Page 1

Drive Technology \ Drive Automation \ System Integration \ Services

Operating Instructions

Safety-Related BST Brake Module

for Control Cabinet Installation

Edition 10/2011 19357214 / EN

Page 2

SEW-EURODRIVE—Driving the world

Page 3

Contents

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Contents

1 General Information............................................................................................ 5

1.1 How to use this documentation................................................................... 5

1.2 Structure of the safety notes ....................................................................... 5

1.2.1 Meaning of the signal words........................................................ 5

1.2.2 Structure of the section-related safety notes ............................... 5

1.2.3 Structure of the embedded safety notes...................................... 5

1.3 Right to claim under warranty ..................................................................... 6

1.4 Exclusion of liability..................................................................................... 6

1.5 Copyright..................................................................................................... 6

1.6 Product names and trademarks.................................................................. 6

1.7 Applicable documentation........................................................................... 6

2 Safety Notes ........................................................................................................ 7

2.1 Preliminary information ............................................................................... 7

2.2 General information .................................................................................... 7

2.3 Target group ............................................................................................... 8

2.4 Designated use ........................................................................................... 8

2.5 Transport..................................................................................................... 8

2.6 Installation/assembly................................................................................... 8

2.7 Startup/operation ........................................................................................ 9

2.8 Inspection/maintenance .............................................................................. 9

2.9 Disposal ...................................................................................................... 9

3 Integrated Safety Technology.......................................................................... 10

3.1 Safe condition ........................................................................................... 10

3.2 Safety concept .......................................................................................... 10

3.2.1 Block diagram BST .................................................................... 11

3.3 Safety function .......................................................................................... 11

3.4 Restrictions ............................................................................................... 12

4 Safety-Relevant Conditions ............................................................................. 13

4.1 Permitted unit combinations...................................................................... 13

4.2 Requirements on the installation............................................................... 14

4.3 Requirements on external safety controller .............................................. 16

4.3.1 Sample circuit for a "safety switching device"............................ 17

4.4 Requirements on startup........................................................................... 17

4.5 Requirements on the operation................................................................. 18

5 Unit Design ........................................................................................................ 19

5.1 Nameplate, type designation .................................................................... 19

5.1.1 Example: Type designation ....................................................... 19

5.1.2 Example: Nameplate ................................................................. 19

5.2 Scope of delivery of BST .......................................................................... 20

5.3 Safety-related BST brake module............................................................. 20

5.4 Terminal assignment................................................................................. 20

Operating Instructions – Safety-Related BST Brake Module

3

Page 4

Contents

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

6 Installation ......................................................................................................... 21

6.1 Mechanical Installation.............................................................................. 21

6.1.1 Support rail mounting................................................................. 21

6.2 Electrical Installation ................................................................................. 23

6.2.1 Information on electrical installation........................................... 23

6.2.2 Double-pole safe disconnection................................................. 24

6.2.3 Single-pole safe disconnection.................................................. 25

7 Startup................................................................................................................ 26

7.1 Operating states........................................................................................ 26

7.1.1 Brake module control under normal operating conditions, e.g.

automatic operation of the plant ................................................ 26

7.1.2 Brake module control under special operating conditions, e.g.

teach or jog mode...................................................................... 27

7.1.3 Operating state display .............................................................. 27

8 Inspection/Maintenance ................................................................................... 28

8.1 Inspection and maintenance intervals....................................................... 28

8.2 Checking the brake function ..................................................................... 28

8.3 Service ...................................................................................................... 29

8.4 Unit replacement....................................................................................... 29

9 Applications....................................................................................................... 30

9.1 Disconnection of single drives via inverter (example MOVIDRIVE

9.2 Disconnection of single drives via inverter and DFS11B/21B fieldbus

interface .................................................................................................... 32

9.3 Disconnection of group drives................................................................... 33

10 Technical Data................................................................................................... 34

10.1 General technical data .............................................................................. 34

10.2 Safety-related control voltage ................................................................... 35

10.3 Safety characteristics of BST brake modules ........................................... 35

10.4 Dimension drawing of BST in control cabinet design................................ 36

11 Address List ...................................................................................................... 37

®

B) .... 31

Index................................................................................................................... 48

4

Operating Instructions – Safety-Related BST Brake Module

Page 5

General Information

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

How to use this documentation

1

1 General Information

Safety-Rated BST Brake Module

1.1 How to use this documentation

The documentation is part of the product and contains important information. The

documentation is for everyone who works with this product.

The documentation must be accessible and legible. Make sure that persons responsible

for the system and its operation, as well as persons who work independently with the

software and the connected units from SEW-EURODRIVE, have read through the documentation carefully and understood it. If you are unclear about any of the information

in this documentation, or if you require further information, contact SEW-EURODRIVE.

1.2 Structure of the safety notes

1.2.1 Meaning of the signal words

The following table shows the grading and meaning of the signal words for safety notes,

notes on potential risks of damage to property, and other notes.

Signal word Meaning Consequences if disregarded

DANGER Imminent danger Severe or fatal injuries

WARNING Possible dangerous situation Severe or fatal injuries

CAUTION Possible dangerous situation Minor injuries

NOTICE Possible damage to property Damage to the drive system or its

INFORMATION Useful information or tip: Simpli-

fies the handling of the drive

system.

environment

1.2.2 Structure of the section-related safety notes

Section safety notes do not apply to a specific action, but to several actions pertaining

to one subject. The used symbols indicate either a general or a specific hazard.

This is the formal structure of a section safety note:

SIGNAL WORD

Type and source of danger.

Possible consequence(s) if disregarded.

• Measure(s) to prevent the danger.

1.2.3 Structure of the embedded safety notes

Embedded safety notes are directly integrated in the instructions just before the description of the dangerous action.

This is the formal structure of an embedded safety note:

• SIGNAL WORD Nature and source of hazard.

Possible consequence(s) if disregarded.

– Measure(s) to prevent the danger.

Operating Instructions – Safety-Related BST Brake Module

5

Page 6

1

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

General Information

Right to claim under warranty

1.3 Right to claim under warranty

A requirement of fault-free operation and fulfillment of any rights to claim under limited

warranty is that you adhere to the information in the documentation at hand. Therefore,

read the documentation before you start working with the software and the connected

units from SEW-EURODRIVE.

Make sure that the documentation is available to persons responsible for the machinery

and its operation as well as to persons who work independently on the devices. Also

ensure that the documentation is legible.

1.4 Exclusion of liability

You must adhere to this documentation and the documentation of the connected

devices from SEW-EURODRIVE to ensure safe operation and to achieve the specified

product characteristics and performance features.

SEW-EURODRIVE assumes no liability for injury to persons or damage to equipment or

property resulting from non-observance of the documentation. In such cases, any liability for defects is excluded.

1.5 Copyright

© 2011 – SEW-EURODRIVE. All rights reserved.

Unauthorized duplication, modification, distribution or any other use of the whole or any

part of this documentation is strictly prohibited.

1.6 Product names and trademarks

All brands and product names in this documentation are trademarks or registered trademarks of their respective titleholders.

1.7 Applicable documentation

Observe the following applicable documents:

• Certificates and characteristic safety values

Make sure you always use the latest documentation and software version.

Our documentation is available in various languages for download from the SEW

homepage. If you are unclear ab

if you require further information, please contact SEW-EURODRIVE.

If required, you can order printed copies of the documentation from SEW-EURODRIVE.

out any of the information in this documentation, or

6

Operating Instructions – Safety-Related BST Brake Module

Page 7

2 Safety Notes

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

The following basic safety notes must be read carefully to prevent injury to persons and

damage to property. The operator must ensure that the basic safety notes are read and

adhered to. Make sure that persons responsible for the plant and its operation, as well

as persons who work independently on the unit, have read through the operating instructions carefully and understood them. If you are unclear about any of the information in

this documentation, or if you require further information, please contact SEWEURODRIVE.

