Page 1

SERVICE MANUAL

CODE: 00ZMXCFX2/S1E

INSERTER

MODEL

CONTENTS

[1] SPECIFICATION

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

2. Paper Size/Type/Weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

[2] MAINTENANCE LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

[3] REPLACEMENT AND ADJUSTMENT

1. COVERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

2. 1ST, 2ND TRAYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

3. FEED UNITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

4. BOARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

5. MOTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3

6. SENSORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 4

7. ROLLERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 7

MX-CFX2

[4] DETAILS

1. PAPER PATH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

2. PAPER FEED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

[5] OVERALL MACHINE INFROMATION

1. MAIN LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

2. DRIVE LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

3. ELECTRICAL COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

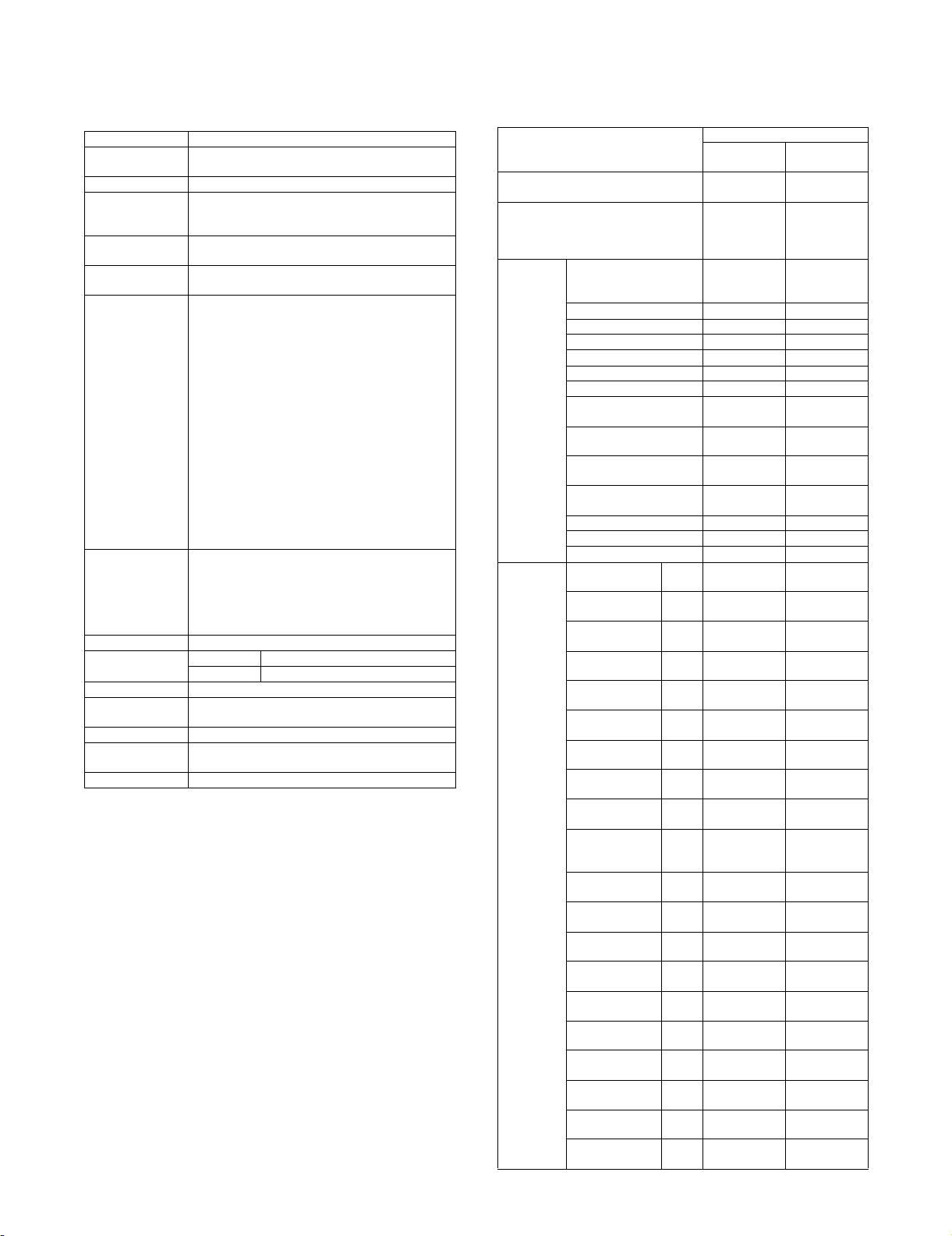

MX-CFX2

[1] SPECIFICATION

Service Manual

1. General

Form Floor standing type

Productivity 85-110 sheets/minute

Tray 2 Tray

Paper Capacity Upper tray: 200 sheets

Paper Weight

(Feeder)

Paper Weight

(Through pass)

Paper Size

(Feeder)

Paper size

(Through pass)

Operation Key No. Uses the operation panel.

Reliability MCBJ in compliance with the main unit

Life 5 years or 3,000K

Power

Consumption

Power Source DC24V (supplied by the main unit)

Dimensions

(W x D x H)

Weight 50kg or less

(A4 / 8.5”x11”), continuously transport inserted paper.

Lower tray: 200 sheets

2

(80 g/m

)

60-205 g/m

52-300 g/m

Auto-AB:

A3W, A4W, A3, B4, A4, A4-R, B5, B5-R, A5, A5-R,

8.5”x13”

Auto-Inch:

12”x18”, 11”x17”, 9”x12”, 8.5"x14", 8.5”x13.4”,

8.5”x11”,8.5”x11”-R*, 5.5”x8.5”, 5.5”x8.5”-R,

7.25”x10.5”-R, A3, B4, A4

Manual:

SRA3 (320x450mm), SRA4, 318x234.75mm,

312.5x220mm, 318x469.5mm, 312.5x440mm, 8K,

16K, 16KR

Custom Size:

Main scanning: 140-320 (5.5-12.5)

Sub scanning: 140-470 (5.5-18.5)

* 8.5x13.4/8.5x14/8.5x11R and A4R/8.5x13/

* A5/5.5”x8.5” are feeded from Inserter Tray of

A3W, A4W, A3, B4, A4, A4-R, A5, B5, B5-R, A5-R,

8K, 16K, 16KR, 12"x18", 11"x17", 9”x12”, 8.5”x14”,

8.5”x13.4”, 8.5”x13”, 8.5"x11", 8.5"x11"-R,

7.25”x10.5”R, 5.5"x8.5"-R, 5.5”x8.5”,

SRA3 (320x450mm), SRA4, 318x234.75mm,

312.5x220mm, 318x469.5mm, 312.5x440mm

MCBF in compliance with the main unit

100W

545mm x 732mm x 1271mm

(Tray extended: 690mm x 732mm x 1271mm)

2

16lbs Bond - 110lbs Index

2

16lbs Bond - 170lbs Index

8.5x13.4 is exclusion.

Inserter Unit.

2. Paper Size/Type/Weight

Paper supply

Minimum paper weight 60g/m

Maximum paper weight 205g/m

Paper type Thin paper No Yes

Plain paper Yes Yes

Recycled paper Yes Yes

Colored paper Yes Yes

Letter head Yes Yes

Pre-printed paper Yes Yes

Pre-punched paper Yes Yes

Heavy paper1

(106-128g/m

Heavy paper2

(129-176g/m

Heavy paper3

(177-205g/m

Heavy paper4

(206-300g/m

Tab paper No Yes

Transparency paper No Yes

Label paper No Yes

Paper size 12"x18" (A3W) 305

Ledger (11"x17") 279

Ledger (11"x17")

Z folding

Legal (8.5"x14") 216

Legal (8.5"x14")

Z folding

Mexican Legal

(8.5"x13.4")

Foolscap

(8.5"x13")

Letter (8.5"x11") 279

Letter R

(8.5"x11"R)

Letter R

(8.5"x11"R)

Z folding

Invoice

(5.5"x8.5")

Invoice R

(5.5"x8.5"R)

Exective R

(7.25"x10.5")

9x12 (A4W) 305

A3 297

A3 Z folding 297

B4 257

B4 Z folding 257

A4 297

A4-R 210

2

)

2

)

2

)

2

)

(16lbs bond)

(40lbs bond)

(110lbs index)

(65lbs cover)

x457

x432

279

x216

x356

216

x178

216

x340

216

x330

x216

216

x279

216

x140

216

x140

140

x216

184

x266

x229

x420

x210

x364

x182

x210

x297

Inserter

2

Through

pass section

52g/m2

(14lbs bond)

300g/m2

(40lbs bond)

(140lbs index)

(100lbs cover)

