In the absence of confirmation by device specification sheets, SHARP takes no responsibility for any defects that may occur in equipment using any SHARP devices shown in

catalogs, data books, etc. Contact SHARP in order to obtain the latest device specification sheets before using any SHARP device.

1

DESCRIPTION

The LZ2416J is a 1/4-type (4.5 mm) solid-state

image sensor that consists of PN photo-diodes and

CCDs (charge-coupled devices) driven by dualpower-supply . With approximately 270 000 pixels

(542 horizontal x 492 vertical), the sensor provides a

stable high-resolution B/W normal or mirror image.

FEATURES

• Number of effective pixels : 512 (H) x 492 (V)

• Number of optical black pixels

– Horizontal : 2 front and 28 rear

• Pixel pitch : 7.2 µm (H) x 5.6 µm (V)

• Low fixed-pattern noise and lag

• No burn-in and no image distortion

• Blooming suppression structure

• Built-in output amplifier

• Built-in pulse mix circuit

• Variable electronic shutter (1/60 to 1/10 000 s)

• Normal or mirror image output available from

common output pin

• Compatible with EIA standard

• Package :

14-pin half-pitch WDIP [Plastic]

(WDIP014-P-0400A)

Row space : 10.16 mm

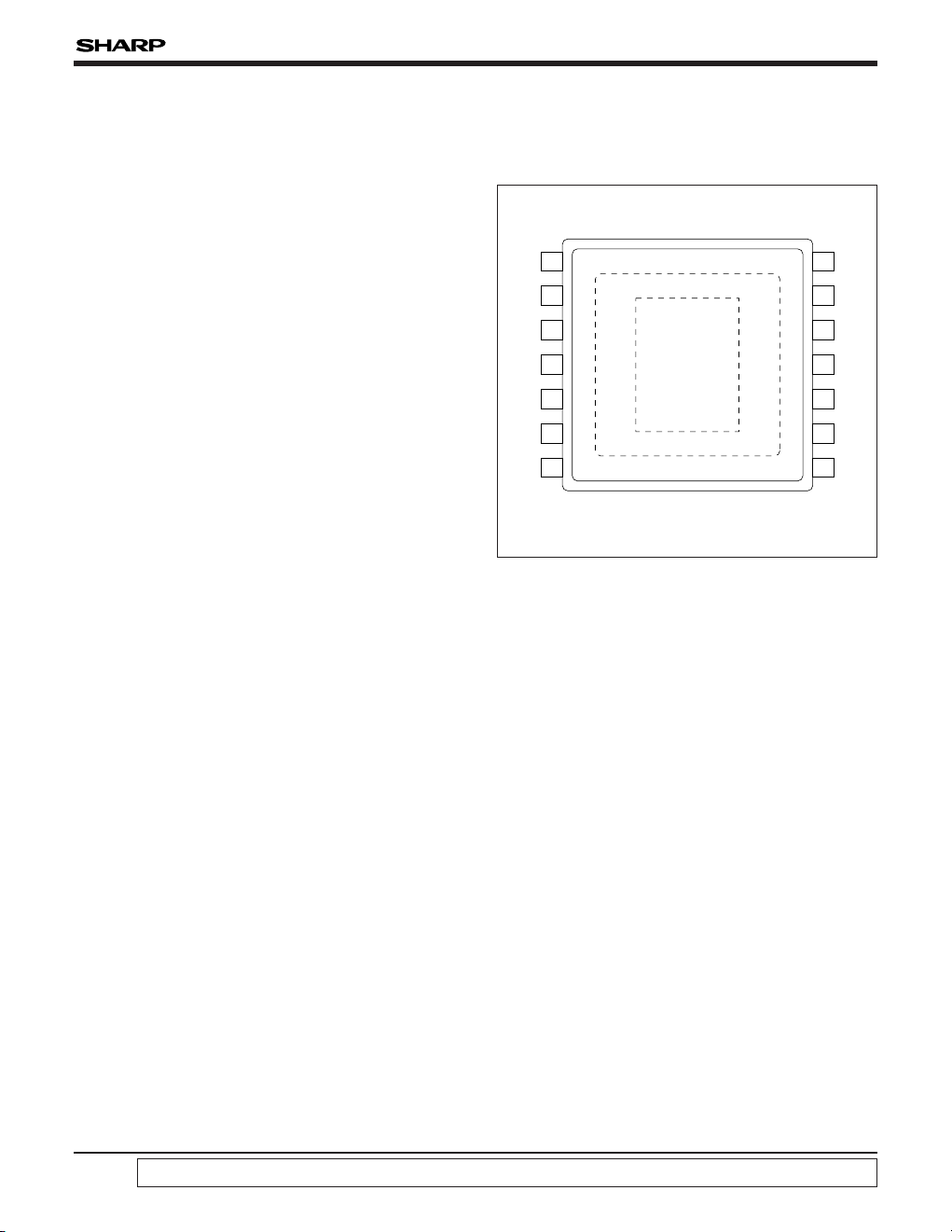

PIN CONNECTIONS

PRECAUTIONS

• The exit pupil position of lens should be more

than 20 mm from the top surface of the CCD.

• Refer to "PRECAUTIONS FOR CCD AREA

SENSORS" for details.

LZ2416J

Dual-power-supply (5 V/12 V) Operation

1/4-type B/W CCD Area Sensor with 270 k Pixels

LZ2416J

1ØRS

2GND

3OS

4OD

5Ø

H2B

6ØH2

7ØH1B

14

13

12

11

10

9

8

OFD

Ø

TG

ØV2

ØV1

ØV4

ØV3

ØH1

14-PIN HALF-PITCH WDIP

TOP VIEW

(WDIP014-P-0400A)

LZ2416J

2

PIN DESCRIPTION

SYMBOL PIN NAME

OD Output transistor drain

OS Output signals

ØRS Reset transistor clock

Ø

V1, ØV2, ØV3, ØV4 Vertical shift register clock

ØH1, ØH2, ØH1B, ØH2B Horizontal shift register clock

OFD Overflow drain

GND Ground

Transfer gate clockØ

TG

1

NOTE

NOTE :

1. ØV1-ØV4 : Input the clock through a 0.1 µF capacitor.

