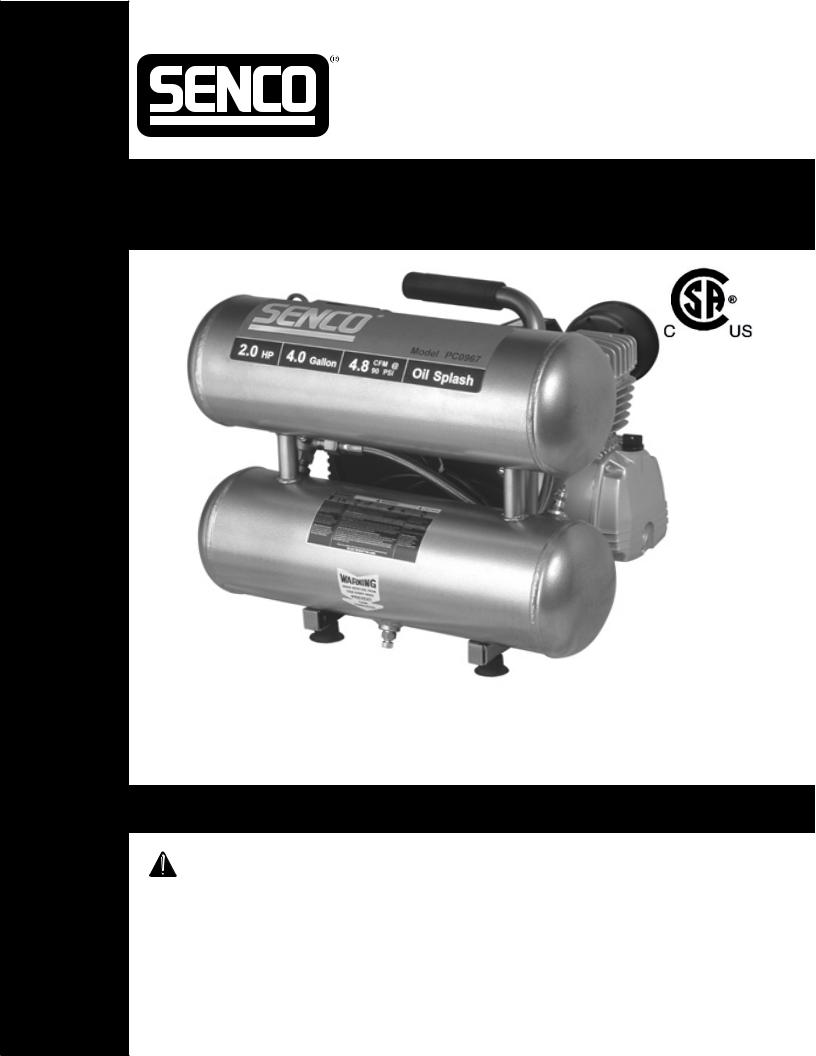

Senco PC0967 User Manual

Questions? Comments? call SENCO's toll-free Action-line: 1-800-543-4596 or e-mail: toolprof@senco.com

PC0967 Electric Air Compressor

Senco Products, Inc.

8485 Broadwell Rd.

Cincinnati, OH 45244

Operating Instructions

© 2003 by Senco Products, Inc.

PC0967 Issued June 25, 2003

Warnings for the safe use of this compressor are included in this manual. Des mises en garde pour une utilisation en toute sécurité de ce compresseur sont incluses dans ce manuel.

En este manual se incluyen avisos para el uso seguro de este compresor.

