Page 1

TopPage

JAPAN KIT ( VER.1 )

SERVICE MANUAL

No. SX5M78LC-505865U35T

LCD COLOR TELEVISION

CONTENTS

SAFETY PRECAUTION

SAFETY PRECAUTION......................................i

CHAPTER 1. OUTLINE

[1] OUTLINE........................................................ 1-1

CHAPTER 2. SPECIFICATIONS

[1] SPECIFICATIONS ........................................ 2-1

CHAPTER 3. OPERATION MANUAL

[1] OPERATION MANUAL .................................. 3-1

CHAPTER 4. DIMENSIONS

[1] DIMENSIONS ............................................... 4-1

MODEL:

LC-50U35T

LC-58U35T

LC-65U35T

[2] MAIN UNIT ................................................... 9-2

[3] MAIN UNIT ( POWER ) ...............................9-14

[4] LED IR UNIT ...............................................9-15

Parts Guide

CHAPTER 5. ADJUSTMENT

[1] ADJUSTMENT .............................................. 5-1

CHAPTER 6. TROUBLESHOOTING TABLE

[1] TROUBLESHOOTING TABLE ....................... 6-1

CHAPTER 7. MAJOR IC INFORMATION

[1] MAJOR IC INFORMATION ........................... 7-1

CHAPTER 8. OVERALL WIRING /SYSYTEM BLOCK

DIAGRAM/PRINTED WIRING BOARD

[1] OVERALL WIRING/SYSYTEM BLOCK DI-

AGRAM ......................................................... 8-1

[2] PRINTED WIRING BOARD SIDE A / SIDE

B..................................................................... 8-3

CHAPTER 9. DESCRIPTION OF SCHEMATIC DIAGRAM

[1] DESCRIPTION OF SCHEMATIC................... 9-1

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the

safety and performance of the set.

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

LC50/58/65U35T

i

SAFETY PRECAUTION

SAFETY PRECAUTION

IMPORTANT SERVICE SAFETY PRECAUTION

WARNING

1. For continued safety, no modification of any circuit should be

attempted.

2. Disconnect AC power before servicing.

BEFORE RETURNING THE RECEIVER (Fire &

Shock Hazard)

Before returning the receiver to the user, perform the following

safety checks:

3. Inspect all lead dress to make certain that leads are not pinched,

and check that hardware is not lodged between the chassis and

other metal parts in the receiver.

4. Inspect all protective devices such as non-metallic control knobs,

insulation materials, cabinet backs, adjustment and compartment

covers or shields, isolation resistor-capacitor networks, mechanical

insulators, etc.

5. To be sure that no shock hazard exists, check for leakage current

in the following manner.

• Plug the AC cord directly into a 120 volt AC outlet.

• Using two clip leads, connect a 1.5k ohm, 10 watt resistor paralleled by a 0.15PF capacitor in series with all exposed metal cabinet

parts and a known earth ground, such as electrical conduit or electrical ground connected to an earth ground.

• Use an AC voltmeter having with 5000 ohm per volt, or

higher, sen-

sitivity or measure the AC voltage drop across the resistor.

• Connect the resistor connection to all exposed metal parts having a

return to the chassis (antenna, metal cabinet, screw heads, knobs

and control shafts, escutcheon, etc.) and measure the AC voltage

drop across the resistor.

All checks must be repeated with the AC cord plug connection

reversed. (If necessary, a nonpolarized adaptor plug must be used

only for the purpose of completing these checks.)

Any reading of 0.75 Vrms (this corresponds to 0.5 mA rms AC.) or

more is excessive and indicates a potential shock hazard which

must be corrected before returning the monitor to the owner.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

SAFETY NOTICE

Many electrical and mechanical parts in LCD color television have

special safety-related characteristics.

These characteristics are often not evident from visual inspection, nor

can protection afforded by them be necessarily increased by using

replacement components rated

for higher voltage, wattage, etc.

Replacement parts which have these special safety characteristics are

identified in this manual; electrical components having such features

are identified by " " and shaded areas in the Replacement Parts List

and Schematic Diagrams.

For continued protection, replacement parts must be identical to those

used in the original circuit.

The use of a substitute replacement parts which do not have the same

safety characteristics as the factory recommended replacement parts

shown in this service manual, may create shock, fire or other hazards.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Service work should be performed only by qualified service technicians who are thoroughly familiar with all safety checks and the

servicing guidelines which follow:

CAUTION: F O R CO NT IN UE D PROTECTION

AGAINST A RISK OF FIRE REPLACE ONLY WITH

SAME TYPE FUSE.

F7001

(LC-65/58/50U35T :250V 5A)

DVM

AC SCALE

1.5k ohm

10W

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

0.15µF

TEST PROBE

Page 3

LC50/58/65U35T

ii

PRECAUTIONS FOR USING LEAD-FREE SOLDER

Employing lead-free solder

• “PWBs” of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on the PWBs and service manuals. The

alphabetical character following LF shows the type of lead-free solder.

Example:

Using lead-free wire solder

• When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 qC, we recommend you to use a dedicated soldering

bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit, contact our service station or service branch in your area.

Soldering

• As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 qC which is higher than the conventional lead solder by 40 qC, and as it has poor

solder wettability, you may be apt to keep the soldering bit in contact with the PWB for extended period of time. However, Since the land may be

peeled off or the maximum heat-resistance temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the

steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on and off the power of the bit as

required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

• Be careful when replacing parts with polarity indication on the PWB silk.

L

ead-free wire solder for servicing

Indicates lead-free solder of tin, silver and copper. Indicates lead-free solder of tin, silver and copper.

PARTS CODE

PRICE

RANK

PART

DELIVERY

DESCRIPTION

ZHNDAi123250E BL J I0.3mm 250g (1roll)

ZHNDAi126500E BK J I0.6mm 500g (1roll)

ZHNDAi12801KE BM J I1.0mm 1kg (1roll)

Page 4

LC50/58/65U35T

1 – 1

CHAPTER 1. OUTLINE

[1] OUTLINE

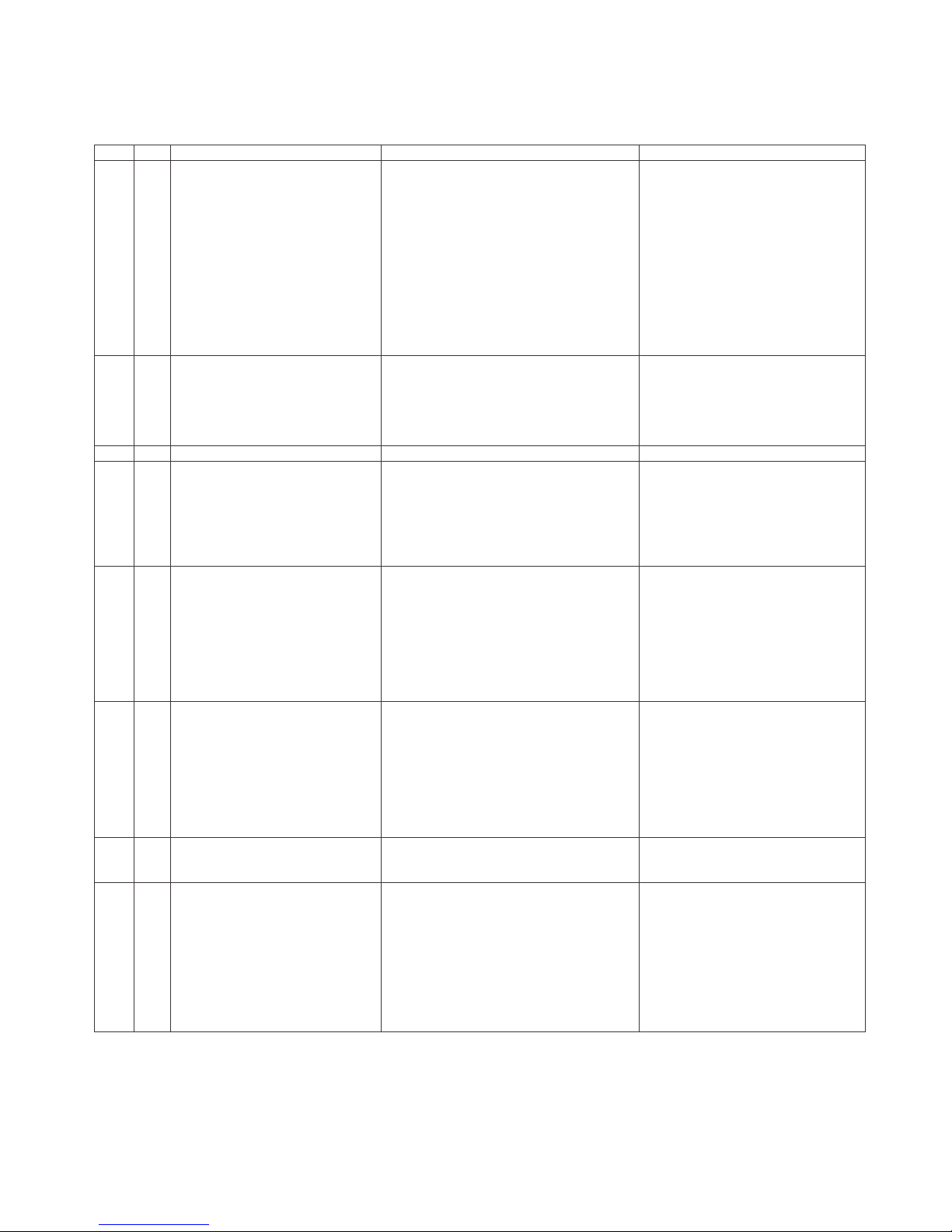

MAJOR SERVICE PARTS

Ref.No

LC-65U35T

Note

N

DKEYMG506FEG1

N

RDENCA493WJN1

N

DUNTKG448FEG1

N

DUNTKG447FEG2

N

RUNTKB330WJQZ

N

QANTZA020WJQZ

N

RLCUCA143WJZZ

BT ANTENNA ZQJW020AZTNAQZQJW020AZTNAQTINU

LCD PANEL MODULE UNIT

LCD PANEL MODULE UNIT RLCUCA152WJZZ RLCUCA155WJZZ

LED / IR UNIT DUNTKG447FEG2 DUNTKG447FEG2

WiFi/BT ZQJW033BKTNURZQJW033BKTNURTINU

POWER UNIT RDENCA491WJN1 RDENCA491WJN1

KEY UNIT DUNTKG448FEG1 DUNTKG448FEG1

ĞƐĐƌŝƉƟŽŶ LC-50U35T LC-58U35T

PRINTED WIRING BOARD ASSEMBLIES

MAIN UNIT DKEYMG506FEG3 DKEYMG506FEG2

Page 5

LC50/58/65U35T

2 – 1

CHAPTER 2. SPECIFICATIONS

[1] SPECIFICATIONS

規格

項目 型號 LC-50U35T LC-58U35T LC-65U35T

mc461mc641mc621器示顯晶液

解析度

8,294,400像素(3840 g2160)

06LAP/34.4CSTN/85.3CSTN/MACES/LAP式模色彩頻視

電視功能 電視標準 類比 NTSC:M

數位 DVB-T

接收頻道 類比VHF/UHF 44.25863.25MHz

數位UHF 470806MHz

hc531設預動自統系諧調視電

統系CSTB語雙/聲體立

音頻放大器

10Wg2

端子 (無線電視/有線電視)ANT(天線輸入)

UHF/VHF/CATV75qF型

頭接公nip9buS-DC232-SR

輸入1(ARC)HDMI HDMI(HDMI輸入),ARC

輸入2(MHL)HDMI HDMI(HDMI輸入),MHL

入輸頻音,)入輸IMDH(IMDHIMDH3入輸

)入輸IMDH(IMDHIMDH4入輸

輸入5 音頻輸入,視頻輸入,色差輸入(480I,576I,480P,576P,720P/50Hz,

720P/60Hz,1080I/50Hz,1080I/60Hz)

BSU1BSU

BSU2BSU

BSU)碟硬(3BSU

卡存內CHDS/DSCHDS/DS

*1

乙太網絡(10/100BASE-T) 網路接頭

聲音輸入(HDMI3)