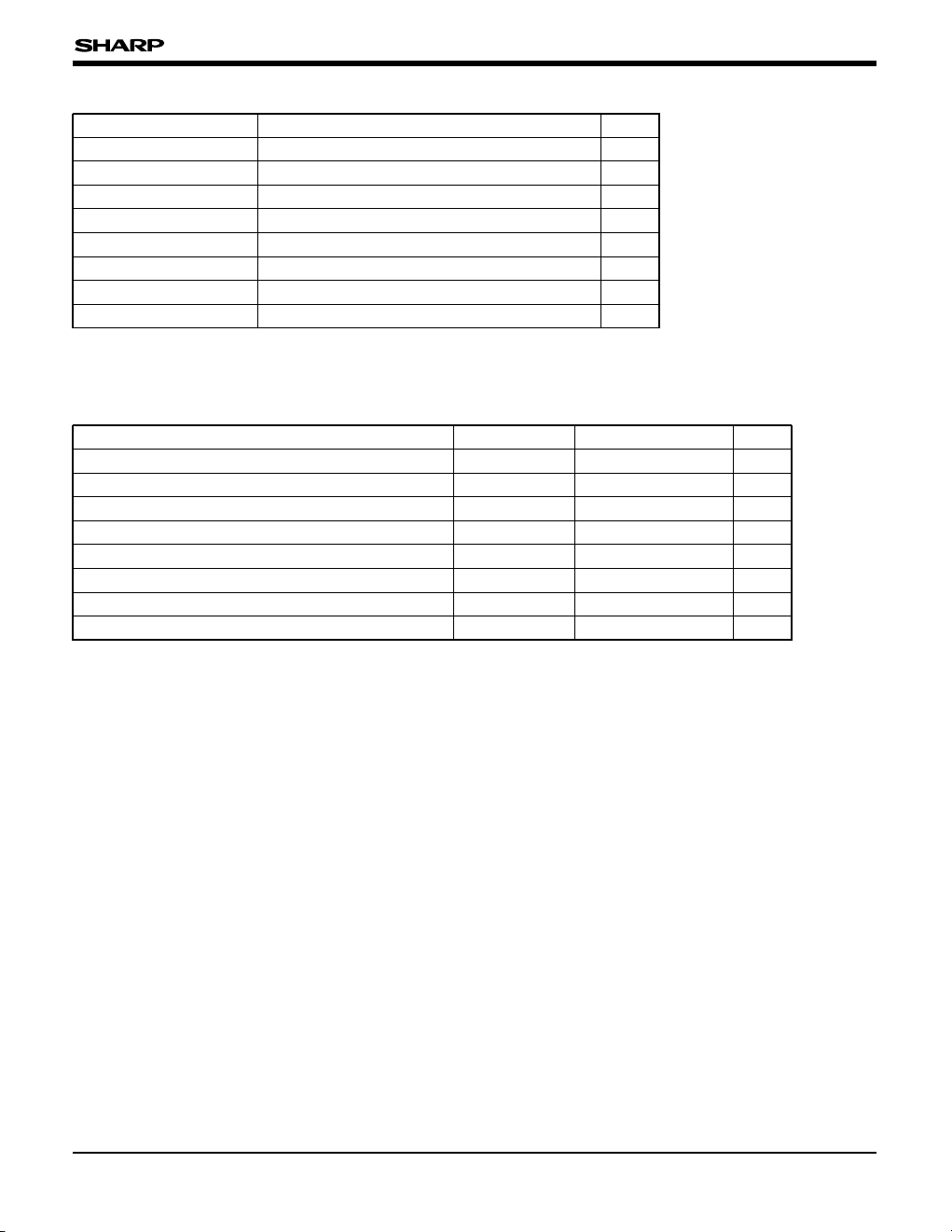

ABSOLUTE MAXIMUM RATINGS (TA = +25 ˚C)

PARAMETER SYMBOL RATING UNIT

Output transistor drain voltage V

OD 0 to +15 V

Overflow drain voltage

V

ØRS –0.3 to +15

V

Reset gate clock voltage

VØV 0 to +7.5 VVertical shift register clock voltage

V

ØH –0.3 to +7.5 VHorizontal shift register clock voltage

VØTG –0.3 to +15 VTransfer gate clock voltage

V

OFD 0 to +30

V

Storage temperature T

STG –40 to +85 ˚C

Ambient operating temperature TOPR –20 to +70 ˚C

LZ2416J

3

RECOMMENDED OPERATING CONDITIONS

PARAMETER SYMBOL MIN. TYP. MAX. UNIT NOTE

Ambient operating temperature T

OPR 25.0 ˚C

Output transistor drain voltage V

OD 12.0 12.5 13.0 V

Ground GND 0.0 V

Horizontal shift

register clock

LOW level

V

ØH1L, VØH2L

VØH1BL, VØH2BL

–0.05 0.0 0.05 V

HIGH level

V

ØH1H, VØH2H

VØH1BH, VØH2BH

4.7 5.0 5.5 V

Reset gate clock

LOW level V

ØRSL 0.0

Vertical shift register clock frequency

f

ØV1, fØV2

fØV3, fØV4

15.73 kHz

Horizontal shift register clock frequency

f

ØH1, fØH2

fØH1B, fØH2B

9.53 MHz

Reset gate clock frequency f

ØRS 9.53 MHz

NOTES :

1. When DC voltage is applied, shutter speed is 1/60-second.

2. When pulse is applied, shutter speed is less than 1/60-second.

3.

* To apply power, first connect GND and then turn on V

OD and then turn on other powers and pulses. Do not connect the

device to or disconnect it from the plug socket while power is being applied.

