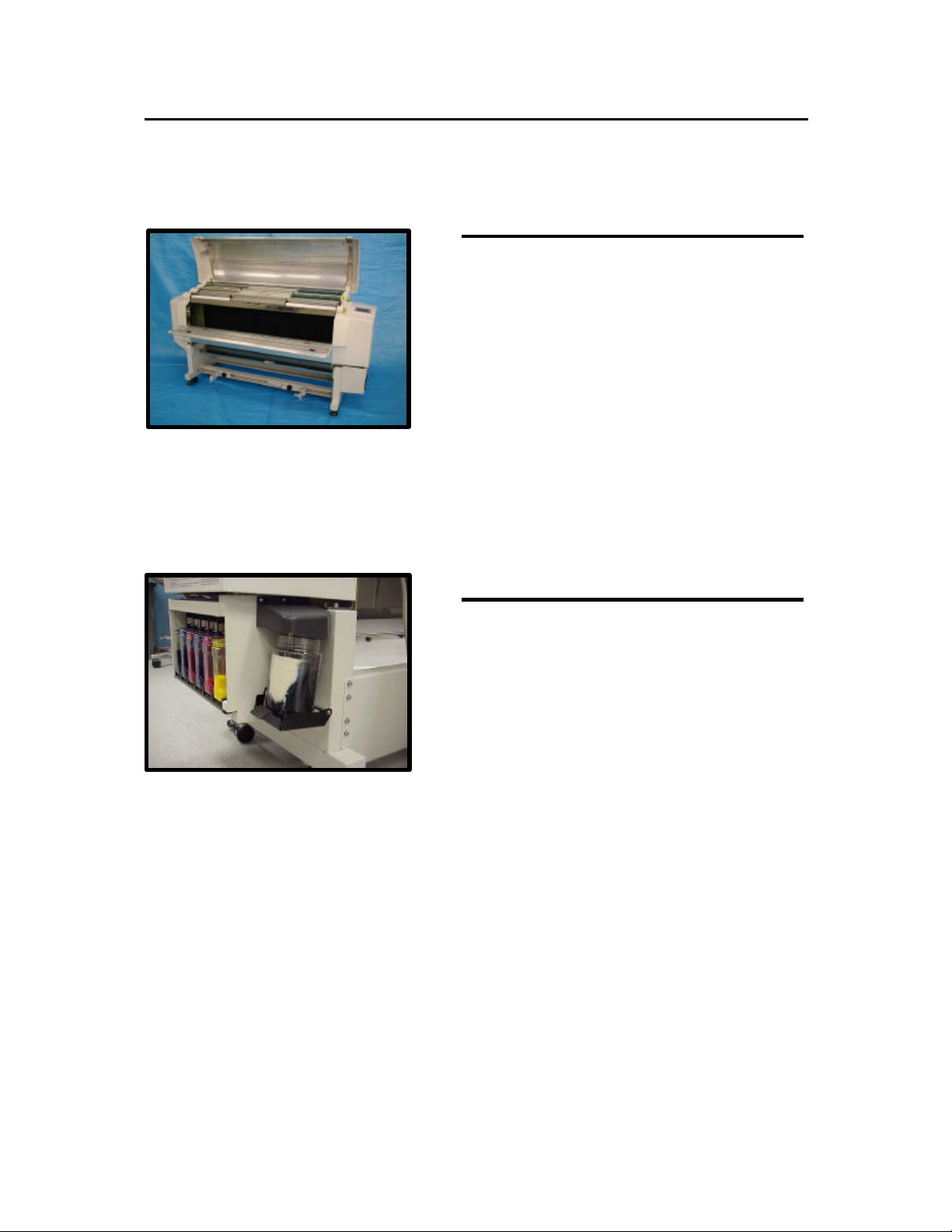

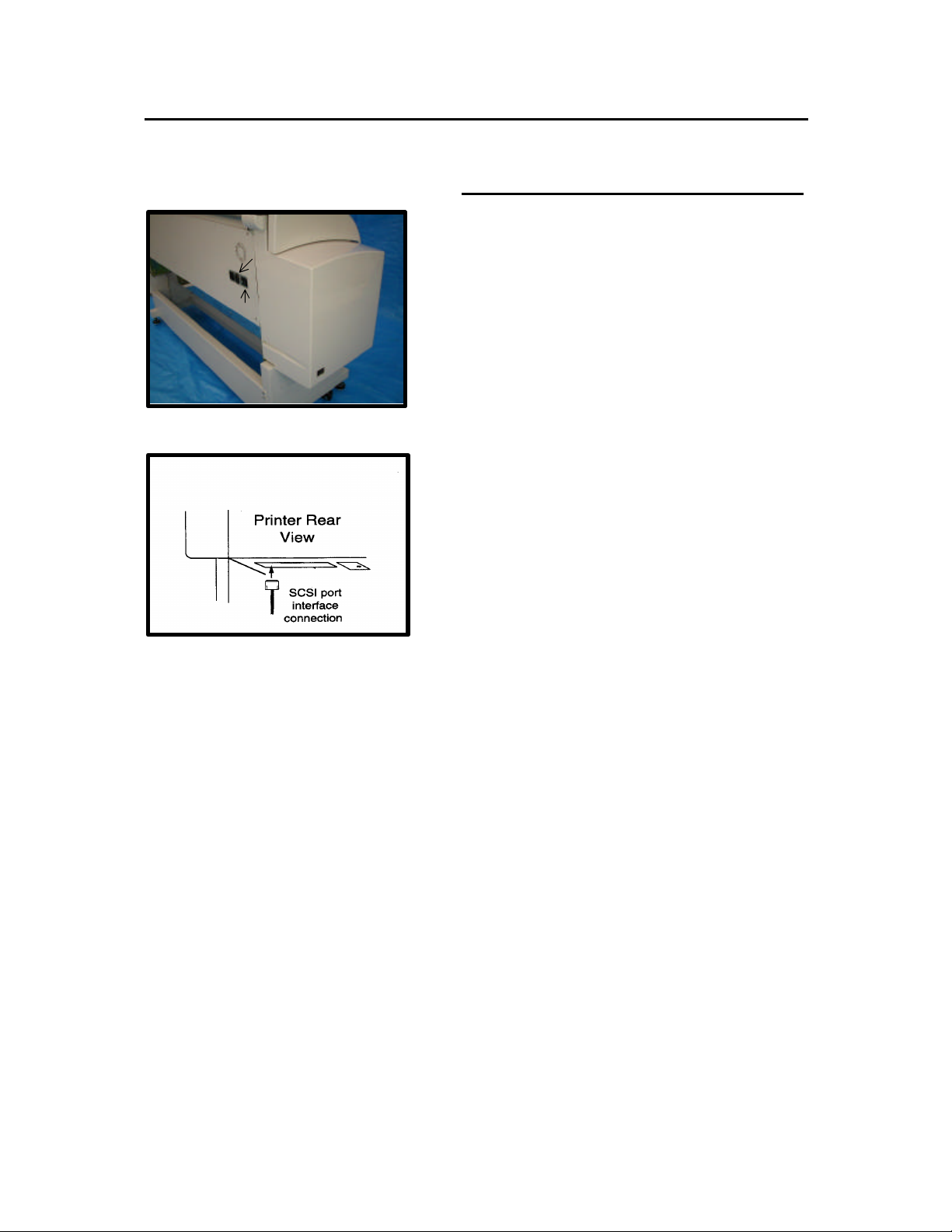

Rear view

The power connection, circuit breaker, and on/off

switch are located at the rear of the printer.

1. Power connector

2. Circuit breaker

3. Power switch

4. SCSI port interface connection

6 Getting to Know Your ColorgrafX X2

Page 19

Printer components (con’t)

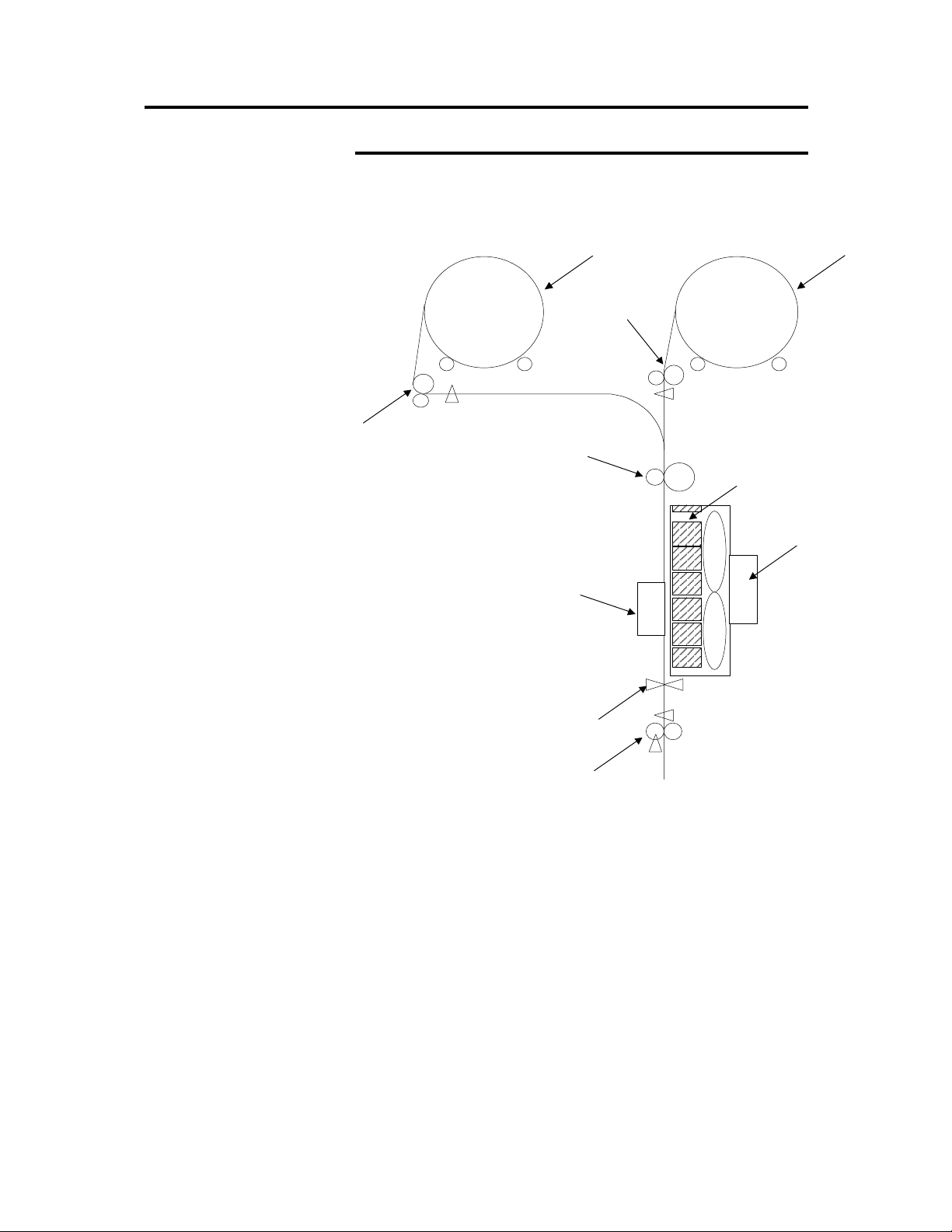

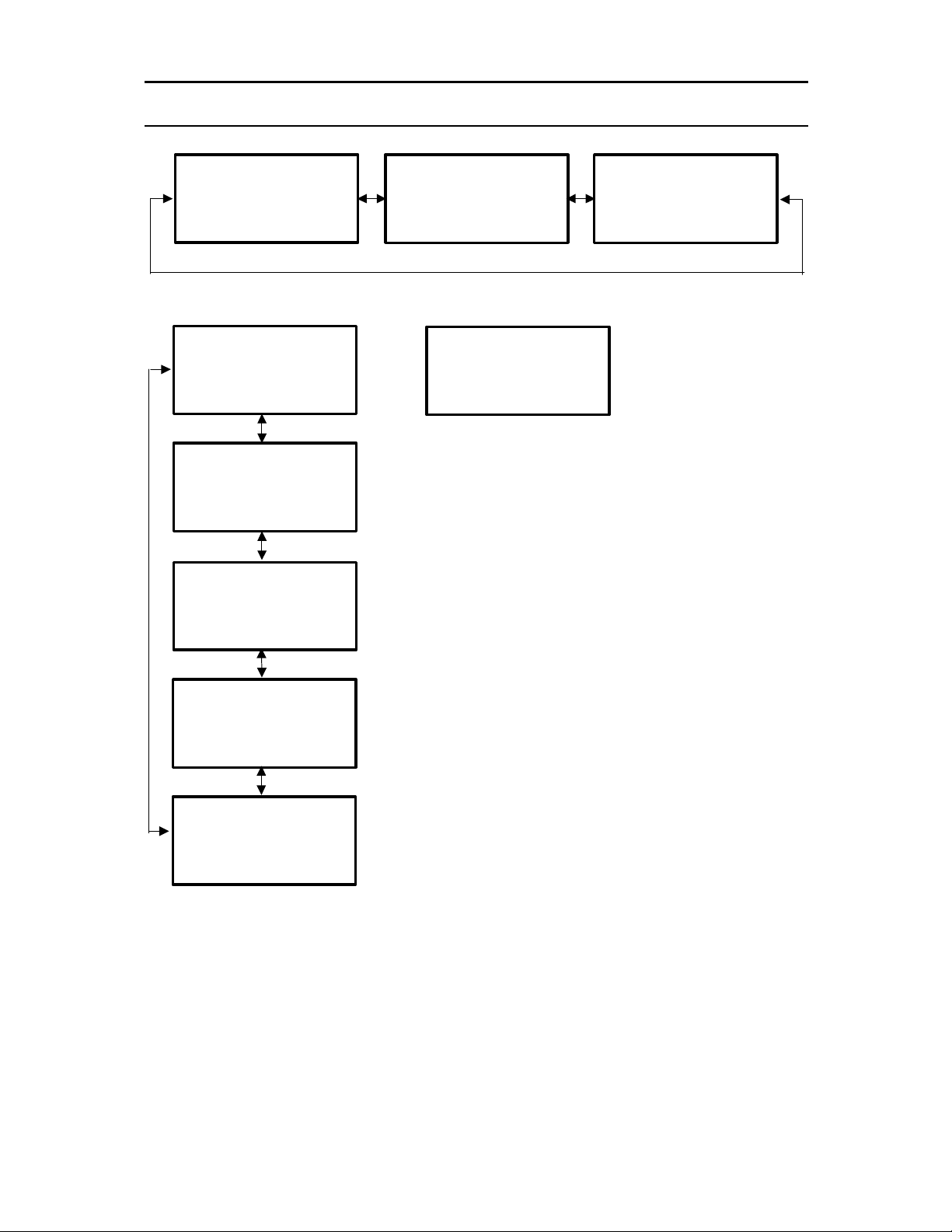

Media transport

To thoroughly know your printer, you need to know how the print

passes through the printer. Refer to the illustration on the next page.

