Page 1

SERVICE MANUAL

CODE: 00ZMXFNX6/S2E

FINISHER/

SADDLE STITCH FINISHER

/PUNCH MODULE

MX-FNX6

MX-FNX7

CONTENTS

[1] SPECIFICATION

1. MX-FNX6/PNX4 . . . . . . . . . . . . . . . . .1 - 1

2. MX-FNX7/PNX4 . . . . . . . . . . . . . . . . .1 - 2

3. Paper size/Type/Weight . . . . . . . . . . .1 - 3

[2] MAINTENANCE LIST . . . . . . . . . . . . 2 - 1

[3] MECHANISM

1. Composition layout (* In the figure:

For the MX-FNX7 only) . . . . . . . . . . .3 - 1

2. Electric parts layout . . . . . . . . . . . . . .3 - 1

3. Drive layout . . . . . . . . . . . . . . . . . . . .3 - 3

4. Branch mechanism. . . . . . . . . . . . . . .3 - 3

5. Pre-stack mechanism. . . . . . . . . . . . .3 - 4

6. Rise-fall mechanism . . . . . . . . . . . . . .3 - 5

7. Staple jogger mechanism . . . . . . . . . .3 - 5

8. Center binding staple mechanism

(MX-FNX7 only) . . . . . . . . . . . . . . . . .3 - 7

9. Discharge mechanism . . . . . . . . . . . .3 - 8

10. Punch mechanism . . . . . . . . . . . . . . .3 -

10

11. Punch dust collection mechanism . . .3 -

10

MODEL

[4] REPLACEMENT AND ADJUSTMENT

1. External cover replacement . . . . . . . 4 - 1

2. Tray assembly, left cover

replacement . . . . . . . . . . . . . . . . . . . 4 - 1

3. Shift roller replacement . . . . . . . . . . . 4 - 2

4. Rollers . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

5. Proof tray paper exit sensor

replacement . . . . . . . . . . . . . . . . . . . 4 - 2

6. Shift tray paper surface sensor

upper/lower replacement. . . . . . . . . . 4 - 2

7. Shift tray paper exit sensor, proof tray

paper surface sensor replacement . . 4 - 4

8. Finisher inlet sensor replacement . . . 4 - 4

9. Staple paper exit sensor

replacement . . . . . . . . . . . . . . . . . . . 4 - 5

10. Punch unit replacement . . . . . . . . . . 4 - 5

11. Center folding horizontal shift

adjustment (MX-FNX7 only) . . . . . . . 4 - 6

12. Center folding vertical shift

adjustment (MX-FNX7 only) . . . . . . . 4 - 7

13. Center folding unit replacement and

center binding stapler replacement

and adjustment (MX-FNX7 only). . . . 4 - 8

14. Horizontal resist adjustment . . . . . . . 4 -

10

MX-PNX4

[5] ELECTRICAL COMPONENTS

1. Block diagram . . . . . . . . . . . . . . . . . . 5 - 1

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

ABAA

B

A

B

C

MX-FNX6

[1] SPECIFICATION

Service Manual

1. MX-FNX6/PNX4

Form Floor type

Transport

speed

Paper

Transport

standard

Pause Switch Available

Tray form Top tray Fixed

Paper size

allowed

Stored paper

weight (Nonstitched)

Stored

Sheets

Stacking

performance

Number of

sheets to be

stitched

Paper weight

to be stitched

Number of

stored sheets

when stapled

(80g/m

Stap le

position

Stapling

method

Adjustment of

Stap le

position

Detection of

no staple

Manual

staple

Life 5 year or 9,900K

Dimensions

(WxDxH)

Weight 46.0kg

Power source DC24V (supplied by the main unit)

Supports 85 sheets/minute

Center alignment

Stacker Section

Offset tray Up and down tray

Top tray A3W, A4W, A3, B4, A4, A4-R, B5, B5Offset tray

R, A5-R, 8K,16K,16KR, Postcard,

11”x17”, 8.5”x14”, 8.5”x13.4”,

8.5”x13”, 8.5"x11", 8.5"x11"-R,

5.5"x8.5"-R,12"x 18", 9"x12",

7.25"x10.5"R

Top tray: 52-205g/m

2

, 16lbs Bond-110lbs Index

Offset tray :52-300g/m

Top tray

250 sheets: A4, 8.5"x11" or less (80g/m

50 sheets: B4, 8.5"x14" or more (80g/m

* A5/5.5x8.5 are feeded from Inserter Tray of Inserter Unit.

Offset tray

3000sheets: A4, 8.5"x11" (80g/m

1500sheets: A3W, A4W, A3, B4, A4-R, B5, B5-R, 8K, 16K,

16KR, 12"x18", 11"x17", 8.5"x14", 8.5"x13.4", 8.5"x13",

8.5"x11"-R, 9"x12" (80g/m

100 sheets:

A5-R*, 5.5"x8.5"-R*, Postcard* (80g/m

*Impossible to Offset.

Non-offset 12 mm or less

(B5R and A5R are 50mm or less)

Offset 12 mm or less

(B5R and A5R are 50mm or less)

Offset volume 30 mm

Stitched 3mm or less

Staple section

50 sheets: A4, 8.5"x11" or less

30 sheets: B4, 8.5"x14" or more

Mixed (same width): 30 sheets

Max. 176g/m

2

(65lbs Index) paper 2 sheets+80g/m2 paper

48 sheets

2

60-105g/m

,16lbs-28lbs Bond

A4, 8.5x11 2-19 sheets 150 bundles

20-50 sheets 150-60 bundles

A4R, B5, 8.5x11R 2-14 sheets 100 bundles

2

)

15-50 sheets 100-30 bundles

Others: 2-14 sheets 100 bundles

15-30 sheets 100-50 bundles

When mixed size:

2-30 sheets 50 bundles

A3 and A4,

B4 and B5,

11x17 and 8.5x17

4 position (Top, Top Slant, Bottom, 2 Staples)

Staple cartridge (5,000 staples)

Changeable by user

-1 - +3.5mm (For 1 position staple only), Adjustment pitch

0.5mm, Controlled by main unit.

Available

(When the inserter is installed, it can be operated on the

operation panel of the main unit.)

640mm x 614mm x 960mm

745mm x 614mm x 960mm (Tray extended)

2

, 16lbs Bond-170 lbs Index

2

, 20lbs Bond)

2

, 20lbs Bond)

2

, 20lbs Bond)

2

, 20lbs Bond)

2

, 20lbs Bond)

MX-FNX6 SPECIFICATION 1 – 1

Power

96W (Include Punch module)

consumption

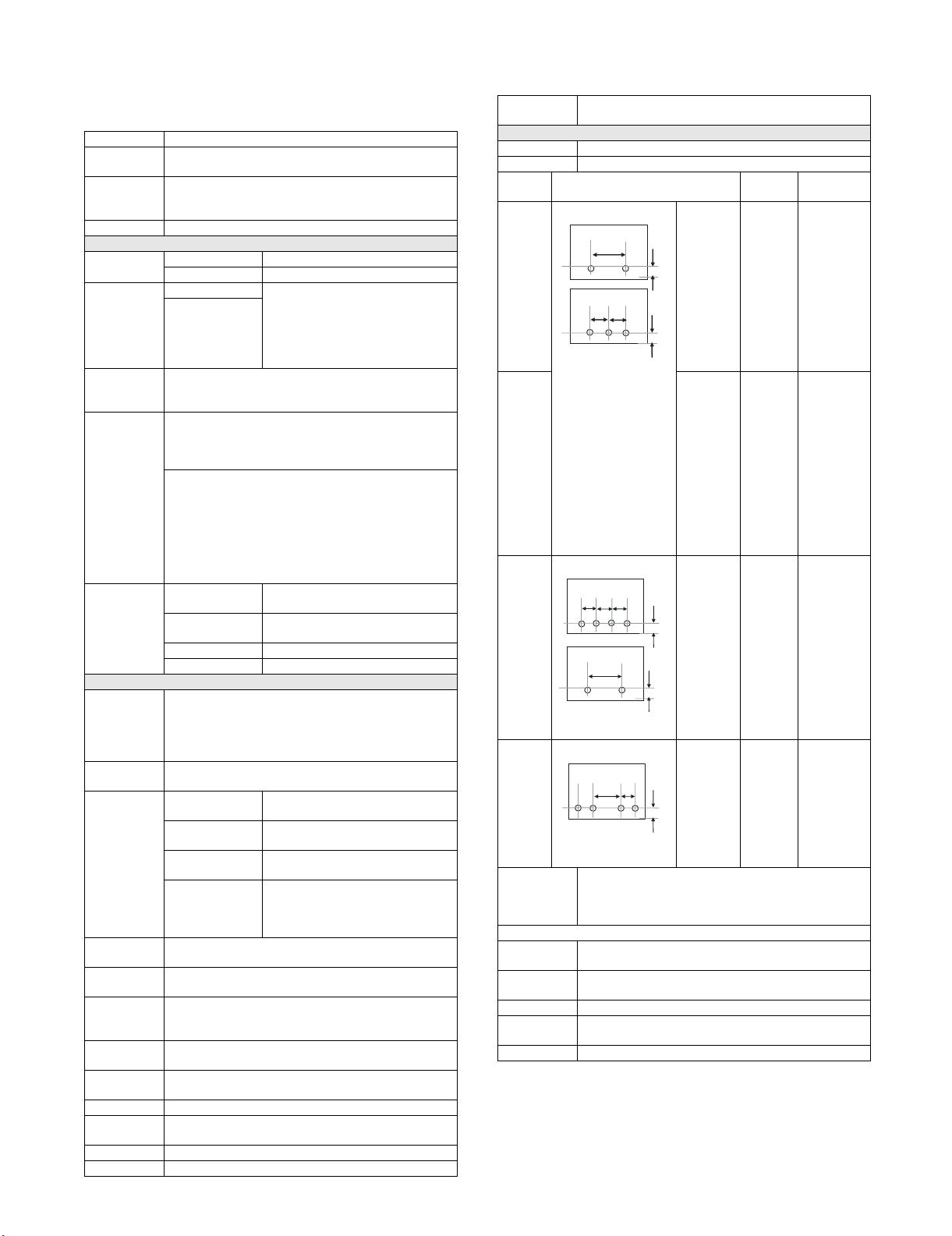

Punch Module for 50 sheets stapling (Option) *3

Form Built in the Finisher

Punch style Reciprocal type

Type Hole location Hole

diameter

2-hole 2-hole:

A:

B

B

80±1mm

B:

12±3mm

2-hole:

A:

70±1mm

B:

North

America

2-hole

3-hole*1

A

A

A

2-hole:

φ6.5mm

φ8.0mm 3-hole:

12±3mm

3-hole:

A:

108±1mm

B:

9.5±3mm

2-hole

4-hole*2

2-hole:

A:

φ6.5mm 4-hole:

80±1mm

B:

12±3mm

4-hole:

A:

80±1mm

B:

12±3mm

4-hole

wide

A:

70±1mm

φ6.5mm A3, A4,

B:

12±3mm

C:

21±1mm

Adjustment of

Punch

position

Feeding direction(X): ±3mm, Adjustment pitch 0.5mm,

Control by main unit.

Y direction: ±2mm, Adjustment pitch 0.4mm, Control by

main unit.

Can be manually adjusted in the B direction.

Manual

Punch

Punchable

Yes (When the inserter is installed, it can be operated on

the operation panel of the main unit.)

52-163g/m

2

,16lbs Bond, 90lbs Index

Paper Weight

Power source In the finisher

Dimensions

130mmx515mmx140mm

(WxDxH)

Weight 1.4kg

*1: Manual (OPE) Switching: 2-hole/3-hole

*2: Manual (OPE) switching 2-hole/4-hole

Paper Size

2-hole:

A3, A4, A4R, B4, B5,

B5-R,

11"x17",

8.5"x14",

8.5" x13.4",

8.5" x13",

8.5"x11",

8.5"x11"-R,

8K, 16K,

16K-R

A3, A4,

11"x17",

8.5"x11"

2-hole:

A3, A4,

A4R, B5,

B5R,

11”x17”,

8.5"x11"-R,

8.5"x14",

8.5"x13.4",

8.5"x13"

A3, B4, A4,

B5, 11"x17",

8.5"x11"

2-hole:

A3, A4,

A4R, B5,

B5R,

11"x17",

8.5"x11"-R,

8.5"x14",

8.5"x13.4",

8.5"x13"

A4-R, B4,

B5, B5-R,

11"x17",

8.5"x14",

8.5"x13.4",

8.5"x13",

8.5"x11",

8.5"x11"-R

Page 3

2. MX-FNX7/PNX4 Saddle finisher (85 only)

Form Floor type

Transport

speed

Paper

Transport

standard

Tray Form Top tray Fixed

Paper sizes

allowed

Stored paper

weight (Nonstitched)

Stored sheets Top tray

Stacking

performance

Number of

sheets to be

stitched

Paper weight

to be stitched

Number of

stored sheets

when stapled

(80g/m

Stap le

Position

Stapling

method

Adjustment of

Stap le

position

Detection of

no staple

Manual

Stap le

Paper sizes

allowed for

saddle

Paper type/

weight

allowed for

saddle

Supports 85 sheets/minute

Center alignment

Stacker section

Offset tray Up-down Offset tray

Saddle Tray Fixed

Top tray A3W, A4W, A3, B4, A4, A4-R, B5, B5Offset tray

R, A5-R, 8K, 16K, 16KR, Postcard,

11"x17", 8.5"x14", 8.5"x13.4",

8.5"x13", 8.5"x11", 8.5"x11"-R,

5.5"x8.5"-R, 12"x18", 9"x12",

7.25"x10.5"R

Top tray: 52 - 205g/m

Offset tray: 52 - 300g/m

250 sheets: A4, 8.5"x11" or less

50 sheets: B4, 8.5"x14" or more

Offset tray

2000 sheets: A4, 8.5"x11"

1000 sheets: A3W, A4W, A3, B4, A4-R, B5, B5-R,

8K,16K,16KR, 12"x18", 11"x17", 8.5"x14", 8.5"x13.4" ,

8.5"x13", 8.5"x11"-R, 9"x12"

100 sheets: A5-R*, 5.5"x 8.5"-R*, Postcard*

*Impossible to Offset.

