Page 1

SERVICE MANUAL

CODE: 00ZMXFNX1/S1E

DIGITAL FULL COLOR

MULTIFUNCTIONAL SYSTEM OPTION

FINISHER / PUNCH MODULE

MX-FNX1

MODEL

CONTENTS

[1] PRODUCT OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2] SPECIFICTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

[3] UNPACKING AND INSTALLATION

* For how to unpacking and installation, refer to the installation manual (00ZMX2700/I1E).

[4] EXTERNAL VIEW AND INTERNAL STRUCTURE . . . . . . . . . . . . . 4-1

[5] OPERATIONAL DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[6] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[7] MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[8] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

MX-PNX1A/B/C/D

[9] SELF DIAGNOSTICS AND TROUBLE CODES . . . . . . . . . . . . . . . 9-1

[10] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

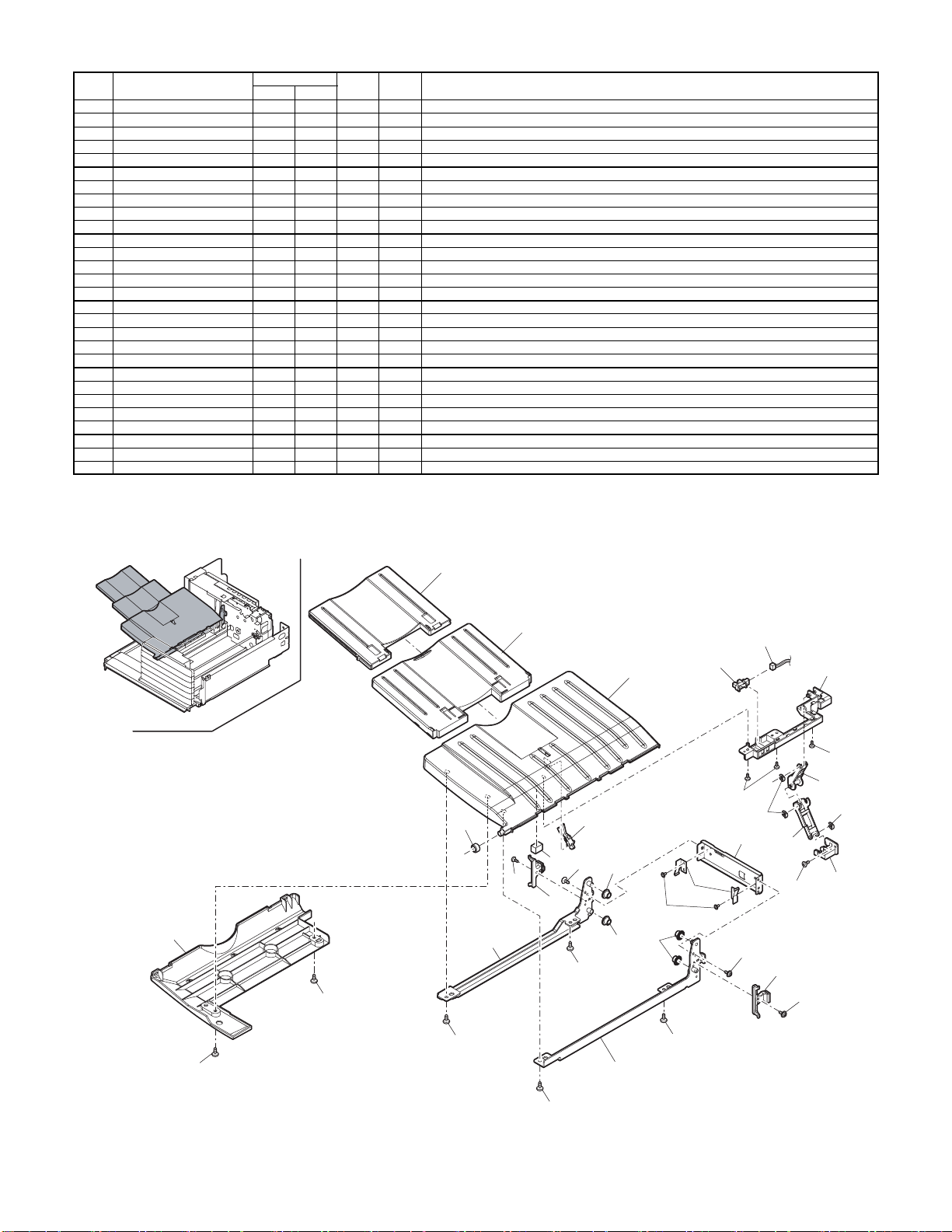

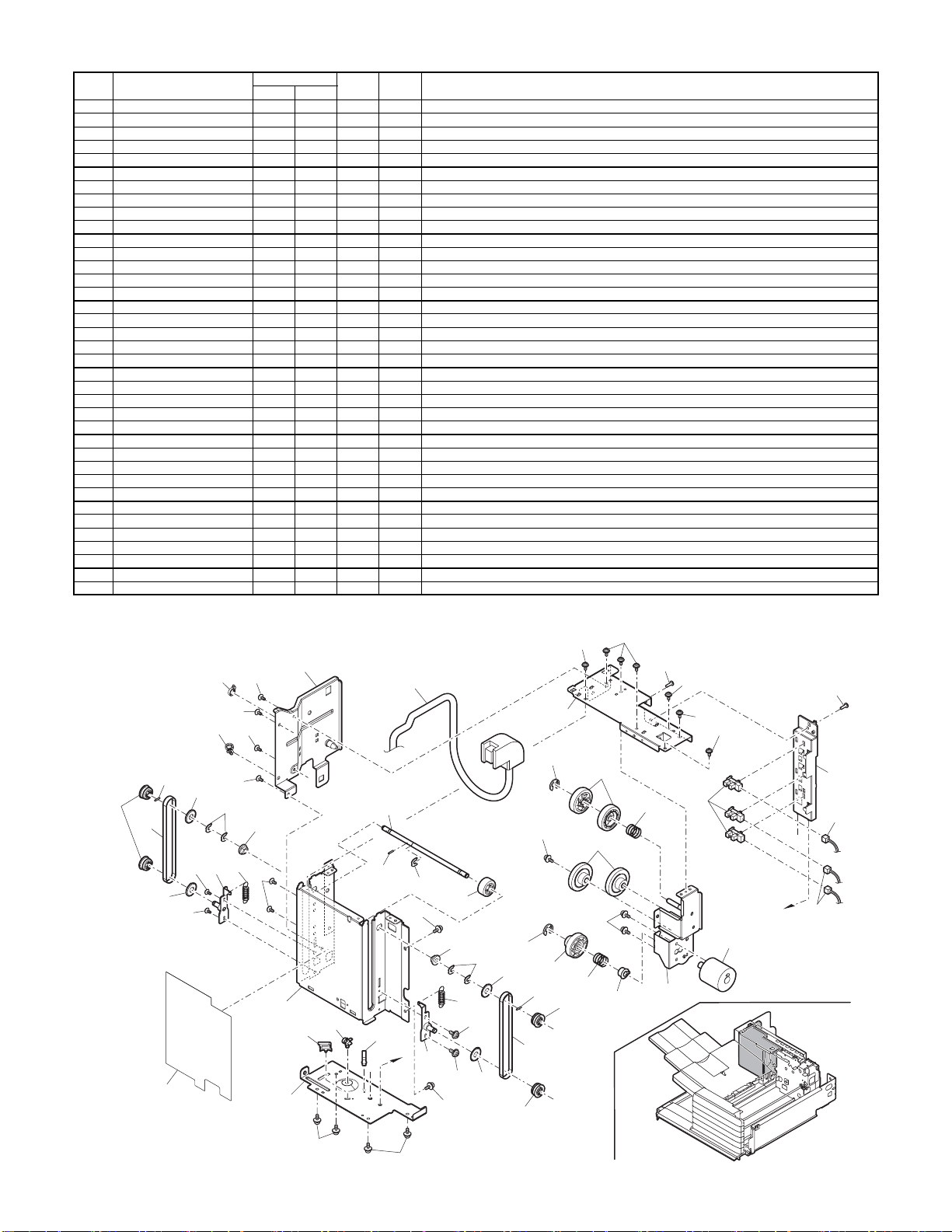

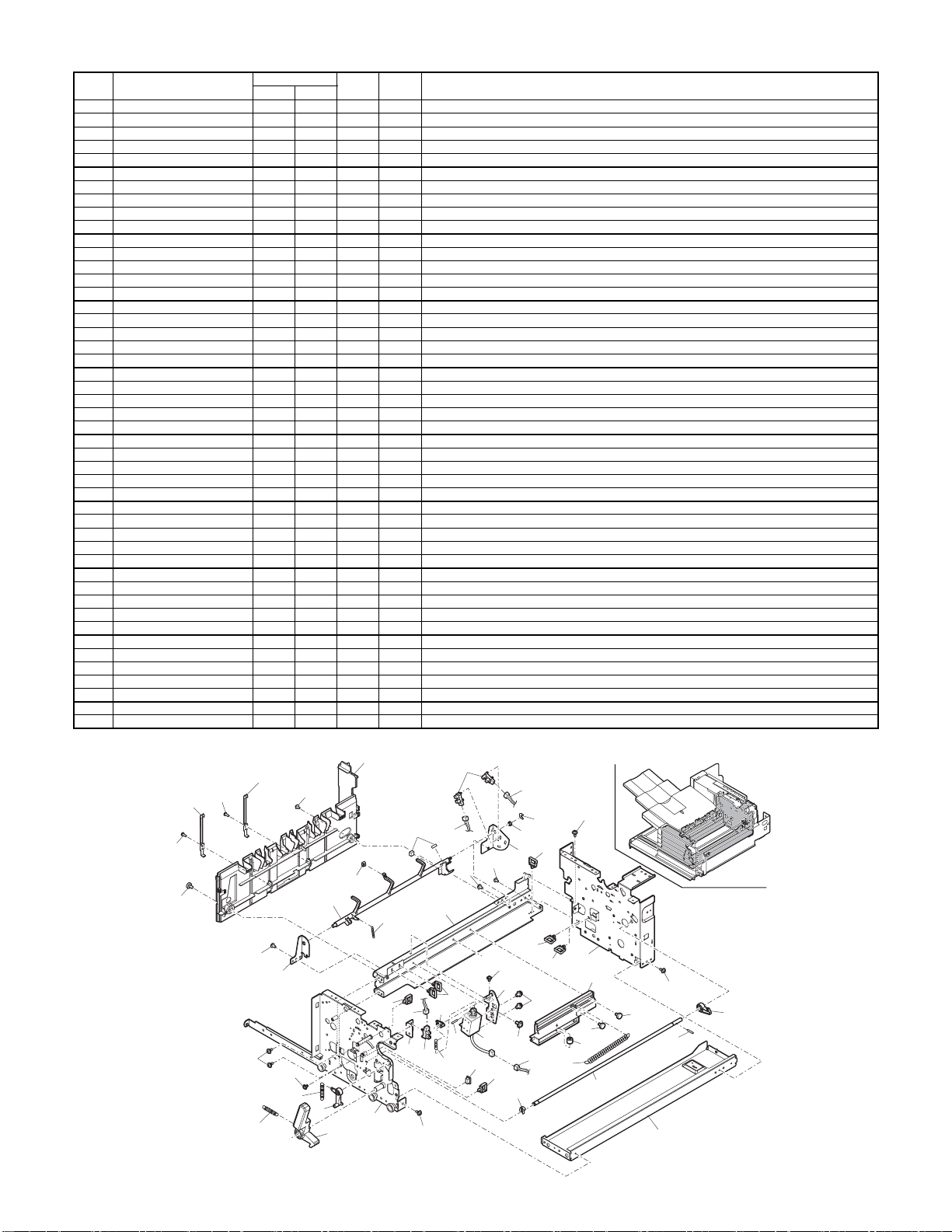

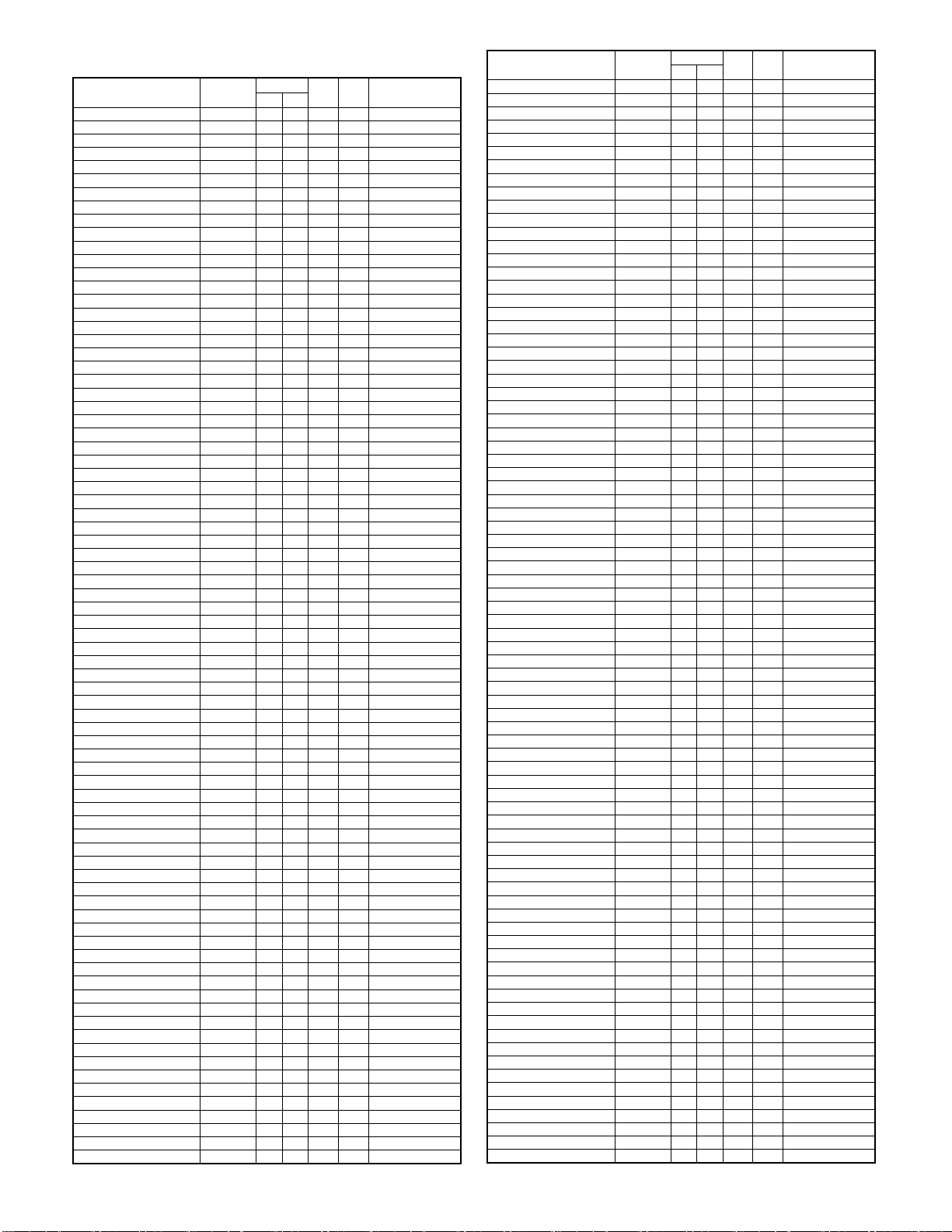

PARTS GUIDE

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

CONTENTS

[1] PRODUCT OUTLINE. . . . . . . . . . . . . . . . . . .1-1

[2] SPECIFICTIONS

1. MX-FNX1 . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2. MX-PNX1A/B/C/D . . . . . . . . . . . . . . . . . .2-1

[3] UNPACKING AND INSTALLATION

* For how to unpacking and installation, refer to the

installation manual (00ZMX2700/I1E).

[4] EXTERNAL VIEW AND INTERNAL

STRUCTURE

1. Identification of each section and

functions . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

[5] OPERATIONAL DESCRIPTIONS

1. Electrical mechanism diagram . . . . . . . . .5-1

2. General. . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

3. Outline of the transport path . . . . . . . . . . .5-5

4. Non-sort mode . . . . . . . . . . . . . . . . . . . . .5-6

5. Offset mode . . . . . . . . . . . . . . . . . . . . . . .5-6

6. Staple mode . . . . . . . . . . . . . . . . . . . . . . .5-7

7. Punching process . . . . . . . . . . . . . . . . . . .5-9

[6] DISASSEMBLY AND ASSEMBLY

1. MX-FNX1 . . . . . . . . . . . . . . . . . . . . . . . . 6-1

2. MX-PNX1A/B/C/D . . . . . . . . . . . . . . . . . 6-11

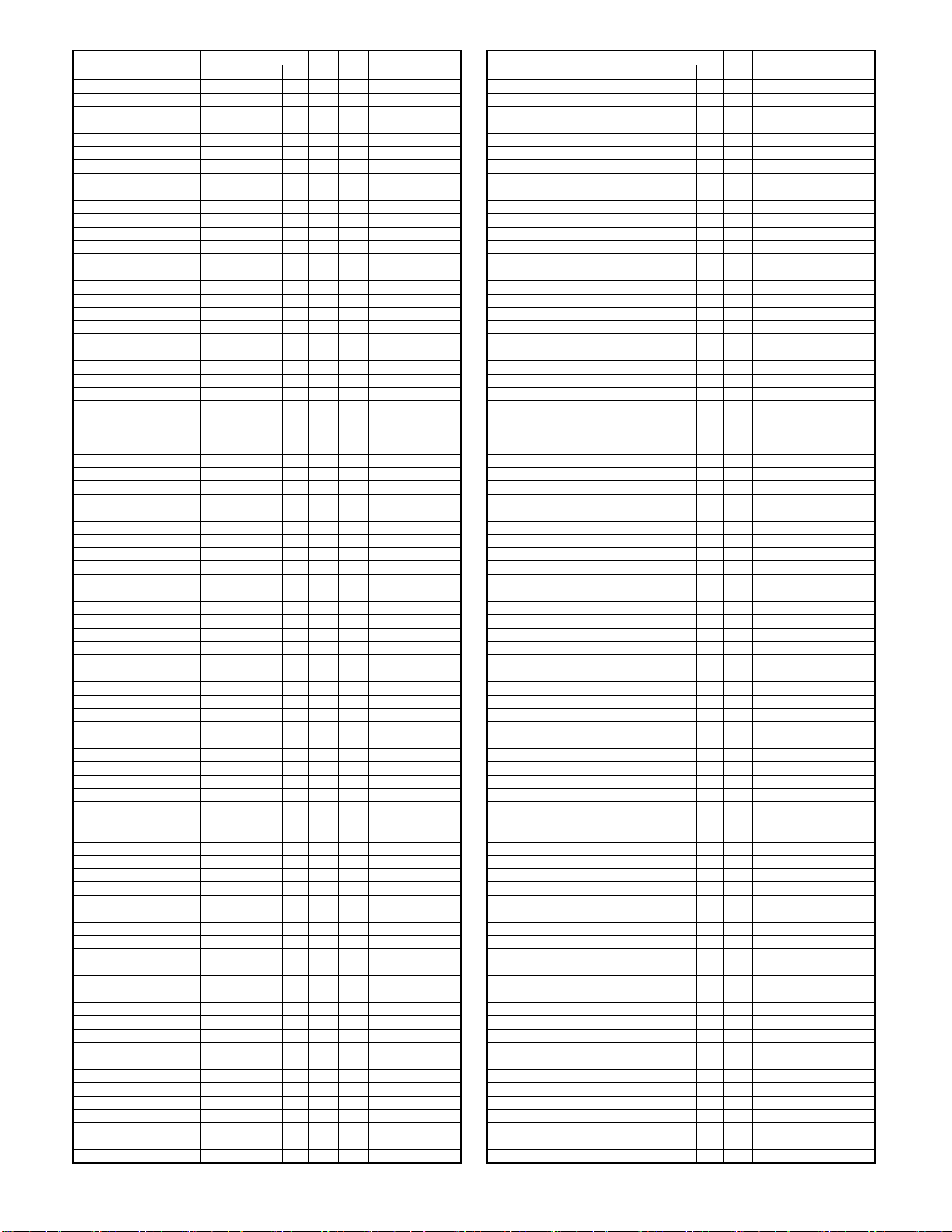

[7] MAINTENANCE

1. Maintenance system table . . . . . . . . . . . 7-1

[8] ADJUSTMENTS

1. Setting item list . . . . . . . . . . . . . . . . . . . . 8-1

2. Details . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[9] SELF DIAGNOSTICS AND TROUBLE CODES

1. Trouble code and troubleshooting. . . . . . 9-1

[10] ELECTRICAL SECTION

1. Circuit descriptions . . . . . . . . . . . . . . . . 10-1

2. Block diagram . . . . . . . . . . . . . . . . . . . 10-12

3. Actual wiring diagram . . . . . . . . . . . . . 10-14

PARTS GUIDE

Page 3

âºíuÇ´

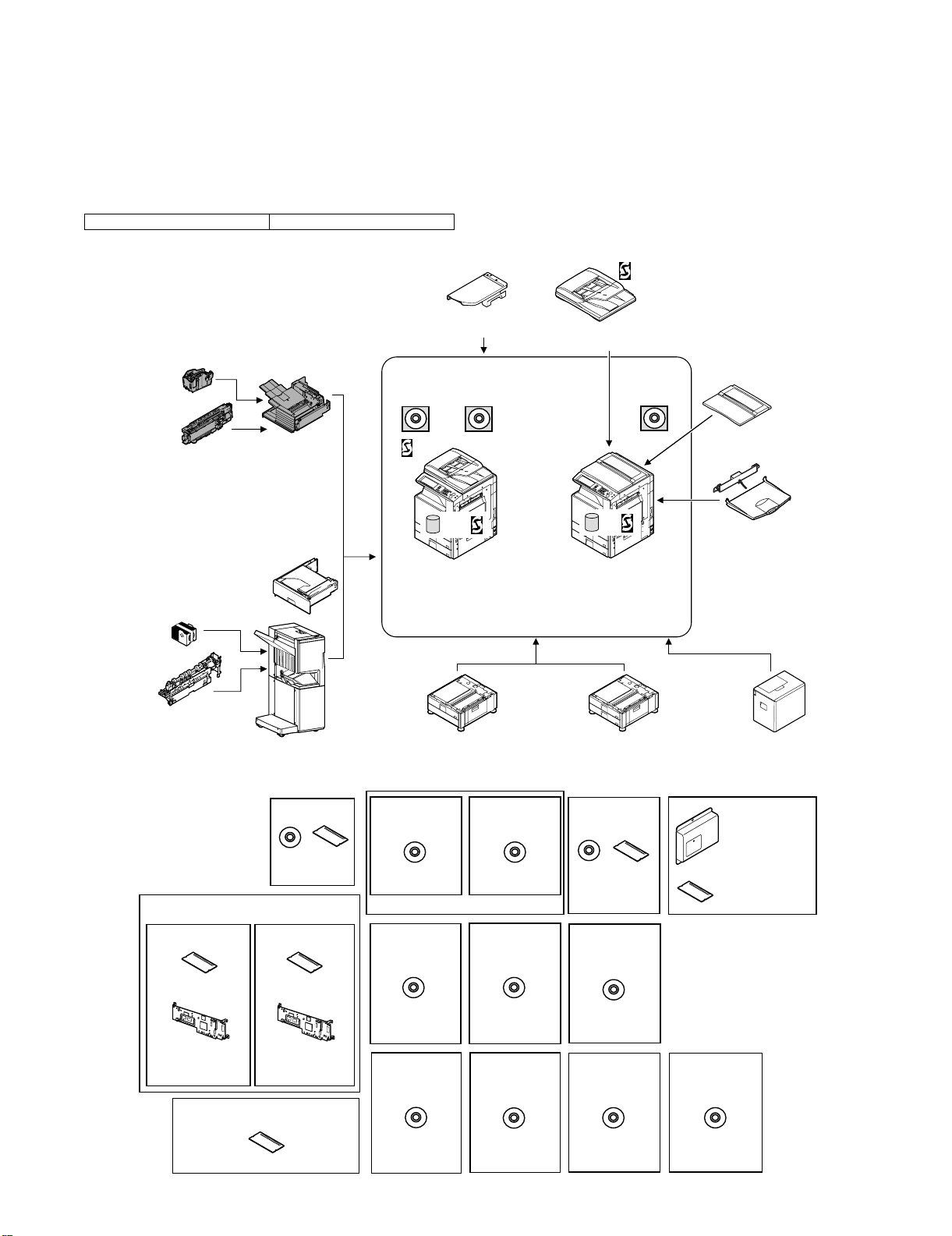

[1] PRODUCT OUTLINE

Service Manual

This unit is used by installing to the main unit for after-process of copy and FAX output paper. It is provided with the offset function which discharges output paper by shifting one by one.

Since it is installed to the center tray section of the main unit, no extra space for installation is required.

1) 3 kinds of auto staple functions: There are 3 kinds of stapling positions. (One position in front, one position backward, 2 positions at the

center).

2

2) Punch function (option): By installing the punch unit, paper can be punched to make binder holes. (Paper of 64 to 128g/m

can be used.

OHP film cannot be used.)