TABLE OF CONTENTS |

|

INTRODUCTION ................................................................... |

3 |

SAFETY ALERT..................................................................... |

3 |

INSPECTION ......................................................................... |

3 |

SAFETY WARNINGS ............................................................ |

4 |

ELECTRICAL................................................................ |

4 |

EXPLOSION OR FIRE.................................................. |

5 |

BURSTING ................................................................... |

5 |

BREATHING ................................................................. |

6 |

BURNS ......................................................................... |

6 |

FLYING OBJECTS........................................................ |

6 |

MOVING PARTS........................................................... |

7 |

NEGLIGENCE .............................................................. |

7 |

AIR COMPRESSOR DAMAGE..................................... |

7 |

COMPRESSOR FEATURES ................................................. |

8 |

PREPARATION.................................................................... |

10 |

INITIAL SET-UP ......................................................... |

10 |

LOCATION.................................................................. |

10 |

ELECTRICAL.............................................................. |

10 |

OPERATION ........................................................................ |

11 |

PRE-START CHECKLIST........................................... |

11 |

START-UP .................................................................. |

11 |

SHUTDOWN .............................................................. |

11 |

MAINTENANCE................................................................... |

11 |

TROUBLESHOOTING ................................................... |

12-14 |

SPECIFICATIONS ............................................................... |

15 |

WARRANTY ........................................................................ |

16 |

2

INTRODUCTION

Congratulations on the purchase of your new SENCO® Air Compressor! You can be assured your SENCO Air Compressor was constructed with the highest level of precision and accuracy. Each component has been rigorously tested by technicians to ensure the quality, endurance and performance of this air compressor.

This operator’s manual was compiled for your benefit. By reading and following the simple safety, installation and operation, and maintenance steps described in this manual, you will receive years of troublefree operation from your new SENCO Air Compressor. The contents. of this manual are based on the latest product information available at the time of publication. The manufacturer reserves the right to make changes in price, color, materials equipment, specifications or models at any time without notice.

SAFETY ALERT!

SAFETY ALERT!

A ”DANGER, WARNING or CAUTION” safety warning will be surrounded by a ”SAFETY ALERT BOX”. This box is used to designate and emphasize Safety Warnings that must be followed when operating this air compressor. Accompanying the safety warnings are “Signal Words” which designate the degree or level of hazard seriousness. The “Signal Words” used in this manual are as follows:

DANGER: Indicates an imminently hazardous situation which, if not avoided, WILL result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided,

COULD result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided MAY result in minor or moderate injury or damage to the air compressor.

The symbols set to the left of this paragraph are “Safety Alert Symbols”. These symbols are used to call attention to items or procedures that could be dangerous to you or other persons using this equipment.

ALWAYS PROVIDE A COPY OF THIS MANUAL TO ANYONE USING THIS EQUIPMENT. READ ALL INSTRUCTIONS IN THIS MANUAL AND ANY INSTRUCTIONS SUPPLIED BY MANUFACTURERS OF SUPPORTING EQUIPMENT BEFORE OPERATING THIS AIR COMPRESSOR AND ESPECIALLY POINT OUT THE “SAFETY WARNINGS” TO PREVENT THE POSSIBILITY OF PERSONAL INJURY TO THE OPERATOR.

INSPECTION

Unbox the air compressor and write in the serial number in the space provided below. Inspect for signs of obvious or concealed freight damage. Be sure that all damaged parts are replaced and any mechanical problems are corrected prior to the operation of the air compressor.

SERIAL NUMBER__________________________________________

If you have Questions or Comments call SENCO’s toll-free Action-line: 1-800-543-4596 or, e-mail: toolprof@Senco.com

Please have the following information available for all service calls:

1.Model Number

2.Serial Number

3.Date and Place of Purchase

Senco, 8485 Broadwell Road, Cincinnati, OH 45244

3

SAFETY WARNINGS

READ ALL SAFETY WARNINGS BEFORE USING AIR COMPRESSOR

|

HAZARD |

POTENTIAL CONSEQUENCE |

PREVENTION |

|

|

|

|

|

|

|

|

Serious injury or death could occur if |

Make sure the air compressor is |

|

|

RISK OF |

the air compressor is not properly |

plugged into a properly grounded |

|

|

ELECTRIC SHOCK |

grounded. Your air compressor is |

outlet which |

provides correct |

|

OR |

powered by electricity and may cause |

voltage and |

adequate fuse |

|

ELECTROCUTION |

electric shock or electrocution if not |

protection. |

|

|

|

used properly. |

|

|

|

|

Electrical shock may occur from |

Check power cord for signs of |

|

|

|

electrical cord. |

crushing, cutting or heat damage. |

|

|

|

|

Replace faulty cord before use. |

|

|

|

|

Keep all connections dry and off the |

|

|

|

|

ground. Do not allow electrical |

|

|

|

|

cords to lay in water or in such a |

|

|

|

|

position where water could come in |

|

|

|

|

contact with them. Do not touch |

|

|

|

|

||

|

|

|

plug with wet hands. |

|

|

|

|

Do not pull on the electrical cord to |

|

|

|

|

disconnect from the outlet. |

|

|

|

Electrical shock may occur if air |

Never operate air compressor in |

|

|

|

compressor is not operated properly. |

wet conditions or outdoors when it |

|

|

|

|

is raining. |

|

|

|

|

Never operate air compressor with |

|

|

|

|

safety guards/covers removed or |

|

|

|

|

damaged. |

|

|

|

Serious injury or death may occur if |

Any electrical wiring or repairs |

|

|

|

electrical repairs are attempted by |

performed on this air compressor |

|

|

|

unqualified persons. |

should be done by Authorized |

|

|

|

|

Service Personnel in accordance |

|

|

|

|

with National and Local electrical |

|

|

|

|

codes. |

|

|

|

|

Before opening any electrical |

|

|

|

|

enclosure, always shut off the air |

|

|

|

|

compressor, relieve pressure and |

|

|

|

|

unplug the air compressor from the |

|

|

|

|

power source. Allow air compressor |

|

|

|

|

to cool down. Never assume the air |

|

|

|

|

compressor is safe to work on just |

|

|

|

|

because it is not operating. It could |

|

|

|

|

restart at any time! |

|

4

SAFETY WARNINGS

READ ALL SAFETY WARNINGS BEFORE USING AIR COMPRESSOR

|

HAZARD |

|

POTENTIAL CONSEQUENCE |

PREVENTION |

|

|

|

|

|

|

|

|

RISK OF |

|

Serious injury or death may occur from |

Always operate air compressor in a |

|

|

EXPLOSION OR FIRE |

|

normal electrical sparks in motor and |

well ventilated area free of |

|

|

|

|

pressure switch. |

|

flammable vapors, combustible |

|

|

|

|||

|

|

|

|

|

dust, gases or other combustible |

|

|

|

|

|

materials. |

|

|

|

|

|

If spraying flammable material, |

|

|

|

|

|

locate the air compressor at least |

|

|

|

|

|

20 feet away from the spray area. |

|

|

|

|

|

(An additional hose may be |

|

|

|

|

|

required.) |

|

|

|

Serious injury may occur if any air |

Never place objects against or on |

|

|

|

|

|||

|

|

|

|||

|

|

|

compressor ventilation openings are |

top of air compressor. Operate air |

|

|

|

|

restricted, causing the air compressor |

compressor at least 12 inches away |

|

|

|

|

to overheat and start on fire. |

from any wall or obstruction that |

|

|

|

|

|

|

would restrict proper ventilation. |

|

|

|

|

|

|

|

|

|

|

|

|

|

RISK OF |

|

Serious injury or death may occur from |

Drain air tank daily or after each use |

|

|

BURSTING |

|

an air tank explosion if air tanks are |

to prevent moisture buildup in the |

|

|

|

|

not properly maintained. |

air tank. |

|

|

|

|

|

|

If air tank develops a leak, replace |

|

|

|

|

|

the air tank immediately. Never |