Non-offset 12 mm or less

(B5R and A5R are 50mm or less)

Offset 12 mm or less

(B5R and A5R are 50mm or less)

Offset volume 30 mm

Stitched 3 mm or less

Staple section

50 sheets: A4, 8.5"x11" or less

30 sheets: B4, 8.5"x14" or more

Mixed size: 30 sheets

Max. 2 x 176g/m

+ 48 sheets x 80g/m

60 - 105g/m

2

(65lbs Index) paper

2

2

,16lbs-28lbs Bond

A4, 8.5x11 2-12 sheets 150 bundles

13-50 sheets 150-40 bundles

A4R, B5, 8.5x11R 2-9 sheets 100 bundles

2

)

10-50 sheets 100-20 bundles

Others: 2-9 sheets 100 bundles

10-30 sheets 100-33 bundles

When mixed size:

2-30 sheets 50 bundles

A3 and A4,

B4 and B5,

11x17 and 8.5x17

4 position (Top, Top Slant, Bottom, 2 Staples)

Staple cartridge (5000 staples) Changeable by user

-1 - +3.5mm (For 1 position staple only), Adjustment pitch

0.5mm, Controlled by main unit.

Available

No

Saddle section

A3W, A3, B4, A4-R, B5-R, 11"x17", 8.5"x14", 8.5"x11"-R,

12"x18"

60 - 90g/m

176g/m

2

, 16lbs-24lbs Bond, Cover is possible up to

2

.

2

, 16lbs Bond-110lbs Index

2

, 16lbs Bond-170lbs Index

paper

Stit ching

2-point center stitch

method

Stitched

15 sheets

sheet

Folding

Center folding

location

Loading

number of

sheet

Adjustment of

Centre staple

2 - 5 sheets staple: 30 bundles

6 - 10 sheets staple: 15 bundles

11 - 15 sheets staple: 10 bundles

±3mm (Feeding direction), Adjustment pitch 0.2mm,

Controlled by main unit.

position

Adjustment of

Centre

±3mm (Feeding direction), Adjustment pitch 0.2mm,

Controlled by main unit.

folding

position

Detection of

Available

no staple

Stapling

method

Staple cartridge (2000 staples) x2

Changeable by user

Reliability MCBJ in compliance with the main unit

MCBF in compliance with the main unit

Life 5 year or 9,900K

Dimensions

(W x D x H)

640mm x 614mm x 960mm

745mm x 614mm x 960mm (Tray extended)

Weight 60.6Kg

Power

DC24V (supplied by the main unit)

Source

Power

96W (Include Punch module)

Consumption

Manual

No

Stap le

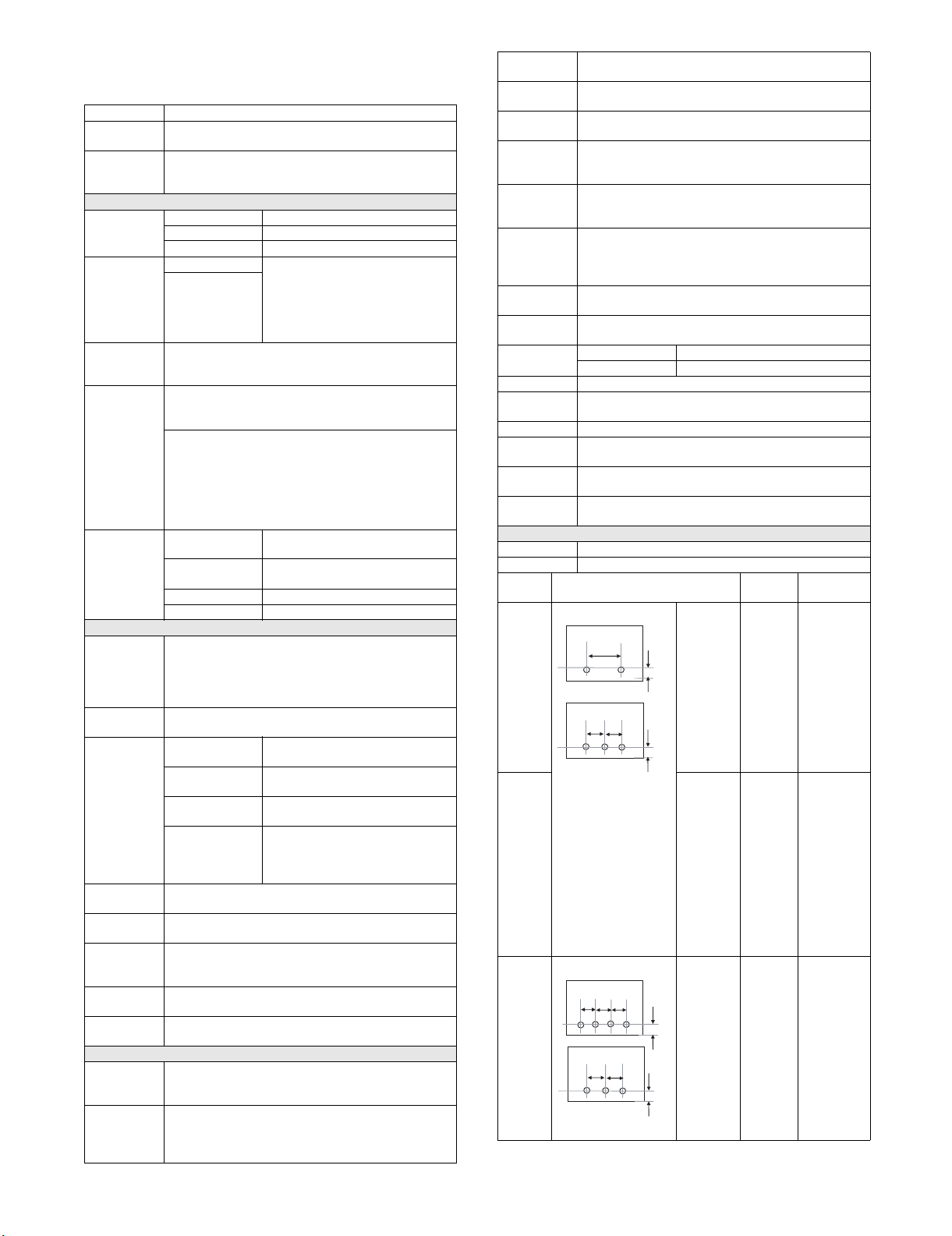

Punch Module for 50 sheets stapling(Option) *3

Form Built in the finisher

Punch style Reciprocal

Type Hole location

2-hole 2-hole

A:

80±1mm

B:

12±3mm

B

Hole

diameter

2-hole:

φ6.5mm

Paper Size

2-hole:

A3, A4,

A4-R, B4,

B5, B5-R,

11"x17",

8.5"x14",

8.5" x13.4",

8.5"x13",

"8.5"x11",

8.5"x11"-R,

8K, 16K,

16K-R

A3, A4,

11"x17",

8.5"x11"

2-hole:

North

America

2-hole

3-hole*1

A

A

B

2-hole:

φ8.0mm 3-hole:

A:

70±1mm

B:

12±3mm

A3, A4,

3-hole:

A:

108±1mm

B:

9.5±3mm

A4R, B5,

B5R,

11"x17",

8.5"x11"-R,

8.5"x14",

8.5"x13.4",

8.5"x13"

2-hole

4-hole*2

A

A

A

A

A

B

B

2-hole:

A:

80±1mm

B:

12±3mm

4-hole:

A:

80±1mm

B:

12±3mm

φ6.5mm 4-hole:

A3, B4, A4,

B5, 11"x17",

8.5"x11"

2-hole:

A3, A4,

A4R, B5,

B5R,

11"x17",

8.5"x11"-R,

8.5"x14",

8.5"x13.4",

8.5"x13"

MX-FNX6 SPECIFICATION 1 – 2

Page 4

4-hole

wide

Adjustment of

Punch

position

C

A

Feeding direction(X): ±3mm, Adjustment pitch 0.5mm,

Controlled by main unit.

Y direction: ±2mm, Adjustment pitch 0.4mm, Control by

B

A:

70±1mm

B:

12±3mm

C:

21±1mm

main unit.

B-direction can be adjustable manually.

Manual

No

Punch

Punchable

Paper Weight

2-hole/ 2-hole3-hole: 52-163g/m

4-hole/ 4-hole-broad space: 52-163g/m

90lbs Index

Power

Supplied by the finisher

Source

Dimensions

130mm x 515mm x 140mm

(WxDxH)

Weight 1.4kg

*1: Manual (OPE) switching: 2-hole/3-hole

*2: Manual (OPE) switching: 2-hole/4-hole

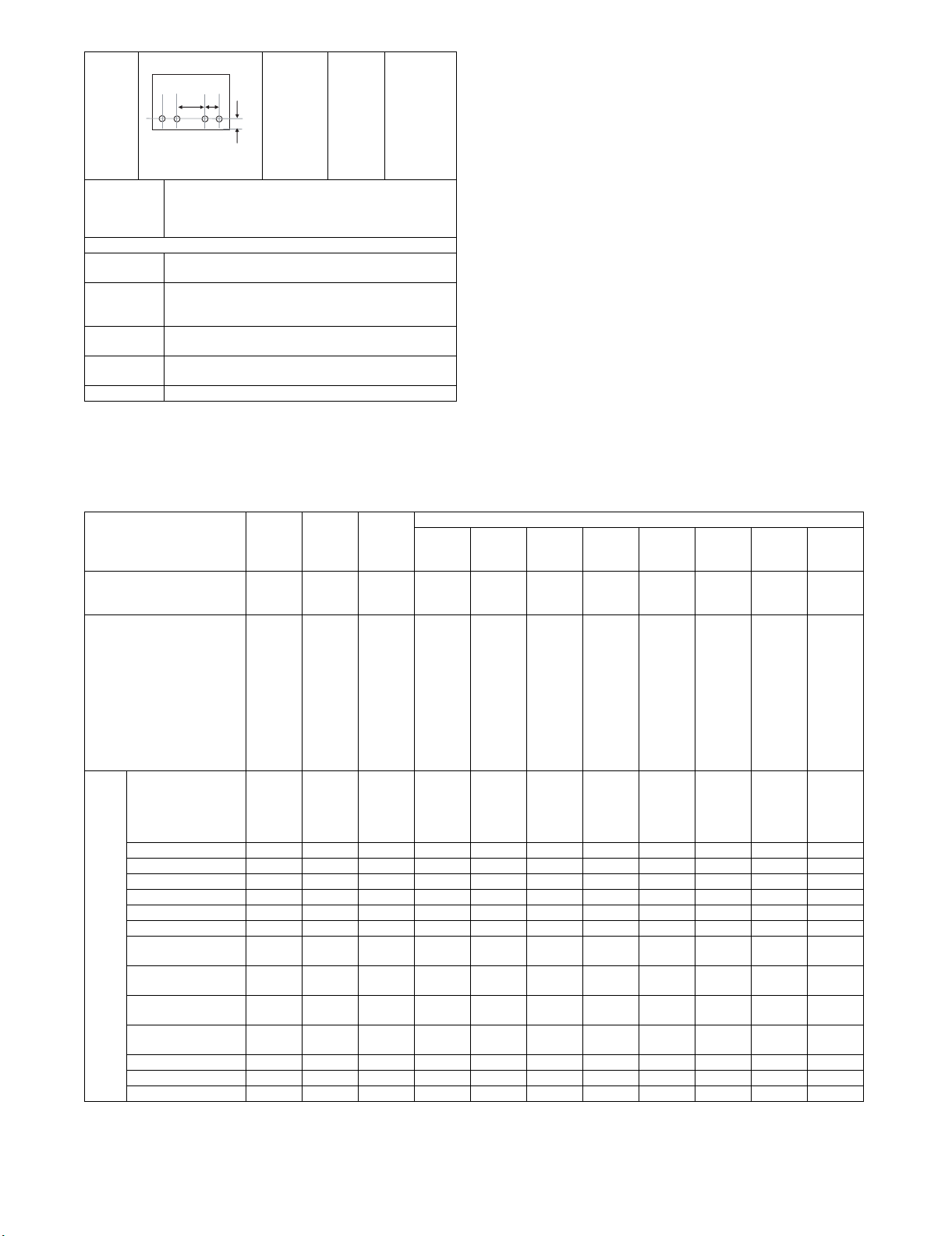

3. Paper size/Type/Weight

φ6.5mm A3, A4,

A4-R, B4,

B5, B5-R,

11" x17" ,

8.5"x14",

8.5" x13.4",

8.5"x13",

8.5"x11",

8.5"x11"-R

2

/16lbs Bond-90lbs Index

2

/16lbs Bond-

2- sided

pass

Minimum paper weight 60g/m

(16lbs

bond)

Maximum paper weight 205g/m

(40lbss

bond)

(110lbss

index)

(65lbs

cover)

2

2

Reverse

Output

Pass

52g/m2

(14lbs

bond)

205g/m2

(40lbss

bond)

(110lbss

index)

(65lbs

cover)

Straight

Output

Pass

52g/m2

(14lbs

bond)

300g/m2

(40lbs

bond)

(140lbs

index)

(100lbs

cover)

Top tr ay Of fs et

tray

52g/m2

(14lbs

bond)

205g/m2

(40lbs

bond)

(110lbs

index)

(65lbs

cover)

52g/m2

(14lbs

bond)

300g/m2

(40lbs

bond)

(140lbs

index)

(100lbs

cover)

Saddle Finisher/ Finisher (For 85 sheets)

At the

staple

60g/m2

(16lbs

bond)

105g/m2

(28lbs

bond)

Punch

(2-

holes)

52g/m2

(14lbs

bond)

163g/m

(90lbs

Index)

2

Punch

(2/3 -

holes)

