Page 1

SERVICE MANUAL

CODE: 00ZMXFNX2/S1E

DIGITAL FULL COLOR

MULTIFUNCTIONAL SYSTEM OPTION

SADDLE STITCH FINISHER

PUNCH MODULE

PAPER PASS UNIT

MX-FNX2

AR-PN1A/B/C/D

MODEL

[1] PRODUCT OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2] SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

[3] UNPACKING AND INSTALLATION

* For how to unpacking and installation, refer to the installation manual (00ZMX2700/I1E).

[4] EXTERNAL VIEWS AND INTERNAL STRUCTURES . . . . . . . . . . 4-1

[5] OPERATIONAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[6] DISASSEMBLY AND ASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[7] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[8] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[9] SELF DIAG MESSAGE AND TROUBLE CODE. . . . . . . . . . . . . . . 9-1

MX-RBX1

CONTENTS

[10] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

PARTS GUIDE

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

CONTENTS

[1] PRODUCT OUTLINE

1. Product outline. . . . . . . . . . . . . . . . . . . . .1-1

2. Configuration . . . . . . . . . . . . . . . . . . . . . .1-1

[2] SPECIFICATIONS

1. MX-FNX2 . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2. AR-PN1A/B/C/D. . . . . . . . . . . . . . . . . . . .2-2

3. MX-RBX1. . . . . . . . . . . . . . . . . . . . . . . . .2-2

[3] UNPACKING AND INSTALLATION

* For how to unpacking and installation, refer to the

installation manual (00ZMX2700/I1E).

[4] EXTERNAL VIEWS AND INTERNAL

STRUCTURES

1. Part names and functions . . . . . . . . . . . .4-1

[5] OPERATIONAL DESCRIPTION

1. Basic operations . . . . . . . . . . . . . . . . . . .5-1

2. Feed/Drive System . . . . . . . . . . . . . . . . .5-4

3. Stapling Operation . . . . . . . . . . . . . . . . . .5-7

4. Delivery Tray Operation. . . . . . . . . . . . .5-10

5. Saddle Unit . . . . . . . . . . . . . . . . . . . . . .5-10

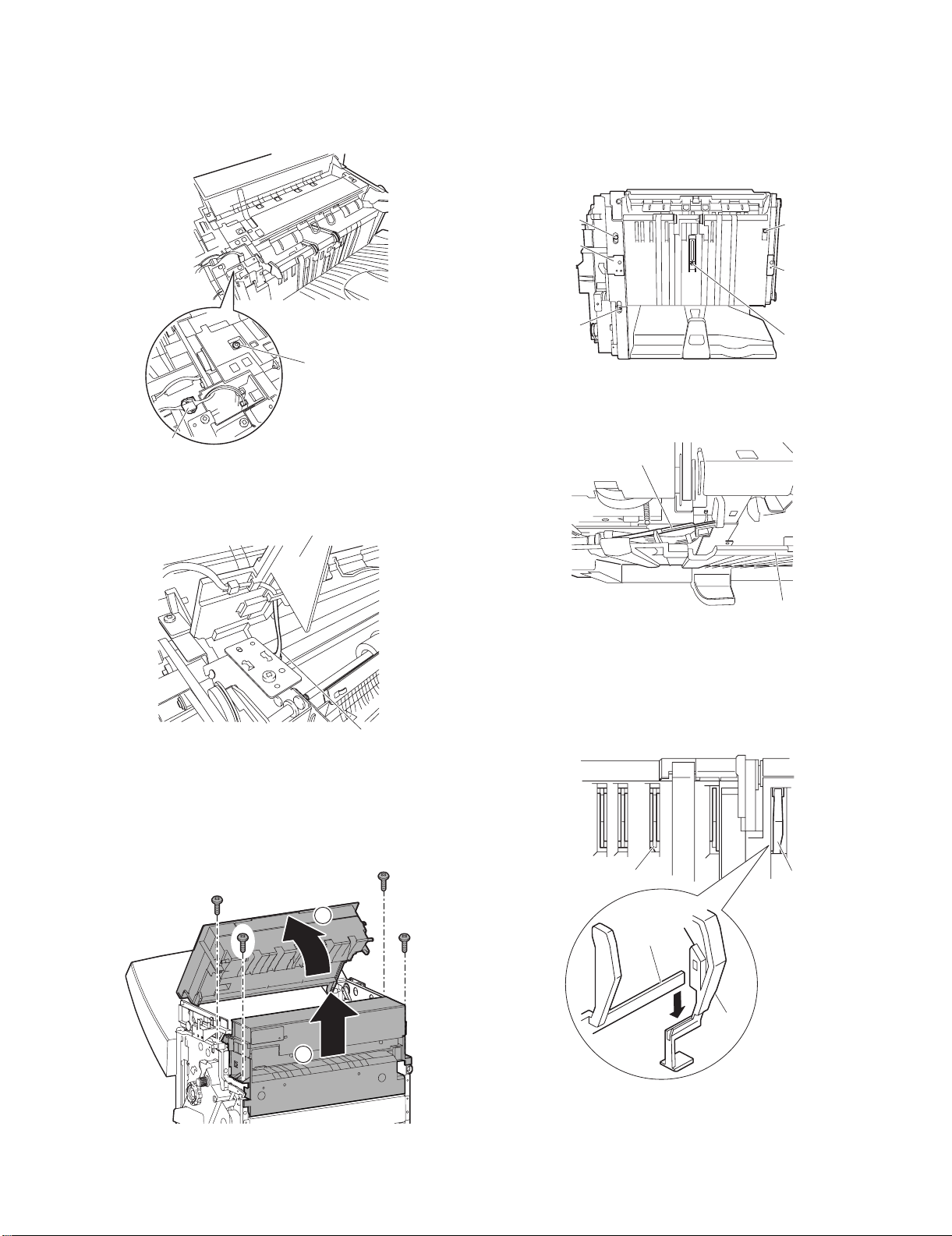

[6] DISASSEMBLY AND ASSEMBLY

1. Saddle stitch finiser (MX-FNX2) . . . . . . 6-1

2. Paper Transport Section (MX-RBX1) . . 6-11

3. Punch Unit (AR-PN1A/B/C/D) . . . . . . 6-14

[7] MAINTENANCE

1. Maintenance System Table . . . . . . . . . 7-1

[8] ADJUSTMENTS

1. Finisher/saddle unit . . . . . . . . . . . . . . . 8-1

2. Punch unit (option) . . . . . . . . . . . . . . . . 8-1

[9] SELF DIAG MESSAGE AND TROUBLE CODE

1. Self diag message . . . . . . . . . . . . . . . . 9-1

2. Trouble code . . . . . . . . . . . . . . . . . . . . 9-1

[10] ELECTRICAL SECTION

1. Block diagram. . . . . . . . . . . . . . . . . . . 10-1

2. Wiring diagram . . . . . . . . . . . . . . . . . . 10-3

3. LEDs and Check Pins by PCB . . . . . . 10-8

PARTS GUIDE

Page 3

âºíuÇ´

[1] PRODUCT OUTLINE

Service Manual

1. Product outline

This unit is installed to the following machines to perform the after-process of output paper from a copier, or a fax machine. The output paper is

passed to the saddle finisher by the interface unit (MX-RBX1). Each sheet is discharged one by one by the offset function.

1) Employment of the through-type stapler: Employment of the through-type stapler allows to make saddle stitch by one stapler.

2) 3 kinds of auto staple functions:

There are 3 staple positions available. (One position in the front, one position at the back, 2 positions at the center)

3) Saddle stitch function: Up to 10 sheets of paper can be stapled at the center and folded into two and discharged.

4) Punch function (Option):

2

By installation of a puncher unit, paper can be punched to make holes for a binder. (Applicable for 64 – 128g/m

. OHP films cannot be

used.)

Applicable models MX-2300N/2700N/2300G/2700G

The finisher requires staple cartridge as a consumable part. (Staple cartridge (About 5000 staples x 3) AR-SC2)

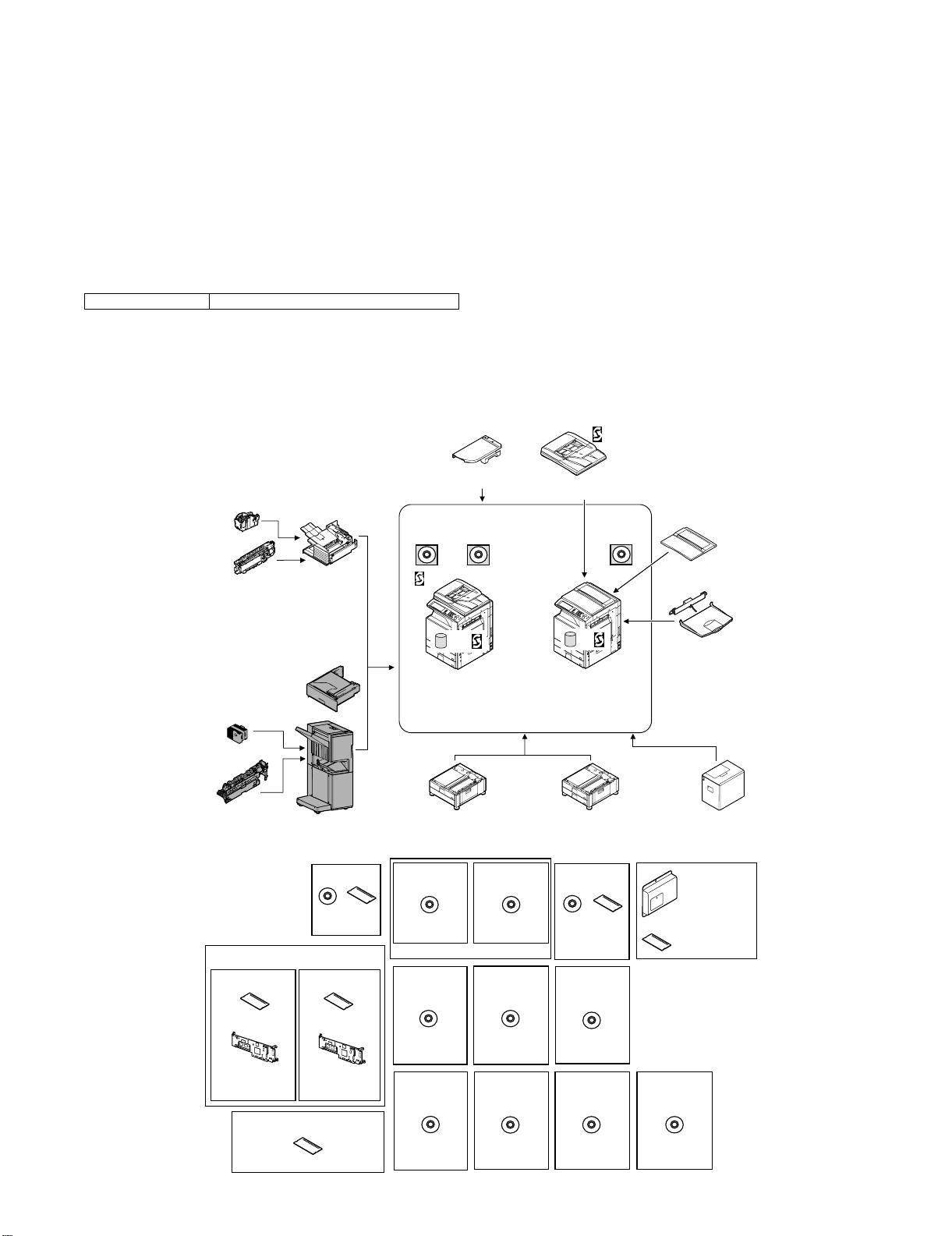

2. Configuration

1) When installing this unit, the paper feed desk (MX-DEX1/DEX2) and the interface unit (MX-RBX1) must be installed together.

2) This unit cannot be installed with the finisher (MX-FNX1) simultaneously.

Staple cartridge

(Approx. 5000 x 3)

(MX-SCX1)

Punch module

●

2-hole (MX-PNX1A)

●

3-hole (MX-PNX1B)

●

4-hole (MX-PNX1C)

●

4-hole (broad space)

(MX-PNX1D)

Staple cartridge

(Approx. 5000 x 3)

(AR-SC2)

Punch module

●

2-hole (AR-PN1A)

●

3-hole (AR-PN1B)

●

4-hole (AR-PN1C)

●

4-hole (broad space)

(AR-PN1D)

(Including document control)

CC authentication

version

Security

ROM

For document

control PWB

(MX-FRX1)

Finisher

(MX-FNX1)

Paper pass unit

(MX-RBX1)

Saddle stitch finisher

(MX-FNX2)

Barcode font kit

CD

ROM

(AR-PF1)

Data security kit

Commercial

version

Security

ROM

For document

control PWB

(MX-FRX1U)

256MB expansion memory board

(MX-SMX1)

(For MX-2300G/2700G)

Device Tray with

USB Hub (MX-RKX1)

PCL5c/PCL6

driver

RSPF

HDD

Copier/Printer (PCL)

/Scanner model

(MX-2300N)

(MX-2700N)

Stand/1x500 sheet

paper drawer

(MX-DEX1)

Printer expansion

kit (PCL)

CD

(MX-PBX1)

(For MX-2300G/2700G)

Internet Fax

expansion kit

CD

(MX-FWX1)

Application

integration

module

CD

(MX-AMX1)

Network

scanner

(Sharpdesk 1 license)

Network scanner

expansion kit

CD

(MX-NSX1)

Sharpdesk

1 license kit

Sharpdesk

5 license kit

CD

(MX-USX1/

USX5)

Sharpdesk

100 license kit

CD

(MX-USA0)

Reversing single pass feeder

(MX-RPX1)

SPLC-c

driver

HDD

Copier/Printer (SPLC-c)

model

(MX-2300G)

(MX-2700G)

Stand/2x500 sheet

paper drawer

(MX-DEX2)

PS3 expansion

kit

CD ROM

(MX-PKX1)

Sharpdesk

10 license kit

Sharpdesk

50 license kit

CD

(MX-US10/

US50)

Application

communication

module

CD

(MX-AMX2)

Document cover

(MX-VRX1)

Exit tray unit

(MX-TRX1)

Large capacity tray

(MX-LCX1)

Facsimile

expansion kit

(MX-FXX1)

FAX memory (8MB)

(packed together)

External

account module

CD

(MX-AMX3)

MX-FNX2/AR-PN1/MX-RBX1 PRODUCT OUTLINE 1 – 1

Page 4

âºíuÇ´

[2] SPECIFICATIONS

Service Manual

1. MX-FNX2

A. Basic specifications

Type Console type finisher

Loading method Ascending offset tray

Transport speed 23/27/35/45 ppm

Transport reference Center reference

Mode types Non-staple, staple

Paper sizes allowed for offset A3, B4, A4, A4R, B5, B5R, 8K, 16K, 11" x 17", 8.5" x 14", 8.5" x 13", 8.5" x 11", 8.5" x 11"R

Offset quantity 20mm, 0.8 inch

Tray type (Number of trays) Upper tray: Lift-up/down offset tray

Paper exit direction Face down

Paper exit paper size A3W, A3, B4, A4, A4R, B5, B5R, A5R, 16K, 16KR

Power consumption 52W

Power source Supplied from the host machine power (DC24V/DC5V)

External dimensions (W x D x H) When the paper exit tray is on the storge position: 555 x 610 x 1010 (mm), 21 27/32 x 24 1/64 x 39 49/64 (inch)

Occupying dimensions (W x D) When the tray is on pull-out position: 665 x 610 (mm), 21 27/32 x 24 1/64 (inch)

Weight Approx. 46kg (101.4 lbs)

Installation/maintenance Installed by service personnel

Optional detection Auto detection supported

Packaged items Parts for mounting, operational sheet, staple directional instruction label, punch directional instrucrtion label,

B. Finishing section

Lower tray: Book tray for saddle stitch

12" x 18", 11" x 17", 8.5" x 14", 8.5" x 13", 8.5" x 11", 8.5" x 11"R, 5.5" x 8.5"R, 7.25" x 10.5"R

When the paper exit tray is on the pull-out position: 665 x 610 x 1050 (mm), 26 11/64 x 24 1/64 x 41 21/64 (inch)

* Distance from the main unit: 300mm, 11 13/16 inch

installation cautionary note

Capacity of paper exit and load Non-staple: 1,000 sheets (Small size) Max. 500 sheets for A5R, INV-R (Plain paper 60 to 80g/m

Staple sort: 30 sets * (Max. 50 sets for small size, one-position stapling at the rear)

Max: 1,000 sheets (Small size)

*: Less than 1,000 sheets and less than 30 sets depending on the use environment and paper curl.

