Service Manual

Variants:

7661321009

7661321109

7661321139

7671321009

7671321004

for seca 766, 767

Description:

Electronic scale with DETF -module.

Mod. 766: Column scale, kg/lbs switch, body mass index, background iluminated

display Mummy baby function.

Mod. 767: column scale, kg/lbs switch, body mass index

Content:

Function description 30-34-00-629 a

Description DETF modul 30-34-00-617

Description Display modul 30-34-00-618 a

Service Manual Number

17-05-01-309-d

Valid as of: 02.12.2010

Description of Faults 30-34-00-588 c

Description of Calibration (lin.) 30-34-00-603

PC configuration program 30-34-00-672 b

Replacement 30-34-00-697

Spare parts 30-34-00-698 d

Manual number: 17-05-01-309-d

Service Manual

Functional description

Functional description

together, but also exert an initial load which is

necessary to reduce the hysteresis.

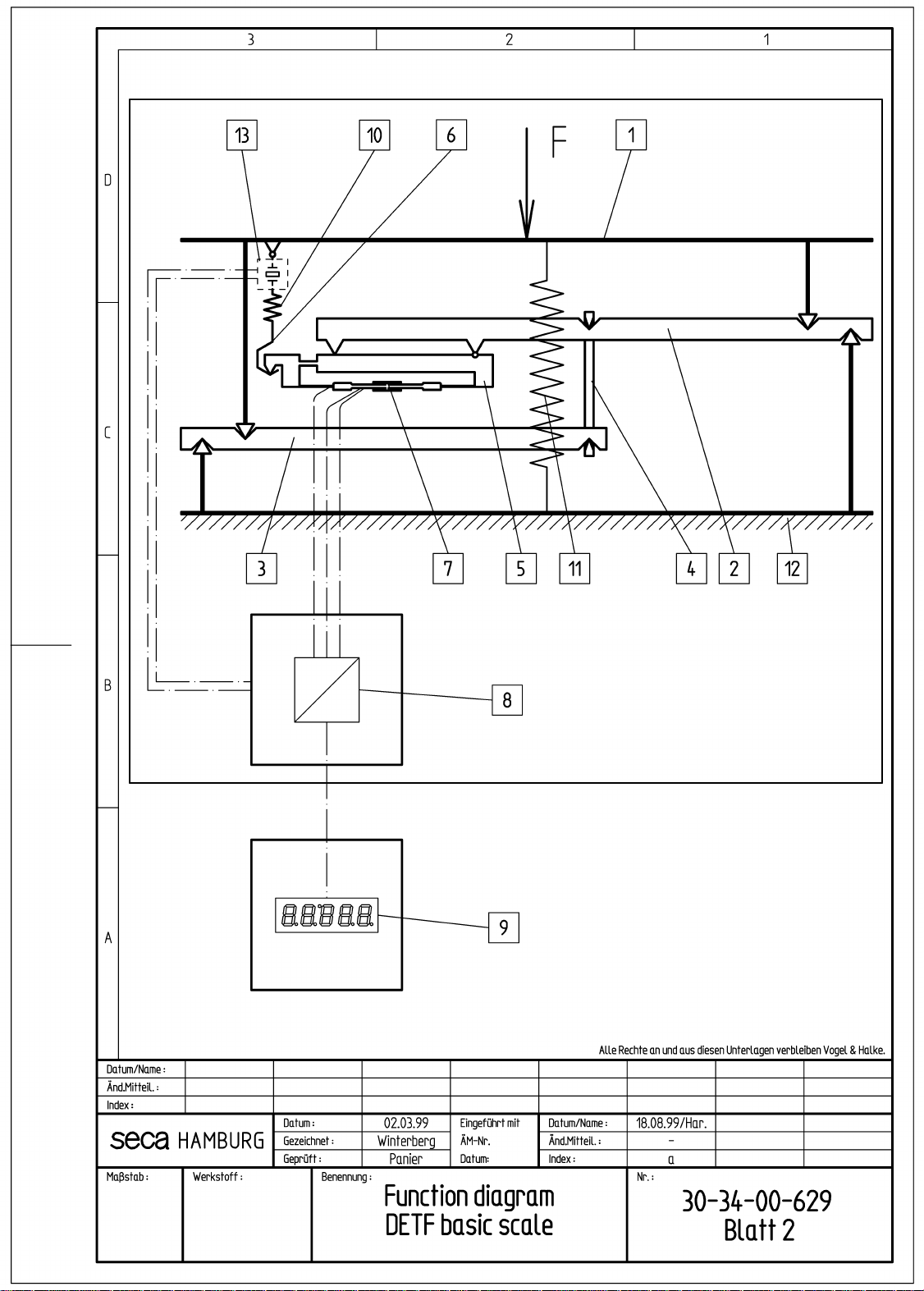

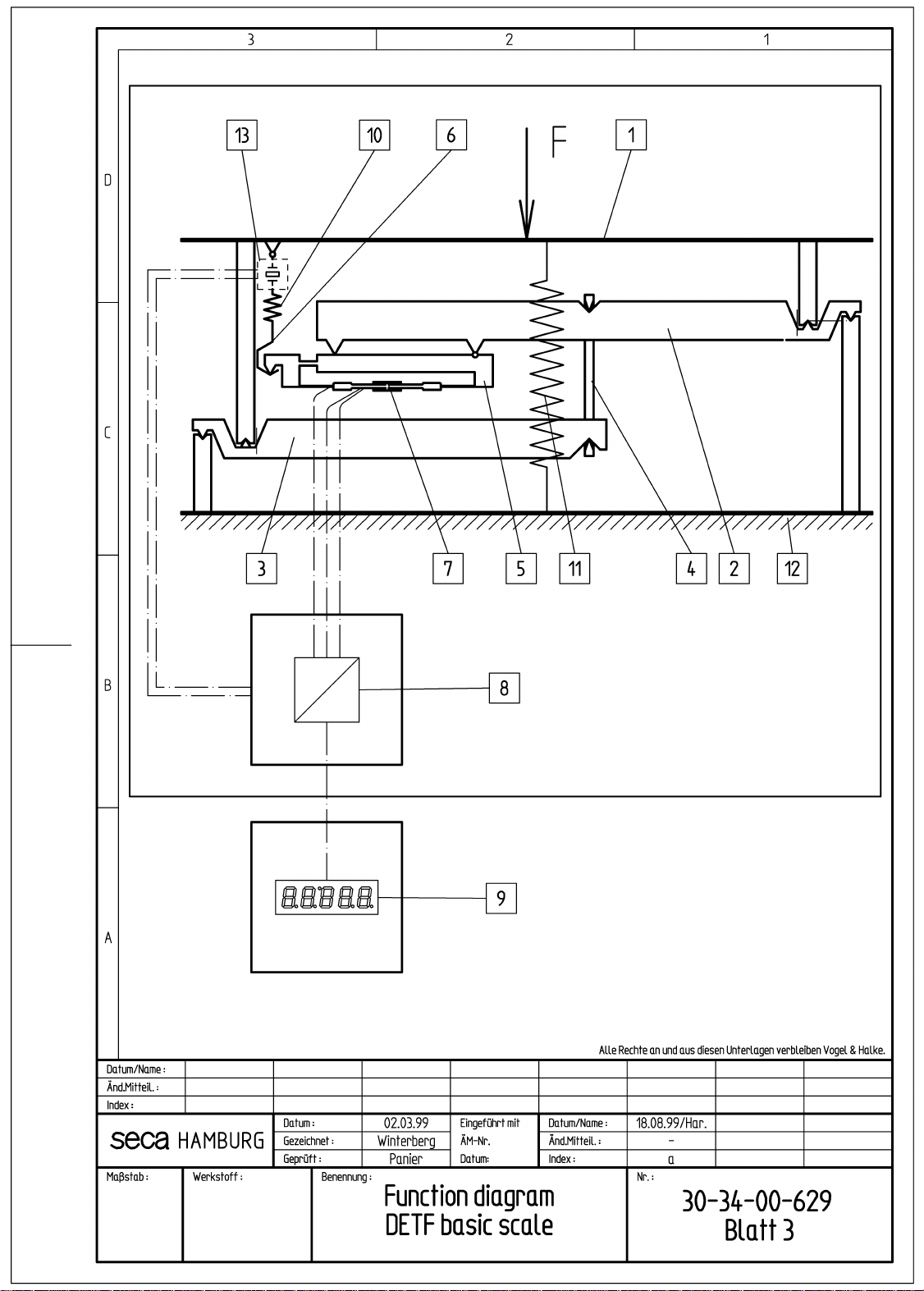

DETF basic scale

Introduction

The DETF basic scale is a mechanical basic

module for various seca scales. It is used for the

electronic determination of the weight of adults.