52g/m2

(16lbs

bond)

163g/m2

(90lbs

Index)

Punch

(2/4 -

holes)

52g/m2

(14lbs

bond)

163g/m2

(90lbs

Index)

As for

the

cover

sheet,

Even

2

176g/m

is

possible

Paper

Thin paper No Yes

type

(Even

52g/m

is

possible)

2

Ye s

(Even

52g/m2

is

possible)

Ye s

(Even

52g/m2

is

possible)

Ye s

(Even

52g/m2

is

possible)

No Yes

(Even

52g/m2

is

possible)

Ye s

(Even

52g/m2

is

possible)

Ye s

(Even

52g/m2

is

possible)

Plai n p a p er Ye s Yes Yes Yes Yes Yes Yes Ye s Yes Yes Yes

Rec y c l e d p a per Yes Yes Yes Yes Yes Yes Ye s Yes Yes Yes Yes

Colored paper Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

Le tt er head Yes Ye s Yes Yes Yes Yes Ye s Yes Ye s Yes Yes

Pre-printed paper Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

Pre-punched paper Yes Yes Yes Yes Yes Yes No No No No Yes

Heavy paper1

(106-128g/m

Heavy paper2

(129-176g/m

Heavy paper3

(177-205g/m

Heavy paper4

(206-300g/m

2

)

2

)

2

)

2

)

Ye s Ye s Ye s Yes Ye s Ye s Ye s Ye s Ye s Ye s Ye s

Ye s Ye s Ye s Yes Ye s Ye s Ye s Ye s Ye s Ye s Ye s

YesYesYesYesYesNoNoNoNoNoNo

No No Yes No Yes No No No No No No

Tab paper No Yes Yes Yes Yes Yes Yes Yes Yes Yes No

Transparency paper No No Yes Yes No No No No No No No

Label paper No No Yes Yes No No No No No No No

Punch

(4-holes

wide)

52g/m2

(14lbs

bond)

163g/m2

(90lbs

Index)

Ye s

(Even

52g/m2

is

possible)

Saddle

tray

60g/m2

(16lbs

bond)

90g/m2

(24lbs

bond)

As for

the

cover

sheet,

Even

176g/m

is

possible

No

2

MX-FNX6 SPECIFICATION 1 – 3

Page 5

2- sided

pass

Paper

12"x18"

size

(A3W)

Ledger

(11"x17")

Ledger

(11"x17")

Zfolding

Legal

(8.5"x14")

Legal

(8.5"x14")

Z folding

Mexican

Legal

(8.5"x13.4")

Foolscap

(8.5"x13")

Letter

(8.5"x11")

Letter R

(8.5"x11"R)

Letter R

(8.5"x11"R)

Z folding

Invoice

(5.5"x8.5")

Invoice R

(5.5"

x8.5"R)

Exective R

(7.25"x10.5")

9x12 (A4W) 305

A3 297

A3

Z folding

B4 257

B4

Z folding

A4 297

A4-R 210

A4-R

Z folding

B5 257

B5-R 182

A5 210

A5-R 148

SRA3 320

SRA4 320

318x234.75mm Yes Yes Yes No No No No No No No No

312.5x220mm Yes Yes Yes No No No No No No No No

318x469.5mm Yes Yes Yes No No No No No No No No

312.5x440mm Yes Yes Yes No No No No No No No No

8K 270

16K 270

16K-R 195

305

x457

279

x432

279

x216

216

x356

216

x178

216

x340

216

x330

279

x216

216

x279

216

x140

216

x140

140

x216

184

x266

x229

x420

297

x210

x364

257

x182

x210

x297

210

x148

x182

x257

x148

x210

x450

x225

x390

x195

x270

Reverse

Output

Pass

YesYesYesYesYesNoNoNoNoNoYes

Ye s Ye s Ye s Yes Ye s Ye s Ye s Ye s Ye s Ye s Ye s

-----------

Ye s Ye s Ye s Yes Ye s Ye s Ye s y e s

-----------

Ye s Ye s Ye s Yes Ye s Ye s Ye s y e s

Ye s Ye s Ye s Yes Ye s Ye s Ye s y e s

Ye s Ye s Ye s Yes Ye s Ye s Ye s Ye s Ye s Ye s N o

Ye s Ye s Ye s Yes Ye s Ye s Ye s y e s

-----------

NoNoNo--------

Ye s Ye s Ye s Yes ye s

Yes Yes Yes Yes Yes Yes No No No No No

YesYesYesYesYesNoNoNoNoNoNo

Ye s Ye s Ye s Yes Ye s Ye s Ye s Ye s Ye s Ye s Ye s

-----------

Ye s Ye s Ye s Yes Ye s Ye s Ye s y e s

-----------

Ye s Ye s Ye s Yes Ye s Ye s Ye s Ye s Ye s Ye s N o

Ye s Ye s Ye s Yes Ye s Ye s Ye s y e s

-----------

Ye s Ye s Ye s Yes Ye s Ye s Ye s y e s

Ye s Ye s Ye s Yes Ye s Ye s Ye s y e s

NoNoNo--------

Ye s Ye s Ye s Yes ye s

YesYesYesNoNoNoNoNoNoNoNo

YesYesYesNoNoNoNoNoNoNoNo

Ye s Ye s Ye s Yes Ye s Ye s Ye s Ye s Ye s Ye s N o

Ye s Ye s Ye s Yes Ye s Ye s Ye s Ye s Ye s Ye s N o

Ye s Ye s Ye s Yes Ye s Ye s Ye s y e s

Straight

Output

Pass

Top tr ay Of fs et

tray

(Impossi

ble to

offset)

(Impossi

ble to

offset)

Saddle Finisher/ Finisher (For 85 sheets)

At the

staple

No No No No No No

No No No No No No

Punch

(2-

holes)

Punch

(2/3 -

holes)

(2-holes)

(2-holes)

(2-holes)

(2-holes)

(2-holes)

(2-holes)

(2-holes)

(2-holes)

(2-holes)

Punch

(2/4 -

holes)

yes

(2-holes)

yes

(2-holes)

yes

(2-holes)

yes

(2-holes)

Ye s Ye s Ye s

yes

(2-holes)

Ye s Ye s No

yes

(2-holes)

yes

(2-holes)

Punch

(4-holes

wide)

Ye s Ye s

Ye s No

Ye s No

Ye s Ye s

Ye s Ye s

Ye s Ye s

Ye s No

Saddle

tray

MX-FNX6 SPECIFICATION 1 – 4

Page 6

Paper

Postcard 100

size

Special-Custom size No Yes Yes Yes yes

(Custom

Range)

Special-Size

uncertain

x148

min

Main

max

Main

min

Sub

max

Sub

*1: Cover and back cover only.

*2: 2-holes only.

2- sided

pass

Reverse

Output

Pass

No No Yes Yes yes

- 140

- 320

(12.5)

- 182

(7.25)

- 470

(18.5)

NoYesYesYesNoNoNoNoNoNoNo

(5.5)

Straight

Output

Pass

100

(4.0)

320

(12.5)

140

(5.5)

470

(18.5)

Top tr ay Of fs et

100

(4.0)

320

(12.5)

140

(5.5)

470

(18.5)

tray

(Impossi

ble to

Offset)

(Impossi

ble to

Offset)

140

(5.5)

306

(12.1)

140

(5.5)

470

(18.5)

Saddle Finisher/ Finisher (For 85 sheets)

At the

staple

No No No No No No

No No No No No No

Punch

holes)

------

------

------

------

(2-

Punch

(2/3 -

holes)

Punch

(2/4 -

holes)

Punch

(4-holes

wide)

Saddle

tray

MX-FNX6 SPECIFICATION 1 – 5

Page 7

1

:07’.07.27

MX-FNX6

[2] MAINTENANCE LIST

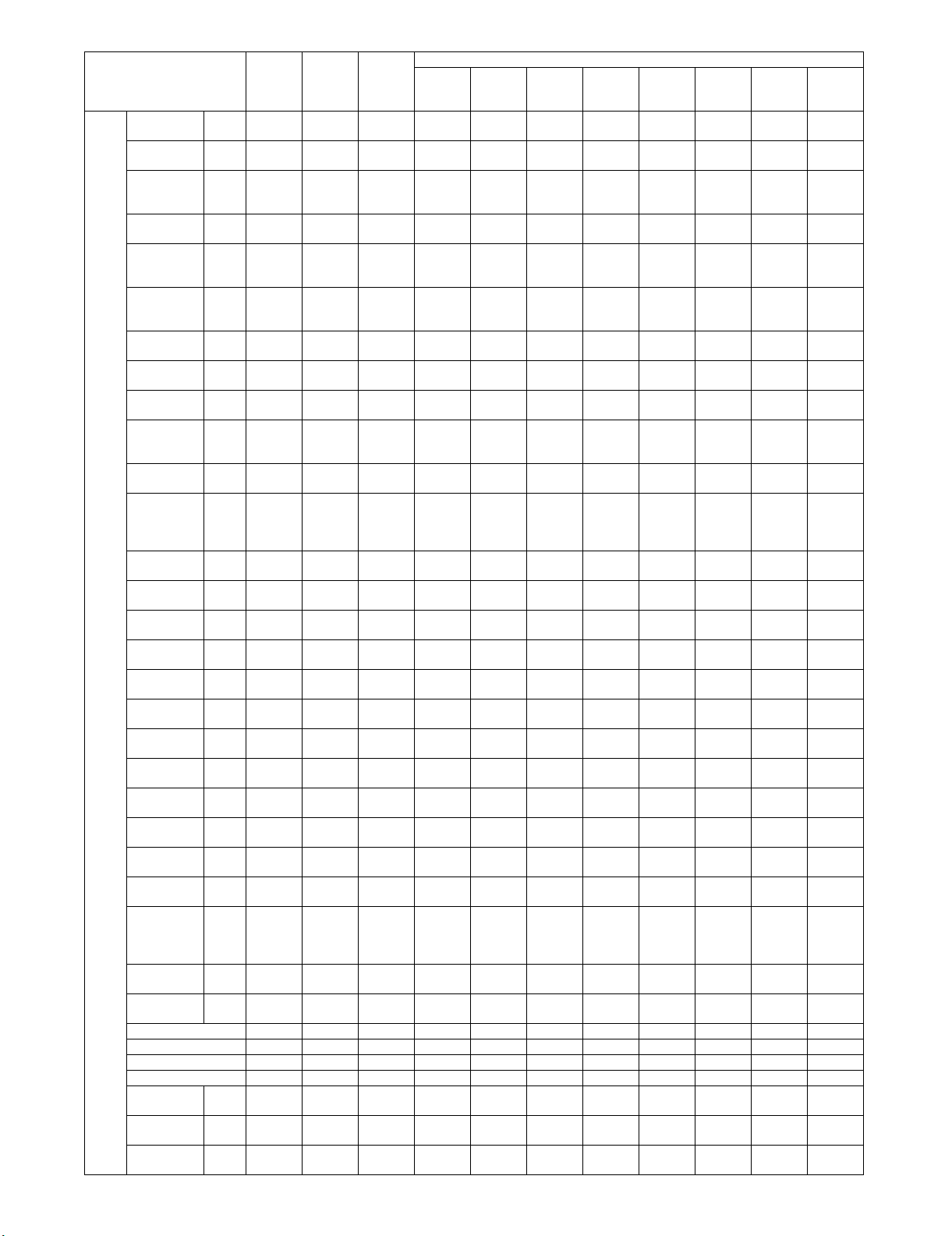

✕ : Check {: Clean S: Replace U: Adjust ✩ : Lubricate : Shift position

(Clean, replace, or adjust as needed.)

Service Manual

Unit name No. Part name

Finisher

(for 85-sheet

machine)

[MX-FNX6]

1

Saddle

finisher

(for 85-sheet

machine)

[MX-FNX7]

1

1 Transport rollers ✕ { { { { { { When there is dirt,

2 Transport paper guide ✕ { { { { { { When there is dirt,

3Gears ✕ ✕ ✕ ✕ ✕ ✕ ✕ UKOG-0307FCZZ

4 Discharge brush ✕ ✕ ✕ ✕ ✕ ✕ ✕ When there is dirt,

5 Sintered bearing ✕ ✕ ✕ ✕ ✕ ✕ ✕ Lubricate when an

6 Sensor ✕ { { { { { { Clean by air

7 Edge binding stapler Replacement reference: Replace the unit after 500K of staple.

8 Punch Replacement reference: Replace the unit after 1,000K of panch.

9

Drag roller ✕ SSSSSS

1 Drive roller ✕ { { { { { { When there is dirt,

2 Follower roller ✕ { { { { { { When there is dirt,

3 Discharge brush ✕ ✕ ✕ ✕ ✕ ✕ ✕ When there is dirt,

4 Sintered bearing ✕ ✕ ✕ ✕ ✕ ✕ ✕ Lubricate when an

5 Sensor ✕ { { { { { { Clean by air

6 Edge binding stapler Replacement reference: Replace the unit after 500K of staple.

7 Center binding stapler Replacement reference: Replace the unit after 200K of staple.

8 Punch Replacement reference: Replace the unit after 1,000K of panch.

9

Drag roller ✕ SSSSSS

When

calling

500K 1000K 1500K 2000K 2500K 3000K

NOTE: Discharge brush cleaning

Wipe the brush with wet cloth with a small amount of water. (Recommend)

Handle the brush carefully.

Life judgement

(Reference)

abnormal sound is

heard.

abnormal sound is

heard.

Tool, oil, chemicals

Procedure

Treatment after

procedure

wipe with wet cloth

and water.

wipe with wet cloth

and water.

wipe brush part with

wet cloth and water.

* Refer to the NOTE:

Tellus oil:

0CW4110K701//

wipe with wet cloth

and water.

wipe with wet cloth

and water.

wipe brush part with

wet cloth and water.