The process is as follows:

1. Media roll - The media roll is mounted in the printer.

2. Media feed roller - The media feed roller pulls the media from the

media roll. It is driven through a clutch which couples to the

timing belt driven by the Pinch roller drive motor. The clutch and

its associated electronics allow the printer to select which media

roll is used to make each print.

3. Media pinch rollers - These rollers are the main media transport

rollers in the printer. The media Pinch roller is driven through a

worm gear connected to a precision stepper motor.

4. Vacuum fans - Six vacuum fans, behind the vacuum platen,

provide the vacuum that holds the media in place on the platen.

5. Vacuum platen - The vacuum platen is a flat surface that holds

the media against its surface using vacuum pressure. Media

held by the vacuum platen presents a flat, unmoving precisionaligned surface to the printer heads while ink is being applied.

6. Print heads - The print heads move across the surface of the

media, depositing ink as required, driven by the carriage motor

and carriage belt.

7. Cutter - After a print is completed, the cutter separates the print

from the media roll completing the print cycle.

8. Media exit roller - The exit roller has a series of star wheels and

exit rollers that gently move the finished print out of the printer.

Getting to Know Your ColorgrafX X2 7

Page 20

Printer components (con’t)

Media transport (con’t)

2

11

2

3

5

4

6

7

8

8 Getting to Know Your ColorgrafX X2

Page 21

Printer components (con’t)

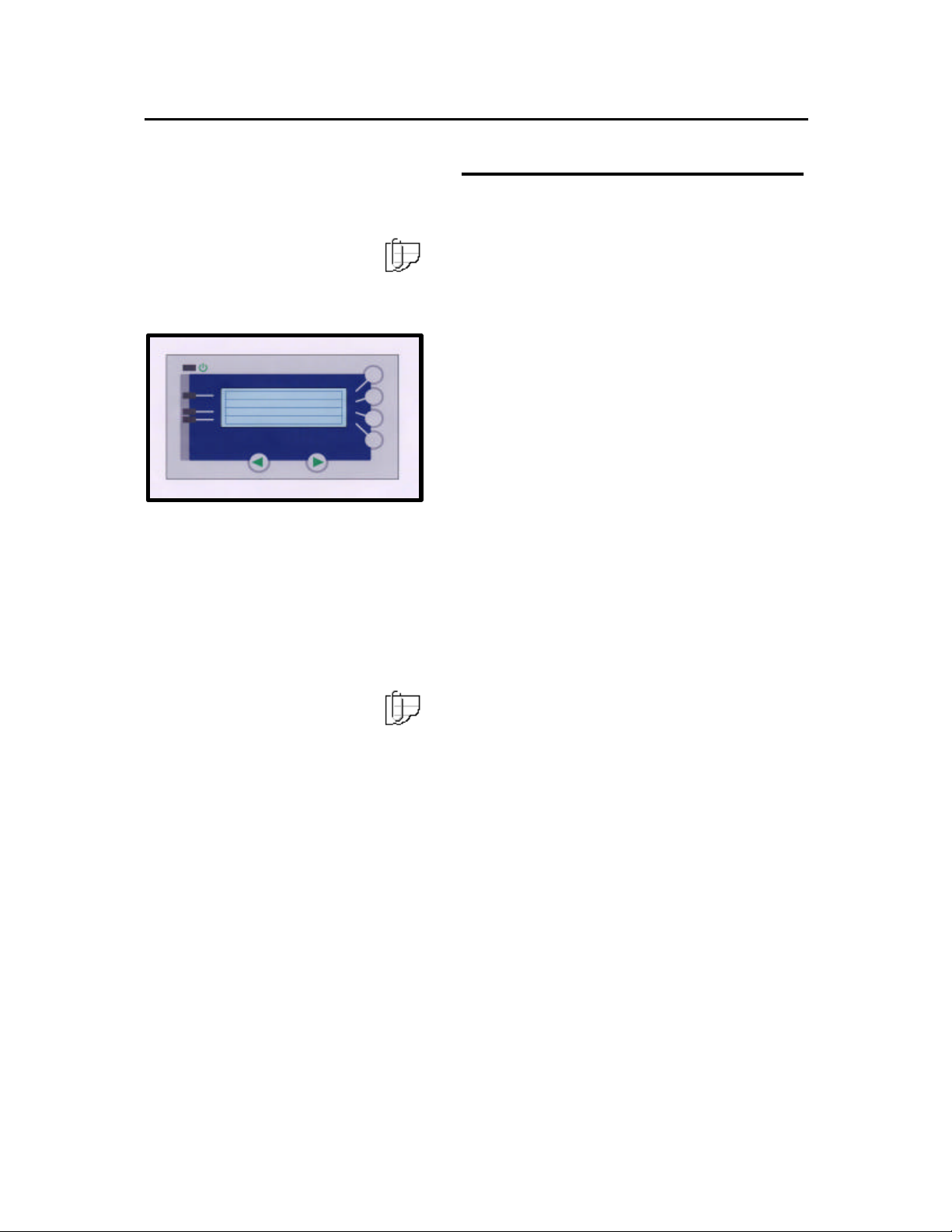

Operation panel

The printer’s operation panel is used to control the

printer.

Note: The operation panel can over-ride a print job

being received from a remote computer. Always

check that there is not a job in progress before

assuming control of the printer using the operation

panel.

The operation panel includes the:

LCD display -- The LCD display shows the

•

current status of the printer. Menu items,

parameters, or error messages are displayed on

the 20 characters x 4 rows LCD (Liquid Crystal

Display).

Power LED, the top LED on the left side of the

•

LCD display. When the printer is turned on, the

green LED is lit and is dark when the printer is

off.

Ready LED, the second LED from the top.

•

When the printer is ready, the green LED is lit

and is dark when the printer is not ready.

Error LED, the third LED from the top. When

•

the printer is in error status, the red LED is lit

and the printer stops.

Warning LED, the bottom LED on the left side

•

of the LCD display. When the printer is in

warning status, the red LED is lit.

Note: LEDs 3 and 4 are also used to indicate a low

media status. If the media roll contains 20% or less

media, the associated LED will flash.

The right and left arrow buttons, located at

•

the bottom of the operation panel. They are

used to select menu options within a menu level.

Getting to Know Your ColorgrafX X2 9

Page 22

Printer components (con’t)

READY MENU

R: 360 PRES 36

F: 720 PRES 54

ggg Î

ggg

Î

Î

Operations panel (con’t)

The ColorgrafX X2 has three top-level menus, and

four if the Color Direct option is installed. The button

functionality is indicated by the display.

1. The default display, which is initially displayed,

identifies the installed media (type and size) as

well as provides an illustration of approximate

usage.

Note: The media type and size MUST be set at the

operation panel, and the media must be installed

before setting further options

Also, note that the illustration to the right is what

will appear if 360 Presentation Paper is set on the

rear roll and 720 Presentation Paper on the front

roll.

.

This display has the following functionality:

Button 1, the top button on the right side of the

•

LCD. Button 1 provides the Menu button.

Pressing the Menu button shifts the printer to

menu mode, from which you can select printing

options.

Button 2, the 2nd button on the right side of the

•

LCD is not used for this display.

Button 3, the 3

•

LCD. This button is used to change the front

media type.

Button 4, the 4th button on the right side of the

•

LCD. This button is used to change the rear

media type.

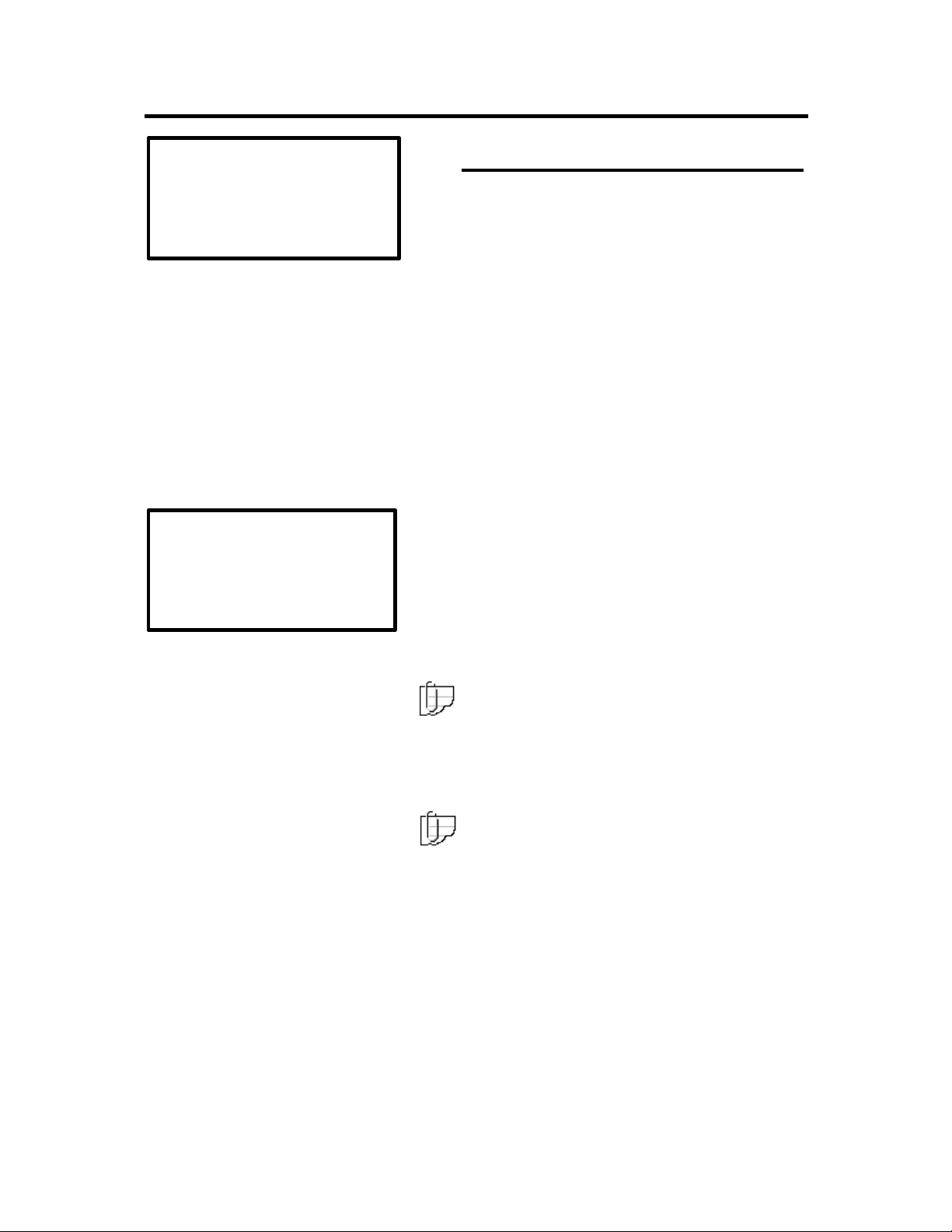

2. The second display, accessed using the right

arrow from the default display, has the following

functionality:

rd

button on the right side of the

10 Getting to Know Your ColorgrafX X2

Page 23

Printer components (con’t)

w

READY MENU Î

RWD ALL Î

RWD Î

<MORE> FWD Î

READY MENUÎ

HEAD MAINTENANCE Î

CUT Î

Operations panel (con’t)

Button 1, the top button on the right side of the

•

LCD provides the Menu button. Pressing the

Menu button shifts the printer to menu mode,

from which you can select printing options.

Button 2, the second button is used to

•

completely rewind the media. Current selected

media will be rewound automatically to the start

feed position.

Button 3, the third button rewinds the media as

•

long as the button is pressed. Current selected

media will be rewound.

Button 4, the fourth button moves the media

•

forward. Current selected media will be fed.

3. The third display, accessed using the left arro

from the default display, has the following

functionality:

Button 1, the top button on the right side of the

•

LCD. Button 1 provides the Menu button.

Pressing the Menu button shifts the printer to

menu mode, from which you can select printing

options.

<MORE>

Note: By using the left and right arrow buttons,

Button 2, the second button accesses the

•

maintenance

Note: Head maintenance options can be

accessed from MENU mode as well.

Button 3, the third button is used to

•

media.

Button 4, the fourth button has no functionality

•

directly from this display.

the multiple menus at any level can be cyclically

accessed.

options.

cut

head

the

Getting to Know Your ColorgrafX X2 11

Page 24

Operations

Your ColorgrafX X2 inkjet printer is optimized for easy, automatic

print production requiring minimum attention by an operator. This

chapter describes the procedures to:

1. Use the operation panel

2. Start a print job

3. Operate the cutter

4. Operate the take-up roller

Operations panel menu

IMPORTANT! At the operations panel, you MUST set the media type(s)

installed on the front and rear rollers before starting a print job;

otherwise, the printer will NOT function correctly. Please

familiarize yourself with the menu items before beginning a print

job.