1V12.02.7VOFDOverflow drain

voltage

V0.050.0–0.05V

ØTGLTransfer gate

clock

LOW level

HIGH level VØTGH 12.0 12.5 13.0 V

p-p level

Vertical shift

register clock

V

ØV1, VØV2

VØV3, VØV4

4.7 5.0 5.5 V

When DC is applied

VOD– 9.0

V

3ns18.013.08.0tw

1, tw2Horizontal shift register clock phase

ØH1, ØH2

ØH1B, ØH2B : Normal image output mode

Ø

H1B, ØH2B : Mirror image output mode

tw1 tw2

When pulse is applied p-p level

VØOFD 12.0 12.5 13.0 V 2

V9.5

VOD– 4.5

VØRSHHIGH level

LZ2416J

4

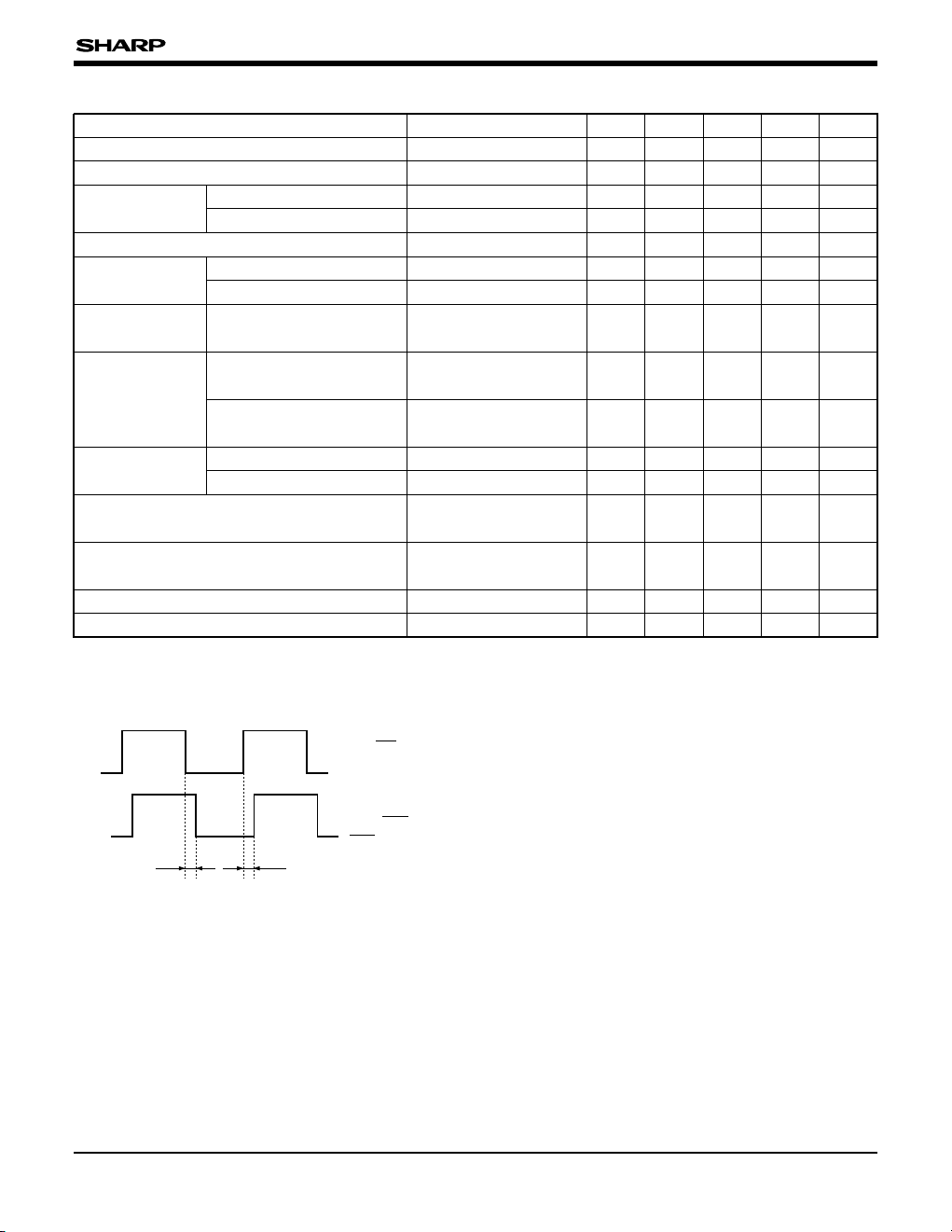

CHARACTERISTICS (Drive method : Field accumulation)

(T

A = +25 ˚C, Operating conditions : The typical values specified in "

RECOMMENDED OPERATING CONDITIONS

".