* Refer to the NOTE:

Silicon oil

MX-FNX6 MAINTENANCE LIST 2 – 1

Page 8

M18

S5

S8

S6

M10

M4

SOL2

S7

S10

S1

S9

S12

Tray upper limit

SW

S13

M19

M2

SOL1

S11

MX-FNX6

[3] MECHANISM

Service Manual

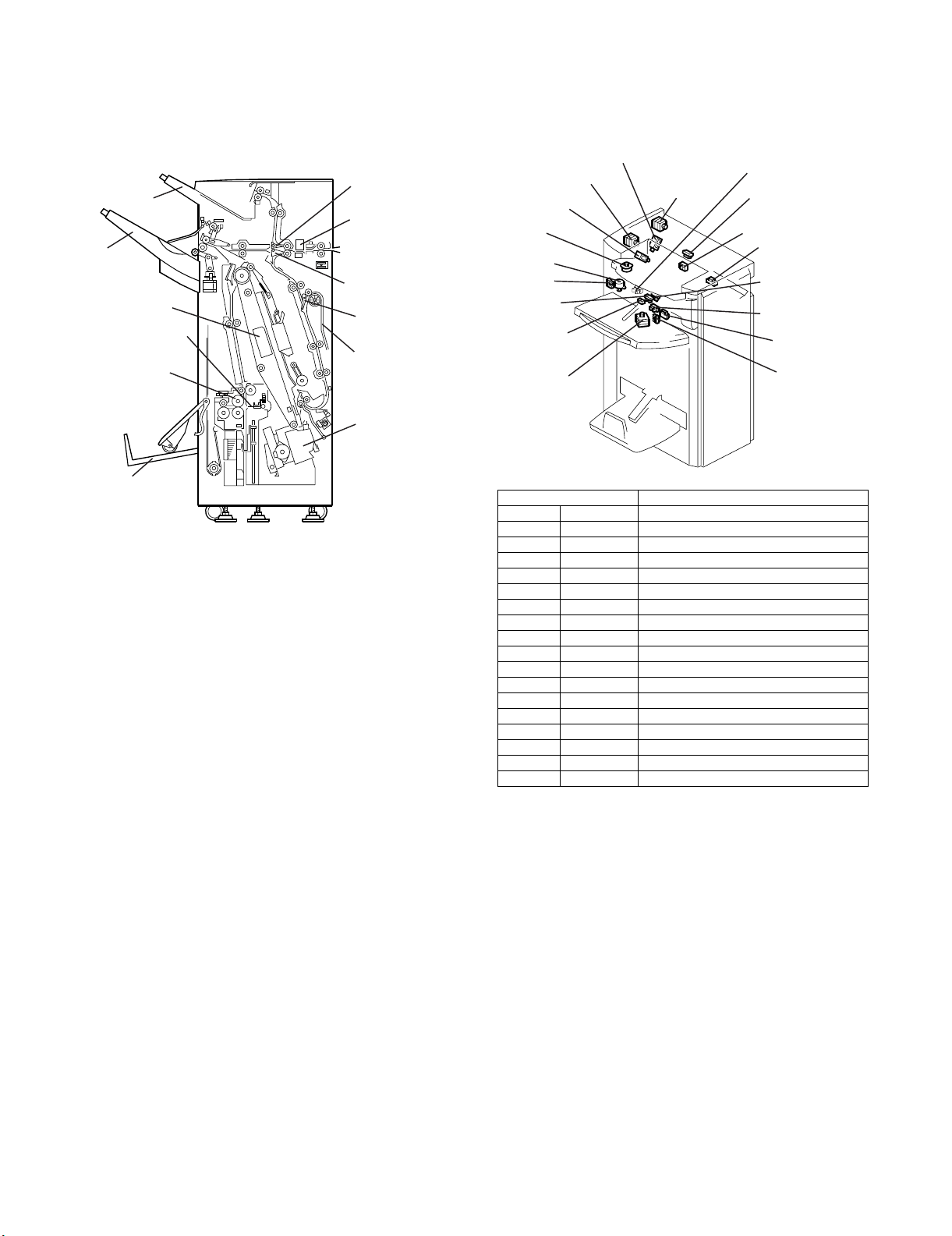

1. Composition layout (* In the figure: For the MX-FNX7 only)

Proof tray

Tr ay

assembly

* Center binding

stapler

* Folding plate

* Folding roller

Tr ay

*

paper folding

section

1) Proof branch, staple branch

The paper path is selected between the path to the proof tray

and the path to the upper tray depending on presence of sort

or staple.

2) Proof tray

When the sort mode and the staple mode are not selected,

copy paper is discharged to this tray.

3) Tray assembly

This tray lifts up or moves down in the sort mode depending on

the copy discharge quantity (the number of copy sets).

4) Tray paper folding section (The MX-FNX7 only)

Center binding copy is discharged to this tray in the sort mode.

5) Pre-stack section

The first page of the second or later sets is switch-back transported and kept in standby, and fed together with the second

page to the staple tray.

6) Center binding staple section (The MX-FNX7 only)

Sheets of copy paper are aligned by the alignment roller and

the jogger fence, performing stapling.

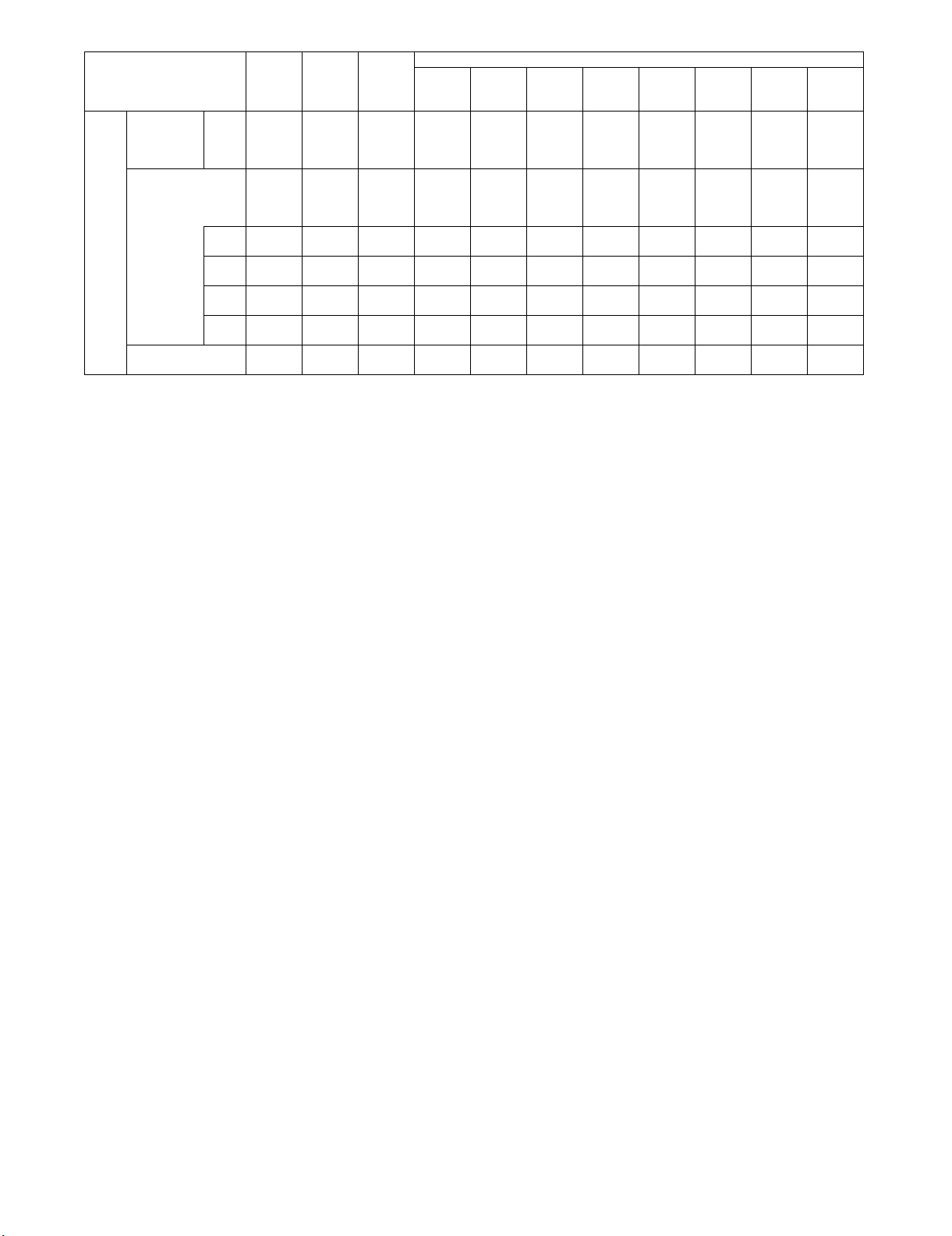

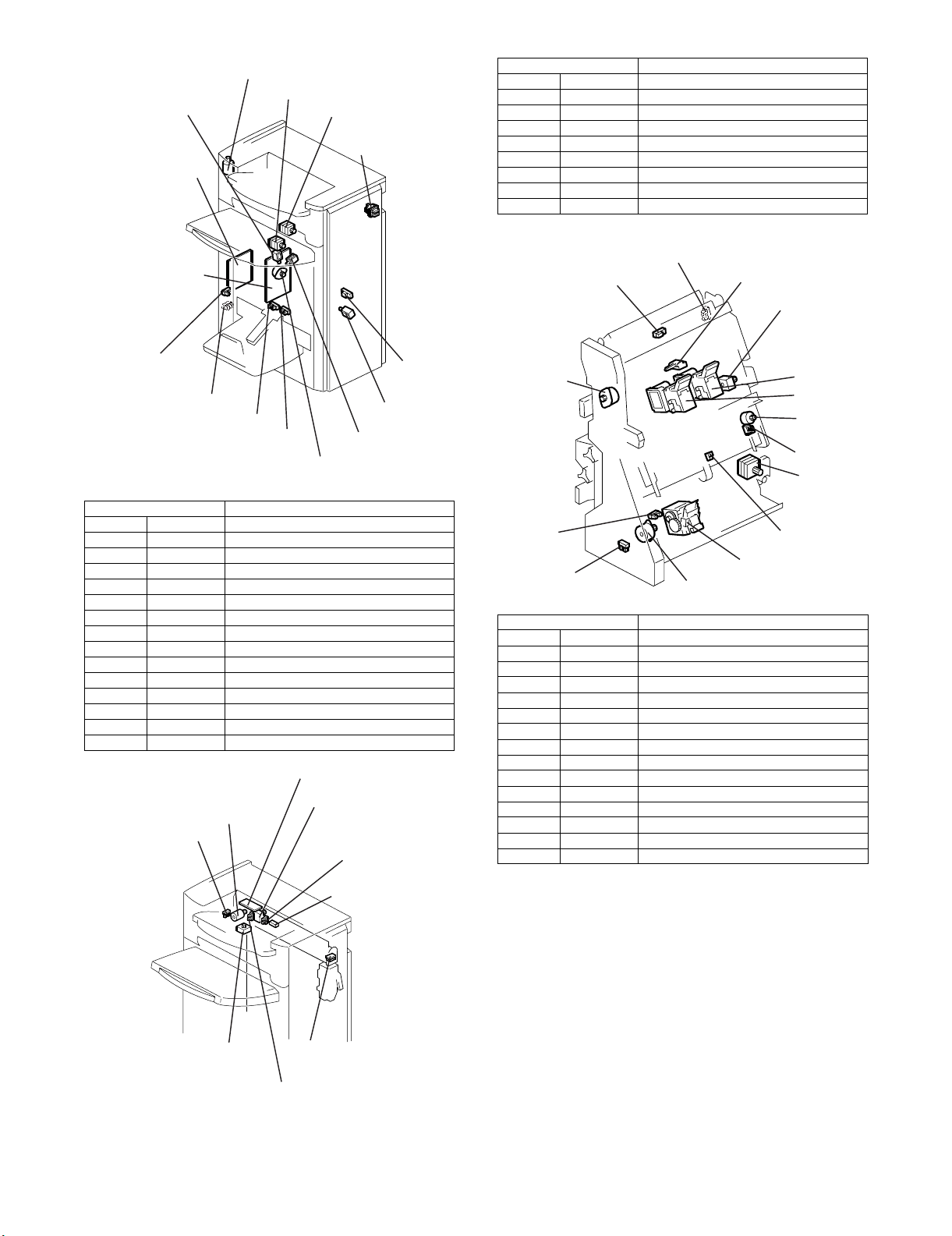

2. Electric parts layout

Proof branch

pawl

Punch unit

Staple branch

pawl

Pre-stack

branch pawl

Pre-stack tray

Edge binding

stapler

Signal name Parts name

M2 UPTRS_M Upper transport motor

M4 EXIT_M Paper exit motor

M10 STRLVI_M Return roller oscillation motor

M18 SFT_M Shift motor

M19 EXGPLT_M Paper exit guide plate open/close motor

S1 FINENT Inlet sensor

S5 SFTROLHP Shift HP sensor

S6 UPTRYEXT Shift tray paper exit sensor

S7 EXGPLTHP Paper exit guide plate HP sensor

S8 UTRPHNST Staple mode paper surface detection

S9 UTRPHSTP Shift mode paper surface detection

S10 PRFTRYEX Proof tray paper exit sensor

S11 PRFTRYFL Proof tray full sensor

S12 UPTRYLMT Shift mode rear edge detection

S13 STKROLHP Oscillation return roller HP sensor

SOL1 UPJCTG_S Proof branch pawl SOL

SOL2 LOJCTG_S Staple branch pawl SOL

- - Tray upper limit SW

MX-FNX6 MECHANISM 3 – 1

Page 9

* SOL5

* S27

* M17

S18

S17

M13

M20

S14

M6

S15

M15

* M23

* M22

M5

S16

*S32

PCB: STP:

Control plate

PCB: Main:

