Page 1

SERVICE MANUAL

CODE: 00ZMXCF10/S1E

DIGITAL COPIER/PRINTER/

MULTIFUNCTIONAL SYSTEM OPTION

INSERTER

MODEL MX-CF10

CONTENTS

[1] PRODUCT OUTLINE . . . . . . . . . . . . . .1-1

[2] SPECIFICATIONS

1. Basic specifications . . . . . . . . . . . .1-1

2. Electrical specifications . . . . . . . . .1-1

3. Environmental conditions. . . . . . . .1-1

4. Compliance . . . . . . . . . . . . . . . . . .1-1

[3] EXTERNAL VIEWS AND INTERNAL

STRUCTURES

1. External components . . . . . . . . . . .3-1

2. Sensors and switches . . . . . . . . . .3-1

3. Motors, solenoid, and clutch . . . . .3-2

[4] OPERATIONAL DESCRIPTION

1. Structure . . . . . . . . . . . . . . . . . . . .4-1

2. Function outline . . . . . . . . . . . . . . .4-1

3. Operational description . . . . . . . . .4-1

4. Offline mode setting. . . . . . . . . . . .4-4

5. LED indication on operator panel. .4-5

[5] ADJUSTMENTS

1. Paper width detection level setting (ad-

justment) . . . . . . . . . . . . . . . . . . . .5-1

[6] DISASSEMBLY AND ASSEMBLY

1. Paper Feed Separation Unit . . . . .6-1

2. Paper Feed Unit . . . . . . . . . . . . . .6-2

3. Drive Unit . . . . . . . . . . . . . . . . . . . .6-4

4. Other Parts . . . . . . . . . . . . . . . . . .6-4

5. Note on assembly . . . . . . . . . . . . .6-4

[7] MAINTENANCE

1. Maintenance list. . . . . . . . . . . . . . .7-1

[8] TROUBLESHOOTING

[9] ELECTRICAL SECTION

1. Actual Wiring Chart . . . . . . . . . . . .9-1

2. Circuit Description . . . . . . . . . . . . .9-2

6. Paper jam/error detection . . . . . . .4-6

Parts marked with “ ” are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

[1] PRODUCT OUTLINE

This inserter is an optional unit for the MX-M623/M753 series of digital

complex machines. With the inserter installed, blank sheets or printed

sheets can be inserted as covers (made of cardboard) or tabbed

sheets without being subject to the printing process (and without passing through a fixing unit). When the inserter is combined with a finisher

(optional) and a punch unit (optional), printed sheets can proceed to

the hole punching or stapling process without being subject to the

copying process (or without passing through the main unit).

[2] SPECIFICATIONS

1. Basic specifications

A. Performance

Type of Installation Floorstanding

Delivery speed Through mode

Productivity 50 cpm (when A4 or letter-sized insert sheets

Transport

reference

Loading capacity 100 sheets max. (80 g/m

Offline function Provided

Manual operation

section

Stapling Possible

Saddle stitching

(With folding)

Punching Possible

Paper jam handling Paper feed/Transport unit Paper feeding

(Horizontal transportation):

Straight mode: 800mm/sec

Saddle mode (Reverse): 420mm/sec

are continuously transported/saddle mode not

applicable)

Center reference through (when horizontally

transported)

Maximum loading height: 12 mm (80g/m

Maximum loadable sheets: 30 (127g/m

Factor 0.6 or less applied to above limitations

for special papers

Equipped with keys and LEDs

Possible

Horizontal transport unit Transportation

B. Compatible paper types

2

Paper weight 60 – 256gm

should be less than 256μm)

Types Normal paper, special paper (OHP films, colored

paper, punched paper, tabbed paper)

Special papers OHP films: Saddle mode (reverse) not applicable

Punched paper: 2, 3, or 4 holes

2 holes (φ6.5): Hole pitch: 80mm

2 holes (φ8): Hole pitch: 70mm

3 holes (φ8): Hole pitch: 108mm+108mm

4 holes (φ6.5): Hole pitch:

4 holes (φ6.5): Hole pitch:

Paper sizes Ledger (LD), Legal (LG), Letter (LT), Letter R

(LTR), Foolscap, Executive R, Invoice R

(Normal paper, whose thickness

80mm+80mm+80mm

21mm+70mm+21mm

800mm/sec

2

or less)

greater)

greater)

cover open/close

guide open/close

2

or

2

or

Size detection The 3 destinations below are user-definable

cm: A3, B4, A4, A4R, B5, B5R, A5R

(Foolscap is manually specified on the

operation panel of main unit)

inch: LD, LG, LT, LTR, Executive R, Invoice R

∗ Mixed loading is not possible. When offline, sta-

pling and punching are possible only for papers

that have the identical width (A3 and A4, B4 and

B5, LD and LT). Note that compatibility with the

finisher is not considered.

Paper sizes that

can be stapled

Paper sizes that

can be saddle

stitched

Paper sizes that

can be punched

Compliant with the specifications both of the main

unit and the finisher.

Compliant with the specifications both of the main

unit and the saddle finisher.

Compliant with the specifications both of the main

unit and the punch unit.

C. Mechanical specifications

External

dimensions

Footprint (W) 270 x (D) 583 mm

Weight Product weight Approx. 23kg

Item enclosed Inserter: 1

Product

dimensions

Packaged

dimensions

Package weight Approx. 32kg

(W) 270 x (D) 583 x (H) 1113 mm

∗ Latch unit and tray unit

excluded.

(W) 1295 x (D) 680 x (H) 516 mm

∗ Latch unit and tray unit

excluded.

2. Electrical specifications

Input voltage Supplied from the main unit

Power consumption DC+24V: 58.3W max.

DC+24V ± 10%

DC +5V ± 5%

DC +5V: 1.1W max.

3. Environmental conditions

Operating

conditions (normal

operation)

Transport/storage

environment

Temperature 5 – 35°C

Humidity 20 – 85%RH (No condensing)

Temperature –20 – 50°C

Humidity 10 – 90%RH (No condensing)

4. Compliance

Safety standard UL: 60950 the 3rd edition

Electromagnetic

Compliance

C-UL: CAN/CSA-C22. 2 No.60950 the 3rd edition

CE: EN60950 ITS (German GS mark)