(Even 52g/m

is possible)

section

2

Ye s Ye s

Ye s Ye s

Ye s Ye s

No Yes

Ye s Ye s

Ye s Ye s

--

Ye s Ye s

--

Ye s Ye s

Ye s Ye s

Ye s Ye s

Ye s Ye s

--

Ye s Ye s

Ye s Ye s

Ye s Ye s

Ye s Ye s

Ye s Ye s

--

Ye s Ye s

--

Ye s Ye s

Ye s Ye s

2

MX-CFX2 SPECIFICATION 1 – 1

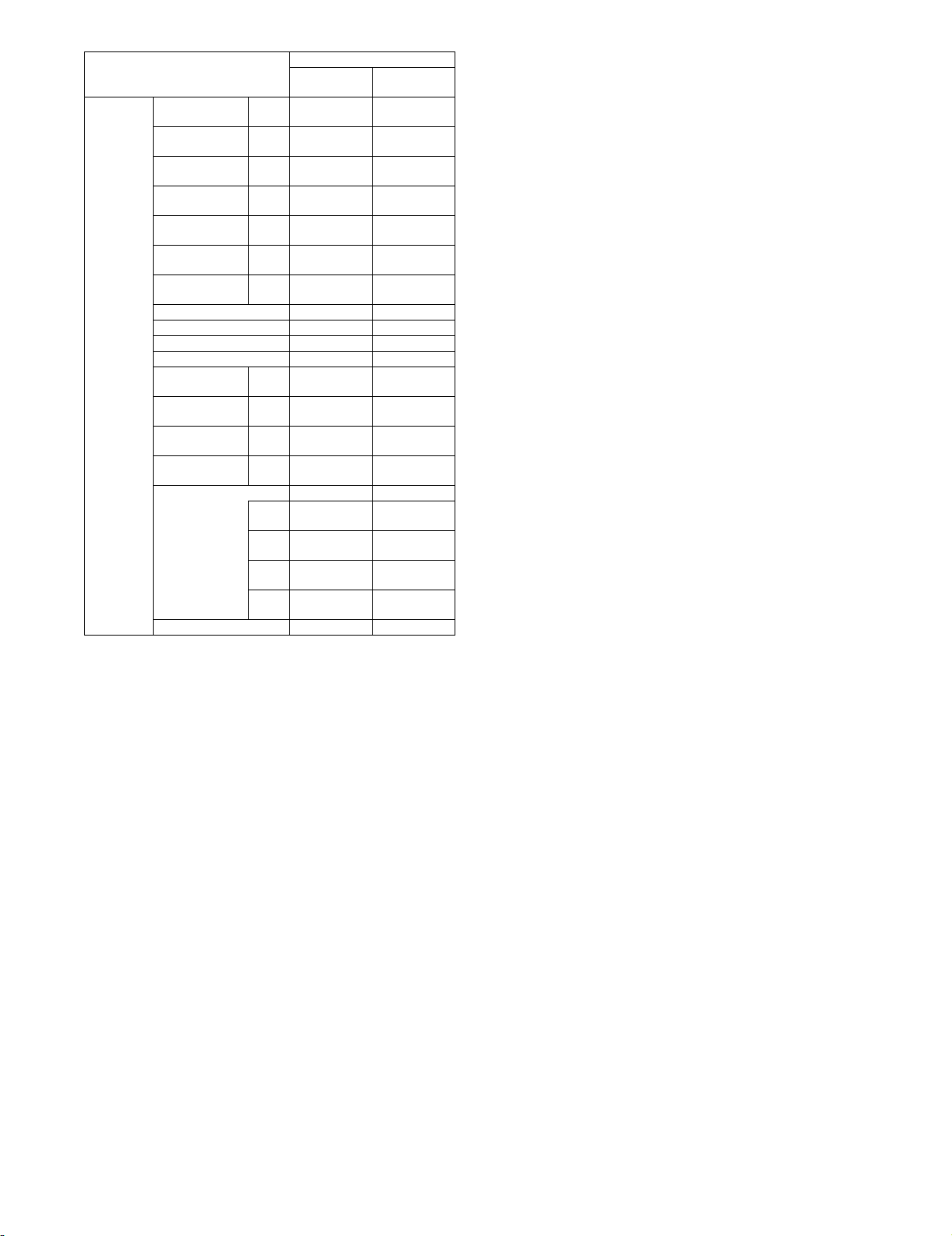

Page 3

Paper size A4-R Z folding 210

x148

B5 257

x182

B5-R 182

x257

A5 210

x148

A5-R 148

x210

SRA3 320

x450

SRA4 320

x225

318x234.75mm Yes Yes

312.5x220mm Yes Yes

318x469.5mm Yes Yes

312.5x440mm Yes Yes

8K 270

x390

16K 270

x195

16K-R 195

x270

Postcard 100

x148

Special-Custom size No Yes

(Custom Range) min

Main

max

Main

min

Sub

max

Sub

Special-Size uncertain No Yes

Paper supply

Inserter

section

--

Yes Yes

Yes Yes

Yes Yes

Yes Yes

Yes Yes

Yes Yes

Yes Yes

Yes Yes

Yes Yes

No Yes

- 100 (4.0)

- 320 (12.5)

- 140 (5.5)

- 470 (18.5)

Through

pass section

MX-CFX2 SPECIFICATION 1 – 2

Page 4

MX-CFX2

[2] MAINTENANCE LIST

✕: Check {: Clean S: Replace U: Adjust ✩ : Lubricate : Shift position

(Clean, replace, or adjust as needed.)

Service Manual

No. Part name

1 Drive roller ✕ {{{{{{ When there is dirt, wipe with

2 Follower roller ✕ {{{{{{ When there is dirt, wipe with

3 Paper feed belt ✕✕✕✕✕✕✕Roller life 60K

4 Reverse roller ✕✕✕✕✕✕✕Roller life 60K

5 Pick-up roller ✕✕✕✕✕✕✕Roller life 60K

6 Sensor ✕ {{{{{{

7 Paper feed drive gear ✕✕✕✕✕✕✕ UKOG-0307FCZZ

8 Punch hole horizontal

resist adjustment

9 Transport guide plate ✕ {{{{{{

10 Torque limiter ✕✕✕✕✕✕✕

When

calling

500K 1000K 1500K 2000K 2500K 3000K Life judgement (Reference)

✕✕✕✕✕✕✕

* Refer to the NOTE:

* Refer to the NOTE:

* Refer to the NOTE:

Tool, oil, chemicals

Procedure

Treatment after procedure

wet cloth and water.

wet cloth and water.

Specified with the use ratio

of 10%.

Specified with the use ratio

of 10%.

Specified with the use ratio

of 10%.

NOTE: Replacement reference: Replace according to each paper feed counter value.

• Roller (MX-CFX2) : 60K or 1 year

Torque limiter : 800K

* Paper feed section roller life

The life of roller used in paper feed section of each option is

different. (See the table below.) When a certain paper feed unit

is used greater than usual, its life may be expired before the

maintenance timing.

Actually, however, different sizes of paper are used with different paper feed trays, and it is quite rare that the roller replacement must be made before the maintenance timing.

IF a certain paper size is used more than normal, set feed

trays for that paper size and explain the frequency of maintenance to the client.

When servicing, check the use frequency of each paper feed

tray, and replace the rollers as needed.

When cleaning the roller, it is advisable to use a wet cloth with

a small quantity of water.

The amount of friction applied to the rollers increases from pick

up to paper feed to paper separation.

[Roller life of each paper feed section]

MX-LCX6 200K

MX-LCX3 N 100K

MX-MFX1 100K

MX-LCX4 (Paper feed tray 1, 2, 3) 200K

MX-LCX5 (Paper feed tray 1, 2, 3) 200K

MX-MFX2 200K

MX-CFX2 60K

Model name Life

MX-CFX2 MAINTENANCE LIST 2 – 1

Page 5

MX-CFX2

[3] REPLACEMENT AND ADJUSTMENT

Service Manual

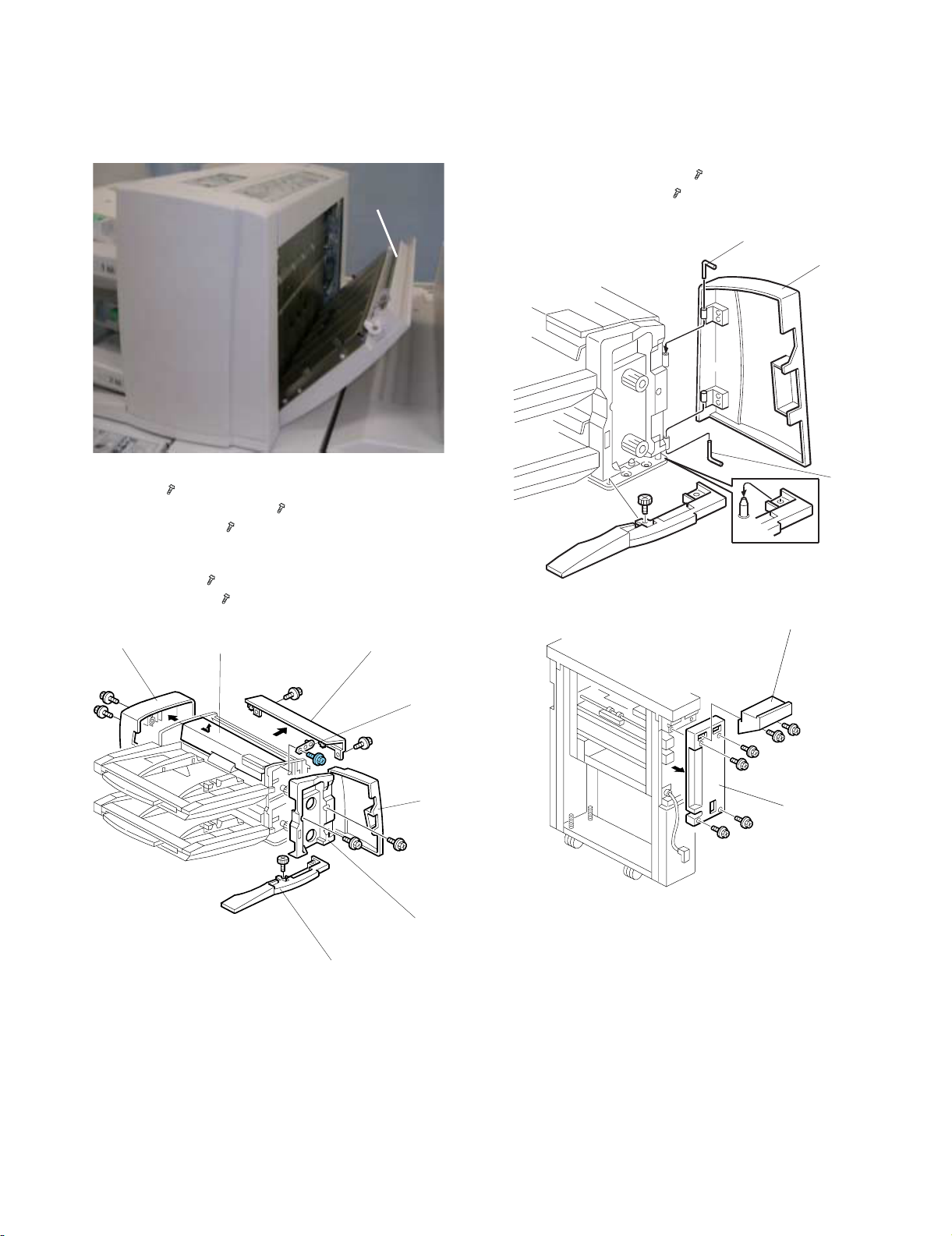

1. COVERS

• Open the vertical feed cover [A].