The following describes the operations panel in detail.

The printer’s operation panel menu functions when the printer is in

the offline mode. The menu has two levels:

1. Normal

2. Service

This manual covers only the normal default menu options. The

service options are only used when the printer is being serviced by a

field service engineer. Access to and visibility of service menu

options are password protected and are covered in the optional

ColorgrafX X2 inkjet printer Service Manual.

XES

Procedures

Entering menu mode

The following explains how to enter the menu mode, select, and then

execute a command from the operation panel:

1. Press the button associated with the menu option, button 1 (top

button), to enter Menu mode.

2. Press the LEFT or RIGHT arrow buttons to select a desired top

level menu item.

3. Press the button associated with the menu item to access

options within that item.

4. Press the button associated with the ENTER or EXECUTE option

to accept the option.

12 Operations

Page 25

Operations panel menu (con’t)

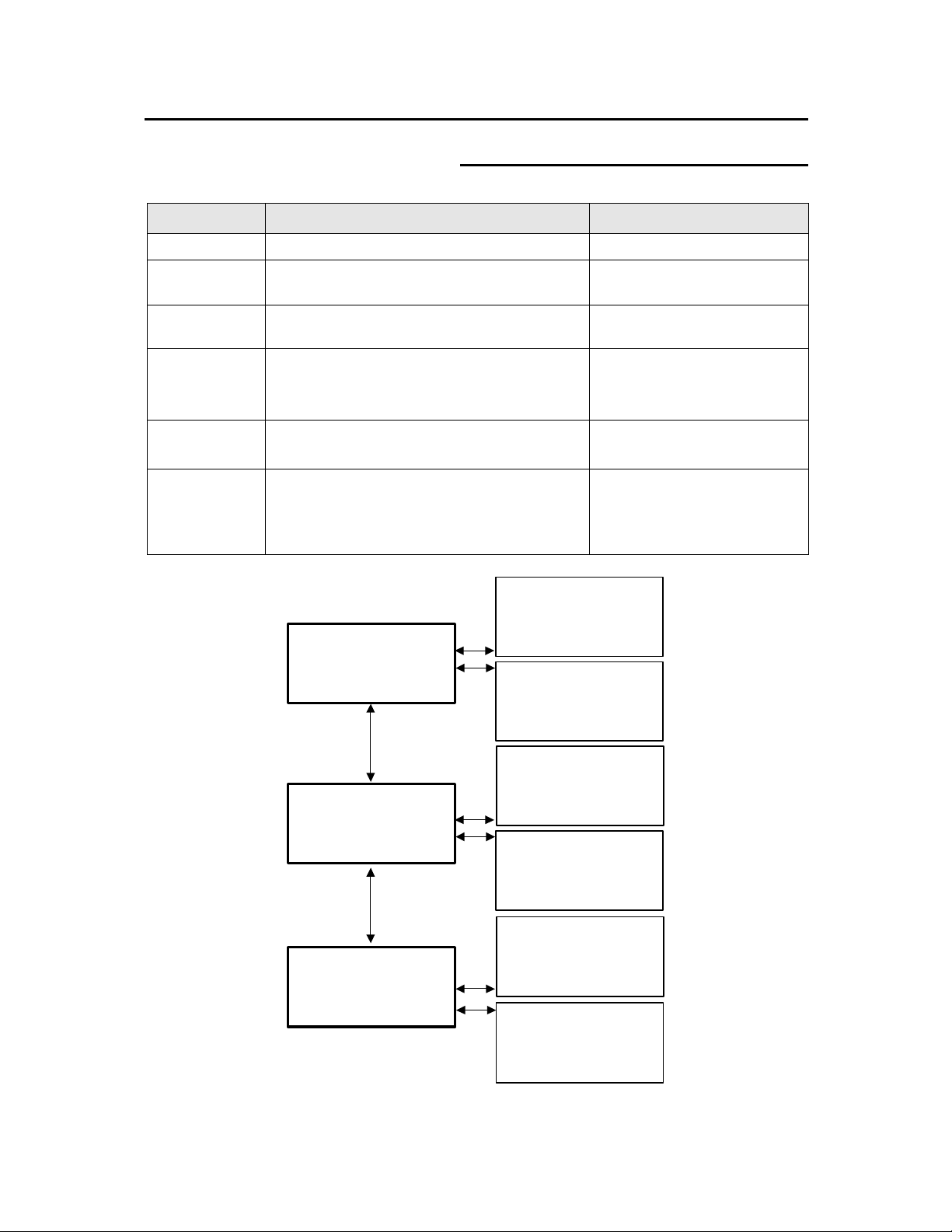

Menu options

The top level menu consists of the following options:

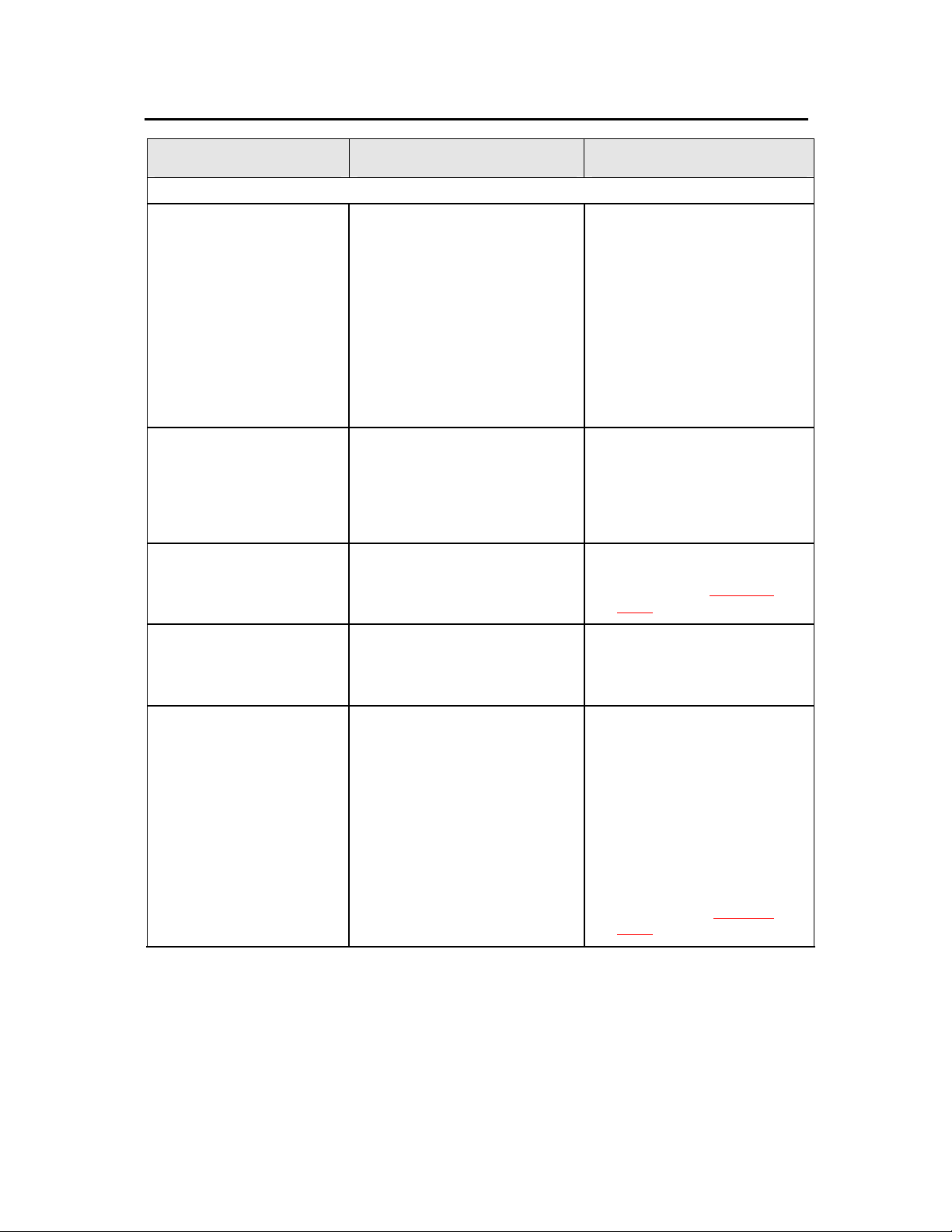

Option Description

SET

TEST PRINT

HEAD MAINTENANCE

ADJUSTMENT, AUTO

REPLACING BLADE

LIFE COUNTER

Sets printer options, such as media type, media attributes,

winding direction, language, etc.

Prints the nozzle test pattern for printer diagnostics.

Carries out print head maintenance, such as purging and

wiping print heads.

Sets the adjustment parameters for the printer.

Moves the cutter unit to the center position in order to replace

the cutter blade.

Provides feedback on usage, in feet/meters.

The SET, REPLACING BLADE, and LIFE COUNTER options are

described in this section. HEAD MAINTENANCE is addressed in the

Maintaining Print

AUTO are addressed in Appendix A,

Quality section.

TEST PRINT

In Case of Difficulty

and

ADJUSTMENT,

.