For the electronic measurement of the mechanical

quantitiy “force” a double-ended tuning fork

sensor (DETF) is used.

The above principle of operation has been realized

on the one hand with a knife-edged load lever

system to meet higher accuracy requirements and

on the other hand with a more cost effective

bearing-determined load lever system to meet

slightly lower requirements.

Weighing

When a load is placed on the scale, the force due

to gravity is transferred from the platform (1) to the

load lever system.

In the bearing-determined load lever system two

springs exert a force which corresponds to a

preload of approx. 15 kg.

In the knifed-edged load lever system 4 springs

exert a force which corresponds to a preload of

approx. 11 kg. The platform is prevented from

being lifted by an additional locking device onto

which the long load lever hits if the platform starts

to rise (not for flat scales).

Vibration-sensitive switch (optional)

Any force exerted on the platform acts via load

lever system, hook and overload protection device

on the vibration-sensitive swich (13) which is fitted

between overload protection device and platform.

The load causes the vibration-sensitive switch to

generate an electrical pulse which starts the

connected electronics.

The long load lever (2) transmits the force via the

bending element (5) on to the hook (6). The force

is reduced in accordance with the transmission

ratio of the load lever. The force applied to the

short load lever (3) is added to the force on the

long load lever via the centre suspension (4).

A bending load acts on the bending element that

increases the tensile force acting on the

pretensioned tuning-fork sensor (7). This increases

its resonant frequency in a non-linear way, which is

measured by the connected electronics (8) and

converted into a weight using the stored

characteristic curve. The weight is output on the

digital display (9).

Overload protection device

The force acting on the hook is transferred to the

overload protection device (10). This device is

pressed against the platform by a pretensioned

spring. If the load on the scale exceeds a

permitted value, the spring yields and the load

lever system is lowered.

Platform locking device

The platform retaining springs (11) do not only

hold platform, frame (12) and load lever system

18.08.99 Har. 30-34-00-629A

Brief description of the DETF module

Introduction

The DETF module belongs to the family of seca electronic modules and is used to determine weight by means of

a tuning-fork sensor system. The weight obtained is displayed on a separate display module. To allow the

module to be adapted to different scales, an EEPROM is integrated with which it can be configured. A connection

to the SeSAM bus (Seca’s Serial Autoconfiguring Multicontroller bus) is provided via which the scale can be

calibrated and additional modules can be connected.