[A]

Remove:

[A] Top cover ( x2)

[B] Inner cover with front door [C] ( x2)

[D] 1st tray cover holder ( x1)

[E] 1st tray cover. Slide the cover toward you to remove it from the

inside pins.

[F] Base cover (Knob x1)

[G] Tray unit rear cover ( x2)

[G]

[E]

[A]

Remove:

[A] Front door (L-pins x2)

• Swing the upper L-pin [B] out of its groove and pull it up.

• Swing the lower L-pin [C] out of its groove and pull it down.

[D] Rear top cover of the feed unit ( x2)

[E] Feed unit rear upper cover ( x4)

[B]

[A]

[C]

[D]

[F]

[D]

[B]

[C]

[E]

MX-CFX2 REPLACEMENT AND ADJUSTMENT 3 – 1

Page 6

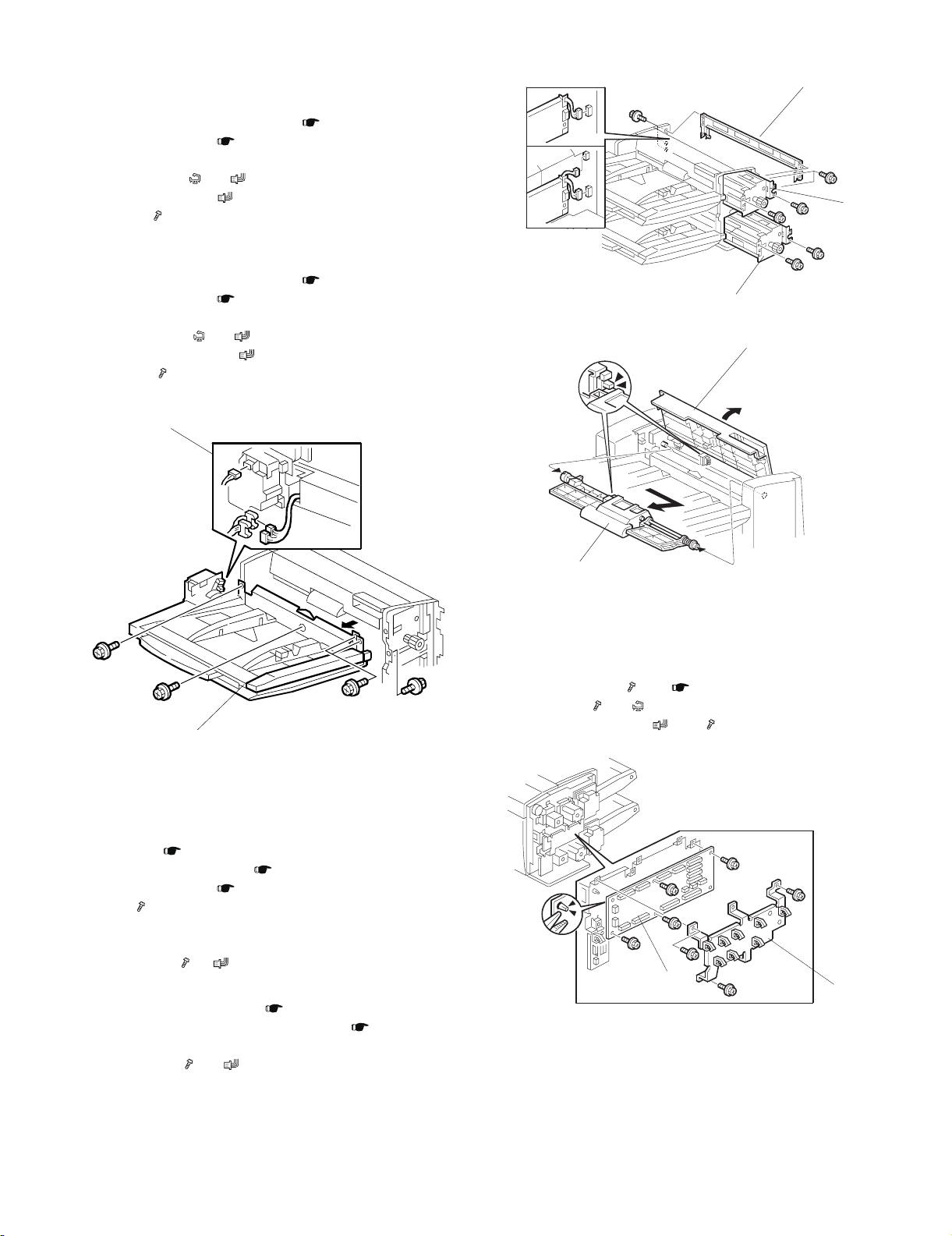

2. 1ST, 2ND TRAYS

[A]

[D]

[E]

1st Tray

2nd Tray

A. 1st Tray

Remove:

• Inner cover with tray unit front door ( 1. COVERS)

• Tray unit rear cover ( 1. COVERS)

[A] Disconnect:

• 1st lift motor ( x1, x1)

• White connectors ( x2)

[B] 1st tray ( x5)

B. 2nd Tray

Remove:

• Inner cover with tray unit front door ( 1. COVERS)

• Tray unit rear cover ( 1. COVERS)

[C] Disconnect:

• 2nd lift motor ( x1, x1)

• Red, blue connectors ( x2)

[D] 2nd tray ( x5)

[A], [C]

[B]

[B], [D]

3. FEED UNITS

A. 1st Feed Unit

Remove:

• Top cover ( 1. COVERS)

• Inner cover with front door ( 1. COVERS)

• Tray unit rear cover ( 1. COVERS)

[A] Stay ( x5)

[B] Open the 1st tray cover and hold it open

[C] 1st feed belt unit

[D] 1st feed unit ( x, x )

B. 2nd Feed Unit

• Open the vertical feed cover ( 1. COVERS)

• Remove inner cover with tray unit front door ( 1. COVERS)

• 2nd feed belt unit (same as [C])

[E] 2nd feed unit ( x2, x2)

[C]

4. BOARDS

A. TRAY UNIT CONTROL BOARD

Remove:

• Tray unit rear cover ( x2) ( 1. COVERS)

[A] Board cover ( x3, x8)

[B] Tray unit control board ( x 17, x5, Standoff x1)

[B]

[A]

MX-CFX2 REPLACEMENT AND ADJUSTMENT 3 – 2

Page 7

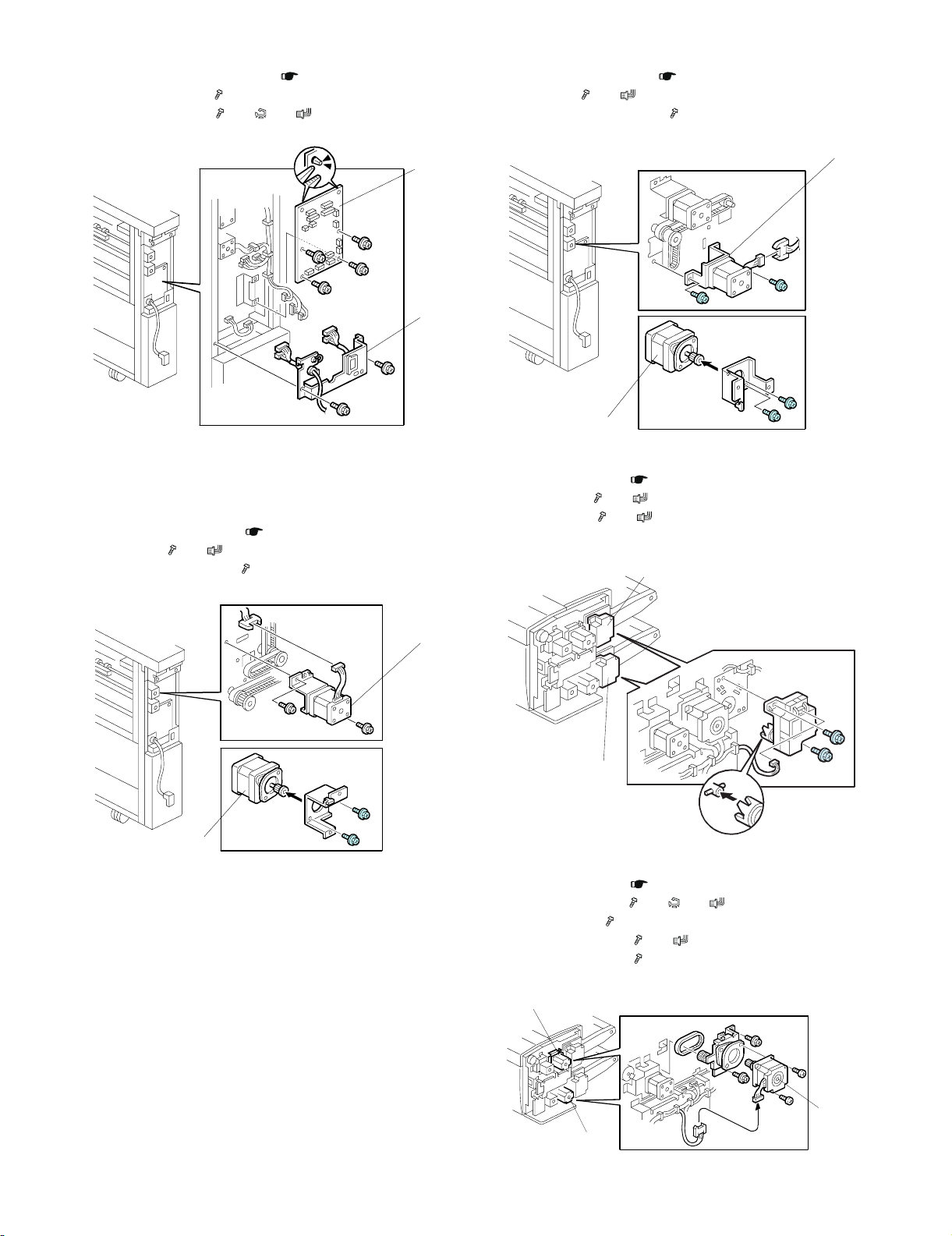

B. MAIN CONTROL BOARD

[A]