VCCI: Class B

FCC: Class B

CE: EN50081-1 EN55024

MX-CF10 PRODUCT OUTLINE 1 - 1

Page 3

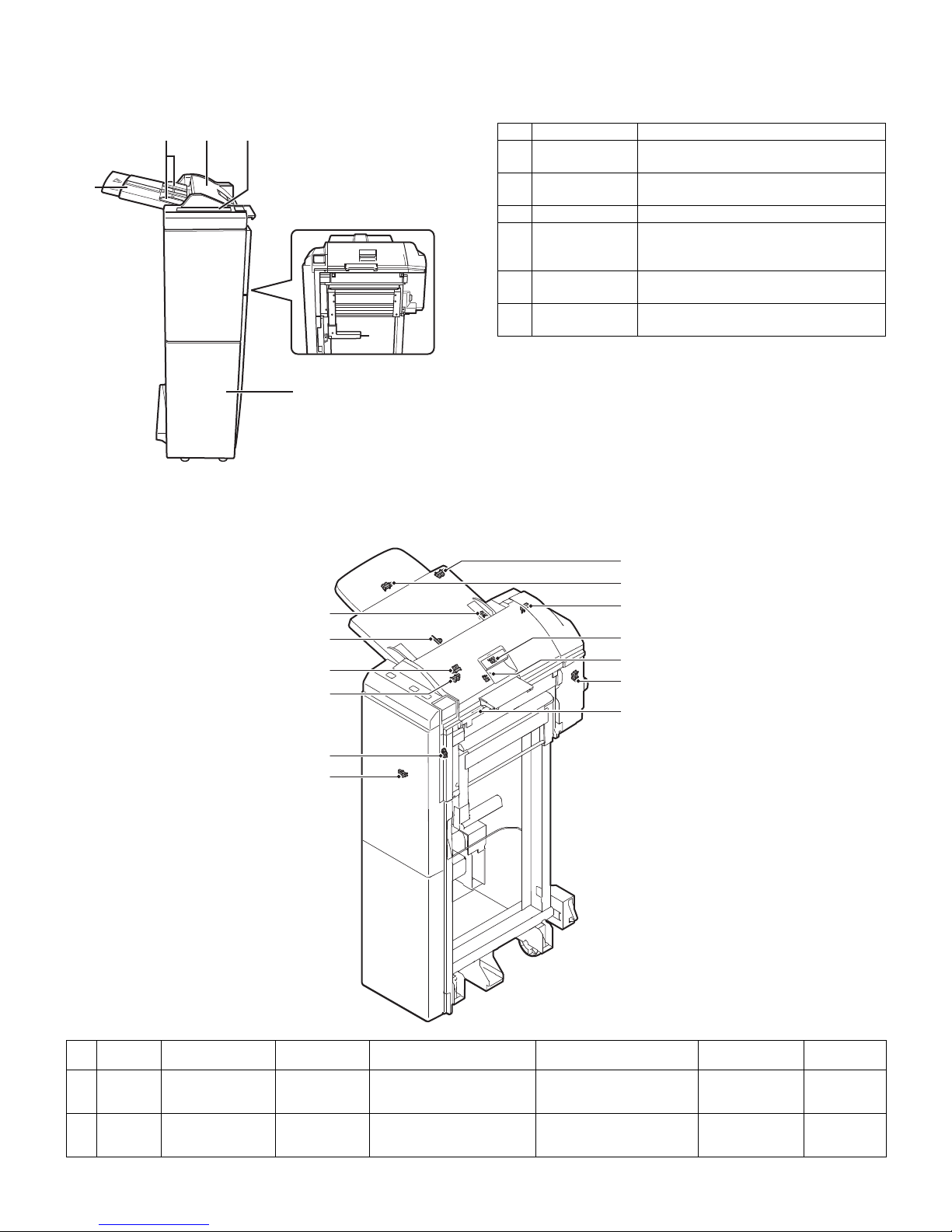

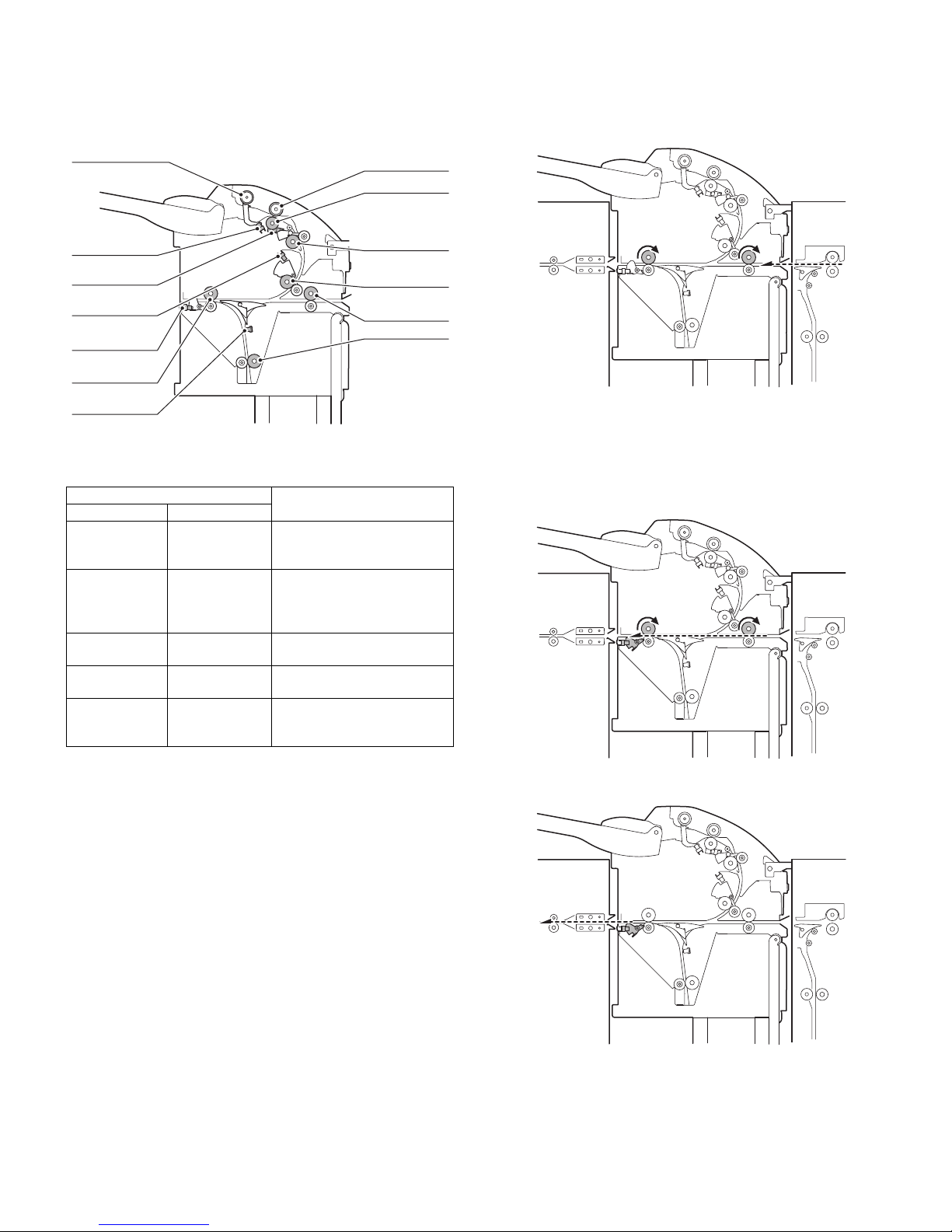

[3] EXTERNAL VIEWS AND INTERNAL STRUCTURES

1. External components

2 3 4

1

2. Sensors and switches

No. Description Function

1 Paper feed tray Place blank or printed sheets to be

inserted in this tray.

2 Paper guide Adjust this guide according to the paper

size.

3 Top cover Open this cover to clear a paper jam.

4 Operator panel Used to staple and punch during off-line.

(The same operation can be made with the

operation panel of the main unit.)

5 Paper guiding

section (Lever)

Unlock the paper guiding section to clear a

paper jam.

6 Front cover Open this cover to remove jammed paper

5

from the finisher or saddle finisher.

6

12

11

13

10

7

3

1

8

9

6

2

4

5

No. Symbol Description Type Function and operation Output

1 JCK_S W Inserter cover open/

close switch

2 H_SEN Inserter reverse

sensor

Microswitch Detects that the JAM cover is

Reflective sensor Detects that a sheet to be

MX-CF10 EXTERNAL VIEWS AND INTERNAL STRUCTURES 3 - 1

opened or closed.

inserted is transported to the

inserter reverse sensor.

When the JAM cover is opened,

TP37 turns HIGH.

When a sheet is detected, TP1

turns HIGH.

Product name

(Model)

DE2L-FAAA HIROSE

SENSOR

(SNS - SPI-337-01)

Manufacturer

CHERRY

PRECISION

SANYO

Page 4

No. Symbol Description Type Function and operation Output

3 HI_SEN Inserter paper exit

sensor

4 HYK_SEN Inserter reverse unit

open/close sensor

5 KC_SEN Inserter stand cover

open/close sensor

6 S_SEN Inserter set sensor Photointerrupter Detects that the inserter is joined

7 EMP_SEN Inserter empty sensor Photointerrupter Detects presence/absence of a

8 REG_SEN Inserter registration

sensor

9 TIM_SEN Inserter timing sensor Photointerrupter Detects that a sheet to be

10 T_VR Sheet width detection

potentiometer

11 T_SEN Inserter tray sensor Photointerrupter Detects the length of a sheet to

12 TH_SEN Sub tray pullout

detection sensor

13 TS_SEN Sub tray retraction

detection sensor

Photointerrupter Detects that a sheet to be

inserted is transported to the

inserter paper exit sensor.

Photointerrupter Detects that the reverse unit is

opened or closed.

Photointerrupter Detects that the stand cover is

opened or closed.

to the main unit.

sheet to be inser ted in the paper

feed tray.

Photointerrupter Detects that a sheet to be

inserted is transported to the

inserter registration sensor.

inserted is transported to the

inserter timing sensor.

Potentiometer Detects the width of a sheet to

be inserted in the tray.

be inserted in the tray

Photointerrupter Detects the pullout status of the

sub tray.

Photointerrupter Detects the retracted status of

the sub tray.

When a sheet is detected, TP7

turns LOW.

When the reverse unit is

opened, TP9 turns LOW.

When the stand cover is

opened, TP10 turns LOW.

When the inserter is joined to

the main unit, TP16 turns HIGH.

When a sheet is detected, TP4

turns HIGH.

When a sheet is detected, TP5

turns LOW.

hen a sheet is detected, TP6

turns LOW.

The voltage of TP12 varies

between 0 V and 5 V depending

on the sheet width.

When a sheet is detected, TP13

turns LOW.

When the pullout status is

detected, TP14 turns LOW.

When the retracted status is

detected, TP15 turns LOW.

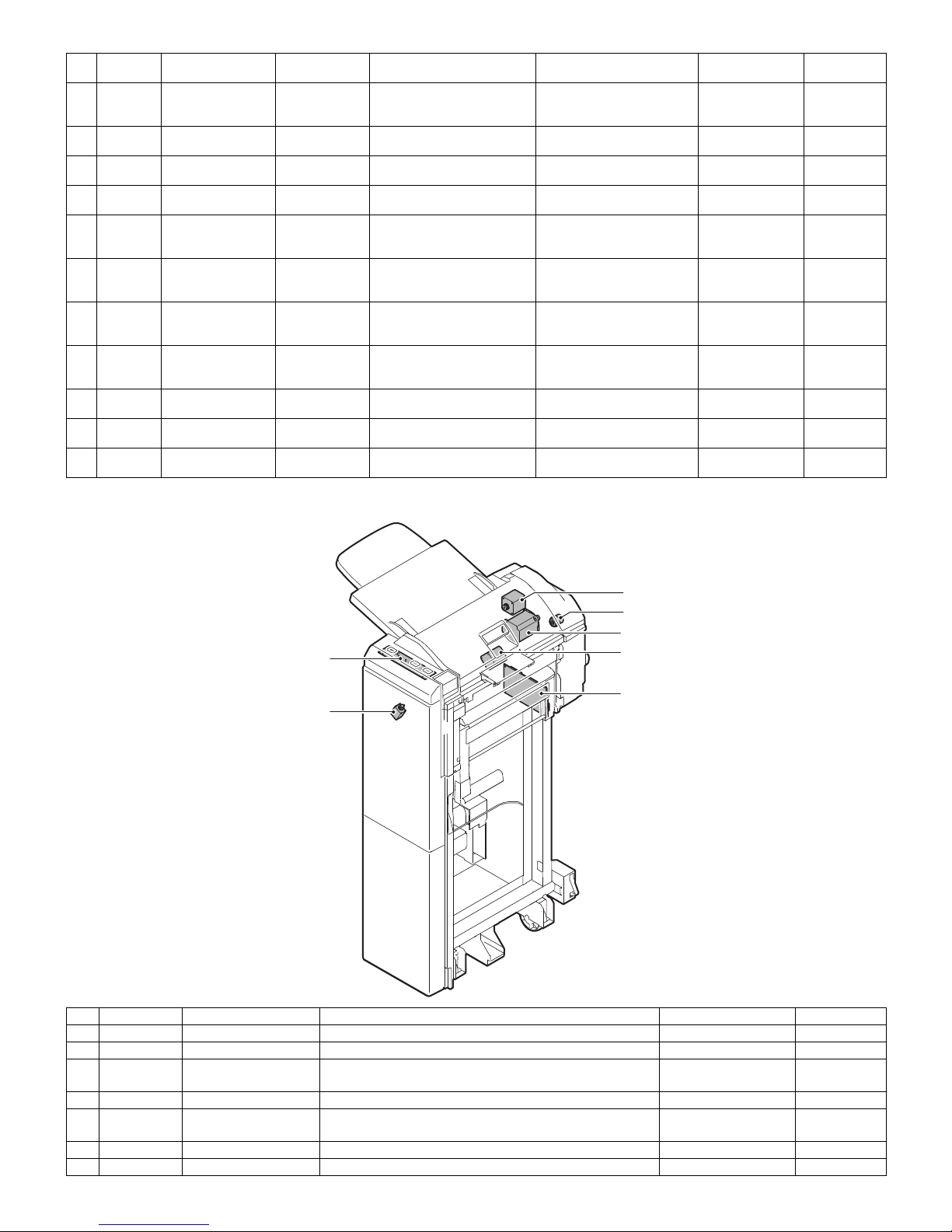

3. Motors, solenoid, and clutch

Product name

(Model)

TLP1241 (C5) TOSHIBA

TLP1241 (C5) TOSHIBA

TLP1241 (C5) TOSHIBA

TLP1241 (C5) TOSHIBA

TLP1241 (C5) TOSHIBA

TLP1241 (C5) TOSHIBA

TLP1241(C5) TOSHIBA

RDC505003A ALPS

GP1A73A SHARP

GP1A73A SHARP

GP1A73A SHARP

Manufacturer

3

5

1

6

2

7

4

No. Symbol Description Function Product name (Model) Manufacturer

1K_MOT

Inserter paper feed motor

Feeds a sheet to be inserted from the tray. 23KM-K112-P5V MINEBEA

2 H_MOT Inserter reverse motor Reverses and ejects a sheet to be inserted. 17PM-J507-P2VS MINEBEA

3 Y_MOT Inserter horizontal

transport motor

Transports a sheet to be inserted on the horizontal transport

path.

