Seca 606 Service Manual

6061321009

01.05.03

Variants:

6061321619

for seca

Description:

electronic veterinarian scale

606

Content:

Operation 17-10-06-293

Service Manual Number:

17-05-01-316-

Valid as of:

Description display modul 30-34-00-618

Description DMS modul 30-34-00-645 a

Description of faults 30-34-00-588 c

Calibration (lin.) 30-34-00-603

PC configuration program 30-34-00-672 b

cableplan 08-02-06-022 a

Replacement 30-34-00-704

Spare parts 30-34-00-705

Manual number: 17-05-01-316-

Brief description of the display modul e

Introduction

The display modules belong to the family of seca electronic modules and are used to display a weight

measured with a suitable module and transferred via the SeSAM bus (Seca’s Serial Autoconfiguring

Multicontroller bus). Furthermore, the display modules accommodate the operating elements and can

process the weight (hold, tare, etc.).

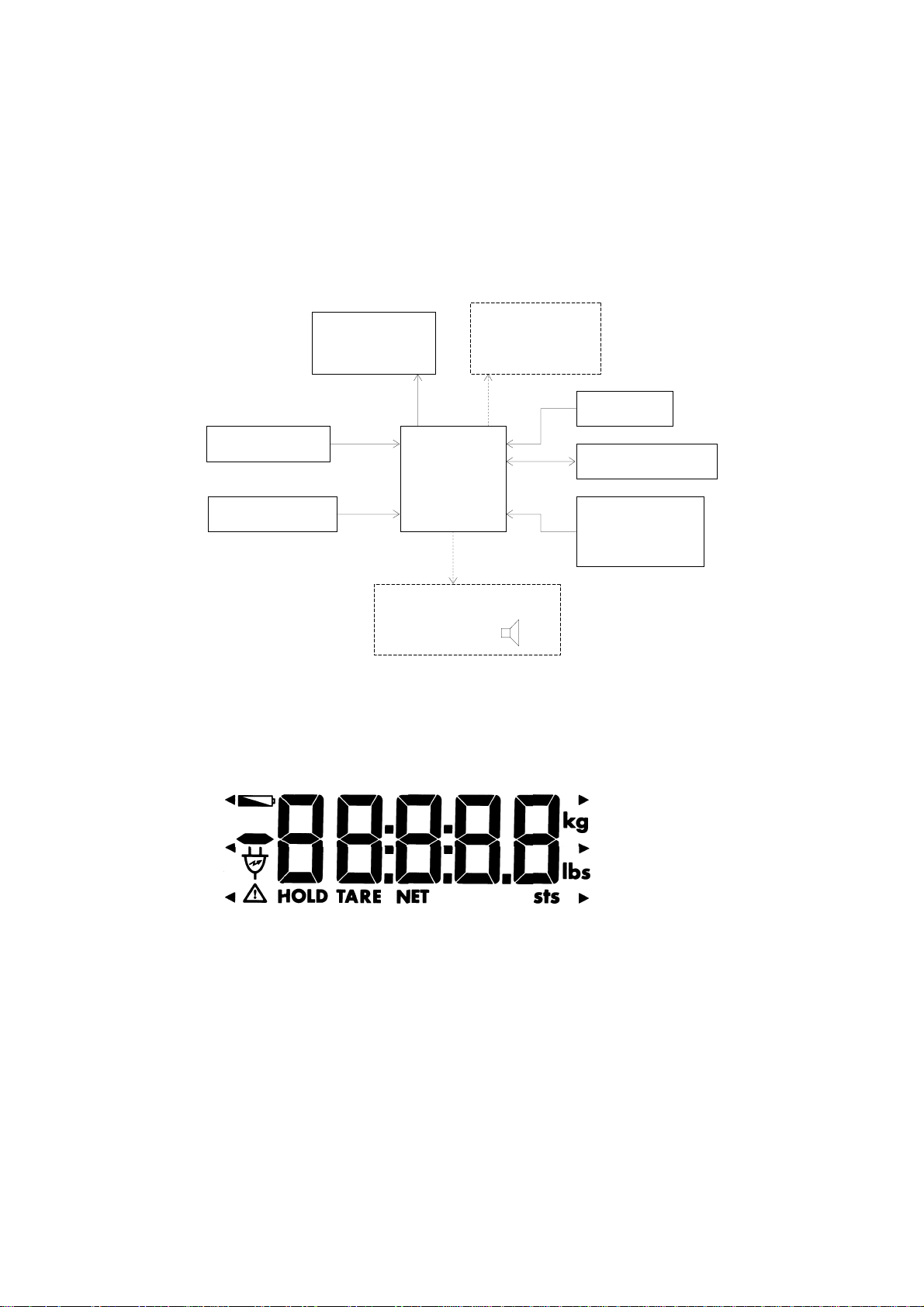

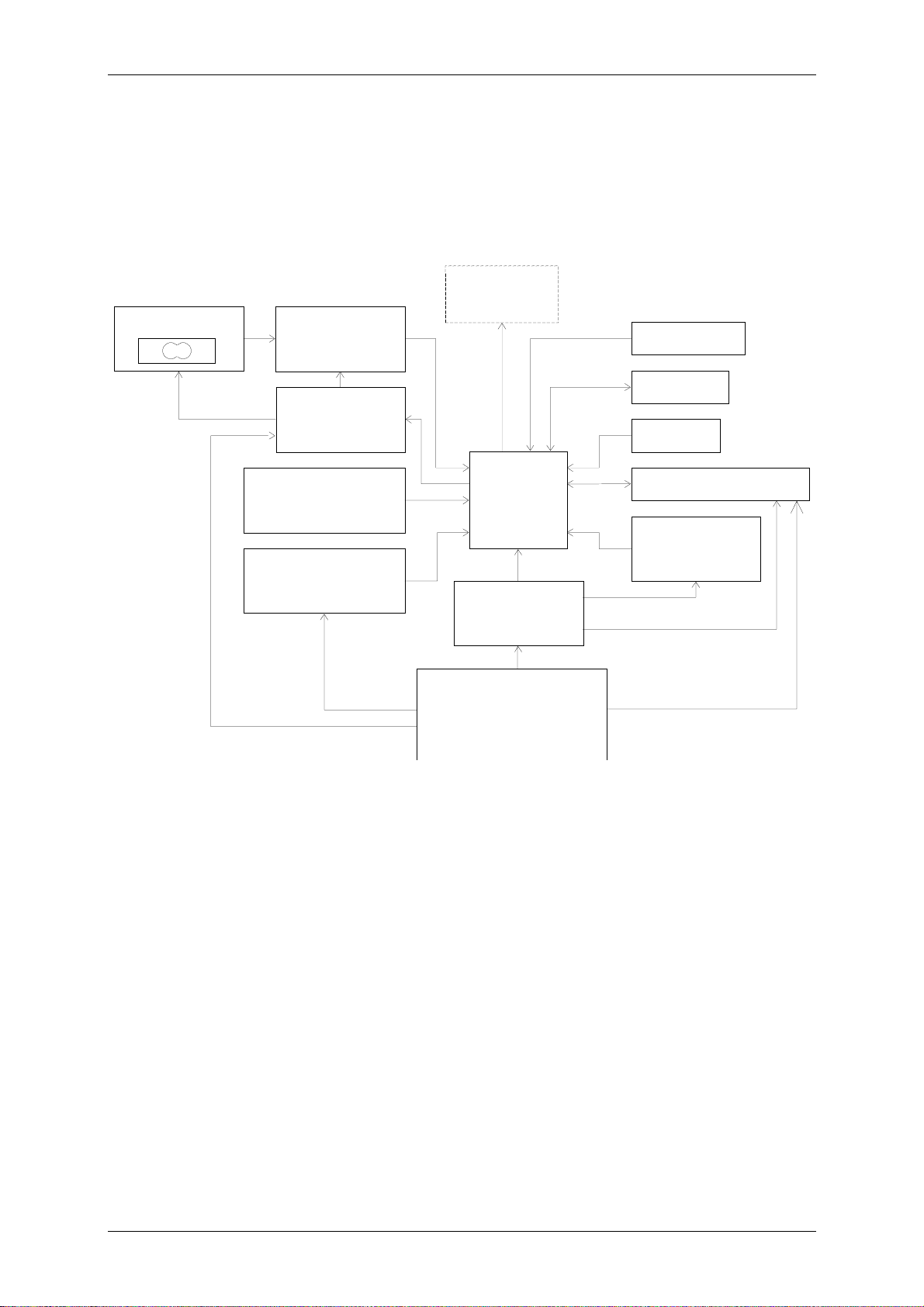

The following block diagram shows the most important function blocks of the display modules:

Display

I00.00

Backlighting

optional

Quarz

Op eration

SeSAM bus

µC

Id e n tific a tio n

Power on

re set

Signal transm itter

optional

Display

The weight displayed on the LCD is updated approximately every 0.8s. A maximum of five digits as

well as a few special characters can be displayed, which can appear as shown below:

Explanation of the special characters:

• The battery symbol is used to alert of the fact that the battery is going flat.

