Sharp MX-FNX9,MX-PNX1D,MX-PNX1A,MX-PNX1B,MX-PNX1C Service Manual

TopPage

SERVICE MANUAL

CODE: 00ZMXFNX9/S1E

DIGITAL FULL COLOR

MULTIFUNCTIONAL SYSTEM OPTION

FINISHER / PUNCH MODULE

MX-FNX9

MODEL

CONTENTS

[1] PRODUCT OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2] SPECIFICTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

[3] UNPACKING AND INSTALLATION

* For how to unpacking and installation, refer to the installation manual (00ZMX3100/I1E).

[4] EXTERNAL VIEW AND INTERNAL STRUCTURE . . . . . . . . . . . . . 4-1

[5] OPERATIONAL DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[6] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[7] MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[8] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

MX-PNX1A/B/C/D

[9] SELF DIAGNOSTICS AND TROUBLE CODES . . . . . . . . . . . . . . . 9-1

[10] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

SHARP CORPORATION

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

CONTENTS

[1] PRODUCT OUTLINE. . . . . . . . . . . . . . . . . . .1-1

[2] SPECIFICTIONS

1. MX-FNX9 . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2. MX-PNX1A/B/C/D . . . . . . . . . . . . . . . . . .2-2

[3] UNPACKING AND INSTALLATION

* For how to unpacking and installation, refer to the

installation manual (00ZMX3100/I1E).

[4] EXTERNAL VIEW AND INTERNAL

STRUCTURE

1. Identification of each section and

functions . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

[5] OPERATIONAL DESCRIPTIONS

1. Electrical mechanism diagram . . . . . . . . .5-1

2. General. . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

3. Outline of the transport path . . . . . . . . . . .5-5

4. Non-sort mode . . . . . . . . . . . . . . . . . . . . .5-6

5. Offset mode . . . . . . . . . . . . . . . . . . . . . . .5-6

6. Staple mode . . . . . . . . . . . . . . . . . . . . . . .5-7

7. Punching process . . . . . . . . . . . . . . . . . . .5-9

[6] DISASSEMBLY AND ASSEMBLY

1. MX-FNX9 . . . . . . . . . . . . . . . . . . . . . . . . 6-1

2. MX-PNX1A/B/C/D . . . . . . . . . . . . . . . . . 6-11

[7] MAINTENANCE

1. Maintenance system table . . . . . . . . . . . 7-1

[8] ADJUSTMENTS

1. Setting item list . . . . . . . . . . . . . . . . . . . . 8-1

2. Details . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[9] SELF DIAGNOSTICS AND TROUBLE CODES

1. Trouble code and troubleshooting. . . . . . 9-1

[10] ELECTRICAL SECTION

1. Circuit descriptions . . . . . . . . . . . . . . . . 10-1

2. Block diagram . . . . . . . . . . . . . . . . . . . 10-12

3. Actual wiring diagram . . . . . . . . . . . . . 10-14

DIGITAL FULL COLOR

MULTIFUNCTIONAL SYSTEM

MX-2600N/3100N

MX-2600G/3100G

MX-FNX9

[1] PRODUCT OUTLINE

Service Manual

This unit is used by installing to the purpose of this unit is to provide post processing of fax and copy output paper. It is provided with the offset

function which discharges output paper by shifting one by one.

Since it is installed to the center tray section of the main unit, no extra space for installation is required.

1) 3 kinds of auto staple functions: There are 3 kinds of stapling positions. (One position in front, one position backward, 2 positions at the

center).

2

2) Punch function (option): By installing the punch unit, paper can be punched to make binder holes. (Paper of 64 to 128g/m

can be used.

OHP film cannot be used.)

Models enable to install the unit MX-2600G/MX-2600N/MX-3100G/MX-3100N

The finisher requires a staple cartridge as a consumable part. (Staple cartridge (about 5,000 staples x 3 pcs.) MX-SCX1)

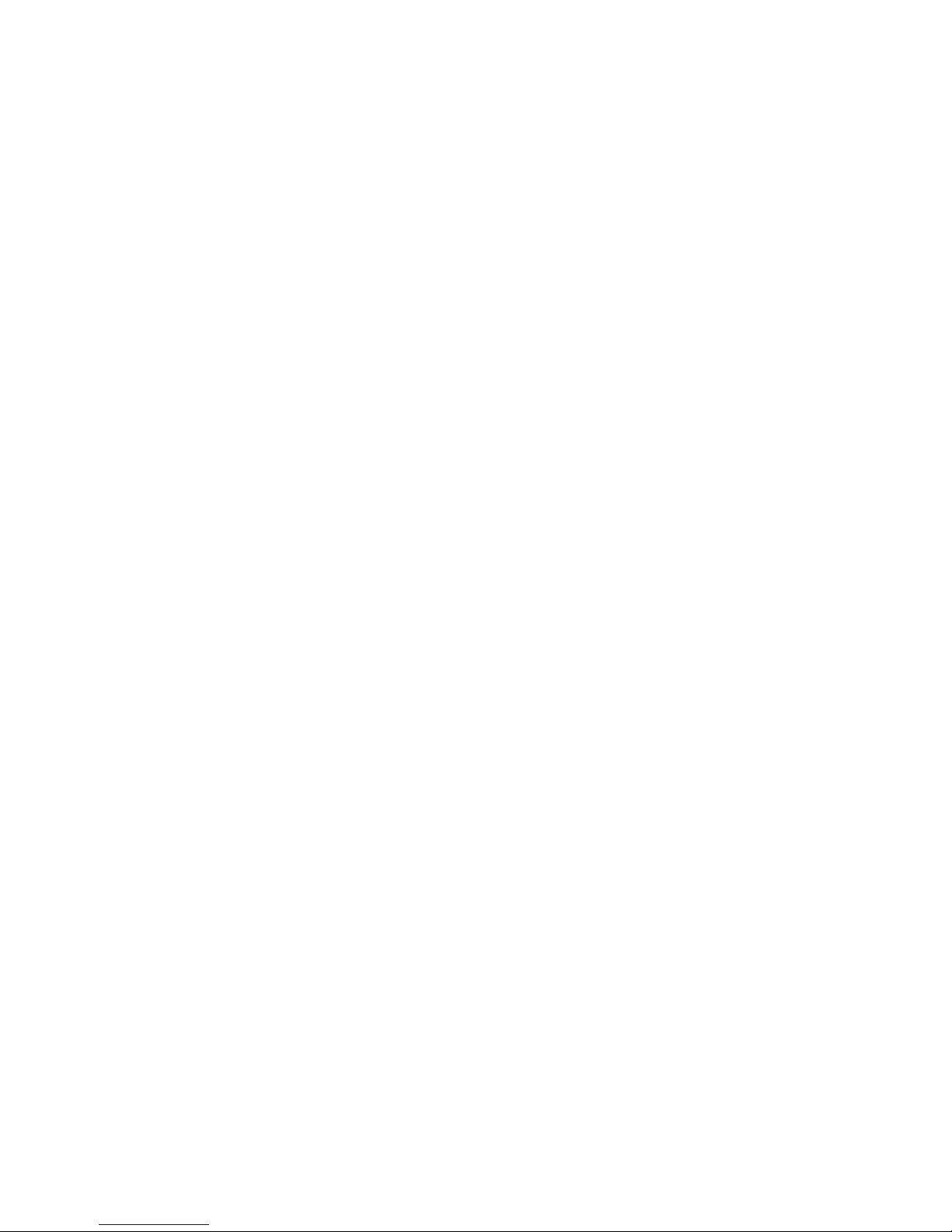

Paper exit system Document feeder system

STAPLE CARTRIDGE

12

MX-SCX1

PUNCH MODULE

10

MX-PNX1

A/B/C/D

FINISHER

7

MX-FNX9

EXIT TRAY UNIT

6

MX-TRX1

DIGITAL FULL COLOR

MULTIFUNCTIONAL SYSTEM

MX-2600N/3100N

MX-2600G/3100G

REVERSING

SINGLE PASS FEEDER

1

MX-RPX2

DOCUMENT COVER

2

MX-VRX1

Paper feed system

STAPLE CARTRIDGE

12

MX-SCX1

STAPLE CA

13

11

RTRIDGE

(For saddle)

AR-SC3

PUNCH MODULE

MX-PNX5

A/B/C/D

SADDLE STITCH

FINISHER

9

MX-FN10

Printer expansion

PRINTER

EXPANSION KIT

14

MX-PBX3

PS3 EXPANSION KIT

15

MX-PKX1

XPS EXPANSION KIT

16

MX-PUX1

BARCODE FONT KIT

17

AR-PF1

Authentication/Security

PAPER PASS UNIT

8

MX-RBX3

Image send expansion

FACSIMILE

EXPANSION KIT

18

MX-FXX2

Application/Solution

STAMP UNIT

19

AR-SU1

STAMP CARTRIDGE

20

AR-SV1

STAND/1 x 500 SHEET

PAPER DRAWER

3

MX-DEX6

INTERNET FAX

EXPANSION KIT

21

MX-FWX1

NETWORK SCANNER

EXPANSION KIT

22

MX-NSX1

LARGE CAPACITY TRAY

5

MX-LCX1

STAND/2 x 500 SHEET

PAPER DRAWER

4

MX-DEX7

APPLICATION

INTEGRATION MODULE

23

MX-AMX1

DATA SECURITY KIT

24

MX-FR10U

DATA SECURITY KIT

25

MX-FR10

Memory

EXPANSION

MEMORY BOARD

34

MX-SMX3

26

27

28

SHARPDESK

1 LICENSE KIT

MX-USX1

SHARPDESK

5 LICENSE KIT

MX-USX5

SHARPDESK

10 LICENSE KIT

MX-US10

SHARPDESK

50 LICENSE KIT

29

MX-US50

SHARPDESK

100 LICENSE KIT

30

MX-USA0

MX-FNX9 PRODUCT OUTLINE 1 – 1

APPLICATION

COMMUNICATION MODULE

31

MX-AMX2

EXTERNAL

ACCOUNT MODULE

32

MX-AMX3

33

KEYBOARD

MX-KBX1

MX-FNX9

[2] SPECIFICTIONS

Service Manual

1. MX-FNX9

Type Inner finisher

Loading method Offset tray

Transport speed 26, 31 PPM

Tray type Offset tray

Transport reference Center reference

Paper exit direction Face down

Mode type Non-stapled, stapled

Offset quantity 30mm, 1.2 inch

Stapling 3 kinds (One position in front, one position backward, 2 positions).