17PM-J507-P3VS MINEBEA

4 F_SOL Inserter flapper solenoid Sw itches over the flapper in the reversing operation. TDS-10SL-134 TDS

5 R_CL Inserter registration

Holds the registration rollers to maintain registration. BJ-2.6-184 SHINKO

clutch

6 PBA-PANEL Operation panel PWB –

7 PBA-CONT Main control PWB –

MX-CF10 EXTERNAL VIEWS AND INTERNAL STRUCTURES 3 - 2

Page 5

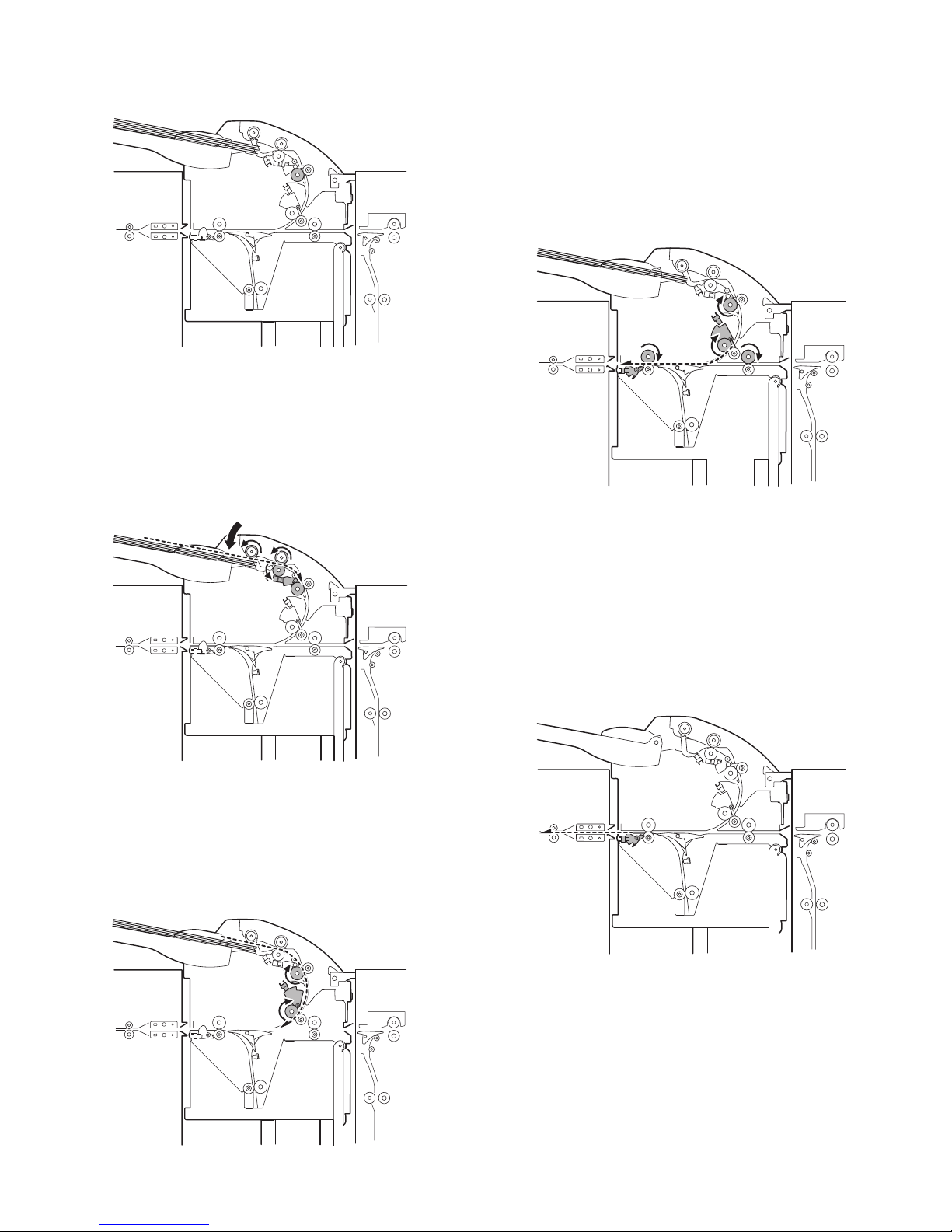

[4] OPERATIONAL DESCRIPTION

Pickup roller

Paper feed roller

Separation roller

Registration roller

Vertical

transport roller

Horizontal

transport roller 1

Reverse roller

Horizontal

transport roller 2

Inserter empty

sensor

Inserter registration

sensor

Inserter timing

sensor

Inserter paper

exit sensor

Inserter reverse

sensor

1. Structure

A. Cross-sectional view (Main body)

B. Drive system

[List of actuators]

Actuator

Description Type

Inserter paper

feed motor

Transport motor Pulse motor Inlet rollers (horizontal

Inserter reverse

motor

Reverse flapper

solenoid

Inserter

registration

clutch

Pulse motor Pickup roller, feed rollers,

Pulse motor Reverse rollers

Solenoid Switch-over flapper in reverse

Electromagnetic

clutch

Components to be driven

separation rollers, registration

rollers, vertical transport rollers

transport rollers 1), paper exit

rollers (horizontal transport

rollers 2)

section

Registration roller lock clutch

3. Operational description

A. Through-mode operation of inserter (Online)

Step 01: The inserter receives an operation command sent by the

main unit.

Step 02: The transport motor rotates at a speed specified by the main

unit.

Horizontal transport rollers 1 (inlet rollers) and horizontal

transport rollers 2 (paper exit rollers) rotate.

Step 03: A sheet exits from the main unit.

2. Function outline

A. Operation mode

(1) Normal (online mode)

• Through (horizontal transport)

• Straight mode (normal paper feeding from inserter)

• Reverse mode (reverse paper feeding from inserter)

(2) Offline mode

• Punching mode (inserter operation = normal paper feeding)

• Stapling mode (inserter operation = normal paper feeding)

B. Delivery speed

(1) Delivery speed

• Straight mode: 800 mm/sec

• Saddle mode (reverse): 420 mm/sec

Step 04: The inserter paper exit sensor detects the leading edge of

the sheet.

Step 05: The inserter paper exit sensor detects the trailing edge the

sheet.

Step 06: The transport motor stops.

Horizontal transport rollers 1 and horizontal transport rollers

2 stop.

MX-CF10 OPERATIONAL DESCRIPTION 4 - 1

Page 6

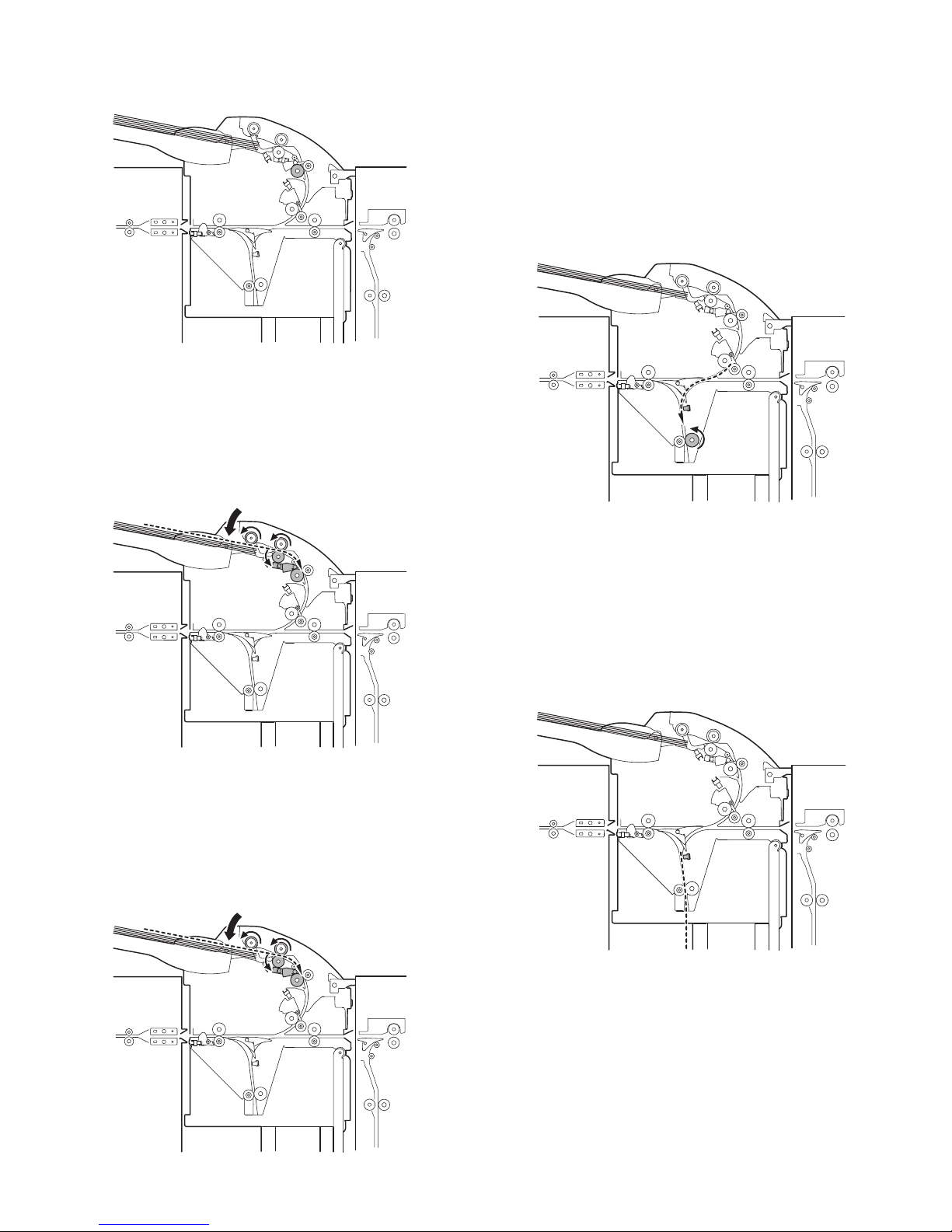

B. Normal paper feed operation of inserter (online/

offline)

[Paper loading]

Step 01: A sheet is placed in the paper feed tray of the inserter.

Step 02: The START LED lights up in blue on the operator panel of the

inserter.