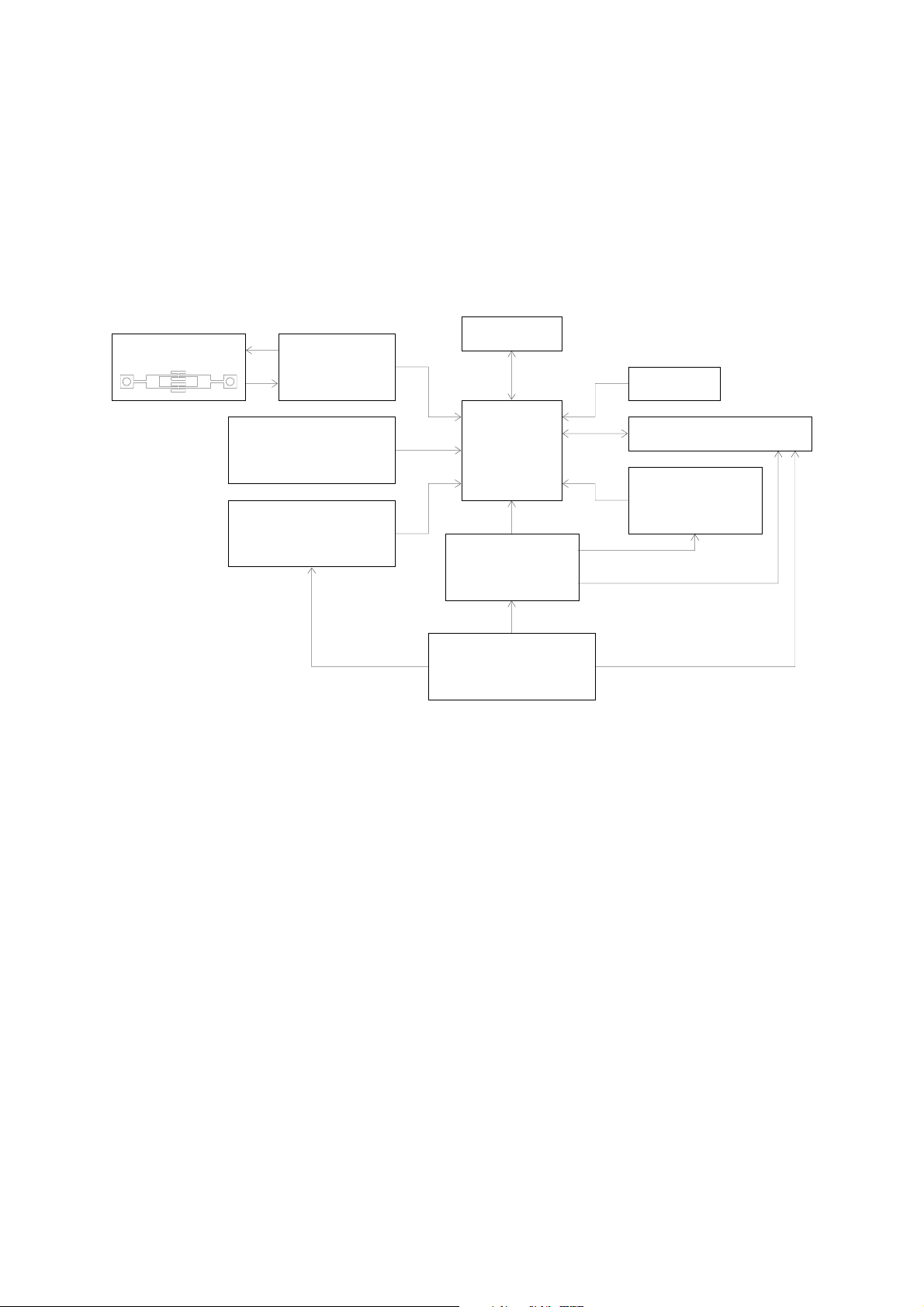

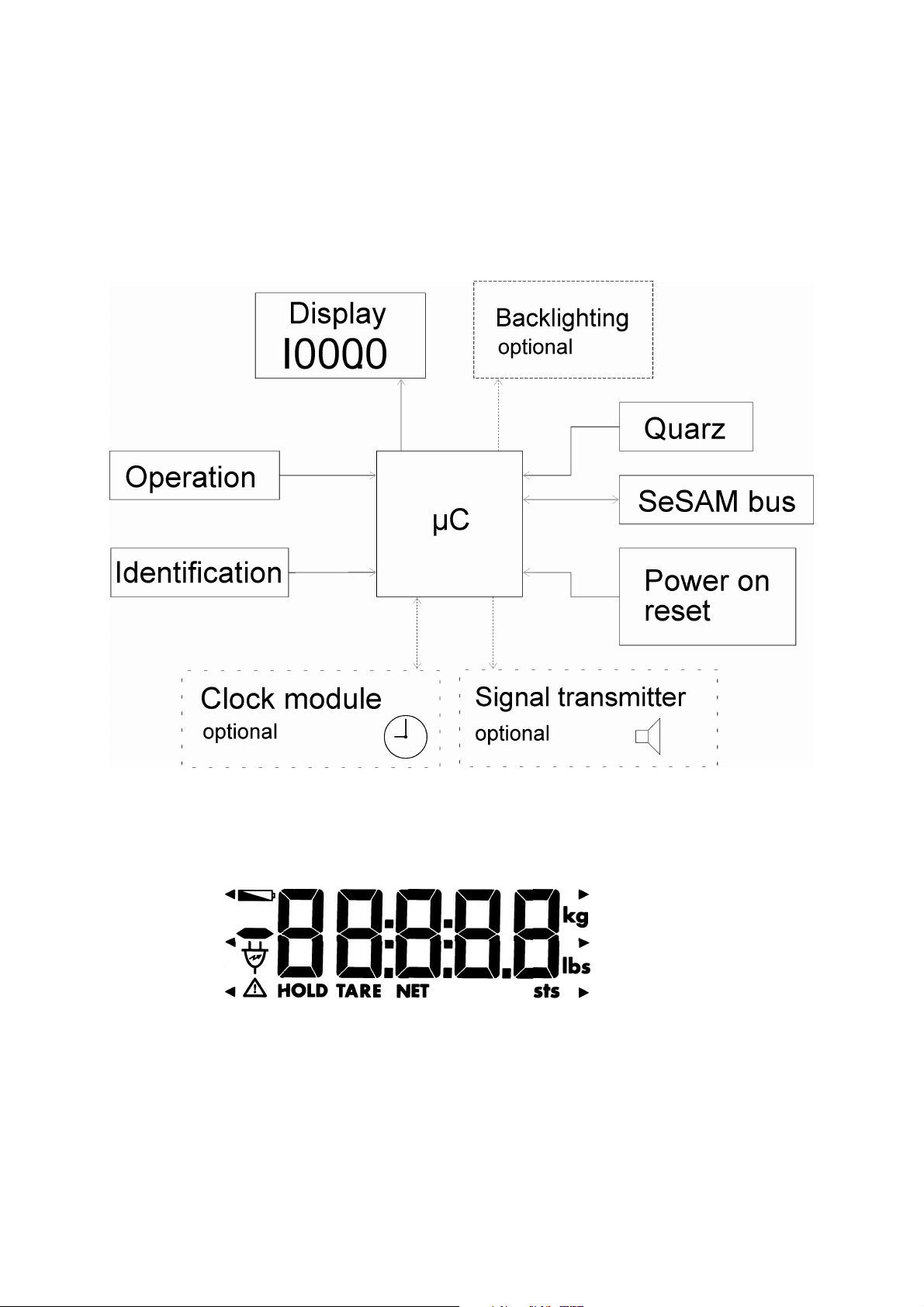

The following block diagram shows the most important function blocks of the force sensor and the DETF module:

EEPROM

Sensor

Bandpass

filter

Quartz

Temperature

measurement

µC

SeSAM bus

Power on

reset

Voltage

measurement

Voltage

control

Battery/mains

connection

Weight measurement

A tuning-fork sensor screwed to a bending element is used as the weight sensor. If the scale is loaded, the

bending element exerts a tensile force on the tuning-fork sensor, thus increasing its resonant frequency. By

means of the bandpass filter the sensor is set vibrating at this frequency which is then measured by the

microcontroller.

Using the value obtained and the individual calibration data stored in the EEPROM the controller calculates the

weight.

The first value obtained after switch-on is used as the zeropoint. If the values obtained later on do not deviate

strongly from this value, the zeropoint is corrected in order to compensate for possible drifts.

When the sensor is connected, care must be taken that the wires are not twisted to prevent crosstalk from the

output to the input.

Temperature measurement

As the value measured by the tuning-fork sensor is affected by temperature, the temperature is measured

regularly and compensated for accordingly.

Power supply

Power supply is provided by four AA size batteries and / or a seca mains transformer / desktop mains unit. From

the power supply the voltage is passed via a reverse voltage protection diode to an in-phase regulator which

provides a stabilized 3V supply voltage.

30-34-00-617 15.11.00

1

EE/Jensen

In order to avoid measuring errors due to almost flat batteries, their voltage is measured at regular intervals. If