[B]

[A]

[B], [D]

[C]

• Transport unit rear upper cover ( 1. COVERS)

[A] Connector bracket ( x2)

[B] Main control board ( x4, x2, x14, Standoff x2)

B. HORIZONTAL TRANSPORT MOTOR

• Transport unit rear cover ( 1. COVERS)

[A] Motor unit ( x2, x1, Timing belt x1)

[B] Horizontal transport motor ( x2)

5. MOTORS

A. VERTICAL TRANSPORT MOTOR

Remove:

• Transport unit rear cover ( 1. COVERS)

[A] Motor unit ( x2, x1, Timing belt x1)

[B] Vertical transport motor ( x2)

[B]

[A]

[A]

[B]

C. 1ST, 2ND LIFT MOTORS

• Tray unit rear cover ( 1. COVERS)

[A] 1st lift motor ( x2, x1)

[B] 2nd lift motor ( x2, x1)

[A]

[B]

D. 1ST, 2ND FEED MOTORS

• Tray unit rear cover ( 1. COVERS)

[A] 1st feed motor unit ( x3, x2, x1)

[B] 1st feed motor ( x2, Timing belt x1)

[C] 2nd feed motor unit ( x3, x1)

[D] 2nd feed motor unit ( x2, Timing belt x1)

MX-CFX2 REPLACEMENT AND ADJUSTMENT 3 – 3

Page 8

E. 1ST, 2ND TRANSPORT MOTORS

[A], [C]

[B], [D]

• Tray unit rear cover ( 1. COVERS)

(1) 1st Transport Motor

[A] 1st transport motor unit ( x3, x1)

[B] 1st transport motor ( x2, Timing belt x1)

(2) 2nd Transport Motor

• (1) Tray unit control board unit (Hooks, x3, x9 (Motor x8,

CN216))

[C] 2nd transport motor unit ( x3)

[D] 2nd transport motor ( x2, Timing belt x1)

[A], [C]

[B], [D]

(1)

(1)

F. 1ST, 2ND PICK-UP MOTORS

• Tray unit rear cover ( 1. COVERS)

(1) 1st Pick-up Motor

[A] 1st pick-up motor unit ( x3, x1)

[B] 1st pick-up motor ( x2, Timing belt x1)

(2) 2nd Pick-up Motor

• (1) Tray unit control board unit (Hooks, x3, x9 (Motor x8,

CN216))

[C] 2nd pick-up motor unit ( x3, x1)

[D] 2nd pick-up motor ( x2, Timing belt x1)

6. SENSORS

A. PAPER WIDTH SWITCH, SET SENSORS,

LENGTH SENSOR

Remove:

• 1st or 2nd paper tray ( 2. 1ST, 2ND TRAYS)

[A] Front cover ( x1)

[B] Rear cover ( x1)

[C] Bottom cover ( x2)

[D] Holder pin ( x1, Spring x1)

[E] Bottom plate ( x1)

• Turn over the bottom plate so it is facing up.

[B]

[A]

MX-CFX2 REPLACEMENT AND ADJUSTMENT 3 – 4

Page 9

[C]

[A]

[B]

Remove:

[A] Harness cover (Hooks x2)

[B] Paper width switch (Hooks x2, x4, x1)

[C] Paper set sensor (Hook x1, x1)

[D] Paper length sensor (Hooks x1, x1)

[A]

[E]

[D]

B. TRAY COVER SENSORS

(1) 1st Tray Cover Sensor

• Remove the tray unit rear cover ( 1. COVERS)

• Open the 1st tray cover

Remove:

[A] Sensor unit ( x1, x1)

[B] Tray cover sensor (Pawls x2)

(2) 2nd Tray Cover Sensor

• Remove the tray unit control board unit ( 5. MOTORS)

Remove:

[A] Sensor unit ( x1, x1). Remove with the 2nd tray cover

open.

[B] Tray cover sensor (Pawls x2)

[B]

[C]

C. 1ST TRANSPORT SENSOR

• Top cover

• Vertical feed cover

• Stay ( 5. MOTORS)

Remove:

[A] Upper paper guide ( x2)

[B] Sensor unit ( x2, x1, x1)

[C] 1st transport sensor (Pawls x2)

[D]

[B]

[A]

[C]

MX-CFX2 REPLACEMENT AND ADJUSTMENT 3 – 5

Page 10

D. FEED UNIT SENSORS

[A]

[B]

[C]

[D]

[E]

[F]

Remove:

[A] 1st feed unit ( 3.FEED UNITS)

[B] 2nd feed unit ( 3.FEED UNITS)

[C] Sensor bracket ( x1, x1)

[D] Pick-up roller HP sensor (Pawls x2)

[E] Sensor bracket ( x1, x1, x1)

[F] Bottom plate position sensor (Pawls x2)

[G] Sensor bracket ( x1, x1) (2nd feed unit only)

[H] 1st Vertical transport sensor (Pawls x2) (2nd feed unit only)

[I] Sensor bracket ( x1, x1, x1)

[J] Paper Feed sensor (Pawls x2)

E. 2ND VERTICAL TRANSPORT, EXIT SENSORS

Remove:

[A] Sensor unit ( x1, x1, x1)

[B] 2nd vertical transport sensor (Pawls x2)

[C] Sensor unit ( x2, x1, x1)

[D] Vertical exit sensor (Pawls x2)

[E] Sensor unit ( x2, x1, x1)

[F] Exit sensor (Pawls x2)

[A]

[B]

[C]

[D]

[E]

[F]

[G]

[H]

[I]

[J]

F. ENTRANCE SENSOR

[A] Sensor unit ( x2, x1, x1)

[B] Entrance sensor (Pawls x2)

[B]

[A]

MX-CFX2 REPLACEMENT AND ADJUSTMENT 3 – 6

Page 11

7. ROLLERS

[A]

[B]

[D]

[E]

A. SEPARATION ROLLER

• 1st (or 2nd) feed unit ( 3.FEED UNITS)

[A] Cover

[B] Separation Roller ( x1)

[A]

[B]

C. FEED BELT

• Feed belt unit ( 7. ROLLERS - B.)

[A] Pick-up roller unit.

• Pull the unit away from the bushings in the direction of the

arrow.

[B] Feed belt holder

• Hold the feed belt holder by the sides, then lift up to separate

from the holder.

• Pull slowly to avoid losing the springs.

[C] Feed belt.

B. FEED BELT UNIT AND PICK-UP ROLLER

• Open the 1st tray cover.

[A] Feed belt unit

• The unit is spring loaded. Push it to the right to release it, then

lift it out.

[B] Pick-up roller ( x 2, bushings x 2)

[A]

[B]

[F]

[C]

Re-assembly

1) Position the pick-up roller unit [A] and feed belt holder [B] as

shown above.

2) On the rear side, slide out the bushing, and rotate guide plate

[D] until its stepped side attaches at [E] as shown above, then

snap the guide plate on.

3) On the front side, rotate guide plate [F] until its flat side is parallel with [D], then snap it on. Viewed from the bottom, the

plates must be aligned.

MX-CFX2 REPLACEMENT AND ADJUSTMENT 3 – 7

Page 12

MX-CFX2

[4] DETAILS

1. PAPER PATH

1

2. PAPER FEED

Service Manual

A. FEED MECHANISM

[C]

2

3

4

[B]

[A]

5

6

8

7

9

10

11

12

13

Interposer Tray

1 1st Paper Feed Motor

2 1st Paper Feed Sensor

3 1st Transport Motor

4 1st Transport Sensor

5 1st Vertical Transport Sensor

6 2nd Paper Feed Motor

7 2nd Paper Feed Sensor

8 2nd Transport Motor

9 2nd Transport Sensor

10 2nd Vertical Transport Sensor

11 Vertical Transport Motor

12 Vertical Exit Sensor

13 Interposer Exit Sensor

14 Interposer Entrance Sensor

15 Horizontal Transport Motor

15

14

Mainframe

[D]

[E]

[F]

[G]

[H]

When paper is placed on the tray, the 1st paper set sensor in the

tray actuates and switches on the 1st tray lift motor. The pick-up

roller unit drops and the top of the stack in the tray pushes up the

pick-up roller unit until its actuator actuates the 1st bottom plate

position sensor [A] and switches the motor 1st tray lift motor off.

The 1st pick-up roller HP sensor [B] controls the operation of the

1st pick-up motor [C]. The 1st pick-up motor is off when the actuator is up and there is no paper in the tray. This is the pick-up roller

home position. When the actuator de-actuates the sensor after the

tray lifts, this switches on the 1st pick-up roller motor. At the end of

the job, the actuator descends with the bottom plate and switches

the motor off.

The pick-up roller [D] picks up the sheet, and the feed belt [E] feeds

the sheet to the paper feed roller [F]. The separation roller [G]

reverses if more than one sheet is fed.

This is a standard FFR device

The paper feed sensor [H] detects the timing of the feed and signals a jam if the paper does not arrive or if the paper stops.

As sheets feed from the top of the stack:

• The pick-up roller unit descends until the actuator on the pick-up

roller unit drops out of the 1st bottom plate position sensor [A].

This activates the 1st tray lift motor.

MX-CFX2 DETAILS 4 – 1

Page 13

• The 1st tray lift motor switches on to raise the stack until the

actuator enters the pick-up roller unit position sensor again and

switches the lift motor off.

• This cycle repeats until the end of the job or until paper runs out.

B. PAPER NEAR END/PAPER END

[C]

[A]

[B]

[D]

When feed starts with a full tray, the actuator [A] on the rotating

shaft of the bottom plate lift arm [B] is at the 1st tray lower limit sensor [C].

As paper feeds and the stack grows smaller, the lift arm rises and

the actuator descends until the actuator reaches the 1st tray upper

limit sensor [D]. At this time the operation panel signals near-end

for the 1st tray.

When the last sheet feeds, the paper feed sensor, a photosensor

(not shown) signals that paper has run out.