Models enable to install the unit MX-2300G/2700G/2300N/2700N

The finisher requires a staple cartridge as a consumable part. (Staple cartridge (about 5,000 staples x 3 pcs.) MX-SCX1)

Staple cartridge

(Approx. 5000 x 3)

(MX-SCX1)

Punch module

●

2-hole (MX-PNX1A)

●

3-hole (MX-PNX1B)

●

4-hole (MX-PNX1C)

●

4-hole (broad space)

(MX-PNX1D)

Staple cartridge

(Approx. 5000 x 3)

(AR-SC2)

Punch module

●

2-hole (AR-PN1A)

●

3-hole (AR-PN1B)

●

4-hole (AR-PN1C)

●

4-hole (broad space)

(AR-PN1D)

(Including document control)

CC authentication

version

Security

ROM

For document

control PWB

(MX-FRX1)

256MB expansion memory board

Finisher

(MX-FNX1)

Paper pass unit

(MX-RBX1)

Saddle stitch finisher

(MX-FNX2)

Barcode font kit

CD

(AR-PF1)

Data security kit

Commercial

version

Security

ROM

For document

control PWB

(MX-FRX1U)

(MX-SMX1)

(For MX-2300G/2700G)

ROM

Device Tray with

USB Hub (MX-RKX1)

PCL5c/PCL6

driver

RSPF

HDD

Copier/Printer (PCL)

/Scanner model

(MX-2300N)

(MX-2700N)

Stand/1x500 sheet

paper drawer

(MX-DEX1)

Printer expansion

kit (PCL)

CD

(MX-PBX1)

(For MX-2300G/2700G)

Internet Fax

expansion kit

CD

(MX-FWX1)

Application

integration

module

CD

(MX-AMX1)

Network

scanner

(Sharpdesk 1 license)

Network scanner

expansion kit

CD

(MX-NSX1)

Sharpdesk

1 license kit

Sharpdesk

5 license kit

CD

(MX-USX1/

USX5)

Sharpdesk

100 license kit

CD

(MX-USA0)

Reversing single pass feeder

(MX-RPX1)

SPLC-c

driver

HDD

Copier/Printer (SPLC-c)

model

(MX-2300G)

(MX-2700G)

Stand/2x500 sheet

paper drawer

(MX-DEX2)

PS3 expansion

kit

CD ROM

(MX-PKX1)

Sharpdesk

10 license kit

Sharpdesk

50 license kit

CD

(MX-US10/

US50)

Application

communication

module

CD

(MX-AMX2)

External

account module

Document cover

(MX-VRX1)

Exit tray unit

(MX-TRX1)

FAX memory (8MB)

(packed together)

CD

(MX-AMX3)

Large capacity tray

(MX-LCX1)

Facsimile

expansion kit

(MX-FXX1)

MX-FNX1/MX-PNX1 PRODUCT OUTLINE 1 – 1

Page 4

âºíuÇ´

[2] SPECIFICTIONS

Service Manual

1. MX-FNX1

Type Inner finisher

Loading method Offset tray

Transport speed 23, 27, 35, 45 PPM

Tray type Offset tray

Transport reference Center reference

Paper exit direction Face down

Paper weight Plain paper: 60 to 105g/m

Mode type Non-stapled, stapled

Paper sizes allowed for offset A3, B4, A4, A4R, B5, 8K, 16K, 11" x 17", 8.5" x 14", 8.5" x 13", 8.5" x 11", 8.5" x 11"R

Offset quantity 30mm, 1.2 inch

Discharged paper size A3, B4, A4, A4R, A5R, B5, B5R, 8K, 16K, 16KR, 12" x 18", 11" x 17", 8.5" x 14", 8.5" x 13", 8.5" x 11", 8.5" x 11"R,

Sortable size Metric series Large size: A3, B4, 8K

Stack tray max. load capacity Large size: Max. 250 sheets or max. 30 sets or 35.5mm

Staplable paper weight 60 to 128g/m

Staplable paper size A3, B4, A4, A4R, B5, 8K, 16K, 16KR, 11" x 17", 8.5" x 14", 8.5" x 13", 8.5" x 11", 8.5" x 11"R

Staplable paper quantity (Max.) Max. 50 sheets (for small size, 90g/m

Stapling 3 kinds (One position in front, one position backward, 2 positions).

Staple supply system Staple sheet cartridge replacement system (Staple cartridge (Approx. 5,000 x 3 pcs.) MX-SCX1)

Staple detection Staple empty detection (Near empty detection: 20 staples remained)

Manual stapling No

External dimensions (W x D x H) 440 x 595 x 205 (mm), 17 21/64 x 23 27/64 x 8 5/64 (inch)

Weight Approx. 13kg (28.7 lbs)

Power source Supplied from the main unit power source. (DC24V, DC5V)

Power consumption 55.2W

Installation/maintenance Installed by service personnel

Optional detection Auto detection supported

Packaged items Parts for mounting, operational sheet, staple directional instruction label, installation cautionary note

Thin paper: 55 to 59g/m

Heavy paper: 106 to 209g/m

Special paper: OHP sheet, label sheet, envelopes, tab paper: Limited to non-sort (up to 10 sheets).

5.5" x 8.5"R, 7.25" x 10.5"R, A3 wide, special paper

Inch series Large size: 11" x 17", 8.5" x 14", 8.5" x 13"

Small size: Max. 500 sheets (For special paper, max. 10 sheets can be loaded on the tray.) or max. 30 sets or 71mm

Max. 30 sheets (for large size, 90g/m

(with tray extended: 640 x 595 x 205 (mm), 25 12/64 x 23 27/64 x 8 5/64 (inch))

Small size: A4, A4R, B5, 16K

Small size: 8.5" x 11", 8.5" x 11"R

2

(16 to 34 lbs) * However, "106 to 128g/m2 (28 to 34 lbs)" is enable only for two sheets.

2

(16 to 28 lbs)

2

(15 to 16 lbs)

2

(28 to 56 lbs)

2

(24 lbs))

2

(24 lbs))

2. MX-PNX1A/B/C/D

Type Punch unit for the inner finisher

Punch type 2 holes / 3 holes / 4 holes / 4 holes (wide)

Transport speed 23, 27, 35, 45 PPM

Transport reference Center reference

Punch dust full detection YES (Lever system)

Paper exit direction Face down

Paper weight Plain paper: 60 to 105g/m

Punchable paper size 2 holes

Power source Supplied from the inner finisher. (DC24V, DC5V)

External dimensions (W x D x H) 105 x 518 x 170 (mm), 4 9/64 x 20 25/64 x 6 45/64 (inch)

Weight Approx. 3.5kg (7.7 lbs)

Packaged items Parts for mounting, instructional label for punch direction, instructional label for garbage pickup, installation cautionary note

*1: Auto switching: 2 holes/3 holes

A punch unit that provides all of these 4 types can be installed.

2

(16 to 28 lbs)

2

Thin paper: 55 to 59g/m

Heavy paper: 106 to 209g/m

(MX-PNX1A)

3 holes *1

(MX-PNX1B)

4 holes

(MX-PNX1C)

4 holes (wide)

(MX-PNX1D)

A3, B4, A4, A4R, B5, B5R, 11" x 17", 8.5" x 14", 8.5" x 13", 8.5" x 11", 8.5" x 11"R, 8K, 16K, 16KR

3 holes: A3, A4, 11" x 17", 8.5" x 11"

2 holes: 8.5" x 14", 8.5" x 13", 8.5" x 11"R

A3, A4

A3, B4, A4, A4R, B5, B5R, 11" x 17", 8.5" x 14", 8.5" x 13", 8.5" x 11", 8.5" x 11"R

(15 to 16 lbs)

2

(28 to 56 lbs)

MX-FNX1/MX-PNX1 SPECIFICTIONS 2 – 1

Page 5

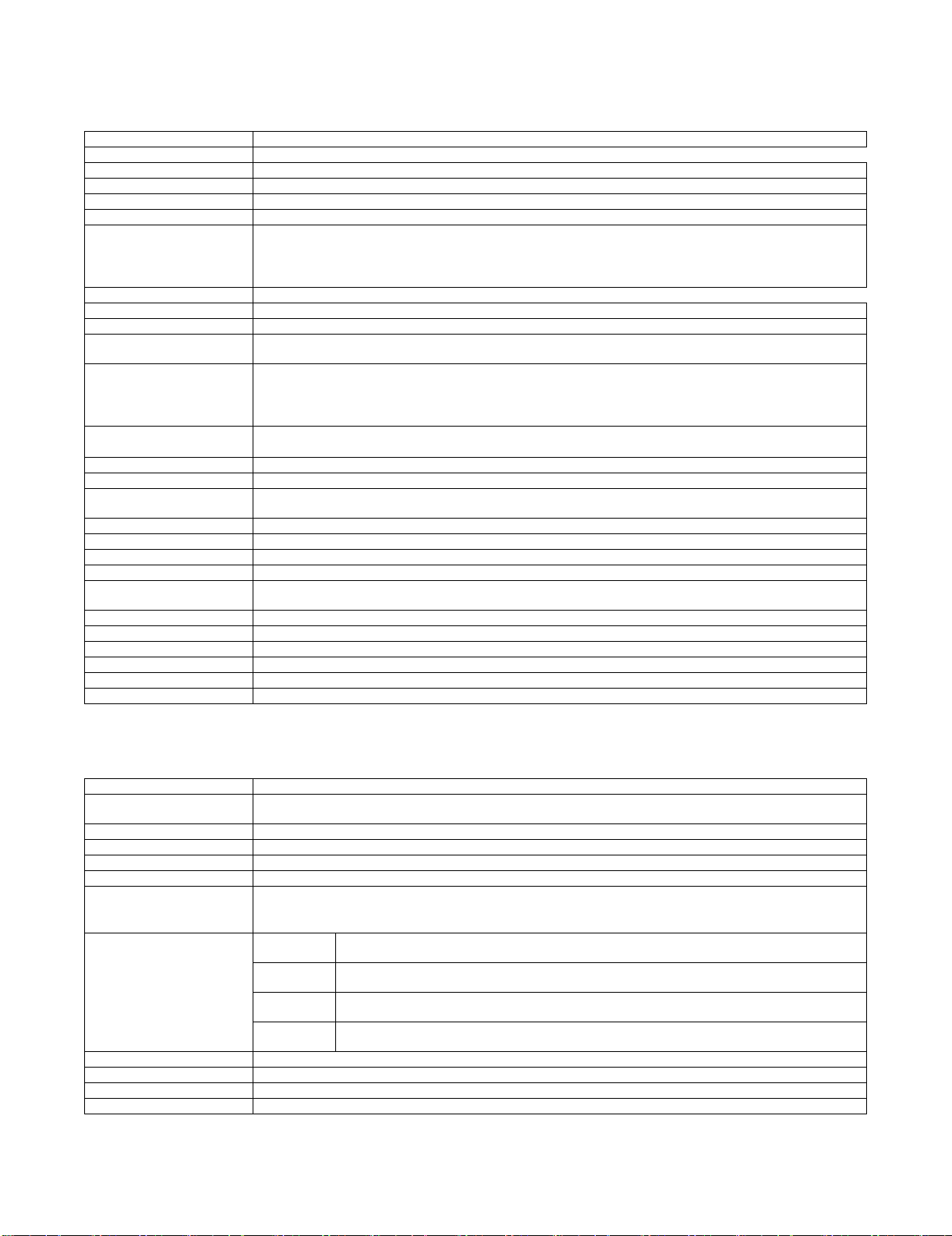

Kind of hole punch

A

ABA

ABA

A

A

Kind Hole position Hole size

2 holes (MX-PNX1A) A: 80±1mm

B: 12±3mm

B

φ6.5mm

3 holes (MX-PNX1B) A: 108±1mm

B: 12±3mm

4 holes (MX-PNX1C) A: 80±1mm

B: 12±3mm

4 holes (wide) (MX-PNX1D) A: 70±1mm

B: 12±3mm

C: 21±1mm

C

B

φ8.0mm

φ6.5mm

φ6.5mm

MX-FNX1/MX-PNX1 SPECIFICTIONS 2 – 2

Page 6

âºíuÇ´

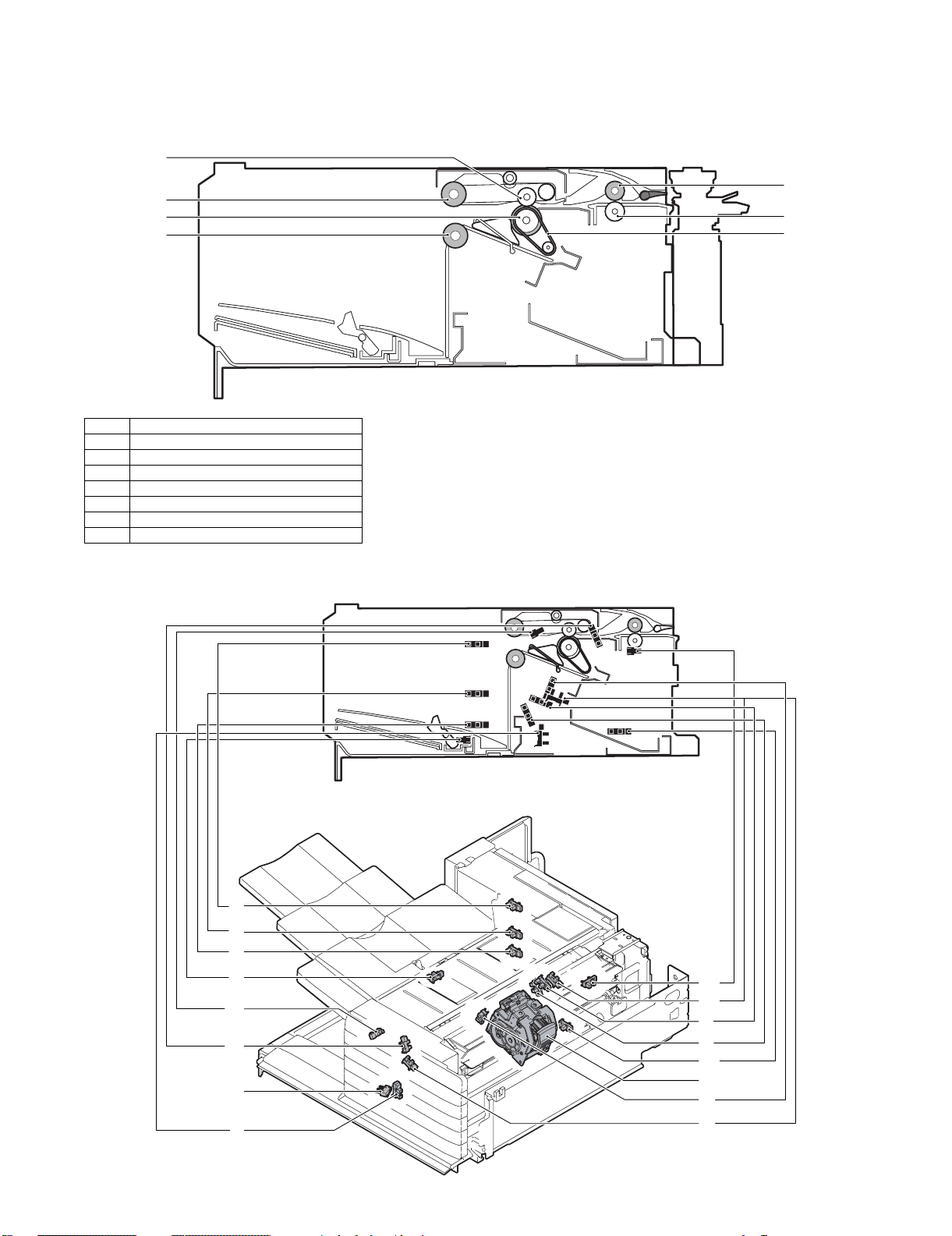

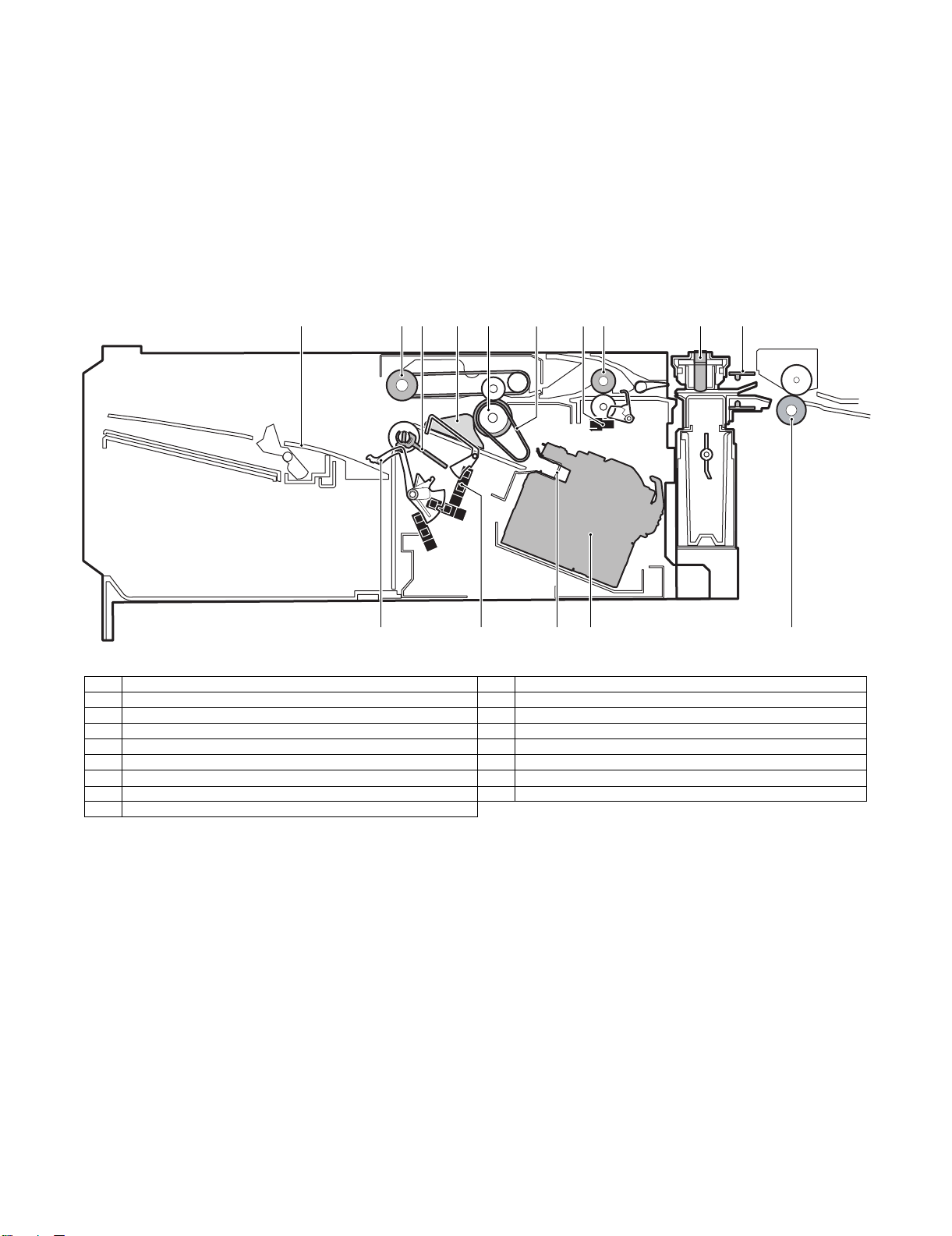

[4] EXTERNAL VIEW AND INTERNAL STRUCTURE

Service Manual

1. Identification of each section and functions

A. Internal structure

1

2

3

4

No. Name

1 Paper exit roller

2 Bundle exit paper transport roller

3 Paper exit roller

4 Bundle exit paper transport roller

5 Inlet port paper transport roller

6 Inlet port paper transport roller

7 Take-up belt

B. Sensors and switches

(1) MX-FNX1

5

6

7

1

2

3

4

12

13

14

7

MX-FNX1/MX-PNX1 EXTERNAL VIEW AND INTERNAL STRUCTURE 4 – 1

11

10

5

6

15

16,17,18

8

9

Page 7

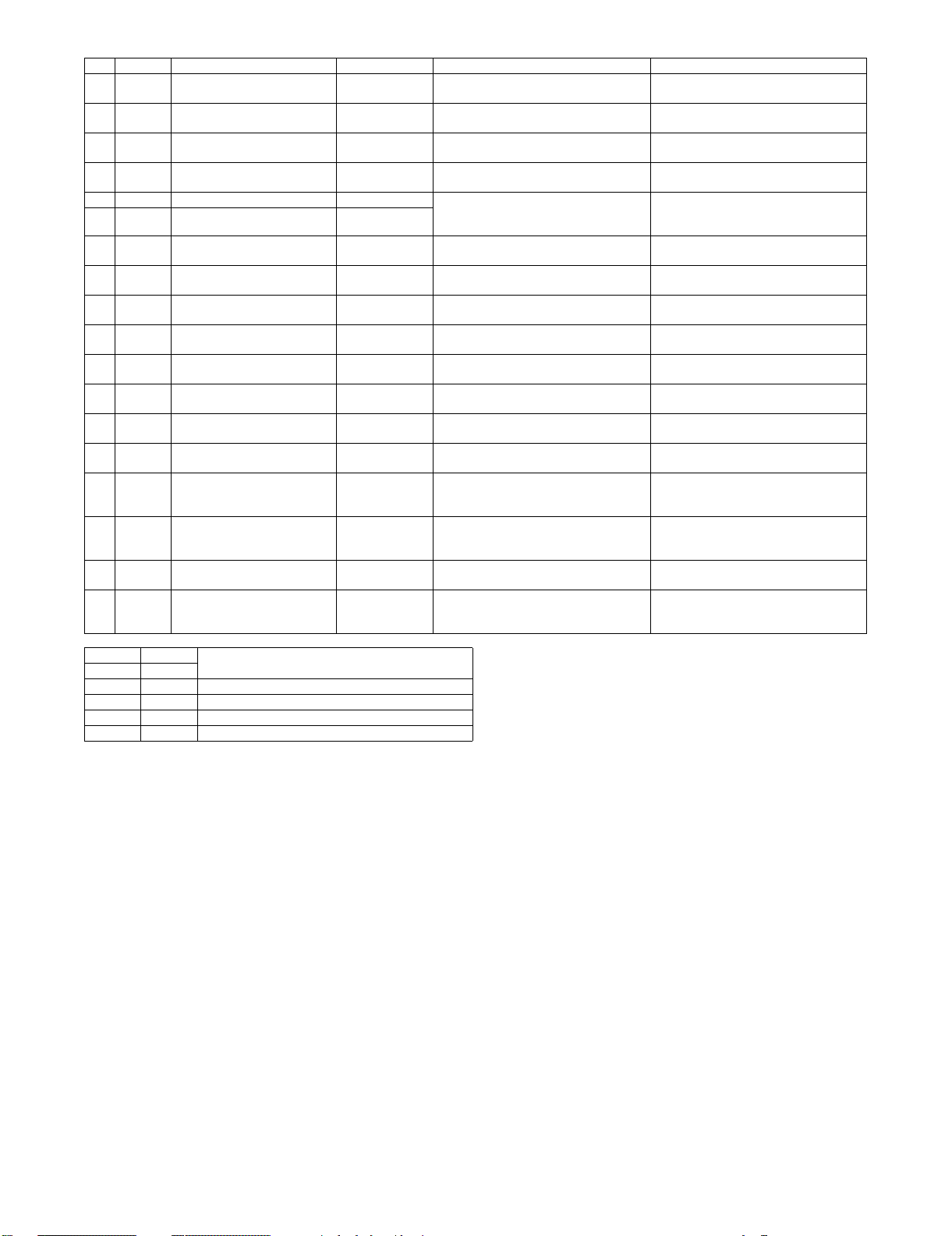

No. Signal Name Type Function/Operation Output

1 FULD Tray upper limit sensor Photo interrupter Detects the upper limit position of the

2 FMLLD Tray intermediate lower limit

sensor

3 FLLD Tray lower limit sensor Photo interrupter Detects the lower limit position of the

4 FBED Tray paper empty sensor Photo interrupter Detects paper empty in the paper load

5 FSLD1 Paper surface sensor 1 Photo interrupter Detects the surface position of paper on

6 FSLD2 Paper surface sensor 2 Photo interrupter

7 FSTHPD Stapler HP sensor Photo interrupter Detects the home position of the stapler

8 FSTPD Empty sensor Photo interrupter Detects paper empty on the process tray. TP8 is driven to “H” when paper is

9 FFJHPD Alignment plate HP sensor F Photo interrupter Detects the home position of the alignment

10 FRJHPD Alignment plate HP sensor R Photo interrupter Detects the home position of the alignment

11 FED Inlet port sensor Photo interrupter Detects paper in the inlet port of the

12 FRLD Roller up/down sensor Photo interrupter Detects the upper standby position of up/

13 FBRD Take-up belt sensor Photo interrupter Detects up/down positions of the take-up

14 FDSW Front cover switch Photo interrupter Detects open/close of the jam release

15 FJPD Alignment plate position sensor Photo interrupter Detects entry of the process section rear

16 FSHPD Stapler home sensor Detects the home position of the stapling

17 FSD Staple empty sensor Detects staple empty. (Sensor built in the

18 FSTD Self priming sensor Detects the staple feed is completed and it

Photo interrupter Detects the intermediate position of the

paper load tray up/down shift area.

paper load tray up/down shift area.

paper load tray up/down shift area.

tray.

the tray in combination of the both sensors

outputs.

unit in F/R direction shift.

guide on F side.

guide on R side.

finisher.

down movement of the bundle exit roller.

belt.

cover in the front section.

edge stopper into the opening of the

stapler and inhibits stapling.

mechanism. (Sensor built in the stapler

unit)

stapler unit)

is ready for stapling. (Sensor built in the

stapler unit)

TP1 is driven to “L” at the upper limit

position.

TP2 is driven to “L” at the intermediate

position.

TP3 is driven to “L” at the lower limit

position.

TP4 is driven to “L” when paper is

provided.

*Refer to the separate table outside the

column.

TP7 is driven to “H” at the home position.

provided.

TP9 is driven to “L” at the home position.

TP10 is driven to “L” at the home position.

TP11 is driven to “H” when paper is

provided.

TP12 is driven to “L” when the roller

reaches the upper standby position.

TP13 is driven to “L” when the take-up belt

is on the upper side.

TP15 is driven to “L” when the cover is

closed.

TP50 is driven to “L” when the stopper

enters the opening of the stapler.

TP51 is driven to “H” at the home

(standby) position.

TP53 is driven to “L” when staple empty.