Large size: A3W, A3, B4, 8K, 12" x 18", 11" x 17", 8.5" x 14", 8.5" x 13"

Small size: A4, A4R, B5, B5R, A5R, 16K, 16KR, 8.5" x 11", 8.5" x 11"R, 5.5" x 8.5"R, 7.25" x 10.5"R

Offset function Provided

Paper size which can be stapled A3, B4, A4, A4R, B5, B5R, 8K, 16K, 16KR, 11" x 17", 8.5" x 14", 8.5" x 13", 8.5" x 11", 8.5" x 11"R

Ejectable paper size Determinate

size

Indeterminate

size

Paper weight Thin paper:

Plain paper:

Heavy paper:

Quantity of paper to be stapled (Max.) 30 sheets (Small size, 90g/m

25 sheets (Large size, 90g/m

Stapling 3 kinds (One in the front, one at the back, two positions)

Staple supply Staple cartridge replacement

Staple detection Staple empty detection: Provided (Nearly empty: 40 pcs. remained)

Manual stapling No

or equivalent)

500 sheets (Large size) (Plain paper 60 to 80g/m

500 sheets (Large size)

AB type A3W, A3, B4, A4, A4R, B5, B5R, A5R, 8K, 16K, 16KR

Inch type 12" x 18", 11" x 17", 8.5" x 14", 8.5" x 13", 8.5" x 11", 8.5" x 11"R, 5.5" x 8.5"R,

AB type 148 x 100 to 432 x 297

Inch type 5 1/2" x 5 1/2" to 17" x 11 5/8"

55 to 59g/m

60 to 105g/m

106 to 209g/m

7.25" x 10.5"R

2

(15 to 16 lbs)

2

(16 to 28 lbs)

2

(28 to 56 lbs)

2

(24 lbs))

2

(24 lbs))

2

(16 to 21 lbs) or equivalent)

C. Saddle stitch section

Stapling type Common to the staple specifications. 2-position stapling (center stapling), face down

Folding location Center folding

Paper size A3, B4, A4R, 8K, 16KR, 11" x 17", 8.5" x 11"R

Weight of paper applicable for saddle stitch 55 to 209g/m

Quantity of paper to be stapled 10 sets (6 to 10 sheets), 20 sets (1 to 5 sheets)

2

(15 to 56 lbs)

2

(16 to 21 lbs)

D. Consumable parts

Name Content Life Product name

Staple cartridge Staple cartridge x 3 5000 x 3 AR-SC2

MX-FNX2/AR-PN1/MX-RBX1 SPECIFICATIONS 2 – 1

Page 5

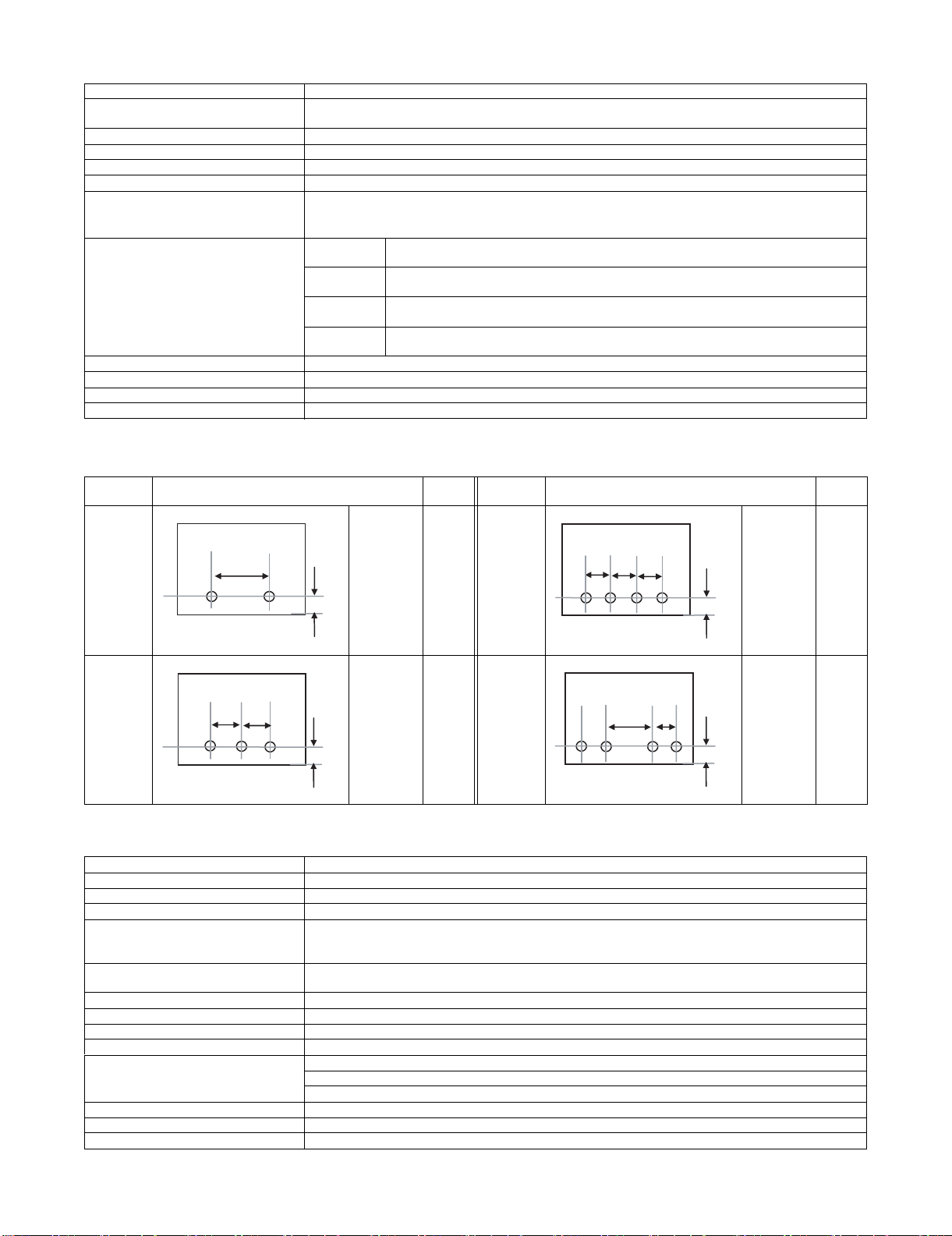

2. AR-PN1A/B/C/D

A

ABA

A

ABA

A

B

C

Type Punch unit for saddle finisher

Punch type 2 holes / 3 holes / 4 holes / 4 holes (wide)

Transport speed 23, 27, 35, 45, sheets/min.

Transport reference Center reference

Punch dust full detection Provided

Paper exit direction Face down

Paper weight Plain paper: 60 to 105g/m

Puchable paper size 2 holes

Power source Supplied from the finisher

External dimensions (W x D x H) 105 x 560 x 175 (mm), 4 9/64 x 22 3/64 x 6 57/64 (inch)

Weight Approx. 2.9kg (6.4 lbs)

Packaged items Parts for mounting, instructional label for garbage pickup

*1: Auto switching: 2 holes/3 holes

Kind of hole punch

A punch unit that provides all of these 4 types can be installed.

2

(16 to 28 lbs)

Thin paper: 55 to 59g/m

Heavy paper: 106 to 209g/m

(AR-PN1A)

3 holes *1

(AR-PN1B)

4 holes

(AR-PN1C)

4 holes (wide)

(AR-PN1D)

A3, B4, A4, A4R, B5, B5R, 11" x 17", 8.5" x 14", 8.5" x 13", 8.5" x 11", 8.5" x 11"R, 8K, 16K, 16KR

3 holes: A3, A4, 11" x 17", 8.5" x 11"

2 holes: 8.5" x 14", 8.5" x 13", 8.5" x 11"R

A3, A4

A3, B4, A4, A4R, B5, B5R, 11" x 17", 8.5" x 14", 8.5" x 13", 8.5" x 11", 8.5" x 11"R

2

(15 to 16 lbs)

2

(28 to 56 lbs)

Kind Hole position

2 holes

(AR-PN1A)

A: 80±1mm

B: 12±3mm

Hole

size

φ6.5mm 4 holes

Kind Hole position

(AR-PN1C)

B

3 holes

(AR-PN1B)

A: 108±1mm

B: 12±3mm

φ8.0mm 4 holes

(wide)

(AR-PN1D)

3. MX-RBX1

Type Paper pass unit

Paper reception reference Center referance

Receiving speed 62 to 450mm/sec (23 to 45cpm)

Receiving and sending speed 23 to 45cpm

Paper weight Thin paper:

Plain paper:

Heavy paper:

Transportable paper sizes A3W, A3, B4, A4, A4R, B5, B5R, A5R, 16K, 16KR

12" x 18", 11" x 17", 8.5" x 14", 8.5" x 13", 8.5" x 11", 8.5" x 11"R, 5.5" x 8.5"R, 7.25" x 10.5"R

External dimensions (W x D x H) 555 x 535 x 165 (mm), 21 27/32 x 21 1/16 x 6 1/2 (inch)

Weight Approx. 7kg (15.4 lbs)

Power source Supplied by saddle finisher

Power consumption Included with saddle finisher power consumption

Interface Mechanical: Fixed to the main unit with screws.

Electrical: Cable connection from the finisher

Control: Controlled by the communication command from the main unit through the finisher.

Installation/maintenance Installed by service personnel

Optional detection Auto detection supported

Packaged items Parts for mounting, installation cautionary note

55 to 59g/m

60 to 105g/m

106 to 209g/m

2

(15 to 16 lbs)

2

(16 to 28 lbs)

2

(28 to 56 lbs)

A: 80±1mm

B: 12±3mm

A: 70±1mm

B: 12±3mm

C: 21±1mm

Hole

size

φ6.5mm

φ6.5mm

MX-FNX2/AR-PN1/MX-RBX1 SPECIFICATIONS 2 – 2

Page 6

âºíuÇ´

[4] EXTERNAL VIEWS AND INTERNAL STRUCTURES

Service Manual

1. Part names and functions

A. External view

1

6

3

5

1 Staple compiler 4 Front cover

2 Top cover 5 Saddle stitch tray

3 Staple section 6 Offset tray

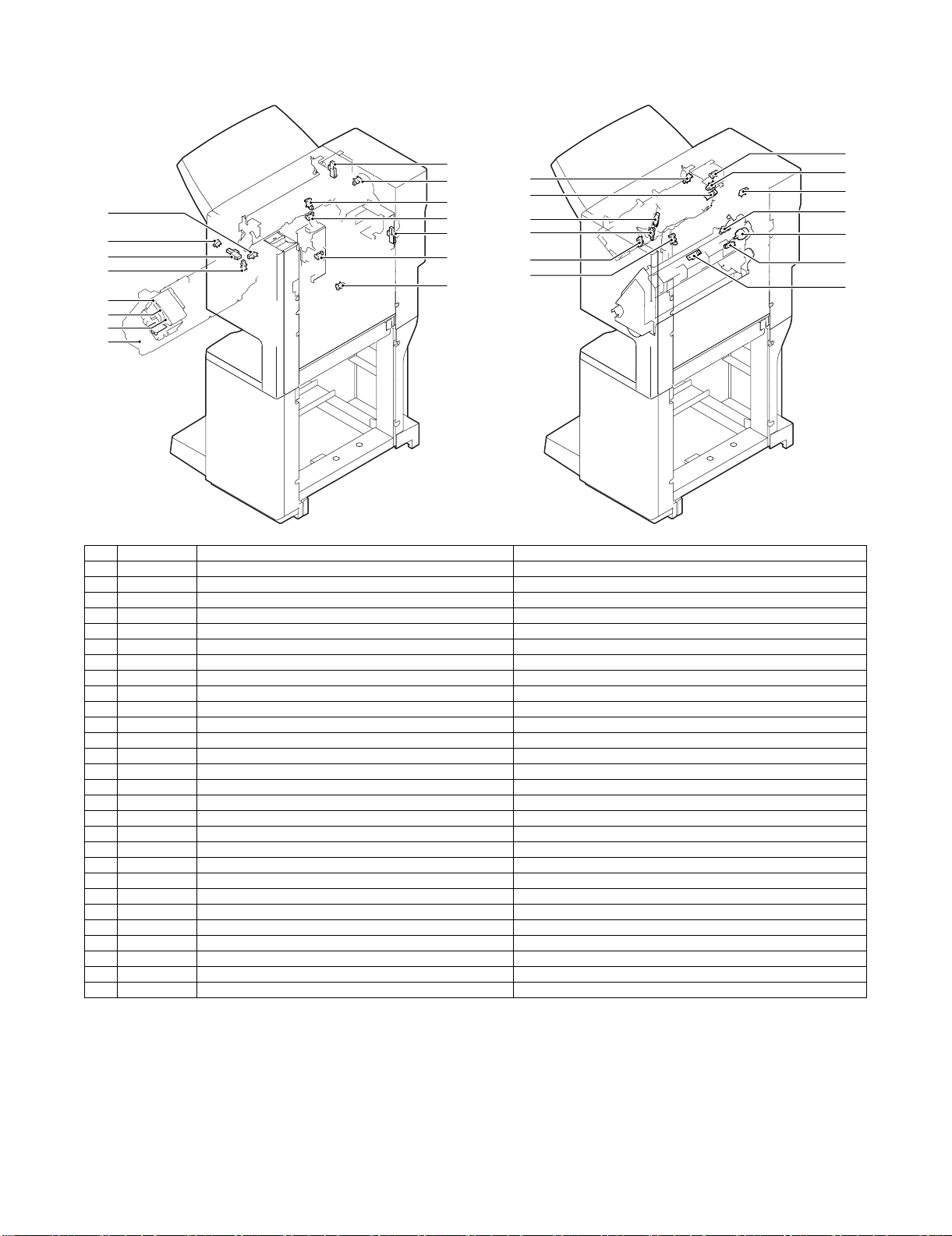

B. Internal structure

(1) Finisher section

1 2 3 754 6

2

4

1614 1513 17128 9 10 11

1 Paper exit tray 10 Stapler

2 Alignment plate (Front, back) 11 Saddle section

3 Paddle 12 Book making stopper

4 Paper exit roller 13 Book making tray

5 Process tray stopper 14 Bundle transport roller

6 Transport roller 15 Book making exit roller

7 Punch section (Option) 16 Paper folding roller

8 Paper exit belt 17 Paper pushing plate

9 Bundle exit roller

MX-FNX2/AR-PN1/MX-RBX1 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4 – 1