3.5 毫米立體聲插孔(音頻輸入)

出輸頻音位數FIDP/S學光出輸音聲位數

輸出/耳機

3.5毫米插孔(音頻輸出)

螢幕顯示語言 英文(美國)/英文(英國)/中文(繁體)

zH06、V011CA求要源電

功率消耗

171W(待機時0.5W) 200W(待機時0.5W) 239W(待機時0.6W)

尺寸 不包含台座

1123 (寬) g 656 (高)

g82(深)mm

1298 (寬) g 763 (高)

g85(深)mm

1457 (寬) g 847 (高)

g65(深)mm

包含台座

1123 (寬) g 685 (高)

g305(深)mm

1298 (寬) g 789 (高)

g305(深)mm

1457 (寬) g 882 (高)

g374(深)mm

)gk5.93(gk5.63)gk03(gk82)gk42(gk22)座支括包(座支括包不量重

操作溫度

0°C到 e40°C

I

如果插入的卡不是SD/SDHC(6級或以上),則無法工作。

• 作為不斷改進產品效能的方針,SHARP公司保留權利,在不需事先通知的情況下,為提升產品而改變設計與規格。所示之效能規

格指標,為生產本機之標準。個別機器之指標不見得能完全符合此標準。

注意

• 安裝液晶電視需要專業技術,因此必須由合格的維修人員進行。顧客不應自己嘗試進行。對於不正確的安裝,或是由於安裝引起

的事故或傷害,SHARP不承擔任何責任。

• 在開始操作之前,請先仔細閱讀托架隨附的使用說明書。

Page 6

LC50/58/65U35T

3 – 1

CHAPTER 3. OPERATION MANUAL

[1] OPERATION MANUAL

連接台座單位

HLC-58U35T 和LC-50U35T

1

2

支座

1

角板

3

螺絲

LC-50U35T

LC-58U35T

HLC-65U35T

1

3

螺絲

2

支座

1

角板

2

4

軟墊

5

5

3

6

短螺絲

Page 7

LC50/58/65U35T

4 – 1

CHAPTER 4. DIMENSIONS

[1] DIMENSIONS

/ Dimensional Drawing

LC-50U35T

Unit : mm

300

1123

1103*

1

973

622*

1

646

685

82*

3

61*

2

300

137

305

656

LC-58U35T

Unit : mm

400

400

1298

85*

3

135

305

69*

2

1275.3*

1

1089

726.7*

1

763

753

789

Page 8

LC50/58/65U35T

4 – 2

/ Dimensional Drawing

LC-65U35T

Unit : mm

400

400

1457

65*

3

53*

2

1432.3*

1

882

847

836

1341

162

374

807.3*

1

*1

有效區域

*2

最薄的零件

*3

包含突出部份

註

• 尺寸並未包含突出物,如螺絲和某些零件。

*1

Active area

*2

Thinnest part

*3

Including projecting parts

NOTE

• Dimensions do not include protrusions such as screws and

some parts.

Page 9

LC50/58/65U35T

5 – 1

CHAPTER 5. ADJUSTMENT

[1] ADJUSTMENT

[1] ADJUSTMENT PROCEDURE

The adjustment values are set to the optimum conditions at the factory before shipping. If a value should become improper or an adjustment is

required due to part replacement, make an adjustment according to the following procedure.

1. After replacement of any PWB unit and/or IC for repair, please note the following.

x When replacing the following units, make sure to prepare the new units loaded with updated software.

x

When replacing the LCD control PWB, perform the VCOM adjustment.

2. Upgrading of each microprocessor software

CAUTION: Never “POWER OFF” the unit when software upgrade is ongoing.

Otherwise the system may be damaged beyond recovery.

2.1. Software version upgrade

The model employs the following software.

• Main software (please use a software version after upgrade_loader_Malacca_XXXXX.pkg

The main software can be upgraded by using a general-purpose USB Memory.

The followings are the procedures for upgrading, main software can be upgraded as the same time.

2.2. Main software version upgrade

2.2.1 Get ready before you start

• USB Memory of 1GB or higher capacity.

• PC running on Windows 98/98SE/ME/2000/XP/Vista/Win7/Win8 operating system.

• USB Memory reader/writer or PC with a USB port.

• The file system of a USB memory is FAT. (FAT32 supports)

• Use the USB memory without other functions. (lock and memory reader...etc)

2.2.2 Preparations

To upgrade the main software, it is necessary to get ready the USB Memory for version upgrade before you start.

Follow the steps below and create the USB Memory for version upgrade.

1. Copy the file upgrade_loader_Mealacca_XXXXX.pkg for version upgr ade to the root directory (folder) of the USB Memory.

NOTE: In the USB Memory drive, do not store other folders or unrelated files, or more than one file for version upgrade.

Now the USB Memory for version upgrade is ready.

MAIN Unit: DKEYMG506FEG1 (LC-65U35T )

DKEYMG506FEG2 (LC-58U35T)

DKEYMG506FEG3 (LC-50U35T)

Page 10

LC50/58/65U35T

5 – 2

2.2.3 How to upgrade the software

1. Prepare the following items before working.

USB memory (Copy the file to a USB memory)

AC code

2. Connect USB memory.

* Insert the USB Memory for version upgrade into the service socket (USB2 or USB3 port)

3. Connect AC-code Pushing POWER key

*Upgrade software starts automatically.

*MAIN softwares are written at the same time.

*The upgrade menu is displayed after about 10second.

*Never turn off the power while upgrading.

4. It is completion if displayed, "UPGRADE SUCCESS".

*Check Upgrade condition. "100%"

5. If you failed to upgrade, "E999" is displayed.

6. Disconnect AC Plug and USB memory.

x VerUP LED pattern of USB version UP

Ver UP LED

*Please check the "LED pattern", If you are unable to check the monitor.

*LED pattern detail is please check the "VerUP LED pattern of USB version UP" below.

MAIN Ver CHECK

Case of Ver UP OK Case of Ver UP Error

If you tried upgrade some times but still E999 is displayed,

please give feedback to the service center.

WHITE

Writeing

High

Low

Completion

250ms 250ms

High

Low

Fail

200ms

High

Low

800ms

500ms 500ms

Page 11

LC50/58/65U35T

5 – 3

3. Entering and exiting the adjustment process mode

1) Before entering the adjustment process mode, the AV position RESET in the video adjustment menu.

2) While holding down the “VOL (–)” and “ENTER” keys at a time, plug in the AC cord of the main unit to turn on the power.

The letter “S” appears on the screen.

3) Next, hold down the “VOL (–)” and “CH ( )” keys at a time.

(The “VOL (–)” and “CH ( )” keys should be pressed and held until the display appears.)

Multiple lines of blue characters appearing on the display indicate that the unit is now in the adjustment process mode.

When you fail to enter the adjustment process mode (the display is the same as normal startup), retry the procedure.

4) To exit the adjustment process mode after the adjustment is done, unplug the AC cord from the outlet to make a forced shutdown. (When the

power was turned off with the remote controller, once unplug the AC cord and plug it again. In this case, wait 10 seconds or so before plugging.)

CAUTION: Use due care in handling the information described here lest your users should know how to enter the adjustment process mode. If the

settings are tampered in this mode, unrecoverable system damage may result.

4. Remote controller key operation and description of display in adjustment process mode

1) Key operation

2) Description of display

noitcnuFyek tinu niaMyek rellortnoc etomeR

CH ( / )

CH ( / )

Moving an item (line) by one (UP/DOWN)

VOL (+/–) VOL (+/–) Changing a selected item setting (+1/ –1)

Cursor (UP/DOWN) ————— Turing a page (PREVIOUS/NEXT)

Cursor (LEFT/RIGHT) ————— Changing a selected line setting (+10/ –10)

ENTER ENTER Executing a function

(1) Current page/

Total pages

1/17

09500 LMY47M TEST -KEYNOISREVNIAM

09500

_ _ _

BOOT VERSION

T-CON VERSION

No deviseNOISREVCRF

(2) Parameter

1010001NOISREVWSIMDH

KOyekledomydaeryalPYEKYDAERYALP

0C70D5AF4882VTDCLYEKENIVEDIW

WV SECURESTOP KEY WVSecureStop model key OK

1-RRE

YEKPI-PCTD

511118205ONLAIRES

0C70D5AF4882SSERDDACAM

0RORREPMAL

ERROR STANDBY CAUSE 11 00 00 00

CI + KEY

53-41-01-03-00- 00-00-16

Page 12

LC50/58/65U35T

5 – 4

5. List of adjustment process mode menu

The character string in brackets [ ] will appear as a page title in the adjustment process menu header.

).cte ,liated tnemtsujda( skrameRnoitpircseDmetIeniLegaP

noisrev erawtfos niaMnoisreV NIAM11

2 BOOT VERSION

noisrev erawtfos rellortnoc DCLNOISREV NOC-T3

noisrev WF CRFNOISREV CRF4

5 HDMI SW VERSION

6 PLAYREADY KEY

7 WIDEVINE KEY

8 WV SECURESTOP KEY

YEK CI +9

10 SERIAL NO

11 MAC ADDRESS

rorre pmal ot eud noitanimret fo rebmuNRORRE PMAL21

13 ERROR STANDBY CAUSE

2 1 INDUSTRY INIT Initialization to factory settings

2 BACKLIGHT ACUTIME Accumulated monitor operation time

3 RESET Reset BACKLIGHT TIME

4 LAMP ERROR RESET Reset LAMP ERROR

5 ERROR STAND BY CAUSE RESET Reset ERROR STANDBY CAUSE

6 TIME COUNTER RESET

3 1 VCOM ADJ VCOM adjustment value

4 1 LEV1 Standard value 1 Adjustment gradation setting.

2 LEV2 Standard value 2

3 LEV3 Standard value 3

4 LEV4 Standard value 4

5 LEV5 Standard value 5

6 LEV6 Standard value 6

7 LEV7 Standard value 7

5 1 MG1R WB adjustment Point 1, R adjustment value Parameter for seven-point adjustment

2 MG1G WB adjustment Point 1, G adjustment value

3 MG1B WB adjustment Point 1, B adjustment value

4 MG2R WB adjustment Point 2, R adjustment value

5 MG2G WB adjustment Point 2, G adjustment value

6 MG2B WB adjustment Point 2, B adjustment value

7 MG3R WB adjustment Point 3, R adjustment value

8 MG3G WB adjustment Point 3, G adjustment value

9 MG3B WB adjustment Point 3, B adjustment value

6 1 MG4R WB adjustment Point 4, R adjustment value Parameter for seven-point adjustment

2 MG4G WB adjustment Point 4, G adjustment value

3 MG4B WB adjustment Point 4, B adjustment value

4 MG5R WB adjustment Point 5, R adjustment value

5 MG5G WB adjustment Point 5, G adjustment value

6 MG5B WB adjustment Point 5, B adjustment value

7 MG6R WB adjustment Point 6, R adjustment value

8 MG6G WB adjustment Point 6, G adjustment value

9 MG6B WB adjustment Point 6, B adjustment value

7 1 MG7R WB adjustment Point 7, R adjustment value

2 MG7G WB adjustment Point 7, G adjustment value

3 MG7B WB adjustment Point 7, B adjustment value

8 1 LO 1R WB adjustment Point 1, R adjustment value Parameter for D65 seven-point adjust-

ment

2 LO 1G WB adjustme

nt Point 1, G adjustment value

3 LO 1B WB adjustment Point 1, B adjustment value

4 LO 2R WB adjustment Point 2, R adjustment value

5 LO 2G WB adjustment Point 2, G adjustment value

6 LO 2B WB adjustment Point 2, B adjustment value

7 LO 3R WB adjustment Point 3, R adjustment value

8 LO 3G WB adjustment Point 3, G adjustment value

9 LO 3B WB adjustment Point 3, B adjustment value

Page 13

LC50/58/65U35T

5 – 5

For the system spec, error"0x11" is always recorded after Factory Reset execution. It is not recorded as problem so that please be careul when you

find out.