|

|

|

|

|

repair, weld or make modifications |

|

|

|

|

|

to the air tank or its attachments. |

|

|

|

|

|

Never make adjustments to the |

|

|

|

|

|

factory set pressures. |

|

|

|

Serious injury may occur from an air |

Never exceed manufacturers |

|

|

|

|

compressor malfunction or exploding |

maximum allowable pressure rating |

|

|

|

|

accessories if |

incorrect system |

of attachments. |

|

|

|

components, |

attachments or |

Because of extreme heat, do not |

|

|

|

accessories are used. |

||

|

|

|

|

|

use plastic pipe or lead tin soldered |

|

|

|

|

|

joints for a discharge line. |

|

|

|

|

|

Never use air compressor to inflate |

|

|

|

|

|

small, low pressure objects such as |

|

|

|

|

|

toys. |

|

|

|

|

5 |

|

|

|

|

|

|

|

SAFETY WARNINGS

READ ALL SAFETY WARNINGS BEFORE USING AIR COMPRESSOR

|

HAZARD |

POTENTIAL CONSEQUENCE |

PREVENTION |

|

|

|

|

|

RISK TO |

Serious injury or death could occur |

Never inhale air from the air |

|

BREATHING |

from inhaling compressed air. The air |

compressor either directly or from a |

|

|

stream may contain carbon monoxide, |

breathing device connected to the air |

|

|

||

|

|

toxic vapors or solid particles. |

compressor. |

|

|

Sprayed materials such as paint, paint |

Operate air compressor only in a well |

|

|

solvents, paint remover, insecticides, |

ventilated area. Follow all safety |

|

|

weed killers, etc. contain harmful |

instructions provided with the |

|

|

vapors and poisons. |

materials you are spraying. Use of a |

|

|

|

respirator may be required when |

|

|

|

working with some materials. |

|

|

|

|

|

|

|

|

|

RISK OF |

Serious injury could occur from |

Never allow any part of your body or |

|

BURNS |

touching exposed metal parts. |

other materials to make contact with |

|

|

These areas can remain hot for some |

any exposed metal parts on the air |

|

|

||

|

|

time after the air compressor is |

compressor. |

|

|

shutdown. |

|

|

|

|

|

RISK |

Soft tissue damage can occur from the |

Always wear OSHA required “Z87” |

safety glasses to shield the eyes |

||

OF FLYING |

compressed air stream. |

from flying debris. |

OBJECTS |

|

Never point the air stream at any part |

|

|

|

|

|

of your body, anyone else or animals. |

|

|

Never leave pressurized air |

|

|

|

|

|

compressor unattended. Shut off air |

|

|

compressor and relieve pressure |

|

|

before attempting maintenance, |

|

|

attaching tools or accessories. |

|

Serious injury can occur from loose |

Alwaysmaintainasafedistancefrom |

|

debris being propelled at a high speed |

people and animals while operating |

|

from the compressed air stream. |

the air compressor. |

|

|

Do not move the air compressor |

|

|

while air tank is under pressure. Do |

|

|

not attempt to move the air |

|

|

compressor by pulling on the hose. |

6

|

|

|

|

|

SAFETY WARNINGS |

|

|

|

|

|

READ ALL SAFETY WARNINGS BEFORE USING AIR COMPRESSOR |

|

|||||

|

|

|

|

|

|

|

||

|

HAZARD |

|

POTENTIAL CONSEQUENCE |

|

PREVENTION |

|||

|

|

|||||||

|

|

|

|

|

|

|

||

|

RISK FROM |

|

Riskofbodilyinjuryfrommovingparts. |

Always turn off air compressor when |

||||

|

MOVING PARTS |

|

This air compressor cycles |

not in use. Bleed pressure from the |

||||

|

|

|

|

|

automatically when the pressure |

air hose and unplug from electrical |

||

|

|

|

|

|

||||

|

|

|

|

|

switch is in the “On/Auto” position. |

outlet |

before |

performing |

|

|

|

|

|

|

maintenance. All repairs to the air |

||

|

|

|

|

|

|

compressor should be made by an |

||

|

|

|

|

|

|

Authorized Service person. Never |

||

|

|

|

|

|

|

assume the air compressor is safe |

||

|

|

|

|

|

|

to work on just because it is not |

||

|

|

|

|

|

|

operating. It could restart at any time! |