• The plug symbol indicates that the scale is operated on a mains transformer.

• The warning triangle signals that the weight displayed on the scale is not verifiable.

• Hold indicates that the weight display has frozen.

• Tare or Net show that a weight on the scale has been tared out.

• The left and right arrows point to additional explanations next to the display.

• The weight units on the right show in which unit the measured weight is displayed.

Power supply

Power supply is provided via the SeSAM bus.

30-34-00-618 20.04.99

1

EE/Jensen

Operation

With the exception of a start button that might be available, the connected buttons can be configured

as required for the particular model. These buttons can be pressed just lightly or longer (longer than

1.5s).

If you press another button when switching on the sc ale, the s cale will s witc h to the v er ification c ounter

and recalibration mode.

SeSAM bus

The SeSAM bus connects the display modules to the other modules. On this bus the stabilized and

non-stablized supply voltages are available. Via a data and a clock pulse line all relevant data is

exchanged. A special start line is prov ided via which the scale can be switc hed on or the module can

signal that it wants to send data.

Identification code

If several display modules are connec ted, an unmistakable ID code must be assigned to them using

soldering jumpers to ensure that the different modules are correctly addressed via the bus.

Backlighting

Some display modules are equipped with a power supply for LCD bac klighting. It c an either be lit when

the scale is switched on or only when the scale is loaded.

Signal transmitter

Some display modules are equipped with a signal transmitter. A piezo diaphragm is used which is

controlled with a 4 kHz square-wave signal.

(optional)

(optional)

Fault handling

If faults occur, the SeSAM bus initiates a fault message with the r elevant fault c ode. F urther mor e, each

fault message includes the number of the module type on which the fault has occ urred and a code

which indicates how long the message is to stay on display and which displays are to be suppressed.

The display module displays its own fault messges on its LCD. Module type (for the display module =

3) and fault number are output. In addition, the fault messages that other modules have transfer red to

the SeSAM bus are displayed.