Color temperature of light source : 3 200 K, IR cut-off filter (CM-500, 1 mmt) is used.)

PARAMETER SYMBOL MIN. TYP. MAX. UNIT NOTE

Standard output voltage V

O 150 mV 2

Photo response non-uniformity PRNU 15 % 3

Saturation output voltage V

SAT 500 mV 4

Dark output voltage V

DARK 0.5 mV 1, 5

Dark signal non-uniformity DSNU 0.5 mV 1, 6

Sensitivity R 450 mV 7

Smear ratio SMR –84 dB 8

Image lag AI 1.0 % 9

Blooming suppression ratio ABL 1 000 10

Output transistor drain current I

OD 4.0 8.0 mA

Output impedance RO 400 $

NOTES :

•VOFD should be adjusted to the minimum voltage such

that ABL satisfy the specification, or to the value

displayed on the device.

1. T

A = +60 ˚C

2. The average output voltage under uniform illumination.

The standard exposure conditions are defined as when

Vo is 150 mV.

3. The image area is divided into 10 x 10 segments under

the standard exposure conditions. Each segment's

voltage is the average output voltage of all pixels within

the segment. PRNU is defined by (Vmax – Vmin)/Vo,

where Vmax and Vmin are the maximum and minimum

values of each segment's voltage respectively.

4. The image area is divided into 10 x 10 segments. Each

segment's voltage is the average output voltage of all

pixels within the segment. V

SAT is the minimum

segment's voltage under 10 times exposure of the

standard exposure conditions.

5. The average output voltage under non-exposure

conditions.

6. The image area is divided into 10 x 10 segments under

non-exposure conditions. DSNU is defined by (Vdmax –

Vdmin), where Vdmax and Vdmin are the maximum and

minimum values of each segment's voltage respectively.

7. The average output voltage when a 1 000 lux light

source with a 90% reflector is imaged by a lens of F4,

f50 mm.

8. The sensor is exposed only in the central area of V/10

square with a lens at F4, where V is the vertical image

size. SMR is defined by the ratio of the output voltage

detected during the vertical blanking period to the

maximum output voltage in the V/10 square.

9. The sensor is exposed at the exposure level

corresponding to the standard conditions. AI is defined

by the ratio of the output voltage measured at the 1st

field during the non-exposure period to the standard

output voltage.

10. The sensor is exposed only in the central area of V/10

square, where V is the vertical image size. ABL is

defined by the ratio of the exposure at the standard

conditions to the exposure at a point where blooming is

observed.

LZ2416J

5

PIXEL STRUCTURE

TIMING CHART

512 (H) x 492 (V)

1 pin

OPTICAL BLACK

(2 PIXELS)

OPTICAL BLACK

(28 PIXELS)

484

+

485

486

+

487

488

+

489

492

490

+

491

1

+

2

3

+

4

5

+

6

7

+

8

9

+

10

11

+

12

OS

Ø

TG

ØV4

ØV3

ØV2

ØV1

VD

HD

(ODD FIELD)

VERTICAL TRANSFER TIMING <NORMAL OUTPUT>

483

+

484

485

+

486

487

+

488

489

+

490

491

+

492

2

+

3

1

4

+

5

6

+

7

8

+

9

10

+

11

OS

Ø

TG

ØV4

ØV3

ØV2

ØV1

VD

HD

(EVEN FIELD)

525 1 10 17 19

263 272 279 282

LZ2416J

6

OS

Ø

RS

ØH2

ØH1

HD

OB (28)

OB (2)

ØOFD

ØV4

ØV3

ØV2

ØV1

HORIZONTAL TRANSFER TIMING <NORMAL OUTPUT>

606, 1

84.5

60

24

24

49

39

54

29

34

62 72

PRE SCAN (4)

...