Page 7

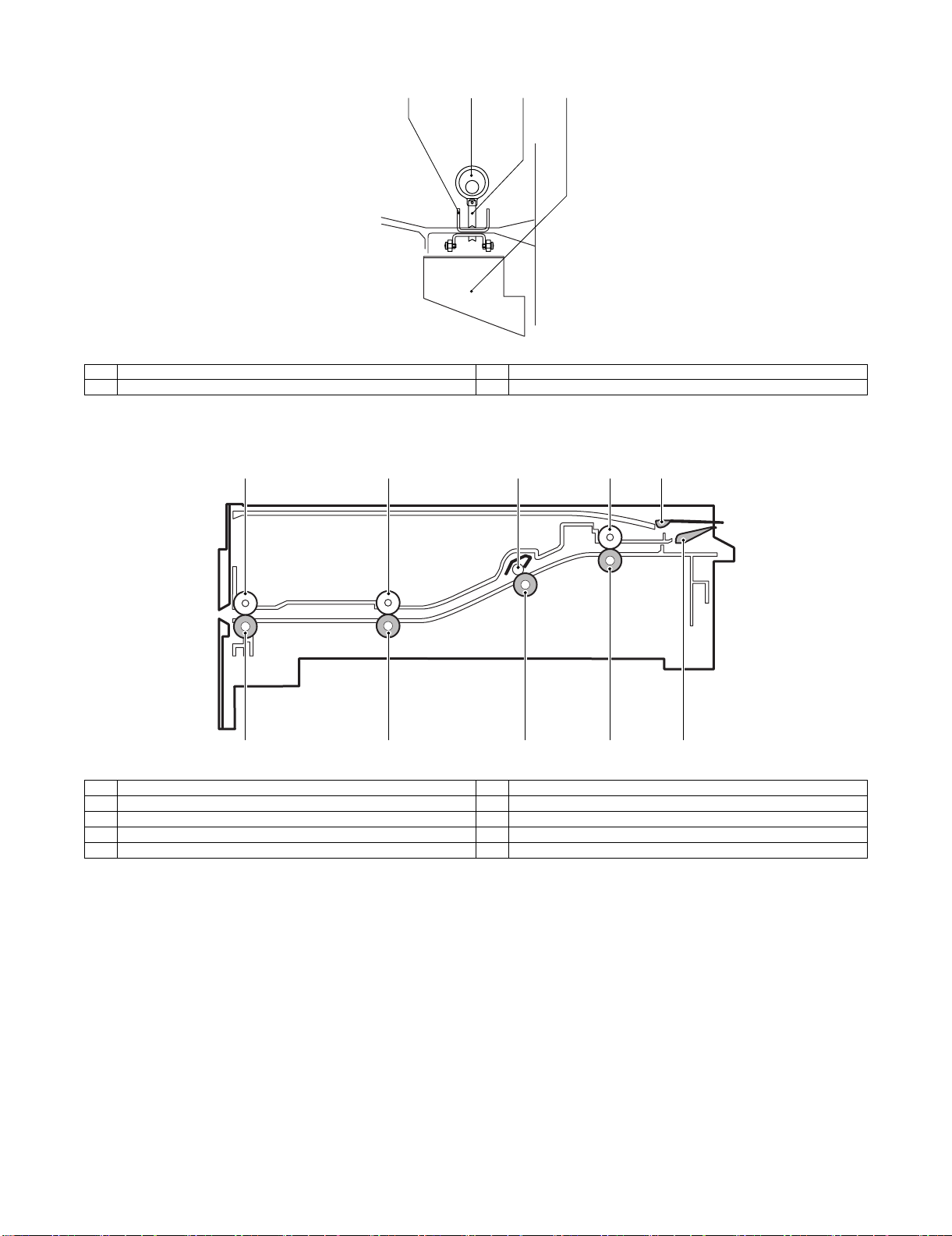

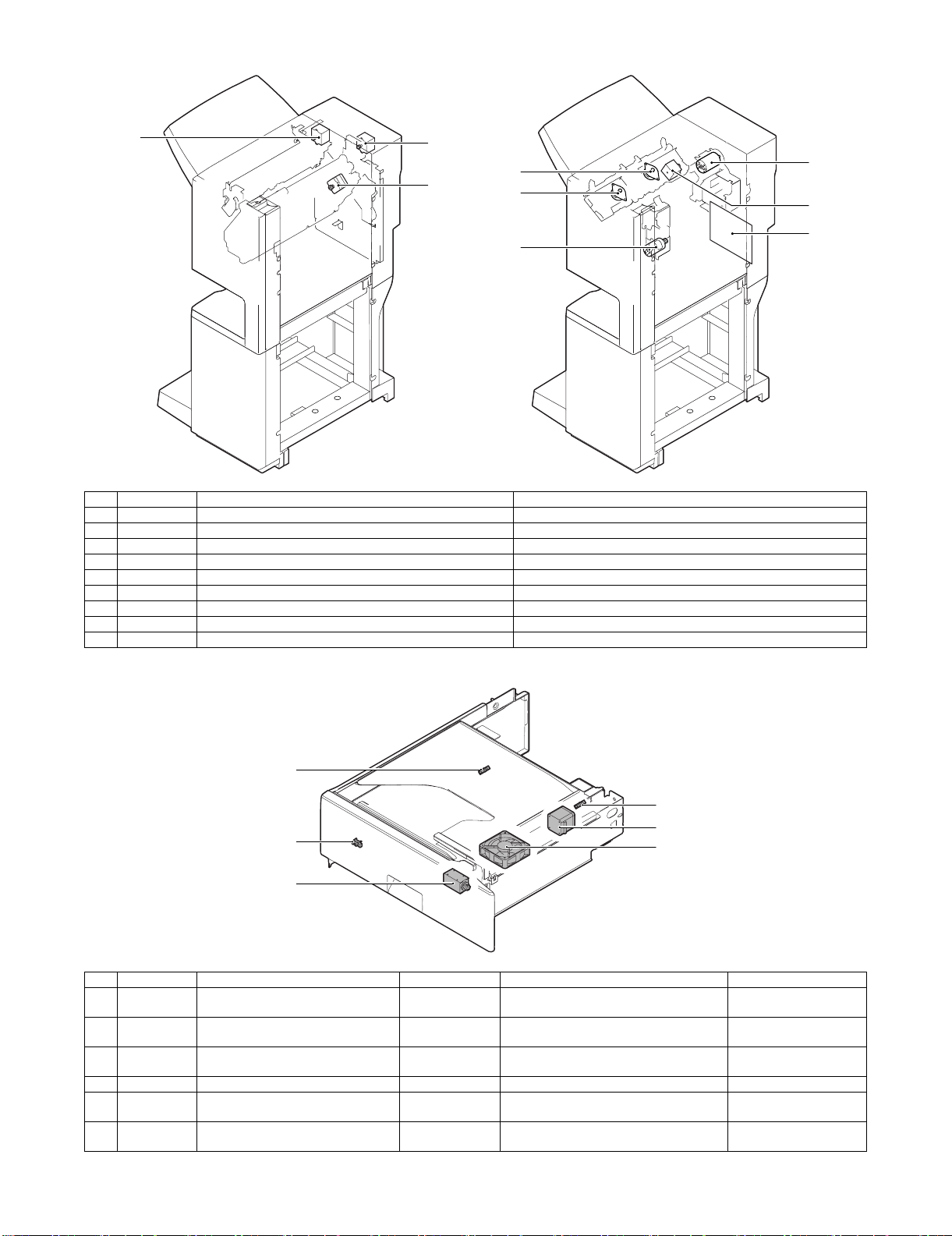

(2) Punch section (Option: AR-PN1A/B/C/D)

31 2 4

1 Die 3 Punch

2 Cam 4 Punch dust box

(3) Interface transport section (MX-RBX1)

1

5

1 Paper exit roller 6 Paper exit front roller

2 Paper exit front roller 7 Inlet port rear roller

3 Inlet port rear roller shaft 8 Inlet port roller

4 Inlet port roller 9 Reverse flapper

5 Paper exit roller 10 Upper guide flapper

2

6

3

7

4

8

9

10

MX-FNX2/AR-PN1/MX-RBX1 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4 – 2

Page 8

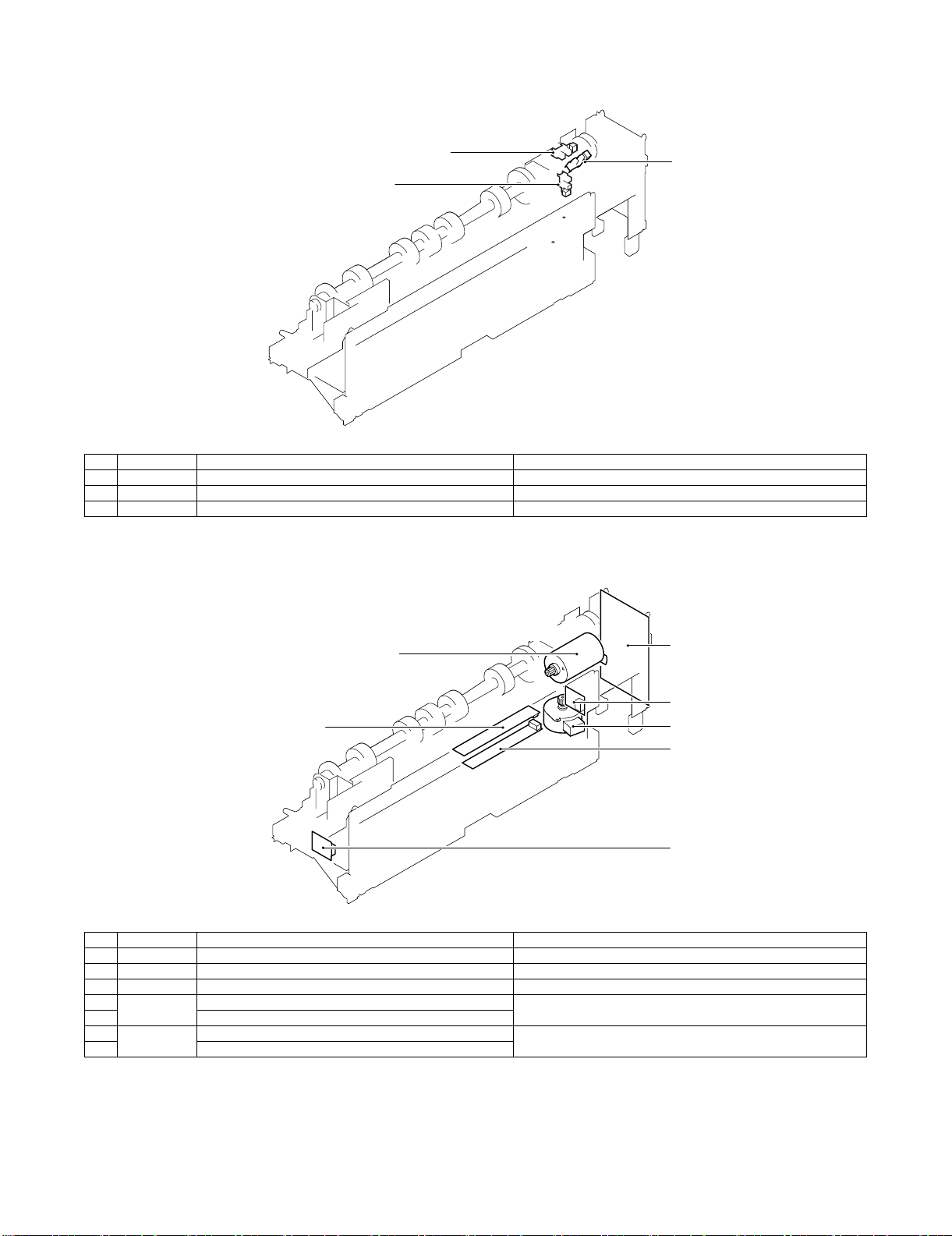

C. Finisher and saddle section

(1) Sensor, switch and clutch

26

5

2

7

6

8

9

23

24

22

14

28

16

4

25

17

13

19

20

21

18

No. Signal Name Active condition

1 FED Entry paper sensor Paper detected: "H"

2 FPDHPD Paddle home position sensor Paddle HP: "H"

3 FARHPD Bundle roller home position sensor Oscillation guide HP: "H"

4 FFJHPD Alignment home position sensor (front) Alignment tray (F) HP: "H"

5 FRJHPD Alignment home position sensor (rear) Alignment tray (R) HP: "H"

6 FAD Alignment tray sensor Paper detected: "H"

7 FOBHPD Exit belt home position sensor Paper exit belt HP: "H"

8 FBED Tray paper sensor Tray paper detected: "H"

9 FSLD Paper level sensor Paper detected: "H"

10 FFPD Bookbinding position sensor Paper detected: "L"

11 FFHPD Bookbinding home position sensor Folding operation HP: "L"

12 FFRHPD Bookbinding roller home position sensor Bundle transport roller HP: "H"

13 FFED Bookbinding paper sensor Paper detected: "H"

14 FFE Bookbinding lock sensor

15 FULD Lift upper sensor Tray upper limit detected: "H"

16 FLLD Lift lower sensor Tray lower limit detected: "H"

17 FLE Lift lock sensor

18 FSTHPD Staple shift home position sensor Stapler HP: "H"

19 FSHPD Staple drive home position sensor Stapler stapling HP: "L"

20 FSPD Self prime sensor Cartridge staple detected: "L"

21 FSD Staple empty sensor Stapler cartridge detected: "L"

22 FFDD Front door sensor Front cover open: "H"

23 FCD Upper cover sensor Upper cover open: "H"

24 FFDDW Front door switch Front door closed: "H"

25 FJSW Joint switch Printer connected: "H"

26 FSSSW Staple safety switch Oscillation guide closed: "H"

27 FCC Bookbinding clutch When drive is transmitted: "H"

28 FMLD Tray middle sensor Tray middle detected: "H"

15

3

1

12

27

11

10

MX-FNX2/AR-PN1/MX-RBX1 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4 – 3

Page 9

(2) Motor and PCB

2

1

5

8

4

6

No. Signal Name Active condition

1 FFM Transport motor Paper transport

2 FPM Paddle motor Oscillation guide drive, paper exit to offset tray

3 FAM Bundle exit motor Paper exit operation

4 FFJM Alignment motor (front) Alignment plate (F) drive

5 FRJM Alignment motor (rear) Alignment plate (R) drive

6 FLM Lift motor Paper exit tray up/down

7 FFSM Staple motor Stapling/paper folding

8 FSM Staple shift motor Staple unit sliding

9 PBA-CONT Control PCB Finisher control

7

3

9

D. Interface transport section (MX-RBX1)

2

1

3

5

No. Signal Name Type Function/Operation Output

1 FJPID Interface transport unit inlet port sensor Photointerrupter Interface inlet port paper detection LO light is interrupted

2 FJPOD Interface transport unit outlet port

sensor

3 FJPDD Interface transport unit cover sensor Photointerrupter Interface cover open detection Light is interrupted when

4 FJPM Interface transport motor Paper transport roller drive

5 FINRPS Interface reverse path solenoid Drive of the flapper which selects the path in

6 FJFM Interface fan Temperature rise protection fan in the

Photointerrupter Interface outlet port paper detection LO light is interrupted

the finisher and the reverse path

finisher inlet port section

4

6

when paper is provided.

when paper is provided.

the cover is open.

MX-FNX2/AR-PN1/MX-RBX1 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4 – 4

Page 10

E. Punch section (AR-PN1A/B/C/D)

(1) Sensor

3

1

2

No. Signal Name Active condition

1 FPHPD Punch home position sensor Punch HP detected: "L"

2 FPSHPD Punch side resist home position sensor Punch slide unit HP detected: "H"

3 FPMCK Punch motor lock sensor

(2) Motor and PCB

1

3

6

4

2

5

7

No. Signal Name Active condition

1 FPNM Punch motor Punch drive

2 FPSM Punch side resist motor Punch slide unit transverse move

3 Punch control PCB

4FPTD

FPSD1 – 4

5 Side resist LED PCB

6 FPDD Dust full photo sensor PCB Punch dust full detection

7 Dust full LED PCB

Side resist photo sensor PCB Punch horizontal resist and punch timing detection

MX-FNX2/AR-PN1/MX-RBX1 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4 – 5

Page 11

âºíuÇ´

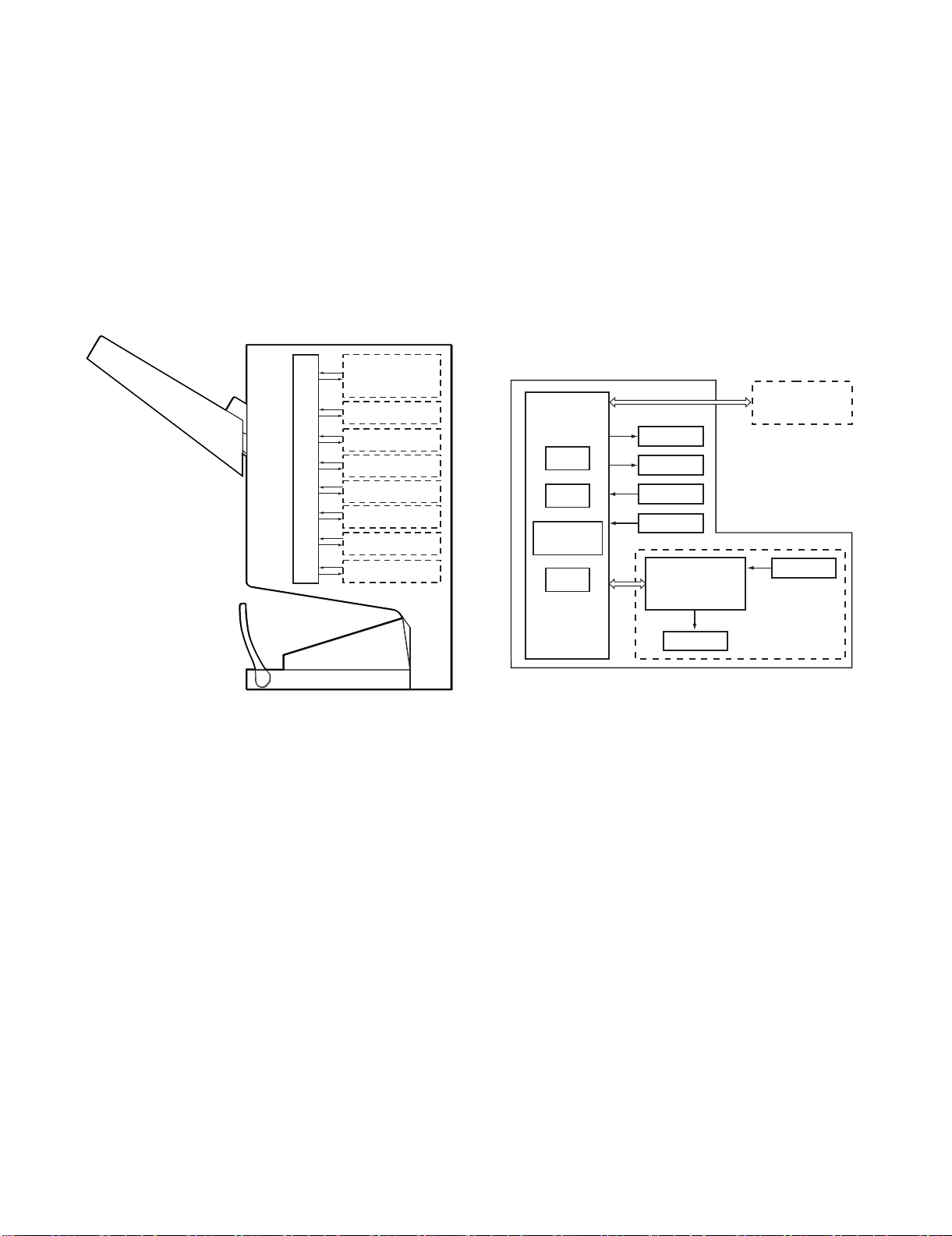

[5] OPERATIONAL DESCRIPTION

1. Basic operations

A. Specifications

The finisher serves to deliver sheets coming from its host machine.