Staple supply system Staple sheet cartridge replacement system (Staple cartridge (Approx. 5,000 x 3 pcs.) MX-SCX1)

Staple detection Staple empty detection (Near empty detection: 20 staples remained)

Manual stapling No

External dimensions (W x D x H) 440 x 595 x 205 (mm), 17 21/64 x 23 27/64 x 8 5/64 (inch)

Weight Approx. 13kg (28.7 lbs)

Power source Supplied from the main unit power source. (DC24V, DC5V)

Power consumption 55.2W

Installation/maintenance Installed by service personnel

Optional detection Auto detection supported

Packaged items Parts for mounting, operational sheet, staple directional instruction label, installation cautionary note

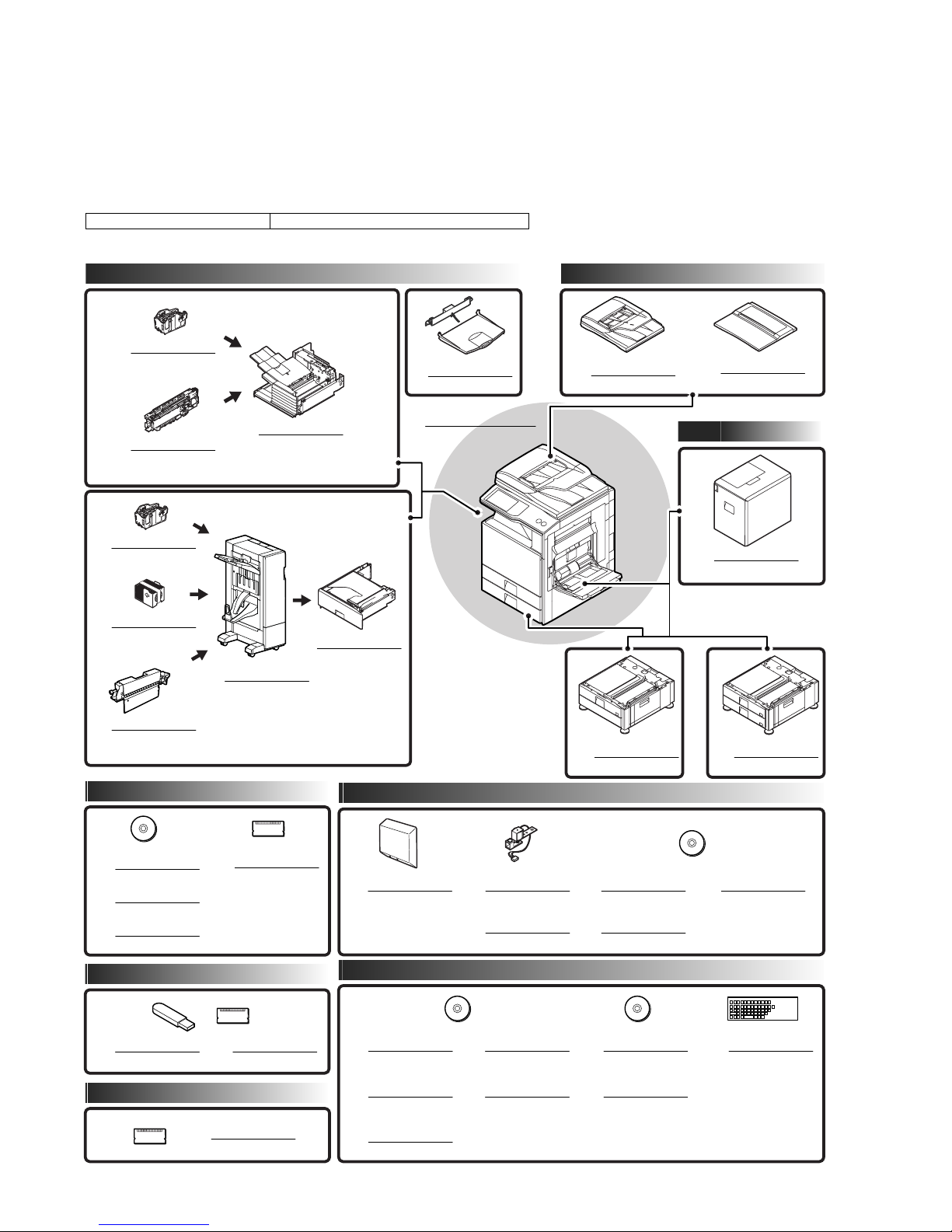

A. Allowable paper size fo paper exit/Weight

(with tray extended: 640 x 595 x 205 (mm), 25 12/64 x 23 27/64 x 8 5/64 (inch))

Allowable

paper size

Paper size 12 x 18 (A3W) Yes - -

11 x 1 7 Yes Yes 30 sheets

8.5 x 14 (216 x 356) Yes Yes 30 sheets

8.5 x 13.5 (216 x 343) Yes Yes 30 sheets

8.5 x 13.4 (216 x 340) Yes Yes 30 sheets

8.5 x 13 (216 x 330) Yes Yes 30 sheets

8.5 x 11 Yes Yes 50 sheets

8.5 x 11R Yes Yes 50 sheets

7.25 x 10.5R Yes - -

5.5 x 8.5R Yes - A3 Yes Yes 30 sheets

B4 Yes Yes 30 sheets

A4 Yes Yes 50 sheets

A4R Yes Yes 50 sheets

B5 Yes Yes 50 sheets

B5R Ye s - A5R Ye s - 8K Yes Yes 30 sheets

16K Yes Yes 50 sheets

16KR Yes - 50 sheets

Envelope *1 Yes - Custom *2 Yes - -

Paper type Thin paper 55 - 59g/m2 13 lb bond - 16 lb bond Yes Yes Yes

Plain paper 60 - 105g/m2 16 lb bond - 28 lb bond Yes Yes Yes

Recycled paper Yes Yes Yes

Colored paper Yes Yes Yes

Letterhead Yes Yes Yes

Printed paper Yes Yes Yes

punched paper Yes Yes Yes

Thick paper 106 - 209g/m2 28 lb bond -110 lb index Yes Yes *3 Yes *4

210 - 256g/m2 110 lb index - 140 lb index Yes Yes *3 Yes *4

Envelope 75 - 90g/m2 Yes - OHP Ye s - label paper Yes - Tab paper *3 Yes - Gloss paper Yes Yes User type 1 - 7 Yes Yes Yes *5

Offset

Allowable paper

quantity for stapling

*1: Supported kinds of envelopes: Monarch/Com-10/DL/C5/Long type 3/ Western type 2/ Western type 4/Long type 2

*2: Custom size support area

~

Tray (supporting soft SW) X: 182 - 432mm (7_1/

~

Manual feed X: 148 - 432mm (5_1/

217) Y: 100 - 297mm (5_1/~211_5/8)

417) Y: 132 - 297mm (5_1/~411_5/8)

*3: Thick paper (129g/m2 or above: Out of performance assurance)

MX-FNX9 SPECIFICTIONS 2 – 1

*4: Thick paper (In the cover paper mode, allowable only 2 (in total of the front cover paper and the back cover paper) + plain paper.))

*5: Follows the paper type registration setting.

B. Allowable load quantity for each size

Function/Mode Non-offset Offset Staple

Paper size Plain paper

(60 - 105g/m2 paper)

Envelope 10*3 No No

Thin paper 500 *6 500 *6 500 *6

Thick paper 500 *6 500 *6 Cover only

gloss paper A4/8.5 x 11 500 *6 500 *6 No

Tab paper A4/8.5 x 11 100 *7 No No

Label paper A4/8.5 x 11 100 *7 No No

OHP A4/8.5 x 11 100 *7 No No

*1: 250 sheets or height of 35.5mm or less

*2: 500 sheets or height of 71mm or less

*3: Up to 10 envelopes can be loaded on the load tray.

*4: 250 sheets or 30 sets, or height of 35.5mm or less

*5: 500 sheets or 30 sets or height of 71mm or less

*6: Similarly with plain paper, the load capacity of thin paper, heavy paper, and glossy paper is limited to the earliest reach of the above number

of sheets or the limited height.