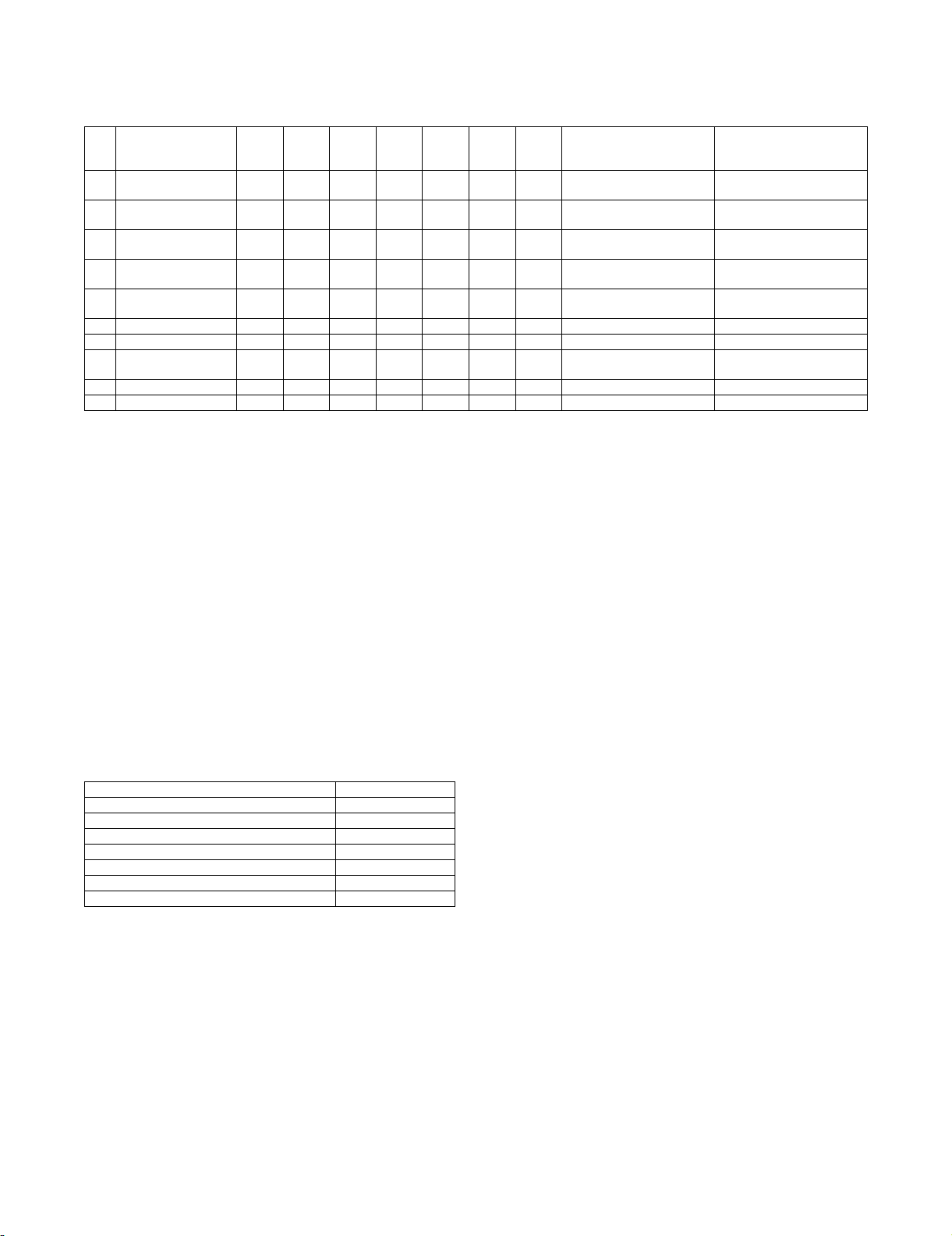

C. PAPER SIZE DETECTION

[A]

Paper Size Detection Bits Area

Paper Size W1 W2 W3 W4 W5 L1 NA EU

Large

Size

Large

Size

Large

Size

A3

SEF

A4LEF 297×210 mm H H H L L H YES YES

DLT

SEF

LT LEF 11×8

B4

SEF

B5

LEF

A4

SEF

LT

SEF

A5LEF 210×148 mm H H L H H H * YES

HLT

LEF

B5

SEF

F SEF 8×13 in. H L L H H L YES YES

A5

SEF

HLT

SEF

12×18 in. HHHH L LYESYES

13×19 in. HHHH L L * *

320×450 mmHHHHL L * *

297×420 mm H H H L L L YES YES

11×17 in. H H H L H L YES YES

1

/2 in. H H H L H H YES YES

257×364 mm H H L L H L YES YES

257×182 mm H H L L H H YES YES

210×297 mm H H L H H L YES YES

1

8

/2×11 in. H H L H H L YES *

1

8

/2×5 1/2 in. H H L H H H YES *

182×257 mm H L L H H L * *

148×210 mm H L H H H H YES YES

1

5

/2×8 1/2 in. L L H H H H YES YES

(Yes) Width and length sensors can detect paper sizes automatically.

(*) Accurate paper size detection requires setting with the "Tray

Paper Setting" key on the operation panel.

(H) 5V

(L) 0V

[B]

(1)

[D]

[C]

The side fences (1) and (2) can be adjusted to standard and nonstandard paper sizes.

When the side fences are moved to match the paper width, a feeler

[A] slides along the wiring patterns on the paper width switch terminal plate [B].

The combination of the following two factors determines the paper

size:

• The position where the feeler activates the terminal

• The status of the paper length sensor [C] (ON or OFF).

The paper end sensor [D] de-activates when the last sheet is fed

and reports that the paper tray is empty.

The paper size is detected by six sensors whose combined readings are used to detect the following paper sizes.

(2)

MX-CFX2 DETAILS 4 – 2

Page 14

M2

M4

M3

M7

M8

M5

1

MX-CFX2

[5] OVERALL MACHINE INFROMATION

Service Manual

1. MAIN LAYOUT

M7

M10

M9

3

1 Driver Board

2 Control Board

3 Door Open Switch (Interlock)

M1 1st Lift Motor

M2 1st Paper Feed Motor

M3 1st Pick-up Motor

M4 1st Transport Motor

M5 2nd Paper Feed Motor

M6 2nd Lift Motor

M7 2nd Pick-up Motor

M8 2nd Transport Motor

M9 Horizontal Transport Motor

M10 Vertical Transport Motor

M3

M4

M8

2. DRIVE LAYOUT

1

M2

M1

2

1

M10

M6

M5

M9

2

1 1st Transport roller

2 2nd Transport roller

M9 Horizontal Transport Motor

M10 Vertical Transport Motor

The 1st transport roller [1] (driven by the 1st transport motor) pulls

the paper from the 1st tray and feeds it into the vertical paper path.

The 2nd transport roller [2] (driven by the 2nd transport motor) pulls

the paper from the 2nd tray and feeds it into the vertical path.

The vertical transport motor [3] drives the vertical transport rollers

(1) and (2) that feed the sheets into the horizontal feed path.

The horizontal transport motor [4] drives the horizontal transport

rollers (3) and (4) that feed the covers (and paper passing straight

through) out of the cover interposer tray.

(4)

(2)

(1)

(3)

3. ELECTRICAL COMPONENTS

A. OVERVIEW

(1) FEED MOTORS, PCB

MX-CFX2 OVERALL MACHINE INFROMATION 5 – 1

1 Tray Unit Control Board

M2 1st Paper Feed Motor

M3 1st Pick-Up Motor

M4 1st Transport motor

M5 2nd Paper Feed Motor

M7 2nd Pick-Up Motor

M8 2nd Transport motor

Page 15

(2) LIFT MOTORS, TRAY SENSORS

(4) PAPER PATH SENSORS 2, PCB

M1

S2

S6

S5

M6

S16

S15

M1 1st Lift Motor

M6 2nd Lift Motor

S2 1st Lower Limit Sensor

S3 1st paper set sensor

S5 1st Paper Length Sensor

S6 1st paper upper limit sensor

S11 2nd Lower Limit Sensor

S13 2nd paper set sensor

S15 2nd Paper Length Sensor

S16 2nd paper upper limit sensor

(3) PAPER PATH SENSORS 1

S7

S1

S10

S3

S8

S11

S13

S4

S20

M10

M9

1

1 Main Control Board

M9 Horizontal Transport Motor

M10 Vertical Transport Motor

S20 2nd Vertical Transport Sensor

S21 Entrance Sensor

S22 Exit Sensor

S23 Vertical Exit Sensor

SW1 Feed Unit Front Door Safety Switch

(5) ELECTRICAL COMPONENT SUMMARY

S21

S23

S22

SW1

S12

S17

S19

S14

S1 1st Tray Cover Sensor

S4 1st Paper Feed Sensor

S7 1st Pick-Up Roller HP Sensor

S8 1st Transport Sensor

S9 1st Vertical Transport Sensor

S10 1st bottom plate position sensor

S12 2nd Tray Cover Sensor

S14 2nd Paper Feed Sensor

S17 2nd Pick-Up Roller HP Sensor

S18 2nd Transport Sensor

S19 2nd bottom plate position sensor

SW1 Vertical Feed Cover Switch

S18

SW1

S9

Motors

No. Name Description

M1

TRYLFT1M

M2

FEED1_M

M3

PIKUP1_M

M4

PLOUT1_M

M5

FEED2_M

M6

TRYLFT2M

M7

PIKUP2_M

M8

PLOUT2_M

M9

TRSH_M

M10

TRSV_M

PCBs

No. Name Description

PCB1 Driver Board Controls operation of the unit. (All

PCB2 Main Control Board

1st Lift Motor Drives the bottom plate of the 1st

1st Paper Feed

Motor

1st Pick-up Motor Moves the 1st pick-up roller up and

1st Transport Motor Drives the 1st Transport roller that

2nd Feed Motor Rotates the feed rollers that feed

2nd Lift Motor Drives the bottom plate of the 2nd

2nd Pick-up Motor Moves the 2nd pick-up roller up and

2nd Transport

Motor

Horizontal

Transport Motor

Vertical Transport

Motor

tray up and down.