Operations 13

Page 26

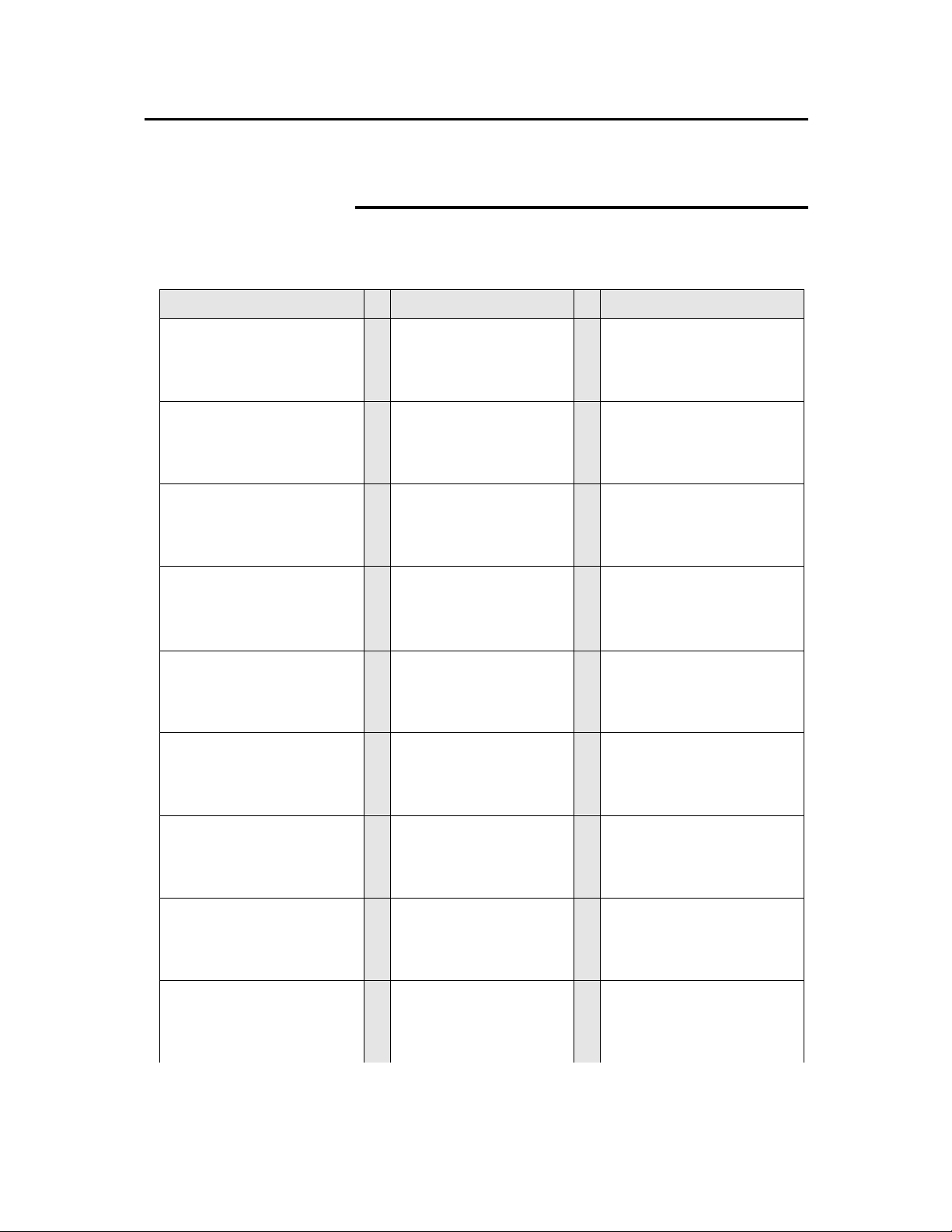

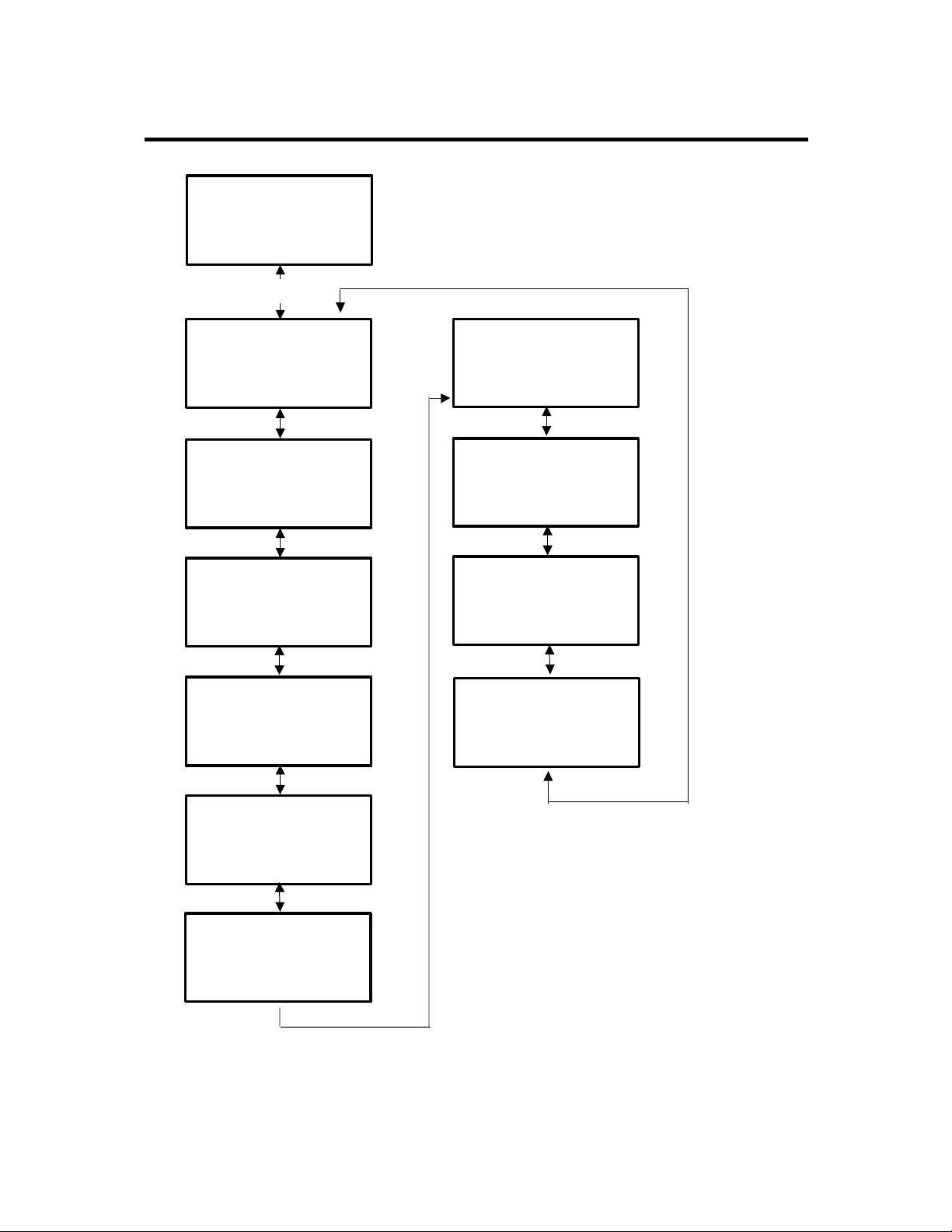

Set mode

The SET mode lets you select a media roll, set the media type, set

the media roll’s attributes, set date and time, set SCSI interface ID

and time out, set rewind delay, and set the winding direction for the

Take Up Roller.

<MENU> S

SET Î

<MORE>

SET

From

<SET> S

ROLL SELECT Î

<MORE>

<SET> S

MEDIA TYPE, REAR Î

MEDIA TYPE, FRONT Î

<MORE>

<SET> S

SCSI ID

I/F TIME OUT

<MORE>

<SET> S

UNIT SELECT

WINDING DIRECTION

<MORE>

Î

Î

Î

Î

<SET> S

MEDIA ATTRIBUTE Î

POWER SAVE Î

<MORE>

<SET> S

MAINT. INTERVAL

INIT CUT

<MORE>

<SET> S

DATE SET

TIME SET

<MORE>

Î

Î

Î

Î

<SET> S

AUTO CAP Î

REWIND DELAY

<MORE>

<SET> S

FEED CORRECTION

INTER PAGE GAP

<MORE>

<SET> S

MEDIA FLATTENING

LANGUAGE Î

<MORE>

Î

Î

Î

Î

14 Operations

Page 27

Menu options (con’t)

Set mode (con’t)

Option Description Parameters

Roll Select

Media Type

This command selects which of the two media

rolls, rear or front feeder, on the printer is to be

used for the next print job. Each roll, once

selected, then displays the roll attributes.

Note - Each roll will have separate settings of

various values. This allows loading media with

different characteristics onto the printer and

having the printer settings optimized for each

media type.

Selects either the front or the rear loaded

media type.

<SET> S

ROLL SELECT

Î

<ROLL SELECT> S

* FRONT +

FRONT

BACK

360 PRESENTATION

720 PRESENTATION

WHITE MATTE FILM

BACKLIT FILM 360

BACKLIT FILM 720

POLY CLOTH

POLY CANVAS

PHOTO-BASE PAPER

REINFORCED 360

PSV 360

LINE ART PAPER

-

<MORE>

<SET> S

MEDIA TYPE, REAR Î

MEDIA TYPE, FRONT

<MORE>

Î

<MEDIA TYPE, REAR> S

* 360 PRESENTATION +

<MEDIA TYPE, FRONT> S

* 720 PRESENTATION +

ENTER

ENTER Î

Operations 15

ENTER

Î

-

-

Î

Page 28

Menu options (con’t)

Set mode (con’t)

Option Description Parameters

Media

Attribute

Selects the attributes for each roll of media in

the printer.

Note: the following media do NOT have the

WAIT CUT option as these media must be cut

manually: Poly Cloth, Poly Canvas, Reinforced

360, and PSV 360. Additionally, CUT MODE is

visible for these media, but is automatically

disabled and cannot be changed.

<SET> S

MEDIA ATTRIBUTE Î

POWER SAVE Î

<MORE>

<MEDIA ATTRIBUTE> S

* 360 PRESENTATION Î

* 720 PRESENTATION Î

<MORE>

<MORE> cycles through

all available media

<360 PRESENTATION> S

WAIT CARRIAGE Î

WAIT CUT Î

<MORE>

360 PRESENTATION

720 PRESENTATION

WHITE MATTE FILM

BACKLIT FILM 360

BACKLIT FILM 720

POLY CLOTH

POLY CANVAS

PHOTO-BASE PAPER

REINFORCED 360

PSV 360

LINE ART PAPER

<WAIT CARRIAGE> S

* 0.0 sec +

-

ENTER Î

<WAIT CUT> S

* 0.0 sec +

-

ENTER Î

<MAGNIFICATION> S

* 0.00 % +

-

<360 PRESENTATION> S

MAGNIFICATION Î

CUT MODE Î

<MORE>

<CUT MODE> S

* NORMAL CUT +

ENTER Î

-

ENTER Î

16 Operations

Page 29

Menu options (con’t)

Set mode (con’t)

The following describes the attribute available for

each media:

Option Description Parameters

Wait Carriage

Wait Cut

Magnification

Cut Mode

The Wait Carriage attribute determines the

time delay in seconds that the printer waits

between passes to allow the ink to be

absorbed by the media.

The Wait Cut attribute determines the amount of

time, in seconds, the printer waits after the last

pass before performing the cut operation. This

allows time to let the print image stabilize to

avoid possible smearing before cutting the print

from roll.

The vertical movement of media between

passes of the carriage head is governed by the

number of cycles of the media transport

system's forward motor. This fine-tunes the

amount of media vertical movement that is

associated with each pass of the print heads.

This value is set at the factory and may vary

slightly from media to media.

Note: Changing magnification is only

recommended to fine tune an image. A setting

change can affect other modes for different

images and different media types. True size

proportions can be compromised.

Sets automatic media cutting.

0 – 30 seconds in 0.1 second

intervals.

0 – 30 seconds in .1 second

intervals

-0.50% -- and +0.50% in 0.01

intervals.

NORMAL CUT / NO CUT

Operations 17

Page 30

Menu options (con’t)

Set mode (con’t)

Additional options available through the SET menu.

Option Description Parameters

Power Save

Maintenance

Interval

Init Cut

Date & Time

Set

Sets the idle time before the printer goes into its

power save mode.

Sets the frequency in which the printer runs the

maintenance routine.

Enables/disables a media cut during new media

initialization.

(Enable only when loading new

media and you know the media has a straight

edge.)

Sets the date and time. Use the cursor arrow

buttons <CSR> to move from year>month>date

or hour>minutes>seconds. Use the + or –

buttons to change the time and date numbers.

<SET> S

MEDIA ATTRIBUTE

POWER SAVE Î

<MORE>

<SET> S

MAINT. INTERVAL Î

INIT CUT Î

<MORE>

Î

<POWER SAVE> S

* OFF +

<MAINT. INTERVAL> S

* LONG +

<INIT CUT> S

* YES +

OFF -- 60min

(in 5min interval)

NONE/SHORT/MIDDLE/LONG

YES/NO

YYYY/MM/DD

HH/MM/SS

-

ENTER Î

-

ENTER Î

-

Î

ENTER

<DATE SET> S

* 2000/01/01 +

<SET> S

DATE SETÎ

TIME SETÎ

<MORE>

YYYY/MM/DD -

<CSR> ENTER Î

<TIME SET> S

* 12:34:56 +

HH:MM:SS -

<CSR> ENTER Î

18 Operations

Page 31

Menu options (con’t)

Set mode (con’t)

Option Description Parameters

SCSI ID

I/F Time Out

Unit Select

Normally set during printer installation and

should not require resetting. The host computer

automatically senses the SCSI ID and sets the

software in the host computer to the correct ID

number. The SCSI ID set in the host computer

must agree with the SCSI ID set on the printer.

Determines the amount of time the printer waits

for the next command from the host computer

before aborting the print job.

Sets the measurement unit. Feet/Meters

1 – 6

OFF/10/30/60/120 SEC

Winding

Direction

The winding direction mode is for the take-up

roll. You can select the direction the roll moves.

<SCSI ID> S

* 1 +

<SET> S

SCSI ID

I/F TIME OUT Î

<MORE>

<SET> S

UNIT SELECTÎ

WINDING DIRECTION

<MORE>

Î

Î

<I/F TIME OUT> S

* OFF +

<UNIT SELECT> S

* FEET +

<WINDING DIRECTION> S

* OFF +

OFF/IMAGE OUT/IMAGE IN

In IMAGE OUT selection, the

printer rolls the media as the

printed side becomes the outer

side of the roll.

-

Î

ENTER

-

Î

ENTER

-

Î

ENTER

-

ENTER Î

Operations 19

Page 32

Menu options (con’t)

Set mode (con’t)

Option Description Parameters

Auto Cap

Rewind Delay

Feed

Correction

Inter Page Gap

Media

Flattening

Language

Automatically caps the heads. ON/OFF

Determines the amount of time the printer waits

OFF/1 minute – 60 minutes

for the media rewind.

Compensates for errors in the paper path.

EXECUTE / NON-EXECUTE

Handled by the firmware.

Sets the spacing between images.

UNCONTROLLED

0 – 12 (1 inch interval)

Sets the delay to let the media flatten after

advancing.

Set the language for the operations panel.

NONE/SHORT/MIDDLE/LONG

ENGLISH / GERMAN /

FRENCH / PORTUGUESE /

SPANISH / ITALIAN /

JAPANESE

<AUTO CAP> S

* OFF +

<SET> S

AUTO CAP Î

REWIND DELAY Î

<MORE>

<REWIND DELAY> S

* OFF +

ENTER Î

-

-

ENTER Î

<FEED CORRECTION> S

<SET> S

FEED CORRECTION Î

INTER PAGE GAP Î

<MORE>

<SET> S

MEDIA FLATTENING Î

LANGUAGE Î

<MORE>

* NOT EXECUTE +

<INTER PAGE GAP> S

* 1 INCH +

<MEDIA FLATTENING> S

* NONE +

<LANGUAGE> S

* ENGLISH +

ENTER

ENTER Î

ENTER Î

ENTER

-

Î

-

-

-

Î

20 Operations

Page 33

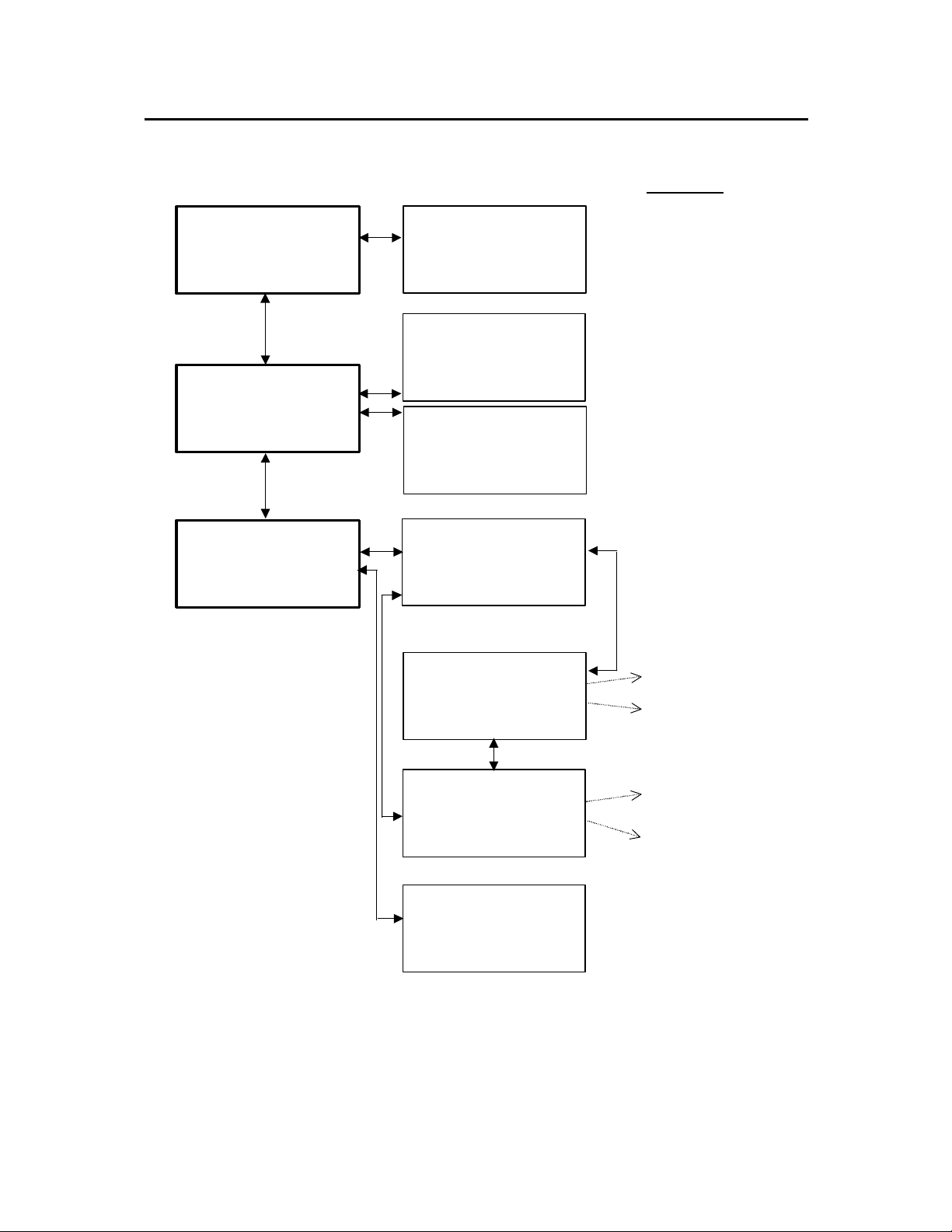

Menu options (con’t)