*7: 100 sheets or height of 35.5mm or less

A3W 250 *1 No No

A3 250 *1 250 *1 250 *4

B4 250 *1 250 *1 250 *4

A4 500 *2 500 *2 500 *5

A4R 500 *2 500 *2 500 *5

B5 500 *2 500 *2 500 *5

B5R 500 *2 No No

A5R 500 *2 No No

12 x 18 250 *1 No No

11 x 17 250 *1 250 *1 250 *4

8.5 x 14 250 *1 250 *1 250 *4

8.5 x 13.5 (216 x 343) 250 *1 250 *1 250 *4

8.5 x 13.4 (216 x 340) 250 *1 250 *1 250 *4

8.5 x 13 (216 x 330) 250 *1 250 *1 250 *4

8.5 x 11 500 *2 500 *2 500 *5

8.5 x 11R 500 *2 500 *2 500 *5

7.25 x 10.5R 500 *2 No No

5.5 x 8.5R 500 *2 No No

8K 250 *1 250 *1 250 *4

16K 500 *2 500 *2 500 *5

16KR 500 *2 No 500 *5

Special (Custom) 250 *1 No No

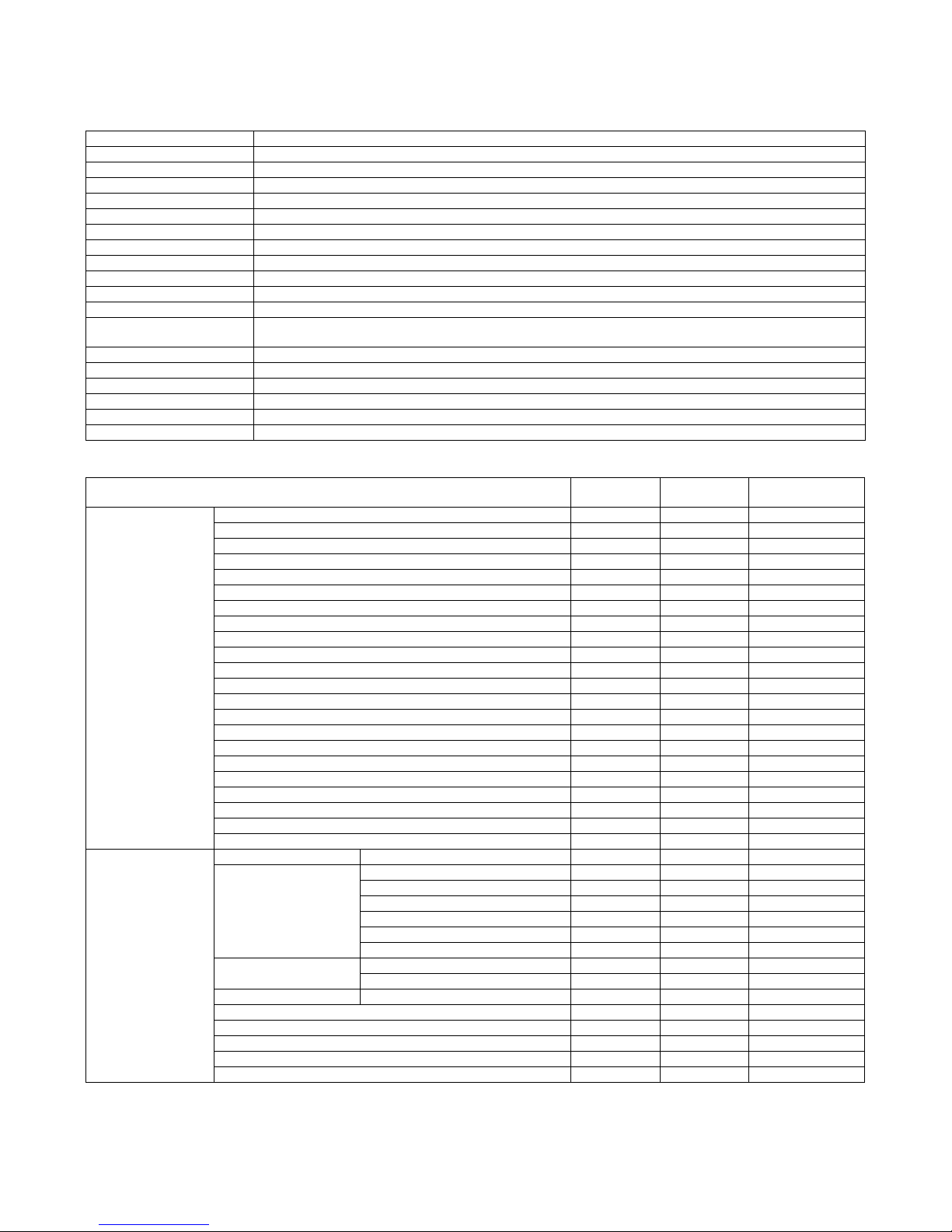

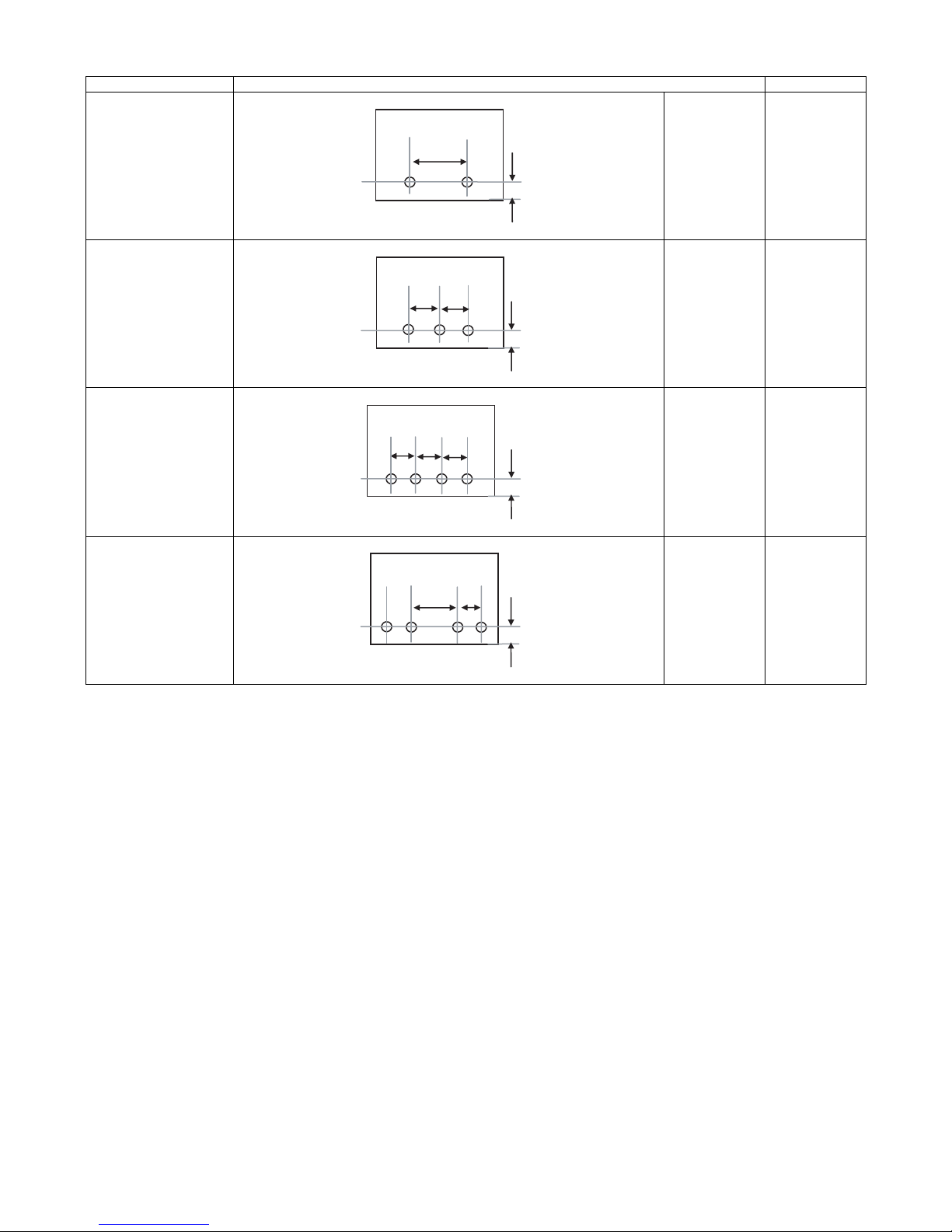

2. MX-PNX1A/B/C/D

Type Punch unit for the inner finisher

Punch type 2 holes / 3 holes / 4 holes / 4 holes (wide)

A punch unit that provides all of these 4 types can be installed.

Transport speed 23, 27, 35, 45 PPM

Transport reference Center reference

Punch dust full detection YES (Lever system)

Paper exit direction Face down

Paper weight Plain paper: 60 to 105g/m

Thin paper: 55 to 59g/m

Heavy paper: 106 to 209g/m

Punchable paper size 2 holes

(MX-PNX1A)

3 holes *1

(MX-PNX1B)

4 holes

(MX-PNX1C)

4 holes (wide)

(MX-PNX1D)

Power source Supplied from the inner finisher. (DC24V, DC5V)

External dimensions (W x D x H) 105 x 518 x 170 (mm), 4 9/64 x 20 25/64 x 6 45/64 (inch)

Weight Approx. 3.5kg (7.7 lbs)

Packaged items Parts for mounting, instructional label for punch direction, instructional label for garbage pickup, installation cautionary note

*1: Auto switching: 2 holes/3 holes

2

(16 to 28 lbs)

2

(15 to 16 lbs)

2

(28 to 56 lbs)

A3, B4, A4, A4R, B5, B5R, 11" x 17", 8.5" x 14", 8.5" x 13", 8.5" x 11", 8.5" x 11"R, 8K, 16K, 16KR

3 holes: A3, A4, 11" x 17", 8.5" x 11"

2 holes: 8.5" x 14", 8.5" x 13", 8.5" x 11"R

A3, A4

A3, B4, A4, A4R, B5, B5R, 11" x 17", 8.5" x 14", 8.5" x 13", 8.5" x 11", 8.5" x 11"R