the voltage drops below a certain limit, the user is alerted by the battery symbol in the LCD. If the next threshold

is undershot, „bAtt“ is displayed and weighing is no longer possible.

In order to extend the on-time when the scale is mains operated, the microcontroller receives a signal when a

mains transformer is connected.

It is possible to use rechargeable batteries, but the batteries will not be charged in the scale.

EEPROM

The DETF module accommodates an EEPROM on which all parameters are stored that can be used to influence

the program sequence, for example various limit values or the coefficients for determining the weight and for

temperature compensation.

Furthermore, the scale can store values to be retrieved when the scale is switched on the next time, e.g. the

modules last connected.

Serial bus

To allow the scale to be calibrated and additional modules, such as displays, to be connected, the DETF module

is equipped with an interface to the SeSAM bus.

On this bus the stabilized and non-stablized supply voltages are available. Via a data and a clock pulse line all

relevant data is transmitted to other modules. A special start line is provided via which the scale can be switched

on or other modules can signal that they want to send data.

Fault handling

If faults occur, the SeSAM bus initiates a fault message with the relevant fault code. Furthermore, each fault

message includes the number of the module type on which the fault has occurred and a code which indicates

how long the message is to stay on display and which displays are to be suppressed.

The fault messages are transferred to the SeSAM bus and can be output by the display module (module type for

the DETF module = 1).