2.1 Preliminary information

This document contains safety-related conditions for the operation of the safety-relevant

BST brake module with safe disconnection of the brake.

The classification to category 3 according to EN 954-1, or performance level d according

to EN ISO 13849-1 applies to the control and not to the brake.

Safety Notes

Preliminary information

2

2.2 General information

Never install or start up damaged products. Submit a complaint to the shipping company

immediately in the event of damage.

All work related to transportation, storage, setup/mounting, connection, startup, maintenance and repair may only be carried out by qualified personnel, in strict observance of:

• The relevant detailed operating instructions

• The warning and safety signs

• All other project planning documents, operating instructions and wiring diagrams

related to the drive

• The specific regulations and requirements for the system

• The national/regional regulations governing safety and the prevention of accidents

The requirements for the safety switching device and the permitted circuit variants are

specified in detail in section "Requirements for external safety switching devices"

(page 16) and must be strictly observed.

The system/machine manufacturer must perform a system/machine-specific risk

assessment. This is to take into account the safety-relevant BST brake module as well

as the mechanical brake design.

Removing covers without authorization, improper use as well as incorrect installation or

operation may result in severe injuries to persons or damage to property.

Refer to the documentation for additional information.

Operating Instructions – Safety-Related BST Brake Module

7

Page 8

2

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2.3 Target group

2.4 Designated use

Safety Notes

Target group

Only qualified personnel is allowed to perform installation, startup, fault repair and

servicing (observe IEC 60364 or CENELEC HD 384 or DIN VDE 0100 and IEC 60664

or DIN VDE 0110 as well as national accident prevention guidelines).

Qualified electricians in the context of these basic safety notes are persons familiar with

installation, assembly, startup and operation of the product who possess the required

qualifications.

Any activities regarding transportation, storage, operation, and disposal must be carried

out by persons who have been instructed appropriately.

The safety-relevant BST brake module is responsible for the power supply and control

of disk brakes from SEW-EURODRIVE. For the permitted combination of safety-related

BST brake module and SEW disk brake, refer to the section "Permitted unit combinations" in the "Safety-Relevant Conditions" chapter. The safety-relevant BST brake

module is intended for industrial systems and may only be used in accordance with the

information provided in SEW-EURODRIVE's technical documentation and the information given on the nameplate.

2.5 Transport

Inspect the shipment for any damage that may have occurred in transit as soon as you

receive the delivery. Inform the shipping company immediately. It may be necessary to

preclude startup.

2.6 Installation/assembly

Observe the notes in chapter "Mechanical Installation" (page 21).

8

Operating Instructions – Safety-Related BST Brake Module

Page 9

2.7 Startup/operation

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety Notes

Startup/operation

2

• When the safety-related control voltage V

is disconnected, the DC link voltage V

• The safety concept is only suitable for performing mechanical work on the system/

machine components.

• All poles must be disconnected from the supply system when work is carried out on

the electrical section of the system. Dangerous voltages may still be present for up

to 10 minutes after disconnection from the power supply system.

• You have to take into account that, in case of a fault, the application time of the

connected brake is longer, which means the drive might coast.

– For maximum brake application times, refer to chapter "Technical Data" of the

operating instructions for the BST and SEW disk brakes.

– Note: If coasting to a halt results in application-dependent hazards, take addi-

tional protective measures (e.g. movable covers with closure), which cover the

hazardeous area until persons are no longer in danger.

– The additional protective covers must be designed and integrated to meet the

requirements stipulated in EN ISO 12100:2010 and the requirements determined

for the machine based on the risk assessment.

– After activating the stop command, access to the machine must remain blocked

until the drive has reached standstill, or the access time has to be determined to

ensure that an adequate safety distance is maintained.

• The states of LED V1 and LED V2 must not be regarded as safety-relevant. The fact

that the LED V1 and LED V2 are no longer illuminated does not indicate that the

safety-relevant BST brake module is de-energized and the brake is applied. Even if

LED V1 and LED V2 are not illuminated, DC link voltage V

the BST brake module.

• The safety-related BST brake module does not detect a mechanical fault (such as

brake lining wear) of the disk brakes of SEW-EURODRIVE.

24 V safe

DC link

/ functional control voltage V

is still present at the brake module.

might be present at

DC link

24 V in

2.8 Inspection/maintenance

Observe the notes in chapter "Inspection/Maintenance" (page 28).

2.9 Disposal

Dispose the BST in accordance with the material structure and the regulations in force

for instance as:

•Iron

• Copper

•Aluminum

• Plastic

Operating Instructions – Safety-Related BST Brake Module

9

Page 10

3

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Integrated Safety Technology

Safe condition

3 Integrated Safety Technology

The safety technology of the safety-related BST brake module described in this document has been developed and tested in accordance with the following safety requirements:

• Category 3 according to EN 954-1

• Performance level d according to EN ISO 13849-1

This was certified by TÜV Nord. A copy of the TÜV certificate can be obtained from

SEW-EURODRIVE.

3.1 Safe condition

Safety-relevant use of the BST brake module means the de-energized condition of

the connected brake is defined as safe condition. This is the basis of the safety

concept.

3.2 Safety concept

• The safety-related BST brake module enables the connection of an external fail-safe

• Disconnecting the safe control voltage V

• Instead of separating the brake control galvanically from the power supply using

safety switching device/safety controller. The safety switching device disconnects

the safe control voltage V

stop device) is activated.

disconnected from the power supply. The power supply required for releasing the

connected brake is interrupted safely.

contactors or switches, the disconnection procedure described here prevents the

power semiconductors in the safety-related BST brake module from being activated,

in this way ensuring safe disconnection. This means that all connected brakes are

de-energized although the supply voltage is still present at the safety-related BST

brake module.