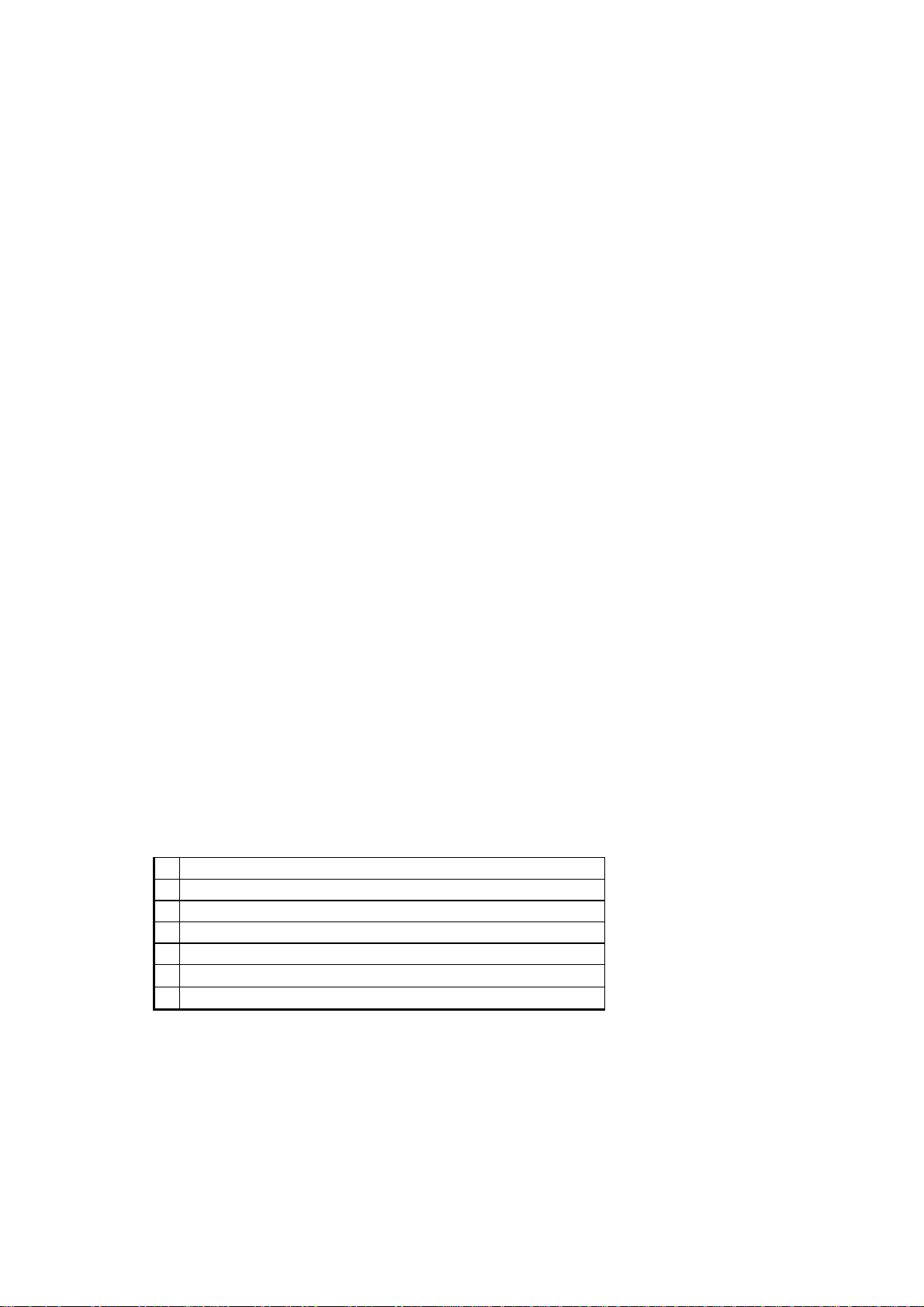

The following fault messages are implemented:

14 Fault in the kg value calculation

15 Recalibration fault

30 General bus fault

32 Command buffer full

33 More than 8 slaves detected

50 Other fault

51 Menu fault

Time base

From the quartz’s 4.19MHz a time base is derived which controls all timed processes in the scale.

These are, for instance, various timeouts.

Recalibration

In order to compensate for linear measuring errors of the scale, which can, for instance, oc cur as a

result of the different forces of gravity at differ ent geographical points, the module has a recalibration

30-34-00-618 20.04.99

2

EE/Jensen

function. To initiate the function, another button must be pressed when the scale is started. The

verification counter is then displayed which is incremented whenever the scale is recalibrated. It

enables the user to check whether the scale was manipulated. If, within five seconds, the button is

pressed longer than 1.5 s, the scale switches to recalibration mode. The scale now measures the

zeropoint and waits to be loaded with at least ¼ of the maximum load. By briefly pressing the button

the weight displayed can be decremented or incremented in steps of 10g until the weight of the load

placed on the scale is reached. The direct ion can be changed by pressing the button longer. To stop

recalibration the button must be pressed longer than 5s. T he scale can be switc hed off any time using

the on/off button or by not actuating it for a while, thus aborting recalibration.

Optional functions

The functions “Tare“ , “ Hold“, “ Autohold“ and “ Replace weight in repeat measurements” and various

menu functions can be implemented via a program on the EEPROM (on the weight measuring

module). The functions are explained below:

Tare:

The tare function can be assigned to a button by the EEPROM program. If the button is pressed, the

weight is tared out as soon as the display has settled, if it is within the permissible range. Pressing the

button again alternatively switches the tare function off or causes the weight to be tared out again.

Hold and Autohold:

If the hold function is assigned to a button by means of the EEPROM, the weight reading is held on

display when the button is pressed as soon as the value has stabiliz ed. Alternatively, the hold function

can be automated so that the weight will always be frozen when it has exceeded a certain threshold

and is stable.

The hold function is switched off after expiry of a predetermined time or by pressing the button again.

In addition the scale can be configured so that the hold function will be deactivated when the scale is

relieved, when the scale is relieved and then loaded again and / or when the load on the scale changes

significantly.

Replace weight in repeat measurements:

The scale can be configured so that the weight last displayed is dis played again in a measurement

when the scale detects that it has been loaded with almost the same weight.

Menu functions:

Not all the functions listed below can be activated on the same scale.

When the menu button is pressed long enough, the scale switches to the setting mode. Here, damping

and weight display settings can be made.