MX-FNX9 SPECIFICTIONS 2 – 2

Kind of hole punch

A

A

A

A

A

A

A

Kind Hole position Hole size

2 holes (MX-PNX1A) A: 80±1mm

B: 12±3mm

B

φ6.5mm

3 holes (MX-PNX1B) A: 108±1mm

B: 12±3mm

B

4 holes (MX-PNX1C) A: 80±1mm

B: 12±3mm

B

4 holes (wide) (MX-PNX1D) A: 70±1mm

B: 12±3mm

C: 21±1mm

C

B

φ8.0mm

φ6.5mm

φ6.5mm

MX-FNX9 SPECIFICTIONS 2 – 3

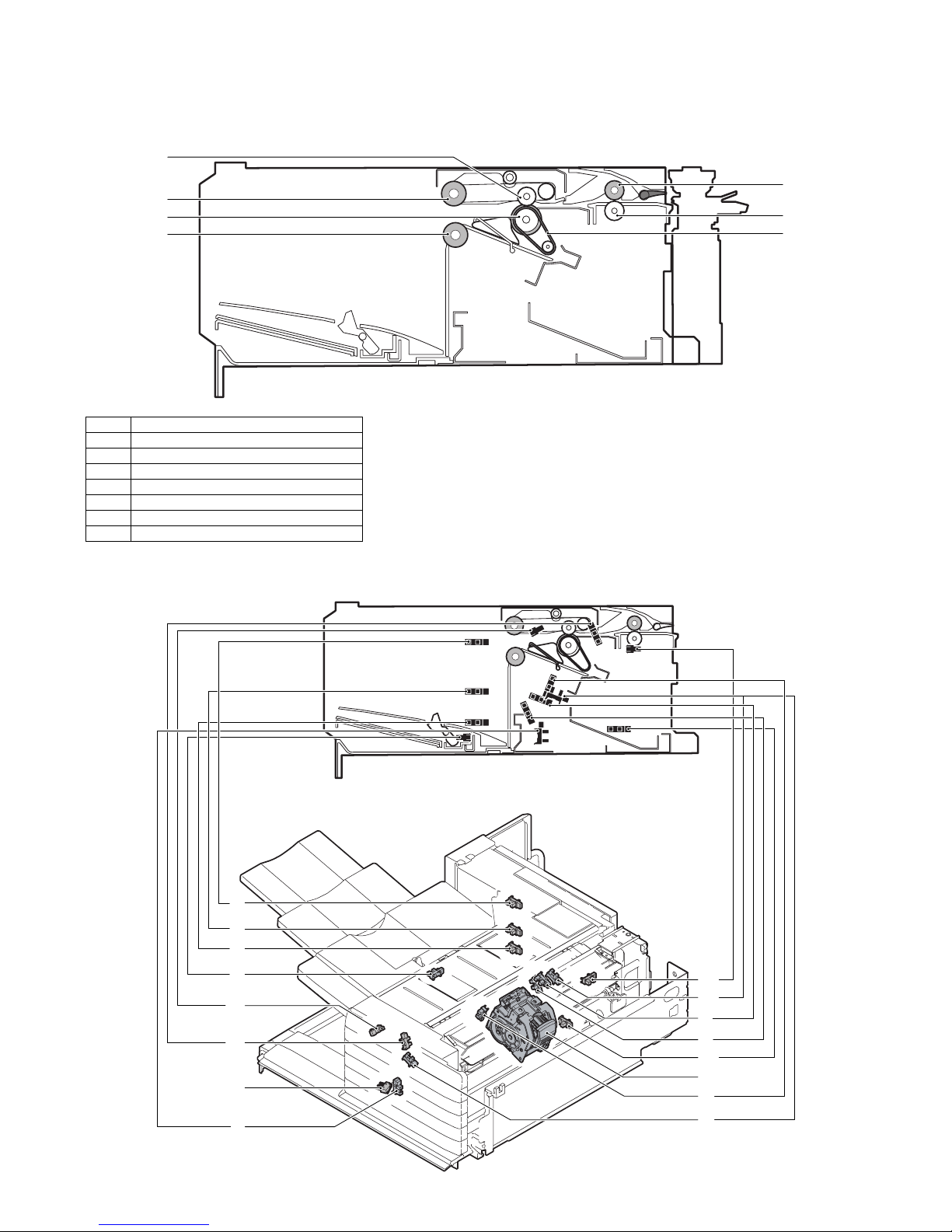

MX-FNX9

[4] EXTERNAL VIEW AND INTERNAL STRUCTURE

Service Manual

1. Identification of each section and functions

A. Internal structure

1

2

3

4

No. Name

1 Paper exit roller

2 Bundle exit paper transport roller

3 Paper exit roller

4 Bundle exit paper transport roller

5 Inlet port paper transport roller

6 Inlet port paper transport roller

7 Take-up belt

B. Sensors and switches

(1) MX-FNX9

5

6

7

1

2

3

4

12

13

14

7

MX-FNX9 EXTERNAL VIEW AND INTERNAL STRUCTURE 4 – 1

11

10

5

6

15

16,17,18

8

9

No. Signal Name Type Function/Operation Output

1 FULD Tray upper limit sensor Photo interrupter Detects the upper limit position of the

2 FMLLD Tray intermediate lower limit

sensor

3 FLLD Tray lower limit sensor Photo interrupter Detects the lower limit position of the

4 FBED Tray paper empty sensor Photo interrupter Detects paper empty in the paper load

5 FSLD1 Paper surface sensor 1 Photo interrupter Detects the surface position of paper on

6 FSLD2 Paper surface sensor 2 Photo interrupter

7 FSTHPD Stapler HP sensor Photo interrupter Detects the home position of the stapler

8 FSTPD Empty sensor Photo interrupter Detects paper empty on the process tray. TP8 is driven to “H” when paper is

9 FFJHPD Alignment plate HP sensor F Photo interrupter Detects the home position of the alignment

10 FRJHPD Alignment plate HP sensor R Photo interrupter Detects the home position of the alignment

11 FED Inlet port sensor Photo interrupter Detects paper in the inlet port of the

12 FRLD Roller up/down sensor Photo interrupter Detects the upper standby position of up/

13 FBRD Take-up belt sensor Photo interrupter Detects up/down positions of the take-up

14 FDSW Front cover switch Photo interrupter Detects open/close of the jam release

15 FJPD Alignment plate position sensor Photo interrupter Detects entry of the process section rear

16 FSHPD Stapler home sensor Detects the home position of the stapling

17 FSD Staple empty sensor Detects staple empty. (Sensor built in the

18 FSTD Self priming sensor Detects the staple feed is completed and it

Photo interrupter Detects the intermediate position of the

paper load tray up/down shift area.

paper load tray up/down shift area.

paper load tray up/down shift area.

tray.

the tray in combination of the both sensors

outputs.

unit in F/R direction shift.

guide on F side.

guide on R side.

finisher.

down movement of the bundle exit roller.

belt.

cover in the front section.

edge stopper into the opening of the

stapler and inhibits stapling.

mechanism. (Sensor built in the stapler

unit)

stapler unit)

is ready for stapling. (Sensor built in the

stapler unit)

TP1 is driven to “L” at the upper limit

position.

TP2 is driven to “L” at the intermediate

position.

TP3 is driven to “L” at the lower limit

position.

TP4 is driven to “L” when paper is

provided.

*Refer to the separate table outside the

column.

TP7 is driven to “H” at the home position.

provided.

TP9 is driven to “L” at the home position.

TP10 is driven to “L” at the home position.

TP11 is driven to “H” when paper is

provided.

TP12 is driven to “L” when the roller

reaches the upper standby position.

TP13 is driven to “L” when the take-up belt

is on the upper side.

TP15 is driven to “L” when the cover is

closed.

TP50 is driven to “L” when the stopper

enters the opening of the stapler.

TP51 is driven to “H” at the home

(standby) position.

TP53 is driven to “L” when staple empty.

TP52 is driven to “H” when in the ready

state.

FSLD1 FSLD2

TP5 TP6

“L” “H” The paper detection lever is in the save position.

“H” “H” The paper surface is upper than the reference level.

“H” “L” The paper surface is at the reference level.

“L” “L” The paper surface is lower than the reference level.

State

MX-FNX9 EXTERNAL VIEW AND INTERNAL STRUCTURE 4 – 2

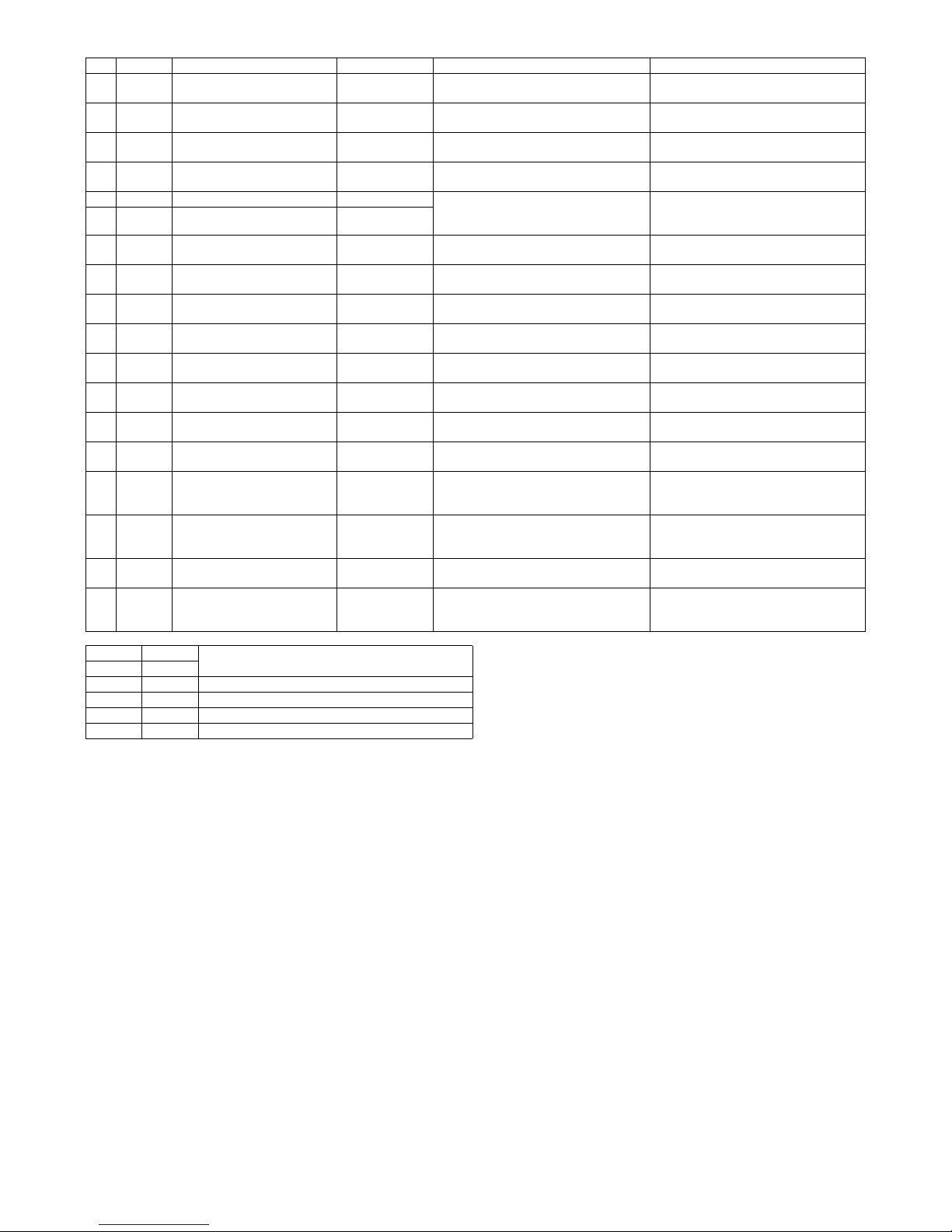

(2) MX-PNX1A/B/C/D

3

2

11

10

9

8

7

6

4

5

No. Signal Name Type Function/Operation Output

1 FPDD Full sensor Photo interrupter Detects full of the punch dust container. When full, TP2 on the punch PWB remains

2 FPHPD Punch position

sensor

3 FPRPD Rear position

sensor

4 FPSHPD Horizontal shift

HP sensor

5 FPPEND Paper rear edge

sensor

6 FPPD1 Paper horizontal

resist sensor 1

7 FPPD2 Paper horizontal

resist sensor 2

8 FPPD3 Paper horizontal

resist sensor 3

9 FPPD4 Paper horizontal

resist sensor 4

10 FPPD5 Paper horizontal

resist sensor 5

11 FPPD6 Paper horizontal

resist sensor 6

Photo interrupter Detects the home position of the punch up/down

Photo interrupter Detects the lower limit position of 3-hole side up/

Photo interrupter Detects the home position in the punch position

Transmission type

sensor

Transmission type

sensor

Transmission type

sensor

Transmission type

sensor

Transmission type

sensor

Transmission type

sensor

Transmission type

sensor

shift.

down shift in 2/3-hole punching.

horizontal resist correction mechanism.

Detects the lead edge and the rear edge of paper

to be punched.

Detects the paper edge in the rear side of B5R or

7.25" x 10" R size width direction of the machine.

Detects the paper edge in the rear side of 16K-R

size width direction of the machine.

Detects the paper edge in the rear side of 8.5"

x14", 8.5" x 11"R, 8.5" x 13", or A4R size width

direction of the machine.

Detects the paper edge in the rear side of B4 or

B5 size width direction of the machine.

Detects the paper edge in the rear side of 11" x

17", 8.5" x 11", 8K, or 16K size width direction of

the machine.

Detects the paper edge in the rear side of A3 or

A4 size width direction of the machine.

“H” level.

TP47 on the control PWB of the inner finisher

is driven to “H” at the home position.

TP48 on the control PWB of the inner finisher

is driven to “H” at the lower limit position.

TP49 on the control PWB of the inner finisher

is driven to “H” at the home position.

TP54 on the control PWB of the inner finisher

is driven to “L” when paper is provided.

TP55 on the control PWB of the inner finisher

is driven to “L” when paper is provided.

TP55 on the control PWB of the inner finisher

is driven to “L” when paper is provided.

TP55 on the control PWB of the inner finisher

is driven to “L” when paper is provided.

TP55 on the control PWB of the inner finisher

is driven to “L” when paper is provided.

TP55 on the control PWB of the inner finisher

is driven to “L” when paper is provided.

TP55 on the control PWB of the inner finisher

is driven to “L” when paper is provided.