24 V safe

when a connected control device (e.g. emergency

24 V safe

means the connected brake is

10

Operating Instructions – Safety-Related BST Brake Module

Page 11

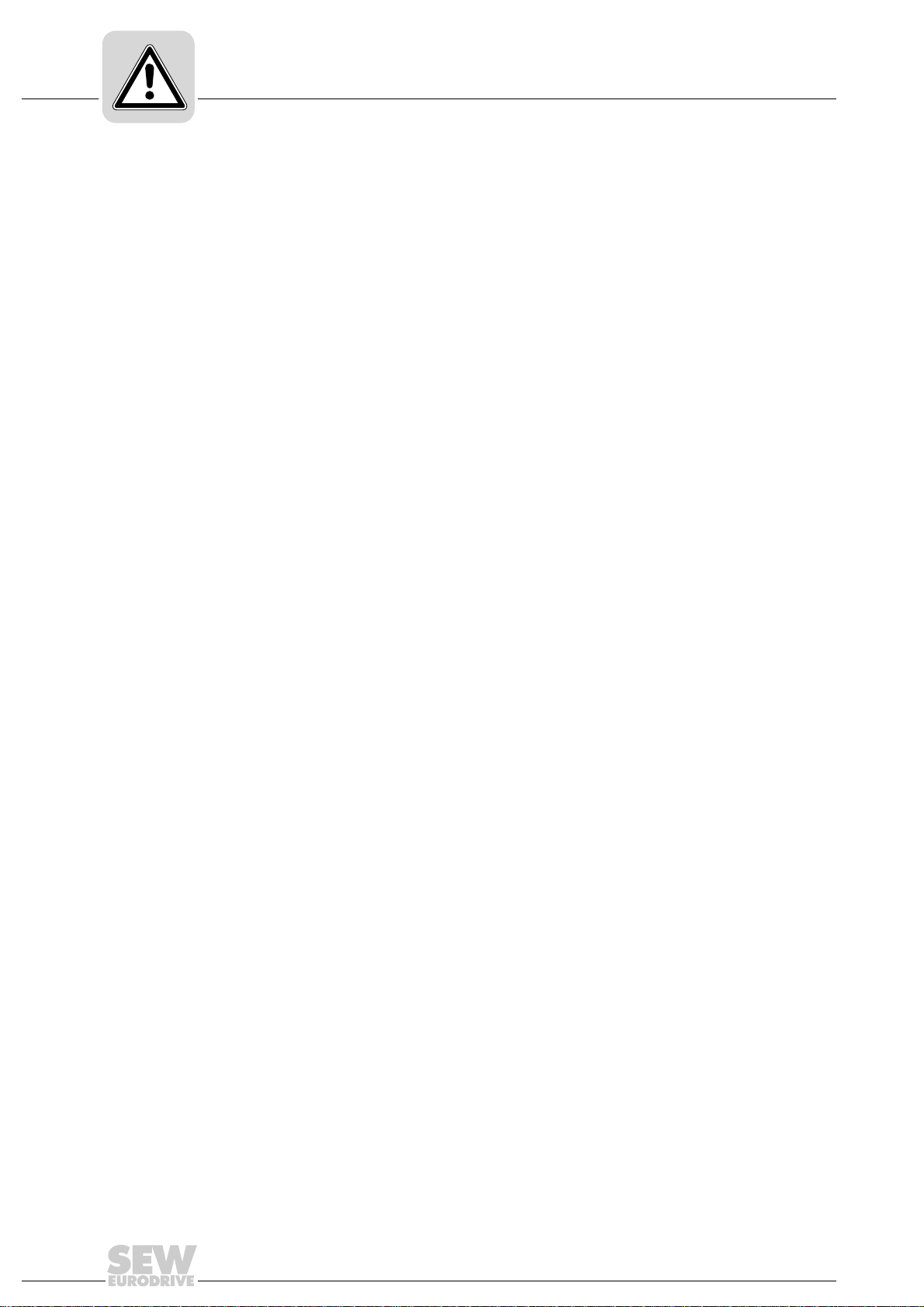

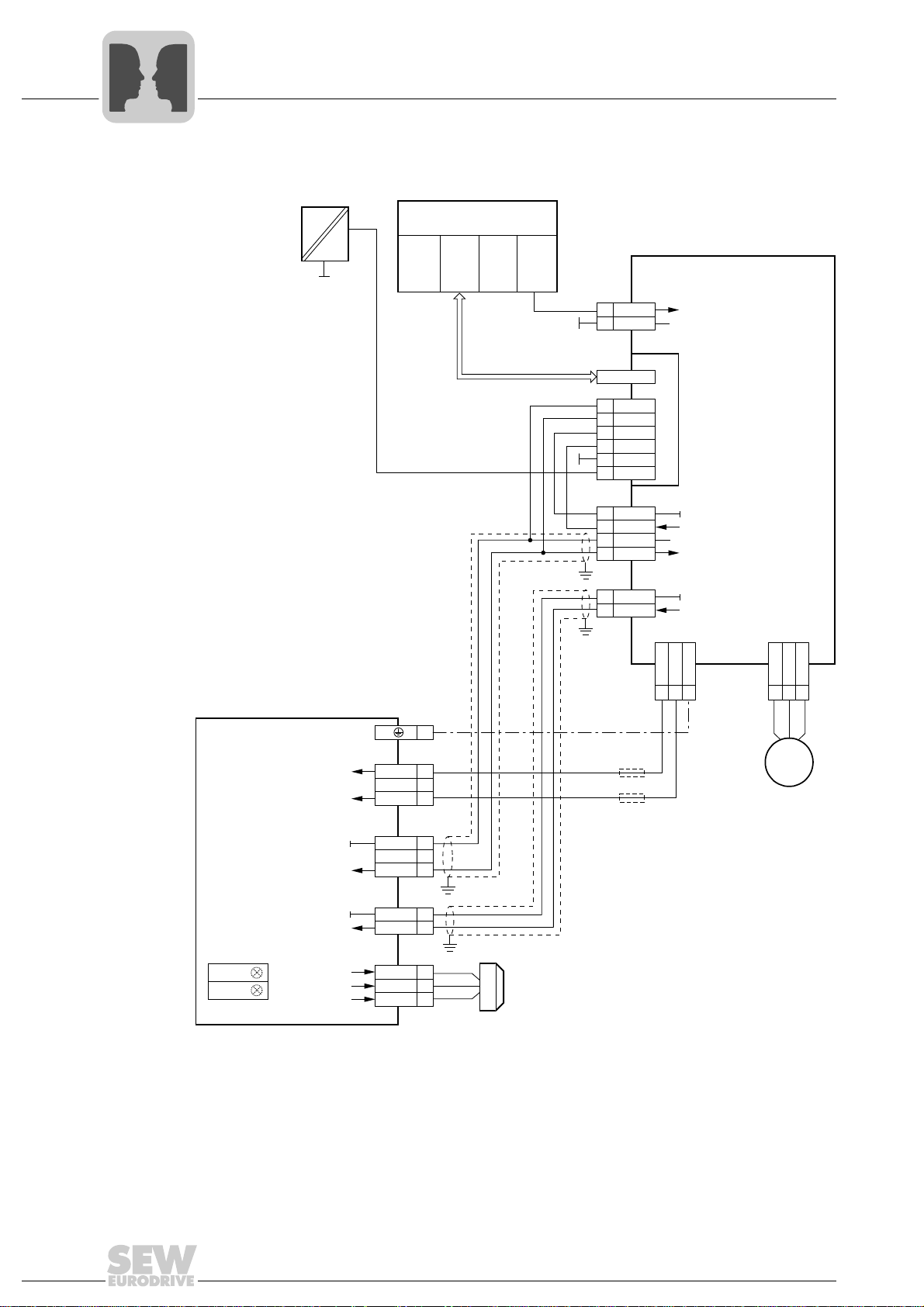

3.2.1 Block diagram BST

34

56

13 14 15

12

[1]

[4]

[3]

[2]

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

[1] DC link voltage input V

[2] Brake output (terminals 13/14/15)

[3] Functional control voltage input V

[4] Safety-related control voltage input V

Integrated Safety Technology

Safety function

(terminal 1/2)

DC link

(terminal 3/4)

24 V in

24 V safe

(terminal 5/6)

3

9007201124185483

3.3 Safety function

The following drive-related safety function can be used:

• SBC (Safe Brake Control according to IEC 61800-5-2)

The SBC function safely de-energizes the connected brake by disconnecting the

safety-related control voltage V

disconnected using a suitable external safety switching device/safety controller.

INFORMATION

Safety-related brake control must be carried out using the safety-related control

voltage V

24 V safe

(terminal 5/6) only.

24 V safe

. The safety-related control voltage must be

Operating Instructions – Safety-Related BST Brake Module

11

Page 12

3

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

3.4 Restrictions

Integrated Safety Technology

Restrictions

WARNING

Voltage is still present at the DC link connection of the frequency inverter even when

disconnecting the safety-related control voltage V

V

Severe or fatal injuries from electric shock.

• If work is carried out on the electrical section of the brake system, the supply

.

24 V in

voltage must be disconnected using an external maintenance switch.

24 V safe

/ functional control voltage

INFORMATION

• The safety concept is only suitable for performing mechanical work on the system/

machine components.

• A system/machine-specific risk assessment must be carried out by the system/

machine manufacturer and be observed when using the drive system with BST.

12

Operating Instructions – Safety-Related BST Brake Module

Page 13

4 Safety-Relevant Conditions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

The safety function of BST can only be used for safe operation of the system/machine

if it is integrated correctly in an application-specific, higher-level safety function or safety

system. It is essential that the system/machine manufacturer conducts a system/

machine-specific risk assessment (e.g. according to EN ISO 12100) and validates the

required safety conditions and functions prior to startup. The system/machine manufacturer and the operator are responsible for compliance of the system/machine with

applicable safety regulations.

The following requirements are mandatory when installing and operating the BST brake

module in safety-related applications.