TP52 is driven to “H” when in the ready

state.

FSLD1 FSLD2

TP5 TP6

“L” “H” The paper detection lever is in the save position.

“H” “H” The paper surface is upper than the reference level.

“H” “L” The paper surface is at the reference level.

“L” “L” The paper surface is lower than the reference level.

State

MX-FNX1/MX-PNX1 EXTERNAL VIEW AND INTERNAL STRUCTURE 4 – 2

Page 8

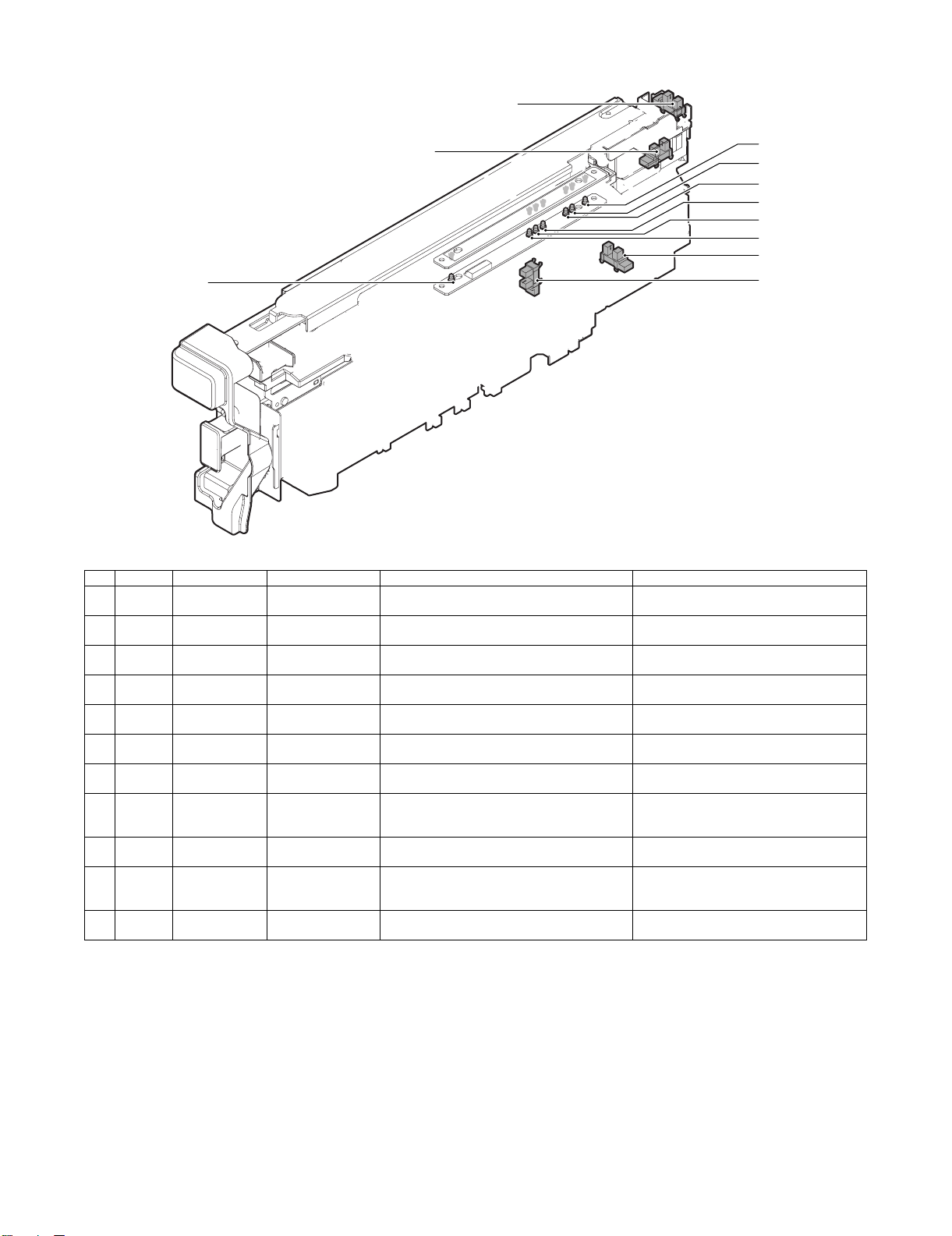

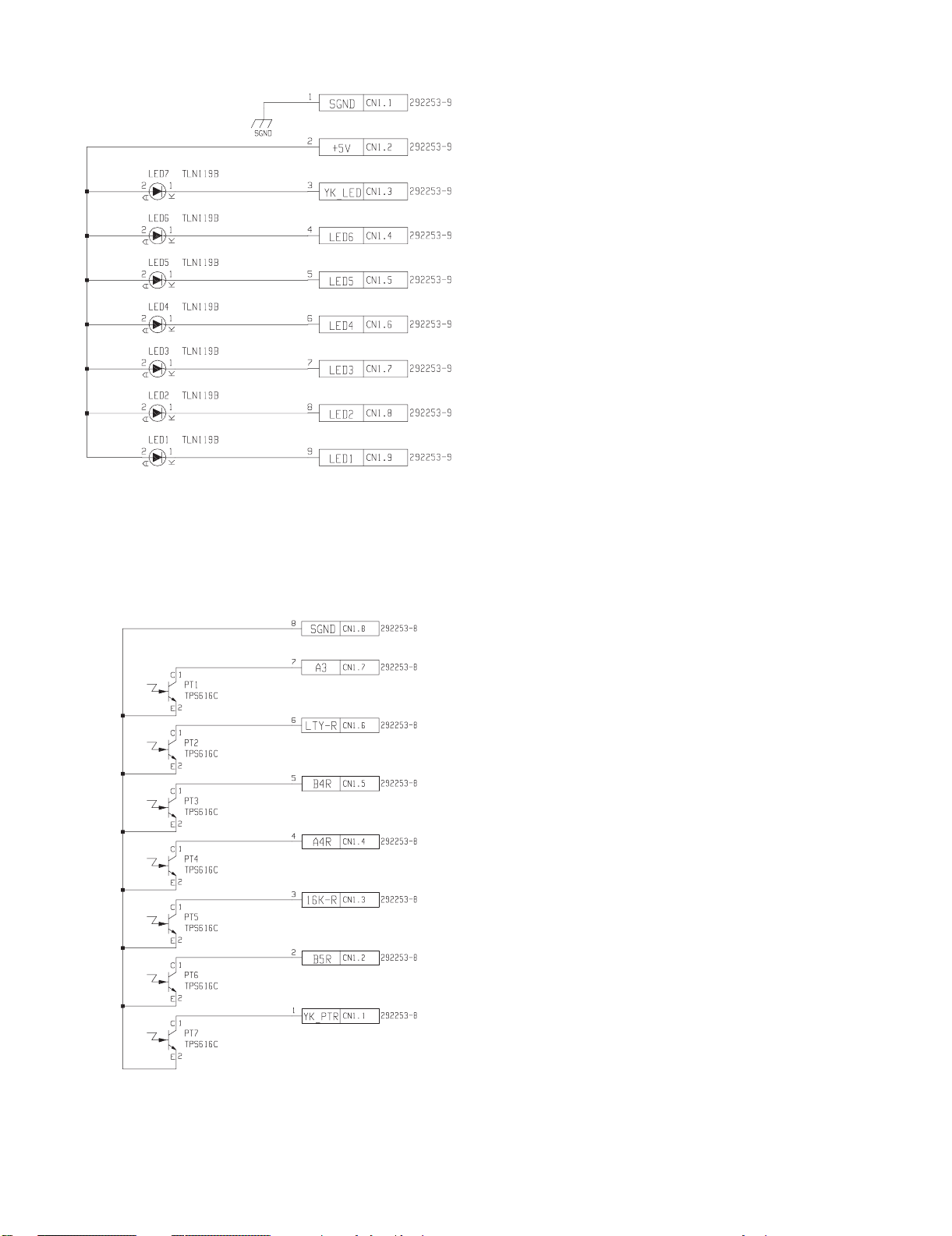

(2) MX-PNX1A/B/C/D

3

2

11

10

9

8

7

6

4

5

No. Signal Name Type Function/Operation Output

1 FPDD Full sensor Photo interrupter Detects full of the punch dust container. When full, TP2 on the punch PWB remains

2 FPHPD Punch position

sensor

3 FPRPD Rear position

sensor

4 FPSHPD Horizontal shift

HP sensor

5 FPPEND Paper rear edge

sensor

6 FPPD1 Paper horizontal

resist sensor 1

7 FPPD2 Paper horizontal

resist sensor 2

8 FPPD3 Paper horizontal

resist sensor 3

9 FPPD4 Paper horizontal

resist sensor 4

10 FPPD5 Paper horizontal

resist sensor 5

11 FPPD6 Paper horizontal

resist sensor 6

Photo interrupter Detects the home position of the punch up/down

Photo interrupter Detects the lower limit position of 3-hole side up/

Photo interrupter Detects the home position in the punch position

Transmission type

sensor

Transmission type

sensor

Transmission type

sensor

Transmission type

sensor

Transmission type

sensor

Transmission type

sensor

Transmission type

sensor

shift.

down shift in 2/3-hole punching.

horizontal resist correction mechanism.

Detects the lead edge and the rear edge of paper

to be punched.

Detects the paper edge in the rear side of B5R or

7.25" x 10" R size width direction of the machine.

Detects the paper edge in the rear side of 16K-R

size width direction of the machine.

Detects the paper edge in the rear side of 8.5"

x14", 8.5" x 11"R, 8.5" x 13", or A4R size width

direction of the machine.

Detects the paper edge in the rear side of B4 or

B5 size width direction of the machine.

Detects the paper edge in the rear side of 11" x

17", 8.5" x 11", 8K, or 16K size width direction of

the machine.

Detects the paper edge in the rear side of A3 or

A4 size width direction of the machine.

“H” level.

TP47 on the control PWB of the inner finisher

is driven to “H” at the home position.

TP48 on the control PWB of the inner finisher

is driven to “H” at the lower limit position.

TP49 on the control PWB of the inner finisher

is driven to “H” at the home position.

TP54 on the control PWB of the inner finisher

is driven to “L” when paper is provided.

TP55 on the control PWB of the inner finisher

is driven to “L” when paper is provided.

TP55 on the control PWB of the inner finisher

is driven to “L” when paper is provided.

TP55 on the control PWB of the inner finisher

is driven to “L” when paper is provided.

TP55 on the control PWB of the inner finisher

is driven to “L” when paper is provided.

TP55 on the control PWB of the inner finisher

is driven to “L” when paper is provided.

TP55 on the control PWB of the inner finisher

is driven to “L” when paper is provided.

1

MX-FNX1/MX-PNX1 EXTERNAL VIEW AND INTERNAL STRUCTURE 4 – 3

Page 9

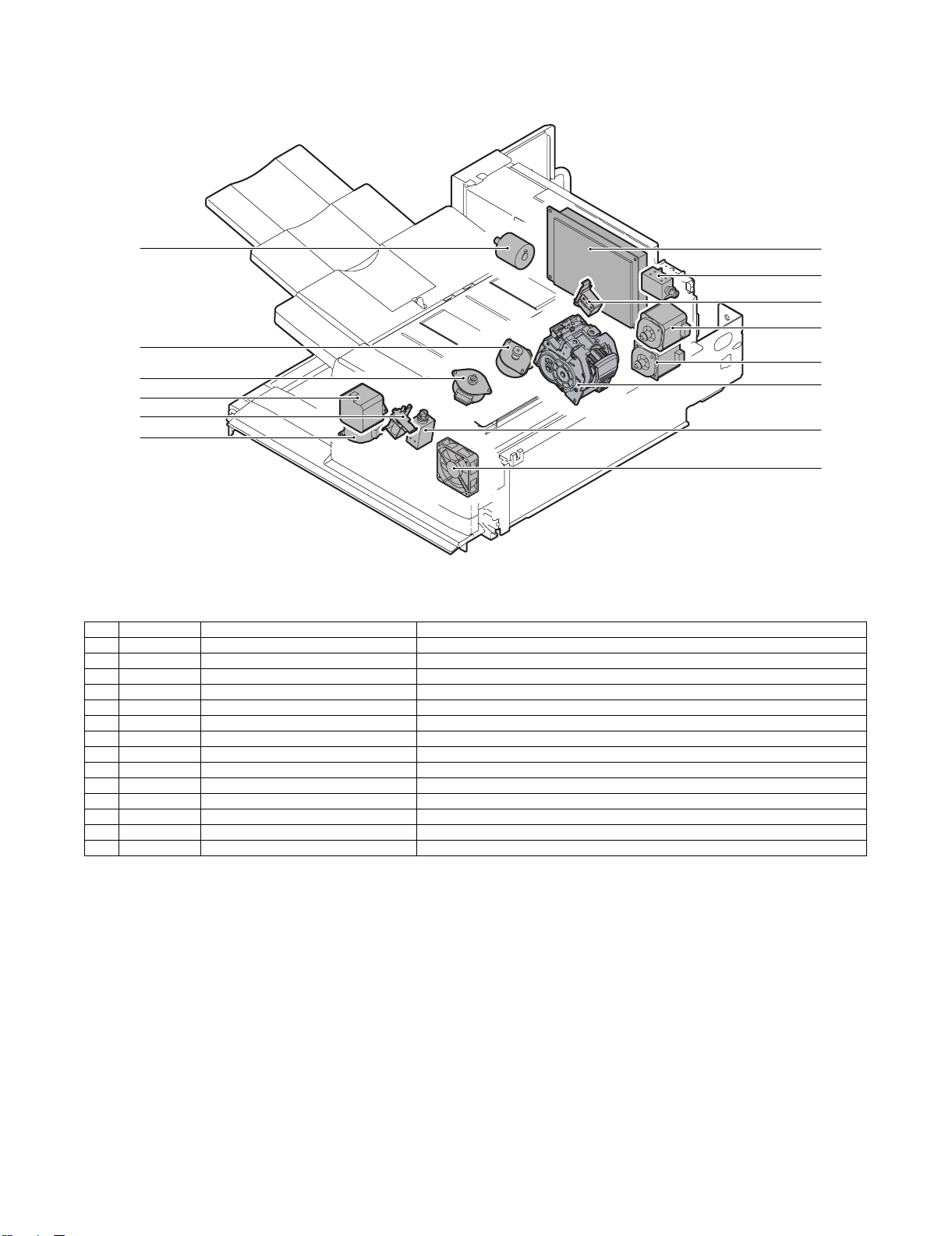

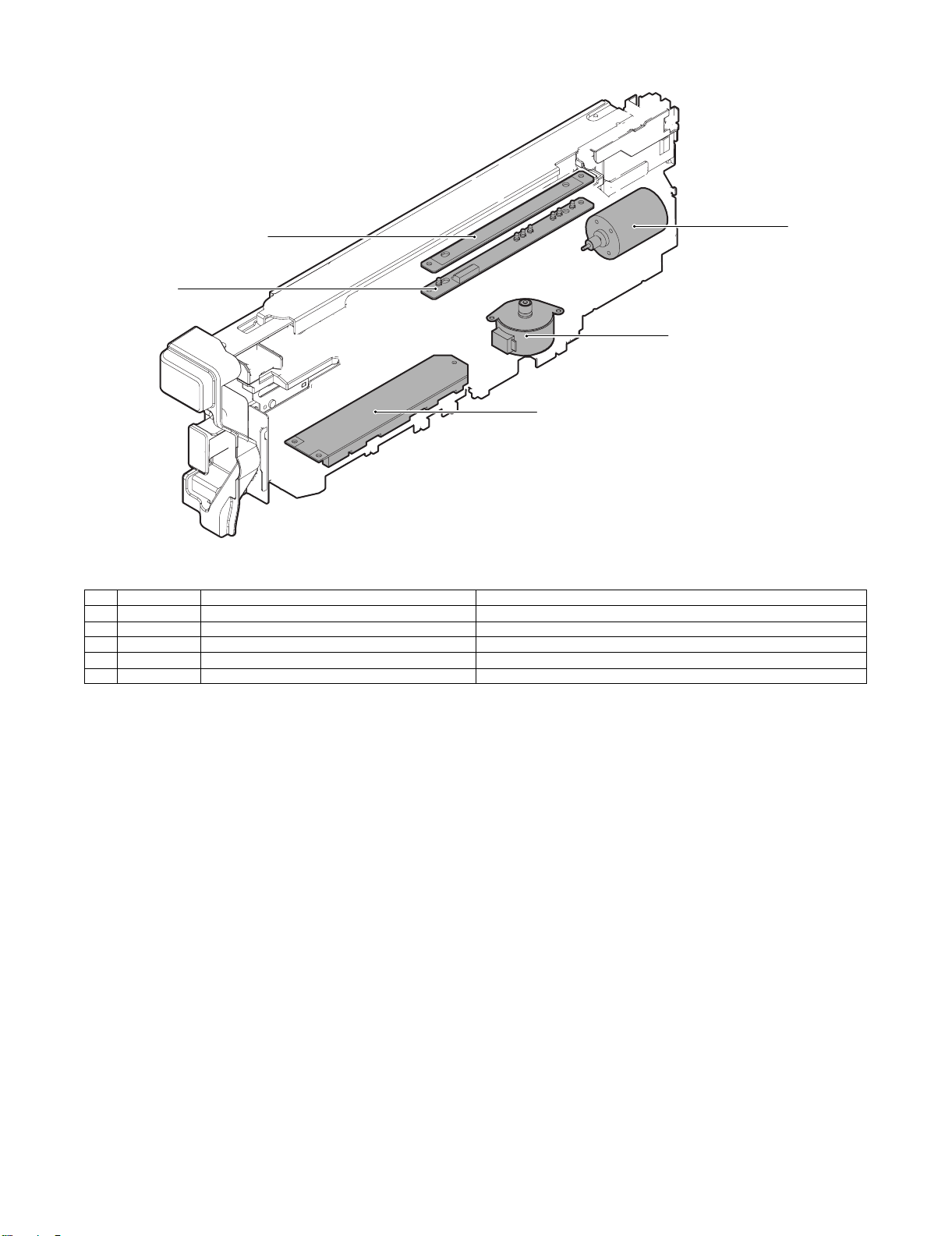

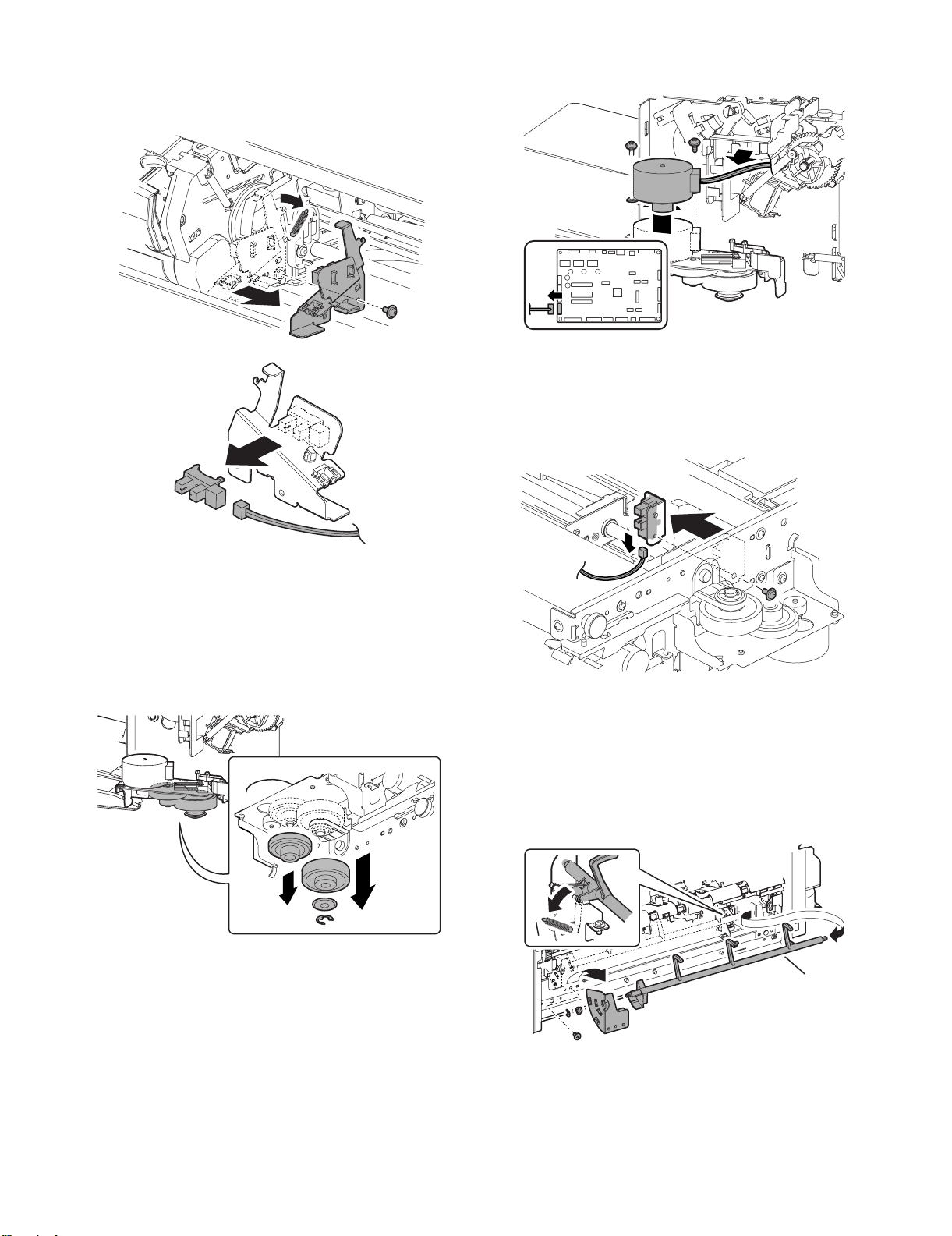

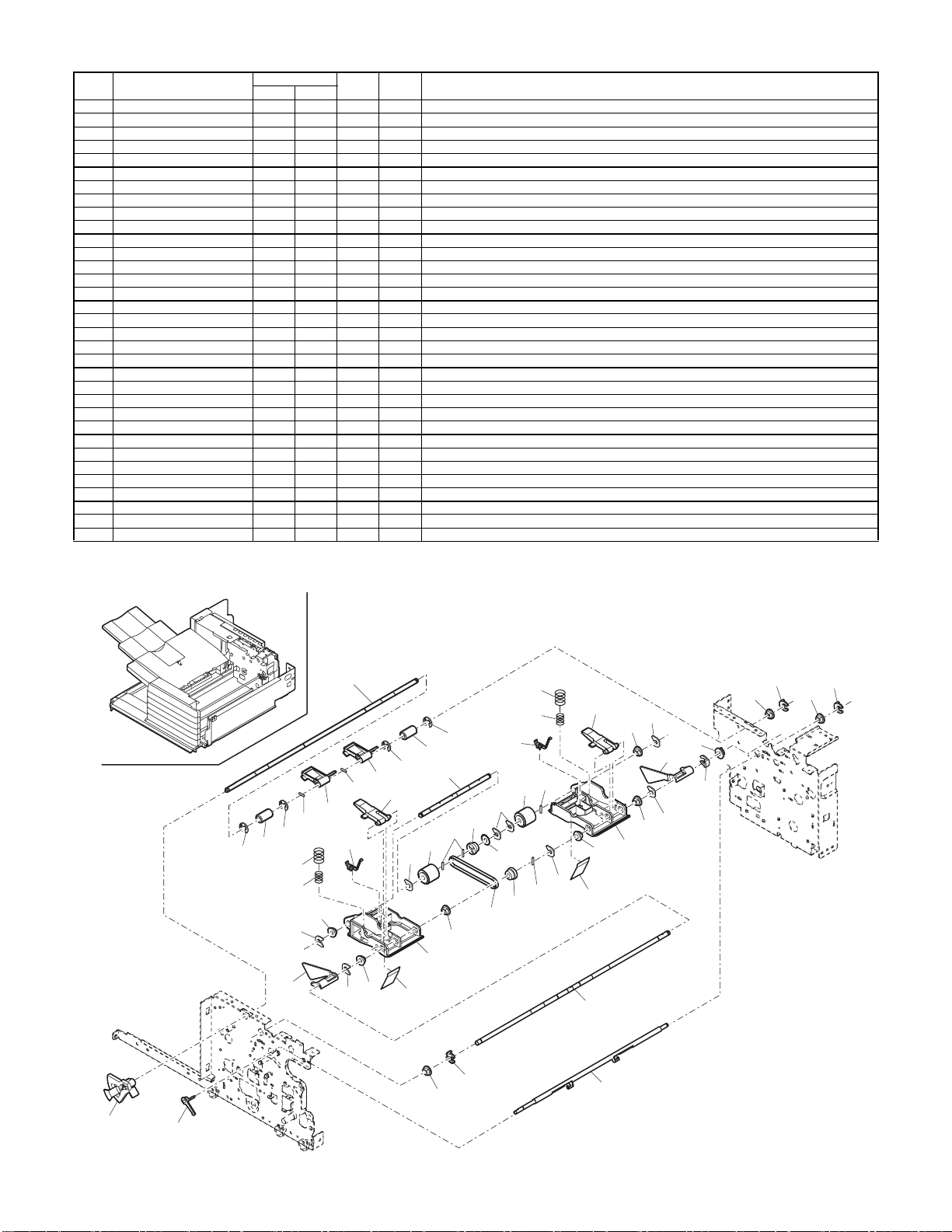

C. Motors, solenoids, and PWB

(1) MX-FNX1

3

14

12

9

8

5

7

4

6

1

11

2

10

13

No. Signal Name Function

1 FFSM Staple motor Drives the stapling mechanism. (Stapler unit built-in motor)

2 FSM Staple shift motor Shifts the stapler unit in the F/R direction.

3 FTLM Tray motor Drives the paper load tray up/down.

4 FFJM Alignment motor F Drive the alignment guide on the F side.

5 FRJM Alignment motor R Drive the alignment guide on the R side.

6 FSWM Roller upper/lower roller Drives the bundle exit roller up/down.

7 FAM Bundle exit motor Drives the bundle exit roller and the paddle.

8 FRM Transport motor Drives the inlet port roller, the feed roller, and the take-up belt.

9 FPDS Paddle one-rotation solenoid Trigger solenoid for paddle one-rotation.

10 FSLS Paper surface detection solenoid Drives the lever for paper holding and detection of the tray paper surface.

11 FBRS Belt separation solenoid Trigger solenoid for up/down shift of the take-up belt.

12 FINRPS Flapper solenoid Drives the flapper to select the entry path between the finisher inside and the reverse path.

13 FFAN Fan Cools the inlet port of the finisher.

14 – Control PWB Controls the inner finisher.