The mode of delivery may be non-sort stack, job offset *, or staple

delivery.

The saddle unit built into the finisher is used to fold a stack of

sheets coming from the finisher unit in half for delivery.

The punch unit (option) is designed for installation to the pickup

assembly of the finisher, and is used to punch holes in sheets coming from the host machine.

The above operations are controlled with various commands from

the finisher controller PCB as well as the commands from the

punch controller PCB.

Punch unit drive

system (punch unit;

option)

Alignment drive system

Stapler drive system

Delivery drive system

Feed drive system

Control system

Tray drive system

Saddle section

drive system

Interface pass

drive system

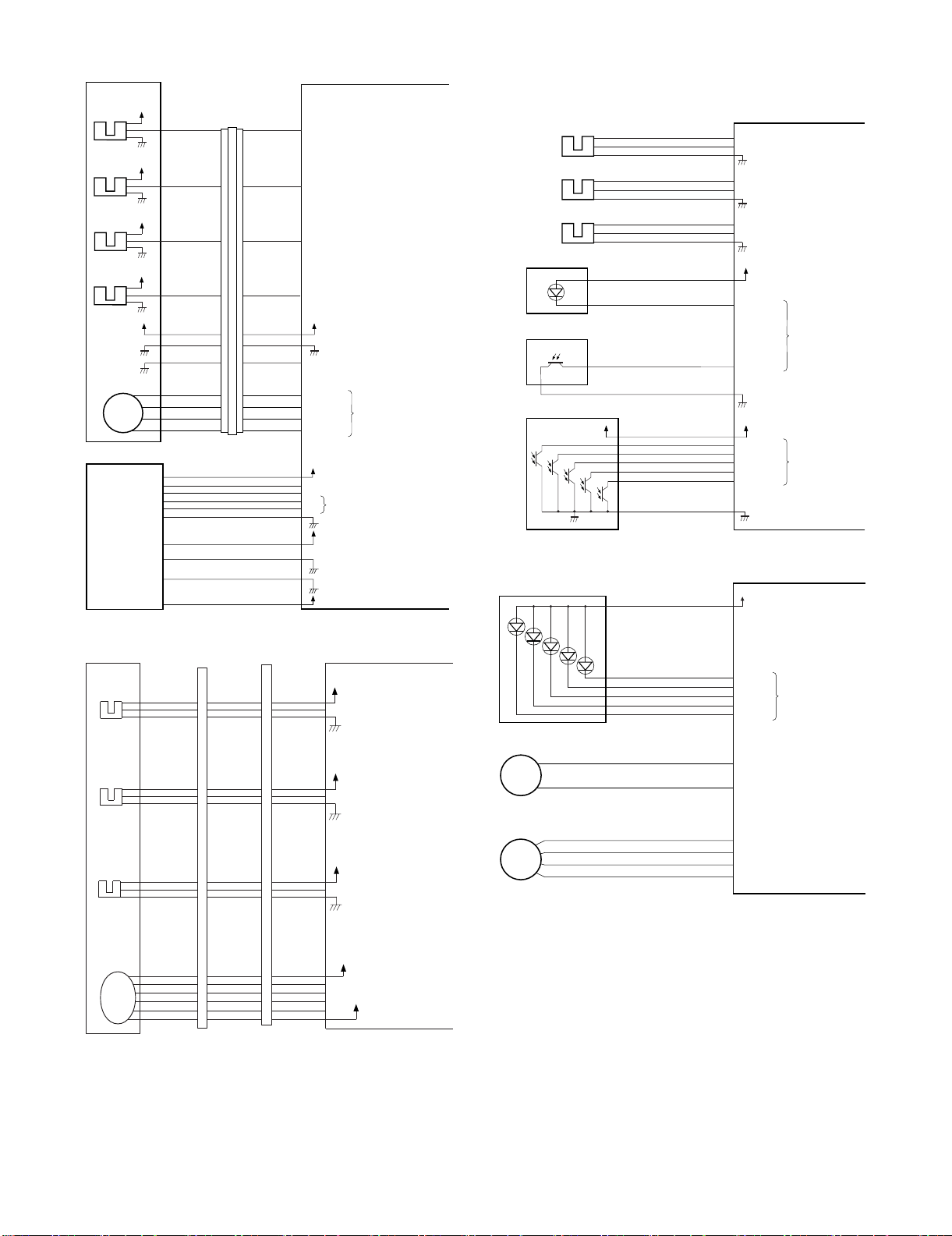

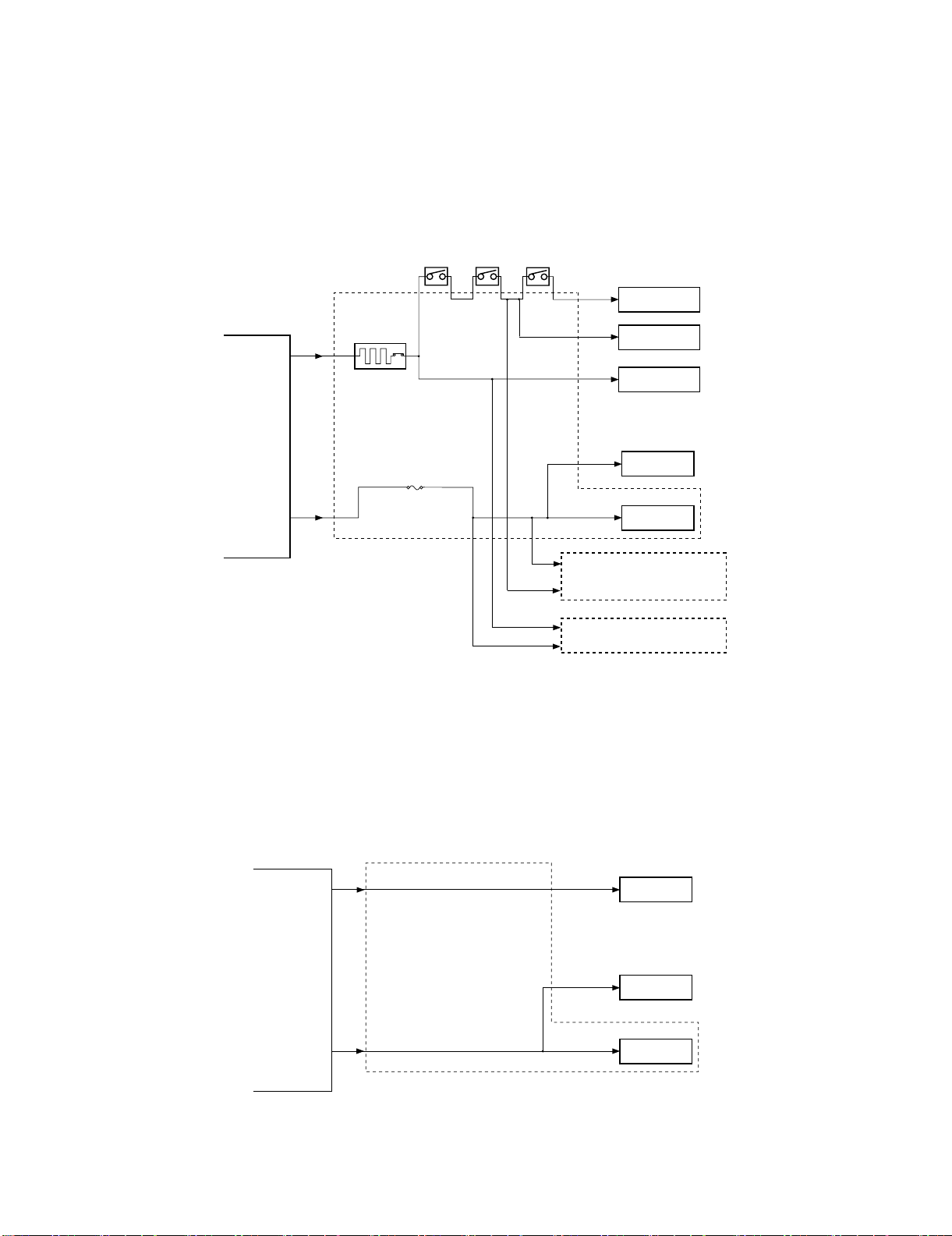

B. Outline of the Electrical Circuitry

Service Manual

The sequence of finisher operations is controlled by the finisher

controller PCB. The finisher controller PCB is a 16-bit microprocessor (CPU), and is also used for combination with the host machine

(serial).

The finisher controller PCB drive motors and other loads in

response to the various commands from the host machine. It also

communicates such data as on the states of various sensors and

switches to the host machine by way of the serial communication

line.

The ICs mounted to the finisher controller PCB have the following

functions:

• IC13 (CPU): Controls sequence of operations.

• IC12 (EEP-ROM): Backs up adjustment settings.

• IC6: Stores sequence programs.

• IC11 (expansion port): I/O port

The flow of signals between finisher and options controller is shown

as below.

Finisher unit

Host machine DC

Finisher

controller

PCB

IC13

CPU

IC12

EEP-ROM

IC11

Communication

IC

IC6

ROM

Motor

Clutch

Switch

Sensor

Punch unit (option)

Punch controller

PCB

controller PCB

CPU

Sensor

*: The position of delivery is shifted to the front/rear for each stack

to assist sorting.

Motor

MX-FNX2/AR-PN1/MX-RBX1 OPERATIONAL DESCRIPTION 5 – 1

Page 12

C. Inputs to and Outputs from the Finisher

When the drive is transmitted,

‘1’.

Switches between ‘1’and

‘0’ according to the

direction of motor rotation.

Switches between ‘1’and

‘0’ according to the

direction of motor rotation.

Switches between ‘1’and

‘0’ according to the

direction of motor rotation.

Switches between ‘1’and

‘0’ according to the

direction of motor rotation.

Switches between ‘1’and

‘0’ according to the

direction of motor rotation.

Finisher controller PCB

Feed motor

FEEDMTR_A

+24V

CN10-1

-1

CN62-5

Paddle motor

+24V

FPM

FFC

B_CLU

+24V

CN72

-1

-2

-2

-1

CN18-1

-2

Binding clutch

Bundle exit motor

+24V

FAM

Alignment motor

(front)

+24V

FFJM

Alignment motor

(rear)

+24V

FRJM

-2

-3

-4

-5

-6

FFM

-2

-3

-4

-5

-6

CN56

-6

-5

-4

-3

-2

-1

FEEDMTR_*A

FEEDMTR_B

FEEDMTR_*B

PDLMTR_A

PDLMTR_*A

PDLMTR_B

PDLMTR_*B

CN10-7

-8

-9

-10

-11

-12

-1

-2

-3

-4

-5

-6

CN57

-6

-5

-4

-3

-2

-1

EJCTMTR_A

EJCTMTR_*A

EJCTMTR_B

EJCTMTR_*B

CN13-1

-1

-2

-3

-4

-5

-6

-2

-3

-4

-5

-6

CN59

-6

-5

-4

-3

-2

-1

CN3-1

-2

-3

-4

-5

FJOGMTR_A

FJOGMTR_*A

FJOGMTR_B

FJOGMTR_*B

CN63-1

-2

-3

-4

-5

-4

-3

-2

-1

CN64-5

CN3-6

-7

-8

-9

-10

CN65-1

-2

-3

-4

-5

-4

-3

-2

-1

RJOGMTR_A

RJOGMTR_*A

RJOGMTR_B

RJOGMTR_*B

Finisher controller PCB

Lift motor

SIFTMTR_1

Switches between ‘+’and

‘–’ according to the

direction of motor rotation.

CN6-1

-2

FLM

-2

-1

CN70

-2

-1

SIFTMTR_0

-2

-1

-2

-1

-2

-1

CN70

-2

-1

Staple motor

BINDMTR_1

Switches between ‘+’and

‘–’ according to the

direction of motor rotation.

CN6-3

-4

FFSM

BINDMTR_0

CN71

Controller PCB

• Inputs to the Finisher Controller PCB (1/2)

Entry paper

sensor

Paddle home

position sensor

Bundle roller

home position

sensor

Aligning plate

home position

sensor (front)

Aligning plate

home position

sensor (rear)

Alignment

tray sensor

Delivery belt

home position

sensor

Tray paper sensor

Paper surface

sensor

Bookbinding

position sensor

FED

FPDHPD

FAR HPD

FFJHPD

FRJHPD

FAD

FOBHPD

FBED

FSLD

FFPD

CN44-3

CN51-1

CN55-3

CN23-3

CN36-3

CN30-3

CN31-3

CN32-3

CN35-3

CN39-3

CN43-1

CN42-3

-3

-1

-2

-2

-3

-2

CN54-1

-3

-1

-2

-2

-1

-2

-1

-2

CN29-1

-3

-1

-2

-2

-4

-6

-1

-2

-5

-7

-9

-1

-8

-2

CN34-1

-3

-1

-2

-2

CN38-1

-2

-2

-3

-1

CN53-3

CN28-9

CN33-3

CN37-9

-1

-2

-1

-2

-7

-8

-6

-4

-5

-3

-1

-2

-1

-2

-8

-7

CN16-10

CN9-1

CN9-7

CN4

CN5-13

CN5-1

CN5-10

CN16-1

-12

-11

-3

-2

-9

-8

-3

-2

-15

-14

-3

-2

-4

-6

-5

-7

-9

-8

-12

-11

-2

-3

Finisher controller PCB

+5V

ENT_S

+5V

PDL_HP

+5V

BDL_ROL_HP

+5V

FJOG_HP

+5V

RJOG_HP

+5V

ADJ_TRAY_S

+5V

EJCT_BLT_HP

+5V

TRY_EMPS

+5V

LVL_S

+5V

BIND_P

BIND_L

When the sensor

detects paper, ‘1’ .

When the paddle is at

home position, ‘1’.

When the swing guide

is at home position, ‘1’.

When the aligning

plate (front) is at

home position, ‘1’.

When the aligning

plate (rear) is at

home position, ‘1’.

When the sensor

detects paper, ‘1’.

When the delivery belt

is at home position, ‘1’.

When paper is present

on the tray,‘1’.

When the paper

surface is detected,

‘1’.

When paper is

detected, ‘0’.

When LED is lit, ‘1’.

• Outputs from the Finisher Controller PCB (1/2)

• Inputs to the Finisher Controller PCB (2/2)

FFHPD

Bookbinding

home position

sensor

Bookbinding

roller home

position sensor

Bookbinding

paper sensor

Bookbinding

lock sensor

Lift upper sensor

Lift lower sensor

Lift lock sensor

Front door sensor

Upper cover sensor

Tray middle sensor

Joint switch

Front door switch

Stapler safety

switch

FFRHPD

FFED

FFE

FULD

FLLD

FLE

FFDD

FCD

FMLD

FJSW

N. O.

FFDDW

N. O.

FSSSW

N. O.

CN40-3

CN41-3

CN47-3

CN52-1

CN50-3

CN49-3

CN48-3

CN25-3

CN24-3

CN73-3

-1

-2

-1

-2

-1

-2

-2

-3

-1

-2

-1

-2

-1

-2

-1

-2

-1

-2

-1

-2

CN69-2

CN68-2

CN66-2

-1

-1

-1

CN38-4

-6

-5

-7

-9

-8

CN16-4

CN37-6

-4

-5

-3

-1

-2

CN15-1

CN15-10

CN15-7

CN15-4

CN19-1

• Outputs from the Finisher Controller PCB (2/2)

Finisher controller PCB

+5V

CN9-6

CN4-7

CN4-4

CN8-6

CN8-4

CN8-2

-6

BIND_HP

-5

-7

+5V

-9

BIND_ROL_HP

-8

+5V

-3

BIND_EMPS

-2

+5V

-5

BIND_CLK

-4

+5V

-12

SIFT_UPLMT

-11

+5V

-9

SIFT_DNLMT

-8

+5V

-6

SIFT_CLK

-5

+5V

-9

FDOOR_S

-8

+5V

-6

TOPCOV_S

-5

+5V

-3

PAPE R_ F

-2

+24VP

-5

-3

-1

JOINT SW

FRONT SW

STPLSAFE SW

When at folding home

position, ‘0’.