Step 03: An operation command is sent by the main unit, or a user

presses the START switch on the operator panel of the

inserter.

Step 04: The inserter registration clutch is turned ON to lock the regis-

tration rollers.

[Separation]

Step 09: The inserter paper feed motor starts to rotate in the forward

direction. The registration rollers and vertical transport rollers rotate.

Step 10: The inserter timing sensor detects the leading edge of the

sheet.

Step 11: The leading edge of the sheet passes between the vertical

transport rollers.

Step 12: When sheet transport needs to be suspended for adjusting

the space between sheets, the inserter paper feed motor

stops to stop the sheet.

[Transport]

Step 13: When a predetermined waiting time period has passed, The

inserter paper feed motor restarts.

(If the transport motor has stopped, it is started.)

Step 14: The inserter paper exit sensor is turned ON, and detects the

leading edge of the sheet.

Step 15: The inserter timing sensor is turned OFF, and the trailing

edge of the sheet is detected.

Step 16: When the trailing edge of the sheet leaves the vertical trans-

port rollers, the inserter paper feed motor stops.

(When there is a next sheet to be inserted, the inserter paper

feed motor reverses to take it in.

[Paper exit]

Step 05: The inserter paper feed motor reverses to lower the pickup

roller, thereby taking in the sheet from the paper feed tray.

Step 06: The inserter registration sensor detects the leading edge of

the sheet.

Step 07: The sheet makes contact with the registration rollers to form

a loop, thereby stopping the inserter paper feed motor.

Step 08: The inserter registration clutch is turned OFF.

[Leading-edge registration]

Step 17: The inserter paper exit sensor is turned OFF, and the trailing

edge of the sheet is detected.

Step 18: When there aren’ t any more sheets to be inserted, the trans-

port motor stops.

Note: When the transport motor (horizontal transport rollers 1 and

horizontal transport rollers 2) rotates at a speed specified by

the main unit in the online mode, it rotates at either of the

speeds shown below in the offline mode.

∗ Transport speed in offline mode

Small-sized sheet (of which length detected in the tray is 216 mm or

less): 1000 mm/sec

Large-sized sheet (of which length detected in the tray is more than

216 mm): 800 mm/sec

MX-CF10 OPERATIONAL DESCRIPTION 4 - 2

Page 7

C. Reverse paper feeding operation of inserter

[Paper loading]

Step 01: A sheet is placed in the paper feed tray of the inserter.

Step 02: The START LED lights up in blue on the operator panel of the

inserter.

Step 03: The inserter reserves an operation command sent by the

main unit.

Step 04: The inserter registration clutch is turned ON to lock the regis-

tration rollers.

[Separation]

Step 09: The inserter paper feed motor starts to rotate in the forward

direction. The registration rollers and vertical transport rollers rotate. If the sheet is the first sheet, the flapper solenoid

in the reverse section is turned ON at this time.

Step 10: The inserter timing sensor detects the leading edge of the

sheet.

Step 11: The leading edge of the sheet passes between the vertical

transport rollers.

Step 12: When sheet transport needs to be suspended for adjusting

the space between sheets, the inserter paper feed motor

stops to stop the sheet.

[Entering reverse section]

Step 05: The inserter paper feed motor reverses to lower the pickup

roller, thereby taking in the sheet from the paper feed tray.

Step 06: The inserter registration sensor detects the leading edge of

the sheet.

Step 07: The sheet makes contact with the registration rollers to form

a loop, thereby stopping the inserter paper feed motor.

Step 08: The inserter registration clutch is turned OFF.

[Leading-edge registration]

Step 13: When a predetermined waiting time period has passed, the

inserter flapper solenoid is turned ON, the inserter paper

feed motor restarts, and the inserter reverse motor starts to

rotate in the forward direction.

Step 14: The inserter reverse sensor is turned ON, and detects the

leading edge of the sheet.

Step 15: When the trailing edge of the sheet leaves the inserter timing

sensor, the inserter paper feed motor starts to slow down to

stop.

(After the inserter paper feed motor has completely stopped,

if there is a next sheet to be inserted, the inserter paper feed

motor starts to reverse to take it in.)

Step 16: The inserter reverse sensor is turned OFF. The trailing edge

of the sheet is detected, and the flapper solenoid in the

reverse section is turned OFF. When the sheet travels a predetermined distance, the inserter reverse motor stops.

MX-CF10 OPERATIONAL DESCRIPTION 4 - 3

Page 8

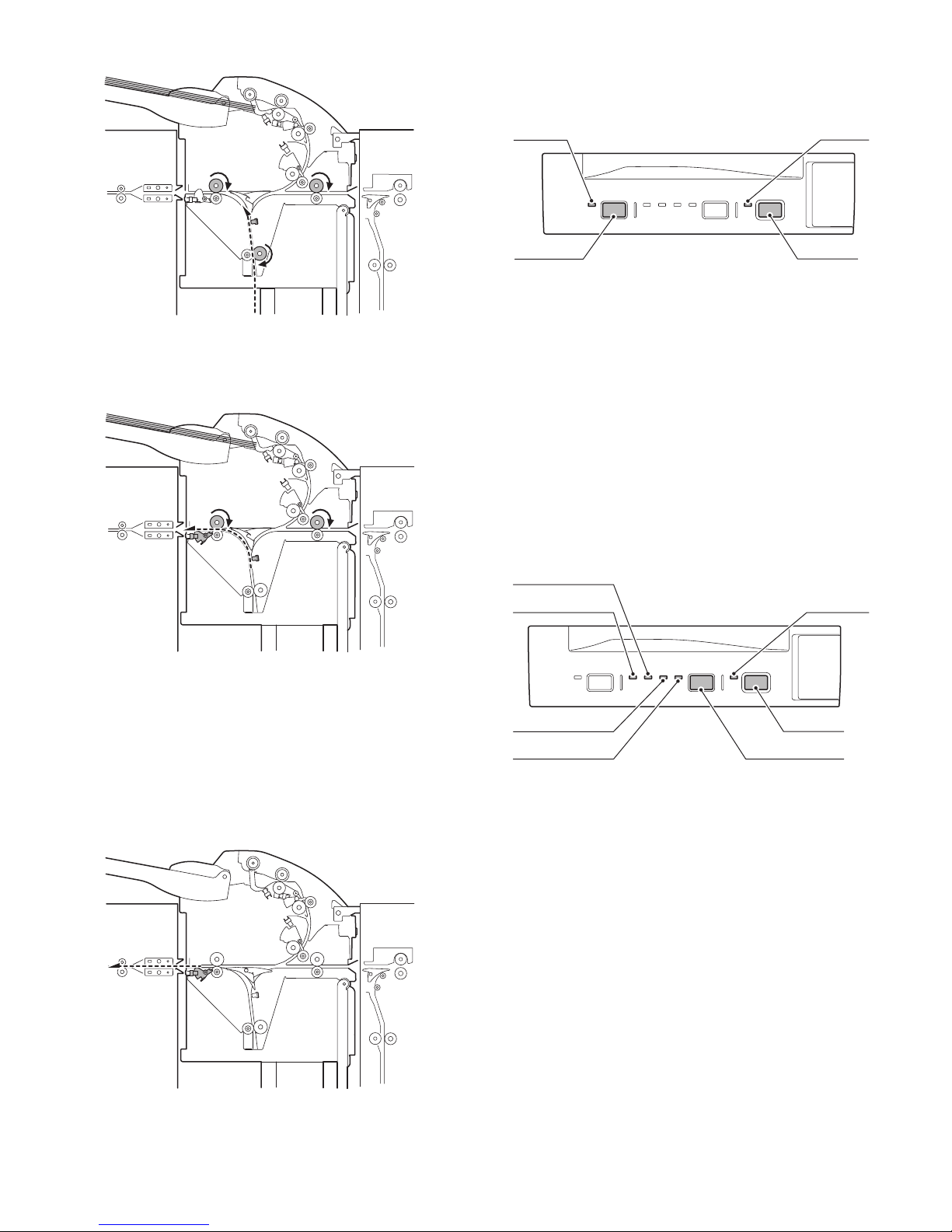

[Exiting from reverse section]

Punch switch

Punch LED

Start switch

Start LED

Start switch

Staple mode switch

Start switch

Staple mode LED 4

Staple mode LED 3

Staple mode LED 2

Staple mode LED 1

Step 17: When the inser ter reverse motor has completely stopped, the

inserter reverse motor starts to reverse, and the transport

motor starts.

Step 18: The inser ter reverse sensor is turned ON, and detects the

leading edge of the sheet.

4. Offline mode setting

A. How to set punching mode

The figure below shows the operator panel.

Setting procedure:

Step 01: Place a sheet in the tray.

Step 02: Press the PUNCH switch on the operator panel.

Step 03: The PUNCH LED lights up to indicate that setting has been

completed.

Step 04: Press the START switch to start operation.

Canceling procedure:

Step 01: Press the PUNCH switch on the operator panel.

Step 02: The PUNCH LED goes out to indicate that setting has been

canceled.

Note: If you cannot make or cancel setting by following the respective

procedures above, refer to section “5.” shown later. When no

LEDs are lit, check the setting made by the main unit and the

inserter status.

B. How to set stapling mode

Step 19: The inserter paper exit sensor is turned ON, and detects the

Step 20: The inserter reverse sensor is turned OFF. When the sheet

[Paper exit]

Step 21: The inserter paper exit sensor is turned OFF, and the trailing

Step 22: If there are no more sheets to be inserted, the transport

leading edge of the sheet.

travels a predetermined distance after its trailing edge is

detected, the inserter reverse motor stops.

(If the next sheet waits at the leading-edge registration position, the flapper solenoid in the reverse section is turned ON,

the inserter paper feed motor starts to rotate in the forward

direction, and the inserter reverse motor starts to rotate in the

forward direction.)

edge of the sheet is detected.

motor stops.

Setting procedure:

Step 01: Place a sheet in the tray.

Step 02: Press the STAPLE MODE switch on the operator panel.

Step 03: Each time you press the switch, the STAPLE MODE LEDs

light up by turns in the following order: 1 → 2 → 3 → 4 → All

LEDs OFF → 1 → ... (When the saddle mode cannot be

used, the order is: 1 → 2 → 3 → All LEDs OFF → 1 → ...)

Step 04: When the desired LED lights up, press the START switch to

start operation.

(Refer to the correspondence between the stapling modes and LEDs

shown later.)

Canceling procedure:

Step 01: Press the STAPLE MODE switch on the operator panel.

Step 02: All the STAPLE MODE LEDs go out to indicate that setting

has been canceled.

Note 1: If you cannot make or cancel setting by following the respec-

tive procedures above, refer to section “5.” shown later.