Rotates the feed rollers that feed

paper from the 1st tray.

down.

takes the paper fed from the 1st feed

roller and feeds it to the vertical path.

paper from the 2nd tray.

tray up and down.

down.

Drives the 2nd Transport roller that

takes the paper fed from the 1st feed

roller and feeds it to the vertical path.

Drives the rollers in the horizontal

path that feed paper from the copier

and covers from the vertical path out

of the cover interposer tray.

Drives the rollers in the vertical path

that feed the covers down to the

horizontal path.

DIP SWs should be set to OFF.)

MX-CFX2 OVERALL MACHINE INFROMATION 5 – 2

Page 16

Sensors

No. Name Description

S1

FECVROP1

S2

LWR LMT1

S3

PPREND1

S4

INSFEED1

S5

PPRLNG1

S6

NEREND1

S7

INSHP1

S8

PLOUT1

S9

VTRS1

S10

UPRLMT1

S11

LWR LMT2

S12

FECVROP2

S13

PPREND2

S14

INSFEED2

S15

PPRLNG2

S16

NEREND2

S17

INSFEED2

S18

PLOUT2

S19

UPRLMT2

S20

VTRS2

S21

INSENT

S22

INSEXT

S23

INSOUT

1st Tray Cover

Sensor

1st Lower Limit

Sensor

1st paper set

sensor

1st Paper Feed

Sensor

1st Paper Length

Sensors

1st paper upper

limit sensor

1st Pick-up Roller

HP Sensor

1st Transport

Sensor

1st Transport

Sensor

1st bottom plate

position sensor

2nd Lower Limit

Sensor

2nd tray cover

sensor

2nd paper set

sensor

2nd Paper Feed

Sensor

2nd Paper Length

Sensor

2nd paper upper

limit sensor

2nd Pick-up Roller

HP Sensor

2nd Transport

Sensor

2nd bottom plate

position sensor

2nd Vertical

Transport Sensor

Entrance Sensor Detects paper jams where paper

Exit Sensor Detects jams where through-paper

Vertical Exit Sensor Detects jams where through-paper

Detects when the 1st tray cover is

open/closed.

Detects 1) whether the 1st tray is

down or not when the tray is not

operating, and 2) detects when the

tray is full when the 1st tray is

operating.

Detects paper end after the last

sheet feeds from the 1st tray.

Detects paper placed on the tray and

starts the 1st lift motor to raise the

bottom plate. This sensor also

detects a jam if the paper stops and

does not leave the 1st tray.

Used in combination with 1st tray

width sensors to determine the size

of paper in the 1st tray.

When an actuator falls into the gap

of this sensor, this signals paper

near end in the 1st tray.

Detects whether the 1st pick-up

roller is up or not.

Detects jams at the point where the

1st Transport roller pulls paper from

the 1st tray.

Detects jams in the path of the 1st

tray.

Detects the top of the paper stack in

the 1st tray when it is at the proper

height for feeding and stops the 1st

lift motor.

Detects 1) whether the 2nd tray is

down or not when the tray is not

operating, and 2) detects when the

tray is full when the 2nd tray is

operating.

Detects when the 2nd tray cover is

open/closed.

Detects paper placed on the tray and

starts the 2nd lift motor to raise the

bottom plate. This sensor also

detects a jam if the paper stops and

does not leave the 2nd tray.

Detects jams when the feed roller

feeds paper from the 2nd tray.

Used in combination with 1st tray

width sensors to determine the size

of paper in the 1st tray.

When an actuator falls into the gap

of this sensor, this signals paper

near end in the 2nd tray.

Detects whether the 2nd pick-up

roller is up or not.

Detects jams at the point where the

2nd Transport roller pulls paper from

the 1st tray.

Detects the top of the paper stack in

the 2nd tray when it is at the proper

height for feeding and stops the 2nd

lift motor.

Detects jams in the vertical path after

a sheet is fed from the 2nd tray.

from the copier enters the unit in the

horizontal feed path.

and covers exit the unit.

and covers exit the vertical feed

path.

Switches

No. Name Description

SW1 Front Door Switch Detects whether the front door is

SW2 Transport Cover

Switch

SW3 1st Paper Width

Switch

SW4 2nd Paper Width

Switch

properly closed. The unit will not

operate when the front door is open.

This is the cover on the right side of

the tray unit. Detects whether the

cover is opened or closed.

Used in combination with the length

sensors to determine the size of

paper in the 1st tray.

Used in combination with the length

sensors to determine the size of

paper in the 2nd tray.

MX-CFX2 OVERALL MACHINE INFROMATION 5 – 3

Page 17

B. BLOCK DIAGRAM

Interlock SW

INSERT FEEDER

5Vdc

24Vdc

24Vdc

SIGNAL

SW2

5Vdc

Pick Up Motor 1

STM1

Inter lock SW

SIGNAL

Feed Motor 1

STM3

SW1

Pull Out Motor 1

STM5

Vertical Transport

Mot or

STM7

Rise Motor 1

M1

Horizont al Transpor t

Pick Up Motor 2

STM2

Mot or

STM8

Feed Motor 2

STM4

Exit Sensor 1 (Sensor 1)

Exit Sensor 2 (Sensor 2)

Entr ance Sensor (Sensor 3)

Ver t ical Trans por t Sensor 2

(Sensor 4)

Pull Out Motor 2

STM6

Rise Motor 2

M2

Paper Lengt h Sensor 1, 2 (Sensor 5, 6)

Paper End Sensor 1, 2 (Sensor 7, 8)

Feed Sensor 1, 2 (Sensor 9, 10)

Home Position Sensor 1, 2 (Sensor 11, 12)

Pull Out Sensor 1, 2 (Sensor 13, 14)

Upper Limit Sensor 1, 2 (Sensor 15, 16)

Lower Limit Sensor 1, 2 (Sensor 17, 18)

Near End Sensor 1,2 (Sensor 19 ,20)

Cover Open Sensor 1, 2 (Sensor 21, 22)

Vert ical Transport Sensor 1 (Sensor 23)

PWB

Control

24Vdc

5Vdc

SIGNAL

D/D

FU100

CP100

Main PWB

MX-CFX2 OVERALL MACHINE INFROMATION 5 – 4

DC POWER LINE

SIGNAL LINE

Page 18

B835 5314A

B835 5315B

CN357

CN358

CN363

CN362

CN361

CN360

CN359

CN356

CN386

CN2 0 5 CN20 5

CN2 0 7 CN20 7

CN2 0 9

CN2 0 9

CN2 0 6 CN20 6

CN200 CN200

54321

CN104

CN1 0 4

CN2 0 8 CN20 8

CN2 1 0

CN2 1 0

CN2 1 1 CN21 1

CN1 0 9 CN1 0 9

CN105

CN1 0 5

CN1 0 6 CN1 0 6

CN1 0 7 CN1 0 7

CN1 0 8

CN201 CN201

CN2 0 2

CN2 0 2

CN2 0 3 CN2 0 3

CN2 0 4

CN1 0 8

CN2 0 4

Main control PWB

C4175110

Motor control PWB

B8355120

CN1 5 4

CN1 5 7

CN1 8 4

CN1 8 7

CN1 5 9 CN1 8 9

CN3 5 0

CN3 5 1

CN3 5 2

CN3 53

CN35 4 CN3 55

CN3 6 4

CN3 6 5

CN3 6 6

B835 5330

B835 5312

B835 5313

B835 5321A

(MOLEX 2.5mm)

(MOLEX 2.5mm)

AW010129

AW010129

CN1 1 3 CN1 1 3

AX040157A

AX040158A

AX040157A

AX040158A

AX060333A

AW010122

AW010122

B8355130A

AX040211A

AX040211A

AX060333A

PMOQFGN

PMOQFGN

CN1 5 6

CN1 8 6

CN1 5 8

CN1 8 8

CN1 5 5

CN1 8 5

CN1 6 3

CN1 9 3

CN258

B835 5323

11

10

987654321

54321

11

10

987654321

123456789

10

11

11

10

987654321

123456789

10

11

123456789

10

11

123

4

12345

12345

1514131211

10

987654321

1514131211

10

987654321

1514131211

10

987654321

123456789

1011121314

15

123456789

1011121314

15

123456789

1011121314

15

1413121110

987654321

1413121110

987654321

1413121110

987654321

123456789

1011121314

123456789

1011121314

123456789

1011121314

123456789

1011121314

15

123456789

1011121314

15

123456789

1011121314

15

1514131211

10

987654321

1514131211

10

987654321

1514131211

10

987654321

321

321

123

321

123

123

Vcc (5V)

No. 2 vertical transport sensor

CGND

12

11

123

12

11

987

123

123

123456789

101112

123456789

101112

65432165432

1

1234567

1234567

8

6543212

1

M

CGND

No. 1 paper size sensor 5

No. 1 paper size sensor 4

No. 1 paper size sensor 3

No. 1 paper size sensor 2

No. 1 paper size sensor 1

Vcc (5V)

No. 1 paper length sensor

CGND

Vcc (5V)

No. 1 paper end sensor

CGND

121110

987654321

121110

987654321

12345

6

12345

6

123

123

123

123

181716151413121110

987654321

123

123

123

123

123

123

181716151413121110

987654321

123

123

123

123

123

123

321

321

123

123

123456789

101112

13

123456789

101112

13

65432165432

1

65432

1

1234567

2

1234567

8

CN3 7 9

CN3 9 3

A

COM(A)

/A

B

COM(B)

/B

M

A

COM(A)

/A

B

COM(B)

/B

M

A

COM(A)

/A

B

COM(B)

/B

M

A

COM(A)

/A

B

COM(B)

/B

M

A

COM(A)

/A

B

COM(B)

/B

M

A

COM(A)

/A

B

COM(B)

/B

M

123

4

B835 5311

B835 5320A

B835 5324A

CN288

CN268

CN298

12345

6

65432

1

CN267 CN297

123456789

101112

121110

987654321

123456789

101112

121110

987654321

B835 5322A

Yellow

Brown

AW010107

AW010122

AW020160

AW020160

AW020160

AW020160

AW020160

B835 5331

Inserter

PGND [0]