MX-FNX1/MX-PNX1 EXTERNAL VIEW AND INTERNAL STRUCTURE 4 – 4

Page 10

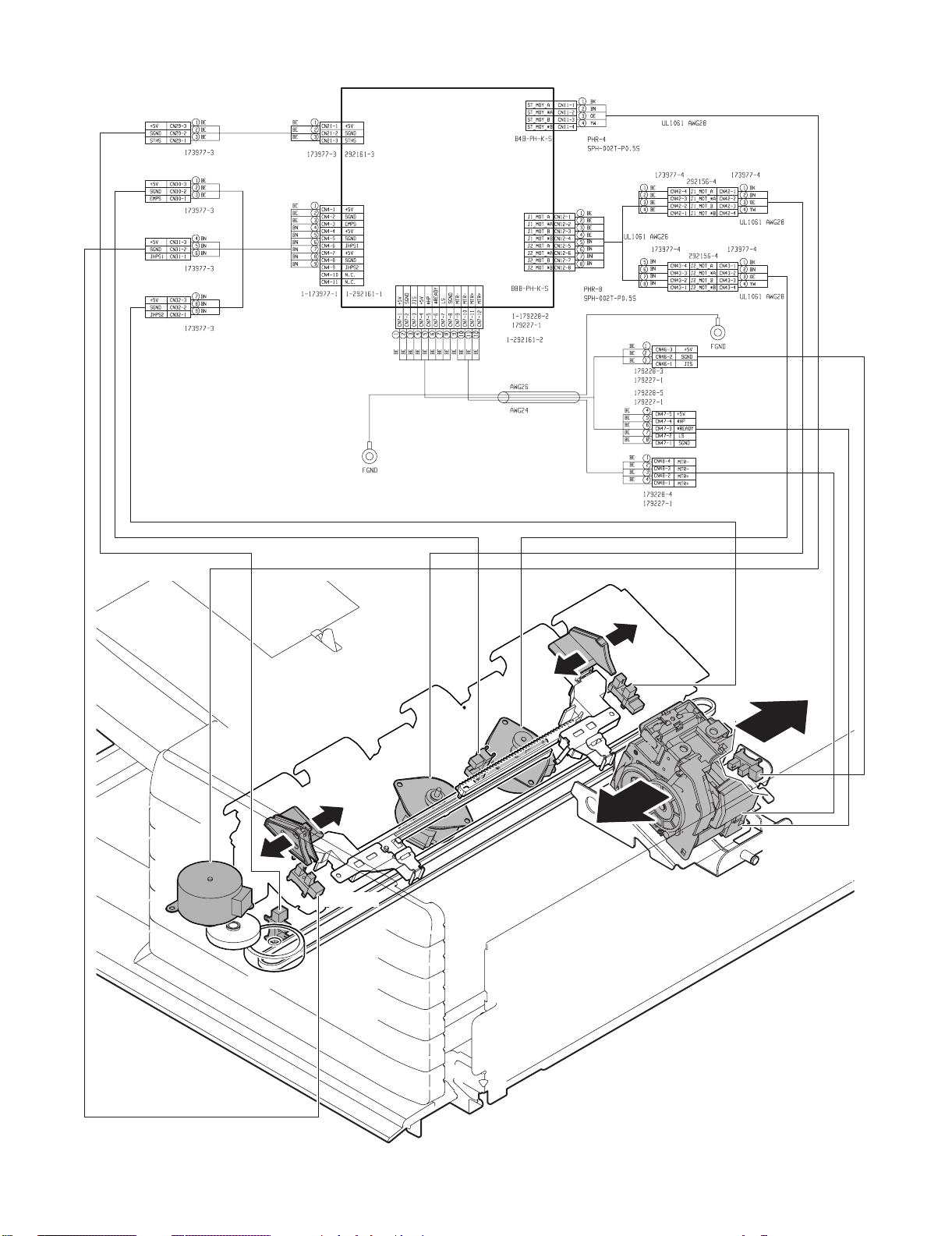

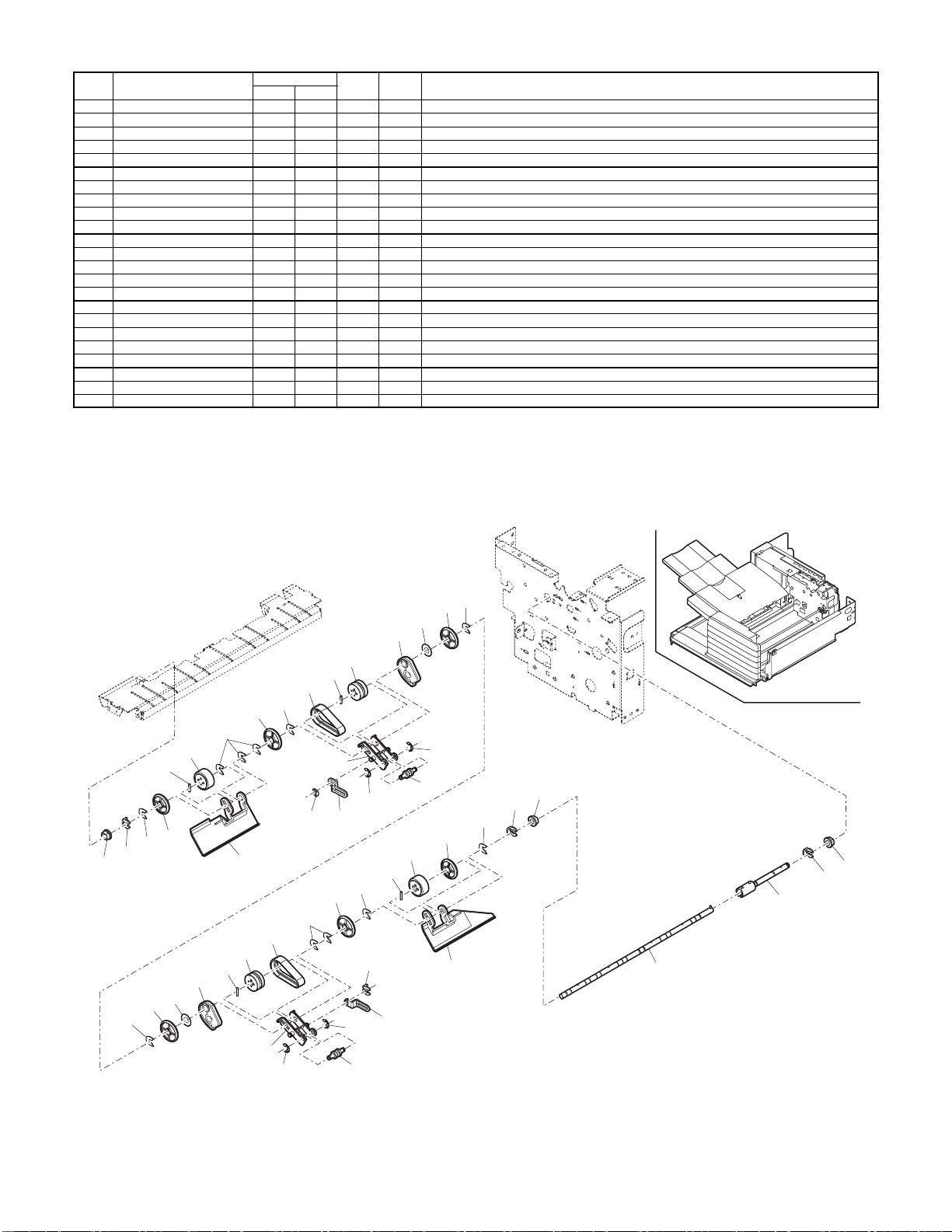

(2) MX-PNX1A/B/C/D

5

4

2

3

No. Signal Name Function

1 FPNM Punch motor Drives the punch unit up/down.

2 FPSM Punch horizontal resist motor Shifts the punch unit to the center of paper.

3 – Punch PWB Controls the punch unit.

4 – LED light emitting PWB Detects the paper rear edge and the punch horizontal resist.

5 – LED light receiving PWB Detects the paper rear edge and the punch horizontal resist.

1

MX-FNX1/MX-PNX1 EXTERNAL VIEW AND INTERNAL STRUCTURE 4 – 5

Page 11

âºíuÇ´

[5] OPERATIONAL DESCRIPTIONS

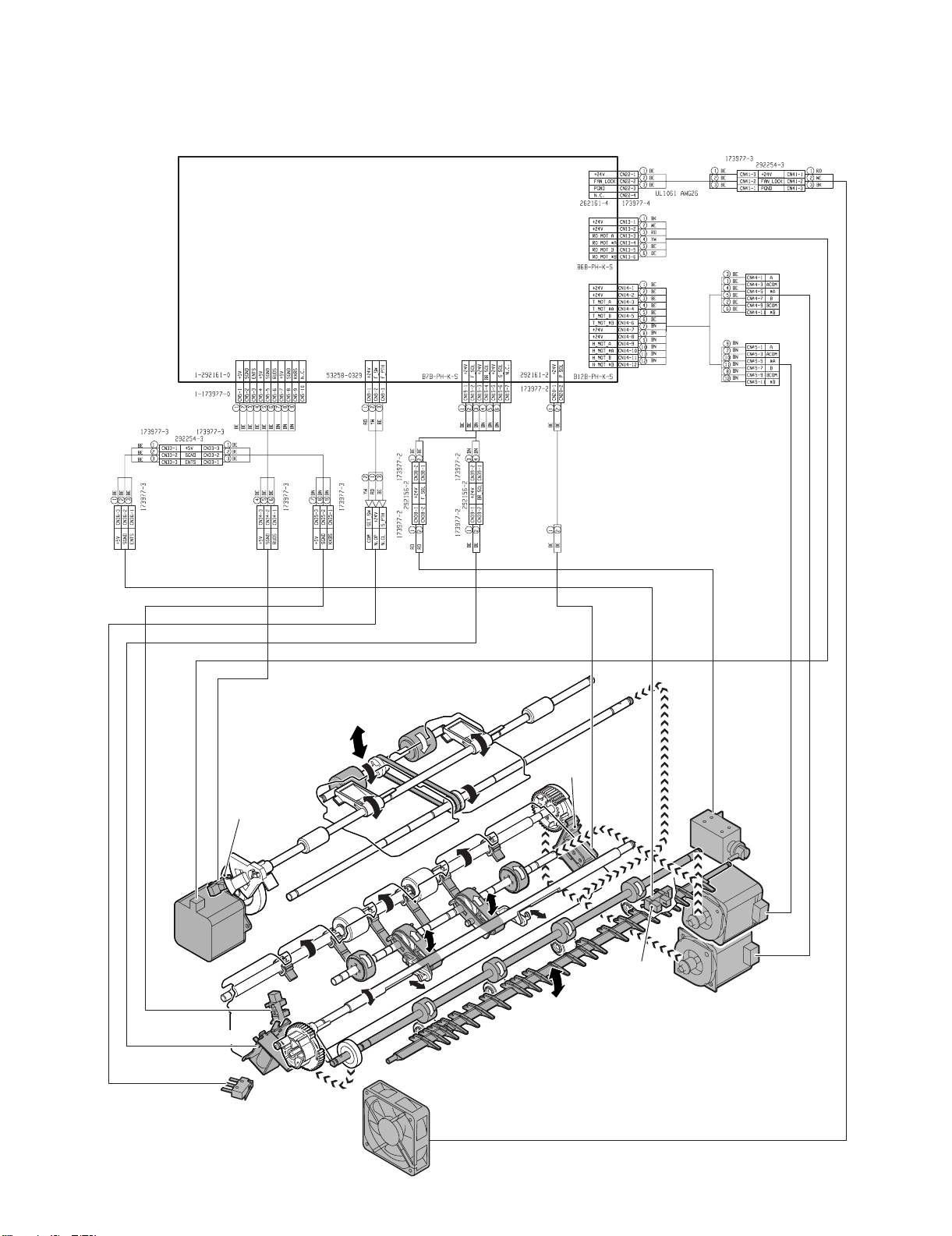

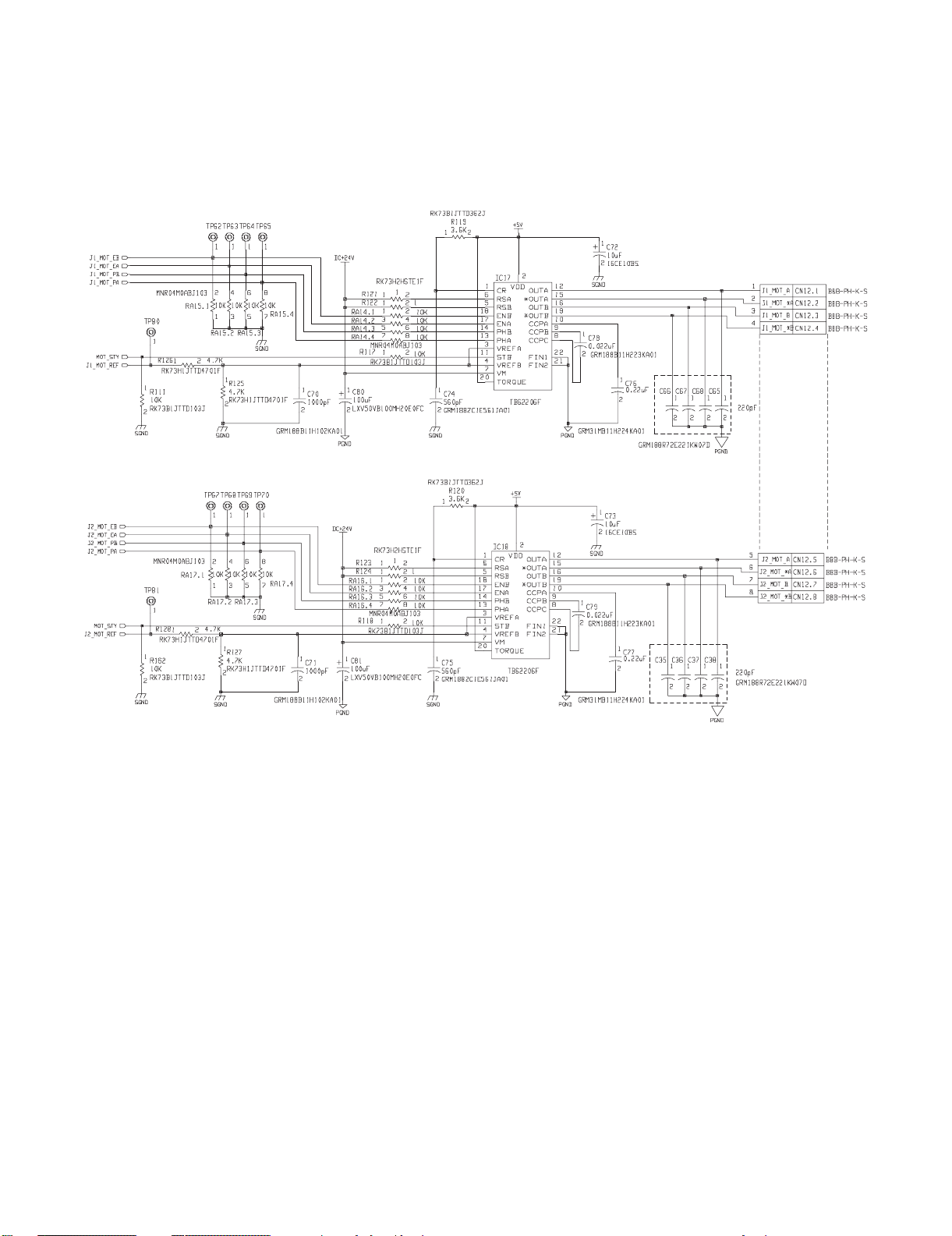

1. Electrical mechanism diagram

A. Transport, paper exit section

PCB-CONT

PF4141K200

Service Manual

FSWM

FRLD

FBRS

FPDS

FINRPS

FRM

FED

FAM

FBRD

FDSW

FFAN

MX-FNX1/MX-PNX1 OPERATIONAL DESCRIPTIONS 5 – 1

Page 12

B. Staple section and aligment section

PCB-CONT

PF4141K200

FSM

FSTHPD

FFJHPD

FFJM

FSTPD

FRJHPD

FRJM

FJPD

FFSM

FSHPD(*HP)

FSD(LS)

FSTD(*READY)

MX-FNX1/MX-PNX1 OPERATIONAL DESCRIPTIONS 5 – 2

Page 13

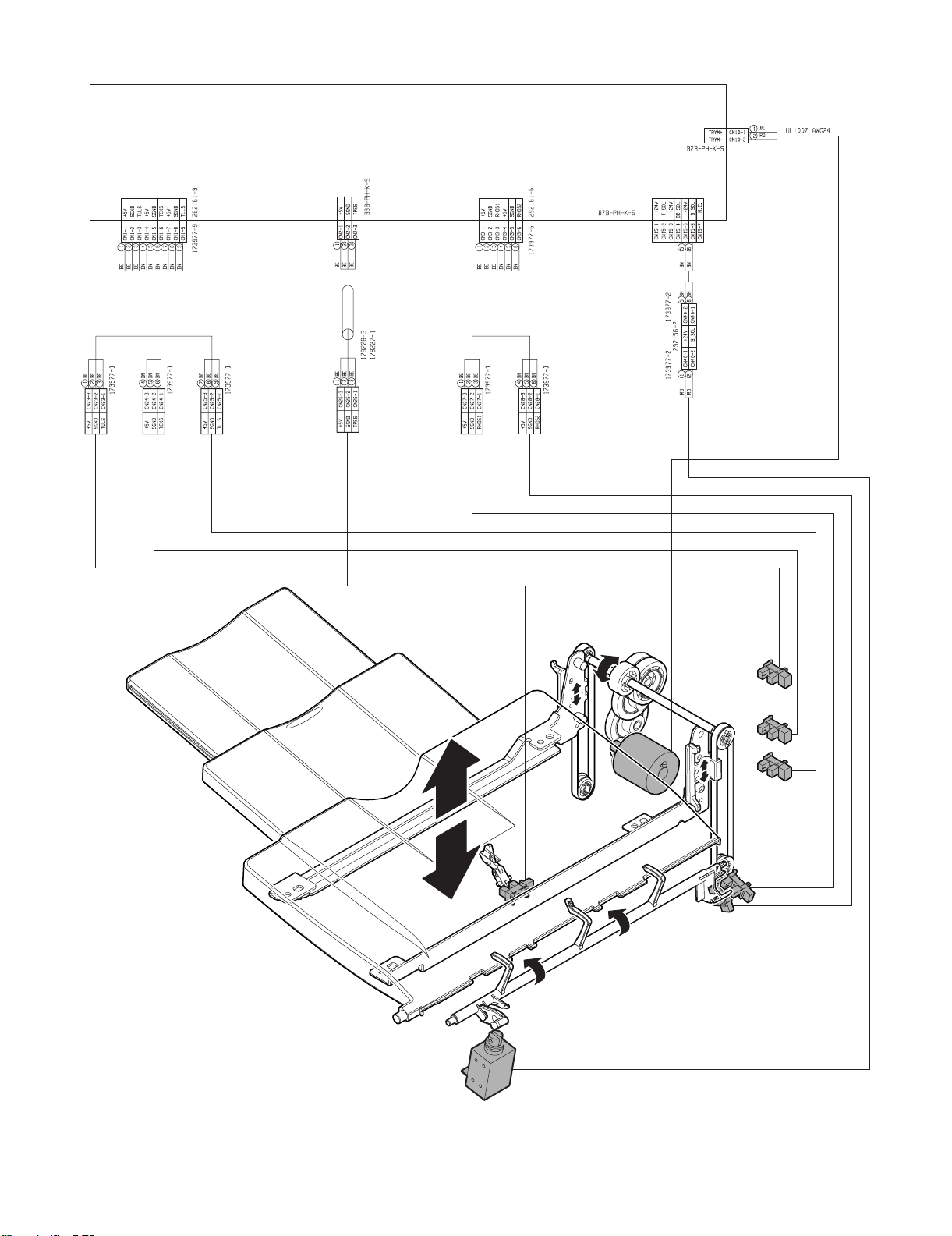

C. Paper exit tray section

PCB-CONT

PF4141K200

FBED

FSLS

FTLM

FULD

FMLLD

FLLD

FSLD1

FSLD2

MX-FNX1/MX-PNX1 OPERATIONAL DESCRIPTIONS 5 – 3

Page 14

D. Punch unit (MX-PNX1A/B/C/D)

FPPEND

FPDD

FPPD1~FPPD6

FPRPD

FPHPD

FPNM

FPSHPD

FPSM

MX-FNX1/MX-PNX1 OPERATIONAL DESCRIPTIONS 5 – 4

PCB-PUNCH

YA1035K200

Page 15

2. General

This chapter describes operations of the inner finisher. The major operation modes are as follows:

• Non-sort mode

• Offset mode

• Staple mode

• Non-sort mode + punch

• Offset mode + punch

• Staple mode + punch

In this chapter, the basic operations of the non-sort mode, the offset mode, and the staple mode are described.

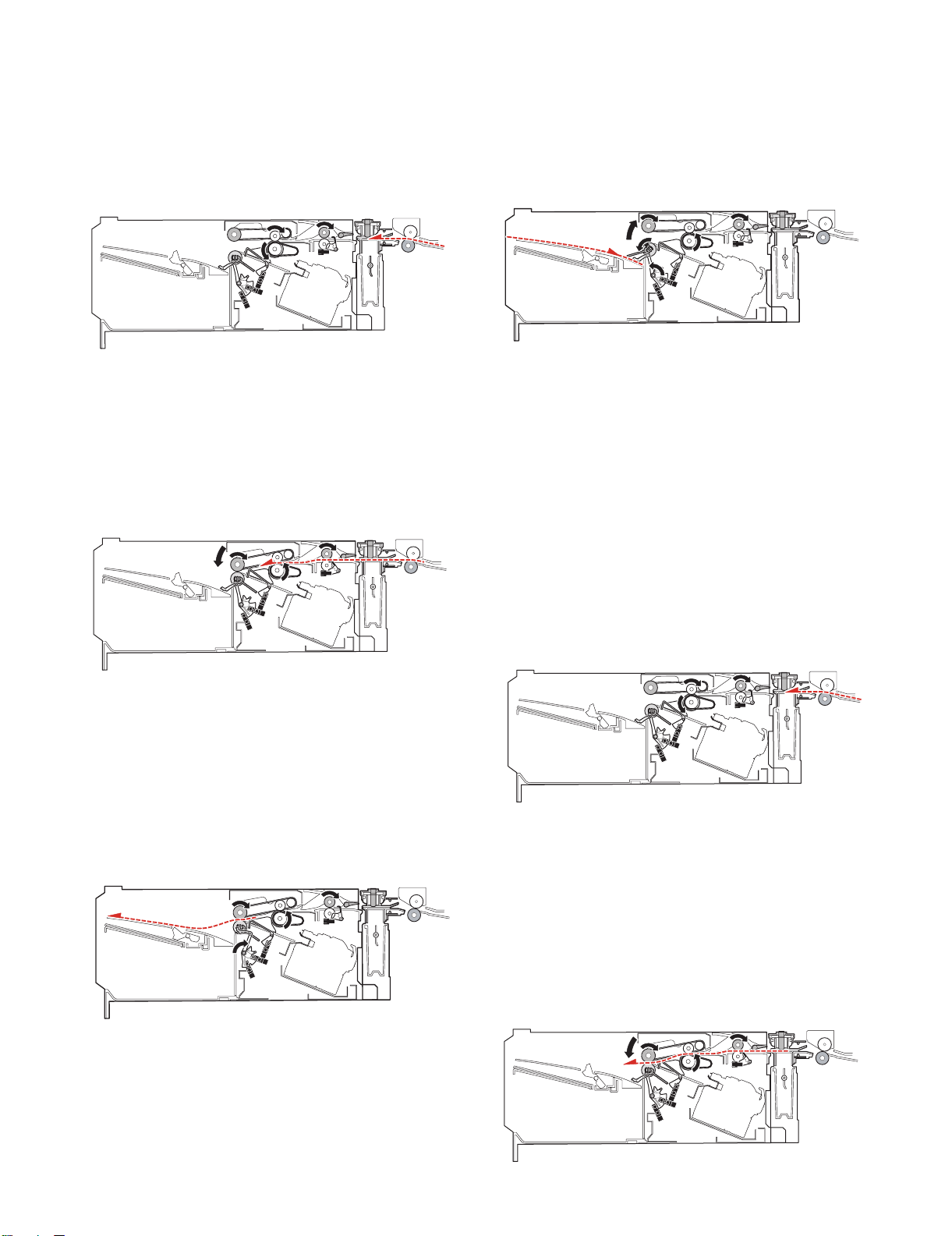

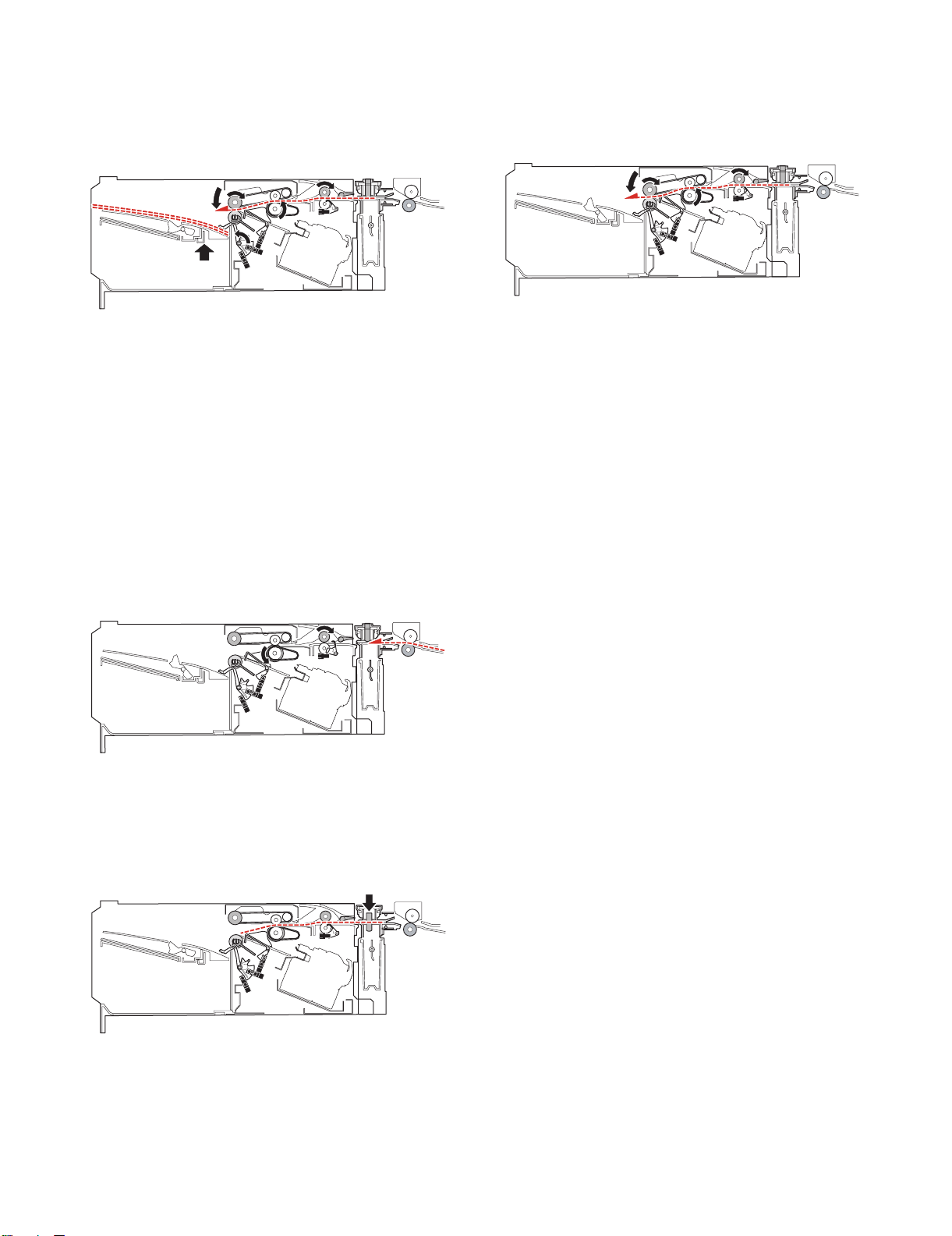

3. Outline of the transport path

The outline of the path is shown below.