When no LEDs are lit, check the setting made by the main

unit and the inserter status.

Note 2: The punching mode and saddle mode cannot be used at the

same time.

MX-CF10 OPERATIONAL DESCRIPTION 4 - 4

Page 9

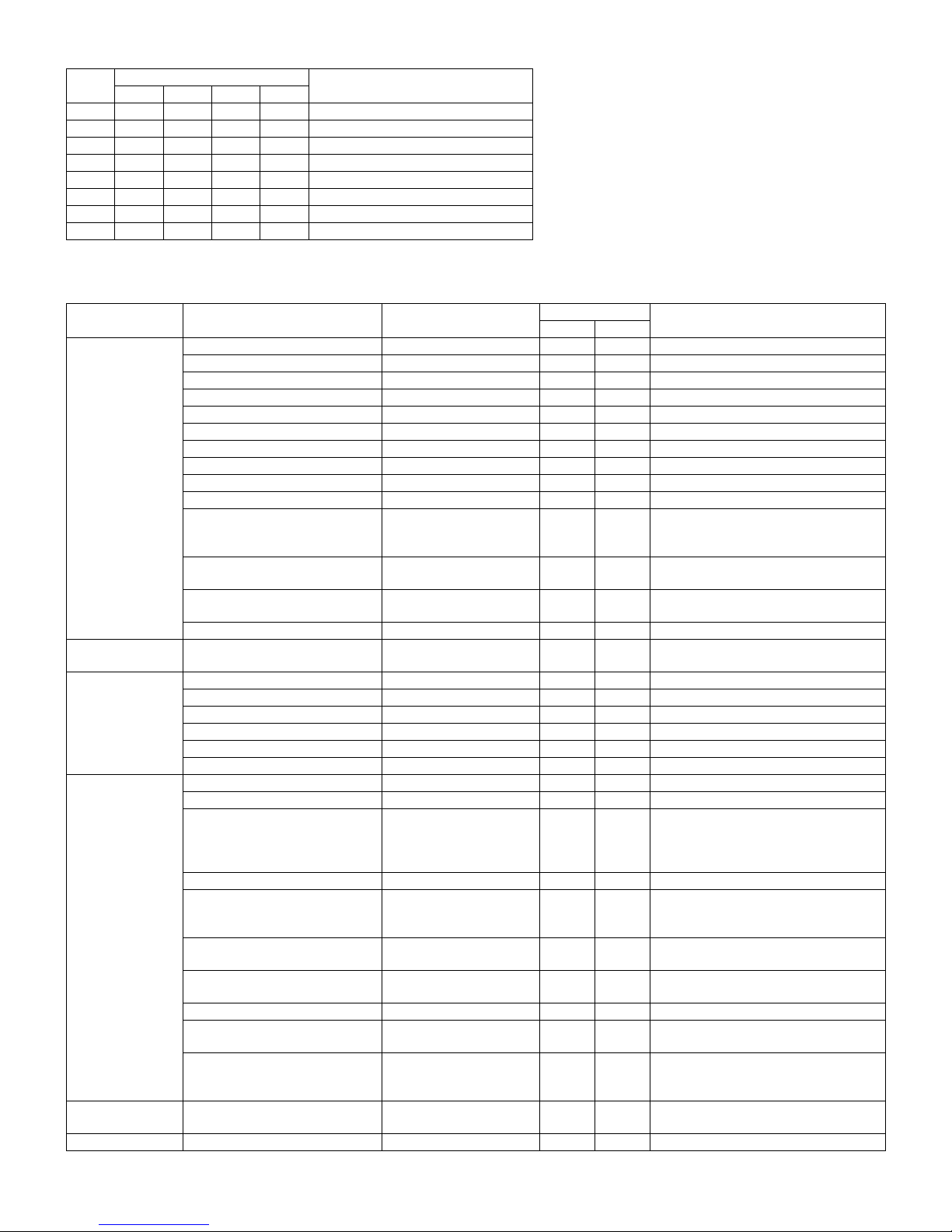

The correspondence between the punching/stapling mode settings and LEDs is shown below.

Punch

LED

❍●❍❍❍1-point stapling at back

❍❍●❍❍2-point stapling

❍❍❍●❍1-point stapling at front

❍❍❍❍●Saddle stapling (saddle stitching)

●❍❍❍❍Punching

●●❍❍❍Punching + 1-point stapling at back

●❍●❍❍Punching + 2-point stapling

●❍❍●❍Punching + 1-point stapling at front

∗ ●: means "Lit."

Staple mode LEDs

LED1 LED2 LED3 LED4

Stapling mode

5. LED indication on operator panel

Status Cause Explanation

Empty tray The selected MODE LED is lit.

Inserter problem

Finisher problem

Paper jam in inserter Lit The LED of the selected mode is lit.

Paper jam in finisher Lit The LED of the selected mode is lit.

Inserter alarm The LED of the selected mode is lit.

Finisher alarm The LED of the selected mode is lit.

Open inserter cover The LED of the selected mode is lit.

Open finisher cover The LED of the selected mode is lit.

Offline operation disabled

Inserter tray specified stapling

mode non-usable

Punching non-usable

Operation mode Stapling disabled

Punching disabled

Full tray (considered as a kind of

finisher alarms)

Other

Paper-loaded tray

(Operable)

Paper-loaded

tray(Non-operable)

Paper-loaded tray

(Non-operable)

Waiting for start of

offline operation

In offline operation Blinking The LED of the selected mode is lit.

Note: For LED status, each blank means "not lit."

Inserter problem Lit

Finisher problem Lit The LED of the selected mode is lit.

Paper jam in inserter Lit

Paper jam in finisher Lit The LED of the selected mode is lit.

Inserter alarm Blinking The LED of the selected mode is lit.

Finisher alarm Blinking The LED of the selected mode is blinking.

Open inserter cover The LED of the selected mode is lit.

Open finisher cover The LED of the selected mode is lit.

Incompatible paper size

Offline operation disabled

Inserter tray specified stapling

mode non-usable

Punching non-usable

Operation mode Stapling disabled

Punching disabled

Full tray (considered as a kind of

finisher alarms)

Over loaded Blinking The LED of the selected mode is blinking.

Paper loaded in the finisher

intermediate process tray

Other Main unit status "operation

A non-usable paper size "A4

lateral," etc. is added when

the saddle mode is selected:

Extra size

The selected mode is nonusable.

The selected mode is

disabled.

The tray corresponding to

the selected mode is full.

disabled," finisher status

"non-operable," etc.

After a user presses the

START switch

START LED

Red Green

Blinking

Blinking

Blinking

Blinking

MODE LED

The LED of the selected mode is lit.

The LED of the selected mode is blinking.

The LED of the selected mode is lit.

The LED of the selected mode is lit.

Lit

The LED of the selected mode is lit.

The LED of the selected mode is blinking.

The LED of the selected mode is blinking.

The LED of the selected mode is blinking.

The LED of the selected mode is lit.

The LED of the selected mode is lit.

The LED of the selected mode is lit.

MX-CF10 OPERATIONAL DESCRIPTION 4 - 5

Page 10

6. Paper jam/error detection

A. List of Paper jams

Description Detection timing Explanation

Not arrived at inserter

registration sensor

Not arrived at inserter

timing sensor

Not arrived at inserter

paper exit sensor

Not arrived at inserter

reverse sensor

Stay at inserter

registration sensor

Stay at inserter timing

sensor

Stay at inserter paper exit

sensor

Stay at inserter reverse

sensor

At a time of separating a sheet A paper jam is detected if the inserter registration sensor is not turned ON, which

At a time of leading-edge

registration

At a time of paper exit in through

mode

At a time of paper exit in normal

paper feed mode

At a time of paper exit in reverse

paper feed mode

At a time of entering reverse

section

At a time of exiting from reverse

section

At a time of paper exit in normal

paper feed mode

At a time of entering reverse

section in reverse paper feed mode

At a time of paper exit in normal

paper feed mode

At a time of entering reverse

section in reverse paper feed mode

At a time of paper exit in through

mode

At a time of paper exit in normal

paper feed mode

At a time of paper exit in reverse

paper feed mode

At a time of entering reverse

section

At a time of exiting from reverse

section

means absence of a sheet, even when the inserter paper feed motor has been

driven for a fixed distance after the pickup roller starts to lower.

A paper jam is detected if the inserter timing sensor is not turned ON, which

means absence of a sheet, even when the registration rollers (inserter paper feed

motor) have been driven for a fixed distance after they are started.

A paper jam is detected if the inserter paper exit sensor is not turned ON by the

leading edge of a sheet, which means absence of a sheet, even when the

transport motor has been driven for a fixed distance after the main unit sends a

paper exit command.

A paper jam is detected if the inserter paper exit sensor is not turned ON, which

means absence of a sheet, even when the leading edge of a sheet has traveled a

fixed distance after it reaches the paper exit rollers (horizontal transport rollers 2).

A paper jam is detected if the inserter paper exit sensor is not turned ON, which

means absence of a sheet, even when a sheet has been transported a fixed

distance by the transport motor after the inserter reverse sensor is turned ON,

which means presence of a sheet.

A paper jam is detected if the inserter reverse sensor is not turned ON, which

means absence of a sheet, even when the inserter reverse motor has been driven

for a fixed distance after leading-edge registration.

A paper jam is detected if the inserter reverse sensor is turned ON, which means

absence of a sheet, even when the inserter reverse motor has been driven for a

fixed distance while a sheet is exiting from the reverse section.

A paper jam is detected if the inserter registration sensor is not turned OFF, which

means presence of a sheet, even when the inserter paper feed motor has been

driven for a predetermined amount after a sheet reaches the starting position of

leading-edge registration.

A paper jam is detected if the inserter timing sensor is not turned OFF, which

means presence of a sheet, even when the inserter paper feed motor has been

driven for a fixed distance after the inserter registration sensor is turned OFF,

which means absence of a sheet.

A paper jam is detected if the inserter paper exit sensor is not turned OFF, which

means presence of a sheet, even when the transport motor has been driven for a

predetermined amount after the inserter paper exit sensor is turned ON, which

means presence of a sheet.

A paper jam is detected if the inserter paper exit sensor is not turned OFF, which

means presence of a sheet, even when the transport motor has been driven for a

fixed distance after the trailing edge of a sheet reaches the paper exit rollers

(horizontal transport rollers 2).

A paper jam is detected if the inserter reverse sensor is not turned OFF, which

means presence of a sheet, even when the inserter reverse motor has been

driven for a fixed distance after the inserter timing sensor is turned OFF, which

means absence of a sheet.

A paper jam is detected if the inserter reverse sensor is not turned OFF, which

means presence of a sheet, even when the inserter reverse motor has been

driven for a predetermined amount after the inserter reverse sensor is turned ON,

which means presence of a sheet.