-tsujda tniop-neves 56D rof retemaraPeulav tnemtsujda R ,4 tnioP tnemtsujda BW4

R

OL19

ment

eulav tnemtsujda G ,4 tnioP tnemtsujda BW4 G OL2

eulav tnemtsujda B ,4 tnioP tnemtsujda BW4 B OL3

eulav tnemtsujda R ,5 tnioP tnemtsujda BW5 R OL4

eulav tnemtsujda G ,5 tnioP tnemtsujda BW5 G OL5

eulav tnemtsujda B ,5 tnioP tnemtsujda

BW5 B OL6

eulav tnemtsujda R ,6 tnioP tnemtsujda BW6 R OL7

eulav tnemtsujda G ,6 tnioP tnemtsujda BW6 G OL8

eulav tnemtsujda B ,6 tnioP tnemtsujda BW6 B OL9

10 1 LO 7R WB adjustment Point 7, R adjustment value Parameter for D65 seven-point adjust-

ment

2 LO 7G WB adjustment Point 7, G adjustment value

3 LO 7B WB adjustment Point 7, B adjustment value

11 1 CD MIN Input parameterfor gamma adjustment

2 CD MID1

3 CD MID2

4 CD MID3

5 CD MID4

6 CD MID5

7 CD MID6

8 CD MID7

9 CD MAX

12 1 VAL1 Parameter for gamma adjustment

2VAL2

3VAL3

4VAL4

5VAL5

6VAL6

7VAL7

8 GAMMA ADJ TEMP

13 1 MONITOR TIME OUT

14 1 LCD TEST PATTERN1

2 LCD TEST PATTERN2

3 TV TEST PATTERN

15 1 DUMMY

16 1 USB BACKUP Save the parameter of WB and Gamma

data as USB data file.

2 USB RESTORE Restore the parameter of WB and

Gamma data from USB data file.

17 1 MODEL Set model name.

2 PANEL SIZE

Set panel size.

3 VOLUME TYPE Set speaker volume type.

Error Standby Cause

Outline: Communication/Power failure detected by the monitor microprocessor is stored in EEPROM, and last 4 abnormal

can be confirmed in the Process mode A.

Location: Page 1 of the process mode A: MONITOR ERR CAUSE. “0” if there is no error. It is cleared to 0 on the last page of

the process mode A.

Display Error description

0x11 Regular communication time-out ---0x16 Backlight error Refer to Troubleshooting Table

0x1A Monitor temperature error - Check TV setting environment.

- Check the other monitor (ref No.)

0x1E DET_13V failure Check 13V power line.

0x1F DET_VCORE failure Check CPU core power line.

0x21 DET_POW_T failure Check T-CON or FRC power line.

Page Line Item Description Remarks (adjustment detail, etc.)

4 DESTINATION Set destination.

Page 14

LC50/58/65U35T

5 – 6

6. Special features

* Error Standby Cause(Page 1/17)

Display of a cause (code) of the last standby

The cause of the last standby is recorded in EEPROM whenever possible.

Checking this code will be useful in finding a problem when you repair the troubled set.

7. Writing the microprocessor software

7.1. Writing the main microprocessor software and monitor microprocessor software

(Main PWB: QPWBXG506WJ**)

Adjustment item Adjustment conditions Adjustment procedure

1 Writing the main micropro-

cessor software and monitor microprocessor software

<Main PWB>

Checker process

Checking the file version

1) Only boot part, write firmware with Gang Programmer.

IC: RH-iXD775WJQZQ (IC3303)

2) Confirm the software version and operation verification by test checker.

8.1 . WHITE BALANCE ADJUSTMENT/ GAMMA ADJUSTMENT

ERUDECORP NOITIDNOC METI

1 Setting

Brightness㸸MAX (+16)

AV MODE: DYNAMIC

Active Backlight: off

OPC: off

*Set the luminance

meter at the center

of the screen

1. TV is set to below condition.

AV Mode : DYNAMIC

Backlight : +16

Active Backlight : OFF

2. Connect White Balance Adjustment jig to TV set.

2 [1] Auto

Adjustment

[DYNAMIC]

Adjustment

[Command]

Adjustment mode

KRSW0001

KKT10037

Multi point adjustment

mode

MSET0001

Point 7

LEV70229

MG7G****

MG7B****

MG7R****

[Adjustment procedure]

1. Using R/C, set the LCD TV to adjustment mode.

[DYNAMIC] Adjustment

2. Set the strongest color as fixed color, minus adjust by

changing the value by 4 at a time to be the reference

value, adjust RGB at MG7***** command.

3. For Point 6, set the correction value of G (1840 x Point 7

G val

ue/3664)

(a fraction is rounded up), change the value

by 4 at a time to be the reference value, adjust RB.

4. For Point 5, set the correction value of G (640 x Point 7 G

value/3664) (a fraction is rounded up), change the value

by 4 at a time to be the reference value, adjust RB.

5. For point 4 to 1 : no use, all set to 0

6. Write the adjustment value at MSET0003 command.

*Initial value of RGB at Point 7 = Setting level 3664

*Initial value of RGB at Point 5,6

= correction value of G of e

ach point

LCD TV ADJUSTMENT ITEM

8.White Balance adjustment.

Page 15

LC50/58/65U35T

5 – 7

Point 6

LEV60115

MG6G****

MG6B****

MG6R****

Point 5

LEV50040

MG5G****

MG5B****

MG5R****

Point 4

LEV40000

MG4G0000

MG4B0000

MG4R0000

Point 3

LEV30000

MG3G0000

MG3B0000

MG3R0000

Point 2

LEV20000

MG2G0000

MG2B0000

MG2R0000

Point 1

LEV10000

MG1G0000

MG1B0000

MG1R0000

W/B adj. value data

input

MSET0003

[Adjustment value]

Based on Teaching set

After adjust luminance spec: Min 280cd/m2

[Reference value for adjustment]

Equipment : Luminance meter [Minolta CS-2000]

(DYNAMIC MODE)

Level

Referenc

e value

Adjustment

Spec .

Inspection

Spec .

Point 7 3664

x=0.2685

±0.0010 ±0.0020

y=0.2670

Point 6 1840

x=0.2685

±0.0015 ±0.0030

y=0.2670

Point 5 640

x=0.2685

±0.0045 ±0.0090

y=0.2670

Point 4 0

NO USE

Point 3 0

Point 2 0

Point 1 0

Remarks

For inspection set condition

AV MODE : [DYNAMIC]

Monochrome : ON

Active Backlight : OFF

Aging time : Minimum 60 min.

Page 16

LC50/58/65U35T

5 – 8

8.2) GAMMA 2.2 Adjustment

ERUDECORP NOITIDNOC METI

1 Setting Backlight : MAX(+16)

Active Backlight: Off

Regarding the details of white balance adjustment procedure, refer

to the latest Gamma adjustment spec.

1. Confirm the set condition.

2. Connect the jig.

3. Place the probe at the White Balance adjustment screen

location.

2 Auto

Adjustment

[Command]

Adjustment Mode

KRSW0001

KKT10037

Multi Point

Adjustment Mode

MSET0001

Measurement Pattern

LEV00000

LEV50040

LEV60115

LEV70229

LEV80255

Adjustment Value

Input

GCCX****

(X is Level, **** is

adjustment value

MIN X=0, MAX X=8)

Input Data

GCST0001

࣭Set the MIN adjustment level, and measure the luminance.

Measured luminance is increased 100 times, set the integer as

adjustment value (a fraction is rounded up).

࣭Set the MID5 adjustment level, and measure the luminance.

Measured luminance is increased 10 times,

set the integer as

adjustment value (a fraction is rounded up).

࣭Set the MID6 adjustment level, and measure the luminance.

Measured luminance is increased 10 times,

set the integer as

adjustment value (a fraction is rounded up).

࣭Set the MID7 adjustment level, and measure the luminance.

Measured luminance is increased 10 times,

set the integer as

adjustment value (a fraction is rounded up).

࣭Set the MAX adjustment level, and measure the luminance.

Measured luminance is increased 10 times,

set the integer as

adjustment value (a fraction is rounded up).

[Adjustment Level] (Adjustment level is determined before sales

approval set making)

MIN ADJ LEVEL 0 /255 LEVEL

MID1 ADJ LEVEL 0 /255 LEVEL

MID2 ADJ LEVEL 0 /255 LEVEL

MID3 ADJ LEVEL 0 /255 LEVEL

MID4 ADJ LEVEL 0 /255 LEVEL

MID5 ADJ LEVEL 40 /255 LEVEL

MID6 ADJ LEVEL 115 /255 LEVEL

MID7 ADJ LEVEL 229 /255 LEVEL

MAX ADJ LEVEL 255 /255 LEVEL

3 Adjustment

Check

Check that the adjustment result is no problem.

࣭Check that the Gamma adjustment value is in spec.

VAL Spec 100±15

Page 17

LC50/58/65U35T

5 – 9

9. KEY WRITING

(1) MAC Address Data Input (Main PWB: QPWBXG506WJN1)

Please refer to Caution Item for Production

(2) Widevine, PlayReady, WVSecureStop

Key Data Input (Main PWB: QPWBXG506WJN1)

Please refer to Caution Item for Production

(3) Serial No. (Main PWB: QPWBXG506WJN1)

Please refer to Caution Item for Production

Display format (example)

1/17

MAIN VERSION

BOOT VERSION

T-CON VERSION

FRC VERSION

HDMI SW VERSION

PLAYREADY KEY

WIDEVINE KEY

WV SECURESTOP KEY

DTCP-IP KEY

CI+ KEY

SERIAL NO

MAC ADDRESS

LAMP ERROR

ERROR STANDBY CAUSE

09500 LMY47M test-keys

0.95

------

No device

1000101

Playready model key OK

LCDTV2884FAB73D41

WVSecureStop model key OK

------

53-41-01-03-00 00-00-3A

506711119

2884FAB73D41

0

00 00 00 00

Page 18

LC50/58/65U35T

5 – 10

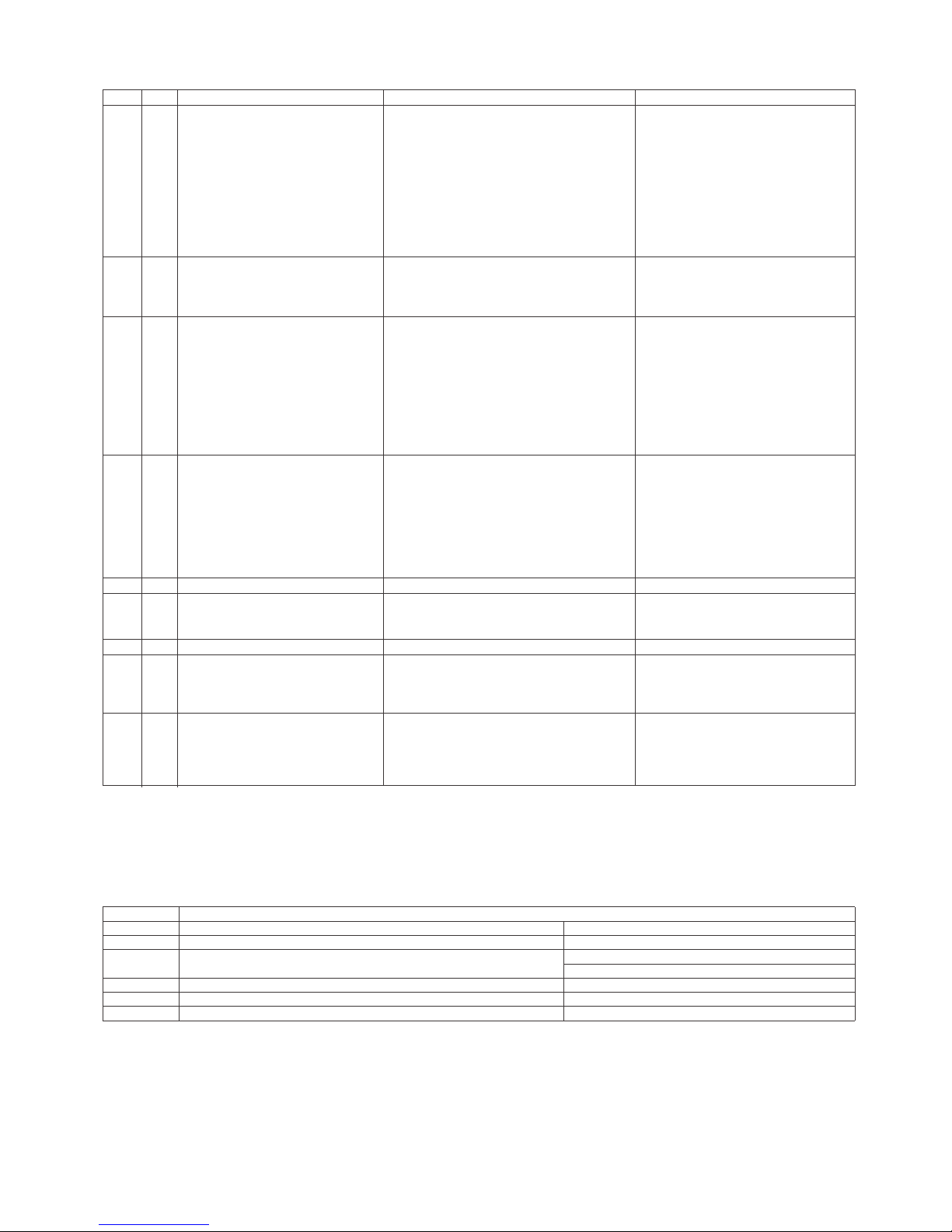

Writing the Panel size, volume, type and destination

1) Enter the adjustment process mode

2) Point the cursor to [PANEL SIZE]

3) Select Panel Size and press [enter] key

4) “OK” is displayed

5) Point the cursor to [VOLUME TYPE]

6) Select Volume Type and press [enter] key

7) “OK” is displayed

8) Point the cursor to [INDUSTRY INITIAL]

9) Select Destination and press [enter] key

10) “OK” is displayed

Volume

Type

50U35T 58U35T 65U35T

0 1 2

10. FACTORY SETTING

AC power is plug off after shipment setting is done.