||

|

|

|

|

|

Risk of injury from negligent use. |

Do not operate without protective |

||

|

|

|

|

|

covers/guards. Replace damaged |

|||

|

|

|

|

|

||||

|

|

|

|

|

|

covers/guards before using the air |

||

|

|

|

|

|

|

compressor. |

|

|

|

|

|

|

|

|

|

||

|

RISK FROM |

|

|

Never allow children or adolescents |

||||

|

|

|

to operate this air compressor! |

|||||

|

NEGLIGENCE |

|

|

|||||

|

|

|

|

|

|

|||

|

|

|

|

|

|

Stay alert-watch what you are doing. |

||

|

|

|

|

|

|

Do not operate the air compressor |

||

|

|

|

|

|

|

when fatigued or under the influence |

||

|

|

|

|

|

|

of alcohol or drugs. |

|

|

|

|

|

|

|

|

Know how to stop the air |

||

|

|

|

|

|

|

compressor. Be thoroughly familiar |

||

|

|

|

|

|

|

with controls. |

|

|

|

|

|

|

|

|

|

||

|

|

RISK |

|

Risk of major repair. |

Do not operate air compressor |

|||

|

|

|

without an air filter. |

|

||||

|

OF AIR COMPRESSOR |

|

|

|||||

|

|

|

|

|

|

|||

|

|

DAMAGE |

|

|

Do not operate air compressor in a |

|||

|

|

|

|

|

|

|||

|

|

|

|

|

|

corrosive environment. |

|

|

|

|

|

|

|

|

Always operate the air compressor |

||

|

|

|

|

|

|

in a stable, secure position to prevent |

||

|

|

|

|

|

|

air compressor from falling. |

||

|

|

|

|

|

|

Follow all maintenance instructions |

||

|

|

|

|

|

|

listed in this manual. |

|

|

|

|

|

|

|

|

Fill with oil to level marked on |

||

|

|

|

|

|

|

dipstick |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

! SAVE THESE INSTRUCTIONS ! |

|

|

||

7

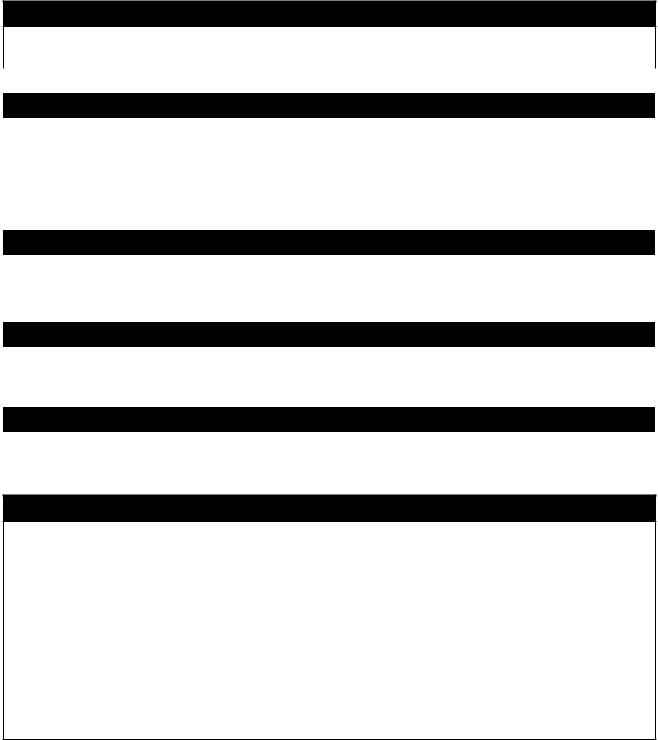

COMPRESSOR FEATURES

4

4

10

11

2

1 Motor/Pressure Switch

2 Air Compressor Pump

3Pressure Regulator

4 |

Safety Relief Valve (lower tank) |

5 |

Outlet PressureGauge |

6Discharge Line

7Tank Pressure Gauge

8Ventilation Openings / Protective Shroud

9 Quick Disconnect

10Air Filter

11Oil Dipstick

12Tank Drain

1

7

5

3

3

6

6

12

9

8

8

COMPRESSOR FEATURES

1) MOTOR/PRESSURE SWITCH: This switch is used to start or stop the air compressor. Moving the switch to the Auto (On) position will provide automatic power to the pressure switch which will allow the motor to start when the air tank pressure is below the factory set cut-in pressure. When in the Start/ Stop Option, the pressure switch stops the motor when the air tank pressure reaches the factor set cut-out pressure. For safety purposes, this switch also has a pressure release valve located on the side of the switch designed to automatically release compressed air from the air compressor pump head and its discharge line when the air compressor reaches cut-out pressure or is shut off. This allows the motor to restart freely. Moving the switch to the Off position will remove power from the pressure switch and stop the air compressor.

2)MOTOR THERMAL OVERLOAD: The electric motor has a thermal overload protector. If the motor overheats for any reason, the thermal overload will cut off power, thus preventing the motor from being damaged. Wait until the motor is cool. Motor also has a magnetic breaker. Reset switch if it is tripped.

3)AIR INTAKE FILTER: This filter is designed to clean air coming into the pump. To ensure the pump continually receives a clean, cool, dry air supply this filter must always be clean and ventilation opening free from obstructions. The filter can be

removed for cleaning by using warm, soapy water. Rinse the filter and air dry.

4)AIR COMPRESSOR PUMP: To compress air, the piston moves up and down in the cylinder. On the downstroke, air is drawn in through the air intake valve while the exhaust valve remains closed. On the upstroke, air is compressed, the intake valve closes and compressed air is forced out through the exhaust valve, into the discharge line, through the check valve and into the air tank.