B. Error detection

(1) EEPROM errors

Explanation:

1) Timeout error

The EEPROM is being programmed even after a predetermined

time period (150 msec) has passed.

2) Writing error

The written data does not match the read data even when writing

and reading are retried.

3) Reading error

Checking pieces of data read from three sources results in mismatch even when checking is retried.

(2) Inserter reverse sensor adjustment error

Explanation:

1) When the DA output exceeds the upper limit

Even when the DA output is increased, the AD input value does not

fall within the appropriated range.

2) When the DA output is less than the lower limit

Even when the DA output is decreased, the AD input value does

not fall within the appropriated range.

C. Alarm detection

Explanation:

An alarm is issued because the size of a sheet in the tray cannot be

correctly detected when both the sub tray pullout detection sensor and

the sub tray retraction detection sensor are turned OFF.

Indication:

Shown by a LED on the operator panel of the inserter or of the main

unit as an inserter alarm.

MX-CF10 OPERATIONAL DESCRIPTION 4 - 6

Page 11

[5] ADJUSTMENTS

LED 6 LED 5 LED 4 LED 3 LED 2 LED 1

START keyPUNCH key Operator panel STAPLE key

654321

1. Paper width detection level setting (adjustment)

1) Enter the diag mode.

Press and hold PUNCH key and START key, and turn on the

power of the main unit.

The LCD display of the main unit turns on and off, then turns on

again.

Check that LED1 is flashing, and release PUNCH key and START

key.

2) Press START key.

The display changes to the diag mode.

3) Press PUNCH key and STAPLE key to set to the paper width

detection level setting (adjustment) mode.

The diag mode is displayed by combination of LED lighting.

: Lighting : OFF

Diag mode

No.

11 Paper width detection level

setting (adjustment) mode

Diag mode LED lighting

4) Press START key. (The selected diag mode is executed.)

5) Check that LED2 is flashing, and set the paper guide to the max.

width position.

6) Press START key.

7) Check that LED3 is flashing, and set the paper guide to A4R width

position.

8) Press START key.

9) Check that LED4 is flashing, and set the paper guide to A5R width

position.

10) Press START key.

11) Check that LED5 is flashing, and set the paper guide to the min.

width position.

12) Press START key.

When setting (adjustment) is completed normally, LED1 lights up.

When it is failed, LED1 flashes more rapidly.

MX-CF10 ADJUSTMENTS 5 - 1

Page 12

[6] DISASSEMBLY AND ASSEMBLY

A

B

1. Paper Feed Separation Unit

A. Pickup Roller & Paper Feed Roller

1) Open the top cover

2) Remove the maintenance cover.

B. Torque Limiter & Separation Roller

1) Open the top cover.

2) Remove the maintenance cover.

3) Turn the separation roller unit to remove.

3) Turning the paper feed unit, remove the paper feed roller guide.

4) Remove the pickup roller and paper feed roller.

A: Pickup roller

B: Paper feed roller

4) Remove the torque limiter and the separation roller.

A: Torque limiter

B: Separation roller

A

B

MX-CF10 DISASSEMBLY AND ASSEMBLY 6 - 1

Page 13

2. Paper Feed Unit

B

A

A. Horizontal Pass Roller 1 and Registration Roller

1) Open the top cover.

2) Open the mount cover.

3) Remove the front cover.

A: Horizontal pass roller 1

B: Registration roller

B. Horizontal Pass Roller 2 and Timing Roller

1) Open the top cover.

2) Remove the front cover and rear cover.

3) Disconnect the connector to remove the operating unit.

4) Remove the rear cover.

5) Remove the open/close cover fulcrum and two E-rings (F/R), and

remove the upper door section.

4) Disconnect the connector, tray support and tray spring guide spindle to remove the tray unit.

MX-CF10 DISASSEMBLY AND ASSEMBLY 6 - 2

Page 14

5) Remove the finisher latch cover.

A

B

A: Horizontal pass roller 2

B: Timing roller

5) Remove the cover bracket.

D. Paper Guide

C. Reverse Roller

1) Open the top cover.

2) Remove the front cover and rear cover.

3) Remove the finisher fixing bolt to remove the finisher positioning

stay unit.

4) Remove the reverse supports and E-rings to remove the reverse

unit.

MX-CF10 DISASSEMBLY AND ASSEMBLY 6 - 3

Page 15

3. Drive Unit

LVR-FM-SOL

Stopper E-ring

Rubber spacer

Solenoid

main unit

Screw

BKT-FM-SOL

4. Other Parts

A. Belts

1) Open the top cover.

2) Remove the rear cover.

B. Gears

1) Open the top cover.

2) Remove the rear cover.

3) Disconnect the connector to remove the drive unit.

A. Sensors

5. Note on assembly

A. Reverse flapper solenoid adjustment

1) Rotate the solenoid lever (LVR-FM-SOL) fully clockwise.

2) Adjust the position of the bracket (BKT-FM-SOL) of the solenoid so

that the solenoid's arm is completely retracted (that there is no

clearance in the rubber spacer, the stopper E-ring, and the main

unit of the solenoid). When adjusted, fix the bracket with screws.

MX-CF10 DISASSEMBLY AND ASSEMBLY 6 - 4

Page 16

[7] MAINTENANCE

1. Maintenance list

Sequence of the maintenance works

The work sequence numbers are marked to the maintenance works on the maintenance list in the following three divisions.

• Large division

• Middle division

• Small division

Follow the above work sequence for efficient maintenance.

Work sequence number Division Description

*1 Work sequence for a section/unit Large division Indicates a section/unit to be worked.

*2 Work sequence for a sub unit Medium division Indicates the work sequence of the sub units in a section/unit.

*3 Work sequence of parts Small division Indicates the work sequence of the par ts in a section/unit.

✕: Check (Clean, replace, adjust, or grease as needed.) ❍: Clean ▲: Replace Δ: Adjust ✩: Lubricate ❏: Shift position

Work

Unit name

Inserter 1 Transport

[Note 4] Replacement reference: For replacement, refer to the inserter paper feed port counter value.

• Paper feed roller related section: 150K or 1 year

• Torque limiter: 400K

[Note 7] Check when jams occur frequently.

[Note 8] Grease when noises are generated.

[Note 9] Check when noises are generated.

[Note 10] Check when a trouble or a jam is generated due to a sensor or a detector.

sequence

(Sub unit)

(*2)

2 Paper feed

3 Other 5 Sensors ✕ ✕✕✕[Note 10]

4Drive

Section/

Sub unit

name

section

separation

section

section

Work

sequence

(Parts)

(*3)

1 Transport rollers ✕ ❍❍❍ Wipe with cloth

2 Transport paper

3 Pickup roller/

4 Torque limiter ✕ ✕✕✕[Note 4]

6 Gears ✕ ✩✩✩(Specified

7Belts ✕✕✕[Note 9]

Part name

guides

Paper feed

rollers

When

calling

300K600K900

❍ ❍❍❍ Ethyl alcohol

✕ ❍❍❍[Note 4] Wipe with cloth

NOTE Process / Material

K

immersed in

water to clean.

immersed in

water to clean.

[Note 7]

position)

[Note 8]

FLOIL G5000H

3

1

4

7

6

7

5

1

2

5

MX-CF10 MAINTENANCE 7 - 1

5

5

2

5

Page 17

[8] TROUBLESHOOTING

Problem The inserter does not perform at all when the main

Case1 Cause Loose contact with the main unit

Case2 Cause Loose contact of the connector terminal of

Case3 Cause Inserter cover open/close switch fault

Case4 Cause Controller PCB fault

Problem

Case1 Cause Loose contact of the motor connector

Case2 Cause Disconnection of the motor coil

Case3 Cause Controller PCB fault

Problem

Case1 Cause Connector terminal fault of the reverse

Case2 Cause Disconnection of the solenoid coil

Case3 Cause Controller PCB fault

switch of the main unit is turned ON.

Check and

remedy

Check and

remedy

Check and

remedy

Check and

remedy

The inserter paper feed motor does not operate.

The inserter reverse motor does not operate.

The inserter horizontal transport motor does not

operate.

Check and

remedy

Check and

remedy

Check and

remedy

The paper is delivered without being reversed in

the reverse paper feed mode.

Check and

remedy

Check and

remedy

Check and

remedy

Check that each connector is firmly

connected.

the wire (interface harness) connecting

with the main unit

Check continuity in between the

connector terminals. Replace the

connection wire if no continuity is

measured

Check continuity between the switch

contacts., Replace the contacts if no

continuity is measured.

Check that 24 V DC and 5 V DC are

supplied from the main unit after the

above cases 1 to 3 are confirmed. If 24 V

and 5 V are not present at CN1-2 pin and

IC5-32 pin on the PCB, replace the

controller PCB.

terminal

Check continuity of the connector

contacts.(CN1 to 3)

Check continuity between the connector

terminals. Replace the connection wire if

no continuity is measured.

If the motor does not operate in the motor

single operation mode, replace the

controller PCB.

solenoid

Check continuity of the connector

contact.(CN4)

Inspect the coil for continuity. Replace the

coil if no continuity is measured.

If the solenoid does not perform in the

solenoid single operation mode, replace

the controller PCB.

Problem Paper jam is displayed on the system display.

Case1 Cause Paper jam

Check and

remedy

Case2 Cause Inserter reverse sensor fault

Check and

remedy

Case3 Cause Inserter paper exit sensor fault

Check and

remedy

Case4 Cause Inserter empty sensor fault

Check and

remedy

Case5 Cause Inserter registration sensor fault

Check and

remedy

Case6 Cause Inserter timing sensor fault

Check and

remedy

Case7 Cause Controller PCB fault

Check and

remedy

Problem

Case1 Cause Inserter tray sensor fault

Case2 Cause Controller PCB fault

The machine does not detect the paper.

Check and

remedy

Check and

remedy

Visual observation. Take out paper jams.

Measure a voltage of TP2 on the

controller PCB and check that 3 to 3.6 V

is observed when no paper is stacked,

and that 1.5 V or less is observed when

paper is stacked. Replace the sensor if

the measured voltage exceeds these

ranges.

Measure a voltage of TP7 on the

controller PCB and check that 5 V is

observed when no paper is stacked, and

that 1 V or less is observed when paper is

stacked. Replace the sensor if the

measured voltage exceeds these ranges.

Measure a voltage of TP4 on the

controller PCB and check that 1 V or less

is observed when no paper is stacked,

and that 5 V is observed when paper is

stacked. Replace the sensor if the

measured voltage exceeds these ranges.