When the stack feed roller

(upper) is at home position, ‘1’.

When the sensor

detects paper, ‘1’.

When the staple/fold motor is

rotating, alternates between

‘1’ and ‘0’.

When the tray is at the

upper limit, ‘1’.

When the tray is at the

lower limit, ‘1’.

While the lift motor

is rotating, alternates

between ‘1’ and ‘0’.

When the front door

is open, ‘1’.

When the upper cover

is open, ‘1’.

When the paper is

full, ‘1’.

When connected to

the host machine, ‘1’.

When the front

door is closed, ‘1’.

When the swing

guide is closed, ‘1’.

MX-FNX2/AR-PN1/MX-RBX1 OPERATIONAL DESCRIPTION 5 – 2

Page 13

• Inputs to and Outputs from the Finisher Controller PCB (1/2)

Punch controller PCB

-1

J2008-3

+5V

PUNCH

-2

-6

J1006-4

-5

SREG1*

SREG2*

SREG3*

-9

-10

-11

J1007-12

-13

SREG4*

-8

PAEND*

-7

Horizontal

registration

home position

sensor

FPMCK

-1

J2009-3

+5V

CLOCK

-2

-9

J1006-7

-8

Punch home

position sensor

+5V

+5V

PT1

PT2

PT3

PT4

PT5

FPSHPD

FPHPD

-1

J2007-3

+5V

SLIDE

-2

-3

J1006-1

-2

Punch motor

lock sensor

Side resist photo sensor PCB (FPTD)

DUSTLED

Waste full LED PCB

J1005-1

PT131

LED121

DUSTPTR

+5V

4

Waste full photosensor PCB (FPDD)

-2

J1005-3

When the hole puncher is

at home position, ‘0’.

While the punch motor

is rotating, alternates

between ‘0’and ‘1’.

When the punch slide

unit is at home position,

‘1’.

When paper is

detected, ‘0’.

When the light is

blocked, ‘0’.

Stapler unit

Staple shift home

position sensor

FSTHPD

Staple driver home

position sensor

FSHPD

Staple empty

sensor

FSD

Self prime

sensor

FSPD

Staple shift motor

FSM

Host

machine

+5V

+5V

+5V

+5V

+5V

CN72-5

CN72-4

CN72-3

CN72-2

CN72-6

CN72-1

CN72-7

CN72-10

CN72-11

CN72-12

CN72-13

CN72A-5

CN72A-4

CN72A-3

CN72A-2

CN72A-6

CN72A-1

CN72A-7

CN72B-5

CN72B-4

CN72B-3

CN72B-2

CN72A-5

CN72A-4

CN72A-3

CN72A-2

CN72A-6

CN72A-1

CN72A-7

CN72B-5

CN72B-4

CN72B-3

CN72B-2

CN11-3

CN11-4

CN11-5

CN11-6

CN11-2

CN11-7

CN11-1

CN7-3

CN7-4

CN7-5

CN7-6

CN2-1

CN1-5

CN1-3

CN1-2

CN1-1

SLID_HP

STPL_HP

HOOK_S

SELF_P

STPL_CNCT

SLIDMTR_A

SLIDMTR_*A

SLIDMTR_B

SLIDMTR_*B

-3

GND

-4

GND

-5

TXD

-7

RXD

-6

+5V

+24V

+24V

+5V

Finisher controller PCB

When the stapler is at home

position, ‘1’.

When the stapler is at

stapling home position, ‘0’.

When the cartridge has

staples, ‘0’.

When the staple is at top

the stapler, ‘0’.

When the stapler is

connected, ‘0’.

Switches between ‘1’and

‘0’ according to the direction

of motor rotation.

Communication line

• Inputs to and Outputs from the Finisher Controller PCB (2/2)

-2

-3

Finisher control PWB

+5V

"0" when paper is detected.

LVL_E_S

Interface transport

unit inlet port

sensor

FJPID

CNFJ2-1

-3

-2

CNFJ1-

-17

-16

CNFJ1-

-17

-16

CN73C-1

-2

-3

CN73A-8

-7

-6

CN21-

D. Inputs to and Outputs from the Punch

Controller PCB (option)

• Inputs to and Outputs from the Punch Controller PCB

• Outputs from the Punch Controller PCB

LEDON5

LEDON4

LEDON3

LEDON2

LEDON1

Punch controller PCB

When ‘1’, LED goes ON.

Side resist LED PCB (FPSD)

LED5

LED4

LED3

LED2

LED1

J1007-6

+5V

-1

-5

-4

-3

-2

Interface transport

unit outlet port

sensor

FJPOD

Interface transport

unit cover sensor

FJPDD

Interface

transport

motor

FJPM

Punch motor

J1002-1

CNFJ3-1

-3

-2

CNFJ4-3

-2

-1

CNFJ5

-4

-3

-1

-2

-5

CNFJ1-

-14

-13

CNFJ1-

-11

-10

CNFJ1-2

-7

-6

-5

-4

-3

CNFJ1-

-14

-13

CNFJ1-

-11

-10

CNFJ1-2

-7

-6

-5

-4

-3

CN73C-4

CN73C-7

CN73D-2

CN73D-9

CN73A-5

-5

-4

-6

-3

CN73A-2

-1

-8

CN73B-8

CN73B-

-6

-4

-5

-5

-6

-4

-3

-7

-2

-8

MX-FNX2/AR-PN1/MX-RBX1 OPERATIONAL DESCRIPTION 5 – 3

CN21-4

-5

LVL_P_S

-6

CN21-7

-8

LVL_C_S

-9

CN19-

-2

A

-3

*A

-4

B

-5

*B

-6

+5V

"0" when paper is detected.

+5V

"0" when the interface

transport cover is open.

+24V

The pulse signal is

switched depending

on the motor RPM.

+24V

FPNM

Punch side resist motor

FPSM

J1001-1

-2

-2

-3

-4

A

B

A*

B*

Switches between ‘+’

and ‘–’ according to

the direction of motor

rotation.

Switches the pulse

signals according to

the rotation of the motor.

Page 14

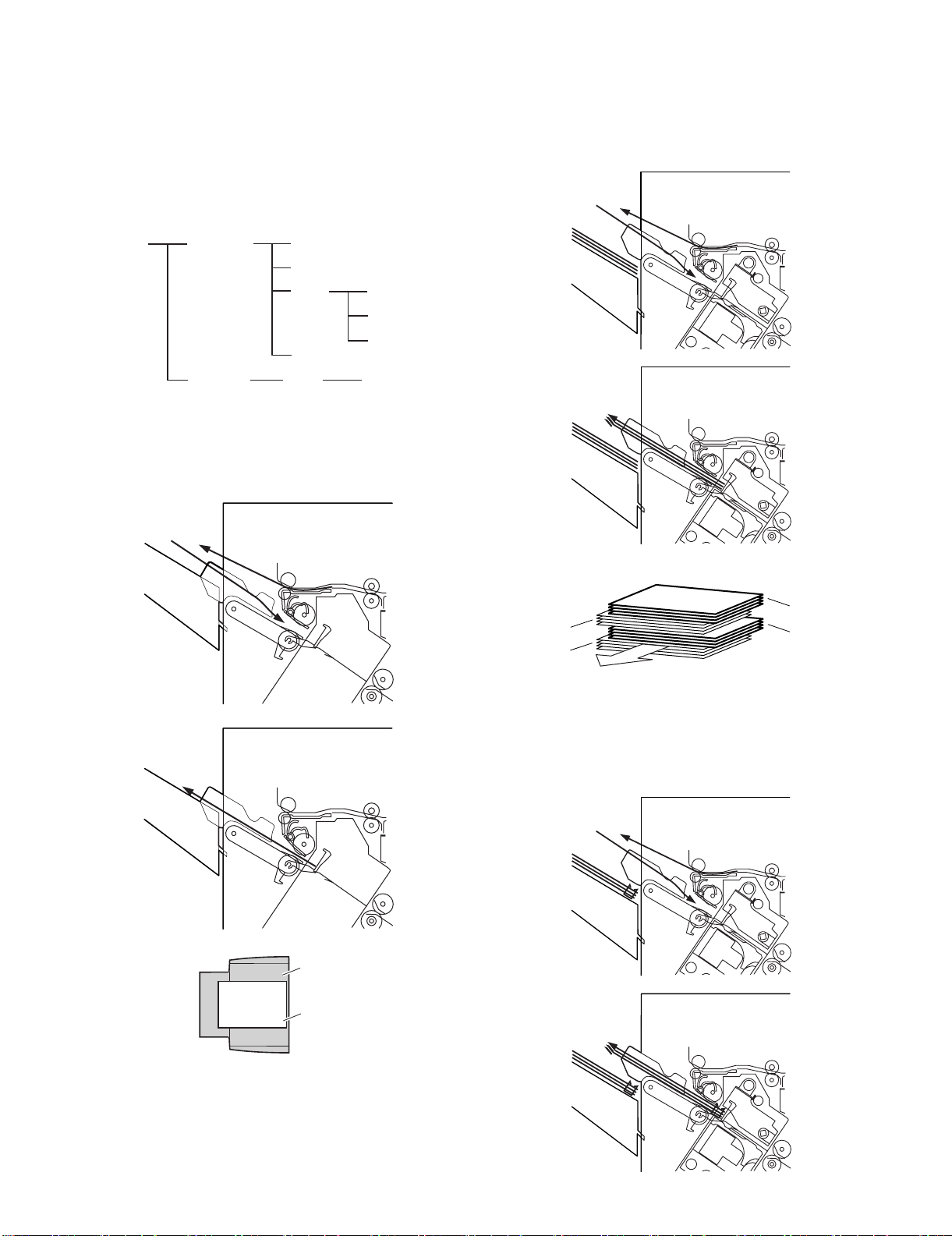

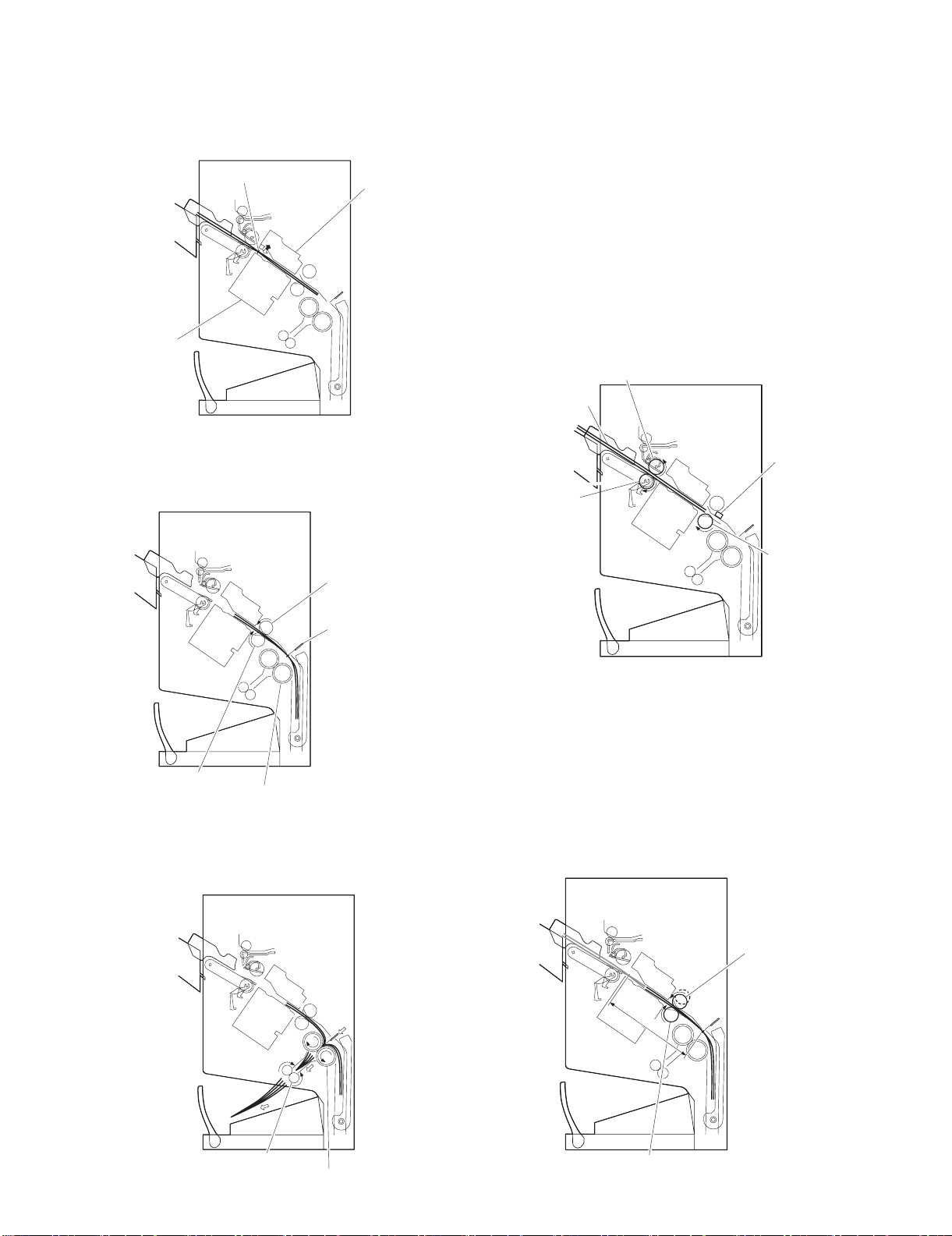

2. Feed/Drive System

(

y)

A. Outline

The machine performs the following in response to the commands

coming from its host machine on the sheets arriving from the host

machine for delivery: simple stacking, job offset, and stapling or

folding (in two).

If a punch unit (option) is installed, the sheets are pouched and

delivered to the delivery tray.

Sheets may be delivered in either of five ways (including one for

the punch unit):

Normal deliveryDelivery method

(1) Normal Delivery

a. Simple Stacking

The machine pulls in the sheet once to the processing tray and

then delivers it to the delivery tray.

Simple stacking

Job offset

Stapling Front 1-point stapling

Rear 1-point stapling

Middle 2-point stapling

Punching

StitchingSaddle delivery

Middle 2-point stapling

b. Job Offset

The machine pulls the sheet once to the processing tray. It then

moves the sheet to the front or the rear using the aligning plate.

When it has deposited a specific number of sheets, it delivers them

in the form of a aligning plane. When the number of sheets stacked

on the processing tray reaches a specified value, the sheets are

delivered in a form of a stack.

Tray

Paper

Results of offset delivery (4 jobs)

4th set

3rd set

1st set

direction of deliver

2nd set

c. Stapling

The machine stacks sheets coming from its host machine on the

processing tray. When the number of sheets stacked on the processing tray reaches a specified value, the finisher staples them

delivers the stapled stack to the delivery tray.