1

MX-FNX9 EXTERNAL VIEW AND INTERNAL STRUCTURE 4 – 3

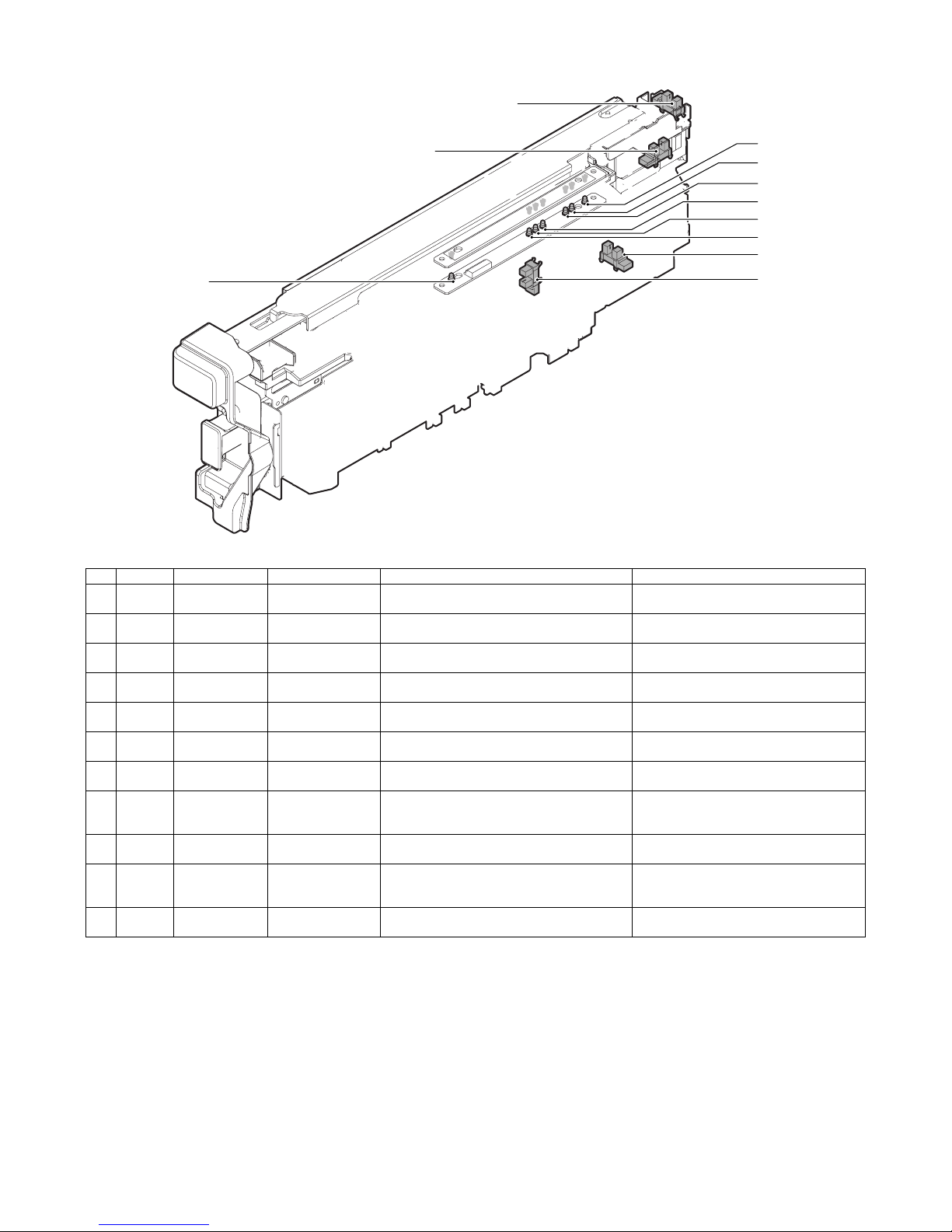

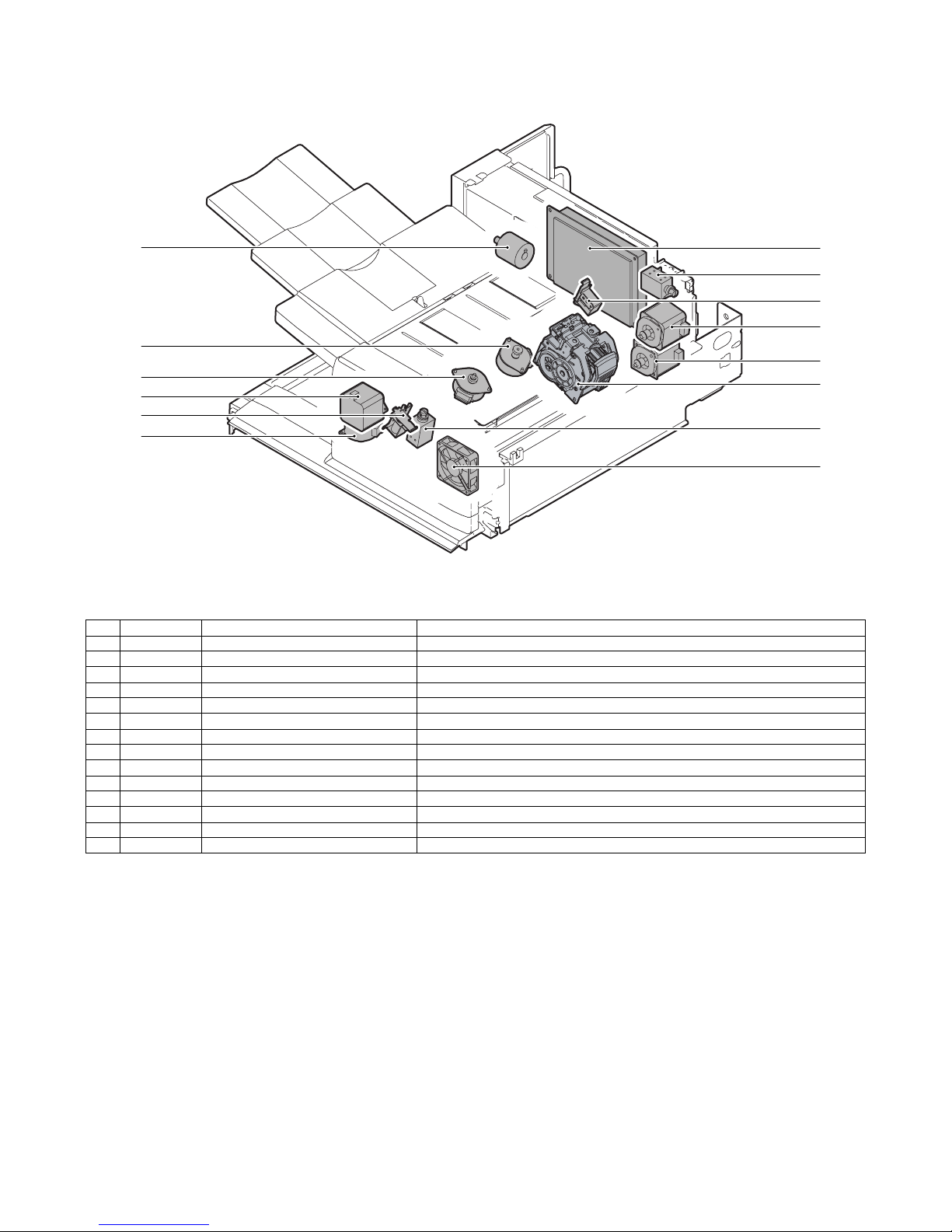

C. Motors, solenoids, and PWB

(1) MX-FNX9

3

14

12

9

8

5

7

4

6

1

11

2

10

13

No. Signal Name Function

1 FFSM Staple motor Drives the stapling mechanism. (Stapler unit built-in motor)

2 FSM Staple shift motor Shifts the stapler unit in the F/R direction.

3 FTLM Tray motor Drives the paper load tray up/down.

4 FFJM Alignment motor F Drive the alignment guide on the F side.

5 FRJM Alignment motor R Drive the alignment guide on the R side.

6 FSWM Roller upper/lower roller Drives the bundle exit roller up/down.

7 FAM Bundle exit motor Drives the bundle exit roller and the paddle.

8 FRM Transport motor Drives the inlet port roller, the feed roller, and the take-up belt.

9 FPDS Paddle one-rotation solenoid Trigger solenoid for paddle one-rotation.

10 FSLS Paper surface detection solenoid Drives the lever for paper holding and detection of the tray paper surface.

11 FBRS Belt separation solenoid Trigger solenoid for up/down shift of the take-up belt.

12 FINRPS Flapper solenoid Drives the flapper to select the entry path between the finisher inside and the reverse path.

13 FFAN Fan Cools the inlet port of the finisher.

14 – Control PWB Controls the inner finisher.