Caution: Do not plug on again after shipment setting is done. If do, please re-do the shipment setting.

ERUDECORP NOITIDNOC METI

Factory setting AC power off to exit the

factory setting.

࣭Move cursor to [INDUSTRY INIT] on 2

nd

page, change the option from

NO to YES, then press [ENT].

Version confirmation screen is displayed on the green screen, if

[SUCCESS] is displayed on the top side, it is complete.

࣭Power AC OFF.

The followings are initialised to factory setting

1) User Setting

2) Channel Data (broadcast frequencies etc.)

3) Password Setting Value

4) Operating Hours

5) Standby Cause

6) Auto Installation Flag

Page 19

LC50/58/65U35T

5 – 11

11. SOFTWARE VERSION

Confirmation on Software version will be done during meeting.

egakcaP erawtfoS ledoM

LC-65U35T

LC-58U35T

LC-50U35T

upgrade_loader_Malacca_XXXXX.pkg

Main Software Filename : XXXXX is Software version

If any changes of software, will be informed by MARUHEN

Page 20

LC50/58/65U35T

5 – 12

12. Writing the inch and model name and volume type on EEPROM.

1. Enter the adjustment process mode.

2. Point the cursor to [MODEL](Page 17/17)

3. Select model(U35T), and press [Enter] key.

4. “OK” is displayed.

5. Point the cursor to [PANEL SIZE] (Page 17/17).

6. Select size(65,58,50) and press [Enter] key.

7. Moments later image is displayed.

8. Point the cursor to [Volume Type]

9. Select Volume Type, and press [Enter]key.

10."OK" is displayed.

11.Turn off power

12.Turn on power

Page 21

LC50/58/65U35T

5 – 13

13. How to write Serial Number

After change New Main board, change “Model and Panel Size” and write “Serial Number”.

13.1. Change Model and Panel Size and Volume type.

1. Enter the adjustment process mode.

2. Point the cursor to [MODEL NAME].

3. Select model, and press [Enter] key.

4. “OK” is displayed.

5. Point the cursor to [PANEL SIZE].

6. Select Panel Size and press [Enter] key.

7. Moments later image is displayed.

8. Point the cursor to [Volume Type]

9. Select Volume Type, and press [Enter]key.

10."OK" is displayed.

11.Turn off power.

12.Turn on power.

Example

VOLUME TYPE

50U35T

58U35T

65U35T

0 1 2

U35T

Page 22

LC50/58/65U35T

5 – 14

13.2. Write Serial Number

13.2.1 Get ready before you start

• USB Memory of 128MB or higher capacity.

• PC running on Windows 98/98SE/ME/2000/XP/Vista/Win7/Win8 operating system.

• USB Memory reader/writer or PC with a USB port.

• The file system of a USB memory is FAT. (FAT32 supports)

• Use the USB memory without other functions. (lock and memory reader...etc)

• Use the USB memory without other files.

• Check Serial Number. (Model Label)

14.2.2 Preparations

To write serial number, it is necessary to get ready the USB Memory before you start.

Follow the steps below and create the USB Memory for writing serial number.

Copy the file *********.SEN to the root directory (folder) of the USB Memory.

NOTE: SEN file name is Serial No (9-digit)

e.g.) 407811119.SEN => Serial No: 407811119

Example: LC-65U35T

Page 23

LC50/58/65U35T

6 – 1

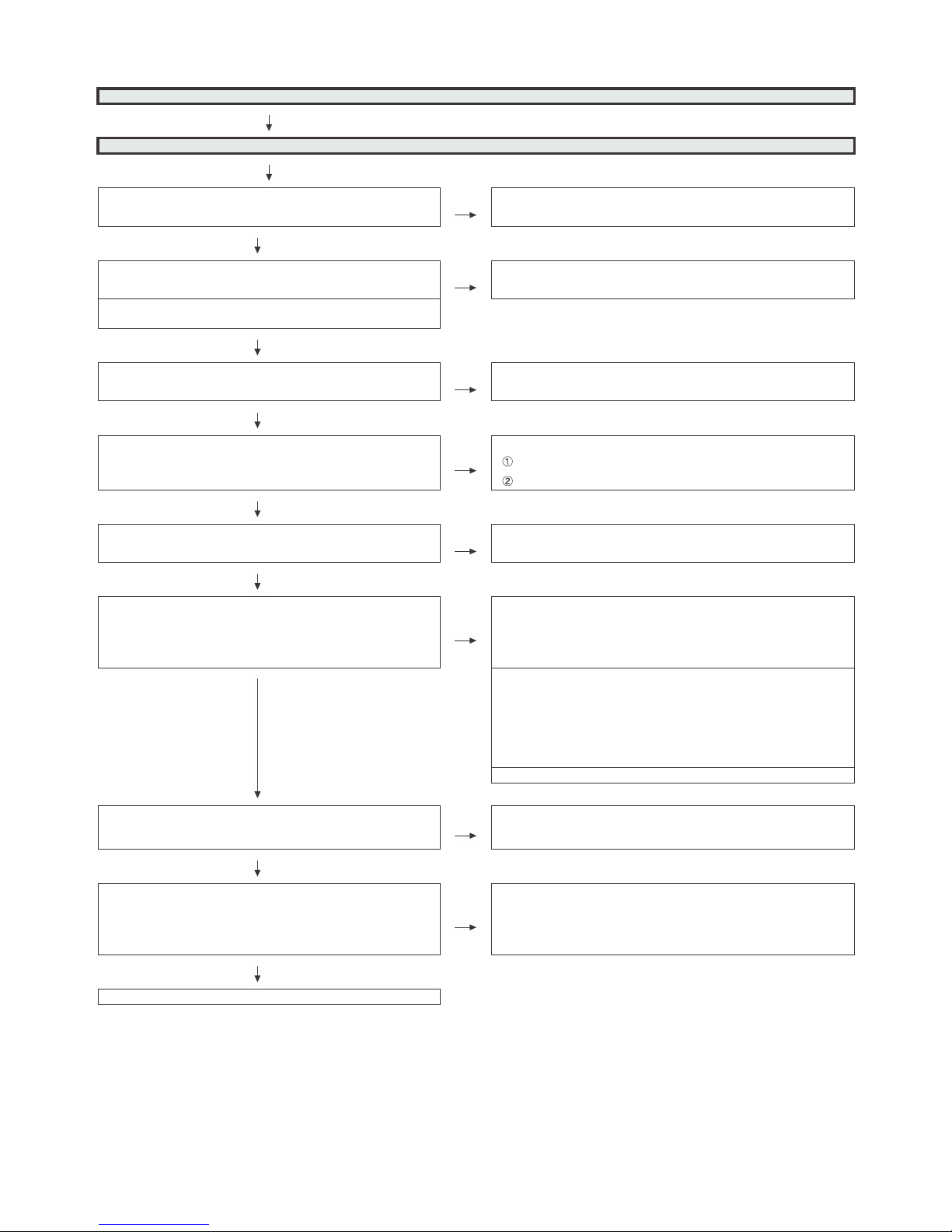

CHAPTER 6. TROUBLESHOOTING

TABLE

[1] TROUBLESHOOTING TABLE

[1] Failure diagnosis by LED in front of cabinet

[2] LED flashing specification at the time of an error (POWER LED used)

1. Display method

• Since only the POWER LED can be used, slow flashing and fast flashing are combined.

• After recovering from an error, if the same error cannot be generated again, refer to MONITOR ERR CAUSE on the adjustment process mode.

2. LED flashing method

Error flashing

Table 1. Concrete flashing pattern

*2: They depend on the system. Power supply error is defined from product to product.

*3: For details, refer to ERROR STANDBY CAUSE on the adjustment process mode.

Item

Detail display

Cause

Slow flashing Fast flashing

Inverter/Lamp system failure Flashes once Flashes once Lamp error

Power PWB failure Flashes twice Flashes twice Power supplly error (*2) UR+13V error

rorre )V3.3D(EROCV )2*( rorre yllppus rewoPsemit 3 sehsalF ).cte ,eruliaf rewoP(

Main PWB failure

(Communitacion failure, etc.)

Flashes 3 times Flashes 3 times Regular communication error

Others

Flashes 4 times

Flashes once Temperature error

No

Yes

No

Yes

No

Yes

Is the POWER LED flashing?

START

Is the POWER LED lighting

When AC plug on?

Is the Backlight lighting?

Check "[2] LED flashing specification at the time of an error (POWER LED used)".

Check Power-Unit and AC-cable.

Check "

LED Backlight does not turn on.".

Check "

Picture does not display.".