MX-FNX2/AR-PN1/MX-RBX1 OPERATIONAL DESCRIPTION 5 – 4

Page 15

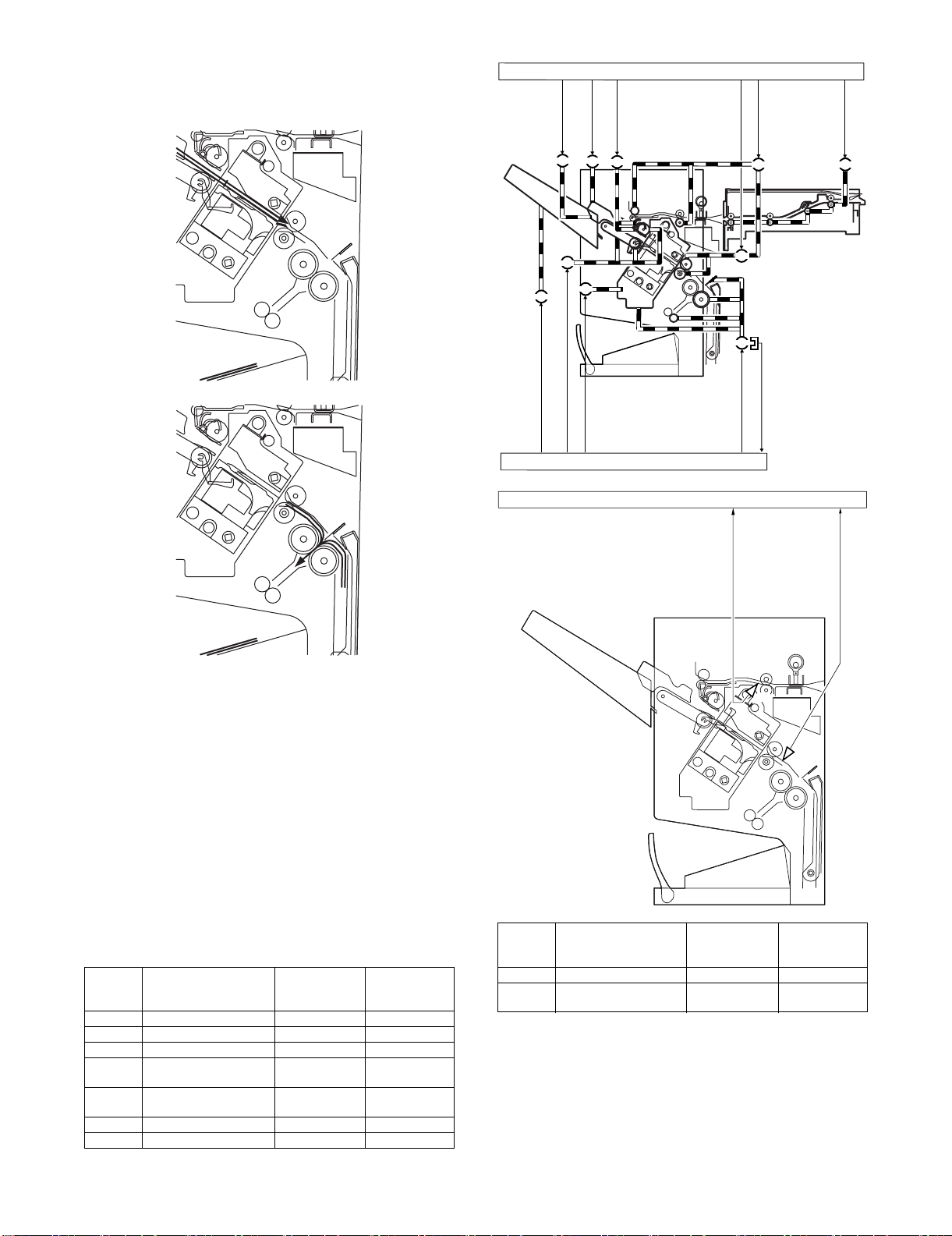

d. Saddle Delivery

Staple motor

drive signal BINDMTR

Bookbinding lock sensor

detect signal BIND_CLK

Finisher controller PCB (1/2)

Lift motor drive signal SIFTMTR

Bundle exit motor drive signal EJCTMTR

Staple slide motor drive signal

SLIDMTR

Paddle motor

drive signal PDLMTR

Alignment motor (rear)

drive signal RJOGMTR

Bind clutch

drive signal B_CLU

Interface transport motor

drive signal RIM

Alignment motor (front)

drive signal FJOGMTR

FFE

FRJM

FPM

FFSM

FFC

FAM

FSM

FLM

FFJM

FJPM

FFM

Finisher controller PCB (2/2)

Feed motor

drive signal FEEDMTR

Finisher controller PCB

FFPD

Bookbinding position

detect signal BIND_P

FED

Entry paper detect signal

ENT_S

The machine deposits a stack of sheets on the processing tray, staples it (middle 2-point), and then moves it to the saddle unit. The

saddle unit folds the stack in two, and delivers it to the bind tray.

B. Feed/Delivery

(1) Outline

The machine forwards the sheets coming from its host machine to

the delivery tray, processing tray, or saddle unit according to the

type of delivery used. The sheets forwarded to the processing tray

or the saddle unit are offset, stapled, or folded.

The following table shows the motors that are associated with moving and aligning sheets. These motors are controlled (rotated clockwise or counterclockwise) by the microprocessor (CPU) on the

finisher controller PCB.

The paper path is equipped with the sensors shown in the following

figure used to monitor the arrival or passage of sheets.

If a sheet fails to arrive at or move past a specific sensor within a

specific period of time, the finisher controller will assume a jam, and

stops the ongoing operation and, at the same time, communicates

the presence of a jam to the host machine.

Notation Name Description

FFM Feed motor Stepping motor CN10

FPM Paddle motor Stepping motor CN10

FAM Bundle exit motor Stepping motor CN13

FFJM Alignment plate motor

(front)

FRJM Alignment plate motor

(rear)

Stepping motor CN3

Stepping motor CN3

FFSM Staple motor Brush DC motor CN6

FJPM Interface transport motor Stepping motor CN21

Connector on

finisher

controller PCB

Notation Name Description

Connector on

controller PCB

FED Entry paper sensor Photointerrupter CN16

FFPD Bookbinding position

Photointerrupter CN16

sensor

finisher

MX-FNX2/AR-PN1/MX-RBX1 OPERATIONAL DESCRIPTION 5 – 5

Page 16

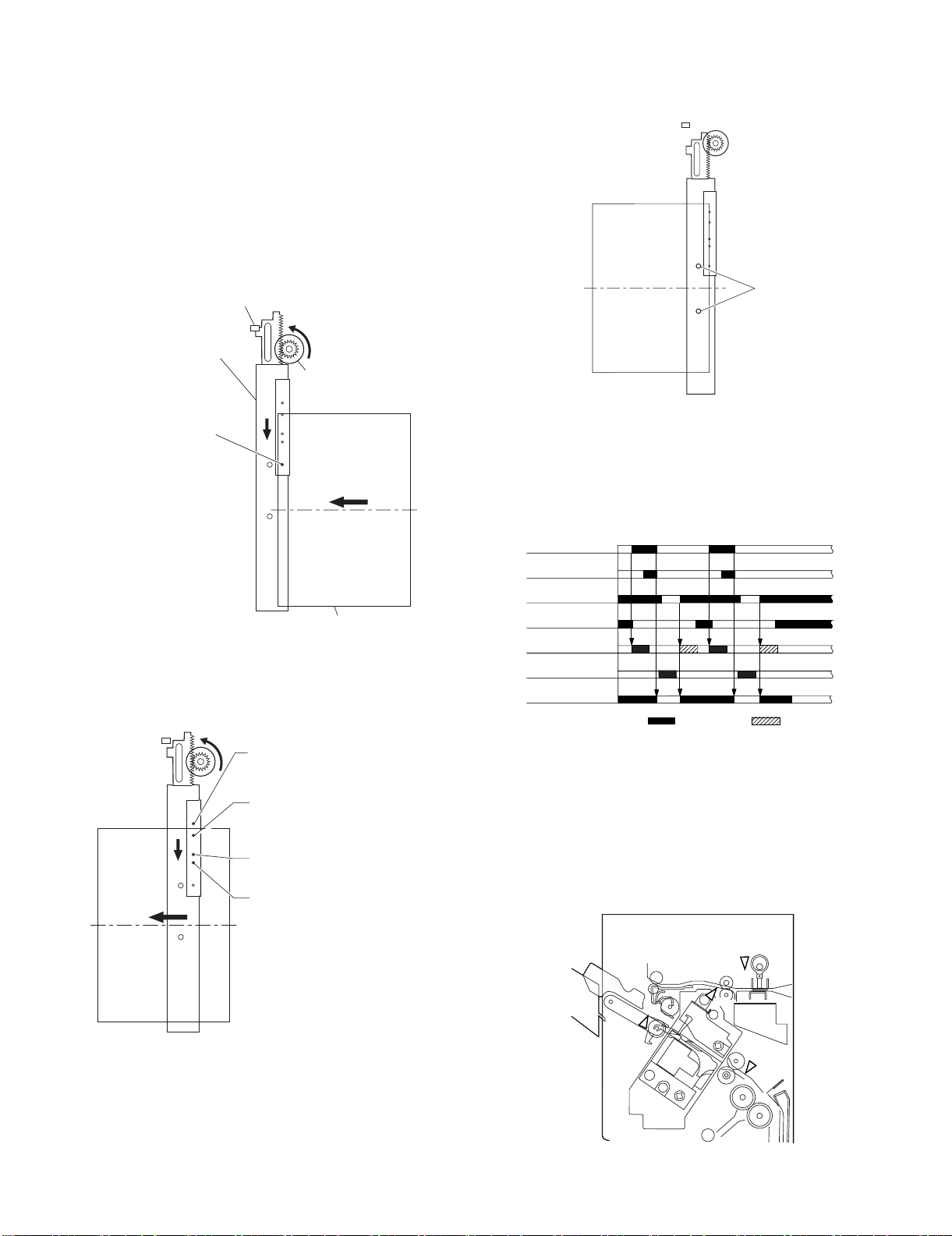

C. Job Offset

(1) Outline

"Job offset" refers to the operation by which the machine delivers a

set of sheets with them pulled forward or backward for sorting.

Switching between the forward and backward directions is made

using an aligning plate (front) and an aligning plate (rear).

The sheet coming between the delivery rollers is fed onto the processing tray and then fed toward the stopper by the paddle.

A swing guide is at the up position while a sheet is being pulled

onto the processing tray or during alignment. It is at the down position during stack feeding, stack delivery, or stapling.

At power-on, the finisher controller PCB drives the aligning motor

(front) (FFJM) and the aligning motor (rear) (FRJM) to return the

two aligning plates to their home positions.

Sensor Symbol Connector

Aligning home position sensor (front) FFJHPD CN4-3

Aligning home position sensor (rear) FRJHPD CN5-15

Stack roller home position sensor FARHPD CN9-9

Paddle home position sensor FPDHPD CN9-3

(3) Offset Operation

Each sheet is pulled forward or backward using the aligning plate

(front) and the aligning plate (rear).

The offset operation is performed each time a sheet is pulled onto

the processing tray.

Offsetting in the forward direction

Aligning plate (rear)

Sheet to be offset

Tr ay

Aligning plate (front)

Function Motor Symbol

Drives the aligning plate (front) Aligning motor (front) FFJM

Drives the aligning plate (rear) Aligning motor (rear) FRJM

Drives the swing guide drive Paddle motor FPM

Drives the paddle (feeds paper) Paddle motor FPM

Aligning home position sensor (rear)

(FRJHPD)

Light-shielding plate

Paper

Alignment motor (front)

(FFJM)

Aligning plate

(front)

(Front)

Light-shielding plate

Aligning home position sensor (front)

(FFJHPD)

Aligning plate

(rear)

Alignment

motor (rear) (FRJM)

(2) Processing Tray Paper Stacking Operation

A sheet coming between the delivery rollers is fed onto the processing tray. Then, the paddle taps on the sheet surface to locate

the sheet against the processing tray stopper.

Paper

Aligning plate

Paddle

Stack delivery roller (upper)

Offsetting in the backward direction

Aligning plate (rear)

Sheet to be offset

Tray

Aligning plate (front)

(4) Stack Delivery Operation

Stack delivery takes place when 1 sheet of large-size paper or 25

sheets of small-size paper have been stacked on the processing

tray with them offset in either direction.

The paddle motor (FPM) rotates and the swing guide descends to

hold the paper stack between the upper and lower stack delivery

rollers. The stack delivery motor (FAM) rotates in the forward direction to rotate the delivery rollers, feeding the paper stack in the

delivery direction. The delivery belt home position sensor is turned

OFF. The delivery motor is driven a specified number of pulses,

causing the swing guide to ascend. Next, the paper delivery motor

is driven. Next, the delivery motor is driven to deliver the paper

stack with the nails of the delivery belt that rotates in sync with the

stack delivery rollers.

Delivery belt

Swing guide

Swing guide

Processing tray stopper

Stack delivery roller (lower)

MX-FNX2/AR-PN1/MX-RBX1 OPERATIONAL DESCRIPTION 5 – 6

Page 17

Job offset sequence

Start signal

Entry paper sensor

(FFD)

Alignment tray sensor

(FAD)

Feed motor (FEM)

Bundle exit motor(FAM)

Delivery belt home

position sensor (FOBHPD)

Paddle motor (FPM)

Paddle home position

sensor (FPDHPD)

Bundle roller homeposition

sensor (FARHPD)

Staple safety switch

(FSSSW)

Alignment motor (front)

(FFJM)

Alignment home position

sensor (front) (FFJHPD)

Alignment motor (rear)

(FRJM)

Alignment home position

sensor (rear) (FRJHPD)

Host machine delivery signal

∗

4 ms (A4)

∗

Variable by the size

60msec

4ms(A4)

∗

30msec

∗∗

4ms(A4)

220msec

: CW rotation : CCW rotation

4ms(A4)

3. Stapling Operation

A. Outline

Staple operation is performed to staple a specified sheets of paper

using a stapler unit.

The stapling position depends on the staple mode and paper size.

When the machine starts immediately after power-on, the finisher

controller PCB drives the staple shift motor (FSM) to return the stapler unit to the home position. The stapler unit starts moving toward

the front of the stapler frame. It stops when the staple shift home

position sensor (FSTHPD) on the slide PCB located under the stapler unit. Next, the staple shift motor (FSM) is driven a specified

number of pulses. The stapler unit moves to rear standby position

at the back of the machine, entering the standby state.

B. Stapling Operation

When stacking and alignment of paper on the processing tray are

complete, the finisher controller PCB drives the paddle motor

(FPM) in the reverse direction and lowers the swing guide. When

the swing guide descends, the paper stack is sandwiched between

the upper and lower stack delivery rollers.

The finisher control PCB shifts the stapler according to the specified staple position to perform stapling. (Only for B5-R, 1-position

bottom stapling is made at the rear side of 2-posiiton stapling.)

When the stapler shifts toward you, the process tray stopper is put

down to the lower side.

Paper stack

Swing guide

Stack delivery roller (upper)

Processing tray

stopper

Delivery tray

Paddle motor (FPM)

Stack

delivery

roller

(lower)

Stapler

Bundle roller home

position sensor

(FARHPD)

Light-shielding plate

Sensor Symbol Connector Function Remarks

Staple shift

home position

sensor

FSTHPD CN11-3 Detects the home

position for the

stapler moving

back and forth.

Staple drive

home position

sensor

Self prime

sensor

FSHPD CN11-4 Detects the home

position for the

stapling operation

FSPD CN11-5 Detects presence

or absence of

In the

stapler

In the

stapler

staples in the

cartridge.

Staple empty

sensor

FSD CN11-6 Cartridge empty

detection

In the

stapler

Function Motor Symbol Remarks

Moves the stapler. Staple shift motor FSM —

Performs stapling operation Staple motor FFSM —

Stapler

(Deliver direction)

Light-shielding plate

Staple

shift motor

(FSM)

Paper stack

—

Staple safety

switch (FSSSW)

Swing guide

Stack delivery

roller (upper)

Stack delivery

roller (lower)

Staple shift home position sensor (FSTHPD)

MX-FNX2/AR-PN1/MX-RBX1 OPERATIONAL DESCRIPTION 5 – 7

Page 18

C. Delivery Operation after Stapling

When stapling is complete, the finisher controller PCB drives the

stack delivery motor (FAM) in the forward direction to feed the

paper stack (sandwiched between the stack delivery rollers) in the

delivery direction. The delivery belt home position sensor (FOBHPD) is turned OFF. The stack delivery motor (FAM) is driven a

specified number of pulses, causing the swing guide to ascend. At

the same time, the staple shift motor (FSM) is driven to return the

stapler back to the standby position, followed by driving of the stack

delivery motor (FAM). Then, the paper stack is delivered with the

nails of the delivery belt that rotates in sync with the stack delivery

rollers.

Paper stack

Swing guide

Delivery tray

Paddle motor (FPM)

Delivery belt

Stack delivery

roller (lower)

Stack roller home position

sensor (FARHPD)

Light-shielding plate

Stapler

D. Stapler Unit

The staple motor (FFSM) is used to perform stapling operation.

This motor rotates the cam one turn for stapling. The home position

of this cam is detected by the staple drive home position sensor

(FSHPD).

The staple motor (FFSM) is rotated in the forward or reverse direction under the control of the macro computer (IC13) on the finisher

controller PCB.

When the staple drive home position sensor (FSHPD) is OFF, the

finisher controller PCB rotates the staple motor (FFSM) in the forward direction until the sensor turns ON, allowing the staple cam to

the original position.

The staple empty sensor (FSD) is used to detect presence/

absence of a staple cartridge in the machine. The self prime sensor

(FSPD) is used to detect presence/absence of staples in the cartridge.

The finisher controller circuit does not drive the staple motor

(FFSM) unless the staple safety switch (FSSSW) is ON (the swing

guide is close). This assures safety in case where you happen to

put your finger in the stapler.

Staple safety

switch (FSSSW)

Swing guide

Stack delivery

roller (lower)

Stack delivery roller

(upper)

Staple drive home position detect signal

Staple empty detect signal

Cartridge detect signal

Finisher controller PCB

FFSM

Staple motor drive signal

MX-FNX2/AR-PN1/MX-RBX1 OPERATIONAL DESCRIPTION 5 – 8

Page 19

(1) Stapler Movement Controller

The stapler unit is moved by the staple shift motor (FSM). Its home

position is detected by the staple shift home position sensor

(FSTHPD). The stapler waits at the back irrespective of the staple

mode and paper size. After paper has been stacked on the processing tray, the stapler is moved to the specified stapling position

in response to the stapling command from the host machine.