Measure a voltage of TP5 on the

controller PCB and check that 5 V is

observed when no paper is stacked, and

that 1 V or less is observed when paper is

stacked. Replace the sensor if the

measured voltage exceeds these ranges.

Measure a voltage of TP6 on the

controller PCB and check that a 5 V is

observed when no paper is stacked, and

that 1 V or less is observed when paper is

stacked. Replace the sensor if the

measured voltage exceeds these ranges.

If the problem is not solved with the

sensors whose level changes when each

is turned ON/OFF, replace the controller

PCB.

Measure a voltage of TP13 on the

controller PCB and check thatV is

observed when no paper is stacked, and

that 1 V or less is observed when paper is

stacked. Replace the sensor if the

measured voltage exceeds these ranges.

If the problem is not solved with a change

in the sensor level after the above case 1

is confirmed, replace the controller PCB.

MX-CF10 TROUBLESHOOTING 8 - 1

Page 18

Problem

Case1 Cause Sub-tray pulling detection sensor fault

Case2 Cause Sub-tray pulling detection sensor fault

Case3 Cause Controller PCB fault

Tray alarm is displayed on the system display.

Check and

remedy

Check and

remedy

Check and

remedy

Measure a voltage on TP14 on the

controller PCB and check that 5 V is

observed when the sub-tray is in place,

and that 1 V or less is observed when the

sub-tray is pulled out. Replace the sensor

if the measured voltage exceeds these

ranges.

Measure a voltage of TP15 on the

controller PCB and check that 5 V is

observed when the tray is in place, and

that 1 V or less is observed when the tray

is pulled. Replace the sensor if the

measured voltage exceeds these ranges.

If the problem is not solved by a change in

the sensor level after the above cases 1

and 2 are confirmed, replace the

controller PCB.

Problem The inserter registration clutch does not perform.

Case1 Cause Loose contact of the clutch connector

terminal

Check and

remedy

Case2 Cause Disconnection of the clutch coils

Check and

remedy

Case3 Cause Controller PCB fault

Check and

remedy

Check continuity of the connector

contacts. (CN4)

Inspect the coils for continuity. Replace

the coils if no continuity is measured.

If the clutch does not perform in the clutch

single operation mode, replace the

controller PCB.

Problem

Case1 Cause Inserter cover open/close switch fault

Case2 Cause Inserter reverse unit open/close sensor

Case3 Cause Inserter stand cover open/close sensor

Case4 Cause Controller PCB fault

Cover open is displayed on the system display.

Check and

remedy

Check and

remedy

Check and

remedy

Check and

remedy

Check continuity between the switch

contacts., Replace the switch if no

conduction is measured.

fault

Measure a voltage of TP9 on the

controller PCB and check that 1 V or less

is observed when the reverse unit is

open, and that 5 V is observed when the

reverse unit is closed. Replace the sensor

if the measured voltage exceeds these

ranges.

fault

Measure the voltage of TP10 on the

control PWB and check that it is 1V or

less when the base cover is opened and

5V when closed.

If the voltage is outside the above

specifications, replace the sensor with a

new one.

If the problem is not solved by a change in

the sensor level after the above cases 1

to 3 are confirmed, replace the controller

PCB.

Problem

Case1 Cause Inserter set sensor fault

Case2 Cause Controller PCB fault

Inserter unset is displayed on the system display.

Check and

remedy

Check and

remedy

Measure a voltage of TP16 on the

controller PCB and check that 5 V is

observed when the inserter is set, and

that 1 V or less is observed when the

inserter is not set. Replace the sensor if

the measured voltage exceeds these

ranges.

If the problem is not solved by a change

in the sensor level after the above case 1

is confirmed, replace the controller PCB.

MX-CF10 TROUBLESHOOTING 8 - 2

Page 19

[9] ELECTRICAL SECTION

Inserter Reverse Sensor

Inserter Paper exit Sensor

Inserter Reverse unit

Open/close Sensor

Inserter Stand cover

Open/close Sensor

Inserter Set Sensor

Inserter Empty Sensor

Inserter Registration Sensor

Inserter Timing Sensor

Tra y

Tray Volume

Operation Panel

Housing

Contact

Housing

Contact

Housing

Contact

Housing

Contact

Housing

Contact

Inserter

Tray Sensor

Tray Drawn

Sensor

Tray Folded

Sensor

Housing

Contact

Housing

Contact

Housing

Contact

Housing

Contact

Housing

Contact

Housing

Contact

Housing

Contact

Housing

Contact

Contact

Housing

Contact

Contact

Sleeve

FASTON Terminal

Inserter Cover Open/close Switch

Finisher I/F

Main Unit I/F

Inserter Flapper

Solenoid

Inserter Registration

Clutch

Inserter

Horizontal

transport Motor

Inserter

Reverse Motor

Inserter Paper Feed

Motor

BE:

BN:

BK:

RD:

YW:

WE:

OE:

GY:

SB:

PK:

VT:

Blue

Brown

Black

Red

Yellow

White

Orange

Gray

Sky-blue

Pink

Violet

1. Actual Wiring Chart

MX-CF10 ELECTRICAL SECTION 9 - 1

Page 20

2. Circuit Description

Inserter

Main Unit

RXD0

SGND

TXD0

DC+24V

DC+24V

DC+5V

Finisher

RXD1

SGN

TXD1

DC+24V

S_SEN

EMP_SEN

T_VR

REG_SEN

TIM_SEN

T_SEN

TH_SEN

TS_SEN

HYK_SEN

KC_SEN

SENSORS

INPUT

CIRCUIT

COMMU-

NICATION

CIRCUIT

CPU

DRIVER

F_SOL

R_CL

K_MOT

H_MOT

Y_MOT

ROM

EEP ROM

INRUSH

CURRENT

LIMITING

CIRCUIT

DC+5V

P_ST_SW

P_MO_SW

P_PN_SW

P_PN_LED

P_MO_LED4

P_MO_LED3

P_MO_LED2

P_MO_LED1

P_ST_LED2

P_ST_LED1

SW

INPUT

CIRCUIT

LED

DRIVE

CIRCUIT

JAM COVER

OPEN/CLOSED

DETECTION

CIRCUIT

(24V

CONDUCTIVE

DETECTION)

HI_SEN

H_SEN

JCK_SW

A. Outline

This circuit controls paper feed, transport, reverse, and delivery.

This circuit consists of the following divisions: managing signals from

the sensors, the switches, and the main unit; driving the motors, the

solenoid, and the clutch; the CPU and associated circuits.

B. Block Diagram

MX-CF10 ELECTRICAL SECTION 9 - 2

Page 21

C. Circuit Detail

Main Unit

Finisher

Main Unit

Finisher

Inserter Reverse

Sensor

(1) Communication Circuit

<1> TxD signal <2> RxD signal

This circuit communicates with the main unit and the finisher.

TxD0 and TxD1 are data signals transmitted from the main unit and the finisher to the inserter. RxD0 and RxD1 are data signals transmitted from the

inserter to the main unit and the finisher. Logical 1 is represented by +5V, and logical 0 is represented by 0V.

(2) Sensor Input Circuits

<1> Inserter Reverse Sensor (H_SEN)

H_SEN uses the reflective sensor integrated with an LED and a phototransistor.

The sensor detects a sheet between the sensor and the opposite

reflector interrupting the light path.

The CPU (IC6-Pin94, 95, 96) output is transmitted to the sensor to light

the LED through the D/A converter (IC13), the operational amplifier

(IC15.2), and the transistor (Q1). Meanwhile the signal is transmitted to

the CPU (IC6-Pin30) through the noise filters (R4, C2) and the comparator (IC1.1).

The signal input to the CPU follows the logic: "H" when a sheet is

detected, "L" when not detected.

The analog signal is transmitted to CPU (IC-Pin105) through no comparator.

R1 and R10 divide the +5V voltage which is applied to the comparator

as the reference voltage.

R13 is used to make the reference voltage have hysteresis.

MX-CF10 ELECTRICAL SECTION 9 - 3

Page 22

<2> Inserter Paper exit Sensor (HI_SEN)

Inserter Paper exit Sensor

Inserter Reverse unit

Open/close Sensor

Inserter Stand cover

Open/close Sensor

Inserter Set Sensor

Inserter Empty Sensor

Inserter Registration Sensor

Inserter Timing Sensor

HI_SEN uses the photointerrupter integrated with an LED and a phototransistor.

The sensor detects a sheet with the lever actuator interrupting the light

path of the photointerrupter.

The signal is transmitted to the CPU (IC6-Pin106) through the noise filters (R25,C9).

The signal input to the CPU follow the logic: "L" when a sheet is

detected, "H" when not detected.

R39 is a current limiting resistor for the LED. R34 is a load resistor for

the sensor.

<3> Inserter Reverse unit Open/close Sensor (HYK_SEN)

HYK_SEN uses the photointerrupter integrated with an LED and a

phototransistor.

The sensor detects state of the reverse unit with the lever actuator

interrupting the light path of the photointerrupter.

The signal is transmitted to the CPU (IC6-Pin108) through the noise filters (R21,C7).

The signal input to the CPU follows the logic: "L" when the reverse unit

is open, "H" when closed.

R37 is a current limiting resistor for the LED. R32 is a load resistor for

the sensor.

<4> Inserter Stand cover Open/close Sensor (KC_SEN)

KC_SEN uses the photointerrupter integrated with an LED and a phototransistor.

The sensor detects state of the chassis cover with the lever actuator

interrupting the light path.

The signal is transmitted to the CPU (IC6-Pin109) through the noise filters (R29,C11).

The signal input to the CPU follows the logic: "L" when the chassis

cover is open, "H" when closed.

R41 is a current limiting resistor for the LED. R36 is a load resistor for

the sensor.

<5> Inserter Set Sensor (S_SEN)

S_SEN uses the photointerrupter integrated with an LED and a phototransistor.

The sensor detects the main unit with the lever actuator interrupting the

light path.

The signal is transmitted to the CPU (IC6-Pin2) through the noise filters (R56,C16).

The signal input to the CPU follows the logic: "H" when the inserter is

connected to the main unit, "L" when not connected.

R59 is a current limiting resistor for the LED. R58 is a load resistor for

the sensor.

<6> Inserter Empty Sensor (EMP_SEN)

EMP_SEN uses the photointerrupter including the LED and the phototransistor in one unit.

The sensor detects a sheet with the lever actuator interrupting the light

path.

The signal is transmitted to the CPU (IC6-Pin31) through the noise filters (R7,C4).

The signal input to the CPU is the following logic: the signal is "H" when

a sheet is detected, "L" when not detected.

R12 is the current limiting resistor for the LED. R11 is the load resistor

for the sensor.

<7> Inserter Registration Sensor (REG_SEN)

REG_SEN uses the photointerrupter integrated with an LED and a

phototransistor.