Control plate

M21

M3

M1

Door SW

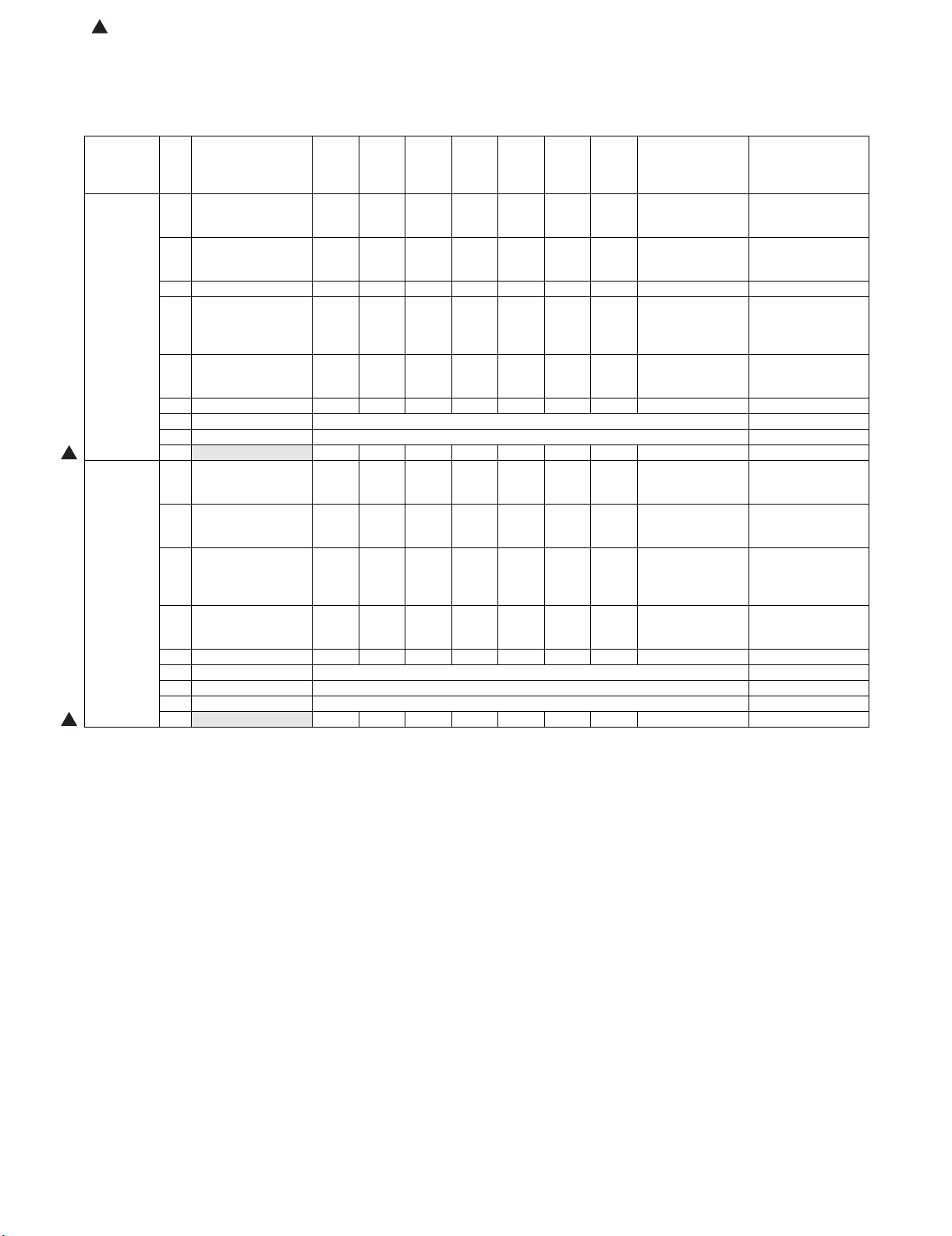

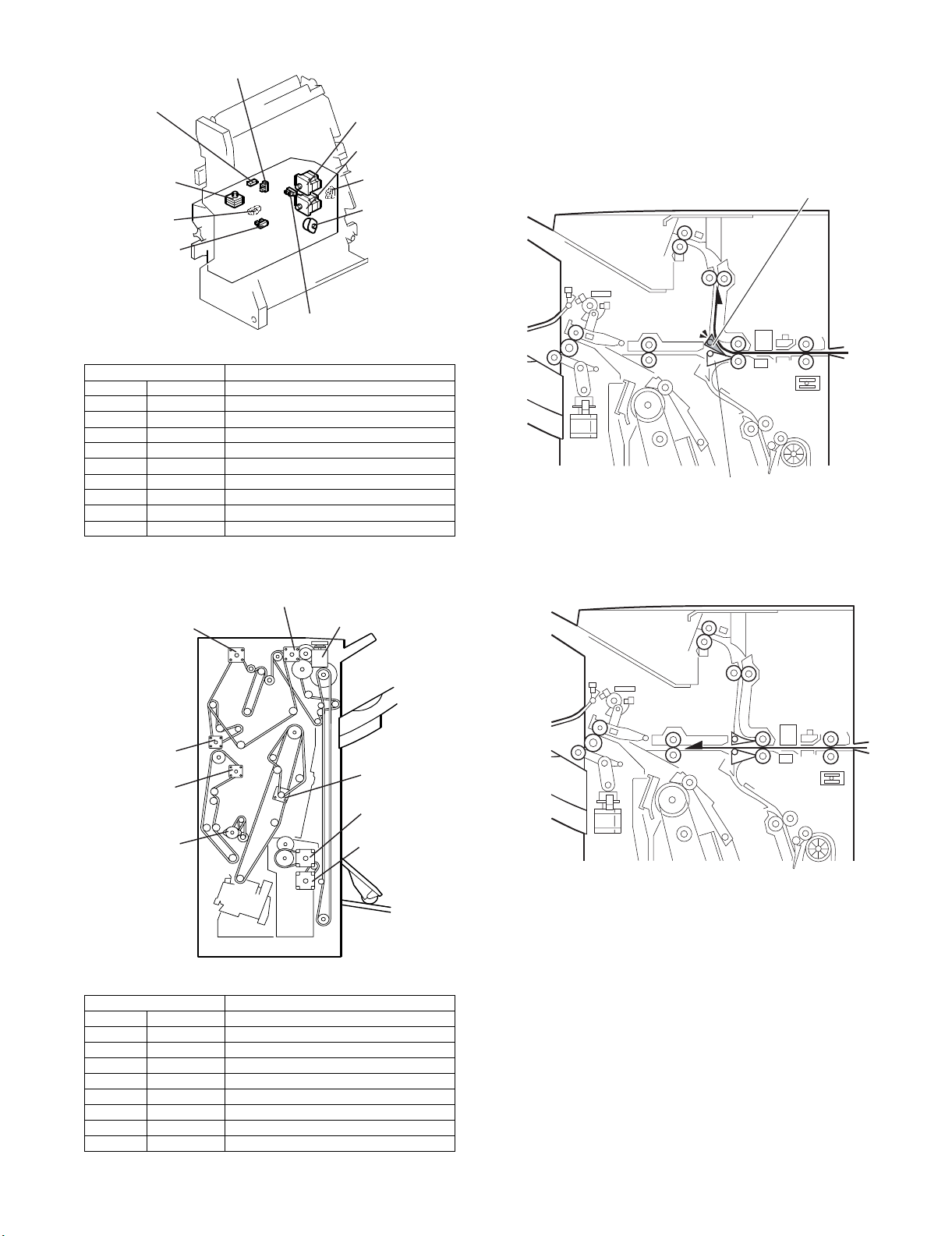

Signal name Parts name

M7 STSMOV_M Horizontal resist detection sensor shift motor

M9 PNCHMV_M Punch shift motor

M24 PNCH_M Punch drive motor

S21 PNCHMVHP Punch shift HP sensor

S22 PAPPOSHP Horizontal resist detection HP sensor

S24 PNCHENC Punch HP sensor

S3 PAPPOS Horizontal resist detection sensor

S4 PNCHHPFL Punch dust full sensor

- - PCB: Punch: Control plate

* S19

S20

* S34

* S33

SOL4

SOL3

M14

* MX-FNX7 only

Signal name Parts name

M1 ENT_M Inlet motor

M3 LOTRS_M Lower transport motor

M14 POP_M Beating roller drive motor

M21 TRYLFT_M Tray up/down motor

S2 PSTRYEXT Staple paper exit sensor

S19 UPTRFLSD Full sensor: Center binding (*)

S20 UPTRFLNS Full sensor: Without center binding

S33 SDLFLLR Center binding tray full sensor (*)

S34 SDLFLLF Center binding tray full sensor (*)

SOL3 POS_S Beating SOL

SOL4 TEGPRS_S Rear edge holding SOL

SOL5 SDLPRS_S Center binding holding SOL (*)

- - PCB: STP: Control plate

- - PCB: Main: Control plate

- - Door SW

PCB: Punch: Control plate

M7

M24

S24

S22

S2

Signal name Parts name

M5 BLT_M Discharge motor

M6 STPMV_M Stapler shift motor

M13 STPROT_M Stapler slant motor

M15 JOG_M Jogger motor

M17 BDJCTG_M Bundle branch open/close (*)

M20 STPMOV_M Stapler

M22 SDLSTF_M Center binding stapler (*)

M23 SDLSTR_M Center binding stapler (*)

S14 STPTRPAP Stapler tray paper presence sensor

S15 JOGHPS Jogger HP sensor

S16 BLTHPS Discharge pawl HP sensor

S17 CONSTPHP Stapler shift HP sensor

S18 STPROTHP Stapler slant HP sensor

S27 STJCTGHP Bundle branch open/close HP (*)

S32 STKPRST Lead edge detection sensor (*)

M9

S21

S4

S3

MX-FNX6 MECHANISM 3 – 2

Page 10

* S31

When in the proof mode:

Staple branch pawl

Proof branch pawl

In the shift mode:

* S25

* M12

* M11

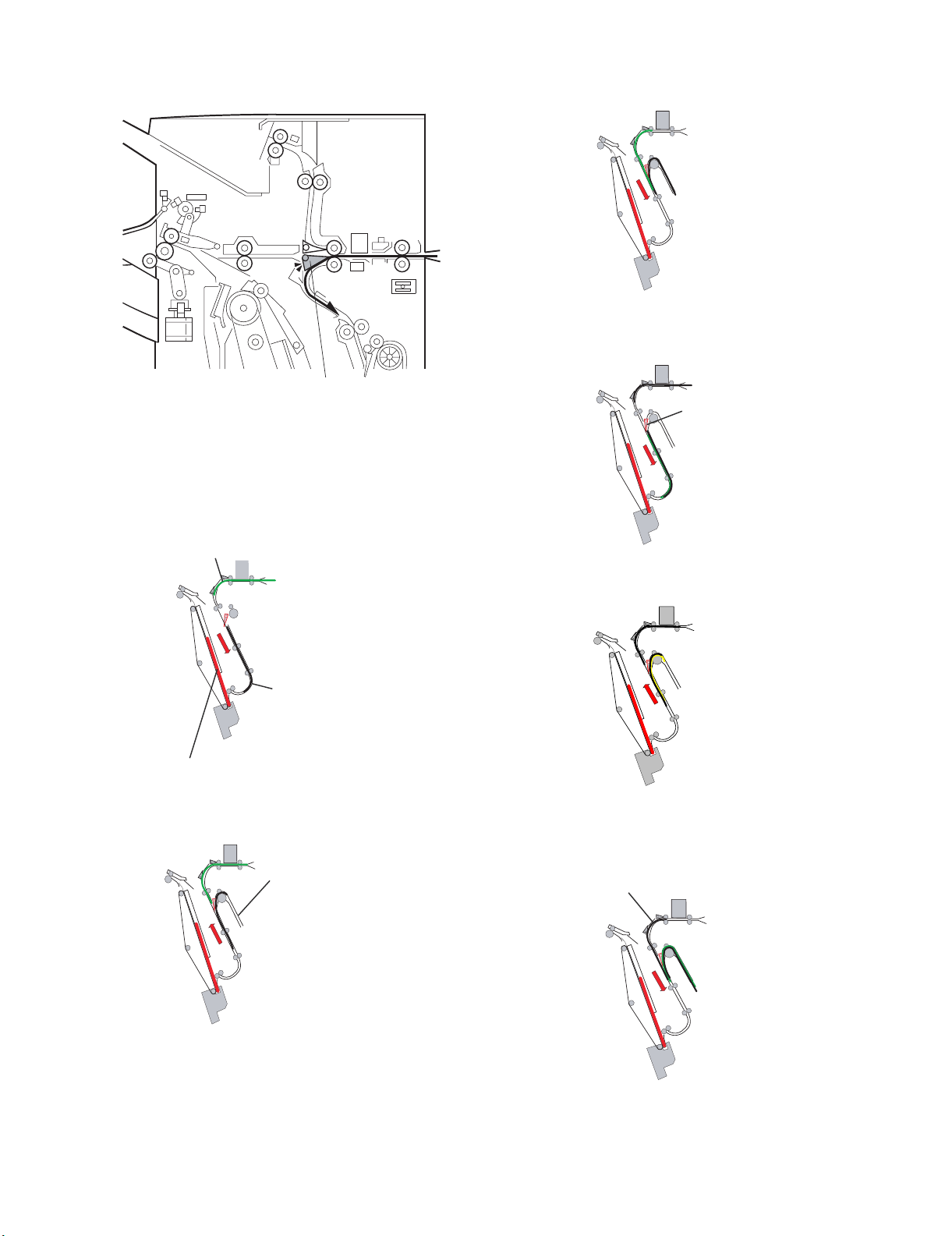

4. Branch mechanism

1) Paper is branched to the three directions by the proof branch

pawl and the staple branch pawl.

2) In the proof mode, when discharging to the proof tray, copy

paper is transported to the proof tray by the proof branch pawl.