PGND [0]

N.C

Vaa(24V) [24]

Vaa(24V) [24]

No. 1 paper feed M_CLK [0/5]

No. 1 paper feed M_EN [0/5]

No. 1 paper feed M_CWB [0/5]

No. 1 pull-out M_EN [0/5]

No. 1 pull-out M_CLK [0/5]

No. 1 pull-out M_CWB [0/5]

No. 1 pick-up M_CLK [0/5]

No. 1 pick-up M_EN [0/5]

No.1liftM(-)[0/5]

No. 1 lift M(+) [0/5]

(Upper cover open detection) [0/5]

No. 2 paper feed M_CLK [0/5]

No. 2 paper feed M_EN [0/5]

No. 1 paper feed M_CWB [0/5]

No. 2 pull-out M_EN [0/5]

No. 2 pull-out M_CLK [0/5]

No. 2 pull-out M_CWB [0/5]

No. 2 pick-up M_CLK [0/5]

No. 2 pick-up M_EN [0/5]

No. 2 lift M(-) [0/5]

No. 2 lift M(+) [0/5]

Vertical transport cover open/close SW [0/5]

CGND [0]

CGND [0]

Vcc (5V) [5]

Vcc (5V) [5]

No. 1 paper feed cover sensor

No. 1 paper size sensor 5

No. 1 paper size sensor 4

No. 1 paper size sensor 3

No. 1 paper size sensor 2

No. 1 paper size sensor 1

No. 1 paper length sensor

No. 1 paper end sensor

No. 1 HP sensor

No. 1 near end sensor

No. 1 lower limit sensor

No. 1 upper limit sensor

No. 1 pull-out sensor

No. 1 paper feed sensor

No. 2 paper feed cover sensor

No. 2 paper size sensor 5

No. 2 paper size sensor 4

No. 2 paper size sensor 3

No. 2 paper size sensor 2

No. 2 paper size sensor 1

No. 2 paper length sensor

No. 2 paper end sensor

No. 2 HP sensor

No. 2 near end sensor

No. 2 lower limit sensor

No. 2 upper limit sensor

No. 2 pull-out sensor

No. 2 paper feed sensor

No. 1 vertical transport sensor

Vcc (5V)

Paper exit sensor

CGND

Paper exit sensor

No. 2 vertical

transport sensor

PGND [0]

PGND [0]

N.C

Vaa(24V) [24]

Vaa(24V) [24]

No. 1 paper feed M A [0/24]

No. 1 paper feed M COM [24]

No. 1 paper feed M /A [0/24]

No. 1 paper feed M B [0/24]

No. 1 paper feed M COM [24]

No. 1 paper feed M /B [0/24]

No. 1 pull-out M A [0/24]

No. 1 pull-out M COM [24]

No. 1 pull-out M /A [0/24]

No. 1 pull-out M B [0/24]

No. 1 pull-out M COM [24]

No. 1 pull-out M /B [0/24]

No. 1 paper feed M_CLK [0/5]

No. 1 paper feed M_EN [0/5]

No. 1 paper feed M_CWB [0/5]

No. 1 pull-out M_EN [0/5]

No. 1 pull-out M_CLK [0/5]

No. 1 pull-out M_CWB [0/5]

No. 1 pick-up M_CLK [0/5]

No. 1 pick-up M_EN [0/5]

No. 1 lift M(-) [0/5]

No. 1 lift M(+) [0/5]

(Upper cover open detection) [0/5]

No. 1 pick-up M A [0/24]

No. 1 pick-up M COM [24]

No. 1 pick-up M /A [0/24]

No. 1 pick-up M B [0/24]

No. 1 pick-up M COM [24]

No. 1 pick-up M /B [0/24]

No. 1 lift M_OUT(-) [0/24]

No. 1 lift M_OUT(+) [0/24]

No. 1 paper feed

motor

No. 1 pull-out

motor

No. 1 pick-up

motor

No. 1 lift motor

No. 2 paper feed M_CLK [0/5]

No. 2 paper feed M_EN [0/5]

No. 1 paper feed M_CWB [0/5]

No. 2 pull-out M_EN [0/5]

No. 2 pull-out M_CLK [0/5]

No. 2 pull-out M_CWB [0/5]

No. 2 pick-up M_CLK [0/5]

No. 2 pick-up M_EN [0/5]

No. 2 lift M(-) [0/5]

No. 2 lift M(+) [0/5]

Vertical transport cover open/close SW

[0/5]

CGND [0]

CGND [0]

Vcc (5V) [5]

Vcc (5V) [5]

(CT)

(MiniMiII)

(CT)

(CT)

(CT)

(CT)

No. 1 paper size sensor

No. 1 paper length

sensor

No. 1 paper end

sensor

No. 1 paper feed sensor

No. 1

paper feed cover sensor

No. 1 paper size sensor 5

No. 1 paper size sensor 4

No. 1 paper size sensor 3

No. 1 paper size sensor 2

No. 1 paper size sensor 1

No. 1 paper length sensor

No. 1 paper end sensor

No. 1 HP sensor

No. 1 near end sensor

No. 1 lower limit sensor

No. 1 upper limit sensor

No. 1 pull-out sensor

No. 1 paper feed sensor

Vcc (5V) [5]

No. 1 paper feed sensor

CGND [0]

Vcc (5V) [5]

No. 1 pull-out sensor

CGND [0]

Vcc (5V) [5]

No. 1 HP sensor

CGND [0]

Vcc (5V) [5]

No. 1 upper limit sensor

CGND [0]

Vcc (5V) [5]

No. 1 lower limit sensor

CGND [0]

Vcc (5V) [5]

No. 1 near end sensor

CGND [0]

No. 1 pull-out sensor

No. 1 HP sensor

No. 1 upper limit sensor

No. 1 lower limit sensor

No. 1 near end sensor

No. 2

paper feed cover sensor

No. 2 paper size sensor 5

No. 2 paper size sensor 4

No. 2 paper size sensor 3

No. 2 paper size sensor 2

No. 2 paper size sensor 1

No. 2 paper length sensor

No. 2 paper end sensor

No. 2 HP sensor

No. 2 near end sensor

No. 2 lower limit sensor

No. 2 upper limit sensor

No. 2 pull-out sensor

No. 2 paper feed sensor

No. 1 vertical transport sensor

Vcc (5V) [5]

No. 1 paper feed cover sensor

CGND [0]

No. 2 paper feed M A [0/24]

No. 2 paper feed M COM [24]

No. 2 paper feed M /A [0/24]

No. 2 paper feed M B [0/24]

No. 2 paper feed M COM [24]

No. 2 paper feed M /B [0/24]

No. 2 pull-out M A [0/24]

No. 2 pull-out M COM [24]

No. 2 pull-out M /A [0/24]

No.2 pull-out M B [0/24]

No. 2 pull-out M COM [24]

No. 2 pull-out M /B [0/24]

NC

No. 2 pick-up M A [0/24]

No. 2 pick-up M COM [24]

No. 2 pick-up M /A [0/24]

No. 2 pick-up M B [0/24]

No. 2 pick-up M COM [24]

No. 2 pick-up M /B [0/24]

No 2 lift M OUT(-) [0/24]

No. 1 paper feed

cover sensor

No. 2 paper feed motor

No. 2 pull-out motor

No. 2 pick-up motor

C. ACTUAL WIRING CHART

MX-CFX2 OVERALL MACHINE INFROMATION 5 – 5

Page 19

4

3

4

B

No

2pick

up M B [0/24]

sensor

B835 5325A

CN29 5

CN2 6 5

AW010122

CN388

123

123

321

123

No. 2 vertical transport

AW010107

AW010122

AW020160

AW020160

AW020160

AX040211A

No.2liftmotor

B8355130A

No. 2 paper size sensor

AW010129

No. 2 paper length sensor

AW010129

No. 2 paper end sensor

No. 2 paper feed sensor

No. 2 pull-out sensor

No. 2 HP sensor

No. 2 upper limit sensor

No. 2 lower limit sensor

AW020160

No. 2 near end sensor

AW020160

No. 2 paper feed cover sensor

M

CN371

CN370

6

123

123

123

123

6

(CT)

987654321

101112

2

1

CN3 6 9

12345

12345

CN3 6 8

CN3 6 7

(CT)

B835 5322 A

121110

CN299

(CT)

123456789

CN269

/B

COM(B)

2

1

(CT)

CN372

123

123

B835 5323A

121110

CN3 0 0

123456789

CN2 6 3

CN374

CN373

123

123

123

123

987654321

123

123

101112

CN375

CN376

123

123

65432

12345

123

123

CN377

1

CN387

123

123

CN301

6

CN270

(Not installed)

1

2

1

2

12042529

open/close SW

Vertical transport cover

High active

SYMBOL TABLE

Low active

[ ] Voltage

Pulse

Signal flow

AC LINE

DC LINE

B835 5327

Vaa.SW(N.O)

Vaa(COM)

••• •••

132

123

• • SW(N.C)

CN3 9 0

123

123

CN3 8 9

CN266 CN296

B835 5326

56789

56789

-

.