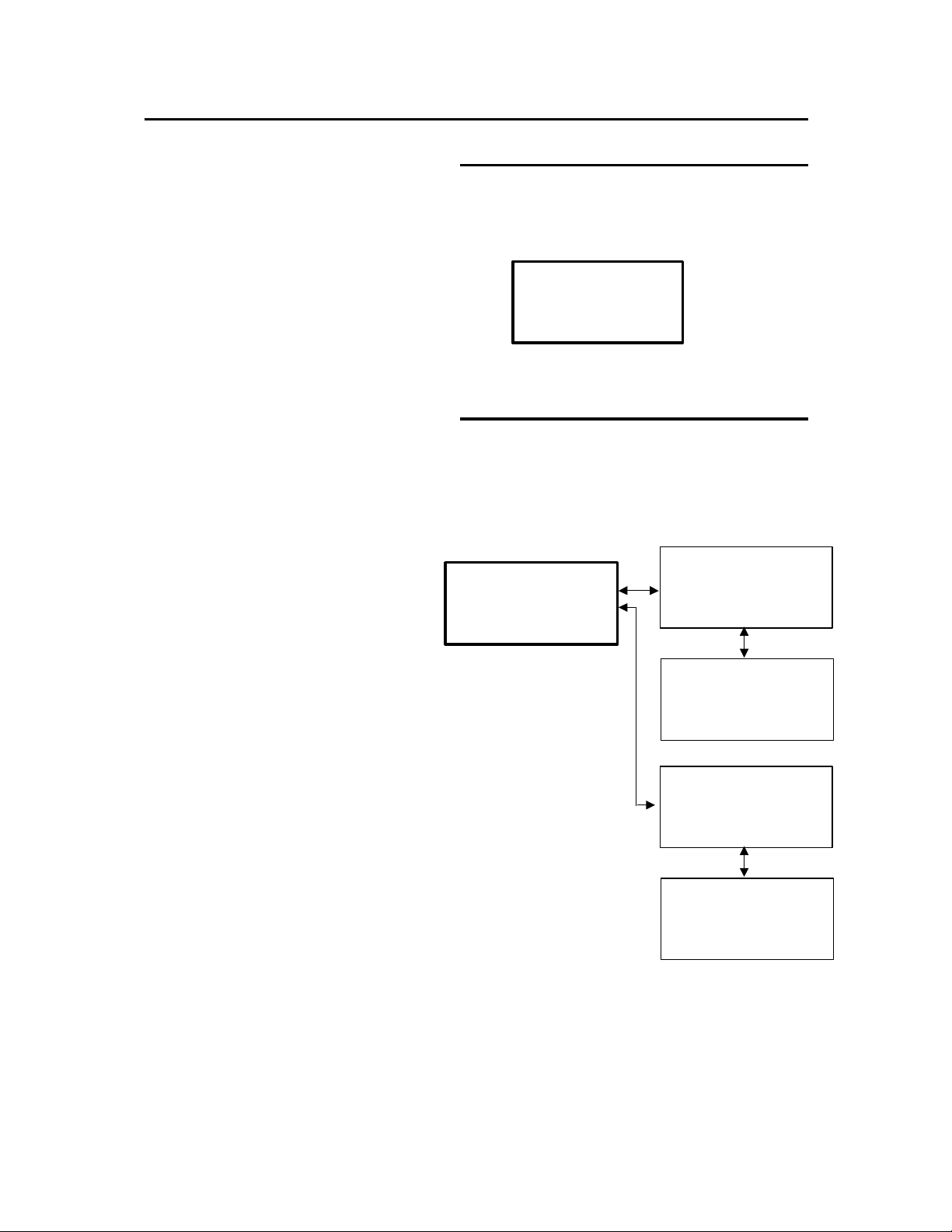

REPLACING BLADE

When selected, the REPLACING BLADE option

moves the cutter unit to the center position in order

to replace the cutter blade.

<REPLACING BLADE> S

MOVE TO THE CENTERÎ

LIFE COUNTER 1 and 2

LIFE COUNTER 1 provides media transport usage

information for the life of the printer. LIFE

COUNTER 2 provides media transport usage

information since the last counter reset.

Press CLEAR to reset the counter.

<FRONT ROLL USAGE> S

<LIFE COUNTER>

LIFE COUNTER 1 Î

LIFE COUNTER 2 Î

<MORE>

S

* xxx.x feet

<MORE>

<REAR ROLL USAGE> S

* xxx.x feet

<MORE>

<FRONT ROLL USAGE>

* xxx.x feet

<MORE> ENTER Î

<REAR ROLL USAGE> S

* xxx.x feet

<MORE> ENTER Î

S

CLEAR Î

CLEAR Î

Operations 21

Page 34

Starting a print job

To successfully start a print job, perform the following:

1. Visually check that the printer has adequate media available and

that the ink bottles have enough ink to complete the print.

IMPORTANT!

You must turn the printer on

allows the computer to recognize the printer as a SCSI device.

2. When starting the printer, use the printer’s power switch to turn

the printer ON. The printer will go through an internal self-check

and media initialization to verify that it is ready to print. You will

hear the printer’s motors operate as each printer component is

verified and the media is initialized.

3. Check the printer’s operation panel LCD to verify that it is online

and that there are no error messages displayed.

READY MENUÎ

R: 360 PRES 36 ggg Î

F: 720 PRES 54 ggg Î

<MENU> S

SET Î

<MORE>

4. Verify at the operations panel that the appropriate media

types are set. Refer to the default display. This information

MUST match the installed media. If this is not the case, set

the media type for both the front and rear rollers. The

procedures are as follows:

a. To set the media type for the rear roller, press the MENU

button, the SET button, and then use the arrow button to

scroll to MEDIA TYPE, REAR.

b. Press the button associated with either the + or – until

the media type installed on the rear roller is displayed

and then press the ENTER button. This will return you

<SET> S

MEDIA TYPE, REAR Î

MEDIA TYPE, FRONT Î

<MORE>

to the SET menu.

c. To set the media type for the front roller, use the arrow

button to scroll to MEDIA TYPE, FRONT.

d. Press the button associated with either the + or – until

the media type installed on the front roller is displayed

and then press the ENTER button.

5. Verify that the printer software in the host computer is operating,

and verify that the interface between the host computer and the

printer is working (no error messages on the host computer).

6. Using a print file in a format that your printer software can

process, make any needed modifications to the print. After

verifying that there is a roll of media on the printer of the type and

width you need, send the print to the printer.

Note: Do not open any of the printer’s covers while the printer is

operating. If a cover is opened, the printer immediately stops

printing. The job in progress will be terminated when the cover is

closed again.

before

the digital front end. This

22 Operations

Page 35

Operating the cutter

The cutter can automatically cut the media from the roll to the

selected print size after printing is completed. The cutter then stops

at the left rest position after the cut is completed.

If the cutter stops without completing the cut cycle due to a media

jam, e.g., the printer being turned off or a power failure, turn off the

printer using its power switch. After correcting the source of the

problem, turn on the printer’s power switch. The cutter will return to

the left position.

Note – The cutter has been designed to last the life of the printer.

However, the cutter blade is replaceable. If you have problems with

the cutter, replace the cutter blade. Directions to replace the blade

follow this section.

Caution – Do not pull the media while the cutter is cutting. You may

damage the cutter or the print.

There are two cut modes available:

1. Normal cut mode

2. No cut mode

Normal weight coated media or film can be cut using the normal cut

mode. When heavy media or film cannot be cut with the normal

mode, select the No Cut mode. In the No Cut mode, after printing is

finished and the media is forwarded, the operator then cuts manually

using a knife or scissors. The printer halts and waits for the next

operation.

To avoid injury, the print job will not start if the printer’s cover is open,

even if data is sent to the printer. Use the manual no cut mode

whenever the media cannot be cut in the normal cut mode.

The operator can then manually cut the print using an appropriate

cutting tool.

Operations 23

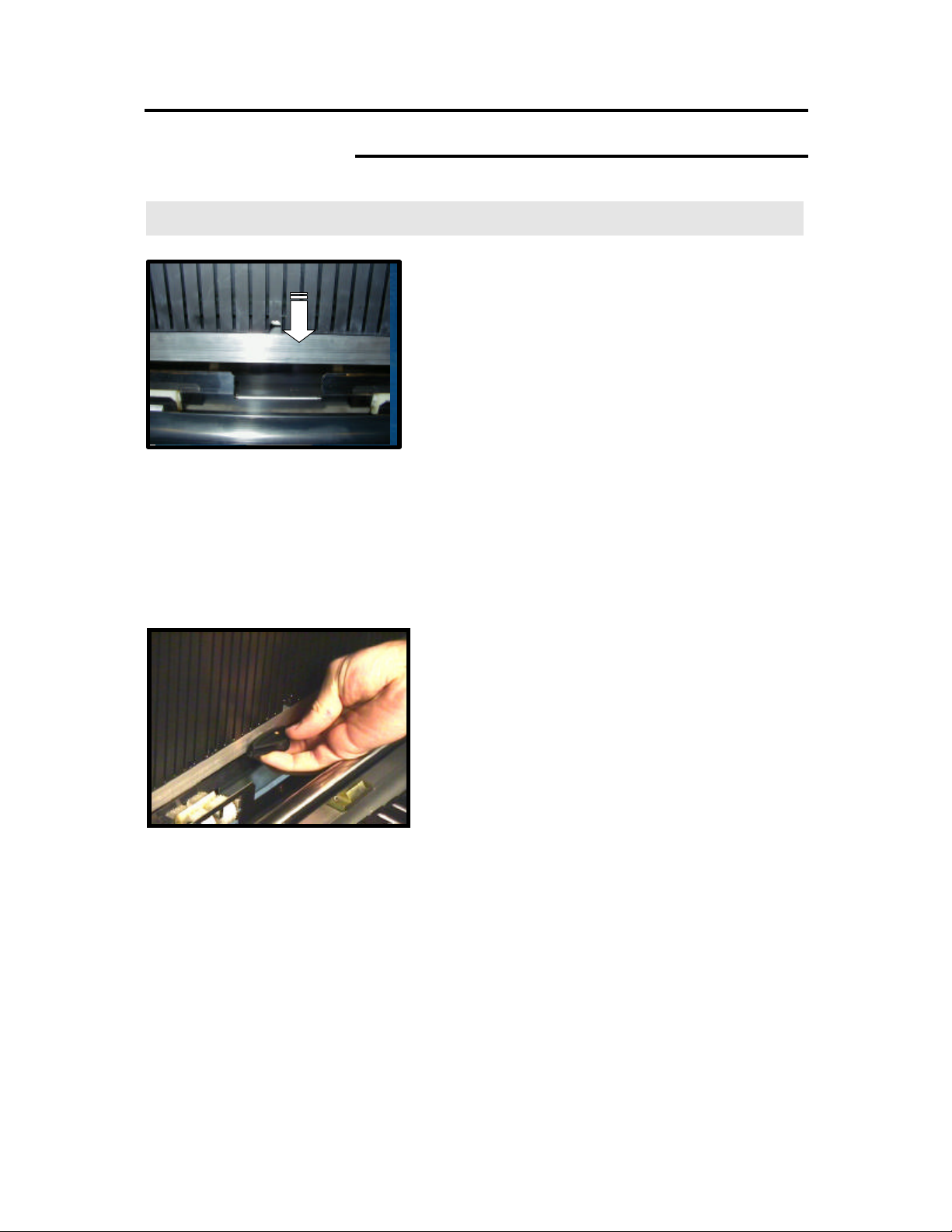

Page 36

Operating the cutter (con’t)

Replacing cutter blade

The procedures to replace the cutter blade are:

Procedures

Platen guide

1

2

3

1. At the printer’s operations panel, press the

Menu button (top button) to enter menu mode.

2. Use the arrow buttons to scroll to Replacing

Blade and press the associated button to

proceed.

3. The operation panel will display: "Move to the

center". Press the associated button to move

the cutter blade to the center.

4. The operation panel will display: "Open

top/front cover". Open the top cover. After

opening the top cover, the panel will again

instruct to open the front cover.