*M8

* S26

* S28

* S30

* MX-FNX7 only

Signal name Parts name

M8 DRRLVI_M Drive roller oscillation motor (*)

M11 FLDPLT_M Folding plate drive motor (*)

M12 FLDROL_M Folding roller motor (*)

M16 TALFNC_M Rear edge fence motor (*)

S25 CLPROLHP Drive roller HP sensor (*)

S26 FLDUNENT Reach sensor (*)

S28 FLDBTMHP Rear edge fence HP sensor (*)

S29 FLDPLTHP Folding plate HP sensor (*)

S30 FLDCMHP Folding HP sensor (*)

S31 FLDUNEXT Folding pass sensor (*)

3. Drive layout

M4

M2

* S29

* M16

3) In the shift mode, the proof branch pawl and the staple branch

pawl do not operate, and copy paper is transported to the shift

tray.

M21

M1

M3

M14

* MX-FNX7 only

Signal name Parts name

M1 ENT_M Inlet motor

M2 UPTRS_M Upper transport motor

M3 LOTRS_M Lower transport motor

M4 EXIT_M Paper exit motor

M5 BLT_M Discharge motor

M11 FLDPLT_M Folding plate drive motor (*)

M12 FLDROL_M Folding roller motor (*)

M14 POP_M Beating roller drive motor

M21 TRYLFT_M Tray up/down motor

M5

* M12

* M11

MX-FNX6 MECHANISM 3 – 3

Page 11

4) In the staple mode, the staple branch pawl operates to transport copy paper to the staple section.

In the staple mode:

Staple branch pawl

5. Pre-stack mechanism

Four sheets can be discharged with max. three sheets of pre-stack.

In the example below, descriptions are made on discharge of three

sheets with two sheets of pre-stack.

1) Stapling the first set is performed.

3) The first sheet of the second set is transported from the prestack tray. At the same time, transport of the second sheet of

the second set is started.

4) Transport of the first sheet of the second set is completed. At

the same time, the rear edge of the second sheet of the second set passes the branch pawl.

Pre-stack Branch pawl

2nd sheet of 2nd set

1st sheet of 2nd set

Bundle of 1st set

2) The first sheet of the second set is switch-back transported to

the pre-stack tray.

Pre-stack tray

5) The first sheet and the second sheet of the second set are

switch-back transported together to the pre-stack tray.

6) Stapling of the first set is completed. At the same time, the first

sheet and the second sheet of the second set are transported

together from the pre-stack. Transport of the third sheet of the

second set is also started.

3rd sheet of 2nd set

MX-FNX6 MECHANISM 3 – 4

Page 12

7) The first set is discharged.

8) The first sheet, the second sheet, and the third sheet of the

second set are discharged together to the staple tray.

6. Rise-fall mechanism

<Tray assembly>

The Tray assembly rises or falls depending on the copy paper

quantity (paper stack height) discharged on the tray. The height is

always adjusted by the OFF state of the paper surface sensor.

• When discharging in the shift mode:

Paper surface sensor on the end fence side

• When discharging in the staple mode:

Paper surface sensor on the filler

Filler paper surface sensor

Lift motor

1) Falling operation

When the discharged copy paper is loaded on the tray and the

filler is lifted to turn on the paper surface detection sensor

lower for 3 sec or more, the lift motor rotates to fall the shift

tray. The falling operation varies depends on the mode.

Staple:

The lift motor rotates for a certain time to lower the tray height

for a certain interval, adjusting the height.

Shift:

The shift tray lifts up to the position where the paper surface

sensor is turned on. Then, the tray falls to turn off the paper

surface sensor, adjusting the height.

The shift tray full detection is made when the sensor is turned

on and it is displayed on the operation panel, and copying is

stopped. Cancel is made by removing copy paper.

2) Rising operation

When copy paper is removed from the shift tray and the paper

surface sensor upper is turned on, the shift tray rises. It stops

when the sensor is turned off.

7. Staple jogger mechanism

A. Stack mechanism

Copy paper branched to the staple tray is transported to the staple

tray. After the staple paper exit sensor turns off (A4Y), the alignment roller SOL turns on for a certain time (varying depending on

the size and the quantity). The alignment roller pushes paper to the

tray stopper to align the rear edges of paper.

B. Jogger mechanism

Copy paper rear edges are aligned by stack operation of (A), then

copy paper side edges are aligned by jogger operation.

First, the jogger fence closes to 7mm open from the right and the

left edges of paper by the ON signal (copy start).

When the lead edge of the transported paper passes the staple

paper exit sensor, the jogger fence closes 5mm to receive paper

and performs the operation of (A) to align the rear edges.

Then, the jogger fence closes 2.6mm furthermore to align the side

edges.

When the jogger operation is completed, the jogger fence opens

again to 7mm open from the paper edges and the machine enters

the standby state of the next paper.

Shift tray lower

limit sensor

Jogger fence

Jogger motor

Jogger HP

sensor

Paper surface

sensor on the end

fence side

Sliding roller

MX-FNX6 MECHANISM 3 – 5

Page 13

C. Stapler

The stapling operation is performed by the drive motor in the stapler. When an overload of the motor is generated by a staple jam,

etc., “Staple jam” is displayed on the operation panel.

The stapler is provided with the cartridge set sensor and the staple

end sensor. When they are OFF, the staple supply message is displayed on the operation panel.

When staple end occurs during copying, the job is completed and

the staple supply message is displayed.

When a staple jam occurs, copying is stopped.

Staple hammer

D. Stapler shift mechanism

The stapler shifts horizontally or rotates to make stapling according

to the four staple modes.

1) Staple shift mechanism

The stapler is supported by the rod, and shifted horizontally by

the timing belt. When the copy start key is pressed, the jogger

fence moves to the standby position. Then the stapler shift

motor turns ON to shift the stapler to the stapling position, and

the stapler enters the standby state of stapling.

The shift quantity differs depending on the paper size and the

stapling position.

When stapling at two positions, the front side is stapled first,

then the rear side is stapled.

2) Staple rotating mechanism

In one-position diagonal staple mode, the stapler is shifted horizontally and then rotated diagonally. Then stapling is performed. Rotation is made by the stapler rotation motor.

Staple motor

Stapler

Set sensor End sensor

Rear edge guide

Arm

Stapler rotation motor

Rear edge

reference fence

Oscillation SOL

Stapler

shift motor

E. Rear edge holding mechanism

In the edge binding or the center binding bookmaking mode (MXFNX7 only), curls and slacks on paper stacked to the rear edge reference fence are pressed to the staple tray, allowing the next paper

to feed to the rear edge reference fence, improving the alignment

accuracy when binding.

1) When stacking paper to the rear edge reference fence (staple

tray), paper is first aligned by the jogger fence (horizontal

alignment), then aligned by the shift roller (vertical alignment).

When the horizontal alignment and the vertical alignment are

completed, the oscillation SOL is turned ON to move the rear

edge guide to the holding position via the arm.

2) When the next paper enters the staple tray, the SOL is turned

OFF to save the rear edge guide to the standby position. After

completion of alignment operation, the SOL is turned ON again

to hold the rear edge section of paper.

3) The above operations are repeated until the last paper and

binding are completed. When binding operation is completed,

the SOL is turned OFF to save the rear edge guide to the

standby position until the next job is started.

MX-FNX6 MECHANISM 3 – 6

Page 14

F. Center binding holding mechanism

Discharge fence 1

Center binding staple

First set paper bundle

Discharge fence 2

(MX-FNX7 only)

In the center binding bookmaking mode, curls and slacks on paper

stacked on the staple tray are pressed to the staple tray side,

improving the paper edge detection accuracy and preventing paper

bundle shift when binding.

1) In the center binding bookmaking mode, paper is stacked to

the staple tray and vertical alignment and horizontal alignment

are completed. Then, paper bundle is transported to the center

binding stapler position at the center of the staple tray, and the

paper bundle rear edge is detected by the photo sensor.

The paper bundle is stopped according to the detection information, and binding is performed.

2) During these operations (after completion of horizontal/vertical

alignment, transport of paper bundle to the center binding position, completion of binding - *), the holding SOL is turned ON,

and the roller is moved to the holding position via the arm to

hold the paper bundle.

3) After completion of binding, the holding SOL is turned OFF to

save the roller to the standby position until the next job is

started.

* When the paper for center binding bookmaking is A3T, B4T, DLT,

or LG size, in order to detect the paper bundle rear edge with the

photo sensor, the paper bundle is moved up and down (normal/

reverse operation) inside the staple tray. When in reverse operation (moving down), the holding SOL is turned OFF to save the

roller in order not to prevent reverse operation of the paper bundle by the roller.

8. Center binding staple mechanism (MX-FNX7 only)

1) The first set is transported to the center binding staple section.

2) The center binding stapling of the first set is completed.

Discharge fence 2

Holding SOL

Arm

Holding roller

Discharge fence 1

3) The discharge fence 1 starts transport of the first set, and the

bundle branch guide pushes the first set to the transport roller

to start transport to the folding process section.

Bundle branch guide

Transport roller

Discharge fence 2

Discharge fence 1

MX-FNX6 MECHANISM 3 – 7

Page 15

4) Transport of the first set is completed. At the same time, the

second set is transported to the staple section.

Second set

paper bundle

Folding roller

6) The first set folding is completed and discharged. At the same

time, the second set center binding stapling is completed.

5) The folding plate advances and the folding roller rotates to fold

the first set at the center. At the same time, transporting of the

second set to the center binding staple position is completed.

Folding plate

9. Discharge mechanism

After completion of stapling, the discharge motor turns ON to drive the discharge belt, discharging copy paper from the staple tray with the discharge fence attached to the belt.

At that time, the paper exit guide plate remains in the open state until the paper bundle lifted by the discharge pawl moves by a certain distance

from the paper exit roller.

Then, the paper exit guide closes and the paper bundle is discharged to the shift tray by the paper exit roller.

The paper exit guide plate is opened or closed by rotation of the cam caused by the rotation of the paper exit guide plate open/close motor to

move the link up and down.

When discharging paper to the shift tray, the discharge motor is stopped for 300ms to prevent excessive pushing up.

After temporary stopping, the discharge motor is driven again and stops under the state where the discharge fence turns on the home position

sensor filler.

There are two discharge fences to improve productivity of small-lot binding.

MX-FNX6 MECHANISM 3 – 8

Page 16

Discharge belt HP sensor

Guide plate open/close motor

Discharge

motor

Discharge fence

Paper exit

guide plate

MX-FNX6 MECHANISM 3 – 9

Page 17

10. Punch mechanism

Punch unit

Punching is performed for every sheet by punching two holes at the

rear edge of copy paper.

For diagonal shift of copy paper, skew correction is made. For horizontal shift, the punch unit is shifted accordingly.

1) Copy paper is discharged from the machine.

Machine paper exit roller

2) The finisher inlet sensor detects copy paper.

Finisher inlet roller

5) The horizontal resist sensor detects horizontal shift of copy

paper.

Horizontal resist sensor

6) The punch unit is moved by the detected quantity of horizontal

shift to complete punching.

Inlet sensor

3) Copy paper is pushed against the finisher inlet roller to correct

diagonal skew.

7) The punch unit returns to the home position.

4) Diagonal skew is corrected and copy paper is transported.

11. Punch dust collection mechanism

Punch dust made by punching is moved to the front side of the machine by the transport belt to fall into the punch dust holder.

Transport beltTransport belt

Punch dust collection unit

Punch dust collection unit

The height sensor of the punch dust collection unit detects the punch dust height in the punch dust holder, detecting full.

MX-FNX6 MECHANISM 3 – 10

Page 18

Height sensorHeight sensor

MX-FNX6 MECHANISM 3 – 11

Page 19

When this gear is pulled toward you,

the drive is released.

Tray assembly

MX-FNX6

[4] REPLACEMENT AND ADJUSTMENT

Service Manual

1. External cover replacement

Upper cover

Upper cover center

Rear cover

Paper exit

port cover

Blind cover

Left side cover

1) Open the front door, remove the screw (1 screw), and remove

the upper cover center.

Point:

When assembling, open the front cover of the finisher and check to

confirm the rib can be fixed with a screw.

2) Remove the upper cover. (2 screws)

3) Remove the front door shaft bracket, and remove the front

door. (1 screw)

4) Remove the left side cover. (2 screws)

5) Remove the blind cover.

6) Remove the paper exit port cover. (2 screws)

7) Remove the rear cover. (2 screws)

Front door

shaft bracket

Front cover

2. Tray assembly, left cover replacement

1) Remove the rear cover. (Refer to the previous page.)

2) Remove the tray assembly. (1 screw)

Point:

When removing the tray assembly, since the top position is difficult to

remove, hold the tray assembly with your hand and pull the gear in the

ratchet section (1) to release the drive, and the tray can be moved down.

(2)

3) Remove the tray cover. (1 screw for each)

4) Remove the tray bracket. (4 screws, 1 step screw)

Tray cover

Upper cover center

Rib

Tray bracket

Tray assembly

5) Remove the end fence. (3 screws)

End fence

MX-FNX6 REPLACEMENT AND ADJUSTMENT 4 – 1

Page 20

3. Shift roller replacement

1) Open the front door, and pull out the center binding staple unit.

2) Remove the snap fit, and remove the shift roller and the drive belt.

Shift roller

Shift roller

Snap fit

Center binding staple

4. Rollers

A. DRAG ROLLER

1) Above the shift tray, pull the roller mount [A] out.

2) Remove the rollers [B] and [C] ( x 1 each)

[A]

[B]

[C]

5. Proof tray paper exit sensor replacement

1) Remove the upper cover.

2) Remove the proof tray paper exit sensor bracket. (1 screw)

3) Remove the proof tray paper exit sensor from the bracket.

Proof tray paper exit

sensor bracket

Proof tray paper

exit sensor

6. Shift tray paper surface sensor upper/ lower replacement

1) Remove the upper cover.

2) Remove the shift tray paper surface sensor bracket. (1 screw)

3) Remove the shift tray paper surface sensor upper/lower from

the bracket. (1 connector for each)

MX-FNX6 REPLACEMENT AND ADJUSTMENT 4 – 2

Page 21

Shift tray paper

surface sensor bracket

Shift tray paper

surface sensor upper

Shift tray paper

surface sensor lower

MX-FNX6 REPLACEMENT AND ADJUSTMENT 4 – 3

Page 22

7. Shift tray paper exit sensor, proof tray

Proof tray paper surface sensor

Paper surface sensor bracket

Guide plate

paper surface sensor replacement

1) Remove the rear cover, the upper cover, and the front door.