5)SAFETY RELIEF VALVE: This valve is designed to prevent system failures by relieving pressure from the system when the compressed air reaches a predetermined level. The valve is preset by the manufacturer and must not be modified in any way. To verify the valve is working properly, pull on the ring. Air pressure should escape. When the ring is released, it will reseat.

6)AIR TANK DRAIN VALVE: The drain valve is used to remove moisture from the air tank(s) after the air compressor is shut off. NEVER attempt to open the drain valve when more than 10 PSI of air pressure is in the air tank! To open the drain valve,

turn the knob counterclockwise. Tilt tank to ensure that all condensation drains through valve.

7)AIR TANK PRESSURE GAUGE: The air tank pressure gauge indicates the reserve air pressure in the air tank (s).

8)OUTLET PRESSURE GAUGE: The outlet pressure gauge indicates the air pressure available at the outlet side of the regulator. This pressure is controlled by the regulator and is always less or equal to the air tank pressure.

9)PRESSURE REGULATOR: The air pressure coming from the air tank is controlled by the regulator knob. Turn the pressure regulation knob clockwise to

increase discharge pressure, and counterclockwise to decrease discharge pressure.

10)DISCHARGE LINE: Please note that the discharge line is very hot.

11)DIPSTICK: The dipstick will measure the amount of oil in the pump. Oil level should be checked on a daily basis to ensure that it is between the minimum and maximum notch. Air escaping from the vent is normal.

1

2

3

5

6

7

8

9

10

11

9

INITIAL SET-UP: |

PREPARATION |

|

1.Read safety warnings before setting-up air compressor.

2.Add entire contents of oil from enclosed bottle prior to starting compressor

3.Ensure the oil level is above the minimum notch and below the maximum notch on the dipstick. If low, add compressor pump oil.

LOCATION:

CAUTION

In order to avoid damaging the air compressor, do not incline the air compressor transversely or longitudinally more than 10°.

1.Place air compressor at least 12 inches away from obstacles that may prevent proper ventilation.

Do not place air compressor in an area: -where there is evidence of oil or gas leaks.

-where flammable gas vapors or materials may be present.

WARNING

Seriousinjuryordeathmayoccurifelectricalsparksfrommotorandpressureswitch come in contact with flammable vapors, combustible dust, gases or other combustible materials. When using the air compressor for spray painting, place the air compressor as far away I from the work area as possible, using extra air hoses instead of

extension cords.

-where air temperatures fall below 32°F or exceed 104°F.

-where extremely dirty air or water could be drawn into the air compressor.

ELECTRICAL:

DANGER

Improper connection of the equipment-grounding conductor can result in a risk of shock or electrocution. Check with a qualified electrician or service personnel if you are in doubt as to whether the outlet is properly grounded. Do not use any type of

adapter with this product. If repair or replacement of the cord or plug is necessary, do not connect the grounding wire to either flat blade terminal. The wire with insulation having an outer surface that is green with or without yellow stripes is the grounding wire.

WARNING

This product must be grounded. If there should be a malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce the risk of electric shock. This product is equipped with a cord having an equipment-

grounding conductor and a grounding type plug. The plug must be plugged into an appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances.

1. SENCO® DOES NOT RECOMMEND THE USE OF EXTENSION CORDS as this can create power loss and overheating of the motor. Use of an additional air hose is recommended rather than an extension cord. If use of an extension cord is unavoidable, it should be plugged into a GFCI found in circuit boxes or protected receptacles.

When using an extension cord, observe the following: |

Wire Gauge |

|

Cable Length |

||

Up to 25 feet |

12 |

AWG |

Up to 100 feet |

10 |

AWG |

Up to 150 feet |

8 |

AWG |

Up to 250 feet |

6 |

AWG |

Use only 3-blade extension cords that have 3-blade grounding-type plugs and 3-slot cord connectors that will accept the plug from the product. Use only extension cords having an electrical rating not less than the rating of the product. Do not use damaged extension cords. Examine extension cord before using and replace if damaged. Do not abuse extension cord and do not yank on any cord to disconnect. Keep cord away from heat and sharp edges. Always shut off the air compressor switch before removing the plug from the receptacle.