1600ms

300ms

100ms

400ms

400ms

1600ms

OFF

ON

POWER LED

Page 24

LC50/58/65U35T

6 – 2

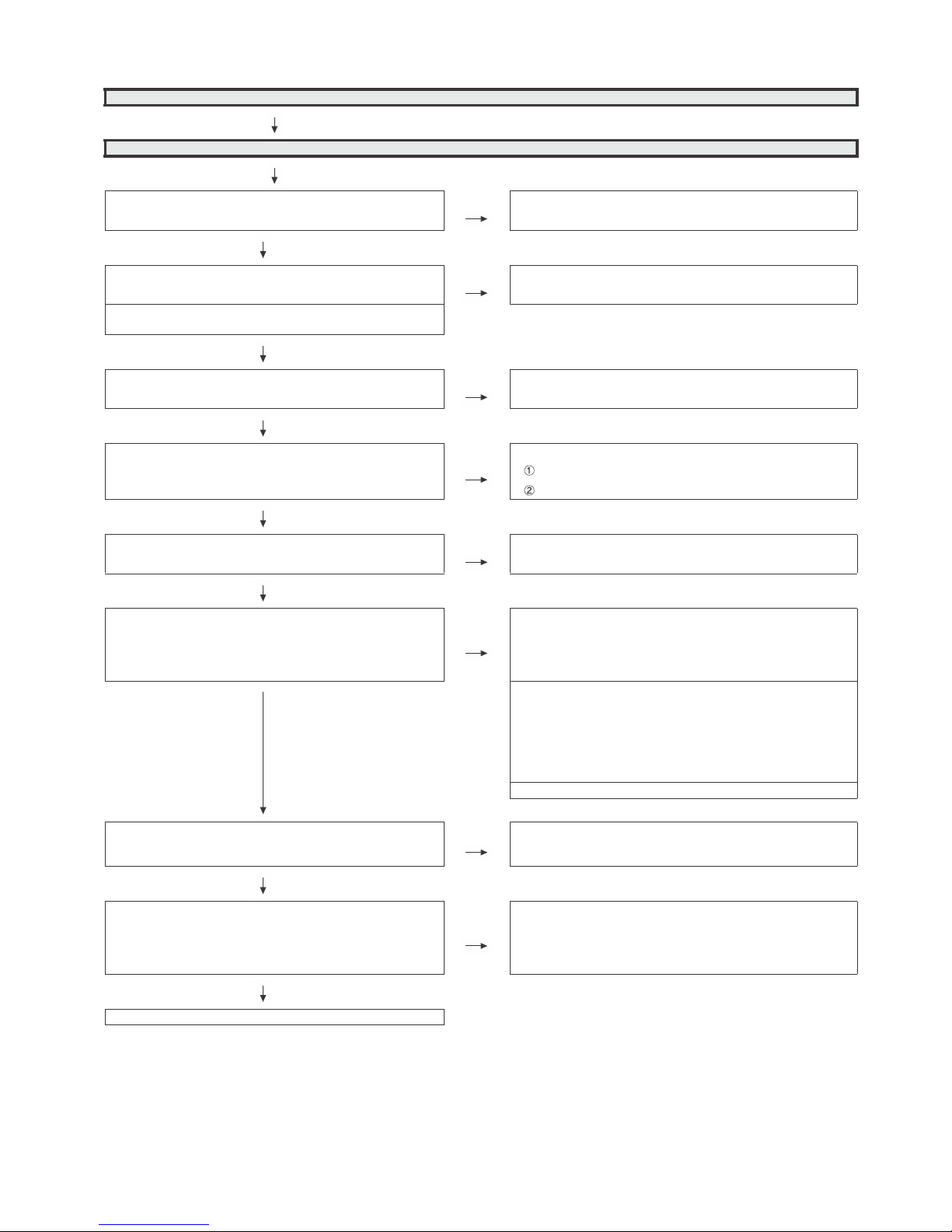

3. New method

LED flashing timing chart at the time of an error

1) Inverter/Lamp failure details (Flashes slowly once and flashes fast) Note

2) Power failure details (Flashes slowly twice and flashes fast) Note

3) Communication failure details (Flashes slowly 3 times and flashes fast) Note

4) Other failure details (Flashes slowly 4 times and flashes fast) Note

noitarepo DEL REWOPepyt rorrE

Pins are monitor microcomputer pins unless other

-wise specified.

Lamp failure

Flashes fast once

H: On

L: Off

LAMP_ERR: failure (H). Inverter/Lamp error is detected.

Note that after five detection counts, the lamp cannot be

activated except in the IgnoreError mode.

Accumulated counts are cleared to 0 by the setting in the

LAMP ERROR RESET on the adjustment process mode.

noitarepo DEL REWOPepyt rorrE

Pins are monitor microcomputer pins unless other

-wise specified.

13V error

Main 13V failure

Flashes fast twice

H: On

L: Off

DET_V12 failure (L). Main 13V is not applied.

VCORE erro

r

D3.3V failure

Flashes fast 3 times

H: On

L: Off

DET_VCORE failure (L). D3.3V is not applied.

noitarepo DEL REWOPepyt rorrE

Pins are monitor microcomputer pins unless other

-wise specified.

Regular communication failure

Flashes fast 3 times

H: On

L: Off

Watchdog reboot consecutively occurred 4 times without keeping stable state 3 minutes.

o Main CPU operation failure

noitarepo DEL REWOPepyt rorrE

Pins are monitor microcomputer pins unless other

-wise specified.

Monitor temperature

failure

Flashes fast once

H: On

L: Off

If the panel temperature is 60qC or more for 15 seconds

or more in a row, CAUTION appears on the OSD

(flashes in red in the lower right screen).

If the panel temperature is 60qC or more for 25 seconds

or more in a row, error standby is activated.

ces6.1sm004sm001

Page 25

LC50/58/65U35T

6 – 3

[3] TROUBLESHOOTING TABLE

If it is not an error of power supply/LED driver,

It is start-up in the lamp error disregard mode.

?trats uoy oD

YES

When main unit is replaced , does it start

normally?

NO

When LCD control unit is replaced

,does it start normally?

NO

When the parts in the panel can be

replaced.

o Replace all LED-bars in the panel module.

When the parts in the panel cannot be

replaced.

oReplace panel module.

YES

YES

.tinu lartnoc DCL ecalpeR .tinu niam ecalpeR

If it is not an error of power supply/LED driver,

It is start-up in the lamp error disregard mode.

?trats uoy oD

NO

When power supply unit is

replaced , does it start normally?

NO

When main unit is

replaced , does it start

normally?

NO

When LCD control unit is

replaced ,does it start normally?

NO

When the parts in the panel

can be replaced.

oReplace all LED-bars in

the panel module.

When the parts in the panel

cannot be replaced.

oReplace panel module.

SEYSEYSEY

Replace power supply unit. Replace main unit. Replace LCD contral unit.

Page 26

LC50/58/65U35T

6 – 4

Trouble Shooting Panel Module

When main unit is replaced, does

screen display normally?

NO

When power unit is replaced, does

screen display normally?

NO

Replace Panel Module.

SEYSEY

. Power unitecalpeR

. e main unit calpeR

Page 27

LC50/58/65U35T

6 – 5

No video (1)-1

HDMI:No external input video [HDMI1]

Is HDMI1 selected on the input select menu screen? NO Select HDMI1 on the input select menu screen for the right input sig-

nal.

YES

eht kcehCON?noitcnuf noitceted GULP TOH eht seoD line between the pin(18) of SC1501 and the pin(102) of

IC2502.

Does the DDC5V signal come from pin(18) of SC1501 to

pin(102) of IC2502(HDMI-SW)?

YES

Does the HPD signal come from pin(142) of IC2502 to pin(19) of

SC1501?

NO Check the line between the pin(19) of SC1501 and the pin(142) of

IC2502.

YES

Is IC2502(HDMI-SW) accessed by I2C, with HDMI connected, to

read the DDC-I2C SCL/SDA data?

NO

Check the DDC-I2C line and its peripheral circuits..

SC1501 pin(15)(SCL), pin(16)(SDA)

IC2502 pin(101)(SCL), pin(99)(SDA)

YES

Does the HPD signal come from pin(F31/F30) of IC3303 to

pin(110/113) of IC2502?

NO Check the line between the pin(F31/F30) of IC3303 and the pin(110/

113) of IC2502.

YES

Are there the TMDS signals at input pins of IC3301(CPU)?

NO

Check the TMDS line (between SC1501 and IC2502) and its peripheral circuits.

[IC2502 TMDS input pins]

pin(145/146)(CLK-/+), pin(149/150)(D0-/+),

pin(151/152)(D1-/+), pin(153/154)(D2-/+).

YES

Check the TMDS line (between IC2502 and IC3303) and its peripheral circuits.

[IC3303 TMDS input pins]

pin(B24/A24)(TMDS0_CLK-/+), pin(D23/C23)(TMDS0_D0-/+),

pin(D22/C22)(TMDS0_D1-/+), pin(B22/A22)(TMDS0_D2-/+).

pin(B21/A21)(TMDS1_CLK-/+), pin(B20/A20)(TMDS1_D0-/+),

pin(B19/A19)(TMDS1_D1-/+), pin(B18/A18)(TMDS1_D2-/+).

Check SC1501, IC2502, IC3303 and its peripheral circuits.

Is the T-CON PWB connected?

V_LOCKN pin(26) of SC3802 become Low if there is no problem

in the connection.

NO

Check the T-CON PWB and harness.

Check IC3303 and SC3802 and their peripheral circuits in Main

PWB.

YES

Are the V-By-One HS signal input to the pin of SC3802?

V_VBO_TX_1+/-(23/24pin), V_VBO_TX_2+/-(20/21pin),

V_VBO_TX_3+/-(17/18pin),

V_VBO_TX_4+/-(14/15pin), V_VBO_TX_5+/-(11/12pin),

V_VBO_TX_6+/-(8/9pin), etc

NO

Check IC3303 and its peripheral circuits.(IC3501/IC3502/IC3503,

etc.)

YES

Check the panel module and harness.

Page 28

LC50/58/65U35T

6 – 6

No video (1)-2

HDMI:No external input video [HDMI2]

Is HDMI2 selected on the input select menu screen? NO Select HDMI2 on the input select menu screen for the right input

signal.

YES

fo )79(nip eht dna 2051CS fo )81(nip eht neewteb enil eht kcehCON?noitcnuf noitceted GULP TOH eht seoD

IC2502.

Does the DDC5V signal come from pin(18) of SC1502 to pin(97)

of IC2502(HDMI-SW)?

YES

Does the HPD signal come from pin(127) of IC2502 to pin(19) of

SC1501?

NO Check the line between the pin(19) of SC1502 and the pin(127) of

IC2502.

YES

Is IC2502(HDMI-SW) accessed by I2C, with HDMI connected, to

read the DDC-I2C SCL/SDA data?

NO

Check the DDC-I2C line and its peripheral circuits..

SC1502 pin(15)(SCL), pin(16)(SDA)

IC2502 pin(96)(SCL), pin(95)(SDA)

YES

Does the HPD signal come from pin(F31/F30) of IC3303 to

pin(110/113) of IC2502?

NO Check the line between the pin(F31/F30) of IC3303 and the

pin(110/113) of IC2502.

YES

Are there the TMDS signals at input pins of IC3301(CPU)?

NO

Check the TMDS line (between SC1502 and IC2502)

and its

peripheral circuits.

[IC2502 TMDS input pins]

pin(130/131)(CLK-/+), pin(134/135)(D0-/+),

pin(136/137)(D1-/+), pin(138/139)(D2-/+).

YES

Check the TMDS line (between IC2502 and IC3303) and its

peripheral circuits.

[IC3303 TMDS input pins]

pin(B24/A24)(TMDS0_CLK-/+), pin(D23/C23)(TMDS0_D0-/+),

pin(D22/C22)(TMDS0_D1-/+), pin(B22/A22)(TMDS0_D2-/+).

pin(B21/A21)(TMDS1_CLK-/+), pin(B20/A20)(TMDS1_D0-/+),

pin(B19/A19)(TMDS1_D1-/+), pin(B18/A18)(TMDS1_D2-/+).

Check SC1502, IC2502, IC3303 and its peripheral circuits.

Is the T-CON PWB connected?

V_LOCKN pin(26) of SC3802 become Low if there is no problem

in the connection.

NO

Check the T-CON PWB and harness.

Check IC3303 and SC3802 and their peripheral circuits in Main

PWB.

YES

Are the V-By-One HS signal input to the pin of SC3802?

V_VBO_TX_1+/-(23/24pin), V_VBO_TX_2+/-(20/21pin),

V_VBO_TX_3+/-(17/18pin),

V_VBO_TX_4+/-(14/15pin), V_VBO_TX_5+/-(11/12pin),

V_VBO_TX_6+/-(8/9pin), etc

NO

Check IC3303 and its peripheral circuits.(IC3501/IC3502/IC3503,

etc.)

YES

Check the panel module and harness.

Page 29

LC50/58/65U35T

6 – 7

No video (1)-3

HDMI:No external input video [HDMI3]

Is HDMI3 selected on the input select menu screen? NO Select HDMI3 on the input select menu screen for the right input signal.

YES

eht kcehCON?noitcnuf noitceted GULP TOH eht seoD line between the pin(18) of SC1503 and the pin(86) of

IC2502.

Does the DDC5V signal come from pin(18) of SC1503 to

pin(86) of IC2502(HDMI-SW)?

YES

Does the HPD signal come from pin(85) of IC2502 to pin(19) of

SC1503?

NO Check the line between the pin(19) of SC1503 and the pin(85) of

IC2502.

YES

Is IC2502(HDMI-SW) accessed by I2C, with HDMI connected,

to read the DDC-I2C SCL/SDA data?

NO

Check the DDC-I2C line and its peripheral circuits..

SC1503 pin(15)(SCL), pin(16)(SDA)

IC2502 pin(84)(SCL), pin(83)(SDA)

YES

Does the HPD signal come from pin(F31/F30) of IC3303 to

pin(110/113) of IC2502?