1345678910

No. Name No. Name

1 Tray 9 Punch pin

2 Bundle exit roller 10 Paper rear edge sensor (FPPEND)

3 Paddle 11 Main unit paper exit roller

4 Alignment plate 12 Stapler

5 Paper exit roller 13 Paper stopper

6 Take-up belt 14 Empty sensor (FSTPD)

7 Inlet port sensor (FED) 15 Paper holding lever

8 Inlet port roller

2

1112131415

MX-FNX1/MX-PNX1 OPERATIONAL DESCRIPTIONS 5 – 5

Page 16

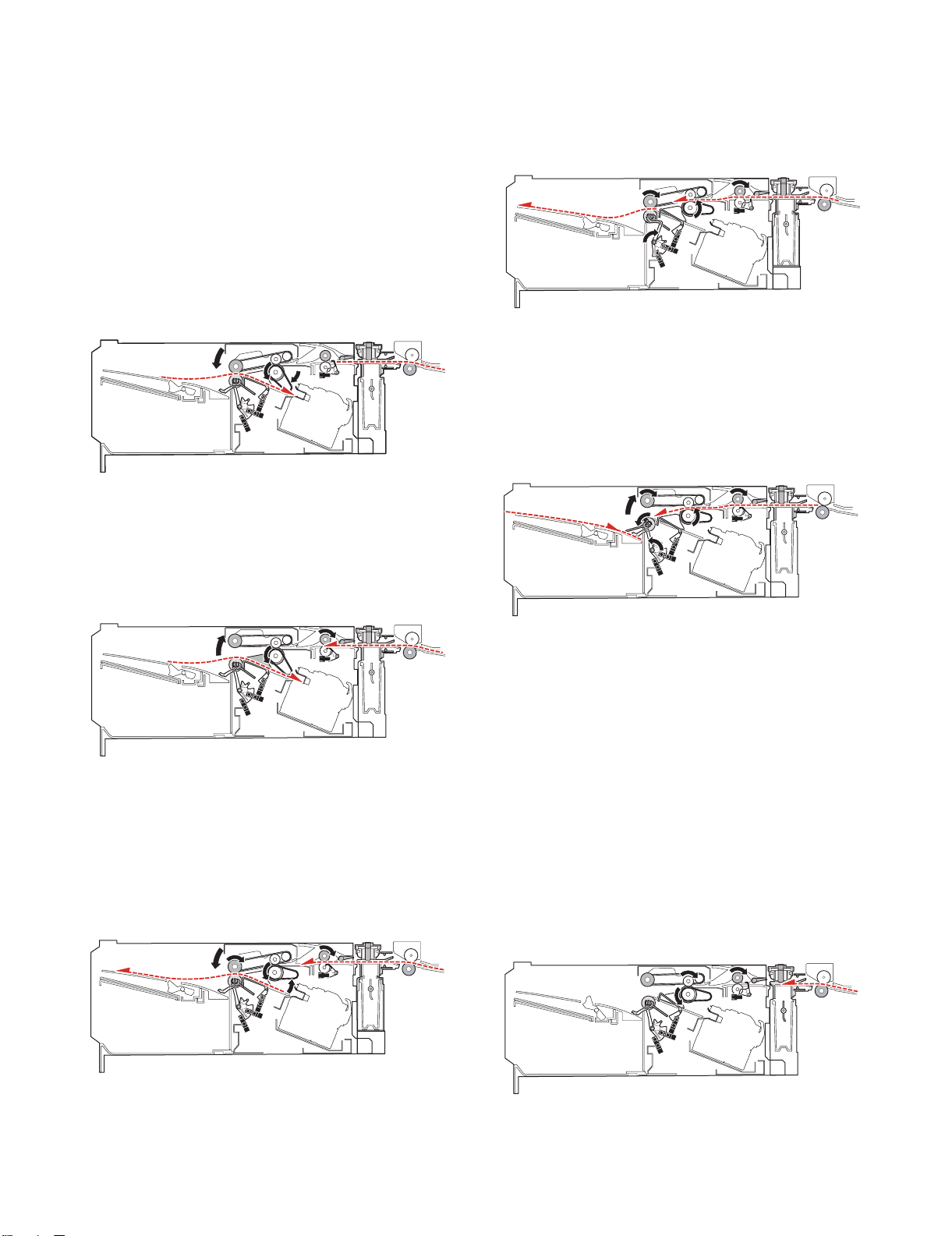

4. Non-sort mode

When the operation mode command is received from the copier,

the finisher makes the finisher operation status command the JOB

and starts the transport operation.

A. Reception of paper discharged from the main

unit

1) The transport motor (FRM) is driven at the paper exit speed of

the main unit to receive paper from the main unit.

2) Immediately after the paper rear edge passes the bundle exit

roller, the paddle one-rotation solenoid (FPDS) is turned ON to

take-up the paper falling onto the tray.

3) When paper is transported by 10mm after the paper rear edge

passes the bundle exit roller, the bundle exit motor (FAM) is

accelerated to 200mm/sec. Just before the paddle passes the

load tray, the paper surface detection solenoid (FSLS) is

turned ON to hold the paper discharged by the paper holding

lever.

2) After turning ON the inlet port sensor (FED), the roller up/down

motor (FSWM) is driven to lower the bundle exit roller. The

bundle exit motor (FAM) is driven at the paper exit speed of the

main unit to drive the bundle exit roller. When the paper width

is 210mm or more, the alignment motor F (FFJM) and the

alignment motor R (FRJM) are driven by turning ON the inlet

port sensor (FED) to shift the alignment plate to 15mm inside

the paper and put it under the paper.

3) In the case of the punch mode, punching is performed as

described in "7. Punching process."

B. Paper exit

1) After the paper rear edge passes the paper exit roller of the

main unit, the transport motor (FRM) and the bundle exit motor

(FAM) are accelerated to 300mm/sec. When the paper rear

edge passes the inlet port sensor (FED) and then transport of

a certain amount is made, the alignment plate is shifted to the

home position.

Before the paper rear edge passes the bundle exit roller, the

paper surface detection solenoid (FSLS) is turned OFF and

the bundle exit roller speed is decelerated to 100mm/sec at the

same time, performing paper exit deceleration of paper.

4) When the paddle rotates one turn, the bundle exit motor (FAM)

is stopped.

5) When there is next paper, repeat the procedures from "A-1)."

6) When there is no next paper, the actuators are turned OFF and

the finisher operation status command is set to READY, and

the transport operation is terminated.

5. Offset mode

When the operation mode command is received from the copier,

the finisher makes the finisher operation status command the JOB

and starts the transport operation.

A. Reception of paper discharged from the main

unit

1) The transport motor (FRM) is driven at the paper exit speed of

the main unit to receive paper from the main unit. When the

paper length is 216mm or less, the paper exit speed of the second and later sheets from the main unit is 280mm/sec.

B. Paper take-up and alignment

1) For the first sheet of a bundle, the inlet port sensor (FED) is

turned ON and the roller up/down motor (FSWM) is driven to

lower the bundle exit roller. The bundle exit motor (FAM) is

driven at the paper exit speed of the main unit to drive the bundle exit roller.

In addition, the alignment motor F (FFJM) and the alignment

motor R (FRJM) are driven by turning ON the inlet port sensor

(FED) to shift the alignment plate to 15mm outside the paper,

and enter the standby state. After transport of a certain

amount, the roller up/down motor (FSWM) is driven to lift the

bundle exit roller, stopping the bundle exit motor (FAM).

MX-FNX1/MX-PNX1 OPERATIONAL DESCRIPTIONS 5 – 6

Page 17

2) For the second and later sheets of a bundle, the inlet port sensor (FED) turns ON and a certain amount is transported, and

then the alignment motor F (FFJM) and the alignment motor R

(FRJM) are driven to shift the alignment plate to 15mm outside

the paper and to put it under the standby state.

3) After the paper rear edge passes the paper exit roller of the

main unit, the transport motor (FRM) is accelerated to 480mm/

sec.

4) In the punch mode, punching is performed as described in "7.

Punching process."

5) When the paper rear edge passes the inlet port sensor (FED)

and a certain amount is transported, the roller up/down motor

(FSWM) is driven to lower the bundle exit roller and the bundle

exit motor (FAM) is driven for a certain amount in the take-up

direction at the paper exit speed of the main unit to take up

paper to the process tray. In addition, the belt separation solenoid (FBRS) is turned ON to lower the take-up belt.

6) After completion of take-up, the roller up/down motor (FSWM)

is driven to lift the bundle exit roller. The alignment motor F

(FFJM) and the alignment motor R (FRJM) are driven for a certain amount to align paper in the process tray. If there are two

or more sheets to be aligned, the procedures are repeated

from "A-1)" for the specified number of sheets. However, the

paper exit operation of "C. Aligned paper exit" is performed for

every 3 sheets.

2) After transport of paper by a certain amount, the alignment

motor F (FFJM) and the alignment motor R (FRJM) are driven

to shift the alignment plate to the home position.

3) When the paper rear edge passes the empty sensor (FSTPD),

the paper surface detection solenoid (FSLS) is turned OFF

and the bundle exit roller speed is decelerated to 100mm/sec

at the same time, decelerating the paper exit operation.

4) Immediately after the paper rear edge passes the bundle exit

roller, the paddle one-rotation solenoid (FPDS) is turned ON to

take up paper falling onto the tray.

5) When the paper rear edge passes the bundle exit roller and

the paper is transported for 10mm, the bundle exit motor

(FAM) is accelerated to 200mm/sec. Before the paddle passes

the load tray, the paper surface detection solenoid (FSLS) is

turned ON to hold the discharged paper with the paper holding

lever.

C. Aligned paper exit

1) After completion of alignment, the belt separation solenoid

(FBRS) is turned ON to lift the take-up belt. The alignment

motor F (FFJM) and the alignment motor R (FRJM) are driven

to separate paper from the alignment plate by 1mm. In addition, the roller up/down motor (FSWM) is driven to lower the

bundle exit roller. The bundle exit motor (FAM) is started at the

speed of 450mm/sec and paper in the process tray is discharged.

6) When the paddle rotates one turn, the bundle exit motor (FAM)

is stopped.

7) When there is next paper, the procedures are repeated from

"A-1)."

8) When there is no next paper, the actuators are turned OFF and

the finisher operation status command is set to READY to terminate the transport operation.

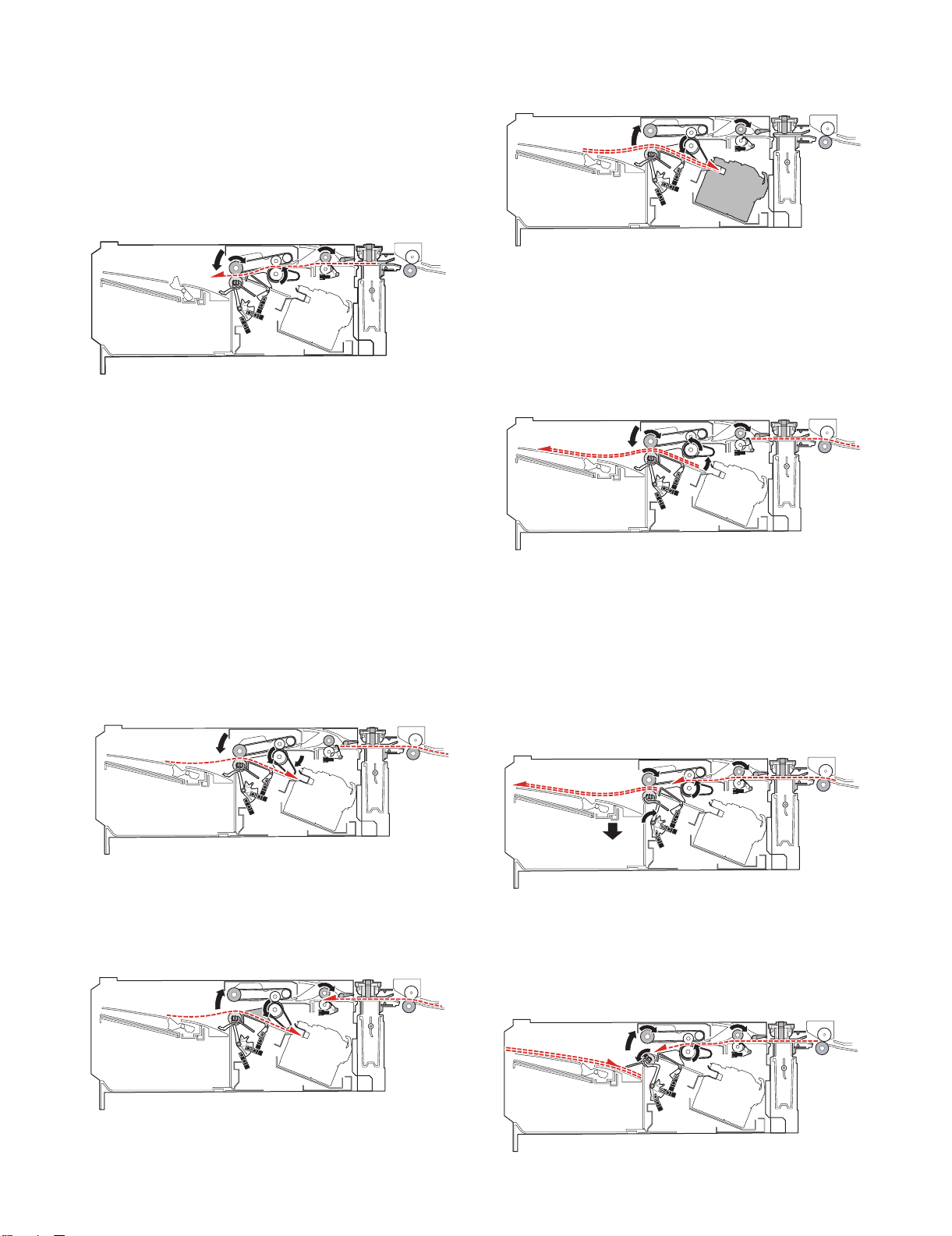

6. Staple mode

When the operation mode command is received from the copier,

the finisher makes the finisher operation status command the JOB

and starts the transport operation.

A. Reception of paper discharged from the main

unit

1) The transport motor (FRM) is driven at the paper exit speed of

the main unit to receive paper from the main unit. When the

paper length is 216mm or less, the paper exit speed of the second and later sheets from the main unit is 280mm/sec.

MX-FNX1/MX-PNX1 OPERATIONAL DESCRIPTIONS 5 – 7

Page 18

B. Paper take-up, alignment and staple

1) For the first sheet of a bundle, after turning on the inlet sensor

(FED), the roller up/down motor (FSWM) is driven to lower the

bundle exit roller. The bundle exit motor (FAM) is driven at the

paper exit speed of the main unit to drive the bundle exit roller.

By turning on the inlet port sensor (FED), the alignment motor

F (FFJM) and the alignment motor R (FRJM) are driven to shift

the alignment plate to 15mm outside the paper and to put it

under the standby state. After transport of a certain amount,

the roller up/down motor (FSWM) is driven to lift the bundle

exit roller to terminate the bundle exit motor (FAM).

2) For the second and later sheets, after transporting paper from

the inlet port sensor (FED) by a certain amount, the alignment

motor F (FFJM) and the alignment motor R (FRJM) are driven

to shift the alignment plate to 15mm outside the paper and to

put it under the standby state.

3) For the last sheet of a bundle, the inlet port sensor (FED) is

turned ON to drive the staple shift motor (FSM) to shift the stapler to the binding position.

4) After the paper rear edge passed the paper exit roller of the

main unit, the transport motor (FRM) is accelerated to 480mm/

sec.

5) In the punch mode, punching is performed as described in "7.

Punching process."

6) When the paper rear edge passes the inlet port sensor (FED)

and paper is transported by a certain amount, the roller up/

down motor (FSWM) is driven to lower the bundle roller and

the bundle exit motor (FAM) is driven in the take-up direction at

the paper exit speed of the main unit by a certain amount to

take up paper to the process tray. In addition, the belt separation solenoid (FBRS) is turned ON to lower the take-up belt.

8) After completion of alignment of a specified number of sheets,

the staple motor (FFSM) is started to staple at the specified

position.

C. Aligned and stapled paper exit

1) After completion of stapling, the belt separation solenoid

(FBRS) is turned ON to lift the take-up belt. The alignment

motor F (FFJM) and the alignment motor R (FRJM) are driven

to shift the alignment plate by 1mm from paper. Then the roller

up/down motor (FSWM) is driven to lower the bundle exit roller

to press, and the bundle exit motor (FAM) is started at 450mm/

sec to discharge paper from the process tray.

2) After transporting paper by a certain amount, the alignment

motor F (FFJM) and the alignment motor R (FRJM) are driven

to shift the alignment plate to the home position.

3) After the paper rear edge passes the empty sensor (FSTPD),

the paper surface detection solenoid (FSLS) is turned OFF

and the bundle exit roller speed is decelerated to 100mm/sec

at the same time to decelerate paper exit of the paper bundle.

At the same time, the roller up/down motor (FSWM) is driven in

the lifting direction to decrease the pressure of the bundle

roller. In addition, the tray motor (FTLM) is driven to lower the

load tray by 5mm.

7) After completion of take-up, the roller up/down motor (FSWM)

is driven to lift the bundle exit roller. The alignment motor F

(FFJM) and the alignment motor R (FRJM) are driven by a certain amount to align paper in the process tray. If there are two

or more sheets to be aligned, the operation is repeated from

"A-1)."

MX-FNX1/MX-PNX1 OPERATIONAL DESCRIPTIONS 5 – 8

4) Immediately after the paper rear edge passes the bundle exit

roller, the paddle one-rotation solenoid (FPDS) is turned ON to

take up roller falling onto the tray.

5) When paper is transported by 10mm after the paper rear edge

passes the bundle exit roller, the bundle exit motor (FAM) is

decelerated to 200mm/sec.

Page 19

6) When the paddle rotates one turn, the bundle exit motor (FAM)

is stopped.

7) After the paddle rotates one turn, the paper surface detection

solenoid (FSLS) is turned ON for 100msec and then OFF.

Then it is turned ON after 400msec. At that time, if the paper

surface level is lower than the reference level, the tray motor

(FTLM) is driven to lift the load tray to the reference level.

8) If there is next paper, the operation is repeated from "A-1)."

9) If there is no next paper, the actuators are turned OFF and the

finisher operation status command is set to READY state, and

the transport operation is terminated.

7. Punching process

When the operation mode command is received from the copier,

the finisher makes the finisher operation status command the JOB

and starts the transport operation.

A. Reception of paper discharged from the main

unit

1) The transport motor (FRM) is driven at the paper exit speed of

the main unit to receive paper from the main unit. When the

paper length is 216mm or less in the offset mode or in the staple mode, the paper exit speed of the second and later sheets

of the same bundle from the main unit is 280mm/sec.

C. Punching process 2

1) After completion of punching, the transport motor (FRM) and

the bundle exit motor (FAM) are driven to transport paper and

the specified after-process is executed. The motor speed is

300mm/sec for the non-sort mode, and 480mm/sec for the offset mode or the staple mode.

B. Punching process 1

1) When the paper rear edge passes the paper rear edge sensor,

the transport motor (FRM) is stopped and paper transport is

stopped.

2) When the paper is stopped, the punch motor (FPNM) is driven

to punch at the paper rear edge.