2) Remove the inner cover. (2 screws)

Inner cover

3) Remove the spring. (Snap fit, 1 position)

4) Remove the paper exit guide plate. (Connector 1 position,

C-ring 1 position)

5) Remove the paper exit sensor from the paper exit guide plate.

Shift tray paper exit sensor

6) Remove the guide plate.

7) Remove the paper surface sensor bracket from the guide

plate. (1 screw)

8) Remove the proof tray paper surface sensor from the bracket.

8. Finisher inlet sensor replacement

1) Remove the finisher inlet sensor bracket. (1 screw)

2) Remove the finisher inlet sensor from the bracket.

Connector

Spring

Snap fit

Paper exit

guide plate

C-ring

Finisher inlet sensor bracketFinisher inlet sensor bracket

MX-FNX6 REPLACEMENT AND ADJUSTMENT 4 – 4

Page 23

9. Staple paper exit sensor replacement

1) Remove the staple paper exit sensor bracket. (1 screw)

2) Remove the staple paper exit sensor from the bracket.

Staple paper exit sensor bracket

Staple paper

exit sensor

10. Punch unit replacement

Since the punch unit is adjusted in the factory before shipping,

there is no need to adjust it in the market. To replace the punch

section, replace the whole punch unit.

Point:

Since the punch unit is adjusted precisely before shipping from the factory,

do not disassemble it.

When removing or replacing the unit, do not drop or traumatize the unit as

it may go out of adjustment.

1) Remove the rear cover.

2) Remove the horizontal resist sensor unit.

(2 connectors, 2 screws)

Horizontal resist sensor

3) Remove the punch unit slide motor bracket.

(1 connector, 2 screws)

Punch unit slide

4) Pull and remove the punch unit. (2 connectors)

Punch unit

MX-FNX6 REPLACEMENT AND ADJUSTMENT 4 – 5

Page 24

11. Center folding horizontal shift adjustment (MX-FNX7 only)

* If there is virtually no shift, this adjustment is not required.

(Basically no need to perform this adjustment in the market.)

1) Turn on the main power switch.

2) Open the front door of the finisher, and pull out the center bind-

ing staple unit.

3) Open the open/close guide plate.

4) Loosen the adjustment screw, and retighten to stop position.

* Stop tightening the screw when it stops.

(Do not use an excessive force.)

5) Loosen the fixing screw.

MX-FNX6 REPLACEMENT AND ADJUSTMENT 4 – 6

Page 25

6) Lift the adjustment screw slightly upward, and let is fall by its

own weight.

Fixing screw

Adjustment

screw

16) Turn the adjustment screw according to the measured shift

quantity in the ratio of 0.1mm/1 scale. If the shift quantity is [+],

turn it clockwise. If the shift quantity is [–], turn it counterclockwise.

Fixing screw

Adjustment screw

Center binding

staple unit

Open/close guide plate

7) Set the center binding staple unit, and close the front door.

8) Set A3 paper (any paper other than black background) on the

DSPF.

9) Set the staple position to the center binding.

(Do not select the image edit.)

10) Press the copy start button, and perform center binding of one

set only.

11) Draw an arrow mark on the paper discharged to the center

binding tray.

12) Align the folded sides as shown below, and fold paper so that

the arrow comes inside.

* Shift the upper side toward you by 2mm so that the paper

edge can be seen.

13) Fix the aligned folded sides, and measure the shift quantity of

the top paper from the bottom paper.

Open/close

guide plate

Center binding

staple unit

17) Lift the adjustment screw upward, and let it fall by its own

weight.

18) Securely tighten the fixing screw which was loosened.

12. Center folding vertical shift

adjustment (MX-FNX7 only)

* If there is virtually no shift, this adjustment is not required.

(Basically no need to perform this adjustment in the market.)

1) Set A3 paper (any paper other than black background) to the

DSPF.

2) Set the staple position to the center binding.

(Do not select the image edit.)

3) Press the copy start button, and perform center binding of one

set only.

4) Draw an arrow mark on the paper discharged to the center

binding tray.

5) Measure the shift quantity of the upper edge from the lower

edge at the center of the rear edge as shown below.

Shift

quantity

2

m

m

* Right side in the figure is [+] side, and the left side [–].

14) Open the front door of the finisher, and pull out the center binding staple unit.

15) Open the open/close guide plate.

MX-FNX6 REPLACEMENT AND ADJUSTMENT 4 – 7

* The right side on the figure is [–], and the left side is [+].

Page 26

6) Turn on the main power switch.

7) Press [SYSTEM SETTING] key on the operation panel and log

in as the administrator. (Password: admin/default)

8) Press [Administrator Adjustment] key and select [Option

Adjustment] on the administrator adjustment menu.

11) After execution of the adjustment, repeat the procedures of 1) -

5). If there is no problem, terminate the adjustment.

If any more adjustment is required, repeat the procedures of 6)

- 10).

13. Center folding unit replacement and center binding stapler replacement and adjustment (MX-FNX7 only)

1) Remove the rear cover, and disconnect the connector of the

center binding staple unit.

(Connector 6 positions, earth wire 1 position)

2) Open the front door, and pull out the center binding staple unit.

3) Lift and remove the center binding staple unit from the finisher.

(4 screws)

9) Select [Finisher] from the option adjustment menu.

10) Adjust the center folding position. (Select the paper size measured in the procedure 5.)

Connector

4) Hold the unit and remove the center folding unit. (Connector 6

positions, 4 screws)

5) Install a new center folding unit.

(Connector 6 positions, 4 screws)

Center folding unit

MX-FNX6 REPLACEMENT AND ADJUSTMENT 4 – 8

Page 27

6) Fit the rank seal on the back of the new folding unit, and set

the DIP switch of the main PWB again.

8) Remove the stay. (4 screws)

9) Remove the plate. (4 screws)

Main PWB DIP switch

<Center folding stapler replacement and adjustment

(MX-FNX7 only)>

* If there is a horizontal shift or a vertical shift in center folding,

perform the center folding shift adjustment in advance.

7) Remove the guide plate.

of the folding unit

Rank seal on the back

Plate

Stay

Disassembly

10) Remove the cover (2 screws)

Guide plate

CoverCover

11) Remove the bracket. (Connector 2 positions, 4 screws)

12) Remove the stapler: upper from the bracket.

(4 screws for each)

13) Remove the stapler: lower.

(Connector 1 position for each, 2 screws)

Replacement and adjustment

14) Install a new stapler: upper to the bracket (4 screws for each),

and set the jig included in the package to the back side.

15) Install the bracket. (Connector 2 positions, 4 screws)

16) Install the new stapler: lower, and fix it temporarily.

(Connector 1 position for each, 4 screws)

17) Turn the staple motor gear with fingers to extend the stapler

hammer to the maximum.

18) With the staple hammer stored in the jig hole and the stapler:

upper pushed in, tighten two fixing screws of the stapler: lower.

MX-FNX6 REPLACEMENT AND ADJUSTMENT 4 – 9

Page 28

19) Turn the staple motor gear to move down the hammer, and

remove the jig.

Staple motor gear

Staple hammer

Jig

Stapler: lower

Bracket

Stapler: upper

Back side of Stapler:

upper

14. Horizontal resist adjustment

* If there is virtually no shift, this adjustment is not required. (Basically this adjustment is not performed in the market.)

When executing the horizontal resist adjustment, remove and shift the screw which fixes the horizontal resist reference bracket and turn the reference bracket 90 degrees. Then the whole connection bracket can be slid horizontally.

Integrated-type connection bracket

Main unit side

Slide

* There is a marking of 2mm pitch in the fixing section on the left upper side of the connection bracket. The bracket can be shifted by max.

±5mm.

Loosen the screw and shift

Rotate the bracket

90 degrees.

Normal position of the

horizontal resist reference bracket

a. When paper is on the front side:

Slide the connection bracket to the front side, and shift the center binding unit to the front side.

b. When paper is on the back side:

Slide the connection bracket to the back side, and shift the center binding unit to the back side.

MX-FNX6 REPLACEMENT AND ADJUSTMENT 4 – 10

Page 29

MX-FNX6

[5] ELECTRICAL COMPONENTS

1. Block diagram

SW1: Door SW (Interlock switch) Only the machines with center binding

24 V

Main unit

M1: Inlet port M

M2: Upper transport M

M3: Lower

transport M

M4: Paper exit M

M10: Return roller

oscillation M

M18: Shift M

M19: Paper exit

guide plate M

SOL1: Lower branch SOL

SOL2: Upper

branch SOL

M1

(STP)

M3

(STP)

M10

(STP)

M19

(STP)

SOL

M2

(STP)

M4

(STP)

M18

(STP)

SOL

1

2

FU 1

250V

T4A L

FU 2

250V

T3.15A L

Reg.

5V

Service Manual

FU 3

250V T4A L

MX-FNX6

center

binding

PWB

M11

(STP)

M16

(STP)

M22

(DC)

SOL

5

S26

S28

S30

S32

M8

M8: Drive roller oscillation M

(STP)

M11: Folding plate M

M12

M12: Folding roller M

(STP)

M16: Rear edge fence M

M17

M17: Bundle branch open/close M

(STP)

M22: Center binding stapler drive M:

M23

(DC)

Front

M23: Center binding stapler drive M:

Rear

SOL5: Center binding holding SOL

S25: Return roller HP sensor

S25

S26: Reach sensor

S27: Bundle branch open/close

S27

HP sensor

S28: Rear edge fence HP sensor

S29

S29: Folding plate HP sensor

S30: Folding HP sensor

S31

S31: Folding pass sensor

S32: Lead edge sensor

S1: Entry port

sensor

S1

S2: Stapler paper exit sensor

S3: Horizontal

resist sensor

S3

S4: Punch dust full sensor

S5: Shift HP sensor

S5

S6: Paper exit sensor

Paper exit guide

S7:

plate HP sensor

S8: Paper surface sensor:

Staple

S9: Paper surface

sensor: Shift

S10: Proof tray paper exit

sensor

S11: Proof tray full

sensor

S7

S9

S11

S12: Rear edge sensor: Shift

Oscillation

S13:

return roller sensor

S14:

Staple tray paper

presence sensor

S15: Jogger HP

sensor

S13

S15

S16: Discharge HP sensor

S17: Stapler shift

HP sensor

S18: Stapler diagonal HP

sensor

Full sensor:

S19:

Center binding YES

S20: Full sensor: Center

binding NO

S17

S19

S2

S4

S6

S8

S10

S12

S14

S16

S18

S20

MX-FNX6

Main PWB

Punch PWB

M5

(STP)

M13

(STP)

M15

(STP)

M20

(DC)

SOL

4

M5: Discharge M

M6

M6: Stapler shift M

(STP)

M13: Stapler diagonal M

M14

M14: Tapping roller drive M

(STP)

M15: Jogger M

M21

M21: Tray lift M

(DC)

M20: Stapler drive M

SOL

SOL3: Tapping SOL

3

SOL4: Rear edge holding SOL

S34

M9

(STP)

S21

S23

S33

S33: Saddle section full sensor:

Rear

S34: Saddle section full sensor:

Front

M7

M7: Horizontal resist shift M

(STP)

M9: Punch shift M

M24

M24: Punch drive M

(DC)

S21: Punch shift HP sensor

S22: Horizontal resist detection HP

S22

sensor

S23: Punch HP sensor

S24: Punch RPS sensor

S24

(Remark)

1: STP: Stepping motor

2: DC: DC brush motor

MX-FNX6 ELECTRICAL COMPONENTS 5 – 1

Page 30

2. Actual wiring chart

b

b

o

Shift HP sensor

Paper exit sensor

Paper exit guideplate

HP sensor

Paper surface sensor:

Staple

Paper surface sensor:

Shift

Proof tray paperexit

sensor

Proof tray fullsensor

Rear edge sensor:Shift

Oscillation return roller

sensor

Staple tray paper

presence sensor

Jogger HP sensor

Discharge HP sensor

Stapler shift HPsensor

Stapler diagonal HP

sensor

Stapler: EH-530R

AJ011015

(sensor section)

Full sensor: Center

binding YES

Full sensor: Center

binding NO

Saddle section full: Front

6. Connection of B7005302/CN660, 661 is shown in Fig. 1 when the punch unit is installed, or in Fig. 2 when it isnot installed.

5. Punch unit (option): C31310 (DOM2 hole), C31317 (NA2/3 holes), C31327 (EU2/4 holes), C31328 (NE4 hole).

4. For the center binding unit/whole circuit diagram, refer to C3095910.

3. The connector is of pressure type unless otherwise specified.

2. The electric cable is UL10368 unless otherwise specified. The electric cable size is AWG26 unless otherwise specified. The

electric cable color is (H) unless otherwise specified.

(Note) 1. Thepart number suffix ofa component part is omitted.