NO Check the line between the pin(F31/F30) of IC3303 and the pin(110/

113) of IC2502.

YES

Are there the TMDS signals at input pins of IC3301(CPU)?

NO

Check the TMDS line (between SC1503 and IC2502) and its peripheral

circuits.

[IC2502 TMDS input pins]

pin(67/68)

(CLK-/+), pin(71/72)(D0-/+),

pin(73/74)(D1-/+), pin(75/76)(D2-/+).

YES

Check the TMDS line (between IC2502 and IC3303) and its peripheral

circuits.

[IC3303 TMDS input pins]

pin(B24/A24)(TMDS0_CLK-/+), pin(D23/C23)(TMDS0_D0-/+),

pin(D22/C22)(TMDS0_D1-/+), pin(B22/A22)(TMDS0_D2-/+).

pin(B21/A21)(TMDS1_CLK-/+), pin(B20/A20)(TMDS1_D0-/+),

pin(B19/A19)(TMDS1_D1-/+), pin(B18/A18)(TMDS1_D2-/+).

Check SC1503, IC2502, IC3303 and its peripheral circuits.

Is the T-CON PWB connected?

V_LOCKN pin(26) of SC3802 become Low if there is no problem in the connection.

NO

Check the T-CON PWB and harness.

Check IC3303 and SC3802 and their peripheral circuits in Main PWB.

YES

Are the V-By-One HS signal input to the pin of SC3802?

V_VBO_TX_1+/-(23/24pin), V_VBO_TX_2+/-(20/21pin),

V_VBO_TX_3+/-(17/18pin),

V_VBO_TX_4+/-(14/15pin), V_VBO_TX_5+/-(11/12pin),

V_VBO_TX_6+/-(8/9pin), etc

NO

Check IC3303 and its peripheral circuits.(IC3501/IC3502/IC3503, etc.)

YES

Check the panel module and harness.

Page 30

LC50/58/65U35T

6 – 8

No video (1)-4

HDMI:No external input video [HDMI4]

Is HDMI4 selected on the input select menu screen? NO Select HDMI4 on the input select menu screen for the right input sig-

nal.

YES

eht kcehCON?noitcnuf noitceted GULP TOH eht seoD line between the pin(18) of SC1503 and the pin(81) of

IC2502.

Does the DDC5V signal come from pin(18) of SC1504 to pin(81)

of IC2502(HDMI-SW)?

YES

Does the HPD signal come from pin(80) of IC2502 to pin(19) of

SC1501?

NO Check the line between the pin(19) of SC1503 and the pin(80) of

IC2502.

YES

Is IC2502(HDMI-SW) accessed by I2C, with HDMI connected, to

read the DDC-I2C SCL/SDA data?

NO

Check the DDC-I2C line and its peripheral circuits..

SC1503 pin(15)(SCL), pin(16)(SDA)

IC2502 pin(79)(SCL), pin(78)(SDA)

YES

Does the HPD signal come from pin(F31/F30) of IC3303 to

pin(110/113) of IC2502?

NO Check the line between the pin(F31/F30) of IC3303 and the pin(110/

113) of IC2502.

YES

Are there the TMDS signals at input pins of IC3301(CPU)?

NO

Check the TMDS line (between SC1503 and IC2502) and its peripheral circuits.

[IC2502 TMDS input pins]

pin(54/55)(CLK-/+), pin(58/59)(D0-/+),

pin(60/61)(D1-/+), pin(62/63)(D2-/+).

YES

Check the TMDS line (between IC2502 and IC3303) and its peripheral circuits.

[IC3303 TMDS input pins]

pin(B24/A24)(TMDS0_CLK-/+), pin

(D23/C23)(TMDS0_D0-/+),

pin(D22/C22)(TMDS0_D1-/+), pin(B22/A22)(TMDS0_D2-/+).

pin(B21/A21)(TMDS1_CLK-/+), pin(B20/A20)(TMDS1_D0-/+),

pin(B19/A19)(TMDS1_D1-/+), pin(B18/A18)(TMDS1_D2-/+).

Check SC1503, IC2502, IC3303 and its peripheral circuits.

Is the T-CON PWB connected?

V_LOCKN pin(26) of SC3802 become Low if there is no problem

in the connection.

NO

Check the T-CON PWB and harness.

Check IC3303 and SC3802 and their peripheral circuits in Main PWB.

YES

Are the V-By-One HS signal input to the pin of SC3802?

V_VBO_TX_1+/-(23/24pin), V_VBO_TX_2+/-(20/21pin),

V_VBO_TX_3+/-(17/18pin),

V_VBO_TX_4+/-(14/15pin), V_VBO_TX_5+/-(11/12pin),

V_VBO_TX_6+/-(8/9pin), etc

NO

Check IC3303 and its peripheral circuits.(IC3501/IC3502/IC3503,

etc.)

YES

Check the panel module and harness.

Page 31

LC50/58/65U35T

6 – 9

No video (2)

COMPONENT:No external input video [Component/VIDEO]

Is Component/VIDEO selected on the input select menu

screen?

Is the Input Settings for the input signal?

NO

Select "Devices" - "Component/VIDEO" - "Component/VIDEO

select" - "Conponent" of user menu. Then, select "Switch to device"

on this menu.

YES

Does the COMP1_PLUG of Component/VIDEO detection function?

Check the line between pin(2) of input terminal(J504) and

pin(AM21) of IC3303(CPU).

J504:pin(2)

IC3303:pin(AM21)

Are there the COMPONENT video signal inputs at

pins(L36)(Y)/(K36)(Pb) and (J37)(Pr) of IC3303(CPU)?

NO

Check the line between the input terminals of J504 and IC3301.

J504 pin(3)(Y), pin(5)(Pb), pin(7)(Pr)

AIC3303 pins(L36)(Y), (K36)(Pb), (J37)(Pr)

YES

Is the T-CON PWB connected?

V_LOCKN pin(26) of SC3802 become Low if there is no problem in the connection.

NO

Check the T-CON PWB and harness.

Check IC3303 and SC3802 and their peripheral circuits in Main

PWB.

YES

Are the V-By-One HS signal input to the pin of SC3802?

V_VBO_TX_1+/-(23/24pin), V_VBO_TX_2+/-(20/21pin),

V_VBO_TX_3+/-(17/18pin),

V_VBO_TX_4+/-(14/15pin), V_VBO_TX_5+/-(11/12pin),

V_VBO_TX_6+/-(8/9pin), etc

NO

Check IC3303 and its peripheral circuits.(IC3501/IC3502/IC3503,

etc.)

YES

Check the panel module and harness.

Page 32

LC50/58/65U35T

6 – 10

No video (5)

No video at UHF/VHF and digital broadcast signal reception

Is the specified TV signal selected on the input select menu

screen?

Are there the IF signal at input pins(P6/P7)(TUN_IFN/P) of

IC3303(CPU)?

NO Check the IF signal line between IC3303 and TU1105, and their

peripheral circuits.

YES

Check the Tuner I2C lines.

TU1105:pin(10)(TUN_SCL), pin(11)(TUN_SDA)

IC3303:pin(E18), pin(F18)

Is the T-CON PWB connected?

V_LOCKN pin(26) of SC3802 become Low if there is no problem in the connection.

NO

Check the T-CON PWB and harness.

Check IC3303 and SC3802 and their peripheral circuits in Main

PWB.

YES

Are the V-By-One HS signal input to the pin of SC3802?

V_VBO_TX_1+/-(23/24pin), V_VBO_TX_2+/-(20/21pin),

V_VBO_TX_3+/-(17/18pin),

V_VBO_TX_4+/-(14/15pin), V_VBO_TX_5+/-(11/12pin),

V_VBO_TX_6+/-(8/9pin), etc

NO

Check IC3303 and its peripheral circuits.(IC3501/IC3502/IC3503,

etc.)

YES

Check the panel module and harness.

Page 33

LC50/58/65U35T

6 – 11

No video (5)

No video at UHF/VHF and digital broadcast signal reception

Is the specified TV signal selected on the input select menu

screen?

Are there the IF signal at input pins(P6/P7)(TUN_IFN/P) of

IC3303(CPU)?

NO Check the IF signal line between IC3303 and TU1105, and their

peripheral circuits.

YES

Check the Tuner I2C lines.

TU1105:pin(10)(TUN_SCL), pin(11)(TUN_SDA)

IC3303:pin(E18), pin(F18)

Is the T-CON PWB connected?

V_LOCKN pin(26) of SC3802 become Low if there is no problem in the connection.

NO

Check the T-CON PWB and harness.

Check IC3303 and SC3802 and their peripheral circuits in Main

PWB.

YES

Are the V-By-One HS signal input to the pin of SC3802?

V_VBO_TX_1+/-(23/24pin), V_VBO_TX_2+/-(20/21pin),

V_VBO_TX_3+/-(17/18pin),

V_VBO_TX_4+/-(14/15pin), V_VBO_TX_5+/-(11/12pin),

V_VBO_TX_6+/-(8/9pin), etc

NO

Check IC3303 and its peripheral circuits.(IC3501/IC3502/IC3503,

etc.)

YES

Check the panel module and harness.

Page 34

LC50/58/65U35T

6 – 12

No audio (1)

Component/VIDEO No audio.

Is Component/VIDEO selected on the input select menu screen?

NO

Refer to "COMPONENT:No external input

video [Component/VIDEO]"

or "COMPOSITE:No external input video

[Component/VIDEO]".

YES

Is selecting "Fixed" of "Audio Out > Stereo Minijack > Output Select" on the setting

menu screen ?

NO Set the audio output to "Fixed".

YES

Does the audio signal come from pins(2)(L) and (4)(R) of input terminal(J502) to

pins(C37)(L) and (A36)(R) of IC3303(CPU)?

NO Check the line between J502 and IC3303.

YES

About the L/R speakers.

Does the digital audio signal come from pins(AP36/AM31/AN30/AN31)(SP_MCLK/

SP_BCLK/SP_LRCLK/SP_LR_DAT) of IC3303(CPU) to pins(5/6/7/8)(SP_MCLK/

SP_LR_DAT/SP_BCLK/SP_LRCLK) of IC1701(Audio AMP) ?

About the Subwoofer speaker.

Does the digital audio signal come from pins(AP36/AM31/AN30/AM30)(SP_MCLK/

SP_BCLK/SP_LRCLK/SP_WF_DAT) of IC3303(CPU) to pins(5/6/7/8)(SP_MCLK/

SP_WF_DAT/SP_BCLK/SP_LRCLK) of IC1801(Audio AMP) ?

NO

Check the line between IC3303 and IC1701 /

IC1801, and their paripheral circuits.

YES

About the L/R Speakers.

Does the audio signal come from pins (10/14/26/30) of IC1701 (Audio AMP) to pin

(6/5/4/3) of P1702 (connector for speaker)?

About the Subwoofer speaker.

Does the audio signal come from pins (10/14/26/30) of IC1801 (Audio AMP) to pin

(1/2) of P1702 (connector for speaker)?

NO

Check IC1701 / IC1801 and its paripheral circuits.

YES

About the L/R Speakers.

Check the connector (P1702) L/R speakers

and their peripheral circuits.

About the Subwoofer Speaker.

Check the connector (P1702) L/R speakers and their peripheral circuits.

Page 35

LC50/58/65U35T

6 – 13

No audio (2)

[HDMI analog audio input] HDMI3 No audio.

Is HDMI3 selected on the input select menu screen? NO Refer to ":No external input video [HDMI3]".

YES

Is selecting "Fixed" of "Audio Out > Stereo Minijack > Output Select" on the

setting menu screen ?

NO Set the audio output to "Fixed".

YES

Is selecting "HDMI+Analog" of "Video In > HDMI3 > Audio Select" on the setting menu screen ?

NO Set the Audio Select to "HDMI+Analog".

YES

Does the audio signal come from pins(2)(L) and (3)(R) of input terminal(J501)

to pins(B35)(L) and (B38)(R) of IC3303(CPU)?

NO Check the line between J501 and IC3303.

YES

About the L/R speakers.

Does the digital audio signal come from pins(AP36/AM31/AN30/

AN31)(SP_MCLK/SP_BCLK/SP_LRCLK/SP_LR_DAT) of IC3303(CPU) to

pins(5/6/7/8)(SP_MCLK/SP_LR_DAT/SP_BCLK/SP_LRCLK) of

IC1701(Audio AMP) ?