MX-FNX1/MX-PNX1 OPERATIONAL DESCRIPTIONS 5 – 9

Page 20

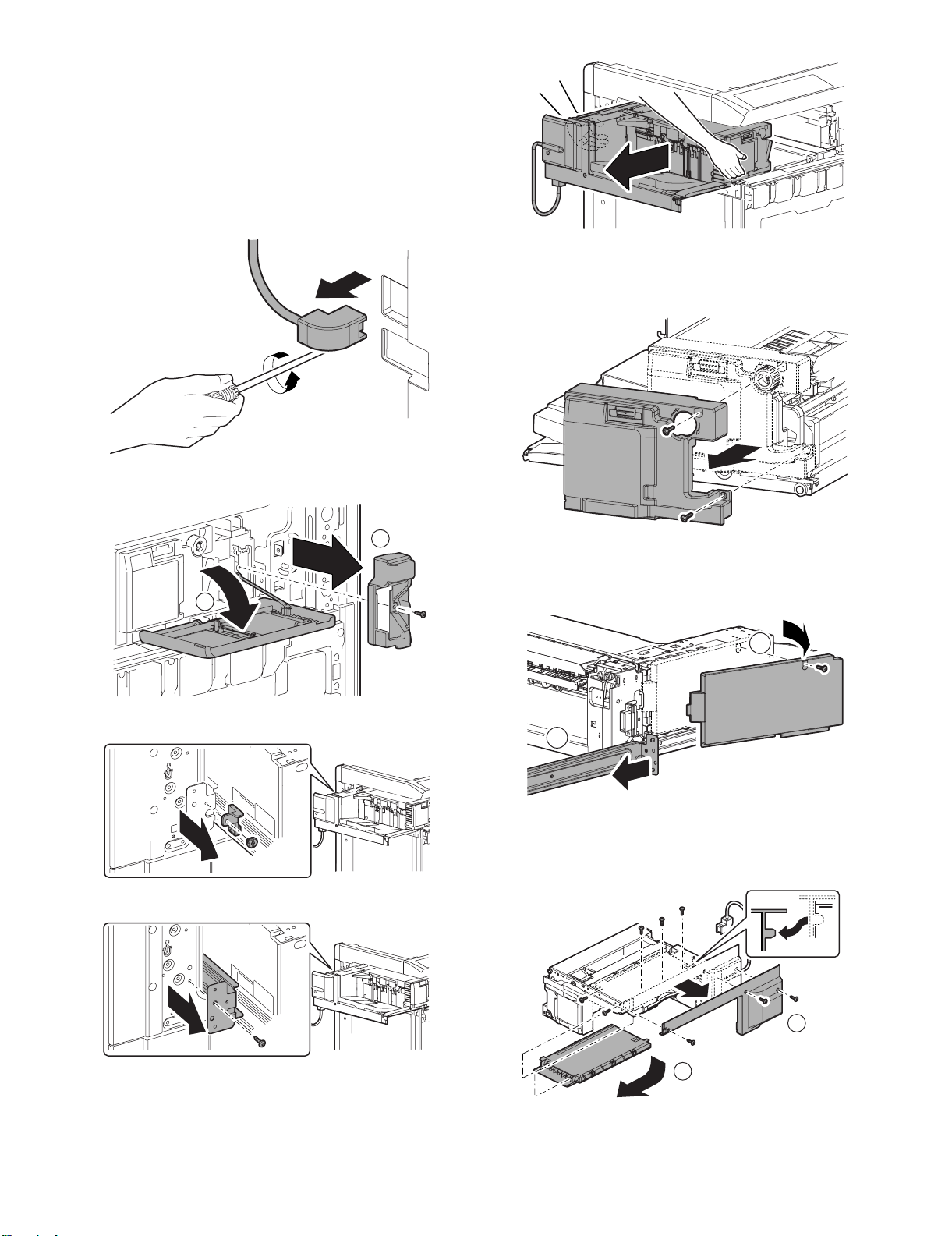

âºíuÇ´

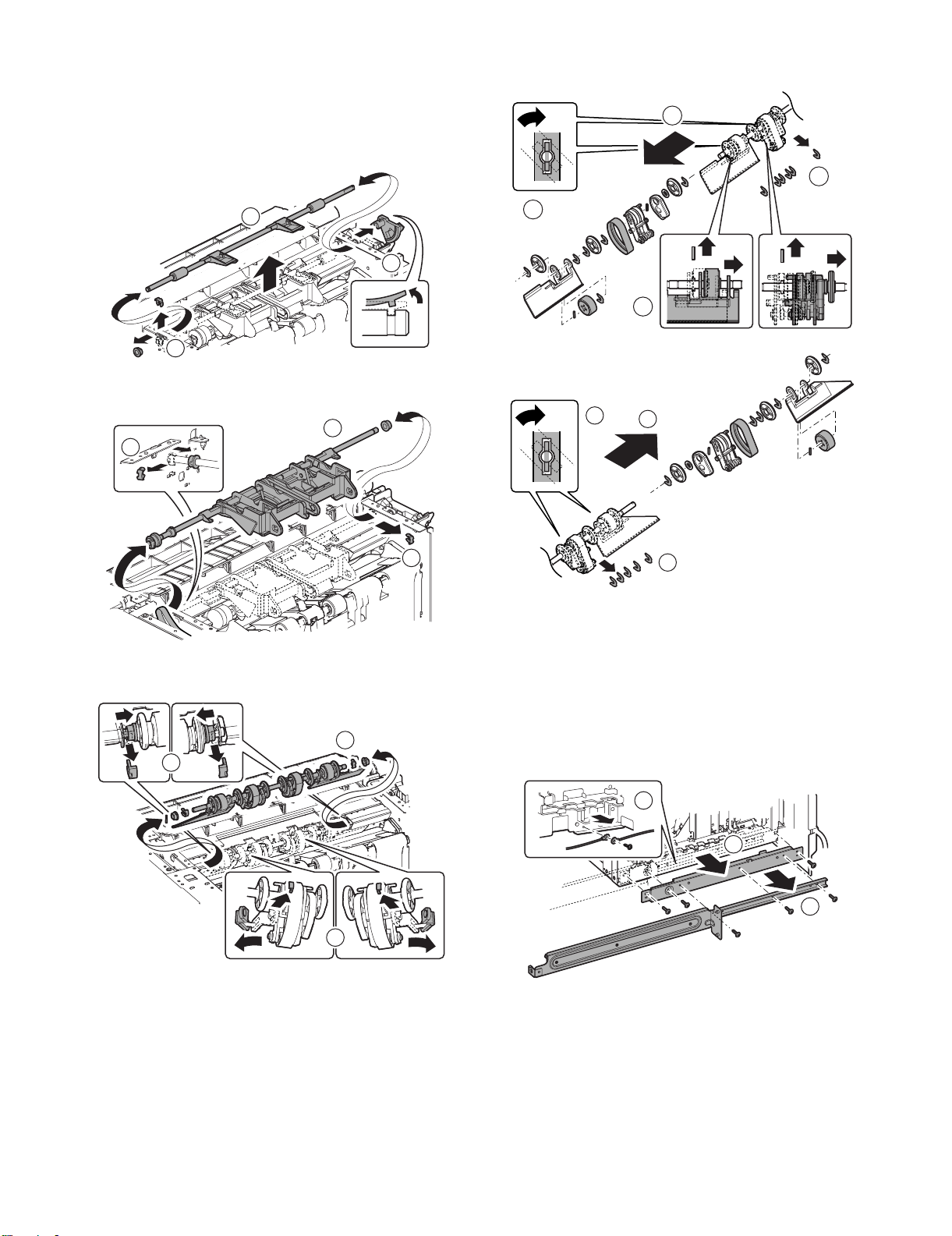

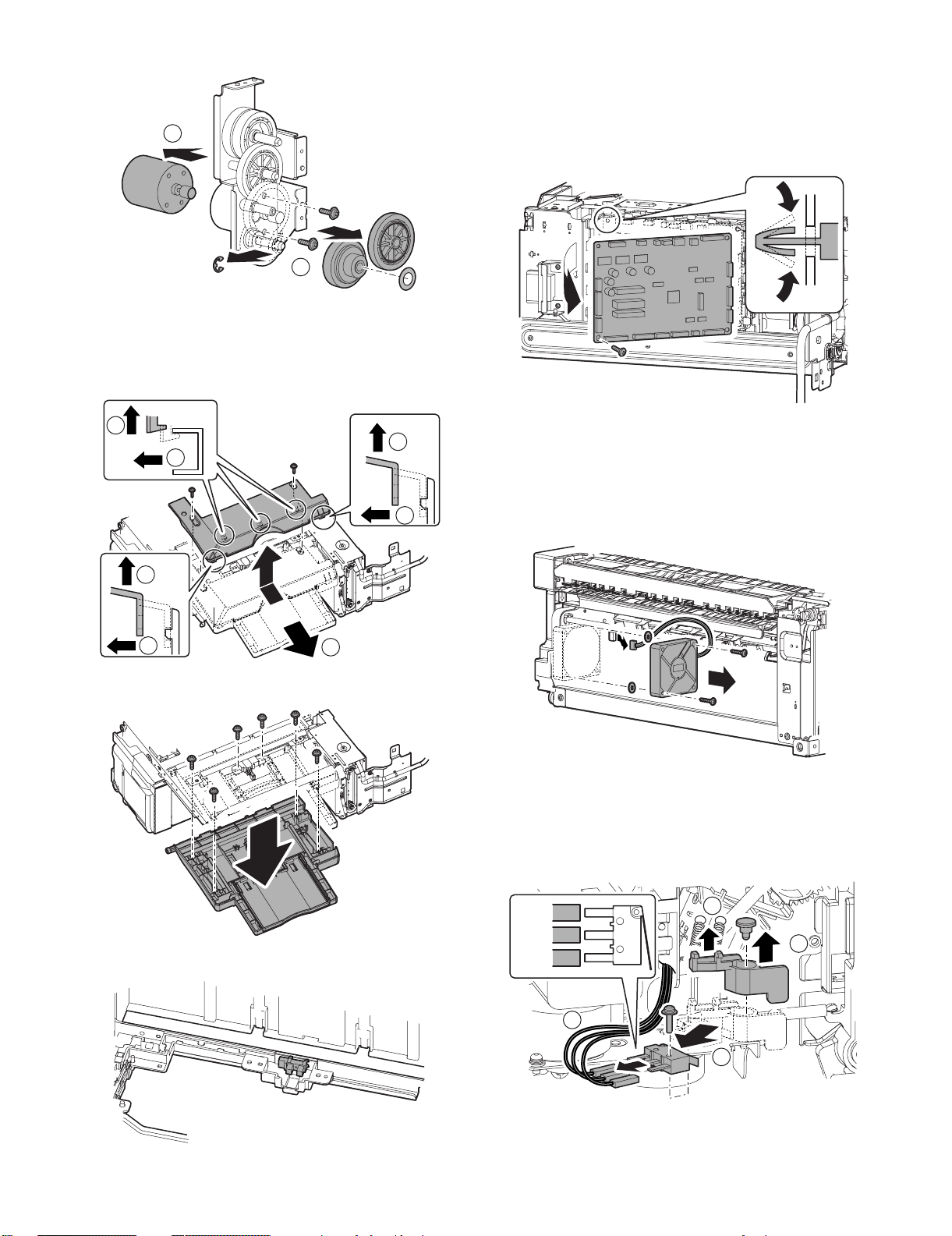

[6] DISASSEMBLY AND

ASSEMBLY

1. MX-FNX1

A. Exterior

(1) Inner finisher

1) Loosen the screw, and disconnect the connector from the main

unit.

2) Open the front cover, and remove the punch unit cover.

Service Manual

(2) Inner cover

1) Remove the inner finisher from the main unit. Refer to A-(1).

2) Remove the inner cover.

1

3) Remove the stopper.

4) Remove the screw, and remove the rail stay.

2

(3) Rear cover

1) Remove the inner finisher from the main unit. Refer to A-(1).

2) Slide the rail, and remove the rear cover.

2

1

(4) Left cover, bottom cover

1) Remove the inner finisher from the main unit. Refer to A-(1).

2) Remove the left cover and the bottom cover.

5) Remove the inner finisher from the main unit.

MX-FNX1/MX-PNX1 DISASSEMBLY AND ASSEMBLY 6 – 1

1

2

Page 21

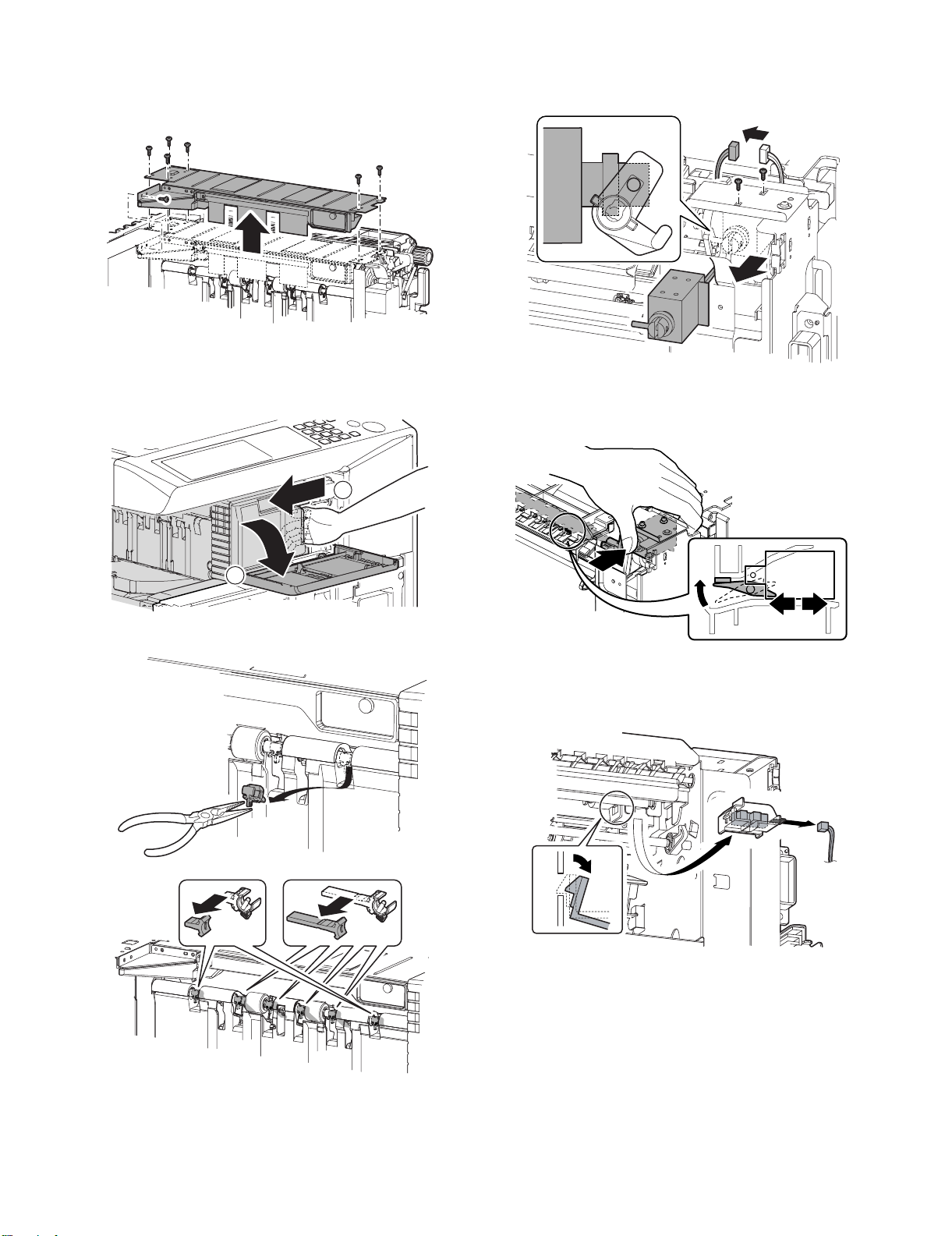

(5) Reverse guide unit

1) Remove the inner finisher from the main unit. Refer to A-(1).

2) Remove the inner cover. Refer to A-(2).

3) Remove the reverse guide unit.

B. Transport section, paper exit section

(1) Paddle

1) Open the front cover, and slide the inner finisher.

2

(2) Flapper solenoid

1) Remove the inner finisher from the main unit. Refer to A-(1).

2) Disconnect the connector, and remove the flapper solenoid.

* When installing, shift and fix the solenoid so that the reverse

flapper and the cushion material are in contact with each

other with the solenoid plunger pushed in.

1

2) Remove the paddle holders, and remove the paddles.

(3) Inlet port sensor

1) Remove the inner finisher from the main unit. Refer to A-(1).

2) Remove the sensor holder, and remove the inlet port sensor.

MX-FNX1/MX-PNX1 DISASSEMBLY AND ASSEMBLY 6 – 2

Page 22

(4) Roller up/down sensor

1) Remove the inner finisher from the main unit. Refer to A-(1).

2) Remove the inner cover. Refer to A-(2).

3) Remove the bracket, and remove the roller up/down sensor.

(5) Take-up belt sensor

1) Remove the inner finisher from the main unit. Refer to A-(1).

2) Remove the inner cover. Refer to A-(2).

3) Slide the harness guide, remove the bracket, and remove the

take-up belt sensor.

2

(7) Belt separation solenoid

1) Remove the inner finisher from the main unit. Refer to A-(1).

2) Remove the inner cover. Refer to A-(2).

3) Remove the reverse guide unit. Refer to A-(5).

4) Remove the parts, and remove the belt separation solenoid.

2

3

1

(8) Bundle exit paper transport roller

1) Remove the inner finisher from the main unit. Refer to A-(1).

2) Remove the inner cover. Refer to A-(2).

3) Remove the reverse guide unit. Refer to A-(5).

4) Remove the parts, and remove the bundle exit paper transport

roller unit.

1

(6) Roller up/down motor

1) Remove the inner finisher from the main unit. Refer to A-(1).

2) Remove the inner cover. Refer to A-(2).

3) Remove the rear cover. Refer to A-(3).

4) Remove the reverse guide unit.

5) Slide the stapler drive unit. Disconnect the connector from the

PWB. Remove the roller up/down motor unit. Remove the

roller up/down motor.

1

3

2

3

2

1

2

5) Remove the parts, and remove the bundle exit paper transport

roller.

3

1

2

1

MX-FNX1/MX-PNX1 DISASSEMBLY AND ASSEMBLY 6 – 3

Page 23

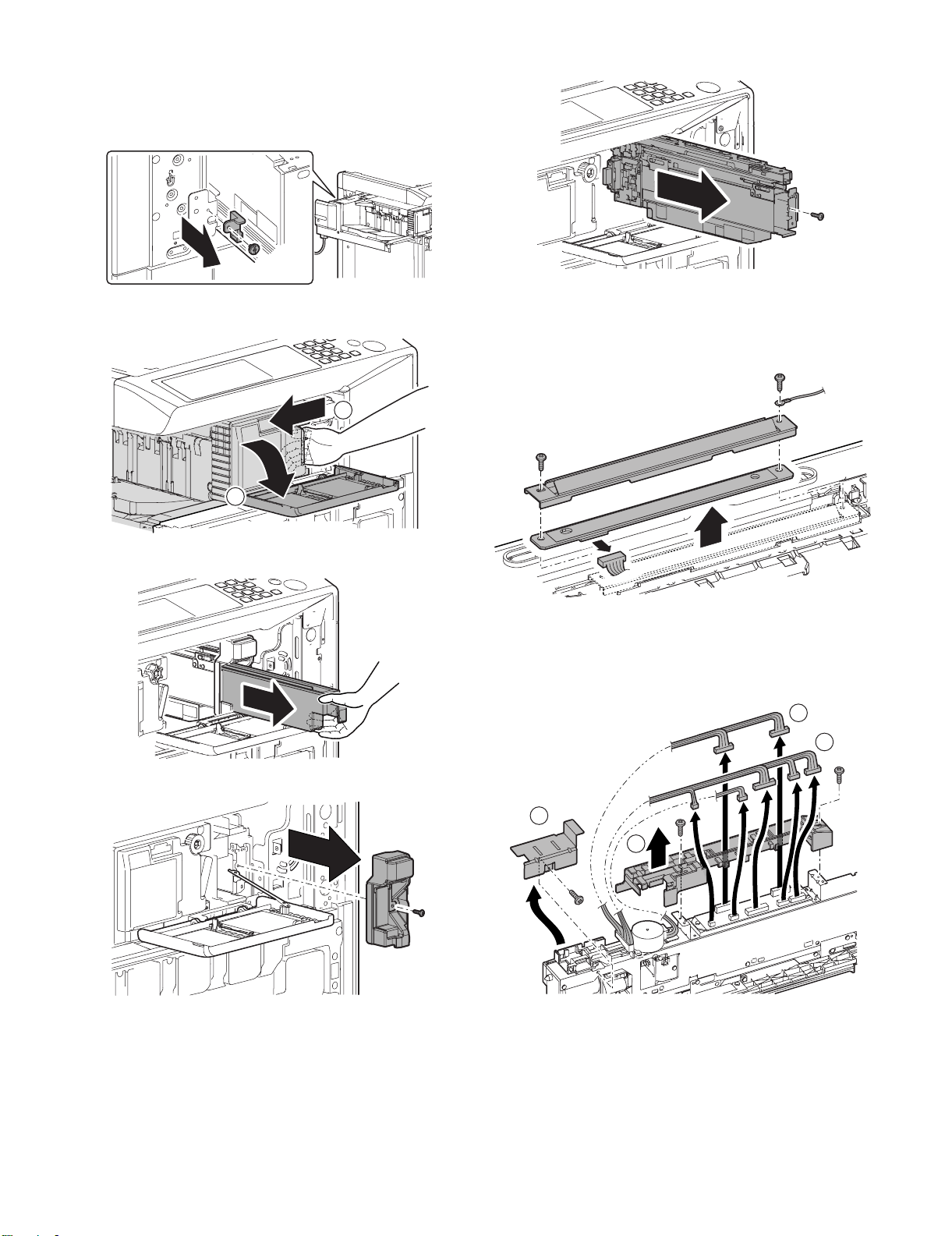

(9) Take-up belt, paper exit roller

1) Remove the inner finisher from the main unit. Refer to A-(1).

2) Remove the inner cover. Refer to A-(2).

3) Remove the reverse guide unit. Refer to A-(5).

4) Remove the parts, and remove the bundle roller up/down lever

unit.

7) Remove the parts, and remove the take-up belt and the paper

exit roller.

3

1

2

1

1

5) Remove the parts, and remove the bundle roller unit.

2

1

1

6) Remove the parts, and pull out the belt unit. Remove the parts,

and remove the belt unit.

3

1

2

2

2

3

1

(10) Inlet port gate

1) Remove the inner finisher from the main unit. Refer to A-(1).

2) Remove the inner cover. Refer to A-(2).

3) Remove the left cover and the bottom cover. Refer to A-(4).

4) Remove the reverse guide unit. Refer to A-(5).

5) Remove the PWB. Refer to F-(1).

6) Remove the flapper solenoid. Refer to B-(2).

7) Remove the slide rail. Remove the slider fixing bracket and

remove the earth terminal.

2

MX-FNX1/MX-PNX1 DISASSEMBLY AND ASSEMBLY 6 – 4

3

2

1

Page 24

8) Remove the tray unit.

9) Remove the harness from the guide, and remove the bottom

plate.

(11) Inlet port paper transport roller

1) Remove the inner finisher from the main unit. Refer to A-(1).

2) Remove the inner cover. Refer to A-(2).

3) Remove the tray unit. Refer to B-(10).

4) Remove the bottom plate. Refer to B-(10).

5) Remove the inlet port upper guide, and remove the transport

guide.

6) Remove the parts, and remove the inlet port paper transport

roller.

10) Remove the inlet port upper guide.

11) Remove the spring, and remove the parts. Remove the inlet

port gate.

2

3

4

1

1

2

3

2

(12) Transport motor

1) Remove the inner finisher from the main unit. Refer to A-(1).

2) Remove the inner cover. Refer to A-(2).

3) Remove the tray unit. Refer to B-(10).

4) Remove the bottom plate. Refer to B-(10).

5) Disconnect the connector, and remove the transport motor.

1

3

1

MX-FNX1/MX-PNX1 DISASSEMBLY AND ASSEMBLY 6 – 5

2

Page 25

(13) Bundle exit motor

1) Remove the inner finisher from the main unit. Refer to A-(1).

2) Remove the inner cover. Refer to A-(2).

3) Remove the tray unit. Refer to B-(10).

4) Remove the bottom plate. Refer to B-(10).

5) Disconnect the connector, and remove the bundle exit motor.

5) Remove the bundle exit paper transport unit.

1

1

1

1

3

2

(14) Paddle one-rotation solenoid

1) Remove the inner finisher from the main unit. Refer to A-(1).

2) Remove the inner cover. Refer to A-(2).

3) Remove the tray unit. Refer to B-(10).

4) Remove the bottom plate. Refer to B-(10).

5) Remove the paddle one-rotation solenoid.

2

6) Remove each parts, and remove the sensor lever.

7) Remove the center weight, and remove the process tray unit.

1

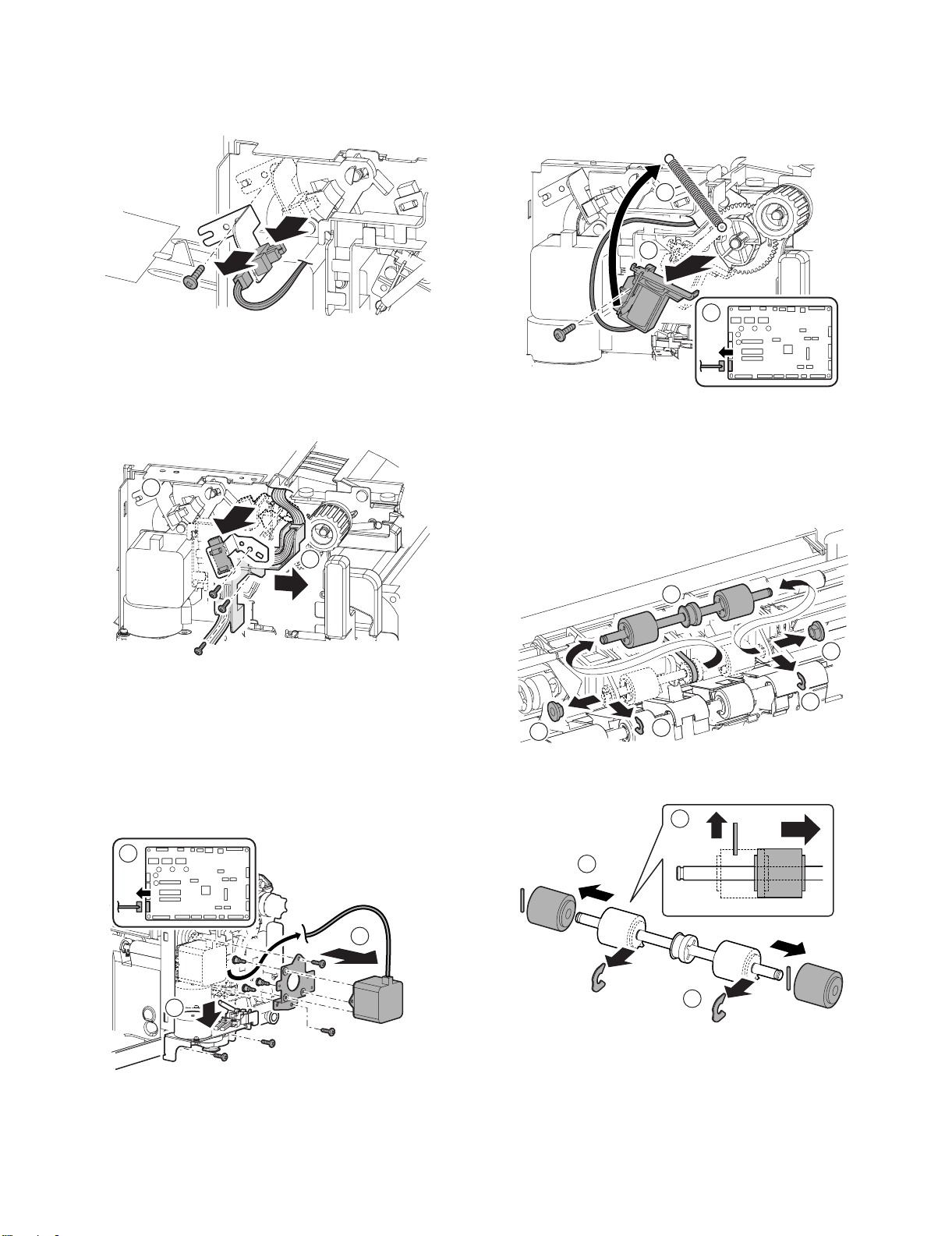

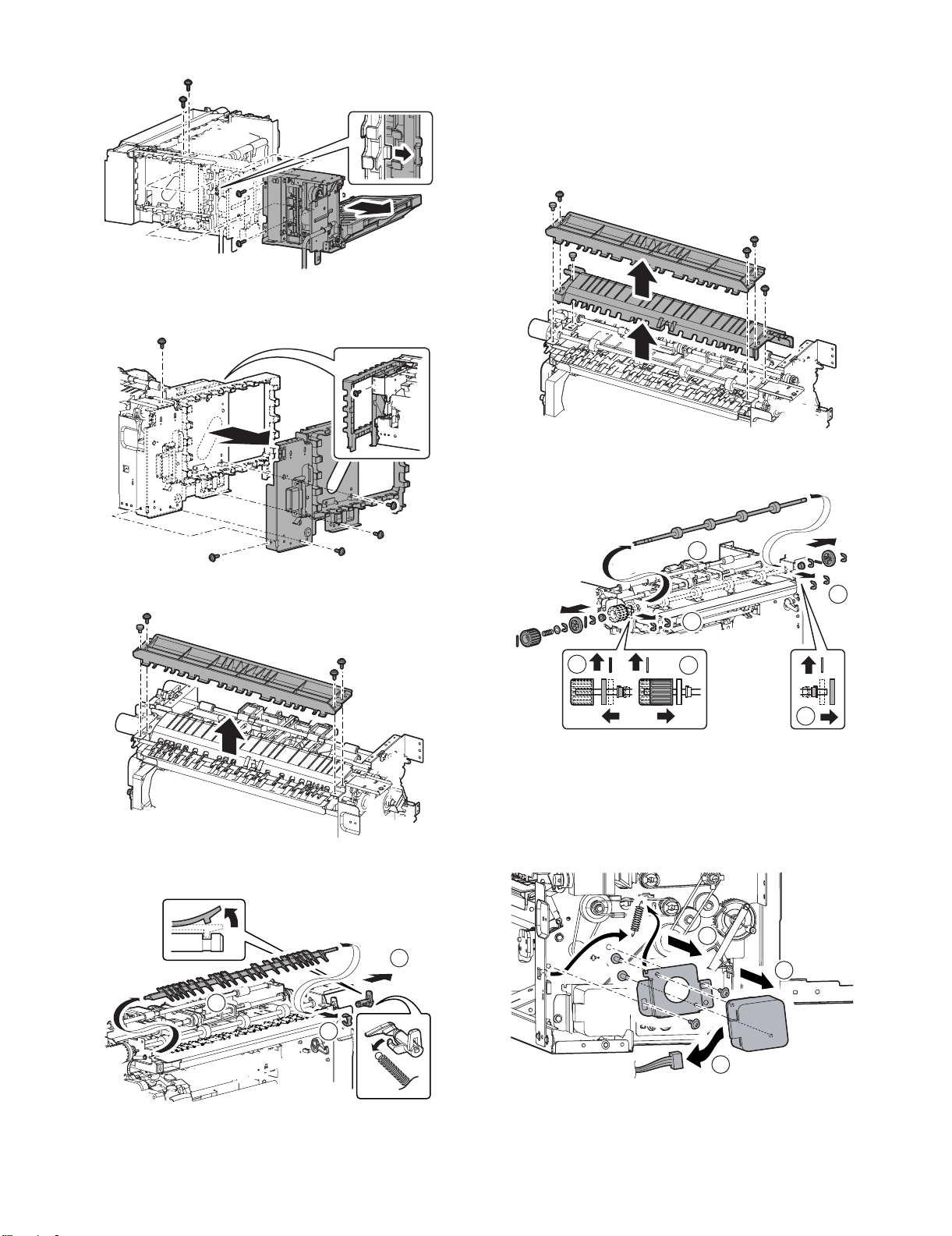

C. Process tray section

(1) Alignment motors F and R

1) Remove the inner finisher from the main unit. Refer to A-(1).