The sensor detects a sheet with the lever actuator interrupting the light

path.

The signal is transmitted to the CPU (IC6-Pin32) through the noise filters (R14,C5).

The signal input to the CPU follows the logic: "L" when a sheet is

detected, "H" when not detected.

R17 is a current limiting resistor for the LED. R16 is a load resistor for

the sensor.

<8> Inserter Timing Sensor (TIM_SEN)

TIM_SEN uses the photointerrupter integrated with an LED and a phototransistor.

The sensor detects a sheet with the lever actuator interrupting the light

path.

The signal is transmitted to the CPU (IC6-Pin33) through the noise filters (R19,C6).

The signal input to the CPU follows the logic: "L" when a sheet is

detected, "H" when not detected.

R18 is a current limiting resistor for the LED. R31 is a load resistor for

the sensor.

MX-CF10 ELECTRICAL SECTION 9 - 4

Page 23

<9> Paper Width Detection Potentiometer (T_VR)

Paper Width Detection Potentiometer

Inserter Tray Sensor

Sub Tray Drawn Detection Sensor

Sub Tray Folded Detection Sensor

T_VR is a potentiometer.

The paper width is detected using the output voltage, which may vary

depending on the potentiometer's knob position.

The signal is transmitted to the CPU (IC6-Pin112) through the noise filters (R48,C12).

<10> Inserter Tray Sensor (T_SEN)

T_SEN uses the photointerrupter integrated with an LED and a phototransistor.

The sensor detects a sheet with the lever actuator interrupting the light

path.

The signal is transmitted to the CPU (IC6-Pin126) through the noise filters (R46,C15).

The signal input to the CPU follows the logic: "L" when a sheet is

detected, "H" when not detected.

R52 is a load resistor for the sensor.

<13> Inserter Cover Open/close Switch (JCK_SW)

<11> Sub Tray Drawn Detection Sensor (TH_SEN)

TH_SEN uses the photointerrupter integrated with an LED and the

phototransistor in one unit.

The sensor detects state of the sub tray with the lever actuator interrupting the light path.

The signal is transmitted to the CPU (IC6-Pin127) through the noise filters (R44,C14).

The signal input to the CPU follows the logic: "L" when the sub tray is

drawn.

R51 is a load resistor for the sensor.

<12> Sub Tray Folded Detection Sensor (TS_SEN)

TS_SEN uses the photointerrupter integrated with an LED and a phototransistor.

The sensor detects state of the sub tray with the lever actuator interrupting the light path.

The signal is transmitted to the CPU (IC6-Pin128) through the noise filters (R42,C13).

The signal input to the CPU follows the logic: "L" when the sub tray is

folded.

R50 is a load resistor for the sensor.

JCK_SW is the inserter cover open/close switch using the microswitch.

+24V is supplied to the switch. The contacts open when the JAM cover

is open.

When the switch turns on, +24V voltage is applied to the cathode of

ZD2, the base current flows to Q12, and Q12 turns on to transmit the

signal to the CPU (IC6-Pin111).

The signal is also used as the +24V conduction signal simultaneously.

The signal input to the CPU follows the logic: "H" when the JAM cover

is open, "L" when closed.

The +24V conduction signal follows the logic: "L" when the +24V voltage is conducted.

MX-CF10 ELECTRICAL SECTION 9 - 5

Page 24

(3) Motor Drive Circuits

Not Mounted

Inserter Paper

Feed Motor

Not Mounted

Inserter Reverse

Motor

Not

Mounted

Inserter Horizontal

transport Motor

<1> Inserter Paper Feed Motor Drive Circuit (K_MOT)

This circuit rotates/stops K_MOT and controls its rotational direction

and the motor current. The circuit consists of the CPU (IC6), the D/A

converter (IC13), the constant-current chopper driver IC (IC9), and

other elements.

The signals of the stepping-motor drive excitation pattern from the

CPU (IC6-Pin37,38,70,71) control the motor rotation speed and rotational direction.

<2> Inserter Reverse Motor Drive Circuit (H_MOT)

This circuit rotates/stops H_MOTand controls its rotational direction

and the motor current. The circuit consists of the CPU (IC6), the D/A

converter (IC13), the constant-current chopper driver IC (IC7), and

other elements.

The analog signal from the D/A converter (IC13-Pin11) is divided into

the constant voltage by R53 and R54. The divided voltage is applied to

IC9-Pin9,11 to set the motor current.

The signals of the stepping-motor drive excitation pattern from the

CPU (IC6-Pin118, 120, 121, 122) control the motor rotation speed and

rotational direction.

The analog signal from the D/A converter (IC13-Pin5) is divided into

the constant voltage by R74 and R75. The divided voltage is applied to

IC7-Pin3,14 to set the motor current.

<3> Inserter Horizontal transport Motor Drive Circuit (Y_MOT)

This circuit rotates/stops Y_MOT and controls its rotational direction

and the motor current. The circuit consists of the CPU (IC6), the D/A

converter (IC13), the constant-current chopper driver IC (IC8), and

other elements.

The signals of the stepping-motor drive excitation pattern from the

CPU (IC6-Pin97, 98, 101, 102) control the motor rotation speed and

rotational direction.

The analog signal from the D/A converter (IC13-Pin6) is divided into

the constant voltage by R76 and R77. The divided voltage is applied to

IC8-Pin3,14 to set the motor current.

MX-CF10 ELECTRICAL SECTION 9 - 6

Page 25

(4) Inserter Flapper Solenoid and Inserter Registration Clutch Drive Circuit (F_SOL and R_CL)

Inserter Registration Clutch

Inserter Flapper Solenoid

Not Mounted

This circuit controls the inserter flapper solenoid operation and the

inserter registration clutch engagement.

When the signal F_SOL is "H", Q2 turns on to activate the solenoid.

Similarly, when the signal R_CL is "H", Q3 turns on to engage the

clutch.

(5) Reset Circuit

The circuit transmits a reset signal to the CPU when the power is

turned on or a power brownout is detected.

The circuit includes a watchdog timer intended to the CPU system

operation diagnosis.

After the power is turned on, normally IC3-Pin8 (*RES) is "H". However, when the +5V voltage falls to 4.2V or less because of the power

turned off or any trouble, IC3-Pin8 turns "L" to reset the CPU.

The clock signal from the CPU is transmitted to IC3-Pin3 (CK) at a regular interval to clear the watchdog timer embedded in IC3. However, if

the clock signal from the CPU disappears because of a system trouble,

IC3-Pin8 turns "L" to reset the CPU and stop the system operation.

The inserter flapper solenoid drive signal is the PWM signal. At the

beginning of the solenoid activation, the signal is adjusted to set the

solenoid at 100% duty cycle. After the plunger of the solenoid is pulled

in, the signal is adjusted to set the solenoid at 70% duty cycle in order

to reduce the temperature rise with the plunger hold.

(6) EEPROM Circuit

This circuit consists of the data storage EEPROM and the peripheral

circuits.

IC4 is a storage memory for the adjustment settings of the inserter

reverse sensor (reflective sensor) and the paper width detection potentiometer, and passes the data to the CPU through the four-wire serial

interface.

Once data is stored, the data is retained and not cleared even if the

power is turned off.

IC4-Pin1 (CS) is the chip selection terminal, and stays "H" during passing data.

IC4-Pin2 (SK) is the serial clock terminal. The serial data is transmitted

synchronizing with the clock signal input to the terminal

IC4-Pin3 (DI) is the serial data input terminal. IC4-Pin4 (DO) is the

serial data output terminal.

MX-CF10 ELECTRICAL SECTION 9 - 7

Page 26

(7) Inrush Current Limiting Circuit

Operator Panel

Inserter Cover Open/close Switch

This circuit limits an inrush current flowing into the regeneration capacitor included in the motor drive system to a certain value or less. The

circuit consists of the PTC thermistor (PTH2) that limits a current and

the FET (Q11) that allows a steady current flowing.

When the inserter cover open/close switch is closed, the cathode voltage of ZD1 starts rising to the zener voltage according to the time constant of R55 and C46. During the rise of the cathode voltage, Q11 is off

because no base current to Q10 keeps Q10 off, and then a current

flows to PTH2 to charge the regeneration capacitor.

(8) Operator Panel Drive Circuit

After the regeneration capacitor is fully charged, and the cathode voltage of ZD1 reaches over the zener voltage according to the time constant of R55 and C46, Q11 is turned on because the base current from

ZD1 to Q10 turns Q10 on. And then the current flows to Q11 instead of

PTH2 to release the current limitation. The circuit consisting of PTH1

and D3 is intended to eliminate the electric charge accumulated in C46

immediately to limit an inrush current generated by momentary opening and shutting of the cover.

This circuit includes the input circuits of the switches on the operator

panel and the drive circuits of the LEDs.

The circuits connected to CN15-Pin1, 2, 3 are the input circuits of the

switches on the operator panel. The input signal from the switch goes

"L" when the switch is on, "H" when off.

The circuits connected to CN15-Pin4,6-11 are the drive circuits of the

LEDs on the operator panel. The LED lights when the signal is "H",

does not light when "L".

MX-CF10 ELECTRICAL SECTION 9 - 8

Page 27

(9) Operator Panel Circuit

This is the circuit of the operator panel board.

The operator panel drive board turns each of the LED1-6 on or off, and

detects weather each of the PSW1-3 is on or off.

MX-CF10 ELECTRICAL SECTION 9 - 9

Page 28

Page 29

Page 30

SHARP CORPORATION

Business Solutions Group

CS Promotion Center

Yamatokoriyama, Nara 639-1186, Japan

2010 February Printed in Japan

Trademark acknowledgements

COPYRIGHT

2010 BY SHARP CORPORATION

All rights reserved.

Printed in Japan.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted,

in any form or by any means,

electronic; mechanical; photocopying; recording or otherwise

without prior written permission of the publisher.

Microsoft

®

Windows® operating system is a trademark or copyright of Microsoft

Corporation in the U.S.A. and other countries.

Windows

®

95, Windows®

98, Windows® Me, Windows NT®

4.0, Windows® 2000,

Windows®

XP, Windows®

Vista, Windows®

2000 Server, Windows®

Server 2003

and

Internet Explorer®

are trademarks or copyrights of Microsoft Corporation

in the

U.S.A. and other countries.

IBM and PC/AT are trademarks of International Business Machines Corporation.

Acrobat

®

Reader Copyright® 1987-2002 Adobe Systems Incorporated. All rights

reserved. Adobe, the Adobe logo, Acrobat, and the Acrobat logo are trademarks

of Adobe Systems Incorporated.

All other trademarks and copyrights are the property of their respective owners.

Loading...

Loading...