When the button is pressed briefly, the scale s witches to function mode. The following functions are

possible:

• BMI: From weight and height the body mass index is calculated using the following formula

2

=

BMI weight kg length m

• IDE: The deviation from the ideal weight calculated using the formula

×-lengthcm

09 100,( [] )

• UL: When a limit weight is overshot or undershot an acoustic signal is generated.

• DIFF: The difference to a second weight is output. The s econd weight can have been measured

using the autohold function, entered manually or stored when the difference function was last

called.

[]/ []

0.9 (height[cm] - 100) is displayed.

BMI = weight [kg] / height [m]2.

Technical data

Supply voltage: 2.7V - 3V and 2.7V - 15V (via SeSAM bus)

Supply current: typ. 0.5mA + power supply for backlighting (typ. 100mA)

Quiescent current: typ. 2µA

Operating temperature: approx. 0°C to 50°C

30-34-00-618 20.04.99

3

EE/Jensen

Storage temperature: -10°C to 60°C

Dimensions: 74mm x 50mm x 23mm small display

100mm x 84mm x 21mm large display

67mm x 38mm x 23mm backlit display

30-34-00-618 20.04.99

4

EE/Jensen

Service manual Description of the electronics

Brief description of the DMS module

Introduction

The DMS modules are used to determine weights using a load cell with strain gauges. The DMS low

end module also accommodates the display and the operating unit. To allow the modules to be

adapted to different scales, an EEPROM is integrated which is used to configure the module. A

connection to the SeSAM bus (Seca’s Serial Autoconfiguring Multicontroller bus) is provided via which

the scale can be calibrated and additional modules can be connected.

Display

I0000.

Load cell

A/D Converter

Voltage

control

Operation

EEPROM

Quartz

Temperature

measurement

µC

SeSAM Bus

Power On

Voltage

measurement

Voltage

Reset

control

Mains connection

Battery/rechargeable

batteries

Weight measurement

The DMS modules use load cells with strain gauges in a double bridge circuit as sensors.

The entire analog part runs on its own supply voltage. This voltage can be s witched by the µC to 3V,

5V or 10V. This voltage is also supplied to the load cells. At full load, they deliver a bridge output

voltage of 2mV/V.

This voltage is meas ured by a dual slope a/d converter. The DMS ext module c an evaluate up to four

load cells which are multiplexed acc ordingly. Only one load cell can be connected to the other types of

DMS modules.

The conversion time is selected so that a new measured value is available every 0.1 s.

The resolution of the a/d converter is 0.05 µV/V. If several load cells are connected, k eep in mind that

the resolution relates to the mean output signal of all the load cells connected.

When these meas ured values are within the expected range, they are converted into a weight value

using a third order polynomial. In order to increase accuracy, eight measured values are used to

calculate the weight to be displayed.

The first value obtained after switch-on is used as the zero point. If the values obtained later on do not

deviate strongly from this value, the zero point is corrected in order to com pensate for possible drifts .

(Please also refer to temperature measurement.)

31.03.2000 /Jensen 34-34-00-645 Index a

1

Service manual Description of the electronics

Display (DMS low-end module only)

Whenever eight new m easured values are available, i.e. approx. every 0.8 s, the weight is displayed.

The display is an LCD which is controlled by duplex operation. A m aximum of five digits as well as a

few special characters can be displayed.

Explanation of the special characters:

• The battery symbol is used to alert of the fact that the battery is going flat.

• Hold indicates that the weight display has frozen.

• Tare or Net indicate that a weight on the scale has been tared off.

• The left arrow indicates if additional explanations are given next to the display.

• The weight units on the right show the unit in which the measured weight is displayed.

Temperature measurement

In order to compensate f or the load cell’s tem perature drift, the tem perature is m easured regularly and

the measured value is adjusted accordingly.

To perform this measurement, a capacitor is charged every 2 seconds alternately via a reference

resistor and an NTC with a linearization resistor connected in parallel. The time until the capacitor has

reached a specific voltage is measured. The temperature is calculated from the ratio of the two times.

To reduce measur ed value fluc tuations, a m ean value of 16 tem perature values is always form ed. The

fluctuation then amounts to approx ±0.2°C.

The difference between the current temperature and the temperature measured when the last zero

point was obtained is used to determine a projected zero point. To do so, one assumes that the weight

change per °C is constant. The weight value is then corrected in accordance with the zero point

calculated and in accordance with the difference to the temperature measured when the scale was

calibrated. A linear and a square term are used for this purpose.