About the Subwoofer speaker.

Does the digital audio signal come from pins(AP36/AM31/AN30/

AM30)(SP_MCLK/SP_BCLK/SP_LRCLK/SP_WF_DAT) of IC3303(CPU) to

pins(5/6/7/8)(SP_MCLK/SP_WF_DAT/SP_BCLK/SP_LRCLK) of

IC1801(Audio AMP) ?

NO

Check the line between IC3303 and IC1701 /

IC1801, and their paripheral circuits.

YES

About the L/R Speakers.

Does the audio signal come from pins (10/14/26/30) of IC1701 (Audio AMP)

to pin (6/5/4/3) of P1702 (connector for speaker)?

About the Subwoofer speaker.

Does the audio signal come from pins (10/14/26/30) of IC1801 (Audio AMP)

to pin (1/2) of P1702 (connector for speaker)?

NO

Check IC1701 / IC1801 and its par

ipheral circuits.

YES

About the L/R Speakers.

Check the connector (P1702) L/R speakers and their peripheral circuits.

About the Subwoofer Speaker.

Check the connector (P1702) L/R speakers and their peripheral circuits.

Page 36

LC50/58/65U35T

6 – 14

No audio (3)

No audio at UHF/VHF broadcast signal reception. No audio at digital broadcast signal reception.

Is TV selected on the input select menu

screen?

NO

Refer to "No video at

UHF/VHF broadcast

signal reception".

Is TV selected on the input

select menu screen?

NO

Refer to "No video

at digital broadcast signal reception".

YES YES

Is selecting "Fixed" of "Audio Out > Stereo Minijack > Output Select" on the setting menu screen ? NO Set the audio out-

put to "FIXED".

YES

About the L/R speakers.

Does the digital audio signal come from

pins(AP36/AM31/AN30/AN31)(SP_MCLK/

SP_BCLK/SP_LRCLK/SP_LR_DAT) of

IC3303(CPU) to pins(5/6/7/8)(SP_MCLK/

SP_LR_DAT/SP_BCLK/SP_LRCLK) of

IC1701(Audio AMP) ?

About the Subwoofer speaker.

Does the digital audio signal come from

pins(AP36/AM31/AN30/AM30)(SP_MCLK/

SP_BCLK/SP_LRCLK/SP_WF_DAT) of

IC3303(CPU) to pins(5/6/7/8)(SP_MCLK/

SP_WF_DAT/SP_BCLK/SP_LRCLK) of

IC1801(Audio AMP) ?

NO

Check the line

between IC3303

and IC1701 /

IC1801, and their

paripheral circuits.

YES

About the L/R Speakers.

Does the audio signal come from pins (10/

14/26/30) of IC1701 (Audio AMP) to pin (6/

5/4/3) of P1702 (connector for speaker)?

About the Subwoofer speaker.

Does the audio signal come from pins (10/

14/26/30) of IC1801 (Audio AMP) to pin (1/

2) of P1702 (connector for speaker)?

NO

Check IC1701 /

IC1801 and its

paripheral circuits.

YES

About the L/R Speakers.

Check the connector (P1702) L/R speakers

and their peripheral circui

ts.

About the Subwoofer Speaker.

Check the connector (P1702) L/R speakers

and their peripheral circuits.

Page 37

LC50/58/65U35T

6 – 15

No audio (4)

HDMI1 No audio (HDMI connected)

HDMI2 No audio (HDMI connected)

HDMI3 No audio (HDMI connected)

HDMI4 No audio (HDMI connected)

[HDMI1 input]

Is HDMI1 selected on the input select menu screen ?

NO Refer to ":No external input video [HDMI1/

2/3/4]".

[HDMI2 input]

Is HDMI2 selected on the input select menu screen ?

[HDMI3 input]

Is HDMI3 selected on the input select menu screen ?

[HDMI4 input]

Is HDMI4 selected on the input select menu screen ?

YES

[HDMI1 input]

If no video appears, refer to "No external input video (HDMI) [HDMI1]".

[HDMI2 input]

If no video appears, refer to "No external input video (HDMI) [HDMI2]".

[HDMI3 input]

If no video appears, refer to "No external input video (HDMI) [HDMI3]".

[HDMI4 input]

If no video appears, refer to "No external input video (HDMI) [HDMI4]".

Is selecting "Fixed" of "Audio Out > Stereo Minijack > Output Select" on the setting menu

screen ?

NO Set the audio output to "FIXED".

YES

About the L/R speakers.

Does the digital audio signal come from pins(AP36/AM31/AN30/AN31)(SP_MCLK/

SP_BCLK/SP_LRCLK/SP_LR_DAT) of IC3303(CPU) to pins(5/6/7/8)(SP_MCLK/

SP_LR_DAT/SP_BCLK/SP_LRCLK) of IC1701(Audio AMP) ?

About the Subwoofer speaker.

Does the digital audio signal come from pins(AP36/AM31/AN30/AM30)(SP_MCLK/

SP_BCLK/SP_LRCLK/SP_WF_DAT) of IC3303(CPU) to pins(5/6/7/8)(SP_MCLK/

SP_WF_DAT/SP_BCLK/SP_LRCLK) of IC1801(Audio AMP) ?

NO

Check the line between IC3303 and

IC1701 / IC1801, and their paripheral circuits.

YES

About the L/R Speakers.

Does the audio signal come from pins (10/14/26/30) of IC1701 (Audio AMP) to pin (6/5/4/3)

of P1702 (connector for speaker)?

About the Subwoofer speaker.

Does the audio signal come from pins (10/14/26/30) of IC1801 (Audio AMP) to pin (1/2) of

P1702 (connect

or for speaker)?

Check IC1701 / IC1801 and its paripheral

circuits.

YES

About the L/R Speakers.

Check the connector (P1702) L/R speakers and their peripheral circuits.

About the Subwoofer Speaker.

Check the connector (P1702) L/R speakers and their peripheral circuits.

Page 38

LC50/58/65U35T

6 – 16

No audio signal at Digital Audio Output terminal (Analog sound heard)

No HDMI1/2/3/4 audio. No audio at digital broadcast signal reception.

If no video appears, refer to "No external input video(HDMI) [HDMI1/2/3/4]".

If no video appears, refer to "No video at digital broadcast signal reception".

Is there the SPDIF signal output(OPT_AUDIO_OUT) at pin(AB34) of IC3303(CPU)? NO Check the IC3303 and its peripheral

circuits.

YES

Is there the SPDIF signal input at

pin(1) of D501(OPT_OUT)?

-ric larehpirep sti dna 105D kcehCON

cuits.

YES

No optical output under the following

conditions as per HDMI requirements.

*Audio contents protected.

*Audio frequency beyond 48kHz.

*Audio bit length beyond 16bits.

Check the speakers and the optical

cable.

Page 39

LC50/58/65U35T

6 – 17

No monitor audio output

Is the audio output from the monitor set at "FIXED" or "VARIABLE" with enough volume on the menu screen?

NO Volume up.

YES

Are there the audio signal outputs at pins (C35)(HP_AUD_L_OUT) and

(D36)(HP_AUD_L_OUT) of IC3303 (CPU)?

NO Check IC3303(CPU) and its peripheral cir-

cuits.

YES

Does the audio signal come from pins (3)(HP_L_AMP_OUT) and

(12)(HP_R_AMP_OUT) of IC501 (Line-out Amplifier) to pins (2)(L) and (3)(R) of

J503?

NO

Check the line between IC501 and J503

and their peripheral circuits.

YES

Check the connector(J503) and their peripheral circuits, and speakers and the

Cable.

Page 40

LC50/58/65U35T

6 – 18

No connect network

Does the signal come to 1pin of LAN-jack J2201?

(see fig-1, fig-2)

NO Check the interface device and peripheral circuits.

(power-LED of hub, LINK-LED of hub)

YES

Does the signal come to Y37 of IC3303?

(see fig-2)

NO Check the line from IC3303 to T2201.

Check the LAN-jack J2201.

YES

Check IC3303 and its peripheral circuits.

Make sure the "Internet setup" is set correctly.

Page 41

LC50/58/65U35T

6 – 19

No detection of USB devices

USB1: Side terminal

Is 5V output from pin(6) of IC1602?

NO

Is pin(3) of IC1602 3.3V?

NO

Check the

peripheral

circuits of

IC3303.

YES

YES

Check the connection of a USB cable, USB devices, and peripheral circuits of IC1602.

Are there the USB signals at input pins

of IC3301(CPU)?

NO

Check the USB line (between J1601 and IC3303) and its peripheral circuits.

[J1601 USB interface pins]

pin(2/3)(USB3.0 D-/+), pin(5/6)(USB3.0 RX-/+),

pin(8/9)(USB3.0 TX-/+).

[IC3303 USB interface pins]

pin(D31/C31)(USB3.0 D-/+), pin(A32/B32)(USB3.0 RX-/+),

pin(A34/B34)(USB3.0 TX-/+).

YES

Check J1601/IC3303 and its peripheral

circuits.

USB2/3: Bottom terminal

s 5V output from pin(6) of IC1603/

IC1604?

NO

Is pin(3) of IC1603/IC1604 3.3V?

NO

Check the peripheral circuits of

IC3303.

YES

YES

Check the connection of a USB cable, USB devices, and

peripheral circuits of IC1603/IC1604.

Are there the USB signals at input pins

of IC1601(USB Hub)?

NO

Check the USB line (between J1602 and IC1601) and its

peripheral circuits.

[J1602 USB interface pins]

pin(2/3)(USB D-/+)

[IC1601 USB interface pins]

pin(15/16)(USB D-/+)

YES

Check the USB line (between J1603 and IC1601) and its

peripheral circuits.

[J1603 USB interface pins]

pin(2/3)(USB D-/+)

[IC1601 USB interface pins]

pin(12/13)(USB D-/+)

Check J1602/J1603/IC1601 and its peripheral circuits.

Are there the USB signals at input pins

of IC3303(CPU)?

NO

Check the USB line (between IC1601 and IC3303) and its

peripheral circuits.

[IC1601 USB interface pins]

pin(1/2)(USB D-/+)

[IC1601 USB interface pins]

pin(B17/A17)(USB D-/+)

YES

Check J1602/J1603/IC1601 and its

peripheral circuits.

Page 42

LC50/58/65U35T

6 – 20

No detection of SD card

Is 3.3V or 1.8V output from pin(6) of

IC1651?

NO

Are pin(3) of IC1651 3.3V?

NO

Check the

peripheral circuits of

IC3303.

YES

YES

Check the connection of SD Card and peripheral circuits of

IC1651.

Are there the SD signals at input pins of

IC3301(CPU)?

NO

Check the SD signals (between SC1651 and IC3303) and its

peripheral circuits.

[SC1651 SD interface pins]

pin(5)(CLK), pin(2)(CMD), pin(7/8/9/1)(DAT0/1/2/3).

[IC3303 SD interface pins]

pin(F3)(CLK), pin(D2)(CMD), pin(D1/E2/E1/F2)(DAT0/1/2/3).

YES

Check SC1651/IC3303 and its peripheral

circuits.

Page 43

LC50/58/65U35T

7 – 1

CHAPTER 7. MAJOR IC INFORMA-

TION

[1] MAJOR IC INFORMATION

1. MAJOR IC INFORMATIONS

1.1. IC2502 (VHiSii9777+-1Q)

This IC is a versatile High Definition Multimedia Interface 2.0 (HDMI® ) transmitter/port processor, with support for Mobile

High-Definition Link 3 (MHL® ) and High-bandwidth Digital Content Protection 2.2 (HDCP). The device’s 18 Gb/s transmitter and receiver features

support delivery of full resolution 4K Ultra High Definition (UltraHD) 4:4:4 video to a 4K television set at 50 Hz or 60 Hz frame rate.

As port processor, all four inputs support HDMI 2.0 at up to 18 Gb/s, and two of the inputs can also support MHL 3 input at resolutions of up to 4K

@30 Hz. The three outputs offer a flexible configuration, including the ability to split an 18 Gb/s signal into two 9 Gb/s outputs. Audio and video can be

routed to separate transmitters and two separate 300 MHz output streams can be routed from two input sources.