The conditions are divided into the following sections:

• Approved device combinations

• Installation requirements (page 14)

• Requirements for the external safety controller (page 16)

• Startup requirements (page 17)

• Operation requirements (page 18)

Safety-Relevant Conditions

Permitted unit combinations

4

4.1 Permitted unit combinations

The following BST unit types are permitted for safety-related applications:

Type designation Part number Approved SEW disk brakes

BST 0.6S-460V-00 0 829 971 4 All brake coils with a coil voltage of AC 460 V and a coil power

BST 0.7S-400V-00 1 300 077 2 All brake coils with a coil voltage of AC 400 V and a coil power

BST 1.2S-230V-00 1 300 133 7 All brake coils with a coil voltage of AC 230 V and a coil power

≤ 120 W.

Several brake coils can be connected for redundant systems.

In this case, the total power must not exceed 120 W.

≤ 120 W.

Several brake coils can be connected for redundant systems.

In this case, the total power must not exceed 120 W.

≤ 120 W.

Several brake coils can be connected for redundant systems.

In this case, the total power must not exceed 120 W.

Operating Instructions – Safety-Related BST Brake Module

13

Page 14

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety-Relevant Conditions

Requirements on the installation

Only SEW disk brakes may be connected to the BST module.

Asynchronous motor type

Brake

type

BE05 xx

BE1 xxx

BE2 xx x

BE5 xxxx

BE11 xxx

BE20 xx

BE30 xxx

BE32 xxx

1) Brakes of the type BM or BM(G) 05 – 30 can be combined.

Brake

type

BY2 x

BY4 x

BY8 x

1) Brakes of the type B can be combined.

DR.71 DR.80 DR.90 DR.100 DR.112 DR.132 DR.160 DR.180 DR.200 DR.225

1)

Synchronous motor type

CMP.71 CMP.80 CMP.100

1)

4.2 Requirements on the installation

The line between the safety switching device/safety controller and the safety-related

BST brake module, terminal 5/6 (V

(for safe disconnection).

Observe the following requirements on the installation:

• Power lines and safety-related control lines have to be installed in separate cables.

• The total cable length between the safety switching device/safety controller and the

safety-related BST brake module is limited to a maximum length of 100 m for EMC

reasons.

• The total cable length between the safety-related BST brake module and the

connected brake must not exceed 200 m.

• Wiring must comply with EN 60204-1.

• The installation space (control cabinet) must have at least degree of protection IP54.

• The safety-related control lines must be routed according to EMC guidelines and as

follows:

– Outside an electrical installation space: Shielded cables must be routed perma-

nently (fixed) and protected against external damage, or other equivalent

measures.

– Individual conductors can be routed inside an electrical installation space.

Observe the respective regulations governing the application.

– It is essential that you apply the shielding at both ends on the housing.

• The safety-related control voltage V

24 V safe

24 V safe

) is referred to as safety-related control line

may not be used for feedback.

14

Operating Instructions – Safety-Related BST Brake Module

Page 15

Safety-Relevant Conditions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Requirements on the installation

• You have to make sure that there is no transient coupling to the safety-related control

voltage V

• Observe the values specified for safety components when designing the safety

circuits.

• Use only voltage sources with safe disconnection (SELV/PELV) according to

EN 60204-1 for any DC 24 V voltage supply (safety-related control voltage V

and functional control voltage V

In case of a single fault, the voltage between the outputs or between any output and

grounded parts must not exceed DC 60 V.

• Do not interconnect brake cables of several brake control systems.

• For disconnection of group drives, observe the switching capacity of the safety

switching device and the maximum permitted voltage drop on the safety-related

control voltage V

• Adhere to the technical data of the BST module and the brake.

• Adhere to the general installation regulations in the "Installation" chapter.

The following figure shows EMC compliant installation.

24 V safe

.

24 V safe

) of the safety-related BST brake module.

24 V in

.

24 V safe

4

Operating Instructions – Safety-Related BST Brake Module

9007199397615115

15

Page 16

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety-Relevant Conditions

Requirements on external safety controller

4.3 Requirements on external safety controller

A safety relay can be used as an alternative to a safety controller. The following requirements apply analogously.

• The safety controller and all other safety-related subsystems must be approved for

at least that safety class which is required in the overall system for the applicationrelated safety function. The following table shows an example of the required safety

class of the safety controller.

Application Safety controller requirements

Category 3 according to EN 954-1 Category 3 according to EN 954-1

Performance level d according to EN ISO 13849-1 Performance level d according to EN ISO 13849-1

• The wiring of the safety controller must be suitable for the required safety class, (see

manufacturer documentation). The safety-related control voltage V

safely disconnected either at the positive, or the positive and negative pole. SEWEURODRIVE recommends bipolar disconnection.

• The values specified for the safety controller must be strictly adhered to when

designing the circuit.

• The switching capacity of the safety relays or the relay outputs of the safety controller

must correspond at least to the maximally permitted, limited output current of the

safety-relevant control voltage V

concerning the permitted contact loads and fusing tha t my be requir ed for the

safety contacts. If there are no manufacturer's instructions for fusing, the

contacts must be protected with 0.6 times the nominal value of the maximum

contact rating specified by the manufacturer.

24 V safe

Performance level d according to EN ISO 13849-1

SIL 2 according to EN 61508

SIL 2 according to EN 61508

24 V safe

can be

. Observe the manufacturer's instructions

• To ensure protection against unintended restart in accordance with EN 1037, the

safety controllers must be designed and connected in such a way that resetting the

control device alone does not lead to a restart. A restart may only be carried out after

a manual reset of the safety circuit.

• The input of the safety-relevant control voltage V

24 V safe

of the safety-relevant BST

brake module (terminal 5/6) is equipped with a serial polarity protection diode and a

buffer capacitor with C = 6 μF. This must be considered as load when dimensioning

the switching output.

• When switching off the BST with tested safe outputs, the switch-off test pulses must

not exceed 1 ms. The next pulse blanking cannot reoccur earlier than after 20 ms.

16

Operating Instructions – Safety-Related BST Brake Module

Page 17

4.3.1 Sample circuit for a "safety switching device"

Safety-related

control voltage V

of the safety switching device

Safety switching device

Fuses according to the

specifications of the

safety switching device

manufacturer

DC 24 V

GND

DC 24 V voltage supply

Approved

emergency stop device

Reset button

24 V safe

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

The following figure shows the basic connection of an external safety switching device

(according to the before mentioned requirements).

Observe the information in the respective manufacturer's data sheets for connection.

Safety-Relevant Conditions

Requirements on startup

4

4.4 Requirements on startup

9007199399082635

• Startup must be documented and the functionality of the safety functions must be

demonstrated. Observe the limitations for the safety functions of the BST brake

module in chapter "Restrictions" for the verification of the safety functions. Nonsafety-relevant parts and components that affect the result of the verification test

(e.g. brake rampe of a frequency inverter) must be deactivated, if necessary.

• For using the BST brake module in safety-relevant applications, it is essential that

you perform and record startup checks for the disconnecting device and correct

wiring.

• During the startup procedure/function test, the correct assignment of the respective

voltage supply connection must be checked by means of a measurement.

– Safety-relevant control voltage V

– Functional control voltage V

24 V in

24 V safe

: Terminal 5/6

: Terminal 3/4

• The function check must be carried out separately for all potentials.

• Observe the notes in the "Startup" chapter.

Operating Instructions – Safety-Related BST Brake Module

17

Page 18

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety-Relevant Conditions

Requirements on the operation

4.5 Requirements on the operation

• Operation is only allowed within the limits specified in the data sheets. This applies

to both the external safety relay as well as the BST.

• You must check the safety functions on a regular basis to ensure proper functioning.

The the test intervals should be specified in accordance with the risk assessment.

• Also observe the information in the "Inspection/Maintenance" chapter.