Power supply

Power supply is provided by AA size batteries (batteries or rechargeable batteries) and a plug-in power

supply unit. The batteries pass the voltage via reverse voltage protection diodes to a 3V in-phase

regulator. A coil which suppresses interference and a buffer capacitor come next. This 3 V supply

voltage is supplied to the digital part of the circuit.

Another in-phase regulator generates the voltage for the analog part. T he µC can set this regulator to

3V, 5V or 10V.

In order to operate the module on rechargeable batter ies a recharging circuit c an be connected. T his

circuit charges the rechargeable batteries at a constant current when a power supply unit is connected.

When the supply voltage is applied, a power-on reset is initiated at the µC via an RC element.

To monitor the condition of the batteries, their voltage is m easured ever y 2s. For this purpose, a 2.2 V

reference voltage is integrated upwards and the time until the voltage has r eached approx. 9% of the

supply voltage is measured. Afterwards, a downwards integration is m ade from 2.2V to the threshold.

From these two results, a measured value for the voltage is calculated. If the voltage drops below a

certain limit, the user is aler ted by the battery symbol in the LCD. If the next threshold is undershot,

„bAtt“ is displayed and weighing is no longer possible.

Operation (DMS low-end module only, with the exception of vibration-sensitive

switch and platform switch)

Four buttons are provided; one is used to switch the module on and off, the others can be programmed

as required. These three buttons can be pressed just lightly or longer (longer than 1.5s), so that six

events are available. The actions tare, hold and unit switch-over can be assigned to them.

If you press another button when switching on the scale, the sc ale will switch to the calibration counter

and recalibration mode.

Instead of the normal star t button a piezo diaphragm c an be soldered to the PI c onnection. If the piezo

diaphragm registers a vibration, a transistor s witches and generates an interrupt signal which causes

the µC to start.

If the start button is directly connected to this interrupt input, a button is obtained which is only active

when the scale is switched off. It can be f itted under the platform, for instance, so that the scale is

started by briefly stepping on it.

31.03.2000 /Jensen 34-34-00-645 Index a

2

Service manual Description of the electronics

Programming

The DMS modules are equipped with an EEPROM which is c ontrolled via the I²C bus protocol. On this

EEPROM all parameters are stored that can be used to inf luence the program s equence. For exam ple

the way the weight is displayed or the allocation of buttons. It also stores the coefficients for

determining the weight and data for temperature compensation, e.g. the factors for the polynomial.

Furthermore, the sc ale can store values to be retrieved when the scale is switched on the next time,

e.g. the weight unit used last.

In order to avoid errors, the EEPROM contents are divided into blocks which are m onitored by cyclic

redundancy checks. The hamming distance is 4 so that single errors can be corrected and double

errors are certainly detected. In addition, values which are recalc ulated when the scale is in operation

can be replaced by default values if an error is detected that cannot be remedied.

Serial bus

To allow the scale to be calibrated and additional modules, such as additional displays, to be

connected, the DMS modules are equipped with an interface to the SeSAM bus.

On this bus the stabilized and non-stabilized supply voltages are available. Via a data and a clock

pulse line all relevant data is transmitted to other modules. A special start line is provided via whic h the

scale can be switched on or other modules can signal that they want to send data.

Both data and start line are open collectors so that they can be switched to low by all modules.

For further details on the bus, please refer to the relevant documentation.

Fault handling

If faults occur, the SeSAM bus initiates a fault mess age with the relevant fault c ode. Fur ther more, each

fault message includes the number of the m odule type on which the fault has occurred and a c ode

which indicates how long the message is to stay on display and which display s are to be suppressed.

The DMS low end module displays its own fault messages on its LCD. Module type (0 for the low-end

module) and fault num ber are displayed. The other DMS modules only transf er fault m essages to the

bus (module type = 1).