The figure below shows the standby position of the stapler and the

stapling position depending on the staple mode.

1) Front 1-point stapling

The stapler waits at the back. The stapler moves to and

returns from the stapling position for each stapling operation.

4) Middle 2-point stapling (bind mode)

The stapler waits at the back. The stapler moves to and

returns from the stapling position for each stapling operation.

The stapler first staples a paper stack at the rear stapling position and then staples it at the front stapling position.

Standby position

Stapler

Stapling position

Standby position

Stapler

Feed direction

Stopper

Stapling position

2) Rear 1-point stapling

The stapler waits at the back. The stapling position is the same

as the standby position. (Except B5R)

Standby position

Stapling position

Stapler

Feed direction

Stopper

Feed direction

Stapling Operation Sequence

Rear 1-point Stapling of 2 Sheets

Start signal

Entry paper sensor (FED)

Alignment tray sensor

(FAD)

Feed motor (FFM)

Bundle exit motor (FAM)

Exit belt home position

sensor (FOBHPD)

Paddle motor (FPM)

Paddle home position

sensor (FPDHPD)

Bundle roller home

position sensor (FARHPD)

Staple safety switch

(FSSSW)

Alignment motor (front)

(FFJM)

Alignment home position

sensor (front) (FFJHPD)

Staple motor (FFSM)

Staple drive home position

sensor (FSHPD)

Host machine delivery signal

4ms (A4)

Stopper

Stapling position

Stack delivery

Staple

10msec

∗

:CWrotation∗ Variable by the size : CCW rotation

4ms (A4)

∗

20msec

3) Middle 2-point stapling

The stapler waits at the back. The stapler moves to and

returns from the stapling position for each stapling operation.

The stapler first staples a paper stack at the rear stapling position and then staples it at the front stapling position.

Standby position

Stapler

Stapling position

Stopper

Feed direction

Stapling position

MX-FNX2/AR-PN1/MX-RBX1 OPERATIONAL DESCRIPTION 5 – 9

Page 20

4. Delivery Tray Operation

5. Saddle Unit

A. Outline

The machine has a delivery tray in the finisher unit and a bind tray

in the saddle unit.

The bind tray in the saddle unit is of the fixed type and all the folded

paper stacks are delivered to this tray. This tray has a bind tray

sensor (FFED) to detect presence/absence of paper.

The delivery tray in the finisher unit is moved up and down using a

lift motor (FLM).

The finisher has a tray paper sensor (FBED) to detect presence/

absence of paper on the stack tray.

The home position sensor of the delivery tray is detected by the

paper surface sensor (FSLD). When paper has already been

stacked on the delivery tray, the home position is on the top surface

of the stacked paper. When paper has not yet been stacked on the

delivery tray, the home position is at the position where the edge of

the delivery tray is detected. At power-on, the finisher controller

PCB drives the lift motor (FLM) to return the delivery tray to the

home position.

When the paper coming from the processing tray is stacked on the

delivery tray, the lift motor (FLM) is driven a specified number of

pulses, causing the delivery tray to descend. Clock pulses are

detected by the lift lock sensor (FLE). Then, the delivery tray

returns to the home position for the next stacking operation.

The upper limit of the delivery tray is detected by the lift upper limit

sensor (FULD). When the lift upper limit sensor (FULD) is turned

ON, the finisher controller PCB stops the lift motor (FLM) that is

ascending.

The lower limit of the delivery tray is detected by the lift lower limit

sensor (FLLD). When the lift lower limit sensor (FLLD) is turned

ON, the finisher controller PCB stops the lift motor (FLM) that is

descending.

The finisher unit has a tray middle sensor (FMLD) to detect overstacking of large-size or mixed paper according to the stack height.

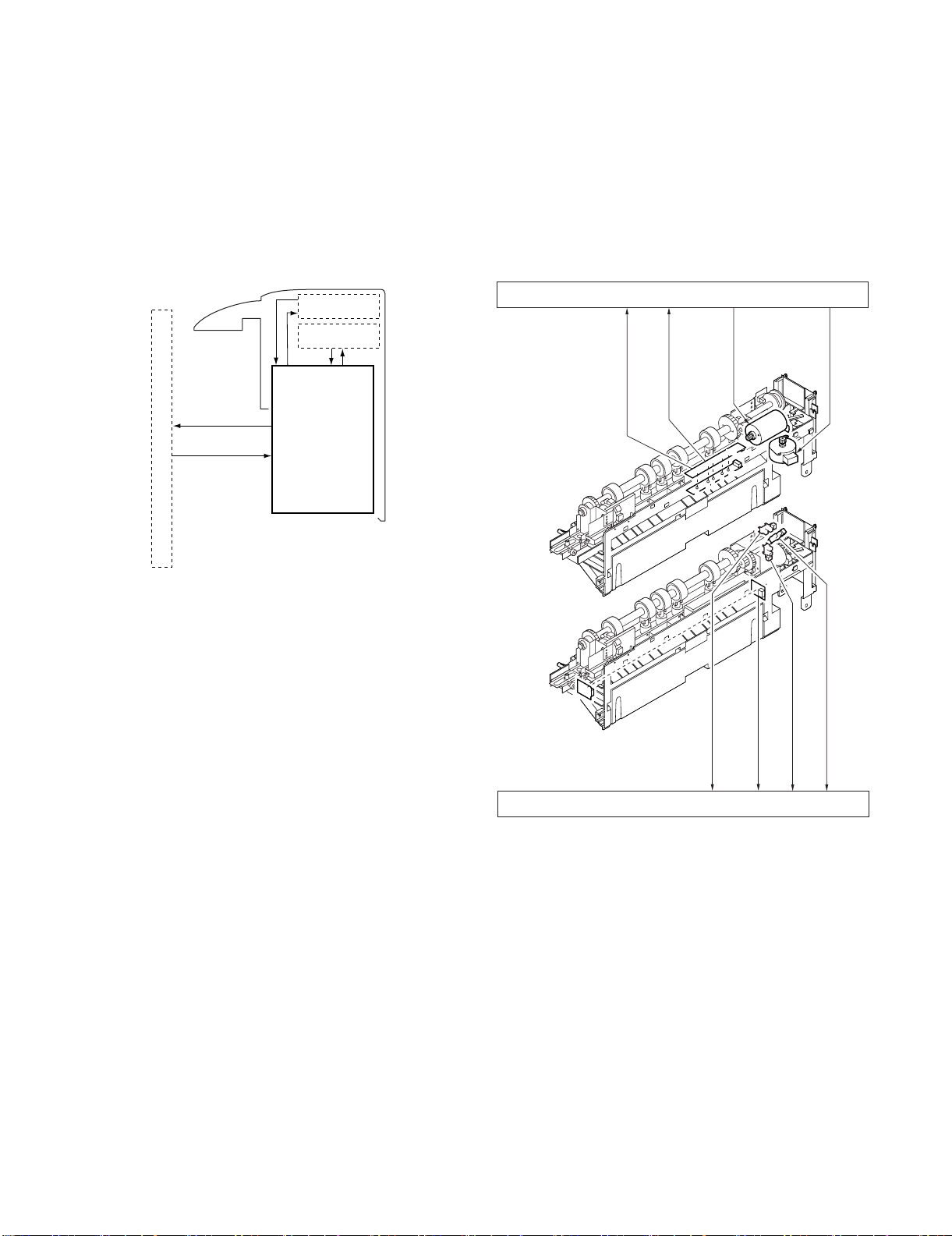

A. Basic Operations

(1) Outline

The machine stitches a stack of sheets (middle 2-point), then folds

the stack in two in the finisher. These operations are controlled by

the finisher controller PCB.

The finisher controller PCB is controlled by the commands from the

host machine.

B. Feed/Drive System

(1) Outline

This machine stitches the paper stack coming from the finisher,

folds it, and delivers it to the bind tray in the saddle unit in response

to the commands from the host machine.

That is, the machine performs the following operations:

a. Paper feed-in

b. Stitching

c. Stack feed

d. Folding/delivery

a) Paper feed-in

d) Folding/delivery

b) Stitching

c) Stack feed

Lift upper sensor

(FULD)

Lift lower sensor

(FLLD)

Lift lock sensor

(FLE)

Tray middle sensor

(FMLD)

Lift motor (FLM)

Tray paper sensor

Paper level sensor

Edge

Delivery tray

(FBED)

(FSLD)

a. Paper feed-in

After being aligned on the processing tray, a stack of sheets is

sandwiched between the stack delivery rollers. As the stack delivery rollers rotate, the stack is fed toward the saddle unit.

Stack delivery roller (upper)

Paper stack

Stack delivery roller

(lower)

MX-FNX2/AR-PN1/MX-RBX1 OPERATIONAL DESCRIPTION 5 – 10

Page 21

b. Stitching

Stack delivery roller (upper)

Paper stack

Stack delivery roller

(lower)

Stack feed roller (lower)

Fold position sensor

When the center of the paper stack (stitching position) reaches the

stapler's staple position, the stapler stitches the paper stack.

When only one sheet is fed from the host machine, the next step

(stack feed) is performed without performing the stitching operation.

Staple

Stapler (lower)

Stapler (upper)

c. Stack feed

The stack feed rollers feed the paper stack to the stack folding/

delivery position where the center of the stack (stitched position) is

level with the paper pushing plate and paper folding roller's nip part.

C. Paper Feed System

(1) Outline

The paper feed system feeds a stack of sheets (coming from the

finisher) to the position where the center of the paper stack (stitching position) is aligned to the stapler's staple, allowing the next step

(stitching and folding) to be performed.

When sheets of paper have been stacked and aligned on the processing tray, the paddle motor (FPM) rotates in the reverse direction, causing the swing guide to descend. As the swing guide

descends, the paper stack is sandwiched between the upper and

lower stack delivery rollers. The stack delivery motor (FAM) rotates

in the reverse direction, feeding the paper stack toward the saddle

unit. When the leading edge of the paper stack reaches the binding

position sensor (FFPD), the finisher controller PCB drives the stack

delivery motor (FAM) a specified number of motor pulses to stop

the center of the paper stack (stitching position) at the stapler's staple position. Before the paper stack passes through the stack feed

rollers, the feed motor (FFM) is driven to rotate the stack feed roller

(lower) so that the leading edge of the paper stack is not bent.

Stack feed roller (upper)

Paper pushing plate

Stack feed roller (lower)

Paper fold roller

d. Folding/delivery

The paper pushing plate pushes in the center of the paper stack to

feed it toward the paper fold rollers. Then, the paper fold rollers and

bind delivery rollers deliver the paper stack to the bind tray.

D. Stack Feed System

(1) Outline

The stack feed system feeds the stitched paper stack to the folding

position.

When stitching is complete, the feed motor (FFM) rotates, causing

the stack feed roller (upper) to descend. The paper stack is sandwiched between the stack feed rollers. Then, the bind clutch (FFC)

is turned ON to rotate the feed motor (FFM) in the forward direction, thus feeding the paper stack to the folding position. The feed

amount is equivalent to the number of pulses used to drive the feed

motor (FFM) until the paper stack reaches the folding position.

Stack feed roller (upper)

Feed amount

Bind delivery rollers

Paper fold rollers

MX-FNX2/AR-PN1/MX-RBX1 OPERATIONAL DESCRIPTION 5 – 11

Stack feed roller (lower)

Page 22

E. Fold/Delivery System

Feed motor (FFM)

Bundle exit motor (FAM)

Paddle motor (FPM)

Paddle home position

sensor (FPDHPD)

Bundle roller home position

sensor (FARHPD)

Staple safety switch

(FSSSW)

Staple shift motor (FSM)

Staple motor (FFSM)

Staple drive home position

sensor (FSHPD)

Bookbinding position

sensor (FFPD)

Bookbinding roller home

position sensor (FFRHPD)

Bookbinding clutch (FFC)

Bookbinding home

position sensor (FFHPD)

Bookbinding paper

sensor (FFED)

: CW rotation : CCW rotation

50msec

Staple

Fold, Delivery

13571msec

(1) Outline

The paper fold mechanism consists of a guide plate, paper fold rollers, and a paper pushing plate.

The guide plate, paper fold rollers, and paper pushing plate are

driven by the staple motor (FFSM). The drive force is transferred

with a combination of gears and cams. Motor operation is monitored by the binding lock sensor (FFE).

Until the paper stack reaches the folding position, the guide plate

covers the paper fold rollers to act as a paper path through which a

paper stack is fed to the saddle unit and to prevent a paper stack

from touching the rollers.

A binding home position sensor (FFHPD) is provided to detect the

positions of the paper fold rollers and paper pushing plate.

The paper stack folded in two by the paper fold rollers is delivered

by bind delivery rollers. The bind delivery rollers are also driven by

the staple motor (FFSM).

A bind tray sensor (FFED) is provided on the bind tray to detect

presence/absence of a paper stack; however, it is not used to

detect a jam.

(2) Paper Folding

Paper is folded using paper fold rollers and a paper pushing plate.

Almost concurrently with the start of roller rotation, the paper pushing plate starts operating to push the paper stack into the gap

between the paper fold rollers. When the paper stack is fed about

10 mm with the rotation of the paper fold rollers, the paper pushing

plate returns to the home position. Then, the paper stack is delivered to the bind tray using the paper fold rollers and bind delivery

rollers.

Half the entire surface of each paper fold roller is uncovered

excluding the central area and the area at the left and right ends.

The uncovered surface of the upper paper fold roller comes in

touch with the uncovered surface of the lower paper fold roller only

at the center and left and right ends, allowing a paper stack to be

fed without causing creases. The other half of the upper paper fold

roller that is covered comes in touch with the other half of the lower

paper fold roller that is also covered, allowing a paper stack to be

folded while being fed.

Paper fold roller (upper)

Staple motor

(FFSM)

FFSM

Paper fold roller (lower)

Paper stack

Outlet

Paper stack

Bookbinding home position

sensor (FFHPD)

Paper pushing plate

Inlet

Paper push plate

Paper fold roller (upper)

Staple motor

(FFSM)

Came

Paper stack

FFSM

Paper fold roller (lower)

Sensor flag

Bookbinding home position

sensor (FFHPD)

MX-FNX2/AR-PN1/MX-RBX1 OPERATIONAL DESCRIPTION 5 – 12

Folds/feeds a paper stack.

Feeds a paper stack.

Paper pushing plate

Page 23

F. Punch Unit (AR-PN1A/B/C/D)

Punch motor

(FPNM)

drive signal

Punch controller PCB (1/2)

Waste full detection signal

(LED121,PT131) FPDD

Punch home position sensor detection signal

(FPHPD)

Horizontal registration home position

(FPSHPD)

detection signal

SREGHP

Punch controller PCB (2/2)

Punch motor lock sensor (

FPMCK

)

detection signal

PUNCHCLK

PT1

LED1

2

3

4

5

5

2

3

4

Trailing edge detection signal

(LED5, PT5) FPTD

Horizontal registration detection

signal (LED1 - 4, PT1 - 4)

FPSD1 - 4

Horizontal registration

motor (FPSM) drive signal

PT131

LED121

(1) Basic Operations

a. Outline

The punch unit is an option, and is designed for installation to the

pickup assembly of the finisher.

The punch unit is not equipped with a paper feeding mechanism,

and the sheets from the host machine move through the punch unit

and then the feed system of the finisher. When the trailing edge of a

sheet from the host machine reaches the punch unit, the sheet is

stopped once, and the punch shaft is rotated to punch a hole along

the trailing edge. These operations are controlled with various commands from the finisher controller PCB as well as the commands

from the punch controller PCB.

Punch drive system

Horizontal registration

drive system

Punch controller PCB

Finisher unit control system

The punch motor (FPNM), punch unit, and sensors make up the

punch slide unit, which moves to the front/rear to suit the selected

paper size. The movement to the front/rear is driven by the punch

horizontal registration motor (FPSM). The home position of the

punch slide unit is detected by the punch horizontal registration

home position sensor (FPSHPD), and the punch horizontal registration motor (FPSM) is a stepping motor.

The punch motor (FPNM) and punch horizontal registration motor

(FPSM) are controlled with various commands from the finisher

controller PCB as well as the commands from the punch controller

PCB. The waste paper occurring as the result of punching is collected in the waste paper case. The case is monitored by the

LED121 on the waste full LED PCB and PT131 on the waste full

photosensor PCB (FPDD).