18

Operating Instructions – Safety-Related BST Brake Module

Page 19

5 Unit Design

US

LISTED

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

5.1 Nameplate, type designation

5.1.1 Example: Type designation

The following characteristic unit data can be read from the type designation:

BST 0.6 S - 460V - 00

Unit Design

Nameplate, type designation

Version/type

Brake

voltage

Design S = Control cabinet module

Nominal output current 0.6 = DC 0.6 A

Series

460 V = AC 460 V (DC 190 V)

400 V = AC 400 V (DC 167 V)

230 V = AC 230 V (DC 96 V)

0.7 = DC 0.7 A

1.2 = DC 1.2 A

5

5.1.2 Example: Nameplate

The following figure shows a nameplate of BST 0.6S-460V-00:

[4]

[3]

[2]

[1]

[1] Output current (I

[2] Functional control voltage (V

[3] DC link voltage (V

[4] Type designation

[5] Serial number

[6] Part number

[7] Nominal output current (I

[8] Safety characteristics

[9] Degree of protection (IP) and ambient temperature (T)

[5]

08299714.1111

0004642

Typ : BST 0.6S−460V −00

Uz=

350 . . . 750V DC

Uin=

24V DC

Ibreak warm=

Usafe=

0.5A DC

24V DC

[9]

brake warm

DC link

[6]

U

DBI24 DGND SVI24 S0V24

B

++ +---

rd wh bu

13 14 15 3 4 5 NC 6 1 NC 2

IN = 0.6A DC (UB=190V DC / 460V AC)

WHEN USED WITH LISTED DRIVE SERIES:

MOVIDRIVE MOVITRAC

EN ISO 13849-1 Kat. 3 / PL d

IP 20 T= -15 ... +60°C

MANUFACTURED BY SEW-EURODRIVE ML 0001

[8]

) in warm condition

) and safety-related control voltage (V

in

)

) and brake voltage (VB)

N

Uz PE

18014398652394507

)

safe

[7]

CE mark to state compliance with European guidelines, such as the Low Voltage Directive.

UL logo to confirm that the component is UL (Underwriters Laboratory) tested, also valid for

US

®

CSA in conjunction with register number 2D06.

LISTED

Operating Instructions – Safety-Related BST Brake Module

19

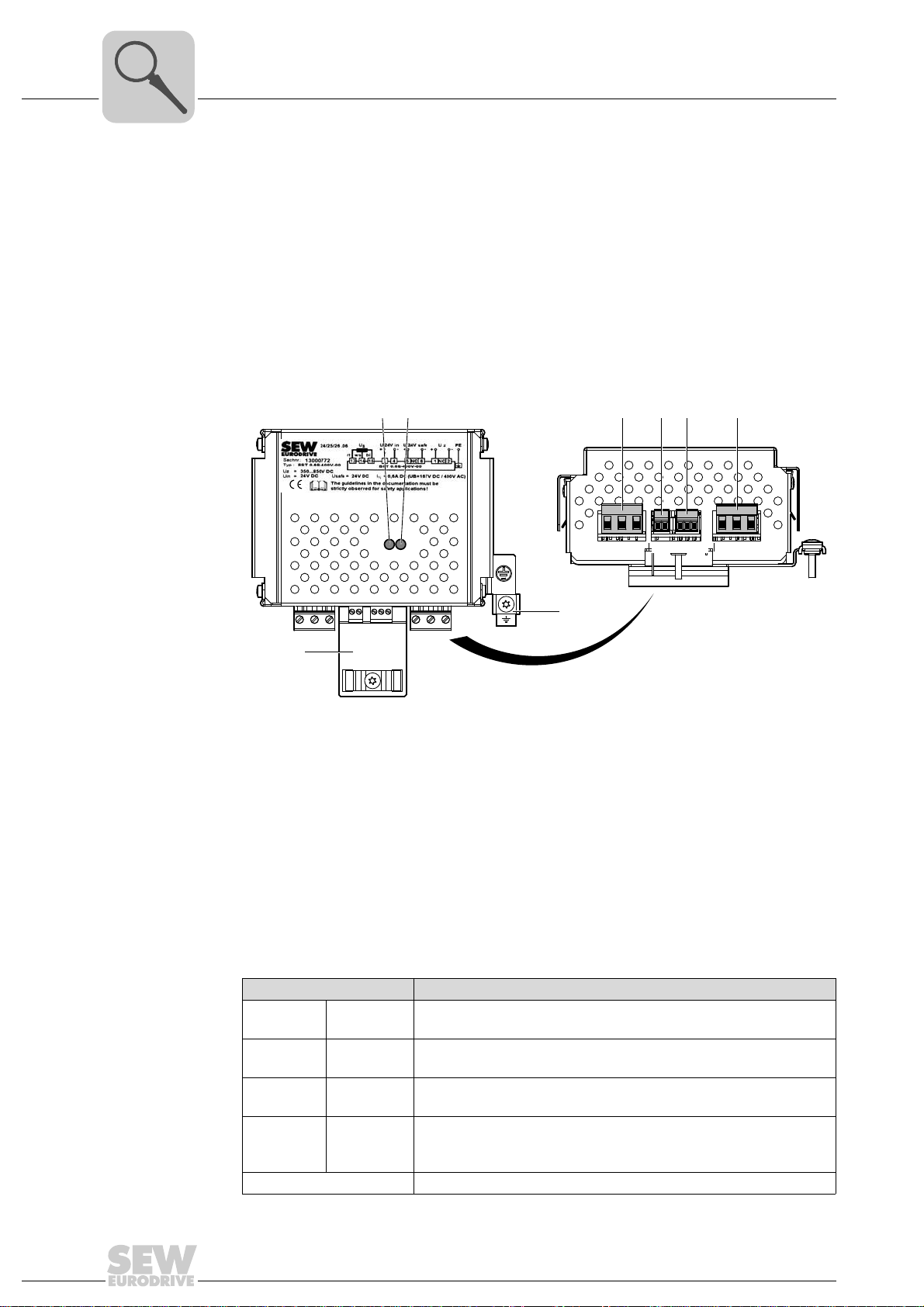

Page 20

5

13/14 /15 1/NC /23/4 5/NC/6

[3] [4] [5] [6]

[8]

[7]

[1] [2]

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Unit Design

Scope of delivery of BST

5.2 Scope of delivery of BST

The scope of delivery includes:

• 1 safety-related BST brake module with installed holding fixture for support rail

mounting

• 4 attached plug connectors for terminal connections

5.3 Safety-related BST brake module

The following figure shows the unit design of BST x.xS-xxxV-00:

[1] LED V1 for indicating the operating state

[2] LED V2 for indicating the operating state

[3] Terminals 13/14/15: Brake connection

[4] Terminals 3/4 : For connecting the functional control voltage V

[5] Terminals 5/6 : For connecting the safety-related control voltage V

[6] Terminals 1/2 : DC link voltage connection V

[7] PE connection

[8] Retaining plate / shield plate

5.4 Terminal assignment

Terminal Function

1

2

5

6

3

4

13

14

15

댷 Protective grounding

+U

Z

- U

Z

SVI24

S0V24

DBI24

DGND

RD

WH

BU

24 V in

24 V safe

DC link

DC link voltage input V

Safety-related control voltage V

Reference potential for safety-related control voltage V

Functional control voltage input V

Reference potential for functional control voltage V

Brake output

z

input

24 V safe

24 V in

24 V in

9007199397613451

24 V safe

20

Operating Instructions – Safety-Related BST Brake Module

Page 21

6 Installation

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

6.1 Mechanical Installation

6.1.1 Support rail mounting

The BST module is mounted onto a support rail in the control cabinet.

Installation

Mechanical Installation

6

Mounting

137090187

[1]

[2]

[3]

[4]

[5]

[6]

1887424139

[1] Safety-related BST brake module

[2] Support rail

[3] Upper holding fixture of the BST

[4] Notch, lower holding fixture of the BST

[5] Upper support rail edge

[6] Lower support rail edge

1. The upper holding fixture of the BST [3] is spring-loaded. First, insert the BST into

the upper support rail edge [5] with the upper holding fixture only.

2. Next, press the BST downward towards the support rail until the notch [4] clicks into

place on the lower support rail edge [6].