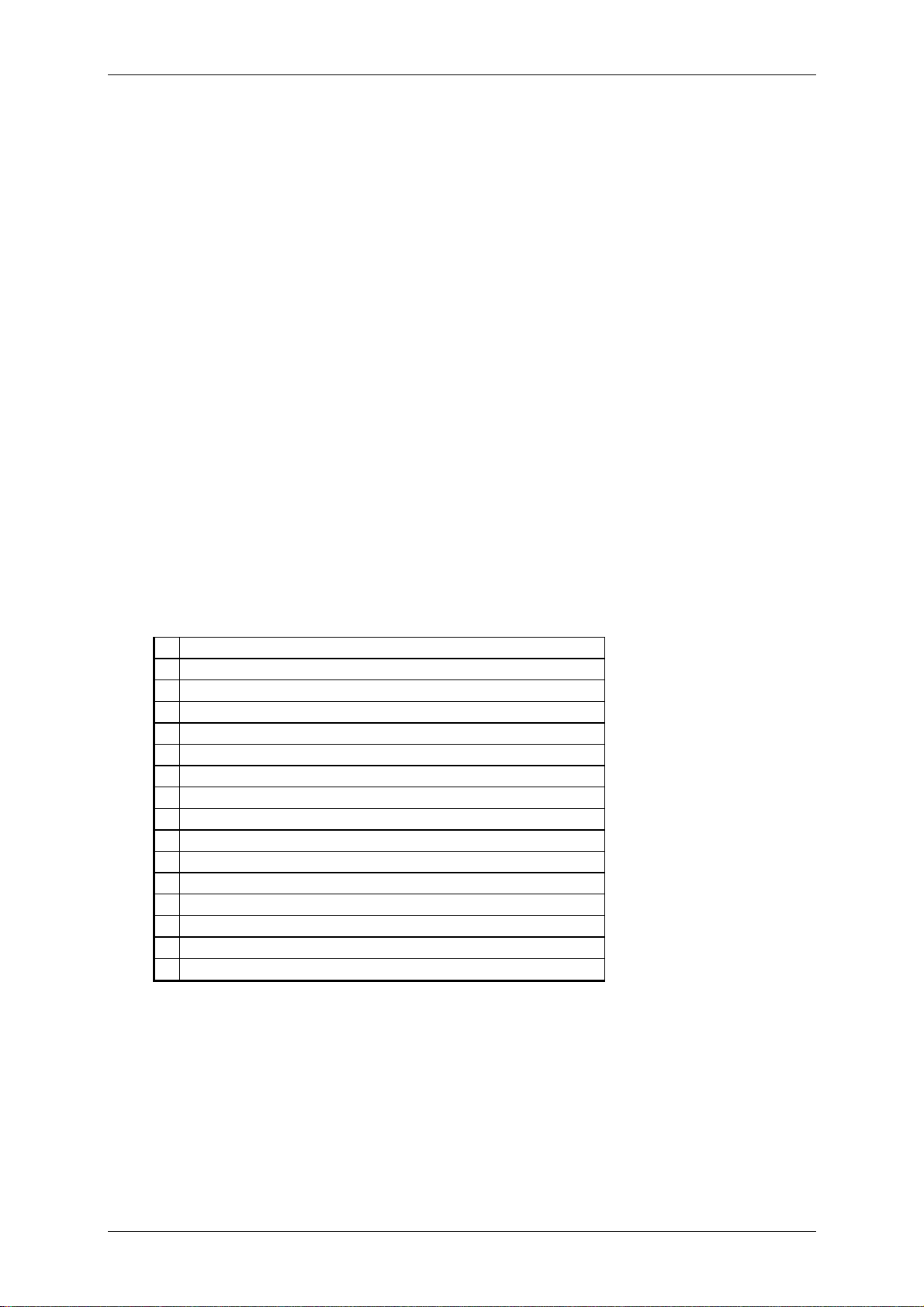

The following fault messages are implemented:

10 20 bit counter overflow

11 Counts outside the permissible range

12 Switch-on zero point outside the permissible range

13 Zero follow-up outside the permissible range

14 Fault in the kg value calculation

15 Recalibration fault

20 Battery voltage too low

21 Fault in battery voltage measurement

22 Fault in temperature measurement

23 Temperature range exceeded ( < 0°C or > 50°C)

30 General bus fault

32 Command buffer full

33 More than 8 slaves detected

40 EEPROM fault

41 Incorrect EEPROM access

50 Other fault

Time base

From the quartz’s 4.19MHz a time base is derived which controls all timed processes in the scale.

These are, for instance, various timeouts and the on-time.

After expiry of the on-time, the supply voltage for the analog part, f or voltage m easur em ent and for the

EEPROM is switched off. T he LCD is switched off, all ports are set to zero-s ignal level and the quartz

is stopped.

31.03.2000 /Jensen 34-34-00-645 Index a

3

Loading...

Loading...