MX-FNX9 EXTERNAL VIEW AND INTERNAL STRUCTURE 4 – 4

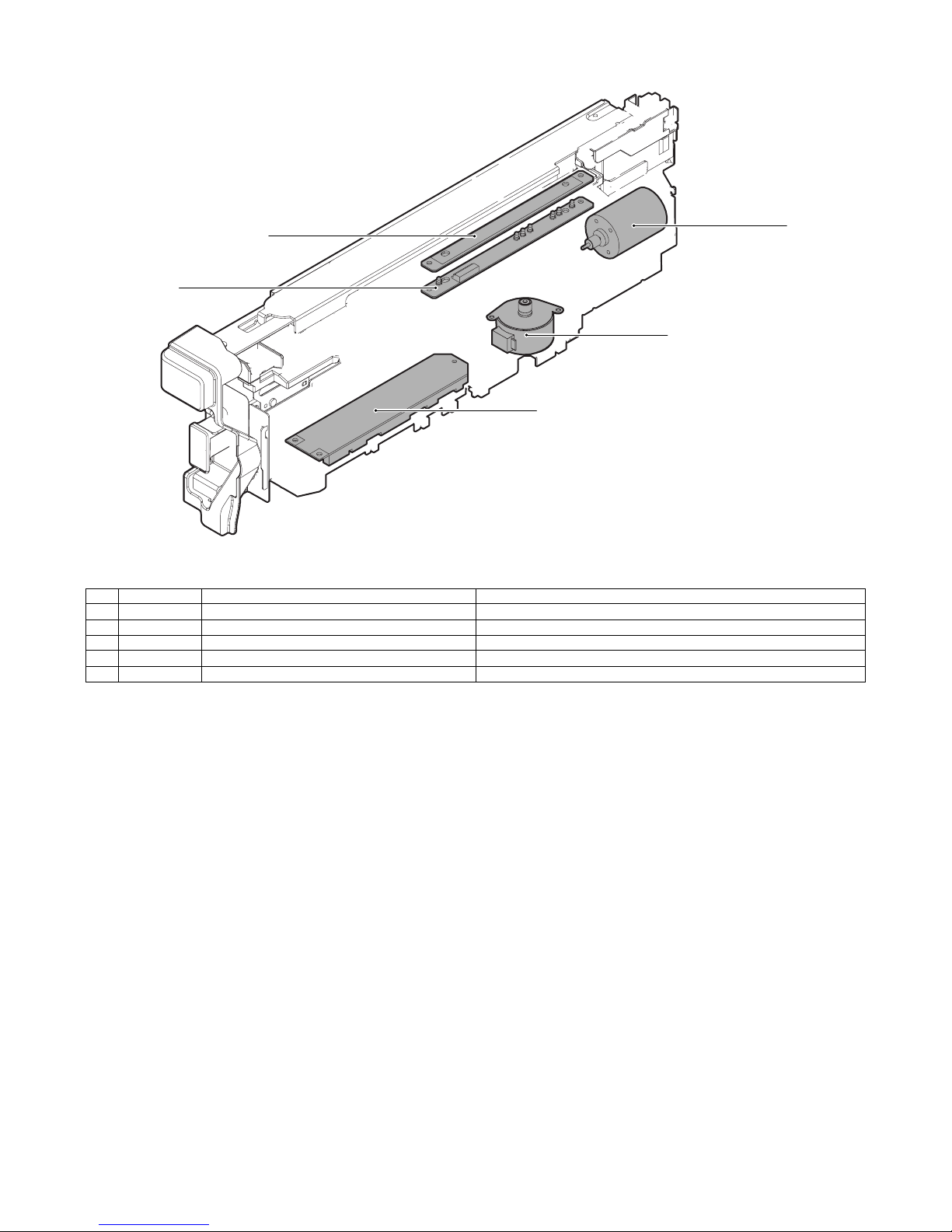

(2) MX-PNX1A/B/C/D

5

4

2

3

No. Signal Name Function

1 FPNM Punch motor Drives the punch unit up/down.

2 FPSM Punch horizontal resist motor Shifts the punch unit to the center of paper.

3 – Punch PWB Controls the punch unit.

4 – LED light emitting PWB Detects the paper rear edge and the punch horizontal resist.

5 – LED light receiving PWB Detects the paper rear edge and the punch horizontal resist.

1

MX-FNX9 EXTERNAL VIEW AND INTERNAL STRUCTURE 4 – 5

MX-FNX9

[5] OPERATIONAL DESCRIPTIONS

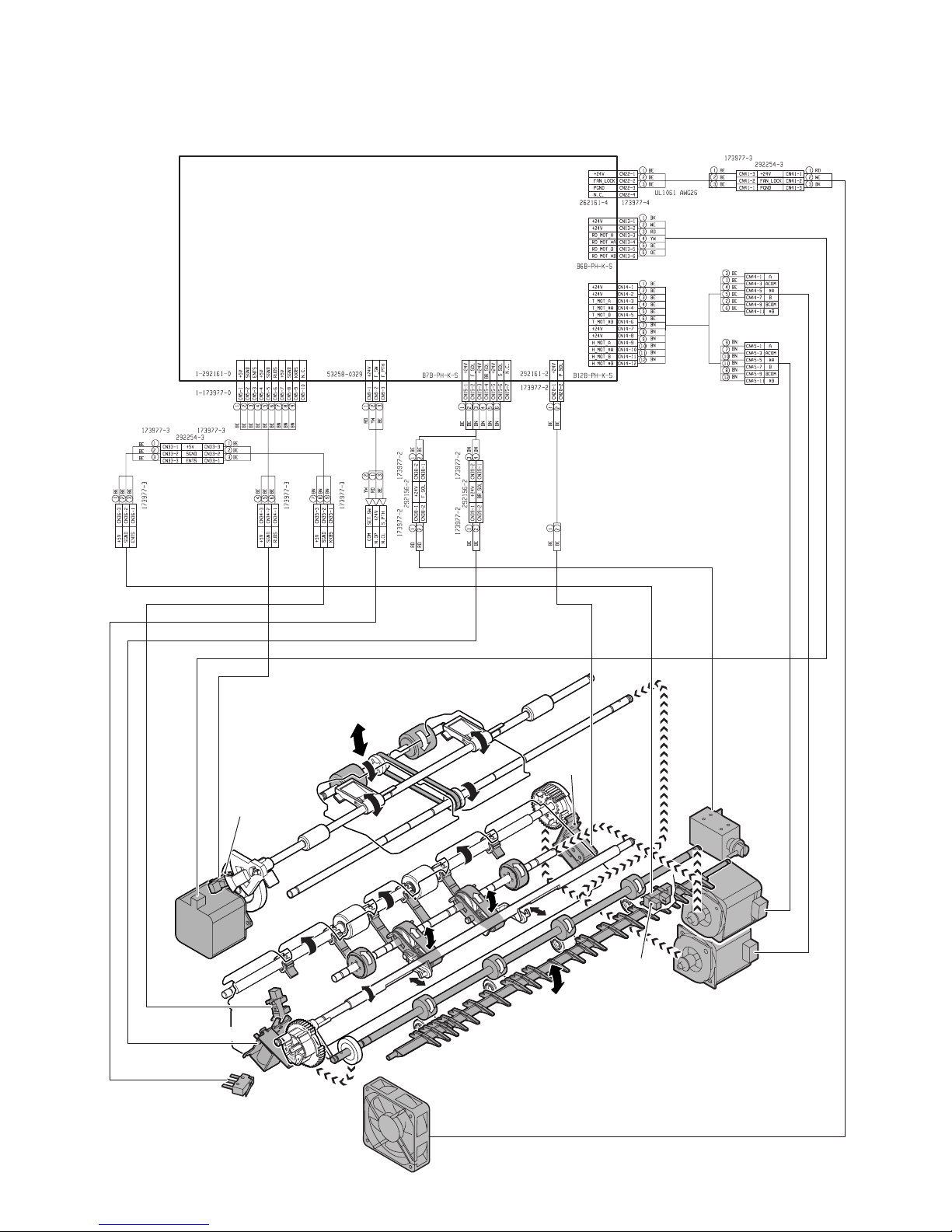

1. Electrical mechanism diagram

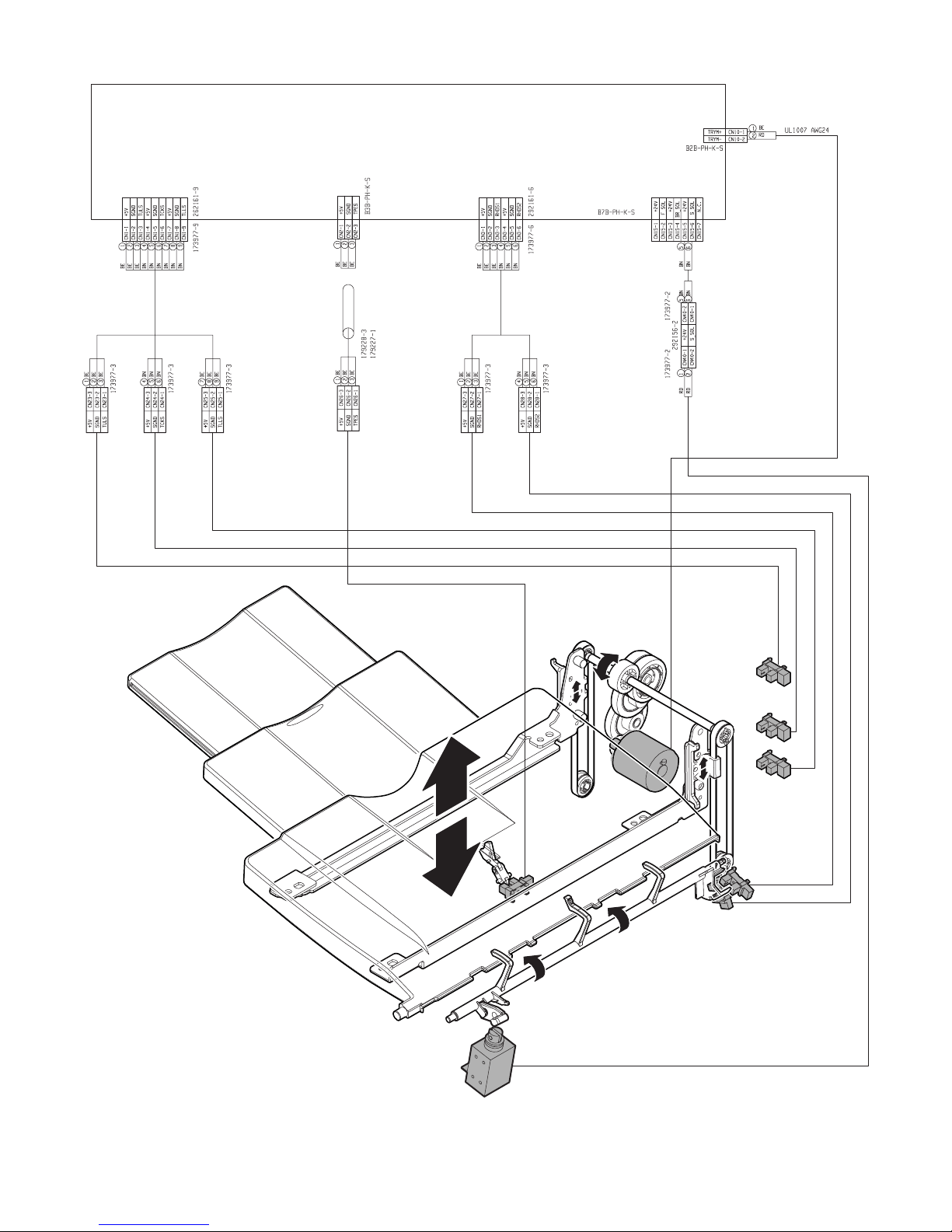

A. Transport, paper exit section

PCB-CONT

PF4141K200

Service Manual

FRLD

FSWM

FBRD

FBRS

FDSW

FPDS

FINRPS

FRM

FED

FAM

FFAN

MX-FNX9 OPERATIONAL DESCRIPTIONS 5 – 1

B. Staple section and aligment section

PCB-CONT

PF4141K200

FSM

FSTHPD

FFJHPD

FFJM

FSTPD

FRJHPD

FRJM

FJPD

FFSM

FSHPD(*HP)

FSD(LS)

FSTD(*READY)