The spring at the upper holding fixture causes the lower support rail edge to be

pressed into the notch so that the BST [1] is secured onto the support rail [2].

Operating Instructions – Safety-Related BST Brake Module

21

Page 22

6

15 15

70

30 (1.18)

(2.76)

(0.59) (0.59)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Removal 1. Press onto the BST from the top. This causes the lower support rail edge [6] to come

Installation

Mechanical Installation

off the notch [4]. At the same time, remove the BST from the lower holding fixture.

2. You can remove the BST from the support rail once the lower lock unfastens.

Minimum

clearance and

mounting position

• Leave 30 mm clearance at the top, 70 mm at the bottom and 15 mm at the sides for

optimum cooling. Make sure air circulation in the clearance is not impaired by cables

or other installation equipment.

• Ensure unobstructed cooling air supply and make sure that the units are not

subjected to heated air from nearby components.

• Install the units vertically only. Do not install the units horizontally, tilted or upside

down.

All dimensions in mm (in).

22

18014398646570507

Operating Instructions – Safety-Related BST Brake Module

Page 23

6.2 Electrical Installation

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

INFORMATION

• The safety-related BST brake module cannot be operated with sine-shaped power

regeneration.

• All poles must be disconnected from the supply system when work is carried out

on the electrical section of the system. Dangerous voltages may still be present for

up to 10 minutes after disconnection from the power supply system.

6.2.1 Information on electric a l ins tall at io n

Supply cable

(terminal 1/2)

The supply cable must meet the following conditions:

• The supply cables to the BST carry a high DC voltage (max. DC 970 V). The rated

voltage of the cable must amount to at least V

DIN VDE 0298).

• The inverter supply system must have a grounded star point (TT/TN). The operation

is not permitted for IT systems or systems grounded via an outer conductor.

• Cable cross section: 0.75 mm

Installation

Electrical Installation

/V = 300 V / 500 V (in accordance with

0

2

–2.5 mm2 (AWG19–AWG13)

6

Functional control

cable (terminal 3/4)

Safety-related

control cable

(terminal 5/6)

• Max. cable length: 100 m (328 ft)

• When several BST are connected to one DC link, the input power of the inverter must

be taken into account.

• All poles of the supply cable are protected with two corresponding DC fuses F1/F2

(recommended 1000 V/4 A).

INFORMATION

The fuses may not be required in compliance with IEC 60364-4-43 ((VDE 100 part

430) and EN 60204-1 if the supply cable to the BST is protected by the input fuse

located in front of the inverter, or if the following conditions are met:

• The cable length to the BST must not exceed 3 m.

• Do not lay cables in the vicinity of inflammable substances.

• Reduce the risk of short cirucits to a minimum.

• Use the greatest possible cable cross section.

The functional control cable must meet the following conditions:

2

• Cable cross section of 0.5 mm

• Max. cable length: 100 m (328 ft)

The safety-related control cable must meet the following conditions:

• Cable cross section of 0.5 mm

• Max. cable length: 100 m (328 ft)

– 1.5 mm2 (AWG20–AWG16)

2

– 1.5 mm2 (AWG20–AWG16)

Brake cable

(terminal 13/14/15)

Operating Instructions – Safety-Related BST Brake Module

• Cable cross section of 0.75 mm

• Max. cable length: 200 m (656 ft)

2

– 2.5 mm2 (AWG 19 – AWG 13)

23

Page 24

6

5

6

Installation space

BST

DC 24 V

Safety

switching device

SVI24

S0V24

N.C.

Safety-related

control voltage

V

24V safe

5

6

Installation space

Installation space

BST

Outside

installation space

Safety-related

voltage supply

24 V

N.C.

+U

24V safe

-U

24V safe

Safety

switching device

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Installation

Electrical Installation

6.2.2 Double-pole safe disconnection

The following figure shows the wiring inside the installation space:

The following figure shows the wiring outside the installation space:

9007199388524427

24

9007199388555019

Operating Instructions – Safety-Related BST Brake Module

Page 25

6.2.3 Single-pole safe disconnection

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

The following figure shows the wiring inside the installation space:

Electrical Installation

Installation space

Installation

6

Installation space

Safety switching

device

DC 24 V

Safety switching

device

SVI24

5

Safety-related

DC 24 V

N.C.

6

S0V24

control voltage

V

24V safe

The following figure shows the wiring outside the installation space:

Outside install. space

Installation space

BST

5

SVI24

Safety-related

N.C.

6

S0V24

control voltage

BST

9007199388553355

V

24V safe

9007199388551691

INFORMATION

Safe single-pole disconnection is only permitted when short circuits in the safetyrelevant control cable between safety relay and BST can be ruled out (fault elimination

according to EN ISO 13849-2).

SEW-EURODRIVE recommends bipolar disconnection.

Operating Instructions – Safety-Related BST Brake Module

25

Page 26

7

t

off

1s

t

off

1s

t

off

1s

t

off

1s

t

on

t

on

t

on

t

on

t/s

Brake

control

signal

00

I

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

7Startup

7.1 Operating states

Startup

Operating states

• The brake is activated with the functional control voltage V

voltage V

V

V

is present Ⳏ Brake released.

24 V in

is not present Ⳏ Brake applied.

24 V in

• If the safety-related control voltage V

and the safety-related control voltage V

DC link

24 V safe

24 V safe

is disconnected, the brake is safely de-

when the DC link

24 V in

are present.

energized (SBC).

• If the DC link voltage V

is disconnected, the brake is de-energized.

DC link

The brake is released with high-sped excitation. Rapid brake application (DC and AC

switch-off) occurs when it is controlled using the V

V

24 V safe

safety-related control voltage.

functional control voltage or the

24 V in

The response time for releasing and applying the brake results from the response time

of the BST t

≤ 6 ms and the response or application time of the brake connected. For

R

information on response or application times, refer to the applicable operating instructions for motors.

INFORMATION

Fast disconnection (cut-off in the DC circuit) of the brake by the BST module is not part

of the safety function (SBC). The brake application time for cut-off in the AC circuit

must therefore be used.

NOTICE

The brake module might be damaged if required off periods are not adhered to.

Damage to the drive system.

• Adhere to the required off periods for the brake module.

7.1.1 Brake module control under normal operating conditions, e.g. automatic ope ration of the plant

With a brake coil power of P ≥ 70 W, you must ensure a timeout of at least 1 second for

brake control.

2950935051

26

Operating Instructions – Safety-Related BST Brake Module

Page 27

Startup

00

I

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Operating states

7.1.2 Brake module control under special operating conditions, e.g. teach or jog mode

For teach or jog mode, for example, timeouts shorter than 1 second are possible. After

20 control pulses, a timeout of minimum 3 min is mandatory in this case.

7

Brake

control

signal

7.1.3 Operating state display

LEDs V1 and V2 indicate the operating state of the control inputs.

• LED V1: State of the safety-relevant control voltage V

• LED V2: State of the brake when the DC link voltage V

LED V1 LED V2 V

Off Off Off Off Brake de-energized

Off Off Off On Brake de-energized

Lights up orange Off On Off Brake de-energized

Lights up orange Lights up green On On Brake energized when V

INFORMATION

• The states of LED V1 and LED V2 must not be regarded as safety-relevant.

• The fact that the LED V1 and LED V2 are no longer illuminated does not indicate

that the safety-relevant BST brake module is de-energized and the brake is

applied.

• Even if LED V1 and LED V2 are not illuminated, DC link voltage V

present at the BST brake module.

max. 20 pulses

t

off

min. 180 s

24 V safe

V

24 V in

t

DC link

.

is present.

24 V safe

Operating state

present

DC link

2951034251

is

DC link

might be

Operating Instructions – Safety-Related BST Brake Module

27

Page 28

8

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Inspection/Maintenance

Inspection and maintenance intervals

8 Inspection/Maintenance

WARNING

Risk of crushing if the hoist falls.

Severe or fatal injuries.