2) Remove the inner cover. Refer to A-(2).

3) Remove the tray unit. Refer to B-(10).

4) Remove the load cover. Refer to B-(10).

MX-FNX1/MX-PNX1 DISASSEMBLY AND ASSEMBLY 6 – 6

2

Page 26

8) Remove the alignment plate. Remove the screws and the

pawl, and remove the process tray.

1

2

D. Staple section

(1) Staple cartridge

1) Open the front cover, and slide the inner finisher. Refer to B(1).

2) Release the lock, and remove the staple cartridge.

(2) Staple unit

1) Remove the inner finisher from the main unit. Refer to A-(1).

2) Remove the inner cover. Refer to A-(2).

3) Remove the latch cover. Remove the parts and the shaft.

9) Slide the unit and remove the alignment motors F and R.

(2) Empty sensor, alignment plate HP sensors F and R

1) Remove the inner finisher from the main unit. Refer to A-(1).

2) Remove the inner cover. Refer to A-(2).

3) Remove the tray unit. Refer to B-(10).

4) Remove the process tray unit. Refer to C-(1).

5) Remove the bracket and the empty sensor. Remove the alignment plate HP sensors F and R.

1

2

4) Remove the screw from the bottom. Remove the staple unit,

and disconnect the connector.

5

4

3

1

2

MX-FNX1/MX-PNX1 DISASSEMBLY AND ASSEMBLY 6 – 7

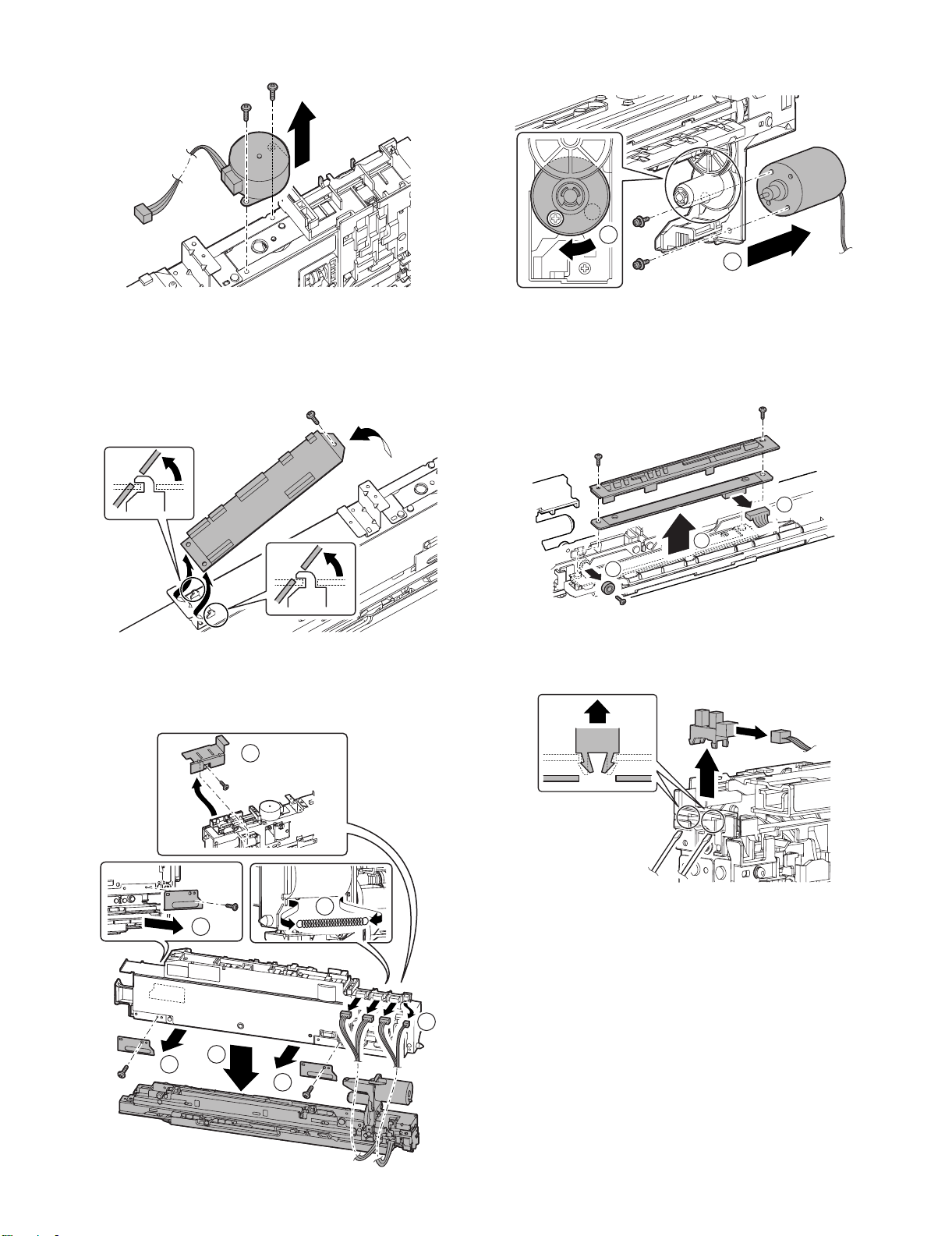

Page 27

(3) Alignment plate position sensor

1) Remove the inner finisher from the main unit. Refer to A-(1).

2) Shift the staple unit to the front side.

3) Remove the bracket and remove the position sensor.

7) Disconnect the connector from the PWB, and remove the staple shift motor.

(5) Stapler HP sensor

1) Remove the inner finisher from the main unit. Refer to A-(1).

2) Remove the inner cover. Refer to A-(2).

3) Put the inner finisher upside down, and remove the stapler HP

sensor.

(4) Staple shift motor

1) Remove the inner finisher from the main unit. Refer to A-(1).

2) Remove the inner cover. Refer to A-(2).

3) Remove the rear cover. Refer to A-(3).

4) Remove the reverse guide unit. Refer to A-(5).

5) Remove the roller up/down motor. Refer to B-(6).

6) Remove the E-ring, the flange and the gear pulley, and remove

the gear.

E. Paper exit tray section

(1) Paper surface sensors 1, 2

1) Remove the inner finisher from the main unit. Refer to A-(1).

2) Remove the inner cover. Refer to A-(2).

3) Remove the tray unit. Refer to B-(10).

4) Remove the load cover. Refer to C-(1).

5) Remove the parts, and remove the sensor lever.

MX-FNX1/MX-PNX1 DISASSEMBLY AND ASSEMBLY 6 – 8

Page 28

6) Remove the bracket, and remove the paper surface sensors 1,

2.

(2) Paper surface detection solenoid

1) Remove the inner finisher from the main unit. Refer to A-(1).

2) Remove the inner cover. Refer to A-(2).

3) Remove the tray unit. Refer to B-(10).

4) Remove the bundle exit paper transport roller unit, the sensor

lever, the process tray unit. Refer to C-(1).

5) Remove the paper surface detection solenoid unit, and

remove the paper surface detection solenoid.

(3) Tray upper limit sensor, tray intermediate lower

limit sensor, tray lower limit sensor

1) Remove the inner finisher from the main unit. Refer to A-(1).

2) Remove the tray unit. Refer to B-(10).

3) Remove the harness guide, and remove the tray upper limit

sensor, the tray intermediate lower limit sensor, and the tray

lower limit sensor.

(4) Tray motor

1) Remove the inner finisher from the main unit. Refer to A-(1).

2) Remove the tray unit. Refer to B-(10).

3) Remove the tray left bracket and the tray drive unit.

4) Remove the tray drive unit.

MX-FNX1/MX-PNX1 DISASSEMBLY AND ASSEMBLY 6 – 9

Page 29

5) Remove the gear, and remove the tray motor.

2

1

(5) Tray paper empty sensor

1) Remove the inner finisher from the main unit. Refer to A-(1).

2) Remove the left cover and the bottom cover. Refer to A-(4).

3) Remove the tray bottom cover.

F. O th er s

(1) Control PWB

1) Remove the inner finisher from the main unit. Refer to A-(1).

2) Remove the rear cover. Refer to A-(3).

3) Disconnect the connector, and remove the screw. Remove the

PWB support and remove the control PWB.

3

3

2

2

3

2

4) Pull out the tray. Remove the screw, and remove the tray.

1

(2) Fan

1) Remove the inner finisher from the main unit. Refer to A-(1).

2) Shift the staple unit to the rear side. Disconnect the connector

and remove the fan.

* When installing, take care that the label of the fan comes to

the direction illustrated.

(3) Front cover switch

1) Remove the inner finisher from the main unit. Refer to A-(1).

2) Remove the inner cover. Refer to A-(2).

3) Remove the spring, and remove the interlock sensor lever.

Remove the front cover switch, and disconnect the connector.

5) Remove the tray paper empty sensor.

MX-FNX1/MX-PNX1 DISASSEMBLY AND ASSEMBLY 6 – 10

Yellow

Red

Blue

1

2

3

4

Page 30

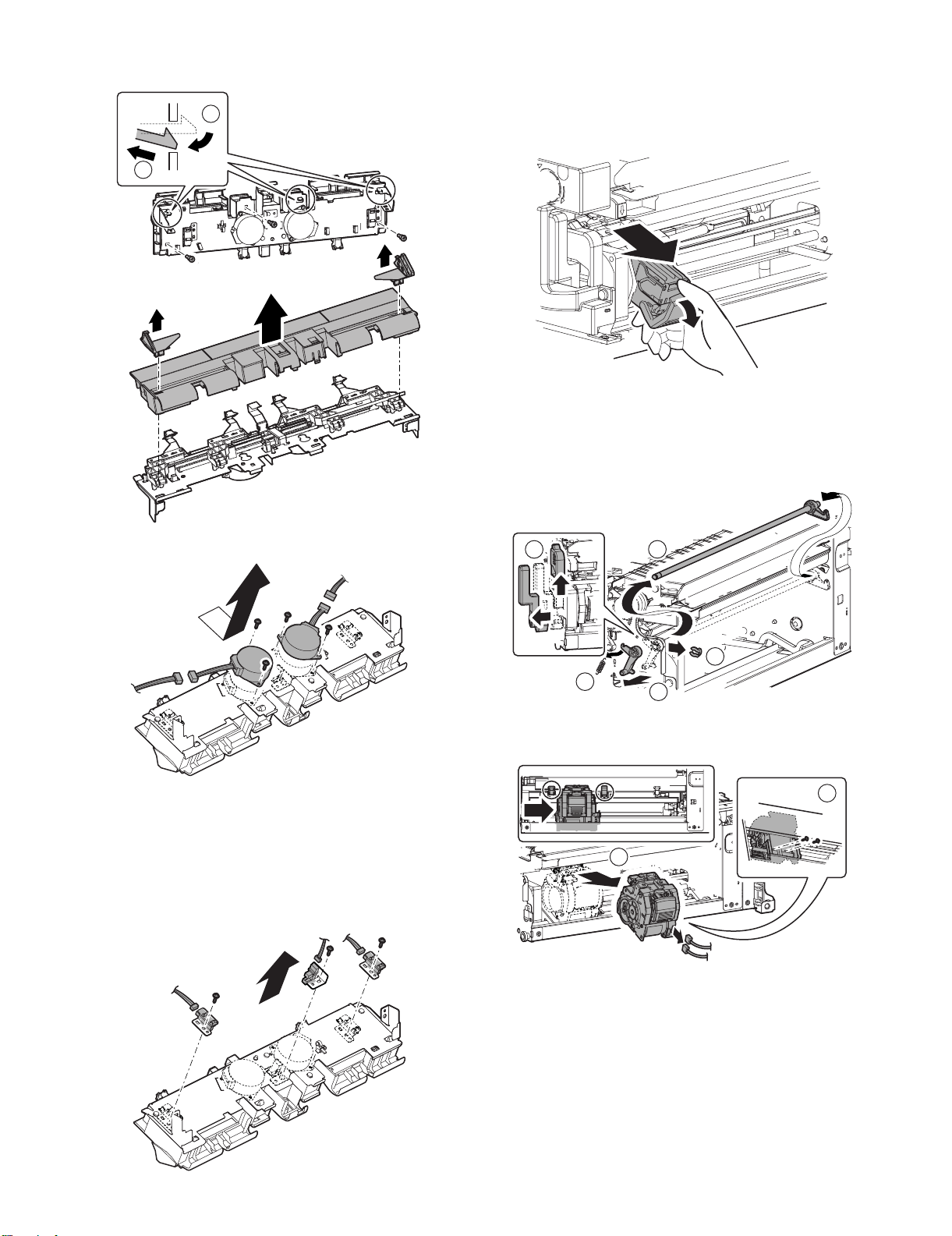

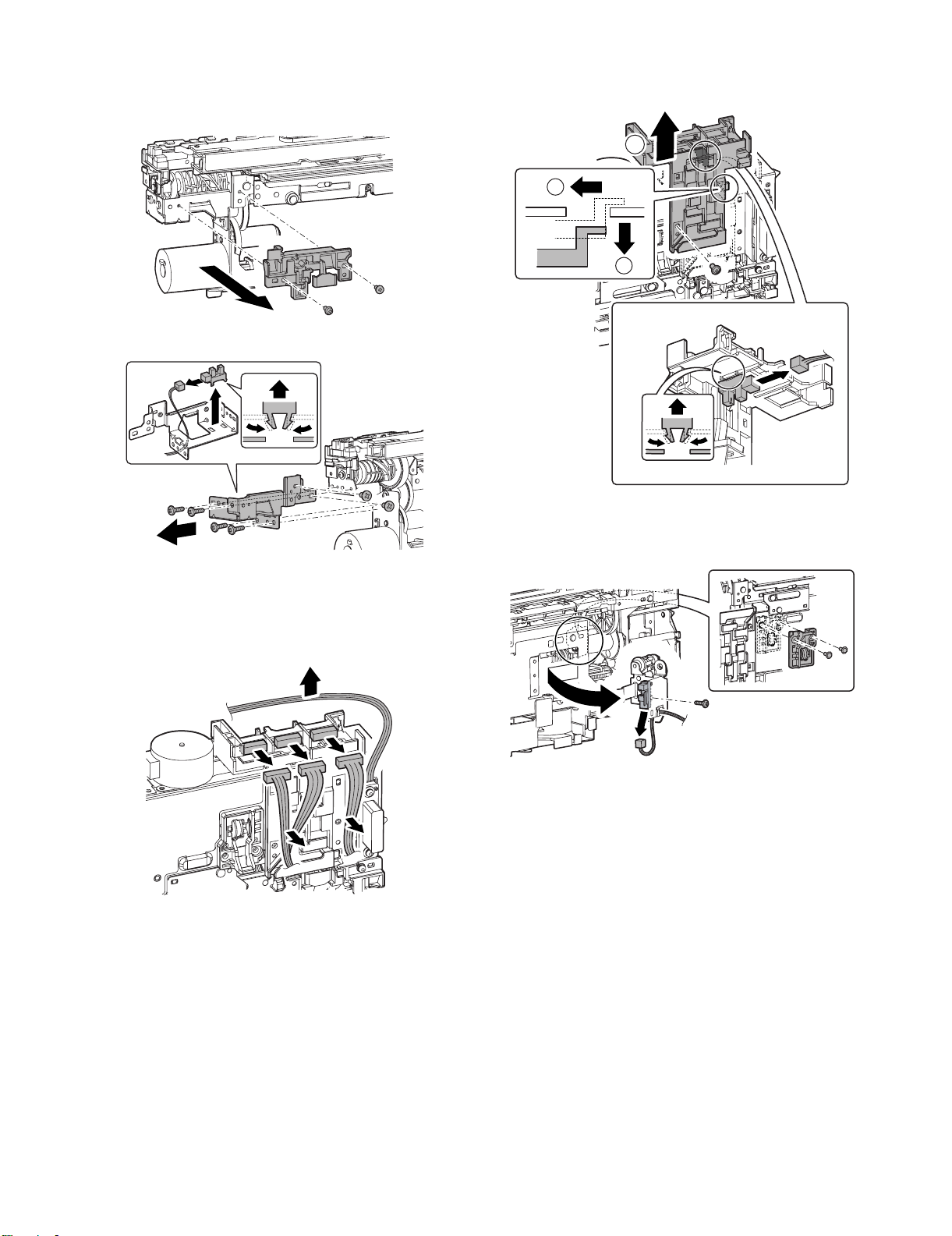

2. MX-PNX1A/B/C/D

A. Punch unit (MX-PNX1A/B/C/D)

(1) Punch unit (MX-PNX1A/B/C/D)

1) Remove the coin screw, and remove the finisher slide stopper.

2) Open the front cover, and slide the inner finisher.

2

1

5) Remove the punch unit from the main unit.

(2) LED light receiving PWB

1) Remove the punch unit. Refer to A-(1).

2) Remove the PWB holder, and remove the LED light receiving

PWB.

3) Remove the dust box.

4) Remove the punch cover.

(3) Punch horizontal resist motor

1) Remove the punch unit. Refer to A-(1).

2) Remove the guide cover. Disconnect the connector, and

remove the harness guide.

2

2

1

3

MX-FNX1/MX-PNX1 DISASSEMBLY AND ASSEMBLY 6 – 11

Page 31

3) Remove the punch horizontal resist motor.

1

2

3) Fit the gear hole with the screw position, and remove the

screw. Remove the punch motor.

(4) Punch PWB

1) Remove the punch unit. Refer to A-(1).

2) Remove the guide cover and the harness guide. Refer to A(3).

3) Remove the punch PWB.

(5) Punch motor

1) Remove the punch unit. Refer to A-(1).

2) Disconnect the connector, and remove the link plate. Remove

the spring, and separate the upper unit and the lower unit.

1

(6) LED light emitting PWB

1) Remove the punch unit. Refer to A-(1).

2) Remove the lower unit. Refer to A-(5).

3) Remove the roller and the PWB holder. Remove the LED light

emitting PWB.

3

2

1

(7) Rear position sensor

1) Remove the punch unit. Refer to A-(1).

2) Remove the rear position sensor.

3

4

2

4

5

4

MX-FNX1/MX-PNX1 DISASSEMBLY AND ASSEMBLY 6 – 12

Page 32

(8) Punch position sensor

1) Remove the punch unit. Refer to A-(1).

2) Remove the upper unit. Refer to A-(5).

3) Remove the harness guide.

4) Remove the punch position sensor.

4) Remove the screws and the pawl, and lift up the harness

guide. Disconnect the connector, and remove the horizontal

shift HP sensor.

3

1

2

(9) Horizontal shift HP sensor

1) Remove the punch unit. Refer to A-(1).

2) Remove the guide cover and the harness guide. Refer to A(3).

3) Disconnect the connector, and remove the harness.

(10) Full sensor

1) Remove the punch unit. Refer to A-(1).

2) Remove the drive bracket, and remove the full sensor.

MX-FNX1/MX-PNX1 DISASSEMBLY AND ASSEMBLY 6 – 13

Page 33

âºíuÇ´

[7] MAINTENANCE

Service Manual

1. Maintenance system table

✕: Check (Clean, replace, or adjust according to the necessity.) {: Clean S: Replace U: Adjust ✩: Lubricate : Shift position

No. Part name When calling

Follows the main unit

cycle.

Remark

1 Transport rollers ✕ {

2 Transport paper guides ✕ {

3Gears ✕✕

4Belts ✕

5 Knurling belt ✕ { Replacement reference: Finisher count value of 1000K.

6 Paddle ✕ {

7Sensors ✕✕

8 Discharge brush ✕✕

9 Stapler unit Replacement reference: Replace the unit for every

200K stapling.

10 Punch unit Replacement reference: Replace the unit for every

1000K punching.

11 Staple cartridge User replacement for every use of 5,000 pcs.

1

1

1

1

1

1

7

7

7

7

7

7

7

7

7

8

6

6

6

8

6

8

6

6

5

7

7

7

7

7

7

7

7

7

7

7

7

10

5

9

11

MX-FNX1/MX-PNX1 MAINTENANCE 7 – 1

Page 34

âºíuÇ´

[8] ADJUSTMENTS

Each adjustment item in the adjustment item list is identified with its

own JOB No. The adjustments are basically executed in the

sequence from a smaller JOB No. to a larger JOB No.

There is, however, no need to perform all the adjustment items.

Only the necessary items may be executed depending on the situation.

Unnecessary items may be skipped to go to the next necessary

item. In this case, of course, the adjustment sequence could be

executed from a smaller to a larger JOB No.

If the above is neglected, the adjustment cannot be completed normally, resulting in a trouble.

[Start of simulation]

1) Press [COPY MODE] key to enter the copy mode.

2) Press [P] (Program) key → [*] (Asterisk) key → [C] (Clear) key

→ [*] (Asterisk) key in this sequence.

3) The display is shifted to the simulation main number entry

screen (entry standby screen).