MX-FNX9 OPERATIONAL DESCRIPTIONS 5 – 2

C. Paper exit tray section

PCB-CONT

PF4141K200

FBED

FSLS

FTLM

FULD

FMLLD

FLLD

FSLD1

FSLD2

MX-FNX9 OPERATIONAL DESCRIPTIONS 5 – 3

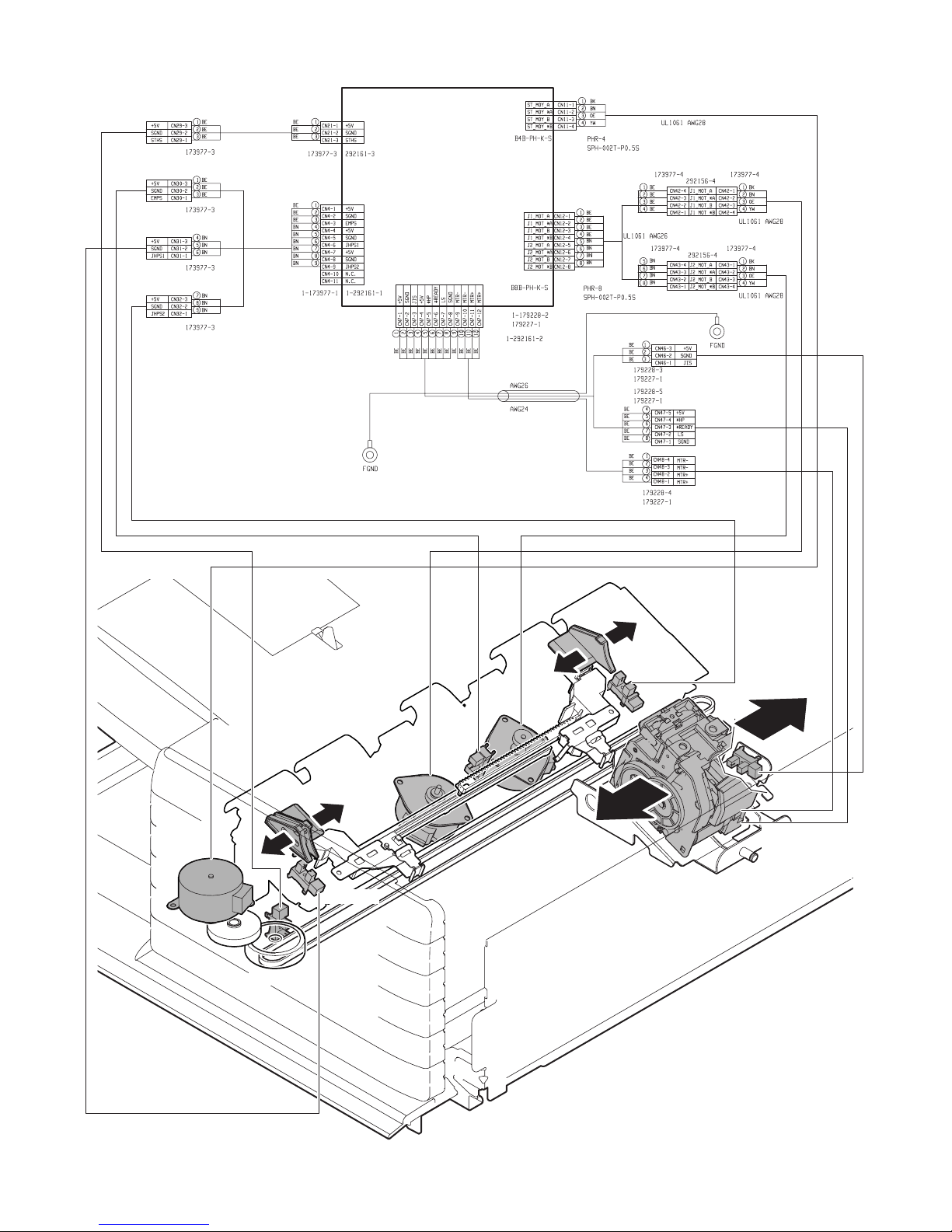

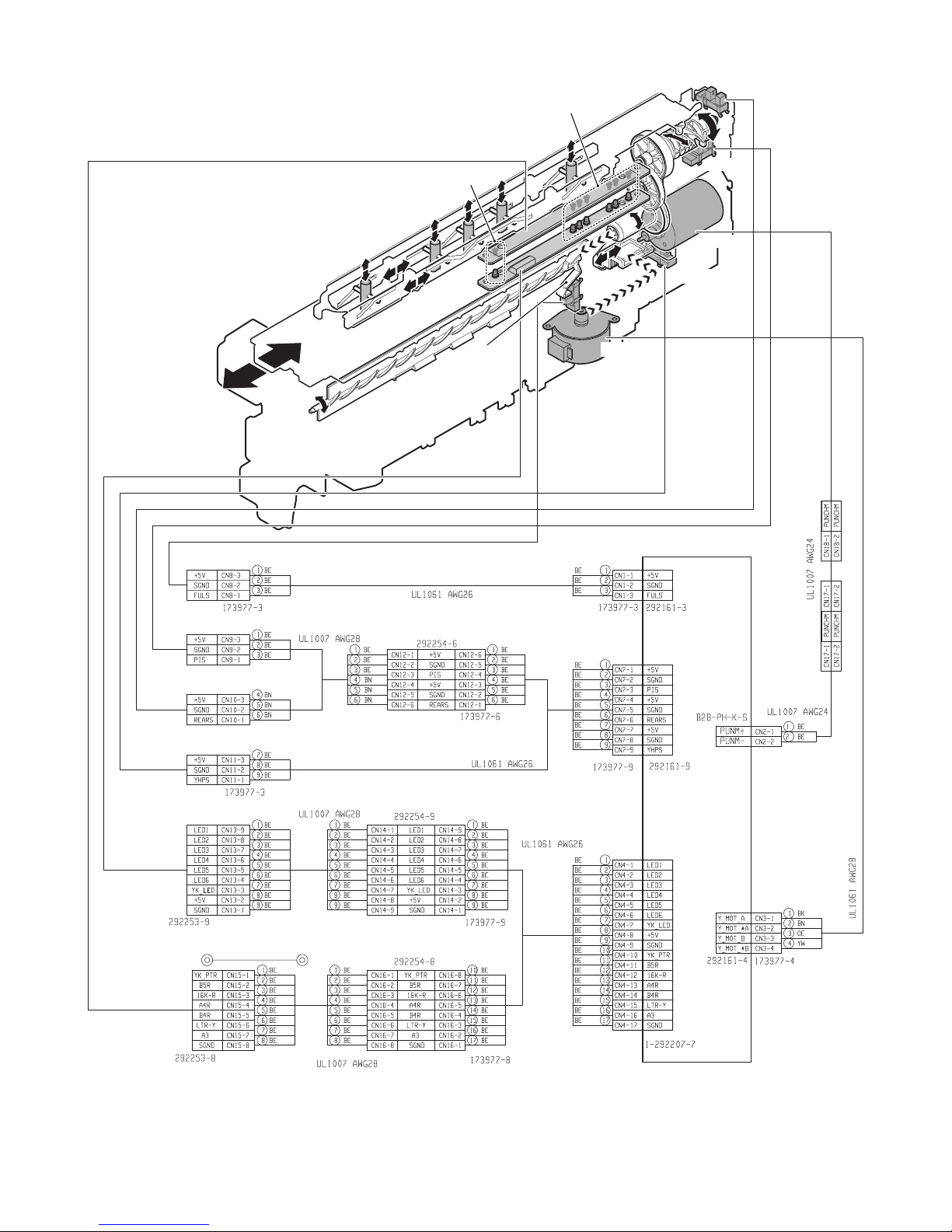

D. Punch unit (MX-PNX1A/B/C/D)

FPPEND

FPDD

FPPD1~FPPD6

FPRPD

FPHPD

FPNM

FPSHPD

FPSM

PCB-PUNCH

YA1035K200

MX-FNX9 OPERATIONAL DESCRIPTIONS 5 – 4

2. General

This chapter describes operations of the inner finisher. The major operation modes are as follows:

• Non-sort mode

• Offset mode

• Staple mode

• Non-sort mode + punch

• Offset mode + punch

• Staple mode + punch

In this chapter, the basic operations of the non-sort mode, the offset mode, and the staple mode are described.

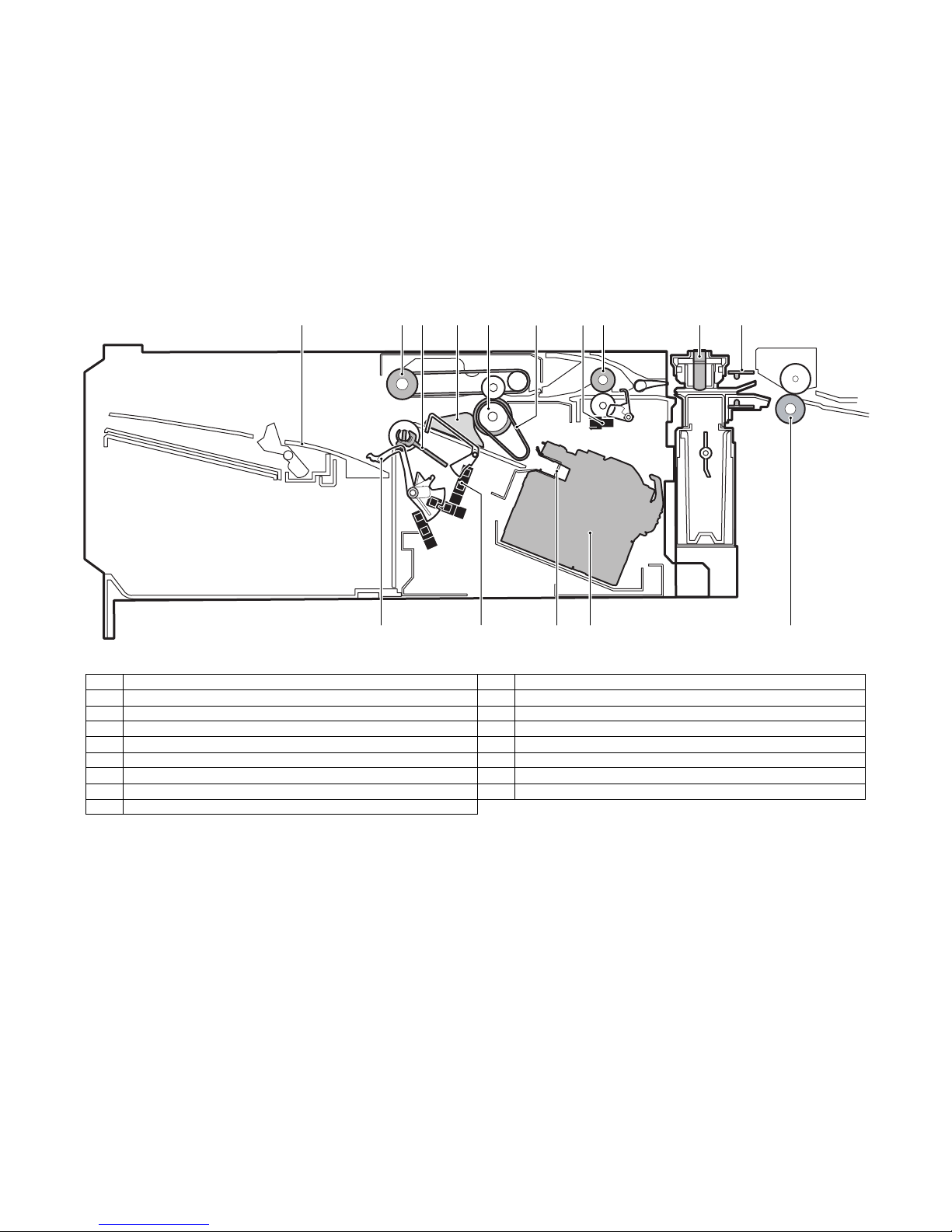

3. Outline of the transport path

The outline of the path is shown below.