512

59

64

ØV4

ØTG

ØV3

ØV2

ØV1

HD

(ODD FIELD)

(EVEN FIELD)

READOUT TIMING <NORMAL OUTPUT>

ØV4

ØTG

ØV3

ØV2

ØV1

HD

1

24

60

29

39

54

6434

59

49

60

1

29

39

24

60

54

6434

59

49

60

338242

25.36 µs (242 bits)

25.36 µs (242 bits)

63.5 µs (606 bits)

63.5 µs (606 bits)

338242

10.06 µs (96 bits)

606, 1

606, 1

10.06 µs (96 bits)

OUTPUT (512) 1

ππππππππππ

LZ2416J

7

482

+

483

484

+

485

486

+

487

490

+

491

492

488

+

489

1

+

2

3

+

4

5

+

6

7

+

8

9

+

10

OS

Ø

TG

ØV4

ØV3

ØV2

ØV1

VD

HD

(ODD FIELD)

VERTICAL TRANSFER TIMING <MIRROR OUTPUT>

481

+

482

483

+

484

485

+

486

487

+

488

489

+

490

491

+

492

2

+

3

1

4

+

5

6

+

7

8

+

9

OS

Ø

TG

ØV4

ØV3

ØV2

ØV1

VD

HD

(EVEN FIELD)

525 1 10 17 19

263 272 279 282

OS

Ø

RS

ØH2

ØH1

HD

OUTPUT (512) 512

ππππππππππ

ØOFD

ØV4

ØV3

ØV2

ØV1

HORIZONTAL TRANSFER TIMING <MIRROR OUTPUT>

606, 1

58.5

60

4

4

29

19

34

9

14

42 52

PRE SCAN (4)

ππππ

1

39

OB (2)

OB (28)

44

LZ2416J

8

ØV4

ØTG

ØV3

ØV2

ØV1

HD

(ODD FIELD)

(EVEN FIELD)

READOUT TIMING <MIRROR OUTPUT>

ØV4

ØTG

ØV3

ØV2

ØV1

HD

1

4

60

29

39

34

4414

19

9

60

1

9

19

4

60

34

4414

39

29

60

318222

23.27 µs (222 bits)

23.27 µs (222 bits)

63.5 µs (606 bits)

318222

10.06 µs (96 bits)

606, 1

606, 1

10.06 µs (96 bits)

63.5 µs (606 bits)

LZ2416J

9

SYSTEM CONFIGURATION EXAMPLE

ØH1

ØV1

ØV4

ØRS

GND

Ø

V3

OFD

Ø

H1B

ØH2

ØH2B

OD

OS

Ø

TG

ØV2

CCD

OUT

2SC4627

2SC4716

1 k$

10 $

1 M$

68 $

1000 pF

390 $

20 k$

22 k$

2.2 k$

0.1 µF

0.1 µF

0.1 µF

0.1 µF

0.1 µF

8910111213

(*1)

14

7654321

LZ2416J

VOD

ØRS

VCC

OFD

TGX

Ø

H2

ØH1B

ØH1

ØH2B

ØV4

ØV1

ØV3

ØV2

(*1) ØV1-ØV4 : Input the clock through a

0.1 µF capacitor.

• Example of drive circuit with LR38580 driver IC.