5. Open the top cover and then press the button

associated with NEXT.

6. Manually move the cutter blade to the very

center if not properly centered.

7. The operation panel will display: "Replace

blade and press reset".

8. To remove the cutter, push down the cutter

blade.

24 Operations

Page 37

Operating the cutter (con’t)

Replacing cutter blade (con’t)

9. Tilt and slide the cutter blade from the cutter

holder.

10. Install the new cutter blade to the cutter

holder.

a. Ensure that the cutter unit is still in the

centered position.

b. Push the new cutter blade into the cutter

holder until the blade snaps into position.

11. Press the button associated with RESET.

Note: RESET moves the cutter unit to the

right, even if the cutter blade has NOT been

successfully installed. Should the RESET

button be accidentally pressed before

successful installation, manually move the

cutter holder to the center and properly install

the cutter blade as specified in step 10b.

12. The operation panel displays: "Close the

covers.” Close them.

13. The final message is "Done. Press ½ key.”

This will put the printer in READY status.

Operations 25

Page 38

Using the take-up roller

Procedures

Setup the take-up assembly

The procedures to set-up the take-up roller:

. Adjust the position of TAKE UP ROLLER

HOLDER for the roll size. Perform this action on

both the left and right sides.

2. Loosen the thumbscrew, and slide the TAKE UP

ROLLER HOLDER to the desirable position then

secure the thumb screw.

26 Operations

Page 39

Using the take-up roller (con’t)

r

Setup the take-up assembly (con’t)

3. Set the FLANGE on the plastic roller bearing on

the right side.

4. Set the left FLANGE on the plastic roller bearing.

If you need to adjust the length, do steps 1 and 2

again. (Note that the end caps for the take-up

roller are black versus the green caps for the

media roller. Use these for optimum

performance.)

5. At the operations panel, enable the take-up roll.

a. Press the Menu button (top button) to enter

menu mode.

b. Press the button associated with the Set

menu option.

c. Press the left arrow button 4 times to display

the Winding direction option.

d. Set to the desired direction: Image In or

Image Out.

Starting the take-up roller

Printing surface

1. When the printed media passes completely ove

the platen and emerges out the exit chute, guide

the media over or under the take-up roll and

tape it to the roll.

2. Monitor the media until it has rolled once around

the take-up roll. From this point on, the media

will wind up automatically.

Operating the printer from RIP software

Instructions for operating the printer using the host computer’s digital

front end (DFE) program are covered in associated DFE software

manuals or release notes.

Operations 27

Page 40

Supplies

This section describes the simple procedures for ink and media

replacement. Additionally, how to properly handle and store these

supplies is addressed to ensure maximum print quality.

Replacing ink bottles

Precautions

The following precautions must be strictly enforced when handling

inks.

WARNING: Combustible. Keep ink away from open flames. Do

not drink, drop into eyes, or spill onto your skin. Keep the ink

out of reach of children. The ink can cause difficulty in

breathing and damage your eyes.

1. Use rubber gloves when replacing the ink bottle.

2. Dispose of the empty bottle and gloves in a plastic bag.

3. Dispose of the ink bottles in accordance with local and federal

regulations.

When to replace ink bottle

1. The printer has a separate bottle, each 0.5 or 0.25 liters, for each

color. The ink bottle should be replaced when either:

2. The ink bottle is empty

3. The ink is too old, as indicated on the expiration date, which is

printed on the bottle. Expired ink can cause light image densities.

* INK EMPTY

LOAD INK CARTRIDGE

PRESS TO RESET→

[ER:4631] MENU→

.

a. For cases where an ink bottle is empty, the LCD will display

the

Ink Empty

b. An ink bottle can be changed at any time, that is, during

operation, idle, or off.

Caution: There will be a small amount of ink left in the bottom of the

ink cartridge. This is normal. Do not attempt to pour the residue from

one bottle into a fresh bottle. Doing so will alter the chemical makeup

of the inks themselves, and the excessive residue can cause damage

to interior machine components as well as impact color quality. There

is extra ink in each of the bottles to compensate for this residue.

message.

28 Supplies

Page 41

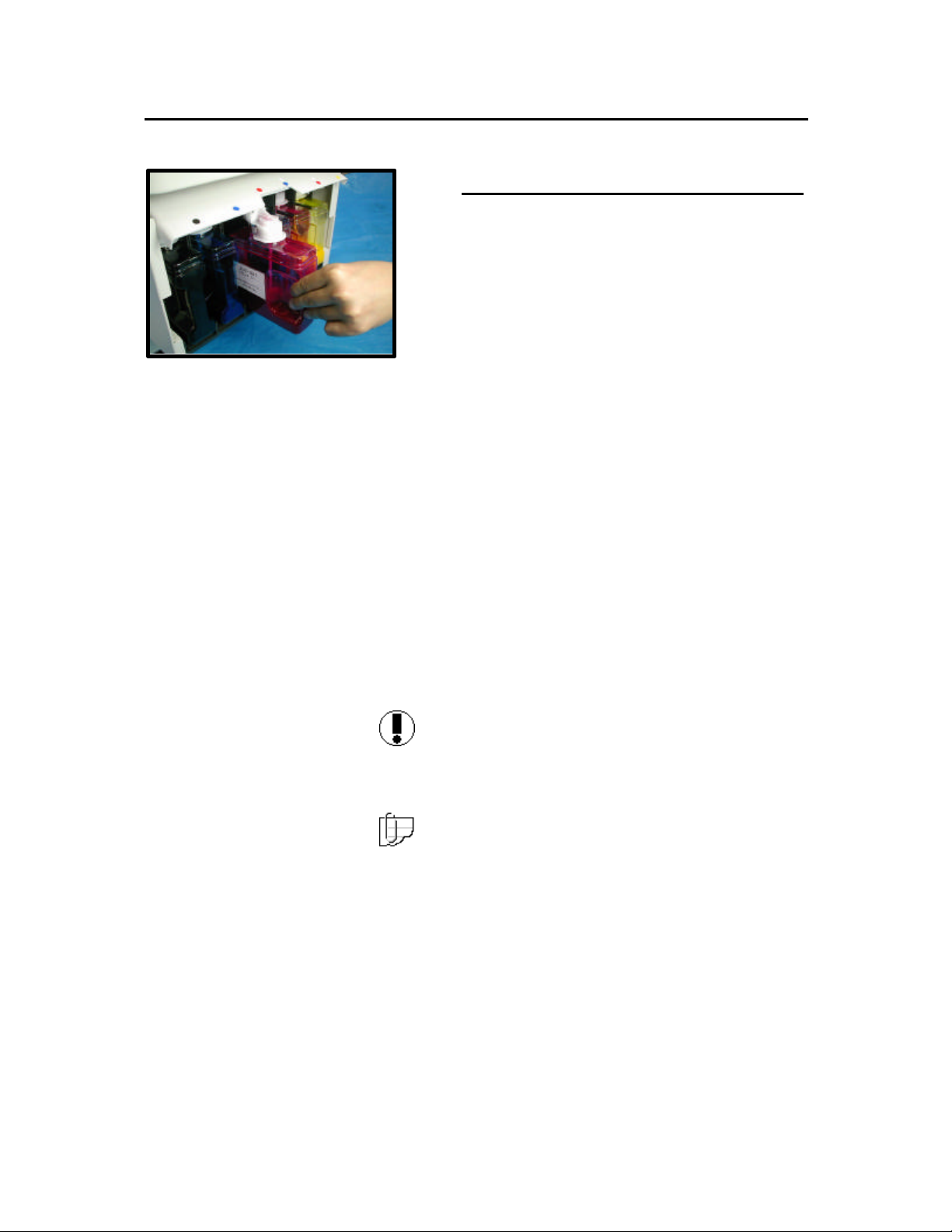

Replacing ink bottles (con’t)

Replacement procedures

The steps to replace ColorgrafX X2 inks are:

Procedures

1. Ensure the ink bottle you replace is the same

color as the original.

– The ink holder labels on the printer are

Tip

color coded with the color ink to be used.

Always match the ink holder label color to the

ink color in the replacement bottle.

2. Remove the ink bottle.

3. Remove the cap from the new ink bottle.

Supplies 29

Page 42

Replacing ink bottles (con’t)

Replacement procedures

4. Insert the new ink bottle in the ink bottle holder.

Important: Ink spills should be cleaned

immediately using soap and water. Dispose of

all used cleaning materials as approved by local

and federal requirements.

5. Ensure that the waste ink bottle is in place and

properly seated.

6. Press Button 3 (PRESS TO RESET). The

printer will automatically replenish the ink.

Replacing the waste ink bottle

Precautions

The following precautions must be strictly enforced when handling

inks.

WARNING: Combustible. Keep ink away from open flames. Do

not drink, drop into eyes, or spill onto your skin. Keep the ink

out of reach of children. The ink can cause difficulty in

breathing and damage your eyes.

The waste ink bottle has an absorber inside the bottle to absorb the

waste ink. Do not take the absorbent materials out of the bottle.

Dispose of the waste ink bottle after packing it into the zip-lock plastic

bag that is included with the new waste ink bottle. Firmly close the

zip-lock seal.

Dispose of the waste ink bottles in accordance with local and federal

regulations.

30 Supplies

Page 43

Replacing the waste ink bottle (con’t)

When to replace the waste ink bottle

The waste ink bottle should be replaced when the waste ink bottle is

filled with the waste ink.

* WASTE BOTTLE FULL

/NOT INSTALLED

SEE USER GUIDE

[ER: 4621]

Procedures

For cases where the waste ink bottle is full, the LCD will display

the

Waste Bottle Full

The amount of waste ink in the waste ink bottle is measured by

the waste ink bottle’s weight. The waste ink bottle tray acts as a

scale and must move freely to properly measure the amount of

waste ink in the bottle and prevent waste ink over-flow.

Caution: If the printer continues to run without detecting the

change in the waste ink bottle’s weight, the waste ink bottle

could overflow and contaminate the printer and floor.

message.

Replacement procedures

The steps to replace waste ink bottle are:

1. Locate the waste ink bottle on the right rear side

of the printer.

2. Pick up the waste ink bottle and tilt it to remove

4. Set the new waste ink bottle on the waste ink

the bottle from the waste ink bottle tray.

3. Place the waste ink bottle into the disposable

plastic bag.

3. Properly dispose of the used waste ink bottle.

bottle tray. Ensure that the bottle is properly

seated on the tray before continuing.

Supplies 31

Page 44

Loading and removing media

Supported media

The ColorgrafX X2 printer can print on a variety of media including

paper, films, vinyl, and other special media. The list of available

media changes to meet customer requirements, so check with your

sales representative to determine what media is currently available

and in what roll sizes.

Procedures

IMPORTANT!

Caution: Using media other than the recommended media can

cause media jams, blurred images, or printer failure.

The printer can hold two large rolls of media with either the same or

different sizes. Refer to the ColorgrafX X2 Inkjet Graphics

Applications Guide to acquire a list of sizes by media type.

Loading media in the printer

The following procedure outlines the process to load media in the

printer.

1. If changing media type, be sure to change the media type

before closing the covers.

After you load the media and close the covers, the printer

will automatically load media through the printer and attempt

to cut it as part of the self-test. If you have not set the cutter,

for example, to handle the newly loaded media correctly, you

could cause a media jam when the printer attempts to cut

the new media.

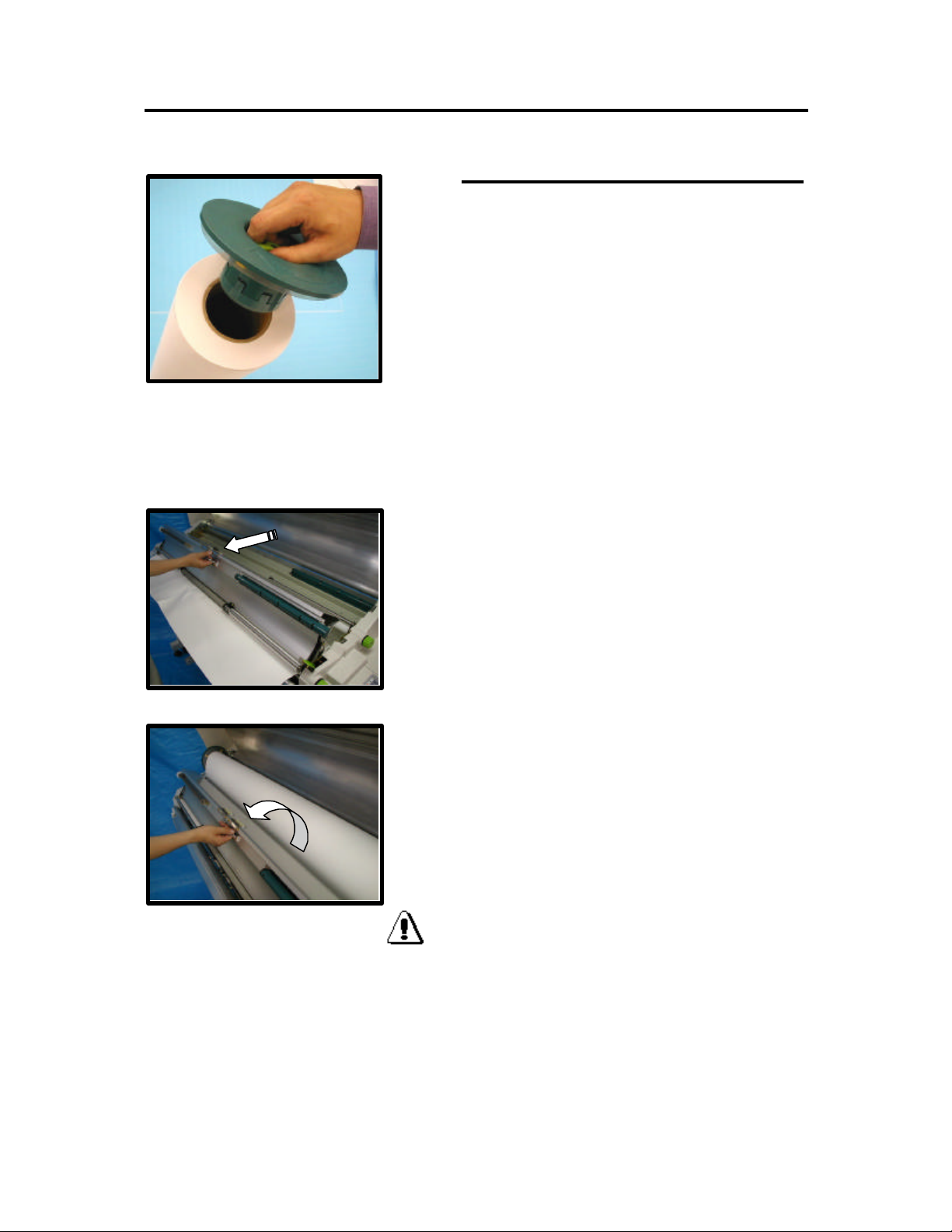

2. Insert an end cap into one end of the new media roll until it

is firmly seated, being careful not to damage the other,

exposed end of the media roll. The end cap should be snug,

but not jammed on the roll for optimum use.