1345678910

No. Name No. Name

1 Tray 9 Punch pin

2 Bundle exit roller 10 Paper rear edge sensor (FPPEND)

3 Paddle 11 Main unit paper exit roller

4 Alignment plate 12 Stapler

5 Paper exit roller 13 Paper stopper

6 Take-up belt 14 Empty sensor (FSTPD)

7 Inlet port sensor (FED) 15 Paper holding lever

8 Inlet port roller

2

1112131415

MX-FNX9 OPERATIONAL DESCRIPTIONS 5 – 5

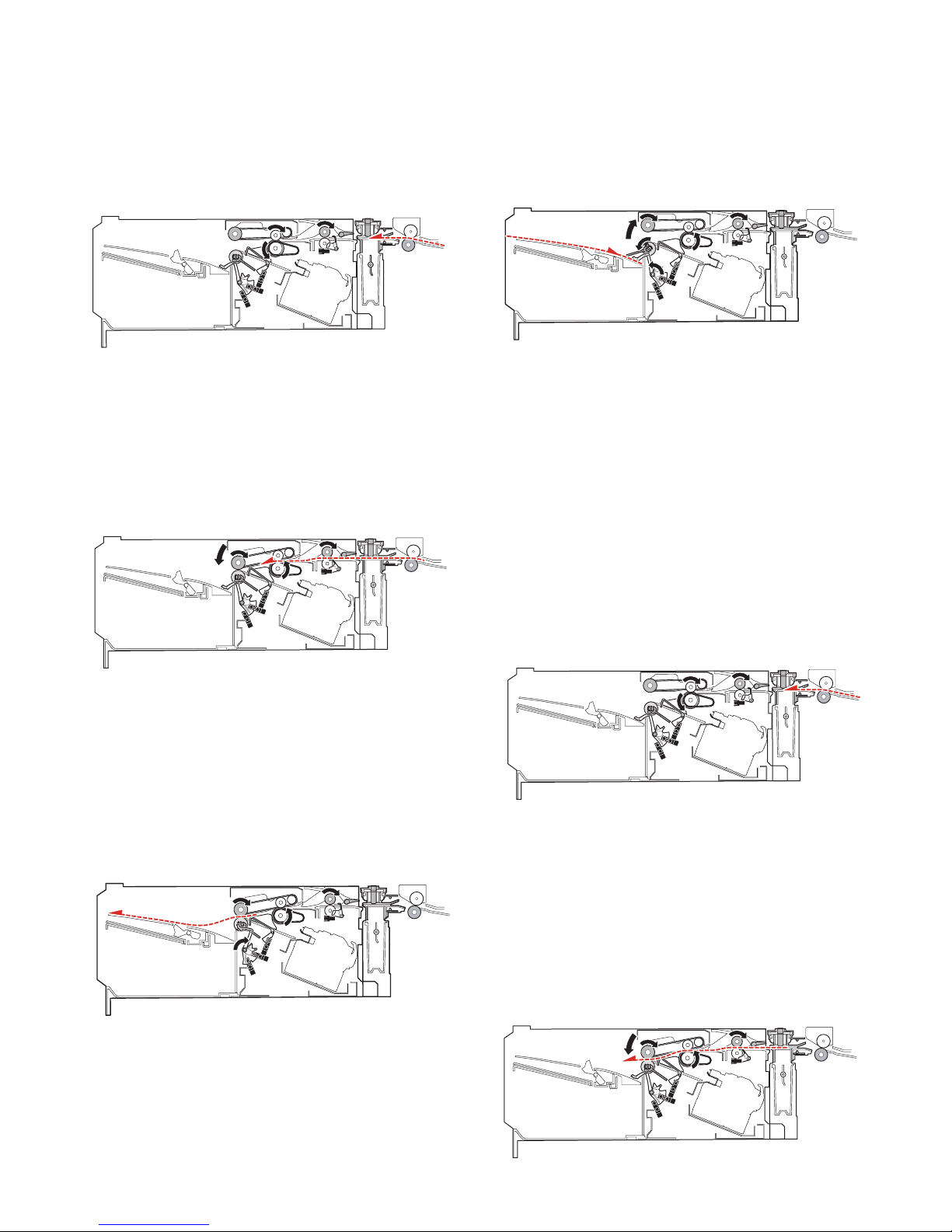

4. Non-sort mode

When the operation mode command is received from the copier,

the finisher makes the finisher operation status command the JOB

and starts the transport operation.

A. Reception of paper discharged from the main

unit

1) The transport motor (FRM) is driven at the paper exit speed of

the main unit to receive paper from the main unit.

2) Immediately after the paper rear edge passes the bundle exit

roller, the paddle one-rotation solenoid (FPDS) is turned ON to

take-up the paper falling onto the tray.

3) When paper is transported by 10mm after the paper rear edge

passes the bundle exit roller, the bundle exit motor (FAM) is

accelerated to 200mm/sec. Just before the paddle passes the

load tray, the paper surface detection solenoid (FSLS) is

turned ON to hold the paper discharged by the paper holding

lever.

2) After turning ON the inlet port sensor (FED), the roller up/down

motor (FSWM) is driven to lower the bundle exit roller. The

bundle exit motor (FAM) is driven at the paper exit speed of

the main unit to drive the bundle exit roller. When the paper

width is 210mm or more, the alignment motor F (FFJM) and

the alignment motor R (FRJM) are driven by turning ON the

inlet port sensor (FED) to shift the alignment plate to 15mm

inside the paper and put it under the paper.

3) In the case of the punch mode, punching is performed as

described in "7. Punching process."

B. Paper exit

1) After the paper rear edge passes the paper exit roller of the

main unit, the transport motor (FRM) and the bundle exit motor

(FAM) are accelerated to 480mm/sec. When the paper rear

edge passes the inlet port sensor (FED) and then transport of

a certain amount is made, the alignment plate is shifted to the

home position.

Before the paper rear edge passes the bundle exit roller, the

paper surface detection solenoid (FSLS) is turned OFF and

the bundle exit roller speed is decelerated to 100mm/sec at the

same time, performing paper exit deceleration of paper.

4) When the paddle rotates one turn, the bundle exit motor (FAM)

is stopped.

5) When there is next paper, repeat the procedures from "A-1)."

6) When there is no next paper, the actuators are turned OFF

and the finisher operation status command is set to READY,

and the transport operation is terminated.

5. Offset mode

When the operation mode command is received from the copier,

the finisher makes the finisher operation status command the JOB

and starts the transport operation.

A. Reception of paper discharged from the main

unit

1) The transport motor (FRM) is driven at the paper exit speed of

the main unit to receive paper from the main unit. When the

paper length is 216mm or less, the paper exit speed of the second and later sheets from the main unit is 280mm/sec.

B. Paper take-up and alignment

1) For the first sheet of a bundle, the inlet port sensor (FED) is

turned ON and the roller up/down motor (FSWM) is driven to

lower the bundle exit roller. The bundle exit motor (FAM) is

driven at the paper exit speed of the main unit to drive the bundle exit roller.

In addition, the alignment motor F (FFJM) and the alignment

motor R (FRJM) are driven by turning ON the inlet port sensor

(FED) to shift the alignment plate to 15mm outside the paper,

and enter the standby state. After transport of a certain

amount, the roller up/down motor (FSWM) is driven to lift the

bundle exit roller, stopping the bundle exit motor (FAM).

MX-FNX9 OPERATIONAL DESCRIPTIONS 5 – 6

2) For the second and later sheets of a bundle, the inlet port sensor (FED) turns ON and a certain amount is transported, and

then the alignment motor F (FFJM) and the alignment motor R

(FRJM) are driven to shift the alignment plate to 15mm outside

the paper and to put it under the standby state.

3) After the paper rear edge passes the paper exit roller of the

main unit, the transport motor (FRM) is accelerated to 480mm/

sec.

4) In the punch mode, punching is performed as described in "7.

Punching process."

5) When the paper rear edge passes the inlet port sensor (FED)

and a certain amount is transported, the roller up/down motor

(FSWM) is driven to lower the bundle exit roller and the bundle

exit motor (FAM) is driven for a certain amount in the take-up

direction at the paper exit speed of the main unit to take up

paper to the process tray. In addition, the belt separation solenoid (FBRS) is turned ON to lower the take-up belt.

6) After completion of take-up, the roller up/down motor (FSWM)

is driven to lift the bundle exit roller. The alignment motor F

(FFJM) and the alignment motor R (FRJM) are driven for a certain amount to align paper in the process tray. If there are two

or more sheets to be aligned, the procedures are repeated

from "A-1)" for the specified number of sheets. However, the

paper exit operation of "C. Aligned paper exit" is performed for

every 3 sheets.

2) After transport of paper by a certain amount, the alignment

motor F (FFJM) and the alignment motor R (FRJM) are driven

to shift the alignment plate to the home position.

3) When the paper rear edge passes the empty sensor (FSTPD),

the paper surface detection solenoid (FSLS) is turned OFF

and the bundle exit roller speed is decelerated to 100mm/sec

at the same time, decelerating the paper exit operation.

4) Immediately after the paper rear edge passes the bundle exit

roller, the paddle one-rotation solenoid (FPDS) is turned ON to

take up paper falling onto the tray.

5) When the paper rear edge passes the bundle exit roller and

the paper is transported for 10mm, the bundle exit motor

(FAM) is accelerated to 200mm/sec. Before the paddle passes

the load tray, the paper surface detection solenoid (FSLS) is

turned ON to hold the discharged paper with the paper holding

lever.

C. Aligned paper exit

1) After completion of alignment, the belt separation solenoid

(FBRS) is turned ON to lift the take-up belt. The alignment

motor F (FFJM) and the alignment motor R (FRJM) are driven

to separate paper from the alignment plate by 1mm. In addition, the roller up/down motor (FSWM) is driven to lower the

bundle exit roller. The bundle exit motor (FAM) is started at the

speed of 450mm/sec and paper in the process tray is discharged.

6) When the paddle rotates one turn, the bundle exit motor (FAM)

is stopped.

7) When there is next paper, the procedures are repeated from

"A-1)."

8) When there is no next paper, the actuators are turned OFF and

the finisher operation status command is set to READY to terminate the transport operation.

6. Staple mode

When the operation mode command is received from the copier,

the finisher makes the finisher operation status command the JOB

and starts the transport operation.

A. Reception of paper discharged from the main

unit

1) The transport motor (FRM) is driven at the paper exit speed of

the main unit to receive paper from the main unit. When the

paper length is 216mm or less, the paper exit speed of the second and later sheets from the main unit is 280mm/sec.

MX-FNX9 OPERATIONAL DESCRIPTIONS 5 – 7

Loading...

Loading...