No. 2 pick-up M /B [0/24]

No. 2 lift M_OUT(-) [0/24]

No. 2 pick-up M COM [24]

AW010122

No. 2 vertical

transport sensor

CN3 7 9

123

123

B835 5315B

987654321

123456789

CN1 5 9 CN1 8 9

121110

121110

CN1 0 9 CN1 0 9

Vcc (5V)

No. 2 vertical transport sensor

131211

131211

CN2 1 2 CN21 2

NC

(CT)

CGND

No. 2 lift M_OUT(+) [0/24]

No. 2 paper size sensor 5

AW010122

(Not installed)

Exit port sensor

CN3 8 1

CN3 8 0

123

123

123

123

987654321

987654321

CGND

CGND

CGND

Vcc (5V)

Vcc (5V)

Exit port sensor

(Vertical transport sensor)

987654321

10

987654321

10

Vcc (5V)

No. 2 paper size sensor 4

No. 2 paper size sensor 3

No. 2 paper size sensor 2

No. 2 paper size sensor 1

AW010122

Inlet port sensor

CN3 8 2

123

123

B835 5316A

321

123

CGND

Vcc (5V)

Inletportsensor

CN1 9 0

CN1 6 0

No. 2 paper length sensor

CGND

Vcc

CGND

No. 2 paper end sensor

A

CN3 8 3

CN1 1 0

CN110

CN2 1 3 CN2 1 3

NC

(Mini Mi II)

AX040158A

Vertical transport motor

M

/A

COM(A)

65432

12345

12345

Vertical transport M A [0/24]

Vertical transport M /A [0/24]

Vertical transport M COM [24]

B

Vertical transport M B [0/24]

191817161514131211

191817161514131211

CGND [0]

CGND [0]

Vcc (5V) [5]

Vcc (5V) [5]

Vcc (5V) [5]

No. 2 pull-out sensor

No. 2 paper feed sensor

AX040158 A

Horizontal transport motor

A

/A

/B

COM(A)

COM(B)

1

65432

CN3 8 4

6

1234567

6

1234567

CN1 1 1 CN1 1 1

Vertical transport M /B [0/24]

Vertical transport M COM [24]

Horizontal transport M A [0/24]

Horizontal transport M /A [0/24]

Horizontal transport M COM [24]

CGND [0]

No. 2 HP sensor

M

B

Horizontal transport M B [0/24]

COM(B)

Horizontal transport M COM [24]

/B

1

Horizontal transport M /B [0/24]

987654321

10

987654321

10

CGND [0]

CGND [0]

Vcc (5V) [5]

Vcc (5V) [5]

Vcc (5V) [5]

No. 2 lower limit sensor

No. 2 upper limit sensor

123

123

CN1 9 1

123

CN1 6 1

123

CN1 1 2

123

CN112

NC

Vaa (COM) [24]

No. 2 near end sensor

12042382

Front door SW [0/5]

432

1

54321

432

1

CN2 1 4 CN2 1 4

NC

CGND [0]

CGND [0]

Vcc (5V) [5]

54321

CN2 1 5 CN21 5

NC

CGND [0]

Vcc (5V) [5]

123

4

(MOLEX 2.5mm)

123

4

CN2 1 6 CN21 6

NC

CGND [0]

Vaa (COM) [24]

Vaa. SW (N. C) [0/24]

No. 2 paper feed cover sensor

(Upper cover open/close detection)

No. 2 vertical transport sensor

Vertical transport cover open/close SW (N.C) [0/24]

Main unit

CN301

Front door SW

C417 5300A

123456789

123456789

CN1 0 0 CN1 0 0

N. C

Vaa (24V) [24]

Vaa (24V) [24]

Vaa (24V) [24]

N. C

Vaa (24V) [24]

Vaa (24V) [24]

Vaa (24V) [24]

987654321

CN1 0 2

F. G

1234567

CN1 0 1

1234567

CN1 0 1

Vaa (24V) [24]

GND1 (PGND) [0]

GND1 (PGND) [0]

Vaa (24V) [24]

GND1 (PGND) [0]

GND1 (PGND) [0]

GND2 [0]

GND1 (PGND) [0]

GND1 (PGND) [0]

GND2 [0]

GND1 (PGND) [0]

GND2 [0]

GND1 (PGND) [0]

8765432

8765432

CN1 0 3 CN10 3

8

8

+5V [5]

+5V [5]

5VE [0/5]

GND2 [0]

TXD0(RXD) [0/5]

RXD0(TXD) [0/5]

ZESM signal [0/5]

+5V [5]

+5V [5]

TXD1 [0/5]

ZESM signal [0/5]

RXD1 [0/5]

5VE [0/5]

1

1

CGND [0]

4

4

4

4

4

Vaa. SW (N. O) [0/240

B835 5318

B835 5317A

CN5 0 0

12345

--

MD2 [0/5]

FWE [0/5]

MD1 [0/5]

123

4

CN5 0 1

CGND [0]

TXD2 [0/5]

RXD2 [0/5]

RESET [0/5]

Vcc (5V) [5]

MX-CFX2 OVERALL MACHINE INFROMATION 5 – 6

1234567

CN4 0 2

8

After-process unit

Page 20

y

LEAD-FREE SOLDER

The PWB’s of this model employs lead-free solder. The “LF” marks indicated on the PWB’s and the Service Manual mean “Lead-Free” solder.

The alphabet following the LF mark shows the kind of lead-free solder.

Example:

<Solder composition code of lead-free solder>

Solder composition

Sn-Ag-Cu

Sn-Ag-Bi

Sn-Ag-Bi-Cu

Sn-Zn-Bi

Sn-In-Ag-Bi

Sn-Cu-Ni

Sn-Ag-Sb

Bi-Sn-Ag-P

Bi-Sn-Ag

5mm

Lead-Free

Solder composition

code (Refer to the

table at the right.)

a

(1) NOTE FOR THE USE OF LEAD-FREE SOLDER THREAD

When repairing a lead-free solder PWB, use lead-free solder thread.

Never use conventional lead solder thread, which may cause a breakdown or an accident.

Since the melting point of lead-free solder thread is about 40°C higher than that of conventional lead solder thread, the use of the

exclusive-use soldering iron is recommended.

Solder composition code

a

b

z

i

n

s

p

(2) NOTE FOR SOLDERING WORK

Since the melting point of lead-free solder is about 220°C, which is about 40°C higher than that of conventional lead solder, and its soldering

capacity is inferior to conventional one, it is apt to keep the soldering iron in contact with the PWB for longer time. This may cause land

separation or may exceed the heat-resistive temperature of components. Use enough care to separate the soldering iron from the PWB when

completion of soldering is confirmed.

Since lead-free solder includes a greater quantity of tin, the iron tip may corrode easily. Turn ON/OFF the soldering iron power frequently.

If different-kind solder remains on the soldering iron tip, it is melted together with lead-free solder. To avoid this, clean the soldering iron

tip after completion of soldering work.

If the soldering iron tip is discolored black during soldering work, clean and file the tip with steel wool or a fine file.

COPYRIGHT©XXXX BYSHARP CORPORATION

COPYRIGHT©XXXX BYSHARP CORPORATION

ALL RIGHTS RESERVED.

ALL RIGHTS RESERVED.

No part of this publication may be reproduced,

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted in

stored in a retrieval system, or transmitted in

any form or by any means, electronic, mechanical,

form or byanymeans, electronic, mechanical,

an

photocopying, recording, or otherwise, without

prior written permission of the publisher.

Page 21

CAUTION FOR BATTERY REPLACEMENT

(Danish) ADVARSEL !

Lithiumbatteri – Eksplosionsfare ved fejlagtig håndtering.

(English) Caution !

Danger of explosion if battery is incorrectly replaced.

Dispose of used batteries according to manufacturer’s instructions.

(Finnish) VAROITUS

Paristo voi räjähtää, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan

(French) ATTENTION

Il y a danger d’explosion s’ il y a remplacement incorrect

de la batterie. Remplacer uniquement avec une batterie du

même type ou d’un type équivalent recommandé par

Mettre au rebut les batteries usagées conformément aux

(Swedish) VARNING

(German) Achtung

Explosionsgefahr bei Verwendung inkorrekter Batterien.

Als Ersatzbatterien dürfen nur Batterien vom gleichen Typ oder

vom Hersteller empfohlene Batterien verwendet werden.

Entsorgung der gebrauchten Batterien nur nach den vom

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandoren.

Replace only with the same or equivalent type

recommended by the manufacturer.

tyyppiin. Hävitä käytetty paristo valmistajan ohjeiden

mukaisesti.

le constructeur.

instructions du fabricant.

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent

typ som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens

instruktion.

Hersteller angegebenen Anweisungen.

CAUTION FOR BATTERY DISPOSAL

(For USA, CANADA)

THIS PRODUCT CONTAINS A LITHIUM PRIMARY

(MANGANESS DIOXIDE) MEMORY BACK-UP BATTERY

THAT MUST BE DISPOSED OF PROPERLY. REMOVE THE

BATTERY FROM THE PRODUCT AND CONTACT YOUR

LOCAL ENVIRONMENTAL AGENCIES FOR INFORMATION

ON RECYCLING AND DISPOSAL OPTIONS.

CE PRODUIT CONTIENT UNE PILE DE SAUVEGARDE DE

MÉMOIRE LITHIUM PRIMAIRE (DIOXYDE DE MANGANÈSE)

QUI DOIT ÊTRE TRAITÉE CORRECTEMENT. ENLEVEZ LA

PILE DU PRODUIT ET PRENEZ CONTACT AVEC VOTRE

AGENCE ENVIRONNEMENTALE LOCALE POUR DES

INFORMATIONS SUR LES MÉTHODES DE RECYCLAGE ET

“BATTERY DISPOSAL”

“TRAITEMENT DES PILES USAGÉES”

DE TRAITEMENT.

Page 22

COPYRIGHT 2007 BY SHARP CORPORATION

All rights reserved.

Printed in Japan.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted,

in any form or by any means,

electronic; mechanical; photocopying; recording or otherwise

without prior written permission of the publisher.

Trademark acknowledgements

Microsoft

Corporation in the U. S.A. and other countries.

Windows

Windows®

and

U.S.A. and other countries.

IBM and PC/AT are trademarks of International Business Machines Corporation.

Acrobat

reserved. Adobe, the Adobe logo, Acrobat, and the Acrobat logo are trademarks

of Adobe Systems Incorporated.

All other trademarks and copyrights are the property of their respective owners.

®

Windows® operating system is a trademark or copyright of Microsoft

®

95, Windows®

XP, Windows®

Internet Explorer®

®

Reader Copyright® 1987-2002 Adobe Systems Incorporated. All rights

98, Windows® Me, Windows NT®

Vista, Windows®

2000 Server, Windows®

4.0, Windows® 2000,

are trademarks or copyrights of Microsoft Corporation

Server 2003

in the

SHARP CORPORATION

Digital Document System Group

CS Promotion Center

Yamatokoriyama, Nara 639-1186, Japan

2007 May Printed in Japan

Loading...

Loading...