• Secure or lower hoist drives (danger of falling)

• Isolate the inverter, the motor and the brake from the power supply before starting

work, safeguarding them against accidental startup.

• Only use genuine spare parts in accordance with the valid parts list.

• Always install a new brake controller at the same time as replacing the brake coil.

• Observe the notes in the operating instructions for AC motors and brakemotors.

• Only qualified personnel may perform maintenance for the brake.

WARNING

There may still be dangerous voltages inside the unit and at the terminal strips for up

to 10 minutes after the BST has been disconnected from the power supply.

Severe or fatal injuries from electric shock.

• Disconnect the BST from the power supply and ensure that the unit cannot be

switched on unintentionally.

• Wait for 10 minutes before carrying out any maintenance or inspection work.

• Prior to maintenance or inspection work, make sure that the BST is de-energized.

CAUTION

The surface of the safety-related BST brake module can be very hot during operation.

Danger of burns.

• Let the BST cool down before you start working on it.

8.1 Inspection and maintenance intervals

The required inspection/maintenance intervals must be calculated by the system

manufacturer according to the specific project planning documents for individual applications, in accordance with the regionally valid standards.

8.2 Checking the brake function

The brake function must be checked according to the instructions of the system

manufacturer after inspection/maintenance work.

28

Operating Instructions – Safety-Related BST Brake Module

Page 29

8.3 Service

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Have the following information available when you require assistance from the SEWEURODRIVE service:

• Nameplate data (complete)

• Type and extent of the problem

• Time the problem occurred and any accompanying circumstances

• Assumed cause

8.4 Unit replacement

Proceed as follows to replace a BST:

• Observe the notes regarding inspection/maintenance work for the BST.

• DANGER There may still be dangerous voltages inside the unit and at the terminal

strips for up to 10 minutes after the BST has been disconnected from the power

supply.

Severe or fatal injuries from electric shock.

– Disconnect the BST from the power supply and ensure that the unit cannot be

switched on unintentionally.

Inspection/Maintenance

Service

8

– Wait for 10 minutes before carrying out any maintenance or inspection work.

– Prior to maintenance or inspection work, make sure that the BST is de-energized.

• Compare the data on the nameplate of the BST to be replaced with the new one.

• Remove all connecting terminals.

• Disconnect the PE and the shield clamps.

• Push lightly on the opposite side of the connection terminals and remove the BST

from the support rail.

• Install the new BST on the support rail. Observe chapter "Mechanical Installation".

• Connect the PE and the shield.

• Connect all connection terminals.

Operating Instructions – Safety-Related BST Brake Module

29

Page 30

9

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

9 Applications

Applications

The following figures show the wiring diagrams for SBC with simultaneous STO

(Safe Torque Off).

INFORMATION

• For safe single- and double-pole disconnection, refer to chapter "Electrical Installation"

• DC fuses F1/F2 are not required if the before mentioned requirements for the

supply cable are met.

• Observe chapter "Electrical Installation".

30

Operating Instructions – Safety-Related BST Brake Module

Page 31

Applications

X13:

X2:

X4:

MOVIDRIVE B

Safety-rated

brake module - BST

®

654

Enable/stop

/Controller inhibit

Reference potential binary signals

87

W

V

U

PE

Uz+

Uz-

1

4

7

DIØØ

DIØ3

X17:

DC+24 V input

Reference potential binary signals

DC+24 V output

Reference potential DC+24 V input

1

2

3

4

DGND

VO24

SOV24

SVI24

DCOM

DC link connection

DC link connection

2

1

Uz-

N.C.

Uz+

X10:

Regerence potential binary signals

/Brake

2

3

DGND

DBØØ

6

5

S0V24

N.C.

SVI24

blue

white

red

4

3

DGND

DBI24

15

14

13

BU

WH

RD

M

B

Feedback

emergency stop

Reset

DC 24 V

Start

Stop

Emergency

stop

~

GND

=

CPU

Higher-level

controller

DI

DO

Safety

relay

~

F1/F2

LED V2

LED V1

Reference potential V

24 V safe

V

24 V safe

Reference potential V

24 V in

V

24 V in

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Disconnection of single drives via inverter (example MOVIDRIVE® B)

9.1 Disconnection of single drives via inverter (example MOVIDRIVE® B)

9

18014398643152907

Operating Instructions – Safety-Related BST Brake Module

31

Page 32

9

X13:

X2:

X4:

MOVIDRIVE B

®

654

/Controller inhibit

Reference potential for binary signals

87

W

V

U

PE

Uz+

Uz-

1

7

DIØØ

X17:

DC+24 V input

Reference potential binary signals

DC+24 V output

Reference potential DC+24 V input

1

2

3

4

DGND

VO24

SOV24

SVI24

DCOM

X10:

Reference potential binary signals

/Brake

2

3

DGND

DBØØ

X30:

X31:

1

2

3

4

5

6 24V_PS

24V_LS

GND

GND

F_DO_P

F_DO_M

M

B

CPU

F_CPU

Higher-level

controller

DI

F_DI

DO

F_DO

PROFIBUS

PROFINET

PROFIsafe

DFS11B/21B

F1/F2

~

Safety-related

brake module - BST

DC link connection

DC link connection

2

1

Uz-

N.C.

Uz+

6

5

S0V24

N.C.

SVI24

blue

white

red

4

3

DGND

DBI24

15

14

13

BU

WH

RD

LED V2

LED V1

~

GND

=

DC 24 V

Reference potential V

24 V safe

V

24 V safe

Reference potential V

24 V in

V

24 V in

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Applications

Disconnection of single drives via inverter and DFS11B/21B fieldbus inter-

9.2 Disconnection of single drives via inverter and DFS11B/21B fieldbus interface

32

Operating Instructions – Safety-Related BST Brake Module

18014399290419595

Page 33

9.3 Disconnection of group drives

X13:

X2:

X4:

MOVIDRIVE B

®

654

Enable/stop

/Controller inhibit

Reference potential binary signals

87

W

V

U

PE

Uz+

Uz-

1

4

7

DIØØ

DIØ3

X17:

DC+24 V input

Reference potential binary signals

DC+24 V output

Reference potential DC+24 V input

1

2

3

4

DGND

VO24

SOV24

SVI24

DCOM

X10:

Reference potential binary signals

/Brake

2

3

DGND

DBØØ

M

B

B

Feedback

emergency stop

Reset

DC 24 V

Start

Stop

Emergency

stop

~

GND

=

CPU

Higher-level

controller

DI

DO

Safety

relay

F1/F2

~

M

~

Safety-related

brake module - BST

DC link connection

DC link connection

2

1

Uz-

N.C.

Uz+

6

5

S0V24

N.C.

SVI24

blue

white

red

4

3

DGND

DBI24

15

14

13

BU

WH

RD

LED V2

LED V1

Reference potential V

24 V safe

V

24 V safe

Reference potential V

24 V in

V

24 V in

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Applications

Disconnection of group drives

9

18014398643154571

Operating Instructions – Safety-Related BST Brake Module

33

Page 34

10

P

i

f

kVA

Hz

n

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Technical Data

General technical data

10 Technical Data

10.1 General technical data

Brake module BST 1.2S-230V-00 BST 0.7S-400V-00 BST 0.6S-460V-00

Part number 1300 1337 1300 0772 0829 9714

Interference immunity According to EN 61800-3

Interference emission with EMC-

compliant installation

Degree of protection IP20

Installation On support rail in control cabinet

(control cabinet must have have at least degree of protection IP54)

Ambient temperature T

Climate class EN 60721-3-3, class 3K3

DC link voltage

Terminal 1/2

Power consumption

Terminal 1/2

Functional control voltage

Terminal 3/4

Brake voltage

Terminal 13/15

AC brake coil voltage AC 230 V AC 400 V AC 460 V

Nominal output current

Terminal 13/15

Output current

Terminal 13/15

Acceleration current

Terminal 13/14

Max. output power P

Brake output

Terminal 13/14/15

Disconnection Cut-off in the DC and AC circuits (rapid application of the brake)