The following fault messages are implemented:

10 20 bit counter overflow

11 Counts outside the permissible range

12 Switch-on zeropoint outside the permissible range

13 Zero follow-up outside the permissible range

14 Fault in the kg value calculation

15 Recalibration fault

20 Battery voltage too low

21 Fault in battery voltage measurement

22 Fault in temperature measurement

23

Temperature range exceeded ( < 0°C or > 50°C)

30 General bus fault

32 Command buffer full

33 More than 8 slaves detected

40 EEPROM fault

41 Incorrect EEPROM access

50 Other fault

Instead of fault message 20 „bAtt“ is displayed and „temP“ instead of fault message 23.

Time base

From the quartz’s 4.19MHz a time base is derived which controls all timed processes in the scale. These are, for

instance, various timeouts and the on-time.

30-34-00-617 15.11.00

2

EE/Jensen

After expiry of the on-time, the supply voltage for the bandpass filter, for voltage measurement and for the

EEPROM is switched off. All ports are set to zero-signal level and the quartz is stopped.

Recalibration

In order to compensate for linear measuring errors of the scale, which can, for instance, occur as a result of the

different forces of gravity at different geographical points, the module has a recalibration function. Recalibration

is performed via the SeSAM bus by means of a display module.

Technical data

Supply voltage: 2.7V - 15V

Supply current: typ. 0.9mA

Quiescent current: typ. 2µA

Operating temperature: approx. 0°C to 50°C

Storage temperature: -10°C to 60°C

Dimensions: 56mm x 38mm x 20mm

30-34-00-617 15.11.00

3

EE/Jensen

Brief description of the display module

Introduction

The display modules belong to the family of seca electronic modules and are used to display a weight

measured with a suitable module and transferred via the SeSAM bus (Seca’s Serial Autoconfiguring

Multicontroller bus). Furthermore, the display modules accommodate the operating elements and can

process the weight (hold, tare, etc.).