10

OPERATION

PRE-START CHECKLIST:

1.Check oil level. Add if necessary.

2.Remove any moisture in the air compressor air tank. Remove excessive pressure with an air tool, then open the air tank drain valve in the bottom of the air tank. Close tightly when drained.

WARNING: Risk of bodily injury. NEVER attempt to open the drain valve when more than 10 PSI of air pressure is in the air tank!

3.Make sure the air compressor Motor Switch is in the "OFF" position.

4.Make sure all safety valves are working correctly.

5.Make sure all guards and covers are in place and securely mounted.

START-UP:

1.Ensure the lever on the pressure switch box is in the "OFF" position.

2.Plug the power cord into a grounded outlet.

3.Move the lever on the pressure switch box to the "AUTO" position.

4.START/STOP OPTION: Turn it completely clockwise to the fully closed position. This will allow the air compressor to "START" building up pressure in the air tanks and "STOP" when correct pressure is achieved. When pressure drops with usage, the air compressor will "START" building up pressure again.

5.Set pressure by adjusting the pressure regulator knob counterclockwise for less pressure and clockwise for more pressure.

6.If you notice any unusual noise or vibration, stop the air compressor and refer to "Troubleshooting".

SHUTDOWN:

1.To stop the air compressor, move the lever on the pressure switch box to the "OFF" position. NEVER stop the air compressor by unplugging it from the power source. This could result in risk of electrocution.

2.Drain air from the air tanks by releasing air with an attached air tool or by pulling on the safety relief valve rings.

3.Once pressure in the air tanks register under 10 pounds, open the drain valve under each air tank to drain any moisture.

4.Allow the air compressor to cool down.

5.Wipe air compressor clean and store in a safe, non-freezing area.

MAINTENANCE

Read the instruction manual before performing maintenance. The following procedures must be performed when stopping the air compressor for maintenance or service.

1. Turn off air compressor.

WARNING: Never assume the air compressor is safe to work on just because it is not operating. It could restart at any time!

2.Disconnect cord from main power supply.

3.Open all drains.

4.Wait for the air compressor to cool before starting service.

MAINTENANCE CHART

PROCEDURE |

DAILY |

WEEKLY |

MONTHLY |

200 HOURS |

Check pump oil level |

X |

|

|

|

Oil leak inspection |

X |

|

|

|

Drain condensation in air tank(s) |

X |

|

|

|

Check for unusual noise/vibration |

X |

|

|

|

Check for air leaks |

X |

|

|

|

Inspect air filter |

|

X |

|

|

Clean exterior of compressor |

|

X |

|

|

Check safety relief valve |

|

|

X |

|

Change pump oil* |

|

|

|

X |

Replace air filter |

|

|

|

X |

*The pump oil must be changed after the first 50 hours of operation and every 200 hours or 3 months, whichever comes first. Recommended non-detergent straight weights.

11

TROUBLESHOOTING

Symptom 1. Motor will not run or restart.

Power cord not plugged in.

Motor/Pressure switch in “OFF” position.

Motor thermal overload switch has tripped.

Fuse blown or circuit breaker has tripped.

Wrong gauge wire or length of extension cord.

Air tank pressure exceeds motor/ pressure switch “cut-in” pressure.

Pressure release valve on motor/ pressure switch has not unloaded pump head pressure.

Defective motor, motor capacitor, motor/ pressure switch, or check valve.

Plug cord into grounded outlet.

Move switch to “ON” position.

Turn air compressor off, wait until motor is cool, then check motor circuit breaker.

Replace fuse or reset circuit breaker.

Check for proper fuse amperage.

Check for low voltage conditions.

Disconnect any other electrical appliances from circuit or operate air compressor on its own branch circuit.

Check chart on page #10 for proper gauge wire and cord length.

Motor will start automatically when air tank pressure drops below “cut-in” pressure of motor/pressure switch.

Bleed the line by moving the switch to the “Off” position.

Contact Senco Customer Service.

Symptom 2. When in the Start/Stop option, motor runs continuously.

PROBABLE CAUSE

Motor/Pressure switch does not shut off motor when air compressor reaches “cut-out” pressure and safety relief valve activates.

Air compressor is incorrectly sized.