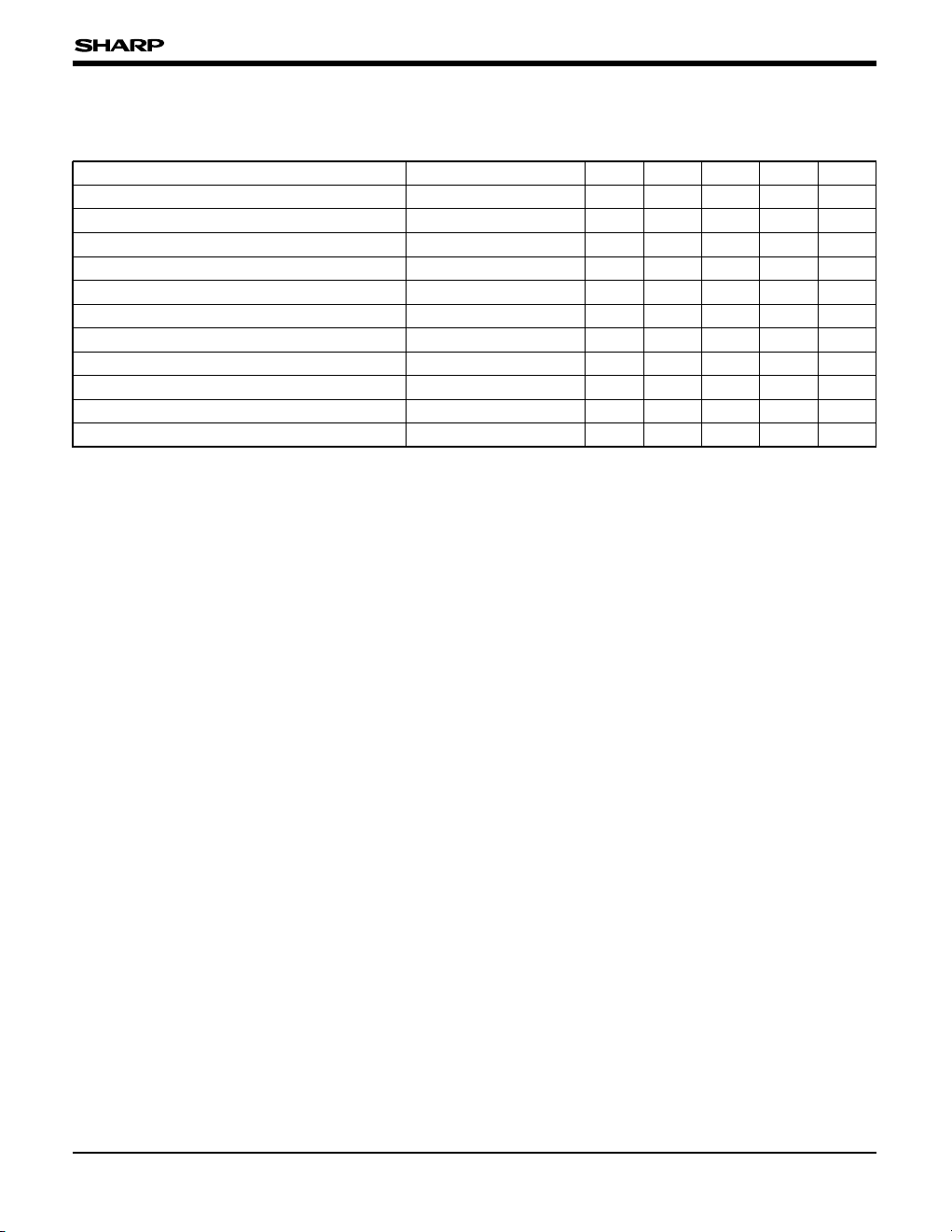

PACKAGES FOR CCD AND CMOS DEVICES

10

¬

(◊ : Lid's size)

10.00

±0.10

0.50

±0.50

0.50

±0.50

10.00

±0.10

0.25

±0.10

9.00

±0.10

(◊)

10.16

5.00

±0.075

5.00

±0.075

CCD

17

814

0.03

0.03

1.39

±0.05

1.96

±0.05

9.00

±0.10

(◊)

Package

Glass Lid

CCD

Rotation error of die : ¬= 1.0˚

MAX.

Center of effective imaging area

and center of package

Cross section A-A'

3.50

±0.30

1.27

±0.25

2.55

±0.10

0.30

TYP.