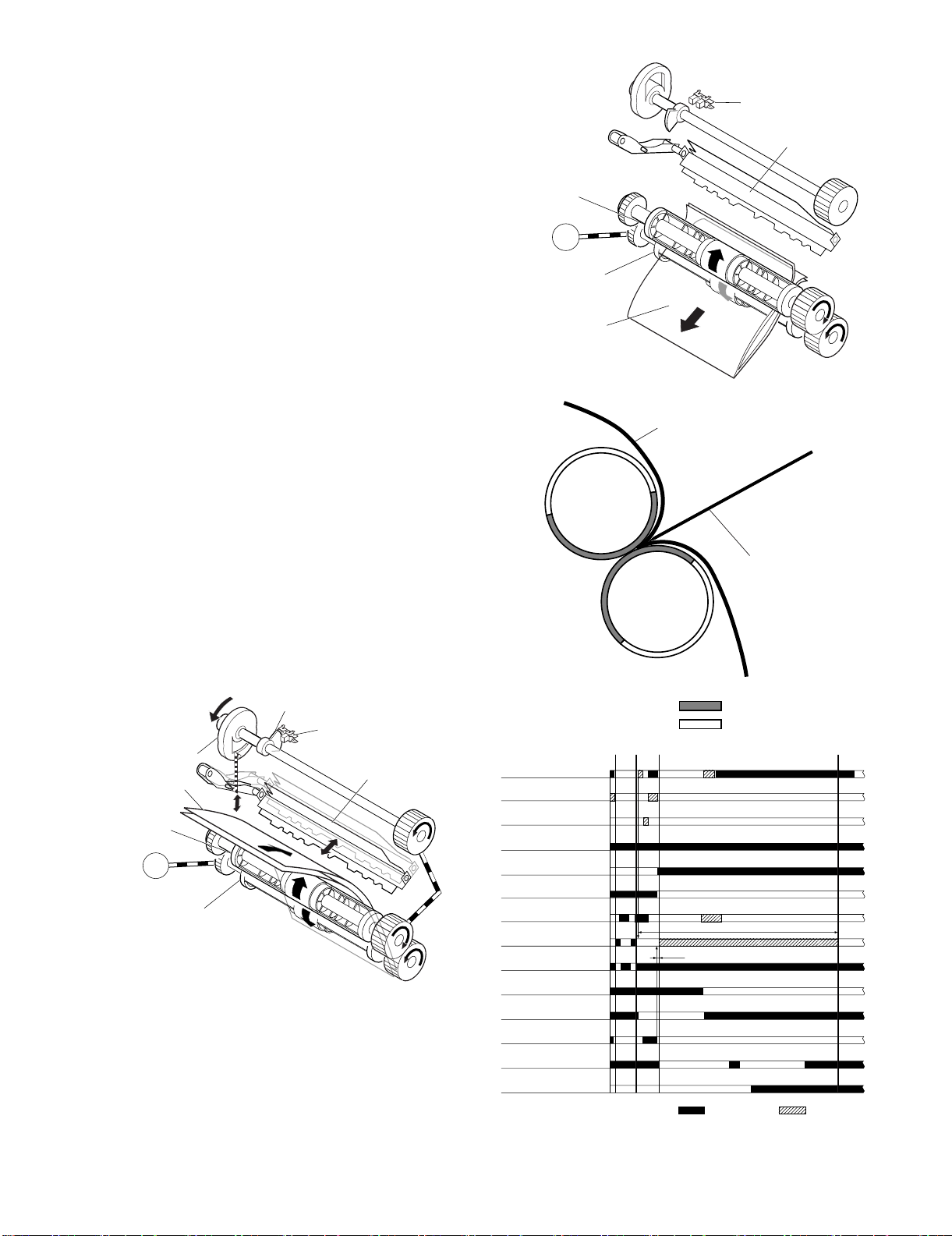

(2) Punching Operation

a. Outline

The punch unit is located in the pickup assembly of the finisher,

and is used to punch holes in sheets that have been sent from the

host machine and stopped inside it. When the trailing edge of a

sheet reaches the punch unit, the inlet roller of the finisher assembly stops the sheet to punch a hole along the trailing edge of the

sheet.

The punch unit consists of a die and hole puncher (punch blade).

The hole puncher is driven by the punch motor (FPNM). It is

attached to the eccentric cam of the punch shaft, and the rotation of

the punch shaft is converted into reciprocating motion for punching

operation.

The punch motor (FPNM) is a DC motor. The home position of the

punch shaft is detected by the punch home position sensor

(FPHPD). To make sure that the punch motor (FPNM), which is a

DC motor, stops exactly at its home position, the punch motor

(FPNM) is stopped in relation to the count of the clock pulses kept

by the punch motor lock sensor (FPMCK). A single punching operation is executed by rotating the punch shaft 180° from its home

position.

As many as five light-receiving transistors (photosensor PCB) are

mounted over the inlet paper path of the punch unit; on the other

hand, as many as five LEDs (LED PCB) are mounted under the

path, together serving as five sensors. The frontmost sensor

(LED5, PT5) is used as a trailing edge sensor (FPTD) to detect the

training edge of sheets, and the remaining four (LED1 through

LED4, PT1 through PT4) are used as horizontal registration sensors (FPSD1 through FPSD4) to detect the rear position of sheets

when punching holes.

MX-FNX2/AR-PN1/MX-RBX1 OPERATIONAL DESCRIPTION 5 – 13

Page 24

b. Punching Operation

(punch shaft at rest/

home position)

(punch shaft CW rotation by 90°/

punch at upper limit)

(punch shaft CW rotation by 180°/

punch back to initial position)

(punch shaft at rest/

home position)

(punch shaft CCW rotation

by 90°/hole made)

(punch shaft CCW rotation by 180°/

end of punching operation)

The hole puncher is driven by the punch motor (FPNM). The home

position for the hole puncher is detected by the punch home position sensor (FPHPD).

The punch unit comes in four types, selected to suit the country of

installation: 2-hole (Punch Unit-J1), 2- and 3-hole (Punch Unit-K1),

or two types of 4-hole (Punch Unit-G1, Punch Unit-H1).

The 2-hole and 4-hole types punch a hole when the punch shaft is

rotated 180° from the home position, causing the punch to make a

single round trip. The 2-/3-hole type punches a hole, but the circumference of the punch shaft is divided into two (half for 2-hole

and the other half for 3-hole).

1) 2-Hole, 4-Hole Type

The home position is identified when the punch home position

sensor (FPHPD) is ON. The punching operation for the first

sheet ends when the punch shaft has rotated 180° and the

punch home position sensor (FPHPD) goes ON; the punching

operation for the second sheet ends when the punch shaft has

rotated 180° in reverse and the punch home position sensor

(FPHPD) goes ON.

<1> A hole is punched along the trailing edge of the 1st sheet.

Sensor flag

Punch home position

sensor (FPHPD)

Punch shaft

<1> A hole is made along the trailing edge of the 1st sheet.

Sensor flag

Punch home position

sensor (FPHPD)

Punch shaft

Eccentric cam

(punch shaft at rest/

Die

Die

home position)

Hole

puncher

Paper

(punch shaft CW rotation

by 90°/hole made)

Waste paper

(punch shaft CW rotation by 180°/

end of punching operation)

While two holes are being made, the 3-hole puncher

makes a single round trip in escape direction.

Eccentric cam

Die

Die

(punch shaft at rest/

home position)

Hole

puncher

Paper

(punch shaft CW rotation

by 90°/hole made)

Waste paper

(punch shaft CW rotation by 180°/

end of punching operation)

<2> A hole is made along the trailing edge of the 2nd sheet.

Sensor flag

Punch home position

sensor (FPHPD)

Punch shaft

Eccentric cam

Die

(punch shaft at rest/

Die

home position)

Hole

puncher

Paper

(punch shaft CW rotation

Waste paper

by 90°/hole made)

(punch shaft CW rotation by 180°/

end of punching operation)

2) 2-/3-Hole Type

The home position is identified when the punch home position

sensor (FPHPD) is ON. To make two holes, the punching operation for the first sheet ends when the punch shaft rotates 180°

(half circumference) and the punch home position sensor

(FPHPD) goes ON. At this time, the 3-hole puncher makes a

single round trip in escape direction (moving up the hole

puncher) on a half circumference of the punch shaft. The

punching operation for the second sheet ends when the punch

shaft has rotated 180° counterclockwise and the punch home

position sensor (FPHPD) goes ON (half circumference).

At this time, the 3-hole puncher makes a single round trip in

escape direction (moving up the hole puncher) on the other

half circumference of the punch shaft.

The punching operation takes place as follows when making

two holes in two sheets of paper:

<2> Holes are made along the trailing edge of the 2nd sheet.

While two hole are being made, the 3-hole puncher makes

a single round trip in escape direction (moving up the hole

puncher).

(punch shaft at rest/

home position)

(punch shaft CCW rotation by

90°/punch at upper limit)

(punch CCW rotation by 180°/

punch back at initial position)

MX-FNX2/AR-PN1/MX-RBX1 OPERATIONAL DESCRIPTION 5 – 14

Page 25

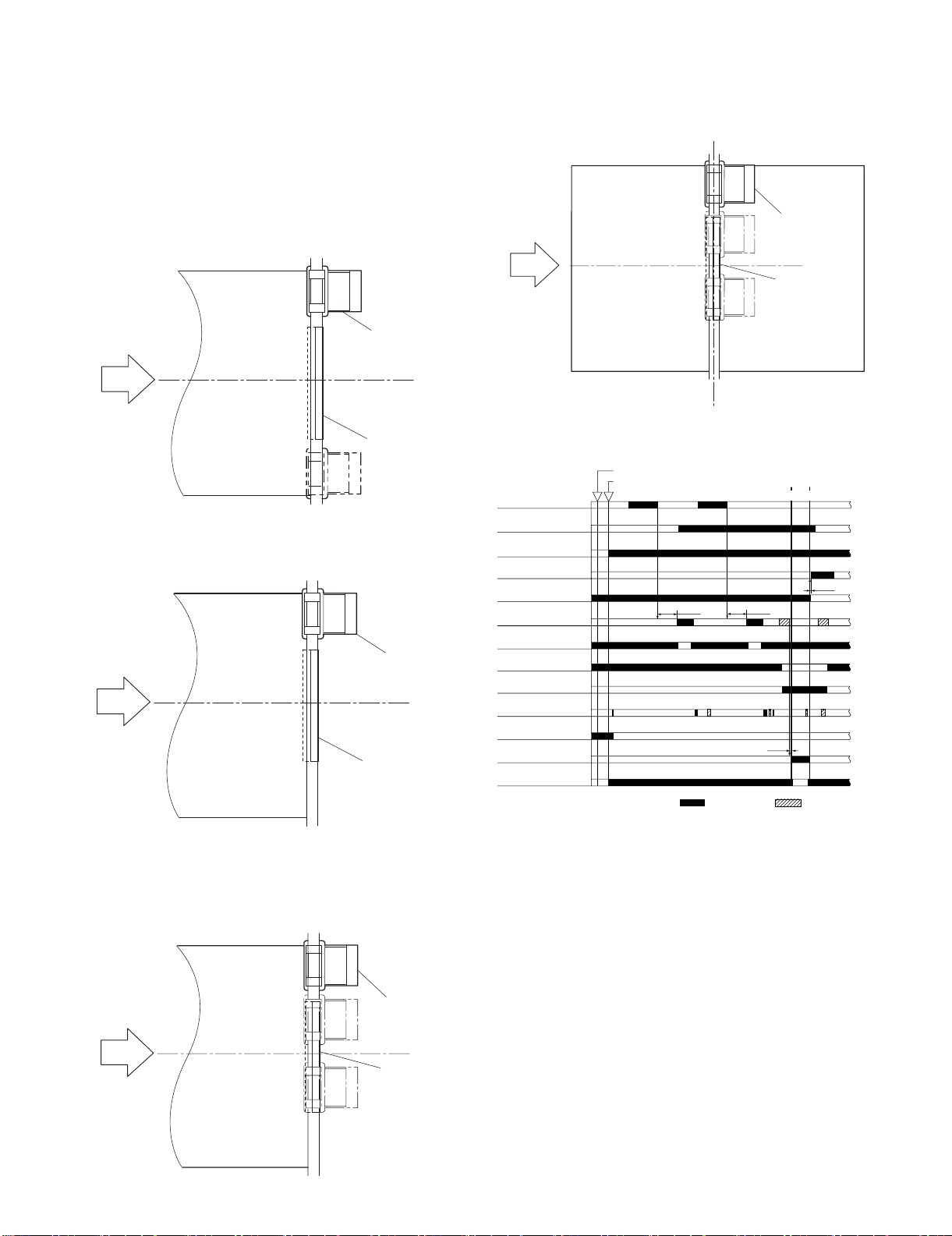

(3) Horizontal Registration Operation

Punch

The horizontal registration drive for the punch slide unit is provided

by the punch horizontal registration motor (FPSM). The home position of the punch slide unit is detected by the punch horizontal registration home position sensor (FPSHPD). The punch slide unit

detects the trailing edge of sheets using the trailing edge sensor

(FPTD) and the horizontal registration sensors (FPSD1 through 4),

and causes a move to a specific position matching the trailing edge

of each sheet (in relation to the size of the sheet).

The horizontal registration operation takes place as follows:

1) When the leading edge of a sheet from the host machine is

detected by the trailing edge sensor (FPTD), the punch horizontal registration motor (FPSM) starts to move the punch

slide unit toward the front.

Punch side resist home position sensor

(FPSHPD)

Punch slide unit

Punch side resist motor

(FPSM)

Trailing edge sensor

(FPTD)

(direction of

paper delivery)

Paper

2) When the horizontal registration sensor (FPSD1 through 4)

suited to the paper size signal from the host machine detects

the rear edge of the sheet, the punch horizontal registration

motor (FPSM) causes a farther move to a specific position,

and stops the punch slide unit.

Horizontal registration sensor 1 (FPSD1);

used to detect the edge of sheets of A3, A4,

8.5" x 11", 11" x 17".

Horizontal registration sensor 2 (FPSD2);

used to detect the edge of sheets of B4, B5,

8.5" x 11"R, 8.5" x 14".

Horizontal registration sensor 3 (FPSD3);

used to detect the edge of sheets of A4R.

Horizontal registration sensor 4 (FPSD4);

used to detect the edge of sheets of B5R.

3) When the trailing edge sensor (FPTD) detects the trailing edge

of the sheet, the drive of the feed motor (FFM) is stopped,

thereby stopping the sheet. Then, the punch motor (FPNM) is

driven to punch holes in the sheet.

4) When the punching operation ends, the feed motor (FFM) of

the fisher unit is driven and, at the same time, the punch horizontal registration motor (FPSM) is rotated in reverse to return

the punch slide unit to its home position.

5) For each sheet that arrives in succession, the punch slide unit

is returned to its home position, and is caused to repeat steps

1 through 4.

Trailing edge sensor

(FPTD)

Horizontal registration

sensor (FPSD1 - 4)

Punch home position

sensor (FPHPD)

Punch horizontal registration

home position sensor (FPSHPD)

Punch horizontal

registration motor (FPSM)

Punch motor (FPNM)

Feed motor (FFM)

: CW rotation : CCW rotation

G. Detecting Jams

(1) Outline

The microprocessor (CPU) on the finisher controller PCB is programmed to check for jams in the finisher/saddle/puncher (option)

at such times as set in advance. It identifies a jam in reference to

the presence/absence of paper at a specific sensor. If a jam is

found, the finisher controller PCB communicates the nature of the

jam to the host machine in the form of a code(which may be

checked in service mode of the host machine).

FAD

FED

: Entry paper sensor

FAD

: Alignment tray sensor

FFPD

: Bookbinding position sensor

FPHPD

: Punch home position sensor

MX-FNX2/AR-PN1/MX-RBX1 OPERATIONAL DESCRIPTION 5 – 15

FPHPD

FED

FFPD

Page 26

a. Inlet Paper Sensor (FED) Delay Jam

Host machine delivery signal

Host machine delivery signal

Jam check

Entry paper sensor

(FED)

Feed motor (FFM)

approx. 1.0sec.

*

Normal

Jam check

Entry paper sensor

(FED)

Feed motor (FFM)

approx. 1.0sec.

*

Jam

* Variable depending on the paper size. (Because the paper feed speed may differ according to the paper size. (A4:1.0 sec.))

b. Inlet Paper Sensor (FED) Stationary Jam

Jam check

Entry paper sensor

(FED)

Feed motor (FFM)

approx. 1.4sec.*

Normal

Jam check

Entry paper sensor

(FED)

Feed motor (FFM)

approx. 1.4sec.*

Jam

* Variable depending on the paper size. (Because the paper feed speed may differ according to the paper size. (A4:1.4 sec.))

c. Binding Position Sensor (FFPD) Delay Jam

Jam check

Binding position

sensor (FFPD)

Stack delivery motor

(FAM)

1080 ms

Normal

Jam check

Binding position

sensor (FFPD)

Stack delivery motor

(FAM)

1080 ms

Jam

d. Binding Position Sensor (FFPD) Stationary Jam

Jam check

Binding position

sensor (FFPD)

Staple motor (FFSM)

approx. 16.2sec. approx.16.2sec.

Normal

Jam check

Binding position

sensor (FFPD)

Staple motor (FFSM)

Jam

e. Power-On Jam