Supply cable

Terminal 1/2

Functional control cable

Terminal 3/4

Brake cable

Terminal 13/14/15

Power loss P

Storage temperature −20 °C to +70 °C (EN 60721-3-3, class 3K3)

Dimensions W × H × D 134 mm × 70 mm × 135 mm (5.28 in × 2.76 in × 5.31 in)

Weight About 0.79 kg (1.7 lb)

A

V

Z

P

E

V

24 V in

V

B

I

N

I

brake warm

I

B

out

V

Z

V

24 V in

V

DC 350 V – 750 V (briefly up to DC 970 V)

Signal level according to DIN EN 61131-2 type 1

DC +15 V to +30 V (> 2mA) => 1 / contact closed

DC −3 V to +5 V (< 2 mA) => 0 / contact open

You must only use grounded voltage sources with safe disconnection (PELV) according to

DC 96 V DC 167 V DC 190 V

DC 1.2 A DC 0.7 A DC 0.6 A

DC 1.0 A DC 0.6 A DC 0.5 A

With P

Several brake coils can be connected for redundant systems. The sum of the individual

EN 60204-1 for the control input at terminals 3 and 4.

= 120 W, the nominal output current reduces in warm condition.

A

4 – 8.5 times the holding current depending on the brake type

The figures relate to SEW standard brake coils (two-coil system)

power levels must not exceed the max. output power.

Rated cable voltage: min. V0 / V = 300 V / 500 V (to DIN VDE 0298)

Cable cross section: 0.75 mm

Cable cross section: 0.5 mm2– 1.5 mm2 (AWG 20 – AWG 16)

Cable cross section of 0.75 mm

Max. cable length: 200 m (656 ft) at min. 1.5 mm

According to EN 61800-3

−15 °C to +60 °C

(at P

≥ 95 W at least DC 450 V)

A

150 W, depending on brake type

Short-term: max. 800 W / 200 ms

P

≤ 120 W

out

Holding coil: Terminal 13

Accelerator coil: Terminal 13

2

Max. cable length: 100 m (328 ft)

Max. cable length: 100 m (328 ft)

2

Max. 30 W

red

– 2.5 mm2 (AWG 19 – AWG 13)

– 2.5 mm2 (AWG 19 – AWG 13)

/ 15

red

/ 14

blue

white

2

(AWG 16)

34

Operating Instructions – Safety-Related BST Brake Module

Page 35

10.2 Safety-related control voltage

P

i

f

kVA

Hz

n

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Technical Data

Safety-related control voltage

10

The following table shows the technical data for safety-related control voltage V

at terminals 5/6:

Safety-related control voltage V

Input voltage range

according to DIN EN 61131-2 DC 24 V

Input current 50 mA

Input capacitance 4.7 μF6μF

Switch-on/switch-off threshold DC 10 V

Input voltage for OFF state

(brake de-energized)

Duration from switching off the safety-related control

voltage at BST until switching off the brake voltage V

plus the brake application time of the connected

1)

brake.

Safety-related control cable

• Cable length

• Cable cross section

1) The brake application time for cut-off in the AC circuit must be used.

24 V safe

10.3 Safety characteristics o f BST brake modules

Min. Typical Max.

DC 20.4 V DC 24 V DC 28.8 V

B

2

0.5 mm

(AWG 20)

24 V safe

DC 6 V

6 ms

100 m

(328 ft)

1.5 mm2

(AWG 16)

Characteristic values to EN ISO 13849-1

Classification/underlying standards PL d

System structure Category 3

Probability of dangerous failure per

hour (PFH value)

Mission time / service life 20 years

Safe condition Brake de-energized

Safety function SBC (safe brake control) according to IEC 61800-5-2

0 (fault exclusion)

Operating Instructions – Safety-Related BST Brake Module

35

Page 36

10

89

101

135

70

99

121.5

74

135

(5.31)

(4.78)

(2.76)

(5.31)

(3.98)

(3.50)

(3.90)

(2.91)

P

i

f

kVA

Hz

n

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Technical Data

Dimension drawing of BST in control cabinet design

10.4 Dimension drawing of BST in control cabinet design

The following figure shows the dimension drawings of BST in control cabinet design:

All dimensions in mm (in).

36

Operating Instructions – Safety-Related BST Brake Module

9007199388556683

Page 37

Index

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Index

A

Applicable documentation........................................6

Applications

Disconnection of group drives............................33

Disconnection of single drives via inverter and

DFS11B/21B fieldbus interface..........................32

®

Disconnection of single drives via MOVIDRIVE

inverter ...............................................................31

B

Block diagram

BST ....................................................................11

Brake function

Checking ............................................................28

BST

Block diagram ....................................................11

Dimension drawings...........................................36

Nameplate..........................................................19

Safety characteristics.........................................35

Technical data....................................................34

Type designation................................................19

Unit replacement................................................29

Unit structure......................................................20

B

I

Information on electrical installation

Brake cable (terminal 13/14/15).........................23

Functional control cable (terminal 3/4)............... 23

Safety-related control cable (terminal 5/6).........23

Supply cable (terminal 1/2) ................................23

Inspection ..............................................................28

Inspection intervals ................................................28

Installation

electrical.............................................................23

Mechanical......................................................... 21

Requirements .................................................... 14

Integrated safety technology.................................. 10

L

Liability.....................................................................6

Liability for defects ................................................... 6

M

Maintenance ..........................................................28

Maintenance intervals............................................28

Mechanical installation........................................... 21

C

Copyright..................................................................6

D

Designated use ........................................................8

Dimension drawings

BST ....................................................................36

Disposal ...................................................................9

Documentation, applicable.......................................6

Double-pole safe disconnection.............................24

E

Electrical installation...............................................23

Double-pole safe disconnection.........................24

Information .........................................................23

Single-pole safe disconnection ..........................25

Embedded safety notes ...........................................5

Exclusion of liability..................................................6

External safety controller

Requirements.....................................................16

N

Nameplate BST .....................................................19

Notes

Designation in the documentation .......................5

O

Operating states ....................................................26

Operation

Requirements .................................................... 18

P

Permitted unit combinations .................................. 13

Product names.........................................................6

R

Requirements

External safety controller ...................................16

Installation.......................................................... 14

Operation...........................................................18

Startup ............................................................... 17

Restrictions ............................................................12

48

Operating Instructions – Safety-Related BST Brake Module

Page 38

Index

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

S

Safe condition ........................................................10

Safe disconnection

double-pole ........................................................24

single-pole..........................................................25

Safety concept .......................................................10

Safety control, external

Requirements.....................................................16

Safety notes .............................................................7

Designation in the documentation........................5

Structure of the embedded safety notes ..............5

Structure of the section-related safety notes .......5

Safety switching device

Sample circuit ....................................................17

Safety technology

Integrated...........................................................10

Safety-relevant conditions......................................13

SBC safety function (Safe Brake Control) according

to IEC 61800-5-2................................................11

SBC, safety function according to IEC 61800-5-2..11

Scope of delivery

BST ....................................................................20

Section-related safety notes ....................................5

Service ...................................................................28

Signal words in the safety notes ..............................5

Single-pole safe disconnection ..............................25

Startup ................................................................... 26

Startup requirements .........................................17

Support rail mounting.............................................21

Minimum clearance and mounting position .......22

Mounting BST onto a support rail ......................21

Removing BST from the support rail..................22

T

Target group ............................................................8

Technical data

BST.................................................................... 34

General ..............................................................34

Safety characteristics.........................................35

Safety-related control voltage ............................35

Terminal assignment

BST.................................................................... 20

Trademarks..............................................................6

Transport ................................................................. 8

Type designation BST ........................................... 19

U

Unit combinations

Permitted ...........................................................13

Unit design

Safety-relevant BST brake module.................... 19

Unit structure

BST.................................................................... 20

Operating Instructions – Safety-Related BST Brake Module

49

Loading...

Loading...