Note: When opening a new roll of media, open one end of

the inner packaging at a time. Stand the roll on end.

Expose the top end, and put the end cap on.

32 Supplies

Page 45

Loading and removing media (con’t)

Loading media in the printer (con’t)

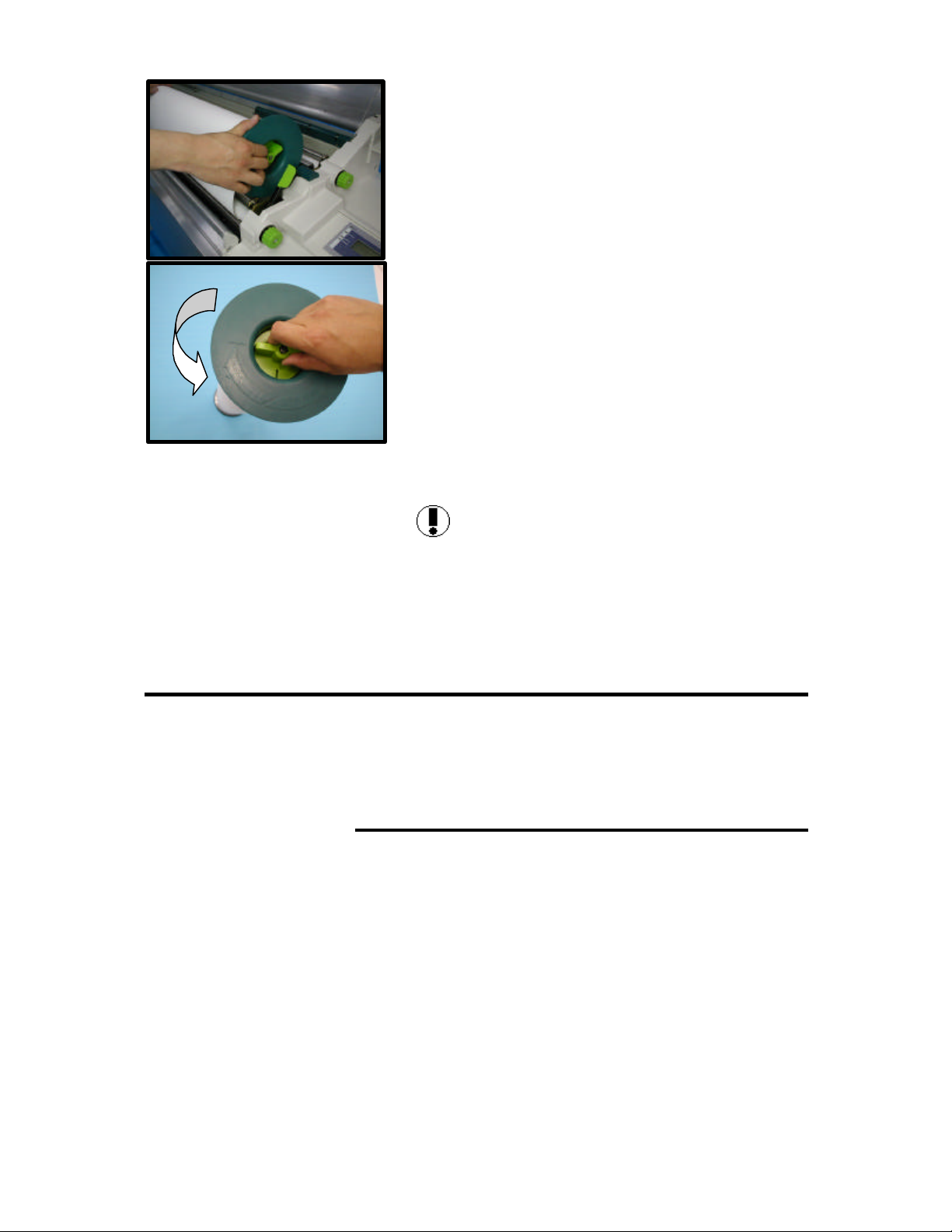

3. Turn the locking knob on the media end cap to its locked

position to secure it in the media roll.

4. Repeat steps 2 and 3 for the opposite end of the media roll.

5. Open the printer’s top cover.

6. Set the new media roll on the printer.

7. Media width guides are provided on the printer’s media roll

feeder.

Set position Media Size

First position 54 inches (1372 mm)

Second position 50 inches (1270 mm)

Third position 42 inches (1067 mm)

Fourth position

Fifth position

36 inches (914 mm)

23.4 inches (594 mm) / 11" (279 mm)

8. Set the right end cap at the position matching the media

width. The front guides are freely–rotating support rollers.

9. Rotate the media end cap to unroll 3 to 4 inches of media

from the roll.

10. Insert the leading edge into the feeder’s media input.

Caution - Media rolls, particularly the larger widths, are

heavy and awkward to handle. Ask for assistance when

installing these media rolls to avoid personal injury, damage

to the printer or damage to the media.

Supplies 33

Page 46

Loading and removing media (con’t)

l

Loading media in the printer (con’t)

Feed roller knob

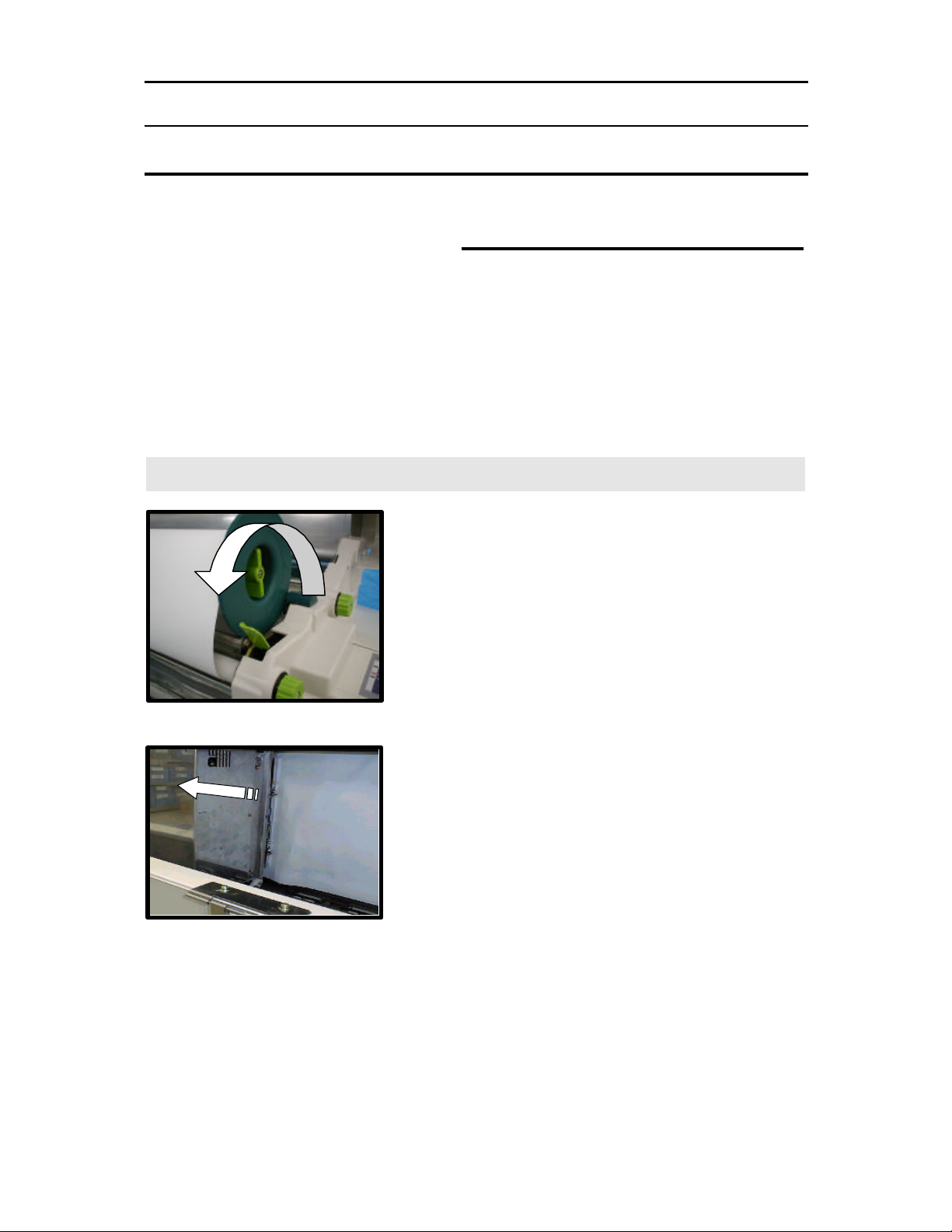

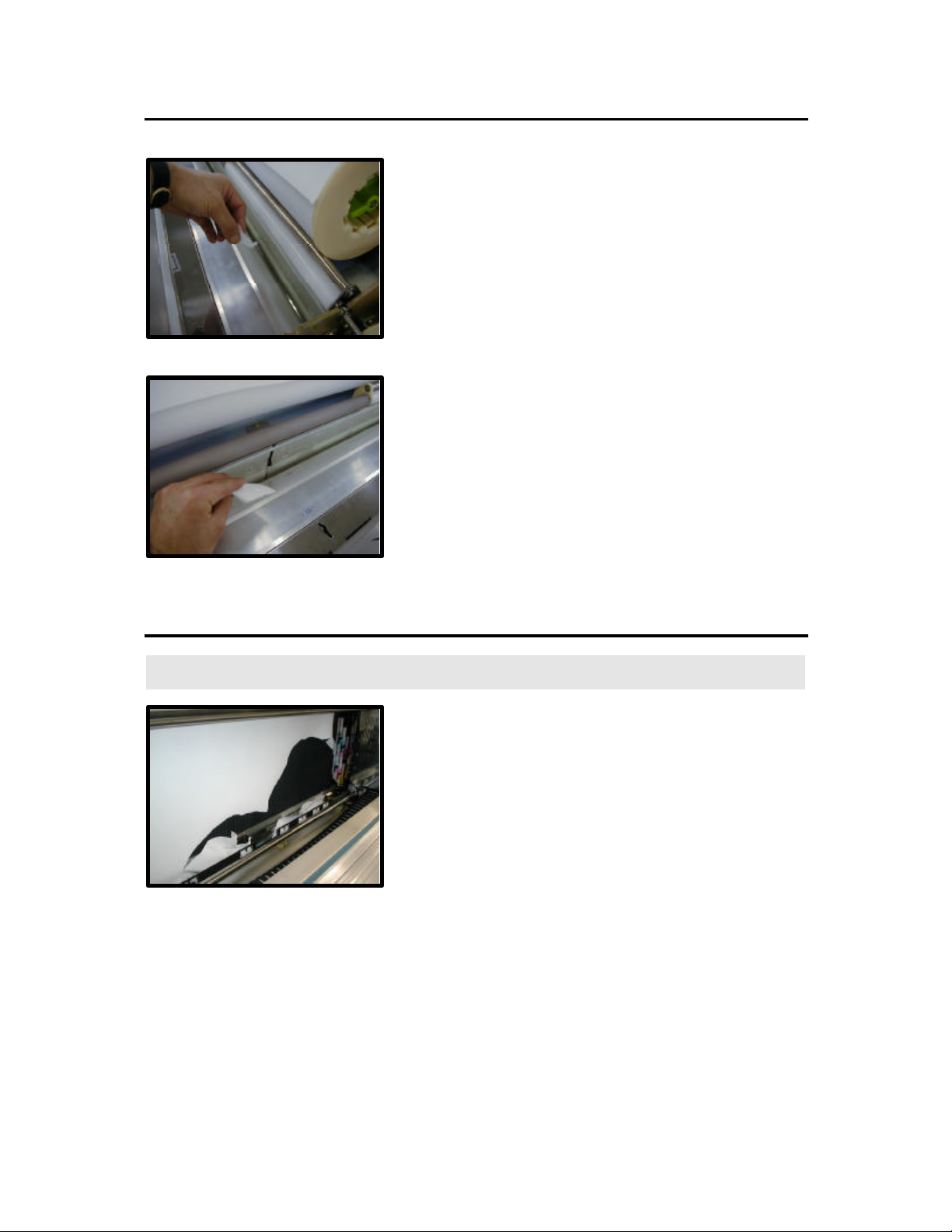

11. Rotate the feed roller knob toward you. Continue

to forward the media until you hear a beep from

the printer. The printer will sense the new

media’s leading edge. Ensure that there is even

tension and no wrinkles on the media.