1.2. IC2501 (VHiW25X40CL-1Y) SPI-Flash for IC2501

This is 4M-bit SPI Flash device stores the F/W of IC2501.

1.3. IC601 (VHiM3221EiP-1Y)

This IC is a high speed, single-channel RS-232 transceiver interface device that operates from a single 3.3V power supply.

The device provides the electrical interface between an asynchronous communication controller and the serial-port connector.

This device operates at data signaling rates up to 460kbit/s.

All RS-232 (Tout and Rin) and CMOS (Tin and Rout) inputs and outputs are protected against electrostatic discharge (up to +/- 15kV ESD protection).

1.4. IC3303 (RH-iXD775WJQZQ)

This IC consists of a DTV front-end demodulator, a backend decoder and a TV controller and offers high integration for advanced applications. It integrates a transport de-multiplexer, a high definition video decoder, an audio decoder, a V-by-One transmitter, and an NTSC/PAL/SECAM TV decoder

with a 3D comb filter (NTSC/PAL).

This IC supports Full-HD MPEG1/2/4/h.264/DiviX/VC1/RM/AVS/VP6/VP8 and UHD h.264/HEVC video decoder standards, and JPEG. A 3D comb filter added to the TV decoder recovers great details for still pictures. The special co

lor processing technology provides a natural, deep colors and true

studio quality video. Moreover, this IC has built-in high resolution and high quality audio codec.

It integrates high-quality HDMI1.4a, high speed VGA ADC, V-by-One, USB2.0/3.0 receiver, Ethernet MAC+PHY, dual core CPU and 1M bytes L2

cache, TCON, panel overdrive, OpenGL ES 1.1/2.0/3.0, OpenVG 1.1, DirectX DX11 compliant 3D graphic engine, and ATSC/DVB-T/DVB-C demodulators.

This IC provides consumers with a true UHD 60Hz and Full-HD 120Hz experience. It integrates high-quality Full-HD ME/MC technology.

1.5. IC3501, IC3502, IC3503, IC3504, IC3505 (RH-iXD751WJQZQ)

These are 4G-bit (256M x 16bit) DDR3-1866 synchronous DRAM.

1.6. IC3151 (VHiM24C64TP-1Y)

This is 64k-bit EEPROM device including the user setting and the uP setting.

1.7. IC3101 (RH-iXD793WJQZQ)

The 16G-byte eMMC flash memory device stores the main CPU program.

1.8. IC501 (VHiNCS603++-1Y)

This IC is audio amplifier for line-out/head-phone.

1.9. IC1701, IC1801 (VHiYDA176DL-1Y)

The Class-D type digital audio power amplifier YDA176 gives high performance 10W x2ch and maximum continuous output of woofer output 15W. It

adjusts TVs audio quality.

1.10. IC1601 (VHiCY65632L-1Q)

This IC is USB 2.0 Hub. Up to four downstream ports support.

Page 44

LC50/58/65U35T

8 – 1

CHAPTER 8. OVERALL WIRING /

SYSYTEM BLOCK DIAGRAM/

PRINTED WIRING BOARD

[1] OVERALL WIRING/SYSYTEM BLOCK

DIAGRAM

87

PD

PD

1

6

1 24

SP

౺ഝ

AC

1

51

1

15

1

10

MAINഝ

LW

RASDUB

USB

LEDছংഝ

1

10

UB

USB USB

LAN

OPT

1 4

KEY

ഝ

KM

ش

ش

(R)

আ

ش

ش

51

T-CONഝ

WiFiഝ

1 10

UB BT ANT

আشش(R) আشش(L)

1 15

RC/LCDഝ

RA

1

Page 45

LC50/58/65U35T

8 – 2

8+

'

B0

2

'

(

/

7

$,

:

$1

6

HU

LH

V

6

<6

7

(

0%

/2&

.'L

DJ

UD

P

㸦0

7

3&%FRGHQDPH5LJHO6RIW3)FRGHQDPH0DODFFD

7&21

0$,1

㼁㻼㻌㻰㻭㼀㻱㻌㻲㼑㼎㻌㻜㻠㼠㼔㻛㻞㻜㻝㻠

㻰㼑㼢㼑㼘㼛㼜㼙㼑㼚㼠㻌㻰㼑㼜㼠㻚㻌䊥

㻭㼐㼢㼍㼚㼏㼑㼐㻌㻭㼡㼐㼕㼛㻙㼂㼕㼟㼡㼍㼘㻌㻿㼥㼟㼠㼑㼙㼟㻌㻰㼑㼢㼑㼘㼛㼜㼙㼑㼚㼠㻌

7

&21

0$,1

5&$B&9%6&203B<3E3U

5&$B$8'B/5

9B9%2B+73'1

9B9%2B/2&.1

-

$8',1

%$&.

6&/6'$B

9B9%2B7;B13

D

-

&

20

3

2

1(17

,1

5&$B&203B3/8*+

/

'B

(1

5;15;35;15;3

5;15;35;15;3

5;15;35;15;3

5;15;35;15;3

/5

/'B(1

-

$8'287

0LQL3OXJ

+3B$8'B/5B287

࠙

/:ࠚ6&SD

'9

6,

'(

+3B3/8*/

+3B$8'B/5B287

31

/

9

D

/'B(1

6&/

6'$

9

&&

*1'

/5B2

&1)

䛆㻿㻼

䛇

㻼

㻝

㻣㻜㻞

6

3(

$

.

(

5

$8'287

0LQL3OXJ

:RRIHU

+3B$8'B/5B287

7KHUPLVWHU

࠙/:ࠚ

5&+B287

/&+B287

,&

+3$03

'9

$//B087(+

$03B567/

$03B3527(&7/

6,

'(

B

3/8*

,&

63

B

$03

<'$'/

46B7(03

+3B$8'B/5B287

3&B$8'B/5

859

9;B287

:RRIHU

,&

H00&

7KHUPLVWHU

,

&

''50ESV

*ELW

.%*%

,

&

'

'

5

0ES

V

*ELW

.%*%

'9

$',1B659

B

567

/

63B/5&/.%&/./5B'$7

,&

''50

ES

V

*ELW

.%*%

,

&

''50ESV

*ELW

.%*%

,

&

''50ESV

*EL

W

'9

'9

&9%63

<3%353

$,1B/5

$,1B/5

H00&B&/.&0''

<'$'/

46B7(03

$/$5B$'$

3&B$8'B/5

)/$6+,2

*3,2

9%B/2&.1

9%B+73'1

*3,2

*

3,2

H00&B567/

*3,2

$,) 31

$'&,131 '(02'

D

26'$26&/

*ELW

.%*%

*ELW

.%*%

6&/6'$B

.+]9

25(6(7

+27B%227B(1+

*3,2

67%B6'$76&/.B.+]

.+]9

67% 6'$ 6&/

86%B3:5B(1

*3,2

X3 &RQWURO

%/2&.

26'$26&/

78B6&/6'$

6&/6'$B

26'$26&/

78B567/

$,)B31

$'&,131B'(02'

*3,2

D

,&

5(6(7

5678

&38B567/

86%B3:5B(1

'9

67%567.((3

*3,2

.+]9

.+]9

,

&

07

'LJLWDO$9GHFRGH0DLQ&38

26'$26&/

(3

:

0

$&B'(7

67%+

/$03B(55

,&

((3B520

%89

6&/6'$

B

]

9

*3,2

*3,2

*3,2

67%B6'$76&/.B.+]

.+]9

67%B6'$6&/

,)B$*&

*3,2

*3,2

%27720

78$$:-4=7:1

$QD

ORJ'LJL

WD

O

6L7XQHU

'9

$,)B31

3

1/

9

$&B'(7

67%+

/$03B(55

/(''5,9(5

859

3& $8' /5

+'0, $8'

,

1

2

37

,

&

$/

$

8' 287

237,&$/B$8'B287

0+]

;

%27

72

0

$',1 6 59

293

&,5&8,7

36B21+

36B21/

%27720

0$,1B32:(5

'9

'9

293

23&

+'0,BB5;

*3,2

$//B087(+

*3,2

$03B567/

*3,2

*3,2

$03B3527(&7/

*3,2

36B21B3

,&

'

/&

,5&8,7

5678

9%/

*1'

(B3:0

%/21

(55

32:(58QLW32:(58QLW

㻮㼛㼛㼟㼠㻌㻯㼛㼚㼢㼑㼞㼠㼑㼞

㻸㻱㻰㻌

㻭㼚㼛㼐㼑㻌㼂㼛㼘㼠㼍㼓㼑

㻯㼛㼙㼙㼛㼚㻌㻭㼚㼛㼐㼑㻌

㻸㻱㻰㻌㼎㼍㼞

㻼㼞㼕㻚㻿㼑㼏㻚

,66'$7$/5&.6&/.

3&B$8'B/5

+

'0

,

$

8

'

,1

0LQL3OXJ

㻵㻯

㻢㻜㻝

56&7[5[

㻹㻟㻞㻞㻝㻱㻵㻼

56

&

'68%

+7/B5&287B,556

$63',)2

2,5,

237,&$/B$8'B287

$5&B287

%27

7

20

$',1B659

%

$&.

'9

&B8$57B7;5;

'9

0+/ 9 %86 (1

%$&.83B32:(5

%89

%8 9

%89

S

D

'

9

'9

'9

'9

'9

86%B9

+'0,B9

'(02'B9

$',1B659

*3,2

,5B3$66

&,5&8,7

,5B3$66B&7/+

%89

'9

:,5('B/$1B3B21+

(7+B9

*3,2

23&

.(<.(<32:B6:

86%B'0'3B'

86%B'0'3B'

86%B'0'3B'

86%B'0'3B'6686%

6',2

0+/B:$.(83B/36%9B(1

*3,2

*3,2

5&

87;5;

*3,2

*3,2

*3,2

*3,2

*3,2

*3,2

B

*3,2

$63',)2

,6B287

$03B3527(&7/

*3,2

*3,2

*3,2

:

(5

9&&,2B6'

$9''B(7+

*3,2

+'0,B&(&

/('B:*

*3,2

3+<

*3,2

&

7/

*3,2

*3,2

&1

9%/

*1'

(B3

:

%/2

1

(5

5

㻭㻯

㻝㻜㻜

㻿㼀㻮䚸㻻㻲㻸䚸㻵㻞㻯䚸㼂㻿㼅㻺㻯

㻱㻾㻾㻻㻾㻔㻱㼞㼞㼛㼞㻦㻴㼕㼓㼔㻙㼆㻌㻘㻌㻺㼛㼞㼙㼍㼘㻦㻸㼛㼣㻕

㻰㻯

㻸㻱㻰㻌㻰㼞㼕㼢㼑

㻴㼕㼓㼔㻌

㼂㼛㼘㼠㼍㼓㼑

㻲㻮

0+/

'(7(&7

6&/6'$B

+7/

B

5&287

B

,556

&(&

+'0,B

+

'0

,

$5&

&$%/(B'(7+9%86B'(7

,1387

,1387

+'0,B9

'9

%89

,17

$5&B287387B+'0,

50,,B7;'50,,B5;

''&B

+3'B

+'0,

+

'0

,

0+/

''&B

+3'B&%86

,&

3RZHU6:

'9

0+/B9B%86B(1+

+'0,B,17UHVHUYH

+'0,B:$.(83

B

%89

%89

'9

32:(5&,5&8,7

࠙3'ࠚ&1S

$5&B287

B

3$66

&,5&8,7

6'B32:(5

P

6'B3:5B&7/

(1

㻼㻲㻯

㼁㻾㻝㻟㼂㻌㻞㻚㻠㻭㼠㼥㼜

㼂㼏㼏㼂㼏㼏

㻝㻜㻜䡚㻞㻠㻜㼂

㼆

㻌

㻘

㻌

㻺㼛㼞㼙㼍㼘㻦㻸㼛㼣㻕

㻰㼕㼛㼐㼑㻌

㻮㼞㼕㼐㼓㼑

㻸㻸㻯

㻠㻜㻜㼂

;

,&

+'0,6:

6,,

,&B

,&

,13

8

7

,1387

0+]

5(6(7

B

+'0,B