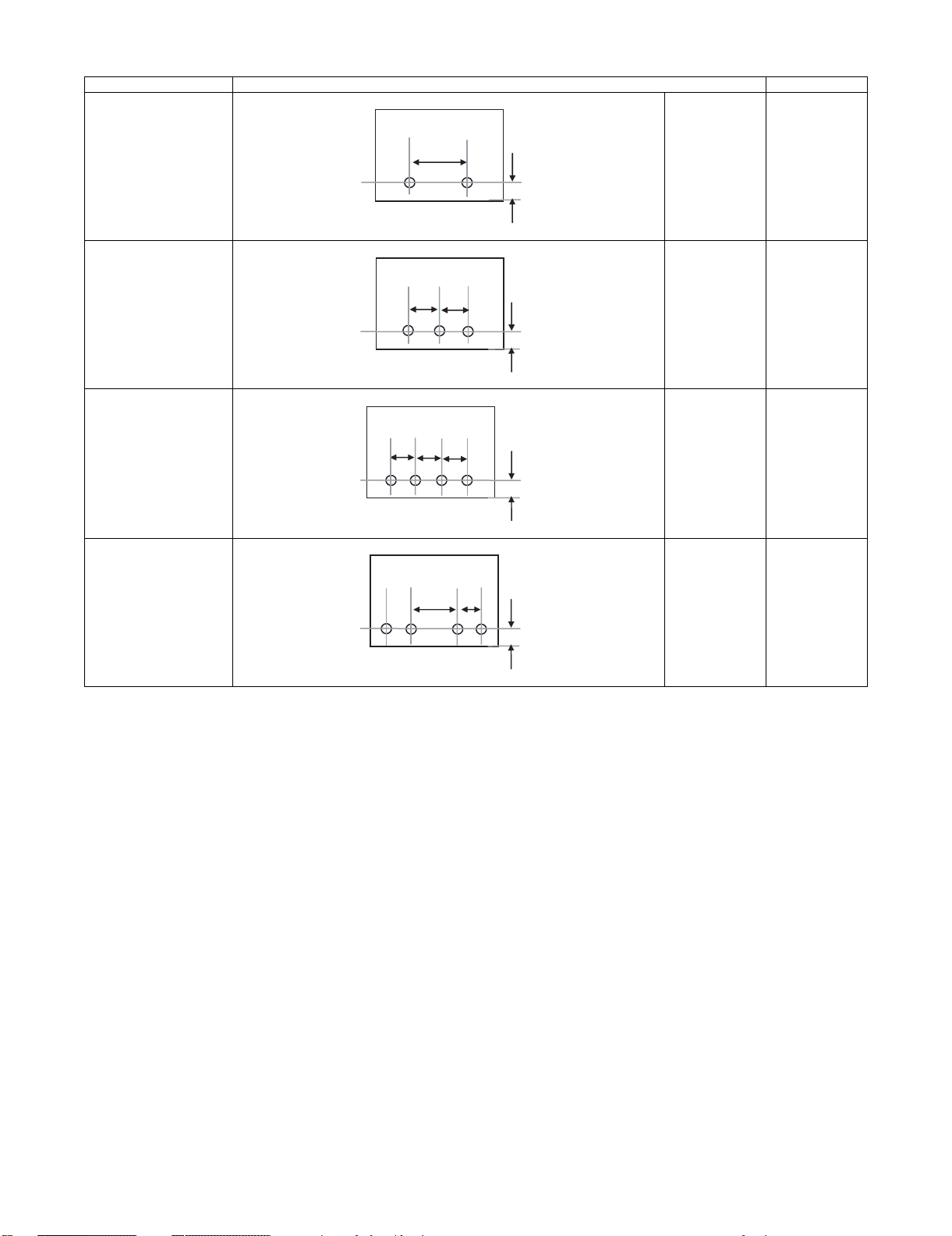

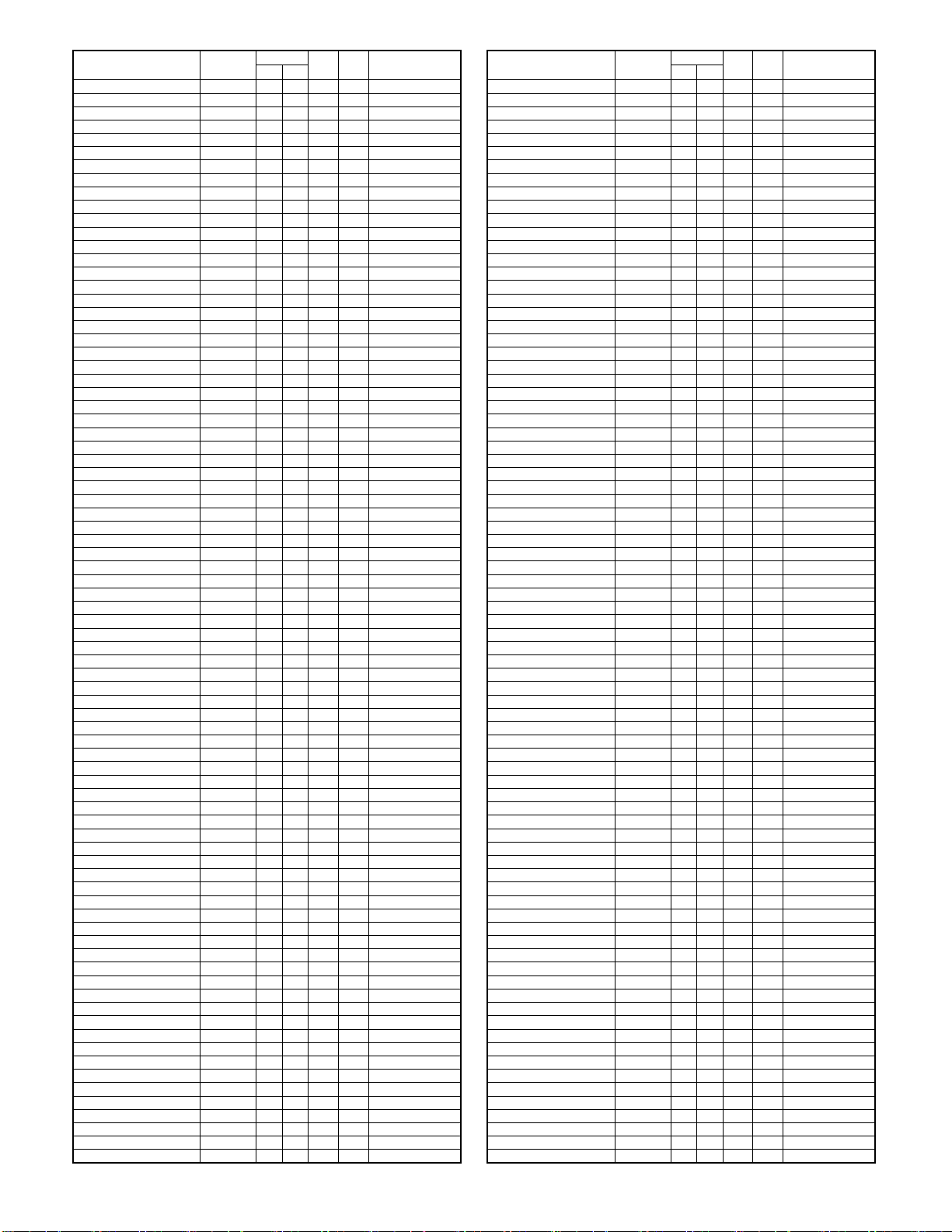

1. Setting item list

JOB No. Adjustment item list

1 Punch unit, punch PWB destination setting –

2 Finisher adjustment 3-10

3 Flapper solenoid adjustment –

4 Punch home position adjustment –

Simulation

to be used

2. Details

1 Punch unit, punch PWB destination

setting

1) When the punch PWB is replaced, the destination setting must

be performed.

2) For destination setting, the DIP switch (SW1) on the punch

PWB is used.

㪦㪥

㪈㪉

3) The relationship between the switches and the destinations is

shown in the table below.

Model Kind of punching 1 2

MX-PNX1A 2-hole type OFF OFF

MX-PNX1B 2/3-hole type ON OFF

MX-PNX1C 4-hole type (France) OFF ON

MX-PNX1D 4-hole type (Sweden) ON ON

Service Manual

2 Finisher adjustment

1) Enter Simulation 3-10.

2) Select a set item with [↑] [↓] buttons. The highlighted section of

the set value is changed and is displayed on the setting area.

* If there is any item over [↑], the display becomes active and

the cursor can be moved.

If there is no item over [↑], the display grays out and the

operation is disabled.

If there is any item under [↓], the display becomes active

and the cursor can be moved.

If there is no item under [↓], the display grays out and the

operation is disabled.

3) Enter the set value with 10-key.

* Press [C] key to clear the entered value.

4) When [OK] button is pressed, it is highlighted and the entered

value is saved to EEPROM and RAM. After completion of setting, [OK] button returns to the normal display.

* When [OK], [↑], [↓] button, [COLOR], or [BLACK & WHITE]

key is pressed, the current set value is saved to EEPROM

and RAM.

* When the reset key is pressed, the simulation is terminated.

* When [SYSTEM SETTINGS] key is pressed, the display

returns to the sub number entry screen.

<Set range and default value of each set value>

Set

Item Display Item

A FRONT

ADJUST

B REAR

ADJUST

C STAPLE

REAR

D STAPLE

FRONT

E STAPLE

BOTH

F STAPLE

PITCH

G PUNCH

CENTER

H PUNCH

HOLE

Alignment position adjustment

(Front)

Alignment position adjustment

(Rear)

Staple binding position

adjustment (One position, rear)

Staple binding position

adjustment (One position, front)

Staple binding position

adjustment (2 positions, center)

Staple binding position (2

positions, pitch)

Punch center adjustment 37 to 63 50

Punch hole position adjustment 42 to 58 50

range

2 to 18 10

2 to 18 10

68 to 132 100

68 to 132 100

68 to 132 100

68 to 132 100

<Variation and change direction of each set value>

Item Display Item Variation Change direction

A FRONT

ADJUST

BREAR

ADJUST

C STAPLE

REAR

Alignment

position

adjustment

(Front)

Alignment

position

adjustment

(Rear)

Staple binding

position

adjustment

(One position,

rear)

0.3665mm Large value: The

alignment plate

position is shifted to

the center.

Small value: The

alignment plate

position is shifted to

the outside.

0.3665mm Large value: The

alignment plate

position is shifted to

the center.

Small value: The

alignment plate

position is shifted to

the outside.

0.155mm Large value: The

distance between the

staple position and th e

paper edge becomes

shorter.

Small value: The

distance between the

staple position and th e

paper edge becomes

longer.

Default

value

MX-FNX1/MX-PNX1 ADJUSTMENTS 8 – 1

Page 35

Item Display Item Variation Change direction

HOME

D STAPLE

FRONT

E STAPLE

BOTH

F STAPLE

PITCH

G PUNCH

CENTER

H PUNCH

HOLE

Staple binding

position

adjustment

(One position,

front)

Staple binding

position

adjustment (2

positions,

center)

Staple binding

position

adjustment (2

positions, pitch)

Punch center

adjustment

Punch hole

position

adjustment

0.155mm Large value: The

distance between the

staple position and th e

paper edge becomes

longer.

Small value: The

distance between the

staple position and th e

paper edge becomes

shorter.

0.155mm Large value: The

staple position is

shifted to the bottom

from the center.

Small value: The

staple position is

shifted to the front

from the center.

0.155mm Large value: The pitch

of 2 positions

becomes greater.

Small value: The pitch

of 2 positions

becomes smaller.

0.1441mm Large value: The hole

position is shifted to

the bottom from the

center.

Small value: The hole

position is shifted to

the front from the

center.

0.2584mm Large value: The

distance between the

hole position and the

paper rear edge

becomes shorter.

Small value: The

distance between the

hole position and the

paper rear edge

becomes longer.

[Screen]

4 Punch home position adjustment

In case the punch unit comes out of order and does not function,

turn the dial to make the punch align to the home position. By making the punch align to the home position, only the paper feed

comes possible.

0

SIMULATION NO.03-10

TEST

FINISHER ADJUSTMENT

10

A:

[ 2~18]

A: 10 ; FRONT ADJUST

B: 10 ; REAR ADJUST

C:100 ; STAPLE REAR

D:100 ; STAPLE FRONT

CLOSE

OK

3 Flapper solenoid adjustment

When the flapper solenoid is disassembled, an adjustment is

required when assembling. (Disassembly and assembly: Refer to

6-2.)

MX-FNX1/MX-PNX1 ADJUSTMENTS 8 – 2

Page 36

âºíuÇ´

[9] SELF DIAGNOSTICS AND

TROUBLE CODES

1. Trouble code and troubleshooting

A. MX-FNX1

Phenomenon Though the main switch of the main unit is turned ON, the

Case 1 Cause Connection failure with the main unit.

Case 2 Cause Connection failure of the connector contact pin

Case 3 Cause Front cover switch (FDSW) trouble

Case 4 Cause Control PWB trouble

Phenomenon The transport motor (FRM) does not operate.

Case 1 Cause Motor connector pin contact failure

Case 2 Cause Motor coil disconnection

Case 3 Cause Control PWB trouble

Phenomenon Roller up/down motor (FSWM) does not operate. Trouble

Case 1 Cause Roller up/down sensor (FRLD) trouble

Case 2 Cause Motor coil disconnection

Case 3 Cause Control PWB trouble

inner finisher does not operate. Trouble code: F1-00

Check &

Remedy

Check &

Remedy

Check &

Remedy

Check &

Remedy

The bundle exit motor (FAM) does not operate.

Check &

Remedy

Check &

Remedy

Check &

Remedy

code: F1-03

Check &

Remedy

Check &

Remedy

Check &

Remedy

Check to confirm the connection state of the

connectors.

(interface harness) with the main unit.

Check to confirm the conduction state of the

connectors. If there is no conduction, replace

the connection wire.

Check to confirm the conduction state of the

connectors. If there is no conduction, replace

the connection wire.

After checking the above 1 to 3, if DC24V and

DV5V are not supplied from the main unit and

if 24V is not supplied to TP14 and 5V is not

supplied to TP17, replace the control PWB.

Check the connection state of the connector.

(CN14)

Perform the conduction test of the coil. If there

is no conduction, replace the motor.

If the motor does not operate in the motor

single operation mode, replace the control

PWB.

Measure the voltage of TP12 on the control

PWB to confirm that it is 5V±5% when the

paper exit roller descends, and 1V or less

when the paper exit roller rises. If the voltage

does not satisfy the said condition, replace the

sensor.

Perform the conduction test of the coil. If there

is no conduction, replace the motor.

After checking the above 1 and 2, if the

phenomenon is not removed though the

sensor level is changed and if the motor does

not operate in the motor single operation

mode, replace the control PWB.

Service Manual

Phenomenon The alignment motor F (FFJM) does not operate.

Case 1 Cause Alignment plate HP sensor F (FFJHPD)

Case 2 Cause Alignment plate HP sensor R (FRJHPD)

Case 3 Cause Motor coil disconnection

Case 4 Cause Control PWB trouble

Phenomenon A paper jam error is displayed on the system display.

Case 1 Cause Paper jam

Case 2 Cause Inlet port sensor (FED) trouble

Case 3 Cause Empty sensor (FSTPD) trouble

Case 4 Cause Control PWB trouble

Phenomenon A document is not detected.

Case 1 Cause Tray paper empty sensor (FBED) trouble

Case 2 Cause Control PWB trouble

Trouble code: F1-19

The alignment motor R (FRJM) does not operate.

Trouble code: F1-20

Check &

Remedy

Check &

Remedy

Check &

Remedy

Check &

Remedy

Check &

Remedy

Check &

Remedy

Check &

Remedy

Check &

Remedy

Check &

Remedy

Check &

Remedy

trouble

Measure the voltage of TP9 on the control

PWB to confirm that it is 5V±5% when the

alignment plate is pushing against the center

portion, and is 1V or less when the alignment

plate is pushing against the front side (home

position). If the voltage does not satisfy the

above condition, replace the sensor.

trouble

Measure the voltage of TP10 on the control

PWB to confirm that it is 5V±5% when the

alignment plate is pushing against the center

portion, and is 1V or less when the alignment

plate is pushing against the rear side (home

position). If the voltage does not satisfy the

above condition, replace the sensor.

Perform the conduction test of the coil. If there

is no conduction, replace the coil.

After checking the above 1 to 3, if the

phenomenon is not removed though the

sensor level is changed and if the motor does

not operated in the motor single operation

mode, replace the control PWB.

Visually check and remove the paper jam

Measure the voltage of TP11 on the control

PWB to confirm that it is 1V or less when

paper is empty, and is 5V±5% when paper is

provided. If the voltage does not satisfy the

above condition, replace the sensor.

Measure the voltage of TP8 on the control

PWB to confirm that it is 1V or less when

paper is empty, and is 5V±5% when paper is

provided. If the voltage does not satisfy the

above condition, replace the sensor.

If the phenomenon is not removed though the

sensor level is changed by turning ON/OFF

each sensor, replace the control PWB.

Measure the voltage of TP4 on the control

PWB to confirm that it is 5V±5% when paper is

empty, and is 1V or less when paper is

provided. If the voltage does not satisfy the

above condition, replace the sensor.

If the phenomenon is not removed though the

sensor level is changed by turning ON/OFF

each sensor, replace the control PWB.

MX-FNX1/MX-PNX1 SELF DIAGNOSTICS AND TROUBLE CODES 9 – 1

Page 37

Phenomenon A document is discharged to the reverse path in the

Case 1 Cause Flapper solenoid (FINRPS) connector pin

Case 2 Cause Solenoid coil disconnection

Case 3 Cause Control PWB trouble

Phenomenon The belt separation solenoid (FBRS) does not operate.

Case 1 Cause Solenoid connector pin trouble

Case 2 Cause Solenoid coil disconnection

Case 3 Cause Control PWB trouble

Phenomenon The take-up belt does not operate normally.

Case 1 Cause Take-up belt sensor (FBRD) trouble

Case 2 Cause Control PWB trouble

Phenomenon The staple shift motor does not operate.

Case 1 Cause Stapler HP sensor (FSTHPD) trouble

Case 2 Cause Motor coil disconnection

Case 3 Cause Control PWB trouble

operation other than reverse operation.

Check &

Remedy

Check &

Remedy

Check &

Remedy

The paper surface detection solenoid (FSLS) does not

operate

The paddle one-rotation solenoid (FPDS) does not

operate.

Check &

Remedy

Check &

Remedy

Check &

Remedy

Check &

Remedy

Check &

Remedy

Trouble code: F1-08

Check &

Remedy

Check &

Remedy

Check &

Remedy

trouble

Check the connection state of the connector.

(CN15)

Perform the conduction test of the coil. If there

is no conduction, replace the coil.

If the flapper solenoid (FINRPS) does not

operate in the solenoid single operation mode,

replace the control PWB.

Check the connection state of the connector.

(CN15, 20)

Perform the conduction test of the coil. If there

is no conduction, replace the coil.

If the solenoid does not operate in the single

operation mode of the belt separation solenoid

(FBRS), the paper surface detection solenoid

(FSLS), or the paddle one-rotation solenoid

(FPDS), replace the control PWB.

Measure the voltage of TP13 on the control

PWB to confirm that it is 5V±5% when the belt

descends, and is 1V or less when the belt

separates. If the voltage does not satisfy the

above condition, replace the sensor.

If the phenomenon is not removed though the

sensor level is changed by turning ON/OFF

each sensor, replace the control PWB.

Measure the voltage of TP7 on the control

PWB to confirm that it is 5V±5% when the

stapler unit is pushing against the front side

(home position), and is 1V or less when the

stapler unit is pushing against the rear side. If

the voltage does not satisfy the above

condition, replace the sensor.

Perform the conduction test of the coil. If there

is no conduction, replace the coil.

After checking the above 1 to 2, if the

phenomenon is not removed though the

sensor level is changed and if the motor does

not operate in the motor single operation

mode, replace the control PWB.

Phenomenon The stapler does not operate. Trouble code: F1-10

Case 1 Cause Alignment plate position sensor (FJPD) trouble

Case 2 Cause Stapler home sensor (FSHPD) trouble

Case 3 Cause Self priming sensor (FSTD) trouble

Case 4 Cause Staple empty sensor (FSD) trouble

Case 5 Cause Motor coil disconnection

Case 6 Cause Control PWB trouble

Phenomenon The tray does not operate. Trouble code: F1-15

Case 1 Cause The paper surface sensor 1 (FSLD1), paper

Case 2 Cause Tray upper limit sensor (FULD) trouble

Case 3 Cause Tray intermediate lower limit sensor (FMLLD)

Case 4 Cause Tray lower limit sensor (FLLD) trouble

Case 5 Cause Motor coil disconnection

Check &

Remedy

Check &

Remedy

Check &

Remedy

Check &

Remedy

Check &

Remedy

Check &

Remedy

Check &

Remedy

Check &

Remedy

Check &

Remedy

Check &

Remedy

Check &

Remedy

Measure the voltage of TP50 on the control

PWB to confirm that it is 1V or less when the

stapler is at the paper rear edge stopper

section, and is 5V±5% when the stapler is not

at that position. If the voltage does not satisfy

the above condition, replace the sensor.

Measure the voltage of TP51 on the control

PWB to confirm that it is 5V±5% at the stapling

mechanism home position, and is 1V or less

when stapling. If the voltage does not satisfy

the above condition, replace the stapler.

Measure the voltage of TP52 on the control

PWB to confirm that it is 5V±5% when a

cartridge is provided (READY state), and is 1V

or less when a cartridge is not provided. If the

voltage does not satisfy the above condition,

replace the stapler.

Measure the voltage of TP53 on the control

PWB to confirm that it is 5V±5% when a

cartridge is provided (with staples), and is 1V

or less when a cartridge is not provided. If the

voltage does not satisfy the above condition,

replace the stapler.

Perform the conduction test of the coil. If there

is no conduction, replace the stapler.

After checking the above 1 to 5, if the

phenomenon is not removed though the

sensor level is changed and if the motor does

not operate in the motor single operation

mode, replace the control PWB.

surface sensor 2 (FSLD 2) trouble

Measure the voltage of TP5 and 6 on the

control PWB to confirm that it is changed in the

range of 1V or less to 5V±5% when the paper

holding lever is moved. If the voltage does not

satisfy the above condition, replace the sensor.

Measure the voltage of TP1 on the control

PWB to confirm that it is 1V or less when the

tray is at the upper limit position, and is 5V±5%

when the tray is not at the upper limit position.

If the voltage does not satisfy the above

condition, replace the sensor.

trouble

Measure the voltage of TP2 on the control

PWB to confirm that it is 1V or less when the

tray is at the intermediate position, and is

5V±5% when the tray is not at the intermediate

position. If the voltage does not satisfy the

above condition, replace the sensor.

Measure the voltage of TP3 on the control

PWB to confirm that it is 1V or less when the

tray is at the lower limit position, and is 5V±5%

when the tray is not at the lower limit position.

If the voltage does not satisfy the above

condition, replace the sensor.

Perform the conduction test of the coil. If there

is no conduction, replace the stapler.

MX-FNX1/MX-PNX1 SELF DIAGNOSTICS AND TROUBLE CODES 9 – 2

Page 38

Case 6 Cause Control PWB trouble

Phenomenon The fan (FFAN) does not operate. Trouble code: F1-

Case 1 Cause Pinching of a foreign material

Case 2 Cause Motor coil disconnection

Case 3 Cause Lock detection trouble

Case 4 Cause Control PWB trouble

Check &

Remedy

Check &

Remedy

Check &

Remedy

Check &

Remedy

Check &

Remedy

After checking the above 1 to 5, if the

phenomenon is not removed though the

sensor level is changed and if the motor does

not operate in the motor single operation

mode, replace the control PWB.

21

Visually check to remove a foreign material from the

inlet port.

Perform the conduction test of the coil. If there is no

conduction, replace the motor.

Measure the voltage of TP88 on the control PWB to

confirm that it is 1V or less when lock is released,

and is 5V±5% when lock is set. If the voltage does

not satisfy the above condition, replace it.

After checking the above 1 to 3, if the fan (FFAN)

does not operate in the motor single operation mode,

replace the control PWB.

B. MX-PNX1A/B/C/D

Phenomenon Though the main switch of the main unit is turned

Case 1 Cause Connection failure with the inner finisher

Case 2 Cause Connection failure of the drawer connector with the

Case 3 Cause Control PWB trouble

Pheno

menon

Case 1 Cause Punch position sensor (FPHPD) trouble

Case 2 Cause Rear position sensor (FPRPD) trouble

Case 3 Cause Motor coil disconnection

Case 4 Cause Control PWB trouble

Check &

Remedy

Check &

Remedy

Check &

Remedy

The punch motor (FPNM) does not operate.

Trouble code: F1-34

Check &

Remedy

Check &

Remedy

Check &

Remedy

Check &

Remedy

ON, the inner punch does not operate at all.

Check to confirm that each connector is connected

properly.

inner finisher

Check the conduction state of the connector pins as

well as the inner finisher. If there is no conduction,

replace the drawer connector.

After checking the above 1 and 2, if DC24V and

DC5V are not supplied from the main unit or if 24V is

not output to TP19 and 5V is not output to TP22 on

the control PWB, replace the control PWB.

Measure the voltage of TP47 on the inner finisher

control PWB to confirm that it is 5V±5% at the home

position, and is 1V or less when punching. If the

voltage does not satisfy the above condition, replace

the sensor.

Measure the voltage of TP48 on the inner finisher

control PWB to confirm that it is 5V±5% at the lower

limit position, and is 1V or less at the upper limit

position. If the voltage does not satisfy the above

condition, replace the sensor.

Perform the conduction test of the coil. If there is no

conduction, replace the coil.

After checking the above 1 to 3, if the phenomenon

is not removed though the sensor level is changed

and if the motor does not operate in the motor single

operation mode, replace the control PWB.

Phenomenon Punch horizontal resist motor (FPSM) does not

Case 1 Cause Horizontal shift HP sensor (FPSHPD) trouble

Check &

Remedy

Case 2 Cause Motor coil disconnection

Check &

Remedy

Case 3 Cause Control PWB trouble

Check &

Remedy

Phenomenon The punch dust container full is not detected.

Case 1 Cause Full sensor (FPDD) trouble

Check &

Remedy

Case 2 Cause Control PWB trouble

Check &

Remedy

Phenomenon A paper jam error is displayed on the system display.

Case 1 Cause Paper jam

Check &

Remedy

Case 2 Cause Paper rear edge sensor (FPPEND) trouble

Check &

Remedy

Case 3 Cause Paper horizontal resist sensor (FPPD1 to 6) trouble

Check &

Remedy

Case 4 Cause Control PWB trouble

Check &

Remedy

operate. Trouble code: F1-33

Measure the voltage of TP49 on the inner finisher

control PWB to confirm that it is 5V±5% at the home

position, and is 1V or less at the upper limit position.

If the voltage does not satisfy the above condition,

replace the sensor.

Perform the conduction test of the coil. If there is no

conduction, replace the coil.

After checking the above 1 and 2, if the

phenomenon is not removed though the sensor level

is changed and if the motor does not operate in the

motor single operation mode, replace the control

PWB.

If there is no punch dust in the punch dust container,

measure the voltage of TP2 on the control PWB to

confirm that it is 5V±5% when the punch dust

container is removed, and is 1V or less when the

lever in the punch dust container is put straight and

stored (the sensor is shaded from the light). It the

voltage does not satisfy the above condition, replace

the sensor.

If the phenomenon is not removed though the

sensor level is changed by turning ON/OFF the

sensor, replace the control PWB.

Visually check and remove the paper jam.

Measure the voltage of TP54 on the inner finisher