0.46

TYP.

P-1.27

TYP.

5.02

MAX.

3.35

±0.10

A'

A

0.80

±0.05

(◊)

M0.25

+0.5

–0

PACKAGE (Unit : mm)

14 WDIP (WDIP014-P-0400A)

PRECAUTIONS FOR CCD AREA SENSORS

1. Package Breakage

In order to prevent the package from being broken,

observe the following instructions :

1) The CCD is a precise optical component and

the package material is ceramic or plastic.

Therefore,

ø Take care not to drop the device when

mounting, handling, or transporting.

ø Avoid giving a shock to the package.

Especially when leads are fixed to the socket

or the circuit board, small shock could break

the package more easily than when the

package isn’t fixed.

2) When applying force for mounting the device or

any other purposes, fix the leads between a

joint and a stand-off, so that no stress will be

given to the jointed part of the lead. In addition,

when applying force, do it at a point below the

stand-off part.

(In the case of ceramic packages)

– The leads of the package are fixed with low

melting point glass, so stress added to a

lead could cause a crack in the low melting

point glass in the jointed part of the lead.

(In the case of plastic packages)

– The leads of the package are fixed with

package body (plastic), so stress added to a

lead could cause a crack in the package

body (plastic) in the jointed part of the lead.

3) When mounting the package on the housing,

be sure that the package is not bent.

– If a bent package is forced into place

between a hard plate or the like, the package may be broken.

4) If any damage or breakage occurs on the surface of the glass cap, its characteristics could

deteriorate.

Therefore,

ø Do not hit the glass cap.

ø Do not give a shock large enough to cause

distortion.

ø Do not scrub or scratch the glass surface.

– Even a soft cloth or applicator, if dry, could

cause dust to scratch the glass.

2. Electrostatic Damage

As compared with general MOS-LSI, CCD has

lower ESD. Therefore, take the following anti-static

measures when handling the CCD :

1) Always discharge static electricity by grounding

the human body and the instrument to be used.

To ground the human body, provide resistance

of about 1 M$ between the human body and

the ground to be on the safe side.

2) When directly handling the device with the

fingers, hold the part without leads and do not

touch any lead.

Glass cap

Package

Lead

Fixed

Stand-off

Fixed

Lead

Stand-off

Low melting point glass

11

PRECAUTIONS FOR CCD AREA SENSORS

3) To avoid generating static electricity,

a. do not scrub the glass surface with cloth or

plastic.

b. do not attach any tape or labels.

c. do not clean the glass surface with dust-

cleaning tape.

4) When storing or transporting the device, put it in

a container of conductive material.

3. Dust and Contamination

Dust or contamination on the glass surface could

deteriorate the output characteristics or cause a

scar. In order to minimize dust or contamination on

the glass surface, take the following precautions :

1) Handle the CCD in a clean environment such

as a cleaned booth. (The cleanliness level

should be, if possible, class 1 000 at least.)

2) Do not touch the glass surface with the fingers.

If dust or contamination gets on the glass

surface, the following cleaning method is

recommended :

ø Dust from static electricity should be blown

off with an ionized air blower. For antielectrostatic measures, however, ground all

the leads on the device before blowing off

the dust.

ø The contamination on the glass surface

should be wiped off with a clean applicator

soaked in Isopropyl alcohol. Wipe slowly and

gently in one direction only.

– Frequently replace the applicator and do not

use the same applicator to clean more than

one device.

◊ Note : In most cases, dust and contamination

are unavoidable, even before the device

is first used. It is, therefore, recommended

that the above procedures should be

taken to wipe out dust and contamination

before using the device.

4. Other

1) Soldering should be manually performed within

5 seconds at 350 °C maximum at soldering iron.

2) Avoid using or storing the CCD at high temperature or high humidity as it is a precise

optical component. Do not give a mechanical

shock to the CCD.

3) Do not expose the device to strong light. For

the color device, long exposure to strong light

will fade the color of the color filters.

12

PRECAUTIONS FOR CCD AREA SENSORS

Loading...

Loading...