12. Close the printer’s top cover. The printer will

start initializing, and you should hear activity as

it checks and positions the newly loaded media

roll.

After completing its self-test, the printer will

forward some of the newly loaded media

through the print path and then cut it. This

assures that the media has a clean-cut leading

edge when printing.

13. Examine the cut edge of the media to verify that

the cutter is properly set and is cutting the media

cleanly. If it is not a clean cut, change the

printer’s cutter setting to match the media type.

Refer to the

Media type

14. Ensure the printer is online and ready to receive

the next print job.

15. Set the media type and attributes at the

operations panel. Refer to the

section.

Menu

This completes installation of a new media roll in

the printer.

Operations

.

chapter as described in

Operations Pane

Feed roller knob

34 Supplies

Page 47

Loading and removing media (con’t)

r

When to replace media

EMPTY MEDIA ROLL

LOAD MEDIA

SEE USER GUIDE

[ER: 3A24]

The media should be replaced whenever the LCD display

displays

Empty Media Roll

Caution: The media rolls are heavy. Handle carefully and ask

for assistance to avoid personal injury, damage to the printer, o

damage to the media.

.

Procedures

Removing media

The steps to remove media are:

1. Open the printer top cover.

Be sure to open or close the top cover slowly,

holding with both hands while standing in front

of the printer. Be careful to not let your fingers

or hands get caught when the cover closes.

When changing media rolls, the release lever on

the right side of the printer is not used and

should be left in its closed position.

Supplies 35

Page 48

2. Rotate the end cap rearward to rewind the

media onto the media roll.

3. Remove the media roll from the feeder.

Supply storage

4. Remove the end caps from both ends of the

media roll by turning the light green locking knob

in the RELEASE direction and then pulling the

caps away from the media roll.

Tip: Use a low-adhesion tape, such as masking

tape, to keep the media from unrolling after it is

removed from the printer. A high-adhesion tape

can damage the leading edge of the media

when it is removed.

5. Store the media roll in the horizontal position,

being careful not to

the exposed ends of the media roll.

Caution: The ends of media roll are vulnerable

to mechanical damage whenever the media roll

end caps are removed. Use caution while

handling media as damaged media can damage

the printer or cause printing problems. Never

store unprotected media rolls upright.

dent or otherwise damage

To keep your supplies in good condition, you should always observe

the following storage requirements.

Ink bottle storage

When storing ink bottles:

Select a cool location with good ventilation.

1. Do not place ink bottles directly on the floor.

2. Use ink within 18 months of date of manufacture.

3. Avoid storing ink bottles where:

The bottles are exposed to direct sunlight.

−

The bottles are exposed to high temperature or humidity.

−

36 Supplies

Page 49

Supply storage (con’t)

Media storage

When storing media:

1. Select a cool, well ventilated area.

2. Don't place media rolls directly on the floor. In humid conditions,

be sure to leave space for air circulation between the floor and

the media.

3. Avoid storing media where it might be exposed to direct sunlight,

high temperature, or high humidity.

4. Use media within 2 years of date of manufacture.

5. Unless otherwise instructed, store all media flat (horizontally).

6. If the media is not to be used immediately after opening the

package, securely reseal the media package.

7. If the media in the printer has not been used for a long time, the

media on the outside of the roll will degrade first. It is a good

practice to feed some media and cut off the degraded or wrinkled

area.

8. If the media storage and printer environments differ greatly, let

the media stand in the printing environment for at least two hours

before using.

Supplies 37

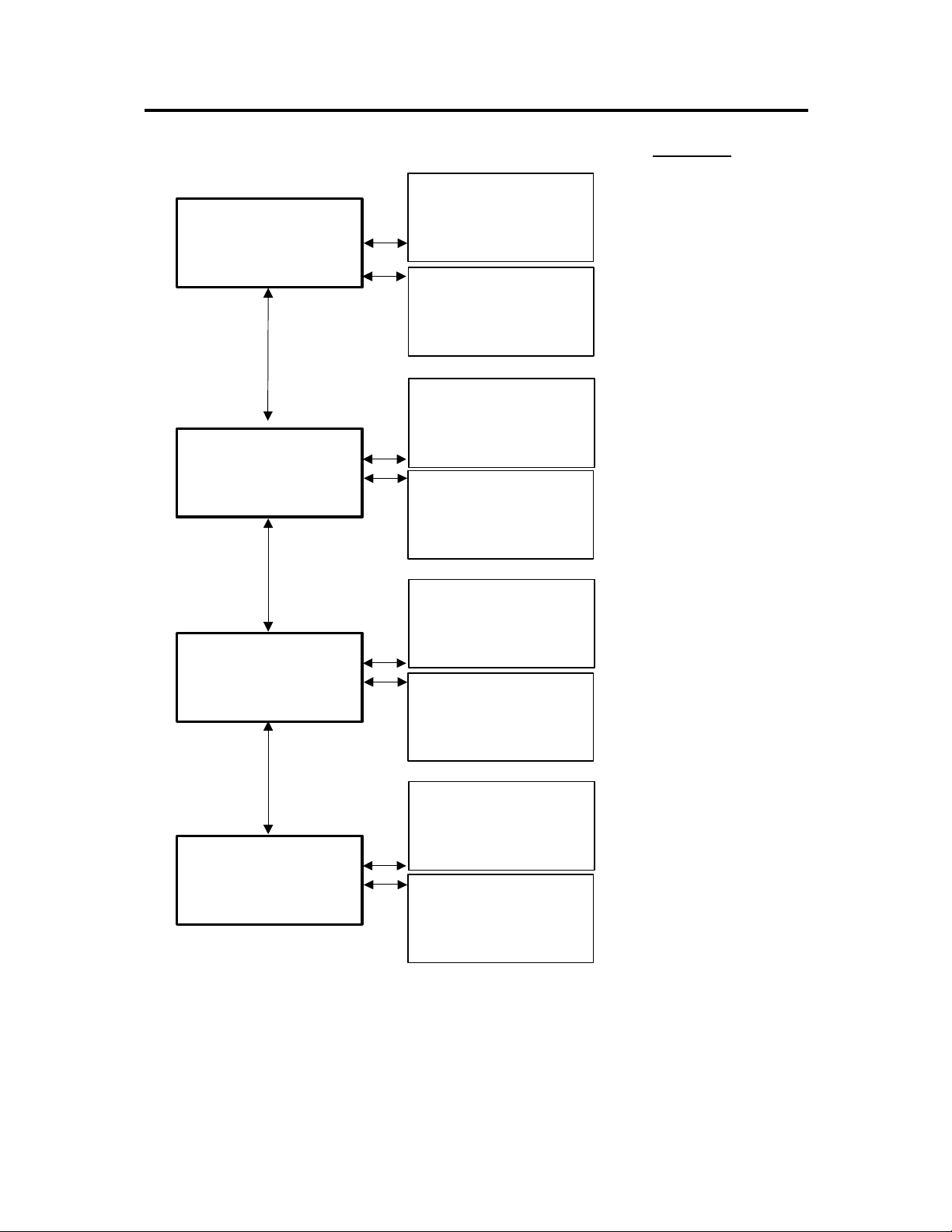

Page 50

Maintaining print quality

Overview

The ColorgrafX X2 inkjet printer is a self-maintaining printer. That is,

it requires no

cover head maintenance for optimum performance, maximum

resolution, and sharp details.

Head Maintenance

Normal maintenance

The printer has, at the print head home position, a vacuum pump

positioned over the print head. During the purging process, the

vacuum pump forcibly pulls ink through the print head nozzles,

removing any debris or dry ink particles. The waste ink from this

process is gathered and sent to the waste ink bottle.

After completing the print head purging process, any remaining ink

on the surface of the print head is removed by an automatic wiper.

Manual maintenance process

maintenance. The procedures in this sections

routine

Procedures

The printer performs automatic head cleaning during routine use.

However, when a void occurs, the trouble can be corrected using the

following head cleaning procedure:

1. If a void occurs, print out the same image again. The automatic

head cleaning operation occurs before each print operation, thus

forcing an extra head cleaning cycle.

2. If the print still has voids, select HEAD MAINTENANCE>

NORMAL PURGING commands on the printer’s operation panel.

READY MENUÎ

HEAD MAINTENANCE Î

CUT Î

<MORE>

3. Each time the HEAD MAINTENANCE command is executed, the

printer’s inking system is purged of a small amount of ink.

4. Print the image once again.

5. If the print still shows voids, return to the HEAD MAINTENANCE

option; however, select STRONG PURGING.

6. Call your service representative if you cannot correct the print

quality.

<HEAD MAINTENANCE> S

STRONG PURGING Î

NORMAL PURGING Î

38 Maintaining print quality

Page 51

Head Maintenance (con’t)

Test Print

You can print the nozzle test pattern through the operation panel.

This is performed to check for clogged nozzles.

Procedures

1. Press the Menu mode button.

2. Press the button associated with the TEST PRINT option to enter

the test print mode.

<MENU> S

TEST PRINT Î

HEAD MAINTENANCE Î

<MORE>

<TEST PRINT>

NOZZLE TEST Î

<MORE>

S

<NOZZLE TEST>

* W/O INFO. +

FRONT -

<ROLL> PRINT Î

3. Press the button associated with the NOZZLE TEST option.

4. Use the arrow buttons to select the FRONT or REAR roll.

4. Press the button associated with the PRINT option to execute the

print.

6. Verify that the adjustment was successful. If not, repeat the

process. If this still does not resolve the problem, call your

service representative.

S

Maintaining Print Quality 39

Page 52

Jam clearance

Clearing a media jam

Procedures

Carriage

Carriage

Wrinkles on

Wrinkles on

the right side

the right side

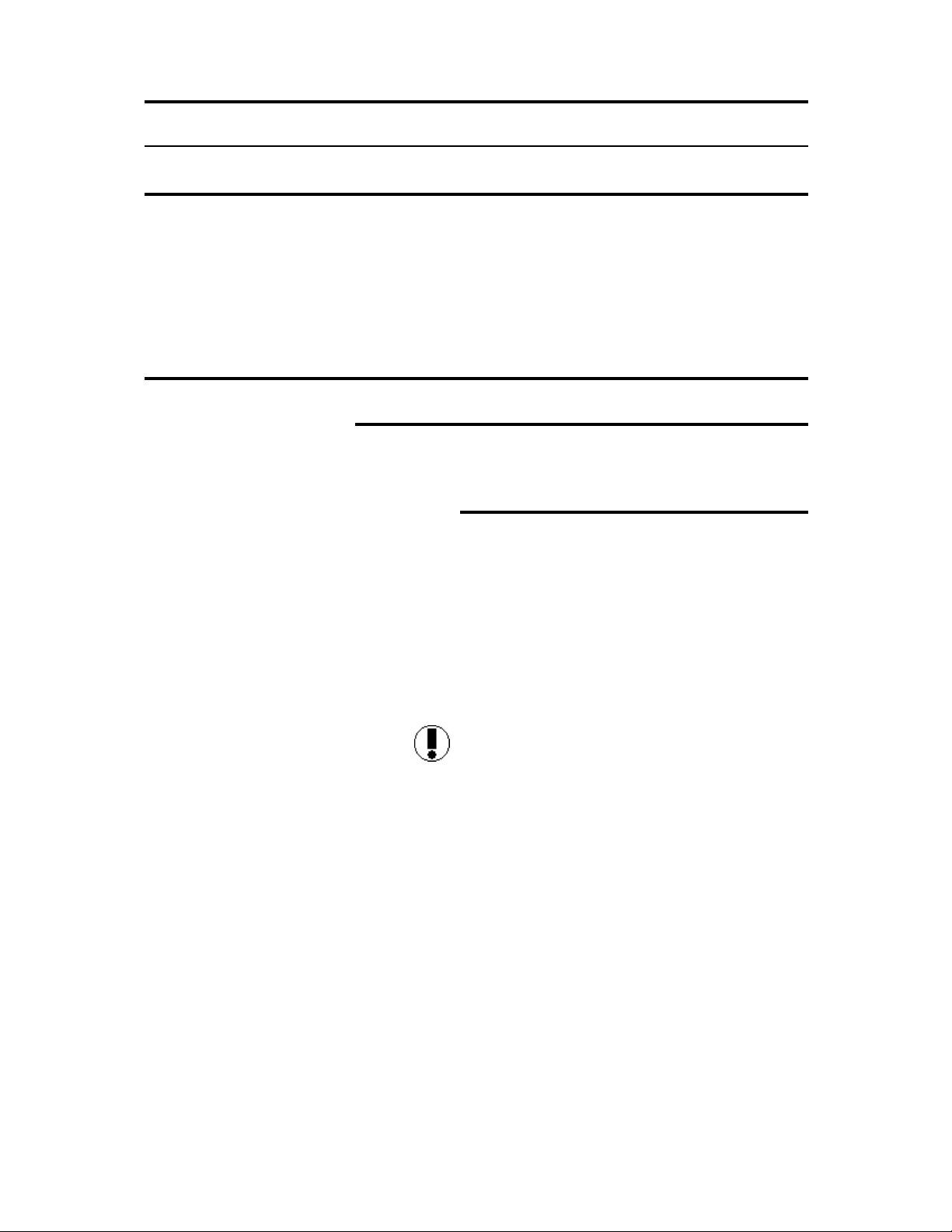

Overview

If the printer has a media jam, clear it using the

following procedure. Diagrammatic labels indicating

the summarized steps are attached inside of the

equipment.

Important - Repeated media jams indicate the

printer is not operating normally. Refer to the

section "Error messages and troubleshooting" from

Appendix A

suggested corrective actions.

1. Open the top and front covers. Pull up the

release lever to release pressure as shown in

illustration to the left.

2. Check the position of the carriage. If it does not

return to the home position, manually move the

carriage away from the platen.

which includes probable causes and

40 Jam clearance

Page 53

Clearing a media jam (con’t)