AMP CT 3P

Shift HP

AMP CT 3P

Paper exit sensor

AMP CT 3P

Paper exit guide: HP

AMP CT 3P Blue

Paper surface detection: Staple

AMP CT 3P

Paper surface detection: Shift

AMP CT 3P

Proof tray paper exit

MOLEX Mi II 3P Pressurebonding

Proof tray full

AMP CT 3P

Rear edge detection: Shift

AMP CT 3P

Oscillation return roller: HP

AMP CT 3P

Staple tray (Paper presence detection)

AMP CT 3P

Jogger HP

AMP CT 3P

Discharge HP

AMP CT 3P

Stapler shift HP

AMP CT 3P

Stapler diagonal HP

1 rotation: Edge binding

Staple set: Edge binding

Edge binding staple presence/empty

AMP CT 3P

Shift tray full: Center bindingYES

AMP CT 3P

Shift tray full: Center bindingNO

Punch unit

(Note 5)

Punch shift HPsensor

Punch shift

monotr

Horizontal resist

shift motor

Horizontal resist

detection HP sensor

Punch HP

sensor

Punch RPS

sensor

Punch

drive motor

AMPCT5PBlue

AMP CT 3P Blue

Paper exit sensor Paperexit sensor

AMP CT 3P

Staple tray (Paper presence detection)

AMP CT 3P

Stapler shift HP Stapler shiftHP

AMP CT + Interface 8PBlue AMP CT 8PBlue

Stapler diagonal HP Stapler diagonal HP

1 rotation: Edge binding

Staple set: Edge binding

Edge binding staple presence/empty

AMP CT + Interface 3P

Staple tray (Paper presence detection)

AMP CT + Interface 3P

1 rotation: Edge binding

Staple set: Edge binding

Edge binding staple presence/empty

AMP CT 3P

Punch shift: HP

5V (Punch)

AMPCT7PPressurebonding

24VSW1 (Punch)

24VSW1 (Punch)

Punch shift M_A

Punch shift M_-A

Punch shift M_B

Punch shift M_-B

AMP CT 7P Pressure bonding

24VSW1 (Punch)

24VSW1 (Punch)

Horizontal resist shift M_A

Horizontal resist shift M_-A

Horizontal resist shift M_B

Horizontal resist shift M_-B

AMP CT 3P

Horizontal resist HP

5V (Punch)

AMP CT 3P

Punch HP

5V (Punch)

AMP CT 3P

Punch control CLK

5V (Punch)

AMP CT + Interface 3PBlue

AMP CT + Interface 7P

24VSW1 (Punch)

24VSW1 (Punch)

Punch shift M_A

Punch shift M_-A

Punch shift M_B

Punch shift M_-B

AMP CT + Interface 7P

24VSW1 (Punch)

24VSW1 (Punch)

Horizontal resist shift M_A

Horizontal resist shift M_-A

Horizontal resist shift M_B

Horizontal resist shift M_-B

Paper exit sensor

Paper exit guide: HP

Paper surface detection: Staple

Paper surface detection: Shift

AMP CT 13P

AMPCT4PBlue

Proof tray paper exit

AMP CT 3P Pressure bonding

Proof tray full

AMP CT 6P

Rear edge detection: Shift

Oscillation return roller: HP

AMP Mini CT 16P AMP Mini CT 16P

(Unit connector detection)

Staple tray (Paper presence detection)

Jogger HP

Discharge HP

AMP Mini CT 14P AMP Mini CT 14P

Stapler shift HP

Stapler diagonal HP

1 rotation: Edge binding

Staple set: Edge binding

Edge binding staple presence/empty

AMPMiniCT12P

Punch shift: HP

5V (Punch)

24VSW1 (Punch)

24VSW1 (Punch)

Punch shift M_A

Punch shift M_-A

Punch shift M_B

Punch shift M_-B

AMP Mini CT 13P

24VSW1 (Punch)

24VSW1 (Punch)

Horizontal resist shift M_A

Horizontal resist shift M_-A

Horizontal resist shift M_B

Horizontal resist shift M_-B

Horizontal resist HP

5V (Punch)

AMP Mini CT 6P

Punch HP

5V (Punch)

Punch control CLK

5V (Punch)

AMP CT 2P

Pressure bonding

Punch M+

Punch M-

Paper exit sensor

Paper exit guide: HP

Paper surface detection: Staple

Paper surface detection: Shift

AMP CT + Interface 13P

AMP CT + Interface 4PBlue

Proof tray paper exit

AMP CT + Interface 3P

Proof tray full

AMP CT + Interface 6P

Rear edge detection: Shift

Oscillation return roller: HP

Unit connector detection

Staple tray (Paper presence detection)

Jogger HP

Discharge HP

Stapler shift HP

Stapler diagonal HP

1 rotation: Edge binding

Staple set: Edge binding

Edgebindingstaplepresence/empty

Punch drive M_IN1

Punch drive M_IN2

Punch shift M ON

Punch shift M CW

Punch shift CLK

Punch horizontal resist ON

Punch horizontal resist CW

Horizontal resist detection CLK

Horizontal resist HP

Punch shift: HP

Punch HP

Punch control CLK

Punch unit detection

Punch SW2

Punch SW1

24VSW1 (Punch)

24VSW1 (Punch)

5V (Punch)

Punch control

PWB

AMP

Mini CT 17P

MOLEX Mi II 6P

Pressure bonding

AMP Mini CT 16P

Shift HP

Paper exit sensor

Paper exit guide: HP

Paper surface detection: Staple

Paper surface detection: Shift

AMP Mini CT 13P

Proof tray paper exit

Proof tray full

Rear edge detection: Shift

Oscillation return roller: HP

AMP Mini CT 14P

Unit connector detection

Staple tray (Pape r presence detectio n)

Jogger HP

Discharge HP

AMP Mini CT 11P

Stapler shift HP

Stapler diagonal HP

1 rotation: Edge binding

Staple set: Edge binding

Edge binding stap le presence/empty

AMP Mini CT 11P

Shift tray full: Centerbinding YES

Shift tray full: Center bindingNO

AMP

Mini CT 17P

Punch drive M_IN1

Punch drive M_IN2

Punch shift M ON

Punch shift M CW

Punch shift CLK

Punch horizontal resist ON

Punch horizontal resist CW

Horizontal resist detection CLK

Horizontal resist HP

Punch shift: HP

Punch HP

Punch control CLK

Punch unit detection

Punch SW2

Punch SW1

MOLEX Mi II 6P

Pressure bonding

24VSW1 (Punch)

24VSW1 (Punch)

5V (Punch)

Inletportsensor

Staple paper exit

Horizontal resist detection sensor

Punch dust full detection

MOLEX Mi II 13P

Pressure bonding

MOLEX

Mi II 9P Red

MOLEX

Mi II 8P Red

I/F: Main unit

JST EL 15P

Pressure bonding

MOLEX Mi II 3P Pressure

Horizontal resist detection sensor

AMP CT 4P Pressure

Punch dust full detection

MOLEXMiII3PPressure

Horizontal resist detection sensor

AMP CT 4P Pressure

Punch dust full detection

Door SW

Center

binding

unit

(Note 4)

STP contr

PWB

MO

MX-FNX6 ELECTRICAL COMPONENTS 5 – 2

Page 31

AMP CT 3P Pressure bonding

AMP CT 3P Pressure bonding

MOLEX Mi II 3P Pressurebonding

Horizontal resist detection sensor

AMP CT 4P Pressure bonding AMP CT+ Interface4P

Punch dust full detection

MOLEXMiII3PPressurebonding

Horizontal resist detection sensor Horizontal resist detection sensor

AMP CT 4P Pressure bonding

Punch dust full detection Punch dustfull detection

MOLEX 51067 4P Pressure bonding

Door SW

Center

binding

unit

(Note 4)

STP control

PWB

Inletportsensor

Staple paper exit

MOLEX Mi II + Interface3P

Horizontal resist detection sensor

Punch dust full detection

MOLEX Mi II + Interface3P Pressurebonding

AMP CT + Interface 4PPressure bonding

Fig. 2

(Note 6)

MOLEX 51114 4P Pressure bonding

T1 F.G.

Round terminal: M3

JST PS #250 Pressure bonding

JST PS #250 Pressure bonding

MOLEX

Mi II 8P Red Pressure bonding

24VSW2 (Center binding)

24VSW2 (Center binding)

24VSW2 (Center binding)

5V (Center binding)

AMP 353294 40P

AMP Mini CT 20P Blue

Center binding holding SOL

Folding roller CLK

Rear edge fence/Folding plate CLK

Bundle branch open/close M CW

Bundle branch open/close M ON

Rear edge fence M CW

Rear edge fence M ON

Rear edge fence M current select

Drive roller oscillation M CW

Drive roller oscillation M ON

Center binding front: IN1

Center binding front: IN2

Center binding rear: IN1

Center binding rear: IN2

Folding plate drive M CW

Folding plate drive M ON

Folding roller M CW

Folding roller M ON

Folding roller M current select

AMP Mini CT 20P

Saddle section full sensor: Rear

Saddle section full sensor: Front

Reach sensor

Rear edge fence: HP

Folding plate HP

Folding cam HP

Folding pass

Bundle branch open/close: HP

Drive roller HP

1 rotation: Center binding: Front

Staple set: Center binding: Front

Center binding staple presence: Front

1 rotation: Center binding: Rear

Staple set: Center binding:

Rear

Center binding staple presence: Rear

Center binding PWB set detection

Lead edge sensor

Drive roller oscillation CLK

Center binding holdi ng SOL

Bundle branch open/close CLK

Inlet port sensor

Stapler paper exitsensor

Punch PWB: Sensor

AMP CT 14P

AMP CT 14P Blue

AMP CT 7P

AMP CT 14P

AMP CT 9P

Pressure bonding

AMP CT 15P

AMP CT 7P

AMP CT 12P

Pressure bonding

Round terminal: M4

T2 F.G.

AMP CT 8P

Pressure bonding

AMPCT7PBlue

MOLEX

Mini Mi II 3P

AMP CT + Interface 4P Pressure bonding

MOLEXMiniMiII3P

Horizontal resist detection sensor Horizontal resist detection sensor Horizontal resist detection sensor

Punch PWB: Sensor

MOLEX

Mi II 8P Pressure bonding

AMP 353294 40P

AMP Mini CT 20P Blue

MOLEX Mi II

8P Pressure bonding

MOLEX 51067 3P

Pressure bonding (3.5mm)

MOLEX 51067 2P

Pressure bonding

24VSW2 (Center binding)

24VSW2 (Center binding)

24VSW2 (Center binding)

5V (Center binding)

Center binding holding SOL

Folding roller CLK

Rear edge fence/Folding plate CLK

Bundle branch open/close M CW

Bundle branch open/close M ON

Rear edge fence M CW

Rear edge fence M ON

Rear edge fence M current select

Drive roller oscillatio n M CW

Drive roller oscillatio n M ON

Center binding front: IN1

Center binding front: IN2

Center binding rear: IN1

Center binding rear: IN2

Folding plate drive M CW

Folding plate drive M ON

Folding roller M CW

Folding roller M ON

Folding roller M current select

AMP Mini CT 20P

Saddle section full sensor: Rear

Saddle section full sensor: Front

Reach sensor

Rear edge fence: HP

Folding plate HP

Folding cam HP

Folding pass

Bundle branch open/close: HP

Drive roller HP

1 rotation: Center binding: Front

Staple set: Center binding: Front

Center binding staple presence: Front

1 rotation: Center binding: Rear

Staple set: Center binding:

Center binding staple presence: Rear

Center binding PWB set detection

Lead edge sensor

Drive roller oscillation CLK

Center binding holding SOL

Bundle branch open/close CLK

Punch: Sensor: Interface:

Total construction

Fig. 1

(Note 6)

MOLEX 53265

2P (7mm)

MOLEX 53258

2P

Rear

Inlet port M COM

Inlet port M COM

Inlet port M A

Inlet port M A

Inlet port M B

Inlet port M B

Lower transport M COM

Lower transport M COM

Lower transport M A

Lower transport M A

Lower transport M B

Lower transport M B

Upper transport M COM

Upper transport M COM

Upper transport M A

Upper transport M A

Upper transport M B

Upper transport M B

Shift M COM

Shift M COM

Shift M A

Shift M A

Shift M B

Shift M B

Tapping roller drive M COM

Tapping roller drive M COM

Tapping roller drive M A

Tapping roller drive M A

Tapping roller drive M B

Tapping roller drive M B

Paper exit M COM

Paper exit M COM

Paper exit M A

Paper exit M A

Paper exit M B

Paper exit M B

Paper exit guide plate M COM

Paper exit guide plate M COM

Paper exit guide plate M A

Paper exit guide plate M A

Paper exit guide plate M B

Paper exit guide plate M B

Lower branch SOL

Upper branch SOL

Rear edge holding SOL

Tapping SOL

Jogger M COM

Jogger M COM

Jogger M A

Jogger M A

Jogger M B

Jogger M B

Discharge M COM

Discharge M COM

Discharge M A

Discharge M A

Discharge M B

Discharge M B

StaplershiftMCOM

StaplershiftMCOM

Stapler shift M A

Stapler shift M A

Stapler shift M B

Stapler shift M B

Stapler diagonal M COM

Stapler diagonal M COM

Stapler diagonal M A

Stapler diagonal M A

Stapler diagonal M B

Stapler diagonal M B

Staple M+

Staple M+

Staple MStaple M-

Tray lift M+

Tray lift M-

Tray upper limit SW

Tray upper limit SW

Return roller oscillation M COM

Return roller oscillation M COM

Return roller oscillation M A

Return roller oscillation M A

Return roller oscillation M B

Return roller oscillation M B

AMP CT + Interface 7P

Paper exit guide pla te M COM

Paper exit guide pla te M COM

Paper exit guide plate M A

Paper exit guide plate M A

Paper exit guide plate M B

Paper exit guide plate M B

AMP CT 12P

Pressure bonding

Stapler diagonal M COM

Stapler diagonal M COM

Stapler diagonal M A

Stapler diagonal M A

Stapler diagonal M B

Stapler diagonal M B

Staple M+

Staple M+

Staple MStaple M-

Tray upper limit SW

Tray upper limit SW

Return roller oscillat ion M COM

Return roller oscillat ion M COM

Return roller oscillation M A

Return roller oscillation M A

Return roller oscillation M B

Return roller oscillation M B

MOLEX Mi II 3P

AMP CT 3P

Punch dust full detection

AMP CT 7P

Paper exit guide plate M COM

Paper exit guide plate M COM

Paper exit guide plate M A

Paper exit guide plate M A

Paper exit guide plate M B

Paper exit guide plate M B

AMP CT + Interface

12P Pressure bonding

Stapler diagonal M COM

Stapler diagonal M COM

Stapler diagonal M A

Stapler diagonal M A

Stapler diagonal M B

Stapler diagonal M B

Staple M+

Staple M+

Staple M-

Staple M-

Round terminal: M4

T3 F.G.

AMP CT 4P Pressure bonding