REMEDY

Move the motor/pressure switch to the “Off” position. If the motor doesn’t shut off, unplug the air compressor. If the electrical contacts are welded together, replace the pressure switch.

Limit the air pressure to the capacity of the air compressor. Either use a smaller tool or a larger air compressor.

Symptom 3. Air continues to leak at motor/pressure switch release valve after motor stops.

PROBABLE CAUSE |

REMEDY |

Defective pilot valve, the check valve is stuck open. |

Remove, clean or replace. |

12

TROUBLESHOOTING

Symptom 4. Air continues to leak at motor/pressure switch release valve while motor is running.

PROBABLE CAUSE |

REMEDY |

Defective motor/pressure switch. |

Replace. |

|

|

|

|

Symptom 5. Air leaks from safety relief valve. |

|

|

|

PROBABLE CAUSE |

REMEDY |

Possible defective safety relief valve. |

Operate safety relief valve manually by pulling on ring. |

|

If it still leaks, it should be replaced. |

Excessive air tank pressure. |

Defective motor/pressure switch. Replace. |

|

|

|

|

Symptom 6. Air leaks at fittings. |

|

|

|

PROBABLE CAUSE |

REMEDY |

Fittings are not tight enough. |

Tighten fittings where air can be heard escaping. Check |

|

fittings with soapy water solution. Do not overtighten. |

|

|

|

|

Symptom 7. Air leak in air tank. |

|

|

|

PROBABLE CAUSE |

REMEDY |

Defective or rusted air tank. |

Air tank must be replaced. Do not attempt to repair |

|

air tank! |

|

|

Symptom 8. Air blowing from inlet filter. |

|

|

|

PROBABLE CAUSE |

REMEDY |

Damaged inlet (reed) valve. |

Contact SENCO Customer Service 888-222-8144. |

|

|

Symptom 9. Insufficient pressure at air tool or accessory.

PROBABLE CAUSE

Pressure regulator knob not turned to high enough pressure or defective pressure regulator.

Restricted air intake filter.

Air leaks.

Air compressor is not large enough for air requirement.

REMEDY

Adjust pressure regulator knob to proper setting or replace.

Clean.

Check for leaks and repair.

Check the accessory air requirement. If it is higher than the CFM or pressure supply of the air compressor, you need a larger air compressor.

13

TROUBLESHOOTING

Symptom 10. Air compressor not making enough air.

PROBABLE CAUSE

Restricted air intake filter.

Defective (reed) valve.

REMEDY

Clean.

Drain air tank and measure pump up time. Compare to specifications. If lower, remove pump head and inspect valve plate, clean or replace.

Symptom 11. Moisture in discharge air.

PROBABLE CAUSE |

REMEDY |

|

Condensation in air tank caused by high level |

Drain air tank after every use. Drain air tank more often |

|

of atmospheric humidity or air compressor is |

||

in humid weather and use an air line filter. |

||

not run long enough. |

||

|

14

|

SPECIFICATIONS |

|

|

|

|

Model # |

PC0967 |

|

|

|

|

Motor |

|

|

|

Horsepower |

2 |

|

Voltage |

115 |

|

Amperage |

14 |

|

Hz. |

60 |

|

Phase |

Single |

|

RPM |

3450 |

Compressor Pump |

|

|

|

Number of Cylinders |

1 |

|

Compression Stage |

1 |

|

Lubrication |

Splash |

|

Oil Type |

SENCO PC 0344 |

|

Crankcase |

Aluminum |

|

Bearings |

Ball |

|

Cylinder |

Aluminum/Steel Sleeve |

|

Valves |

Reed-Single |

|

Head |

Aluminum |

|

Filter |

Canister |

|

Motor/Pressure Switch Setting |

|

|

Cut-out |

125 PSI |

|

Cut-in |

95 PSI |

Controls |

On/Off |

|

Air |

tank |

|

|

Capacity |

4 gallon |

|

Performance |

|

|

CFM Air Displacement |

9.2 |

CFM @ 90 PSI |

4.8 |

|

|

Maximum Pressure |

125 PSI |

|

Pump-up Time: 0-125 PSI |

46 sec. |

|

Recovery Time: 95-125 PSI |

12 seconds |

Weight |

|

|

|

Net |

63 Ibs. |

Dimensions |

|

|

|

Basic LxWxH |

19"x17"x16.5" |

15

Loading...

Loading...