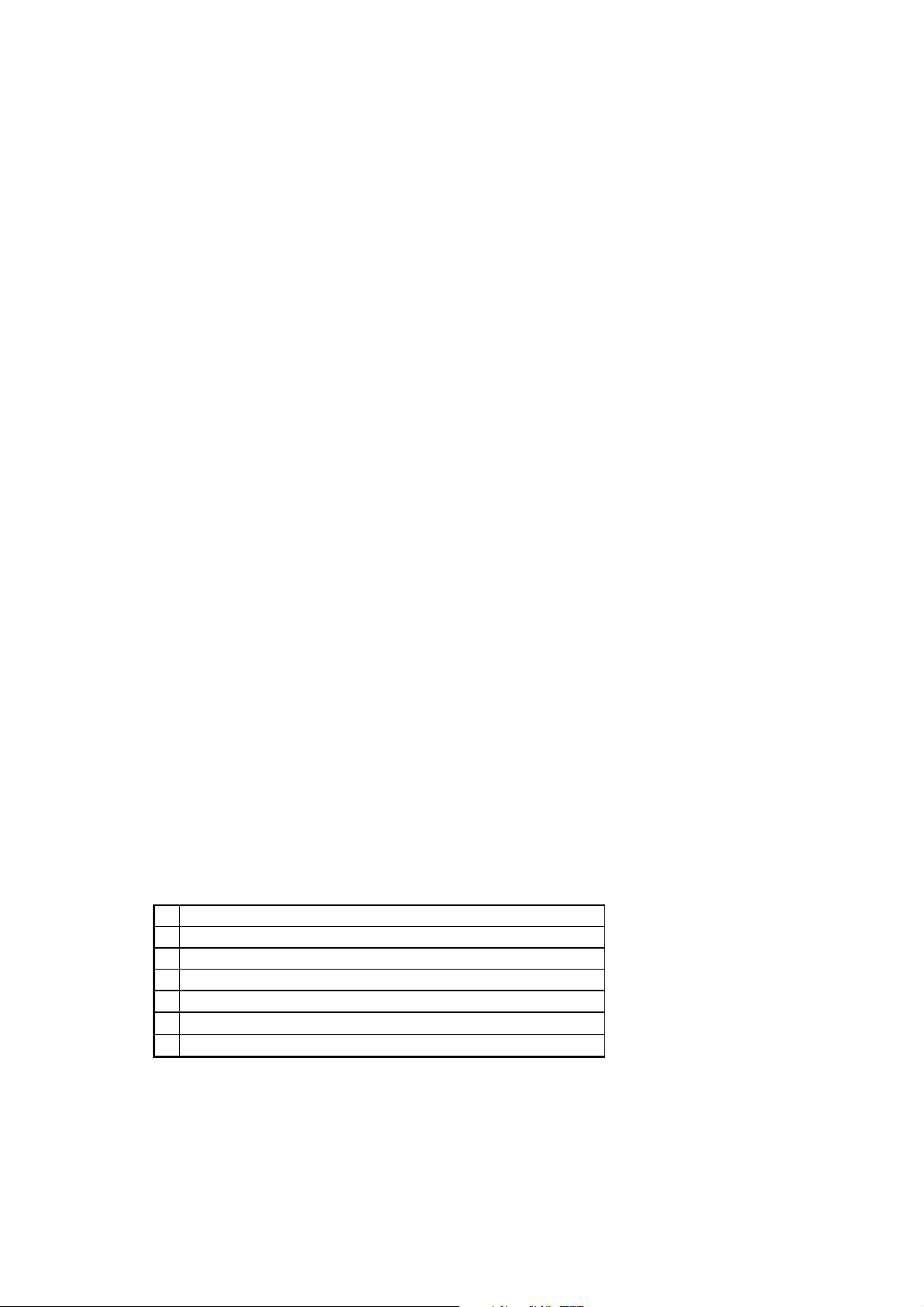

The following block diagram shows the most important function blocks of the display modules:

Display

The weight displayed on the LCD is updated approximately every 0.8s. A maximum of five digits as

well as a few special characters can be displayed, which can appear as shown below:

Explanation of the special characters:

• The battery symbol is used to alert of the fact that the battery is going flat.

• The plug symbol indicates that the scale is operated on a mains transformer.

• The warning triangle signals that the weight displayed on the scale is not verifiable.

• Hold indicates that the weight display has frozen.

• Tare or Net show that a weight on the scale has been tared out.

• The left and right arrows point to additional explanations next to the display.

• The weight units on the right show in which unit the measured weight is displayed.

30-34-00-618a 25.07.06

QS / Eggers

1

Power supply

Power supply is provided via the SeSAM bus.

Operation

With the exception of a start button that might be available, the connected buttons can be configured

as required for the particular model. These buttons can be pressed just lightly or longer (longer than

1.5s).

If you press another button when switching on the scale, the scale will switch to the verification counter

and recalibration mode.

SeSAM bus

The SeSAM bus connects the display modules to the other modules. On this bus the stabilized and

non-stablized supply voltages are available. Via a data and a clock pulse line all relevant data is

exchanged. A special start line is provided via which the scale can be switched on or the module can

signal that it wants to send data.

Identification code

If several display modules are connected, an unmistakable ID code must be assigned to them using

soldering jumpers to ensure that the different modules are correctly addressed via the bus.

Backlighting (optional)

Some display modules are equipped with a power supply for LCD backlighting. It can either be lit when

the scale is switched on or only when the scale is loaded.

Signal transmitter (optional)

Some display modules are equipped with a signal transmitter. A piezo diaphragm is used which is

controlled with a 4 kHz square-wave signal.

Clock module RTC (optional)

Display modules may be equipped with a clock function. If the circuit board is fitted with the relevant

RTC components, when switching on the scale the time is indicated in the display for about 2 seconds.

The power supply of the module results from the supply voltage of the scale. Voltage interruptions are

compensated for a short time

Fault handling

If faults occur, the SeSAM bus initiates a fault message with the relevant fault code. Furthermore, each

fault message includes the number of the module type on which the fault has occurred and a code

which indicates how long the message is to stay on display and which displays are to be suppressed.

The display module displays its own fault messges on its LCD. Module type (for the display module =

3) and fault number are output. In addition, the fault messages that other modules have transferred to

the SeSAM bus are displayed.

The following fault messages are implemented:

14 Fault in the kg value calculation

15 Recalibration fault

30 General bus fault

32 Command buffer full

33 More than 8 slaves detected

50 Other fault

51 Menu fault

Time base

From the quartz’s 4.19MHz a time base is derived which controls all timed processes in the scale.

These are, for instance, various timeouts.

30-34-00-618a 25.07.06

QS / Eggers

2

Loading...

Loading...